Cutting cooling device

A cooling device and cooling wall technology, which is applied in the attachment devices of sawing machines, metal sawing equipment, maintenance and safety accessories, etc., can solve the problems of not being able to cool the blade and affecting the cutting quality of the product, so as to improve the cutting quality and ensure the cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical features, technical content and technical effects of the present invention, the accompanying drawings of the present invention will now be described in more detail in conjunction with the embodiments.

[0019] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

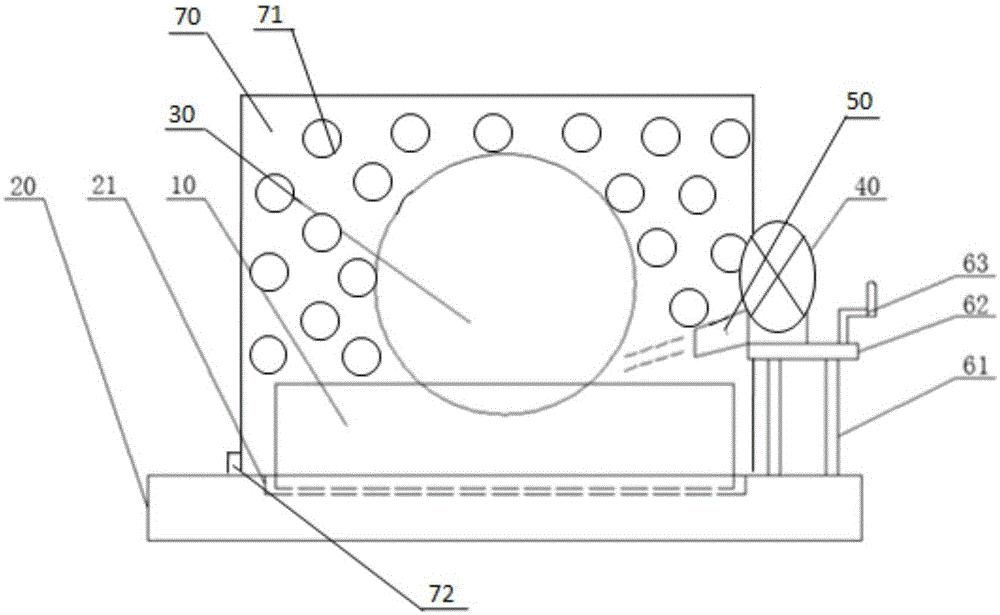

