Patents

Literature

188results about How to "Guaranteed cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cladding surfaces of active material of anode and/or anode and methods manufacturing anode and battery

InactiveCN102244231AStructurally intactStable structureNon-aqueous electrolyte accumulator electrodesMetallurgyLithium-ion battery

The invention provides a method for cladding surfaces of an active material of an anode and / or the anode and methods for manufacturing the anode and a battery. In the cladding method, an atomic layer deposition technology is adopted to deposit surface modification substances on the surfaces of the active material of the anode and / or the anode of a lithium battery. According to the invention, the cycle performance and the specific capacity of the lithium-ion battery can be improved obviously and electrode materials are more stable.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

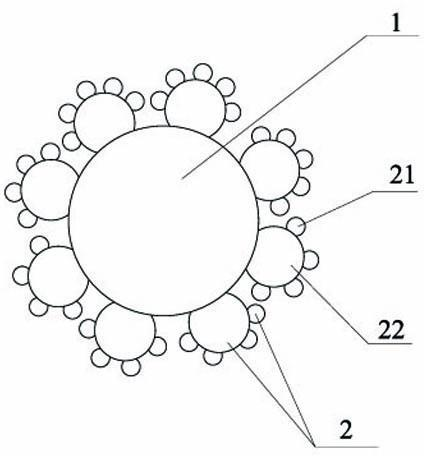

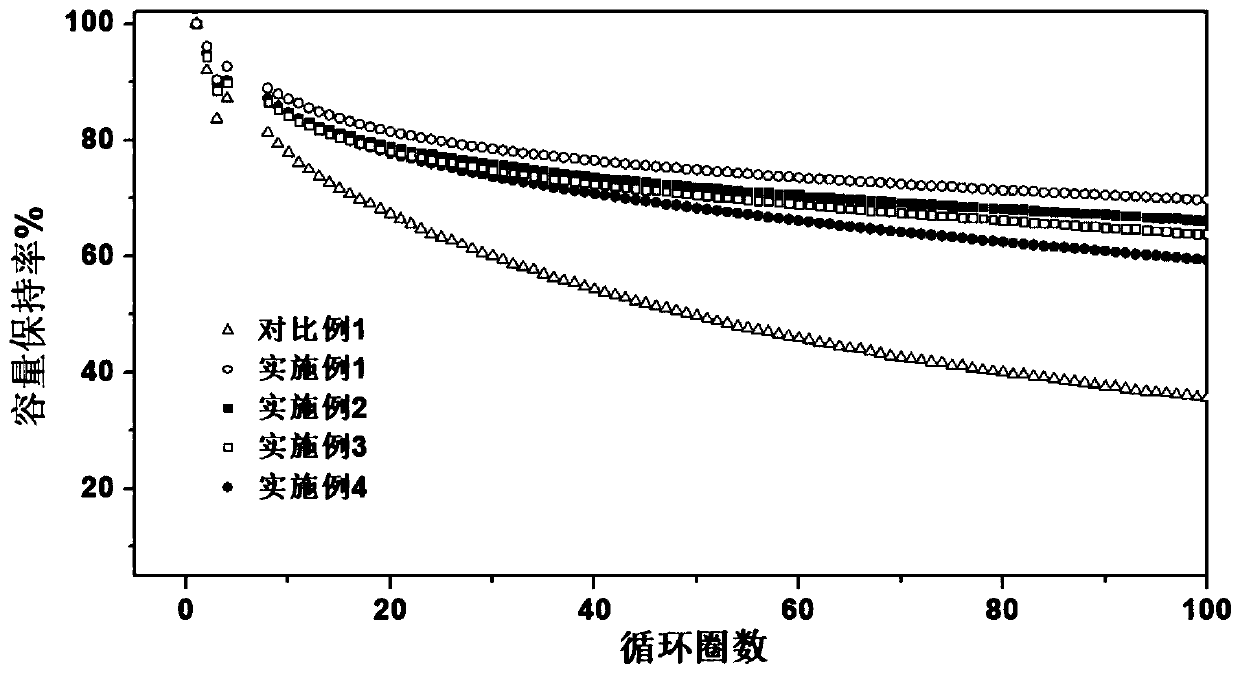

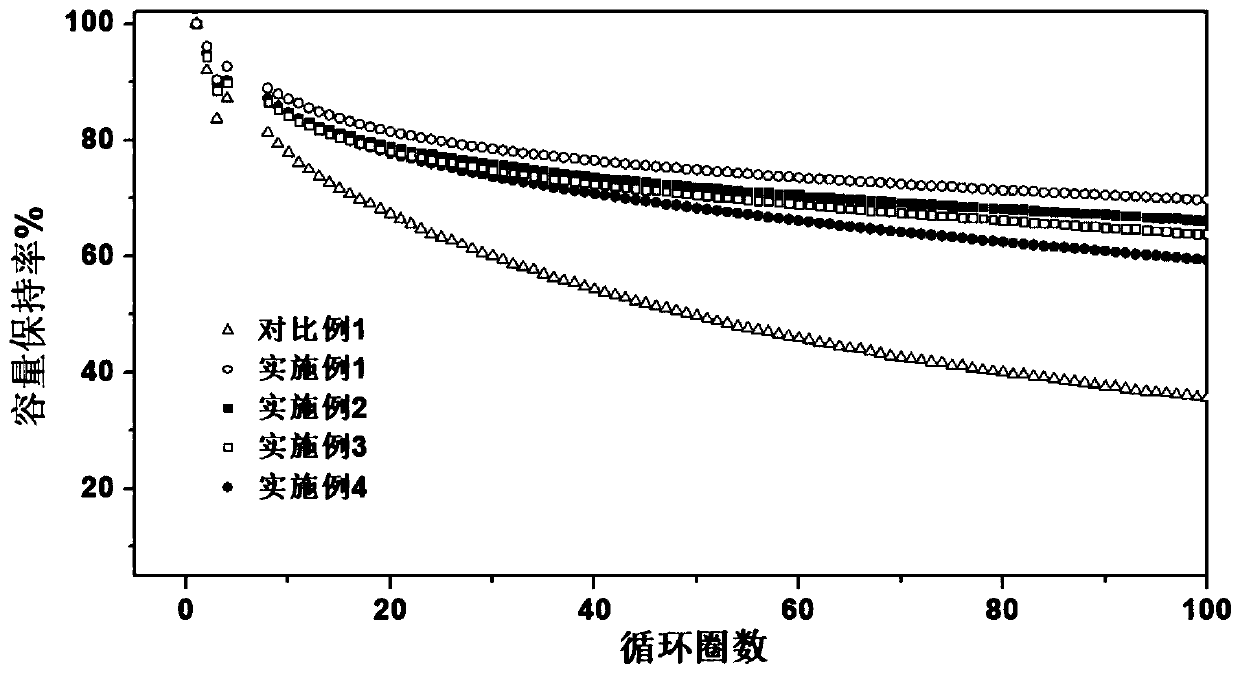

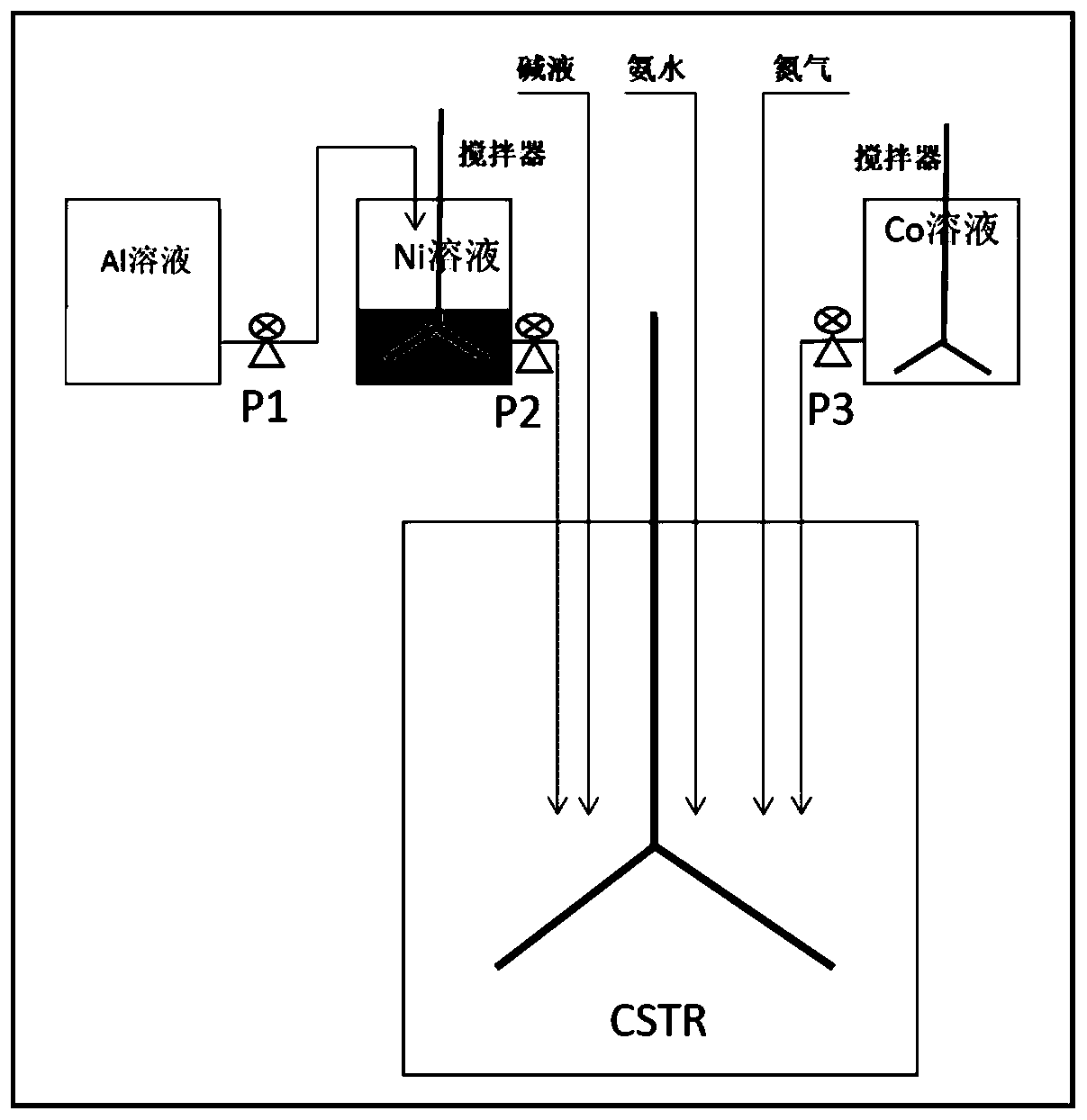

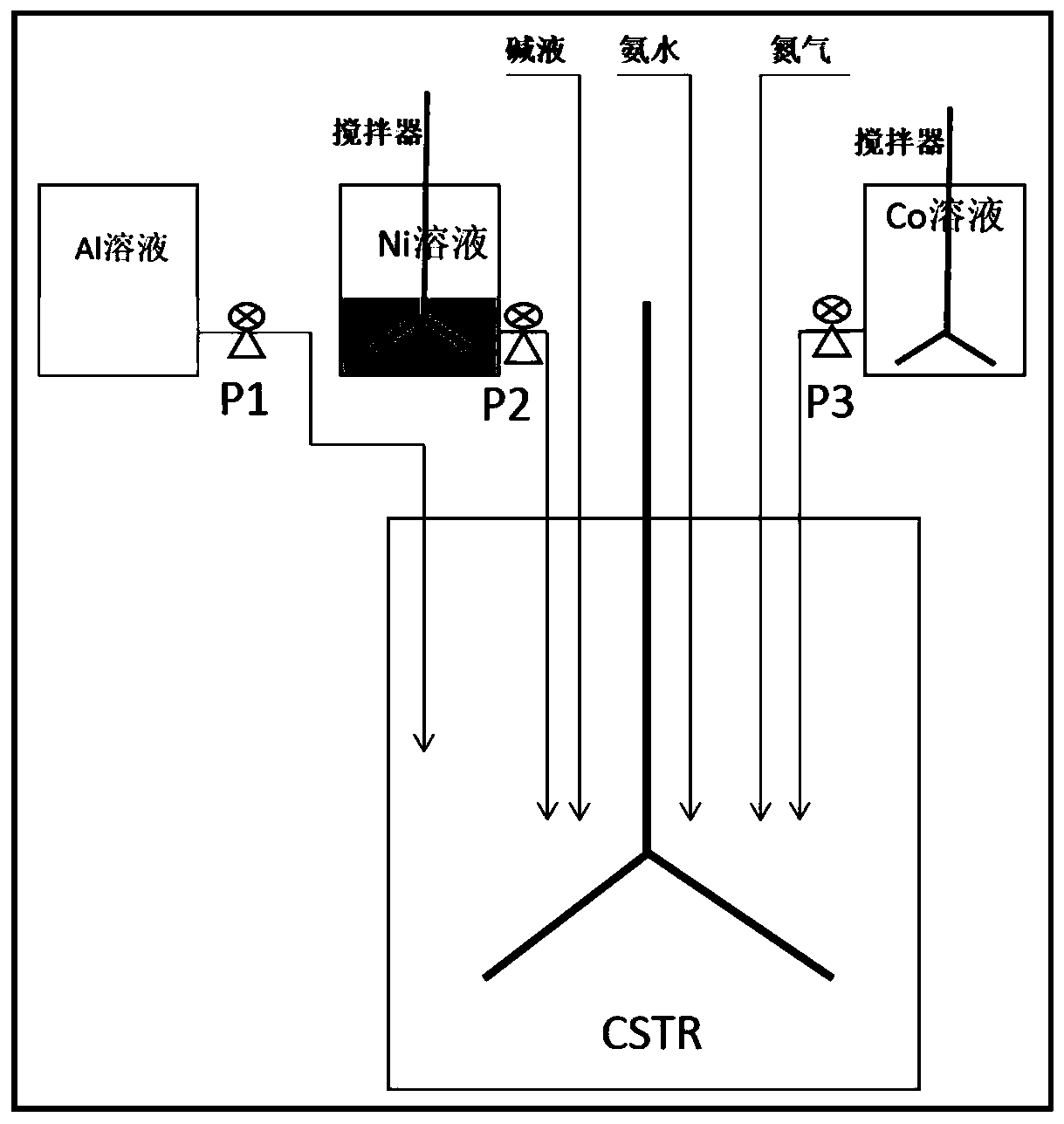

Lithium ion battery gradient core shell cathode material and synthetic method thereof

ActiveCN103236537AGuaranteed cycle performanceGuaranteed rate performanceCell electrodesNickel compoundsElectrical batteryPhysical chemistry

The invention provides a lithium ion battery gradient core shell cathode material and synthetic method thereof, and relates to a lithium ion battery cathode material and synthetic method thereof. The lithium ion battery gradient core shell cathode material provided by the present invention may have two kinds of core shell structures as follows: a two-layer structure: a ternary material is used as a core material, and a binary material or a unitary material is casing material, and the ternary material external layer is covered by the binary material or the unitary material; three-layer structure: the ternary material is used as a core material, and the binary material and the unitary material are casing materials, and the ternary material external layer is covered with the binary material, and the binary material is covered with the unitary material. The synthetic method includes: employing a coprecipitation method for obtaining a precursor, and then adding lithium source, calcining and coating to obtain the ternary gradient core shell material. Under the prerequisite that the structure stability of the material is kept, the cost is reduced, and the gram capacity of the material is improved, and the material circulating performance and rate capability of the material are improved, and the safety performance and low temperature performance of the ternary cathode material are increased, and the preparation technology is optimized and improved.

Owner:HARBIN INST OF TECH

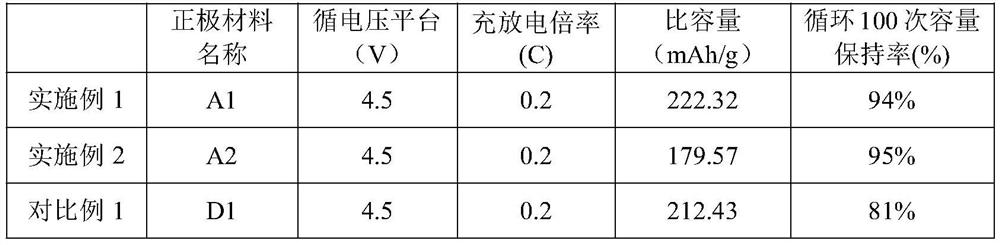

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

Lithium metal alloy negative electrode material and preparation method and application thereof

ActiveCN110120502AUniform depositionWon't happenCell electrodesSecondary cellsCyclic processPower flow

The invention provides a lithium metal alloy negative electrode material. The negative electrode material comprises lithium alloy serving as a framework and metal lithium filling the framework. The lithium alloy has lithium ion conductivity, and compared with a traditional three-dimensional structure only having electron conductivity, a better three-dimensional ion and electron conductivity network can be formed, so that metal lithium is uniformly deposited, lithium dendrites cannot be generated even if charging and discharging are carried out under the condition of great current density, anda remarkable battery polarization phenomenon is not generated. The lithium alloy material which can be subjected to extraction and insertion of lithium is adopted as the structural framework, after metal lithium is used up in the circulating process, the capacity of the alloy framework can be further released, and the circulating performance of the battery is guaranteed. The used raw materials arewide in source, low in price, simple in process and suitable for rapid large-scale production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

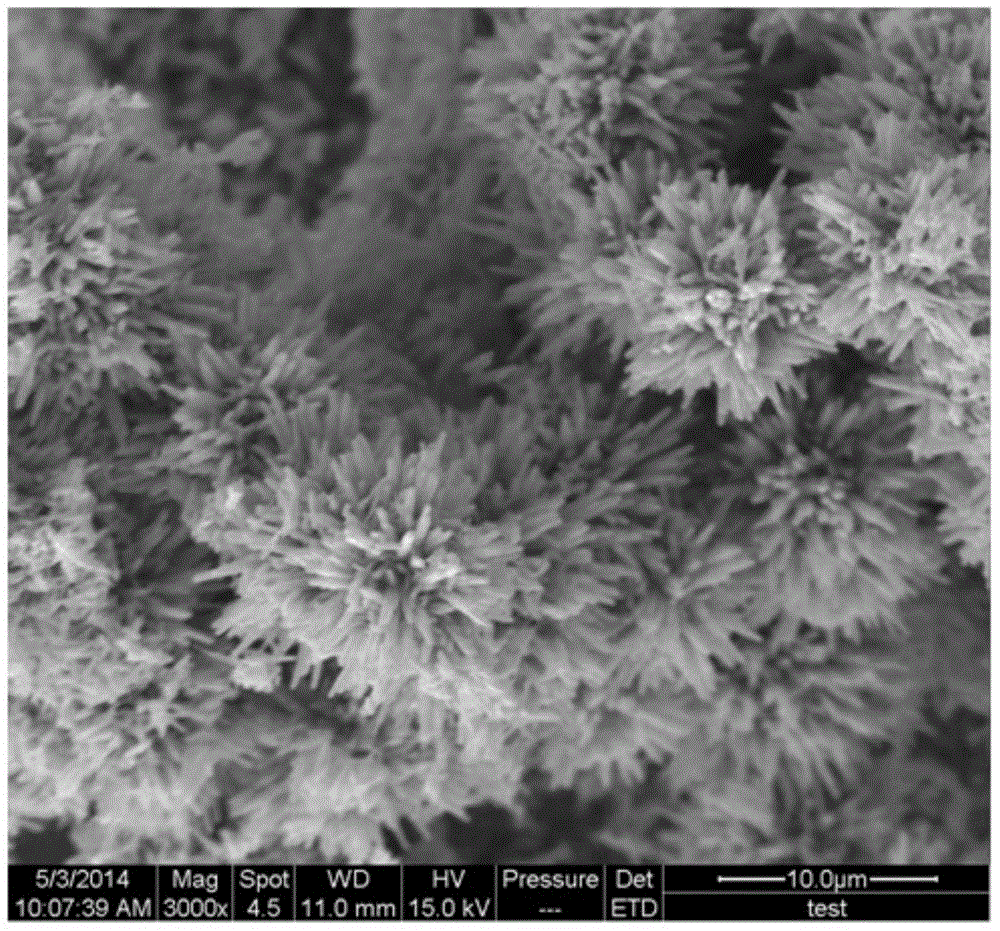

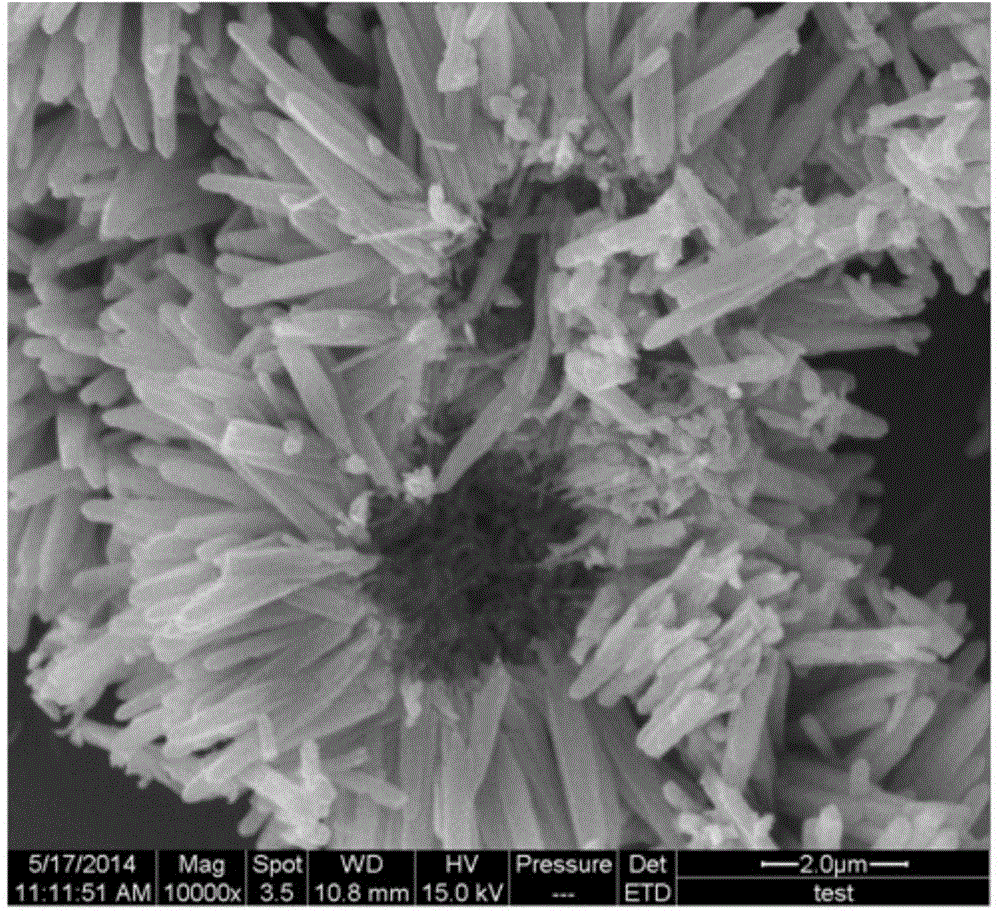

High magnifying power lithium-rich manganese-based cathode material with nano/microstructure

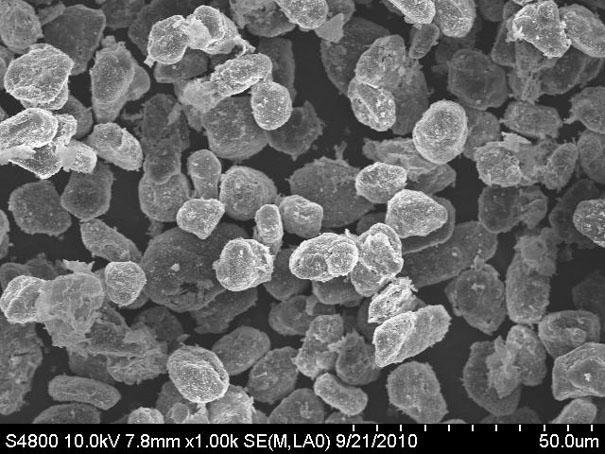

ActiveCN104157844ASimple processSignificant performance improvementMaterial nanotechnologyCell electrodesSodium chlorateChemical stability

The invention relates to a high magnifying power lithium-rich manganese-based cathode material with a nano / microstructure, which belongs to the technical field of material synthesis. A chemical reaction of the cathode material is aLi2MnO3.(1-a)LiMO2, wherein a is greater than or equal to 0.3 and less than 1, M is NixCoyMn1-x-y, wherein x is greater than or equal to 0 and less than 0.5, and y is greater than or equal to 0 and less than 0.5. A preparation method comprises the following steps: 1)weighing manganese salt, a surfactant and sodium chlorate, uniformly mixing, performing a hydrothermal reaction to obtain radicalized hollow nano / microstructure formed by self assembly of a manganese dioxide nanorod; 2)uniformly mixing manganese dioxide with the nano / microstructure obtained in the step 1) with lithium salt, cobalt salt and nickel salt to obtain a precursor; and 3)calcining the precursor at high temperature to obtain the lithium-rich manganese-based cathode material with nano / microstructure. The method uses the advantage of short diffusion path of a carrier of a nanostructure in the nano / microstructure to effectively increase the multiplying power capacity of the material, and the method also uses characteristics of low surface energy, difficult agglomeration and high chemical stability of a micrometer structure for keeping the cycle performance of the material.

