Patents

Literature

261results about How to "Not easy to shrink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

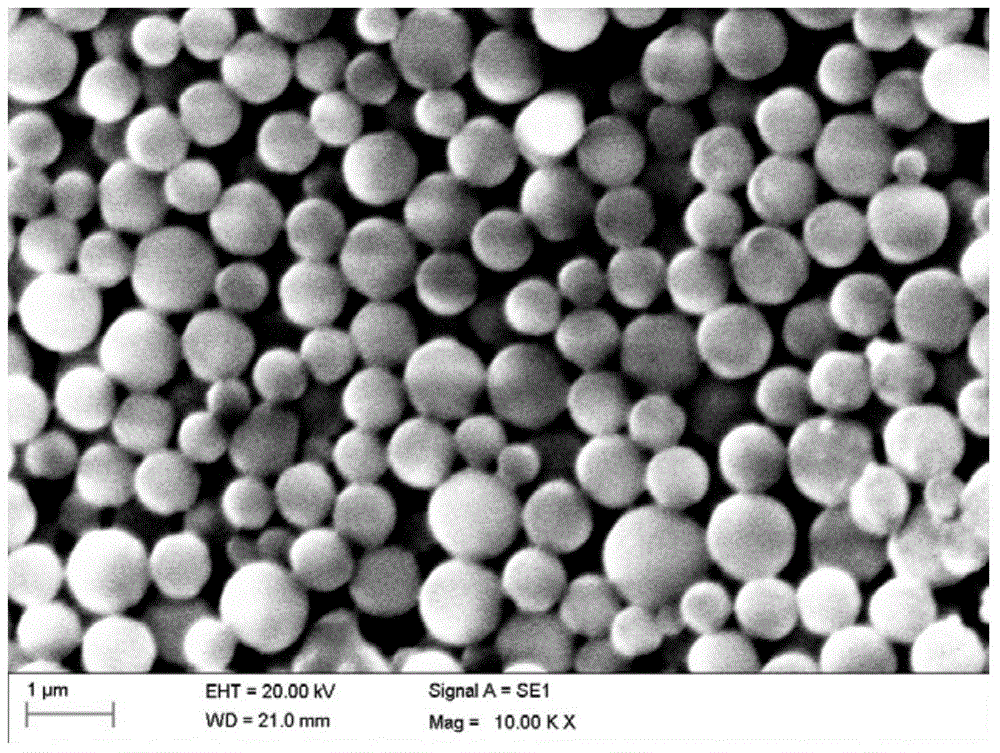

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

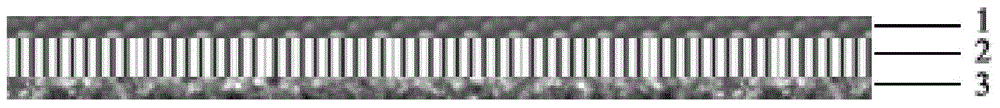

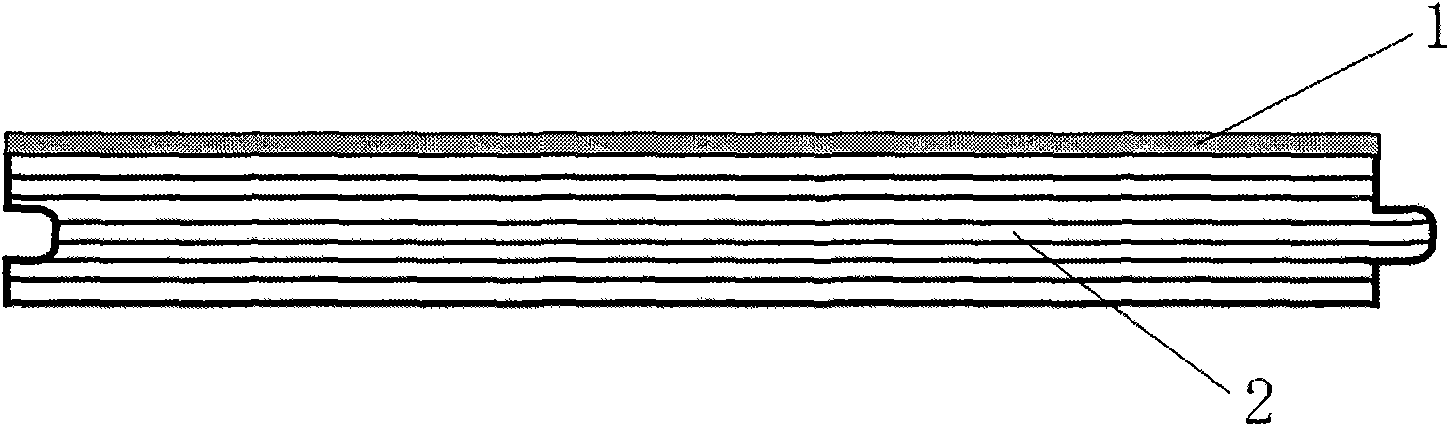

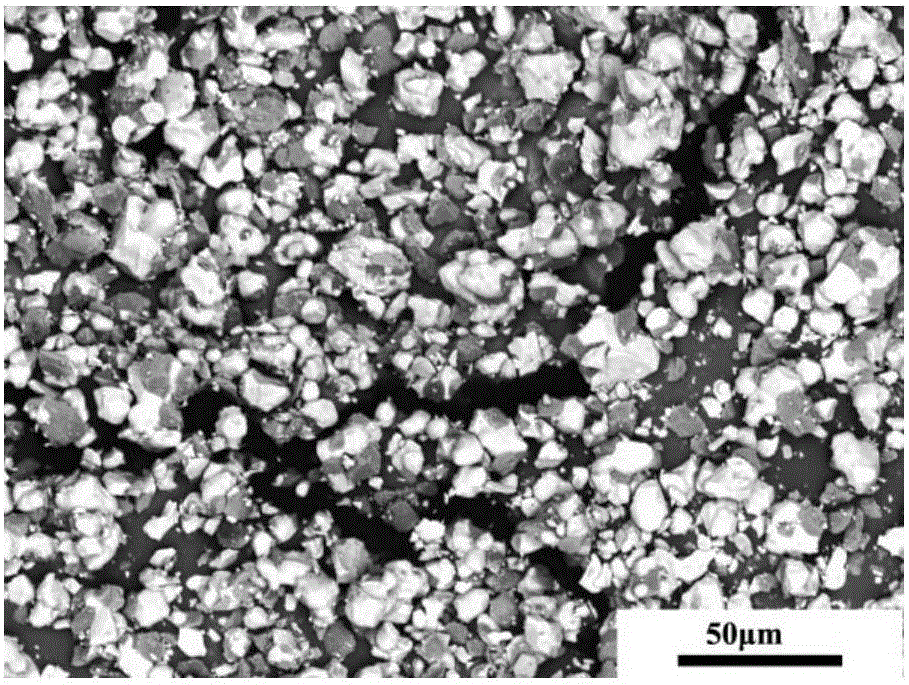

Lithium ion battery composite diaphragm and preparation method and application thereof

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

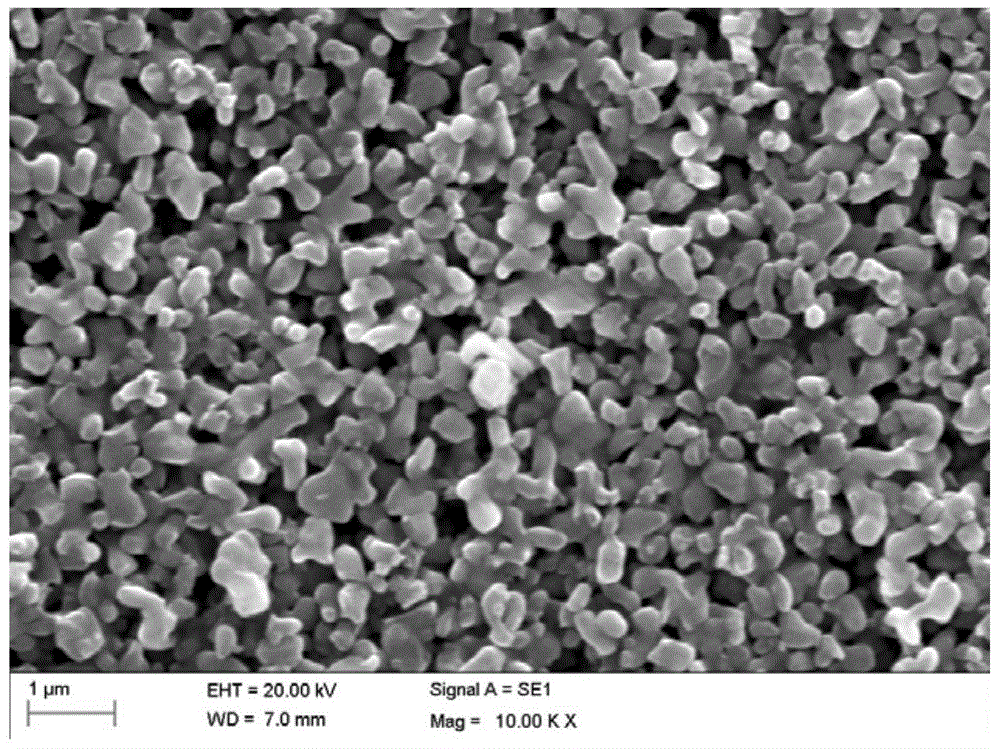

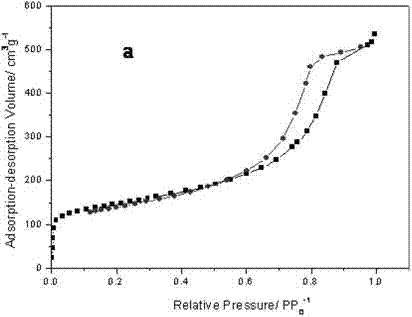

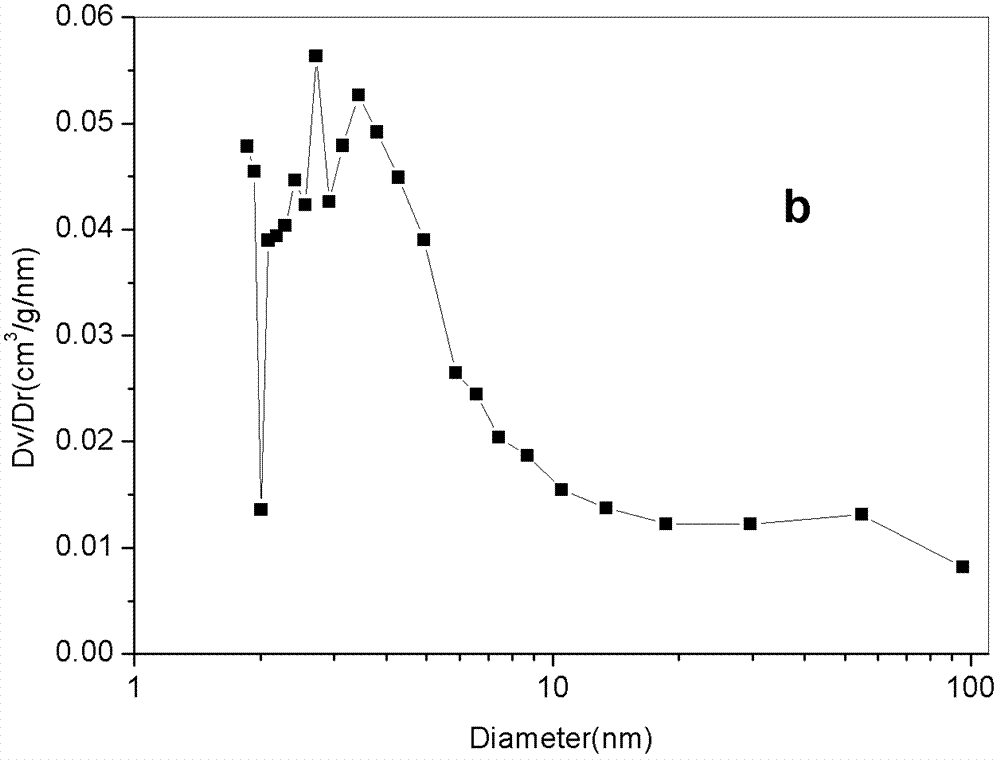

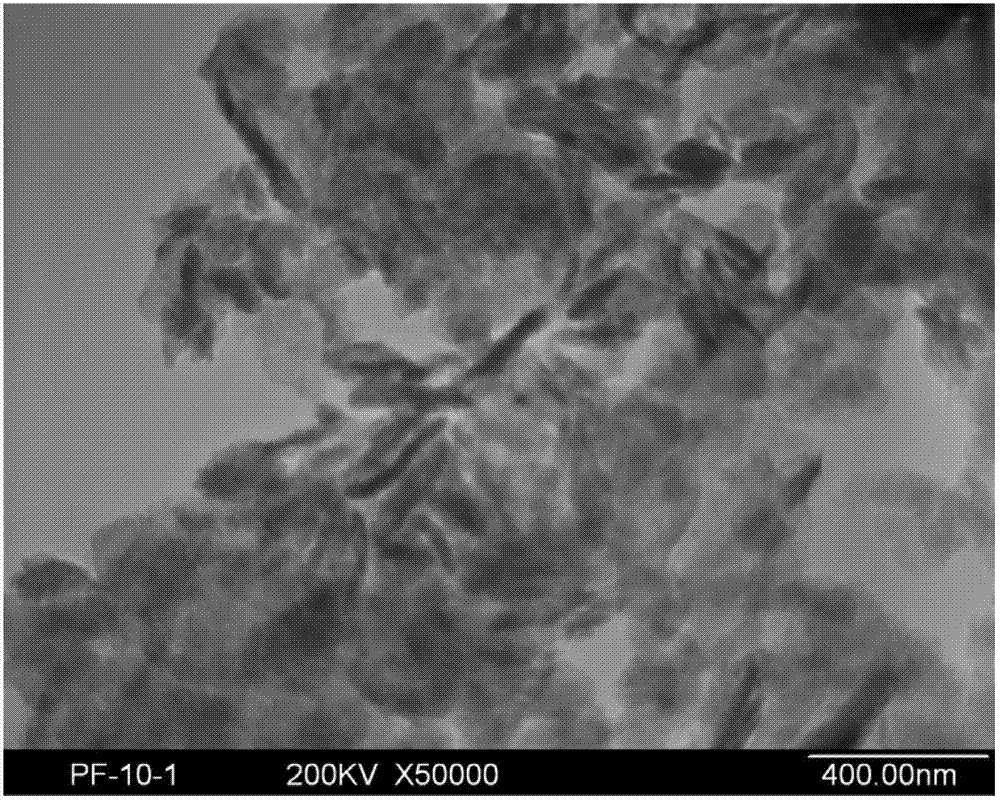

Method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying

InactiveCN102774824AHigh strengthNot easy to shrinkCarbon preparation/purificationSupercritical dryingCross-link

The invention relates to a method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying, which takes phenols (P), amines, aldehydes, catalyst and solvent as a reaction system and graphene substances containing active functional groups as a cross-linking agent. The method comprises the steps of: curing to obtain organogel, and then carrying out normal-pressure drying to obtain the organic aerogel; and carrying out pyrolysis on the organic aerogel in the inert atmosphere at the temperature of 500-1600 DEG C to obtain the graphene crosslinked type carbon aerogel. The preparation method of the organic aerogel and the carbon aerogel is simple and rapid in technology; the conventional supercritical drying technology is avoided, and the prepared novel organic aerogel and carbon aerogel materials taking graphene as framework have new performances and wide application prospect; and the industrial production of the carbon aerogel can be expected to be realized.

