Patents

Literature

266results about How to "Consistent spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

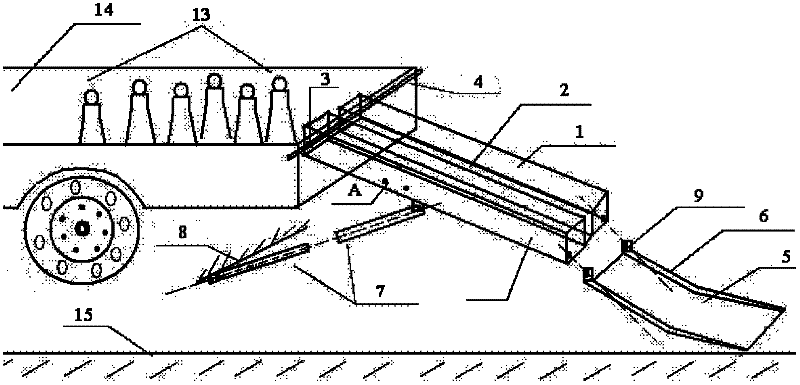

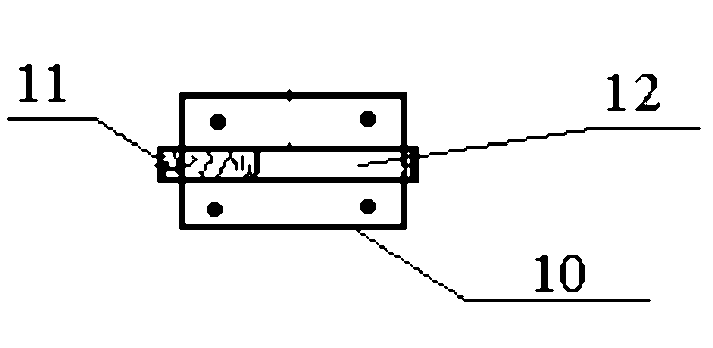

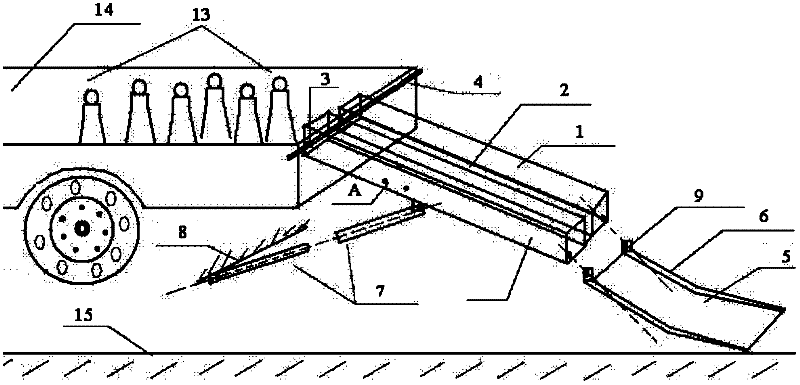

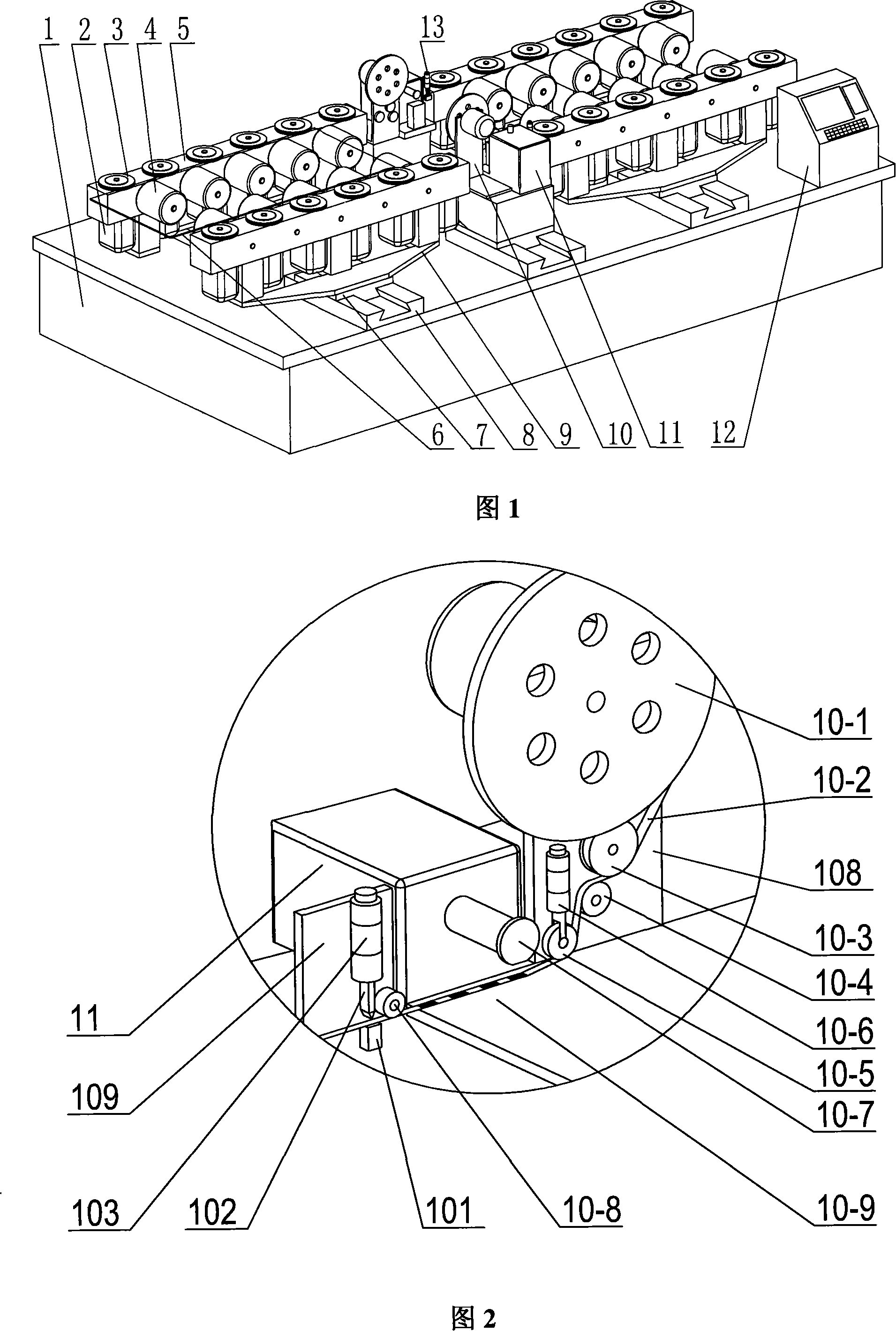

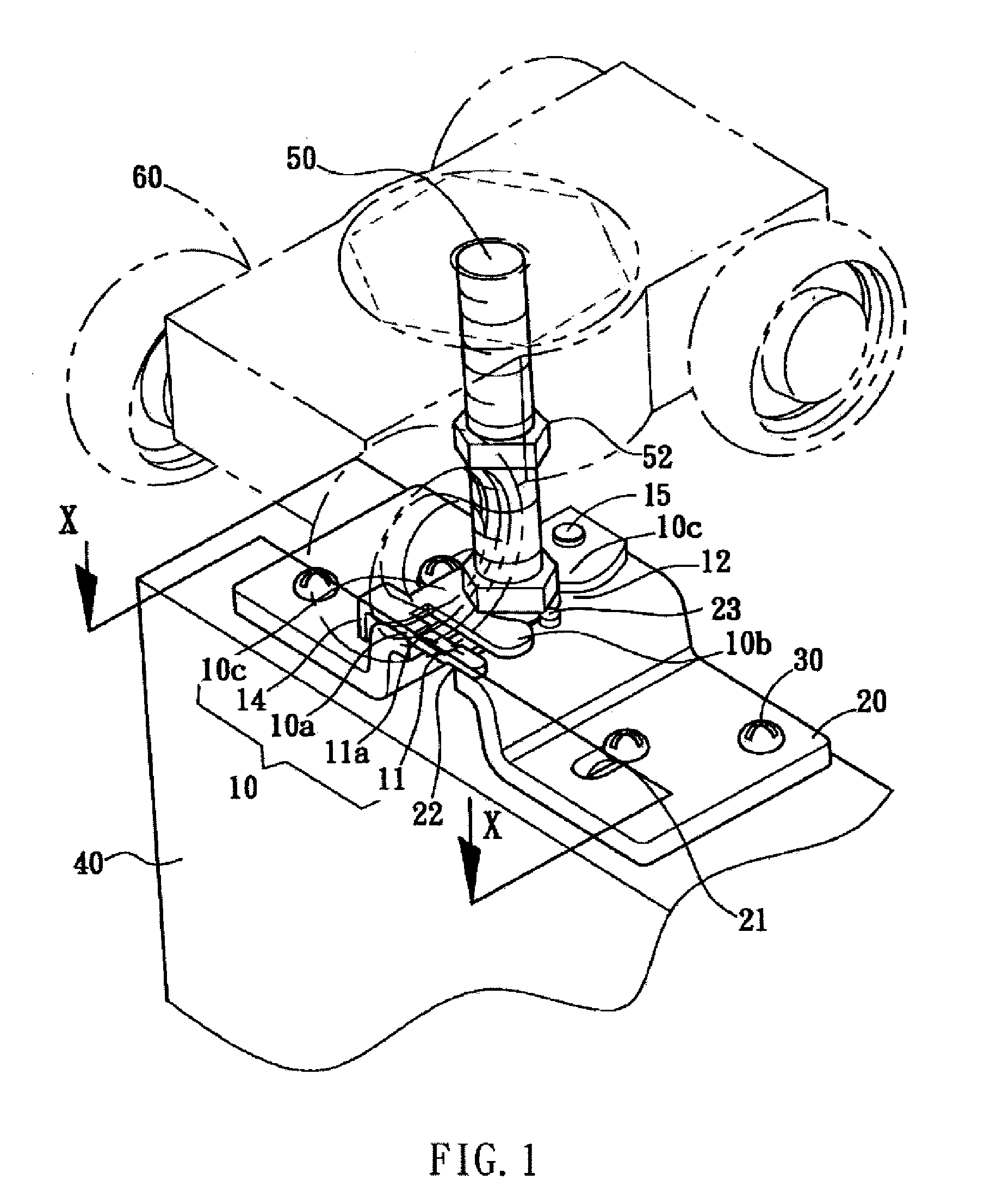

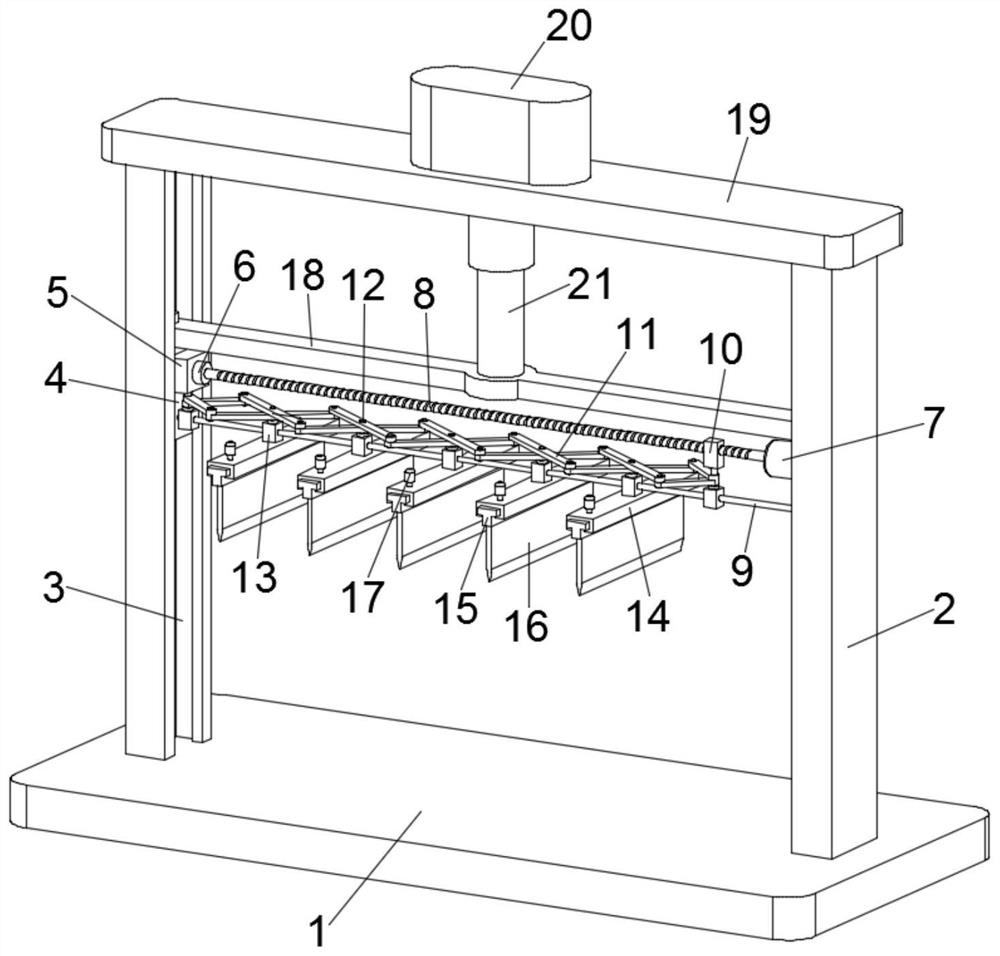

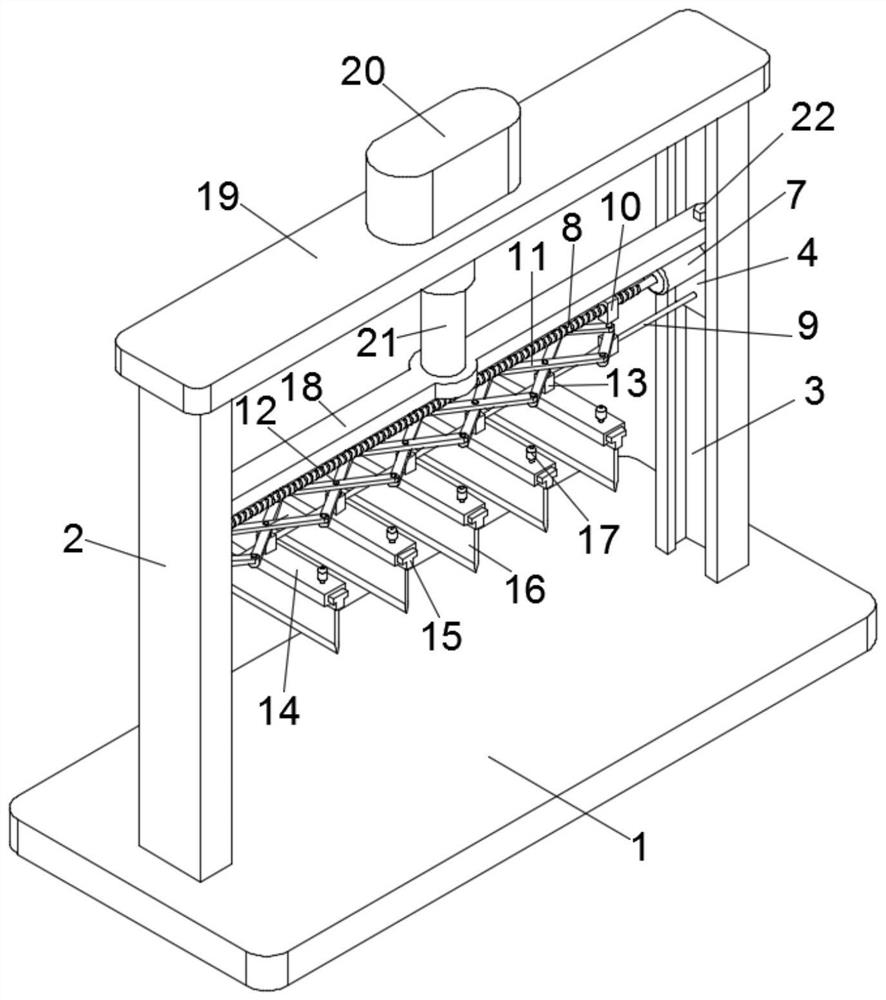

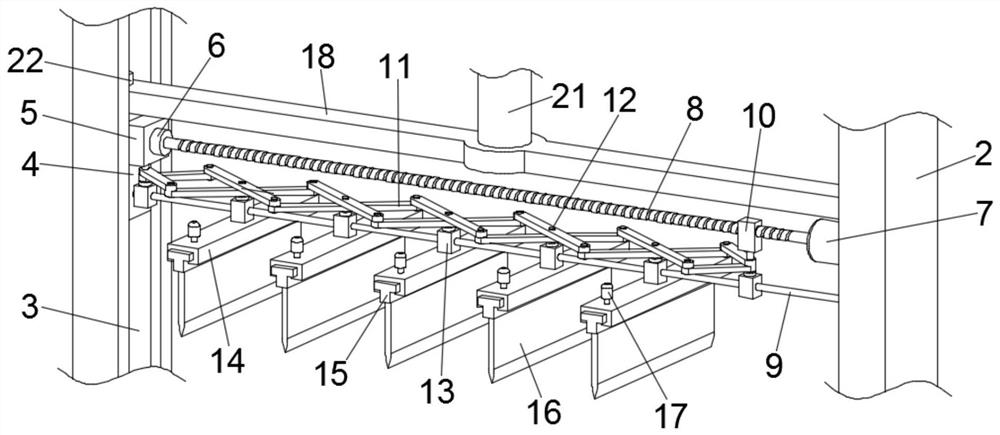

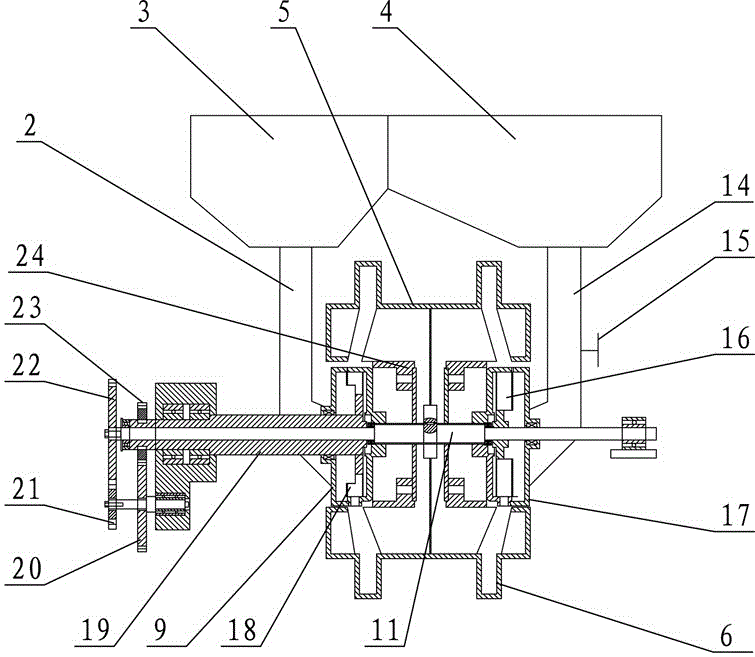

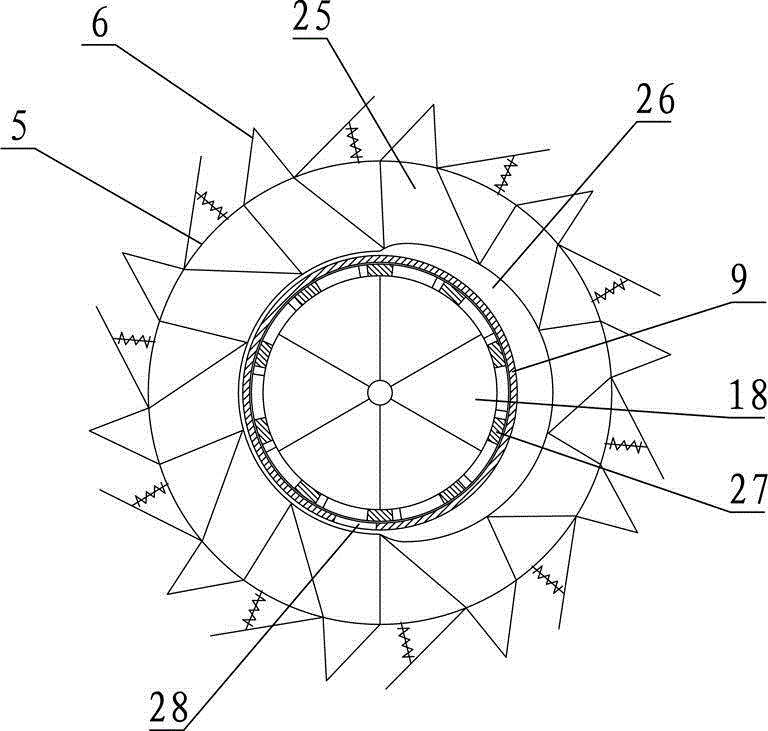

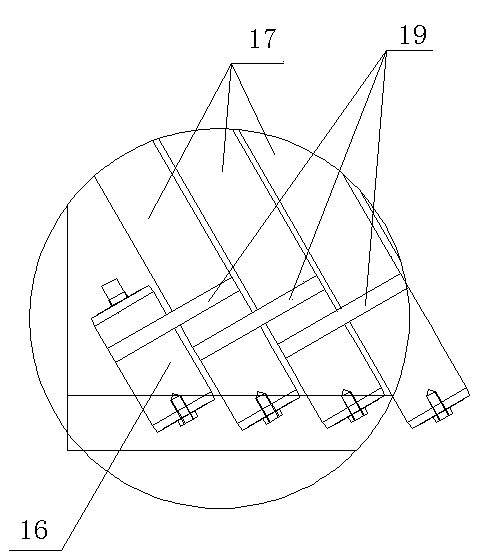

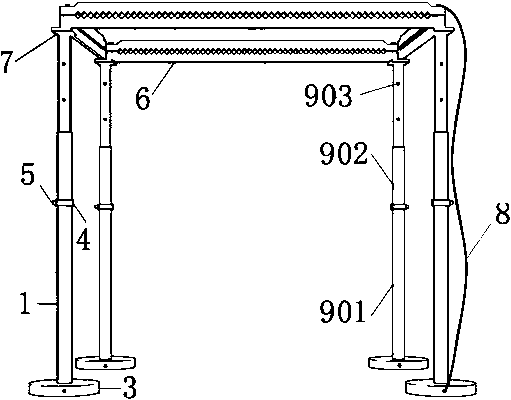

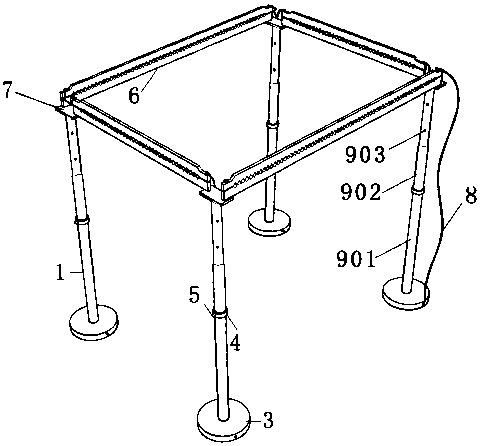

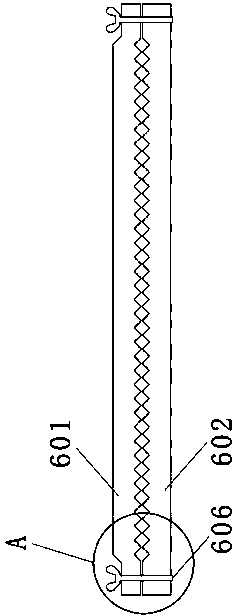

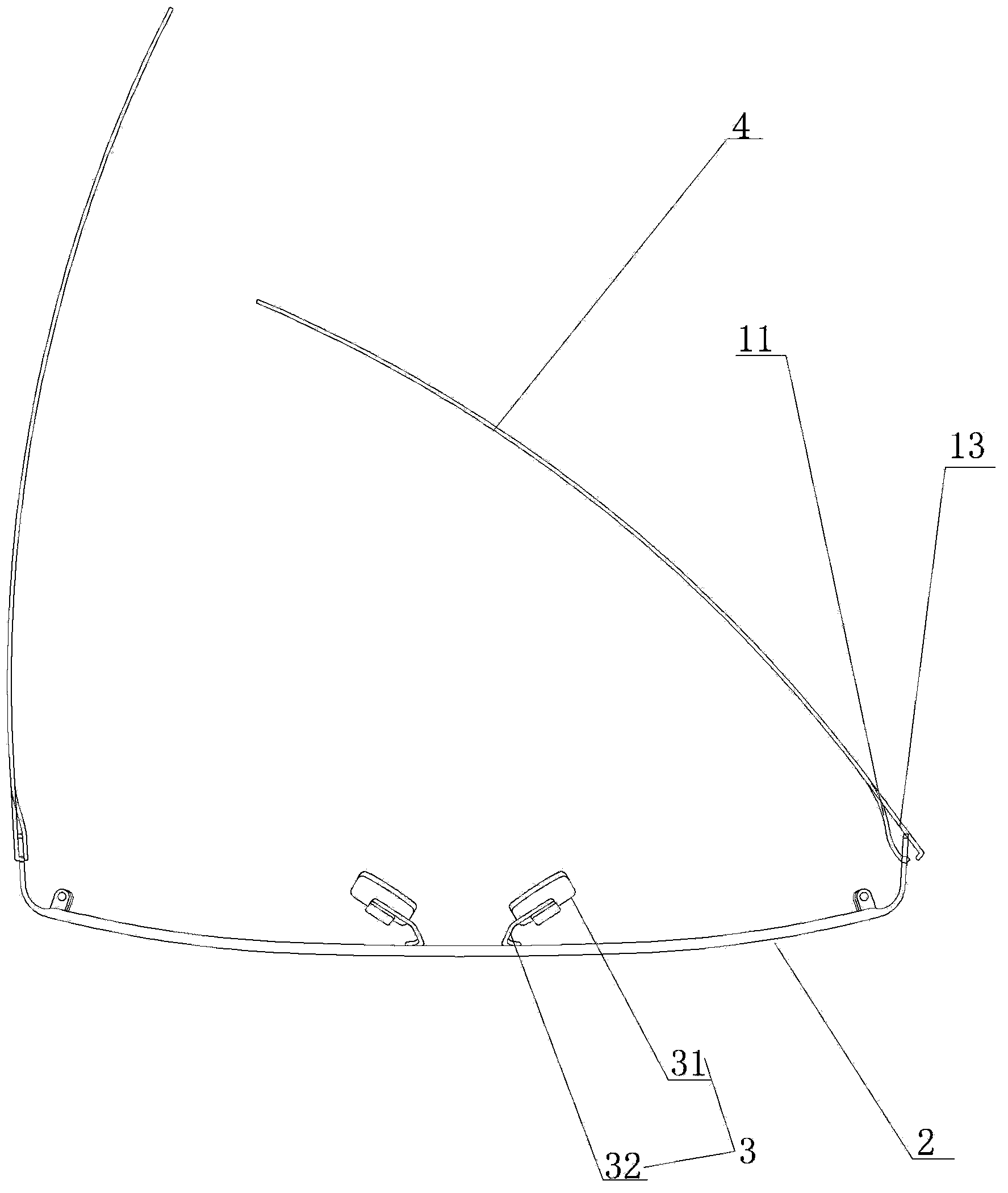

Automatic traffic cone putting device

InactiveCN102400444AIncrease placement speedEnsure safetyTraffic signalsRoad signsMonitoring systemSimulation

The invention relates to an automatic traffic cone putting device, which belongs to the field of traffic machinery, and comprises a cone putting device, a suspension device, a guiding device and a supporting device, wherein the suspension device and the guiding device are arranged at the two ends of the cone putting device, and the supporting device is arranged at the bottom of the cone putting device. Compared with the prior art, the automatic traffic cone putting device provided by the invention has a novel structure and a reasonable design, is simple and convenient to install and maintain, is easy to operate, is flexible to move, and is convenient to regulate and control, a large number of labor can be saved, the speed for putting traffic cones can be obviously improved, the safety of workers can be effectively guaranteed, simultaneously, the putting effect is ensured, stable and accurate putting of the traffic cones can be realized, the consistency in putting intervals of the traffic cones is ensured, the putting intervals can be regulated according to the need, an operator can know running conditions of devices constantly through a monitoring system, the construction safety is fully ensured, and the automatic traffic cone putting device is suitable to be promoted and applied in traffic-related engineer operation requiring putting the traffic cones and similar facilities.

