High-energy-density lithium iron phosphate battery

A lithium iron phosphate battery, high energy density technology, applied in the field of electrochemistry, can solve the problems of difficult infiltration of high pressure, low production quality, and large battery temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

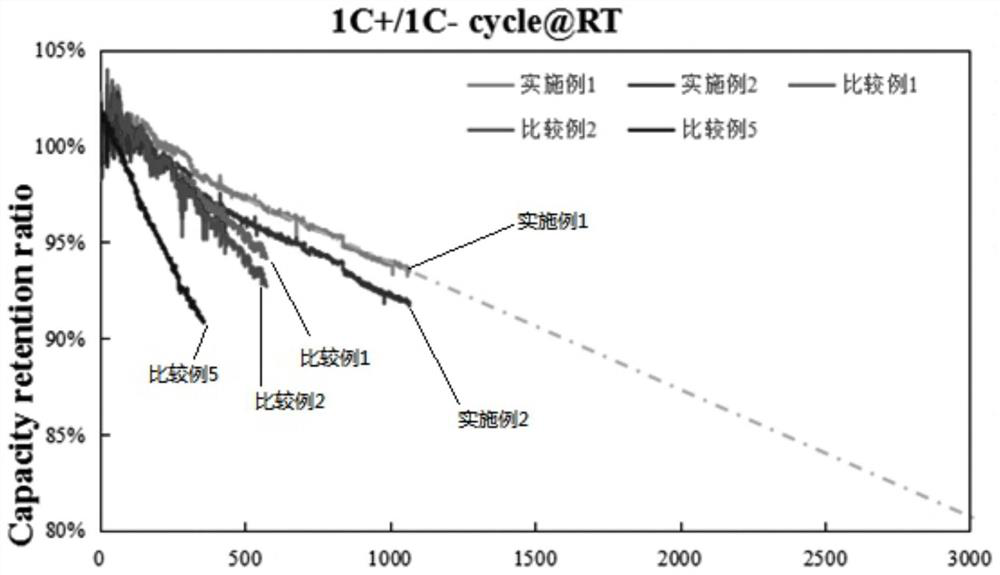

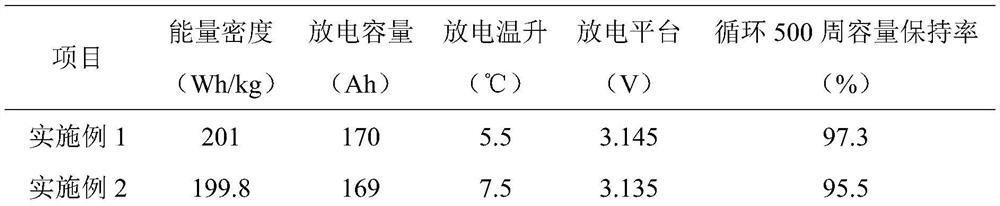

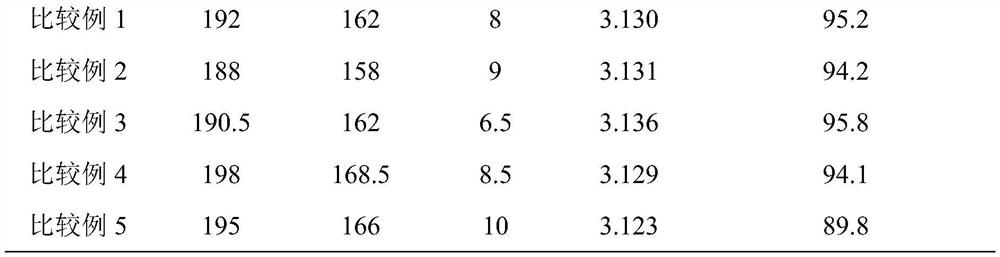

Examples

Embodiment 1

[0029] (1) Positive electrode

[0030] The titanium-doped lithium iron phosphate and the positive conductive binder ZONE80M were mixed with NMP according to the ratio of 98.5:1.5 to make the positive electrode slurry. , the compaction density is 2.65g / cc, and then die-cut to obtain a positive electrode sheet;

[0031] Wherein, in the titanium-doped lithium iron phosphate, the particle size of the large single crystal particles is 600-800 nm, and the particle size of the small single crystal particles is 100-200 nm. Based on the weight of titanium-doped lithium iron phosphate, the weight content of titanium is 800 ppm, and the titanium comes from titanium dioxide or tetrabutyl titanate. Specifically, titanium dioxide is selected in this embodiment.

[0032] (2) Preparation of negative electrode

[0033] The anode active material (carbon-coated single particle and secondary particle needle coke blend artificial graphite, particle D 50≤10μm), conductive carbon black, negative ...

Embodiment 2

[0041] Different from Example 1, the positive electrode conductive binder ZONE80M was added in an amount of 1.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com