Patents

Literature

540results about "Meat shaping/cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

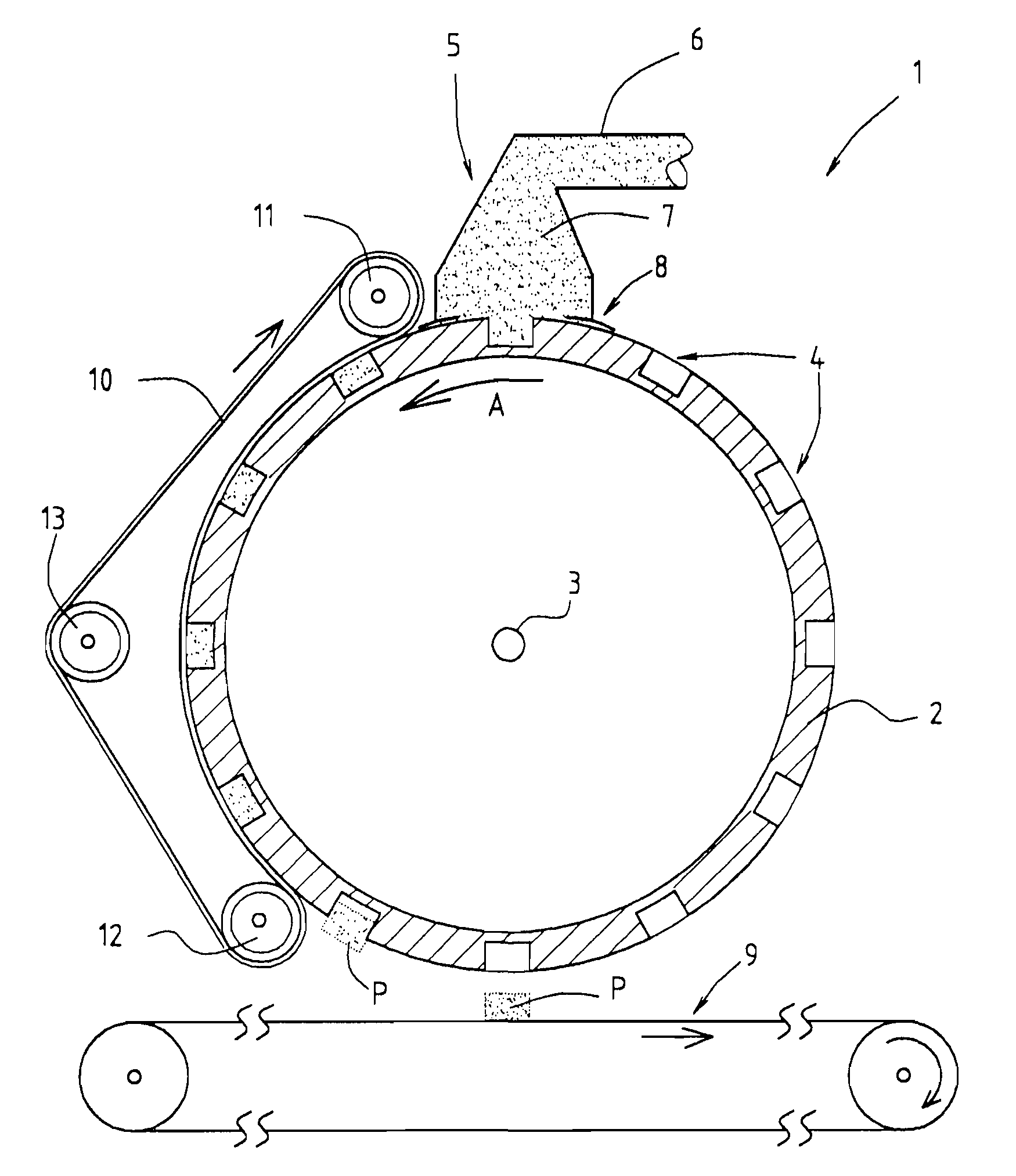

Moulding

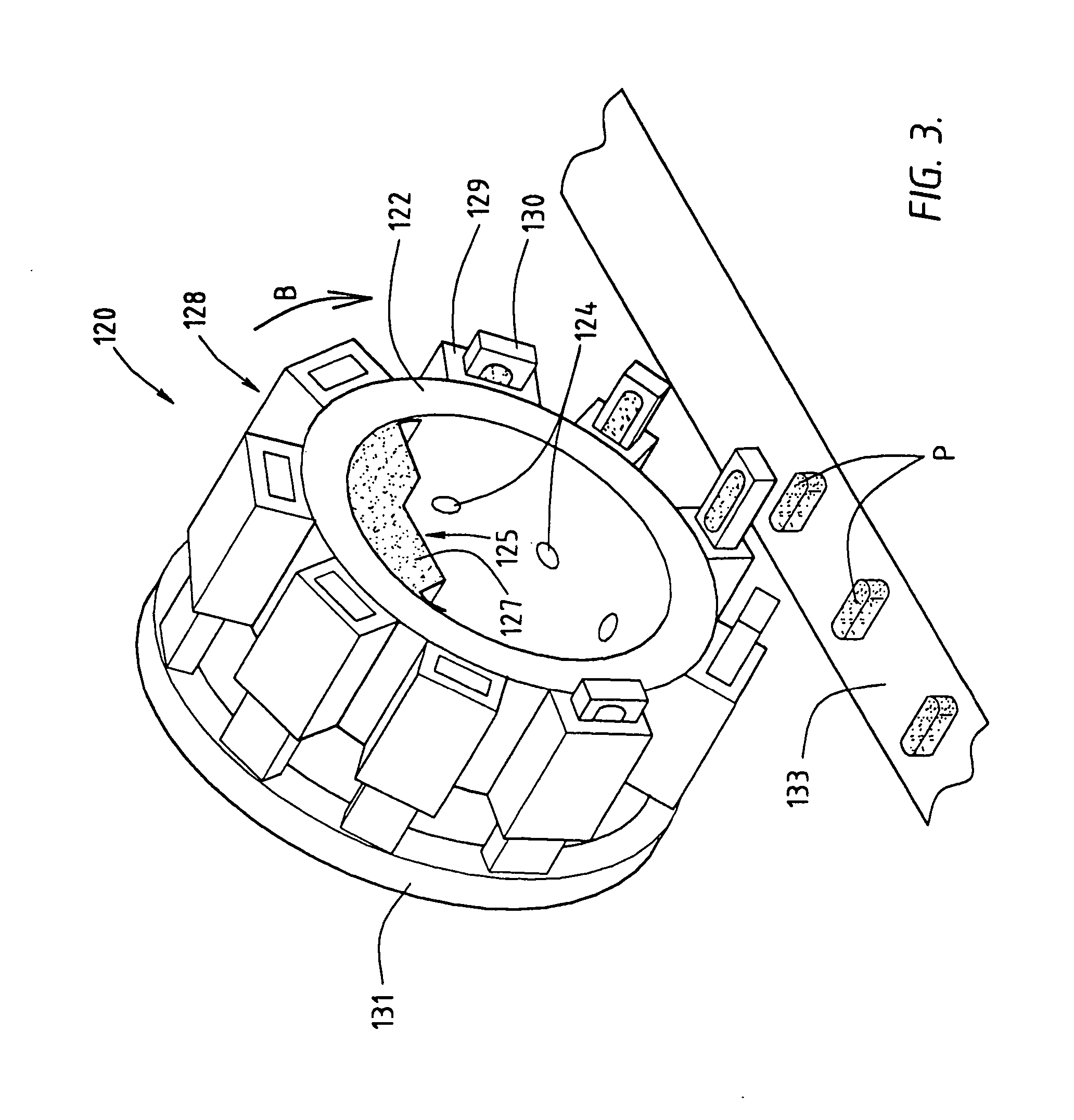

InactiveUS20070224306A1High priceLarge capacityConfectioneryCeramic shaping apparatusPartial fillingMaterials science

Owner:STORK PMT

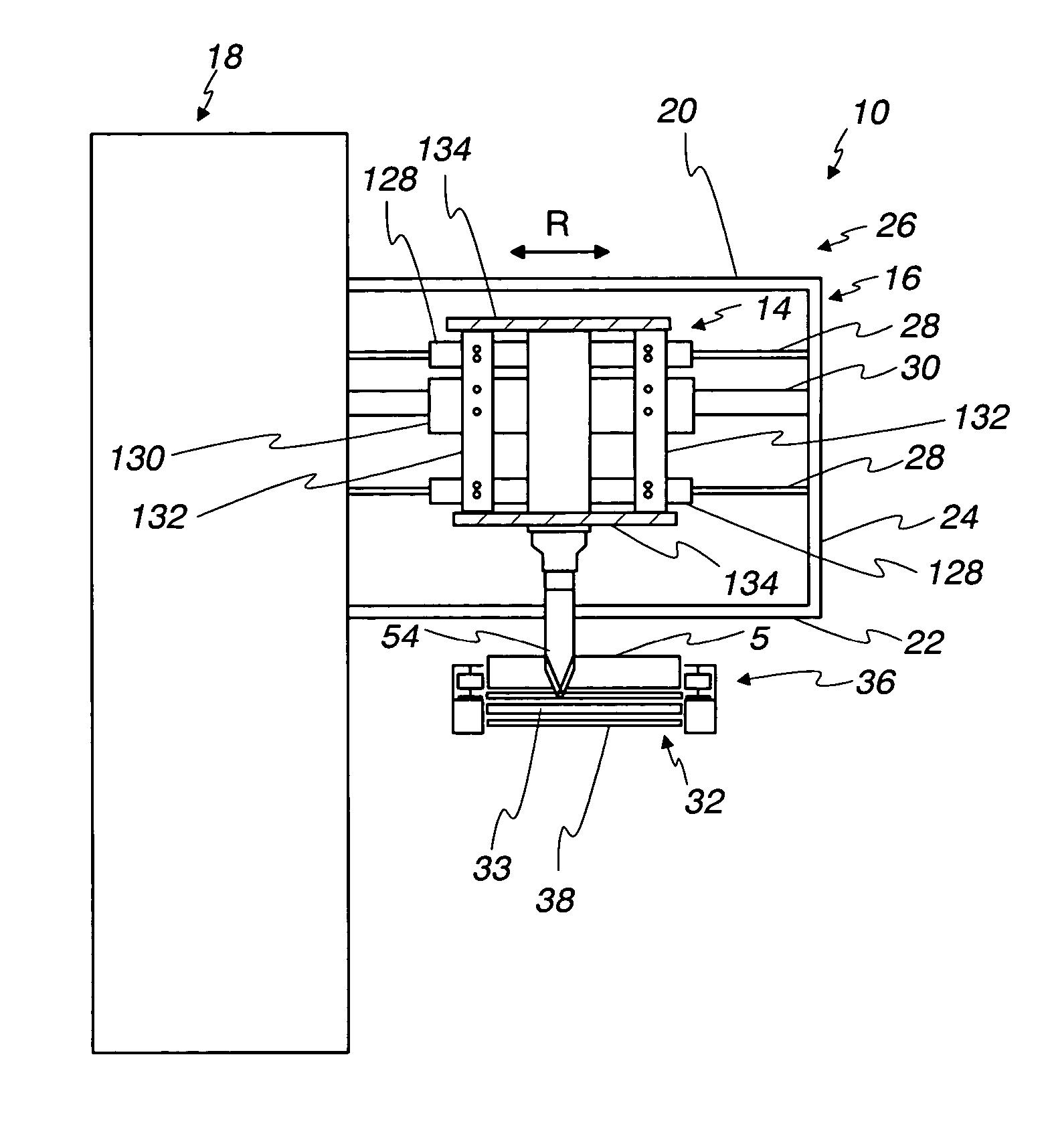

Ultrasonic slitter

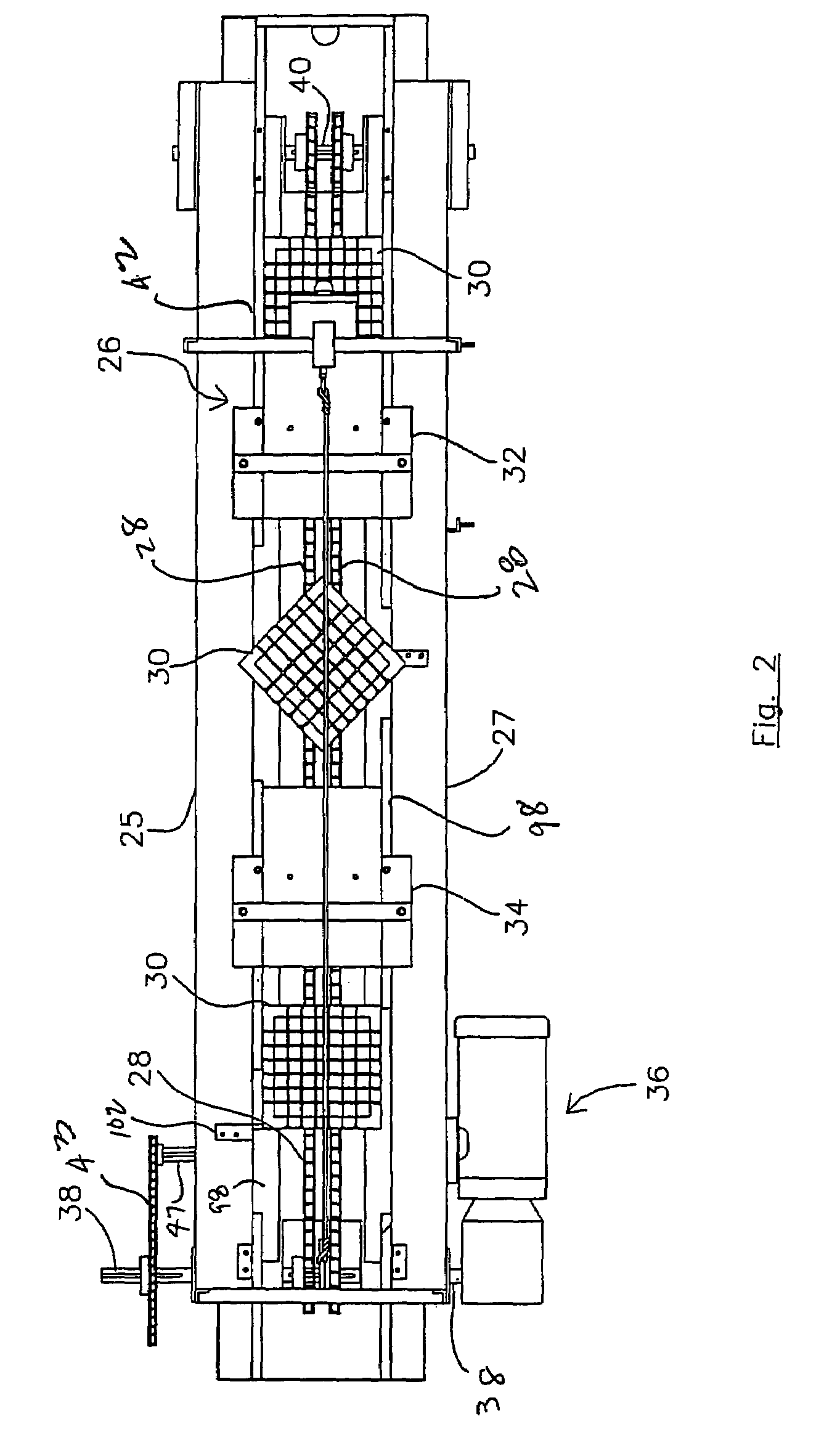

InactiveUS20050081692A1Increase engagementCheese manufactureCircular sawsElectronic controllerThick plate

