Patents

Literature

223results about "Meat packaging/handling/transporting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

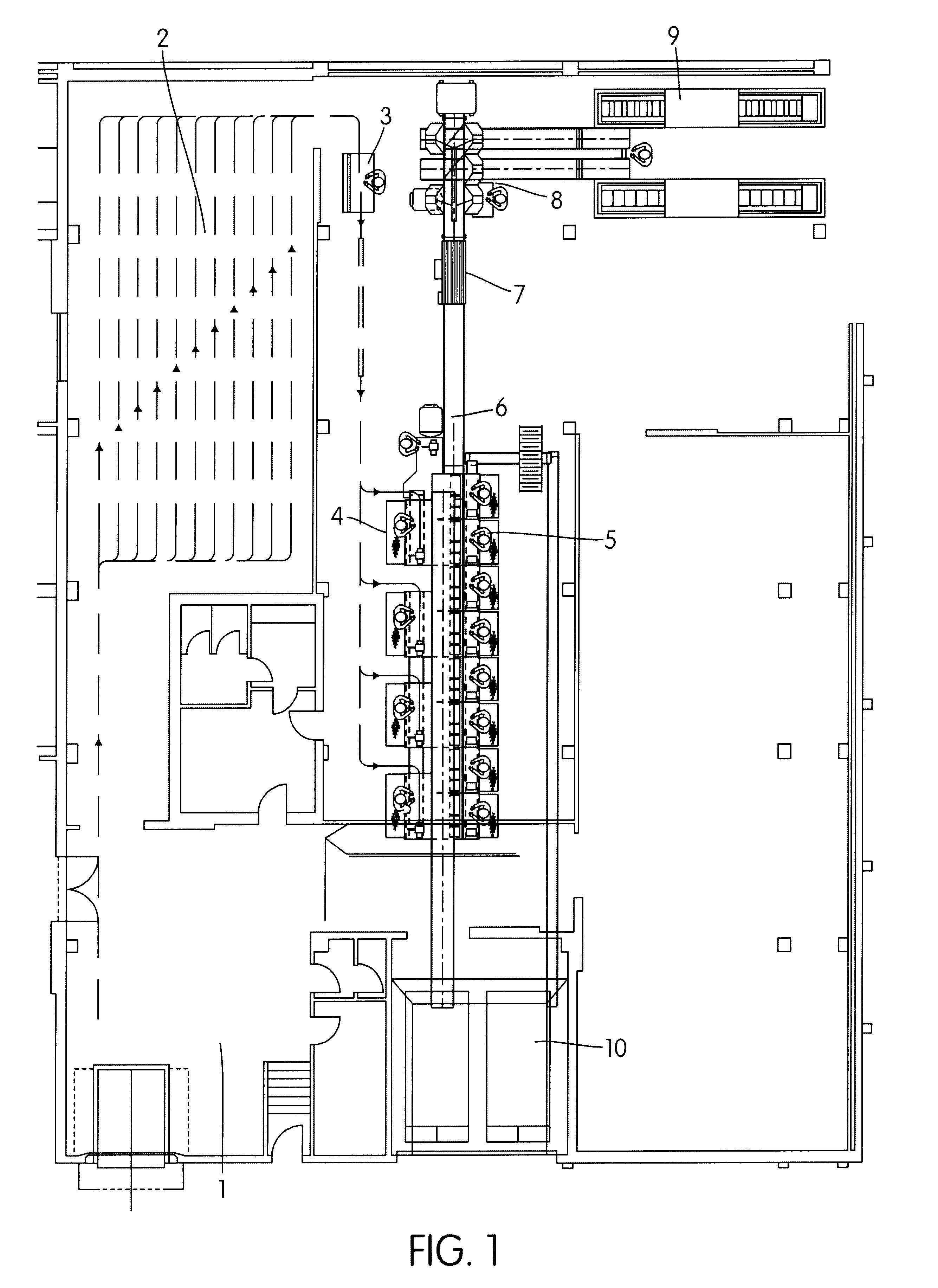

Integrated meat processing and information handling method

InactiveUS6546304B2Meat packaging/handling/transportingCarcasses classification/gradingReady to useWorkstation

The present invention relates to a process and an application for handling information in relation to meat being conveyed through a number of processing stations. The information is used to trace the processing history of a piece of meat, including its origination. The ability to trace the processing history may be used e.g. in order to trace back sources of contamination and for verification of the status and quality, weight etc. of the meat. The information is furthermore useful for the workers processing the meat at the stations or useful for the control and management of the meat processing plant.

Owner:MAREL HF

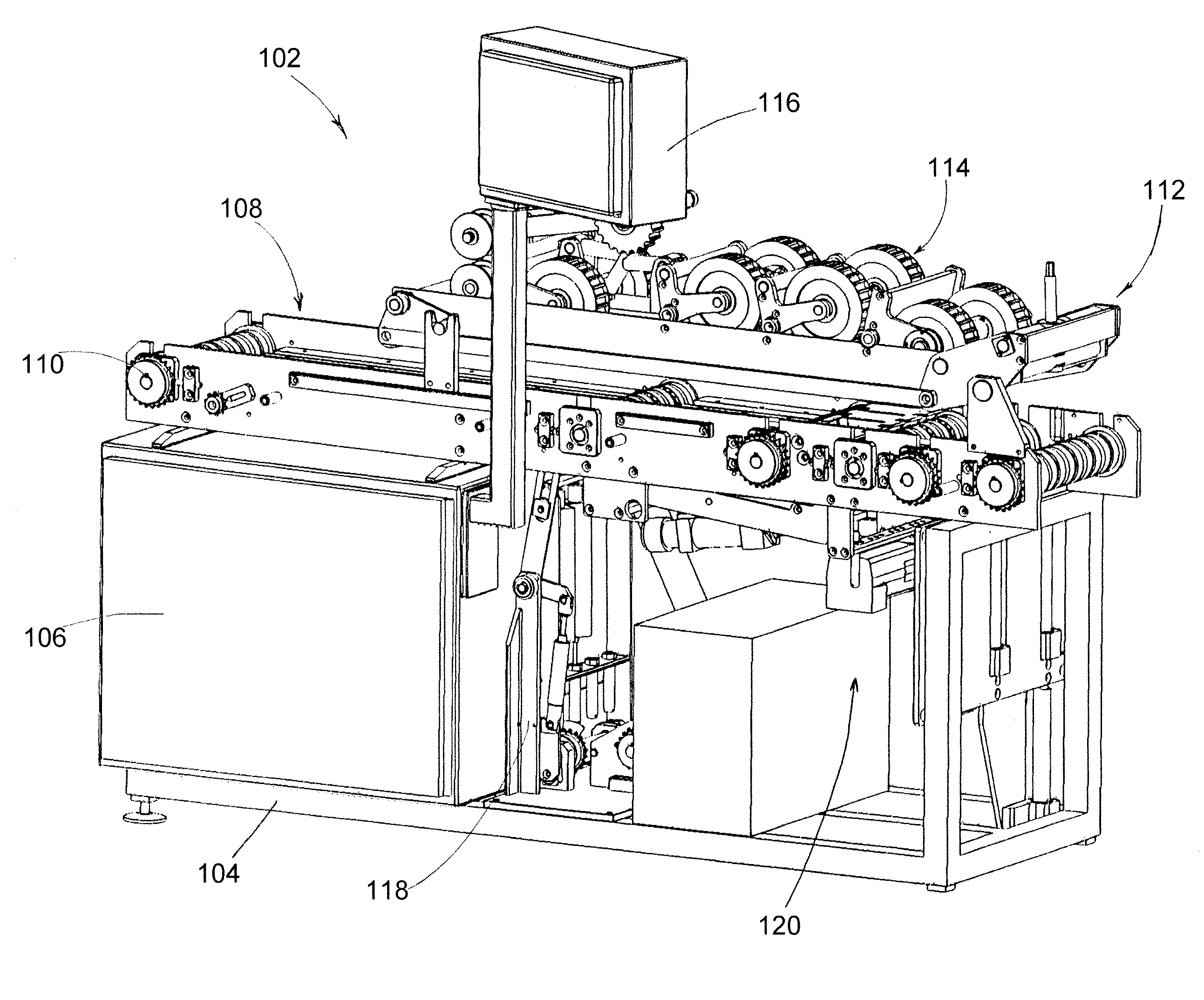

Food Article Feed Apparatus for a Food Article Slicing Machine

ActiveUS20090120256A1Easy to controlHigh yieldMeat packaging/handling/transportingEngineering safety devicesConveyor beltIngested food

A food article feed apparatus for a food article slicing machine. The apparatus has conveyor with a drive belt for connecting a drive source to a drive roller, and a conveyor belt. The drive roller is for driving the conveyor. The drive roller has an outer diameter and a recessed diameter where the drive belt is connected around the recessed diameter and the conveyor belt is connected around the outer diameter. The drive belt operates within an area defined by the first conveyor belt.

Owner:PROVISUR TECHNOLOGIES INC

Method of treating objects according to their individual weights

InactiveUS20110166696A1Maximize probabilityProgramme-controlled manipulatorConveyorsAlgorithmDistributed object

A method of distributing objects, having a random distribution of weights, according to their weights. In the method, the presence of one of the objects is detected, the detected object is grasped by a robot, and the object grasped is weighed by a sensor. The weight measured is associated with the object and stored. The process is repeated for the objects. The weight distribution obtained from the weights measured is used in filling containers with objects so that containers are optimally filled.

Owner:ARBOR

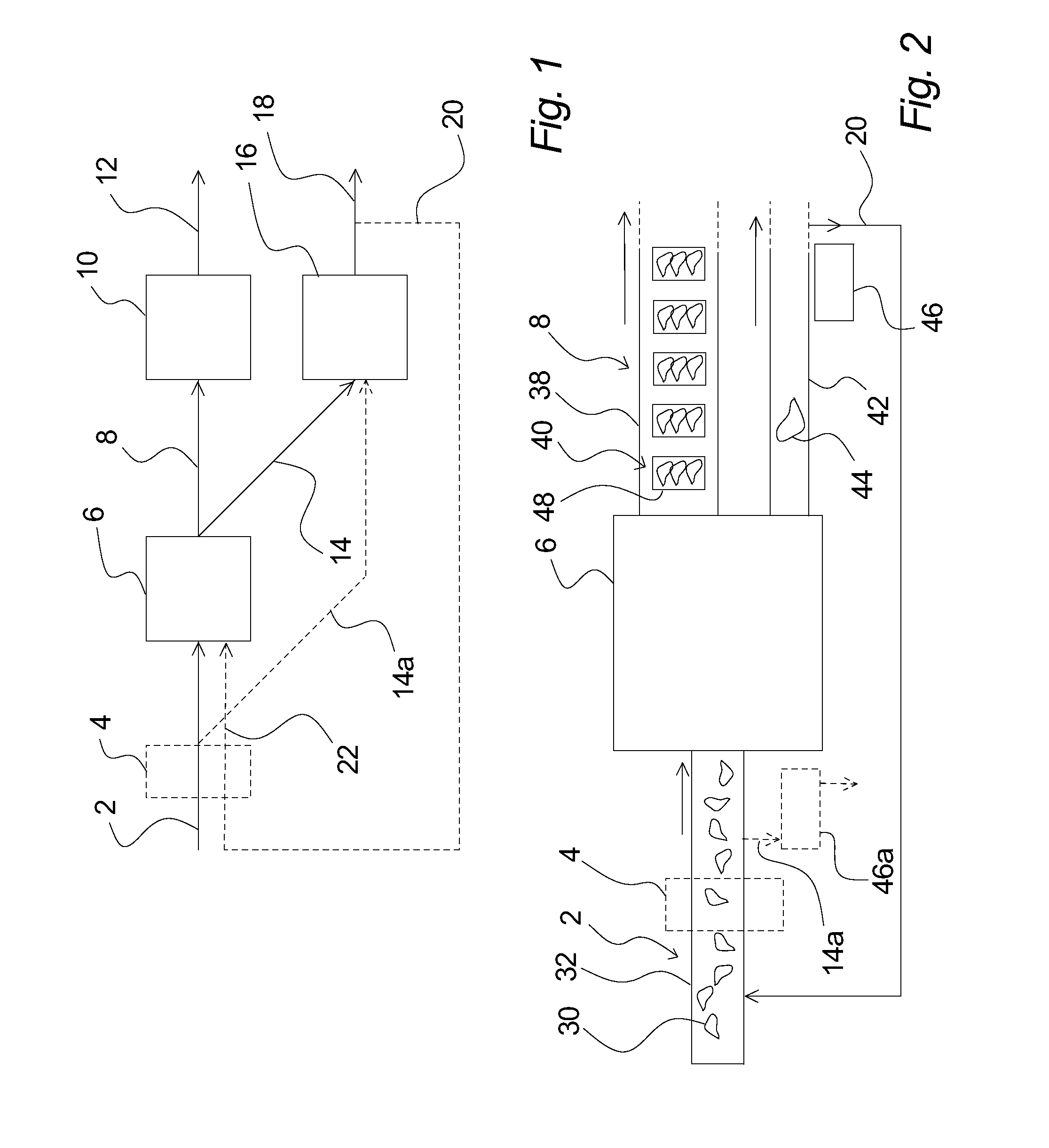

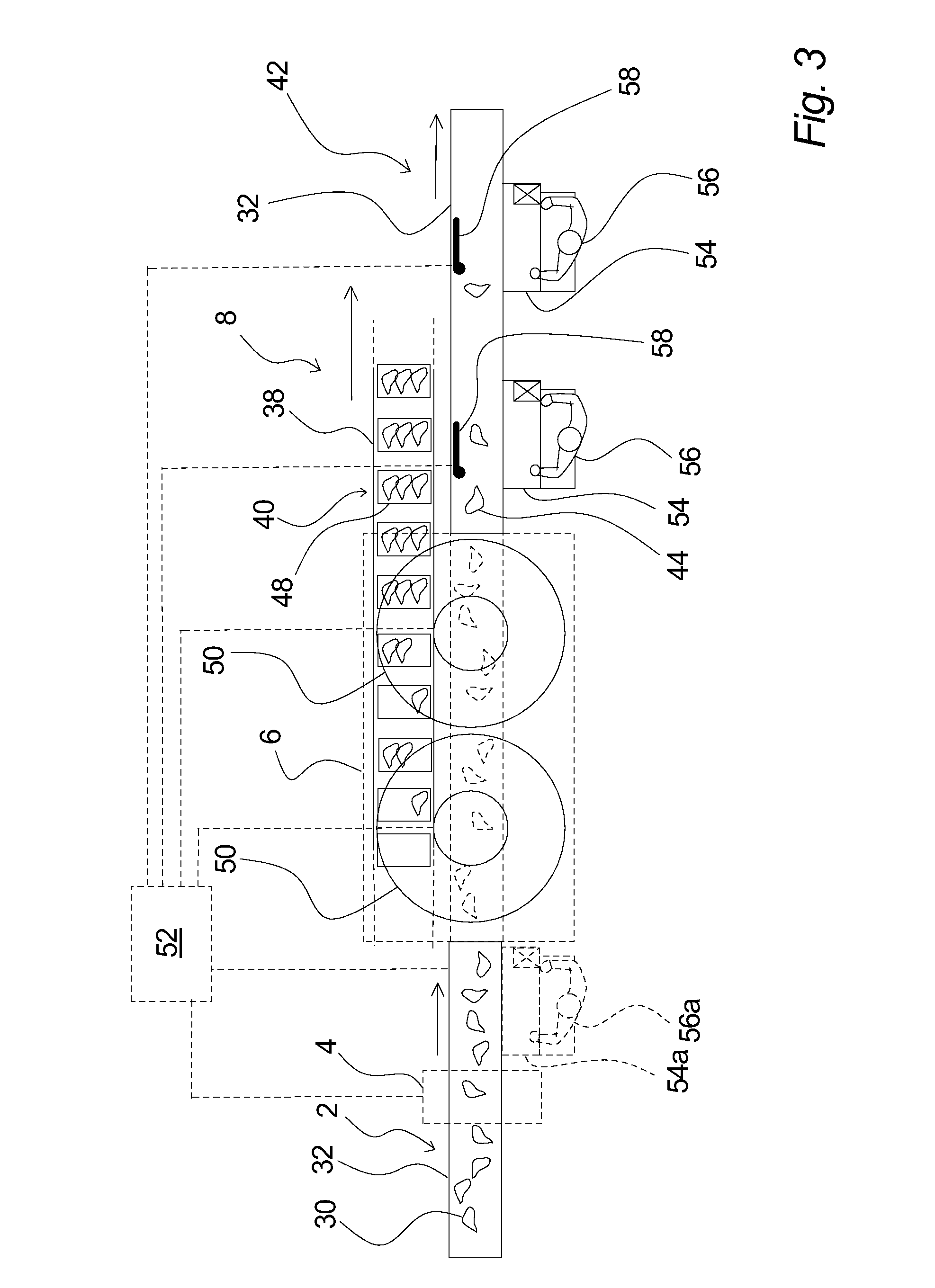

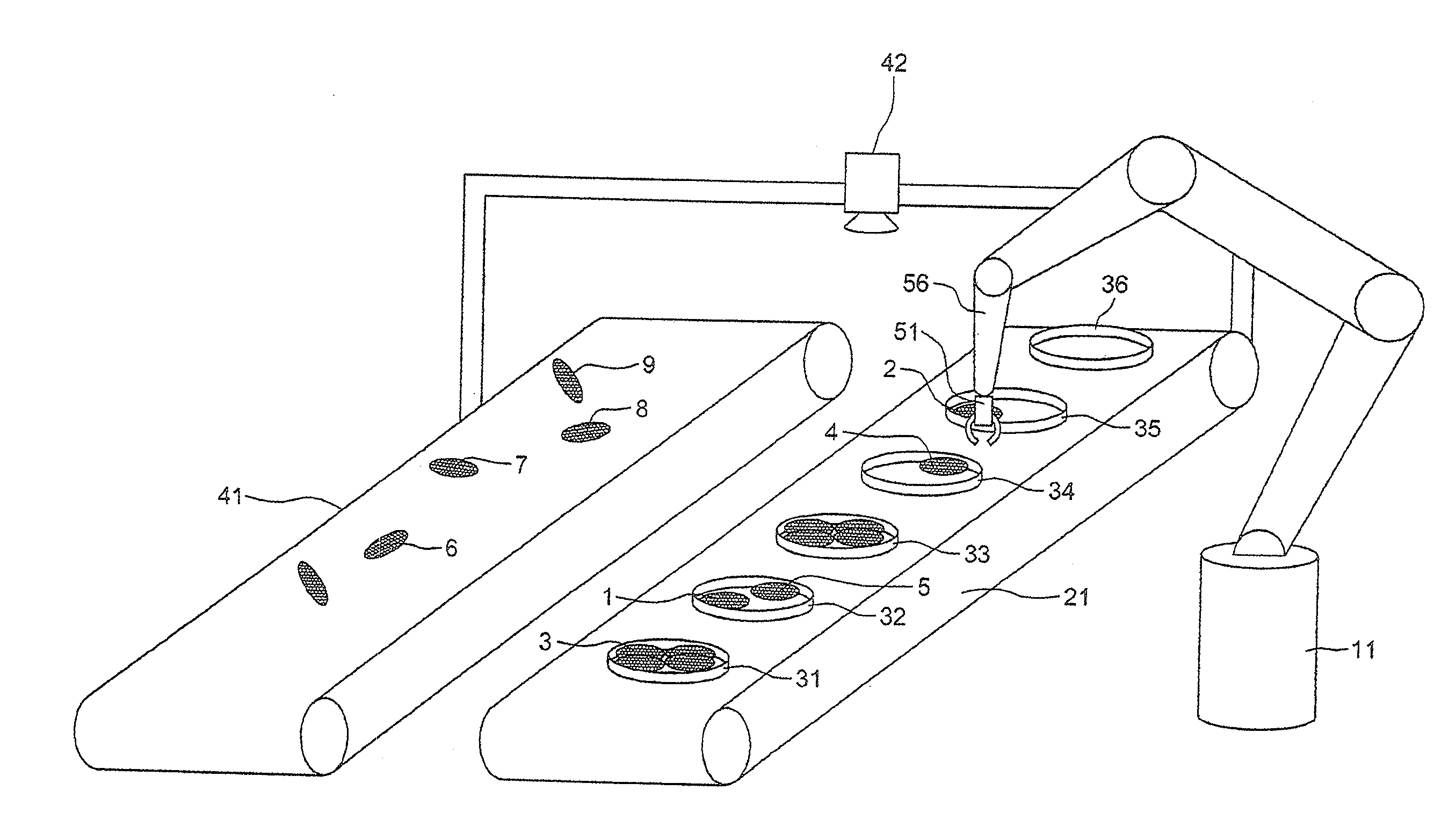

Method and a System for Tracking Food Items

ActiveUS20070293980A1Reduce riskCertainty of the origination of items in a food product is highly improvedFish sortingComputer controlComputer scienceIngested food

The invention relates to an apparatus for processing food wherein food items are conveyed through processing stations where they are cut into pieces and optionally mixed with items originating differently. In particular, the invention relates to a system wherein information related to each food item and the positions of the food items throughout the processing are traced so that the origination of a food item is preserved.

