Patents

Literature

126results about How to "Improve cutting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

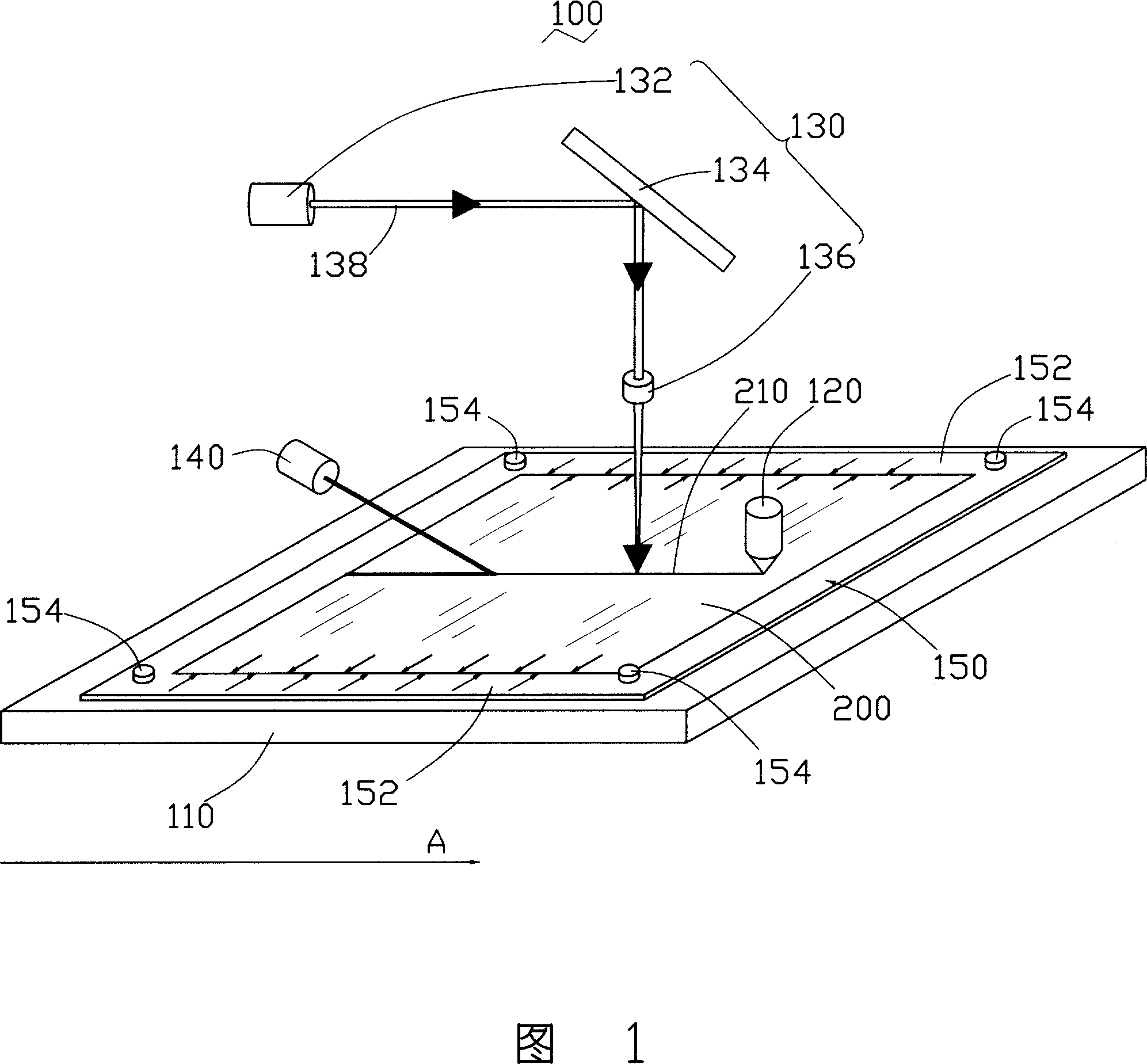

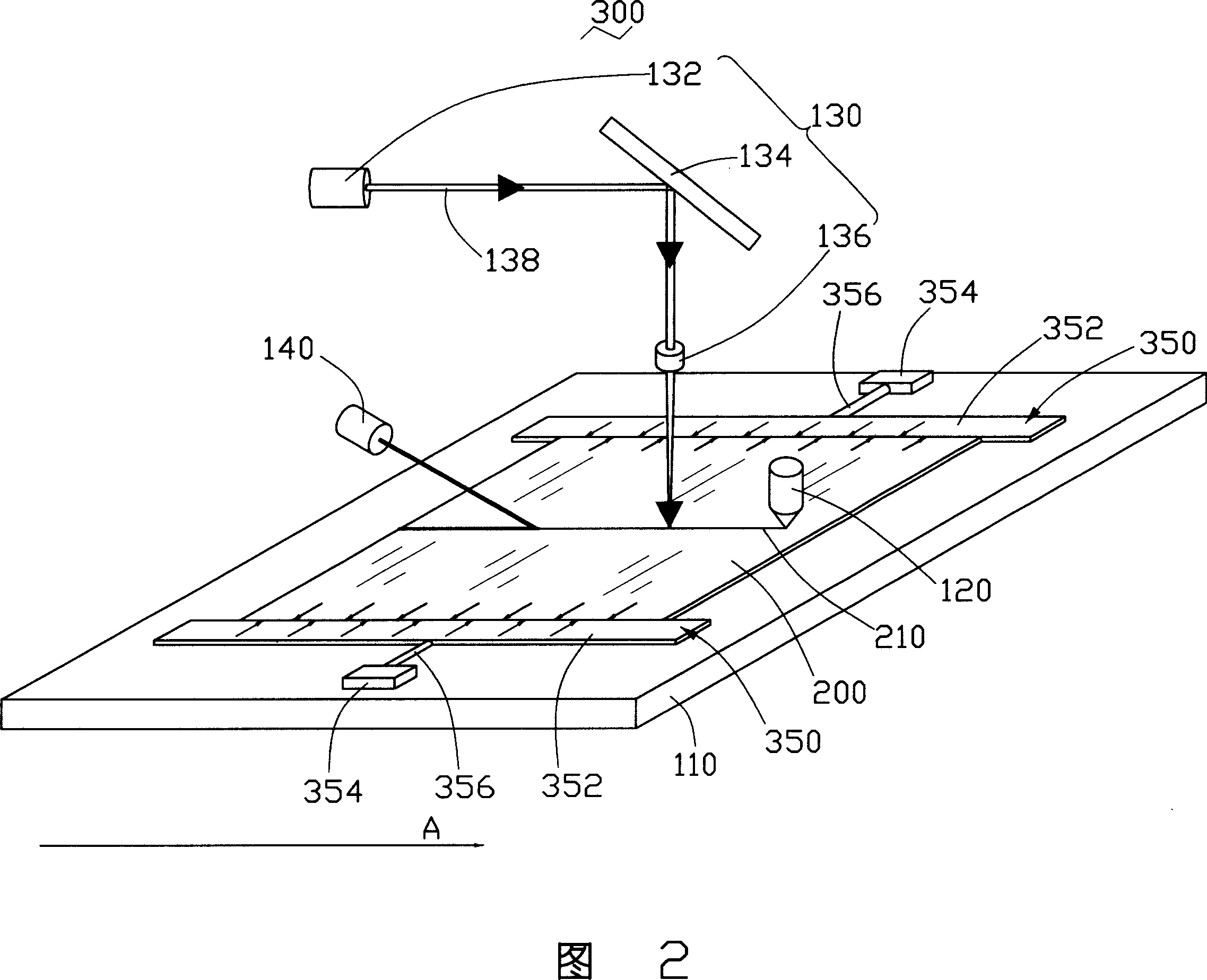

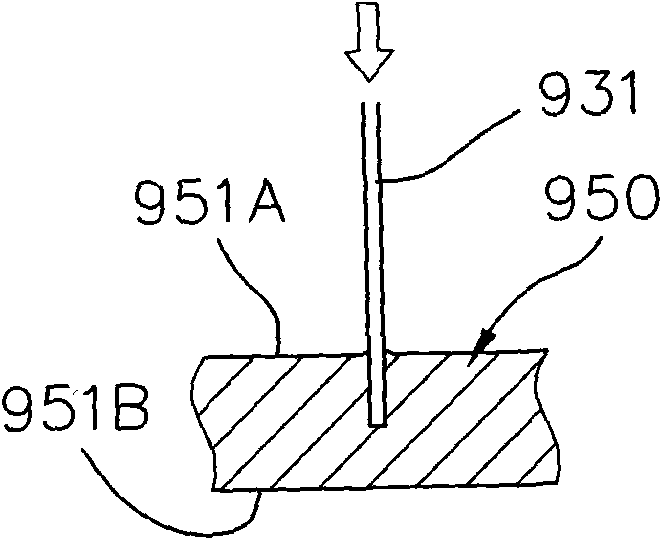

Laser device for cutting and method thereof

InactiveCN101108446AInhibition of long outward expansionImprove cutting qualityWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingLaser cuttingLaser beams

The invention discloses a laser cutting device, which is used for cutting brittle material base board along the preset direction. The laser cutting device comprises: a load device, which is used for loading the brittle material base board; a breakage tool, which is used for forming a pre-cutting line along the preset direction on the brittle material base board; a laser generating device, which is used for producing laser bean to heat the brittle material base board along the pre-cutting line; a cooling device, which is used for providing cooling liquid to cool the heated brittle material base board, to make the brittle base board break along the pre-cutting line; a clamp device, which comprises at least one pair of clamp components, which is used to clamp the brittle material base board from the two corresponding sides of the preset direction. The invention also provides a method of using the laser cutting device to cut brittle material baseboard.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

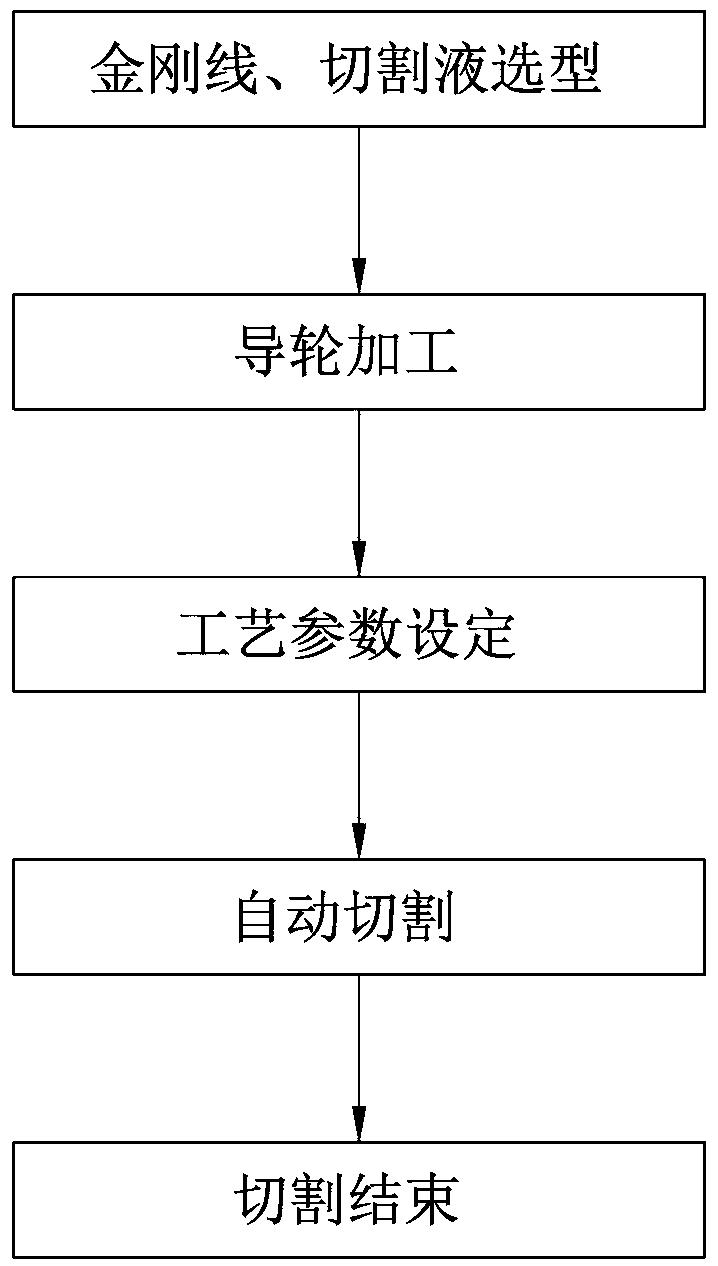

High-efficiency cutting method for crystalline silicon blocks

InactiveCN109304819AThe process takes a short timeIncrease slicing capacityFine working devicesMicrometerCrystalline silicon

The invention discloses a high-efficiency cutting method for crystalline silicon blocks in the field of solar energy application. The high-efficiency cutting method comprises the following steps of 1)diamond wire and cutting liquid selection, wherein a single-polycrystalline mixed sand electroplating diamond wire (the diamond wire diameter ranges from 50 micrometers to 70 micrometers is adopted,the cutting fluid is selected from a low COD coolant and pure water mixture; 2) guide wheel processing; 3) process parameter setting, wherein the diamond wire, the cutting fluid and a guide wheel arematched, after a cutting machine is assembled, the feeding speed of the working table is adjusted to be 800-3000micrometers per minute, the cutting fluid process flow is 110-180 KG / Min, the cutting liquid cooling temperature is 17-23 DEG C; 4) automatic cutting, wherein after the machine is started for warming up by 5-10 minutes, when it is known that the parameters are normal through spot check,automatic cutting starts; and 5) ending of cutting, wherein a rod is lifted to complete silicon block cutting. The high-efficiency cutting method effectively improves the cutting speed and the cuttingefficiency, improves the yield rate, reduces the cost of auxiliary materials like the diamond wire consumption, improves the slice profitability, and can be used for silicon wafer production.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

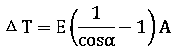

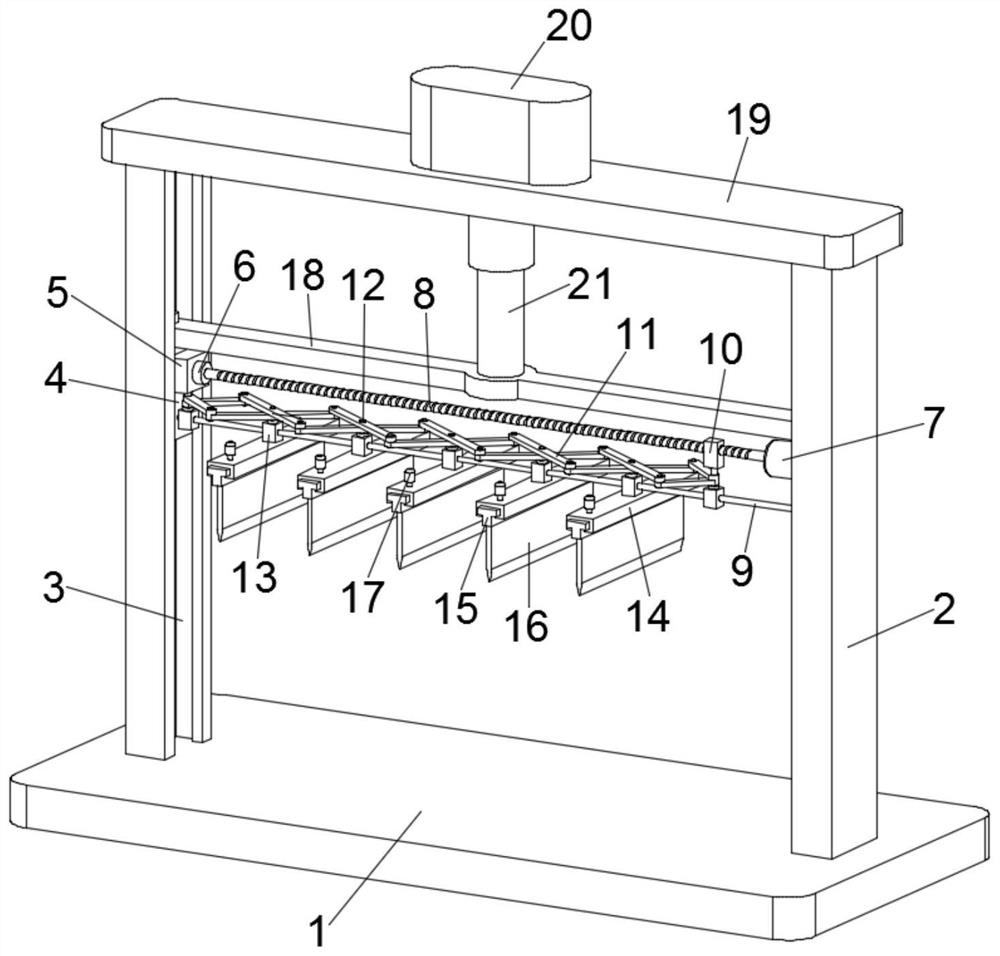

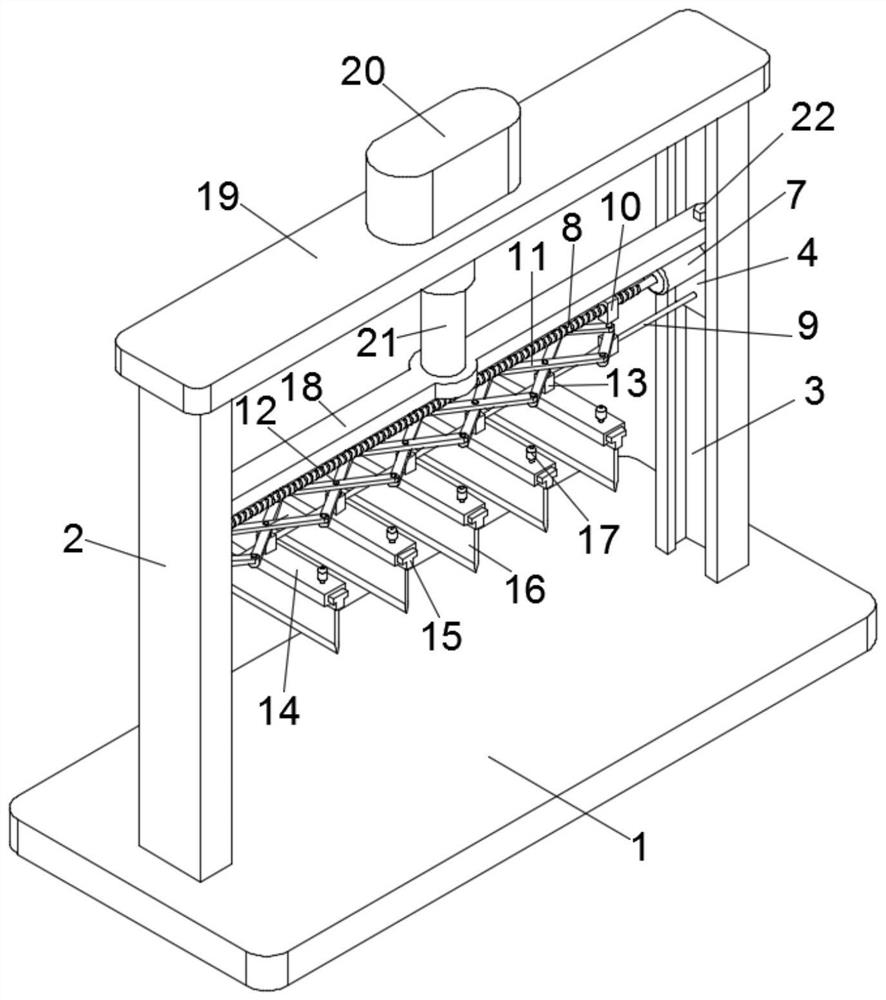

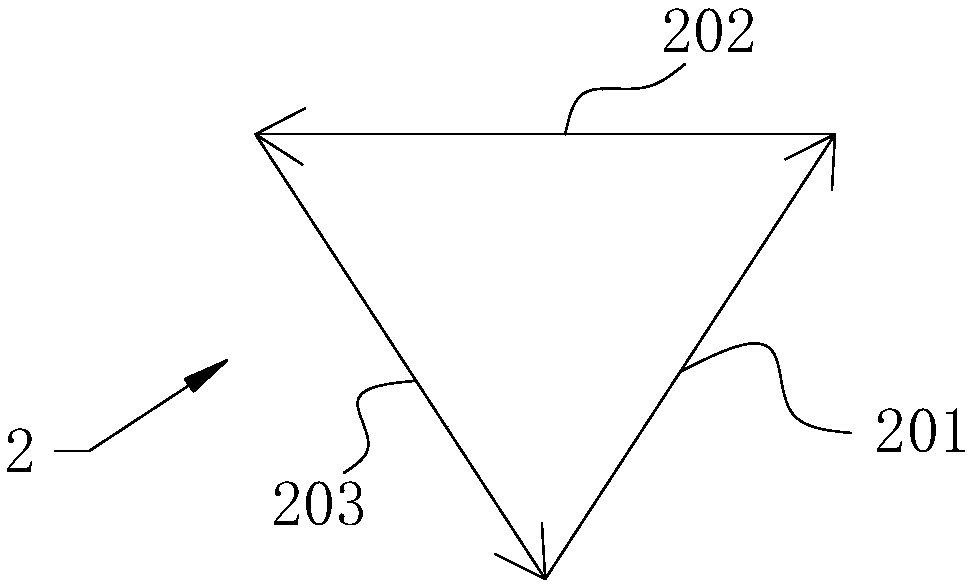

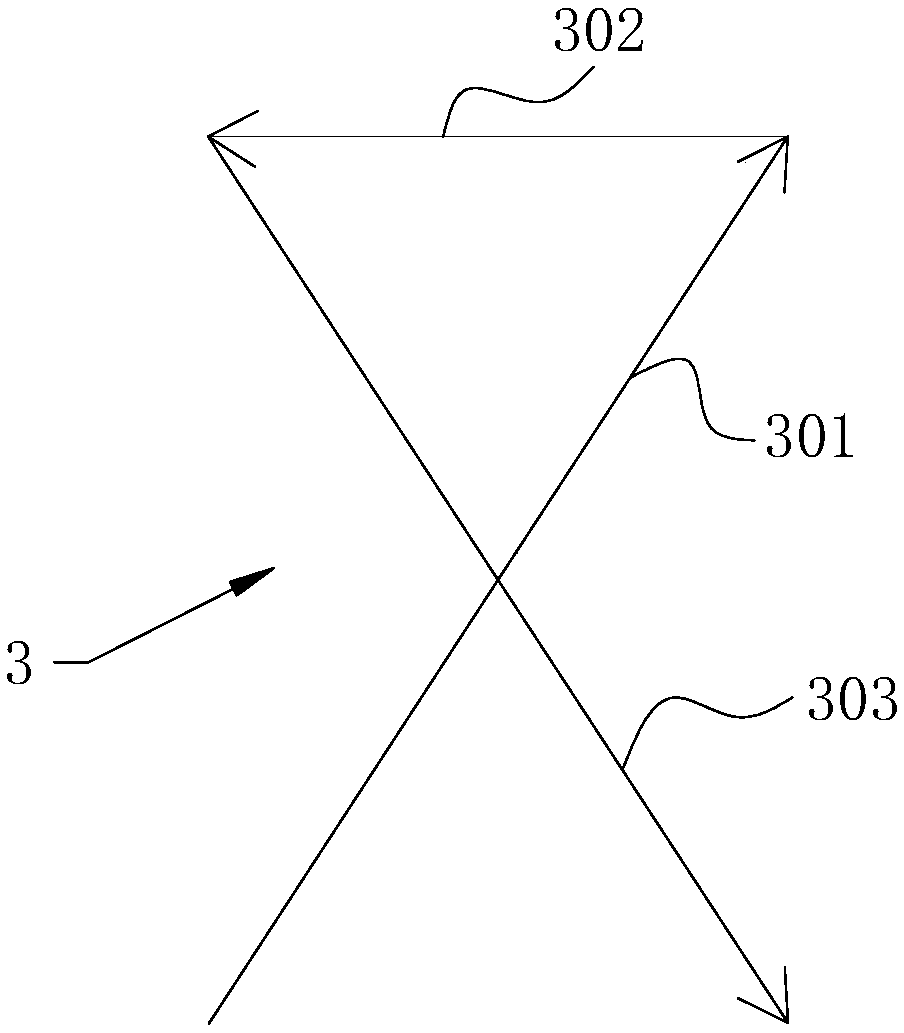

Dicing device for seafood processing

InactiveCN111730653AImprove cutting qualityQuick disassemblyMetal working apparatusFish cuttingEngineeringStructural engineering

The invention discloses a dicing device for seafood processing. The dicing device includes a workbench. Supporting plates are installed on the two sides of the workbench, the supporting plates are internally provided with sliding grooves, and sliding blocks are slidably embedded in the sliding grooves. A screw is rotatably installed between the sliding blocks on the two sides, and a screw sleeve spirally sleeves the screw. A shearing-forking mechanism is connected between the spirally sleeve and a fixed block. A guide rod is horizontally fixed between the sliding blocks on the two sides. A sliding sleeve connected with the shearing-forking mechanism slidably sleeves on the guide rod, and a cutter is installed at the bottom of the sliding sleeve. Lifting mechanisms are further arranged above the supporting plates. The dicing device for seafood processing can adjust the spacing of cutting blades to meet the needs of different cutting block sizes, while the spacing between adjacent cutting blades is always ensured to be same, so that the sizes of cut blocks are equal, and the uniformity of the cut blocks is guaranteed, so that the quality of the cut blocks is improved.

Owner:黄谦明

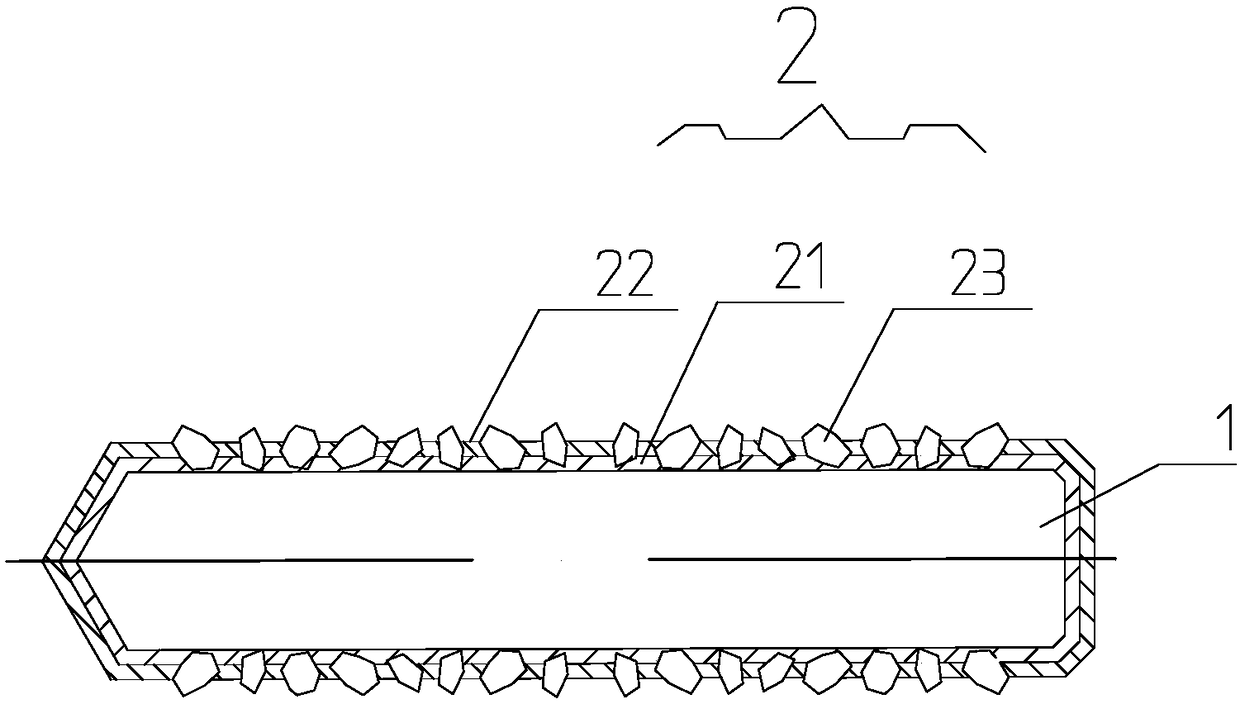

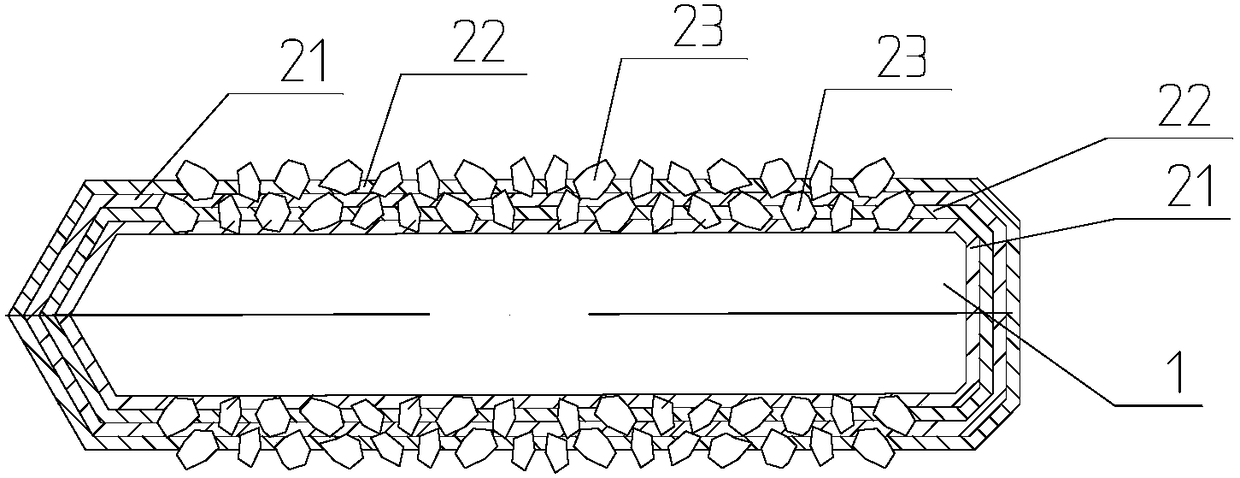

Composite diamond ultra-thin nickel-base blade and preparing method thereof

ActiveCN106521609AIncreased cutting strength and rigidityImprove cutting qualityElectrolytic coatingsElectroplatingNickel based

The invention provides a composite diamond ultra-thin nickel-base blade and a preparing method thereof. The method comprises the steps that 0.1-4 g / L of 1-8um diamond particles are added into every 1 L of nickel-base electroplating solution in a plating tank, electric stirring vanes arranged on the bottom of the plating tank are stirred without stop, and therefore 1-8um diamonds can be distributed in the nickel-base electroplating solution in the plating tank uniformly; qualified base bodies prepared through machining are added into a clamp to be subjected to pretreatment, after pretreatment is completed, the base bodies are placed into the electroplating tank, 1.5A currents are adopted for carrying out electroplating, in the electroplating process, 0.1-1 g / L of 10-50um diamond particles are added every one hour, the electric stirring vanes carry out high-speed stirring, electroplating is carried out for 4 hours, and therefore the 1-8um diamond particles and the 10-50um diamond particles adhere to the surfaces of the base bodies to form diamonds and nickel-base plated layers. The fine diamond particles and the coarse diamond particles are prepared according to the different proportions, the cutting strength, and the rigidity and the cutting quality of the blade are improved greatly to meet cutting requirements of the different materials.

