Patents

Literature

183results about How to "Shorten the migration path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

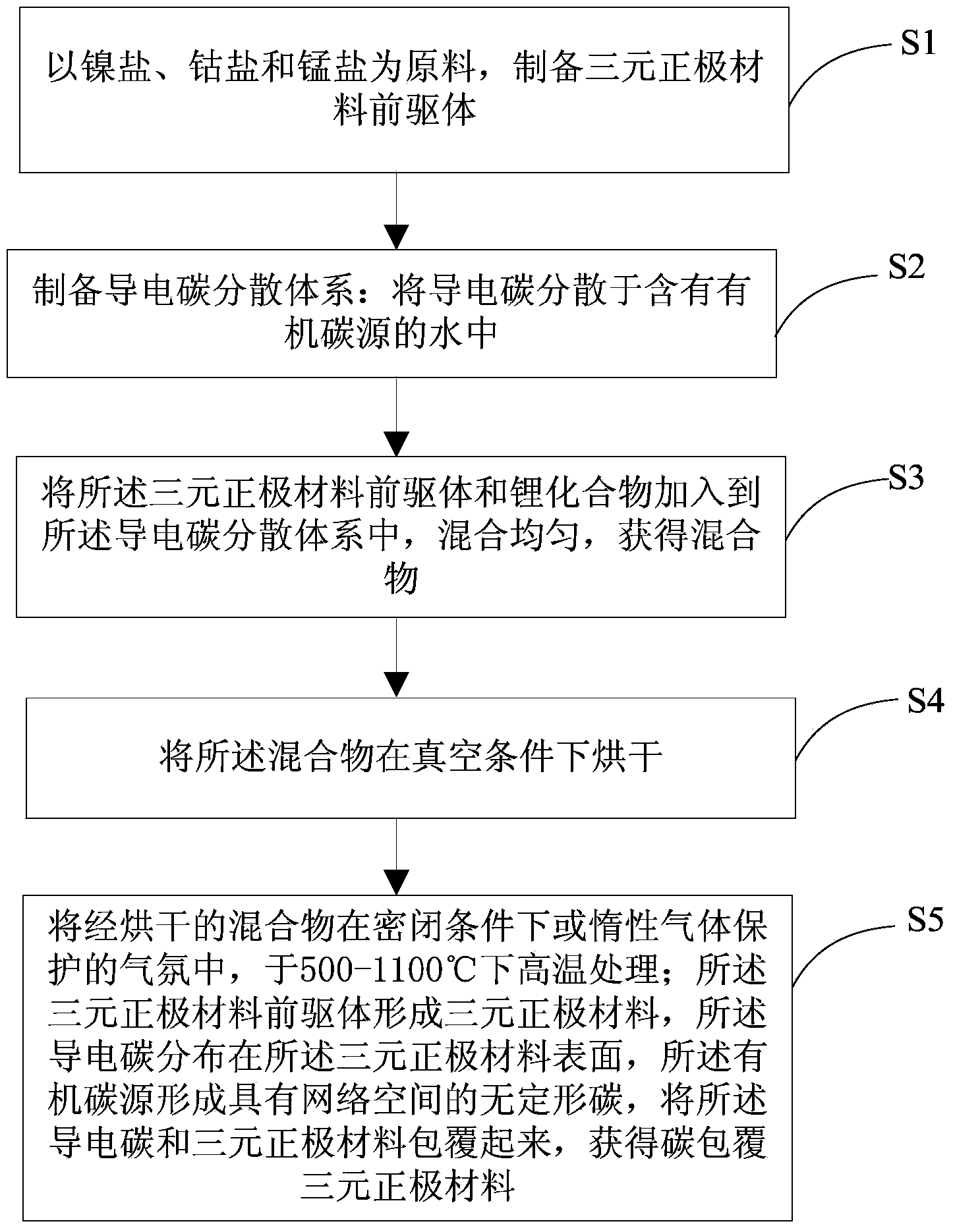

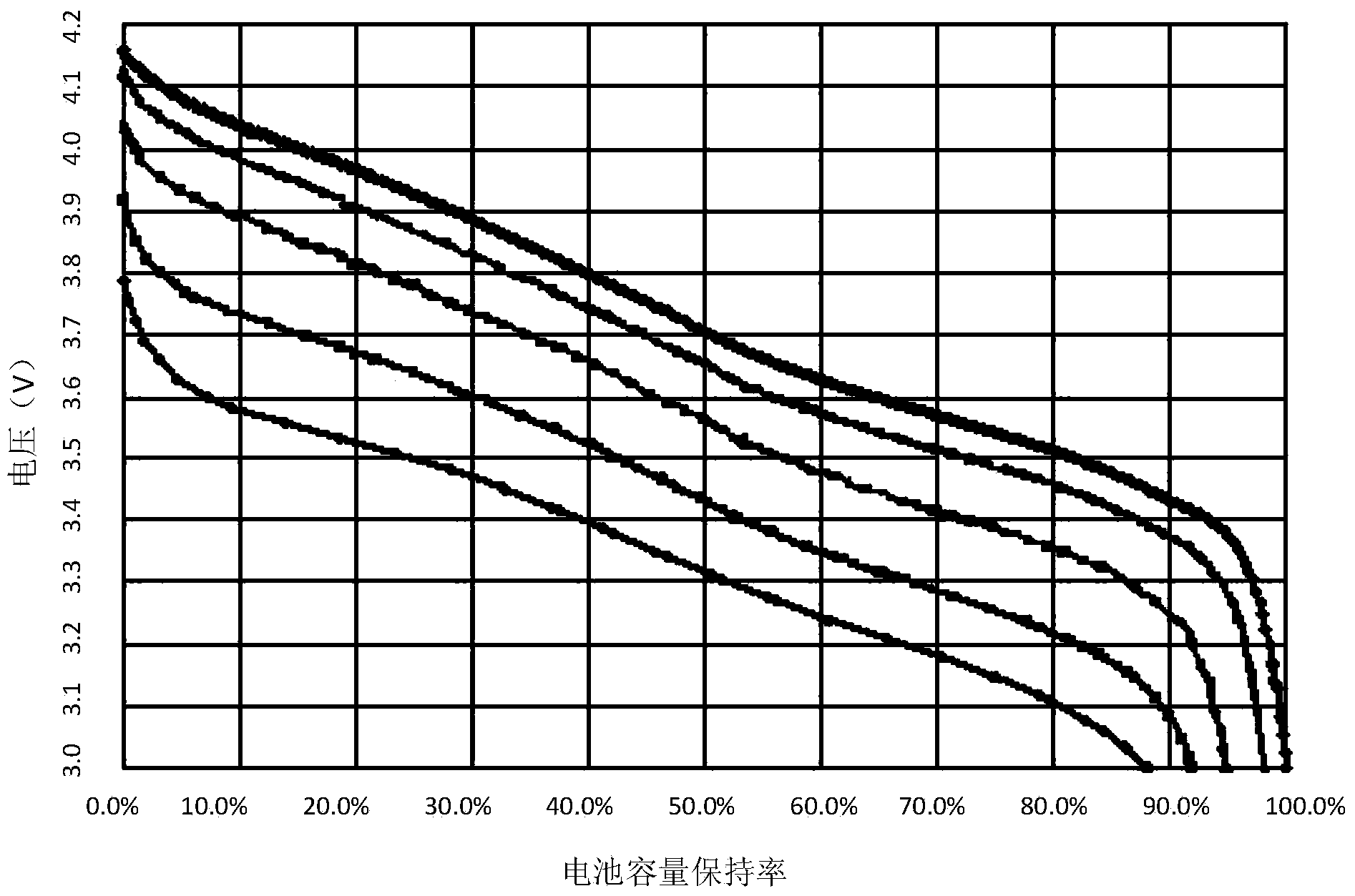

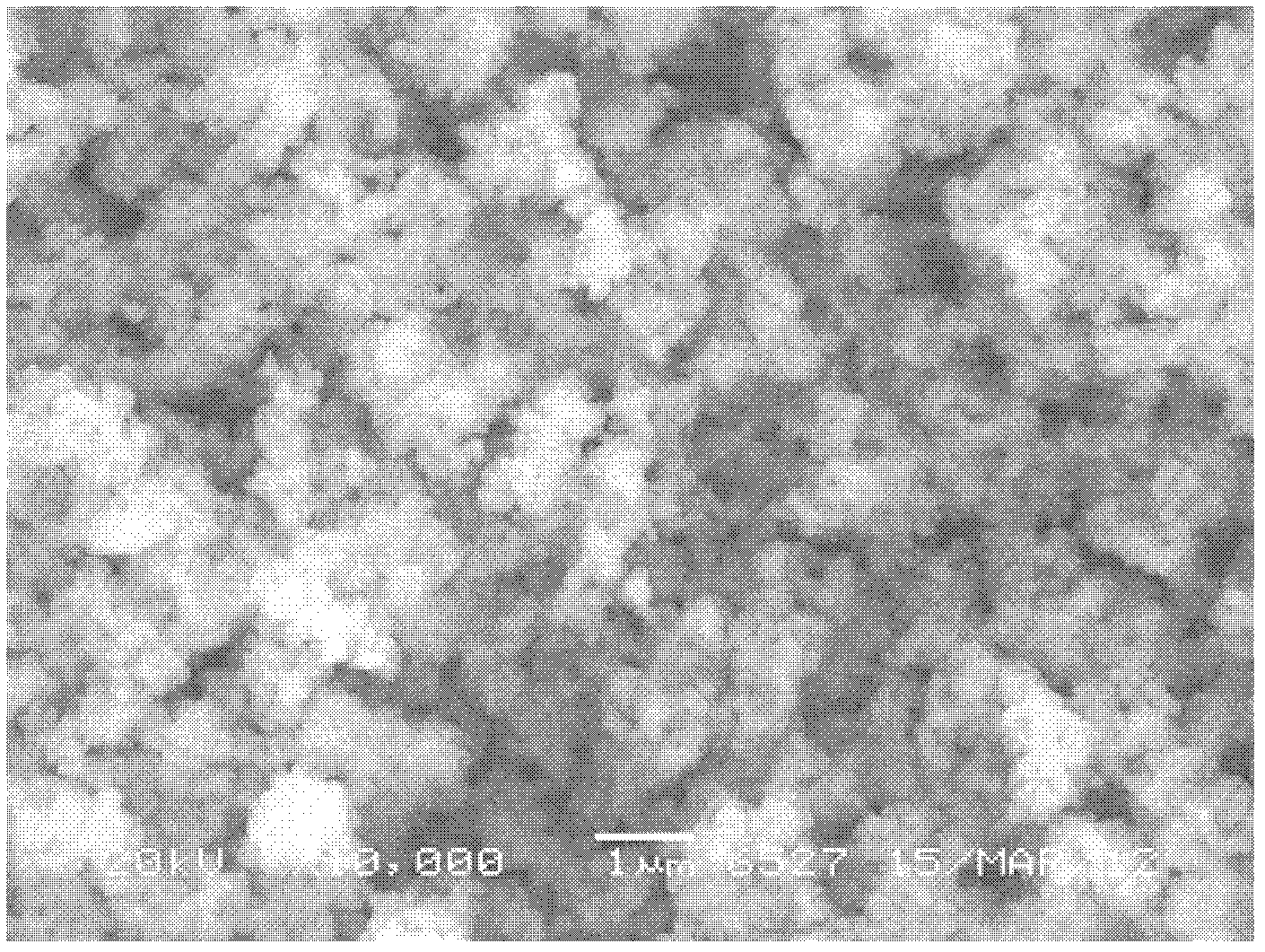

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

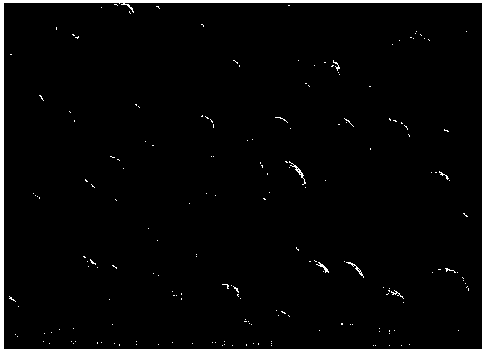

Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

ActiveCN102623680ALow tap densityReduce volume specific capacityCell electrodesCarbon compositesCarbonization

The invention discloses a silicon-carbon composite cathode material with a three-dimensional preformed hole structure and a preparation method thereof. According to the composite cathode material, a carbon material having high electric conductivity and a stable structure is used as a matrix for dispersedly containing high-volume silicon particles, and proper three-dimensional expansion spaces are reserved around one or several silicon particles. The preparation method comprises the following steps of: carrying out surface modification on the silicon particles; coating the silicon particles by silicon dioxide; coating the silicon dioxide / silicon composite particles by carbon source precursors; carrying out high-temperature carbonization treatment; and removing a silicon dioxide template, and the like. When the composite material prepared by the preparation method is used for a lithium ion battery, the reversible specific capacity is high, and the cycle performance is excellent. The silicon-carbon composite cathode material has the advantages of simple preparation process and wide raw material resource and is suitable for industrial production.

Owner:湖南宸宇富基新能源科技有限公司

Method for quickly forming soft power lithium-ion cell

ActiveCN107579302AHelps to formImprove conductivitySecondary cells charging/dischargingElectricityLithium

The invention discloses a method for quickly forming a soft power lithium-ion cell. The method comprises the following steps: (S1) supplying a heat source for heating a cell by using a heating plate;(S2) driving a pressurizing plate to pressurize the cell by using a servo motor; (S3) performing gradient charging on the cell; and (S4) charging the cell till reaching high charge state. According tothe invention, a stable, compact and uniform SEI film is formed on a cathode surface, the performance of the lithium-ion cell is greatly promoted, the early failure of the lithium-ion cell in the circulating process is avoided, the yield of the cell is increased, the cell quality is optimized, the forming time of the cell is shortened, the large-scale production of the cell is realized and the method has wide application prospect.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

Lithium supplement additive for lithium ion cathode material and preparation method thereof

ActiveCN112490415ATightly boundUniform covering thicknessMaterial nanotechnologyCell electrodesCarbon layerPhysical chemistry

The invention discloses a lithium supplement additive for a lithium ion cathode material. The lithium supplement additive comprises a Li5FeO4 matrix and a coating layer positioned on the surface of the Li5FeO4 matrix, wherein the coating layer comprises a first coating layer carbon layer positioned on the surface of the Li5FeO4 matrix and a second coating layer transition metal oxide layer positioned on the surface of the first coating layer. The invention also discloses a preparation method of the lithium supplement additive, which comprises the following steps: preparing carbon layer coatediron oxide, carrying out wet mixing to prepare surface carbon coated Li5FeO4, mixing with a transition metal ion salt solution and an ammonium hydroxide solution, and carrying out high-temperature sintering to obtain the lithium supplement additive. According to the double-layer coated Li5FeO4 lithium supplementing additive disclosed by the invention, the Li5FeO4 matrix is micron-scale or nano-scale particles, and the particles are uniform and controllable, so that the migration path of electrons and ions is shortened, the lithium supplementing performance of the Li5FeO4 material can be exerted, and the service life of a lithium ion battery is prolonged.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

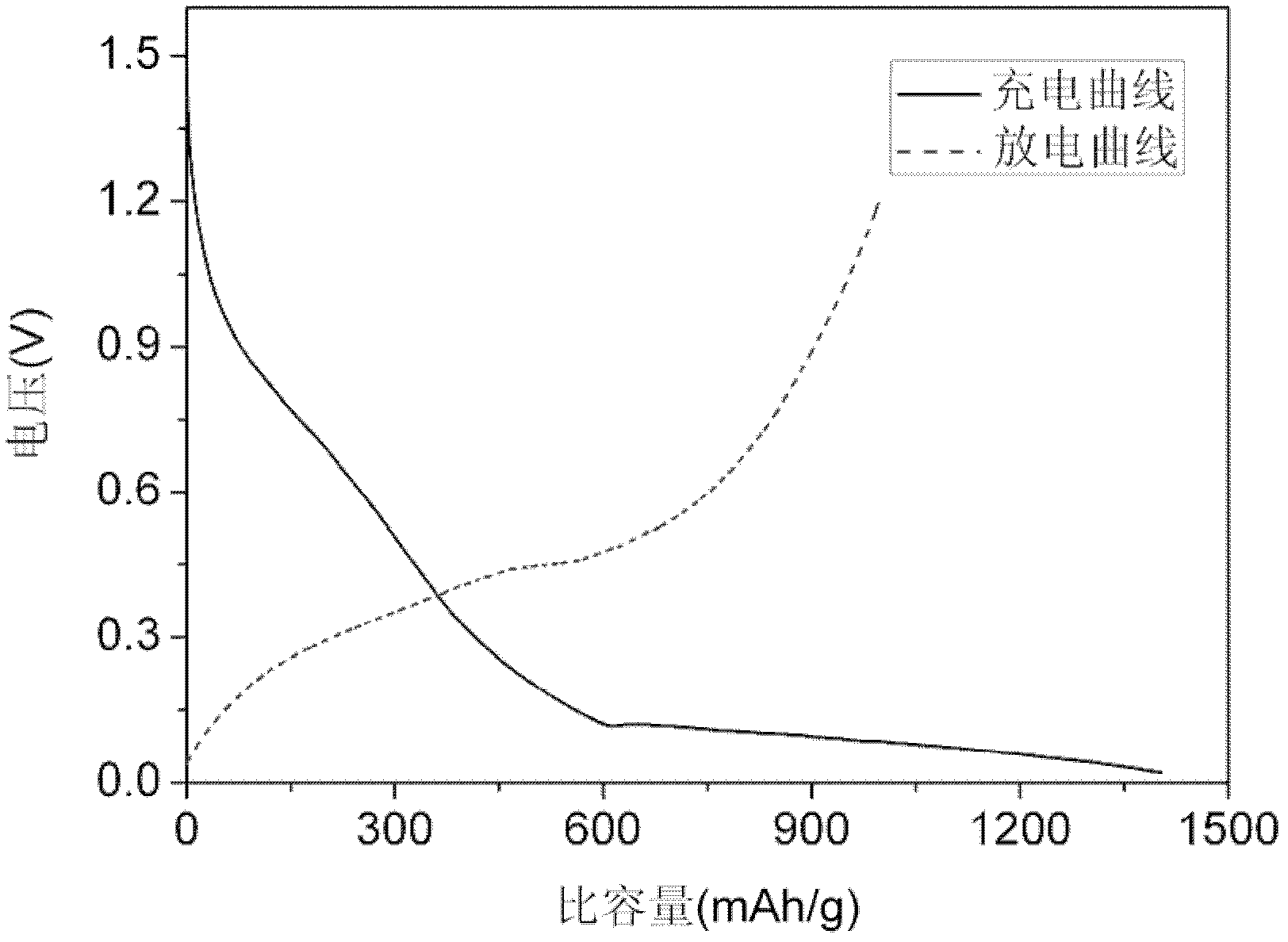

Porous metal oxide-carbon composite thin film electrode and preparation method thereof

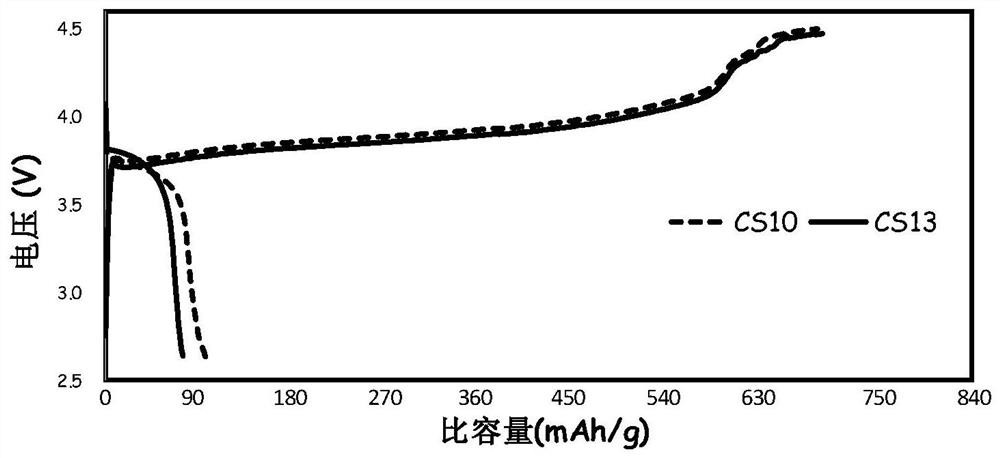

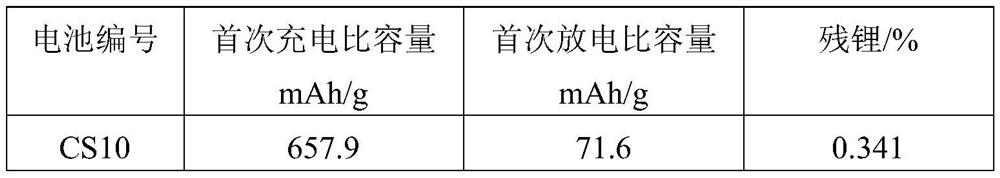

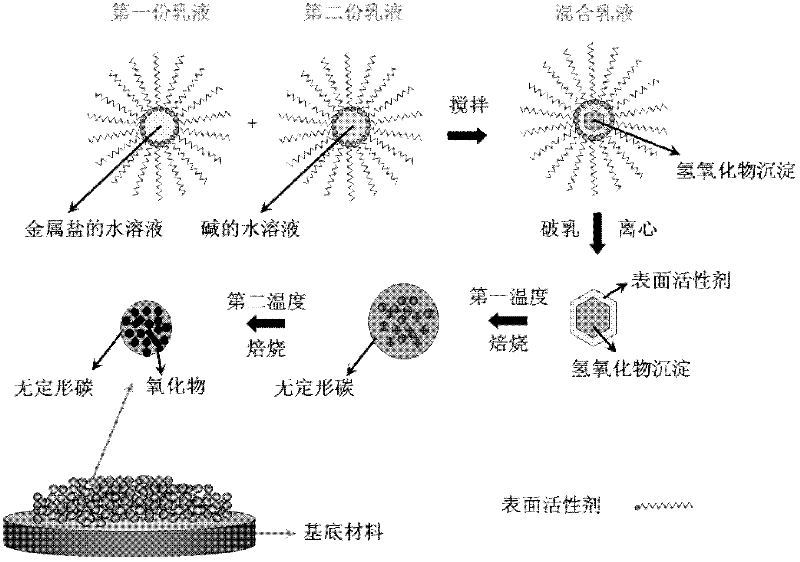

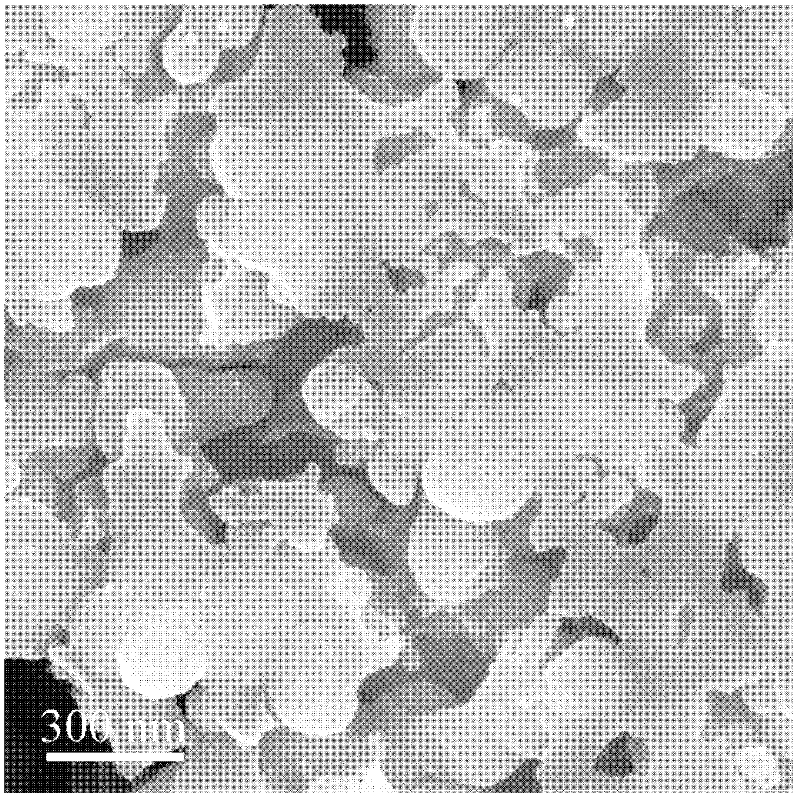

InactiveCN102509786AImprove cycle performanceShorten the migration path of lithium ionsCell electrodesEmulsionCopper foil

