Lithium ion battery and manufacturing method thereof

A lithium-ion battery and manufacturing method technology, applied in the field of lithium-ion batteries, can solve the problems of poor battery high-temperature storage performance and high-temperature cycle performance, poor battery storage performance, and lack of protection for the positive electrode, achieving high energy density and reducing gas The effect of producing and reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

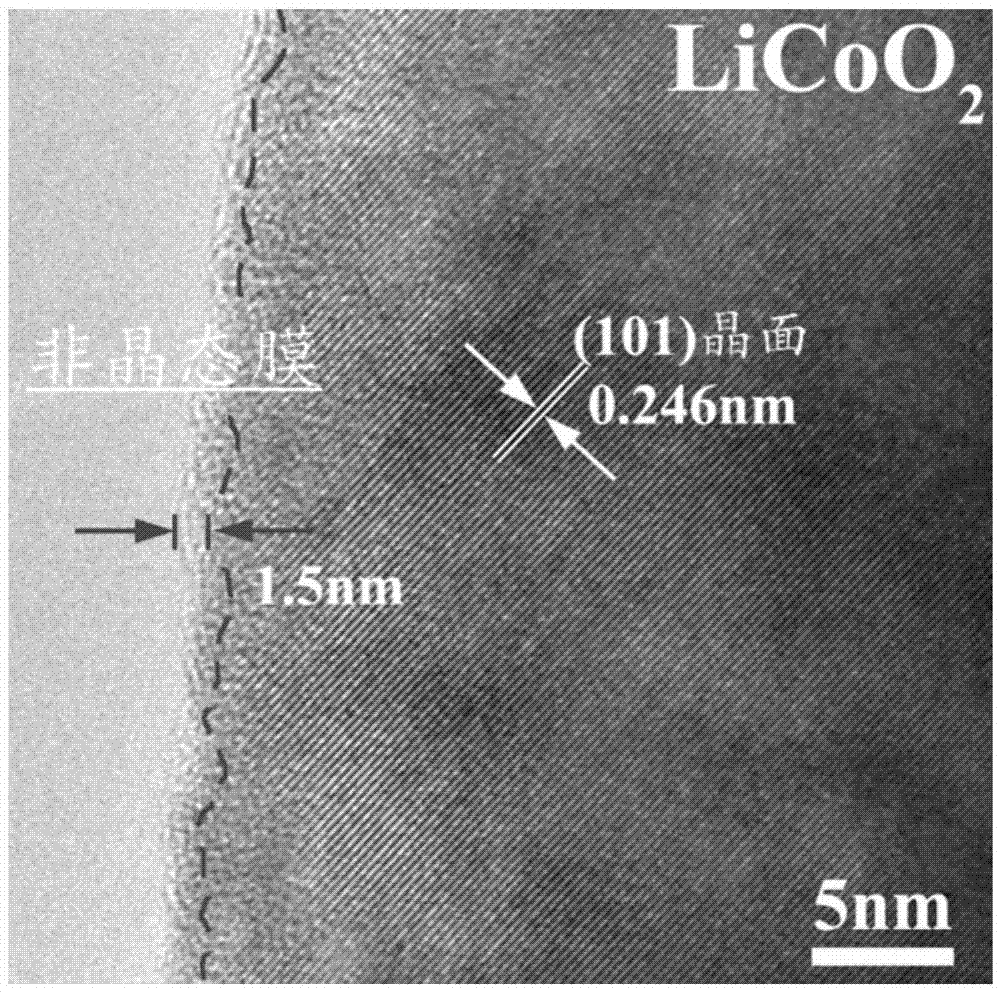

[0039] Such as Figure 1 to Figure 4 as shown, figure 1 It is a schematic diagram of the obtained full battery cell after winding. A lithium ion battery of the present invention includes a sealed package and an electrode group and an electrolyte disposed in the sealed package, the electrode group includes a positive electrode sheet, a negative electrode sheet, and a separator arranged between the positive electrode sheet and the negative electrode sheet The lithium-ion battery further includes a nano-protection layer, the nano-protection layer is arranged on the positive electrode sheet surface, the negative electrode sheet surface and the separator surface of the lithium-ion battery, and the thickness of the nano-protection layer is 0.2-10nm. The nano protective layer is Al 2 o 3 .

