Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

A polyurethane rubber and hydraulic sealing technology is applied in the field of silicone rubber/polyurethane rubber composite hydraulic gasket and its preparation, which can solve the problems of hydraulic device not working normally, gasket deterioration, aging and cracking, etc. performance, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

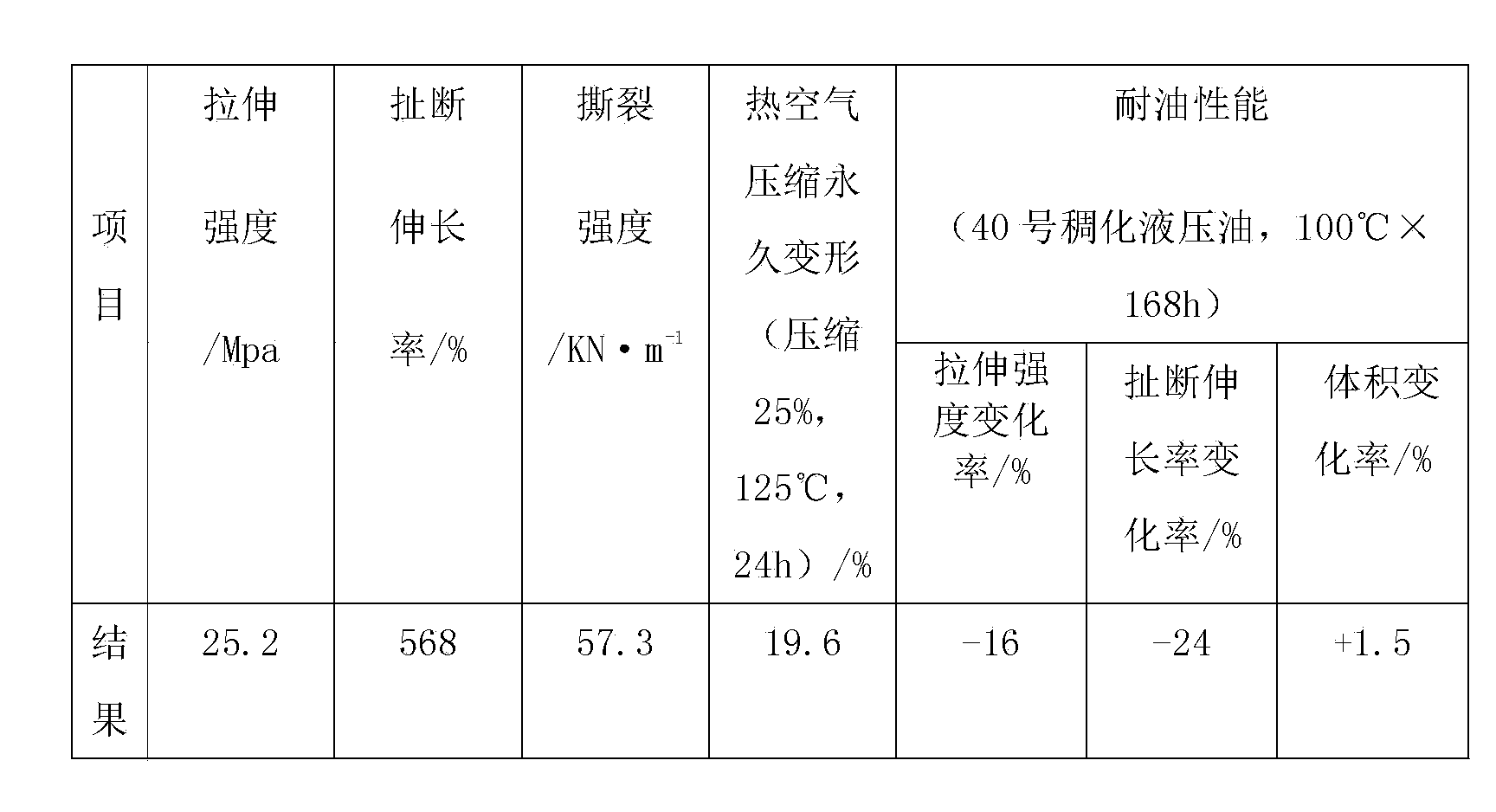

Examples

Embodiment Construction

[0013] A silicone rubber / polyurethane rubber composite hydraulic gasket made of the following raw materials by weight (kg): methyl vinyl silicone rubber (110-2) 75, polyether polyurethane rubber (UR101) 25, 2,5- Dimethyl-2,5-di-tert-butylperoxyhexane 1.5, diphenylsilanediol 3, hexamethyldisilazane 6, fumed silica 26, modified wollastonite 12, antioxidant ODA 1, antioxidant TPPD 3, stearic acid 2, zinc oxide 1.5, antimony trioxide 10, antioxidant MMB 1.5, antioxidant DNP 1, mineral oil 3, coumarone resin 4;

[0014] The preparation method of described modified wollastonite is as follows:

[0015] a. Take the dried wollastonite and crush it to less than 15 μm, put it into a dispersion kettle, add deionized water three times the amount of wollastonite, add 2% sodium polyacrylate, 1.5% tricalcium phosphate, 2 % of cocoic acid monoethanolamide, 1.5% of rice husk ash, 3% of organic bentonite, dispersed at 3000rpm for 20min at high speed, ground into a slurry by a sand mill, and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com