The invention relates to a porous metal oxide-carbon composite thin-film electrode and a preparation method of the porous metal oxide-carbon composite thin-film, which belong to the technical field of lithium ion battery. The porous metal oxide-carbon composite thin film electrode free of other additional conductive agents and adhesives consists of a copper foil collector, and a porous metal oxide-carbon composite thin film on the surface of the copper foil collector. The preparation method of the porous metal oxide-carbon composite thin-film electrode comprises the following steps: blending a metal salt emulsion with an alkaline emulsion for reaction; demulsifying and centrifuging to obtain a precipitate; applying the precipitate on the surface of the copper foil collector; and calcining the copper foil collector twice to obtain the final product. The porous metal oxide-carbon composite thin-film electrode has the advantages of high specific capacity and high rate capability when used as the negative electrode of a lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Composite modified lithium ion battery cathode material and preparation method thereof

InactiveCN104617303AAvoid decompositionImprove cycle performanceCell electrodesSecondary cellsMass ratioLithium-ion battery

The invention relates to a composite modified lithium ion battery cathode material and a preparation method thereof. The chemical general formula of the composite modified lithium ion battery cathode material is LiNi(1-a-b)CoaAlbO2 / M, wherein 0.1<a<0.3, 0.01<b<0.2, and M is a composite coating layer of one of metallic oxides and carbon; the mass ratio of the composite coating layer to the LiNi(1-a-b)CoaAlbO2 is (0.001-0.05):1; the mass ratio of the metallic oxide in the composite coating layer to the carbon is 1: (1-10); the thickness of the composite coating layer is 4-10 mm. The composite modified lithium ion battery cathode material and the preparation method thereof have the maximum advantages and benefits that the cycling performance and the stability of a lithium ion battery are improved; a carbon source forms amorphous carbon under the hypoxic conditions, so that a channel is provided for the migration of lithium ions, and not only is the electronic conductivity of the cathode material is improved, but also the rate capability of the cathode material is greatly improved.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

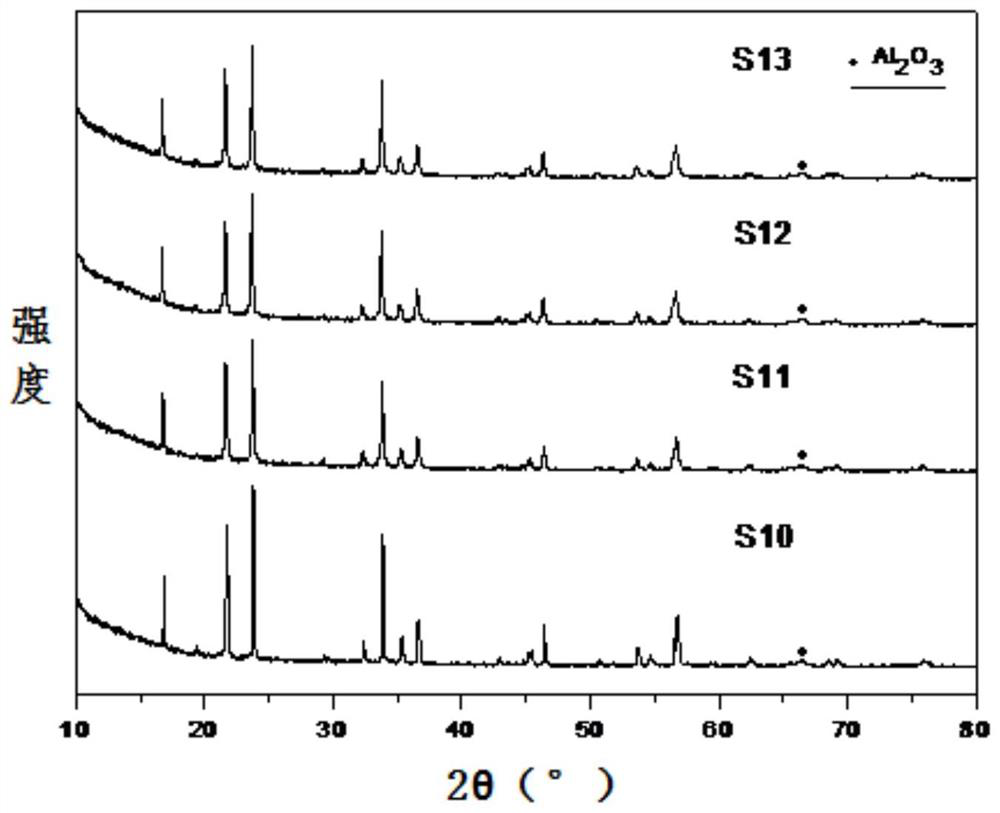

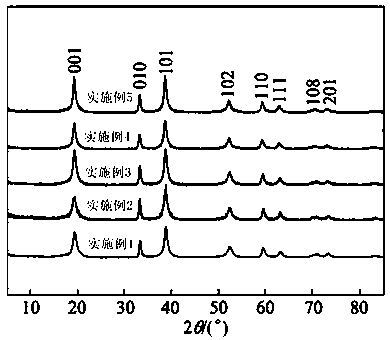

Dual-cladding 622-type Ni-Co-Mn ternary positive electrode material and preparation method thereof

InactiveCN107863514AImprove intrinsic electronic conductivityLarge cell parametersCell electrodesSecondary cellsManganeseHeat treated

The invention discloses a dual-cladding 622-type Ni-Co-Mn ternary positive electrode material. The molecular formula of the dual-cladding 622-type Ni-Co-Mn ternary positive electrode material is xMO.yMF.LiNi<0.6>Co<0.2>Mn<0.2>O2, wherein M is Na, Mg or Al, x is more than or equal to 0 but less than or equal to 0.09, and y is more than or equal to 0 but less than or equal to 0.09. The dual-cladding622-type Ni-Co-Mn ternary positive electrode material is implemented according to the following steps of 1) primary coating, in which lithium carbonate, Ni<0.6>Co<0.2>Mn<0.2>(OH)2 and an oxide are sequentially added into a ball-milling tank, and dry ball-milling is performed for 6-18 hours; 2) pre-sintering, in which powder in the step 1) is subjected to thermal processing for 6 hours under a temperature of 700-800 DEG C and then is naturally cooled; 3) washing, in which the powder in the step 2) is cleaned with deionized water and then is cleaned with ethyl alcohol; 4) secondary coating, inwhich the powder in the step 3) is taken out and mixed with a fluoride, and the product is placed in water bath for drying under 90-100 DEG C after ultrasonic treatment for 30 minutes; and 5) secondary sintering, in which the powder in the step 4) is subjected to heat preservation under a temperature of 800-900 DEG C and is naturally cooled to obtain the dual-cladding 622-type Ni-Co-Mn ternary positive electrode material. The method is safe and efficient, and the obtained dual-cladding 622-type Ni-Co-Mn ternary positive electrode material is fine and uniform distribution in particle, has a favorable microstructure and has relatively good electrochemical performance.

Owner:淮安新能源材料技术研究院

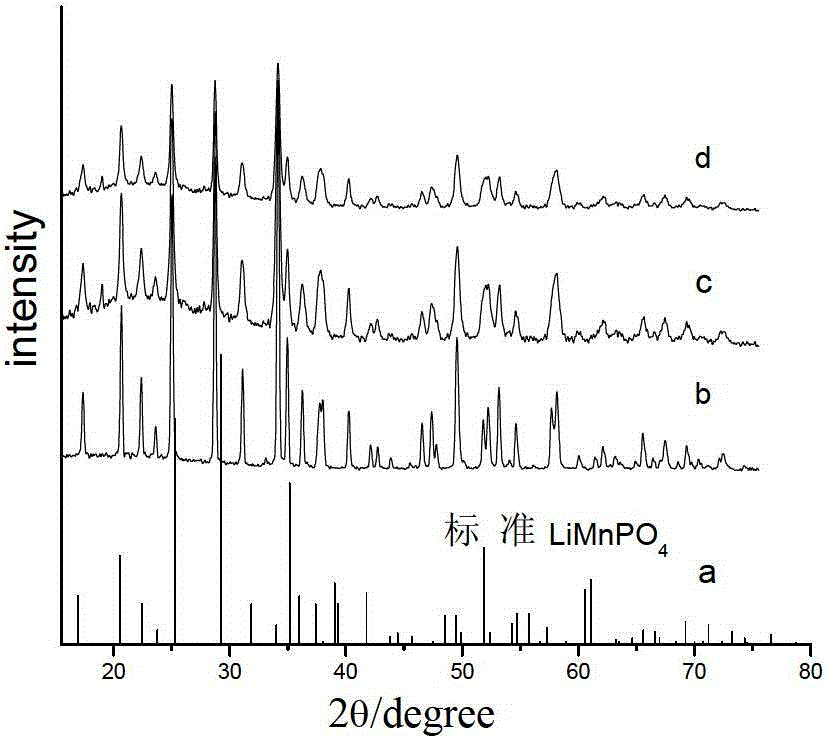

Method for synthesizing positive material nano lithium manganese phosphate of lithium ion battery

The invention discloses a solvothermal synthesis method for a positive material nano lithium manganese phosphate of a lithium ion battery. The method comprises the following steps: uniformly mixing two ethanol solutions containing a lithium source and a phosphate radical source respectively; adding an ethanol solution containing a manganese source, uniformly stirring, and adding an organic additive; and finally, pouring the mixed solution into a reaction kettle, sealing, raising the temperature to be 140-150 DEG C at the speed of 1-5 DEG C per minute, and heating at a constant temperature for 6-24 hours. According to the method, nanoscale LiMnPO4 with the shape of capsules, sheets or cubes can be obtained, and the method has the advantages of low equipment investment, simple process flow, slight pollution, low energy consumption, controllable shape and small product particle size.

Owner:常州孚达新能源科技有限公司

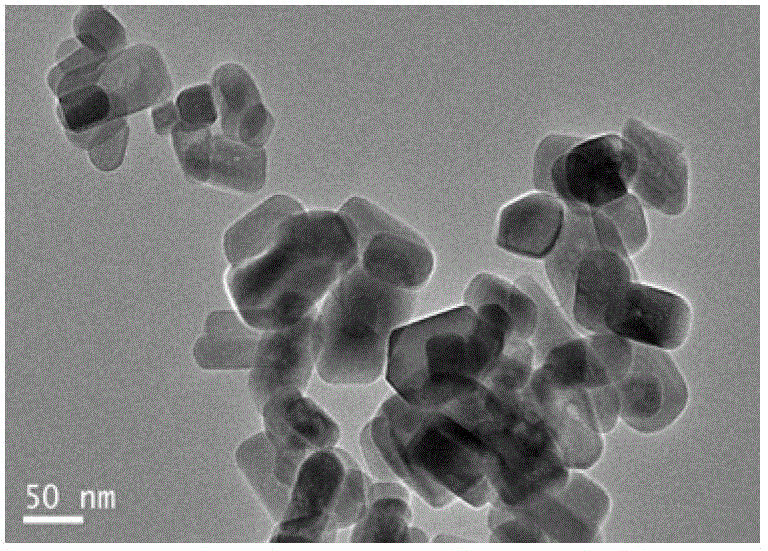

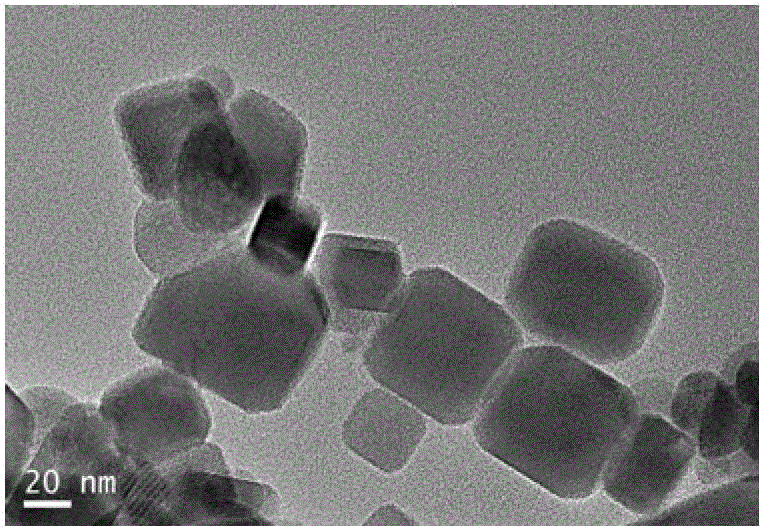

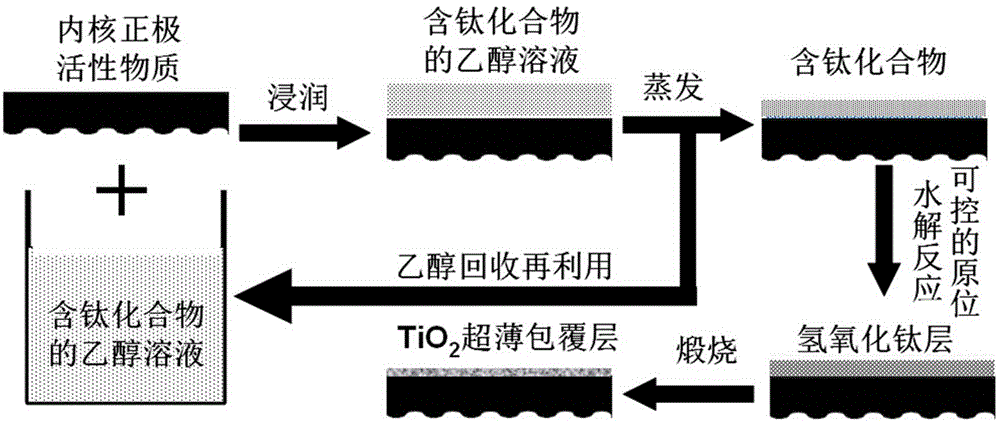

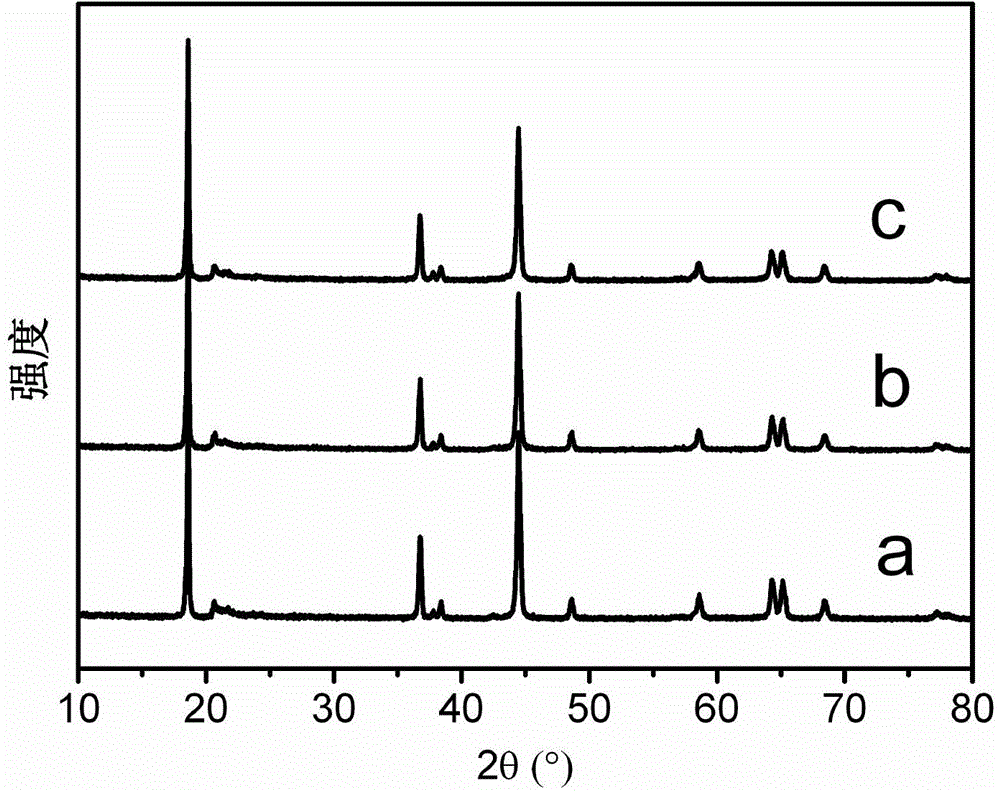

Ultrathin TiO2 coating layer of lithium battery cathode material, lithium battery cathode material and preparation method of lithium battery cathode material

ActiveCN104617267AGood conductivityLower polarization resistanceElectrode manufacturing processesSide reactionCalcination

The invention discloses an ultrathin TiO2 coating layer of a lithium battery cathode material. The coating layer is uniform and compact, and the thickness is only 0.5-20 nm. The lithium battery cathode material with a core-shell type coating structure comprises an inner-core cathode active material and the externally coated ultrathin TiO2 coating layer, wherein a mole ratio of Ti in the coating layer to a transition metal element in the inner-core cathode active material is 0.01%-3%. A preparation method of the lithium battery cathode material comprises steps as follows: a titanium contained compound is dissolved in an organic solvent; the inner-core cathode active material is added to the solution and stirred rapidly, the organic solvent is removed through heating, dry powder is obtained and is placed in dry air for standing to have in-situ hydrolysation with water molecules in air slowly and controllably, and intermediate powder is obtained and placed in an aerobic environment for calcination so as to obtain the lithium battery cathode material. The side reaction between the active material and electrolyte can be effectively inhibited, and the rate capability and the cycle performance of the lithium battery cathode material are improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

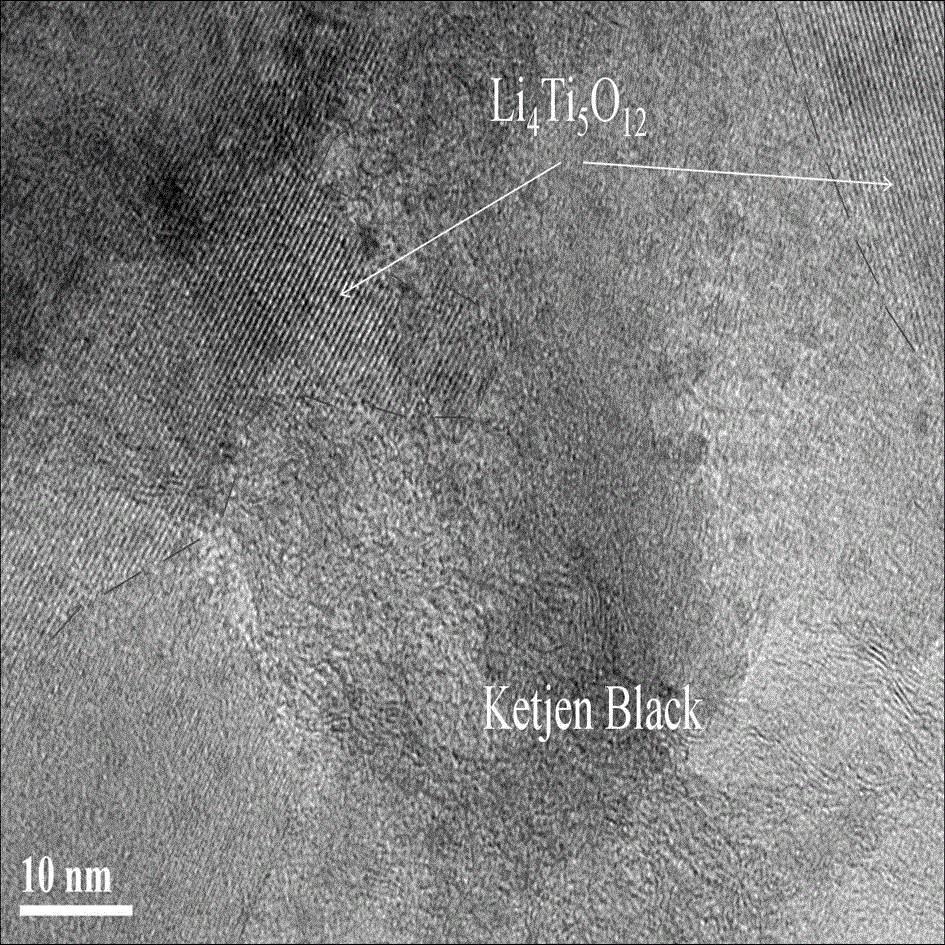

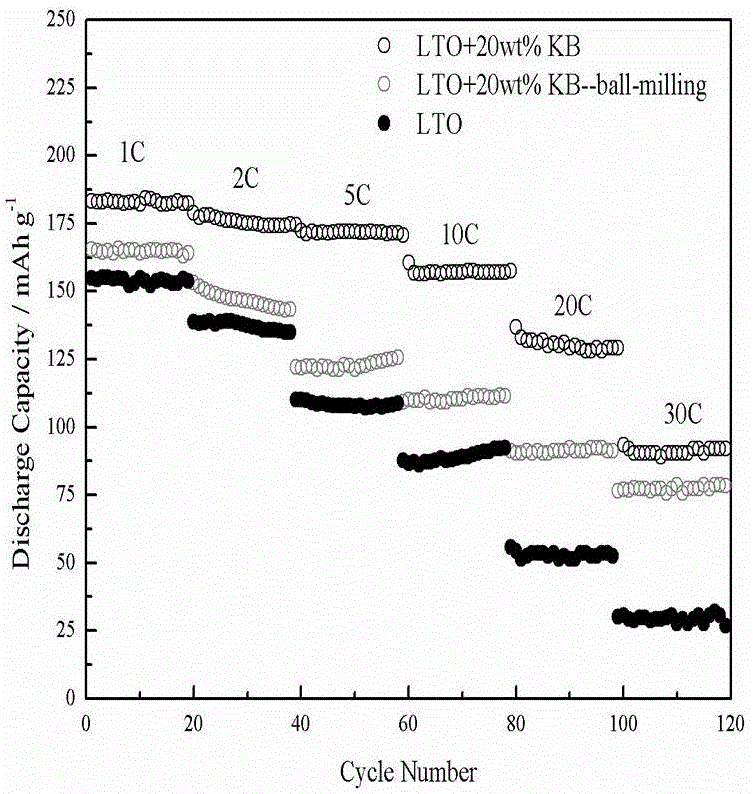

Lithium titanate/porous carbon composite material and preparation method of lithium titanate/porous carbon composite material

InactiveCN105789582AImprove electronic conductivityIncrease the diffusion coefficientCell electrodesSecondary cellsCarbon compositesHydration reaction

The invention discloses a lithium titanate / porous carbon composite material. The invention further discloses a preparation method of the lithium titanate / porous carbon composite material. The prepapration method comprises the following steps: weighing lithium hydroxide monohydrate, tetrabutyl titanate and porous carbon according to a certain stoichiometric ratio; adding ethanol and de-ionized water and uniformly mixing; transferring a stirred suspension solution into a hydrothermal reaction kettle and reacting at 180 DEG C for 24h to 48h to obtain precursor slurry; drying and crushing the precursor slurry to obtain precursor powder; treating the precursor powder in an inert atmosphere at the temperature of 500 DEG C to 700 DEG C for 5 to 10 hours to obtain the lithium titanate / porous carbon composite material. The composite material prepared by the technical scheme provided by the invention has excellent rate performance and low-temperature property.

