Patents

Literature

159results about "Fish cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

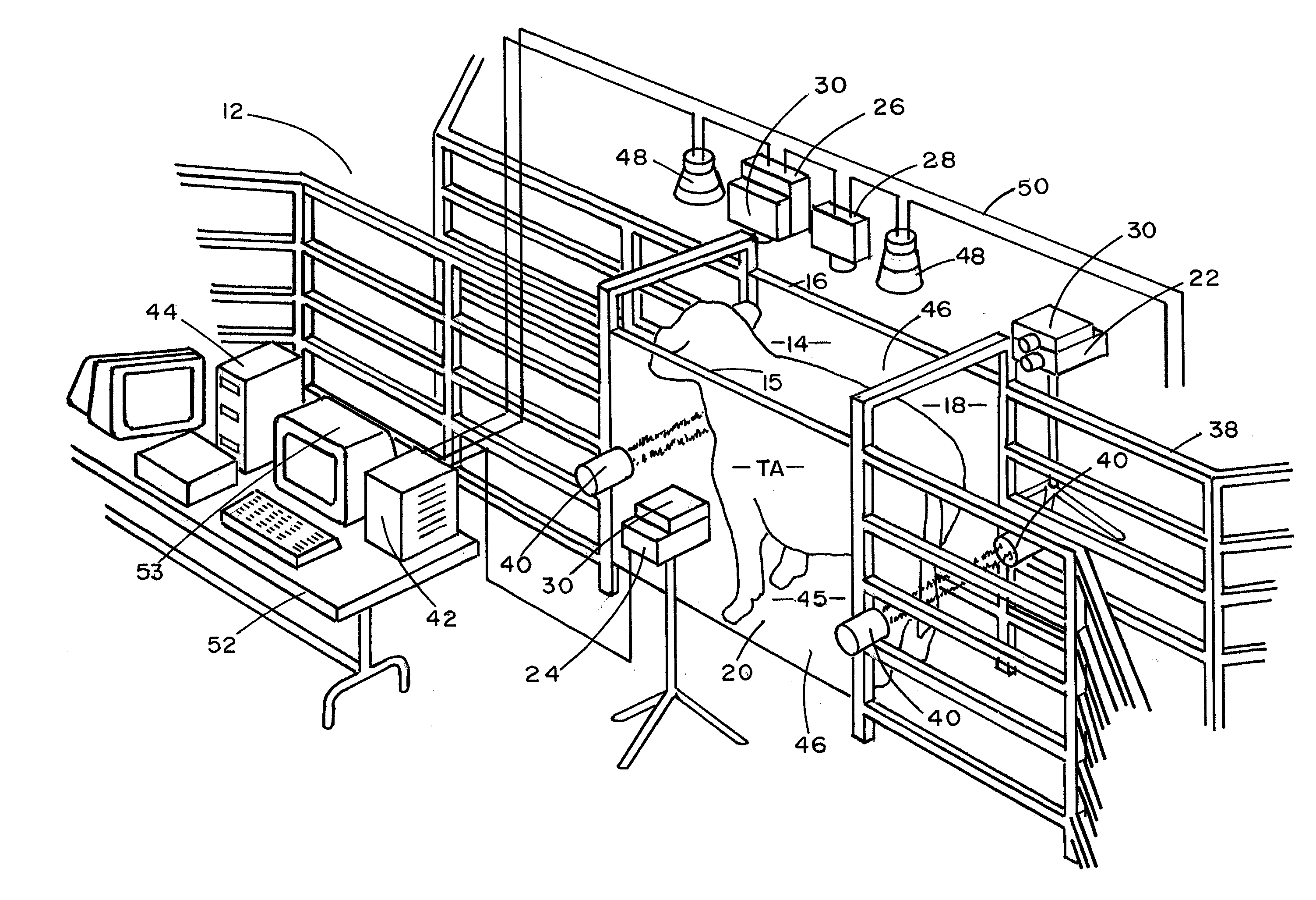

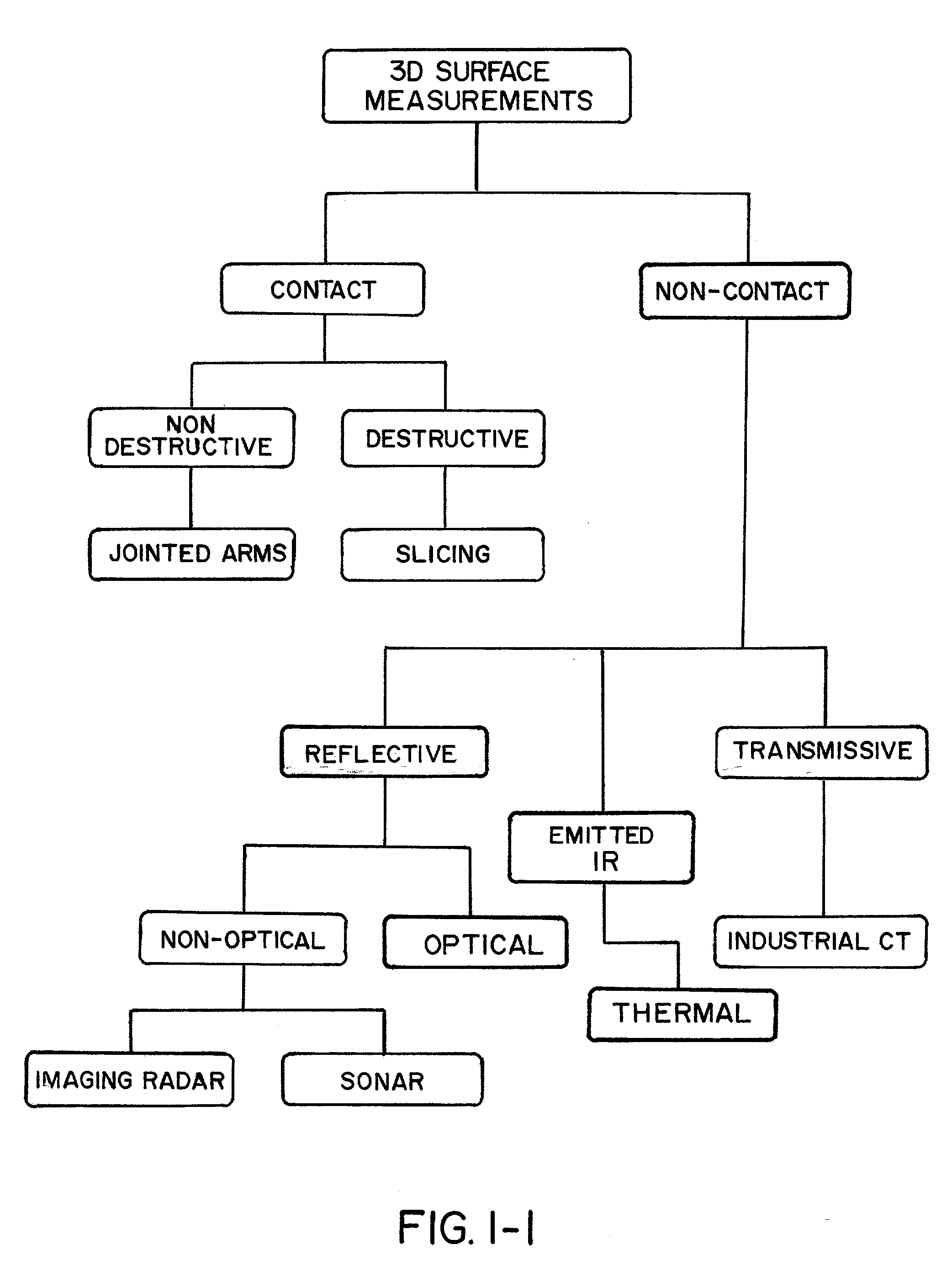

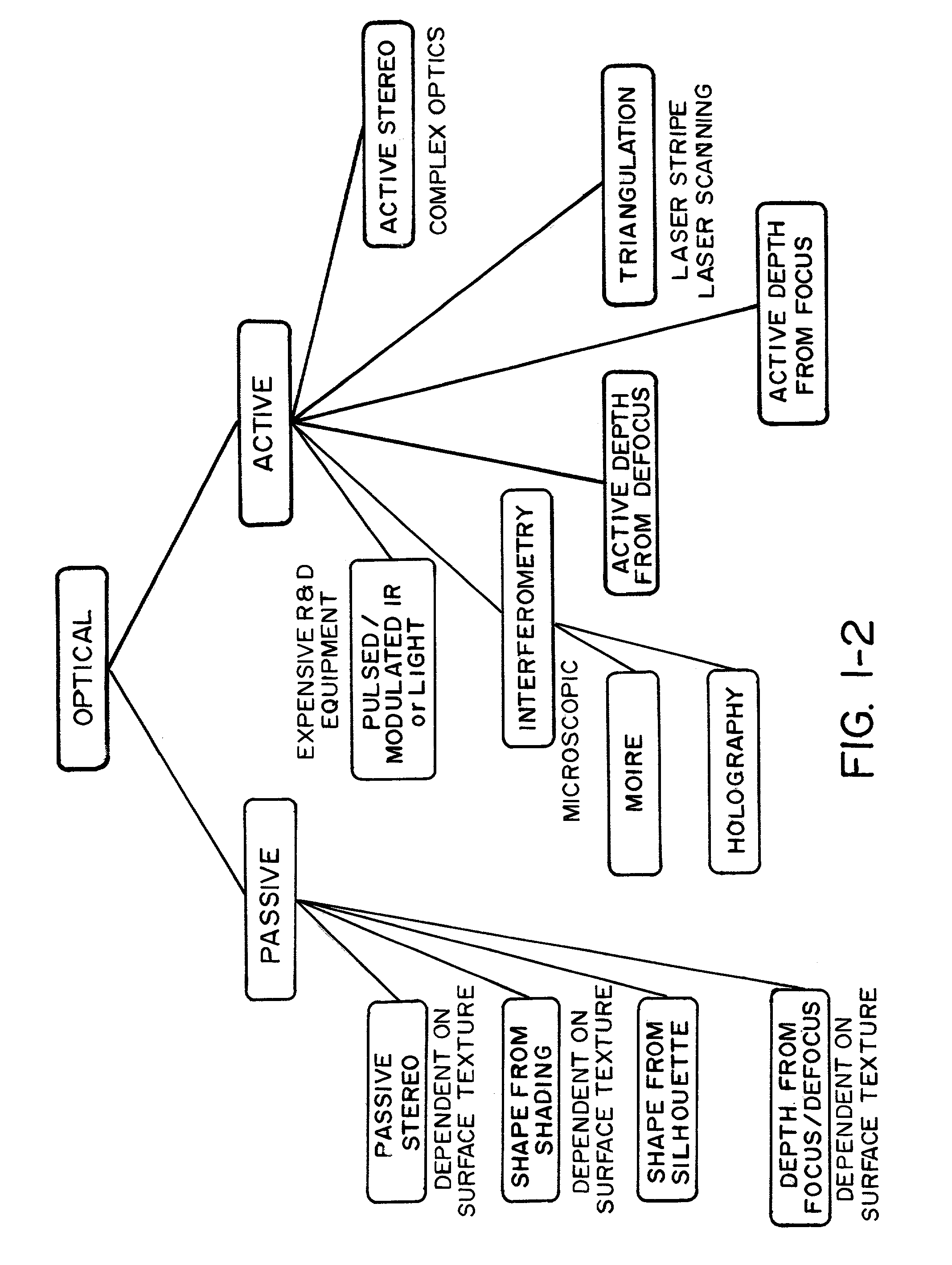

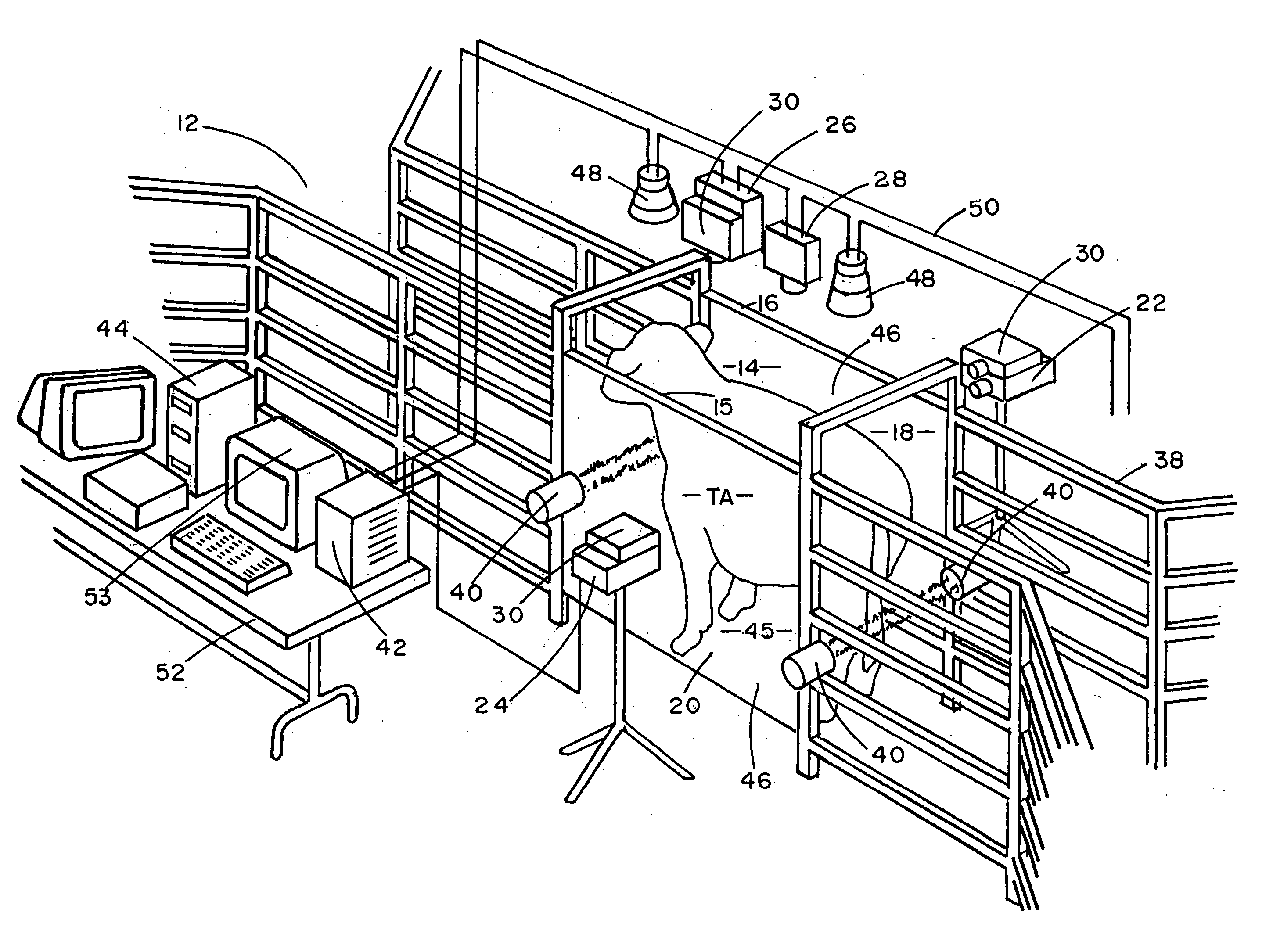

Apparatus and methods for the volumetric and dimensional measurement of livestock

InactiveUS20040023612A1Smooth rotationHigh precisionMeat processing plantsCarcasses classification/gradingAnimal scienceZoology

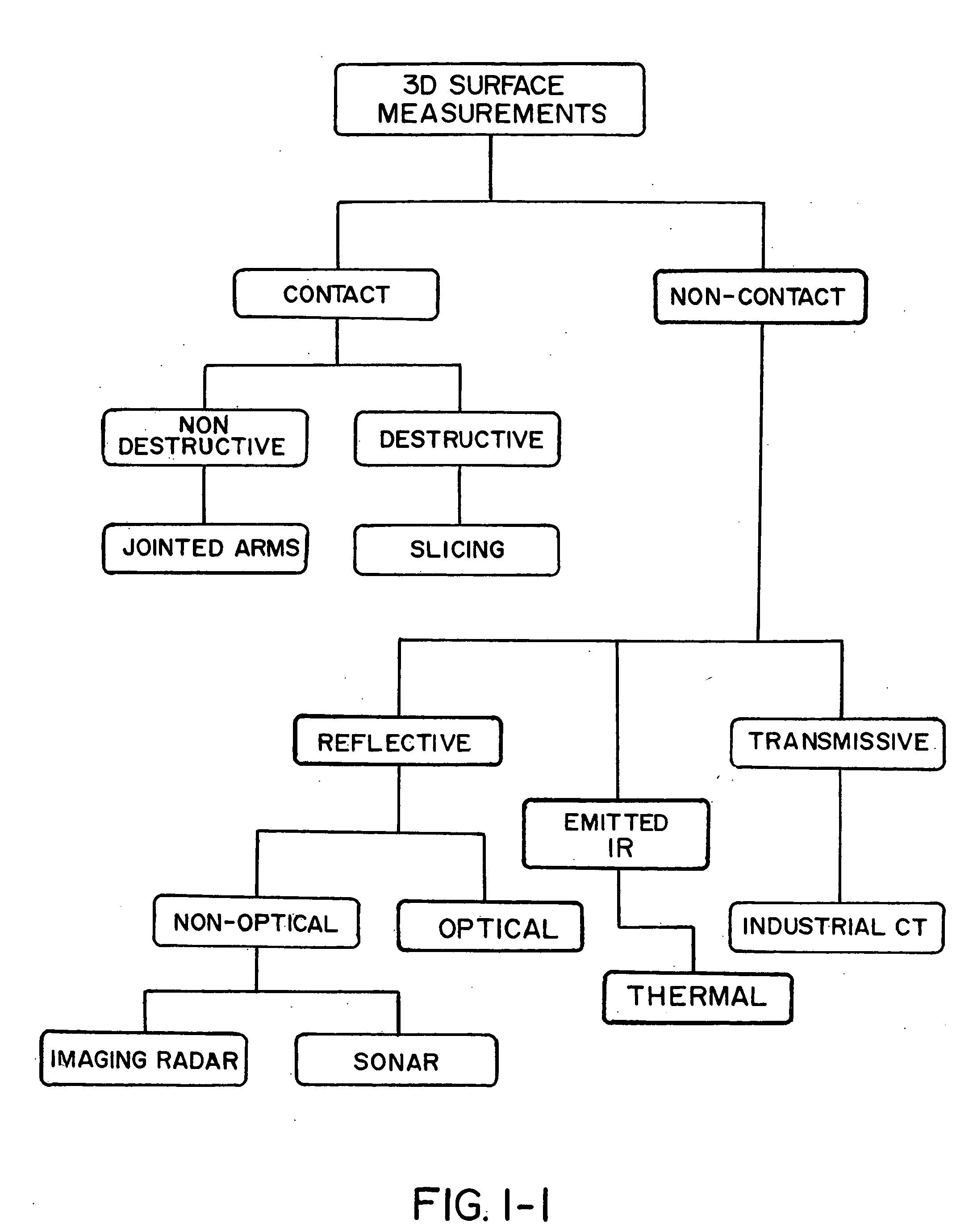

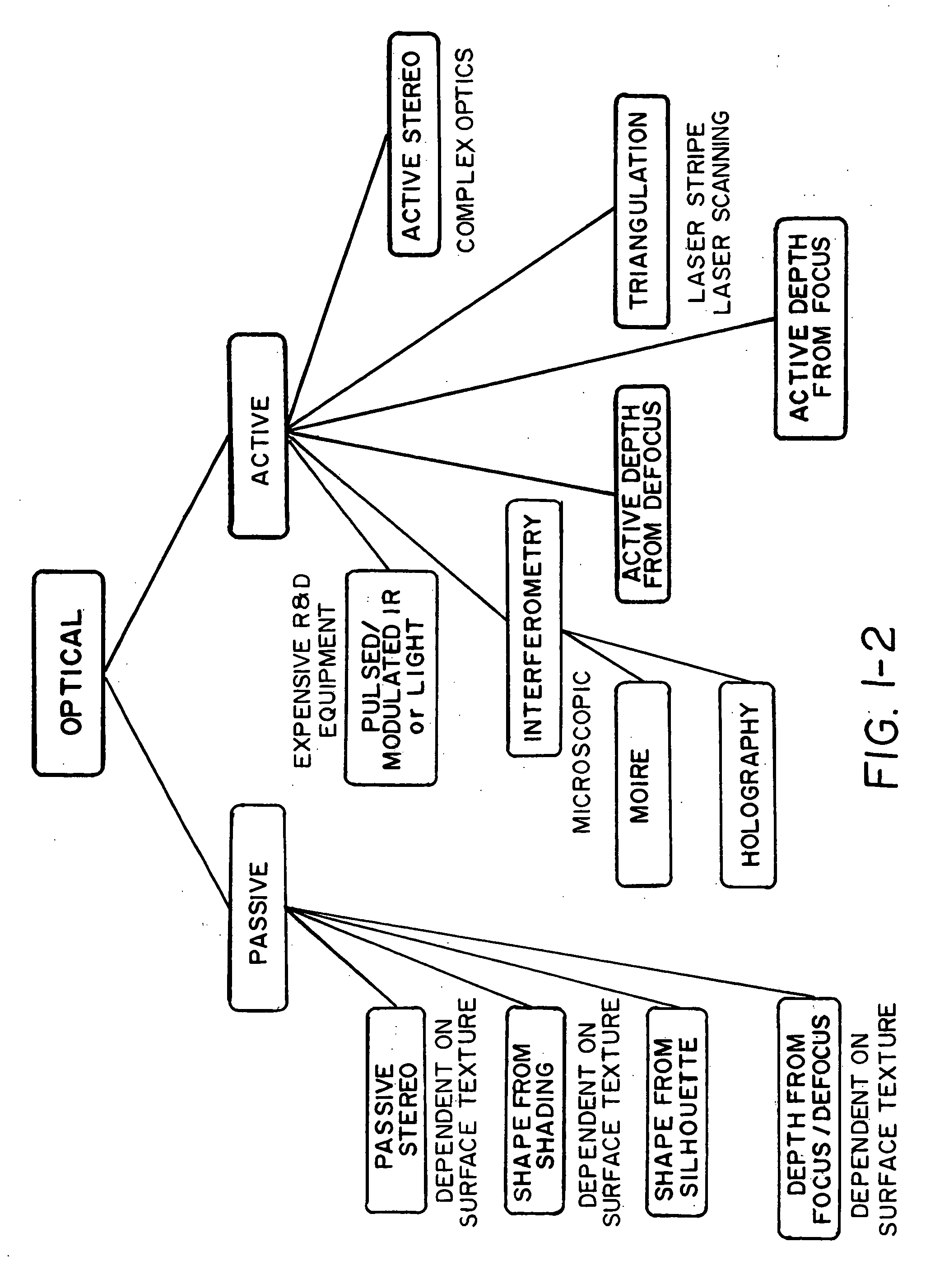

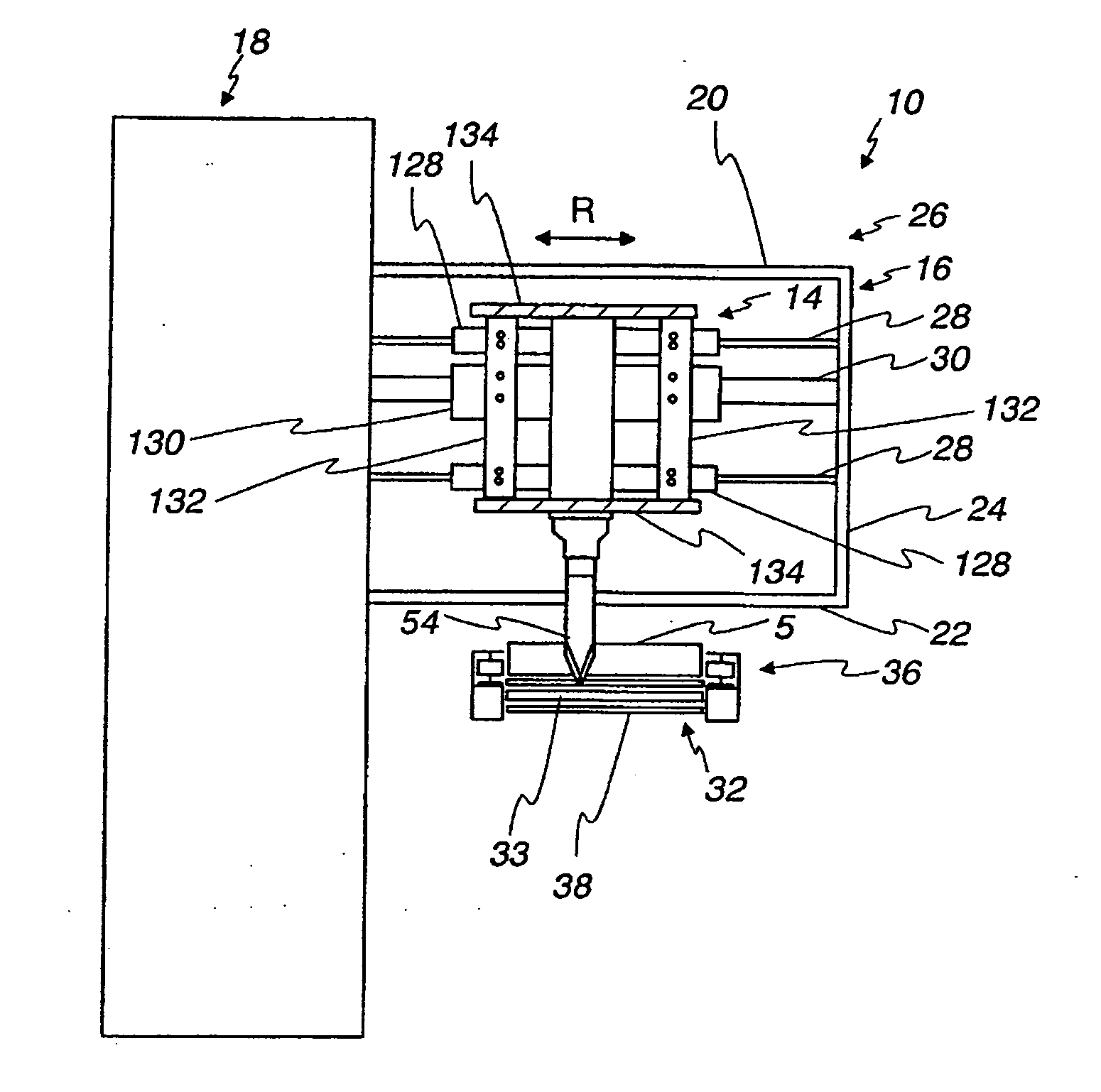

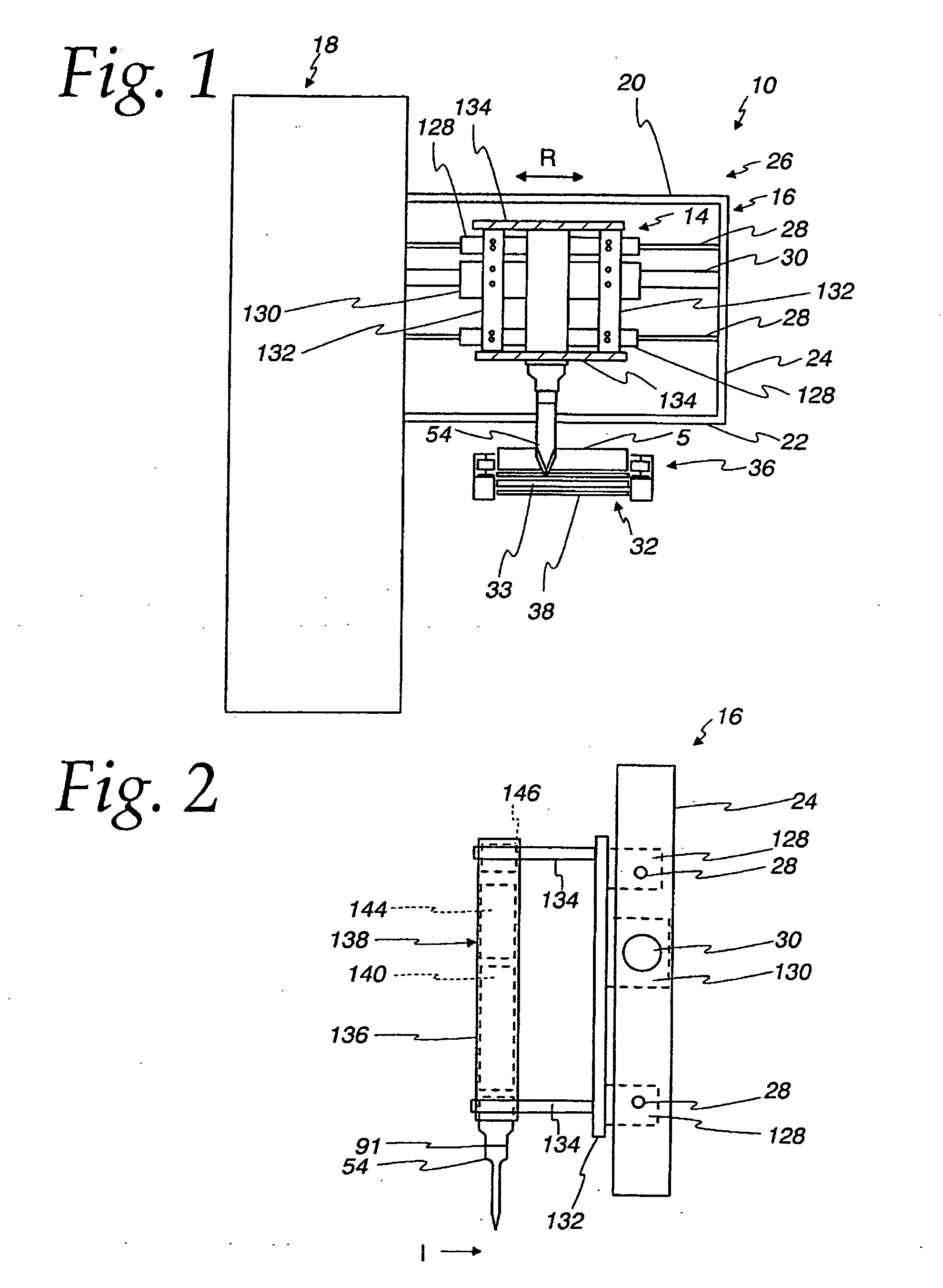

A method and apparatus for measuring the physical characteristics of livestock animals such as cattle and hogs. The apparatus of the invention includes a plurality of strategically positioned cameras that are used to obtain data concerning volumetric, curvilinear (surface) and linear measurements of livestock animals such as cattle and hogs and the full carcasses thereof. In accordance with the method of the invention, the data is analyzed to provide information that substantially assists the commercial producer of livestock animals in producing a high-quality end product for the consumer while adding profitability to the enterprise.

Owner:KALLINA +1

Apparatus and methods for the volumetric and dimensional measurement of livestock

InactiveUS20050136819A1Meat processing plantsCarcasses classification/gradingAnimal scienceLinearity

A method for measuring the physical characteristics of livestock animals such as cattle and hogs. The apparatus of the invention includes a plurality of strategically positioned cameras that are used to obtain data concerning volumetric, curvilinear (surface) and linear measurements of livestock animals such as cattle and hogs and the full carcasses thereof. In accordance with the method of the invention, the data is analyzed to provide information that substantially assists the commercial producer of livestock animals in producing a high-quality end product for the consumer while adding profitability to the enterprise.