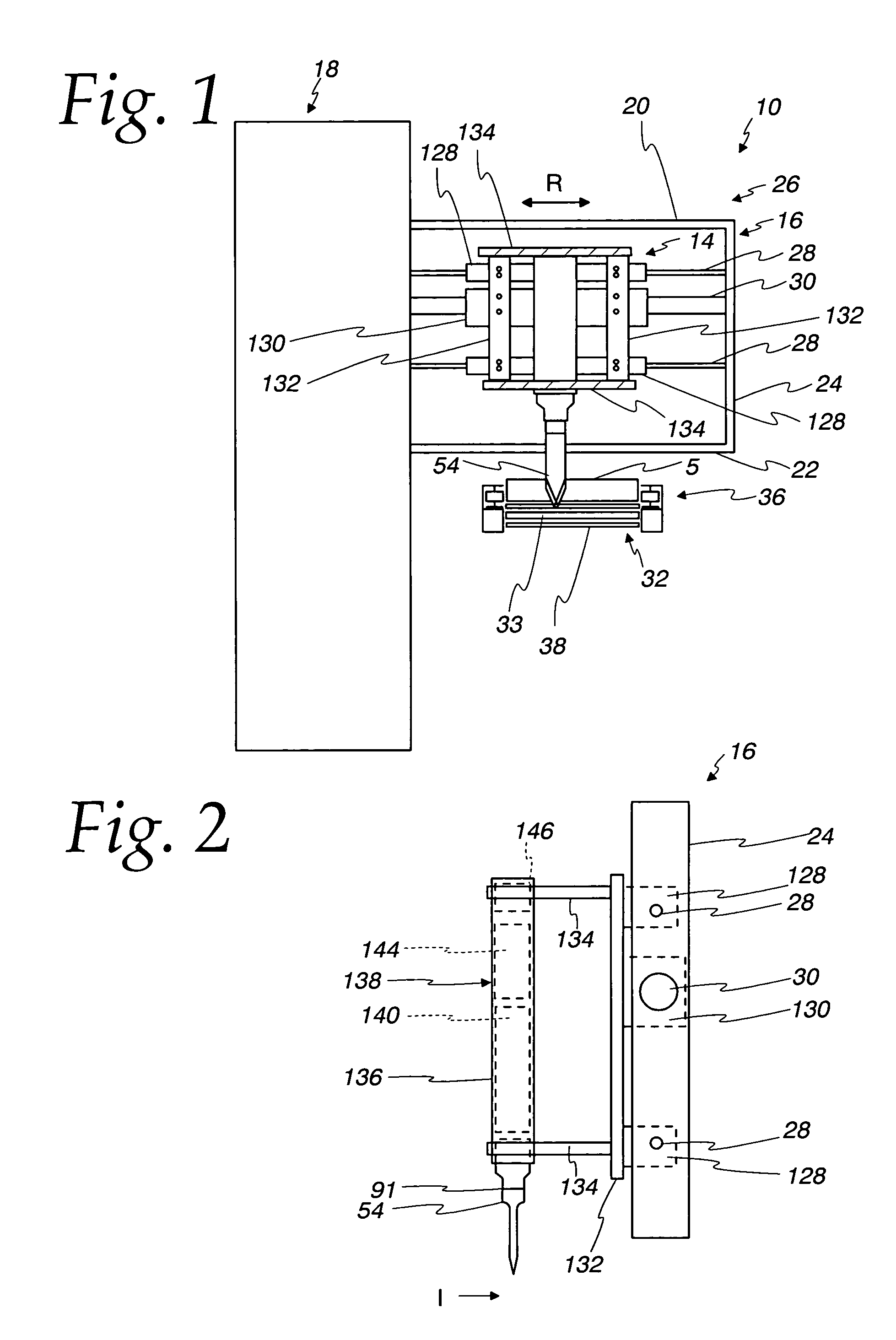

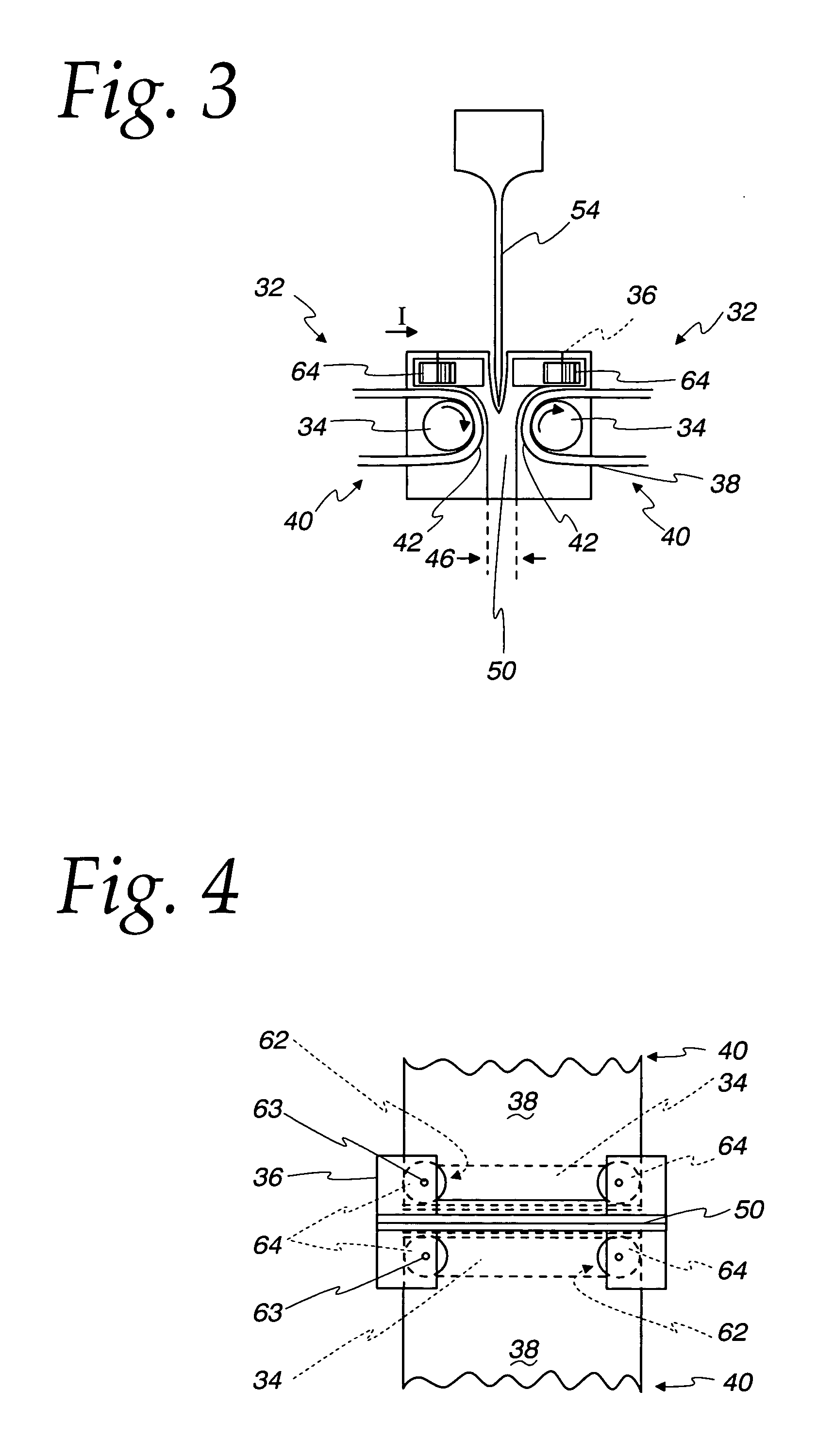

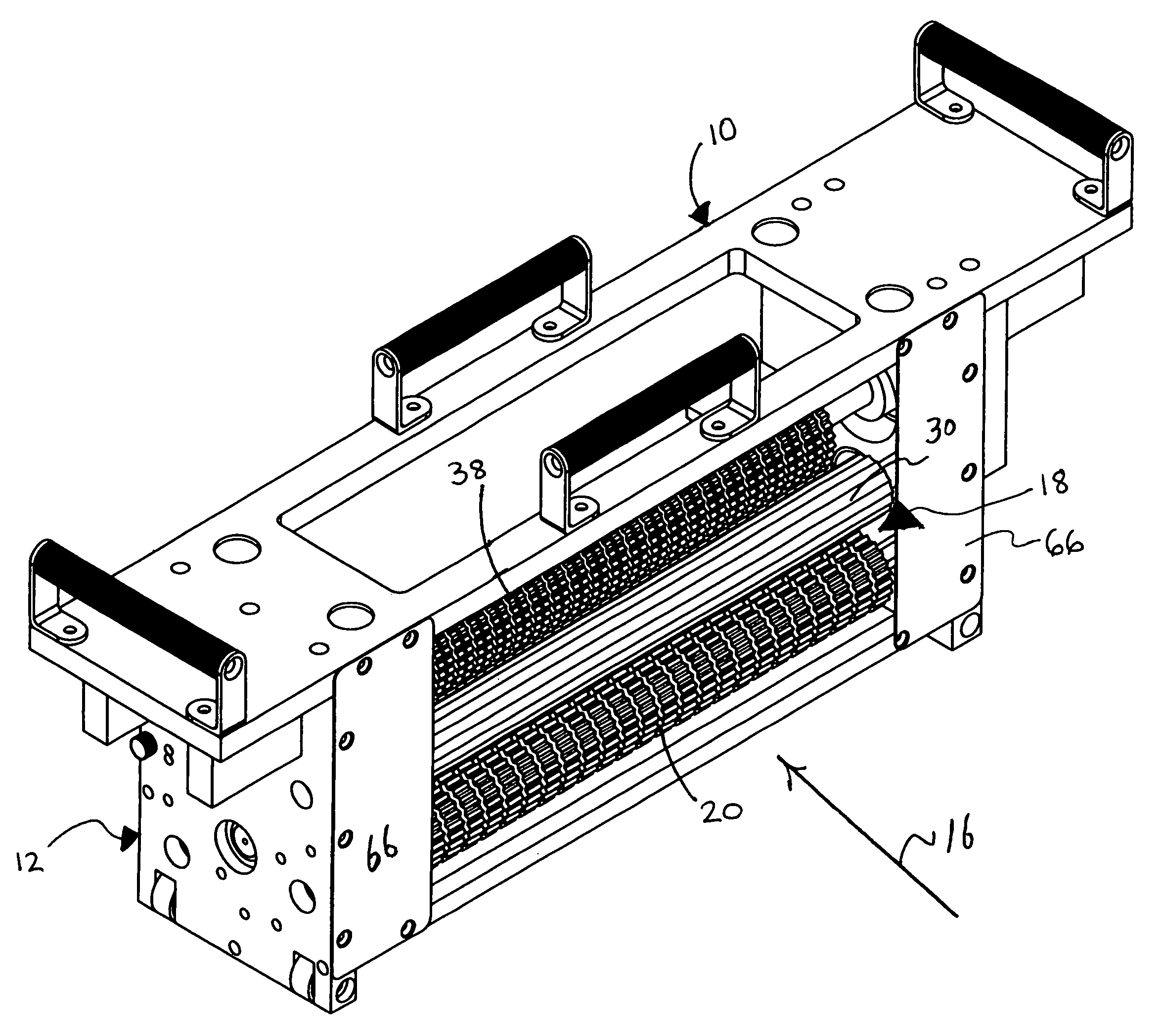

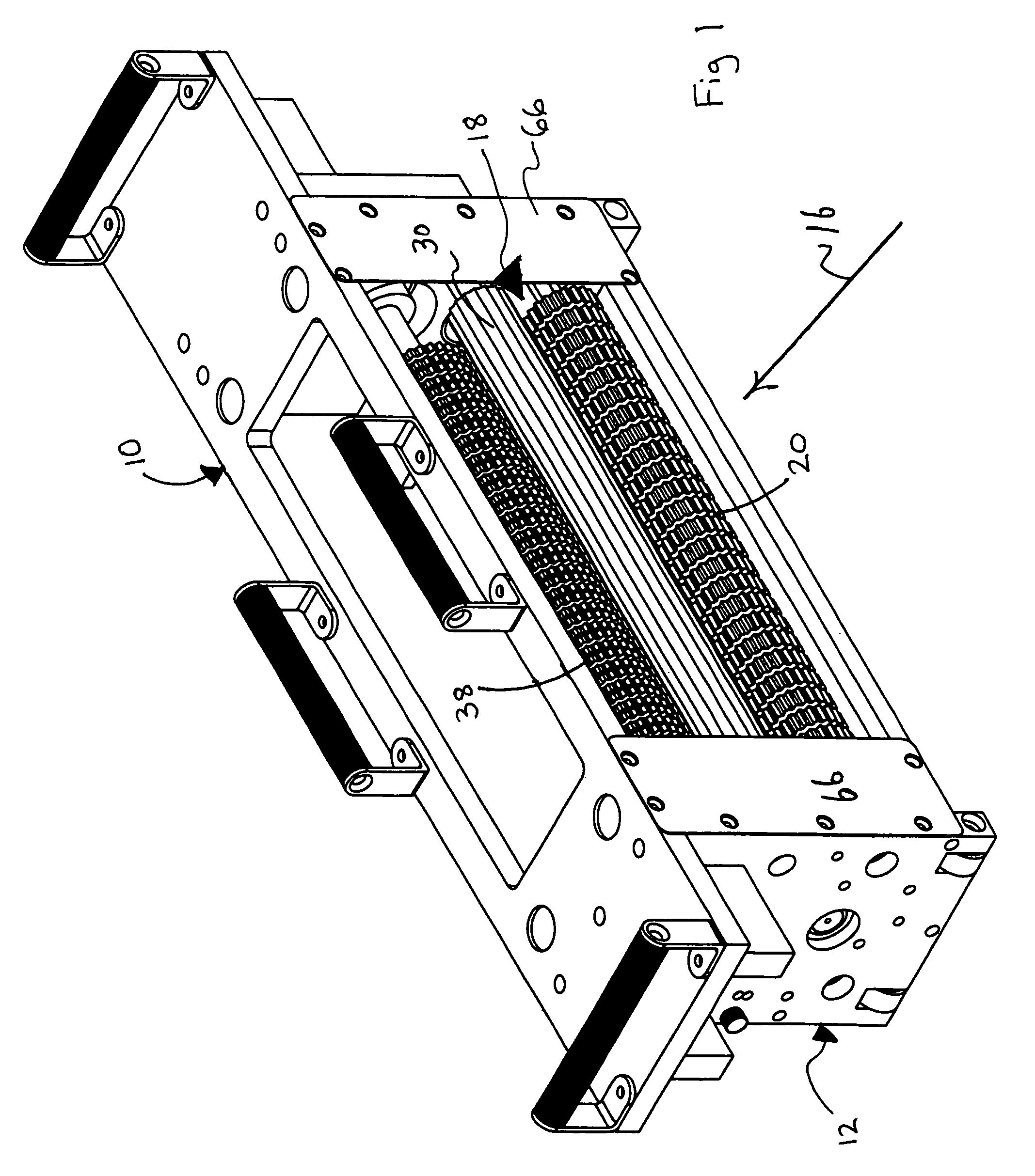

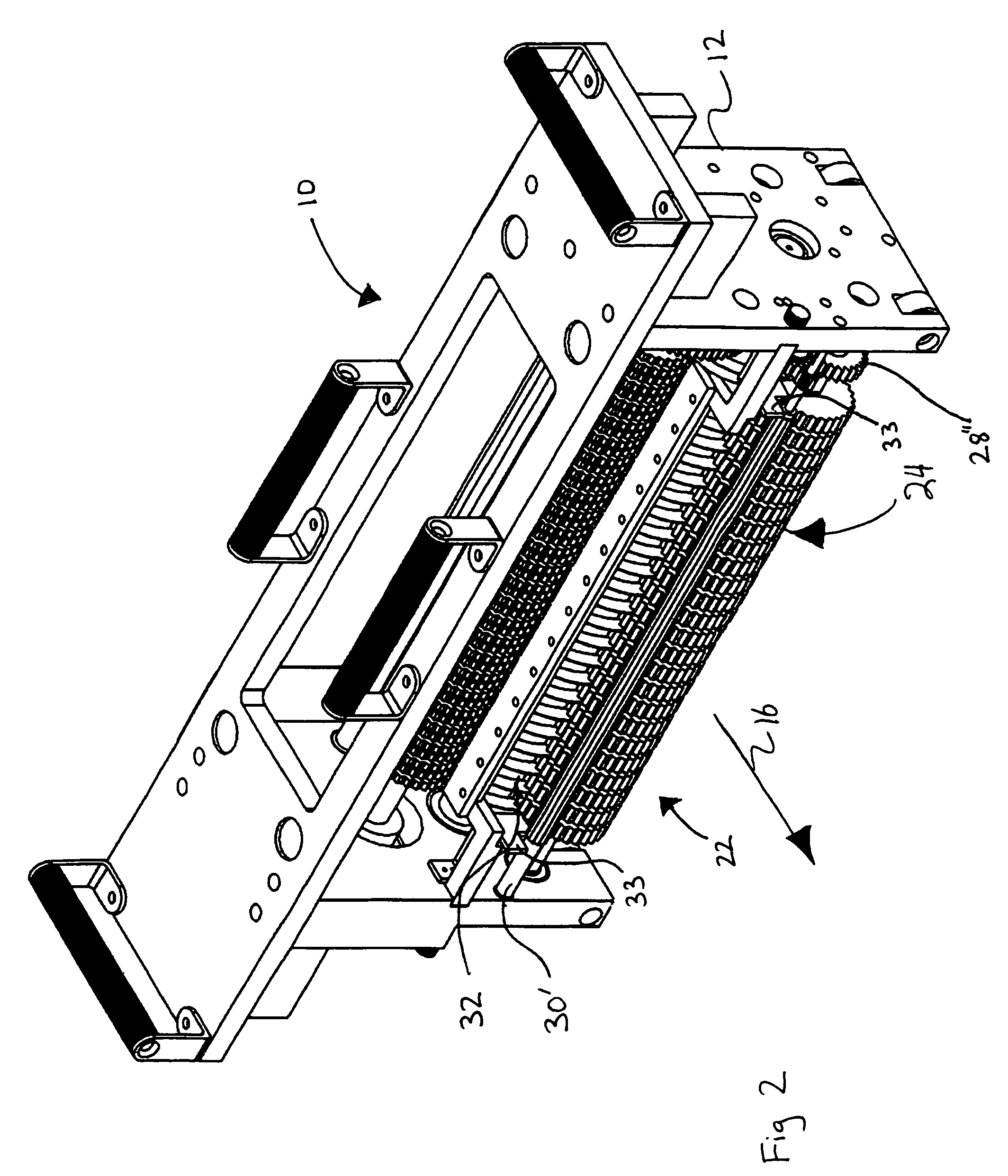

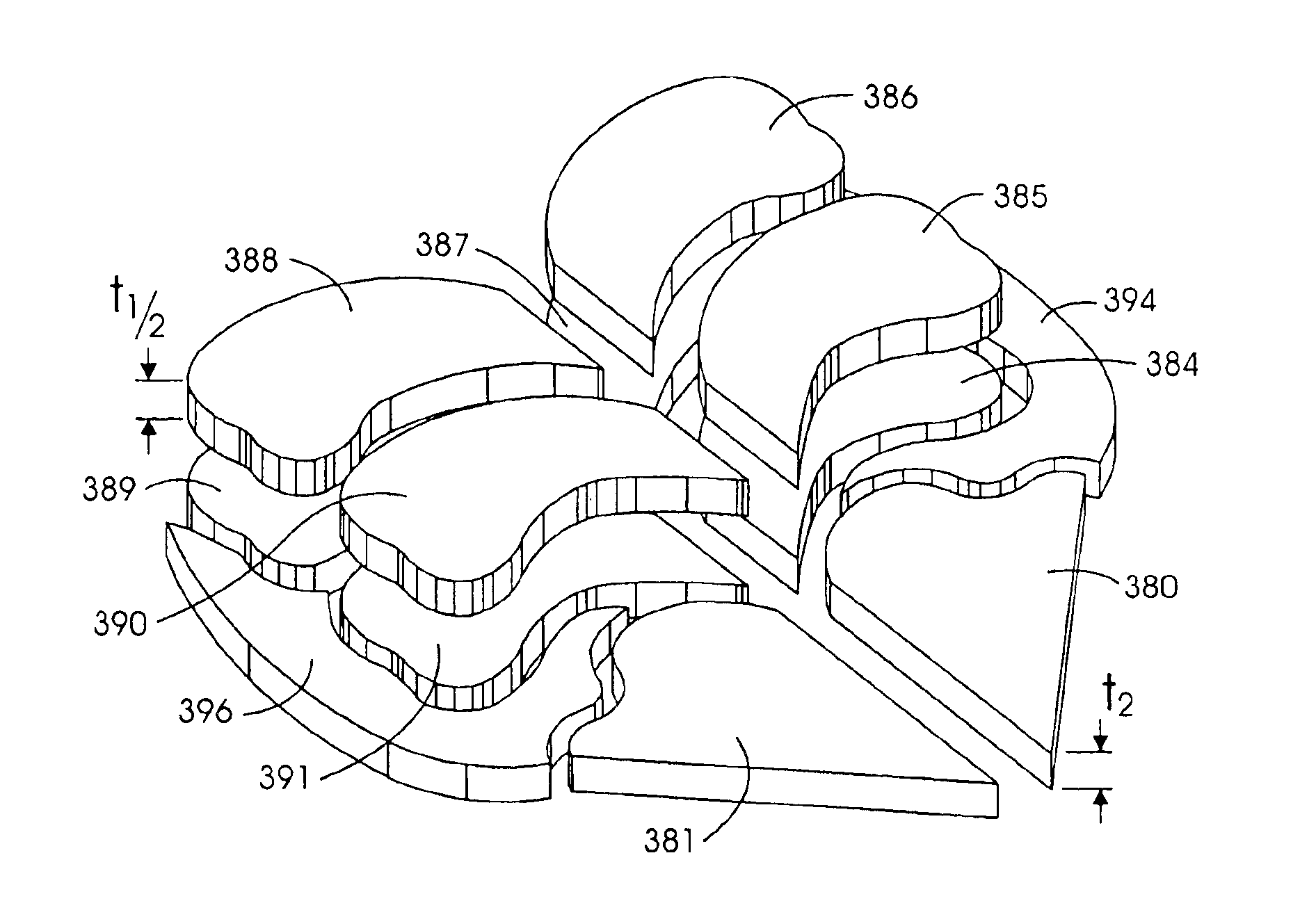

Apparatus for high-volume, high speed ultrasonic cutting or slitting comprising a blade having first and second cutting edges suspended from a reciprocating head, cantilevered over a conveyor supporting and advancing the food product, with the blade including first and second cutting edges on respective opposite sides thereof to cut the food product transversely. The head is preferably controlled for automated operation by an electronic controller to reciprocate transversely at a selected speed and a selected frequency within predetermined ranges over food product advancing on the conveyor. The blade preferably oscillates ultrasonically, and preferably at a frequency of approximately 20,000 Hz. The first and second cutting edges are preferably downwardly convergent, defining an included angle greater than 60 degrees and less than 90 degrees. In one particular embodiment, the internal angle is 70 degrees. In another embodiment, the angle is about 60 degrees. The blade may have a linear translating velocity of 25 to 35 inches per second, and more specifically may have a transverse velocity of approximately thirty inches per second. The apparatus may be used in high-speed, high-volume commercial food production operations for automated cutting of cheese products and other food products from large chunks, slabs and the like into smaller portions, and may also be used in other applications.

Owner:KRAFT FOODS INC

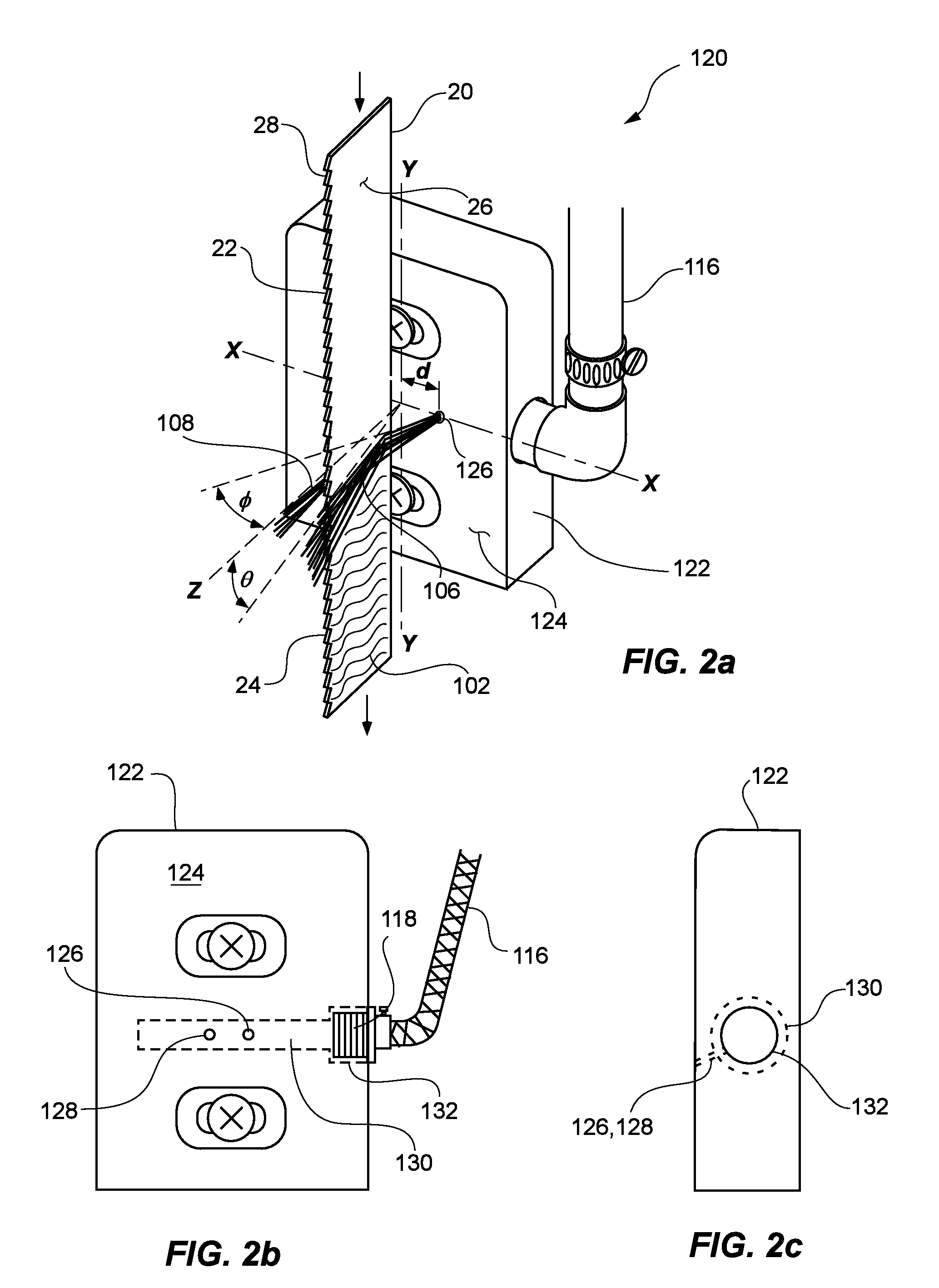

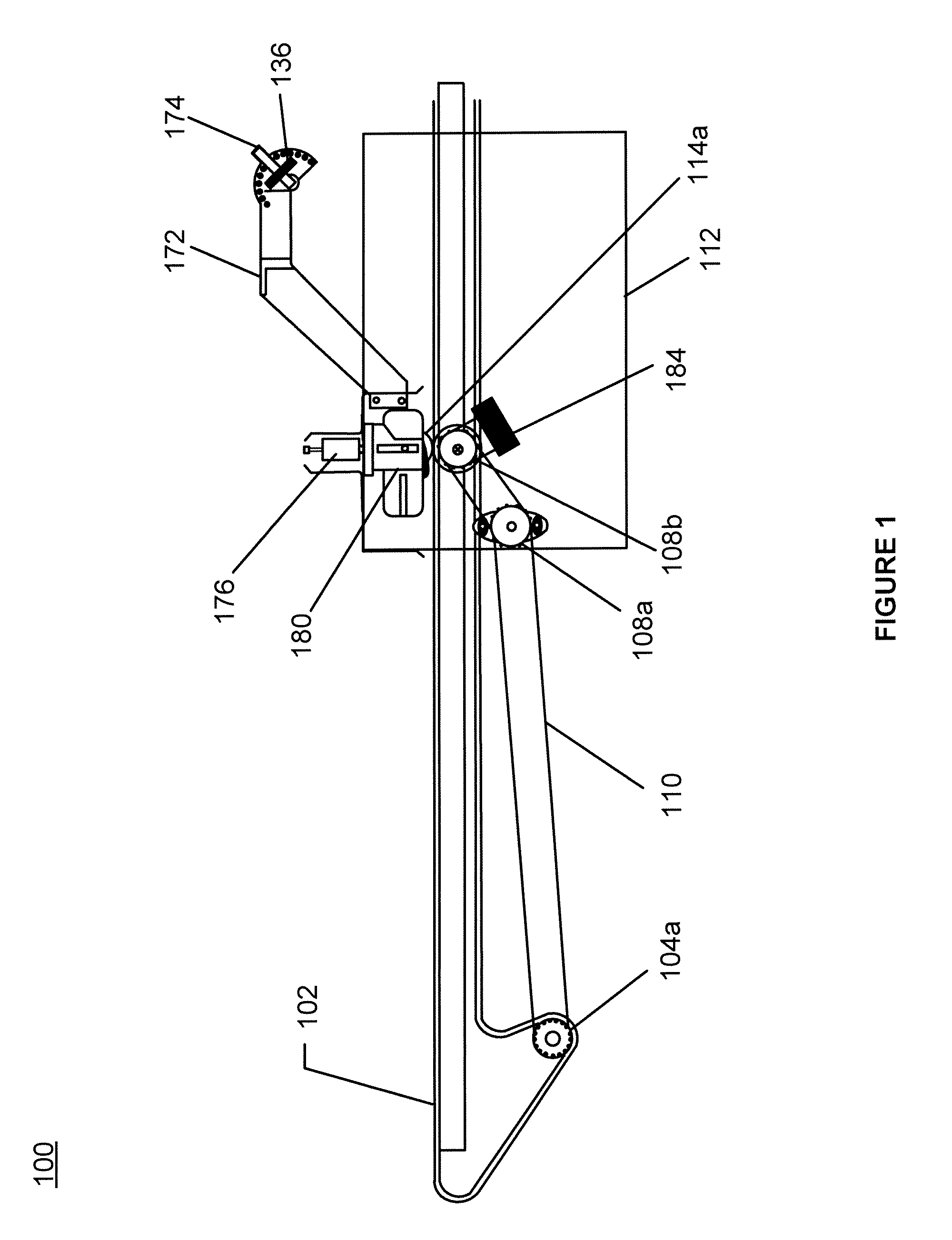

System and method for reducing physiological material on surfaces of cut meat

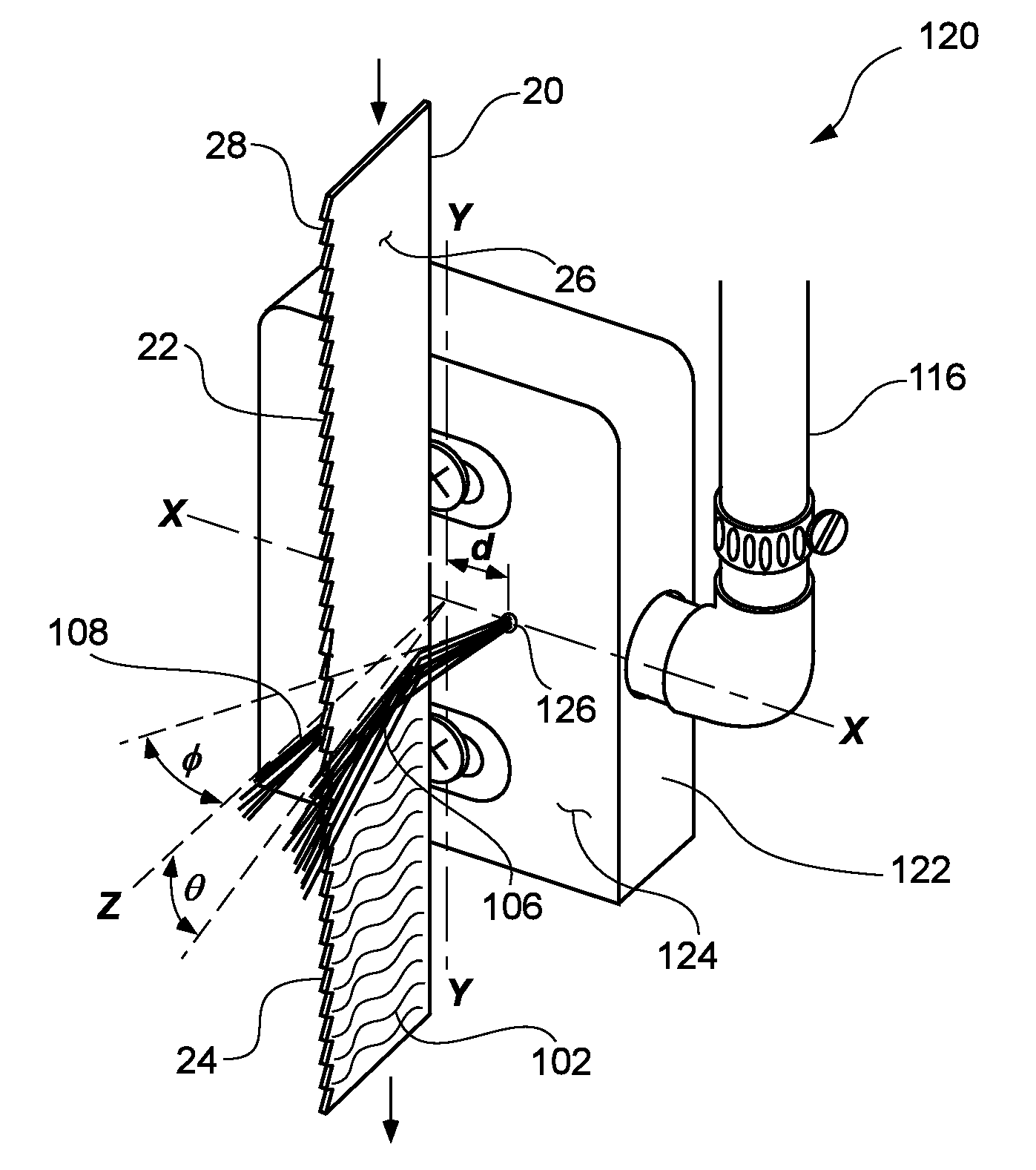

A system and method for reducing physiological material on surfaces of meat cut transferred to surfaces of cut meat by an endless band saw blade is disclosed. The system includes a water jet manifold positioned adjacent the saw blade and having a first and second nozzle orifices formed therein, the first and second orifices operable to be placed in fluid communication with a source of water. The first nozzle orifice is operable to direct a first water jet substantially across and into a first side surface of the saw blade and a second nozzle orifice is operable to direct a second water jet substantially across and into a second side surface of the saw blade. Together, the first and second water jets direct a sufficient volume of water onto the saw blade to remove residual physiological material and to deposit a layer of water onto the first and second side surfaces of the saw blade, which layer of water acts as a lubricant to reduce the residual physiological material that adheres to the saw blade and thereby reduces the residual physiological material transferred to the surfaces of cut meat by the saw blade.