Owner:哈尔滨博尔特能源科技有限公司

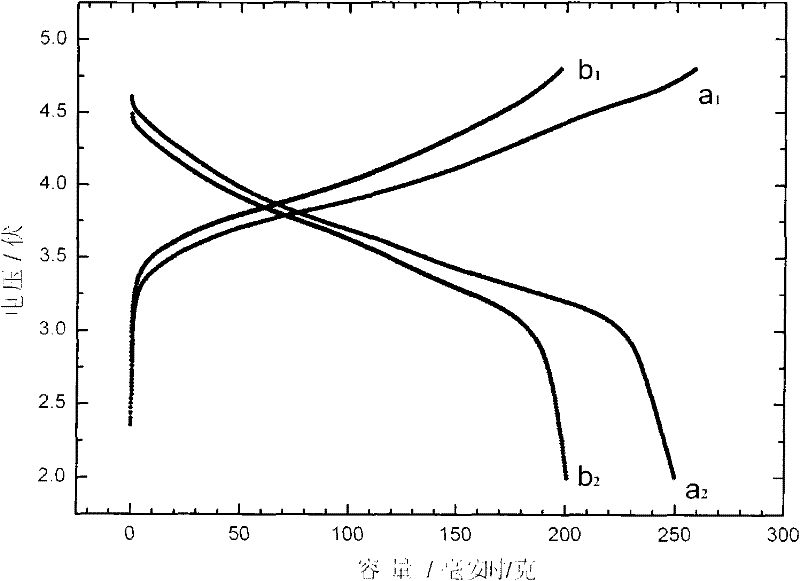

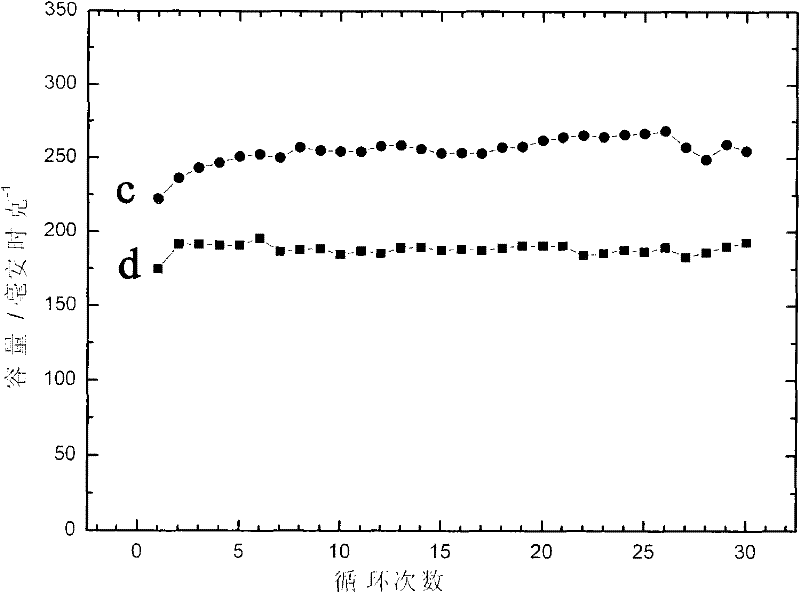

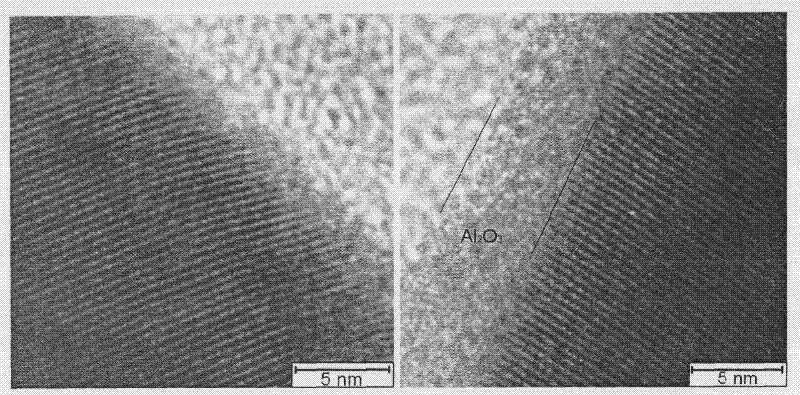

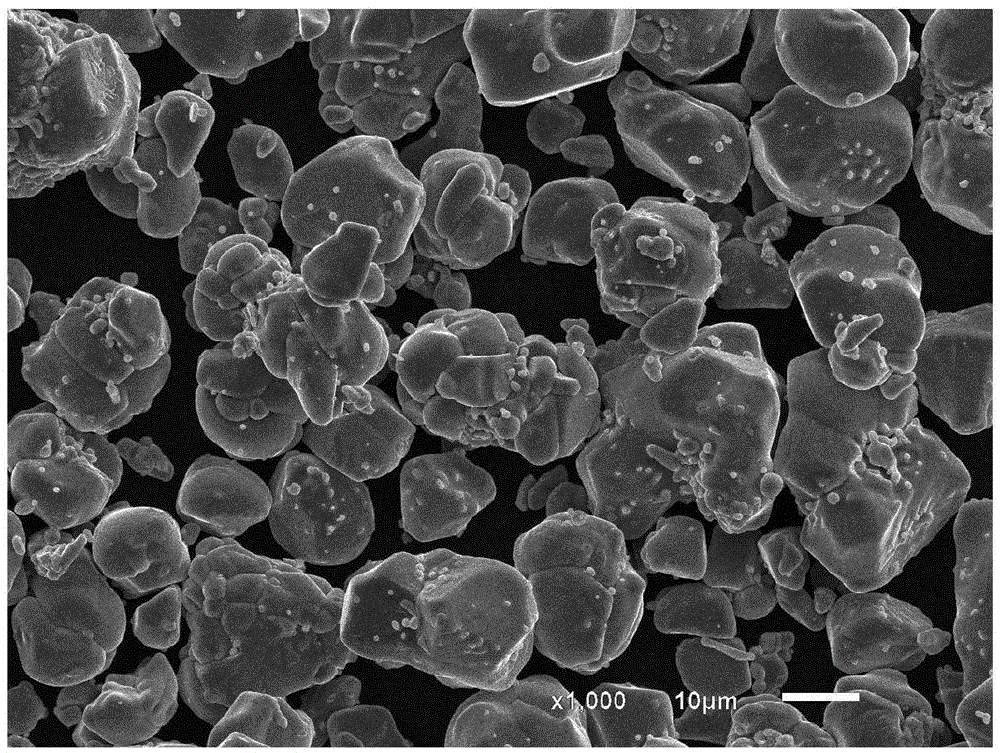

Cathode active material and preparation method and lithium ion battery thereof

ActiveCN102694152AImprove dispersion uniformityGuaranteed cycle performanceCell electrodesSecondary cellsGraphiteAlloy

The invention provides a cathode active material which has a core shell structure; the core shell structure comprises an inner core and an outer shell, and the inner core is graphite; wherein the outer shell is composite particles, and comprises a first shell layer and a second shell layer; the first shell layer is tin or tin alloy, and is coated on the surface of the inner core; the second shell layer is alumina, and is coated on the surface of the tin or tin alloy. The invention also provides a preparation method of the cathode active material and a lithium ion battery containing the cathode active material. The lithium ion battery provided by the invention has good charge and discharge performance and cycle performance.

Owner:BYD CO LTD

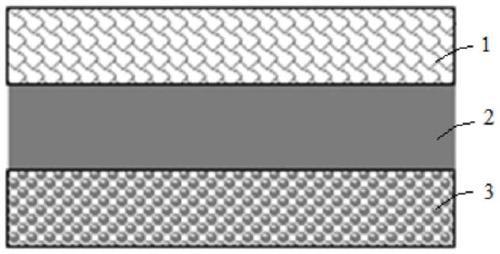

Three-dimensional network water-based composite binder and application thereof in lithium ion battery

ActiveCN111180733AGuaranteed bonding effectGuaranteed cycle performanceNegative electrodesSecondary cellsElectrical batteryCross linker

The invention provides a three-dimensional network water-based composite binder, which is prepared from the following components in percentage by weight: 5 to 50 percent of water-based polymer emulsion, 94.5 to 50 percent of water-soluble polymer and 0.5 to 10 percent of cross-linking agent. The three-dimensional network water-based composite binder is prepared by crosslinking the water-based polymer emulsion and the water-soluble polymer by a crosslinking agent to form a three-dimensional network molecular structure, wherein the water-based polymer emulsion is a water-based polyurethane emulsion or a vinyl acetate water-based copolymer emulsion. The invention also provides a negative electrode prepared from the three-dimensional network water-based composite binder and a lithium ion battery containing the negative electrode. The water-soluble polymer has relatively strong bonding force on the negative electrode material; the water-based polymer emulsion endows the polymer binder witha certain elasticity, and the cross-linking agent endows the binder with a three-dimensional molecular network structure, so that the toughness of the binder is enhanced, the damage of the volume change of active substances to an electrode plate structure in the charging and discharging process of the battery can be buffered, and the cycling stability of the lithium ion battery is maintained.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