Owner:ALLFLEX USA +1

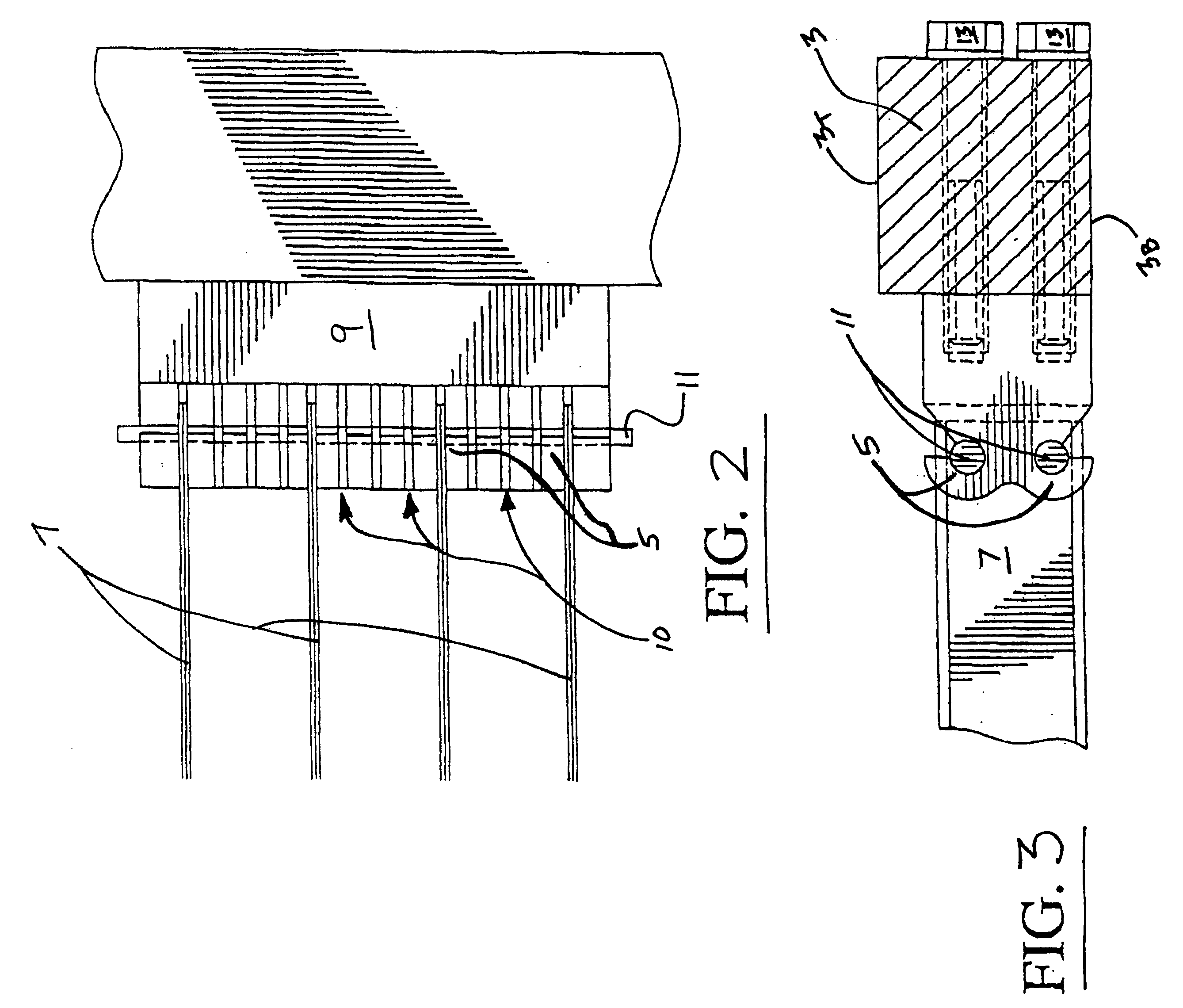

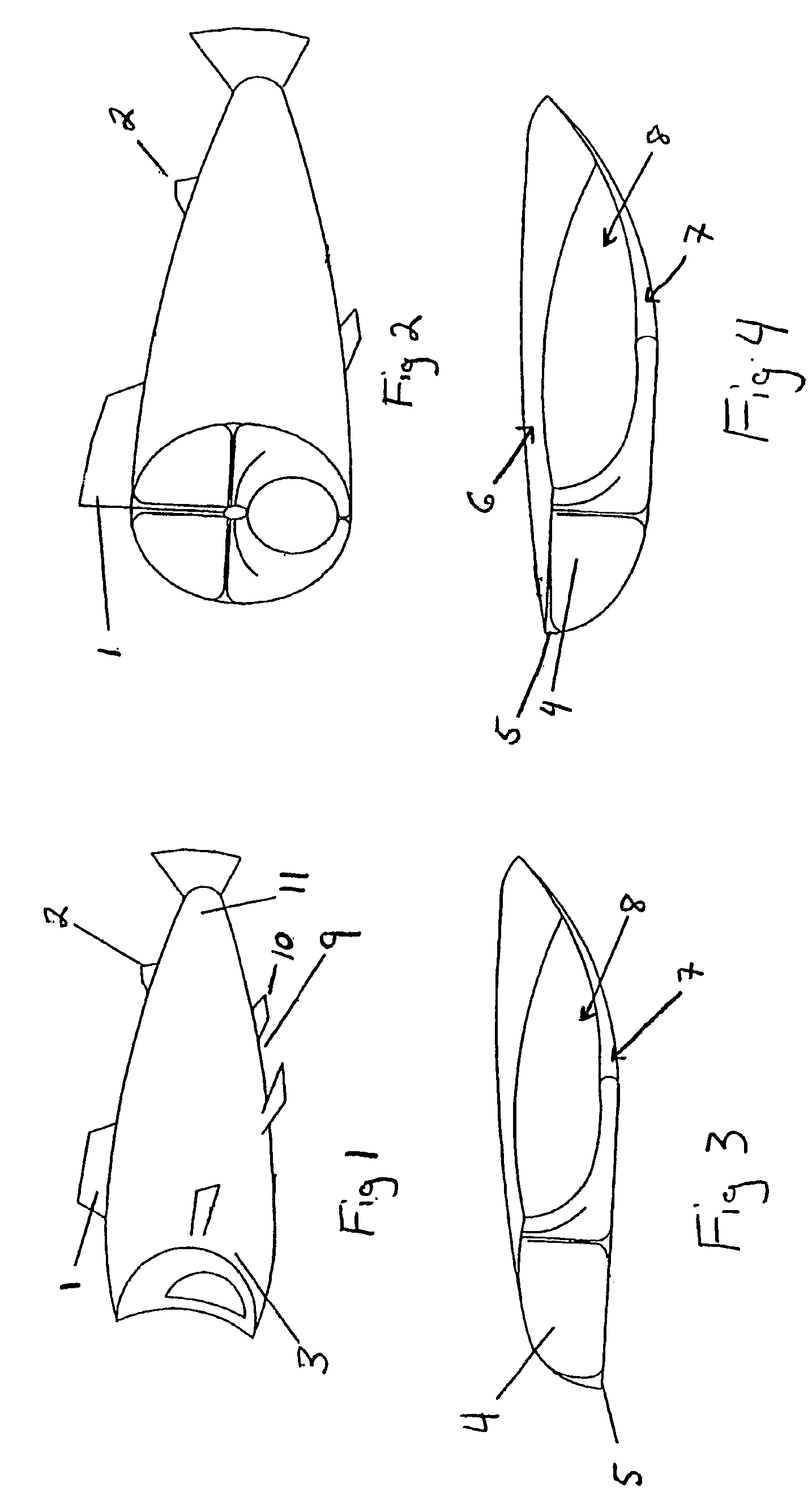

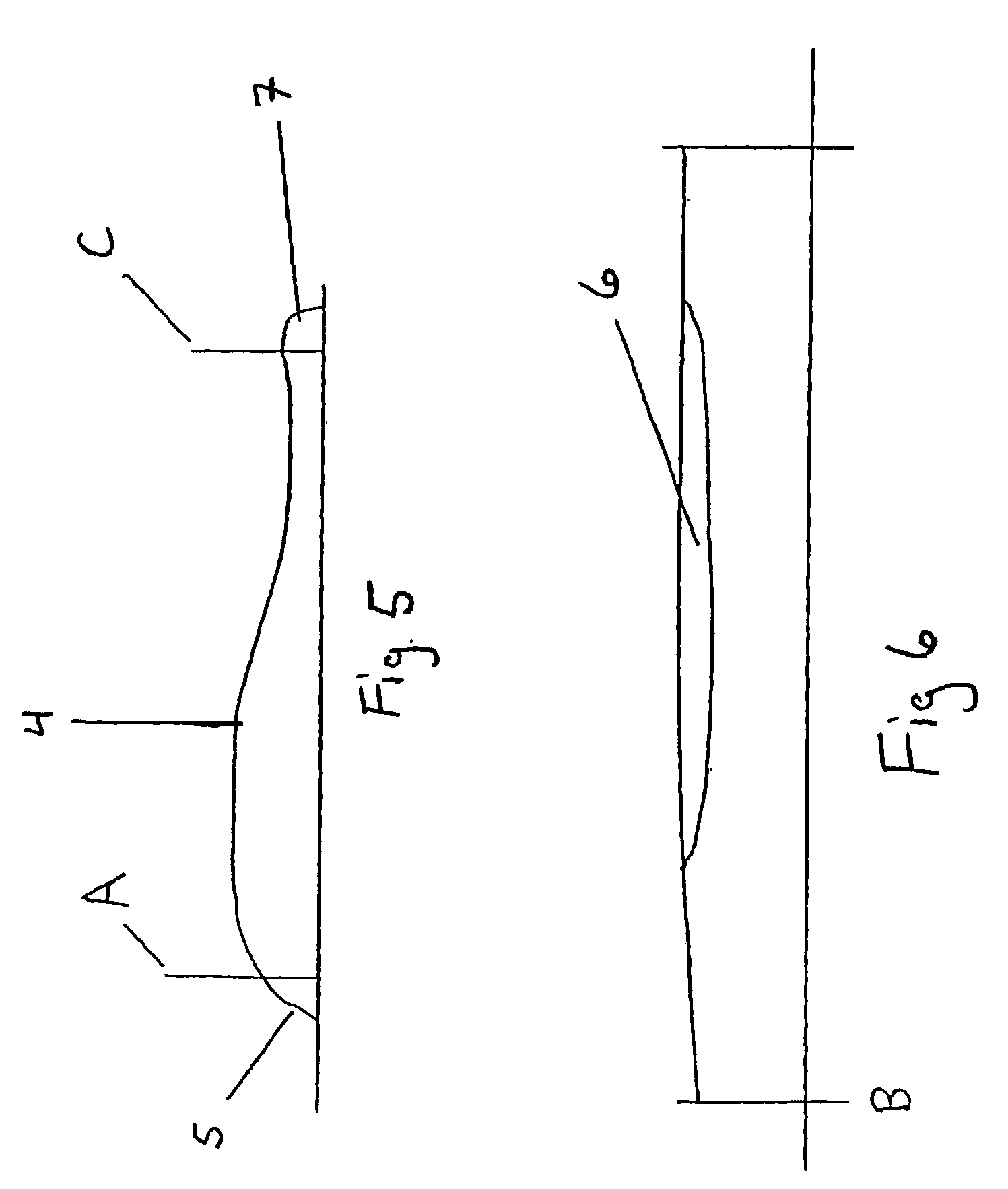

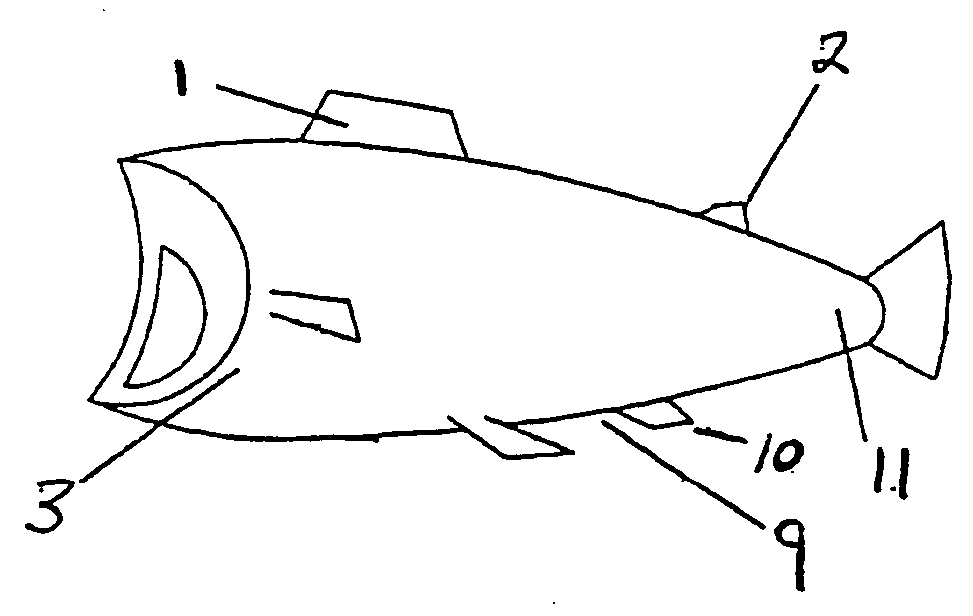

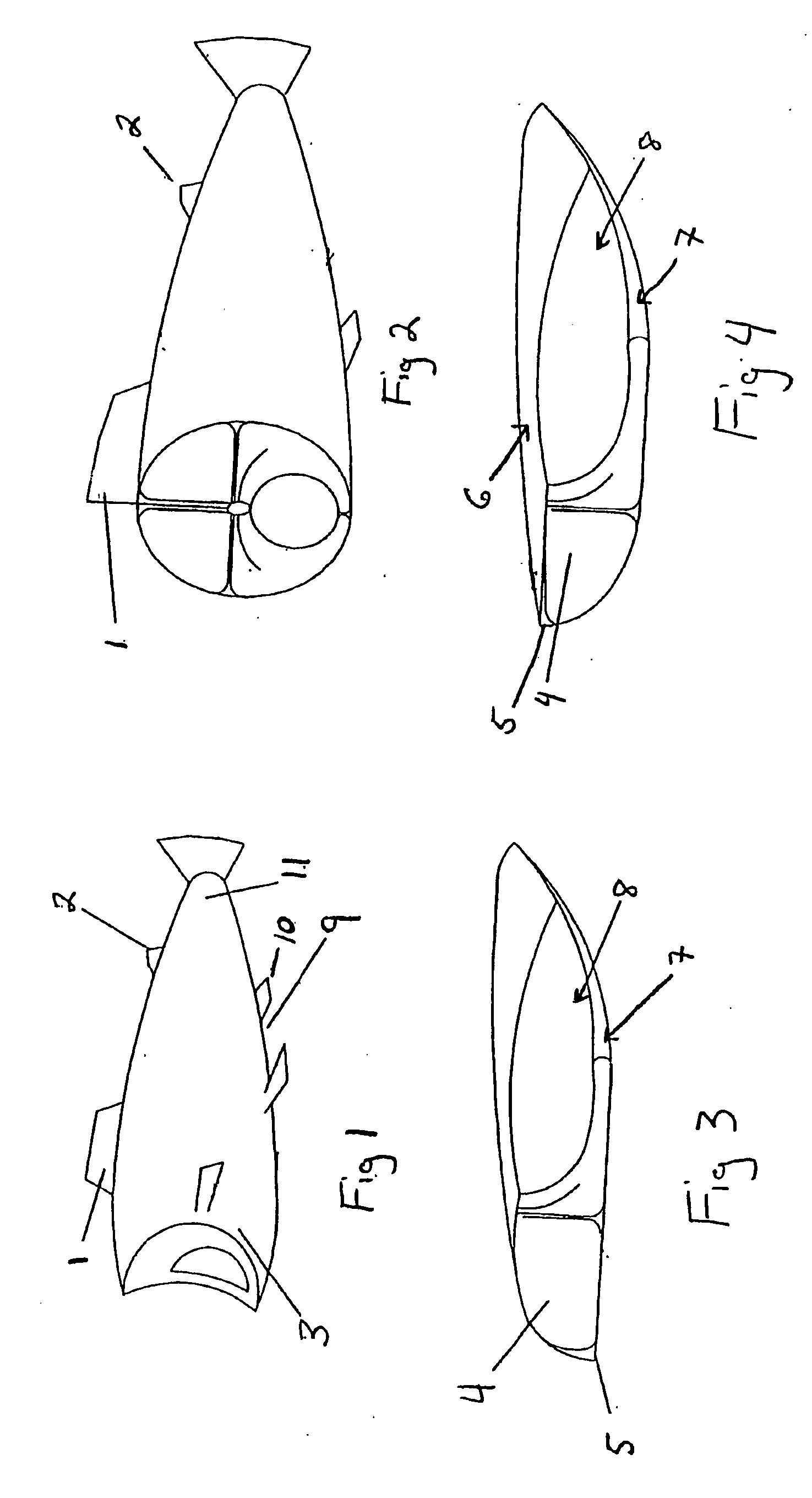

Baitfish chunking apparatus

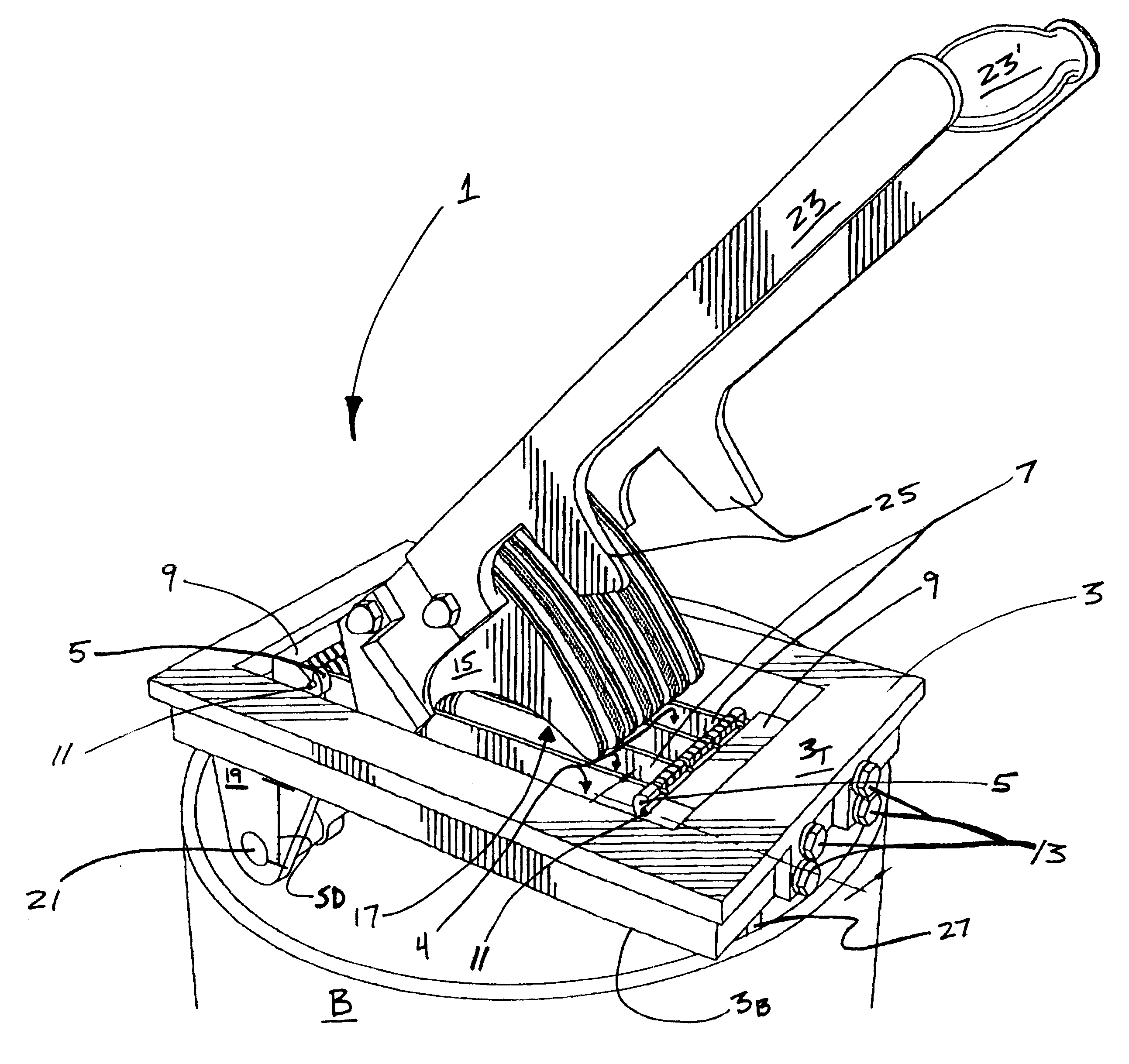

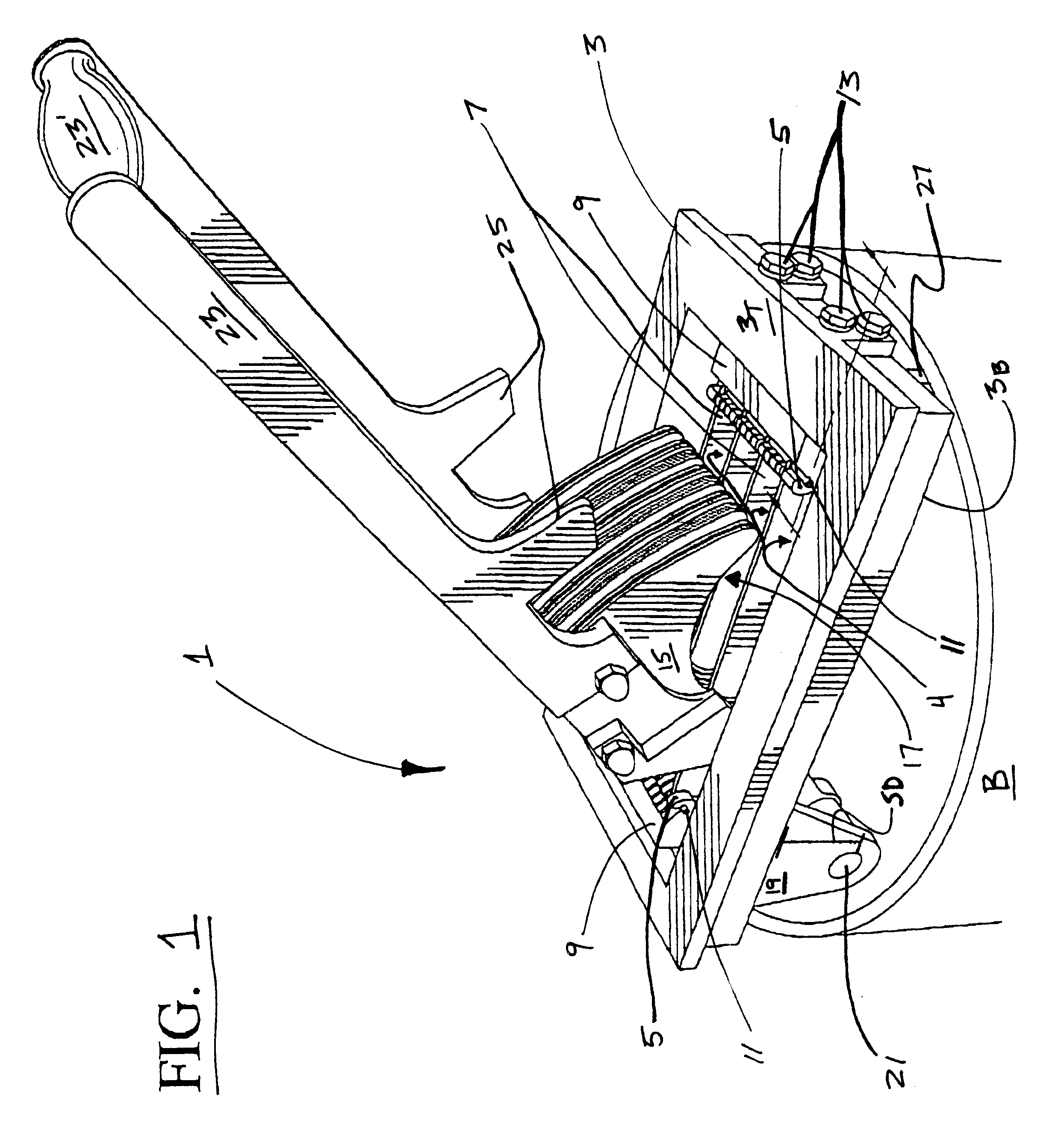

Apparatus for cutting baitfish employing a non-symmetrically arcuate biasing member for angularly articulating a baitfish against a plurality of blade surfaces. In certain embodiments, apparatus having an improved lever arm with increased mechanical advantage.

Owner:NEDELKA JOHN

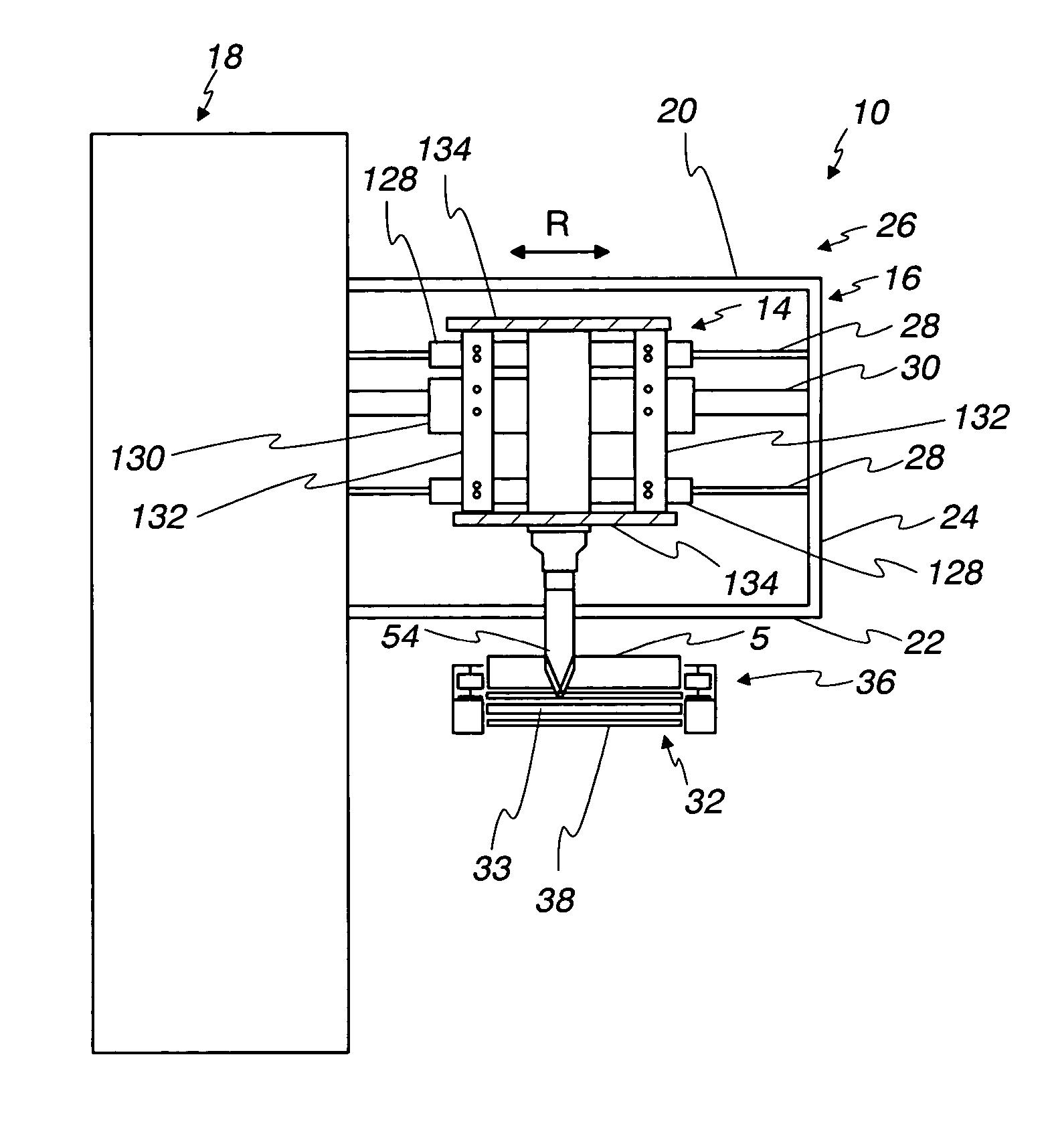

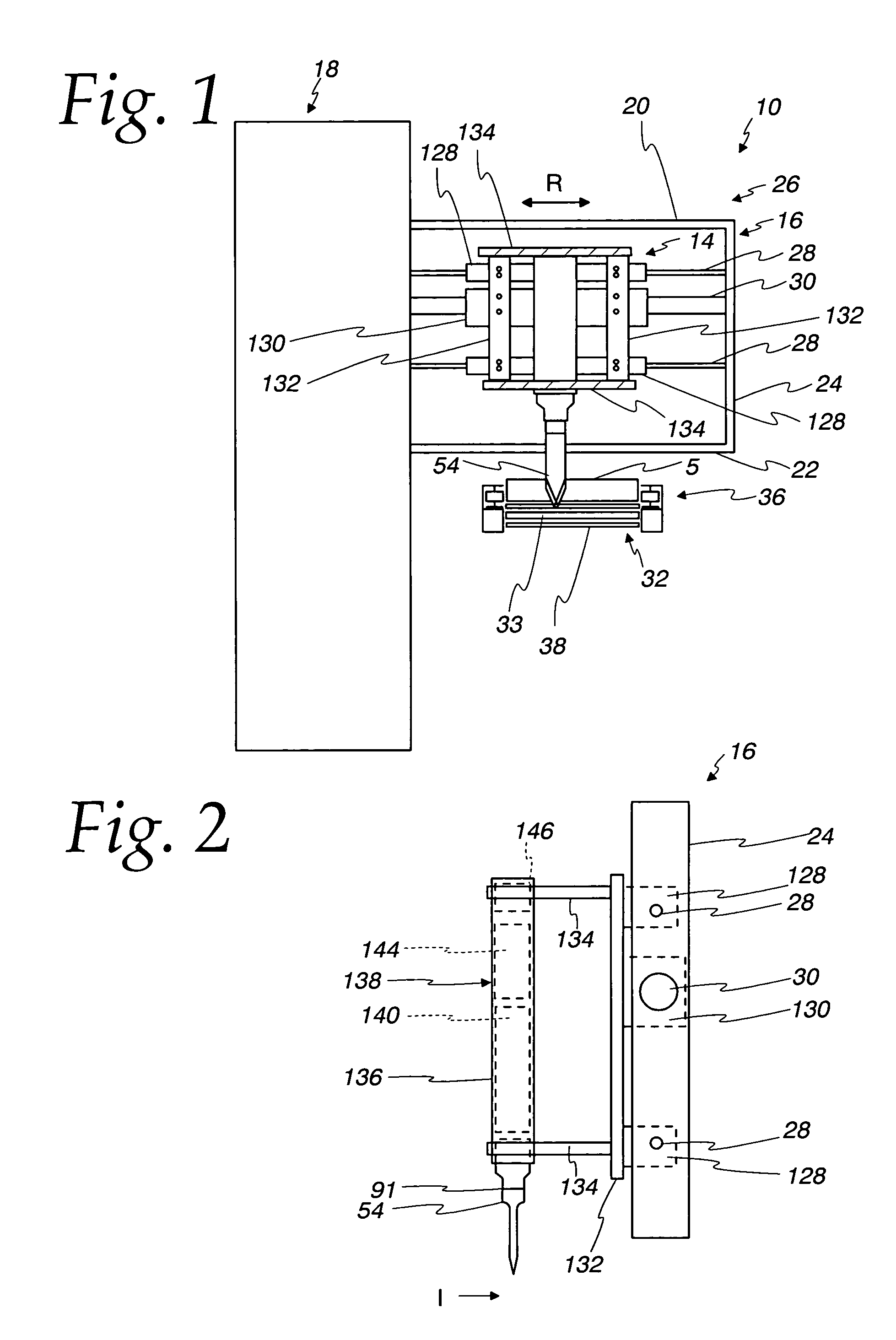

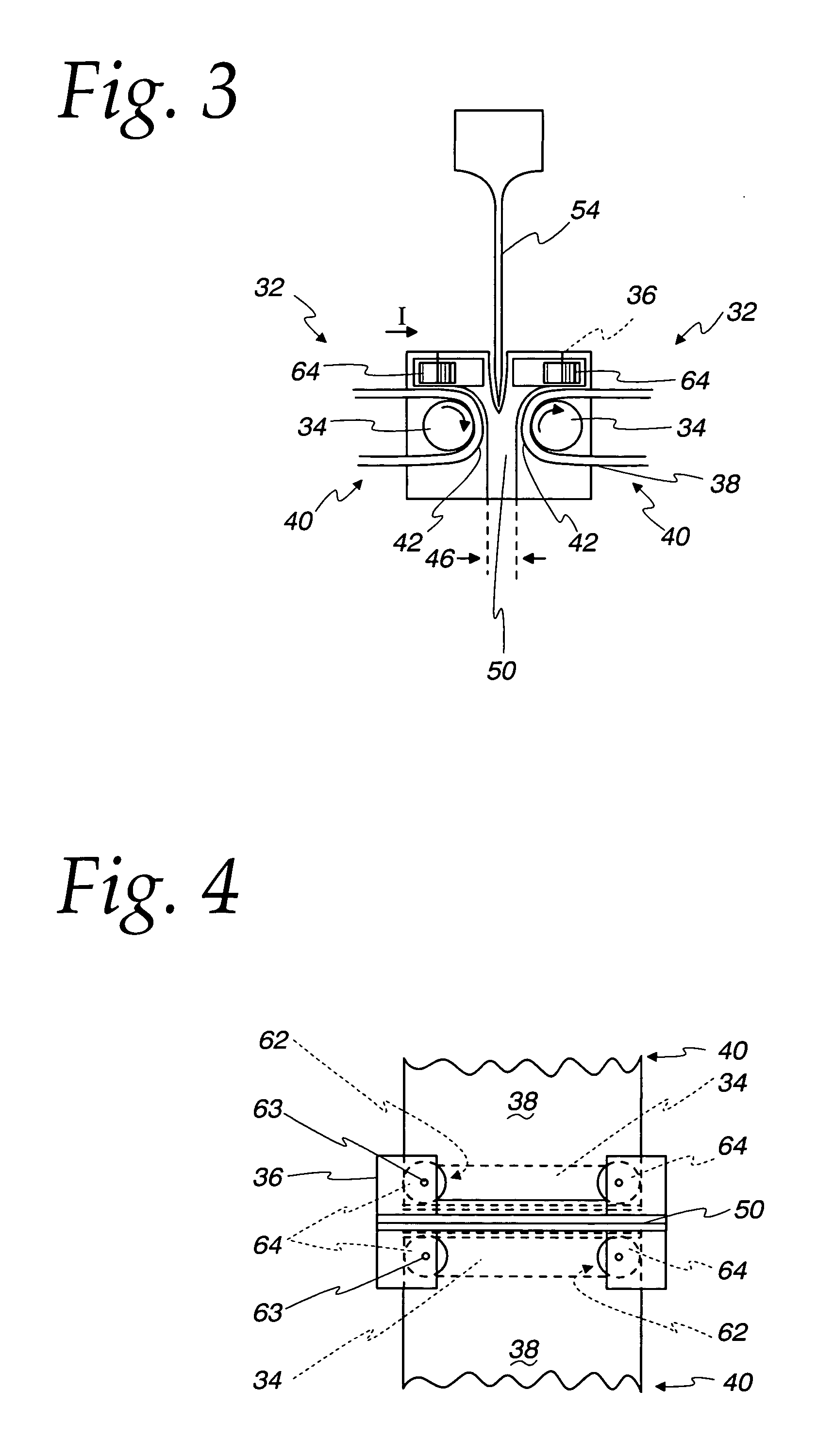

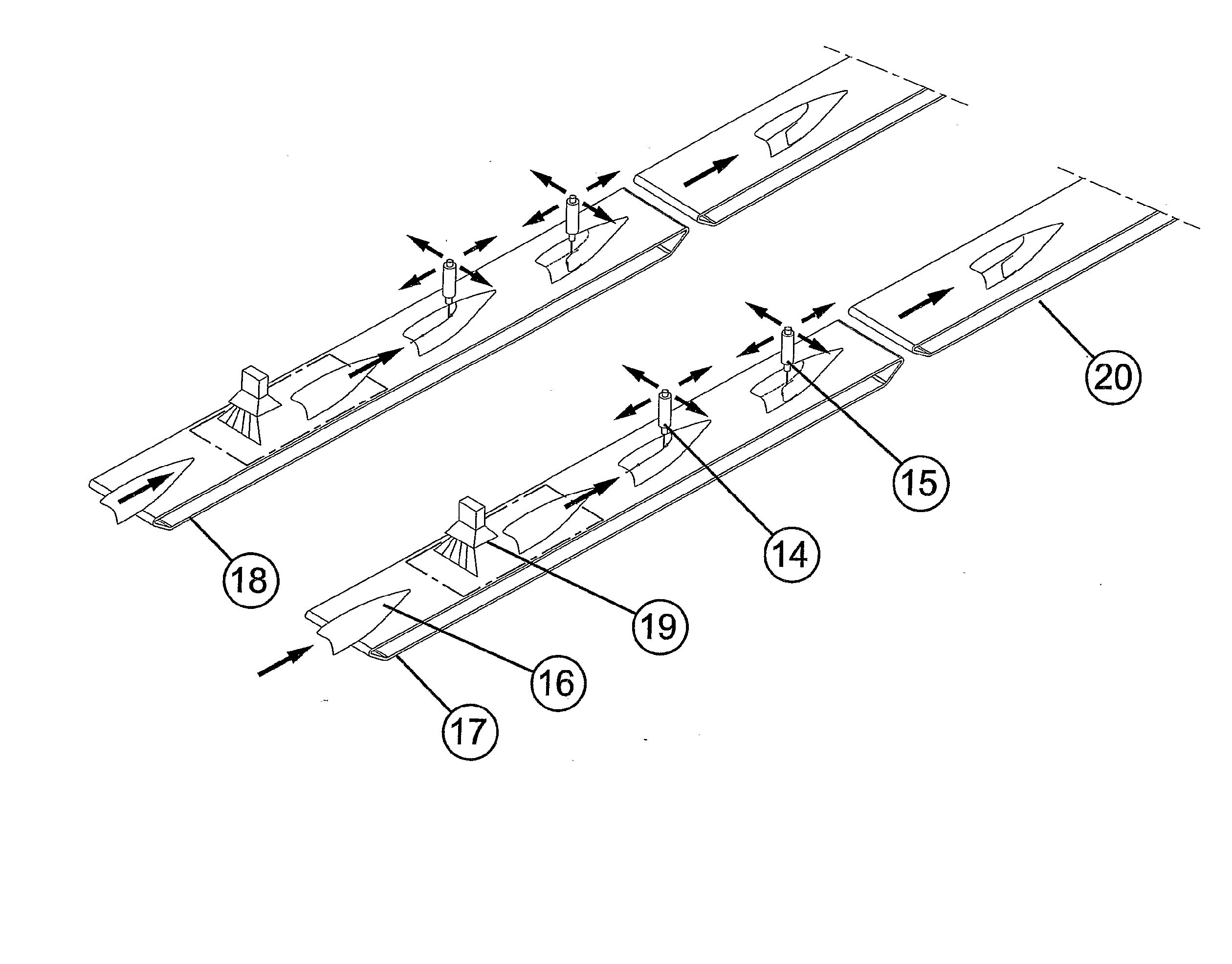

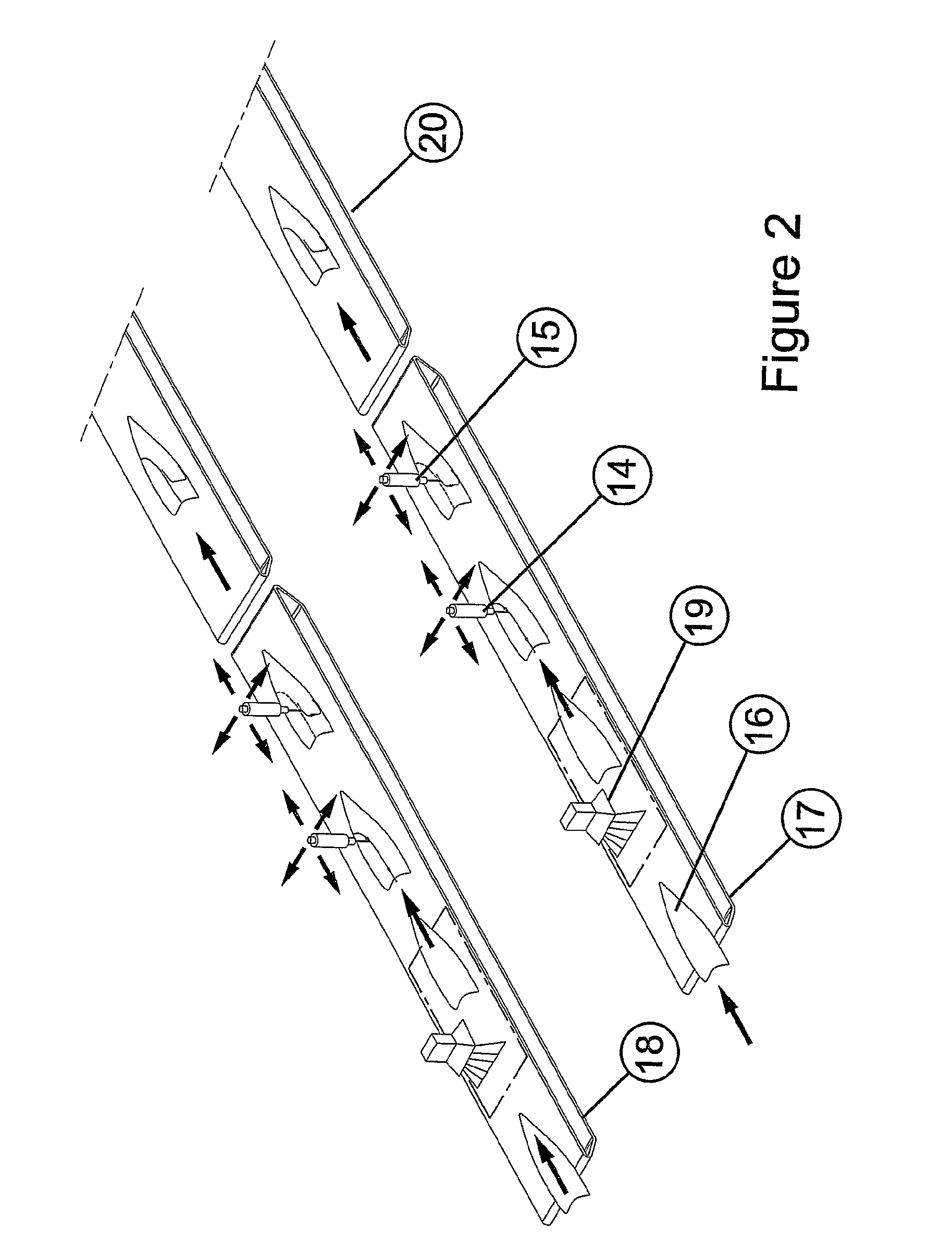

Ultrasonic slitter

InactiveUS20050081692A1Increase engagementCheese manufactureCircular sawsElectronic controllerThick plate

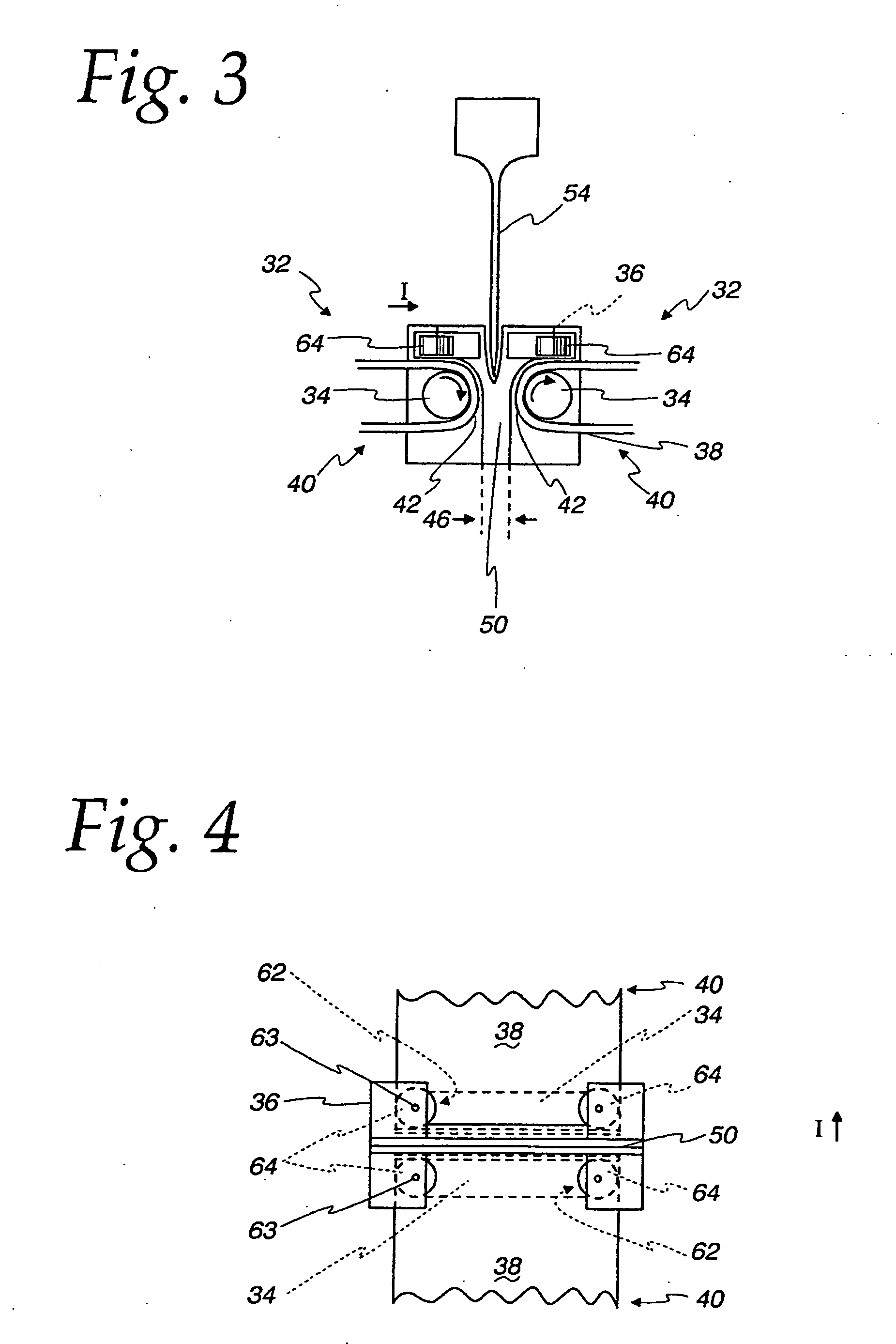

Apparatus for high-volume, high speed ultrasonic cutting or slitting comprising a blade having first and second cutting edges suspended from a reciprocating head, cantilevered over a conveyor supporting and advancing the food product, with the blade including first and second cutting edges on respective opposite sides thereof to cut the food product transversely. The head is preferably controlled for automated operation by an electronic controller to reciprocate transversely at a selected speed and a selected frequency within predetermined ranges over food product advancing on the conveyor. The blade preferably oscillates ultrasonically, and preferably at a frequency of approximately 20,000 Hz. The first and second cutting edges are preferably downwardly convergent, defining an included angle greater than 60 degrees and less than 90 degrees. In one particular embodiment, the internal angle is 70 degrees. In another embodiment, the angle is about 60 degrees. The blade may have a linear translating velocity of 25 to 35 inches per second, and more specifically may have a transverse velocity of approximately thirty inches per second. The apparatus may be used in high-speed, high-volume commercial food production operations for automated cutting of cheese products and other food products from large chunks, slabs and the like into smaller portions, and may also be used in other applications.

