Patents

Literature

40results about How to "Shear evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

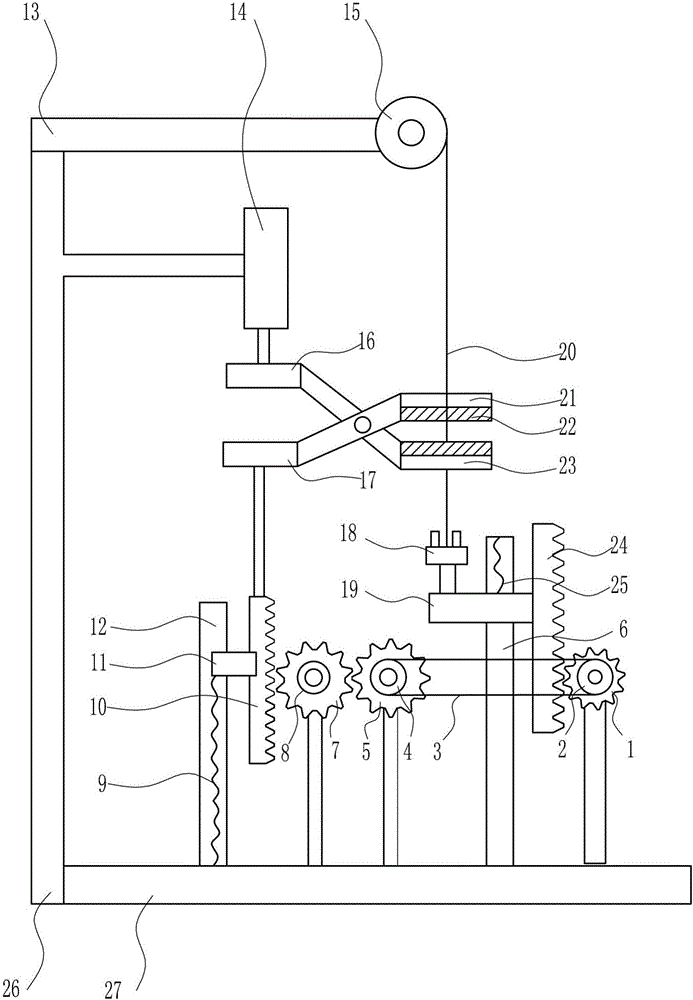

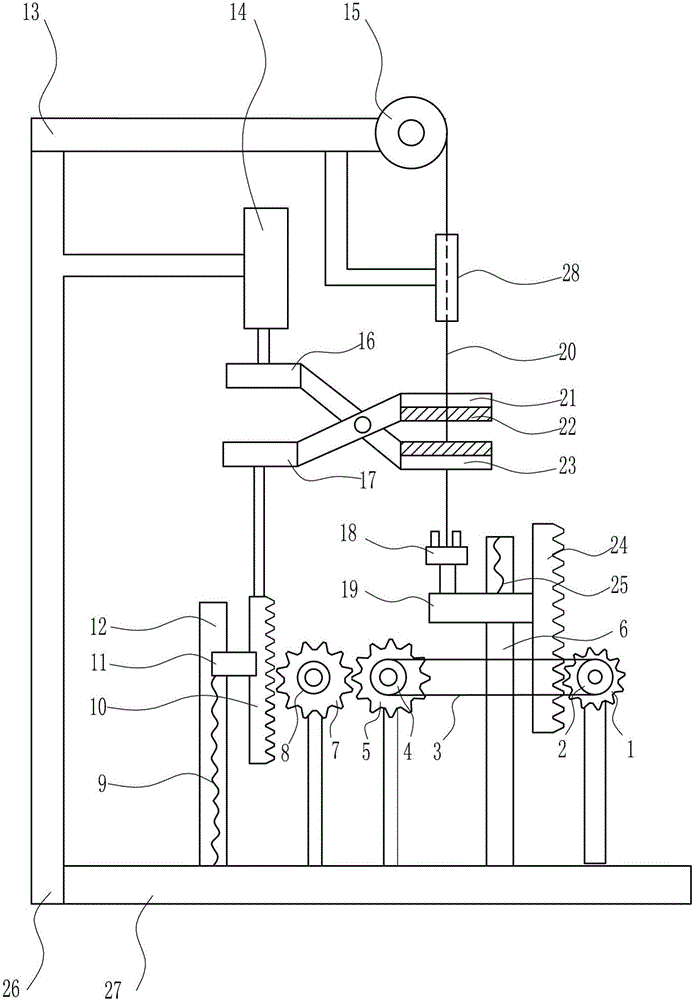

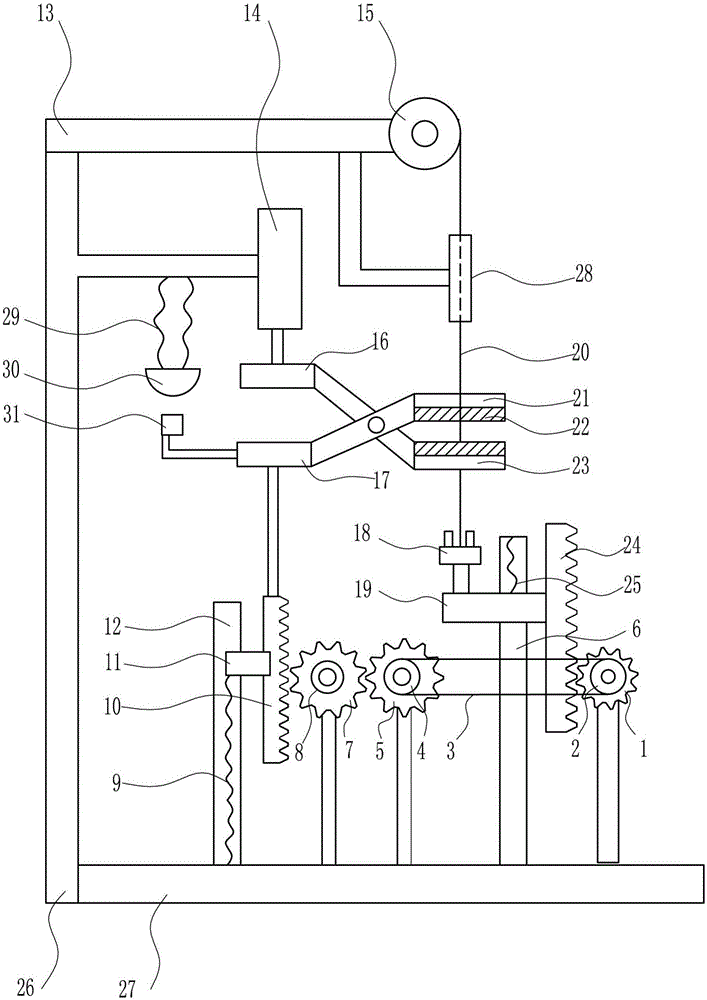

Hardware rebar equidistant efficient cutting device

The invention relates to a hardware rebar cutting device, in particular to a hardware rebar equidistant efficient cutting device which is simple to operate, uniform in cutting and high in cutting efficiency. The hardware rebar equidistant efficient cutting device comprises a first gear, a first belt wheel, a flat belt, a second belt wheel, a second gear, a first sliding rail, a third gear, a speed reducing motor, a first spring and a first rack, and a left frame, a second sliding rail, the speed reducing motor, the second gear, the first sliding rail and the first gear are sequentially arranged at the top of a base from left to right. The hardware rebar equidistant efficient cutting device has the advantages of simplicity in operation, uniformity in cutting and high cutting efficiency; by using the device, rebars can be cut quickly within short time, and sections of the rebars are cut uniformly in the process of cutting.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

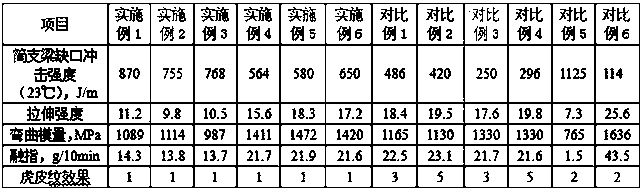

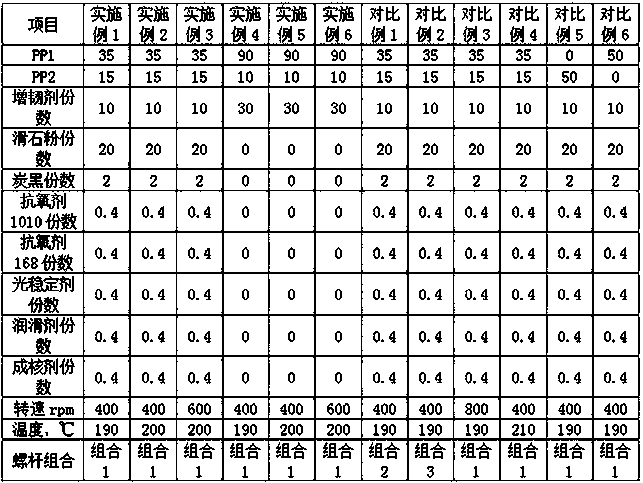

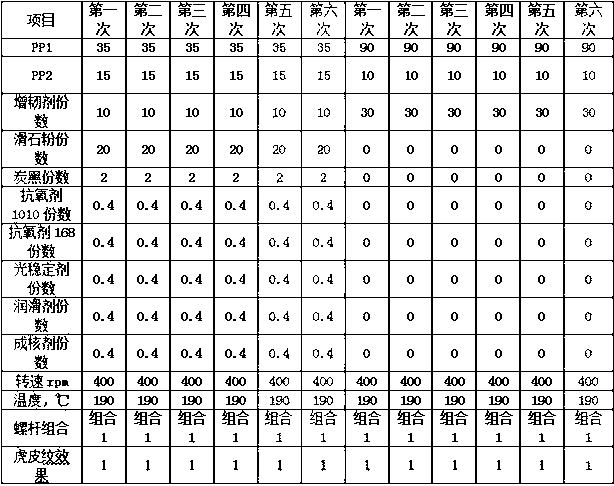

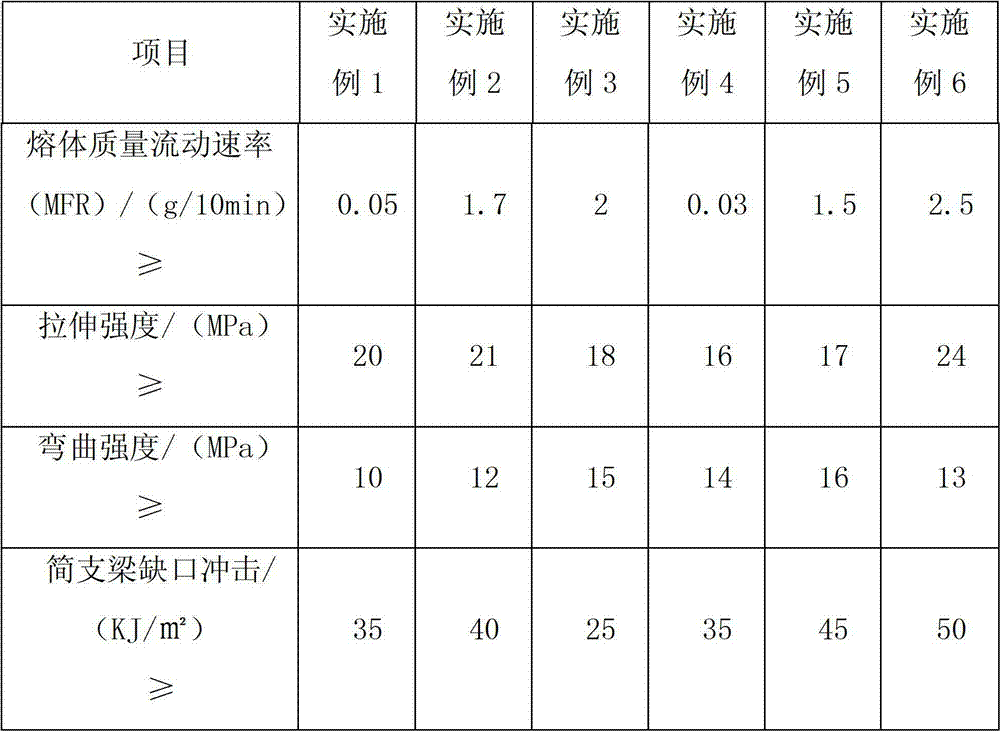

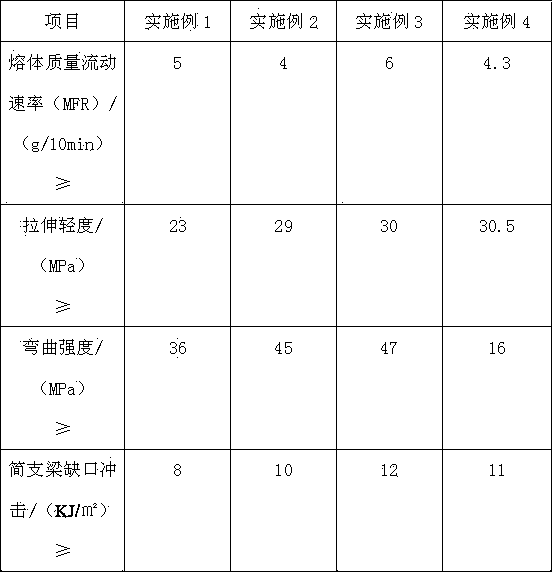

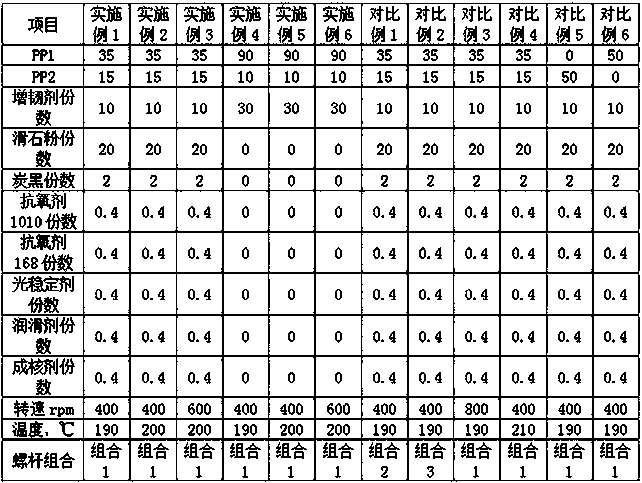

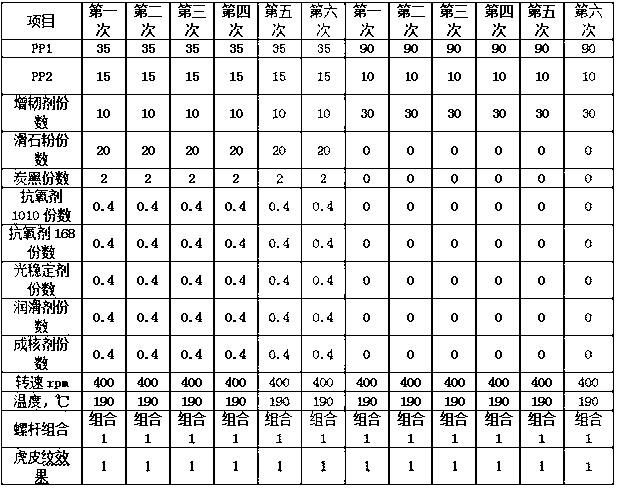

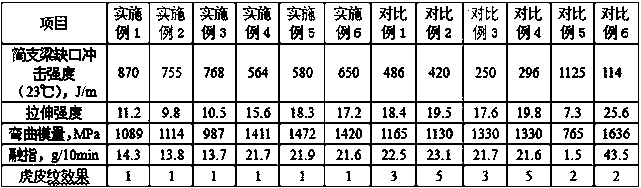

Method for eliminating tiger skin defect of polypropylene composition and polypropylene composition prepared thereby

The invention discloses a method for eliminating a tiger skin defect of a polypropylene composition and the polypropylene composition prepared thereby. The polypropylene composition comprises polypropylene resin, a toughening agent, a filler, a pigment and an auxiliary agent, wherein the polypropylene resin is formed by compounding high-flow polypropylene with the melt mass flow rate (MFR) of 30-120g / 10min and low-flow polypropylene with the melt mass flow rate (MFR) of 0.1-29g / 10min. By a preparation method, through a combined design of screws and adjustment of extrusion process parameters, the tiger skin defect of the prepared polypropylene composition can be eliminated; in addition, the preparation technology is stable and the repeatability is good. The polypropylene composition prepared by the method provided in the invention can be applied to automotive bumpers and interior products.