Owner:BEIJING UNIV OF CHEM TECH

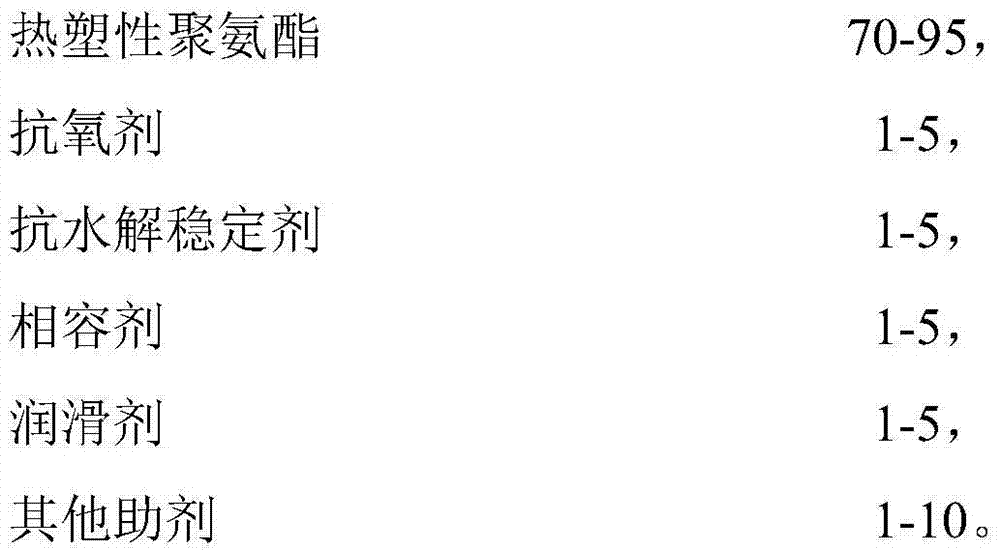

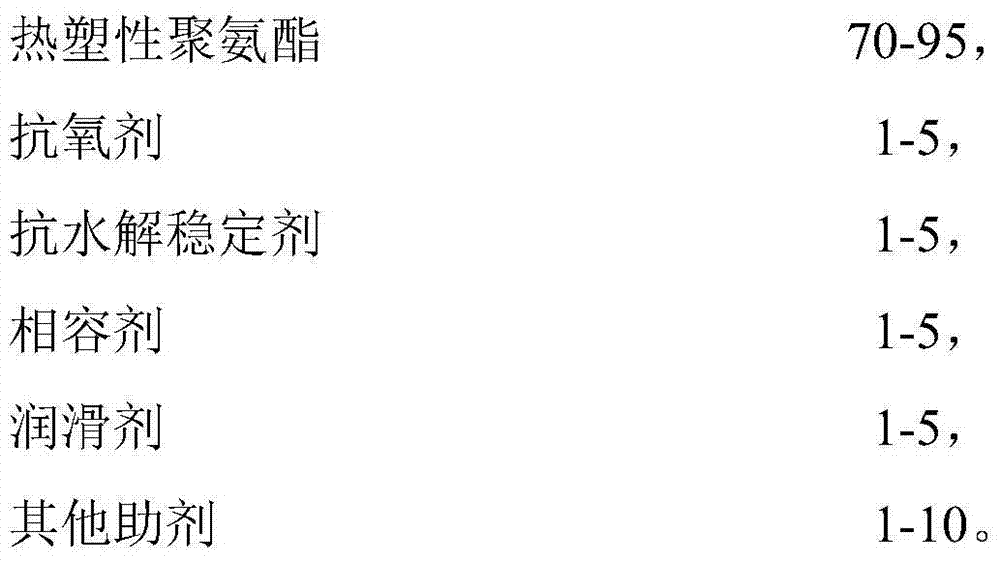

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

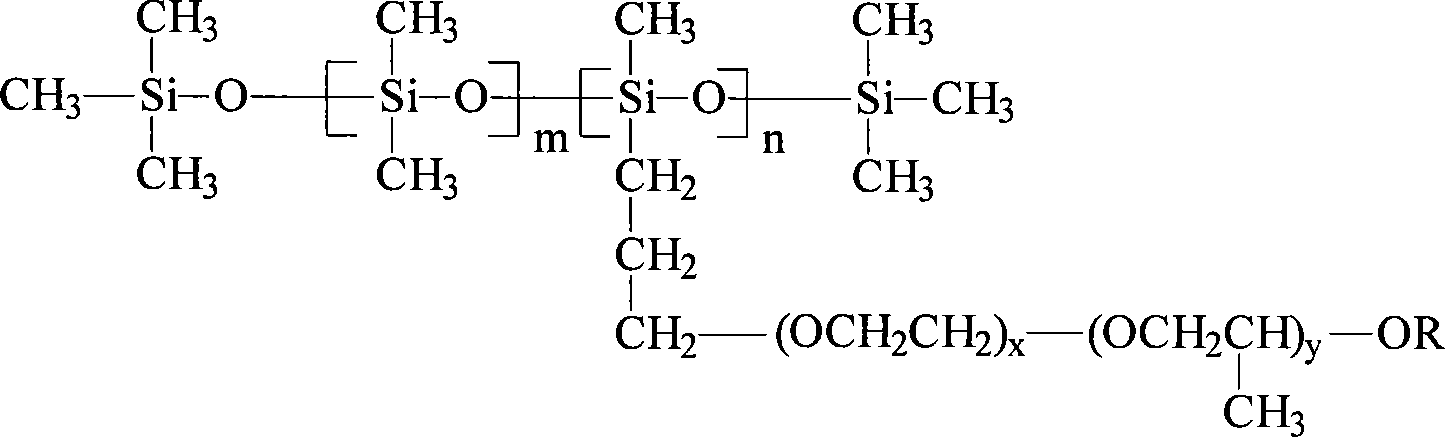

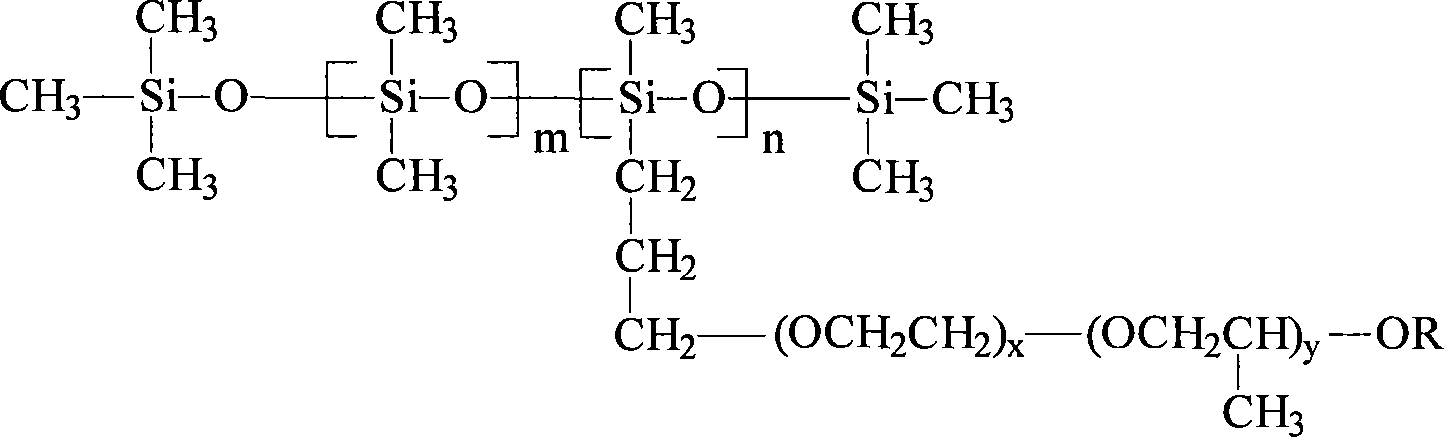

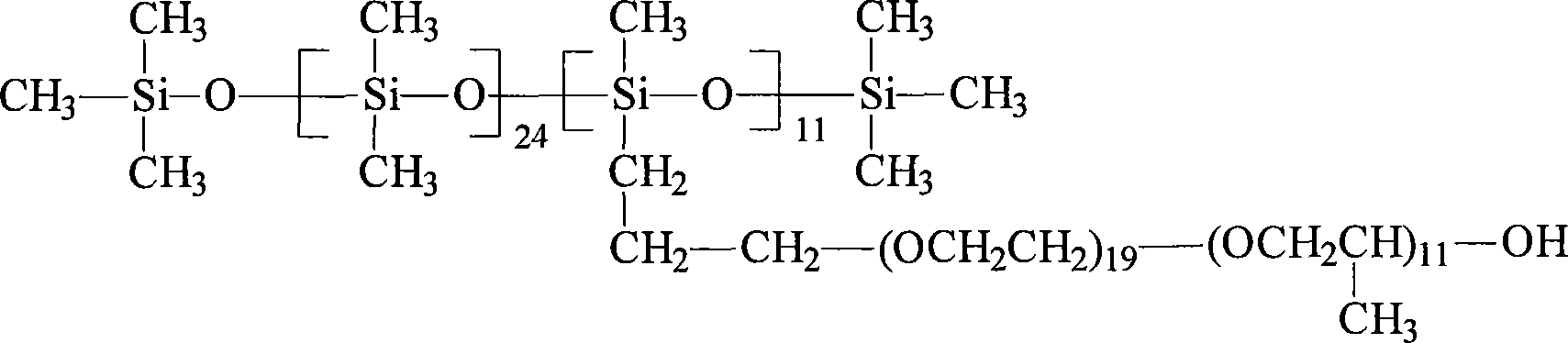

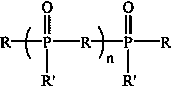

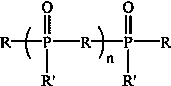

Polyurethane foam stabilizer with low density and low thermal conductivity factor and preparation method thereof

The invention discloses a low-density and low thermal-conduction-index polyurethane foam stabilizer and a preparation method thereof. The stabilizer can be widely used in polyurethane blowing technique, and enable the thermal conduction index of the pentane-blowing polyurethane foam to be lowered down to 0.0195-0.0200W / m.K, and has excellent functions of heat protection and heat preservation. The low-density and low thermal-conduction-index polyurethane foam stabilizer of the invention is provided with the structures: wherein, the figure of m is 10-80, the figure of n is 1-10, the figure of x is 10-70, the figure of y is 0-30, and m plus n is 11-90, x plus y is 10-100; R can be paraffin, radical aromatic, acyloxy or hydrogen atom that contains 1-4 carbon atoms.

Owner:JIANGSU MAYSTA CHEM

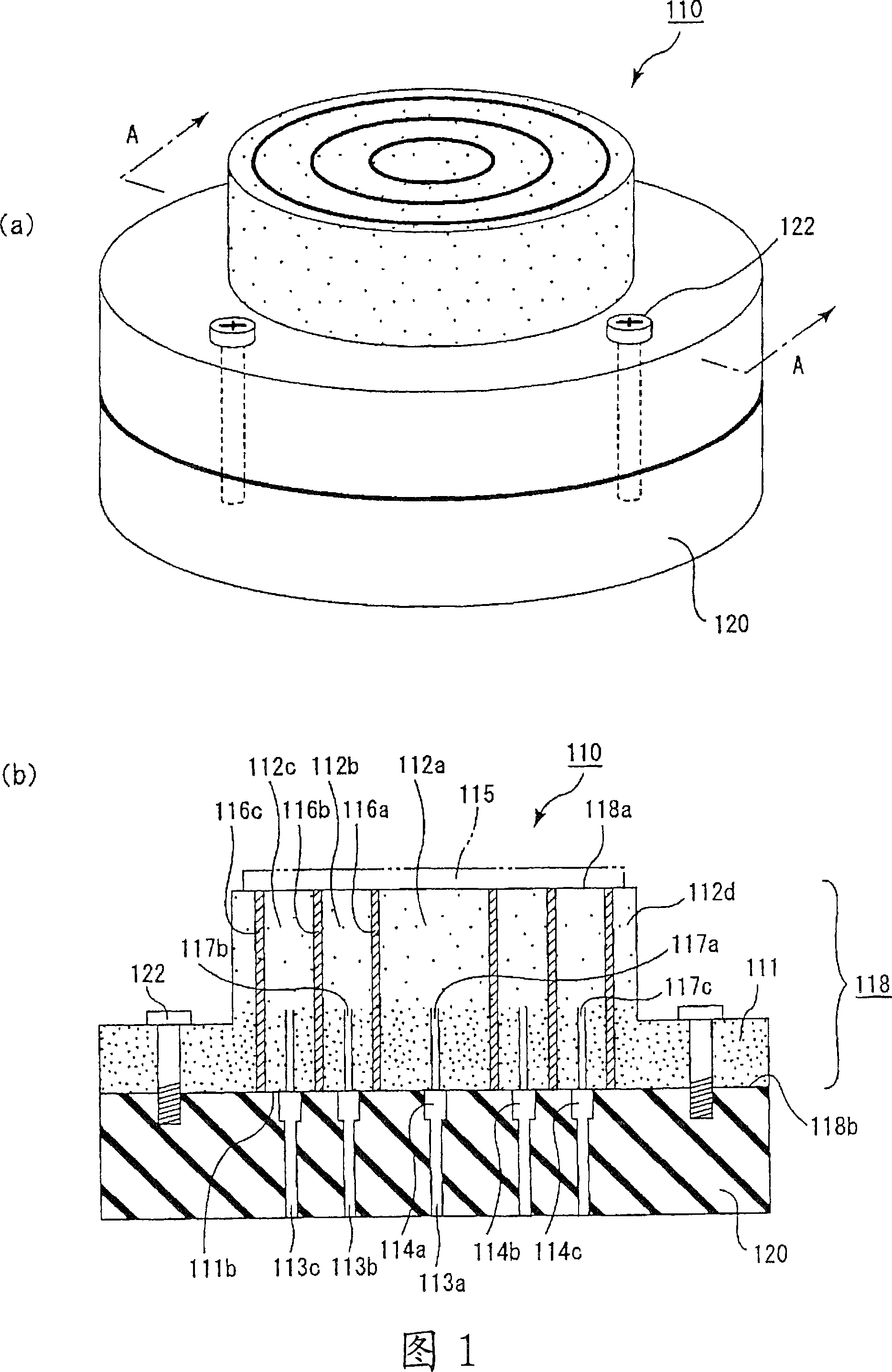

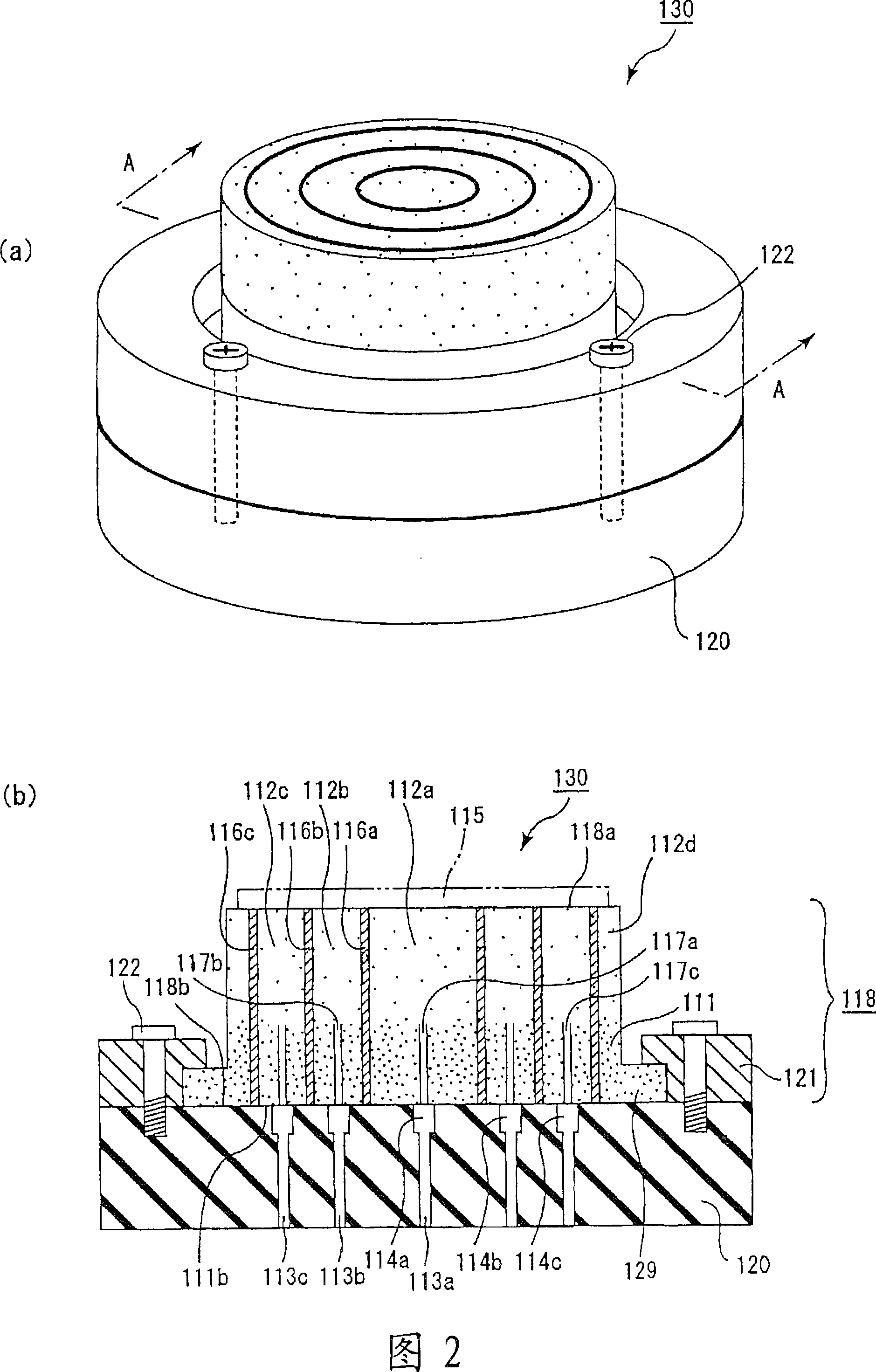

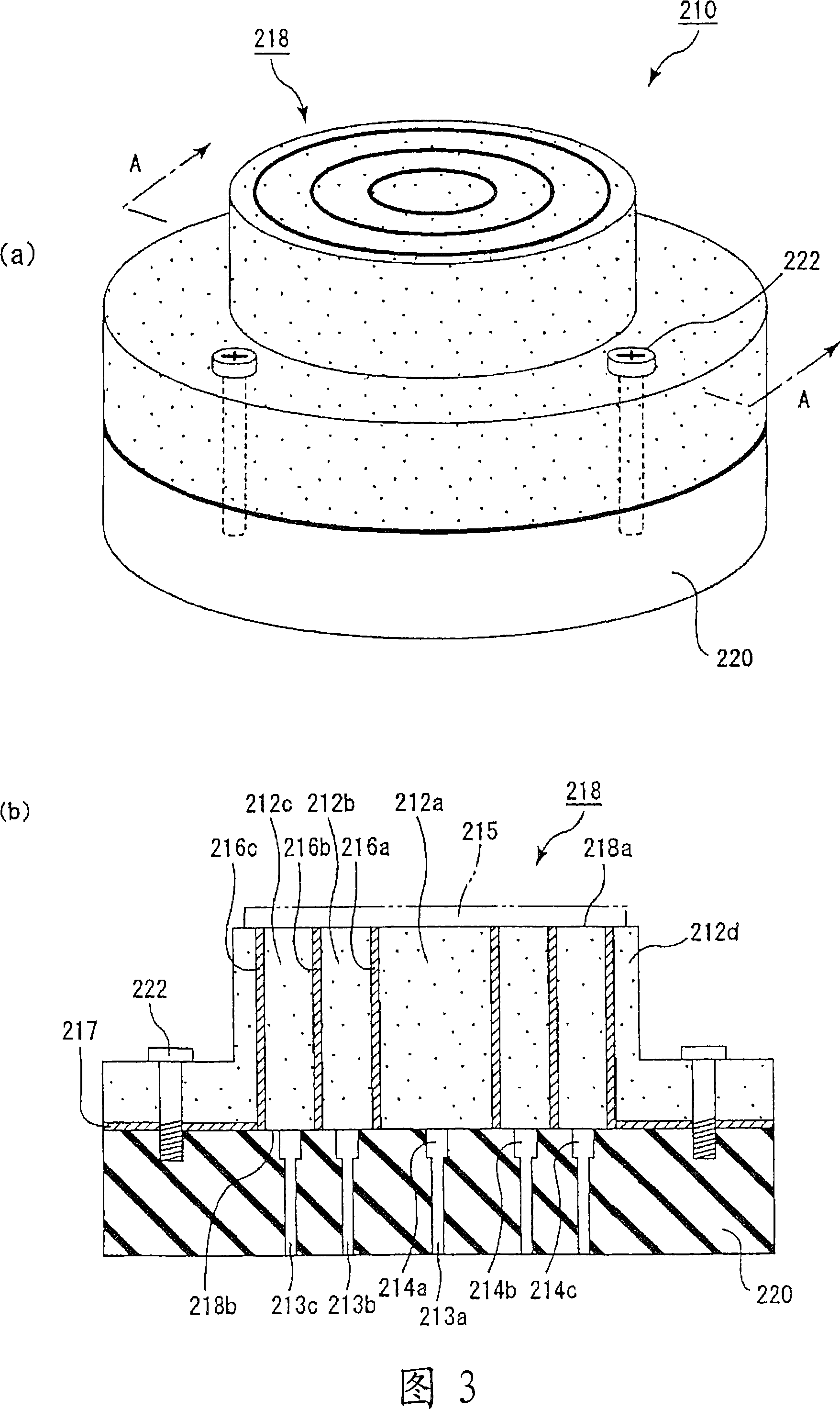

Vacuum chuck and suction board

ActiveCN1938122ADoes not produce uniformityNo situationSleeve/socket jointsSemiconductor/solid-state device manufacturingPorous ceramicsMaterials science

A vacuum chuck is provided for attaining uniform polishing of an object to be sucked. The vacuum chuck is provided by integrating a suction layer and a compact substance layer, which are formed of a porous ceramics, and positioning the suction layer on a side of sucking the object to be sucked. The vacuum chuck is provided with a suction board for sucking and holding the object to be sucked. The compact substance layer is formed by impregnating the porous ceramics with a metal.

