Thermal management system for batteries

A battery thermal management and battery module technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of increasing weight, reducing space utilization, and being unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

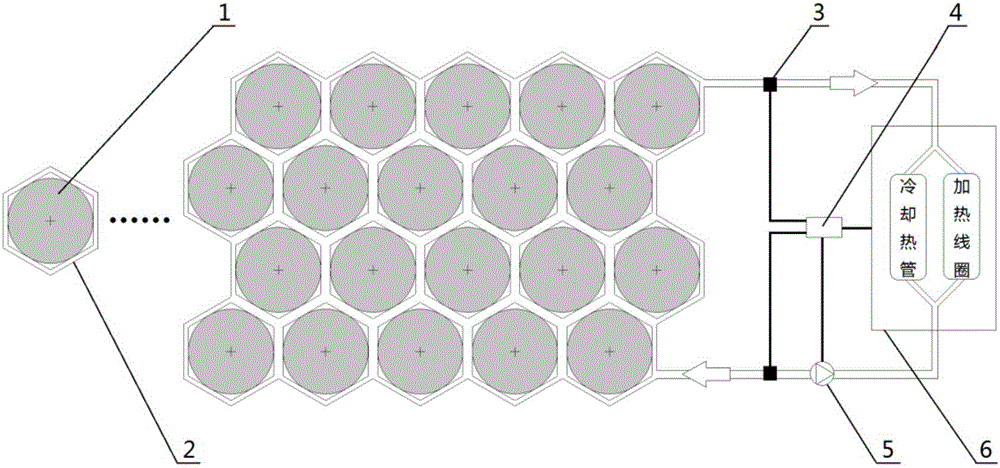

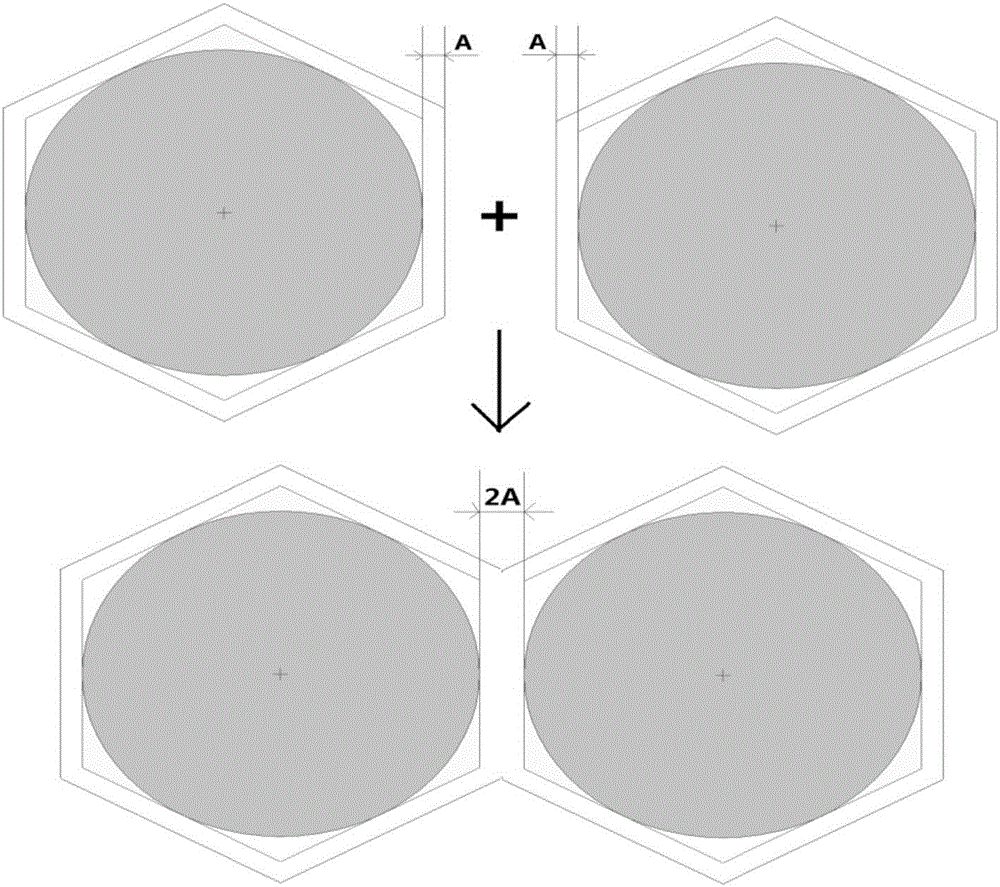

[0036] A battery thermal management system, including: a battery module, a heating and cooling device, a thermocouple, a controller, and a micropump; the battery module includes a regular hexagonal honeycomb aluminum hollow structure and a battery embedded in the hollow structure; the regular hexagonal Channels are arranged between the adjacent regular hexagons of the honeycomb-shaped aluminum hollow structure, each channel communicates with each other to form a passage, and the passage is filled with water glycol; the passage is connected to the heating and cooling device;

[0037] The inlet end of the passage is provided with a first thermocouple, and the outlet end is provided with a second thermocouple; the first thermocouple, the second thermocouple and the heating and cooling device are respectively connected to the controller; according to the The temperature fed back by the first thermocouple and the second thermocouple, the controller controls the heating and cooling d...

Embodiment 2

[0039] An example of an electric vehicle using 18650-type cylindrical batteries has a capacity of 60KWh and a maximum power of 210KW. The number of cylindrical batteries required for this design is about 5,000, which are composed of 12 sets of battery modules connected in series; the battery is assembled in the battery thermal management In the hexagonal honeycomb aluminum hollow structure of the system, the connection relationship of other components is as follows: figure 1 As shown; in the cold winter, the thermocouple detects that the temperature of the battery is lower than -20°C. At this time, the controller starts the heating coil of the heating and cooling device, turns on the micro pump, and conducts heat by heating the heat exchange medium in the aluminum hollow structure. Charge the battery to keep the temperature of the battery at about 25°C; when the battery is in a hot summer environment, the thermocouple detects that the temperature of the battery is higher than 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com