Patents

Literature

45 results about "Shear friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction usually, but not always, accompanies shear. Friction is the force of rubbing two surfaces against one another. Shear is the result of gravity pushing down on the patient's body and the resistance between the patient and the chair or bed.

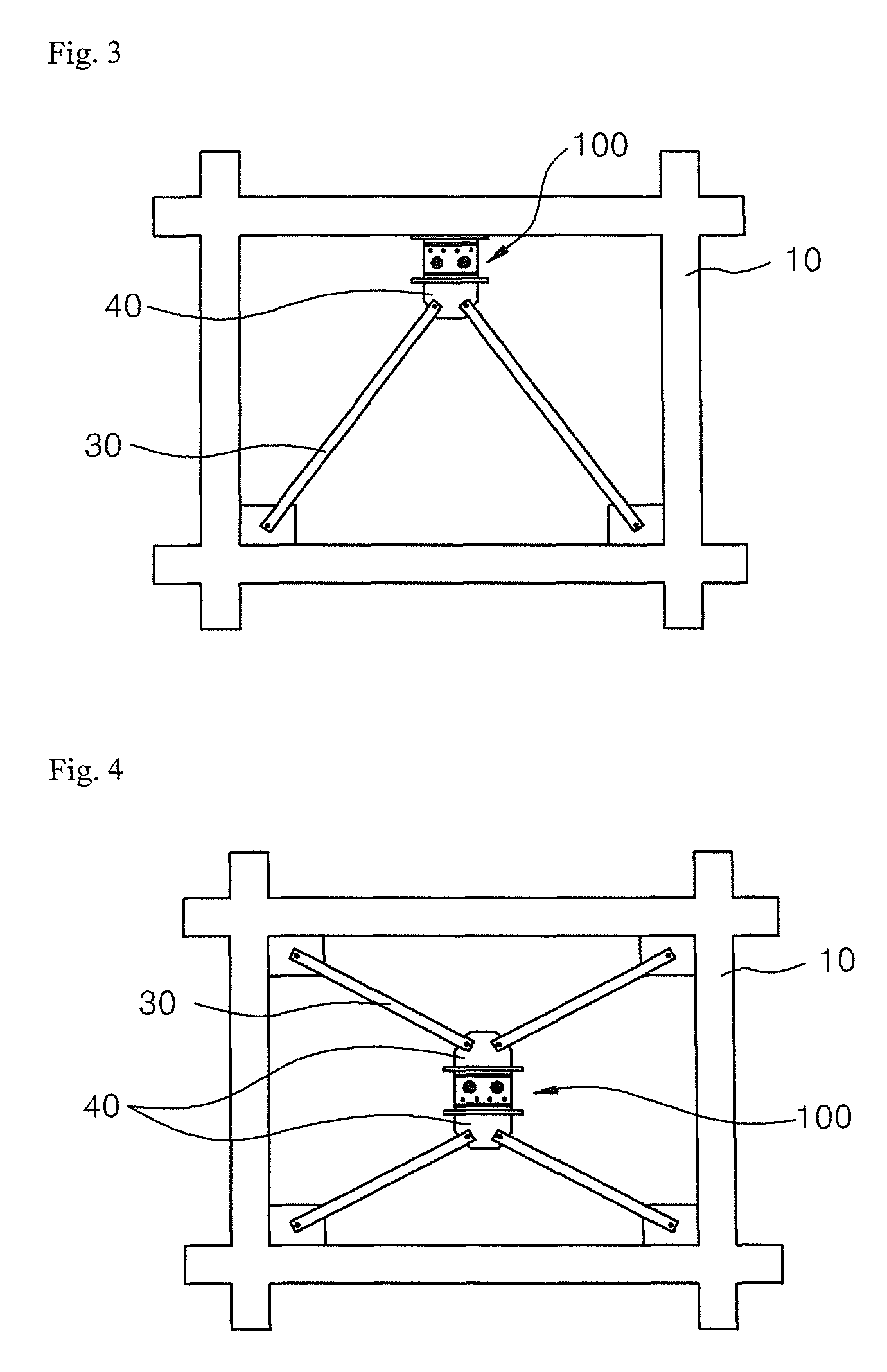

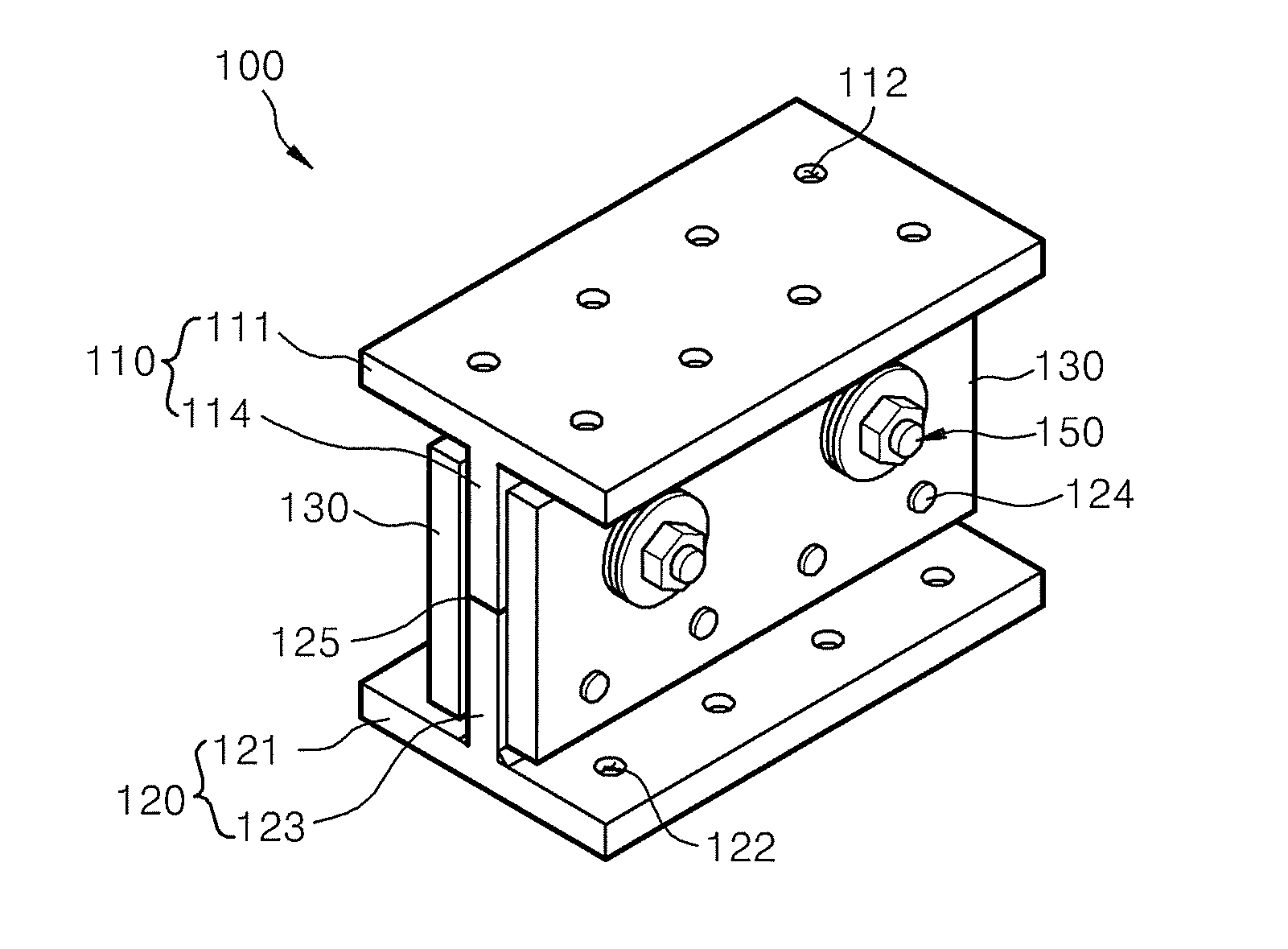

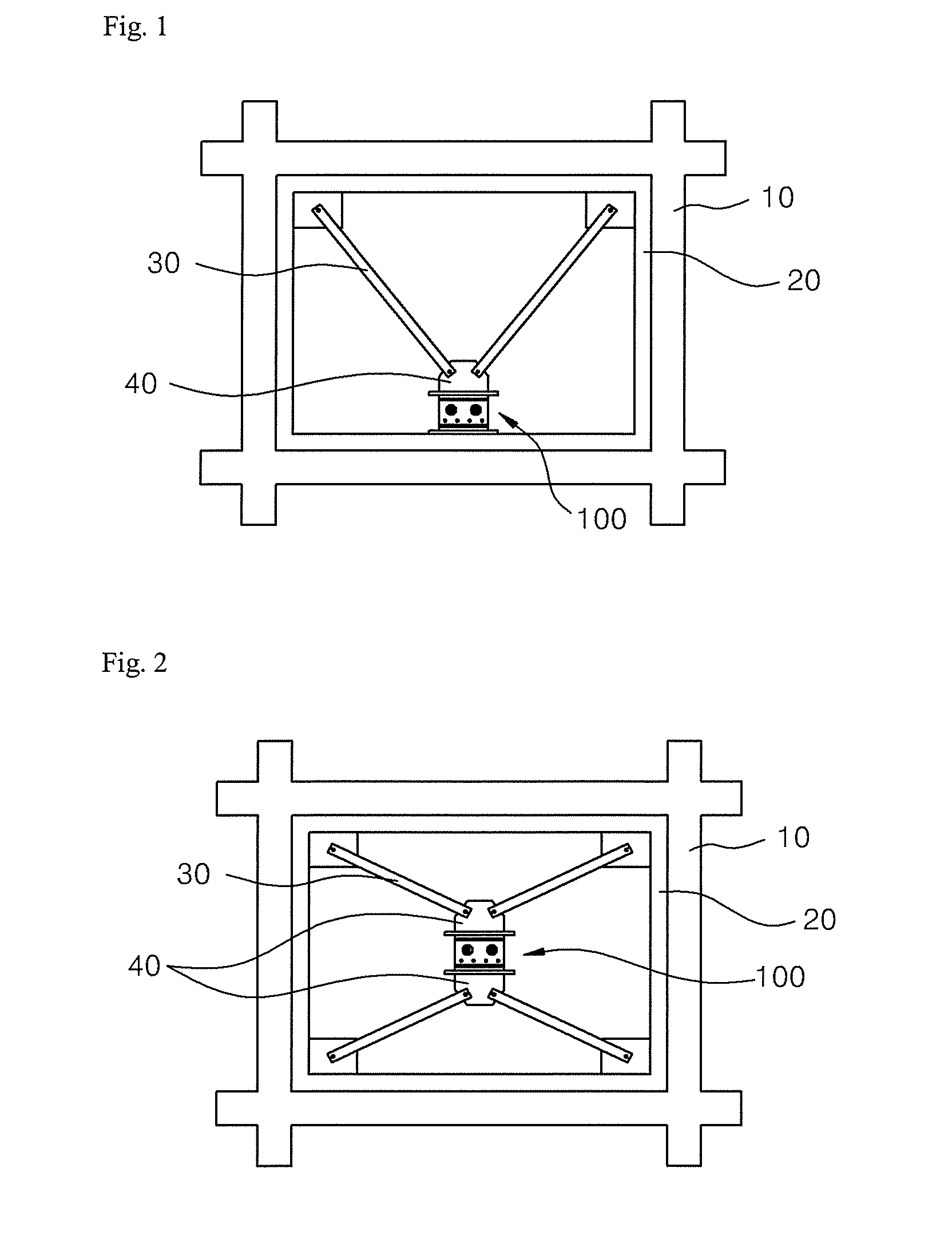

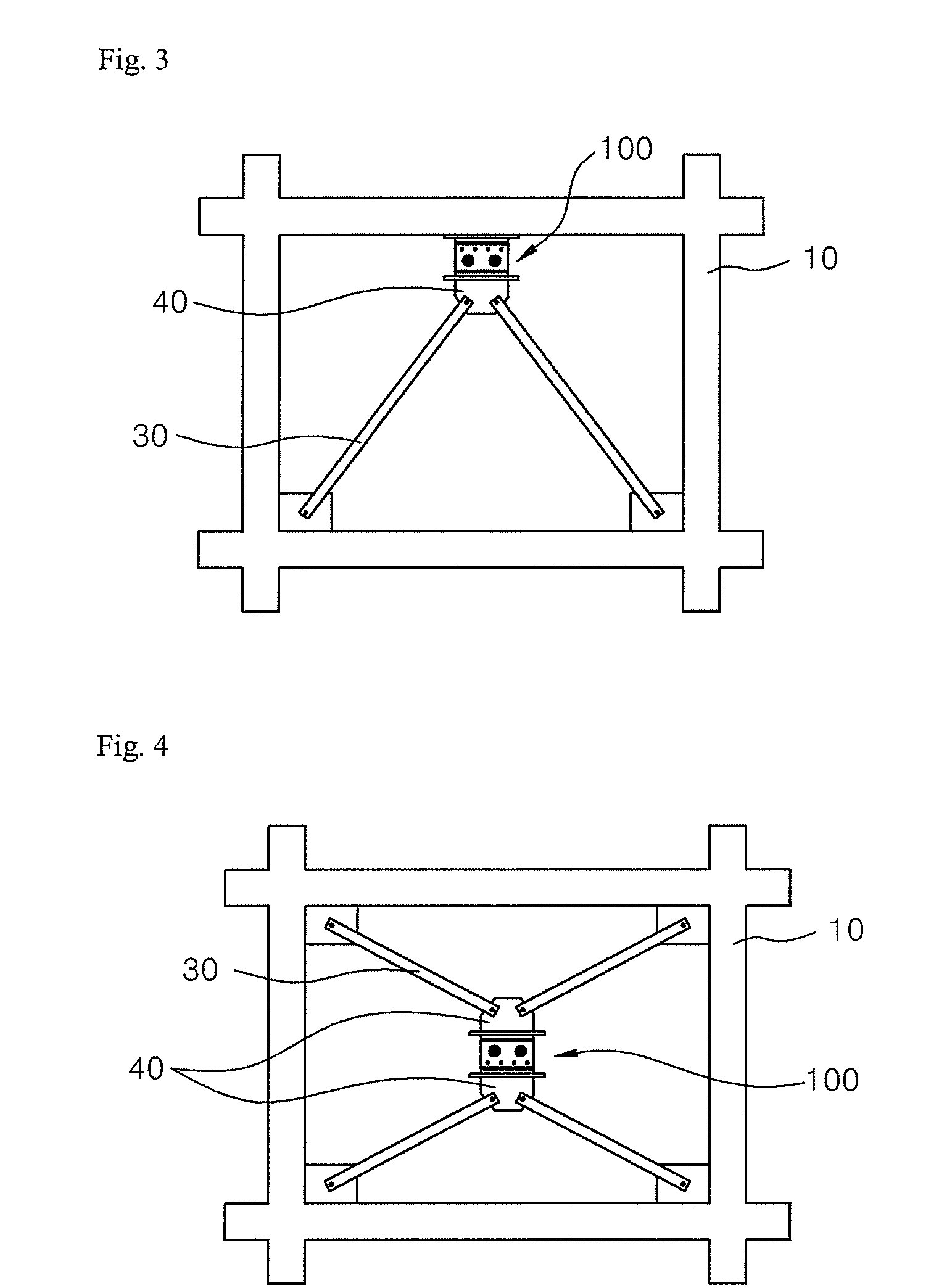

High-performance shear friction damper

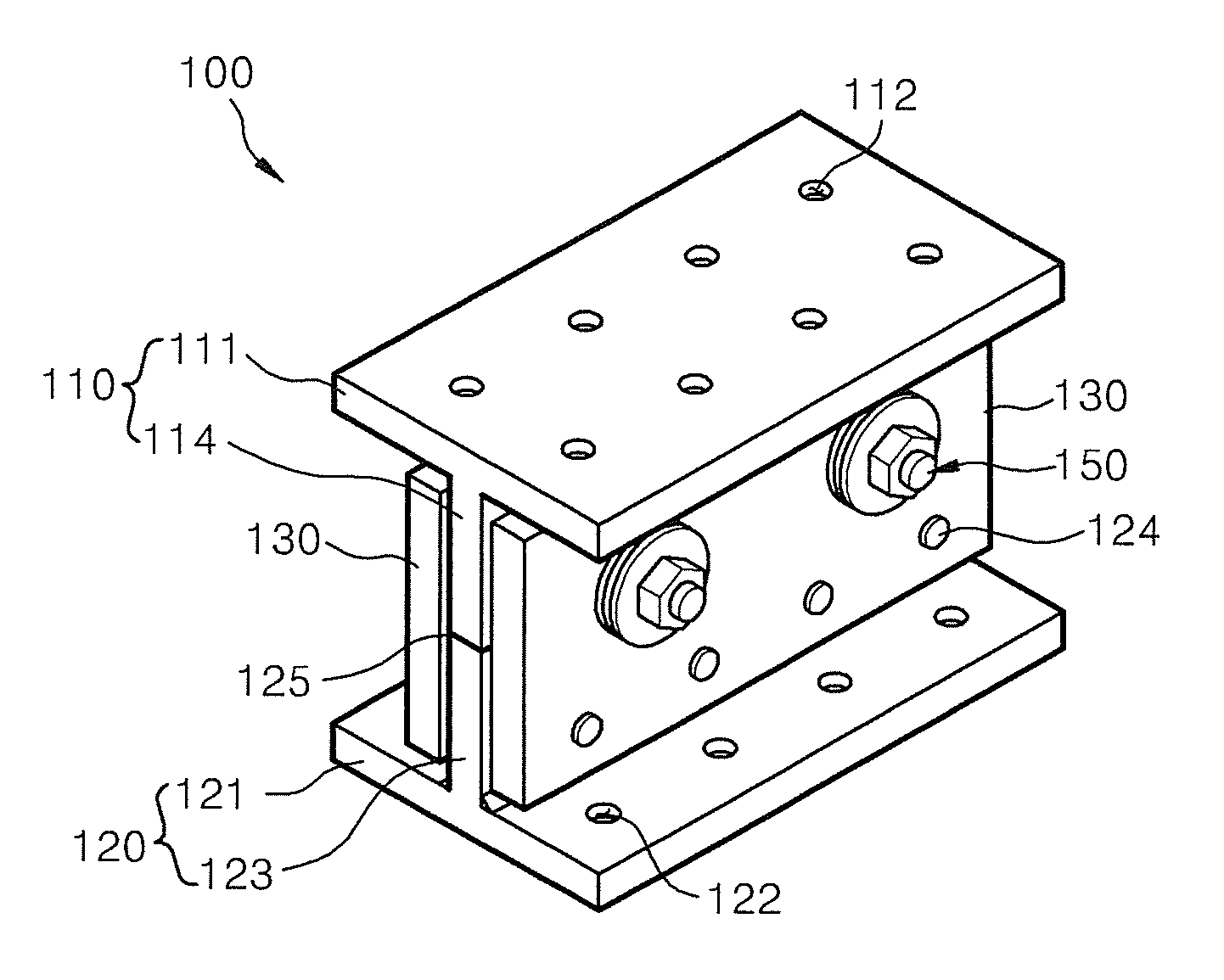

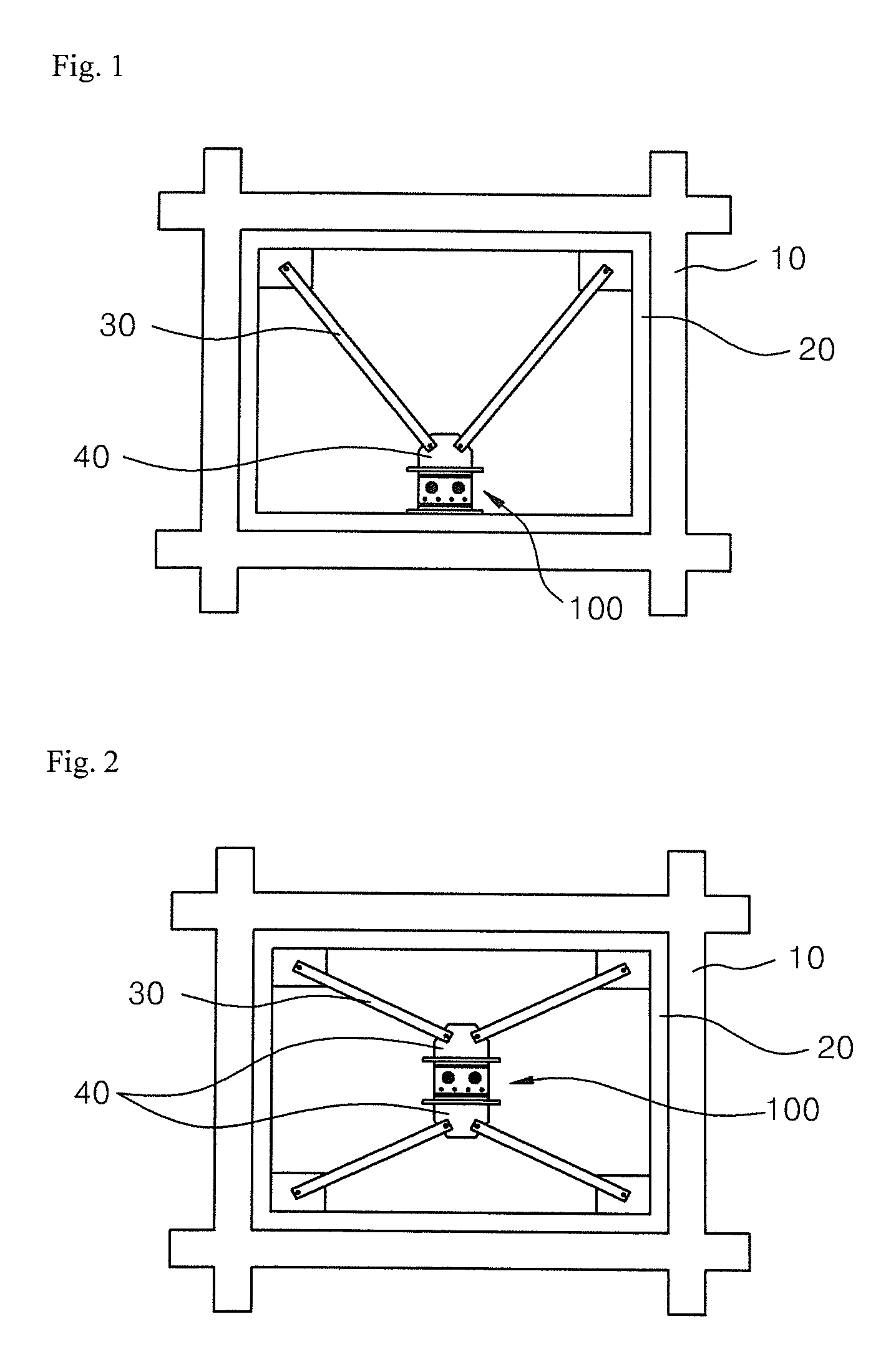

ActiveUS20120138402A1Easy to installEasy maintenanceProtective buildings/sheltersFriction dampersArchitectural engineeringShear friction