Owner:KRAFT FOODS INC

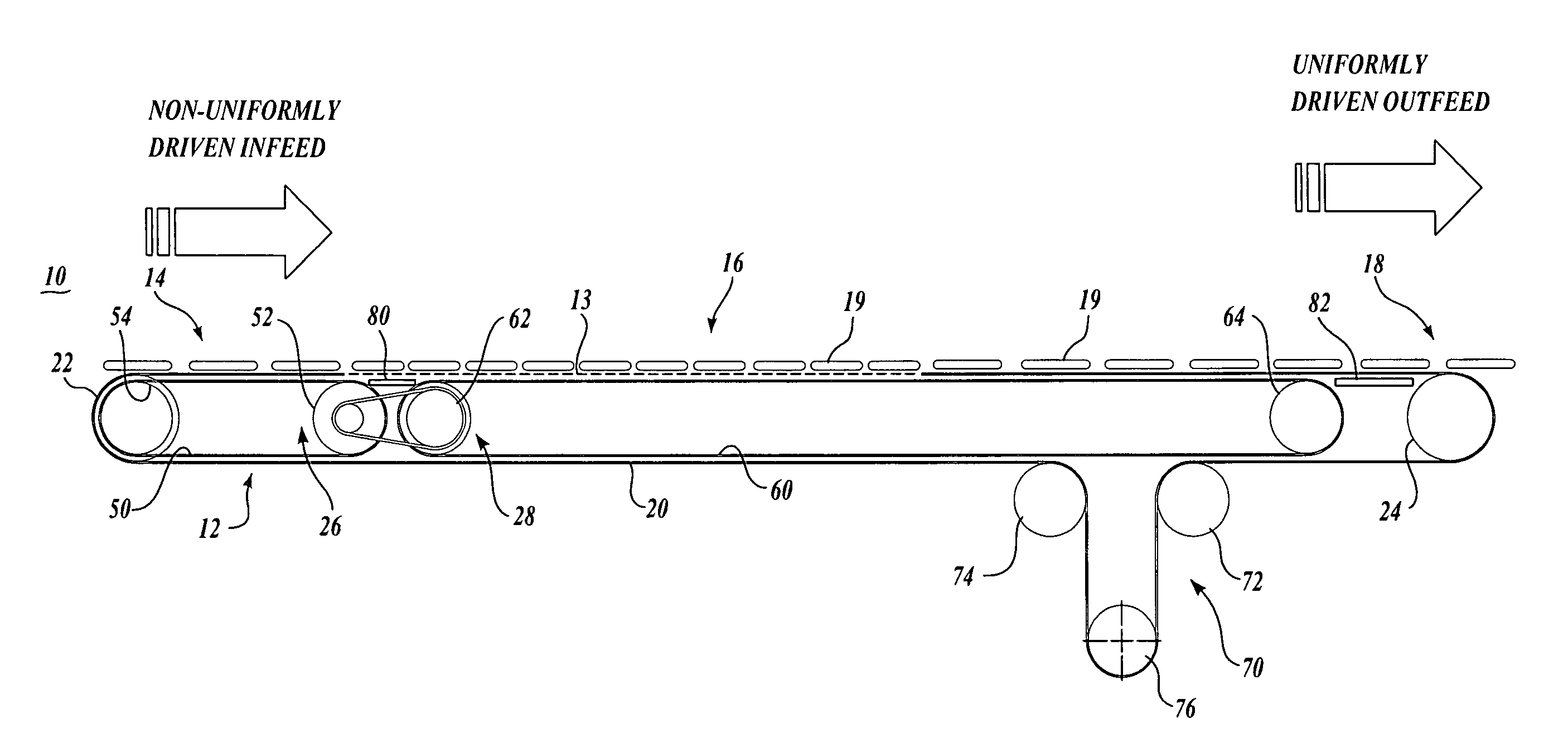

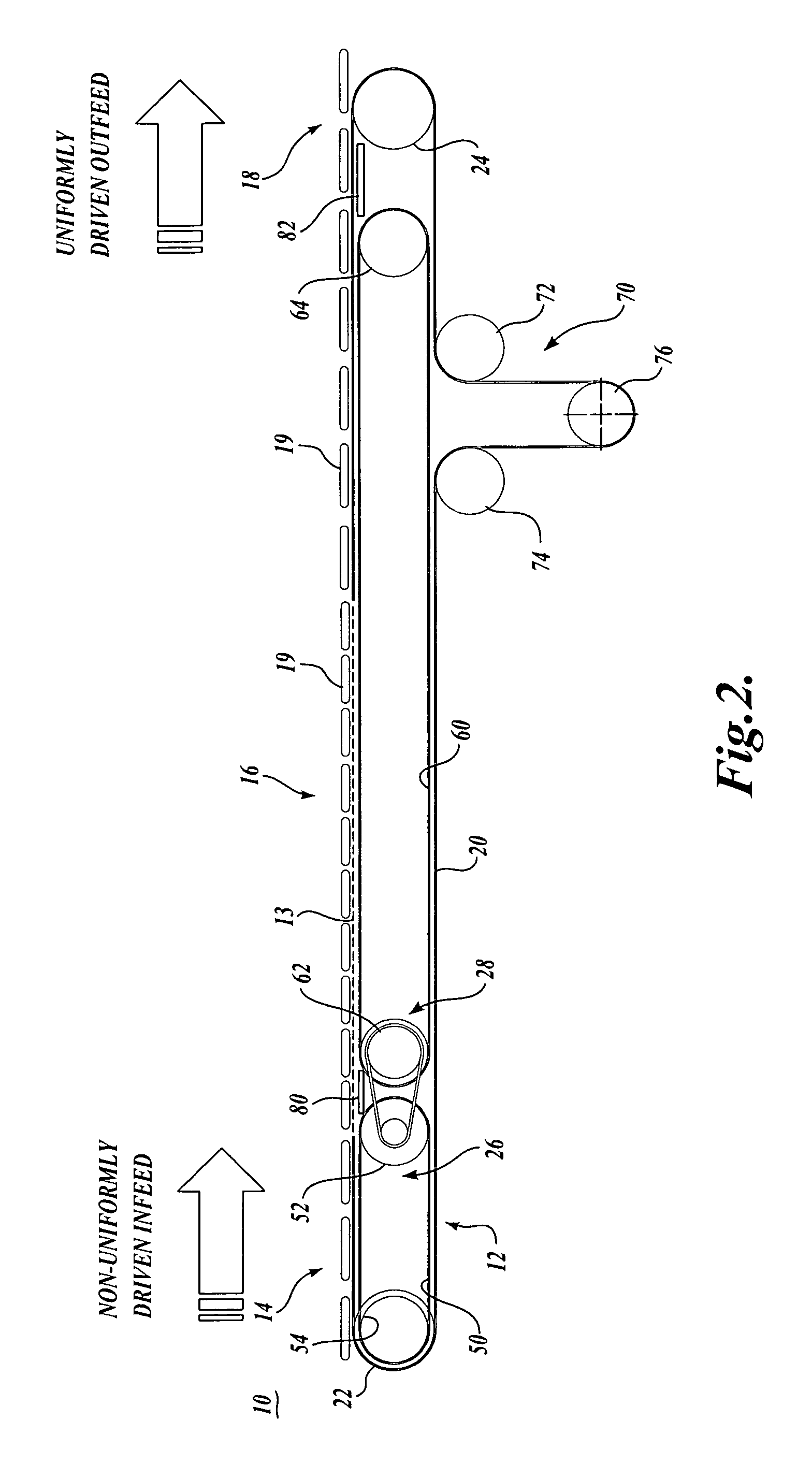

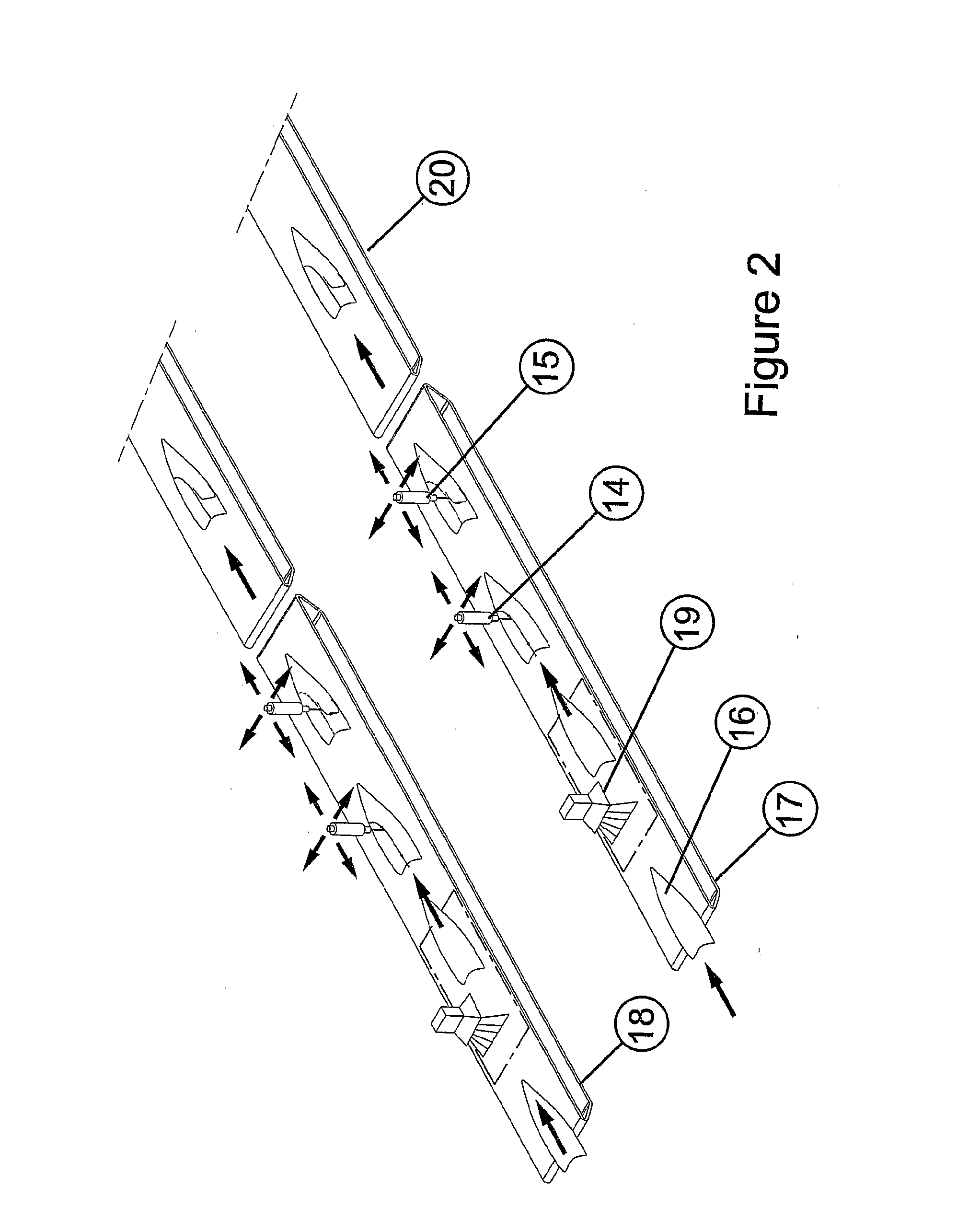

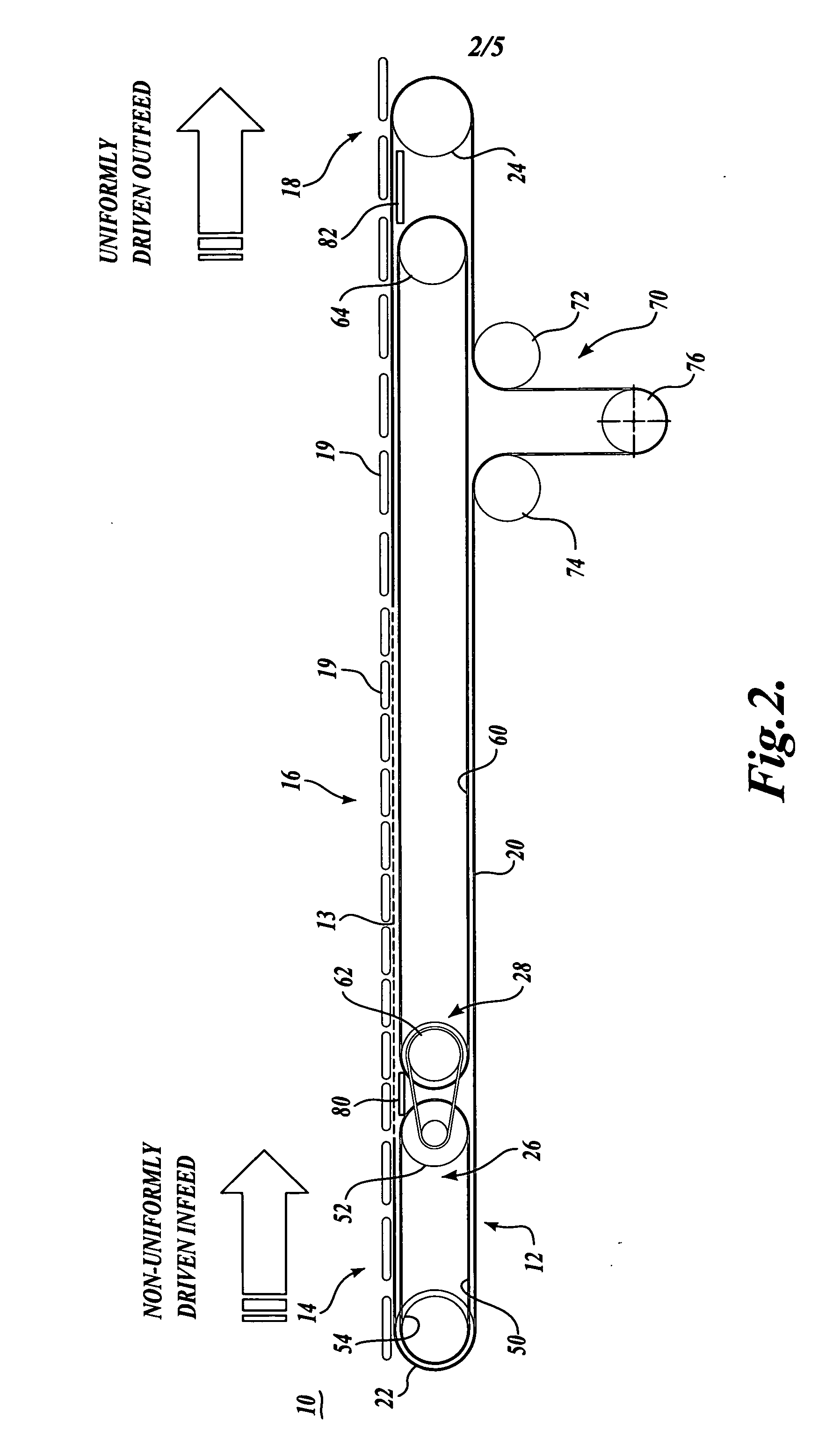

Conveying conformable products

A buffer conveyor (12) for conveying conformable work products (66) includes a collapsible conveyor belt (13) having an infeed section (14), a collapsible intermediate section (16) and an outfeed section (18). The infeed section (14) may be driven at a non-continuous speed, and the outfeed section may also be driven at a uniform, or non-continuous, speed, but the average speed of both the infeed and outfeed sections is the same. The intermediate section of the conveyor is driven at a non-uniform speed that is slower than, but proportional to, the speed of the infeed section.

Owner:JOHN BEAN TECH CORP

Method and an Apparatus for Automatic Bone Removal

ActiveUS20070293132A1Improve efficiencyIncrease valueMeat processing plantsPoultry processingDigital imagingFish fillet

The present invention relates to a method for automatically removing bones and trimming a product such as fish fillets, where the fillets are in an under cooled state. The under cooling makes the fillets sufficiently stiff to remove pin pones and portion a fillet before or after skinning the fillet in a relative still position providing better cutting than conventional methods. This provides more efficiency than prior art methods as well as increasing the value of the product due to less gaping and dehydration of the product. The method of the present invention further provides possibilities for grading of products processed with the three dimensional scanning and digital imaging of the products.

Owner:LAMBHUSASUND EHF

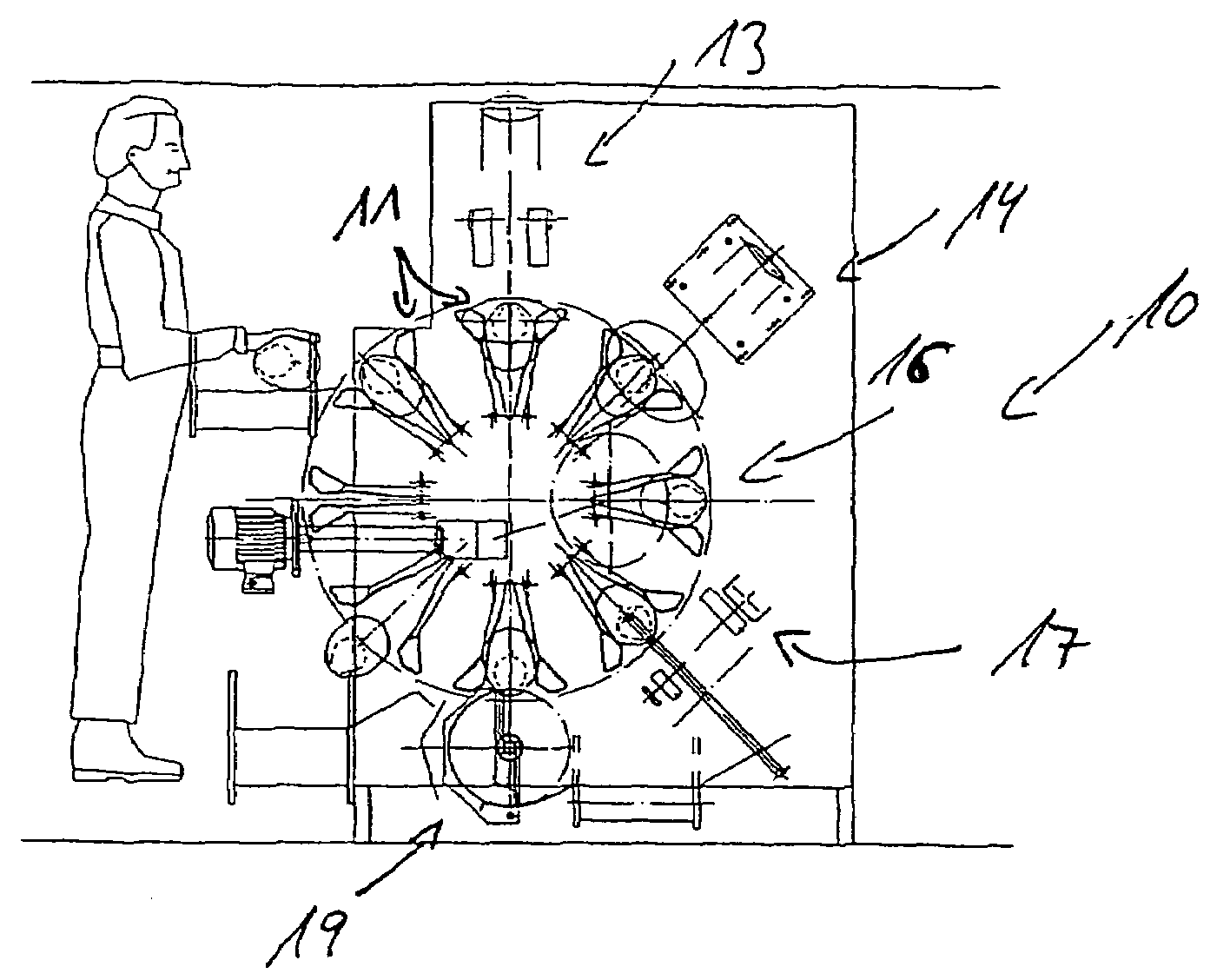

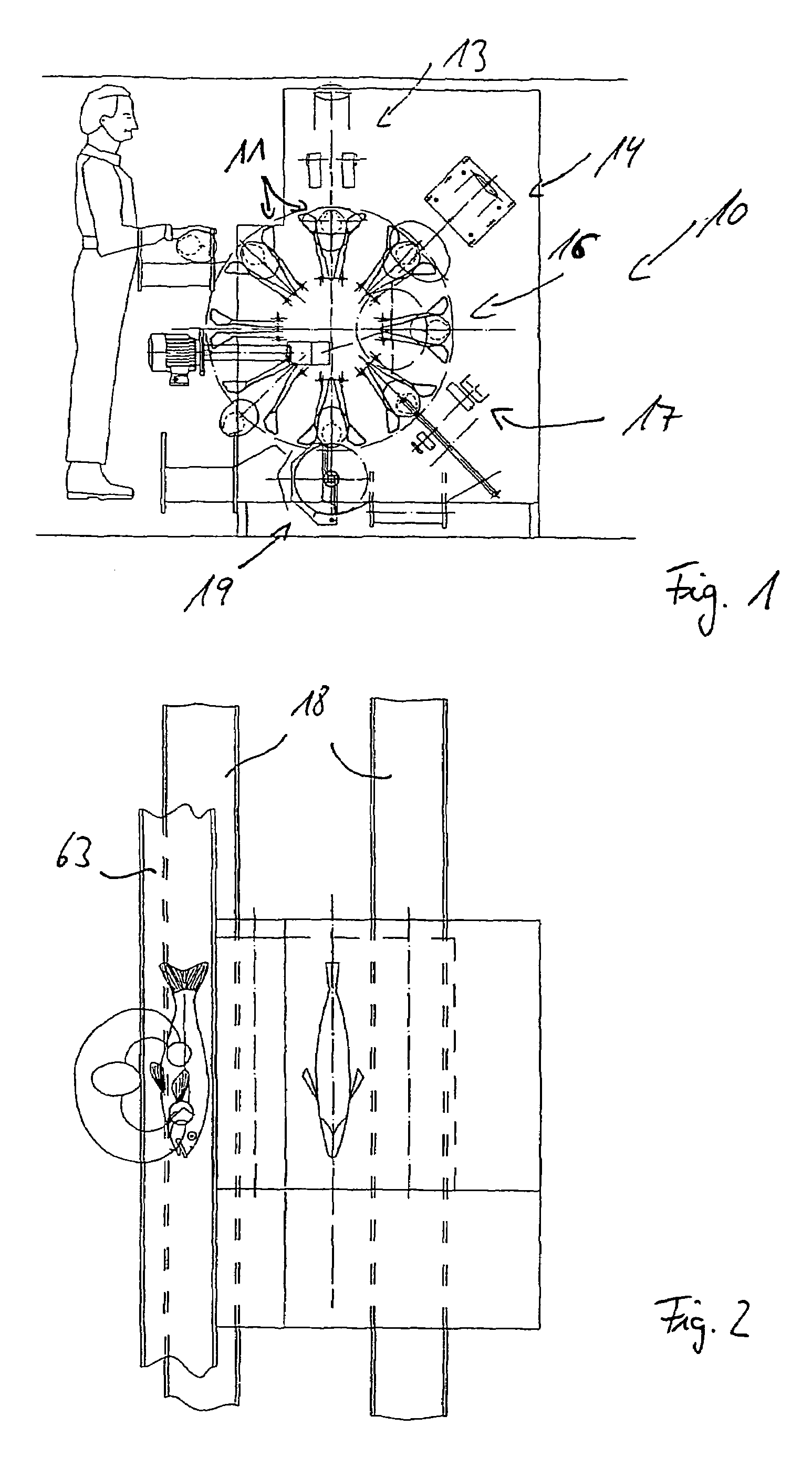

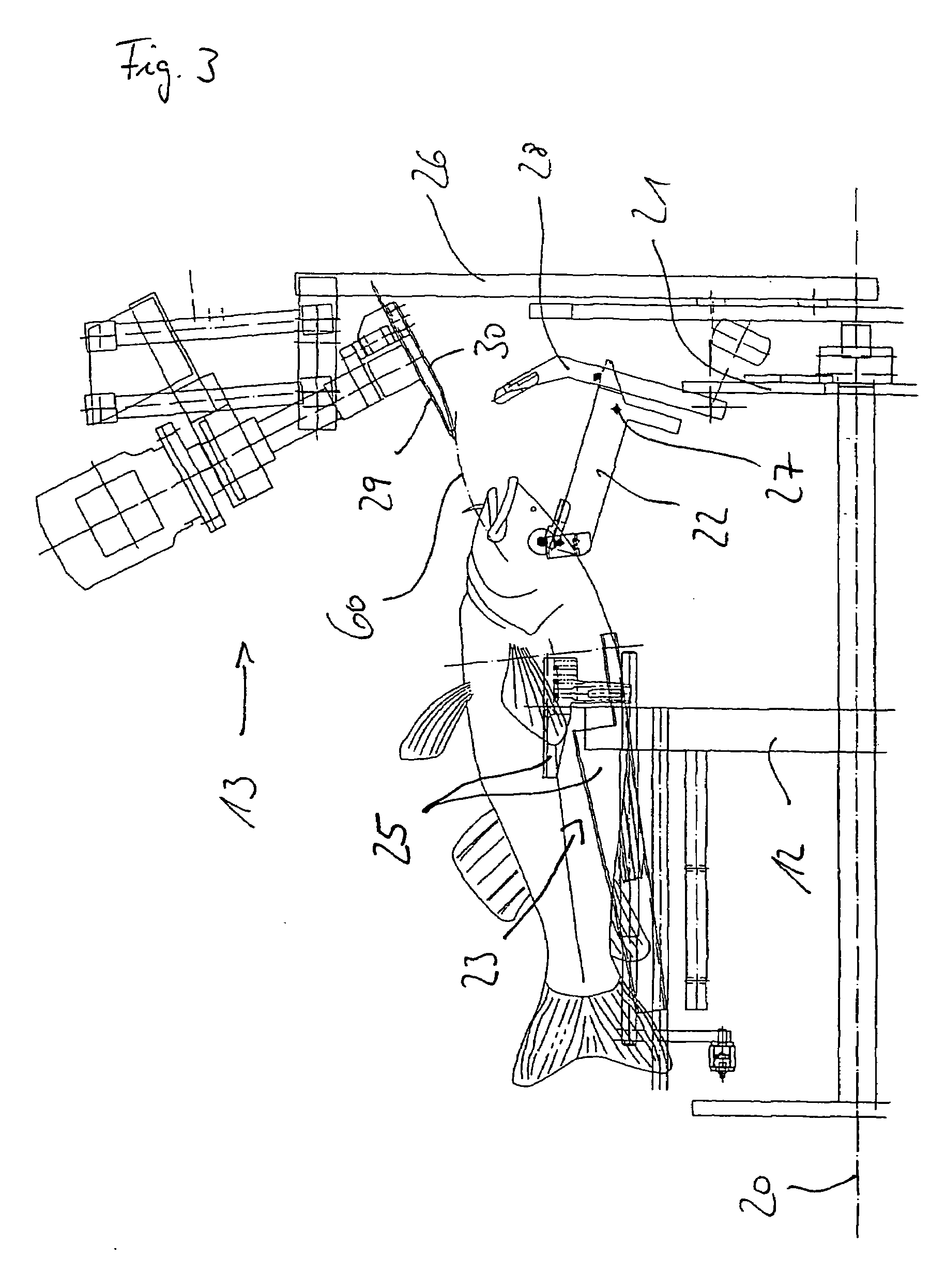

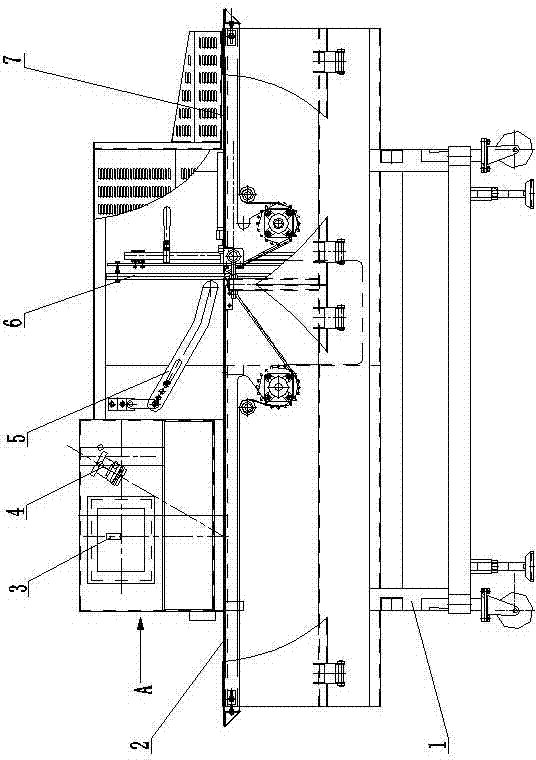

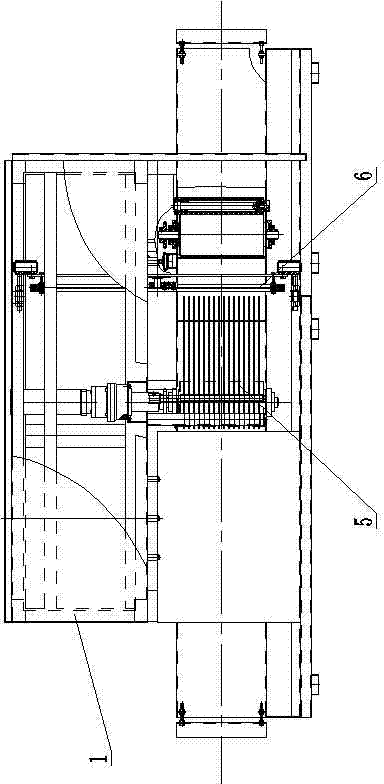

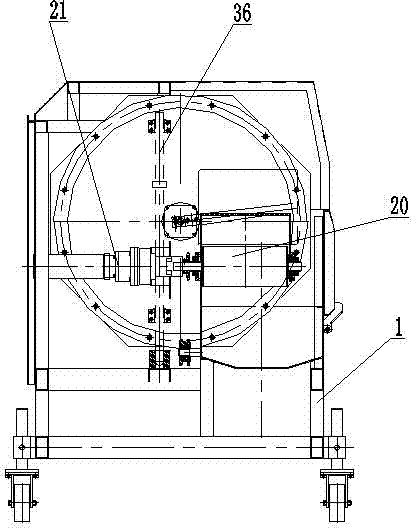

Method and device for slaughtering fish in particular white fish

InactiveUS7056202B2Increased length rangeImprove cut qualityAnimal stomach clearanceKosher slaughtering devicesAbdominal cavityPharynx

A device and method for slaughtering fish, in particular white fish, has at least one fish receptacle for positioning and receiving the fish, a throat cutting apparatus for cutting through the throat in preparation for the pharynx cut, a pharynx cutting apparatus for completely cutting through the pharynx, a slaughtering apparatus for opening the abdominal cavity, a gut severing apparatus for releasing the entrails from the abdominal cavity and a peripheral fish receiving drum with which the fish can be moved to the individual processing stations. The fish receiving drum is driven intermittently in rotation about a horizontal shaft. The fish are movable transversely to their longitudinal axis on an essentially vertical circular path. The fish receptacle includes pectoral fin receptacles and a torso clamp for fixing the fish torsos. Also, a head support with a head clamp is provided.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