Owner:KINGFA SCI & TECH CO LTD +1

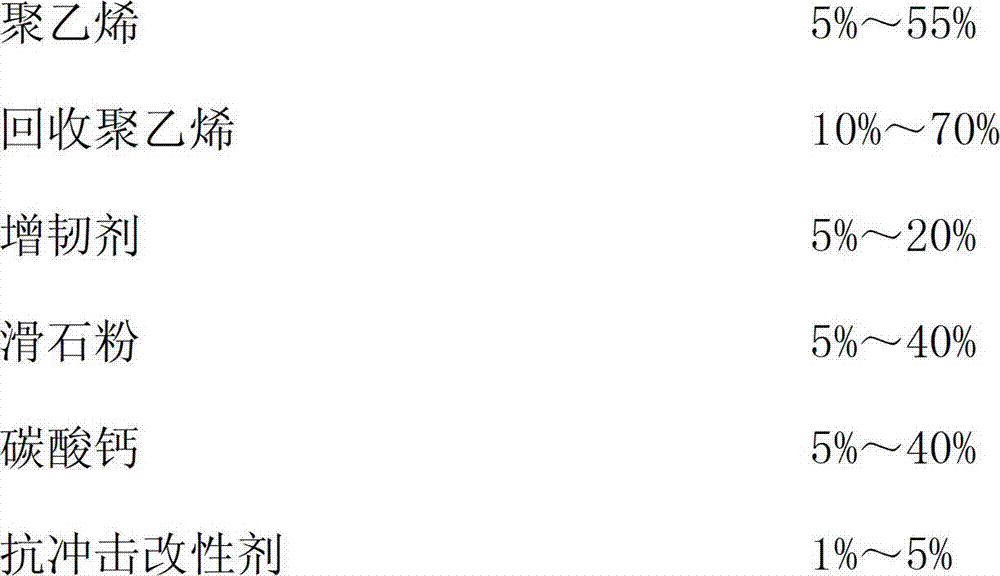

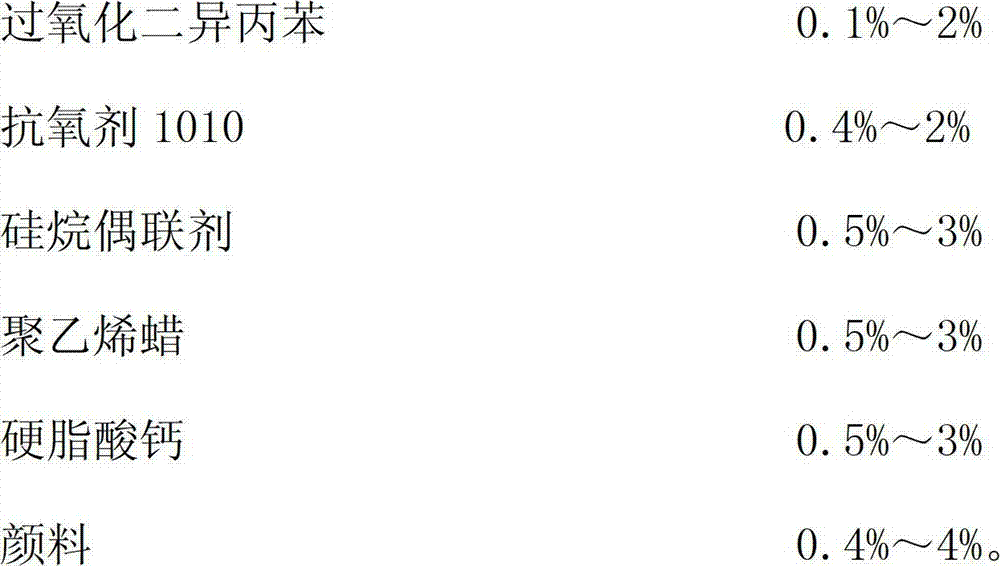

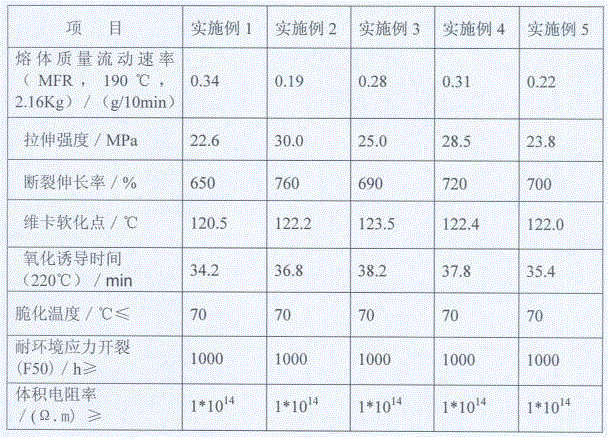

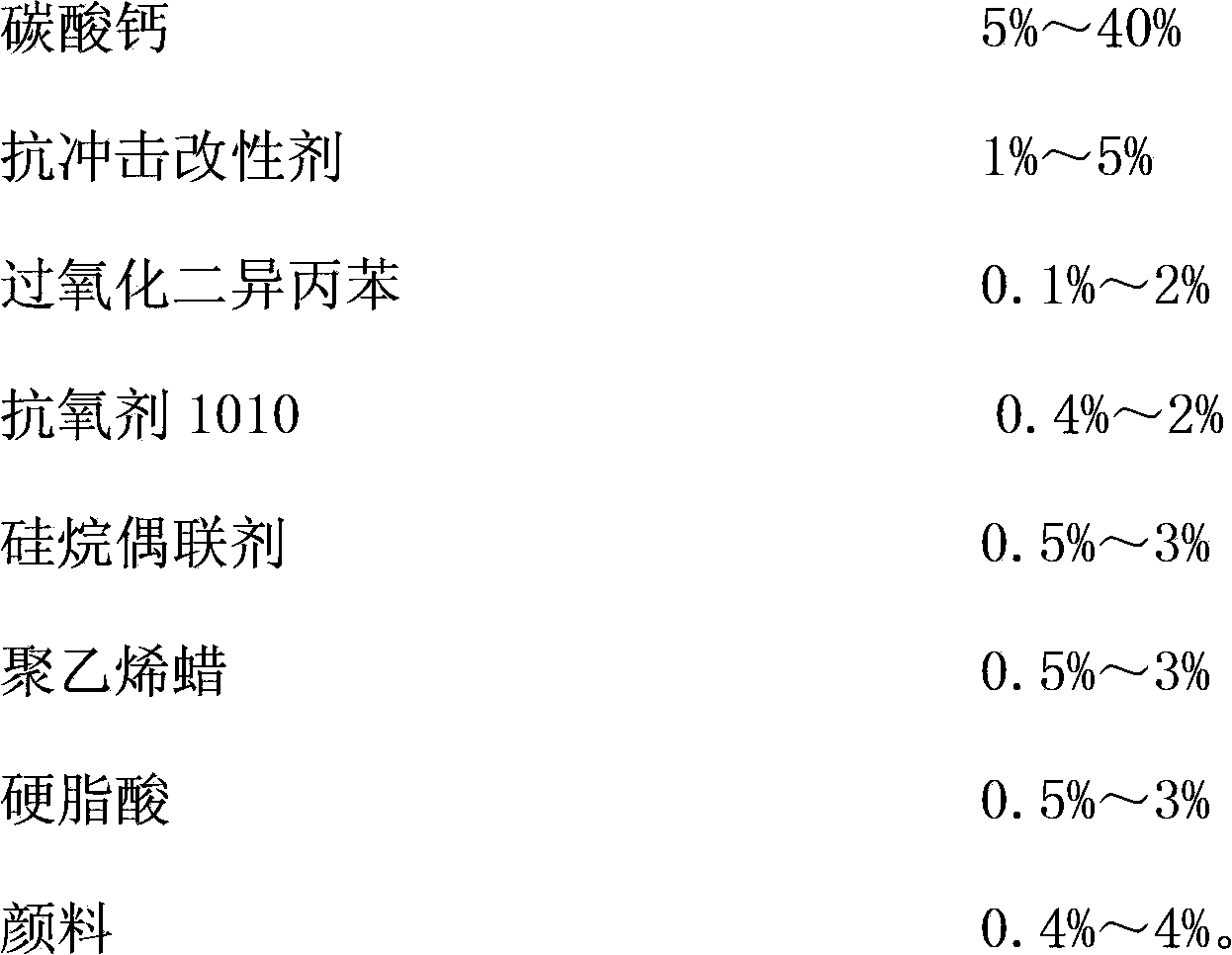

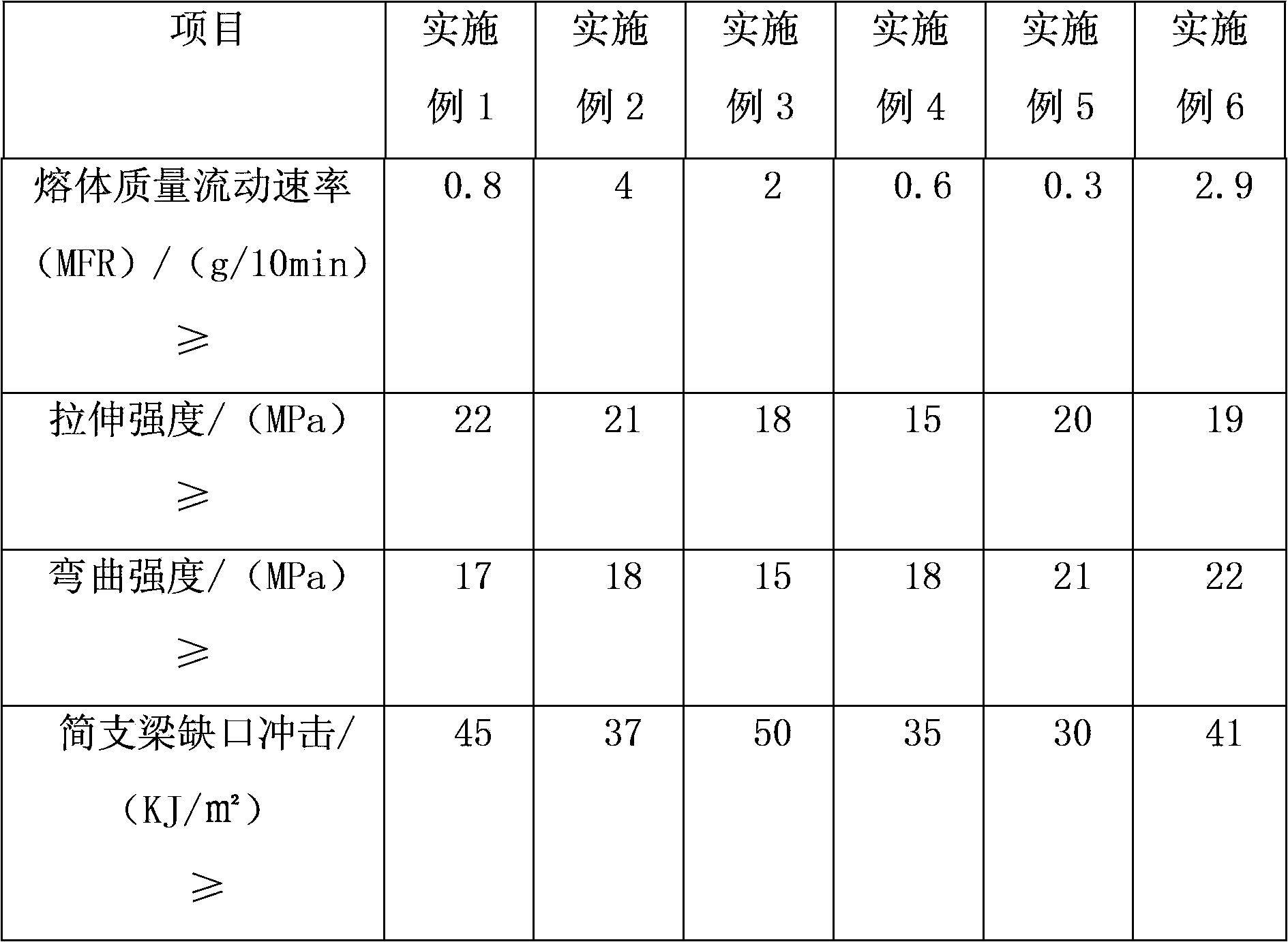

Special modified recycled polyethylene material for pipes and pipe fittings and preparation method of special modified recycled polyethylene material

The invention discloses a special modified recycled polyethylene material for pipes and pipe fittings and a preparation method of the special modified recycled polyethylene material, so that the problems of higher new polyethylene consumption and higher production cost of an existing special modified polyethylene material for pipes and pipe fittings are solved. The special modified recycled polyethylene material mainly comprises, by weight, 5%-55% of polyethylene, 10%-70% of recycled polyethylene, 5%-20% of toughening agents, 5%-40% of talcum powder, 5%-40% of calcium carbonate, 1%-5% of impact modifiers, 0.1%-2% of dicumyl peroxide, 0.4%-2% of antioxidants 1010, 0.5%-3% of silane coupling agents, 0.5%-3% of polyethylene wax, 0.5%-3% of calcium stearate and 0.4%-4% of pigment. Waste polyethylene is recycled and reused effectively, and the special modified recycled polyethylene material for the pipes and the pipe fittings and the preparation method have the advantages of resource saving, environmental protection, cost reduction and the like.

Owner:四川塑金科技有限公司

Special material for waste ABS (acrylonitrile butadiene styrene) plastic regenerated and modified automobile and preparation method of special material

The invention discloses a special material for a waste ABS plastic regenerated and modified automobile and a preparation method of the special material, and solves the problem that the recovery rate of a waste ABS plastic is lower, and resources are wasted in the prior art. The special material comprises the components in parts by weight as follows: 100 parts of a waste ABS broken material, 1-8 parts of ABS, 0.1-0.3 parts of EBS (ethylene bis stearamide), 0.1-0.2 parts of zinc stearate, 0.1-0.2 parts of calcium stearate, 0.1-0.2 parts of antioxidant 10100, 0.2-0.6 parts of antioxidant 168 and 0.1-0.4 parts of montan wax, wherein the waste ABS broken material is obtained by picking, breaking, cleaning, dehydrating, absorbing and drying the waste ABS plastic. The preparation method of the special material for the waste ABS plastic regenerated and modified automobile is further provided. The special material for the waste ABS plastic regenerated and modified automobile and the preparation method of the special material have the advantages that the waste ABS plastic can be recycled, resources are saved, the environment is protected, the cost is reduced, the preparation process is simplified, and the like.

Owner:四川塑金科技有限公司

Recycled waste polystyrene plastic produced special modified material for household appliances, and preparation method thereof

The invention discloses a recycled waste polystyrene plastic produced special modified material for household appliances, and a preparation method thereof, and the material can be used for solving the problem that, in the existing technology, the recovery rate of polystyrene plastic of television shells is lower, and resource is wasted. The material is composed of the following components in parts by weight: 100 parts of waste polystyrene television shell broken material, 5-8 parts of SEBS, 0.1-0.3 parts of EBS, 0.1-0.5 parts of calcium stearate and 0.1-0.3 parts of zinc stearate, wherein the waste polystyrene television shell broken material is obtained by detaching the waste television, smashing the polystyrene broken material, rubbing, cleaning, rinsing, drying, and soaking in brine, screening, then, cleaning again, and drying. The invention also provides the preparation method of the recycled waste polystyrene plastic produced special modified material for the household appliances. The method can be used for effectively recycling the polystyrene plastic of the waste televisions, and has the advantages of saving resource, protecting environment, lowering the cost, simplifying the preparation process, and the like.

Owner:四川塑金科技有限公司

Modified regeneration high impact polystyrene for tubes and pipe fittings and preparation method of high impact polystyrene

InactiveCN102775715ALow costImprove the economic efficiency of the enterpriseSilane couplingCalcium carbonate

The invention discloses modified regeneration high impact polystyrene for tubes and pipe fittings and a preparation method of the high impact polystyrene, which solve the problems of high cost and complex method of the conventional high impact polystyrene for the tubes and pipe fittings. The modified regeneration high impact polystyrene mainly comprises the following components by weight percentage: 10%-50% of high impact polystyrene, 15%-80% of recycled high impact polystyrene, 5%-20% of toughening agent, 5%-40% of calcium carbonate, 0.1%-1% of antioxygen 1010, 0.3%-1% of silane coupling agent and 0.4%-2% of pigment. The invention also provides the preparation method of the modified regeneration high impact polystyrene for the tubes and pipe fittings. The preparation method can be used for effectively recycling waste high impact polystyrene. The modified regeneration high impact polystyrene for the tubes and pipe fittings has the advantages that resources are saved, the environment is protected, the cost is lowered, the preparation process is simplified and the like.

