Patents

Literature

224results about How to "Not easy to expand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

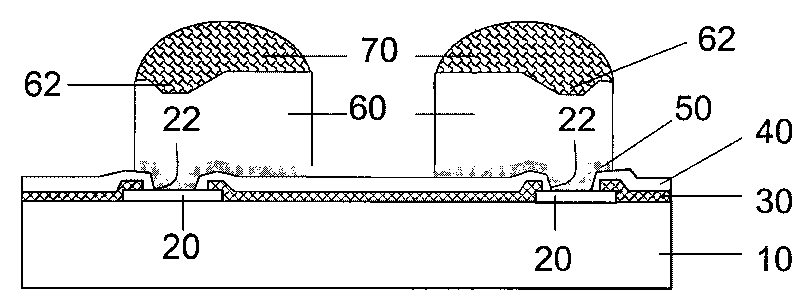

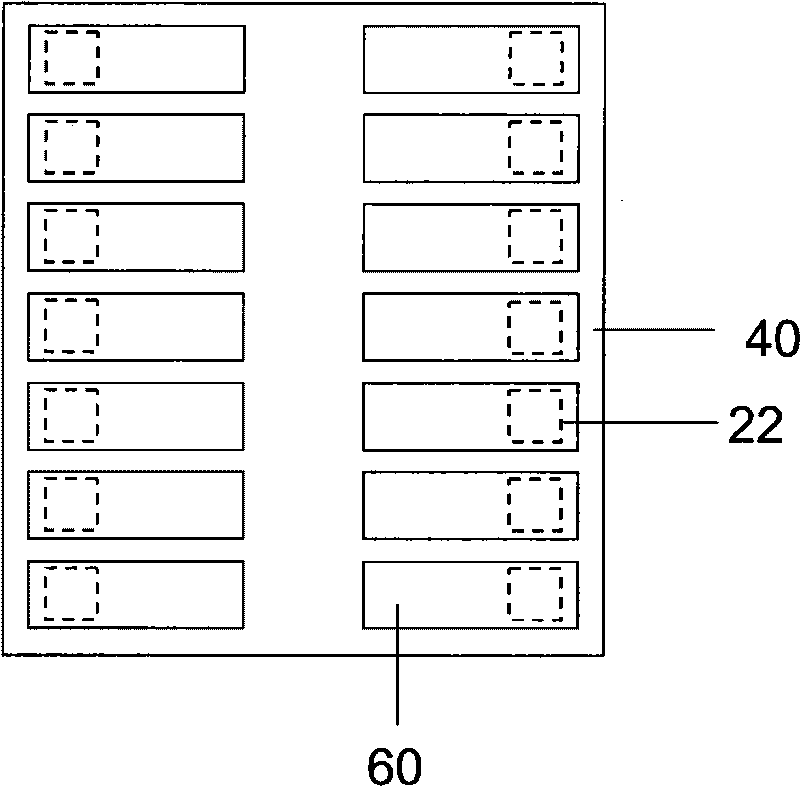

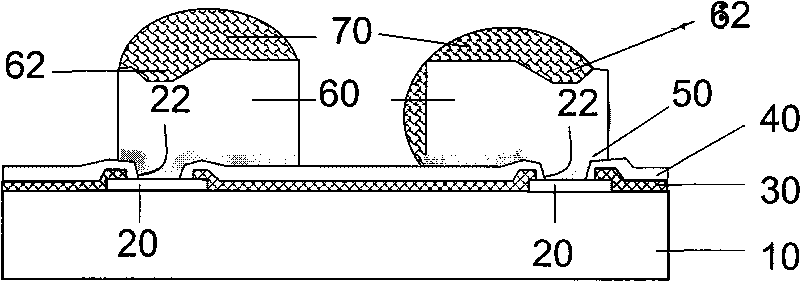

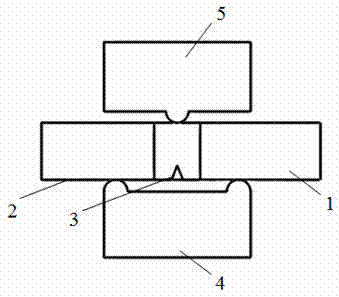

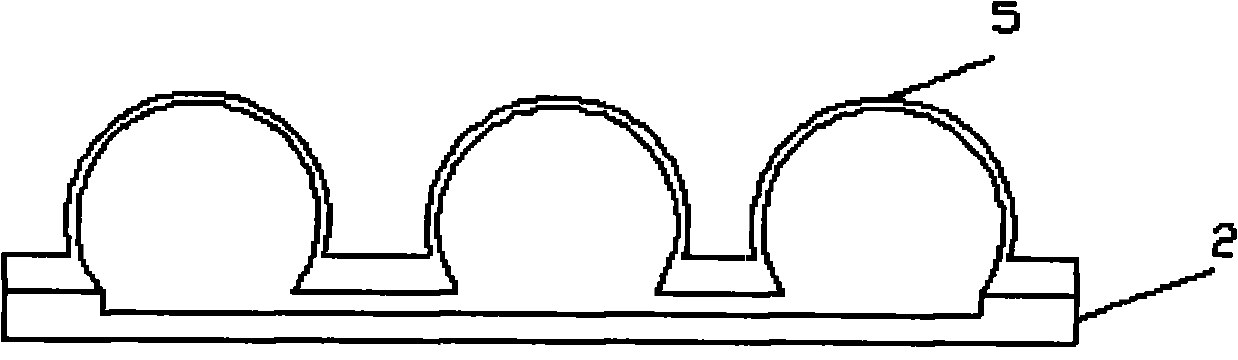

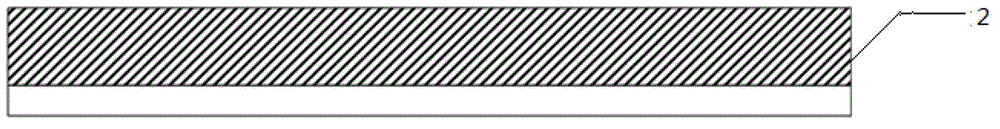

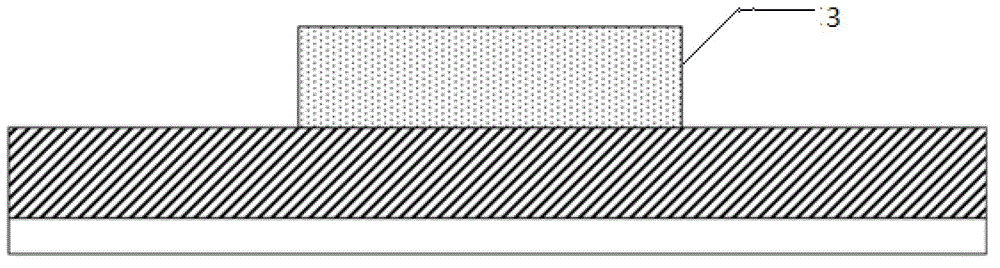

Package structure and manufacture method thereof

InactiveCN101728347AUniform thicknessPrevent collapseSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention provides a package structure and a manufacture method thereof, belonging to the technical field of micro-electronics manufacture. The package structure comprises a semiconductor substrate, a contact welding pad, a passivation layer, a stress buffer layer and columnar lugs formed on the buffer layer, wherein the areas corresponding to any of the columnar lug structures in the stress buffer layer are provided with main openings and one or more than one auxiliary opening, the main openings and the auxiliary openings are distributed evenly in the composition plane range of the corresponding columnar lugs. The package structure provided in the invention can avoid welding flux from collapsing during reflux in the forming process of columnar lugs and has the characteristic of high reliability.

Owner:SEMICON MFG INT (SHANGHAI) CORP

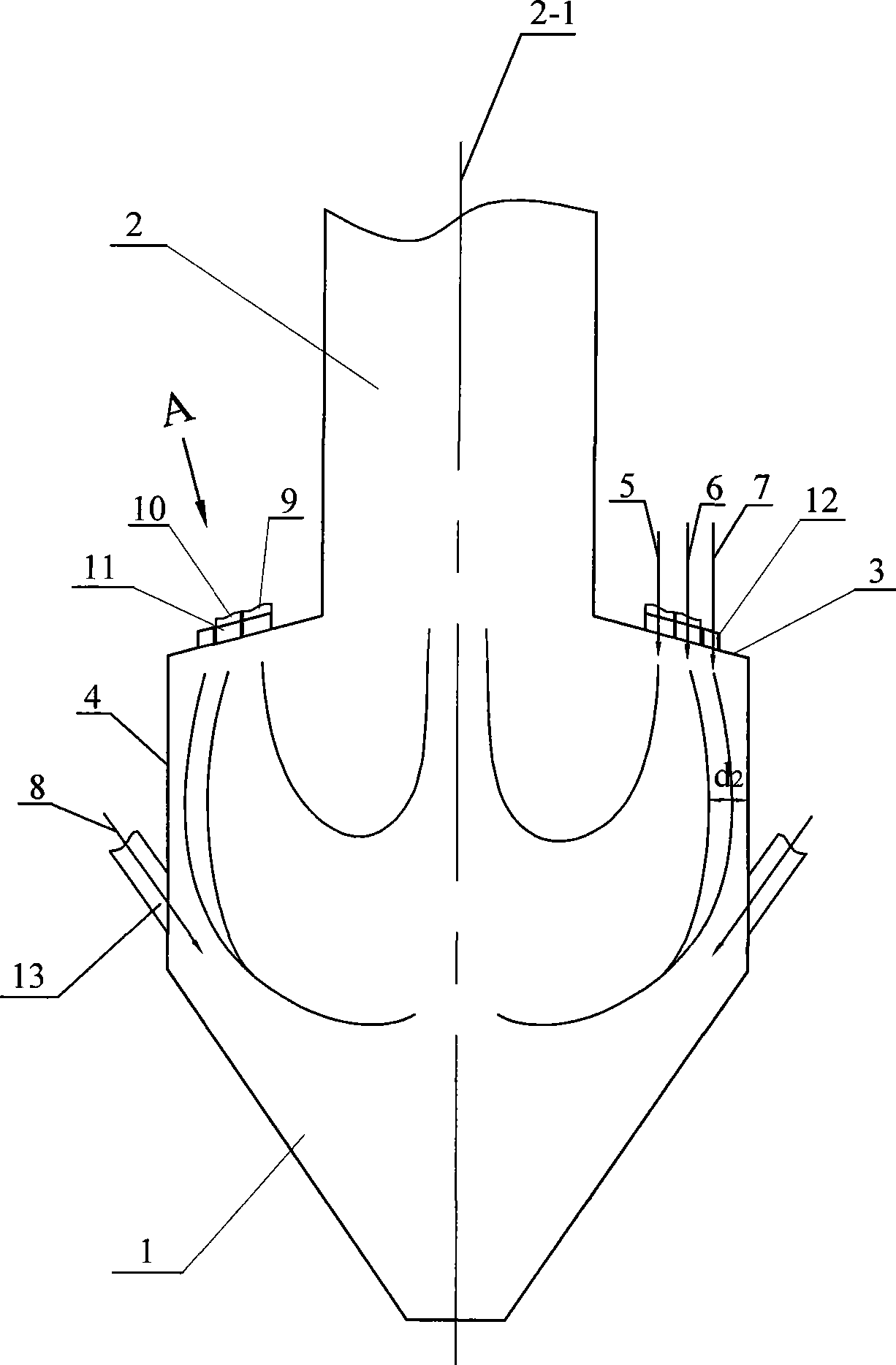

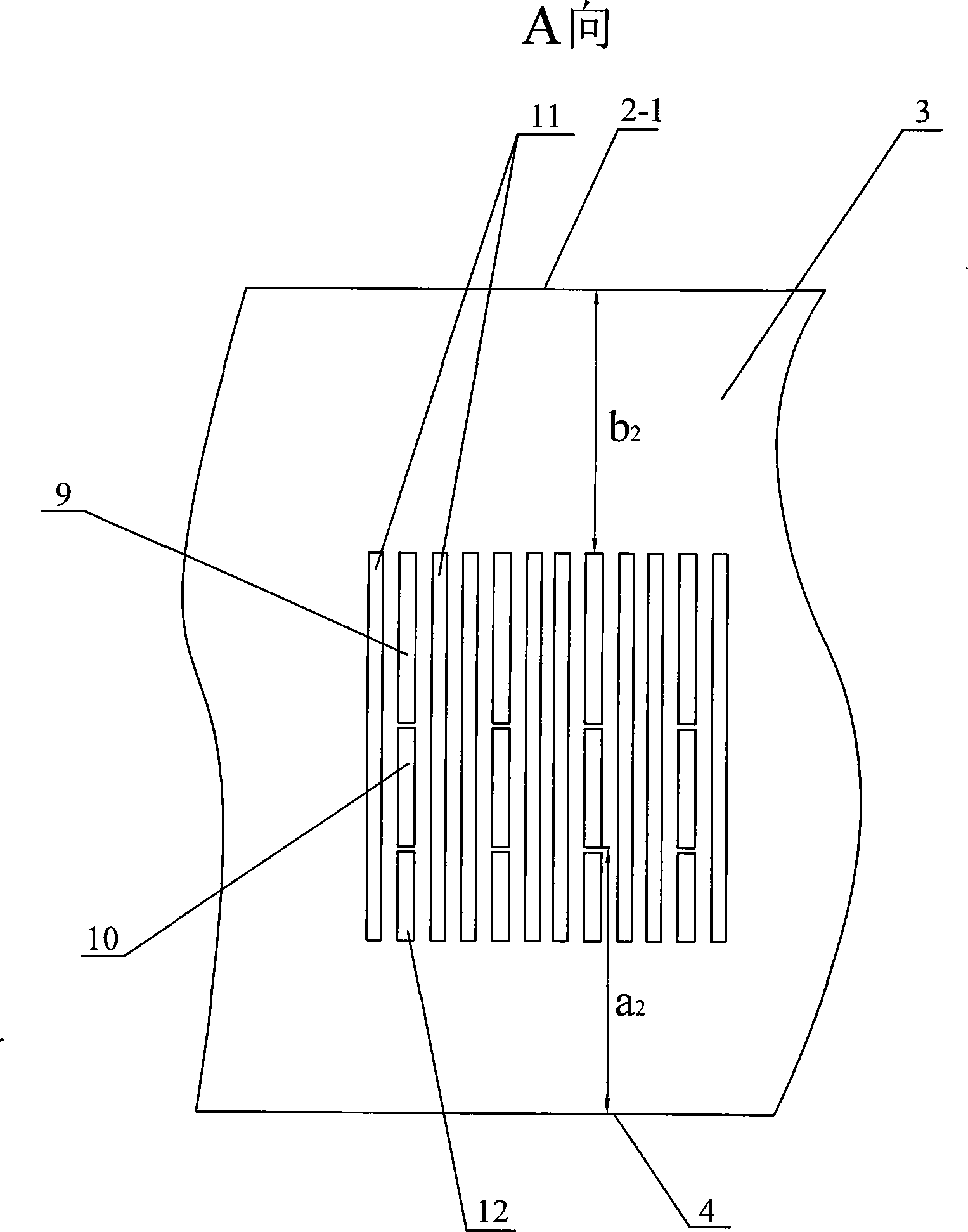

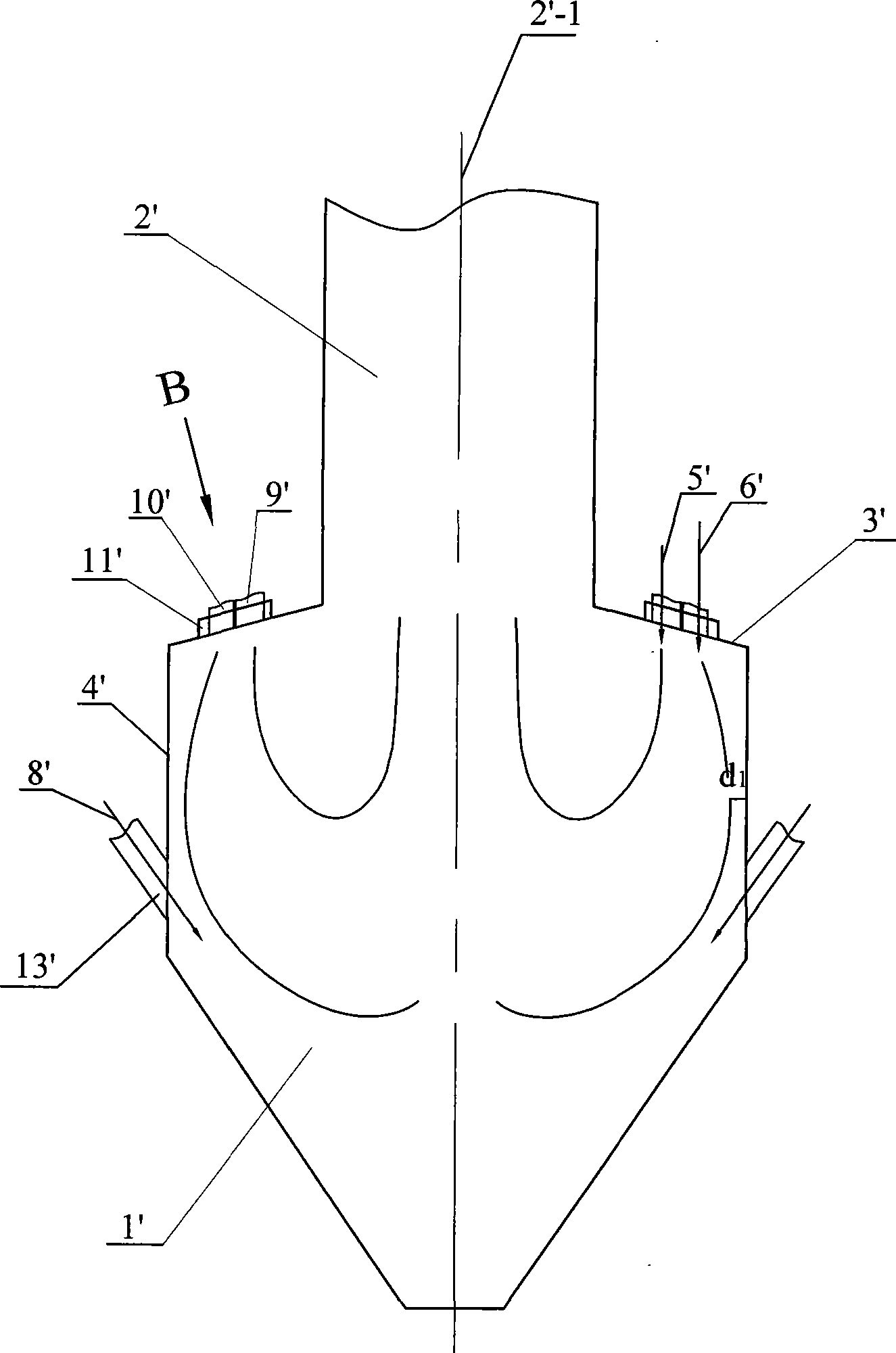

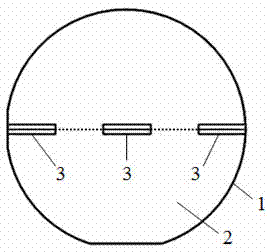

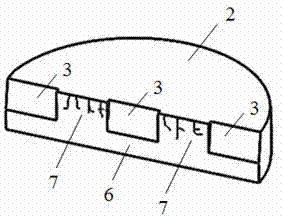

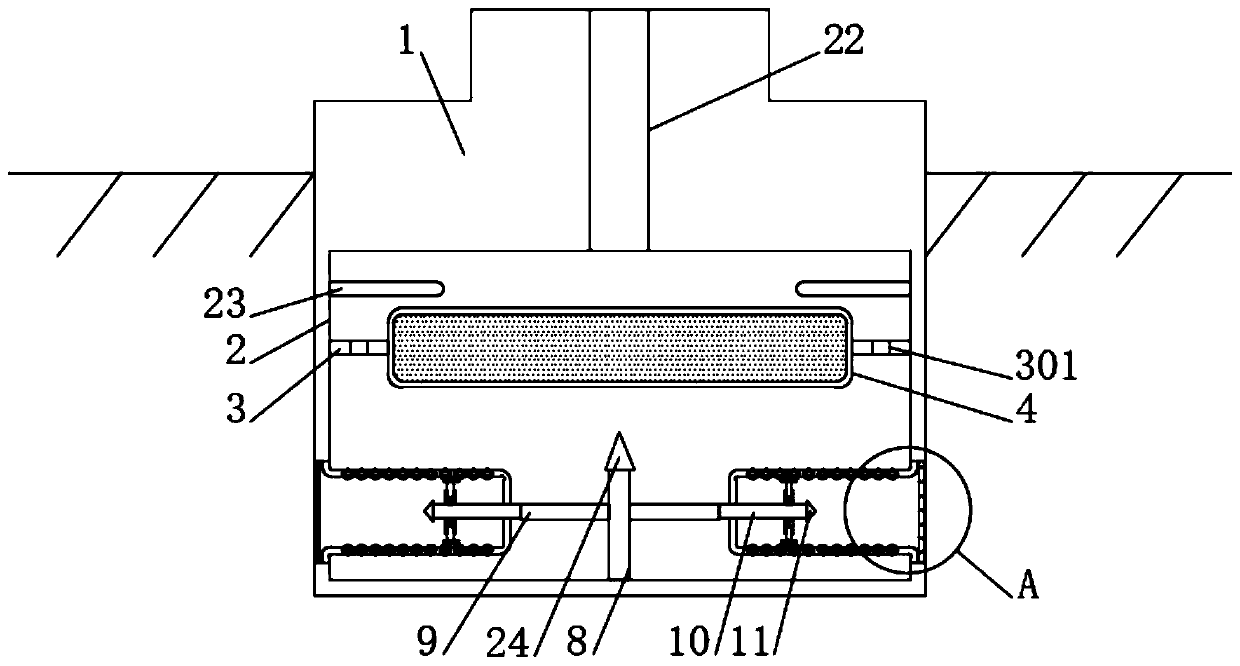

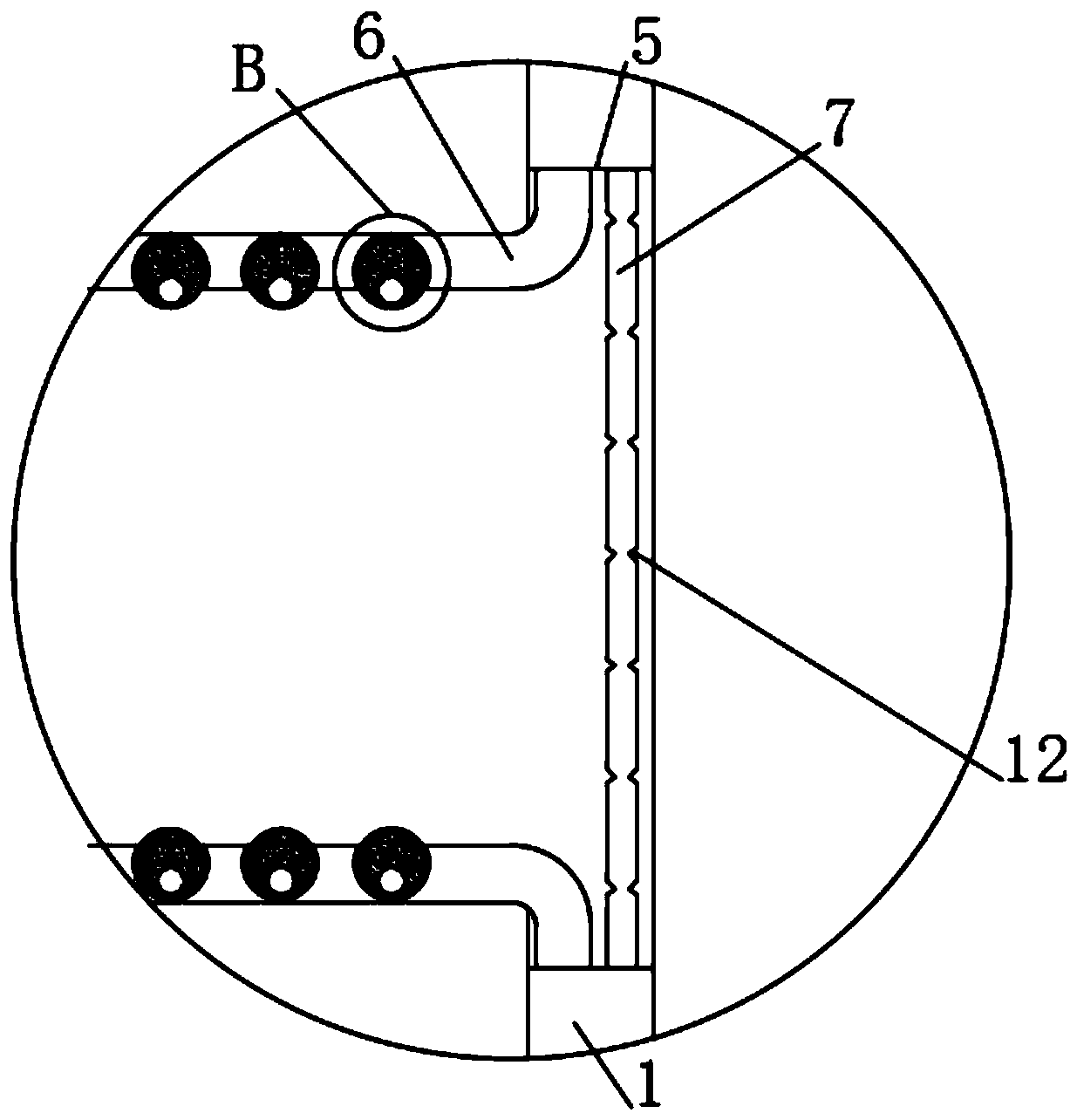

Stable combustion anti-slag gap type W-shaped flame boiler apparatus

ActiveCN101368725AReduce area temperatureImproved airflow flame stabilityCombustion apparatusCombustorSlag

Disclosed is a stable-combustion slagging resistant slit W-type flame boiler device which relates to a W-type flame boiler combustion device. The invention solves the problems of unreasonable combustion organization, easy slagging in the lower hearth and the bad stability of the pulverized coal airflow flame found in the slit W-type flame boiler in the prior art. The front arch and rear arch (3) of the invention are provided with a primary air spout (9), an exhaust spout (10), a secondary air spout (11) and a slagging resistant secondary air spout (12); the primary air spout (9) is arranged on the front and the rear arch (3) close to the central side of the hearth; the secondary air spout (11) and the primary air spout (9) are arranged alternately; the slagging resistant secondary air spout (12) is arranged on the front arch and the rear arch (3) close to the water cooling wall side of the front wall and the back wall and is arranged on the same side where the primary air spout (9) is arranged; the exhaust spout (10) is arranged between the primary air spout (9) and the slagging resistant secondary air spout (12); a combustor spout is distributed through the hearth center (2-1) as the symmetrical surface. The stable-combustion slagging resistant slit W-type flame boiler device has the advantages of reasonable combustion organization, reducing the slagging of the lower hearth and good stability of the pulverized coal airflow flame during the operating process of the slit W-type flame boiler.

