Method and system for optimizing drilling parameters

A technique of drilling parameters and indexes, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of not being able to maintain high efficiency and provide drilling optimization strategies, and achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

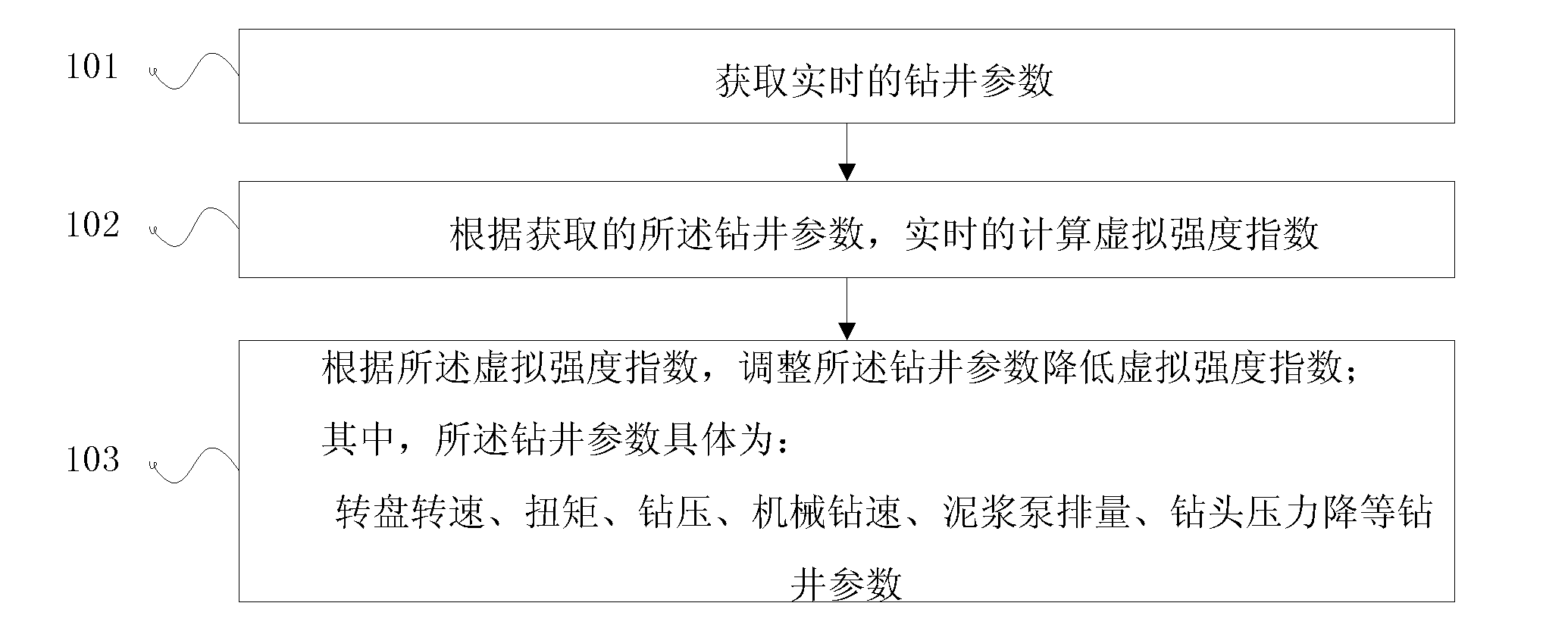

[0040] Embodiment 1 of the present invention proposes a kind of method of drilling parameter optimization, and its flow process is as follows figure 1 shown, including:

[0041] Step 101: Obtain real-time drilling parameters;

[0042] Step 102: Calculate the virtual strength index in real time according to the obtained drilling parameters;

[0043] Step 103: According to the virtual strength index, adjust the drilling parameters to reduce the virtual strength index;

[0044] Wherein, the drilling parameters are specifically:

[0045] Drilling parameters such as rotary speed, torque, pressure on bit, ROP, displacement of mud pump, pressure drop of bit, etc.