Owner:EAST CHINA UNIV OF SCI & TECH

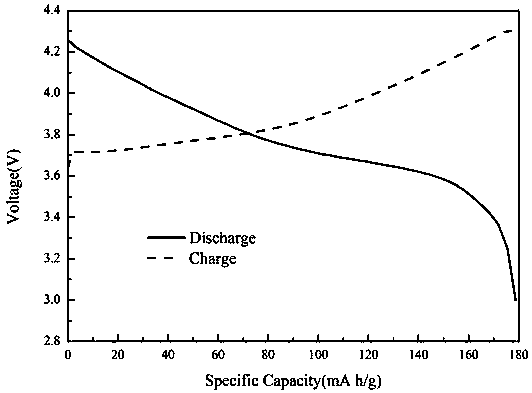

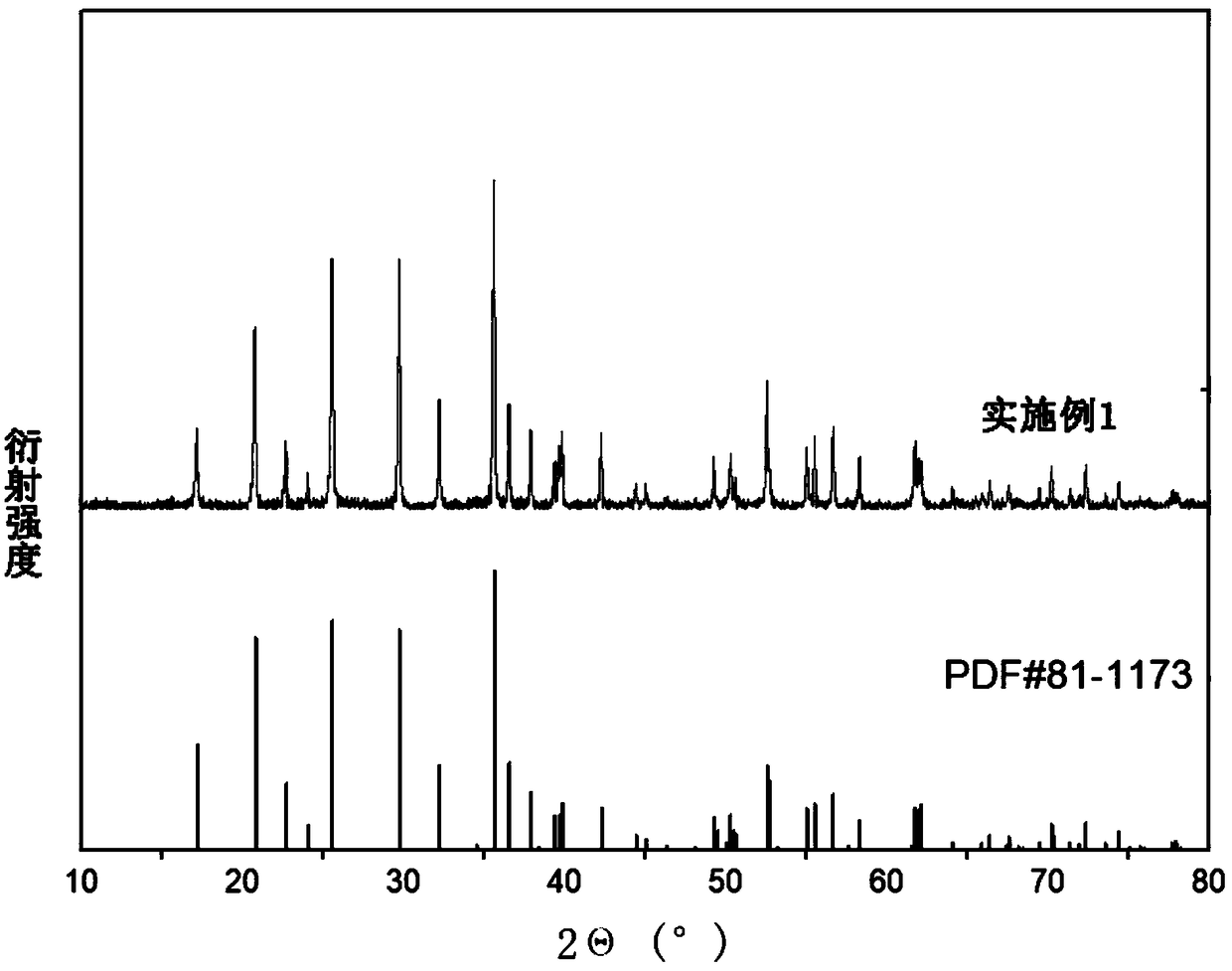

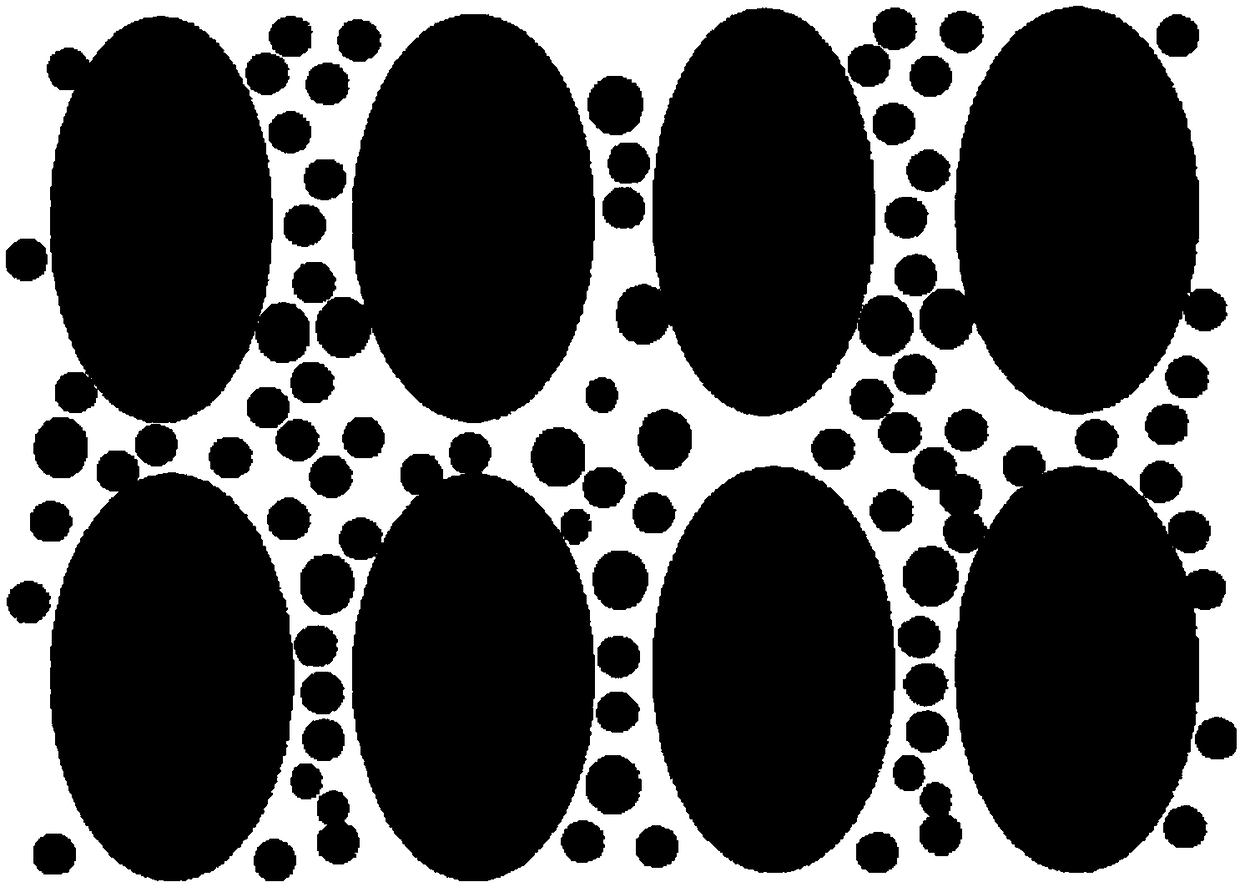

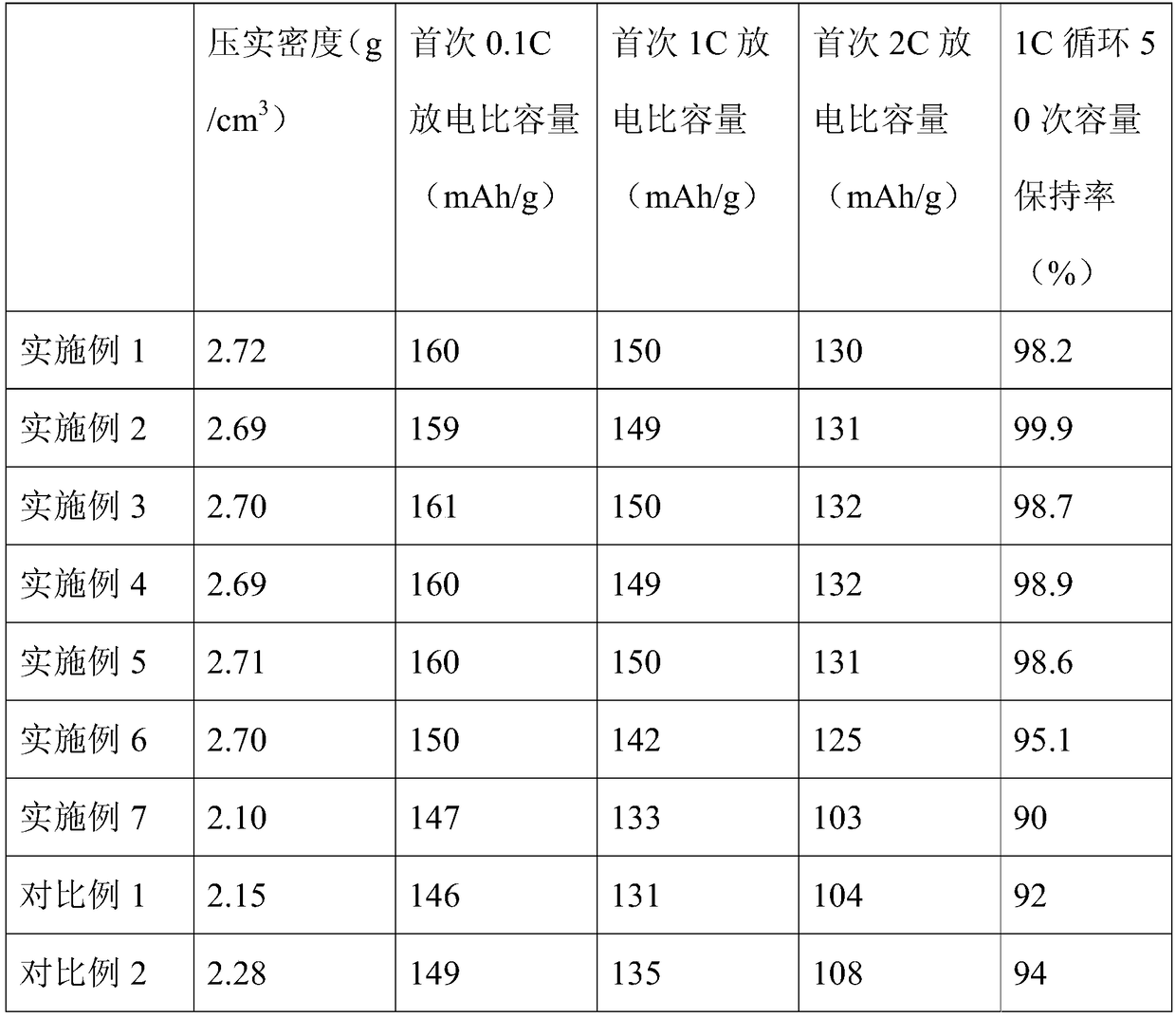

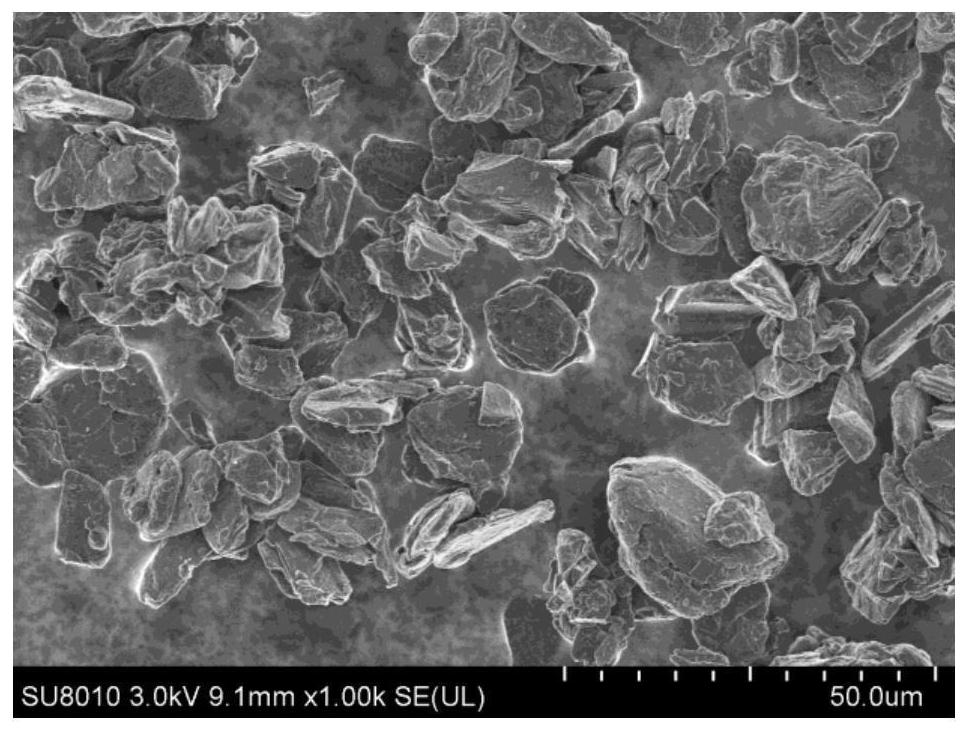

A lithium iron phosphate with high compact density and a preparation method thereof

ActiveCN109192948AIncrease compaction densityReduce porosityCell electrodesSecondary cellsLithium iron phosphateThree stage

The invention provides a lithium iron phosphate with high compact density and a preparation method thereof. The lithium iron phosphate positive electrode material comprise large particles of lithium iron phosphate and small particle of lithium iron phosphate, wherein that small particles of lithium iron phosphate are filled in the voids between the large particle of lithium iron phosphate, and theshape of the small particles of lithium iron phosphate comprises a spherical shape. A method for prepare that lithium iron phosphate precursor comprises sinter the lithium iron phosphate precursor ina protective gas atmosphere, wherein the sintering is three-stage sintering, the sintering temperature of the three-stage sintering is sequentially increased, and aft the three-stage sintering is finished, the lithium iron phosphate positive electrode material is obtained; Wherein the shape of the lithium iron phosphate precursor comprises a spherical shape. The compaction density of the lithiumiron phosphate with high compaction density provided by the invention can reach 2.7 g / cm3, the electrochemical performance is excellent, the first discharge specific capacity of 1C can reach 150 mAh / g, and the capacity retention rate of 50 cycles of 1C can reach 99.9%.

Owner:SHENZHEN DYNANONIC

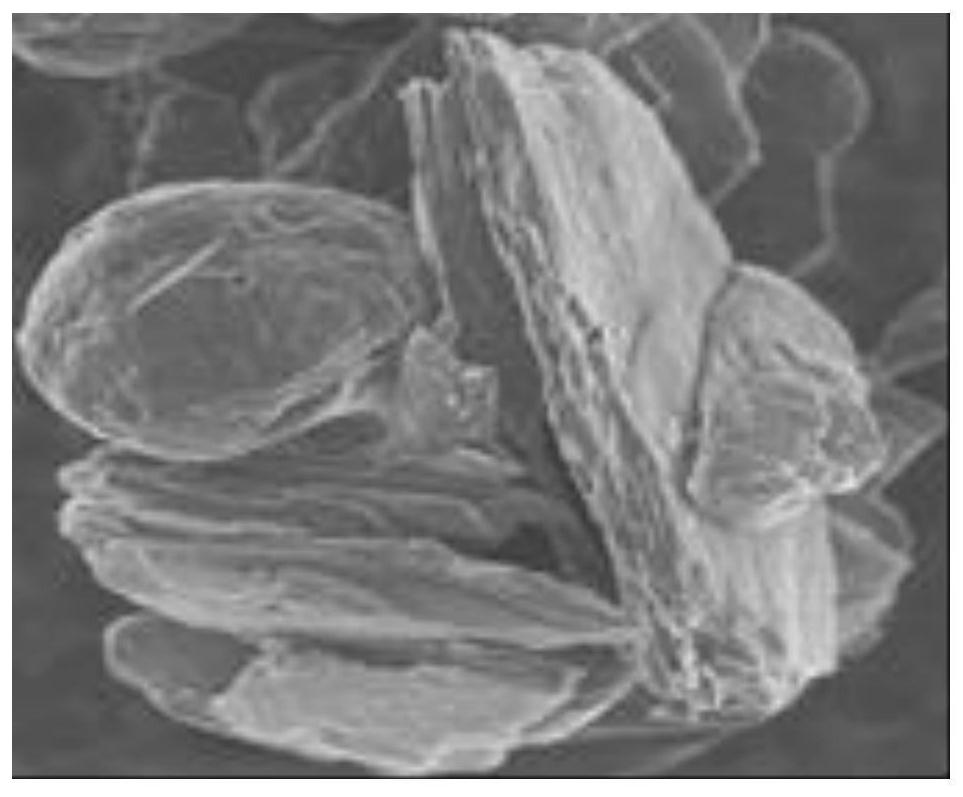

Artificial graphite negative electrode material with gradient structure and preparation and application thereof

ActiveCN109585803AExcellent rate performanceImprove cycle performanceMaterial nanotechnologyCell electrodesPorosityHigh rate

The invention belongs to the technical field of a lithium ion battery negative electrode material, and particularly discloses an artificial graphite negative electrode material with a gradient structure. The artificial graphite negative electrode material is a carbon material with a core / shell structure, and the graphitization degree and the porosity of the carbon material are in gradient distribution in a radial direction; and from core to shell, the graphitization degree is gradually reduced, and the porosity is gradually reduced. The invention also provides the artificial graphite negativeelectrode material with the gradient structure. By pore-forming, catalyst carrying and two-segment electro-forging on anthracite, the negative electrode material with the graphitized and porosity dual-gradient structure can be prepared; and the material with the gradient structure is compatible with the advantages of high reversible capacity, high rate performance, long cycle lifetime and the like.

Owner:湖南宸宇富基新能源科技有限公司

High-capacity, high-compaction and quick-charge composite graphite negative electrode material and preparation method thereof

InactiveCN111646466AReduce bloatExpansion constraintsGraphiteSecondary cellsElectrode materialLithium battery

The invention relates to the field of lithium batteries, and especially relates to a high-capacity, high-compaction and quick-charge composite graphite negative electrode material. Artificial graphiteand natural graphite single particles are tightly anchored together through amorphous carbon to form a composite graphite secondary particle structure, and a layer of amorphous carbon is applied between the artificial graphite and the natural graphite particles and on the surface of each component particle in a coating manner. The defect that a graphite negative electrode material developed in the prior art cannot give consideration to high capacity, high compaction or quick charging performance is overcome, the advantages of the natural graphite are utilized to ensure the high capacity and high compaction performance of the material, meanwhile, the natural graphite is compounded with the artificial graphite with partial isotropy to buffer the expansion of the natural graphite, and the layer of amorphous carbon is formed between the artificial graphite and the natural graphite particles and on the surface of each single particle, so that the migration rate of lithium ions between thesurface of the graphite and different graphite is increased while the surface defects of the natural graphite are improved.