Owner:KLEEN KUT

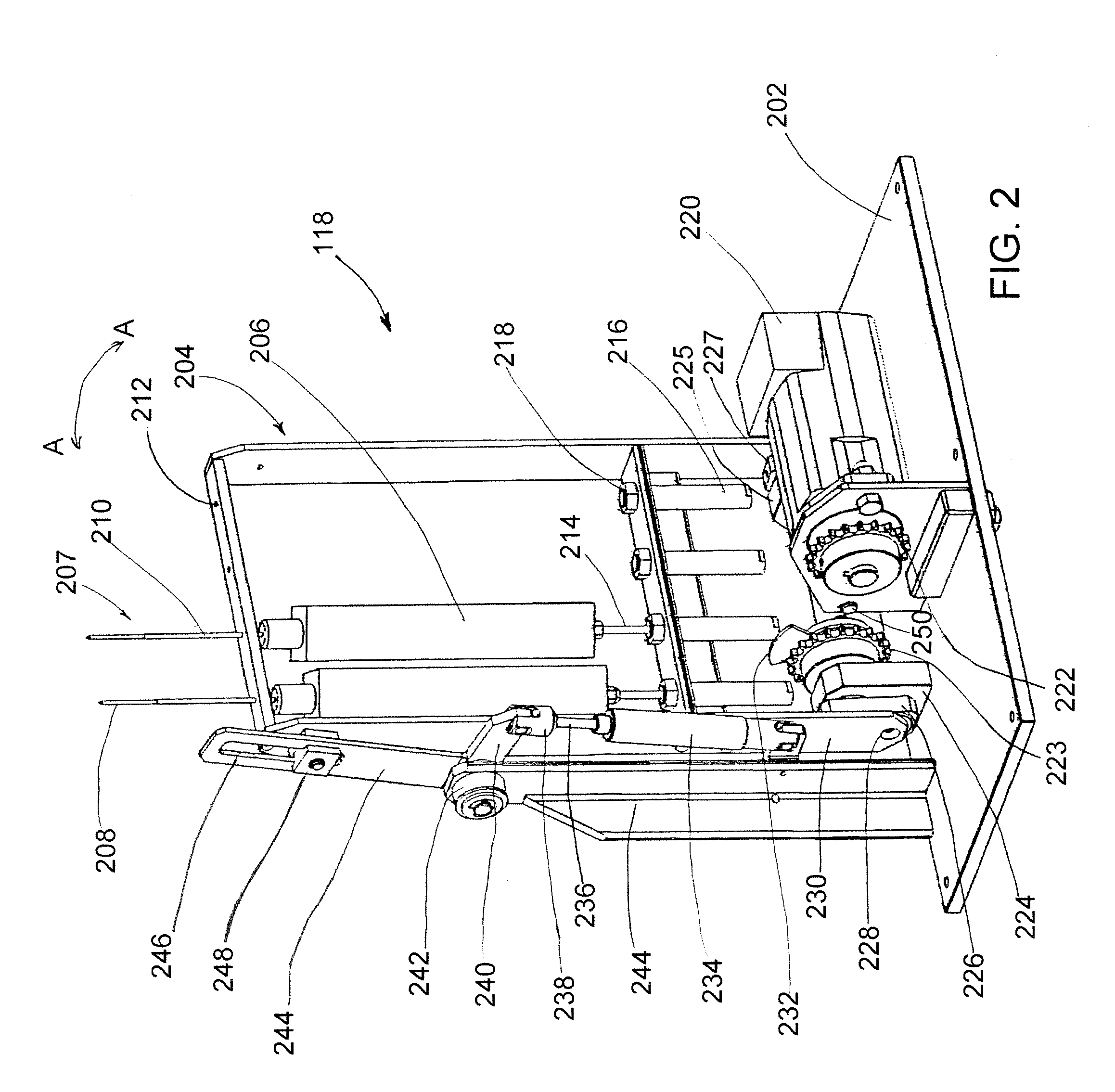

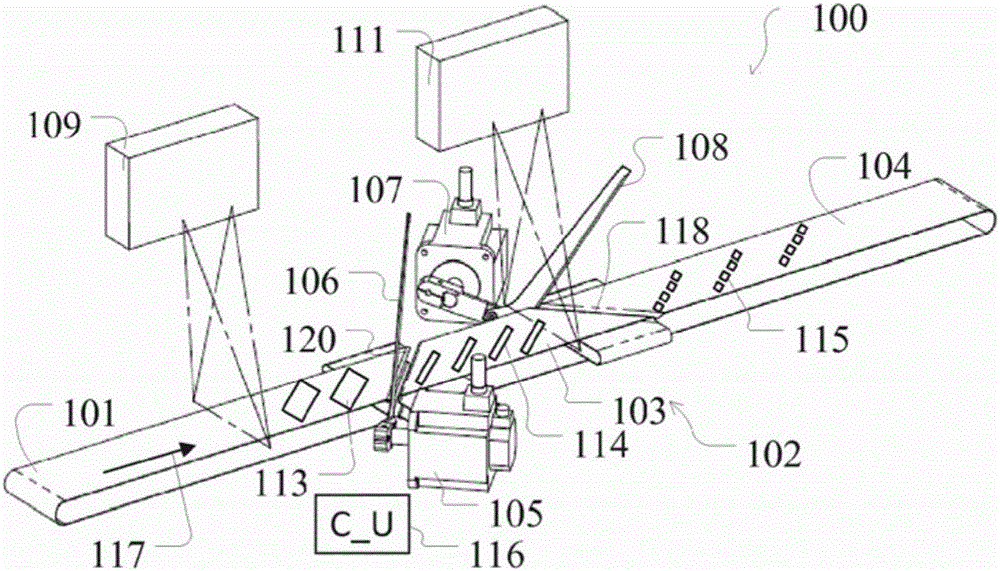

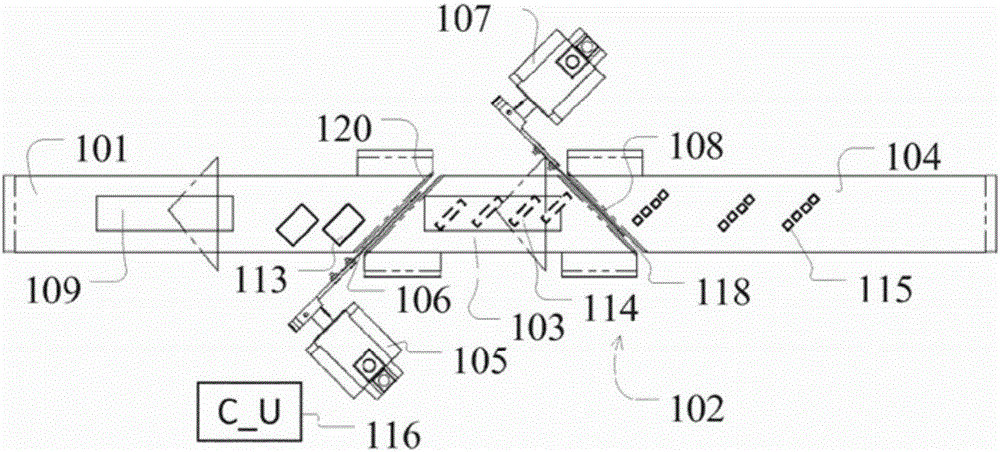

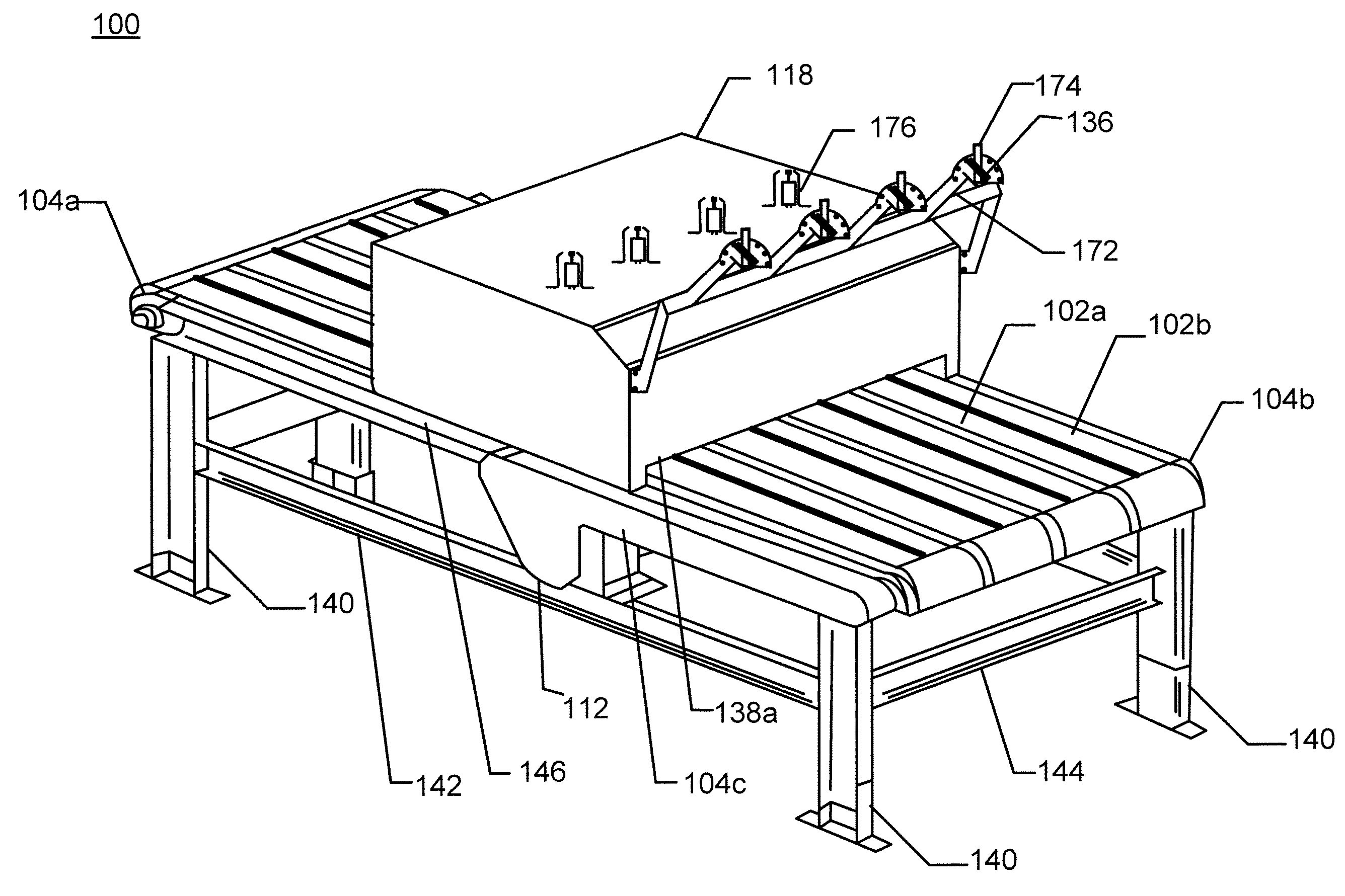

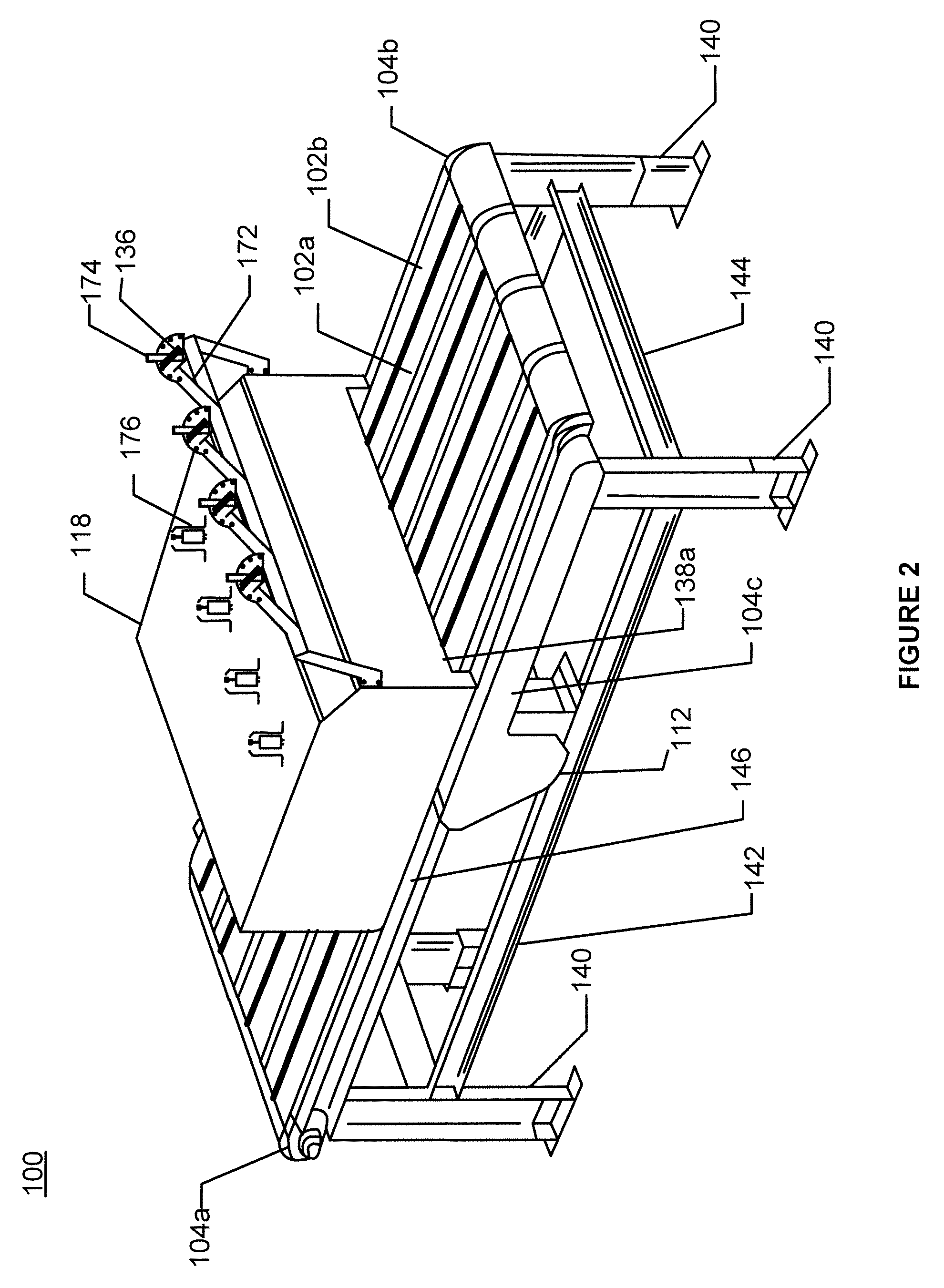

Automated classifier and meat cut fat trimming method and apparatus

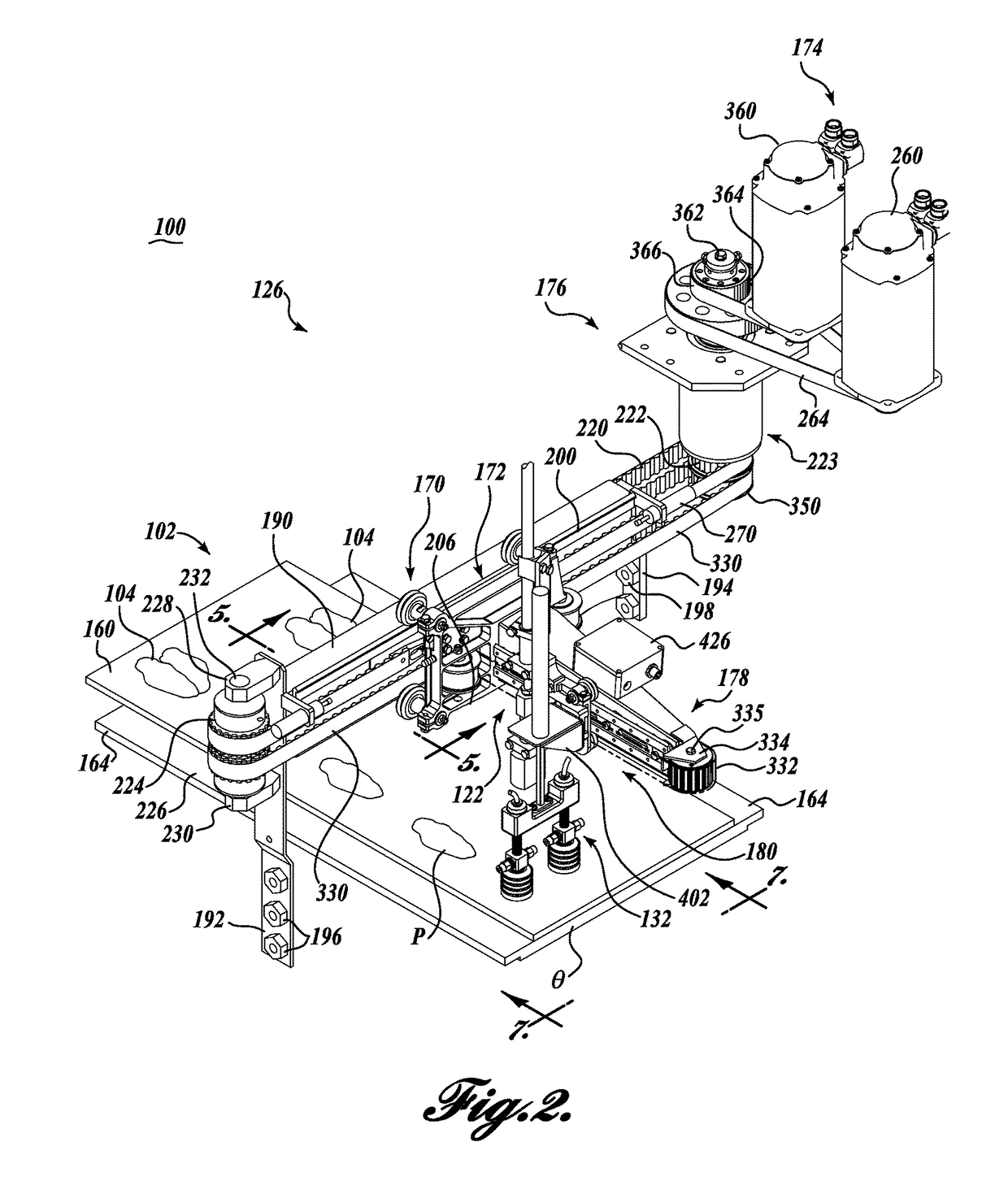

InactiveUS6929540B2Better “mapping”Meat packaging/handling/transportingMeat processing plantsEngineeringBelt conveyor

Apparatus and method for a meat cut classification and fat trimming for sensing the thickness of a layer of fat of a cut of meat and the various contours thereof as it travels along a conveyance and providing the fat thickness or classification information to a downstream system for performing a fat trimming operation. The meat cut classification system comprises a split / multi-belt conveyor having split / multi-belts proximately spaced apart extending in the same direction and having a uniform equidistant gap there between and said conveyor having a drive for conveying the meat cut through the classification system and a multi-probe mechanism assembly.