Owner:HARBIN INST OF TECH

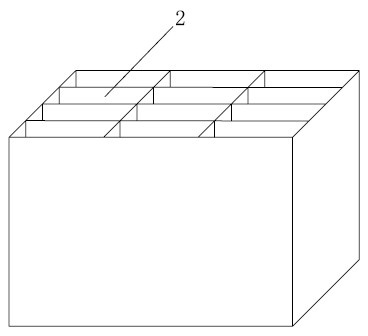

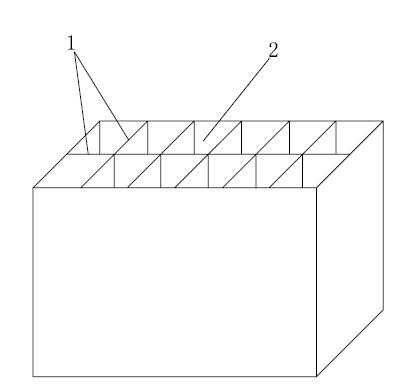

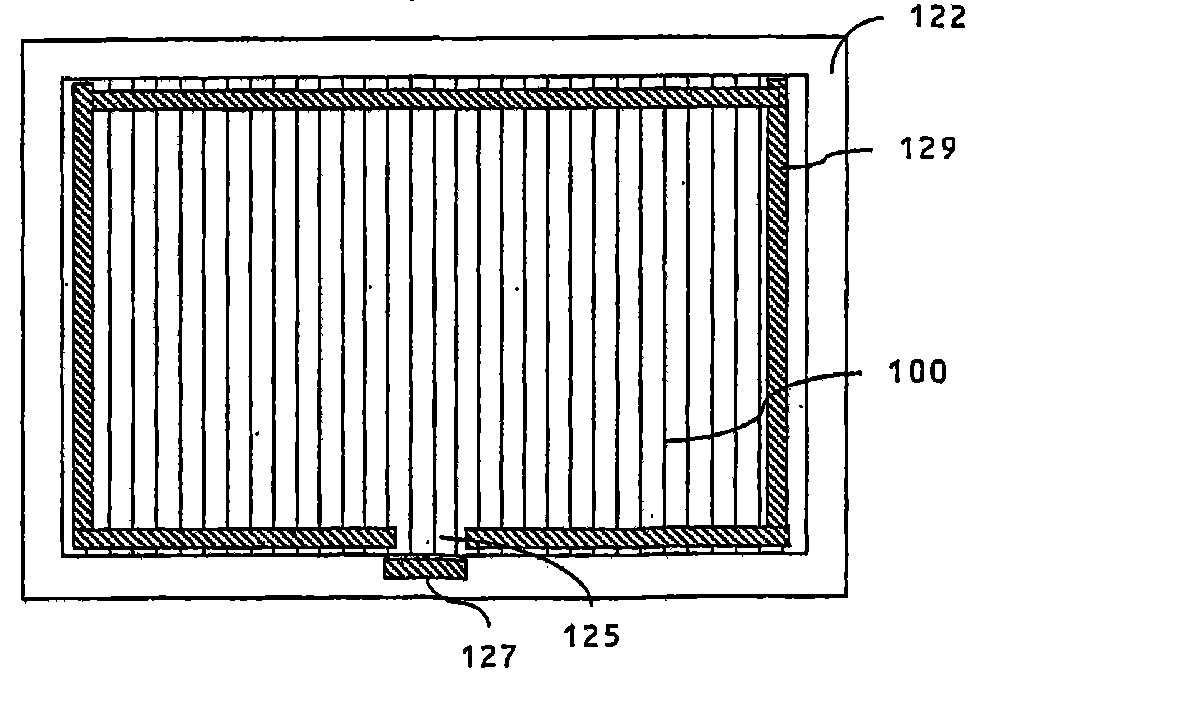

Storage battery shell

InactiveCN101877389AImprove aestheticsImprove electrical performanceCell component detailsElectrical and Electronics engineering

Owner:长兴诺力电源有限公司

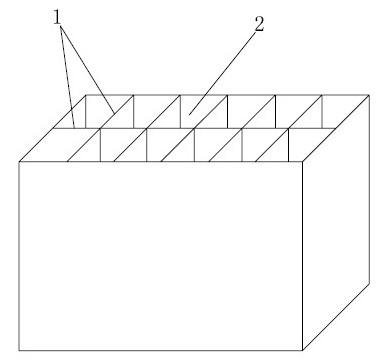

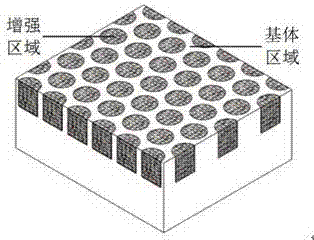

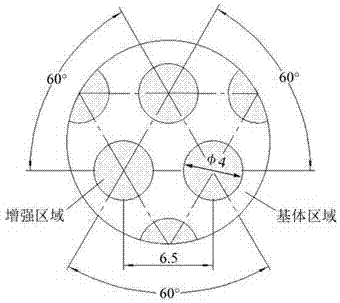

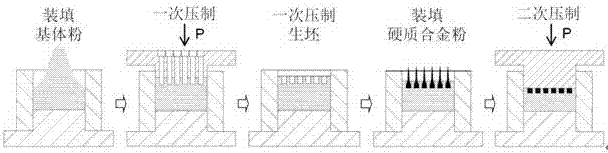

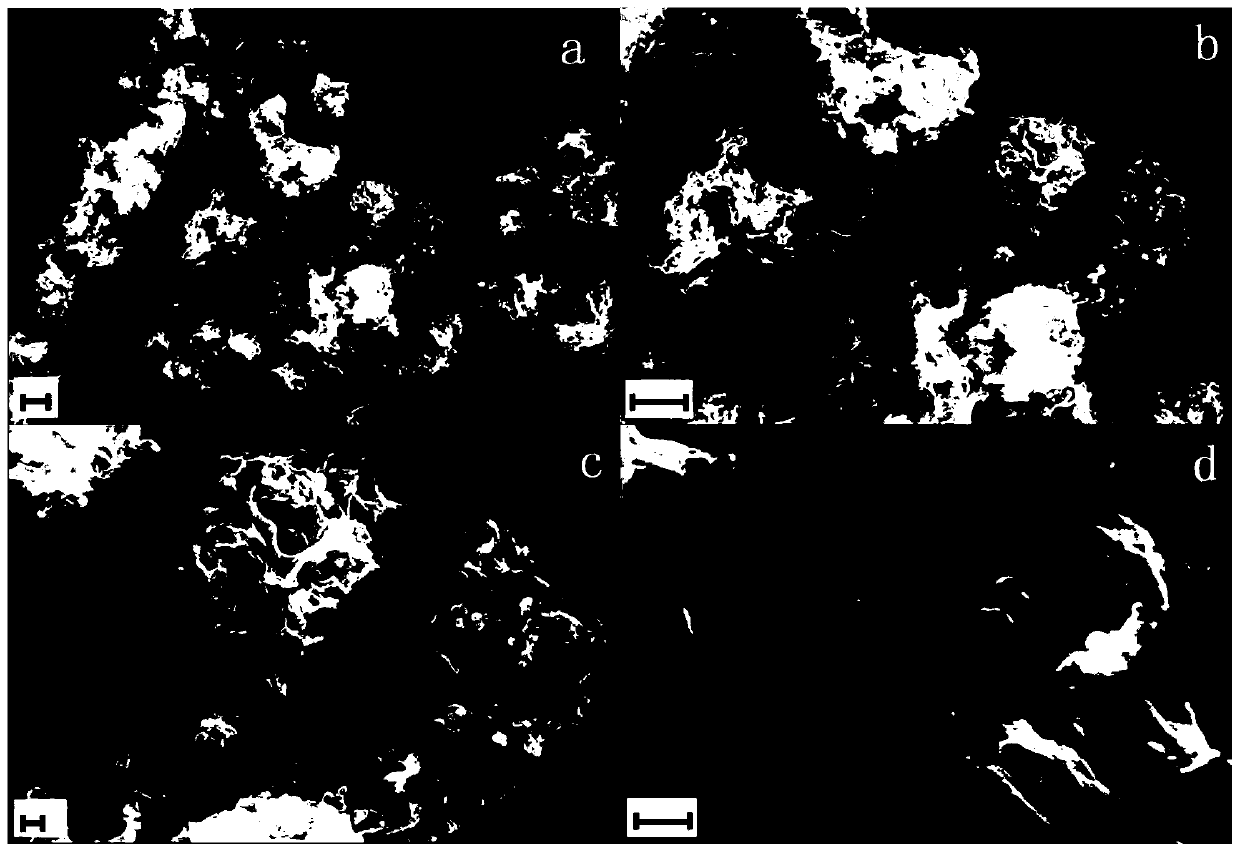

Powder metallurgy preparation method of localization reinforced composite

The invention belongs to the technical field of composite preparation, and particularly relates to a powder metallurgy preparation method of a localization reinforced composite for manufacturing wear-resisting quick-wear parts of mining and building machines. The method comprises the following steps that (1) tungsten carbide powder and titanium carbide powder are used as reinforced particles, reduced iron powder and high-speed steel powder are used as a metal binder, and hard alloy powder is prepared according to a certain proportion; (2) the prepared hard alloy powder is put into a ball mill, and a process control agent is added for ball milling and mixing; and (3) a forming agent is added into the hard alloy powder subjected to uniform ball milling and mixing, and then the steps of mixing, prepressing, smashing, sieving particle making and the like are carried out. In a composite layer of the composite prepared through the method, discontinuous reinforcement areas are uniformly distributed in a continuous matrix area, cracks are not prone to being produced and expanding in the service process of the composite, and strength-toughness matching performance of the composite is achieved well; and the wear resistance of the composite can be obviously improved, and the service life of the composite can be obviously prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

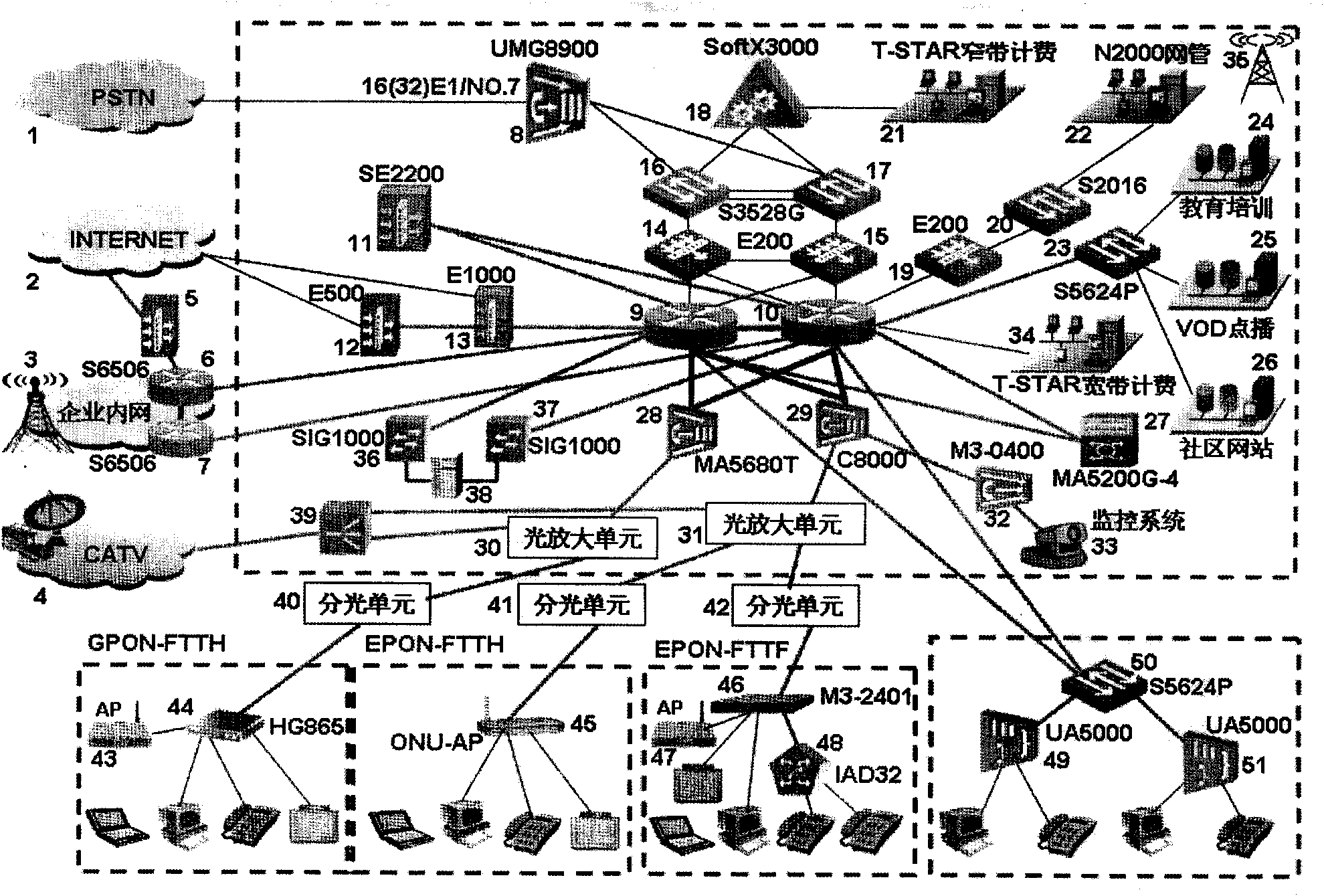

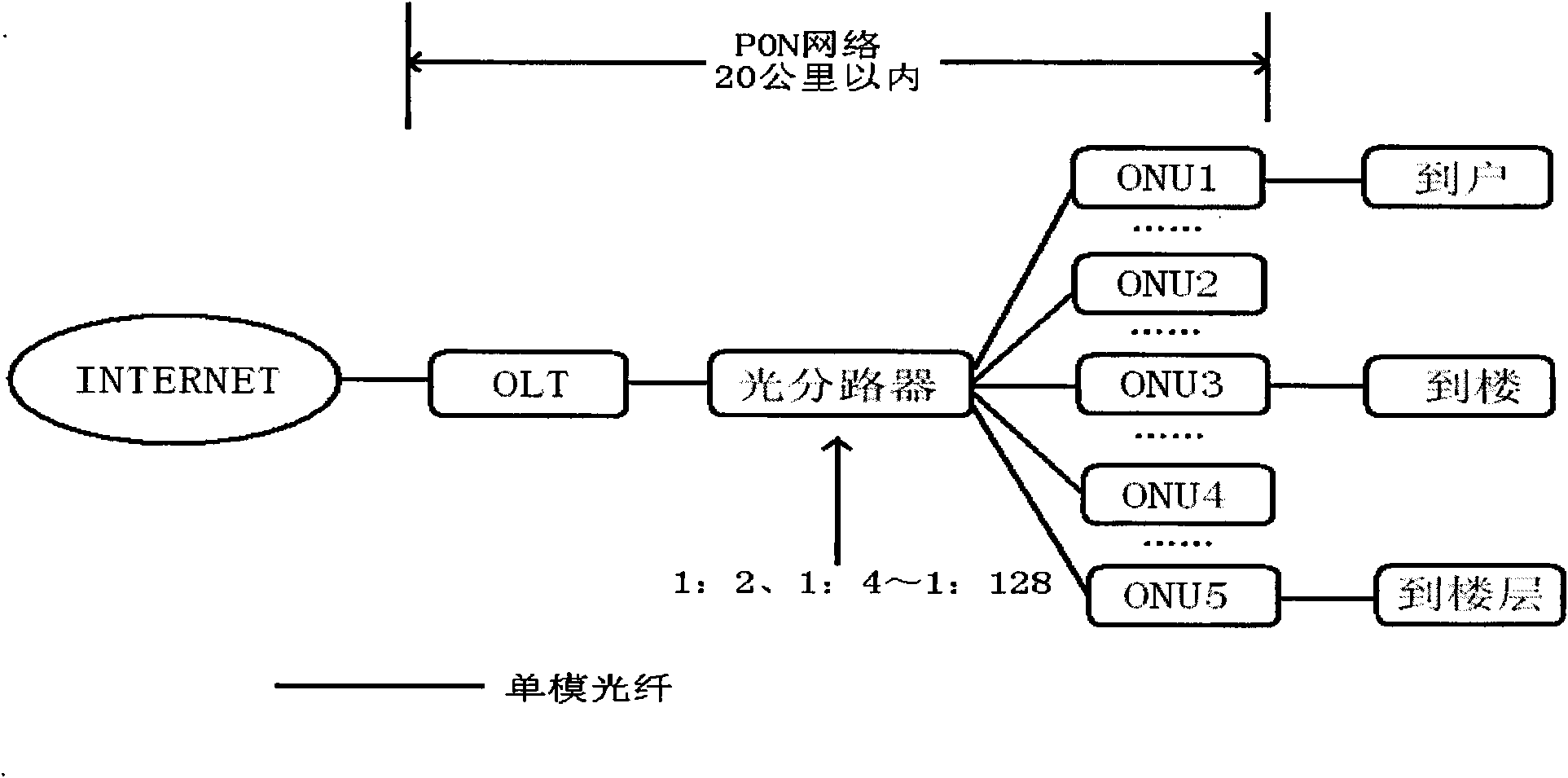

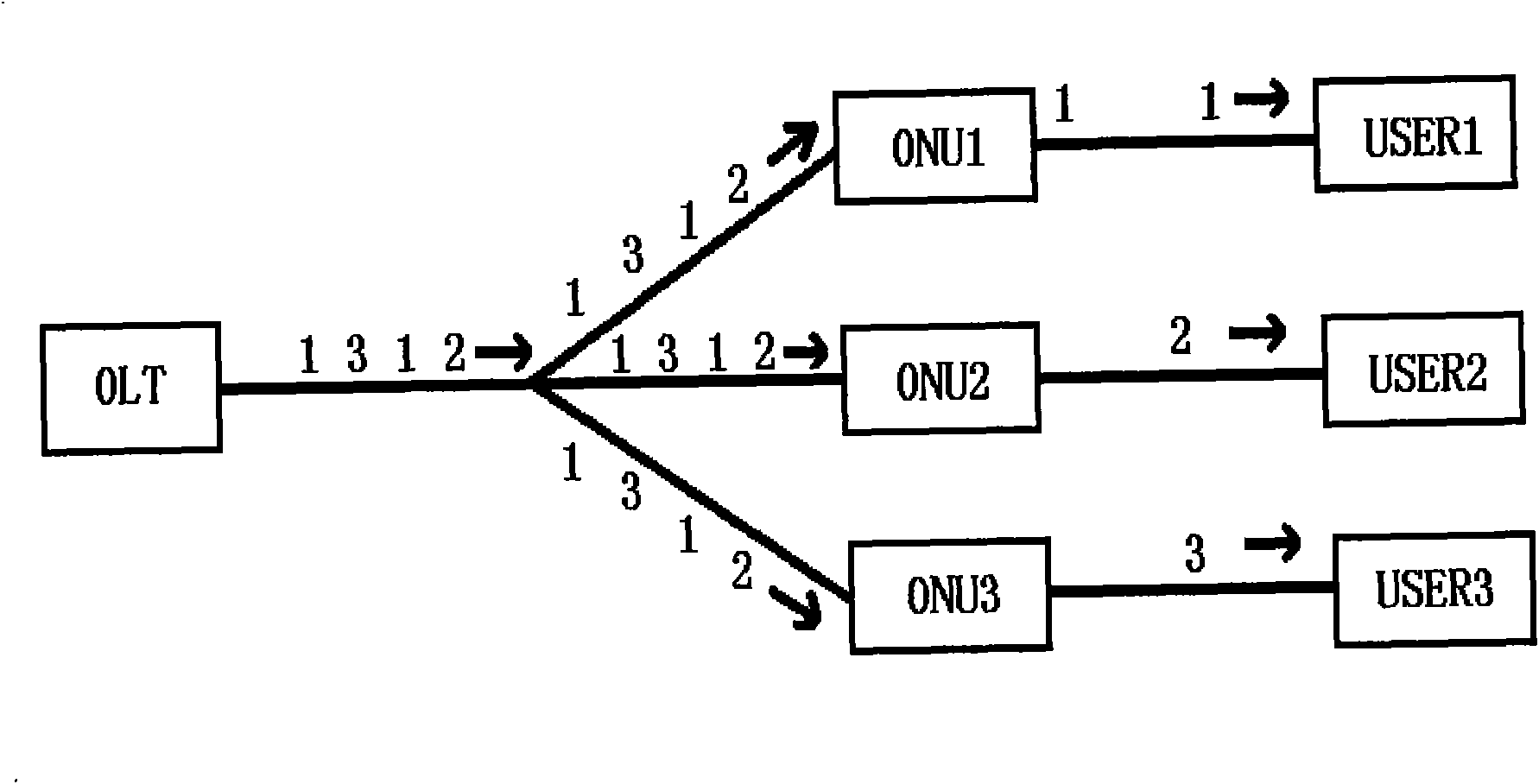

FTTH optical access network architecture based on ''three-network integration''

InactiveCN101588519AReduce usageSave routing duct facilitiesMultiplex system selection arrangementsFibre transmissionThe InternetOptical line termination

An FTTH optical access network architecture based on ''three-network integration'' belongs to the application field of multi-network fusion technology. The FTTH optical access network architecture comprises the following components: an accessed telecommunication public network, an accessed Internet, wireless transmission, a broadcast television access network, the existing local area network fireproof wall of the enterprise, the existing local area network core switch of the enterprise, a media gateway, a three-network integrated first-core switch session boundary controller, the fireproof wall, the switch, a NGN soft switching system, a narrowband charger, a network management system, a first database server, an intelligent service gateway, a gigabit Ethernet passive optical network GPON, an optical fiber line terminal device EPON, an optical amplifying unit, an ONU, a digital monitoring system, a wideband charger, a security service gateway, a server, an optical splitter, an AP, an optical network terminal ONT, an optical network terminal with a wireless home gateway, an optical network terminal M3-2401, an integrated access device and an integrated service aceess plateform. The FTTH optical access network architecture of the invention has the advantages of multi-network fusion, high bandwidth, high stability, low input and high return.