Owner:MAREL HF

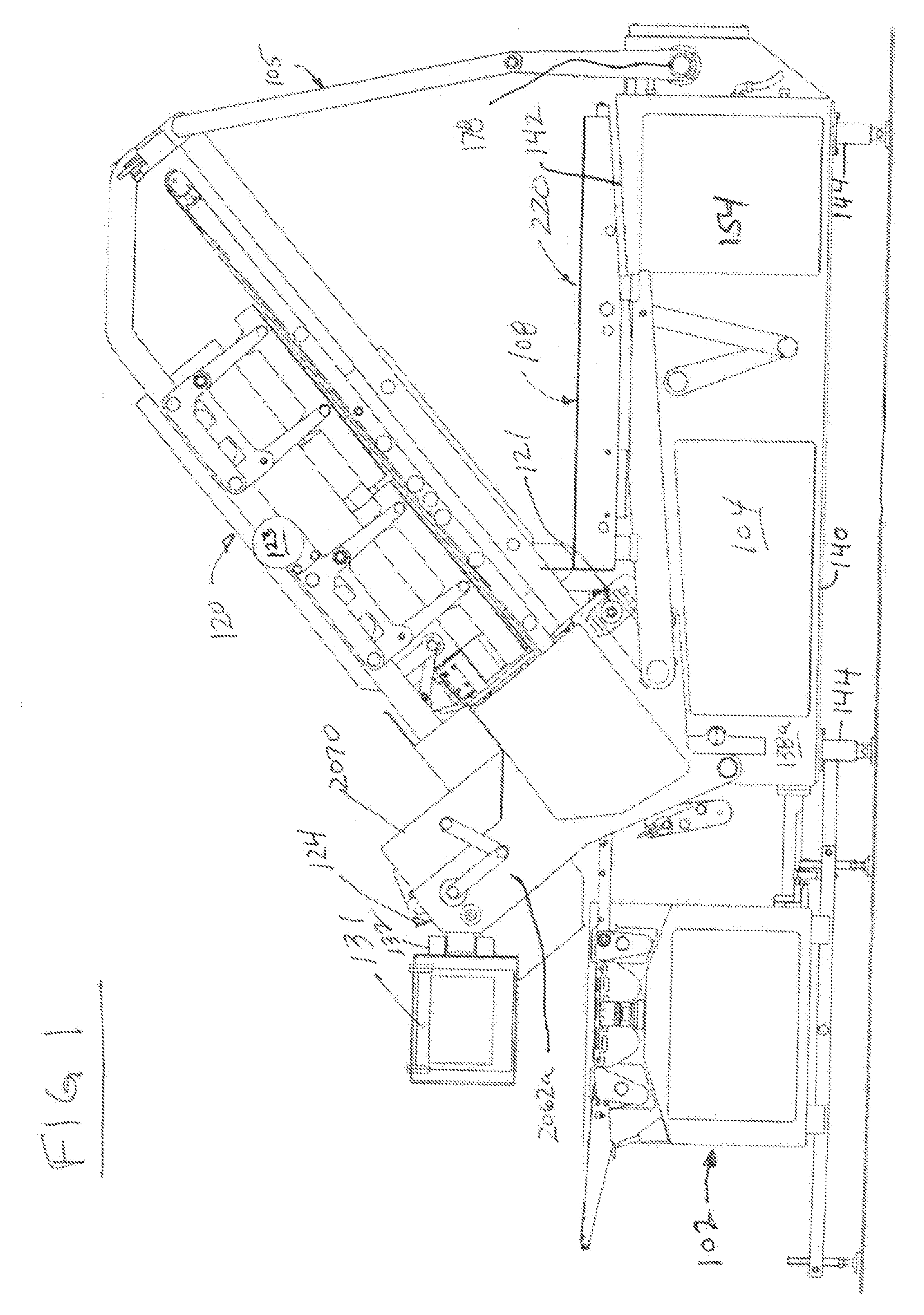

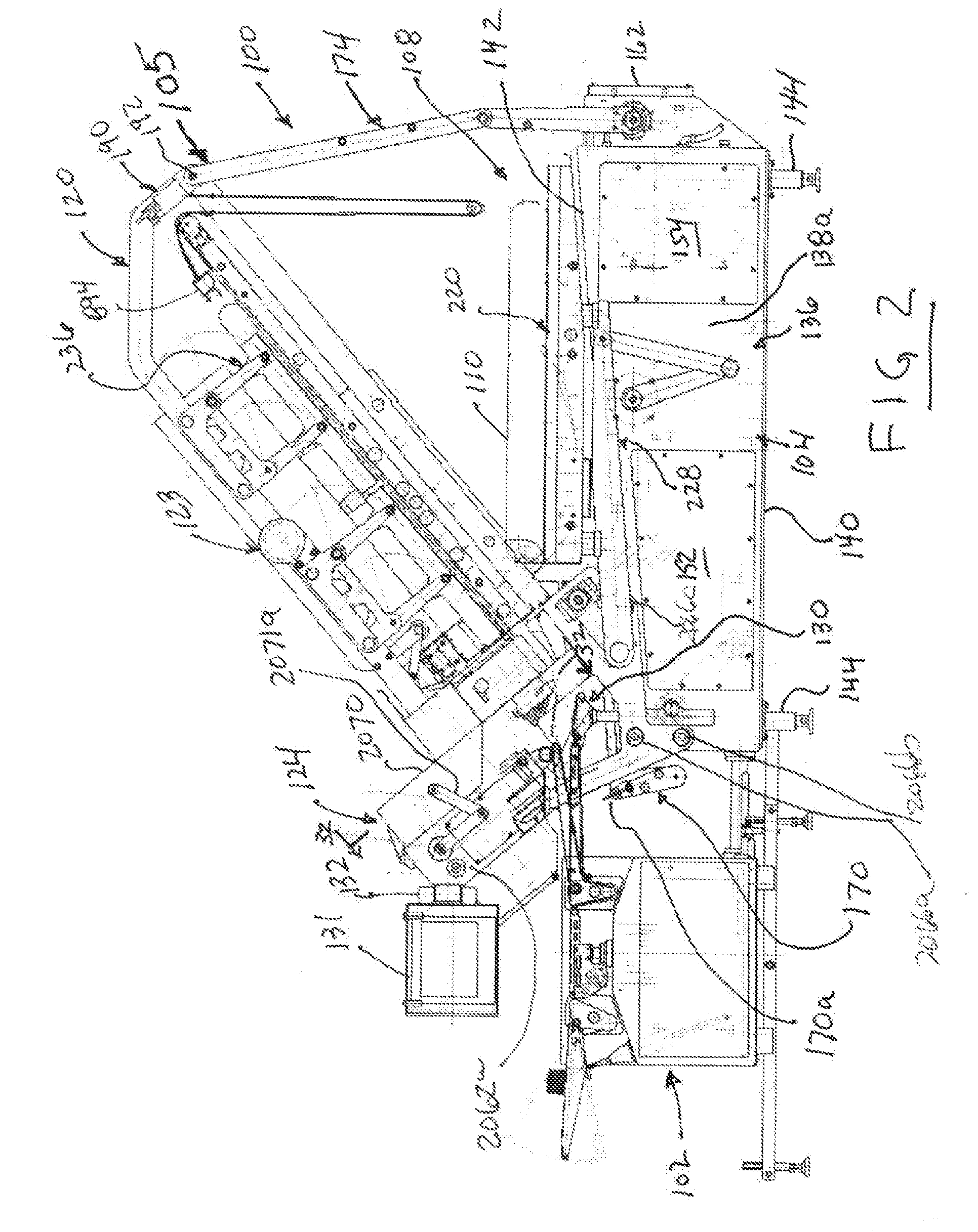

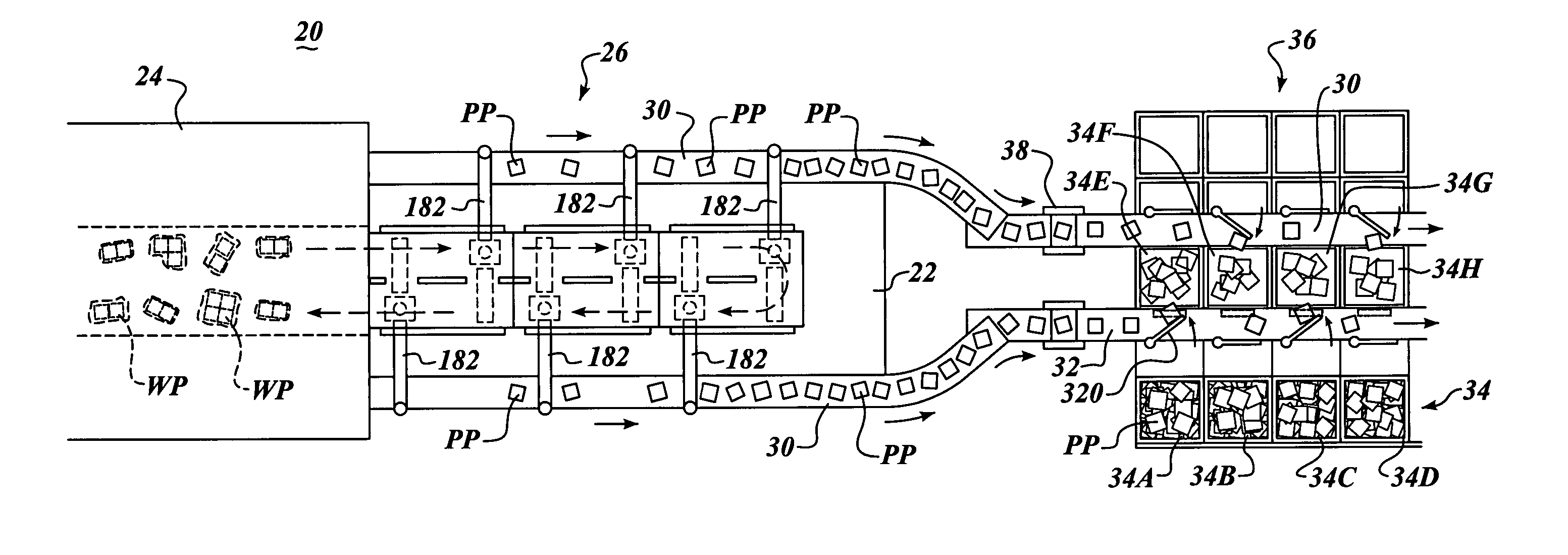

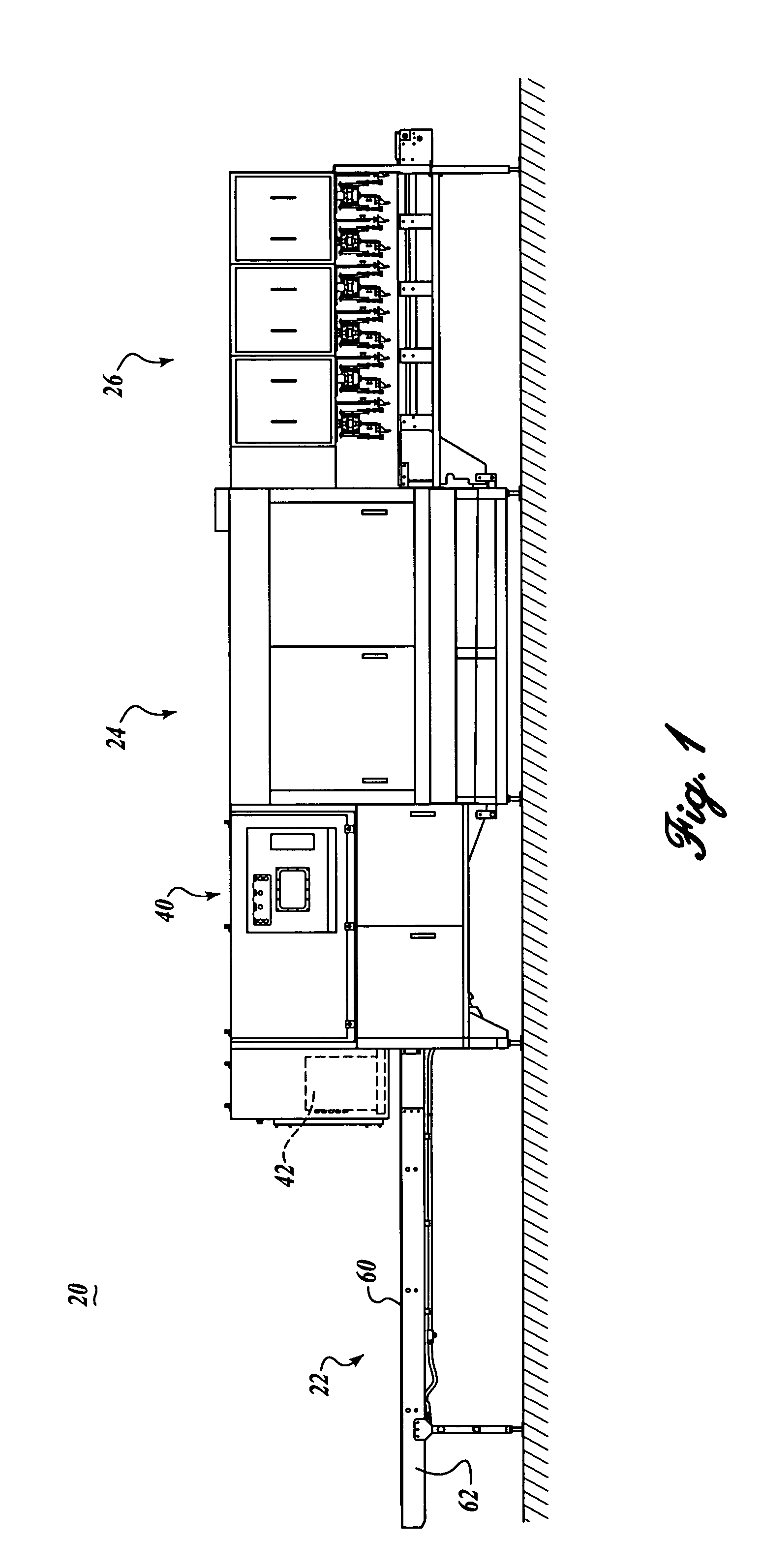

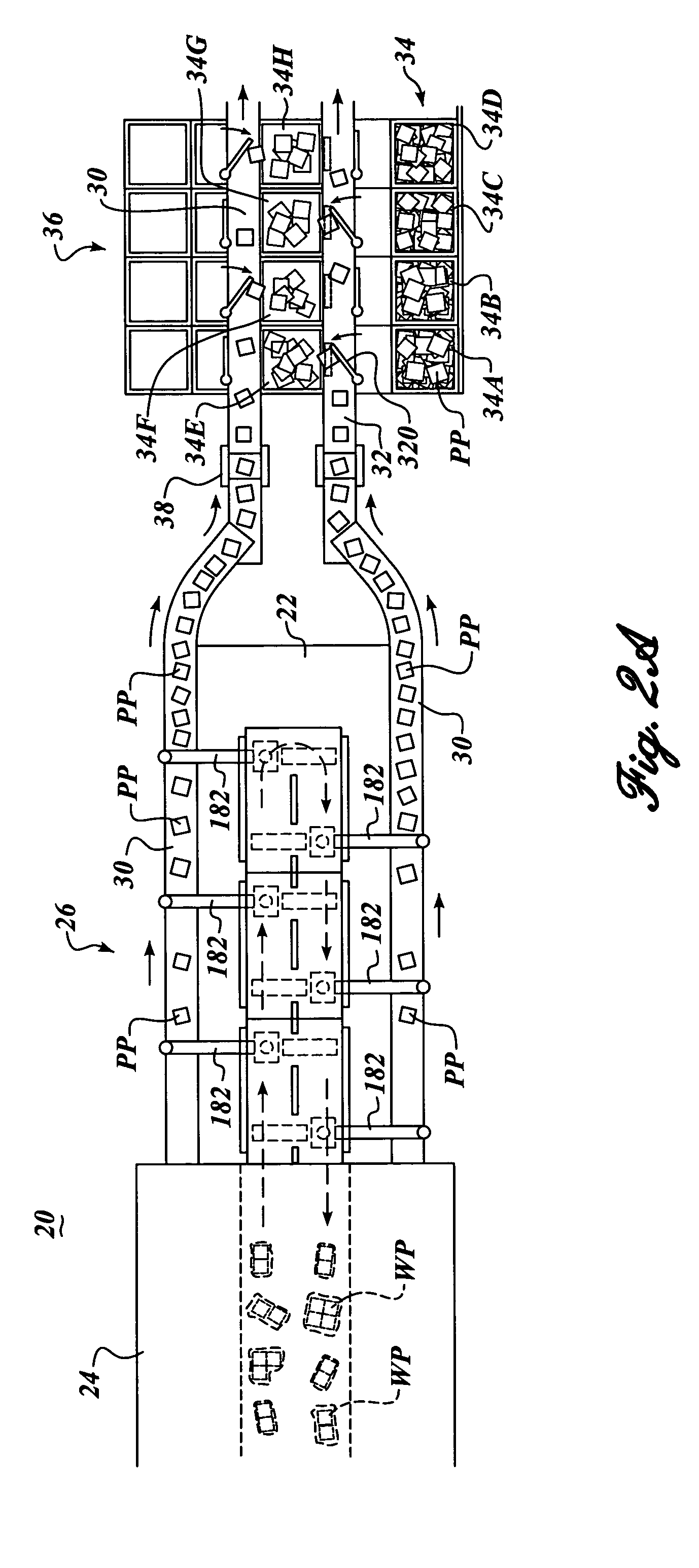

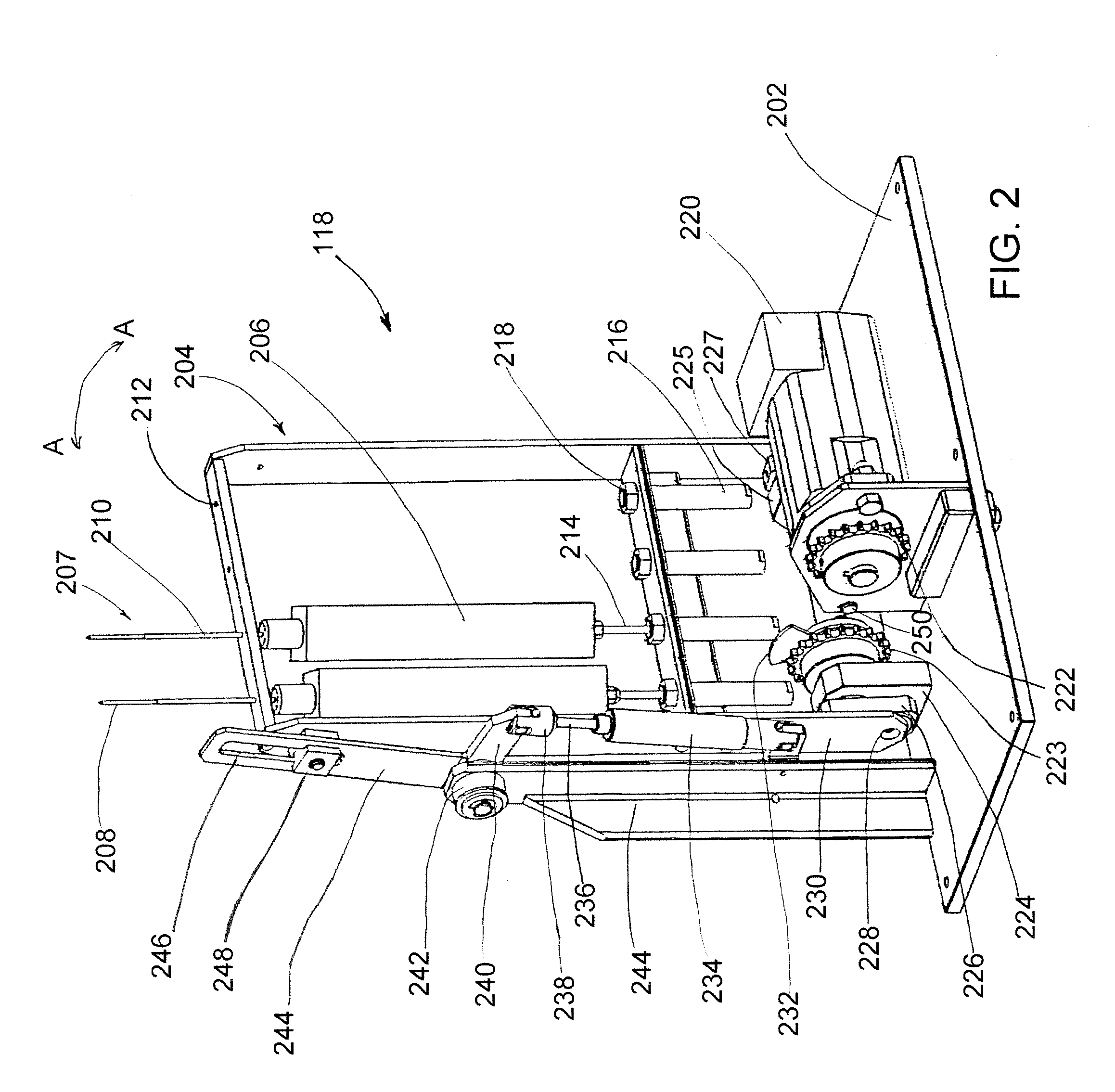

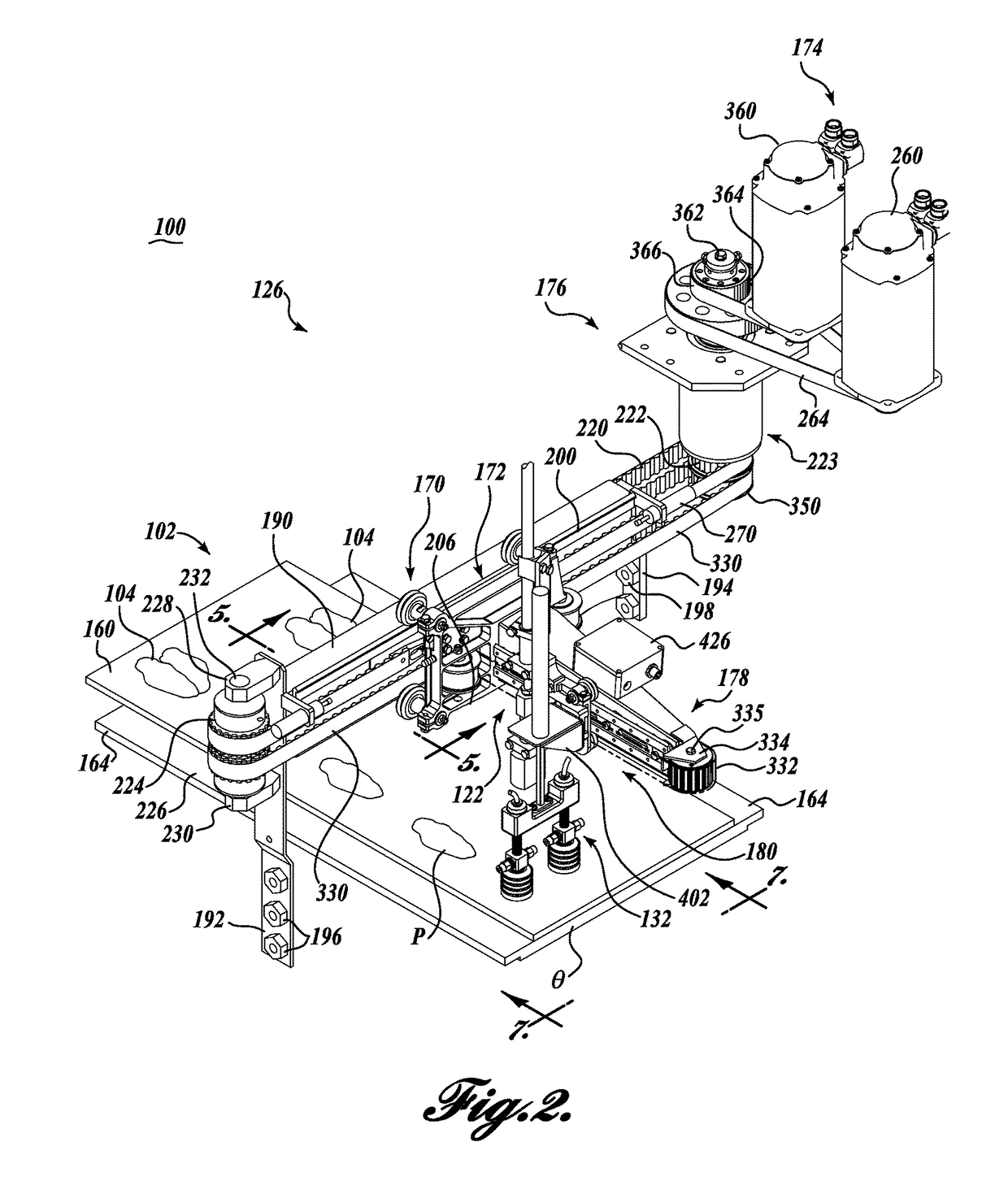

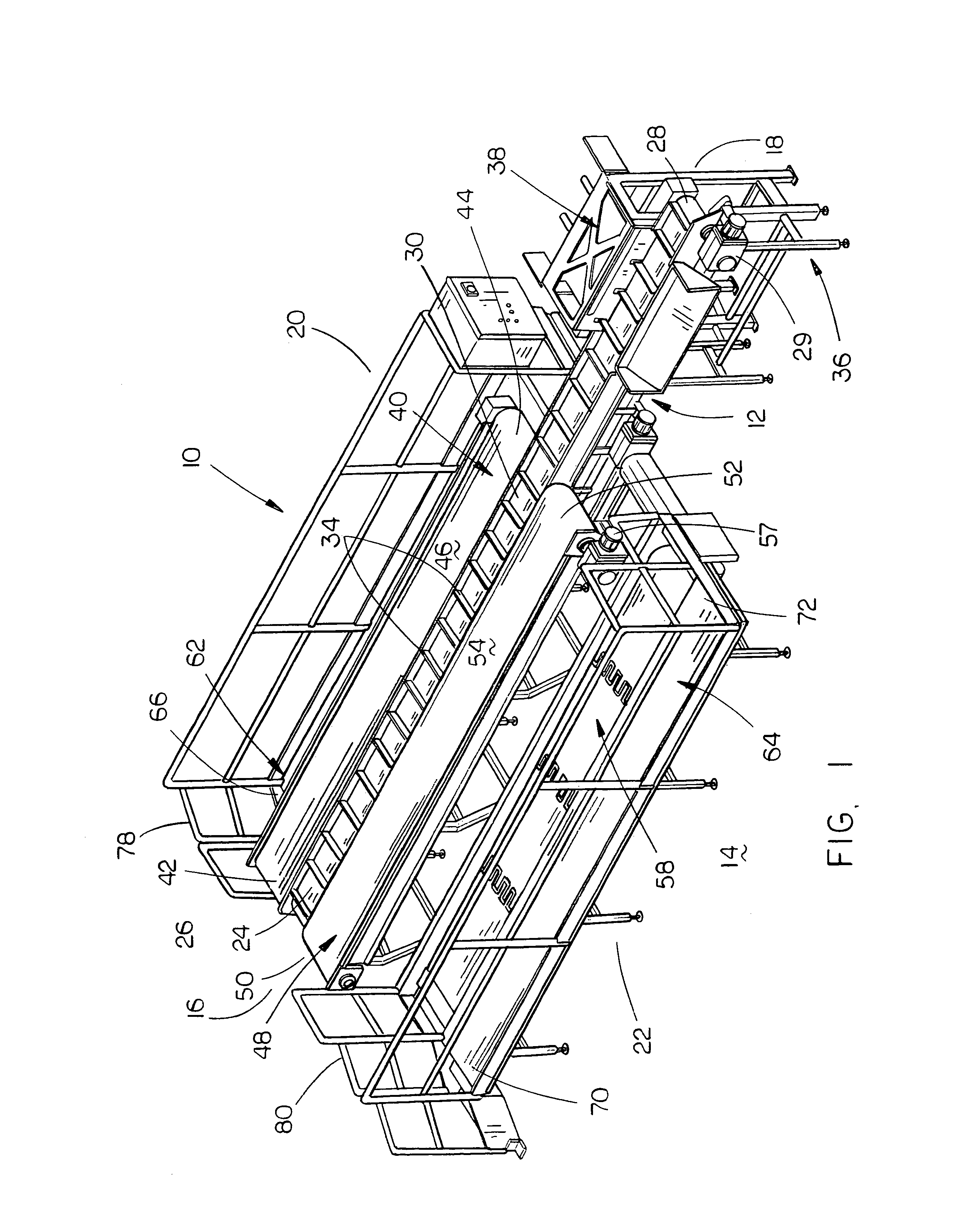

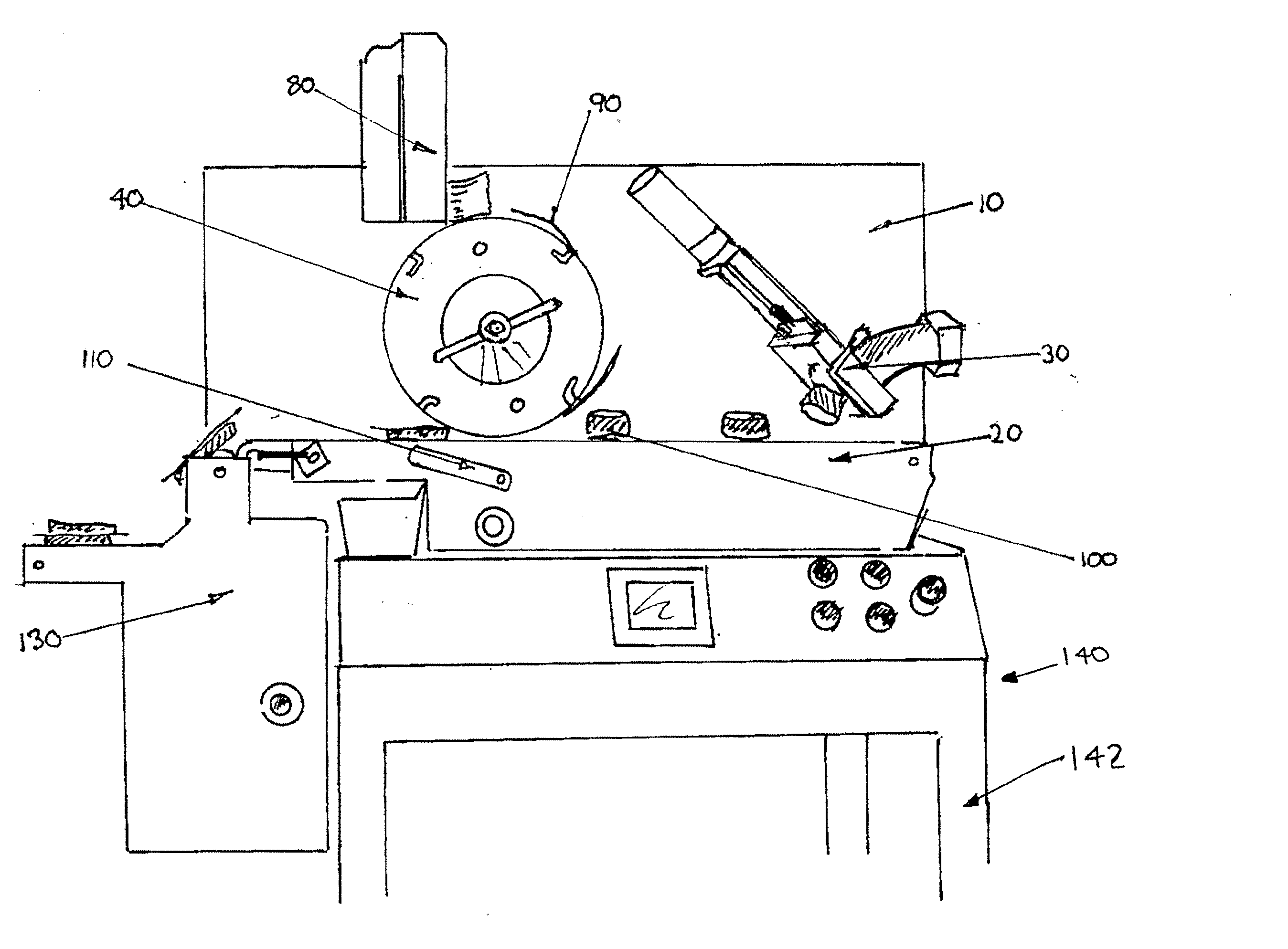

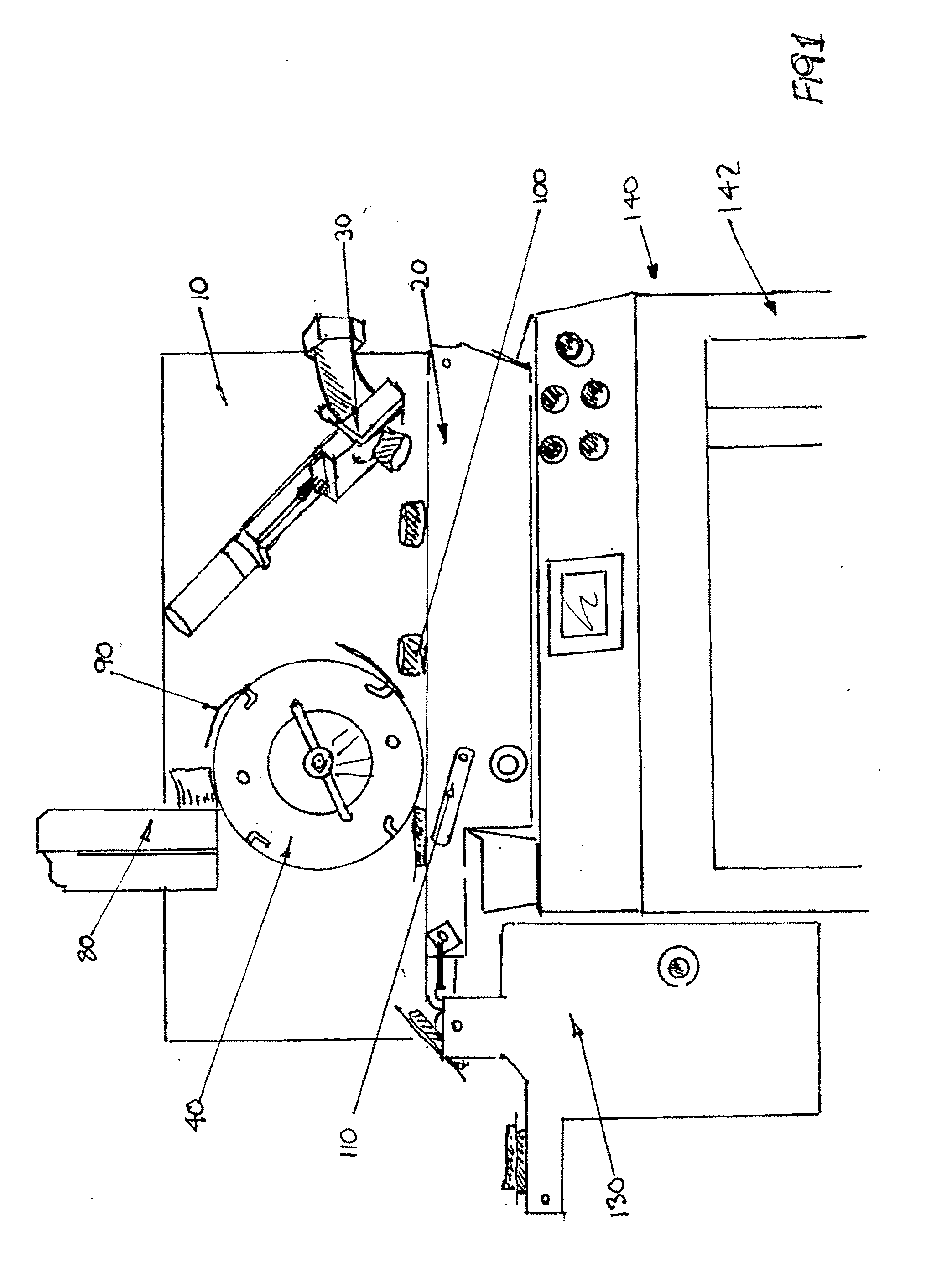

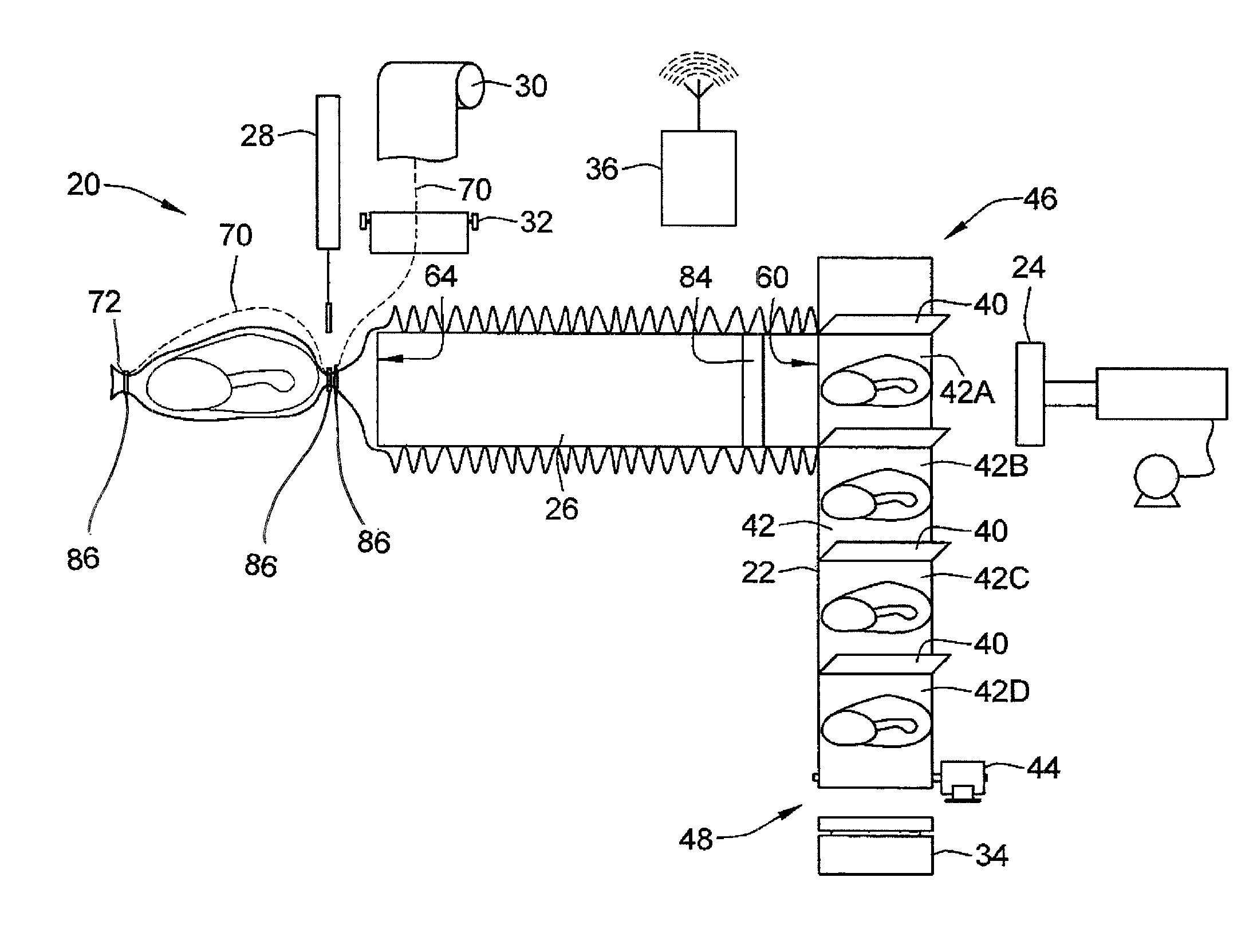

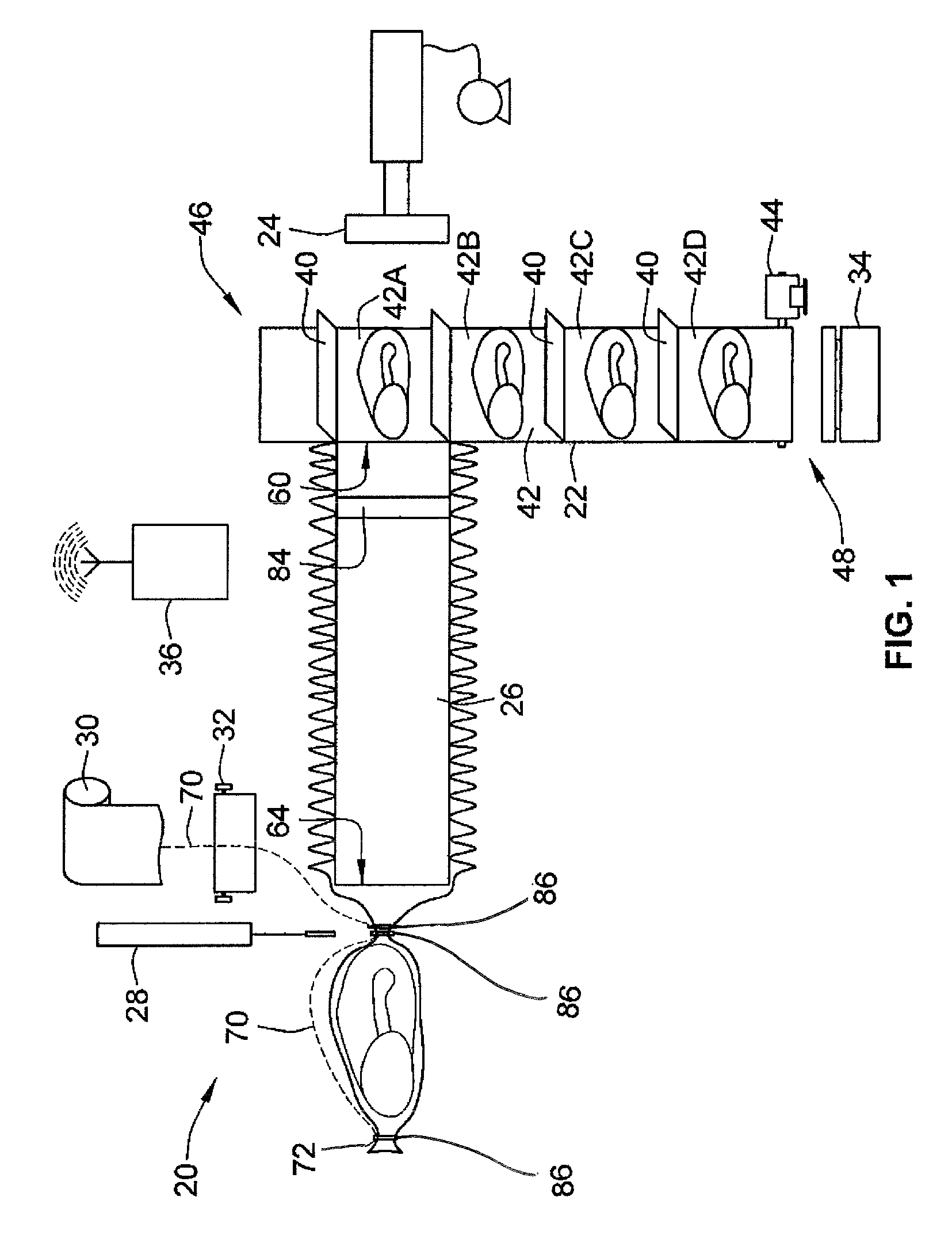

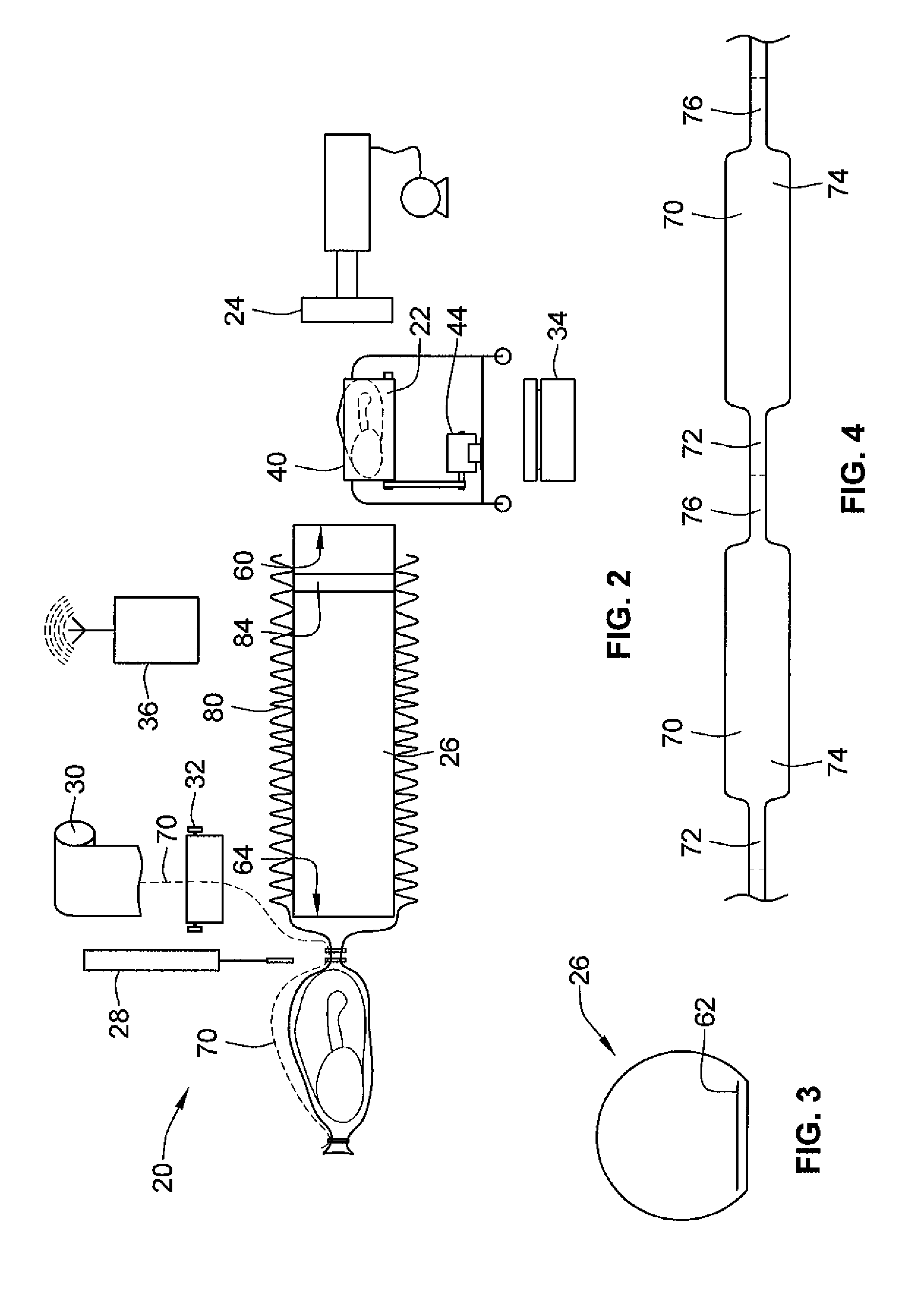

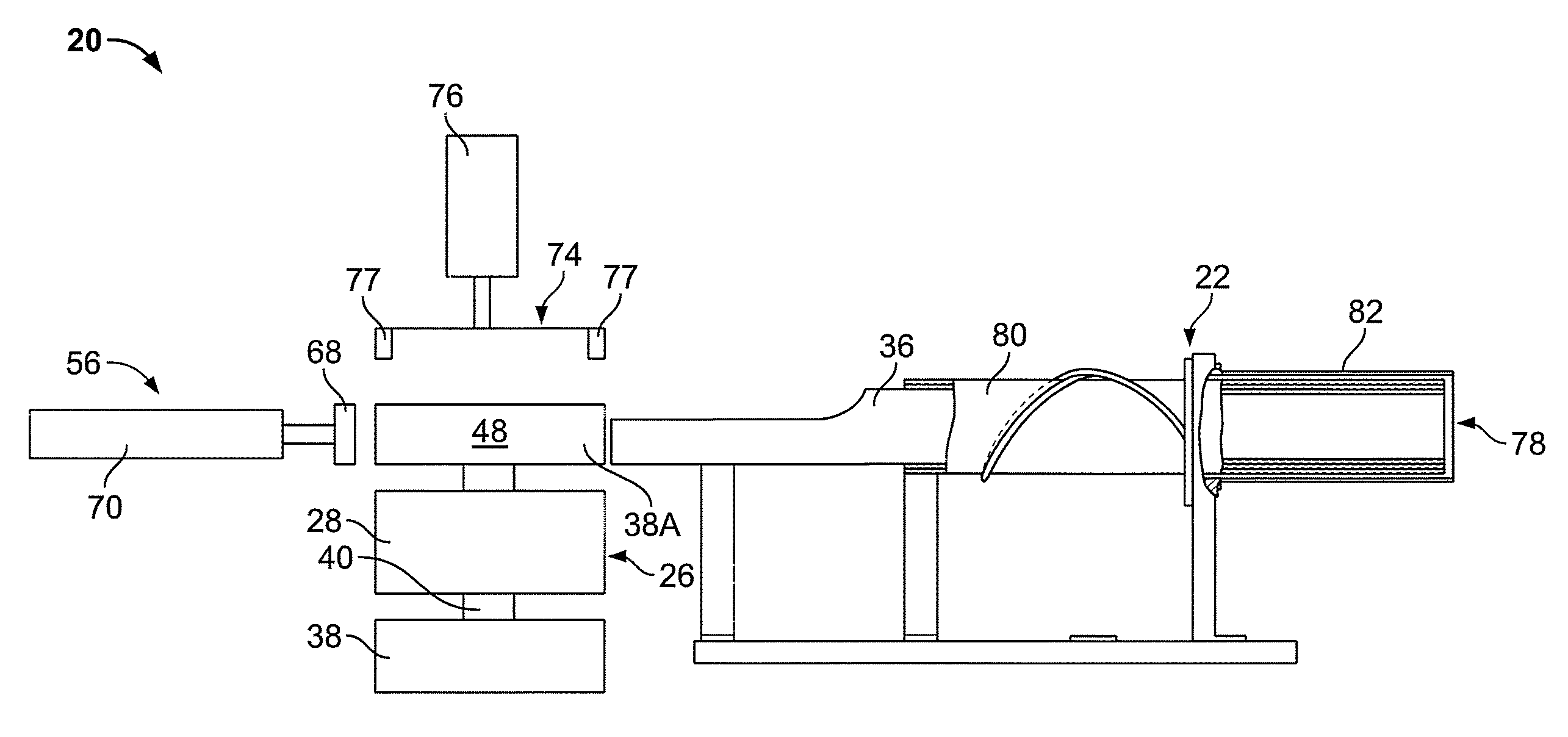

Apparatus and method for portioning and automatically off-loading portioned workpieces

InactiveUS6983678B2Reduce pressureMeat packaging/handling/transportingMetal working apparatusControl systemEngineering

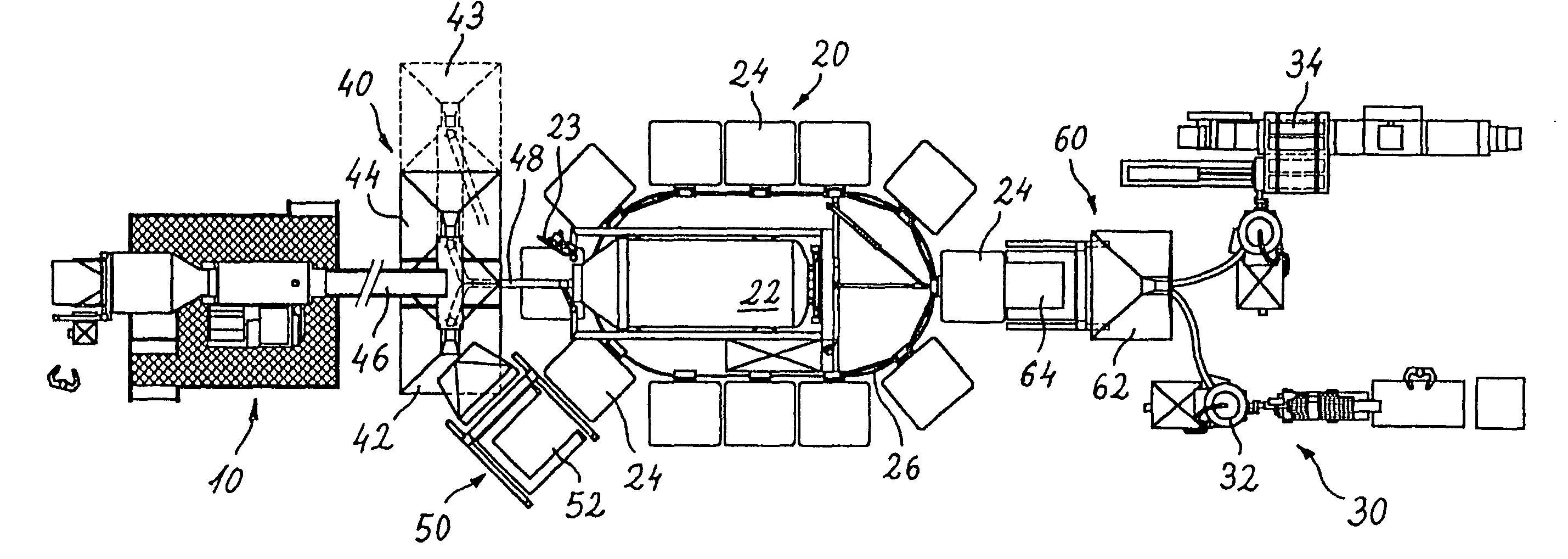

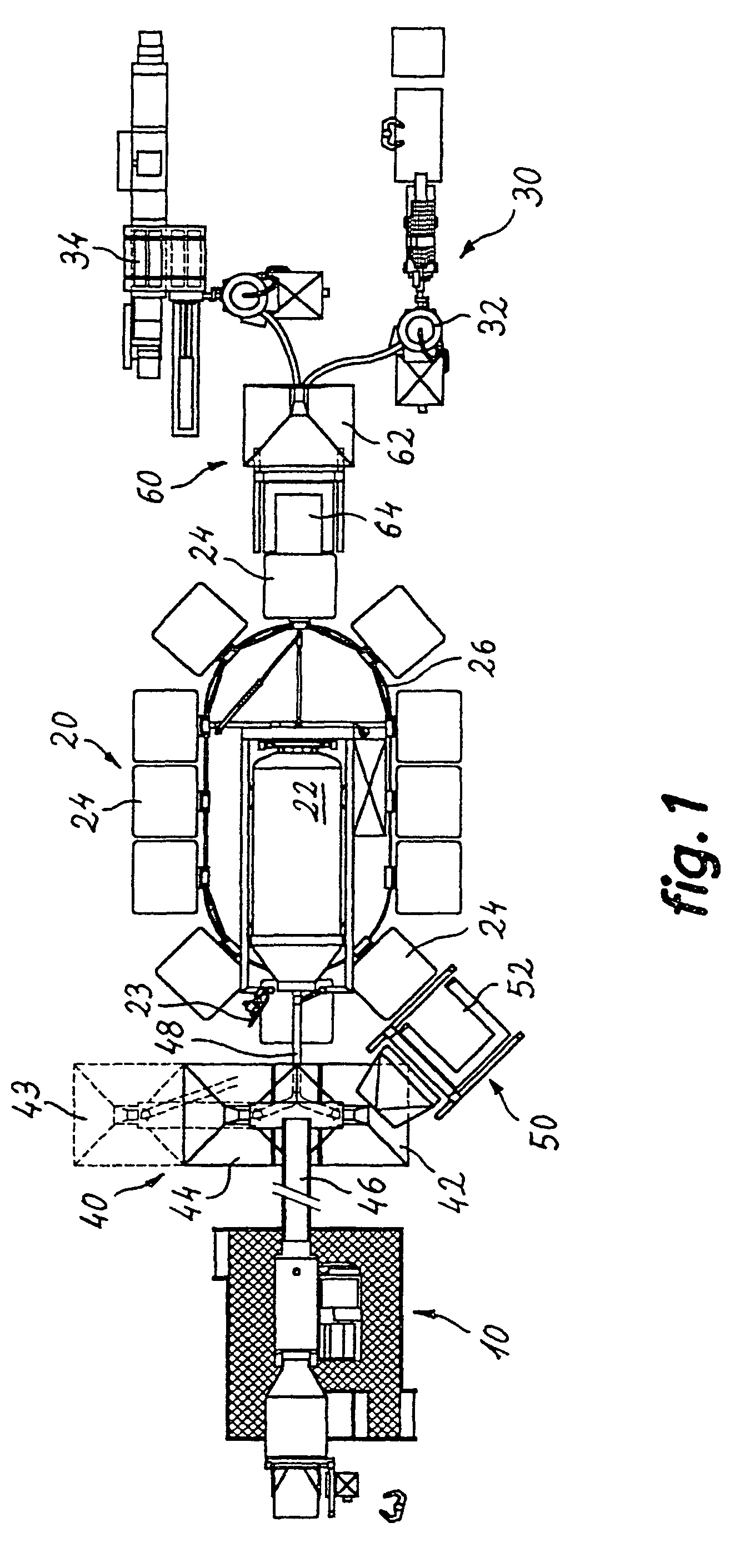

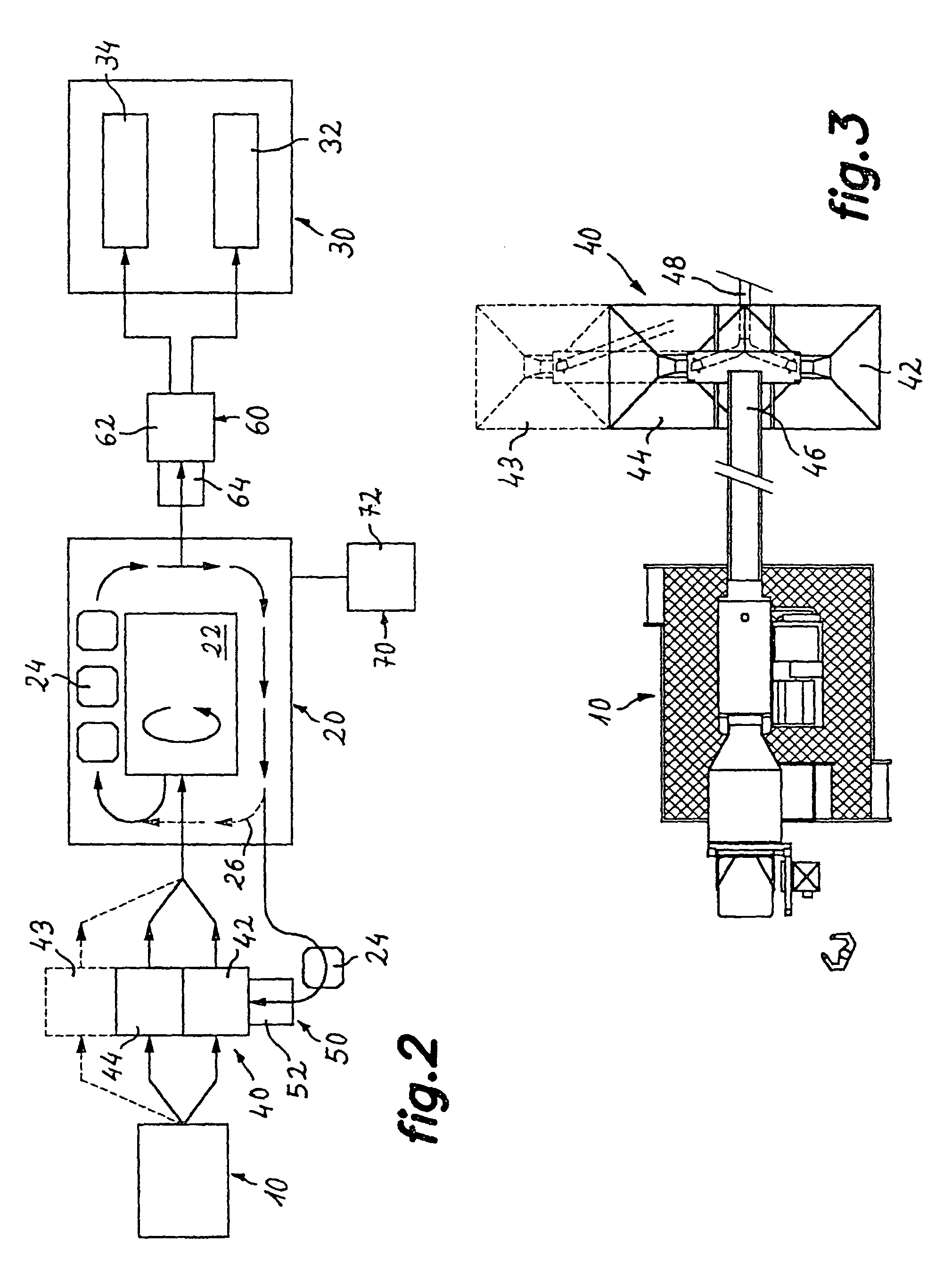

A conveyor (22) moves workpieces (WP) past a scanning station (40) to ascertain one or more physical parameters of the workpiece (WP) and to a portioning station (24) wherein the workpiece (WP) is portioned into desired smaller portions. Thereafter, the conveyor (22) carries a portioned workpiece (WP) to an unloading station (26) where one or more pickup devices (28) removes specific portioned workpieces (PP) from the conveyor and places the portioned workpieces onto take away conveyors (30) for other locations remote from the first conveyor. A control system, composed in part of a computer (42), keeps track of the locations of the workpieces (WP) on the conveyor (22) and also optionally on the take away conveyor (30) so that portioned pieces (PP) are placed at specific desired locations remote from the conveyor (22) by the pickup devices (28).