Owner:TYSON FRESH MEATS

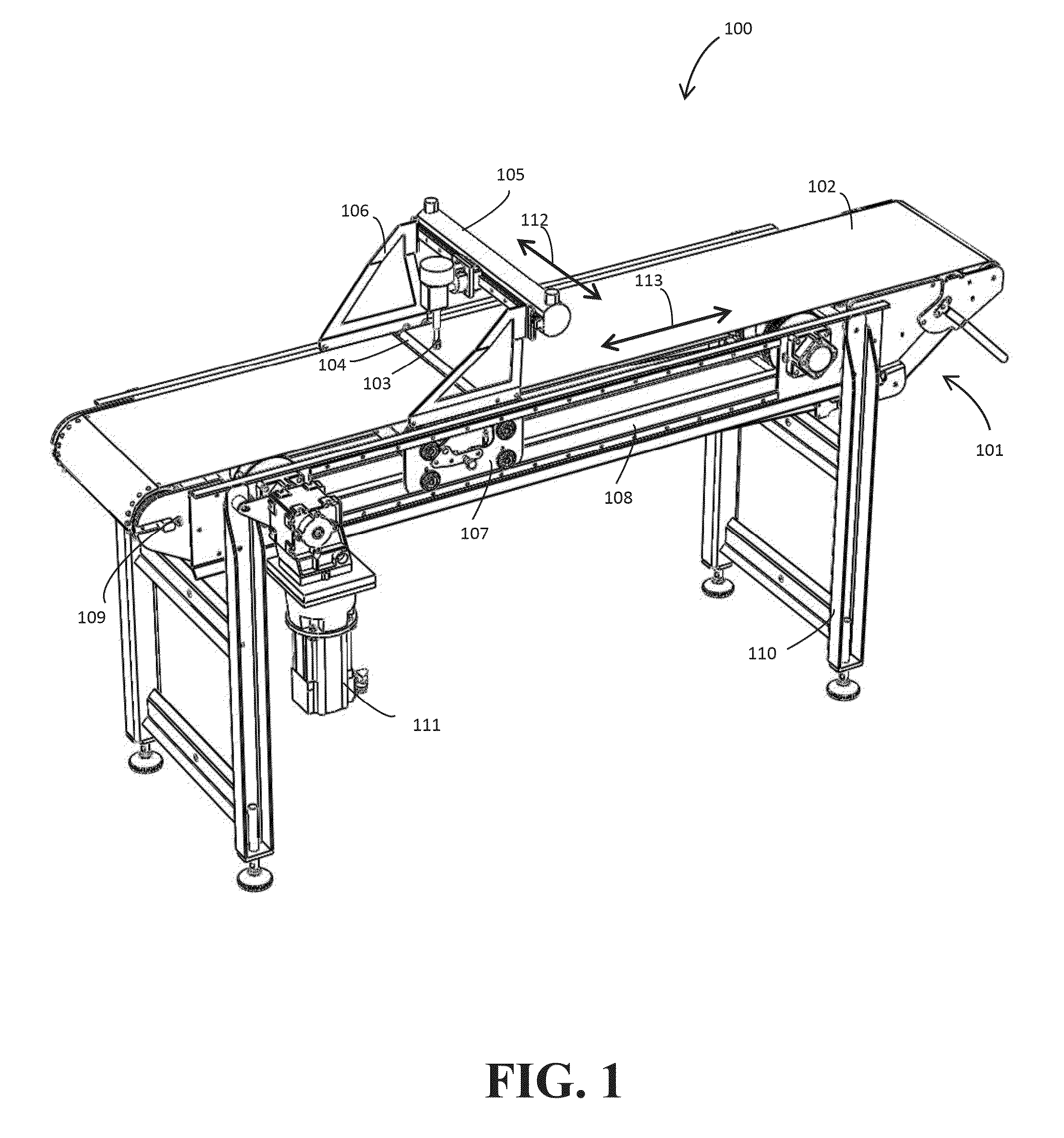

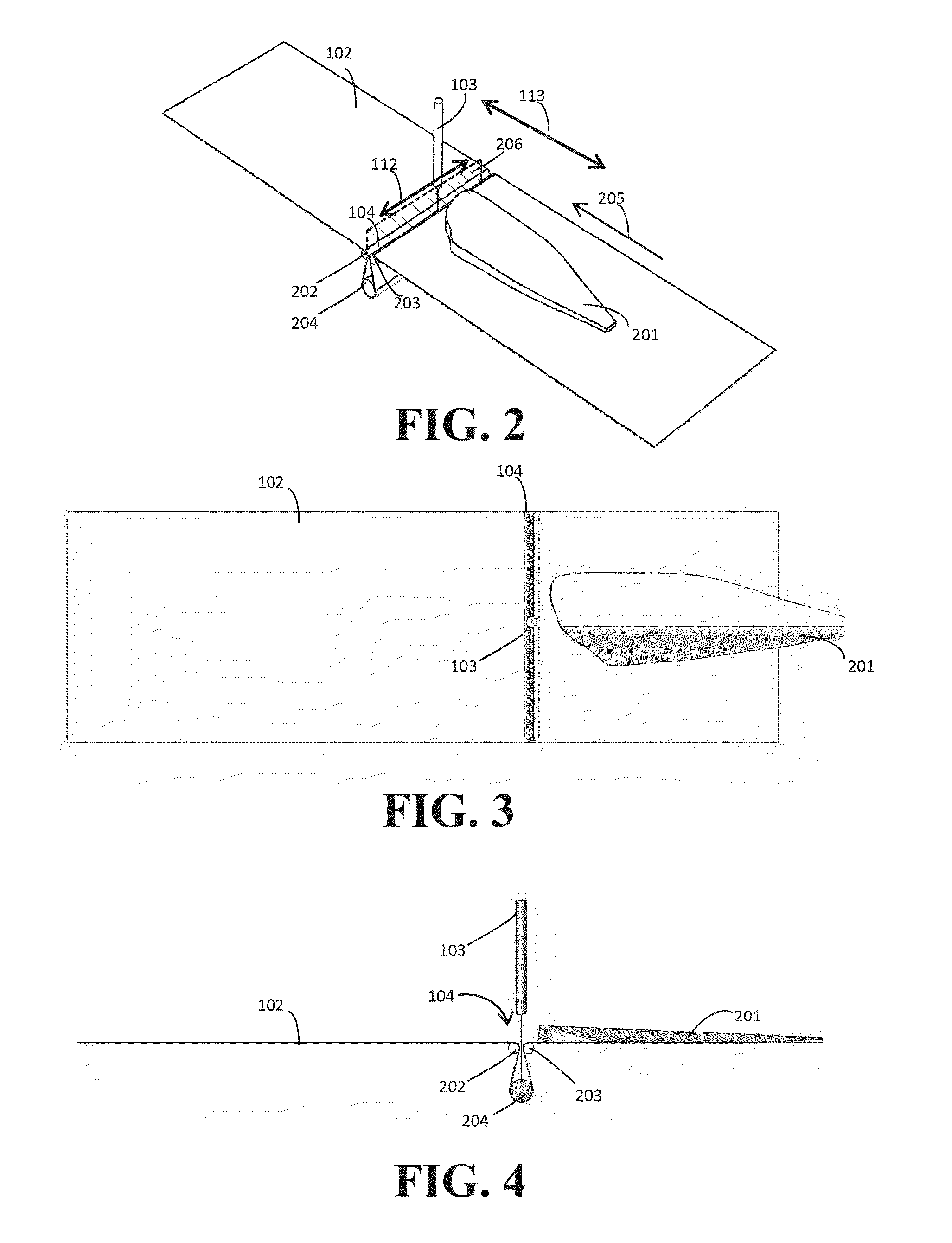

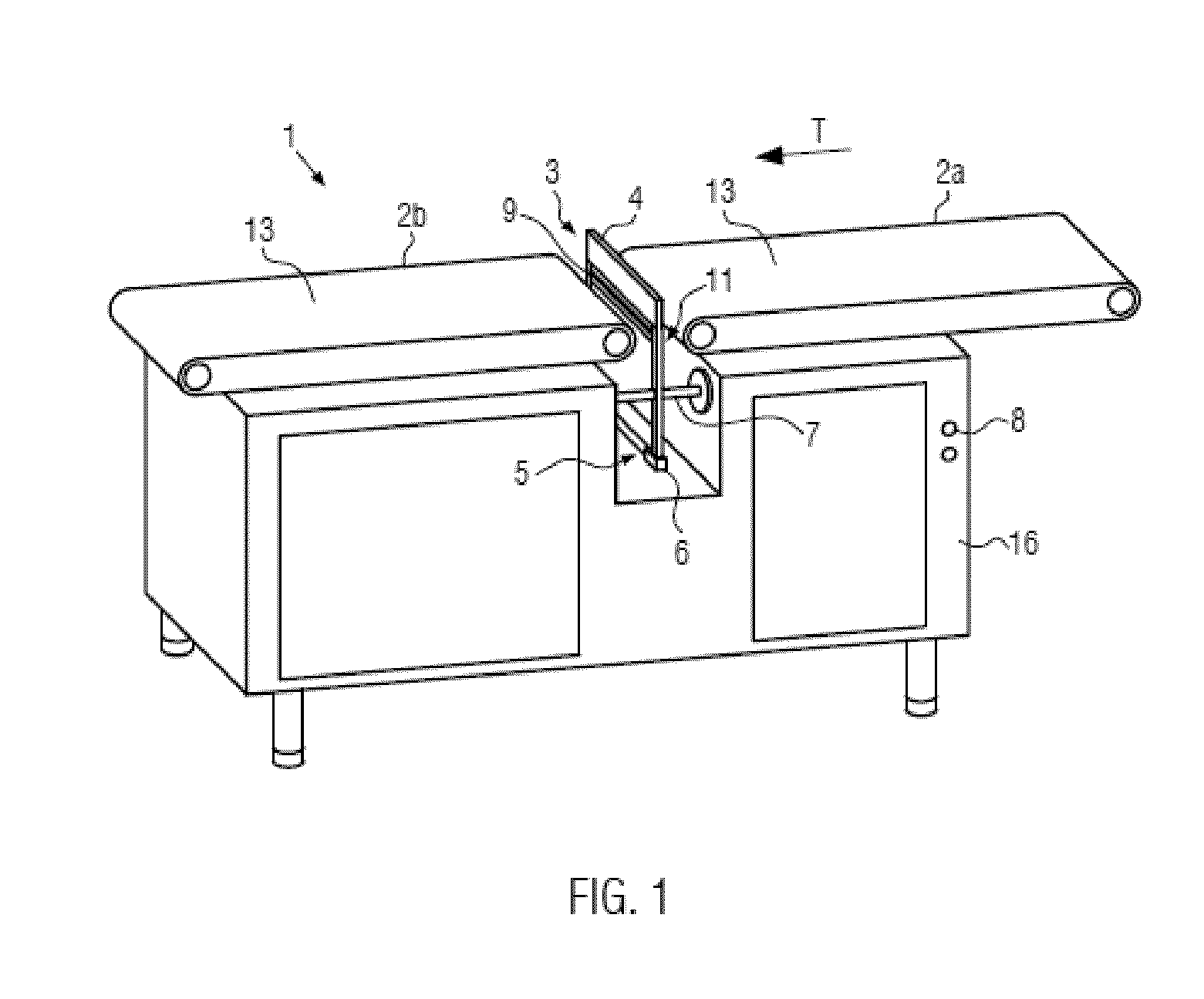

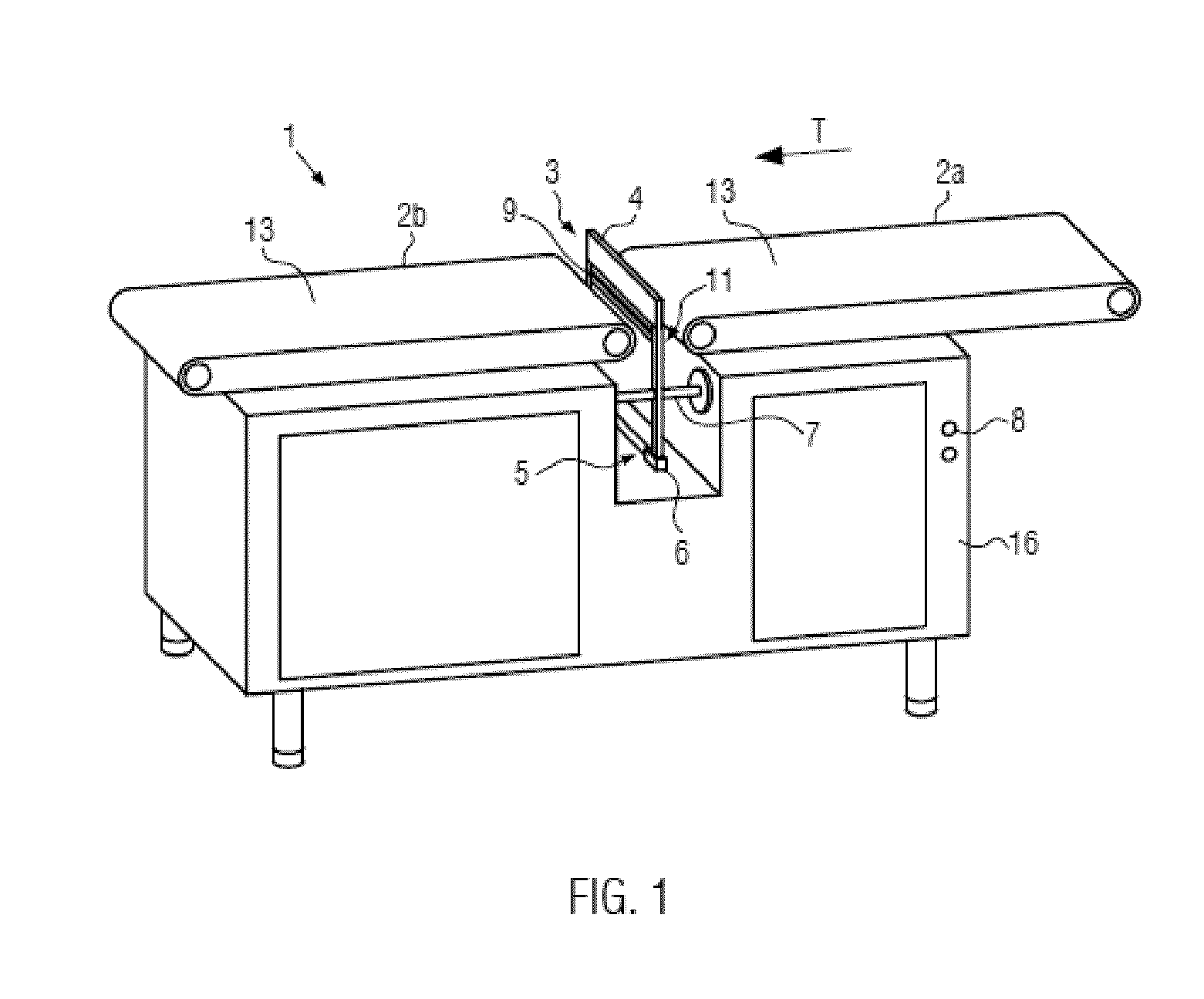

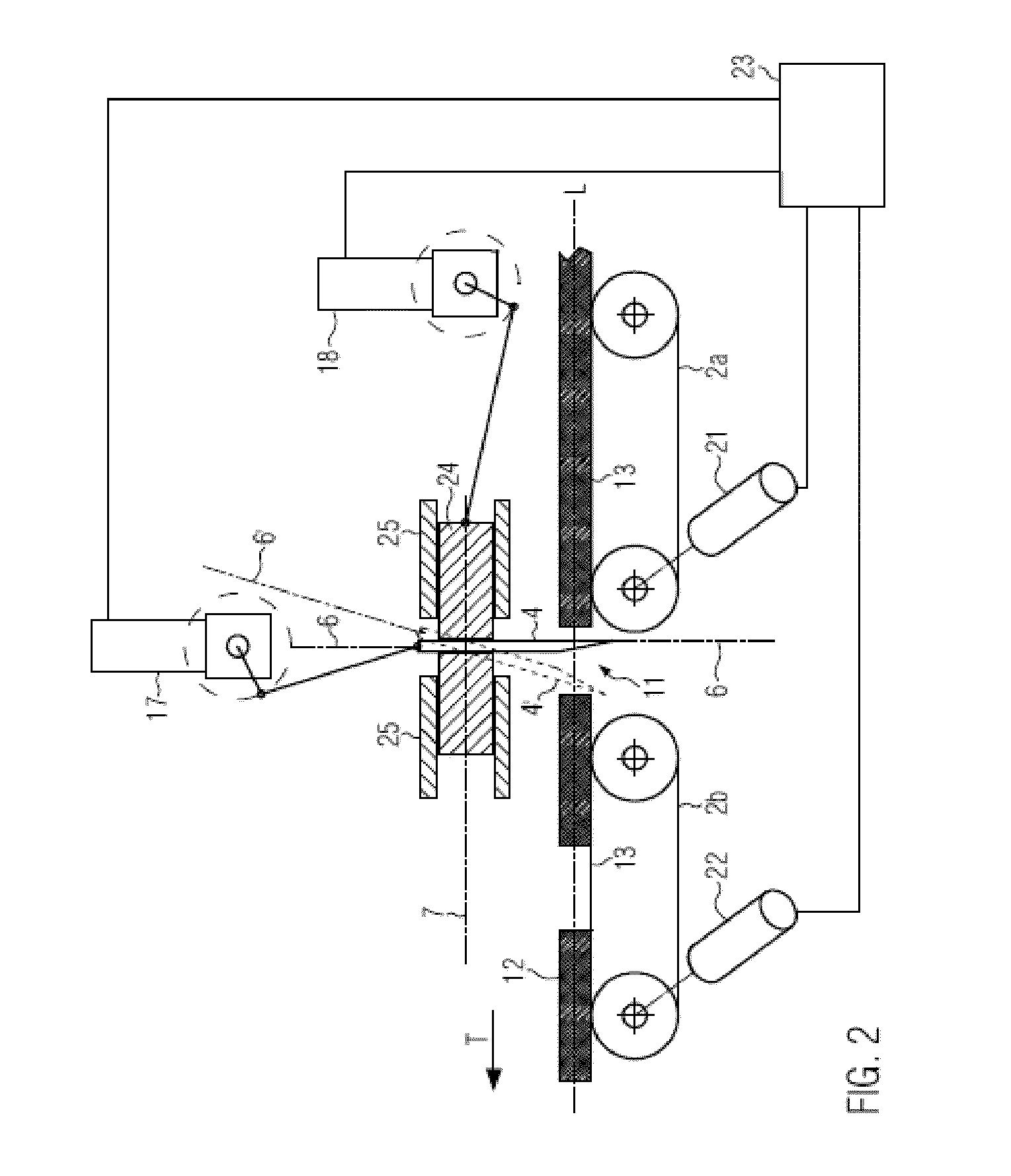

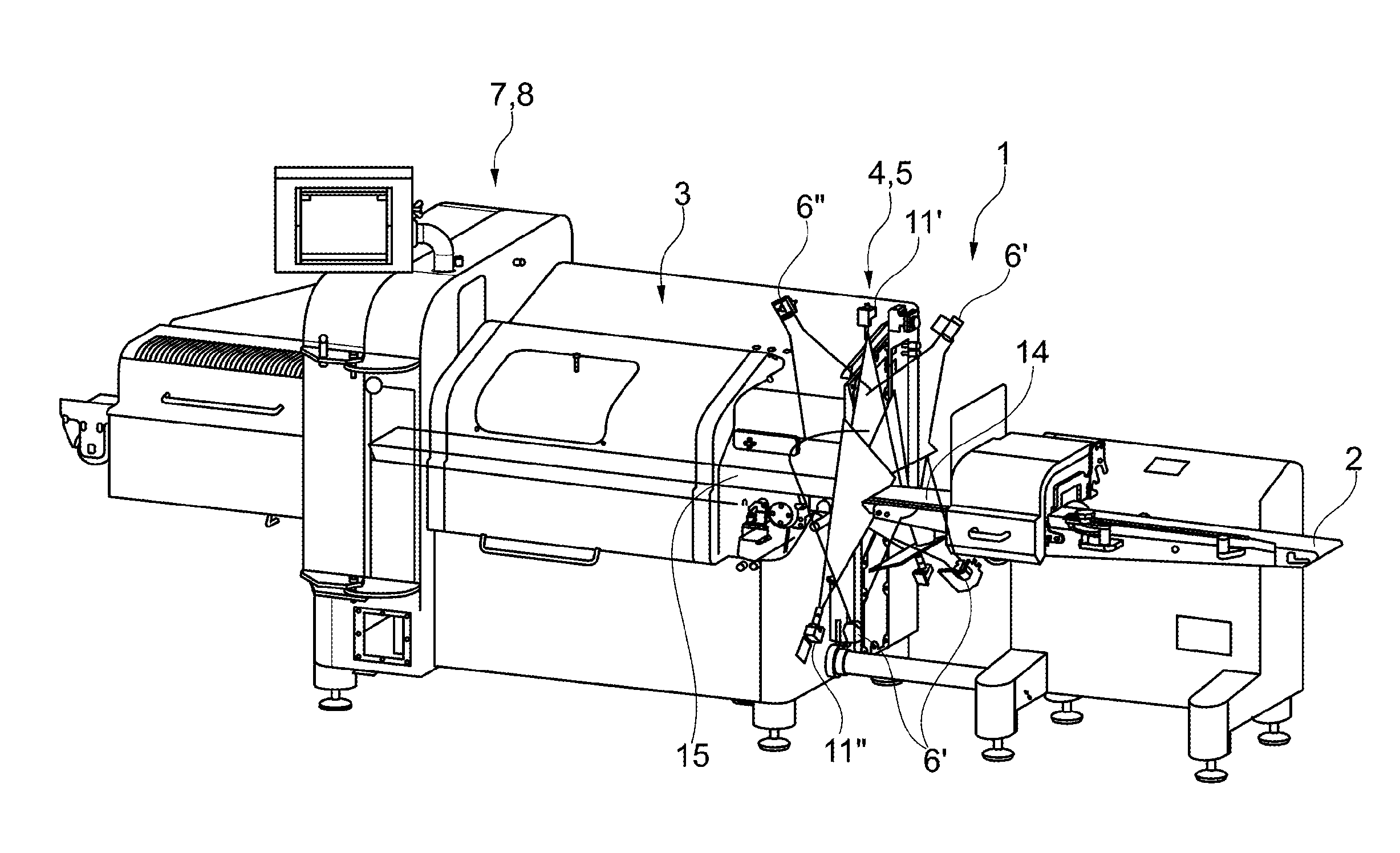

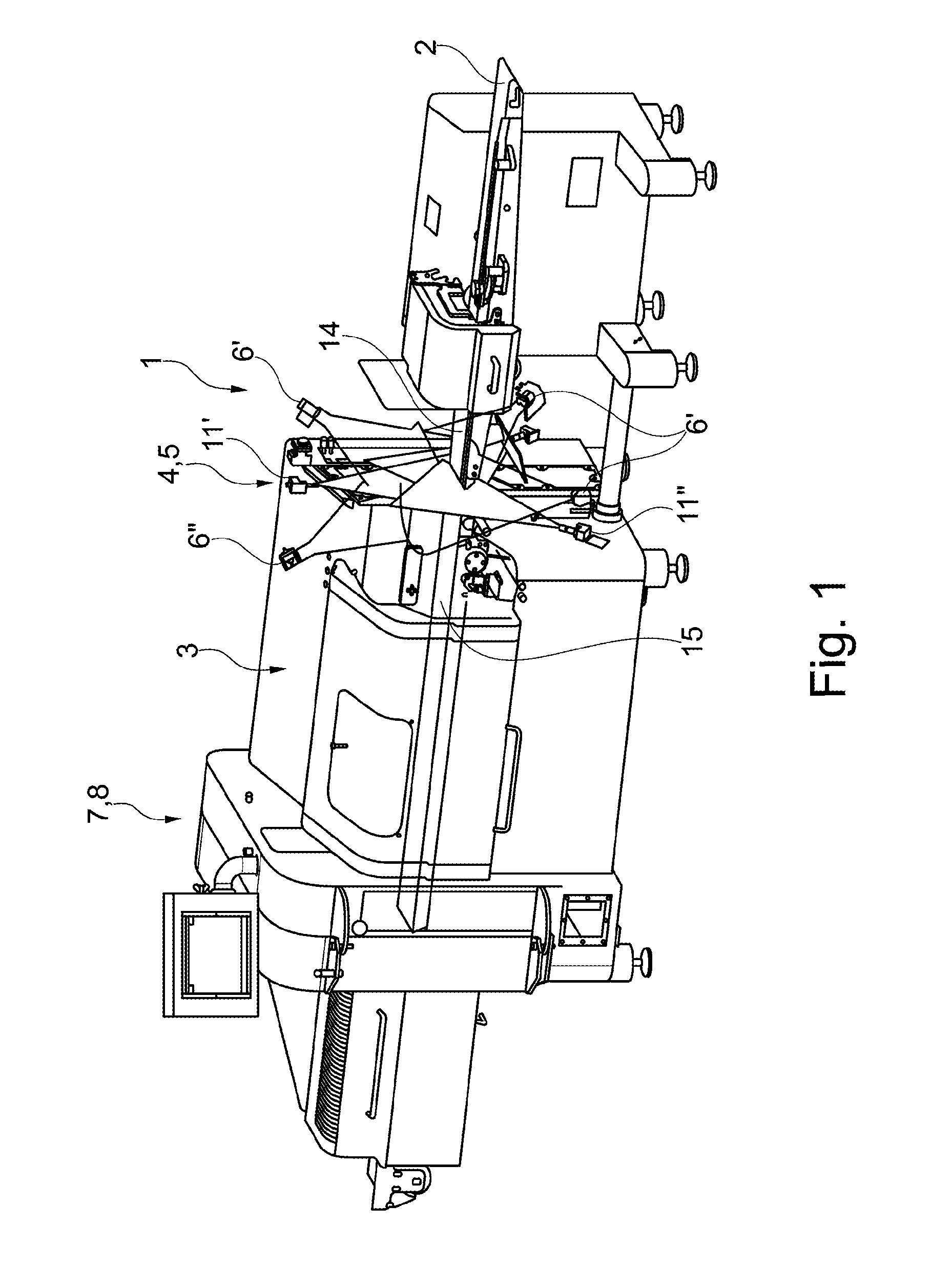

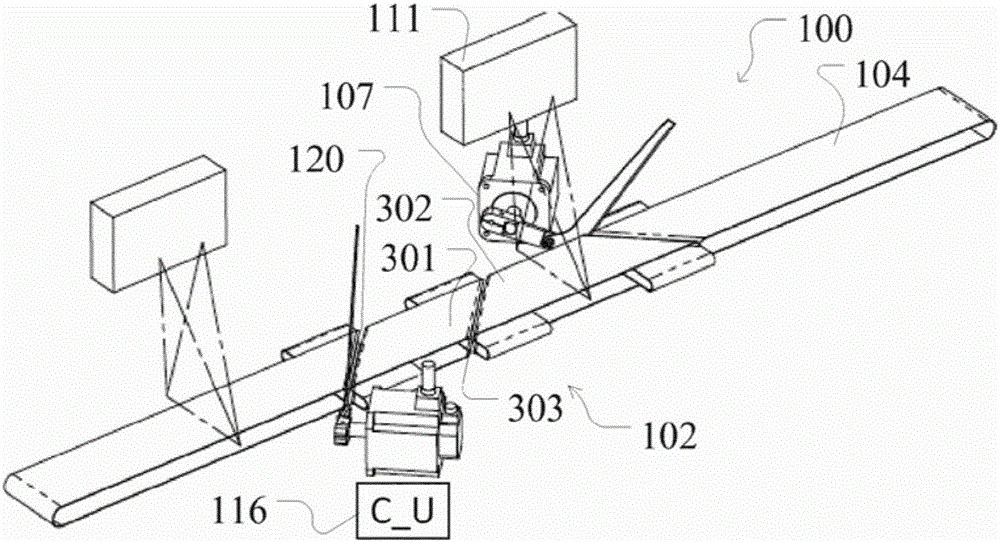

Cutting apparatus for cutting food items conveyed on a conveyor including at least one conveyor belt