Owner:BEIJING SHOUGANG CO LTD

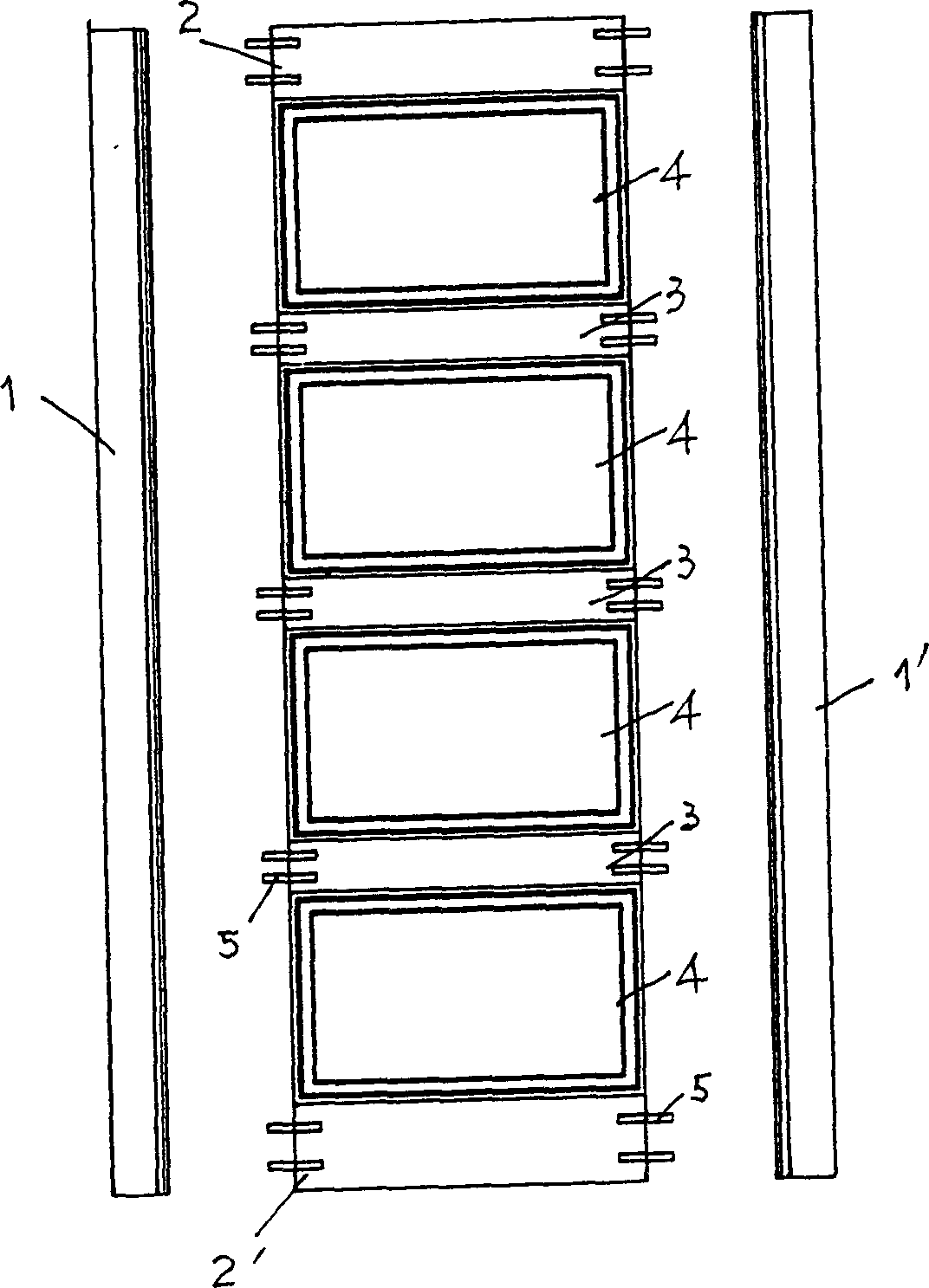

Log door leaf and its manufacturing method

InactiveCN1657735ASave the processImprove bindingWood working apparatusDoor leavesIndustrial engineering

The invention relates to a log door leaf and its manufacturing method, solves the problem of the paint cracking caused by contraction or expansion of transom and closure plate of door, including three steps: produce transom and closure plate of door by wood; pain each of them wholly; pain binder on the linking part of then, making leaf. There is sew for contraction remained on each linking part of each transom and closure plate of door, even if contraction or expansion happens somewhere, it will only affect the width of the sew, no to the whole appearance; the linking part of each transom and closure plate of door is strengthened by transversal cork, making the leaf stabler.

Owner:陈文镇

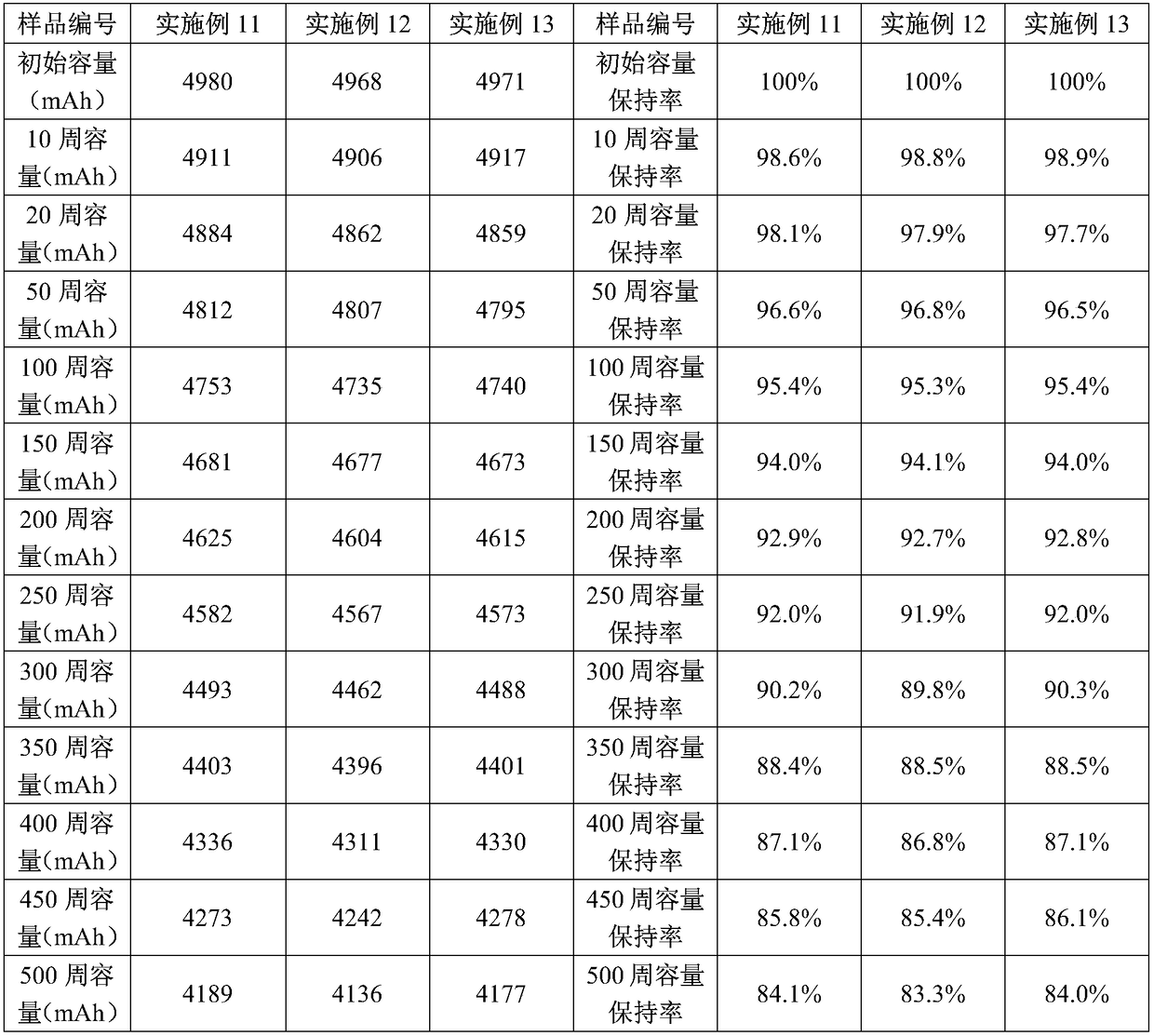

Silicon-containing high-energy-density lithium ion battery

ActiveCN109713367AEnhanced complexationEnergy barrier increaseFinal product manufactureSecondary cells servicing/maintenanceSolubilityHigh energy

The invention relates to a silicon-containing lithium ion battery with high energy density. The lithium ion battery comprises a positive electrode, a silicon-containing negative electrode, a fluorine-containing electrolyte, a diaphragm, electrode lugs and a packaging material. The silicon-containing negative electrode takes a silicon-based material as a whole or a part of electrochemical active substances. The electrolyte contains lithium salt, a non-aqueous organic solvent capable of dissolving the lithium salt, an SEI film-forming additive and hydrofluoroether. The solubility of the lithiumsalt in the non-aqueous organic solvent capable of dissolving the lithium salt is higher than 2 mol / L. The solubility of the lithium salt in the hydrofluoroether is lower than 0.3 mol / L, wherein the non-aqueous organic solvent capable of dissolving the lithium salt is mutually dissolved with the hydrofluoroether, the non-aqueous organic solvent capable of dissolving the lithium salt and the liquidSEI film-forming additive are mutually dissolved, so the solid SEI film-forming additive can be dissolved. The silicon-containing lithium ion battery has the advantages of high energy density, long cycle life, good rate capability, high safety performance, difficulty in expansion and deformation and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

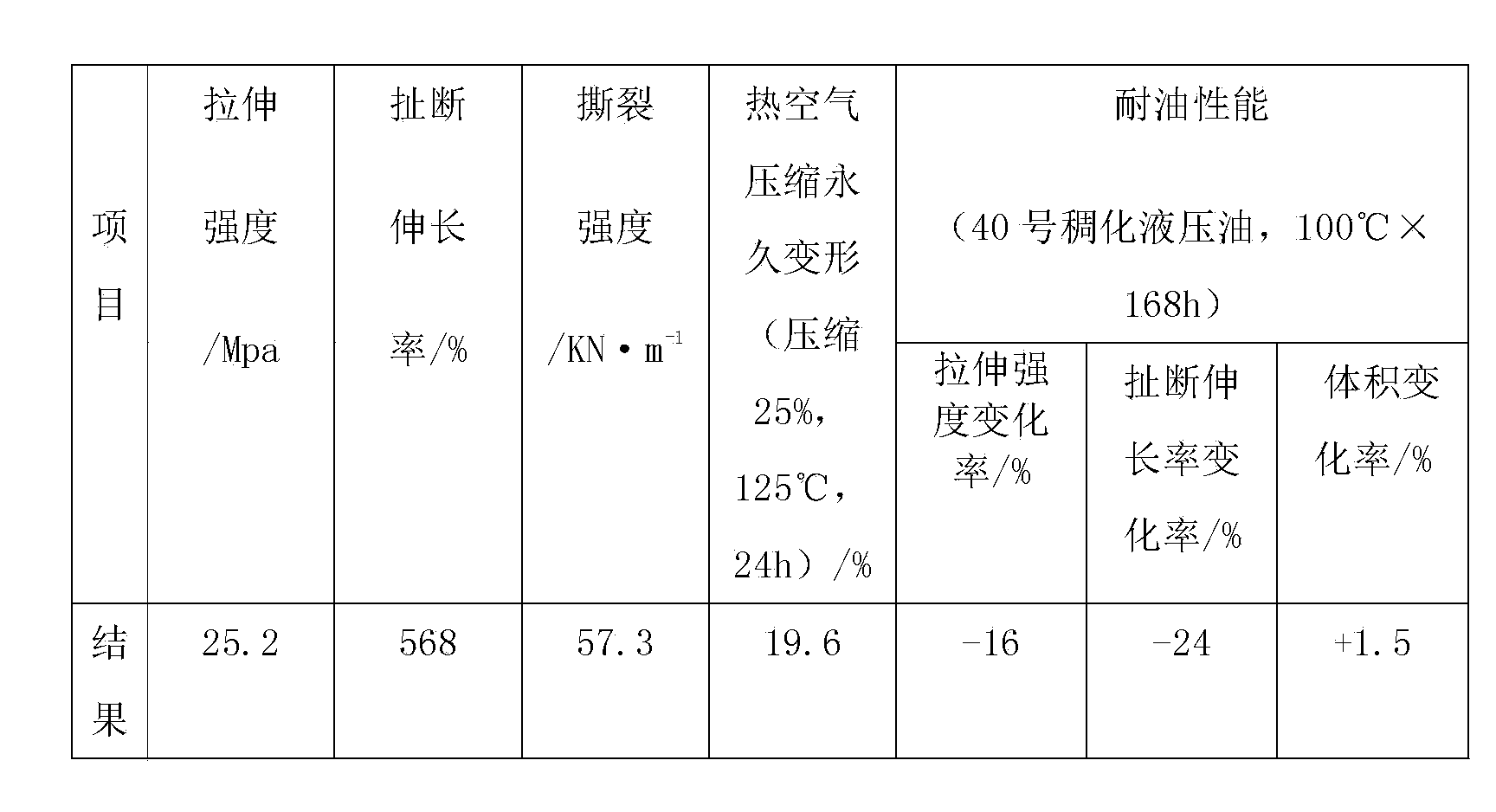

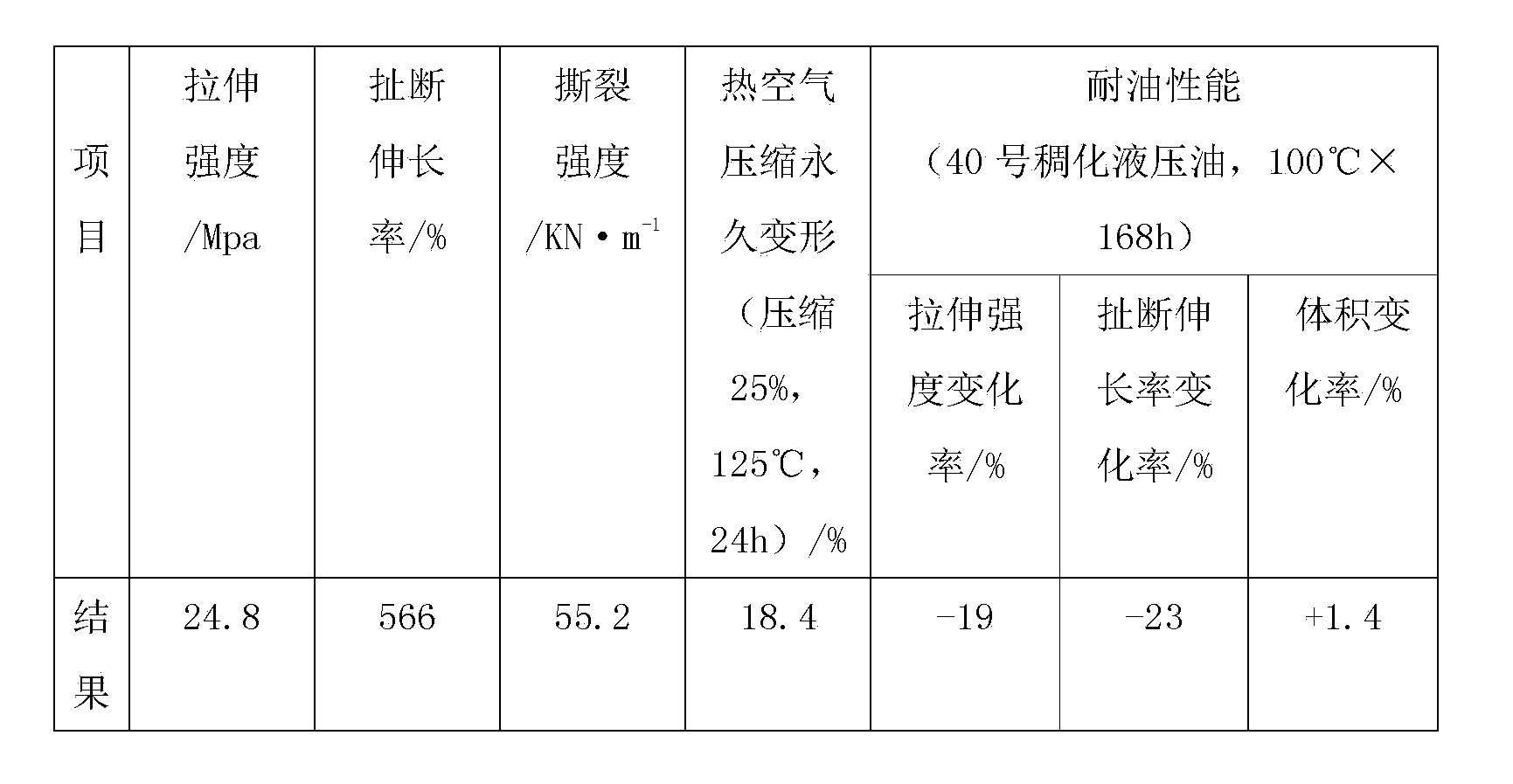

Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

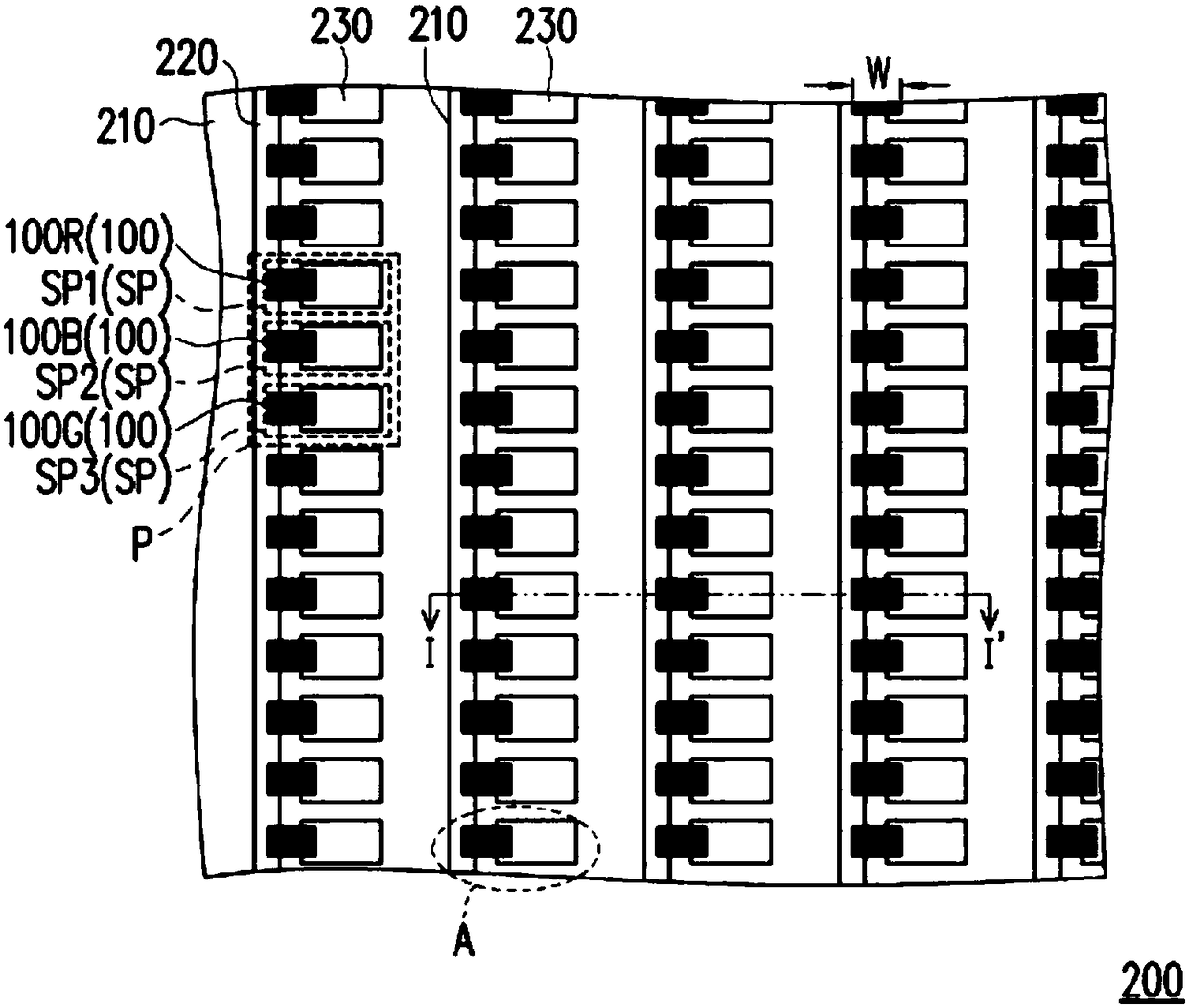

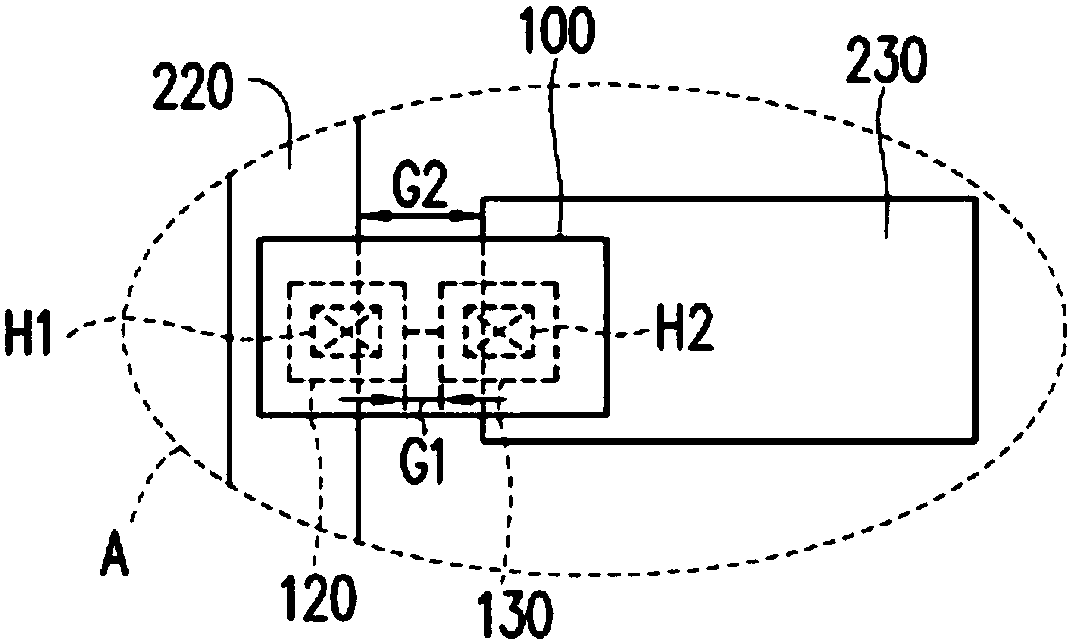

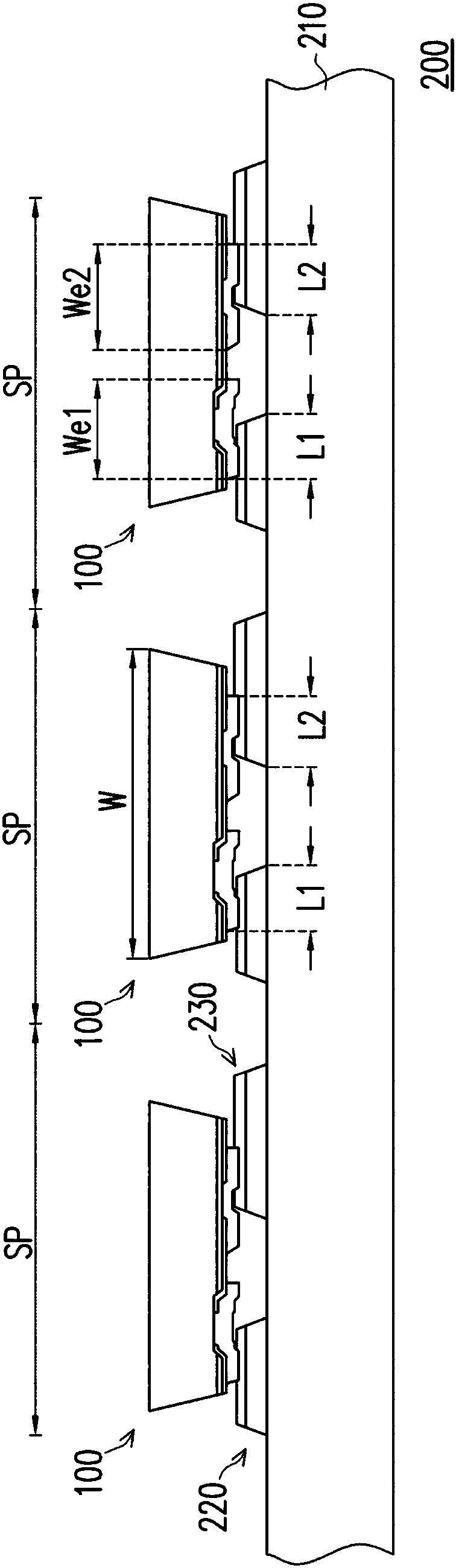

Micro light emitting diode and display panel

ActiveCN109216516AAvoid crackingImprove manufacturing yieldIdentification meansSemiconductor devicesLight-emitting diodeSemiconductor

A miniature light emitting diode includes an epitaxial layer, an insulating layer, a first electrode, and a second electrode. The insulating layer is located on the surface of the epitaxial layer andhas a first consistent hole and a second through hole. The first electrode is electrically connected to the first type semiconductor layer of the epitaxial layer via the first uniform hole, and has aplurality of first electrode plateau portions. These first electrode platforms have different horizontal heights with respect to the epitaxial layer, respectively. The second electrode is electricallyconnected to the second type semiconductor layer of the epitaxial layer via the second through hole, and has a plurality of second electrode platforms. These second electrode platforms have differenthorizontal heights with respect to the epitaxial layer. In addition, a display panel is also proposed.