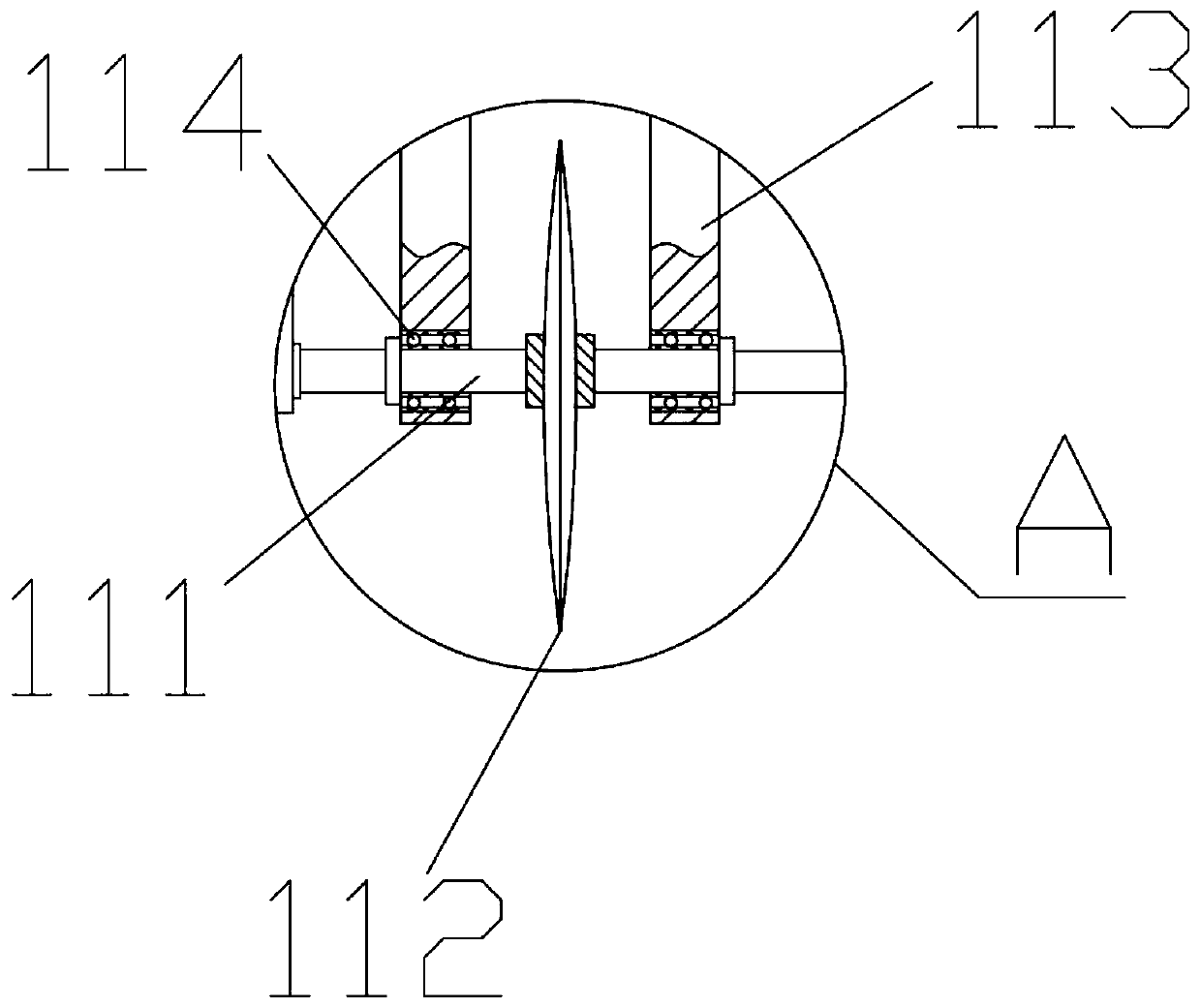

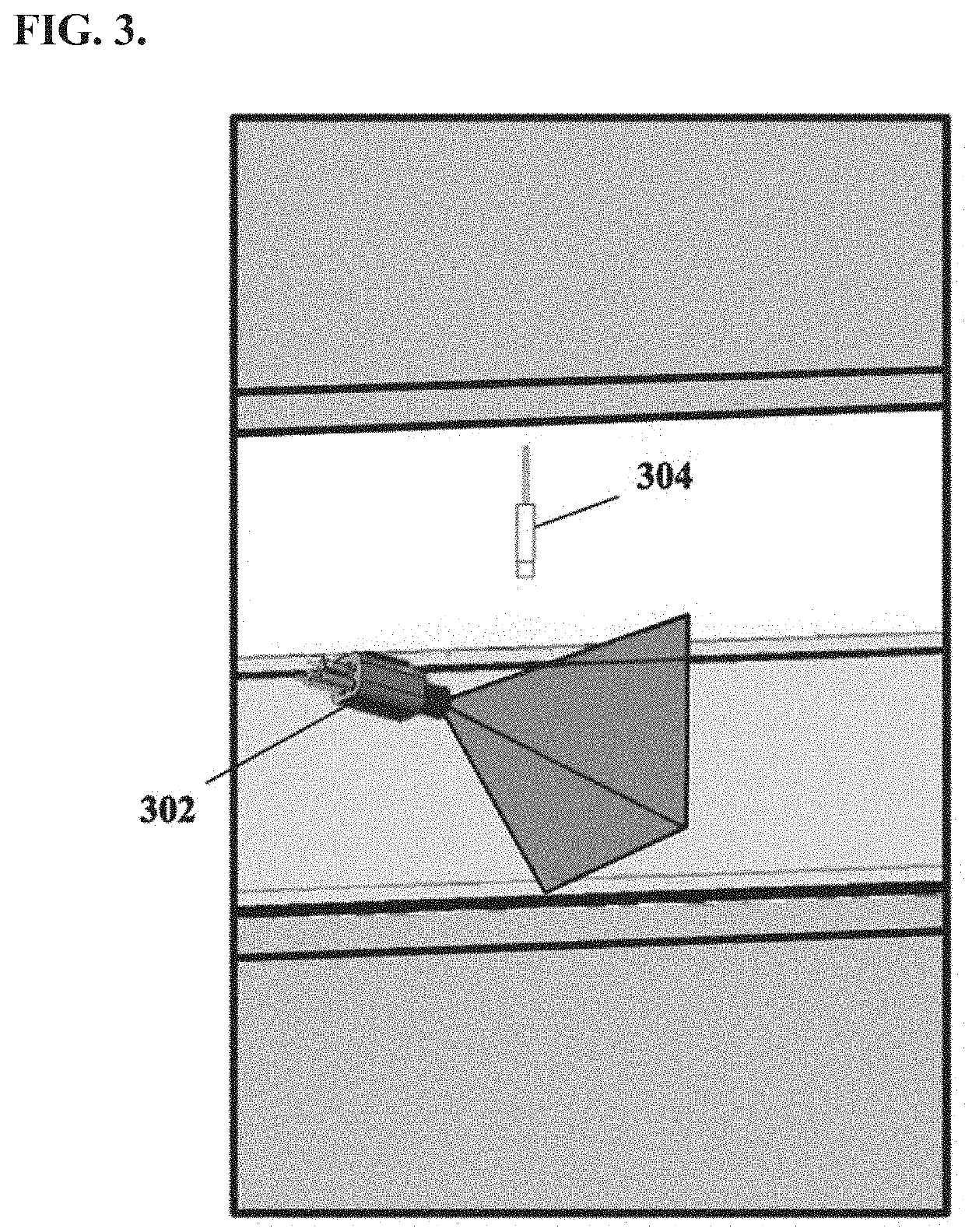

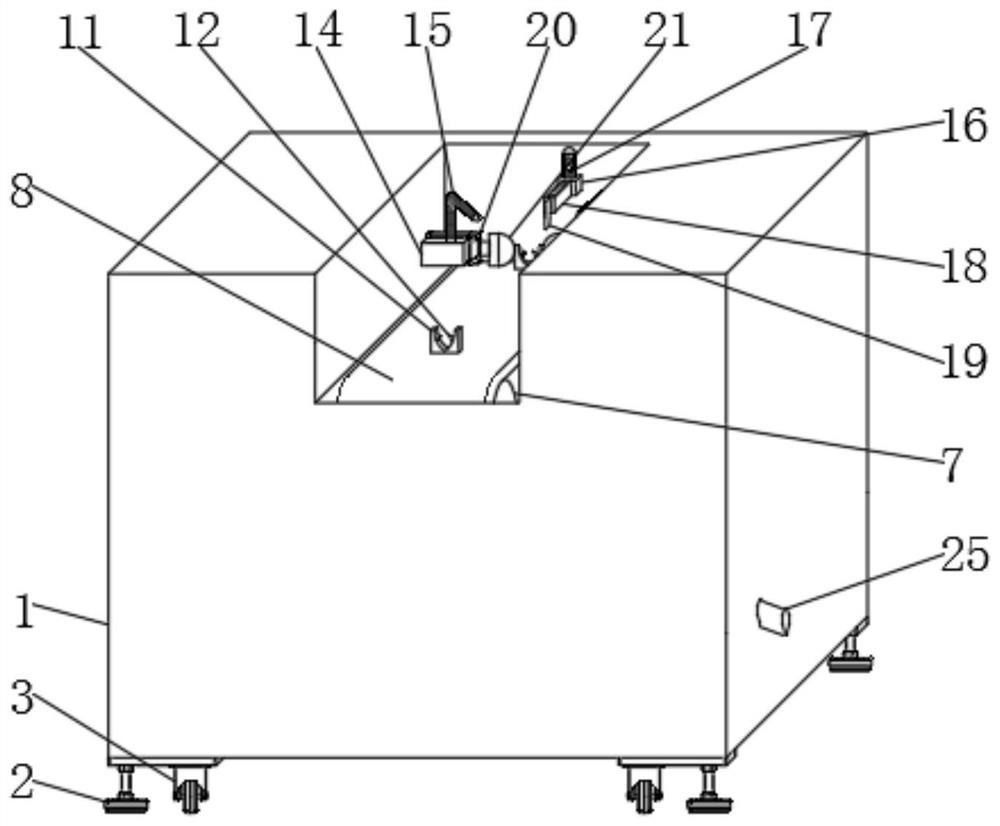

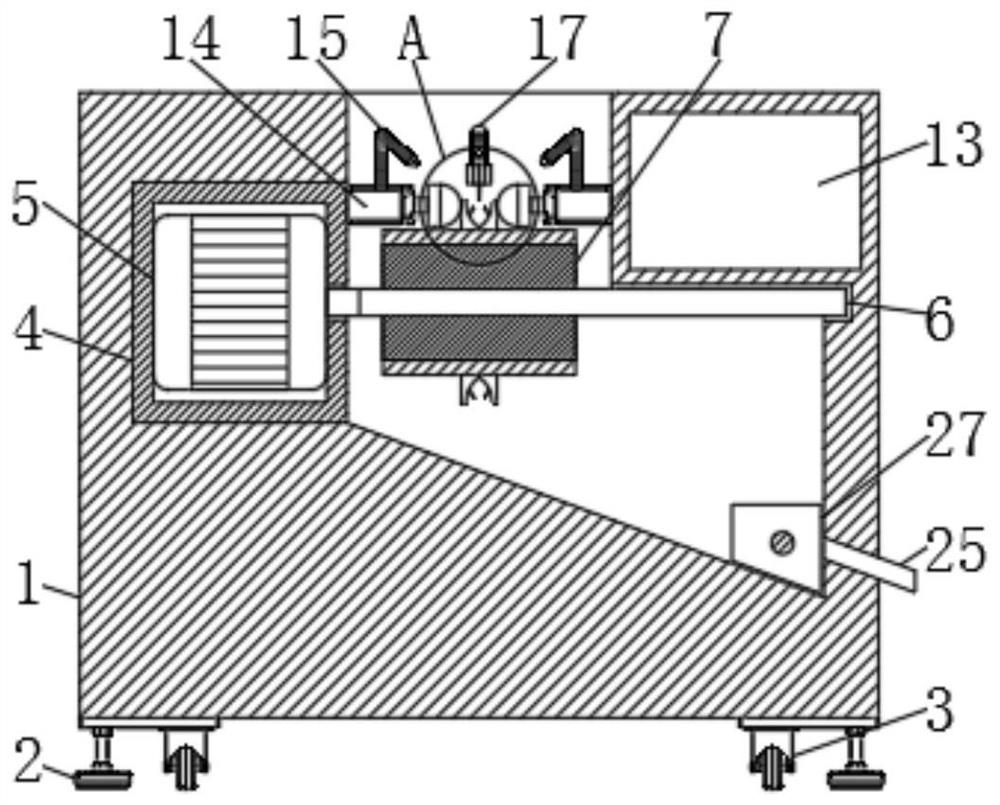

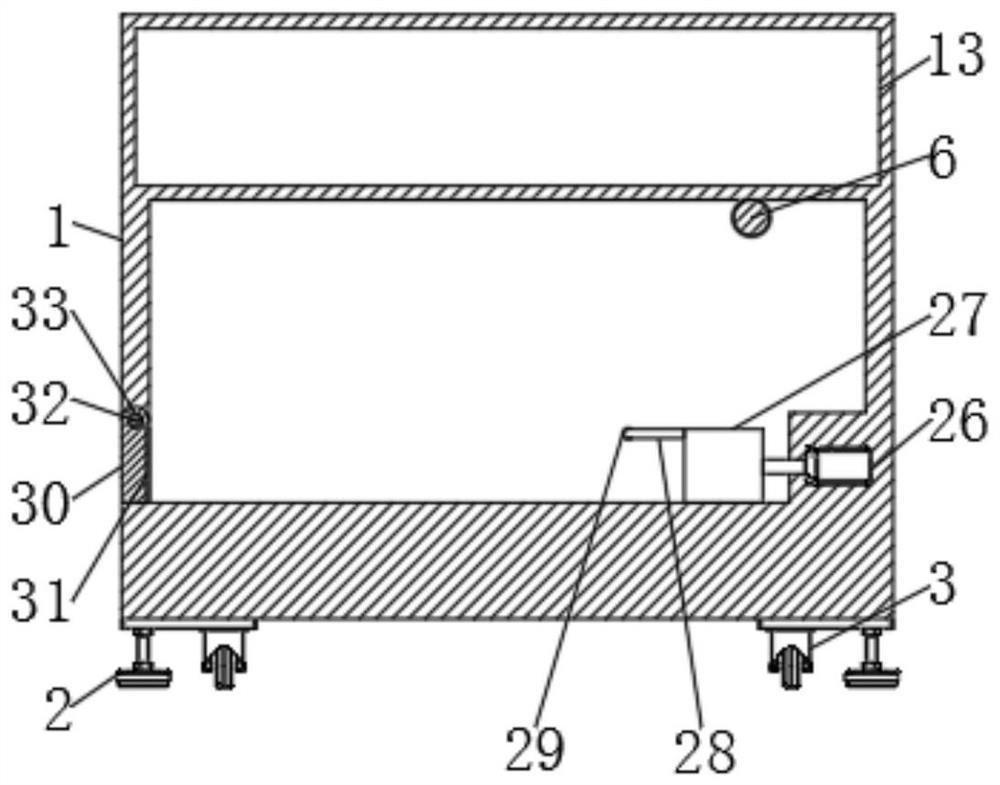

Food weight-fixed cutting method and food cutting machine

ActiveCN102729289ASame weightSolve the technical problems of fixed weight cuttingMetal working apparatusFish cuttingFood materialEngineering

The invention discloses a food weight-fixed cutting method and a food cutting machine, and belongs to the technical field of food processing. The food weight-fixed cutting method comprises the following steps of: (1), performing image acquisition on food materials conveyed on a conveying belt by utilizing a laser source and a camera; (2), performing image processing on acquired images and calculating the weight-fixed cutting length by using a computer with an image processing and weight-fixed calculation system; and (3), when the weight-fixed cutting length is reached, performing cutting by using a cutting device. According to the food weight-fixed cutting method, the lengths of foods to be cut can be calculated accurately by using a visual system which consists of the laser source and the camera and computer software, so that the weight of each cut food is the same, mechanized automatic weight-fixed cutting is realized, the technical problem that the food materials in irregular shapes cannot be cut in a weight-fixed mode is solved, the processing efficiency is improved greatly, and the processing cost is reduced.

Owner:JINAN HIWELL MACHINERY

Apparatus and method for trimming of fish fillets

Owner:MAREL ICELAND EHF

Method and an apparatus for automatic bone removal

ActiveUS7857686B2Improve efficiencyIncrease valueMetal working apparatusFish filletingDigital imagingEngineering

The present invention relates to a method for automatically removing bones and trimming a product such as fish fillets, where the fillets are in an under cooled state. The under cooling makes the fillets sufficiently stiff to remove pin pones and portion a fillet before or after skinning the fillet in a relative still position providing better cutting than conventional methods. This provides more efficiency than prior art methods as well as increasing the value of the product due to less gaping and dehydration of the product. The method of the present invention further provides possibilities for grading of products processed with the three dimensional scanning and digital imaging of the products.

Owner:LAMBHUSASUND EHF

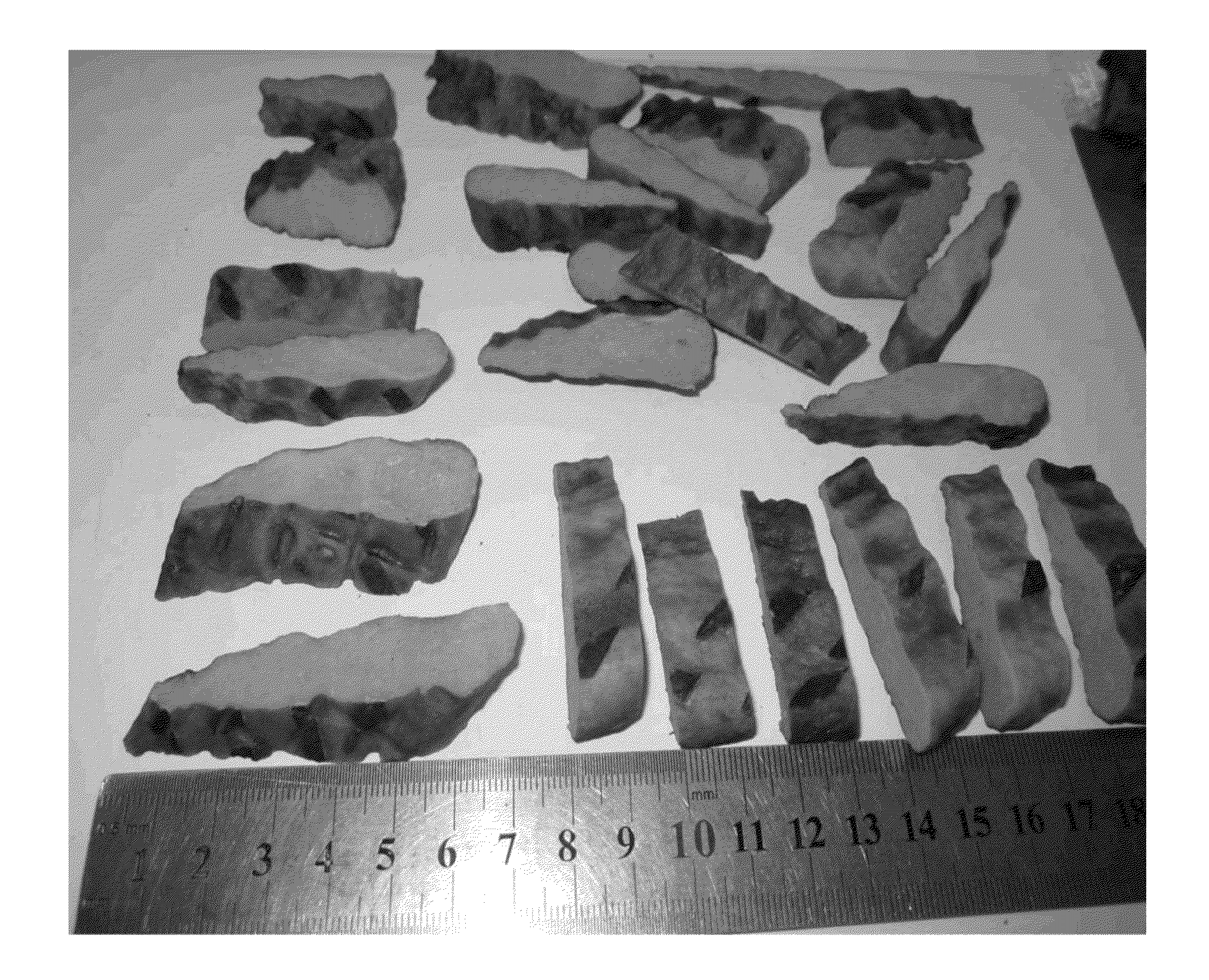

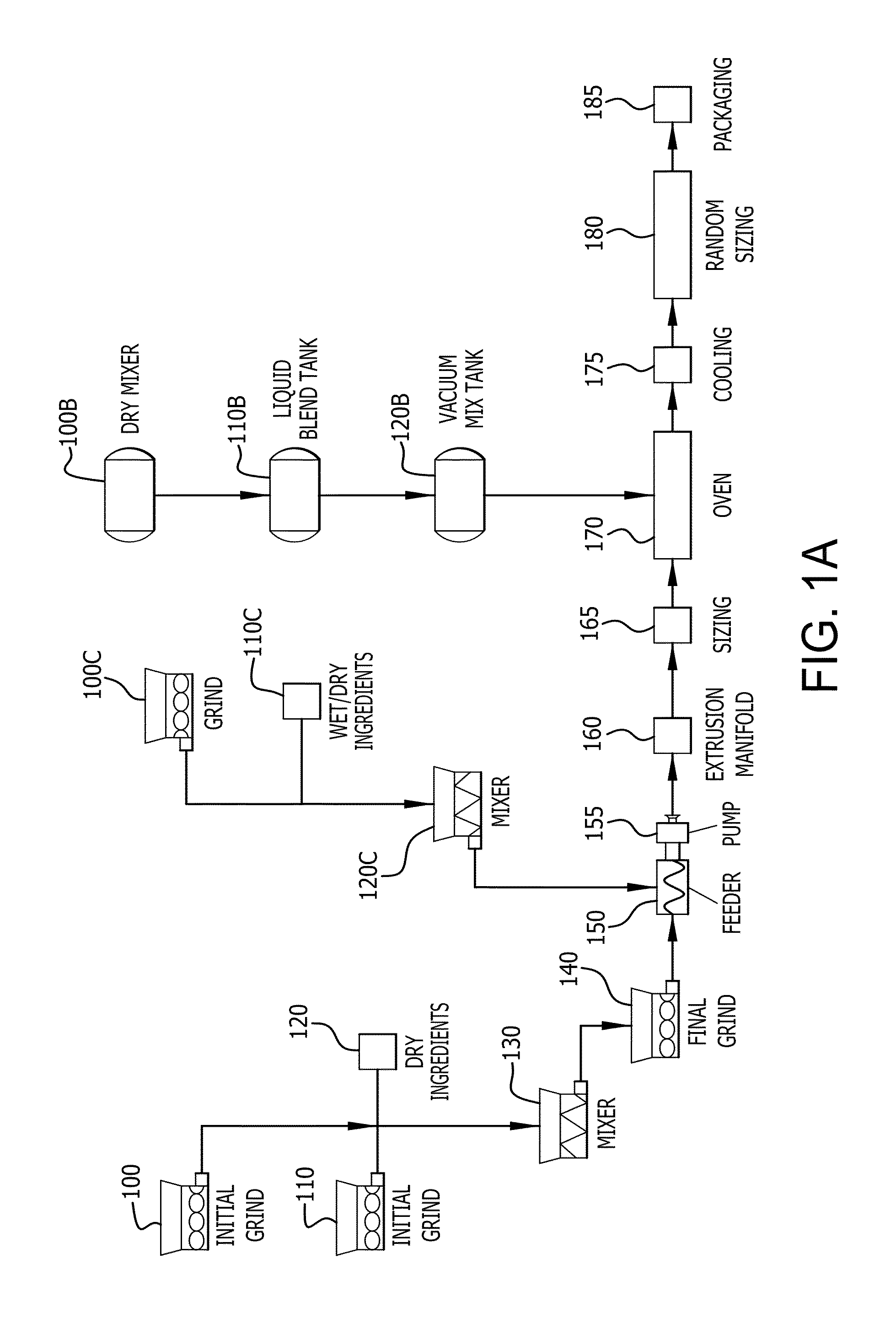

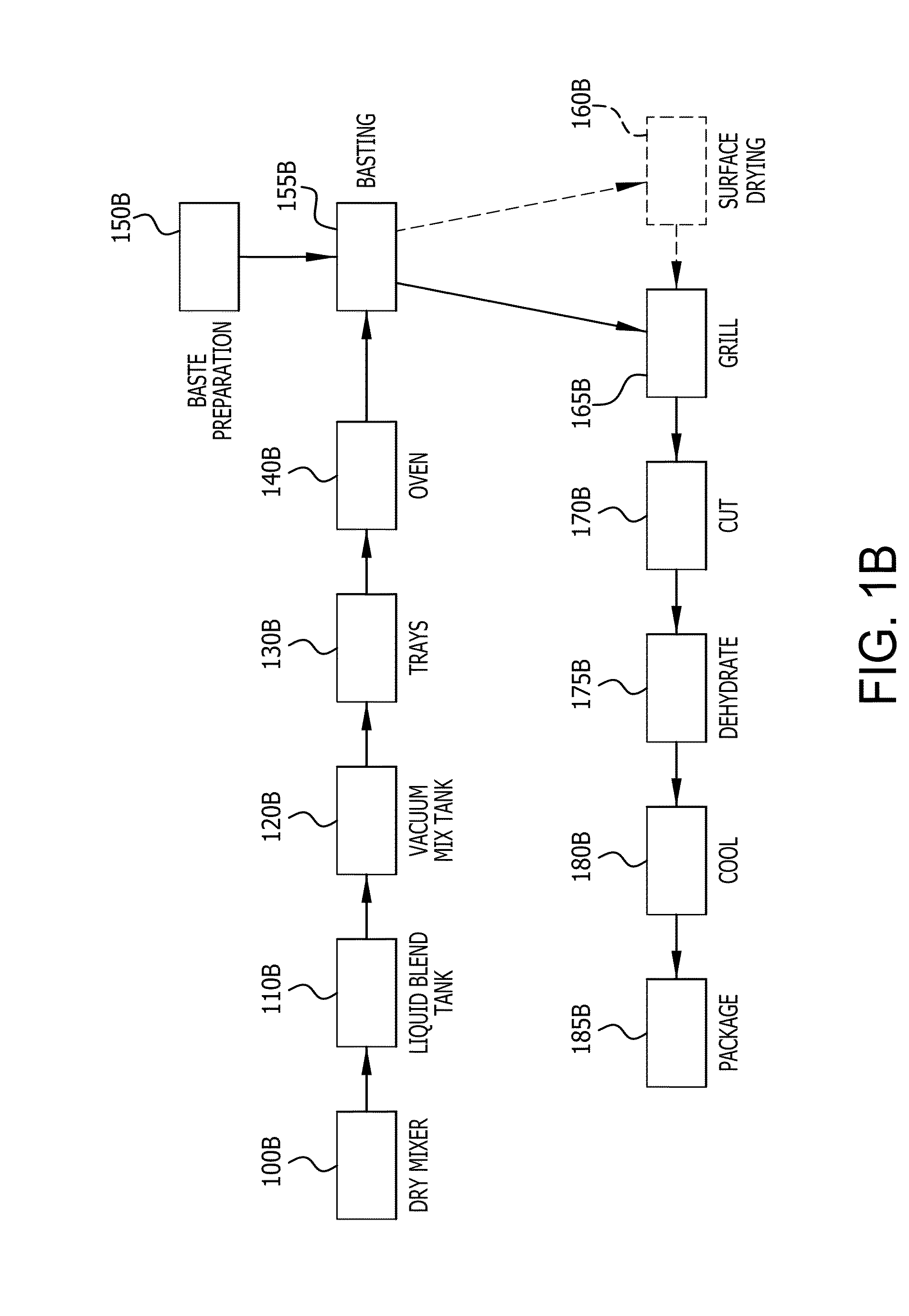

Apparatus, Systems and Methods for Manufacturing Food Products

ActiveUS20120237648A1Improve nutritional qualityFeeding-stuffProteins working-up by texturisingPreservativeEngineering

Processes, systems, and articles of manufacture are disclosed relating to edible meat pieces obtained from a continuous process where each piece generally appears to be home cooked on a grill or cooked in a smoke house with randomized sear and grill marks and smoke aroma. The invention, in its various embodiments, provides processes for manufacturing shelf-stable food treats comprising: starting with proteinaceous material (ground or whole), mixing the proteinaceous material with preservatives and flavor enhancers to form a foodstuff, extruding proteinaceous material (if ground) through at least one die opening that is at least partially irregular to form at least one strip of extrudate, cooking the extrudate or whole proteinaceous material to form a cooked product, coating the cooked product with a basting solution, grilling the basted products to obtain grilled products with searing, grill marks, and smoke aroma; and cutting the grilled product at a cutting angle into pieces.

Owner:BIG HEART PET INC

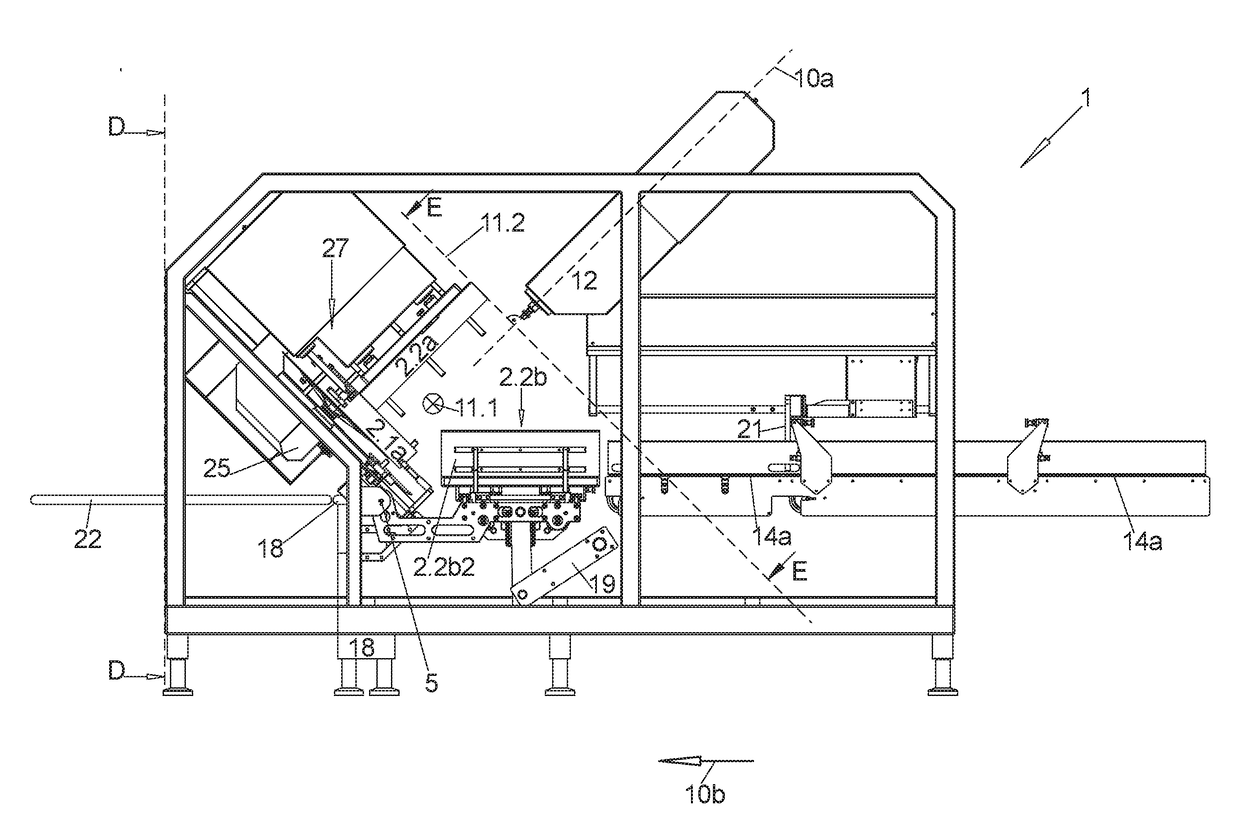

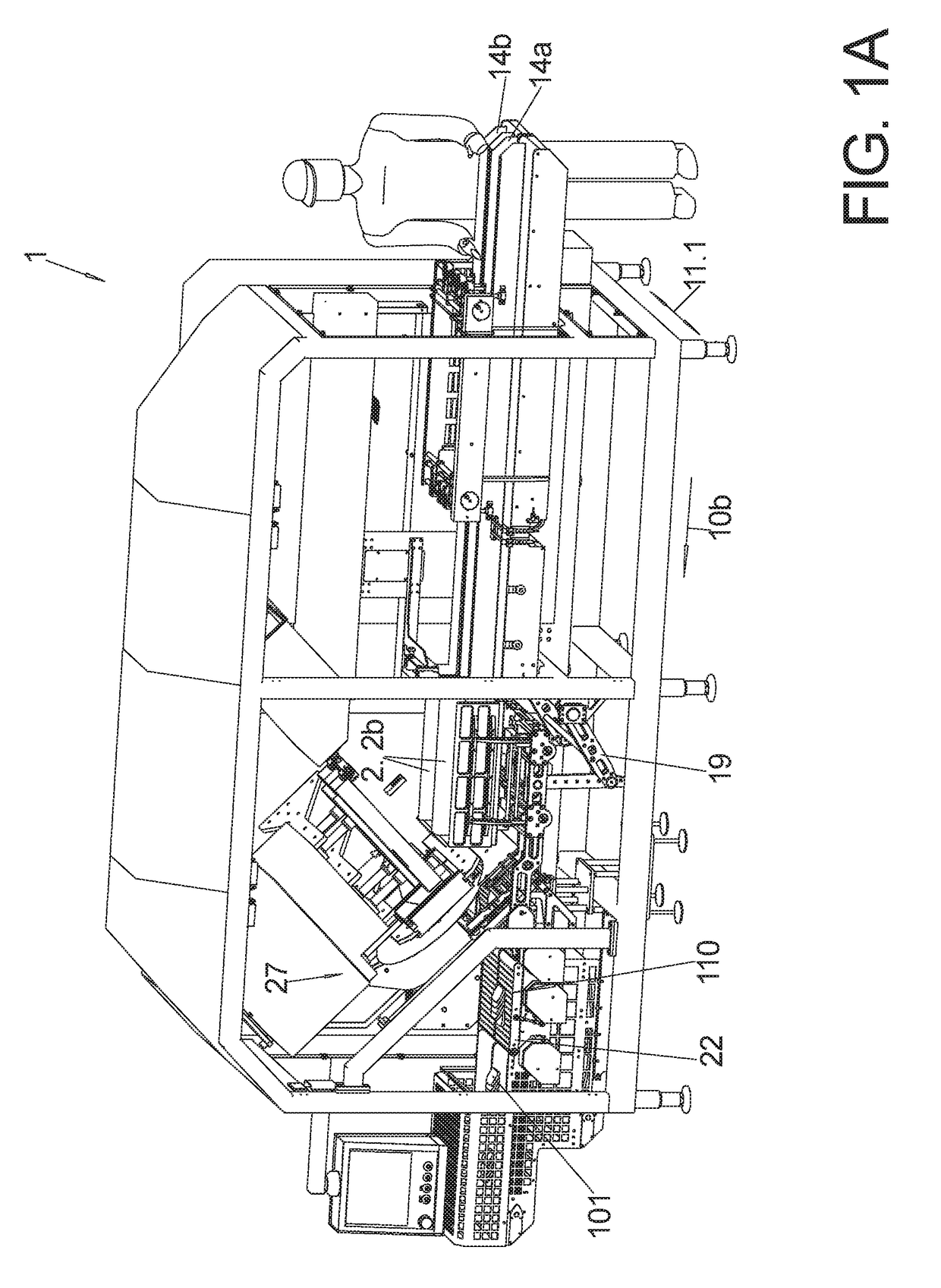

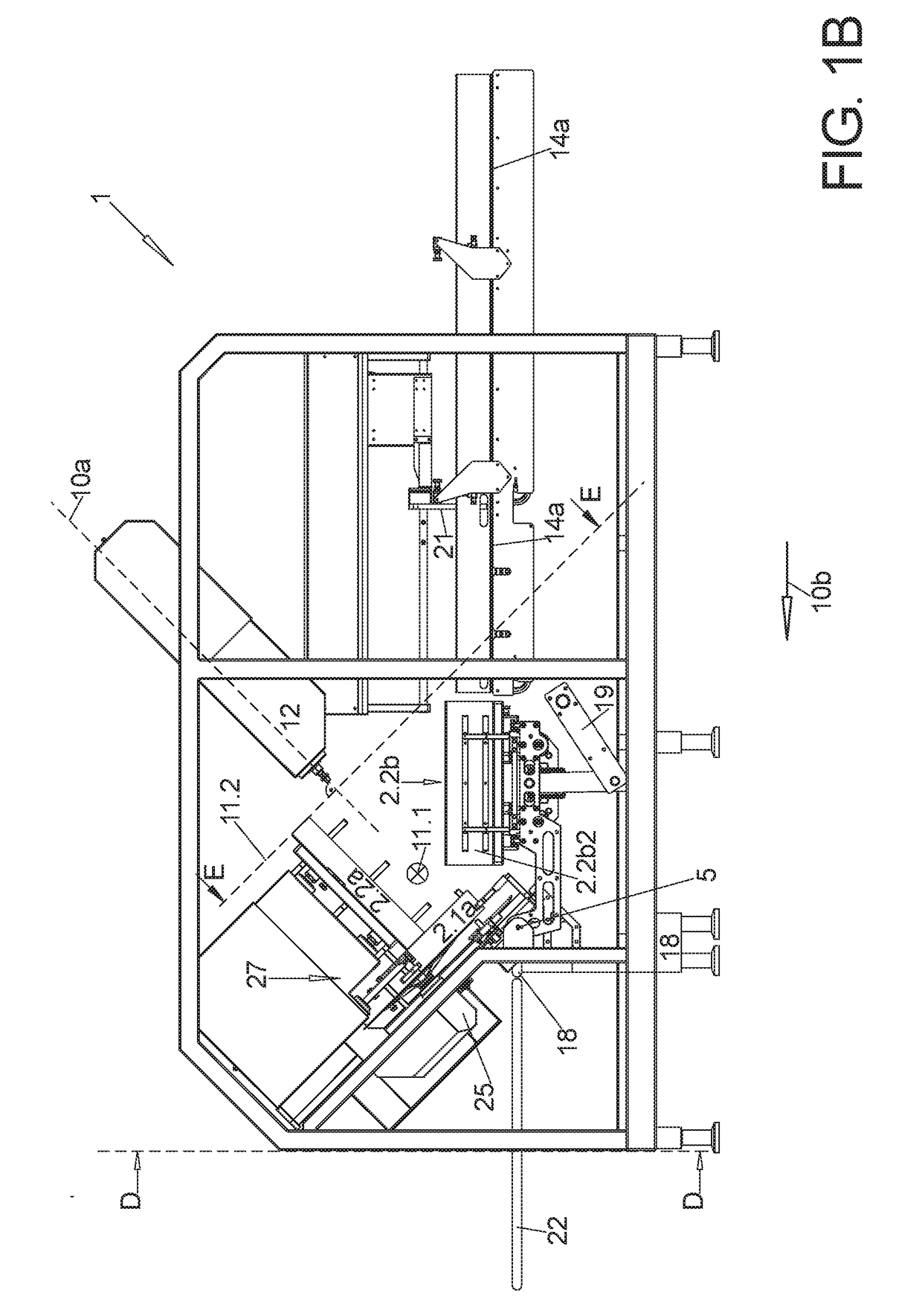

Slicing machine and method for slicing elastic strands in particular meat strands

ActiveUS20170312931A1Facilitates short idle timeImprove throughputMeat holding apparatusFish threading devicesEngineeringMechanical engineering

A slicing machine for slicing meat strands that have a cross section that varies over a longitudinal extension in large numbers and as quickly as possible into weight precise slices. In one embodiment, two meat strands are received adjacent to each other in a respective form tube and pushed against a respective separately adjustable stop plate independently from each other by a controlled longitudinal press plunger and compressed in the longitudinal direction. In addition, a cross section of the form tubes may be reduced in a first transversal direction jointly and in a second transversal direction independently from each other and thus the respective meat strand is transversally compressed to a constant cross section prior to slicing.

