Spiral condenser and manufacturing process of spiral condenser

A condenser and spiral technology, which is applied in the field of spiral condensers and its manufacturing process, can solve the problems of multiple manufacturing processes, poor heat dissipation performance, and damaged tubes, and achieve the effects of simple process, reduced manufacturing difficulty, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

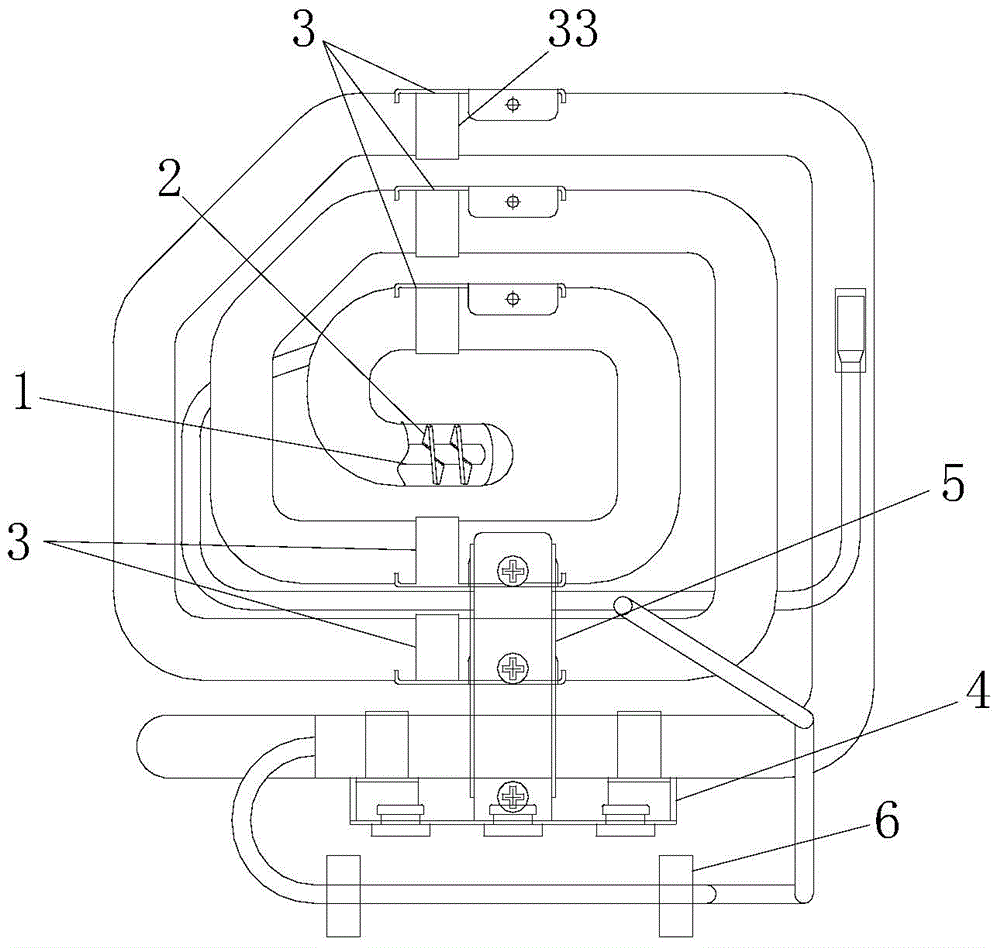

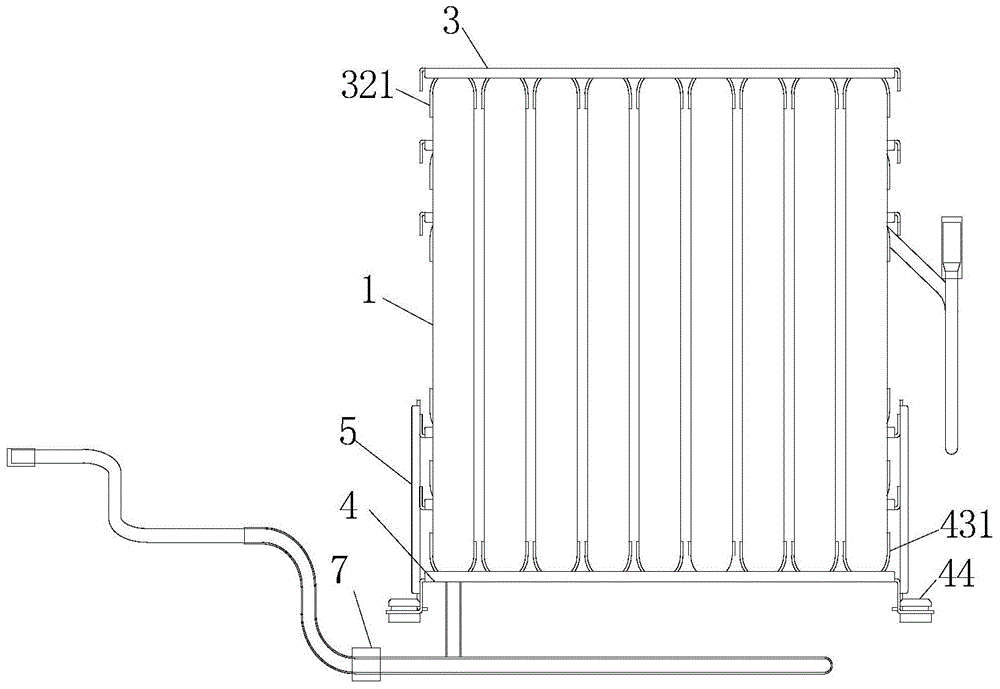

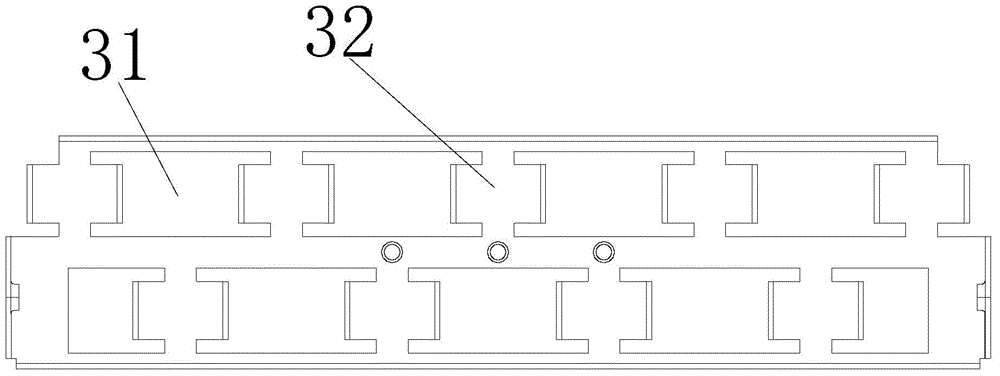

[0034] Such as Figure 1 to Figure 8 , a spiral condenser, including a heat dissipation pipe 1 and fins 2, the heat dissipation pipe 1 is bent and wound to form a cuboid structure composed of multi-layer circuitous heat dissipation pipe units, the heat dissipation pipe units are parallel to each other, and the heat dissipation The spacing between the tube units is the same and set to 10mm-30mm, generally set to 10mm, 15mm, 20mm, 25mm, the fins 2 are spirally wound on the outer surface of the heat pipe 1, and the fins are set as straight fins Type structure, the spacing between adjacent fins 2 is set to 4mm-10mm, generally set to 5mm, 6mm, 7mm, 8mm; also includes a bracket for supporting and fixing the cuboid structure composed of multi-layer circuitous heat pipe units components.

[0035]The connection between the inside of the fin 2 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com