Owner:北京公联洁达公路养护工程有限公司

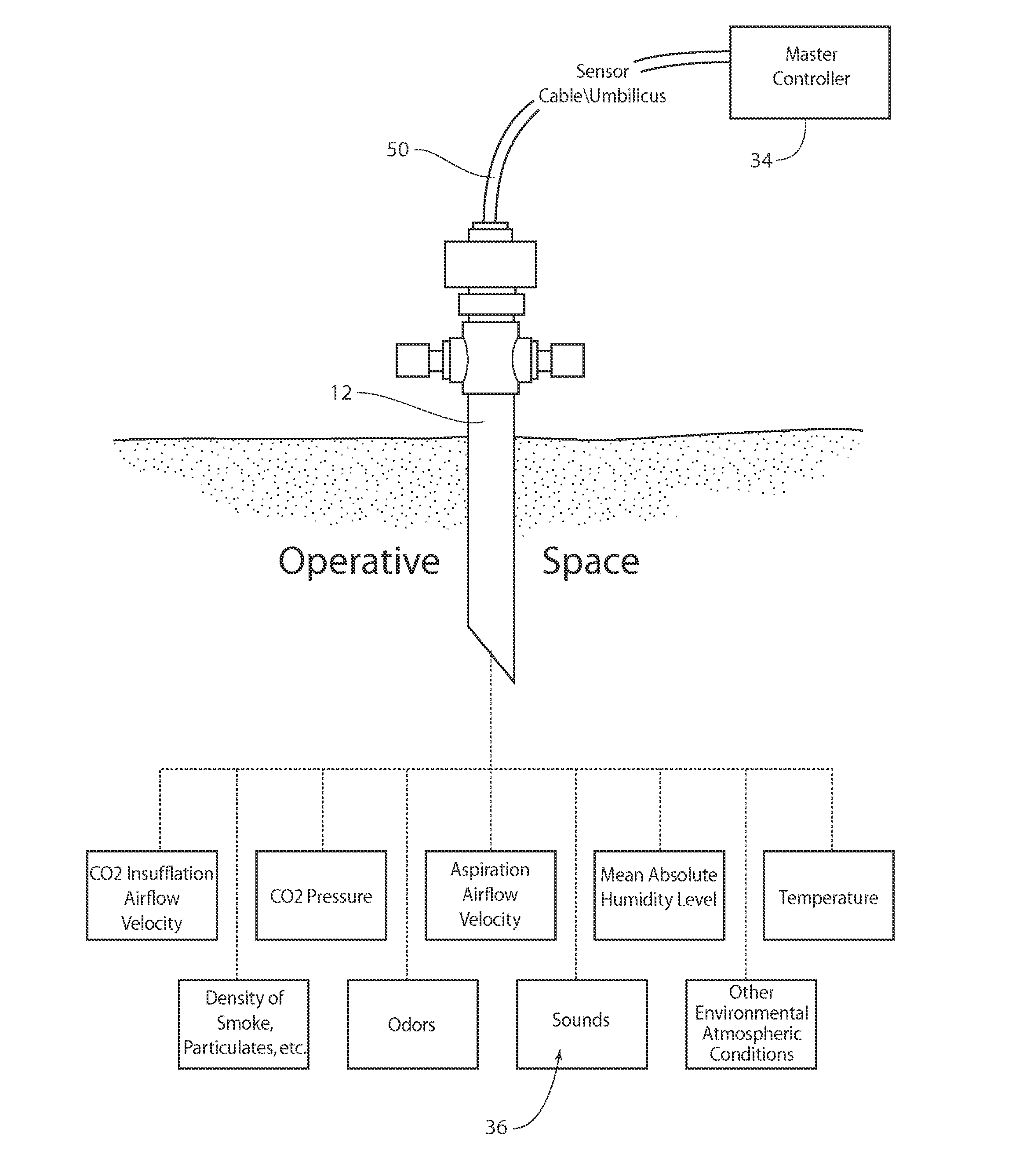

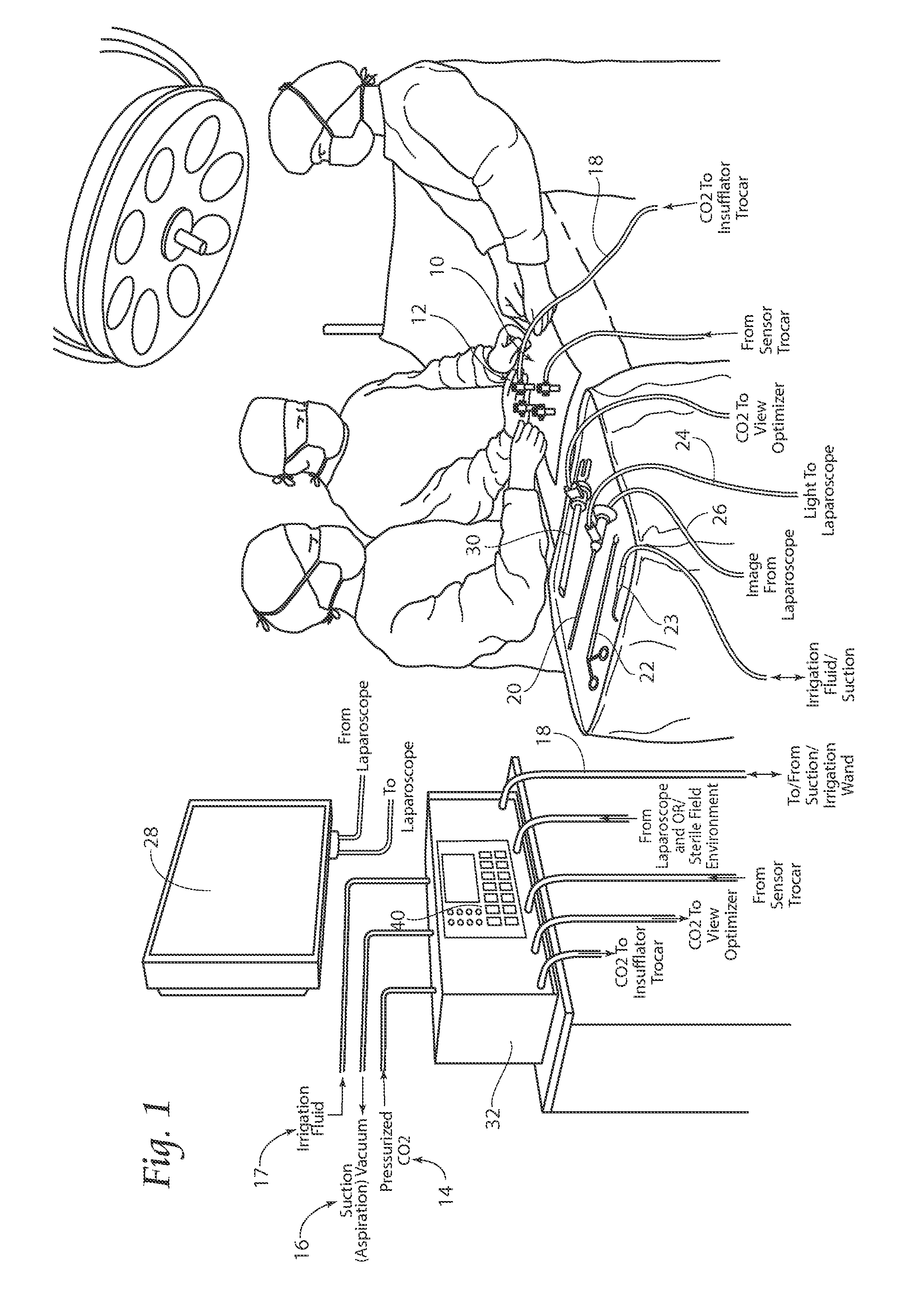

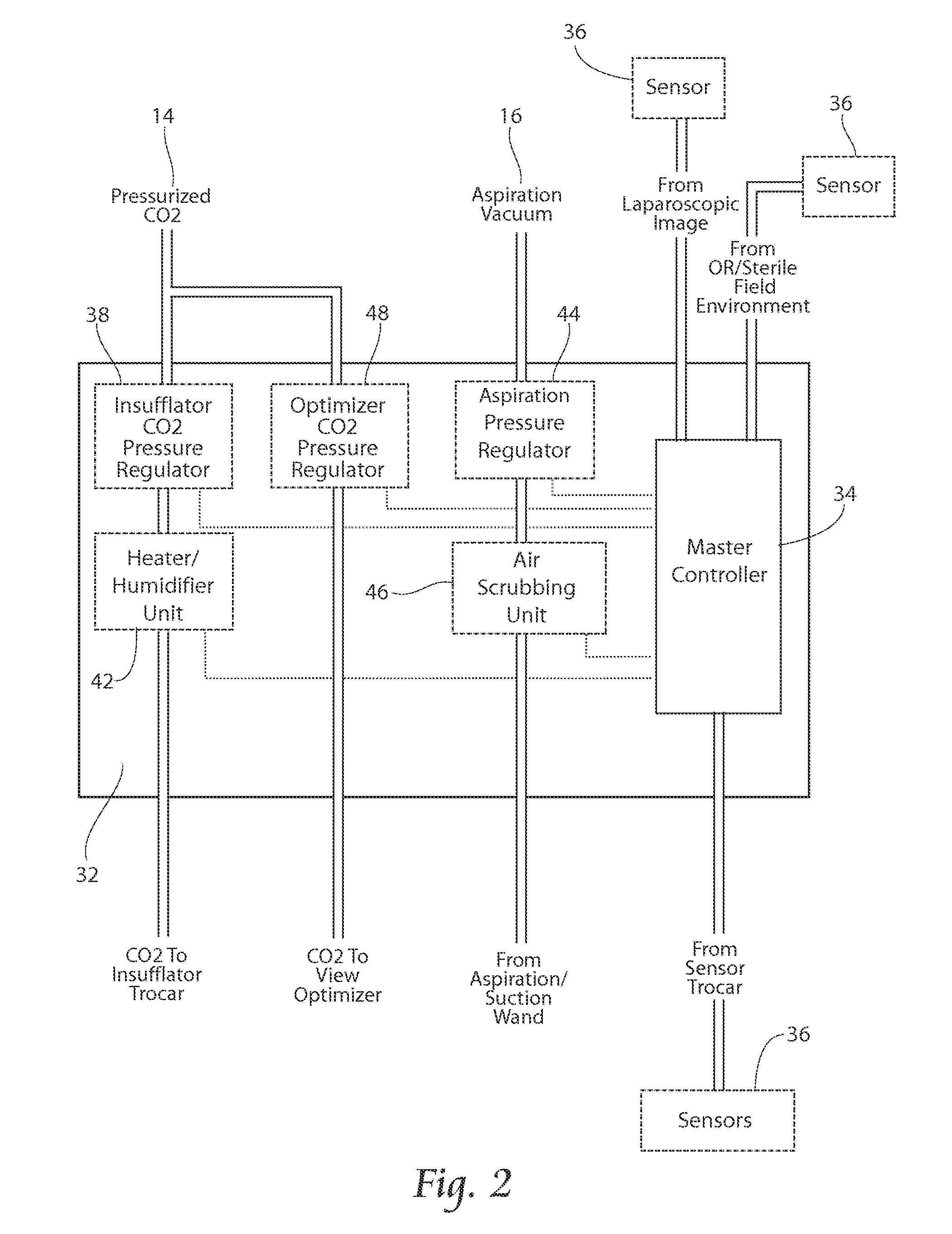

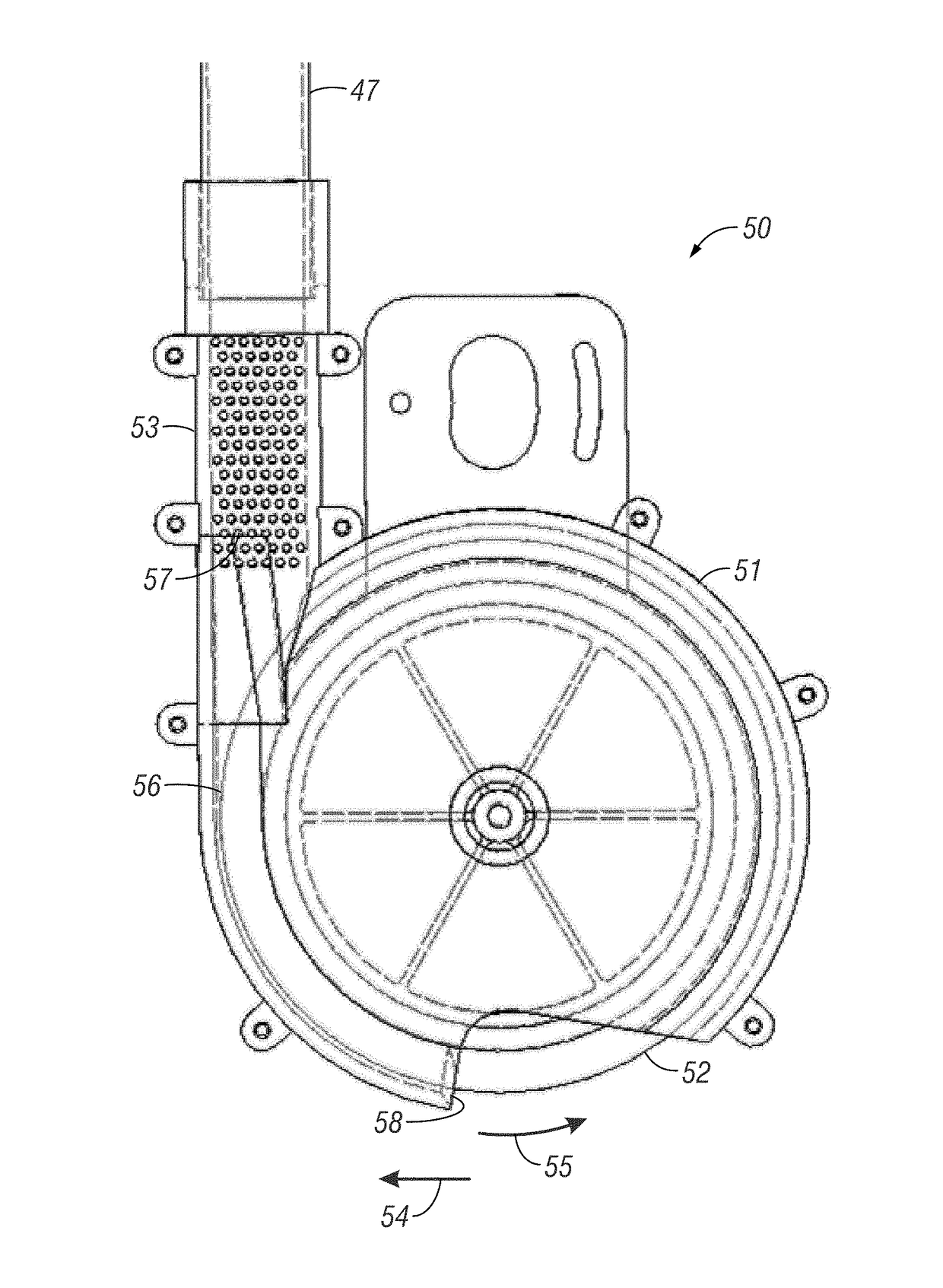

Integrated systems and methods for maintenance and management of an intra-abdominal gas environment during laparoscopic surgery

InactiveUS20120184897A1Improve clarityEfficient suctionRespiratorsEndoscopesParticulatesAir management

Air management control systems and methods maintain and manage an intra-abdominal gas environment during laparoscopic surgery. The systems and methods locate a plurality of in vivo sensors to monitor different environmental conditions within the operative space insufflated with pressurized CO2, e.g., CO2 insufflation airflow velocity, CO2 pressure, aspiration airflow velocity, and at least one of humidity level, temperature, density of smoke / particulates, odors, and sound within the operative space. The systems and methods couple the plurality of in vivo sensors to a master controller. The master controller implements pre-programmed rules to generate control commands that govern the delivery of pressurized CO2 and aspiration pressure into and out of the operative space in response, at least in part, to the different environmental conditions monitored by the in vivo sensors.

Owner:FLOSHIELD INC

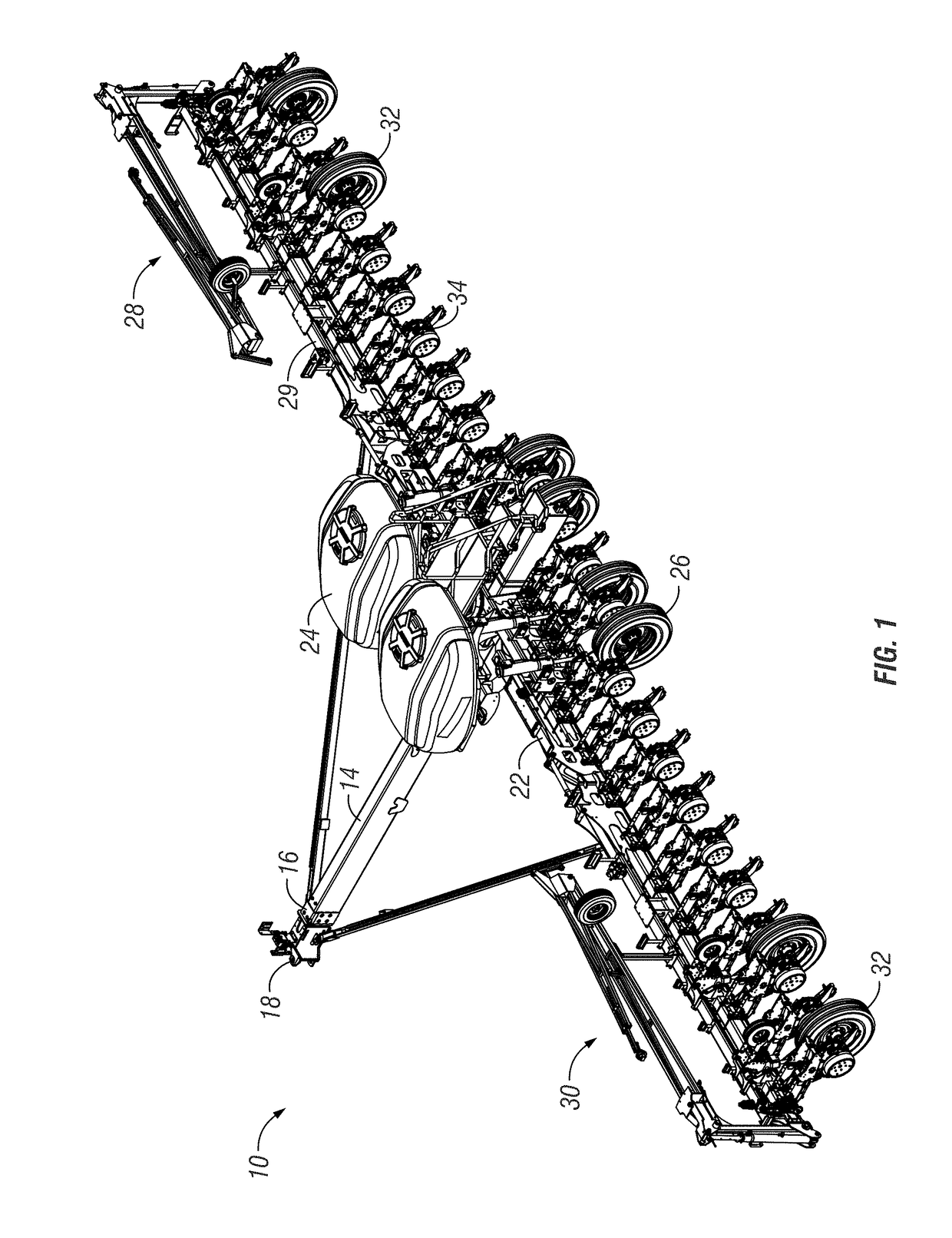

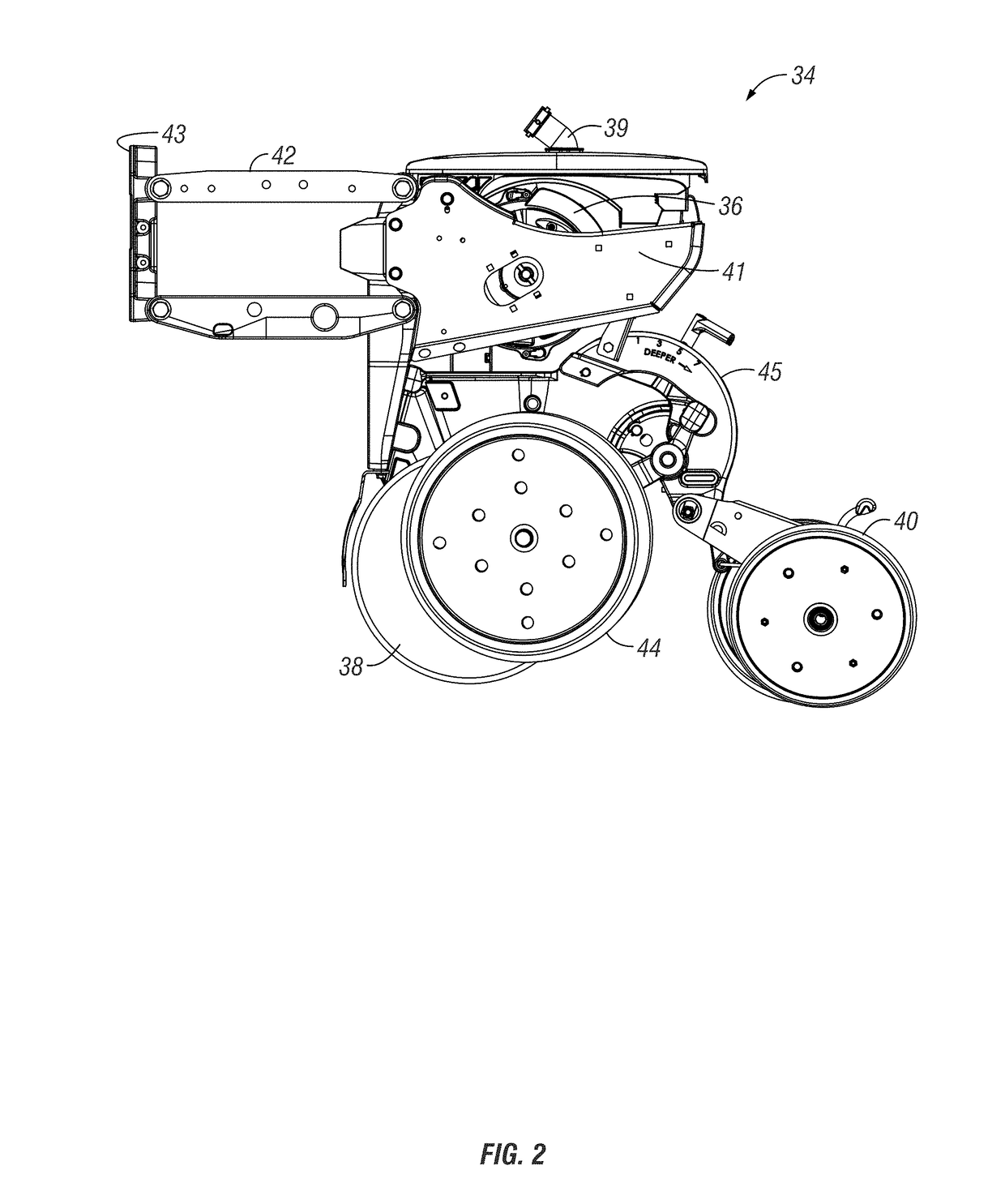

Planter with seed delivery apparatus

ActiveUS9756779B2Overcome deficienciesConsistent spacingSeed depositing seeder partsRegular seed deposition machinesControl mannerEngineering

Owner:KINZE MFG INC

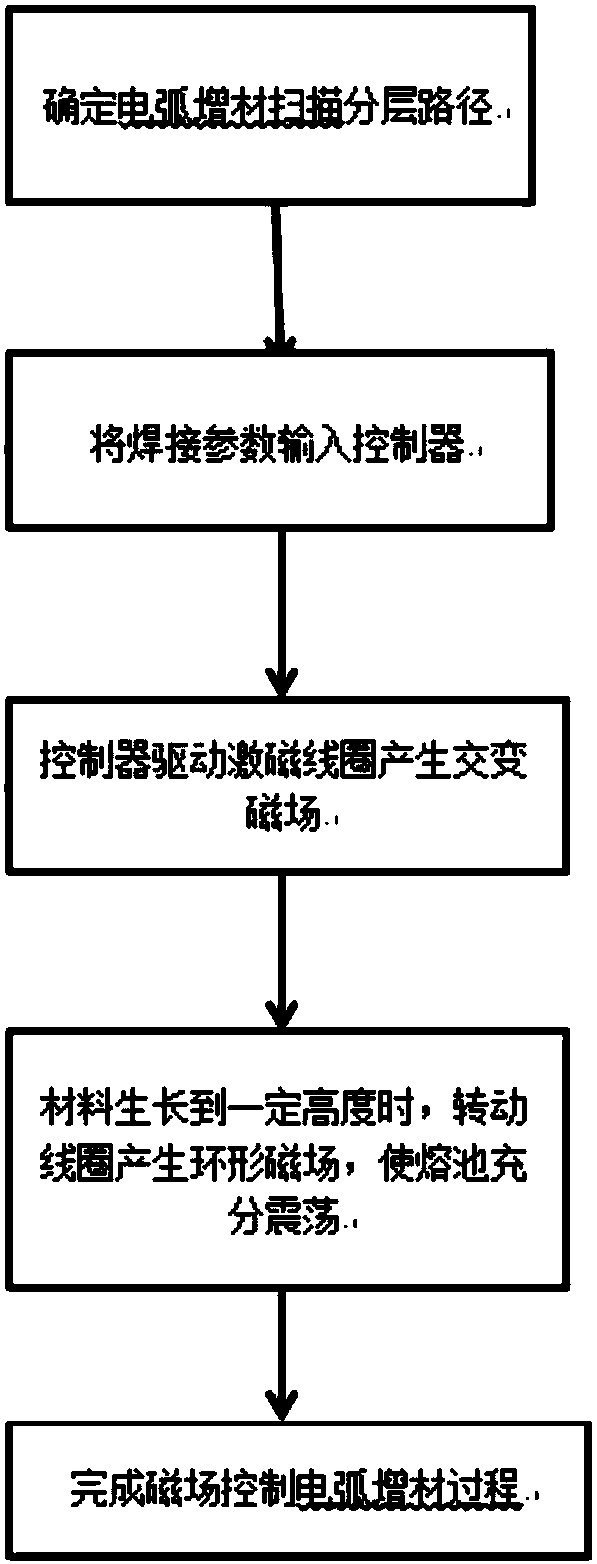

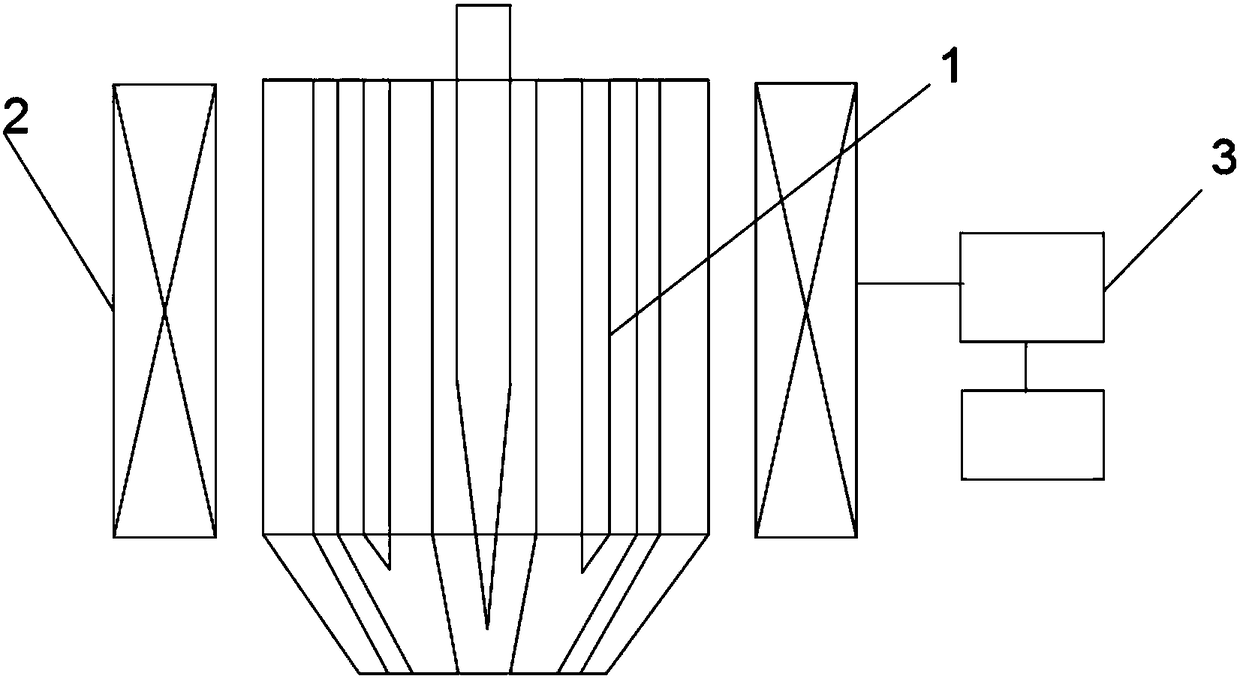

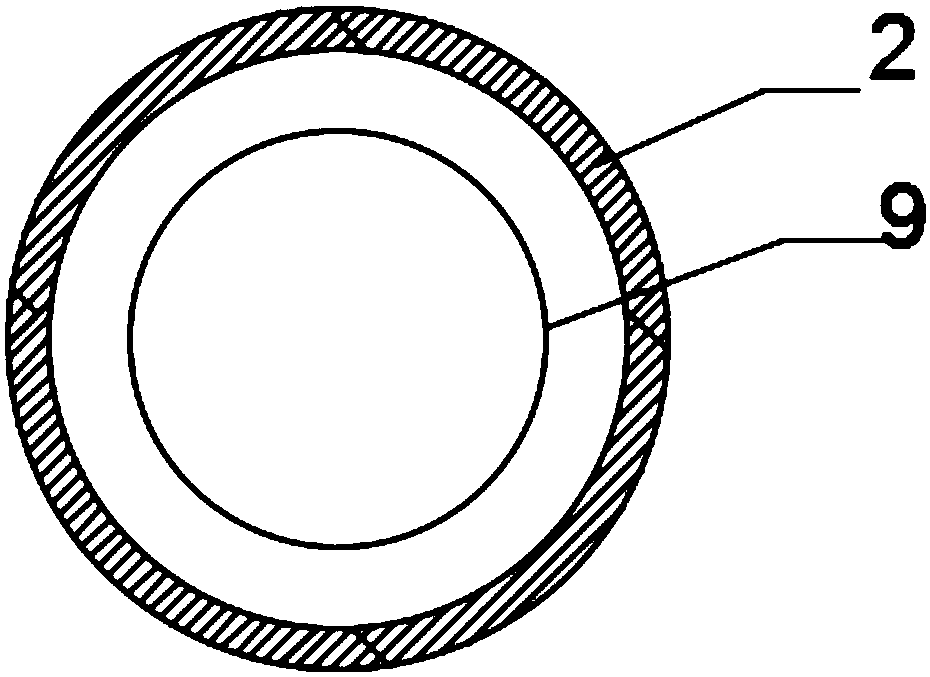

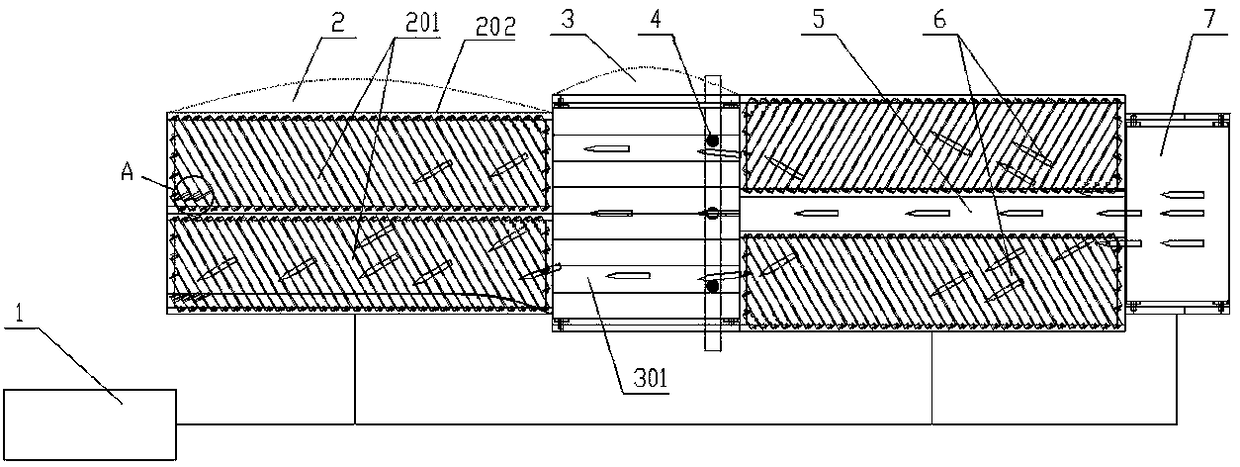

Magnetic field control type additive forming method and device adopting electric arc robot

The invention discloses a magnetic field control type additive forming method adopting an electric arc robot. The method comprises the steps that welding parameters of electric arc additive manufacturing are input into a controller; the controller drives an excitation power supply in a magnetic field generating device to generate longitudinal magnetic fields with different intensities according tothe real-time change of the manufacturing parameters; when air pores are generated on the overlaying surface of an additive part, a hollow shaft motor is used to control exciting coils to rotate to generate an annular magnetic field, and oscillation stirring is carried out on a molten pool at different degrees; and finally the magnetic fields control the electric arc robot to carry out layer-by-layer accumulation for automatic additive forming on molten wire material according to the forming path. According to the magnetic field control type additive forming method adopting the electric arc robot, control over the form and the motion state of an electric arc in the material adding process can be facilitated; and the annular magnetic field is adopted for stirring so that the floating speedof inclusions such as the air pores in the molten pool can be increased, rotary spray transfer with good stability and good controllability can be obtained, the defects of the air pores and the likein an additive manufacturing part can be greatly reduced, and continuous consistency of the forming morphology of an additive forming part formed through the electric arc robot is improved.