Owner:苏州赛尔科技有限公司

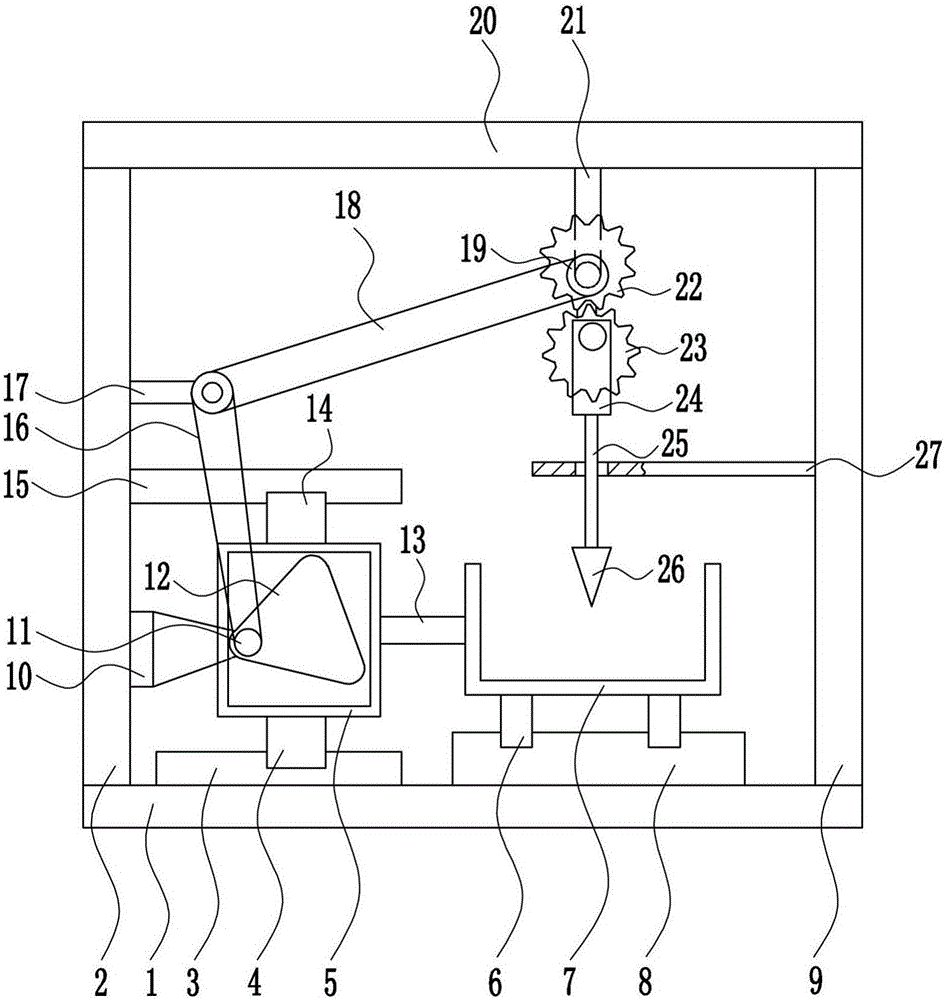

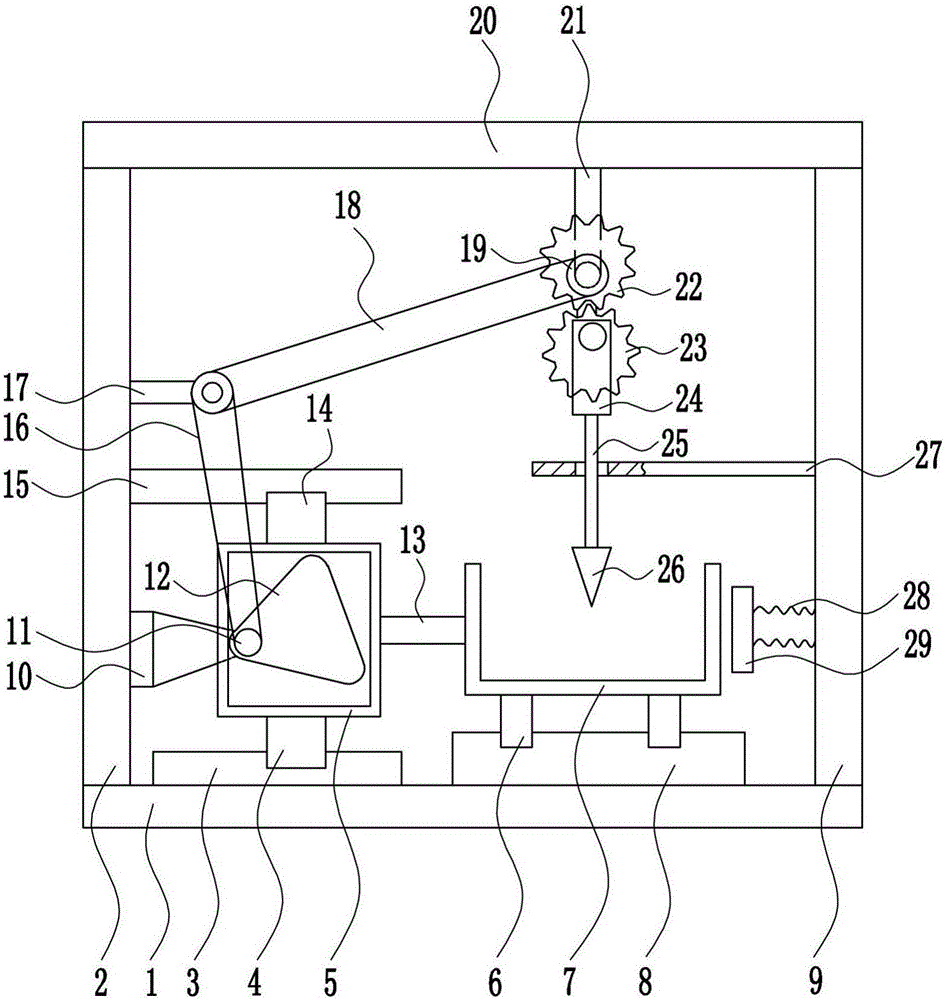

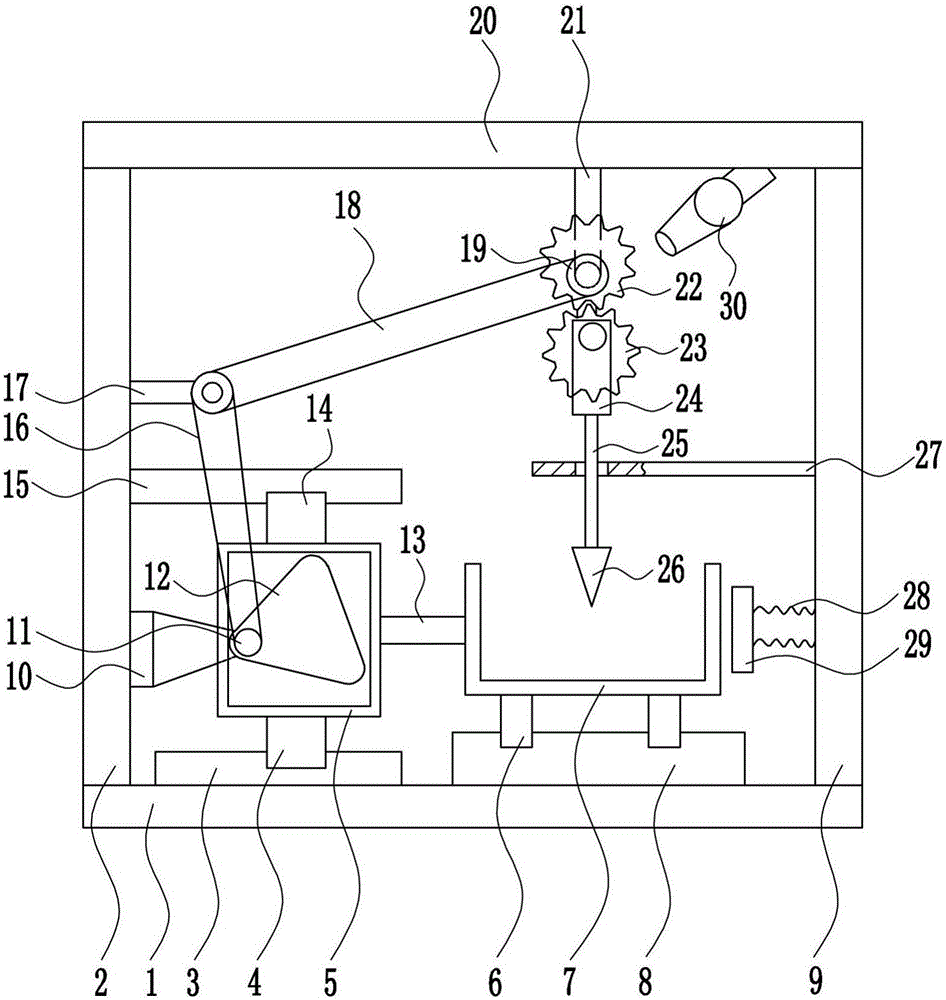

Double-eccentric-gear type forage grass cutting device for animal husbandry

The invention relates to an animal husbandry forage grass cutting device, in particular to a double-eccentric-gear type forage grass cutting device for animal husbandry, and aims to solve the technical problem of providing a double-eccentric-gear type forage grass cutting device which is high in cutting efficiency, rapid in cutting speed and convenient to operate for animal husbandry. To solve the technical problem, the invention provides the double-eccentric-gear type forage grass cutting device for animal husbandry. The double-eccentric-gear type forage grass cutting device comprises a bottom plate, a left rack, a first sliding track, a first sliding block, a moving frame, a second sliding block, a cutting frame, a second sliding track, a right rack, a mounting base, a first belt pulley and the like, wherein the left rack, the first sliding track, the second sliding track and the right rack are sequentially arranged at the top of the bottom plate from left to right; the first sliding block is arranged on the first sliding track in a sliding manner. The double-eccentric-gear type forage grass cutting device has the effects of being high in cutting efficiency, rapid in cutting speed and convenient to operate, and is long in service life, high in production efficiency, excellent in cutting quality and favorably increased in overall levels such as overall properties.

Owner:邵鹏程

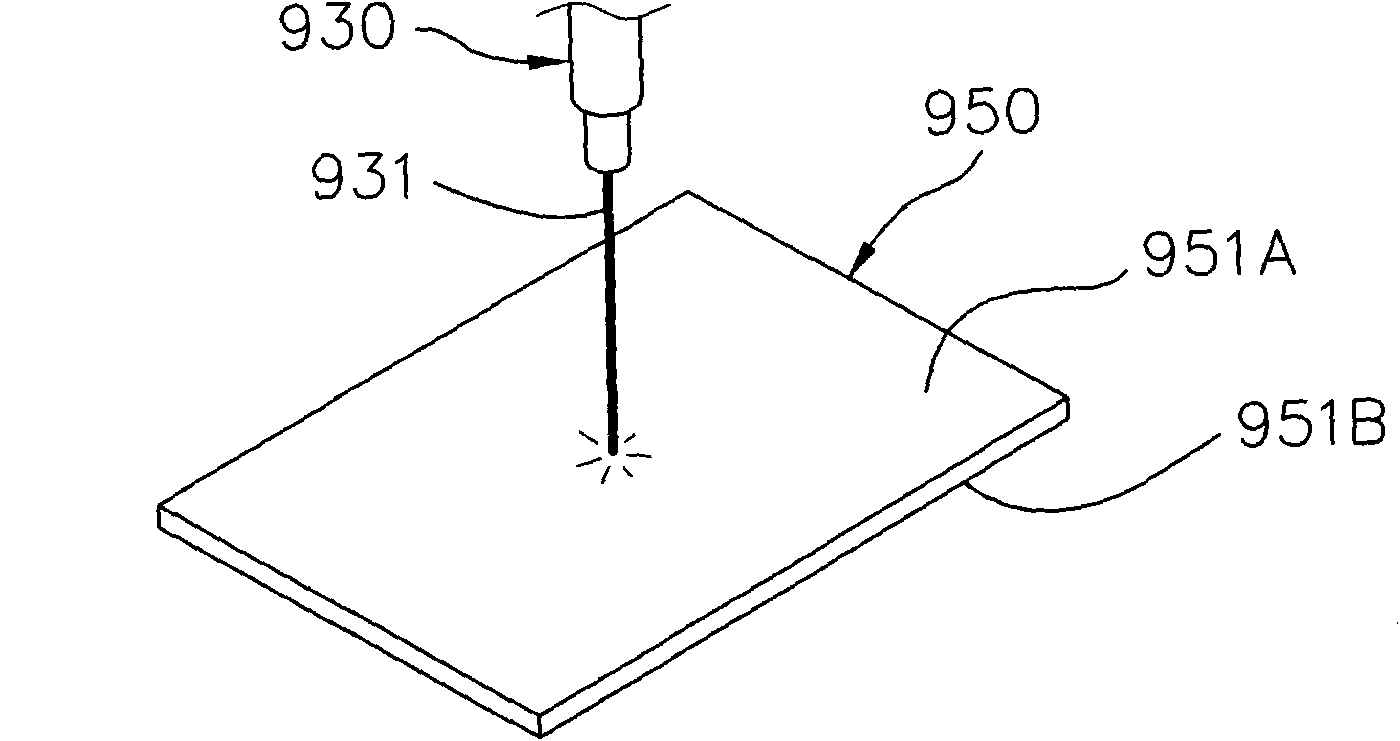

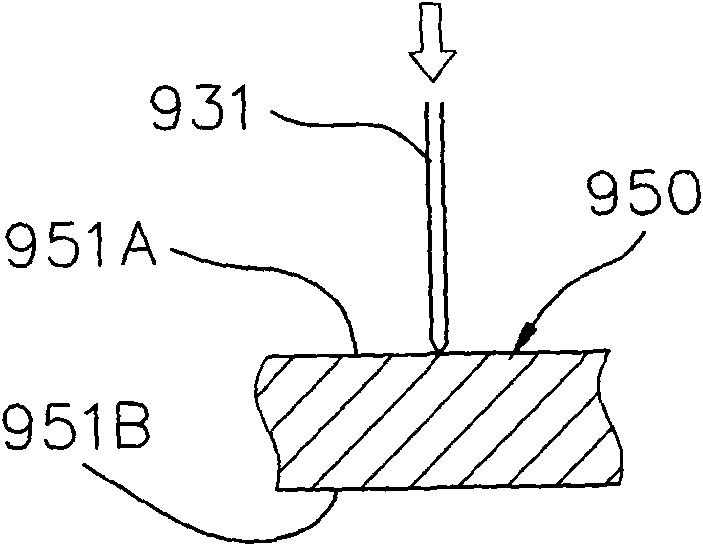

Laser cutting method and equipment for electronic paper

ActiveCN102029468AAchieve laser cuttingImplement half-cut jobsWelding/cutting auxillary devicesAuxillary welding devicesControl systemLaser cutting

The invention discloses a laser cutting method and equipment for electronic paper. The laser cutting equipment for the electronic paper comprises a working platform used for bearing the electronic paper, a laser cutting head which can do longitudinal and lateral movement relative to the working platform, a clamping system which can clamp the electronic paper, and a control system which coordinates all the parts to act. When the electronic paper is cut, the electronic paper is placed on the working platform, clamped and positioned, the laser cutting head cuts the electronic paper under the instruction of the control system, and a ratio of the cutting power to the cutting rate is kept constant in the process of cutting. Therefore, laser cutting of the electronic paper is realized, the defect that the conventional die cutting equipment damages the internal structure of the electronic paper in the production process is overcome, the yield is improved, and the production cost is lowered. Meanwhile, semi-cutting operation can be performed on the electronic paper, and the quality of cutting complex parts such as chamfers is greatly improved.

Owner:HANS LASER TECH IND GRP CO LTD

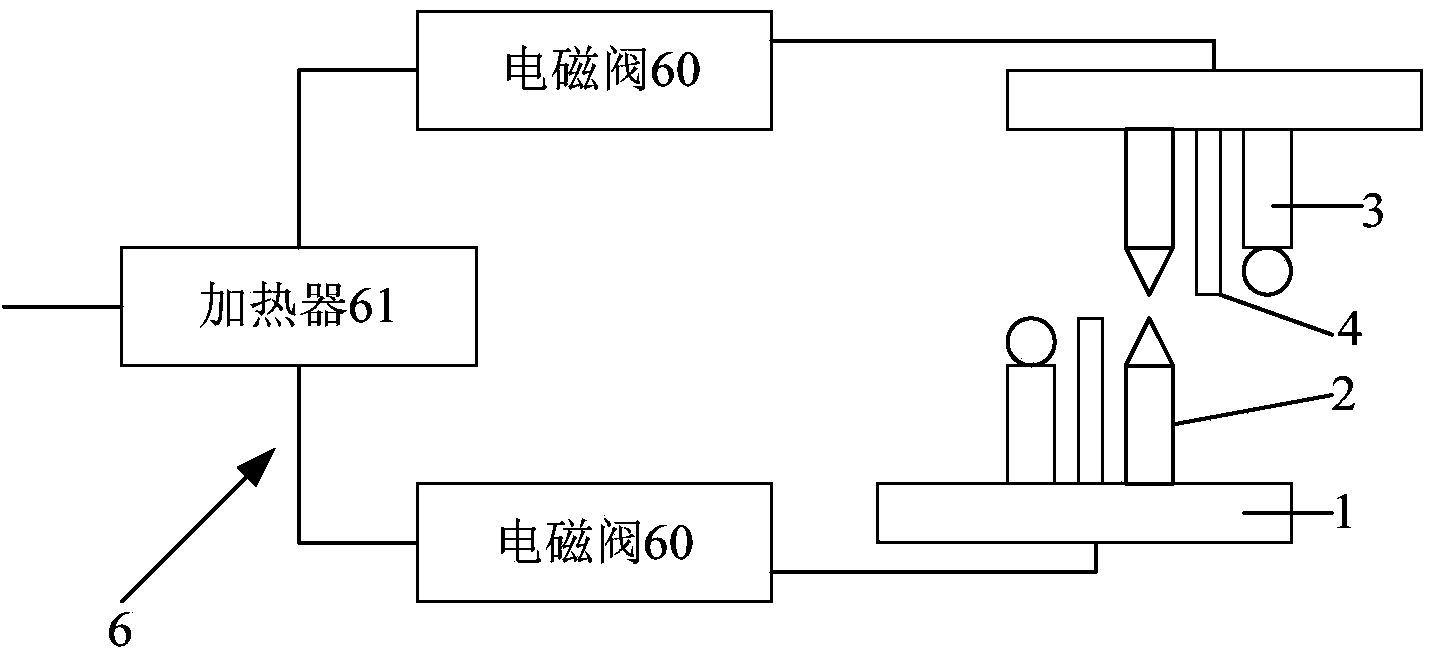

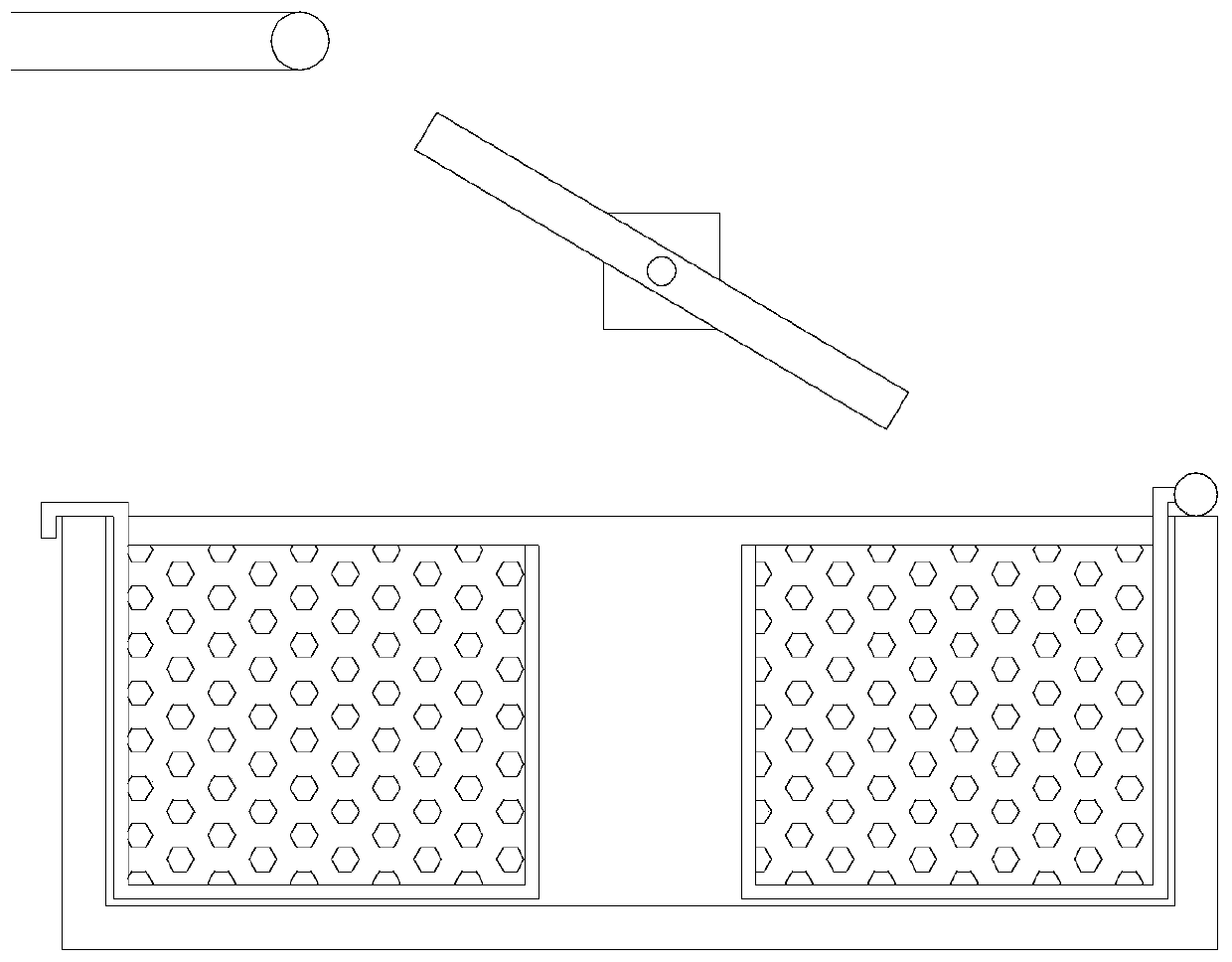

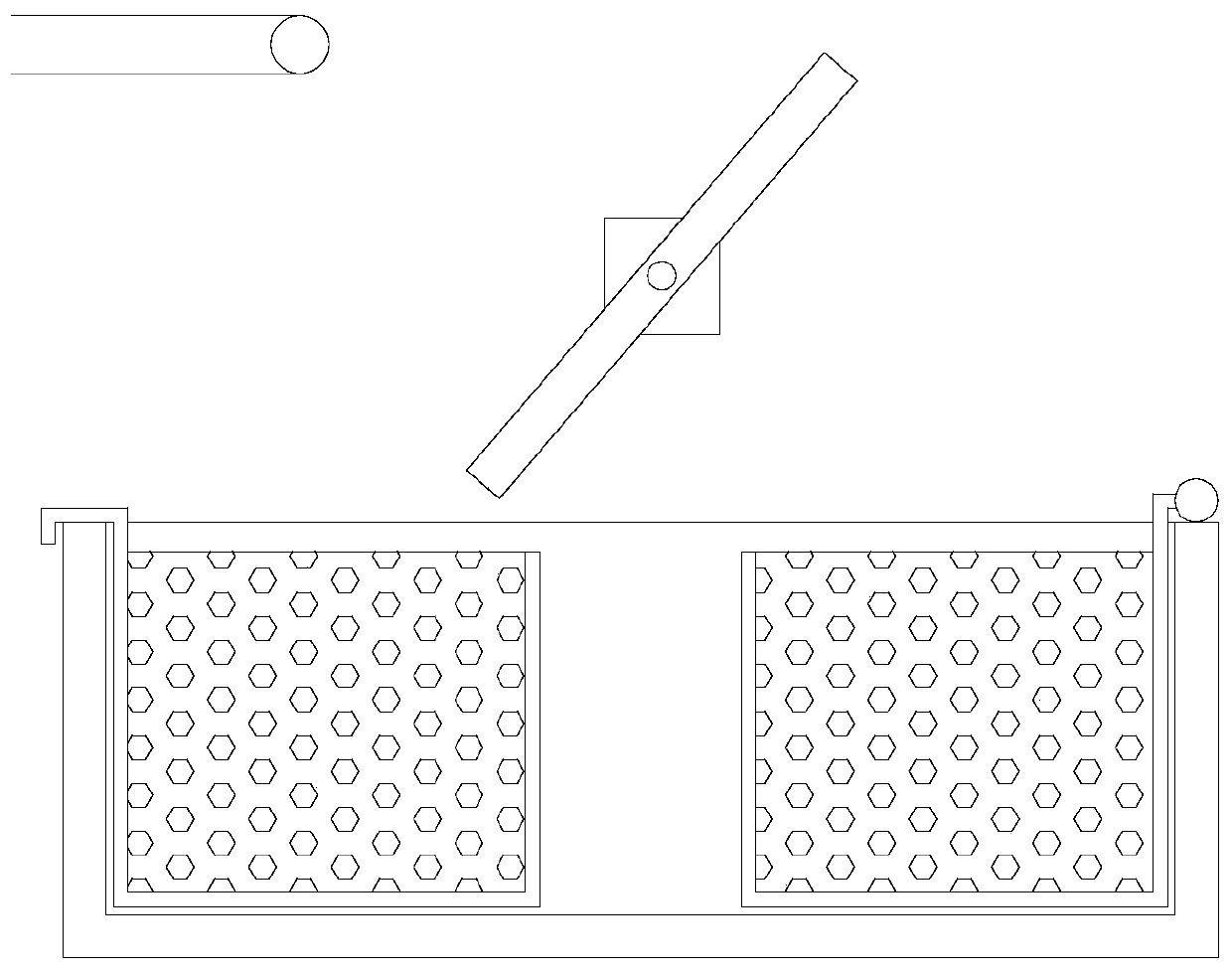

Laser cutting device with workpiece bottom immersed in liquid level

InactiveCN101920398AImprove cutting qualityImprove cooling effectGlass severing apparatusLaser beam welding apparatusEngineeringLaser beams

The invention relates to a laser cutting device with a workpiece bottom immersed in liquid level, comprising a liquid container, a workpiece fixing part, a laser generating part and a circulation system, wherein the liquid container is used for accommodating liquid; the workpiece fixing part is used for fixing a workpiece and comprises a first surface and a second surface, wherein the first surface of the workpiece is immersed into the liquid; the laser generating part is used for generating a laser beam to the second surface of the workpiece in order to cut the workpiece; the circulation system comprises an inlet, a circulation drive part, a circulation filter part and an outlet, wherein the inlet and the outlet are connected with the liquid container, the circulation drive part is used for driving the liquid to flow into the circulation system from the inlet, and the liquid back flows into the liquid container from the outlet after being filtered by the circulation filter part. The invention has the advantages of high cutting quality, good cooling effect, and the like.