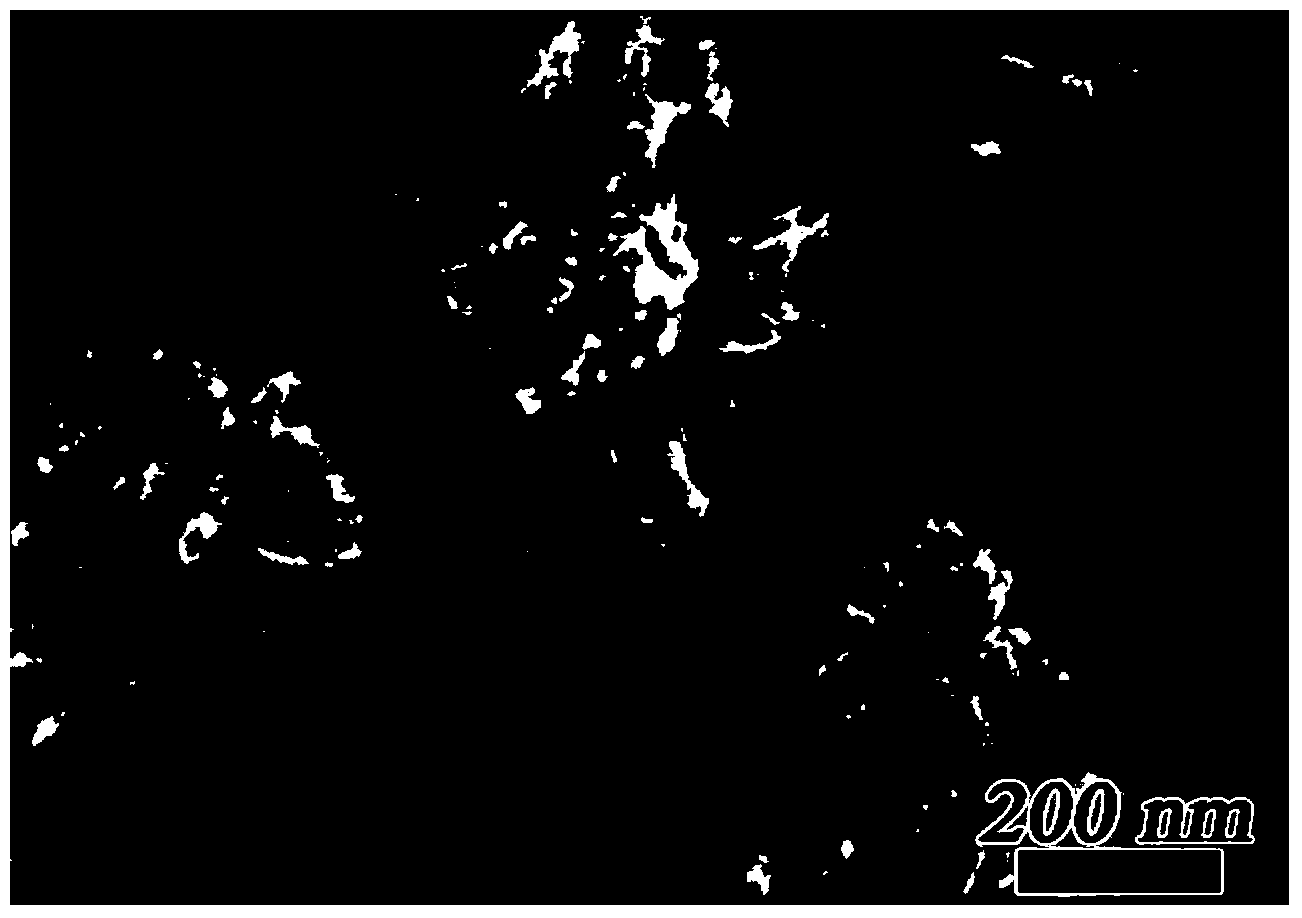

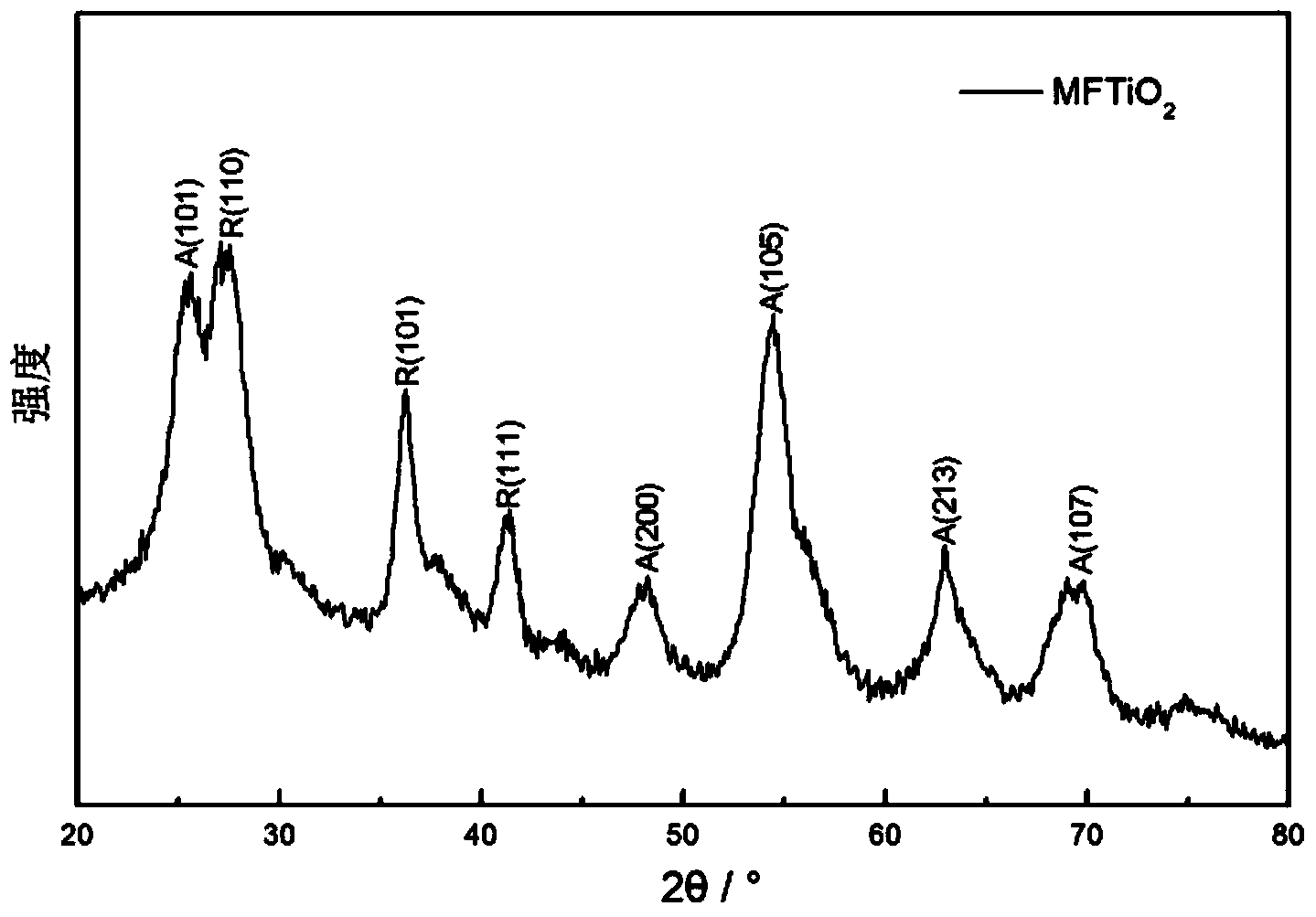

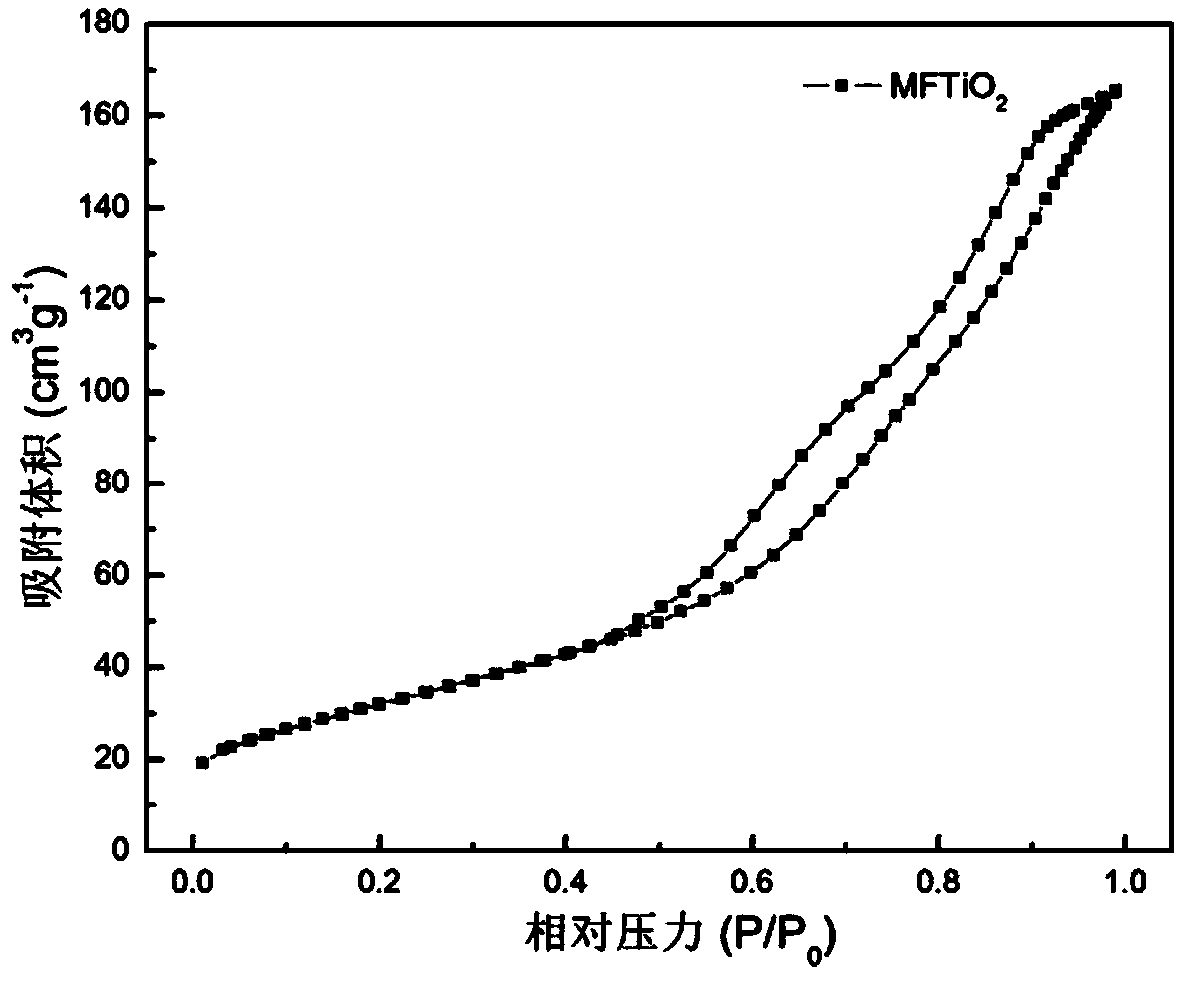

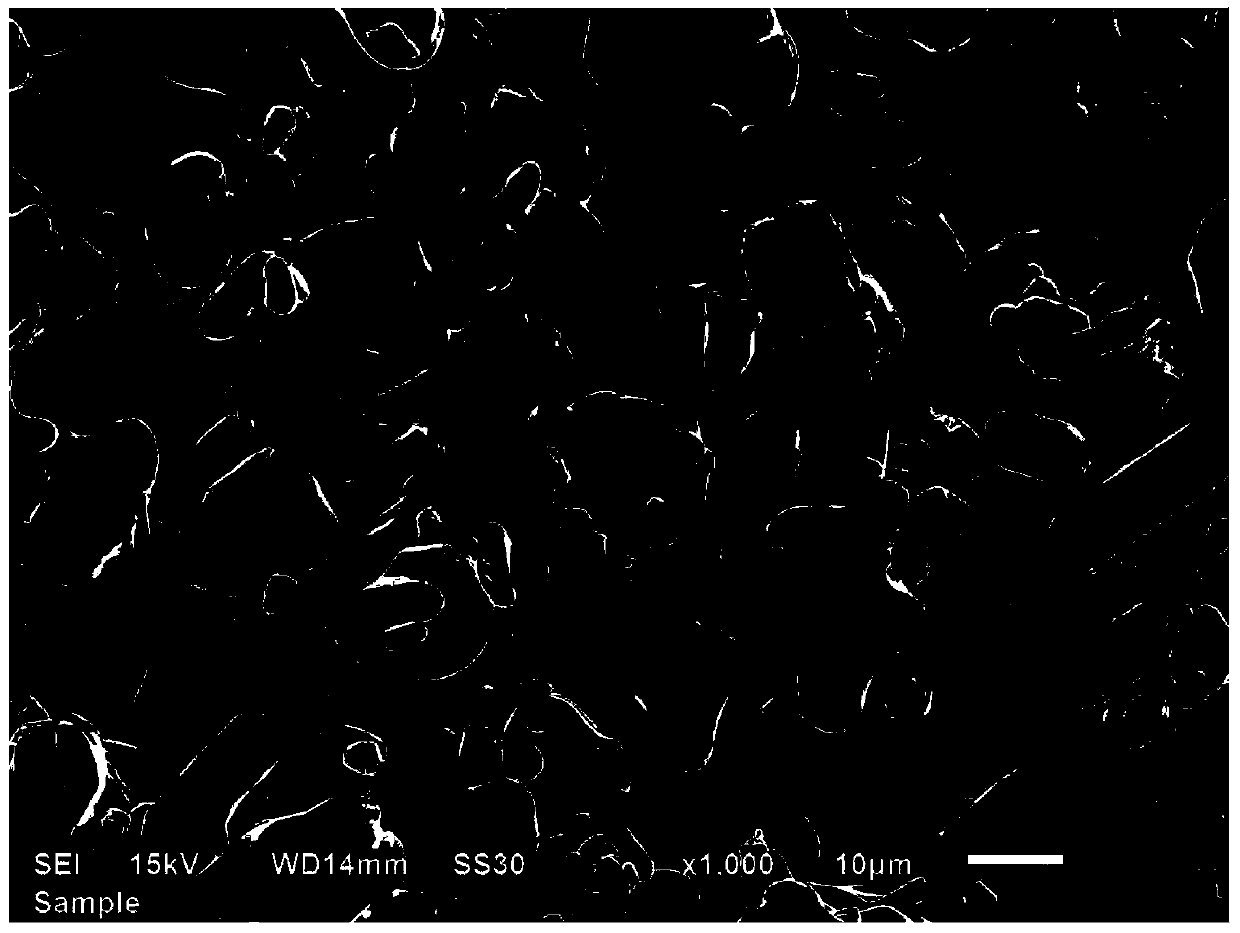

Flower-shaped mesoporous titanium dioxide material and preparation method and application thereof

InactiveCN104016405AEasy to makeLow reaction temperatureMaterial nanotechnologyPhysical/chemical process catalystsHigh ratePhotocatalytic water splitting

The invention discloses a flower-shaped mesoporous titanium dioxide material and a preparation method and application thereof. The material is prepared by the following method: 1) adding a template agent into a diluent, adding concentrated hydrochloric acid, and stirring evenly; 2) adding a titanium source into the solution, and stirring; 3) placing the solution in the conditions of the relative humidity above 60% at the temperature of 40-80 DEG C for 12h-24h, crystallizing at 80-90 DEG C for 6-12h; and 4) refluxing a sample to remove a surface active agent, and drying to obtain the flower-shaped mesoporous titanium dioxide. According to the method, high-temperature calcinations is not needed, the reaction synthesis temperature is lower than 100 DEG C, and the obtained flower-shaped mesoporous titanium dioxide material has the advantages of good monodispersity, high specific surface area and controllable crystalline phase and the like. The flower-shaped mesoporous titanium dioxide material can be used for negative electrode materials of a lithium ion battery, has high charge and discharge specific capacity, stable cycle performance, excellent high rate performance and very good photocatalytic activity, and can be used in the fields of degradation of organic pollutants, photocatalytic water splitting for hydrogen production, dye-sensitized solar cells and the like.

Owner:WUHAN UNIV OF TECH

Preparation method of lithium-rich anode strip of lithium ion battery

ActiveCN102856532AAdvantages of preparation methodQuick Lithium SupplementationCell electrodesMetallic lithiumLithium metal

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation method of a lithium-rich anode strip of a lithium ion battery. The preparation method comprises the following steps of 1, coating anode slurry on an anode current collector and drying to obtain an anode strip which comprises an anode diaphragm and needs lithium supplement, and 2, wetting the anode strip needing lithium supplement by an electrolyte until the anode diaphragm is wetted fully, and carrying out dual-channel contact between the anode diaphragm and lithium metal to obtain a lithium-rich anode strip, wherein in contact, a temperature is in a range of 10 to 150 DEG C and pressure intensity is less than 100MPa and contact time is less than 10 hours. Compared with the prior art, the preparation method has the advantages that an ion channel and an electron channel between lithium metal and the anode diaphragm can be formed simultaneously; a potential difference between an anode material and lithium metal can promote fast ionization of lithium metal so that lithium ions are formed; and the formed lithium ions are transferred and embed into anode active substance particles so that fast lithium supplement is realized. The preparation method has simple processes and can realize industrial batch production easily.

Owner:DONGGUAN AMPEREX TECH +1

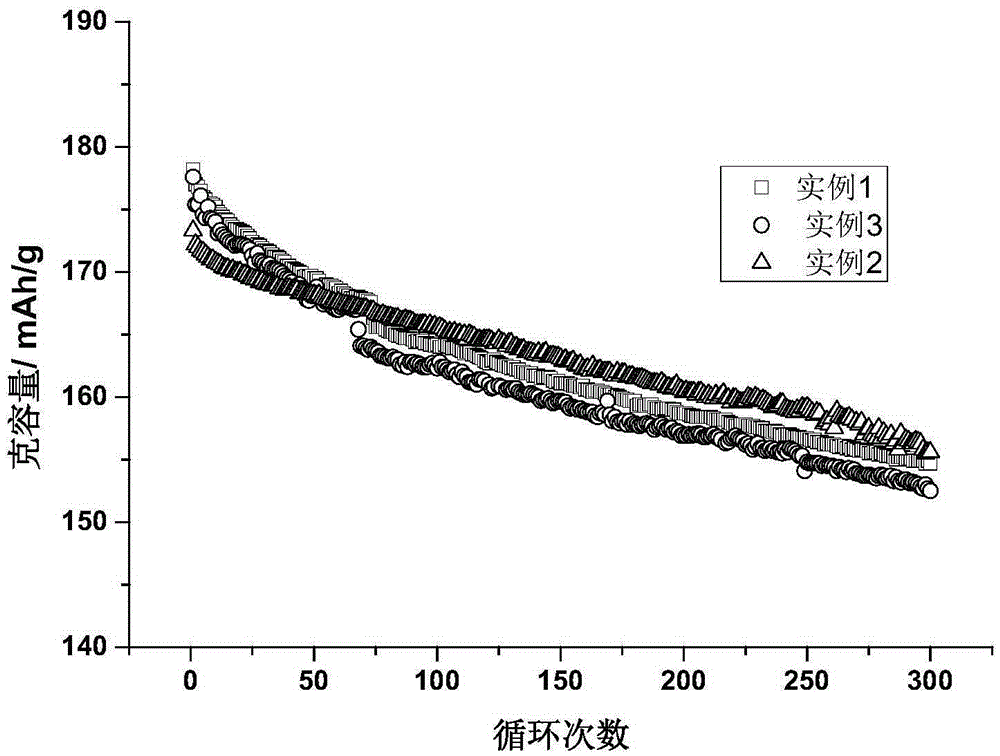

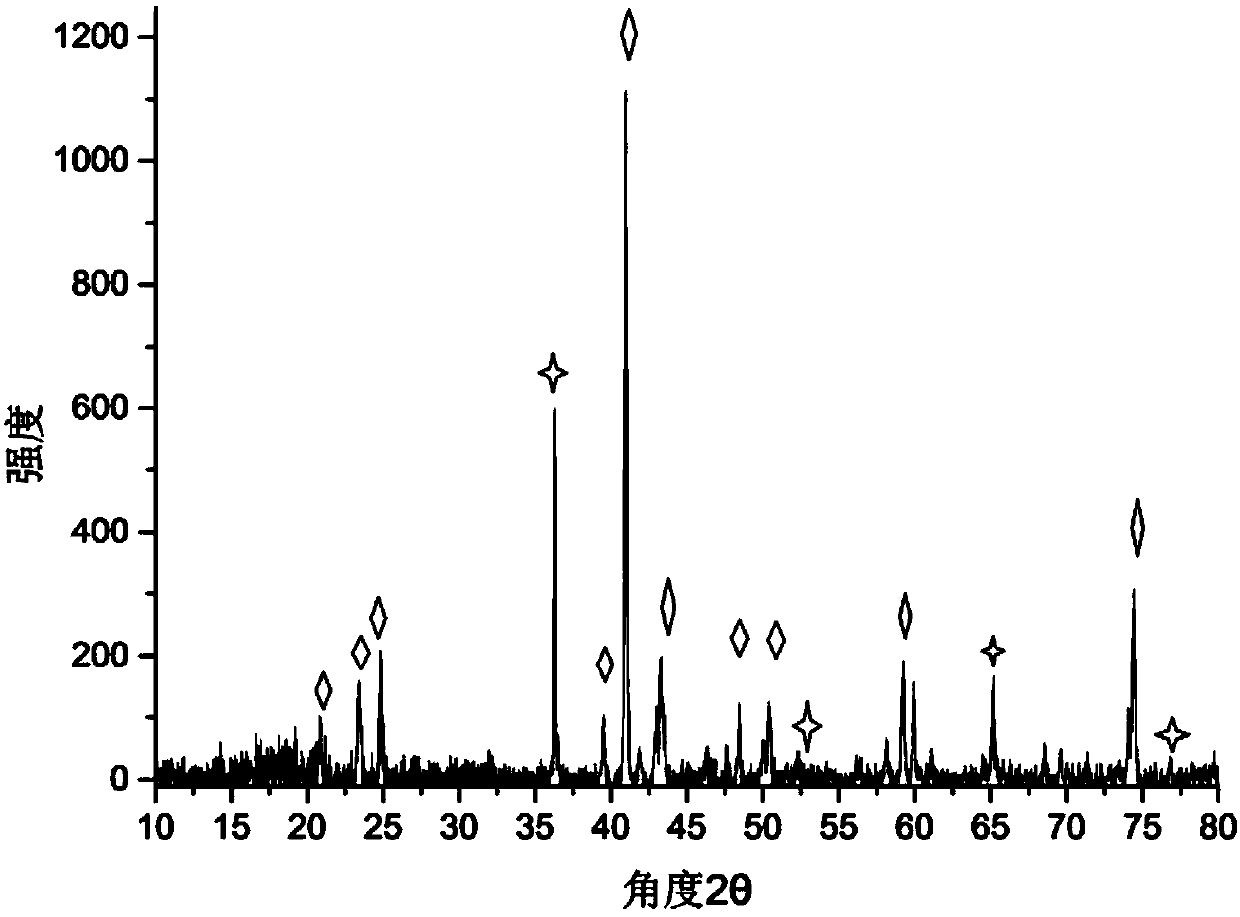

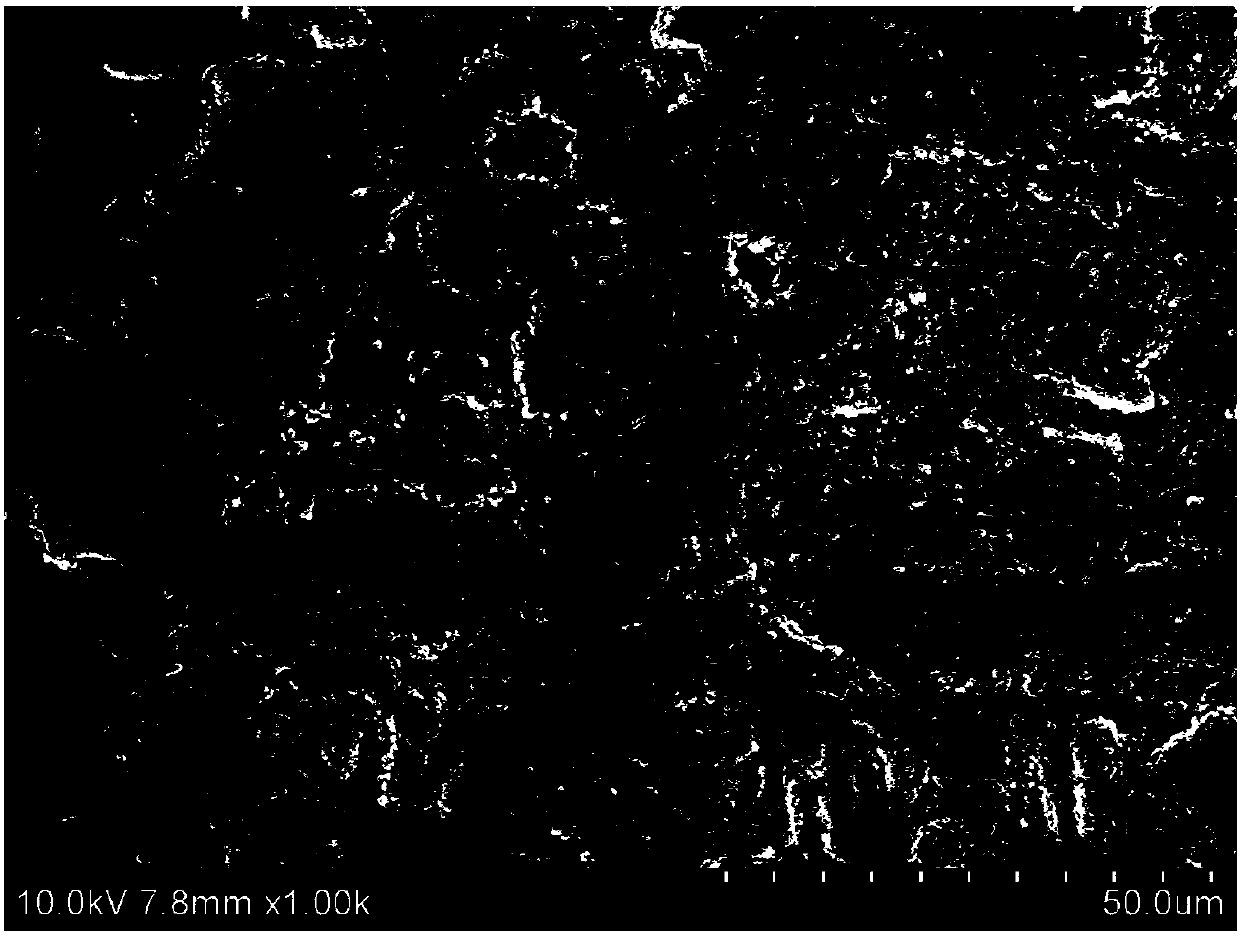

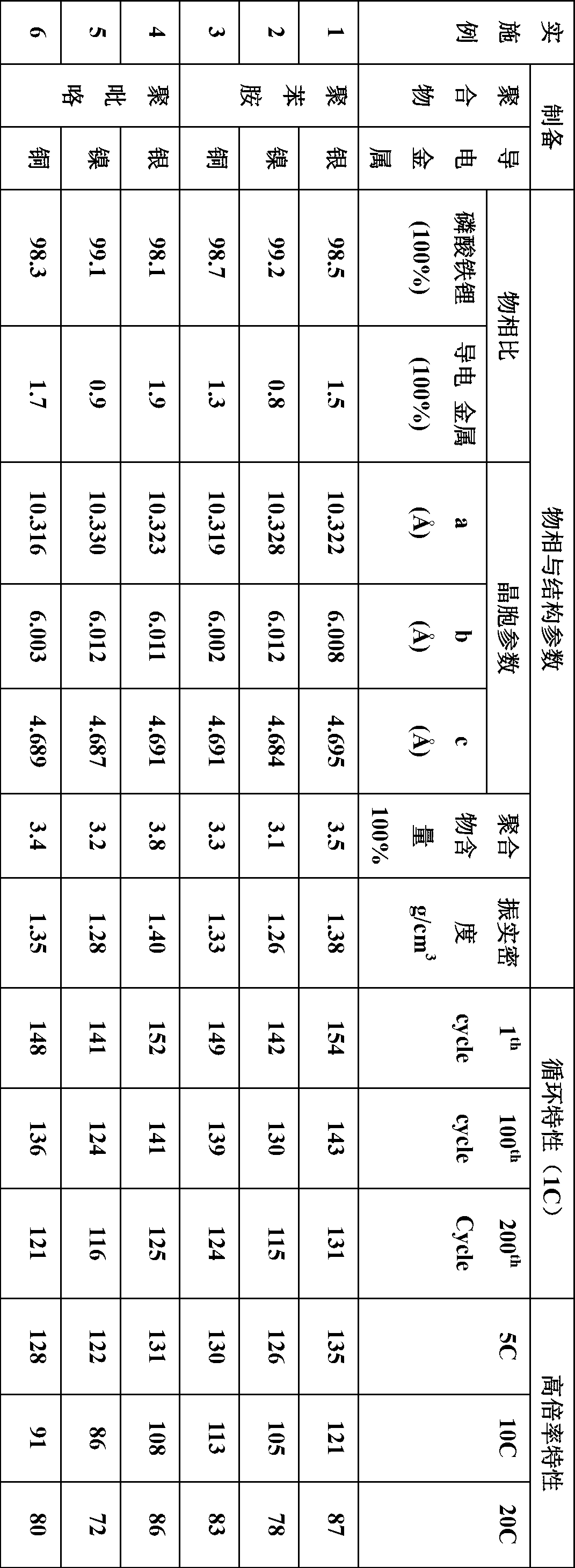

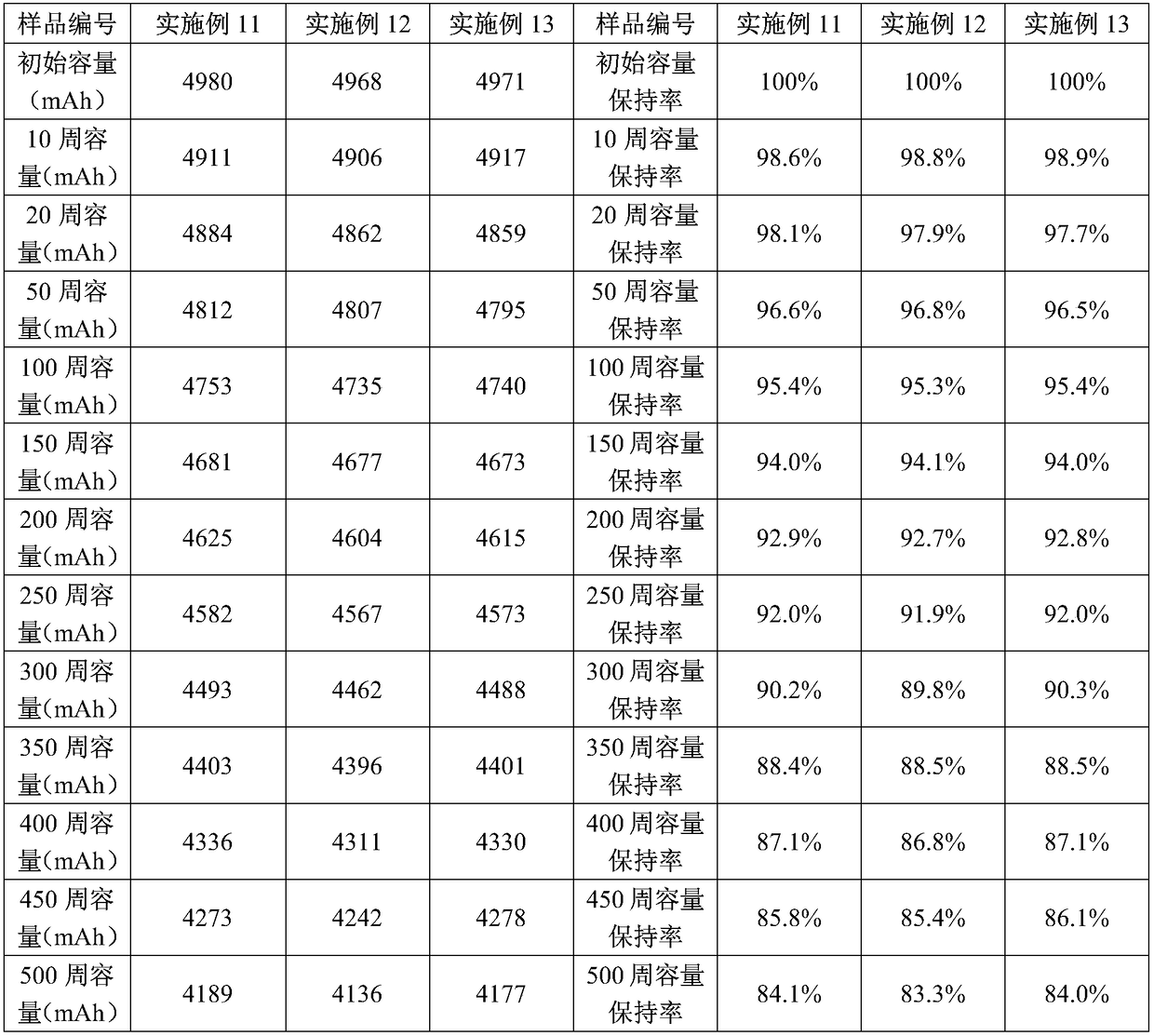

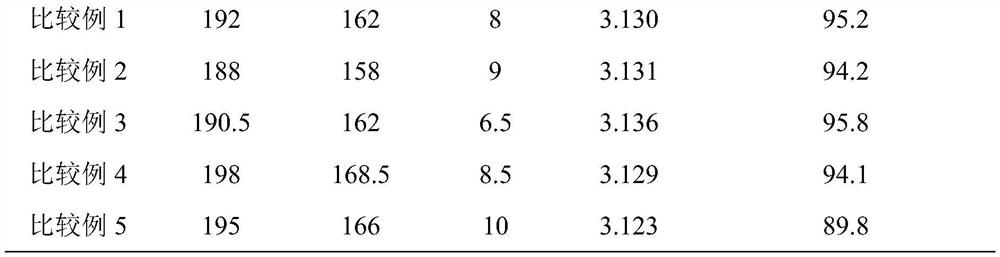

Pretreatment method of cobaltosic oxide for preparing high-voltage lithium cobalt oxide, high-voltage lithium cobalt oxides anode material and preparation method of high-voltage lithium cobalt oxide

