Plant fiber shearing device, shearing method and shearing device manufacturing method

A shearing device and plant fiber technology, which is applied in the field of plant fiber shearing devices, can solve problems such as easy blockage of screen gaps, low processing efficiency, and limited feed particle size, and achieve orderly advancement and regular shearing, avoiding The effect of shearing powder and coarse fibers, reducing resistance and limiting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

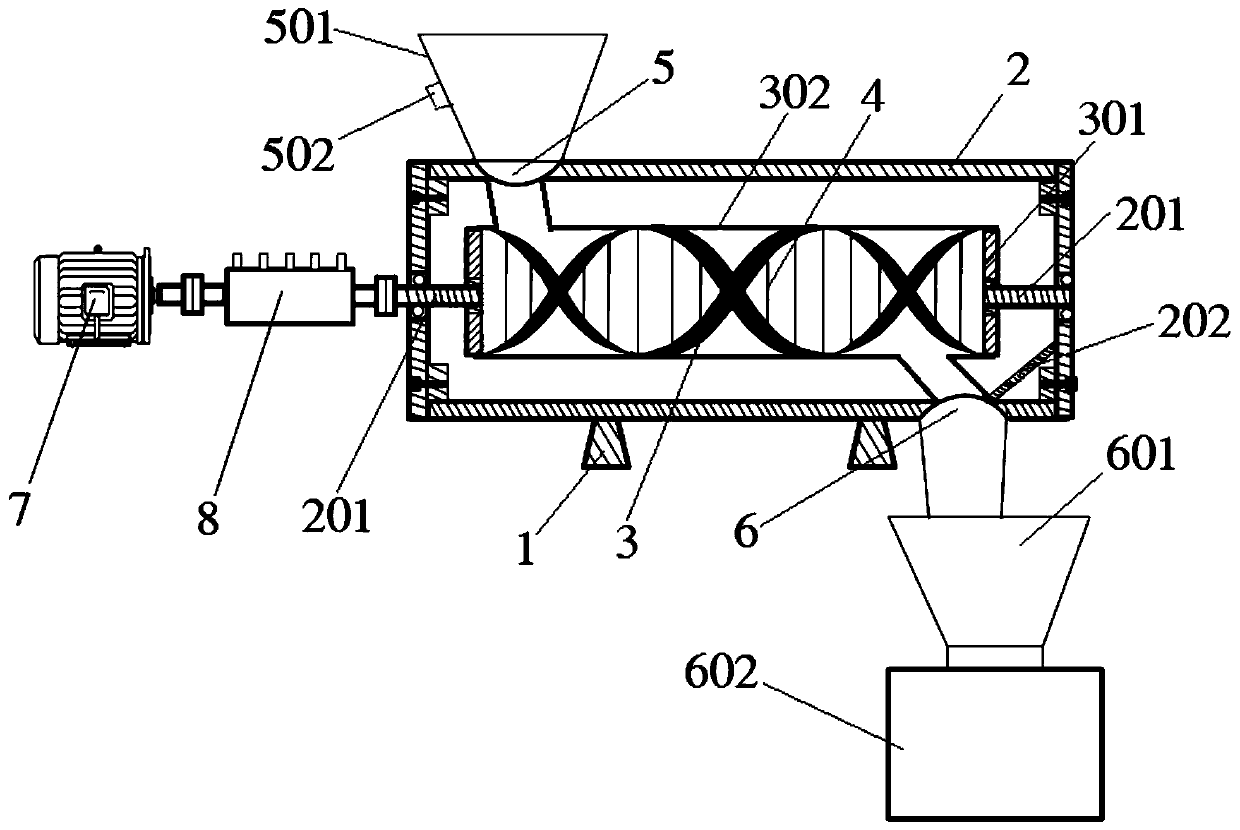

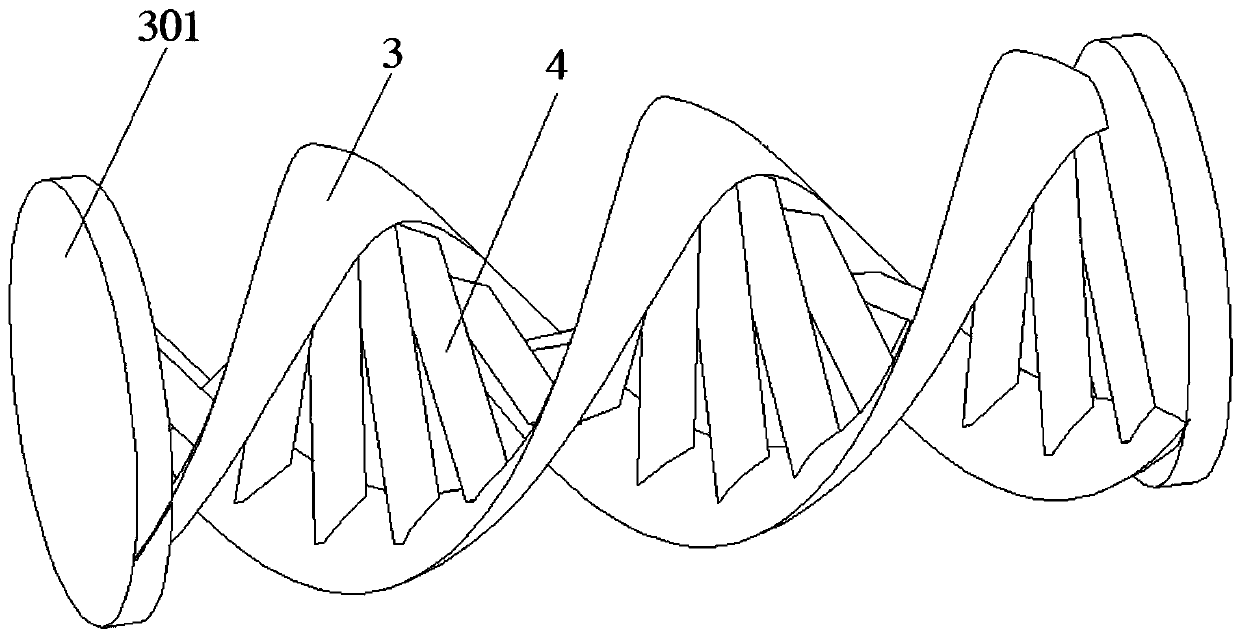

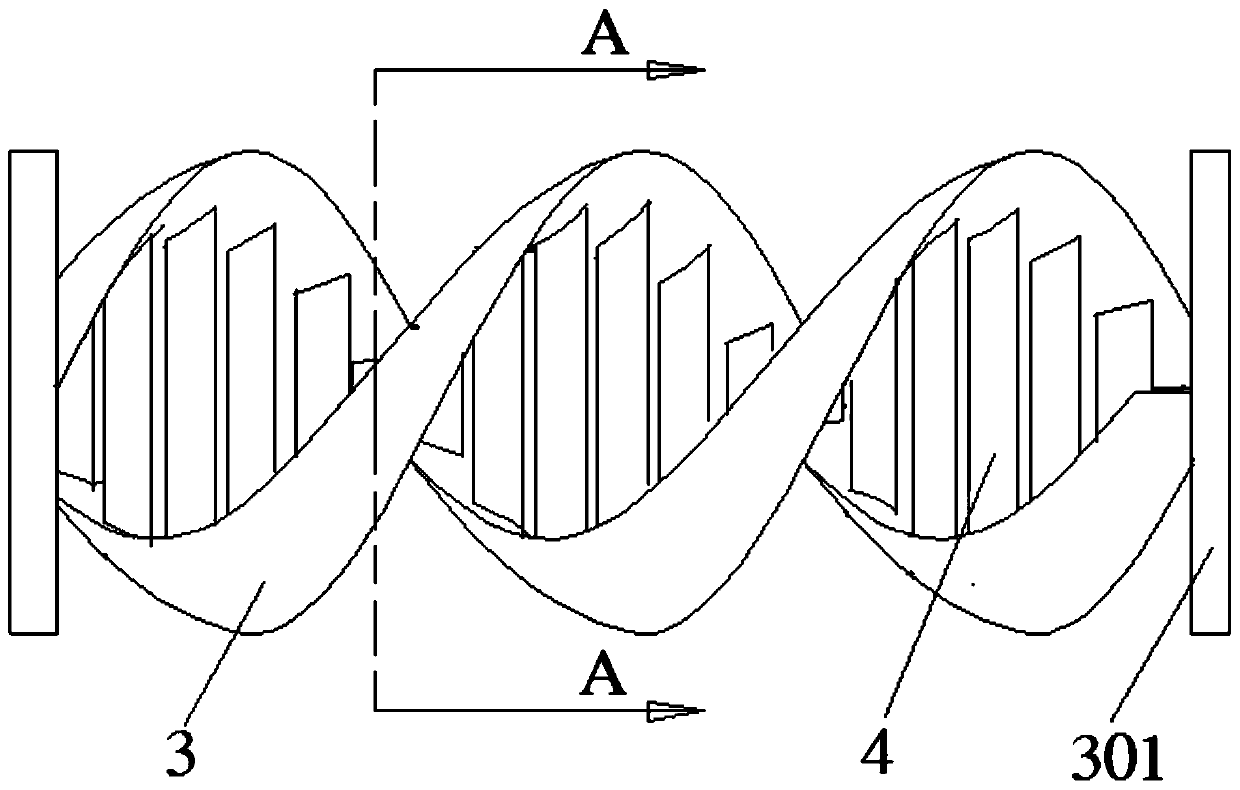

[0050] refer to figure 1 , a plant fiber shearing device of the present invention, comprising a support 1, a shear box 2 is installed on the support 1, and a double-helix shearing mechanism is arranged in the shear box 2; The left end of the top side plate is provided with a feed port 5, and the right end of the bottom side plate of the shear box 2 is provided with a discharge port 6; the left side plate of the shear box 2 is provided