Owner:IBIDEN CO LTD

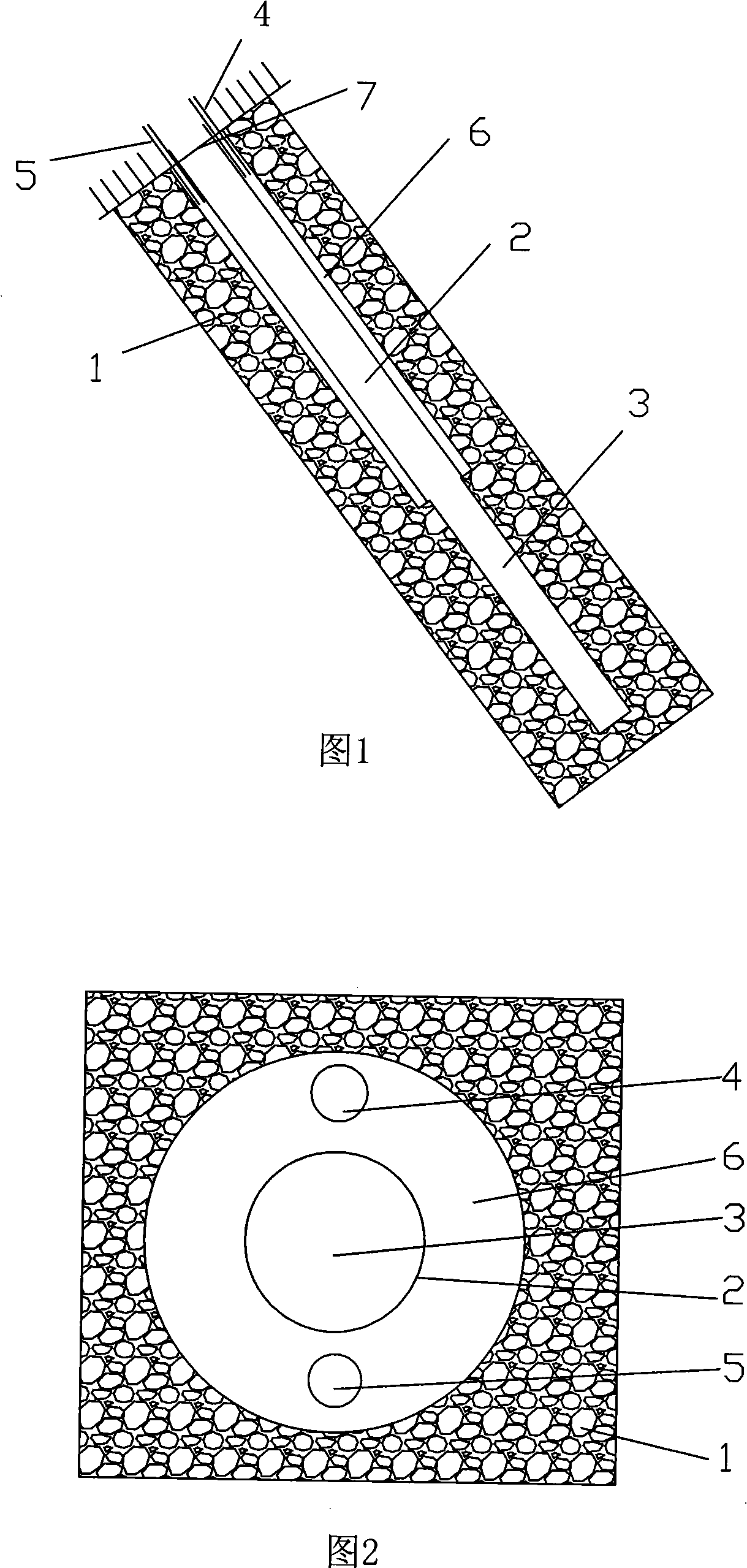

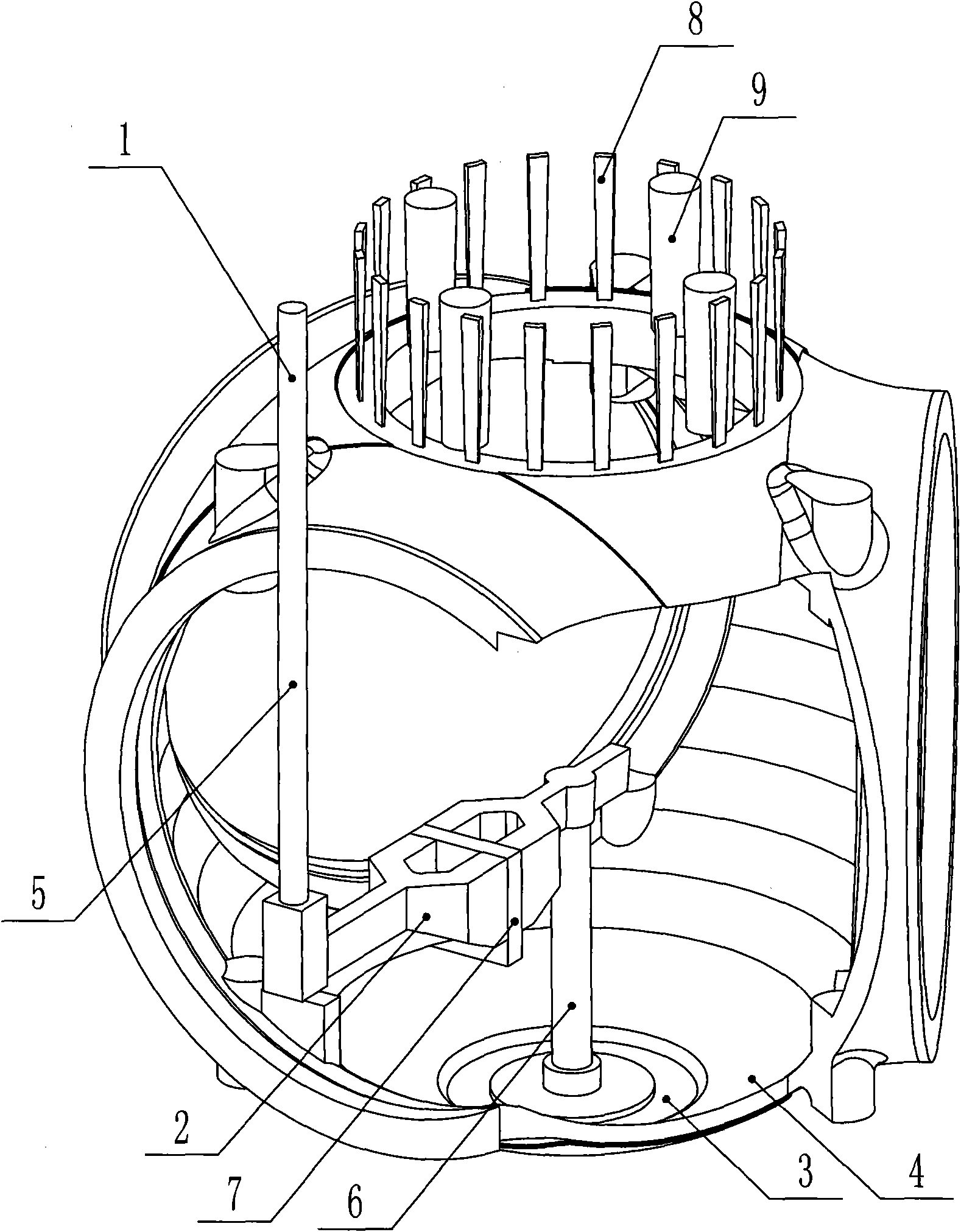

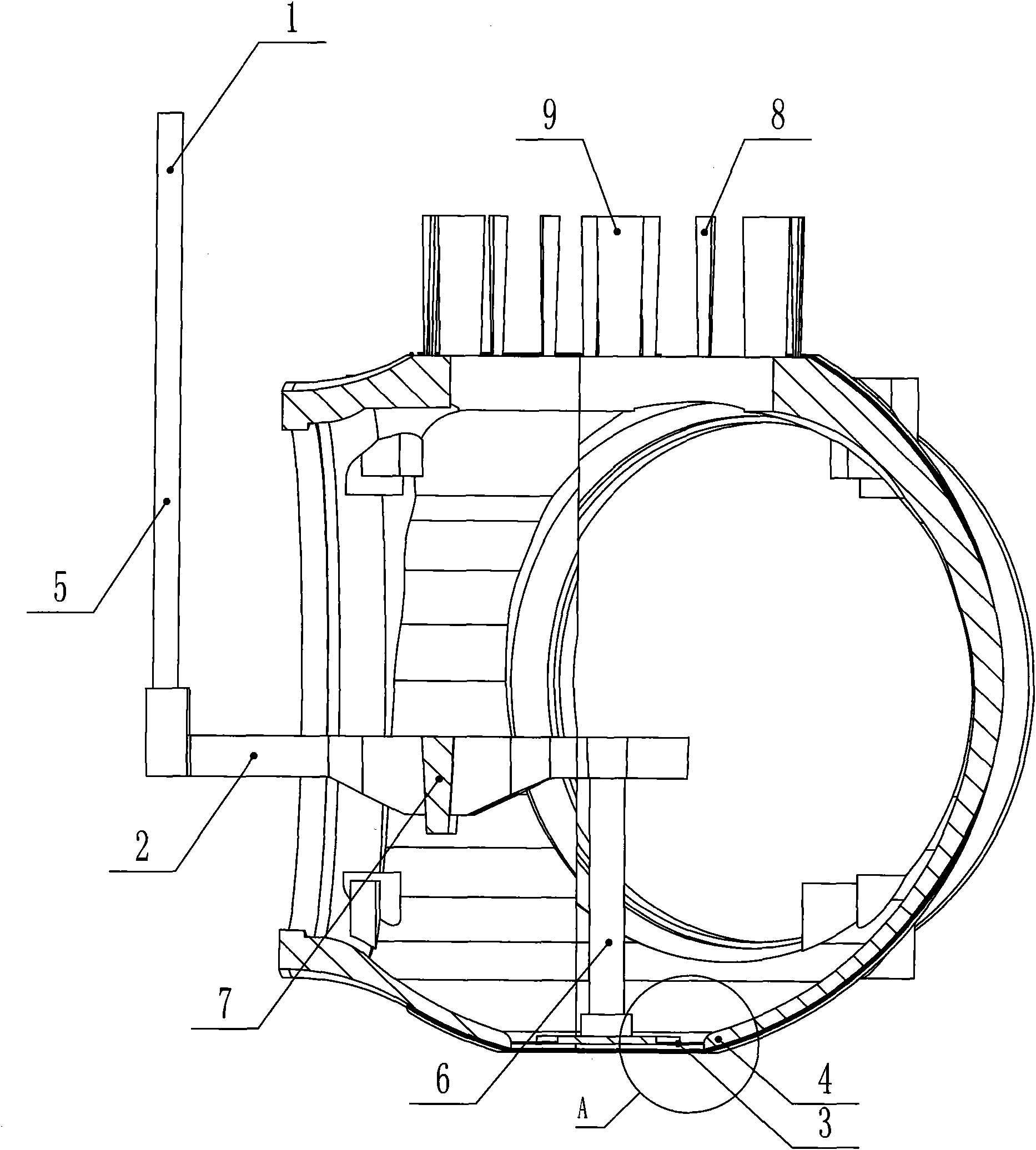

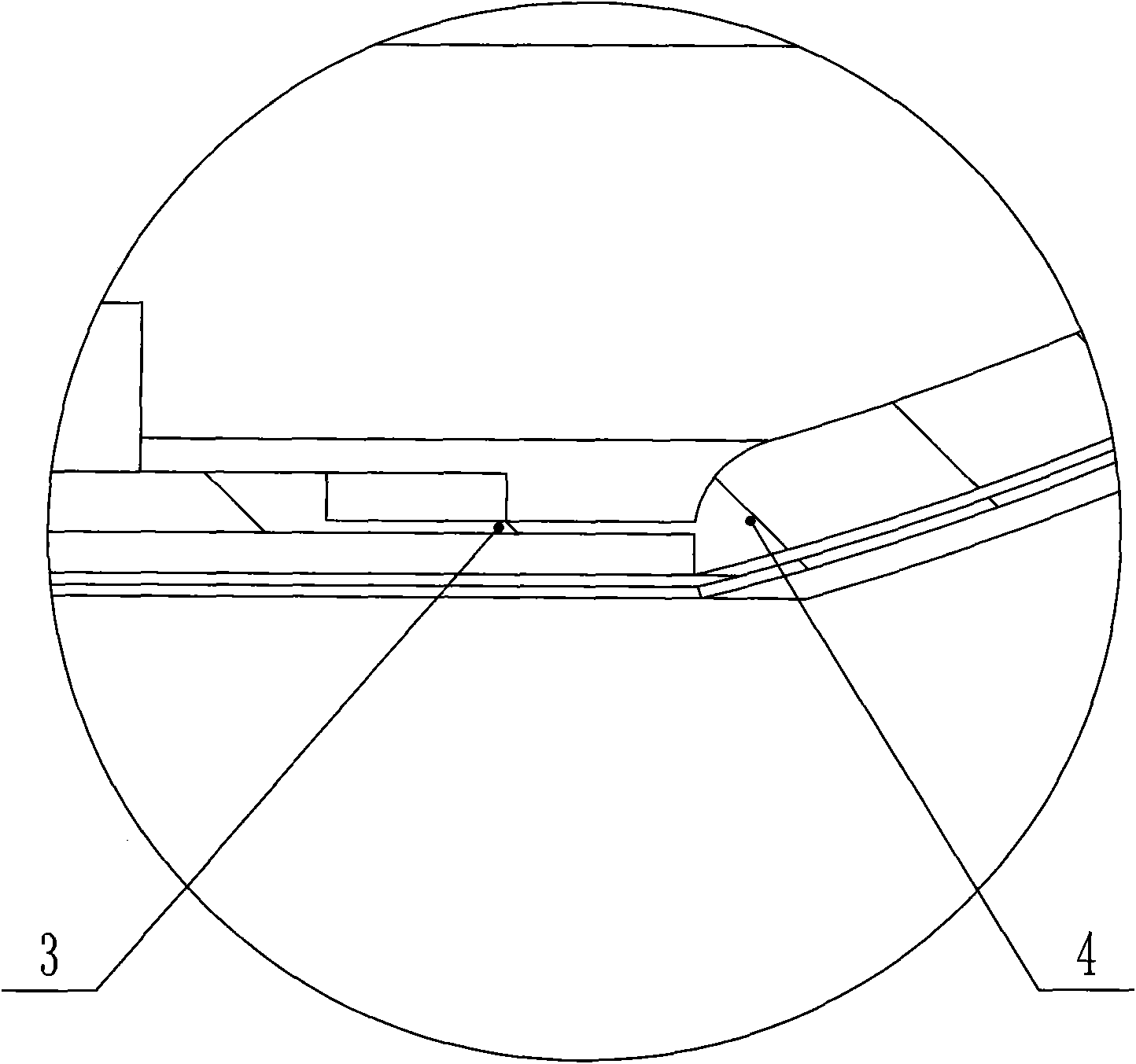

Heavy pressure slip-casting hole-sealing method for large-diameter extraction borehole

The invention relates to a method for large diameter borehole extracting and high-pressure grouting hole sealing, which is characterized in that the method comprises the following steps: at the coal seam top and in the floor roadway rock surface, an across-seam hole drilling and sealing section are constructed in the coal seam; a hole sealing pipe is positioned into the hole sealing stage; a grouting cavity is reserved between the hole sealing pipe and the hole wall of a borehole; a grouting pipe and a return pipe are respectively arranged in the two positions corresponding to the grouting cavity; the output pipe of a high pressure grouting pump communicates with the grouting pipe; grouting material is infused into the grouting cavity by the high pressure grouting pump through the grouting pipe, until the grouting material overflows out of the return pipe; the hole sealing section is formed through maintenance; across-seam hole drilling is constructed in the inner cavity of the hole sealing pipe. The method has the advantages that the hole sealing effect is good, the effective gas extraction time is long, and the construction method is simple.

Owner:HUAINAN MINING IND GRP

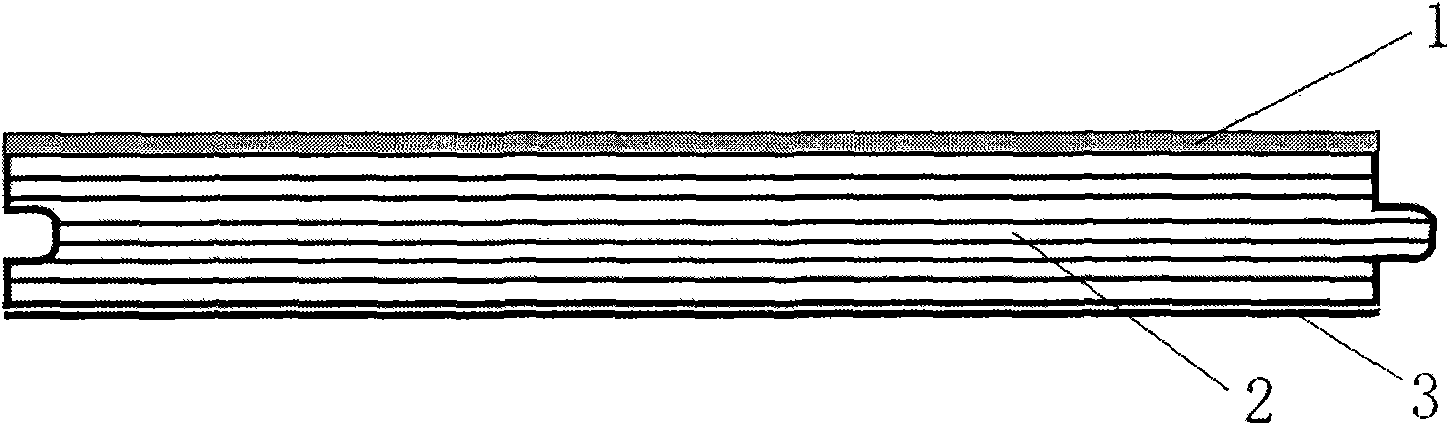

Coated diaphragm for ternary lithium ion battery, and preparation method thereof

PendingCN108550762ANot easy to shrinkImprove thermal safety and stabilitySecondary cellsCell component detailsHigh temperature storagePower battery

The invention discloses a coated diaphragm for a ternary lithium ion battery, and a preparation method thereof. The coated diaphragm comprises a diaphragm substrate, a ceramic / graphene composite coating and a PVDF coating, two sides of the diaphragm substrate are respectively coated with the ceramic / graphene composite coating and the PVDF coating, the ceramic / graphene composite coating correspondsto a battery positive electrode, and the PVDF coating corresponds to a battery negative electrode. The positive electrode side is the ceramic / graphene composite coating, so no shrinkage of the coateddiaphragm at a high temperature is ensured, and short circuit, explosion and other safety hazards of the coated diaphragm are avoided; the negative electrode side is the PVDF coating, so the internalheat conduction performance of the battery is enhanced to a certain degree, the high-temperature storage performance of the battery is improved, the wettability and the liquid retention property of the coated diaphragm are increased, and the coated diaphragm and an electrode sheet are bonded to inhibit structural collapse of the negative electrode in the charging and discharging process; and thesuperposition of the two coatings greatly improves the safety, the cycle performance and the rate performance of the ternary lithium ion battery material are greatly improved, and the large-scale application of the coated diaphragm on a power battery is promoted.