InactiveUS20150033921A1Easy to cleanEasy to monitorAutomatic control devicesConveyorsSurface levelConveyor belt

This invention relates to a cutting apparatus for cutting food items conveyed on a conveyor including at least one conveyor belt. A cutter is arranged above a gap extending across the at least one conveyor belt. The cutter is positioned in relation to the gap such that the cutting path of the cutter extends through the food items and the gap and below the surface level of the at least one conveyor belt. The cutter is adapted to be connected to a control mechanism for operating crosswise movement of the cutter along the gap. The gap is formed between adjacent elongated supporting means such as rollers with a fixed internal arrangement, where the adjacent elongated supporting means and the cutter is adapted to be connected to a control mechanism for operating back and forth movement of the adjacent elongated supporting means and the cutter parallel to the conveying direction while maintaining the internal arrangement of the adjacent elongated supporting means and the cutter fixed.

Owner:MAREL ICELAND EHF

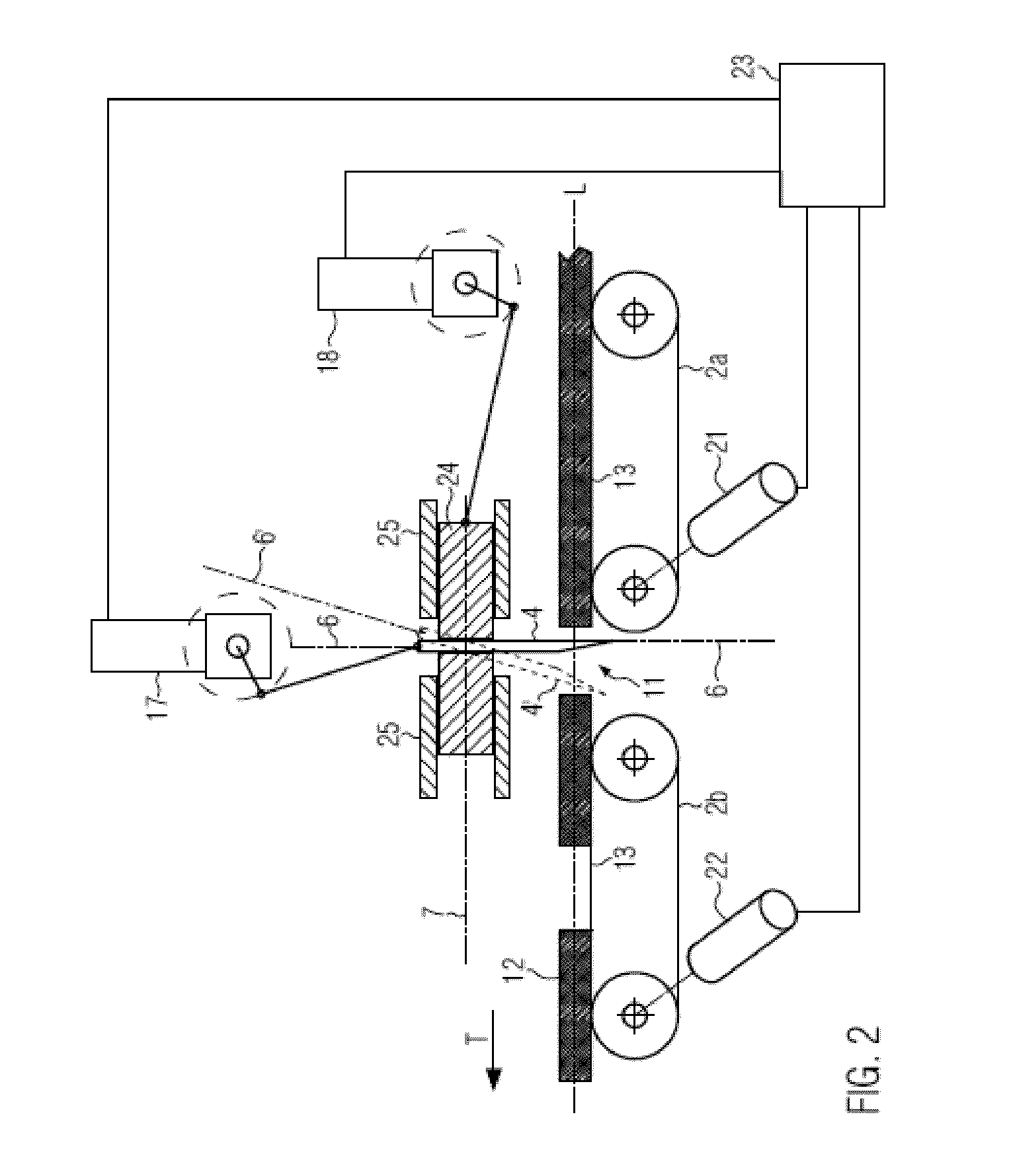

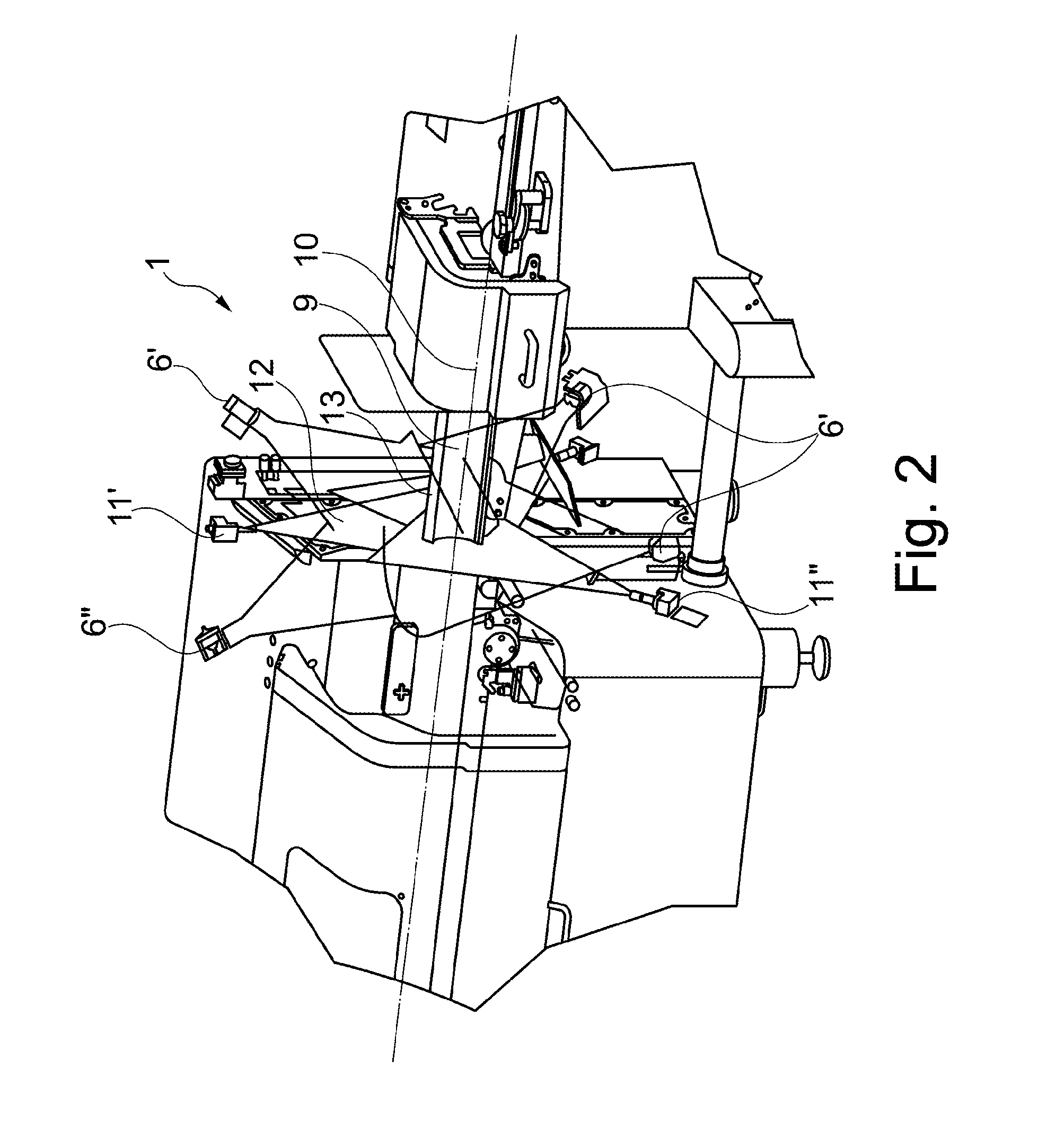

Method and device for separating products

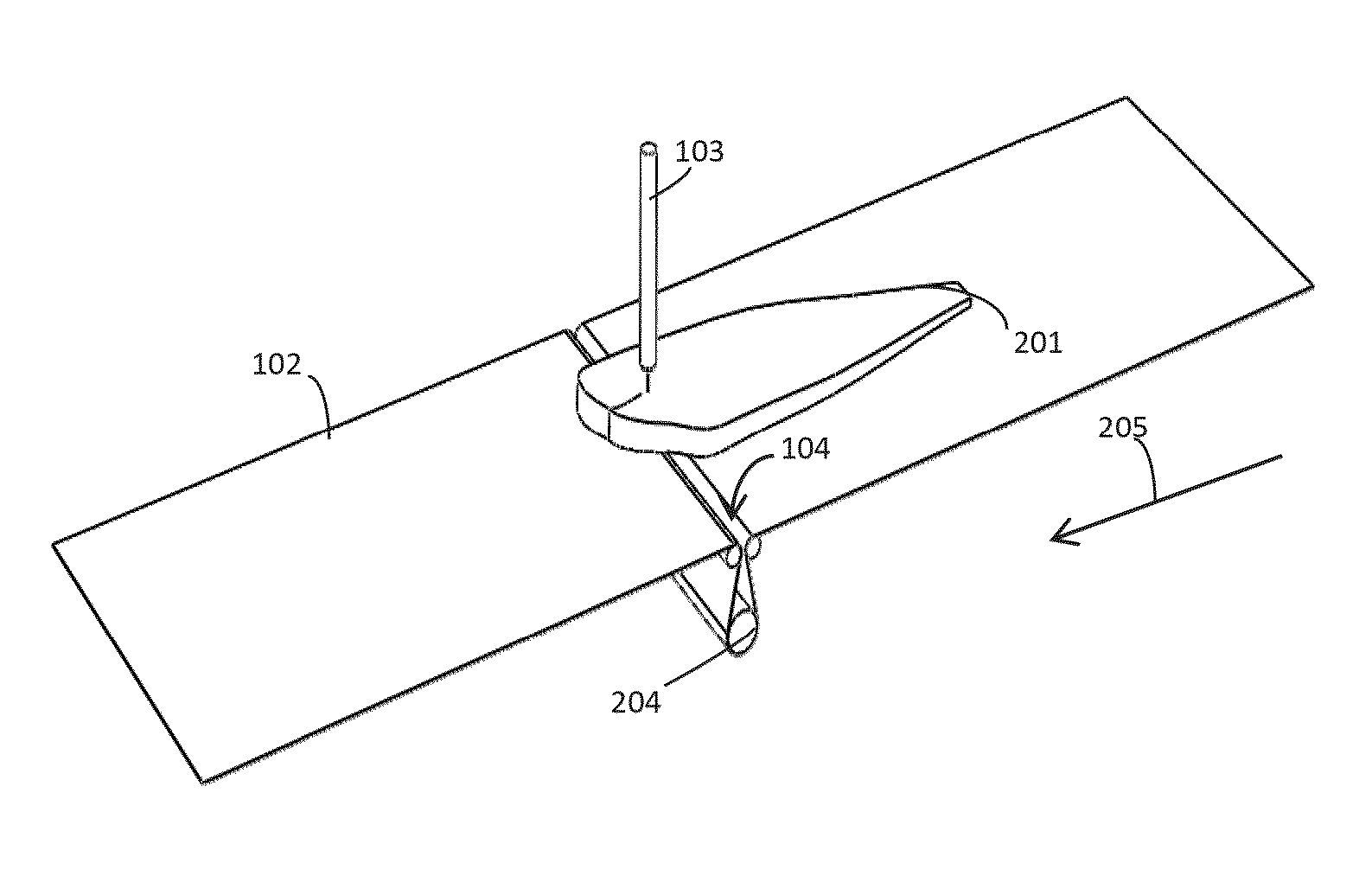

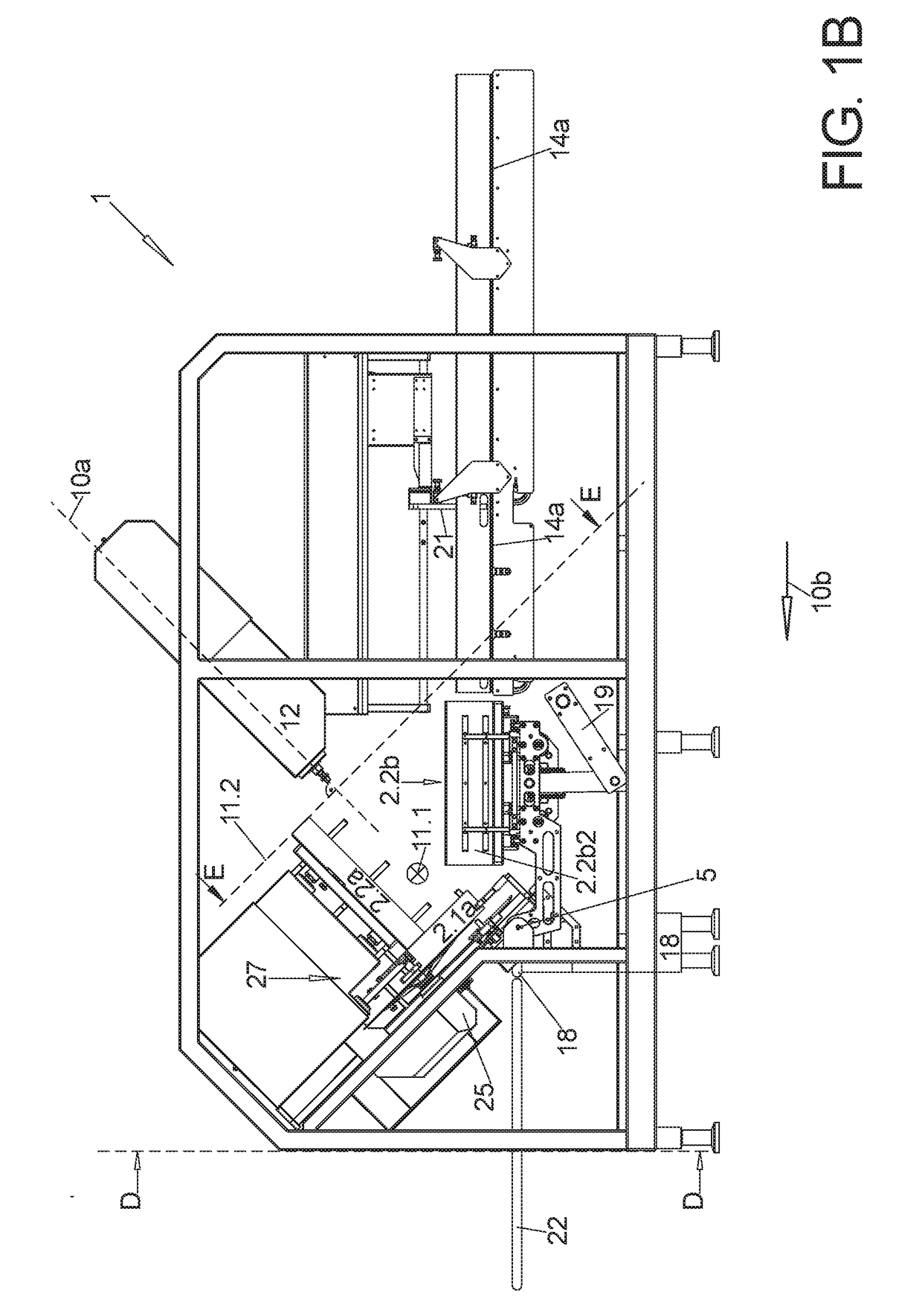

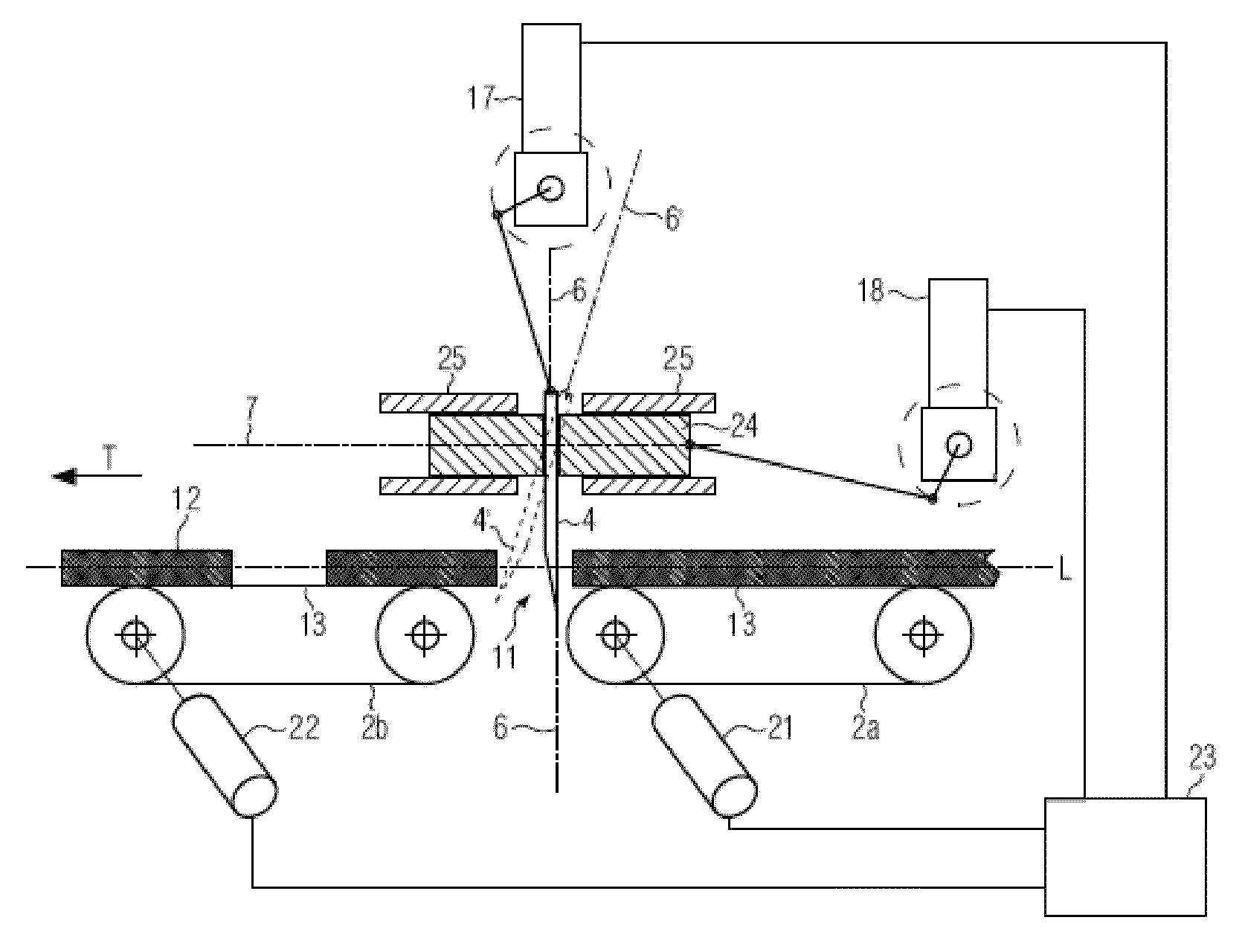

ActiveUS20130205961A1Exact weight precisionIncrease cycle rateStock shearing machinesMetal working apparatusCycle rateEngineering

A method and a device for separating food products, including to permit a straight cut at high cycle rates, the food product is conveyed by a conveying device in the direction of transport. The food product is cut through, where a cutting element is moved in the direction of transport and transverse to the direction of transport, wherein the motion of the cutting element transverse to the direction of transport is controlled independently of its motion in the direction of transport and the food product does not rest on the cutting area on the conveying means.

