A cable winding device

A technology for cables and equipment, applied in the field of cable winding equipment, can solve the problems of inconvenient removal of cables and inability to cut them in time, and achieve the effects of improving efficiency, improving quality and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

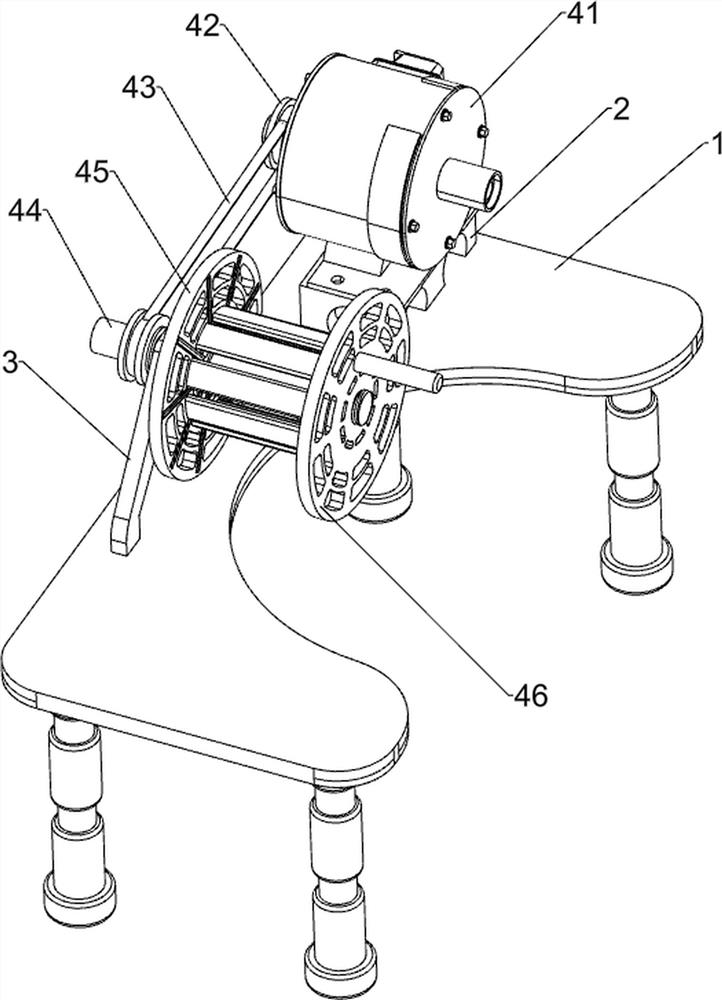

[0023] A cable winding device, such as Figure 1 to Figure 3 As shown, it includes a stand 1, a support 2, a mounting base 3, a winding mechanism 4 and a moving mechanism 5. The left rear side of the top of the stand 1 is connected with the stand 2, and the middle position of the top of the stand 1 is connected with a mounting A winding mechanism 4 is connected between the base 3 , the top of the support 2 and the upper part of the mounting base 3 , and a moving mechanism 5 is connected between the left side of the winding mechanism 4 and the front side of the top of the stand 1 .

[0024] The winding mechanism 4 includes a deceleration motor 41, a first pulley 42, a first flat belt 43, a rotating shaft 44, a winding wheel 45 and a fixed disc 46. The top of the support 2 is connected with a deceleration motor 41, and the upper part of the mounting seat 3 is rotatable. A rotating shaft 44 is connected, the output shaft of the deceleration motor 41 and the left side of the rotat...

