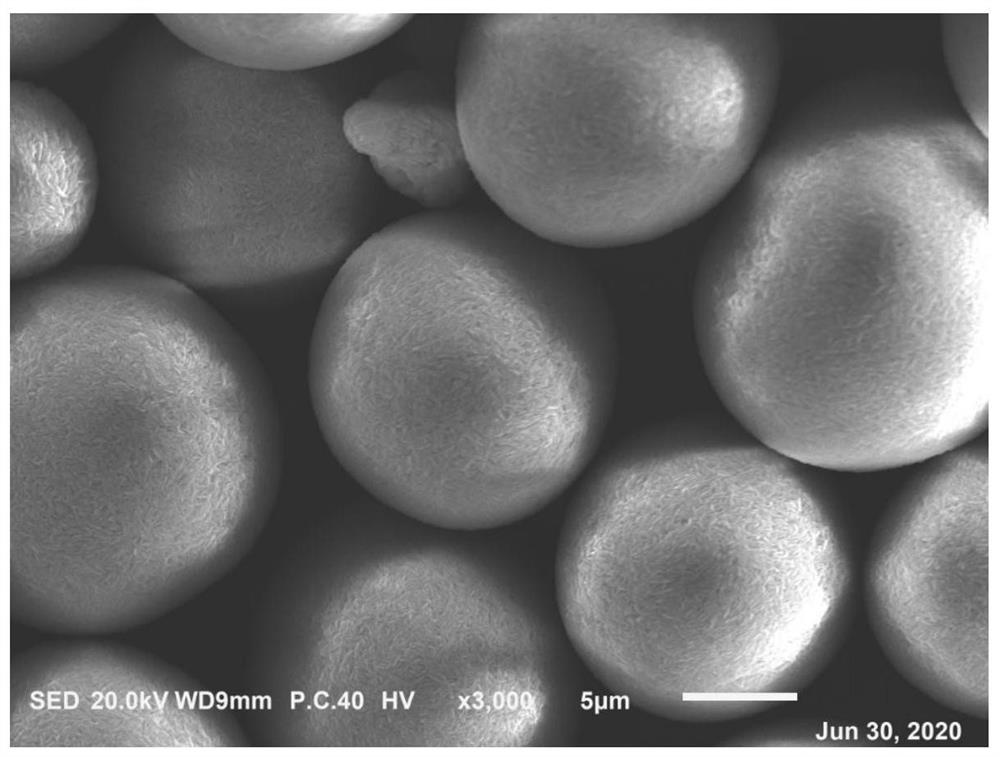

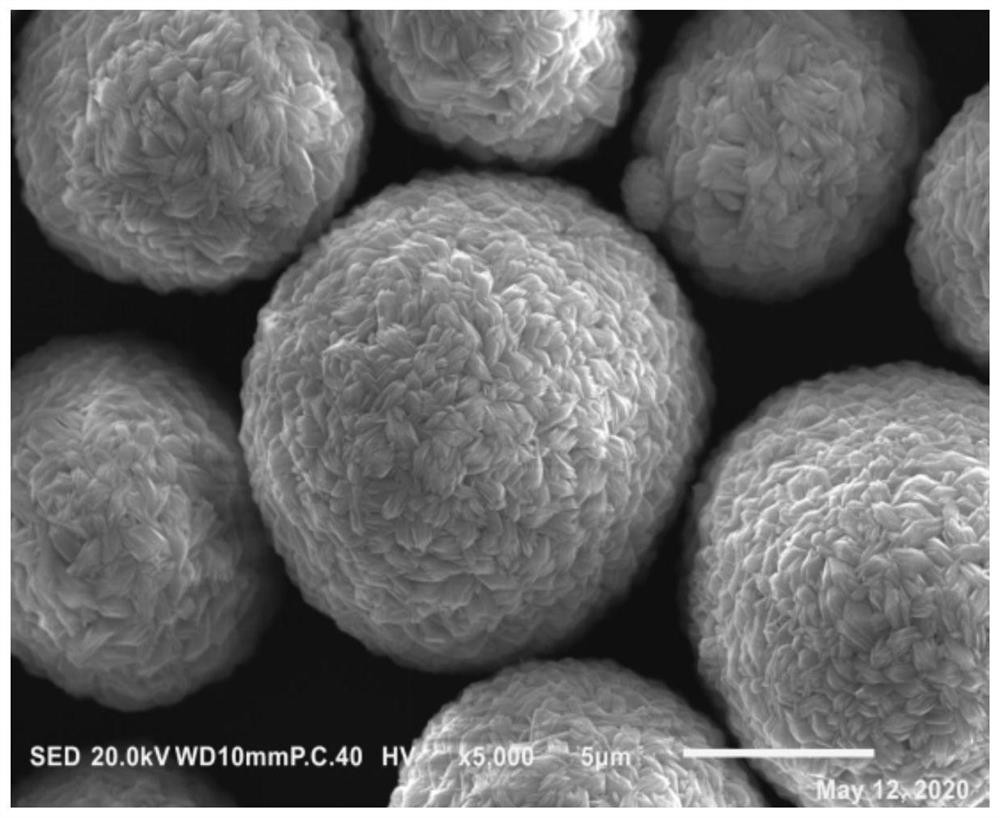

Preparation method of core-shell structure ternary positive electrode material precursor

A technology of positive electrode material and core-shell structure, which is applied in the field of preparation of core-shell structure ternary positive electrode material precursor, can solve the problems of intensified particle collision, cracking of large precursor particles, and affecting the cycle performance of battery materials, so as to ensure the cycle performance , Enhance the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

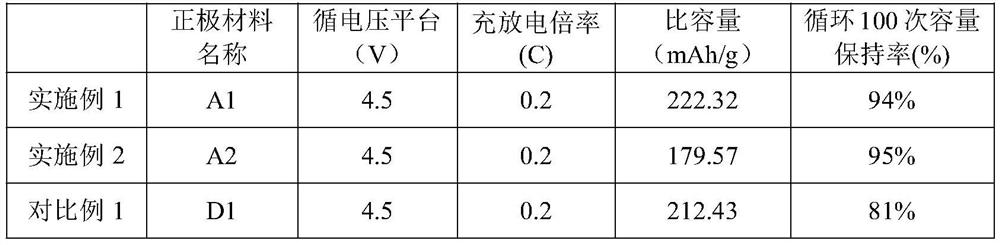

Examples

Embodiment 1

[0024] (1) Mix nickel sulfate, cobalt sulfate, and manganese sulfate in a molar ratio of 85:5:10, add pure water to stir and dissolve, and prepare a metal salt solution with a total concentration of 1.6mol / L. At the same time, prepare 10mol / L sodium hydroxide solution, 40% mass concentration of ammonia solution and 0.6% amphoteric polyacrylamide solution;

[0025] (2) at 2m 3 Add pure water to the reaction kettle to submerge the upper stirring paddle, add ammonia water until the ammonia concentration of the system is 12g / L, heat the system to 50°C, and then add sodium hydroxide solution to adjust the pH to 11.7;