Owner:PLAYNITRIDE

Rapid cross section manufacture and sub-surface micro-crack detection method of single crystal semiconductor substrate

ActiveCN103645078AGuaranteed positioning accuracyHigh hardnessPreparing sample for investigationOptically investigating flaws/contaminationSingle crystalSemiconductor

The invention relates to a rapid cross section manufacture and sub-surface micro-crack detection method of a single crystal semiconductor substrate. The method comprises the steps of cleaning the single crystal semiconductor substrate; processing one micro-groove or more micro-grooves on the single crystal semiconductor substrate along the direction of the same straight line of the surface to be detected; applying pressure onto the crack of the back(s) of the more micro-groove(s) of the single crystal semiconductor substrate, and enabling the single crystal semiconductor substrate to be broken into two along the direction(s) of the micro-groove(s) under the action of the force to complete sample preparation of the cross section of the single crystal semiconductor substrate; horizontally putting the detected cross section of the broken single crystal semiconductor substrate under an optical microscope and observing; moving the single crystal semiconductor substrate to enable the boundary between the surface to be detected and the detected cross section to appear in a visual area; adjusting the multiplying power of a lens of the optical microscope, and shooting the optical micrograph of a target area on the cross section; and measuring the maximum distance between the crack on the detected cross section and the boundary between the surface to be detected and the detected cross section to complete the sub-surface micro-crack detection work of the single crystal semiconductor substrate. The rapid cross section manufacture and sub-surface micro-crack detection method is feasible and dependable in detection result.

Owner:GUANGDONG UNIV OF TECH

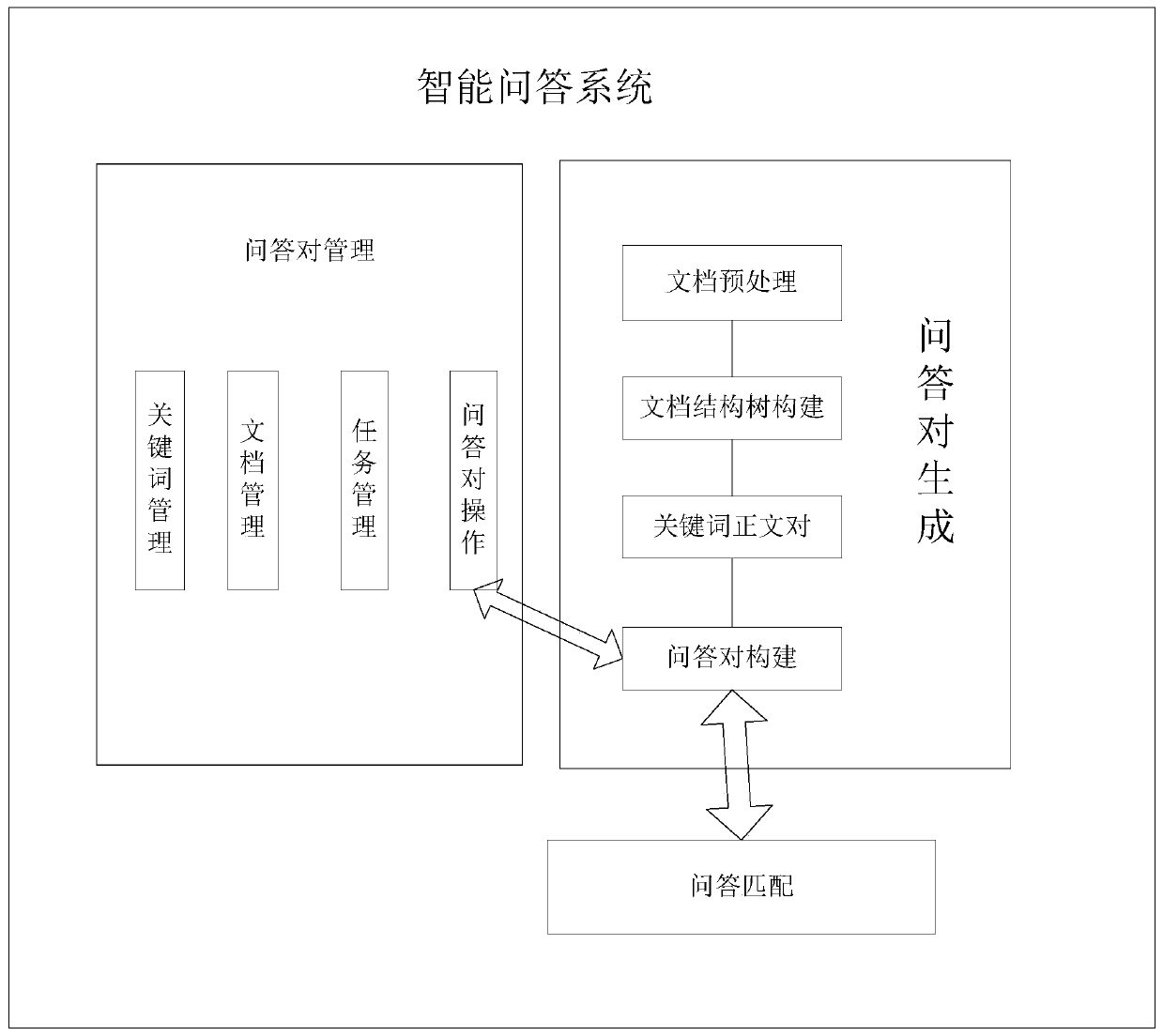

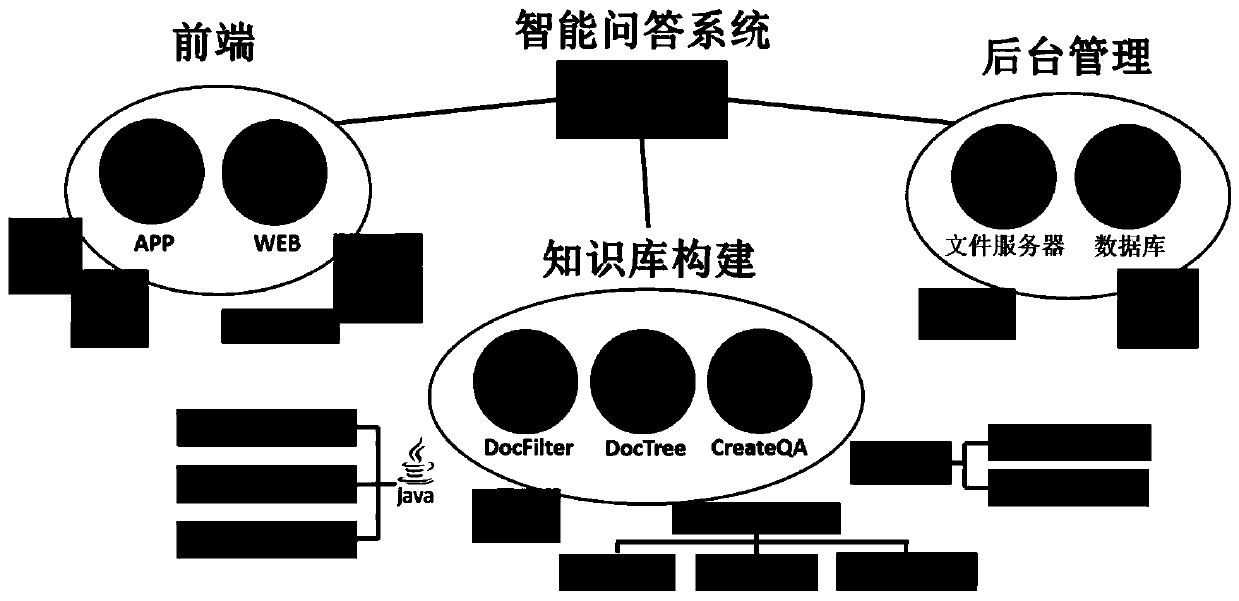

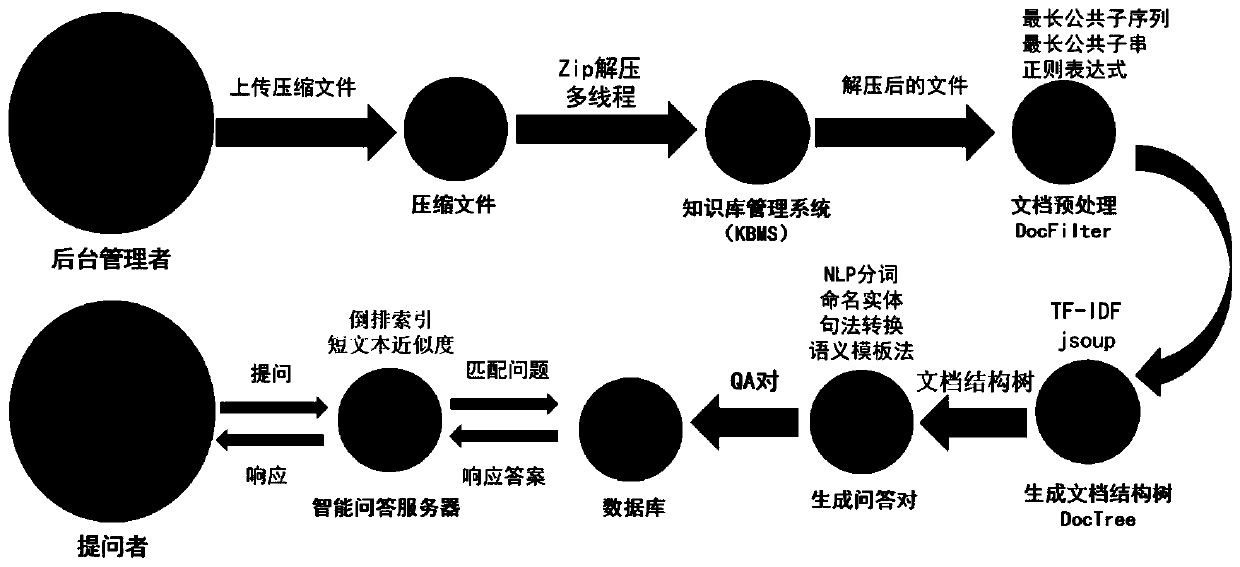

An intelligent question and answer system based on natural language processing

ActiveCN109947921AFlexible storageNot easy to expandText database indexingSpecial data processing applicationsQuestions and answersDocumentation

The invention discloses an intelligent question and answer system based on natural language processing. The system comprises a knowledge base construction module, a question and answer pair managementmodule and a question and answer matching module. The knowledge base construction module comprises a document preprocessing module, a document structure tree construction module and a question and answer pair construction module; the question and answer pair management module comprises a task management module, a document management module, a keyword management module and a question and answer pair operation module; the question and answer matching module is used for matching questions extracted by a user with the question and answer pairs created by the knowledge base generation module. As many as possible high-quality question and answer pairs are extracted from documents, the retrieval efficiency and accuracy of the knowledge base are improved.

Owner:HOHAI UNIV CHANGZHOU

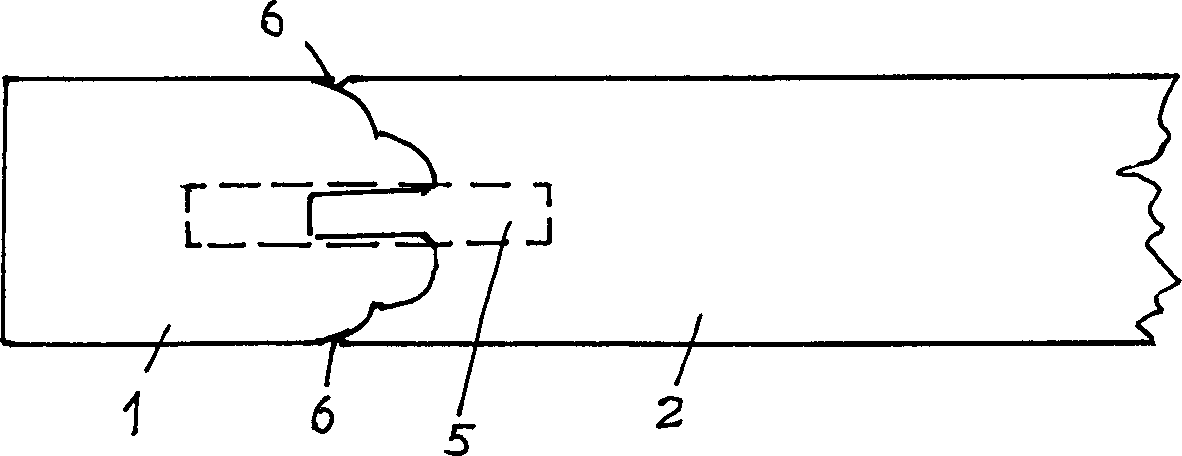

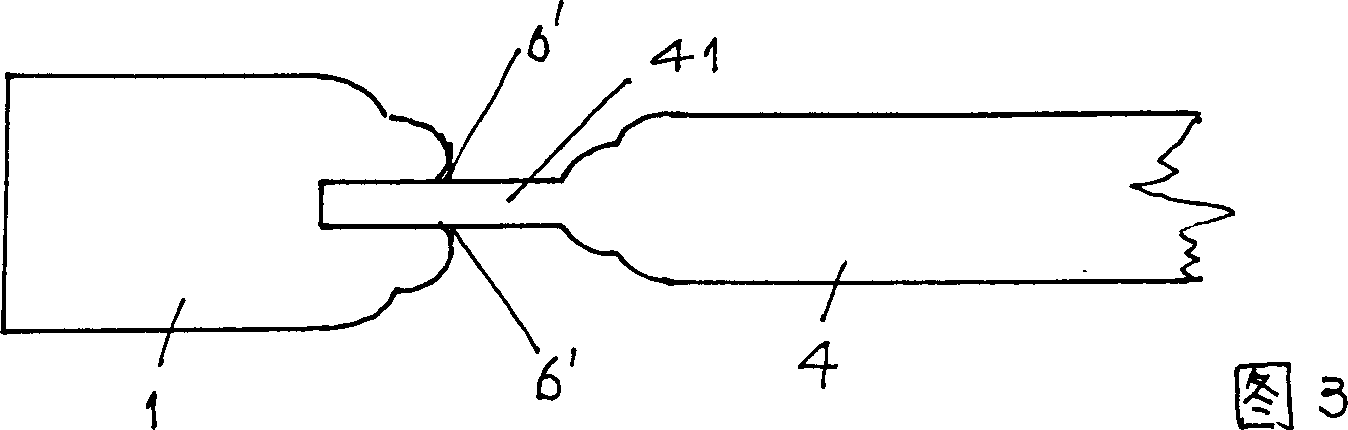

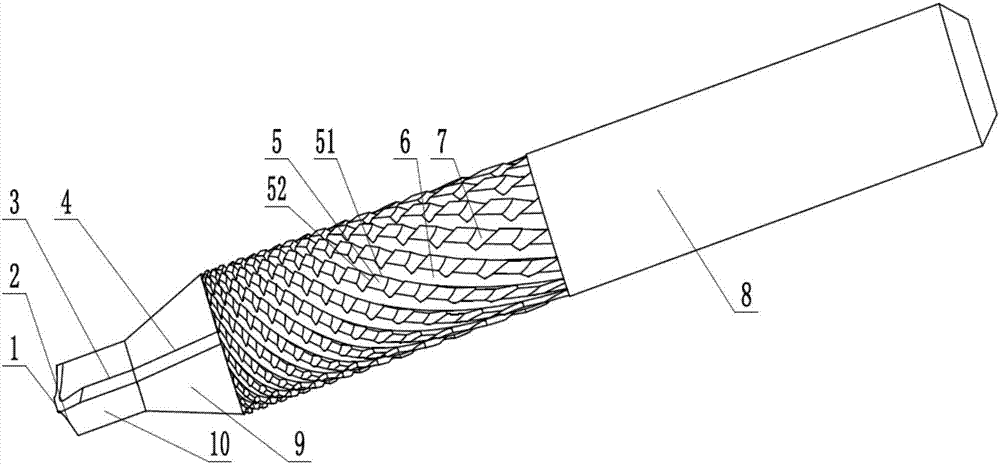

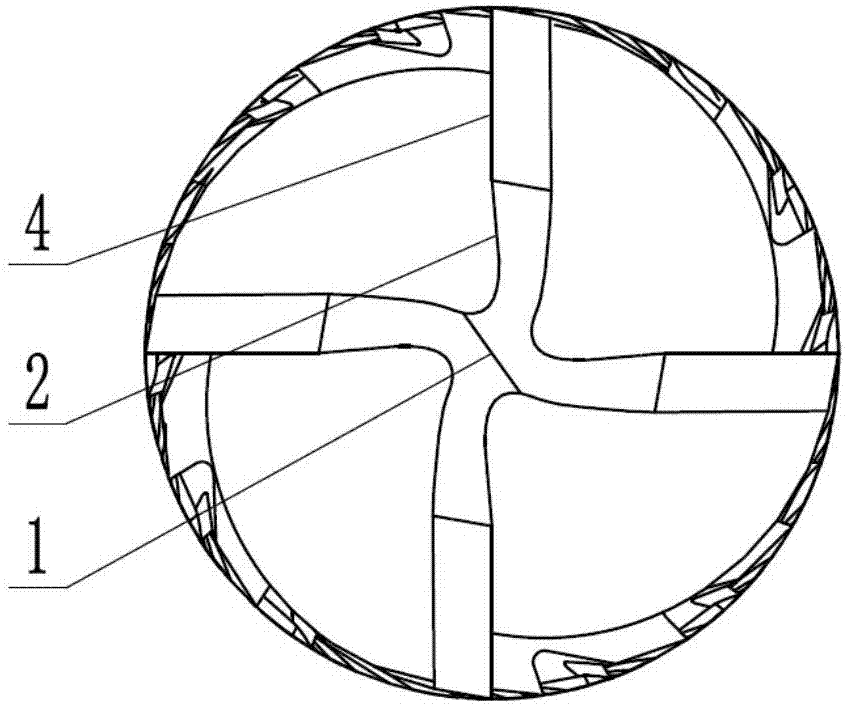

Multi-step multi-edge gradient micro toothed cutter for drilling carbon fiber reinforced plastics

The invention provides a multi-step multi-edge gradient micro toothed cutter for drilling carbon fiber reinforced plastics, which belongs to the technical field of composite material machining. The multi-step multi-edge gradient micro toothed cutter is composed of a straight-edge drilling area, a reaming area, a trimming area and a cutter handle, wherein the straight-edge drilling area is provided with a cross edge, main cutting edges, secondary cutting edges and drilling chip grooves, the reaming area is provided with reaming cutting edges and reaming chip grooves, the trimming area is provided with rhombic micro cutting units, right-handed rotating chip grooves and left-handed rotating chip grooves, the rhombic micro cutting units are structurally divided into micro toothed main cutting edges and micro toothed secondary cutting edges, and the sizes of the rhombic micro cutting units are gradually increased in the direction of the right-handed rotating spiral line. The multi-step multi-edge gradient micro toothed cutter is a complete tool and has sufficient strength and rigidity, the drilling axial force is reduced, and additionally, the sizes of the rhombic micro cutting units are gradually increased, so that the deburring efficiency is greatly improved, the trimming quality of a processed hole wall is guaranteed, the transition of the machining process is smooth, and the machining efficiency is improved.

Owner:DALIAN UNIV OF TECH

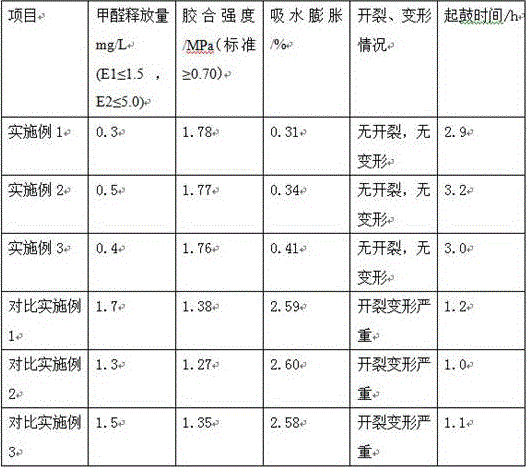

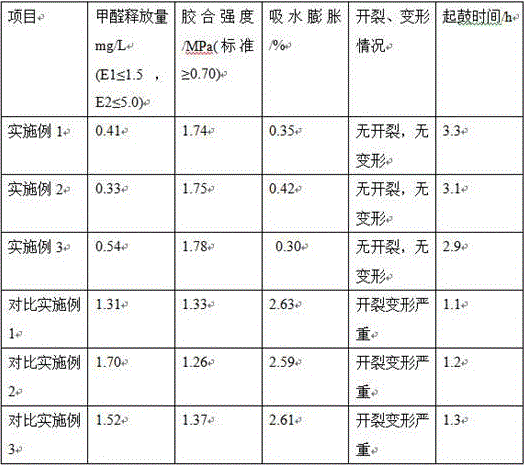

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

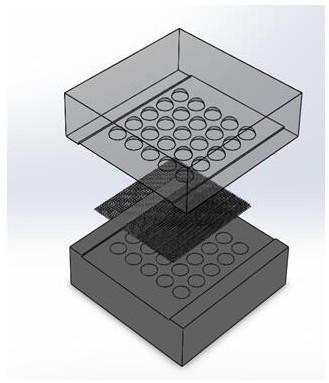

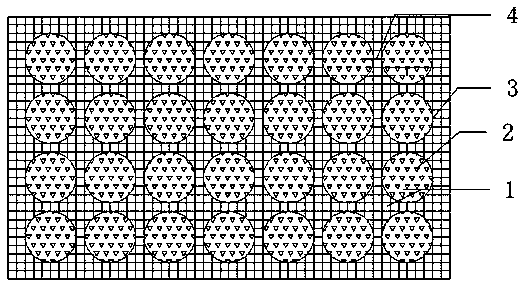

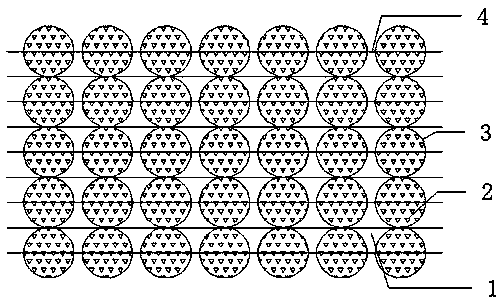

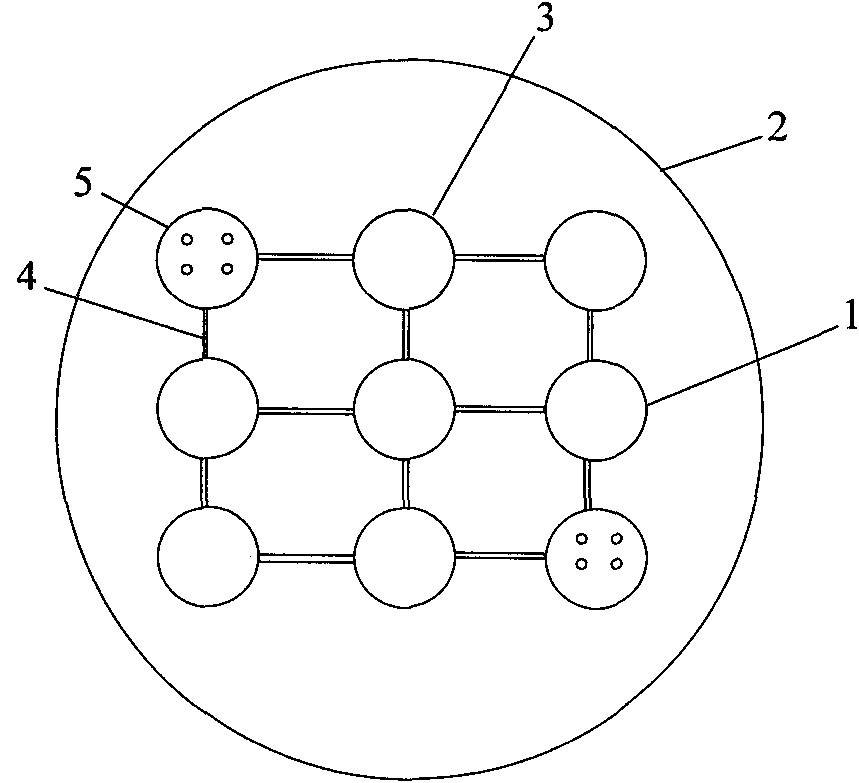

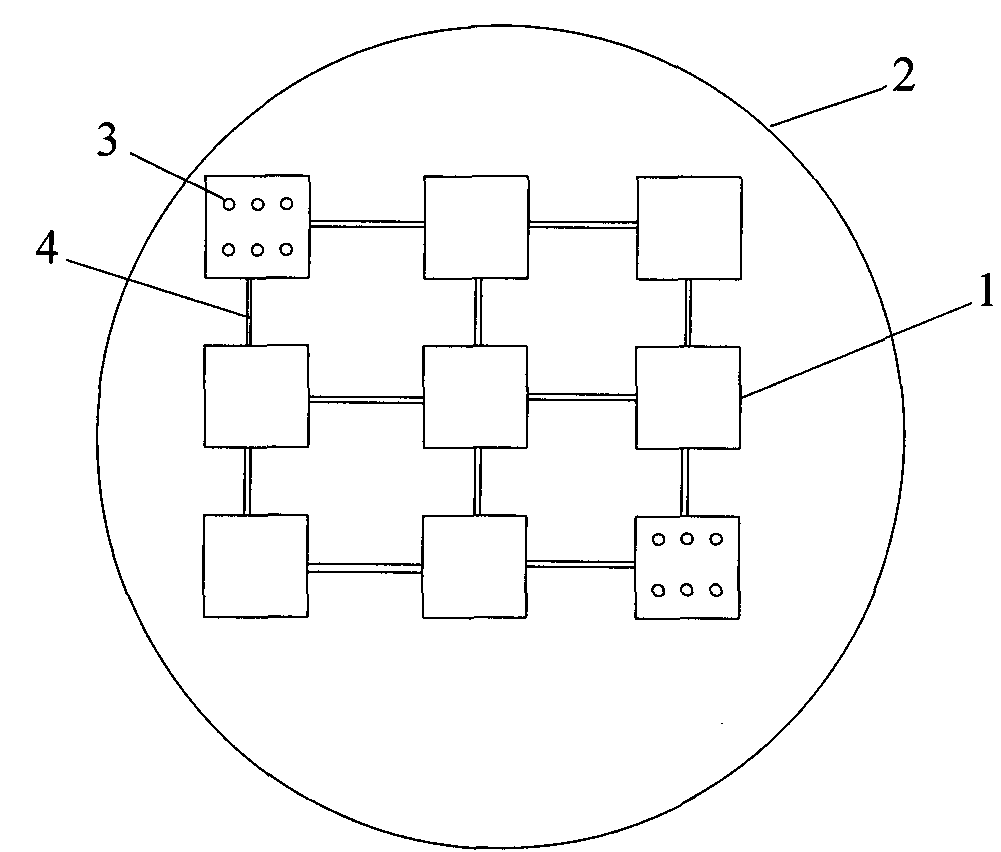

Preparation method for ceramic particle reinforced metallic matrix space lattice composite material

