A high-energy silicon-containing lithium battery and a preparation method thereof-

A high-energy, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low specific energy, silicon structure damage, easy thermal diffusion, etc., to achieve large specific surface contact area, enhanced expansion constraints, The effect of uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

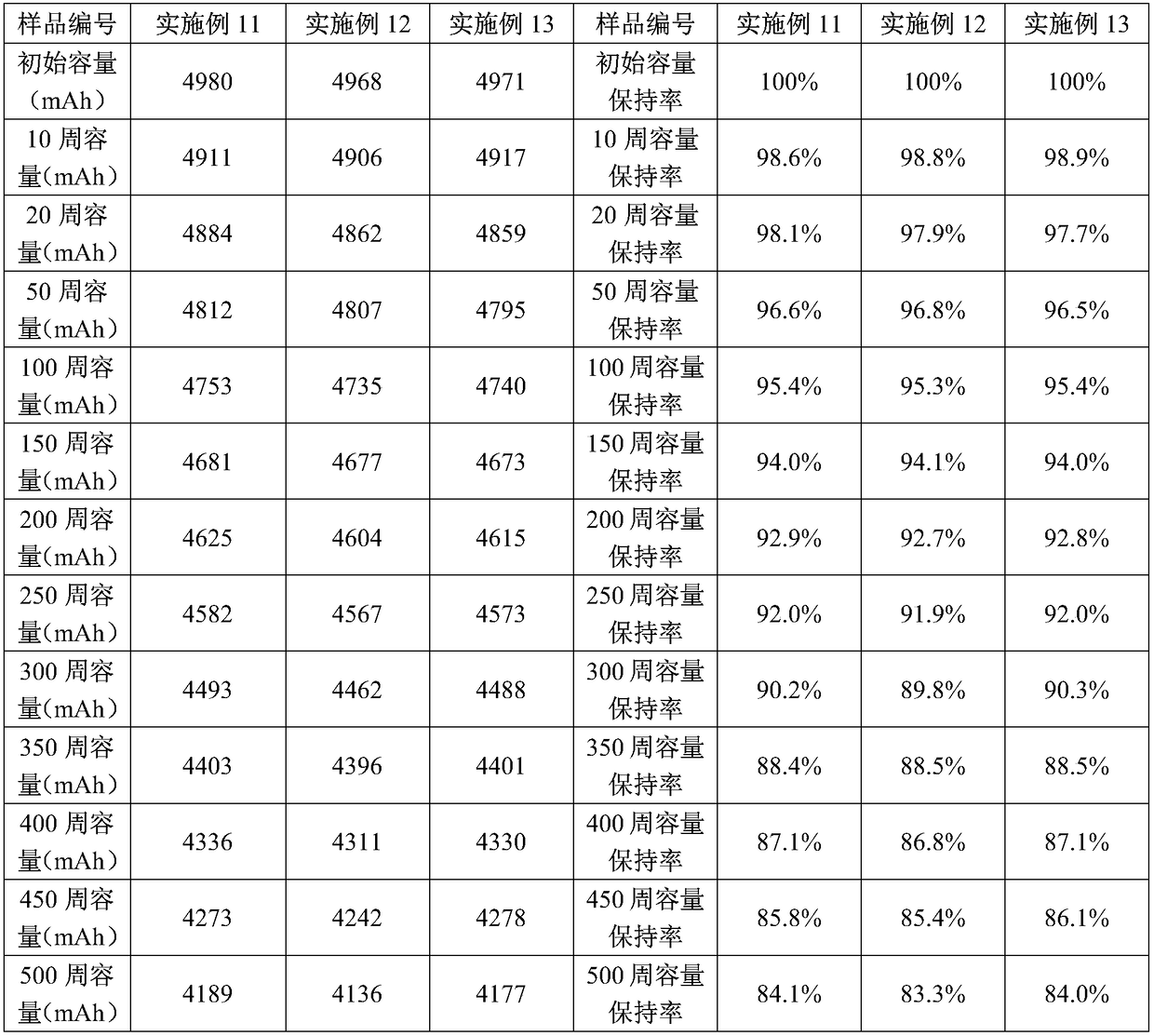

Examples

preparation example Construction

[0048] A negative active material, and its preparation method includes the following steps:

[0049] 1) Take commercially available SiO powder and zirconia spheres with a diameter of 10mm and ball mill for 1h, add 25mol% Mg powder of 200 mesh and continue ball milling for 2h, add 1.5M dilute hydrochloric acid, shake for 6h, filter, and the filter residue is washed and vacuum dried;

[0050] 2) Spread the powder obtained in step 1) vacuum drying on a vessel, put it into a CVD reaction chamber, introduce argon gas and gas phase toluene to deposit to a carbon content of 15 wt%, to obtain a porous silicon carbon / silicon oxide composite material.

[0051] The present invention also provides a method for preparing the above-mentioned high-energy silicon-containing lithium battery, which includes the following steps:

[0052] Preparation of positive electrode sheet: Preparation of positive electrode sheet: add N-methylpyrrolidone to the positive active material, single-walled carbon nanotubes...

Embodiment 1

[0055] A positive electrode sheet is made of the following components by weight percentage: 98.0% lithium nickel cobalt aluminate, 0.03% single-wall carbon nanotube, 0.2% graphene, and 1.77% polyvinylidene fluoride.

[0056] Add N-methylpyrrolidone to the formulated amount of nickel cobalt lithium aluminate, single-walled carbon nanotubes, graphene, and polyvinylidene fluoride. In the double planetary beating machine, the rotation speed is 48 rpm and the revolution speed is 1700 rpm. Pulp at the bottom; then disperse at a speed of 3500rmp under a high-speed disperser until the viscosity reaches 7000mPa·s to obtain the positive electrode slurry. The positive electrode slurry is coated on a metal aluminum foil with a thickness of 13μm at an areal density of 485g / ㎡, and dried After the moisture content is less than or equal to 0.15%, roll compaction to obtain a positive electrode sheet.

Embodiment 2

[0058] A positive electrode sheet is made of the following components by weight percentage: 97.8% lithium nickel cobalt manganate, 0.03% single-wall carbon nanotube, 0.3% graphene, and 1.87% polyvinylidene fluoride.

[0059] Add N-methylpyrrolidone to the formulated amount of lithium nickel cobalt manganate, single-walled carbon nanotubes, and polyvinylidene fluoride, and make pulp in a double planetary beating machine at a rotation speed of 48 rpm and a revolution speed of 1700 rpm. ; Disperse under a high-speed disperser at a speed of 4500rmp until the viscosity reaches 7000mPa·s to obtain a positive electrode slurry. The positive electrode slurry is coated on a metal aluminum foil with a thickness of 10μm according to an areal density of 400g / ㎡, and dried to moisture ≤ After 0.15%, roll compaction to obtain a positive electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com