Owner:WANXIANG 123 CO LTD

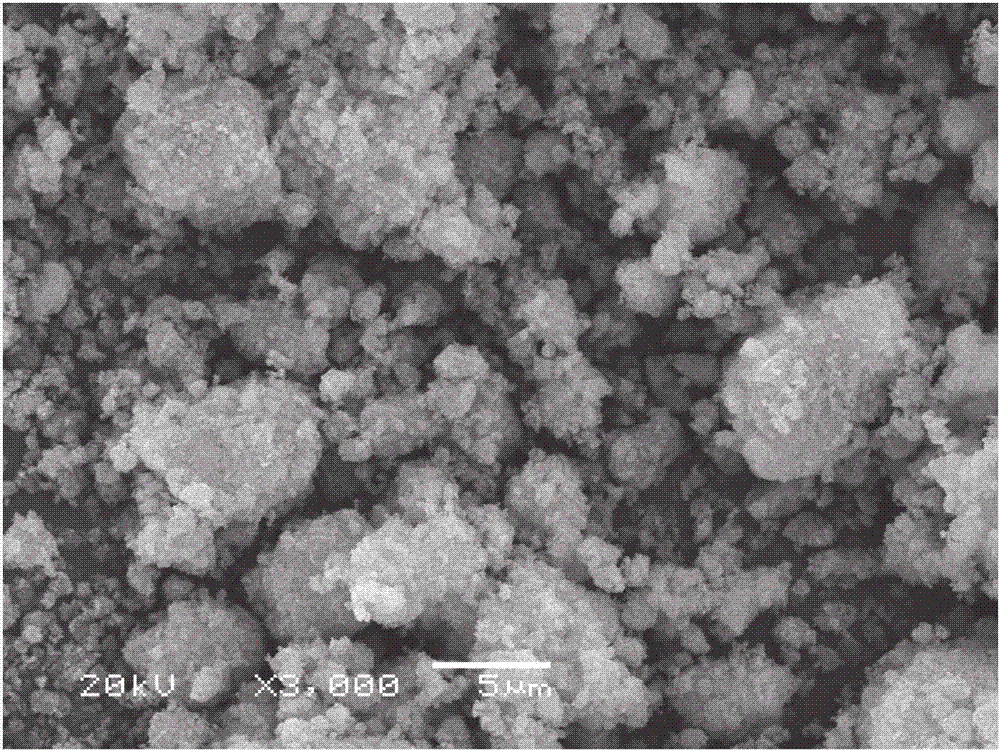

Method for preparing three-dimensional hole carbon/nano NiO composite

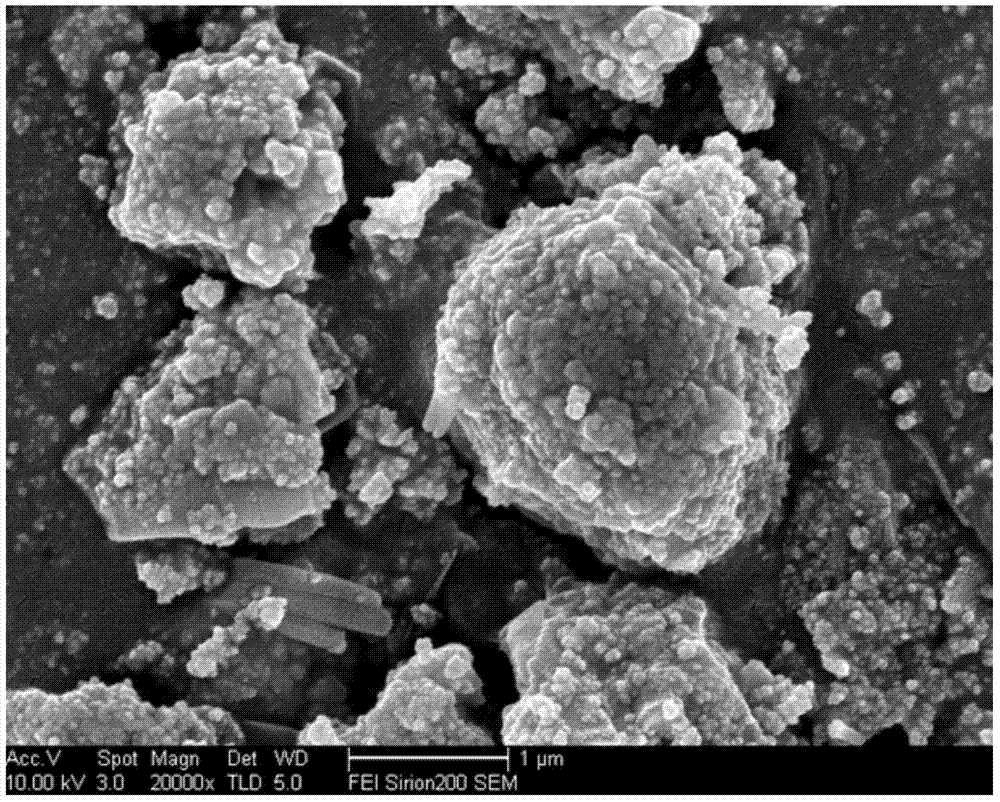

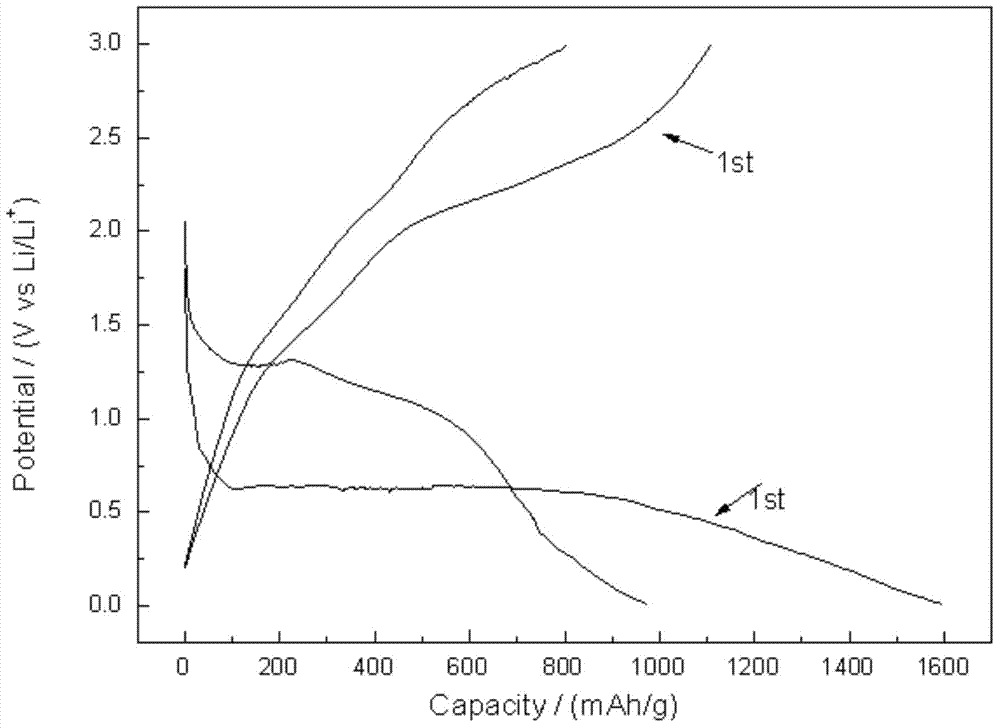

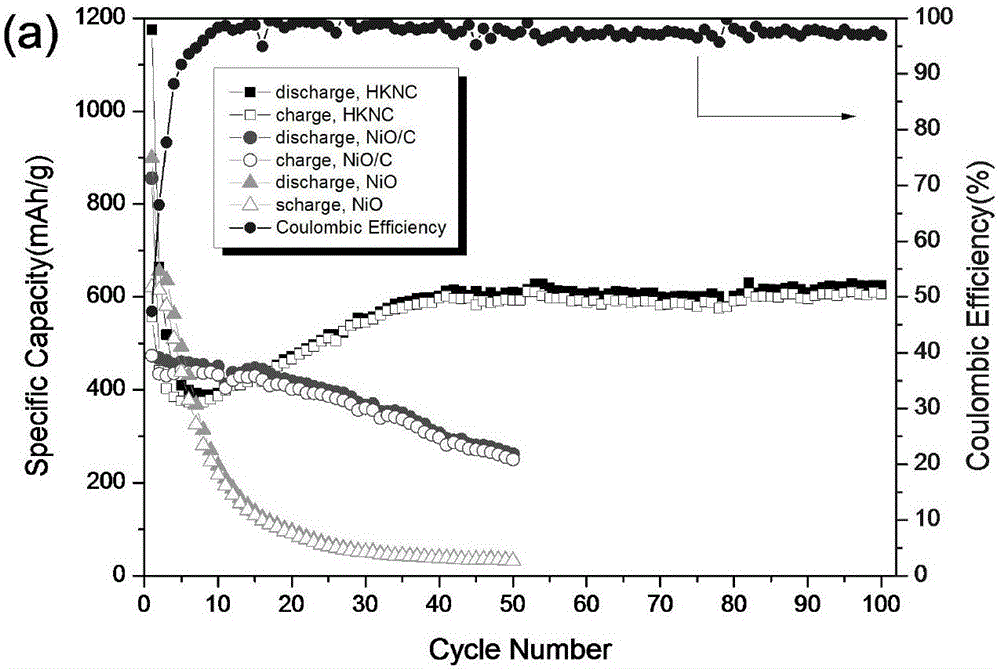

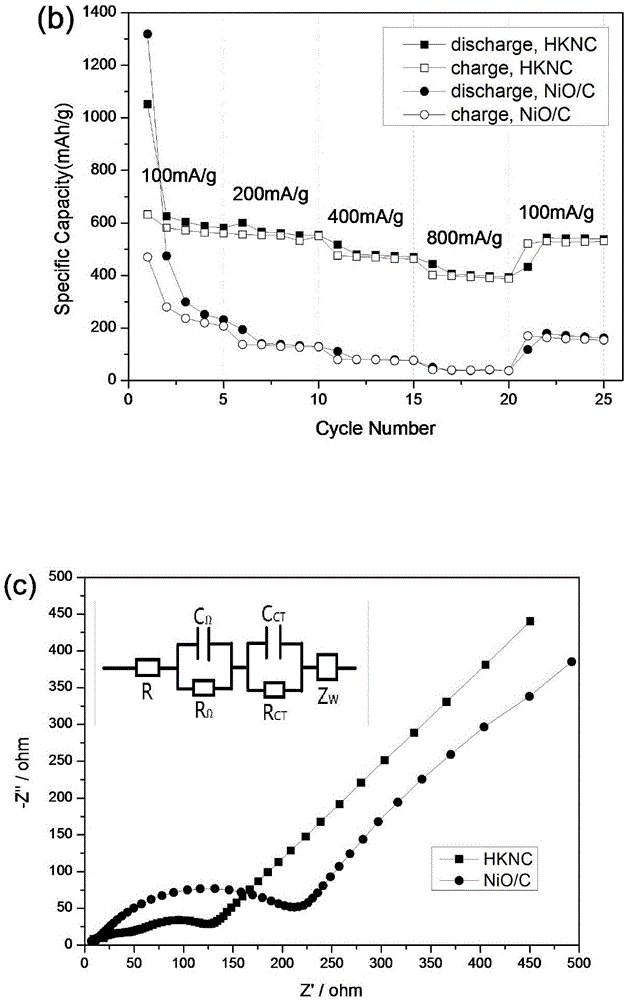

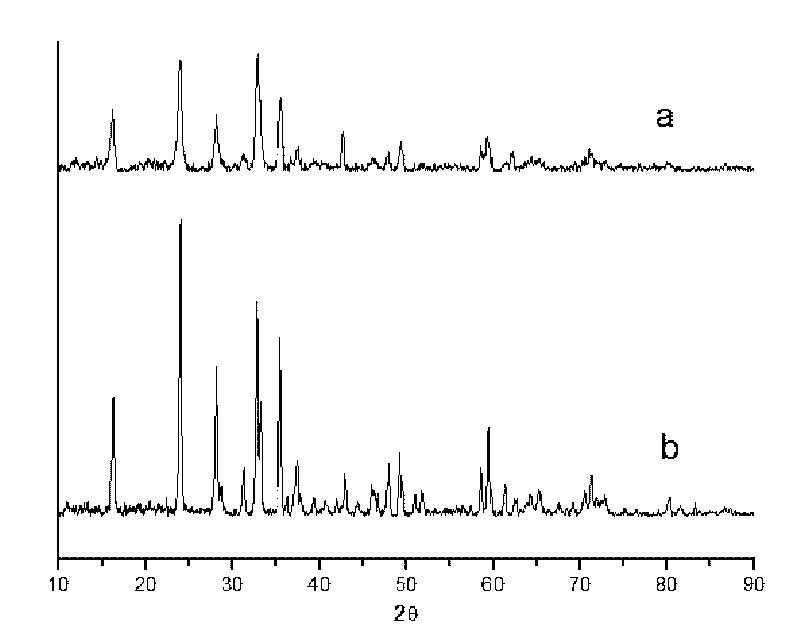

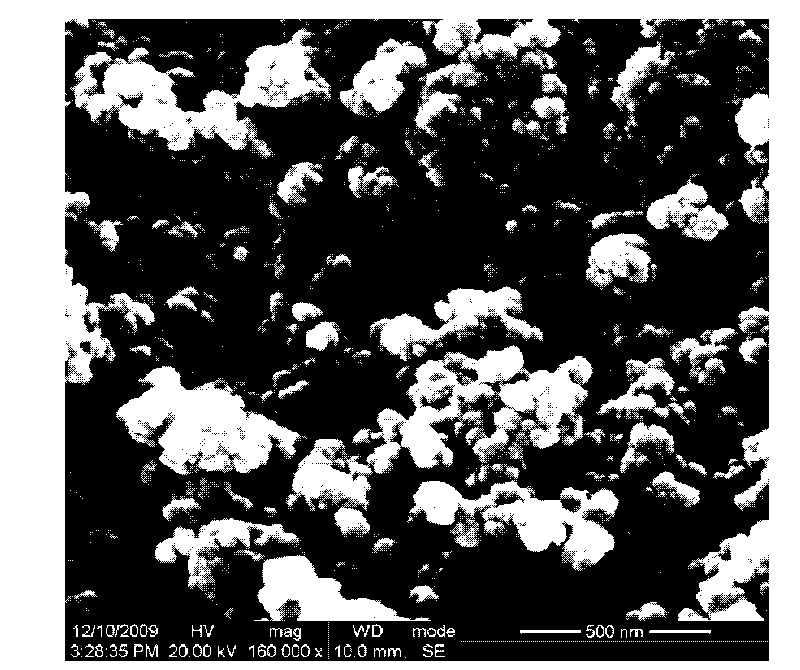

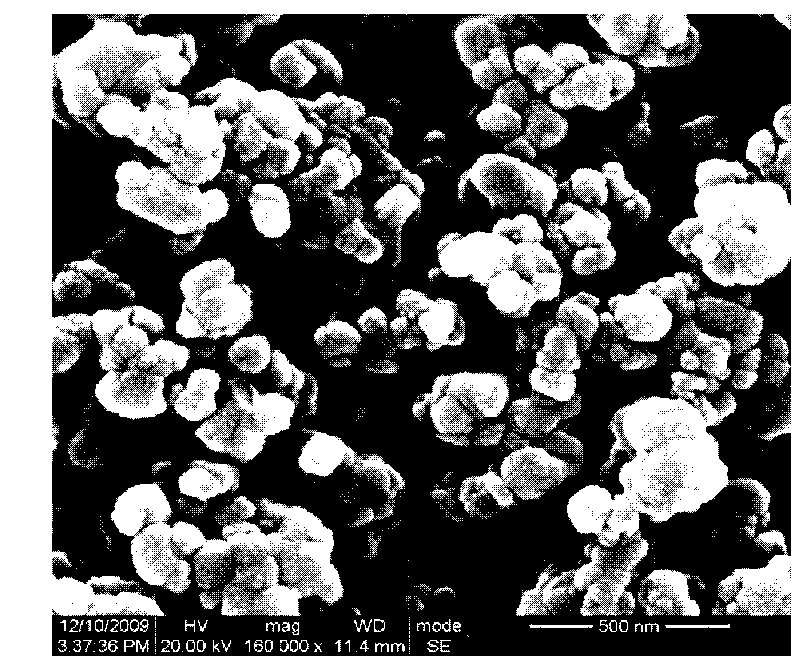

InactiveCN103490047AGood lithium ion extraction performanceGood electrical conductivityMaterial nanotechnologyCell electrodesElectrochemistryLarge capacity

The invention relates to a method for preparing a three-dimensional hole carbon / nano NiO composite. The method is used for preparing a high capacity nano NiO composite to improve the electrochemical performance of a NiO electrode. The composite is formed through cladding the high capacity nano NiO with a stably structured carbon material with high conductivity, appropriate three-dimensional holes are formed around the nano NiO particles, so that the NiO expands and shrinks within a surrounding small zone during the electrode reaction, and the electrode structure is stable.

Owner:SHANDONG UNIV OF TECH

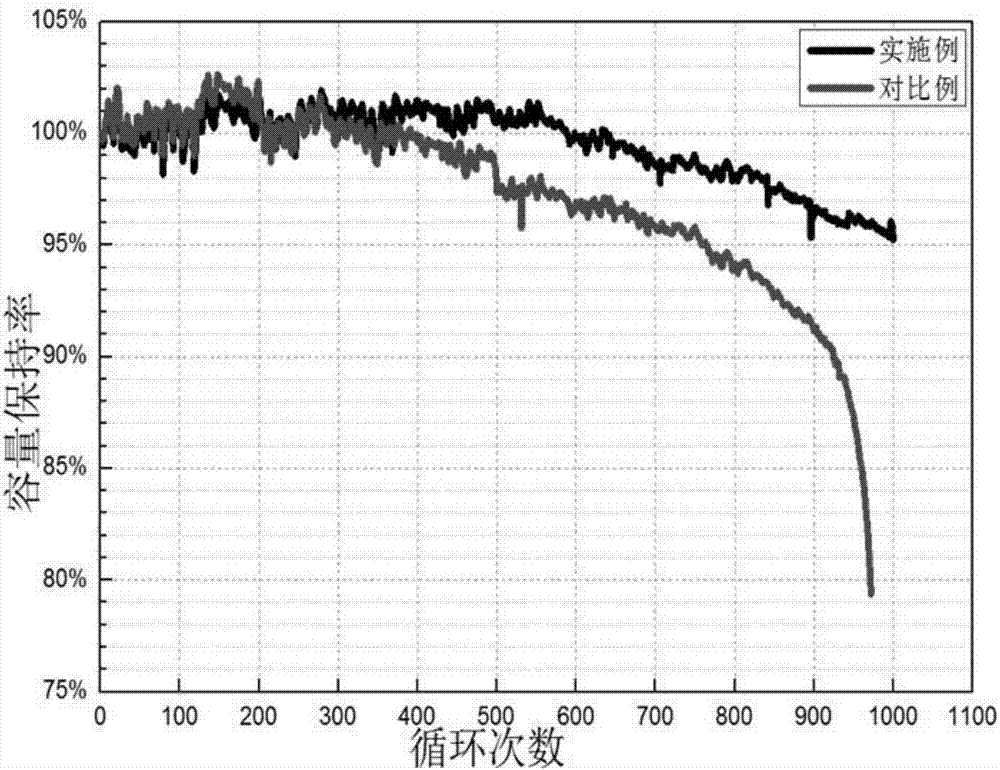

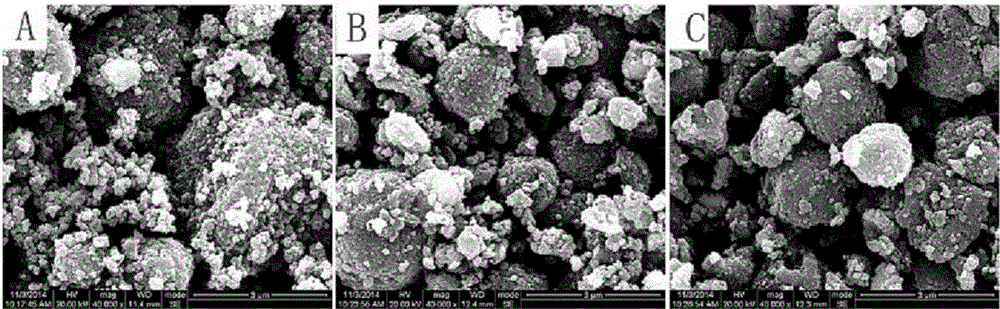

Core-shell NiO/C porous composite lithium ion battery negative electrode material

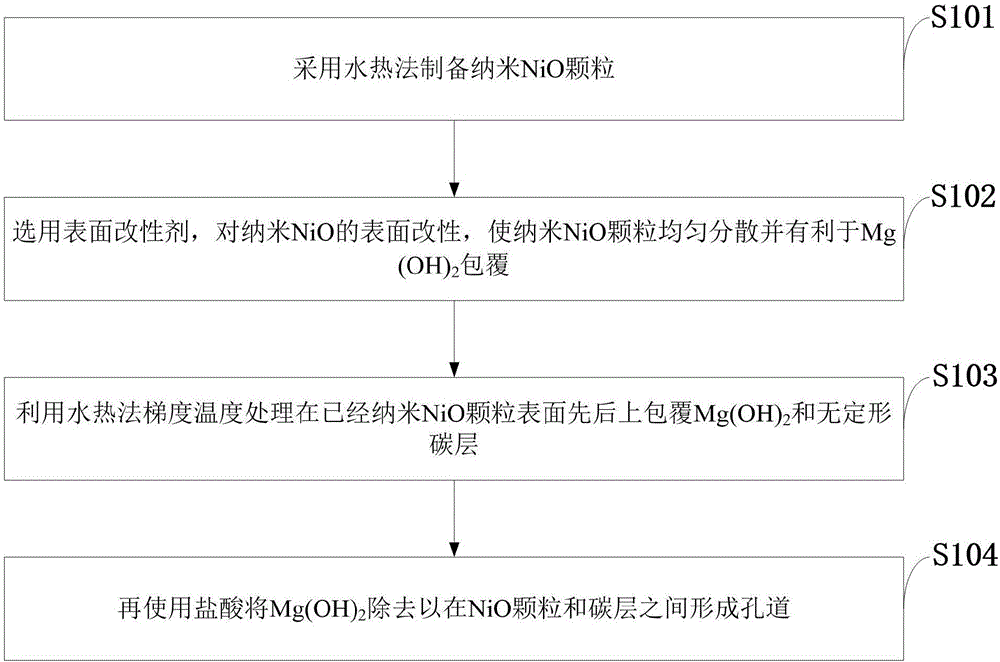

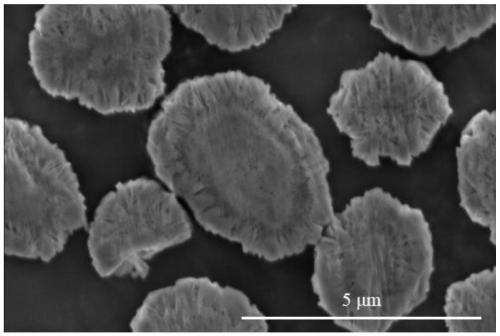

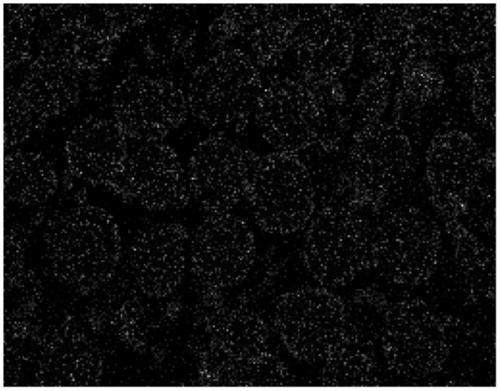

InactiveCN106711419AIncrease capacityEvenly dispersedCell electrodesCarbon layerSurface modification

The invention discloses a core-shell NiO / C porous composite lithium ion battery negative electrode material. The preparation method comprises the following steps: preparing nano NiO particles; carrying out surface modification on nano NiO by using a surface modifier so that the nano NiO particles are uniformly dispersed and beneficial to Mg(OH)2 coating; carrying out gradient temperature treatment by a hydrothermal process to sequentially coat Mg(OH)2 and an amorphous carbon layer on the prepared nano NiO particle surface; and removing the Mg(OH)2 by using hydrochloric acid to form ducts between the NiO particles and carbon layer. The preparation method enhances the electric conductivity of the composite material and ensures the structure stability of the material. In the recycling process, lithium ions are disembedded to prevent NiO from generating powdering aggregation; and elastic expansion space is reserved in the material, thereby avoiding breaking the base material during NiO expansion and enhancing the cycle life. The prepared material provides effective channels for embedding / disembedding of lithium ions, so that the lithium storage characteristic of the NiO material is fully displayed.

Owner:SHANDONG UNIV OF TECH

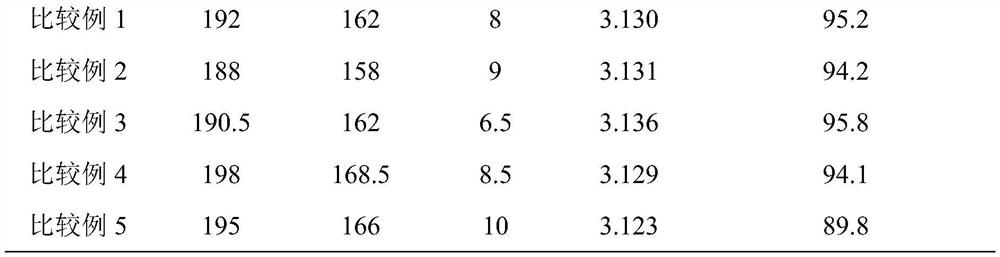

Lithium ferrosilicon silicate/carbon composite cathode material and preparation method thereof

InactiveCN101764227AHigh charge and discharge capacityPromote circulationCell electrodesCarbon compositesHigh rate

The invention relates to a lithium ferrosilicon silicate / carbon composite cathode material and a preparation method thereof, belonging to the technical field of lithium-ion battery manufacture. The technical problem to be solved by the invention is to provide a novel path to prepare the ferrosilicon silicate / carbon composite cathode material with high rate performance. The ferrosilicon silicate / carbon composite cathode material of the invention consists of 20-120nm particles which are formed by evenly coating carbon obtained by heated and carbonized asphalt on the surface of the lithium ferrosilicon silicate, wherein the carbon accounts for 2-30% of the lithium ferrosilicon silicate / thecarbon composite cathode material. In the invention, asphalt is utilized to as a carbon source for doping treatment to prepare the lithium ferrosilicon silicate / the carbon composite cathode material for lithium-ion batteries, and the cathode materialhas higher charging-discharging capacity and good circulation property.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