[0040] A manufacturing method of a lithium ion battery according to the present invention, the manufacturing method of the lithium ion battery is a low temperature coating method. The plasma...

Embodiment 2

[0070] The difference between embodiment 2 and embodiment 1 is: the temperature of PE-ALD is 20 ℃, each cycle process Al 2 o 3 The thickness of the protective layer is increased by 0.05nm, and the process is repeated for 4 cycles to control the Al 2 o 3 Film thickness up to 0.2nm;

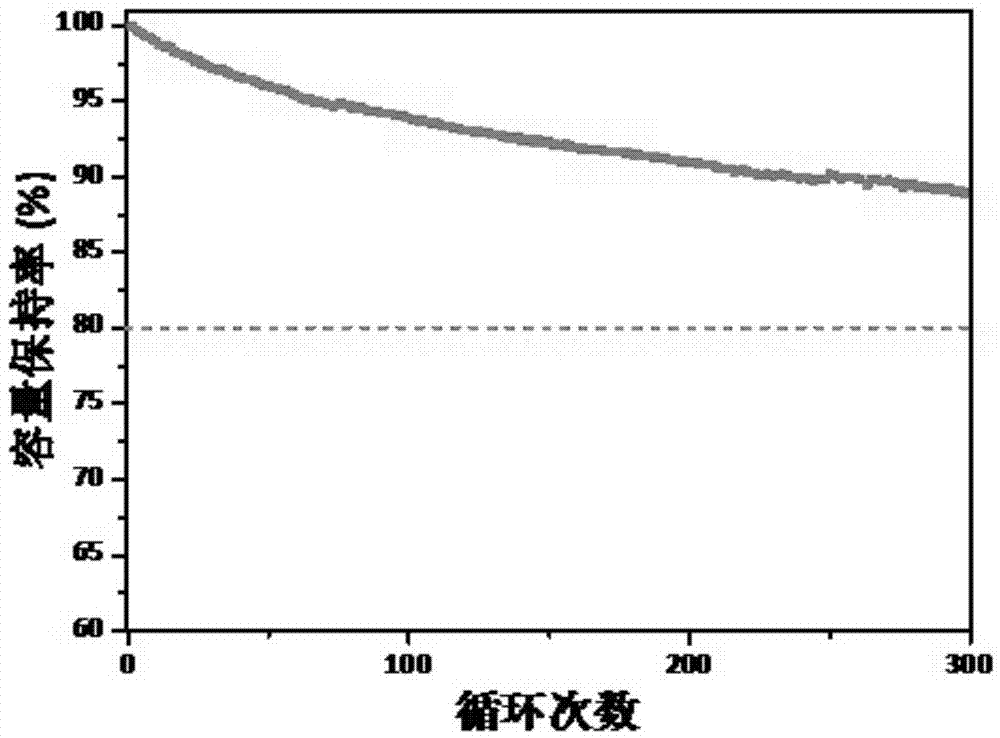

[0071] It is actually measured that the full battery has a capacity retention rate of 71% after 300 charge-discharge cycles at 45°C; at a temperature of 60°C, the 14-day storage capacity retention rate is 77%; at a temperature of Under the condition of 60 ℃, the 14-day storage thickness expansion rate is 10.6%. The test results are listed in Table 1.

Embodiment 3

[0073] The difference between embodiment 3 and embodiment 1 is that: the temperature of PE-ALD is 130°C, and the nano protective layer Al 2 o 3 The thickness of the film is increased by 0.16nm, repeating the 63 cycle process, controlling the Al 2 o 3 The film thickness is up to 10nm;

[0074] It is actually measured that the full battery has a capacity retention rate of 65% after 300 charge-discharge cycles at 45°C; at a temperature of 60°C, the 14-day storage capacity retention rate is 92%; at a temperature of Under the condition of 60 ℃, the 14-day storage thickness expansion rate is 3.5%. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com