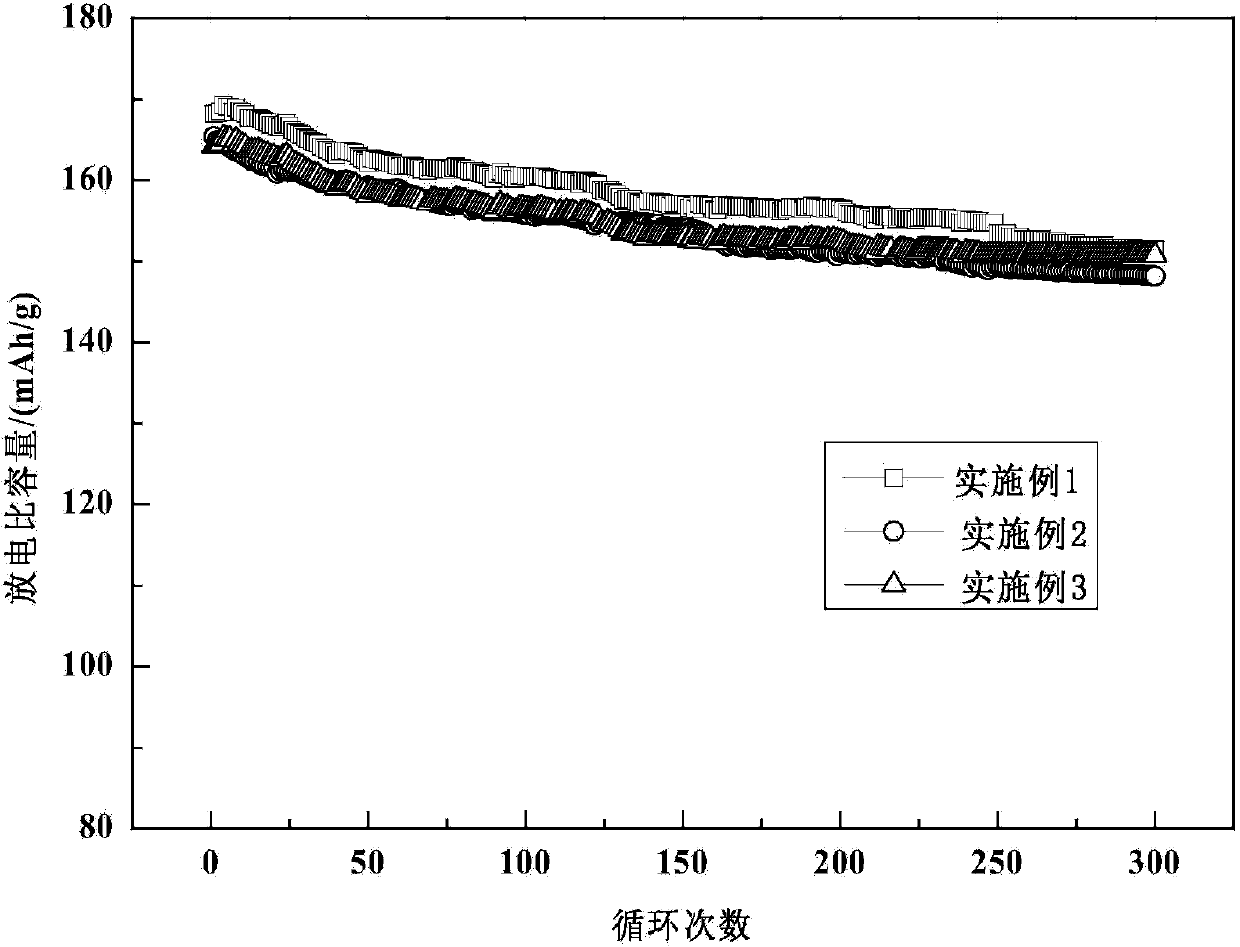

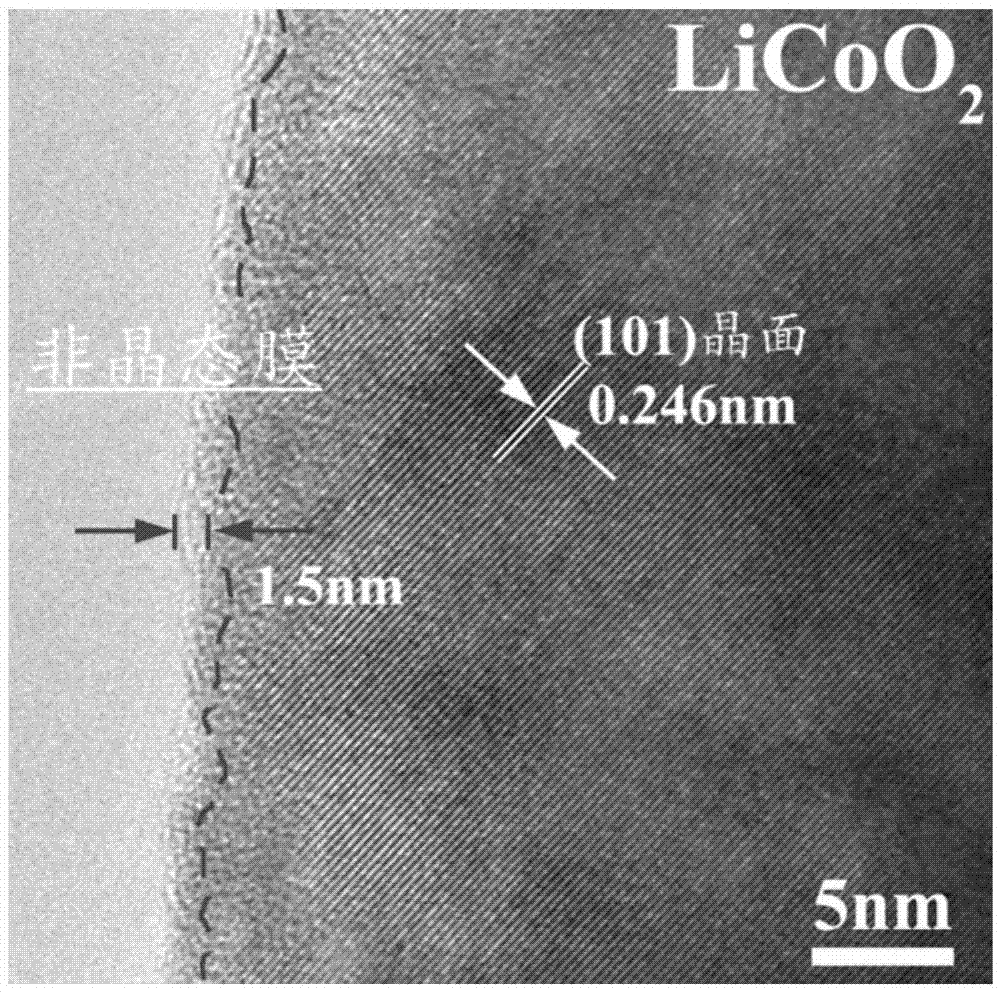

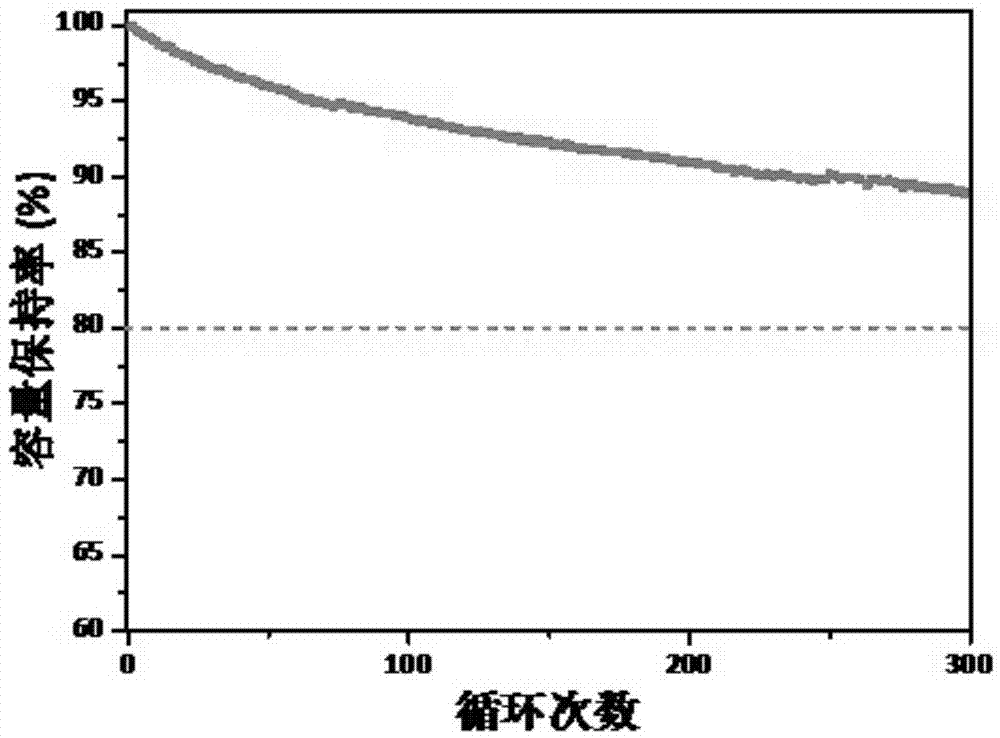

The invention discloses a pretreatment method of cobaltosic oxide. The method comprises the steps of mixing a titanium-containing organic matter with an organic solvent so as to obtain a mixed liquid; adding cobaltosic oxide powder into the mixed liquid under a stirring condition so as to form a turbid liquid, adding deionized water into the turbid liquid, adequately stirring the turbid liquid and the deionized water until a uniform pulp-shaped fluid material is formed, and drying the uniform pulp-shaped fluid material so as to obtain a cobaltosic oxide compound. The high-voltage lithium cobalt oxide can be obtained by adequately mixing the obtained cobaltosic oxide compound, a lithium source and a dopant to obtain a mixture, and performing solid sintering and covering on the mixture at a high temperature. The tap density of the prepared high-voltage lithium cobalt oxide is more than 3.0g / cm<3>, the compaction density is more than 4.2g / cm<3>, the primary discharge gram capacity in the range of 2.8V to 4.34V can reach more than 164mAh / g, and the circulating capacity retention rate in 300 weeks is more than 89 percent. The prepared high-voltage lithium cobalt oxide has the advantages of good processing performance, high tap density, good circulating performance, high specific capacity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

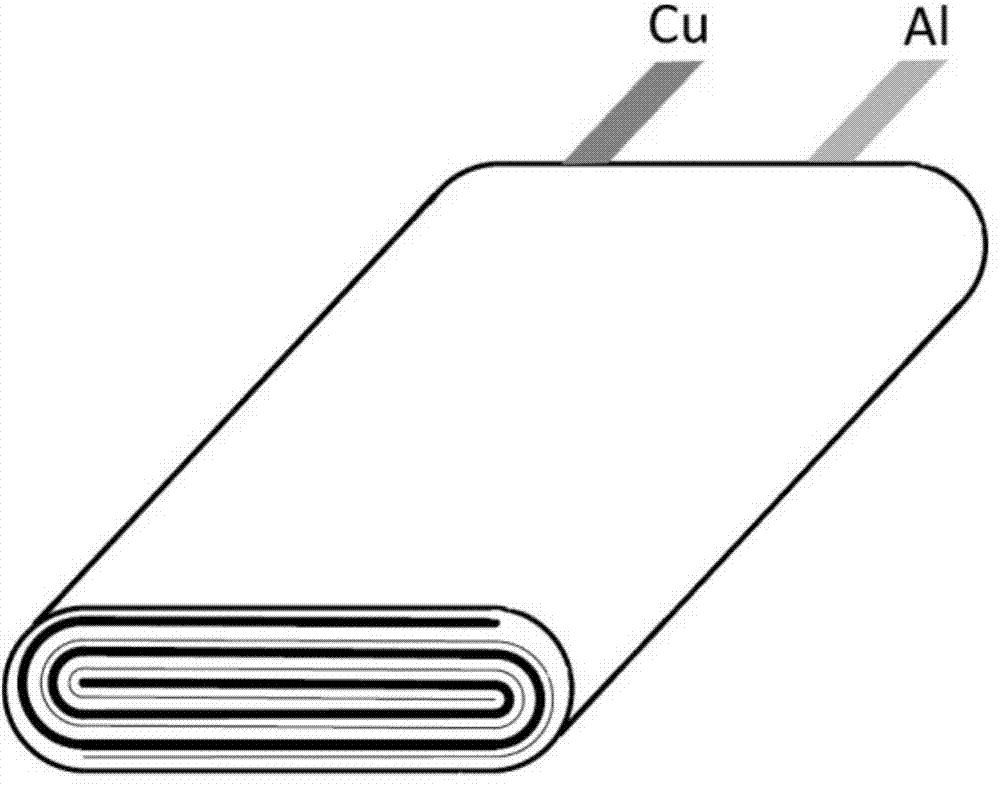

Lithium ion battery and manufacturing method thereof

ActiveCN103928704AGood high temperature storage performanceExcellent high temperature cycle performanceFinal product manufactureSecondary cellsHigh temperature storageElectrical battery

The invention provides a lithium ion battery. The lithium ion battery comprises a sealed packaging piece, and an electrode set and electrolyte which are arranged in the sealed packaging piece, wherein the electrode set comprises an anode piece, a cathode piece and a separation membrane arranged between the anode piece and the cathode piece; the lithium ion battery further comprises nano protection layers; the nano protection layers are arranged on the surface of the anode piece, the surface of the cathode piece and the surface of the separation membrane of the lithium ion battery; the thickness of each nano protection layer is 0.2-10nm. According to the lithium ion battery, a plasma enhanced type atom layer deposition layer is used for putting a wound battery core into a reaction cavity; meanwhile, the nano protection layers are uniformly plated on the surface of the anode piece, the surface of the cathode piece and the surface of the separation membrane, so that the lithium ion battery has excellent high-temperature storage performance, high-temperature cycle performance and safety performance; the lithium ion battery has the advantages of simple preparation method, low reaction temperature, small energy consumption, controllable thickness, wide reaction precursors, rapid deposition speed and capability of being produced in a large batch.

Owner:安普瑞斯(无锡)有限公司

Microphone array and method for implementing voice signal enhancement

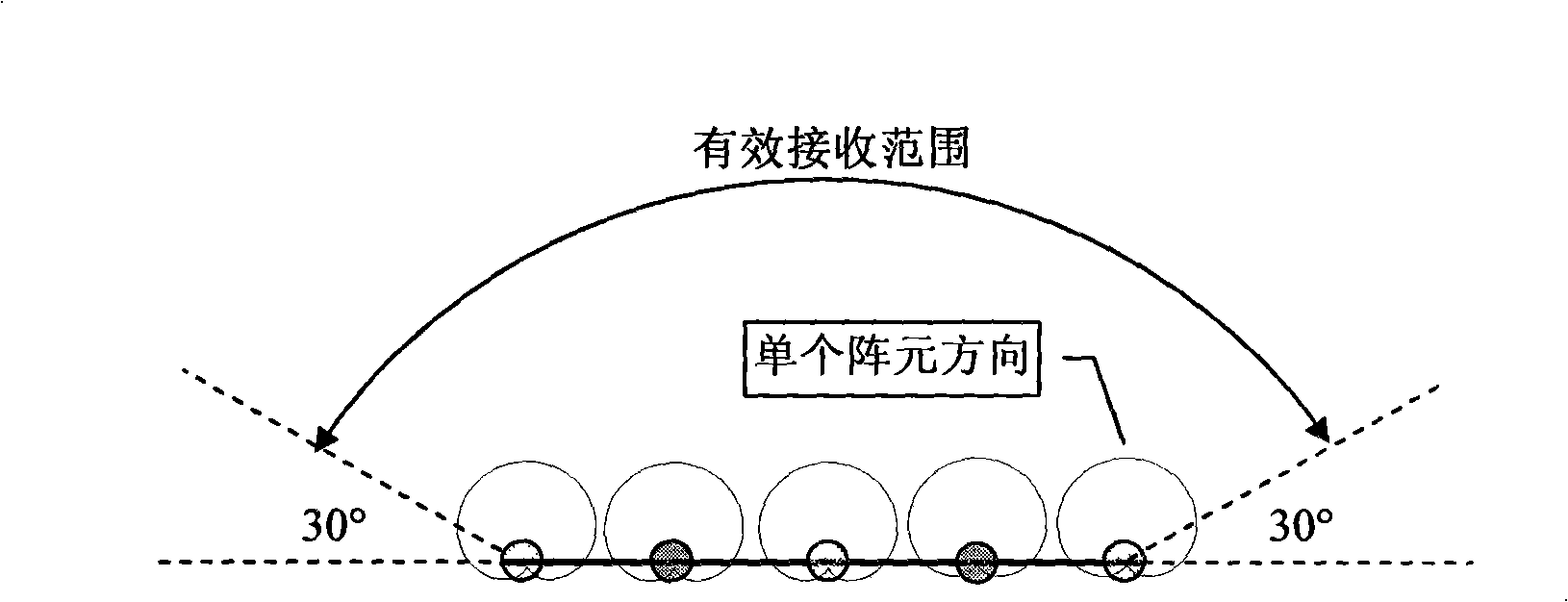

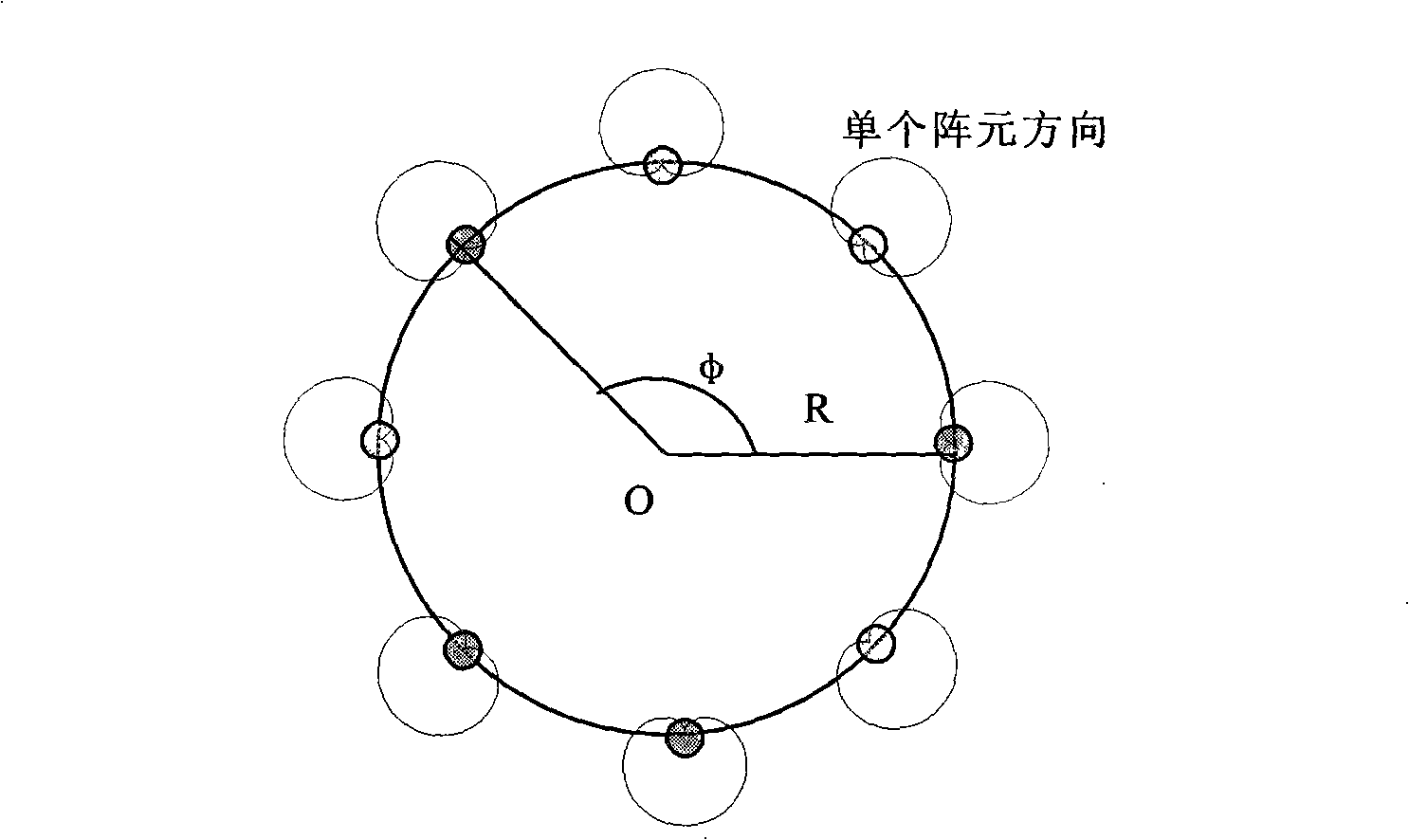

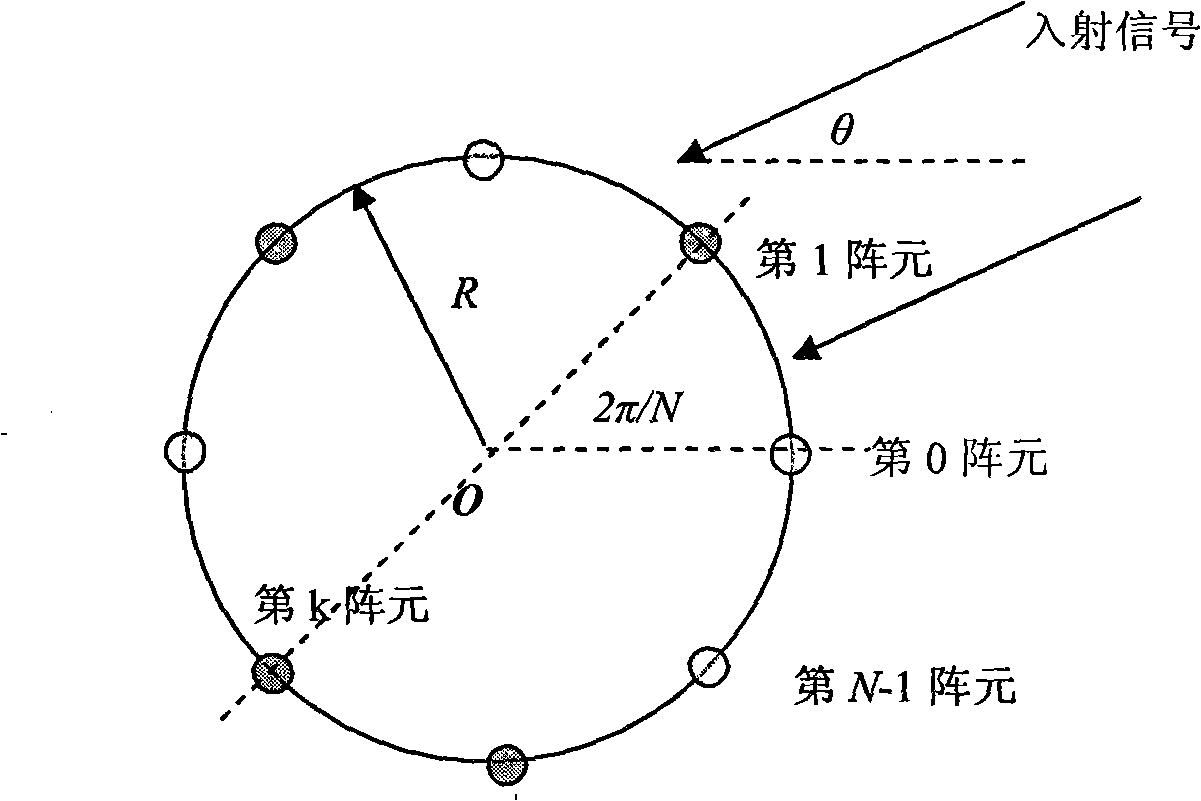

InactiveCN101351058AGuaranteed insensitivityReduce computationSpeech analysisFrequency/directions obtaining arrangementsEngineeringSpeech sound

The invention discloses a microphone array and a method for realizing the speech signal enhancement and is characterized in that firstly N matrix elements with factors in the same unit direction are uniformly and radially arranged outward on a circle with the radius of R; a circular array with radian ranges of 2Pi for receiving and treating signals is formed; or the matrix elements are uniformly and radially arranged outward on a passage of circular arc with the radius of R and a central angle of Phi to form part of a circular array for receiving and treating signals with the radian ranges of Phi; the weighted value of each matrix element and weighted vector corresponding with the incident direction in the radian ranges of 2Pi / N are calculated according to the center frequencies of audio signals of the array to be treated based on the expected signal doa; then weighted vectors of the whole circular array or part of the circular array or other incident directions is obtained by making use of cyclic shifting; finally, signals received on each matrix element are weighted and combined according to calculated weighted values.