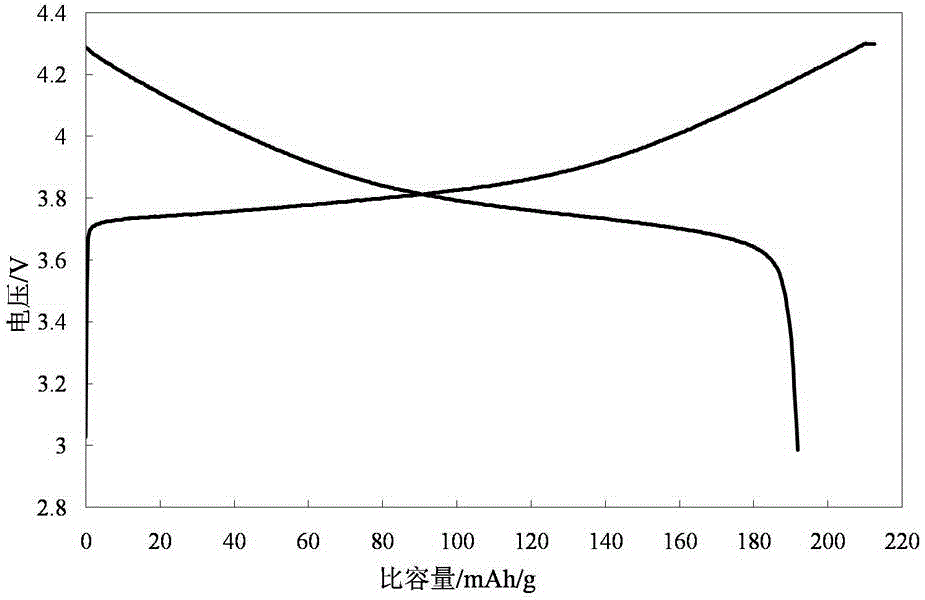

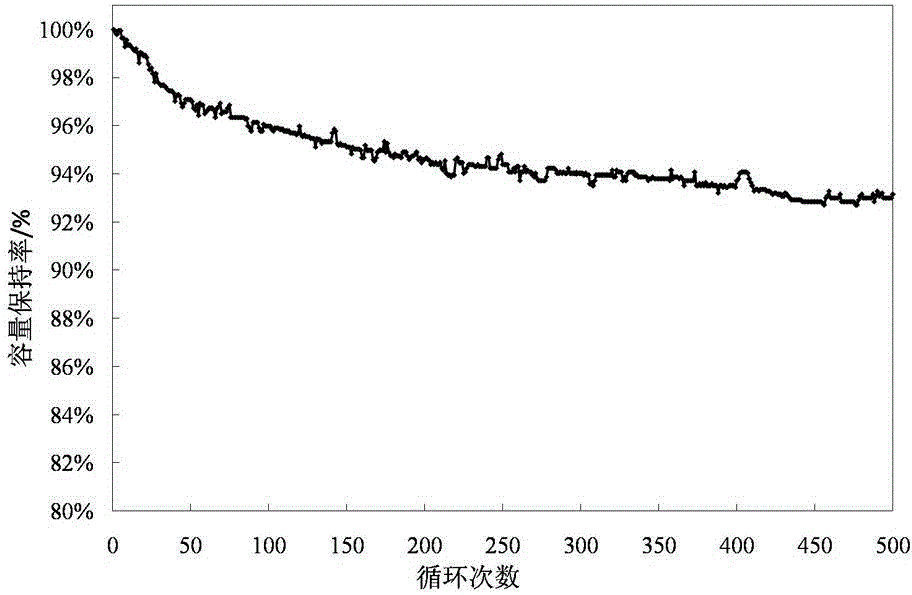

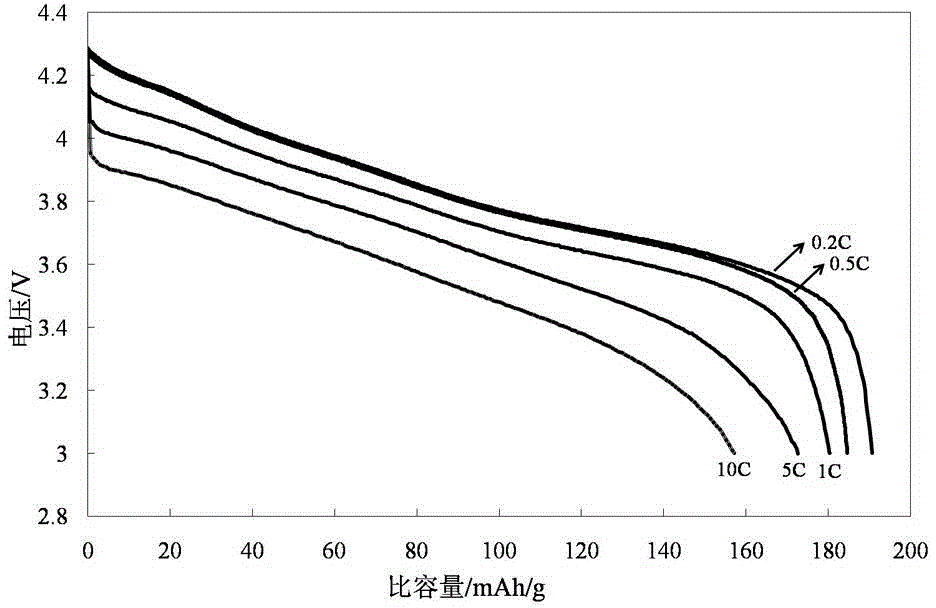

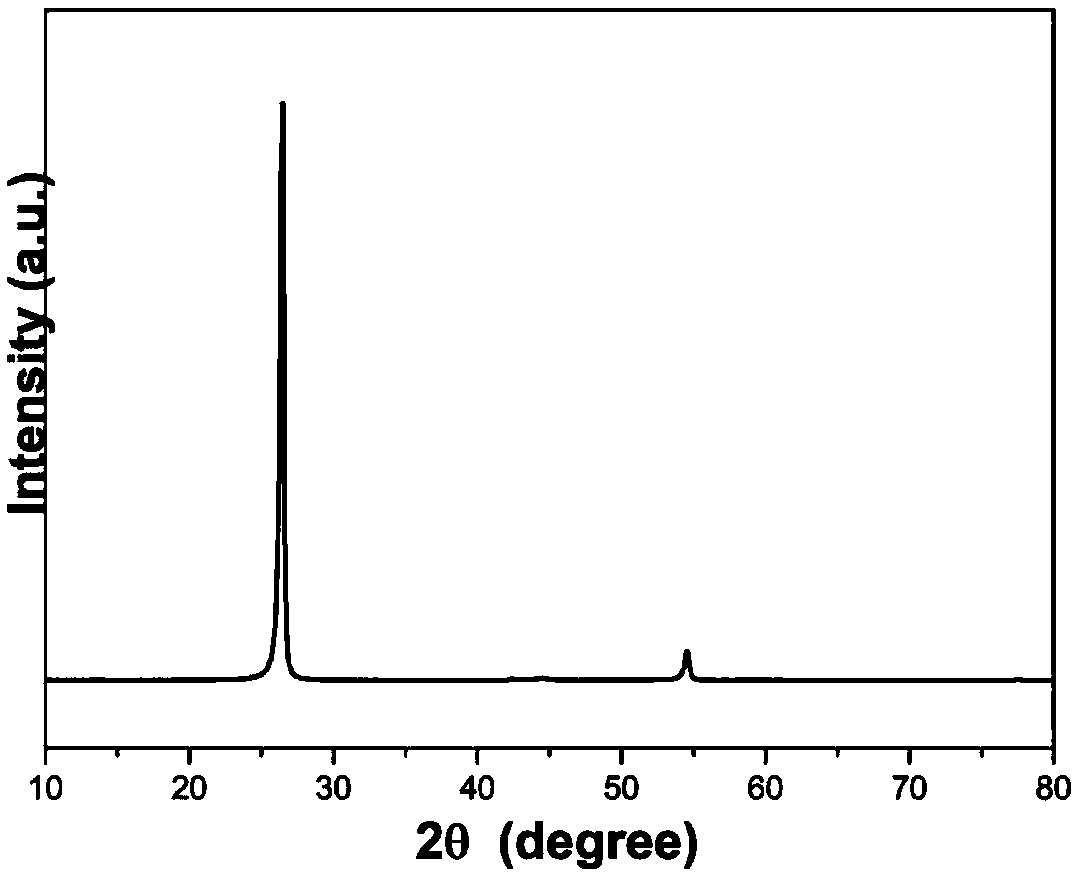

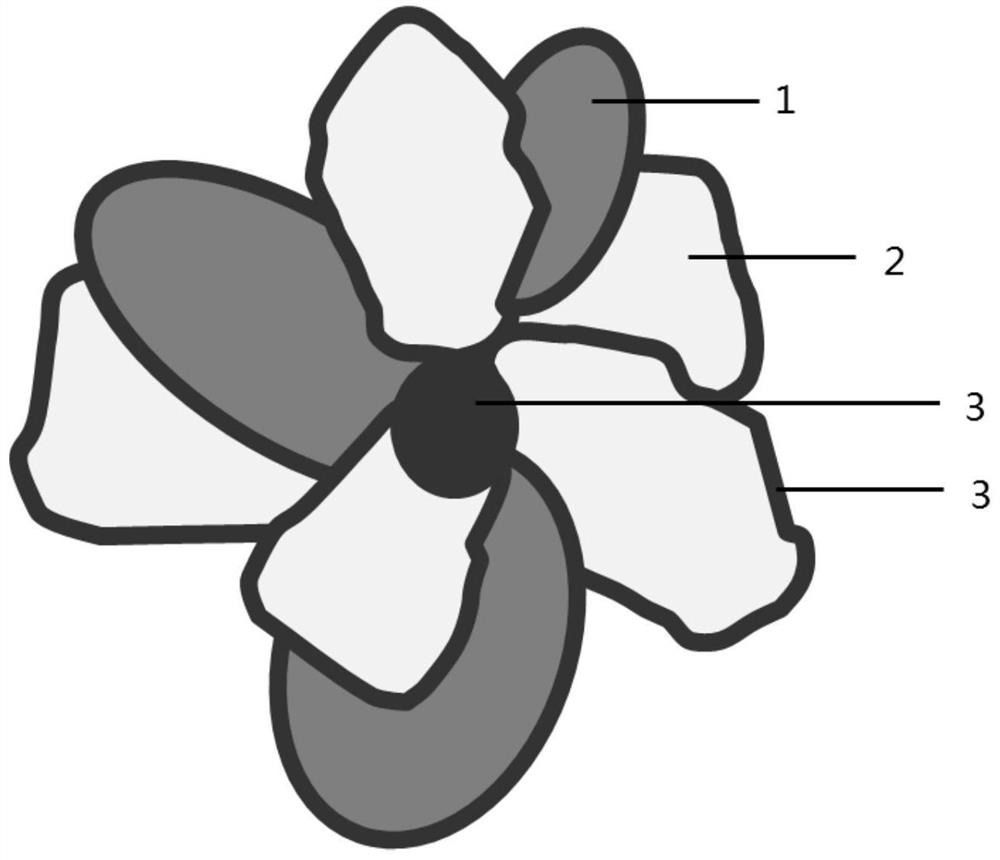

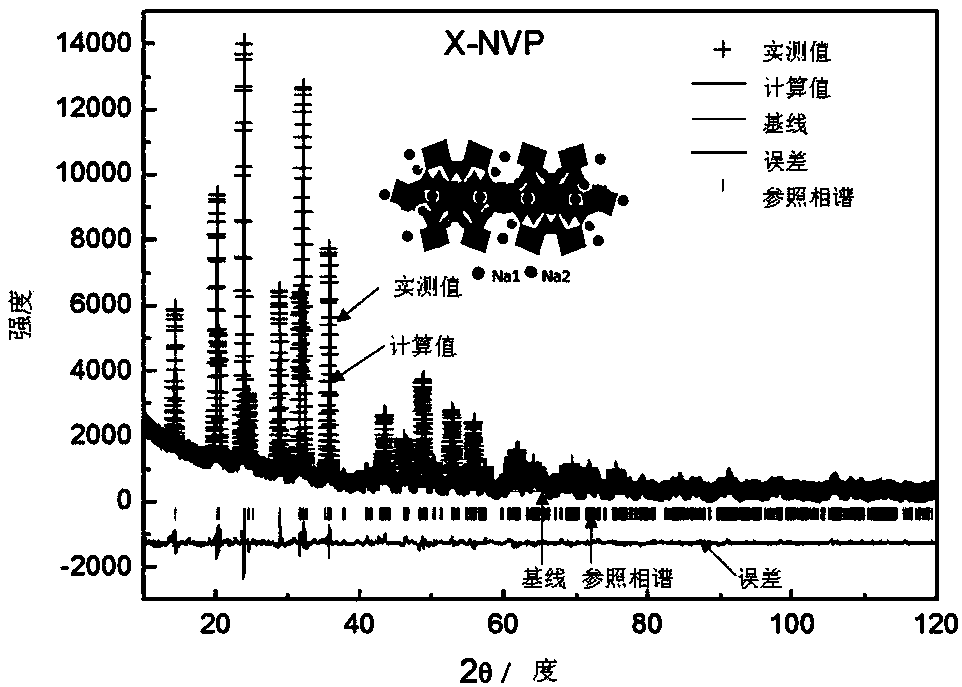

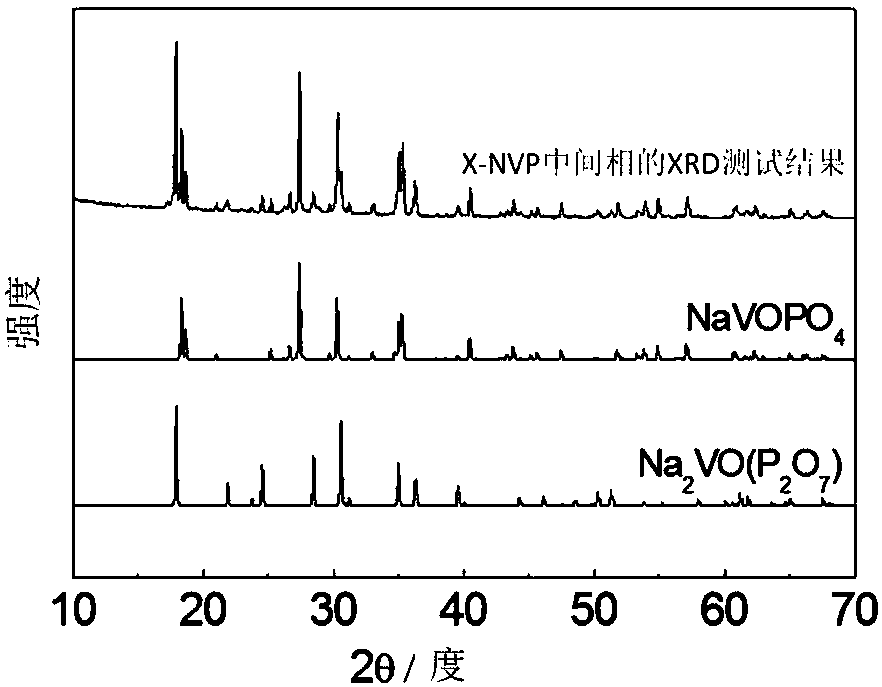

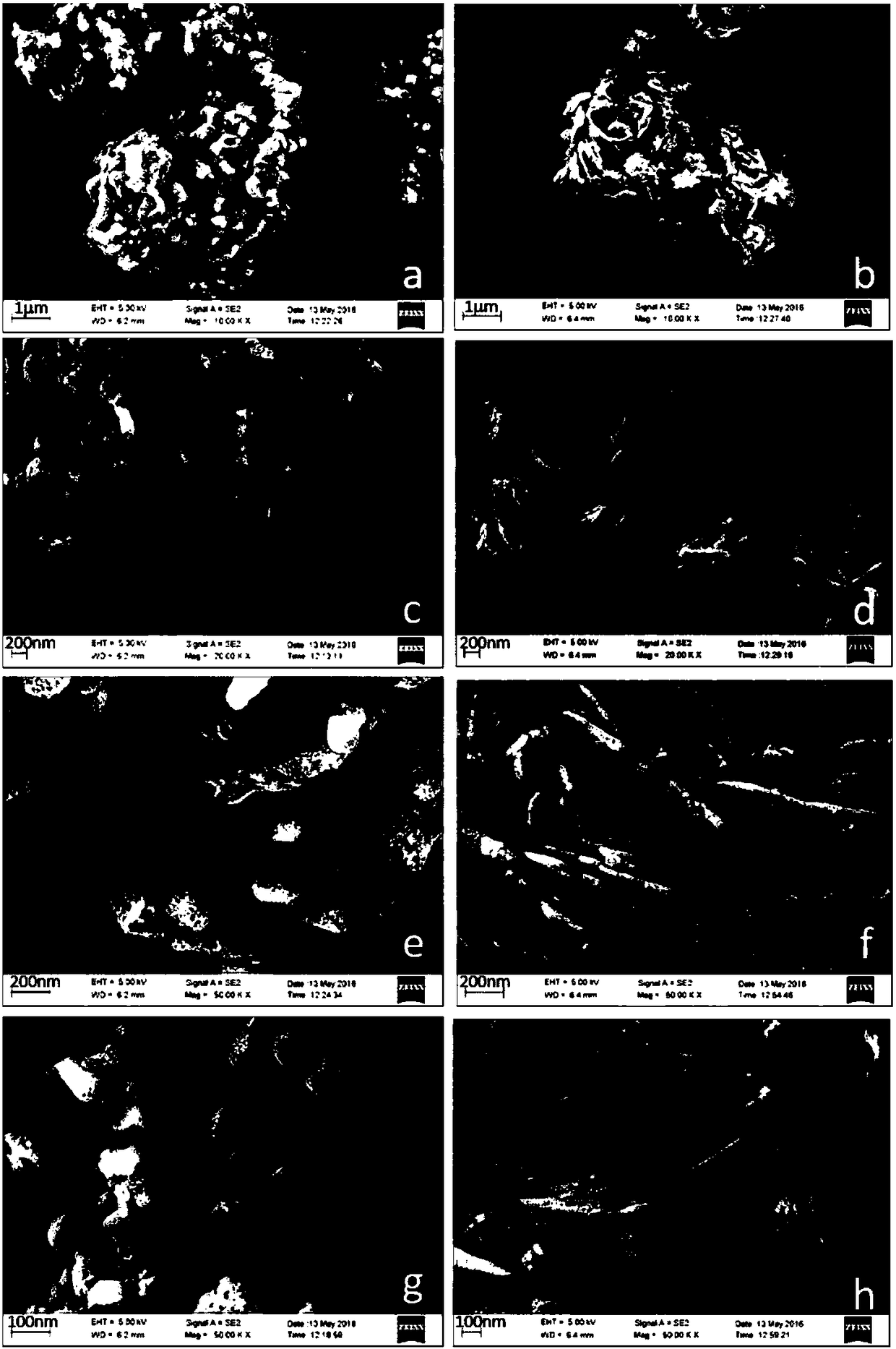

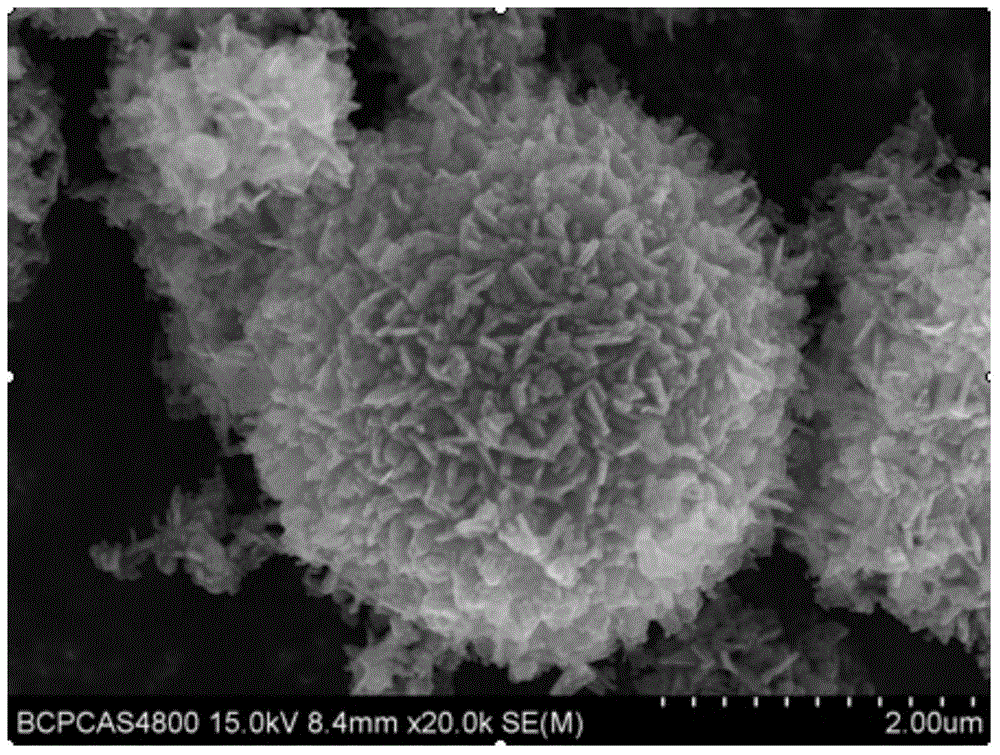

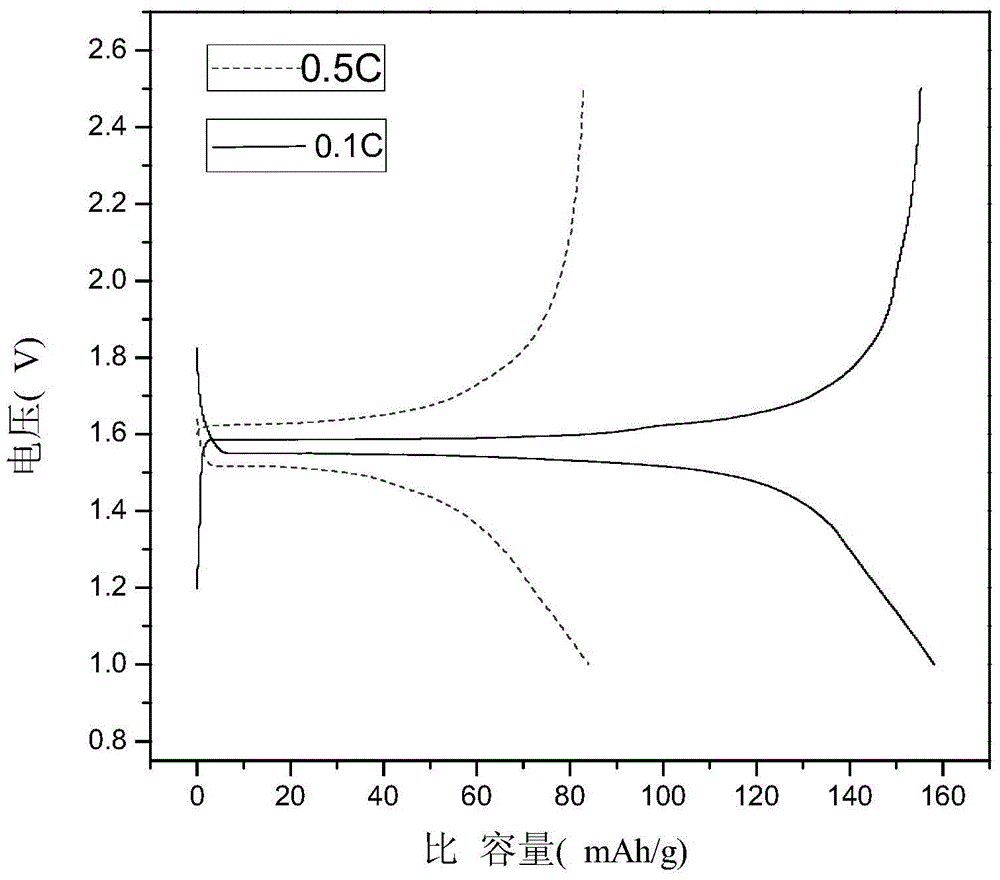

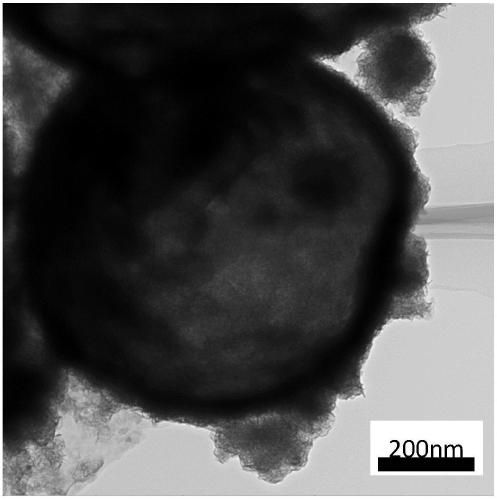

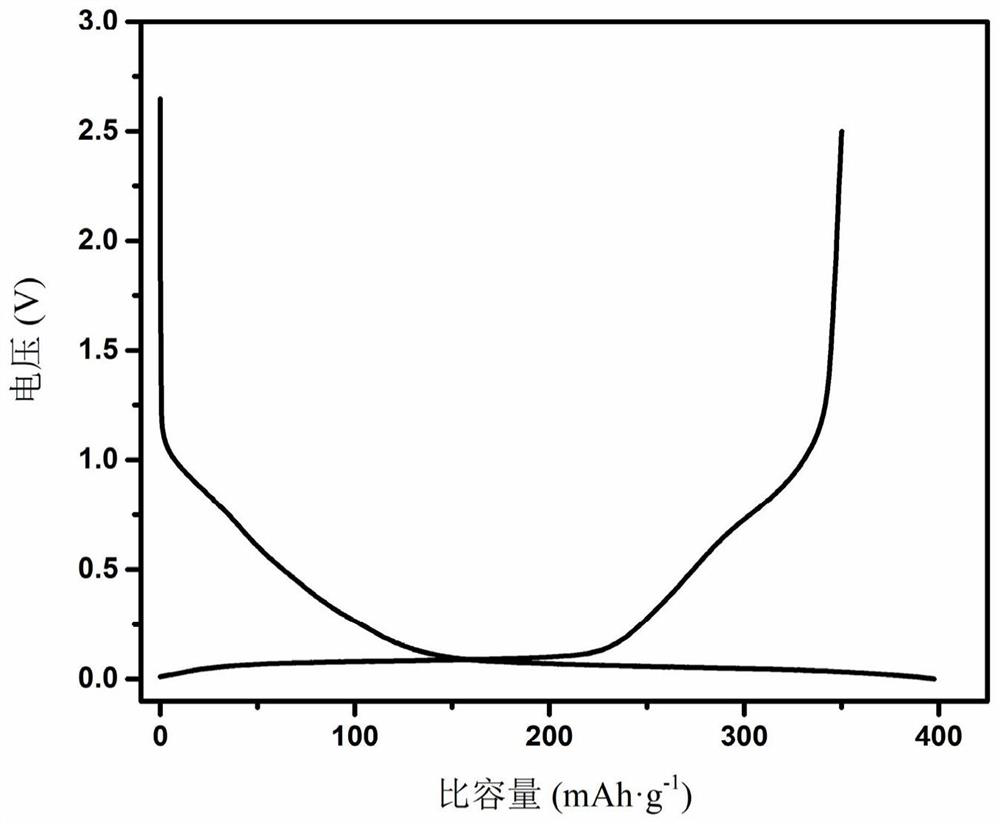

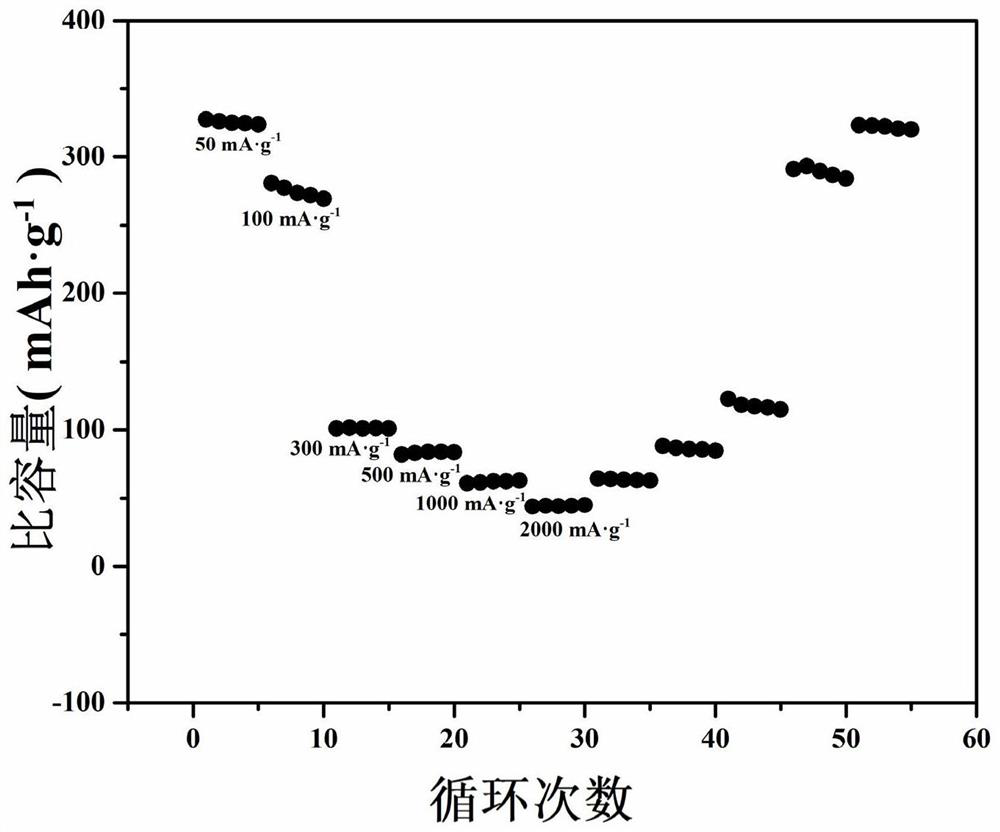

Na3V2(PO4)3 cathode material for sodium-ion battery as well as preparation and application of cathode material

The invention relates to a Na3V2(PO4)3 cathode material for a sodium-ion battery as well as preparation and application of the cathode material. An intermediate phase with laminar morphology and highdegree of crystallinity is synthesized from cheap raw materials to serve as a template, and formation of a final product, namely, nanoscale Na3V2(PO4)3 with laminar morphology, is controlled. According to the preparation method, the raw material cost is low, the preparation process is simple and easy, Na3V2(PO4)3 synthesized from the intermediate phase as the template is of a flower-like structurestacked in a nanosheet shape, and shows excellent rate performance and excellent cycling stability when used as the cathode material to be applied to the sodium-ion battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

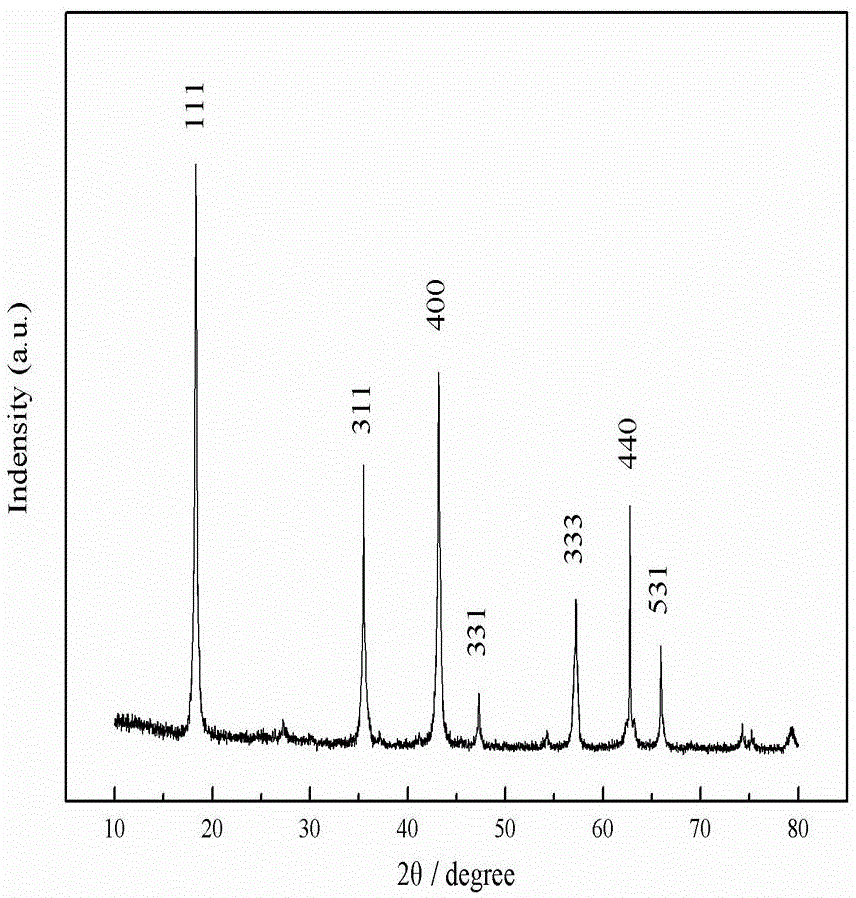

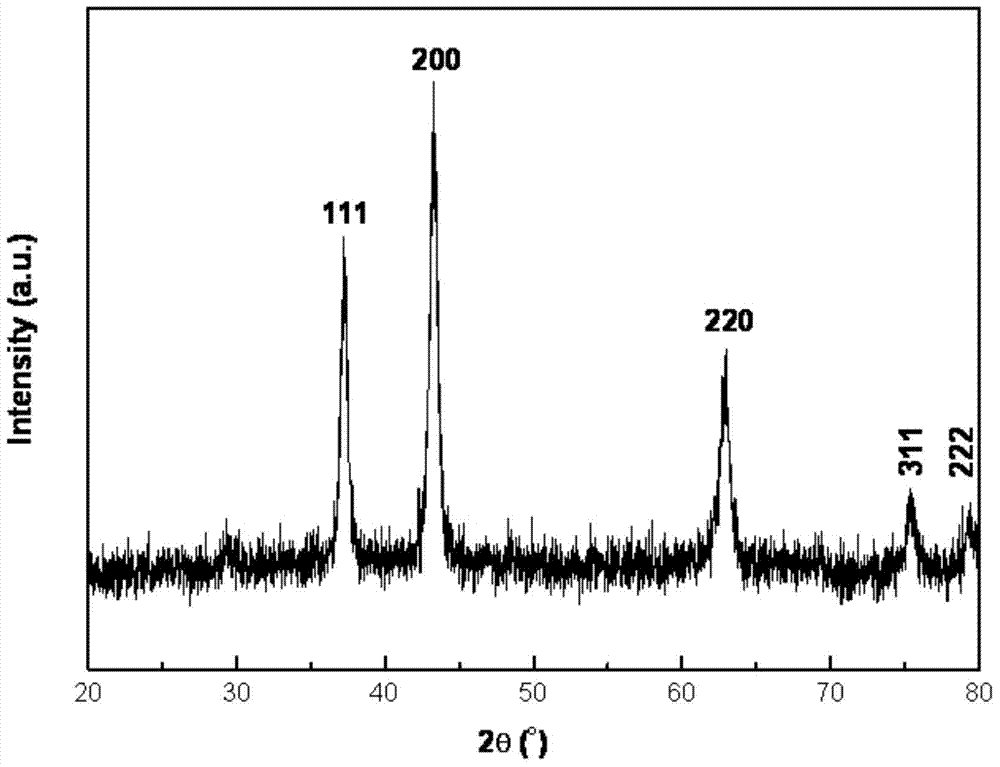

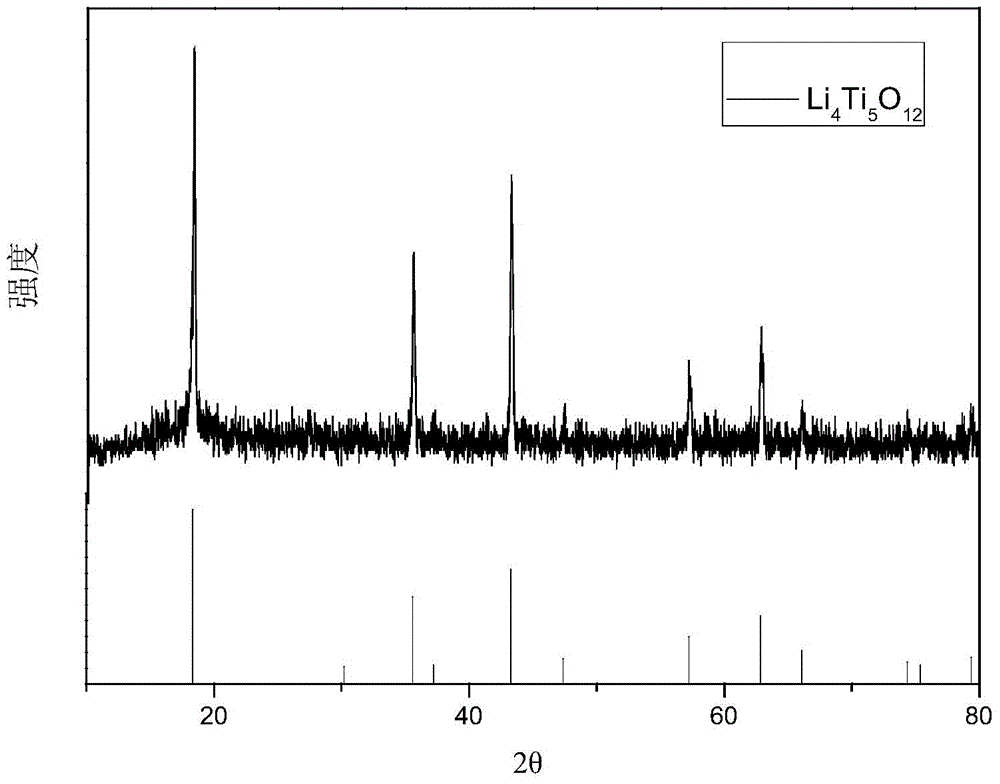

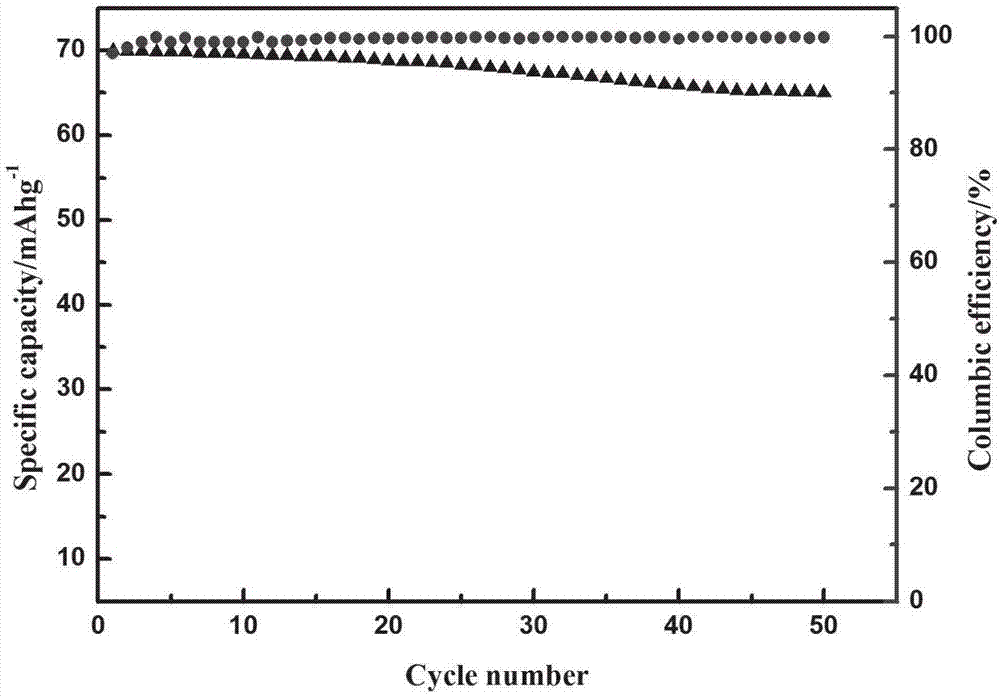

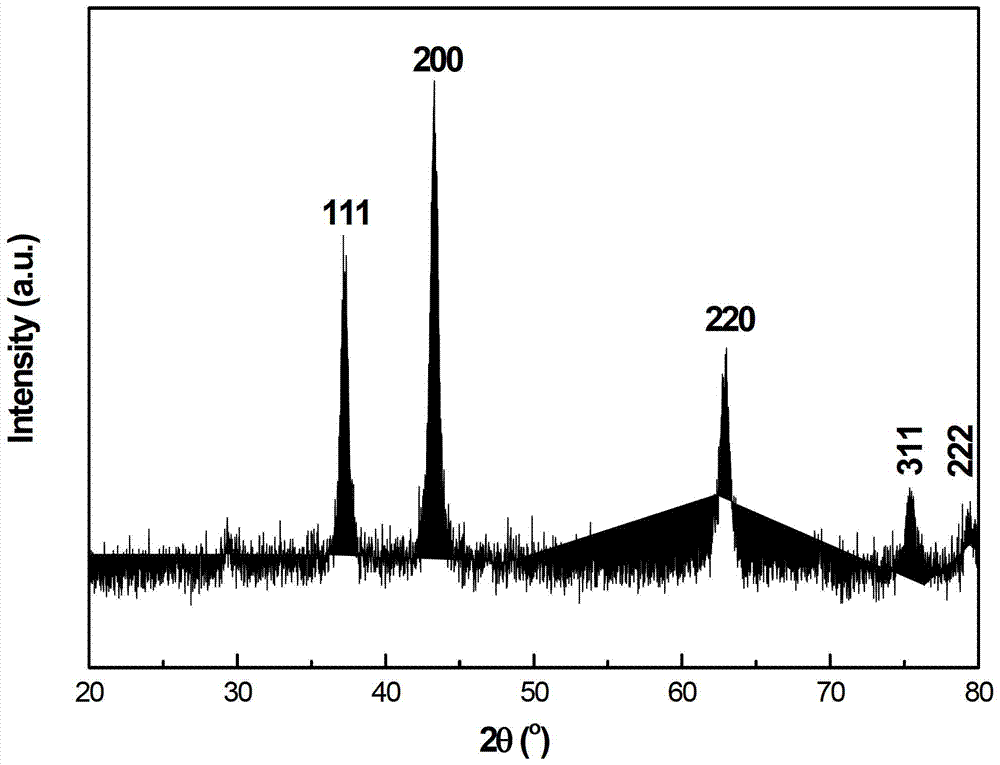

Hydrothermal synthesis preparation method for spherical Li4Ti5O12

InactiveCN104091939ALow costNo pollution in the processAlkali titanatesCell electrodesChemistryMagnetic stirrer

The invention provides a hydrothermal synthesis preparation method for spherical Li4Ti5O12, belonging to the technical field of anode materials of lithium ion batteries. The hydrothermal synthesis preparation method comprises the following steps of sequentially adding absolute ethyl alcohol, HDA, KCL and TIP into a beaker under the stirring action of a magnetic stirrer; standing