ActiveCN109022882ALow costSolve the problem of difficult impregnation into ceramic particlesMatrix spaceSlurry

The invention discloses a preparation method for a ceramic particle reinforced metallic matrix space lattice composite material. The preparation method comprises the following steps that (1) a metal mold comprising a plurality of globular cavities arranged in a plane lattice manner is manufactured, the mold can be divided into upper and lower parts, and a metal net is arranged between the upper and lower parts; (2) ceramic particles and a binder are mixed to prepare slurry, the metal mold is filled with the slurry, compaction and high-temperature sintering are carried out, and single-layer prefabricated bodies are manufactured; (3) metal nets are placed between the single-layer prefabricated bodies for stacking and arranging layer by layer, a binder is added for bonding, high-temperature sintering is carried out, and three-dimensional prefabricated bodies are manufactured; and (4) the three-dimensional prefabricated bodies are placed into a sand mould prepared in advance, pouring of metallic matrix melt is carried out, and infiltration is carried out to prepare the ceramic particle reinforced metallic matrix space lattice composite material. By means of the preparing method, the problem that a micron-order ceramic particle reinforced steel-based composite material is difficult to achieve ordinary pressure permeation and insufficient in toughness is solved.

Owner:KUNMING UNIV OF SCI & TECH

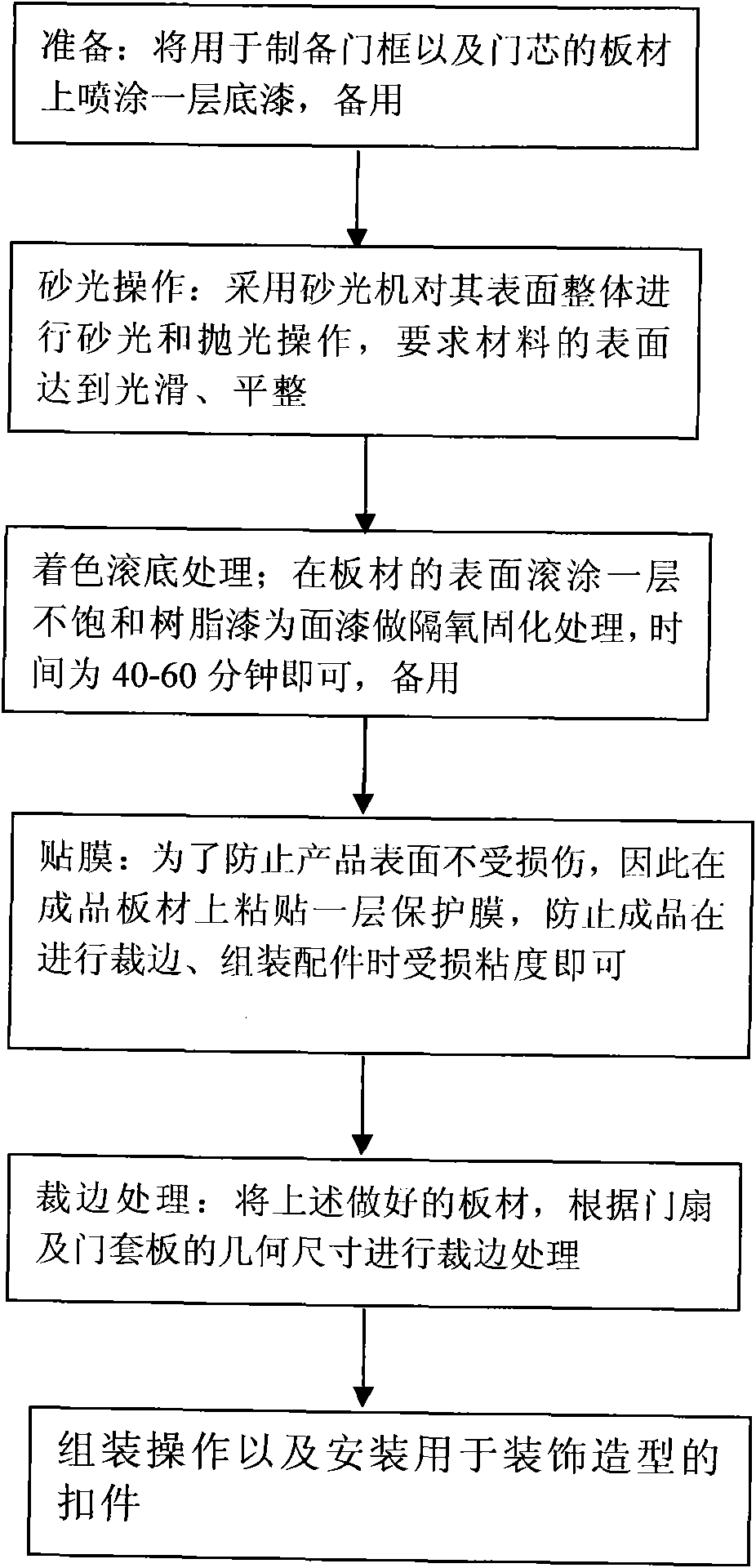

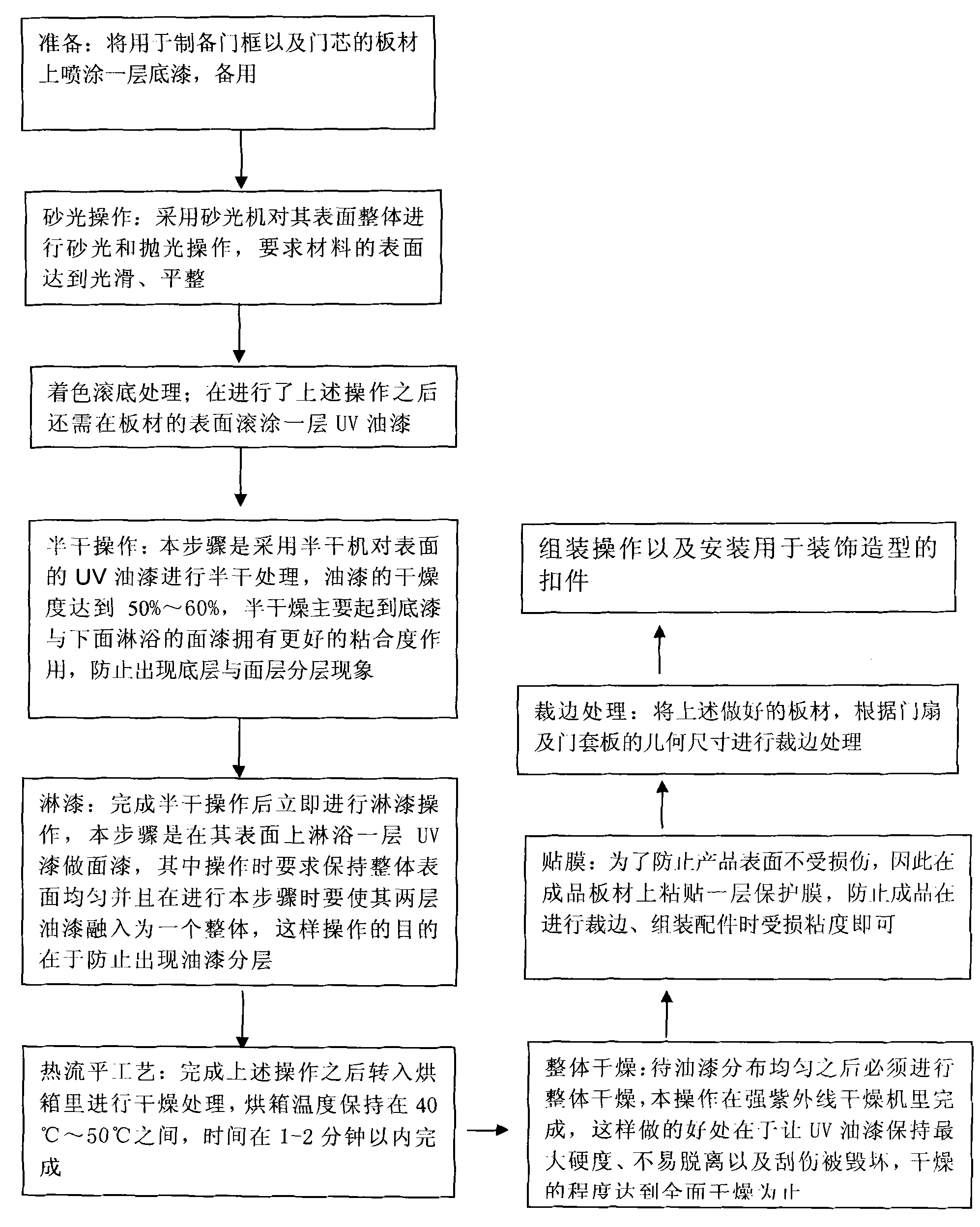

Manufacturing process of wood door and half drying machine

InactiveCN101871307ANot easy to shrinkNot easy to expandPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and other places. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

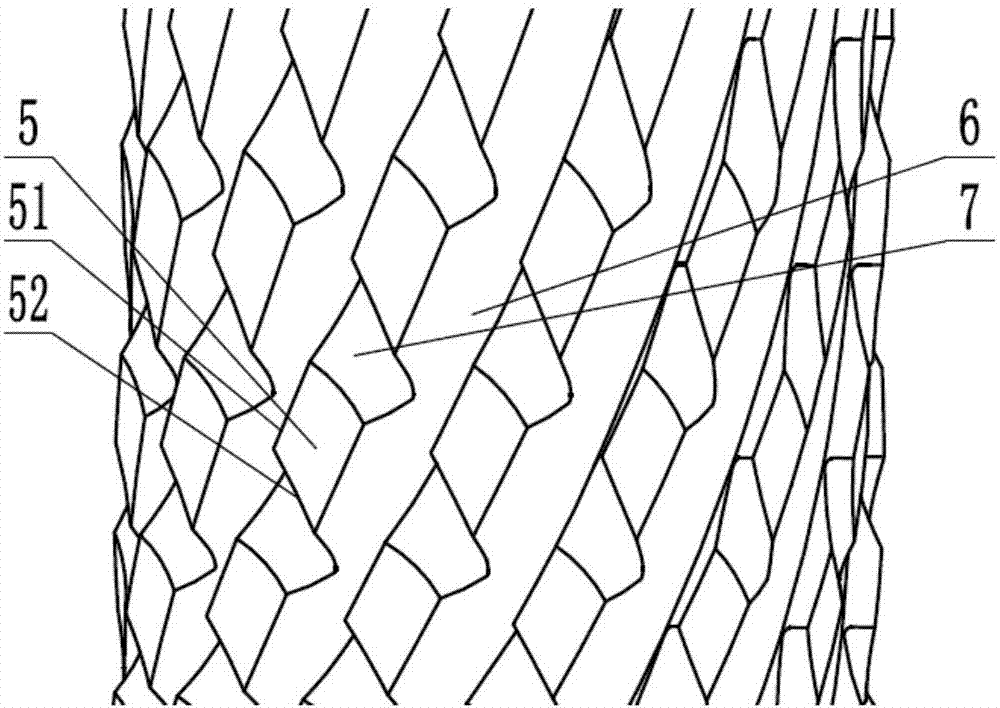

Weaving method of knotless net

Owner:孙以泽 +1

A high-energy silicon-containing lithium battery and a preparation method thereof-

ActiveCN109244386AReduce sheddingReduce electricity lossCell electrodesSecondary cellsHigh energyGram

The invention discloses a high-energy silicon-containing lithium battery, wherein the conductive agent of the positive electrode is 0.02-0.06% single-walled carbon nanotubes and 0.2-0.6% graphene: Thenegative electrode sheet is made of the following ingredients in parts by weight: up to 100% of the negative electrode active material, 0-1% of conductive carbon black, 0.02-0.08% of single-walled carbon nanotubes, 1-2% of CMC and 1.2-2.5% of binder; The negative electrode active material is carbon silicon and / or oxygen silicon, and the gram capacity is more than or equal to 650 mAh / g; The binderis prepared from styrene-butadiene rubber, acrylic acid and PMMA in 5-7: 1: 2-4 by weight ratio. The high-energy silicon-containing lithium battery has better charging and discharging stability, volume expansion resistance, cycle performance and stability under the premise of high energy by optimizing the conductive agent composition of the positive and negative electrodes and optimizing the binder.