Owner:四川塑金科技有限公司

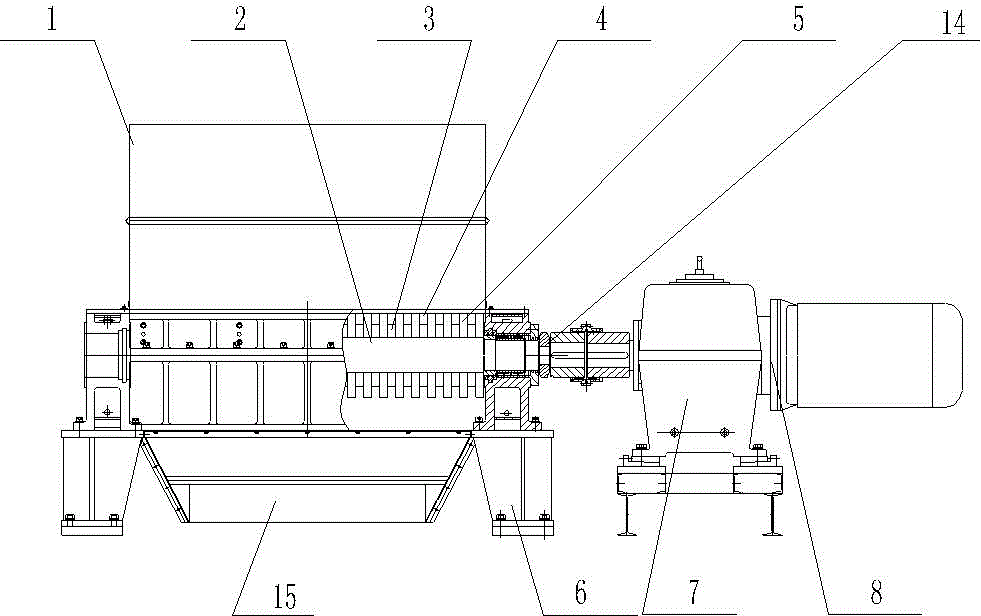

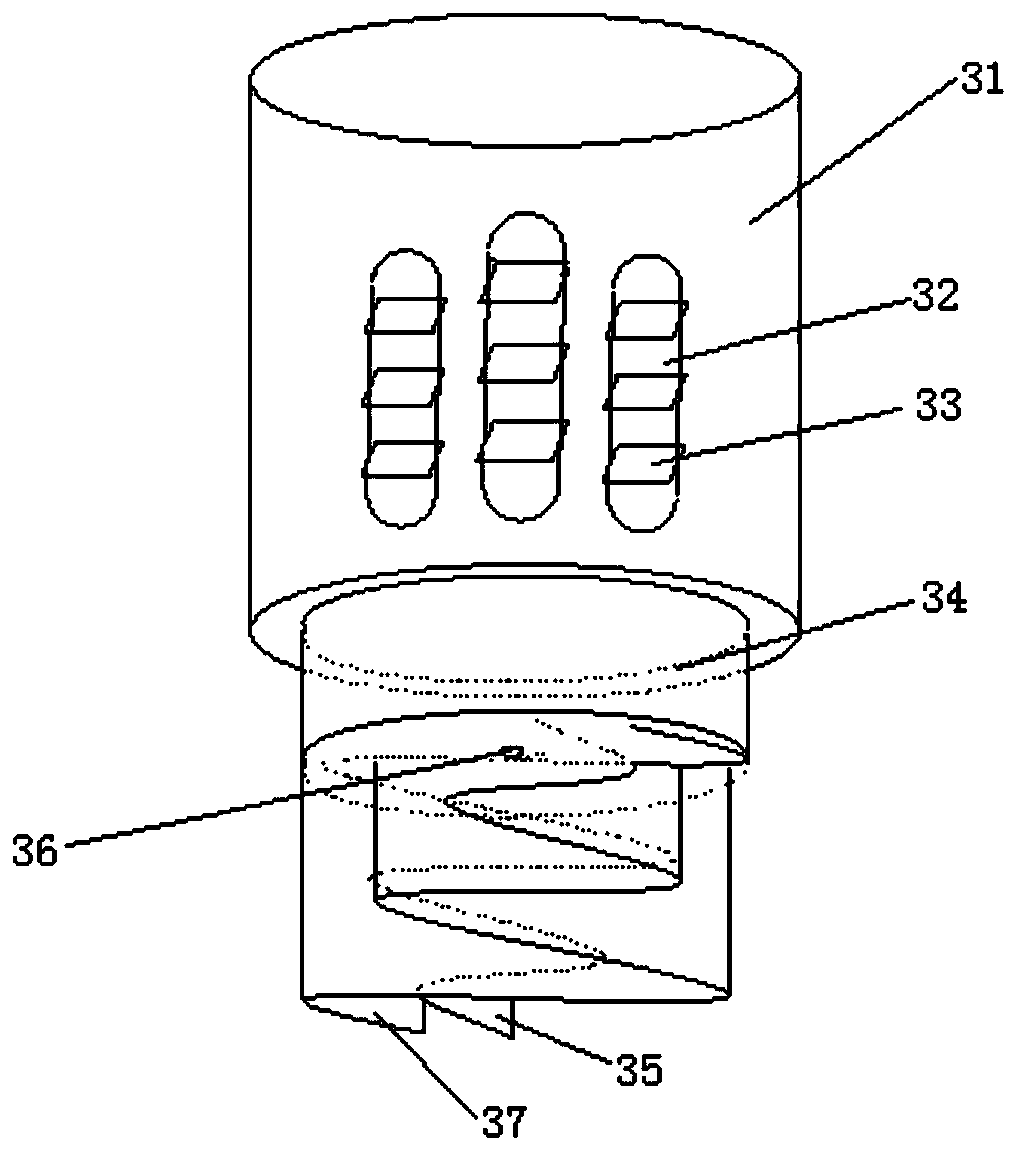

Biomass fuel crusher

The invention provides a biomass fuel crusher. Energy consumption and investment of equipment are reduced by the biomass fuel crusher by reducing the number of driving motors, and at the same time, the biomass fuel crusher enables the crushing speed of cutter shafts to keep the same, and crushing effect is improved. The biomass fuel crusher comprises a hopper and two cutter shafts, wherein the two cutter shafts are arranged side by side and are respectively arranged on a support. One cutter shaft of the two cutter shafts is a driving cutter shaft. The driving cutter shaft is connected with gear reducers through a coupling. The gear reducers are respectively connected with an electrical machine. The two cutter shafts are respectively provided with a cutter head in a sleeved mode. The cutter heads on the two cutter shafts are mutually embedded into each other and are arranged at interval in a dislocated mode. A diffusion knife is arranged along the peripheries of the cutter heads. Rotating directions of the two cutter shafts are contrary to each other. When the two cutter shafts rotate, cutting edges of adjacent diffusion knives on the two cutter shafts are of shearing bite shapes. The lower portion of the hopper is connected with a retainer plate. The retainer plate is guided to cutter head meshed mouths of the two cutter shafts. The biomass fuel crusher is characterized in that one ends of the two cutter shafts are respectively connected with a chain wheel. Gears of the two chain wheels are meshed with each other.

Owner:WUXI YAQING MACHINERY

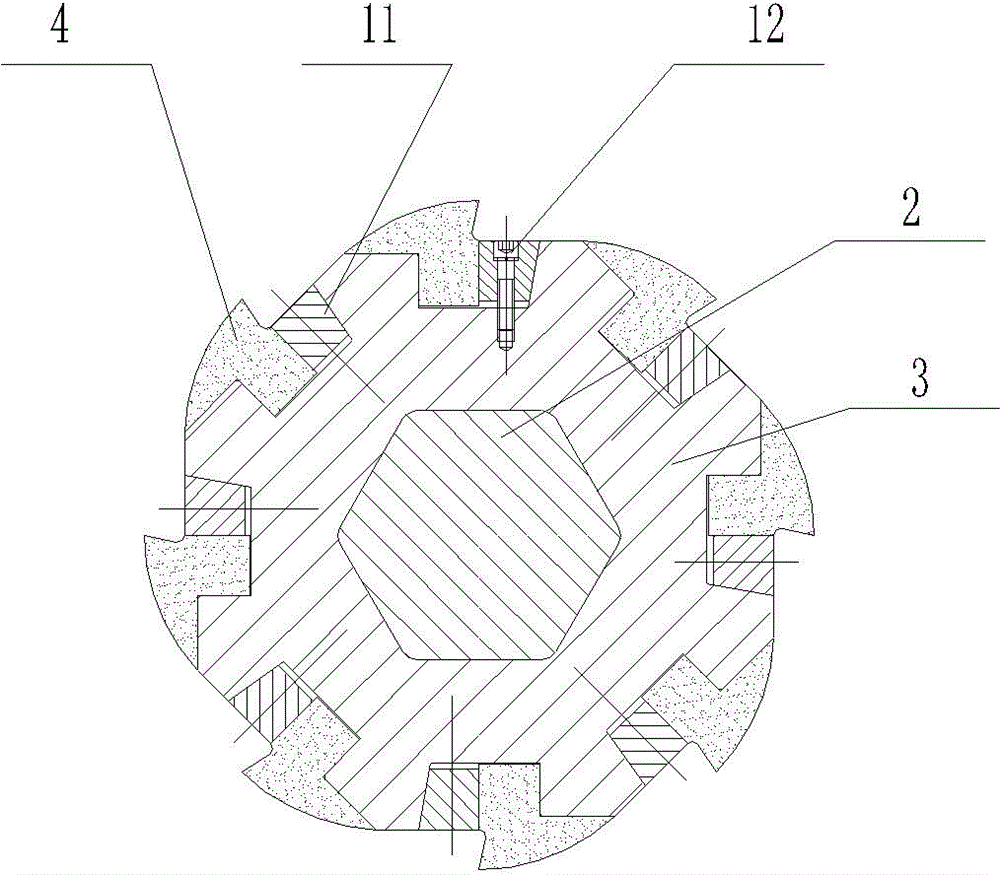

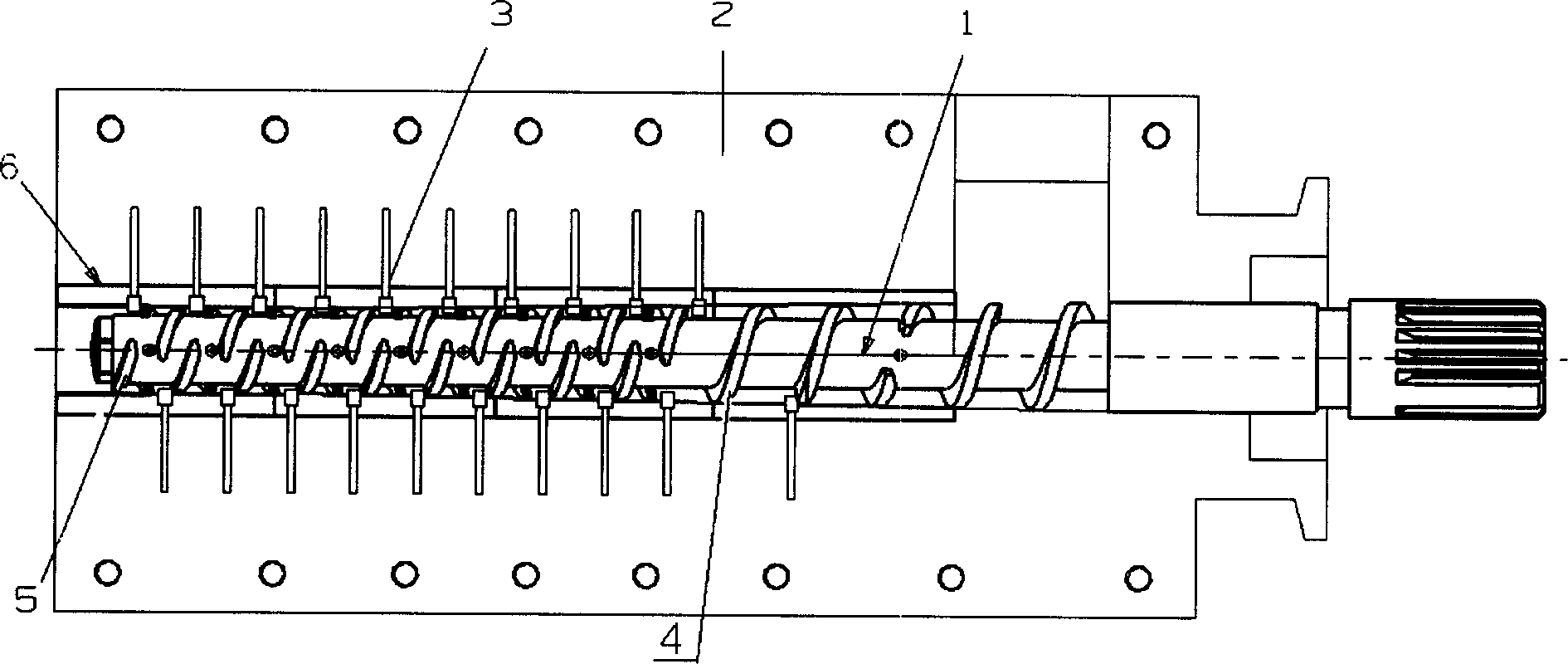

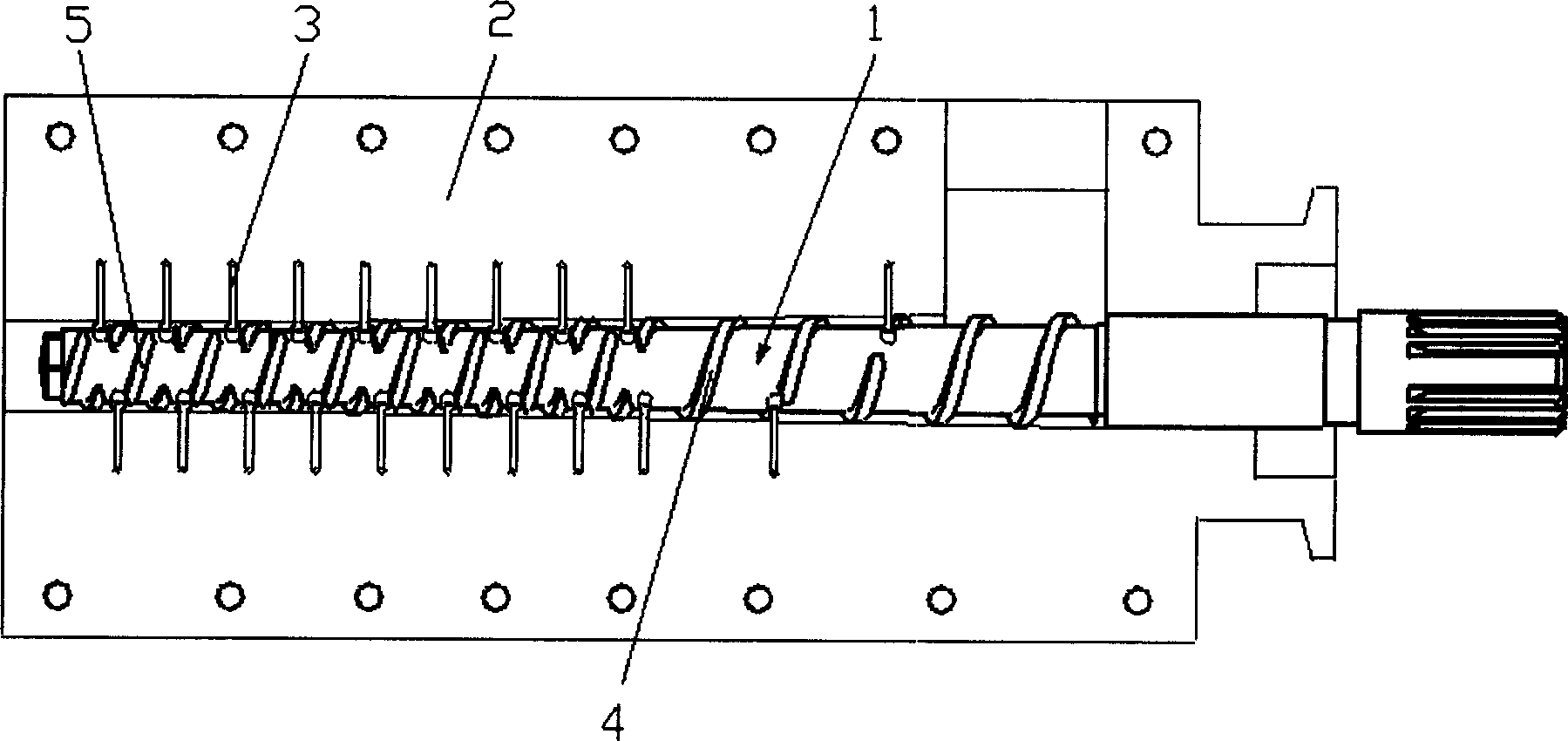

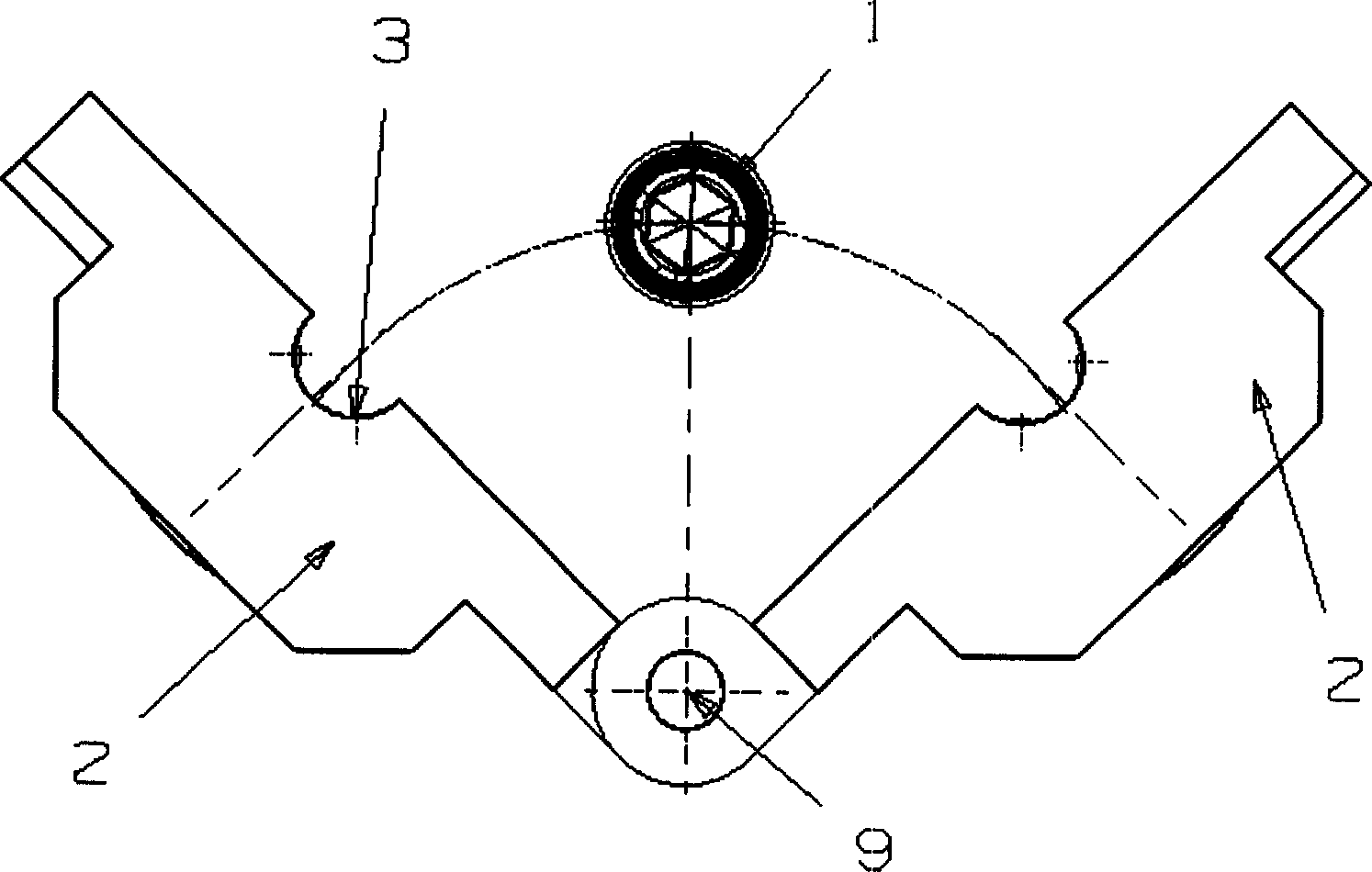

Conic four-piece reciprocating pin scewrod extruder

A reciprocating pin-screw extruder with conic screw bolt whose spiral threads in the extruding out and mixing segments are periodically divided into 4 spiral plates alternatively staggered is composed of extruding system and drive system. The gap between every two spiral plate is used as the channel of pin. Its drive system has a drive box consisting of input shaft, gear set, inclined wheel, connecting rod and swinging axle. Its advantages are stable flow state of material, high effect and low energy consumption.