for 18h after uniformly stirring the mixed solution, then, centrifuging and washing; drying at the temperature of 60 DEG C for 12h to obtain purified TiO2 powder; next, adding LiOH.H2O powder and TiO2 powder into a mixed solution of absolute ethyl alcohol and deionized water, and carrying out hydrothermal reaction at the temperature of 180 DEG C for 12h after uniformly stirring; and centrifuging a reaction product, washing, and then, drying at the temperature of 60 DEG C for 12h to obtain purified spherical Li4Ti5O12 powder. The hydrothermal synthesis preparation method is simple in process and high in repeatability. The material has favorable electrochemical performance so as to be suitable for use as an anode material of a lithium ion battery.

Owner:BEIJING UNIV OF TECH

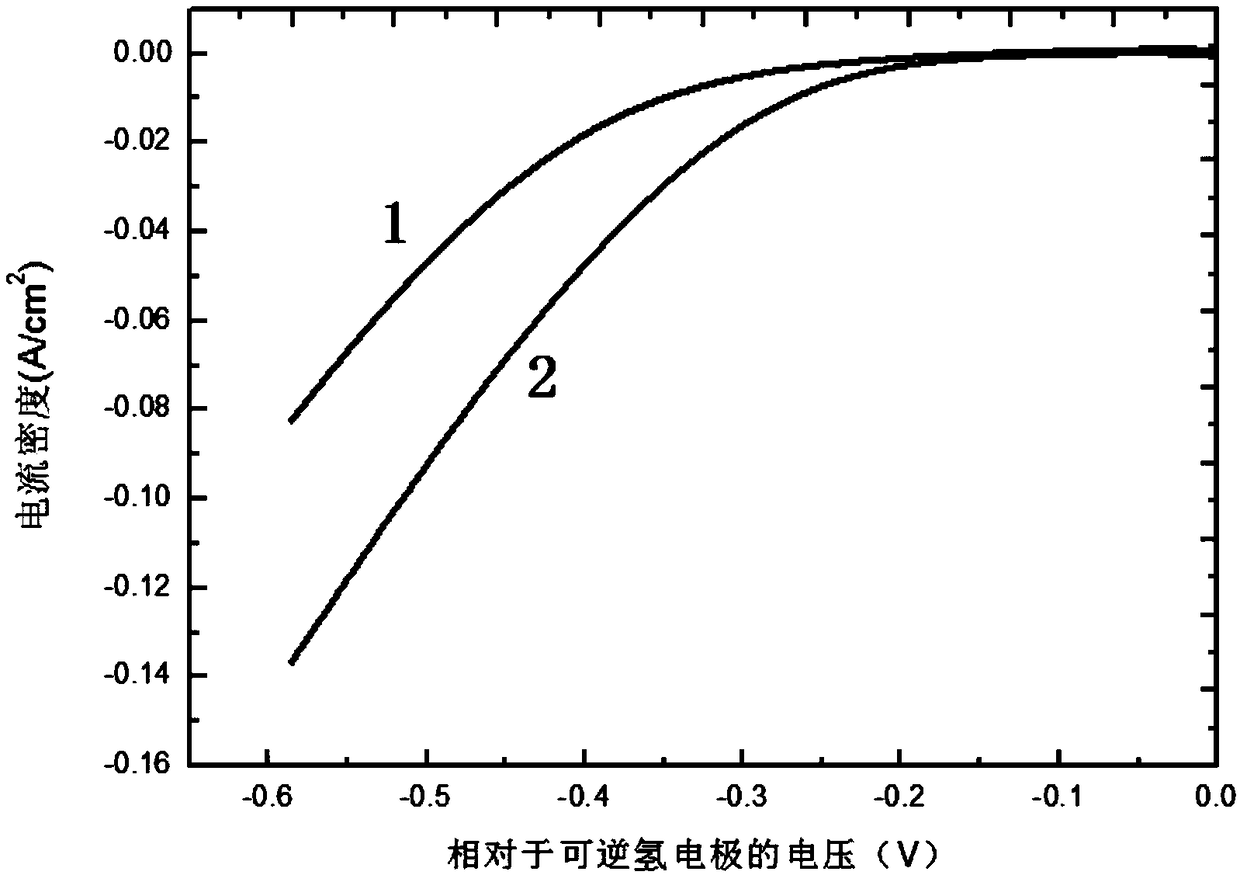

Preparation method for molybdenum selenide two-dimensional layer titanium carbide composite material

ActiveCN109402662AGood electrocatalytic hydrolysis performance for hydrogen productionImprove intrinsic conductivityCell electrodesElectrodesSulfideTitanium carbide

The invention discloses a preparation method for a molybdenum selenide two-dimensional layer titanium carbide composite material, and relates to preparation for a metal carbide / sulfide composite material. The problems that existing molybdenum selenide is poorer in electrical conductivity, and the ion mobility is lower are solved. The method comprises the steps that step one, Se powder and hydrazine hydrate are mixed and stirred, and selenium-hydrazine hydrate dispersion liquid is obtained; MXene-Ti3C2 dispersion liquid and cetyl trimethyl ammonium bromide are mixed, sodium molybdate is added,and a cetyl trimethyl ammonium bromide solution is obtained; step three, the selenium-hydrazine hydrate dispersion liquid and the cetyl trimethyl ammonium bromide solution are subjected to the mixingreaction, and a mixed solution is obtained; step four, the mixed solution is washed by deionized water and ethyl alcohol and centrifuged, vacuum drying is conducted, and the MoSe2@Mxene-Ti3C2 composite material is obtained. The method is used for preparation of the molybdenum selenide two-dimensional layer titanium carbide composite material.