Owner:NANJING UNIV OF SCI & TECH

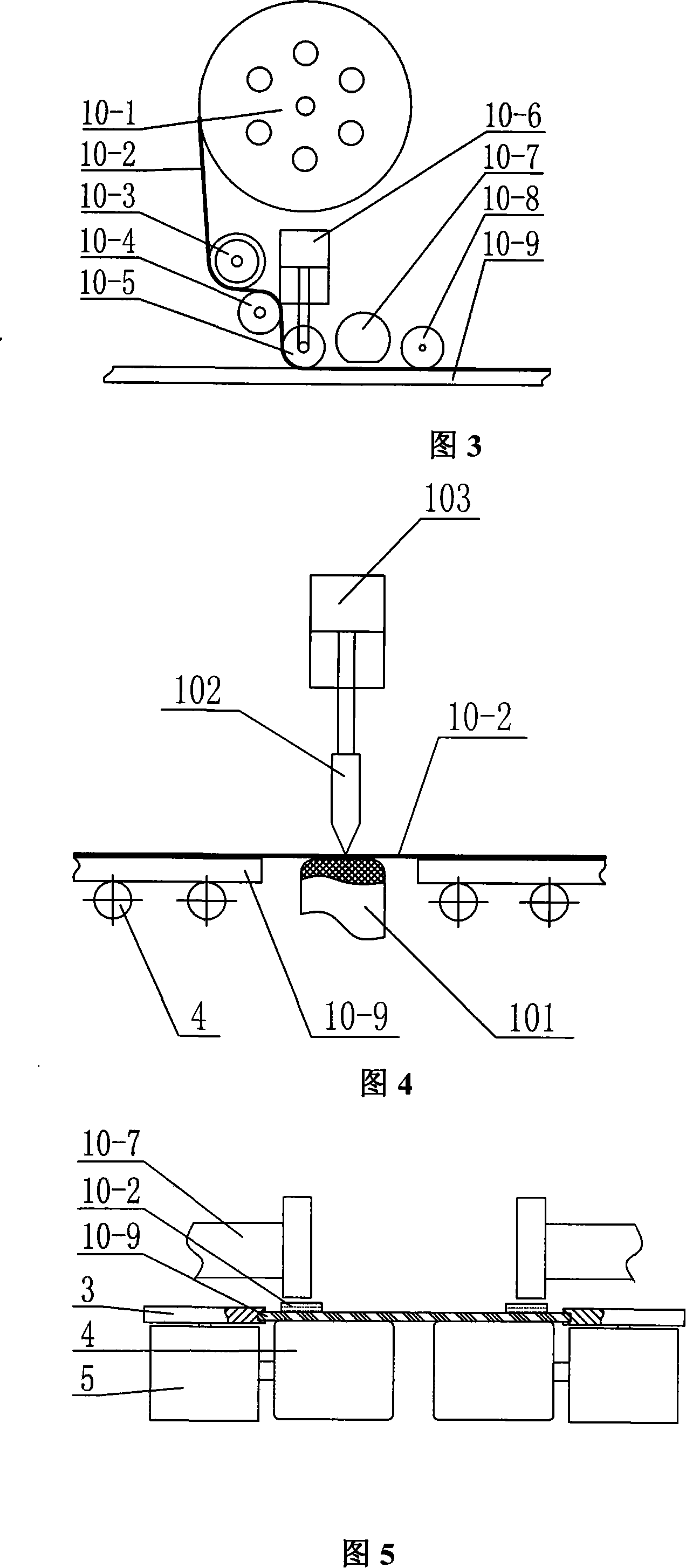

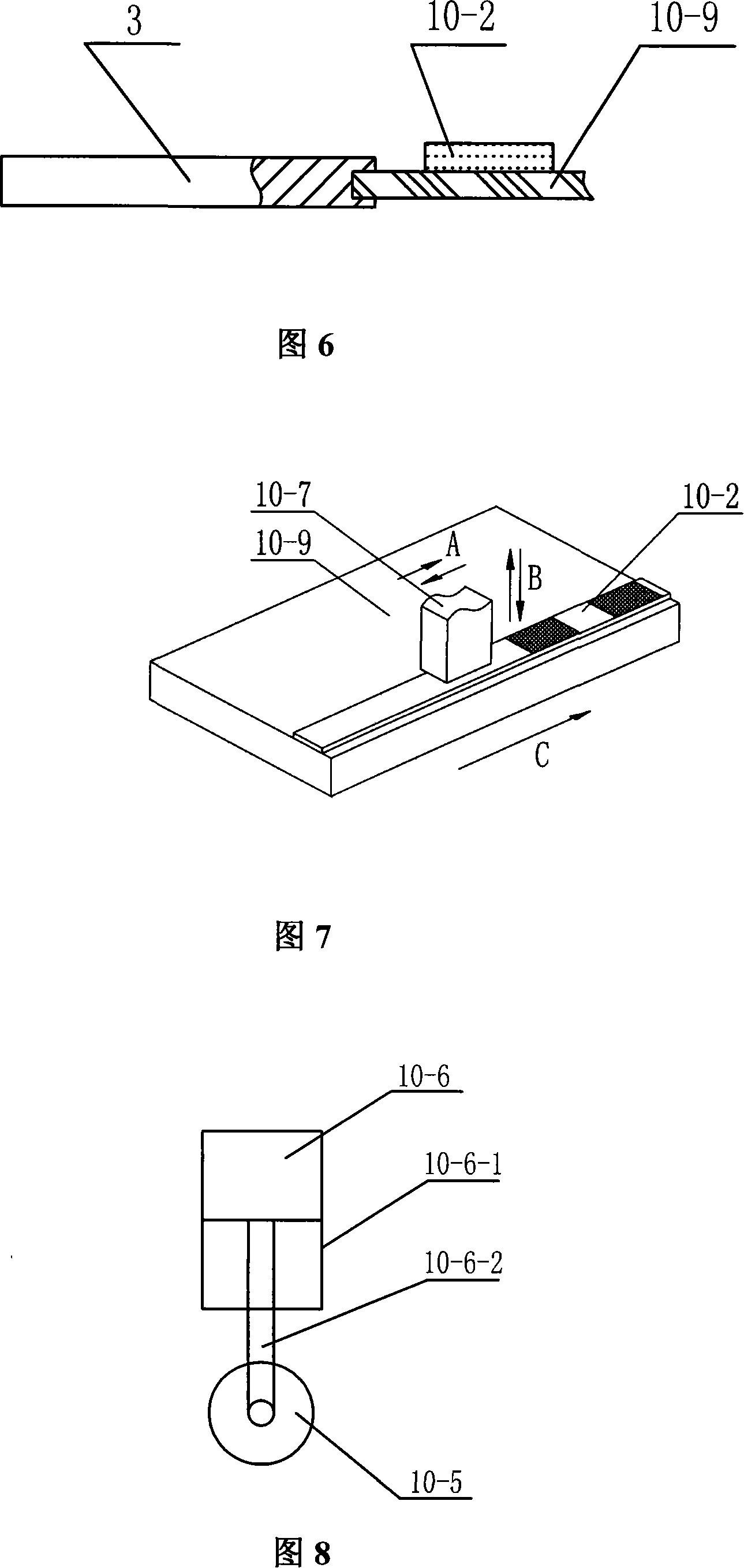

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

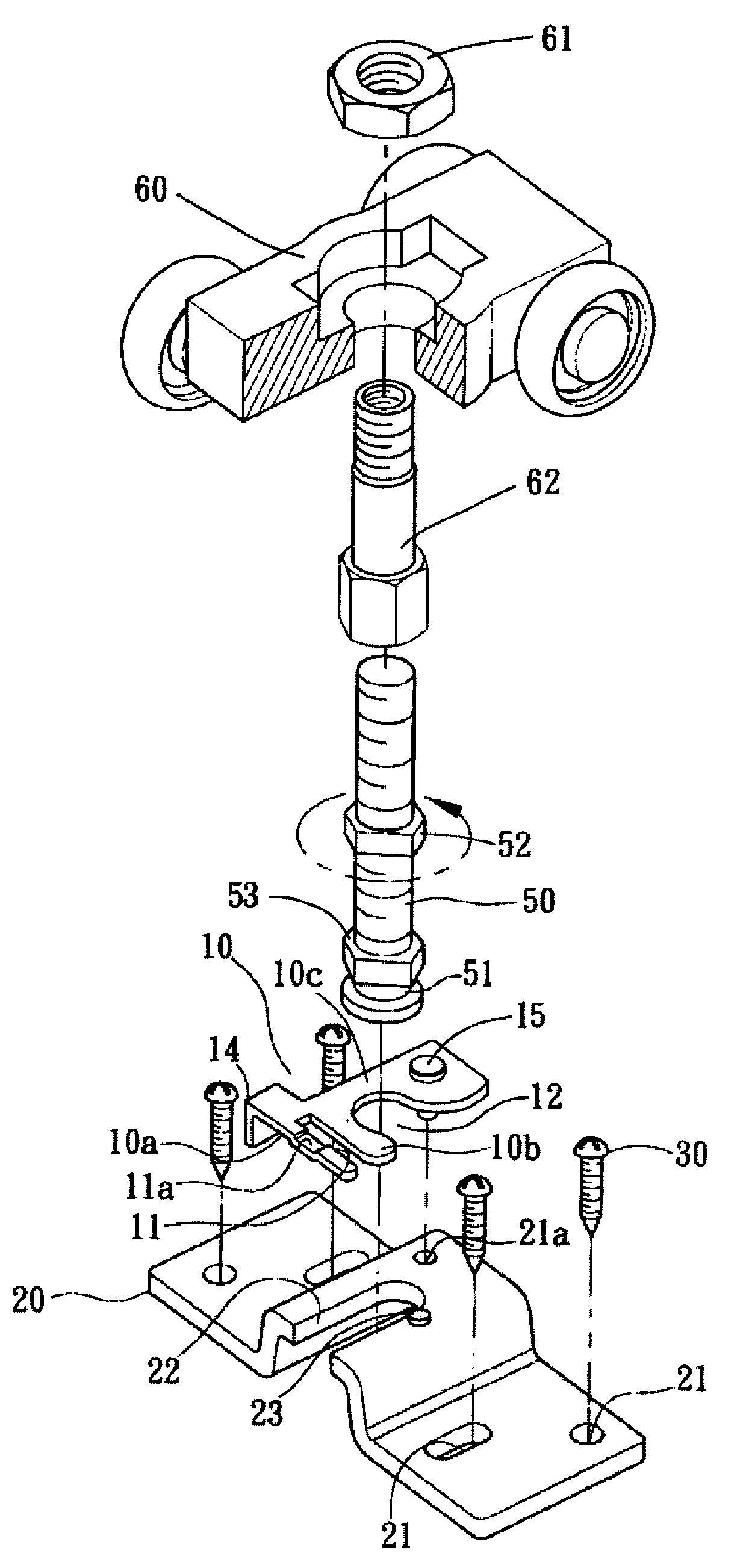

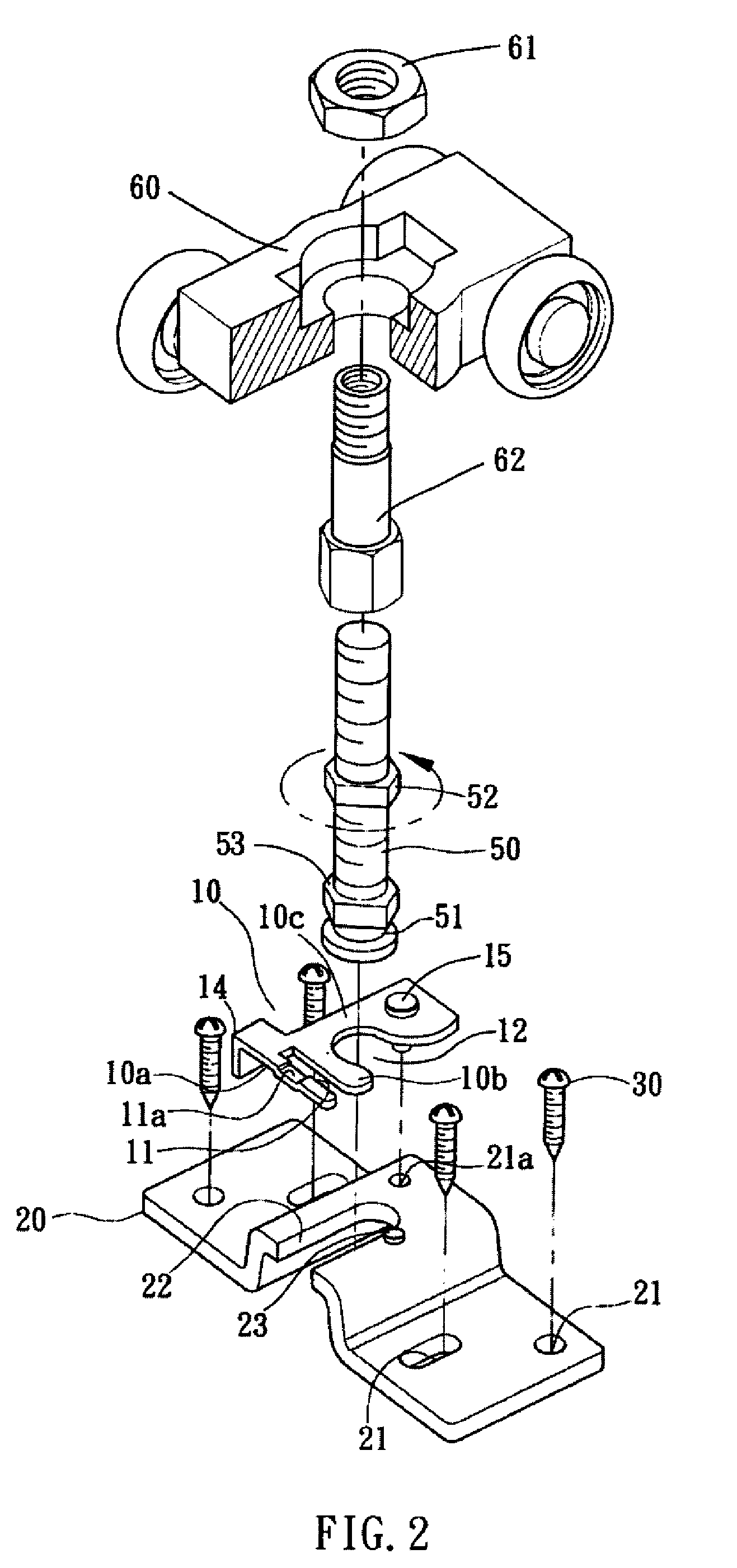

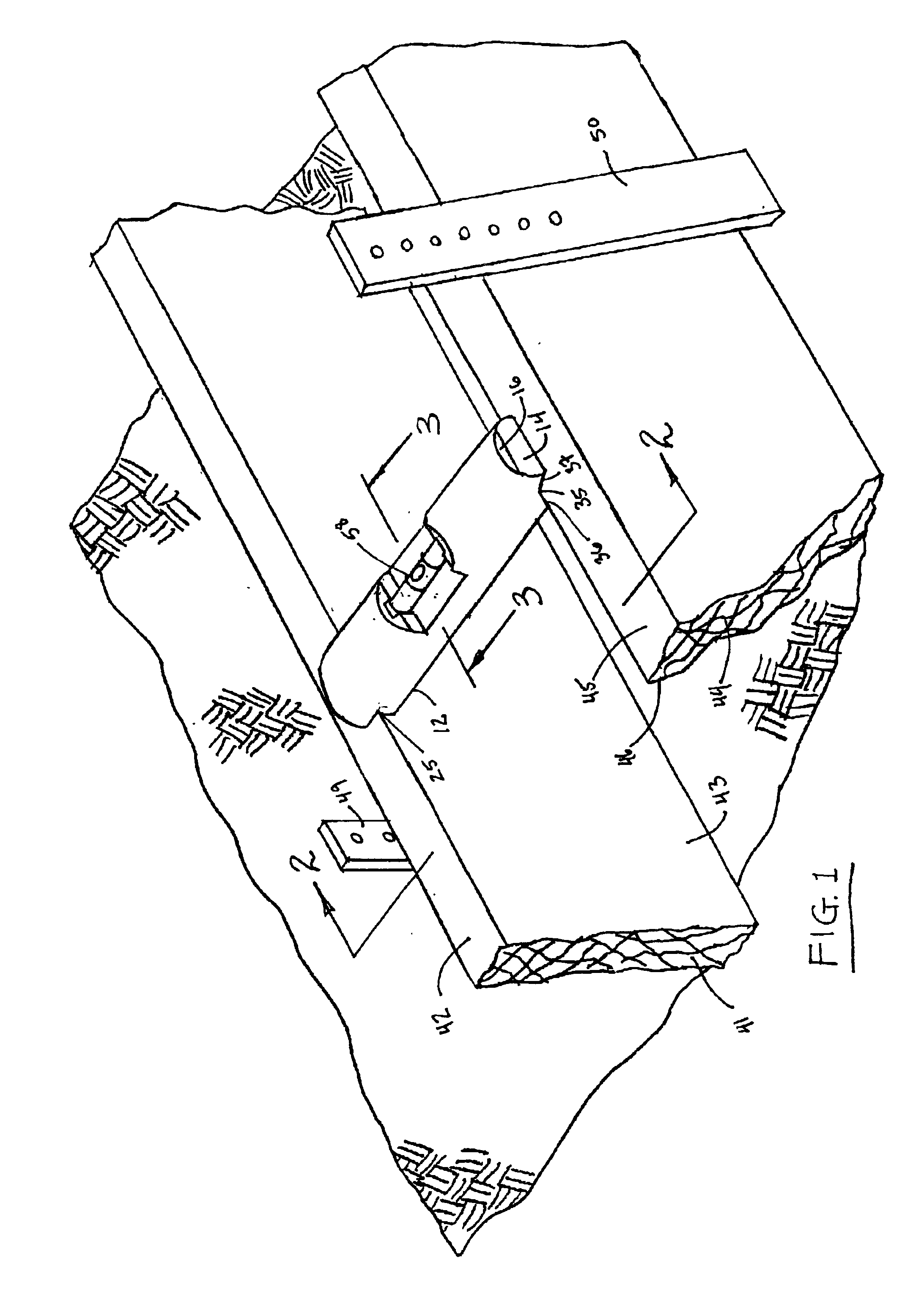

Positioning member for preventing detachment of axle

InactiveUS20090289463A1Prevent disengagementPrevent undesired separationBuilding locksWing suspension devicesRotational axisEngineering

A positioning member is coupled to a mounting plate, which defines a plurality of holes for receiving screws for connection with an end of an external object. An upper adjustment nut sets a distance between a roller seat and the mounting plate and to provide a securing function by cooperating with a roller seat nut and a roller seat bolt. The mounting plate forms in a central portion thereof an elongate slot for slidably receiving a neck of the axle therein. The positioning member includes a plate-like body forming a straight slot and an inclined slot for leading the neck therein and is provided with a rivet or a resilient fork-like fastener at one side of the inclined slot opposite to the straight slot to be fit into the a positioning hole defined beside the elongate slot for serving as a rotational axis of the positioning member.