Owner:XI AN JIAOTONG UNIV

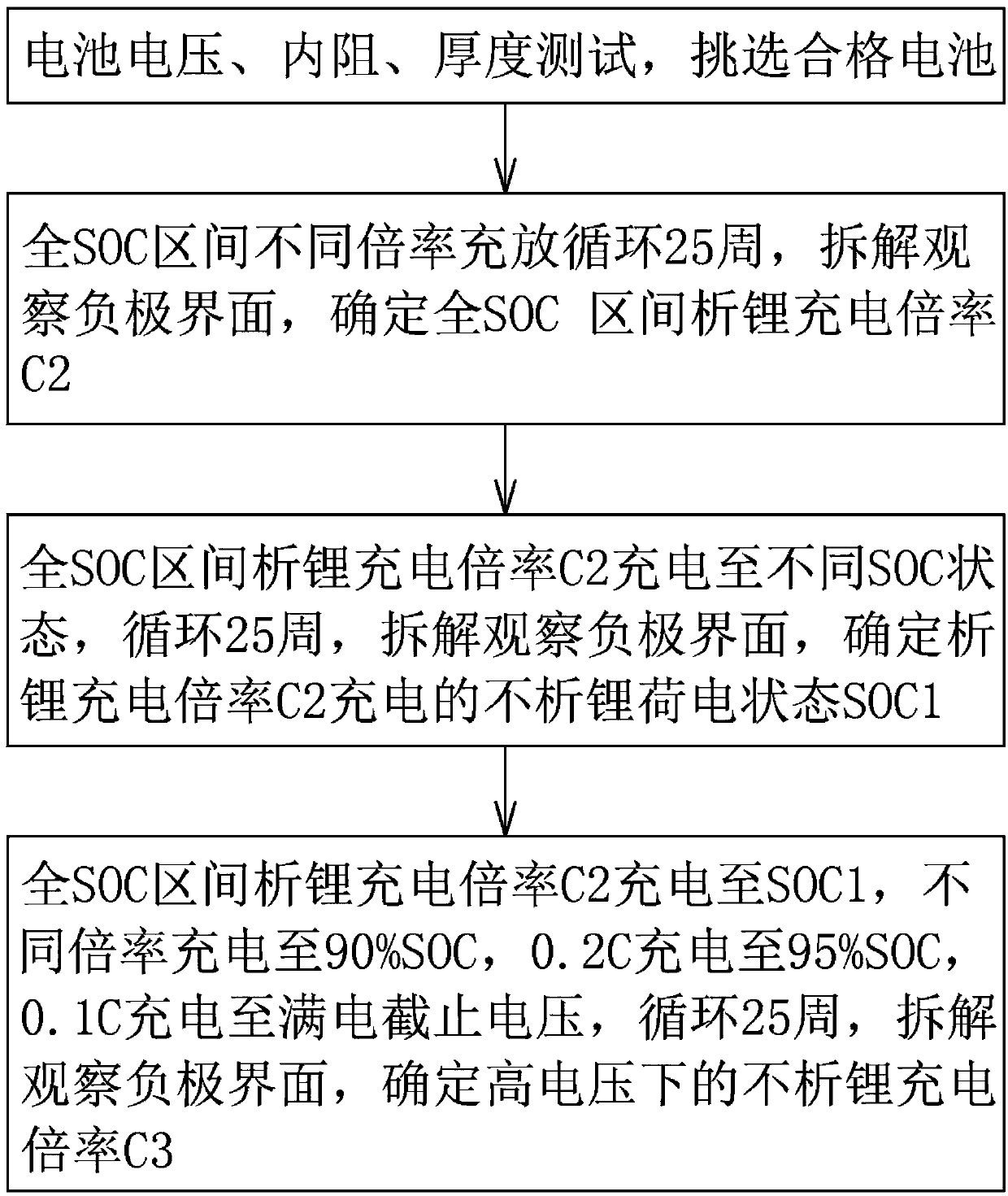

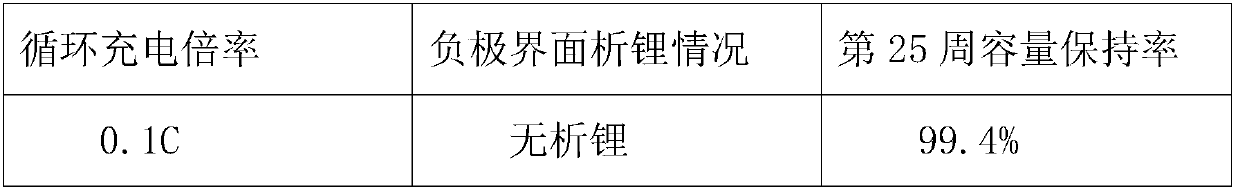

Optimization method for charging strategy of lithium-ion batteries

ActiveCN109546248AGuaranteed cycle performanceShorten charging timeSecondary cells charging/dischargingLithium electrodeBattery charge

The invention discloses an optimization method for the charging strategy of lithium-ion batteries. In a first stage, the lithium precipitation charging rate C2 is determined. In a second stage, the non-lithium-precipitation SOC1 under the lithium precipitation charging rate C2 is determined. In a third stage, the non-lithium-precipitation charging rate C3 under high voltage is determined. According to the optimization method for the charging strategy of lithium-ion batteries disclosed by the invention, a reasonable battery charging strategy is determined by determining the allowable maximum continuous rate of battery charging and the corresponding cut-off SOC state. The method is simple and fast, has guiding significance for the selection of the charging rate parameters of a vehicle charging strategy, ensures the cycle performance of batteries, reduces the actual charging time of batteries, can be used in the benchmarking of the charging performance of batteries from different manufacturers, and is conducive to improving battery design and manufacture technologies.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

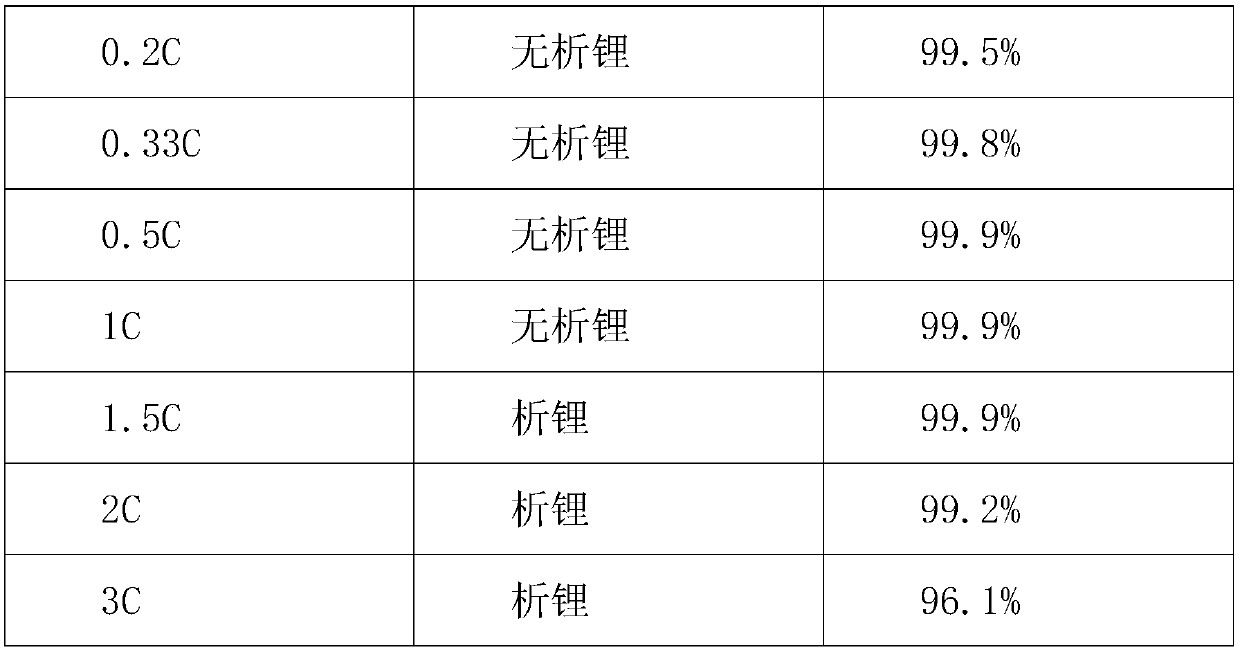

Method for improving durability of lithium-ion power battery, and lithium-ion power battery

ActiveCN104617260AStrong ability to absorb electrolyteIncrease liquid absorptionCell electrodesPower batteryLithium

The invention relates to a method for improving the durability of a lithium-ion power battery, and the lithium-ion power battery. The method comprises the following steps: conducting calcination on needle coke, and then carrying out high-pressure impregnation, graphitization treatment, pulverization for granulation, coating, and halogenation for purification to obtain an anode material capable of effectively improving the durability of the lithium-ion power battery; on the basis of the anode material, further preparing a negative pole piece and the lithium-ion power battery. The method has the advantages that the electrolyte absorptivity and the preserving capability of the anode material are improved, so that the negative pole piece made of the anode material can preserve more electrolyte; when the method is applied to a lithium-ion power battery encapsulated in a vacuum manner with an aluminum-plastic film, the defect that the quantity of preserved electrolyte is too small as the space between an aluminum-plastic film shell body and a battery core is too small can be overcome. Therefore, the aim to improve the durability of the lithium-ion power battery can be achieved.

Owner:苏州悦钠新能源科技有限公司

High practicality lithium nickel manganese oxide and preparation method thereof

InactiveCN104900865ASmall specific surface areaGuaranteed cycle performanceCell electrodesSecondary cellsCarbon layerMaterials processing

The invention discloses a high practicality lithium nickel manganese oxide and a preparation method thereof. The lithium nickel manganese oxide is characterized in that manganese source, lithium source, nickel source and a certain amount of grinding aid are blended by a dry grinding mode, the lithium nickel manganese oxide material with low specific surface area is prepared by using the characteristics of slow crystal nucleation rate and little nucleation of a precursor, contact area of the material and an electrolyte is increased, cycle life of the material is increased; cation disorder degree and crystal structure dislocation of the crystal can be controlled through a multi-step calcining technology for guaranteeing the multiplying power performance of the material; the obtained lithium nickel manganese oxide coats the surface of a carbon layer by using a vapour deposition method, anchoring strength of the material and a current collector is enhanced, peeling intensity of pole sheet is enhanced, material processing property is ensured, and multiplying power performance is increased. The material has the advantages of long service life and good processing property, and is the lithium nickel manganese oxide material with high practicality, the preparation method is economic and easy to operate, and is suitable for commercialization popularization.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

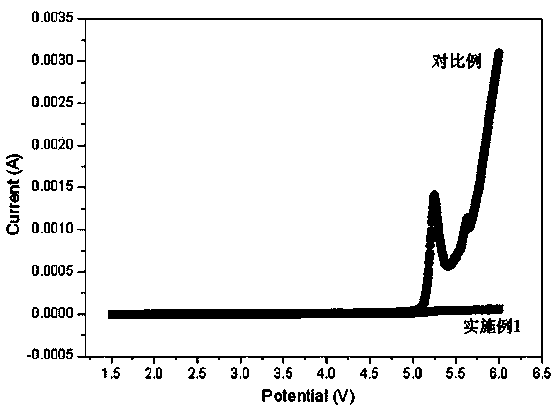

High voltage electrolyte for lithium ion batteries

ActiveCN104282939AImprove solubilityAvoid structural changesSecondary cellsSolubilityHydrofluoroether

The invention discloses a high voltage electrolyte for lithium ion batteries, the high voltage electrolyte is composed of an organic solvent, electrolyte lithium salt and a cathode film-forming additive, wherein the organic solvent is a mixed solvent of fluorinated ethylene carbonate, trifluorinated propylene carbonate and hydrofluoroether, the electrolyte lithium salt mixed is lithium salt of lithium hexafluorophosphate and lithium bis(oxalate)borate. The high voltage electrolyte effectively solves the problems that fluorinated solvents are high in viscosity and the electrolyte lithium salt is poor in solubility in fluorinated organic solvents, so that the fluorinated organic solvents can be directly used as the organic solvents in lithium ion battery electrolyte, the high voltage electrolyte has wide electrochemical window and good oxidation resistance and high voltage resistant characteristics, has high electric conductivity, can guarantee the high magnification and power characteristics of a power battery, is high in safety, and can greatly improve the safety performance of the power battery.

Owner:WANXIANG 123 CO LTD

High-voltage lithium cobalt positive electrode material and preparation method and application thereof

ActiveCN110224123AImprove structural stabilityHigh discharge specific capacitySecondary cellsPositive electrodesLithiumCobalt

The invention discloses a high-voltage lithium cobalt positive electrode material and preparation method and application thereof. The high-voltage lithium cobalt positive electrode material comprisesan inner layer and a coating layer, wherein the inner layer is lithium cobalt particle core gradiently doped with nickel and aluminum, the doping content of the nickel in lithium cobalt particle is gradually reduced from inside to outside, the doping content of the aluminum in the lithium cobalt particle is gradually increased from inside to outside, the coating layer is a lithium cobalt compositeoxide containing M' element, and M' is selected from one or more of Ni, Mn, Al, Ti, Y, Zr, La, P, Nb, Sb and Ce. Meanwhile, the preparation method and application thereof of the high-voltage lithiumcobalt positive electrode material is also provided. The lithium cobalt material has better structure stability under a high voltage, higher discharging specific capacity and excellent cycle property.The preparation method and process of the lithium cobalt material is simple, and the operation process is controllable.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

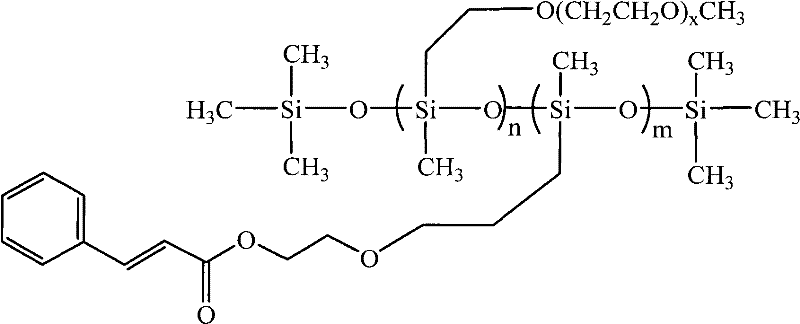

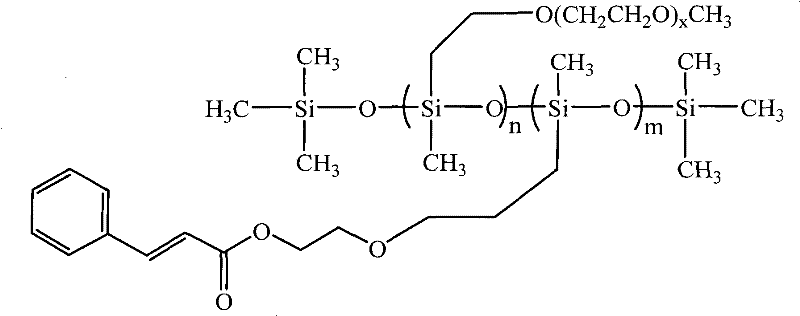

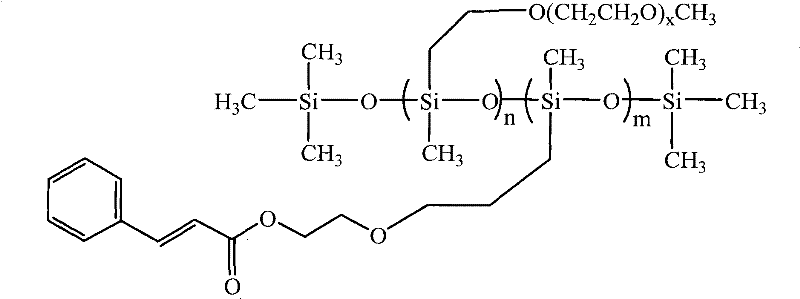

Composition for battery diaphragm, battery diaphragm and lithium-ion secondary battery

ActiveCN102206420AImprove securityGuaranteed cycle performanceSecondary cellsCell component detailsLithiumPolyolefin

The invention provides a composition for a battery diaphragm, containing modified polysiloxane, a solvent and an inorganic filler, wherein the modified polysiloxane has a structure shown as a formula 1. The invention also provides a battery diaphragm prepared from the composition and a lithium-ion secondary battery containing the battery diaphragm. The composition for the battery diaphragm provided by the invention contains the modified polysiloxane shown as the formula 1, the main chain segment of the modified polysiloxane is an inorganic silica chain segment, and the modified polysiloxane has favorable compatibility with the inorganic filler so that anode and cathode circuit breaking can be still ensured when a porous polyolefin film shrinks due to overhigh temperature and the safety performance of the battery is improved; in addition, a lateral group ethyoxyl repeating unit of the modified polysiloxane can enhance the affinity of lithium ions and reduce the internal resistance of the diaphragm, and a lateral group cinnamoyl group can be cured and crosslinked without any initiator or being heated, thus the cycle performance of the battery is ensured effectively.

Owner:BYD CO LTD

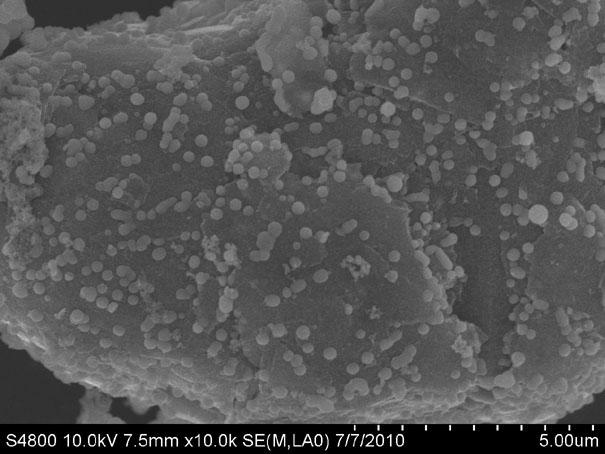

Preparation method of lithium iron phosphate anode material co-coated by conducting polymer/nanometer metal particles

ActiveCN102983329ACapable of deintercalating lithiumEasy accessCell electrodesWater bathsConductive polymer

The invention discloses a preparation method of a lithium iron phosphate anode material co-coated by conducting polymer / nanometer metal particles. The preparation method comprises the following steps of: (1) sufficiently diffusing a polymer monomer and lithium iron phosphate powder in an acid solution, so as to obtain a mixed solution A, wherein the polymer monomer is one or a combination of more than one of aniline, pyrrole, thiophene and 3,4-ethylenedioxythiophene; (2) adding a metallic compound in the mixed solution, and sufficiently diffusing to obtain a mixed solution B, wherein the metallic compound is one of silver nitrate, nickel nitrate, nickel sulfate, copper nitrate, copper sulfate, chloroauric acid and chloroplatinic acid; and (3) adding an oxidant in the mixed solution B, carrying out ultrasonic water bath on the obtained reaction mixtures at a temperature of 0-30 DEG C for 1-4 hours; standing for 1-2 hours at the room temperature, filtering, washing and drying so as to obtain the lithium iron phosphate anode material co-coated by the conducting polymer / nanometer metal particles by. The material provided by the invention has the advantages of high material capacity and good rate capability.

