Large contact surface characteristic direct shear apparatus with cycle loading function

A technology of direct shearing instrument and interface characteristics, applied in the field of shear plane or variable shear plane test, can solve the problems of inability to simulate shear friction characteristics, low level of automation, and reduce the scope of application of shearing instrument, and achieve drawing display. Accurate and efficient, improve processing efficiency, convenient storage and recording effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

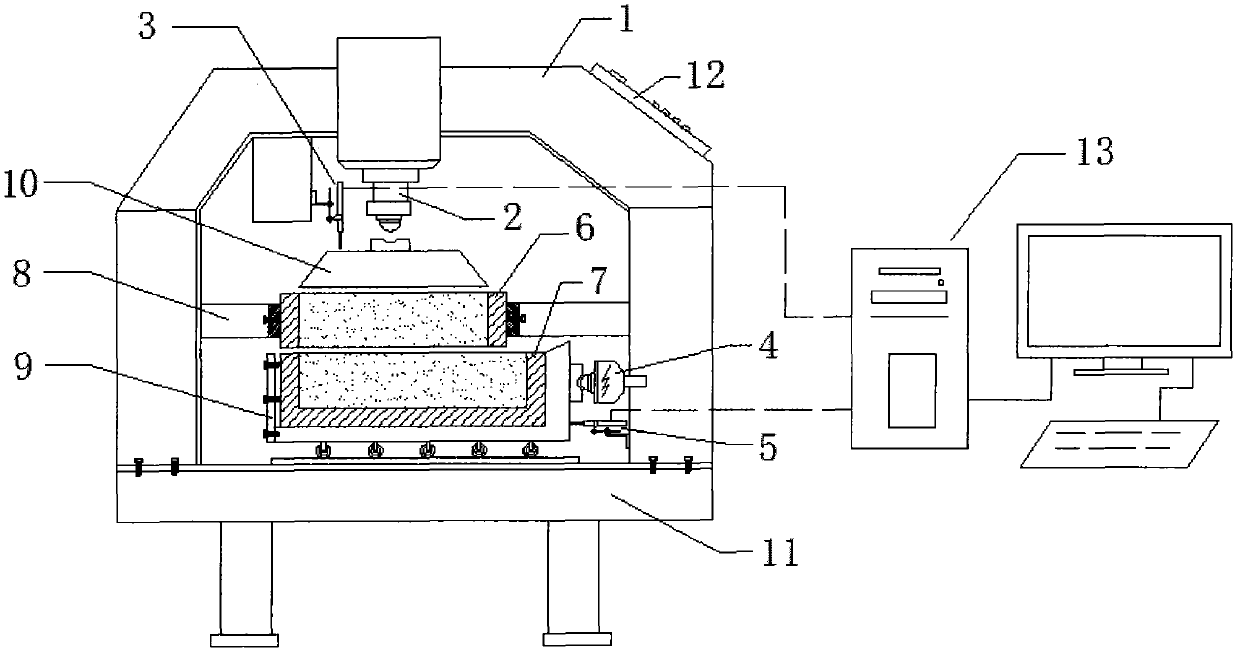

[0028] Example 1, the present invention is a large-scale interface direct shear instrument under cyclic loading.

[0029] See figure 1As shown, its main components include frame structure 1, vertical load application part 2, vertical LVDT displacement sensor 3, upper shear box 6, lower shear box 7, upper shear box fixing bracket 8, water bath box 9, vertical To the pressure loading plate 10 , the horizontal load applying part 4 , the horizontal LVDT displacement sensor 5 and the bottom support device 11 , it also includes an external control device 13 .

