Positive plate and lithium ion battery comprising positive plate

A positive electrode sheet and positive electrode technology, applied in the direction of positive electrodes, battery electrodes, secondary batteries, etc., can solve problems such as fire failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the above positive electrode sheet, the method comprising the following steps:

[0065] 1) preparing the slurry forming the first coating and the slurry forming the second coating respectively;

[0066] 2) Coating the slurry for forming the first coating layer and the slurry for forming the second coating layer on both surfaces of the positive electrode current collector to prepare the positive electrode sheet.

[0067] According to the present invention, in step 2), the coating is double layer coating, gravure coating, extrusion coating, transfer coating.

[0068] Exemplarily, step 2) specifically includes the following steps:

[0069] Coating the slurry for forming the first coating on the surface of the positive electrode collector to form the first coating, and coating the slurry for forming the second coating on the surface of the first coating to form the second coating to obtain a positive electrode shee...

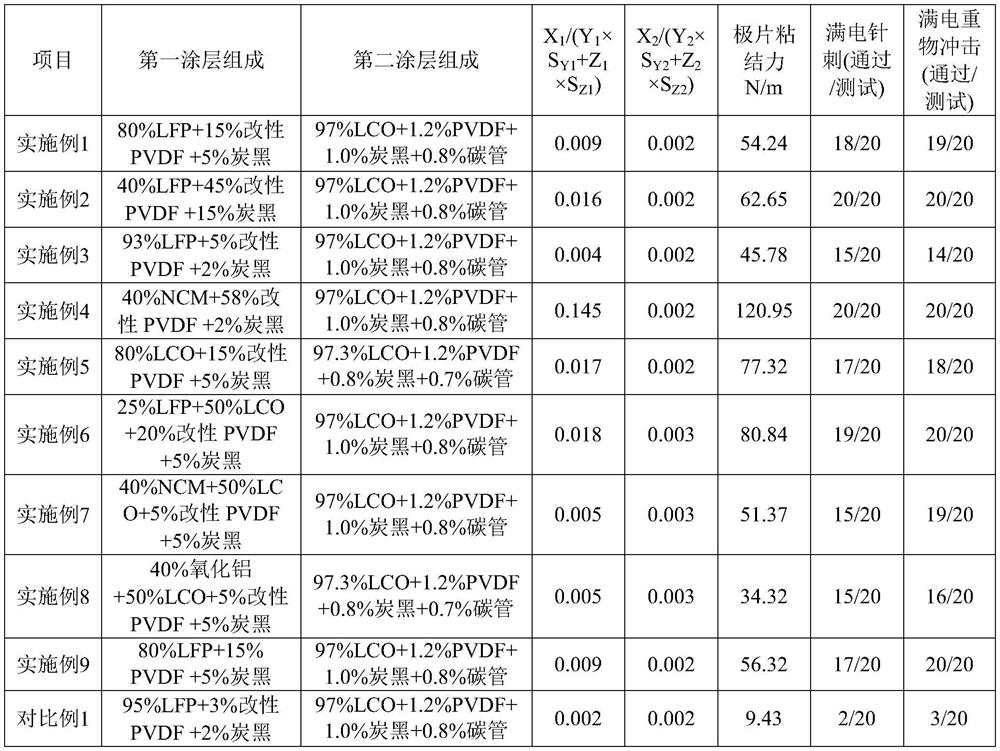

Embodiment 1

[0089] The first step: prepare the first coating slurry, mix 80wt% lithium iron phosphate (LFP), 15wt% modified PVDF, 5wt% carbon black, add NMP, and prepare the slurry by stirring.

[0090] The second step: preparing the second coating slurry, mixing 97wt% lithium cobaltate, 1wt% conductive carbon black, 0.8wt% carbon nanotubes, 1.2wt% PVDF, adding NMP, and stirring to prepare a slurry.

[0091] The third step: preparing negative electrode slurry, mixing 96wt% artificial graphite, 1wt% conductive carbon black, 1.5wt% SBR and 1.5wt% CMC, adding deionized water, and stirring to prepare a slurry.

