Bunch-planting type synchronous sowing and fertilizing machine

A technology of fertilizer applicator and hole seeding, which is applied in the field of hole seeding synchronous seeding fertilizer applicator, can solve the problems of poor bearing capacity, waste of fertilizer, complicated structure, etc., and achieve the effects of ensuring bearing capacity, shortening the length of the whole machine, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

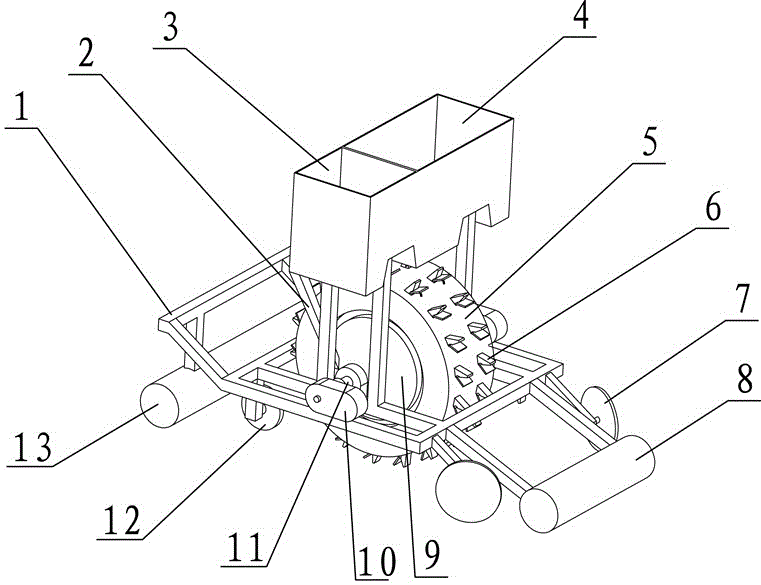

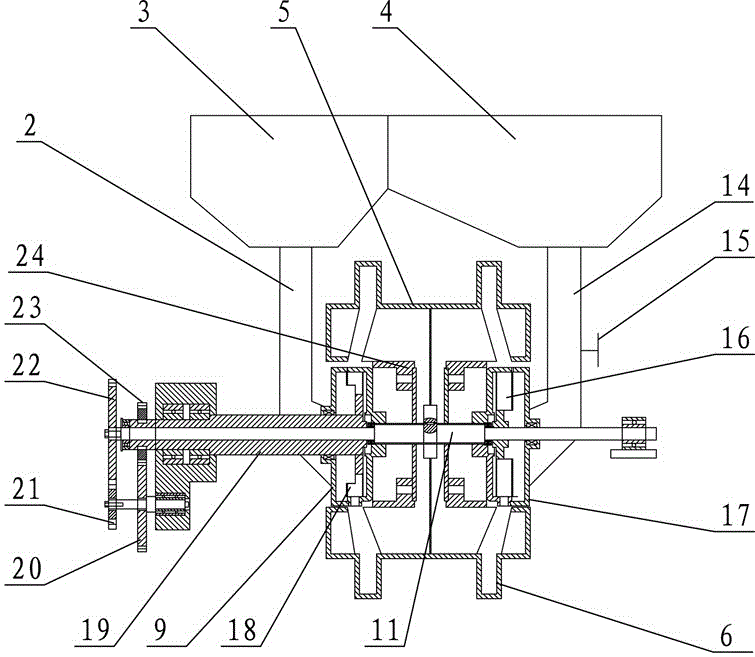

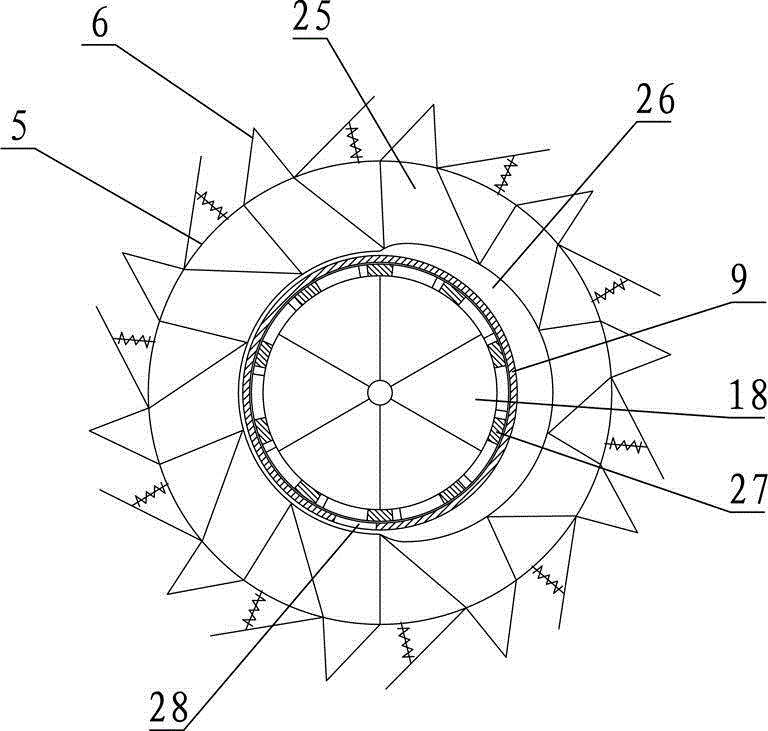

[0020] In order to make the present invention easy to understand, according to the embodiment Figure 1~5 Describe in detail the concrete structure of the present invention, as figure 1 Shown, a kind of hole sowing type synchronous sowing and fertilizing machine, it comprises: frame 1, sowing device, fertilizing device, be provided with grain box 3 and fertilizer box 4 above the frame, also be provided with film-covering roller 13 on the frame , pressing film wheel 12, covering soil dish 7, rear pressing roller 8 and conventional sub-native product and hanging film stand etc. Among them, the sowing device and fertilizing device adopt an integrated sowing and fertilizing device, and both sowing and fertilizing adopt a hole-sowing structure, such as figure 2 As shown, the structure of the sowing and fertilizing device is as follows: the main shaft 11 is arranged on the frame 1 through the bearing seat, and the main shaft passes through the hole sowing wheel fixing plate 24 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com