Owner:HARBIN INST OF TECH

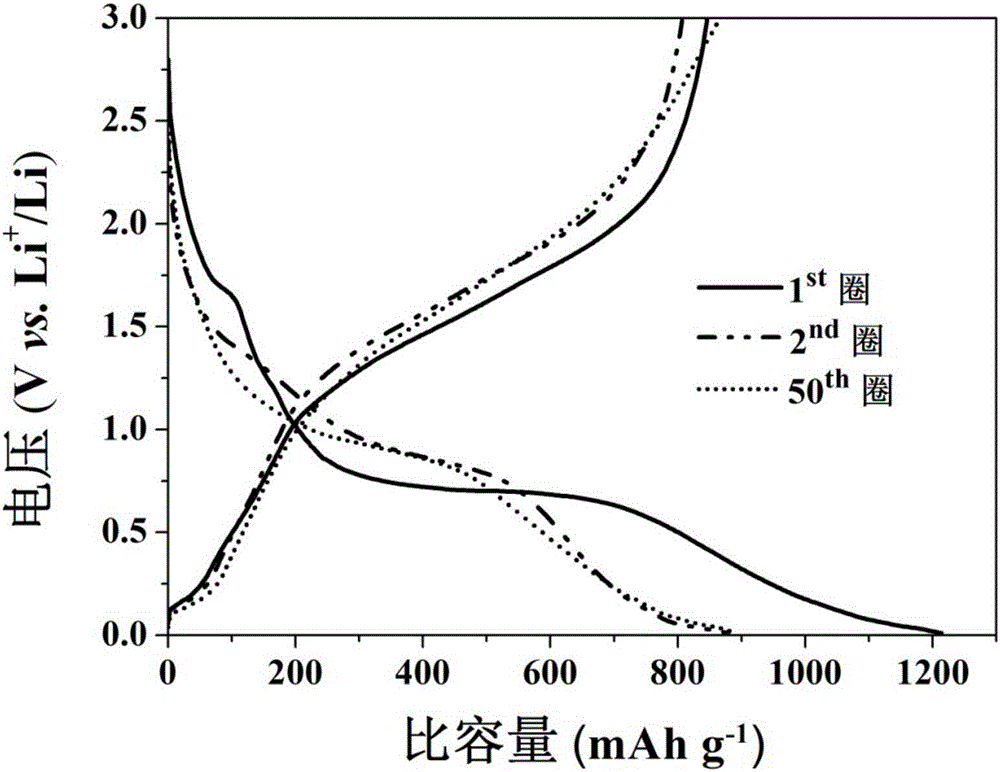

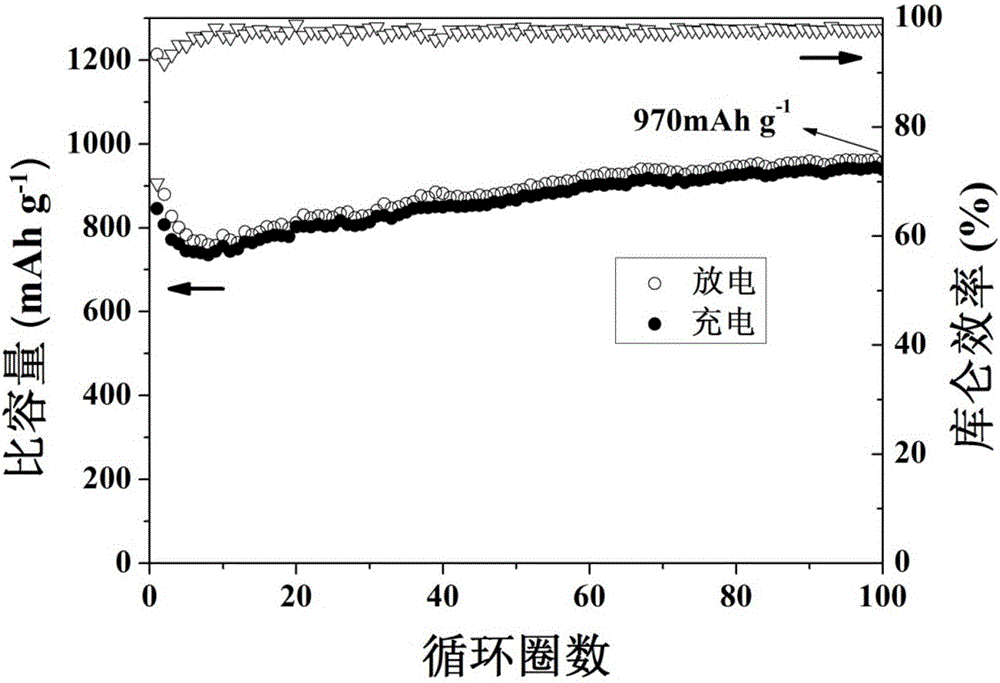

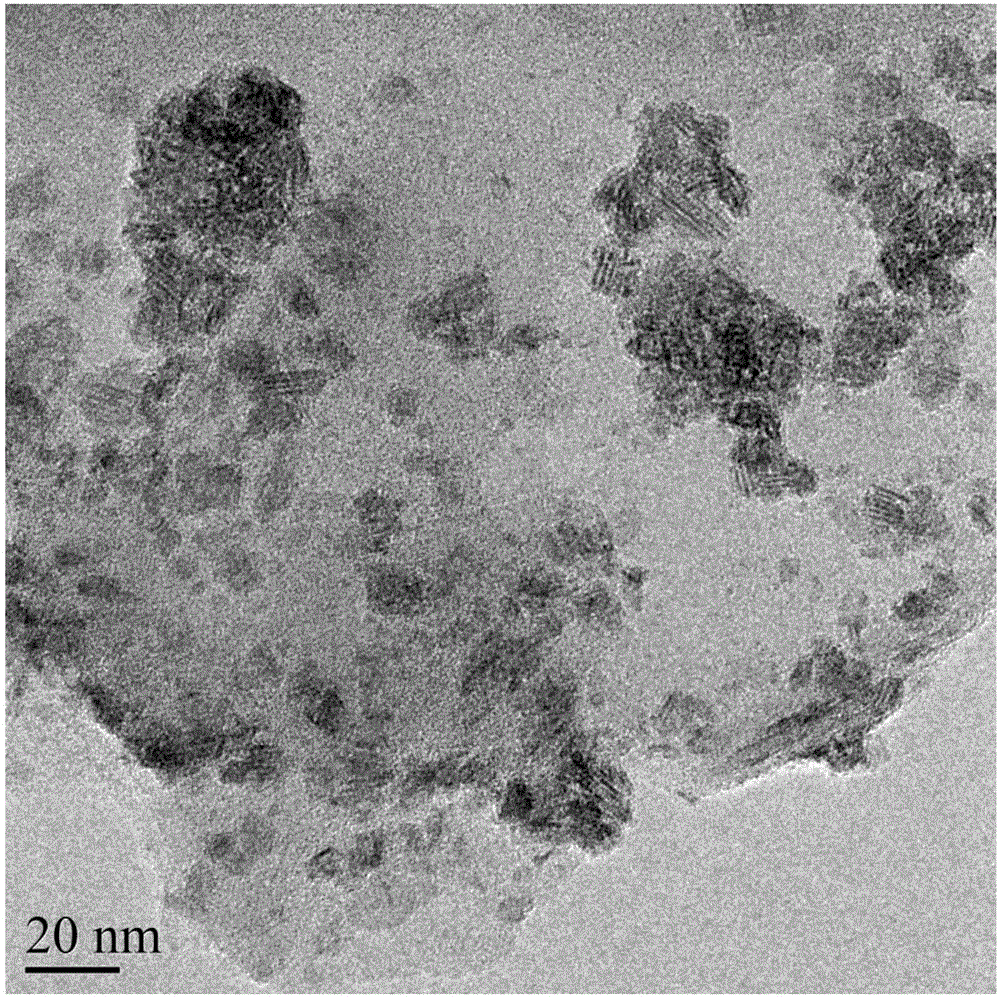

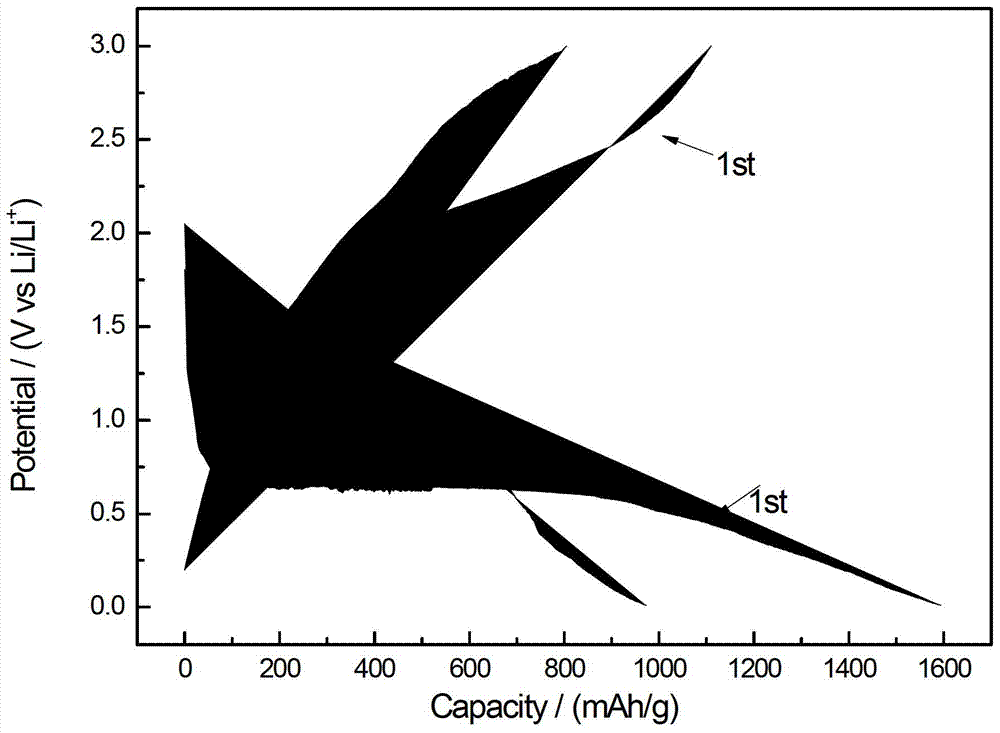

Fe3O4-graphite composite nanometer material and preparation method thereof and application of Fe3O4-graphite composite nanometer material in lithium ion battery

ActiveCN106450210AInhibition of volume changeImprove structural stabilityMaterial nanotechnologyCell electrodesFiltrationPotassium ferrate

The invention discloses a Fe3O4-graphite composite nanometer material and a preparation method thereof and application of the Fe3O4-graphite composite nanometer material in a lithium ion battery, and belongs to the technical field of lithium ion battery electrode materials. The preparation method includes the following steps: using graphite and potassium ferrate as raw materials, and then adding zirconium balls in the raw materials; at a speed of 300-500rpm, conducting ball milling by a planetary ball mill for 12-60 hours; conducting product separation, filtration, washing and drying to obtain the Fe3O4-graphite composite nanometer material. The material is applied in a lithium ion battery cathode and has excellent electrical properties; under the condition of the current density of 200 mA g<-1>, the material can keep a reversible capacity of 970 mAh g<-1> after circulation for 100 turns, the reversible capacity reaches 1132 mAh g<-1)> after circulation for 250 turns, and under the condition of large current density (1000 mA g <-1>), the reversible capacity can still keep at about 650 mAh g<-1> after circulation for 200 turns.

Owner:GUANGDONG ORIENT RESIN

MOF-coated single crystal ternary positive electrode material and preparation method of precursor of MOF-coated single crystal ternary positive electrode material

ActiveCN111129463AGuaranteed uniformityWell mixedPositive electrodesCobalt compoundsOrganic solventCarboxylic salt

Owner:GEM CO LTD +1

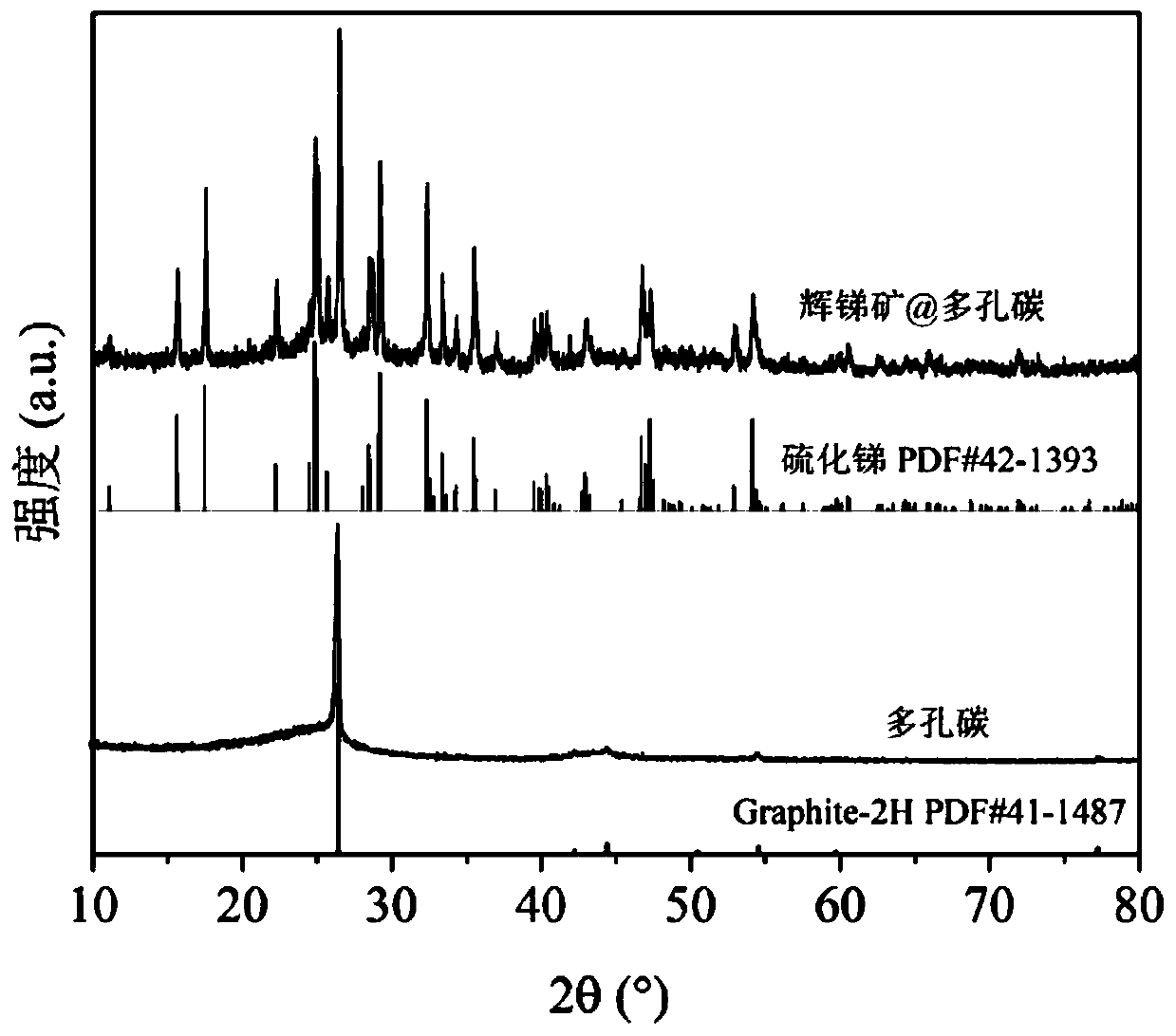

Method for preparing lithium ion battery antimony sulfide nanorod negative electrode

ActiveCN110474049ABroaden the industrial value of the application fieldLow costMaterial nanotechnologyCell electrodesArgon atmospherePorous carbon

The invention discloses a method for preparing a lithium ion battery antimony sulfide nanorod negative electrode. The method includes the following steps: weighing a preset mass of antimony sulfide and porous carbon, adding the antimony sulfide and porous carbon to a ball milling tank, adding ball milling beads according to a preset mass ratio, ball milling the antimony sulfide and the porous carbon to obtain a mixture of the antimony sulfide and the porous carbon; melting and annealing the obtained mixture in an argon atmosphere to reorganize the antimony sulfide, cooling the product to obtain an antimony sulfide nanorod negative electrode material partially or completely coated with porous carbon. The method can directly use natural stibnite as an electrode active material, and melt-combines the natural stibnite with a porous carbon material to prepare the porous carbon-coated stibnite nanorod negative electrode. Using the method to prepare the negative electrode material has advantages of low cost, short process, simple control, no waste water, waste gas or waste residue, excellent performance, and is suitable for large-scale industrialization.

Owner:CENT SOUTH UNIV

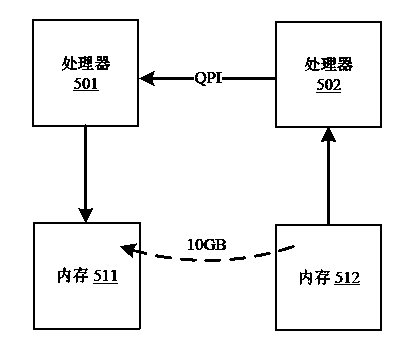

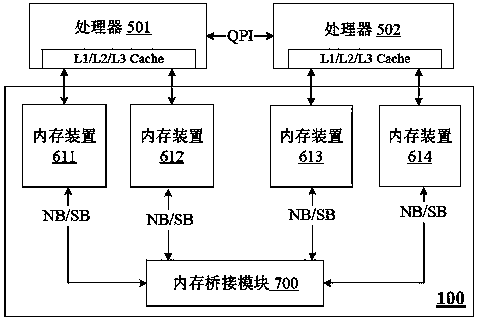

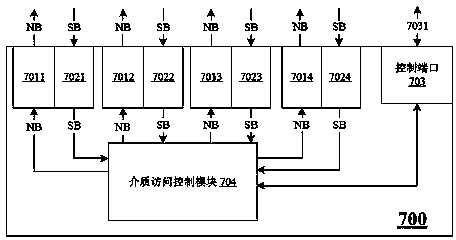

Multi-node memory interconnection device and large-scale computer cluster

InactiveCN103927233AImprove migration efficiencyAvoid occupyingResource allocationDigital computer detailsComputer architectureComputer cluster

The invention belongs to the technical field of computer memory data transmission and provides a multi-node memory interconnection device and a large-scale computer cluster. The multi-node memory interconnection device comprises multiple memory devices connected with appointed processors and further comprises a memory bridge connection module connected with the memory devices in a coupled mode, and the memory bridge connection module comprises multiple transmitting ports, receiving ports and a control port communicating with the processors through system buses. The control port receives a port mapping table generated in the process of computer starting self-checking, and a data link is established between two or more appointed memory devices through the transmitting ports and the receiving ports according to a memory data migration operation instruction transmitted by the processors. Through the multi-node memory interconnection device, loads, on the processors, of memory data migration are avoided, processor resources are saved, the data migration route is shortened, and the efficiency of memory data migration is improved.

Owner:STACKINSIDER TECH

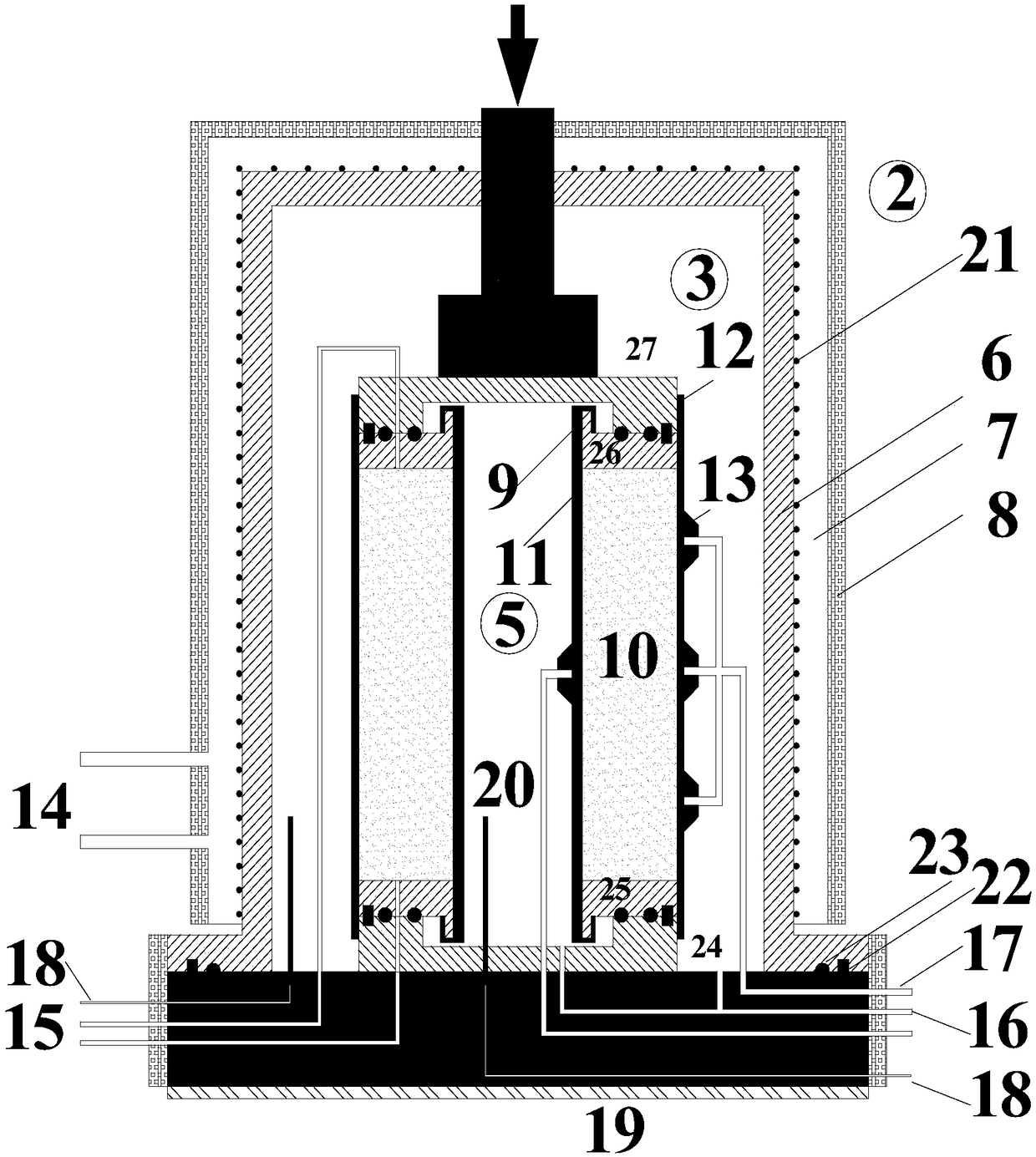

Pressure chamber for in-situ generation and triaxial test of marine gas hydrate and using method thereof

ActiveCN109187215ASimple structureEasy to operateMaterial strength using tensile/compressive forcesTriaxial shear testCopper wire

The invention discloses a pressure chamber for in-situ generation and triaxial test of marine gas hydrates and a using method thereof. The pressure chamber is composed of a base, a sleeve and a pistonrod. The sleeve is sequentially provided with a pressure bearing cavity, a refrigerant circulation cavity with rib edges and a heat preservation layer from inside to outside, and a refrigerant circulation pipeline is arranged on the sleeve. A pore pressure applying pipeline, a confining pressure applying pipeline and an air pressure applying pipeline are arranged on the base, and an insulating heat preservation layer is arranged on the surface of the lower bottom of the base. The using method comprises the following steps of: sequentially installing upper and lower main cushion blocks, upperand lower connection blocks, copper wire meshes, latex films, latex sleeves and hollow cylinder specimens on the base; and sequentially applying pore water pressure, inner and outer confining pressureand the pore air pressure to the hollow specimens until the hydrates are formed inside the specimens. The pressure chamber can provide platform support for the in-situ generation and the triaxial test of the marine gas hydrates under the conditions of gas horizontal migration.