with a shaft hole, and the double The spiral shearing mechanism is connected with a power mechanism through a rotating shaft 201 , and the rotating shaft 201 passes through the shaft hole and extends out of the shearing box 2 .

[0051] In the above embodiments, the bracket 1 is used to support and fix the shearing box 2, and the power mechanism is used to provide power for the rotation of the double helix shearing mechanism. The power mechanism outside the shearing box 2 passes through the shaft hole and shears the One end of the double-helix s...

Embodiment 2

[0081] Below in conjunction with specific embodiment, the present invention will be further described:

[0082] A method for manufacturing a plant fiber shearing device, comprising the following steps:

[0083] Step 1, using resin to prepare a shear box;

[0084] Step 2, use 4Cr13 stainless steel to obtain castings by casting, and perform stress relief annealing on the castings. The process of stress relief annealing is: heating to 500°C at a heating rate of 100°C / h, holding for 4h, and then heating at 20°C / h~50°C / h Cool at a rate of h to 300°C, and then take out the casting for air cooling to obtain the primary product of the double-screw conveying rod; correspondingly set threaded holes on the two screw rods of the primary product of the double-screw conveying rod to obtain the double-screw conveying rod.

[0085] 4Cr13 stainless steel material and forging process are used to prepare the knife blank. The knife blank is kept at 1070°C for 2h, quenched in an oil bath, then ta...

Embodiment 3

[0089] A plant fiber shearing method, comprising the following steps:

[0090] Step 1, wash the bagasse with a length of 3-5cm, remove surface impurities, and then soak in water for 2 days to obtain the material to be sheared;

[0091] Step 2, adding the material to be sheared into the plant fiber shearing device manufactured in Example 2 for shearing, the speed of the double-screw conveying rod is set to 1500r / min, and after the shearing is completed, it is dried at 105°C to a constant weight. Obtain bagasse products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com