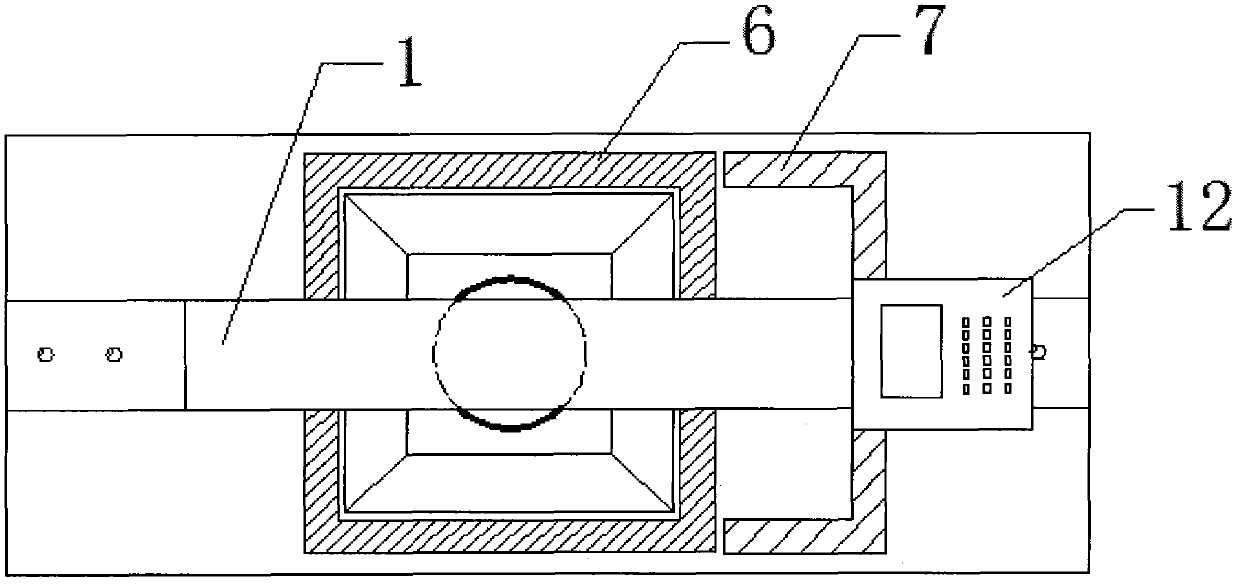

[0030] See figure 2 As shown, it mainly includes an overall frame structure 1 , upper and lower shear boxes 6 , 7 and an airborne control panel 12 for vertical and horizontal loads.

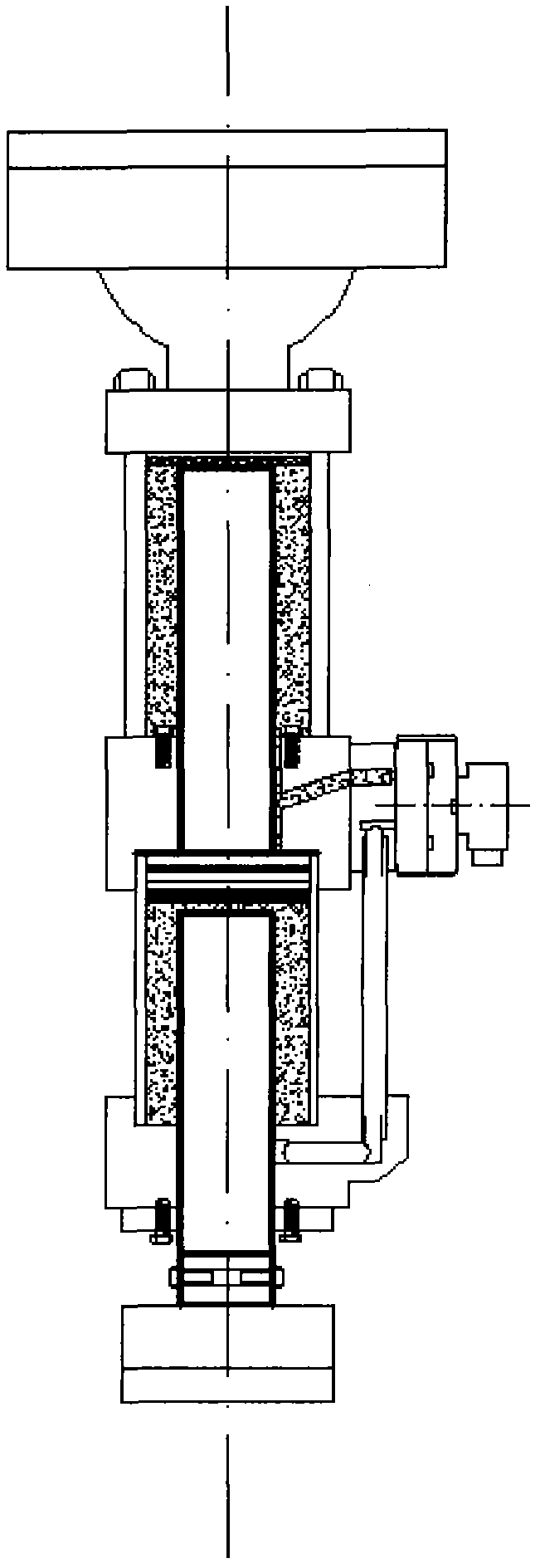

[0031] image 3 Shown is mainly the vertical load applying device of the equipment of the present invention, which is composed of a servo motor, which can apply cyclic loads of different frequencies and amplitudes, and provides support for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com