[0046] The embodiment of the present invention uses the drilling parameters fed back by real-time geological environment changes, and calculates the virtual strength index VSI in real time. According to the virtual strength index VSI related to the real strength index, the drilling parameters are adjusted in real time t...

Embodiment 2

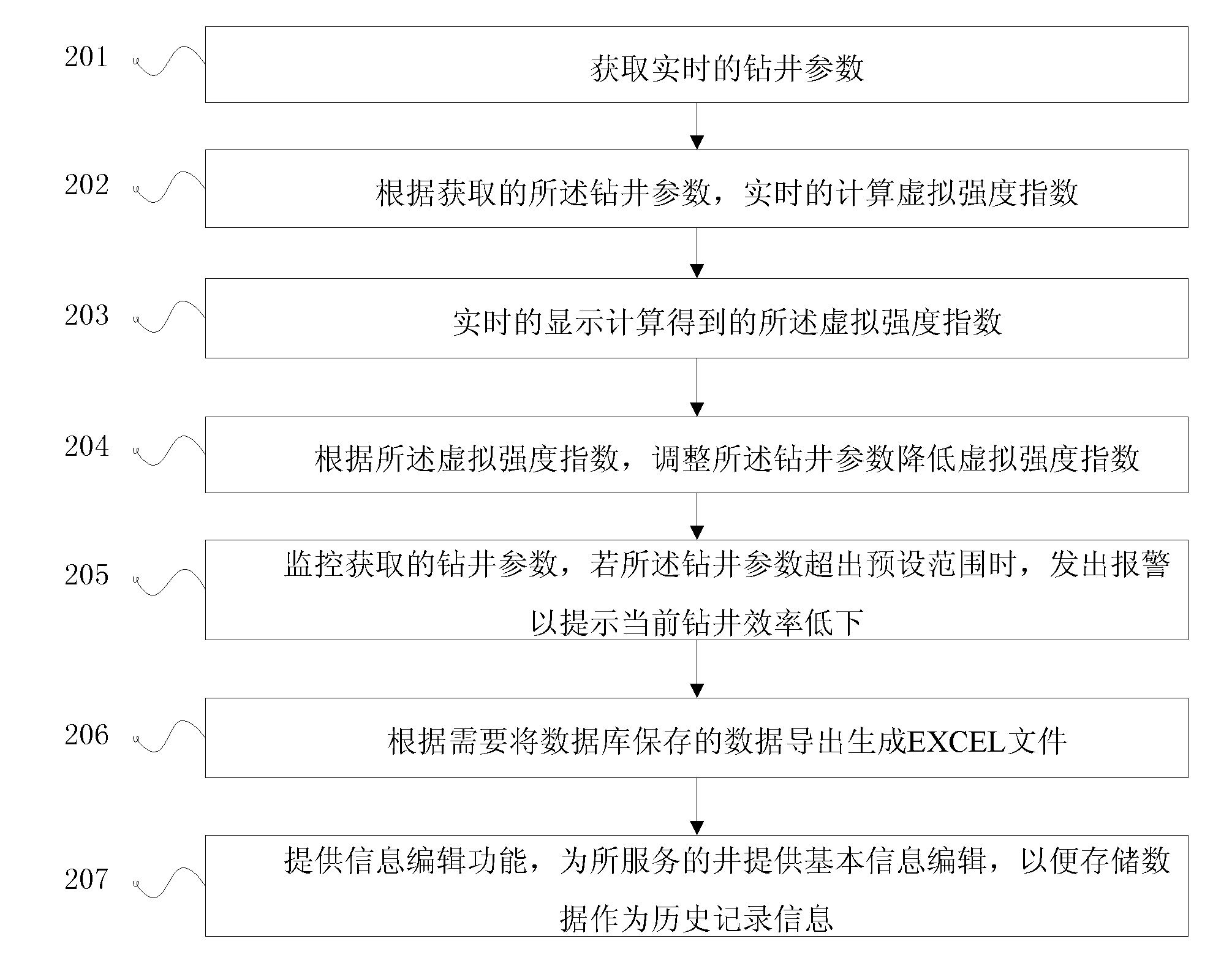

[0048] Embodiment 2 of the present invention proposes a kind of method of drilling parameter optimization, and its flow process is as follows figure 2 shown, including:

[0049] Step 201: Obtain real-time drilling parameters.

