Cutting apparatus for cutting food items conveyed on a conveyor including at least one conveyor belt

a technology of conveyor belts and cutting equipment, which is applied in the direction of feeding apparatus, meat shaping/cutting, automatic control devices, etc., can solve the problems of inability to achieve x-ray imaging, reducing costs, and reducing the cost of using such belts, so as to improve the efficiency and precision of the cutting apparatus, mitigate, alleviate or eliminate one

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

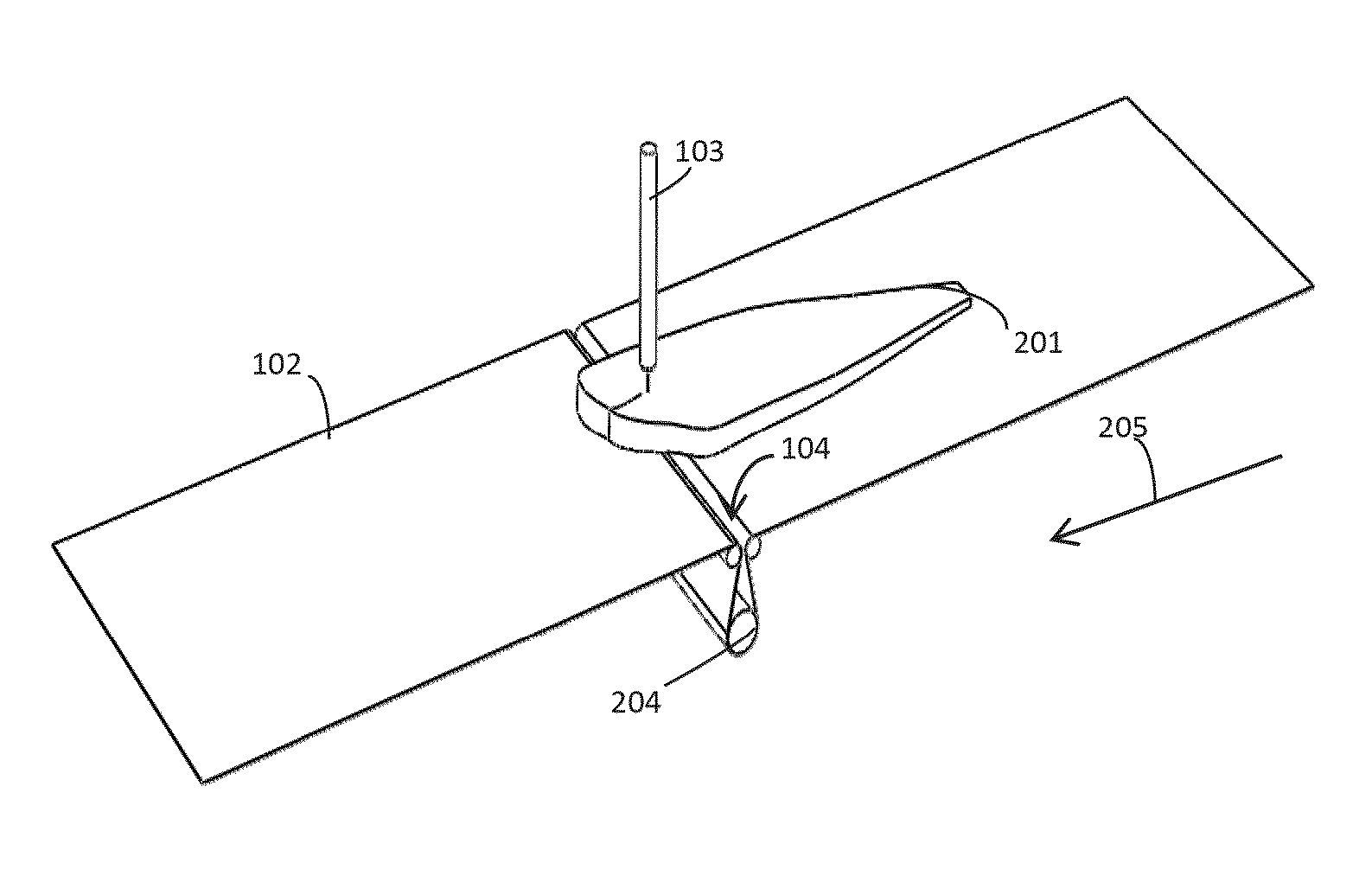