Owner:CONTREL TECH CO LTD

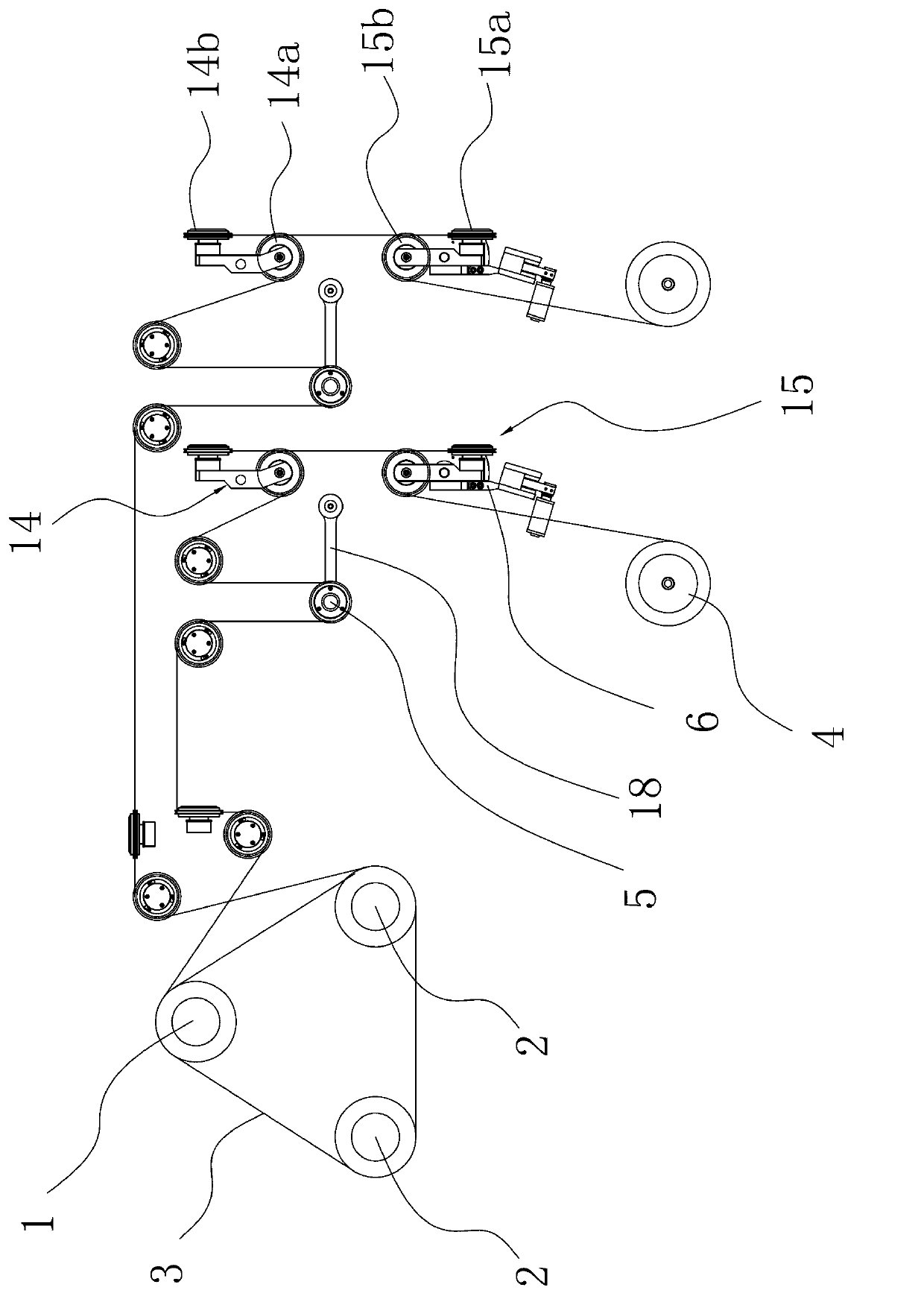

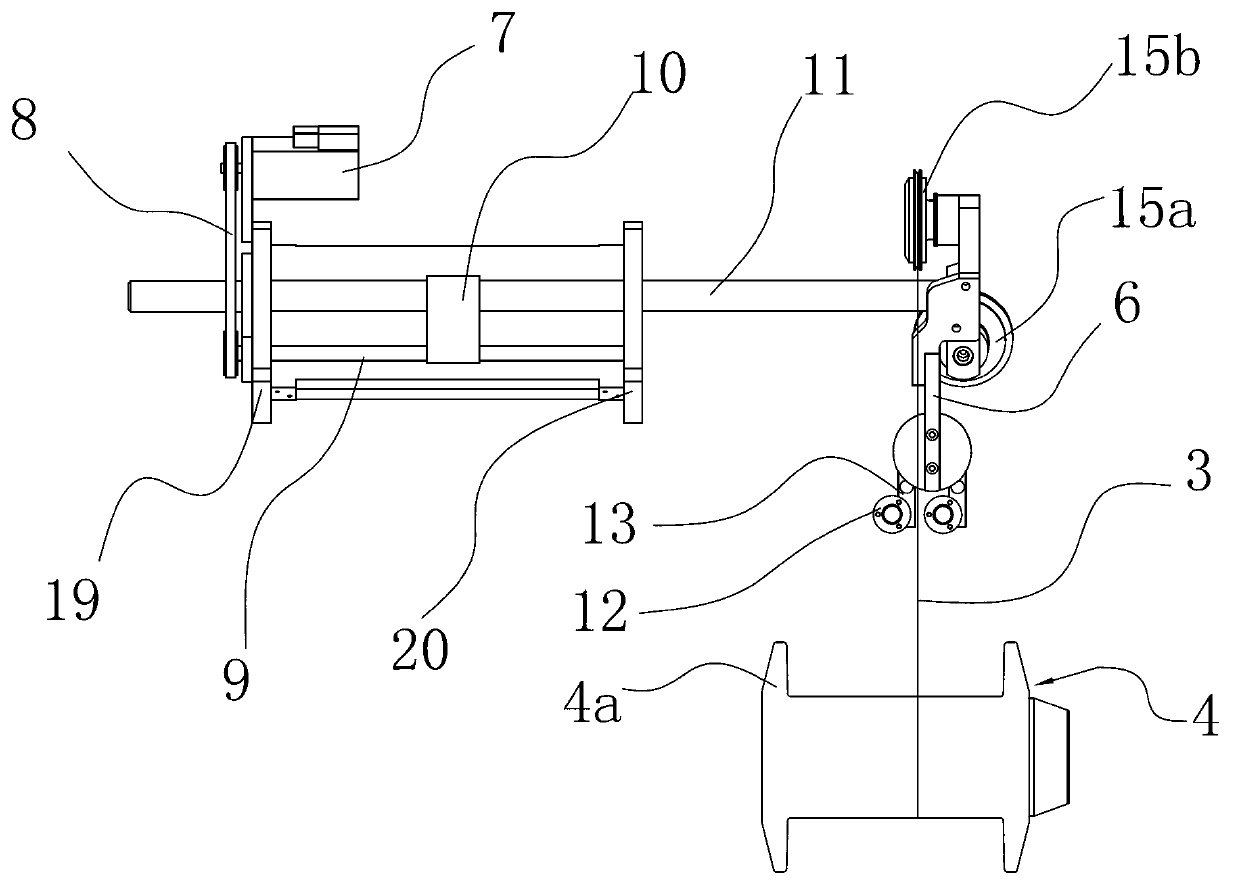

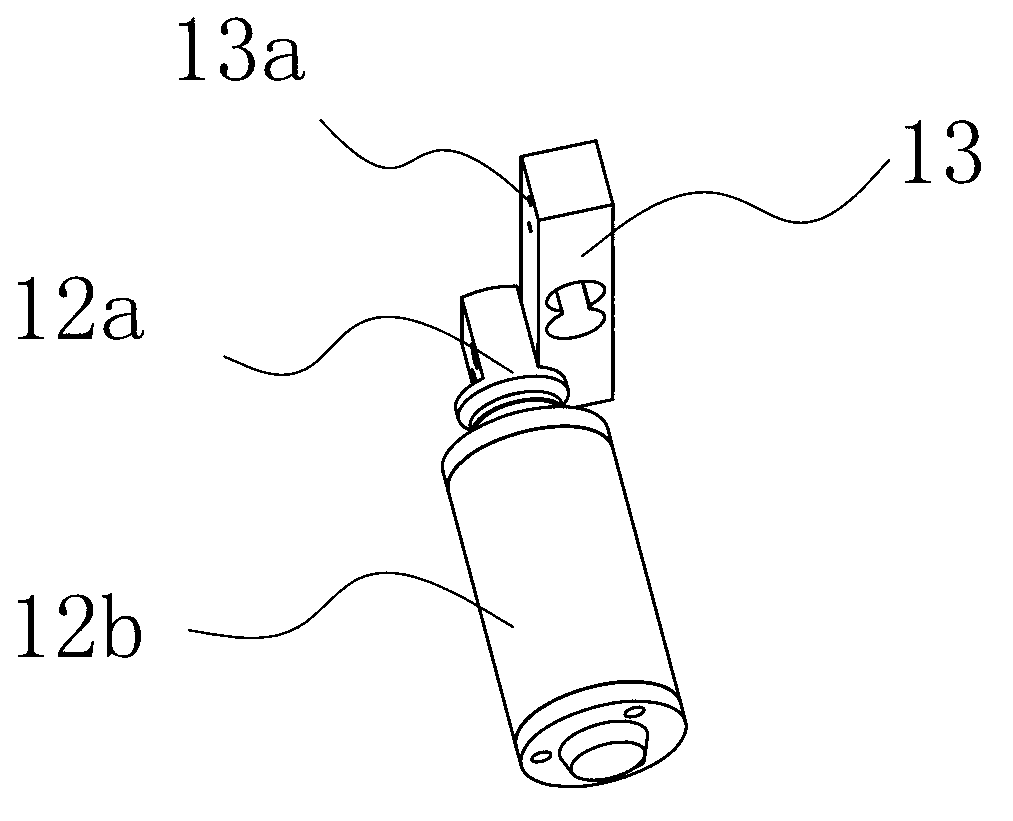

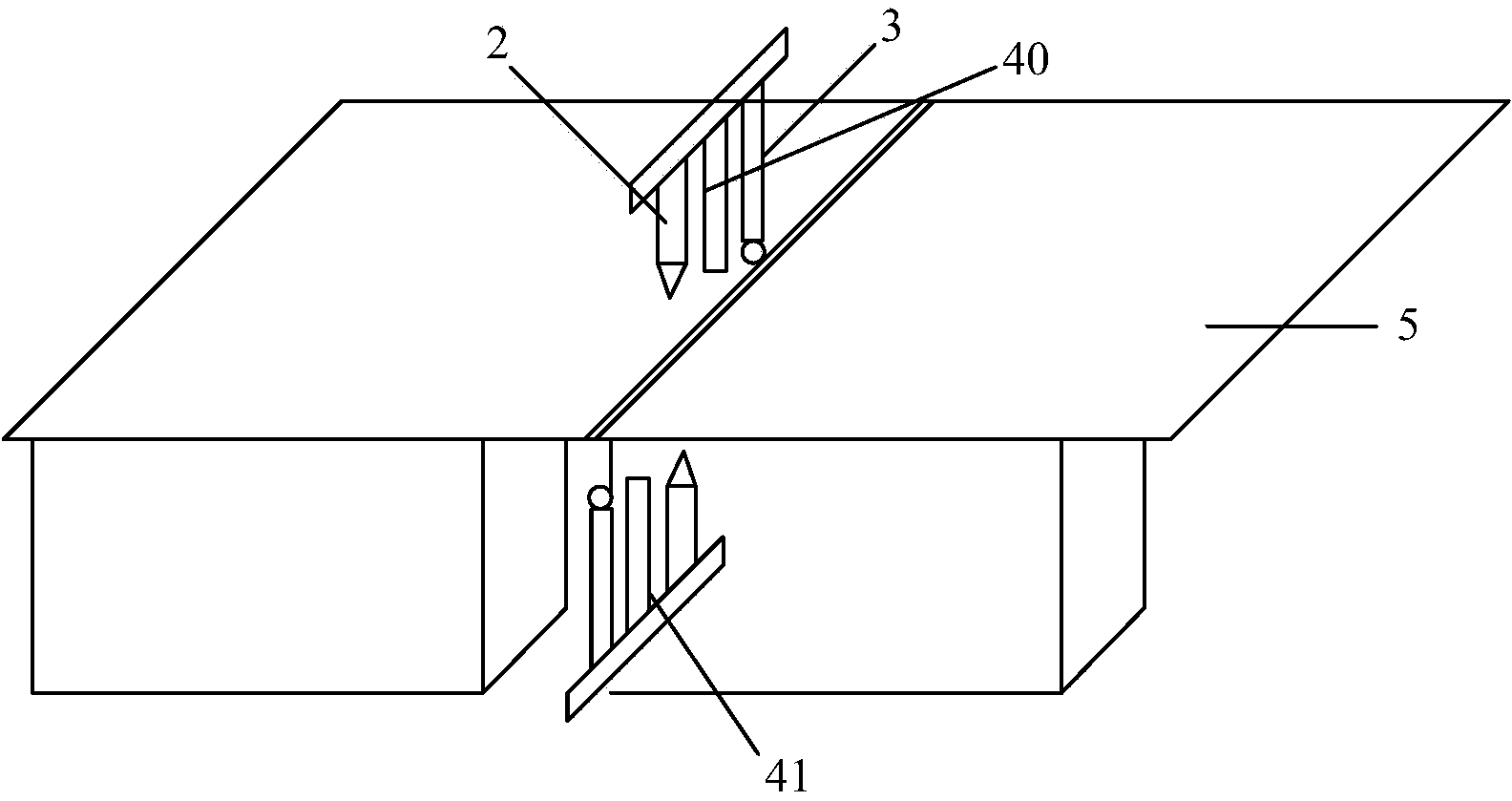

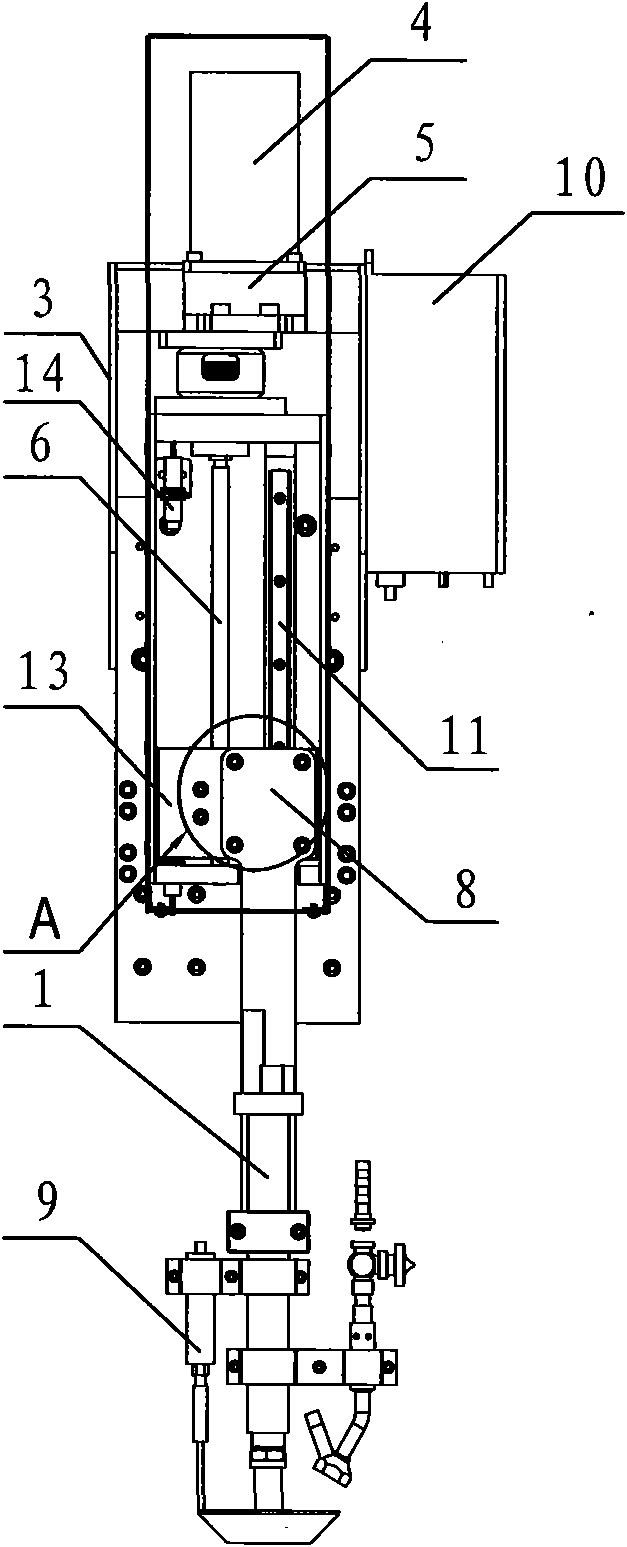

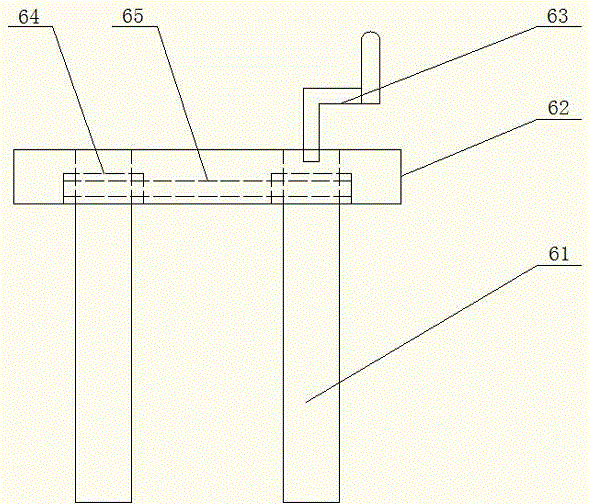

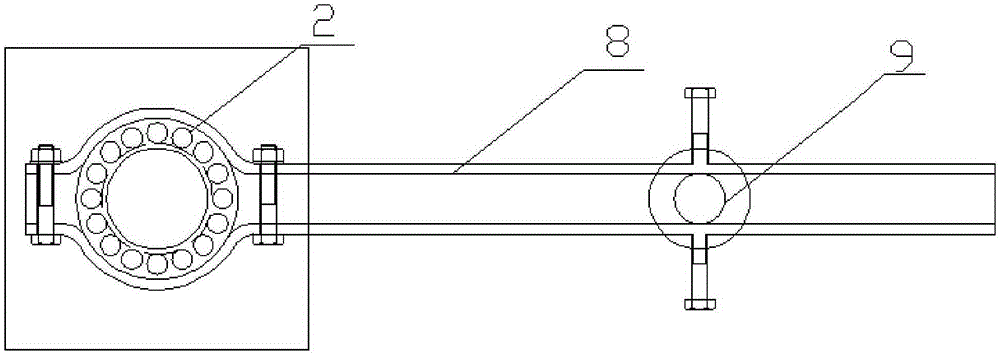

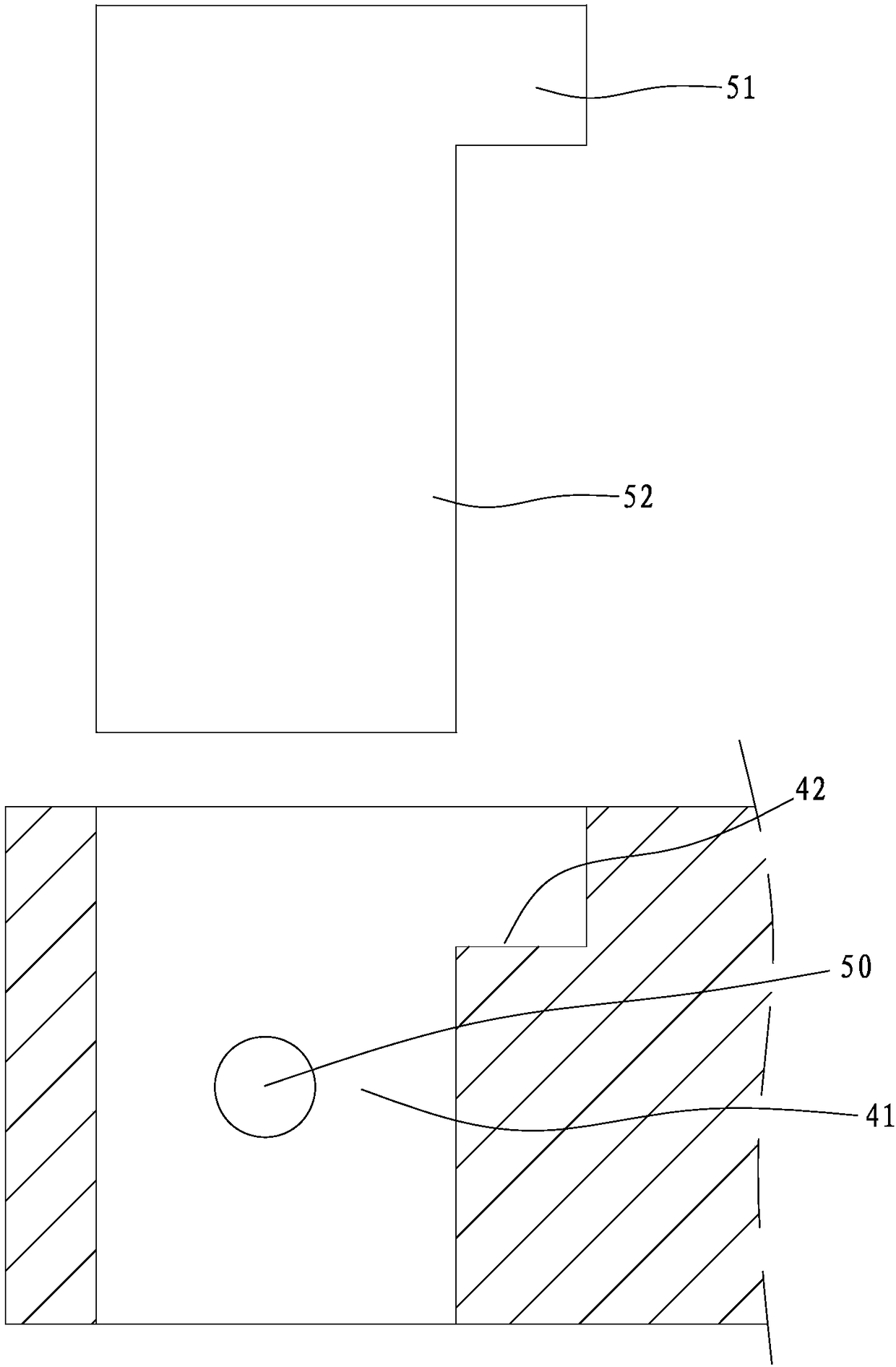

Bidirectional wire arranging device of multi-wire cutting machine and control method of bidirectional wire arranging device

ActiveCN103274264AGuaranteed uniformitySolve the problem of overlapping linesFilament handlingWire cuttingEngineering

The invention provides a bidirectional wire arranging device of a multi-wire cutting machine and a control method of the bidirectional wire arranging device, belongs to the technical field of machinery and solves the problem that cut wires are easy to break due to the fact that wires of existing multi-wire cutting machines are not arranged in place. Two bidirectional wire arranging devices of the multi-wire cutting machine are arranged between a winding and pay-off reel and a tension control pulley, and each of the two bidirectional wire arranging devices is provided with a mounting support, a driving mechanism, a wire arranging guide mechanism, two detecting wheels and a controller, wherein the two detecting wheels are arranged on the mounting support side by side and arranged on two sides of a cutting line, and each detecting wheel is provided with a pressure sensor connected with the controller. By sensing the position of the cutting line through the pressure sensor and adjusting speed of the driving mechanism through the controller, in-place wire arrangement is guaranteed. Besides, the bidirectional wire arranging device is simple in structure, convenient to control and high in accuracy.