Owner:JOHN BEAN TECH CORP

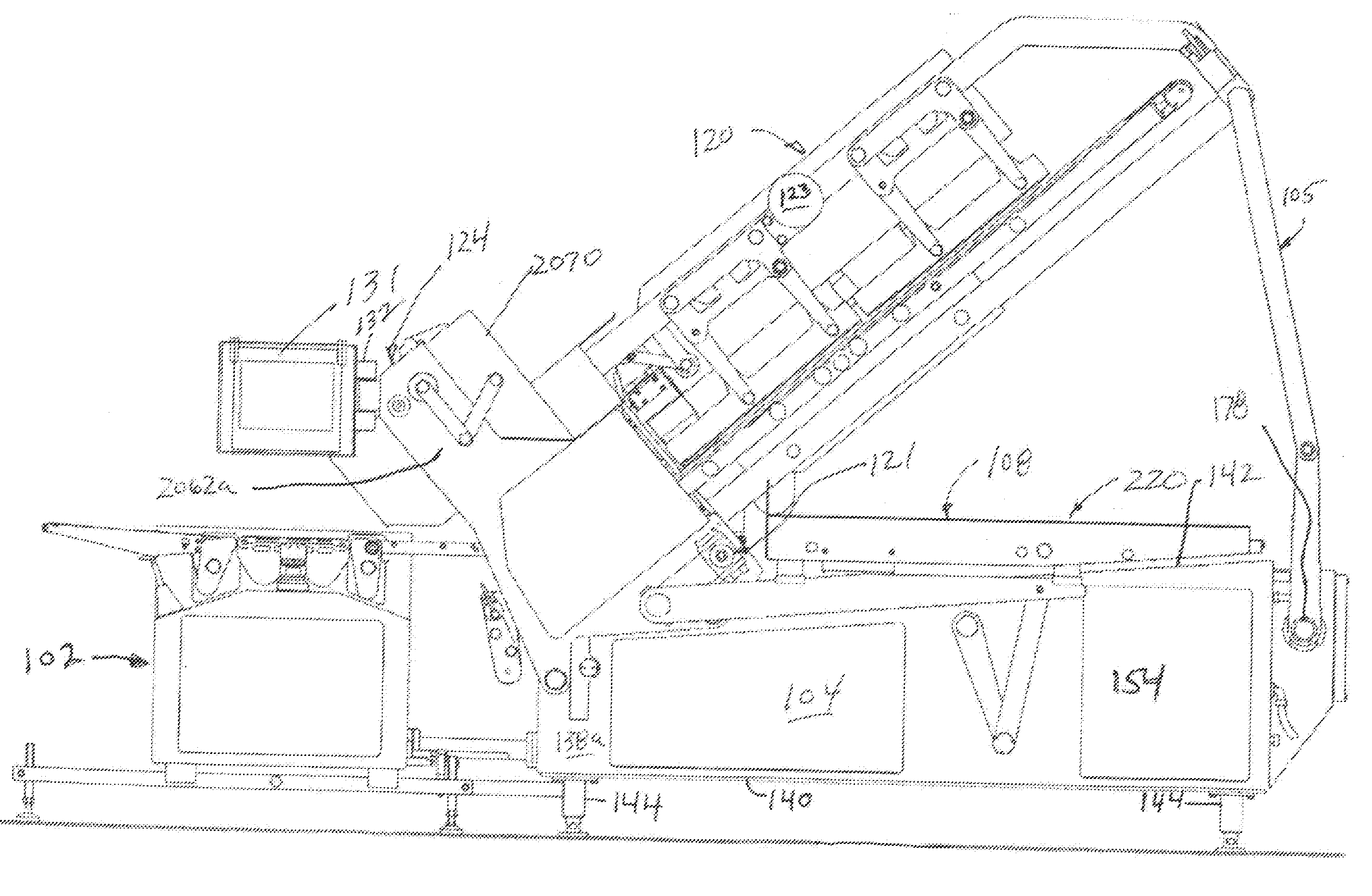

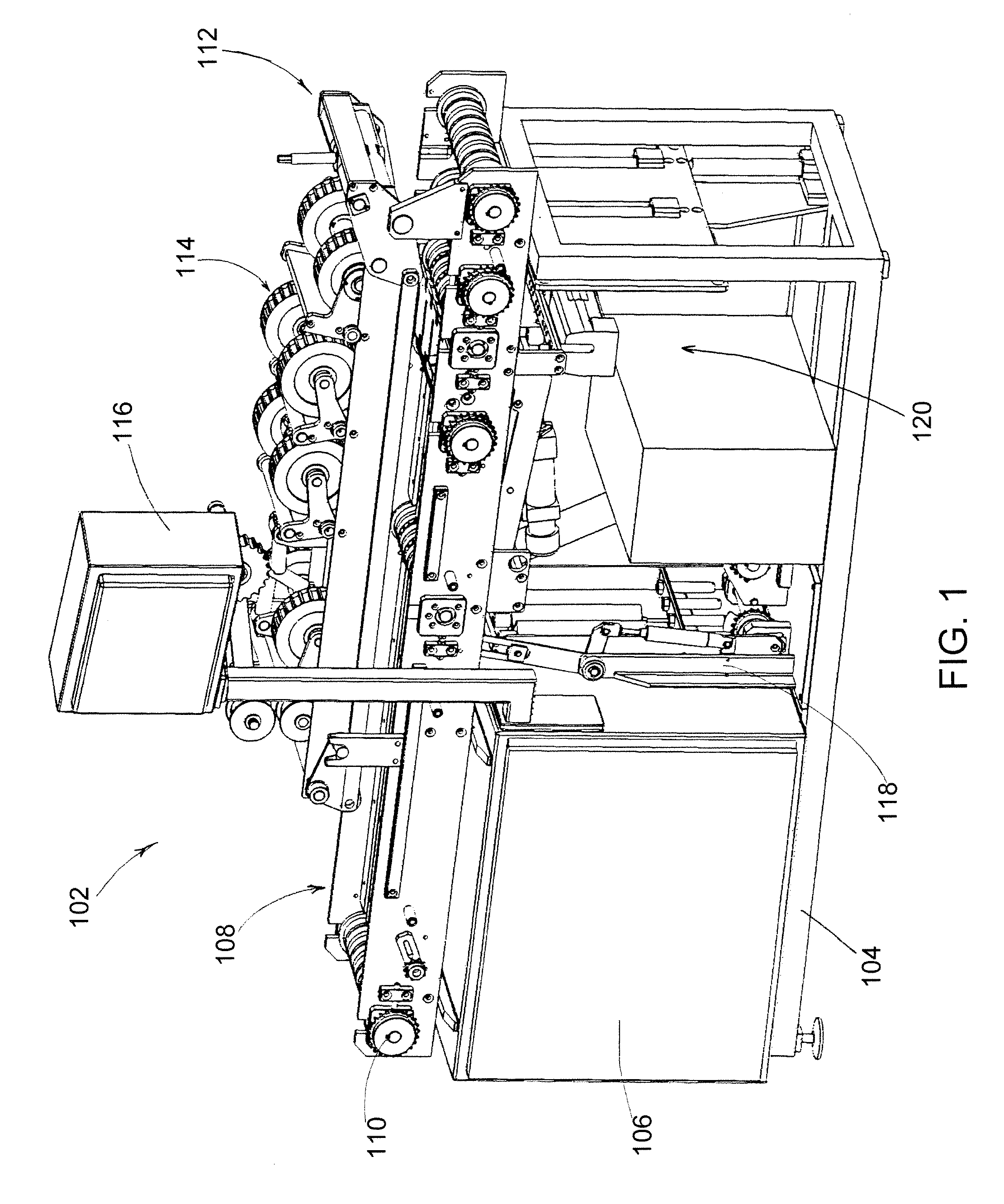

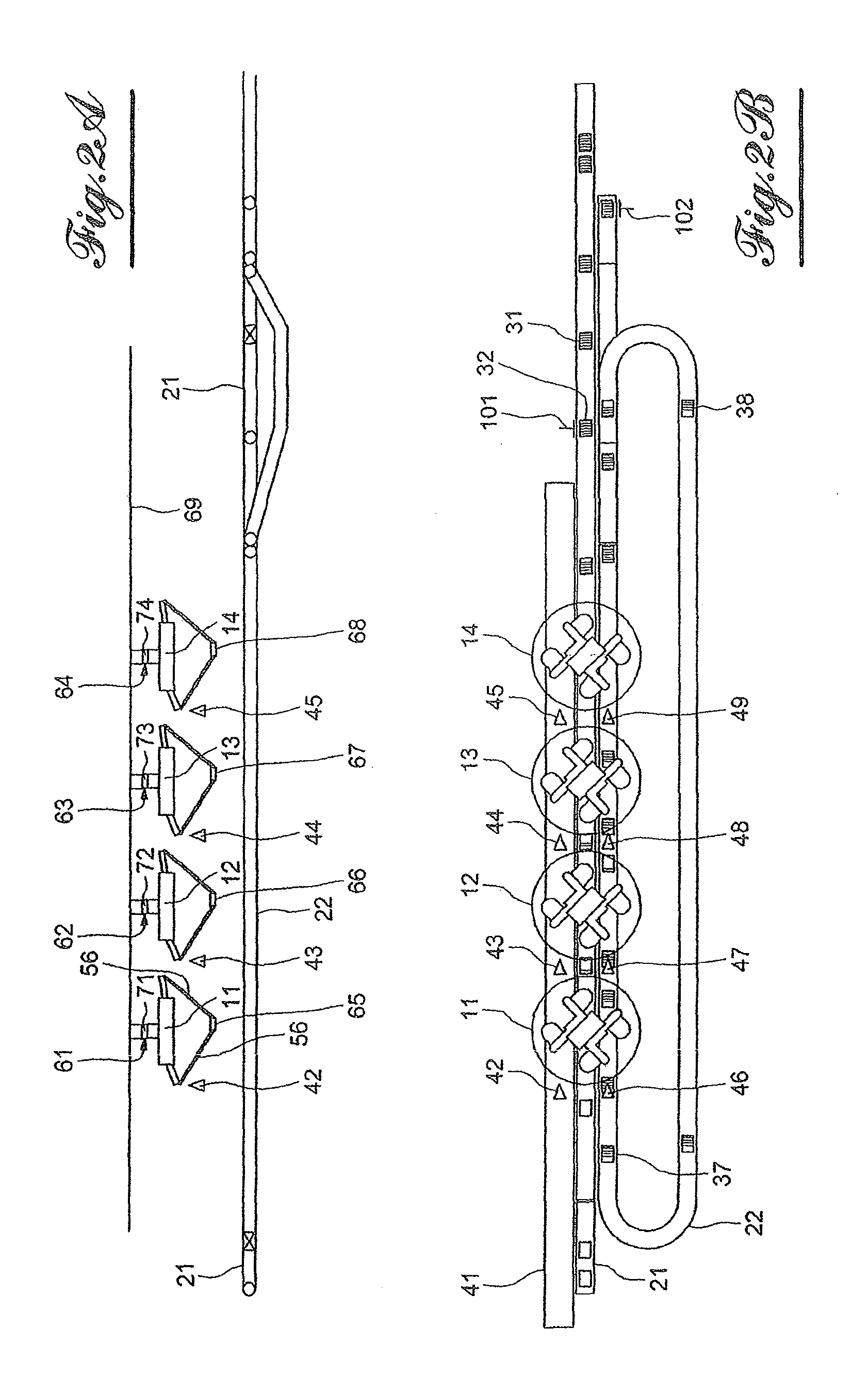

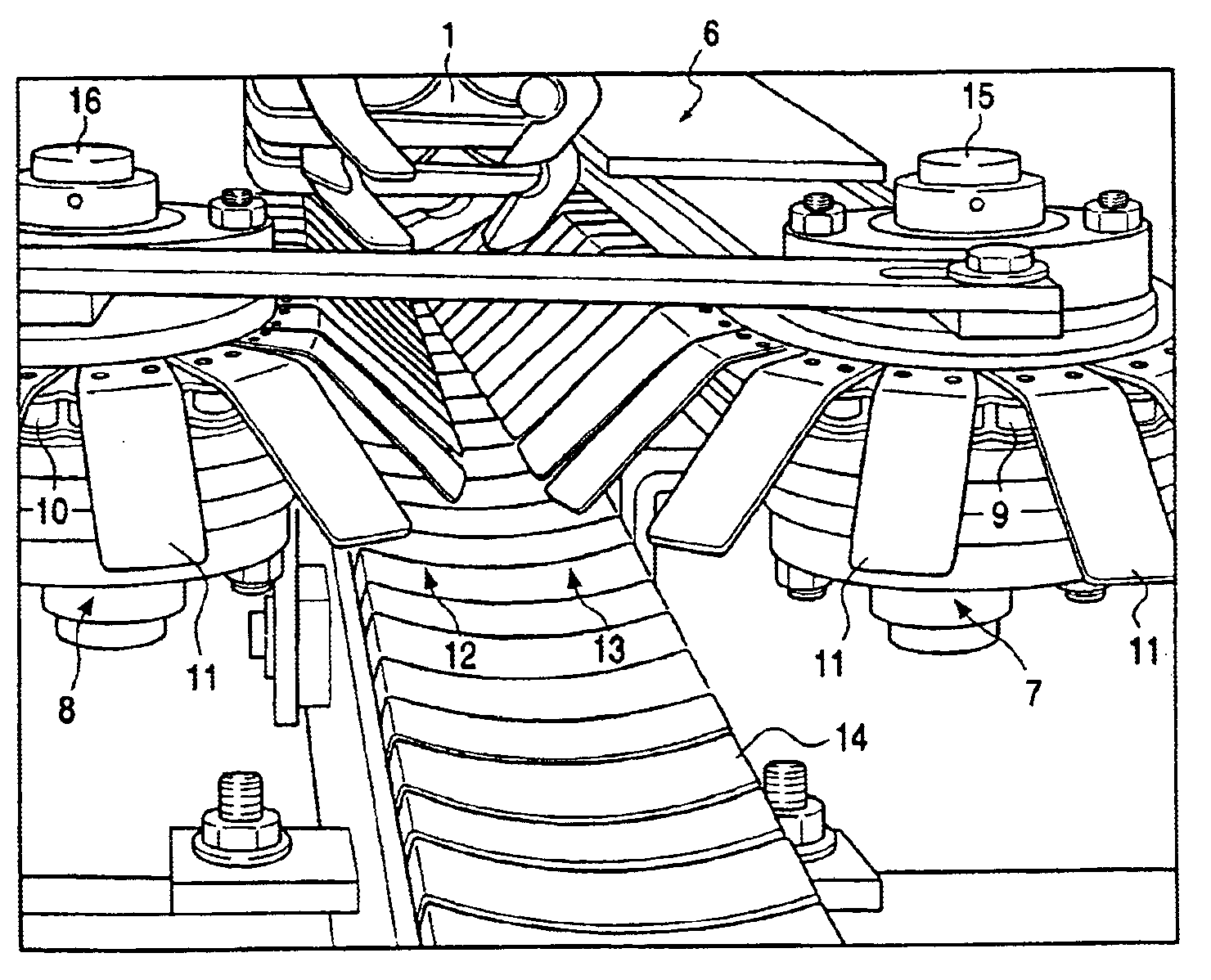

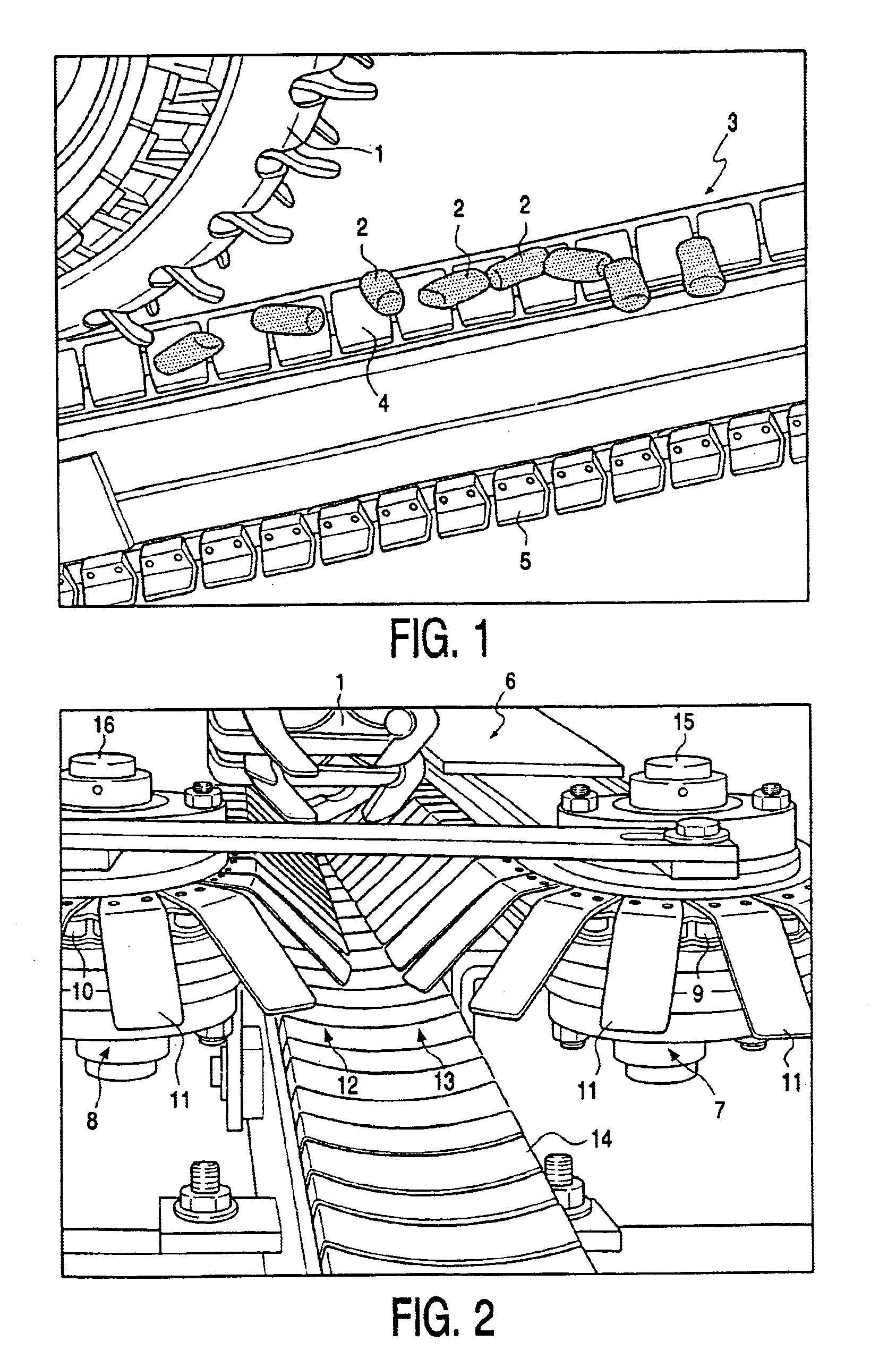

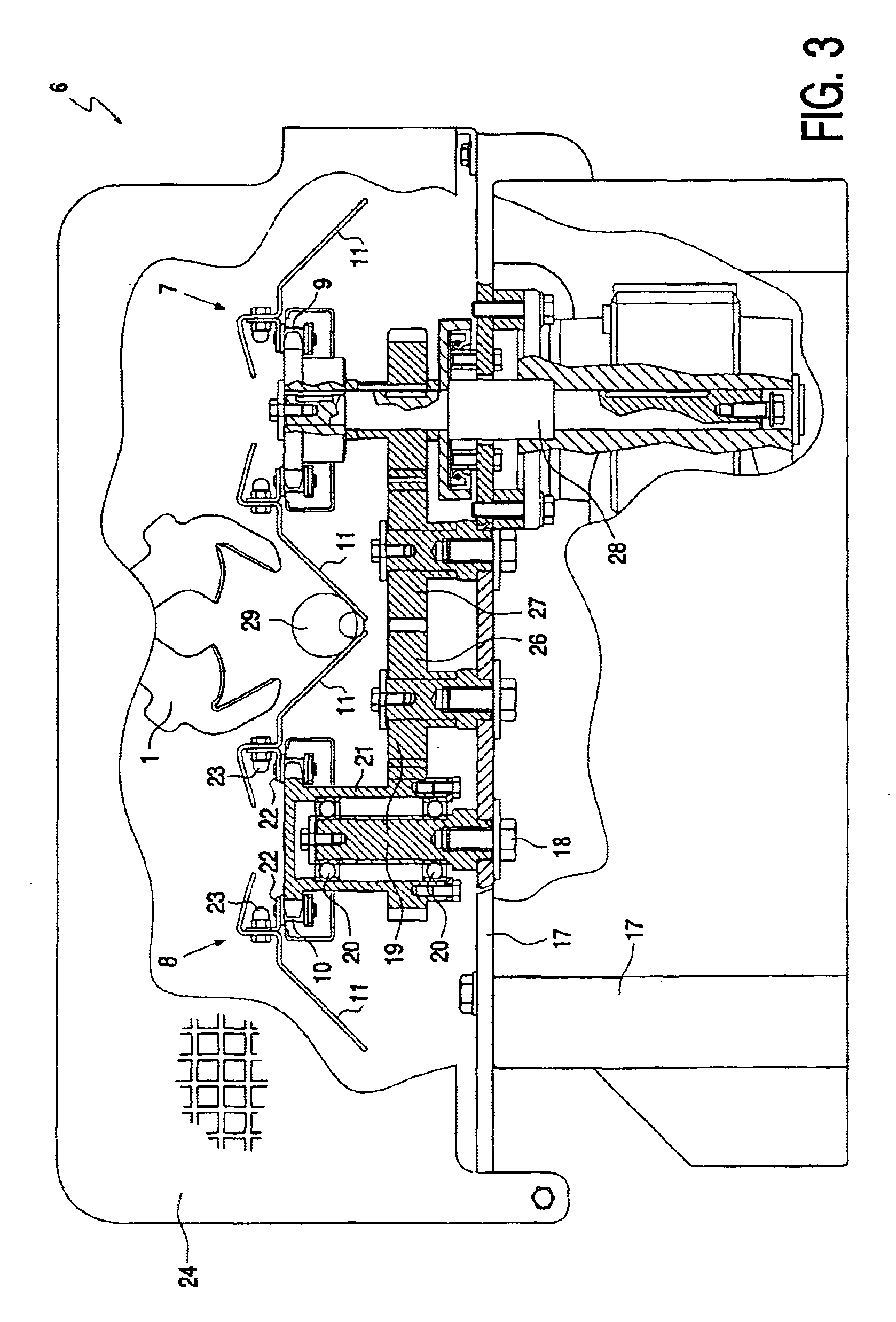

Automated classifier and meat cut fat trimming method and apparatus

InactiveUS6929540B2Better “mapping”Meat packaging/handling/transportingMeat processing plantsEngineeringBelt conveyor

Apparatus and method for a meat cut classification and fat trimming for sensing the thickness of a layer of fat of a cut of meat and the various contours thereof as it travels along a conveyance and providing the fat thickness or classification information to a downstream system for performing a fat trimming operation. The meat cut classification system comprises a split / multi-belt conveyor having split / multi-belts proximately spaced apart extending in the same direction and having a uniform equidistant gap there between and said conveyor having a drive for conveying the meat cut through the classification system and a multi-probe mechanism assembly.

Owner:TYSON FRESH MEATS

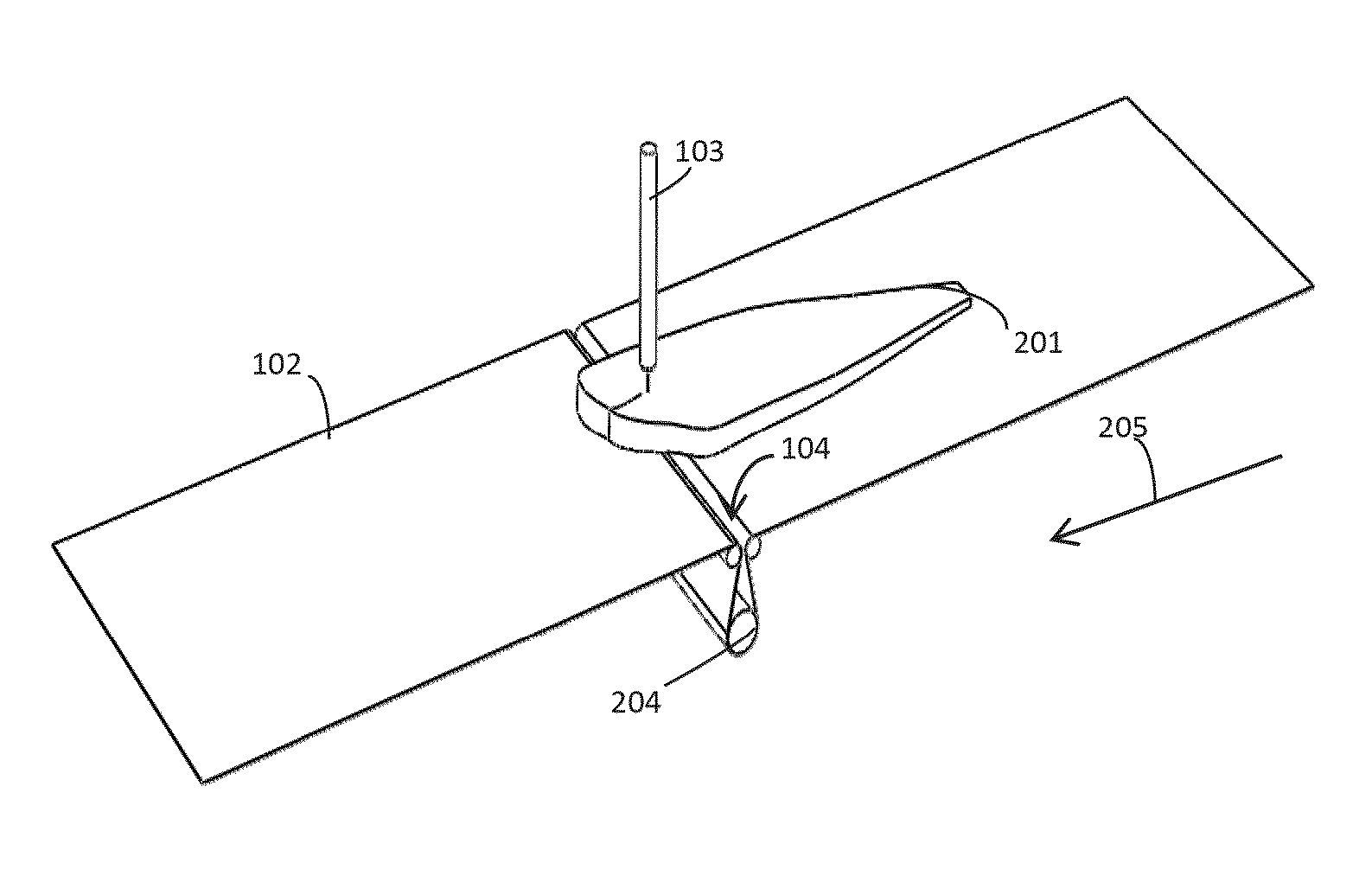

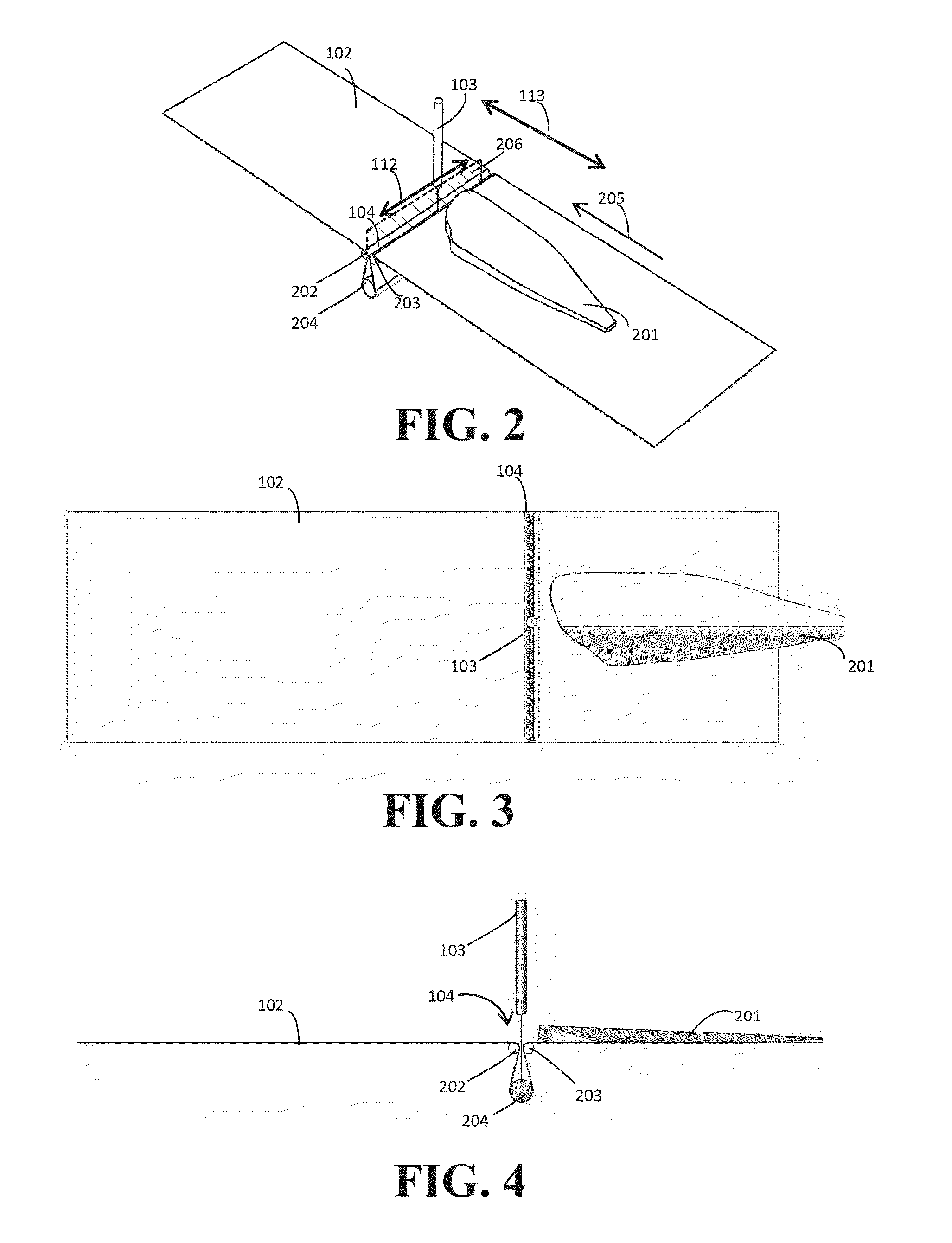

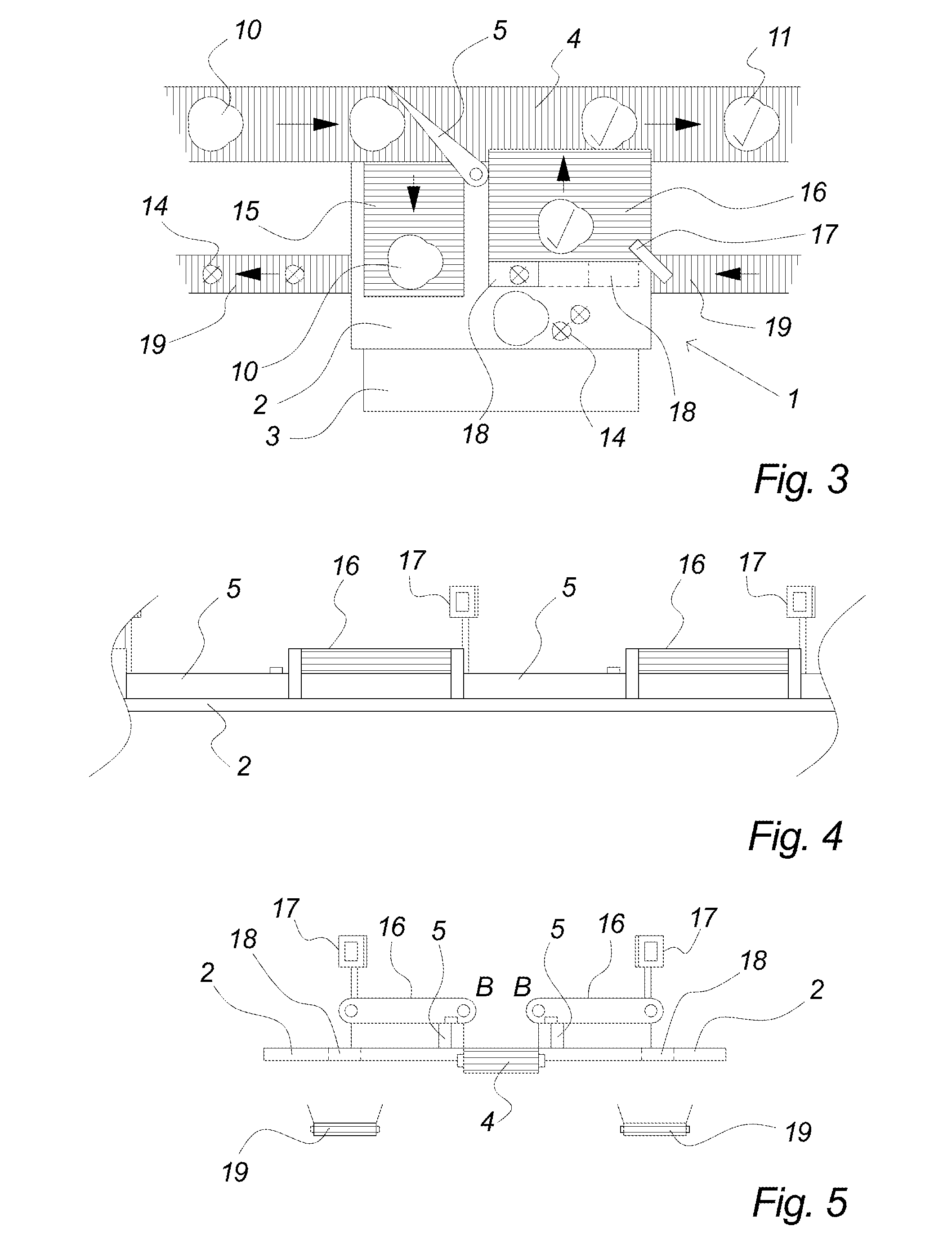

Cutting apparatus for cutting food items conveyed on a conveyor including at least one conveyor belt

InactiveUS20150033921A1Easy to cleanEasy to monitorAutomatic control devicesConveyorsSurface levelConveyor belt

This invention relates to a cutting apparatus for cutting food items conveyed on a conveyor including at least one conveyor belt. A cutter is arranged above a gap extending across the at least one conveyor belt. The cutter is positioned in relation to the gap such that the cutting path of the cutter extends through the food items and the gap and below the surface level of the at least one conveyor belt. The cutter is adapted to be connected to a control mechanism for operating crosswise movement of the cutter along the gap. The gap is formed between adjacent elongated supporting means such as rollers with a fixed internal arrangement, where the adjacent elongated supporting means and the cutter is adapted to be connected to a control mechanism for operating back and forth movement of the adjacent elongated supporting means and the cutter parallel to the conveying direction while maintaining the internal arrangement of the adjacent elongated supporting means and the cutter fixed.

Owner:MAREL ICELAND EHF

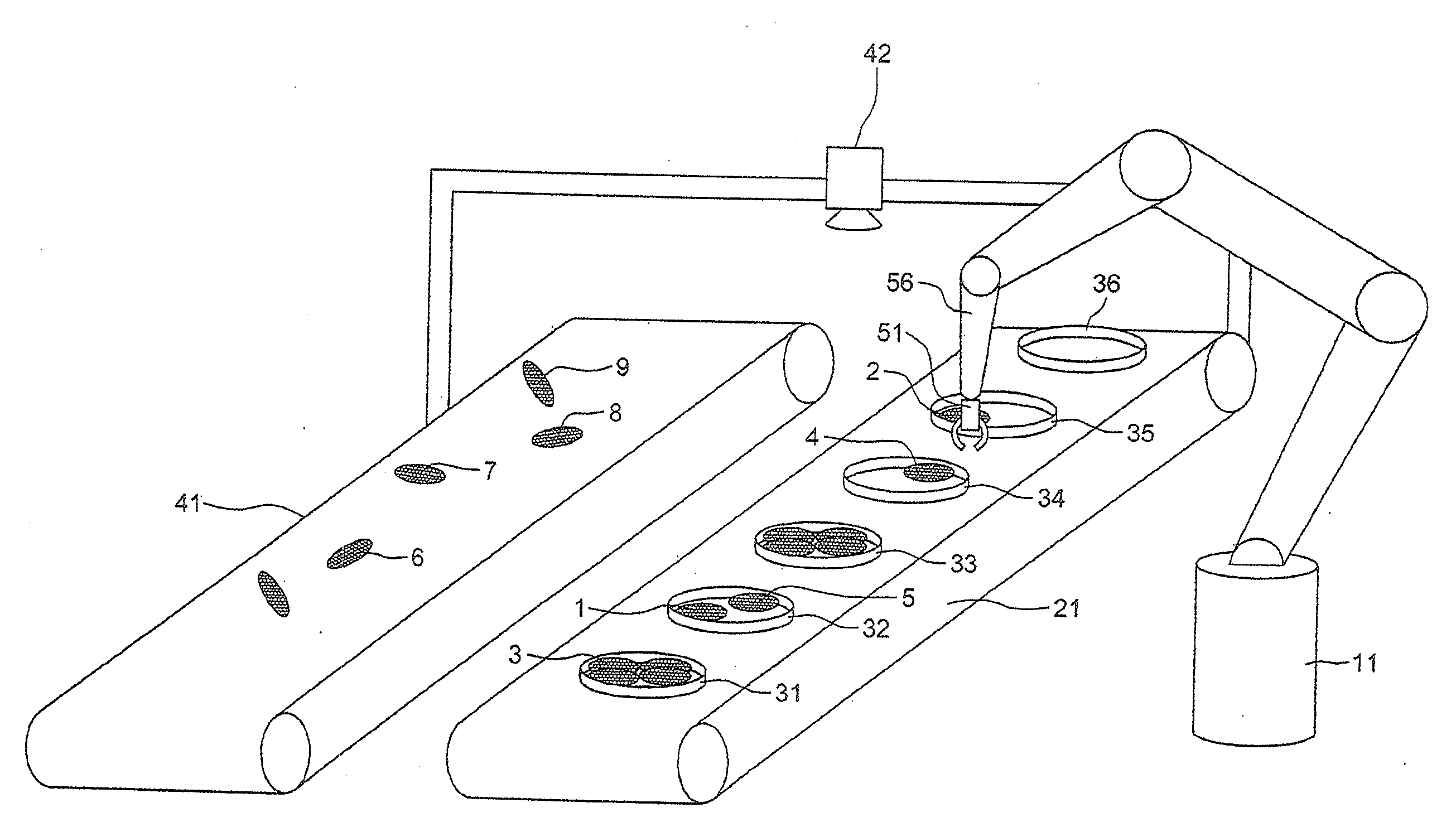

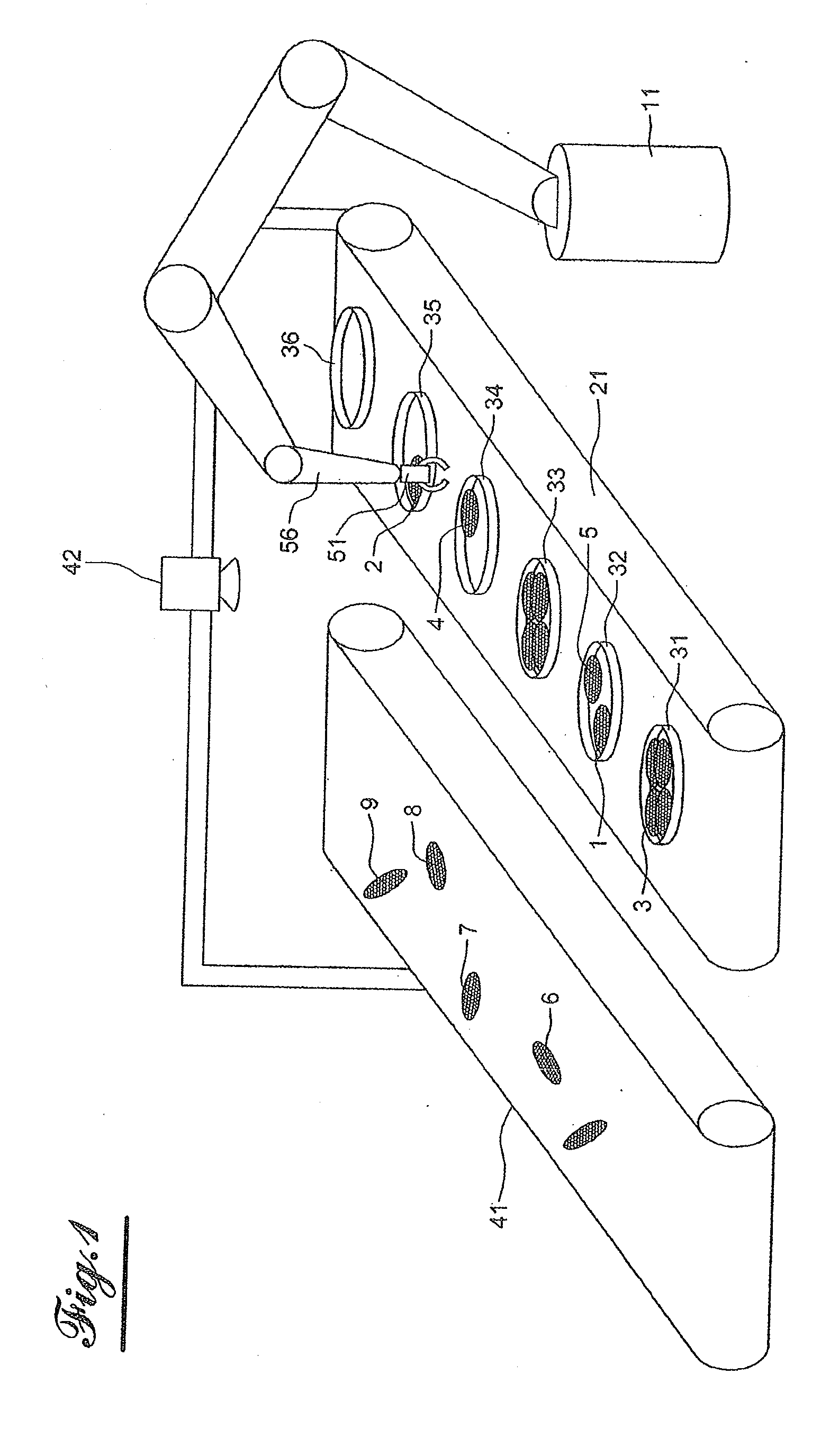

Method and system for processing of items

ActiveUS20100051513A1Operation efficiency can be improvedLittle mutual spacePackaging meatMeat packaging/handling/transportingIndividual itemSoftware engineering

A method and system for the processing of items that are supplied to a batching apparatus, where the batching apparatus comprises at least one handling means of the robotic type. By means of the batching apparatus a first process is performed, according to which items are selectively batched in consideration of measured, detected and / or estimated data for the individual items and in consideration of at least one predefined criterion. Particular items are identified and led to another process, the particular items being items that are deviant in relation to one or more predefined parameter(s) relating to the batching and / or items that have not been selected to be batched during the first process.