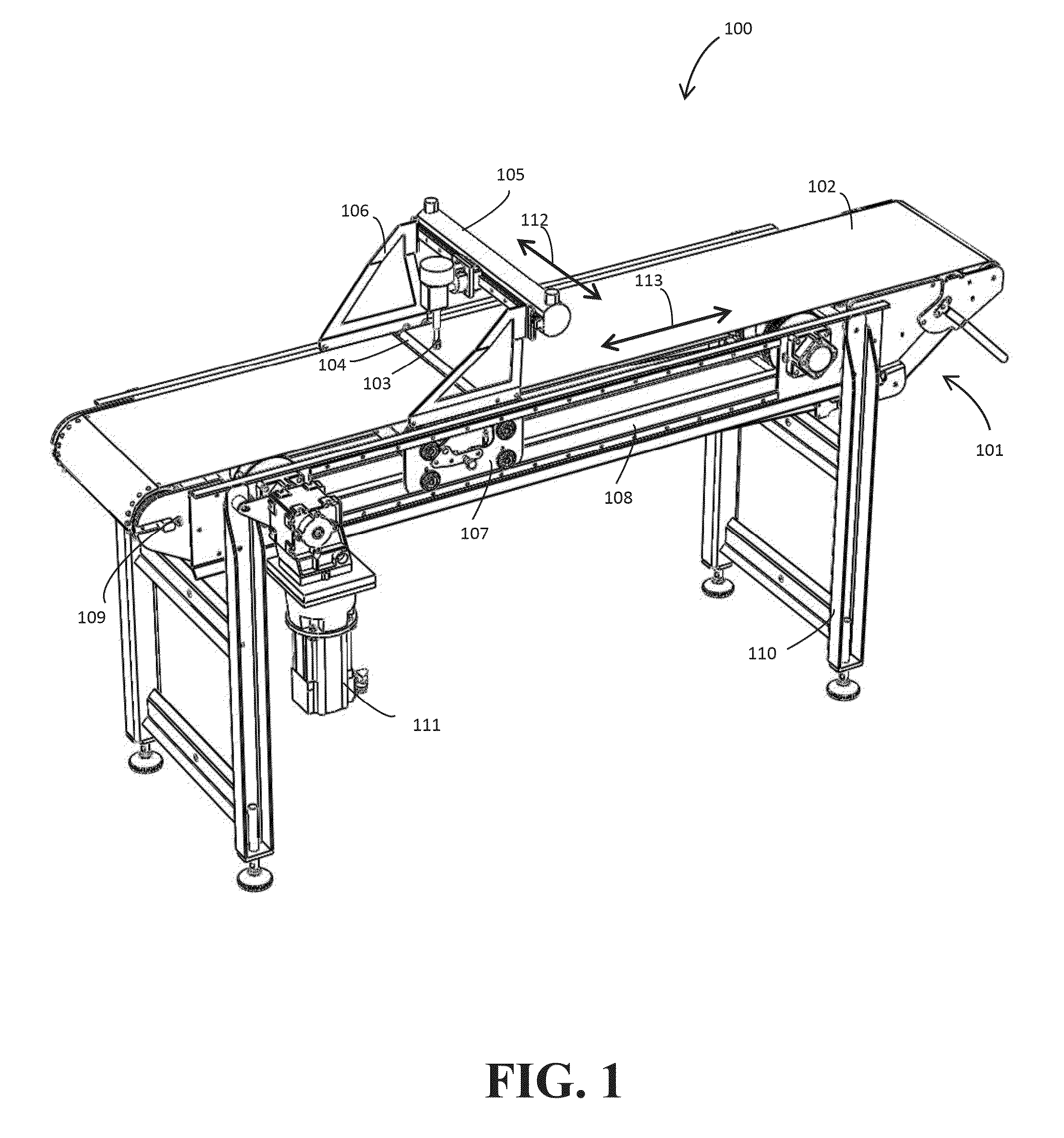

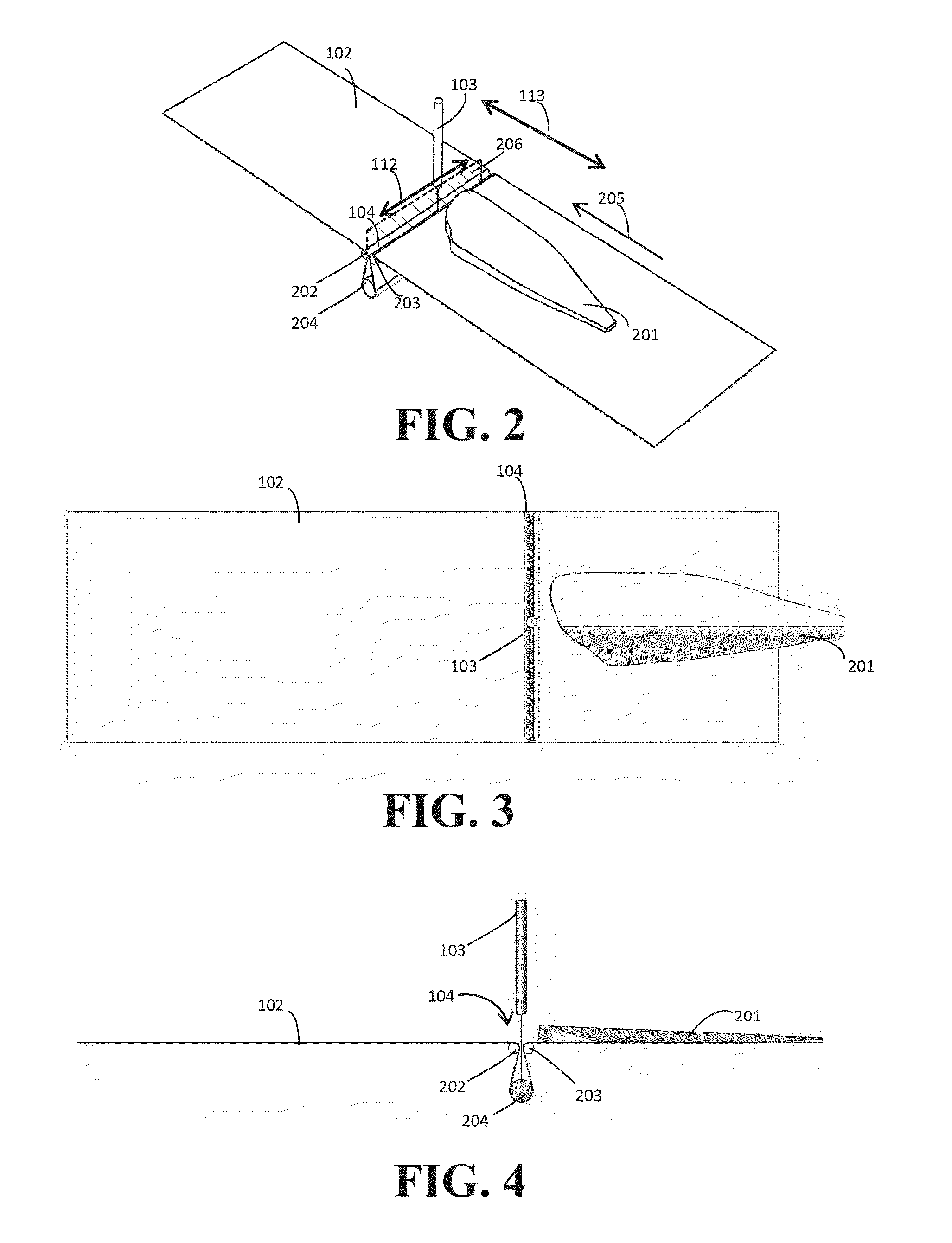

[0071]FIG. 1 shows a perspective view of an embodiment of a cutting apparatus 100 according to the present invention for cutting food items conveyed on a conveyor 101 including a conveyor belt 102. The apparatus comprises a cutter 103 that is arranged above a gap 104 extending across the conveyor belt 102. The gap is formed between adjacent elongated supporting means such as adjacent rollers with a fixed internal arrangement. This will be discussed in more details in relation to the remaining figures. The conveyor belt 102 may be made of any type of deflecting material that may be of solid type such as any type of rubber or plastic material and / or any type of belt that is stiff in the transversal direction and flexible in the longitudinal direction such as an Intralox belt type.

[0072]The cutter may be, but is not limited to, a fluid pressure cutter, a laser beam cutter, a high pressurized gas cutter, or a cutting blade, where the cutter is slideable mounted to a track 105 positioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acute angles | aaaaa | aaaaa |

| acute angle | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com