Owner:TAIZHUO SHUANGHUI MACHINERY EQUIP

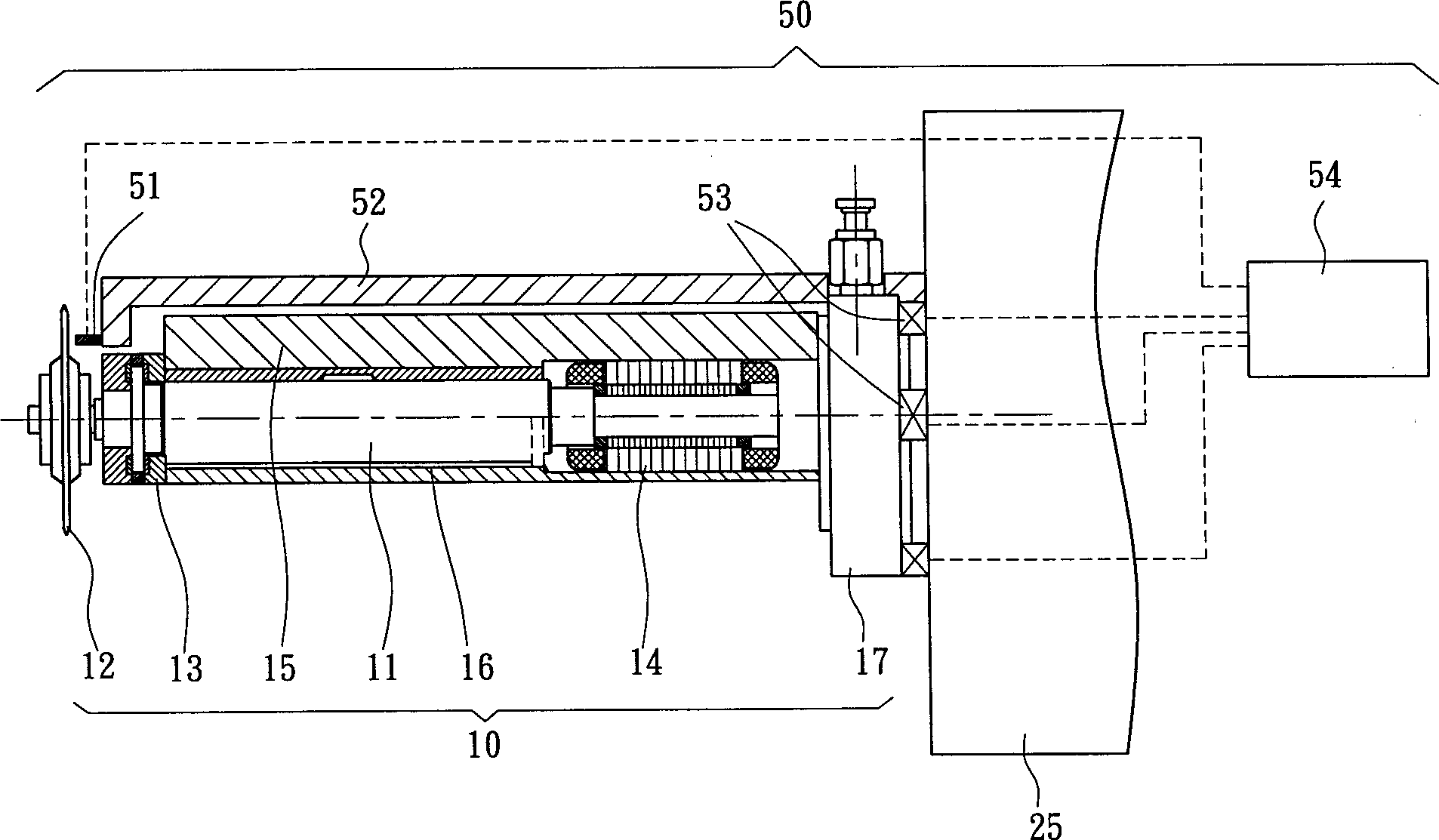

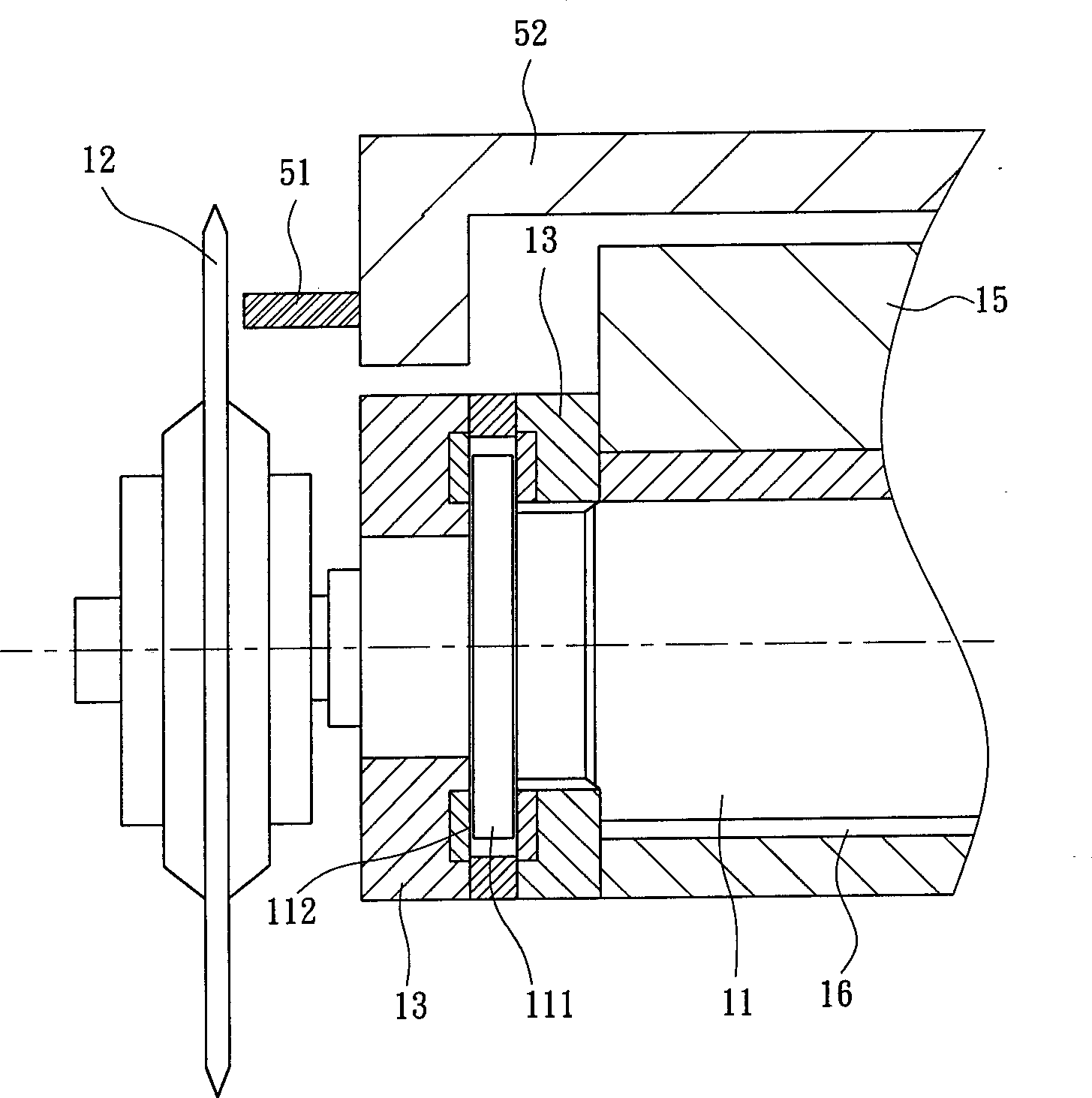

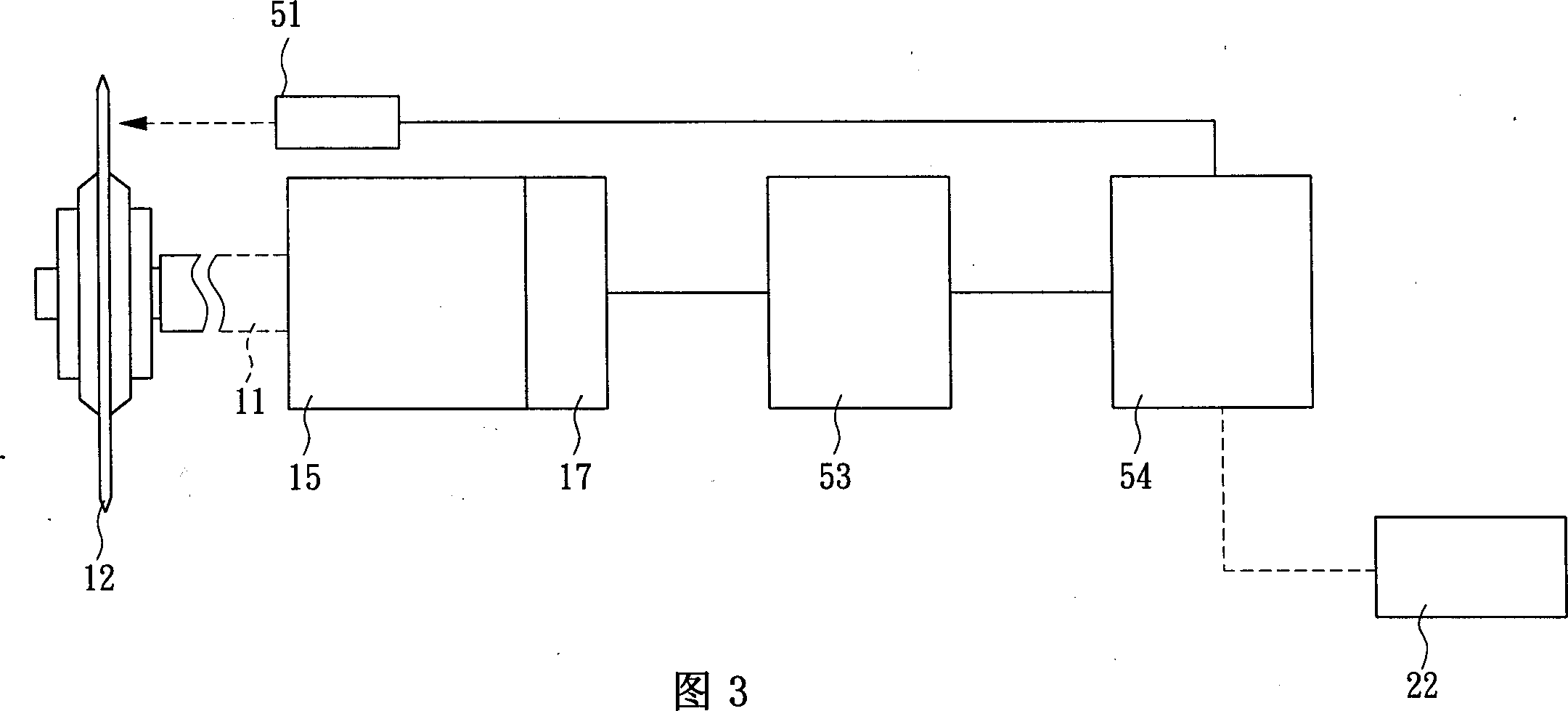

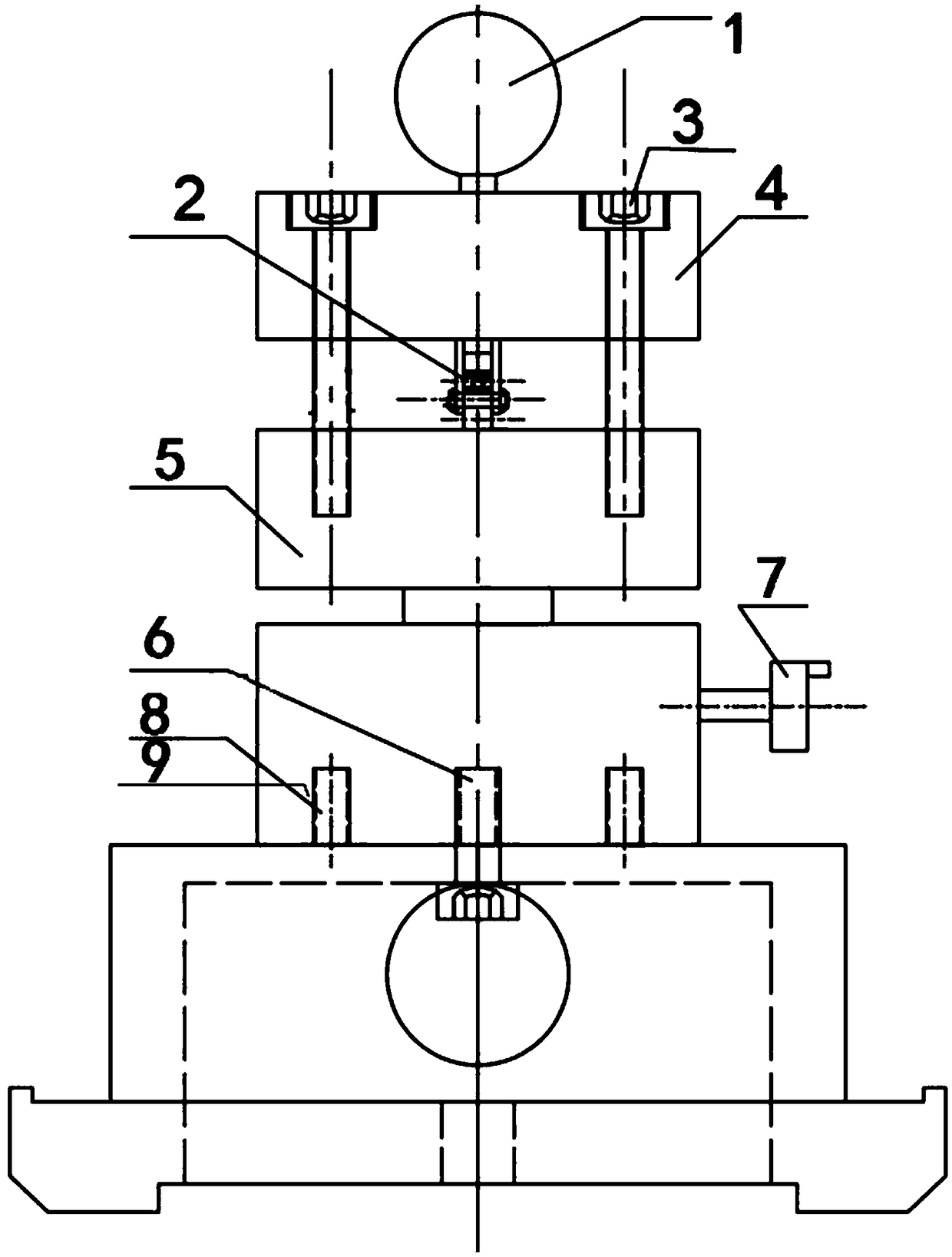

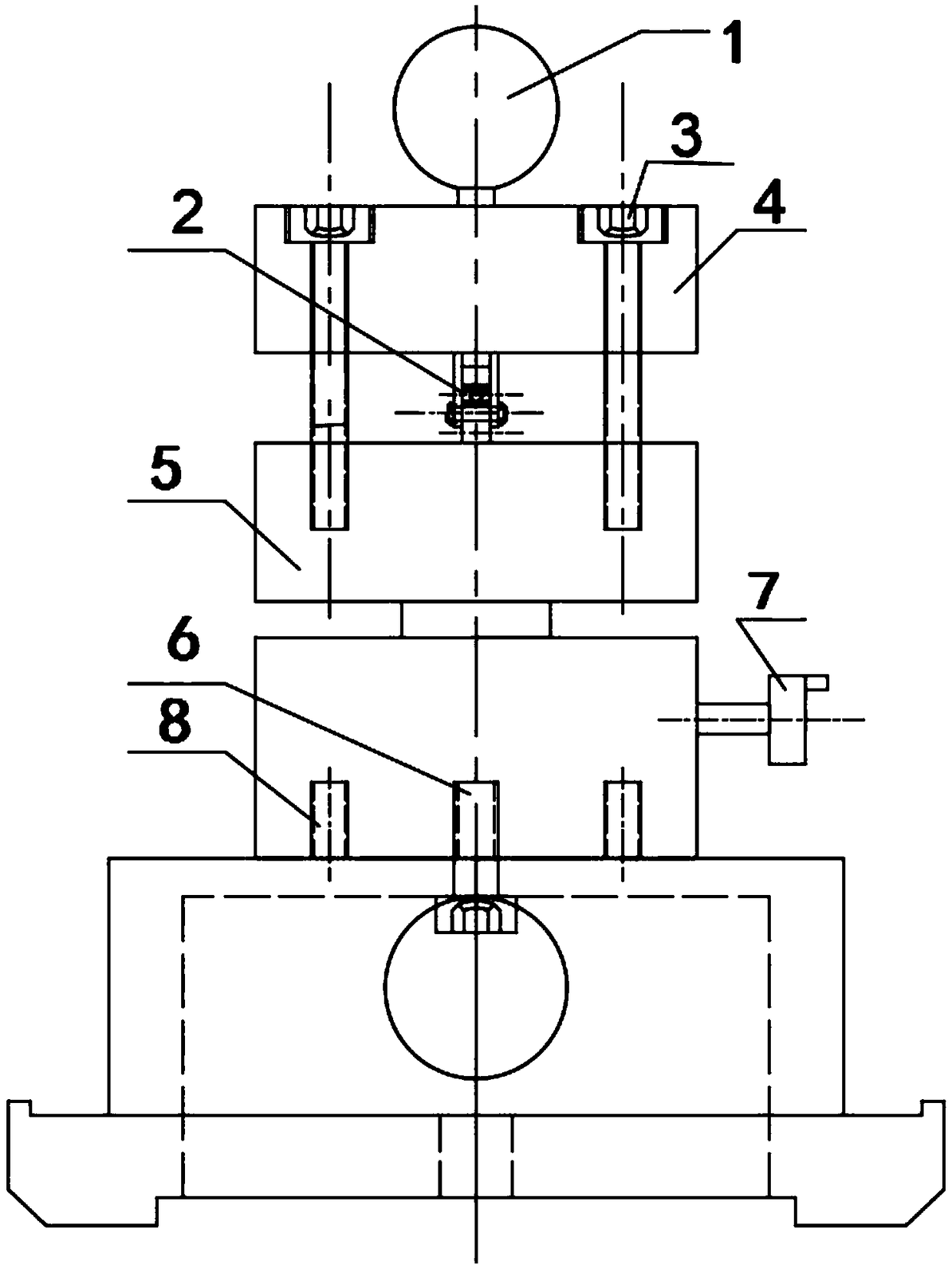

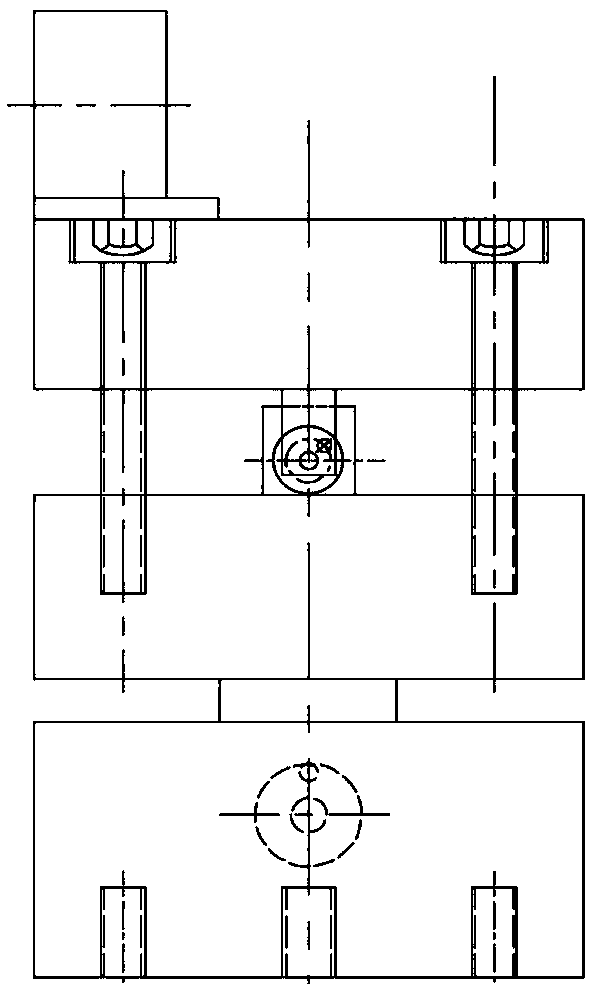

External active axial-shift compensating method and device for rotary main-shaft cutter

InactiveCN1347793AReduce structural complexityLow costMetal working apparatusAxial displacementEngineering

The external active compensator independent from the main shaft includes an extending frame between the base and a position near the cutter, a sensor in the end of the extending frame and corresponding to the cutter, several actuators between the main shaft and the base to drive the whole main shaft for small amount of axial displacement relatively to the base, and a control module. The control module accepts the axial shift displacement of the cutter from the sensor and controls the small amount of feeding for the actuators, so that the whole main shaft together with the cutter produces small amount of axial compensating displacement.

Owner:IND TECH RES INST

Glass substrate cutting equipment and cutting method

ActiveCN103896483AEven by forceCreate pollutionGlass severing apparatusMetal working apparatusEngineeringHigh pressure

The invention provides glass substrate cutting equipment which comprises a worktable, a cutting knife and a roller, wherein the glass substrate is transferred on the worktable; the cutting knife comprises an upper cutting knife and a lower cutting knife which are respectively arranged at the upper and lower ends of the glass substrate, and the knife edges of the cutting knives are opposite so as to cut the glass substrate into two halves from the upper and lower sides of the glass substrate; the roller is arranged at the upper end of the glass substrate, and the glass substrate can be pressed along the cutting crack on the glass substrate to break the glass substrate. The cutting equipment further comprises a high pressure nozzle mouth which is arranged between the cutting knife and the roller and can eject a high pressure air flow along the cutting crack so as to accelerate breakage of the glass substrate. By additionally arranging the high pressure nozzle mouth which ejects the high pressure air flow to the crack during cutting so as to increase the pressure at the crack and deepen the crack, the effect of quickly cracking is realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Tab machining method

The invention relates to the technical field of battery machining and specifically discloses a tab machining method. The tab machining method comprises the steps that raw materials are placed on a feeding mechanism to be fed; and a cutting mechanism cuts the raw materials according to a preset n_shapedcutting path, wherein the cutting mechanism adopts different actual technical parameters to cut the raw materials in different stages of the n_shapedcutting path. The tab machining method provided by the invention has the advantage that the cutting quality of the tab can be effectively improved because the cutting mechanism adopts the different actual technical parameters in the different stages of the n_shapedcutting path.

Owner:DONGGUAN ALI AUTOMATION CO LTD

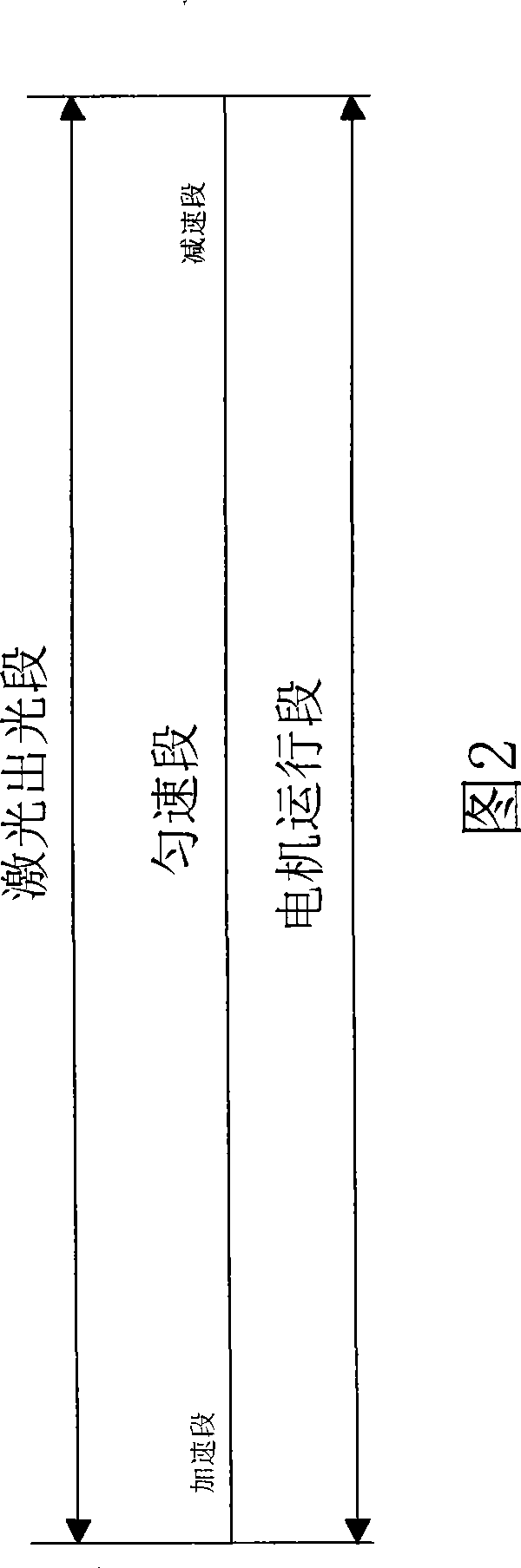

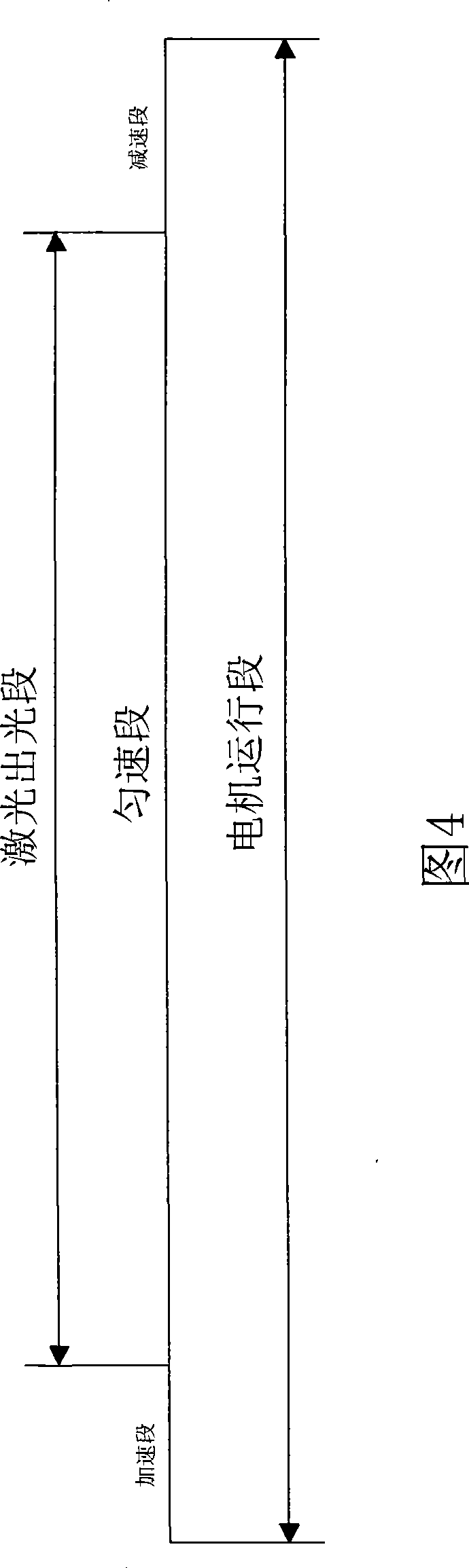

Laser cutting method

ActiveCN101450423AReduce carbonizationImprove cutting qualityLaser beam welding apparatusAngular pointCarbonization

The invention relates to a laser cutting method. Before cutting, a cutting head is accelerated to reach an end point to be cut, and does not emit laser at accelerating sections; after the cutting head reaches the end point to be cut, the laser begins emitting, and the cutting head cuts one side of a rectangle at a uniform speed; and after the cutting of the side is finished, a motor decelerates to drive the cutting head for running, and the laser does not emit at decelerating sections, thereby ensuring that the cutting of rectangular sides is finished under uniform speed state, completely removing angular points, simultaneously reducing carbonization, and improving the cutting quality.

Owner:HANS CNC SCI & TECH

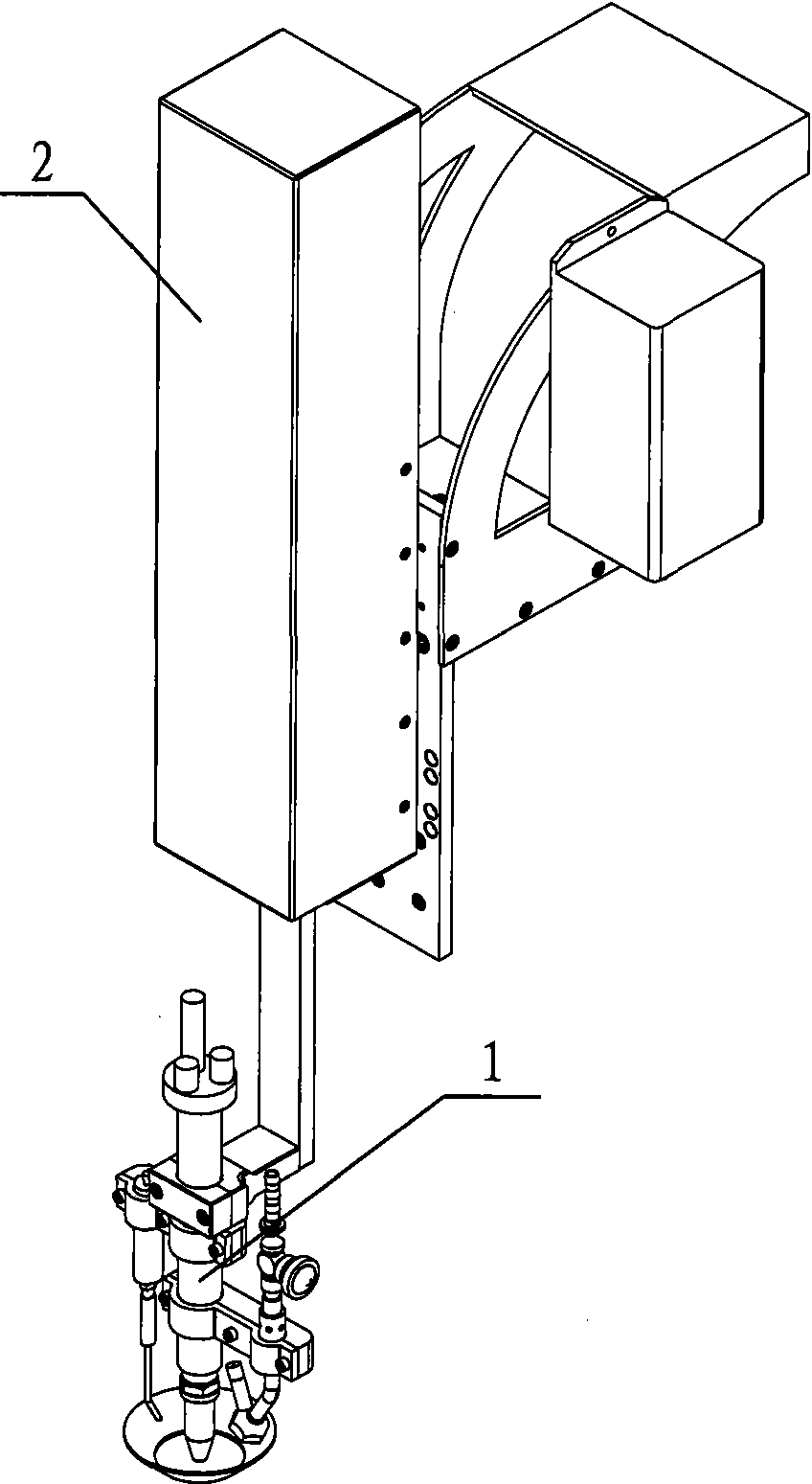

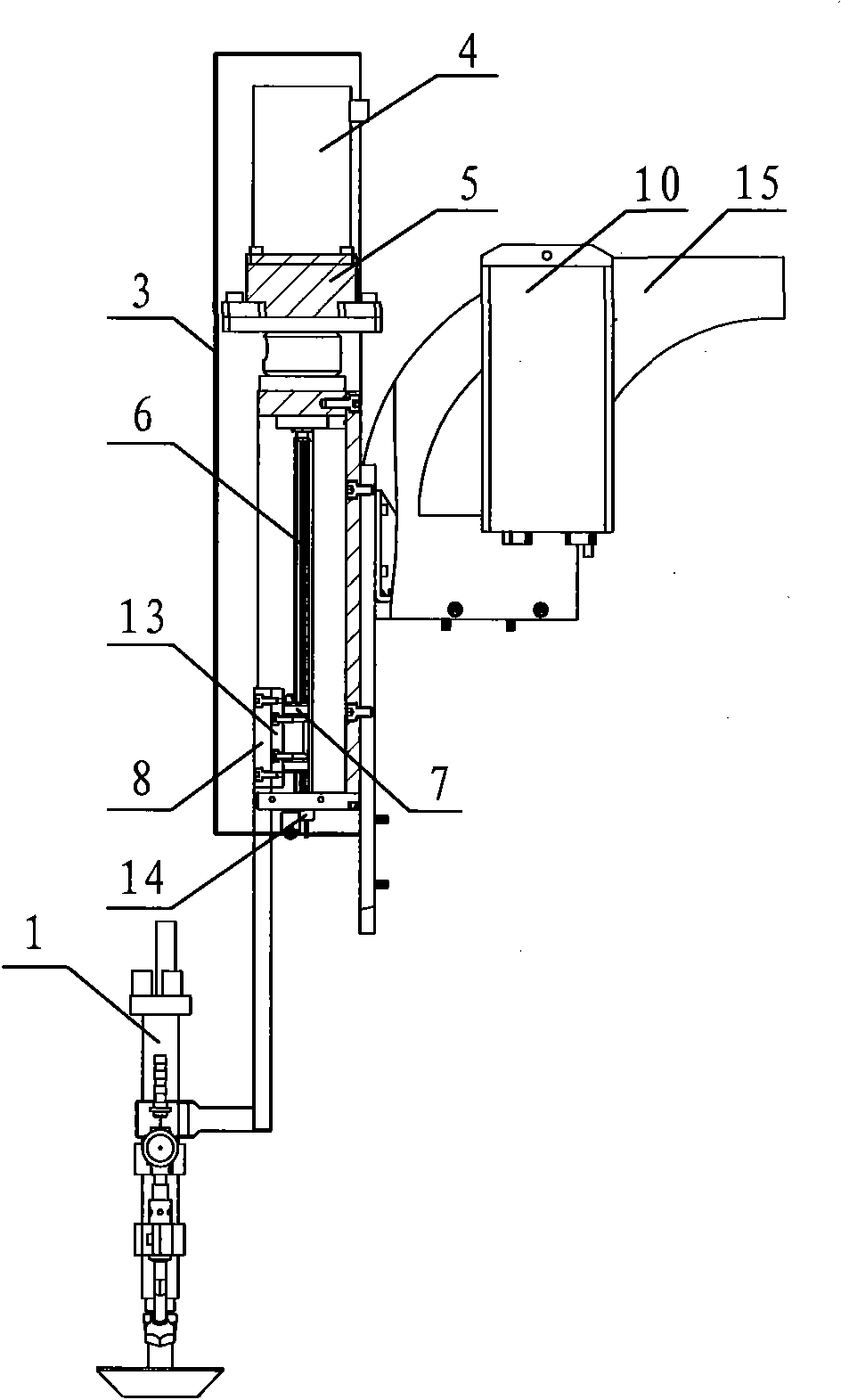

Flame cutting head

ActiveCN101890553AQuality improvementImprove cutting qualityGas flame welding apparatusControl signalSelf locking

A flame cutting head comprises a cutting torch and a lifting device capable of self-locking and automatic height adjusting, wherein the lifting device comprises a housing, a motor arranged in the housing, a speed reducer connected on an output shaft of the motor, a screw rod connected on the speed reducer, a nut matched with the screw rod, a lifting plate fixed on the nut, an arc voltage height adjusting inductor arranged on the cutting torch and a height adjuster connected with the arc voltage height adjusting inductor, wherein the cutting torch is fixedly connected on the lifting plate; thearc voltage height adjusting inductor transfers an induced position signal to the height adjuster; and the height adjuster generates a control signal according to the position signal and transmits the control signal to the motor to drive the motor to work. The flame cutting head adopts the lifting device capable of self-locking and automatic height adjusting and can automatically adjust the position of the cutting torch aiming at the surface of the plate, thus effectively improving the cutting quality.

Owner:XUZHOU HUAHENG ROBOT SYST

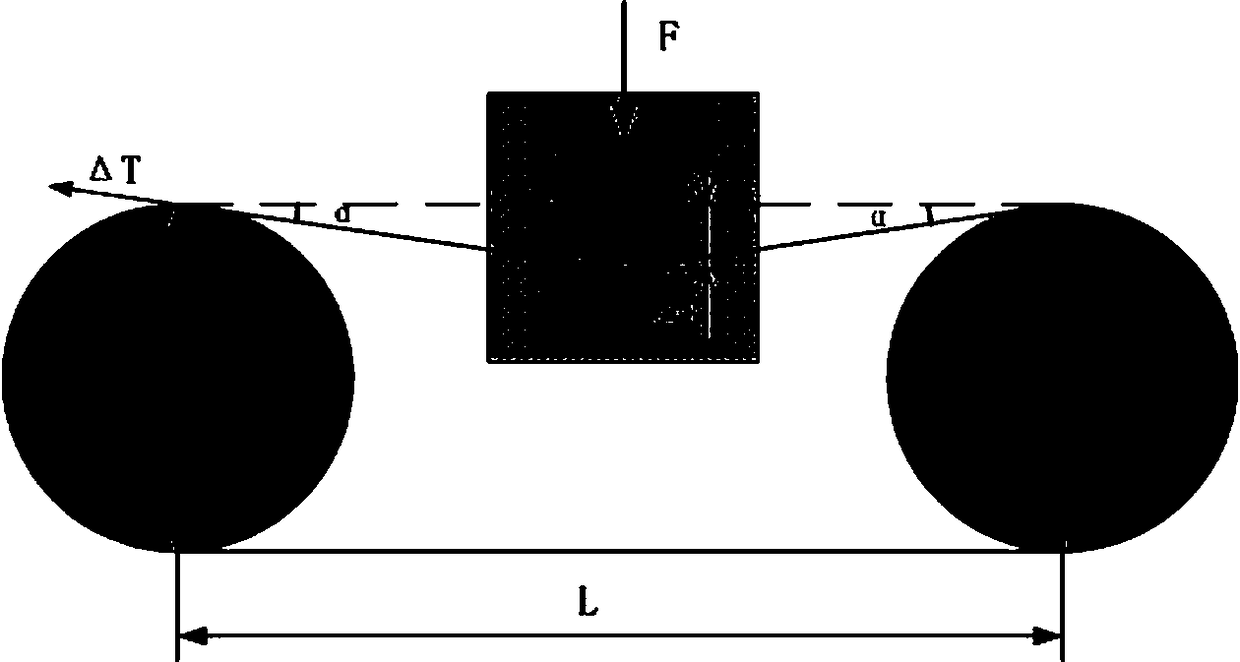

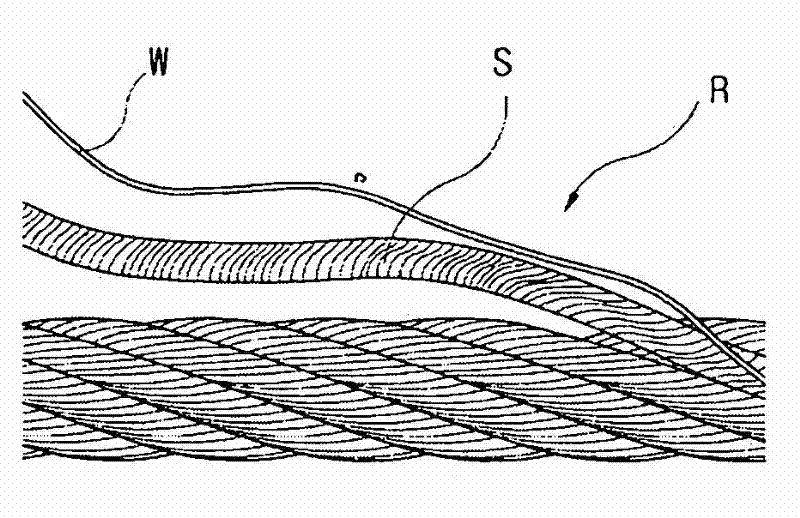

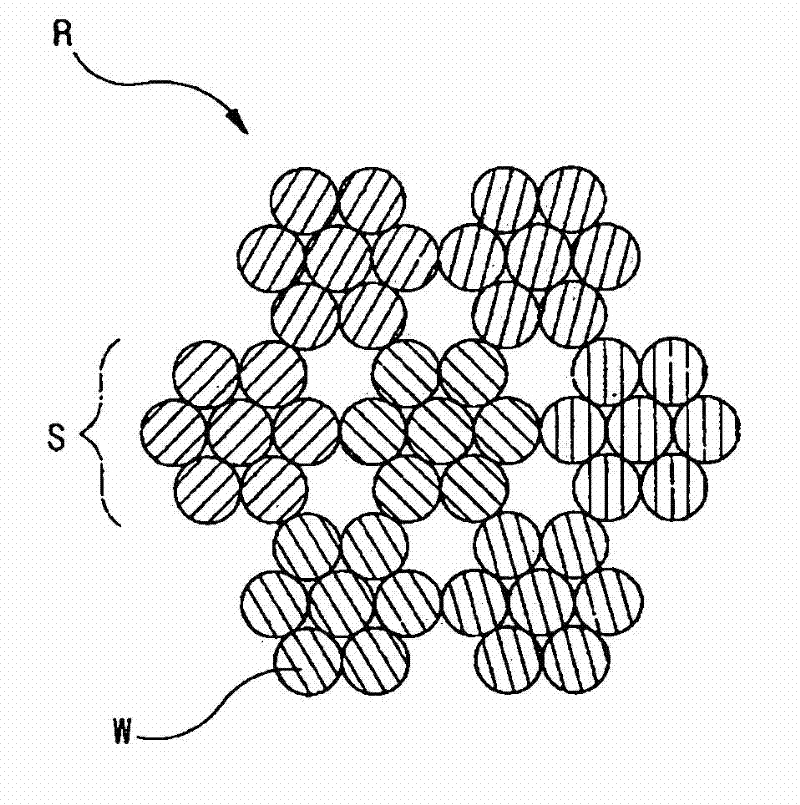

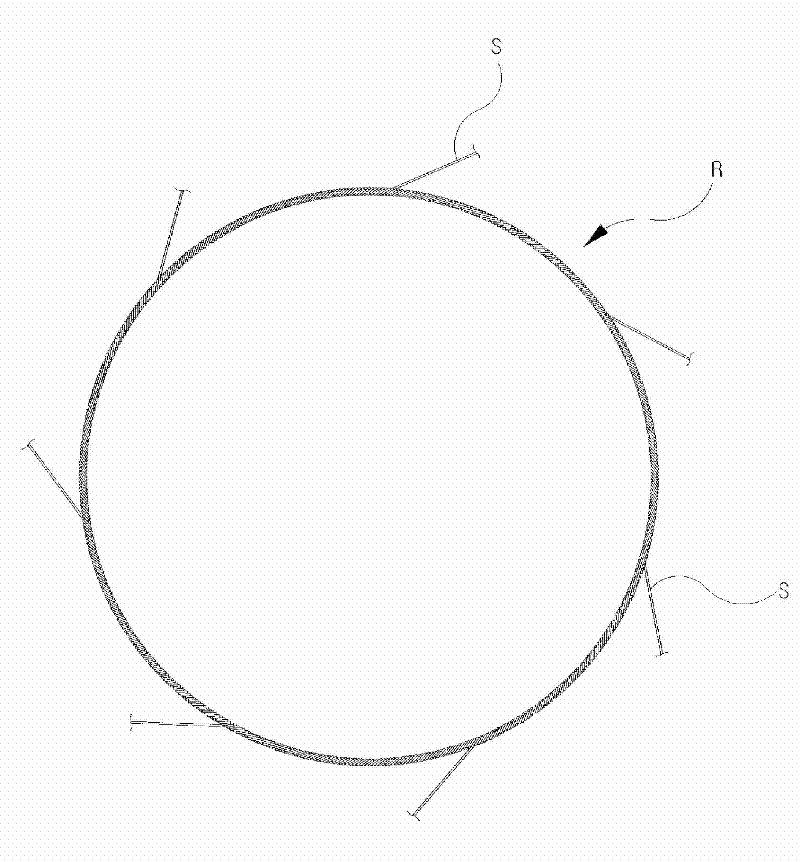

Method for manufacturing endless cutting wire for ingot cutting

InactiveCN102227282AStable fixing forceImprove cutting qualityMetal sawing tool makingMetal sawing toolsEngineeringWire rope

The present invention relates to a method for manufacturing a cutting edge used for cutting a silicon ingot which is grown as a single or poly crystal, especially for an endless cutting wire of a new mechanism which forms a loop without interruption and cuts the ingot while rotating at high speed on a pulley. The method comprises: preparing at least seven wire strands each of which is made by twisting dozens of thin and small-diameter wires to a uniform thickness and then binding and twisting the prepared strand wires into a single wire rope of larger diameter so that the twist-start point and the opposite twist-end point of the wire strands start and end at different positions, putting each wire strand in the center of other wire strands being twisted when twisting the wire strands, and also putting the twist-end point of each wire strand in the center of other wire strands being twisted. Therefore, an integrated endless cutting wire without a weak portion like a cutoff or knot is manufactured.

