Novel fine metal mask plate for producing organic light emitting diode (OLED) display panel and fabrication method of novel fine metal mask plate

一种精细金属掩膜、显示面板的技术,应用在金属材料涂层工艺、图纹面的照相制版工艺、离子注入镀覆等方向,能够解决图像单元损坏、成本昂贵等问题,达到降低制作成本、增加强度、简化制作过程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below in conjunction with accompanying drawing:

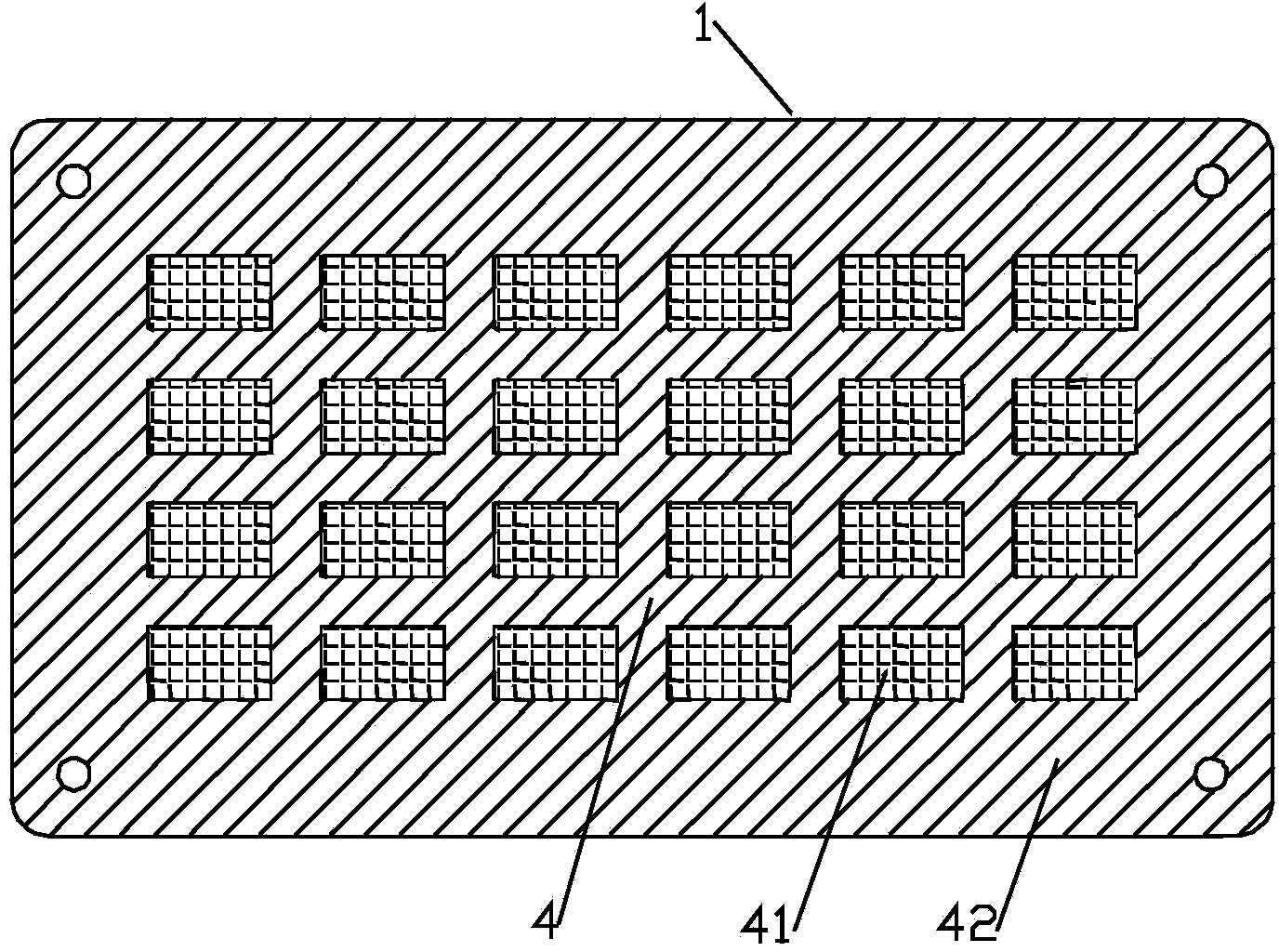

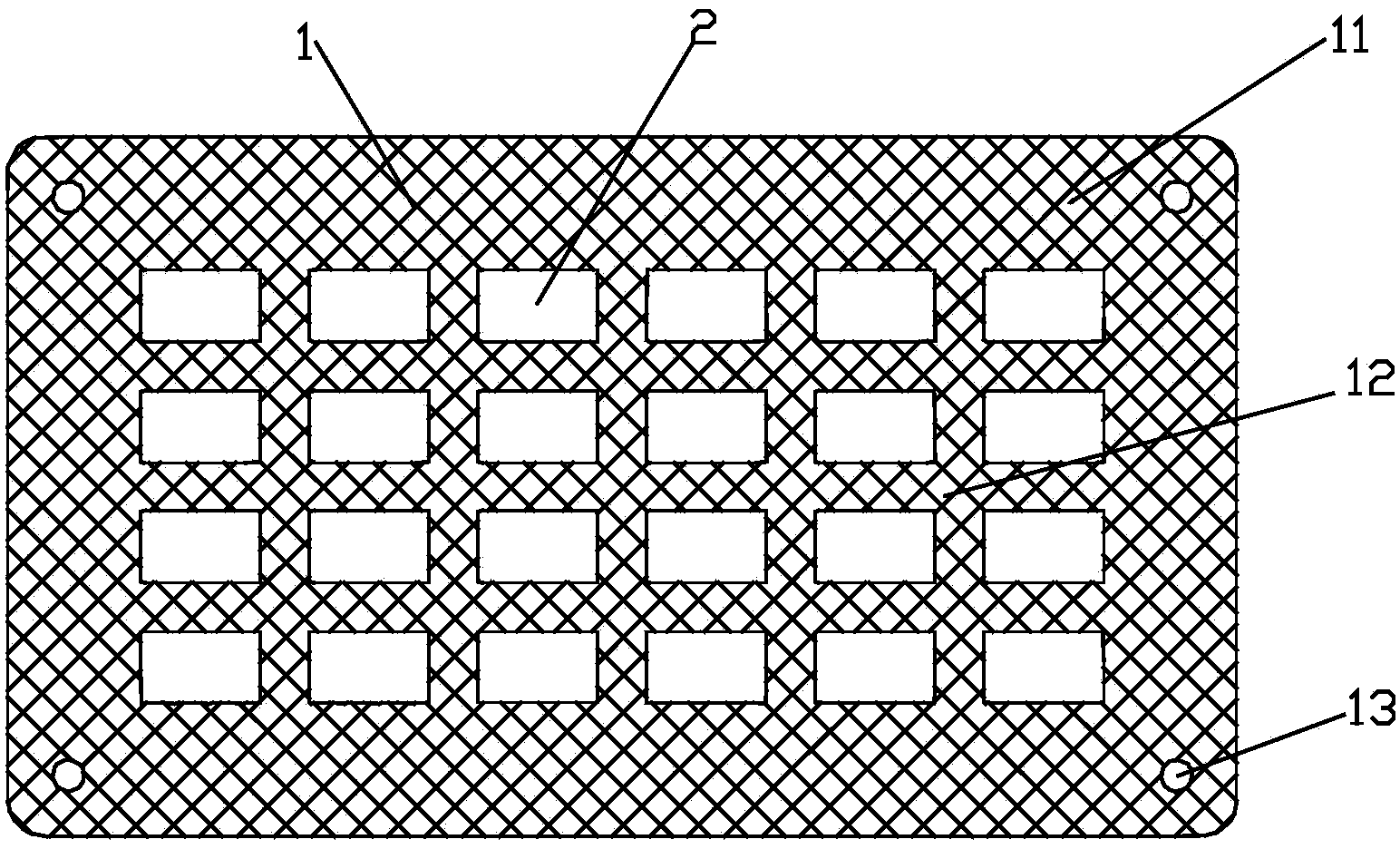

[0056] Such as figure 1 , figure 2 As shown, a new type of fine metal mask plate for OLED display panel production includes a frame 1 composed of an outer frame 11 and an inner partition frame 12, and the frame 1 is formed by setting a plurality of through holes 2 on a metal