Owner:新中法高分子材料股份有限公司 +1

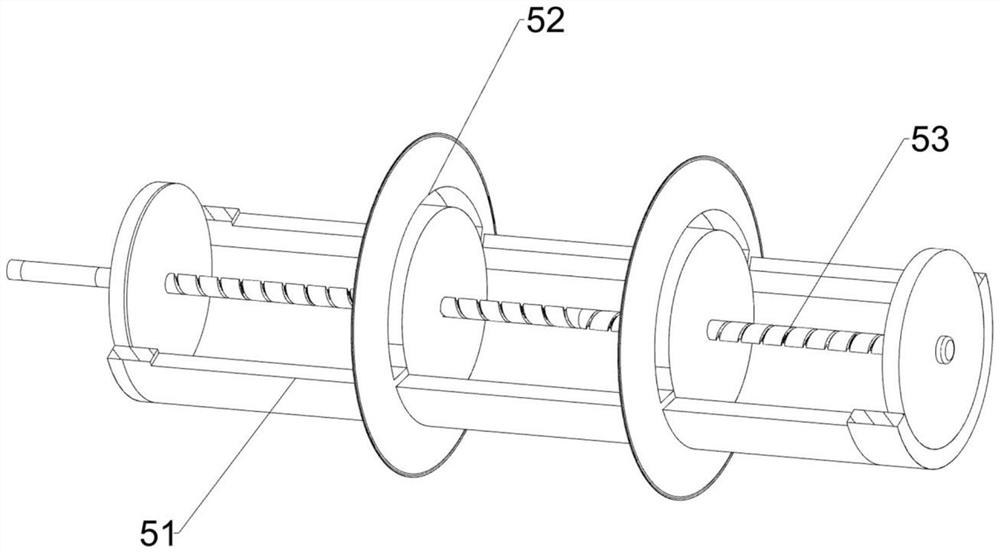

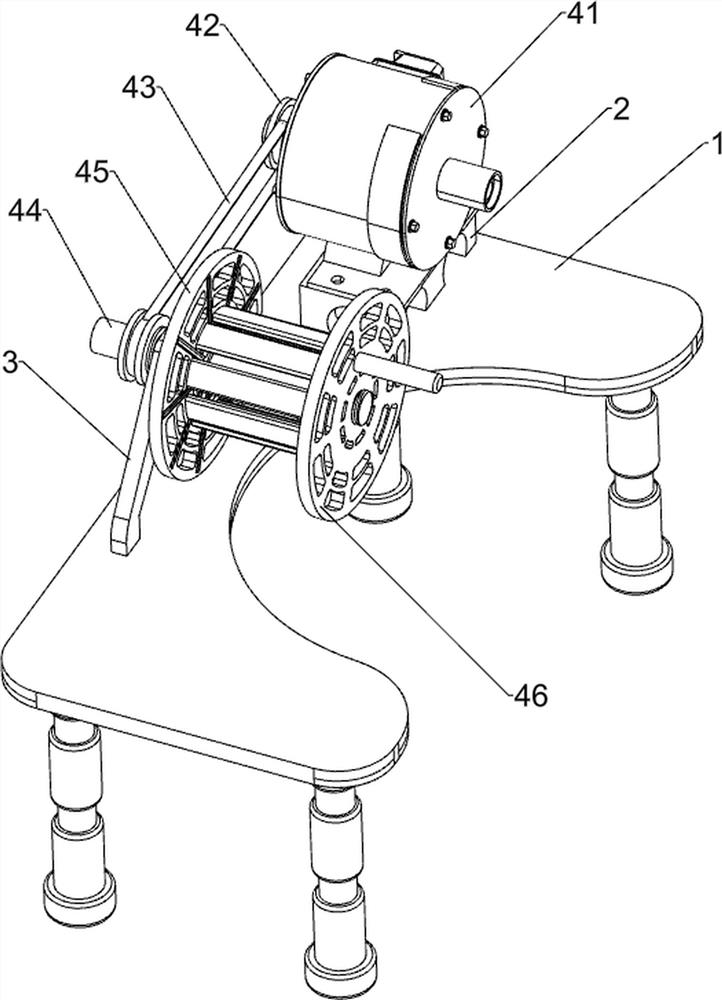

Cable winding equipment

The invention relates to winding equipment, in particular to cable winding equipment. The technical problem to be solved by the invention is to provide the cable winding equipment which can cut off acable in time after the cable is wound and facilitates taking-out of the wound cable. In order to solve the technical problem, the cable winding equipment provided by the invention comprises a support, a mounting base, a winding mechanism and a moving mechanism, wherein the support is connected to one side of a rack; the mounting base is connected to the side, close to the support, of the rack; the winding mechanism is connected between the support and the mounting base; and the moving mechanism is connected between one side of the winding mechanism and the other side of the rack. The cable winding equipment has the beneficial effects that under the action of the winding mechanism and the moving mechanism, the cable can be quickly and uniformly wound, and the cable can be uniformly wound without the need for manual pulling for guiding.

Owner:山东九州电力电线厂

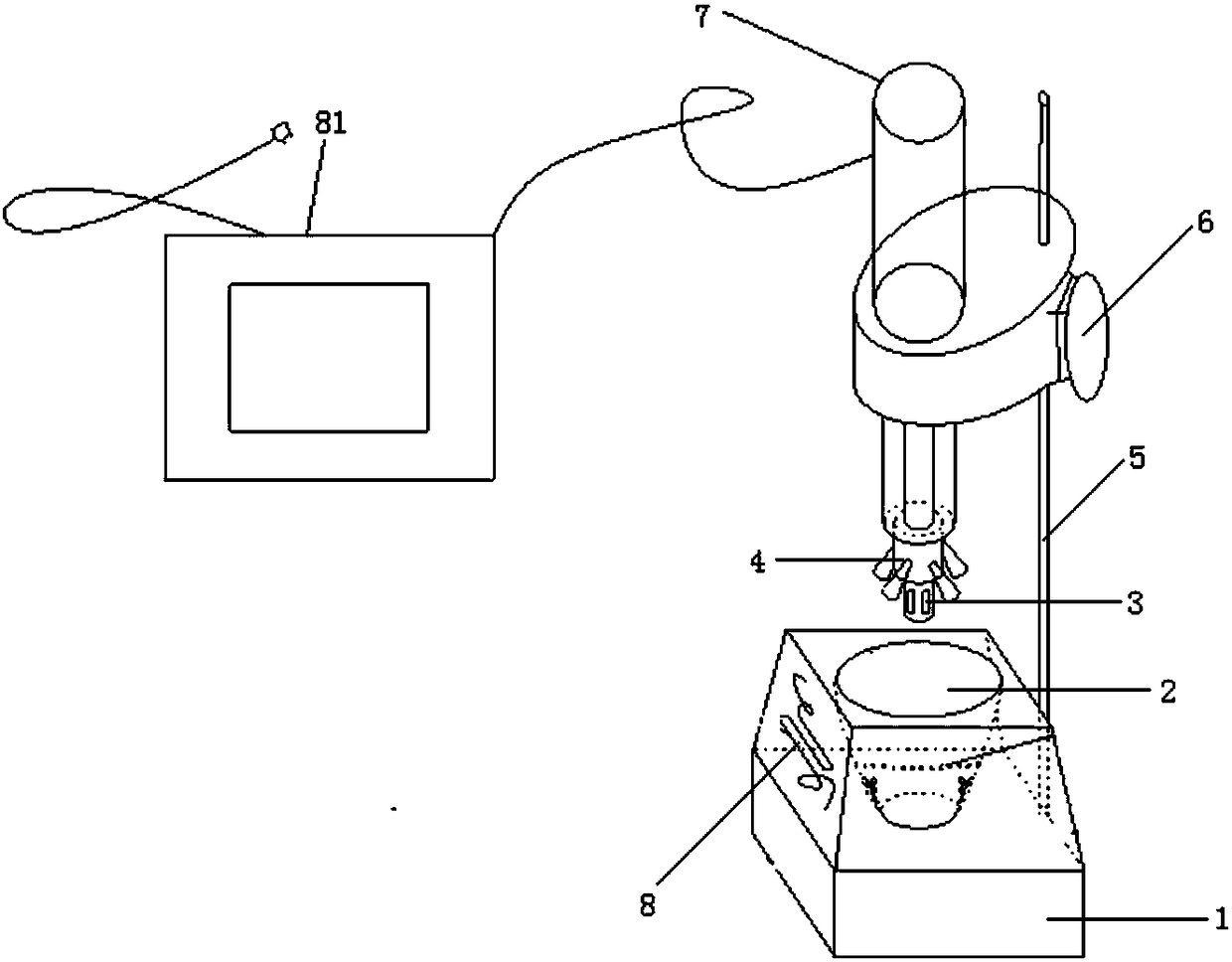

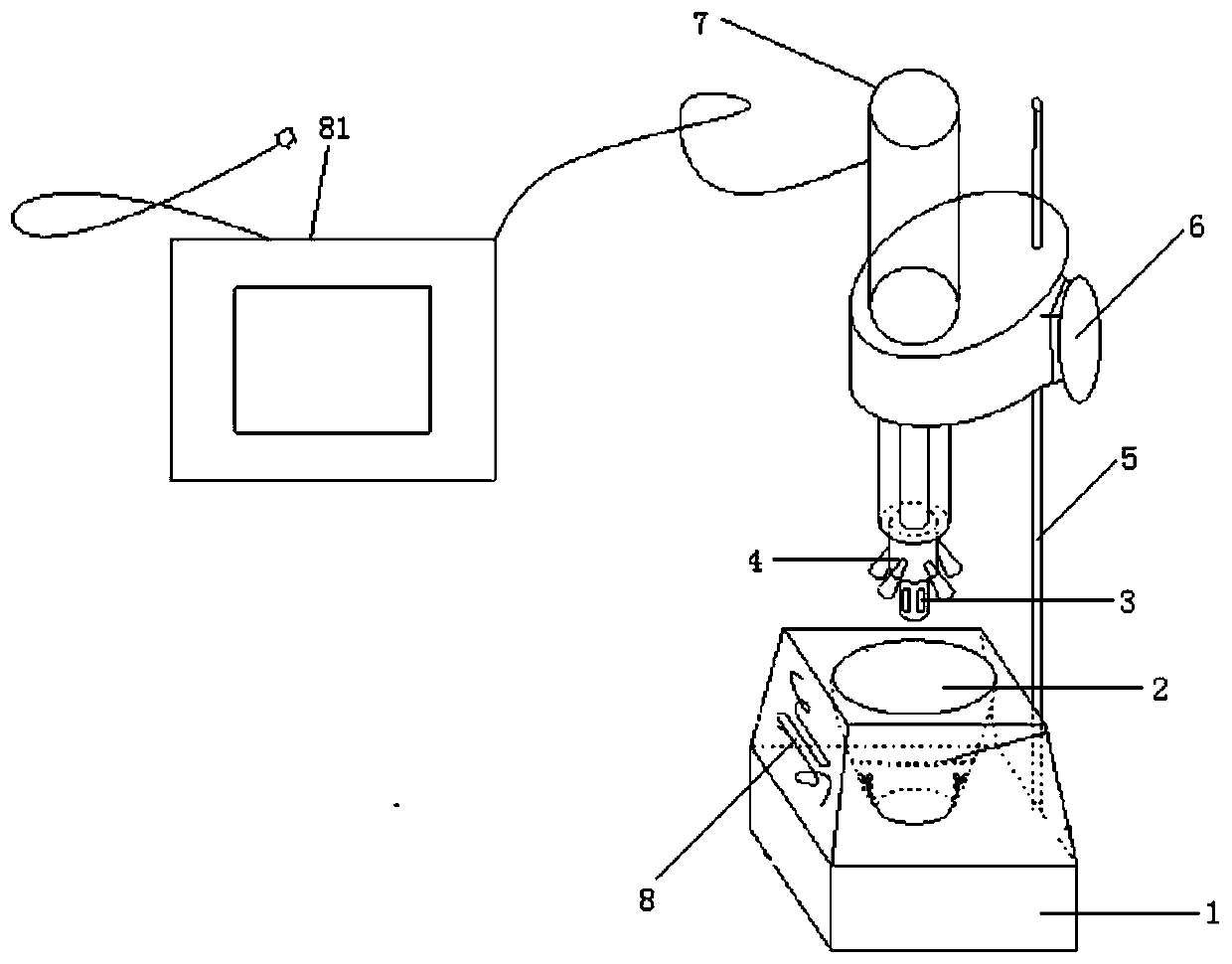

Laboratory high-shear dispersion and emulsion machine

InactiveCN108144466AExtended shear rangeStir wellRotary stirring mixersTransportation and packagingEmulsionMechanical engineering

The invention discloses a laboratory high-shear dispersion and emulsion machine. The dispersion and emulsion machine comprises a base, wherein a detachable material container is mounted above the base, a stirring part is mounted movably in the material container, the stirring part comprises a first stirring part and a second stirring part, the first stirring part is used for circulating the material at the middle and lower parts in the material container to the upper part and performing shearing and dispersing, and the second stirring part is coaxially mounted with the first stirring part andused for circulating the material at the upper part in the material container to the middle and lower parts and performing stirring. By virtue of the two stirring parts connected coaxially up and down, the material in the material container can be subjected to uniform dispersion and shearing to ensure the material to be uniformly stirred without the phenomena of caking and up and down layering.