Owner:ONLY INDAL CORP

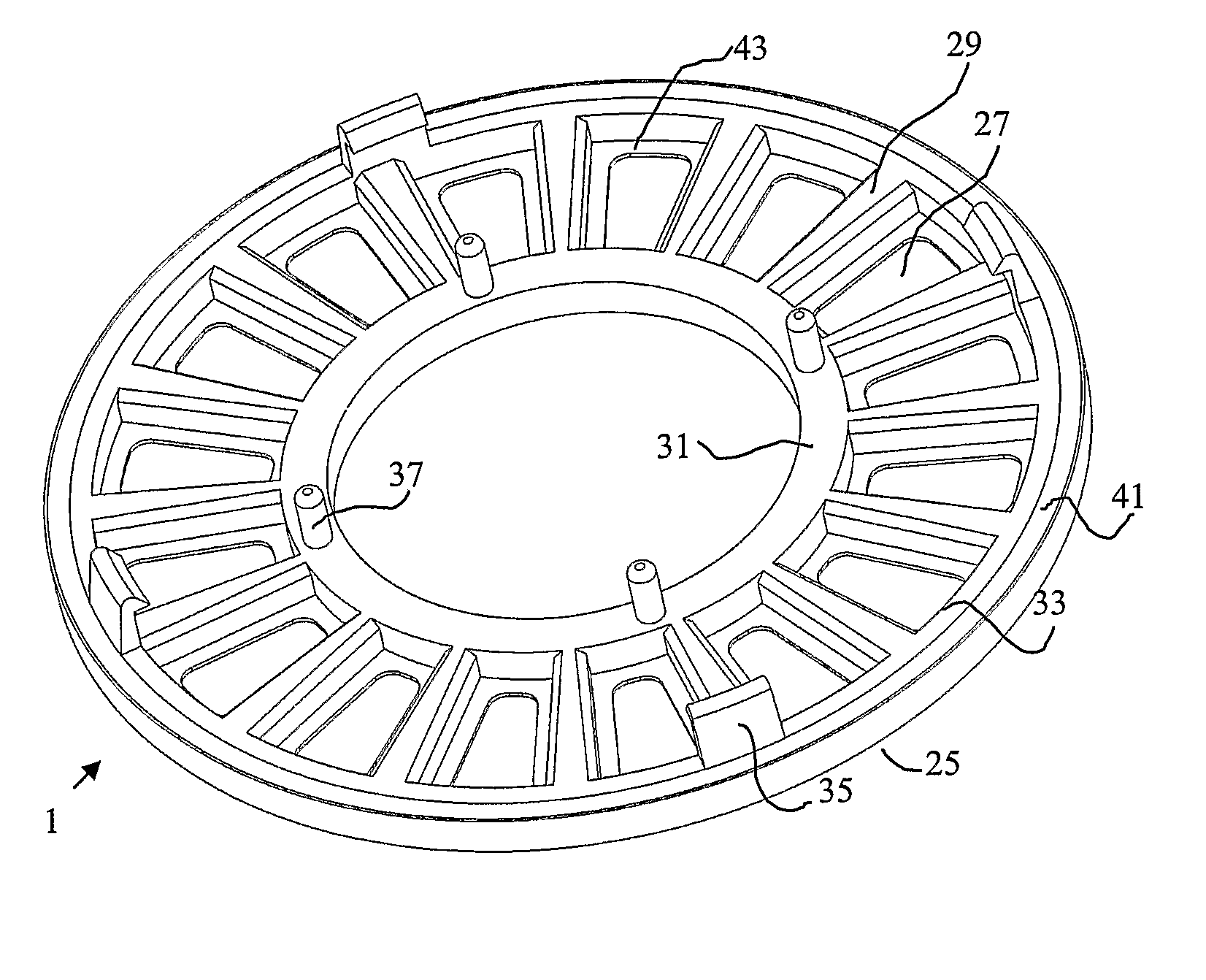

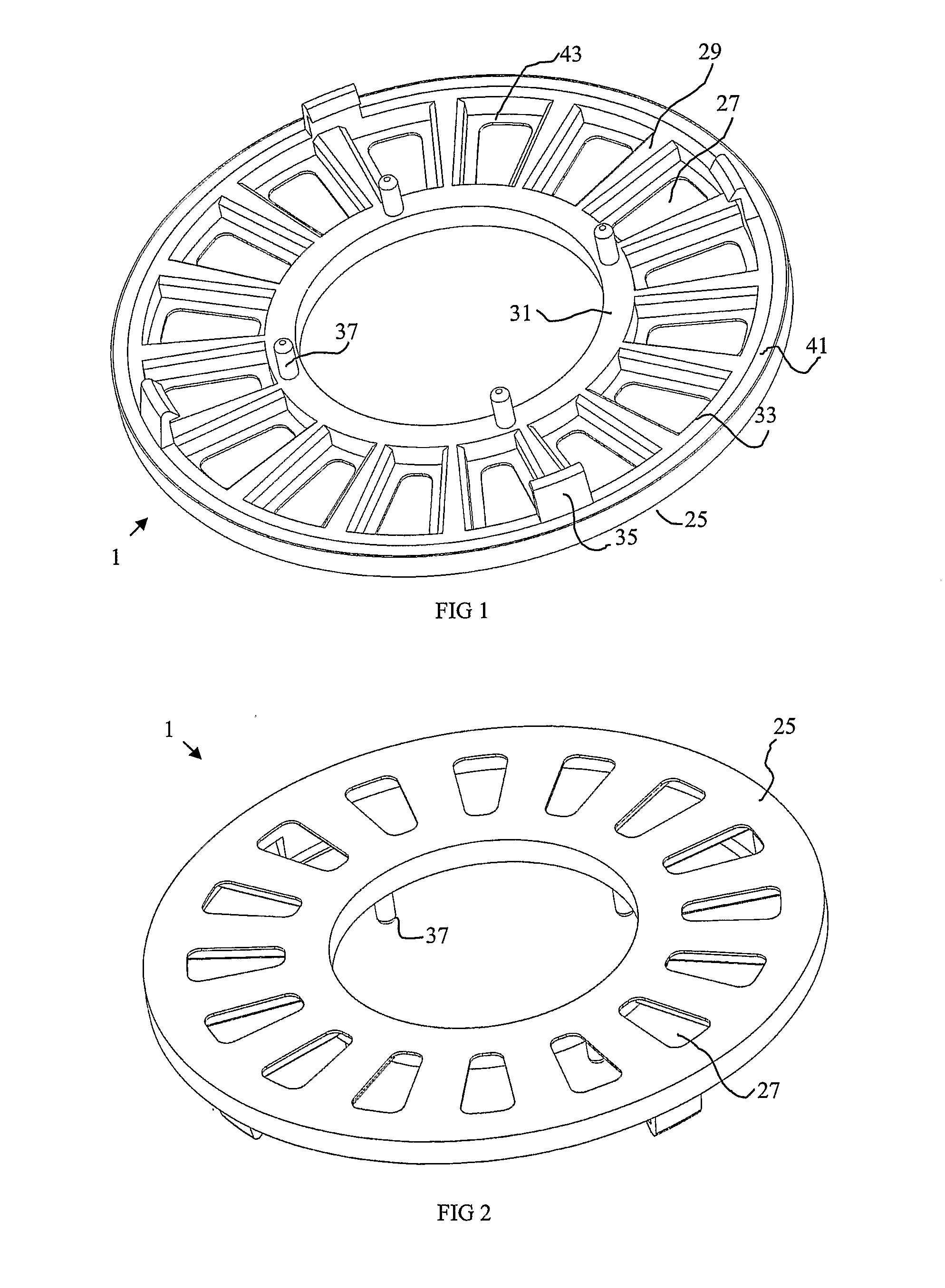

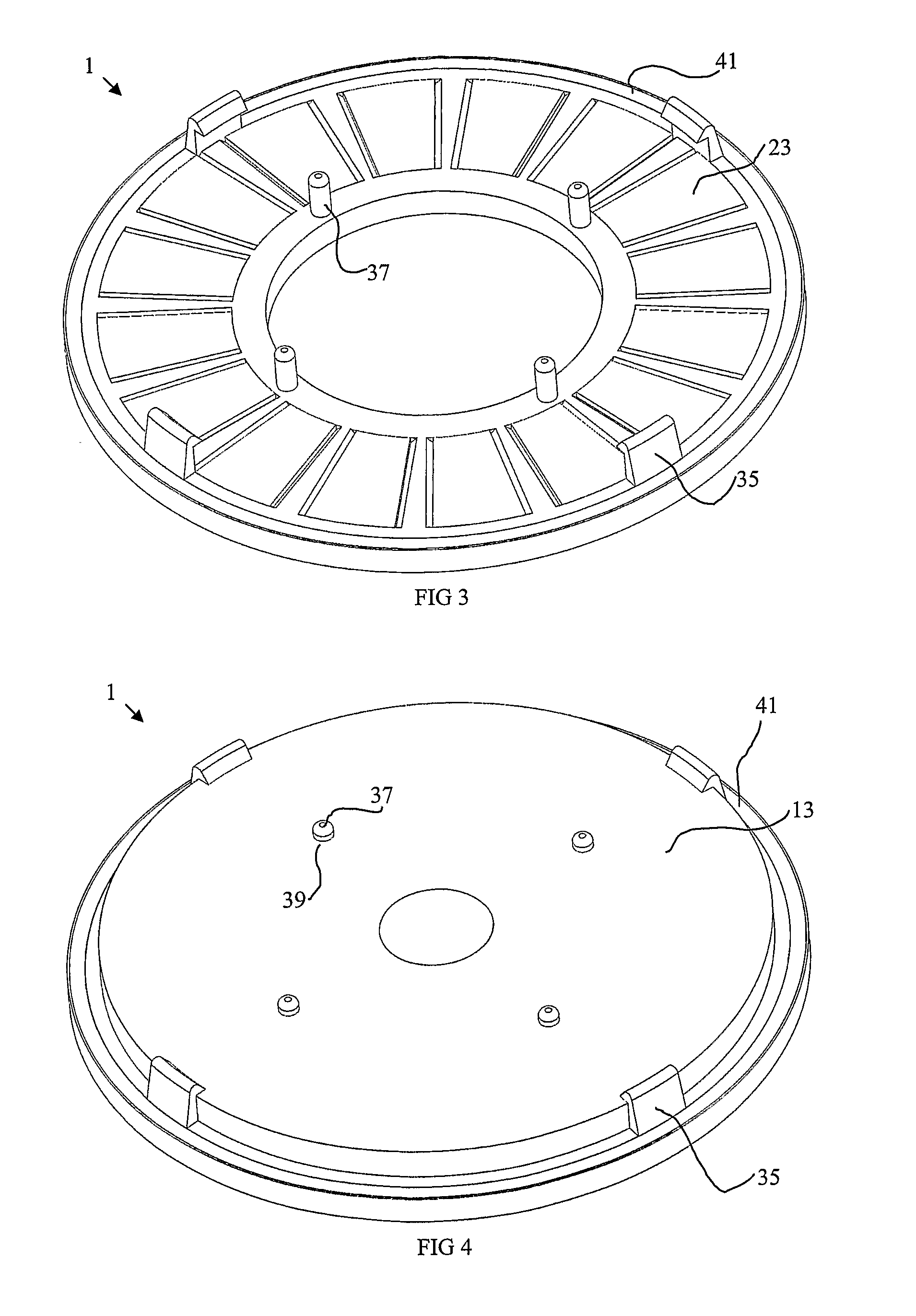

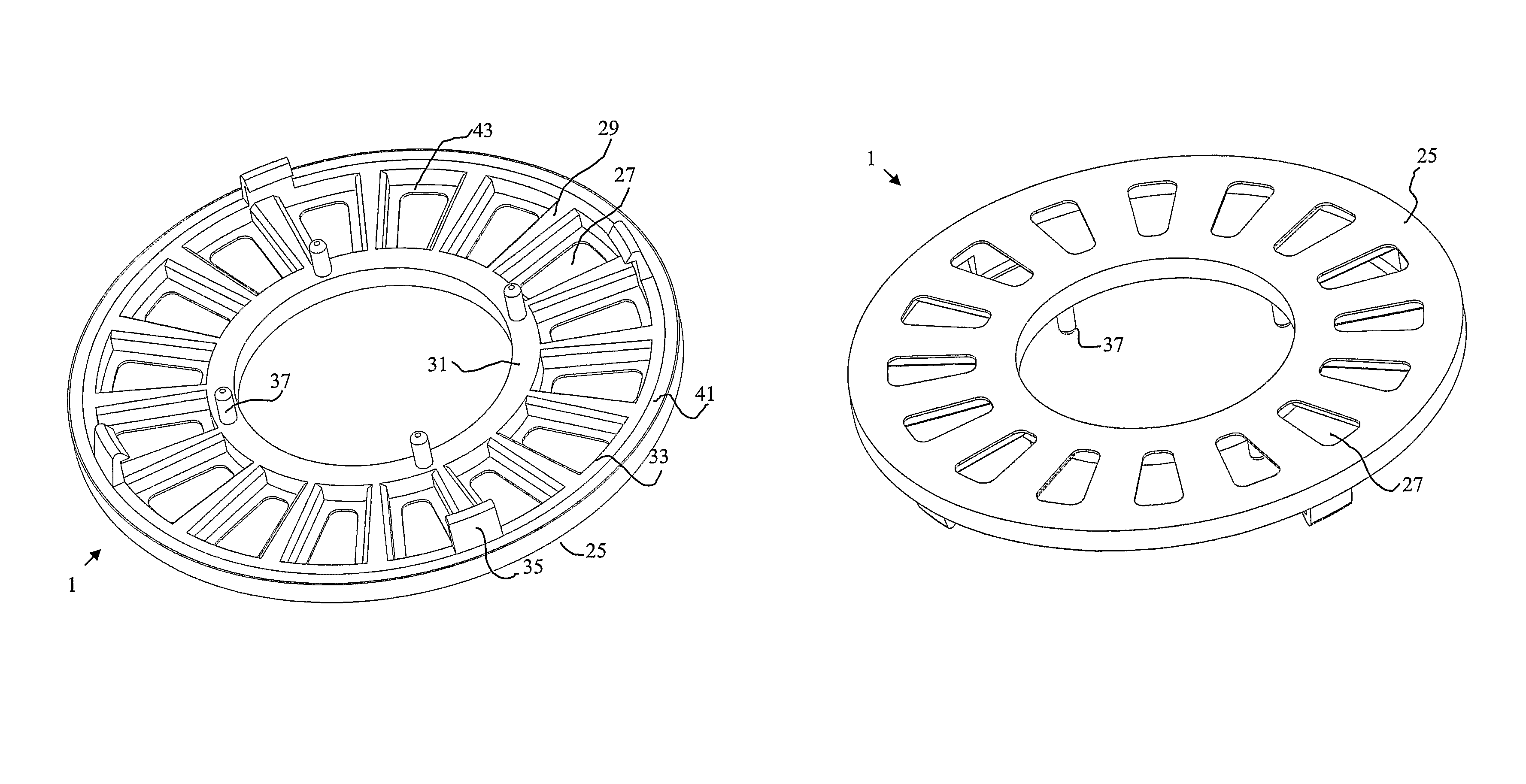

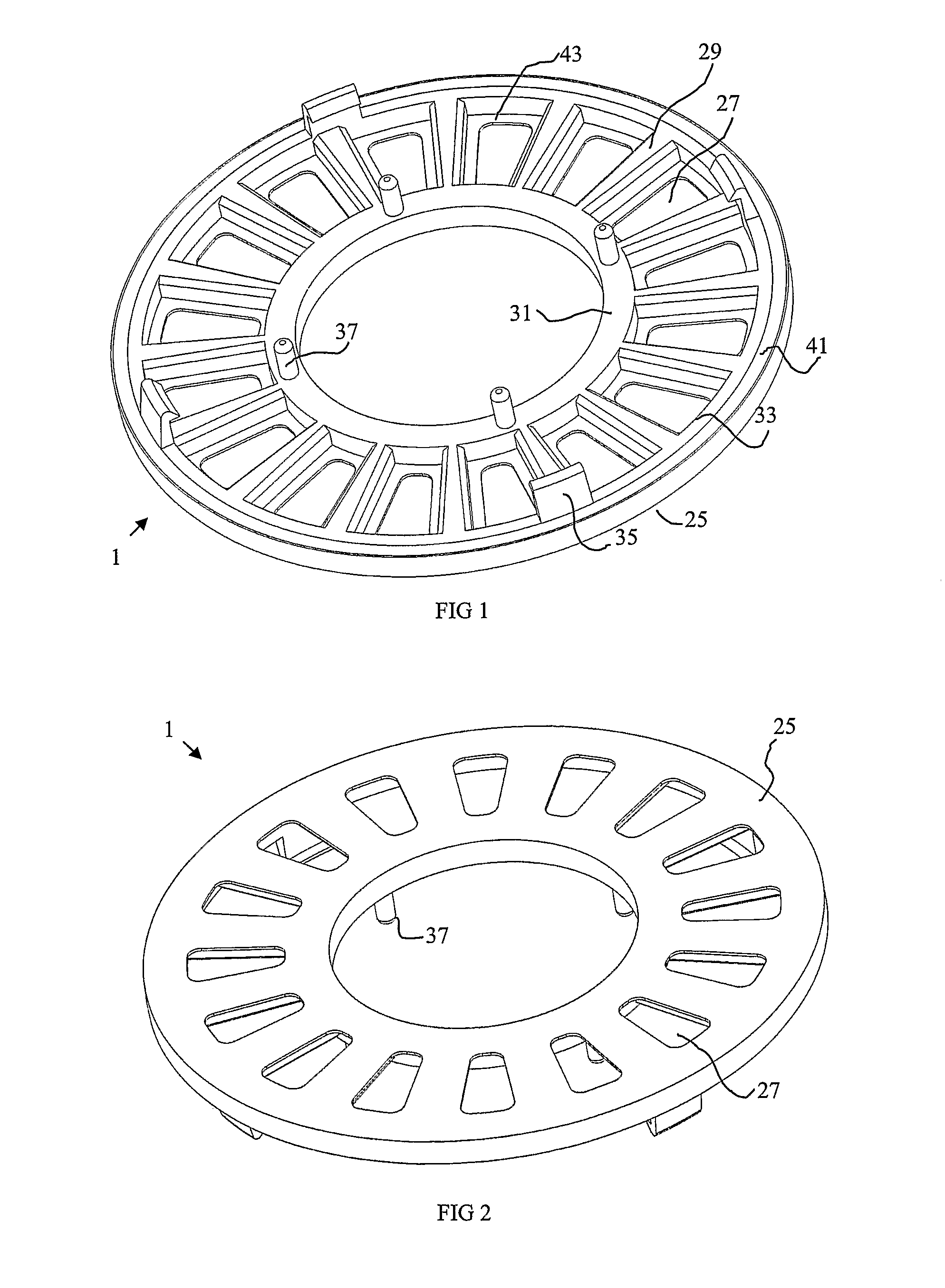

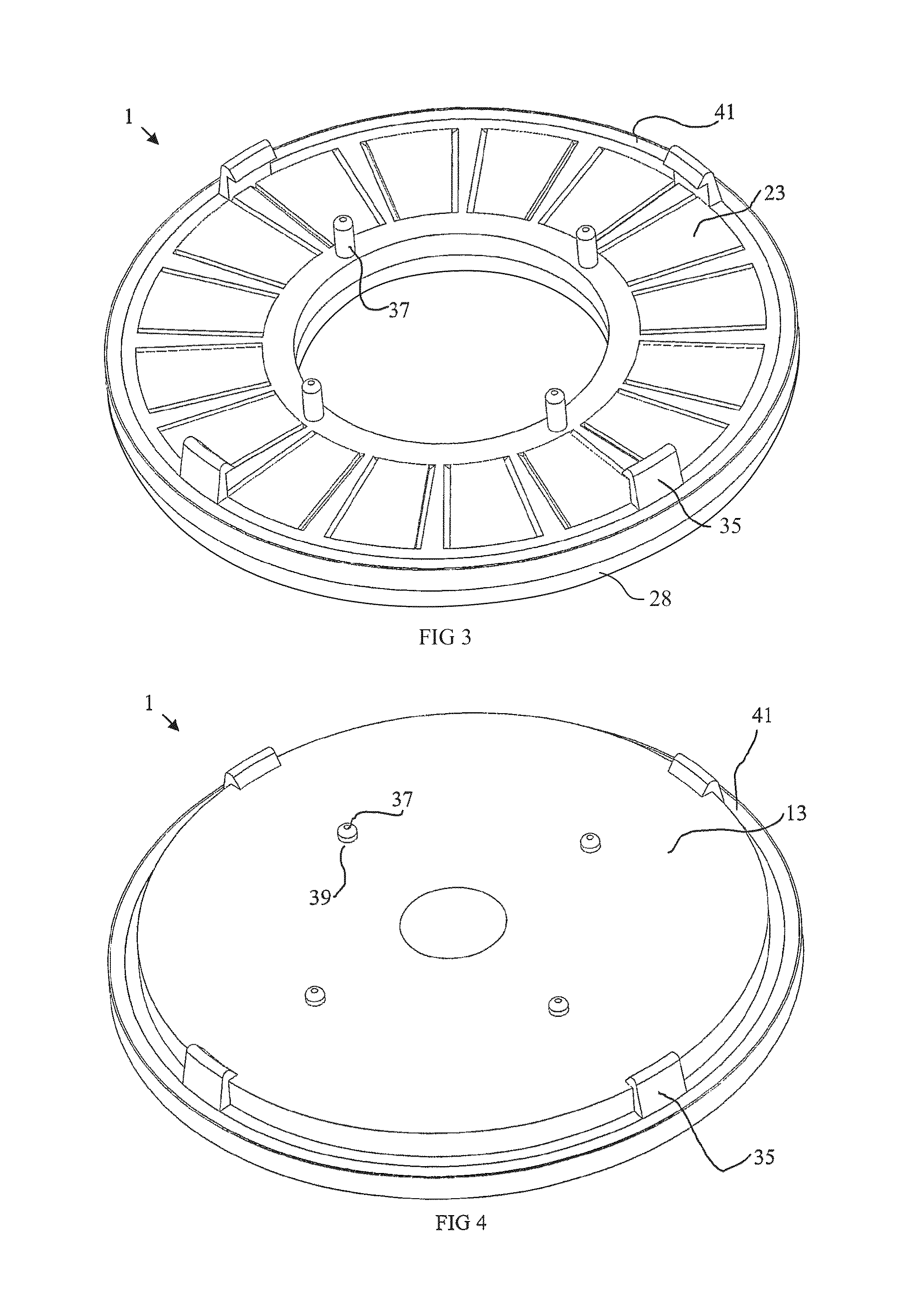

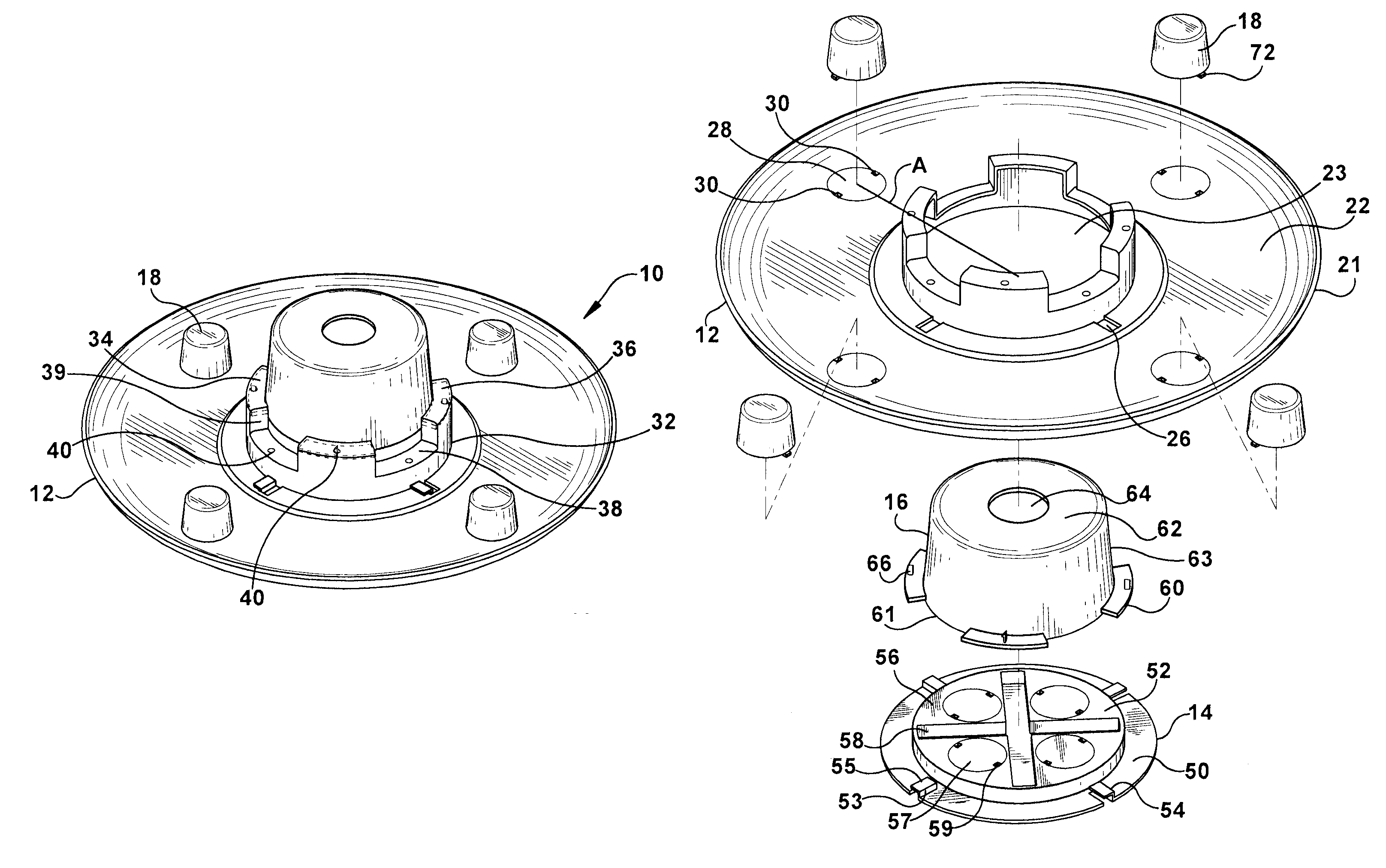

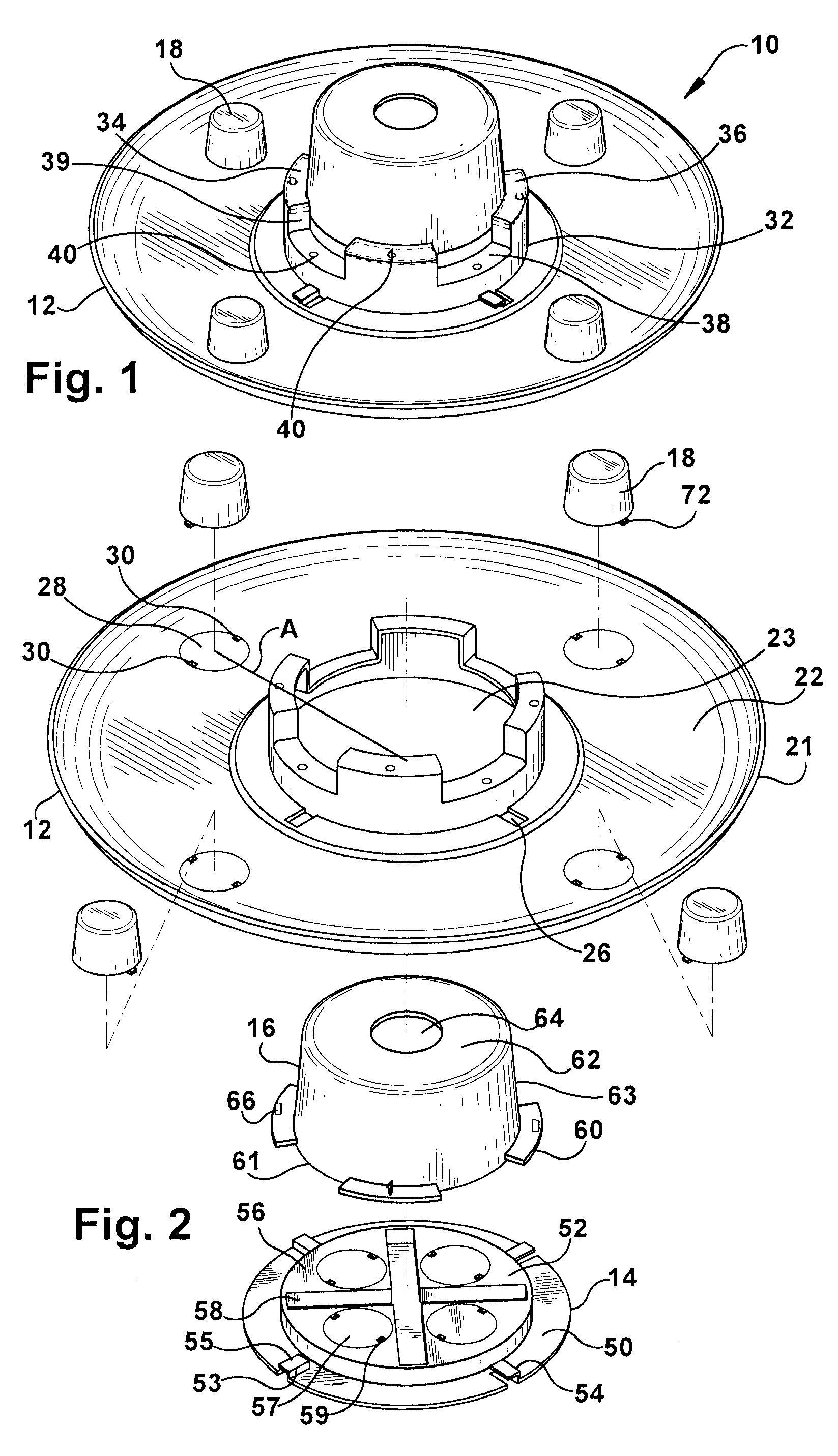

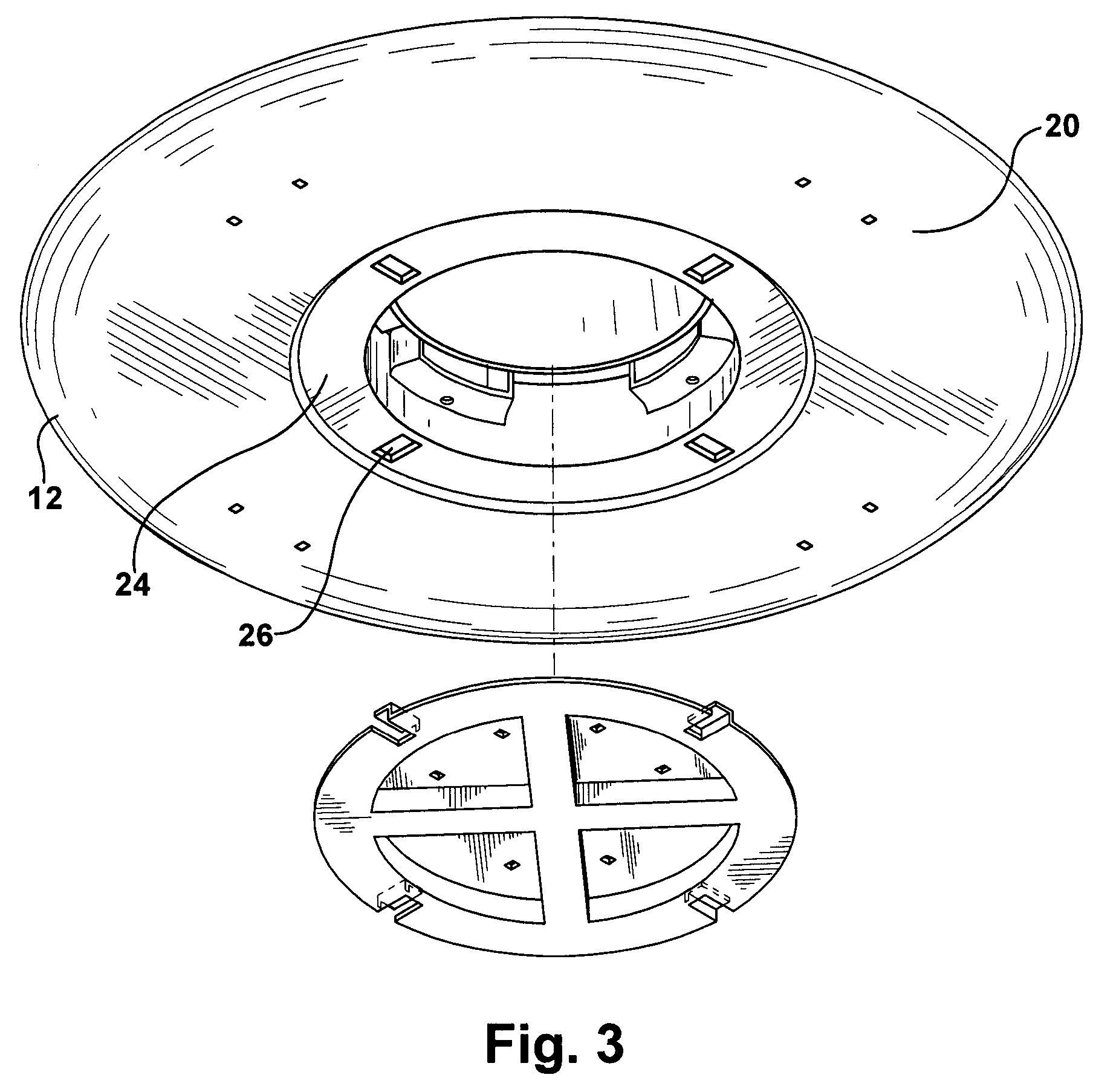

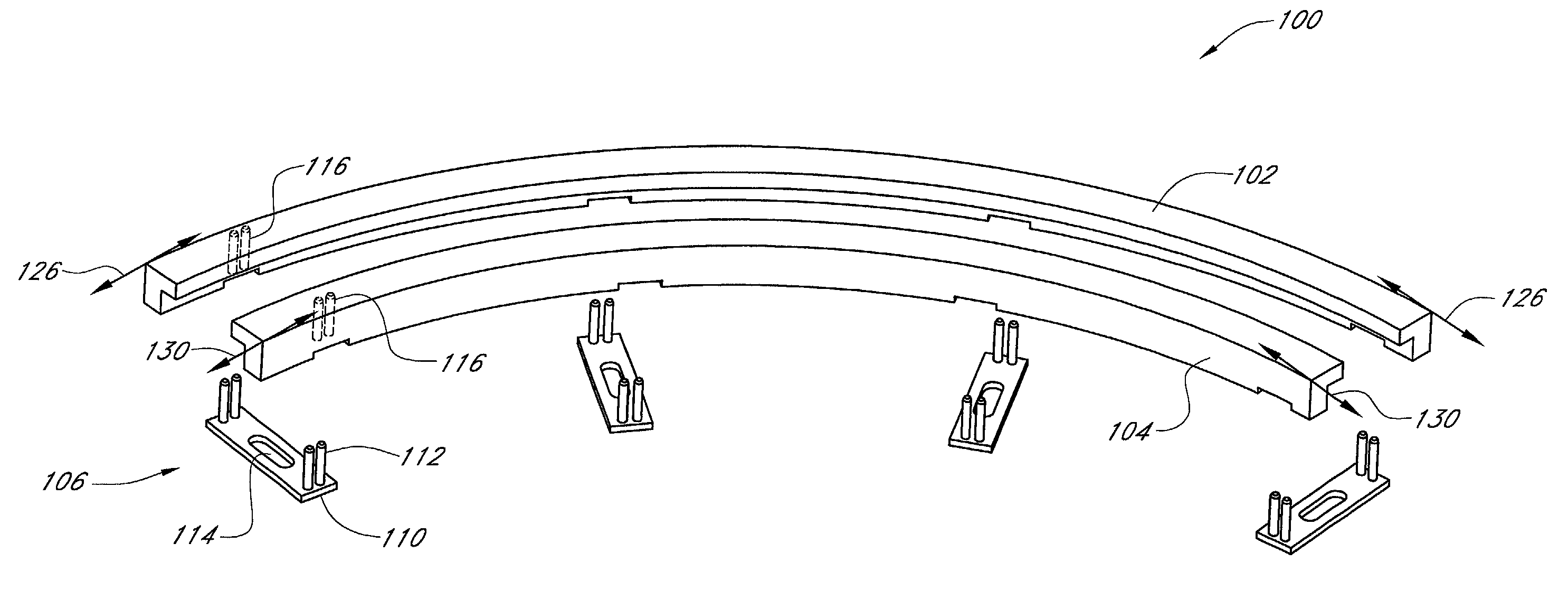

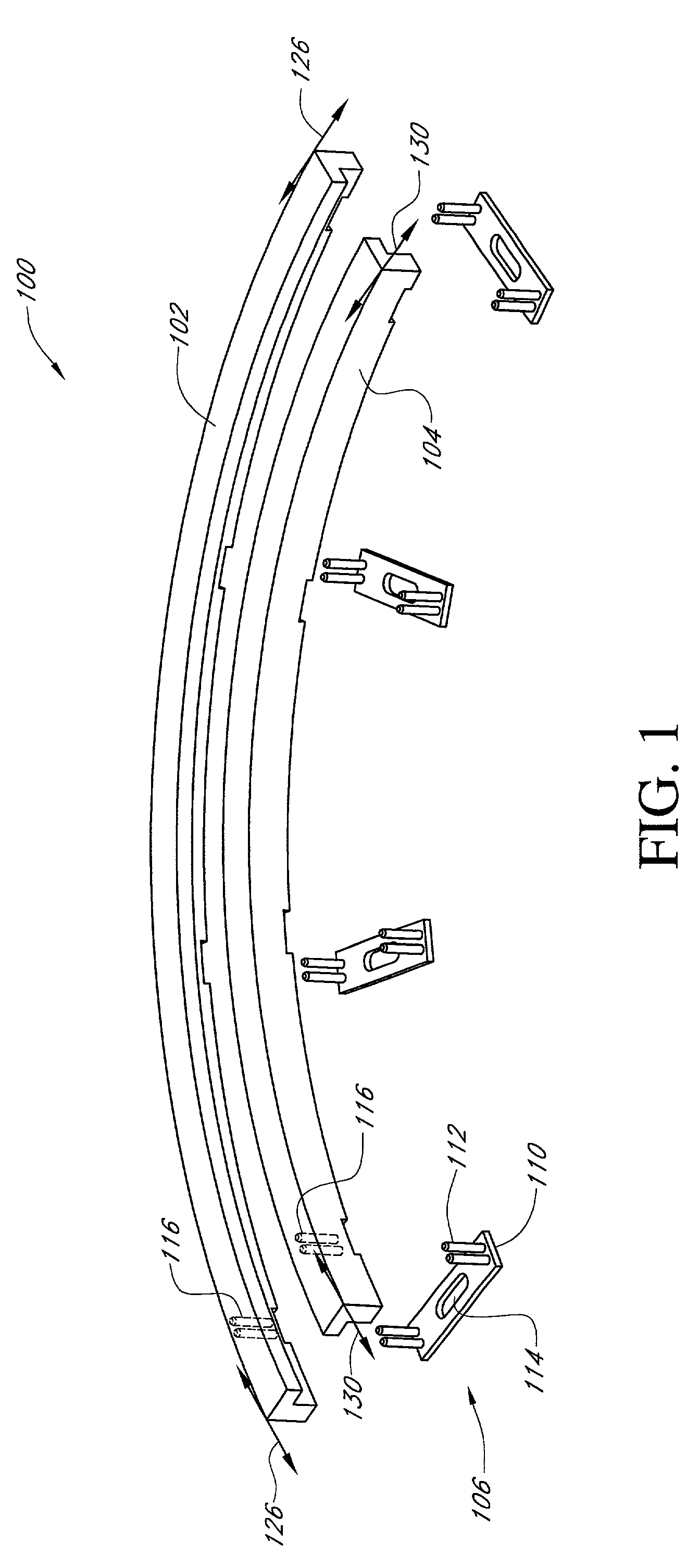

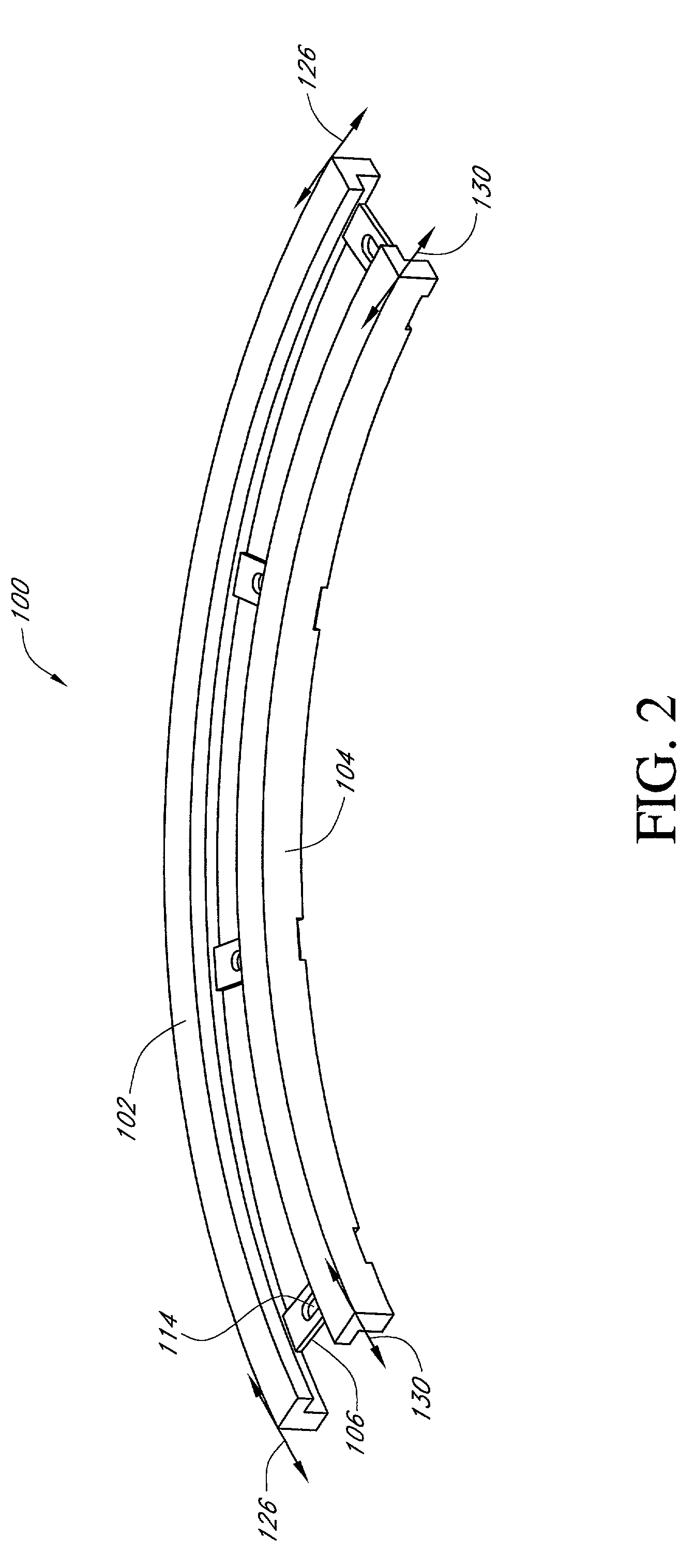

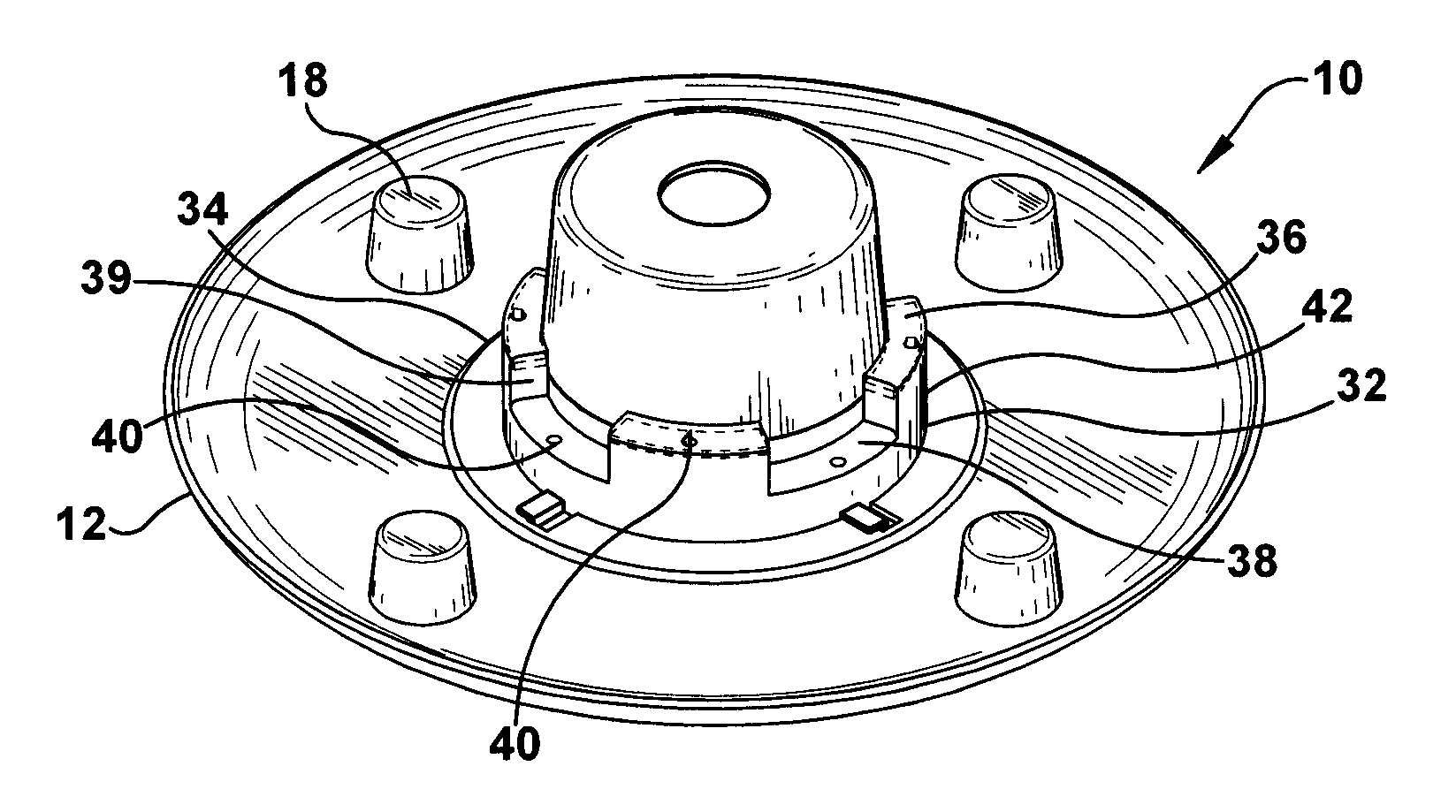

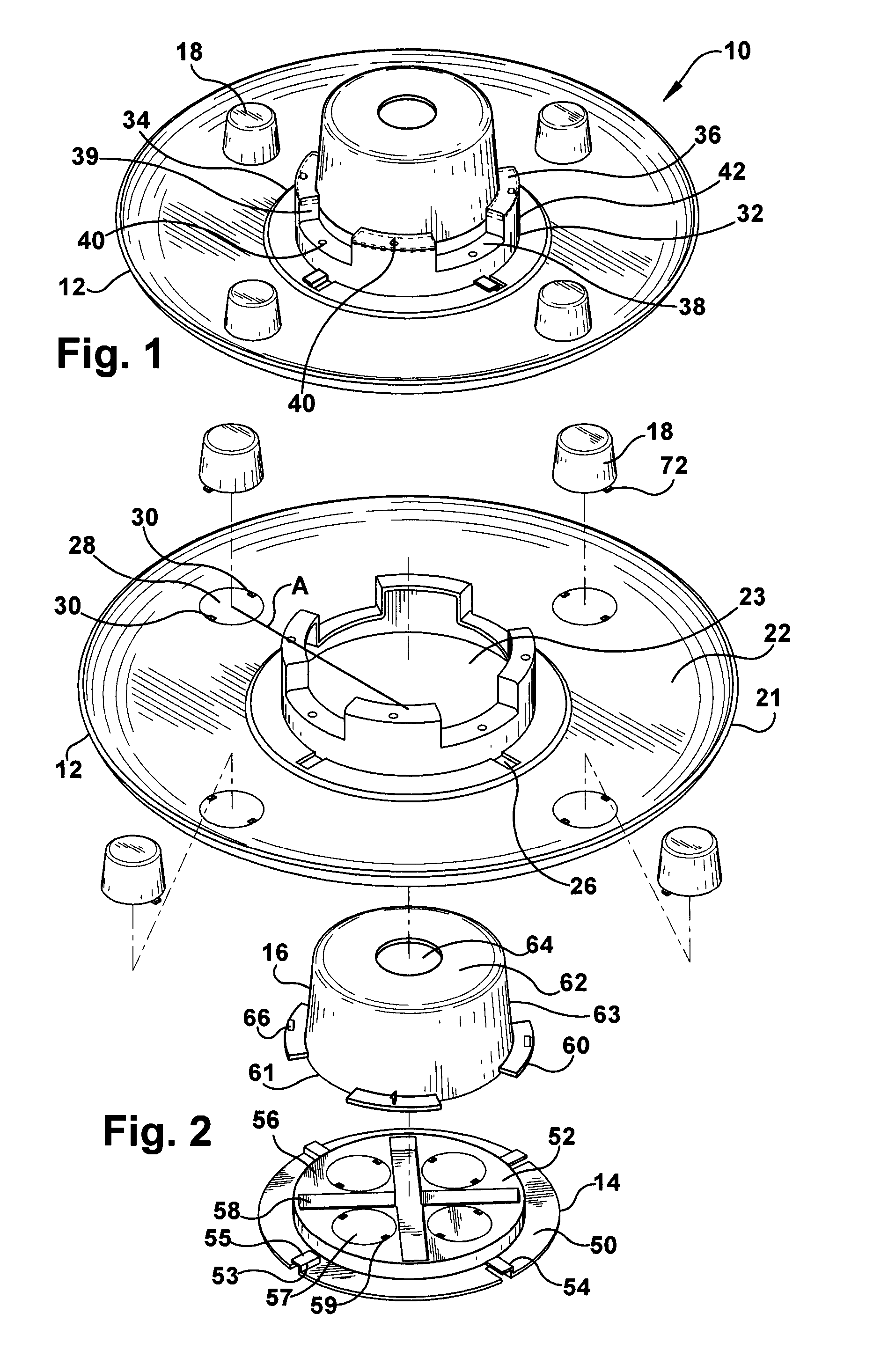

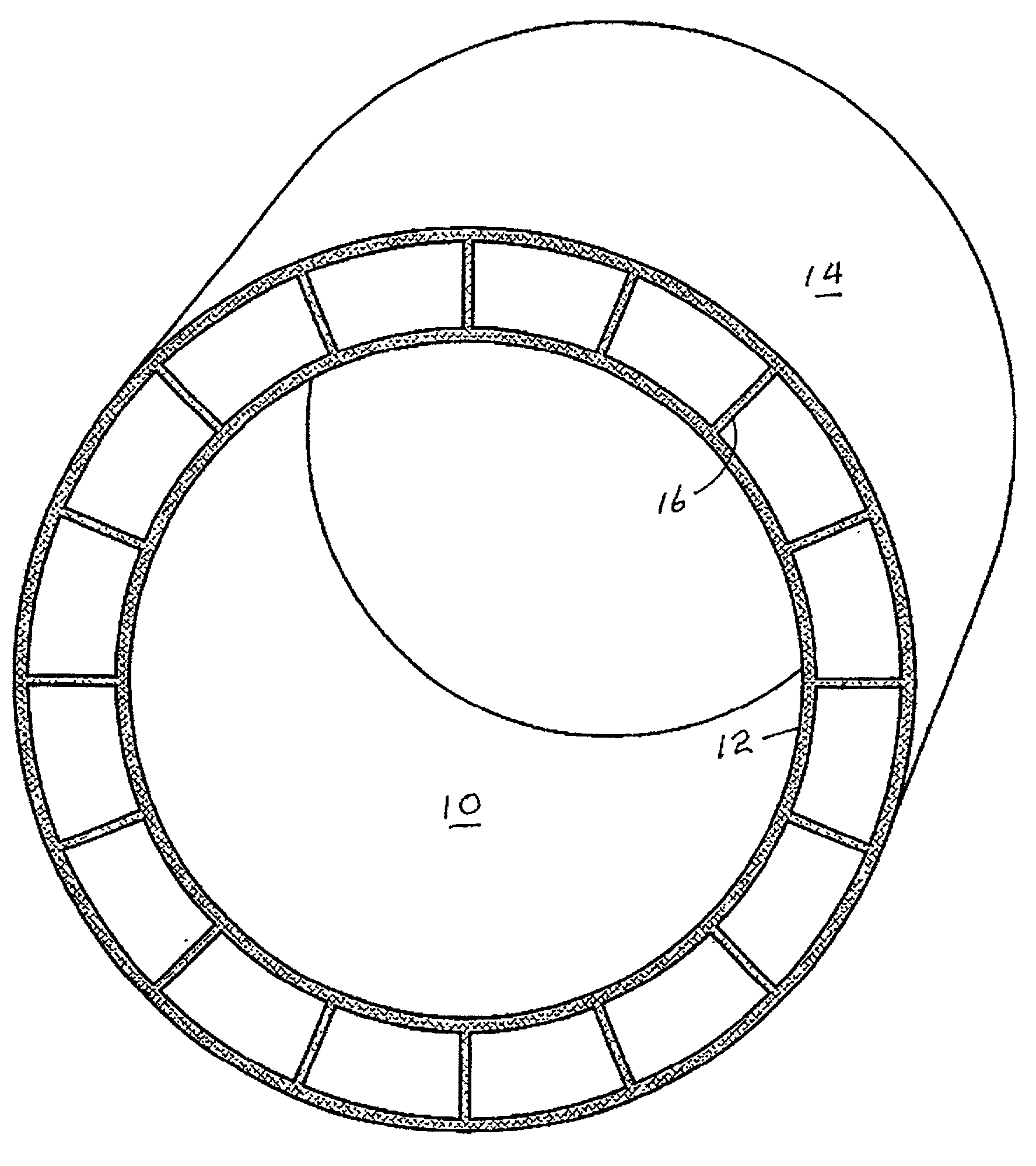

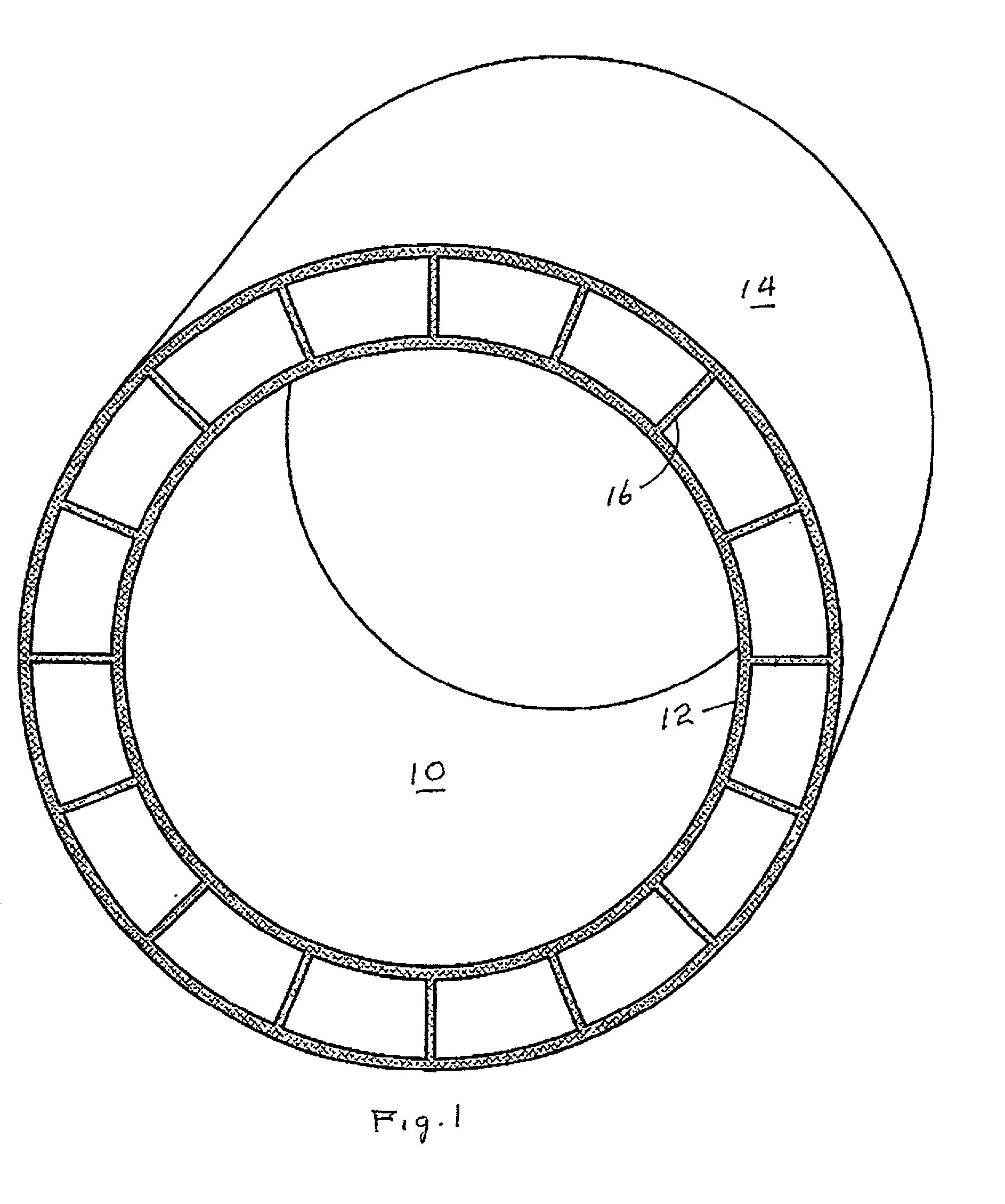

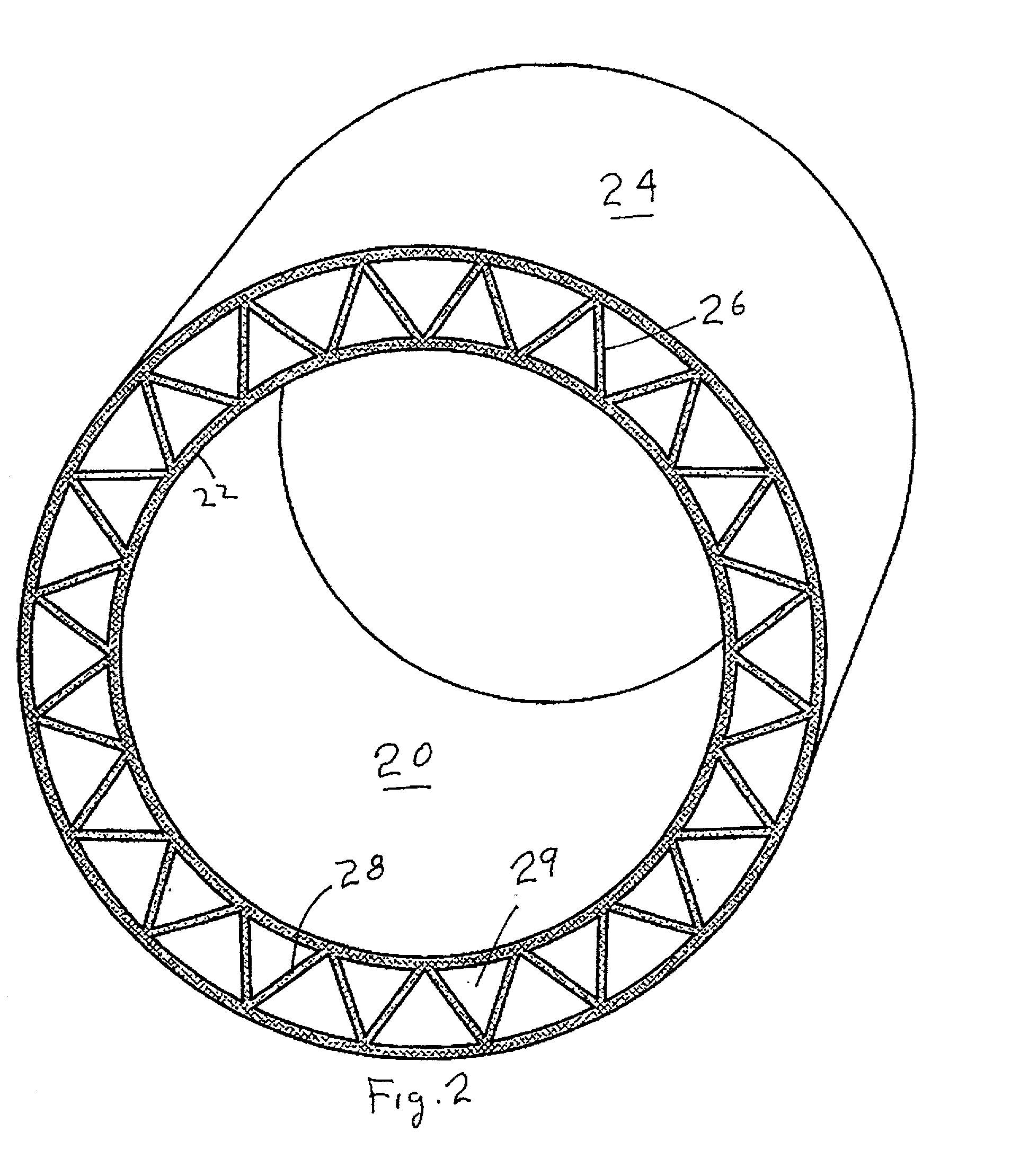

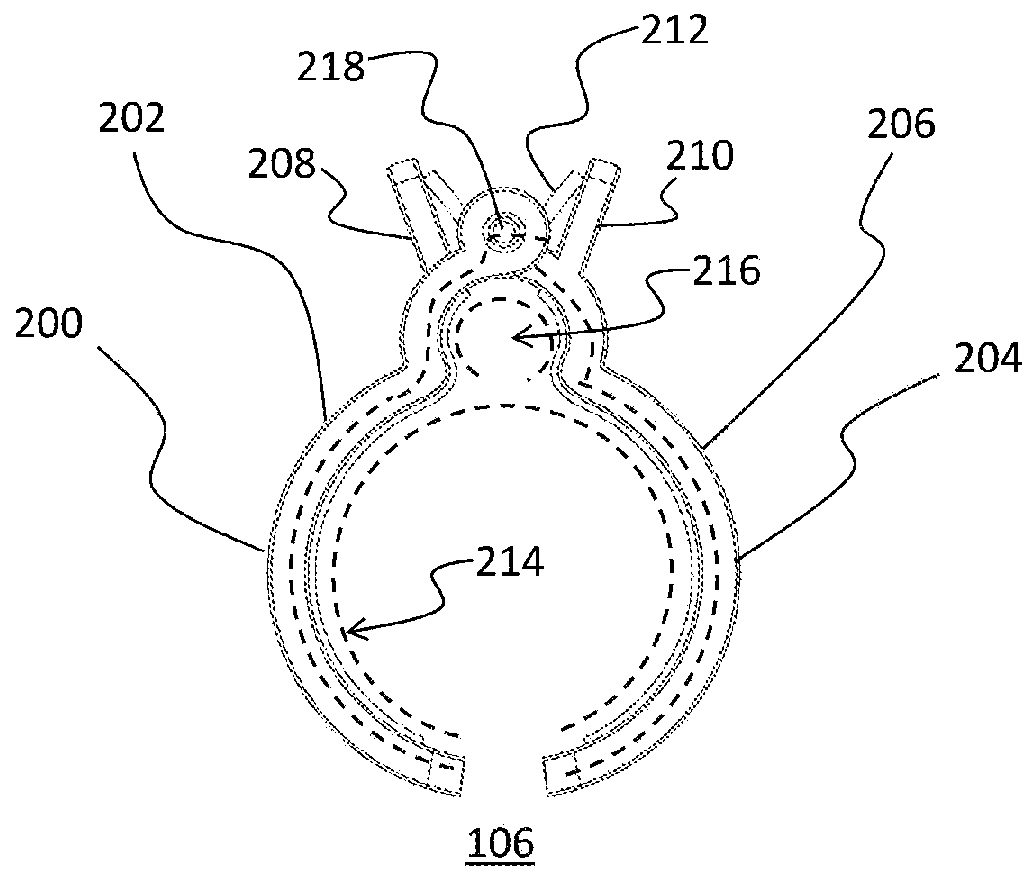

Rotor magnet positioning device

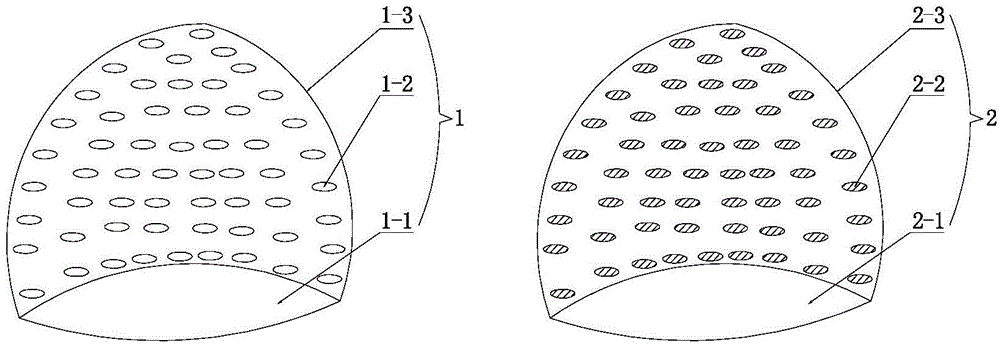

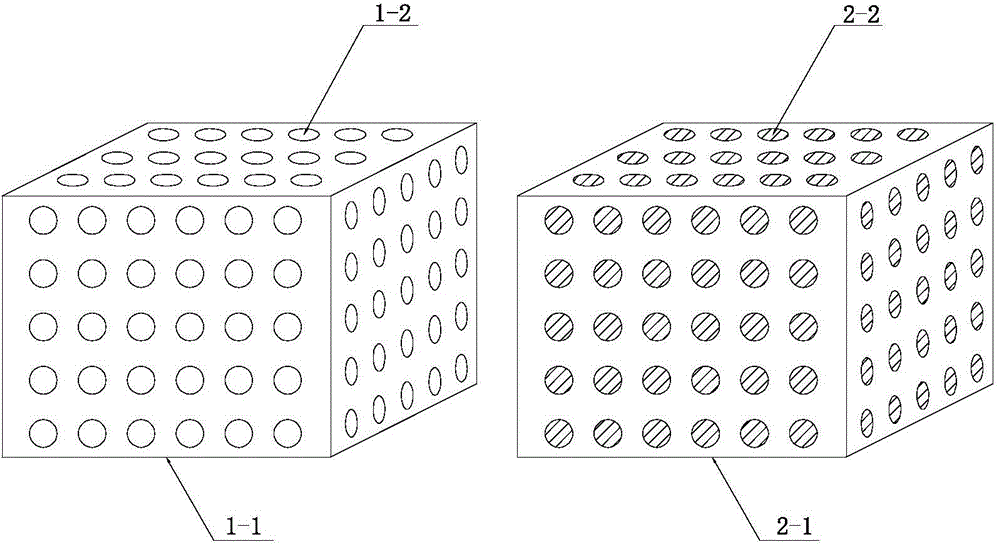

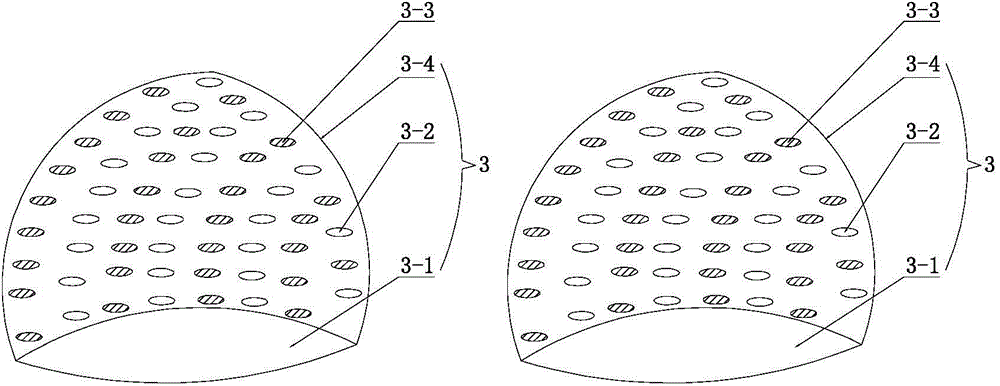

ActiveUS20100164316A1Prevent movementConsistent spacingMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotor magnetsEngineering

A device for positioning a planar array of magnets within a permanent magnet electrical machine of the type having a rotor and stator with an air gap there between. The device includes a body made of non-ferrous material and having a first side which is attachable to the rotor and a second side which, in an assembled machine, faces the air gap. The first side of the body has a plurality of recesses therein for receiving a corresponding plurality of magnets. The recesses are shaped and arranged to separate the magnets from each other and maintain a consistent spacing between them. When the device is attached to the rotor the magnets are held in a fixed position against the rotor. The electrical machine may be a motor or a generator.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

Rotor magnet positioning device

ActiveUS8598761B2Prevent movementConsistent spacingMagnetic circuit rotating partsManufacturing dynamo-electric machinesRotor magnetsEngineering

A device for positioning a planar array of magnets within a permanent magnet electrical machine of the type having a rotor and stator with an air gap there between. The device includes a body made of non-ferrous material and having a first side which is attachable to the rotor and a second side which, in an assembled machine, faces the air gap. The first side of the body has a plurality of recesses therein for receiving a corresponding plurality of magnets. The recesses are shaped and arranged to separate the magnets from each other and maintain a consistent spacing between them. When the device is attached to the rotor the magnets are held in a fixed position against the rotor. The electrical machine may be a motor or a generator.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

