Intelligent cutting method of scrapped motor

A technology of intelligent cutting and cutting methods, which is applied in the direction of manufacturing motor generators, electrical components, electromechanical devices, etc., can solve the problems of difficult automatic cutting, low disassembly efficiency, and high labor intensity of workers, so as to improve cutting efficiency and optimize cutting method, the effect of improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

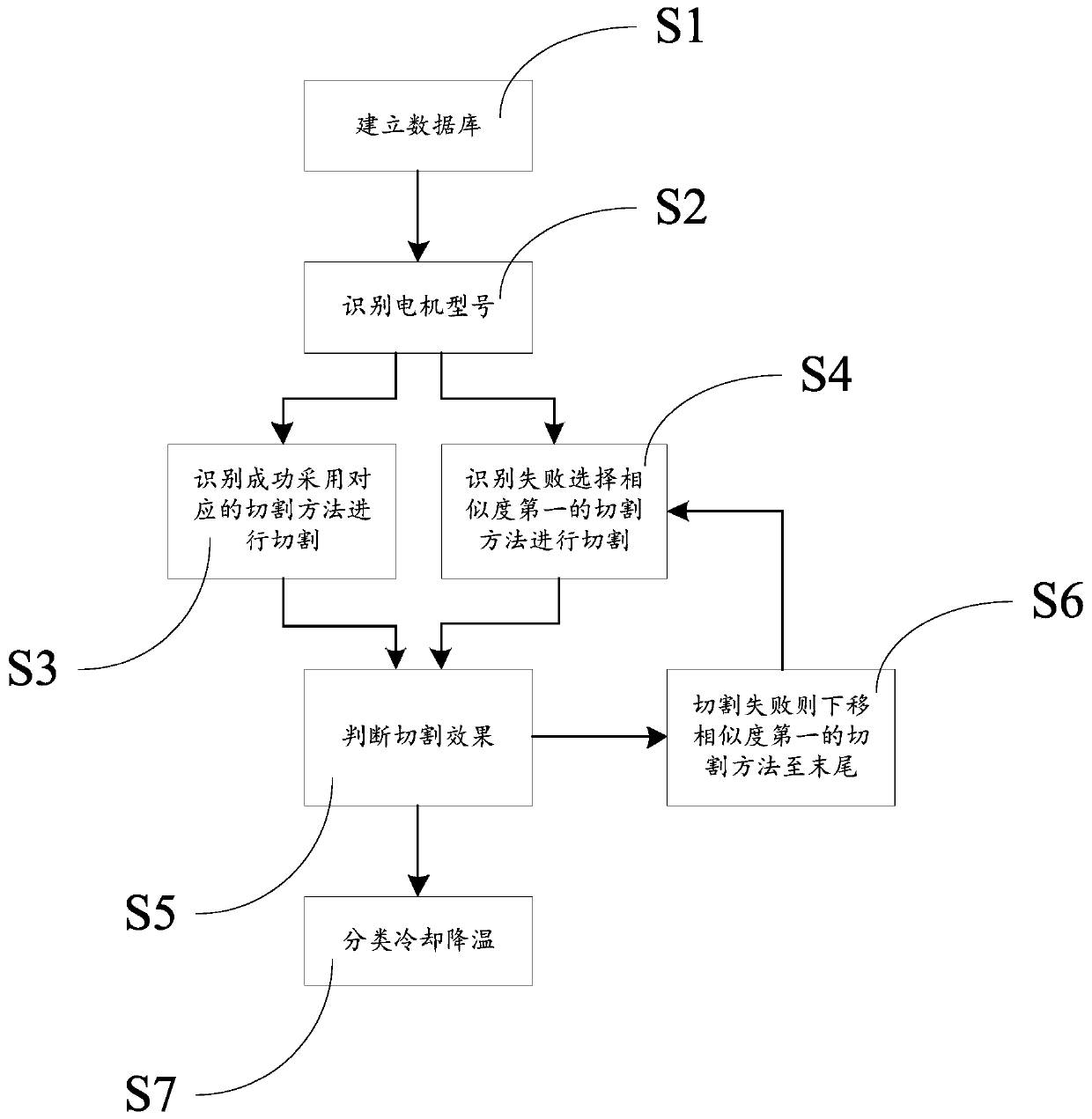

[0011] See figure 1 , figure 1 It is a flowchart of an embodiment of the intelligent cutting method for scrap motors provided by the present invention.

[0012] The intelligent cutting method of scrap motors includes the following steps:

[0013] Step S1, establishing a database corresponding to models of scrapped motors and cutting methods. Existing motor recycling factories have accumulated a large amount of data on the cutting methods of different types of motors during the long-term dismantling and recycling operations in the past, so as to establish a database, which includes motor models and their corresponding cutting methods.

[0014] Step S2, when cutting the motor shell, firstly identify the model of the scrapped motor, so as to determine the corresponding cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com