Owner:TVI ENTWICKLUNG & PROD GMBH

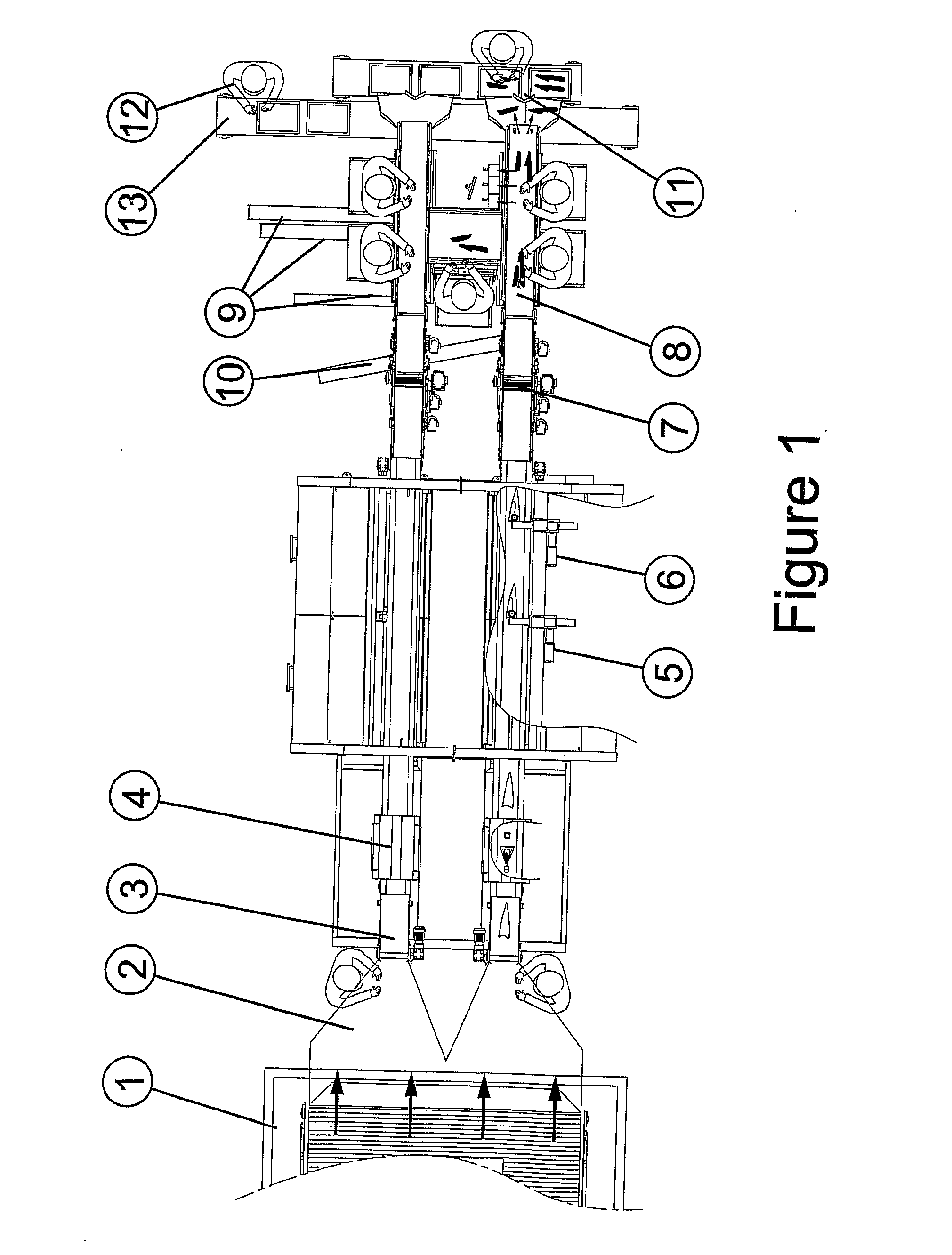

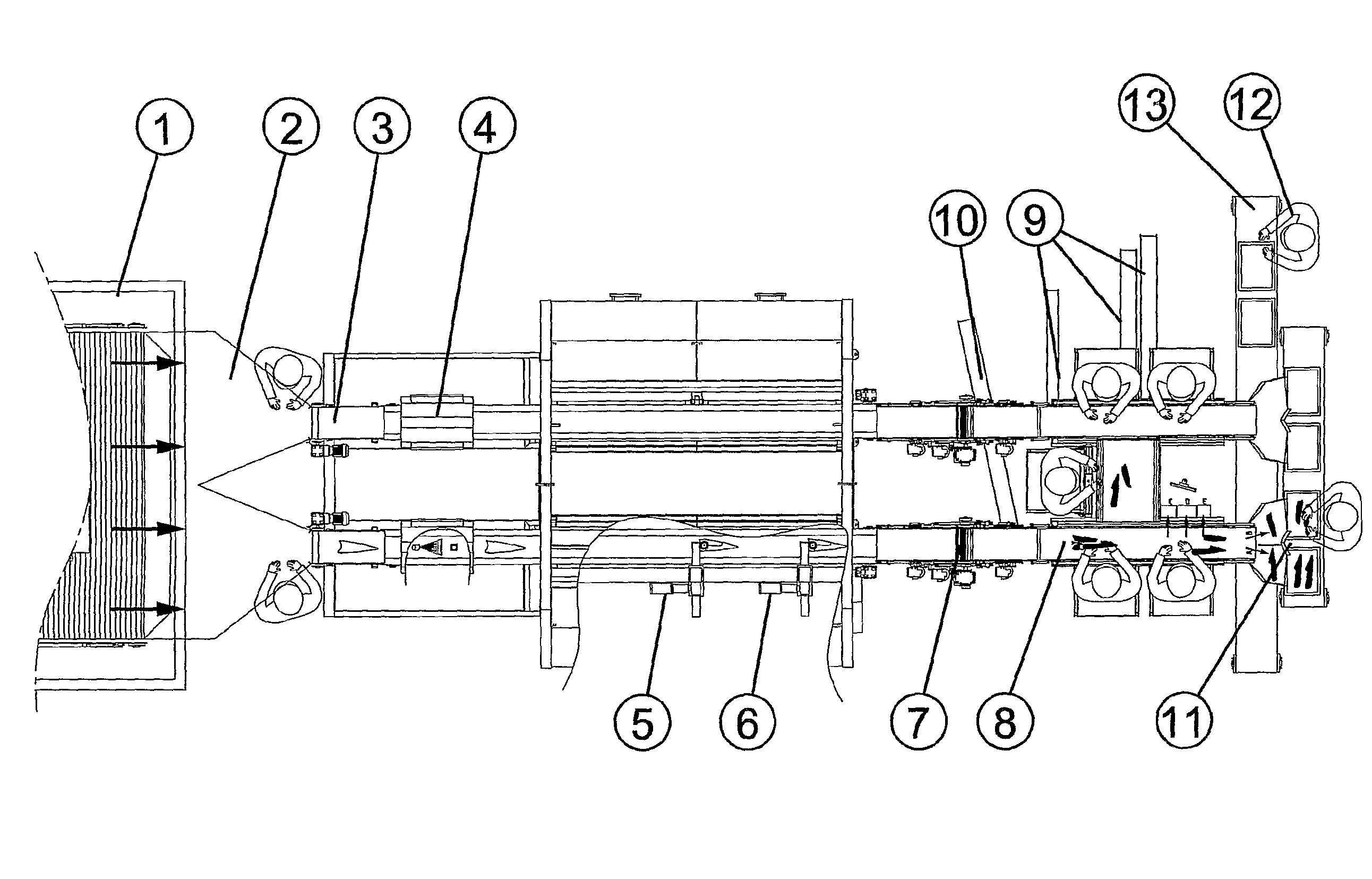

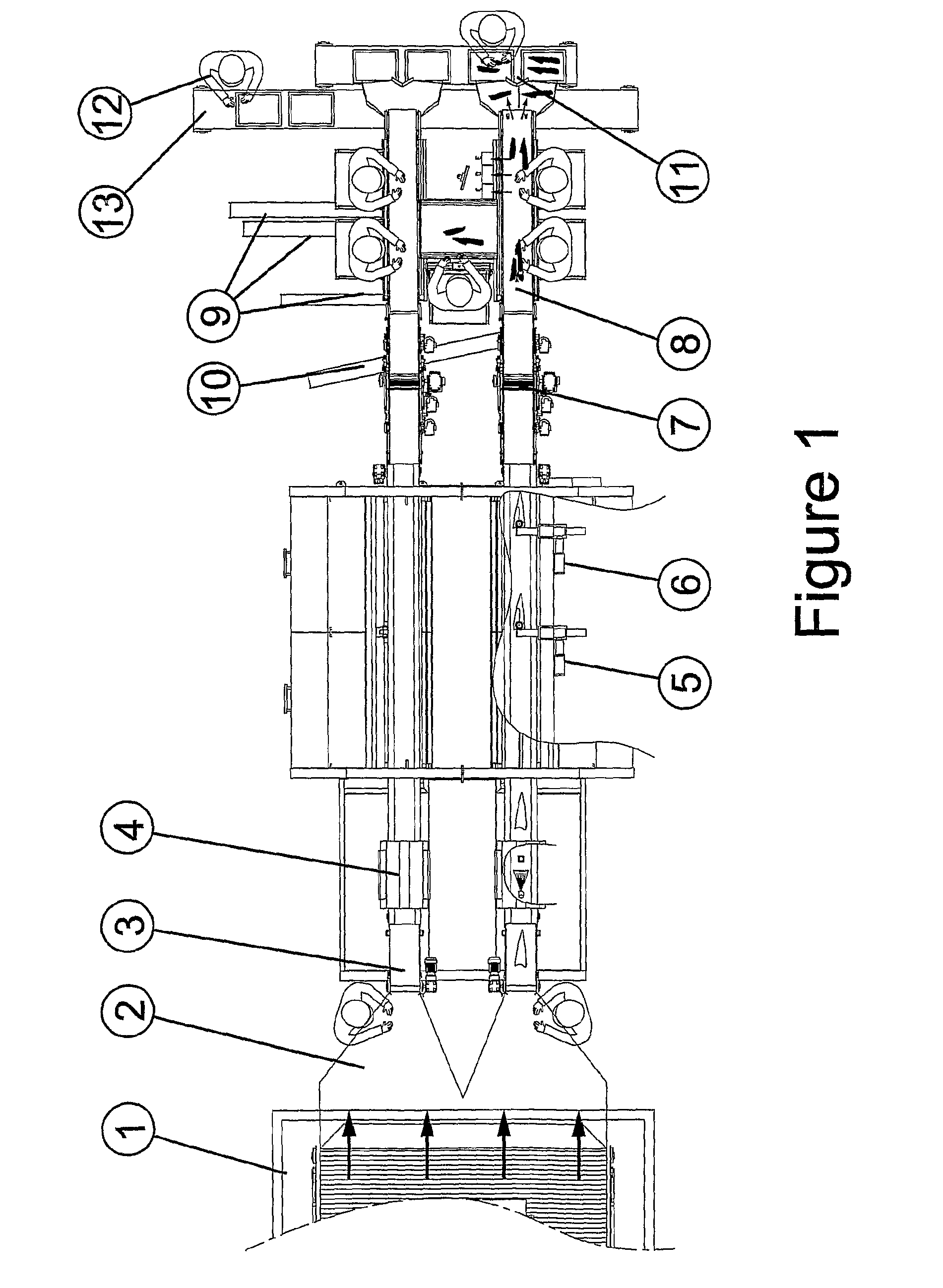

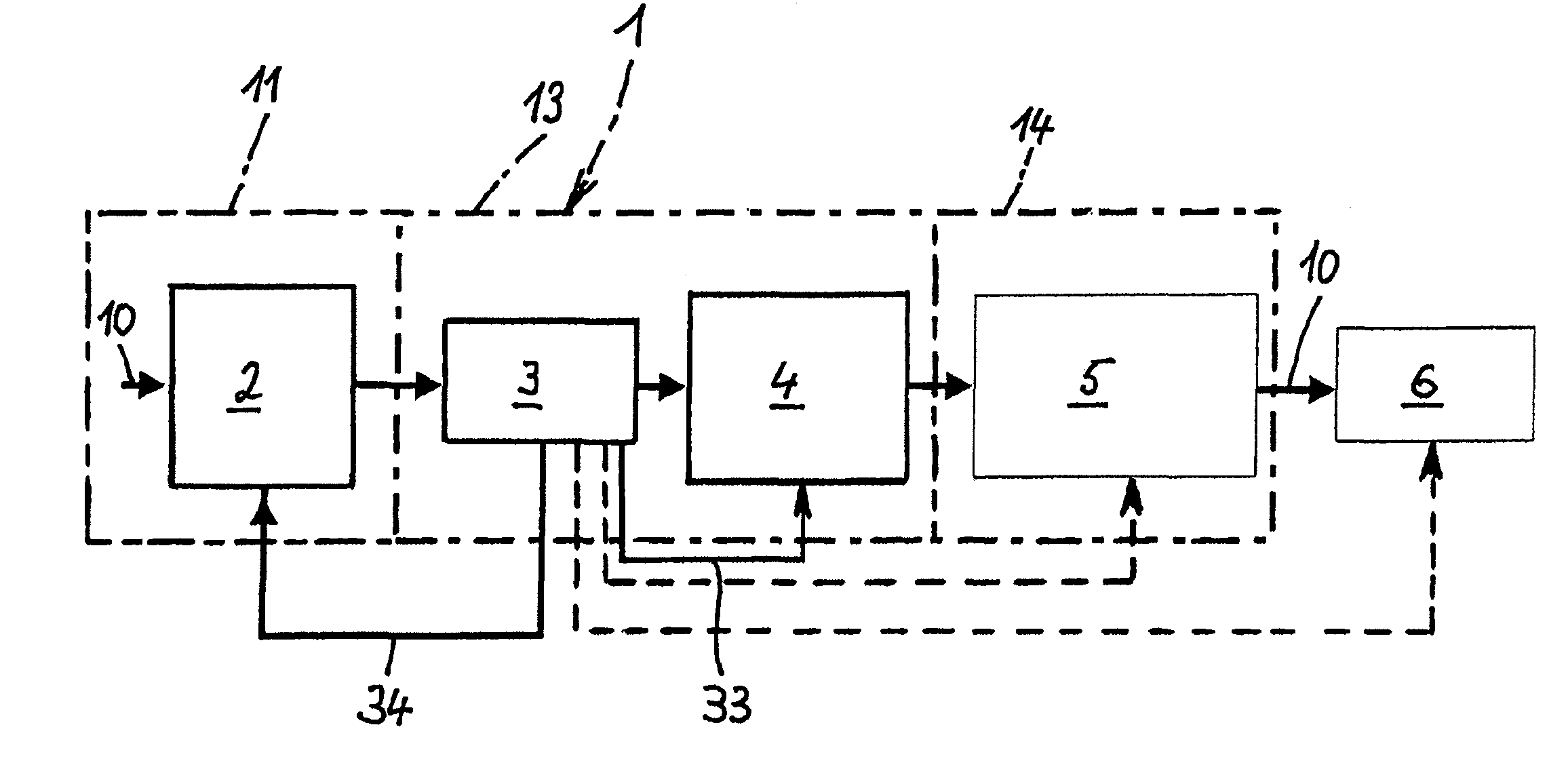

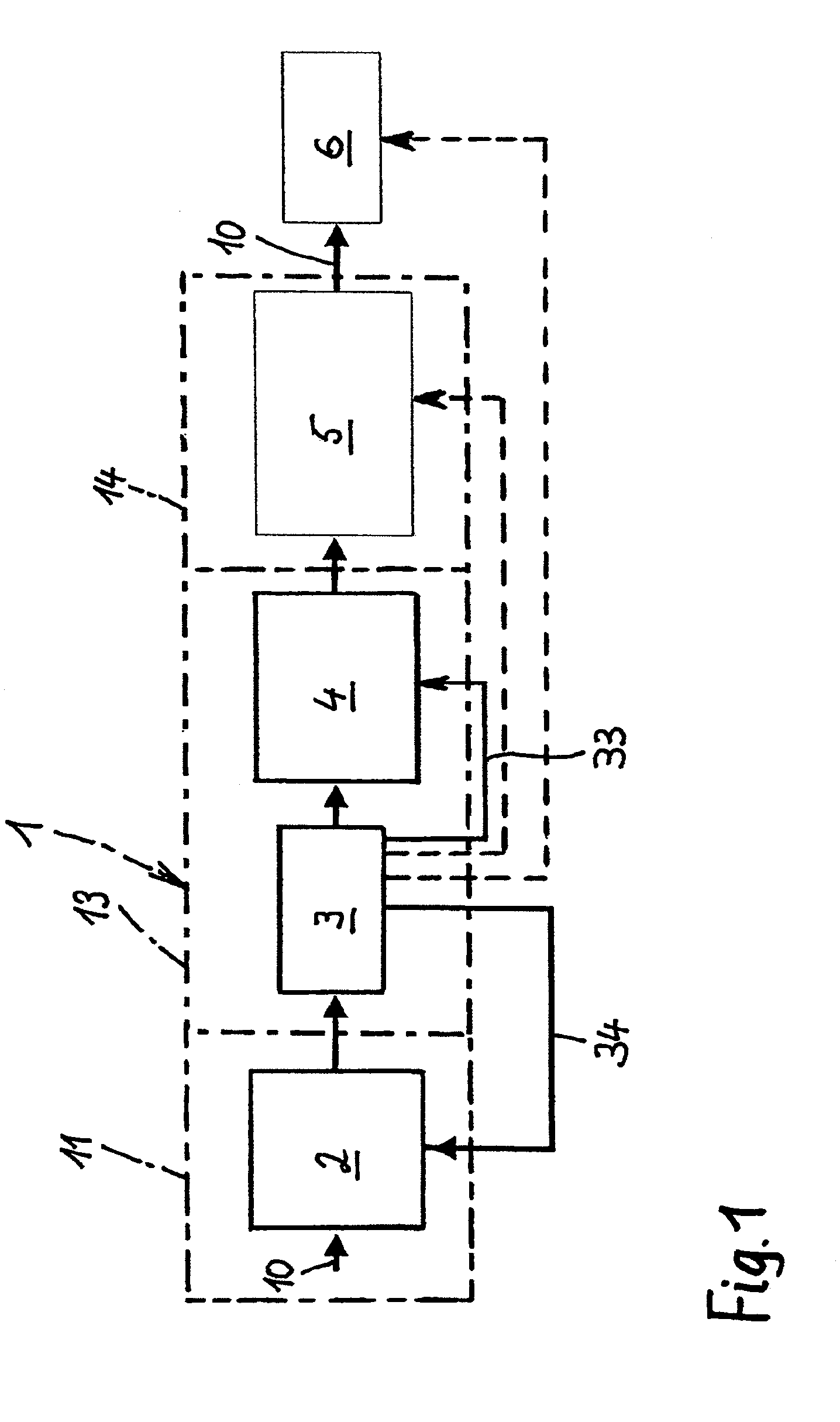

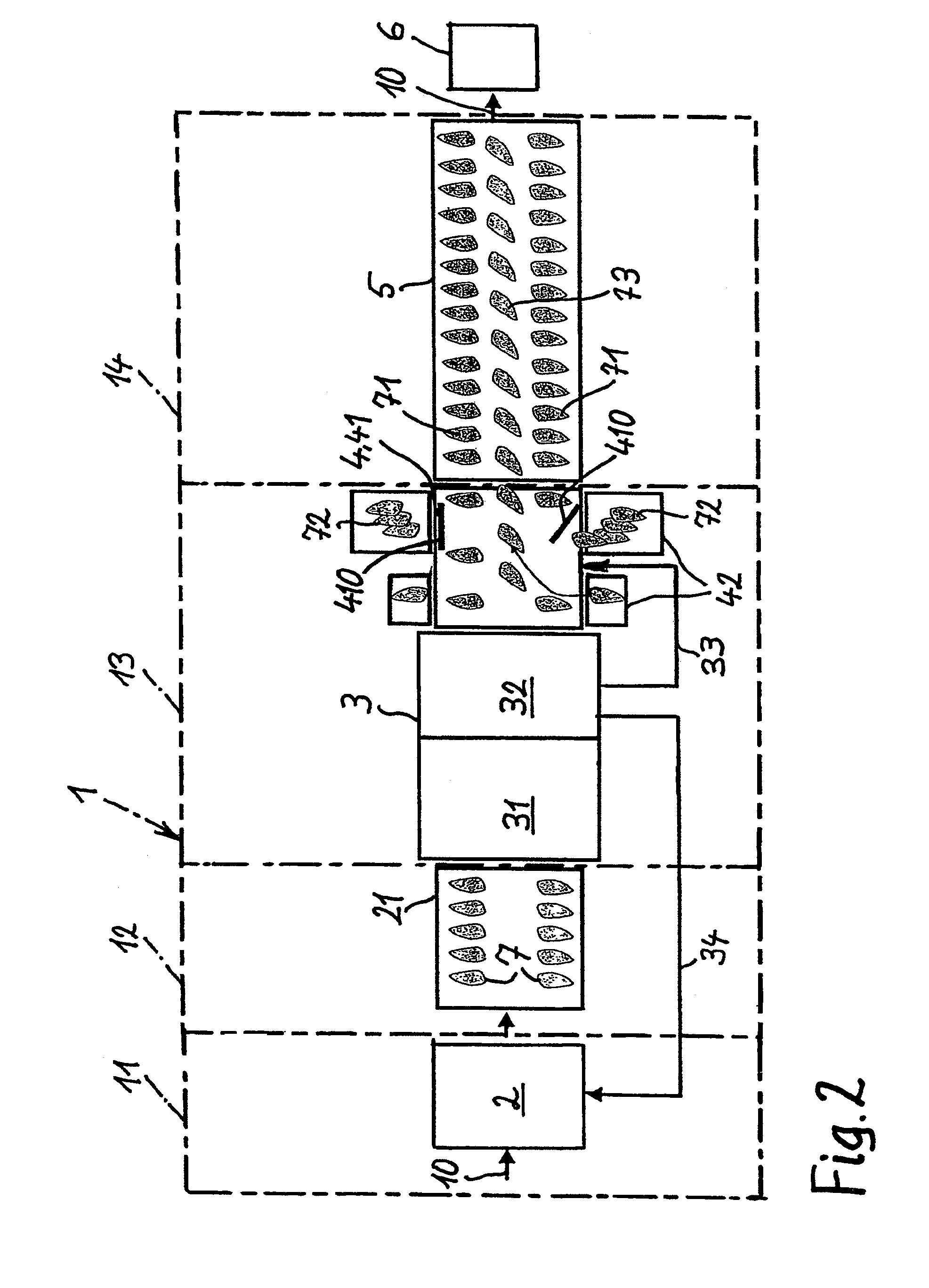

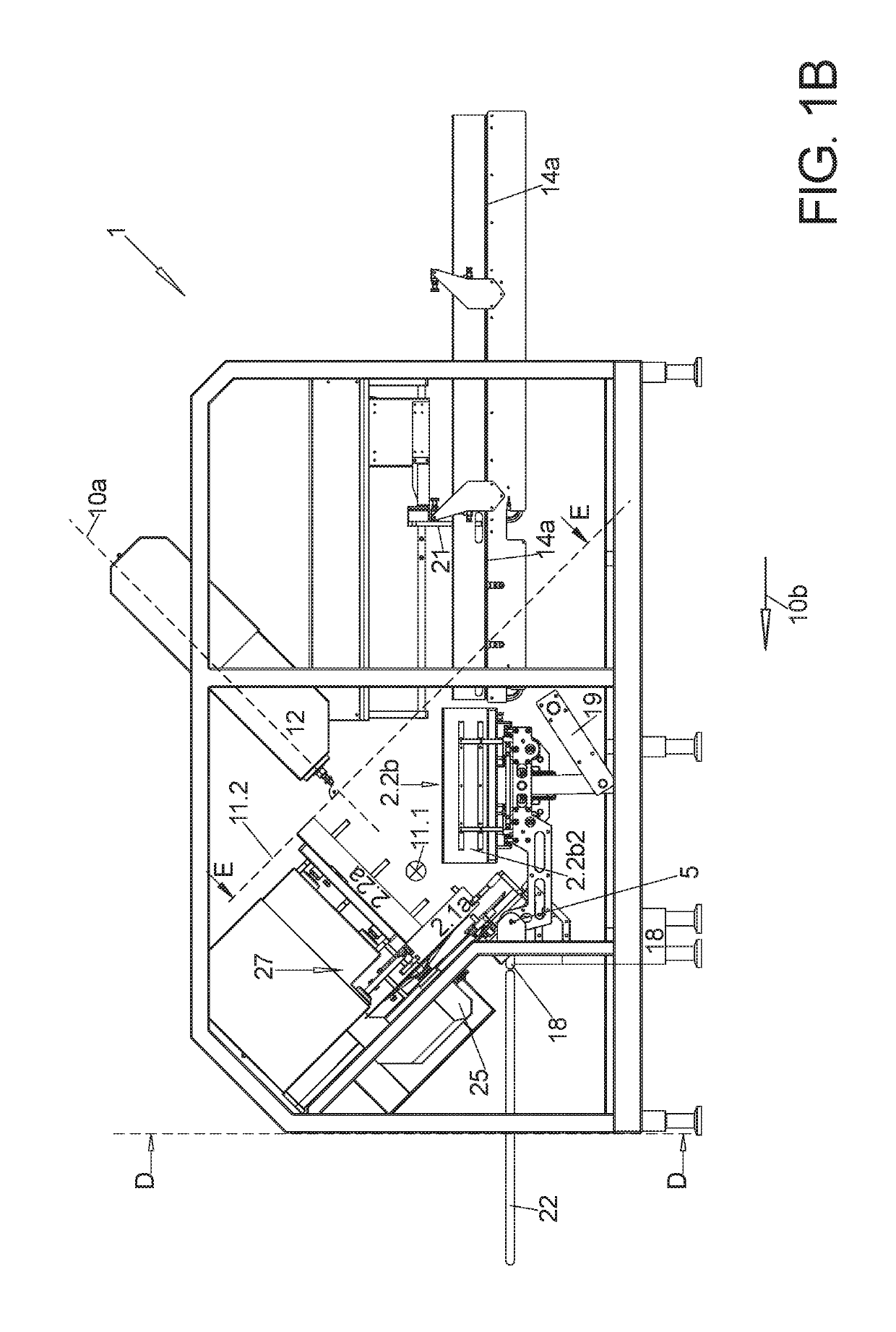

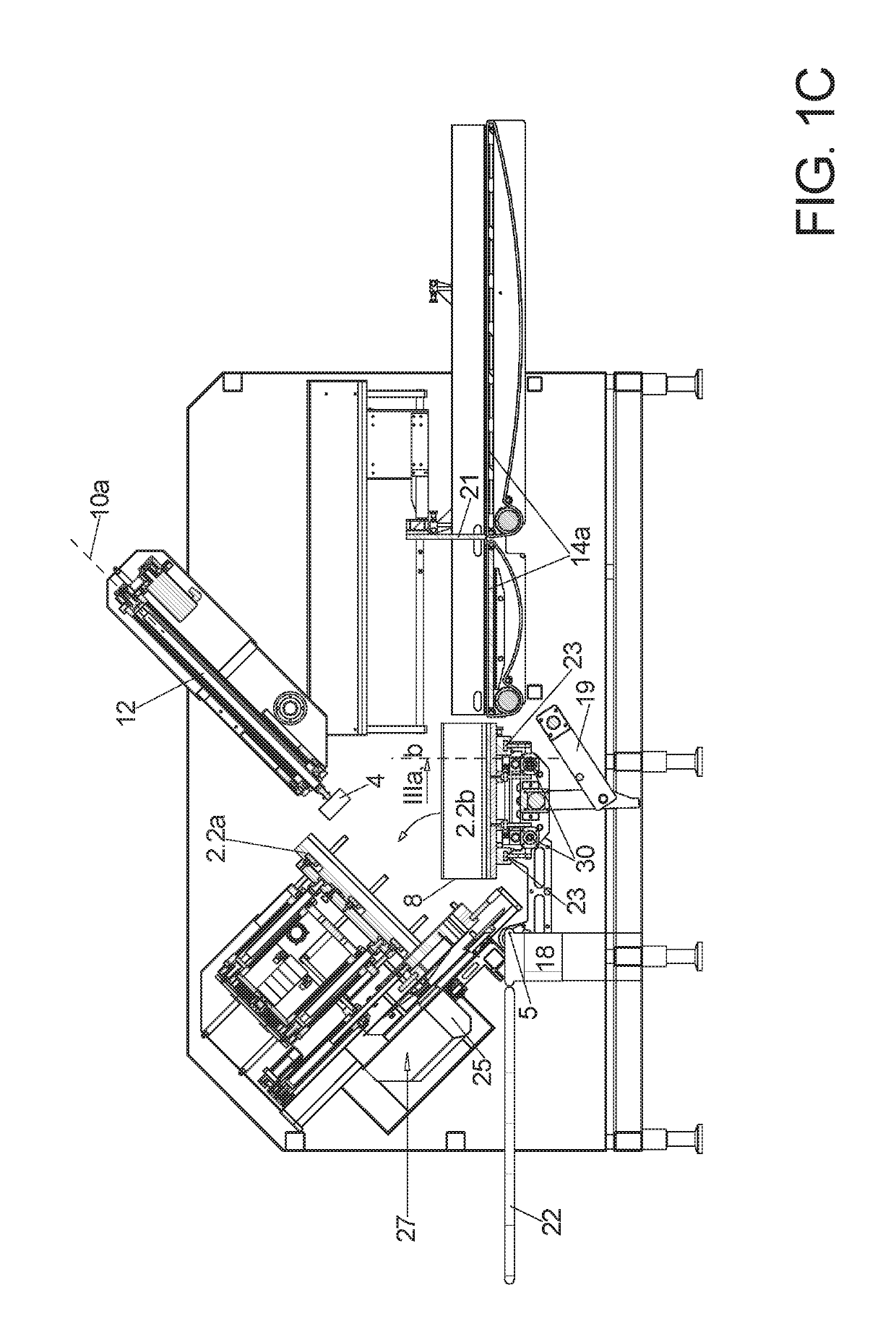

Method and device for processing fish, poultry, or other meat products transported in multitude along a processing line

ActiveUS7976368B2Improve efficiencyMaximum reliabilityFish sortingMeat processing plantsEngineeringProduct recovery

In a method for the processing of fish, poultry or other meat products being conveyed in a plurality along a processing line, components which are to be excluded from consumption are separated and edible products obtained as a result for consumption are checked with an automatic inspection device for residues left behind. Separation takes place in such a way that, in the case of a number of edible products, minimized residues of at least one kind are deliberately permitted and induced for further processing of the edible products, in particular to optimize the edible product recovery. The automatic inspection device is adjusted to detect the minimized tolerance residues, and inspected edible products with and without the tolerance residues are separated from each other. In an apparatus for carrying out the method, a separating device with at least one separating tool is designed in such a way that, in the case of a number of edible products, minimized tolerance residues of at least one kind are left behind for further processing of the edible products, and the inspection device is connected to a separator device which distinguishes edible products with and without residues according to the inspection results and discharges them separately from each other.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

Slicing machine and method for slicing elastic strands in particular meat strands

ActiveUS10245745B2Short idle timeImprove throughputMeat holding apparatusFish threading devicesEngineeringMechanical engineering

A slicing machine for slicing meat strands that have a cross section that varies over a longitudinal extension in large numbers and as quickly as possible into weight precise slices. In one embodiment, two meat strands are received adjacent to each other in a respective form tube and pushed against a respective separately adjustable stop plate independently from each other by a controlled longitudinal press plunger and compressed in the longitudinal direction. In addition, a cross section of the form tubes may be reduced in a first transversal direction jointly and in a second transversal direction independently from each other and thus the respective meat strand is transversally compressed to a constant cross section prior to slicing.