Dicing device for seafood processing

InactiveCN111730653AImprove cutting qualityQuick disassemblyMetal working apparatusFish cuttingEngineeringStructural engineering

The invention discloses a dicing device for seafood processing. The dicing device includes a workbench. Supporting plates are installed on the two sides of the workbench, the supporting plates are internally provided with sliding grooves, and sliding blocks are slidably embedded in the sliding grooves. A screw is rotatably installed between the sliding blocks on the two sides, and a screw sleeve spirally sleeves the screw. A shearing-forking mechanism is connected between the spirally sleeve and a fixed block. A guide rod is horizontally fixed between the sliding blocks on the two sides. A sliding sleeve connected with the shearing-forking mechanism slidably sleeves on the guide rod, and a cutter is installed at the bottom of the sliding sleeve. Lifting mechanisms are further arranged above the supporting plates. The dicing device for seafood processing can adjust the spacing of cutting blades to meet the needs of different cutting block sizes, while the spacing between adjacent cutting blades is always ensured to be same, so that the sizes of cut blocks are equal, and the uniformity of the cut blocks is guaranteed, so that the quality of the cut blocks is improved.

Owner:黄谦明

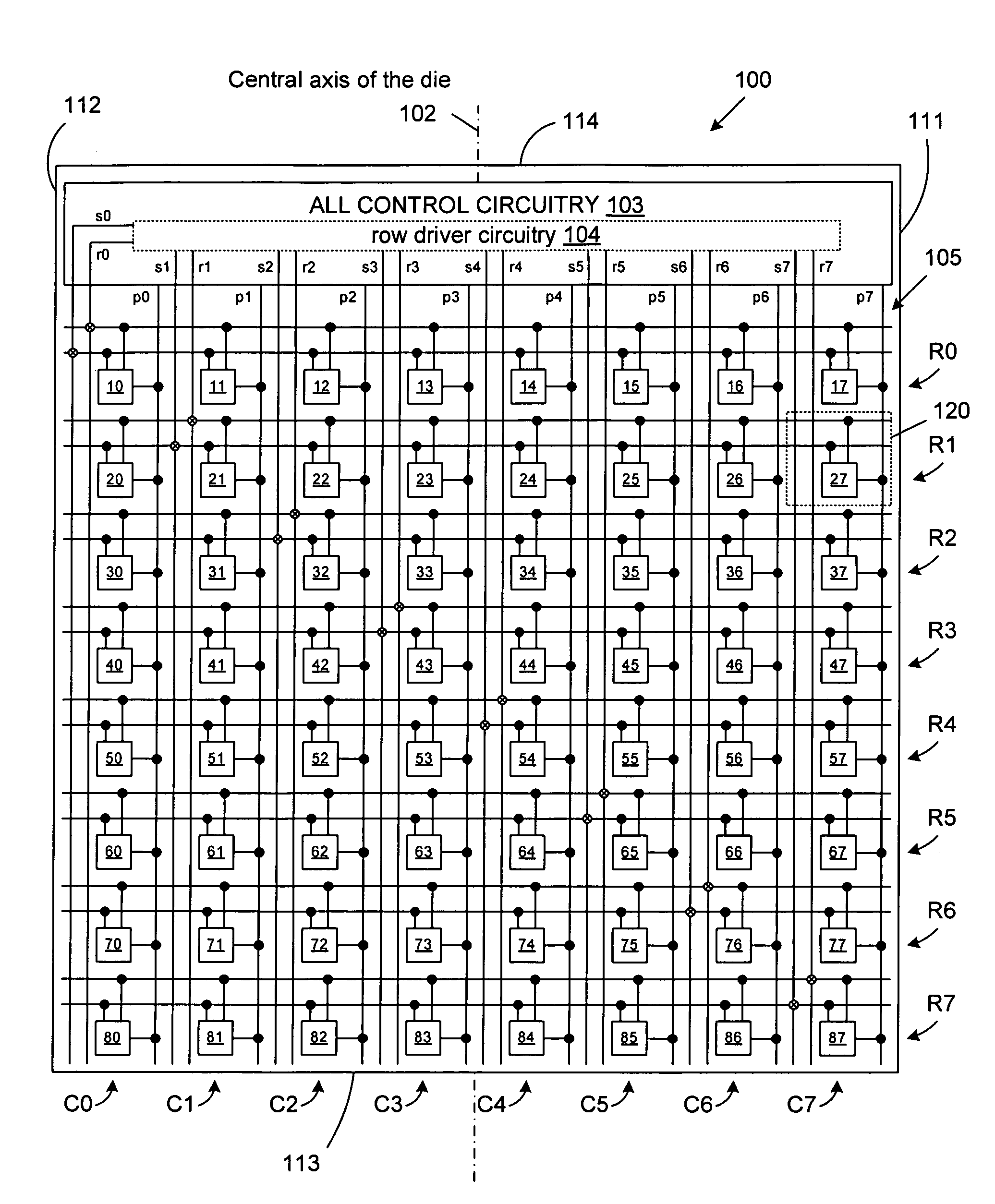

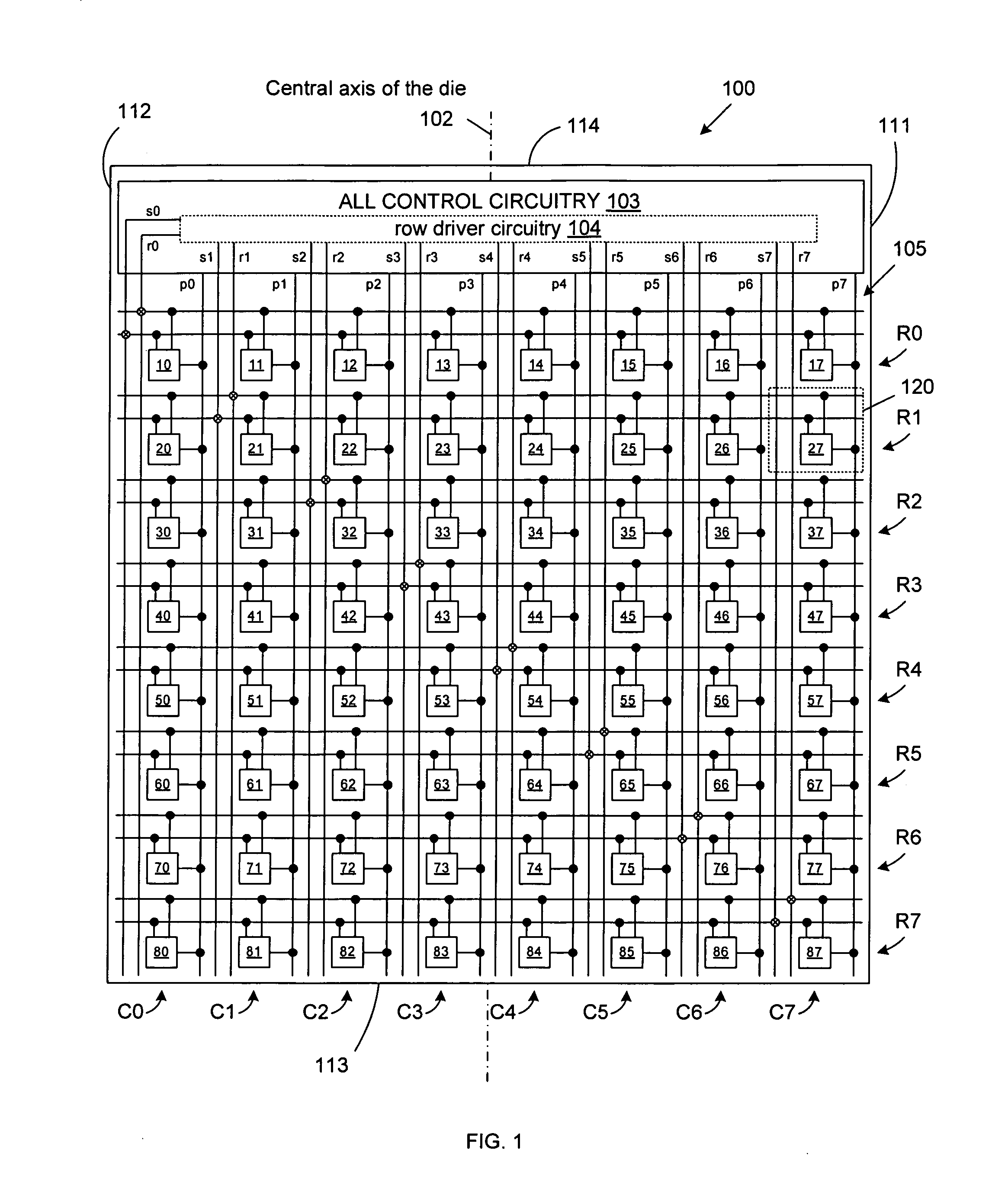

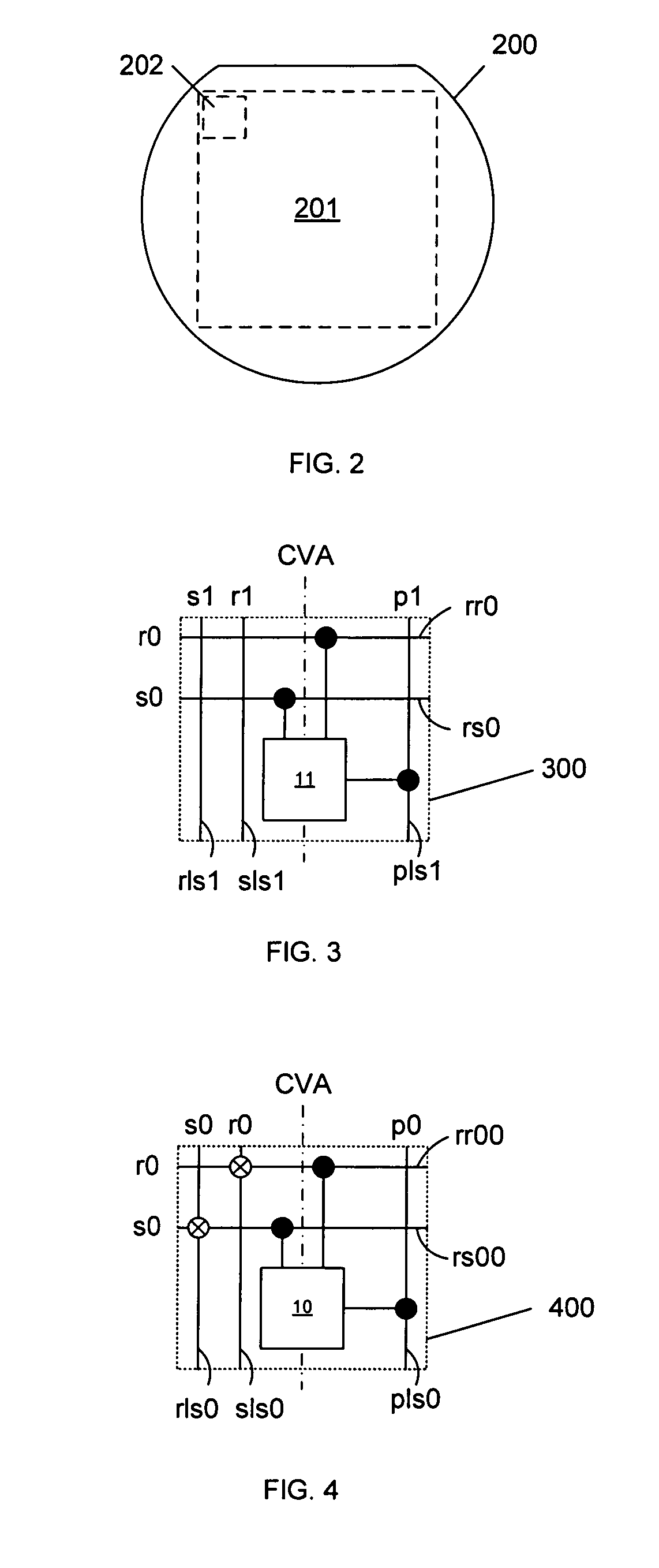

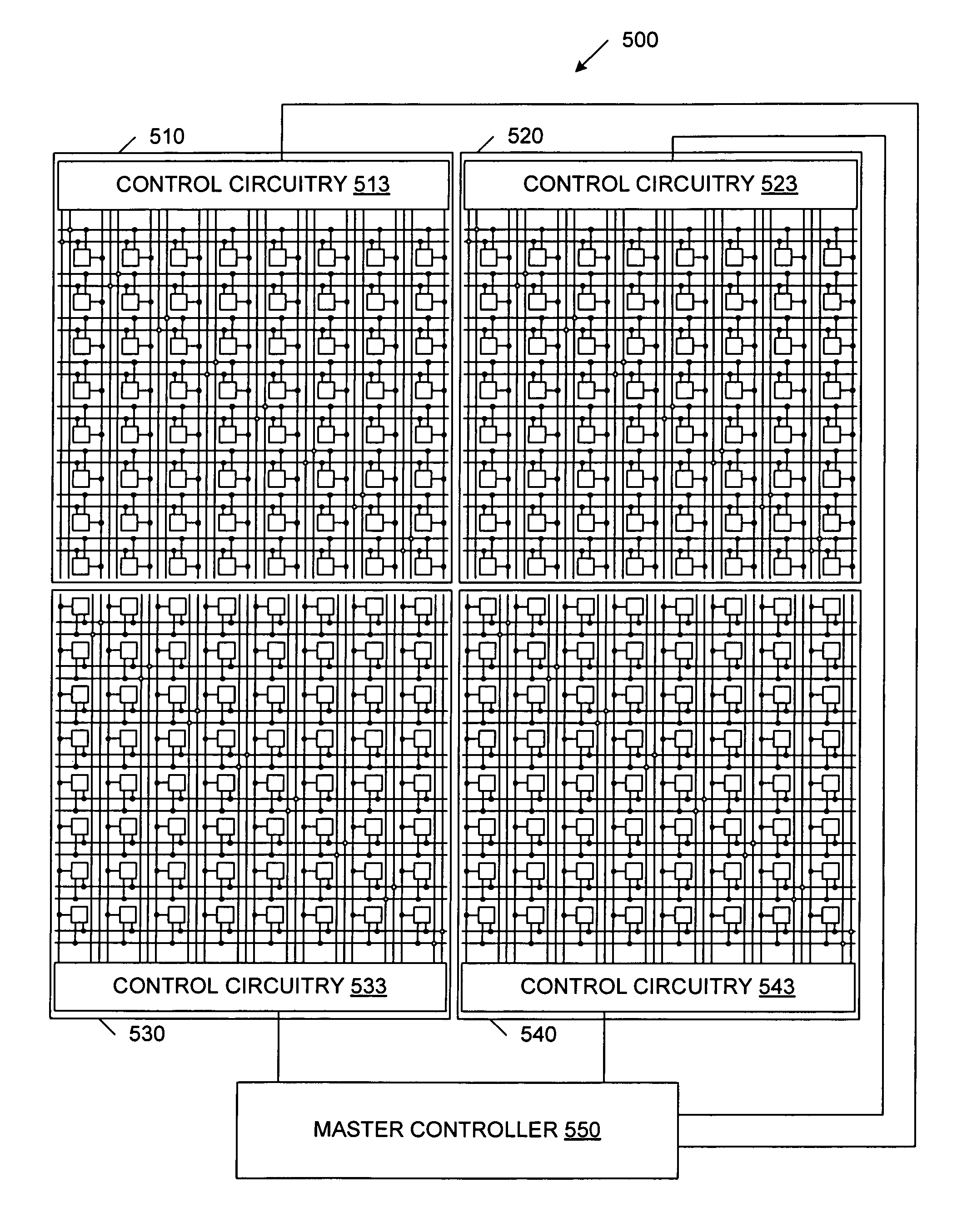

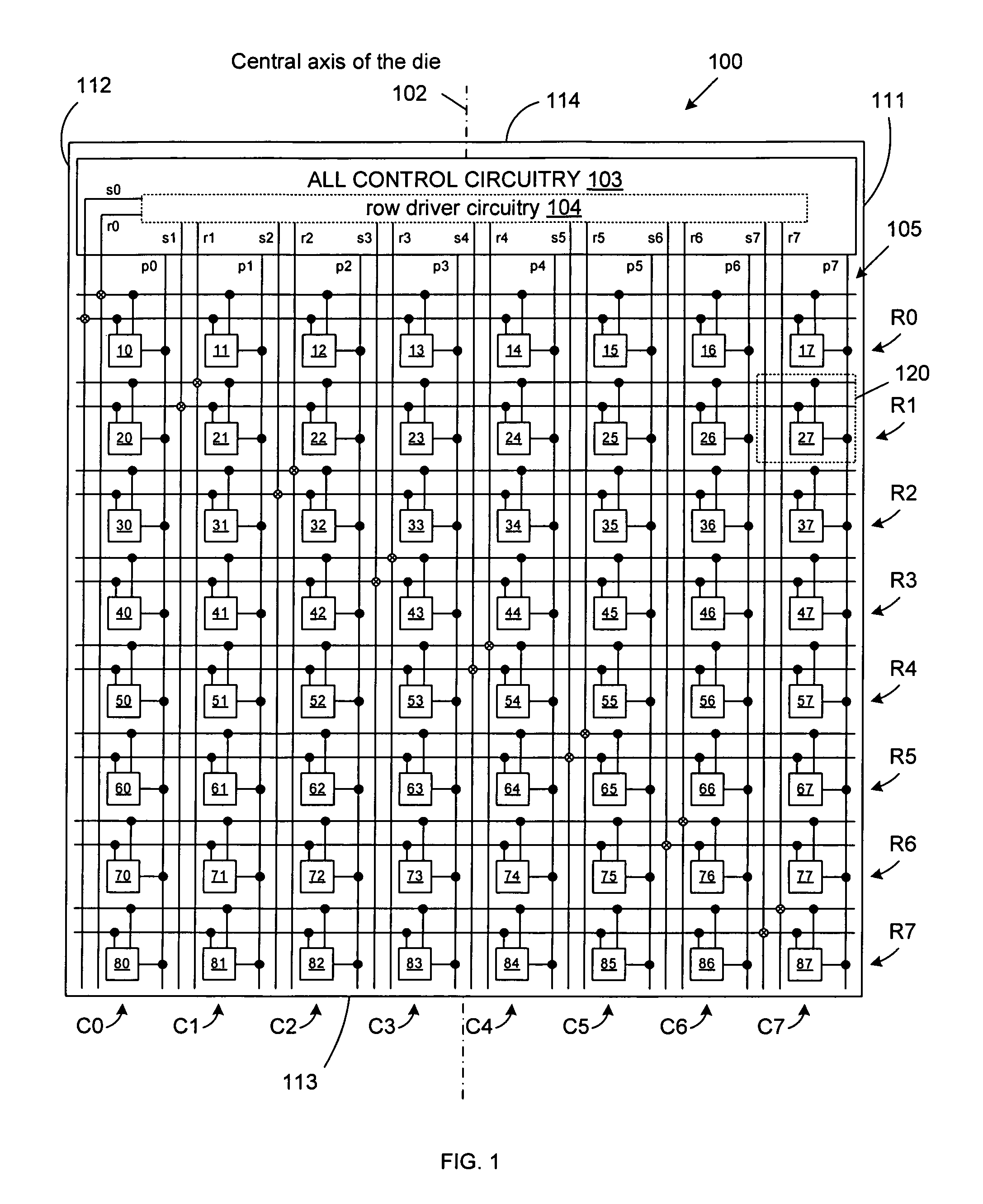

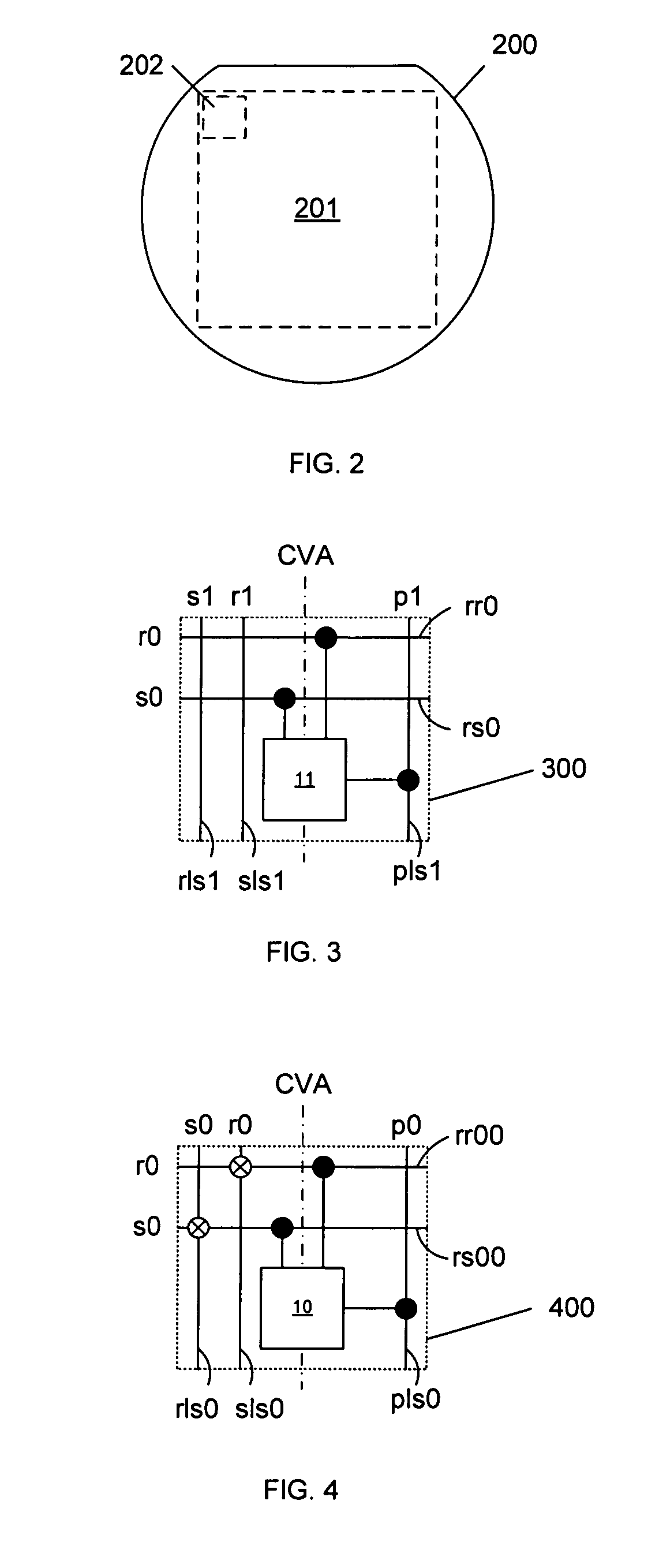

Horizontal Row Drivers For CMOS Image Sensor With Tiling On Three Edges

ActiveUS20090179141A1Improve fill factorHigh sensitivityTelevision system detailsTelevision system scanning detailsCMOSControl circuit

A large image sensor structure is created by tiling a plurality of image sensor dies, wherein each of the image sensor dies includes a pixel array that extends to three edges of the die, and control circuitry located along a fourth edge of the die. None of the control circuitry required to access the pixel array (e.g., none of the row driver circuitry) is located in the pixel array, thereby enabling consistent spacing of pixels across the pixel array. Because the pixel array of each image sensor die extends to three edges of the die, the pixel array of each image sensor die can abut up to three pixel arrays in other image sensor dies to form a large image sensor structure having 2×N tiled image sensor dies.