Owner:广西卓能新能源科技有限公司

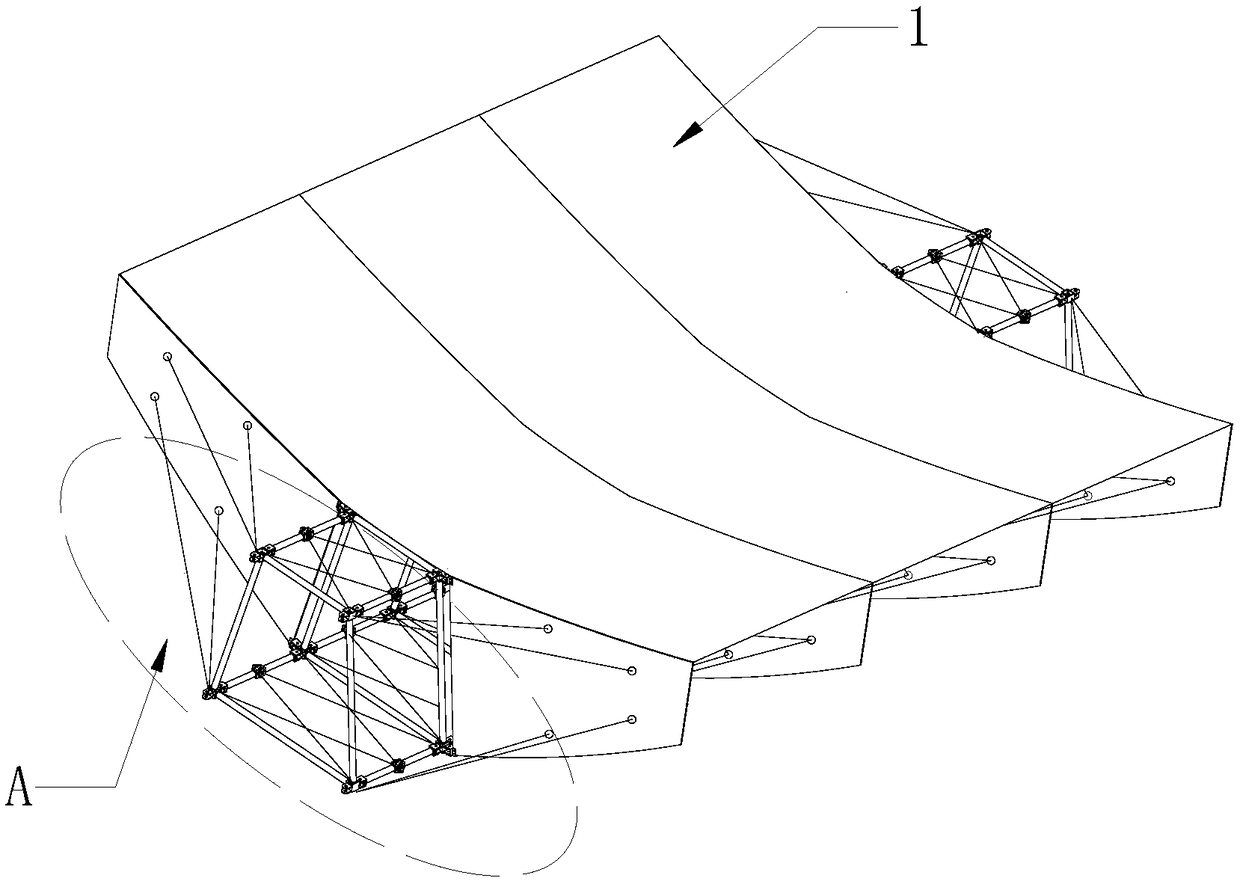

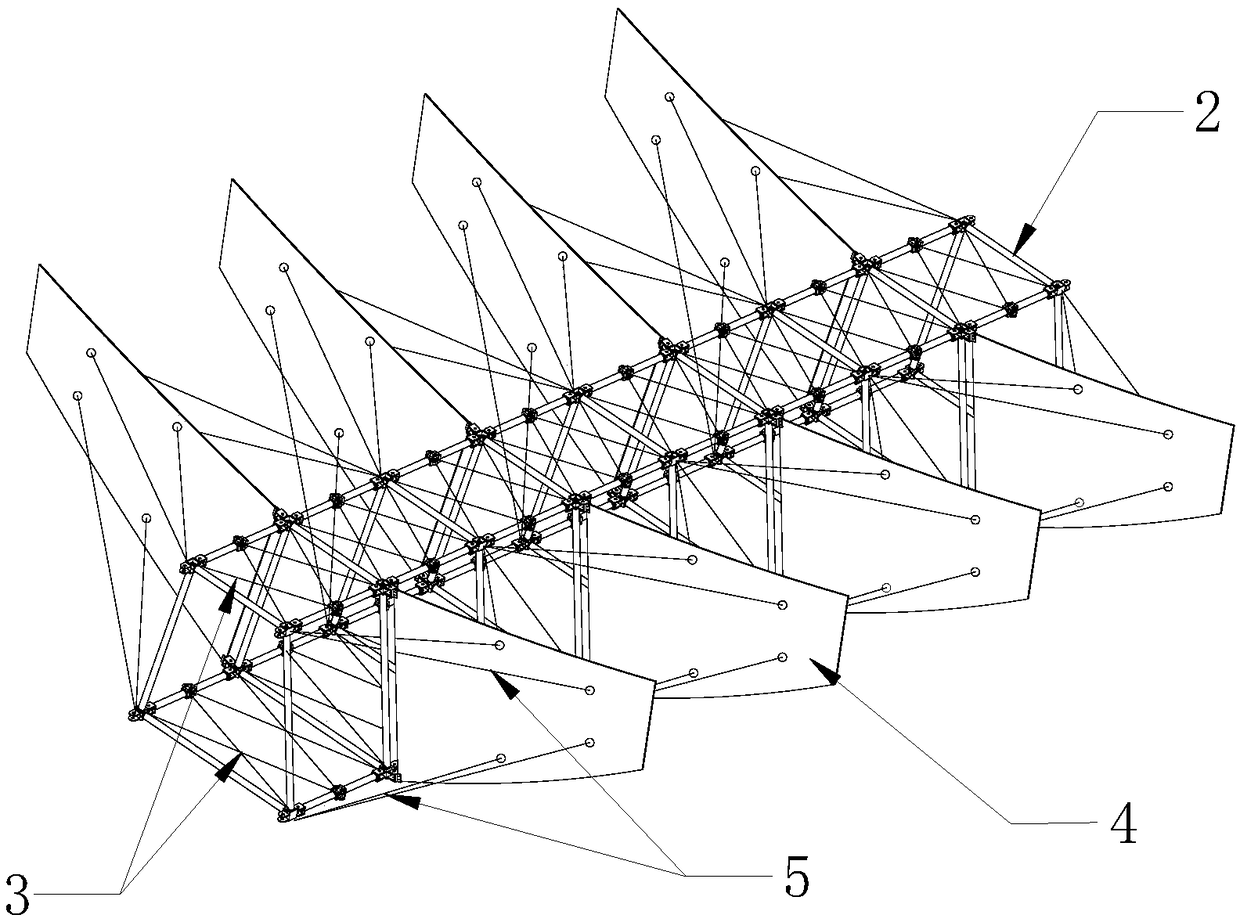

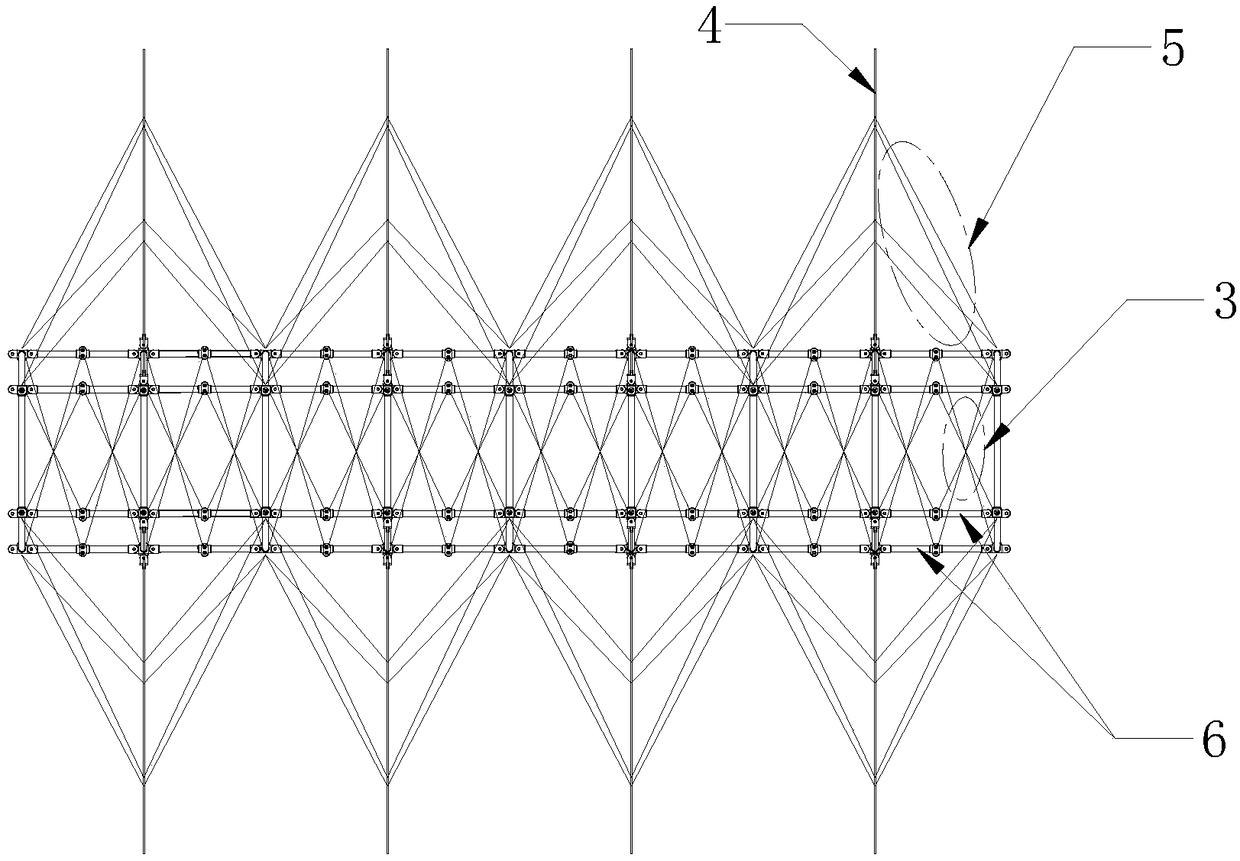

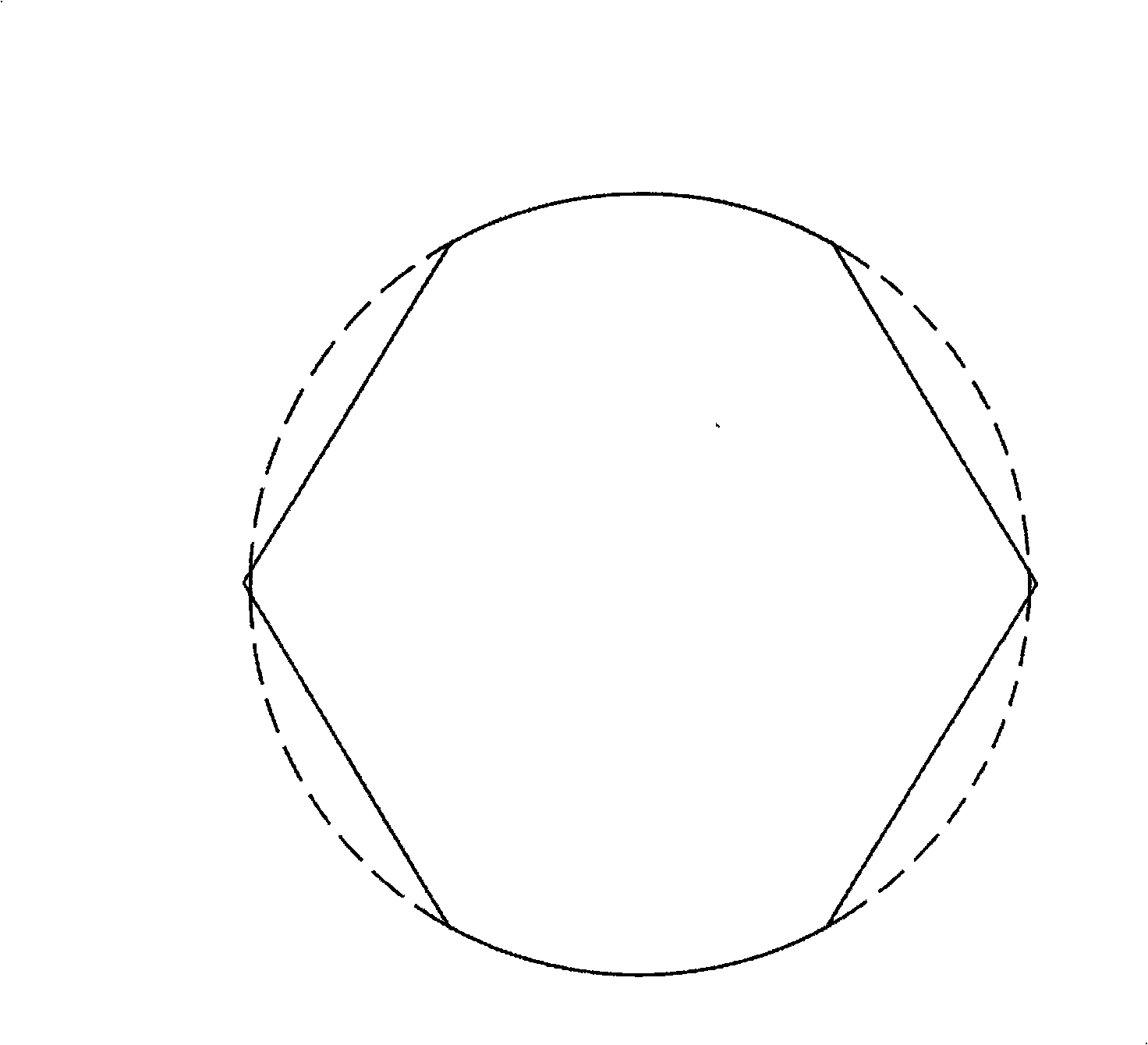

Truss supported flexible rib parabolic cylindrical unfoldable antenna device

The invention belongs to the satellite communication equipment technical field and discloses a truss supported flexible rib parabolic cylindrical unfoldable antenna device. An unfoldable supporting device A supports reflection film surfaces, so that the device can be formed; the unfoldable supporting device A comprises a one-dimensional unfoldable truss, unfolding control cables, rib plates and rib plate adjustment cables; the rib plates are symmetrically hinged to the left side edge and right side edge of the one-dimensional unfoldable truss respectively; the reflection film surfaces are attached onto the upper parabolic edges of the rib plates so as to form a parabolic cylindrical surface; the unfolding control cables are arranged at the upper surface and the lower bottom surface of theone-dimensional unfoldable truss so as to control the unfolding of the one-dimensional unfoldable truss; and the rib plate adjustment cables are arranged at two sides of each rib plate and are used for adjusting the unfolding positions and overall stiffness of the rib plates. According to the truss supported flexible rib parabolic cylindrical unfoldable antenna device of the invention, the one-dimensional truss mechanism is combined with the flexible rib structures, the truss mechanism can be folded and unfolded; the rib plates can be folded through winding, and unfolded flexibly; and after being folded, the device just occupies a small space, and therefore, a storage space for the device is obviously reduced, and the overall weight of the device is significantly reduced.

Owner:XIDIAN UNIV +1

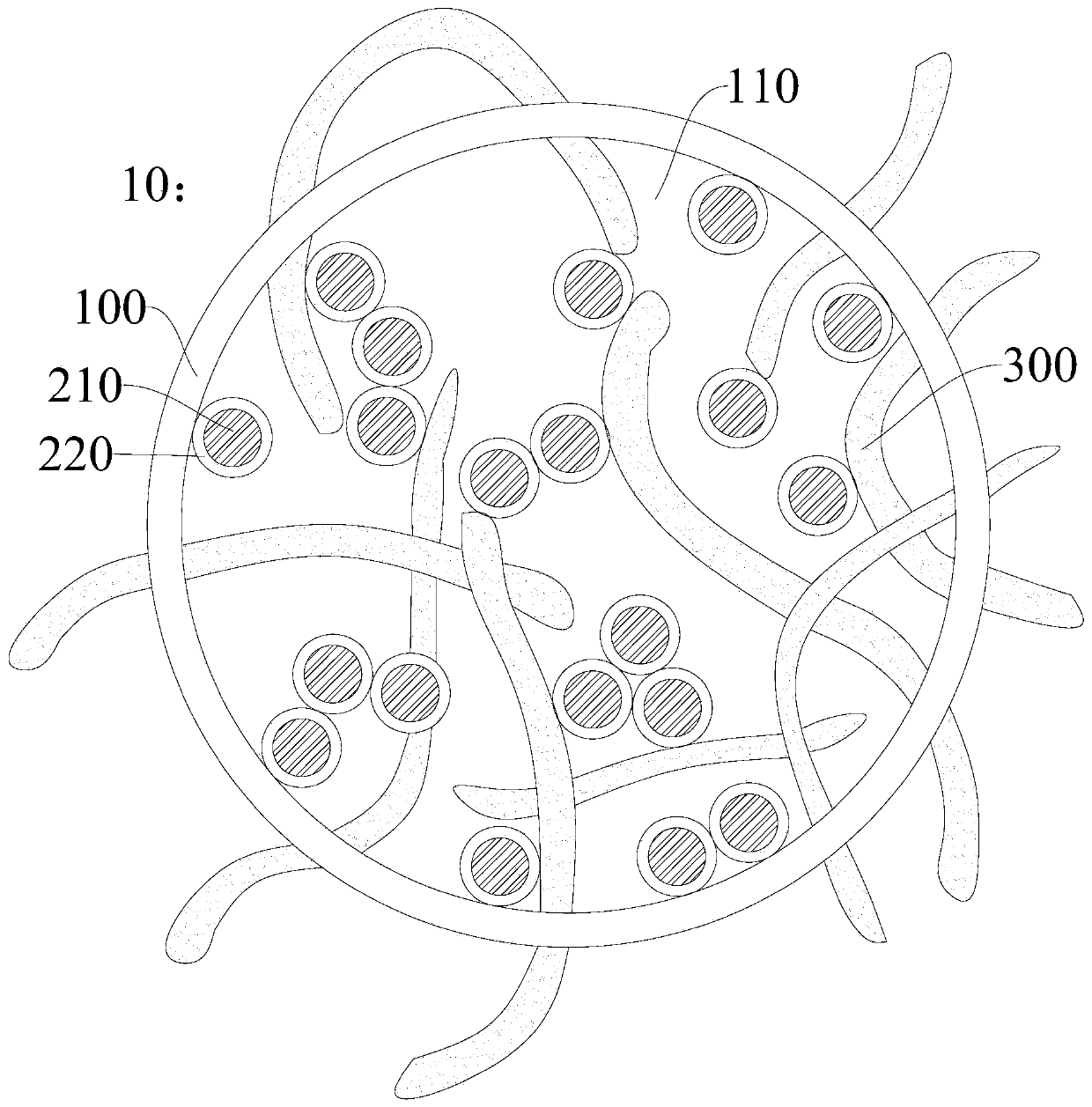

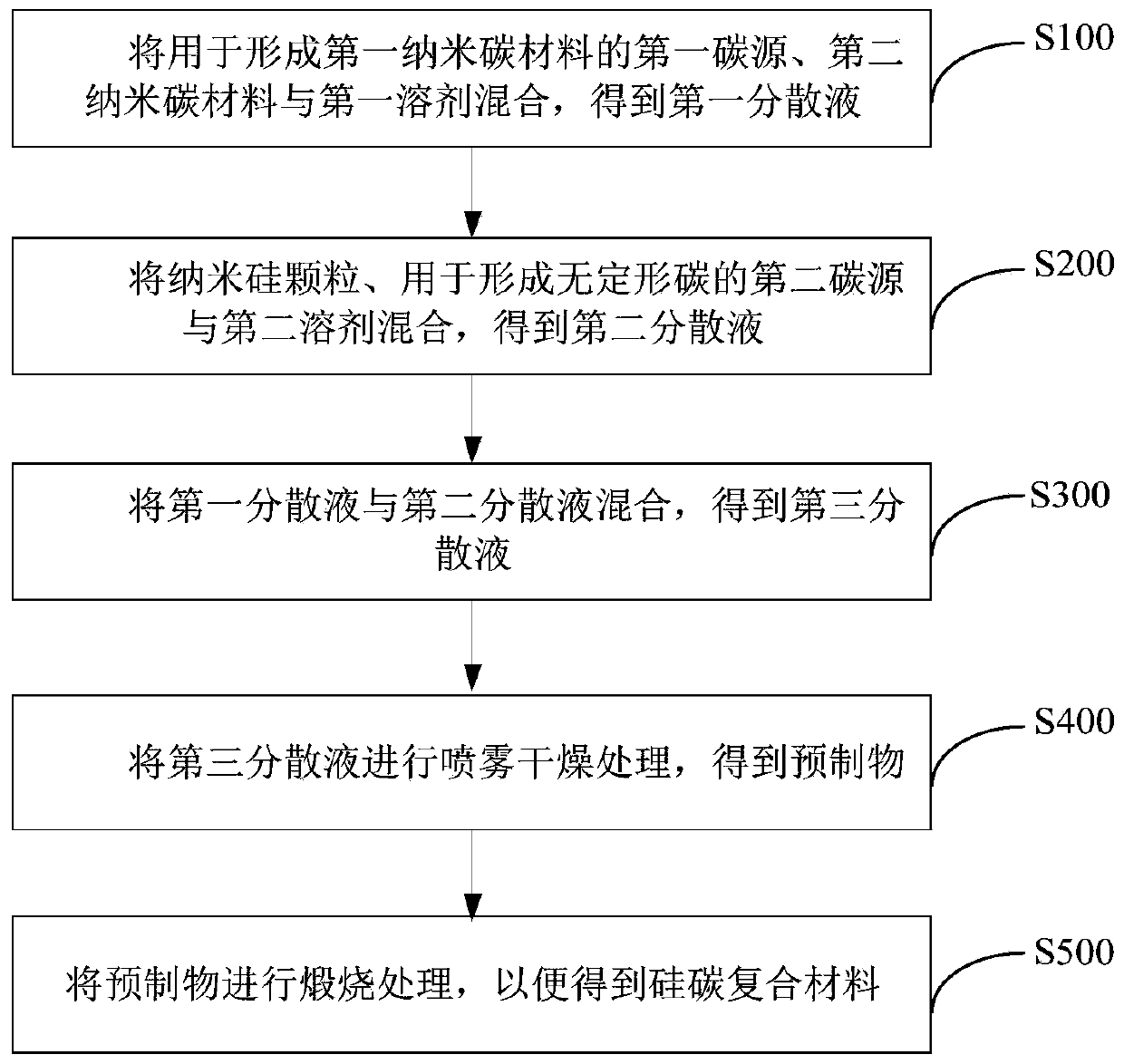

Silicon-carbon composite material, preparation method thereof, negative electrode, power battery and electric automobile

InactiveCN110148732AImprove conductivityIncrease capacityMaterial nanotechnologyCharging stationsCarbon compositesMicrosphere

The invention provides a silicon-carbon composite material, a preparation method thereof, a negative electrode, a power battery and an electric automobile. The silicon-carbon composite material comprises a housing layer, core-shell microspheres and a second nano-carbon material, wherein the material of the housing layer includes a first nano-carbon material, and an accommodating space is defined inside the housing layer; each core-shell structure microsphere is located in the accommodating space and provided with a core and a shell layer, the shell layer coats the core, the core includes nano-silicon particles, and the shell layer includes amorphous carbon; and the second nano-carbon material is linear, one part of the second nano-carbon material is located in the accommodating space, andthe other part of the second nano-carbon material is arranged in the first nano-carbon material in a penetrating manner. The silicon-carbon composite material can be used as a negative electrode material of the power battery, has the advantages of good conductivity, high capacity, good rate performance, and is not easy to expand or be powdered, high in stability and good in cycle performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

ActiveCN101905859ANot easy to expandLow costPrecision positioning equipmentSoldering apparatusPhysical chemistrySilicon

The invention discloses a method for preparing a wafer-level uniform-dimension glass microcavity by positive pressure thermal forming. The method comprises the following steps of: etching an array consisting of microgrooves on a silicon wafer, and etching microchannels connecting the microgrooves, wherein the minimum groove width of the microgrooves is 5 times more than the runner width; and putting a proper amount of thermal outgassing agent into at least one microgroove, correspondingly bonding the plurality of microgrooves to form a sealed cavity by using a glass wafer, heating to soften the glass, making the thermal outgassing agent heated to release gases to generate positive pressure, acting the positive pressure on the softened glass corresponding to the plurality of microgrooves which are connected through the microchannels so as to form a spherical microcavity with uniform dimension, and cooling the microcavity. By connecting the same microgrooves through the microchannel, the inside air pressure of the microgrooves is substantially consistent, and the formed glass microcavity has uniform dimension. When the dimension of the microgrooves is far greater than that of the microchannel, the microchannels with smaller radius hardly expand due to higher additional pressure. Therefore, the glass corresponding to the microchannels can keep smooth.

Owner:SOUTHEAST UNIV

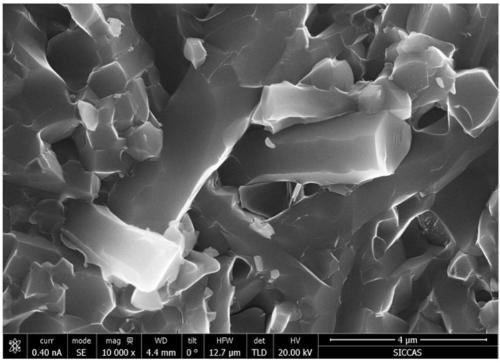

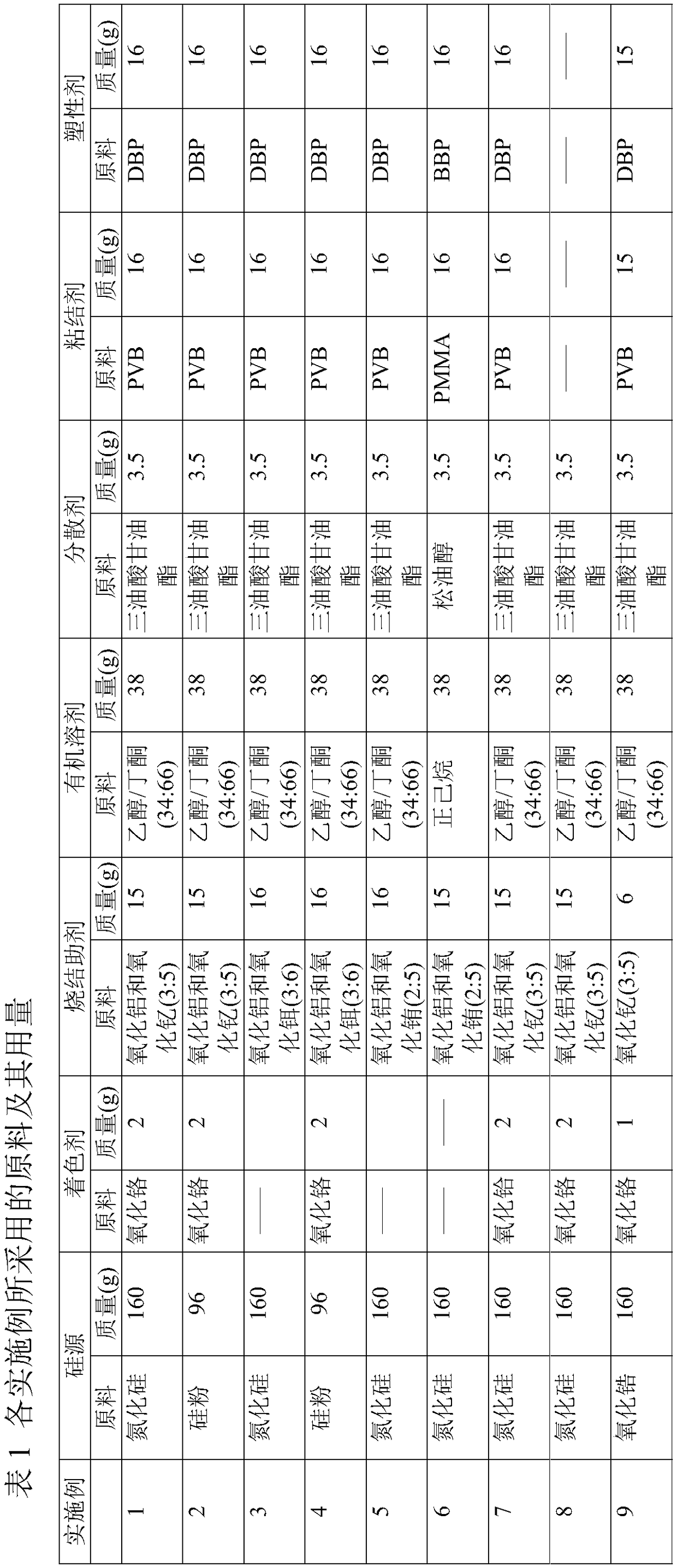

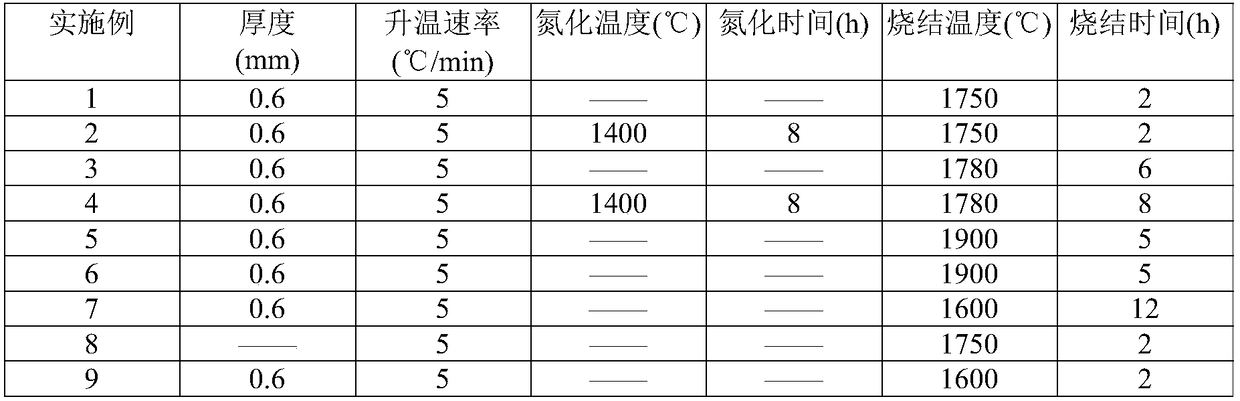

Silicon nitride ceramic material for backboard of mobile phone and preparation method thereof

ActiveCN108947539AMeet the mechanical performance requirementsImprove toughnessTelephone set constructionsDielectric lossHardness

The invention relates to a silicon nitride ceramic material for a backboard of a mobile phone and a preparation method thereof. The preparation method comprises the step of mixing, molding and sintering a raw material component which is a mixture of a silicon source, a coloring agent and a sintering additive to prepare the silicon nitride ceramic material. The invention further provides the silicon nitride ceramic material prepared by the method and application of the silicon nitride ceramic material in a backboard of a mobile phone. The silicon nitride ceramic material is a material with excellent performance and has great application potential, and has the advantages of good toughness reaching 12MPa.m<1 / 2> or more, high strength, good impact toughness, high conductivity reaching 40-70W / m.K, low dielectric loss which is general at 10<-4> order, high hardness to prevent scraping or easy extending even microcrack occurs, small density, transparency, good texture, easy coloring and goodcoloring effect; and the method is simple and reliable in process and easy to operate, and has low raw material cost.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