Owner:嘉善县国创新能源研究院

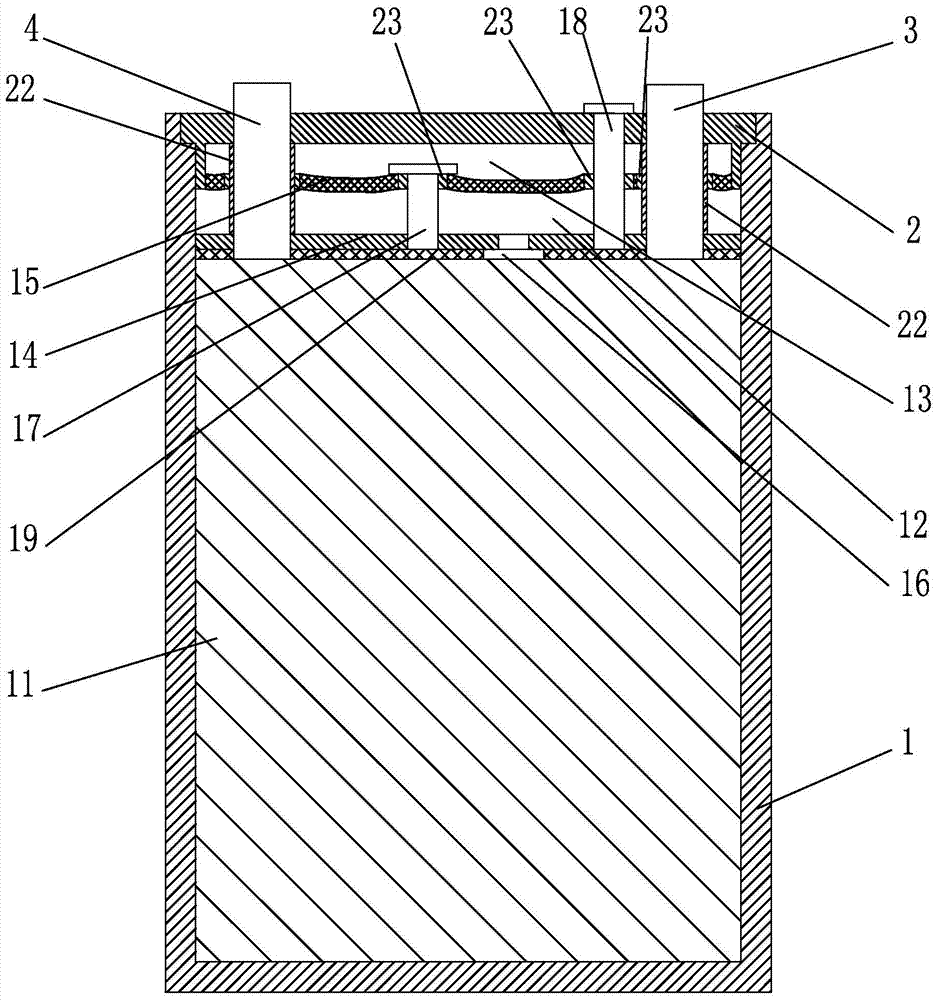

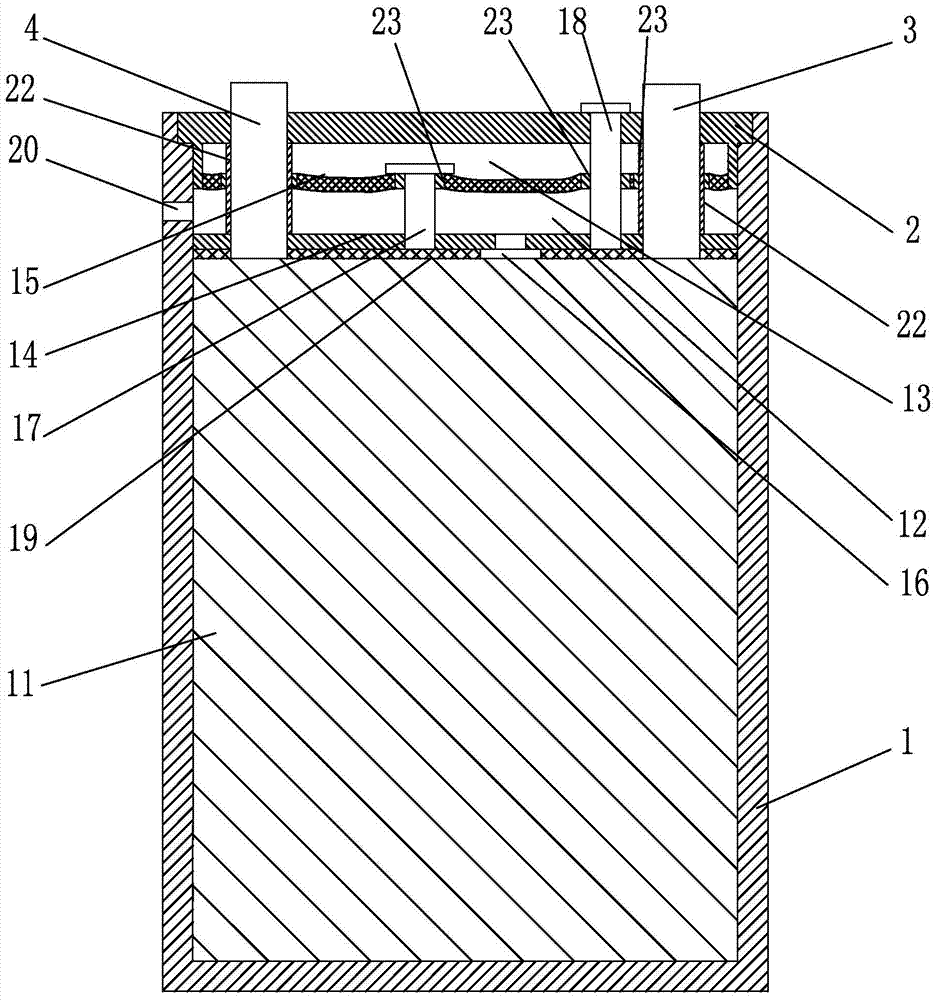

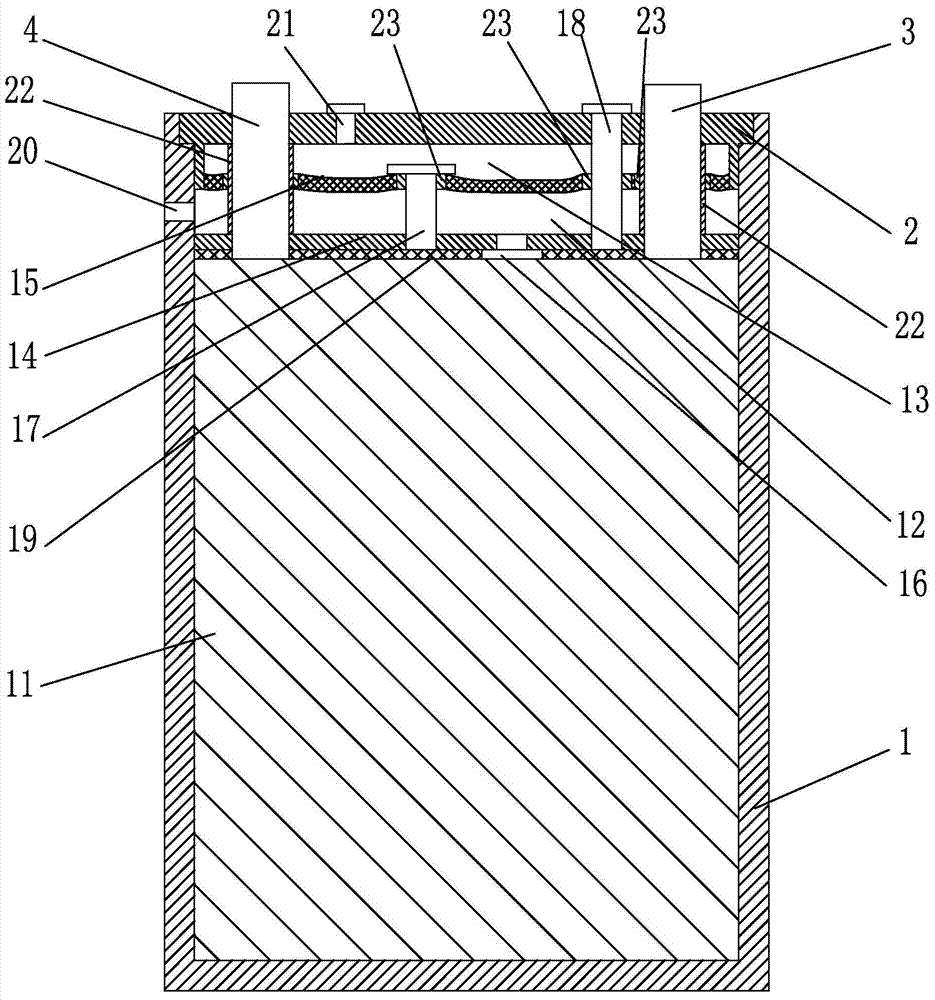

Lithium-ion battery with pneumatic anti-gas-expansion automatic liquid replenishing device

ActiveCN105449152AAvoid safety accidentsImprove safety performanceFinal product manufactureCell component detailsLithium electrodeElectrical and Electronics engineering

The invention relates to the technical field of safety of lithium-ion batteries, and discloses a lithium-ion battery with a pneumatic anti-gas-expansion automatic liquid replenishing device. The lithium-ion battery comprises a battery shell, a battery top cover board, a positive pole, a negative pole and a battery core, wherein the battery core is arranged in the battery shell; the inside of the battery shell is divided into a battery core cavity, a backup electrolyte cavity and a gas buffer cavity; the backup electrolyte cavity is filled with a backup electrolyte; a fixed partition plate is used for partitioning the battery core cavity and the backup electrolyte cavity; a pneumatic elastic film is used for partitioning the backup electrolyte cavity and the gas buffer cavity; a one-way valve A is arranged on the fixed partition plate; one-way valves B are arranged on the fixed partition plate and the pneumatic elastic film; a one-way exhaust valve is arranged on the battery top cover board; and breathable moisture absorption layers are arranged at air inlets of the one-way valve A located at the bottom of the fixed partition plate and the one-way exhaust valve. According to the lithium-ion battery with the pneumatic anti-gas-expansion automatic liquid replenishing device, the potential safety hazard caused by battery gas expansion can be effectively solved; and the electrolyte can be automatically replenished timely.

Owner:WANXIANG 123 CO LTD

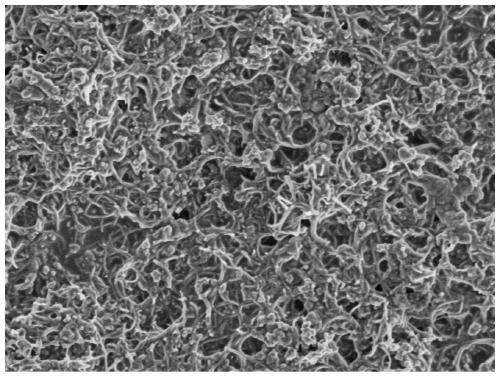

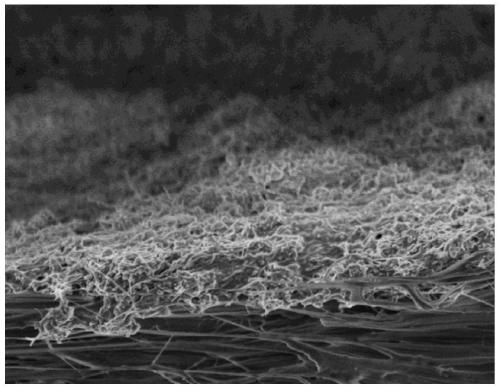

A high-energy silicon-containing lithium battery and a preparation method thereof-

ActiveCN109244386AReduce sheddingReduce electricity lossCell electrodesSecondary cellsHigh energyGram

The invention discloses a high-energy silicon-containing lithium battery, wherein the conductive agent of the positive electrode is 0.02-0.06% single-walled carbon nanotubes and 0.2-0.6% graphene: Thenegative electrode sheet is made of the following ingredients in parts by weight: up to 100% of the negative electrode active material, 0-1% of conductive carbon black, 0.02-0.08% of single-walled carbon nanotubes, 1-2% of CMC and 1.2-2.5% of binder; The negative electrode active material is carbon silicon and / or oxygen silicon, and the gram capacity is more than or equal to 650 mAh / g; The binderis prepared from styrene-butadiene rubber, acrylic acid and PMMA in 5-7: 1: 2-4 by weight ratio. The high-energy silicon-containing lithium battery has better charging and discharging stability, volume expansion resistance, cycle performance and stability under the premise of high energy by optimizing the conductive agent composition of the positive and negative electrodes and optimizing the binder.

Owner:广西卓能新能源科技有限公司

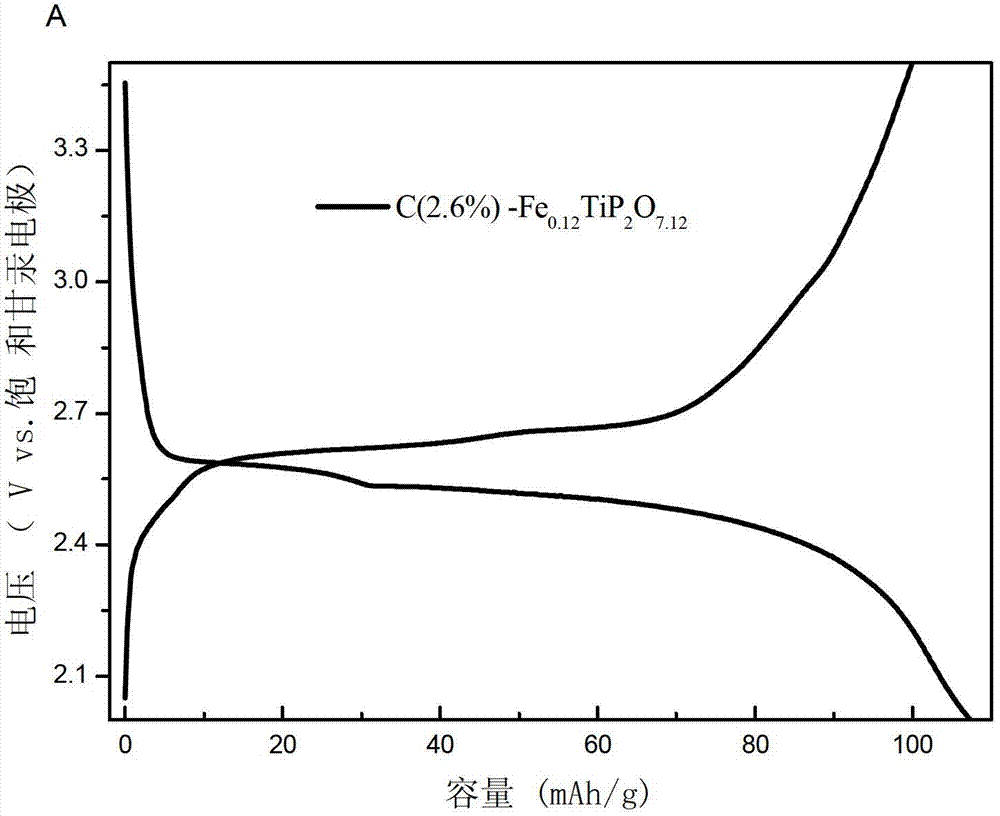

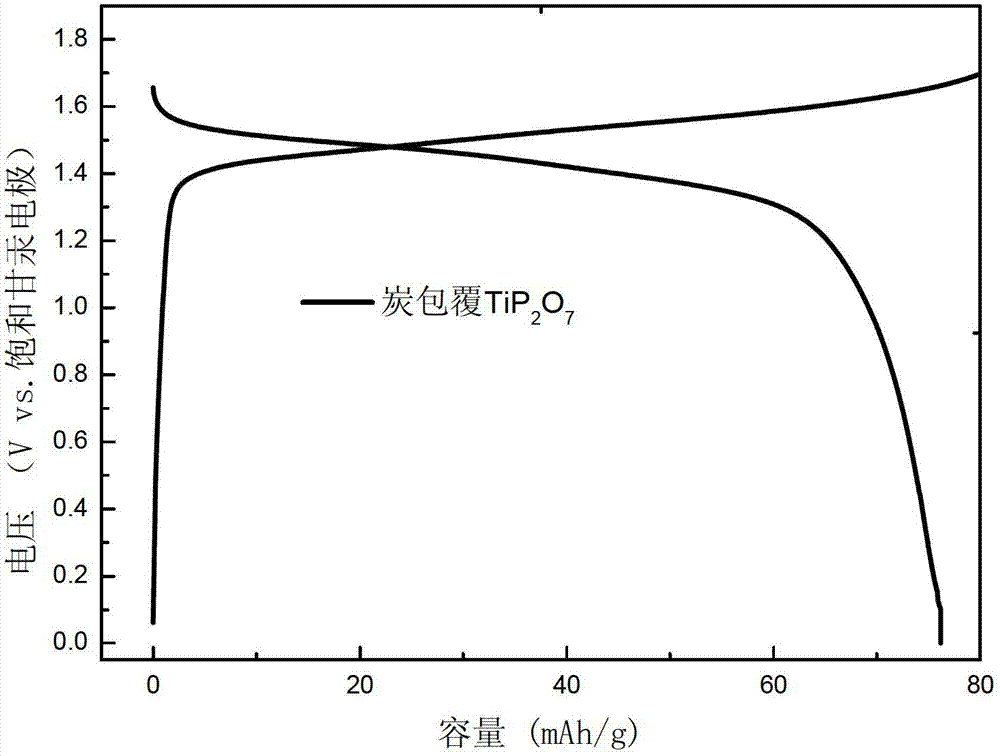

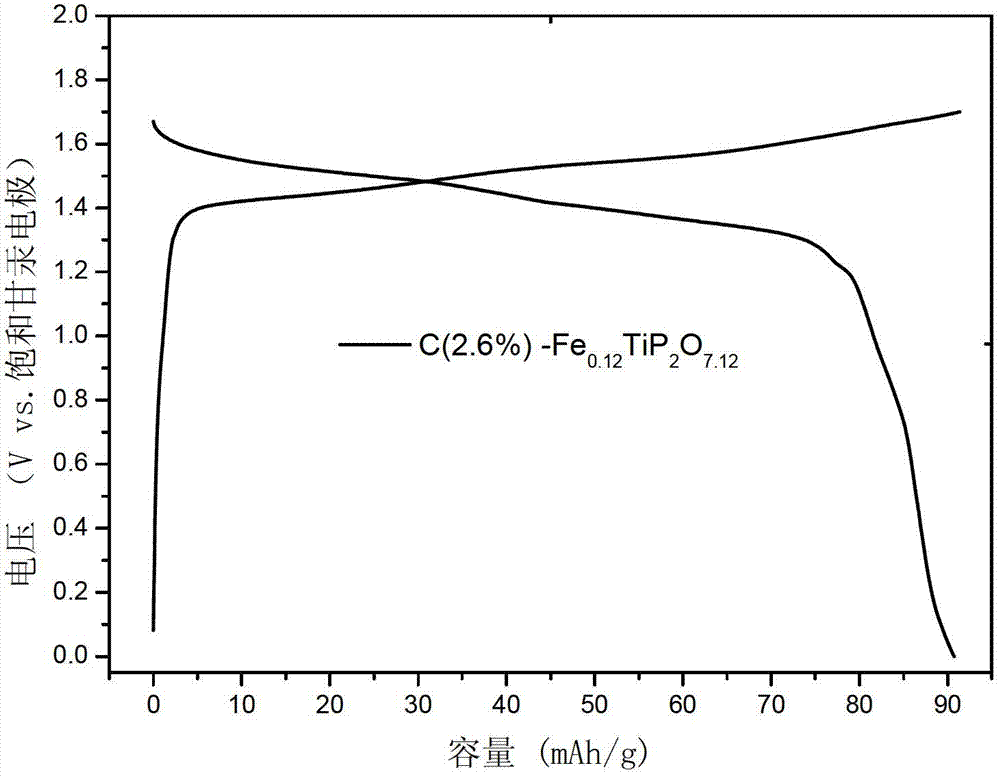

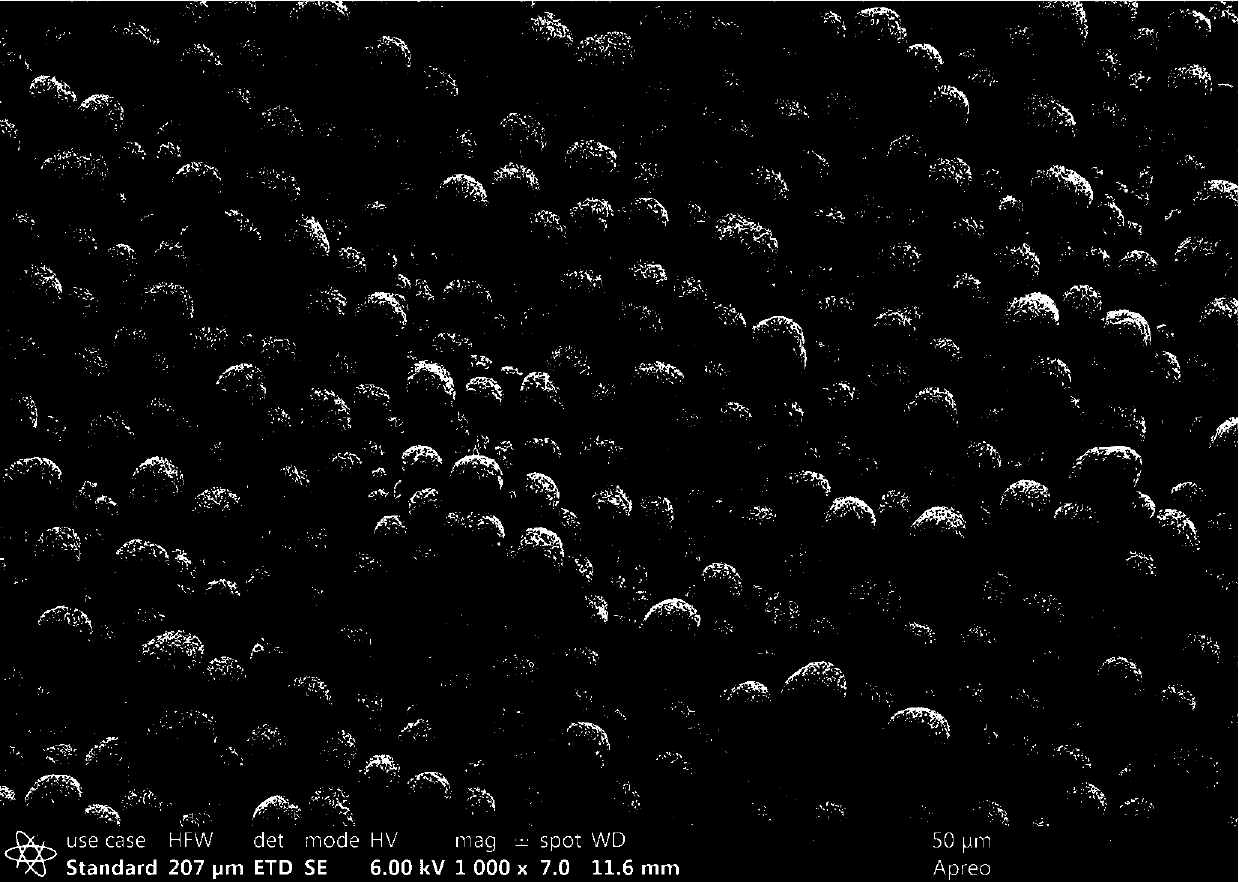

High-performance lithium ion battery electrode material and preparation method

ActiveCN103199245AIncreased rate capacityImproved magnification performanceCell electrodesElectrical conductorPhosphoric acid

The object of the present invention is to provide a novel titanium phosphate electrode material having good lithium ion battery characteristics, and is to solve the problem that the cycle life of a titanium pyrophosphate electrode material is poor in the prior art. The electrode material is intercalation compound carbon-coated C-Fe[x]TiP[2]O[7+x], and is a fast ion conductor electrode material of a three-dimensional structure. A preparation method comprises: (1) mixing and grinding TiO2 and NH4H2PO4, adding distilled water, stirring until the mixture is dried, finally placing the mixture in air for calcination to obtain TiP2O7; and (2) taking TiP2O7 obtained in Step (1) as a raw material, weighing TiP2O7 and an iron source material, mixing evenly, then adding a carbon source aqueous solution, stirring continuously at 40 DEG C until the mixture is dried, and finally calcining the mixture in a nitrogen atmosphere to obtain carbon-coated C-Fe[x]TiP[2]O[7+x].