Owner:TOWER SEMICONDUCTOR

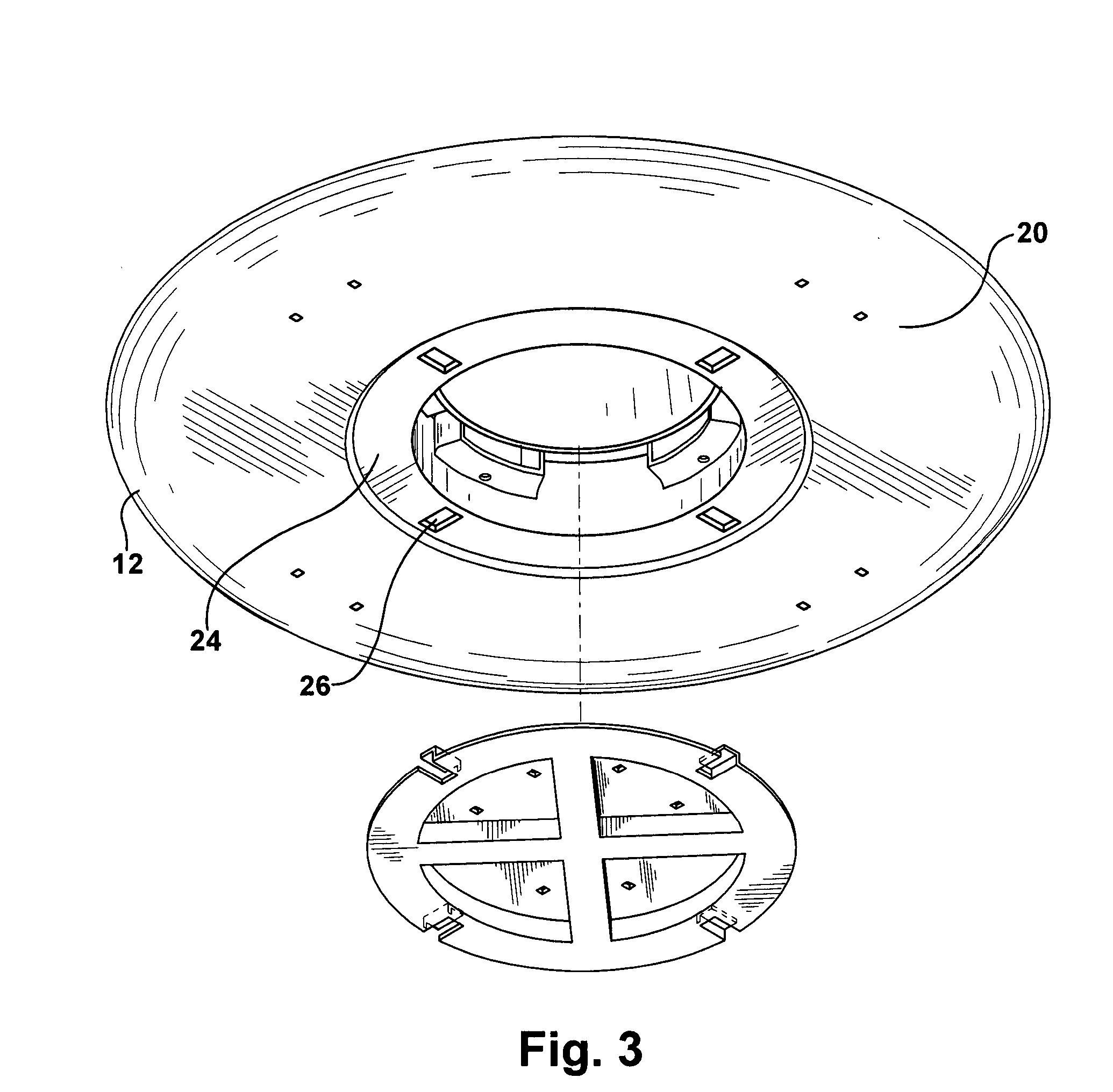

Spare tire undercover

InactiveUS7770764B2Improve stabilityConsistent spacingSupplementary fittingsAerodynamics improvementSpare tireAerodynamics

Owner:HONDA MOTOR CO LTD

Conveyor chain guide system

Owner:SOLUS INDAL INNOVATIONS

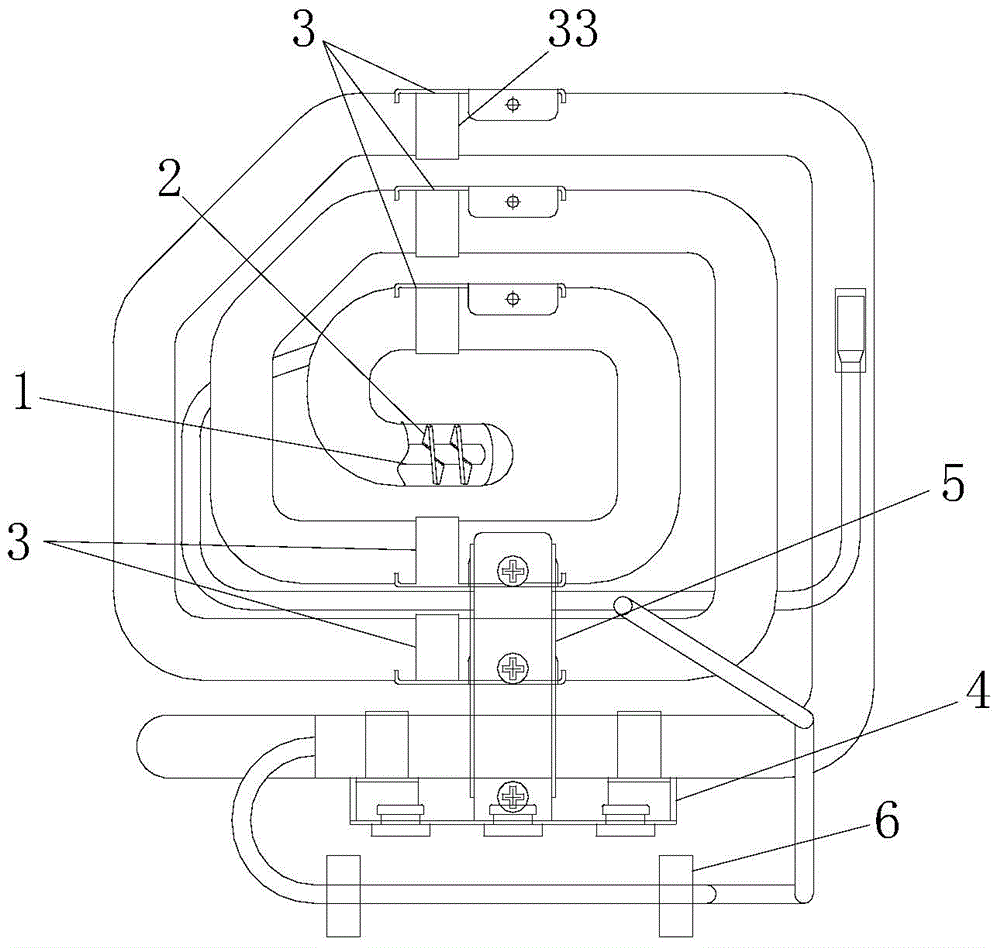

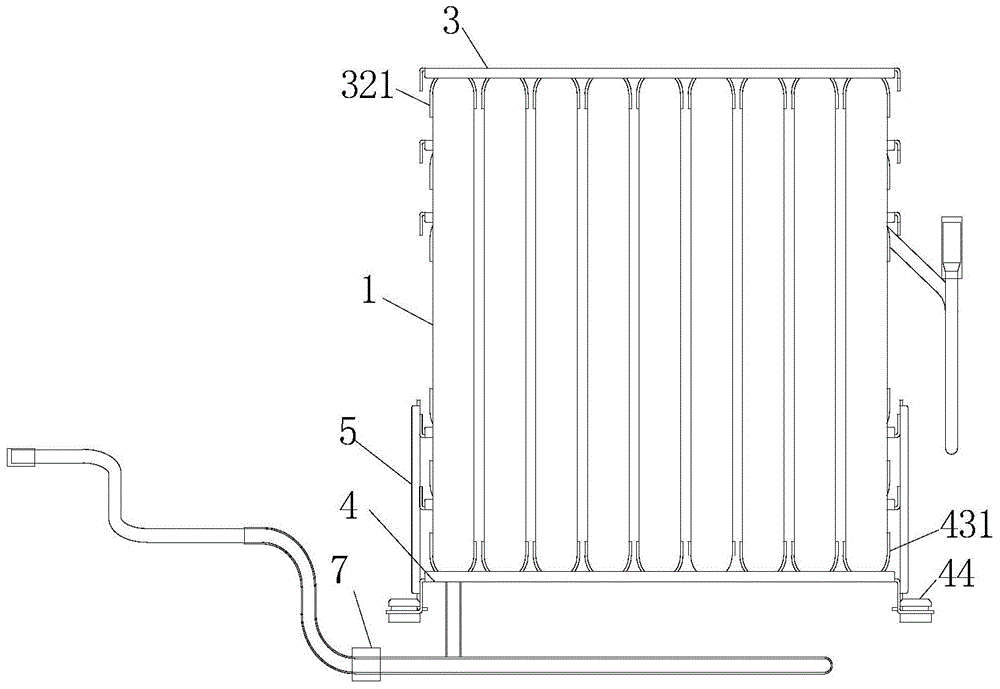

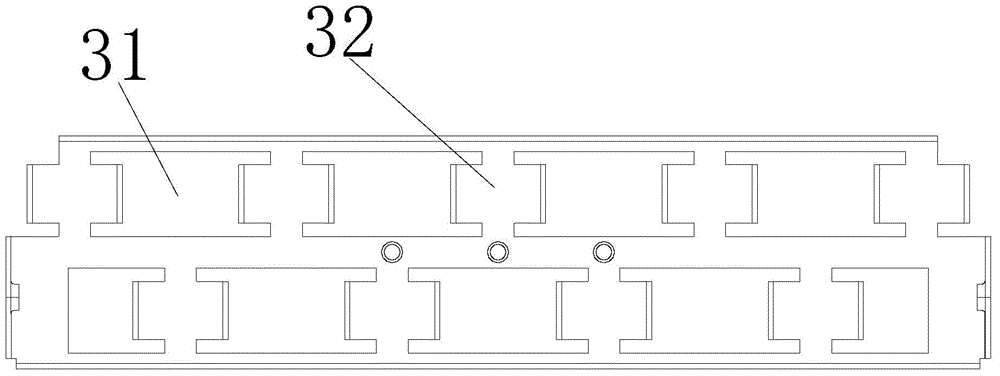

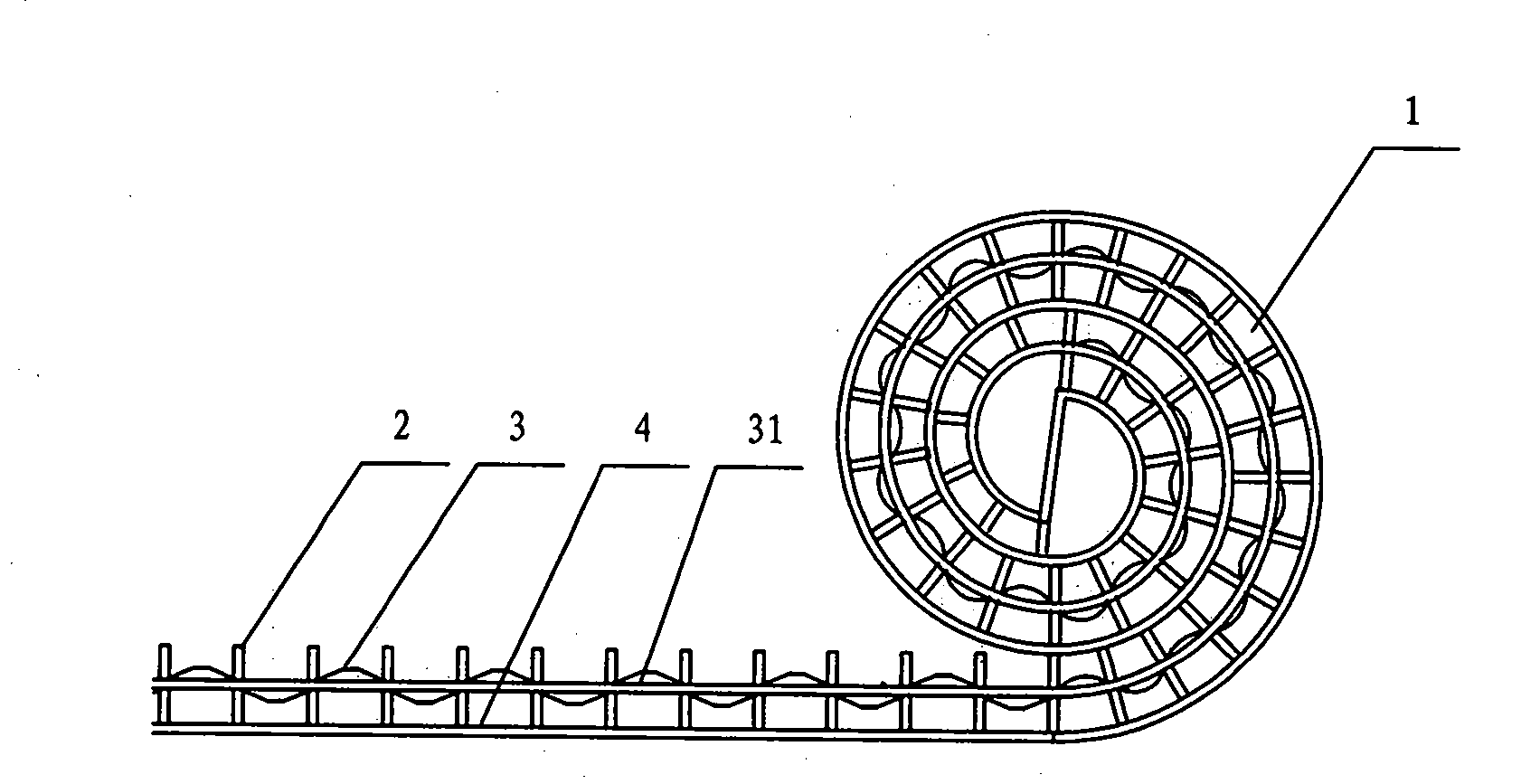

Spiral condenser and manufacturing process of spiral condenser

InactiveCN104315760AReduce labor intensityImprove protectionEvaporators/condensersHeat exchanger casingsEngineeringConductor Coil

The invention relates to a spiral condenser, which comprises a heat radiation pipe and fins, wherein the heat radiation pipe forms a cuboid structure through bending and winding, the cuboid structure consists of a plurality of layers of circuitous heat radiation pipe units, the heat radiation pipe units are mutually parallel, in addition, the gap between the heat radiation pipe units is set to be 10mm to 30mm, the fins are spirally arranged on the outer surface of the heat radiation pipe in a winding way and are of a straight sheet type structure, the gap between the adjacent fin blades is set to be 4mm to 10mm, the spiral condenser also comprises a support frame assembly used for supporting and fixing the cuboid structure consisting of the layers of circuitous heat radiation pipe units. The spiral condenser has the characteristics that the cost is low, the manufacturing is simple, the heat radiation effect is good, the refrigeration is fast, and the like.

Owner:CHANGZHOU CHANGZHENG HEAT EXCHANGER TECH

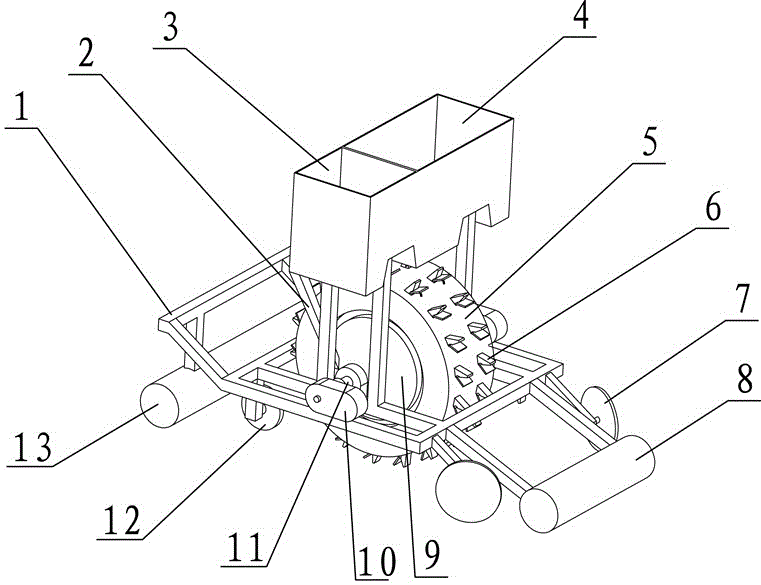

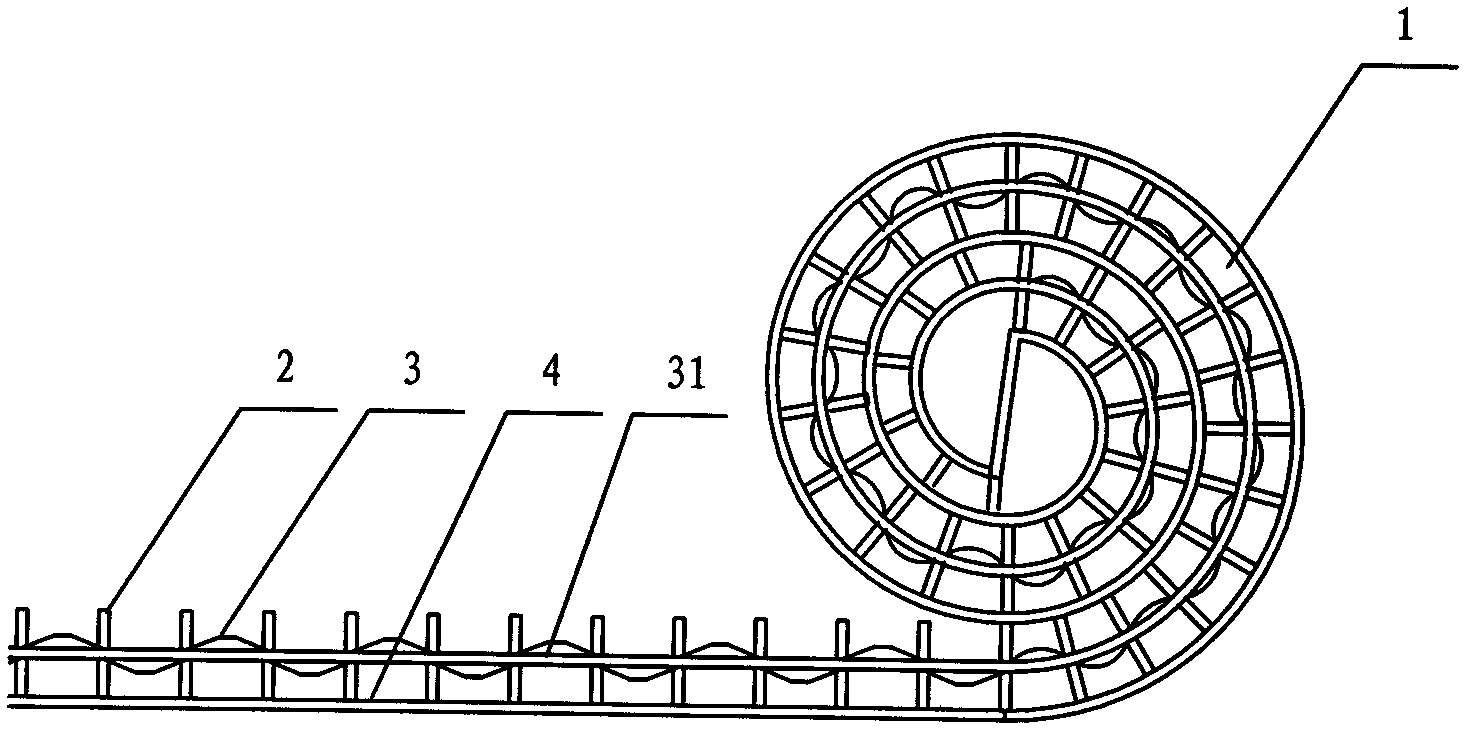

Bunch-planting type synchronous sowing and fertilizing machine

ActiveCN105103726AHeavy loadShorten the lengthRegular seed deposition machinesFertiliser and seeding apparatusAgricultural engineeringUtilization rate

The present invention provides a bunch-planting synchronous sowing and fertilizing machine which solves the technical problems that an current sowing and fertilizing machine cannot synchronously apply a fertilizer according to sowing positions, is serious in fertilizer waste, is complex in structure and large in size. According to the technical scheme, the key point is that a sowing device and a fertilizing device are an integrated type sowing and fertilizing device as follows: a roller-shaped bunch-planting wheel is fixed on a main shaft, wherein left and right chambers are arranged in the bunch-planting wheel; the bunch-planting wheel is provided with a duckbill-shaped soil opener which communicates with the two chambers respectively; the two chambers are respectively provided with a seeding unit assembly and a fertilizing unit assembly; a seed guide slot plate is arranged in the seeding unit assembly; a fertilizer guide slot plate is arranged in the fertilizing unit assembly; the fertilizer guide slot plate is in the shape of a circular slot with a radial fertilizer guide partition plate; a seed tank communicates with the seeding unit assembly; and a fertilizer tank communicates with the fertilizing unit assembly. According to the bunch-planting synchronous sowing and fertilizing machine, the length of the entire machine is shortened, operational flexibility is increased, accurate bunch planting is performed by synchronously implementing seeding and fertilizing, seeding and fertilizing intervals are maintained consistent, the fertilizer waste is reduced, and a fertilizer utilization rate is ensured.

Owner:沈阳市农业机械化研究所

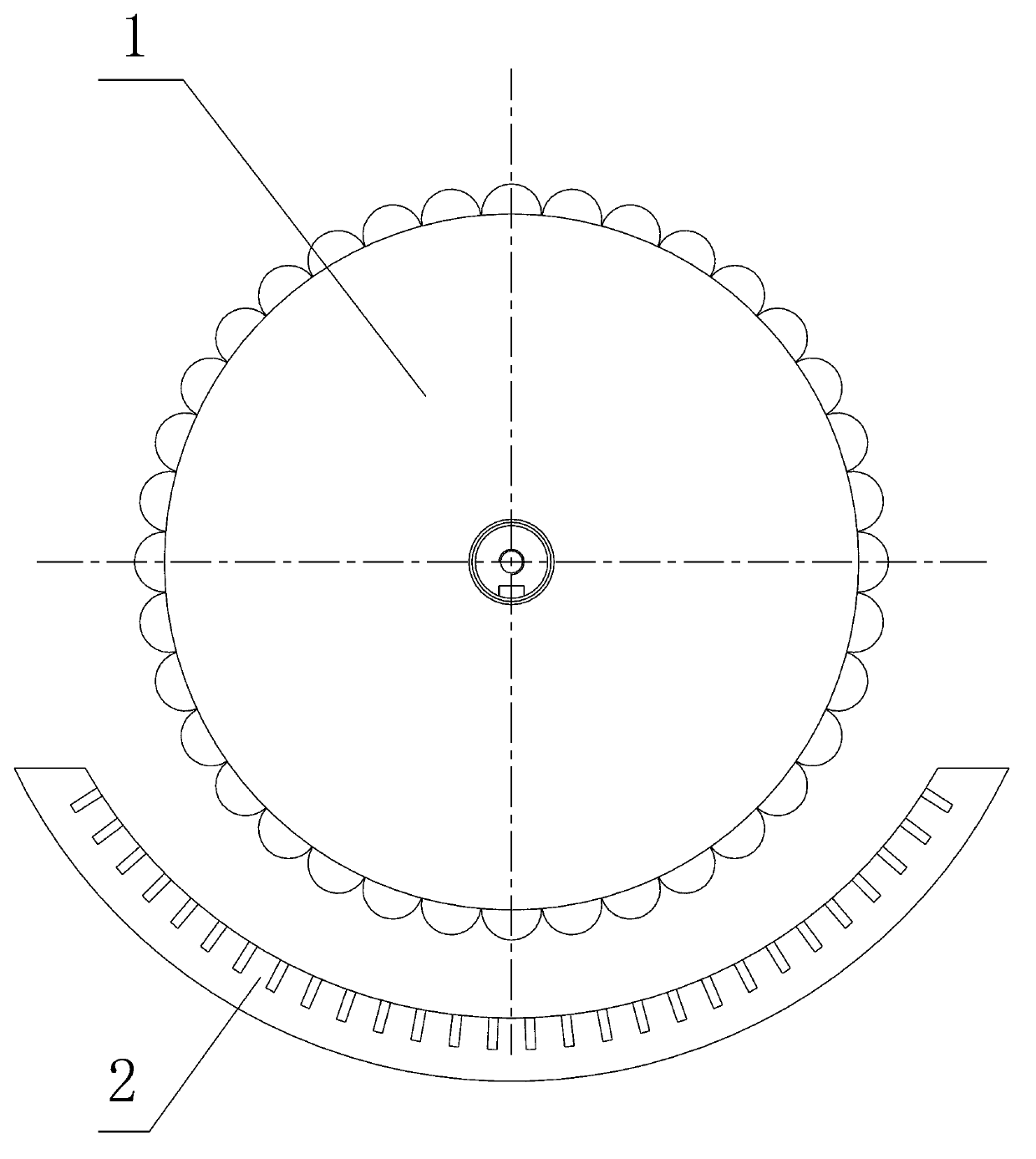

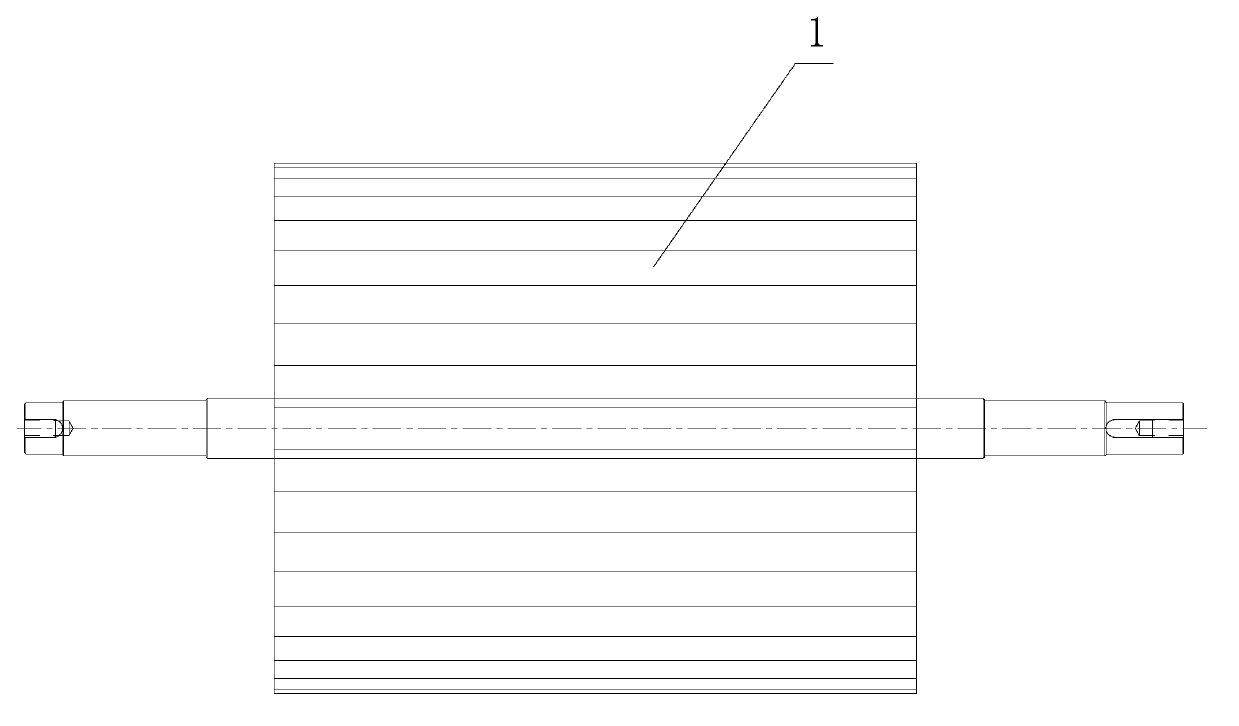

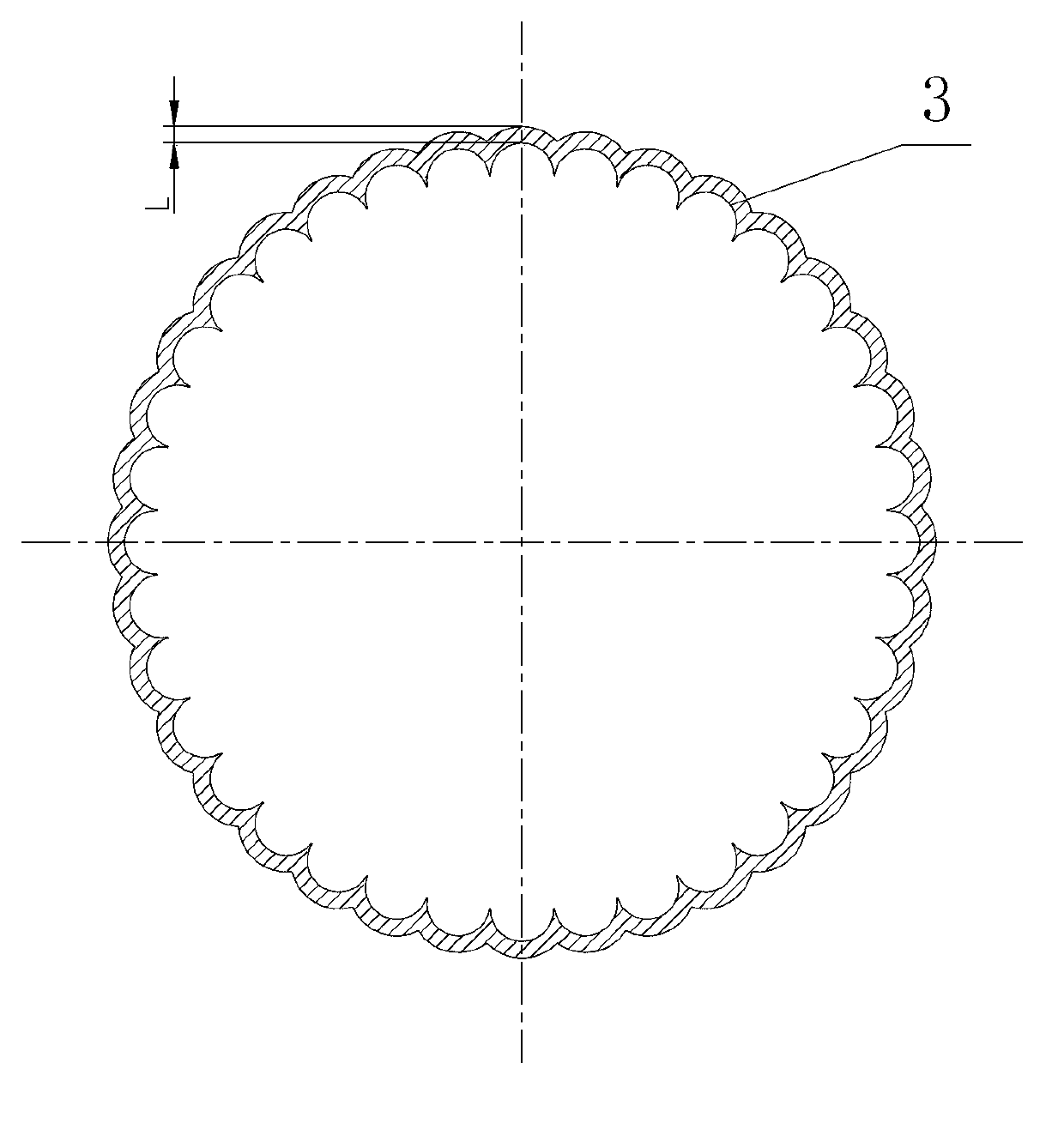

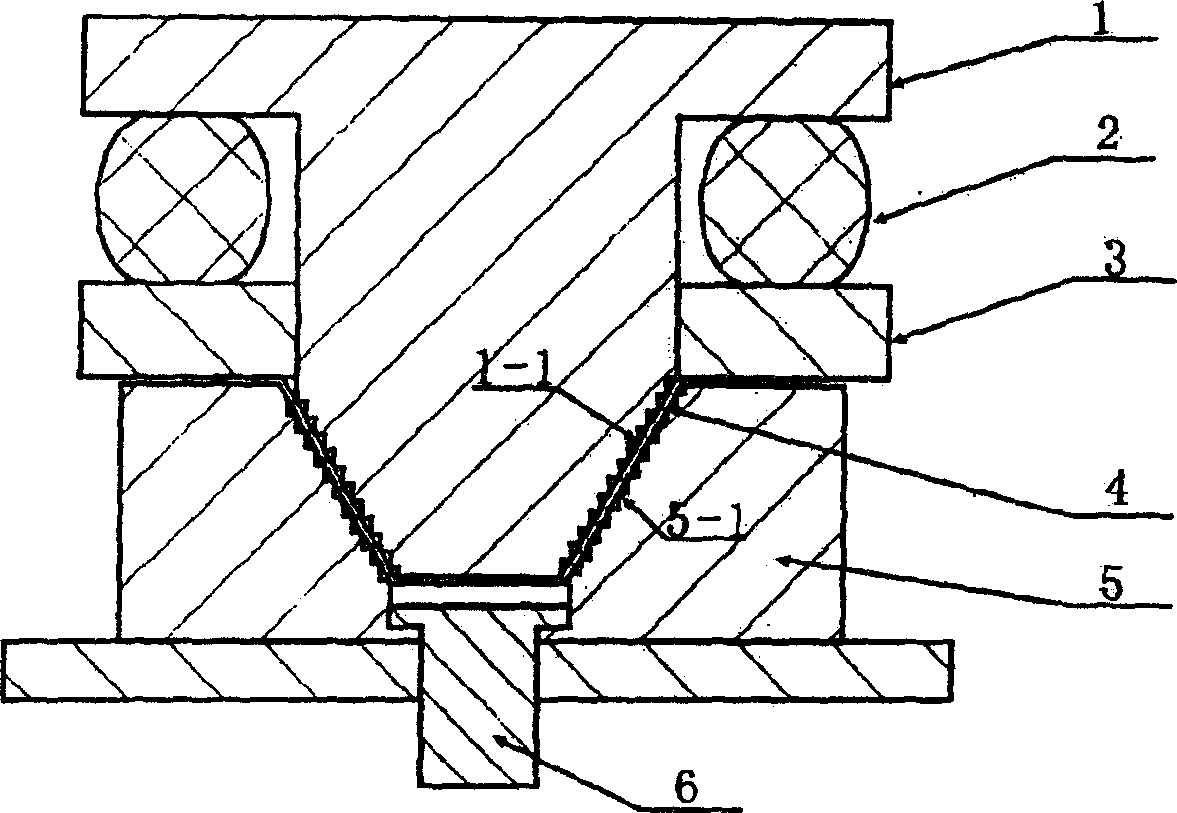

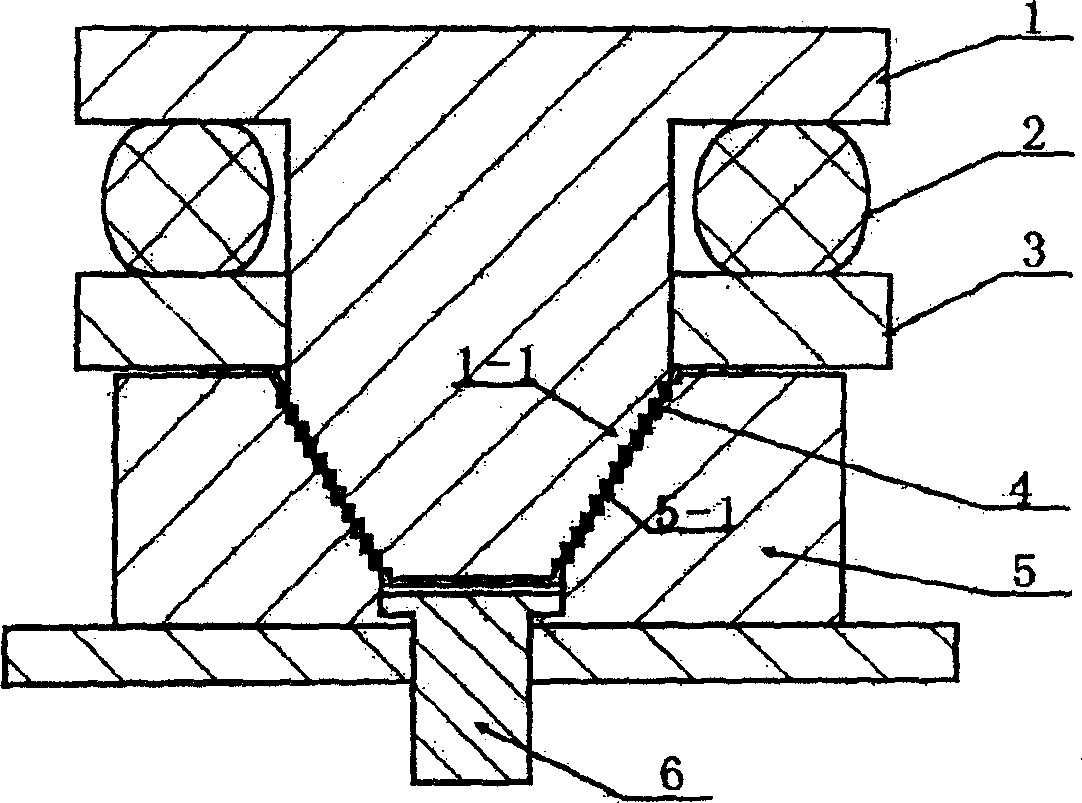

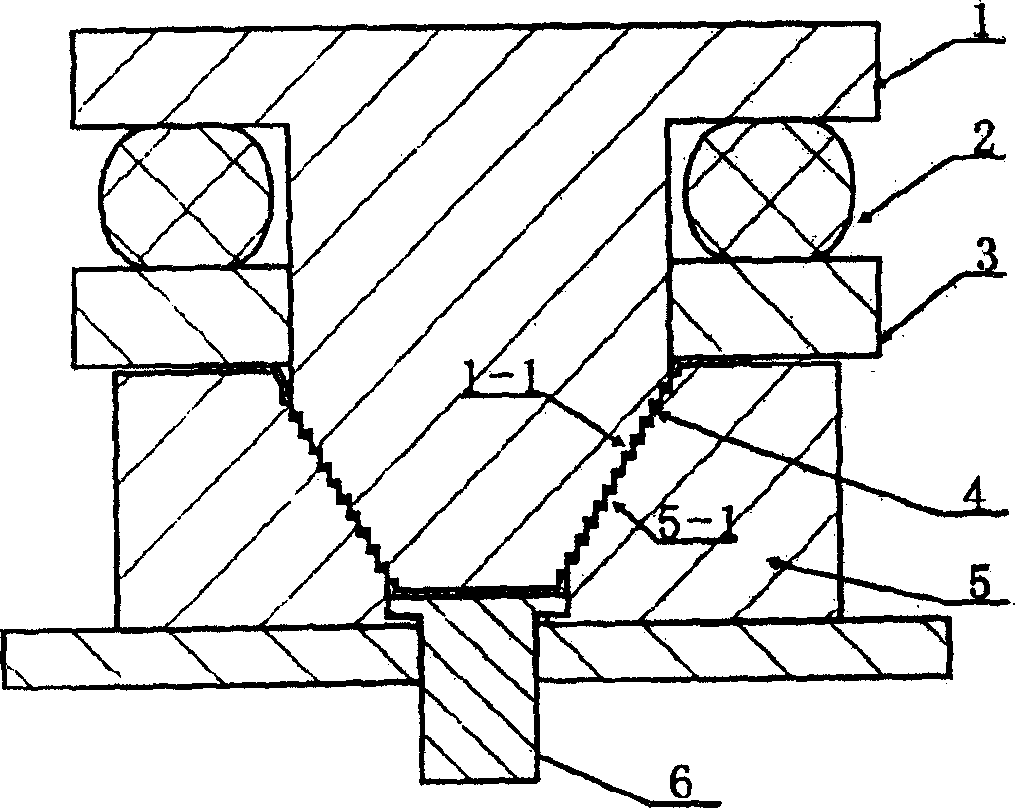

Flexible hitting-rod assembly structure for squeezing type breeding-peanut shelling machine

The invention relates to a component improvement structure for a peanut shelling machine particularly relates to a flexible hitting-rod assembly structure for a squeezing type breeding-peanut shelling machine, and belongs to the agricultural machinery. A hitting-rod roller (1) is a cylindrical soft elastomer, the middle part of the cylindrical soft elastomer is provided with a rotating shaft, and the periphery of the cylindrical soft elastomer is provided with semi-circular raided bars, i.e., the cross section of the cylindrical soft elastomer is in the shape of a flower disc, the middle part of the cross section is a circle, and a plurality of semi-circular raised sheets are raised outwards at the periphery of the circle, wherein the extradius of each semi-circular raised sheet is 1-2cm; a hitting-rod adjusting sleeve (3) can be used or not used according to the volume of the peanut pods; the hitting-rod adjusting sleeve (3) is a ringlike sleeve (soft elastomers) of different thickness; the inner circle of the hitting-rod adjusting sleeve (3) is a semi-circular groove, and the outer circle is a raised semi-circular sheet. The shape of the hitting rod of the existing hitting type peanut shelling machine is changed, the material of the hitting rod roller is changed, and the gap between an upper semi-circular raided bar and a lower concave grid can be adjusted conveniently and rapidly in a shorter time, the adaptability of the peanut shelling machine to the shelling of breeding peanuts of different varieties can be improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Screw electromagnetic coil disk and its producing method

InactiveCN1859817AConsistent spacingImprove insulation performanceCoil arrangementsMetal-working apparatusSquare cross sectionElectromagnetic heating

The present invention discloses spiral magnetic magnet coil disk and manufacturing method. Said spiral magnetic magnet coil disk adopts rectangular tool blank conduct wire material, having plane shape and uniform interturn spacing. Flat plate spiral coil disk production process includes stretching, shearing and shaping aluminum alloy sheet material through press and mould to form wire square cross section spiral coil disk blank, then through stripping, flattening, cutting off hold-down ring and pan bottom, shaping, to make flat plate shape spiral coil disk installed on plastic wire disk bracket, finally riveting aluminum terminal, becoming electromagnetic oven used flat plate shape spiral electromagnetic heating coil disk. The present invention is special suitable for adopting aluminum alloy material made electromagnetic oven used heating coil disk.