Owner:SCANVAEGT INT AS

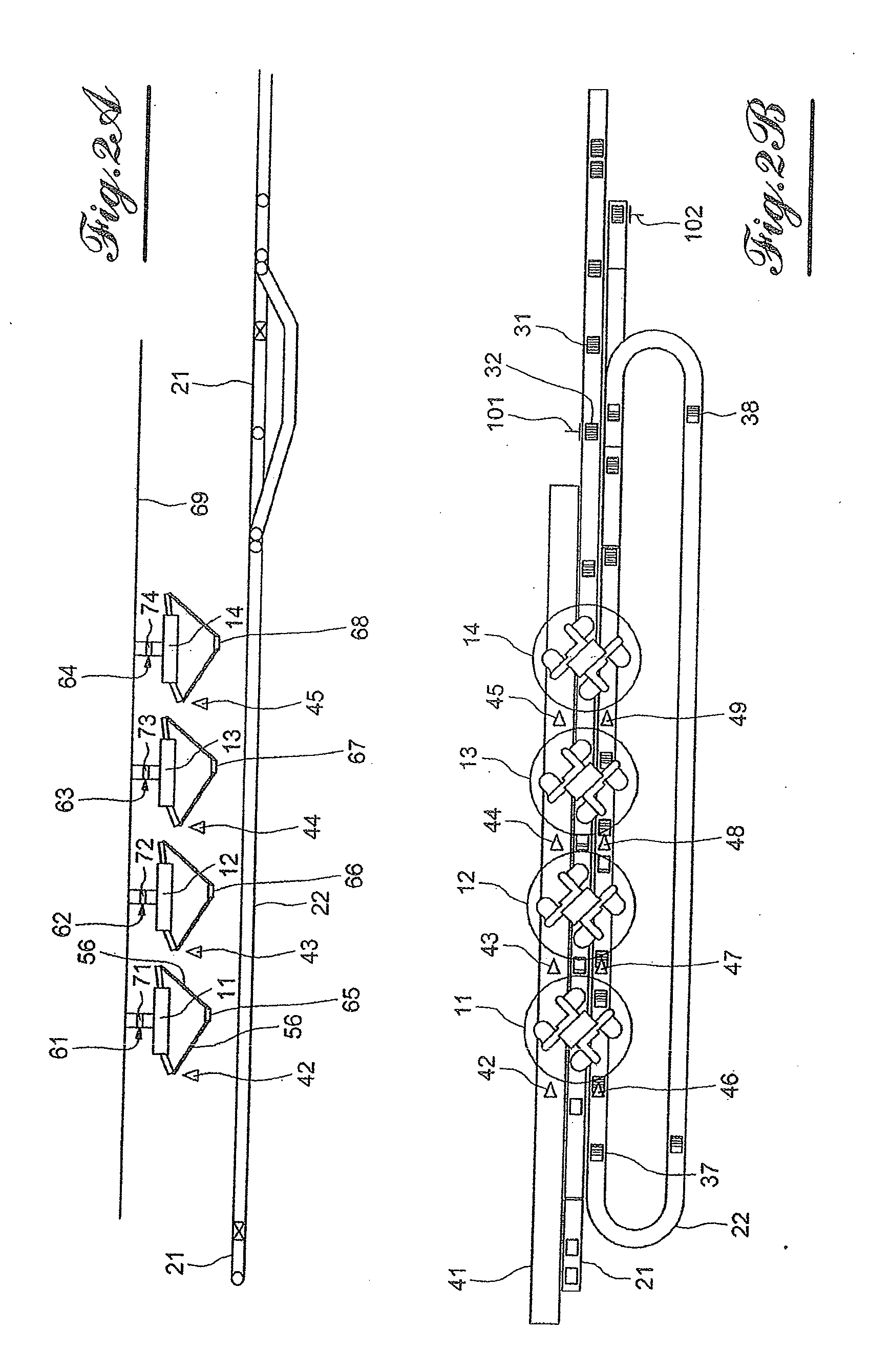

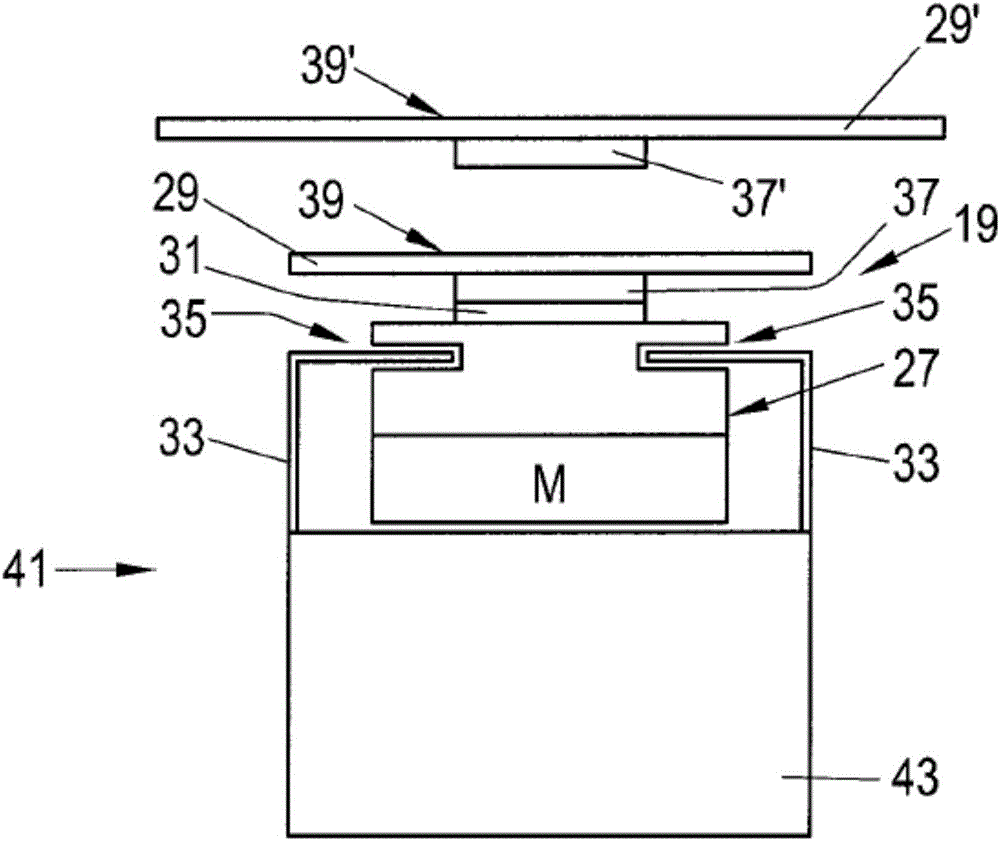

Autonomously electromagnetic transport carrier of food portions

ActiveCN106455591AEasy to cleanMeat packaging/handling/transportingRailway vehiclesMoving partsEngineering

The invention relates to a device for moving portions, which each comprise at least one slice cut from a food product, in particular by means of a slicing device, in particular a high-speed slicer, comprising a plurality of individually movable transport movers each for at least one portion, a track system for the transport movers, in which track system the transport movers can be moved along at least one specified track in a transport direction, and a control apparatus for controlling the movements of the transport movers in the track system, wherein the transport movers each comprise at least one runner that interacts with the track system and at least one carrier for at least one portion, the at least one carrier being attached to the runner by means of a retainer, and wherein the drive for each transport mover is formed by the runner and the track system, which together form an electromagnetic drive for the transport mover.

Owner:WEBER MASCHENBAU

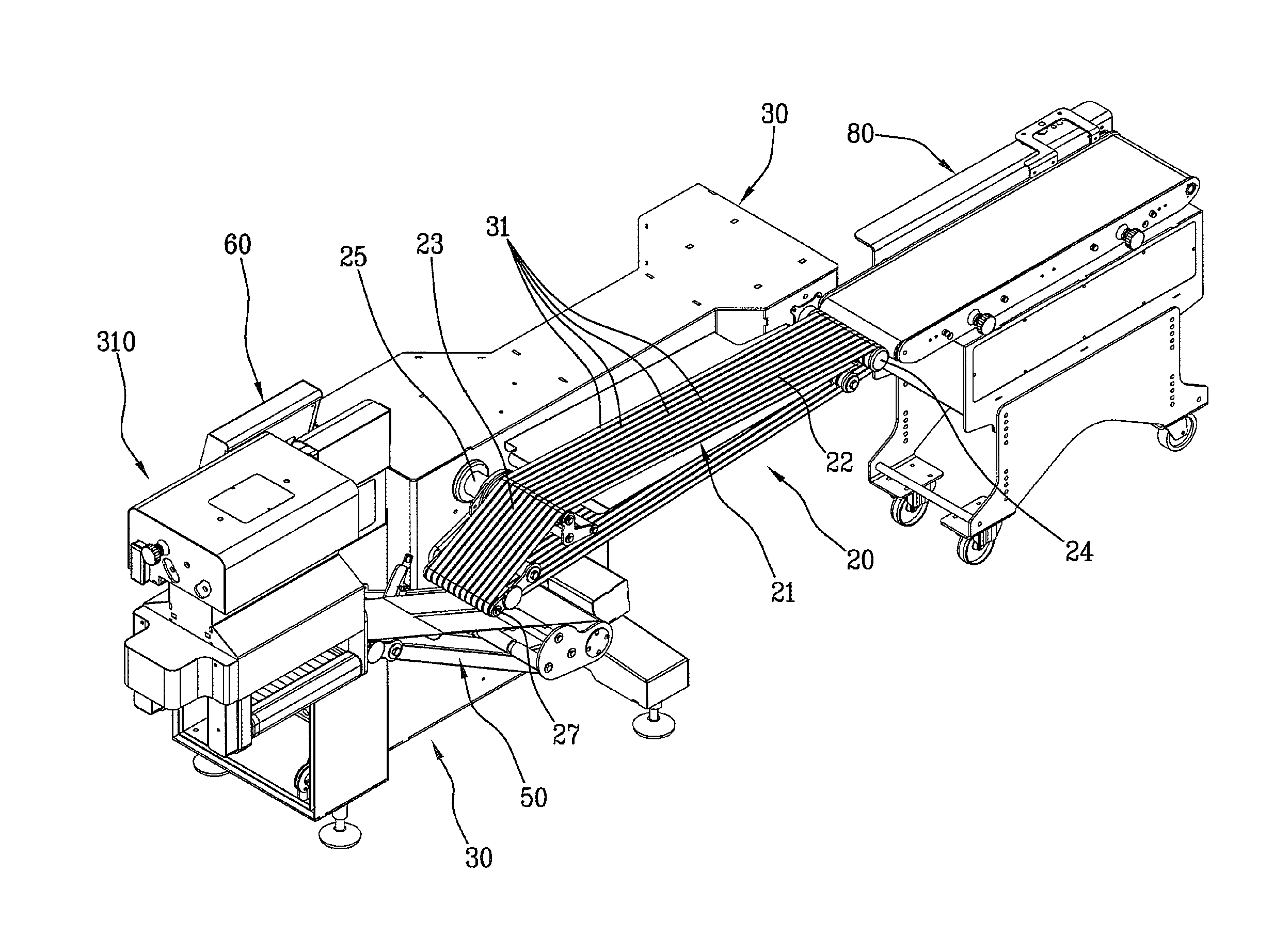

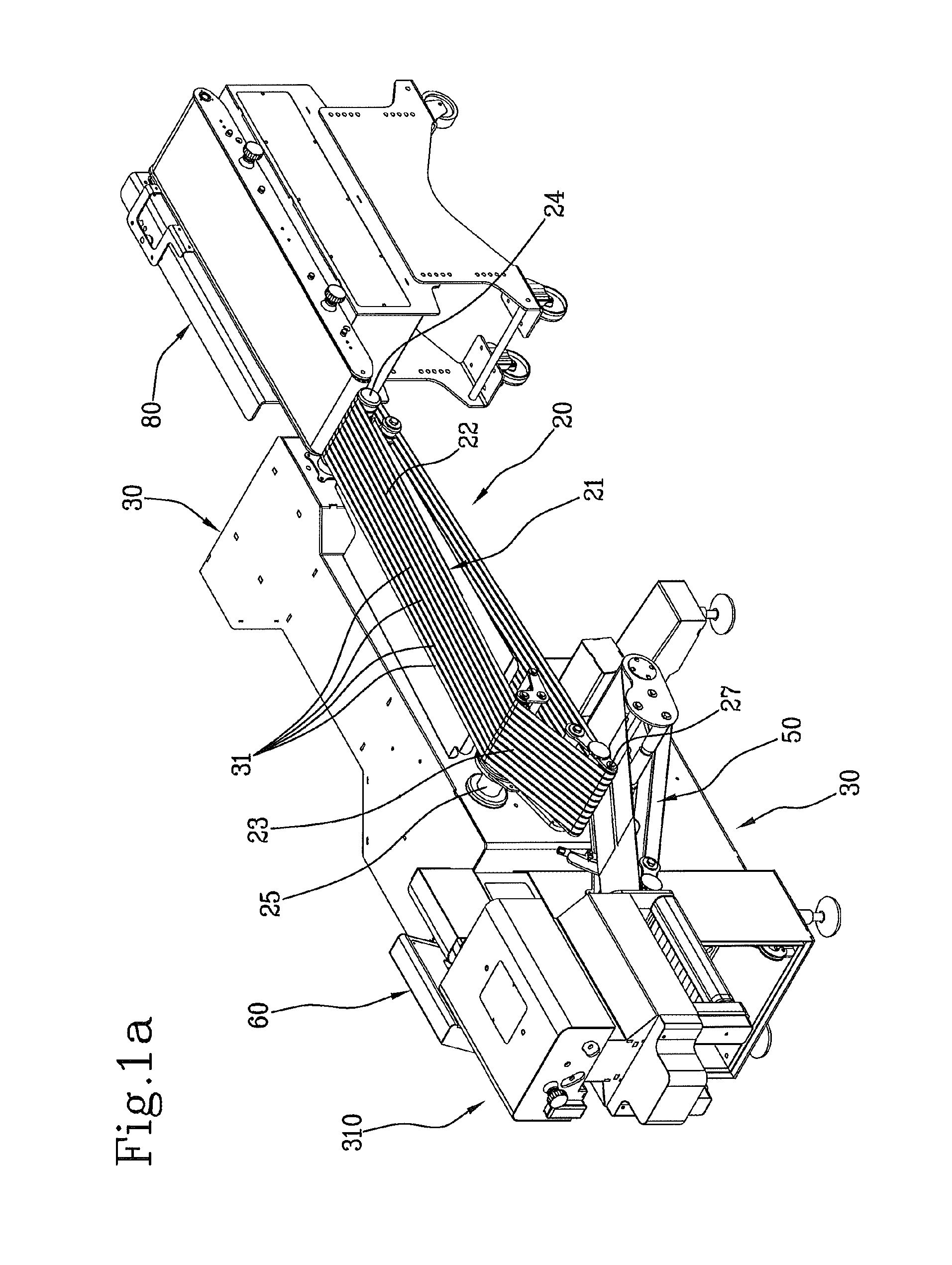

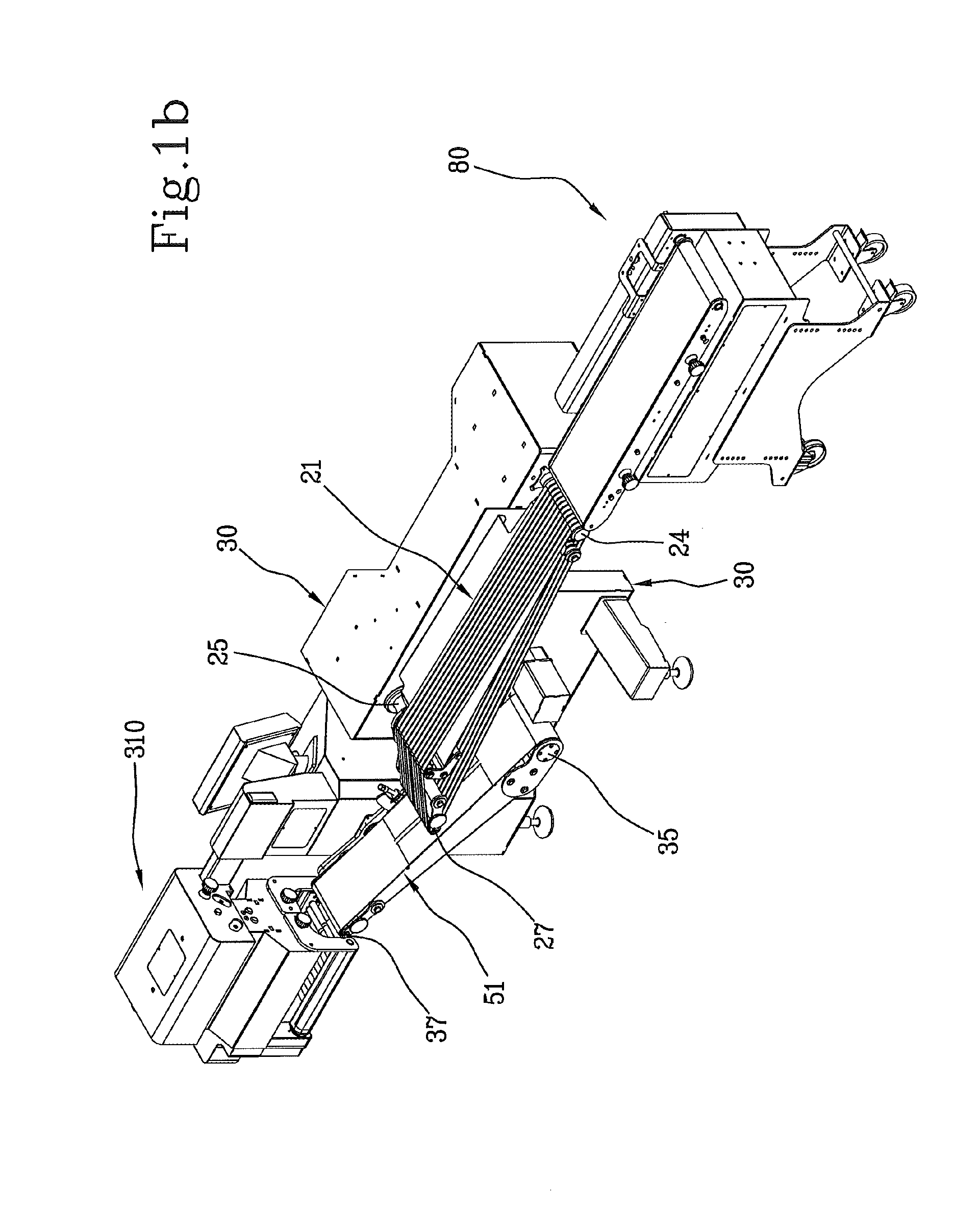

Apparatus for laying sliced foods into containers

InactiveUS20120159900A1Apparent advantageMeat packaging/handling/transportingSolid materialMechanical engineeringUser interface

An apparatus for laying sliced foods (11) into containers (390) comprises a main transport unit (20, 91) and a secondary transport unit (50, 150) downstream of the main unit. The two units are adapted to carry sliced foods (11) from a slicing station to a packaging station.A control unit (40) controls the individual and combined movements of the two transport units based on at least one arrangement parameter (P1, P2) inputted through a user interface (60).The apparatus for laying sliced foods (11) into containers (390) receives these foods from a slicing station through a feeding station (80, 180) and causes advancing of same to a laying unit for arrangement in containers (310).The containers (390) are then routed to a packaging station.

Owner:GRASSELLI GIORGIO

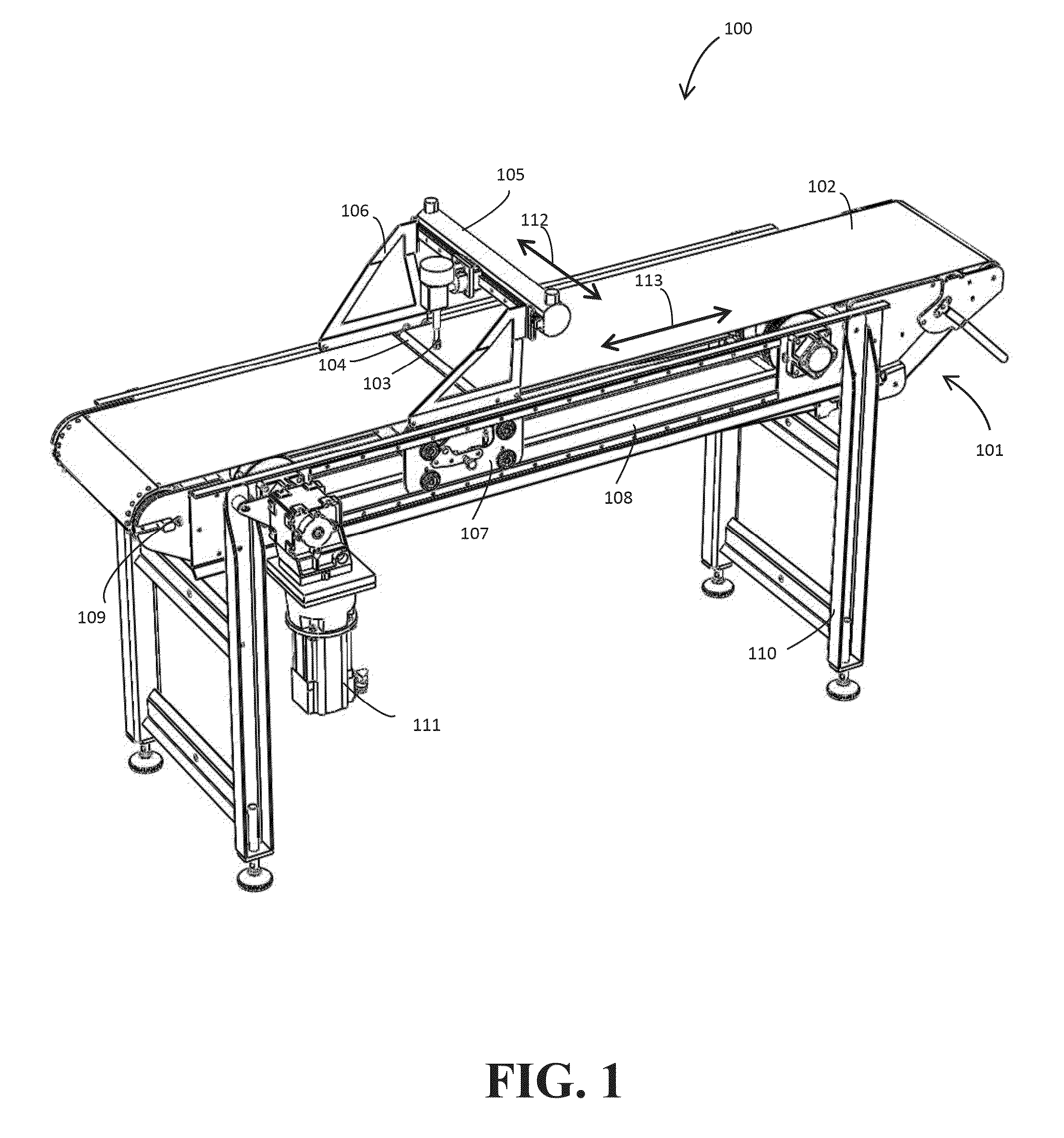

System for cutting and unloading portions

ActiveUS9778651B2Meat packaging/handling/transportingConveyor partsCarrier systemMechanical engineering

Owner:JOHN BEAN TECH CORP

Method of treating objects according to their individual weights

InactiveUS8688264B2Programme-controlled manipulatorDigital data processing detailsDistributed objectAlgorithm

Owner:ARBOR

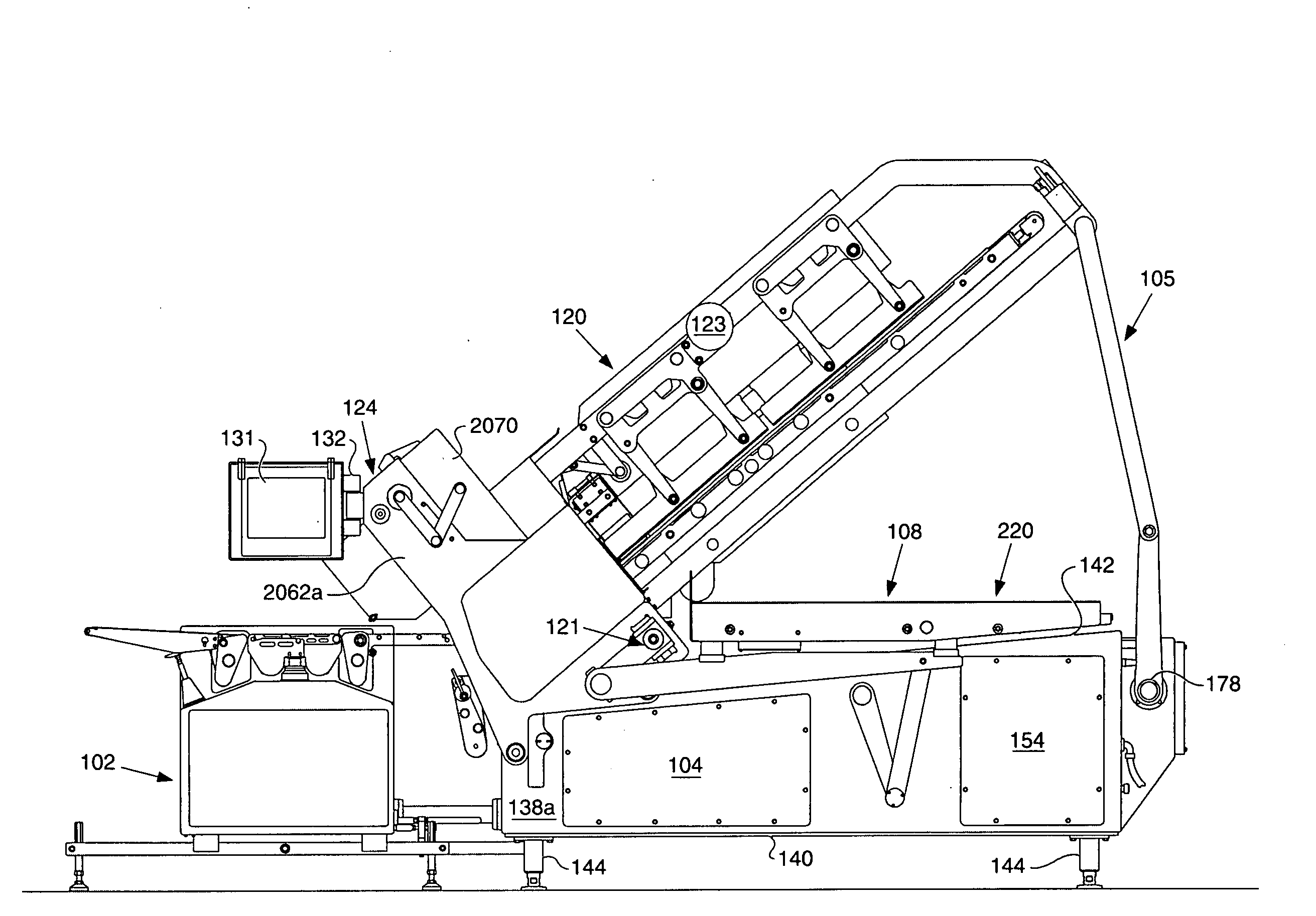

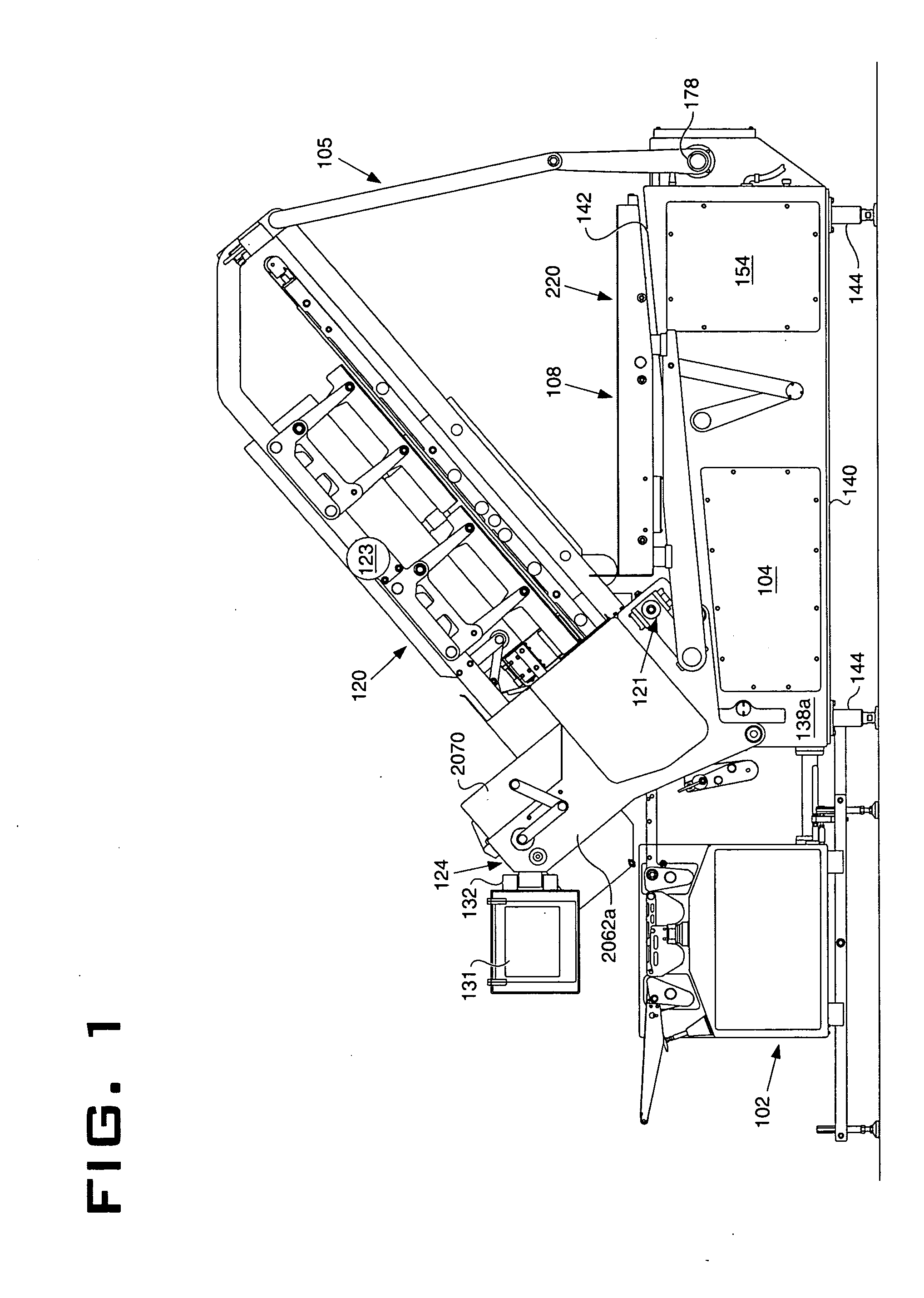

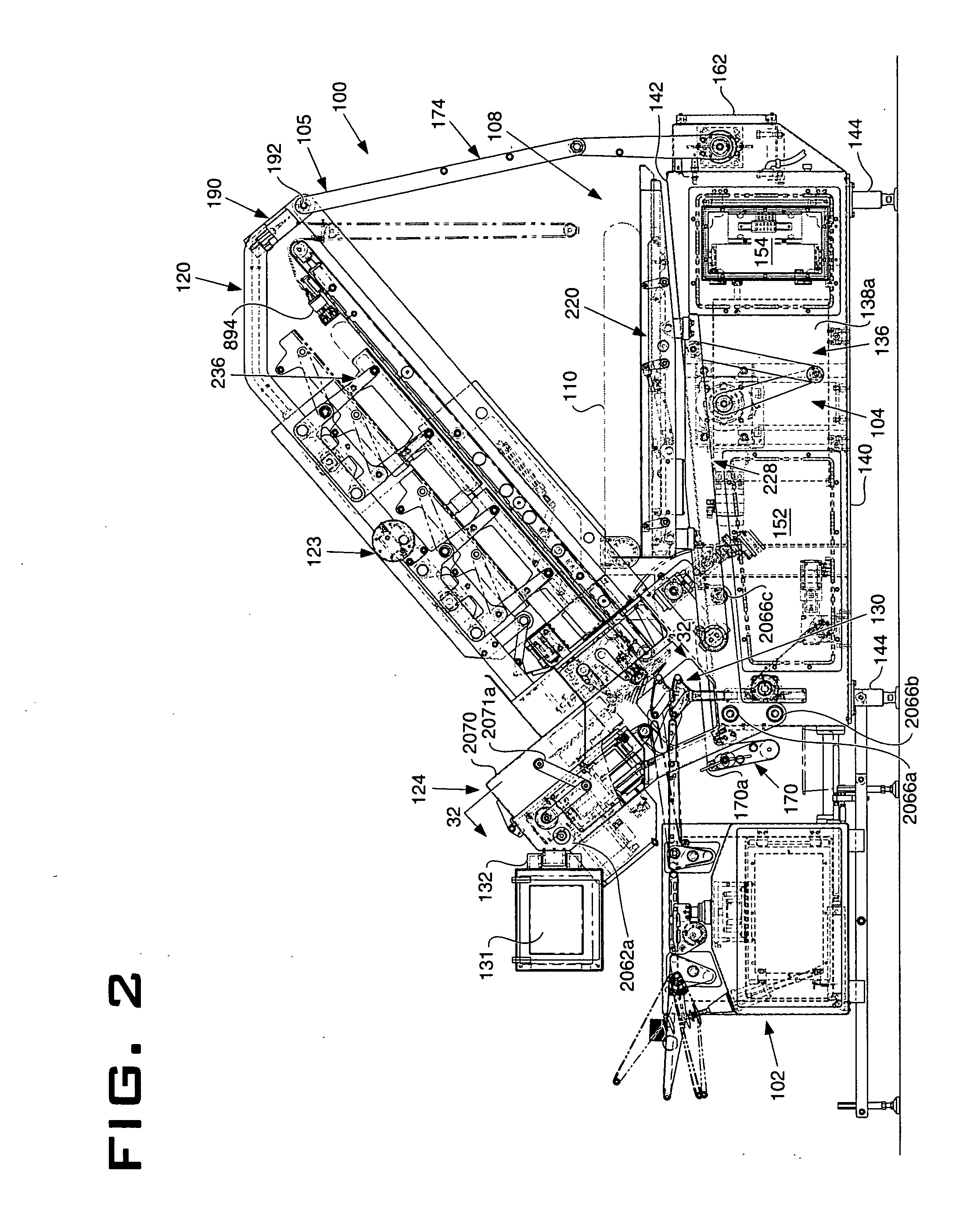

Food Article Loading Mechanism for a Food Article Slicing Machine

ActiveUS20090145272A1Easy to controlHigh yieldMeat packaging/handling/transportingFruit stoningEngineeringOpen structure

An automated sequenced food article tray loading method and apparatus for a high speed slicing machine where food articles can be loaded sequentially into designated and separated lanes of a lift tray and automatically sequentially assume a preload condition. Food article separation is maintained on the lift tray after the food articles are loaded by a plurality of support plates and one or more dividers. A food article sweep mechanism receives the food articles on the lift tray in their separated positions and transfers the food articles into the food article feed mechanism while maintaining the separated positions. The food article sweep mechanism is a substantially open structure without enclosing walls.