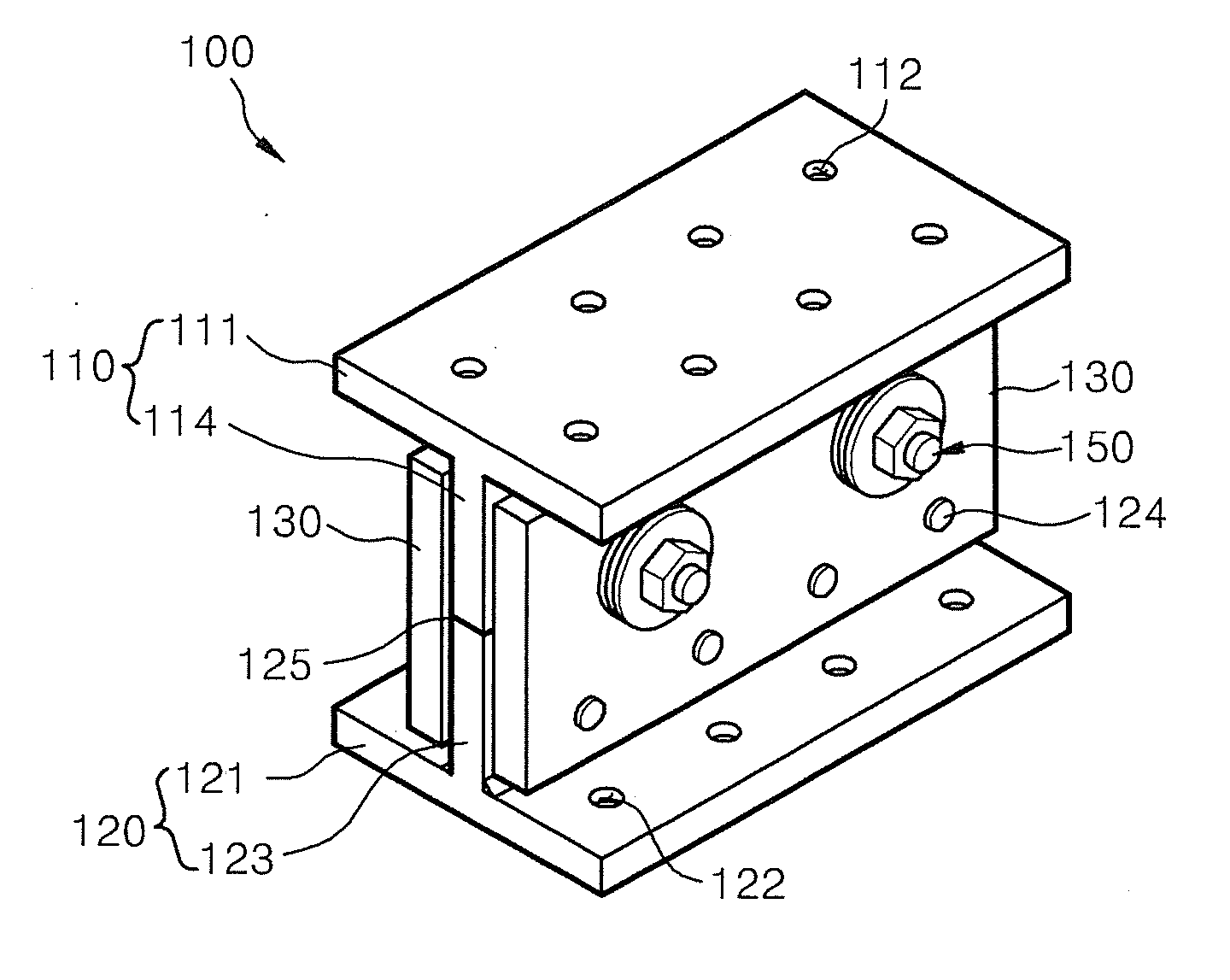

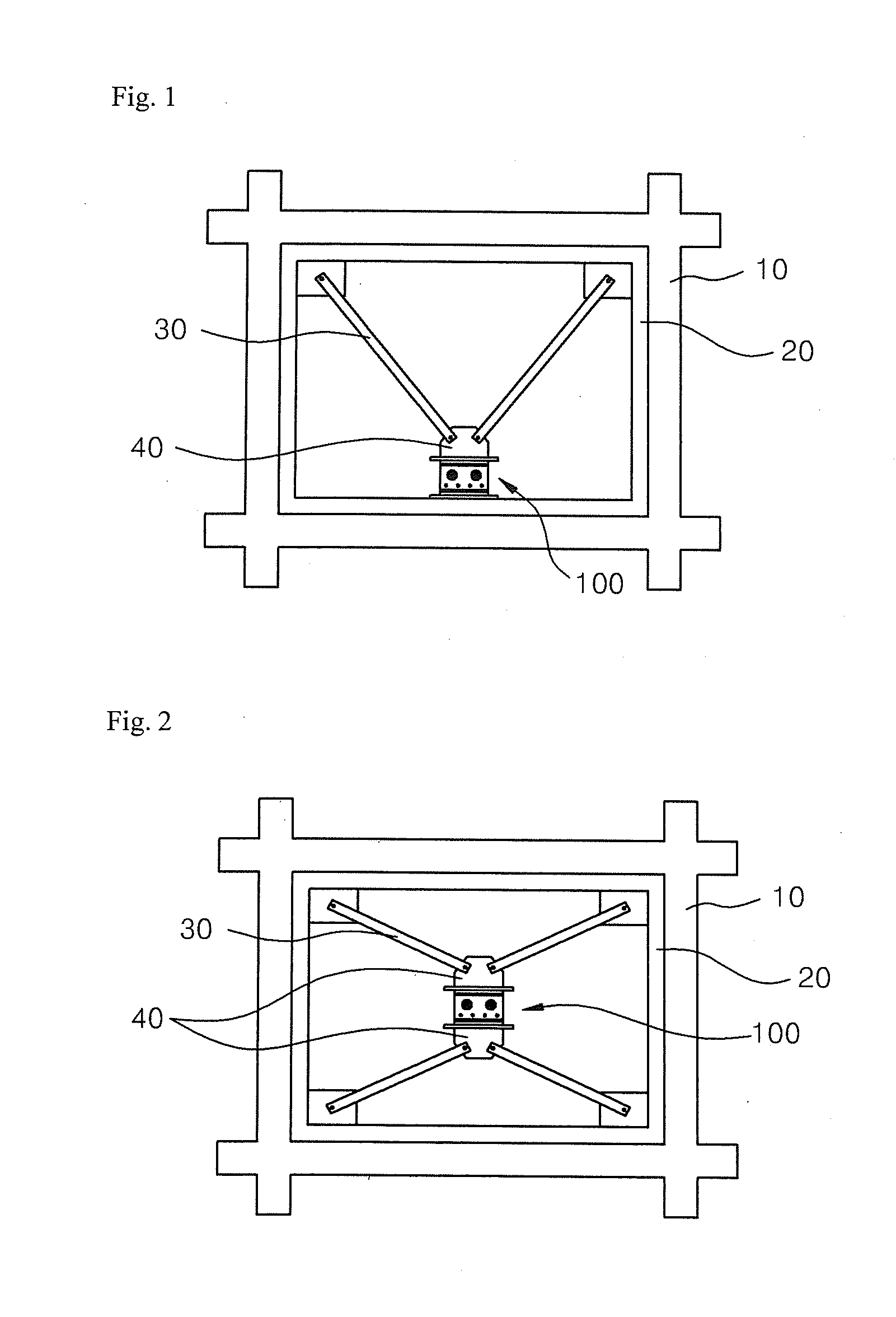

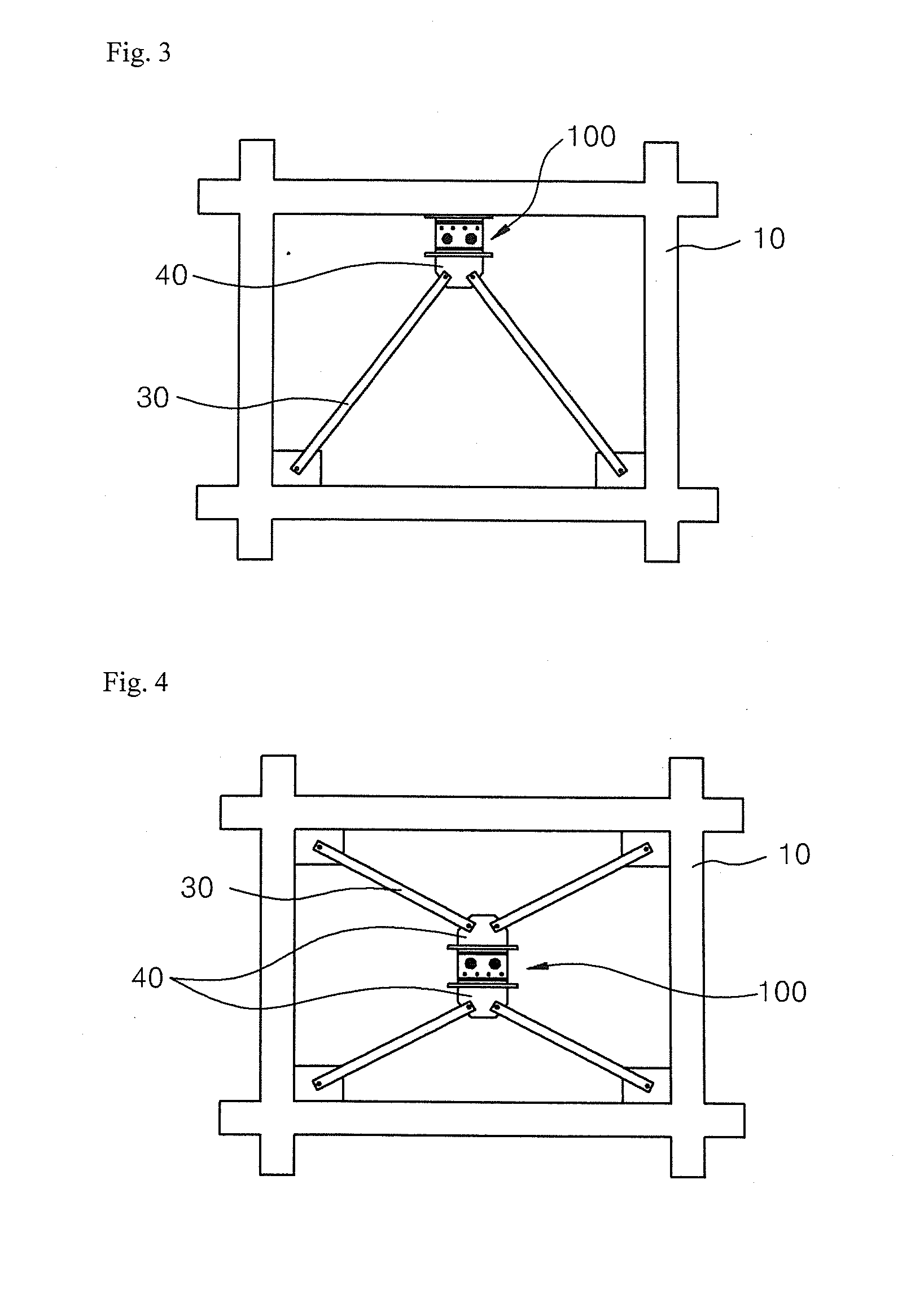

Disclosed is a high-performance shear friction damper provided in a building construction and attenuating a vibration which is applied to the building construction due to external loads such as an earthquake or strong wind. The high-performance shear friction damper includes first and second support bodies supported to a building construction or damping rods, two prop plates fixed to the second support body and extending to surround both side surfaces of the first support body, friction plates mounted between the first support body and the prop plates, and fastening units each including a tension bolt penetrating the first support body, the friction plates and the prop plates, and a nut fastened to an end of the tension bolt, wherein the first support body has slots extending in a horizontal direction, the tension bolts extend while penetrating the slots to allow the first support body to be slidably movable in the horizontal direction with respect to the friction plates.

Owner:IND ACADEMIC COOP FOUND CHOSUN UNIV

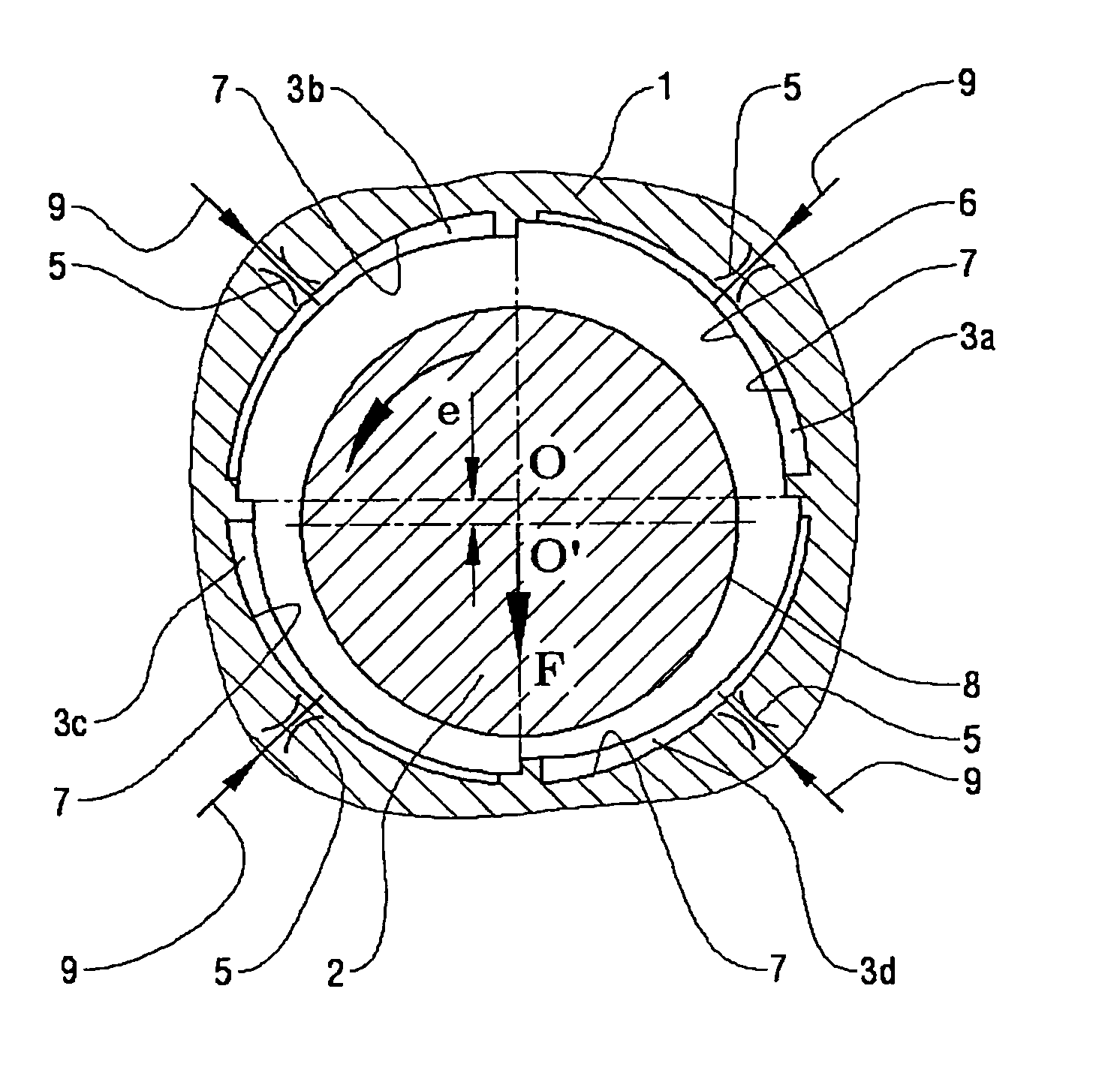

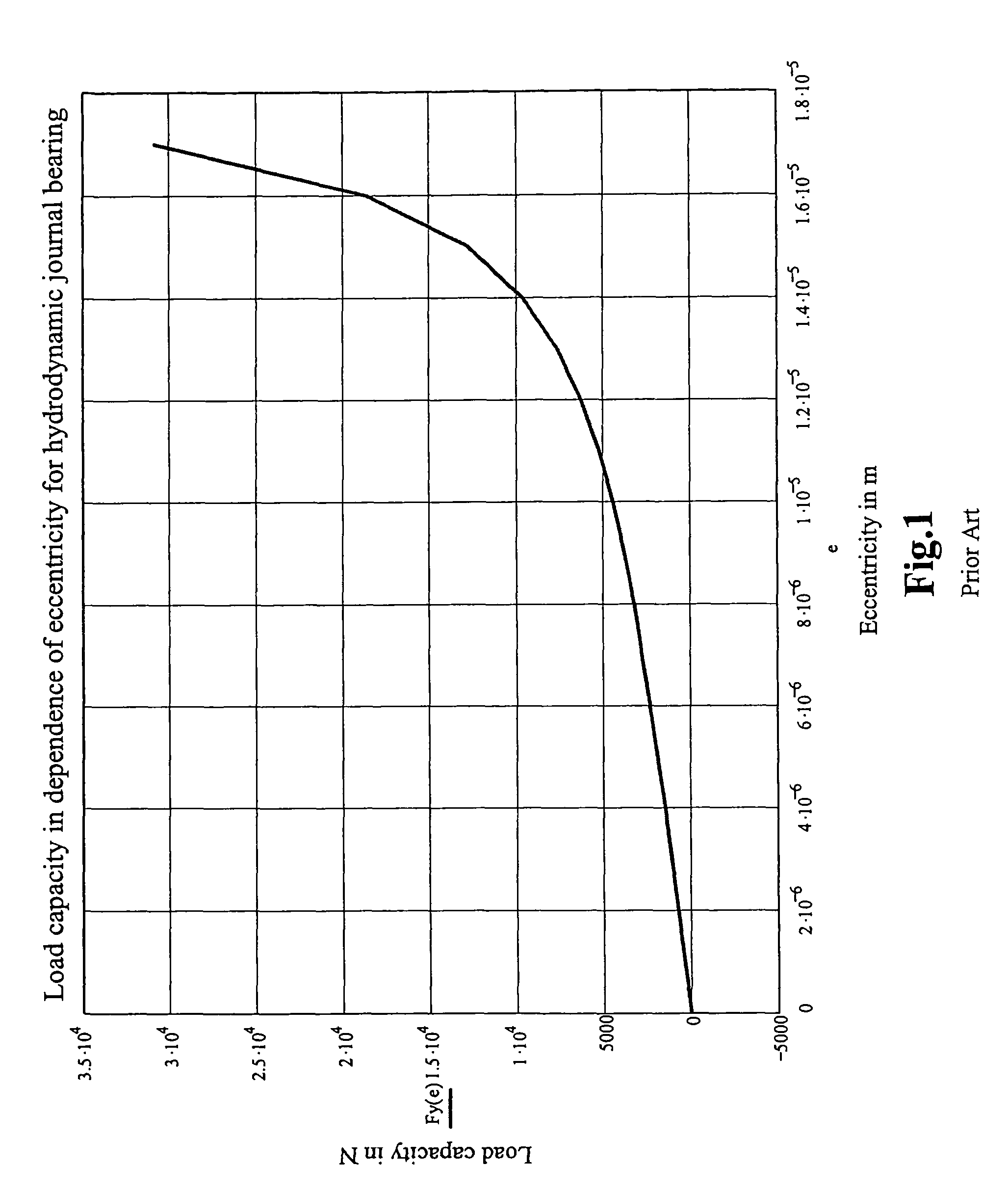

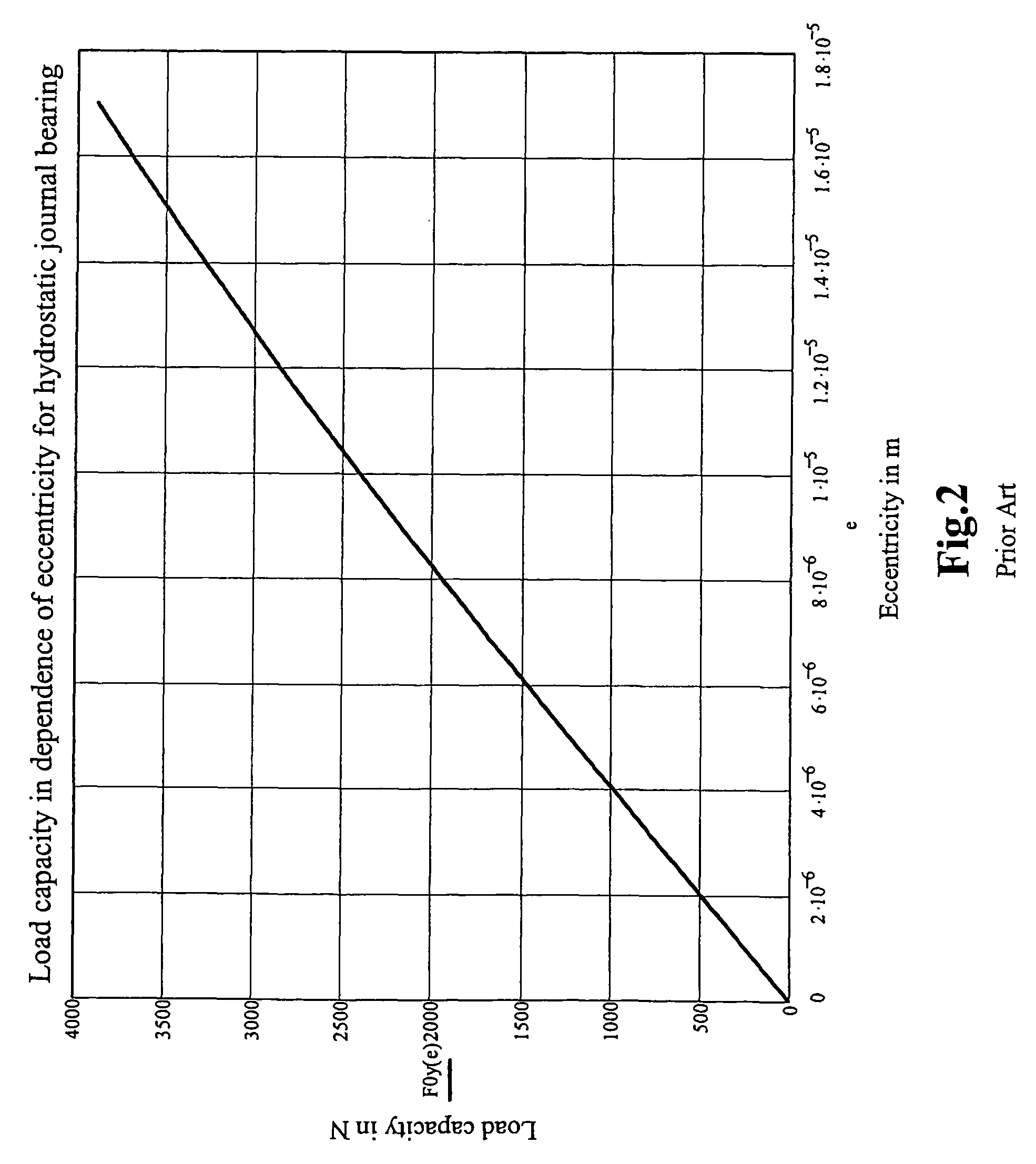

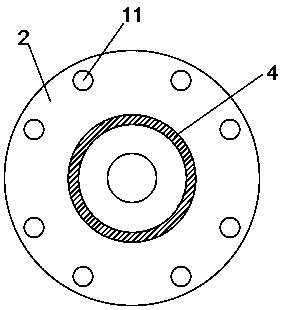

Hybrid hydro (air) static multi-recess journal bearing

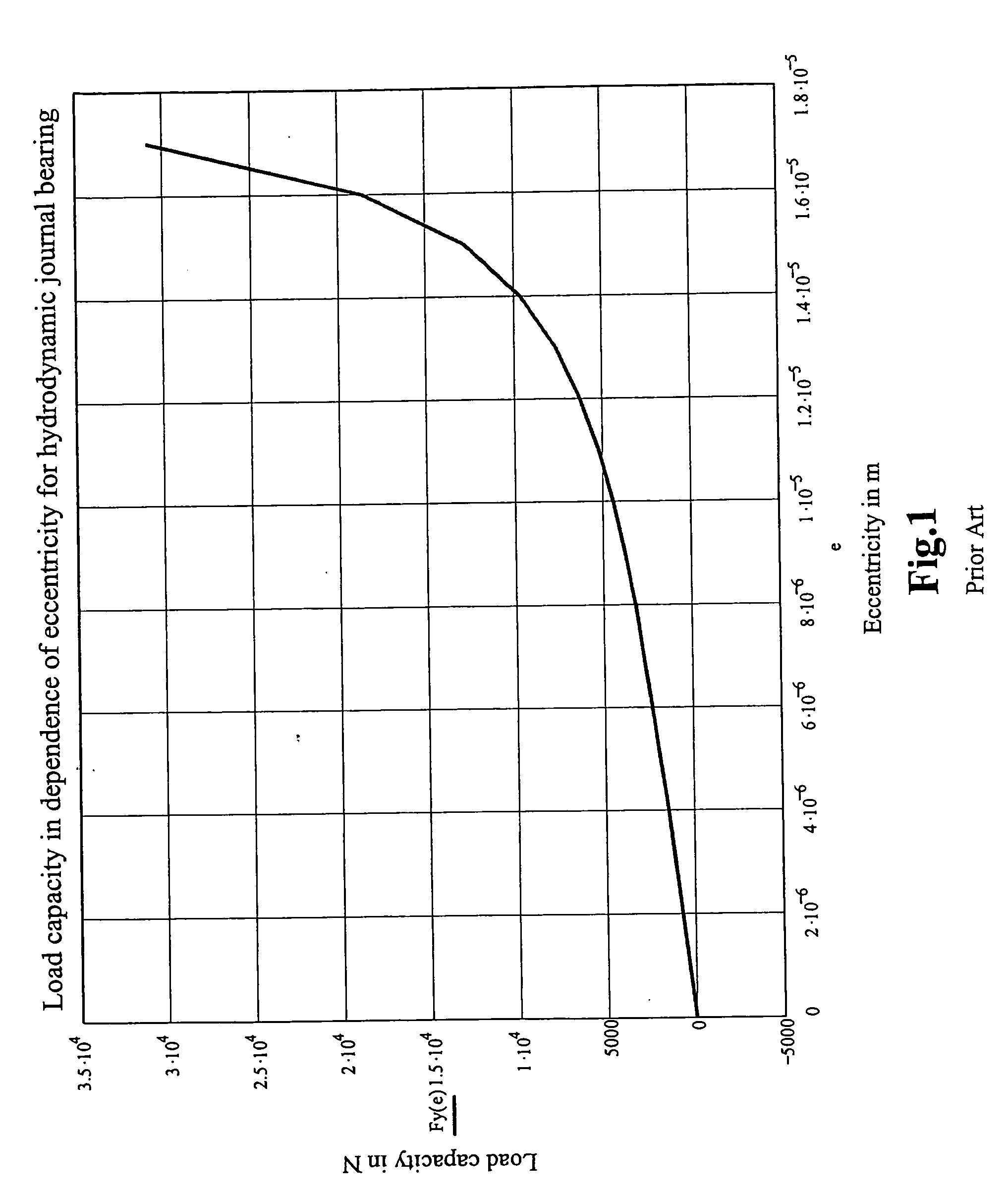

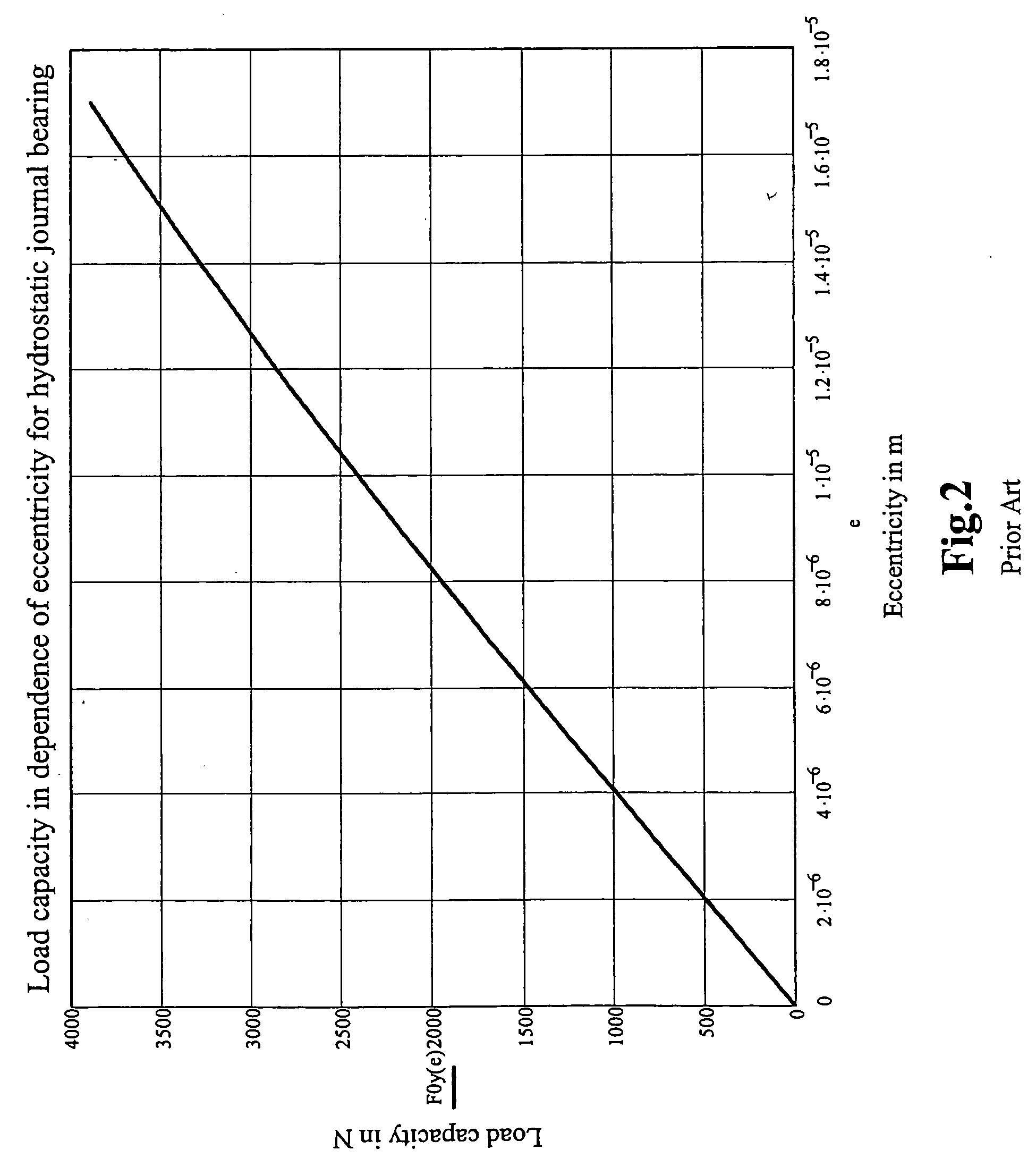

InactiveUS20090074337A1Easy to manufactureReduce frictionBearing componentsSliding contact bearingsRotational axisShear friction

Multi-recess hydrostatic journal bearings support a rotating shaft and have inclined surfaces, each inclined surface forming a variable radial gap with the surface of the shaft, the variable gaps converging in the direction of rotation of the shaft to increase hydrodynamic forces, reduce a turbulent component of shear friction, and improve the thermal stability of the journal bearing. The inclined surfaces can be formed in one or more of portions of recess bottoms in recesses, portions of gap lands surrounding recesses, and portions of an inner surface of a bushing.