Owner:苏润本

Spare tire undercover

InactiveUS20070241144A1Improve stabilityConsistent spacingSupplementary fittingsAerodynamics improvementSpare tireAerodynamics

An aerodynamic spare tire cover system is provided for use with a spare tire stored on a vehicle underbody. The cover system can be used to cover a full sized spare tire or a temporary spare tire, while providing the same aerodynamic qualities. The cover system includes an annular spare tire cover defining a central aperture, a removable center cap for selectively covering the central aperture, a center spacer supported by the annular spare tire cover that is adjustable between a first position and a second position depending on whether a full sized spare or temporary spare is being covered, and removable spacers supported by the annular spare tire cover. A full sized spare tire and the center spacer in the first position space the spare tire cover the same distance from a position on the vehicle underbody, on the opposite side of the spare tire, as a temporary spare tire, and the center spacer in the second position.

Owner:HONDA MOTOR CO LTD

Corrugated spiral plate heat exchanger

InactiveCN102213560AIncrease heat transfer areaImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesSteel platesSheet steel

The invention discloses a corrugated spiral plate heat exchanger which comprises a dual-spiral heat exchanger in a shell, wherein the dual-spiral heat exchanger is formed by rolling a flat steel plate and a corrugated steel plate; the corrugated steel plate is provided with a non-corrugated spacing column welding zone; spacing columns are welded on the positive surface and negative surface of the spacing column welding zone; and the spacing column welding zone is a non-corrugated ribbon along the length direction of the corrugated steel plate. The heat exchanger has the advantages of simple structure, large heat exchange area and high heat exchange efficiency.

Owner:LIAONING DENIXI ENERGY SAVING EQUIP

Visible light signal transceiver

InactiveCN104539368AIncrease signal strengthReduce difficultyClose-range type systemsElectromagnetic transceiversTransceiverLight signal

The invention relates to a visible light signal transceiver, which comprises a light emitting unit capable of emitting a visible light signal and a light receiving unit capable of receiving the visible light signal, wherein the light emitting unit is provided with a light signal emission surface for emitting the visible light signal, and the light receiving unit is provided with a light signal receiving surface for receiving the visible light signal emitted by the light emitting unit. In comparison with the prior art, the light emitting unit and the light receiving unit are capable of emitting and receiving the visible light signal through the forms of the light emitting surface and the light receiving surface respectively, so that the signal intensity of the visible light signal transceiver during communication is improved through increasing the areas of the light emitting unit and the light receiving unit when emitting and receiving the visible light signal.

Owner:FUDAN UNIV

Horizontal row drivers for CMOS image sensor with tiling on three edges

ActiveUS7737390B2Improve fill factorHigh sensitivityTelevision system detailsTelevision system scanning detailsCMOSControl circuit

A large image sensor structure is created by tiling a plurality of image sensor dies, wherein each of the image sensor dies includes a pixel array that extends to three edges of the die, and control circuitry located along a fourth edge of the die. None of the control circuitry required to access the pixel array (e.g., none of the row driver circuitry) is located in the pixel array, thereby enabling consistent spacing of pixels across the pixel array. Because the pixel array of each image sensor die extends to three edges of the die, the pixel array of each image sensor die can abut up to three pixel arrays in other image sensor dies to form a large image sensor structure having 2×N tiled image sensor dies.

Owner:TOWER SEMICONDUCTOR

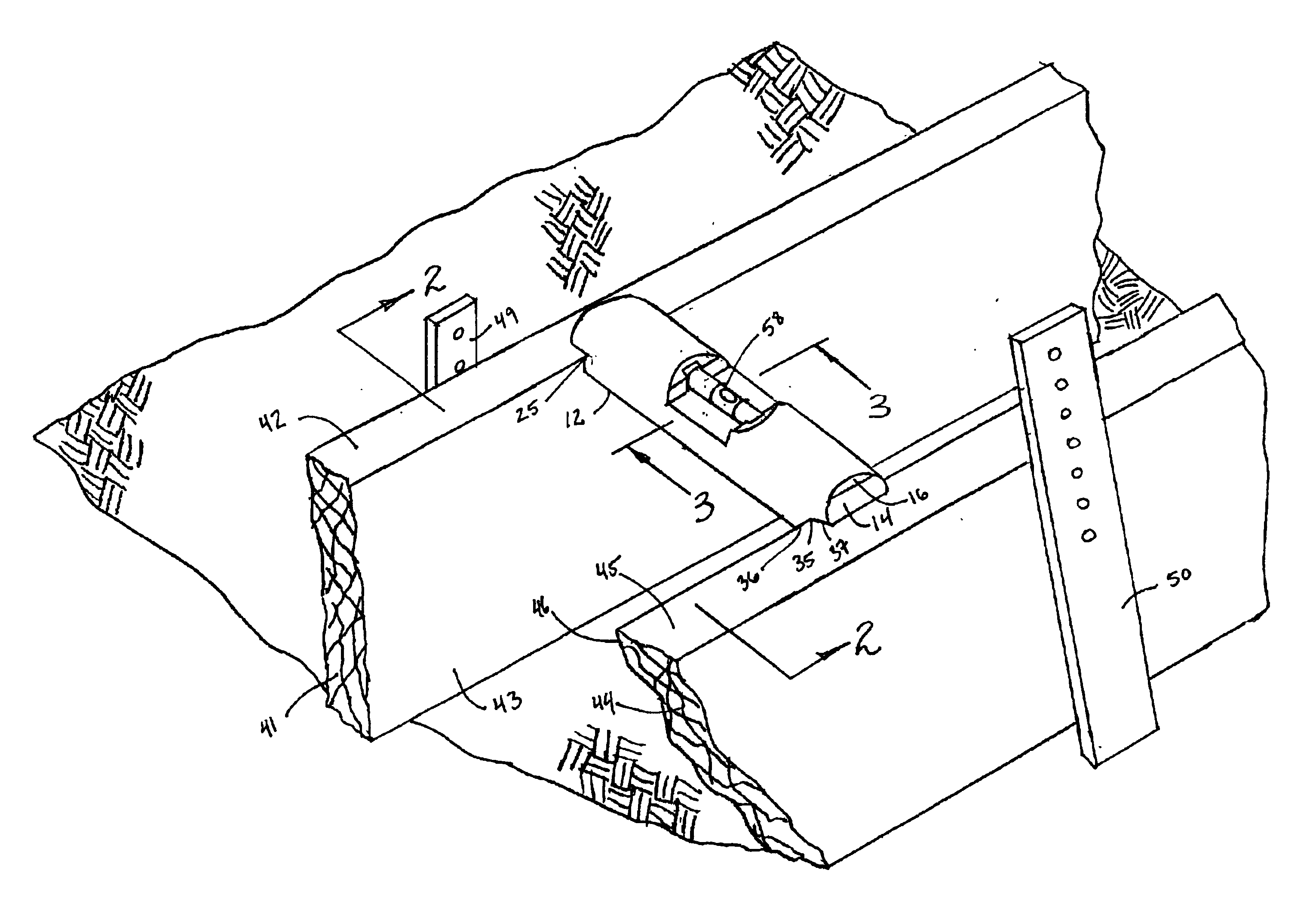

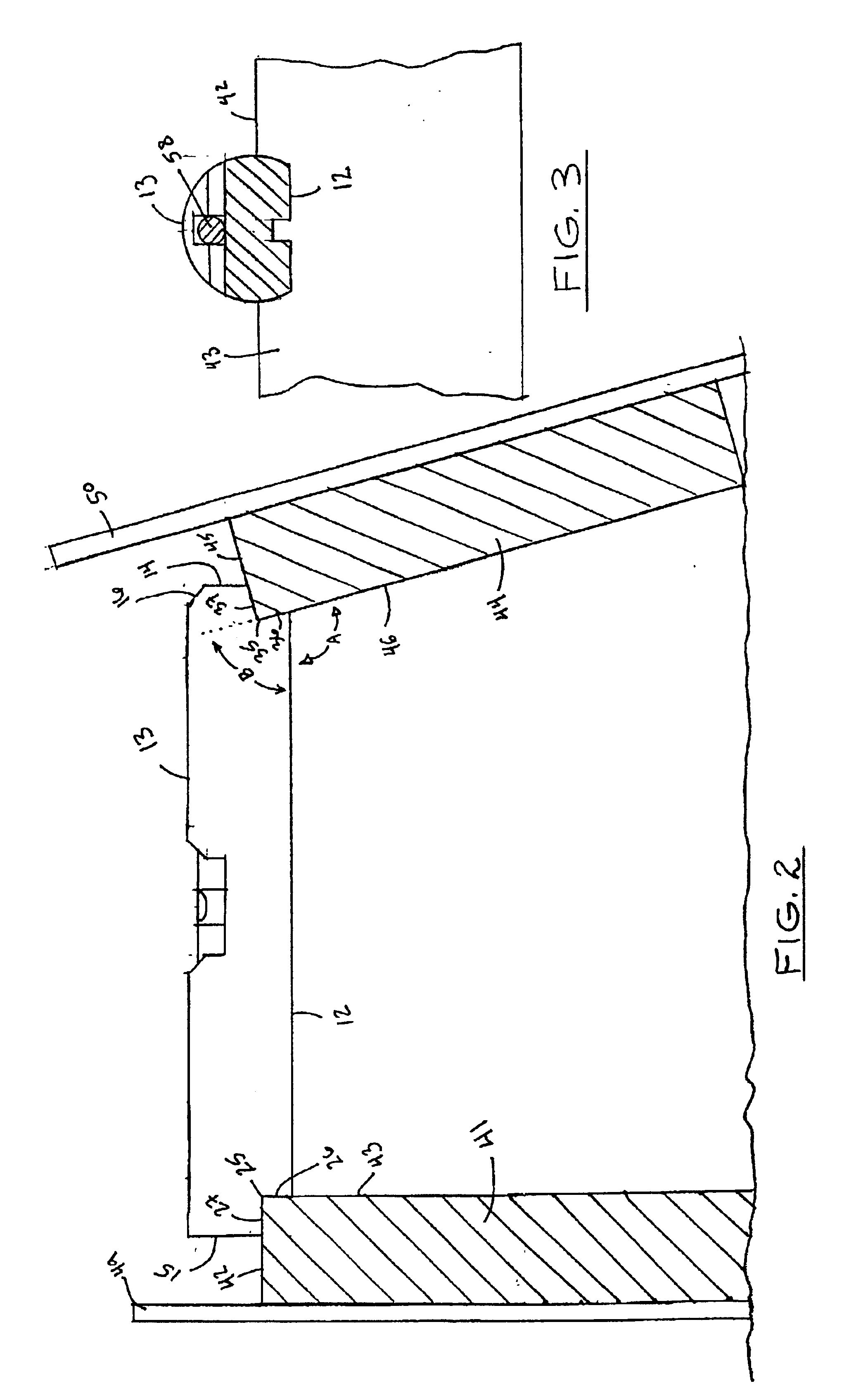

Ribbed core dual wall structure

InactiveUS20020125607A1Improve roundnessConsistent spacingCeramic shaping apparatusHollow wall articlesDouble wallEngineering

An elongated composite tube made up of an inner tube 42 and an outer tube 44 (see FIG. 3) with a plurality of elongated helical ribs disposed between the inner tube and the outer tube in a supporting relationship to both. A slinky like toy made from the composite tube is also disclosed, as is a method of making both.

Owner:PROTEUS

Automatic arranging device for mixed packages

The invention relates to an automatic arranging device for mixed packages. The device comprises a supplying and conveying machine and a controller. The device is characterized in that a differential central conveyor, a differential narrow-belt conveyor and a side-step inclination roller conveyor are sequentially arranged at the back of the supplying and conveying machine; dividing inclination roller conveyors are arranged at two sides of the differential central conveyor; the differential narrow-belt conveyor is formed by transversely combining at least two narrow-belt conveying units at different speeds; the differential central conveyor, the dividing inclination roller conveyor, the differential narrow-belt conveyor and the side-step inclination roller conveyor are all connected to powermechanisms; a flow rate detecting camera is arranged above the differential narrow-belt conveyor; and the flow rate detecting camera, the differential central conveyor, the dividing inclination roller conveyor, each narrow-belt conveying unit of the differential narrow-belt conveyor, and the power mechanism of the side-step inclination roller conveyor are all connected to the controller through conductors. With the adoption of the device, the production cost can be decreased; the production efficiency can be improved; the problem that a warehouse is full of the packages can be avoided; and the device is applicable to the package delivery of the express industry.

Owner:无锡弘宜智能科技股份有限公司

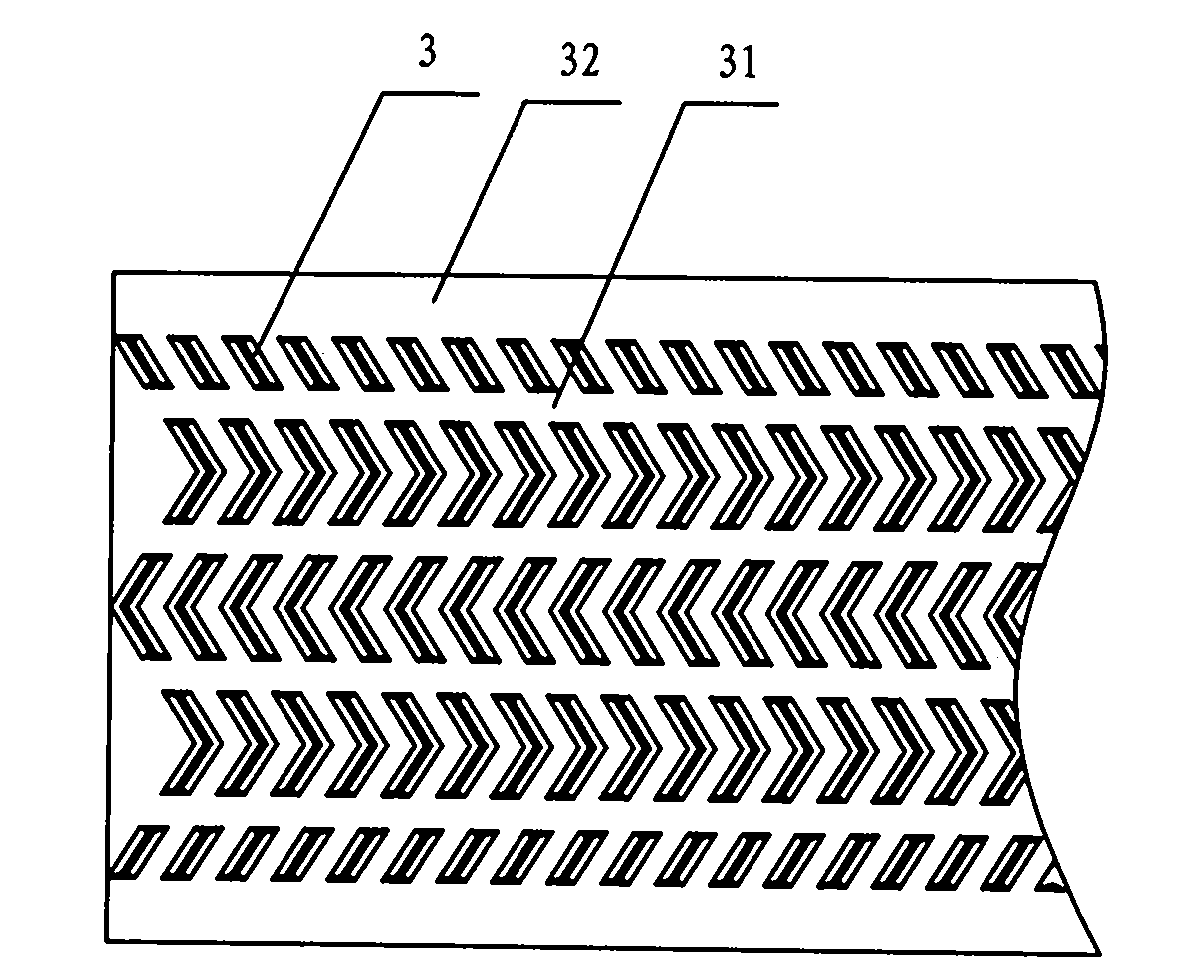

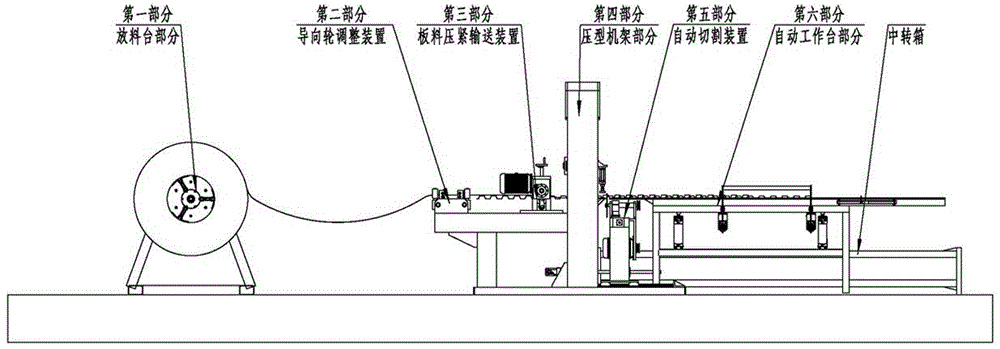

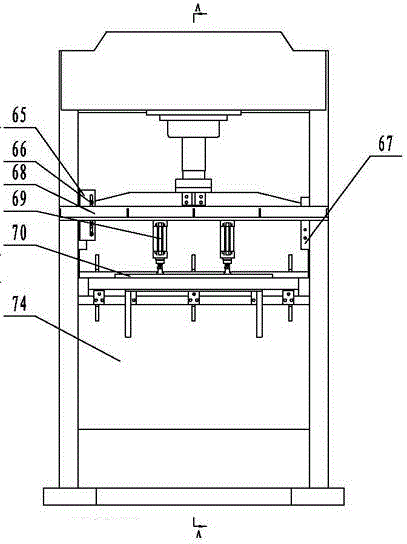

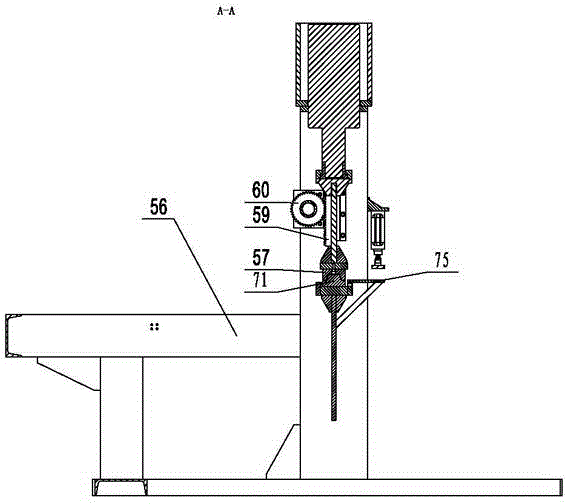

Full-automatic production line for forming corrugated boards

ActiveCN104607551ALoad accuratelyConsistent moldingShaping toolsMetal-working feeding devicesProduction lineEngineering

A full-automatic production line for forming corrugated boards comprises a forming press and a board conveying device. The forming press comprises an n-shaped support. Two upper mold guide seats are arranged on two transverse side stand columns of the n-shpaed support respectively, an upper mold is installed between the two upper mold guide seats, an upper mold installation plate is arranged on the upper mold, the upper mold is in sliding fit with the upper mold guide seats through the upper mold installation plate, a press forming oil cylinder is arranged on the upper portion of the n-shaped support, a piston rod of the press forming oil cylinder is connected with the upper mold installation plate, a lower mold fixing plate is arranged on the lower portion of the n-shaped support, a lower mold is arranged on the lower mold fixing plate, the upper mold and the lower mold vertically correspond to each other, and a rack is arranged on the feeding side of the n-shaped support. The board conveying device comprises two lifting frames, an upper pressing roller and a lower pressing roller are installed between the two lifting frames, the two ends of the upper pressing roller are movably connected with lifting components of the two lifting frames respectively, and one end of the upper pressing roller is connected with a driving device. The full-automatic production line has the advantages of being simple in structure, low in manufacturing cost and convenient to use.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

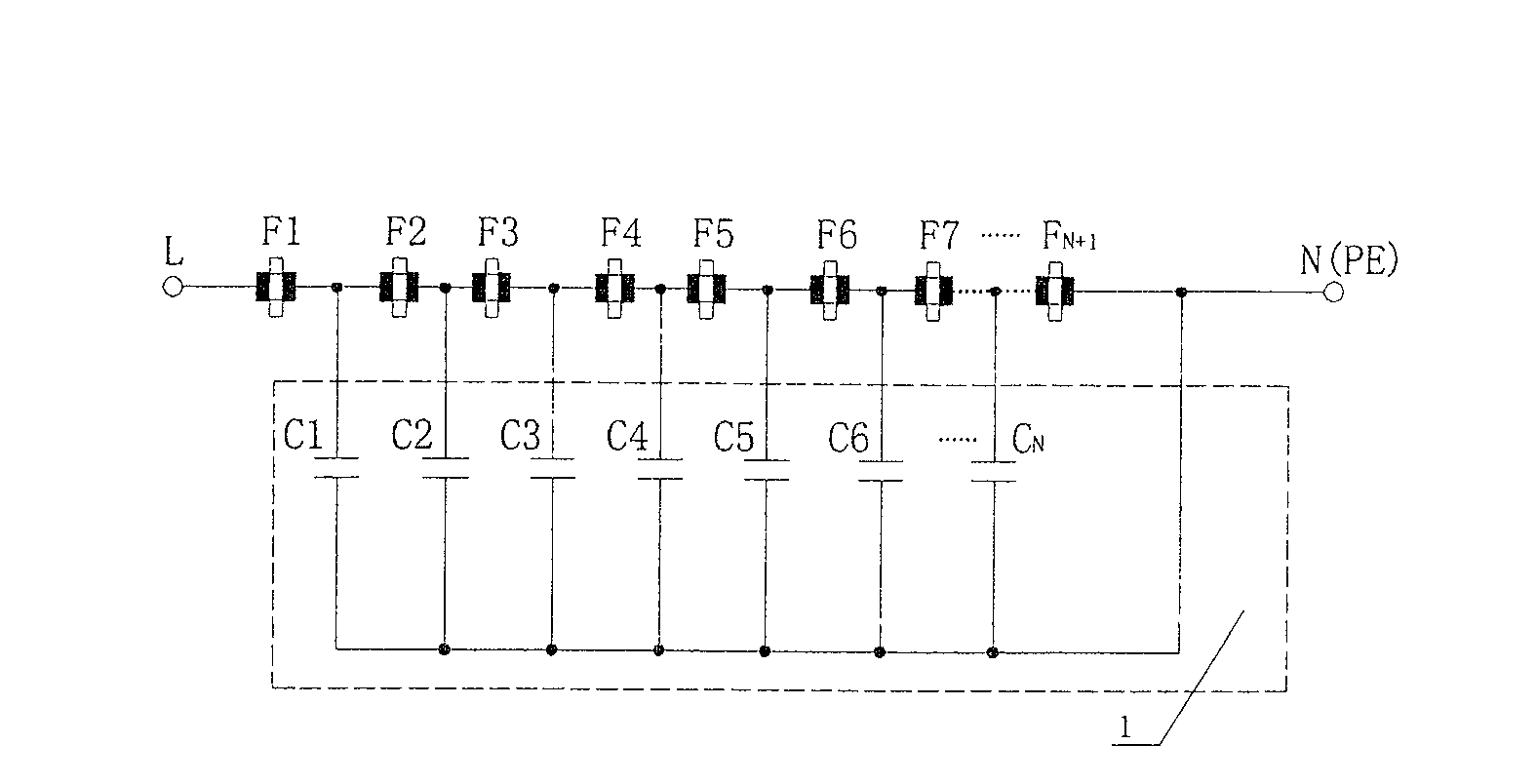

Method for alternating-current voltage withstand testing of 220 kV and 330 kV insulated tools and instruments

InactiveCN104035014AConsistent spacingEliminate potential safety hazardsElectrical testingMeasurement instrument housingTest objectHigh pressure

Provided is a method for alternating-current voltage withstand testing of 220 kV insulated tools and instruments. The method comprises the steps of arranging four insulating lifting supports, two groups of clamp plate electrodes and a grounding device; connecting two ends of each group of clamp plate electrodes to the upper ends of two insulating lifting supports through supporting plates, placing four base discs on the ground to be rectangular, and adjusting the distance between the two groups of clamp plate electrodes to be 1.8 m; arranging a 500 kV testing transformer; adjusting the heights of the top ends of insulating supporting rods to be 2.1 m above the ground; sequentially placing the heads of tested objects in a sawtooth-shaped groove of the group of clamp plate electrodes which is to be connected to a high-voltage wire, sequentially placing the tail ends in a sawtooth-shaped groove of the other group of clamp plate electrodes; installing the grounding device on the lifting support at the tail ends of the tested objects, boosting the voltage to 440 kV, and reducing the voltage at a constant speed after the voltage boosting time is 1 min. According to the method, alternating-current voltage withstand testing of 220 kV and 330 kV insulated tools and instruments is finished through the 500 kV testing transformer on a large scale.

Owner:STATE GRID CORP OF CHINA +2

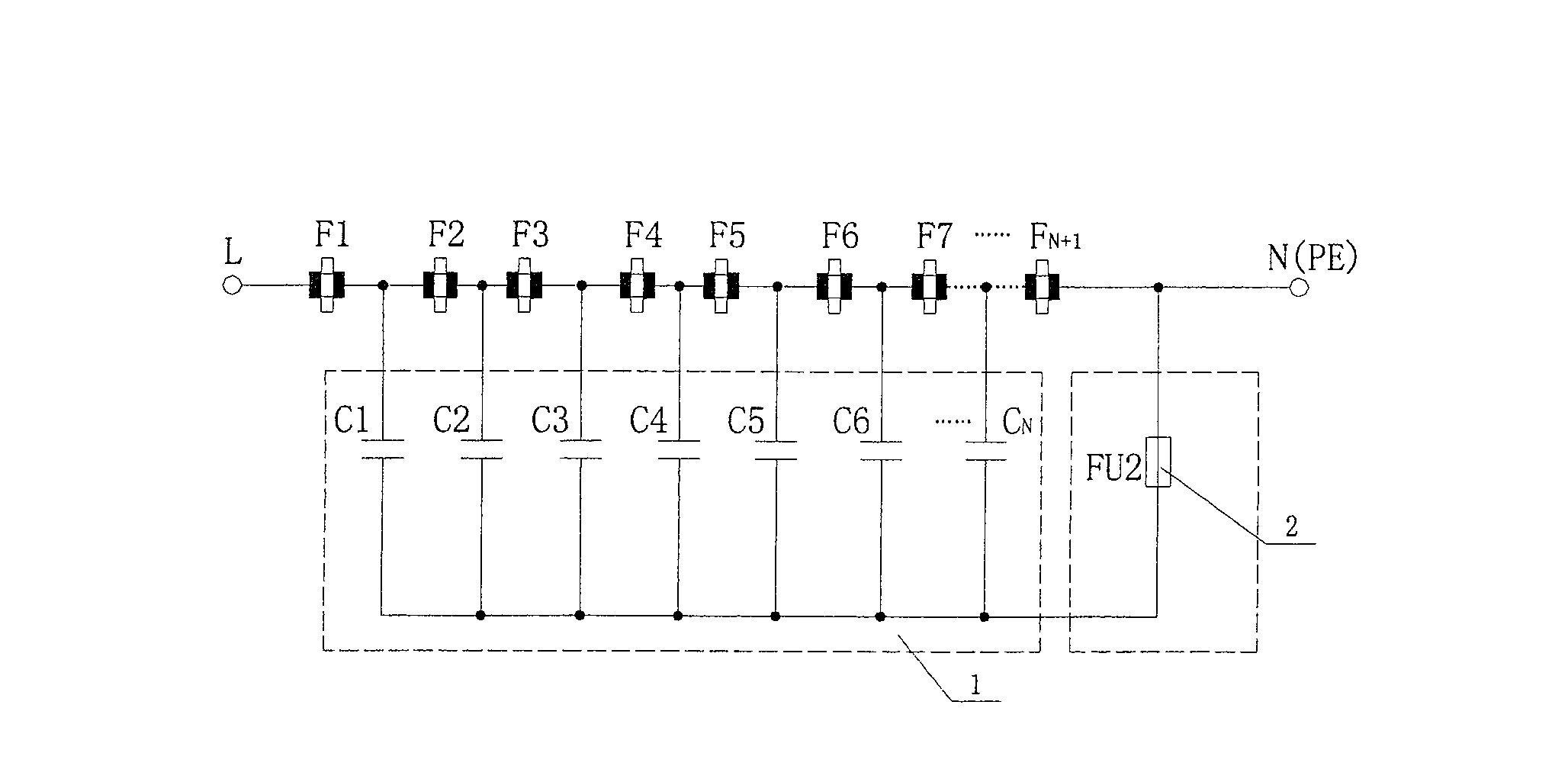

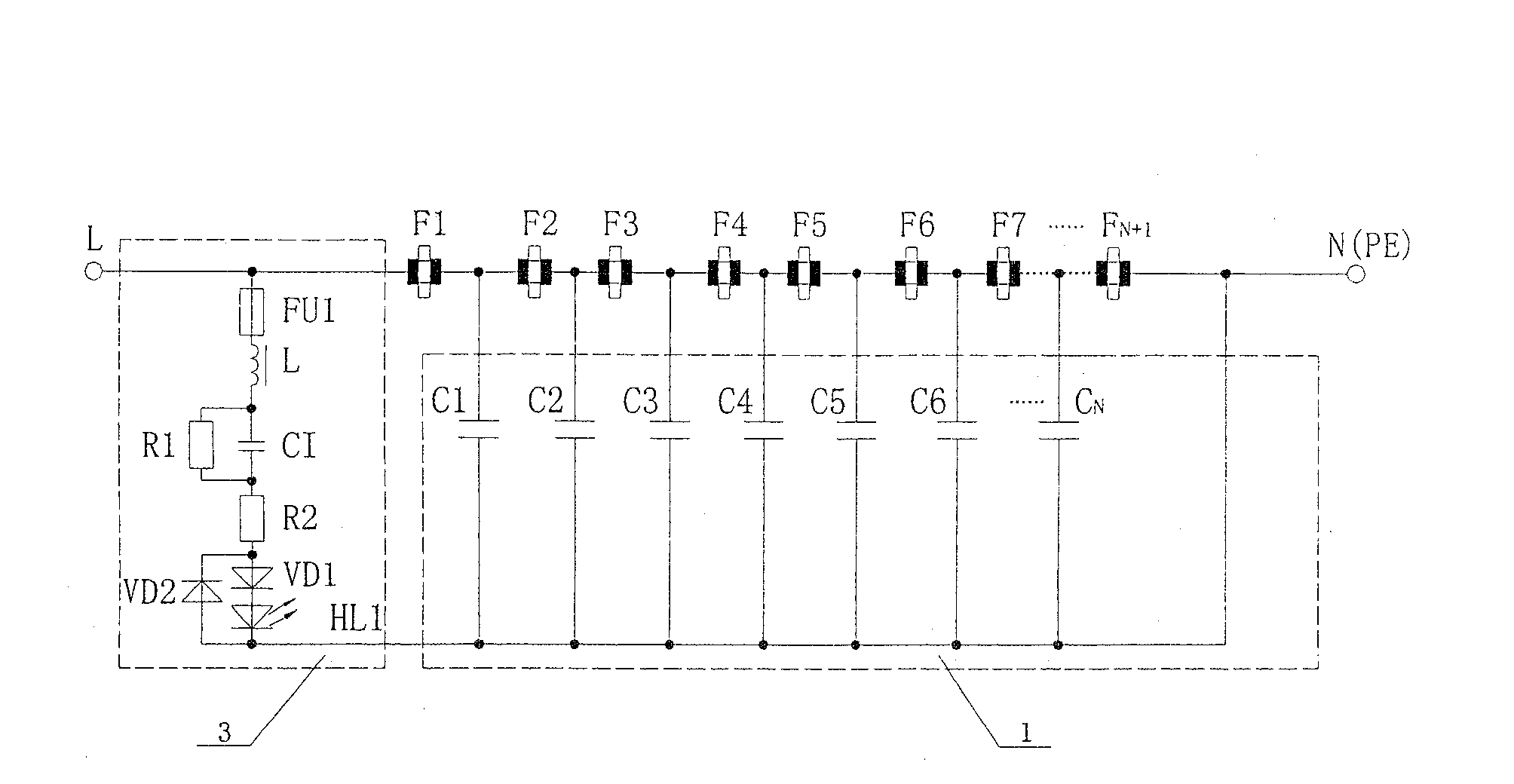

High efficient laminated graphic discharge gap device

ActiveCN100530868CImprove conductivityHigh melting pointOvervoltage arrestors using spark gapsCapacitanceGraphite electrode