[0050] During the drilling process, the mud logging tool acquires and saves various drilling parameters in real time. Mud logging instrument is a set of special mud logging equipment, which is used to record drilling engineering parameters and drilling fluid parameters. Drilling engineering parameters and drilling fluid parameters are used to monitor drilling safety and provide optimized parameters for drilling. It is mainly composed of computer system, sensor, chromatograph and other parts. It is an indispensable and important part of mud logging and drilling construction.

[0051] Connect the computer or server equipped with the VSI (Virtual Strength Index, virtual strength index) drilling parameter optimization software system to the interface o...

Embodiment 3

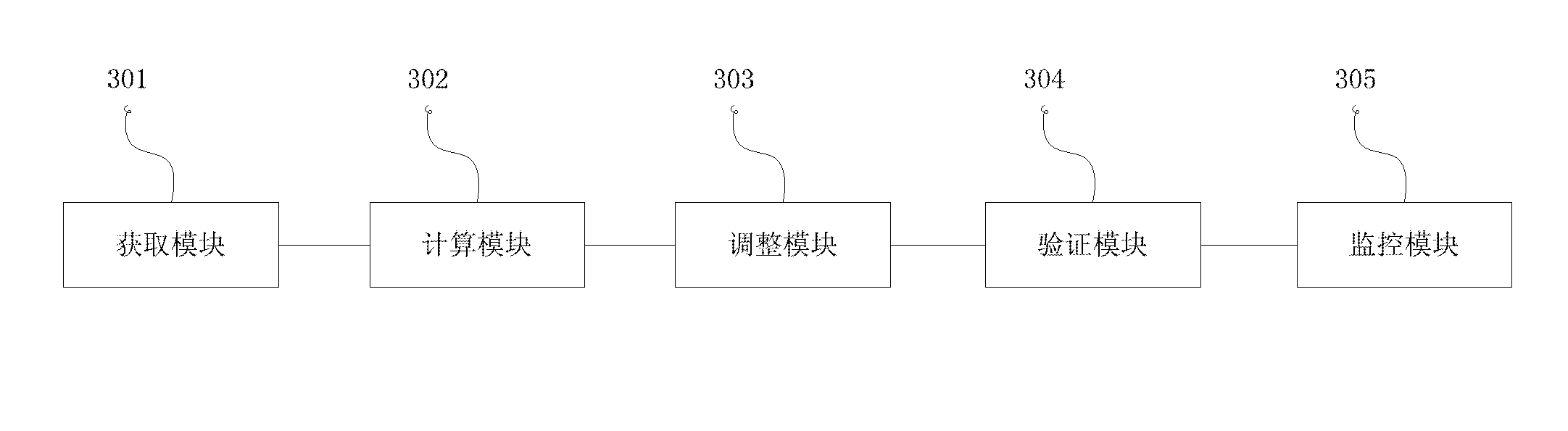

[0084] Embodiment 3 of the present invention proposes a kind of drilling parameter optimization device, its structure is as follows image 3 shown, including:

[0085] The obtaining module 301 is used to obtain real-time drilling parameters.

[0086] The calculation module 302 is used for calculating the virtual intensity index in real time according to the obtained drilling parameters.

[0087] The calculation module 302 is specifically used for:

[0088] VSI = 40 WOB e π d b 2 + 110 T × N ROP × d b 2 + 4 ηΔ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com