Preparation method for composite cathode material of lithium ion battery

A negative electrode material, silicon-carbon composite technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of electrode cycle performance degradation, limited commercial application, material structure damage, etc., to achieve capacity design, cycle performance and large Good current discharge capacity and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

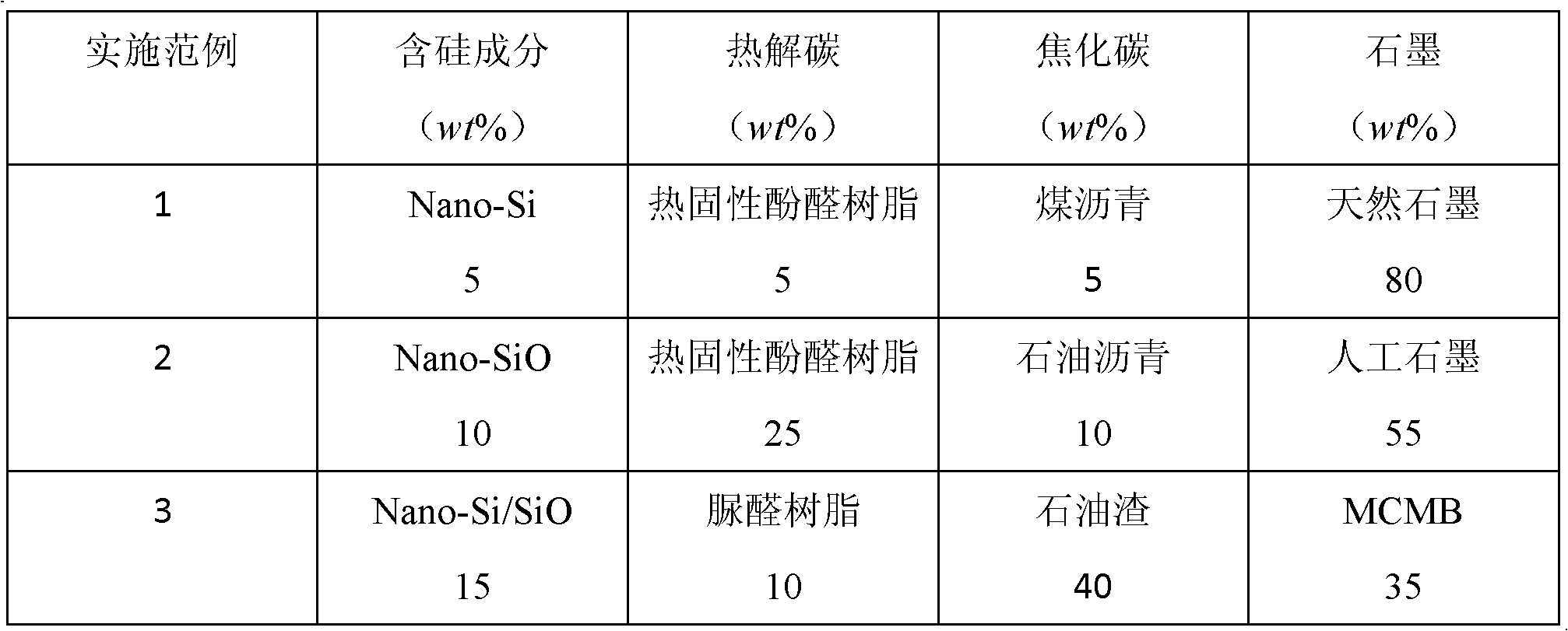

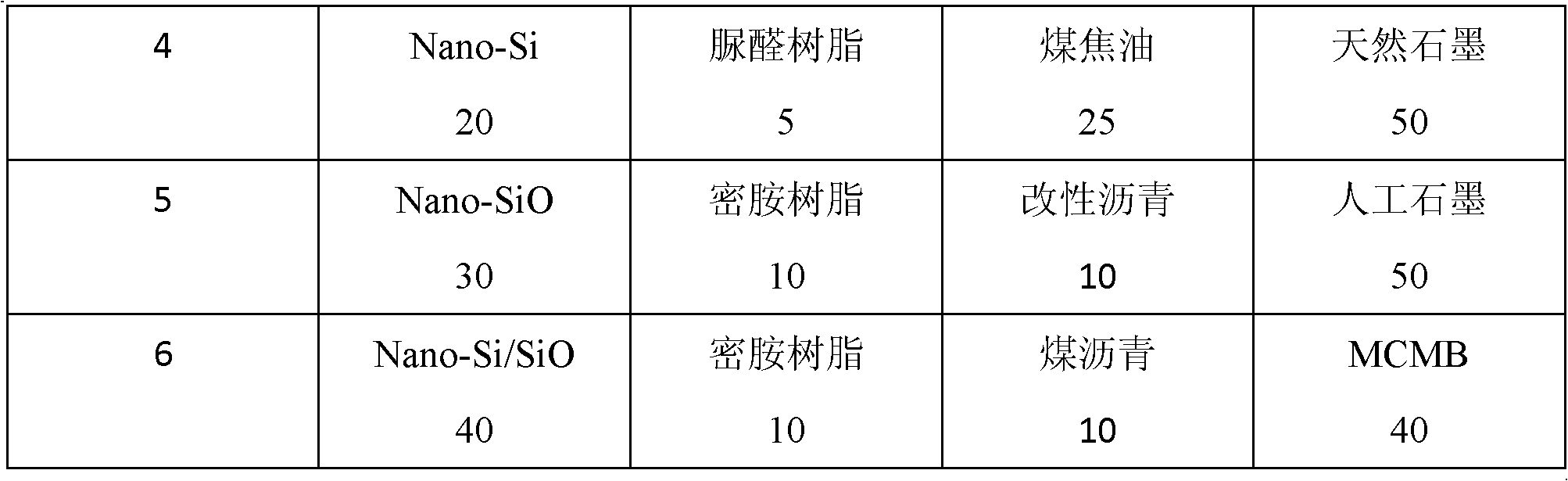

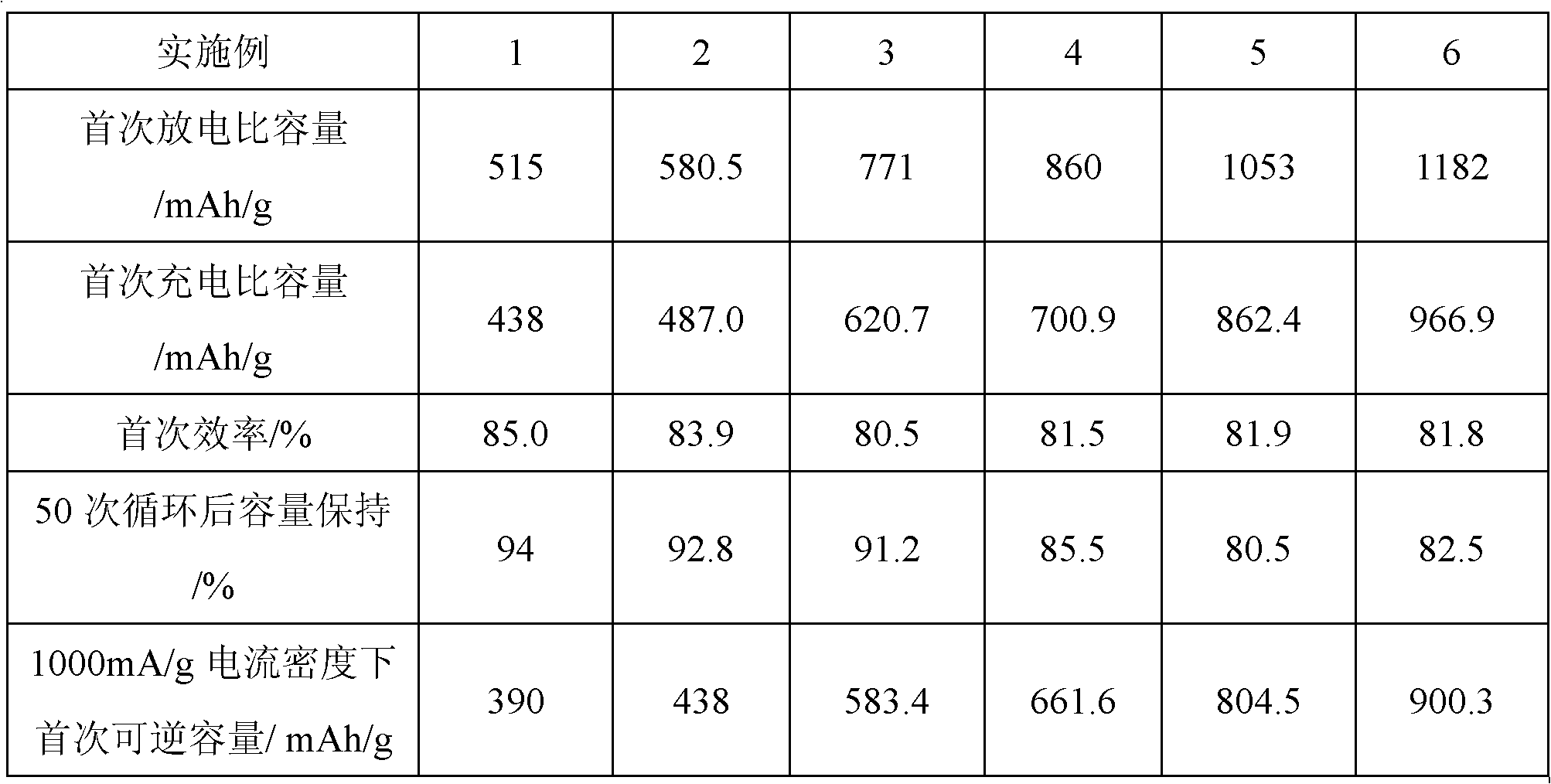

Embodiment 1

[0033] Petroleum pitch was used as raw material, pretreated in a nitrogen atmosphere at 400°C for 10 hours to remove low-temperature volatile organic compounds, and the pretreated coal tar pitch was used as the second type of binder. The first type of binder phenolic resin (according to the 5wt% addition of pyrolytic carbon content in the spherical core material after sintering) is added to an appropriate amount of deionized water, magnetically stirred to form a viscous solution, and then add nano silicon powder (Nano-Si , according to the mass ratio of silicon / carbon in the spherical core material after sintering: 1:19) the