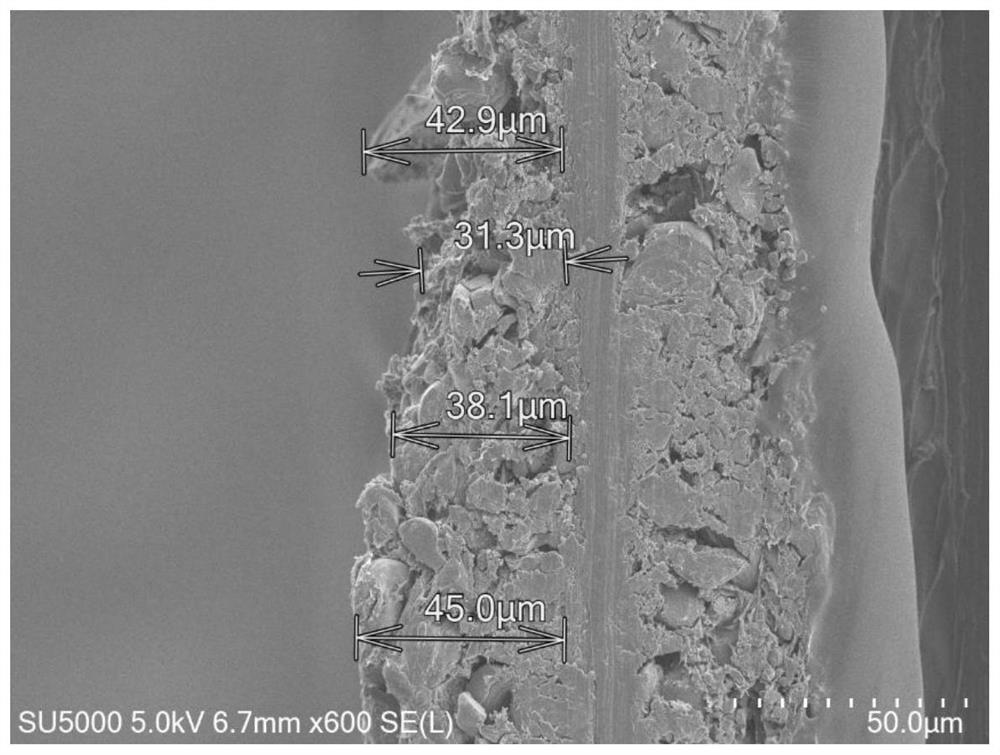

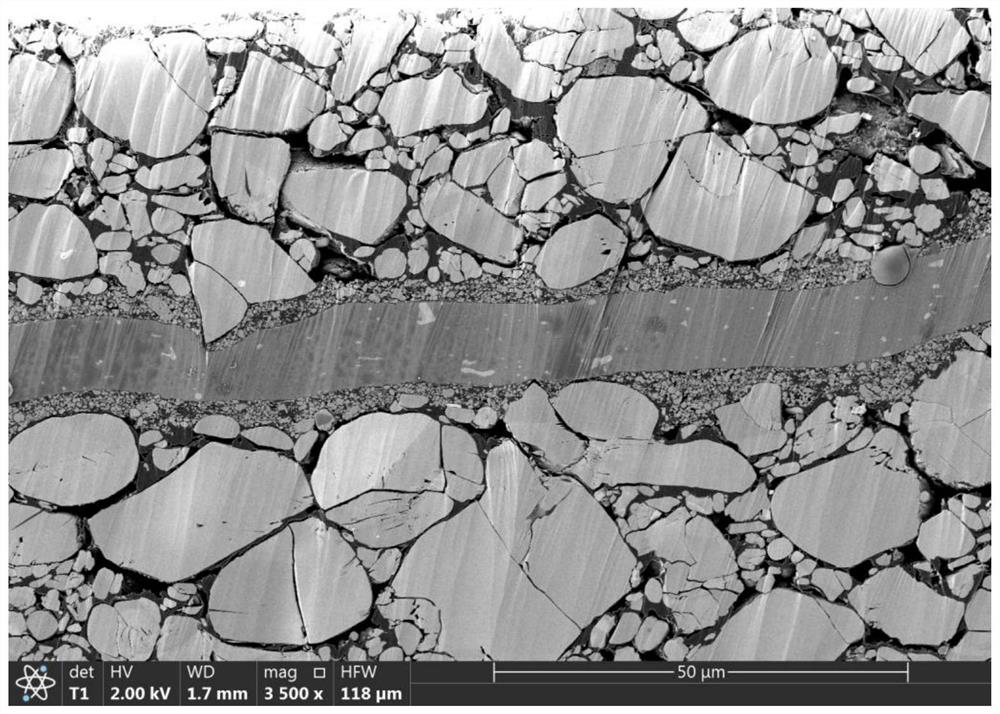

[0092] Step 4: Preparation of the positive electrode sheet. Use the extrusion coating process to coat the first coating slurry in step 1 on the surface of the positive electrode current collector to form a first coating with a thickness of 5 μm, and apply the second coating in step 2 The slurry was coated on the surface of the first coating to form a second coating with a thickness of...

Embodiment 2-9

[0097] The other steps are the same as in Example 1, except that the selection and content of each material in the first step are different, and / or the selection and content of each material in the second step are different, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com