Owner:常州孚达新能源科技有限公司

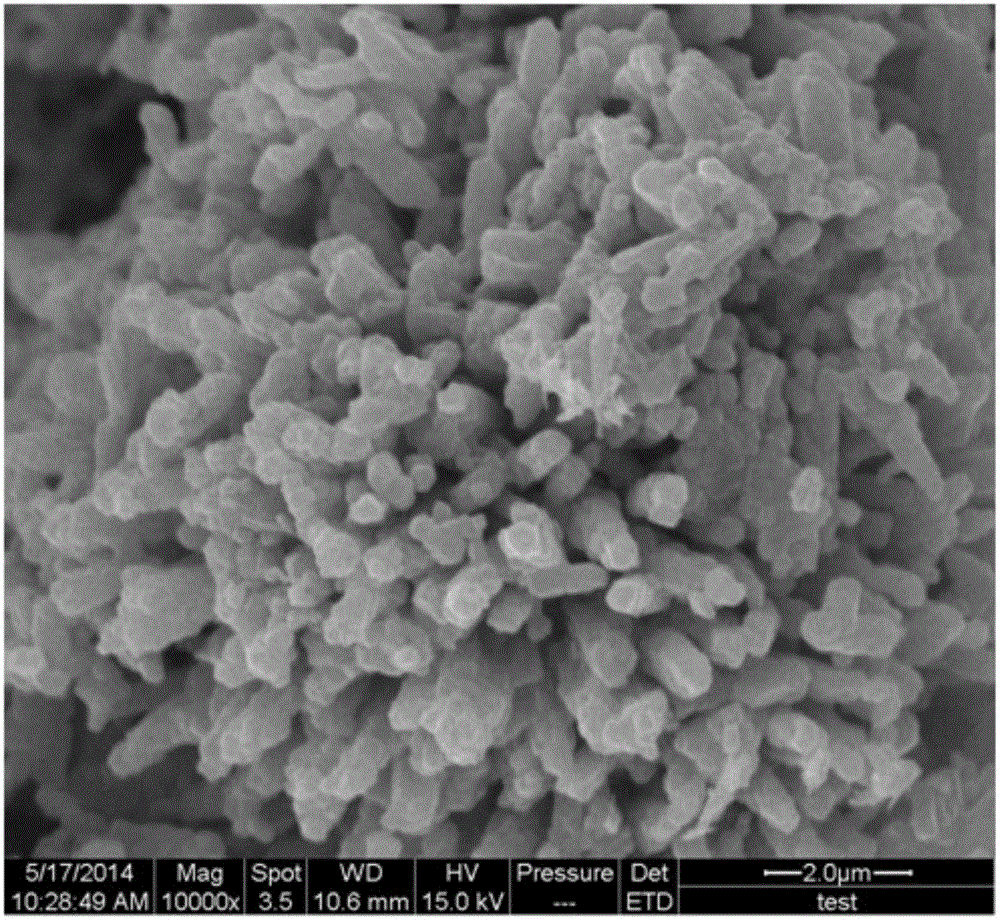

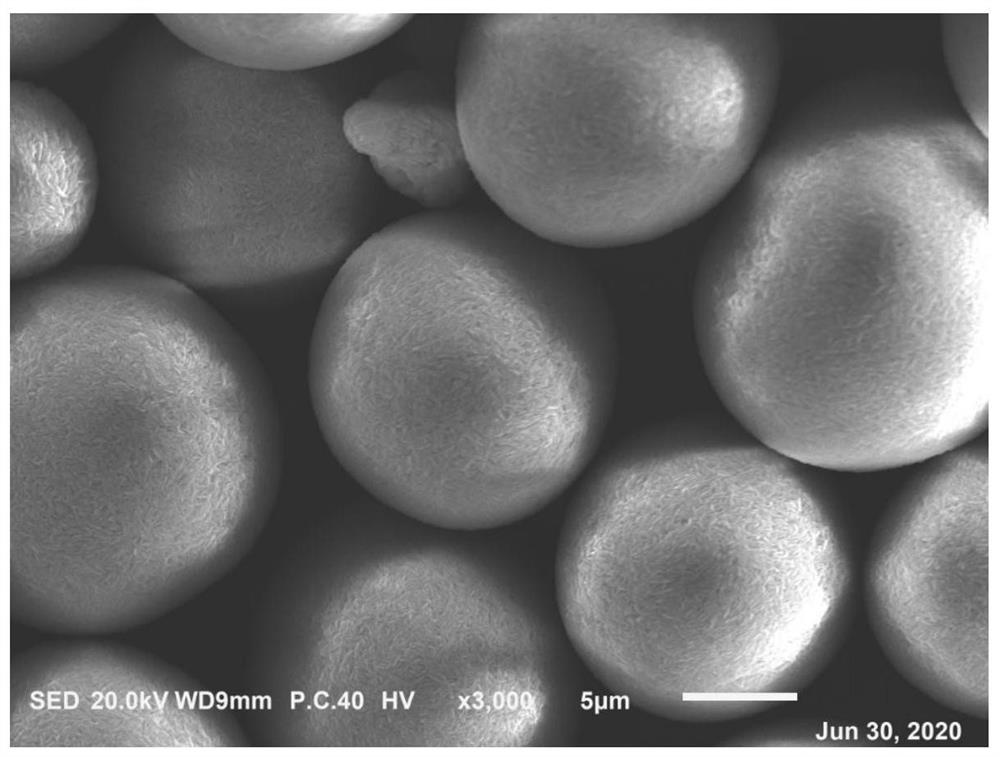

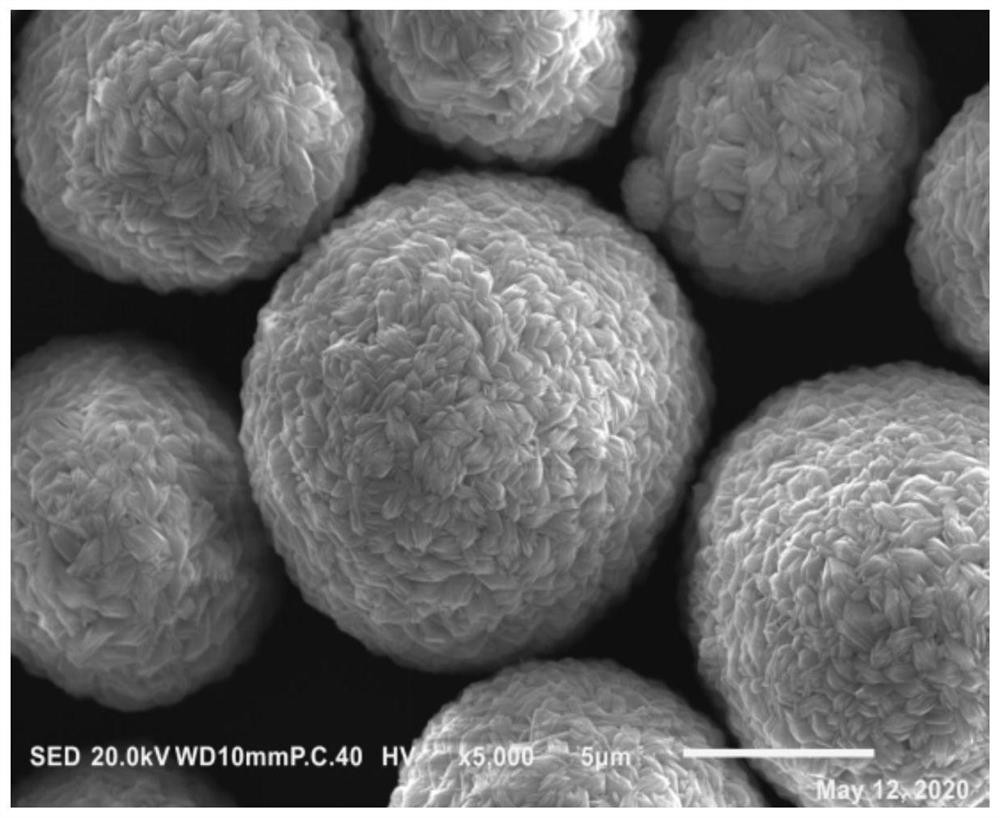

Preparation method of ternary precursor

The invention provides a preparation method of a ternary precursor, and belongs to the technical field of lithium ion battery materials. A technology combining intermittent concentration with a separation kettle is adopted to stably control the reaction condition of each step. The growth of secondary particles of a precursor is controlled by gradually reducing the pH in the reaction process, and the structure of the precursor is gradually changed from loose to dense by setting a precise clearing amount. The solid content of a slurry in a kettle is adjusted through the separation kettle to makethe precursor have a multilayer core-shell design with a loose-compact structure. The precursor prepared in the invention has the advantages of narrow particle size distribution, good sphericity degree and uniform size, has the multilayer core-shell with the loose-compact structure, and has enough space during circulation and crystal form mutation to avoid structural collapse and ensure the circularity, stability and safety of the precursor. Compared with precursors with internal complete voids, the ternary precursor of the invention has the advantages of compact and stable structure, high energy density, and solving of the problems of poor circularity, stability and safety of common ternary precursors.

Owner:帕瓦(兰溪)新能源科技有限公司

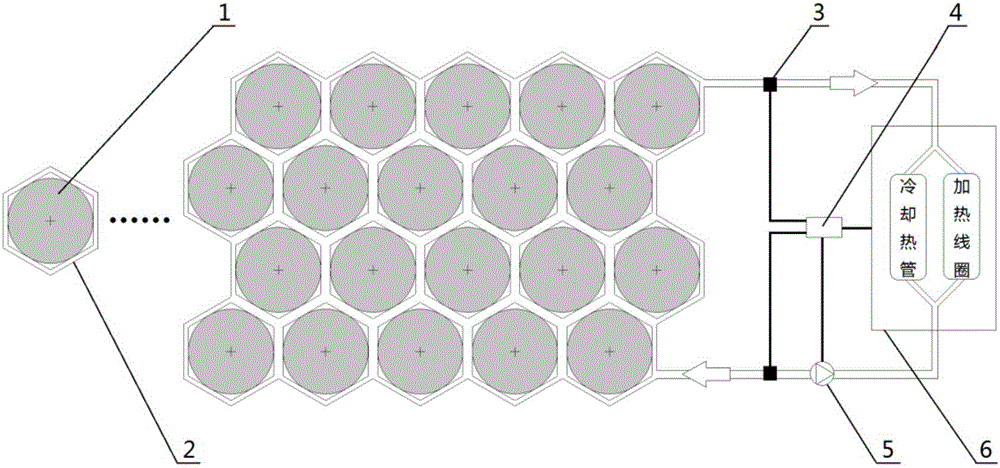

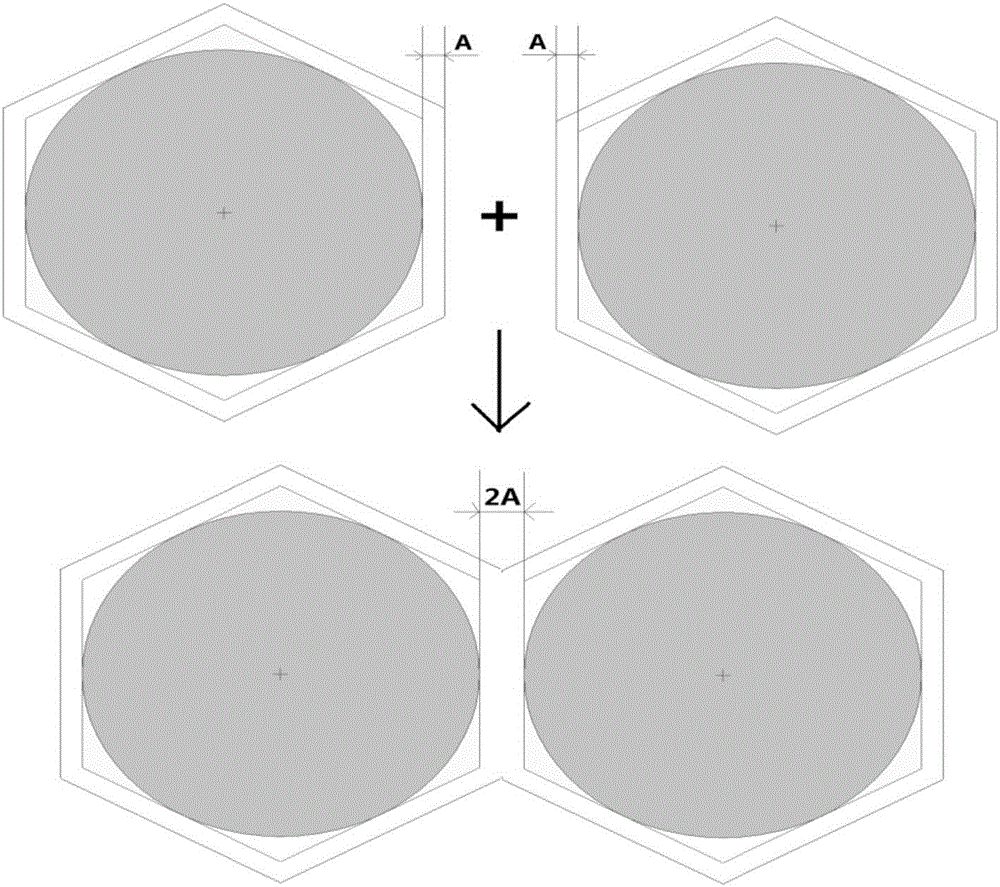

Thermal management system for batteries

PendingCN106374163ANot easy to squeeze and deformGuaranteed uptimeSecondary cellsElectrical batteryHeat conducting

The invention provides a thermal management system for batteries. A battery module comprises a plurality of batteries and a hexagonal honeycomb heat-conducting material hollow structure, wherein the batteries are internally tangentially embedded into the hexagonal honeycomb heat-conducting material hollow structure; channels are arranged between adjacent hexagons of the hexagonal honeycomb heat-conducting material hollow structure; the channels form a passage; the passage is filled with a heat exchange medium; the passage is connected with a heating and cooling device; the passage is provided with a thermocouple; the heating and cooling device and the thermocouple are connected with a controller separately; and the controller controls the heating and cooling device to heat or cool the battery module according to the temperature fed back by the thermocouple. According to the thermal management system for the batteries, the batteries have relatively good safety, and the operation stability of the batteries is improved.

Owner:GREE ELECTRIC APPLIANCES INC

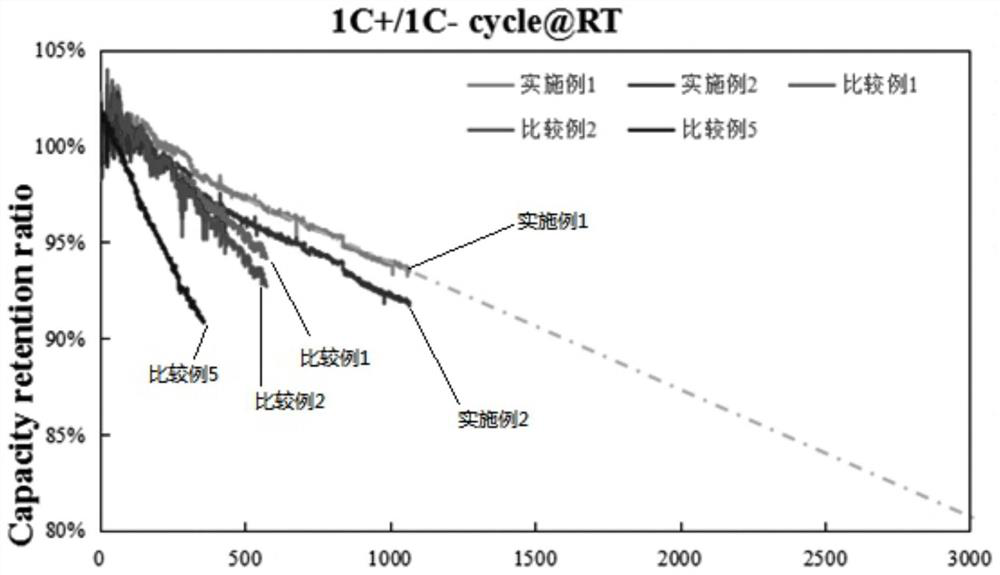

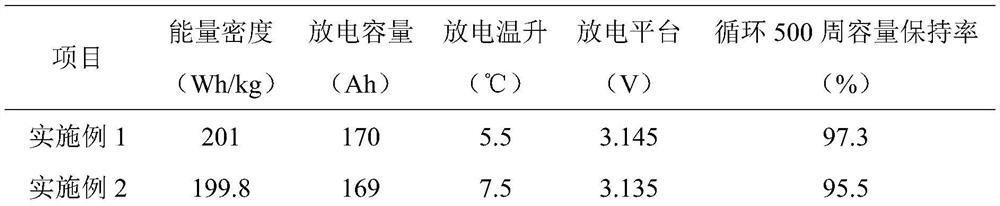

High-energy-density lithium iron phosphate battery

ActiveCN113078305ASignificant progressIncrease capacityMaterial nanotechnologyFinal product manufactureElectrolytic agentMagnesium doping

The invention belongs to the technical field of electrochemistry, and particularly relates to a high-energy-density lithium iron phosphate battery. A positive electrode active material is selected from titanium / magnesium-doped lithium iron phosphate, the surface density of a positive plate is 190-210 g / m<2>, the compaction density is greater than or equal to 2.60 g / cc, a negative electrode active material is carbon-coated single particle and secondary particle needle coke blend artificial graphite, and the compaction density of a negative plate is greater than or equal to 1.70 g / cc. The density of the electrolyte is equal to 1.15 g / cc, the wall thickness of the aluminum shell body is 0.40-0.50 mm, a positive electrode current collector is an aluminum foil with the diameter of 12-13 [mu]m, a negative electrode current collector is a copper foil with the diameter of 4.5 [mu]m, a diaphragm is a 7 + 2C + 2P ceramic gluing diaphragm, a conductive binder is used for replacing a positive electrode, the addition amount is 1.0-2.0%, and the weight ratio of a positive electrode active material to a positive electrode dressing is greater than or equal to 98%. According to the invention, the energy density of the battery is greatly improved and reaches 200Wh / kg.

Owner:江西安驰新能源科技有限公司

Lithium-sulfur battery separator membrane as well as preparation method and application thereof

ActiveCN110492045AInhibition of the shuttle effectImprove ionic conductivityLi-accumulatorsCell component detailsChemistryCyclic process

The invention discloses a lithium-sulfur battery separator membrane as well as a preparation method and application thereof, and belongs to the technical field of battery separator membranes. The lithium-sulfur battery separator membrane comprises a base membrane and a functional layer with which the base membrane is coated, wherein the functional layer comprises a functional material and an auxiliary agent, and the functional material comprises a layered sulfide, a conductive carbon material and nano cellulose. By adopting the technical scheme provided by the invention, the shuttle effect caused by lithium polysulfide in the cycle process of the lithium-sulfur battery can be effectively inhibited, and the capacity retention ratio, the electronic conductivity and the cycle effect of the lithium-sulfur battery are improved.