Owner:余姚市海泰贸易有限公司

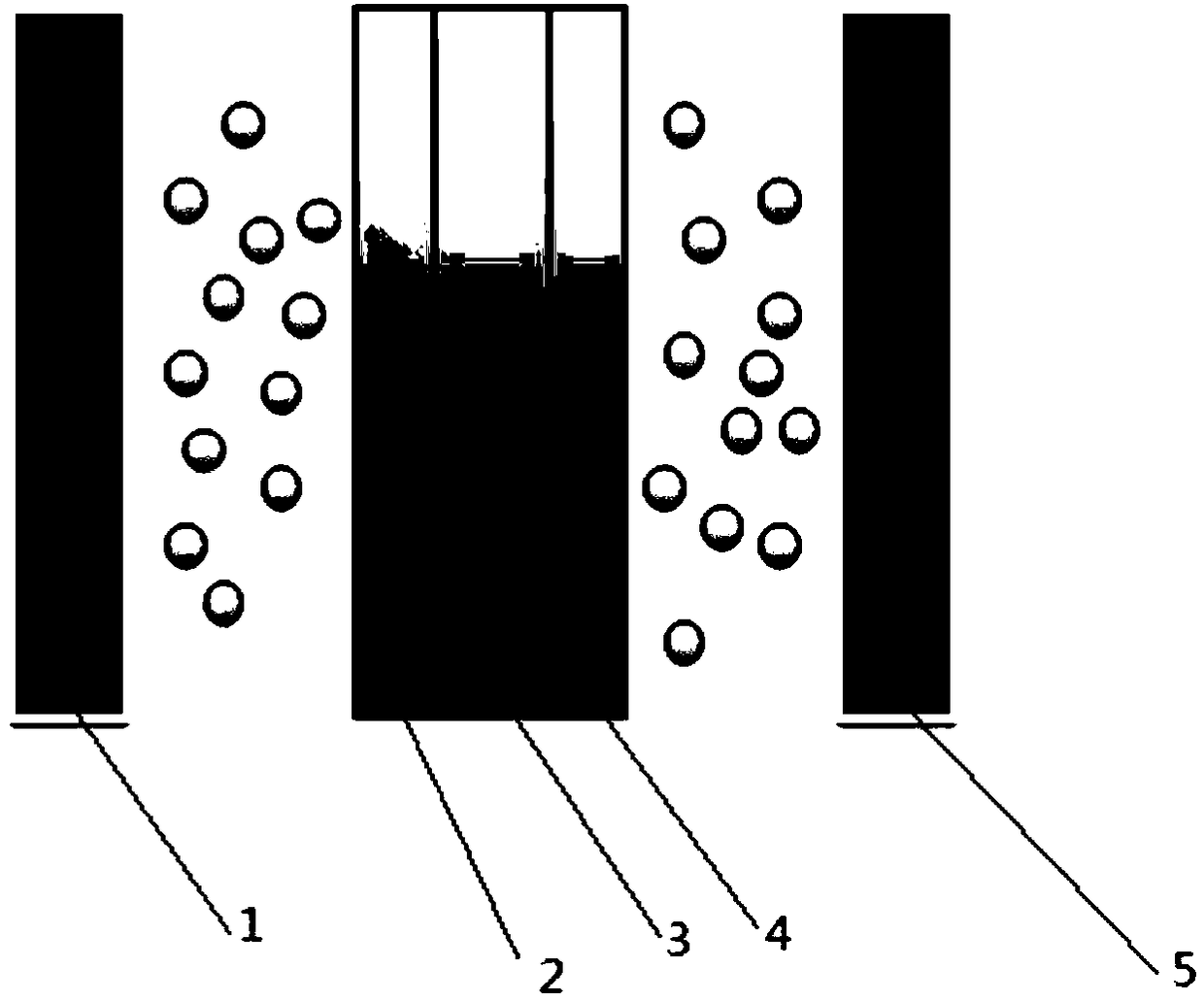

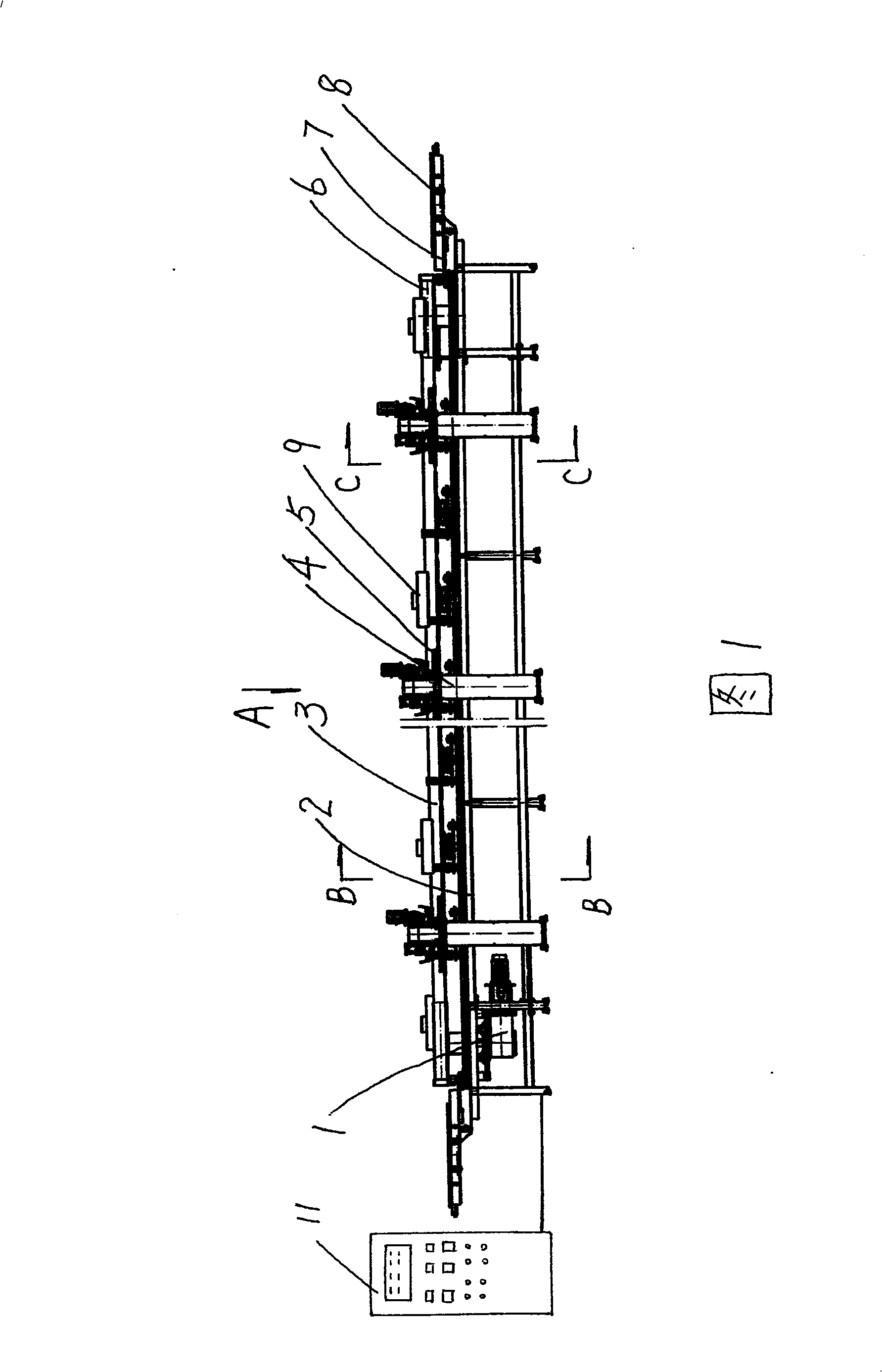

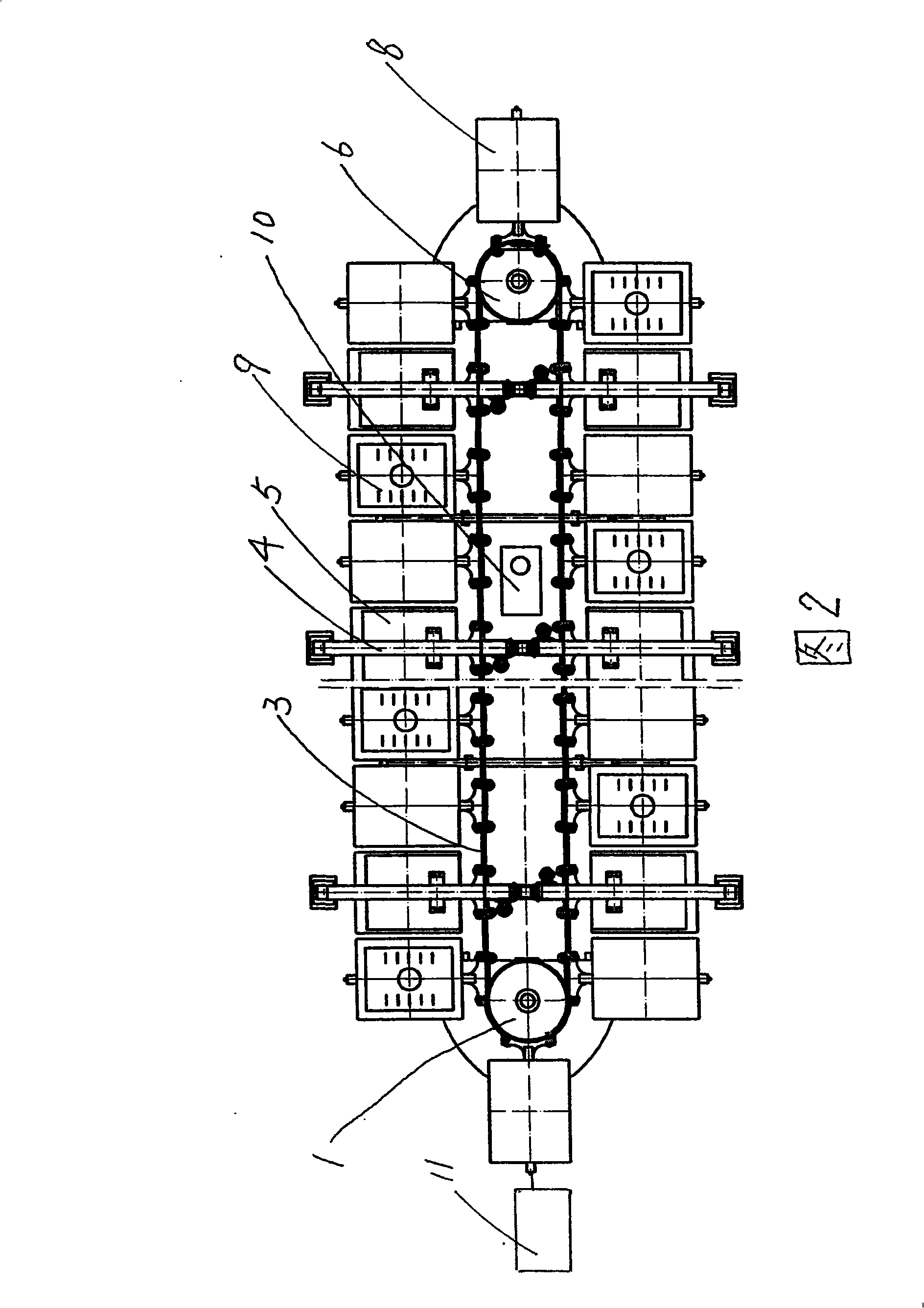

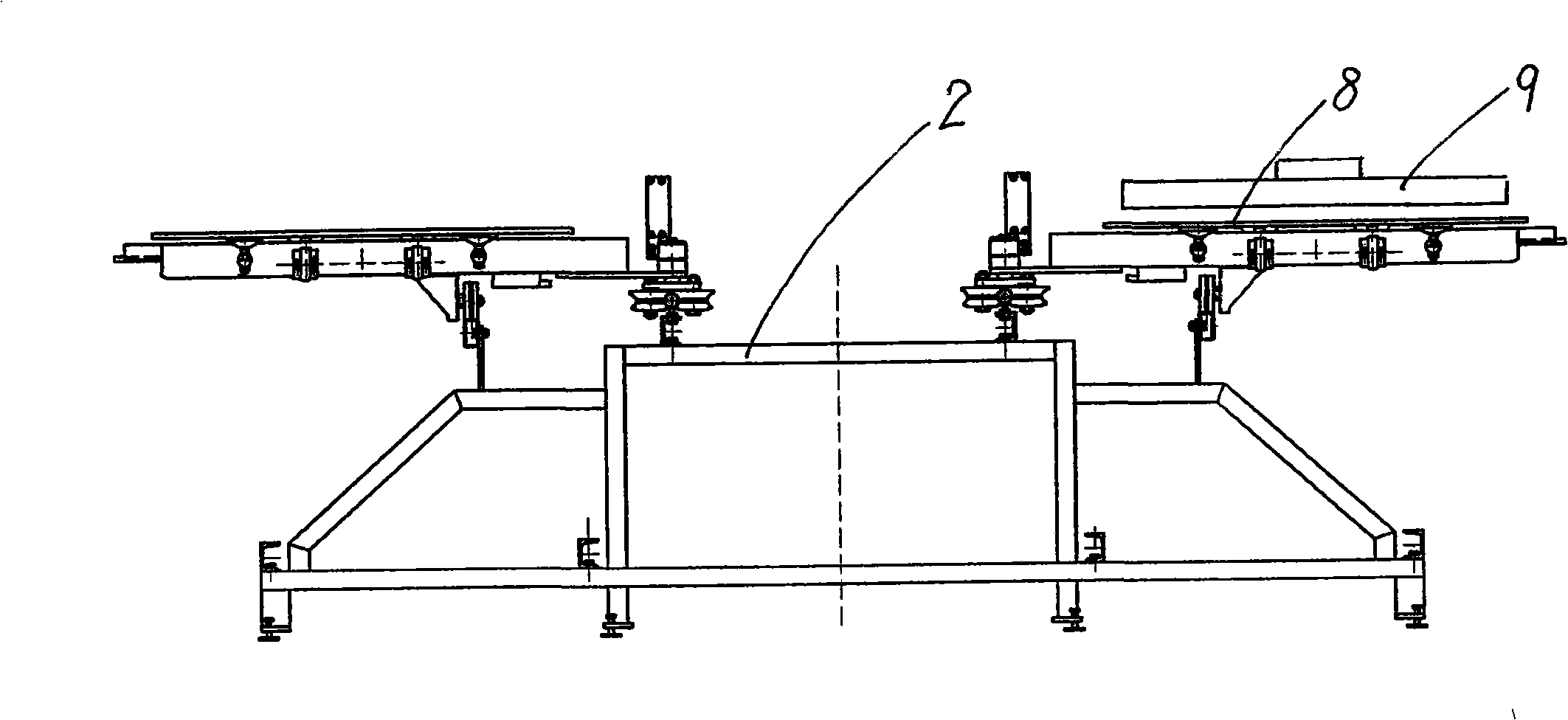

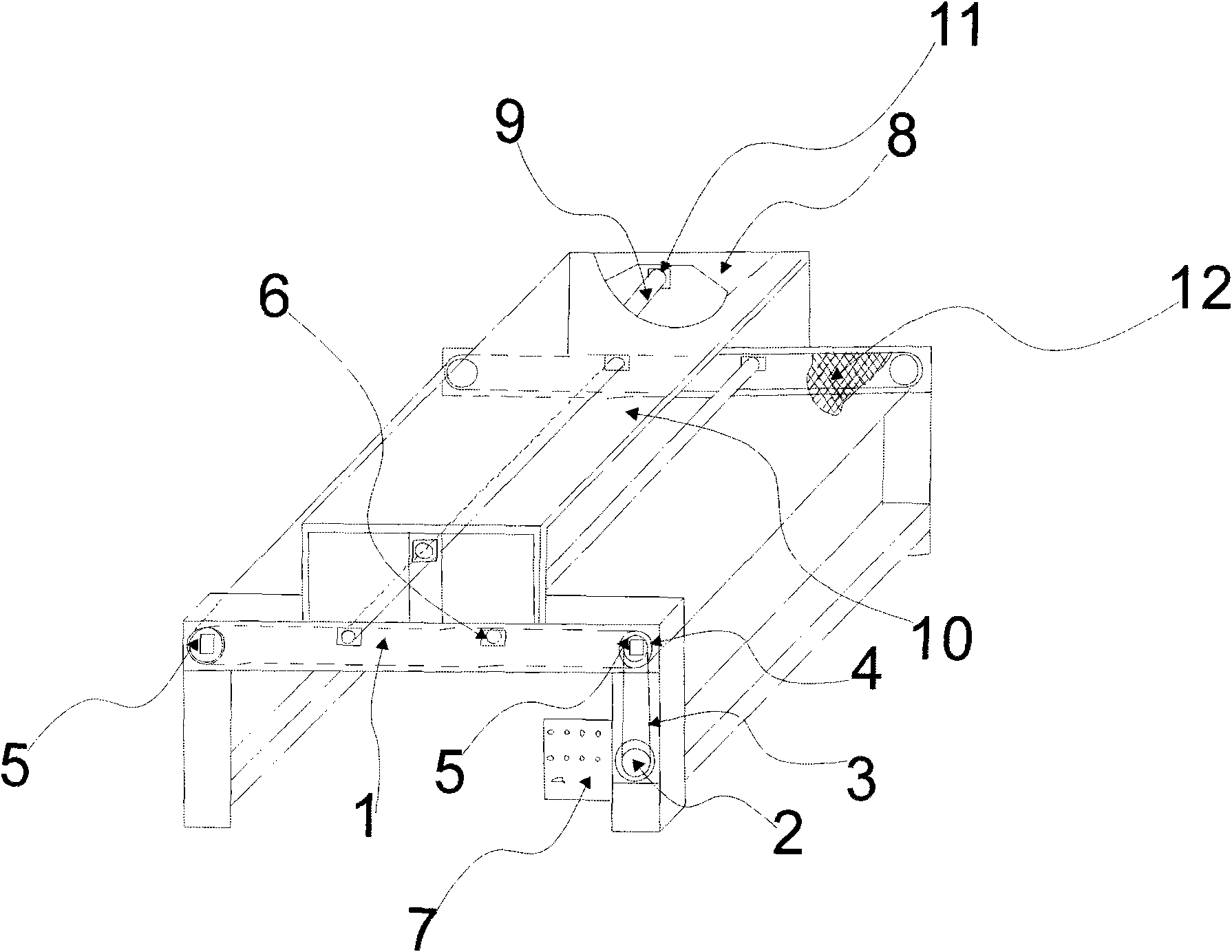

High-precision full-automatic printing machine

The invention relates to a high-precision full-automatic decorating machine. The decorating machine comprises a main drive part, a stander part, a transmission belt part, at least six sets of scraping and printing head parts, a net frame part, an auxiliary transmission part, a bedplate bracket part, a bedplate part, a drying device, a humidification device and a control part; the stander part is provided with the main drive part and the transmission belt part; the scraping and printing head parts are connected with the stander part; the net frame part is arranged on the scraping and printing head parts; the stander part is provided with the bedplate bracket part; as the bedplate part is provided with a positioning block and can be matched with a rotation positioning mechanism, the positioning precision is high; as the scraping and printing head parts are designed into a lifting structural form, the bedplate part can conveniently move along a track; as the drying device is mounted, printed paint is rapidly dried so as to avoid color crossing; as the humidification device is mounted, the printed paint is uneasy to dry and solidify so as to avoid blocking a net; and as a computer is adopted to be combined with photoelectric control, positioning precision and automatic degree are high.

Owner:如皋市天元服饰印业有限公司

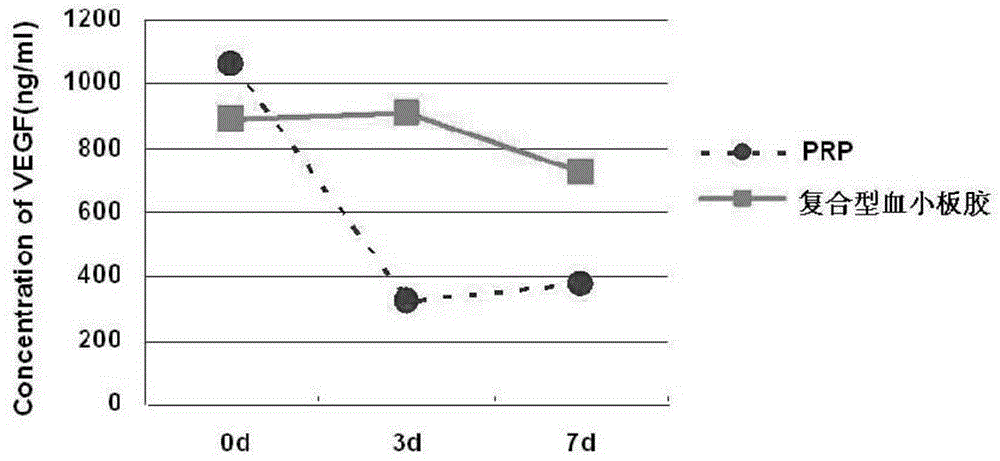

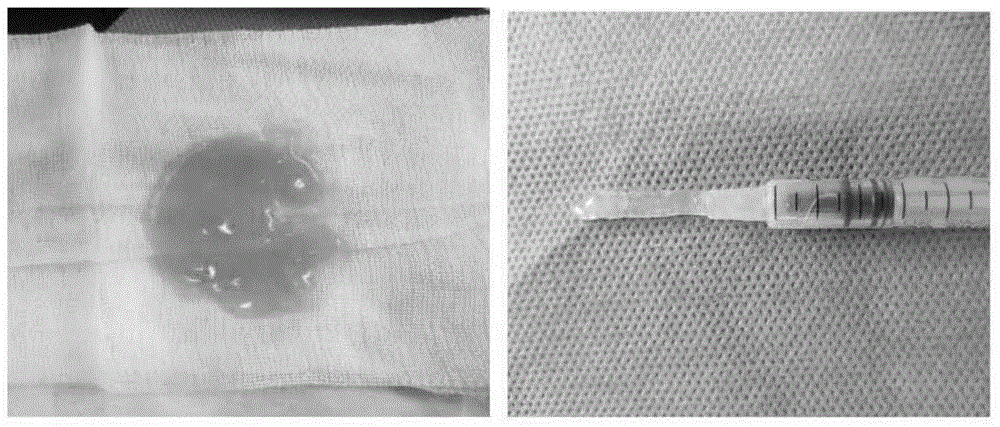

Compound platelet gel and preparation method thereof

InactiveCN105030826APromote degradationMoisturizingAerosol deliveryOintment deliveryBiologic scaffoldCytokine

The invention discloses compound platelet gel and a preparation method thereof. The preparation method includes: taking chitosan which is a natural material high in biodegradability and biocompatibility as a biological scaffold and a drug delivery carrier; activating fibrinogen in PRP to be a fibrin netty structure to be connected to chitosan molecules to form a gel carrier scaffold; and enabling platelet-derived cytokines to be adhered and anchored in the gel carrier scaffold to form the compound platelet gel. The compound platelet gel has multiple functions of quickly promoting tissue regeneration, bleeding stopping, bacterium resisting, pain relieving and humidity maintaining, and is simple to prepare, convenient to use, capable of realizing slow release of platelet-derived growth factors and active substances, lasting in biological effect and suitable for application in restorative treatment of soft or hard tissue defect, skin or mucosa refractory damage or ulcer, articular cartilage degeneration and ischemic tissue necrosis.

