Autonomously electromagnetic transport carrier of food portions

A technology of components and carriers, applied in the field of high-speed slicers, can solve the problems of possibility limitation, flexibility limitation of conveyor circuit design, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

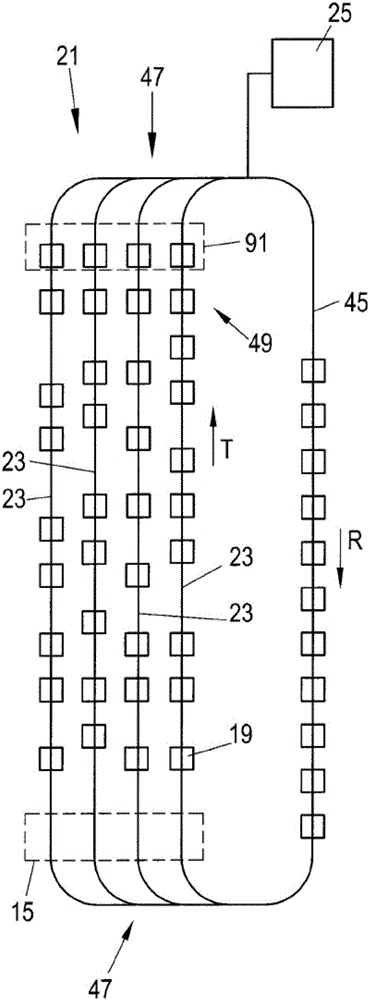

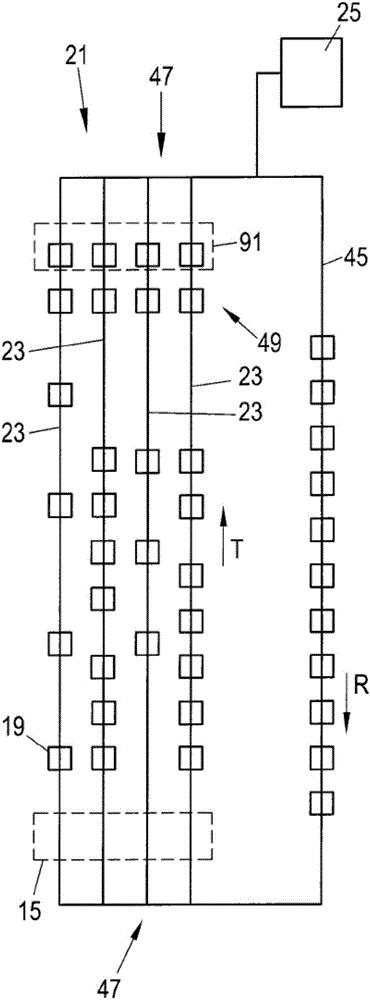

[0402] The embodiments of the invention described below are based on the drive principle of a mover in a rail system by a linear synchronous motor (LSM drive). The transport system of the reference company MagneMotion has already been described as an example in the introduction. Since as many movers as desired in a rail system can be moved in the rail system individually, ie independently of one another, by the control device, they can be positioned and identified by the control device. Furthermore, the movers can be moved and positioned with very high precision in the rail system. The speed of movement and the acceleration and deceleration for the mover can likewise be selected and executed as desired and individually.

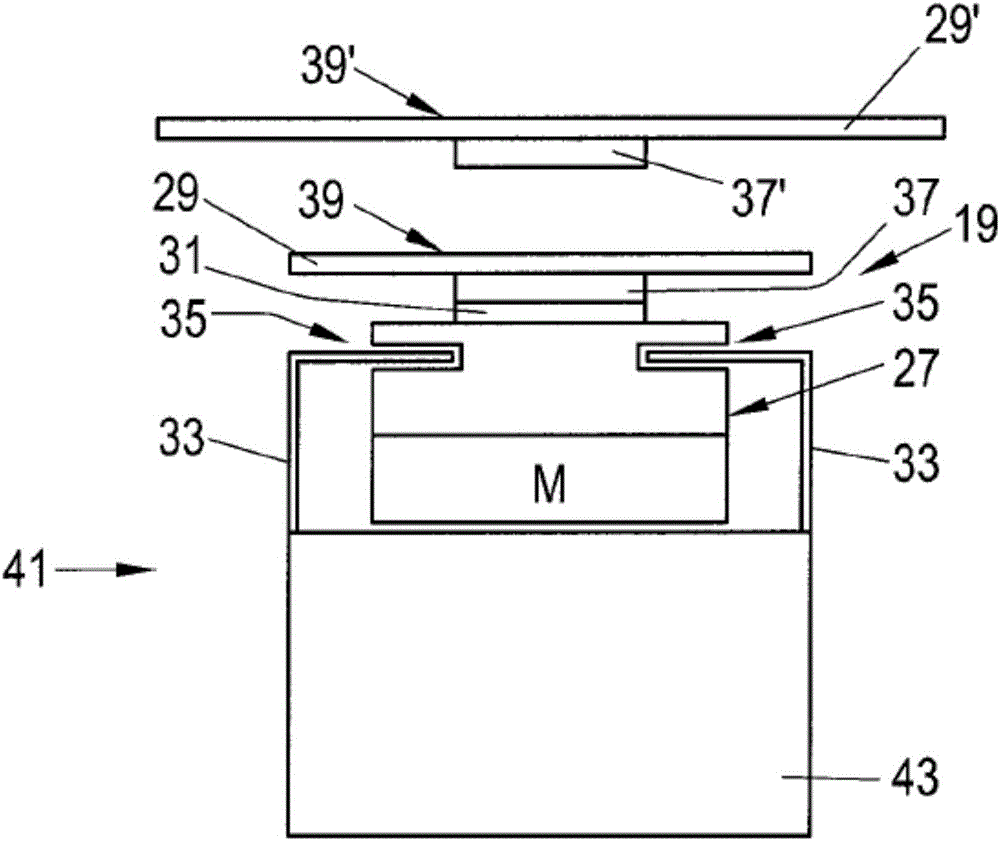

[0403] figure 1 A cross section is shown, ie a section perpendicular to the transport direction, through the rail in which the mover is arranged. The track section 41 of the track system comprises a base which serves as a base for the stator 43 of the LSM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com