Owner:TVI ENTWICKLUNG & PROD GMBH

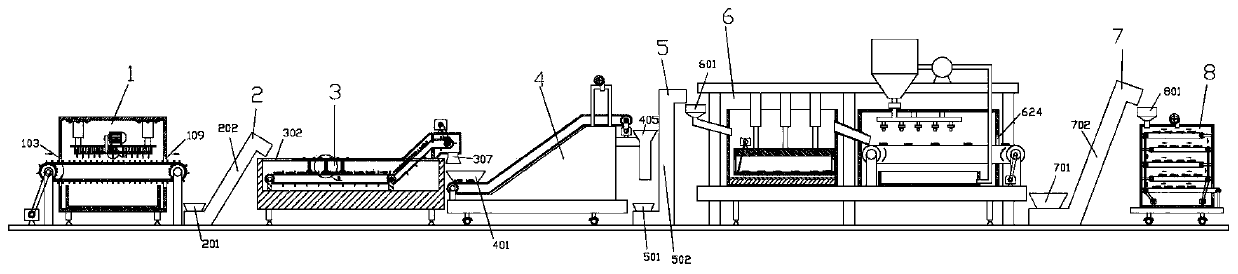

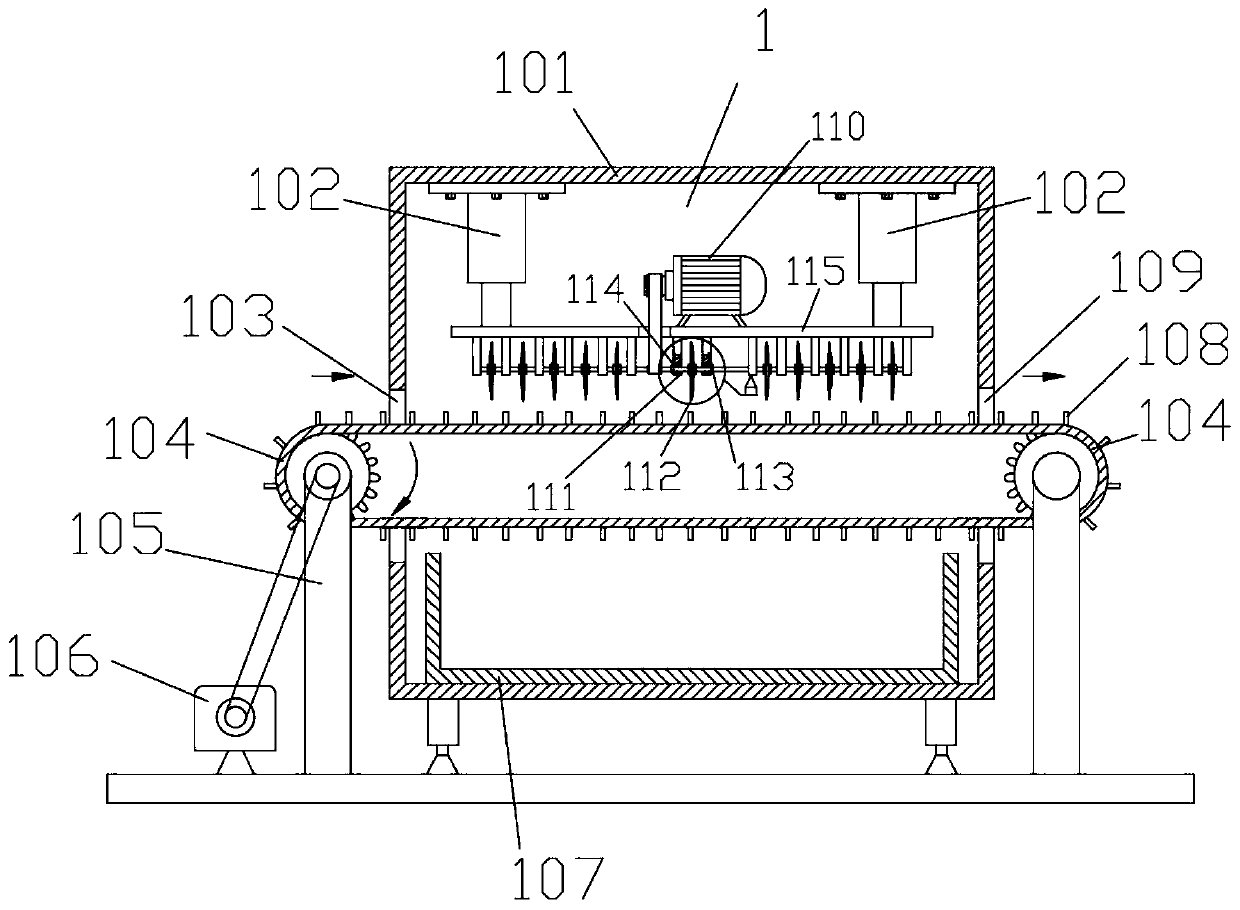

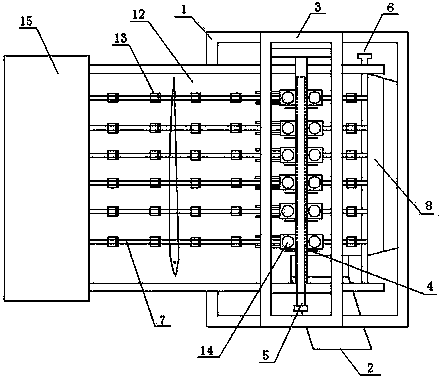

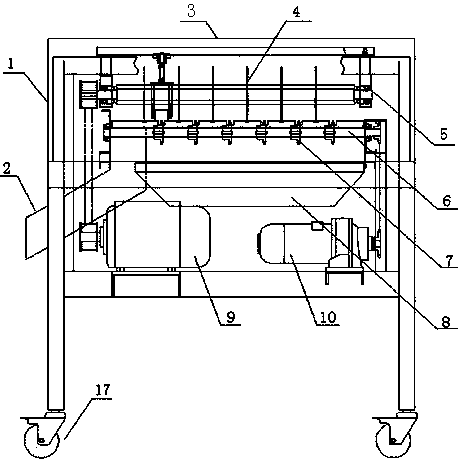

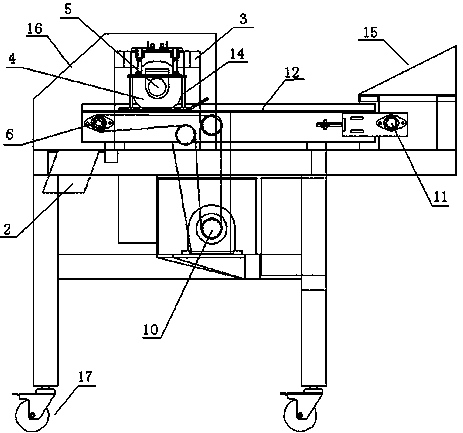

Flavor fish product oil-frying production line

ActiveCN109699725AReduce labor intensityMeet processing and production needsOil/fat bakingBaking plantsProduction lineFlavor

The present invention discloses a flavor fish product oil-frying production line. The flavor fish product oil-frying production line is successively provided with a block cutting device, a first lifting mechanism, a washing device, a lifting and drying mechanism, a second lifting mechanism, an oil-frying and marinating device, a third lifting mechanism and a drying device. Flavored fish enters from an inlet and is subjected to block cutting in the block cutting device, a first lifting machine body sends the flavored fish into the washing device, drying is conducted in the washing device, primary drying is conducted in the lifting and drying mechanism, oil-frying and marinating are conducted in the oil-frying and marinating device, and drying is conducted in the drying device. The present invention aims to provide the flavor fish product oil-frying production line. The flavor fish product oil-frying production line can conduct rapid block cutting, washing, oil-frying, marinating and drying of the fish, is high in degree of automation, greatly reduces labor intensity of workers, is high in labor efficiency, meets processing and production needs of large quantities of freshwater fish,and can create more economic benefits for enterprises.

Owner:湖南喜味佳生物科技有限公司

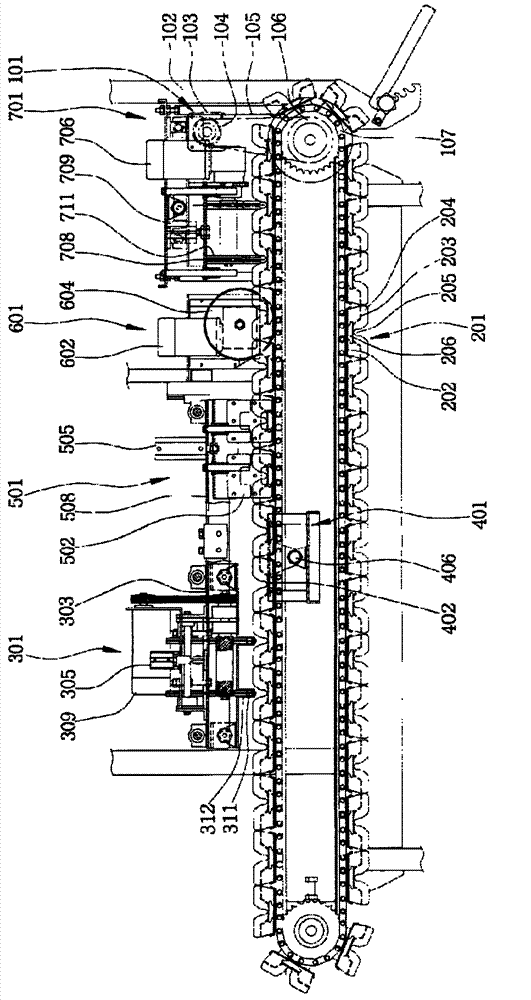

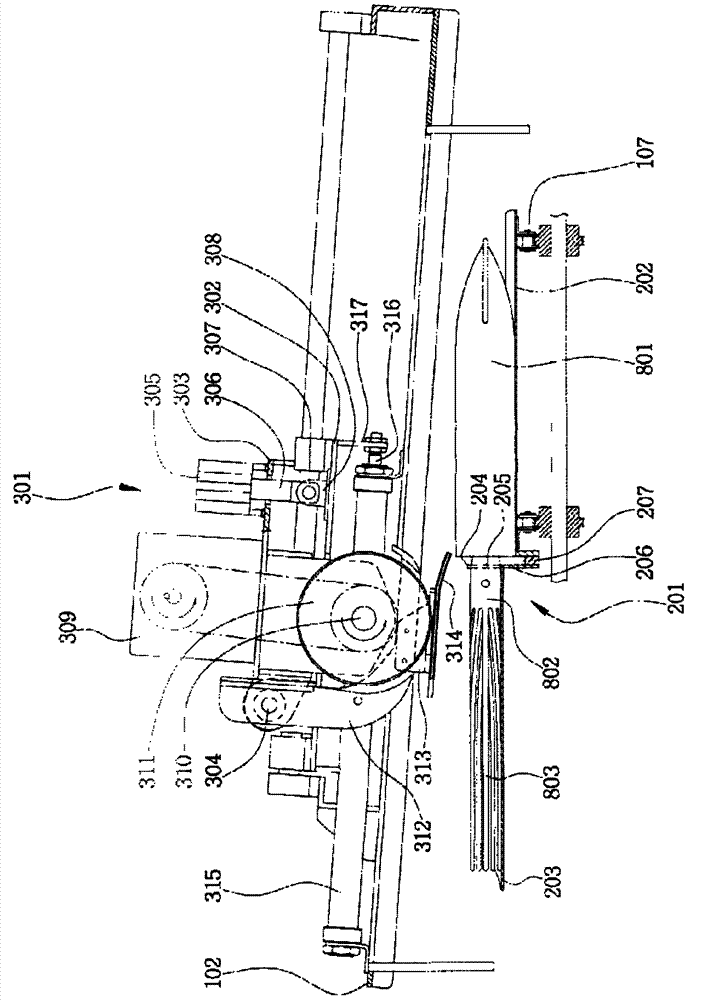

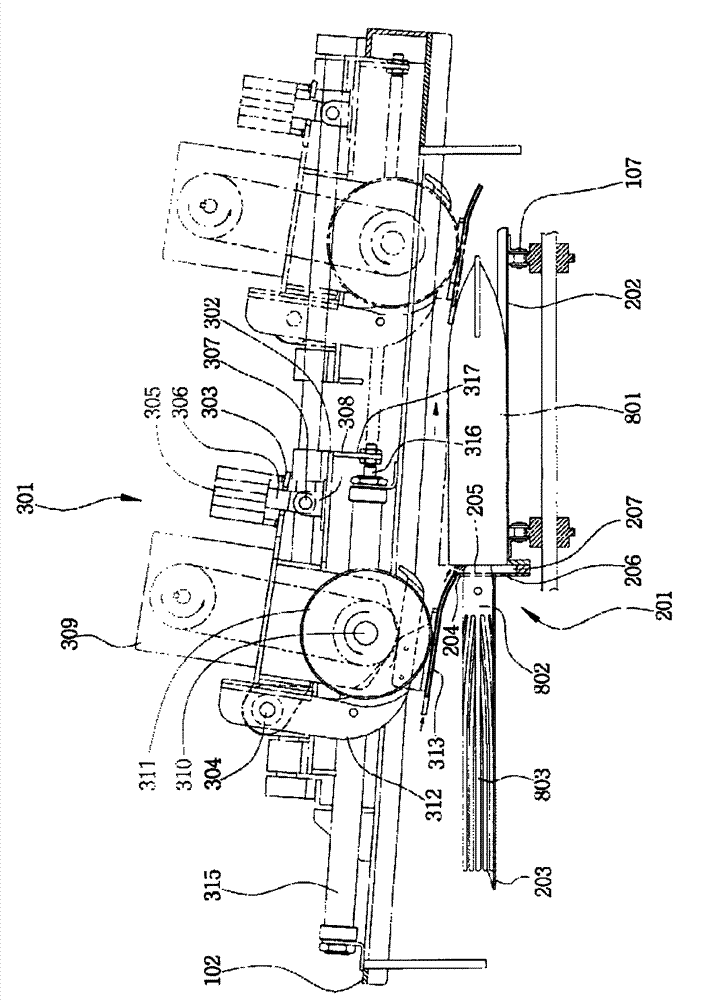

Automatic processing equipment for squids

InactiveCN103238654AImprove processing efficiencyMinimize manual operationsCephalopods processingMetal working apparatusSquidAutomatic processing

The invention relates to automatic processing equipment for squids and particularly relates to automatic processing equipment for squids, which is capable of driving a linkage gear chain arranged at the lower part of a machine body so as to form a horizontal conveying movement. A squid conveying part connected with the linkage gear chain is capable of loading and conveying squids. A trunk cutting part is capable of cutting and expanding squids conveyed by the squid conveying part, so that squids can be conveyed in a cut state.

Owner:梁熙昌

Ultrasonic slitter

InactiveUS20060096434A1Cheese manufactureSlaughtering accessoriesElectronic controllerReciprocating motion

Owner:KRAFT FOODS INC

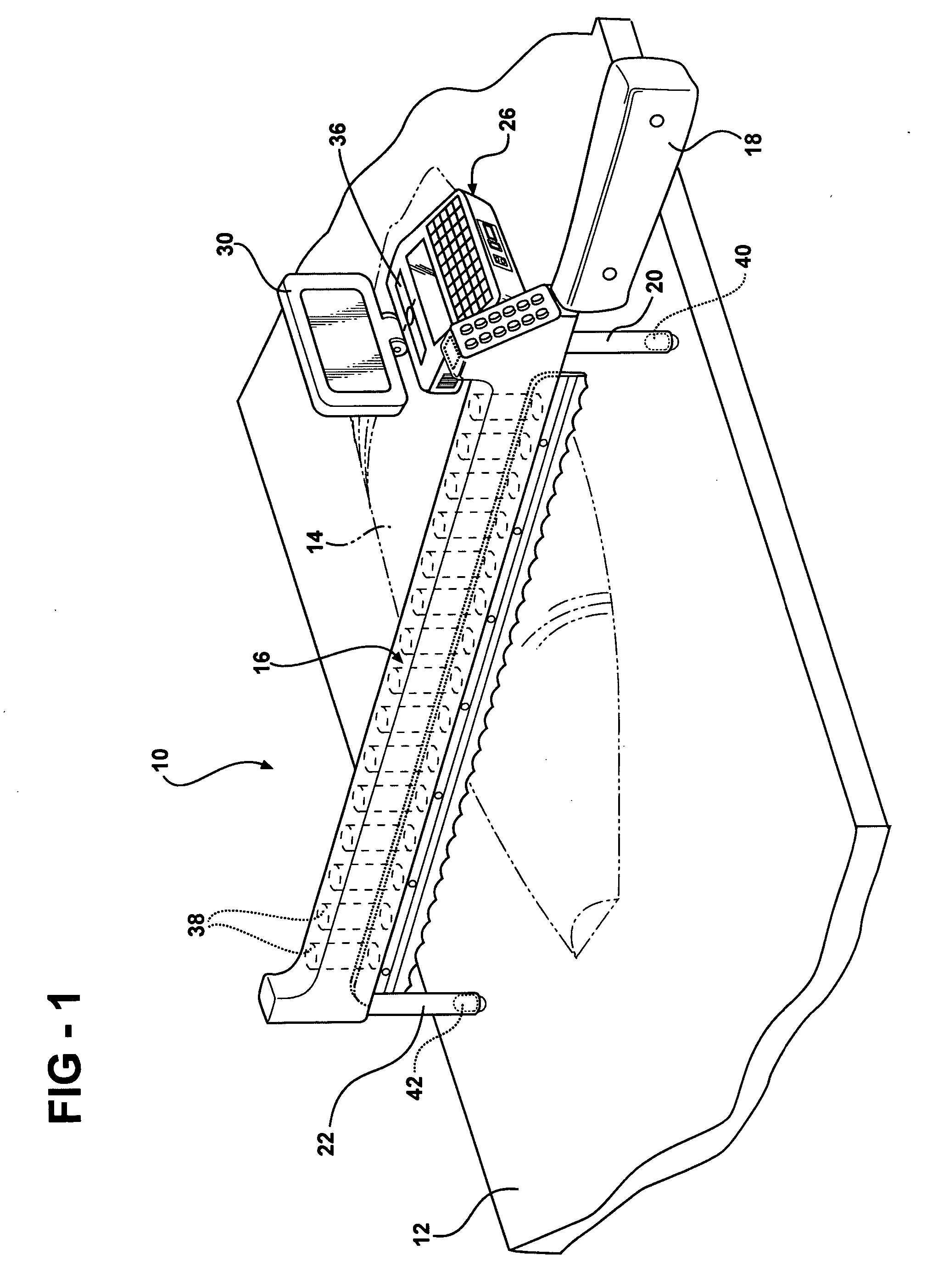

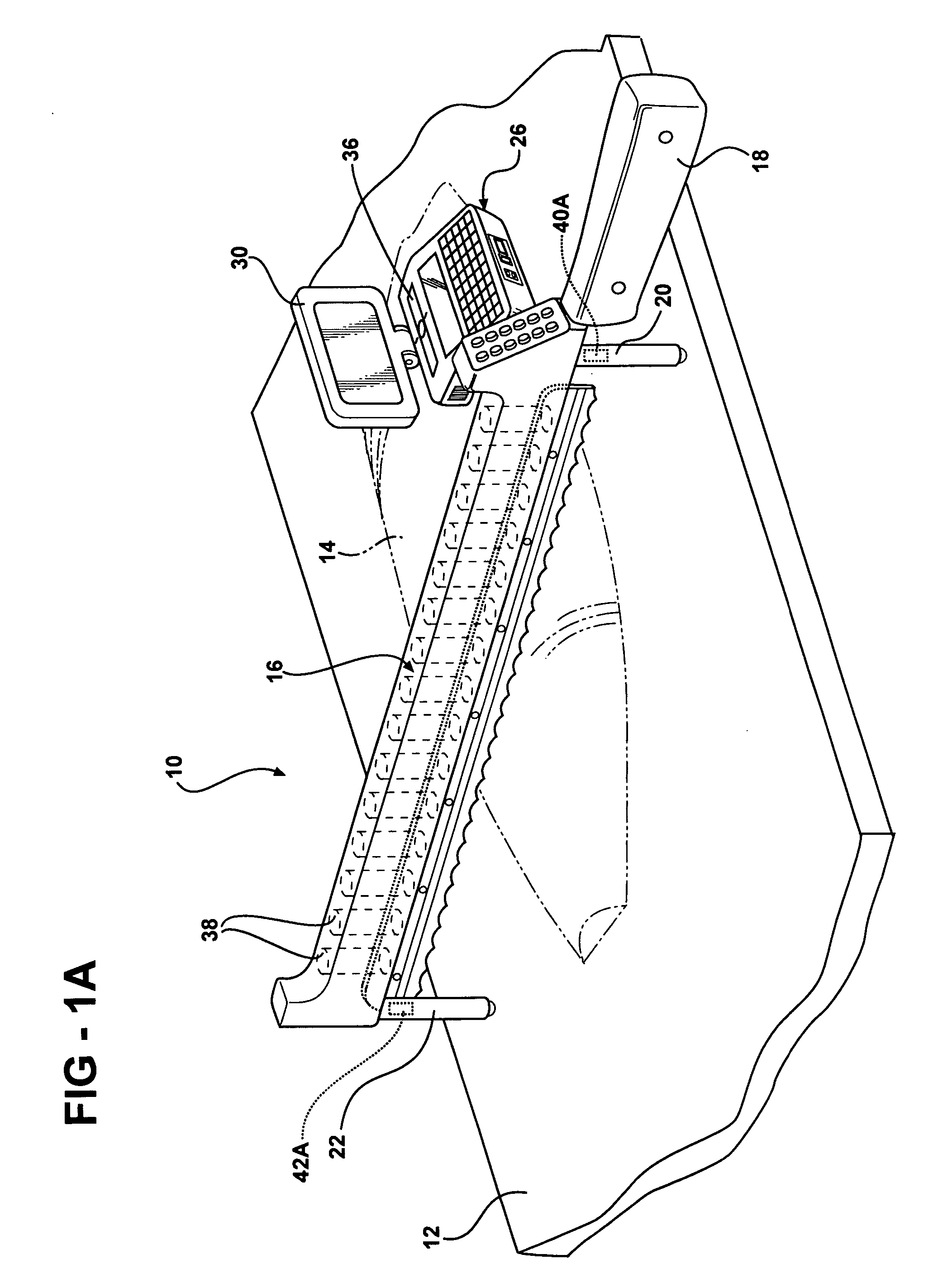

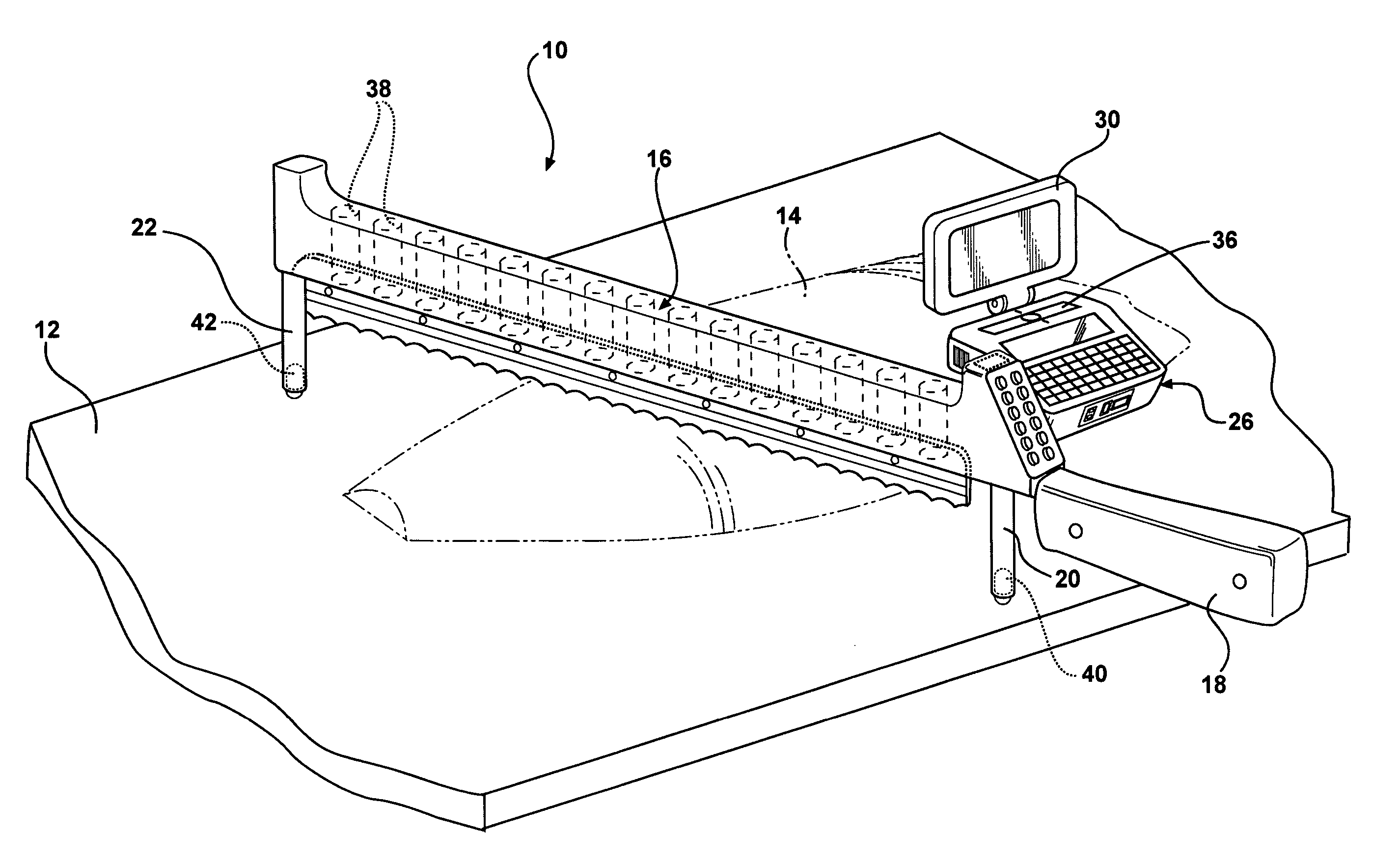

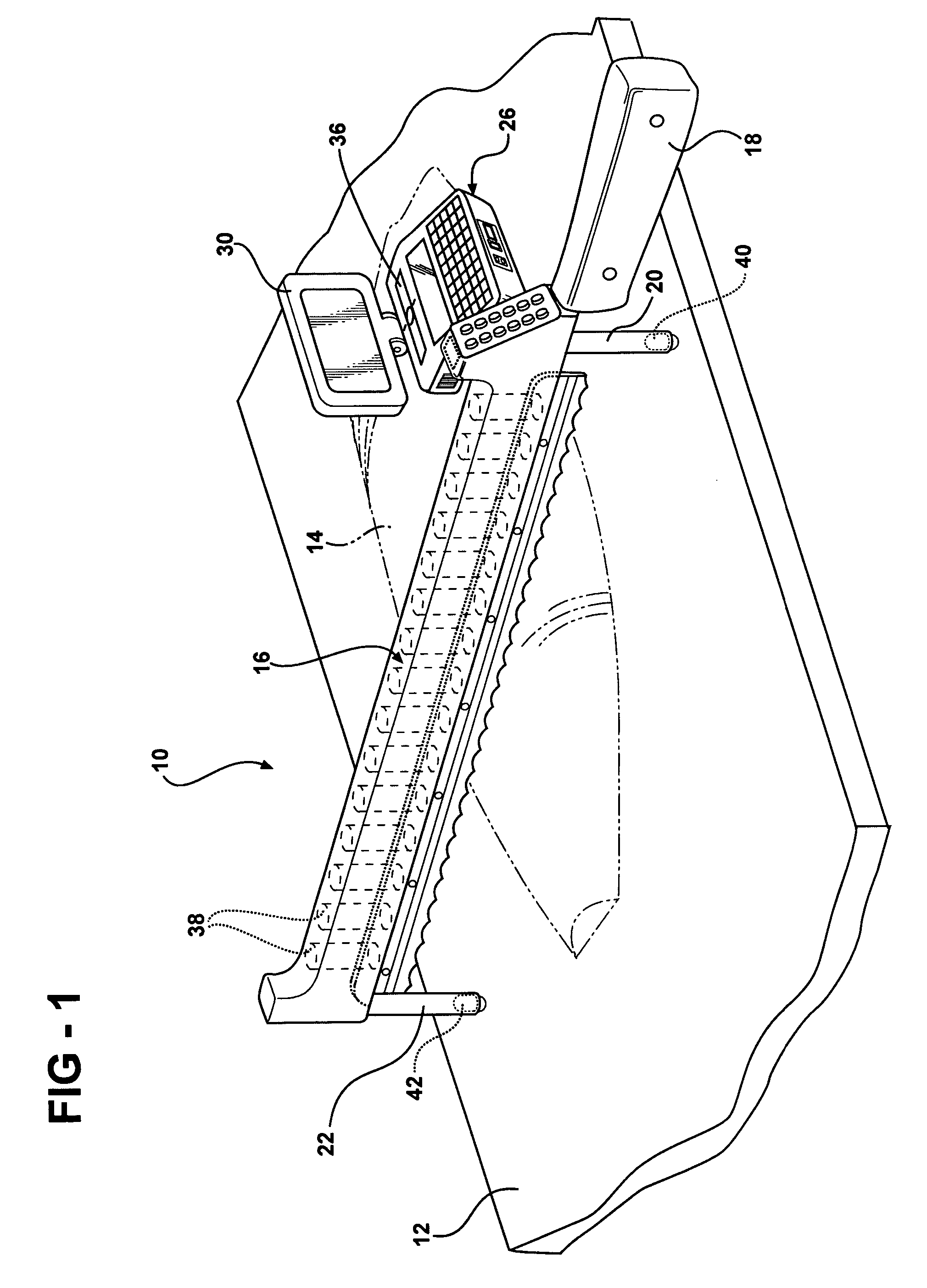

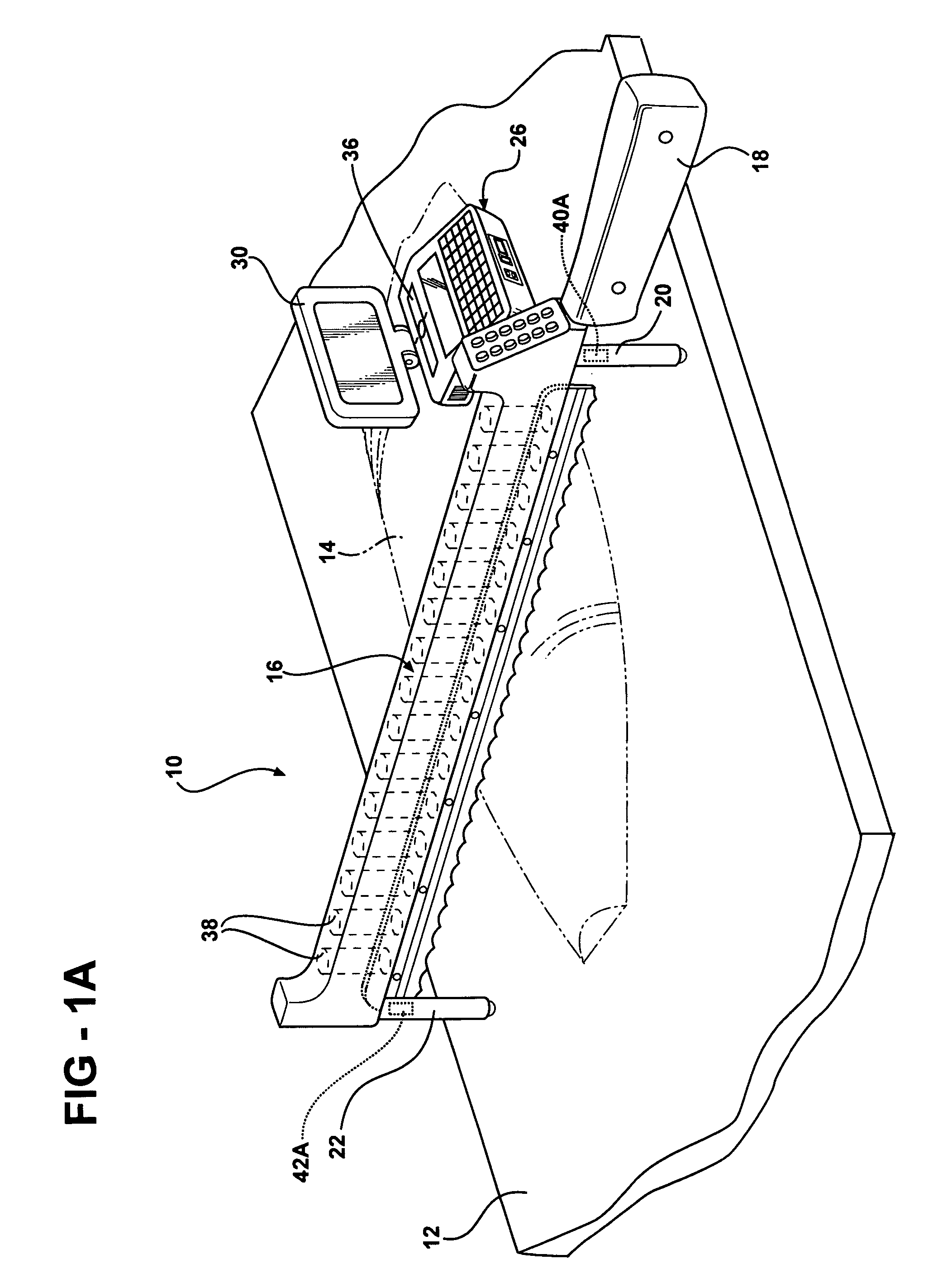

Apparatus and method for producing a numeric display corresponding to the volume of a selected segment of an item

ActiveUS20050222805A1Simplify and improve serviceabilityImprove serviceabilityMechanical area measurementsUsing subsonic/sonic/ultrasonic vibration meansMotion detectorAccelerometer

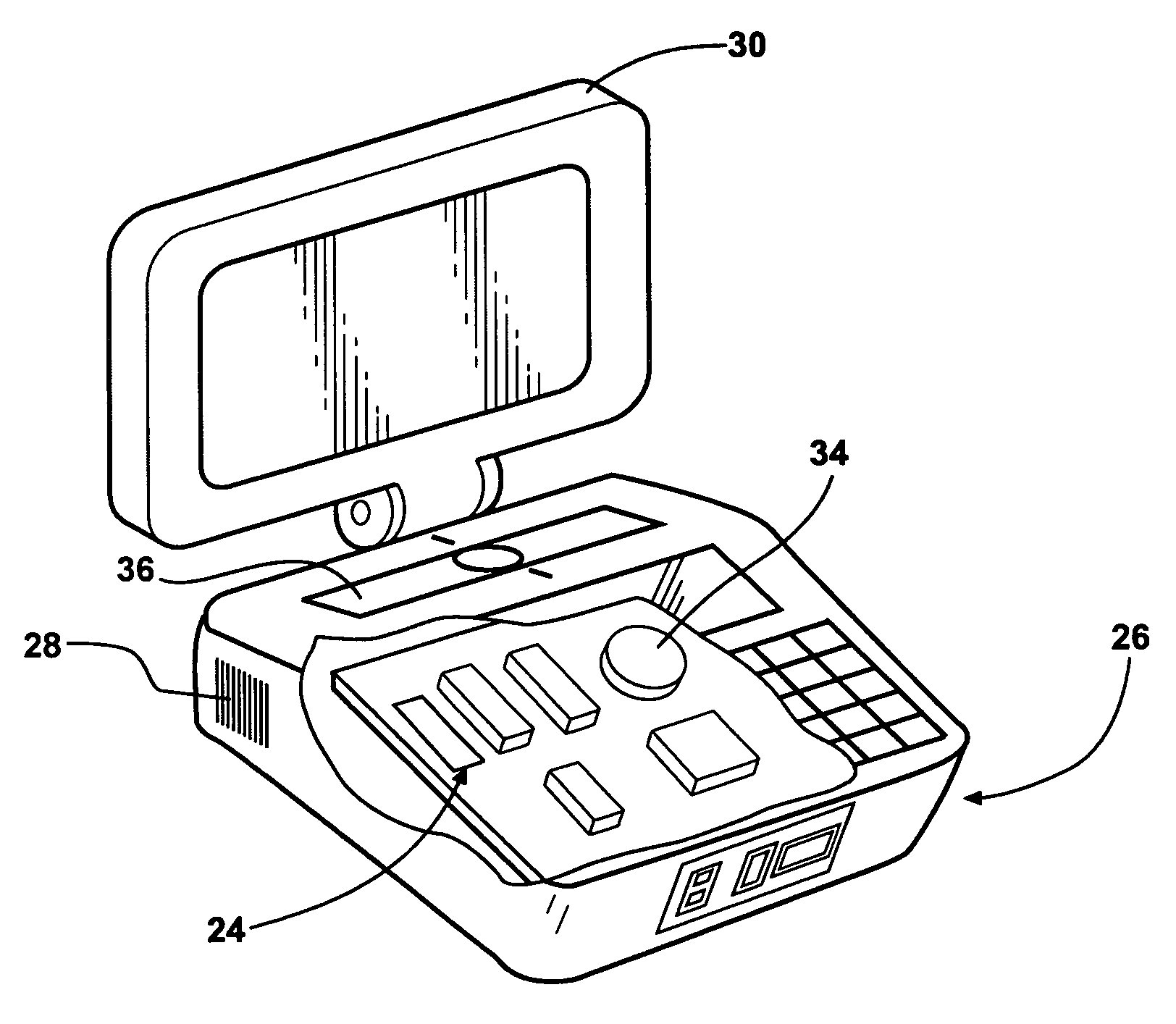

An apparatus and method for displaying the weight or cost of an uncut selected segment of an item involves passing a position indicating member over the item lying on a support surface. The position indicating member carries one or more sensors which generate signals corresponding to succeeding cross sectional contours of the item as the member is traversed along the item from a reference position to a selected other position over this item, defining the selected segment of the item. At the same time, a motion detector arrangement preferably comprised of one or more microelectromechanical (MEMS) accelerometer devices generates signals corresponding to motion of the position indicator support member as it is moved along the item. These signals are processed in a signal processor to determine the volume of the uncut selected segment of the item lying between selected successive positions of the indication member. Each of these cumulative volume determinations are converted into numeric weight or price values based on the density factor for the particular type of item, whereby numeric weight and price values (based on weight) are displayed as the member is traversed along the item, thus enabling the operator to contemporaneously provide an on-looking consumer weight or price information before a particular segment is cut from the item. A visible light band is projected from the sensor bar onto a section of the item to clearly show the selected segment bounds corresponding to the numeric display to the onlooker.