Owner:ELKA PRECISION

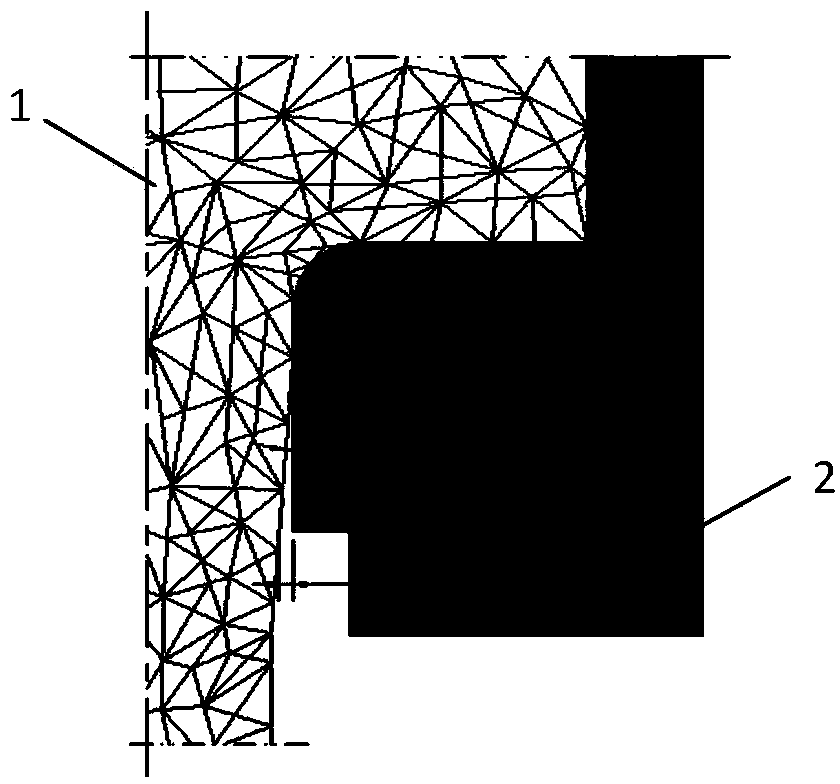

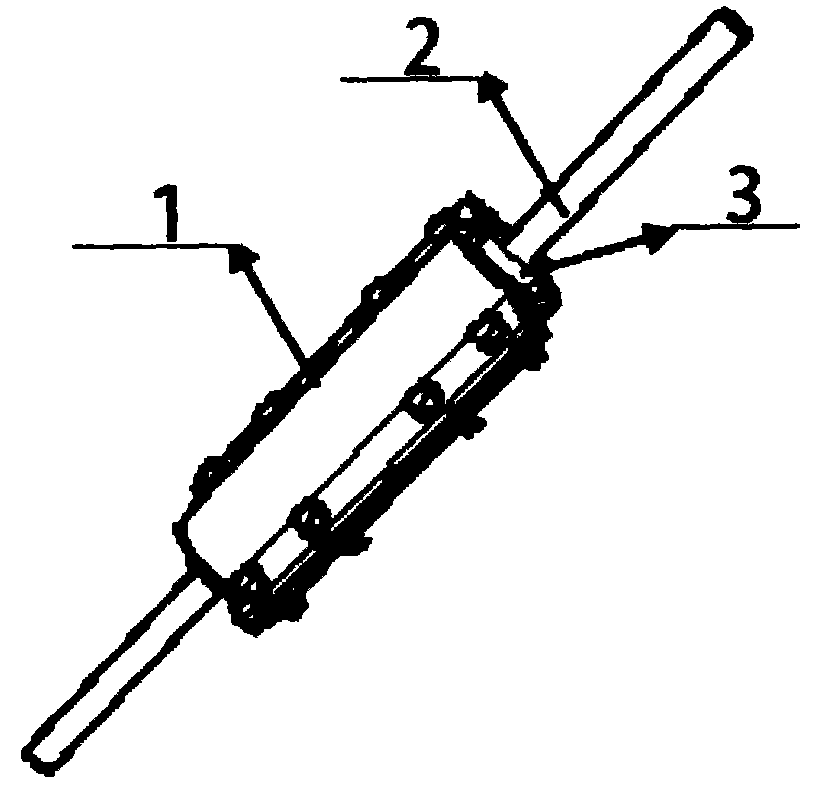

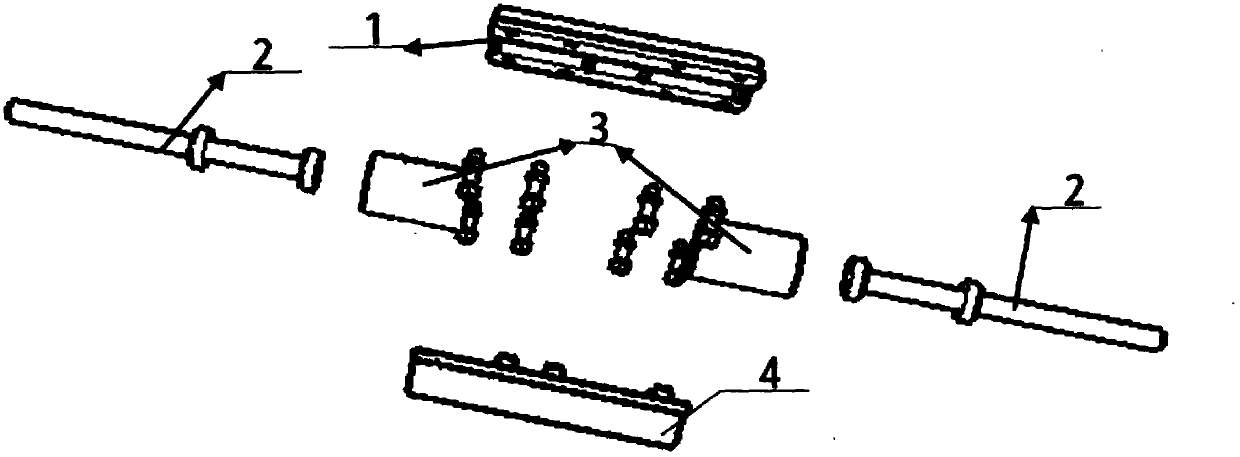

High-performance shear friction damper

ActiveUS8807307B2Easy to installRespond effectivelySpringsStands/trestlesArchitectural engineeringShear friction

Disclosed is a high-performance shear friction damper provided in a building construction and attenuating a vibration which is applied to the building construction due to external loads such as an earthquake or strong wind. The high-performance shear friction damper includes first and second support bodies supported to a building construction or damping rods, two prop plates fixed to the second support body and extending to surround both side surfaces of the first support body, friction plates mounted between the first support body and the prop plates, and fastening units each including a tension bolt penetrating the first support body, the friction plates and the prop plates, and a nut fastened to an end of the tension bolt, wherein the first support body has slots extending in a horizontal direction, the tension bolts extend while penetrating the slots to allow the first support body to be slidably movable in the horizontal direction with respect to the friction plates.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