Owner:SICHUAN ZHONGGUANG LIGHTNING PROTECTION TECH

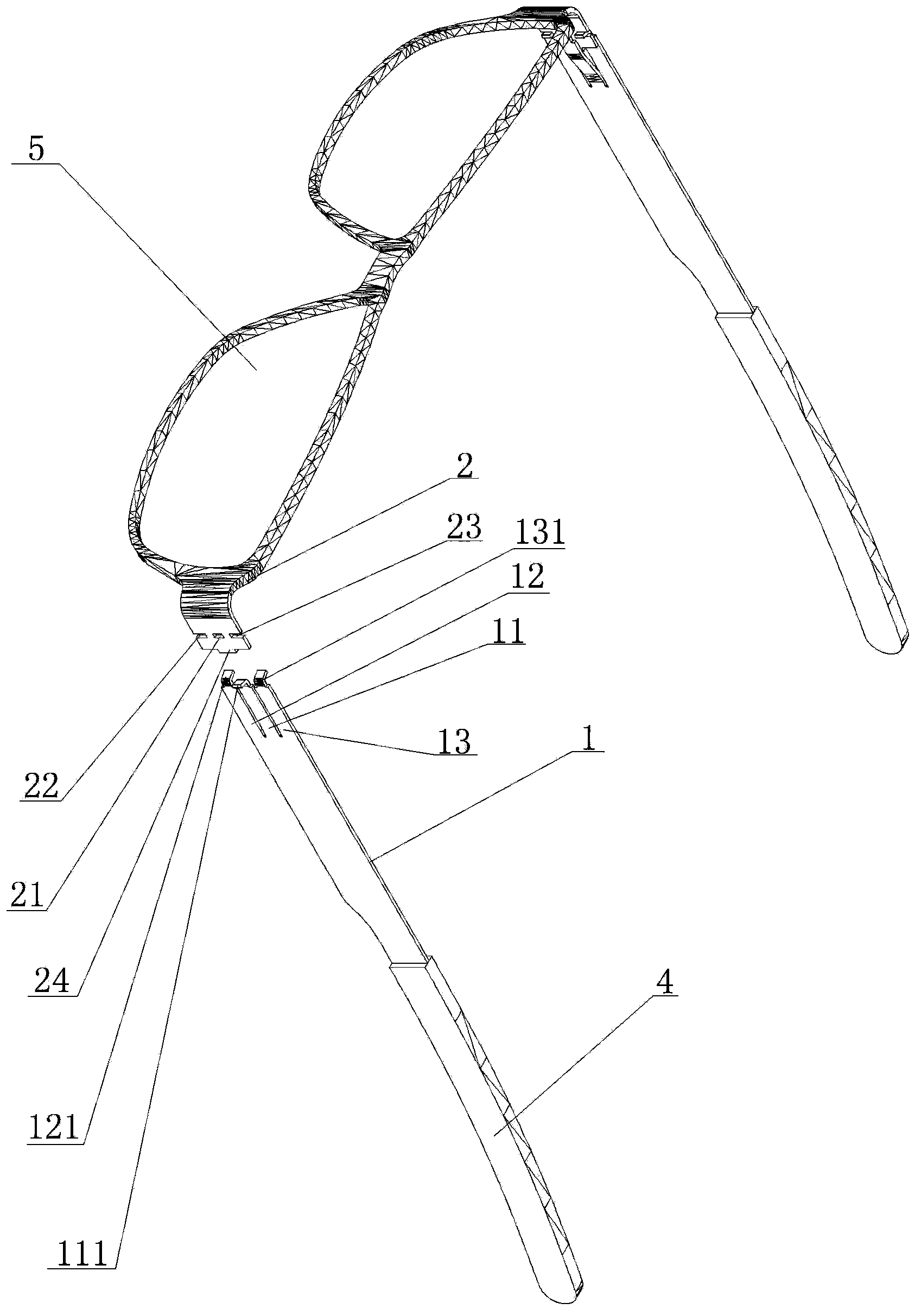

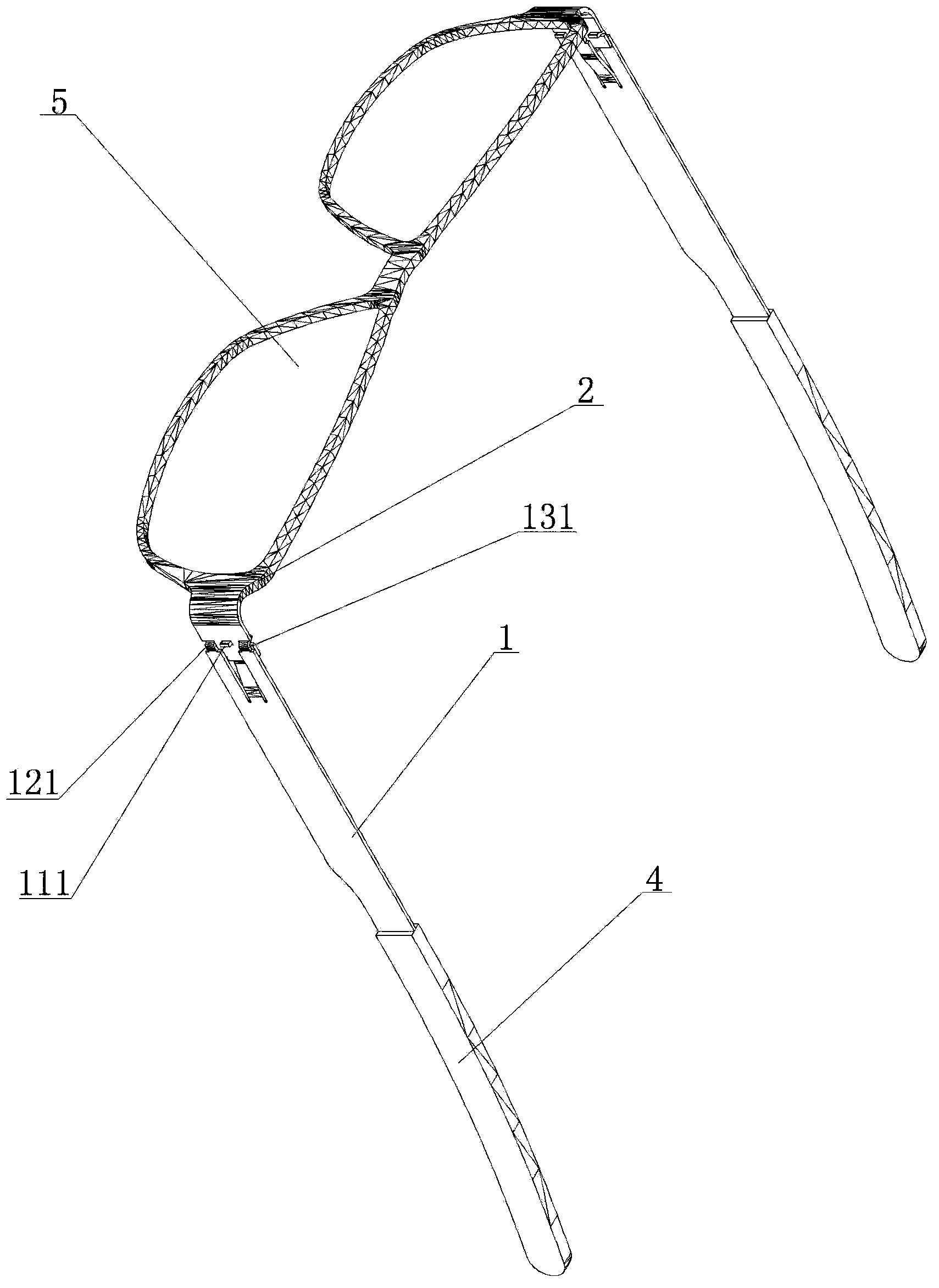

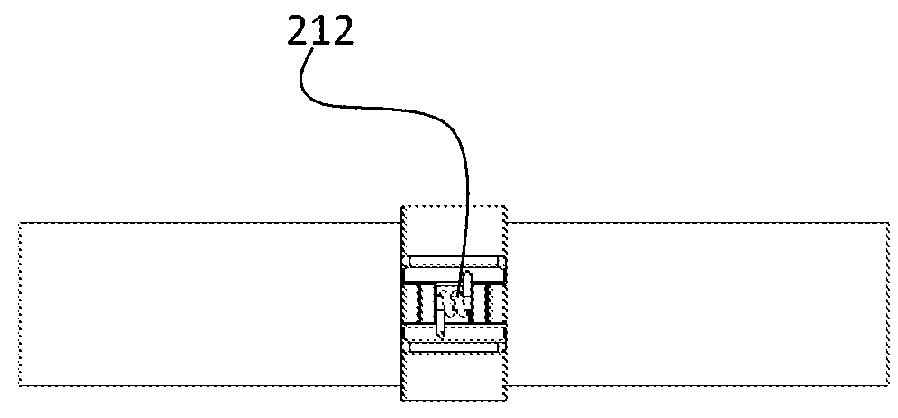

Multifunctional glasses frame

InactiveCN104142580AComfortable to wearAvoid free sloshingSpectales/gogglesNon-optical partsEngineeringAngular variation

The invention discloses a multifunctional glasses frame, which comprises metal glasses legs, a frame, nose bridge racks and ear hanging casing pipes. One ends of the metal glasses legs are equipped with middle metal sheets, first metal sheets and second sheet metals. Each first metal sheet is provided with a first hook, each second metal sheet is provided with a second hook, and each middle metal sheet is provided with a middle hook. The frame is equipped with first gaps in adaptive flexible connection with the first hooks, second gaps in adaptive flexible connection with the second hooks, and middle through holes in adaptive flexible connection with the middle hooks. According to the multifunctional glasses frame provided by the invention, at least three different stable positions are disposed between the metal glasses legs and the frame, thus realizing 0-180 degree angular variation between the frame and metal glasses legs, and allowing expansion of the metal mirror legs over a traditional normal opening degree. And under the action of flexible nose pads, the glasses can be fixed on the wearer's nose bridge bone after wearing. As counterweight members, the ear hanging casing pipes can adjust the barycenter of glasses and improve barycenter balance of glasses.

Owner:RIKEN CO LTD

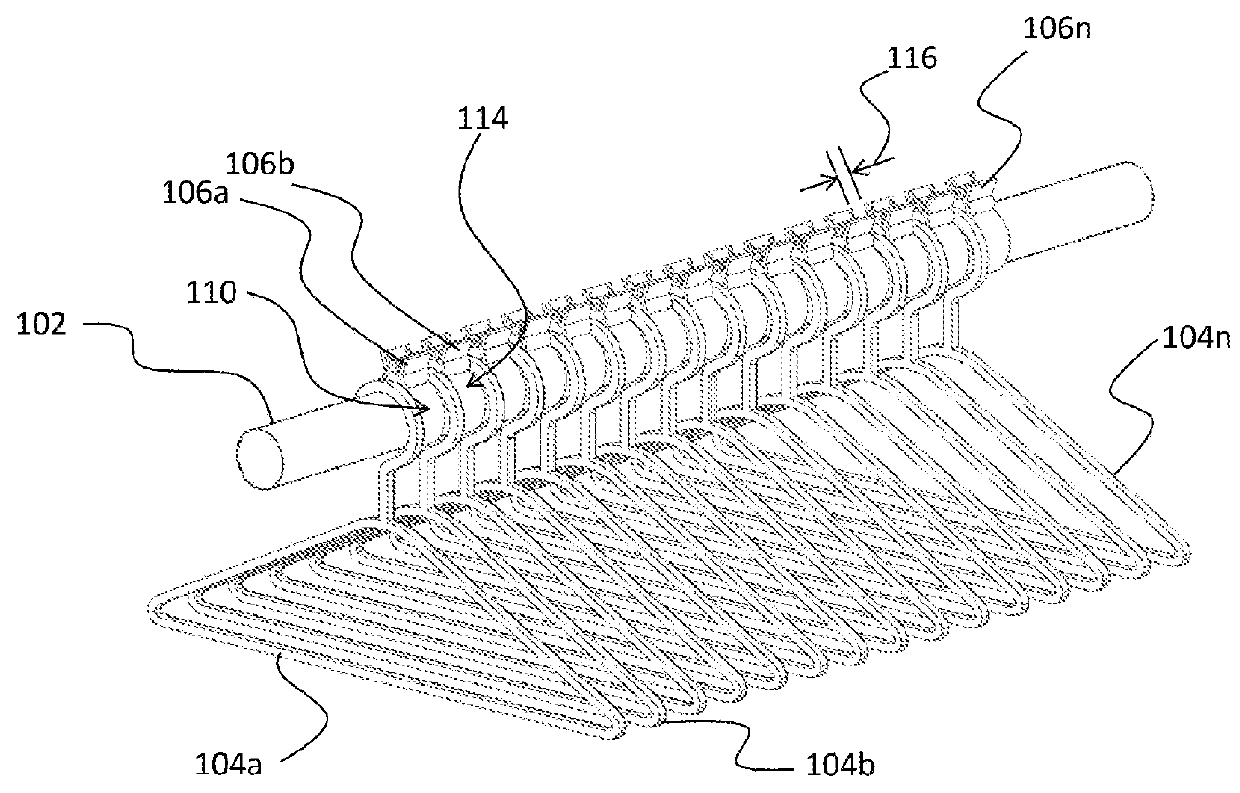

Garment separator

A garment separator assembly is provided including at least two separators. Each separator includes a first member defining a first half of the separator; and a second member defining an opposing second half of the separator. The second member is coupled to the first member and, together with the first member, defines a first inner-surface circumference and a second inner-surface circumference adjacent and non-coaxial with the first inner-surface circumference. The first inner-surface circumference is larger than the second inner-surface circumference. The first inner-surface circumference is shaped and sized to mate with a first outer diameter of a standard clothing rod; and the second inner-surface circumference is shaped and sized to mate with a second outer diameter of a clothing rod, wherein the second outer diameter is smaller than the first outer diameter of the standard clothing rod.

Owner:SAC CONCEPTS

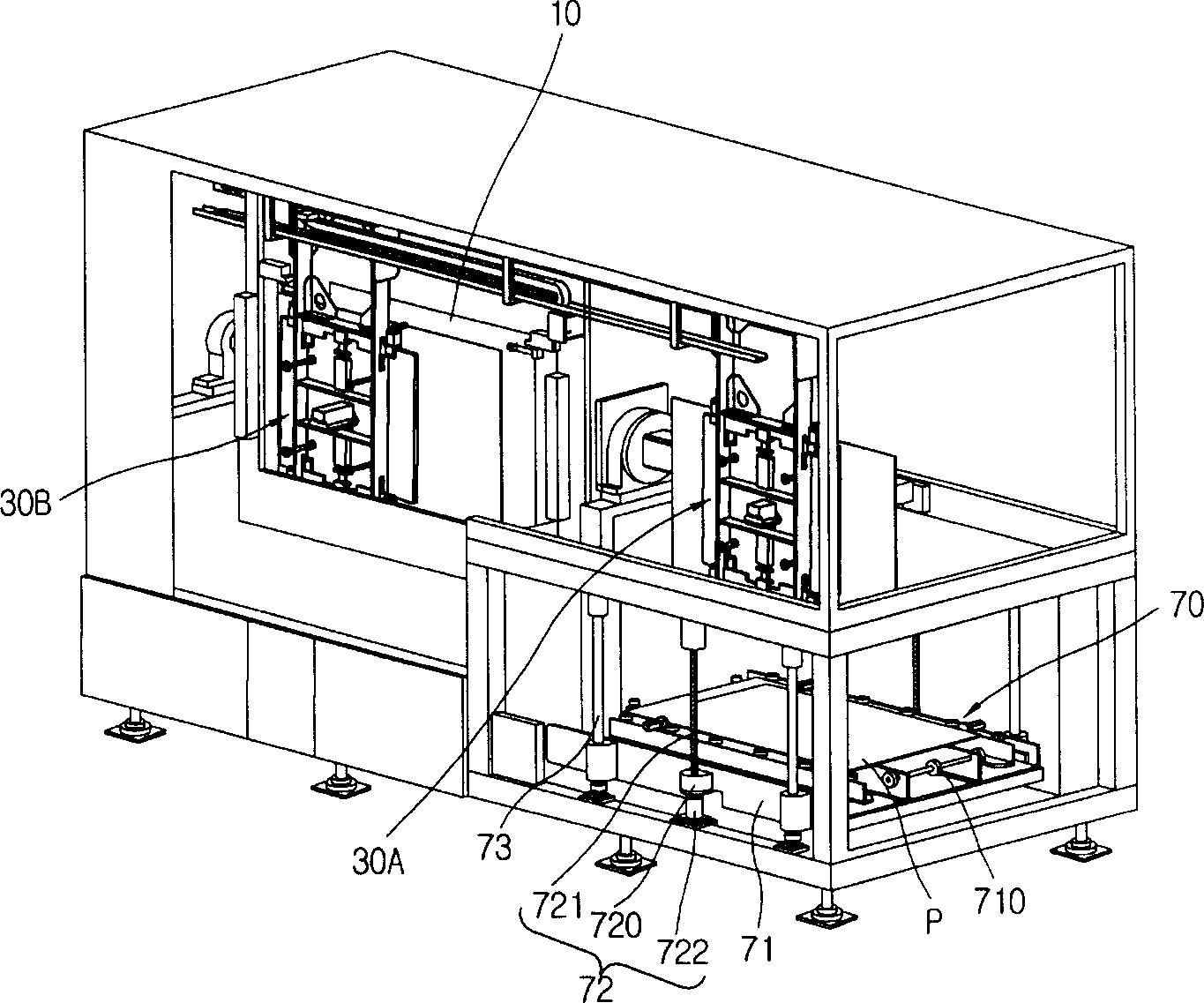

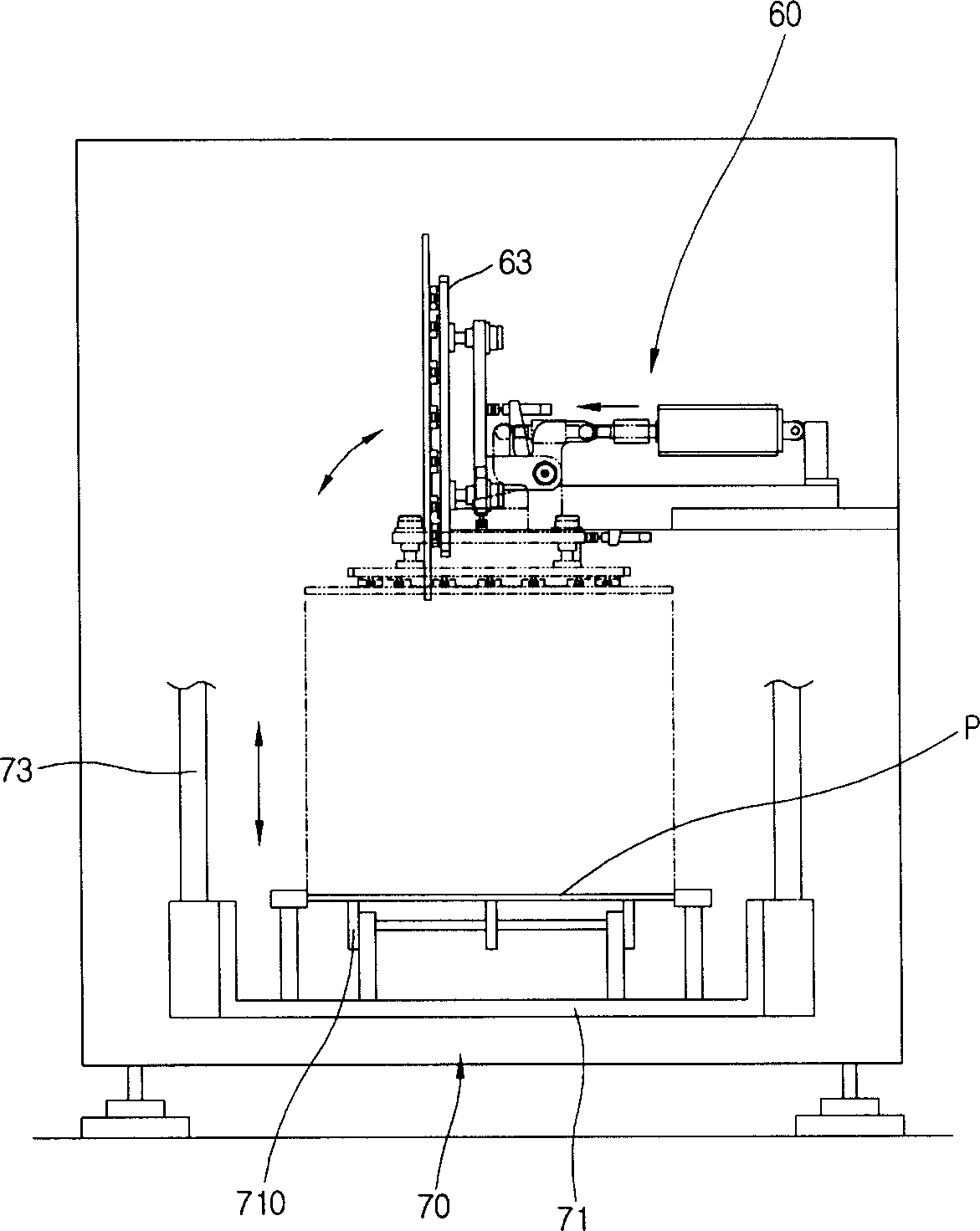

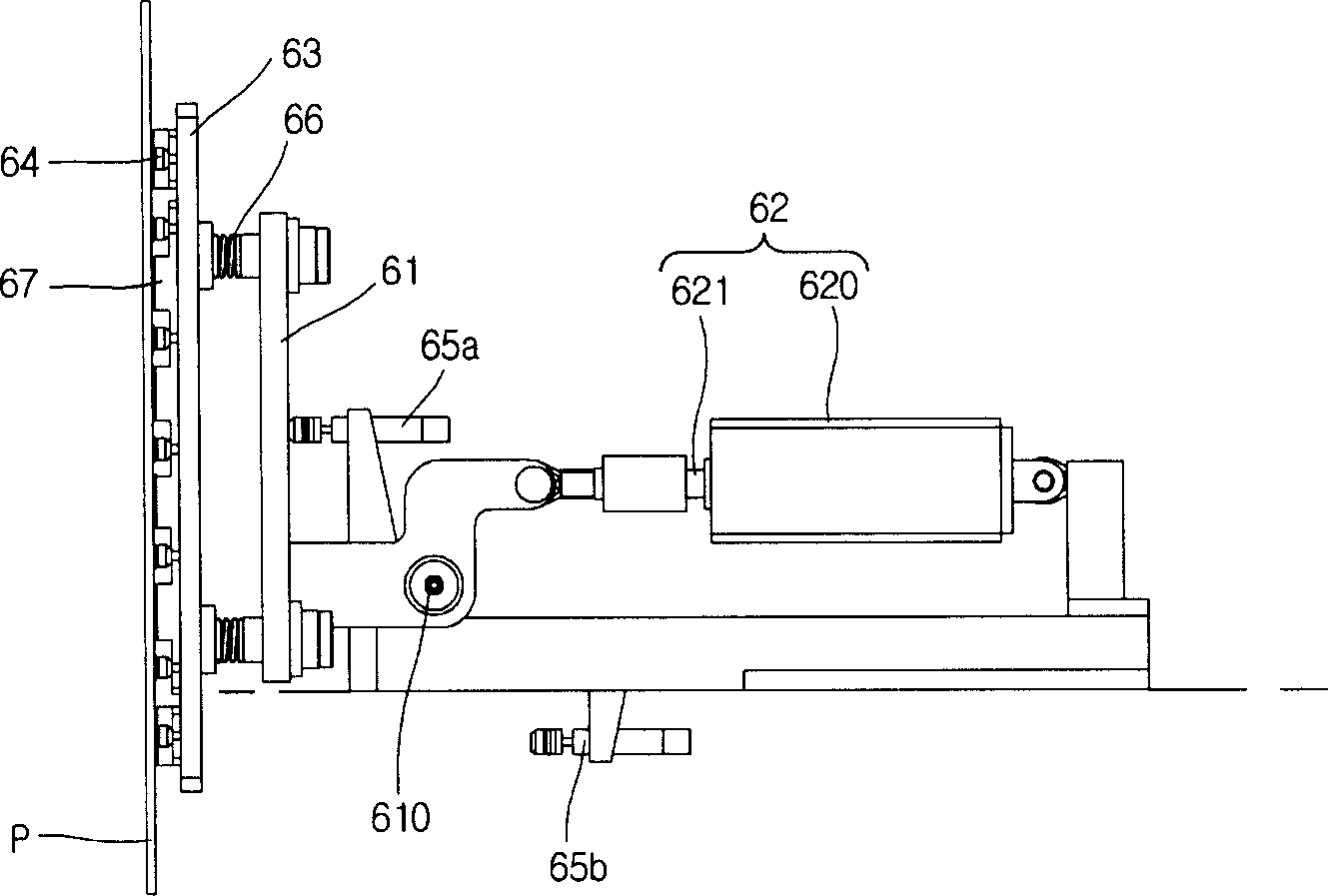

Detector of flat-board display

InactiveCN1677178AReduce impactPrevent disengagementStatic indicating devicesAlternating current plasma display panelsReciprocating motionDisplay device

The present invention provides a flat panel display tester comprising a testing unit including a stage for mounting panels thereon, a panel-conveying unit for separating a tested panel from the stage and simultaneously for feeding an untested panel onto the stage, and a panel-feed unit for discharging the tested panel conveyed by the panel-conveying unit to the outside and for transferring the untested panel to the panel-conveying unit, wherein the panel-conveying unit includes a pair of rails horizontally arranged between the stage and the panel-feed unit; first and second carriers respectively installed on the rails and reciprocating so that panels conveyed along the first and second carriers cross each other; and loaders, respectively provided on the first and second carriers, moving to the stage and the panel-feed unit for directly loading and unloading the panels and then returning to a stand-by state. The flat panel display tester remarkably improves efficiency and productivity of a testing process compared to a conventional flat panel display tester.

Owner:DE&T

Concrete curb form spacer

InactiveUS6752370B2Preventing the spacer from fallingEfficient and reliableCellulosic plastic layered productsCeramic shaping apparatusBuilding constructionGasket

Owner:GONZALES REYES

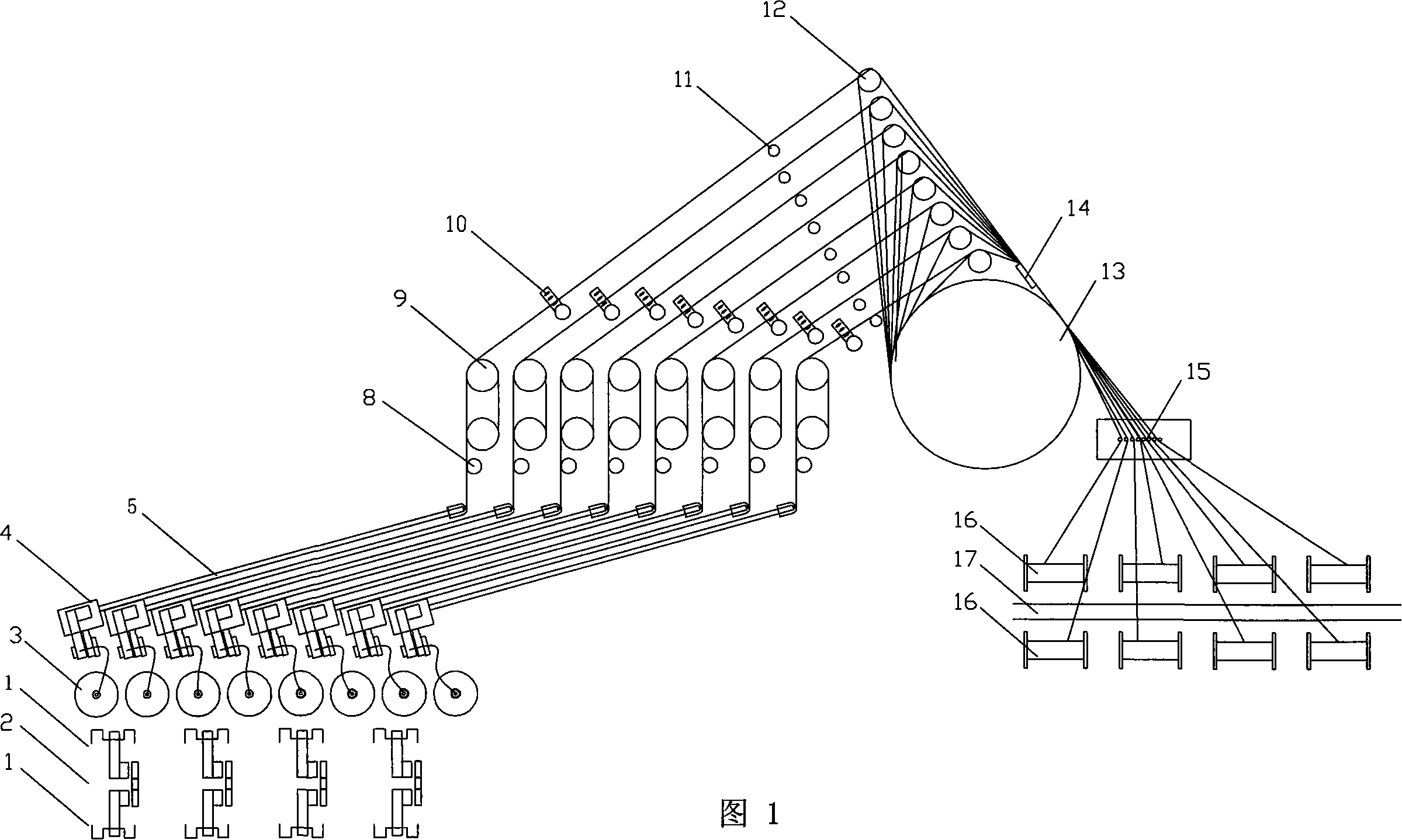

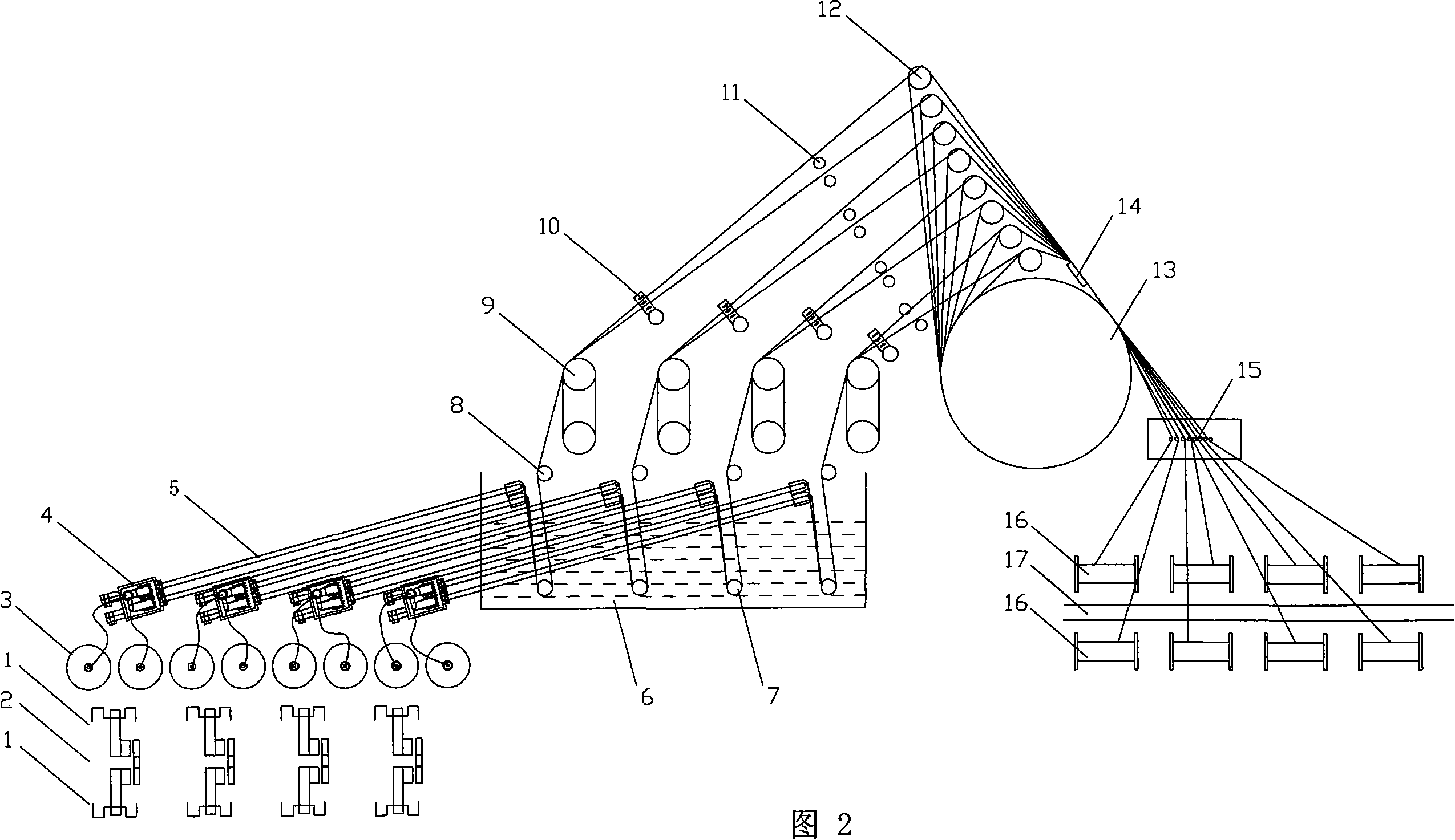

Viscose artificial silk continuous spinning technique and continuous spinning machine

ActiveCN101122052AGuarantee the quality of rayonIncrease productionArtificial filament physical treatmentArtificial thread manufacturing machinesEngineeringContinuous production

The invention discloses an eight-roller eight-silk viscose artificial silk continuous filature technology and a continuous filature machine, which is to solve the problems existing in the four-roller eight-silk continuous filature proposal. The proposal of the invention is a roll-type which includes a big roller and 8 filature small rollers. The big roller and each filature small rollers correspondingly form 8 rollers; 8 silks shaped by 8 sets of gum supply, spinning and shaping devices are respectively corresponding to 8 filature small rollers, which respectively wind on each set of rollers. The invention can effectively control the 8-silk continuous production, so as to really realize the 8-silk continuous spinning production, solve problems existing in the four-roller eight-silk continuous spinning proposal and technical bias of the prior art to the continuous spinning from four-silk to eight-silk.

Owner:YIBIN HIEST FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com