Owner:AFFILIATED HOSPITAL CHINA ACADEMY OF MILITARY MEDICAL SCI

Foaming composition for water tank of solar water heater

InactiveCN102516494APrevent severe shrinkageNo significant deformationSodium bicarbonateFoaming agent

The invention discloses a foaming composition for a water tank of a solar water heater, which is characterized by comprising the following main raw materials: a polyether foaming agent, sodium bicarbonate, chitosan and hollow glass beads. The improved polyether rigid foam composition can be used for reducing the phenomena that after being sprayed from a glossy jar and formed, a polyurethane material has high contractibility, the heat preservation effect of the water tank of the solar water heater is influenced and the water tank is deformed, bulged and barred, or even cracked.

Owner:杜立立

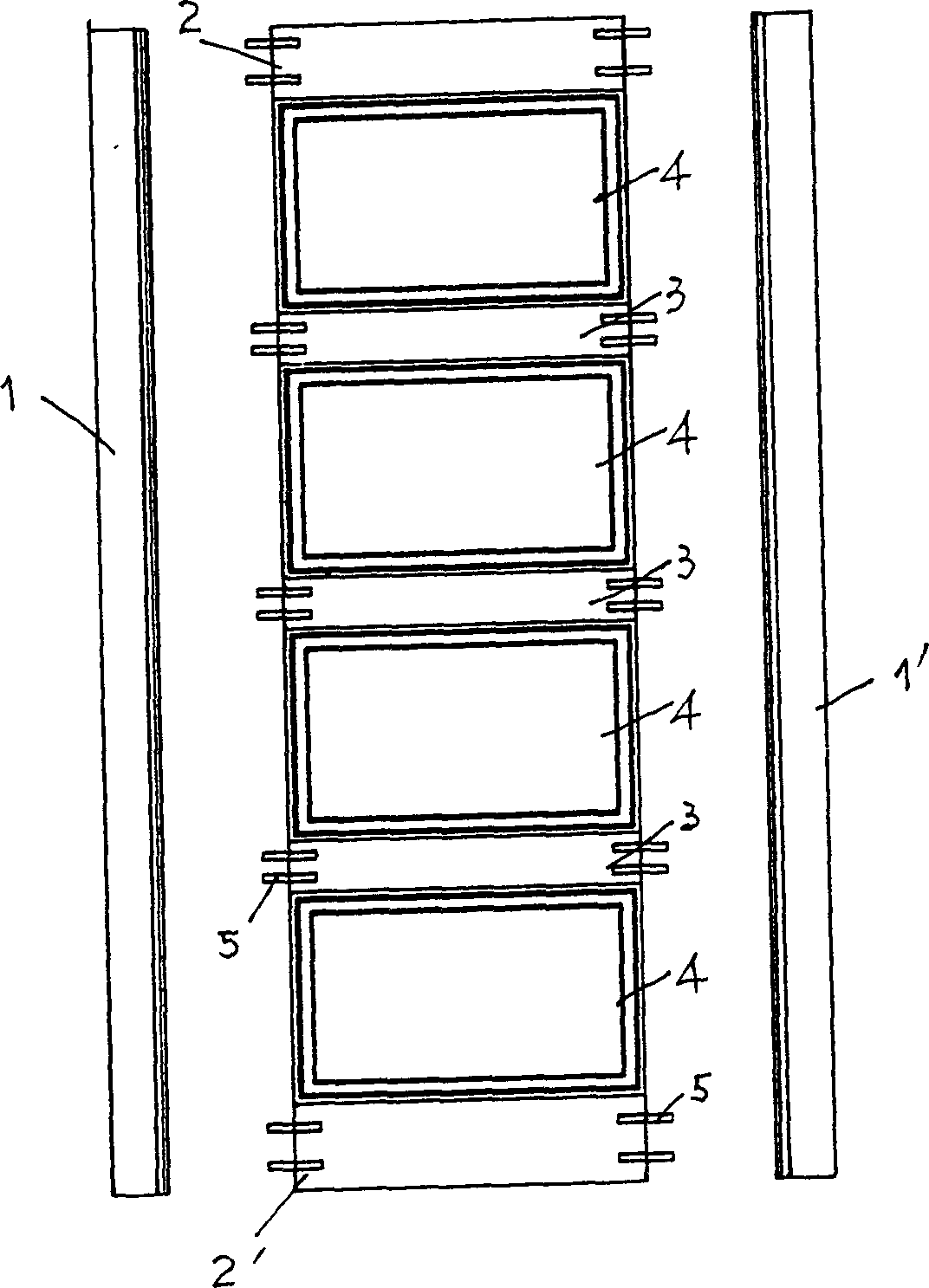

Log door leaf and its manufacturing method

InactiveCN1657735ASave the processImprove bindingWood working apparatusDoor leavesIndustrial engineering

The invention relates to a log door leaf and its manufacturing method, solves the problem of the paint cracking caused by contraction or expansion of transom and closure plate of door, including three steps: produce transom and closure plate of door by wood; pain each of them wholly; pain binder on the linking part of then, making leaf. There is sew for contraction remained on each linking part of each transom and closure plate of door, even if contraction or expansion happens somewhere, it will only affect the width of the sew, no to the whole appearance; the linking part of each transom and closure plate of door is strengthened by transversal cork, making the leaf stabler.

Owner:陈文镇

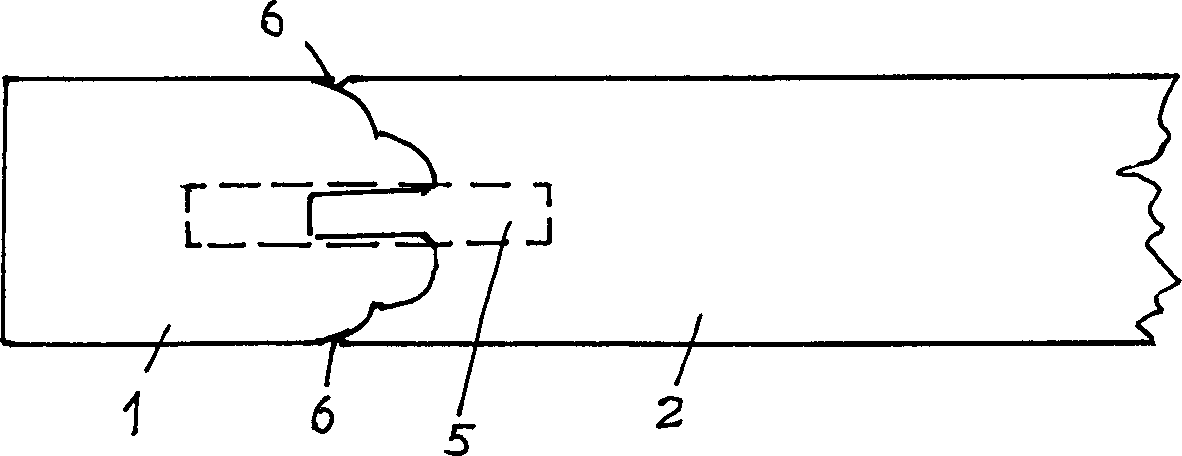

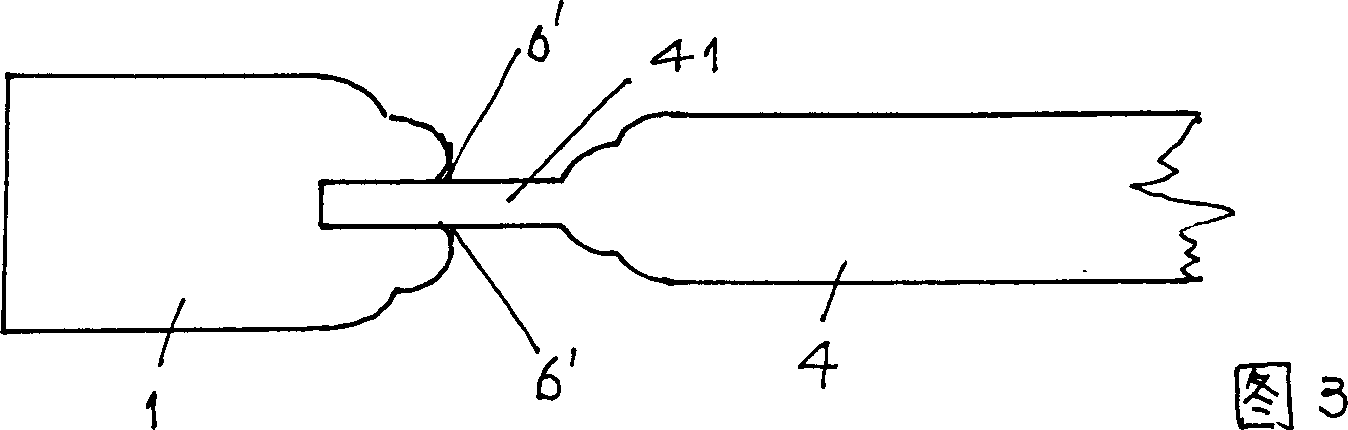

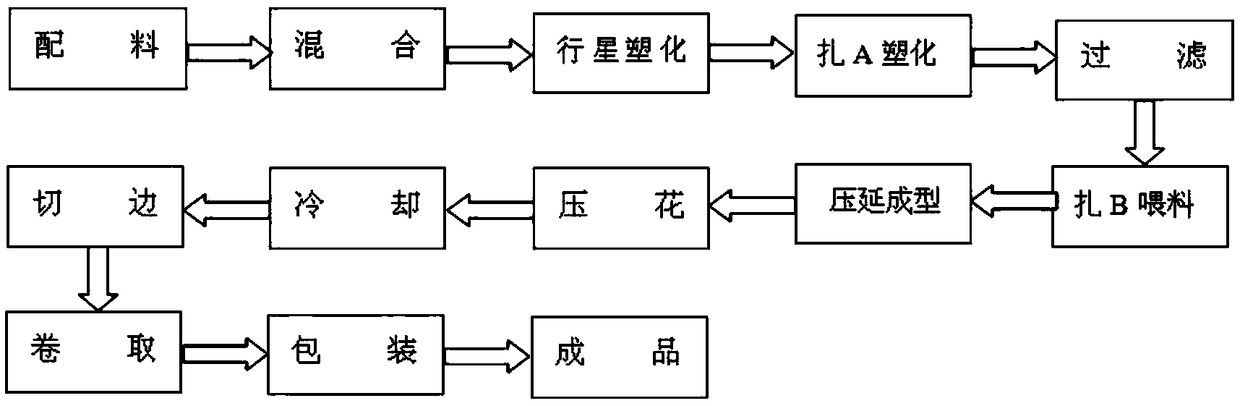

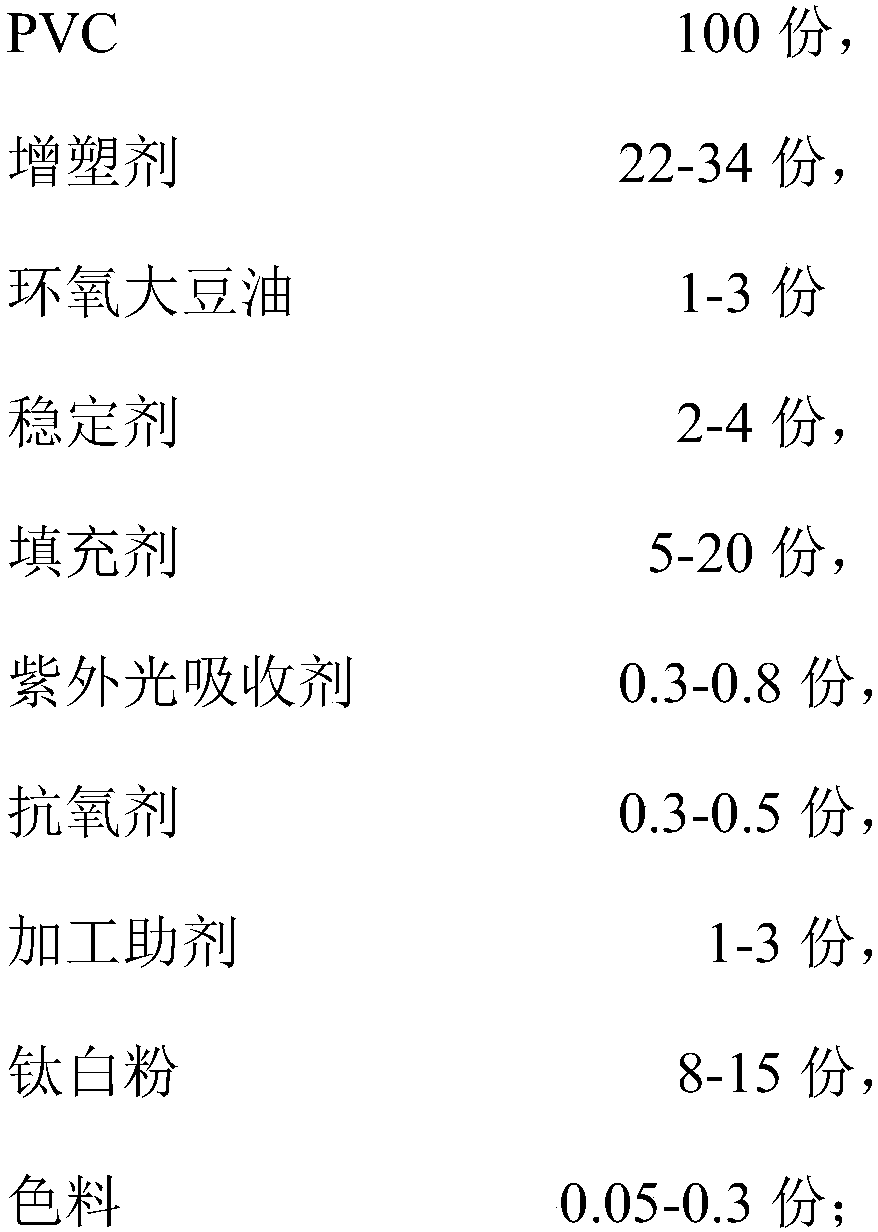

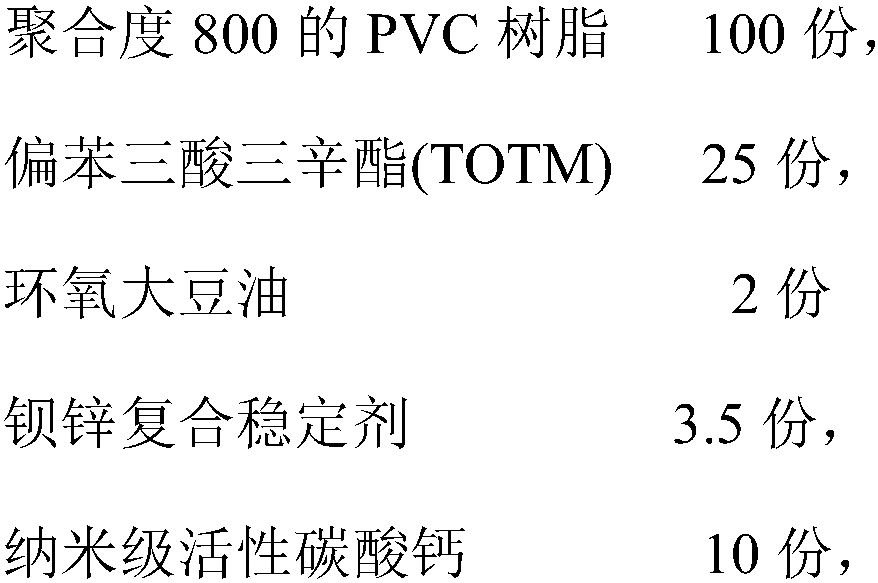

Production formula of high-temperature-resistant PVC painting film and preparation method thereof

The invention discloses a production formula of a high-temperature-resistant PVC painting film and a preparation method thereof. The production formula is characterized in that the high-temperature-resistant PVC painting film is prepared by adding the following raw materials in parts by weight: 22 to 34 parts of plasticizers, 1 to 3 parts of epoxidized soybean oil, 2 to 4 parts of stabilizing agents, 5 to 20 parts of filling agents, 0.3 to 0.8 part of ultraviolet absorbent, 0.3 to 0.5 part of antioxidants, 1 to 3 parts of processing auxiliary agents, 8 to 15 parts of titanium dioxide and 0.05to 0.3 part of pigments into per 100 parts of PVC resin. The preparation method comprises the following steps of proportioning, mixing, planetary machine plasticizing, A milling machine plasticizing,filtering, B milling machine heat insulation material feeding, calendaring shaping, pattern pressing, cooling, edge cutting, reeling and packaging. The PVC painting film has good painting performance,and achieves high-temperature separation resistance and high-temperature shrinkage resistance; the definition of the painting images can be maintained; the edge shrinkage cannot easily occur after the painting; the use and the attractive appearance cannot be influenced; the service life is longer.