Owner:CHINA UNIV OF MINING & TECH

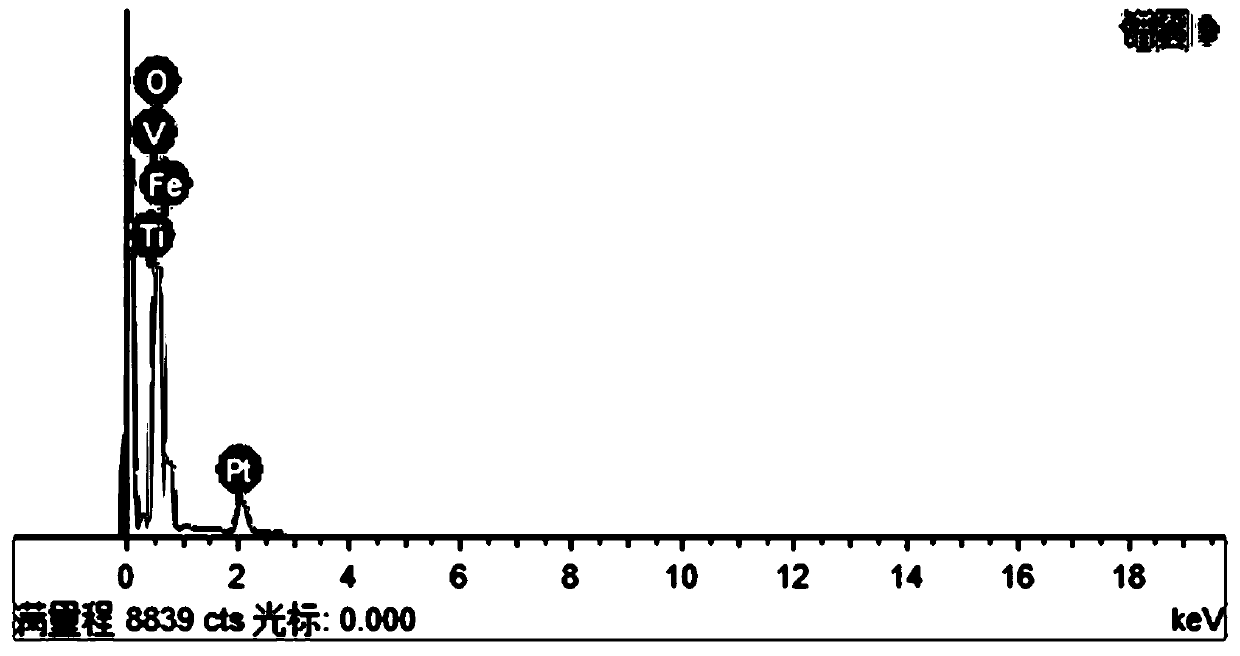

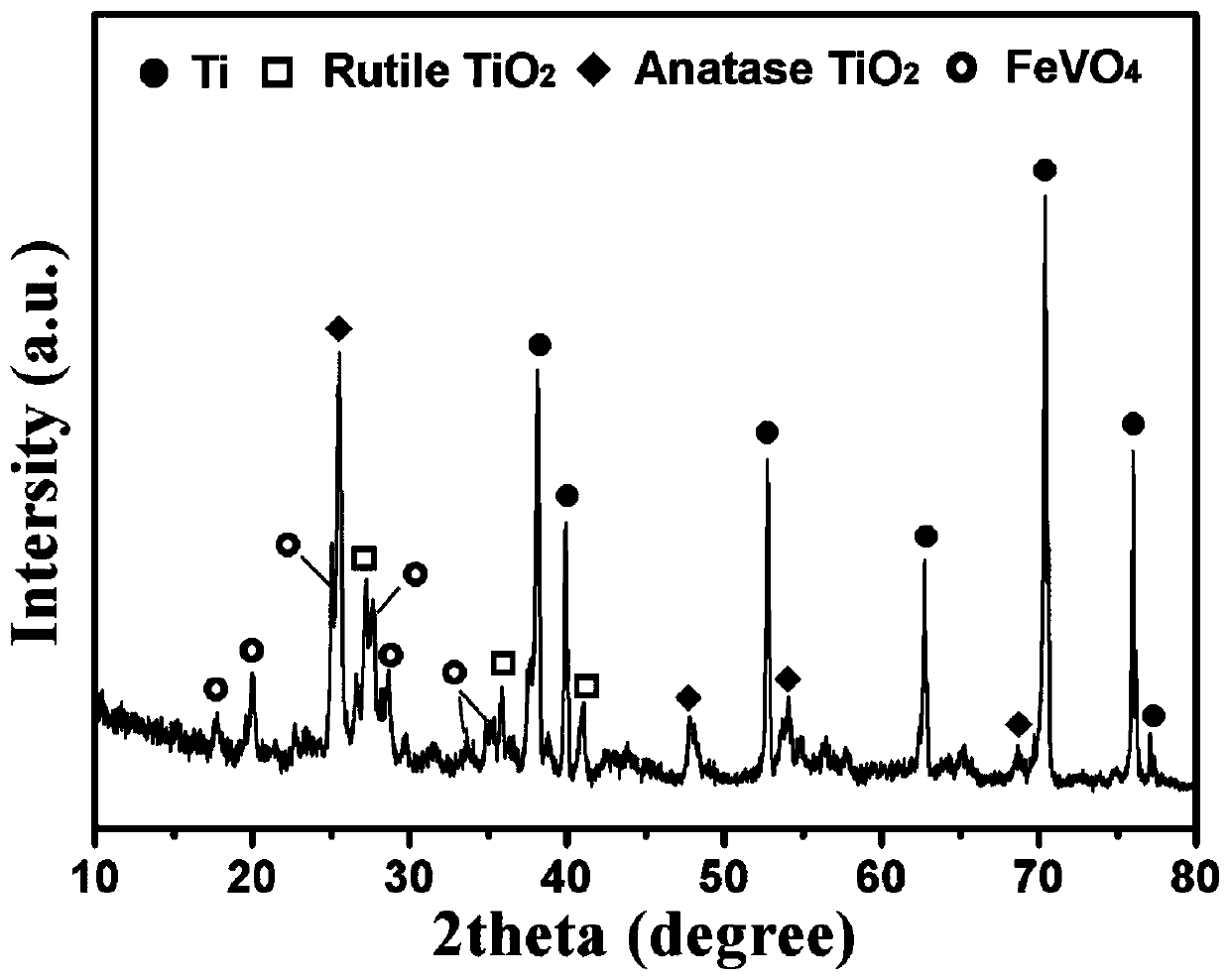

FeVO4/TiO2 porous catalyst film layer material for photo-Fenton combined catalysis and preparation method of FeVO4/TiO2 porous catalyst film layer material

ActiveCN110624560ARealize industrial productionEasy to operateWater/sewage treatment by irradiationWater treatment compoundsMaterials preparationFenton reaction

The invention discloses a FeVO4 / TiO2 porous catalyst film layer material for photo-Fenton combined catalysis and a preparation method of the FeVO4 / TiO2 porous catalyst film layer material, belongs tothe technical field of photo-Fenton combined catalytic material preparation. Aiming at the lack of a method and a catalyst capable of efficiently combining photocatalysis and Fenton reaction at present, a micro-arc oxidation method is utilized; a TiO2 film layer containing Fe and V is generated on the surface of a titanium substrate, then the FeVO4 / TiO2 porous catalyst film layer material is obtained through roasting in a protective atmosphere, photocatalysis and Fenton reaction are successfully and efficiently combined together, and the efficient catalyst capable of being used for degrading organic pollutants is obtained.

Owner:哈尔滨规格科技有限公司

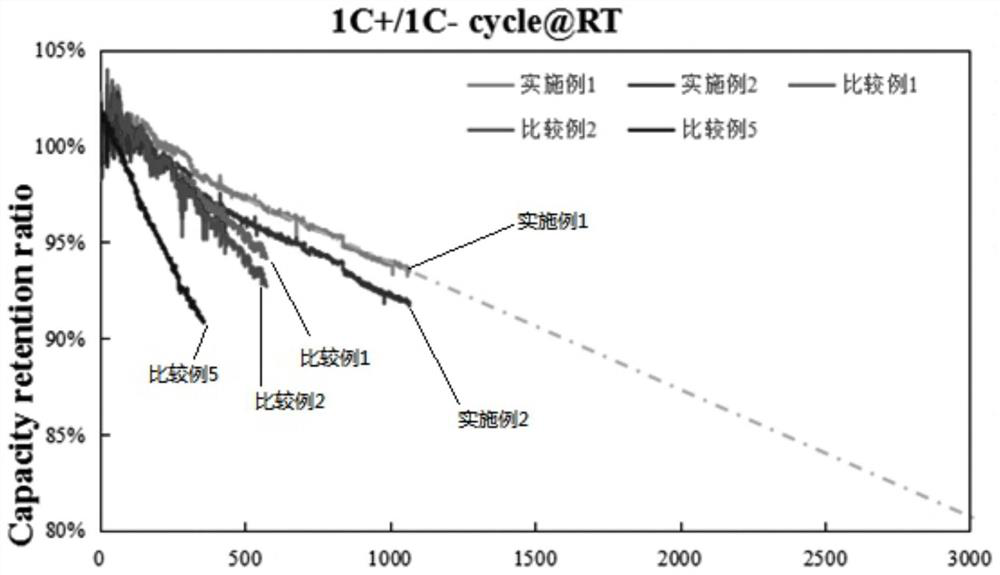

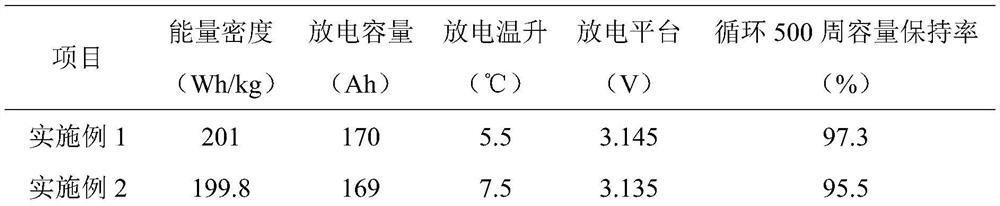

High-energy-density lithium iron phosphate battery

ActiveCN113078305ASignificant progressIncrease capacityMaterial nanotechnologyFinal product manufactureElectrolytic agentMagnesium doping

The invention belongs to the technical field of electrochemistry, and particularly relates to a high-energy-density lithium iron phosphate battery. A positive electrode active material is selected from titanium / magnesium-doped lithium iron phosphate, the surface density of a positive plate is 190-210 g / m<2>, the compaction density is greater than or equal to 2.60 g / cc, a negative electrode active material is carbon-coated single particle and secondary particle needle coke blend artificial graphite, and the compaction density of a negative plate is greater than or equal to 1.70 g / cc. The density of the electrolyte is equal to 1.15 g / cc, the wall thickness of the aluminum shell body is 0.40-0.50 mm, a positive electrode current collector is an aluminum foil with the diameter of 12-13 [mu]m, a negative electrode current collector is a copper foil with the diameter of 4.5 [mu]m, a diaphragm is a 7 + 2C + 2P ceramic gluing diaphragm, a conductive binder is used for replacing a positive electrode, the addition amount is 1.0-2.0%, and the weight ratio of a positive electrode active material to a positive electrode dressing is greater than or equal to 98%. According to the invention, the energy density of the battery is greatly improved and reaches 200Wh / kg.

Owner:江西安驰新能源科技有限公司

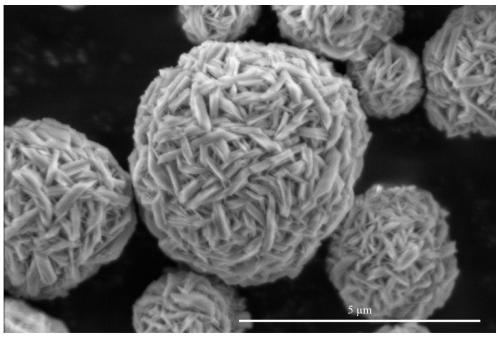

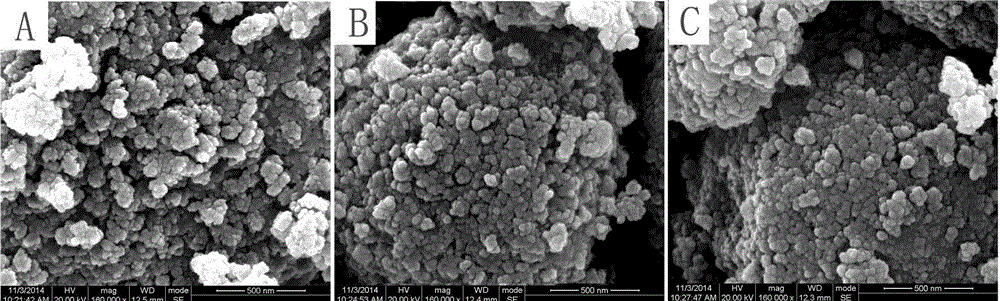

Method for preparing ferrous silicate lithium/carbon composite positive pole material with micropore spherical structure

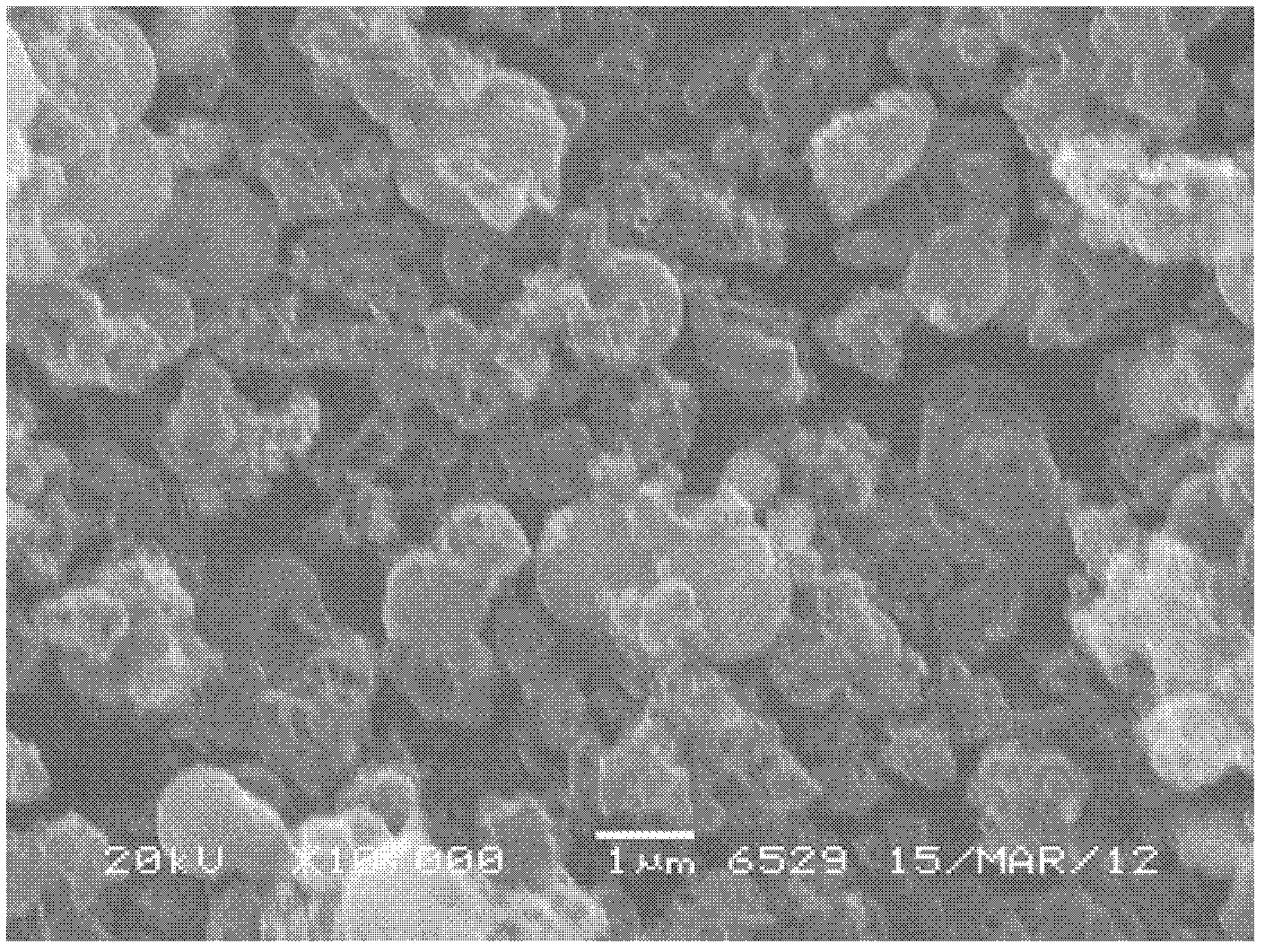

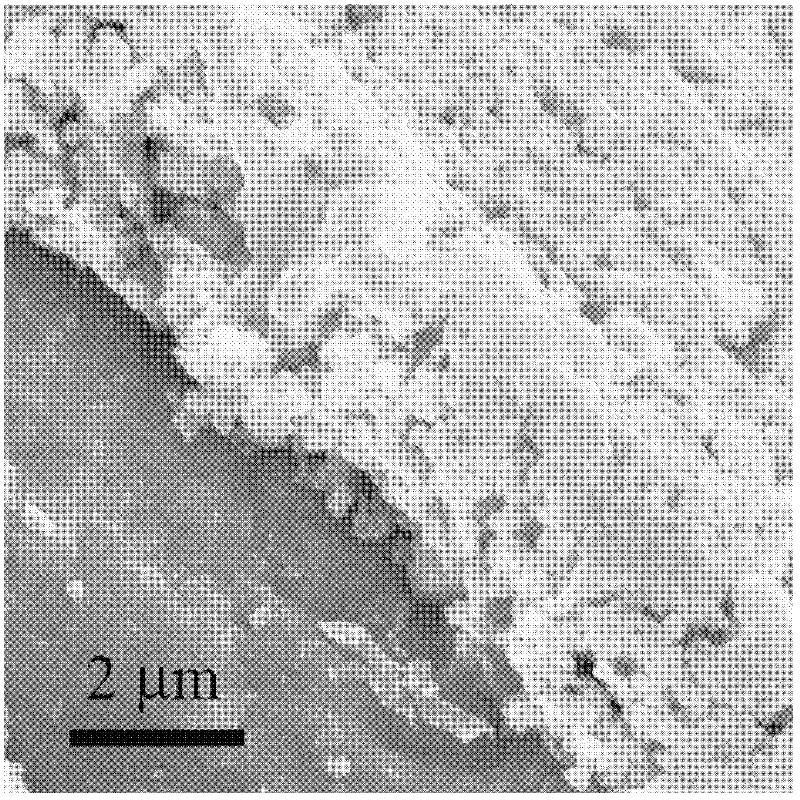

ActiveCN104362318AImprove electronic conductivityImprove conductivityCell electrodesCarbon compositesOxalate

The invention discloses a method for preparing a ferrous silicate lithium / carbon composite positive pole material with a micropore spherical structure. The method particularly comprises the following steps of (1) adding citric acid and lithium hydroxide into water, and stirring for dissolution; adding ferrous oxalate, regulating the pH of a solution to 6-8, carrying out oil bath at 80-95 DEG C, and keeping temperature for 24-72 hours to form a deep green solution; adding nanometer silicon dioxide, carrying out ultrasonography for 20-60 minutes, and stirring at room temperature for 1-3 hours to prepare gel; (2) spray-drying the gel at 100-120 DEG C to obtain a ferrous silicate lithium / carbon composite precursor; (3) calcining the ferrous silicate lithium / carbon composite precursor in argon at 600-800 DEG C for 8-12 hours to obtain the ferrous silicate lithium / carbon composite positive pole material with the micropore spherical structure. The method disclosed by the invention is simple and safe in process and low in cost. The obtained ferrous silicate lithium / carbon composite positive pole material has the advantages of fine granules, uniformity in distribution, excellent microstructure and preferable electrochemical property.

Owner:HUNAN UNIV OF ARTS & SCI

Biomass hard carbon negative electrode material for sodium ion battery as well as preparation method and application of biomass hard carbon negative electrode material

ActiveCN113381016AShorten the migration pathHigh reversible capacitySecondary cellsNegative electrodesElectrical batterySulfuric acid

The invention discloses a preparation method of a biomass hard carbon negative electrode material for a sodium ion battery. The method comprises the following steps: taking one or more of wood, bamboo or camellia oleifera shells as a biomass raw material, immersing the biomass raw material in a sulfuric acid solution, and stirring at room temperature to obtain a suspension; dispersing the suspension in water, filtering and drying to obtain a precursor; heating the precursor under the protection of inert gas, carrying out pre-carbonization treatment, cooling, and carrying out ball milling to obtain pre-carbon powder; and heating the pre-carbon powder under the protection of inert gas, carrying out high-temperature carbonization treatment, and cooling to obtain the biomass hard carbon negative electrode material for the sodium-ion battery. The technical process is simple, and the prepared biomass hard carbon negative electrode material for the sodium ion battery is high in first coulombic efficiency.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Sodium vanadium pyrophosphate/carbon composite positive electrode material, and preparation and application thereof

InactiveCN107017398ASolve the shortcomings of poor conductivityGood electrical propertiesMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention discloses a preparation method for a porous sodium vanadium pyrophosphate positive electrode material of a sodium-ion battery. According to the method, nitrogen-doped carbon-coated porous sodium vanadium pyrophosphate particles with uniform particle sizes are prepared by using a hydrothermal method. The preparation method comprises the following steps: subjecting vanadium-source monomers and nitrogen-containing carbon-source monomers to a hydro-thermal reaction so as to allow a corresponding conductive polymer to grow on vanadium oxide particles in situ; subjecting a hydro-thermal product, a sodium source and a phosphorus source to ball milling so as to obtain a precursor; and successively carrying out calcining, washing and drying so as to obtain the nitrogen-doped carbon-coated porous sodium vanadium pyrophosphate particles with uniform particle sizes. Moreover, the invention also discloses the positive electrode material of the sodium-ion battery prepared by using the preparation method. The preparation method provided by the invention is simple in process and low in cost for raw materials. The prepared material is nitrogen-doped carbon-coated porous sodium vanadium pyrophosphate. The hydrothermal method is employed for in-situ generation of the conductive polymer on the surface of the vanadium source to adjust the morphology of the material and uniformity of a carbon layer; and the material is used for the sodium-ion battery and shows excellent electrochemical performance.

Owner:CENT SOUTH UNIV

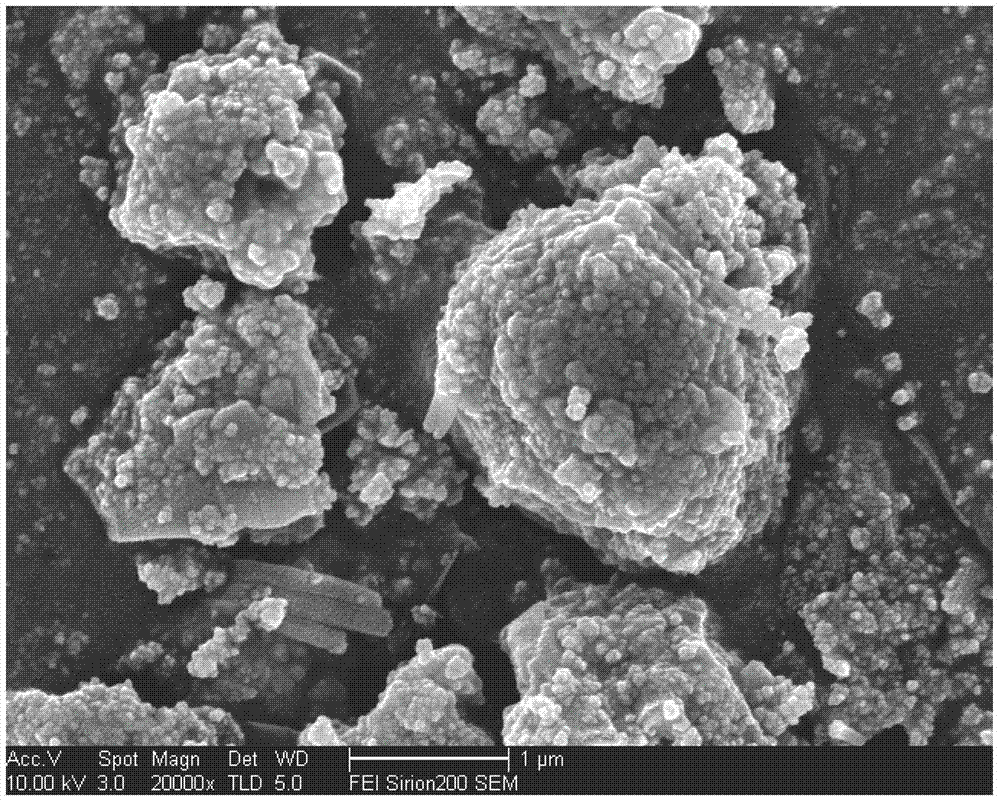

Preparation method for carbon/nanometer NiO composite material

InactiveCN103500828AGood lithium ion extraction performanceImprove conductivityMaterial nanotechnologyCell electrodesNanotechnologyLarge capacity

The invention relates to a preparation method for a carbon / nanometer NiO composite material. A high-capacity NiO composite material can be prepared, and the electrochemical performance of a NiO electrode can be improved. A carbon material with high electrical conductivity and a stable structure is used as a substrate of the composite material, and is stable in structure, and a large pore volume is formed around a nanometer NiO particle, so that a space for the expansion and shrinkage of NiO in charging and discharging processes is reserved, the substrate of the material is prevented from being damaged, and the recycling performance of the material is improved.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com