Hard and brittle material micro cutting processing system under ultrasonic effect

A kind of hard and brittle material, micro-cutting technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of hard and brittle materials plastic domain micro-cutting processing difficulties, to achieve the effect of improving the quality of cutting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

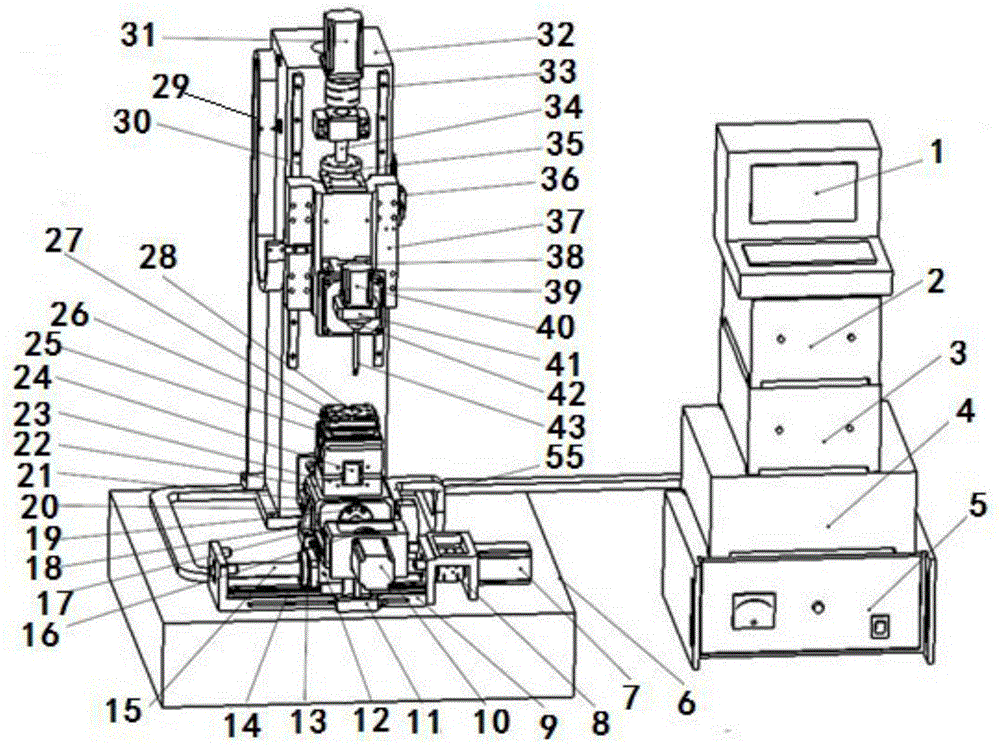

[0028] The micro-cutting processing system of hard and brittle materials under the ultrasonic action of the present invention has a structure such as figure 1 As shown, it consists of a mechanical-detection integration mechanism and a control mechanism connected by drag chain a29 and drag chain b55.