Embodiment 2

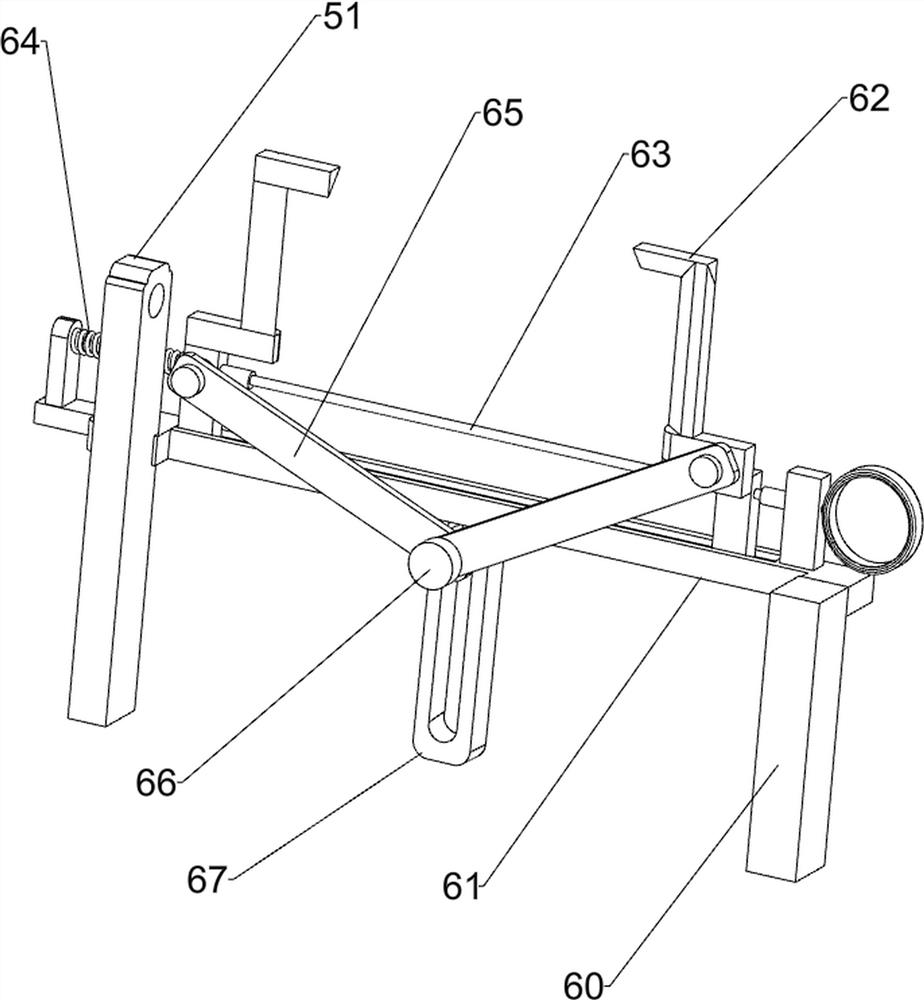

[0028] On the basis of Example 1, as Figure 4 As shown, it also includes a shearing mechanism 6, and the shearing mechanism 6 includes a fixed block 60, a sliding rod 61, an L-shaped blade 62, a pulling wire 63, a first spring 64, a connecting rod 65, a round rod 66 and a connecting block 67, A fixing block 60 is connected to the front right side of the top of the stand 1, a sliding rod 61 is connected between the upper part of the fixing block 60 and the rear side of the middle part of the fixing base 51, and L-shaped blades are slidably connected to the left and right sides of the top of the sliding rod 61. 62, the front sides of the lower parts of the two L-shaped blades 62 are hingedly connected with a connecting rod 65, the middle position of the bottom of the sliding rod 61 is connected with a connecting block 67, and the inner side of the connecting block 67 is slidably connected with a round rod 66, the round rod 66 The front side of the sliding rod 61 is hingedly con...

Embodiment 3

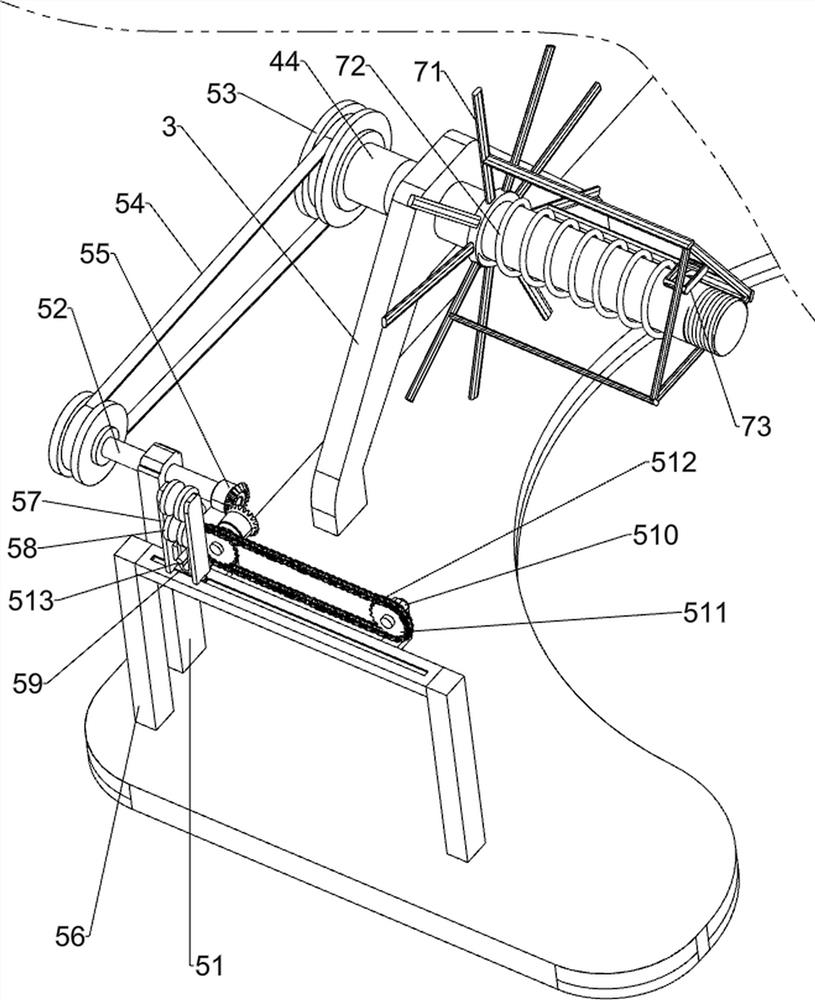

[0031] On the basis of Example 2, as image 3 and Figure 5 As shown, it also includes a push-pull mechanism 7, the push-pull mechanism 7 includes a push-pull frame 71, a second spring 72 and a handle 73, the rotating shaft 44 is slidably connected with the push-pull frame 71, and the rotating shaft 44 is sleeved with a second spring 72, The left and right ends of the second spring 72 are respectively connected with the push-pull frame 71 and the reel 45 .

[0032] When people finish winding and cutting the cable, turn the fixing plate 46 and take it out, then pull the handle 73 to slide to the right, and the second spring 72 shrinks accordingly, under the pushing action of the push-pull frame 71, the cable can be pulled out. Take it out from the reel 45, when the cable is taken out, release the handle 73, under the action of the elastic force of the second spring 72, the push-pull frame 71 and the handle 73 can be driven to reset, so that people can quickly wind up the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com