Owner:ALBERT HANDTMANN MASCHFABRICK

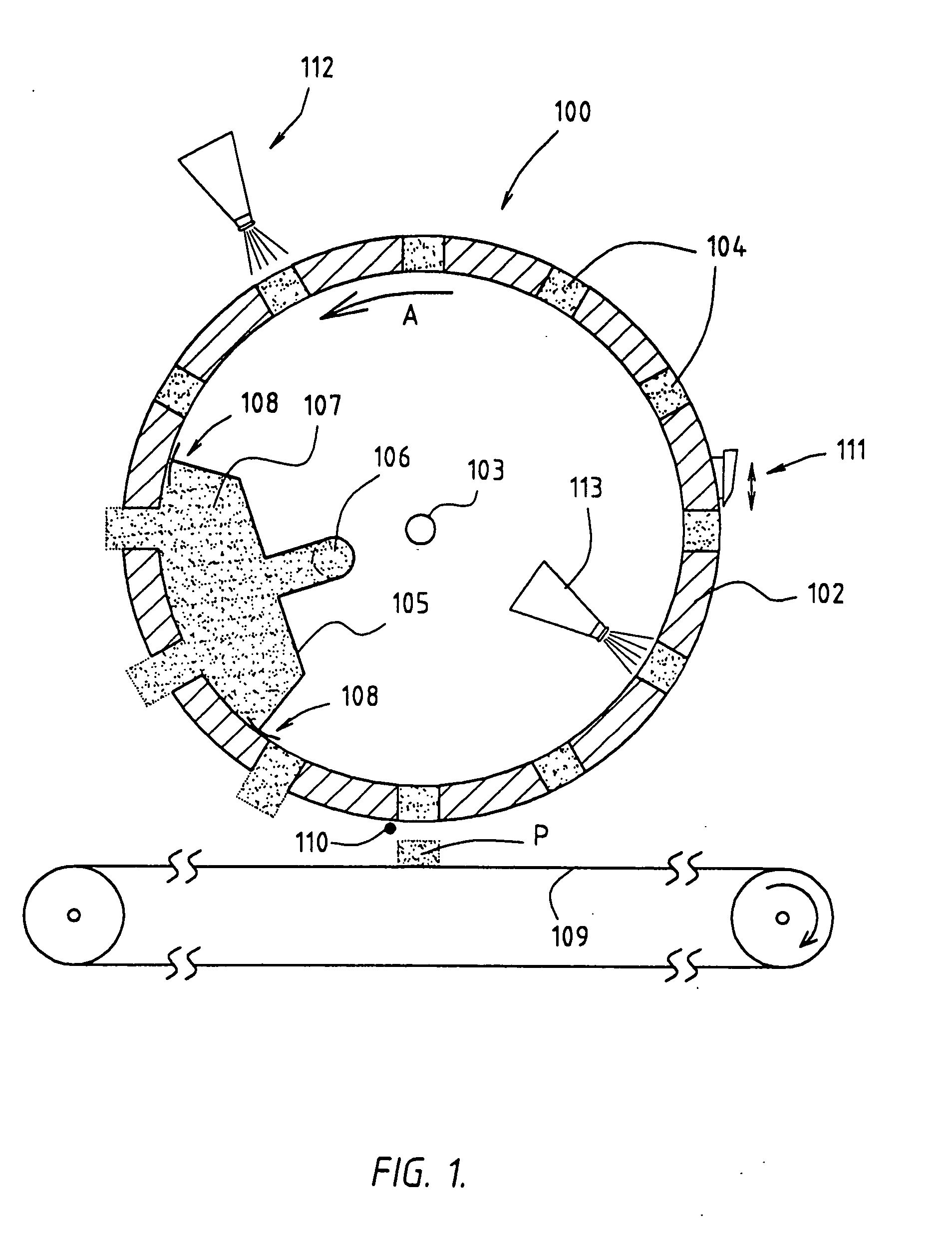

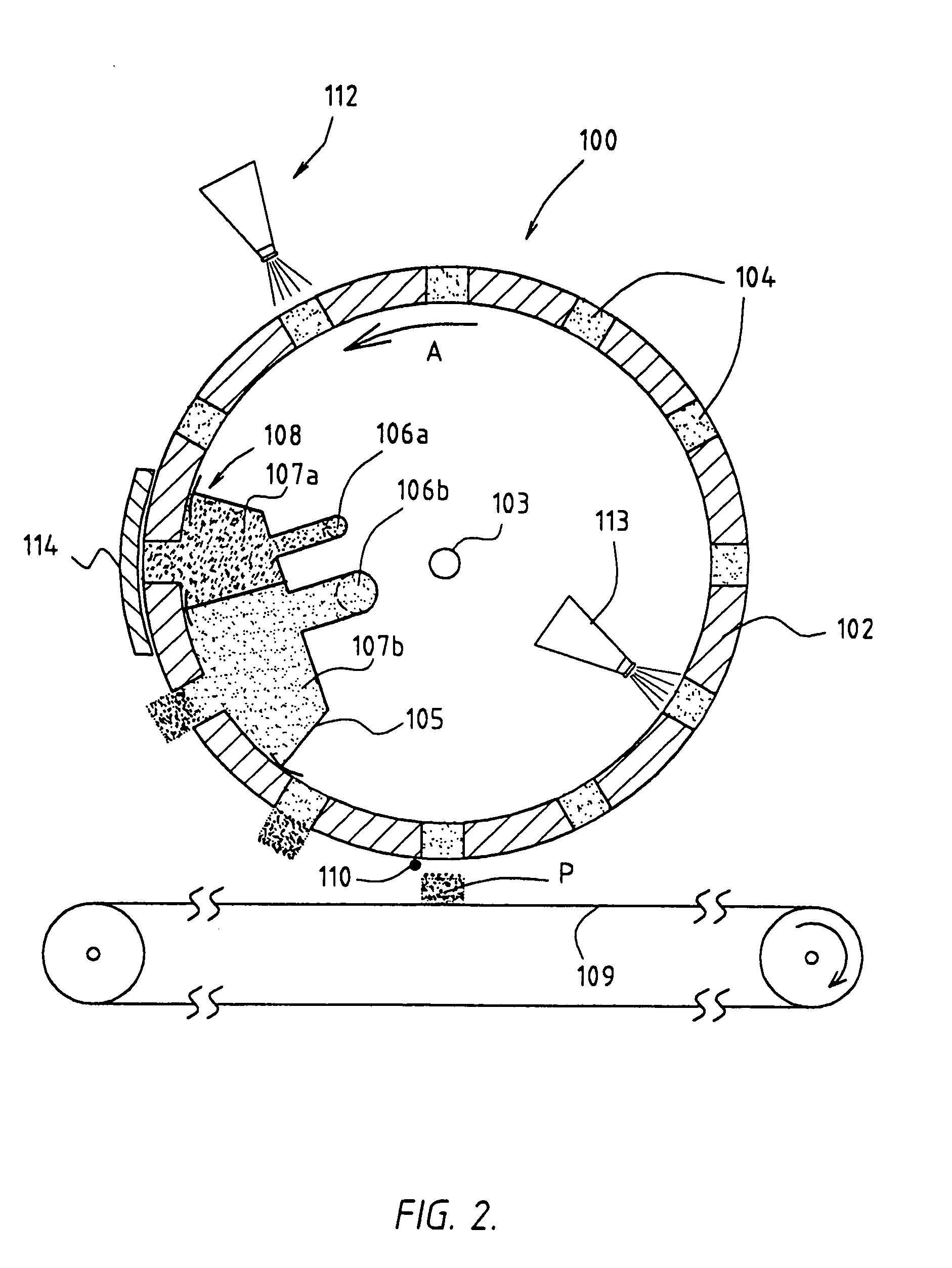

Moulding

InactiveUS20050003062A1Efficient packagingHigh priceConfectionerySweetmeatsPartial fillingMaterials science

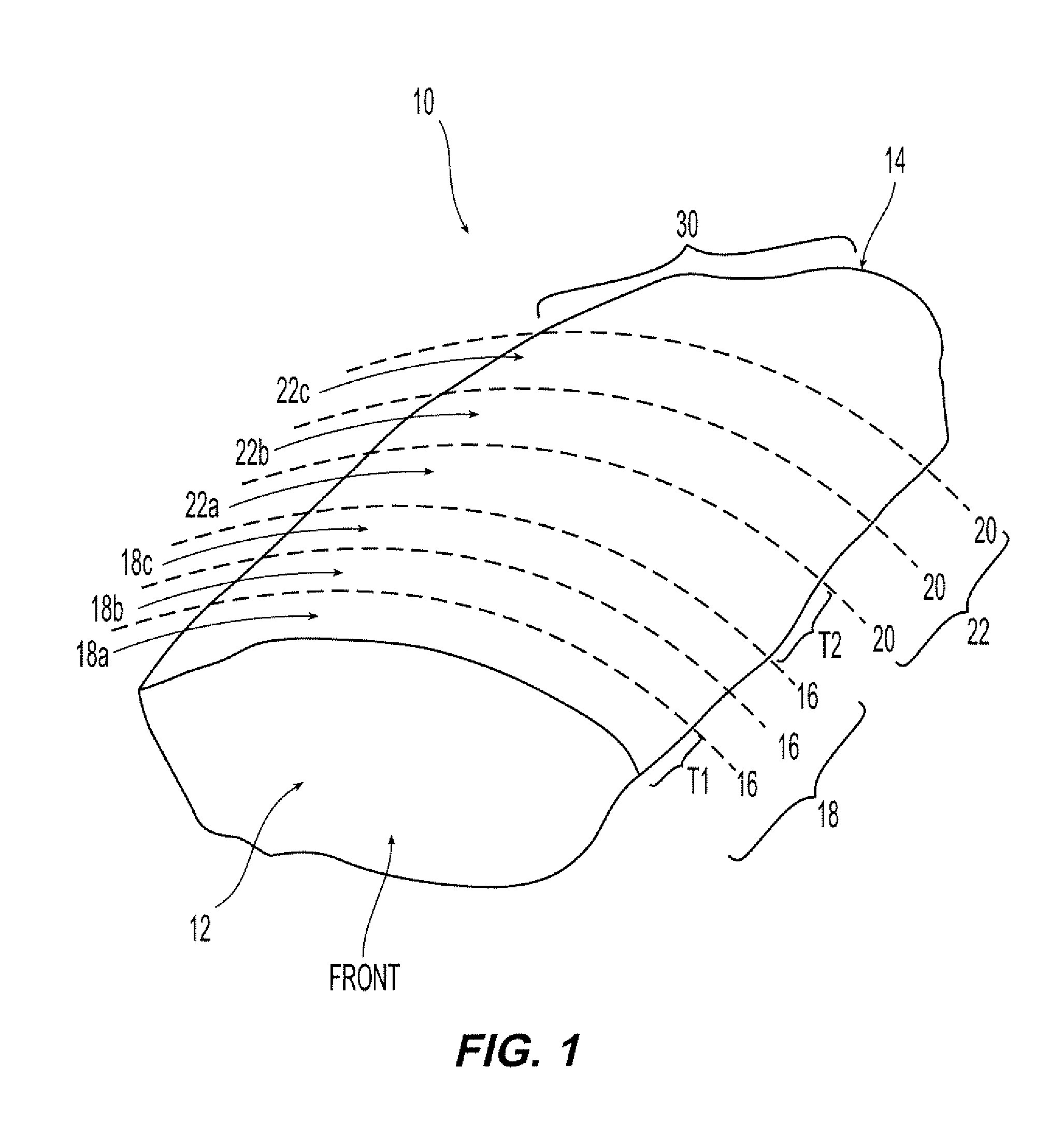

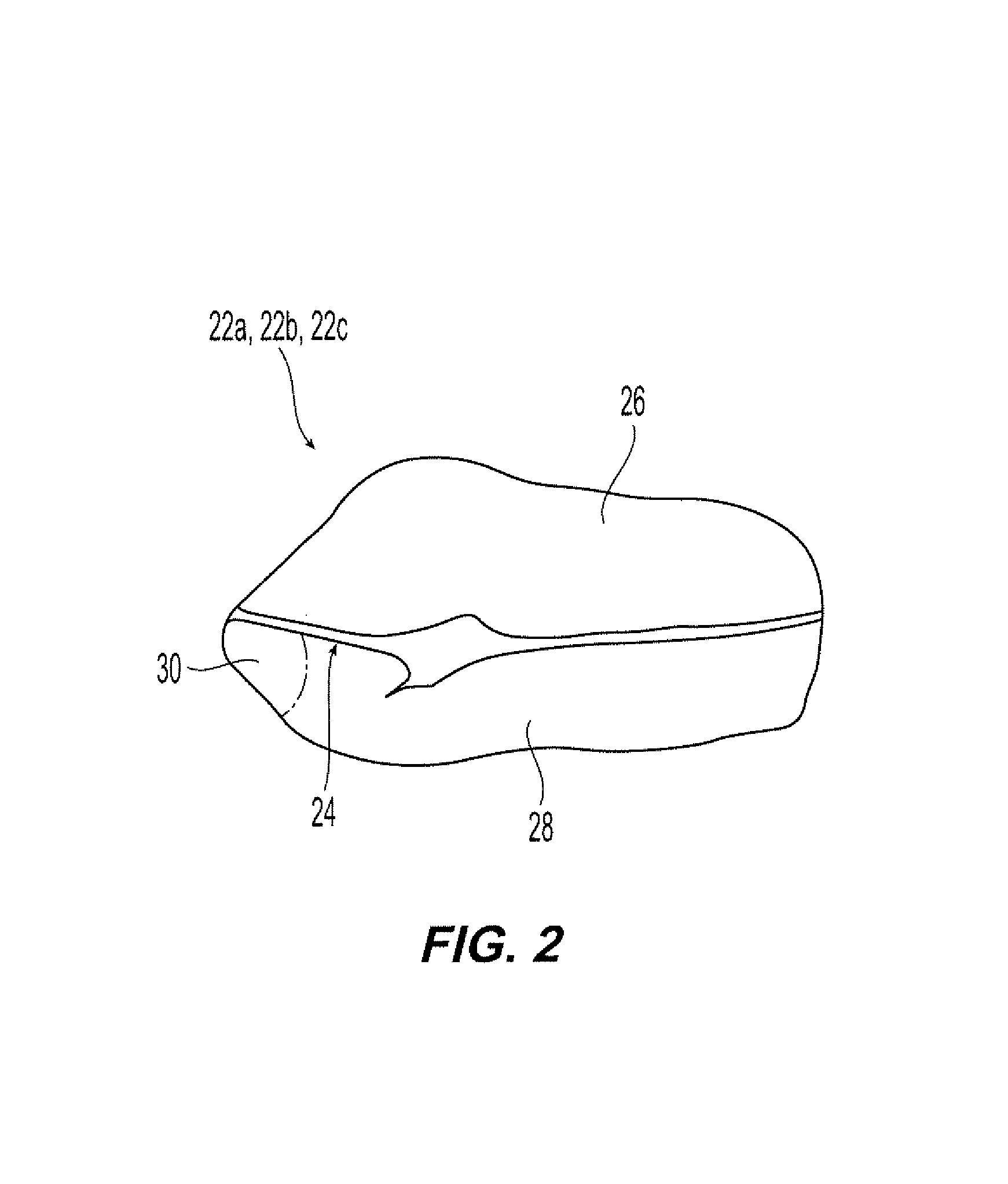

The invention provides methods and moulding devices for moulding three-dimensional products from a mass of foodstuff which is suitable for human consumption, in particular from a mass of meat, in particular chicken. The method comprises filling a mould cavity with a portion of the mass under the influence of a filling pressure exerted on the mass and for a filling period via a filling opening associated with the mould cavity, closing the filling opening of the mould cavity and holding the mass in the mould cavity for a fixing period. Then, the mould cavity is opened and the moulded product is removed from the mould cavity. The method uses fixing-pressure-exerting means which are designed to exert a fixing pressure which acts on the mass in the mould cavity after the filled mould cavity has been closed.

Owner:STORK PMT

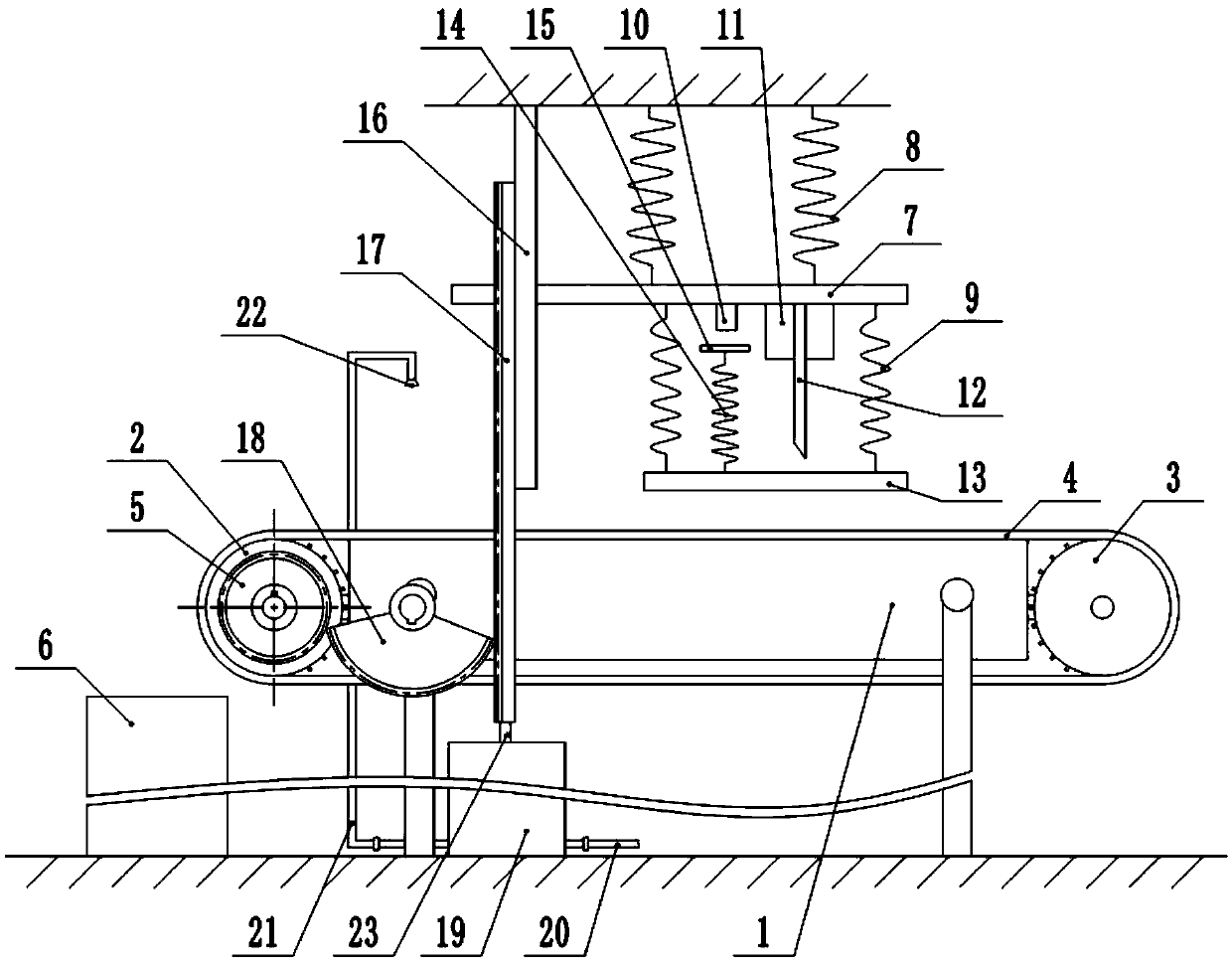

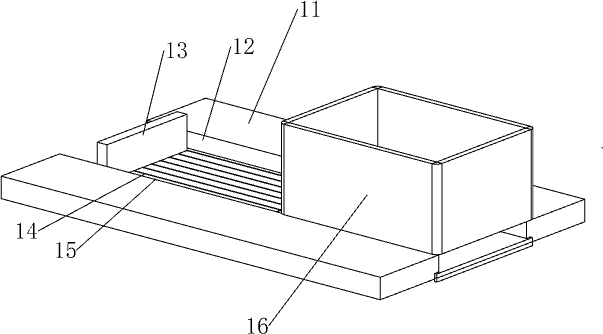

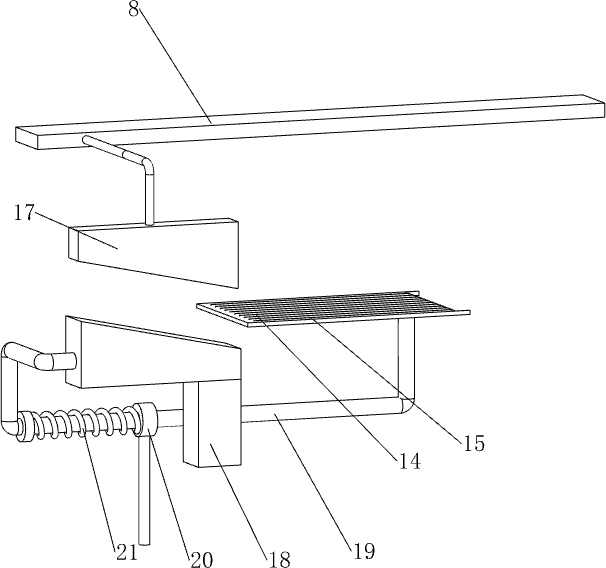

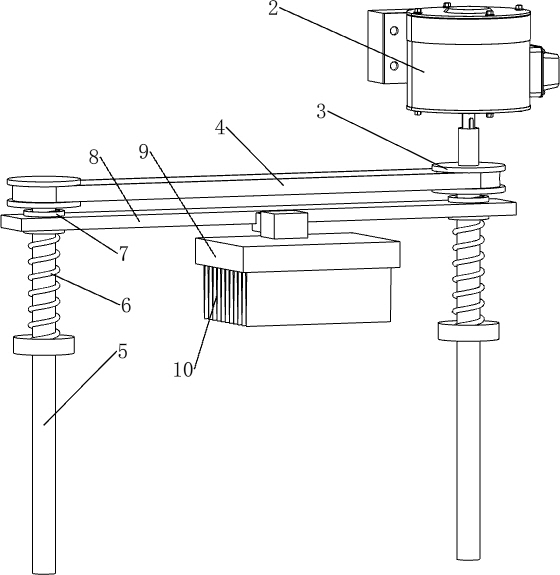

Fresh meat cutting and shredding device

InactiveCN109591091ARealize automatic dischargeImprove cutting and decomposition efficiencyMeat holding apparatusMetal working apparatusDrive wheelEngineering

The invention relates to the technical field of food processing, and in particular discloses a fresh meat cutting and shredding device. The fresh meat cutting and shredding device comprises a rack anda cutting table, where the two ends of the cutting table are rotationally connected with a driving wheel and a driven wheel respectively, the driving wheel and the driven wheel are jointly wound witha plate-chain conveying belt, and the driving wheel is coaxially connected with a gear; a transverse plate is arranged above the cutting table and is connected onto the rack through a spring, and a press plate is arranged under the transverse plate and is connected with the transverse plate through a spring; a cutting knife is arranged on the side, facing the press plate, of the transverse plate,and a knife seam for enabling the cutting knife to pass is formed in the pres plate; the rack is fixedly connected with a fixed strip, and the fixed strip is vertically connected with a toothed rackvertically; the toothed rack is meshed with an incomplete gear; and the incomplete gear can be meshed with the gear in the rotation process. According to the fresh meat cutting and shredding device, by the meshing of the incomplete gear and the gear, the driving wheel is driven to rotate, and therefore automatic feeding and discharging of fresh meat is realized; by the meshing of the incomplete gear and the gear, the cutting knife is driven to move, and therefore cutting and shredding of the fresh meat are realized; and thus, the working efficiency is improved.

Owner:CHONGQING NIANJI FOOD

Meat cutting assembly

ActiveUS7682227B1Accurate and stable placementProhibiting and significantly reducing possibilityPoultry processingMeat tenderisingEngineeringMechanical engineering

A cutting assembly for cutting a meat or food product passing along a path of travel and comprising a blade roller having a plurality of blades transversely connected thereto in aligned relation to the path of travel. A mate roller, an in-feed roller and an out-feed roller interact with the plurality of blades to assure removal of meat portions from the blade and mate rollers during the cutting procedure. The mate roller comprises a plurality of mate roller sections each separated from one another by a first predetermined space and variably or adjustably positioned along the length of the mate roller by interaction with a stabilizing assembly to accommodate receipt of the blades within the first predetermined spaces during concurrent rotation of the blade and mate rollers. The cutting assembly may include a modular construction disposable within and removable from an operative position along a processing line associated with the path of travel.