Owner:CHANGAN UNIV

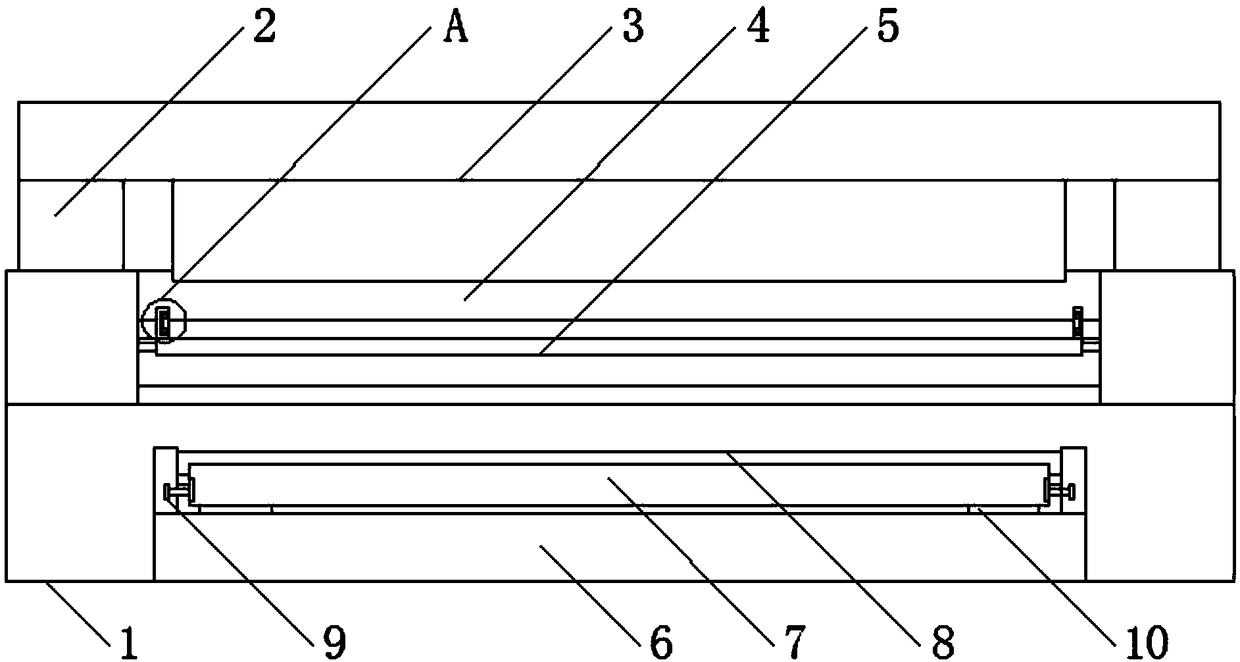

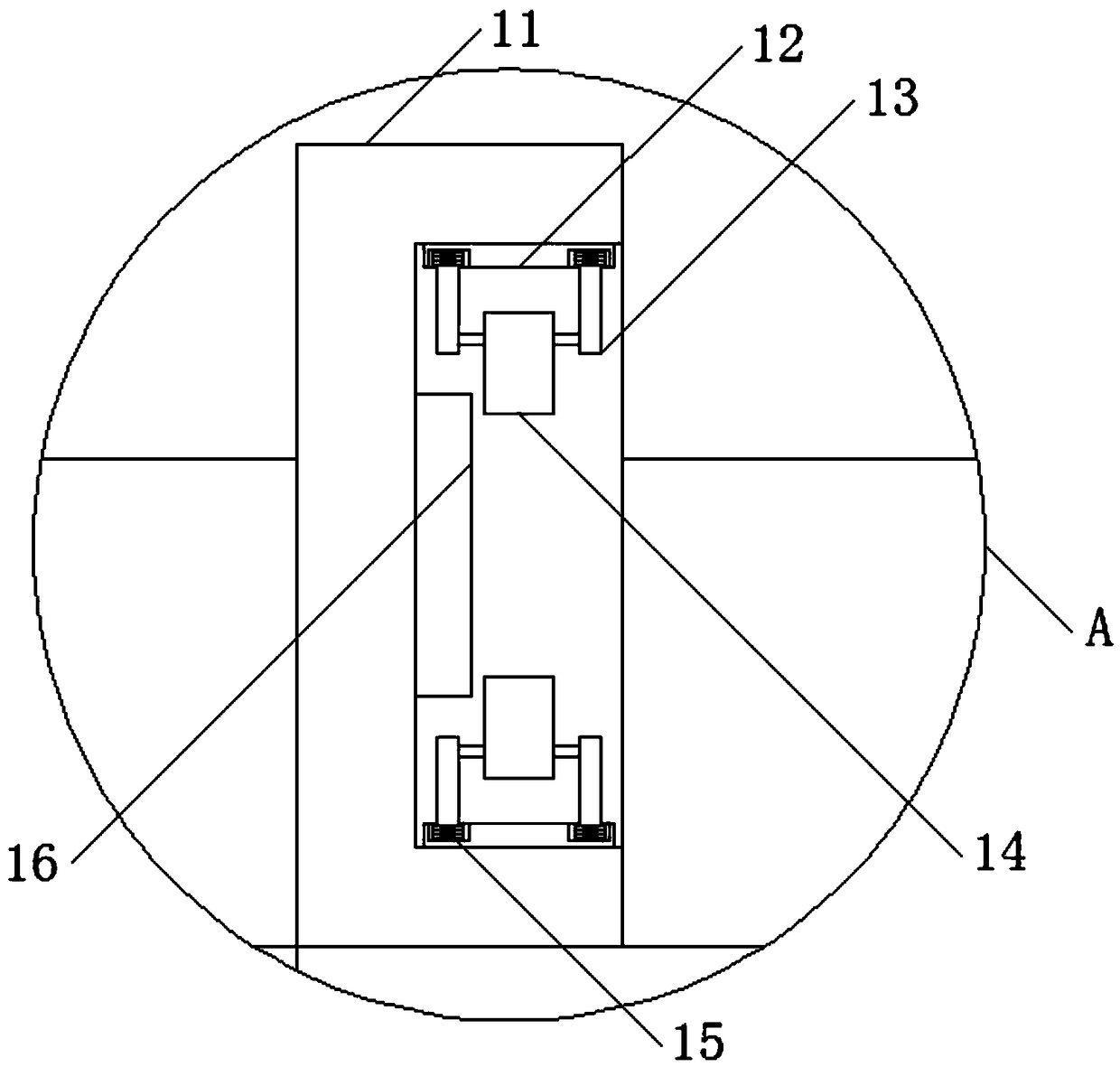

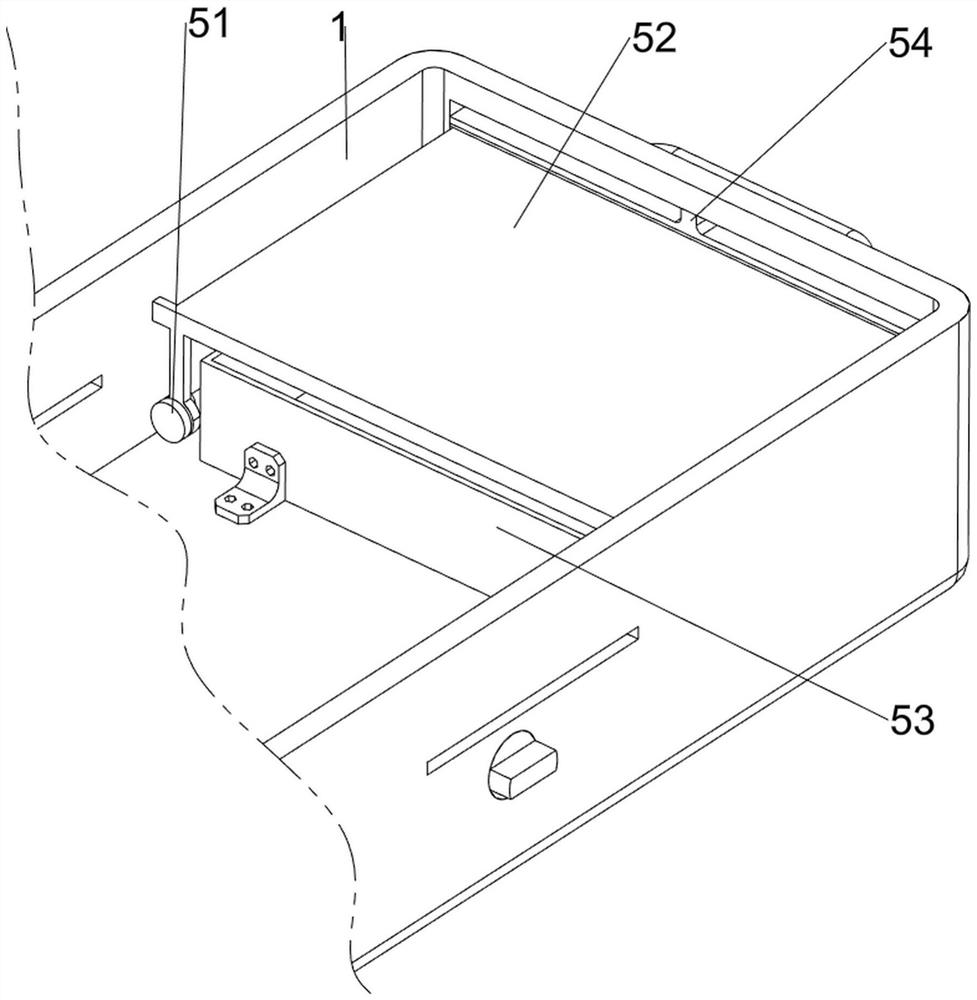

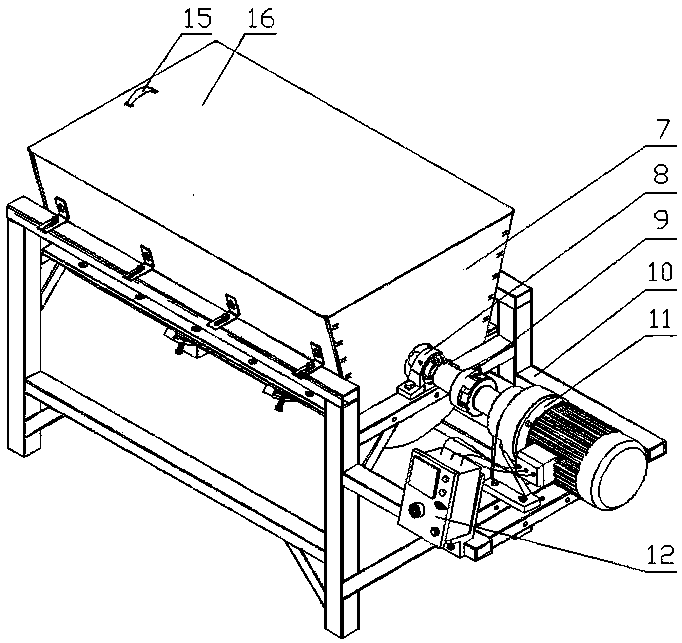

Plate shearing machine capable of cutting multiple plates

PendingCN109108366AAvoid driftingShear evenlyMetal-working feeding devicesNibbling shearing machinesEngineeringMechanical engineering

The invention discloses a plate shearing machine capable of cutting multiple plates, and belongs to the technical field of plate shearing machines. The plate shearing machine capable of cutting the multiple plates comprises a fixing base. Electric telescoping rods are arranged on the left side and the right side of the top of the fixing base, a shearing plate is arranged on the tops of the electric telescoping rods, and a conveying roller is arranged on the top of the fixing base. A limiting plate is connected with the outer walls of the front sides of the fixed ends of the electric telescoping rods through a fixing support. A material receiving tank is arranged at the bottom of the front end face of the fixing base, a material receiving box is movably arranged on the top of the material receiving tank, and baffles are arranged at the rear end, the front side and the rear side of the top of the material receiving tank. Push plates are arranged on the left side and the right side of thematerial receiving box. The plates can be pressed together to be conveyed, the phenomenon of deviation of the multiple plates in the conveying process is avoided, and the multiple plates can be sheared. Meanwhile, the situation that the multiple plates can be uniformly sheared is guaranteed, the push plates facilitates orderly stacking of the plates which fall into the material receiving box, andthe plate shearing machine is simple in structure and convenient to use.

Owner:NANTONG KANGHAI MACHINERY

Special material for waste ABS (acrylonitrile butadiene styrene) plastic regenerated and modified automobile and preparation method of special material

The invention discloses a special material for a waste ABS plastic regenerated and modified automobile and a preparation method of the special material, and solves the problem that the recovery rate of a waste ABS plastic is lower, and resources are wasted in the prior art. The special material comprises the components in parts by weight as follows: 100 parts of a waste ABS broken material, 1-8 parts of ABS, 0.1-0.3 parts of EBS (ethylene bis stearamide), 0.1-0.2 parts of zinc stearate, 0.1-0.2 parts of calcium stearate, 0.1-0.2 parts of antioxidant 10100, 0.2-0.6 parts of antioxidant 168 and 0.1-0.4 parts of montan wax, wherein the waste ABS broken material is obtained by picking, breaking, cleaning, dehydrating, absorbing and drying the waste ABS plastic. The preparation method of the special material for the waste ABS plastic regenerated and modified automobile is further provided. The special material for the waste ABS plastic regenerated and modified automobile and the preparation method of the special material have the advantages that the waste ABS plastic can be recycled, resources are saved, the environment is protected, the cost is reduced, the preparation process is simplified, and the like.

Owner:四川塑金科技有限公司

Special material for regenerating and modifying heel by recycling ABS plastic housing of household appliance and preparation method of special material

The invention discloses a special material for regenerating and modifying a heel by recycling an ABS (Acrylonitrile Butadiene Styrene) plastic housing of a household appliance and a preparation method of the special material in order to solve the problem that a resource is wasted due to the fact that an ABS plastic housing of a household appliance is not recycled in the prior art. The special material comprises the following components in parts by weight: 100 parts of broken material of the ABS plastic housing of the household appliance, 5-20 parts of ABS, 0.1-1 part of calcium stearate, 0.1-1 part of EBS (Ethylene Bis Stearamide) and 0.1-0.5 parts of toner, wherein the broken material of the ABS plastic housing of the household appliance is obtained by breaking, cleaning, rinsing and drying the recycled ABS plastic housing of the household appliance and sucking a label of the recycled ABS plastic housing. The invention further provides the preparation method of the special material for regenerating and modifying the heel by recycling the ABS plastic housing of the household appliance. The special material and the preparation method can effectively recycle the ABS plastic housing of the household appliance, and have the advantages of resource saving, environmental protection, cost reduction, preparation process simplification and the like.

Owner:四川塑金科技有限公司

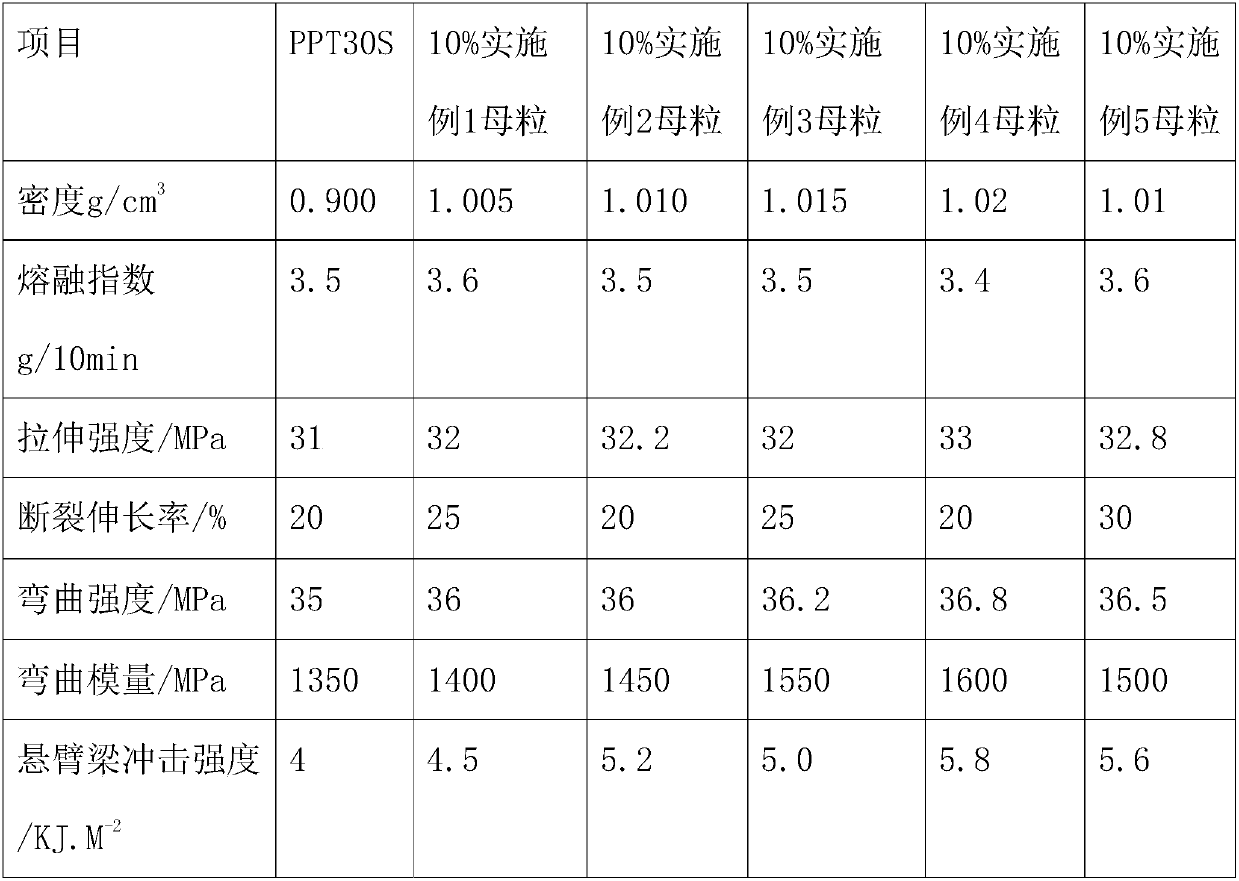

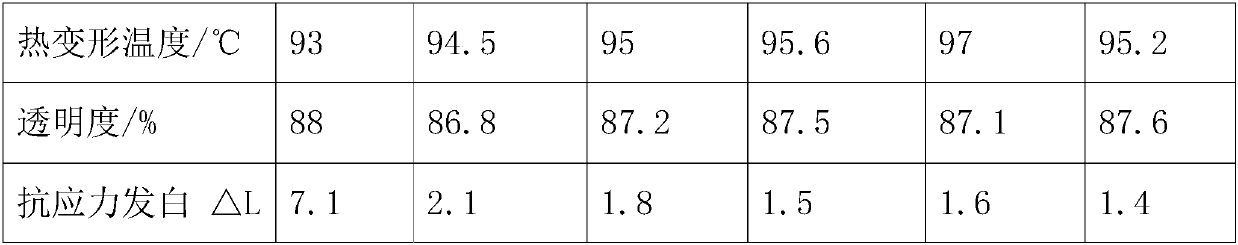

Anti-stress whitening transparent filling master batch for polypropylene and preparation method thereof

InactiveCN107641253AImprove wear resistance and smoothnessIncrease filling volumePolypropyleneAnti stress

The invention discloses an anti-stress whitening transparent filling master batch for polypropylene and a preparation method thereof. The baster batch is prepared from the following raw materials in percentage by weight: 15 to 25 percent of polypropylene, 50 to 65 percent of transparent powder, 10 to 15 percent of polysiloxane, 0.5 to 1 percent of nucleating agents, 8 to 10 percent of compatilizers, 0.5 to 1 percent of coupling agents and 0.5 to 1 percent of antioxidants. The raw materials are weighed according to the mixture ratio; the transparent powder is added into a high-speed material mixing machine; the coupling agents are added into the material mixing machine to be mixed with the transparent powder; the polypropylene, the polysiloxane, transparent powder subjected to surface treatment, compatilizers, nucleating agents and antioxidants are sequentially added; stirring is performed so that the materials are uniformly mixed; the mixed materials are added into a double-screw extrusion machine to be extruded into strip-shaped articles; the master batch is obtained after the cooling. The anti-stress whitening transparent filling master batch has the advantages that the product surface smoothness and wear-resistance can be improved; the moisture absorption is avoided; the filling quantity is great; the transparency of the product is not influenced; the product manufacturing cost can be favorably reduced; good application values are realized.