second type of binder (petroleum pitch after pretreatment, added according to the content of coking carbon in the material after sintering is 5wt%) and 10wt% polypropylene Amide dispersant, ball milling for 5 hours, ultrasonic plus mechanical stirring and dispersion for 1 hour, and then according to the content of natural graphite in the spherical core mate...

Embodiment 2

[0036]Coal tar pitch is used as raw material, pretreated in an argon atmosphere at 400°C for 1 hour to remove low-temperature volatile organic compounds, and the pretreated coal tar pitch is used as the second type of binder. Add the first type of binder polyvinyl alcohol-124 (according to the content of pyrolytic carbon in the composite material after sintering is 25wt%) into an appropriate amount of absolute ethanol, stir magnetically to form a viscous solution, and then add nano silicon monoxide powder (Nano-SiO, according to the mass ratio of silicon / carbon in the spherical core material after sintering: 1:9), the second type of binder (coal tar pitch after pretreatment, according to the content of coking carbon in the spherical core material after sintering is 10wt%) Add) and 0.5wt% polyammonium methacrylate dispersant, ball mill for 1h, ultrasonically add mechanical stirring and disperse for 0.5h, then press the content of artificial graphite in the spherical core materia...

Embodiment 3

[0039] Coal tar pitch is used as raw material, pretreated in a nitrogen atmosphere at 260°C for 20 hours to remove low-temperature volatile organic compounds, and the pretreated coal tar pitch is used as the second type of binder. Add the first type of binder urea-formaldehyde resin (according to the content of pyrolytic carbon in the spherical core material after sintering is 10wt%) into an appropriate amount of deionized water, stir magnetically to form a viscous solution, and then add the mixture of nano-silicon and silicon monoxide (Nano-Si / SiO=1:1, according to the mass ratio of silicon / carbon in the spherical material after sintering is 3:17) the second type of binder (coal tar pitch after pretreatment, according to the coking carbon content in the spherical core material after sintering) Add 40wt% polyethylene glycol dispersant) and 5wt% polyethylene glycol dispersant, ultrasonically add mechanical stirring to disperse for 1h, and then add the graphitized intermediate D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com