Owner:安徽金力新能源有限公司

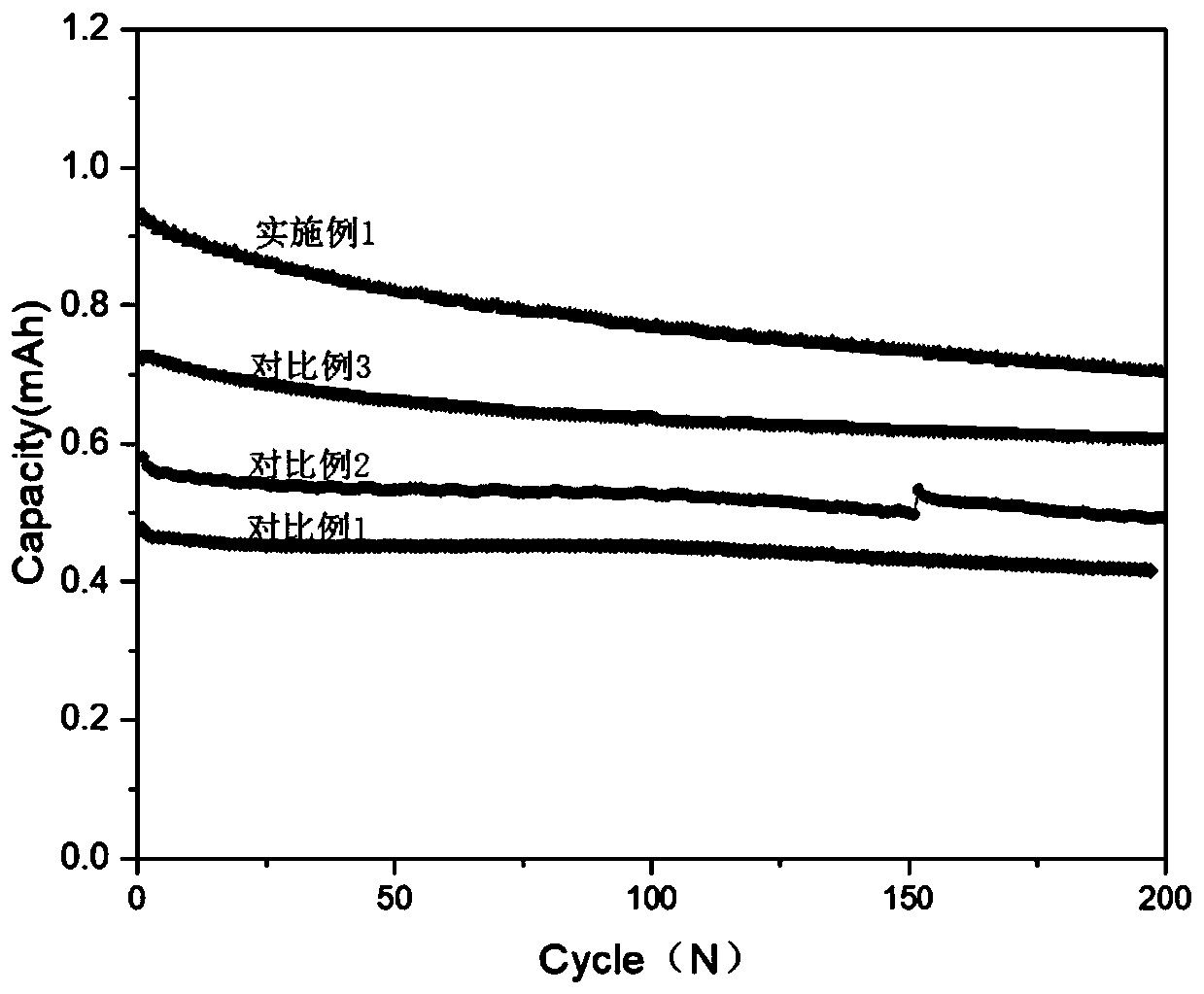

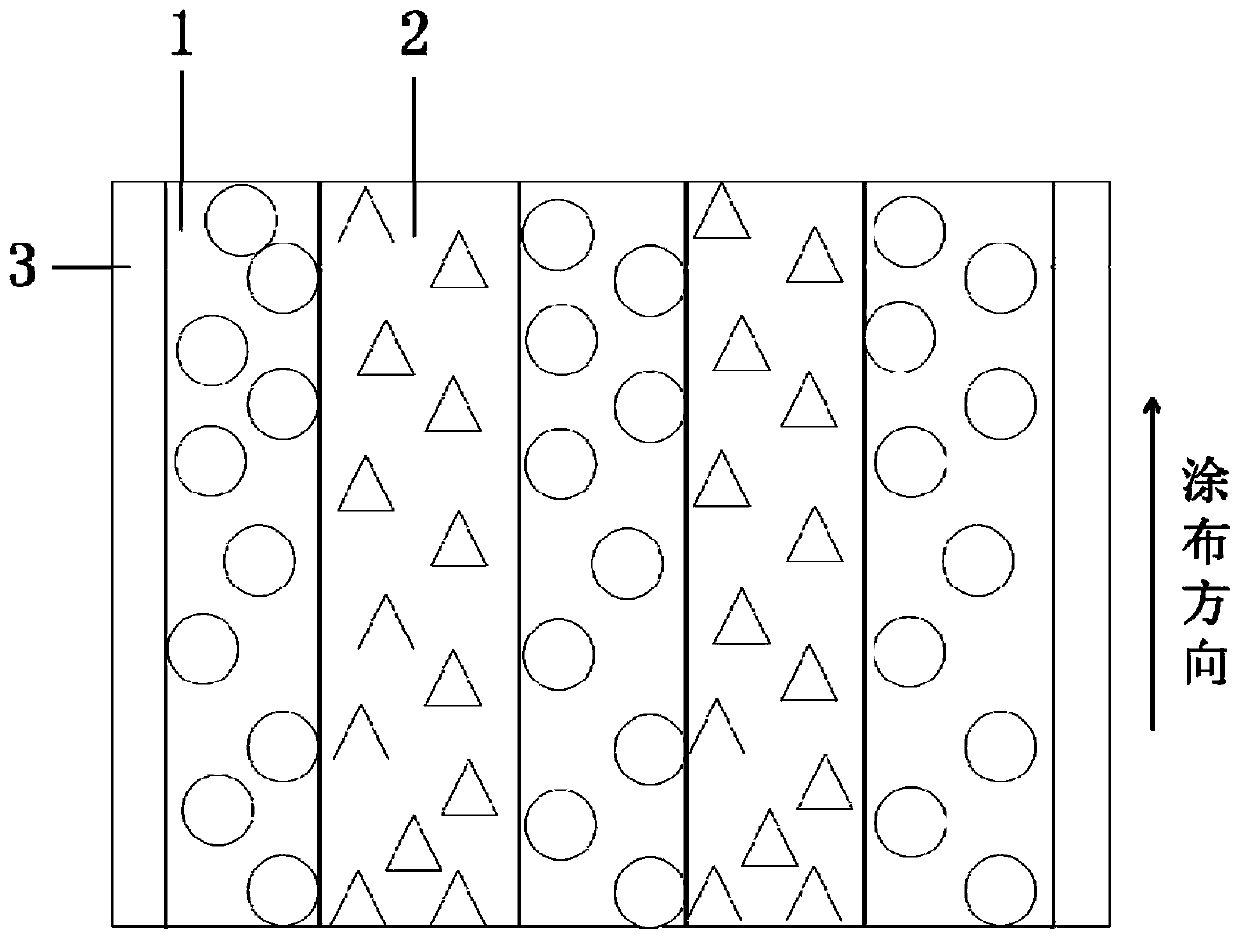

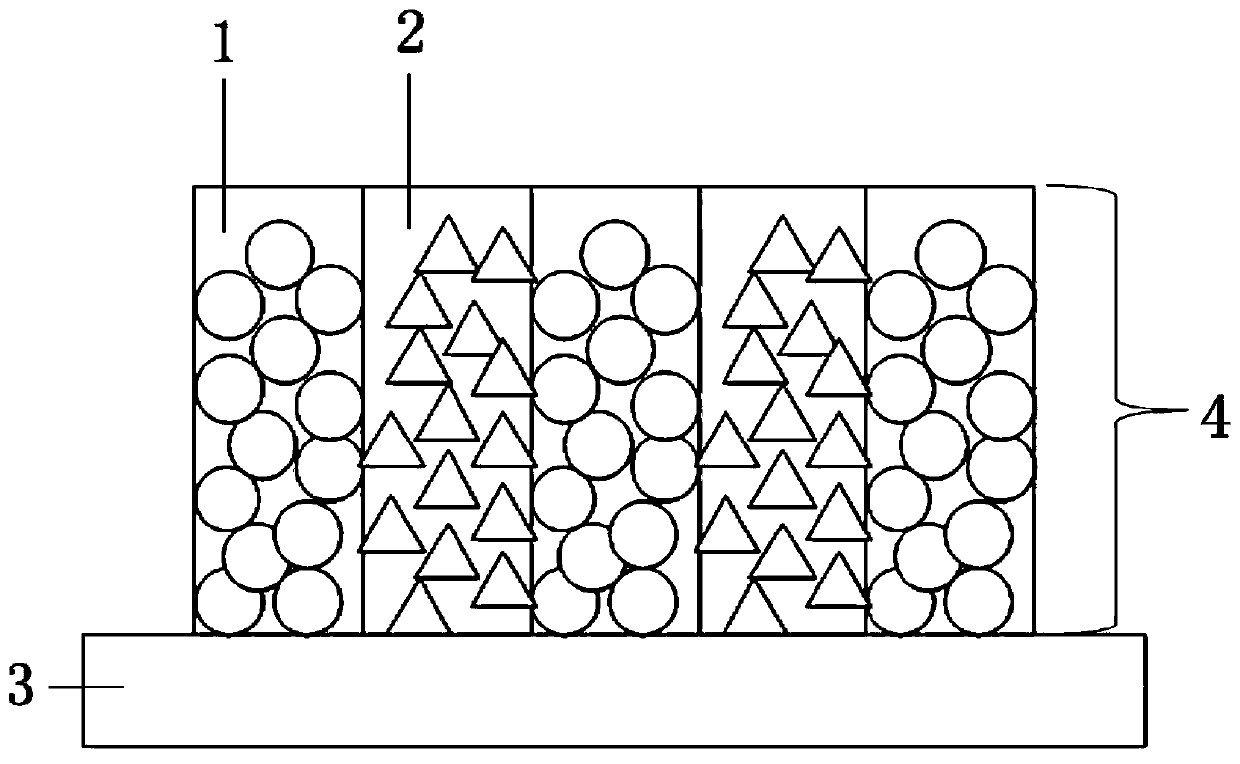

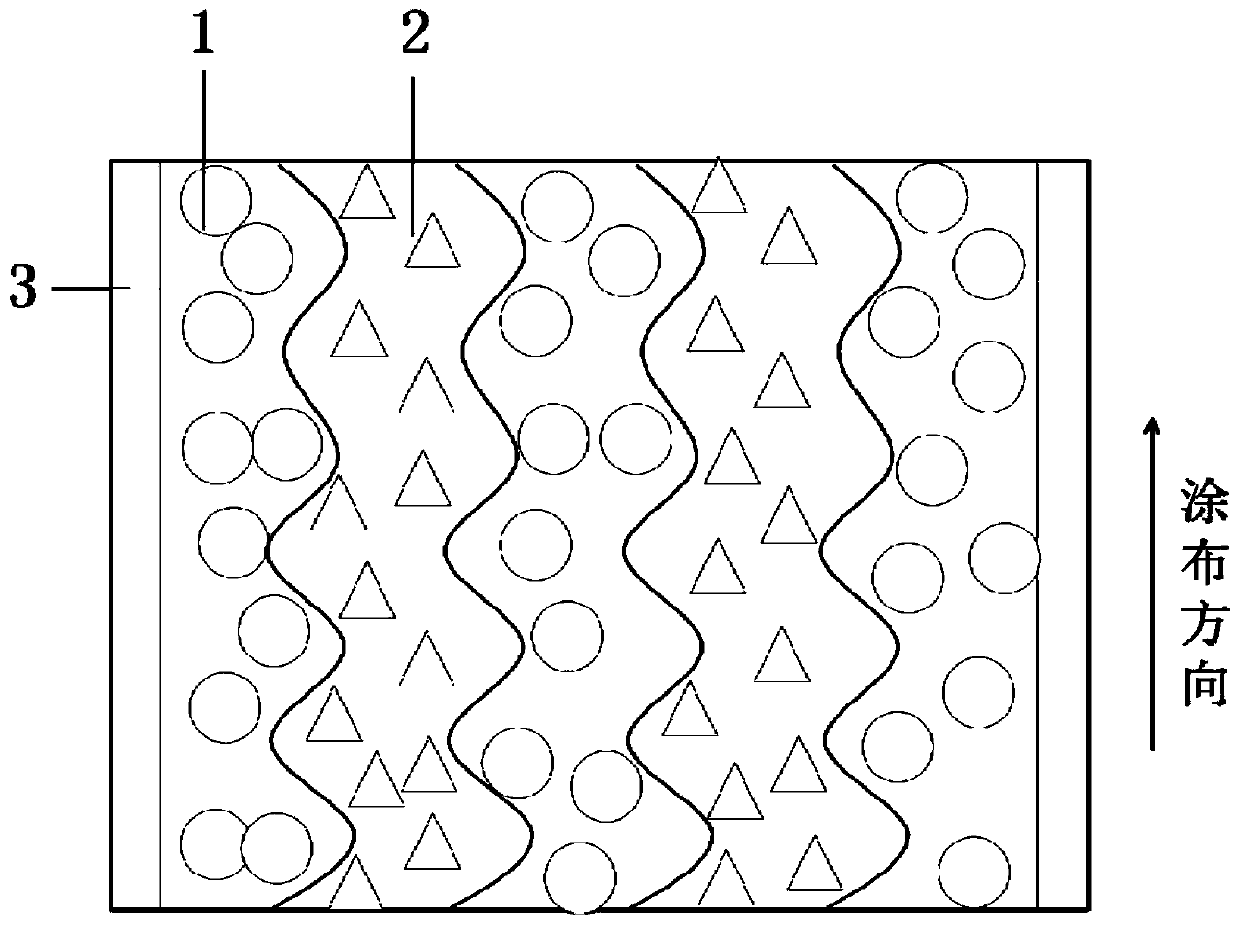

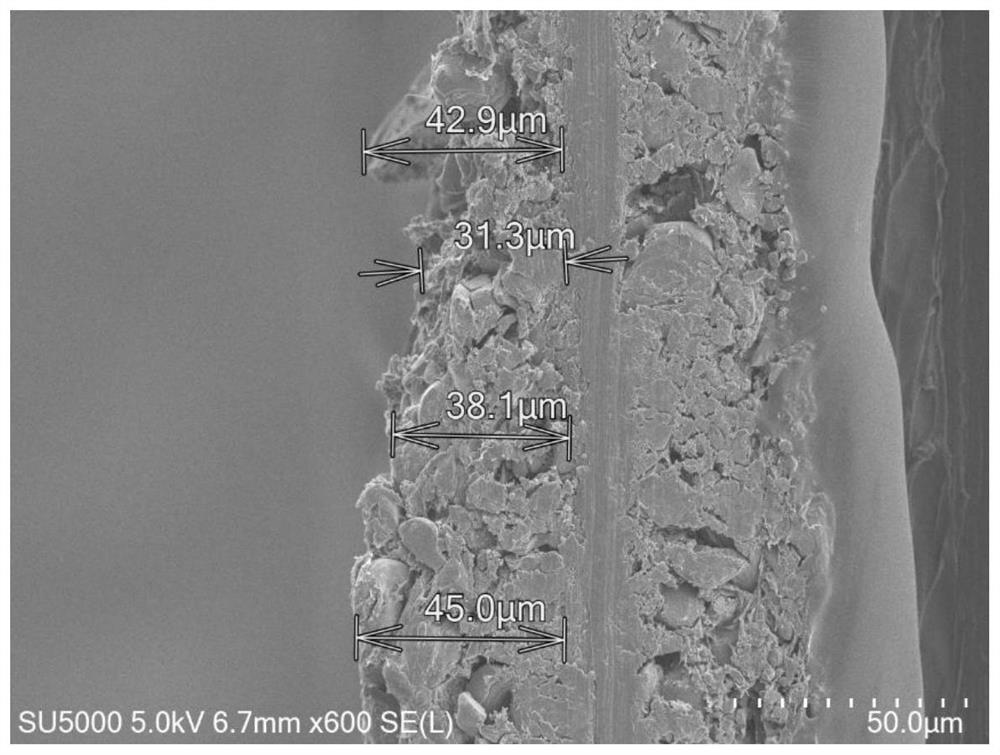

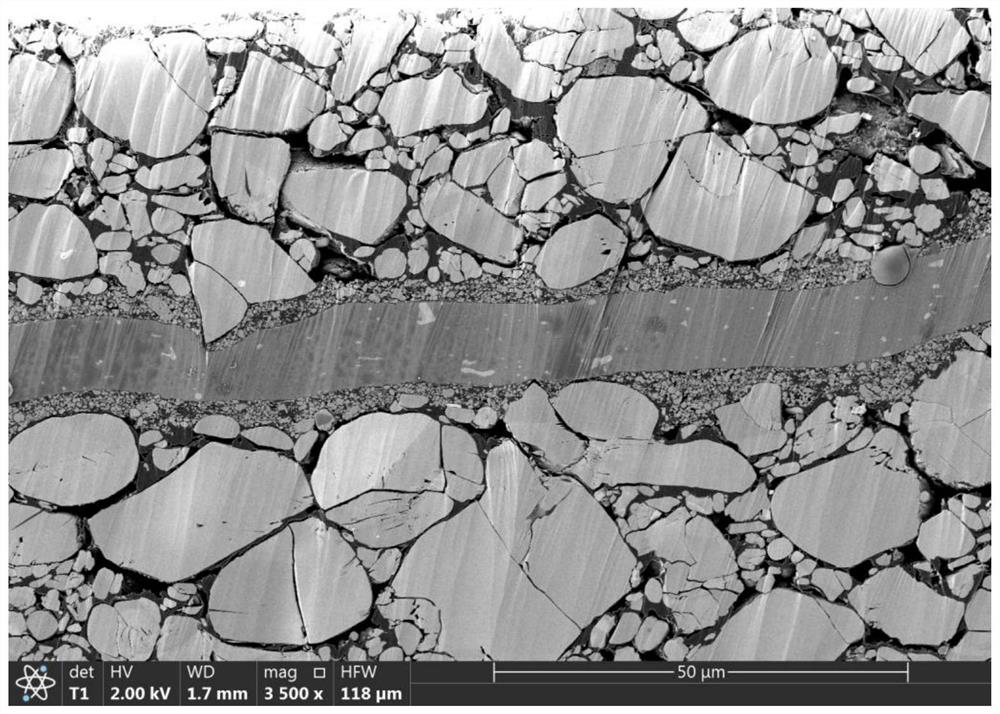

Negative pole piece of lithium ion battery, preparation method of negative plate and lithium ion battery

PendingCN110233240AEasy to prepareIncrease production capacityNegative electrodesSecondary cellsAluminium-ion batteryElectrical battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a negative pole piece of a lithium ion battery. The negative pole piece of the lithium ion battery comprises a negative current collector and a negative material layer arranged on the negative current collector, wherein the negative electrode material layer is composed of carbon material strips and silicon-based material strips which are sequentially and alternately distributed from left to right, namely, the carbon material strip-the silicon-based material strip-the carbon material strip-the silicon-based material strip-the carbon material strip. According to the negative pole piece of the lithium ion battery, the energy density of the battery is effectively improved, and the battery has excellent capacity retention rate and rate performance in the cycling process.

Owner:SHENZHEN UTILITY POWER SOURCE CO LTD

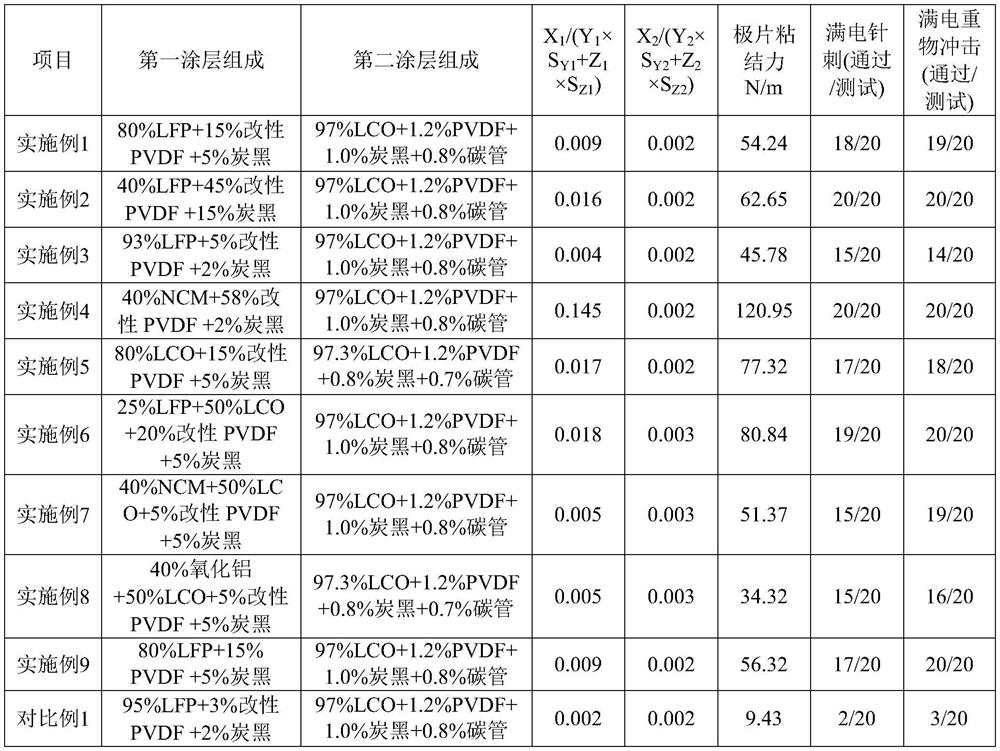

Positive plate and lithium ion battery comprising positive plate

InactiveCN112582580AImprove securityCycle performance is not affectedSecondary cellsPositive electrodesEngineeringPositive current

The invention provides a positive plate and a lithium ion battery comprising the positive plate. The positive plate comprises a positive current collector and a positive coating, and the positive coating comprises a first coating and a second coating. The surface of the positive electrode current collector is coated with the first coating, and the surface of the first coating is coated with the second coating; the first coating comprises an inorganic filler, a first conductive agent and a first binder, and the second coating comprises a positive active material, a second conductive agent and asecond binder. When the relationship X<1> / (Y<1>*SY<1>+Z<1>*SZ<1>) > X<2> / (Y<2>* SY<2>+Z<2>*SZ<2> is satisfied, the lithium ion battery has good safety performance, and the probability of fire failureof the battery is greatly reduced when mechanical abuse (acupuncture and heavy impact) occurs. And meanwhile, the cycle performance of the lithium ion battery is not influenced and is equivalent to the cycle performance effect of the existing lithium ion battery, namely, the safety performance of the lithium ion battery is remarkably improved on the premise of keeping the cycle performance of thelithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Preparation method of core-shell structure ternary positive electrode material precursor

ActiveCN112758991AImprove structural strengthAvoid ball fractureCell electrodesSecondary cellsPhysical chemistryEngineering

The invention discloses a preparation method of a core-shell structure ternary positive electrode material precursor. The preparation method comprises the following steps: (1) preparing a metal salt solution, a precipitator solution, a complexing agent solution and an amphoteric polymeric flocculant solution; (2) adding water, a complexing agent solution and a precipitator solution into a reaction kettle to prepare a reaction kettle base solution; and (3) adding a metal salt solution, a precipitant solution and a complexing agent solution into the reaction kettle base solution, carrying out a co-precipitation reaction, starting to introduce the amphoteric polymeric flocculant solution when the particle size of particles in the reaction kettle grows to be 2-3 microns smaller than the target particle size, then continuing the reaction, and stopping feeding until the average particle size of the particles grows to the target particle size. The polymer flocculant is utilized to form a net structure on the outer layer of the precursor particles, so that the structural strength is enhanced, and ball cracks caused by collision among the particles in the later period of the reaction of the precursor are avoided, thereby ensuring the cyclicity, stability and safety.

Owner:宜宾光原锂电材料有限公司

Lithium-sulfur diaphragm with synergistic effect mechanism, preparation method of lithium-sulfur diaphragm and lithium-sulfur battery

InactiveCN111370626AInhibition of the shuttle effectInhibition formationLi-accumulatorsCell component detailsLithium–sulfur batteryLithium sulfur

The invention discloses a lithium-sulfur diaphragm with a synergistic effect mechanism, a preparation method of the lithium-sulfur diaphragm and a lithium-sulfur battery, and belongs to the technicalfield of battery diaphragms. According to the invention, the porous conductive carbon material is added into the positive electrode side functional layer; a nano oxide material is added into the negative electrode side functional layer; the positive side and the negative side on the two sides of the diaphragm base membrane are coated with the functional layer slurry to prepare the lithium-sulfur diaphragm with a synergistic effect mechanism. The prepared lithium-sulfur diaphragm is applied to the lithium-sulfur battery, so that the shuttle effect caused by lithium polysulfide in the cycle process of the lithium-sulfur battery can be effectively inhibited, the deposition of lithium sulfide on the surface of an electrode can be reduced, lithium dendrites are prevented from piercing a pole piece, and the capacity retention ratio and the cycle effect of the lithium-sulfur battery are improved.

Owner:安徽金力新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com