Owner:BIFULCO PHIL

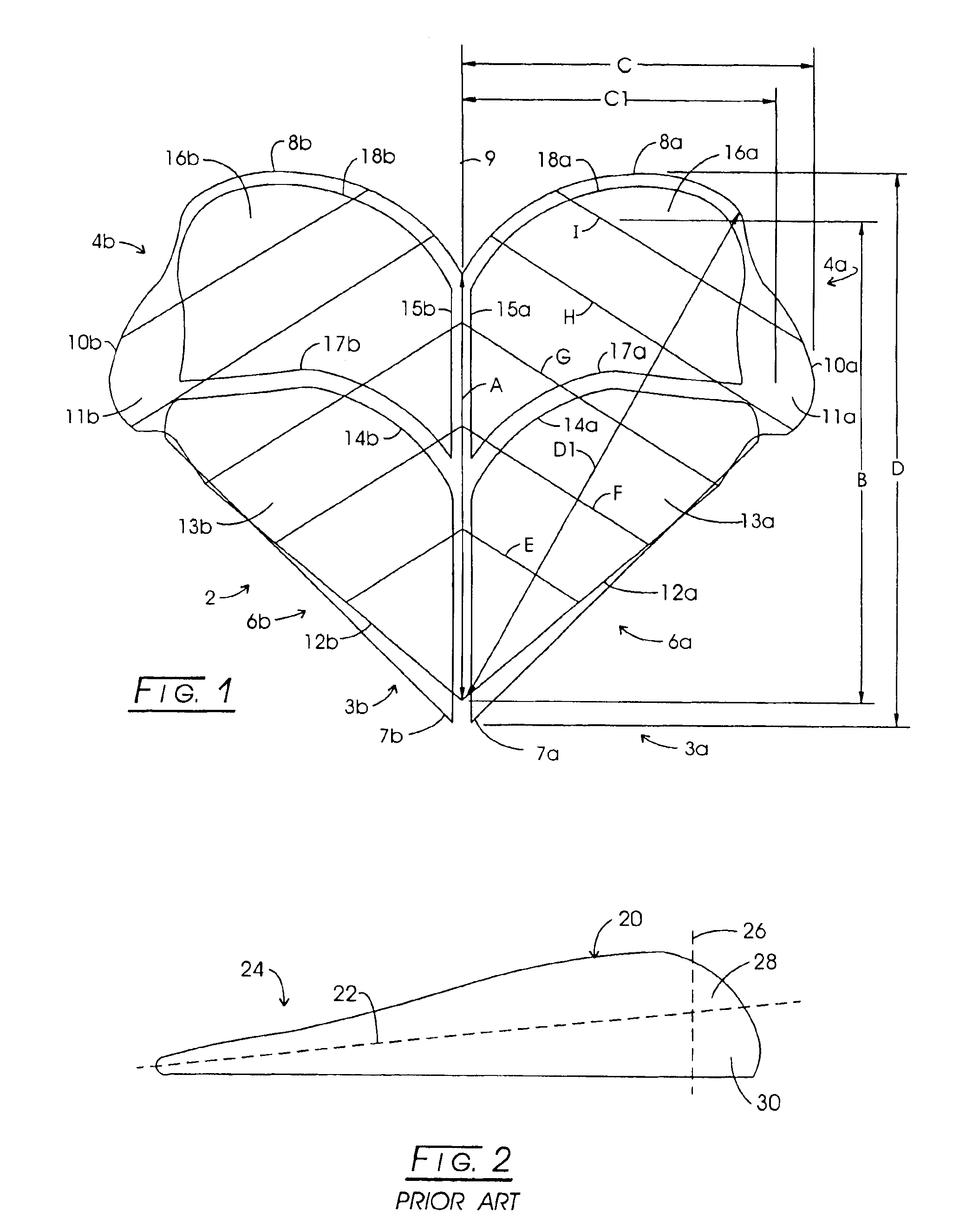

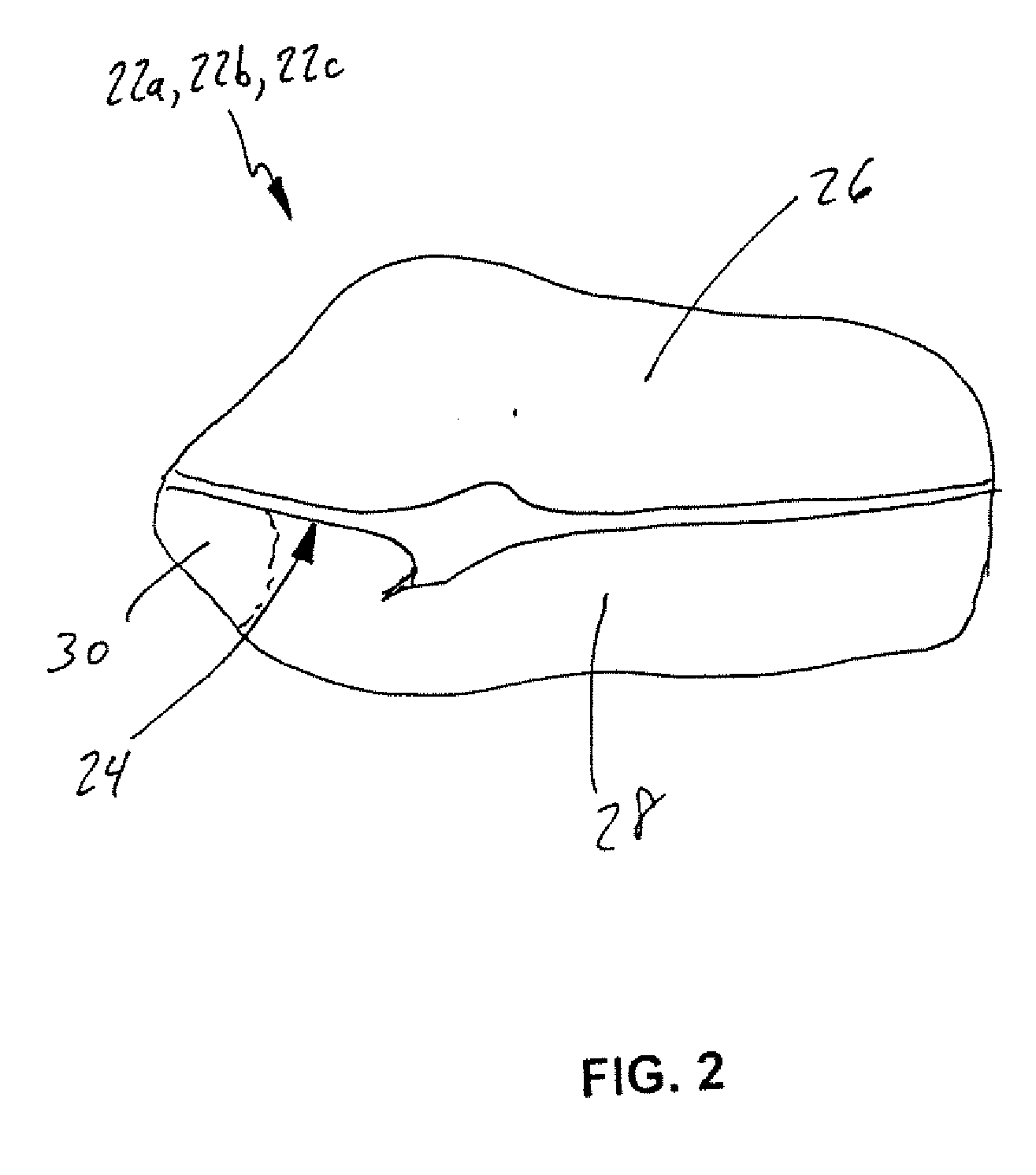

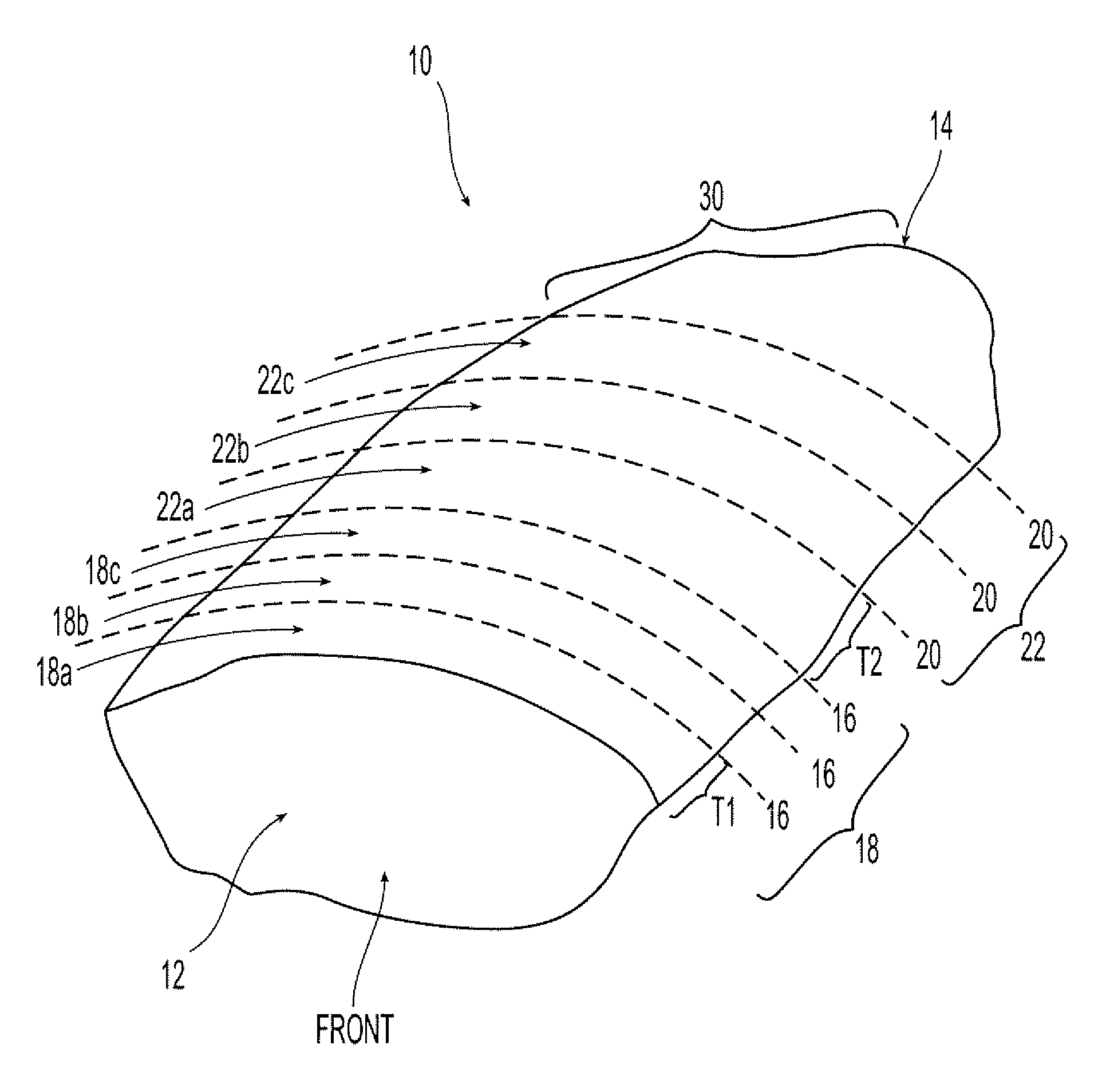

Poultry breast meat apportioning method

InactiveUS6921326B2Increase productionUniform volumeSplitting instrumentsMetal working apparatusBiotechnologyPhysiology

A method for apportioning larger poultry breast wherein two primary meat products are produced by cutting predetermined cutlet shapes from the rearward one half of each breast half. Additionally cut are two or more preparative secondary meat products from the thicker shoulder forward region of each breast half. These preparative secondary meat products are severed horizontally in half to produce four secondary meat products.

