MOF-coated single crystal ternary positive electrode material and preparation method of precursor of MOF-coated single crystal ternary positive electrode material

A cathode material and precursor technology, which is applied in the field of preparation of single crystal ternary cathode material precursors, can solve the problems of incompatibility of specific capacity, cycle life, and safety, and achieve shortened migration path, improved rate performance, and uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

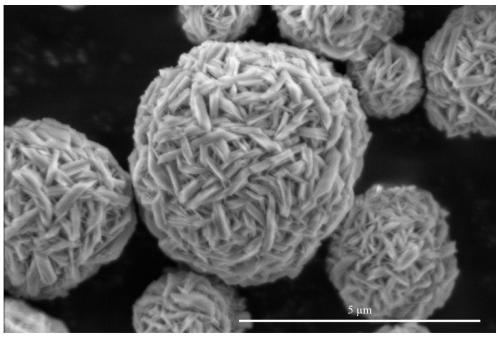

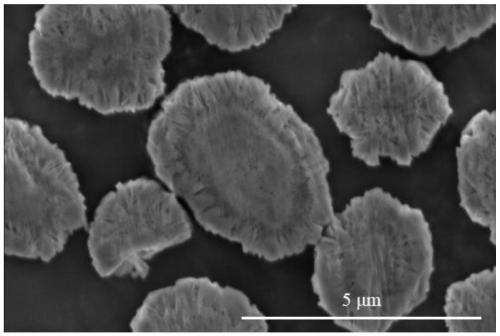

[0031] Step 1, the nickel-cobalt-manganese salt solution (metal concentration is 2mol / L) that metal molar ratio is 82:8:10 joins in the reaction kettle with the flow rate of 6L / h with metering pump, simultaneously adds 12g / The ammonia water of 1 L and the sodium hydroxide of 3mol / L, the flow rate is 1L / h and 2.5L / h respectively, and the pH of the system is maintained between 10.5-12.0 by controlling the flow rate of ammonia water and sodium hydroxide during the reaction. Nitrogen gas was passed into the sealed reaction kettle with a flow rate of 2 L / h. The stirring speed of the stirring blade is 400 r / min, and the reaction temperature of the system is 62°C. During the reaction, use a laser particle size analyzer to detect the particle size of the particles in the reactor every hour. By observing the morphology of the primary particles and secondary particles of the process sample, the primary particles are controlled to be spherical particles that are evenly agglomerated in t...

Embodiment 2

[0035] Step 1, the nickel-cobalt-manganese salt solution (metal concentration is 2mol / L) that metal molar ratio is 75:13:12 joins in the reactor with the flow rate of 6L / h with metering pump, simultaneously adds 12g / The ammonia water of 1 L and the sodium hydroxide of 3mol / L, the flow rate is 1L / h and 2.5L / h respectively, and the pH of the system is maintained between 10.5-12.0 by controlling the flow rate of ammonia water and sodium hydroxide during the reaction. Nitrogen gas was passed into the sealed reaction kettle with a flow rate of 2 L / h. The stirring speed of the stirring blade is 400 r / min, and the reaction temperature of the system is 62°C. During the reaction, use a laser particle size analyzer to detect the particle size of the particles in the reactor every hour. By observing the morphology of the primary particles and secondary particles of the process sample, the primary particles are controlled to be spherical particles that are evenly agglomerated in the form...

Embodiment 3

[0039] Step 1, the nickel-cobalt-manganese salt solution (metal concentration is 2mol / L) that metal molar ratio is 90:5:5 joins in the reaction kettle with the flow rate of 6L / h with metering pump, simultaneously adds 12g / The ammonia water of 1 L and the sodium hydroxide of 3mol / L, the flow rate is 1L / h and 2.5L / h respectively, and the pH of the system is maintained between 10.5-12.0 by controlling the flow rate of ammonia water and sodium hydroxide during the reaction. Nitrogen gas was passed into the sealed reaction kettle with a flow rate of 2 L / h. The stirring speed of the stirring blade is 400 r / min, and the reaction temperature of the system is 62°C. During the reaction, use a laser particle size analyzer to detect the particle size of the particles in the reactor every hour. By observing the morphology of the primary particles and secondary particles of the process sample, the primary particles are controlled to be spherical particles that are evenly agglomerated in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com