Owner:DISEC

Cutting cooling device

InactiveCN104057357AGuaranteed cooling effectImprove cutting qualityMaintainance and safety accessoriesCooling effectSpray nozzle

The invention relates to a cutting cooling device. The cutting cooling device comprises a workbench and a cutter blade, wherein the workbench is used for placing a product to be cut; the cutter blade is used for cutting the product on the workbench; a spray mechanism positioned on the same level as the cutter blade is arranged on the workbench, and comprises a water tank and a spray nozzle; the spray nozzle is arranged on the water tank, faces the cutting feed direction when the cutter blade is in cutting, and sprays cylindrical water columns toward the cutter blade. According to the cutting cooling device, the spray nozzle sprays the cylindrical water columns towards the contact point where the cutter blade cuts the product, a cutting feed opening of the cutter blade can be quickly cooled down, the cooling effect of the cutter blade is ensured, and the cutting quality of the product is greatly improved.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

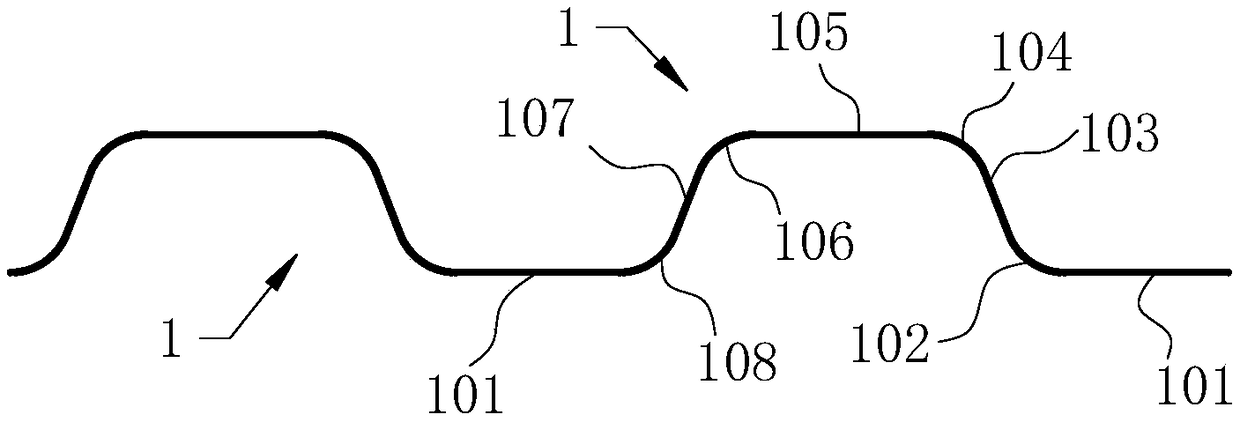

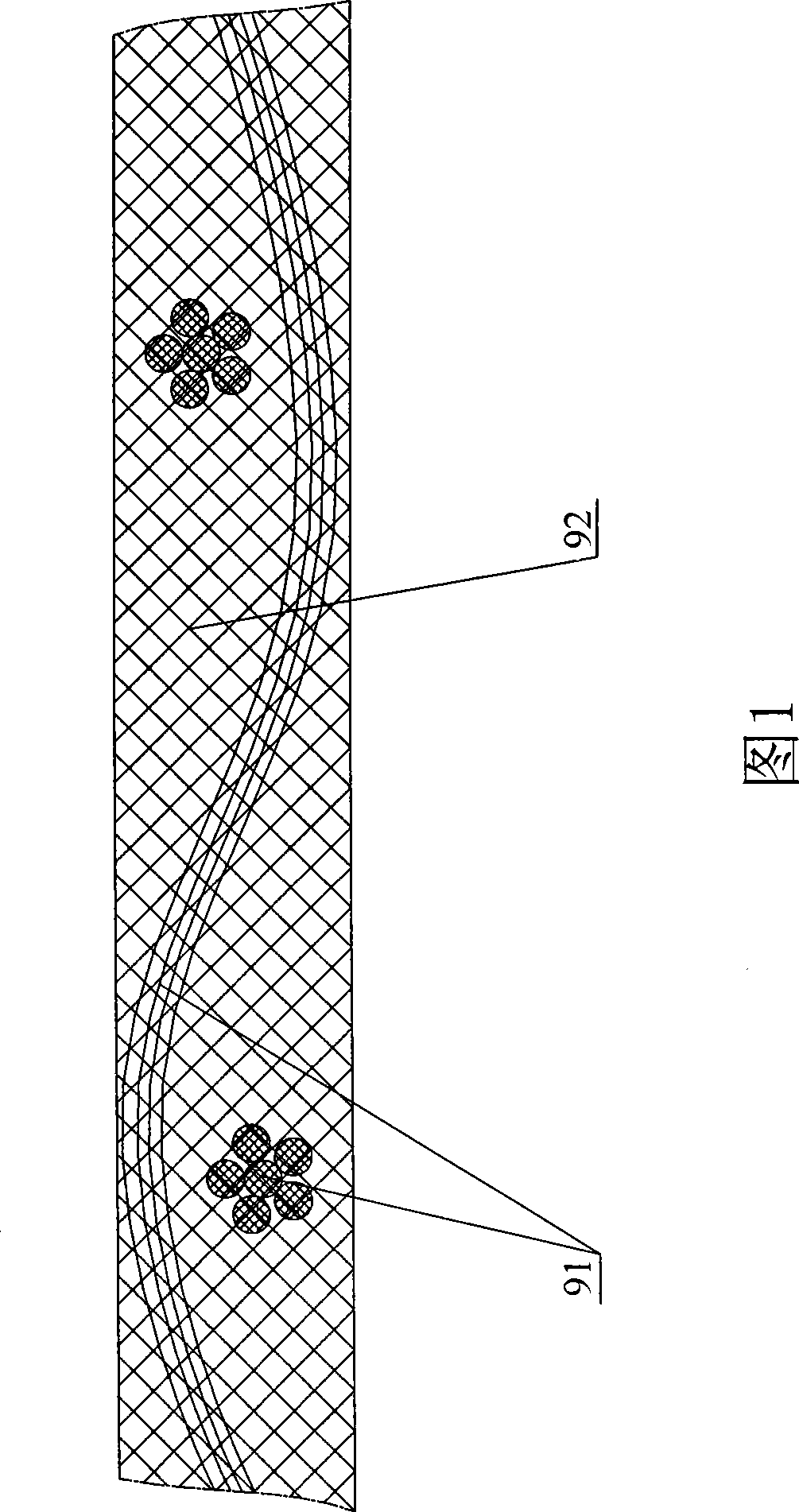

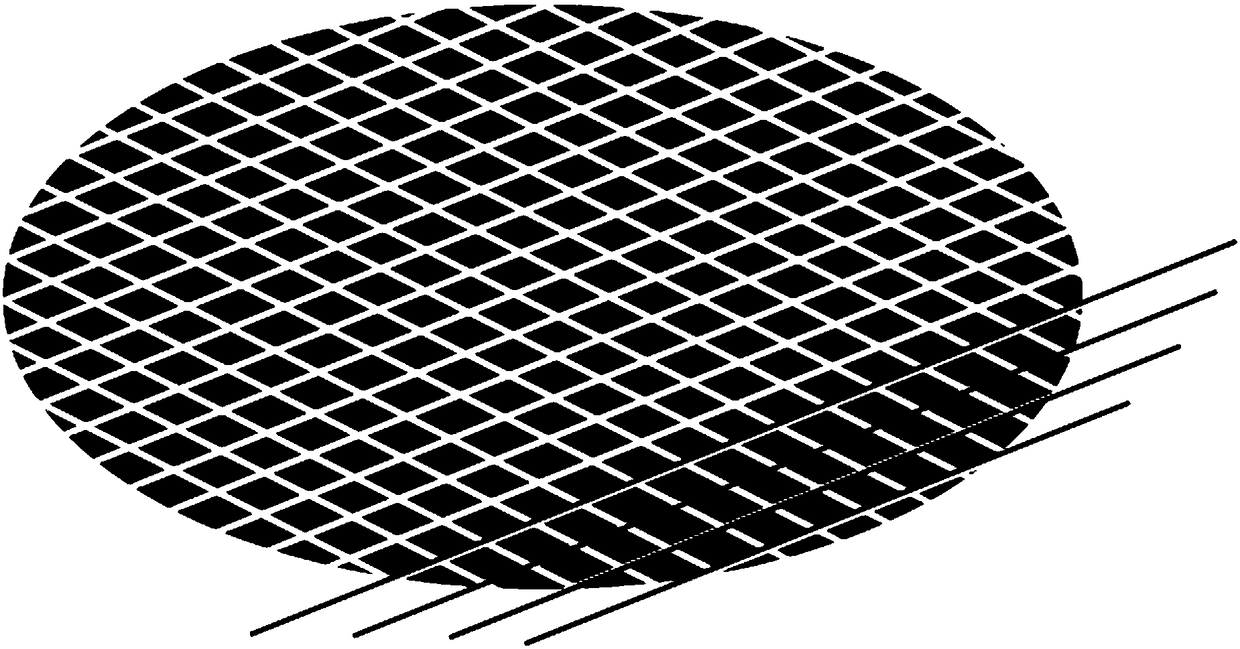

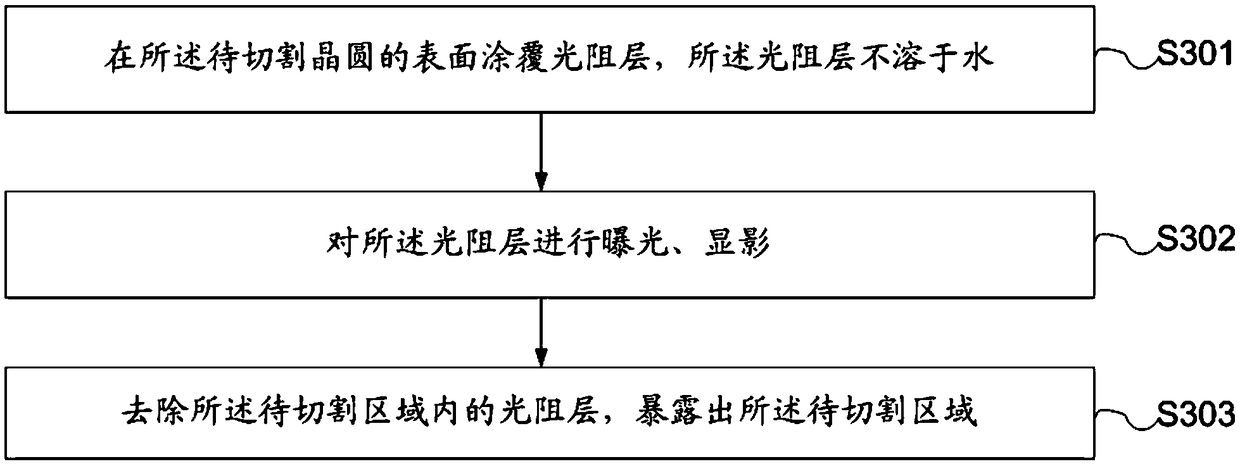

Beam splitting laser cutting method for silicon-based wafer

ActiveCN109352184AReduced Risk of FragmentationReduce heat damageLaser beam welding apparatusGratingBeam splitting

The invention discloses a beam splitting laser cutting method for a silicon-based wafer. The beam splitting laser cutting method for the silicon-based wafer is used for cutting the silicon-based waferinto independent chips, and is characterized by comprising the following steps of a pretreatment step; a diffraction light splitting step, wherein a single beam laser (105) is split into a pluralityof beams of laser (108) through a grating device (106) and a light beam pattern is formed; a beam splitting cutting step, wherein a laser cutter of the style is used for cutting the silicon-based wafer; and a postprocessing step. The beam splitting laser cutting method for the silicon-based wafer achieves the technical effects that the wafer cutting speed is increased, and meanwhile the cutting quality of the wafer is improved.

Owner:SHENZHEN STS MICROELECTRONICS

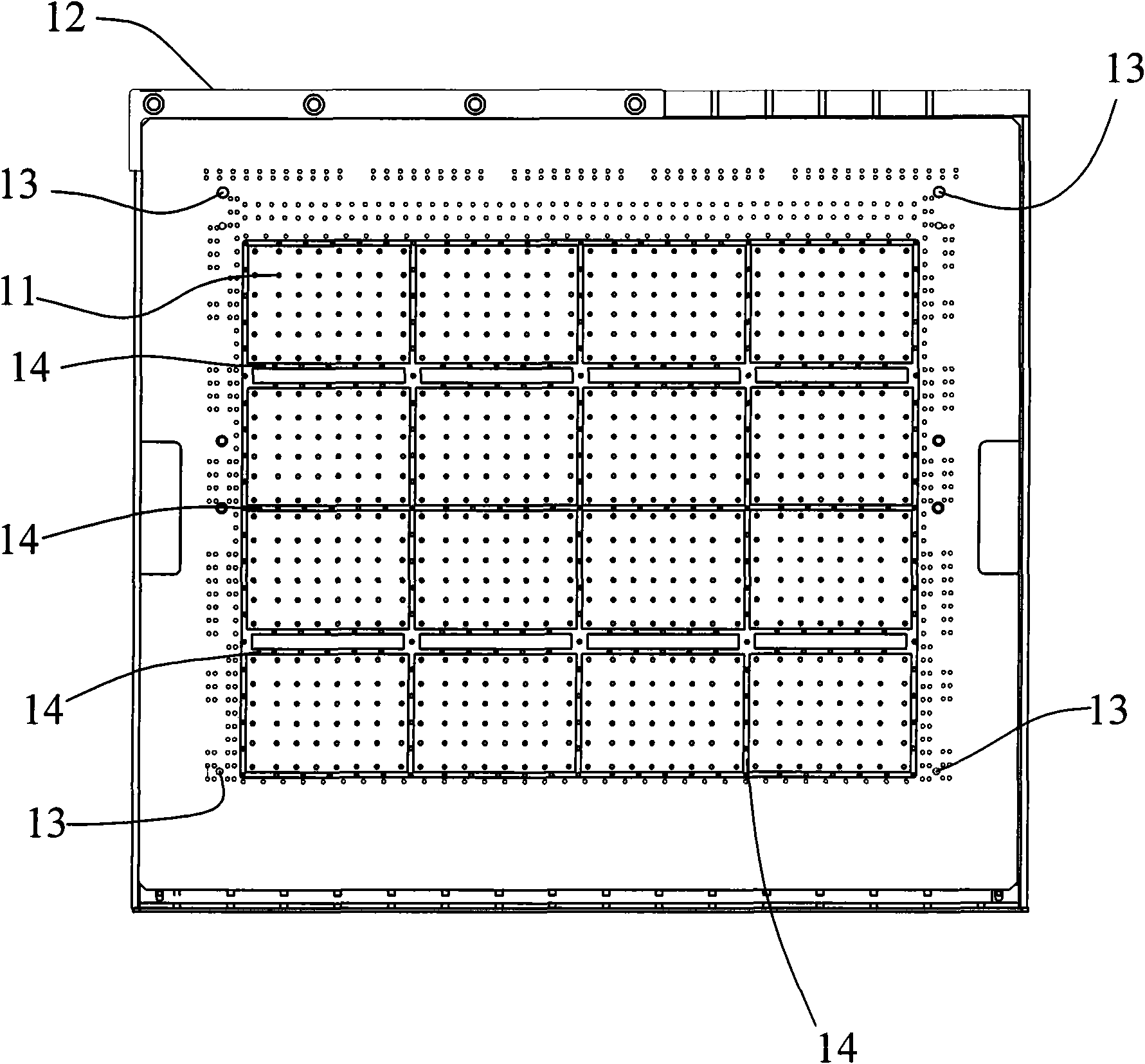

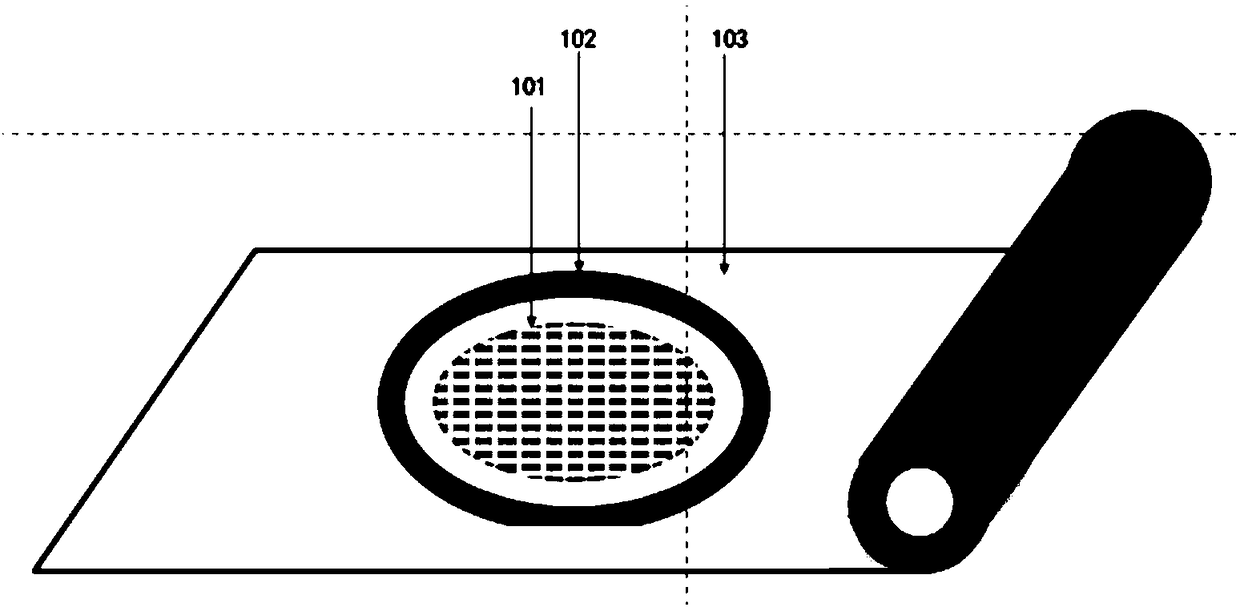

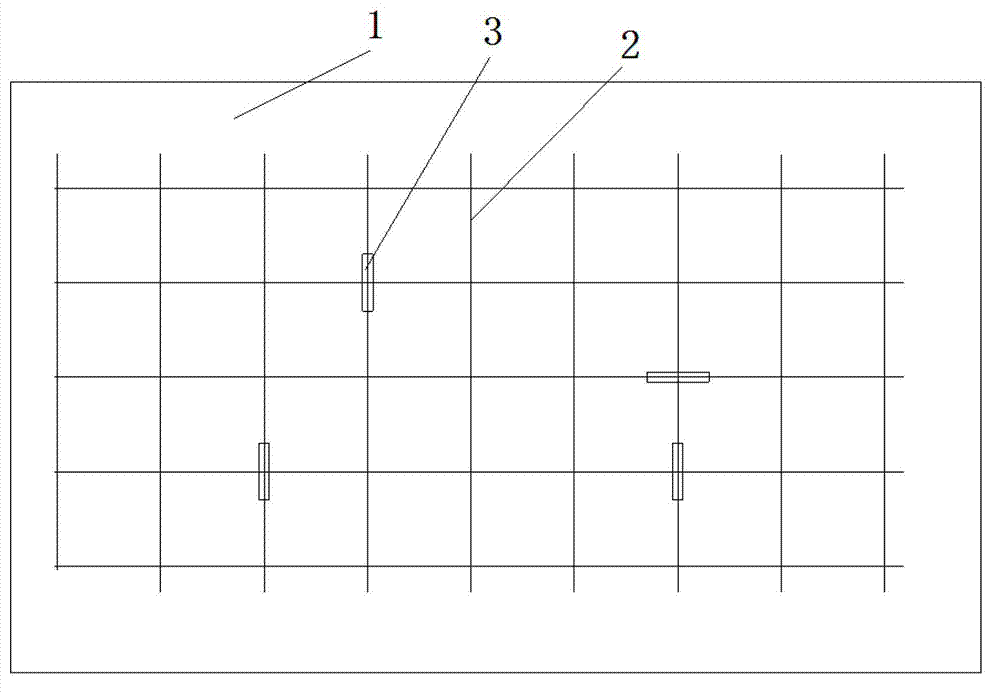

Laser cutting and positioning tool

InactiveCN102861996APrecise positioningImprove cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingEngineering

The invention discloses a laser cutting and positioning tool, comprising a worktable. The laser cutting and positioning tool is characterized by further comprising a plurality of unequal-height supporting blocks and a mark-shaped positioning bracket, wherein rectangular grid lines are machined on the worktable; the unequal-height supporting blocks are arranged on the corresponding grid lines; clamping parts are arranged at the tops of the unequal-height supporting blocks; and the mark-shaped positioning bracket is placed at the clamping parts of the corresponding supporting blocks to be clamped and positioned. According to the laser cutting and positioning tool, the problems in the prior art that a positioning manner is complicated when a work piece is cut, the machining speed is influenced, the positioning precision is worse, and the machining quality is influenced are solved. The invention provides the laser cutting and positioning tool which can rapidly and accurately position the work piece and is suitable for all mould manufacturers and work piece manufacturing enterprises.

Owner:KUNSHAN JIZHICHENG MOLD

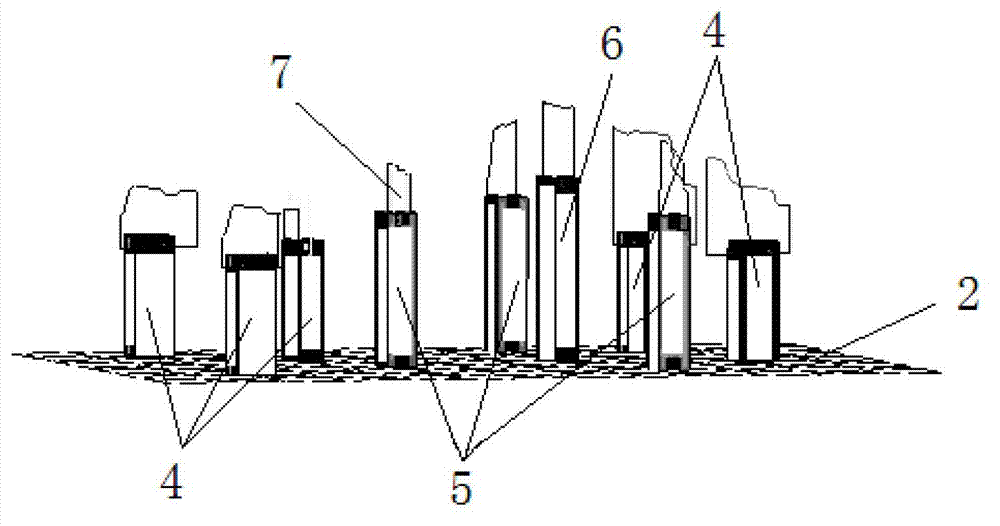

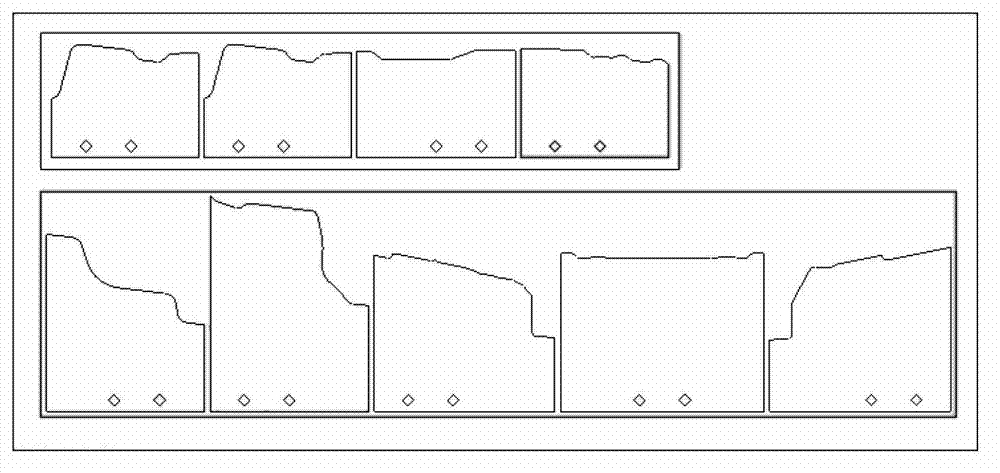

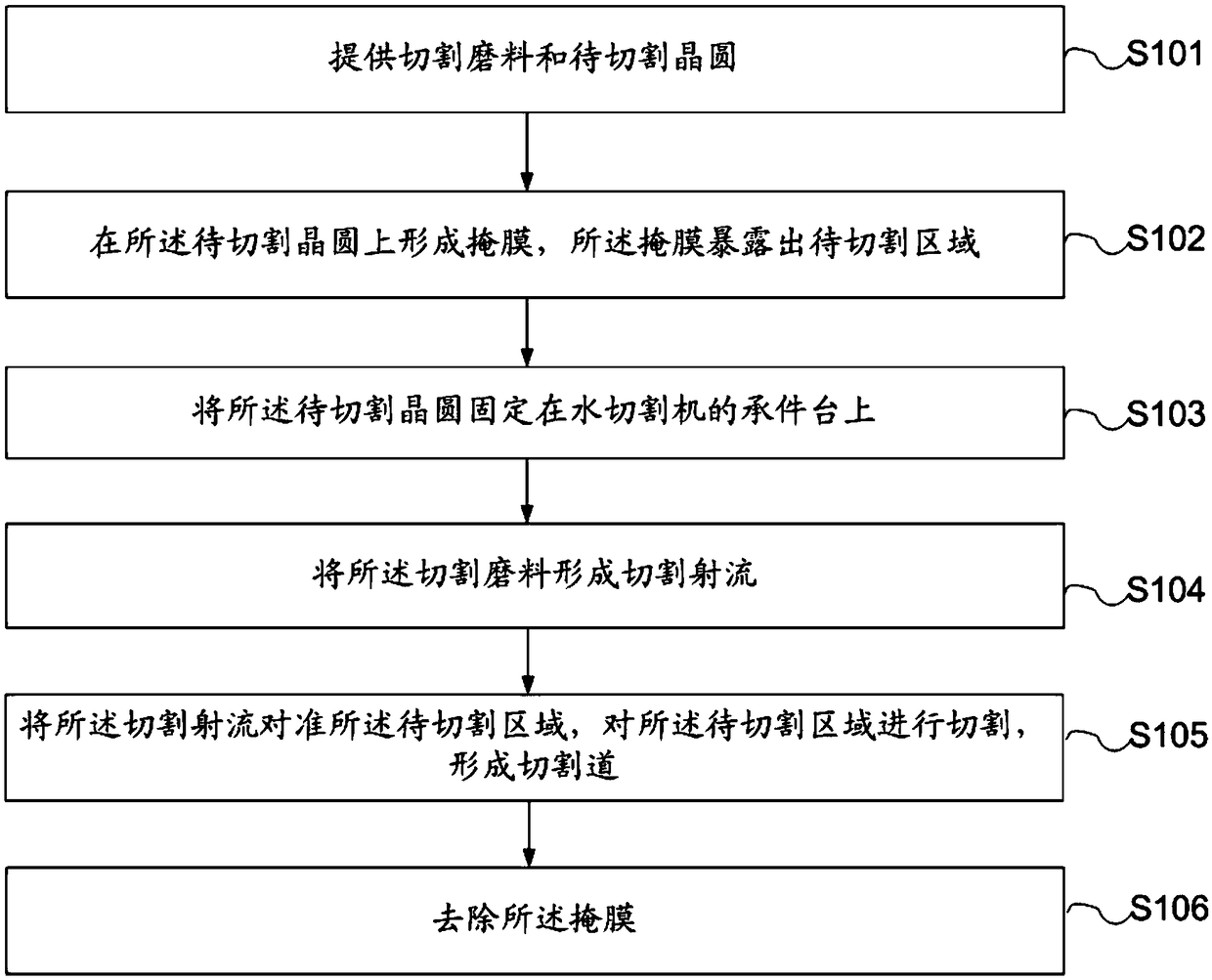

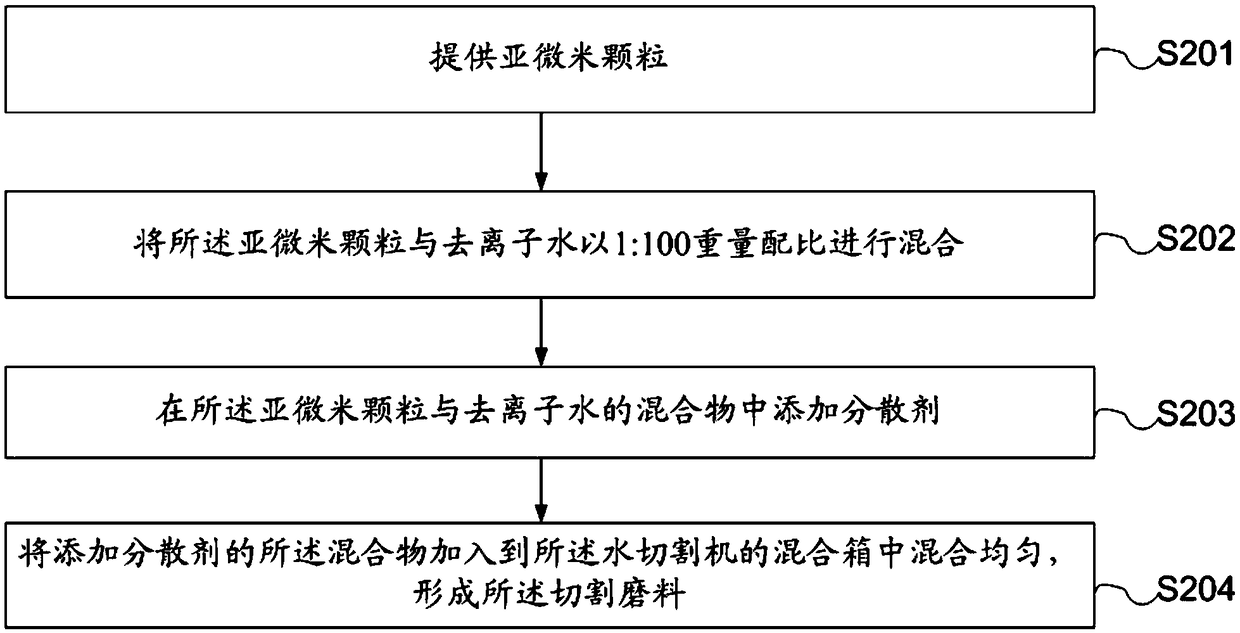

LED chip and cutting method thereof

ActiveCN108899303APrevent leakageAvoid the situationSemiconductor/solid-state device manufacturingAbrasive blasting machinesElectricityEngineering