Owner:ZHEJIANG GANGLONG NEW MATERIAL

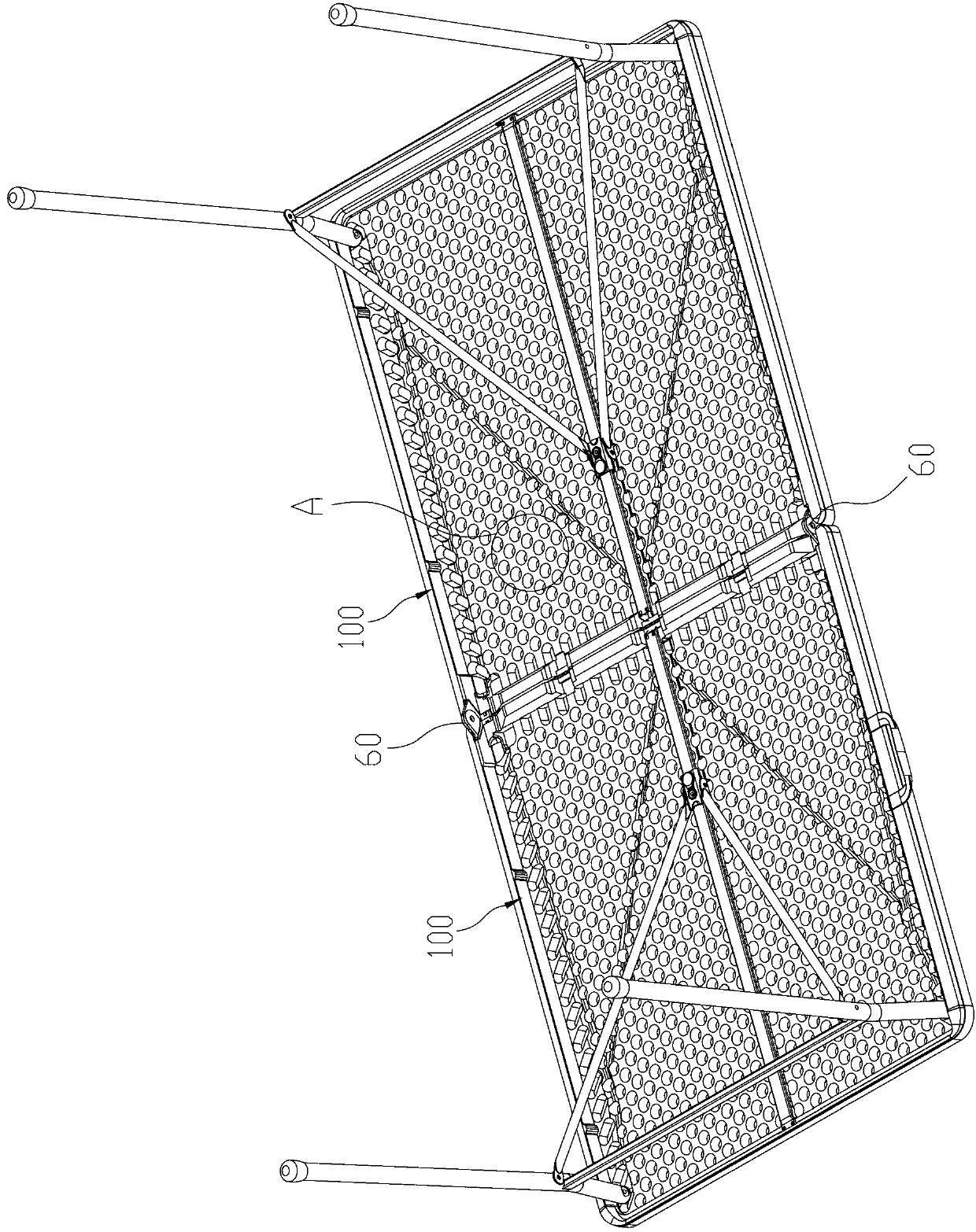

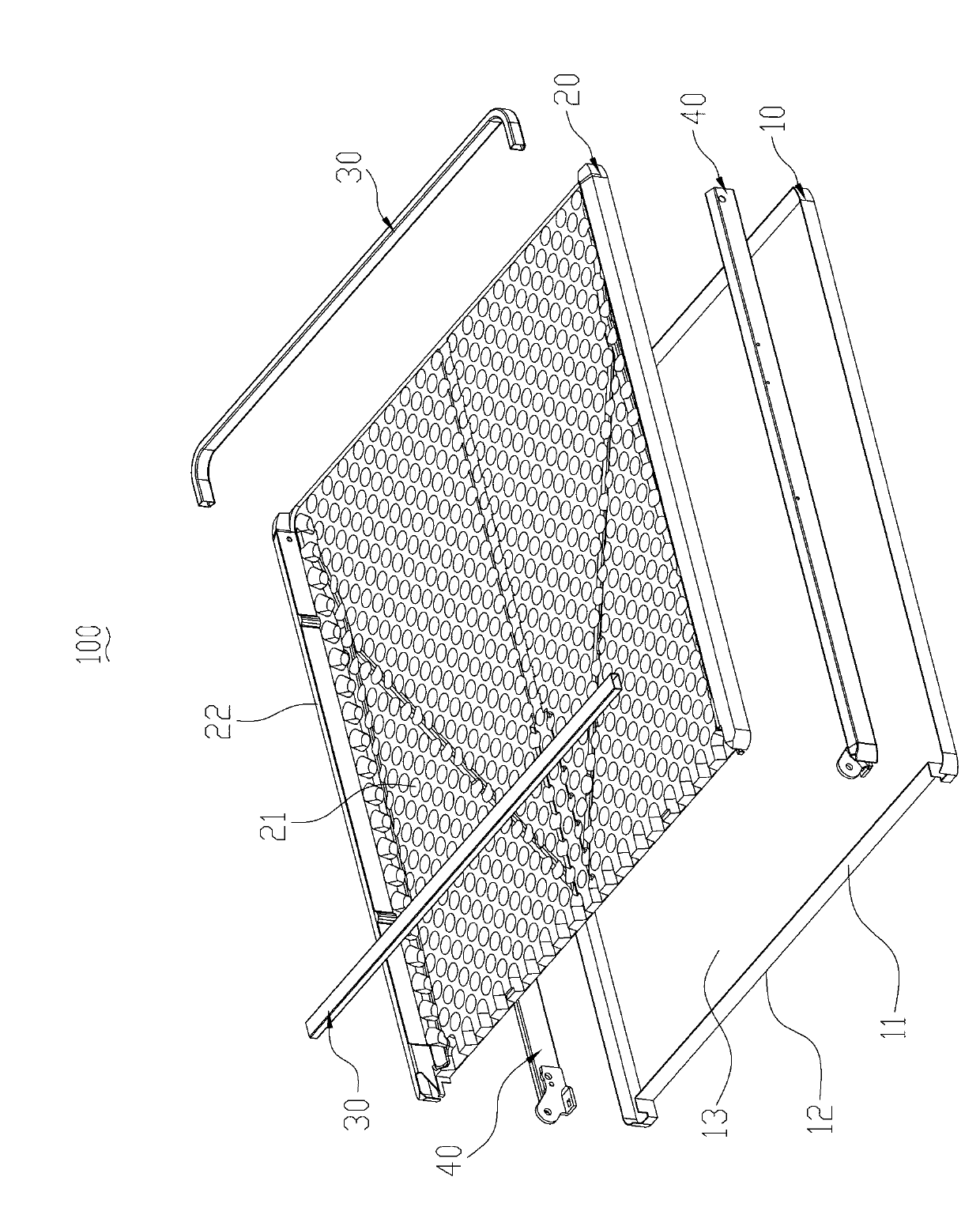

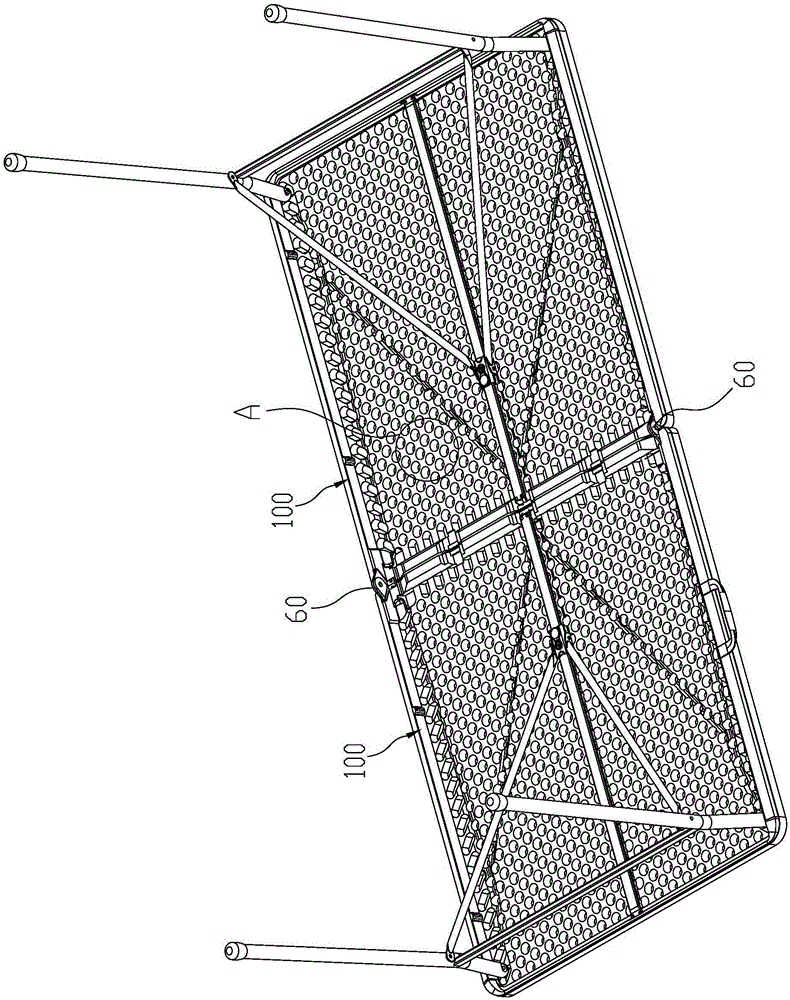

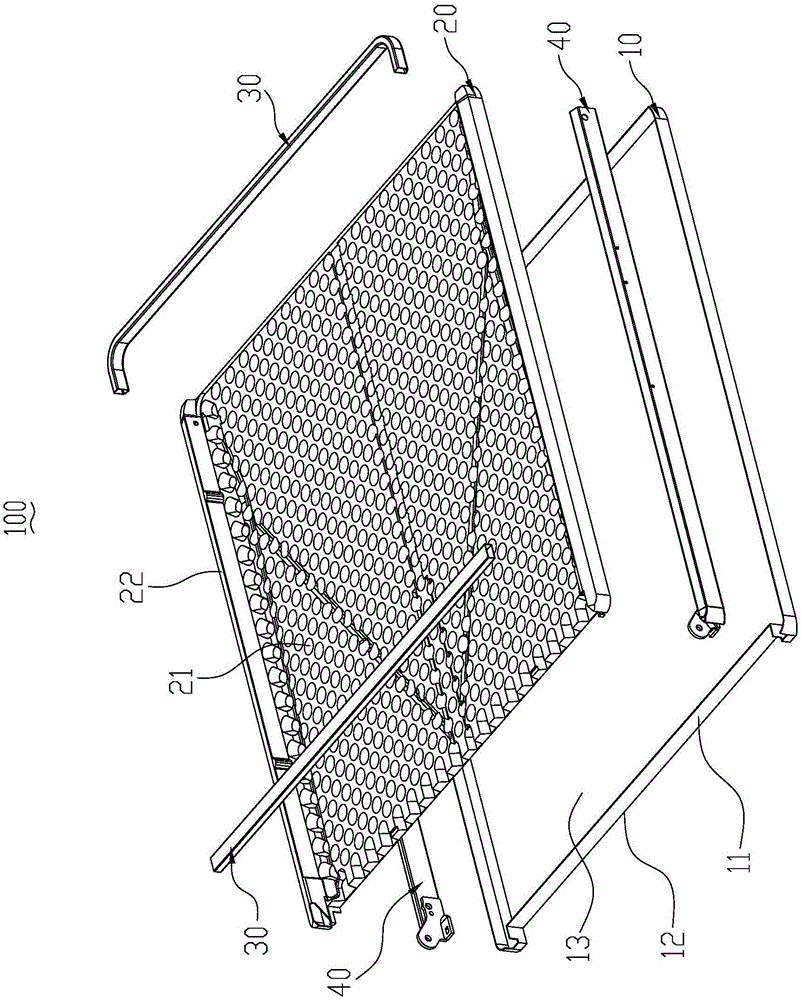

Table panel

InactiveCN103284471AImprove stress resistanceHigh strengthLayered productsFoldable tablesEngineeringSurface plate

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Wood drying process

InactiveCN105202870AIncrease temperatureIncrease moisture contentDrying solid materials with heatHearth type furnacesSurface stressHigh humidity

The invention discloses a wood drying process. The wood drying process comprises the steps of 1, preheating; 2, high-temperature and high-humidity treatment; 3, drying; 4, maintenance. When the wood drying process is adopted for drying wood, the surface stress and internal stress of wood can be eliminated, surface cracking or internal cracking of wood can be prevented, the original quality of wood is maintained, defects such as air shrinkage, bending, crinkling and deformation do not occur easily, the rate of wood damage caused by improper drying is reduced greatly, and meanwhile, energy is saved and drying time is shortened.

Owner:王璐

Ice temperature gas regulation fresh-keeping water-cooking minced fish octopus bolus ball

InactiveCN101496617AExtend freshnessGrowth inhibitionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsIce waterCooling chamber

The invention relates to an ice-temperature modified atmosphere preserved water cooked minced fillet octopus ball. The ice-temperature modified atmosphere preserved water cooked minced fillet octopus ball is prepared by heating, boiling and forming minced fillet, starch, emulsified slurry, egg white, starch glue, sodium glutamate, granulated sugar, a taste promoter, sugar essence, Tarinsan, Tarilin, seafood essence, an octopus head, ice water and muddy garlic. The preparation method comprises the following steps: placing 33kg of refrigerated minced fillet into a kneader for kneading; then adding 2.1ks of salt, 22ks of starch, 24ks of emulsified slurry, 1.1ks of egg white, 0.18ks of starch glue, 1.1ks of sodium glutamate, 2ks of granulated sugar, 0.44ks of taste promoter, 0.03ks of sugar essence, 0.1ks of Tarinsan, 0.1ks of Tarilin, 0.5ks of seafood essence, 9ks of octopus head, 3.6ks of ice water and 1.8ks of muddy garlic; kneading and mixing the raw materials evenly to prepare the fish balls or fish cake; then placing the fish balls or fish cake into a sterile cooling chamber for cooling down the fish balls or fish cake; carrying out the vacuum blowup packaging of the cooled fish balls or fish cake; and then storing the fish balls or fish cake in a non-frozen state at a temperature of between 0 and 3 DEG C below zero so as to reach the aim of preservation.

Owner:周黎明

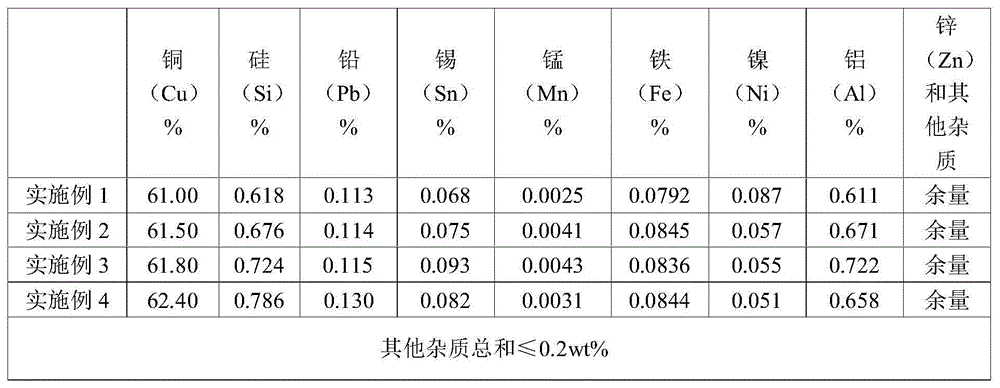

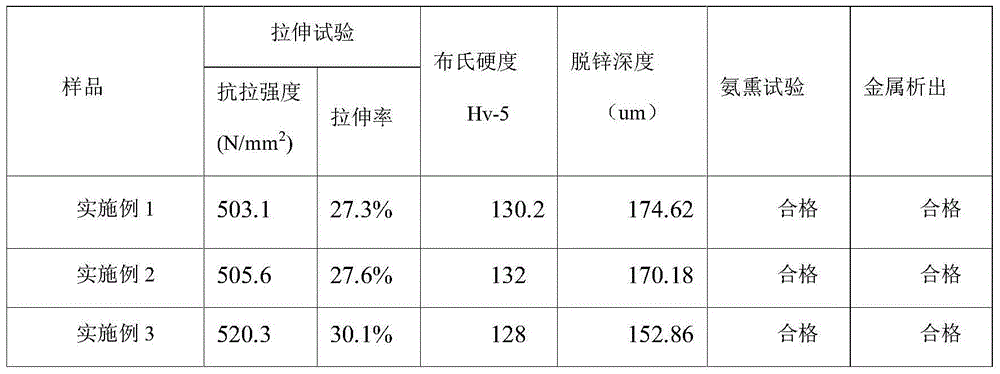

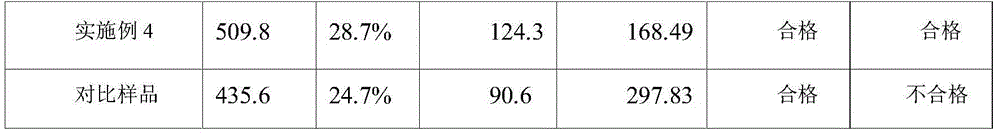

Easily processed silicon brass alloy and preparation method thereof

The invention discloses an easily processed silicon brass alloy. The alloy comprises the following components in percentage by weight: 60-63% of copper (Cu), 0.50-0.90% of silicon (Si), 0.50-0.80% of aluminum (Al), 0.10-0.20% of lead (Pb), less than 0.3% of other elements, and the balance of zinc (Zn) and inevitable impurities, wherein the sum of copper, silicon, aluminum and zinc is more than 99.60%, and other elements are a combination of tin (Sn), manganese (Mn), ferrum (Fe) and nickel (Ni). The invention further comprises a preparation method of the silicon brass alloy. The prepared silicon brass alloy is obviously higher than common lead brass in the performances of tensile strength, elongation rate, hardness and anti-zinc removal, the casting processability is good, practical production and application demands can be met, the precipitation of metals can meet the standard requirements, and the easily processed silicon brass alloy can be widely applied to water heating, valves and other various industries having limit on the precipitation of metal pollutants.

Owner:JOMOO KITCHEN & BATHROOM

Method for casting hub casts of aerogenerators

ActiveCN101618428ANot easy to shrinkAvoid deformationFoundry mouldsFoundry coresSlagShrinkage porosity

The invention discloses a method for casting hub casts of aerogenerators, comprising the steps of mould manufacture, the manufacture of sand moulds and moulding by pouring. During the manufacture of sand moulds, an ingate is designed into a disc shape and is arranged in the center of the bottom surface on the lower end of a cast mould cavity; a bottom pouring type pouring system is adopted; a sprue is a quantitative ladle stopper pouring sprue; the ratio of the areas of the sprue to a runner to the ingate to a side runner is 1 to (2.60 to 3.10) to (1.0 to 1.2) to (4.0 to 6.0); and the moulding by pouring is operated under the following conditions: the taphole temperature of iron liquor is from 1420 DEG C to 1500 DEG C; the magnesium explosion time is from 1.20 minutes to 5.00 minutes; the pouring temperature is controlled from 1280 DEG C to 1350 DEG C; and the pouring time is from 50 seconds to 90 seconds. By adopting the method, a large cast is not easy to deform or to produce a shrinkage hole, shrinkage porosity or entrapped slag, and the rate of finished products is high.

Owner:RIYUE HEAVY IND

Polarizer and liquid crystal display device

ActiveCN106772755APrevent shrinkageBlock deliveryPolarising elementsMountingsLiquid-crystal displayPolarizer

The invention discloses a polarizer and a liquid crystal display device. The polarizer comprises a first protection layer, a polarization layer and a second protection layer, wherein the first protection layer is arranged on one surface of the polarization layer, and the second protection layer is arranged on the other surface of the polarization layer; at least one of the first protection layer and the second protection layer has a porous structure. According to the polarizer, the first protection layer and / or the second protection layer has the porous structure, the porous structure better stops external heat from being transferred to the polarization layer, and shrinkage of the polarization layer can be avoided, and bending of a glass substrate can be effectively prevented when the polarizer is made into a display module.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

Preparation of artificial skin containing hair follicle and artificial skin prepared by the same

InactiveCN101264344ASolve the problem of difficult sourcePromotes normalized healingProsthesisDermal papillaeRectal epithelium

The invention relates to a preparation method of artificial skin, in particular to a preparation method of artificial skin with hair follicles and the skin made by the method, belonging to biomedical field. The preparation method comprises the following steps: (1) preparing the epithelial cells of the hair follicle; (2) culturing the dermal papilla cells; (3) culturing the artificial skin with hair follicles. The preparation method of artificial skin has the advantages that: (1) the invention originally prepares artificial skin with hair follicles on skin support by hair follicle cells, and reduces the antigenicity greatly compared with the artificial skin made by animal cells; (2) the artificial skin comprises hair follicles, and enable to do physiological functions of skin; (3) the artificial skin is not easy to shrink but easy to absorb; (4) the artificial skin can be used as wound-cover material for large area burn wounded person in clinic and accelerates the wound to heal naturally; (5) the invention resolves the trouble of skin source for large area burn; (6) the preparation method is reasonable in design, convenient in operation and easy in scale production.