Owner:PROVISUR TECHNOLOGIES INC

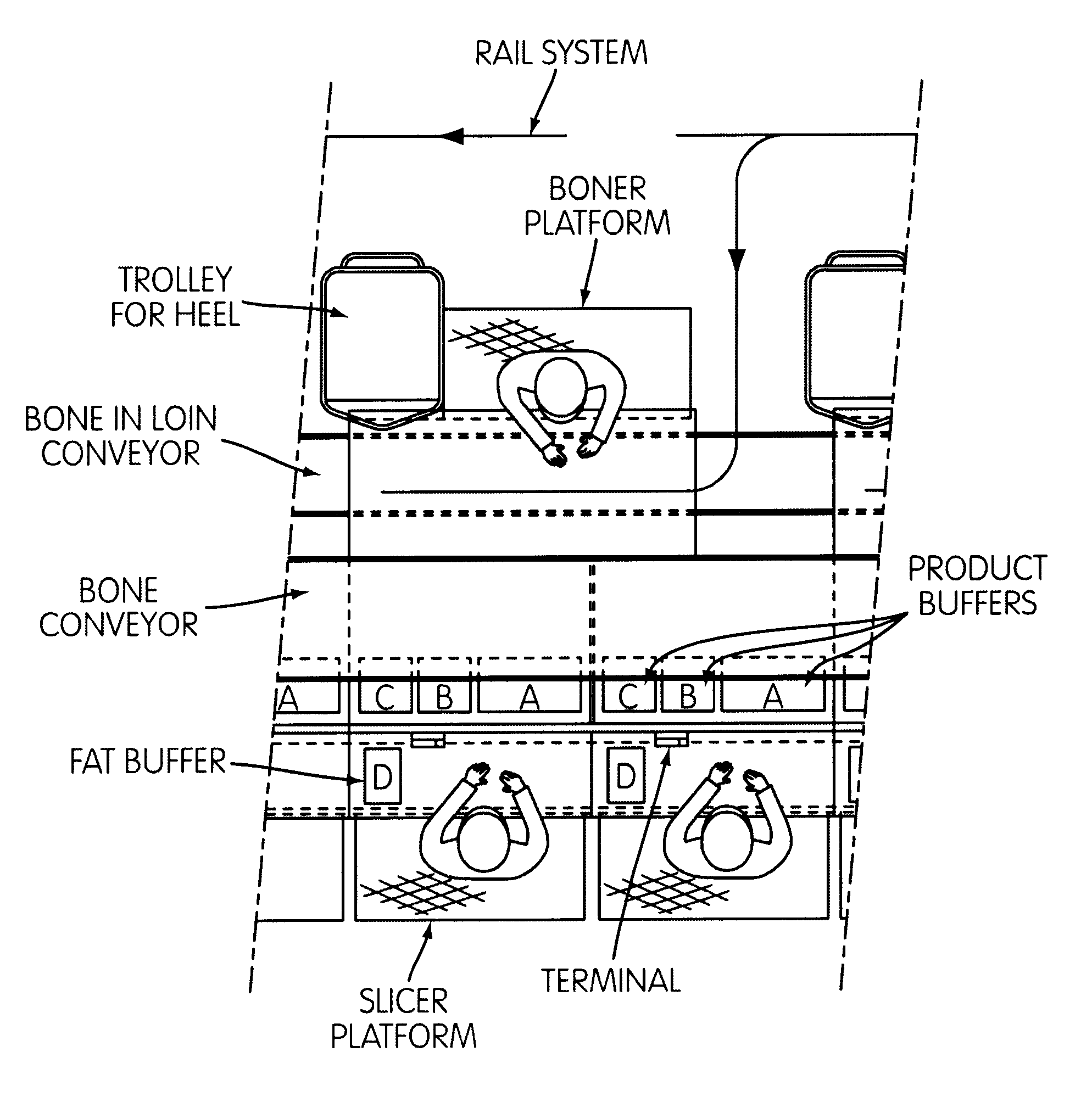

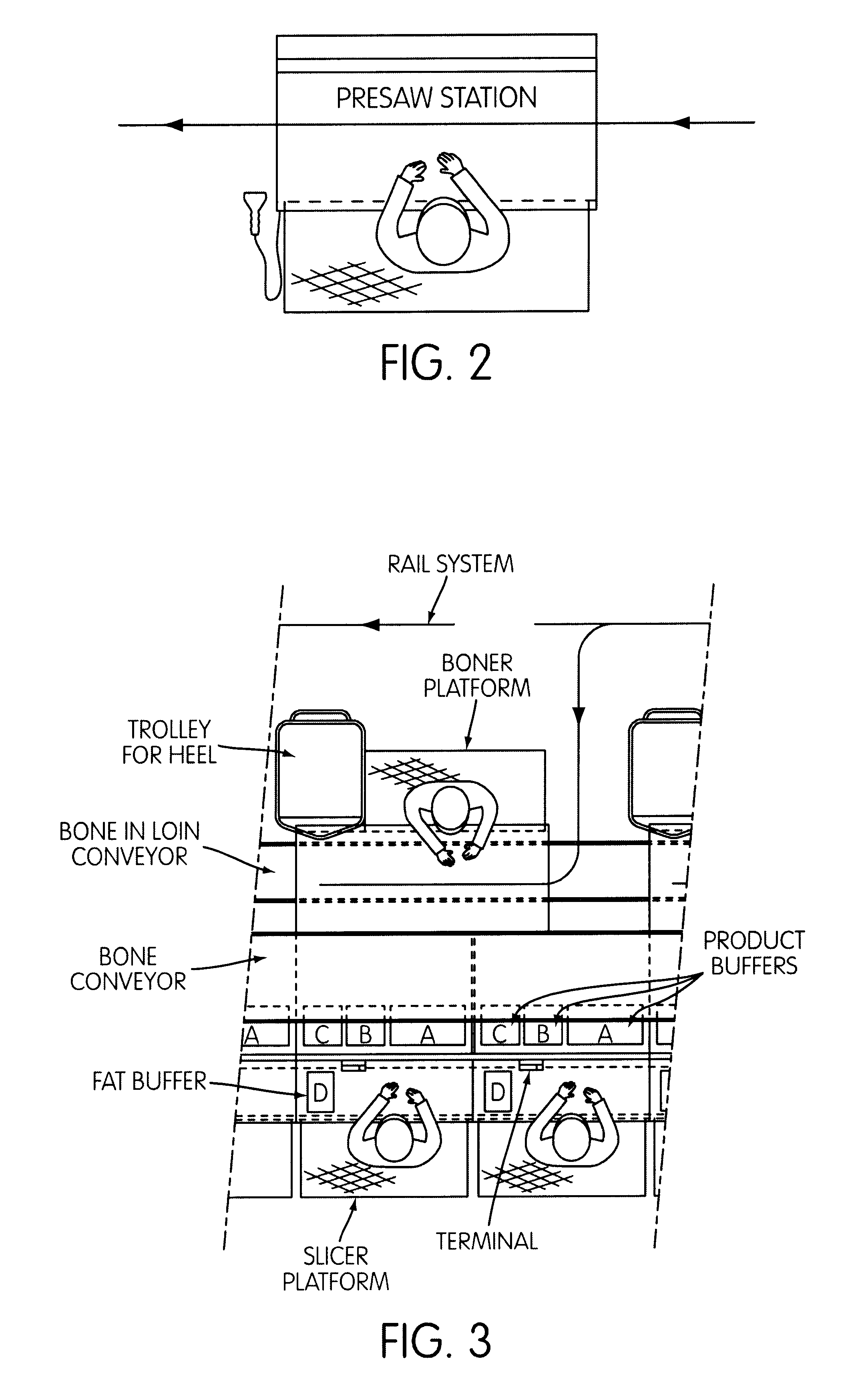

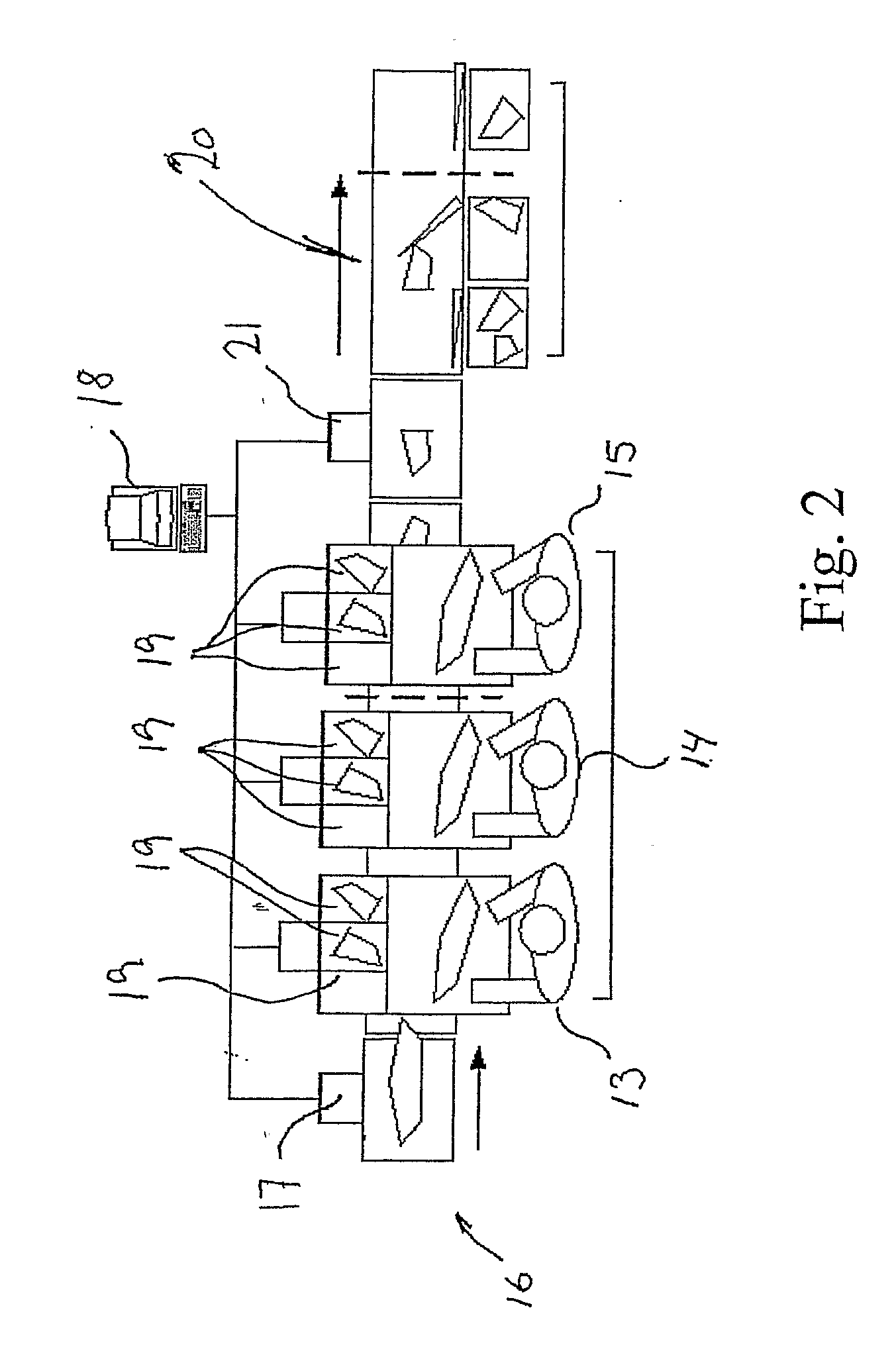

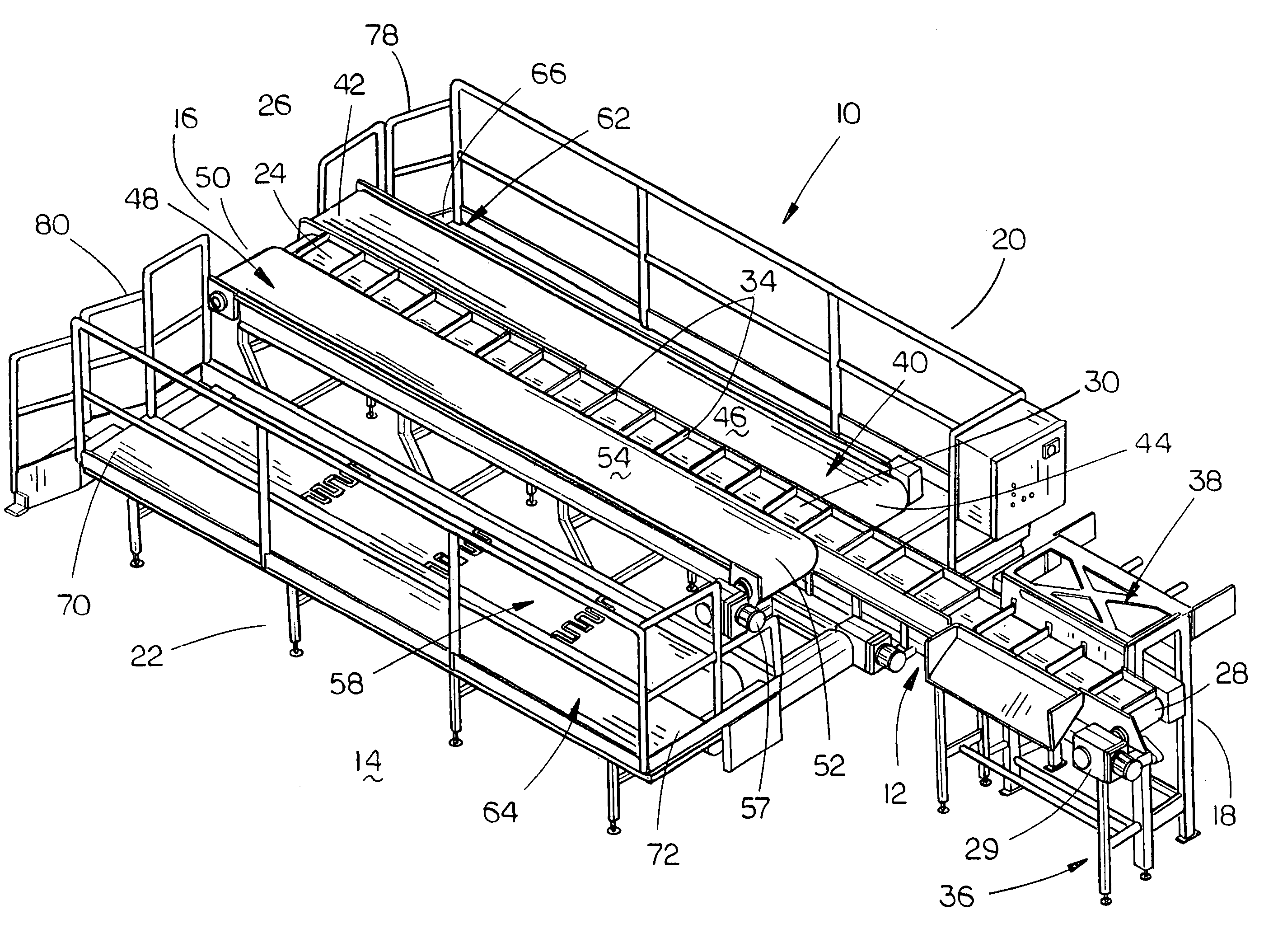

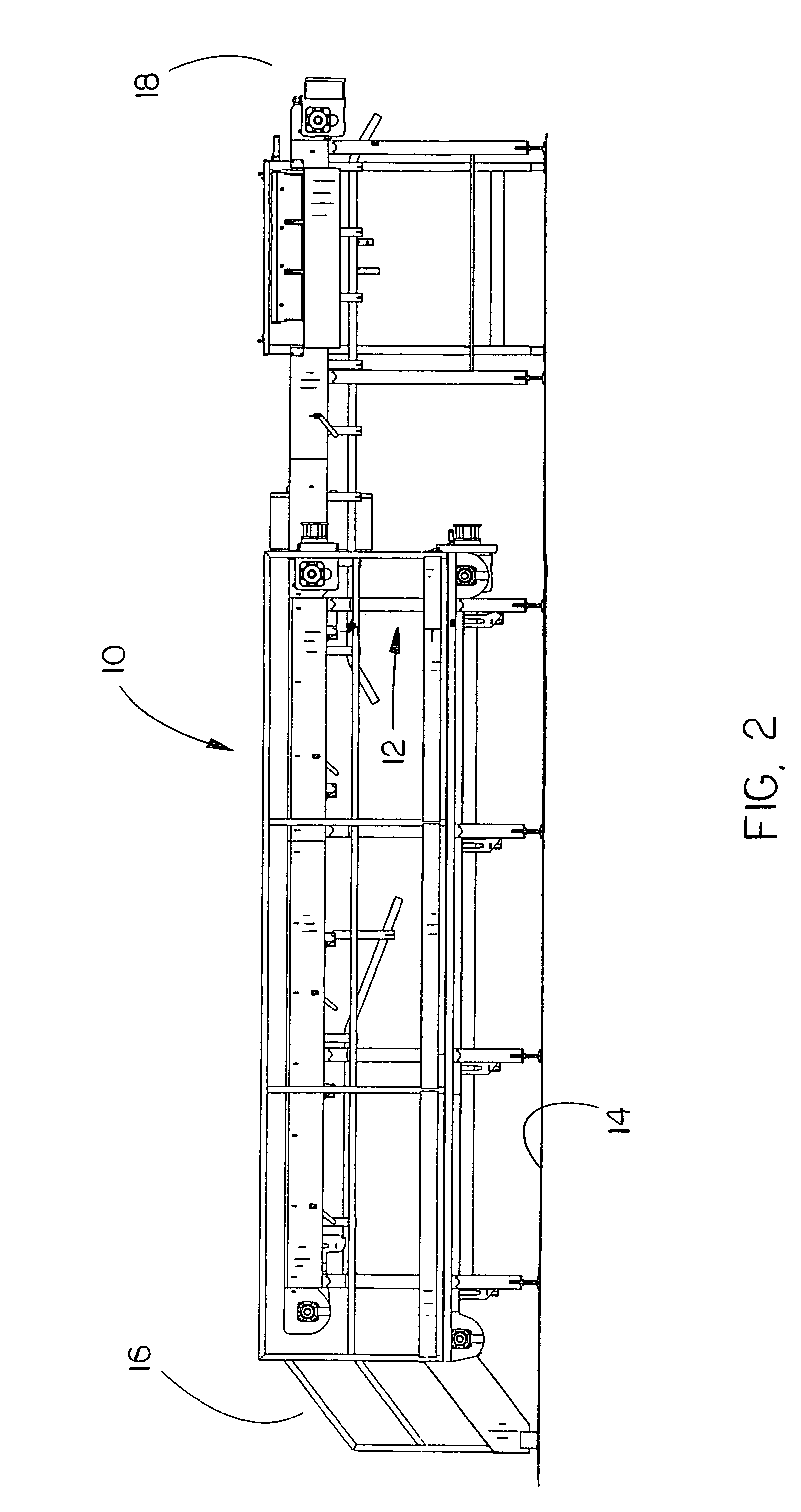

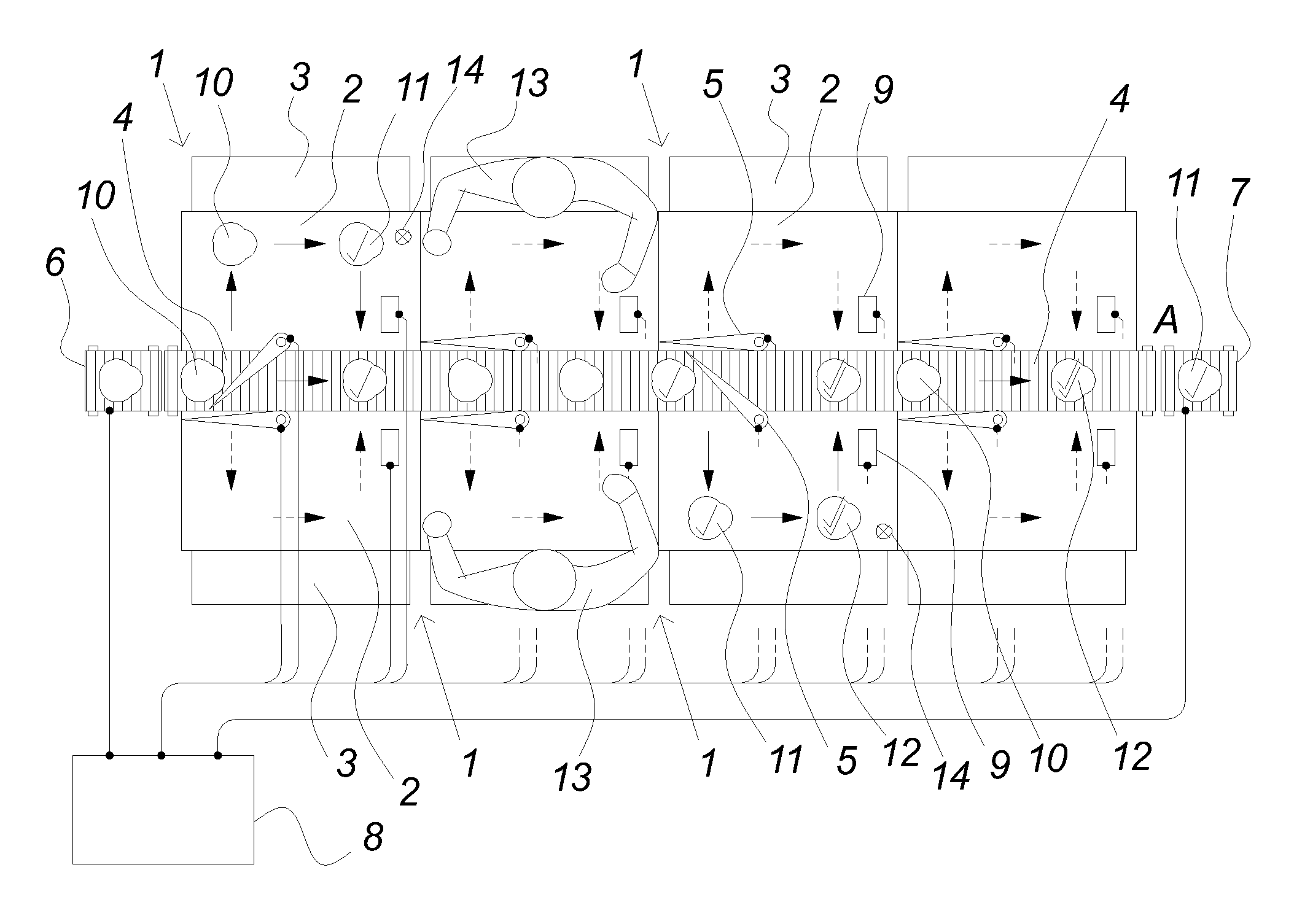

Meat processing conveyor system

ActiveUS7467996B1Less-expensive to operateLess-expensive to purchaseMeat packaging/handling/transportingSlaughterhouse arrangementsEngineeringConveyor belt

A meat processing conveyor system wherein a first trim conveyor belt is positioned between first and second product conveyor belts. First and second personnel conveyor belts are positioned laterally of the first and second product conveyor belts respectively. First and second personnel walkways are positioned laterally of the first and second personnel conveyor belts respectively.

Owner:JAGER TODD G

Method and device for consolidating items into a single unit of a pre-defined total weight

ActiveUS20090249749A1Increase speedSpeed up the processFish sortingMeat packaging/handling/transportingTarget weightEngineering

Proposed are a method and a device for consolidation of a number n of items, whose weight varies within predefined limits, in a container to a single unit with a predefined target weight. For this purpose, n-1 portions are combined and the weight of all of the n-1 portions is determined. Then the difference between the target weight of the n portions on the one hand and the weight of the n-1 portions on the other is determined. Ultimately, an nth portion with a precise weight is cut-off from a piece, where the weight equals the weight of the nth portion of the difference. For this purpose, the device is provided with a first and a second insertion station, a scale, a computer, and a portioning and cutting device.

Owner:MAJA-MASCHINENFABRIK HERMAN SCHILL KG

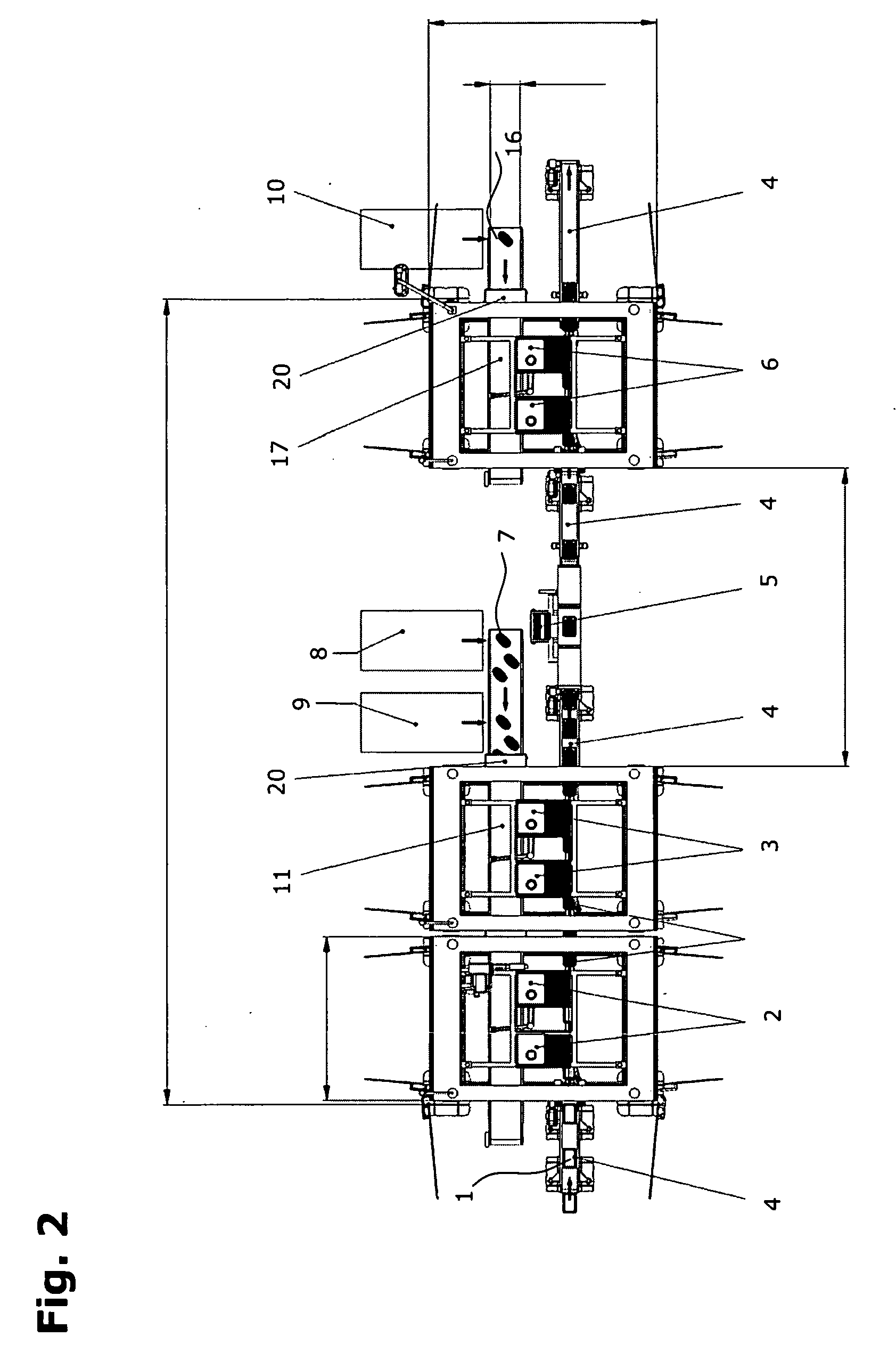

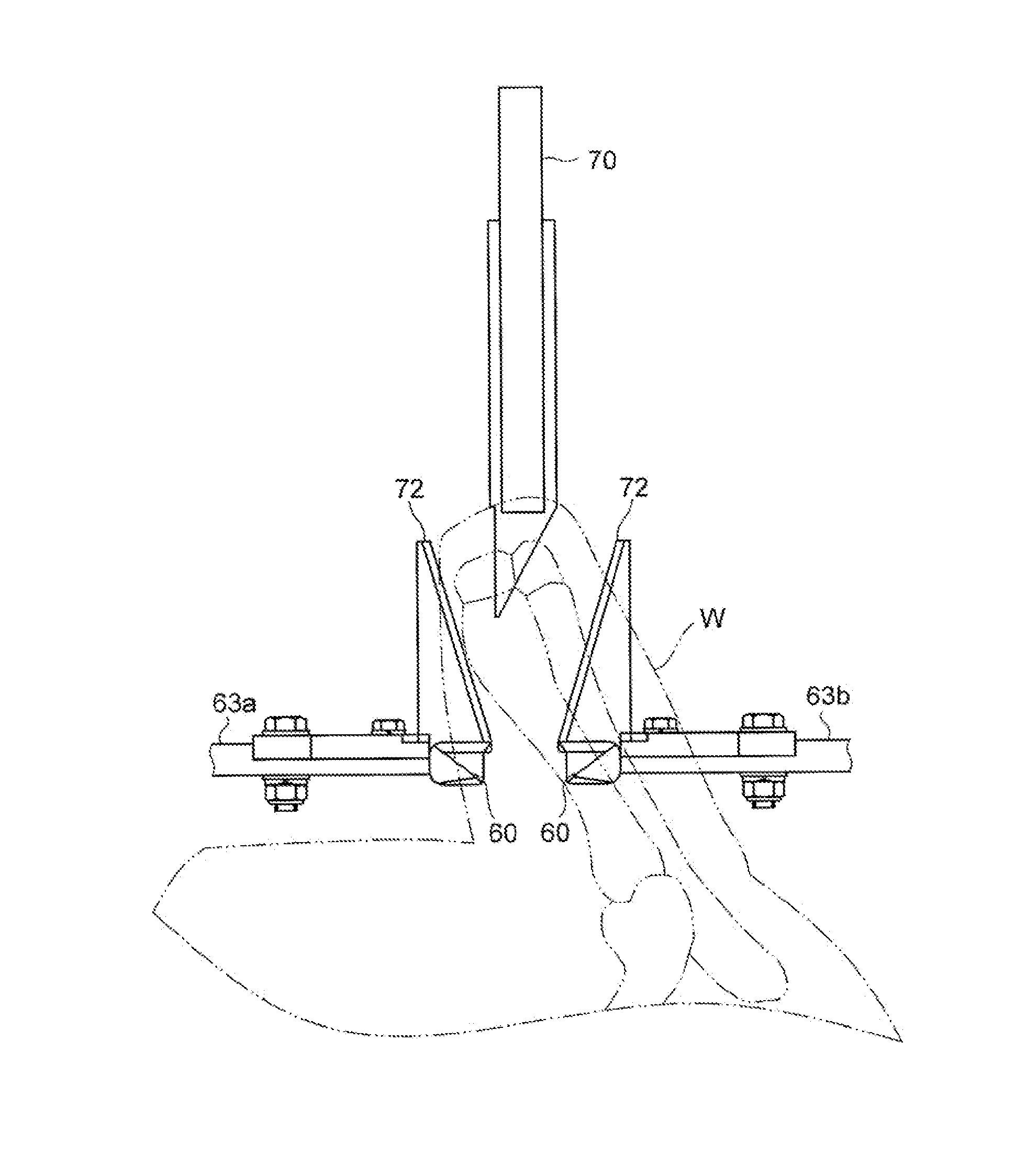

Device and method for conveying bone-in meat and deboning system of bone-in meat including the device

ActiveUS20150004892A1Increase automation rateMeat/sausage hanging-upSlaughtering animals fettering apparatusBand shapeActuator

Two hooking members of a hooking unit used in a device for conveying bone-in meat respectively have belt-like main body parts, blade-like pointed ends provided at ends on one side of the main body parts, and barbs provided on first sides of the main body parts to be continuous with the points. The hooking members are supported so as to be in parallel with each other with an elastically changeable interval therebetween and to be rotatable about rotation axes along longitudinal axes of the main body parts. Further, the hooking unit has an actuator which rotates the hooking members about the rotation axes.

Owner:MAYEKAWA MFG CO LTD

Method and system for processing of food items

ActiveUS8869990B2Improve efficiencySpeed andPackaging meatMeat packaging/handling/transportingIndividual itemSoftware engineering

A method and system for the processing of items that are supplied to a batching apparatus, where the batching apparatus comprises at least one handling means of the robotic type. By means of the batching apparatus a first process is performed, according to which items are selectively batched in consideration of measured, detected and / or estimated data for the individual items and in consideration of at least one predefined criterion. Particular items are identified and led to another process, the particular items being items that are deviant in relation to one or more predefined parameter(s) relating to the batching and / or items that have not been selected to be batched during the first process.

Owner:SCANVAEGT INT AS

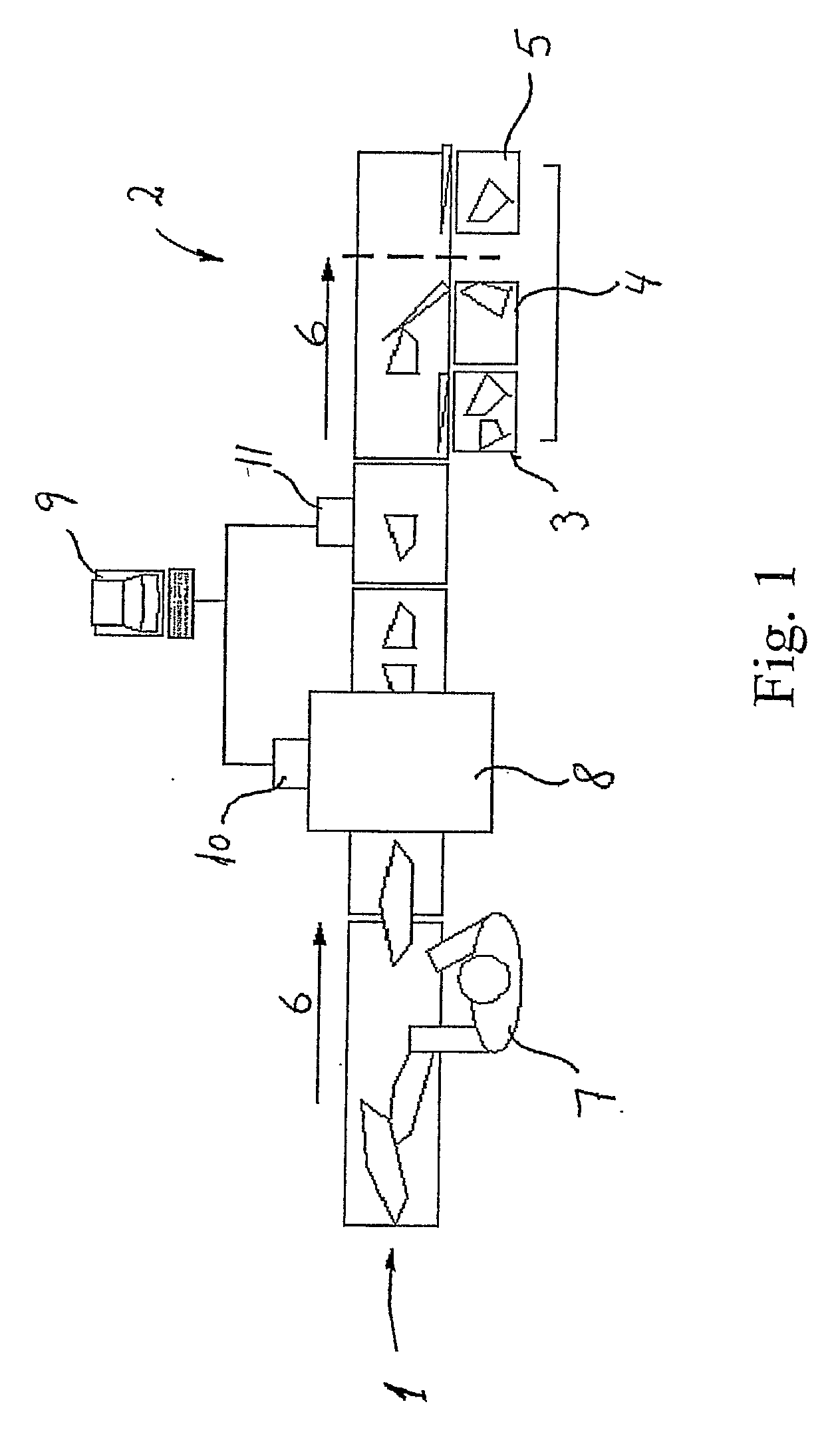

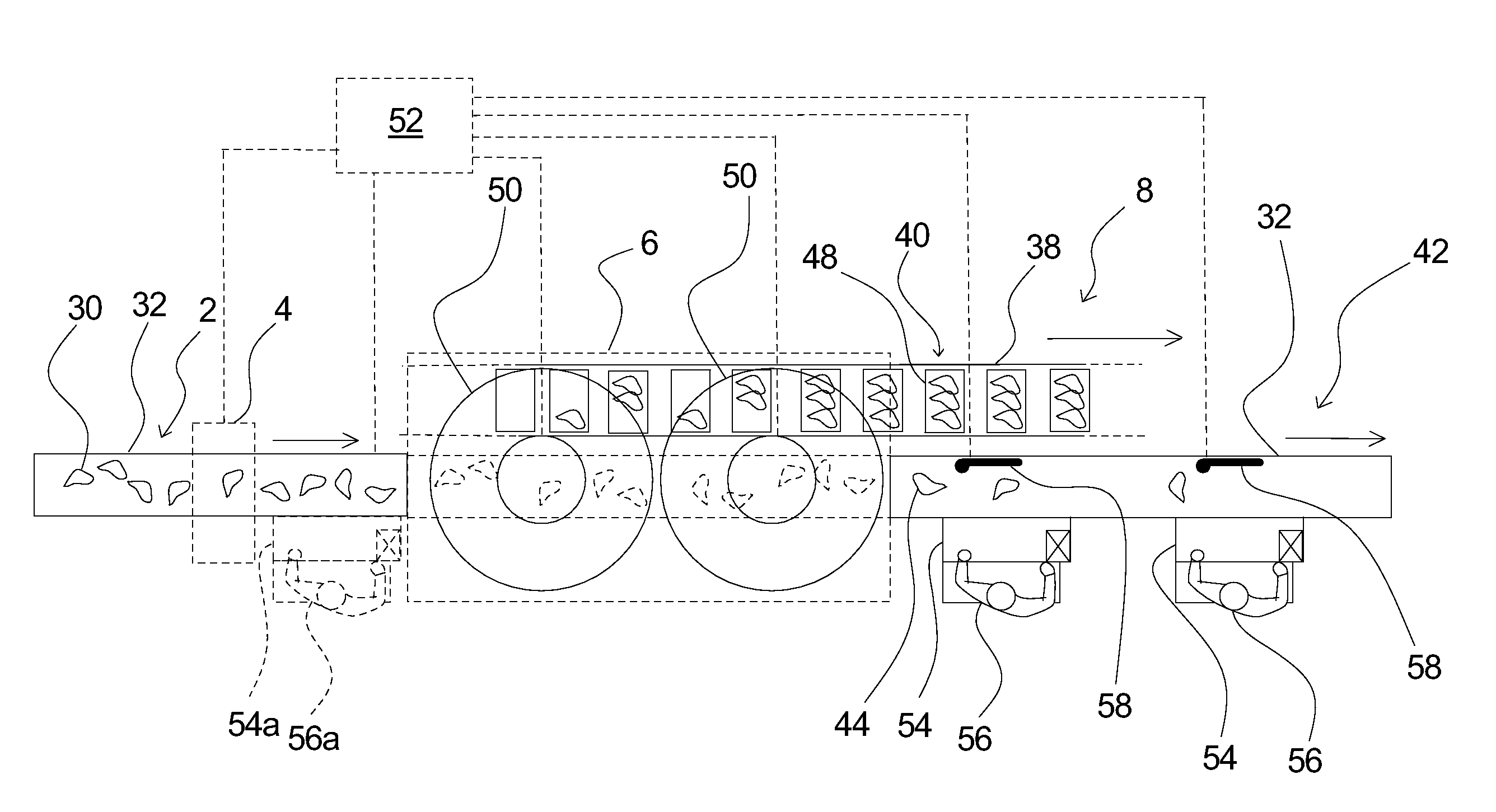

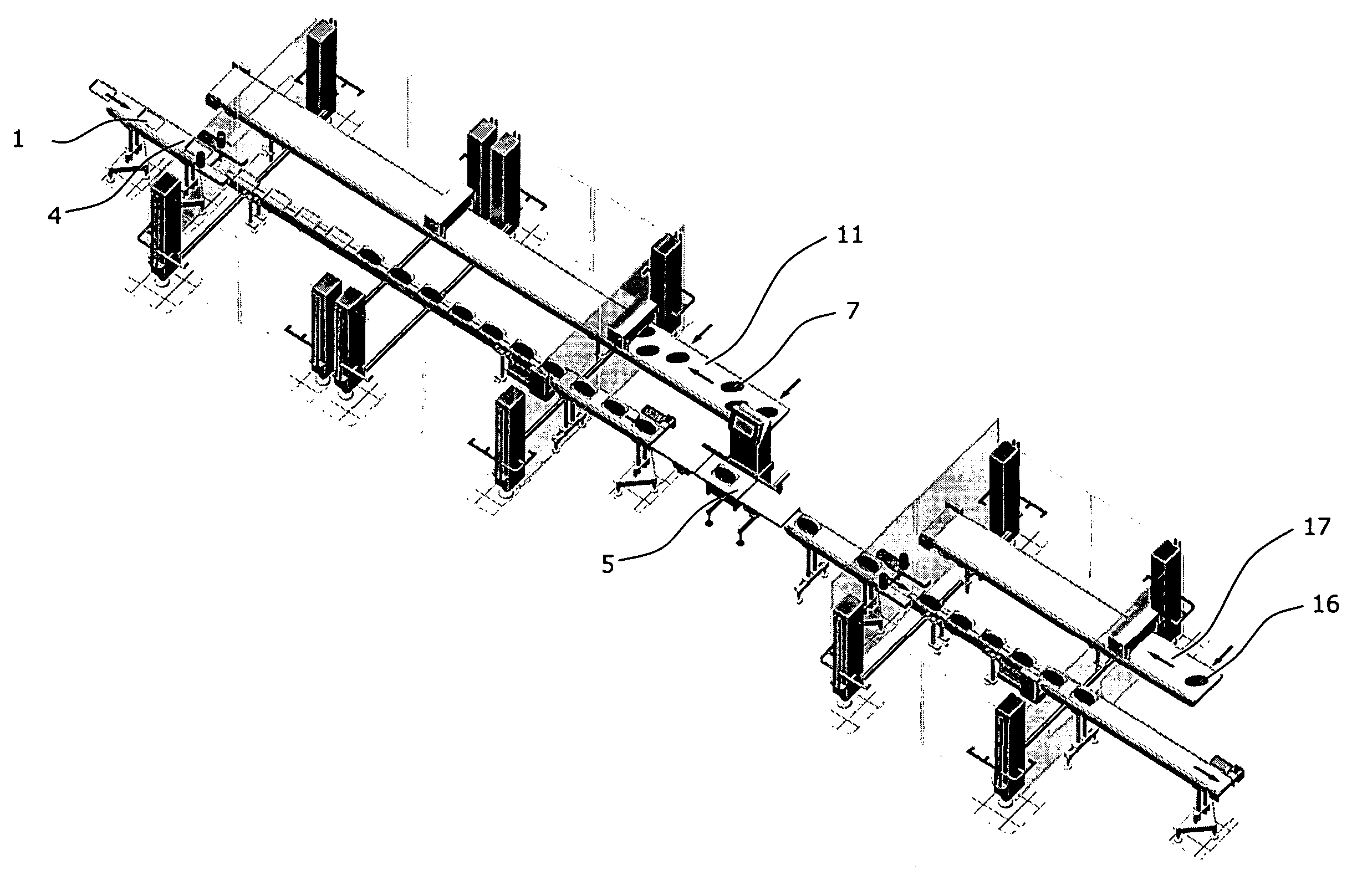

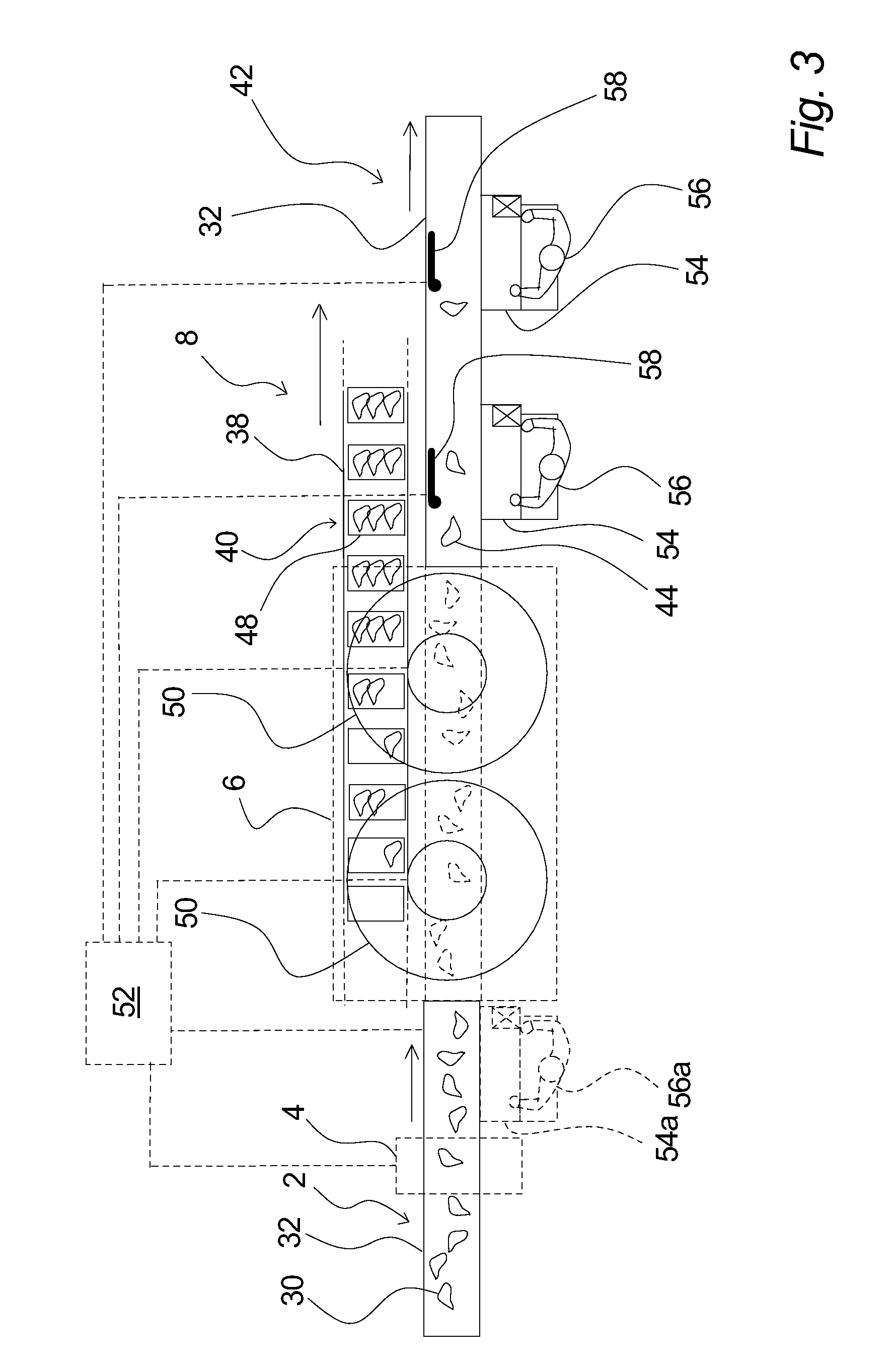

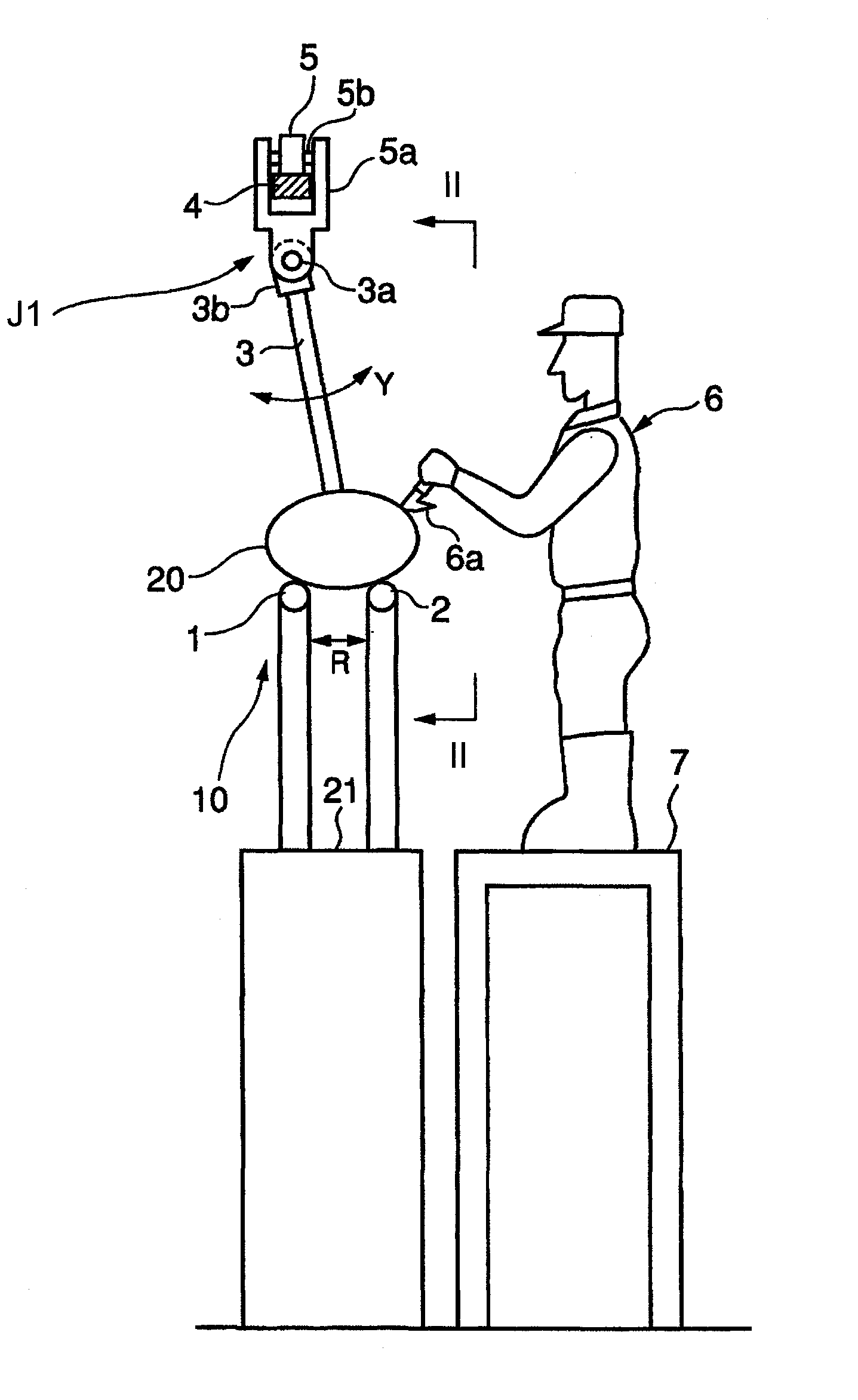

Method for processing items such as pieces of meat

ActiveUS8862262B2Simplify cleaning proceduresSimple methodDigital data processing detailsMeat packaging/handling/transportingHandling systemWorkstation