substrate . A fine mask 4 is electroformed on the frame 1, so that the fine mask 4 and the frame 1 are integrated. The fine mask 4 is divided into two parts: a graphic area (fine structure part) 41 and a frame area 42, and an alignment hole 13 for positioning the mask plate is also provided on the outer frame 11 of the frame 1, and the number of alignment holes is two or more than two, there are four here. The graphic area 41 has the same area and corresponding position as the through hole 2 on the frame.

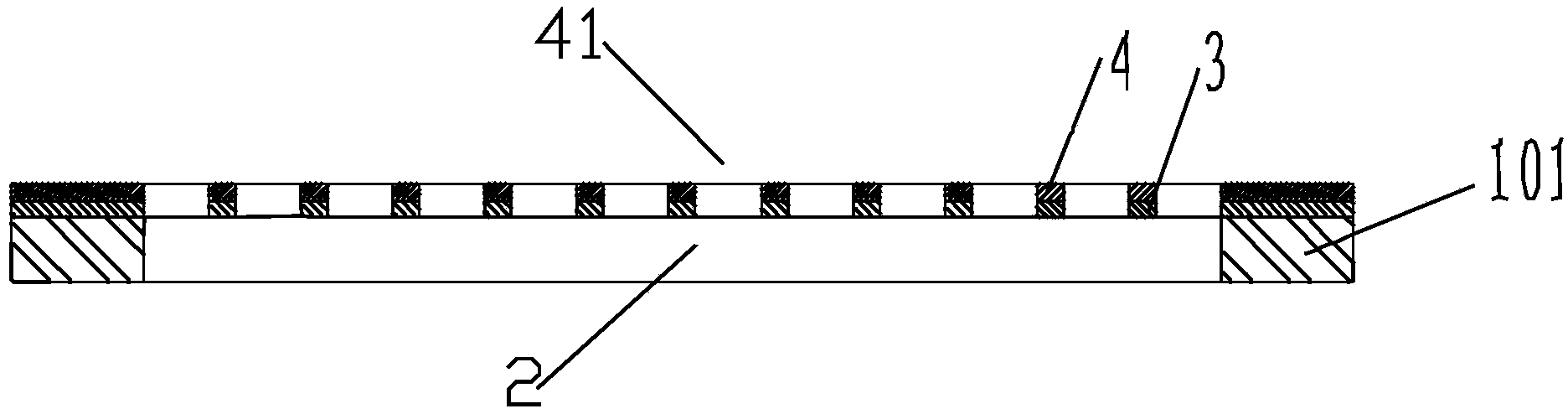

[0057] Such as Figure 3-Figure 15 As shown, a sectional view of a through hole 2 and its sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com