Owner:SECOND AFFILIATED HOSPITAL ZHEJIANG UNIV COLLEGE OF MEDICINE +1

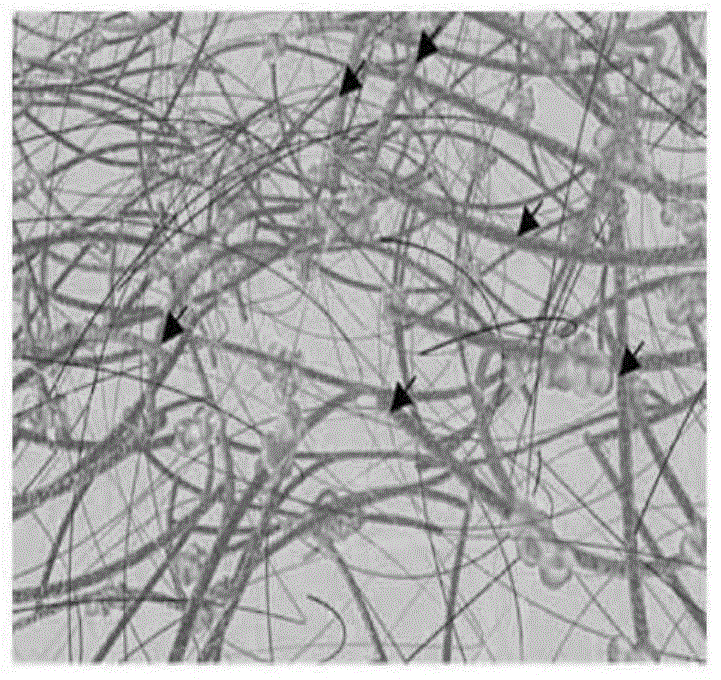

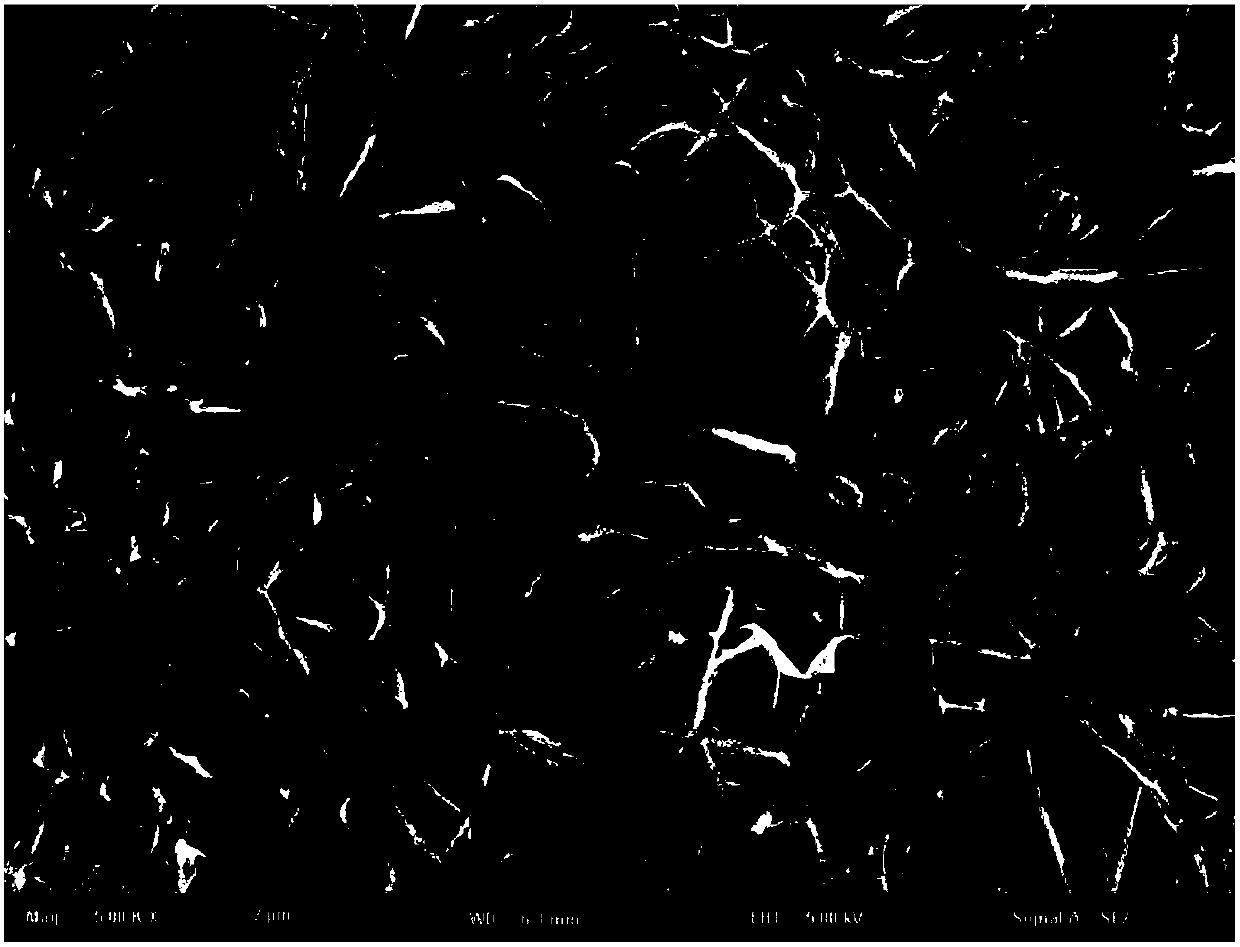

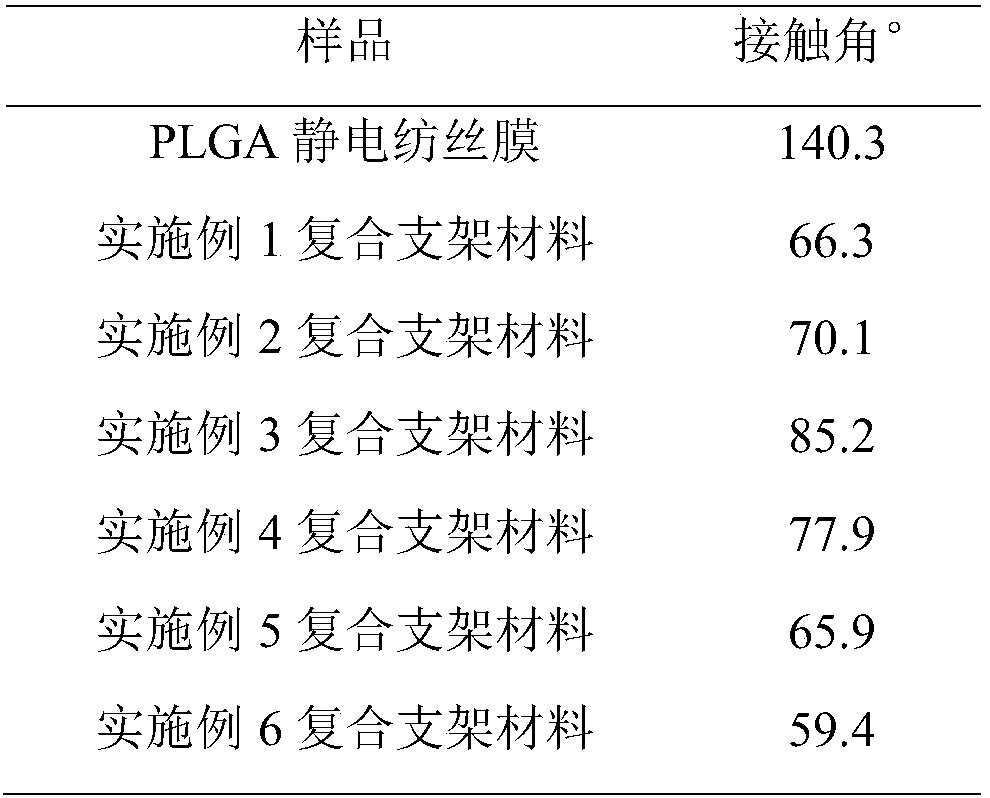

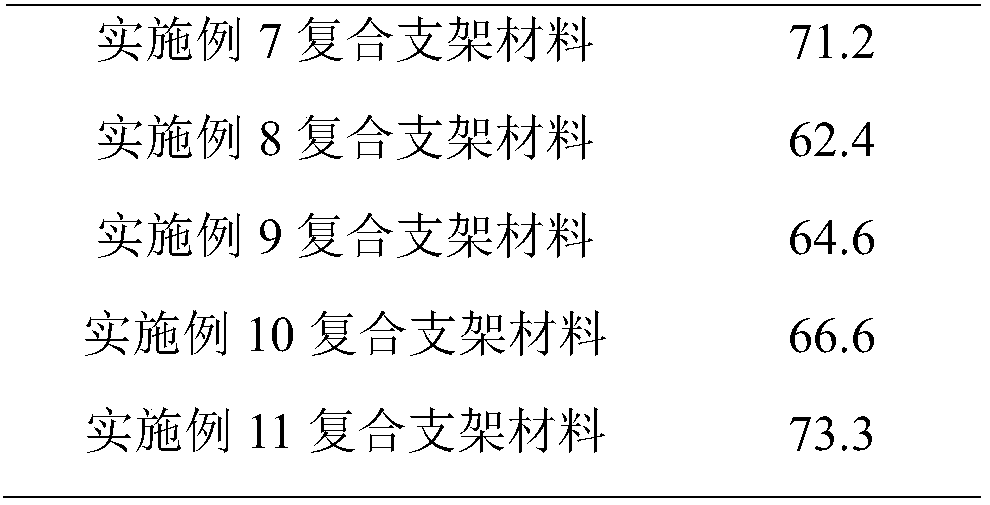

Composite scaffold material and preparation method and application thereof

PendingCN110064074AImprove mechanical propertiesAvoid deformationTissue regenerationCoatingsFiberBiocompatibility Testing

The invention relates to the technical field of medicine, in particular to a composite scaffold material and a preparation method and application thereof. The provided composite scaffold material includes a charged fiber skeleton material, and the fiber skeleton material is coated with alternately superimposed positive charge biocompatibility materials and negative charge biocompatibility materials through electrostatic attraction. As the fiber skeleton material is coated with the alternately superimposed positive charge biocompatibility materials and negative charge biocompatibility materialsthrough electrostatic attraction, the provided composite scaffold material overcomes the defects of an existing scaffold material, such as poor hydrophilicity, poor biocompatibility, poor histocyte adhesion ability and weak biological induction activity, has better applicability when used in tissue adhesion, sealing, leaking stoppage, hemostasis, isolation, repair and adhesion prevention and thelike, and can be used for preparation of carriers (such as sustained release carriers) of drugs, tissue engineering scaffold materials and the like, and thus the composite scaffold material can be widely used.

Owner:SUZHOU BOCHUANG TONGKANG PHARM TECH CO LTD

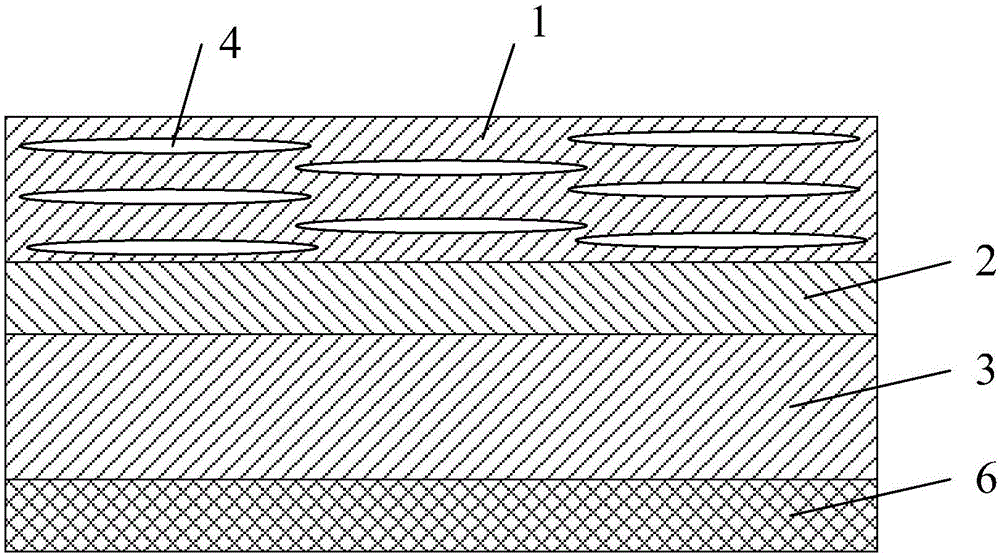

Veneering water-proofing multi-layer solid wood floor

The invention discloses a veneering water-proofing multi-layer solid wood floor, comprising a base material board (2) which is a multi-layer solid wood compound board, the upper part of the base material board (2) is provided with a plastic wear-resisting PVC veneer (1), the surface of the plastic wear-resisting PVC veneer (1) is provided with an aluminium oxide wear-resisting layer. The plastic wear-resisting PVC veneer (1) can adopt various fancies such as wood grains, bamboo grains and various artistic floor surfaces suitable for floors. The wood grains of adjacent solid wood single laminating board of the multi-layer solid wood compound board are intersected vertically and horizontally, and the laminating boards are bonded and heat-pressed into a whole by bonders. The material is stable and is nor easy to expand and deform, the water-proofing effect is good, and the floor can not be foamed and expanded when in water, and is suitable for households or public places; the floor surface has high hardness, the fancy kinds is multiple, and the decorative effect is plentiful; the production speed is rapid, the manufacturing cost is low, and the floor is easy to popularize; the floor not only can meet the using requirements of people, but also can protect forest resource and environment.

Owner:MAC DOUGLAS WOOD FLOORING SUZHOU

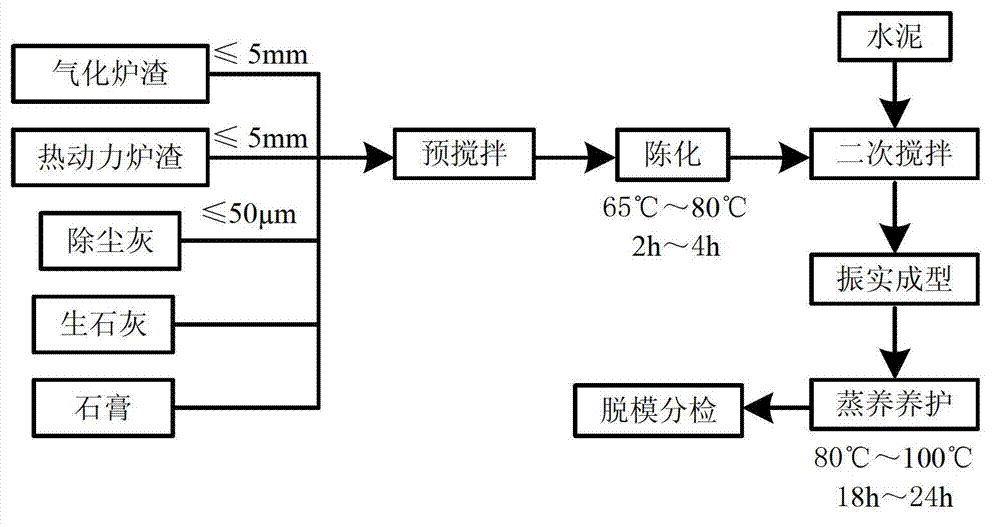

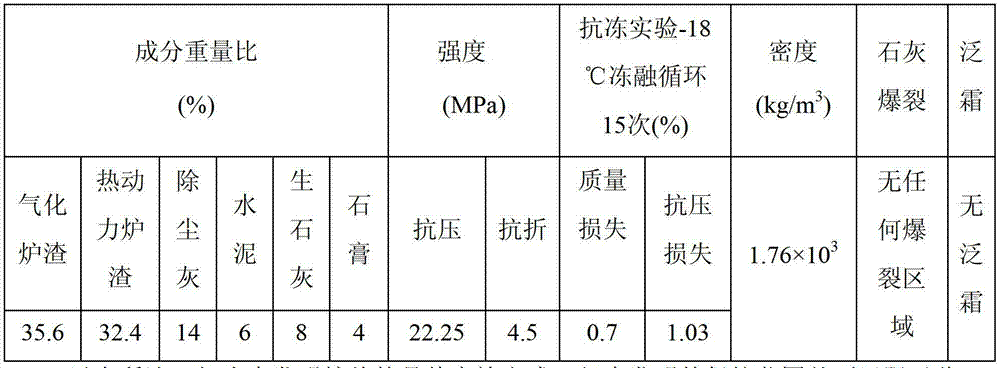

Baking-free brick produced from residual slags generated by indirect coal liquefaction and production method thereof

The invention discloses a baking-free brick produced from residual slags generated by the indirect coal liquefaction and a production method thereof. The baking-free brick comprises the following raw materials in parts by weight: 30 to 40 parts of slags generated by indirect coal liquefaction and gasification, 30 to 50 parts of thermodynamic slags generated by the indirect coal liquefaction, 10 to 20 parts of dust-removing ash generated by the indirect coal liquefaction, 6 to 15 parts of cement, 8 to 10 parts of calcined lime and 3 to 4 parts of gypsum. The production method comprises the following steps of: carrying out pre-stirring, aging, secondary stirring, molding, steam curing, demolding, sorting and the like on the raw materials. The method realizes reutilization of the residual slags, and is simple and convenient in preparation process, low in cost and short in production period. The prepared baking-free brick body is difficult to deform, crack and contract as well as smooth in surface and beautiful in appearance.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Quick-hardening hih-strength cement anchoring agent

The present invention relates to a quick-hardening high-strength cement anchoring agent. It adopts quick-hardening sulfo-aluminite cement clinker as basic gelation material, and adds hemihydrate plaster and quicklime as excitation agent to accelerate hydration process so as to implement quick setting up and can make compression strength and bending strength quickly increase. Said invention has microexpansion property, three-day free expansion rate is greater than 0.3%, and said product solidification speed is quick, its primary solidification is greater than 5 min, and the end solidification is less than 15 min. and its product anchoring strength also can be quickly raised.

Owner:刘茂平

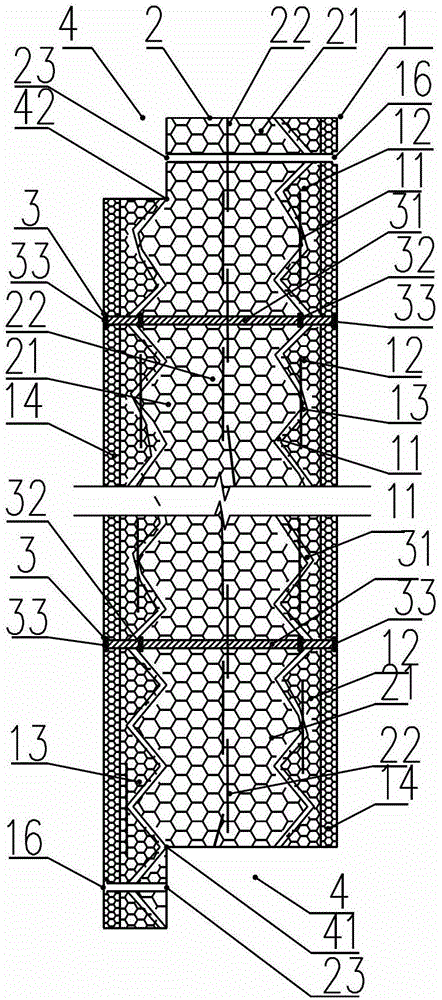

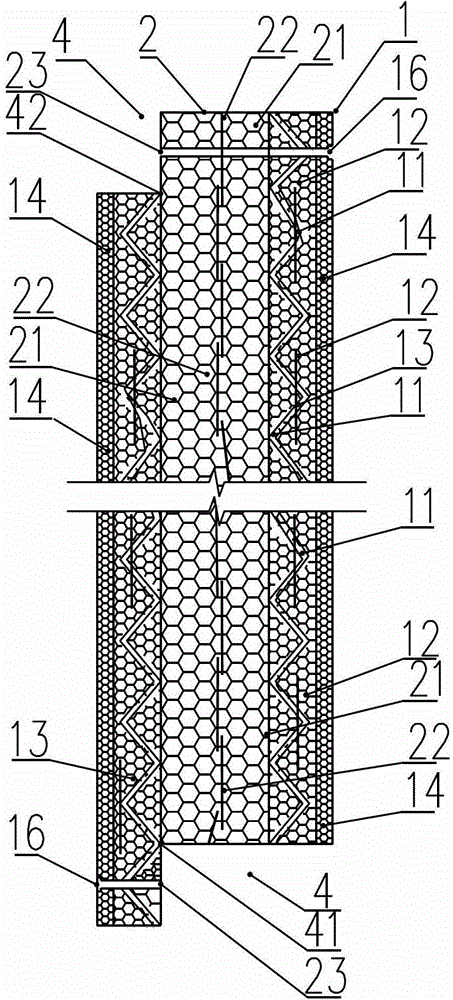

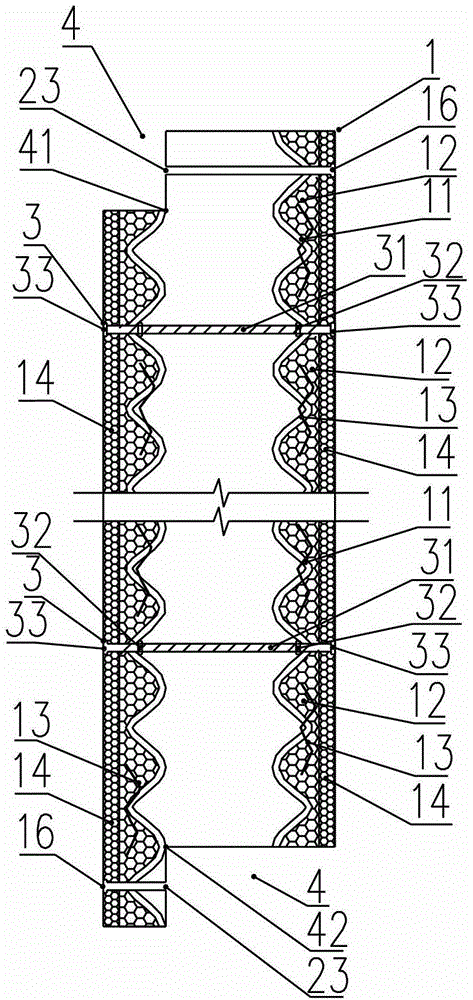

High-strength composite corrugated fiber foam cement heat insulation material

InactiveCN103334504AImprove sound insulation and noise reductionImprove thermal insulation performanceHeat proofingWater-setting substance layered productEnvironmental resistanceFiber

The invention discloses a high-strength composite corrugated fiber foam cement heat insulation material. Aiming at the defects that organic materials such as polyphenyl, extruded sheet and polyurethane, belonging to petroleum extractant, are complicated in structure, easy to age, inflammable, easy to crack, easy to seep and are short in service life, and inorganic materials such as a foam cement heat insulation board cannot reach the use strength of a wall body, the invention designs the high-strength composite corrugated fiber foam cement heat insulation material. The heat insulation material comprises corrugated fiber cement heat insulation material, composite foam cement heat insulation material, a fixed connecting support component, and concave-convex or male-female connecting mortise and tenon joints. The design purposes of meeting the use strength of a building outer wall and reducing the cost are realized by utilizing the performances of low heat conductivity coefficient, non-inflammability, high compression resistance and breaking strength of the foam cement, foamed ceramics and corrugated fiber cement plate and a pouring extrusion and foam technique. The high-strength composite corrugated fiber foam cement heat insulation material has the characteristics that the performances of heat preservation and insulation, non-inflammability and fireproofing, sound insulation and noise reduction, lightweight earthquake and acid rain resistance can be improved, and the material has the advantages on performance that the structure is simple, the material is saved, the mounting and dismounting are convenient, the construction efficiency is high, the service life is long, the cost is low, the material can be used as a finished wall body and recycled, and is energy-saving and environmental-protection.