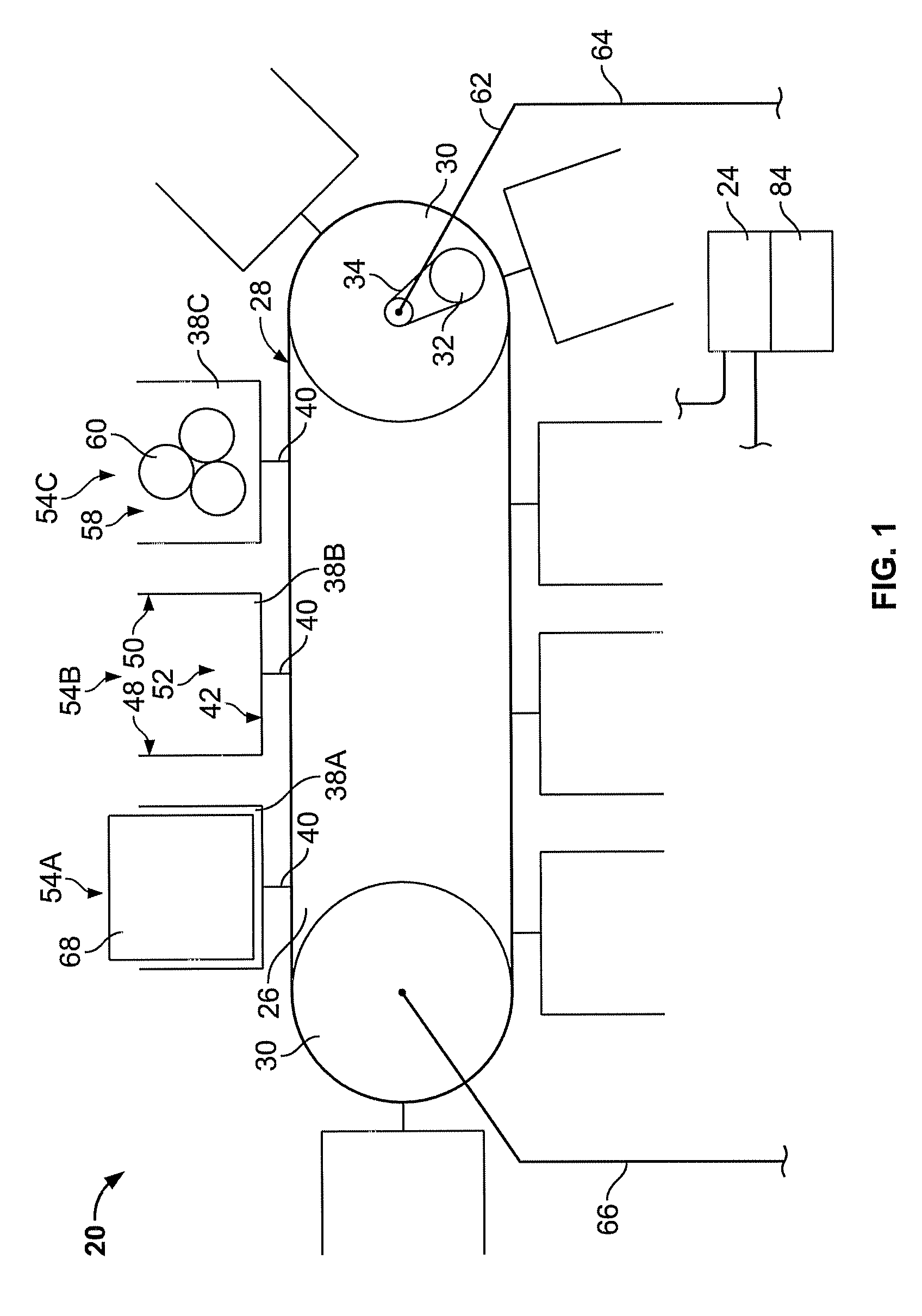

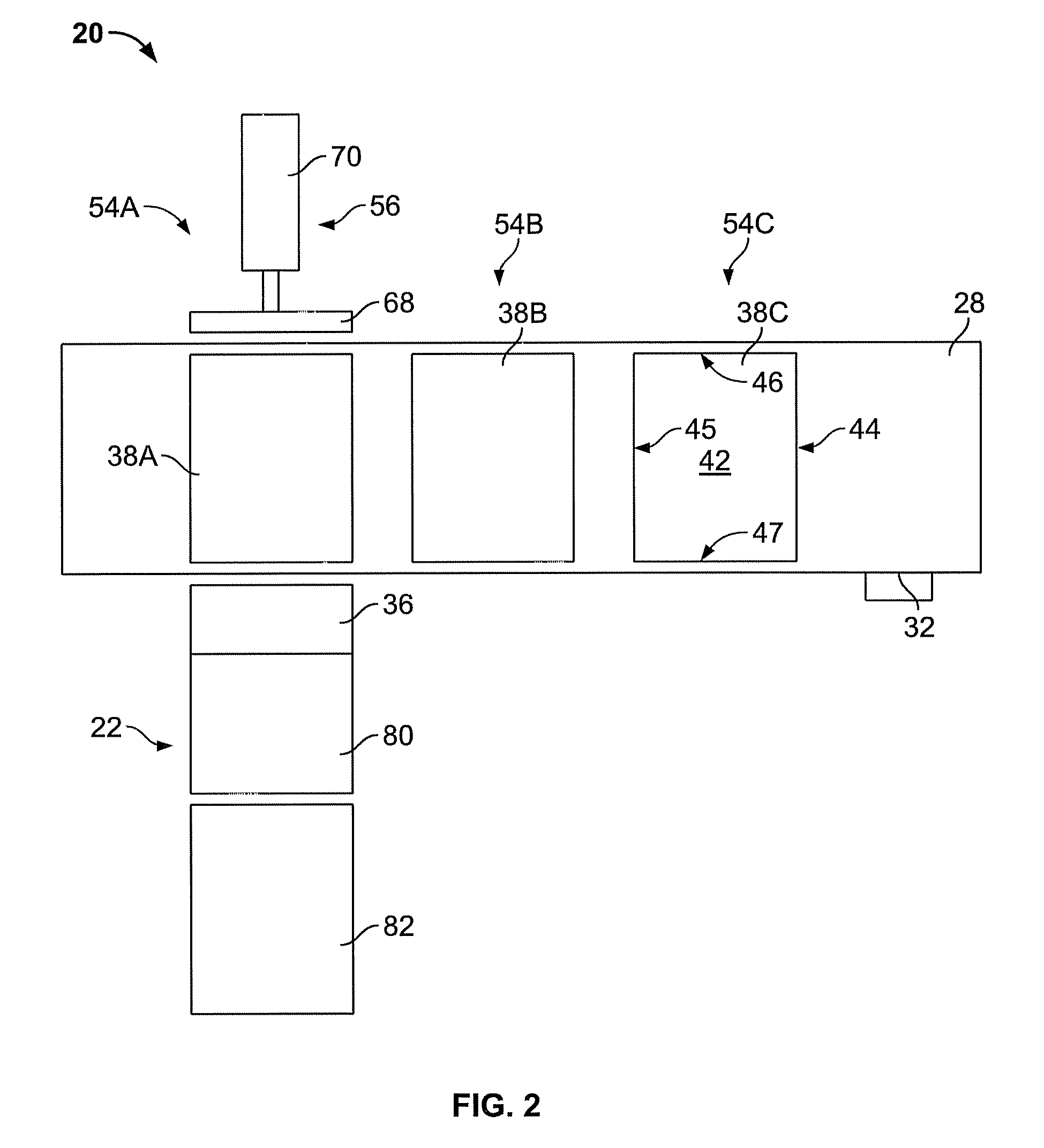

A method of processing items such as pieces of meat, by providing a stream of items by means of a primary conveyor means, allocating at least partly by means of a computer system one or more of said items to one of at least two workstations where said items are processed, e.g. cut and / or trimmed, resulting in one or more processed items, registering in said computer system information about a return of at least one of said one or more processed items to said primary conveyor means, and returning said at least one of said one or more processed items to said primary conveyor means in accordance with said information about a return, wherein the method further comprises keeping track of said items including when they are taken out and put back on the primary conveyor. The invention further relates to a processing system for carrying out the method.

Owner:MAREL HF

Machine for the production of formed patties with a hand made appearance, and method for interleaving paper and stacking

ActiveUS20090087530A1Meat packaging/handling/transportingAuxillary shaping apparatusEngineeringSlip sheet

A cut-off device is used for providing a deposit of known portion weight of the ground meat or paste. This deposit is dropped accurately onto a conveyor belt for transport to a press wheel the height of which, from the conveyor, can be adjusted to provide a finished product of correct thickness. The press wheel has a system of vacuum ducts around the circumference in four chambers that pull paper from a de-nesting tray situated at the top of the press wheel, at the correct interval as to meet up with the deposit at the base of the wheel. This results in the deposit being pressed to the required thickness onto the conveyor, with the interleave paper attached to the top of the now formed patty.