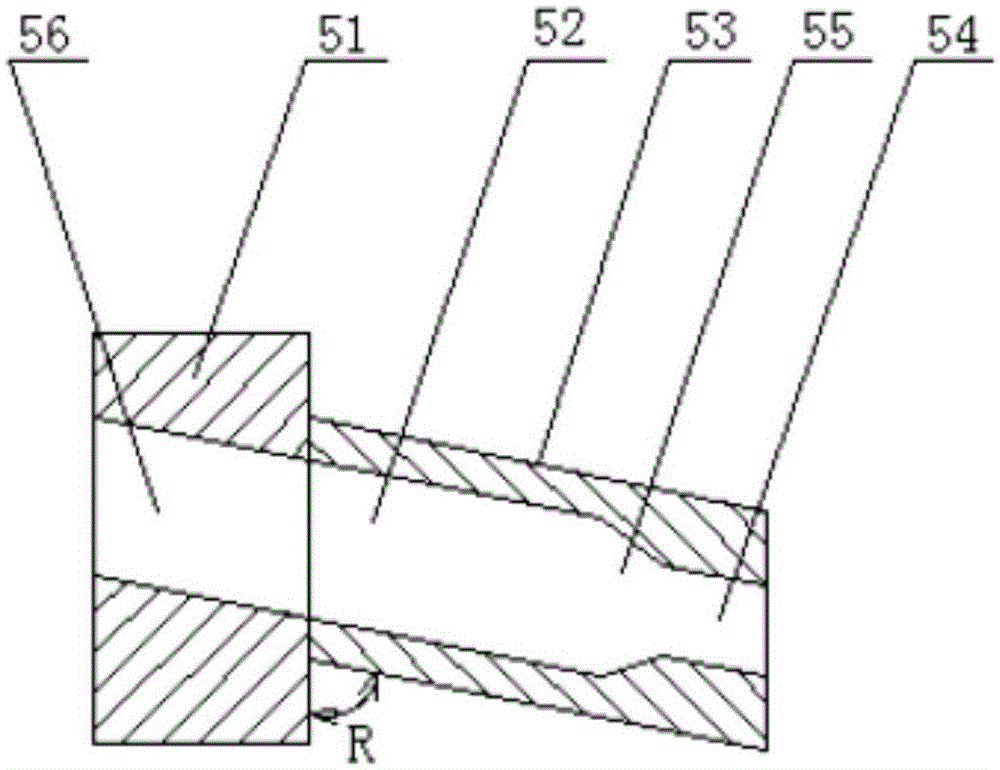

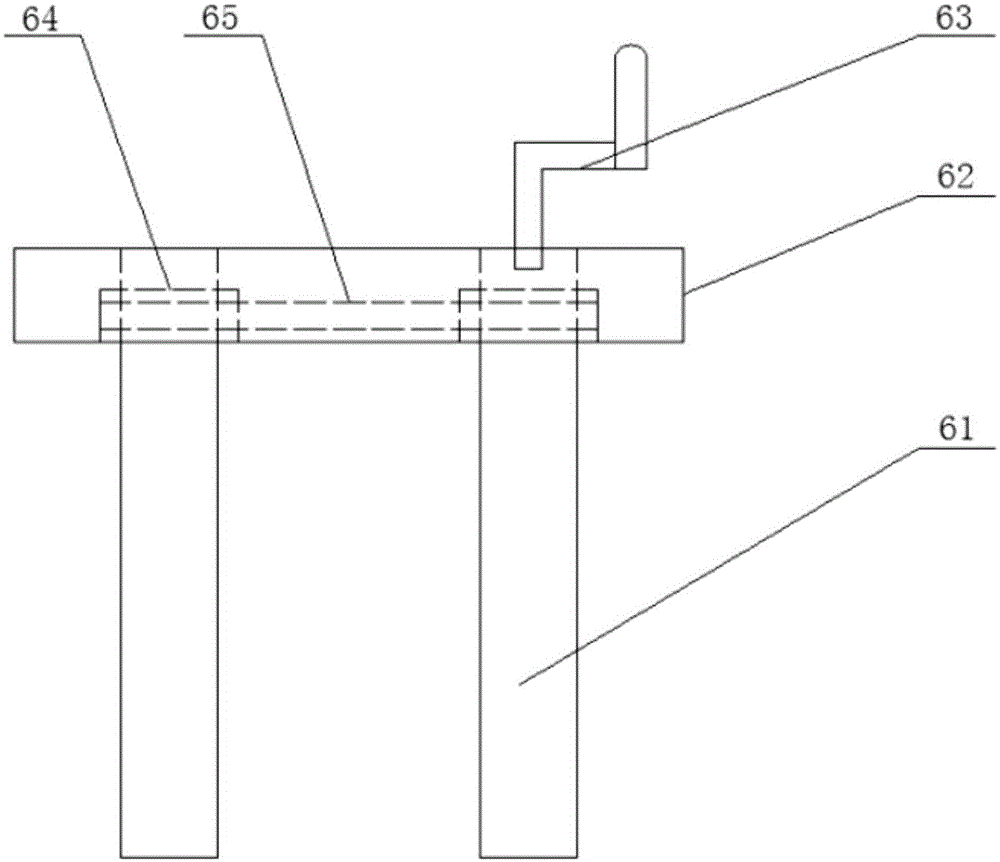

[0020] like Figure 1-3 As shown, a cutting cooling device includes a workbench 20 for placing the product 10 to be cut, and a blade 30 for cutting the product 10 on the workbench 20. For the convenience of the blade 30, the product 10 is cut accurately, A positioning groove 21 can be provided on the workbench 20 , and the product 10 is placed in the positioning groove 21 to position the product 10 . In order to completely cool the blade 30, the workbench 20 is provided with a blower fan 40 positioned on the same horizontal line as the blade 30 among the present invention, and the blower fan is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com