Log door leaf and its manufacturing method

A door leaf and log technology is applied in the production field of wooden doors and wooden doors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

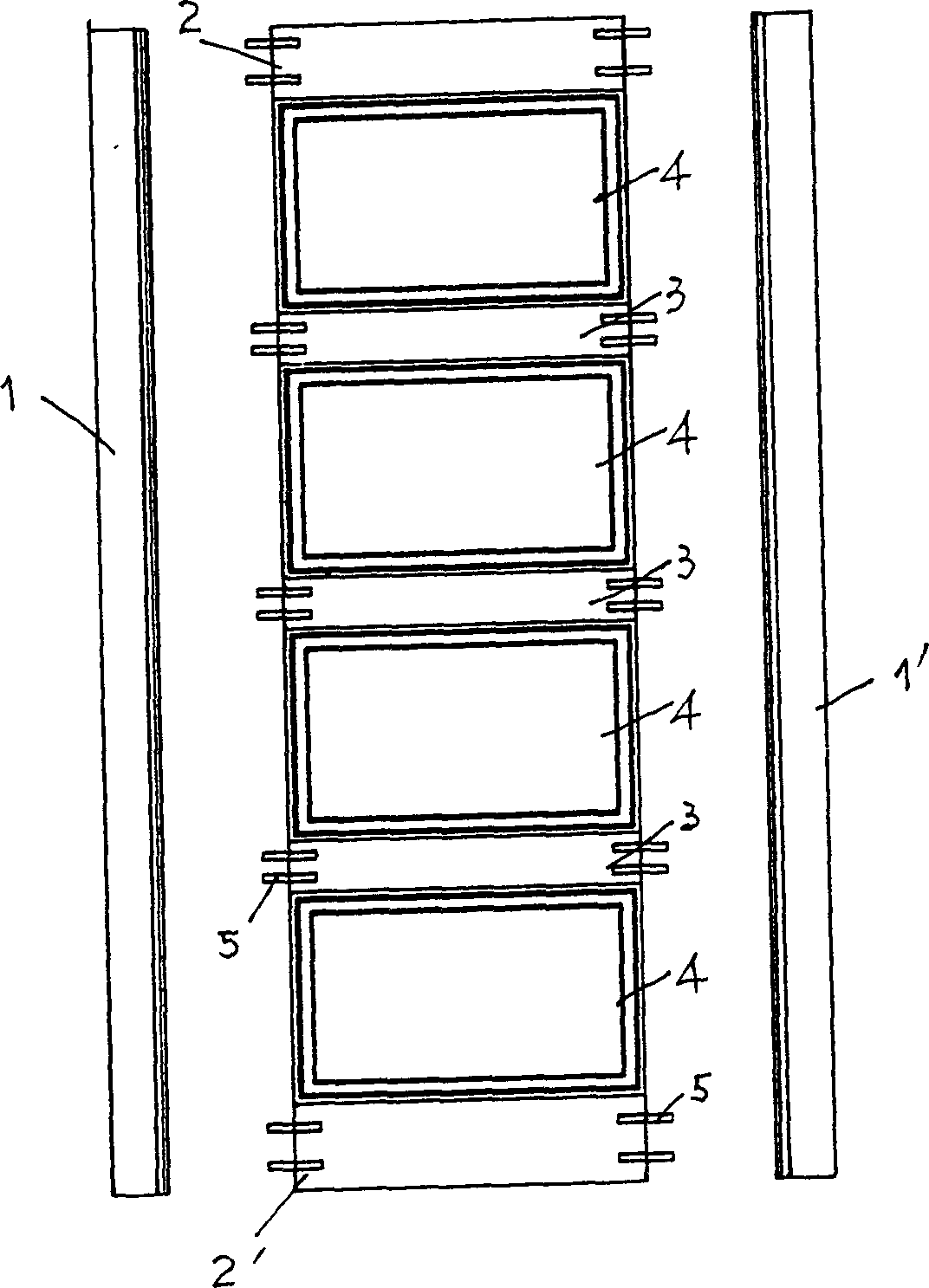

[0016] Now an embodiment of the log door leaf of the present invention will be described in conjunction with its manufacturing process.