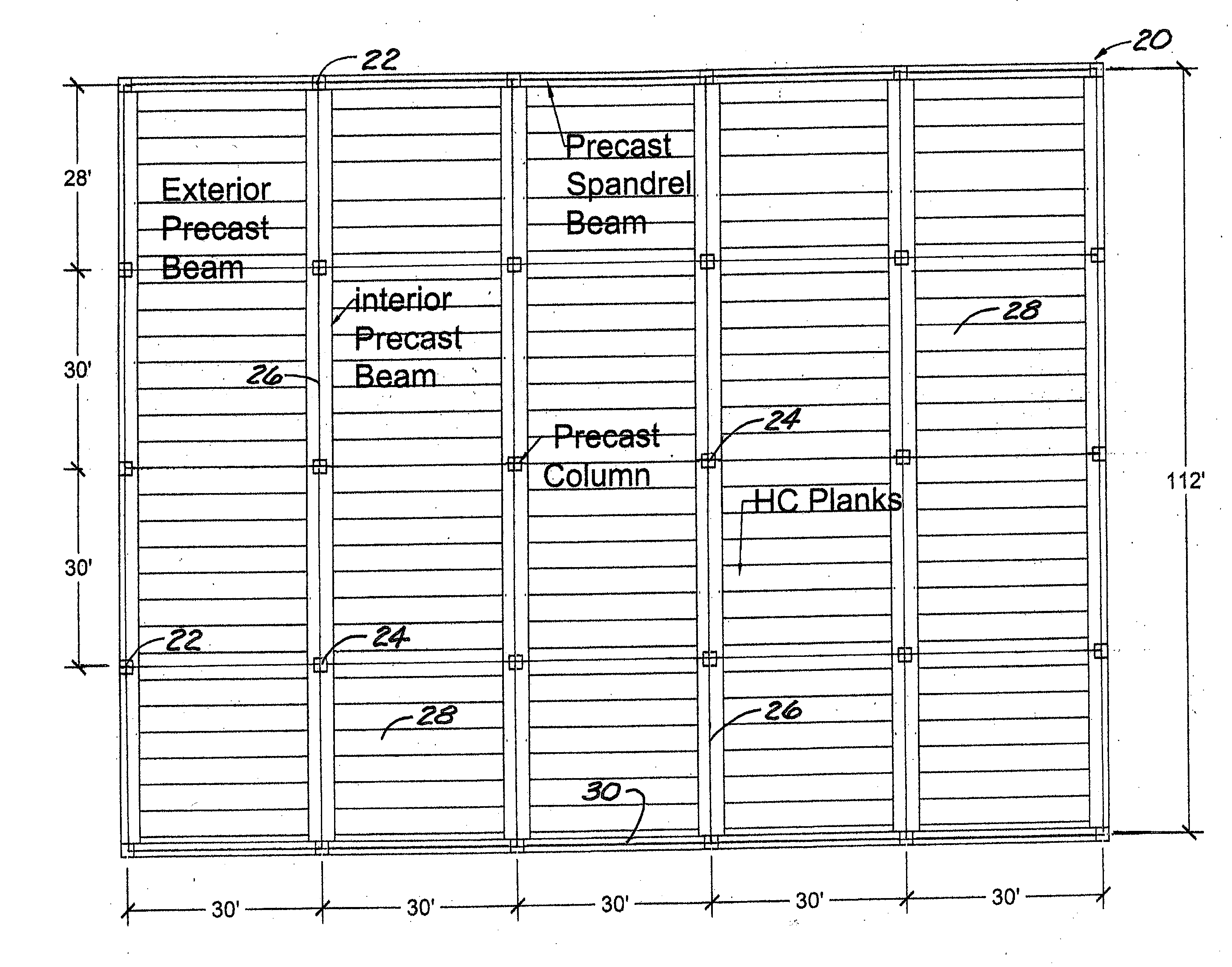

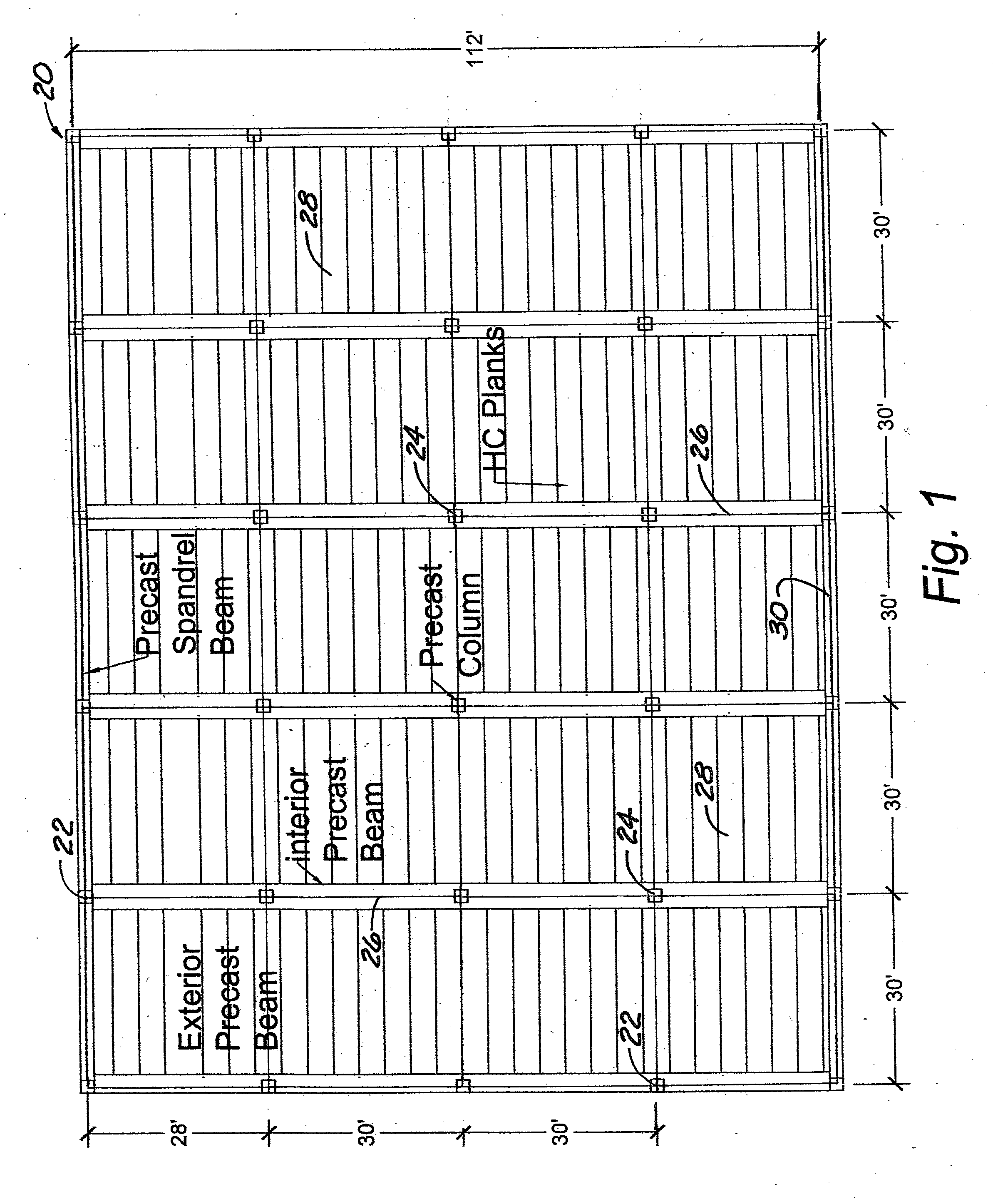

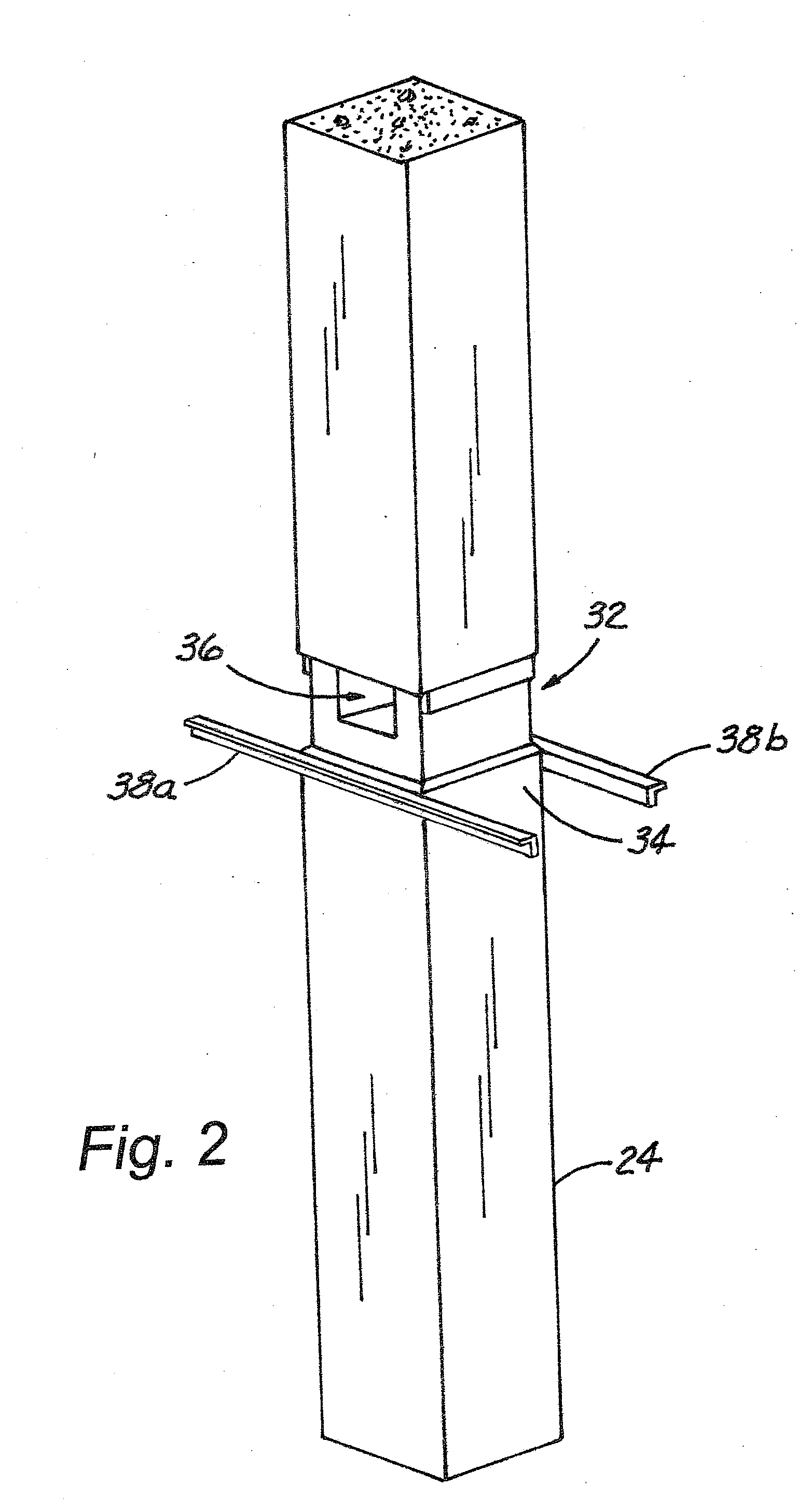

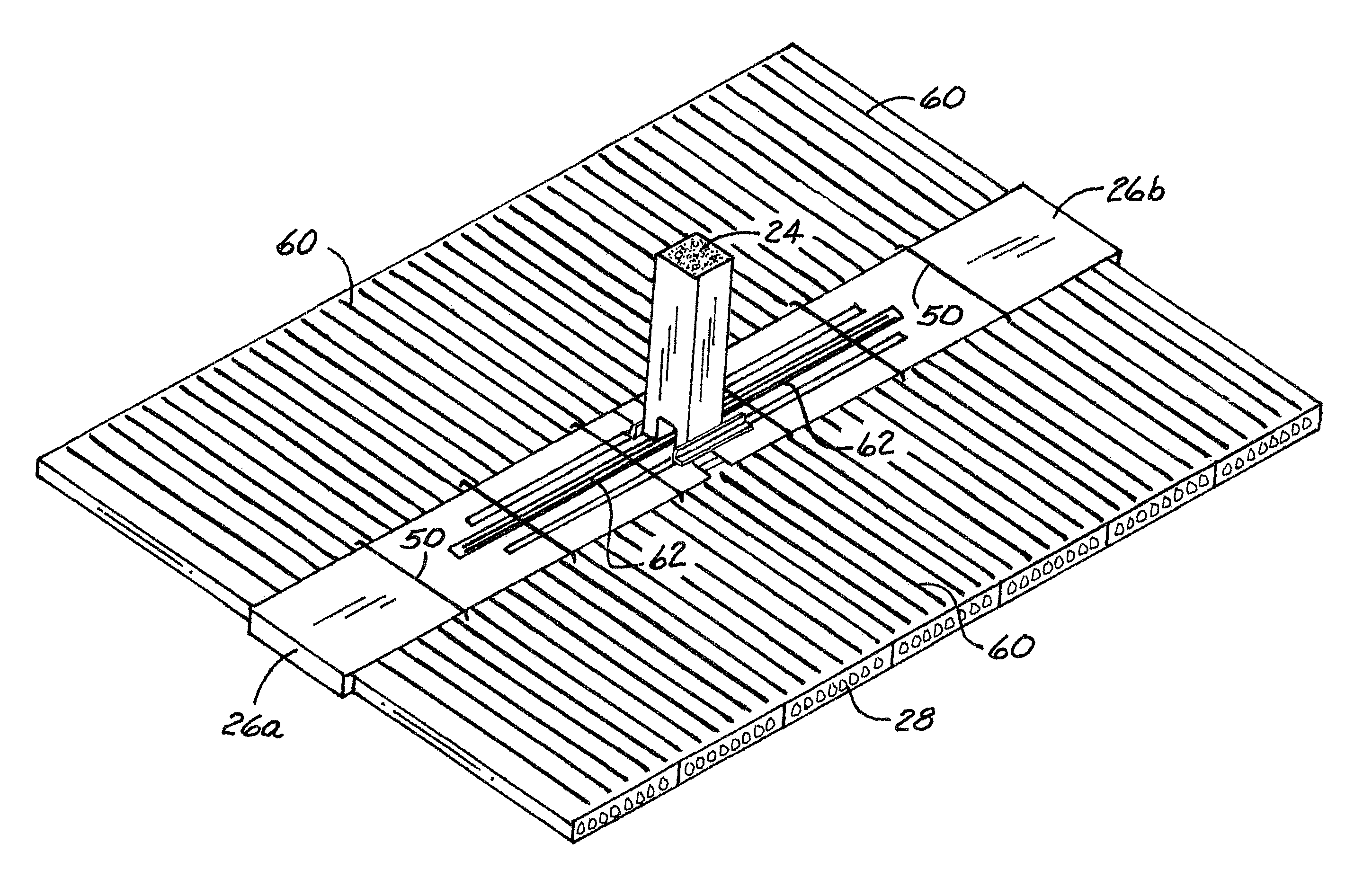

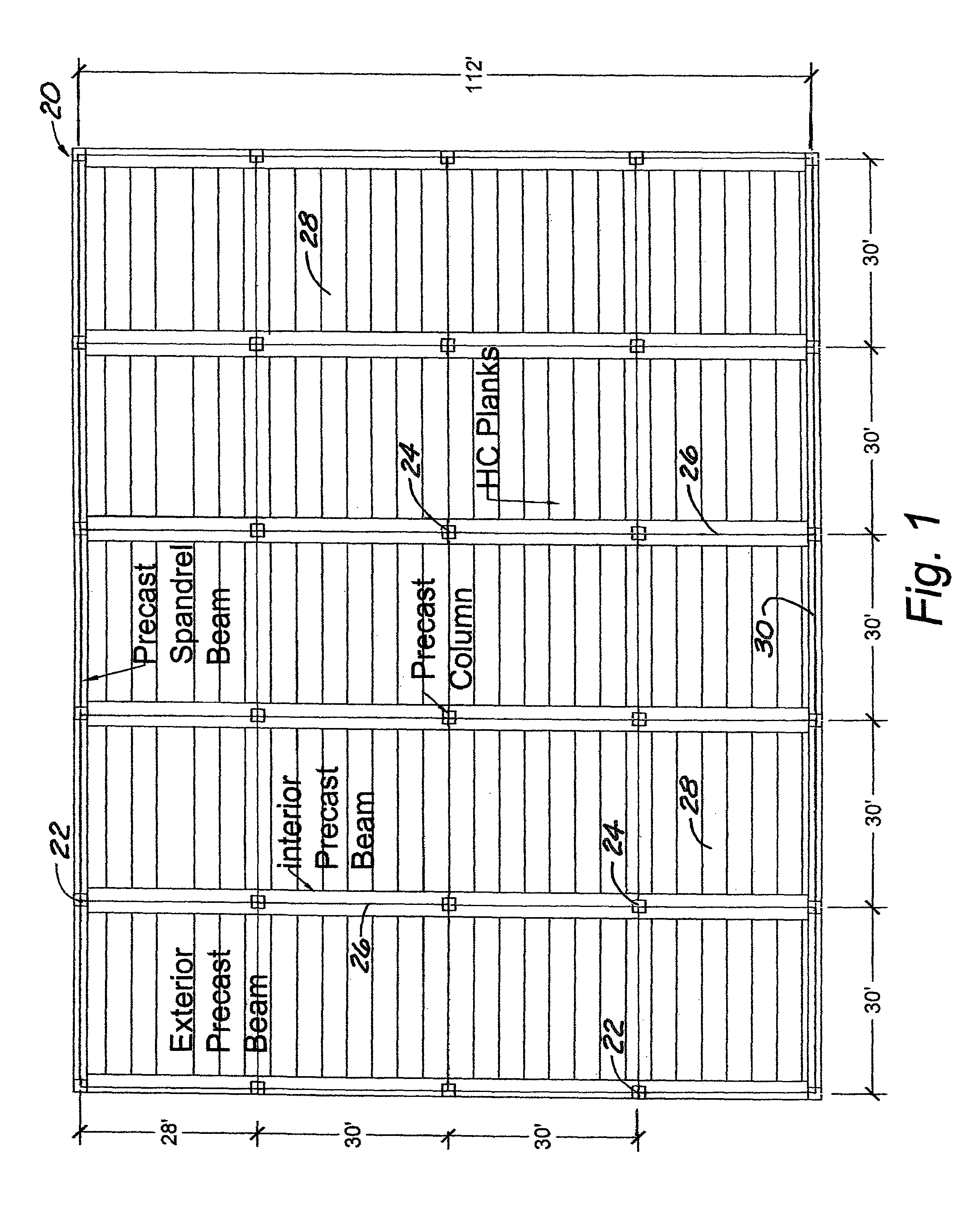

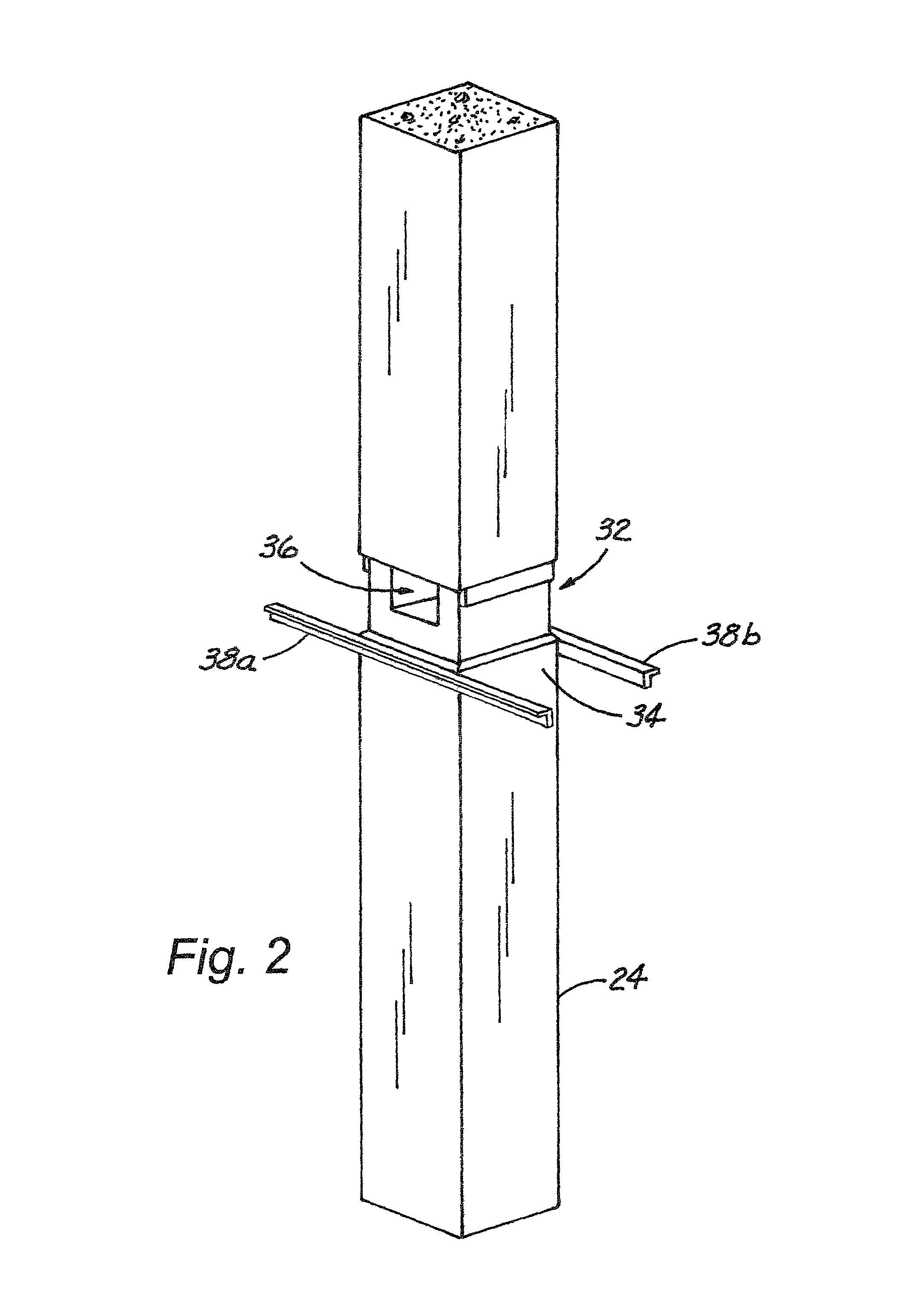

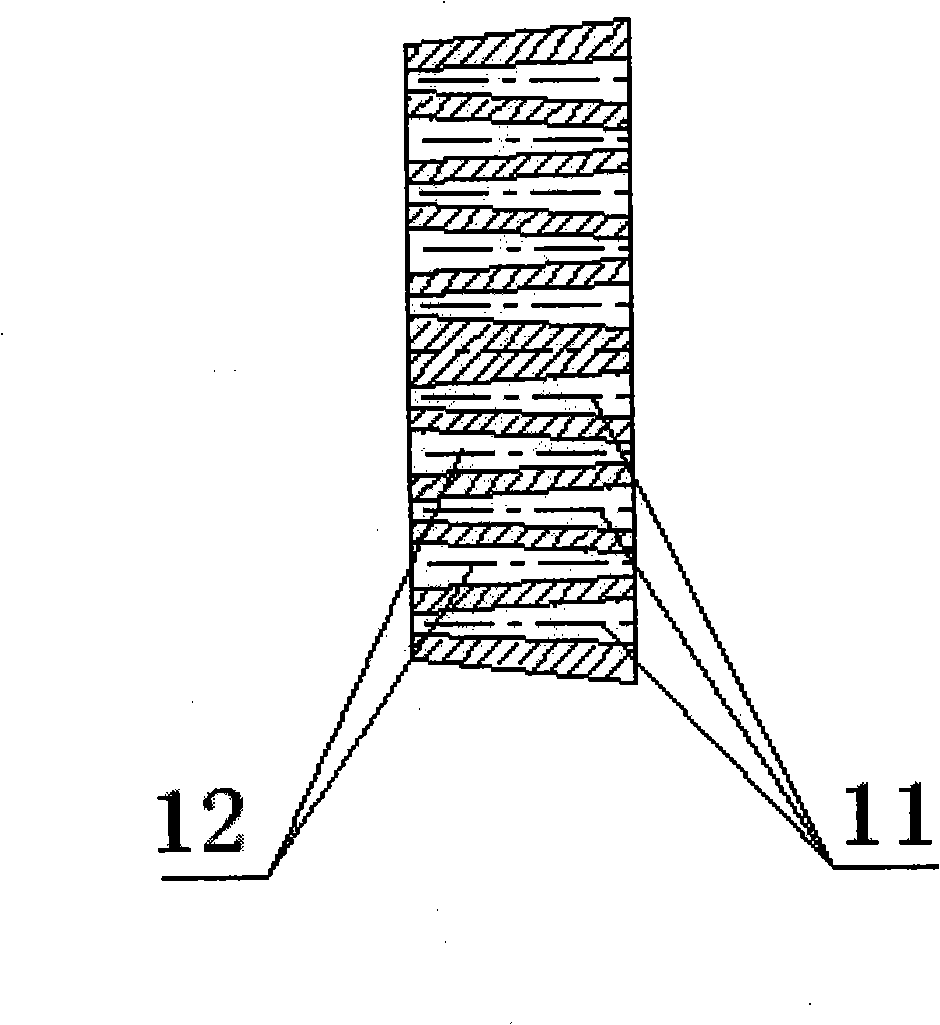

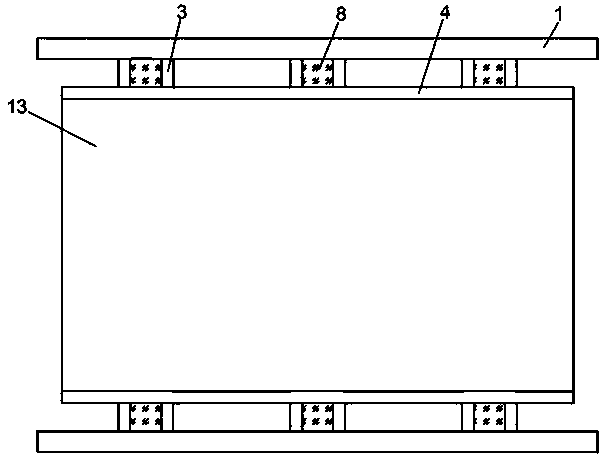

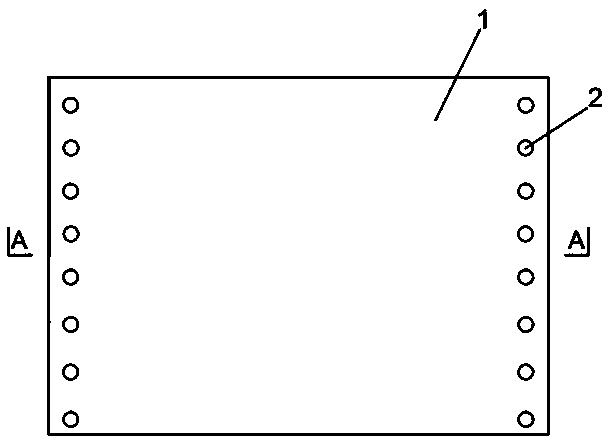

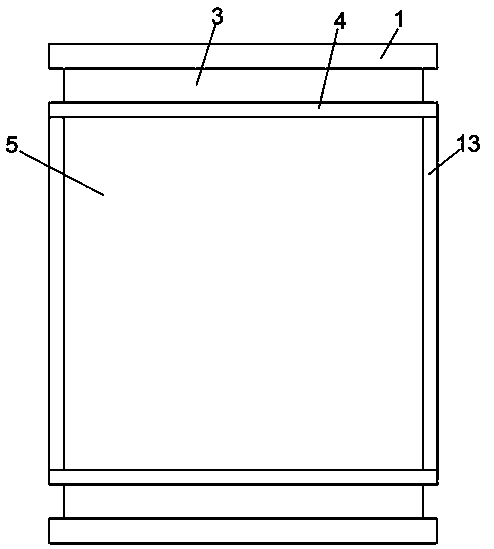

Shallow Flat Soffit Precast Concrete Floor System

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

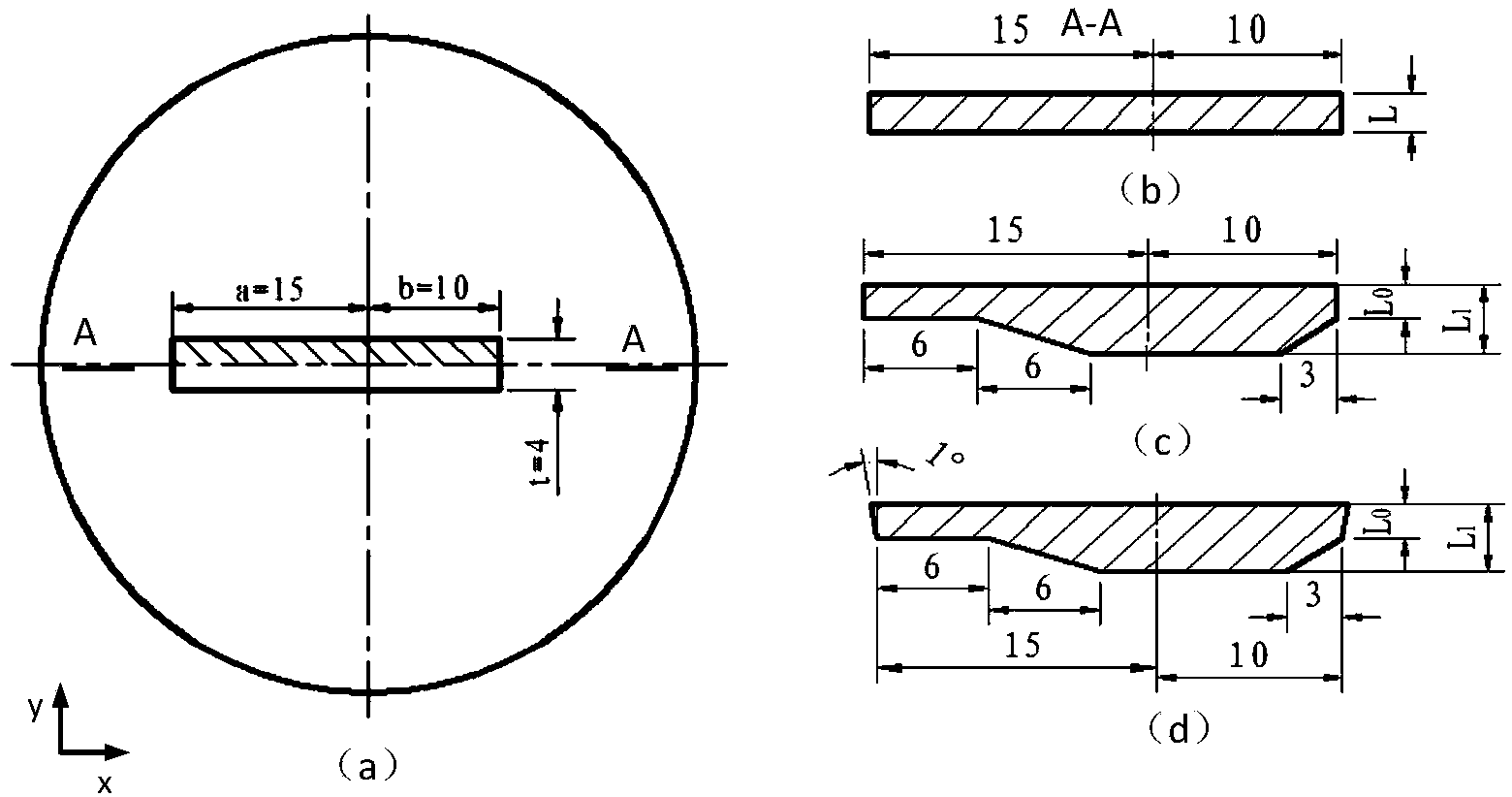

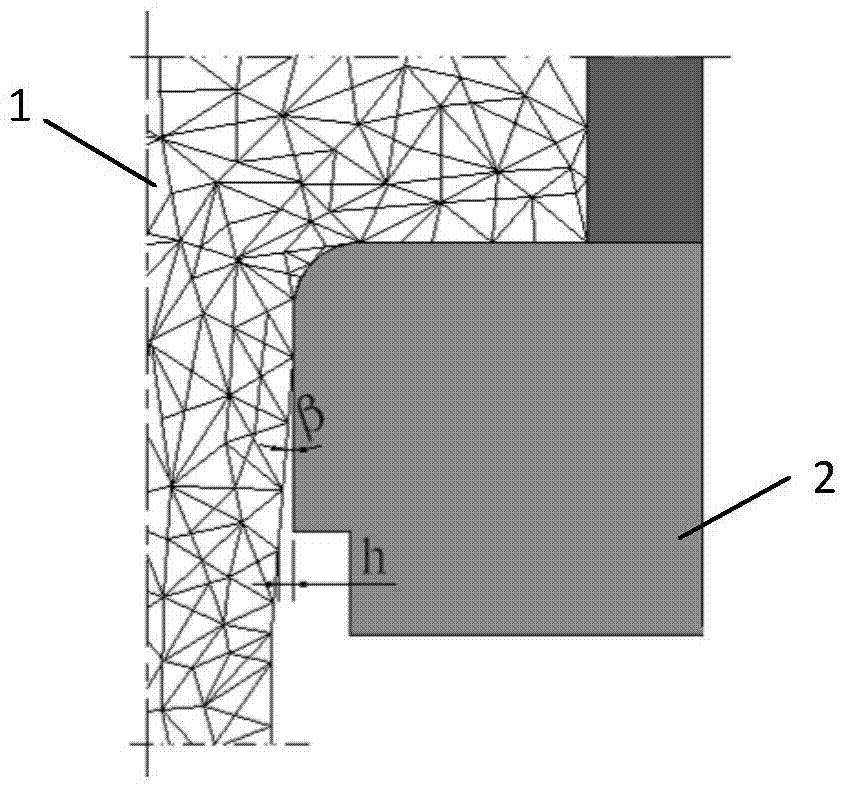

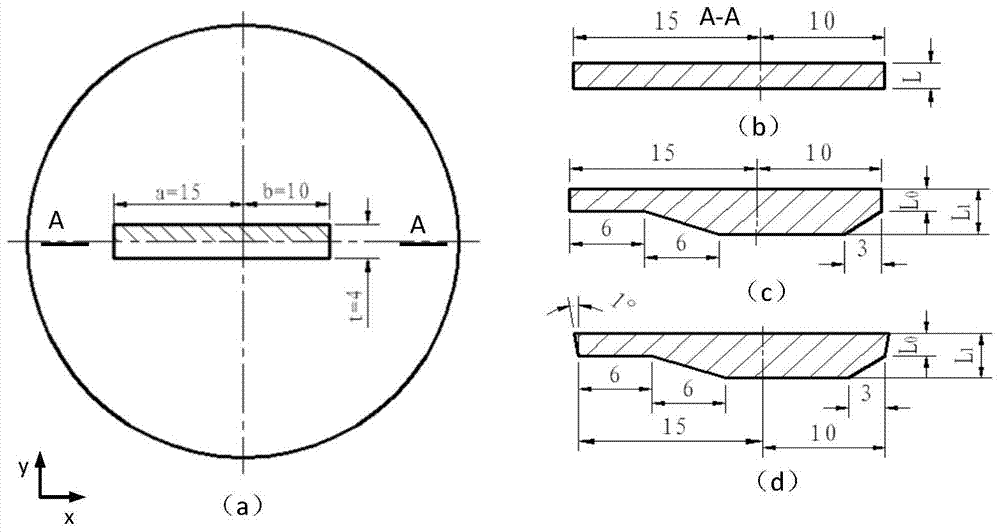

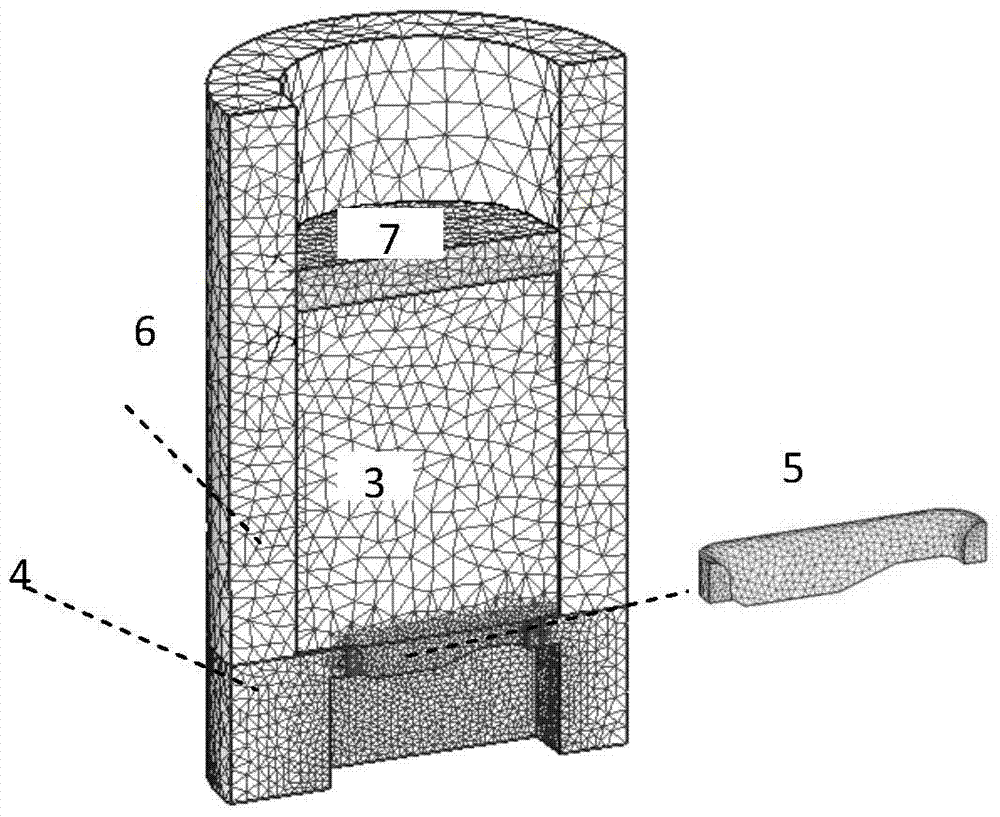

Numerical simulation method for analyzing structure dimensions of unequal-length working tape of extrusion die

Provided is a numerical simulation method for analyzing structure dimensions of an unequal-length working tape of an extrusion die. Simulation is carried out on the sectional material extrusion process, a die surface and the working tape are arranged to be two independent entities, a slope working tape is arranged, the inclination angle between the surface of the working tape and the extrusion direction ranges from 1 degree to 2 degrees, after three-dimensional model assembly is carried out, meshing is carried out, split friction boundary conditions are set, and a common friction model is selected for a deformation body, the inner wall of an extrusion barrel and the die surface, namely, a cutting friction model with a constant friction factor is adopted; a Coulomb friction model related to pressure is adopted for the deformation body and the surface of the working tape; extrusion technological parameters are applied to finite element software, data files are generated, and simulation analysis is carried out. According to the numerical simulation method for analyzing the structure dimensions of the unequal-length working tape of the extrusion die, due to the fact that the method of split modeling, the method of the slope working tape, the method of the split friction boundary conditions and the like are integrated, the problem that the deformation body is separated from the surface of the unequal-length working tape, or makes local contact with the surface of the unequal-length working tape is solved.

Owner:INNER MONGOLIA UNIV OF TECH

Shallow flat soffit precast concrete floor system

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

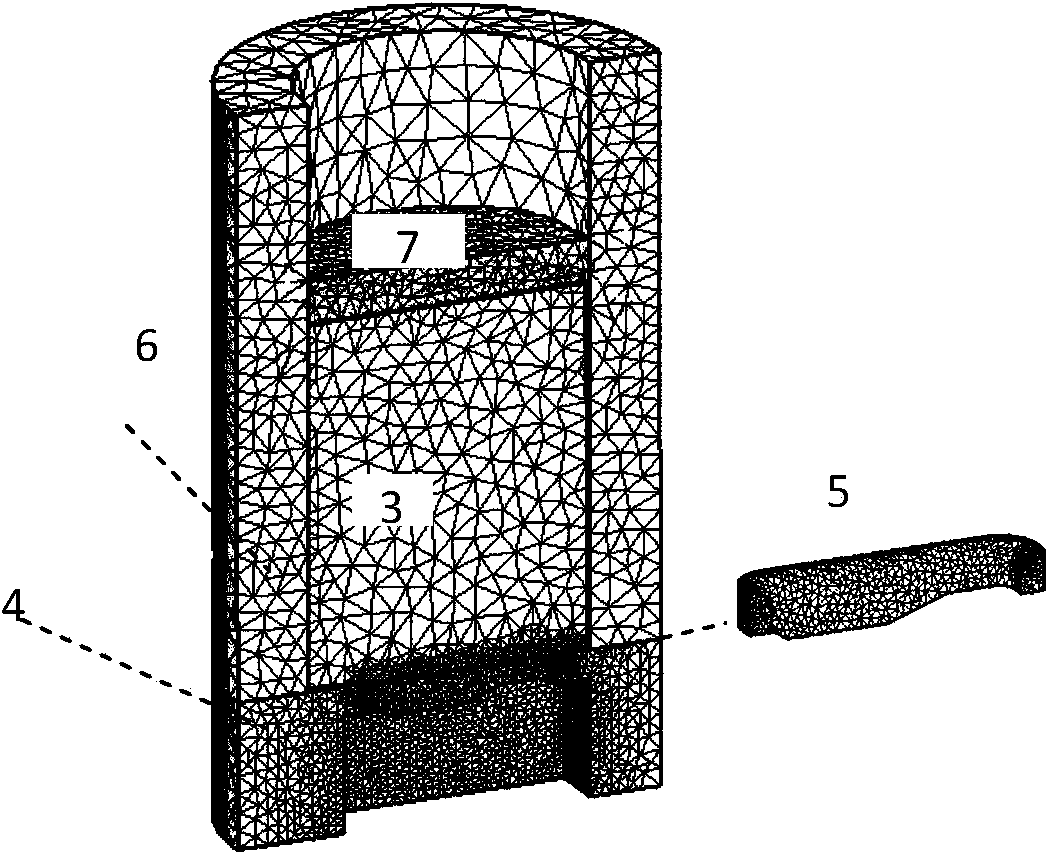

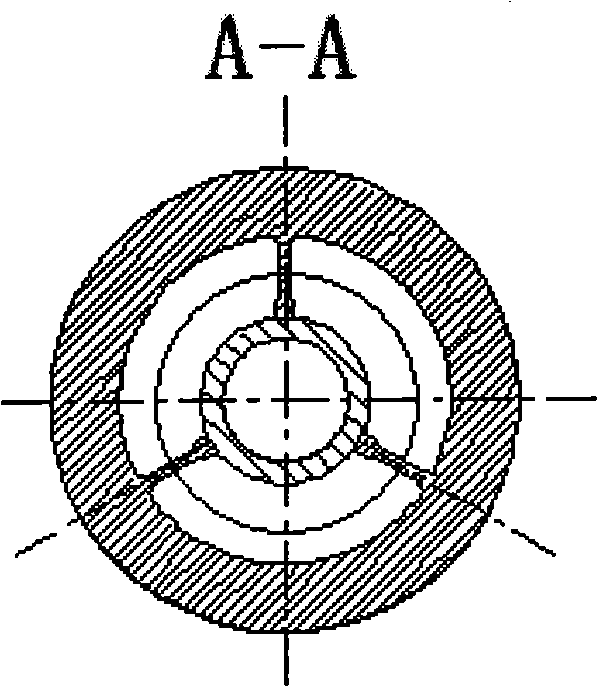

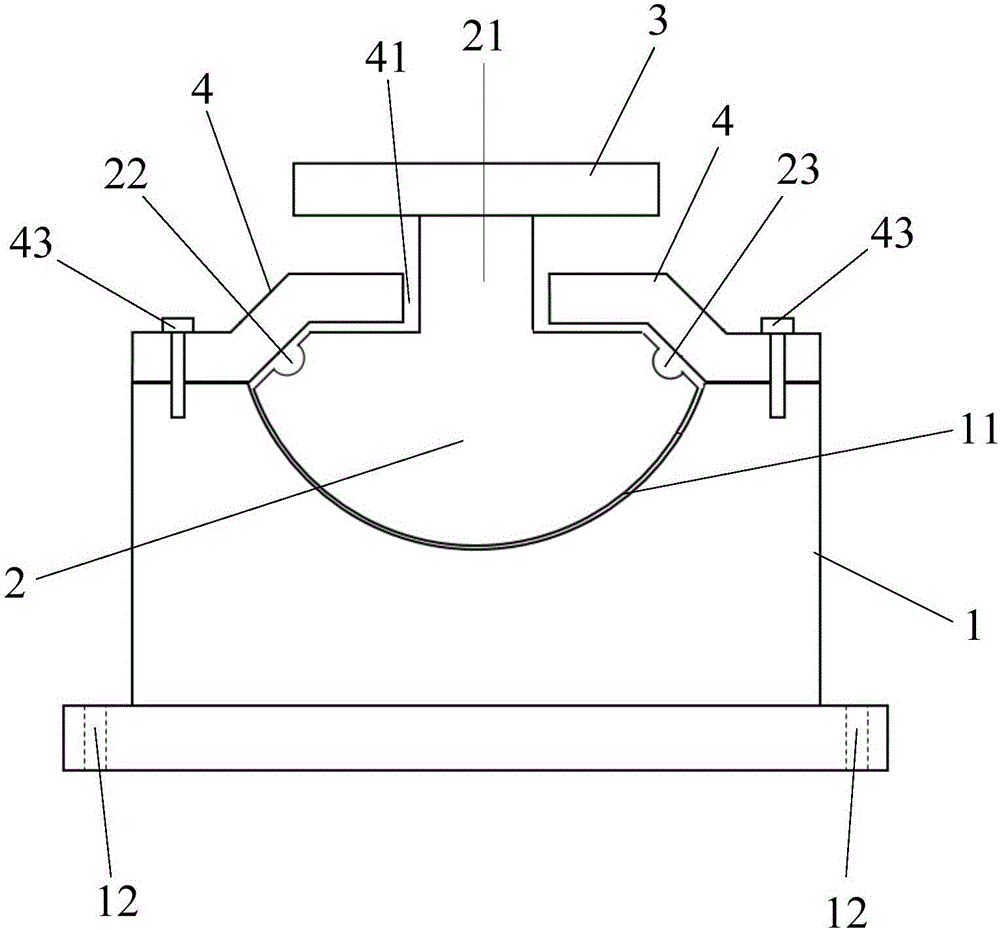

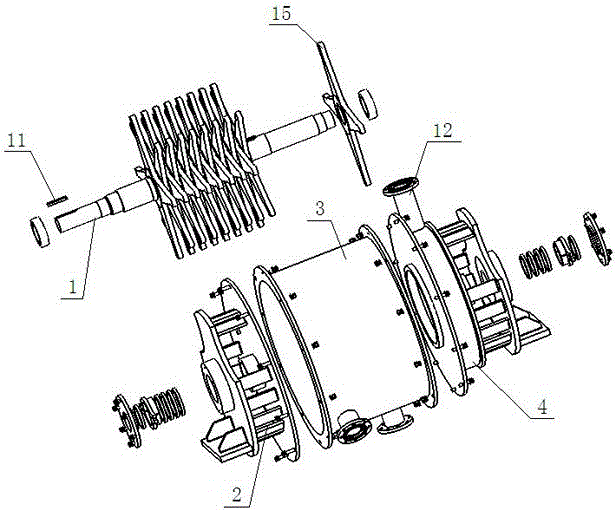

Drum type metal rubber shear friction damper

InactiveCN103696507AHigh initial stiffnessSmall vibration deformation energy consumptionShock proofingShear frictionEngineering

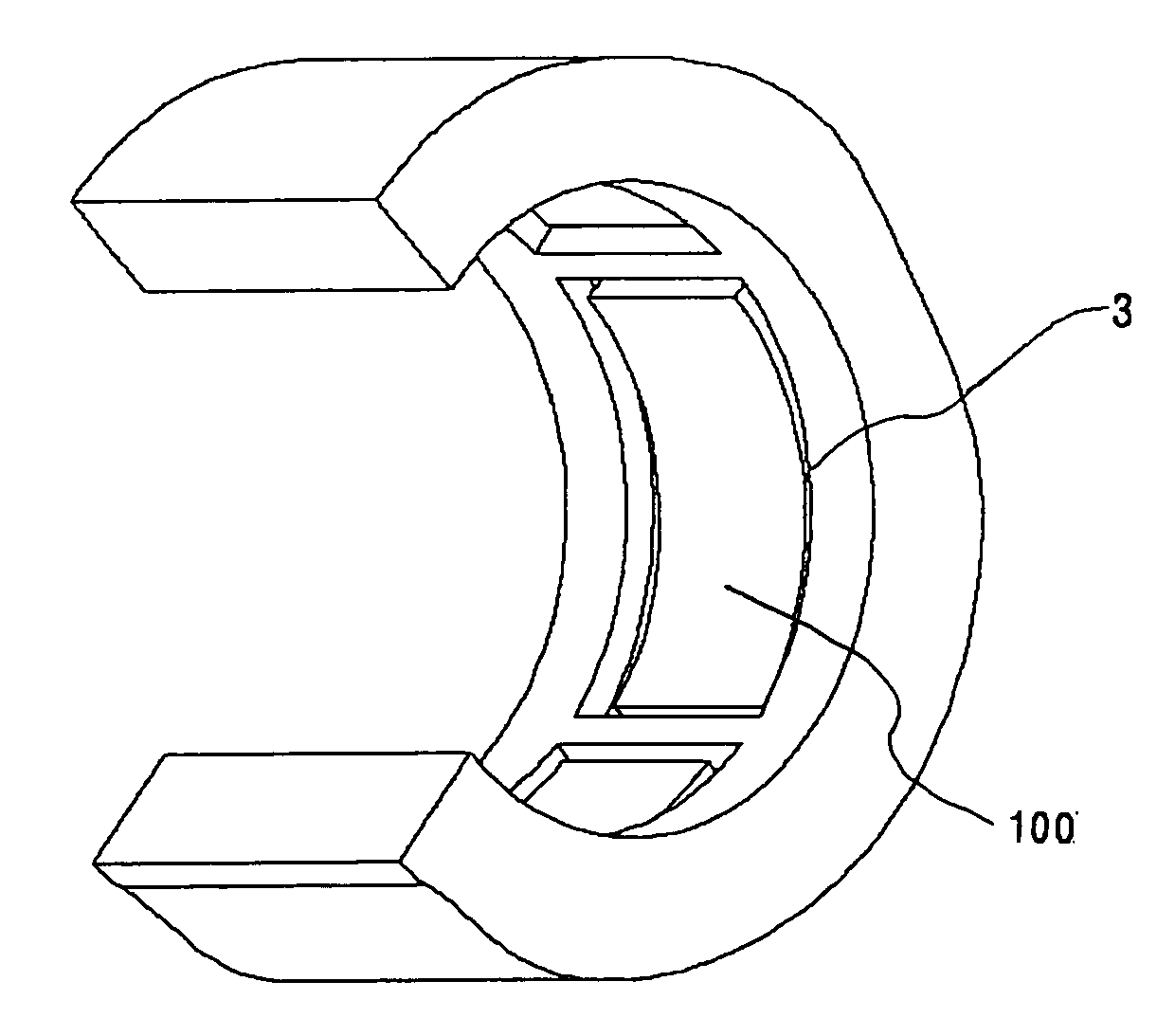

The invention provides a drum type metal rubber shear friction damper which comprises an upper semicircular clamping steel sleeve, a lower semicircular clamping steel sleeve, two drum type metal rubber blocks and two threaded steel bars. The two drum type metal rubber blocks are placed in a drum formed by the upper semicircular clamping steel sleeve and the lower semicircular clamping steel sleeve, each threaded steel bar is arranged on the corresponding drum type metal rubber block, and the upper semicircular clamping steel sleeve and the lower semicircular clamping steel sleeve are connected with each other by fastening bolts to form the drum. The drum type metal rubber shear friction damper has the various advantages that the drum type metal rubber shear friction damper is high in initial stiffness and deformation capacity, obvious in small-vibration deformation energy dissipation effect and good in energy dissipation capacity, and is an excellent energy dissipation element, hysteric curves are full, and the like.

Owner:HARBIN INST OF TECH

Hybrid hydro (air) static multi-recess journal bearing

InactiveUS8646979B2Easy to manufactureReduce frictionBearing componentsSliding contact bearingsRotational axisShear friction

Multi-recess hydrostatic journal bearings support a rotating shaft and have inclined surfaces, each inclined surface forming a variable radial gap with the surface of the shaft, the variable gaps converging in the direction of rotation of the shaft to increase hydrodynamic forces, reduce a turbulent component of shear friction, and improve the thermal stability of the journal bearing. The inclined surfaces can be formed in one or more of portions of recess bottoms in recesses, portions of gap lands surrounding recesses, and portions of an inner surface of a bushing.