The invention discloses an LED chip and a cutting method thereof. The cutting method of the LED chip provided by the invention is characterized in that after a cutting grinding material is prepared, the cutting grinding material is pressurized to form high-pressure cutting jet through a pressurization system in a waterjet cutting machine, so that the high-pressure cutting jet acts on the surface of an LED wafer, so that the goal of cutting the LED wafer is achieved. The LED chip cutting method provided by the invention is a cold cutting mode, so that the heat influence cannot be generated in the cutting process; melts similar to that in laser cutting cannot be generated, so that the condition that the LED chip leaks electricity or is shielded by the melts is effectively avoided; the LED lateral wall light outlet is favorably realized; the luminous efficiency of the LED chip is improved. In addition, the high pressure jet effect is fluid stress and is not mechanical stress, so that thephenomenon of edge crack in the chip cutting process is avoided; the qualification rate of the LED chip is improved.

Owner:YANGZHOU CHANGELIGHT

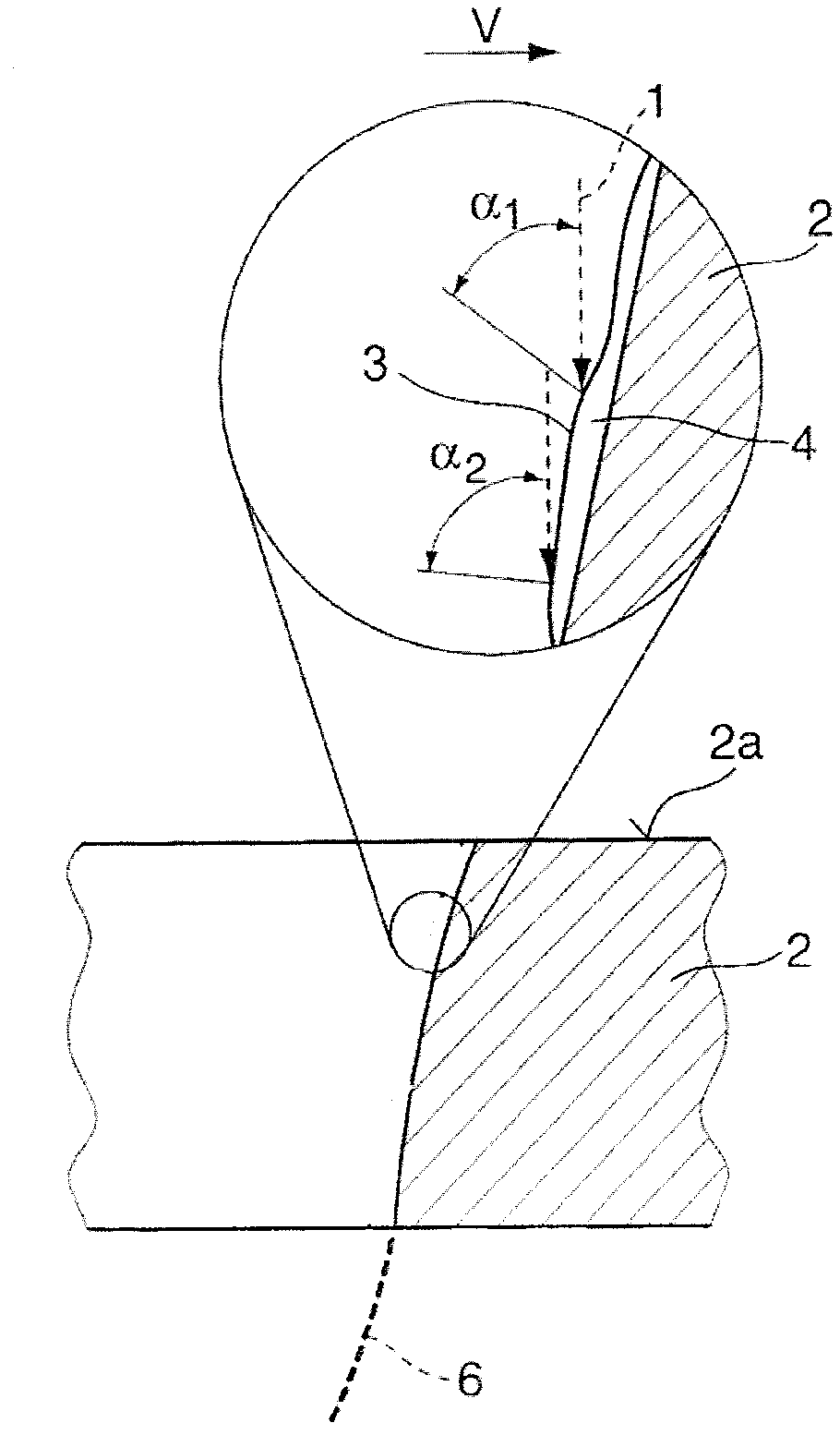

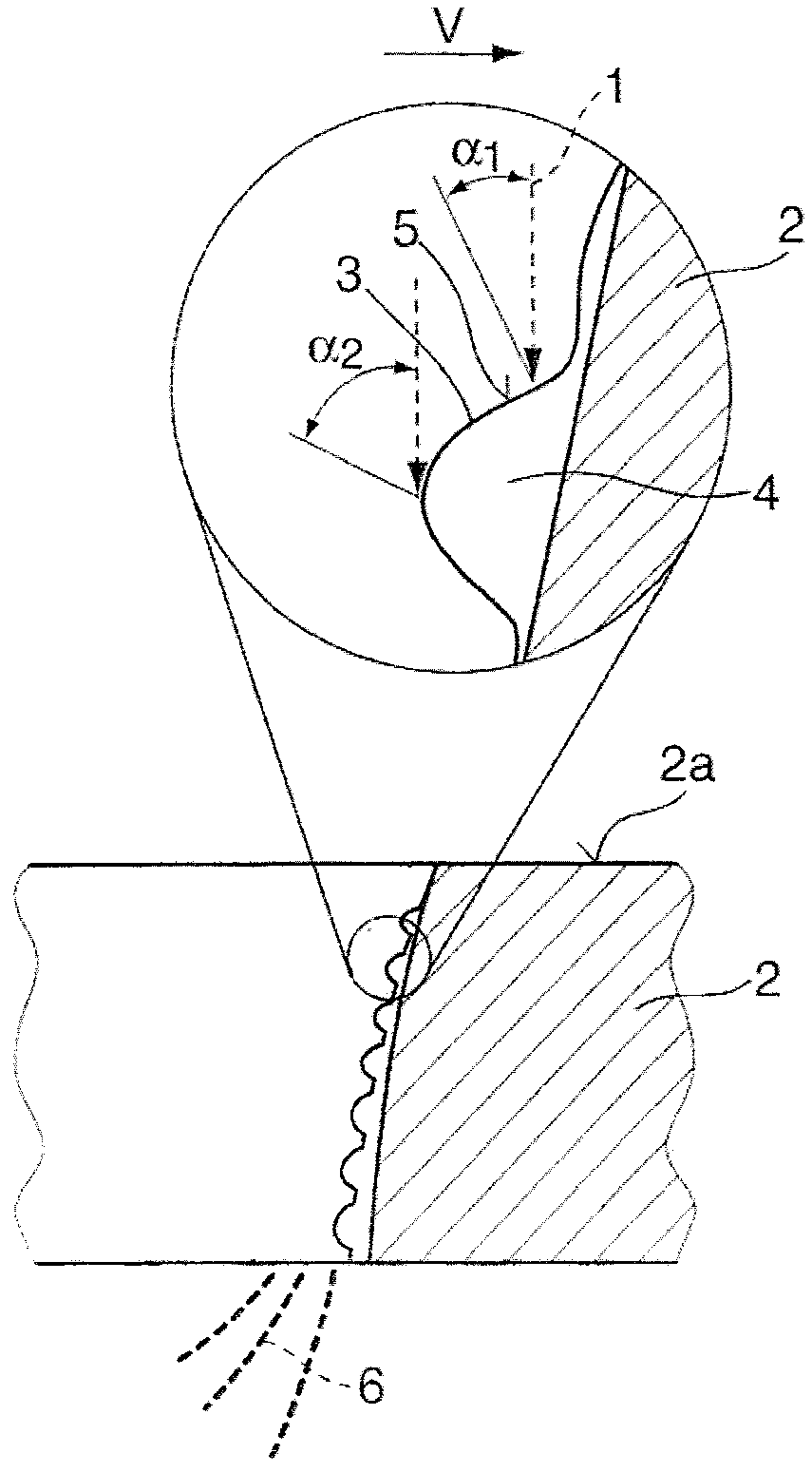

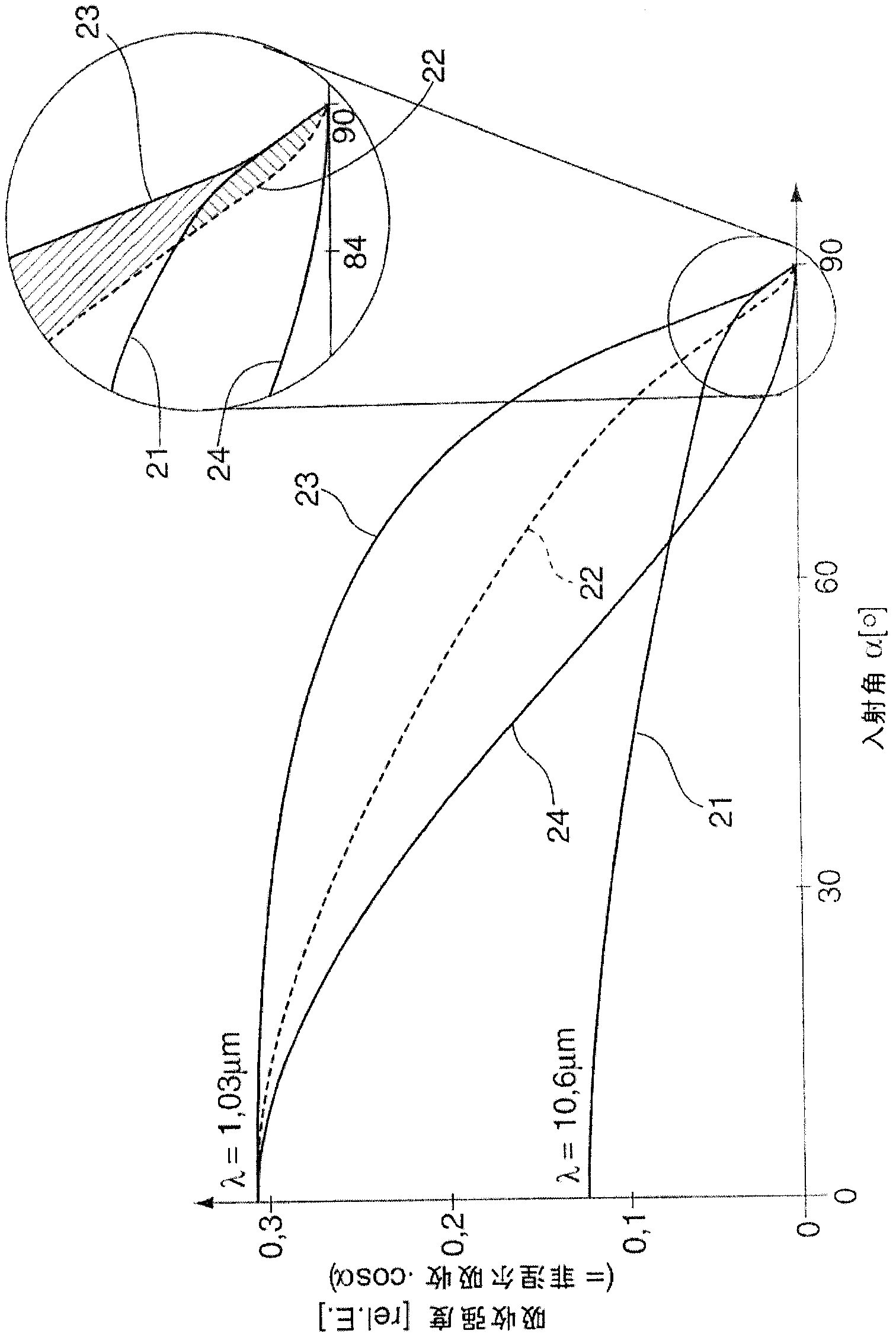

Method and device for laser material processing a workpiece

ActiveCN103228400AUniform temperature distributionReduce superficially salient featuresLaser beam welding apparatusLaser cuttingOptoelectronics

In a method for laser material processing a workpiece (2), in particular for laser cutting or laser welding, wherein by means of a laser beam (1) at least a part of the workpiece (2) is melted and / or vaporized and an irradiation front (3) is formed by adding a relative movement between the laser beam (1) and workpiece (2), according to the invention the surface structure of the irradiation front (3) is adjusted in accordance with a desired processing result. The surface structure of the irradiation front (3) can be adjusted, for example, by suitably selecting beam properties of the laser beam (1), in particular the polarization and / or beam profile.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

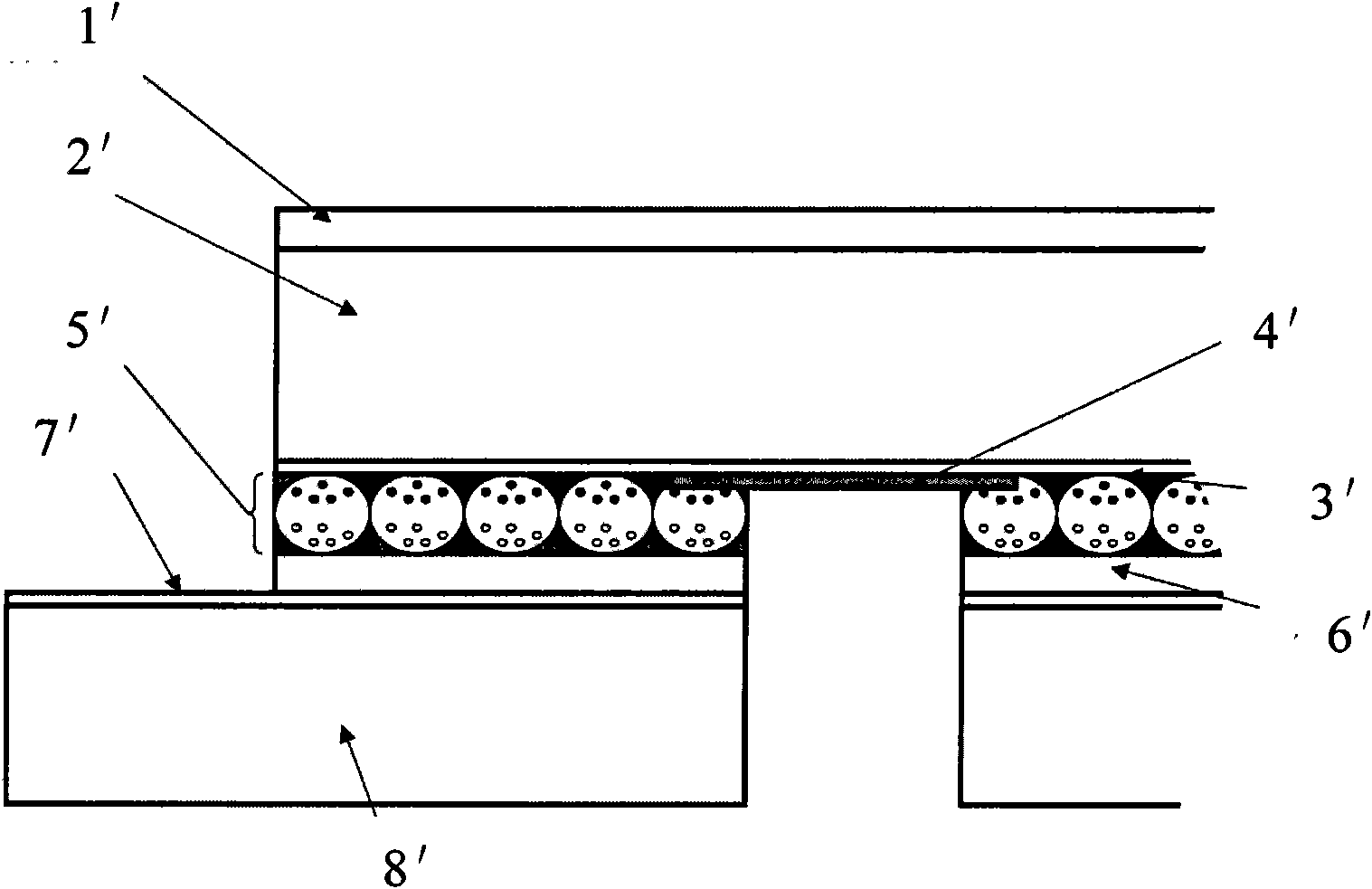

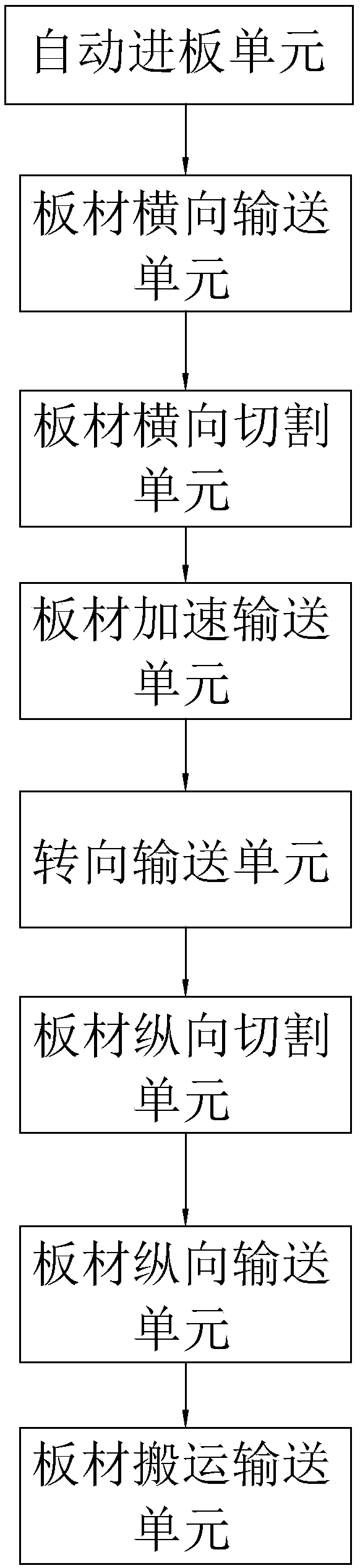

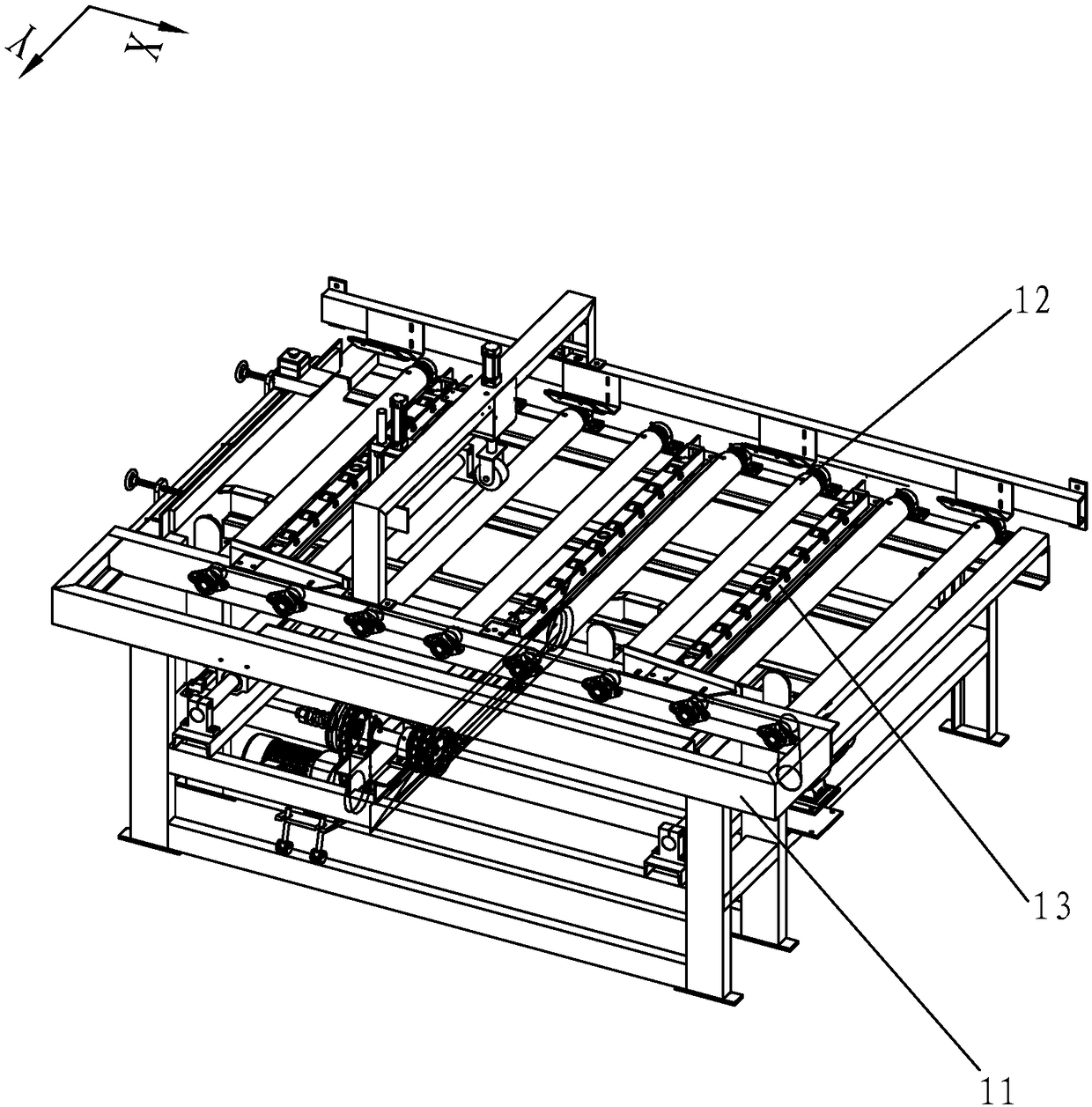

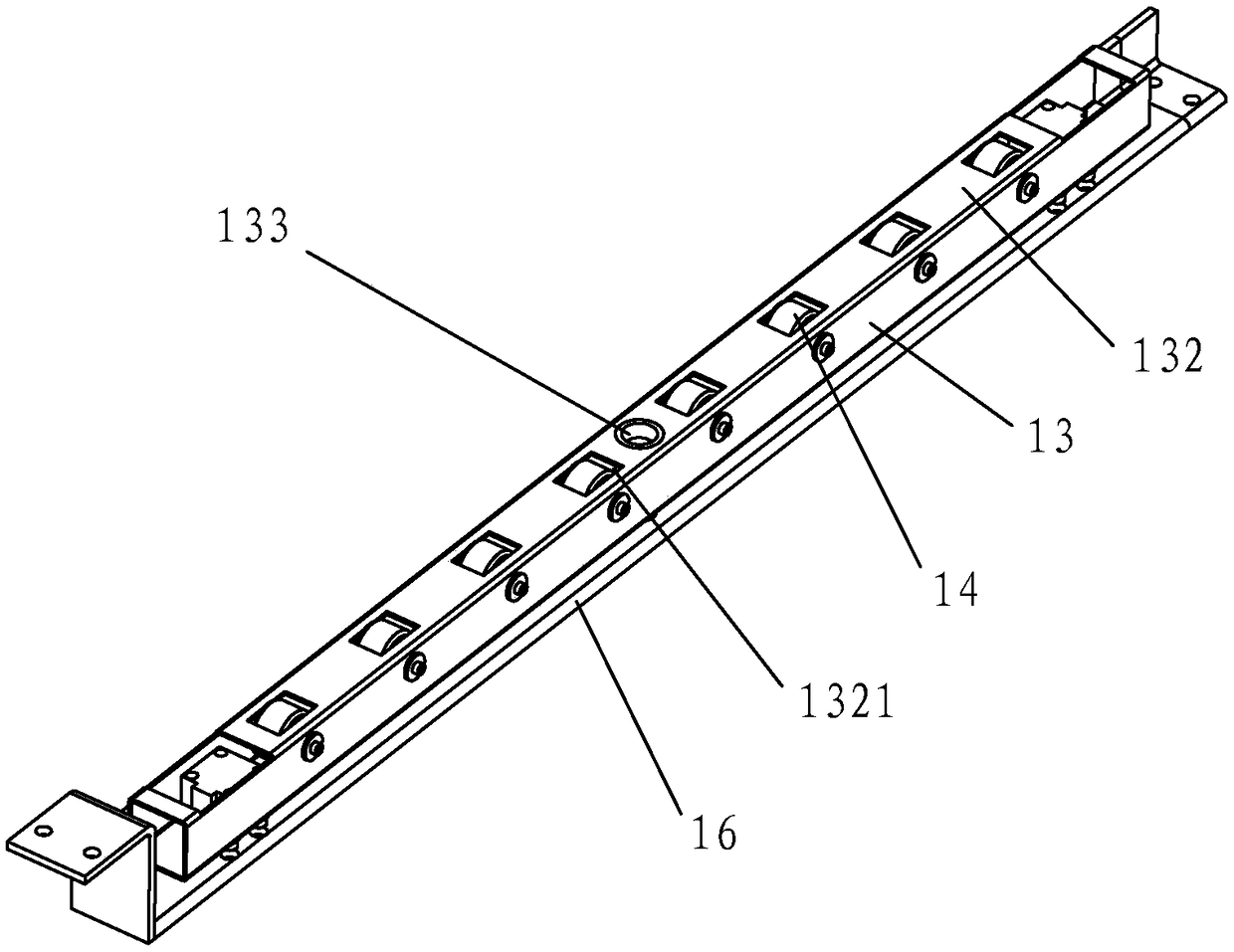

Damage-free high-quality sheet material machining production line

The invention discloses a damage-free high-quality sheet material machining production line. The production line comprises a sheet material transverse cutting unit, a direction turning conveying unitand a sheet material longitudinal cutting unit, wherein the direction turning conveying unit is provided with a direction turning table, and a rolling wheel assembly is arranged on the direction turning table; the rolling wheel assembly comprises a rolling wheel lifting frame, and the rolling wheel lifting frame is switched between an ascending state and a descending state; and the sheet materiallongitudinal cutting unit comprises a cutter body, the cutter body comprises a shell body, a saw blade, a first rotating shaft and a fore-leading cutter, the fore-leading cutter is installed on the shell body and located right ahead of a saw blade cutting path so as to form a cutting-up groove in a lower plane of wood before the saw blade is cut into the wood. According to the production line, a wood plank is conveyed to the sheet material longitudinal cutting unit through the aid of longitudinal rolling wheels, a direction turning process is changed from sliding friction to rolling friction,so that the abrasion of the friction resistance to the surface of the sheet material is greatly reduced, and the cutting-up groove is formed in the lower surface of the sheet material in advance by the fore-leading cutter after the direction turning is carried out, and the saw blade is used for carrying out subsequent cutting on the sheet material along the cutting-up groove so as to effectively prevent the sheet material from cracking.