Owner:ANHUI JIHONG MATERIAL TECH

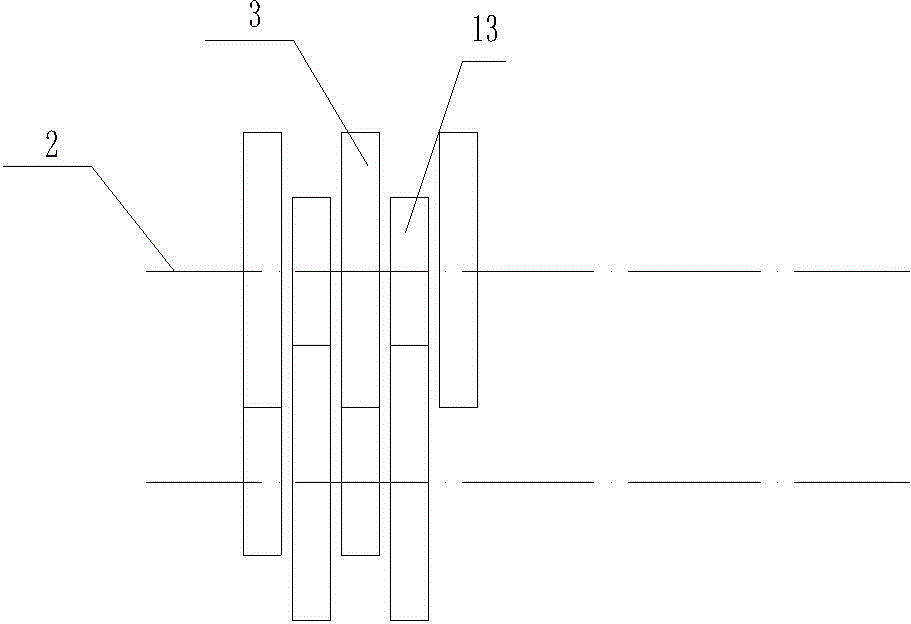

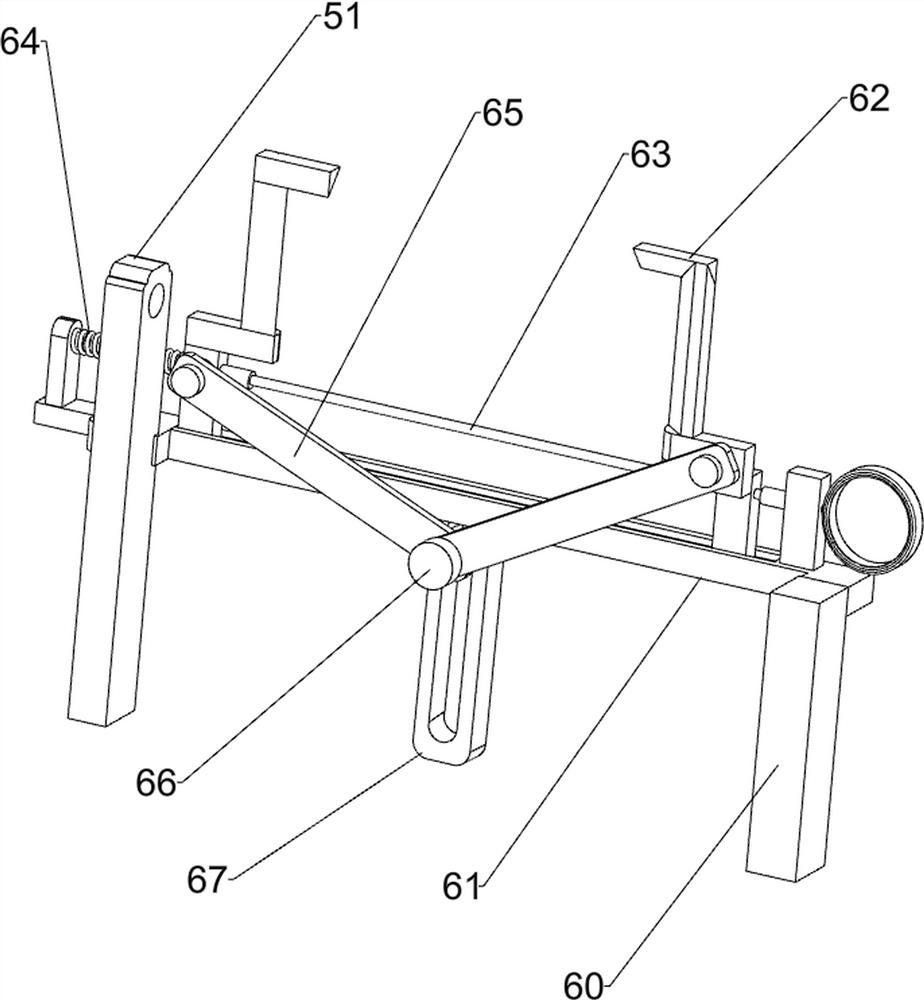

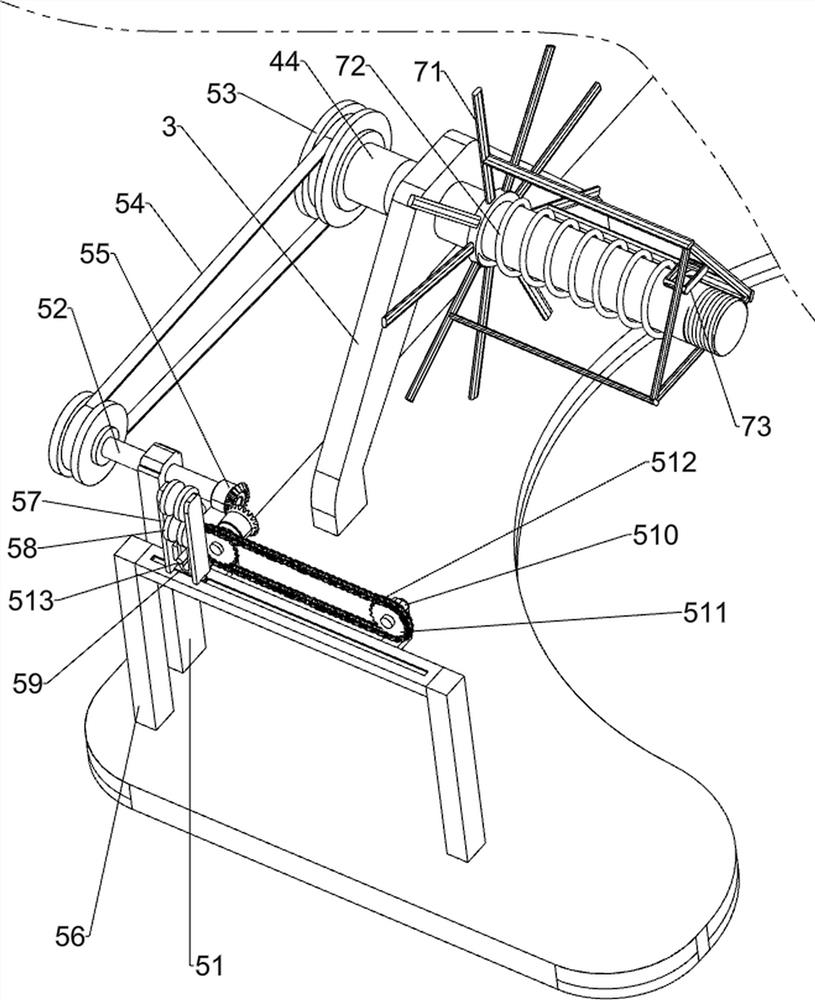

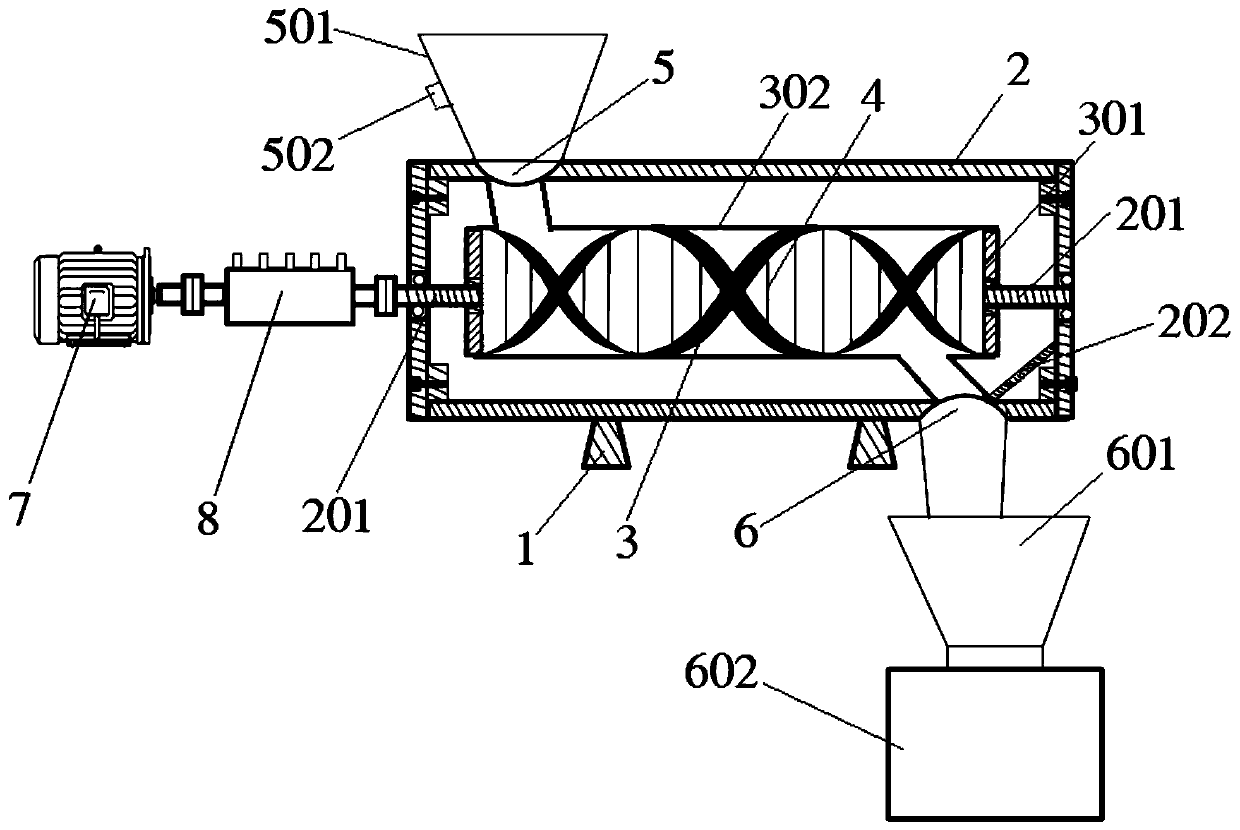

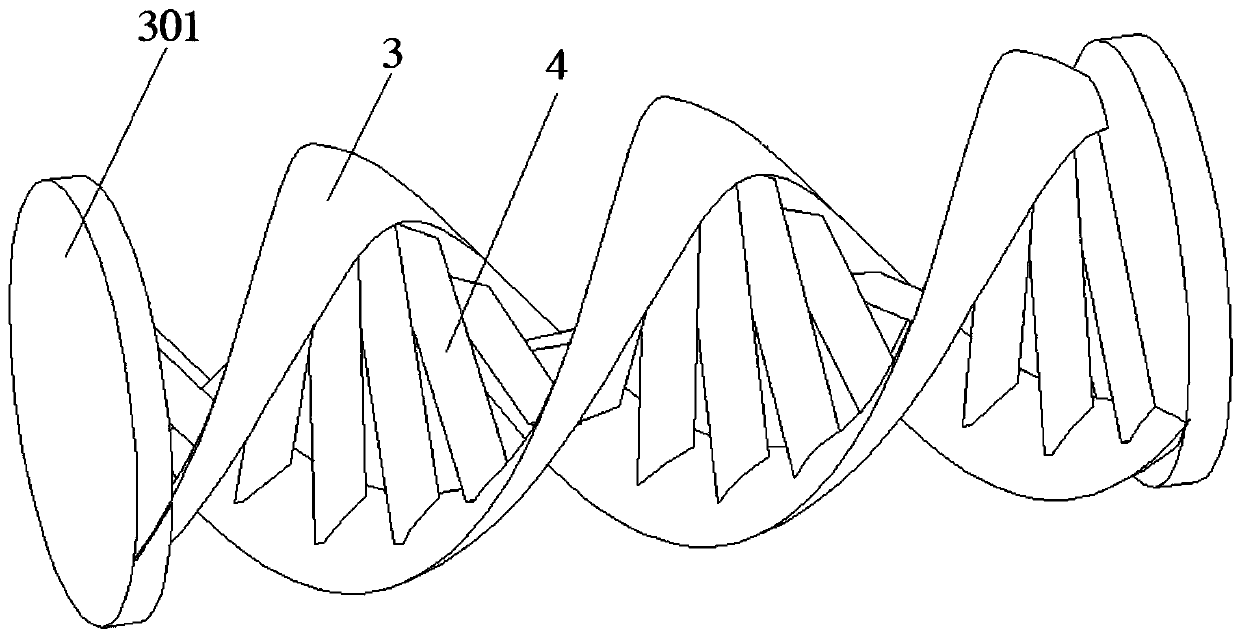

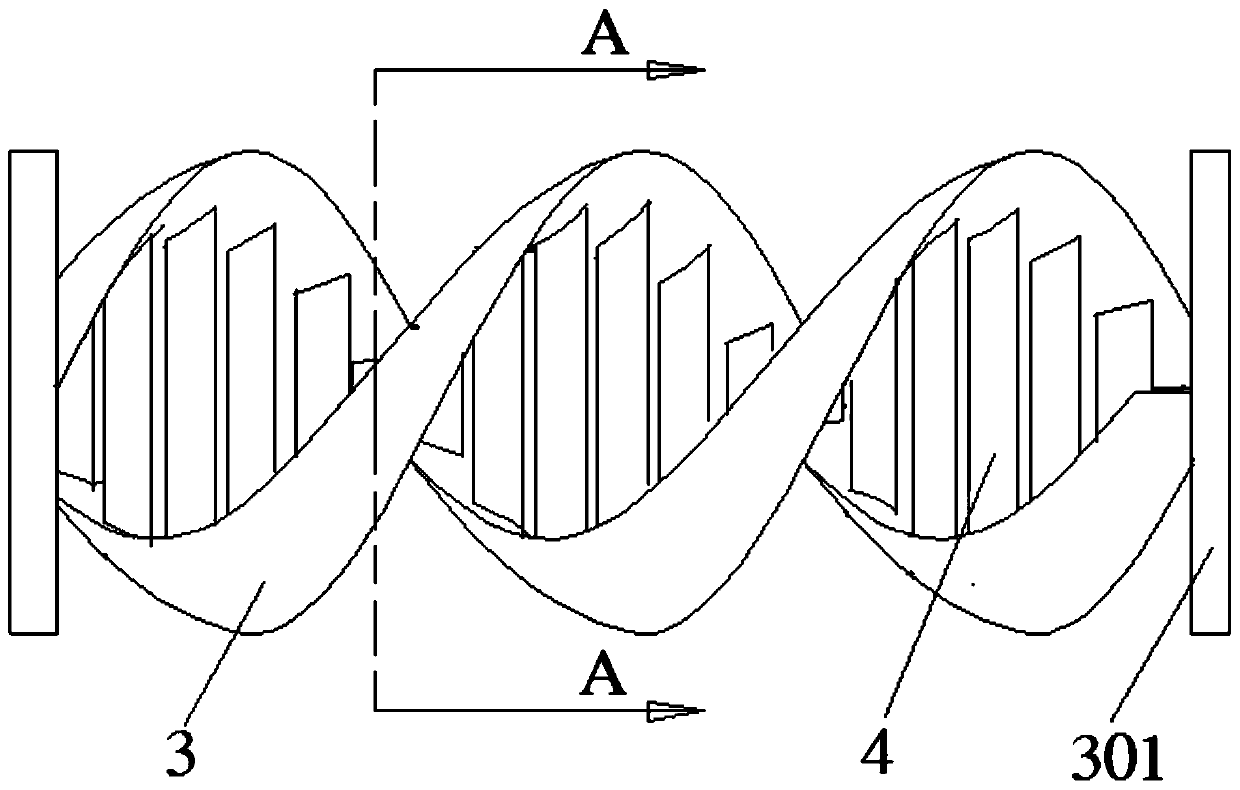

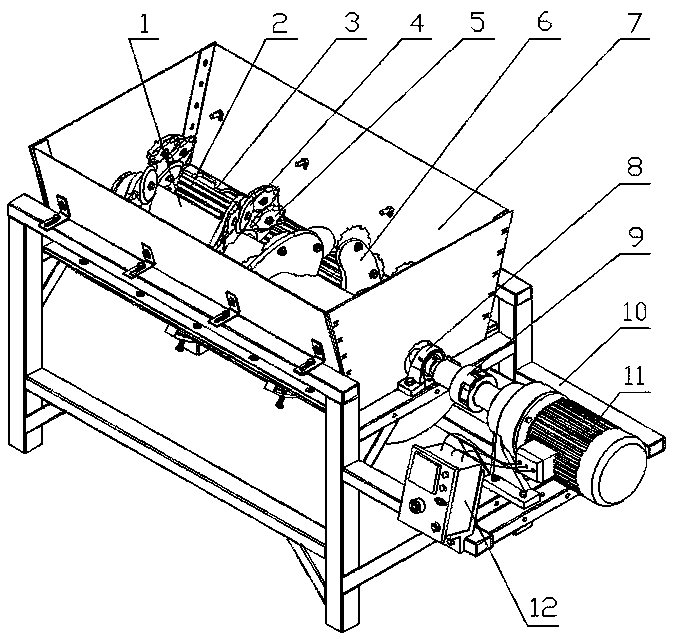

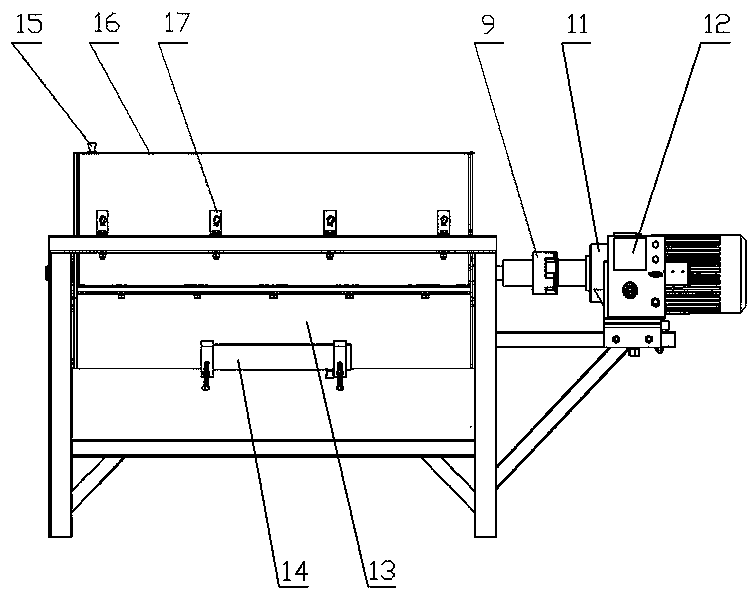

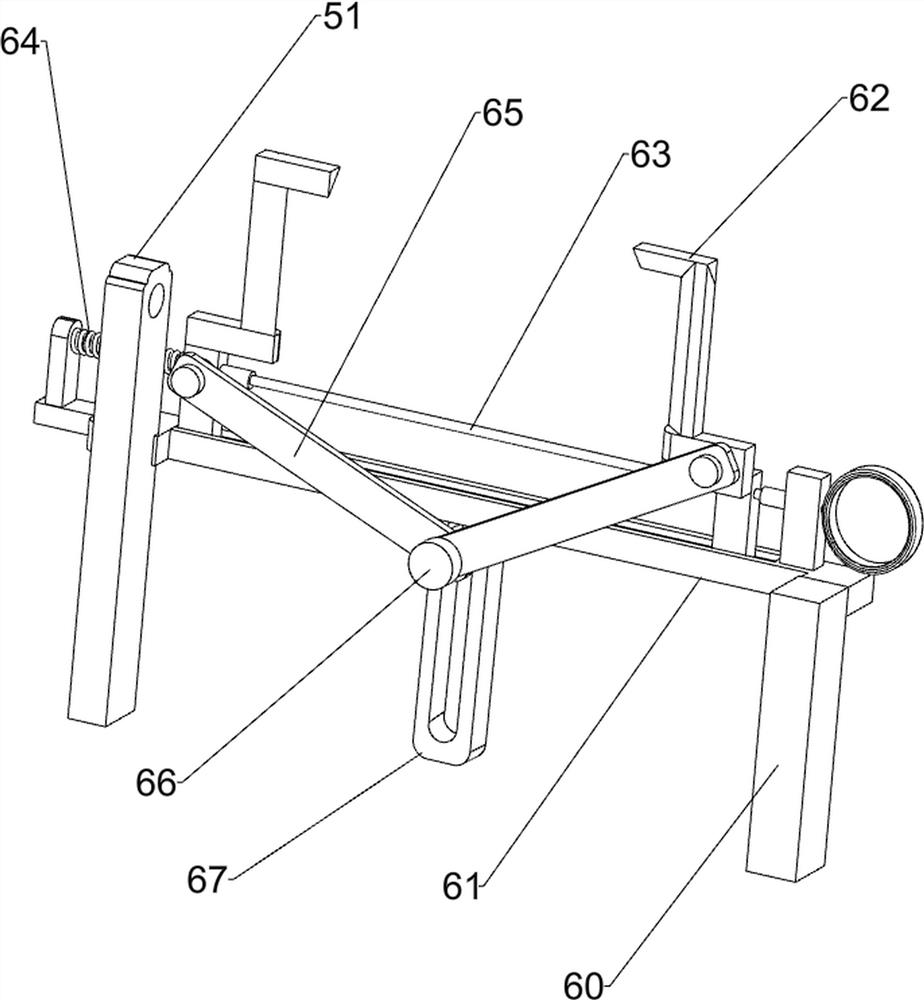

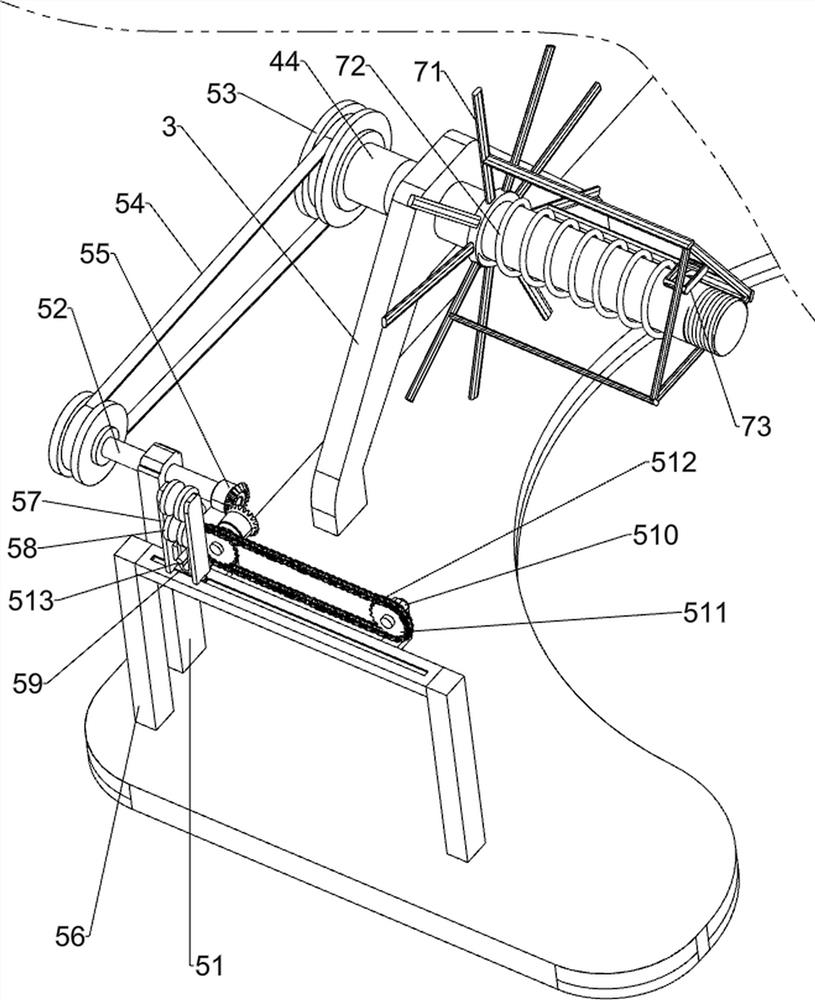

Plant fiber shearing device, shearing method and shearing device manufacturing method

ActiveCN109847885AShear evenlyReduce frictionTextile disintegration and recoveryGrain treatmentsEngineeringMechanical property

The invention discloses a plant fiber shearing device, a shearing method and a shearing device manufacturing method. The plant fiber shearing device comprises a bracket. A shearing box is arranged onthe bracket. A twin-screw shearing mechanism is arranged in the shearing box. A feeding opening is formed in the left end of a top side plate of the shearing box, a discharging opening is formed in the right end of a bottom side plate of the shearing box, and a shaft hole is formed in a left side plate of the shearing box. A power mechanism is connected to the twin-screw shearing mechanism througha rotating shaft. The rotating shaft penetrates through the shaft hole and extends out of the shearing box. By means of the plant fiber shearing device, the shearing method and the shearing device manufacturing method, ordered and regular cutting of plant fibers can be realized, so that the cutting fineness and lengths of the plant fibers can be controllable, and the cutting quality and production efficiency of the plant fibers are guaranteed; and meanwhile, severe collision between the plant fibers and a cutting part and severe collision between the plant fibers in the cutting process are greatly relieved, the structures of the plant fibers are prevented from being damaged, and the mechanical property of the plant fibers is ensured. The shearing method is simple, and the device manufacturing method ensures the stability of the structure.

Owner:CHANGAN UNIV +3

Dry one-step method for preparing glass fiber modified amino molding plastic

The invention discloses a dry-type one-step method for preparing glass fiber modified amino molding plastic. The method comprises the following steps: preparing a dispersing agent, a lubricating agent and a coupling agent I into an aqueous solution A in proportion; the preparation method comprises the following steps: adding amino resin powder, inorganic filler, wood pulp cellulose, a release agent and pigment into a horizontal paddle stirrer according to a ratio, stirring, uniformly spraying the aqueous solution A into the horizontal paddle stirrer by using a spraying machine, and adding the treated glass fiber chopped strands; conveying the mixed materials into a hopper of a metering screw rod by using a spiral conveyor; starting a reciprocating single-screw mixing extruder, and sequentially starting an oil pump, a main machine screw, a lateral feeder screw and a metering screw; and after the materials are extruded and caked from the reciprocating single-screw mixing extruder, the conveying and granulating equipment is started. According to the method, the amino molding compound with excellent performance can be prepared, meanwhile, the preparation procedures of amino molding can be reduced, the production efficiency of the molding compound is greatly improved, and the energy consumption and the labor force are reduced.

Owner:KAIHUA RUIDA PLASTIC TECH

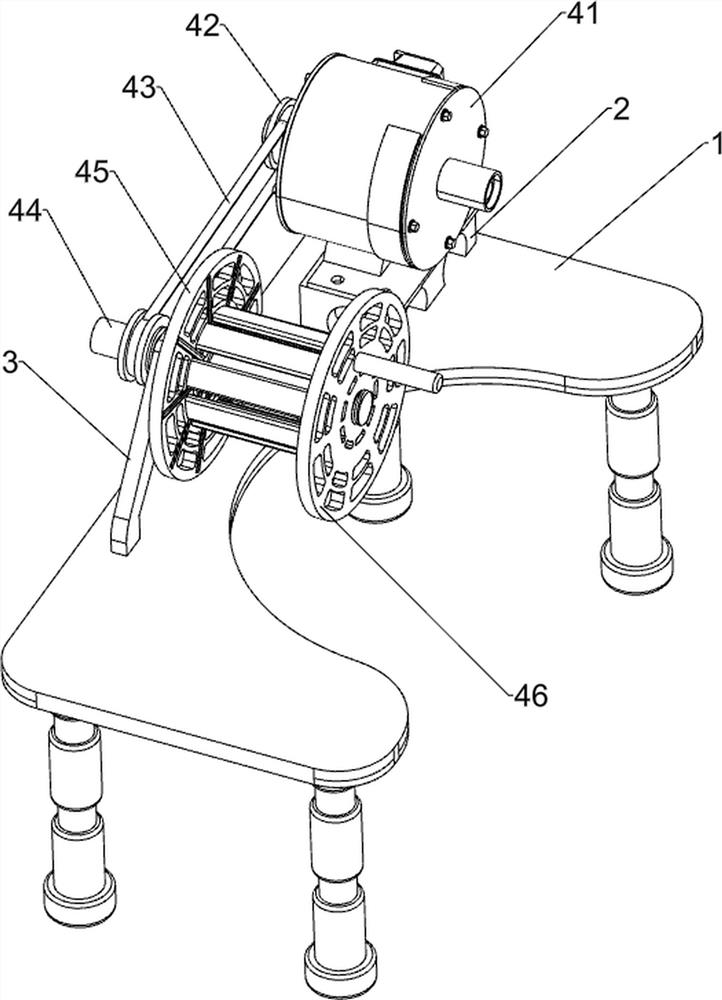

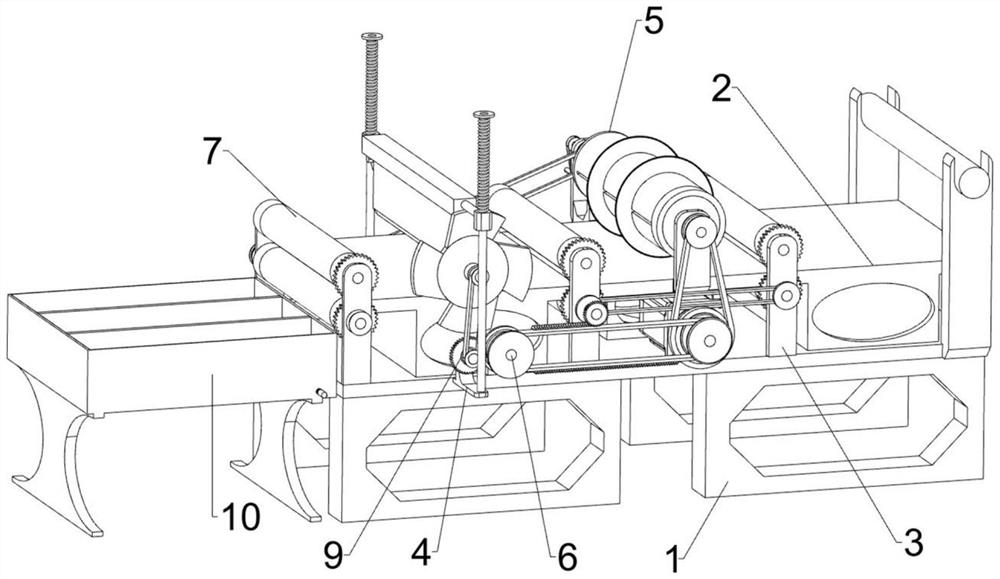

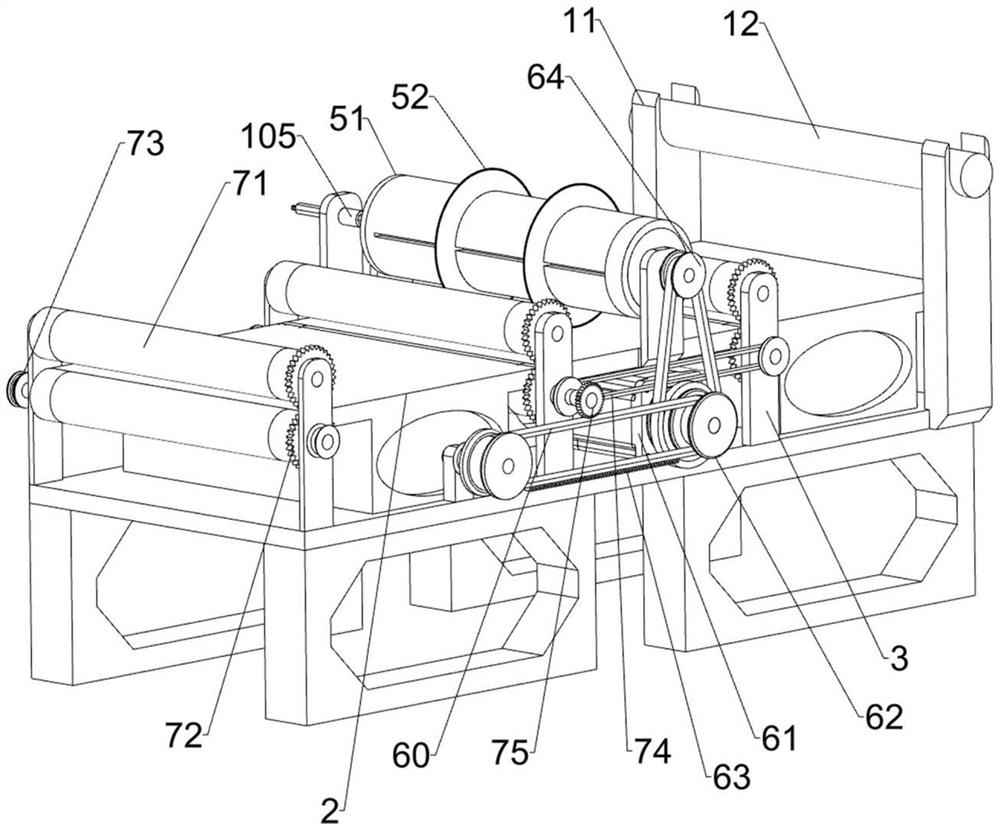