Owner:ELKA PRECISION

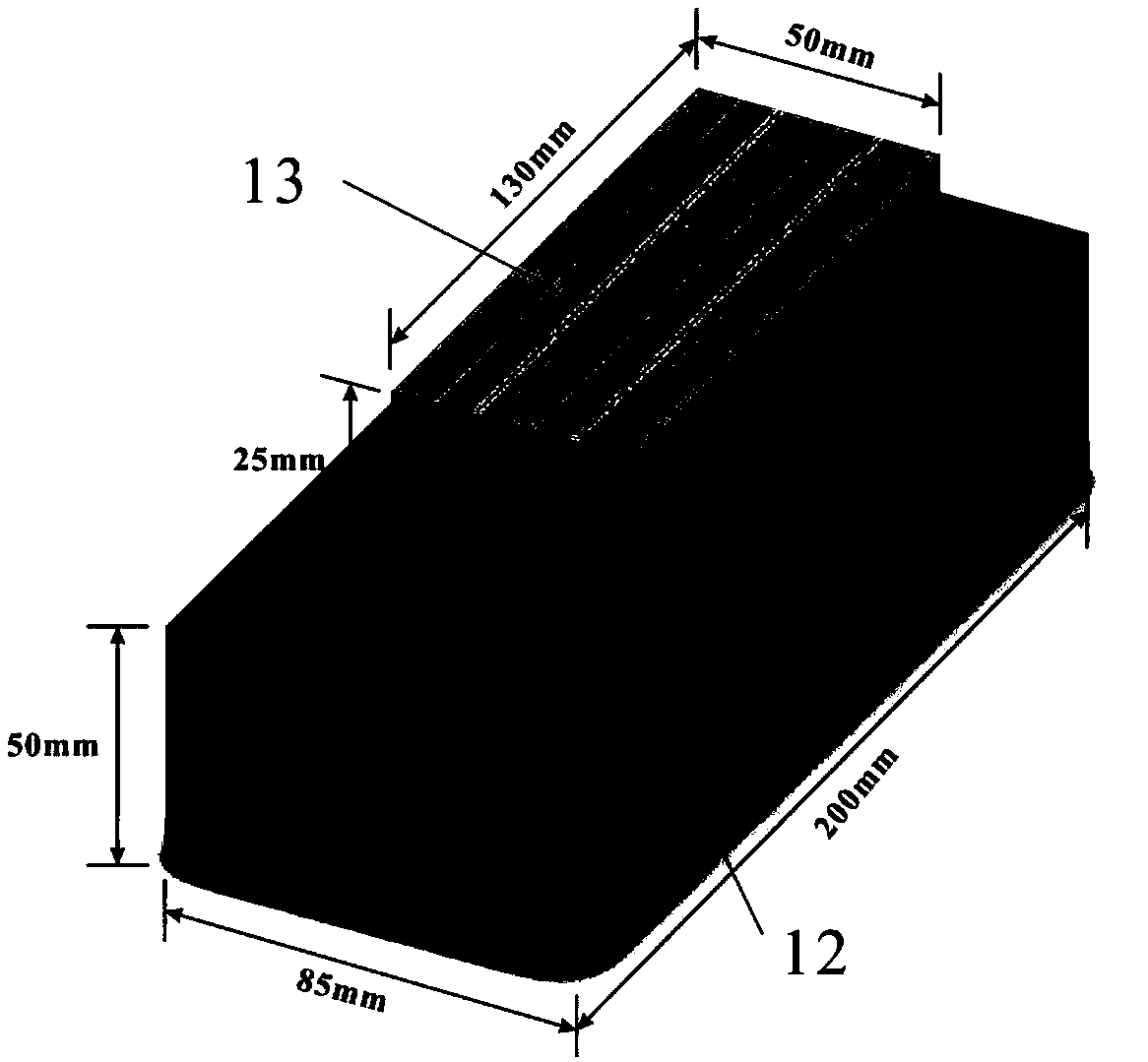

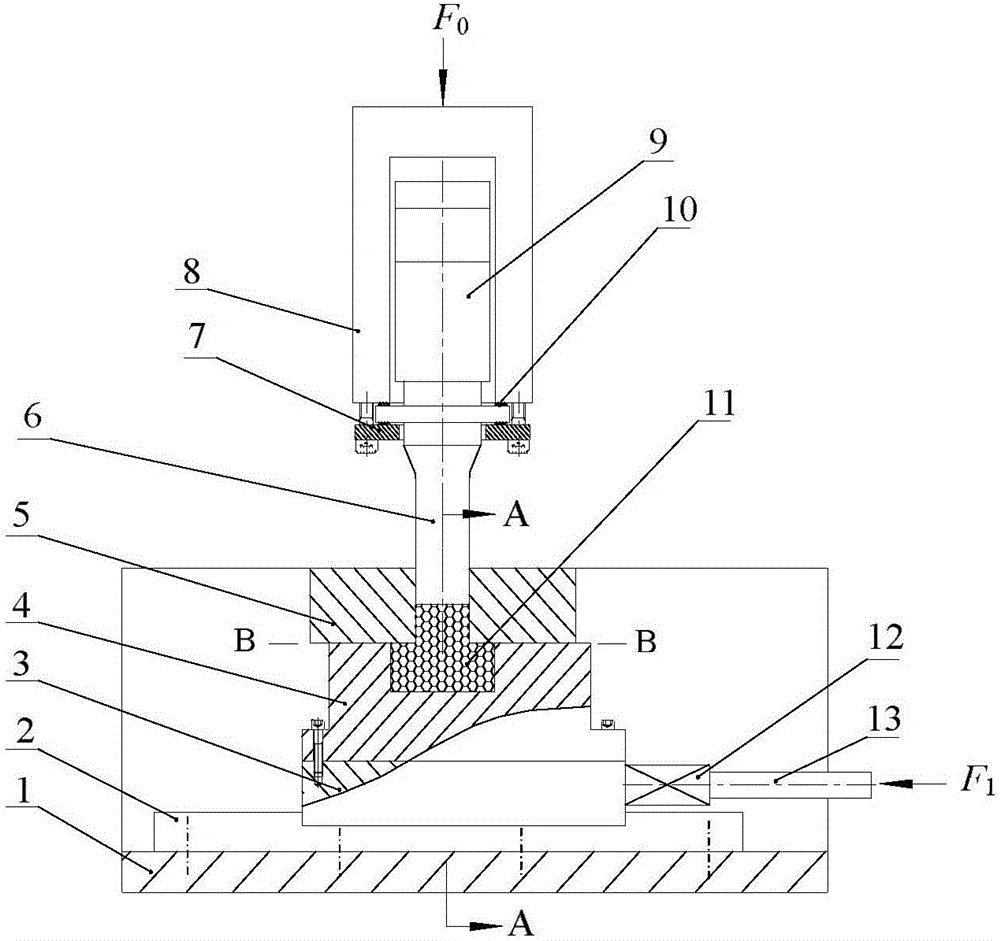

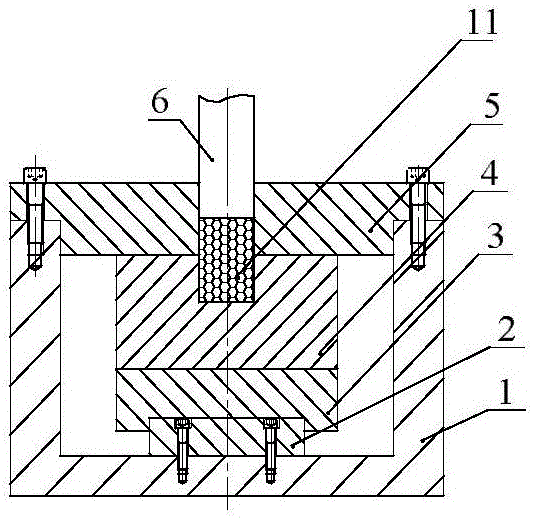

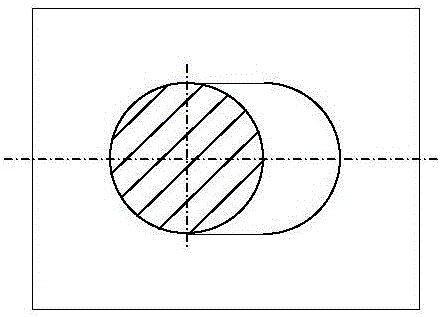

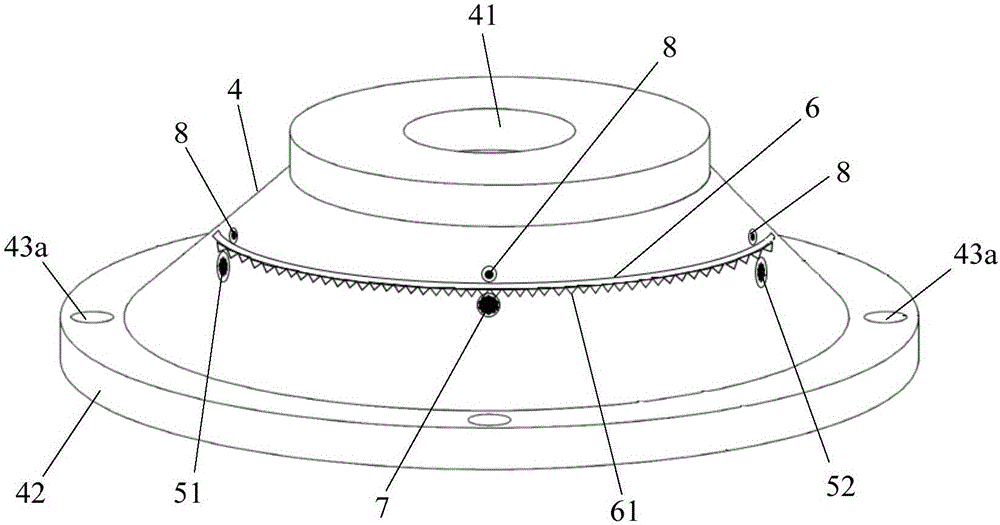

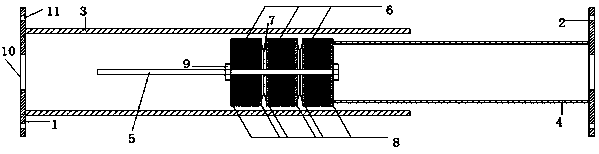

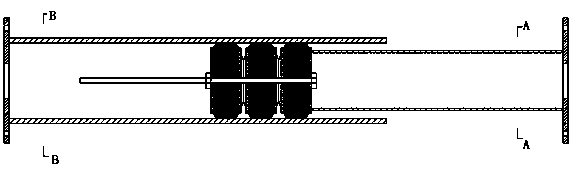

Device for simulating shearing friction of pipe joint of jacking pipe and rocky surrounding rock and testing method

ActiveCN108982250AReal-time simulation of contact conditionsUsing mechanical meansMaterial strength using steady shearing forcesEngineeringShear friction

The invention belongs to the technical field of construction of a pipe jacking method and relates to a device for simulating shearing friction of a pipe joint of a jacking pipe and a rocky surroundingrock and a testing method. A hoisting mechanism is arranged at the bottom of a rigid block; a rock base is arranged above a ball base at the top of the rigid block and a curved-surface groove is formed in the middle of the rock base; the curved-surface groove is internally provided with a concrete test piece matched with the shape of the curved-surface groove; a selfie stick with a selfie stick button is mounted at the outer side of a triggering end of the left side of the rock base; a fixed rod which is detachably connected with the selfie stick is fixedly mounted on a first counter-force wall at the outer side of the selfie stick; a supporting rod and a second counter-force wall are sequentially and fixedly mounted at the right side of a push plate on the ball base at the right side ofthe rock base; the second counter-force wall is fixedly provided with a displacement mechanism which is fixed through a supporting rod; a pressure sensor between the displacement mechanism and the push plate and the displacement mechanism are connected to a computer through lead wires; the whole device can be used for simulating a process of jacking the concrete jacking pipe in the surrounding rock in real time, and a jacking pipe-surrounding rock friction rule in a jacking process is tested and researched.

Owner:重庆大学建筑规划设计研究总院有限公司

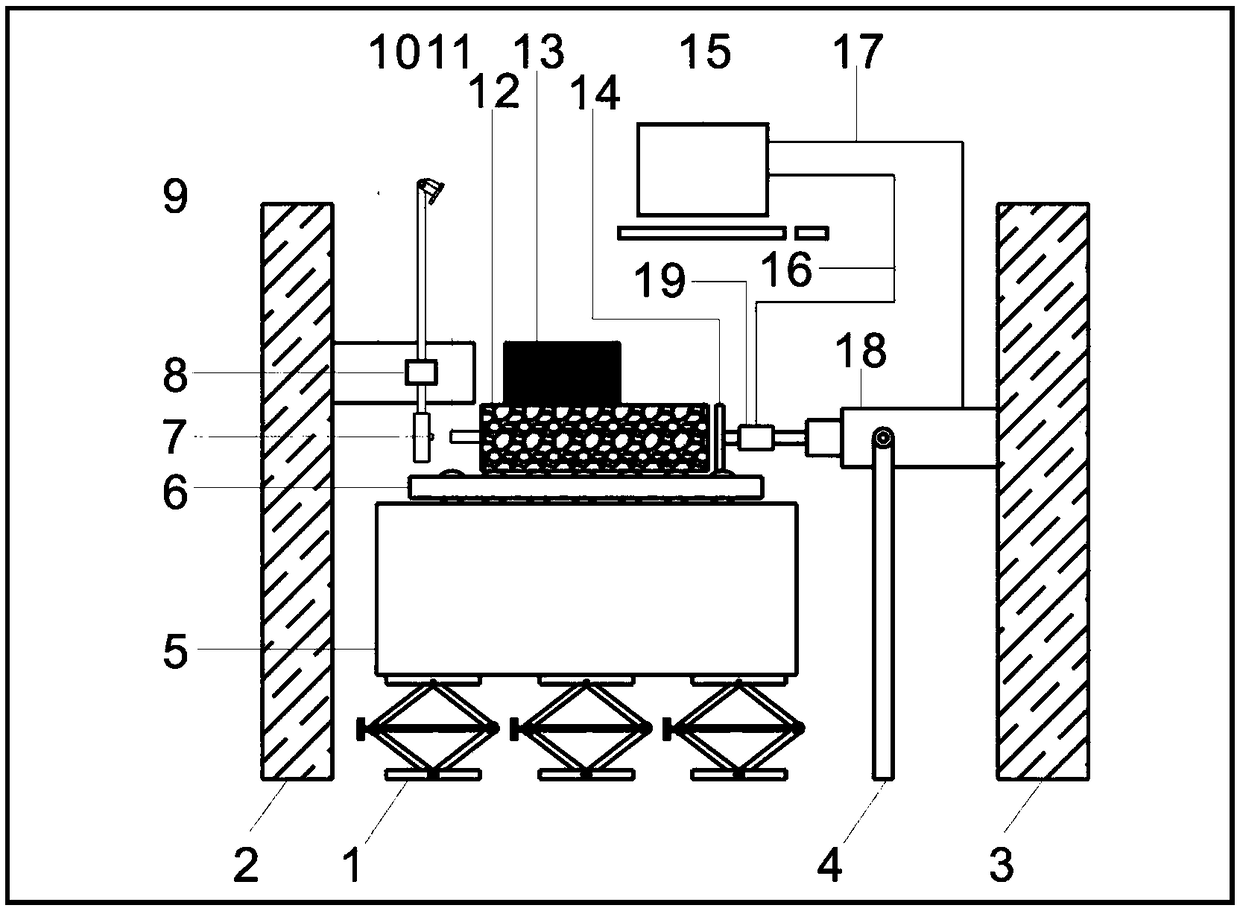

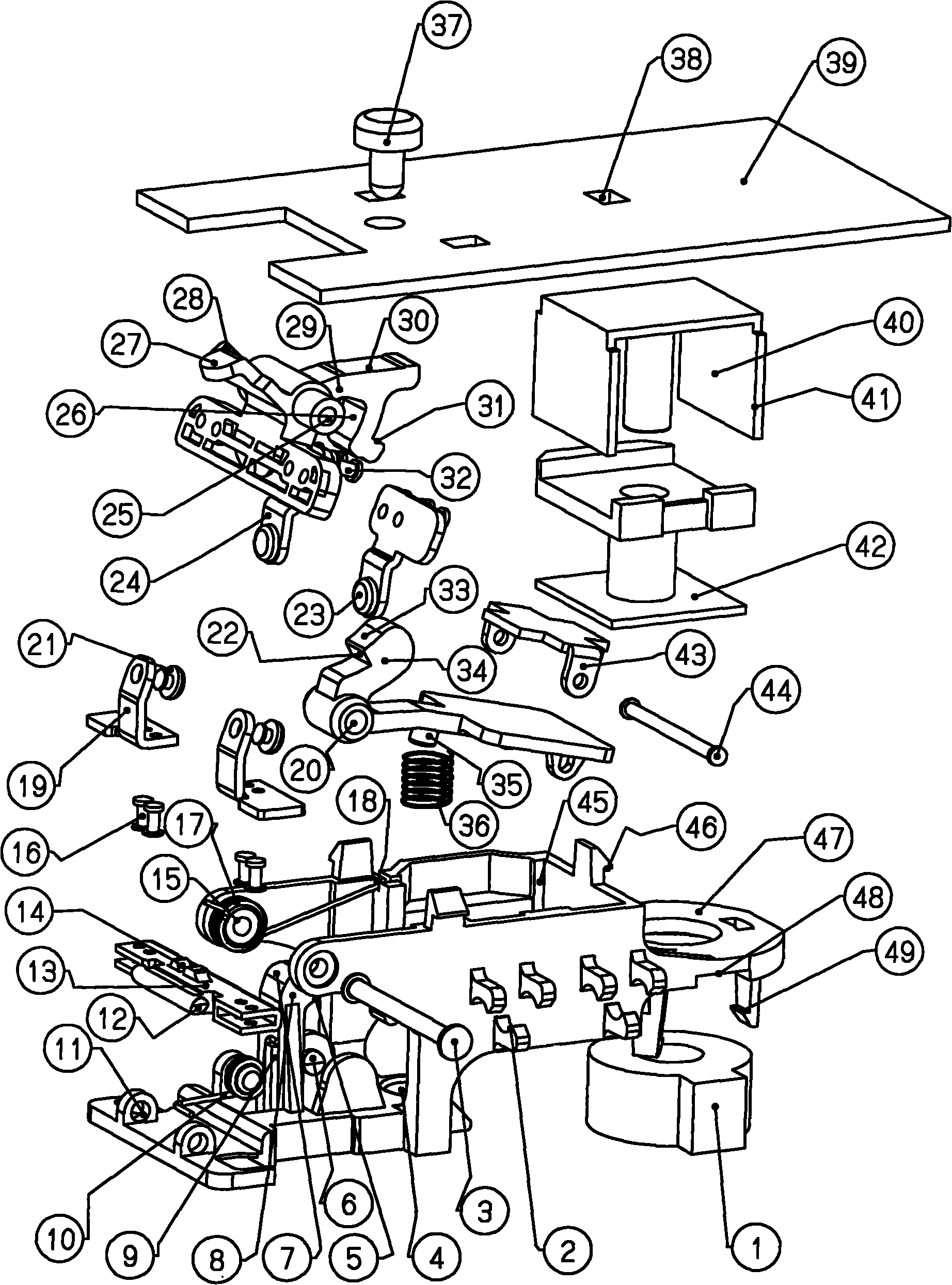

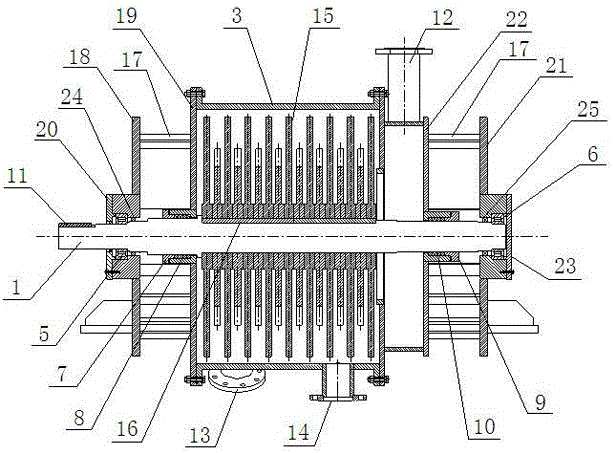

Shear friction test device for pressure-bearing granular medium under vibration condition

InactiveCN106442311ASimple structureSolve the defect of calculation errorUsing mechanical meansMaterial analysisVibration controlData acquisition

The invention discloses a shear friction test device for a pressure-bearing granular medium under a vibration condition. The shear friction test device comprises a vibration shear device and a data detection and analysis device. The vibration shear device comprises a test box, a vibration device, a punch and a side pushing device. The data detection and analysis device comprises a pressure sensor, a data acquisition system and a computer. In testing of the shear friction force of the granular medium, the solid granular medium to be tested is poured into a shear box, then the punch is placed on the upper surface of the granular medium, the vibration device is started, and the punch goes downwards to push; the shear box shears the granular medium under the action of lateral pushing, the sensor inputs shear displacement and force of the granular medium into the data acquisition system, and shear friction on the granular medium is recorded and analyzed by the computer. The shear friction test device can test influences of vibration excitation on the shear friction force of the granular medium under the pressure condition, thus revealing friction characteristics of the granular medium under the vibration condition.