Owner:福建兴恒机械科技有限公司

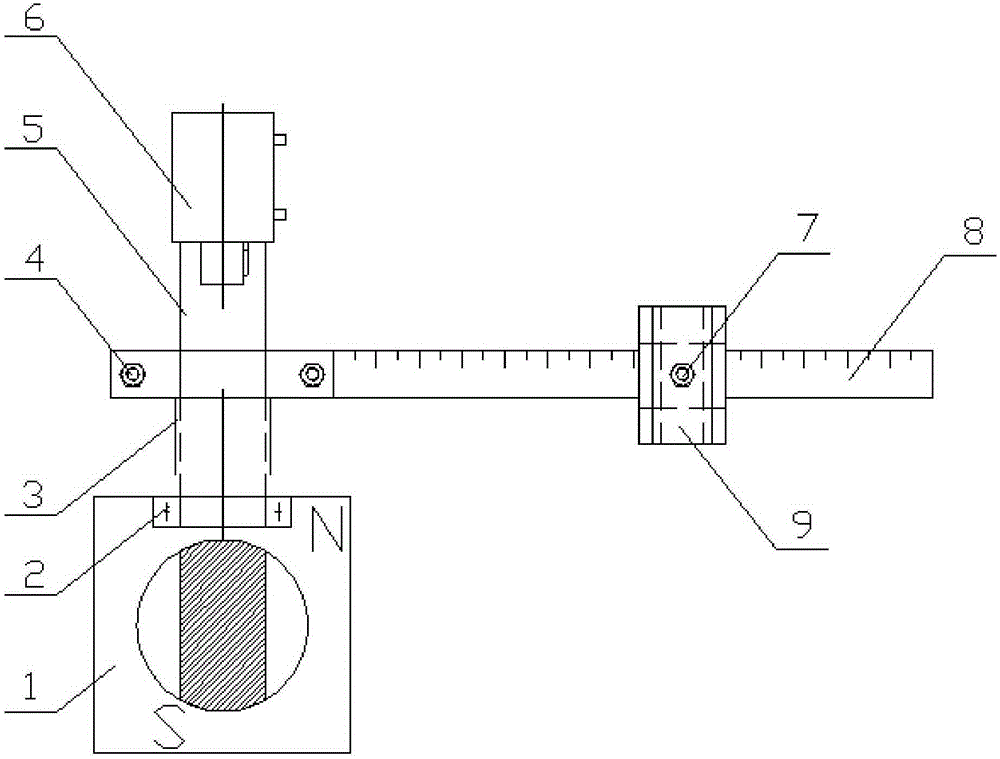

Assistant tool for fast cutting of steel plate

InactiveCN105195854AImprove cutting qualityBest cutting distanceWelding/soldering/cutting articlesMetal working apparatusSheet steelSteel plates

The embodiment of the invention provides an assistant tool for fast cutting of a steel plate, and aims to realize a purpose that the distance between a cutting nozzle and the steel plate is adjusted to be the best according to the thickness of the steel plate during steel plate cutting. According to the technical scheme, the assistant tool for fast cutting of the steel plate comprises a magnetic base, a supporting shaft, a shaft sleeve, a scale and a cutting nozzle sleeve, wherein the lower end part of the supporting shaft is connected with the magnetic base; the shaft sleeve sleeves the supporting shaft; the shaft sleeve can move up and down along the supporting shaft and is fixed to a preset position; the scale is positioned above the shaft sleeve and surrounds the outer surface of the supporting shaft; when the shaft sleeve moves up and down along the supporting shaft, the scale moves up and down along the supporting shaft and is fixed to a preset position; the cutting nozzle sleeve is mounted on the scale.

Owner:LAIWU IRON & STEEL GRP

Silicon carbide crystal rapid orientation method

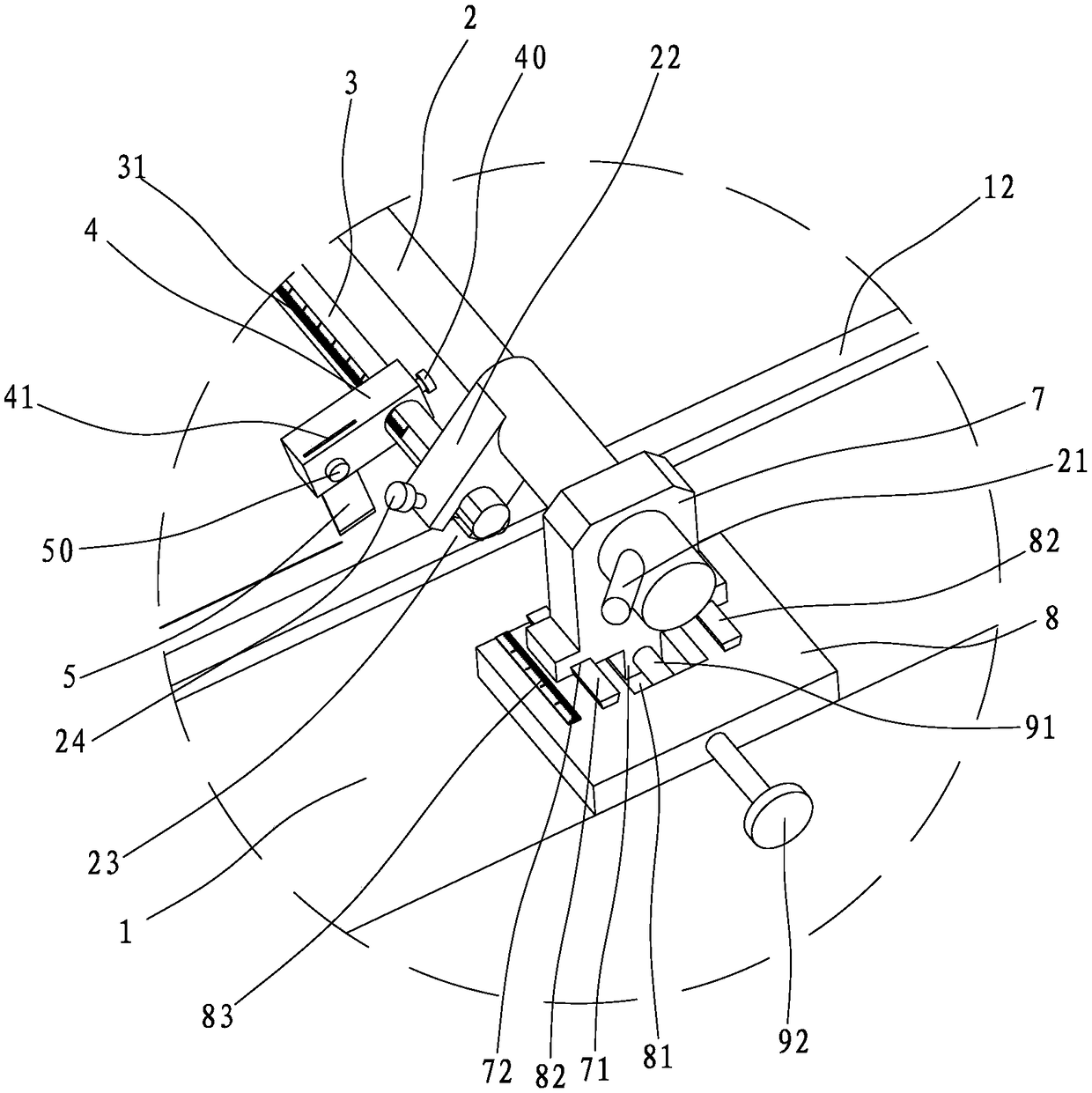

ActiveCN109203266AReduced operating requirementsEasy to operateWorking accessoriesFine working devicesOperabilityHorizontal and vertical

The invention discloses a silicon carbide crystal rapid orientation method. By utilizing a pre-cutting orientation fixture, the silicon carbide crystal bar bonded with a glass rod is directly fixed onthe platform of the pre-cutting fixture through glue, and then screws on the pre-cutting fixture, a worm wheel and a worm are combined to realize the movement of the platform on the pre-cutting fixture in the horizontal and vertical directions, so that the angle measurement and the orientation of the silicon carbide crystal bar in the horizontal and vertical directions can be realized, and the problems of complex operability, low precision, long time consumption of the orientation of the silicon carbide crystal bar before cutting can be solved, and the method is advantageous in that the operation is simple, the time consumption is short, the efficiency is high, the operation requirement for personnel is low, the precision is high, the glass rod is not needed to be grinded on a grinding machine, and the cost is low.

Owner:FUJIAN NORSTEL MATERIAL TECH CO LTD

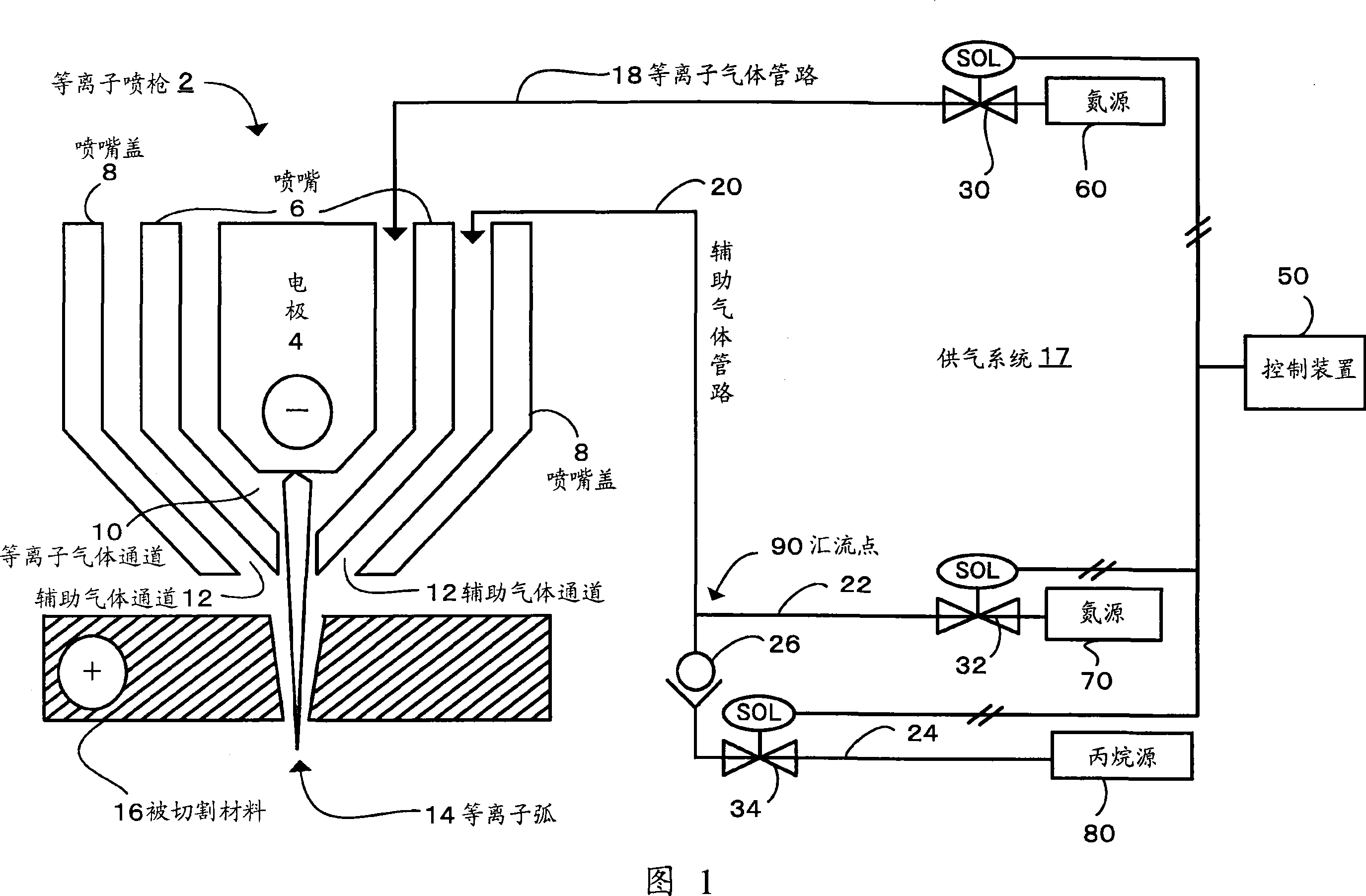

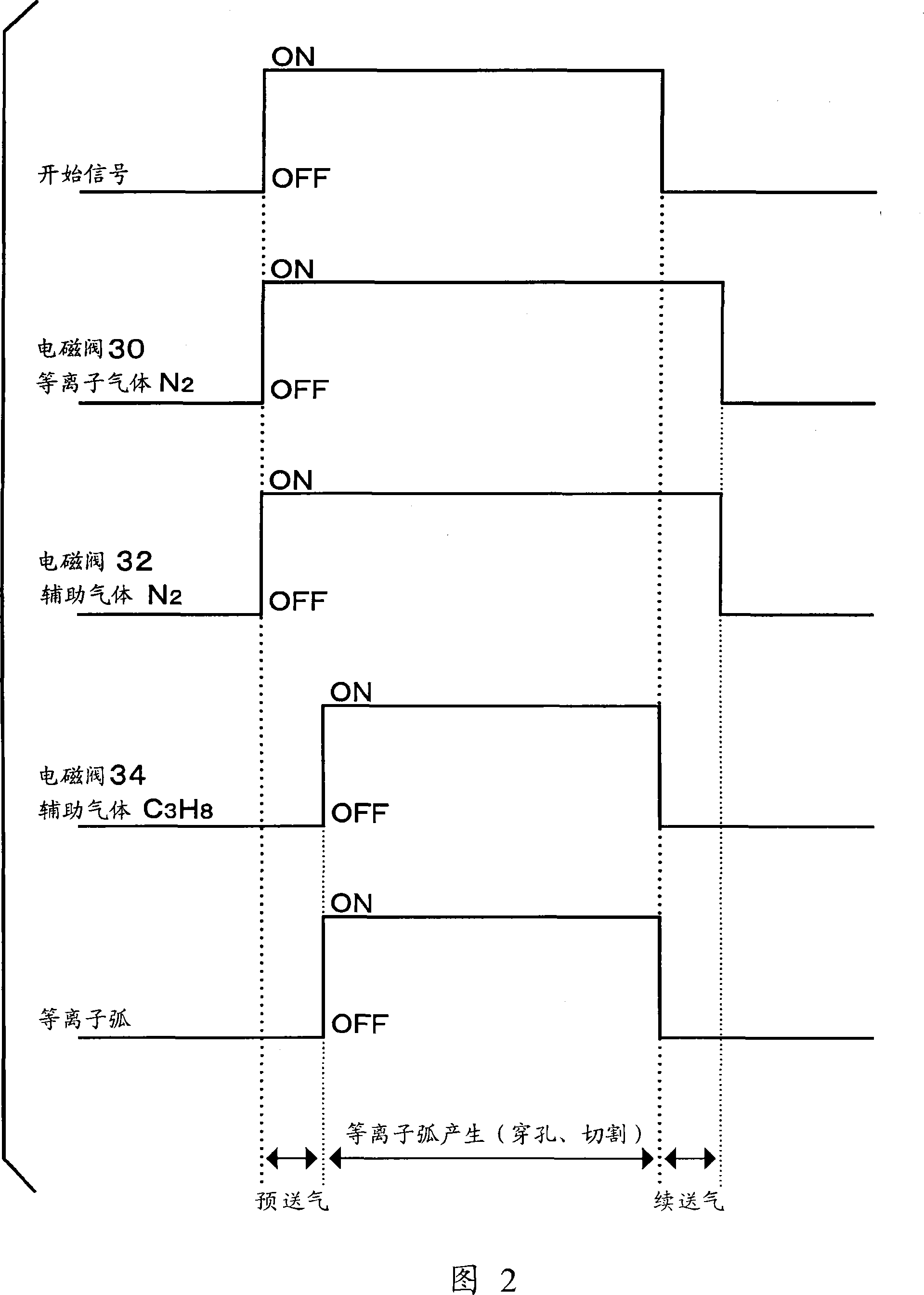

Plasma cutter

InactiveCN1993198AImprove cutting qualityPlasma welding apparatusWelding/soldering/cutting articlesNitrogenCombustible gas

A plasma cutter capable of cutting stainless steel while ensuring excellent quality. To plasma torch (6), there are fed as a plasma gas an inert gas (nitrogen) and as an assist gas a combustible gas (propane) that has a specific gravity greater than that of air and has reducing property or a mixed gas consisting of the above combustible gas (propane) and inert gas (nitrogen). The combustible gas (propane) contained in the assist gas is not fed in a preflow zone and afterflow zone and fed only in a plasma arc generation zone.

