Heavy pressure slip-casting hole-sealing method for large-diameter extraction borehole

A technology of extraction drilling and high-pressure grouting, which is used in mining equipment, earth-moving drilling, gas discharge, etc., can solve the problems of reduced sealing performance, insufficient grouting fluid pressure, easy air leakage, etc., and can lengthen the sealing depth. , The effect of reducing gas pressure and enhancing sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

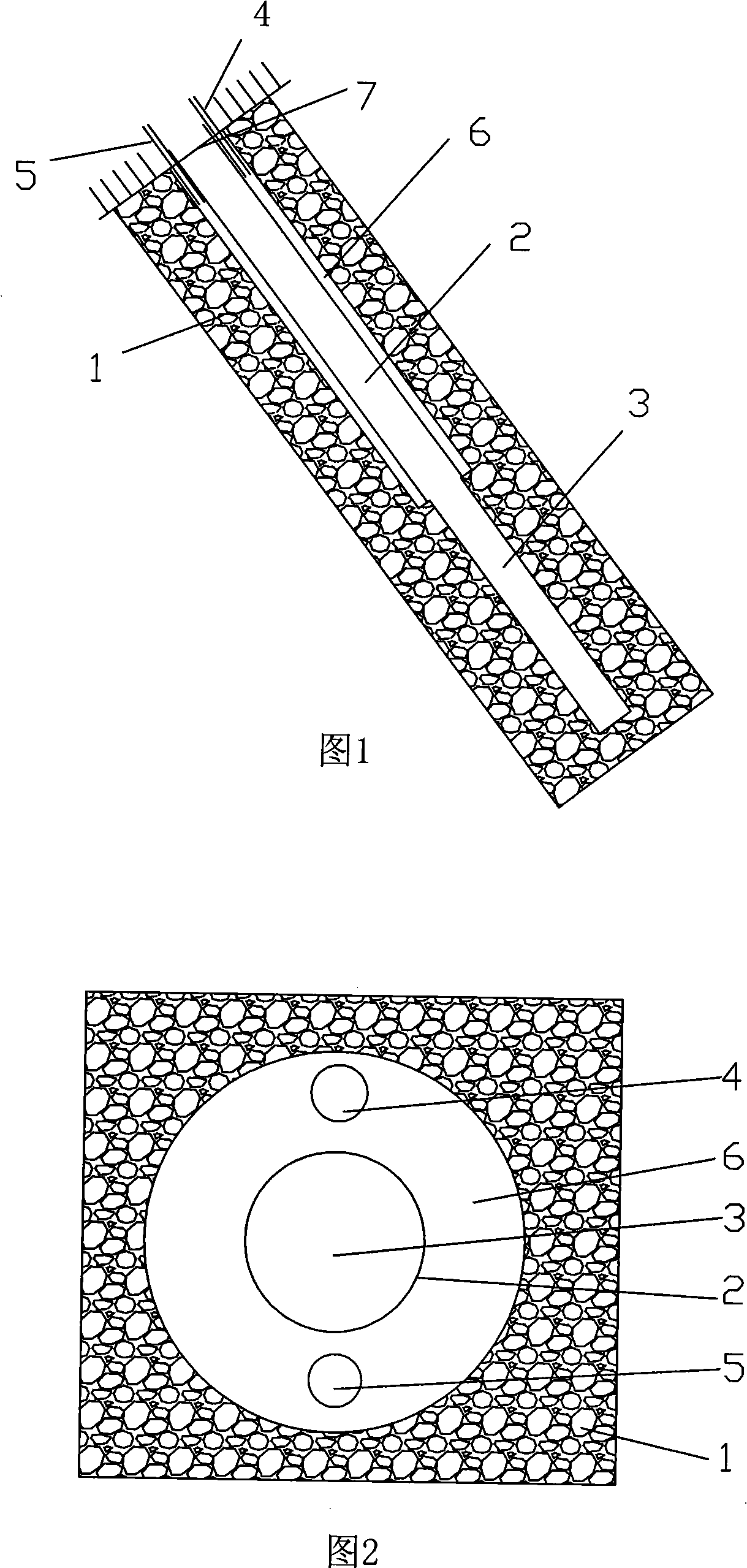

[0029] As shown in the figure, the rock face 1 is the rock layer to be drilled in the top or floor working of the coal seam.

[0030] The hole-sealing pipe 2 is a pipe arranged in the borehole to isolate the hole-sealing section from surrounding rocks.

[0031] The drainage borehole 3 is a borehole constructed for draining gas in the coal seam through the inner cavity of the sealing pipe 2 and entering the coal seam.

[0032] The grouting pipe 4 is a pipeline through which the grouting liquid is injected into the grouting chamber 6 between the rock face and the sealing pipe by a high-pressure pump.

[0033] The grout return pipe 5 is a channel for the grouting liquid to overflow after the grouting chamber is filled with grout, and it is determined whether the grouting chamber is solid by returning the grout.

[0034] The grouting cavity 6 is formed between the sealing pipe 2 and the rock face 1, and is used for injecting grouting liquid to form a seal.

[0035] The sealing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com