Owner:YANSHAN UNIV

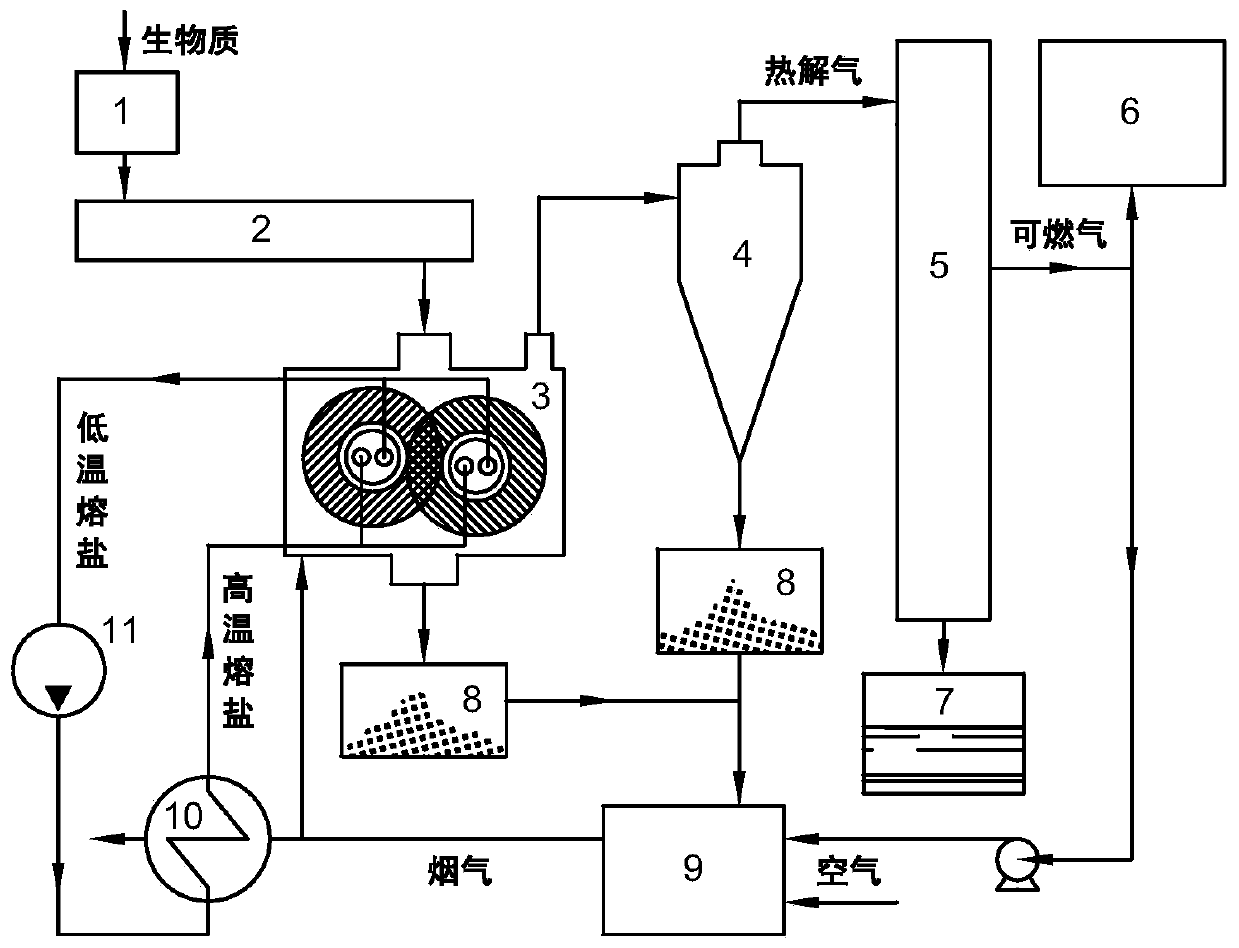

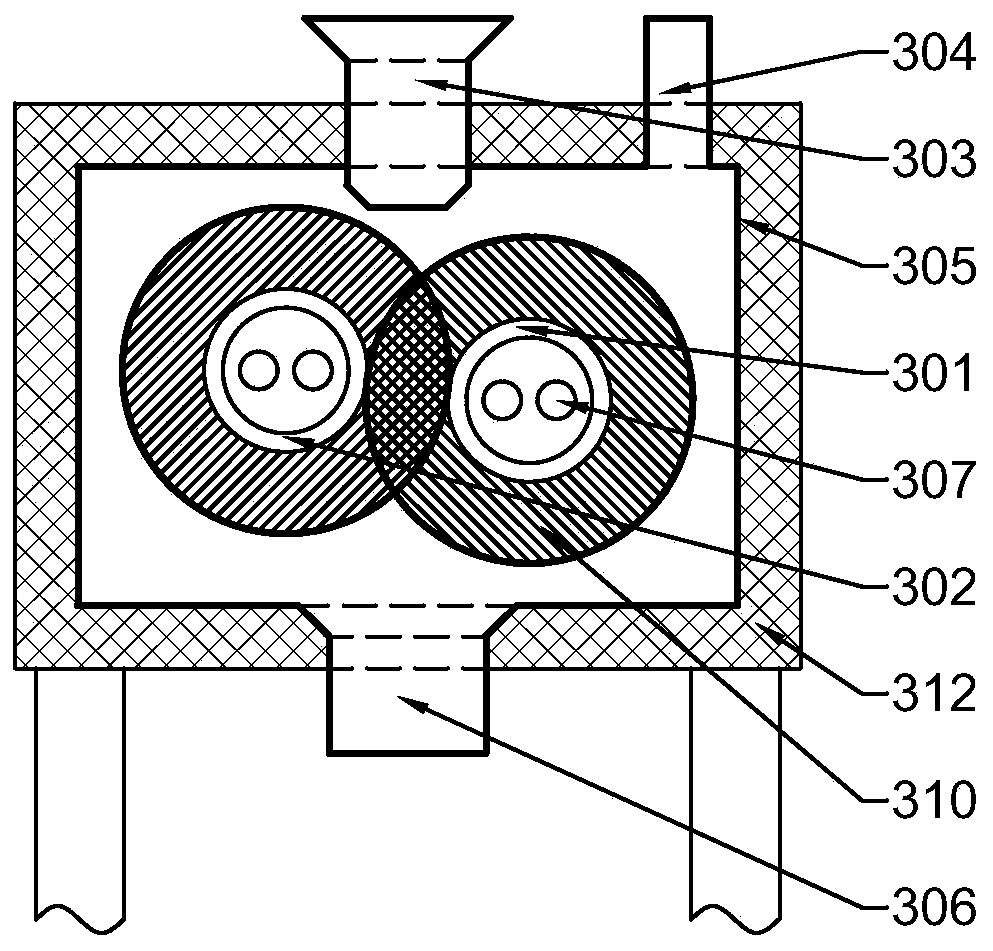

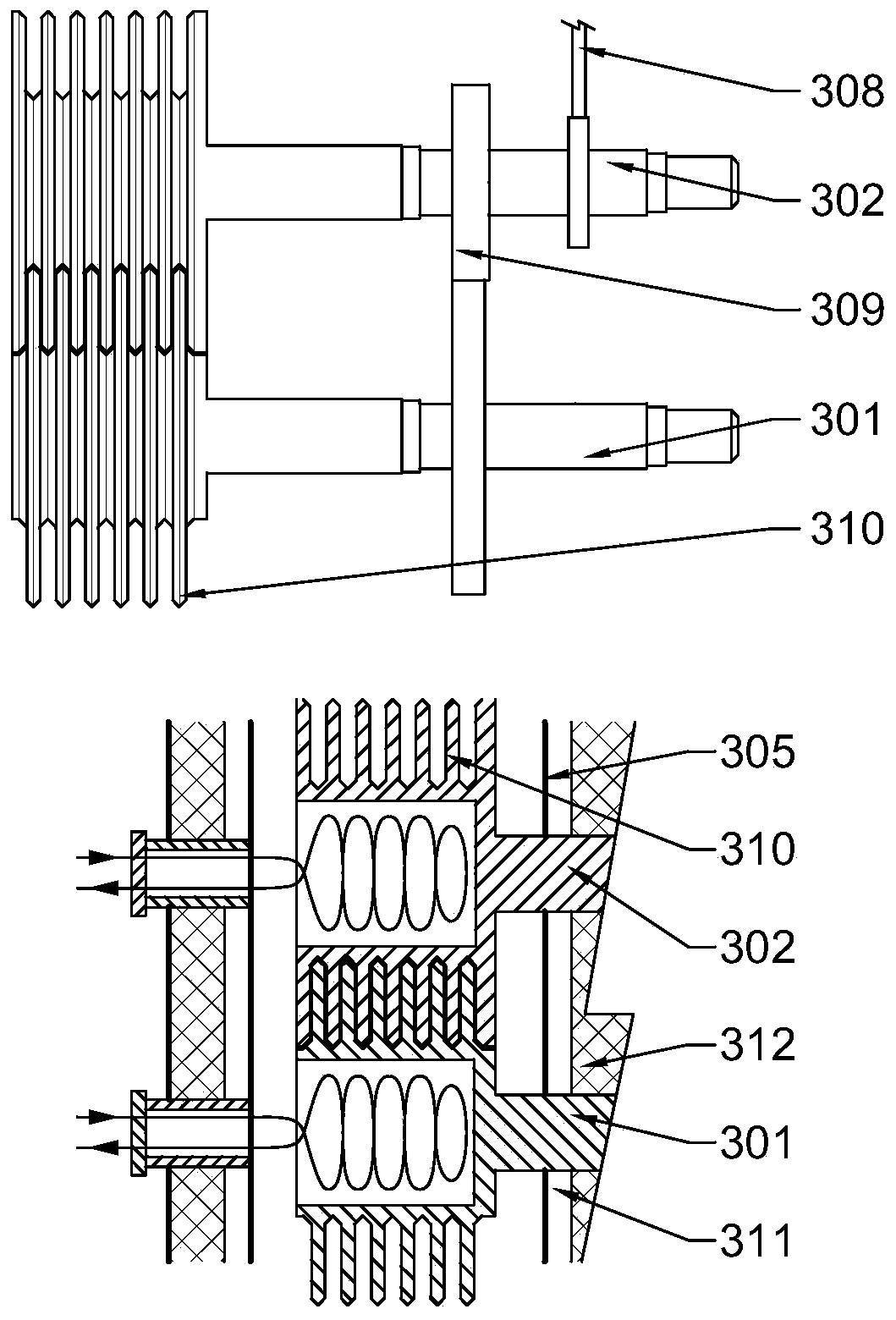

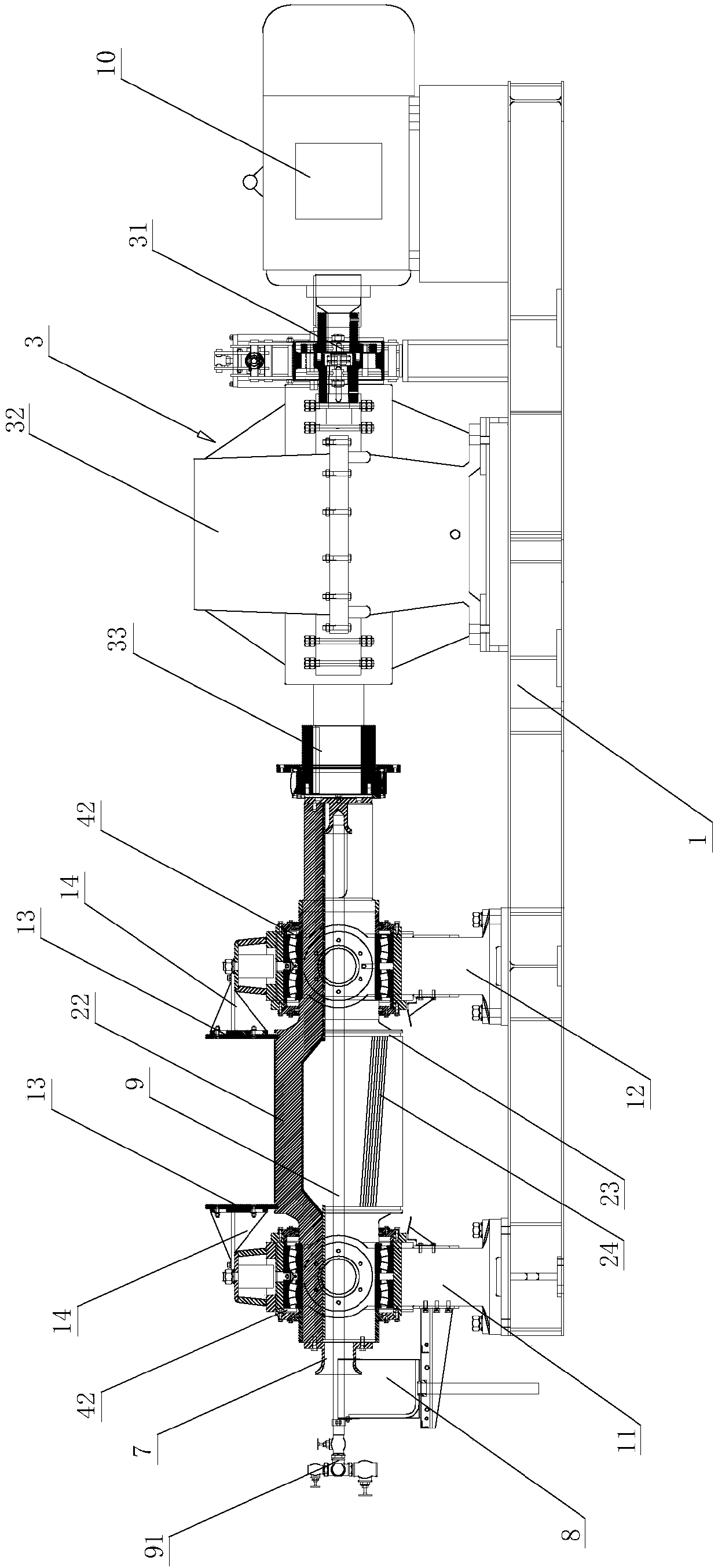

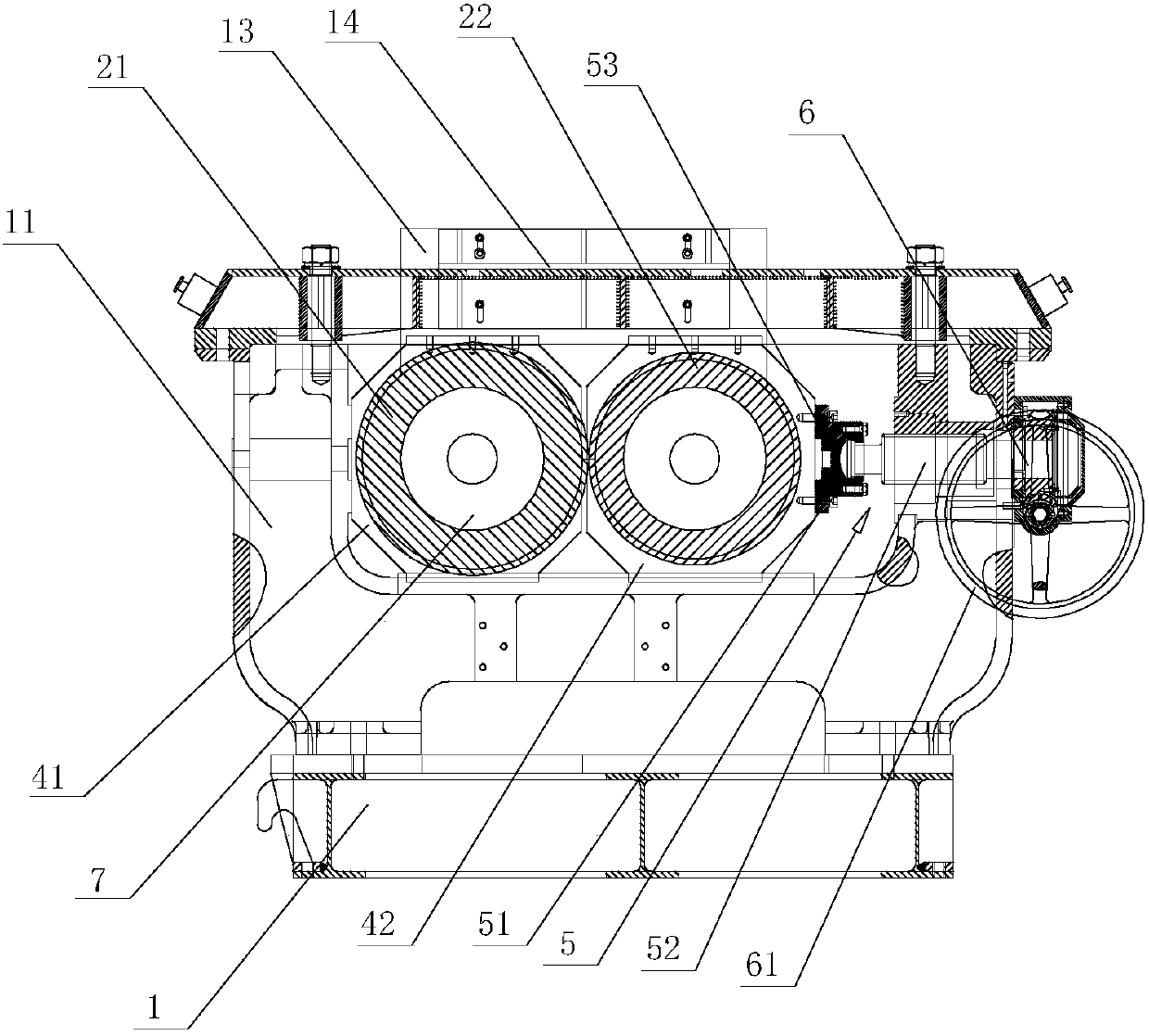

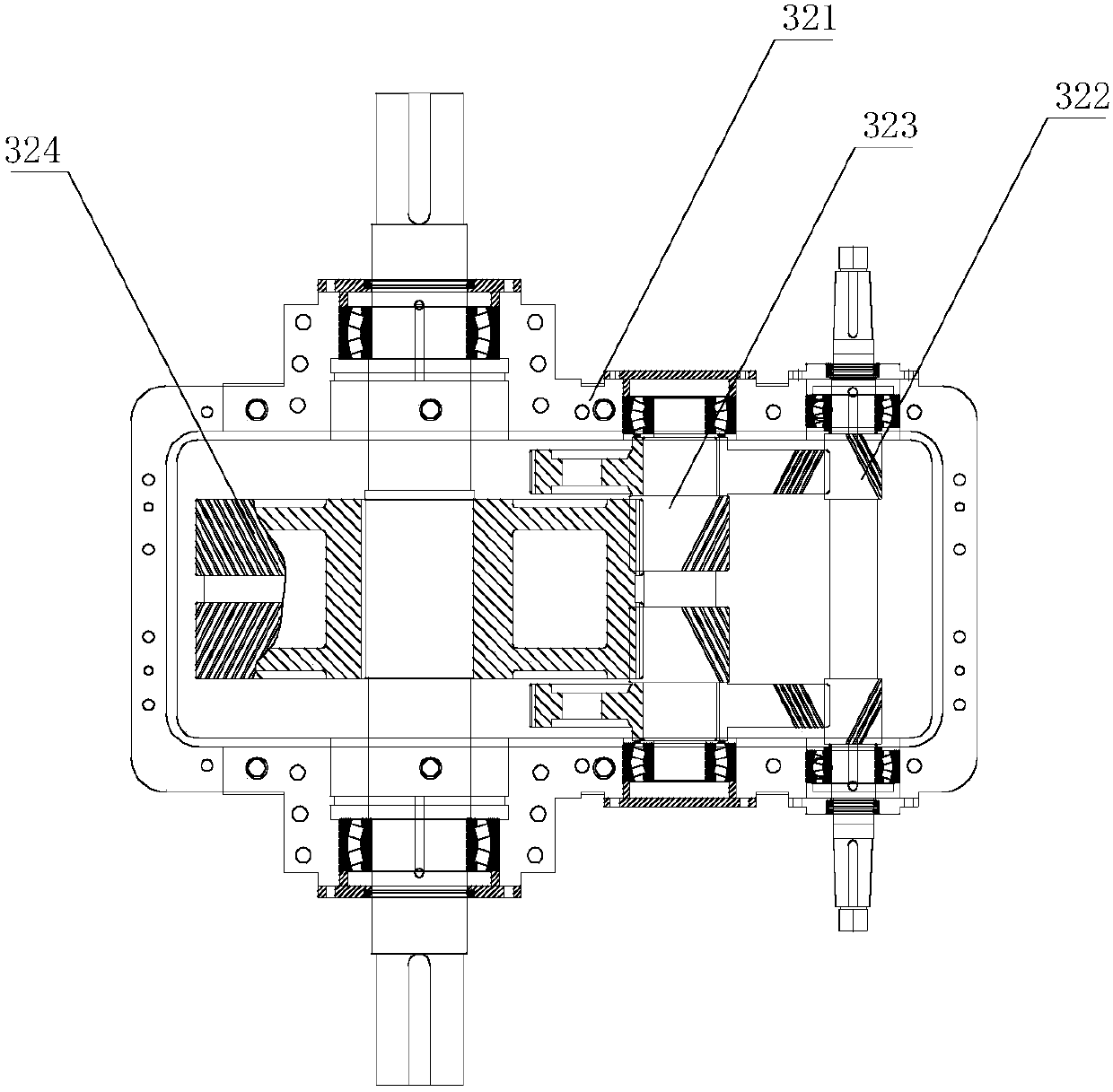

Differential grinding roller type rapid biomass catalytic pyrolysis device and method

ActiveCN110003926AImprove heat transfer efficiencyEfficient heat transferBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisThermal insulation

The invention relates to a differential grinding roller type rapid biomass catalytic pyrolysis device and method. The device comprises a hopper, a feed system, a differential grinding roller type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a bio-oil collection tank, a carbon collection box, a combustion system, a heat exchange system and a fused salt circulation system. The differential grinding roller type pyrolysis reactor comprises a pair of differential grinding rollers, a closed casing, a high-temperature fused salt heat exchange tube, a materialinlet / outlet, a gas outlet, a drive and transmission device and a thermal insulation system. The pretreated biomass raw materials are subjected to heating and shearing friction of cross high-temperature millstones, the surface carbon residues are continuously peeled off, and effective catalytic pyrolysis inside raw material particles is ensured; the pyrolysis gas is rapidly condensed after gas-solid separation so as to obtain high-grade bio-oil fuel or bio-oil enriched in specific high value-added products; meanwhile, the combustible gas and coke are collected and combusted to produce high temperature flue gas, and the flue gas is used for heating the fused salt and conducting heat and further heating the millstone, so that a self-heating pyrolysis process is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

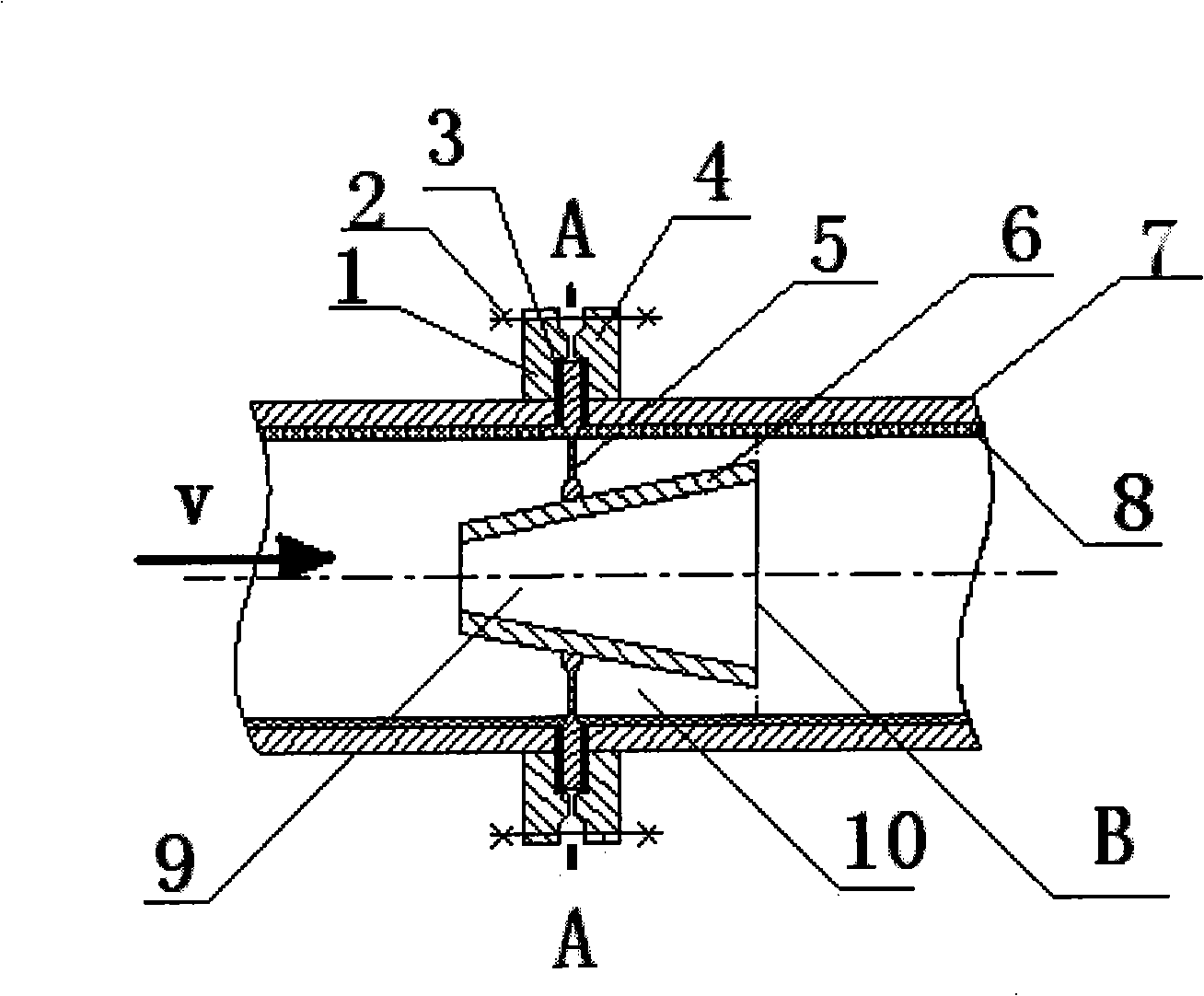

Pneumatic gas heating device and gas heating method

InactiveCN101303178ANot easy to damageFast heatingOther heat production devicesStraight tubeThermal insulation

The invention discloses a pneumatic type gas heating device and a gas heating method. The heating device comprises a pipe which is connected by two sections of straight pipes in a manner of sealing; the inner wall of the pipe is provided with a thermal insulation layer and the joint part of the two sections of the straight pipes is provided with a support component which is connected with a nozzle arranged in the center of the inner cross section of the pipe; an annular channel shrinking along the forward direction gradually and expanding along the negative direction gradually is formed between the nozzle and the thermal insulation layer; the nozzle is internally provided with a cross section changeable flow channel. High speed compressed gas is sent from one end of the pipe at subsonic speed and divided into two strands when going through the nozzle; the middle strand enters the cross section changeable flow channel of the nozzle and the surrounding strand enters the annular channel shrinking along the forward direction gradually between the nozzle and the thermal insulation layer and speed difference of the two strands of flow is generated at the joint surface at the end of the nozzle; shear friction and disturbance take place and gas is heated and the heated gas flows out from the other end of the pipe. The gas heating device has the advantages of simple structure, low production cost, even heating, fast temperature rise, saving energy, being high efficient, clean and sanitary, etc.

Owner:XI AN JIAOTONG UNIV

High-performance shear friction damper

ActiveUS20140326557A1Easy to installRespond effectivelyProtective buildings/sheltersFriction dampersArchitectural engineeringShear friction

Owner:IND ACADEMIC COOP FOUND CHOSUN UNIV

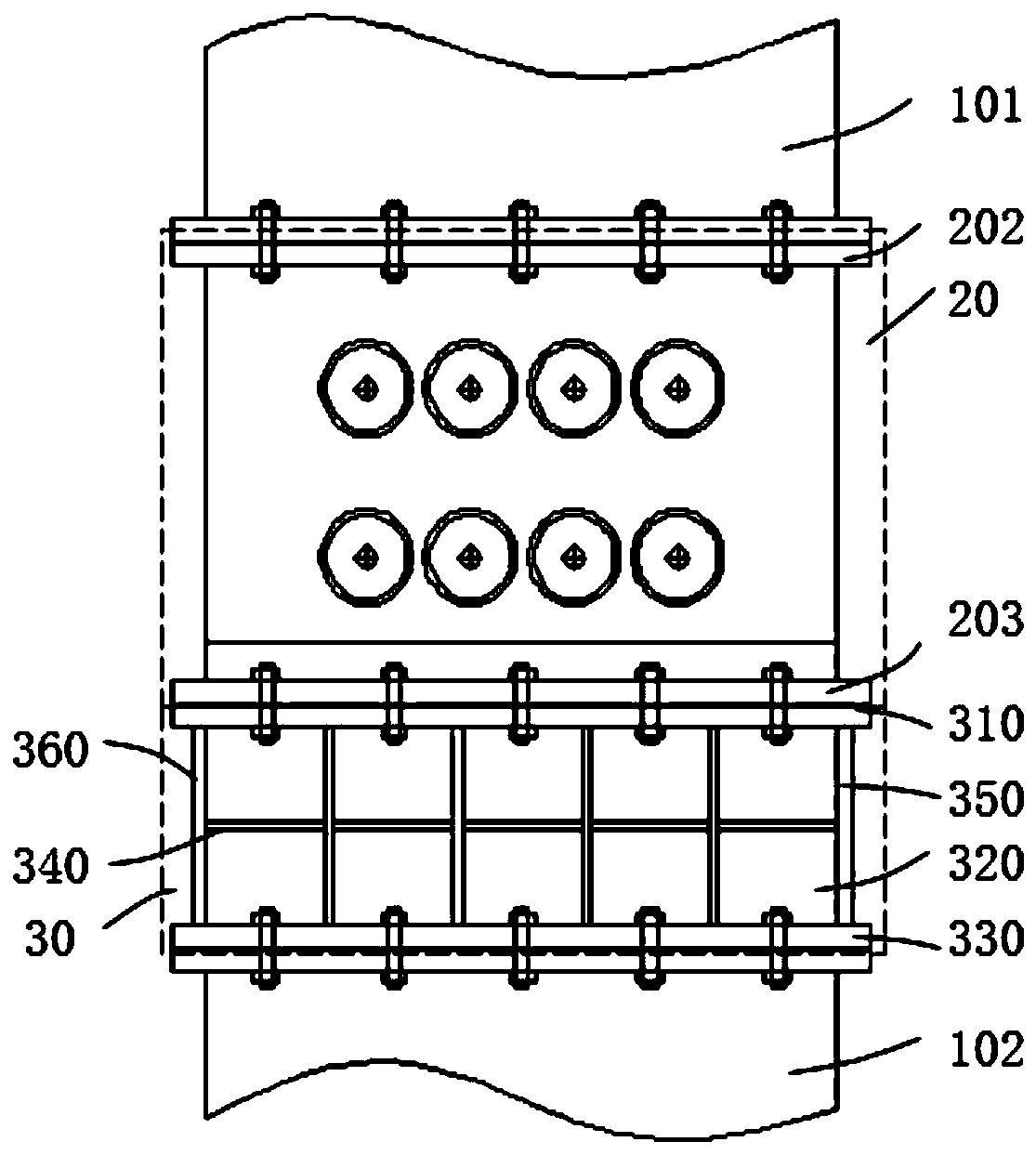

Multi-energy-consuming shearing damper

InactiveCN108951924AShear energy consumption is sufficientReasonable designProtective buildings/sheltersShock proofingVibration controlSnubber

The invention provides a multi-energy-consuming shearing damper, and belongs to the field of architectural structure vibration control. A main body of the multi-energy-consuming shearing damper is a structure enclosed by end plates, side plates and closure plates, a cavity in the enclosed structure is provided with a shearing friction damping layer, the enclosed structure is internally provided with a plurality of energy-consuming steel plates, connecting energy-consuming steel plates, shearing damping core plates and arc-shaped shearing extrusion energy-consuming steel plates respectively, and the energy-consuming steel plates and the shearing damping core plates all stretch out of the end plates and are connected with connecting plates arranged on the outer portion. The multi-energy-consuming shearing damper has the advantages that the energy-consuming steel plates and the connecting energy-consuming steel plates can provide powerful vertical energy-consuming support and have reasonable initial vertical stiffness, the structural design of the energy-consuming steel plates clamping the shearing damping core plates is adopted, the force on the energy-consuming steel plates can be dispersed uniformly when shearing occurs, and the design is reasonable.

Owner:SHENYANG JIANZHU UNIVERSITY

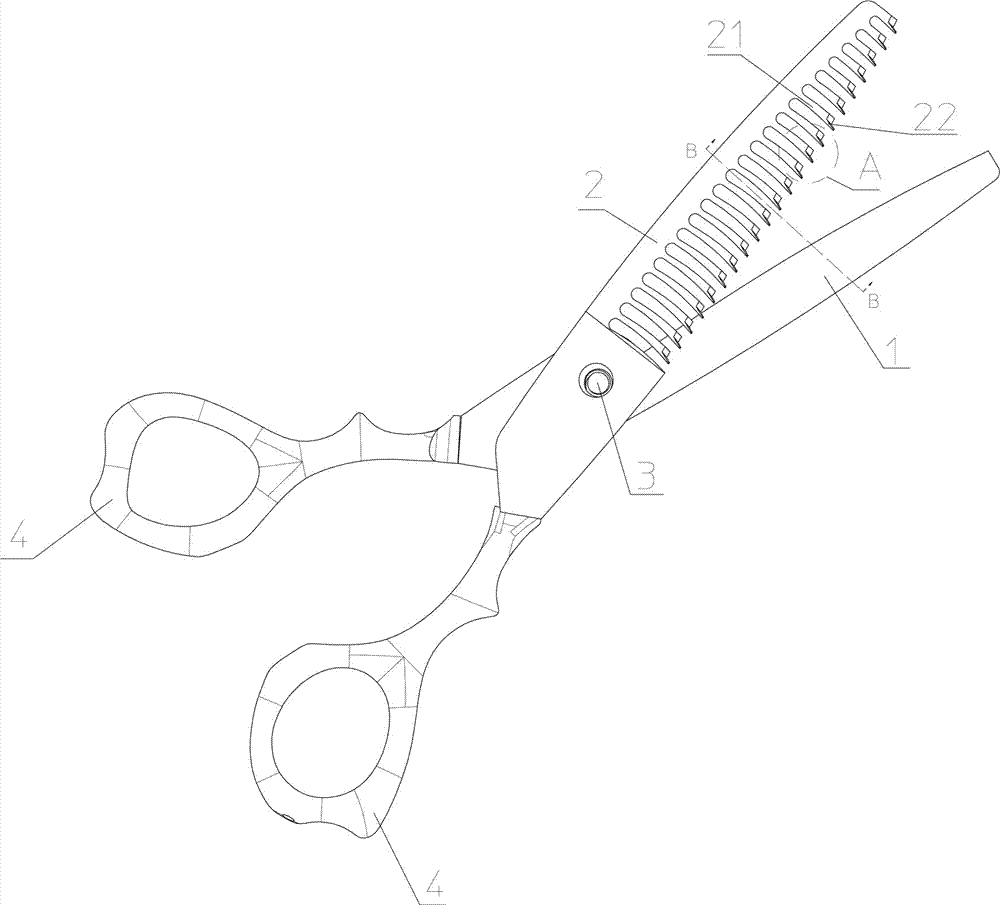

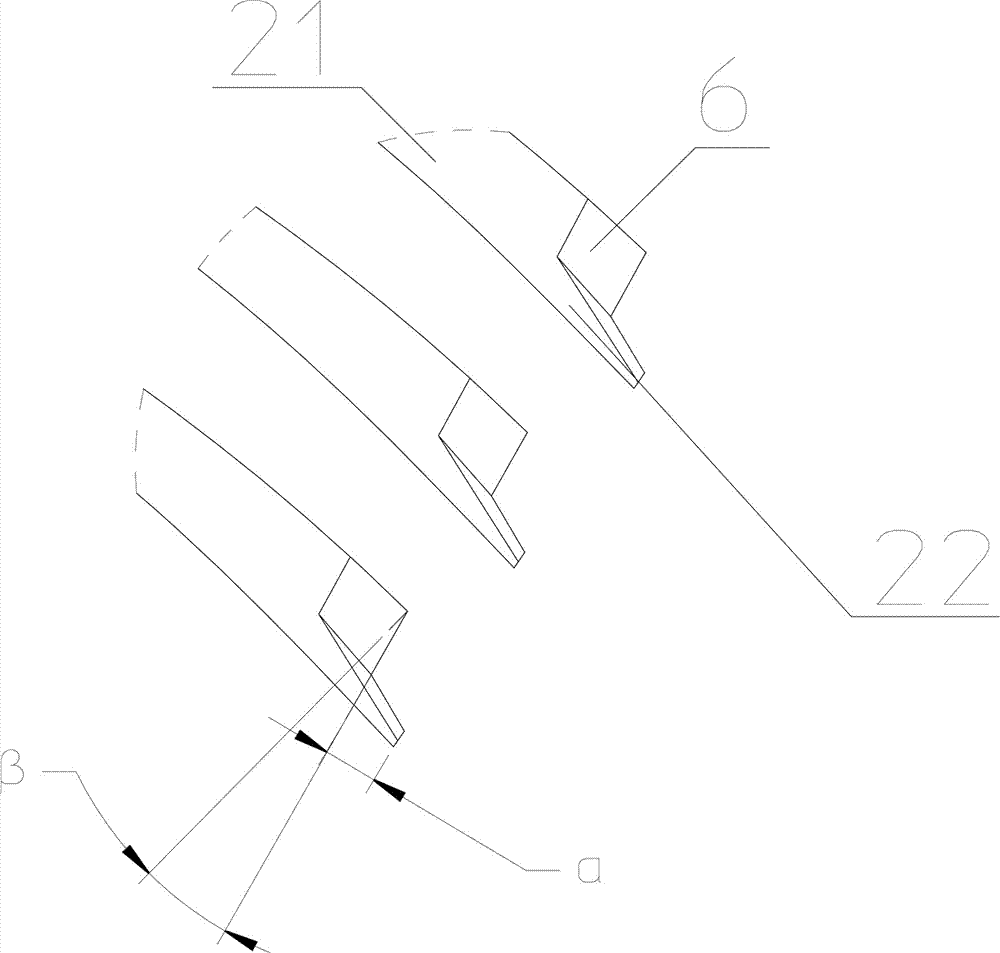

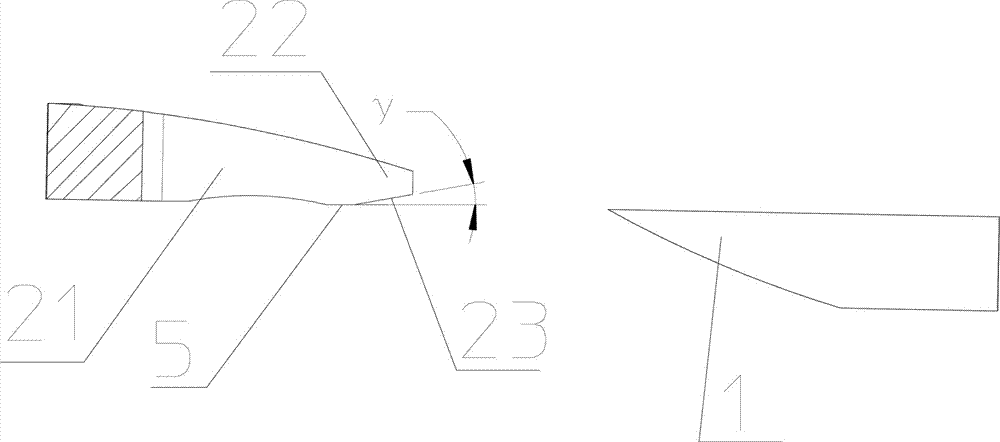

Traceless stage tooth double-face sharp knife edge tooth scissor

The invention discloses a traceless stage tooth double-face sharp knife edge tooth scissor. The traceless stage tooth double-face sharp knife edge tooth scissor comprises a movable knife edge blade and a fixed knife edge blade which are hinged through a pivot; the tail ends of the movable knife edge blade and the fixed knife edge blade are each provided with a finger ring; a knife edge of the fixed knife edge blade is composed of tooth knife edges of a plurality of fixed knife edge comb teeth which are arranged side by side at intervals; the tooth knife edge of each fixed knife edge comb tooth is formed by a horizontal plane and a bevel in an intersection manner; the knife edge opening angle of the tooth knife edge of each fixed knife edge comb tooth ranges from 15 degrees to 45 degrees; the tooth knife edge edge position, close to the pivot side, of each fixed knife edge comb tooth is provided with a guiding convex angle; the surface, making contact with a knife edge of the movable knife edge blade, of each guiding convex angle is provided with a guiding bevel; and after being guided by the guiding bevels, the knife edge of the movable knife edge blade and the tooth knife edges, where the guiding bevels are located, of the fixed knife edge comb teeth get close to each other to perform shearing. When the tooth scissor is used for shearing hair, the hair is not prone to being pulled, the hair shearing friction force is small, and the hair shearing hand sense becomes better; and in addition, the tooth scissor can sharply clip the hair, and the cross section of the hair is made to be relatively smooth.