Owner:WARGON KENNETH

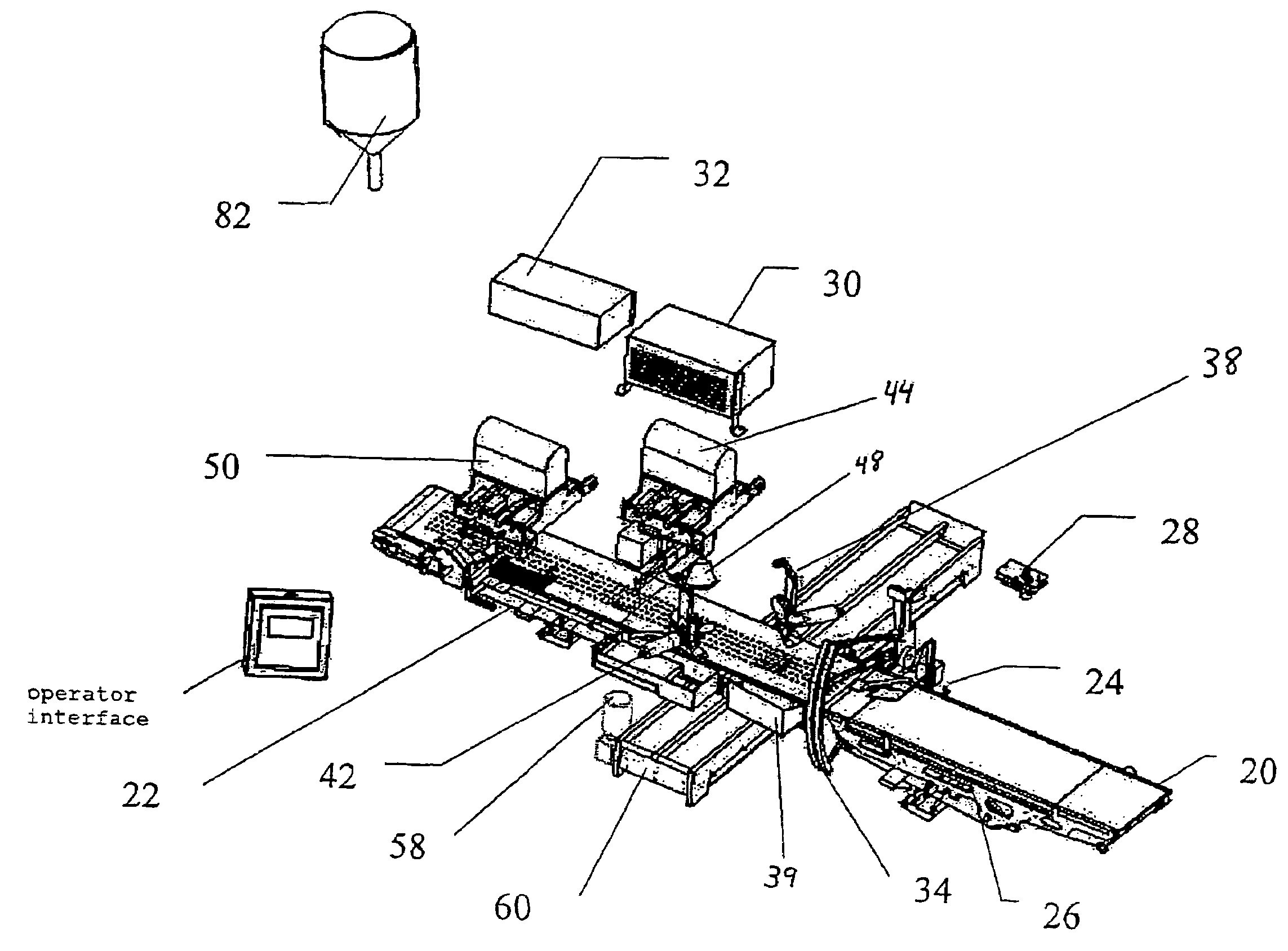

Apparatus and method for trimming of fish fillets

The automatic fillet-trimming machine comprises a first conveyor belt that is capable of registering the weight of the individual fillets, one or more computer-controlled cameras or other imaging means that identifies and localizes the undesired portions of a fish fillet to be removed, a height-measuring apparatus the registers the thickness of the fillets, a second conveyor belt that comprises suction means for securely holding the fillets, and which transports the fillets to a plurality of computer-controlled cutting devices, the movement of which is directed according to coordinates received from the imaging means, and means for weighing and removing waste products.

Owner:MAREL ICELAND EHF

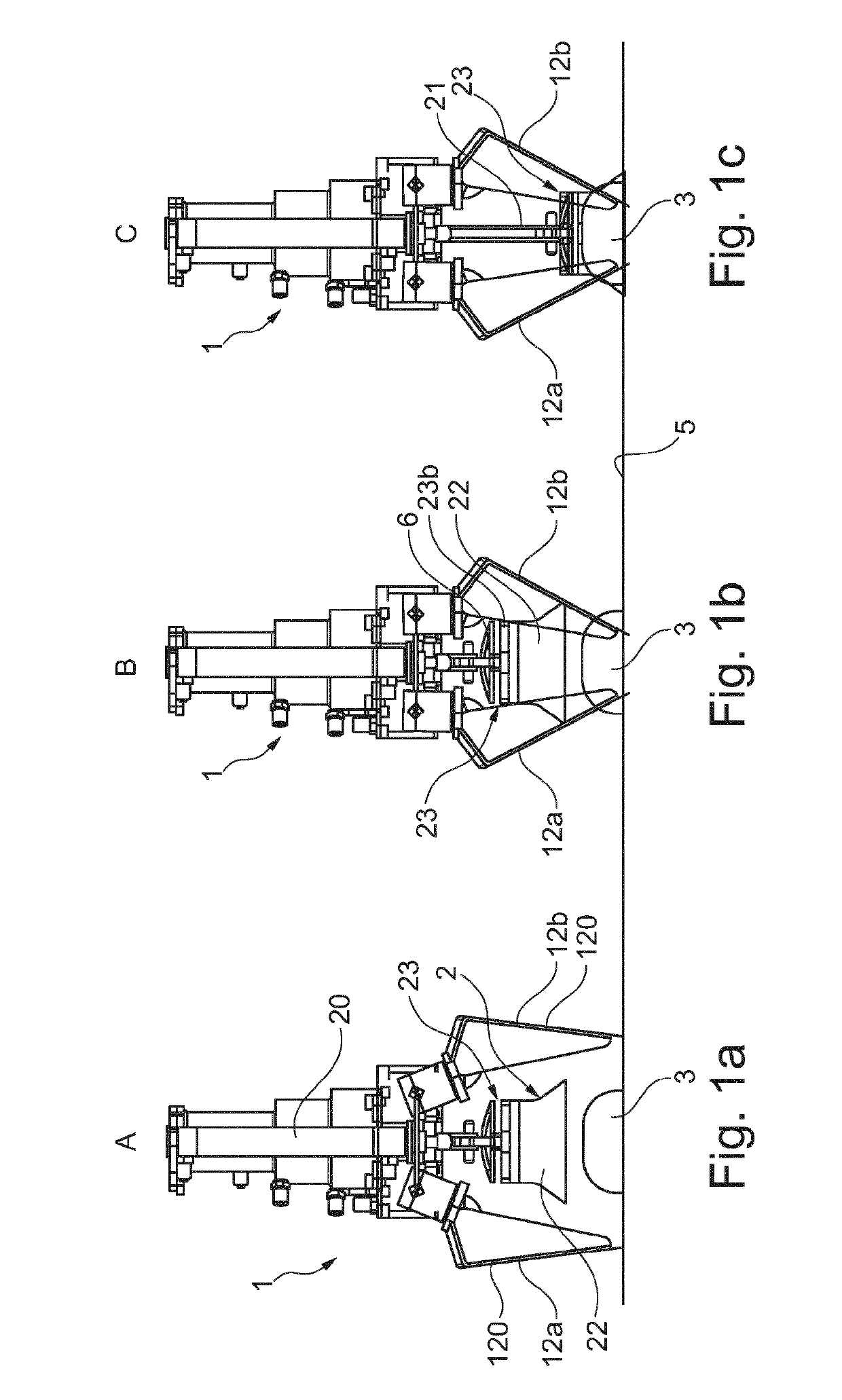

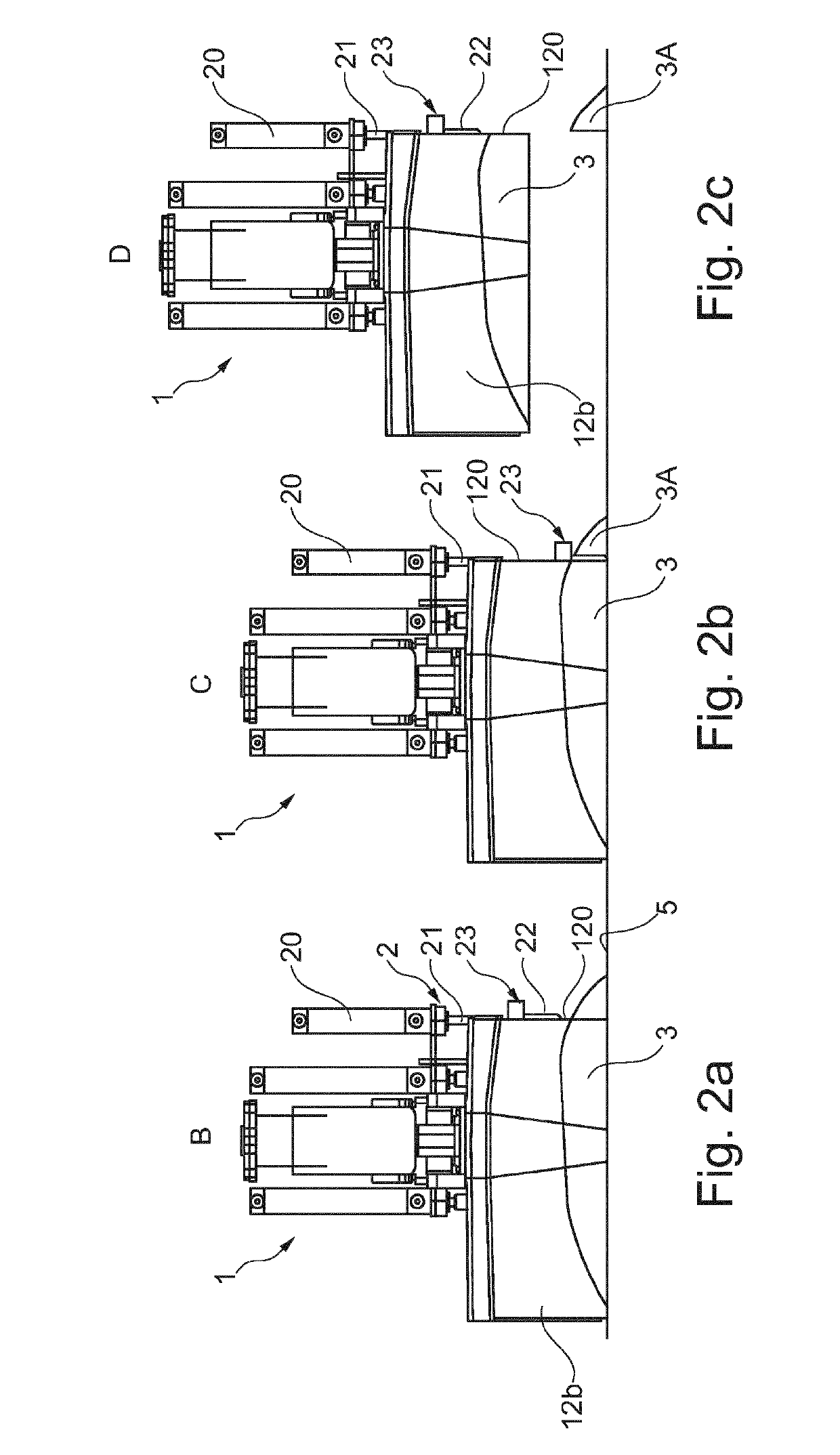

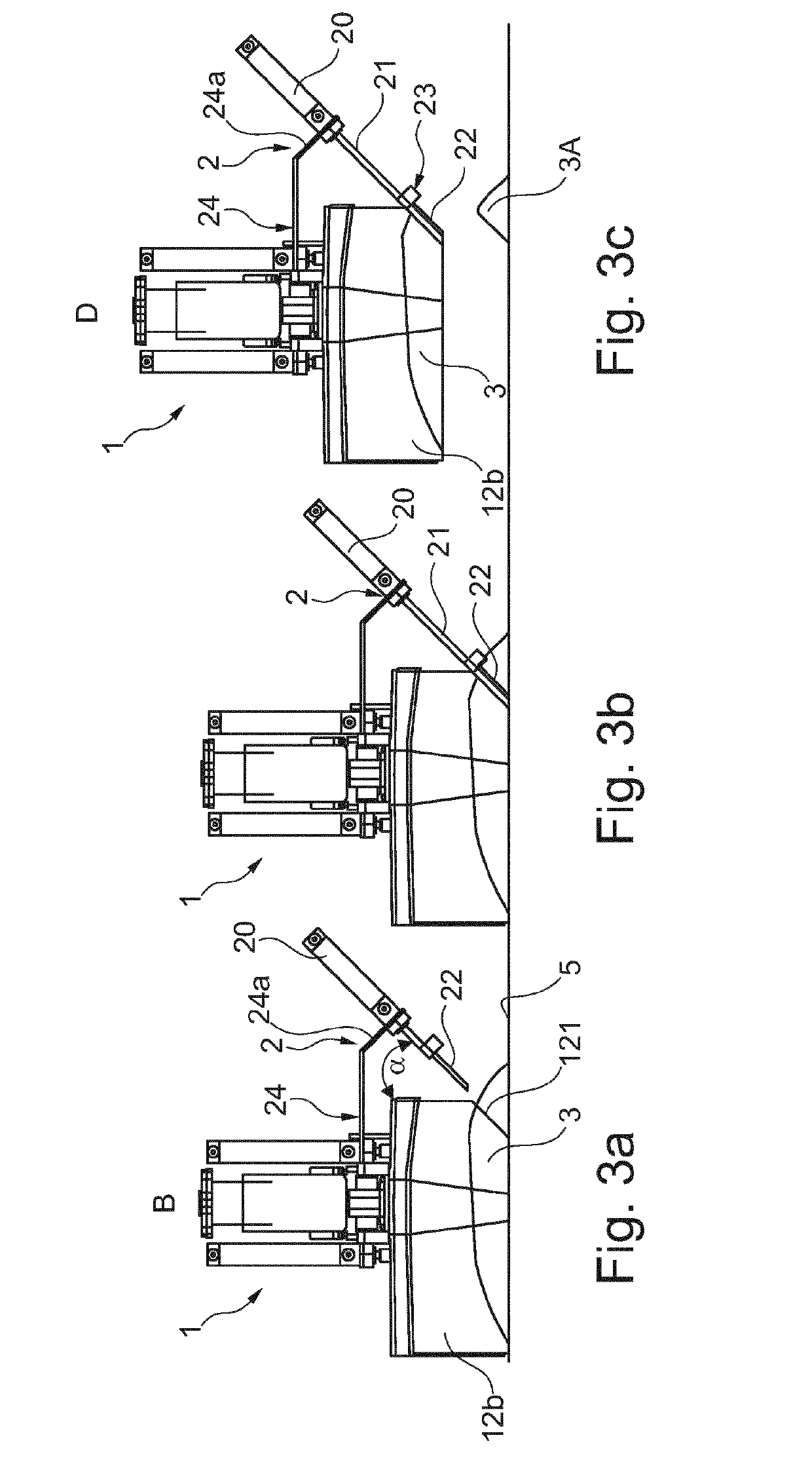

A portioning device and a method for packaging of food products

ActiveUS20190270205A1Simple methodEfficient comprehensive utilizationMeat holding apparatusProgramme-controlled manipulatorEngineeringFood packaging

The invention relates to a portioning device for packaging of food products (3) in a portion carrier, comprising positioning device and gripping device (1), which gripping device comprises first and second articulating jaws (12a, 12b) having first and second ends that together with a belt or table (5) for a food product (3) define an opening between said jaws (12a, 12b) arranged to grip the food product laying on the belt or table (5), wherein said first and second jaws (12a, 12b) are articulately arranged in order to be movable between at least two relative positions, one holding position and one open position, wherein the portioning device also comprises a cutting device (2) arranged at said first and / or second ends of said first and second articulating jaws (12a, 12b), and wherein said cutting device (2) is arranged to use the belt / table (5) as support for cutting. The invention also relates to a method for packaging of food products by use of the portioning device.

Owner:ROBOT GRADER AB

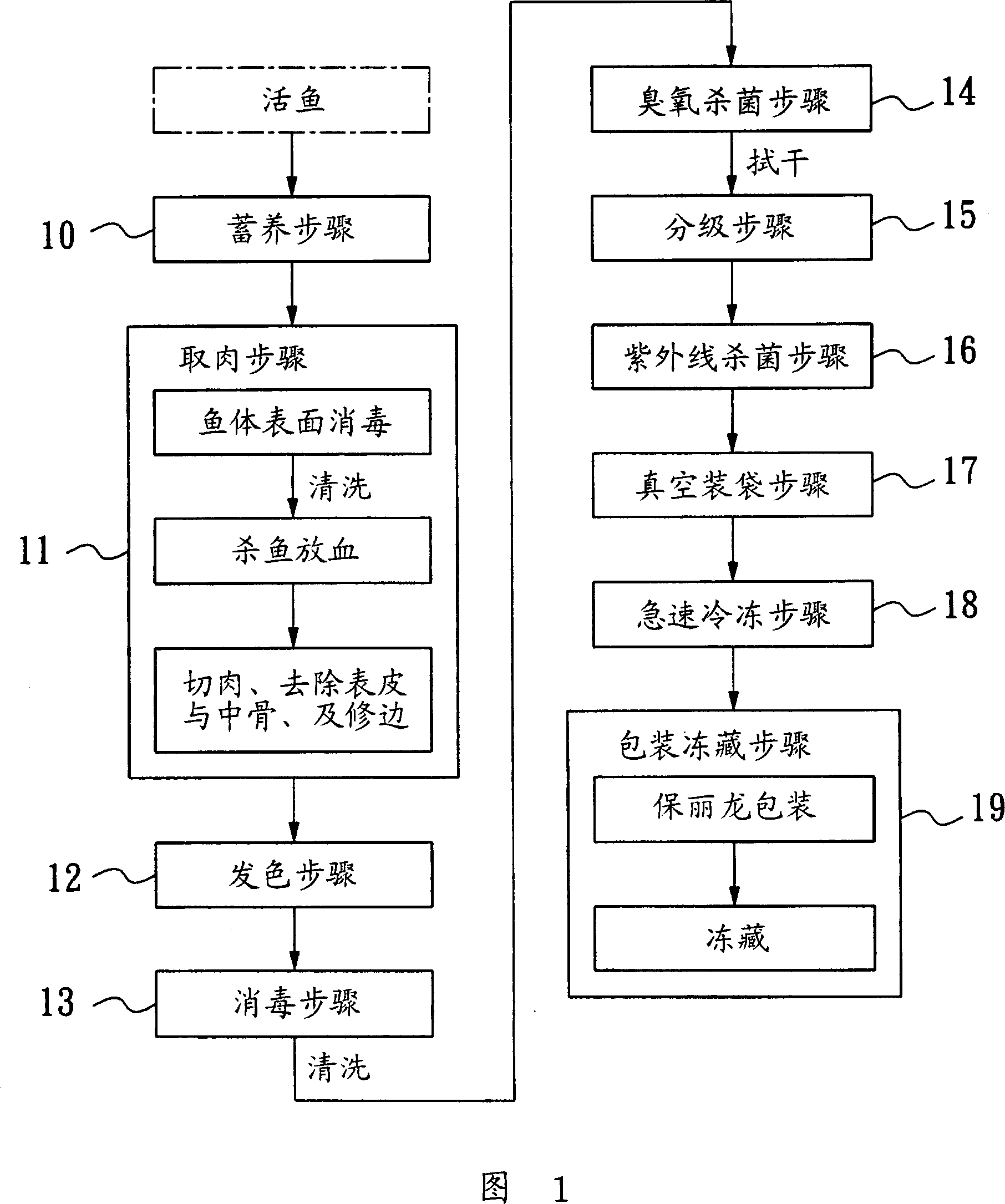

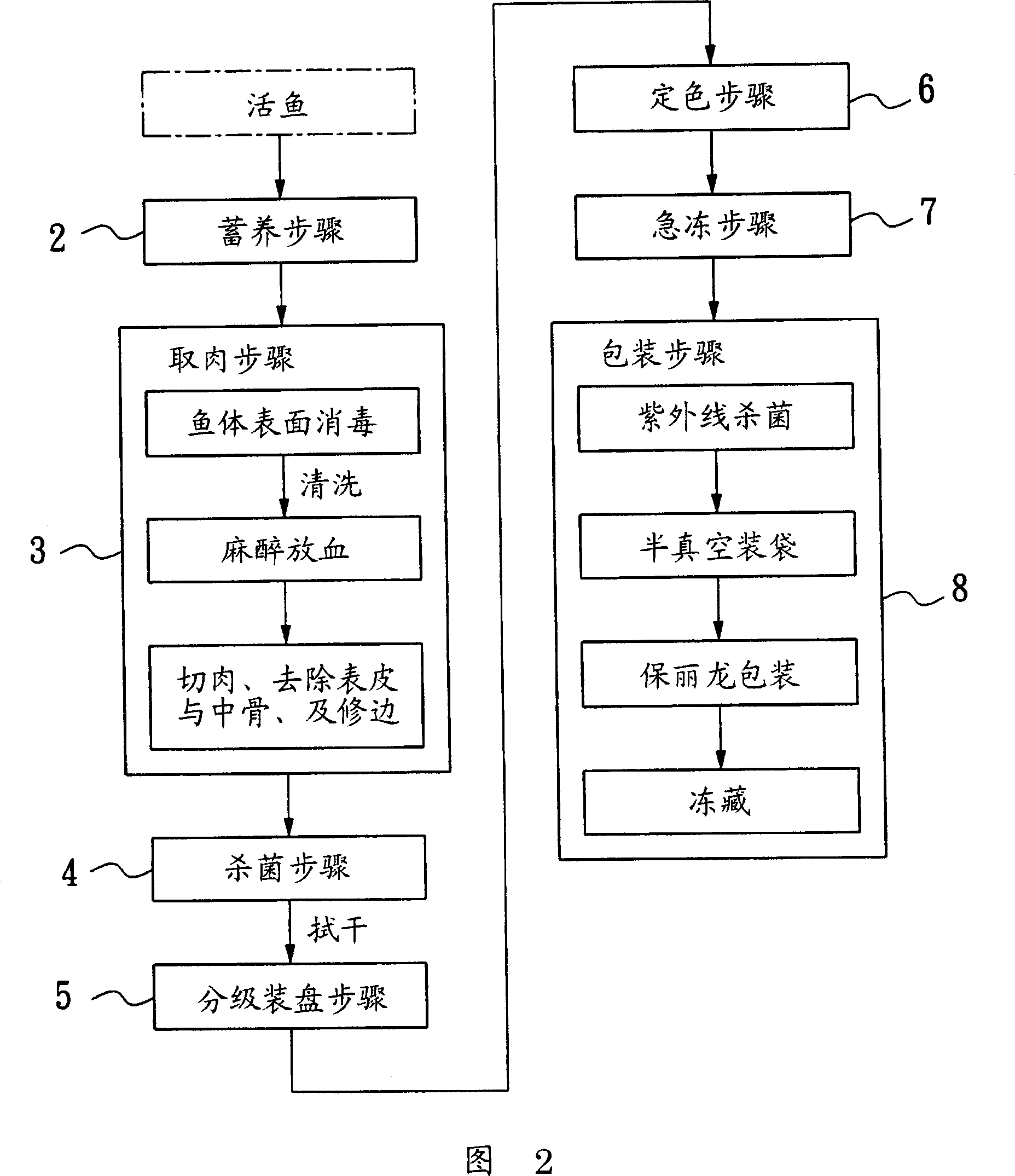

Mehtod for processing the color and lustre of fish meat

InactiveCN101081083AExtension of timeShorten working timeSlaughtering/stunningMeat/fish preservation using chemicalsProcess timeFlesh

The color-maintaining fish flesh treating process includes the following steps: cutting fish flesh through blocking the nerve of live fish to reach anaesthesia effect, bleeding and cutting fish flesh while the fish is live; sterilizing fish flesh in a sterilizing pond; fixing color of fish flesh in a no-oxygen atmosphere; quick freezing fish flesh; and packing in bag. Blocking the nerve of live fish can eliminate blood of fish completely, retard deterioration of protein, increase color maintaining period of fish flesh, shorten fish flesh treating period and ensure the delicious taste of fish flesh.

Owner:李柏兴

Apparatus for processing and grading food articles and related methods

This disclosure concerns methods for processing and grading food articles including x-raying the food articles a first time and taking a 3D image of the food articles.

Owner:VALKA EHF

Novel hairtail segmenting machine

The invention relates to the processing field of marine food products, and in particular relates to a novel hairtail segmenting machine. The novel hairtail segmenting machine comprises a rack, wherein a left chain roll and a right chain roller are respectively mounted on left and right sides above the rack, a plurality of chains are connected between the left chain roll and the right chain roller at equal intervals, panels are fixedly mounted between the chains and between each chain and coaming on the rack, L-shaped baffles are mounted on the chains at equal intervals, a bracket is mounted at the right end above the rack, a rotating shaft is mounted under the bracket, and is connected with a motor B fixedly mounted below the rack, a plurality of cutters are mounted on the rotating shaft at equal intervals, a cross beam is arranged above the bracket, and elastic press rods are mounted on the cross beam at equal intervals. The novel hairtail segmenting machine is simple in structure, is convenient and practical, is high in production efficiency, low in production cost, thus being suitable for being widely popularized and applied.

Owner:济南海之舟食品有限公司

Integrated processing production line and processing technology for red fish aquatic products

InactiveCN112006081APerform cleanup and removalAchieve removalFish washing/descalingFish filletingRedfishAdhesive

The invention discloses an integrated processing production line and processing technology for red fish aquatic products. The technology comprises the following steps: step 1, pretreatment; step 2, cleaning; step 3, slicing; 4, removing burrs; and step 5, freezing. The technology is safe and reliable. Through cooperation of a conveying belt, a limiting block, a fixing rod, a first high-pressure water gun, a second high-pressure water gun, a connecting rod and a first cutter, the structure is simple, use is convenient, and red fish scales and internal organs are cleaned and removed; through thecooperation of a first hydraulic cylinder, a second cutter, a material collecting box, a connecting shaft and a stop block, the removal and collection work of the heads of the red fishes is realized,and the use is convenient; through cooperation of a second hydraulic cylinder, a pushing block, a supporting rod, a rotating door and a spring, the purpose of cleaning scales and internal organs of the red fishes out of the rack is achieved, the rack is convenient to clean, and the use is convenient. According to the invention, an adhesive is used for adhering the damaged parts of the bodies of the red fishes, and the integrity and attractiveness of the processed red fishes are improved.

Owner:DALIAN GUOFU AQUATIC PROD & FOOD

Minced and Heated Fish Meat Material Having a Texture Like Meat of Livestock, and Process for Producing the Same

InactiveUS20070243309A1Little fish odorEasy to eatMeat processingFood preparationAdditive ingredientDecomposition

To provide minced and heated fish meat material having a texture like meat of livestock, and foods utilizing the material. Fish meat, preferably fish meat wherein the decomposition of trimethylamine N-oxide is inhibited and the denaturation of protein is reduced, is chopped while keeping a frozen state, is heated until denaturation and coagulation of protein while keeping a frozen state and followed by seasoning. Alternatively, the seasoning is carried out simultaneously with the heating. According to the procedure, minced and heated fish meat material having a texture like meat of livestock, can be obtained. The material can be provided as it is, or can be provided as an ingredient of food produced from minced meat of livestock.