Owner:RISCO USA CORP

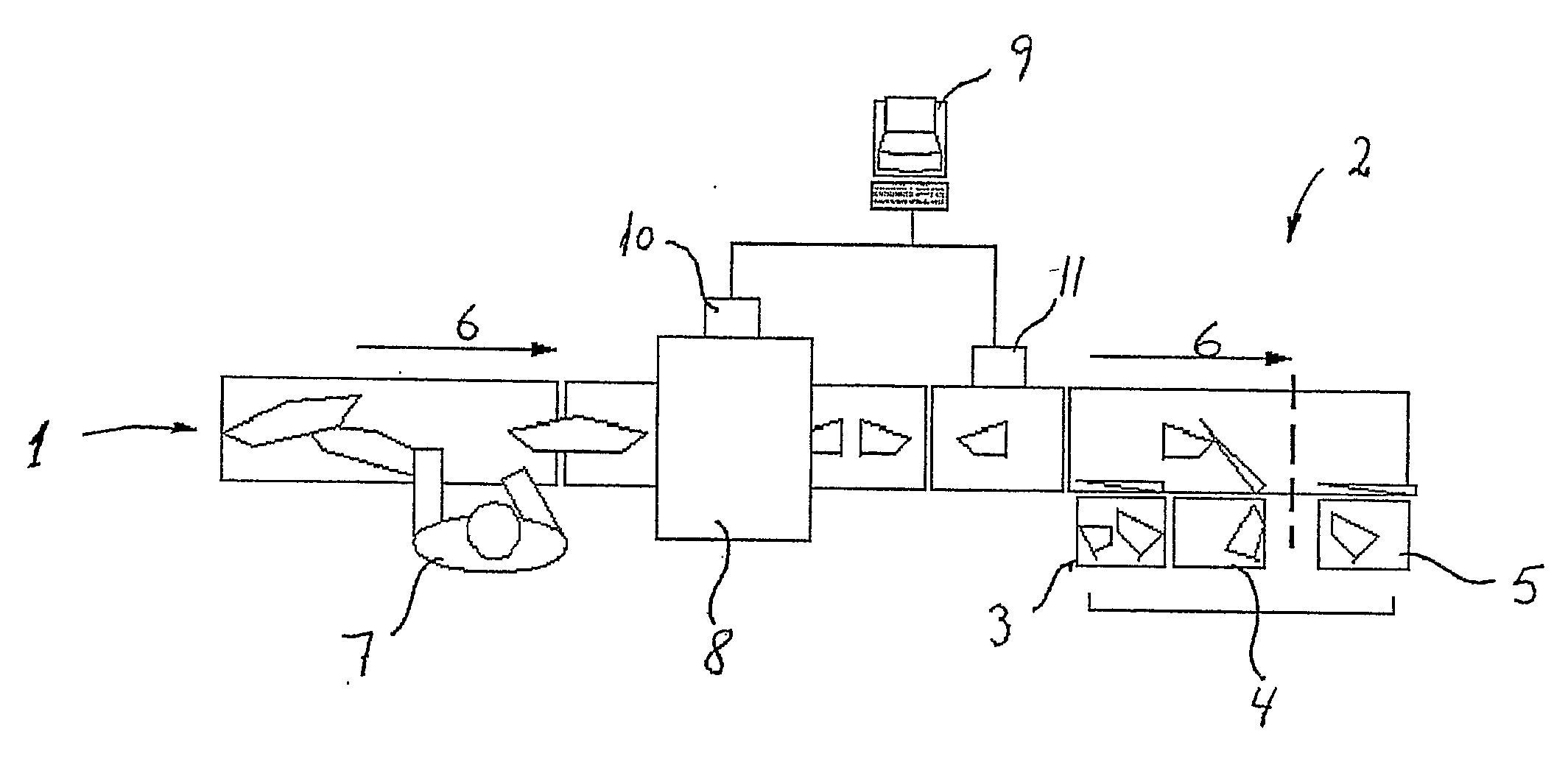

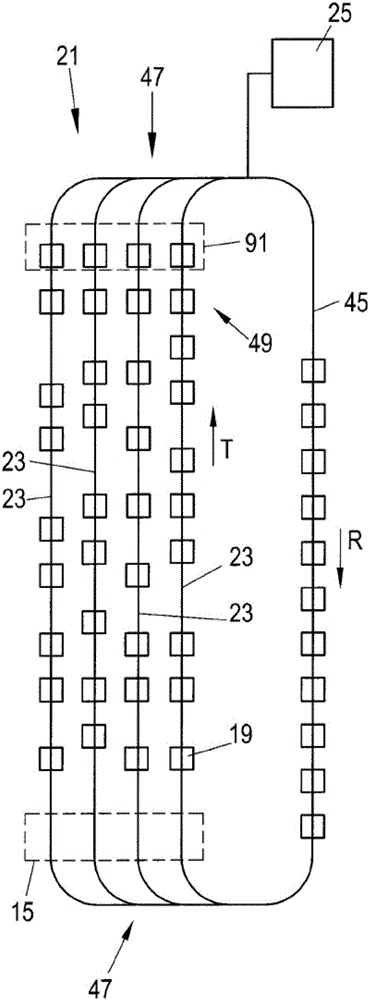

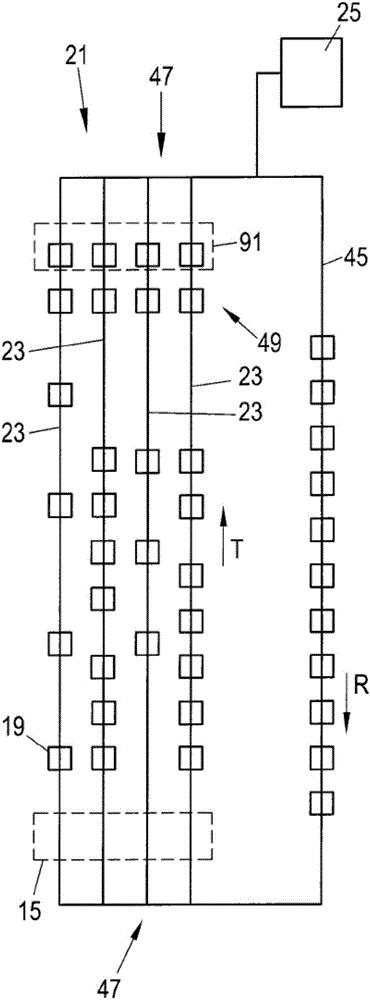

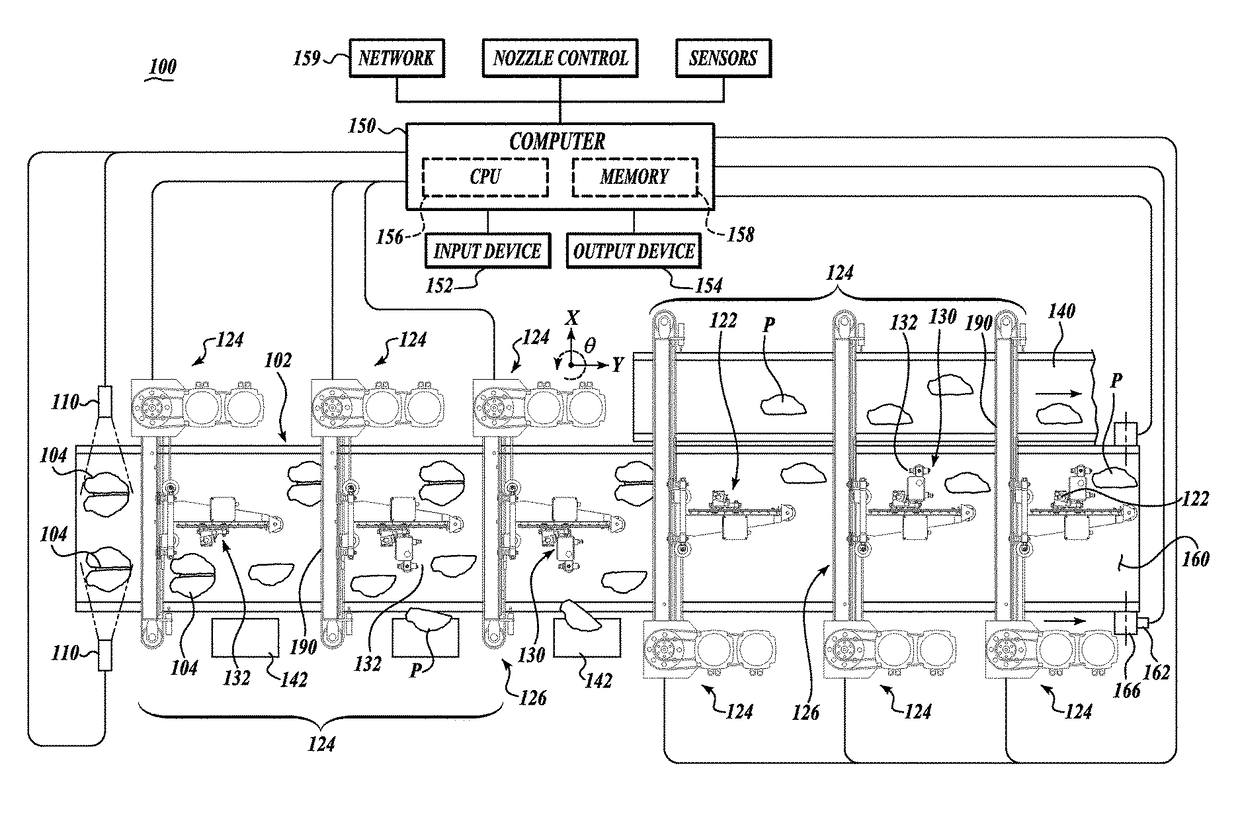

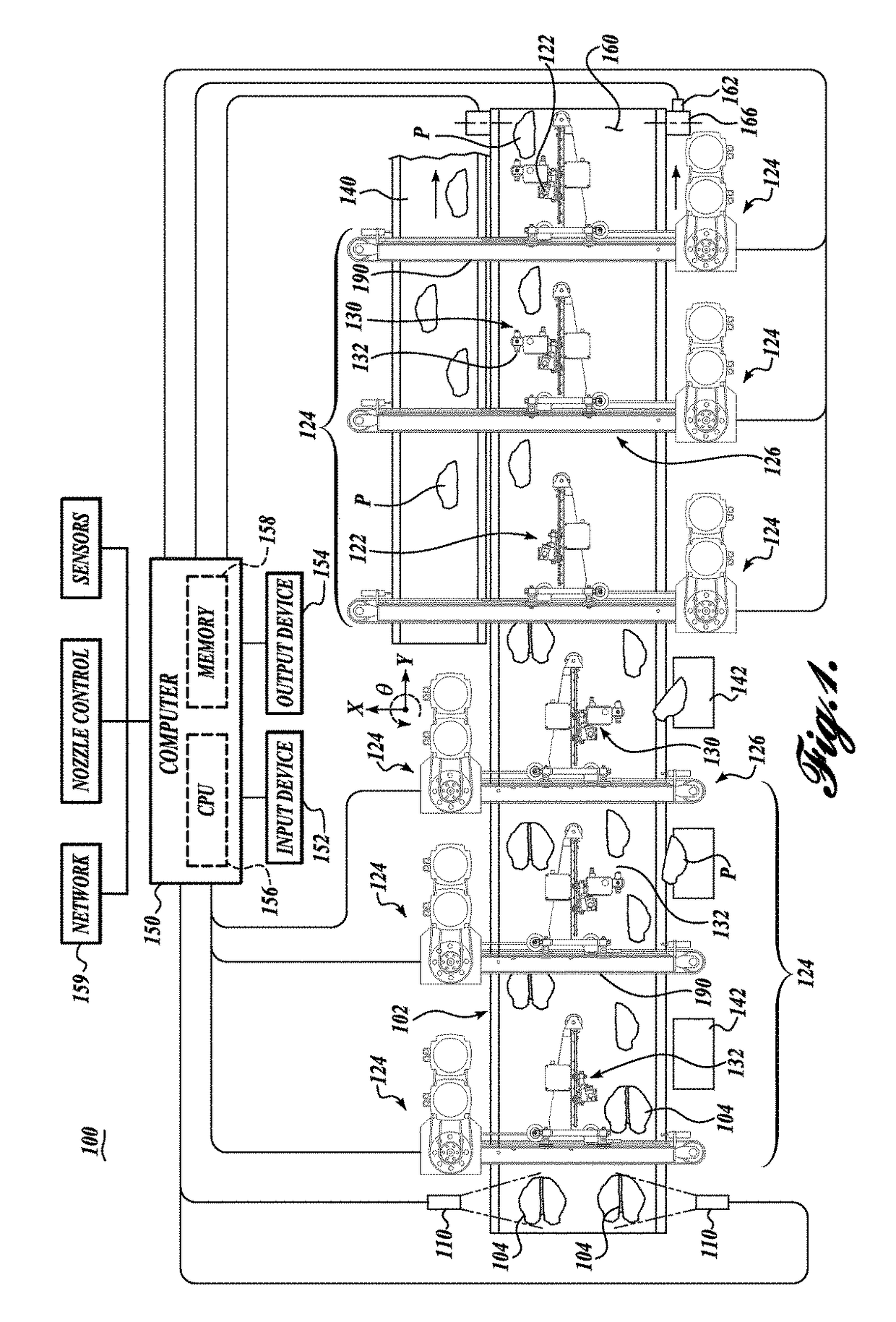

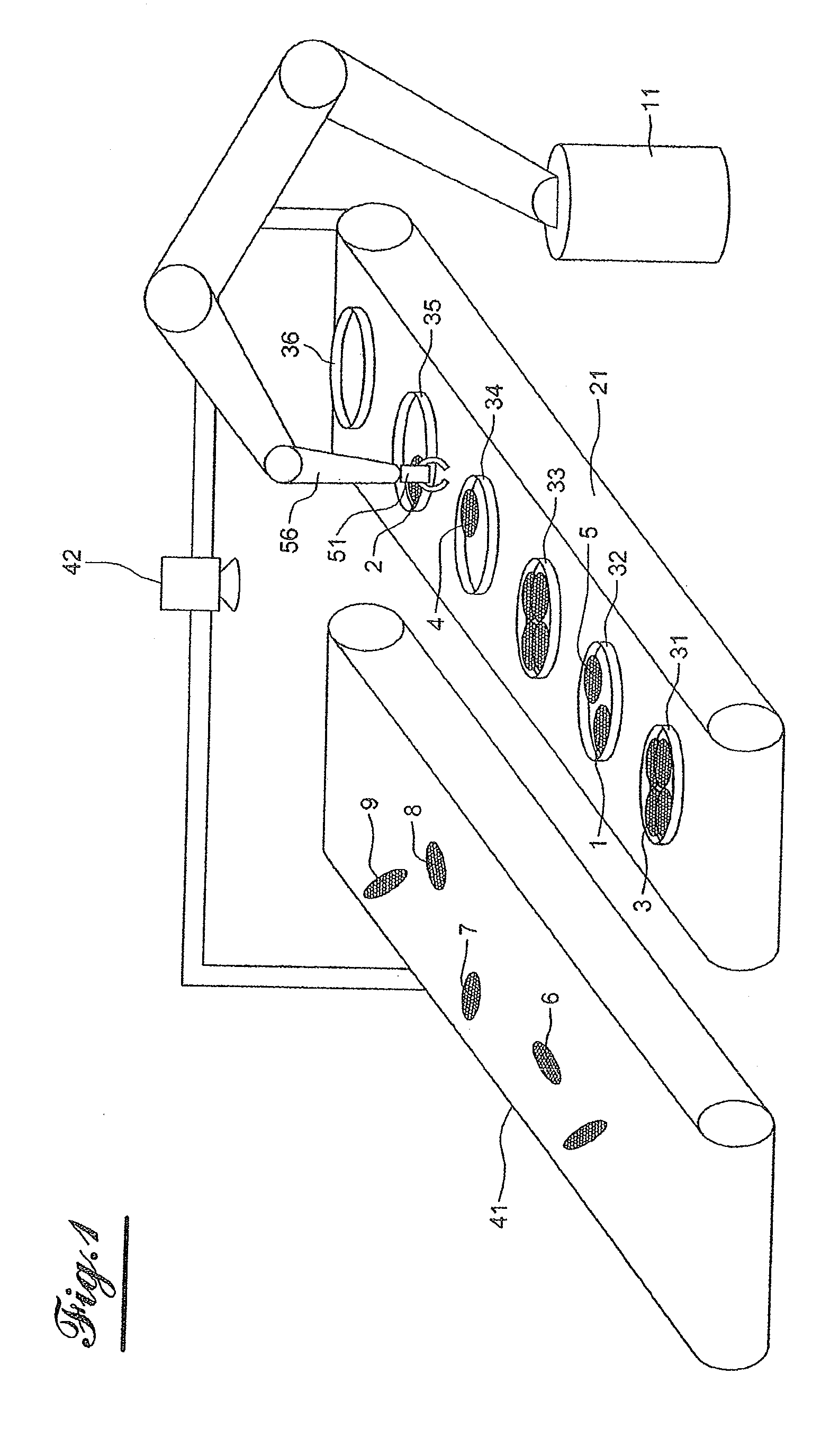

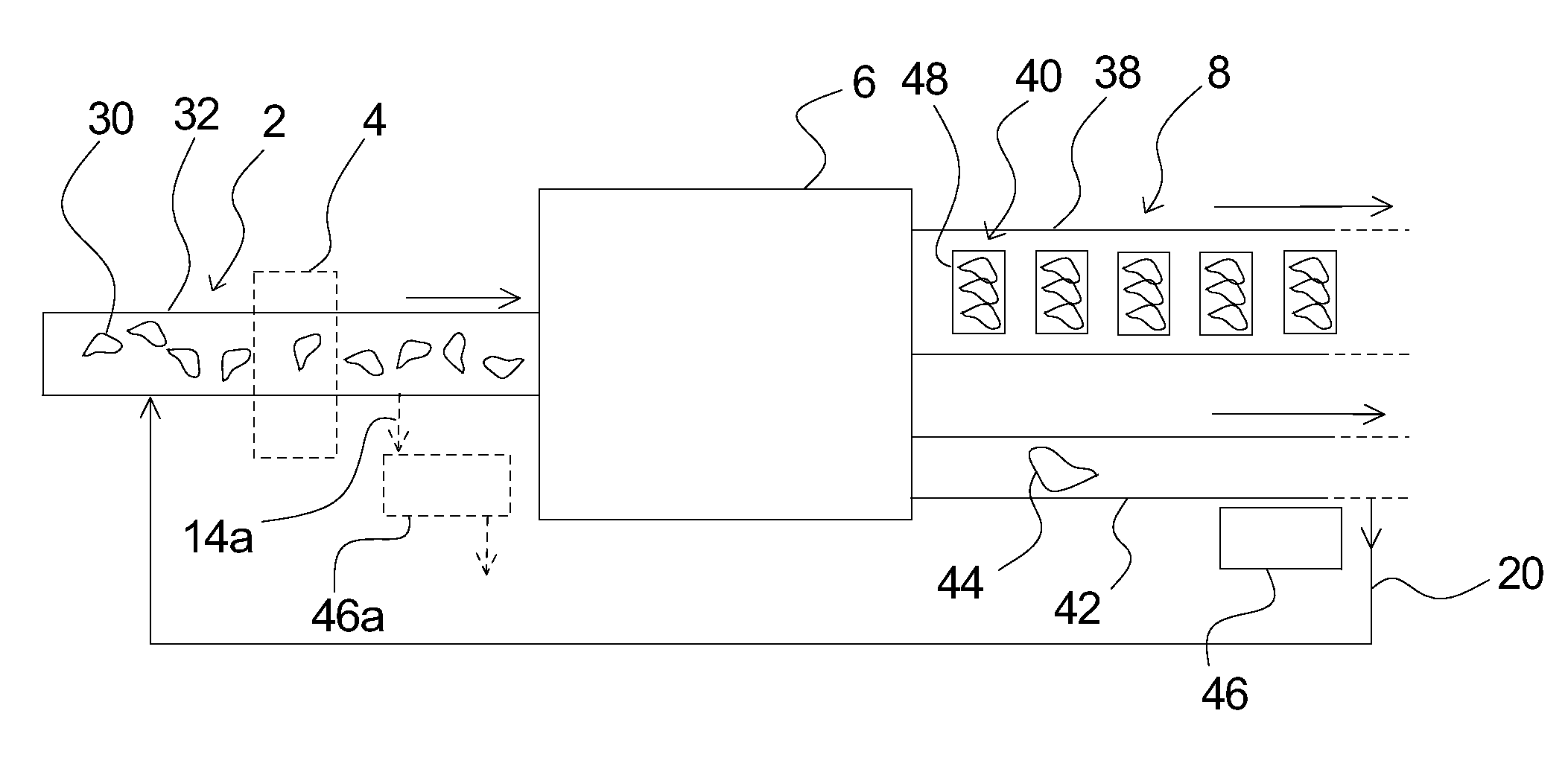

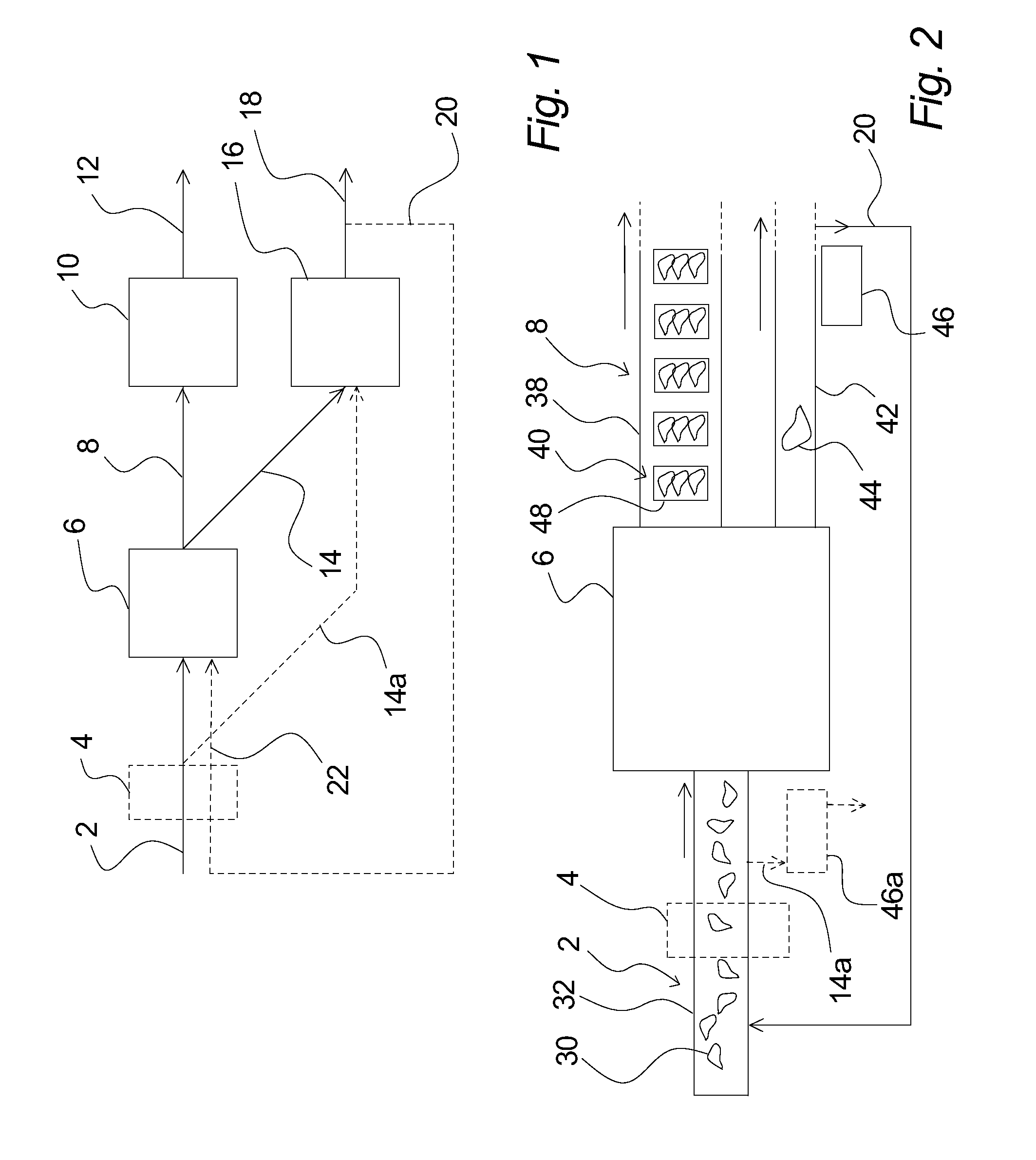

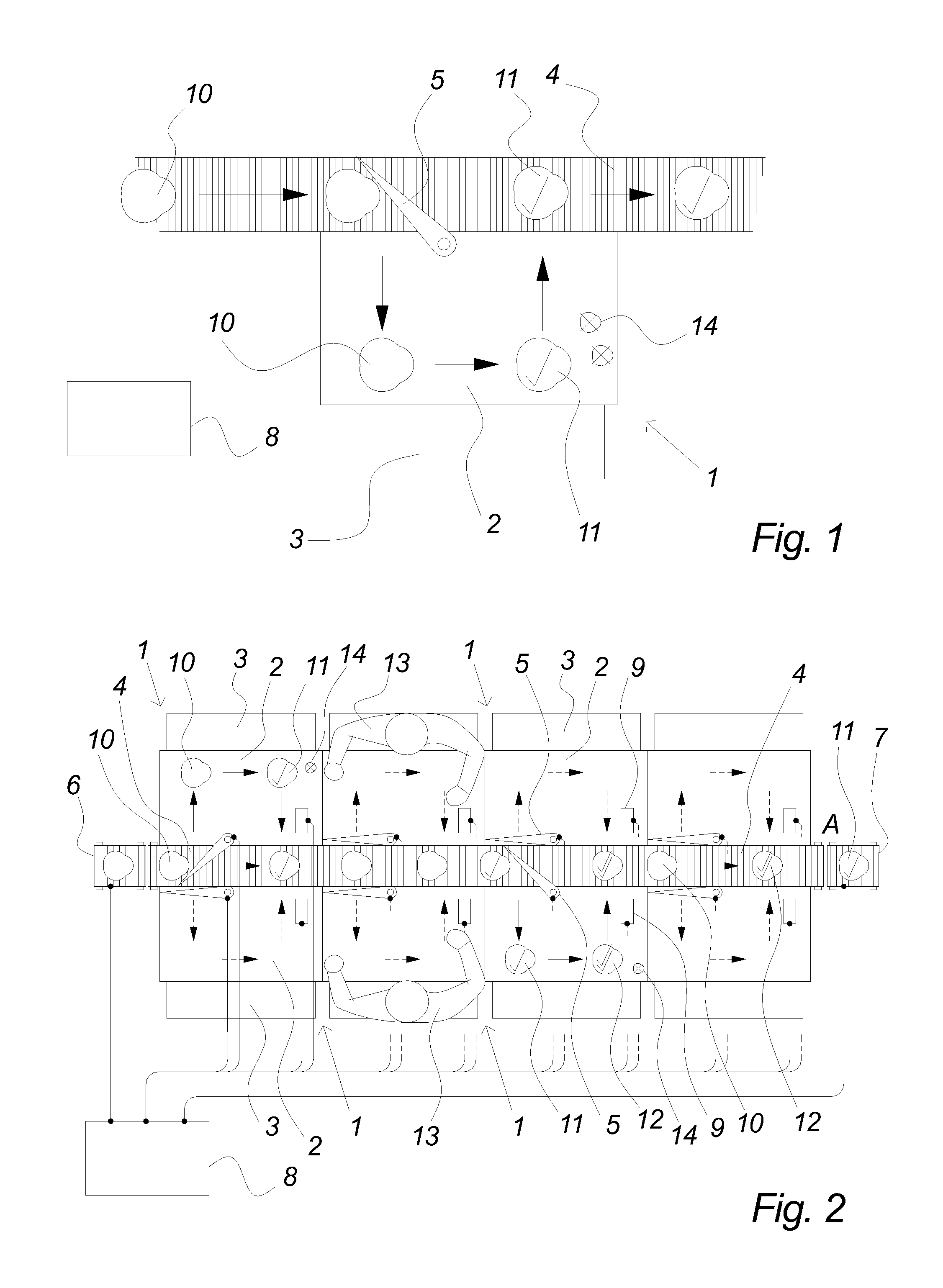

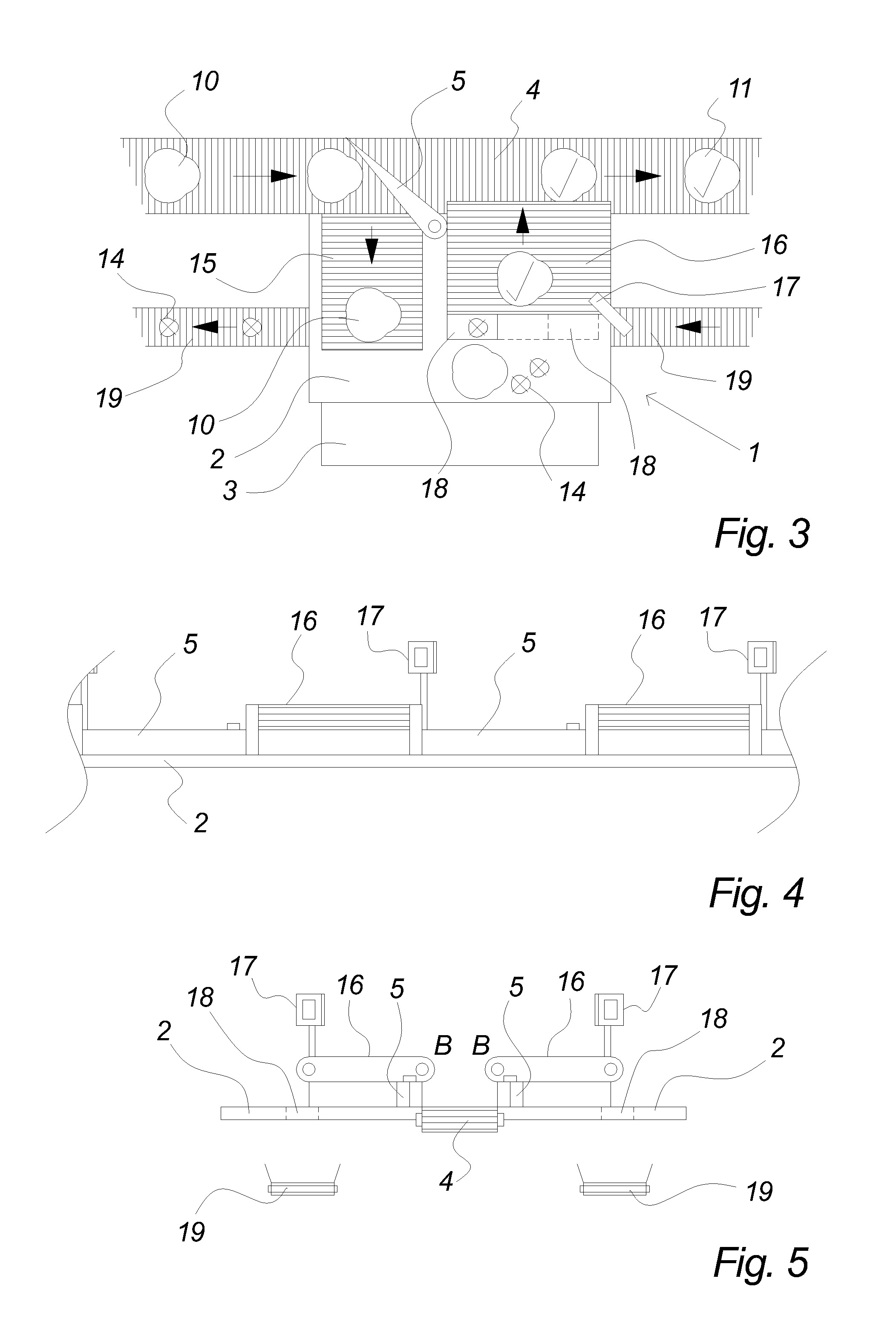

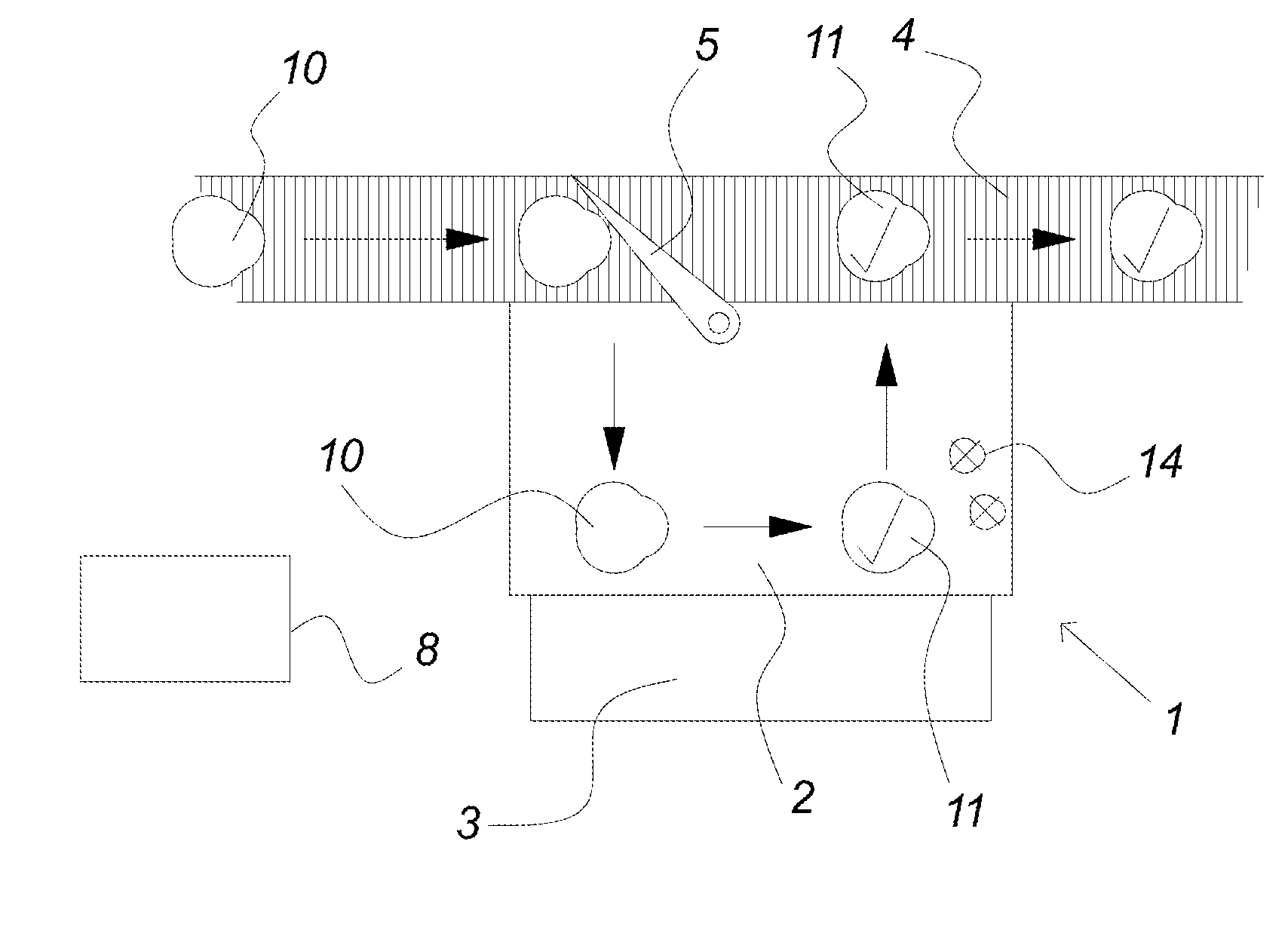

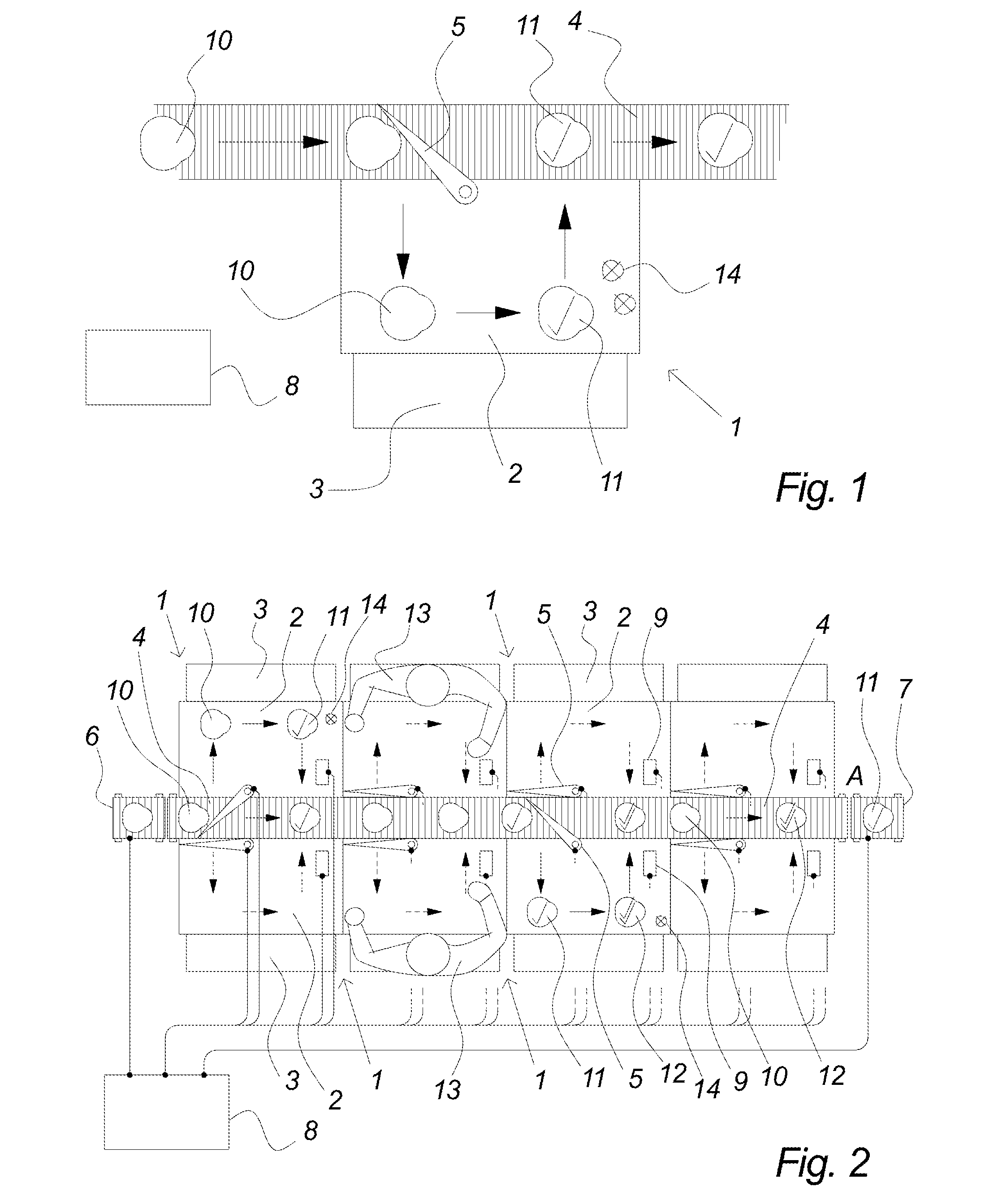

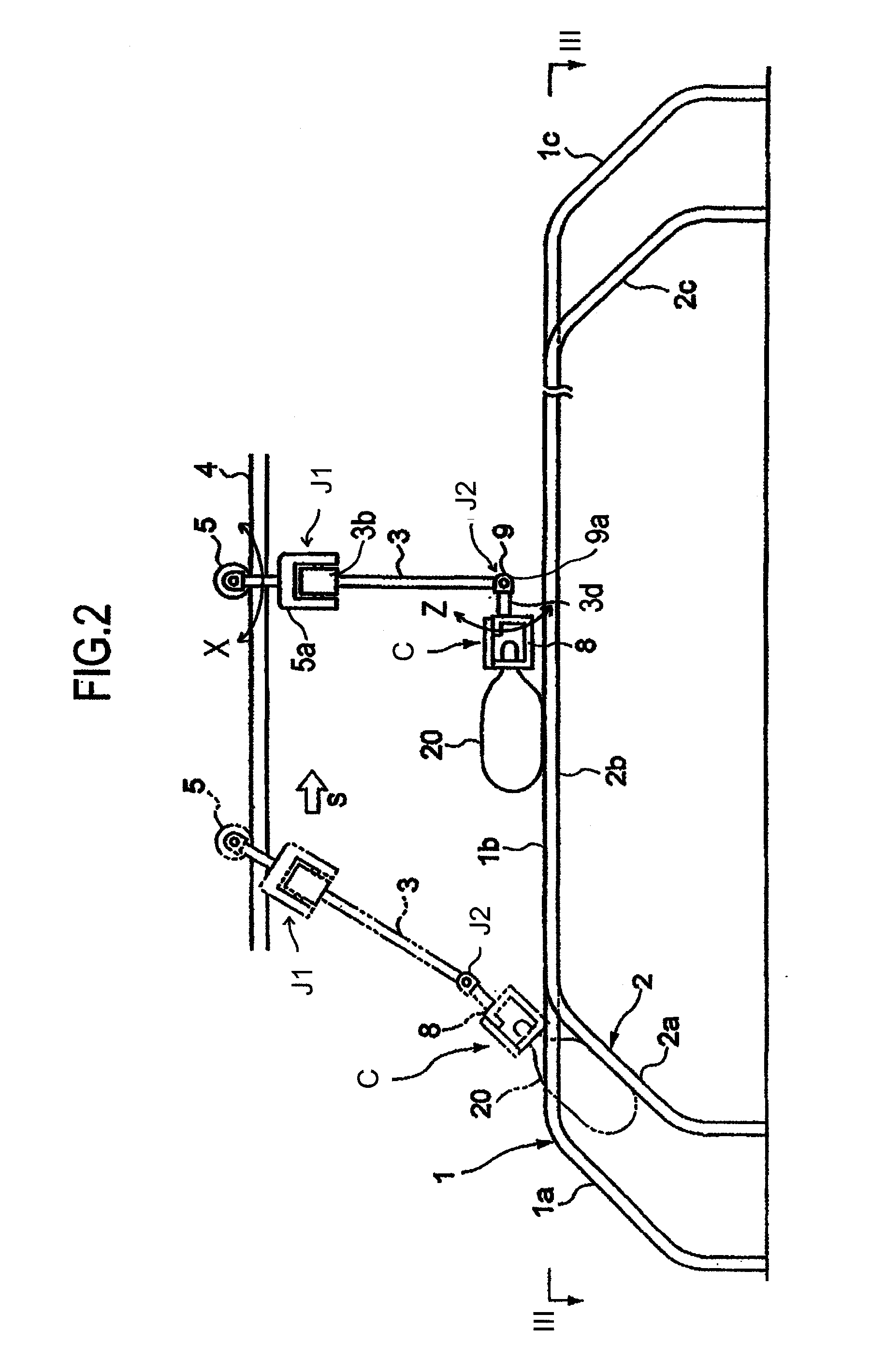

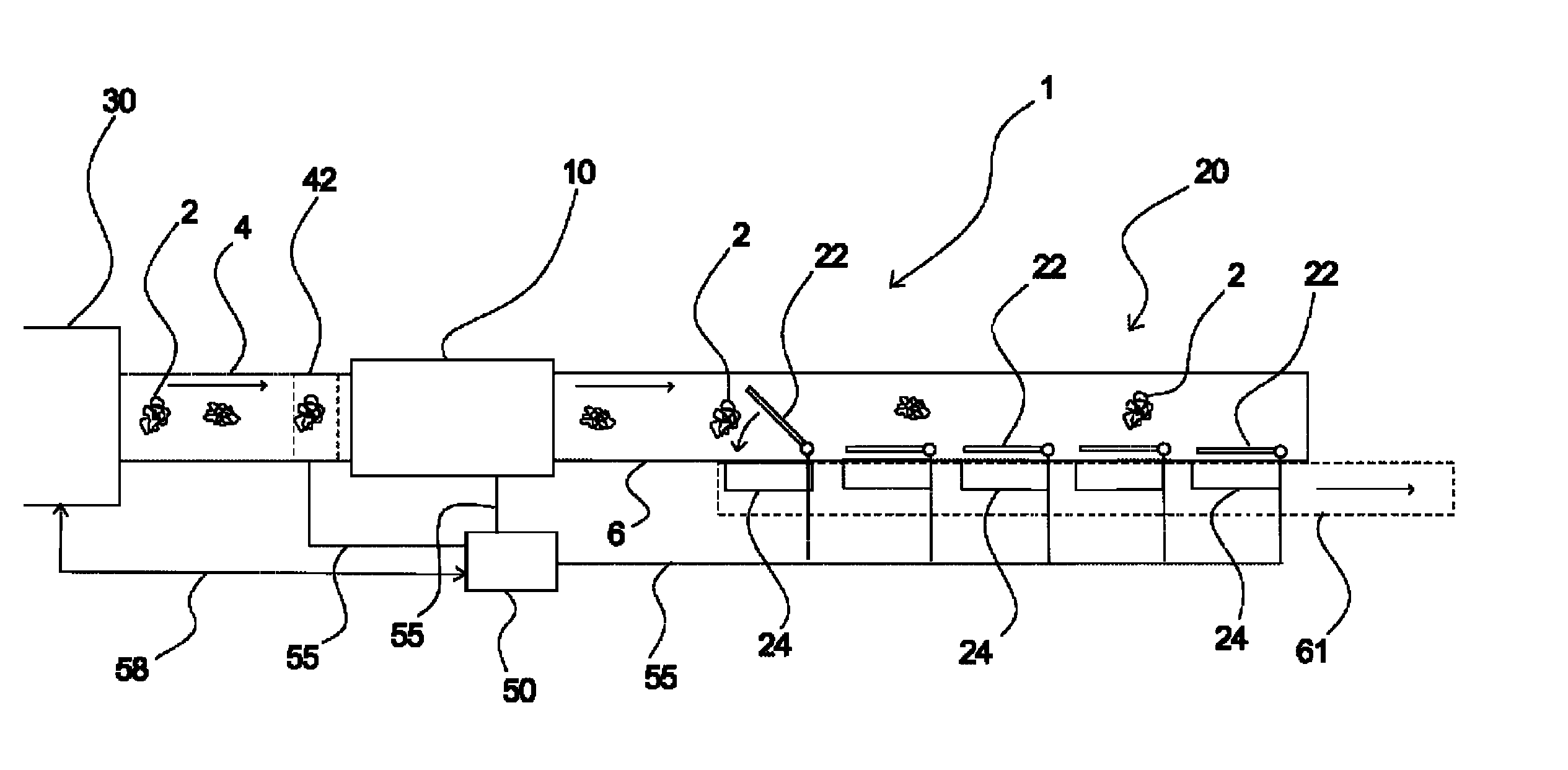

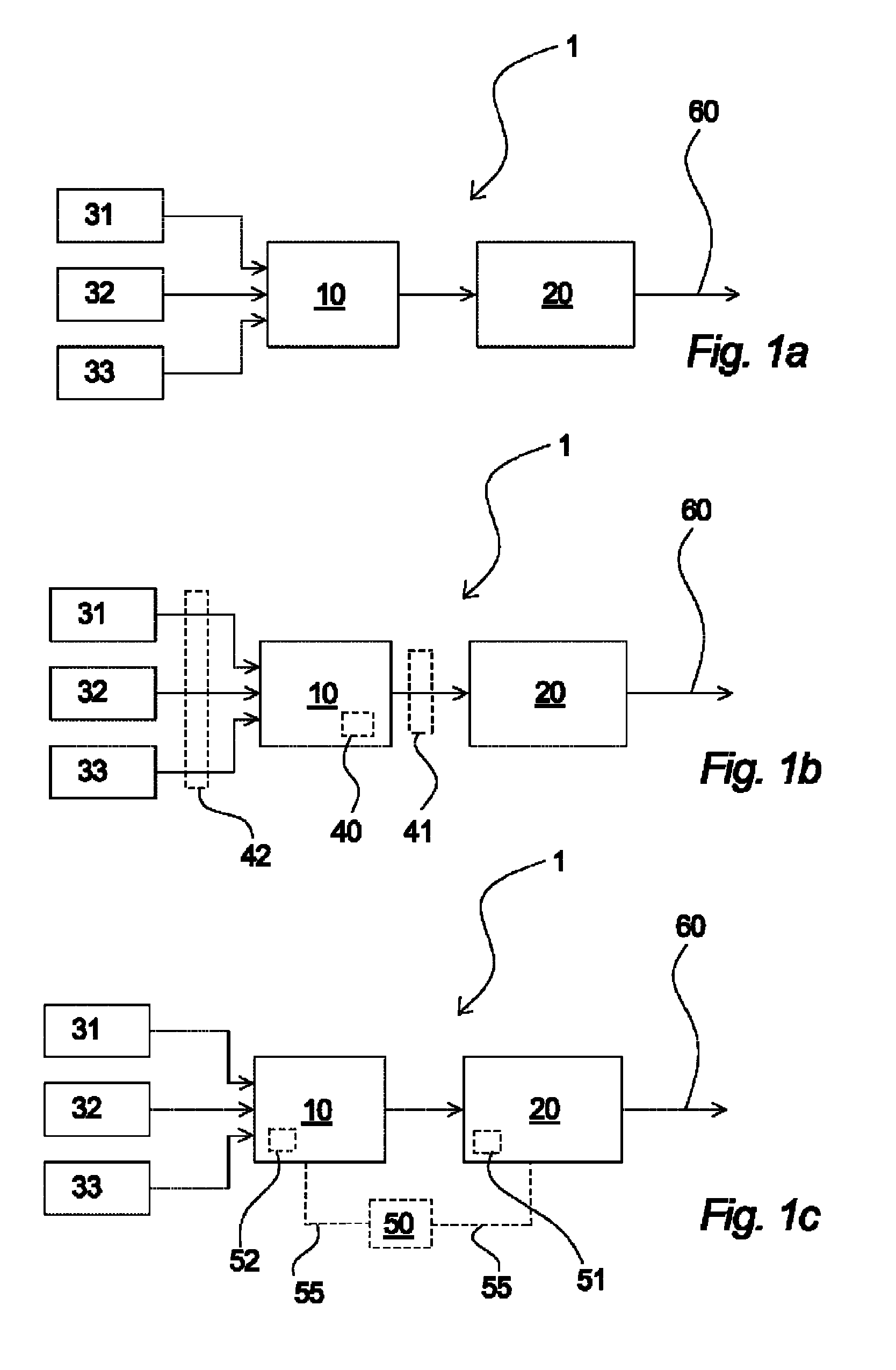

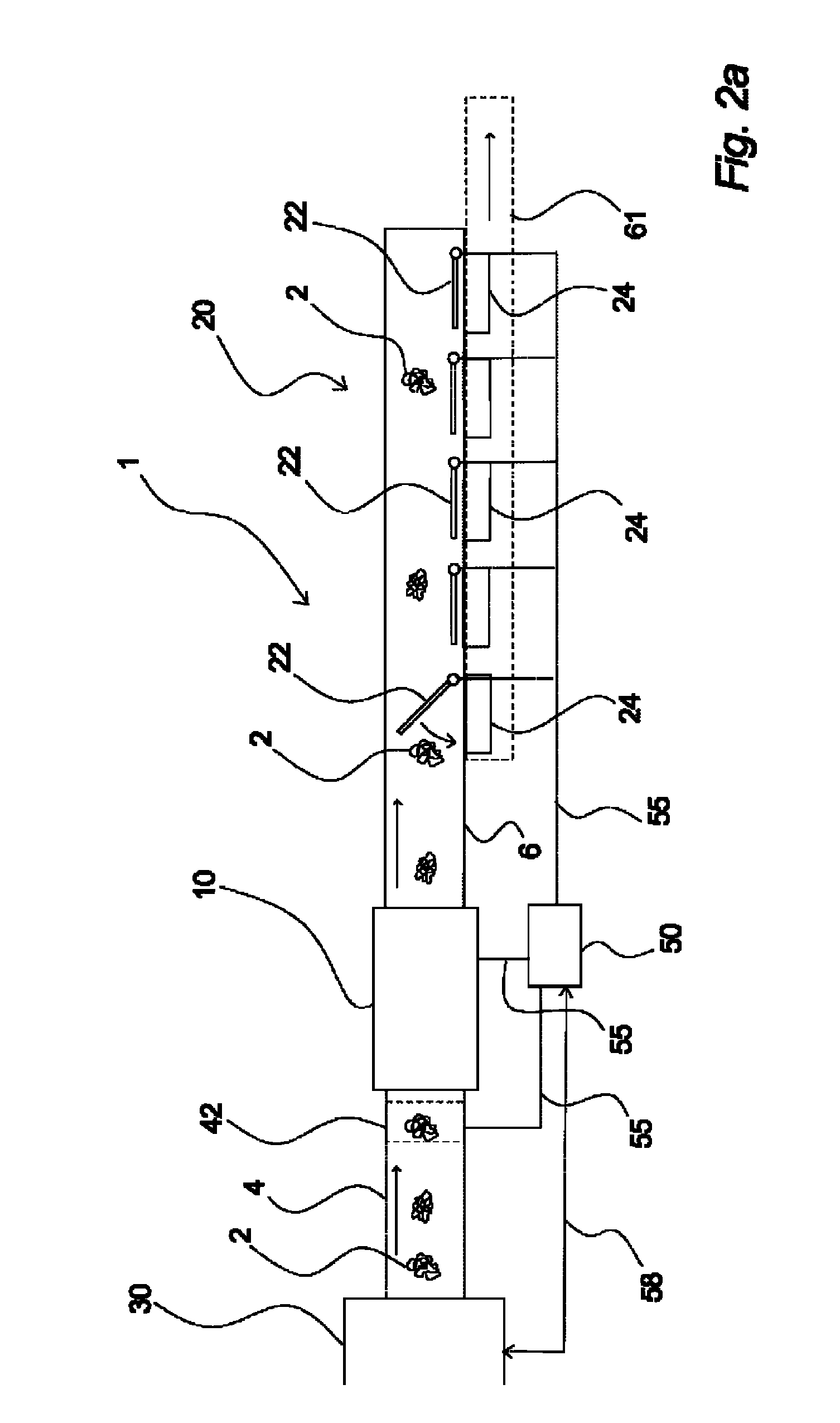

Method for processing items such as pieces of meat

ActiveUS20110054674A1Simplify cleaning proceduresSimple methodDigital data processing detailsMeat packaging/handling/transportingWorkstation

The invention relates to a method for processing items such as pieces of meat, comprising the steps of providing a stream of items 10 by means of a primary conveyor means 4, allocating at least partly by means of a computer system 8, 20 one or more of said items 10 to one of at least two workstations 1 where said items 10 are processed, e.g. cut and / or trimmed, resulting in one or more processed items 11, registering in said computer system 8, 20 information about a return of at least one of said one or more processed items 11 to said primary conveyor means 4, and returning said at least one of said one or more processed items 11 to said primary conveyor means 4 in accordance with said information about a return.The invention further relates to a system for processing items such as pieces of meat, said system comprising the means essential to carry out the above-mentioned method.

Owner:MAREL HF

Method for enclosing products in a package having a handle

An apparatus for encasing product in a tubular material with a handle is described. The apparatus of the preferred embodiment of the invention comprises a delivery conveyor, a ram located on a first side of the delivery conveyor, a product horn located at a side of the delivery conveyor opposite the ram, the product horn having a first end and a second end, the first end adjacent the delivery conveyor and the second end remote from the delivery conveyor, a sealer configured to form tubular seamed casing about the product horn, a printer in data communication with a scale, a clipper located at the second end of the product horn, and a plurality of tag handles feeding through the printer and to the clipper.

Owner:PRETSITEK KORP

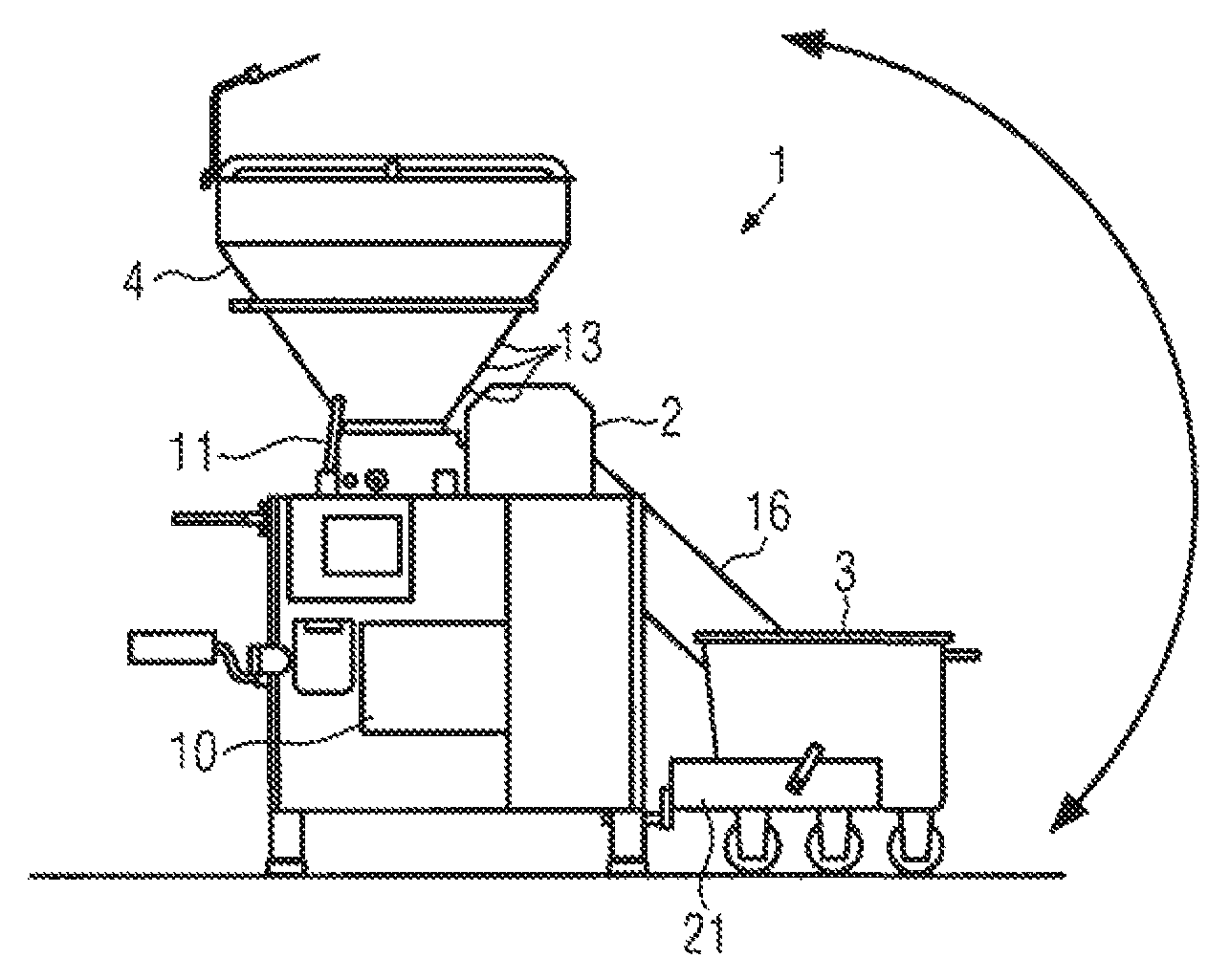

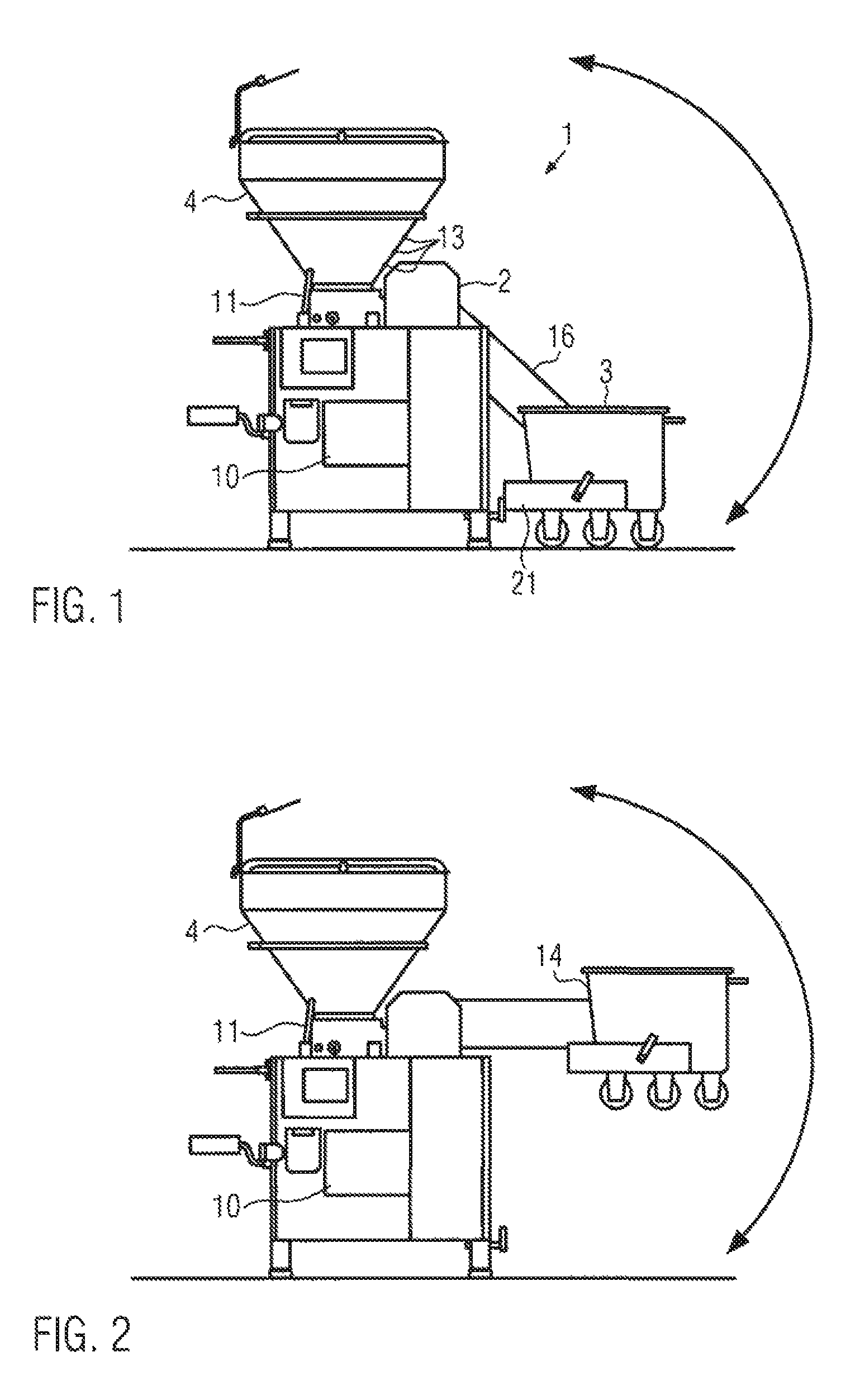

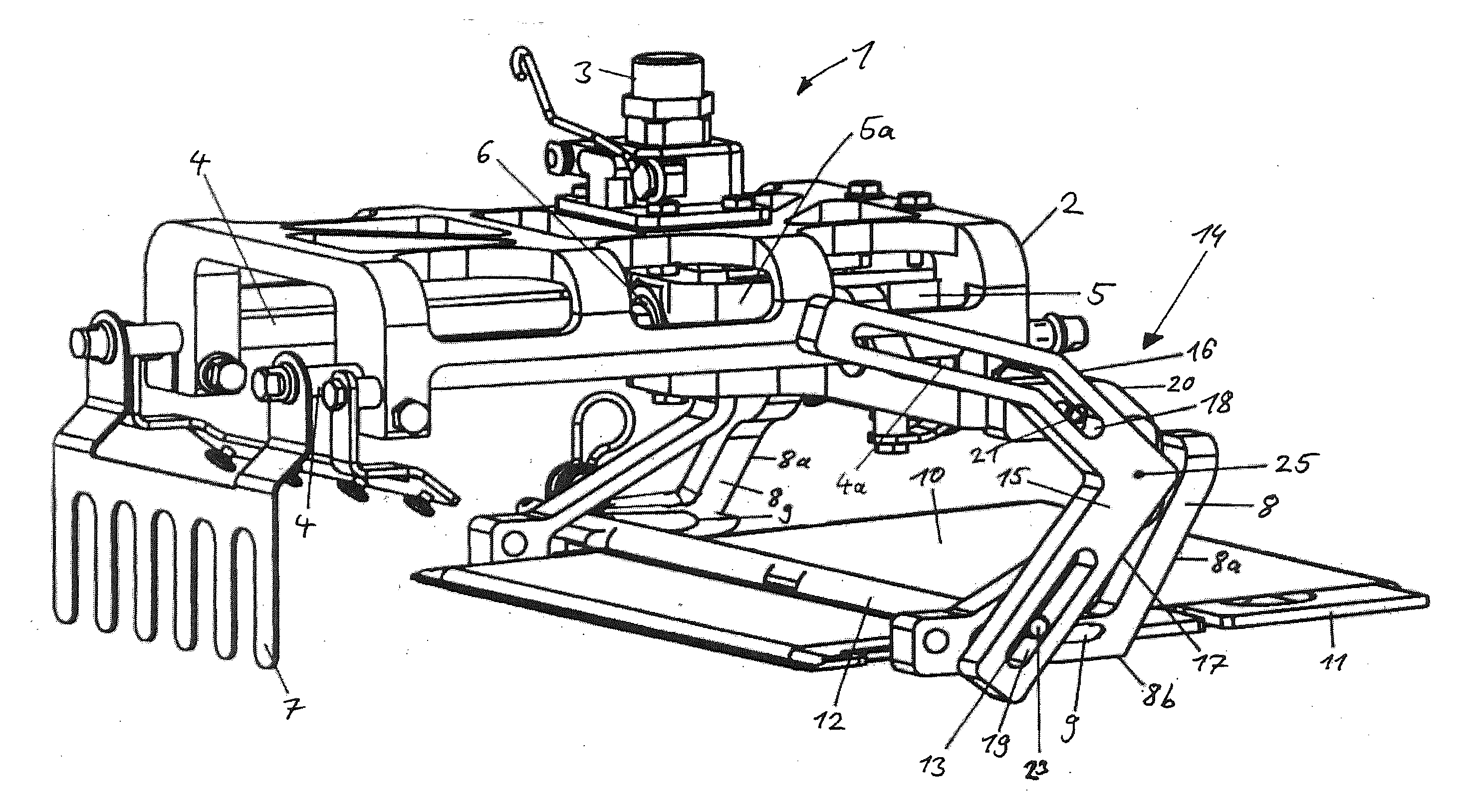

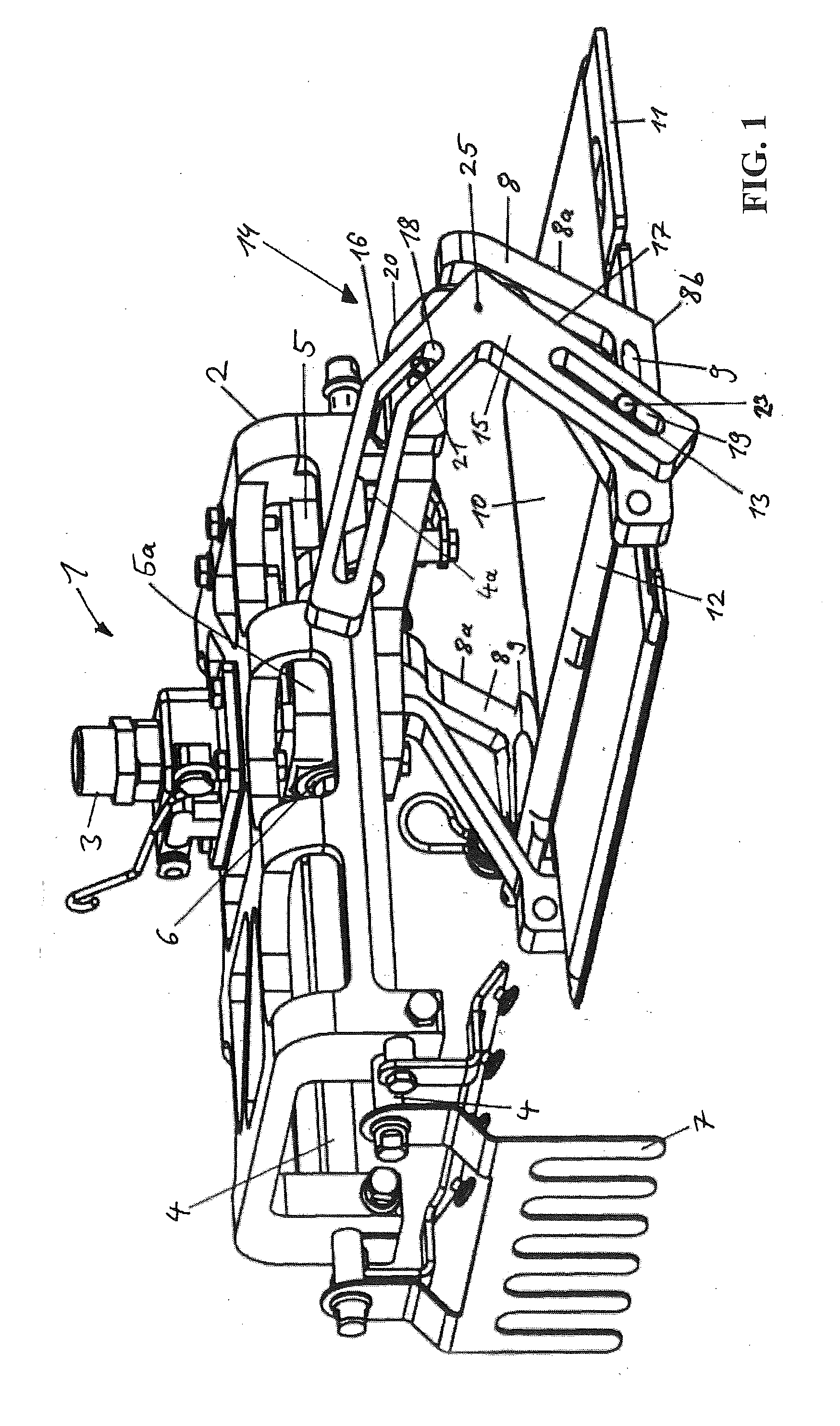

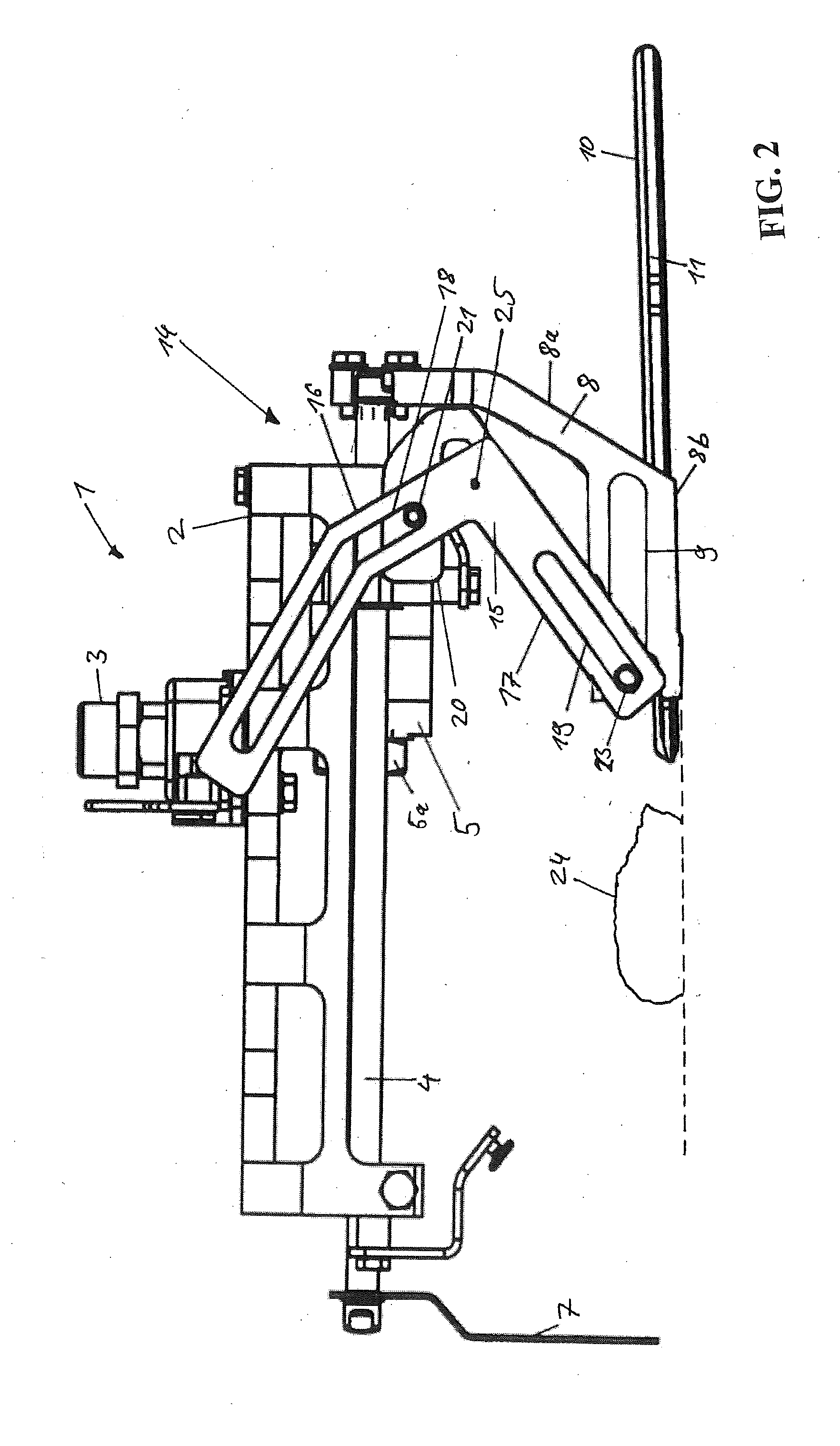

Device and method for loading a food processing machine, in particular a filling machine or a cutter, with food

ActiveUS9089147B2Operational securityMinimize timeSausage filling/stuffing machinesLiquid bottlingEngineeringMechanical engineering

A device and a method for loading a food processing machine, in particular a filling machine or a cutter, with food, including a container for receiving the food, a lifting means by which the container can be driven upwards, a drive for the lifting means, and a measuring means for detecting the amount of food in the container.