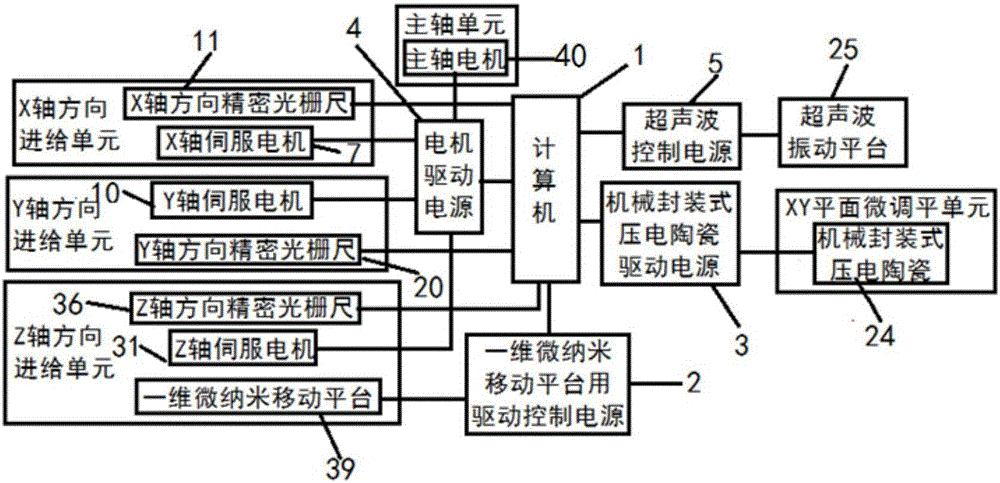

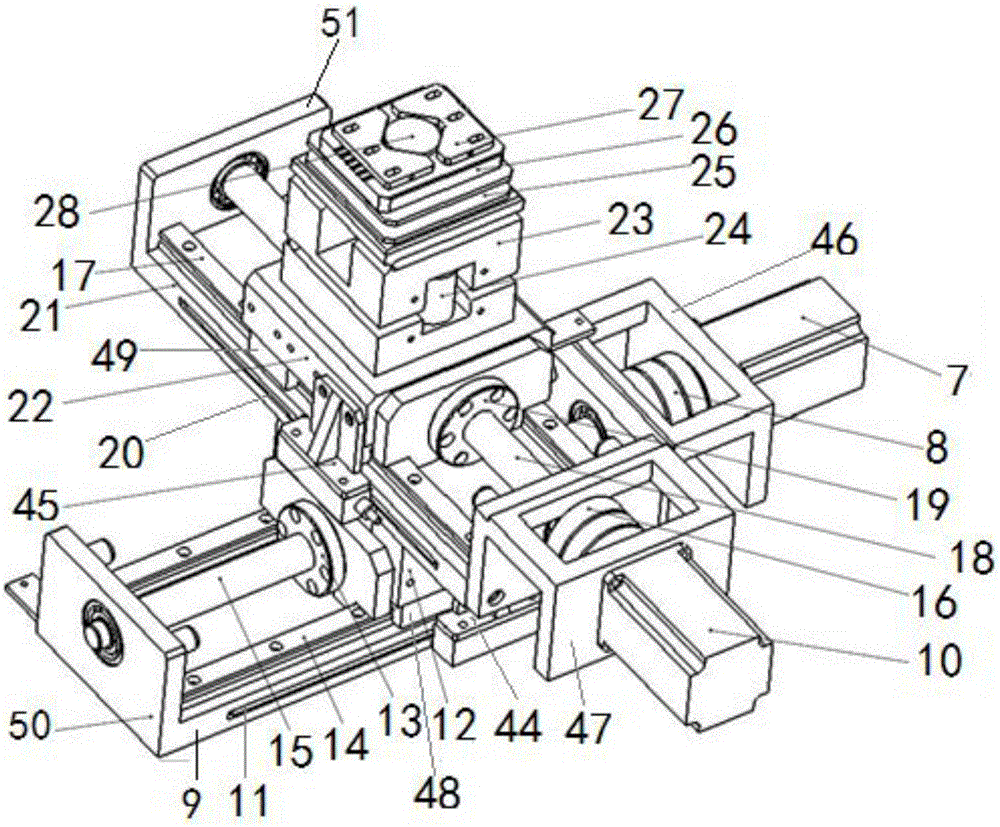

[0029] The mechanical-detection integration mechanism includes a fuselage body, and the fuselage body is composed of a horizontally arranged base 6 and a column 32 vertically arranged on the upper surface of the base 6; the upper surface of the base 6 is provided with an X-axis direction Feed unit, the X-axis direction feed unit is connected with the Y-axis direction feed unit, the Y-axis direction feed unit is provided with an XY plane fine-leveling unit, and the XY-plane fine-leveling unit is provided with an ultrasonic vibration platform 25. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com