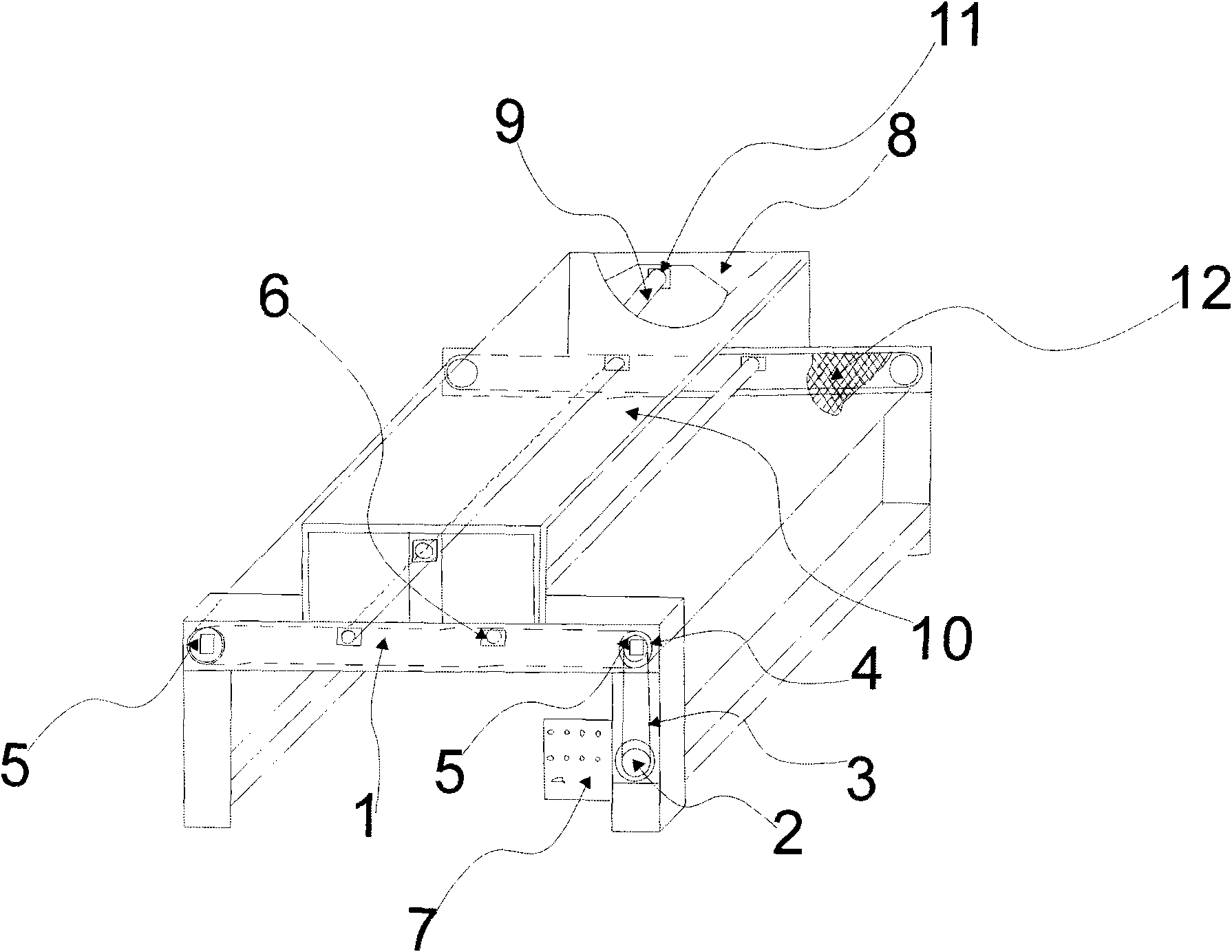

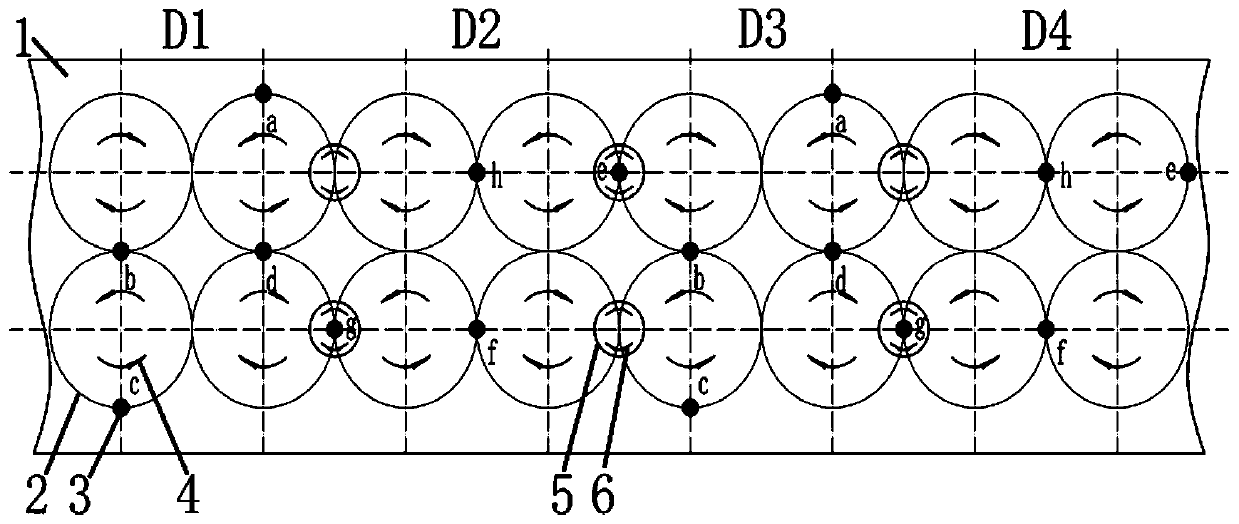

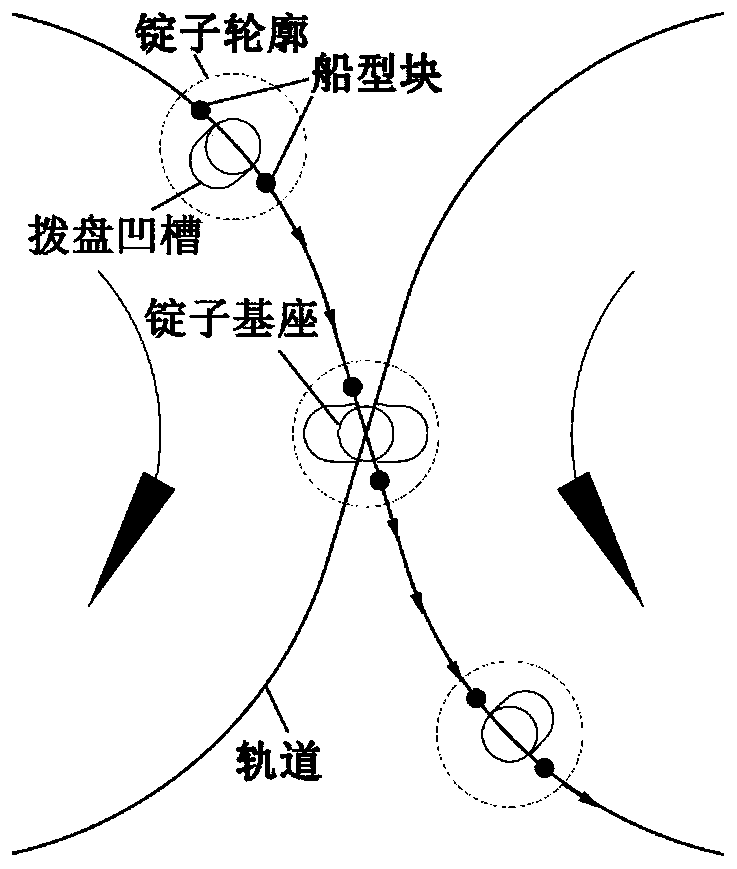

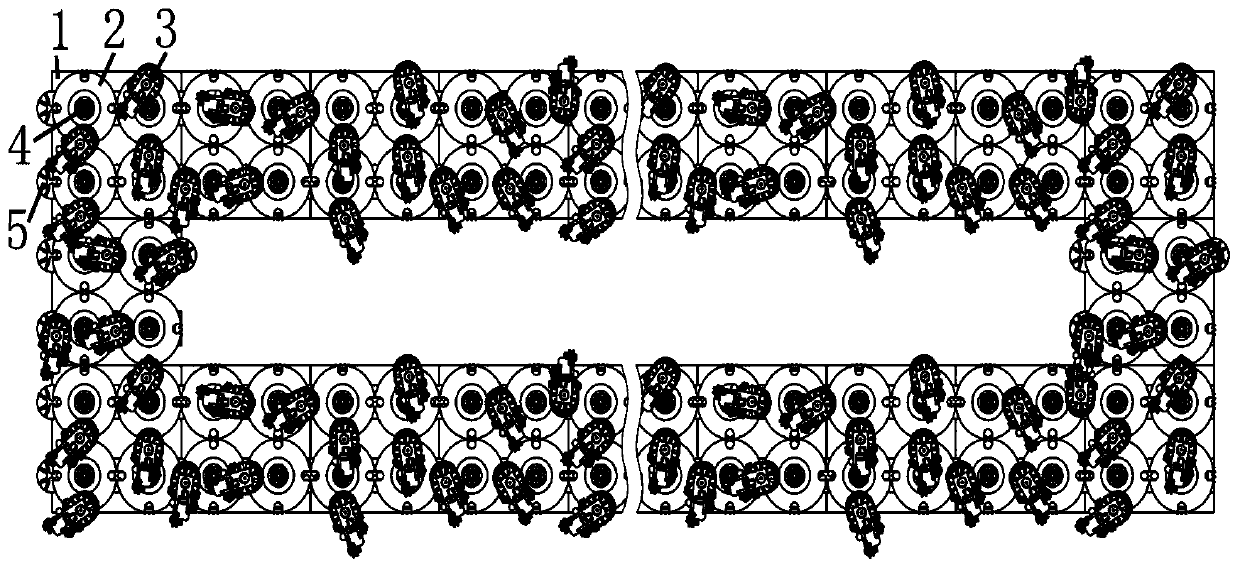

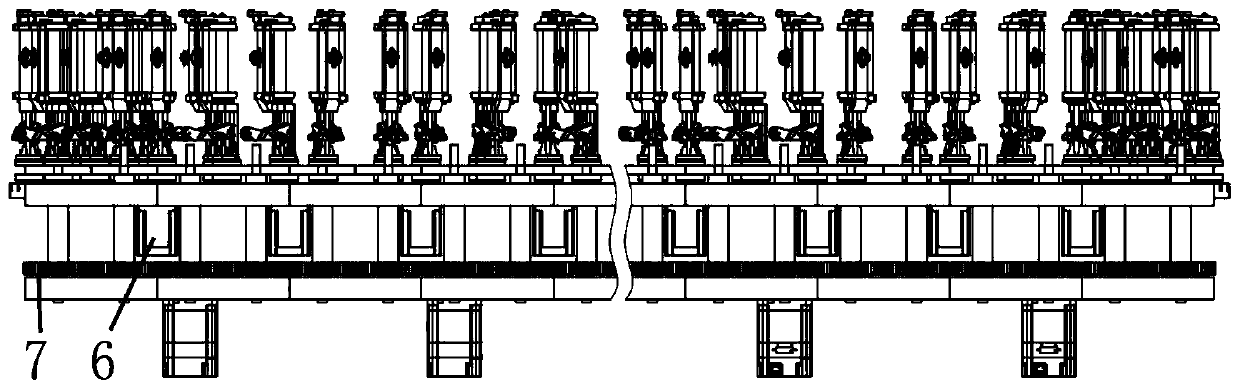

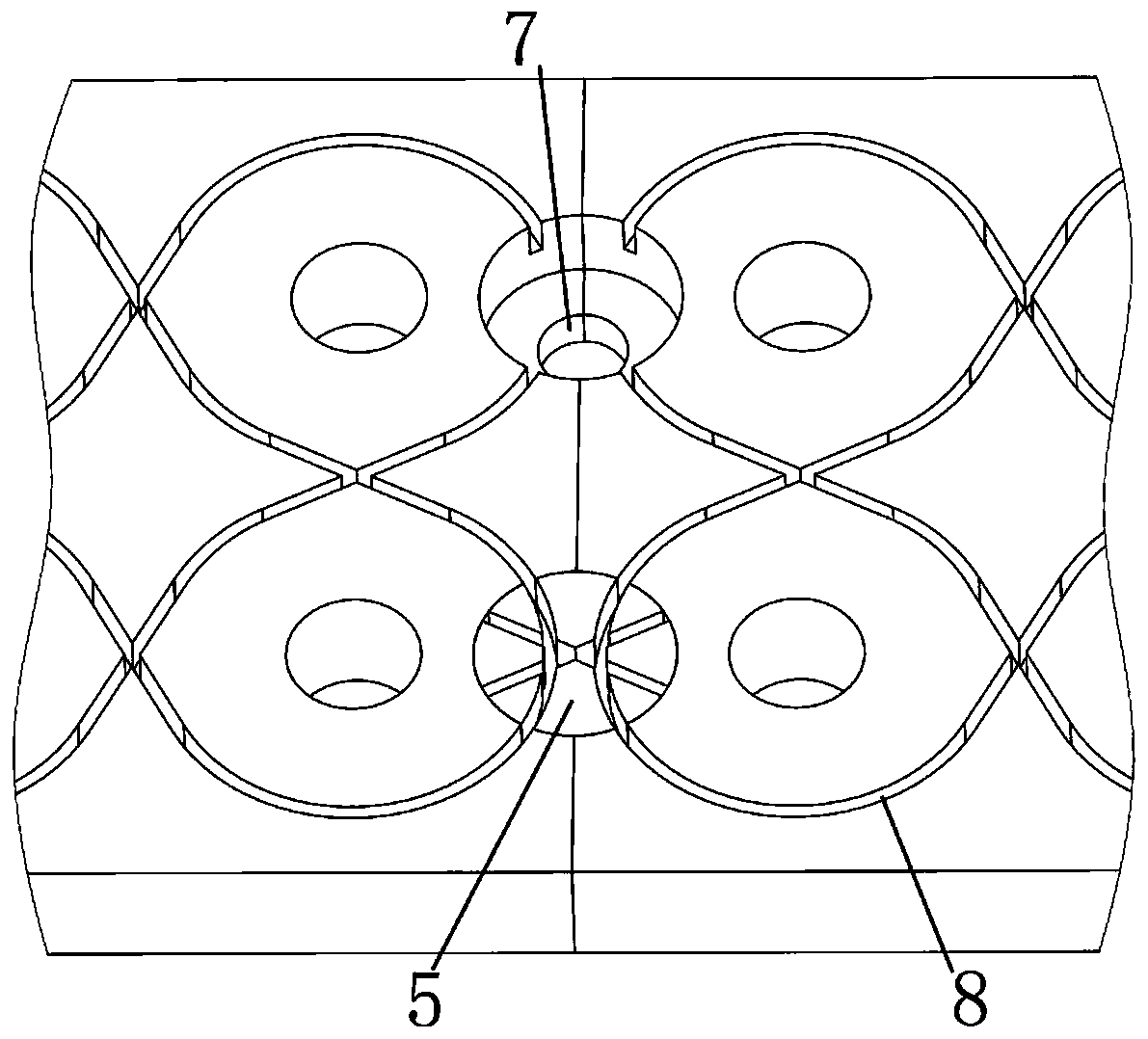

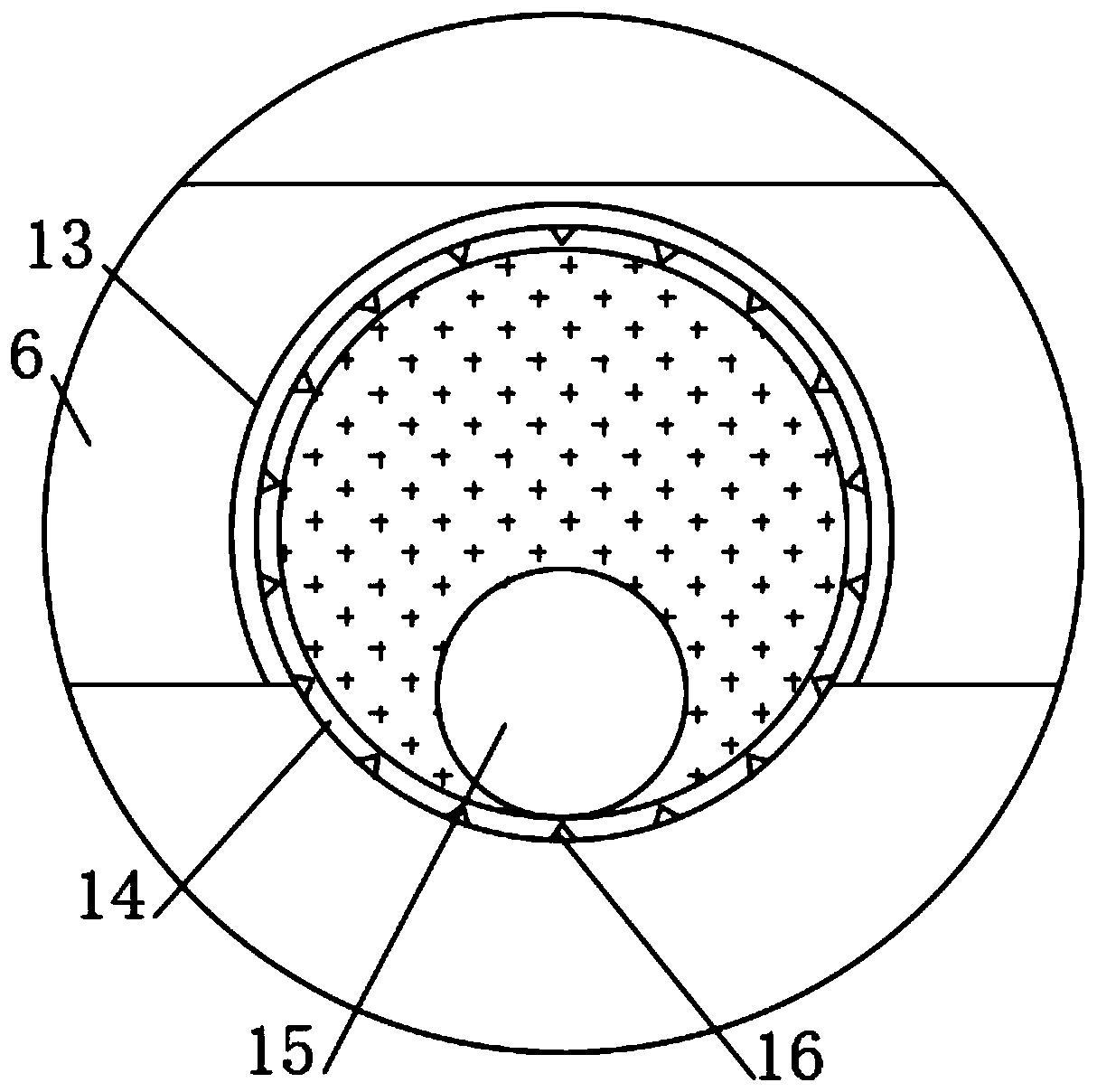

Modularized knotless net weaving equipment

The invention relates to modularized knotless net weaving equipment. The equipment is formed by combining a plurality of modules A and a plurality of modules B. Each module A comprises a weaving chassis, a stirring disc, a spindle and a stirring disc driving part, wherein conversion block semicircular mounting holes are formed in the left and right sides of the upper surface of the weaving chassis, and a fixed spindle rail is arranged on the upper surface of the weaving chassis. Each module B comprises a conversion block and a conversion block driving part, wherein a variable spindle rail is arranged on the upper surface of the conversion block, the variable spindle rail of the conversion block comprises a set of crossed spindle rails and a set of non-crossed spindle rails, the crossed spindle rails are linear grooves with two middle points crossed with each other, the non-crossed spindle rails are composed of two opposite arcs, and the radius of the arcs is equal to that of the fixedspindle rails of the weaving chassis. The fixed spindle rails of the module A and the variable spindle rails of the module B are tangentially connected. The modularized knotless net weaving equipmentcan achieve the aim of weaving knotless nets in various types and specifications by changing the number and layout of the weaving modules.

Owner:孙以泽 +1

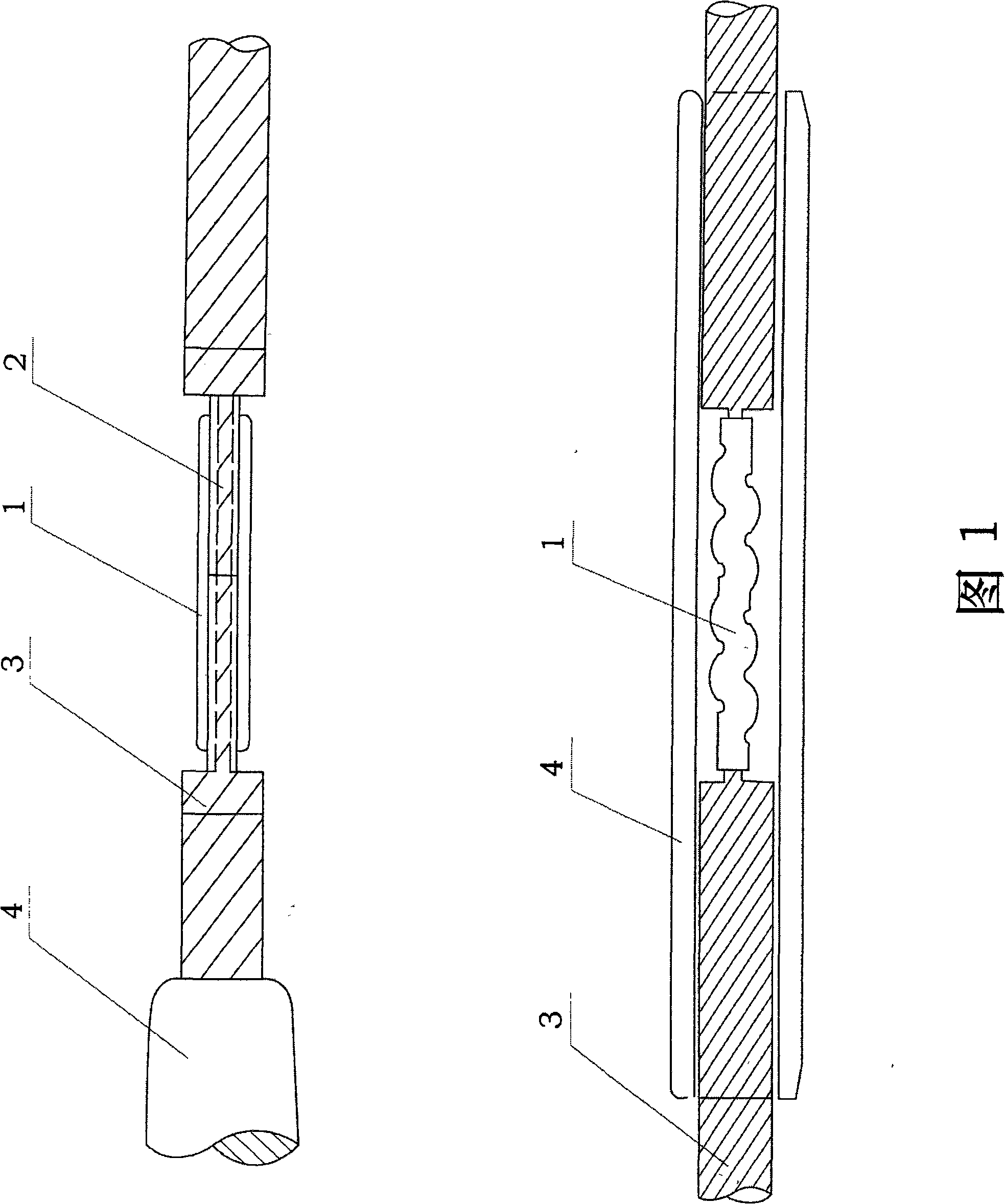

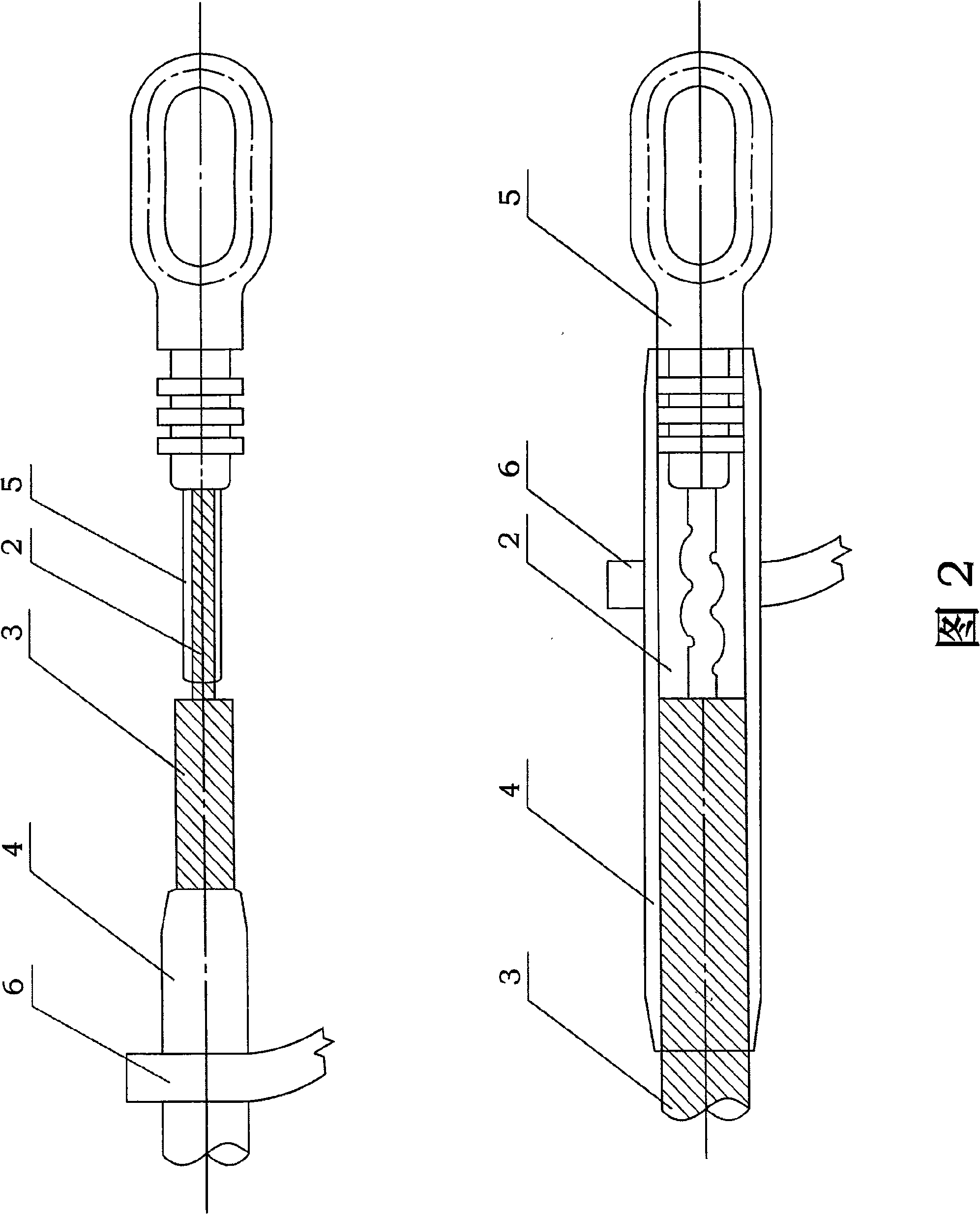

W type connecting method of high-voltage conductive wire

InactiveCN101340048ADo not damage its own strengthNot easy to expandConnections effected by permanent deformationConnection formation by deformationAmbient pressureHigh pressure

The invention discloses a W-typed connection method of a high-voltage conductor, which relates to the field of electrician tools. The method of the invention is realized by adopting the scheme for improving a steel die of the existing manual hydraulic press pliers, and creatively applies a mechanical theoretical basis which brings forward a fundamental law of motion between the acting force and the counteracting force of the connection of a high-voltage conductor. The W-typed connection method includes that the conductor is connected with an aluminum tube at the ambient pressure and then connected with a steel tube in W shape under the action of the fundamental law of motion, thus forming two-in-one connection. By adopting the method of the invention, mechanical strength of the connection is stronger than that of the existing conductor connection standard, and the conductor is not damaged, a connecting tube in action is not easy to be expanded, and the tube is durable and vibration-proof, which reduces fall-off, looseness and burning-out fault.