Owner:NIPPON SUISAN KAISHA LTD

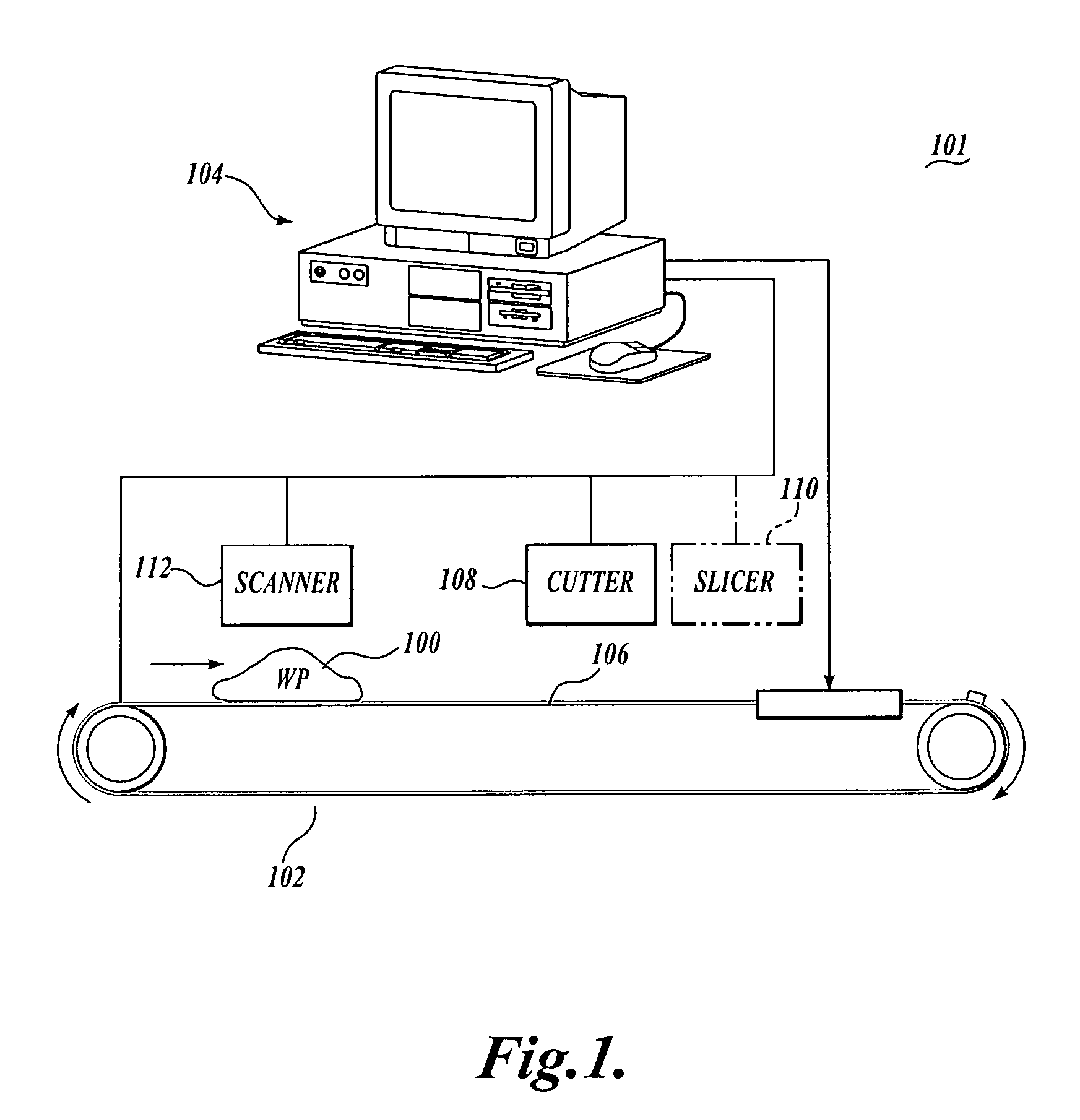

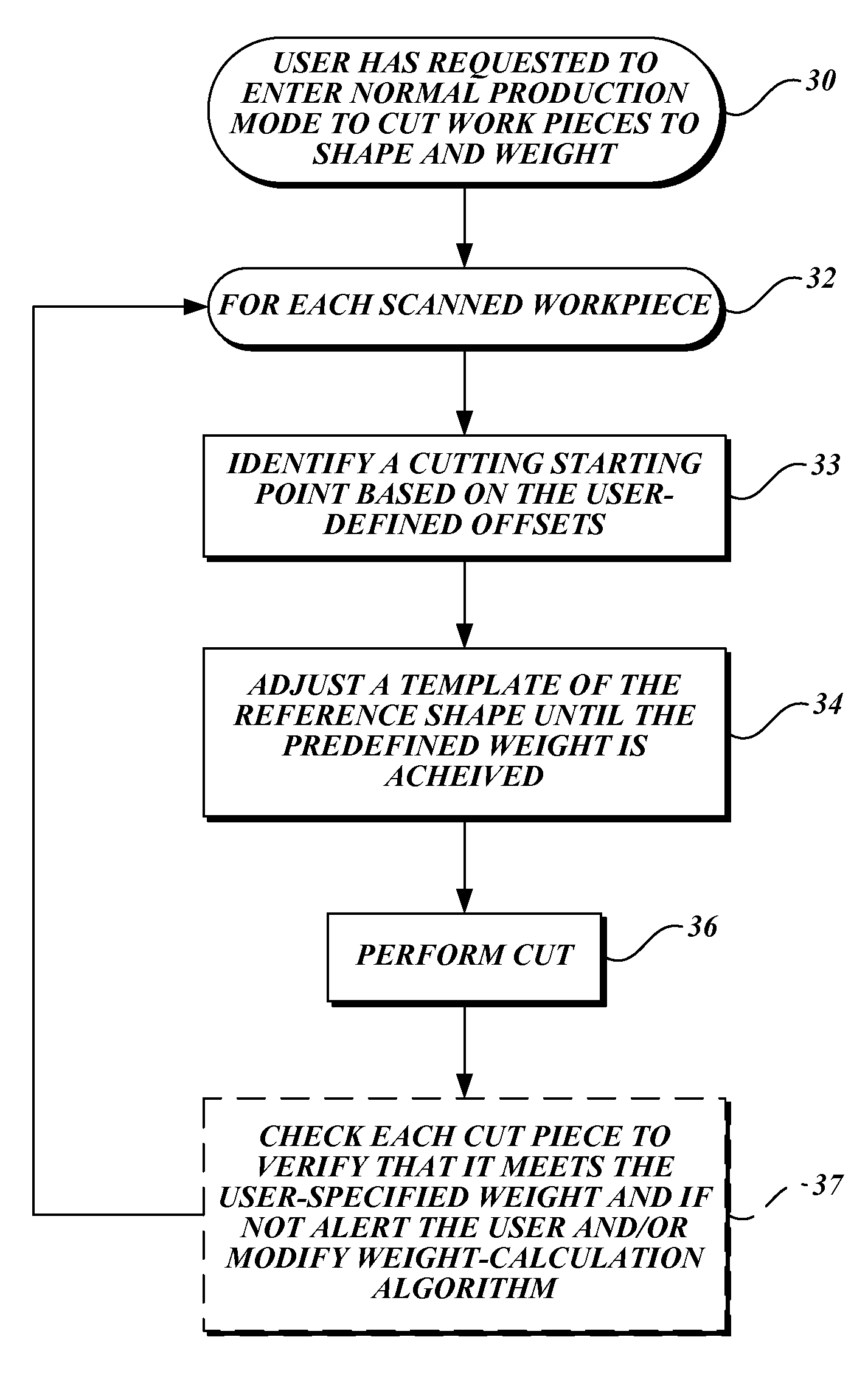

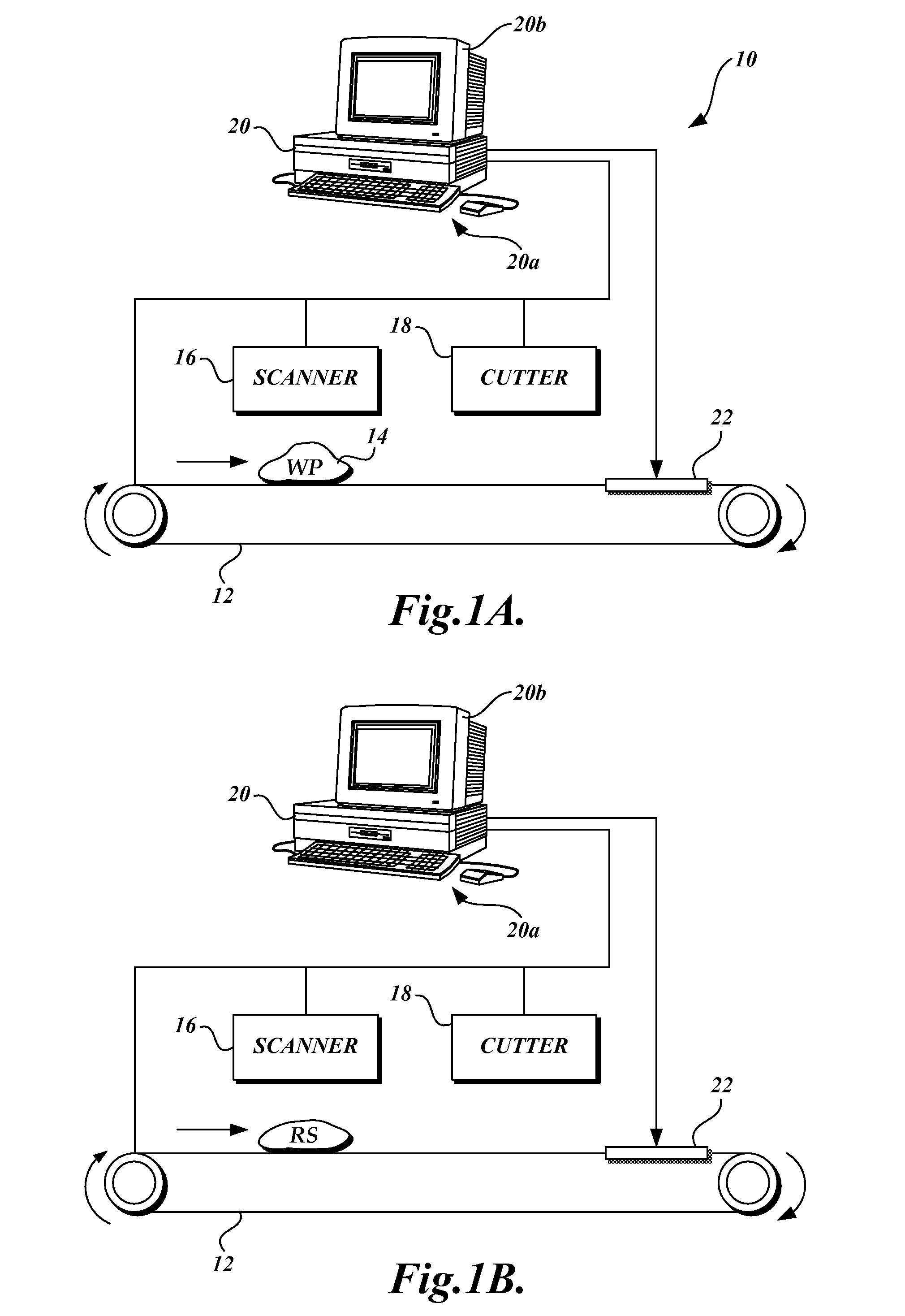

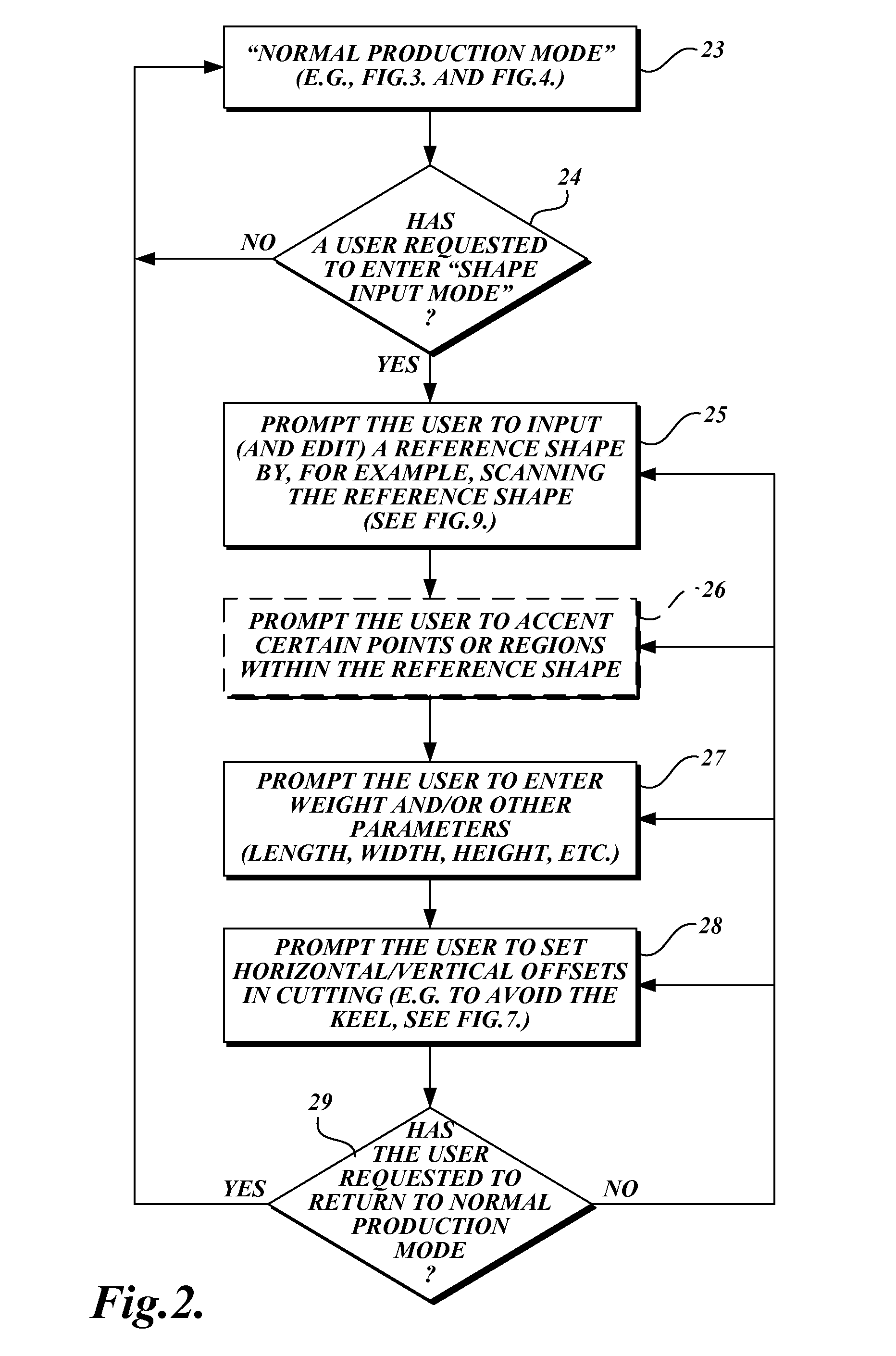

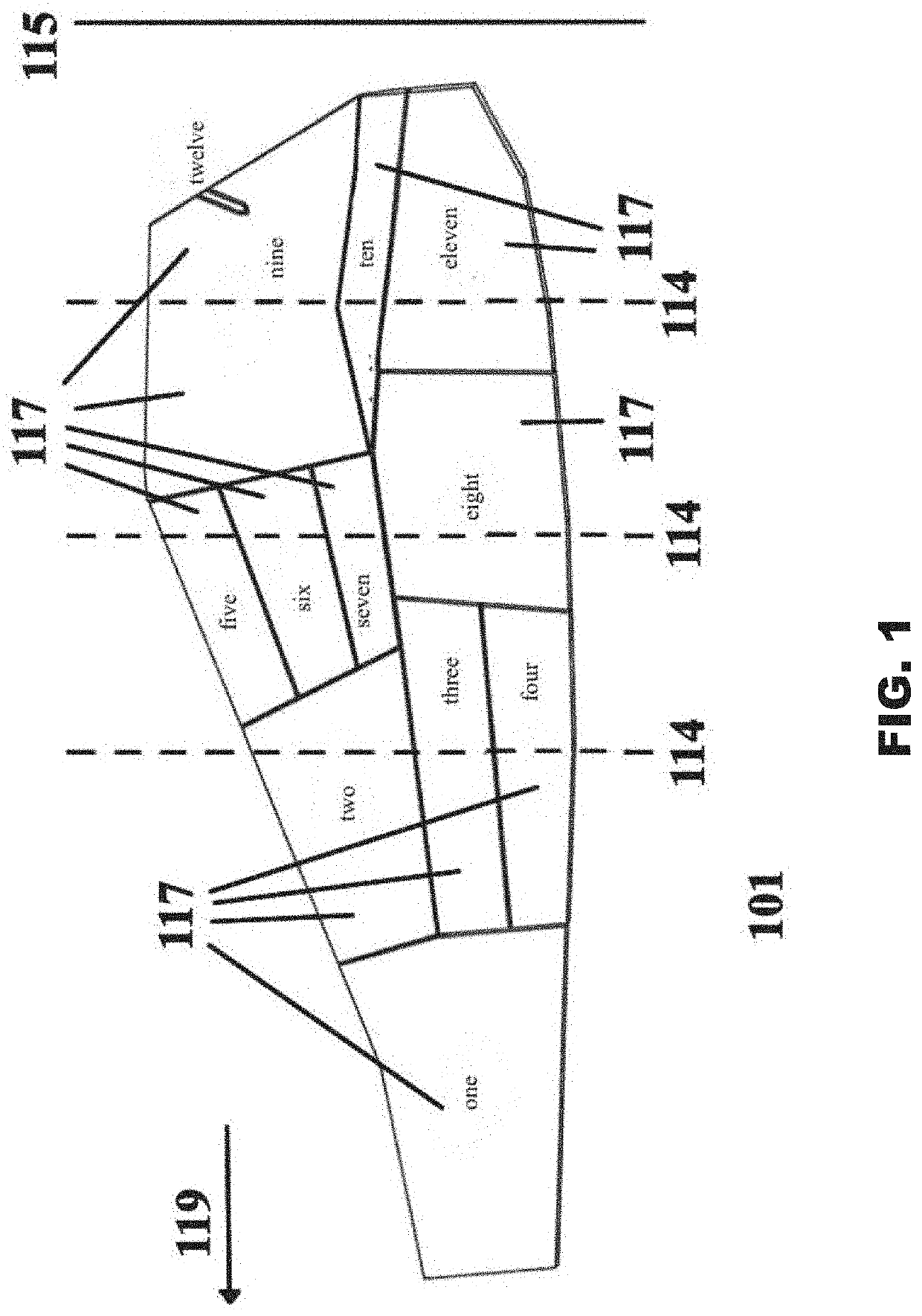

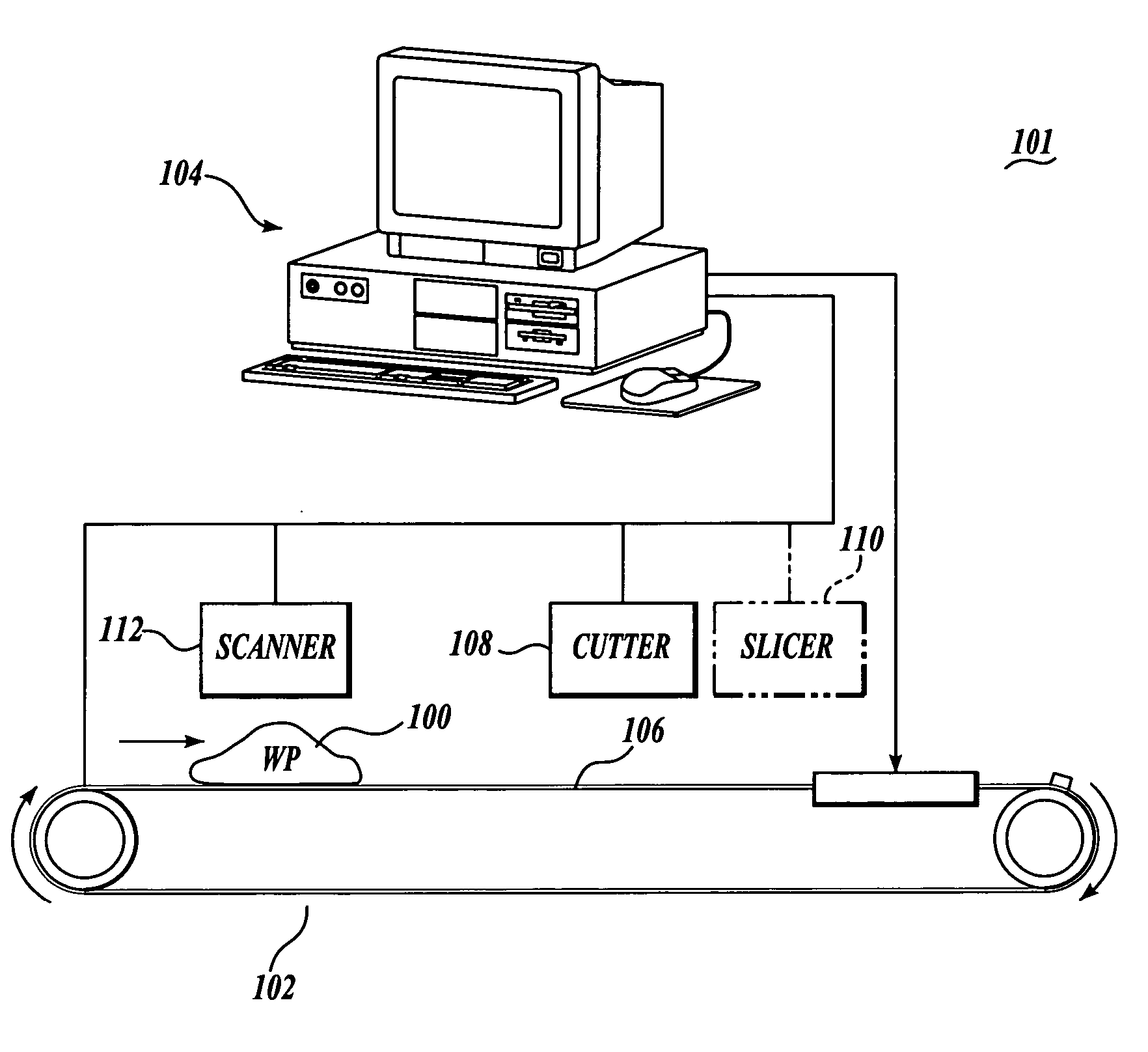

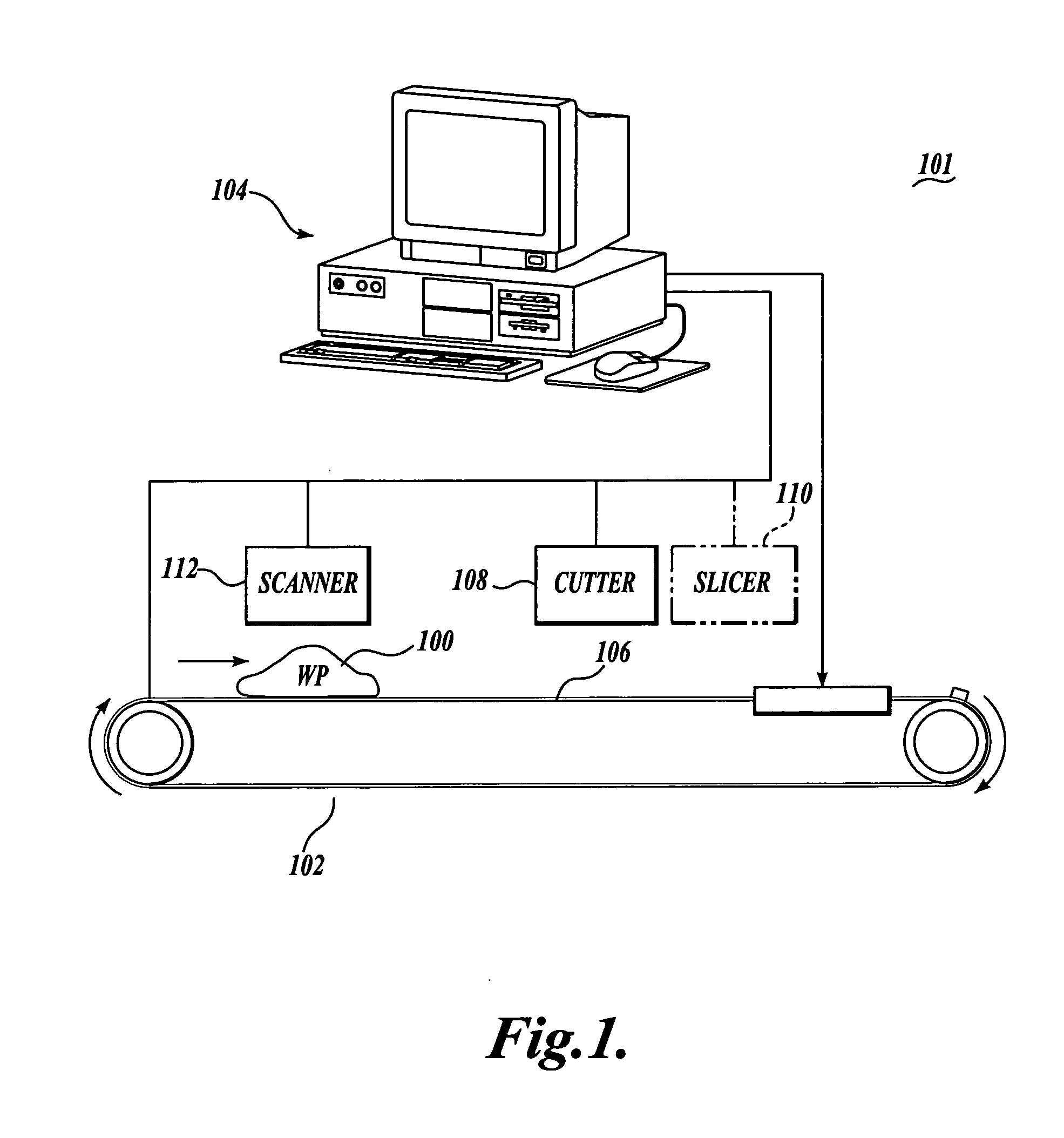

Method and system for portioning workpieces to user-entered shape and other specifications

ActiveUS20090143886A1Metal working apparatusSpecial data processing applicationsUser inputEngineering

A method and system are provided for automatically portioning workpieces, such as food products, into both shape and other user-defined specification(s). Workpieces are portioned both to shape and weight, such as to a weight-specific uniform shape, by adjusting (e.g., scaling up and down or slightly modifying) a desired template shape until the desired weight is achieved depending on the varying thickness of each workpiece. For example, from a thicker workpiece, a smaller-sized piece having a predefined shape and weight is portioned, while from a thinner workpiece, a larger-sized piece having the same predefined shape and weight is portioned. The system permits a user to scan in and edit a desired (reference) shape to be used as a template in the portioning process.

Owner:TESTO AG

Method for improving, by using power-variable ultrasonic waves, frozen fish fillets treated by means of salt-water immersion process

ActiveUS20160050945A1Shorten freeze timeFaster in freezing fish filletsDough treatmentFish washing/descalingSaline waterFrozen storage

A method for improving frozen fish fillets treated by way of a salt-water immersion process includes the following steps: pretreating raw fish to obtain fish fillets; precooling the fish fillets; stacking the precooled fish fillets to obtain a fish fillet stack; freezing the fish fillet stack by using a salt-water immersion process, and performing power-variable ultrasonic wave treatment; and feeding the fish fillets into a cold storage, and performing freezing storage at minus 18 degrees centigrade. The power-variable ultrasonic wave treatment includes: firstly treating for 5 to 10 min under the power of 800 to 600 W, and then changing the power to 200 to 600 W for treating for 5 to 15 min. The freezing time of fish flesh is shortened, and formed ice crystals are fine and uniform, thereby preventing the damage of the formed ice crystals to cell walls.

Owner:SOUTH CHINA UNIV OF TECH

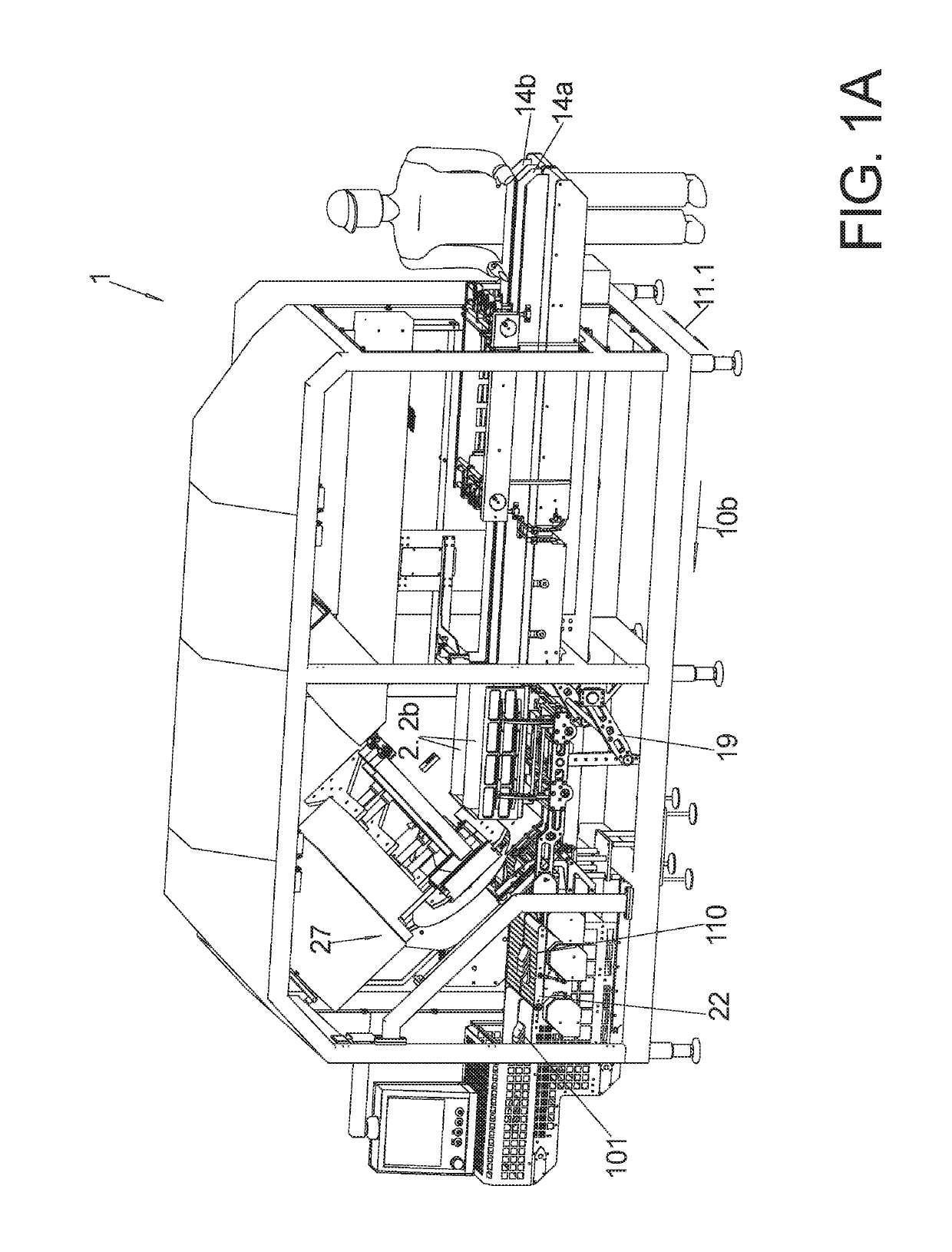

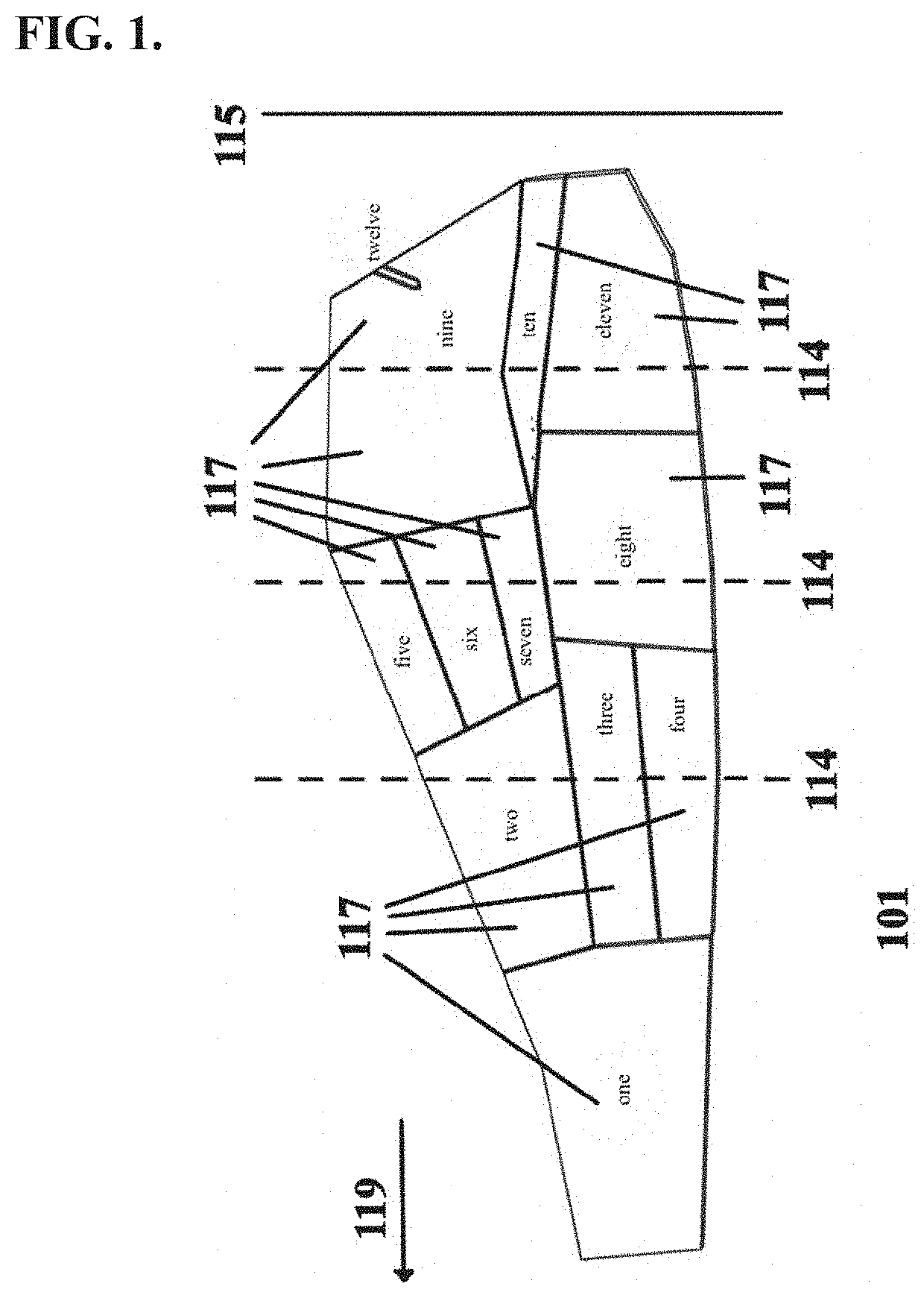

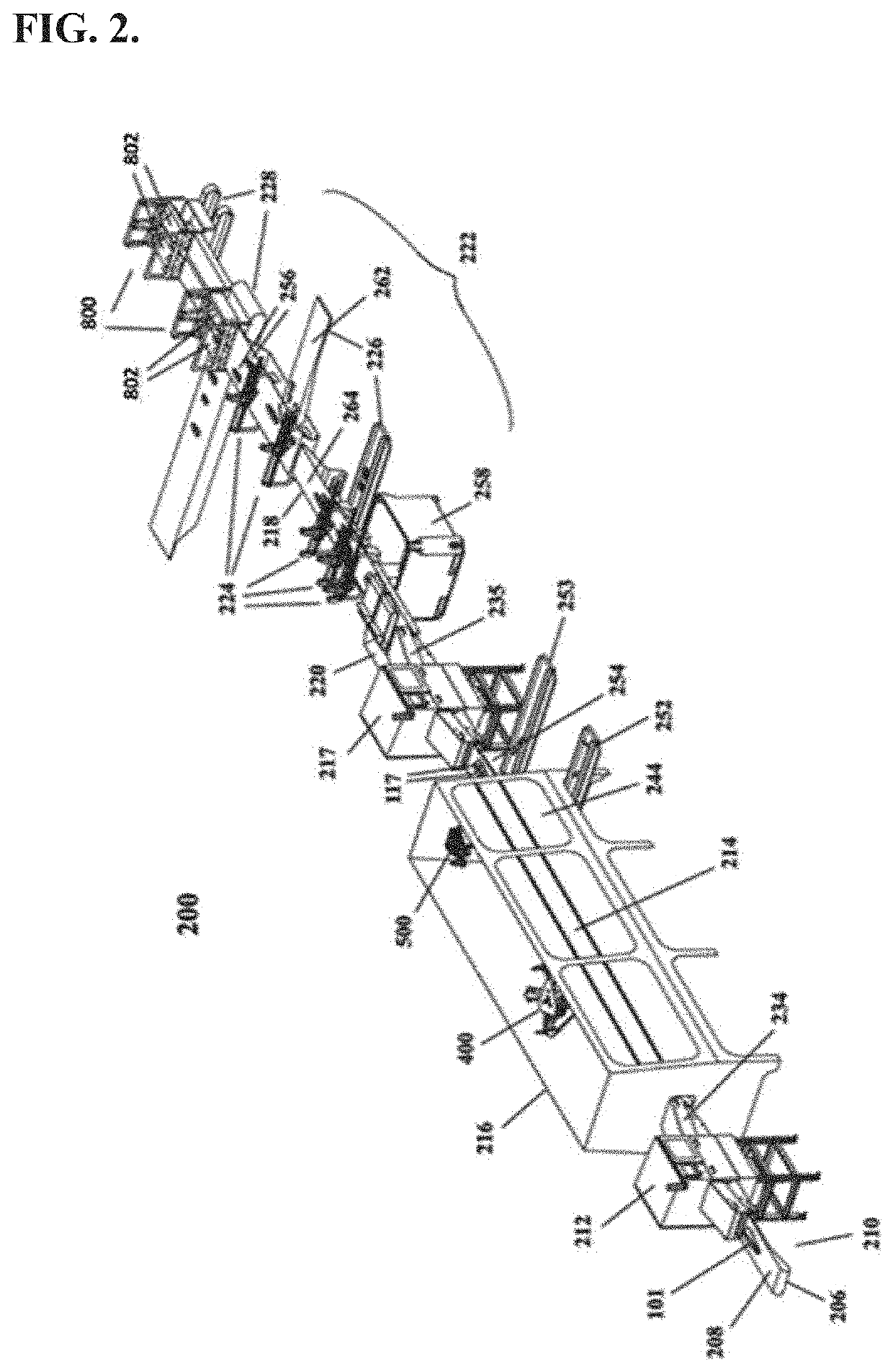

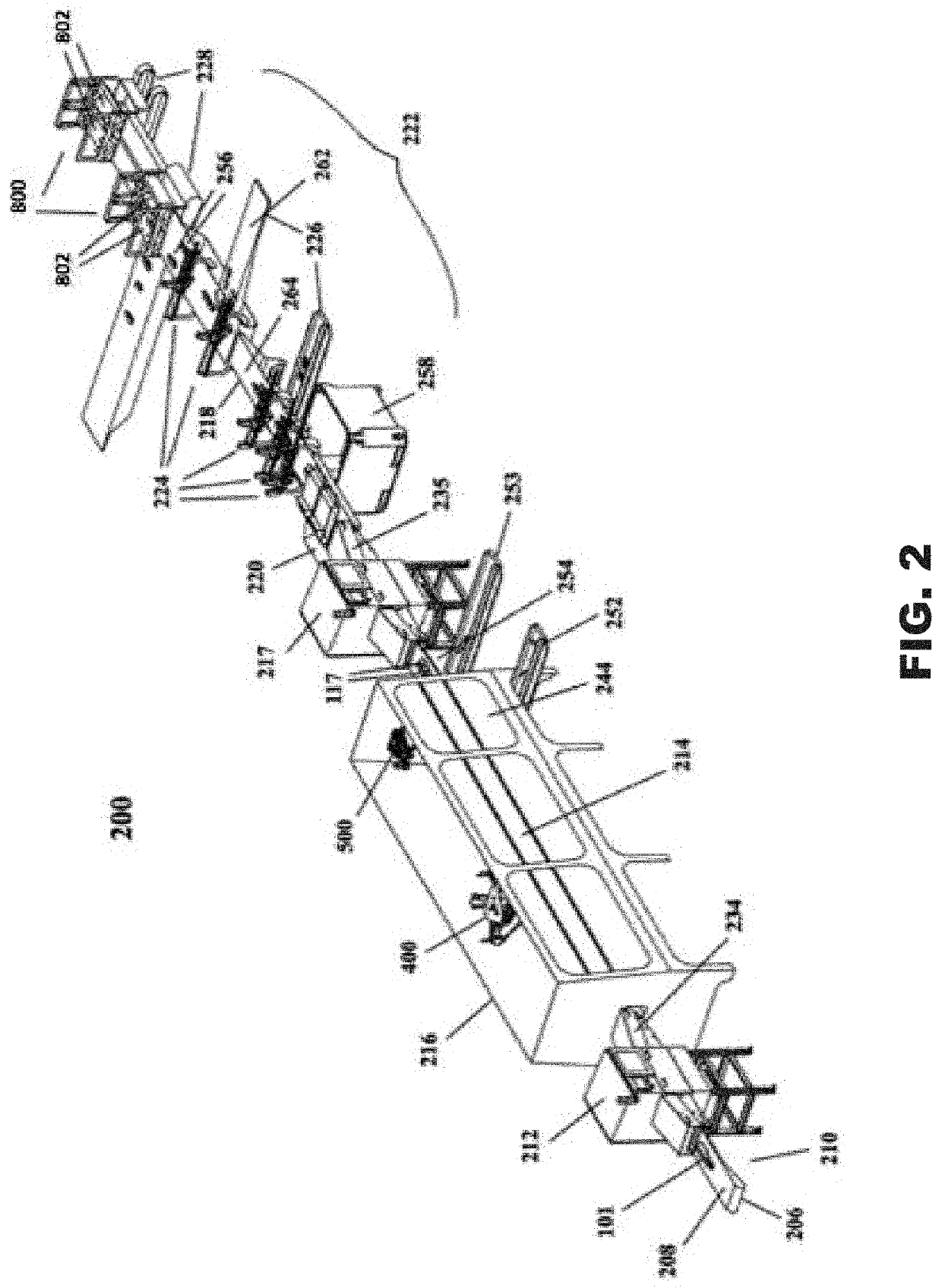

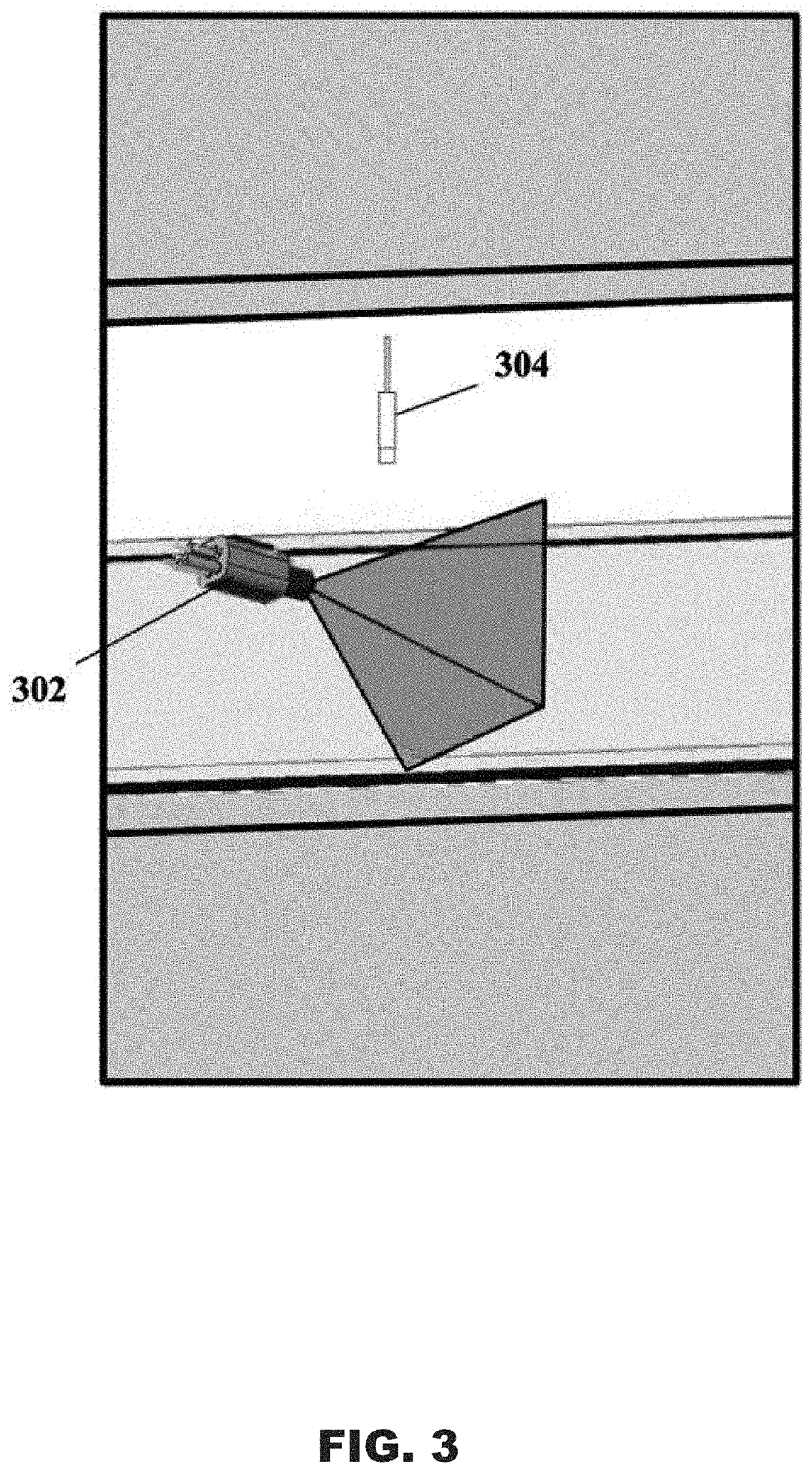

Apparatus for processing and grading food articles and related methods

ActiveUS20200077670A1Programme-controlled manipulatorMeat packaging/handling/transporting3d imageData science

This disclosure concerns methods for processing and grading food articles including x-raying the food articles a first time and taking a 3D image of the food articles.

Owner:VALKA EHF

Conveying conformable products

A buffer conveyor (12) for conveying conformable work products (66) includes a collapsible conveyor belt (13) having an infeed section (14), a collapsible intermediate section (16) and an outfeed section (18). The infeed section (14) may be driven at a non-continuous speed, and the outfeed section may also be driven at a uniform, or non-continuous, speed, but the average speed of both the infeed and outfeed sections is the same. The intermediate section of the conveyor is driven at a non-uniform speed that is slower than, but proportional to, the speed of the infeed section.

Owner:JOHN BEAN TECH CORP

Apparatus and method for producing a numeric display corresponding to the volume of a selected segment of an item

ActiveUS7010457B2Improve serviceabilityMechanical area measurementsUsing subsonic/sonic/ultrasonic vibration meansMotion detectorAccelerometer

An apparatus and method for displaying the weight or cost of an uncut selected segment of an item involves passing a position indicating member over the item lying on a support surface. The position indicating member carries one or more sensors which generate signals corresponding to cross sectional contours of the item as the member is traversed along the item from a reference position to a selected other position over this item, defining the selected segment of the item. A motion detector arrangement preferably comprised of one or more microelectromechanical accelerometer devices generates signals corresponding to motion of the position indicator support member as it is moved along the item. These signals are processed in a signal processor to determine the volume of the segment of the item lying between selected successive positions of the indication member. The segment volumes are converted into numeric weight or price values.

Owner:WARGON KENNETH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com