Owner:ALBERT HANDTMANN MASCHFABRICK

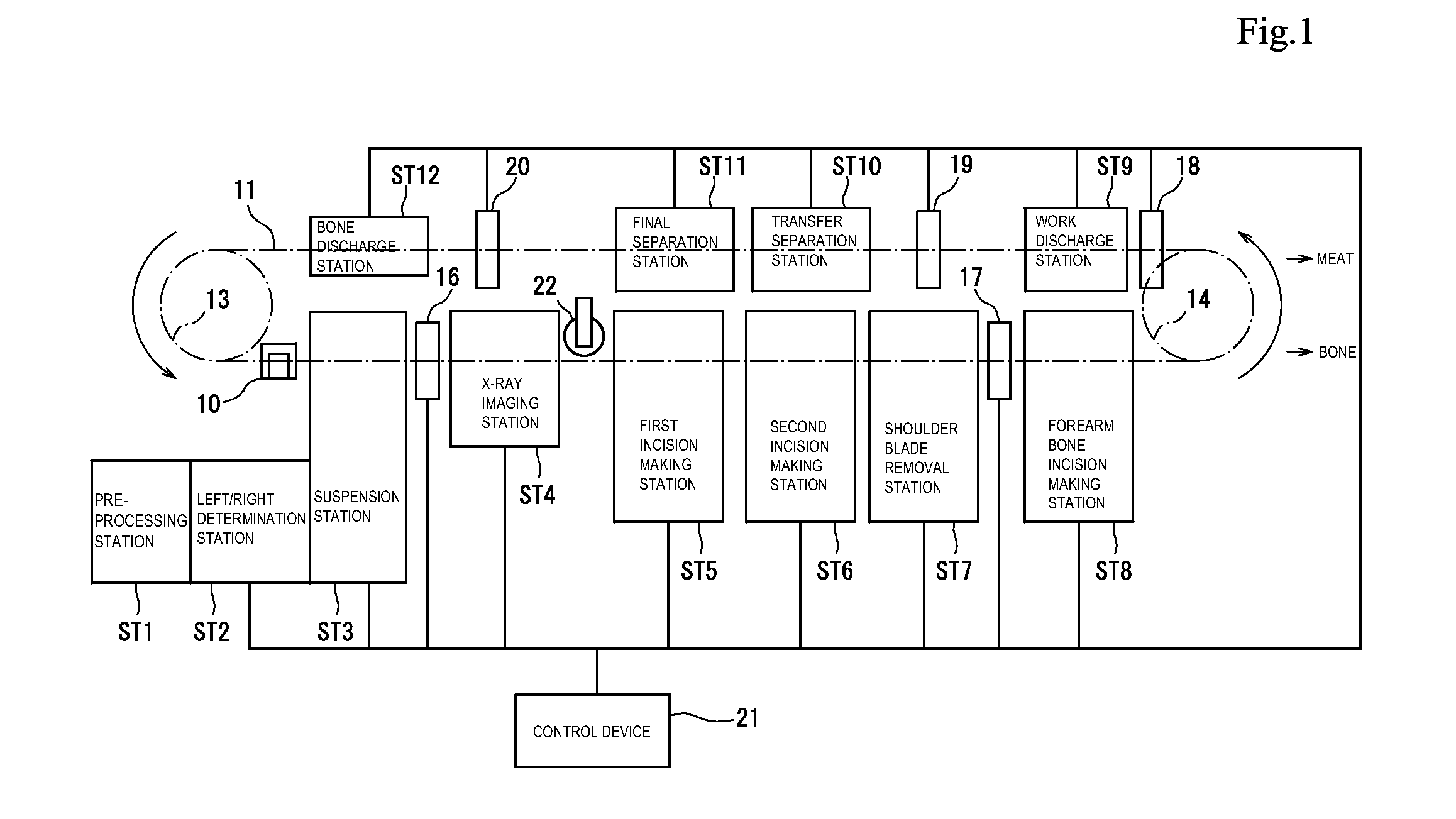

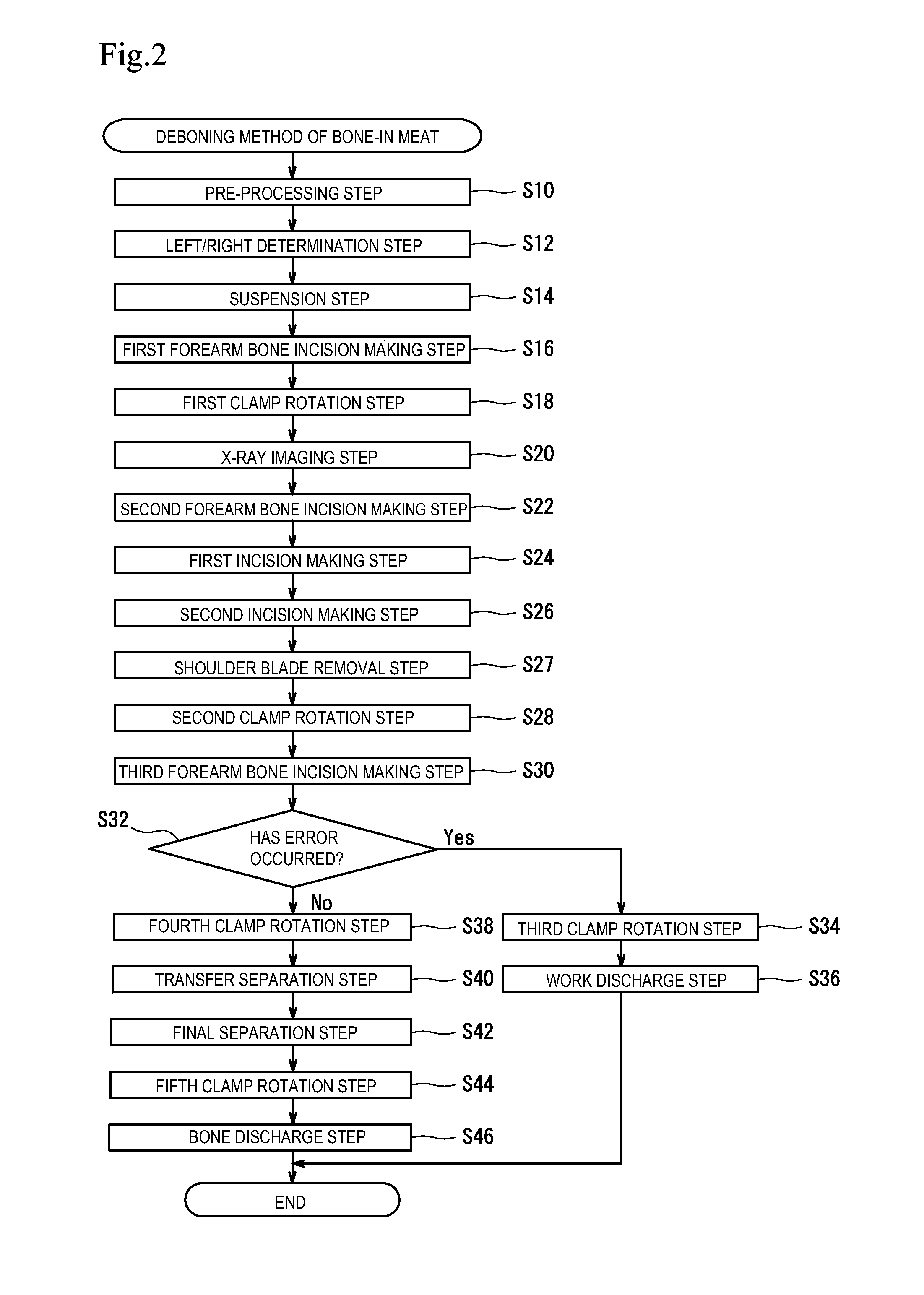

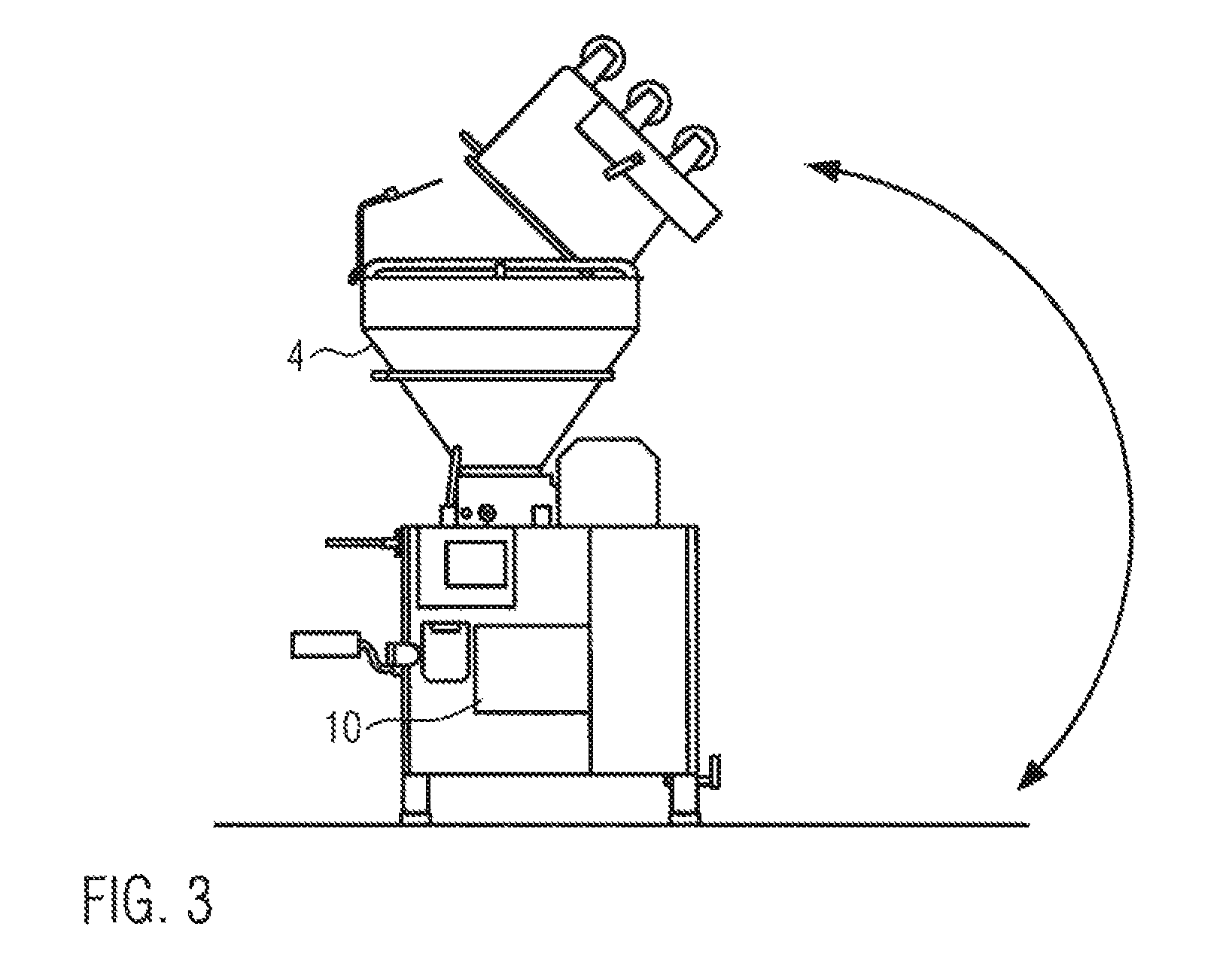

Meat dressing/boning method and system

InactiveUS20070212995A1Restrict movementAvoid contaminationMeat holding apparatusMeat packaging/handling/transportingEngineeringMechanical engineering

A meat dressing and boning method and a system thereof can dress and bone meat and carcass in short work-hours, while avoiding bacterial contamination. The system includes a clamp mechanism for holding a meat block with bones, a hanger connected to clamp mechanism and movably suspended from a support rail, and a guide rail or rails having a tubular or rod-like configuration for supporting the meat block positioned along and below the support rail. The hanger has at least two pivots to allow the meat block held by the clamp mechanism to rotate about at least first and second axes, which are perpendicular to each other. The meat and carcass can be broken up and boned while being moved along the support rail, with the swinging directions of hanger regulated by the guide rail or rails.

Owner:MAYEKAWA MFG CO LTD

Gripper system

ActiveUS20130033049A1Improves the picking up of a productDesign freedomConveyorsMeat packaging/handling/transportingLinear motionEngineering

A gripper system for improving the picking up of a product, in particular of an elastic article. The gripper system having a gripper, wherein the gripper comprises an endless transport belt and a lever system. The lever system includes a rotatably supported lever, a support and an entrainer configured to entrain the transport belt, wherein the lever is connected to the support such that, in response to a linear movement of the support, the lever will be rotated about a center of rotation. The lever is additionally connected to the entrainer such that the transport belt moves in response to the rotational movement of the lever.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

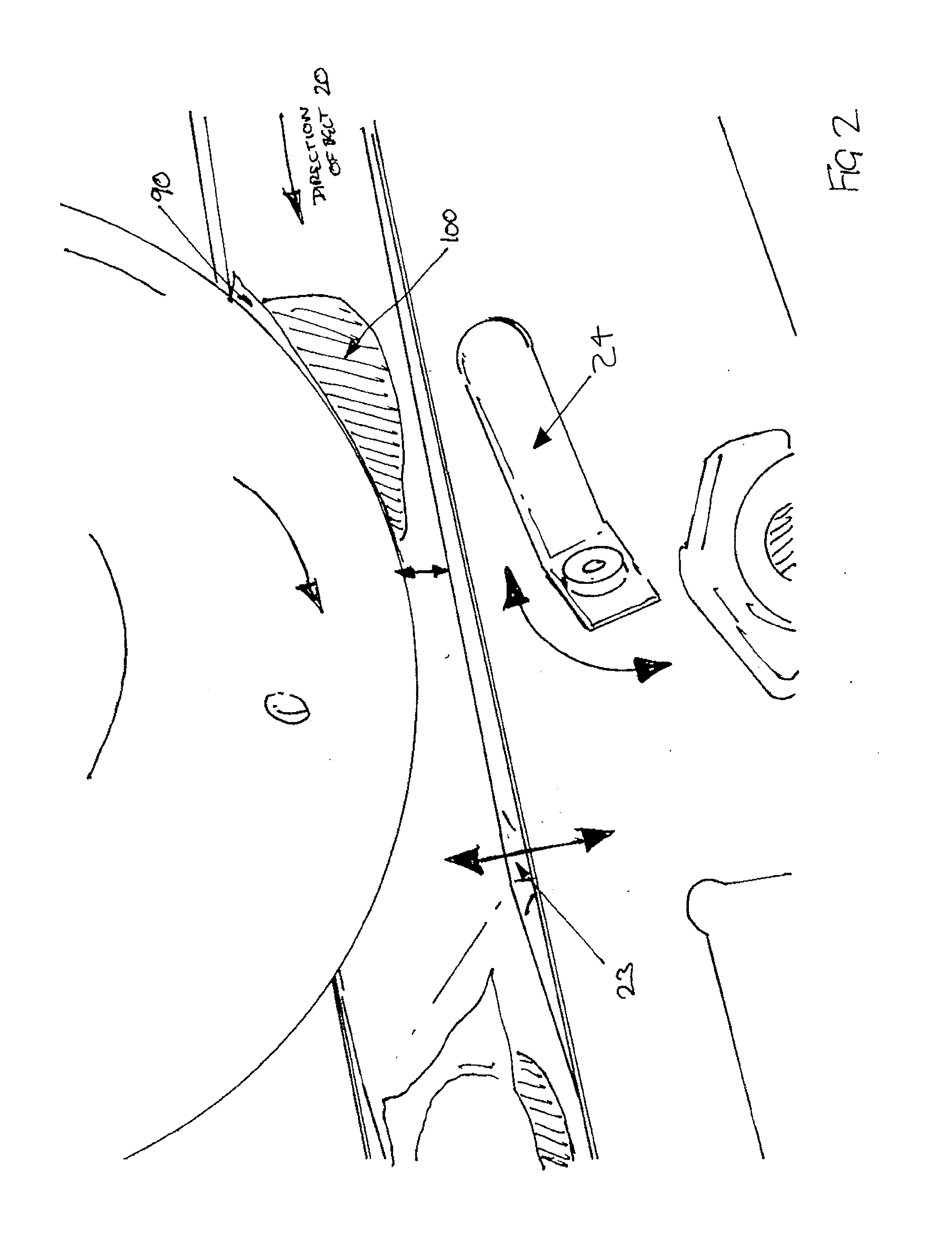

Apparatus and method for positioning separately supplied elongate meat products

InactiveUS6913136B2Easy constructionIncrease freedomMeat packaging/handling/transportingSausage makingMechanical engineeringEngineering

Owner:STORK BV

Breech loader

An apparatus for automatically delivering placed and oriented pieces of meat to a netter for wrapping and netting is described, in which the placement and orientation of the meat pieces remains unchanged from initial placement until final wrapping and netting. The apparatus is a conveyor having a series of compartments in which the meat is placed and oriented. The conveyor is situated below the level of the breech of the feed tube to the netter, so that a compartment carried on said conveyor will be precisely aligned with the opening to the feed tube. A ram pushes the meat pieces out of the compartment and into the feed tube, without changing the placement or orientation of the meat pieces relative to each other. The netter wraps the meat pieces in a collagen film and encases the wrapped meat in a net for further processing.

Owner:POLY CLIP SYST

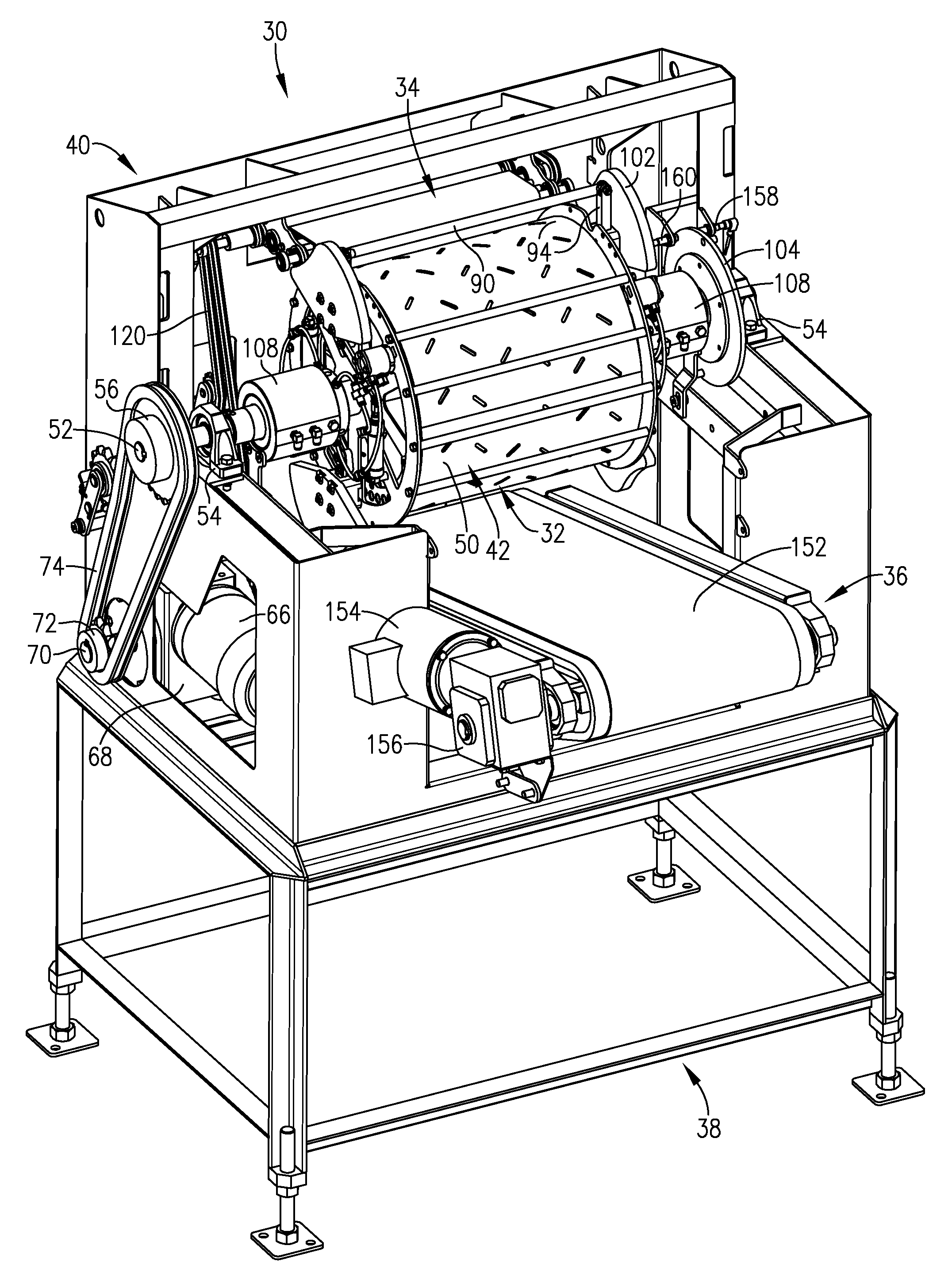

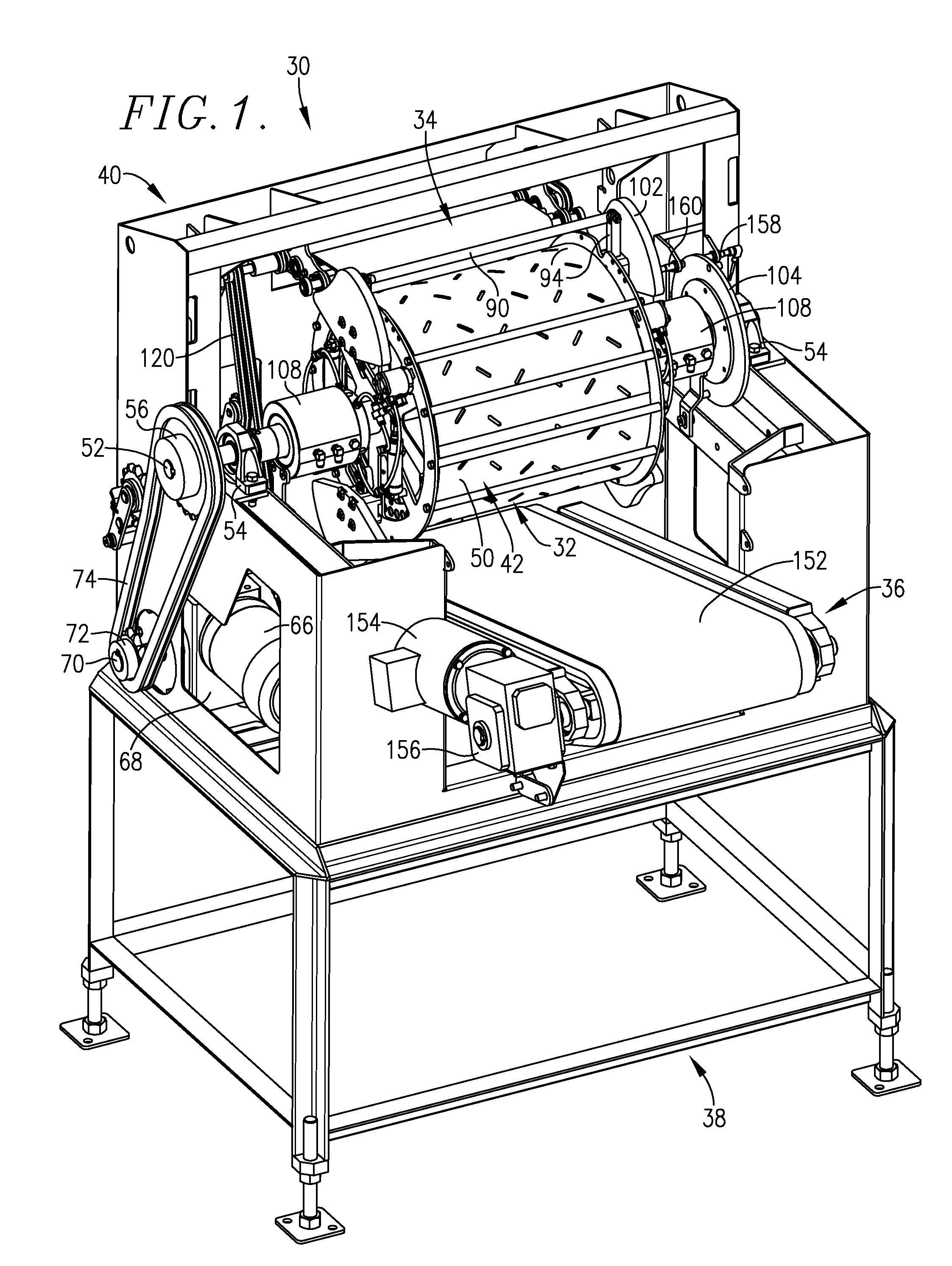

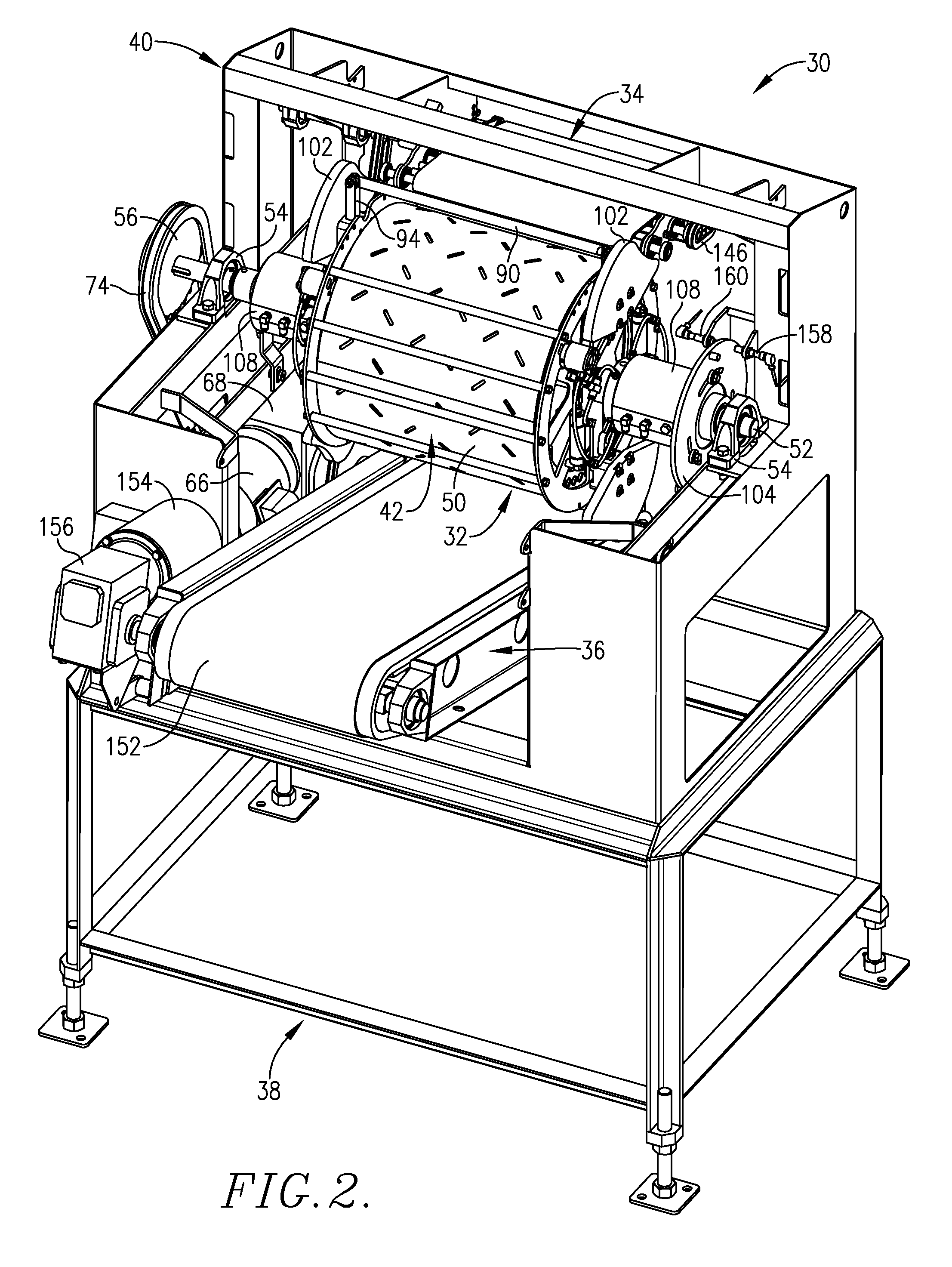

Apparatus and method for processing of pork bellies

A device (30) is provided for the inversion of bodies of meat (e.g., pork bellies 162, 164) during processing thereof in order to eliminate the manual labor involved in conventional packing house operations. The device (30) includes a rotatable inversion drum (32) made up of inner and outer drum subassemblies (42, 44), which are selectively interconnected by means of lock pin cylinders (86). An entry conveyor (34) serves to direct incoming meat bodies to the drum (32) and an exit conveyor (36) is provided to convey inverted meat bodies away from the drum (32). In preferred forms, the drum (32) has a pair of circumferentially spaced apart, elongated, transversely extending clamping rods (90), which are selectively shiftable towards and away from the drum (32) in order to sequentially clamp an incoming meat body to the drum (32) during rotation thereof, and to release the meat body after inversion thereof onto exit conveyor (36). The operation of device (30) is controlled by appropriate sensors (118, 158, 160) operably coupled with a digital controller.

Owner:STAINLESS SYST

Fat/meat grading method and system

ActiveUS8820534B2Quality improvementImprove consistencyMeat packaging/handling/transportingSortingSimulation

Owner:MAREL HF

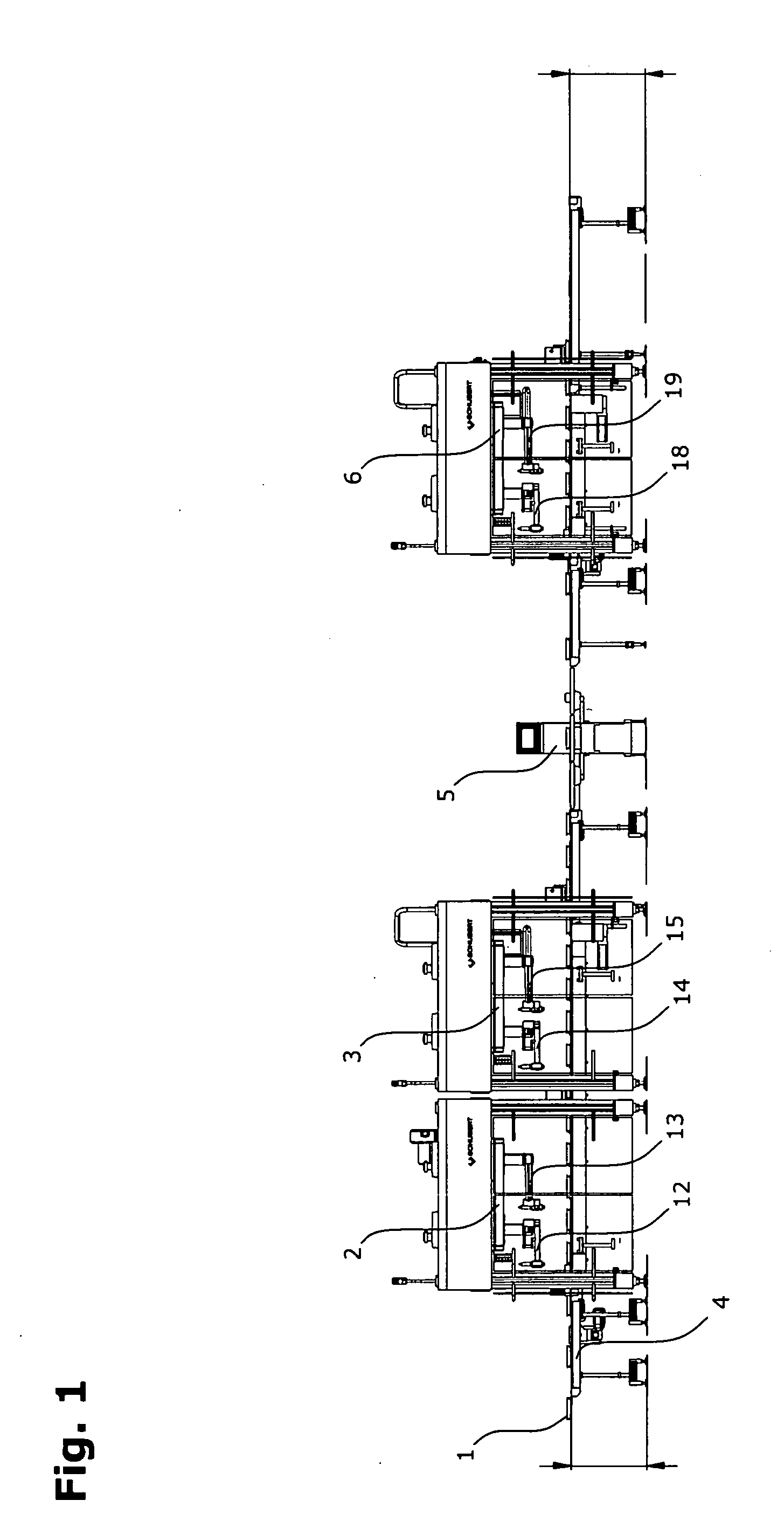

Plant for continuous processing and packing of meat products and method for the implementation thereof

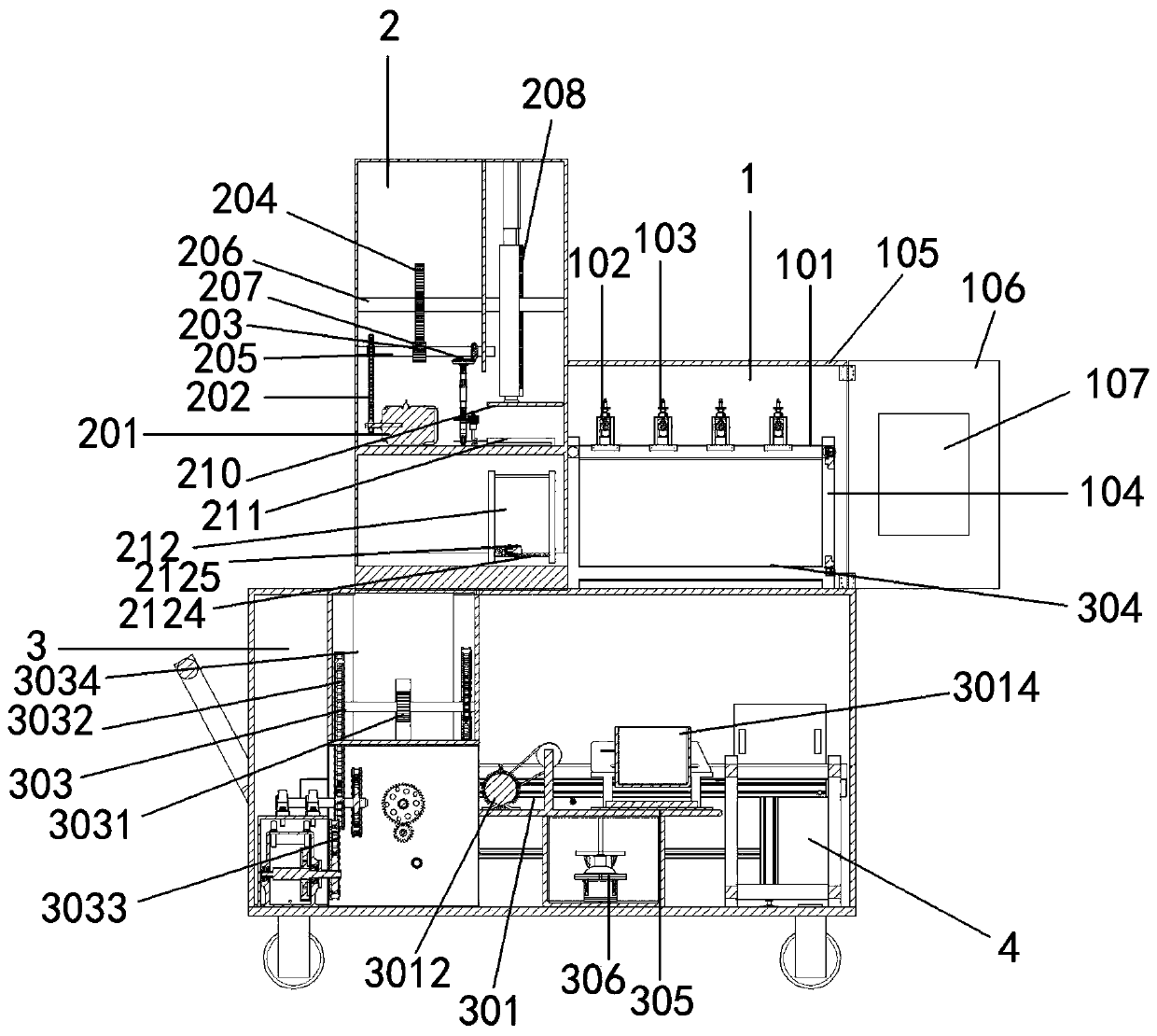

A method and apparatus for a meat processing plant includes an injecting station (10) for injecting meats with brine, a macerating station (20) for massaging the injected meat including movable, plural resting tasks (24) and means (26) for moving these tables with respect to an accumulating and loading station (40) for repeated processing of the injected mean in a rotating drum (22) of the macerating station (20). A packing station (30) can accept treated meat from the resting tanks (24) for final packing in one or more packing machines (32). The method and apparatus can continuously process one or more types of meat products without interruption.

Owner:METALQUIMIA SA

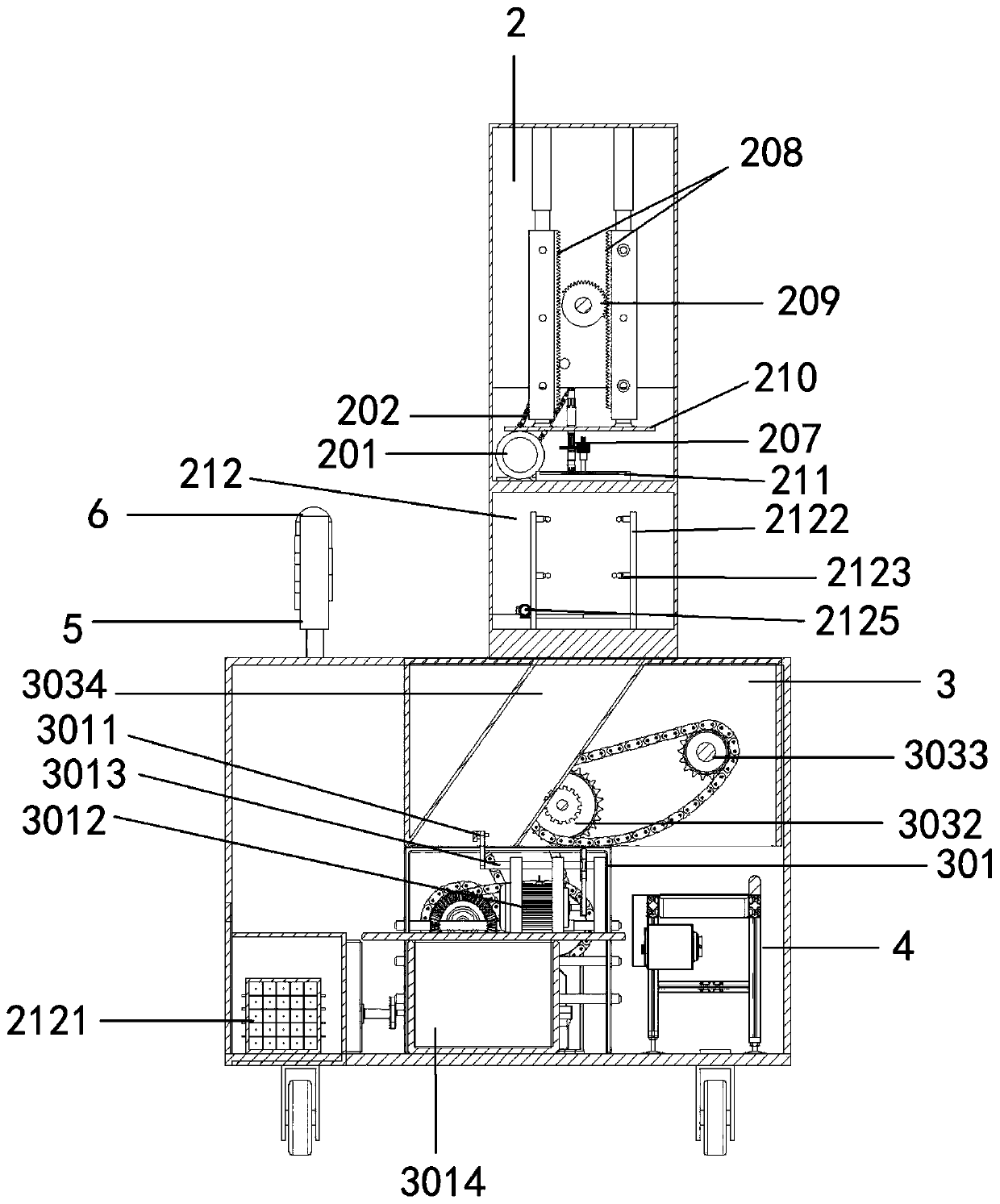

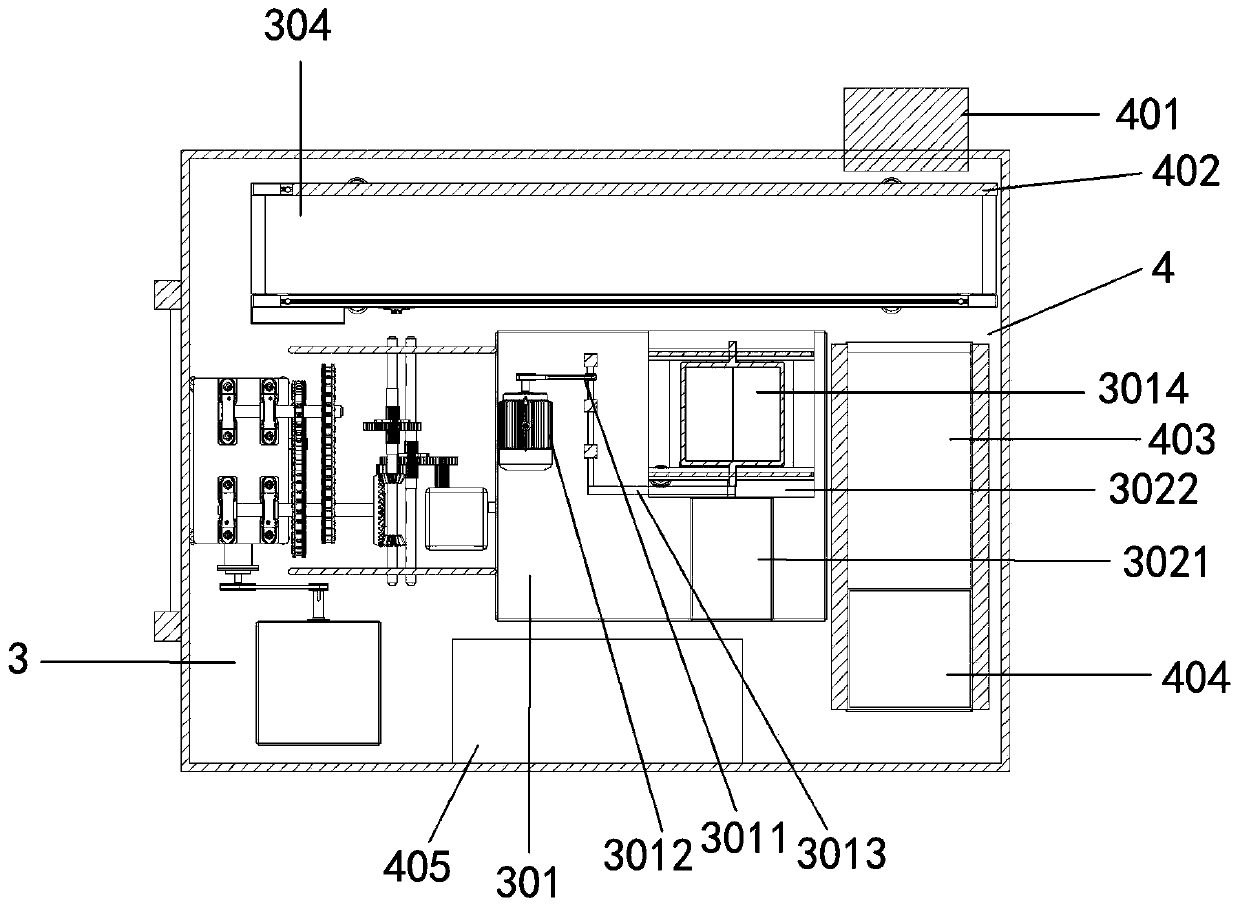

Automatic skewering machine and working method thereof

PendingCN110463742AAvoid stickingAvoid entanglementMeat packaging/handling/transportingEngineeringMaterial resources

The invention discloses an automatic skewering machine and a working method thereof. The automatic skewering machine comprises a meat loaf transfer mechanism, a meat loaf forming mechanism connected with the meat loaf transfer mechanism, a skewer puncturing control mechanism and an unloading mechanism, wherein the skewer puncturing control mechanism and the unloading mechanism are located below the meat loaf forming mechanism; the meat loaf transfer mechanism is provided with an upper transfer belt used for conveying meat loaves, the upper transfer belt is fixed to an upper transfer support, and a plurality of lifting devices are symmetrically fixed to the positions, on the two sides of the upper transfer belt, on the upper transfer support; and a plurality of meat cutting hobs are evenlyarranged on rotary shafts between the symmetrically-arranged lifting devices, the lifting devices are provided with adjusting handles for adjusting the heights of the meat cutting hobs, and the adjusting handles control pulleys connected with the rotary shafts to move in lifting sliding rails. The arranged lifting devices adjust the heights of the meat cutting hobs according to different demands and different meat products, adhering and winding of meat lumps to the meat cutting hobs are avoided, and meanwhile different skewer puncturing boxes are selected according to the different meat products; and the automatic skewering machine is high in automation and suitable for skewering of various kabobs, energy is saved, and manpower and material resources are saved.

Owner:BINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com