Slitting machine capable of adjusting feeding width and length of steel sheet coiled material

ActiveCN112548210AGuaranteed uniformityNo manual feeding requiredShearing machine accessoriesStructural engineeringManufacturing engineering

The invention relates to a slitting machine, in particular to a slitting machine capable of adjusting the feeding width and length of steel sheet coiled material. The technical problem to be solved bythe invention is to provide the slitting machine capable of adjusting the feeding width and length of steel sheet coiled material, and the slitting machine can quickly adjust the distance between cutters, improve the working efficiency and easily cut steel sheets. In order to solve the technical problem, the invention provides the slitting machine capable of adjusting the feeding width and lengthof the steel sheet coiled material. The slitting machine comprises a base, three first installation frames and two second installation frames, and a mounting plate is connected to the top of the base; the three first installation frames are evenly connected to the base at intervals; and the two second installation frames are connected to the two sides of the base respectively. Steel sheets can belongitudinally sheared through a cutting mechanism, a power mechanism and a feeding mechanism, intermittent feeding can be conducted on the steel sheets during shearing, manual feeding is not needed,and time and labor are saved.

Owner:SHANDONG YINGBO ELECTRIC POWER EQUIP

A kind of preparation method of glass fiber reinforced thermoplastic resin composite material

The invention discloses a method for preparing a glass fiber reinforced thermoplastic resin composite material. By selecting a screw with a higher aspect ratio (the aspect ratio of the screw is in the range of 48:1 to 56:1), and by setting the glass fiber on both sides The glass fiber is fed into the feeding port, and the distribution of the shear strength of the special screw shearing element can improve the length of the glass fiber distributed in the resin more uniformly, and the retention length is longer.

Owner:合聚高分子材料科技(广东)有限公司

A special material for polyethylene anti-corrosion pipeline modified regeneration and its preparation method

Owner:HUBEI JIN KE ENVIRONMENT PROTECTION TECH

Special material for pass box for regenerating and modifying waste bottle cap crushed plastic, and preparation method of special material

The invention discloses a special material for a pass box for regenerating and modifying waste bottle cap crushed plastic, and a preparation method of the special material. The special material and the preparation method solve the problems that the special material for the pass box is high in production cost and complicated in production technique in the prior art. The special material comprises the following components in parts by weight: 100 parts of waste bottle cap crushed material, 2-5 parts of EVA (Ethylene-Vinyl Acetate), 3-8 parts of flexibilizer, 5-10 parts of activated talcum powder, 0.1-2 parts of dispersing agent and 0.1-1.5 parts of modifier, wherein the waste bottle cap crushed material is obtained by crushing, cleaning, rinsing, drying and absorbing the recovered waste bottle cap crushed plastic. The invention further provides the preparation method of the special material for the pass box for regenerating and modifying the waste bottle cap crushed plastic. The special material and the preparation method can recycle the waste bottle cap crushed plastic effectively, and have the advantages that resources are saved, an environment is protected, the cost is lowered, and the preparation process is simplified.

