Digital-control laser cutting head and method for making same

A digitally controlled laser and cutting head technology, applied in the direction of manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problem of high strength, high pressure resistance and high thermal conductivity of laser cutting head, loss of increased pressure and light energy, Affect cutting accuracy and cutting quality, etc., to improve cutting quality and cutting efficiency, improve cooling effect and pressure resistance, and achieve good water and air sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

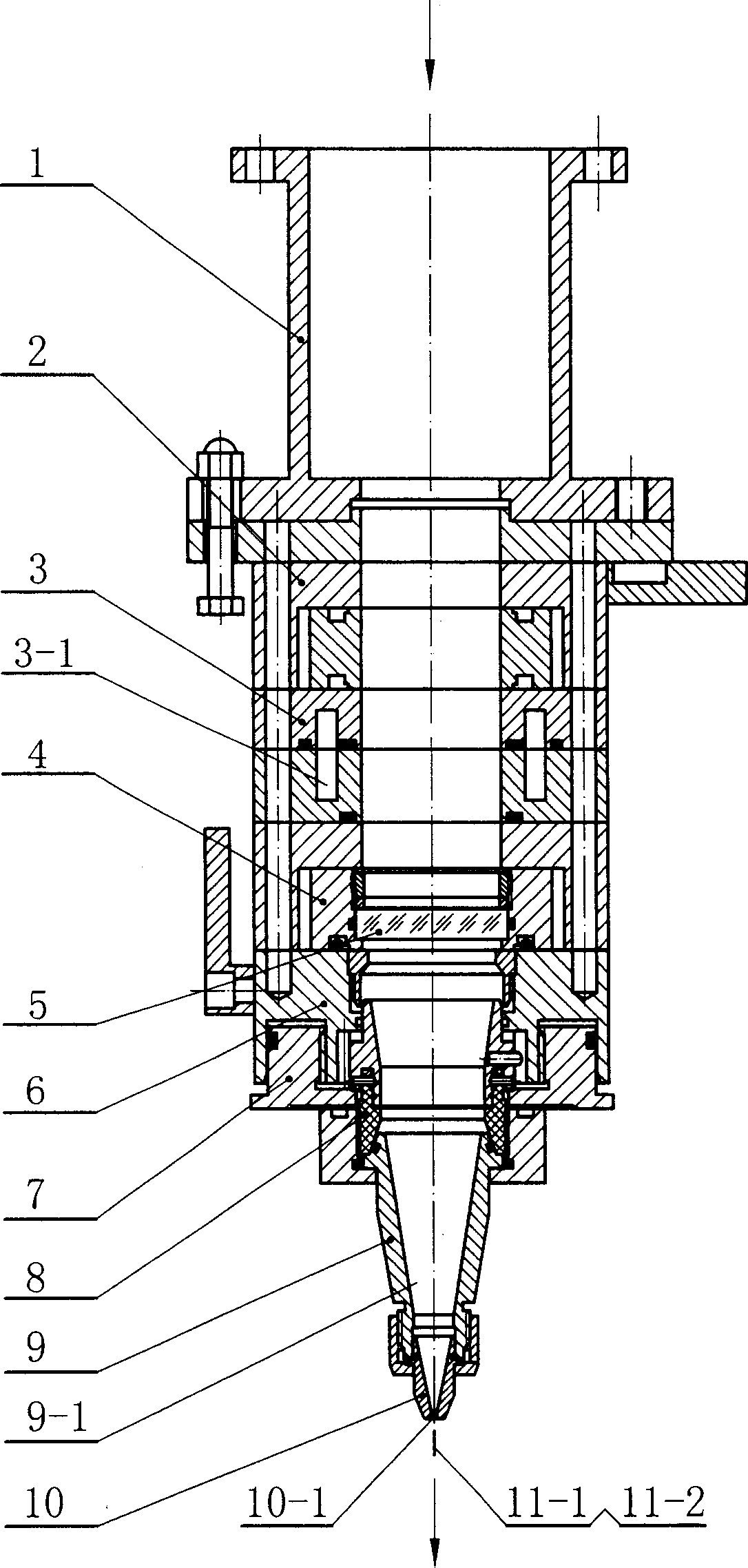

[0011] Such as figure 1 As shown, the CNC laser cutting head of the present invention is mainly composed of a connecting pipe 1, a mirror holder box 2, a water cooling assembly 3, a focusing mirror holder assembly 4, a focusing lens 5, a ventilation assembly 6, an adjusting nut 7, a high-strength insulating spacer sleeve 8, a transition Main components such as mouth 9, cutting nozzle 10 are formed. The inner hole 9-1 of the transition nozzle is an inverted cone with a taper of 18°; the upper and lower parts of the water cooling assembly are integral annular cooling water channel structures, and the annular cooling water tank 3-1 is formed by one-time machining; CNC laser cutting The main parts of the head, the lens base box 2, the water cooling component 3, the focusing lens base component 4, the ventilation component 6 and the adjustment nut 7, are made of ultra-high-strength duralumin LC4. When working, the laser light source is transmitted from the laser generator to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com