Color master batch production device

A production device and color masterbatch technology, which is applied in the field of color masterbatch production devices, can solve the problems of the quality of the rubber compound being deteriorated, the mixing effect is not good, and the production and processing cannot be satisfied, and the heat reduction, stable and reliable quality, shearing uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

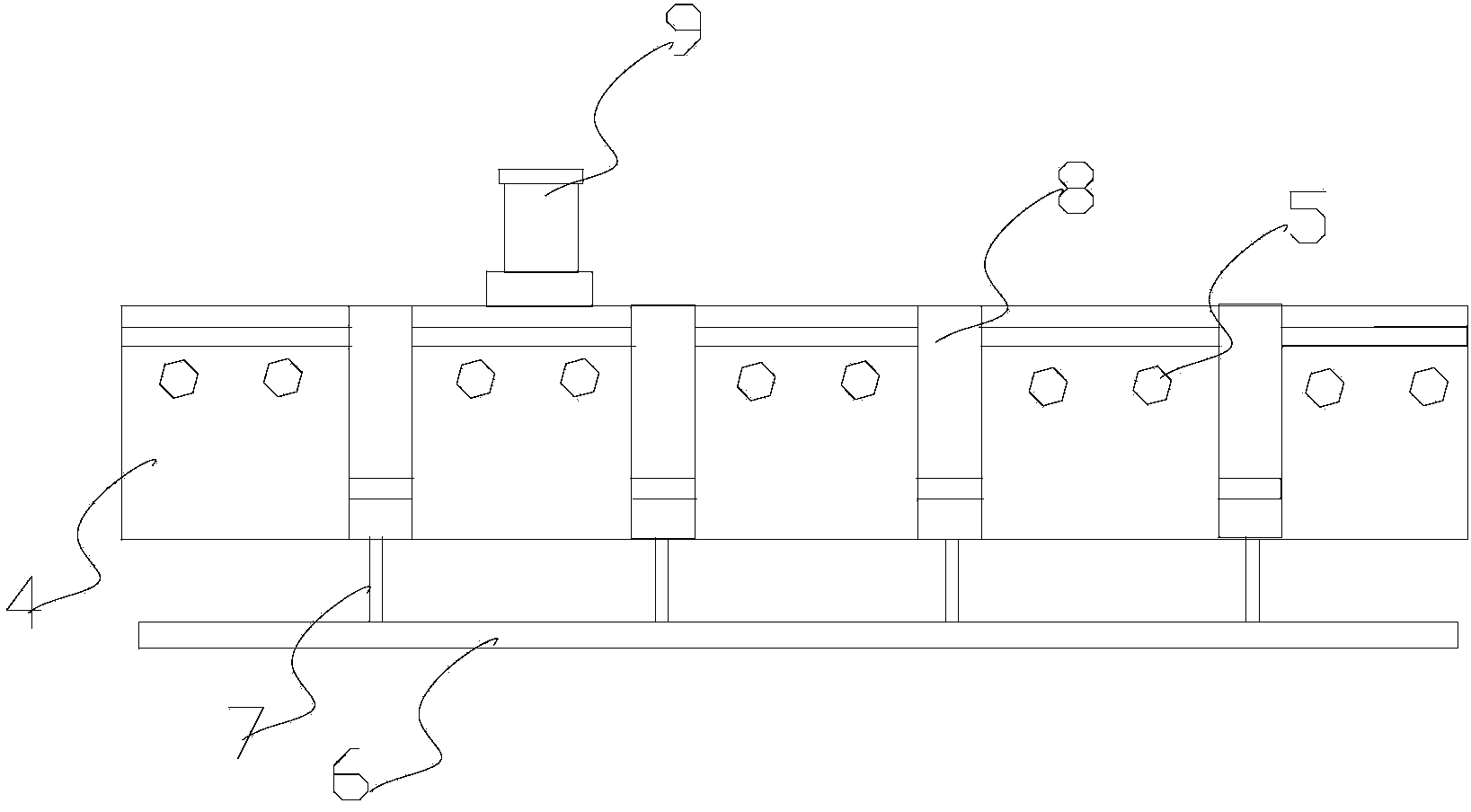

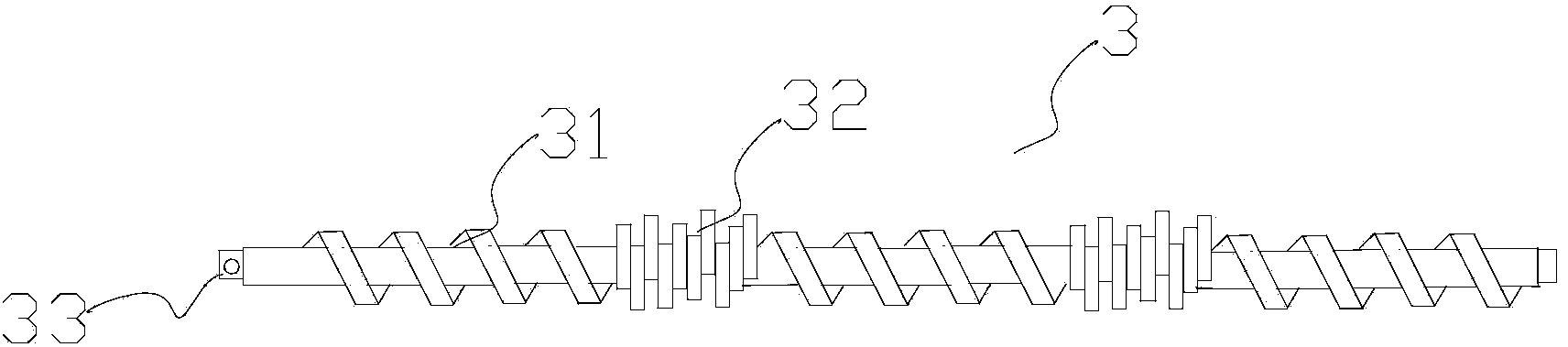

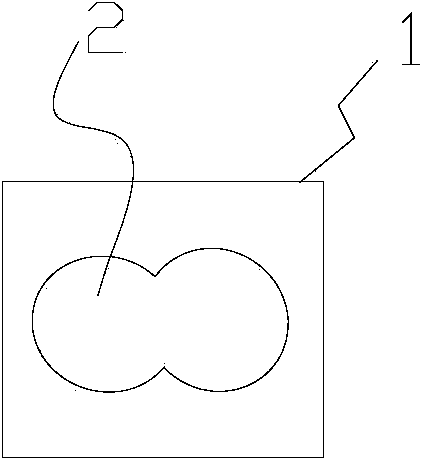

[0013] see Figure 1~3 As shown, the Figure 1~3 The structure of a color masterbatch production device provided by the embodiment of the present invention is shown, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0014] see Figure 1~3 As shown, a color masterbatch production device includes a barrel 1 and a twin-screw 3 arranged in the screw groove 2 of the barrel 1. The screw 3 includes a threaded segment 31, and is composed of a plurality of special-shaped blocks at the outer end. The kneading section 32 is formed in a staggered arrangement of high and low. The kneading section 32 and the threaded section 31 are fixedly connected together through a locking screw 33. A heater 4 is installed on the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com