Owner:KOMATSU SANKI

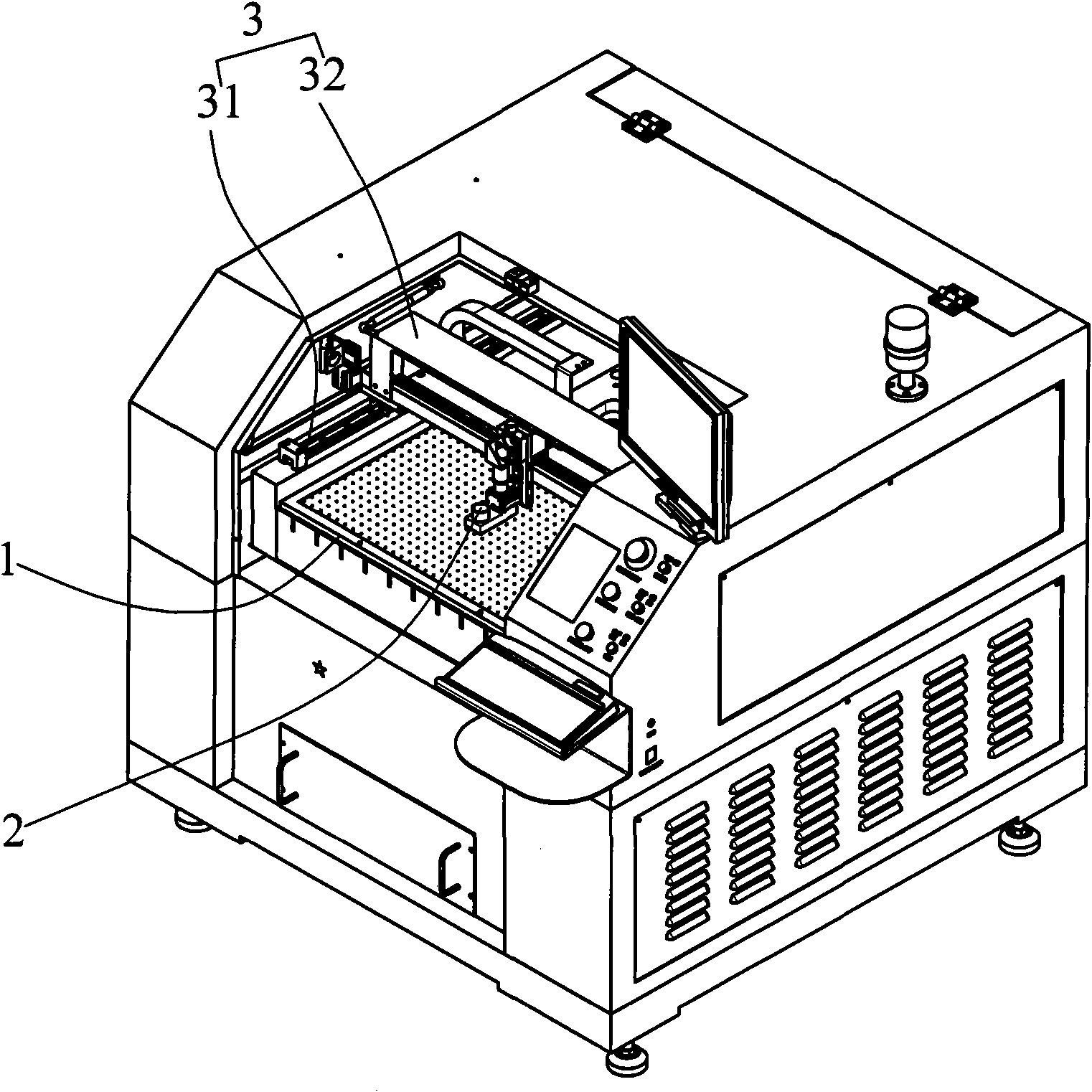

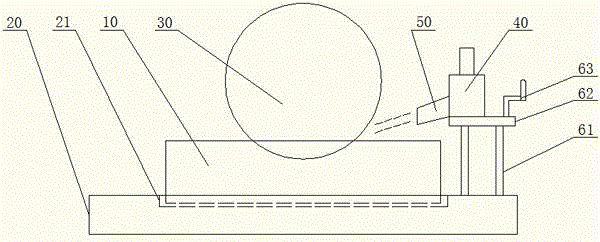

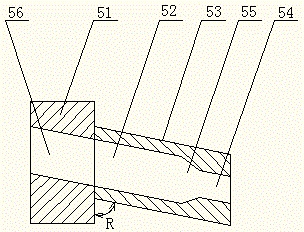

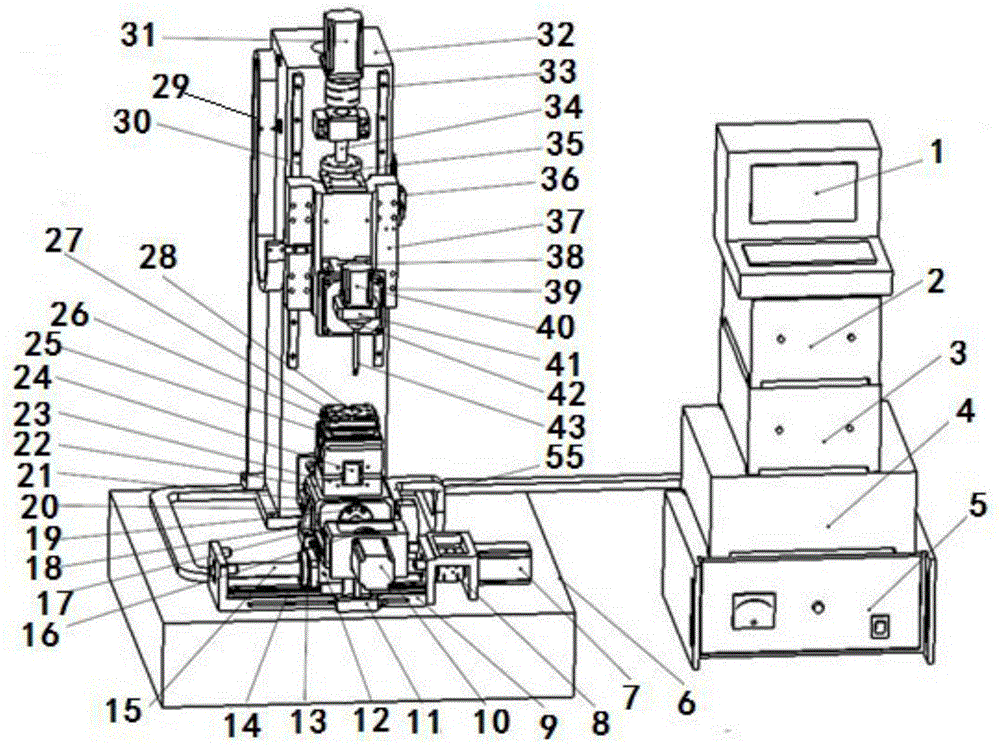

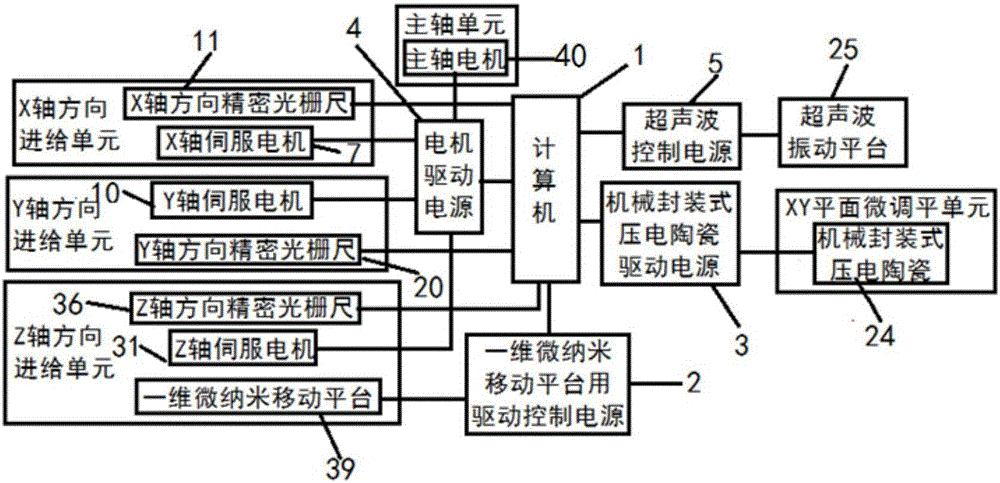

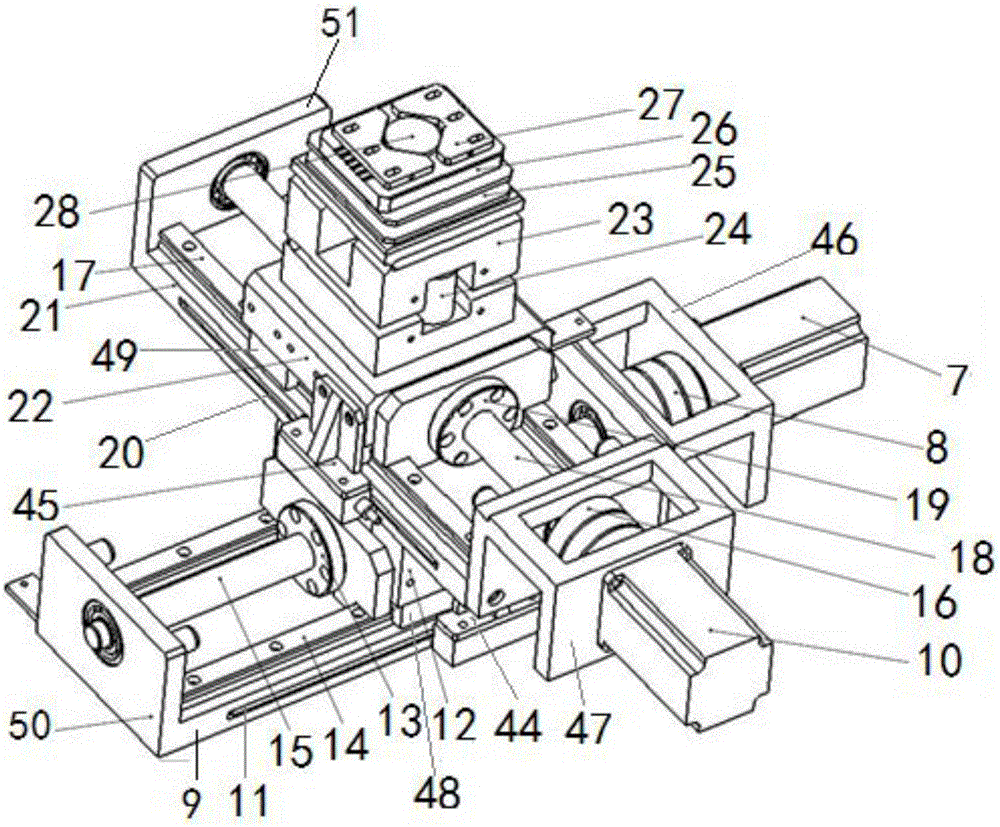

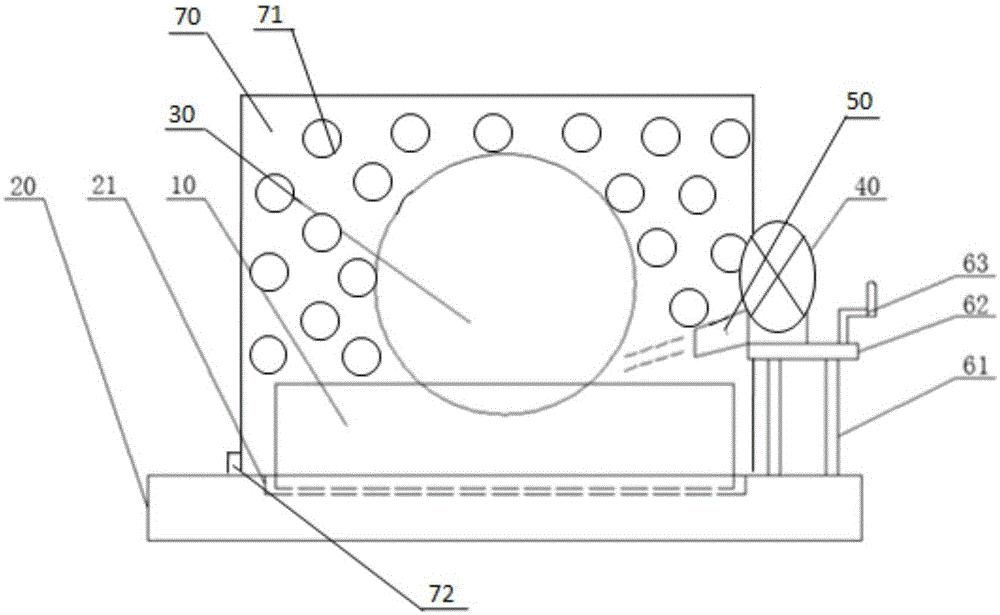

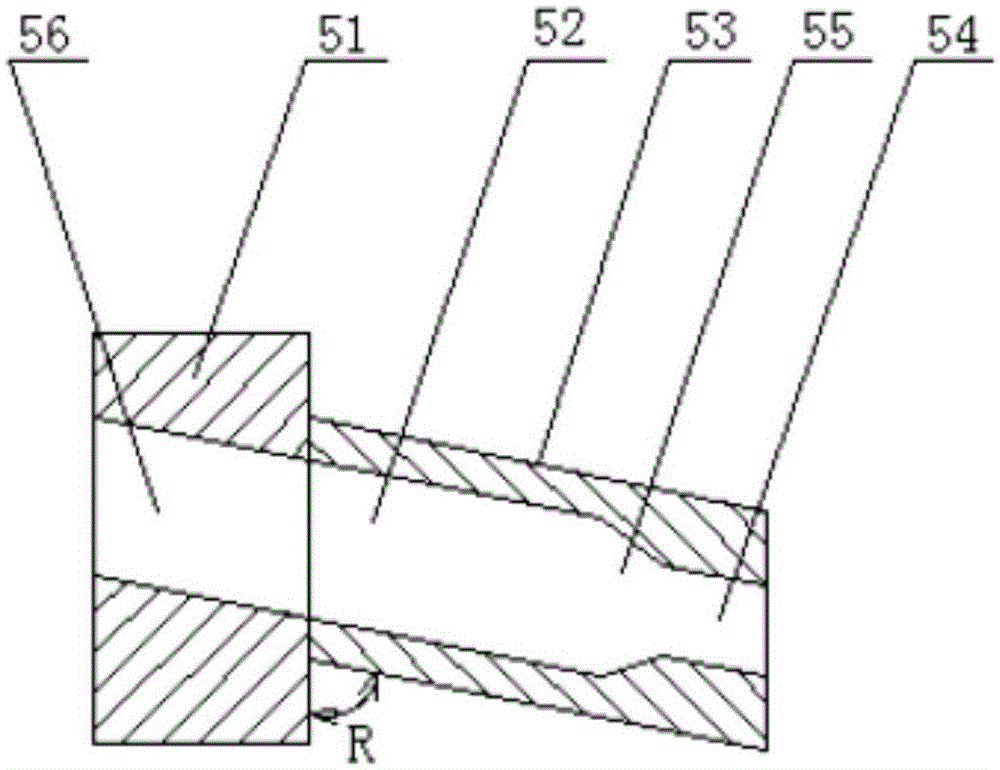

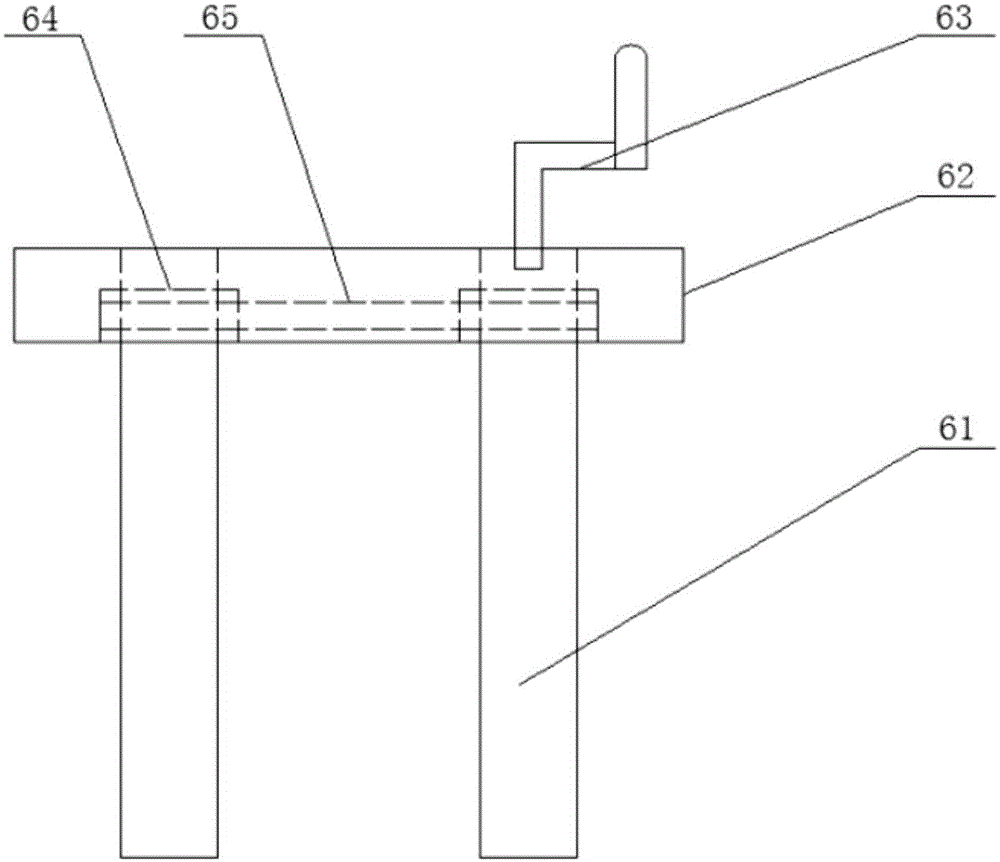

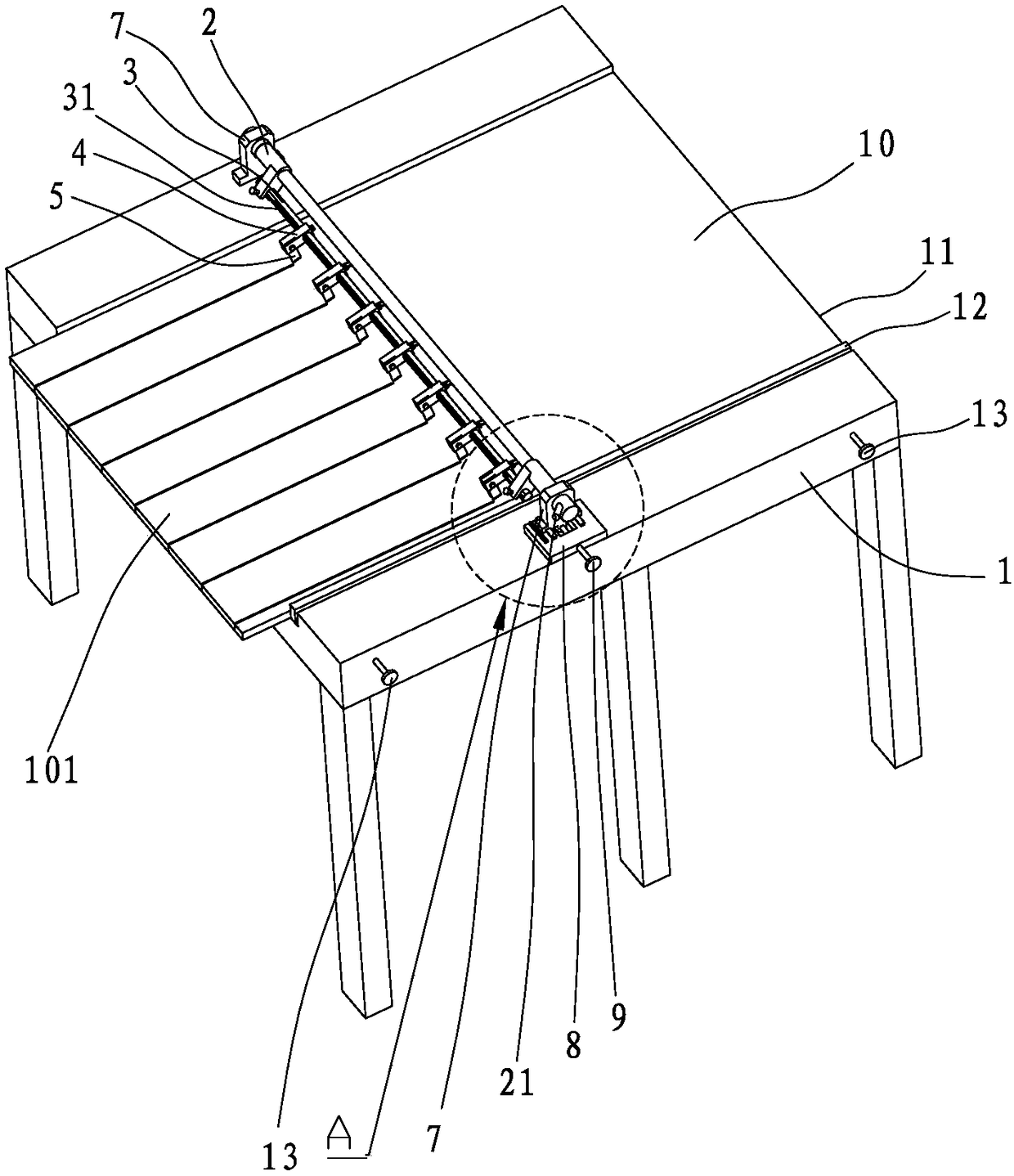

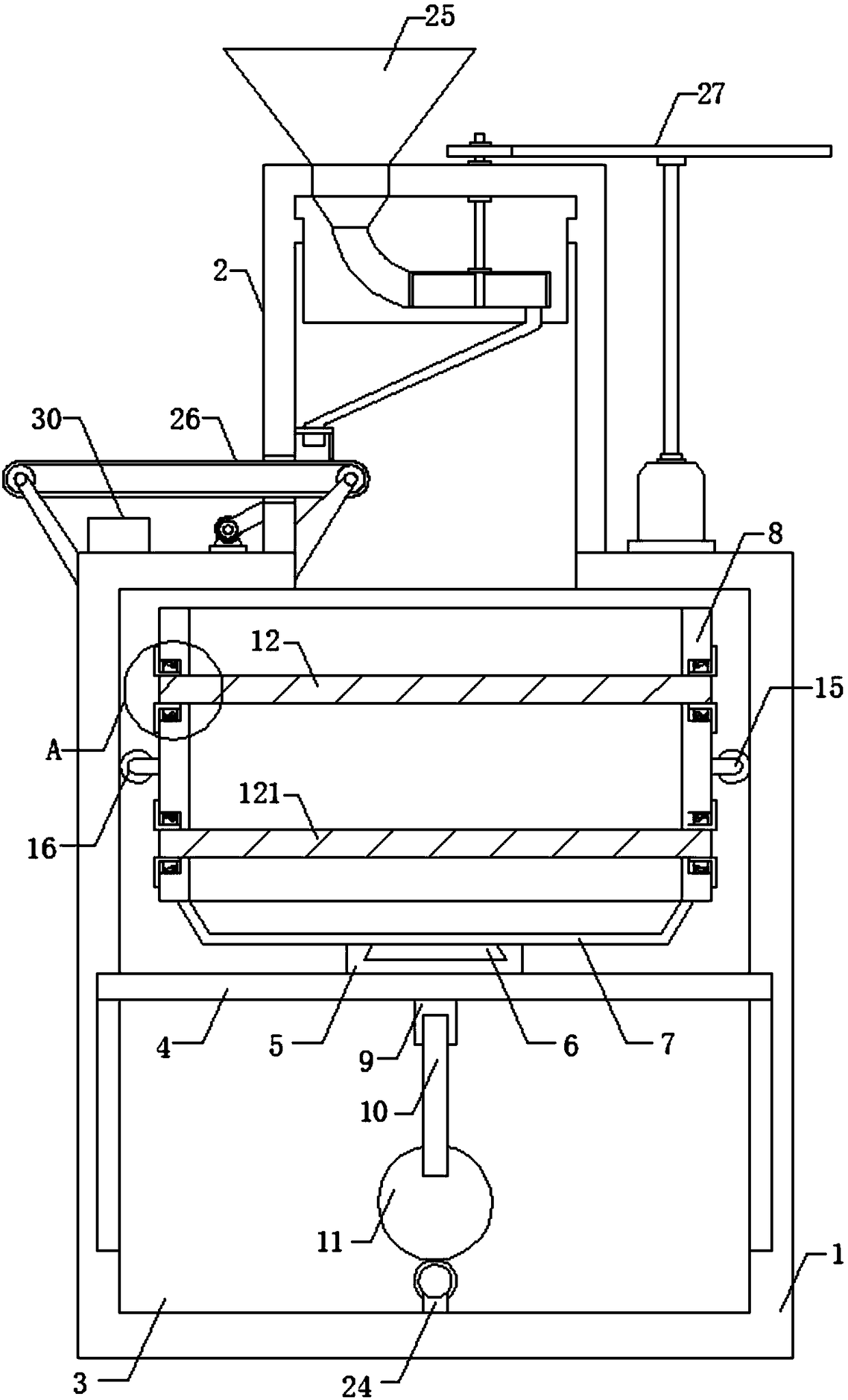

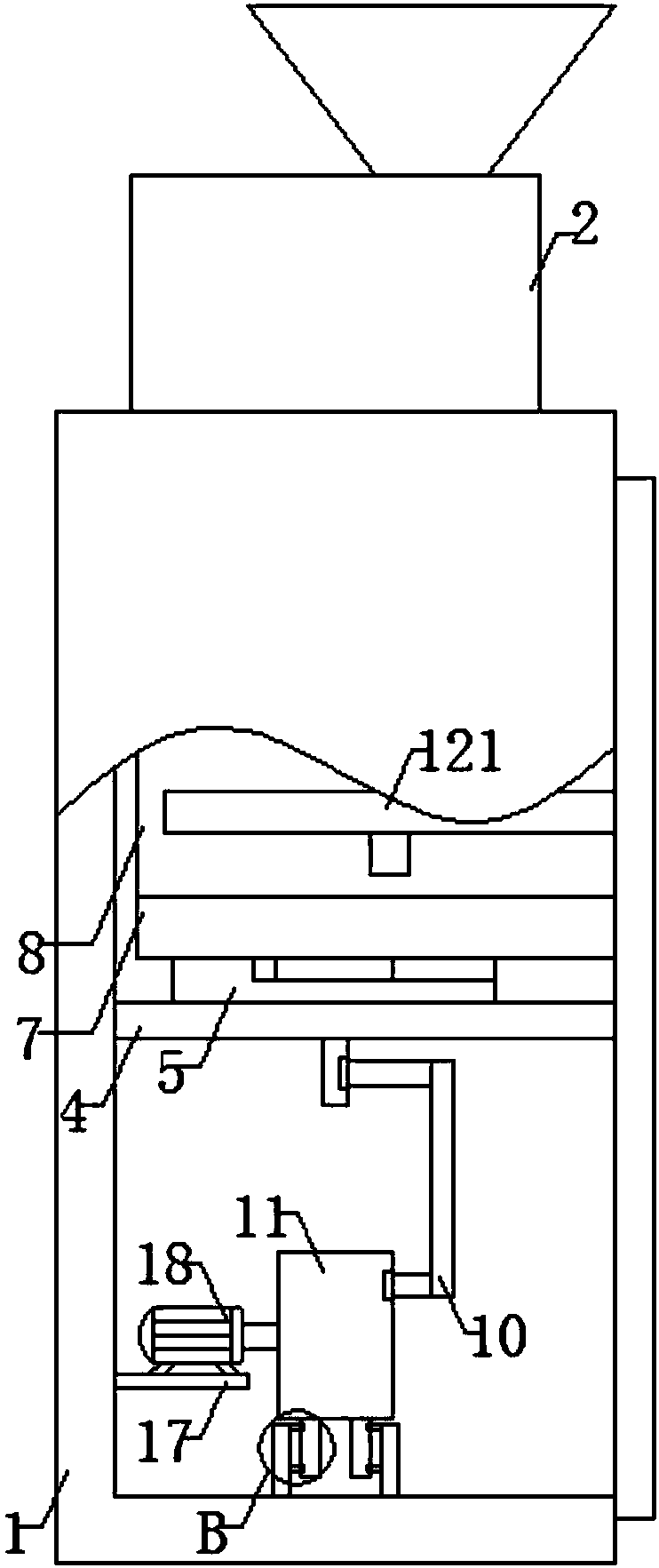

Hard and brittle material micro cutting processing system under ultrasonic effect

InactiveCN106493861AImprove cutting qualityMachining realizationWorking accessoriesStone-like material working toolsEngineeringPlastic property

The invention discloses a hard and brittle material micro cutting processing system under the ultrasonic effect. The system is formed by connecting an integrated machine-detection mechanism and a control mechanism through a drag chain a and a drag chain b. The system solves the problem that micro cutting processing is difficult to carry out on the plastic region of the hard and brittle material.

Owner:XIAN UNIV OF TECH

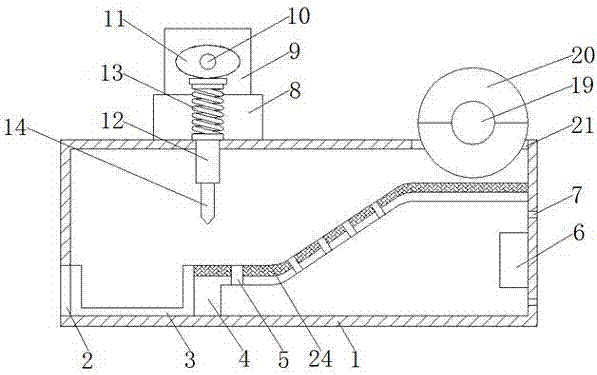

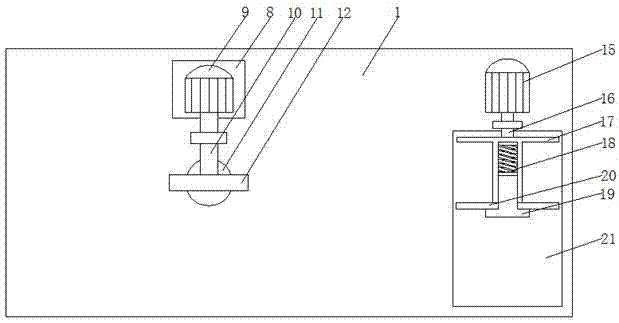

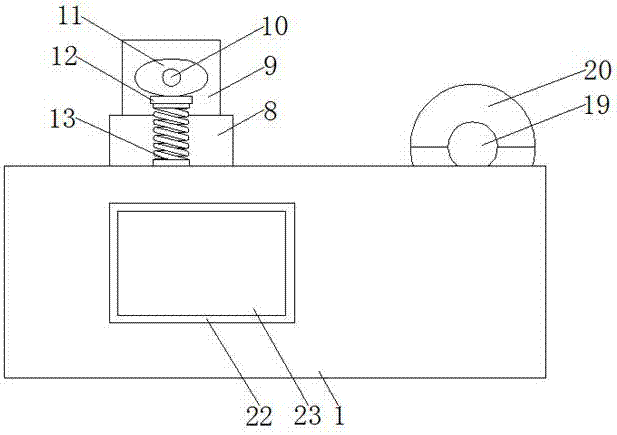

Negative pressure type paper cutting machine for paper making

InactiveCN107972082AThe solution cannot be fixedReduce mistakesMetal working apparatusCouplingPulp and paper industry

The invention discloses a negative pressure type paper cutting machine for paper making. The negative pressure type paper cutting machine comprises a box body. A discharging opening is formed in the bottom of one side of the box body. A discharging box is arranged at one side of the bottom of the inner wall of the box body. A guiding plate is fixedly connected to the other side of the bottom of the inner wall of the box body. One end of the guiding plate is fixedly connected with the inner wall of the box body. The upper surface of the guiding plate is provided with air inlets. An exhaust fanis fixedly mounted at the position, located below the guiding plate, of the inner wall of the box body. Air outlets are formed in the other side of the box body. A support table is fixedly connected to one side of the upper surface of the box body. A first motor is fixedly mounted on the upper surface of the support table. A first rotating shaft is fixedly connected to the output end of the firstmotor through a coupling. The negative pressure type paper cutting machine for paper making is provided with the exhaust fan and the guiding plate, so that when the exhaust fan is started, the negative pressure is generated inside the box body; a paper product is adsorbed onto the guiding plate to be fixed, and thus the problem that the paper product cannot be fixed is effectively solved; and paper cutting quality is improved.

Owner:张斐斐

Cutting cooling device

InactiveCN105108575AGuaranteed cooling effectPlay a role in overall coolingMetal sawing accessoriesMaintainance and safety accessoriesEngineeringWater cooling

The invention provides a cutting cooling device which comprises a cooling wall and a fan. The cooling wall is a hollow cavity, fixed to a workbench and parallel to a blade. A plurality of water spraying openings communicated with the cavity are formed in the surface, close to the blade, of the cooling wall, a water inlet communicated with the cavity is formed in the bottom of the side face of the cooling wall, and a switch is arranged at the water inlet. The fan is arranged on the workbench and located on the same horizontal line with the blade, and an air nozzle facing the blade feeding direction in the blade cutting process is arranged on the fan and blows out an air column to the blade. The dual-cooling mode adopting air cooling and water cooling is adopted, not only can the blade be cooled, but also the blade can be washed.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

Cutting structure for cutting slab rubber into rubber strips

The invention discloses a cutting structure for cutting slab rubber into rubber strips. The cutting structure for cutting the slab rubber into the rubber strips comprises a worktable, the worktable isprovided with a recessed flow channel in which the slab rubber can move longitudinally, and the worktable is also provided with a beam stretching over the flow channel; the beam is detachably connected with a mounting rod parallel to the beam, the mounting rod is provided in a sleeve mode with a plurality of mounting blocks which can slide and rotate on the mounting rod, the mounting rod is alsoprovided with first scale marks serving as the axial sliding reference of the mounting blocks, every mounting block is threadedly connected with a first fastening screw capable of fixing the mountingblock onto the mounting rod and detachably connected with a blade for cutting the slab rubber into the rubber strips; both sides of the worktable are provided with a left support and a right support for supporting the beam, the beam is provided with a wrench for wrenching the beam to rotate on the supports and to turn down the blades for cutting. The cutting structure for cutting the slab rubber into the rubber strips can pull the slab rubber to flow relative to the blades and accordingly cut the slab rubber to be cut into the rubber strips.

Owner:广东邦达实业有限公司

Medicinal solid screening device for removing metal powder

The invention discloses a medicinal solid screening device for removing metal powder. The medicinal solid screening device comprises a device body, wherein a cavity is formed in the device body, a third-stage screening mechanism is arranged in the cavity, the three-stage screening mechanism moves up and down in the cavity through a transmission mechanism, the third-stage screening mechanism is used in cooperation with the transmission mechanism, and the transmission mechanism can drive the three-stage screening mechanism to move up and down, so that the manual shaking action of a professionalpharmacist is simulated, and the discharging quality of the three-stage screening mechanism is high; and first openings are formed in the two sides of a surrounding frame plate in a penetrating mode,and the left end and the right end of a first pharmacopeia screen are respectively inserted into the two first openings, a second pharmacopeia screen is arranged below the first pharmacopeia screen, and after being screened, coarse materials are located on the first pharmacopeia screen, medium materials are located on the second pharmacopeia screen, and fine materials are located in a material receiving tray, and the first pharmacopeia screen, the second pharmacopeia screen and the material receiving tray form a three-stage material distribution.

Owner:全椒倚天机械制造有限公司

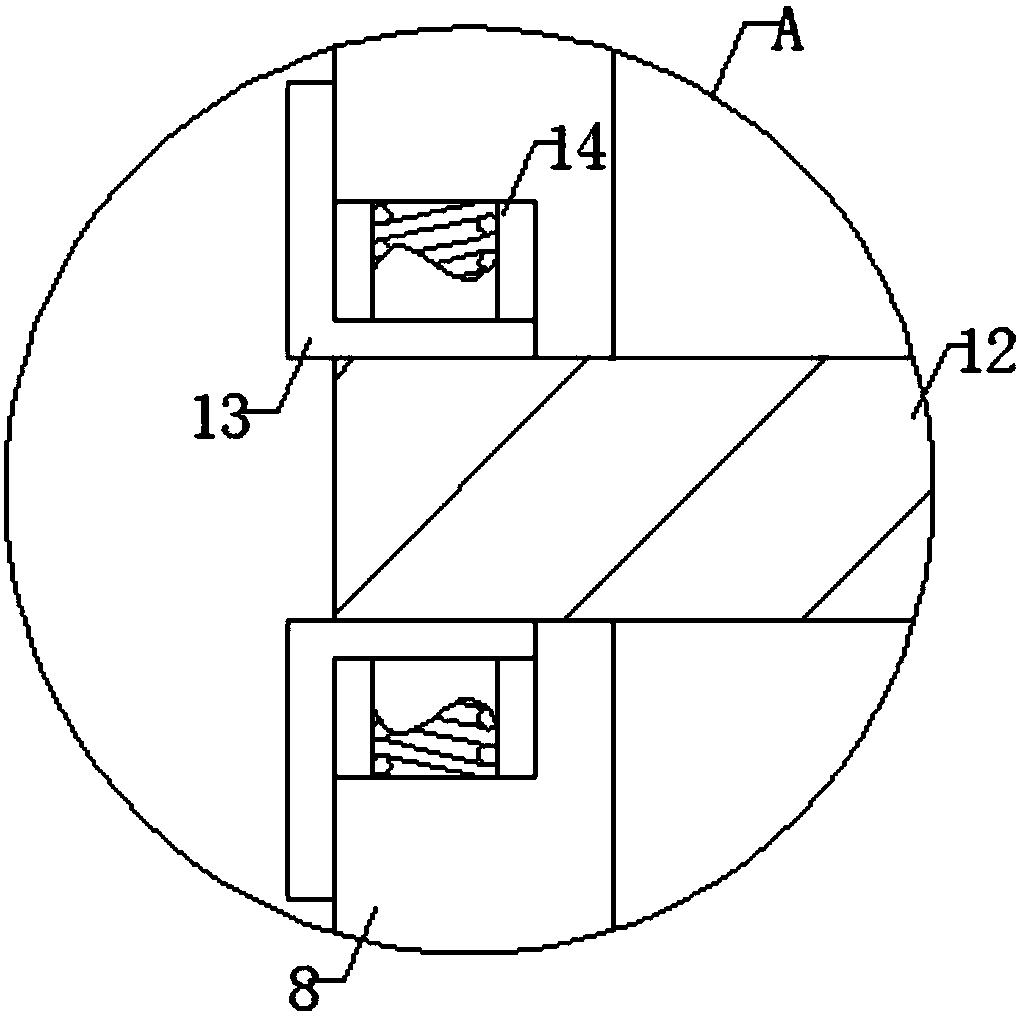

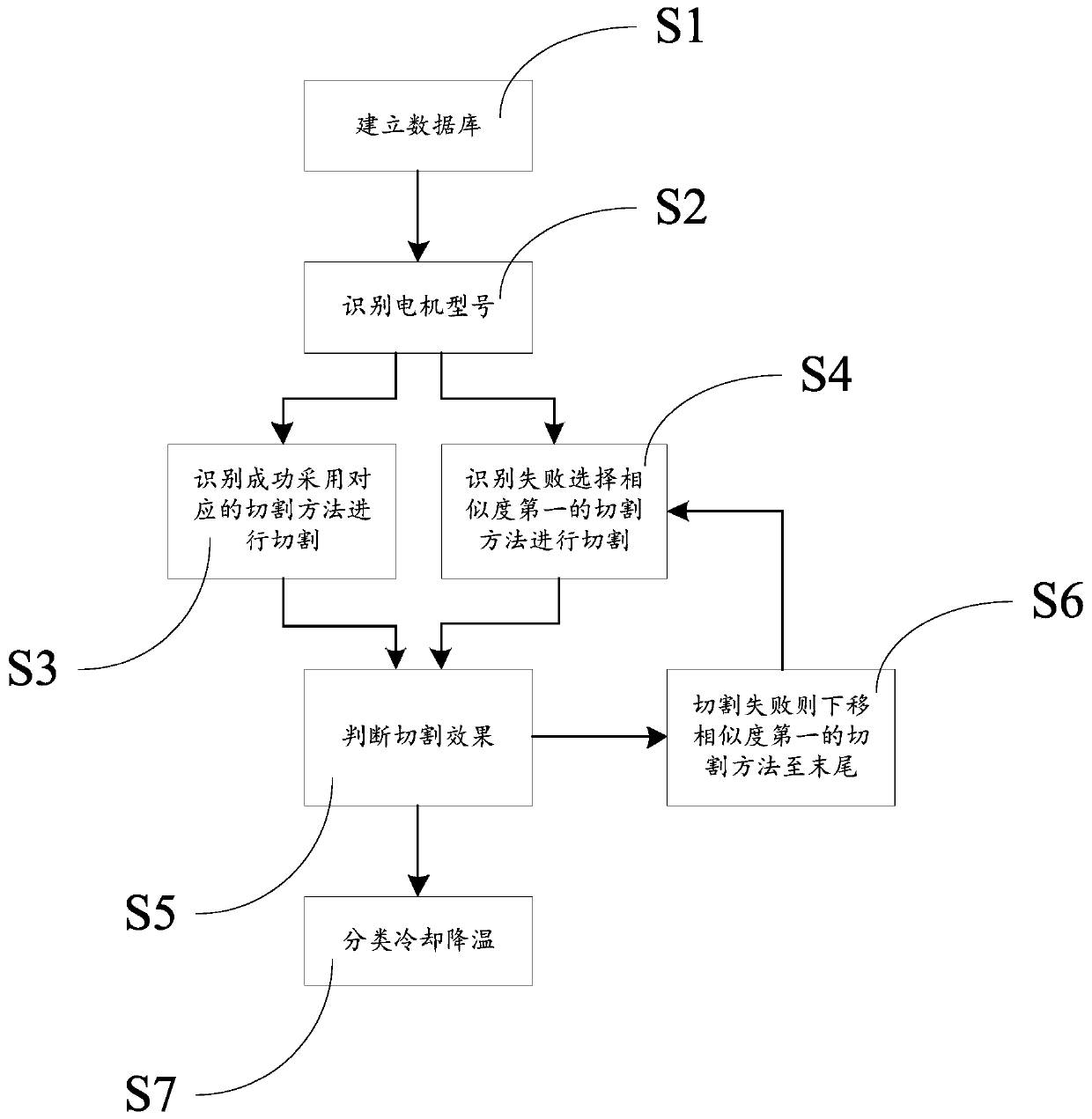

Intelligent cutting method of scrapped motor

ActiveCN110404923AImprove cutting efficiencyReduce labor intensitySolid waste disposalManufacturing dynamo-electric machinesEngineeringCutting-plane method

The embodiment of the invention discloses an intelligent cutting method of a scrapped motor. The intelligent cutting method comprises the following steps that S1, a database corresponding to the modelof the scrapped motor and the cutting method is established; S2, the model of the scrapped motor is identified according to the appearance of the scrapped motor, the step 3 is successfully entered, and if identifying is failed, the step 4 is entered; S3, the cutting method is acquired according to the model of the scrapped motor, the cutting machine is guided to cut, and the step 5 is entered; S4, sorting is carried out in the database according to the sequence from high to low of the appearance similarity of the scrapped motor, the cutting method corresponding to the model of the motor arranged at the first position is selected, the cutting machine is guided to cut, and the step 5 is entered; S5, whether cutting is successful or not is judged according to the appearance of the scrapped motor; and S6, the motor arranged in the first position is moved to the last position in the database for the motor which is failed in cutting. According to the method, automatic cutting can be adopted, so that the cutting efficiency is improved, the labor intensity is reduced, meanwhile, data can be continuously accumulated in the cutting process, and the cutting method is optimized.

Owner:河南格林循环电子废弃物处置有限公司 +1

Coating cutter shaft with diamond abrasive grain layer

PendingCN108214958AReduce wearImprove cutting accuracyVacuum evaporation coatingSputtering coatingGas phaseTitanium carbide

The invention provides a coating cutter shaft with a diamond abrasive grain layer. The coating cutter comprises a cutter shaft body and a diamond grinding grain layer fixedly arranged on the surface of the cutter shaft body, the coating cutter shaft has higher holding force to the cutter flywheel, relative to the common metal cutter shaft, the coating cutter shaft with the diamond abrasive grain layer is good in wear resistance, the service life is long, and the cutter flywheel installed by using the coating cutter shaft is more stable in glass cutting. The invention further provides a methodfor manufacturing the coating cutter shaft, and specifically, a braze welding sub-layer is brazed to the surface of a cutter shaft body, and then a titanium carbide sub-layer is deposited on the brazing sub-layer in a physical vapor deposition mode, raw materials used by the method are wide in source, the diamond abrasive particles can be uniformly brazed on the surface of the cutter shaft body byusing the method, and a titanium carbide sub-layer can be uniformly arranged on the surface of the brazing sub-layer. The method is simple and convenient, the conditions are mild, the diamond abrasive particles are firmly and stably arranged in the brazing sub-layer and the titanium carbide sub-layer.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com