[0026] (3) The above-mentioned metal salt solution is added in the reaction kettle according to a flow rate of 100L / h, and sodium hydroxide solution and ammoniacal liquor are added simultaneously to maintain the system pH and ammonia concentration, and the coprecipitation reaction is carried out under the protection of nitrogen gas continuously fed into at a stirring...

Embodiment 2

[0032] (1) Mix nickel sulfate, cobalt sulfate, and manganese sulfate in a molar ratio of 65:15:20, add pure water to stir and dissolve, and prepare a metal salt solution with a total concentration of 2mol / L. At the same time, prepare 10mol / L of Sodium hydroxide, 40% mass concentration of ammonia solution and 0.4% amphoteric polyacrylamide solution;

[0033] (2) at 2m 3 Add pure water to the reaction kettle to submerge the upper stirring paddle, add ammonia water until the ammonia concentration of the system is 10g / L, heat the system to 55°C and keep it, then add liquid caustic soda to adjust the pH to 11.6;

[0034] (3) Add the above-mentioned metal salt solution into the reaction kettle at a flow rate of 100L / h, and simultaneously add liquid caustic soda and ammonia water to maintain the pH and ammonia concentration of the system, and carry out the co-precipitation reaction at a stirring speed of 600rpm and continuously feed nitrogen protection. The slurry continuously overf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com