Owner:ZHANG JIA GANG CITY JIN CHENG SCISSORS FACTORY

Low-VOC lubricating agent doped with self-assembly core-shell inorganic particles and used for polyolefin and preparation method of low-VOC lubricating agent

The invention relates to a low-VOC lubricating agent doped with self-assembly core-shell inorganic particles and used for polyolefin and a preparation method of the low-VOC lubricating agent and belongs to the field of production and processing of novel high polymer materials. The preparation method aims to solve the problems that high-shear friction occurs and volatile pollutants are easily decomposed due to high-temperature heating during the high-temperature forming process of the lubricating agent for the polyolefin and is characterized in that the electrostatic layer-by-layer self-assembly technique is used to prepare the core-shell inorganic particles with high adsorption performance, shell layer thickness and shell layer particle pores can be controlled, and the core-shell inorganic particles are compounded with other auxiliaries to prepare the low-VOC efficient lubricating agent. The lubricating agent prepared by the method has the advantages that the lubricating agent can greatly improve processing rheological properties and lubricating properties during the high-temperature forming of polymer polyolefin materials, and VOC content can be lowered to below 120 microgram C / g.

Owner:可赛成功(浙江)新材料科技有限公司

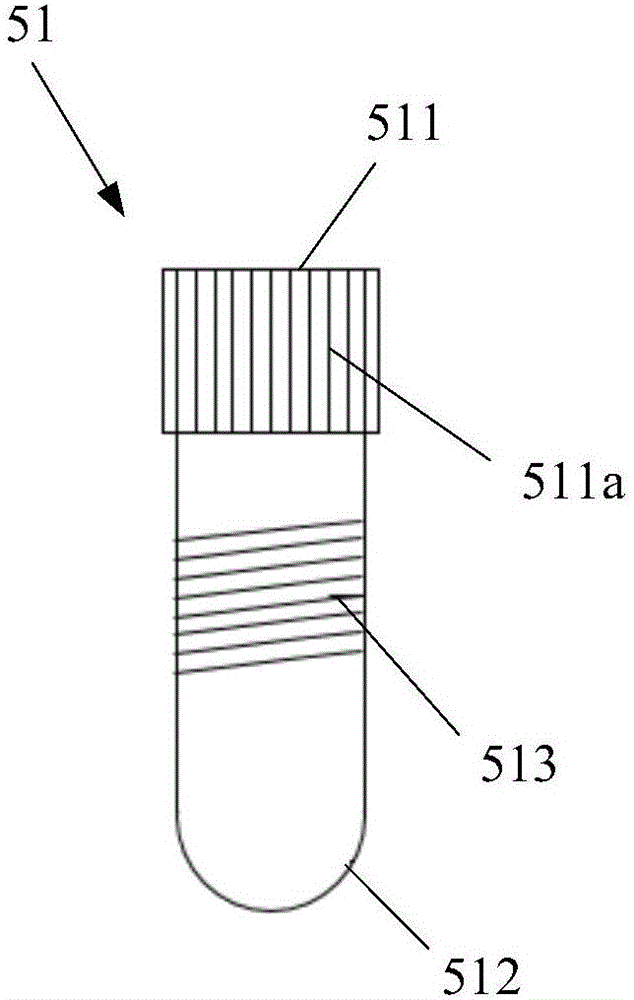

Leveling device for rock direct shear friction experiment

ActiveCN106814030AGuaranteed accuracyGuaranteed surface-to-surface contactUsing mechanical meansMaterial analysisShear frictionEngineering

The invention provides a leveling device for a rock direct shear friction experiment. The leveling device comprises a ball head, a ball seat and an abutting part, wherein the ball seat can be fixed on an experiment table board, the top of the ball seat is provided with a recessed cavity matched with the shape of the ball head, the ball head is located in the recessed cavity, and a platform for fixing a to-be-tested rock sample is connected to the top of the ball head; the ball head can rotate in the recessed cavity and drive the platform to move to allow the friction face of the to-be-tested rock sample on the platform to be located at a preset position; the abutting part can be abutted against the ball head, and the ball head and the ball seat keep relatively still under the friction force of the abutting part when the abutting part is abutted against the ball head. The leveling device has the advantages that the position of the platform is adjusted through the rotation of the ball head until the to-be-tested rock sample on the platform is in face-face contact with a rock sample above the to-be-tested rock sample, and friction experiment precision is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

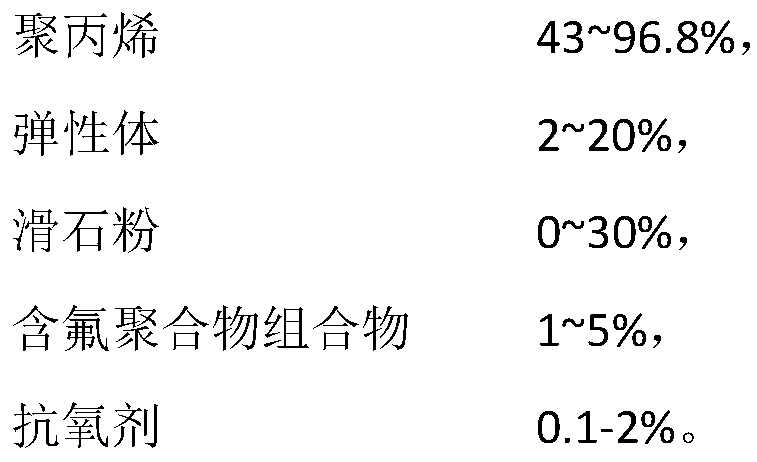

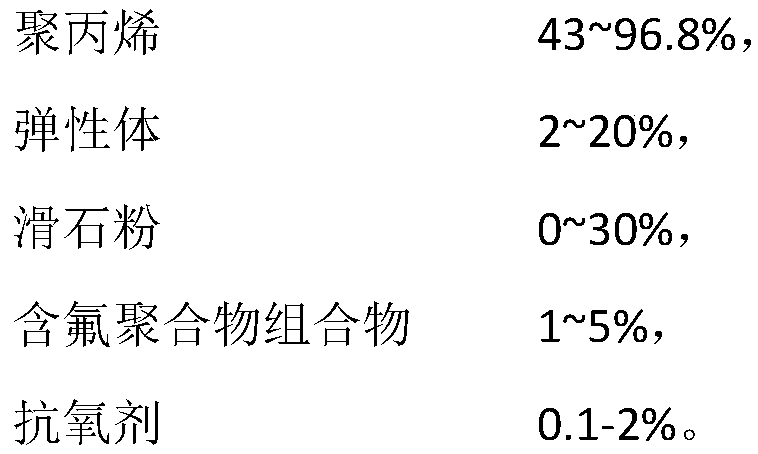

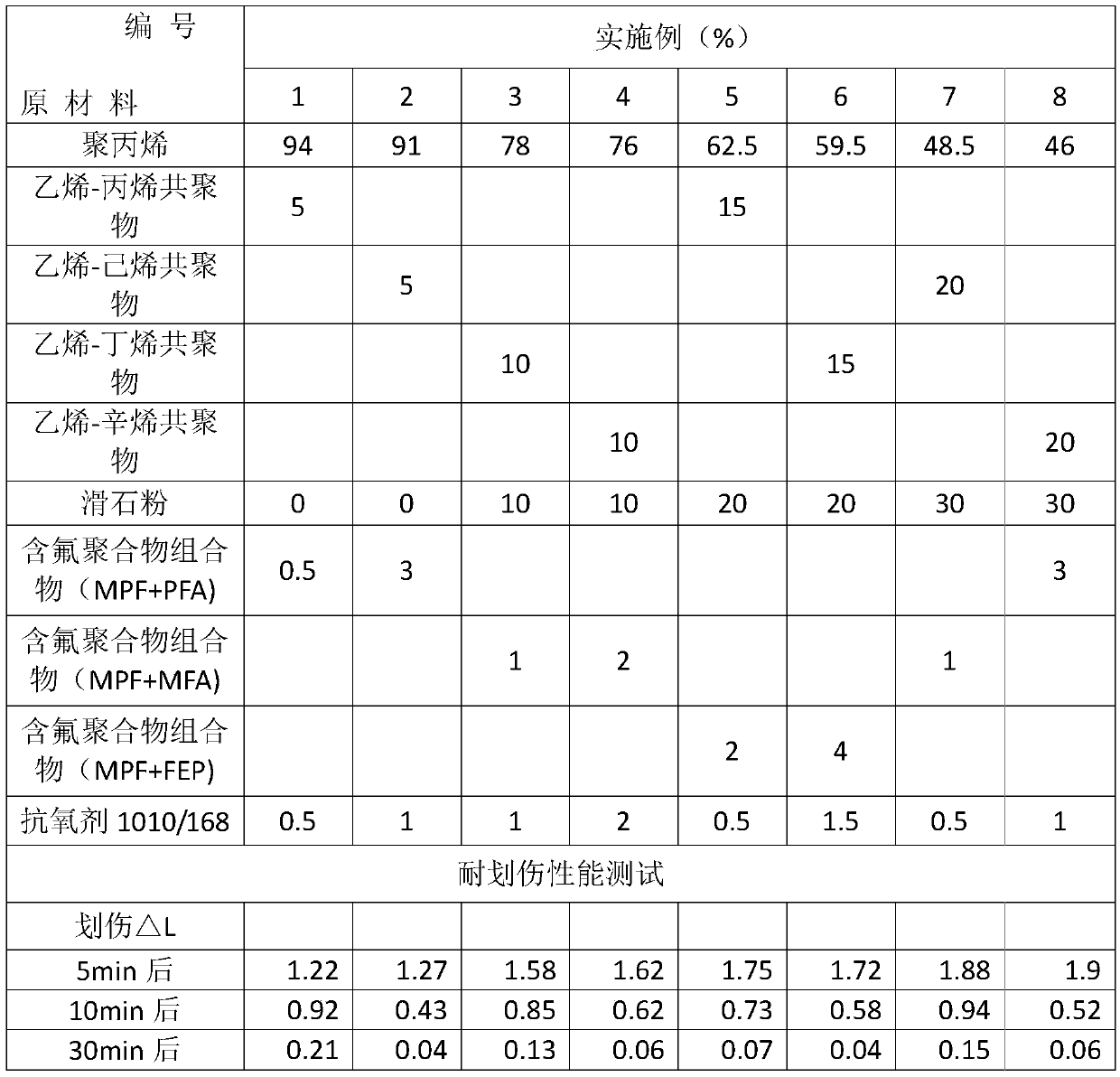

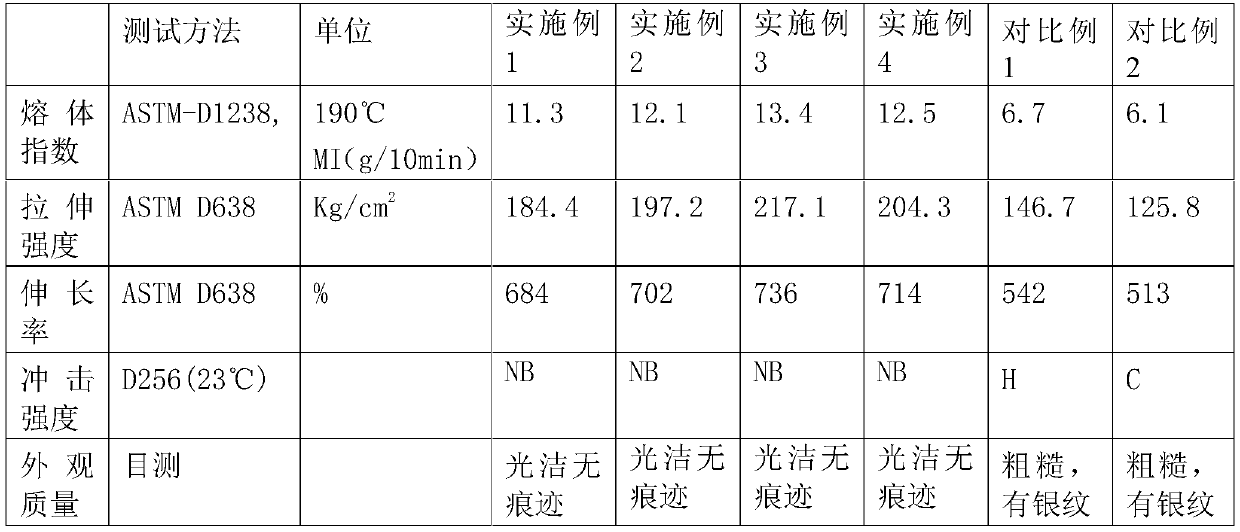

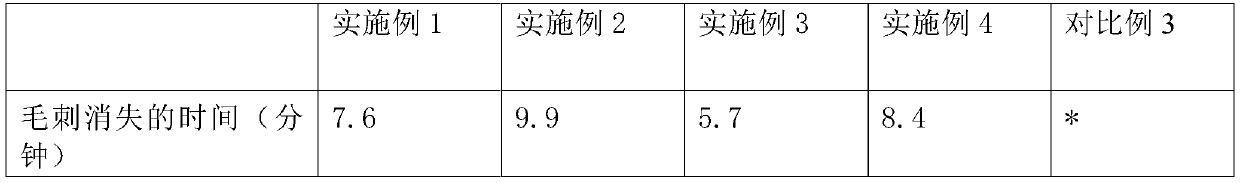

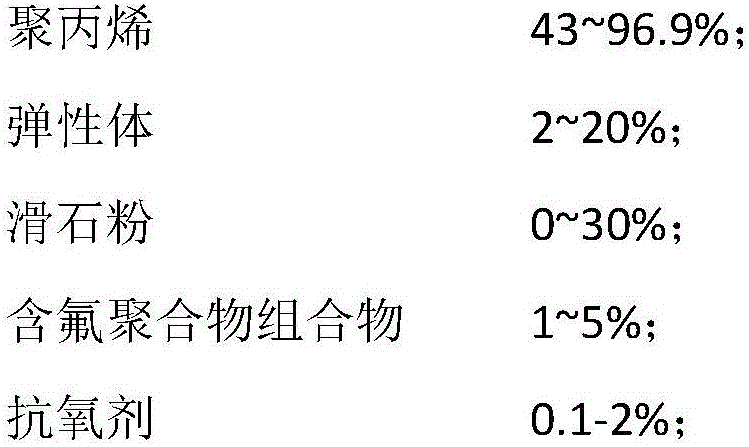

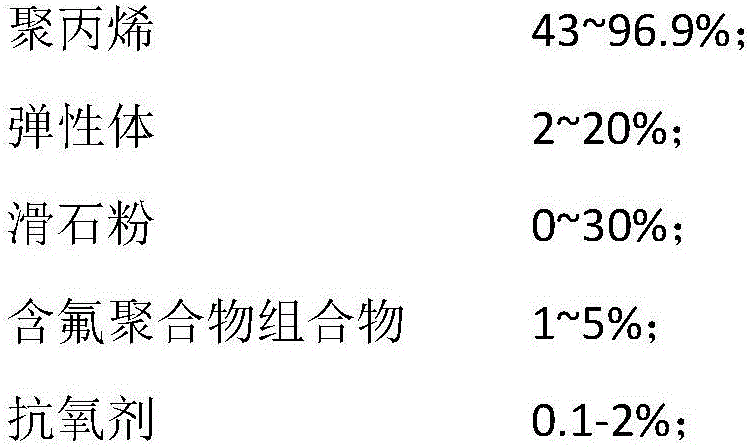

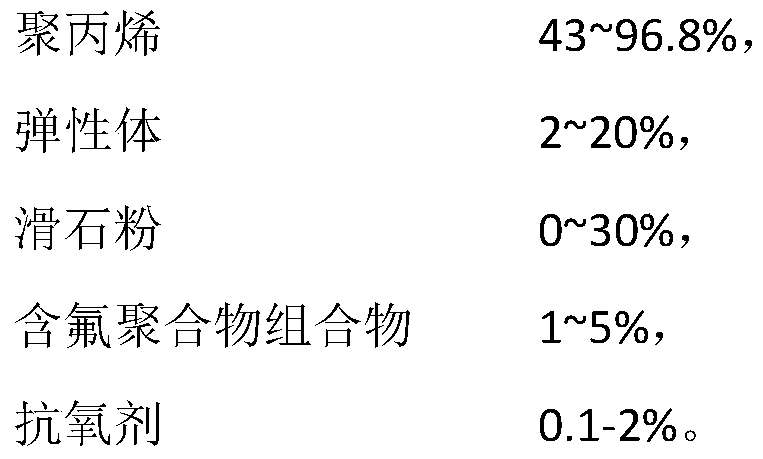

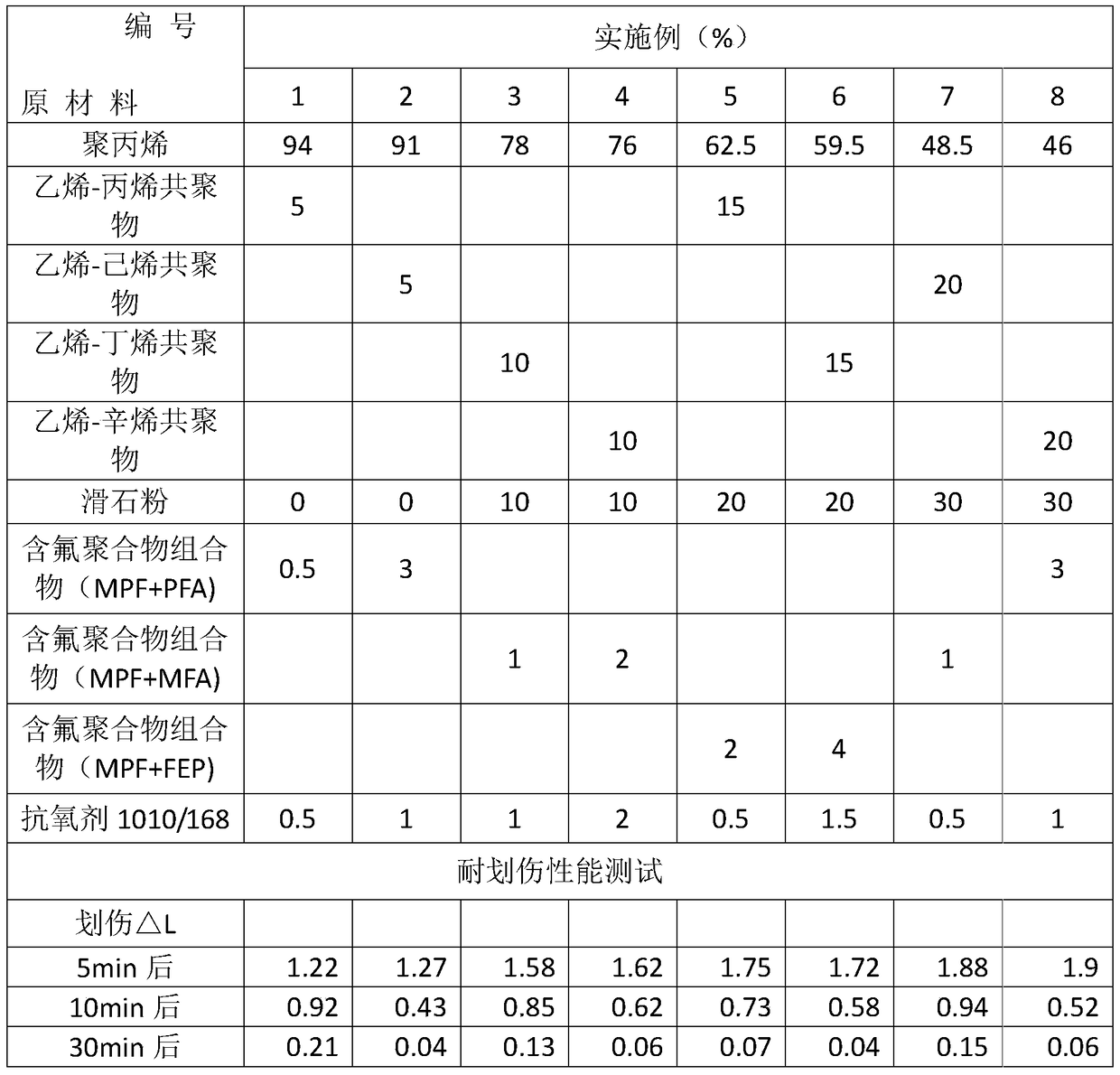

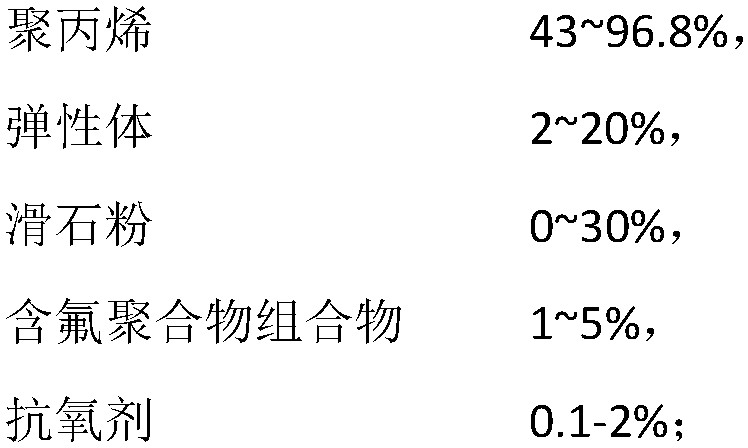

Self-repairing extrusion-grade polypropylene composite material and preparation method thereof

The invention discloses a self-repairing extrusion-grade polypropylene composite material and a preparation method thereof. The polypropylene composite material consists of the following raw materials in percentage by weight: 43-96.8% of polypropylene, 2-20% of elastomer, 0-30% of talc powder, 1-5% of fluorine-containing polymer composition and 0.1-2% of antioxidant. In the invention, the fluorine-containing polymer composition is introduced into the material formula; and in an extrusion moulding process, due to the shear friction between the resin melt and a screw cylinder, the fluorine-containing polymer tends to transfer to the product surface, and the scratch on the product surface is prevented while the micro-surface displacement deformation caused by stress scratch can be quickly repaired. Therefore, the problem in appearance caused by stress scratch in an application process of the polypropylene extrusion product is solved.

Owner:SHANGHAI PRET COMPOSITES

Polyethylene color master batch and preparation method thereof

The invention belongs to the technical field of high polymer materials, in particular to polyethylene color master batch and a preparation method thereof. The polyethylene color master batch is prepared by utilizing the fact that sodium pyrrolidonecarboxylate has a positive effect on the polyethylene color master batch. The polyethylene color master batch is prepared from the following componentsin parts by weight: 100-200 parts of high-density polyethylene, 15-35 parts of an ethylene-ethyl acrylate copolymer, 2-15 parts of nekal, 1-8 parts of 2-heptadecylimidazole, 15-30 parts of white oil,1-10 parts of a dispersing agent and 0.5-5 parts of a stabilizer. The polyethylene color master batch has good compatibility, can be easily mixed with various plastic products uniformly, is stable incolor and luster, excellent in mechanical property, small in shearing friction coefficient, high in surface smoothness and small in equipment abrasion, and facilitates production.

Owner:李丽凤

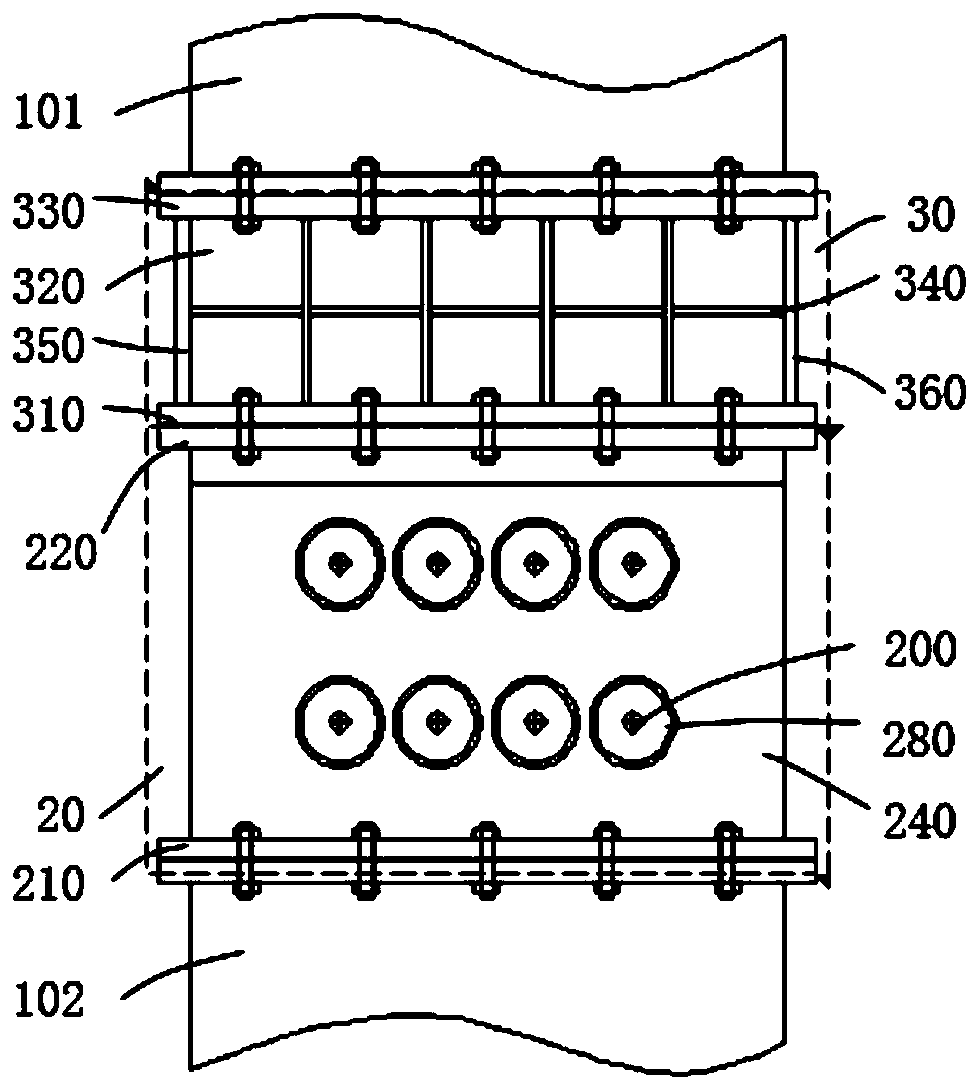

Metal shear friction composite energy dissipation device

ActiveCN110106989AShear energy absorptionEffective absorption of shear energyProtective buildings/sheltersShock proofingEngineeringShear friction

The invention relates to a metal shear friction composite energy dissipation device. The metal shear friction composite energy dissipation device comprises a friction assembly and a shear assembly. The metal shear friction composite energy dissipation device is connected between a first interlayer structure and a second interlayer structure. The friction assembly and the shear assembly are fixedlyconnected. When shear energy exists between the first interlayer structure and the second interlayer structure, the shear energy can be transmitted to the friction assembly and the shear assembly. The friction assembly can absorb the shear energy through internal friction. A first connecting plate and a second connecting plate can further move relative to each other to enable a first core plate to be deformed elastically and deformed plastically to absorb the shear energy. The metal shear friction composite energy dissipation device can effectively absorb the shear energy between the first interlayer structure and the second interlayer structure by three modes of friction, elastic deformation and plastic deformation, and the interlayer displacement between the first interlayer structure and the second interlayer structure is reduced.