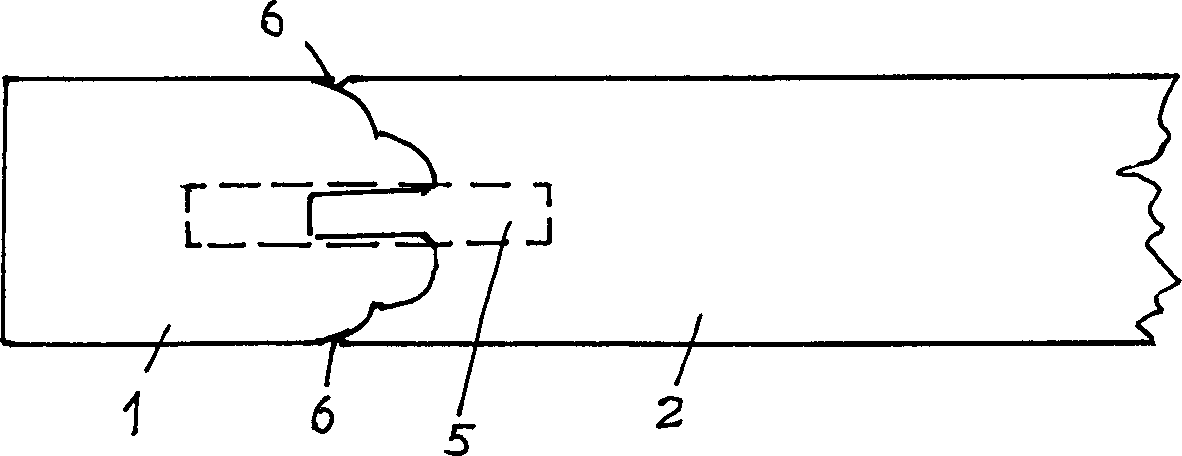

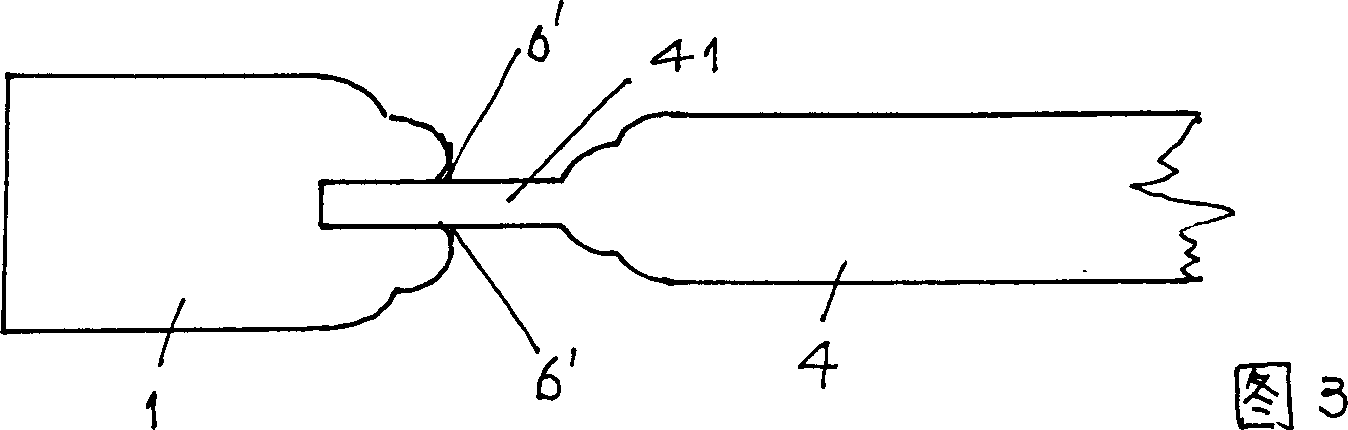

[0017] The first process, woodwork: Carry out woodwork processing to make left and right door frame 1, 1', upper and lower crosspieces 2, 2', middle crosspiece 3, door blocking plate 4, such as figure 1 shown. Wherein: there is a mortise in the center of the mortise of the left and right door stand 1, 1' inside, and the two edges of the mortise are internally chamfered, and its function will be explained later. The upright faces of the upper and lower crosspieces 2, 2' and the middle crosspiece 3 are concave inwards, and their shapes match the inside tenons of the left and right door frame 1, 1'. Mortise, this tenon matches with the tenon groove in the center of the tenon on the inside of the left and right door stand 1,1'. Corresponding horizontal wooden peg holes are set in the joints of the inner side of the left and right door frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com