Owner:四川塑金科技有限公司

Special modified recycled polyethylene material for cables and preparation method of special modified recycled polyethylene material

ActiveCN102863678BReduce cost pressureAvoid destructionPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

Owner:四川塑金科技有限公司

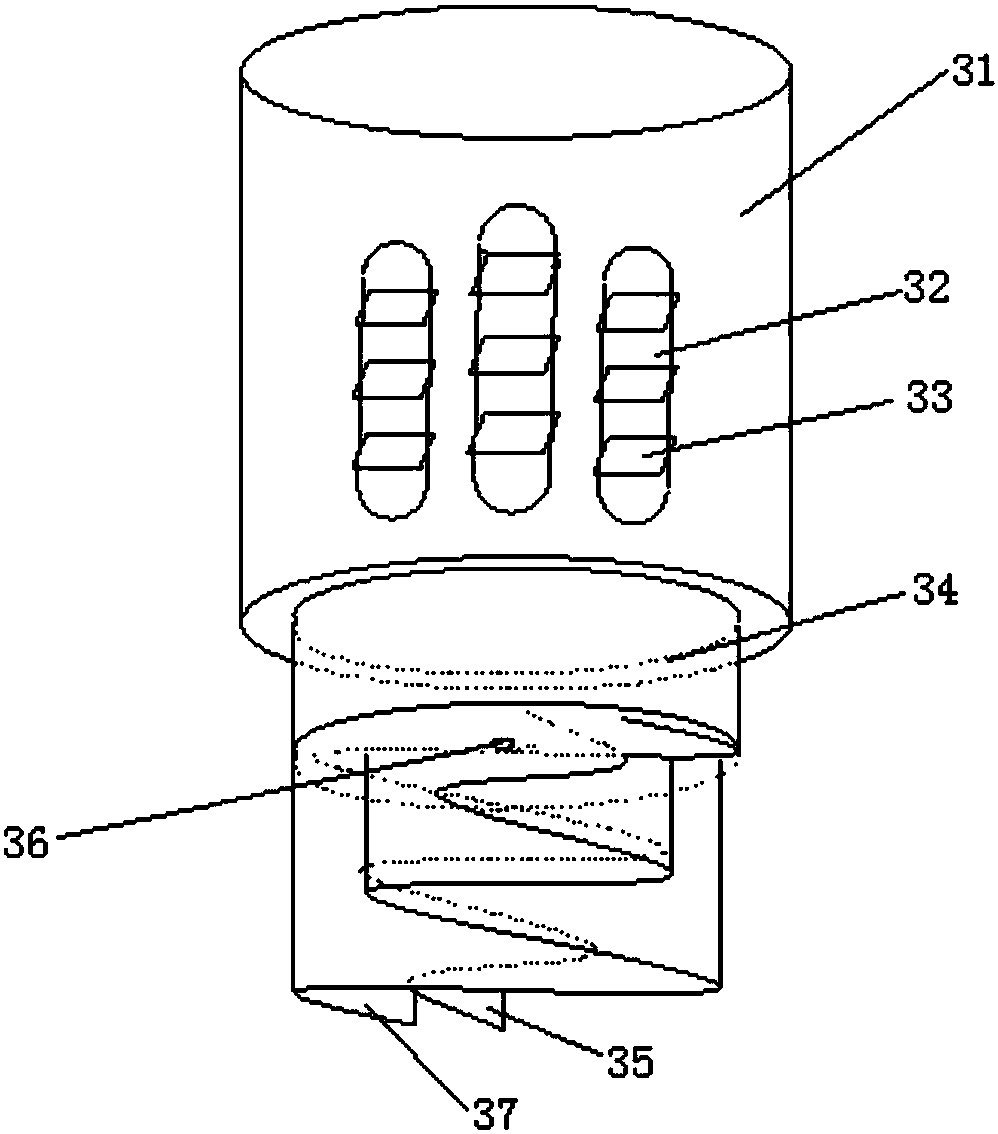

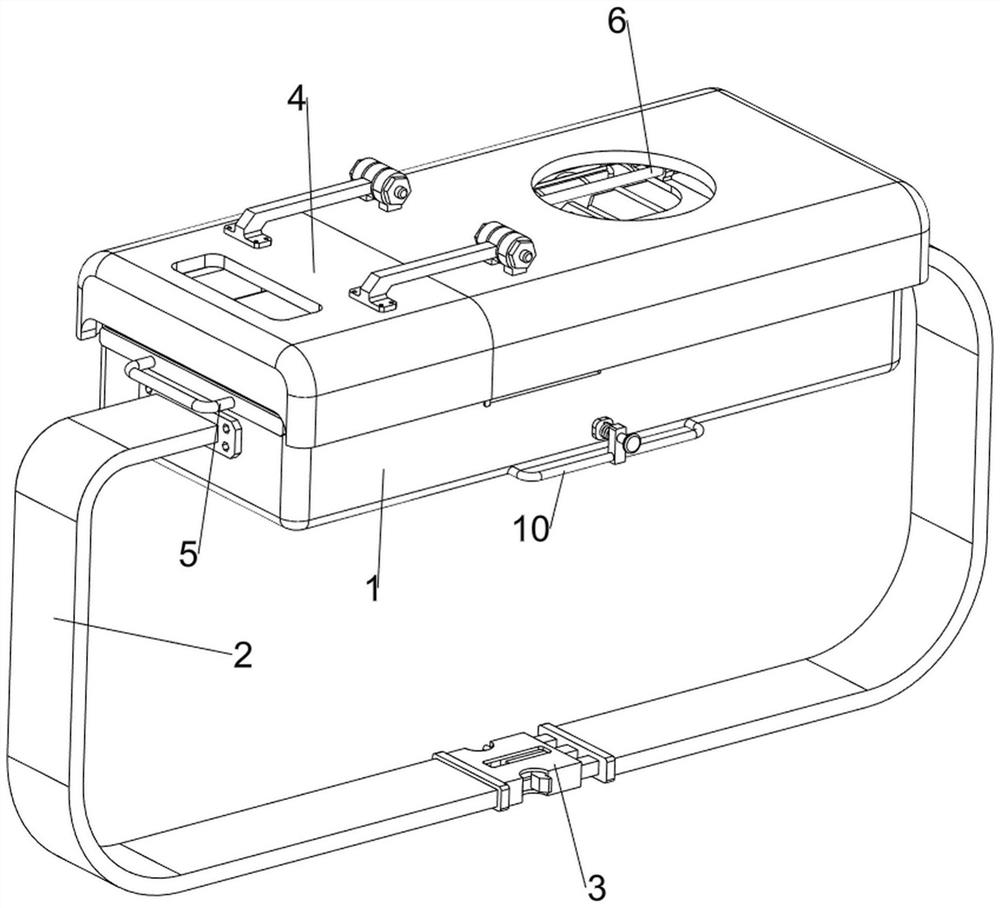

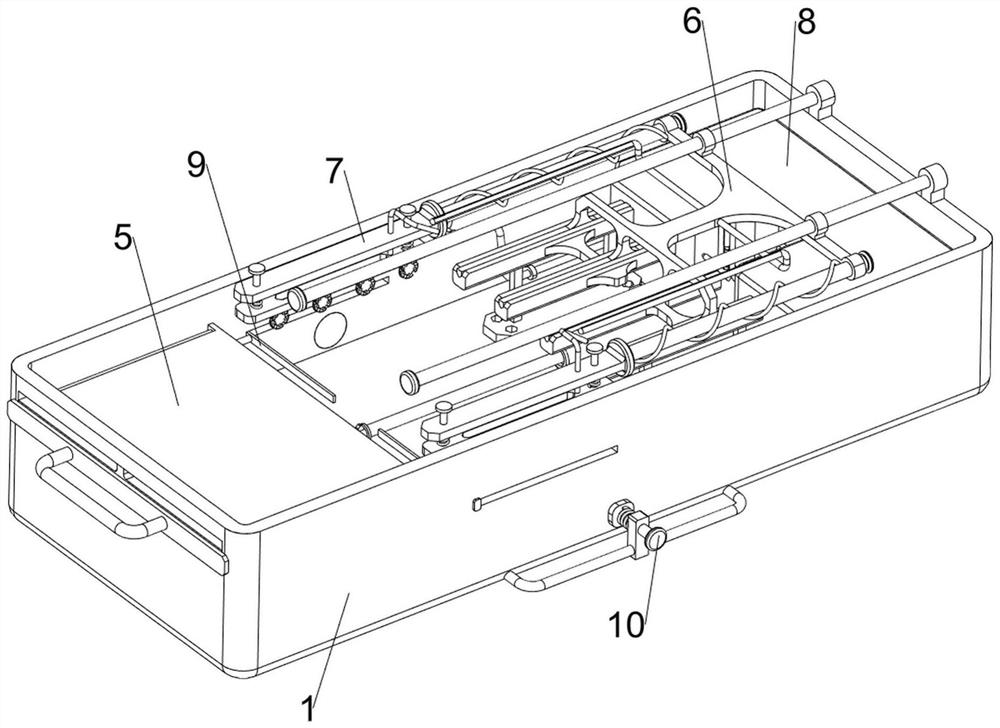

Portable biological amniotic membrane shearing device

ActiveCN113771107AShear evenlyNo need for manual cuttingLavatory sanitoryMetal working apparatusAnatomyAmniotic Sheet

The invention relates to an amniotic membrane shearing device, in particular to a portable biological amniotic membrane shearing device. The invention aims to provide the portable biological amnion shearing device which is simple and easy to operate and does not need manual shearing. According to the technical scheme, the portable biological amniotic membrane shearing device comprises straps, a clamping buckle, a rotating frame and a charging mechanism; a shell is symmetrically provided with the straps used for carrying the portable biological amniotic membrane shearing device; the clamping buckle is arranged on the lower side of the strap on one side, the clamping buckle is matched with the strap on the other side; the rotating frame is rotationally arranged on one side of the top of the shell, the rotating frame is matched with the shell; and the charging mechanism is arranged on one side in the shell. People flatly spread an amniotic membrane on a material placement plate for shearing, and after the amniotic membrane is sheared, people move the material placement plate to the left side, so that the amniotic membrane is in contact with a scraping plate.

Owner:JIANGXI KEXING BIOLOGICAL ENG CO LTD

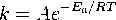

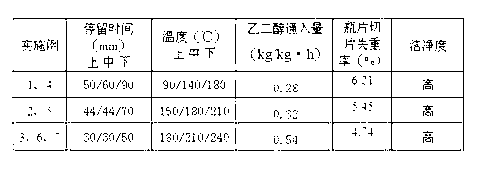

Recovery device and recovery process of waste polyester bottle flakes

ActiveCN103342832AImprove filtration efficiencySmooth feedingPlastic recyclingPolyesterProcess engineering

The invention provides a recovery device and a recovery process of waste polyester bottle flakes, wherein the device comprises a cleaning device, a lifting device, a crusher, and an after-alcoholysis reactor, which are orderly communicated; a plurality of redistributors are fixedly arranged inside the cleaning device from top to bottom at intervals; a rotating shaft penetrates through an opening of each redistributor in a rotating manner; a mixing blade is arranged on the rotating shaft; a through hole is arranged on each redistributor; the cleaning device is communicated with an ethanediol steam pipeline; an ethanediol liquid pipeline is arranged on the after-alcoholysis reactor; a heating device is arranged inside the after-alcoholysis reactor; the temperature of the cleaning device is gradually reduced to 90 DEG C from 240 DEG C from bottom to top. The recovery device is cleaned by ethanediol, so that the recovery device is cleanly cleaned; the alcoholysis reaction is easily controlled; the recovery cost is low. A front-alcoholysis reactor also can be added between the crusher and the after-alcoholysis reactor, so that the section can be cut; the total standing time is shortened.

Owner:福建锦兴环保科技有限公司

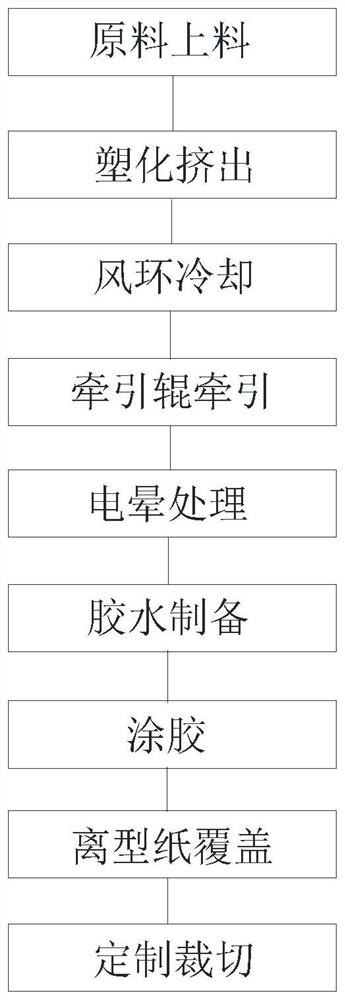

Preparation method of coating protective plastic capable of being bonded with metal

The invention relates to the technical field of coated plastic production, in particular to a preparation method of coated protective plastic capable of being bonded with metal, which comprises the following steps: S1, feeding raw materials; raw materials for manufacturing wrapping plastic are subjected to kneading and cold mixing treatment, kneading of the raw materials is completed through a kneading machine, side-by-side tangent differential arrangement is adopted, namely, the speed of one stirring paddle is high, the speed of the other stirring paddle is low, so that shearing force is generated, the mixed materials can be rapidly sheared due to different paddle speeds, and therefore the materials can be evenly mixed; cold mixing of raw materials is completed through the cold mixing machine, the cold mixing machine is provided with a cooling pipe, a cooling system is used for injecting a cooling agent into the cooling pipe through a water inlet, then the raw materials in a machine body are cooled, an automatic cutting machine is used for cutting a plastic film covered with release paper into a preset shape, and leftover materials are recycled; and the cut wrapping plastic finished products are collected and wrapped in a centralized mode, the metal parts can be directly wrapped after the release paper is torn off, and use is convenient.

Owner:重庆华众新型材料有限公司

Sectional spiral auger testing platform

The invention discloses a sectional spiral auger testing platform which mainly comprises an electromotor, a speed adjuster, a rack, a bottom shell, side plates, sectional spiral augers and the like, wherein the bottom shell is connected with side plates of a material tank through bolts; the side plates of the material tank are connected with the rack through bolts; and a kneading plate matched with the radius of the bottom shell is welded on the bottom shell. Material tank bottom shells of different radiuses can be replaced, the distance between both sides of the material tank can be changed,then shearing and kneading gaps between the material tank bottom shell and the sectional augers can be adjusted and can be adjusted according to different forage grass materials, and the shearing andkneading quality of forage grass can be improved; meanwhile, by adjusting the speed adjuster, the rotation speeds of main shafts of the augers can be adjusted; the number of blades can be also adjusted, and a basis can be made for optimization experiments on optimal structure parameters and working parameters of the sectional spiral augers; and by adopting the sectional spiral auger testing platform, the problems that a conventional spiral auger is low in kneading and shearing quality, low in forage grass utilization rate and the like when materials such as forage grass are subjected to kneading processing, can be solved.

Owner:SHIHEZI UNIVERSITY

A laboratory high shear dispersing emulsifier

InactiveCN108144466BExtended shear rangeStir wellRotary stirring mixersMixing methodsPolymer scienceEngineering

The invention discloses a laboratory high shear dispersing emulsifier, comprising a base, a detachable material container is installed above the base, and characterized in that a stirring part is movably installed inside the material container, and the The stirring part includes a first stirring part for circulating, shearing and dispersing the materials in the middle and lower parts of the material container to the upper part; The second stirring part for stirring; by setting up two coaxially connected upper and lower stirring parts, the material inside the material container can be uniformly dispersed and sheared, so as to ensure that the material is stirred evenly without caking and the phenomenon of upper and lower layers. .

Owner:CHANGAN UNIV

Special material for pass box for regenerating and modifying waste bottle cap crushed plastic, and preparation method of special material

The invention discloses a special material for a pass box for regenerating and modifying waste bottle cap crushed plastic, and a preparation method of the special material. The special material and the preparation method solve the problems that the special material for the pass box is high in production cost and complicated in production technique in the prior art. The special material comprises the following components in parts by weight: 100 parts of waste bottle cap crushed material, 2-5 parts of EVA (Ethylene-Vinyl Acetate), 3-8 parts of flexibilizer, 5-10 parts of activated talcum powder, 0.1-2 parts of dispersing agent and 0.1-1.5 parts of modifier, wherein the waste bottle cap crushed material is obtained by crushing, cleaning, rinsing, drying and absorbing the recovered waste bottle cap crushed plastic. The invention further provides the preparation method of the special material for the pass box for regenerating and modifying the waste bottle cap crushed plastic. The special material and the preparation method can recycle the waste bottle cap crushed plastic effectively, and have the advantages that resources are saved, an environment is protected, the cost is lowered, and the preparation process is simplified.

Owner:四川塑金科技有限公司

A cable winding device

The invention relates to a winding device, in particular to a cable winding device. The technical problem to be solved by the present invention is to provide a cable winding device that can cut off the cable in time after winding and take out the rolled cable more conveniently. In order to solve the above technical problems, the present invention provides such a cable winding device, comprising: a support, which is connected to one side of the stand; an installation seat, which is connected to the side of the stand close to the support; The winding mechanism is connected between the support and the installation seat; the moving mechanism is connected between one side of the winding mechanism and the other side of the stand. The beneficial effects of the present invention are: through the action of the winding mechanism and the moving mechanism, uniform winding of the cable can be quickly realized, and the uniform winding can be realized without relying on manual pulling of the cable for guidance.

Owner:山东九州电力电线厂

Modified renewable high impact polystyrene special material for household appliances and preparation method thereof

Owner:四川塑金科技有限公司

A method for eliminating the tiger skin defect of polypropylene composition and the polypropylene composition prepared thereof

The invention discloses a preparation method of a polypropylene composition for eliminating tiger stripe defects and the prepared polypropylene composition. The polypropylene composition includes a polypropylene resin, a toughening agent, a filler, a pigment, and an auxiliary agent, wherein the polypropylene resin adopts a high-flow polypropylene with a melt mass flow rate (MFR) of 30-120 g / 10min and Low-flow polypropylene with a melt mass flow rate (MFR) of 0.1-29g / 10min is used for compounding. The preparation method enables the prepared polypropylene composition to eliminate tiger skin grains through screw combination design and extrusion process parameter adjustment, and the preparation process is stable and repeatable. The polypropylene composition prepared by the invention can be used in automobile bumpers and interior decoration products.

Owner:KINGFA SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com