Owner:BENXI NATURAL ICE PREPARATION ENG

Method for forging step shaft with electroslag ingots

InactiveCN103008524ASave materialImprove utilization rate and enterprise production costMetal-working apparatusEngine componentsEngineeringConvex side

The invention relates to a method for forging a step shaft with electroslag ingots. The method is suitable for forging the step shaft with large step diameter. A dead head end of an electroslag ingot is disposed on a upsetting drain cap for upsetting. The upset dead head end of the electroslag ingot forms a drum-shaped convex face and is elongated, due to the fact that the dead head end is the drum-shaped convex face, the dead head end is less prone to sinking, only a small part of dead head end needs to be cut off at last, pliers handle pressing with a hydraulic press in the original method is omitted, and the method has the advantages that the method is material-saving, utilization rate of forged piece is improved, and production cost is lowered.

Owner:无锡东鑫铭锻压有限公司

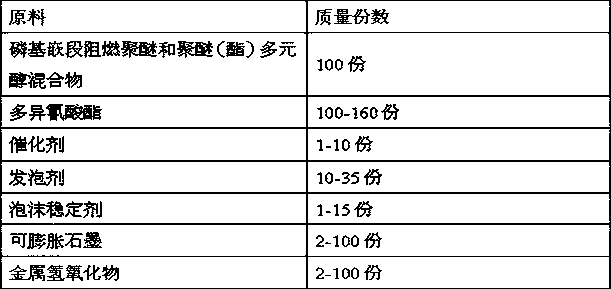

Phosphorus-based flame-retardant block polyether, preparation method thereof and application of phosphorus-based flame-retardant block polyether to rigid polyurethane foam

The invention relates to a phosphorus-based flame-retardant block polyether and a preparation method thereof. The preparation method comprises the steps: reacting a compound containing two P-Cl bondswith low-molecular-weight polyether glycol or polyether diamine according to a certain molar ratio to obtain a hydroxy-terminated or amino-terminated phosphorus-based flame-retardant block polyether which is high in molecular weight, good in compatibility with polyurethane, not easy to migrate and high in flame-retardant efficiency. The hydroxy-terminated or amino-terminated phosphorus-based flame-retardant block polyether serves as a part of raw material to be mechanically stirred together with polyether (polyester) polyols, isocyanate, expansible graphite, metal hydroxides, a foaming agent,a catalyst and a foam stabilizer at normal temperature according to a certain ratio, so that flame-retardant rigid polyurethane foam is prepared. The foam is not easy to shrink, good in dimensional stability and excellent in flame retardance and mechanical property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

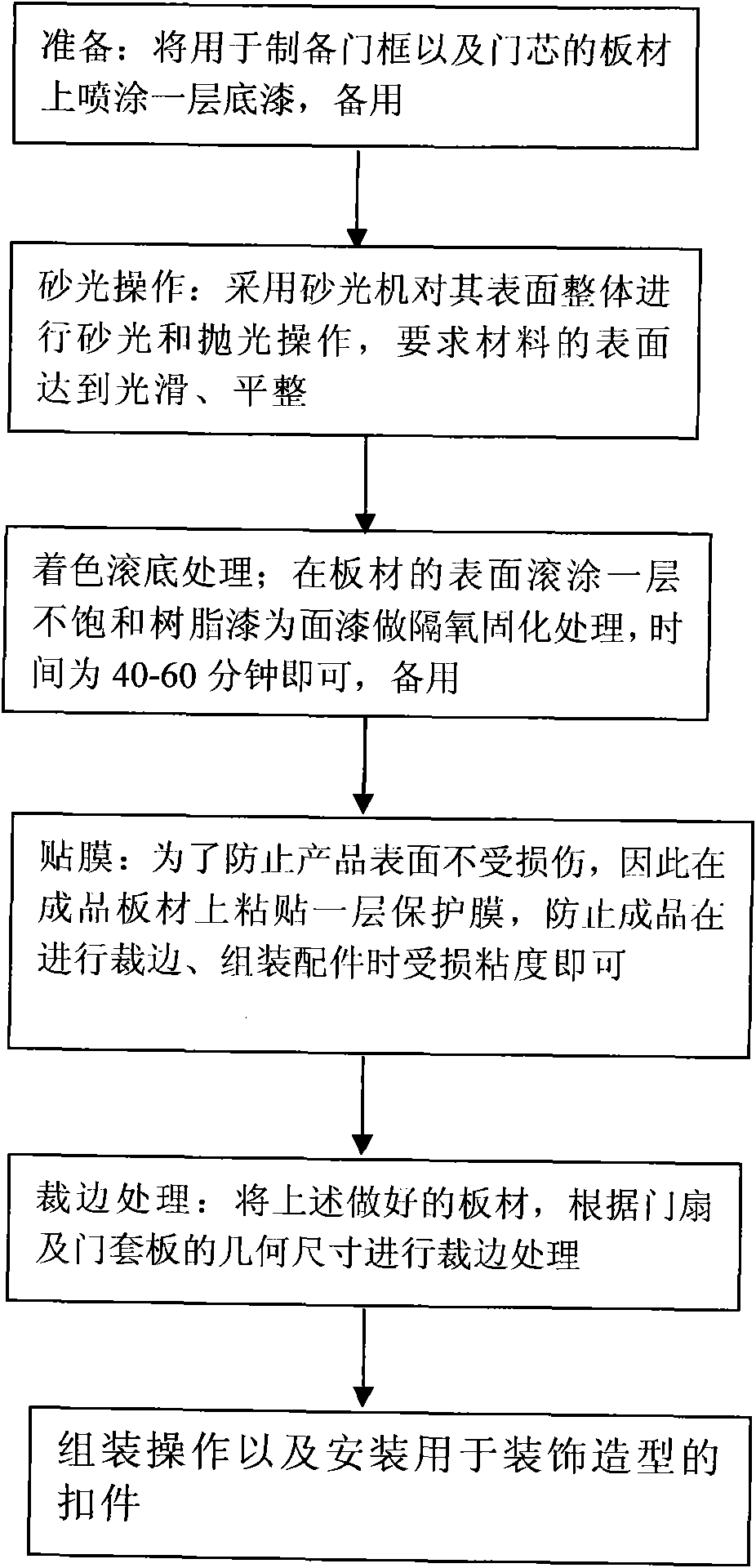

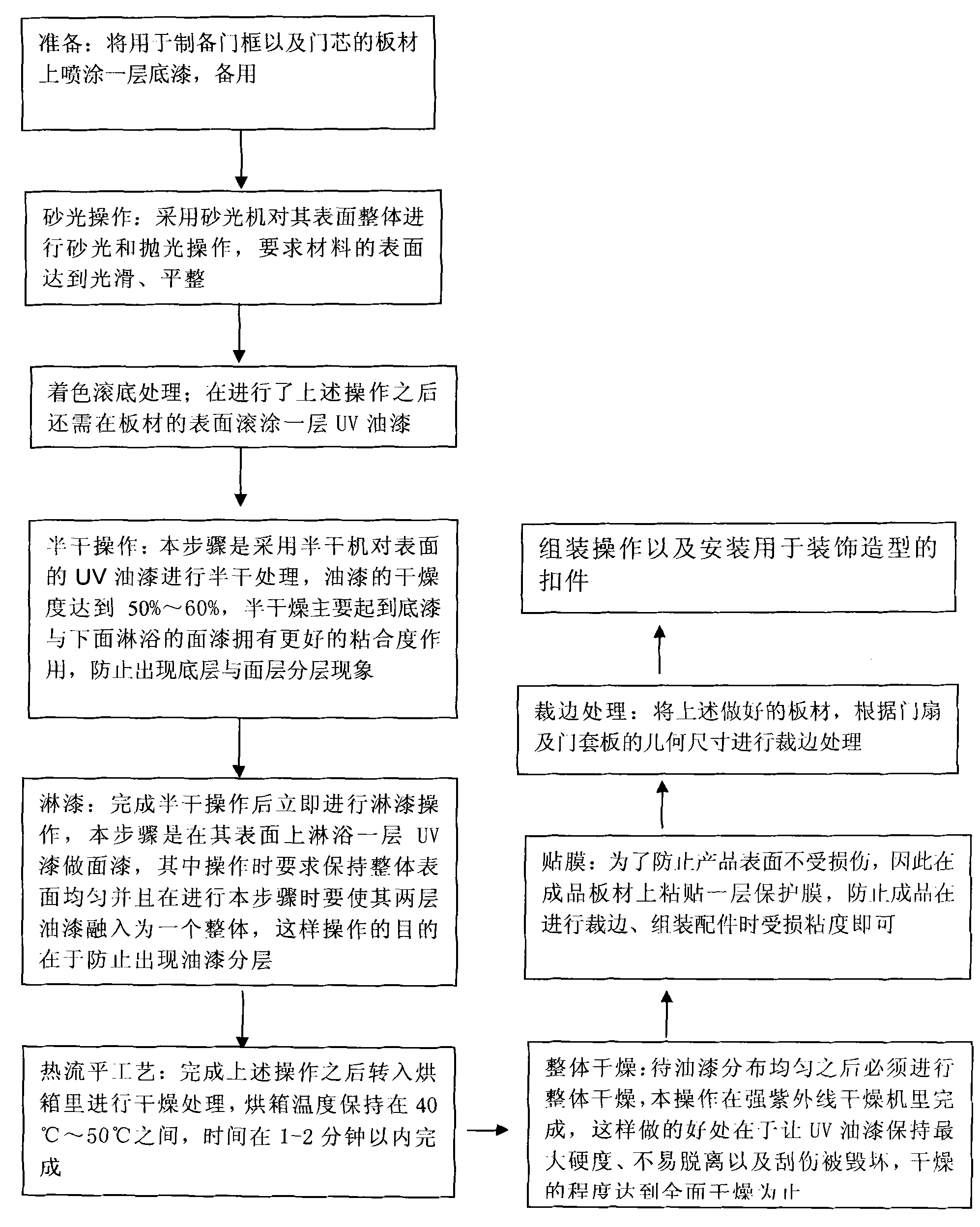

Manufacturing process of wood door and half drying machine

InactiveCN101871307ANot easy to shrinkNot easy to expandPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and other places. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

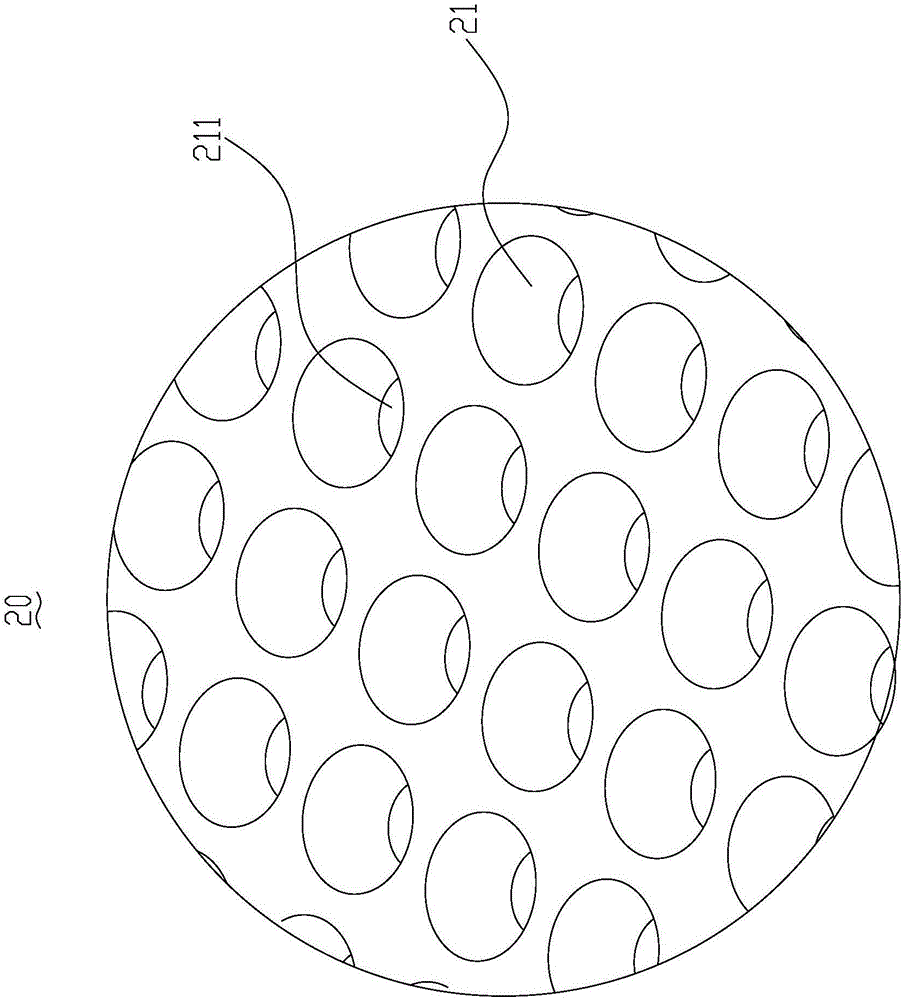

Tabletop board

InactiveCN106617681AImprove stress resistanceHigh strengthFoldable tablesStowable tablesEngineeringUltimate tensile strength

The invention discloses a tabletop board which comprises an upper panel, a lower base plate and at least one pair of internal embedded parts. The upper panel is provided with a flat outer surface, the lower base plate is provided with a plurality of sunken parts, the sunken parts are arranged on the lower base plate in a staggered mode, and the top faces of the sunken parts abut against the inner surface of the upper panel; the internal embedded parts are arranged on the two opposite edges inside the upper panel and the lower base plate. The top faces and the side walls of the sunken parts can well bear pressure from the upper panel, so that the pressure resistance of the upper panel is improved, and the higher strength can be ensured while the wall thickness of the tabletop board is smaller. Particularly, when the total area of the sunken parts accounts for 30-70% the area of the lower base plate, the contact area between the top faces of the sunken parts and the inner surface of the upper panel is large, and the strength of the tabletop board is improved. Particularly, when the area of each sunken part is 1-15 square centimeters, the number of the sunken parts is increased, the areas of the top faces and the side walls of the sunken parts are increased, and the strength of the tabletop board is greatly improved.

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

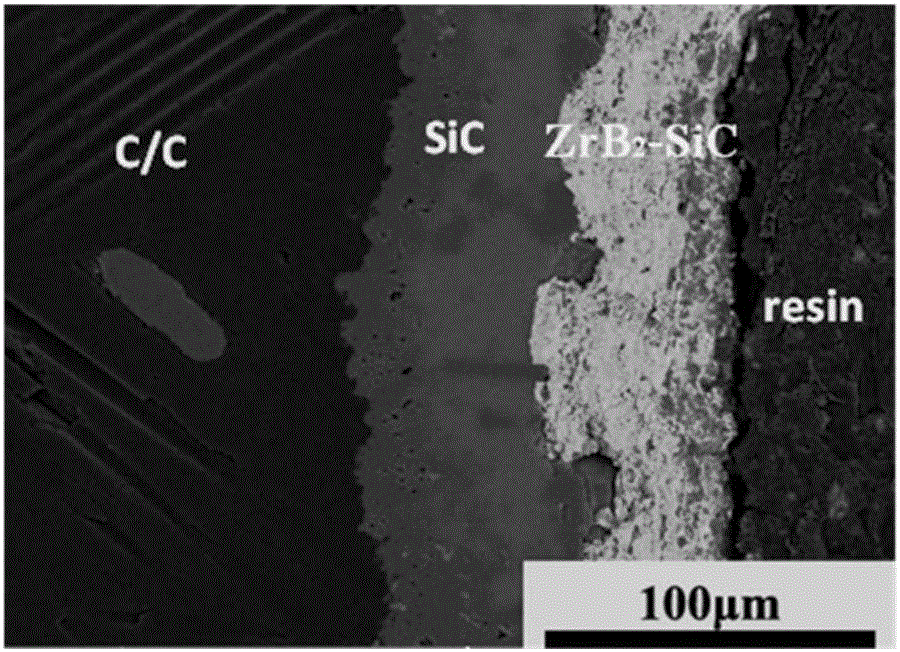

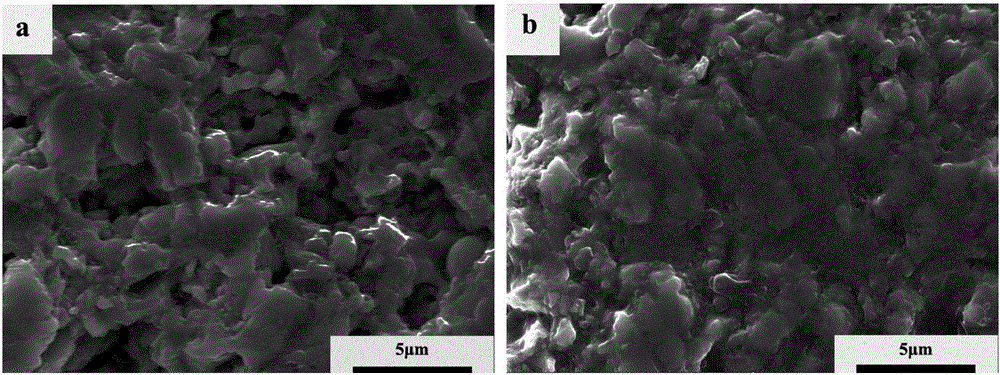

Carbon/carbon (C/C) composite material surface low-porosity complex-phase ceramic coating and preparation method thereof

The invention relates to a carbon / carbon (C / C) composite material surface low-porosity complex-phase ceramic coating and a preparation method thereof. The preparation method comprises the following steps: previously carrying out sintering heat treatment on a ZrB2-SiC powder mixture for ultrasonic plasma spraying in a protective atmosphere, preparing a SiC inner coating and a ZrB2-SiC complex-phase ceramic coating respectively by an embedding process and an ultrasonic plasma spraying two-step process, and carrying out sintering heat treatment on the powder for spraying to sufficiently diffuse molecules so as to form a partial solid solution, thereby preparing the complex-phase ceramic coating with uniform phase distribution and lower porosity. After the ZrB2-SiC powder mixture is subjected to sintering heat treatment in the reducing protective atmosphere, the partial solid solution is formed in the sintering heat treatment process, and the solid solution can not easily shrink in the cooling process, thereby lowering the pores generated in the cooling process after coating spraying and further forming the low-porosity coating. Besides, in the sintering heat treatment process, the molecules interdiffuse, so that the finally prepared complex-phase ceramic coating has more uniform phase distribution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com