Owner:吴岩

Aluminum grid and preparation method thereof as well as thin film transistor with aluminum grid

The invention discloses an aluminum grid, a preparation method of the aluminum grid, and a thin film transistor with the aluminum grid. The aluminum grid comprises an aluminum grid body and a cover layer covering the outer surface and the side walls of the aluminum grid body, wherein the cover layer is made of a metal with the thermal expansion coefficient less than 20. As the metal cover layer is made of the metal with the thermal expansion coefficient less than 20, the aluminum grid is unlikely to expand in high temperature; when the aluminum grid body is subjected to expansion, the compression stress generated is absorbed by the metal cover layer, so that phenomena of hillock and corrosion on the surface or the surface and the side walls of the aluminum grid body are prevented, and the grid, the source, the drain and the lead of the aluminum grid are prevented from short-circuit.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

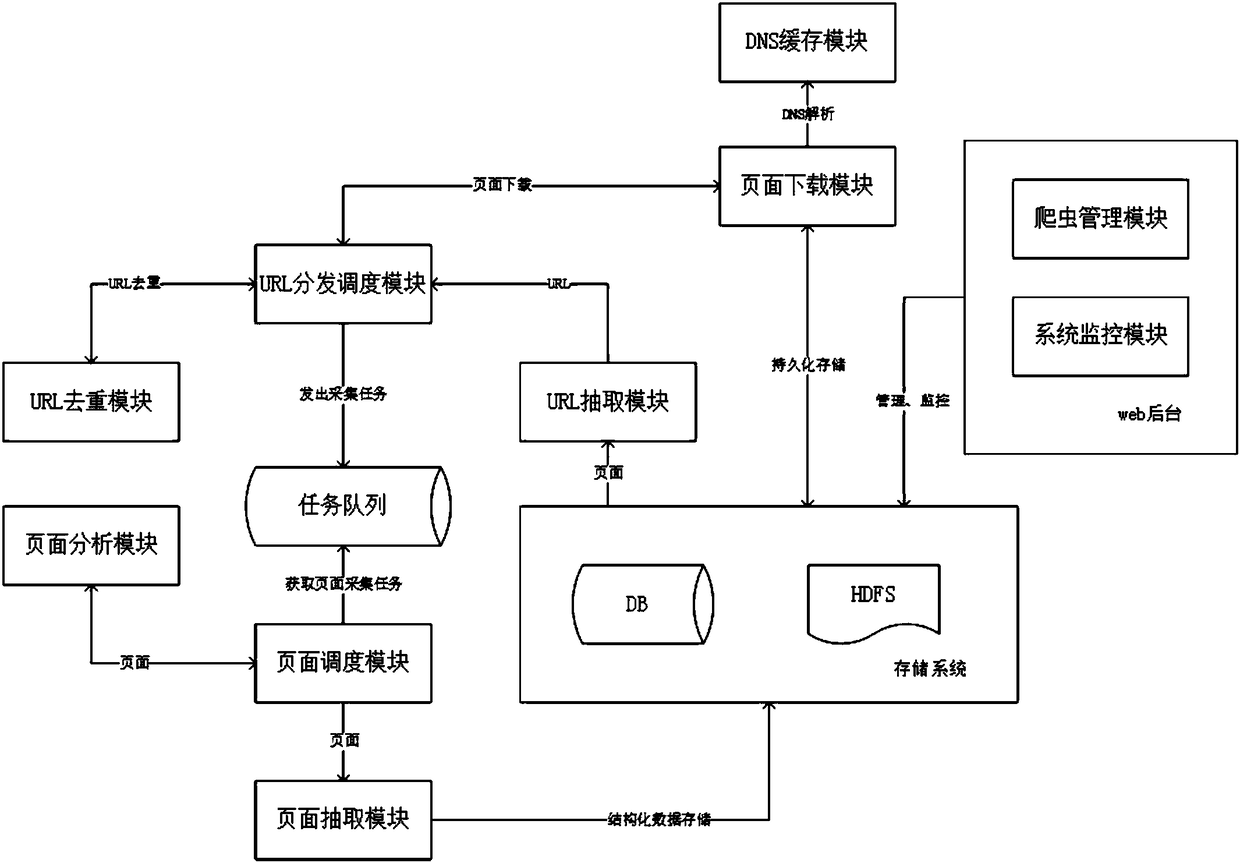

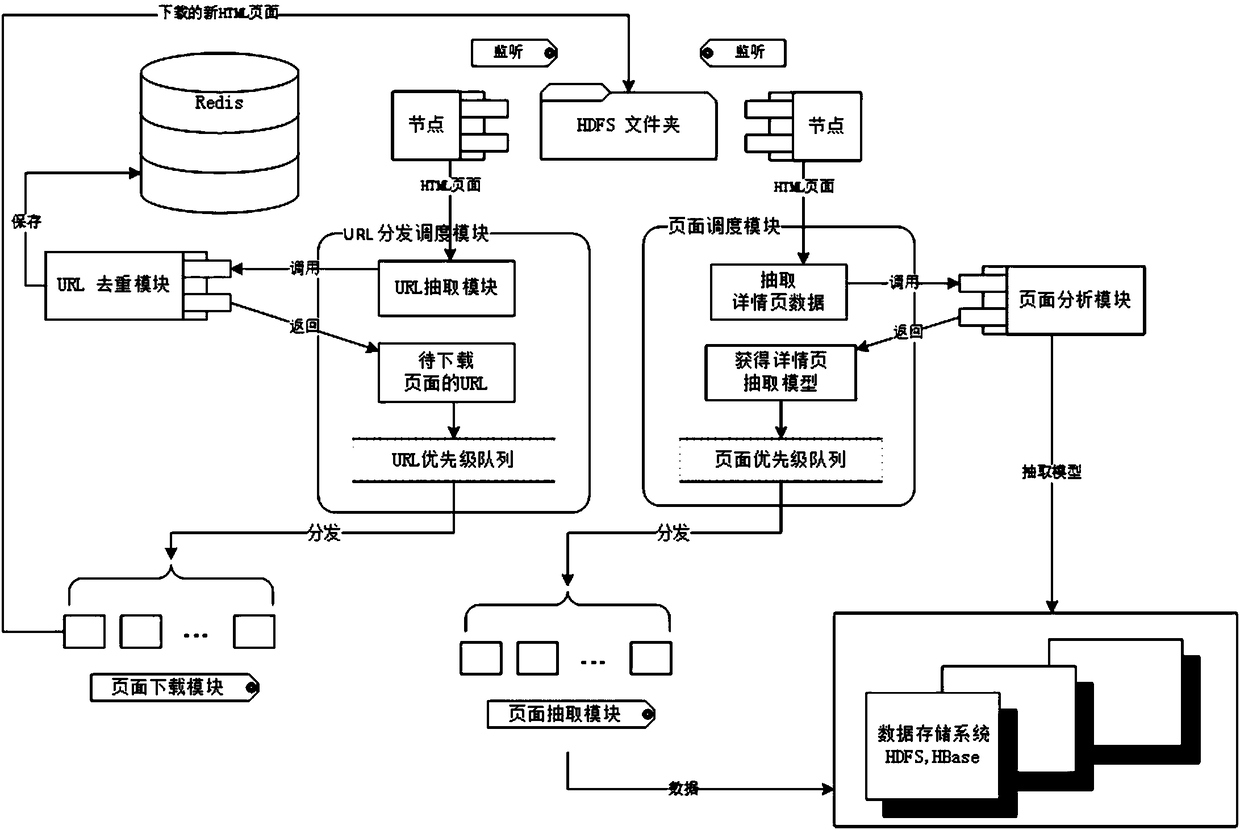

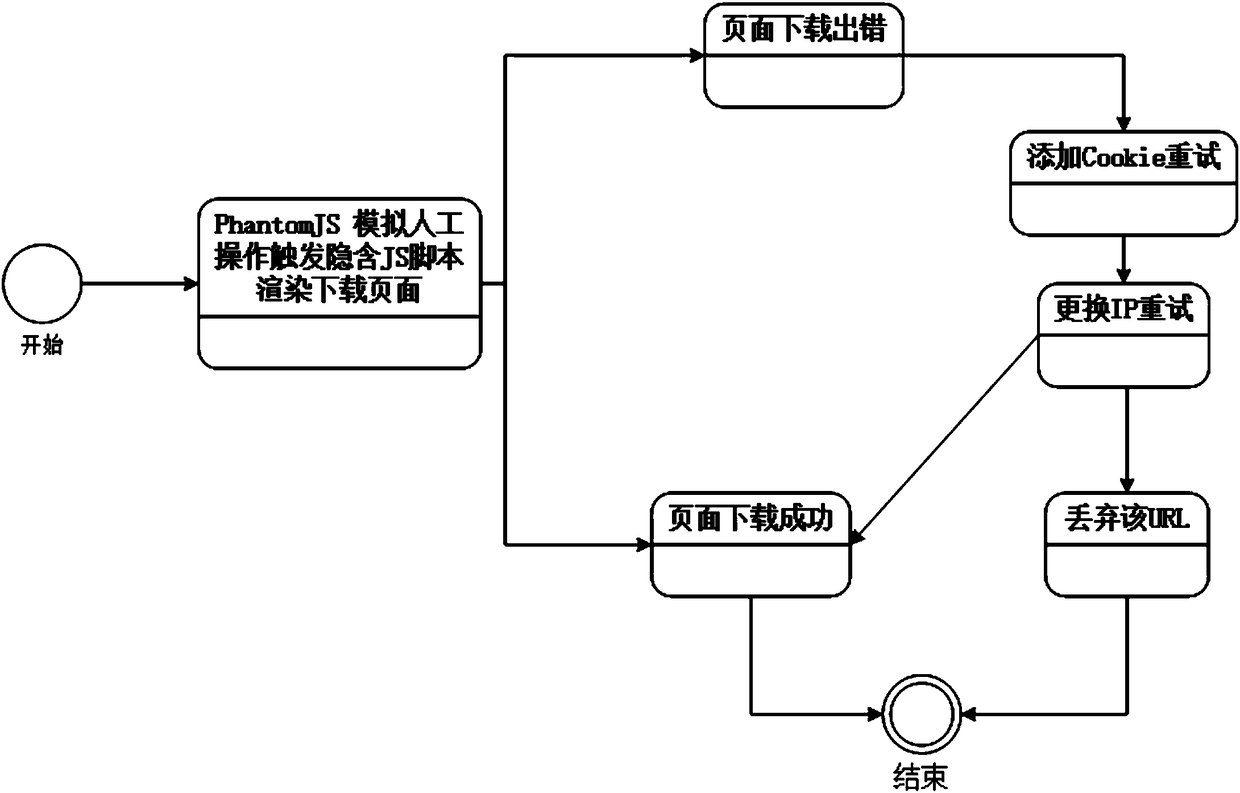

Dicycle crawler system based on Spark Streaming and running method thereof

InactiveCN108520024AImprove general performanceImprove work efficiencySpecial data processing applicationsUniform resource locatorComputer science

The invention discloses a dicycle crawler system based on Spark Streaming and a running method thereof. According to the dicycle crawler system, a page downloading module is responsible for downloading pages, DNS information cached in a DNS cache module is called during downloading, and DNS parsing is accelerated to shorten time of page downloading; a URL distribution scheduling module is responsible for calling a URL extraction module, URLs are extracted from newly downloaded pages, a URL repetition removing module is called to filter repetitive URLs, and the URLs are distributed to the pagedownloading module; a page scheduling module is responsible for calling a page analyzing module, it is determined that a current page accords with an extraction model, data extraction tasks are distributed to a page extracting module, the page extracting module is used for extracting data from the current page, and the extracted data is saved in a distributed storage system; parameter configuration and monitoring management of a whole crawler are both controlled in a web background. The dicycle crawler system based on Spark Streaming and the running method thereof solve the horizontal extension problem of traditional crawlers and have the advantages that module division is clear, a running mechanism is stable and efficient, crawler rule configuration is concise and the universality is high.

Owner:HOHAI UNIV

Corrosion-resistant terafluoroethylene-propylene rubber/chlorosulfonated polyethylene rubber sealing gasket and preparation method thereof

The invention discloses a corrosion-resistant terafluoroethylene-propylene rubber / chlorosulfonated polyethylene rubber sealing gasket and a preparation method thereof. The sealing gasket is prepared from the following raw materials: terafluoroethylene-propylene rubber, chlorosulfonated polyethylene rubber, polyether ether ketone, carbon black N330, nano tin dioxide, calcined argil, modified nano ceramic, mica powder, dicumyl peroxide, 2,5-dimethyl-2,5-hexane-di-tert-butyl peroxide, triallyl isocyanurate, an accelerant CZ2-3, an accelerant ZDC (Zinc Diethyl Dithiocarbamate) and the like. According to the method, when the terafluoroethylene-propylene rubber, the chlorosulfonated polyethylene rubber, the polyether ether ketone and other high-molecular materials with the excellent performance of corrosion resistance are compounded and mixed together, the nano tin dioxide, the calcined argil, the modified nano ceramic, the mica powder and other inorganic filling materials capable of improving the corrosion resistance of the rubber are added at the same time. In addition, the modified nano ceramic can be used for improving the mechanical strength, abrasion resistance, oil resistance and the like of the rubber.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

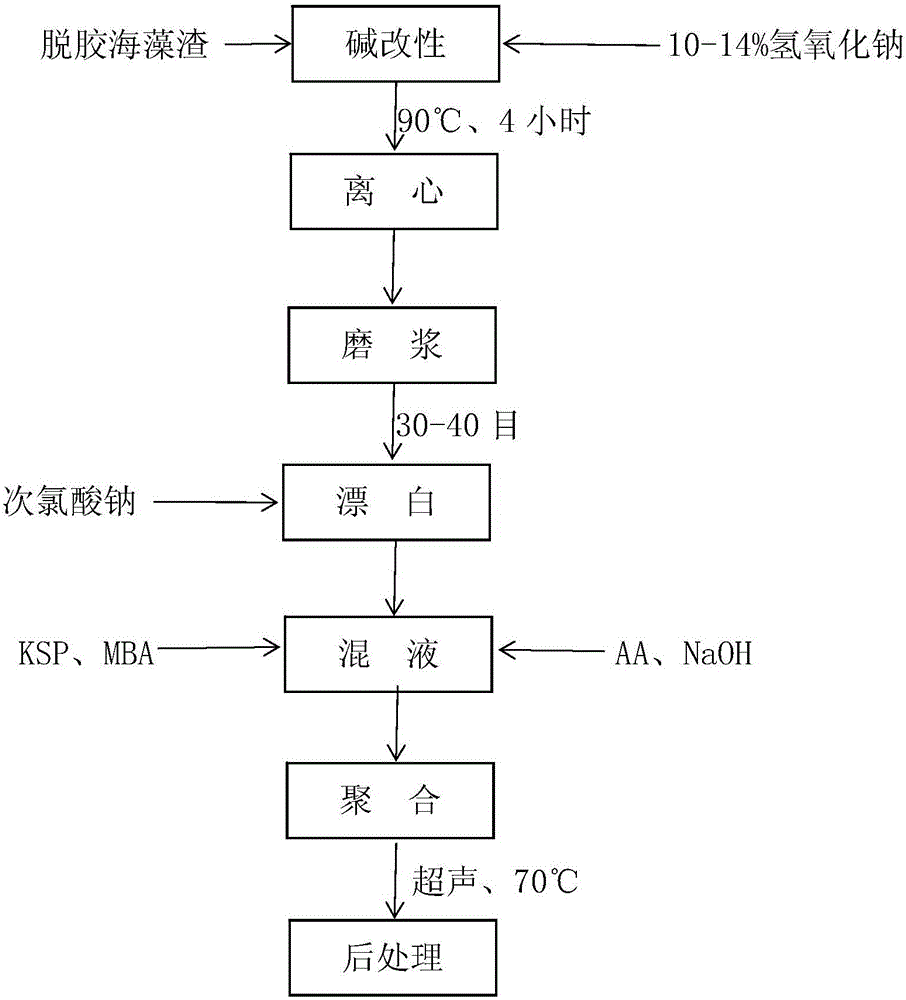

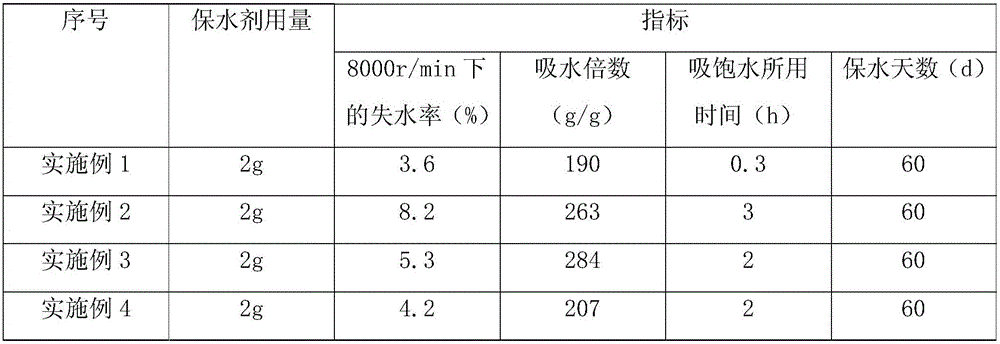

Method for preparing agricultural water-retaining agent from degummed alga dreg

ActiveCN105777993ASimple processLow costAgriculture tools and machinesOrganic fertilisersAbsorption capacityNutrient

The invention discloses a method for preparing an agricultural water-retaining agent from degummed alga dregs. The method comprises the following steps: firstly, selecting a certain amount of degummed alga dregs, and adding an alkali liquid into the degummed alga dregs for alkalization so as to obtain an alga extract I; sequentially centrifuging, pulping, screening, bleaching and washing the alga extract I, and adding acid to adjust the pH value to be 4-5, so as to obtain a fluffy alga extract II; neutralizing crylic acid and sodium hydroxide of equal mass, mixing with the alga extract II, adding potassium peroxodisulfate as a catalyst and N,N-methylene bisacrylamide as a cross-linking agent so as to obtain a mixed liquid, putting the mixed liquid into a container to be placed into an ultrasonic reaction kettle, and setting the temperature to be 70-75 DEG C to perform ultrasonic reaction for a certain time till the mixed liquid is formed into gel; finally, washing the gel, pelletizing, and drying, thereby obtaining the water-retaining agent. The water-retaining agent prepared by using the method is slow in water absorption and release but high in water absorption capacity, and is relatively beneficial to water retention and retention of nutrient elements in soil.

Owner:青岛聚大洋藻业集团有限公司

Concrete pre-embedded pile for soft foundation reinforcement

ActiveCN111424655ARelieve sinkingImprove heat production efficiencyBulkheads/pilesCalcium bicarbonateStructural engineering

The invention discloses a concrete pre-embedded pile for soft foundation reinforcement, and belongs to the technical field of pre-embedded pile reinforcement. According to the concrete pre-embedded pile for soft foundation reinforcement, the scheme is that a pre-embedded pile is pre-embedded into soft soil, and concrete with a temperature is filled into a guide hole, so that concrete is in contactwith a cylindrical gasbag after entering an internal cavity, ammonium hydrogen carbonate in the cylindrical gasbag is heated to decompose and expand and gas pressure at the lower side of the cylindrical gasbag is increased, and therefore, a pre-sealed film is cracked; under return action of an elastic telescopic pole, a deformed rubber bag is extruded towards the outer side, and a contact circular plate is in continuous mutual friction with a spherical gasbag, so that calcium hydrogen carbonate in the spherical gasbag is heated to decompose, the spherical gasbag continuously expands through mutual friction between calcium hydrogen carbonate and quartz sand powder, and a contact area between turned-over deformed rubber bag and soil is increased, and therefore, sink of the pre-embedded pilecan be effectively relieved.

Owner:中交投资咨询(北京)有限公司

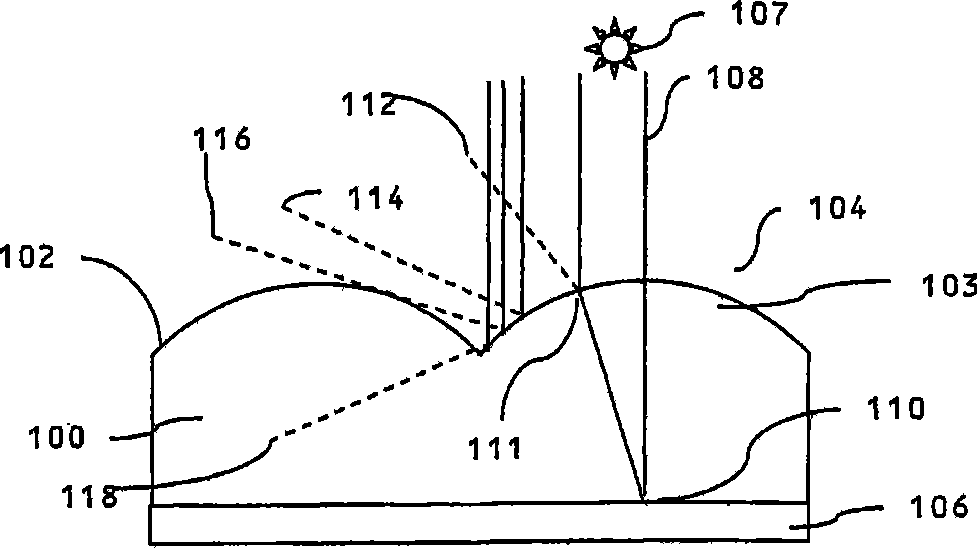

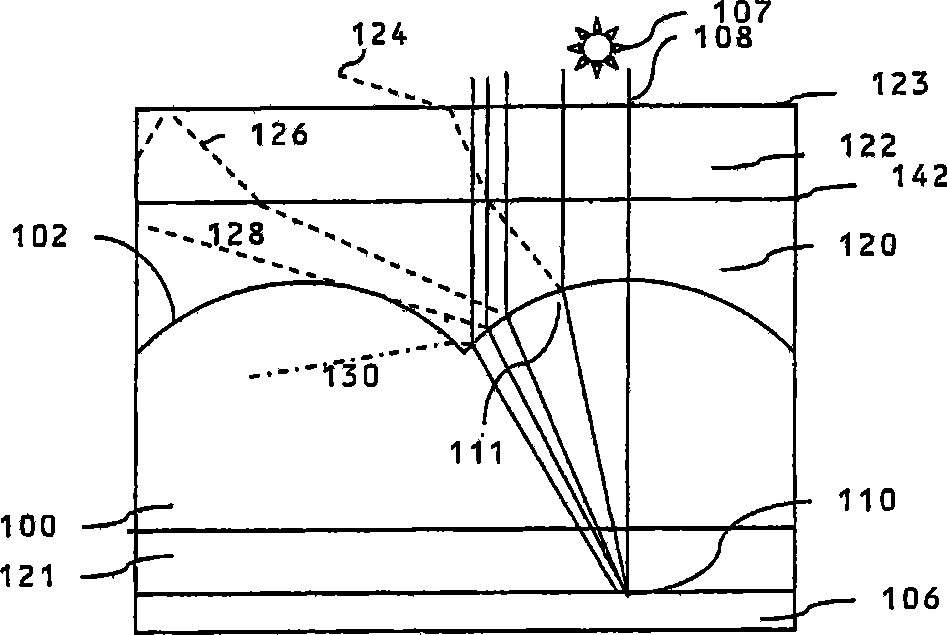

Lenticular lens array element

ActiveCN101371167AReduce surface reflectionLow surface degradationProjectorsLensRefractive indexLenticular lens

A lens element comprises: a rear substrate having a front surface provided with a surface relief having a plurality of zones each capable of providing a lens effect; a front substrate disposed in front of the rear substrate and having a rear surface provided with a surface relief having a plurality of zones each capable of providing a lens effect, the zones of the surface reliefs provided on the rear substrate and the front substrate having the same spatial arrangement over the area of the lens element; and solid or liquid, isotropic, intermediate material disposed between the front surface of the rear substrate and the rear surface of the front substrate, the intermediate material having a refractive index different from the refractive index of each of the rear substrate and the front substrate. This construction reduces the degree of Fresnel reflection which will otherwise degrade the optical performance.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com