Owner:TSINGHUA UNIV

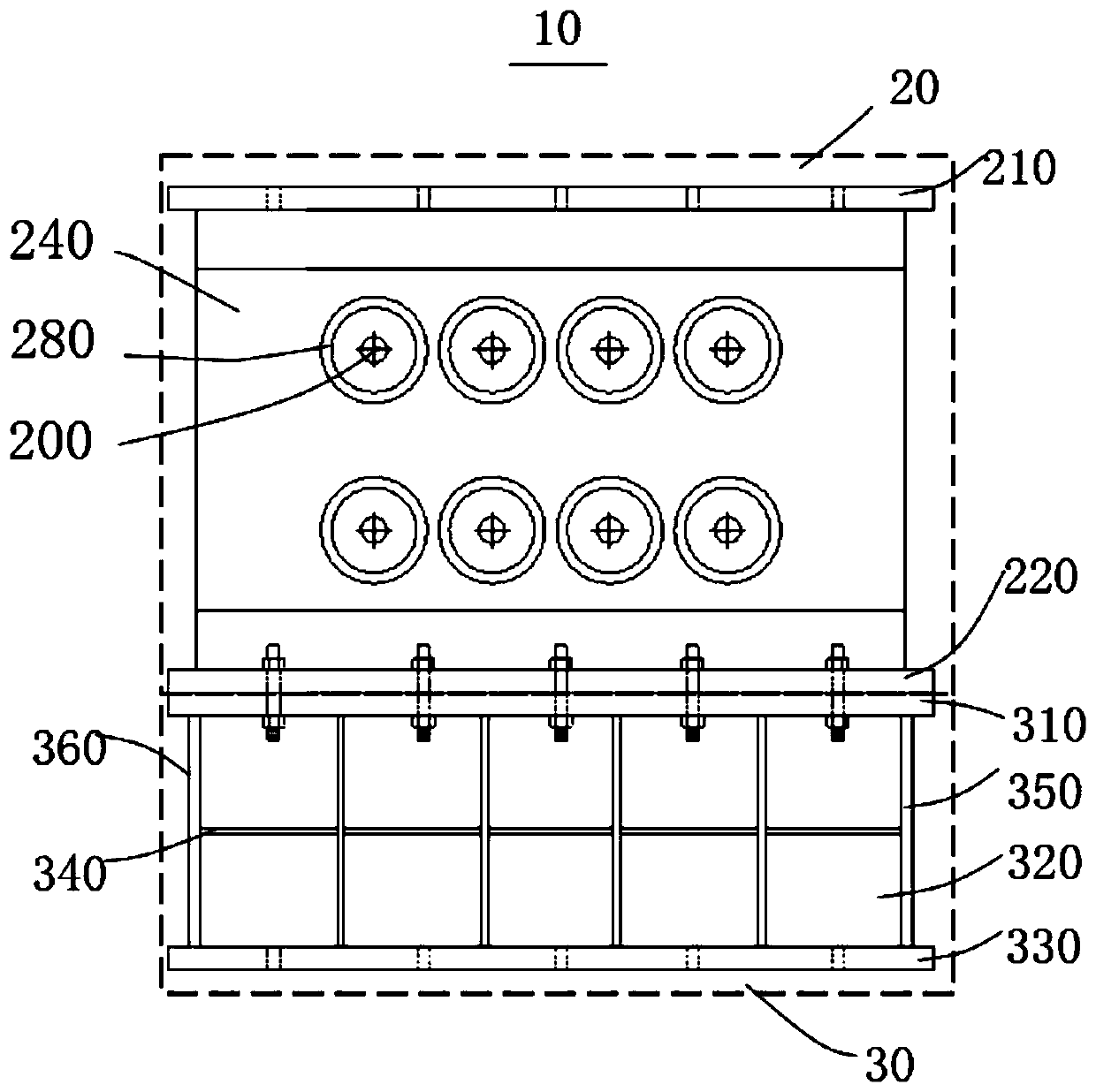

Viscoelastic shearing friction damper and application method

PendingCN108867930AAvoid destructionSimple structureProtective buildings/sheltersShock proofingShear frictionScrew thread

The invention relates to a viscoelastic shearing friction damper and an application method. The viscoelastic shearing friction damper comprises an outer guide sleeve and an inner guide sleeve, whereinthe inner end of the inner guide sleeve is sleeved in the outer guide sleeve; a compression bolt is arranged axially at the middle part of the inner end of the inner guide sleeve; the compression bolt is fixedly connected with the inner guide sleeve; a plurality of damping parts are sleeved on the compression bolt; each damping part comprises a viscoelastic bulk and force transfer steel plates arranged at the two ends of the viscoelastic bulk; a spring is arranged between adjacent damping parts; the spring is sleeved on the compression bolt; the compression bolt is sleeved with a compressionnut in screw thread fit with the compression bolt; the damping part on the innermost side is placed against the inner end of the guide sleeve; the damping part on the outermost side is placed againstthe compression nut; all damping parts are fixed on the compression bolts through the compression nuts. The damping force of the damper is adjustable; by organically combining the shearing energy consumption with speed displacement type sliding energy consumption, the energy consumption effect is good.

Owner:FUZHOU UNIV

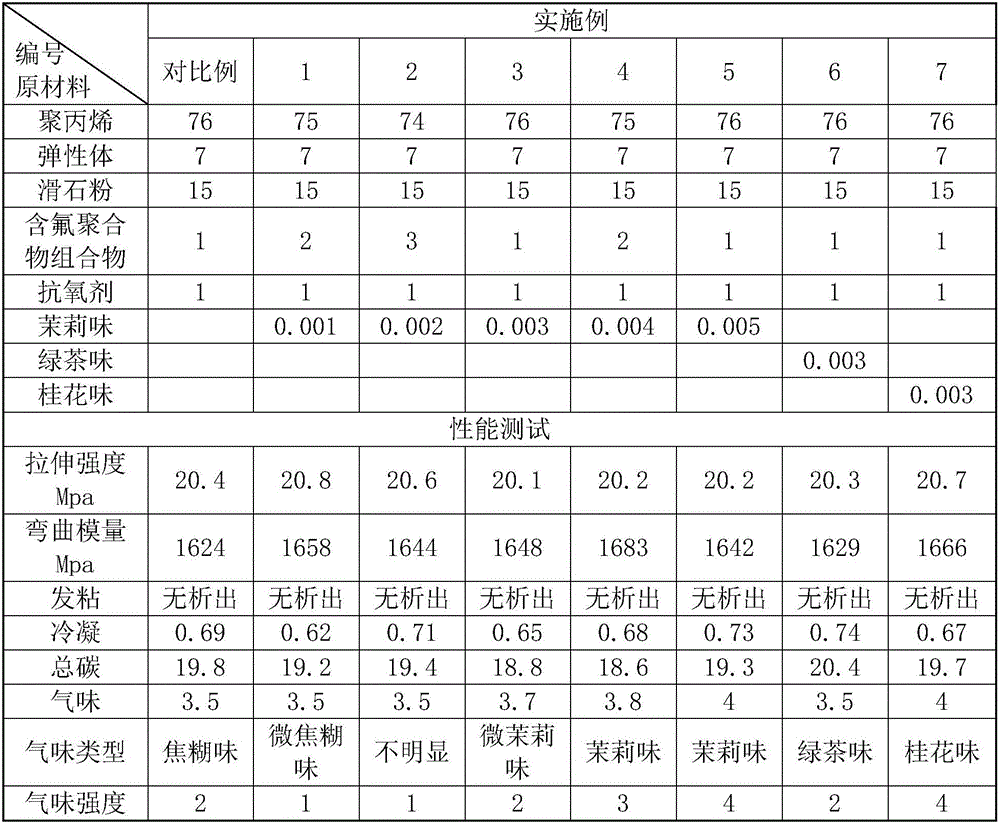

Fragrance self-restoration extrusion stage PP (polypropylene) composite material and preparation method thereof

The invention discloses a fragrance self-restoration extrusion stage PP (polypropylene) composite material and a preparation method thereof. The fragrance self-restoration extrusion stage PP composite material is prepared from the following ingredients in percentage by weight: 43 to 96.9 percent of PP, 2 to 20 percent of elastomers, 0 to 30 percent of talcum powder, 1 to 5 percent of fluoropolymer compositions, 0.001 to 0.005 percent of flavouring agents and 0.1 to 2 percent of antioxidants. The fragrance self-restoration extrusion stage polypropylene composite material has the advantages that in the extrusion molding process of the extrusion stage PP, flux is extruded at a high speed, and receives the high-temperature shearing friction effect of an opening mold, so that the degradation of the PP material can be intensified, so that the emission performance of smell and the like of the product becomes worse; few fragrance agents are added, and are non-toxic and harmless, so that no loss is caused on the original mechanical property of the material and the emission performance such as smell, condensing and VOC; the fragrance can shield the unpleasant smell of plastic smell, charring smell and the like of the high polymer material per se and the material high-temperature degradation; the pleasant fragrance is given out, so that the product acceptability is improved.

Owner:CHONGQNG PRET NEW MATERIAL +4

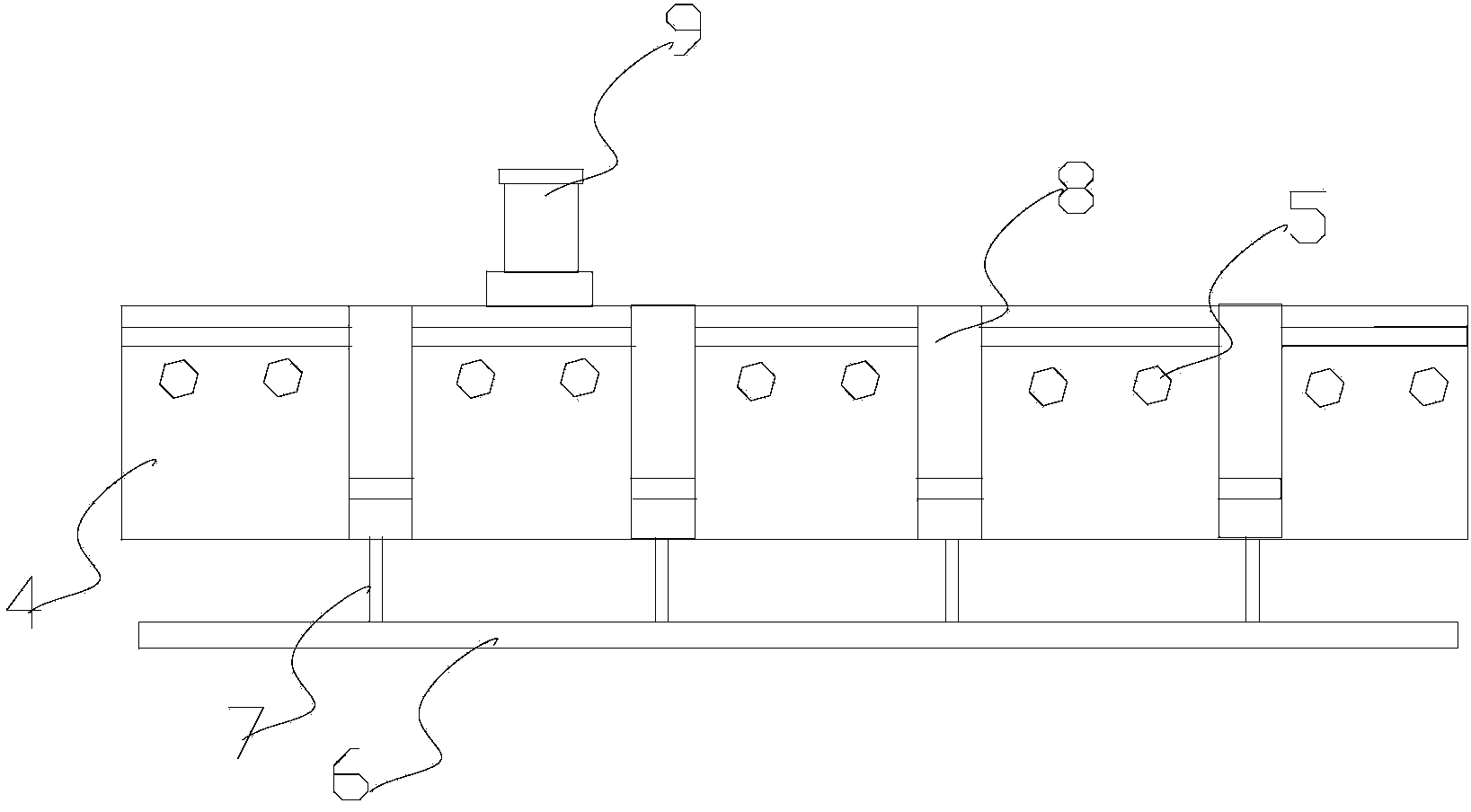

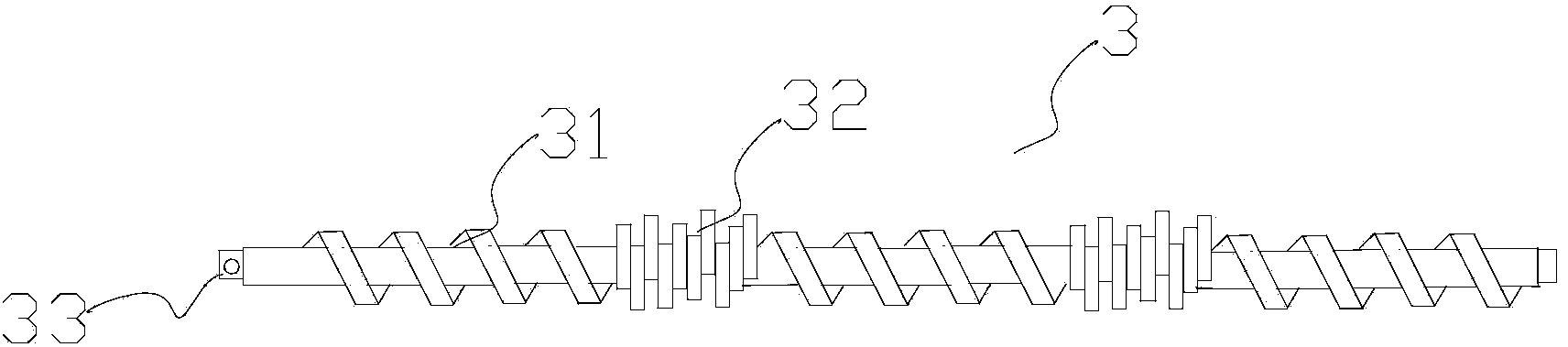

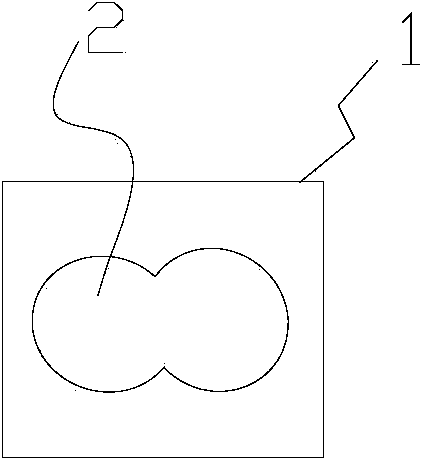

Color master batch production device

The invention relates to a color master batch production device. The color master batch production device comprises a machine barrel as well as double screws arranged in a spiral groove of the machine barrel; each screw comprises a threaded section and a mixing section which is formed by a plurality of high-low staggered special-shaped blocks; the mixing section and the threaded section are fixedly connected together by a locking screw; the machine barrel is provided with heaters by bolts; a plurality of cooling water jackets are arranged among the heaters; each cooling water jacket is connected with a circulation water conveying pipe by respective water circulation pipes; a dust absorption opening is arranged in the upper part of the machine barrel; the dust absorption opening is connected with a vacuum dust absorber by a dust absorption pipe. The color master batch production device provided by the invention can effectively reduce heat generated in the shearing friction process, enables shearing to be uniform, thereby guaranteeing the stable and reliable quality of produced bar materials.

Owner:天津玉普色母粒有限公司

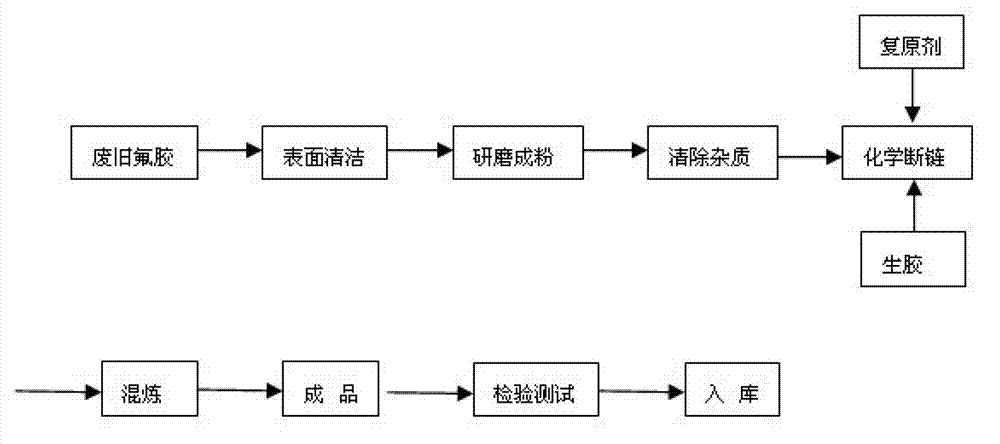

Technique for recovering hydrogenated nitrile-butadiene rubber

The invention discloses a technique for recovering hydrogenated nitrile-butadiene rubber, relating to a processing technique for recovering and regenerating waste and old hydrogenated nitrile-butadiene rubber materials. The invention can promote the rupture of the carbon-sulfur bond in an atmospheric pressure and temperature environment so as to restore the linear structure of the rubber. The technique uses waste and old hydrogenated nitrile-butadiene rubber as the raw material, and sequentially comprises the steps of cleaning, grinding, impurity removal, recovery reaction and mixing, wherein the recovery reaction is implemented by adding 1.5-2.5 wt% of recovering agent into the raw material; the recovering agent is composed of zinc diethyl dithiocarbamate, mercaptobenzothiazole and zinc oxide; and the mixing step is implemented at 18-30 DEG C for 28-48 minutes with a mixer. The technique is implemented in a way that: the recovering agent is added into waste and old hydrogenated nitrile-butadiene rubber particles, evenly stirred, and repeatedly rolled under atmospheric pressure and temperature to initiate replacement reaction by using the shearing force and temperature generated by the shearing friction force, so that the carbon-sulfur bond is ruptured, sulfur is ionized, and the molecular reticular structure in the waste rubber is restored into the linear structure in the rubber mixing process, thereby restoring the plasticity of the rubber.

Owner:JIANGSU GREENSTAR ECO RUBBER TECH CO LTD

Efficient rubber crusher for waste and old tyres

PendingCN108032464AImprove qualityReasonable structural designPlastic recyclingGrain treatmentsFriction effectMotor drive

The invention discloses an efficient rubber crusher for waste and old tyres. The efficient rubber crusher comprises a left rack, a right rack, a rear roller, a front roller and a transmission mechanism. The rear roller and the front roller are arranged between the left rack and the right rack in a parallel and opposite manner. The working face of the rear roller and the working face of the front roller are each full of protruding ridges made of a wear-resistant material in a parallel manner. The transmission mechanism is arranged at one side of the rear roller. The rear roller is connected with a motor through a transmission mechanism. The motor drives the rear roller to rotate through the transmission mechanism. The portions, inside the left rack and the right rack, of the two ends of thefront roller are each internally provided with an adjustment mechanism. Each adjustment mechanism is connected with a worm wheel and worm mechanism on the corresponding rack. Each worm is connected with a hand wheel. The rear roller of the efficient rubber crusher is high in rotating speed, large in torque, high in production efficiency and low in product manufacturing cost; by means of the protruding ridges, the shearing friction effect can be improved; rubber powder quality can be improved; the efficient rubber crusher can work for a long time continuously; safety performance is remarkablyimproved; and the service life is long.

Owner:QINGDAO SHENGHUALONG RUBBER MACHINERY

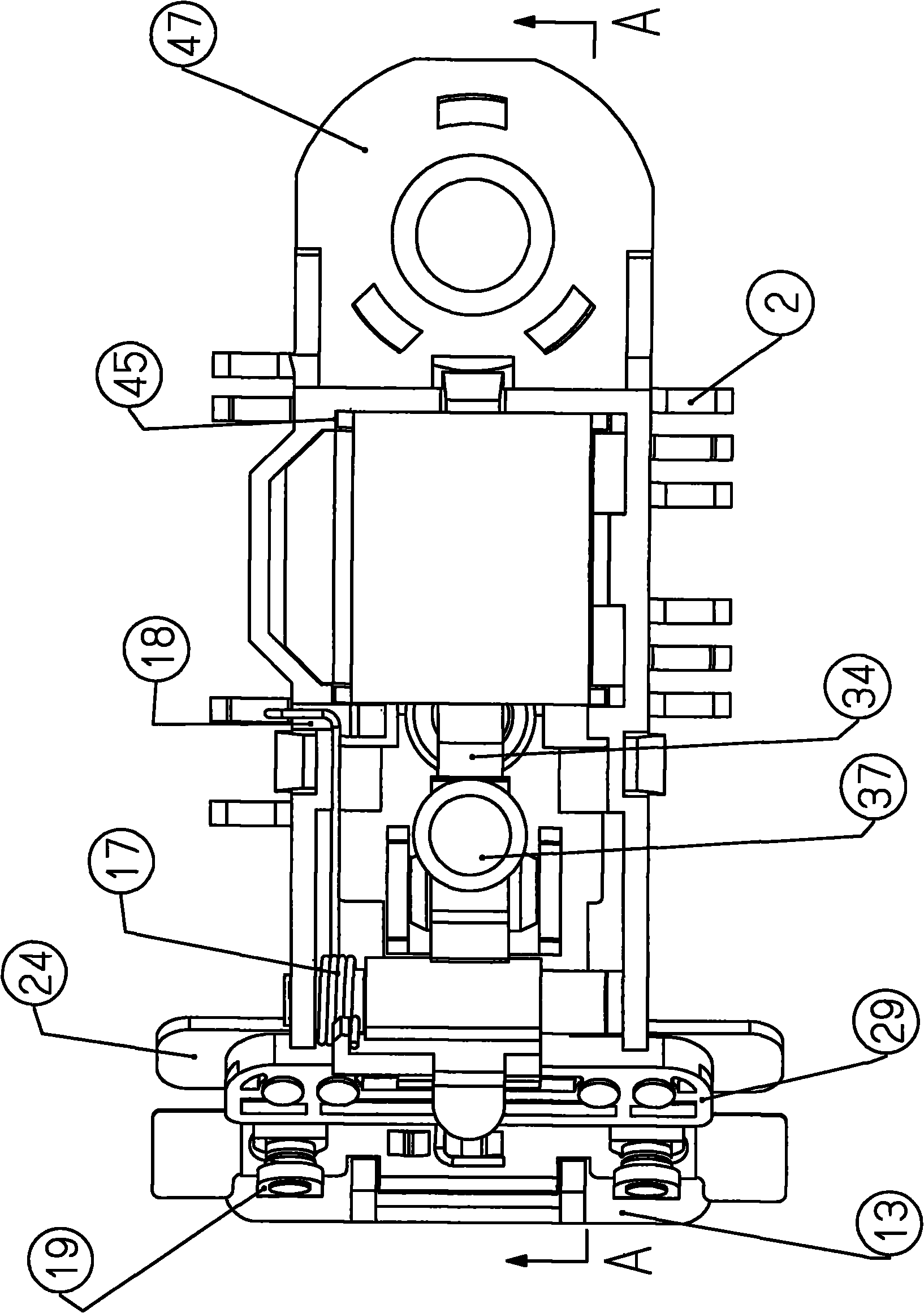

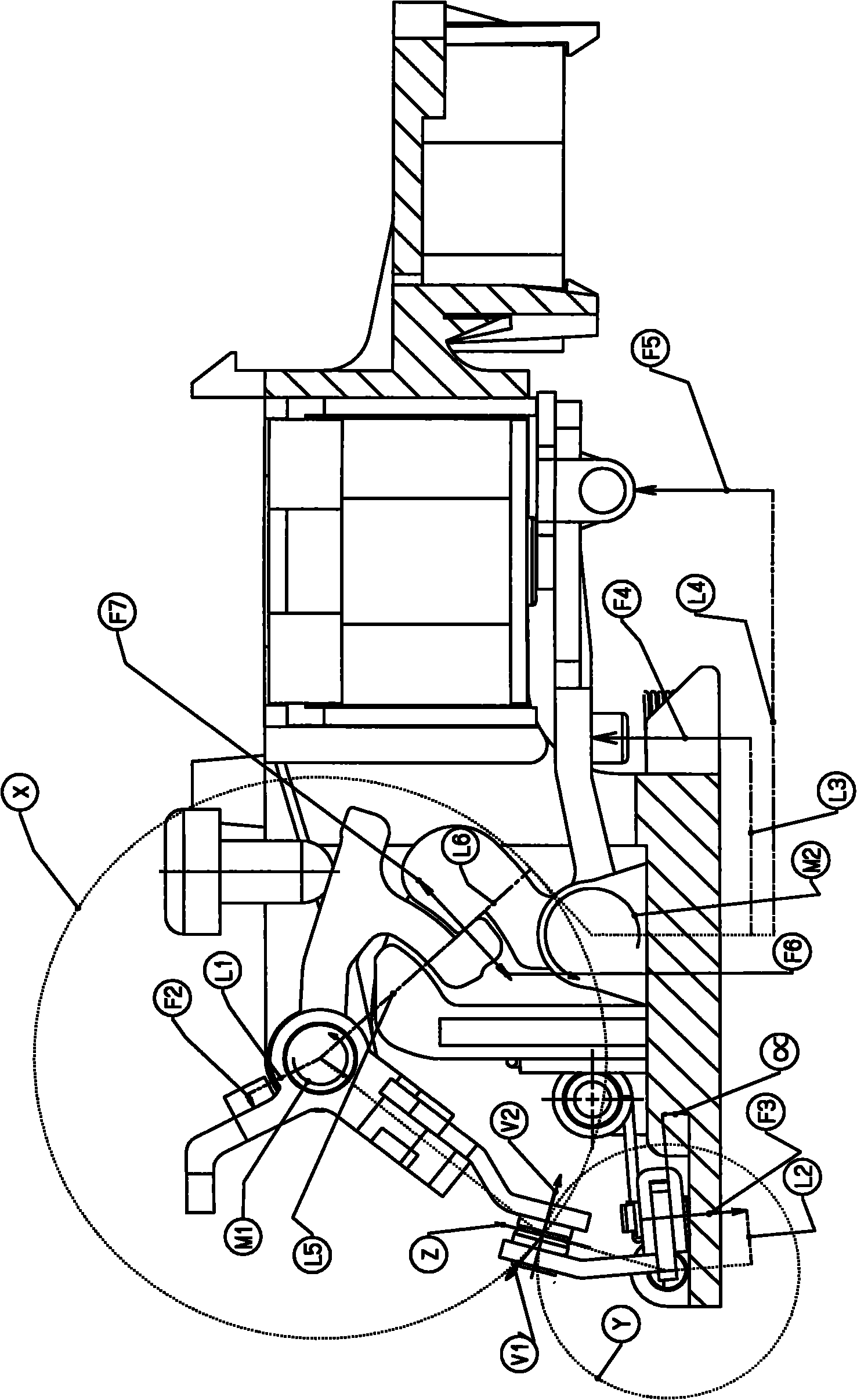

Operating mechanism of leakage protector

ActiveCN101964284AIncrease contact areaImprove self-cleaningProtective switch operating/release mechanismsEngineeringShear friction

Owner:NEXUS ELECTRICAL JIAXING

Special material for cleaning plastic screw extruder and preparation method

ActiveCN107383847AGood effectAvoid damageDetergent compounding agentsOrganic non-surface-active detergent compositionsParticulatesCompound a

The invention relates to the field of functional plastic, and specifically relates to a special material for cleaning a plastic screw extruder and a preparation method. A thermoplastic elastomer is used as a carrier; through compounding a ceramic micro-sphere, a poly-prismatic particulate stripper, which is prepared from polytetrafluoroethylene clad quartz sand, and an activator, the high-efficiency stripping and cleaning on a scale deposit and a residue in the screw extruder are realized; the special material is not only high in cleaning efficiency, but also avoids the damage of high-shearing grinding to a screw. Particularly, the special material is mainly prepared from inorganic matters, keeps stable melt viscosity at both a high temperature and a low temperature, generates stable adhesive stripping and shearing friction to the screw, and has favorable adhesive stripping performance and frictional scraping performance on the scale deposit and the residue in the screw when being used; meanwhile, special plastic can be repeatedly used, has favorable anti-degradation performance and anti-oxidation performance; especially, the special plastic is used for similarly better removing the scale deposit of the screw for processing complicated components of modified plastic, high-viscosity plastic, cross-linked rubber and the like by utilizing the stripping property and the viscoelastic property of the special plastic.

Owner:扬州聚晶塑化有限公司

Three-phase separation device for oily solid wastes

PendingCN106746412ANo secondary pollutionReduce energy consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSlagEmission standard

The invention belongs to the field of dewatering and deoiling equipment of solid wastes generated in the oilfield oil production, transportation, storage and refining processes and particularly relates to a device for performing oil, water and slag three-phase separation on oily solid wastes. The invention adopts the scheme that heat is generated through rotor and solid material collision shear friction, and mechanical energy is converted into heat energy, so that a heat source is provided for material temperature rise; the capillary force among materials is damaged, so that the oil, water and slag three-phase separation is performed on the oily solid wastes; a separated product is non-toxic and harmless to the environment, no secondary pollution is generated, recovered oil can be reused, and the solid wastes can reach environmental protection emission standards.

Owner:CHINA PETROCHEMICAL CORP

A Numerical Simulation Method for Analyzing the Structural Dimensions of Extrusion Dies with Unequal Lengths

Owner:INNER MONGOLIA UNIV OF TECH

A kind of self-healing extrusion grade polypropylene composite material and preparation method thereof

The invention discloses a self-repairing extrusion-grade polypropylene composite material and a preparation method thereof. The polypropylene composite material consists of the following raw materials in percentage by weight: 43-96.8% of polypropylene, 2-20% of elastomer, 0-30% of talc powder, 1-5% of fluorine-containing polymer composition and 0.1-2% of antioxidant. In the invention, the fluorine-containing polymer composition is introduced into the material formula; and in an extrusion moulding process, due to the shear friction between the resin melt and a screw cylinder, the fluorine-containing polymer tends to transfer to the product surface, and the scratch on the product surface is prevented while the micro-surface displacement deformation caused by stress scratch can be quickly repaired. Therefore, the problem in appearance caused by stress scratch in an application process of the polypropylene extrusion product is solved.

Owner:SHANGHAI PRET COMPOSITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com