Owner:SMITH JEFFREY P

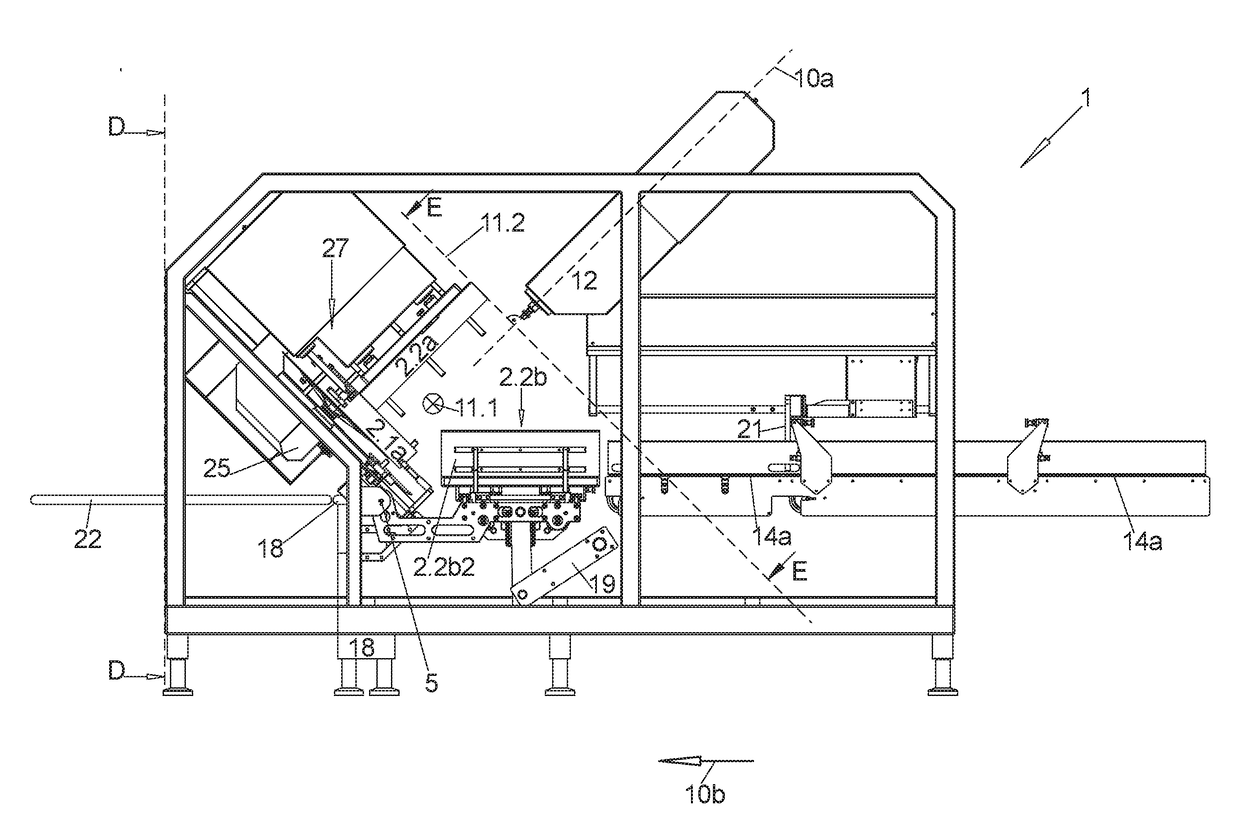

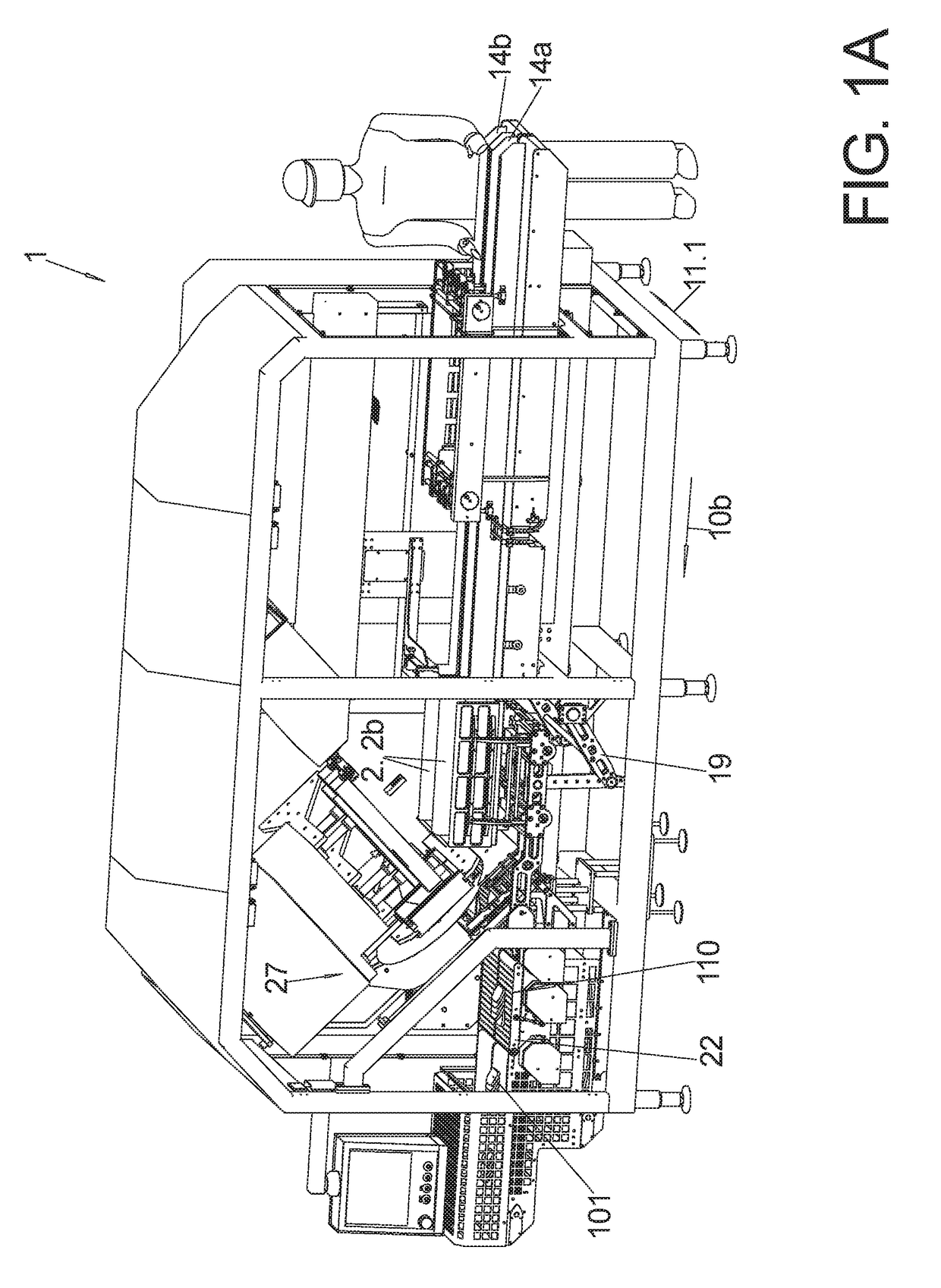

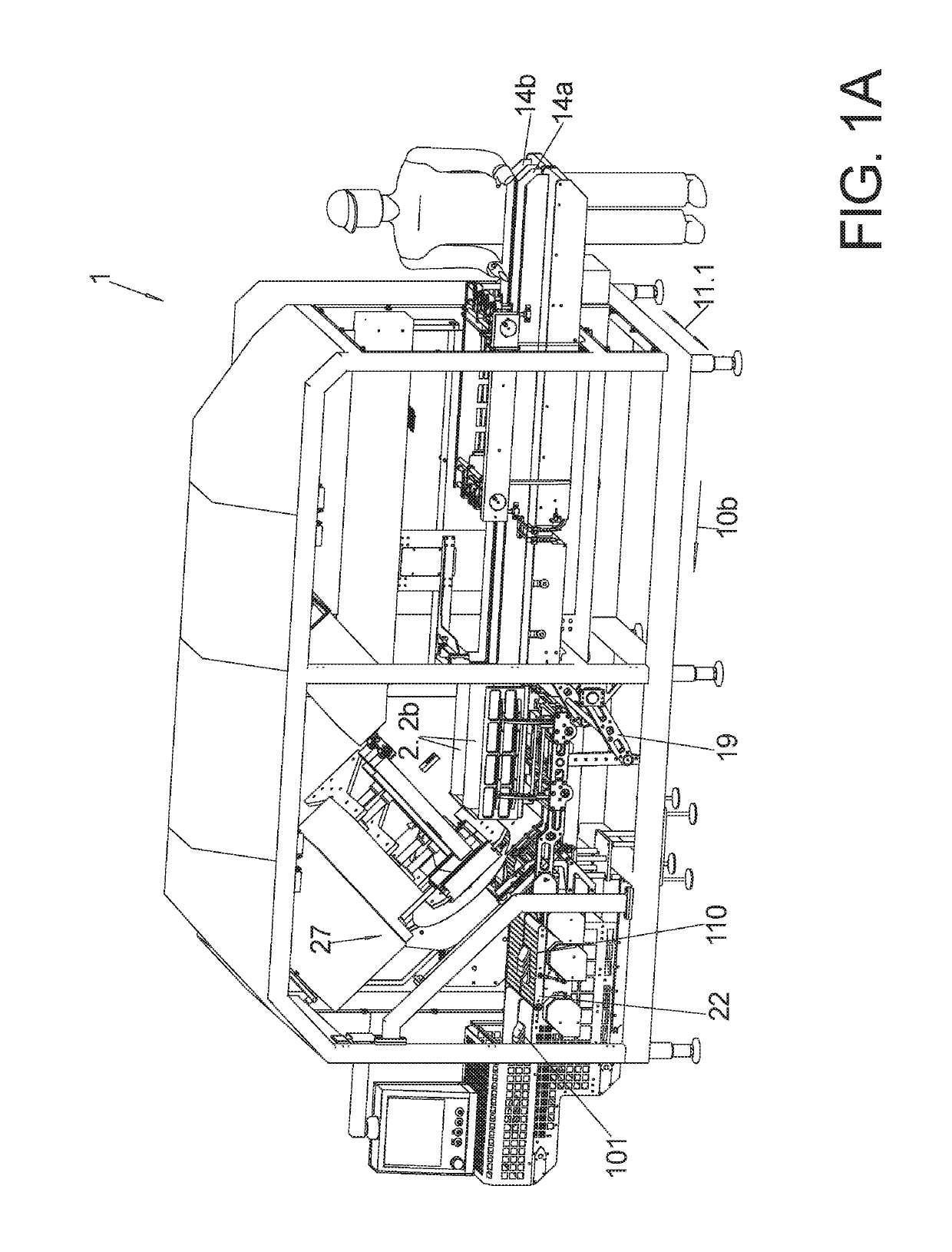

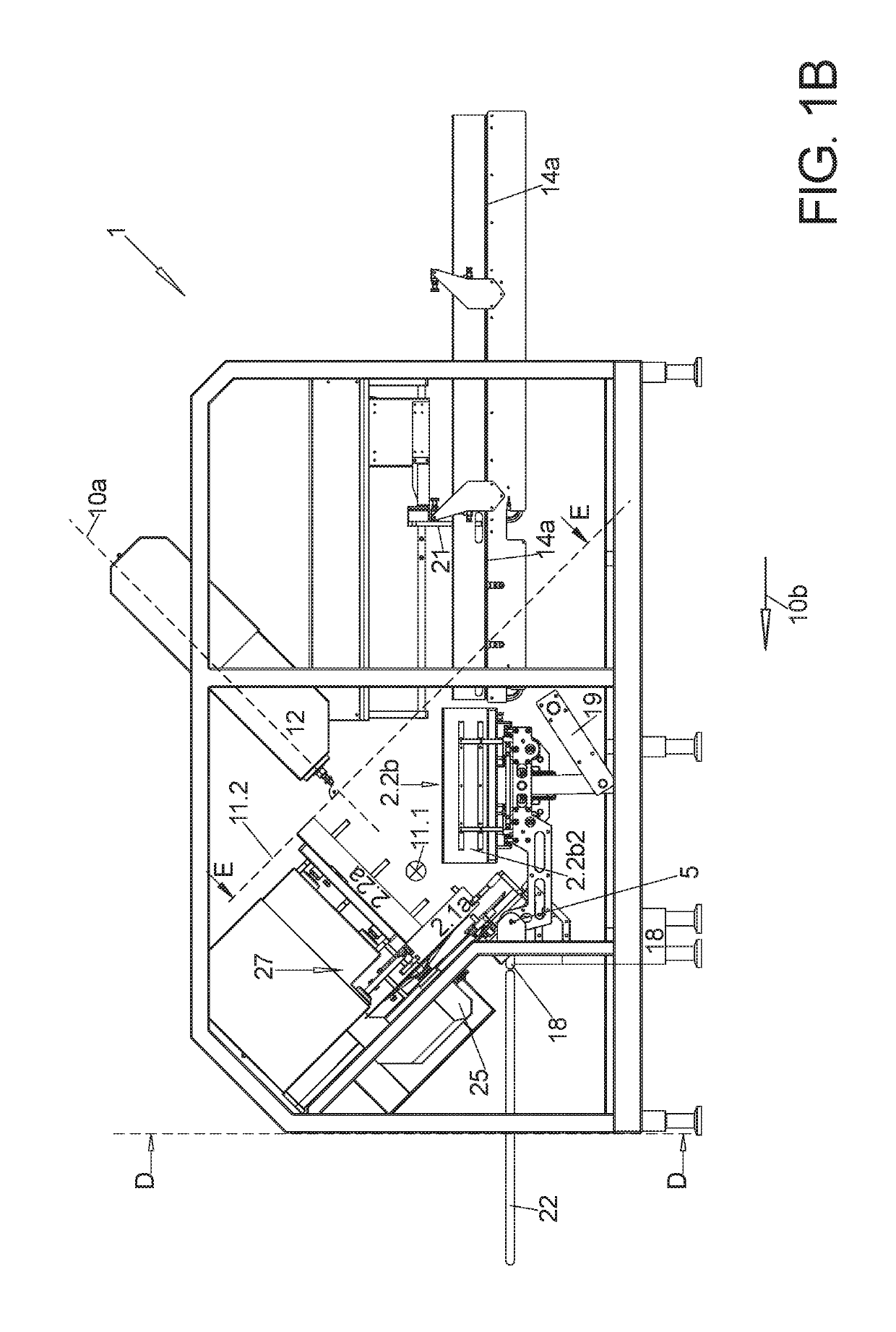

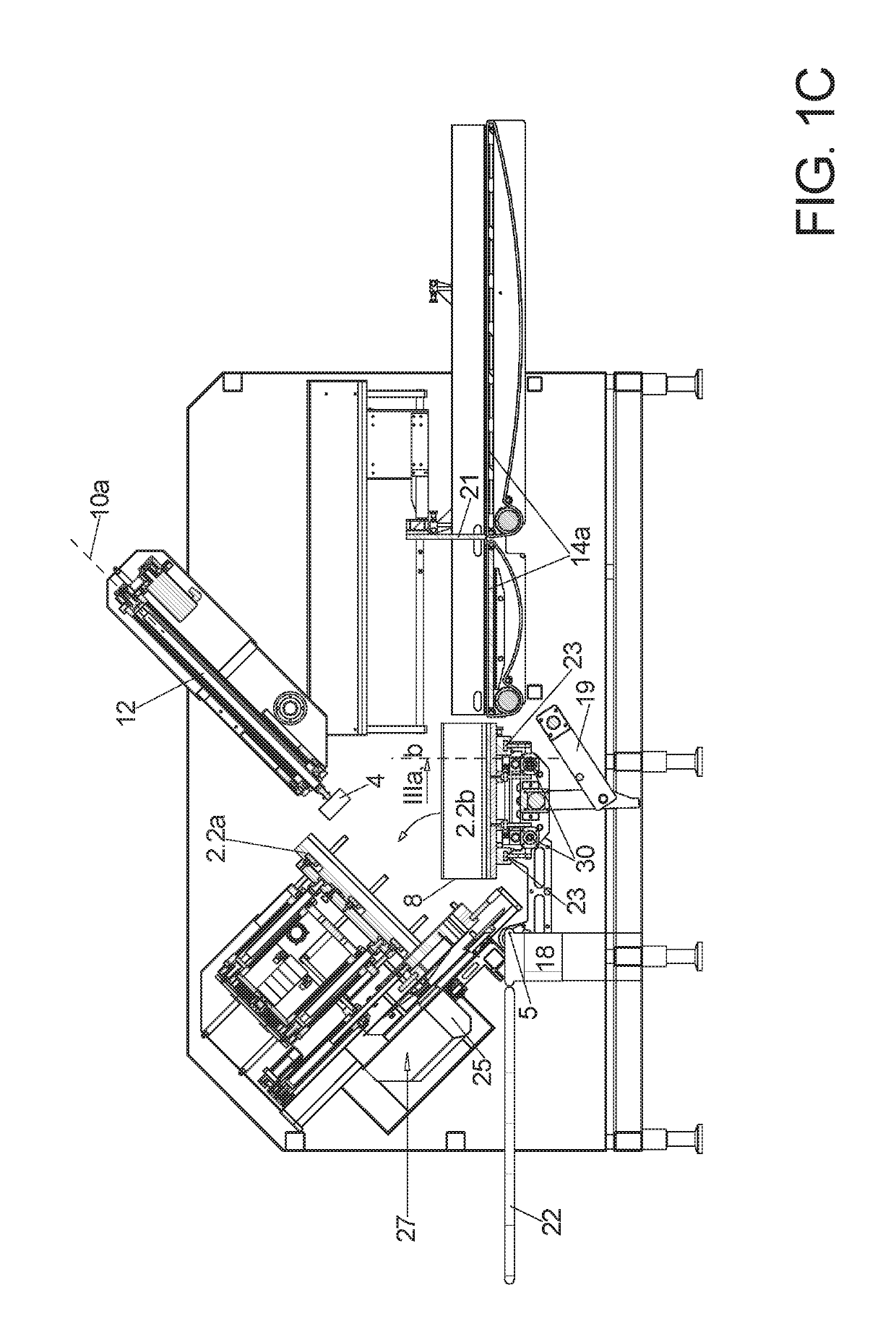

Slicing machine and method for slicing elastic strands in particular meat strands

ActiveUS20170312931A1Facilitates short idle timeImprove throughputMeat holding apparatusFish threading devicesEngineeringMechanical engineering

A slicing machine for slicing meat strands that have a cross section that varies over a longitudinal extension in large numbers and as quickly as possible into weight precise slices. In one embodiment, two meat strands are received adjacent to each other in a respective form tube and pushed against a respective separately adjustable stop plate independently from each other by a controlled longitudinal press plunger and compressed in the longitudinal direction. In addition, a cross section of the form tubes may be reduced in a first transversal direction jointly and in a second transversal direction independently from each other and thus the respective meat strand is transversally compressed to a constant cross section prior to slicing.

Owner:TVI ENTWICKLUNG & PROD GMBH

Method and device for separating products

ActiveUS8997614B2Exact weight precisionIncrease cycle rateStock shearing machinesMetal working apparatusCycle rateEngineering

A method and a device for separating food products, including to permit a straight cut at high cycle rates, the food product is conveyed by a conveying device in the direction of transport. The food product is cut through, where a cutting element is moved in the direction of transport and transverse to the direction of transport, wherein the motion of the cutting element transverse to the direction of transport is controlled independently of its motion in the direction of transport and the food product does not rest on the cutting area on the conveying means.

Owner:ALBERT HANDTMANN MASCHFABRICK

Automatic dicing and collecting device for steaks

InactiveCN111958652AImprove work efficiencyOperational securityMetal working apparatusMeat shaping/cuttingEngineeringKnife blades

The invention relates to a dicing device, in particular to an automatic dicing and collecting device for steaks. The automatic dicing and collecting device for the steaks is high in steak dicing efficiency and safe to operate. The automatic dicing and collecting device for the steaks comprises a rack, a dicing assembly and a placing assembly; the dicing assembly is arranged on the rack; and the placing assembly is arranged on the rack. According to the device, through cooperation of the dicing assembly and the placing assembly, the steaks can be automatically diced; due to the fact that the steaks are cut into multiple meat blocks at a time, the working efficiency is improved; due to the fact that a blade does not need to be manually controlled for dicing, the operation is safe; and when the steaks are sliced, the sliced steaks can be automatically collected, and the steaks can be automatically placed again while the meat blocks are collected, so that the working efficiency is furtherimproved.

Owner:赵志宇

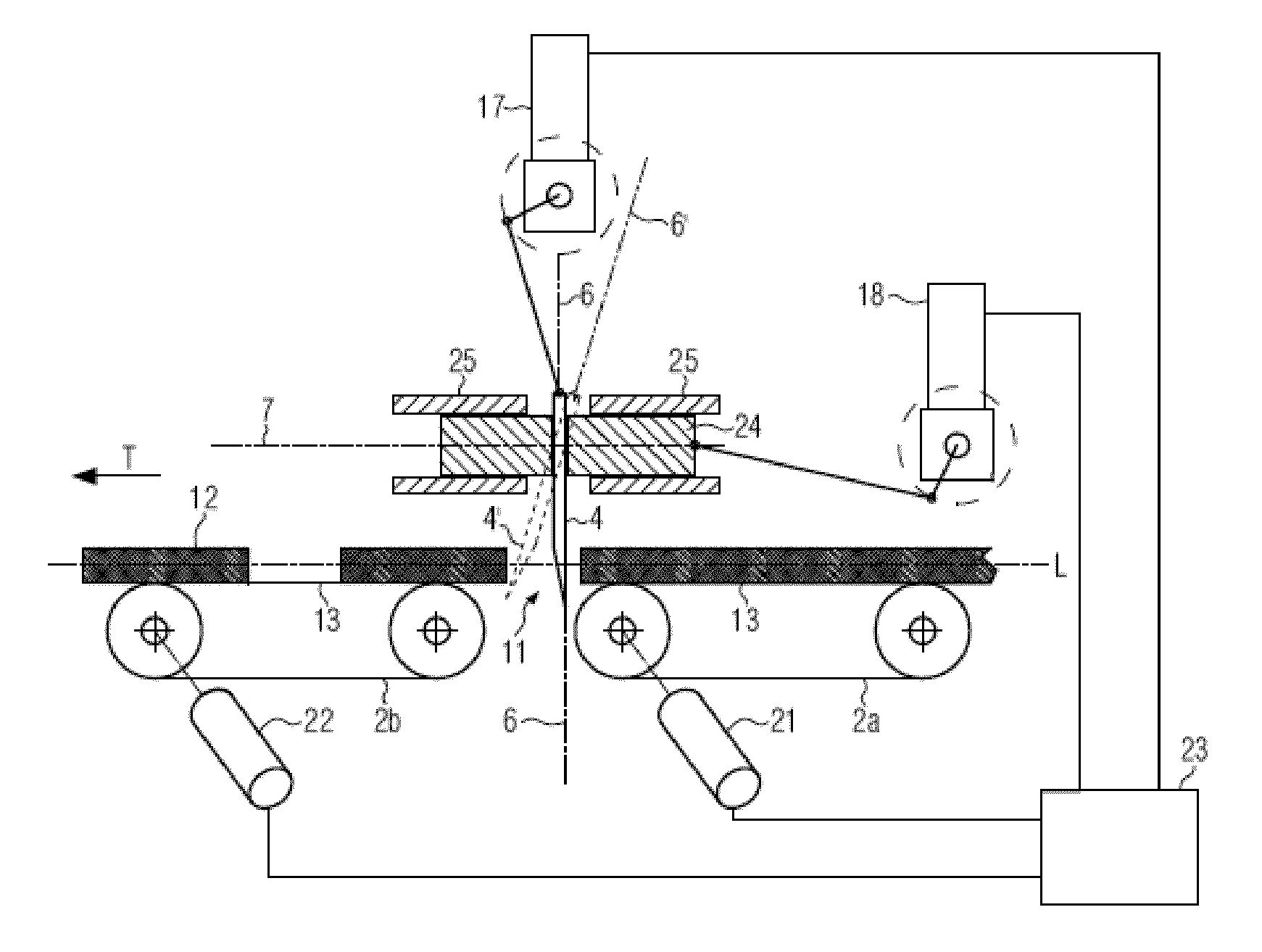

Method and device for weight precise cutting of a food strand

ActiveUS8758099B2Easy to detectImprove accuracyMeat processing plantsPoultry processingData controlMechanical engineering

Owner:REIFENHAEUSER UWE

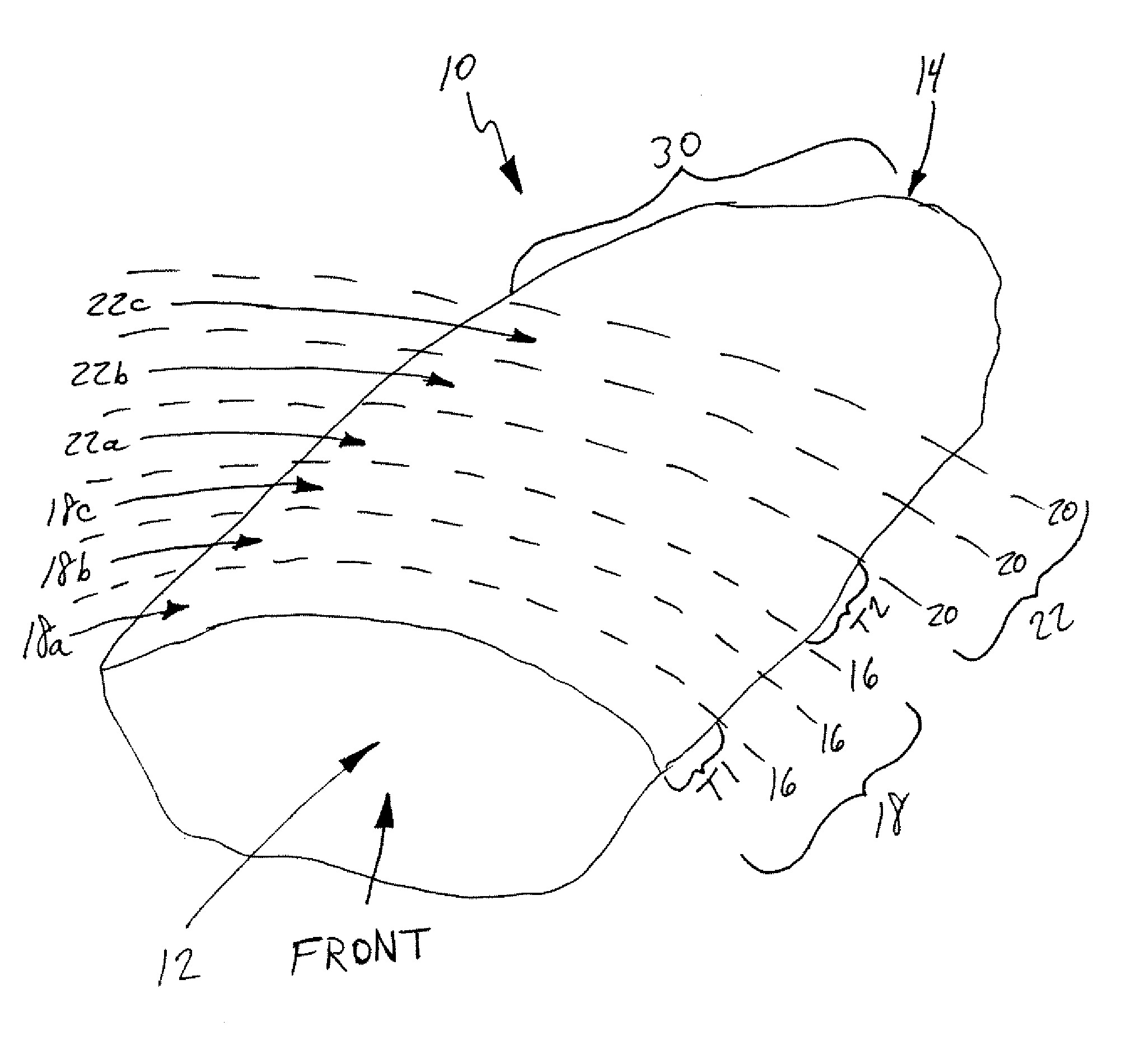

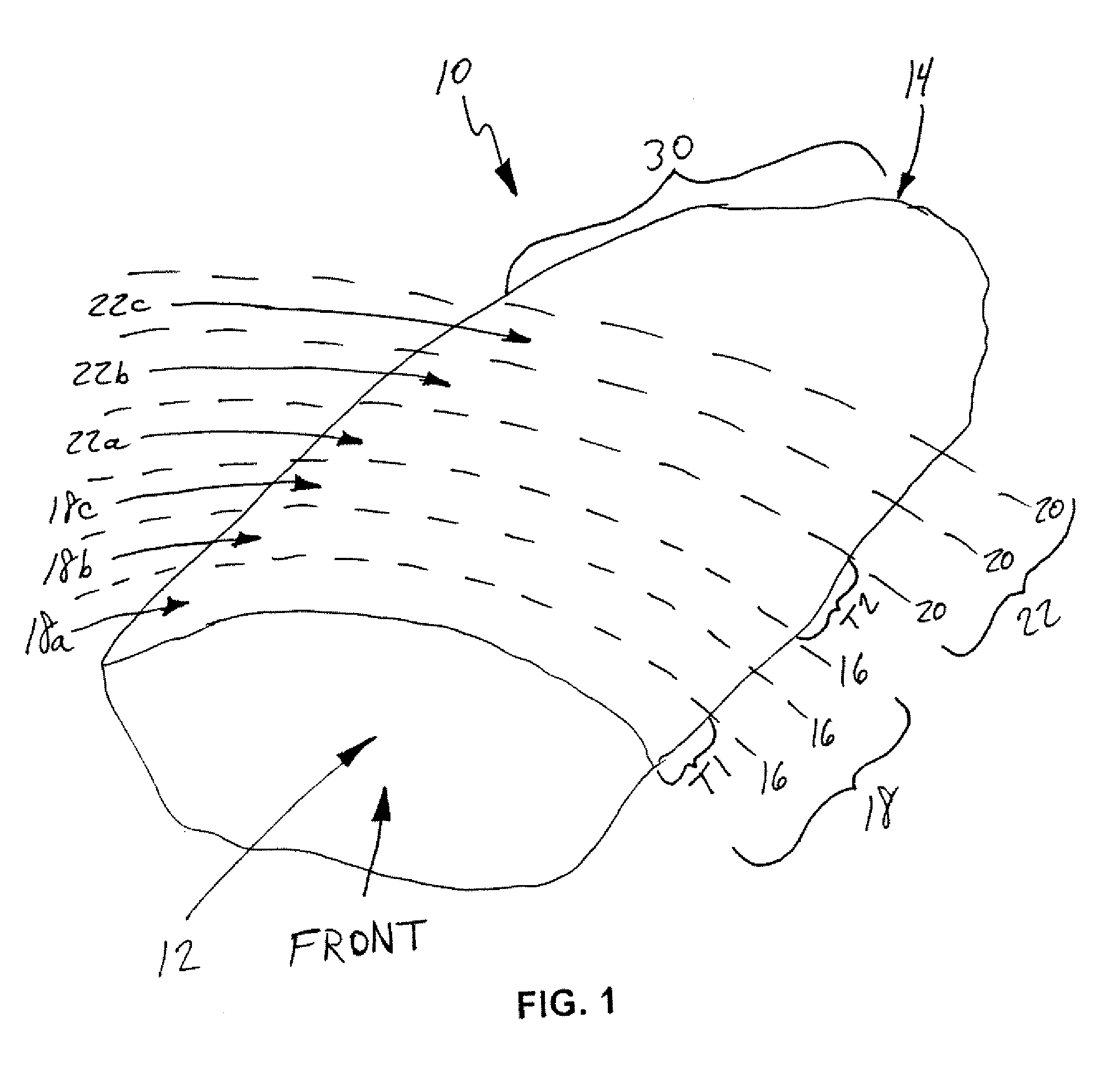

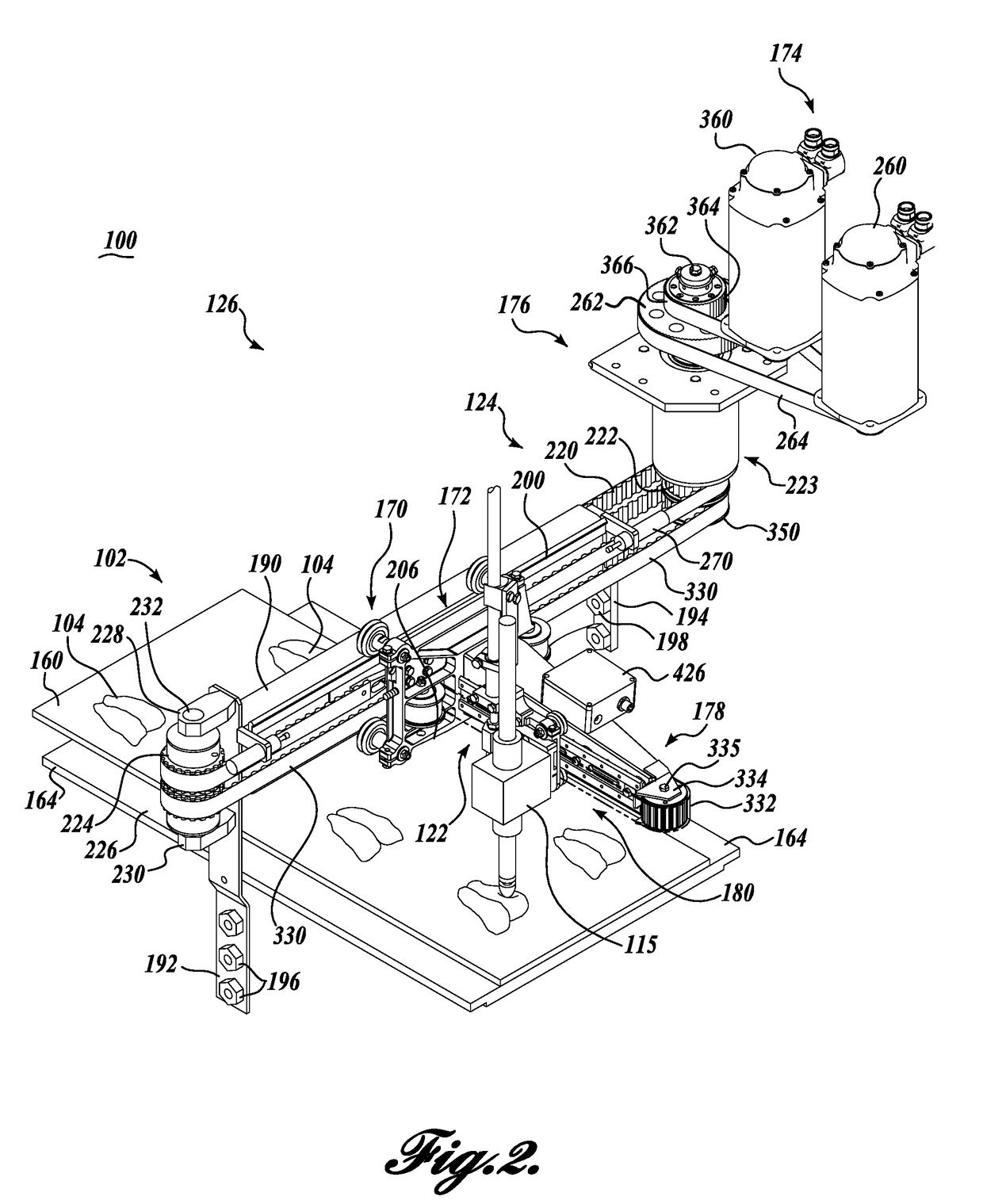

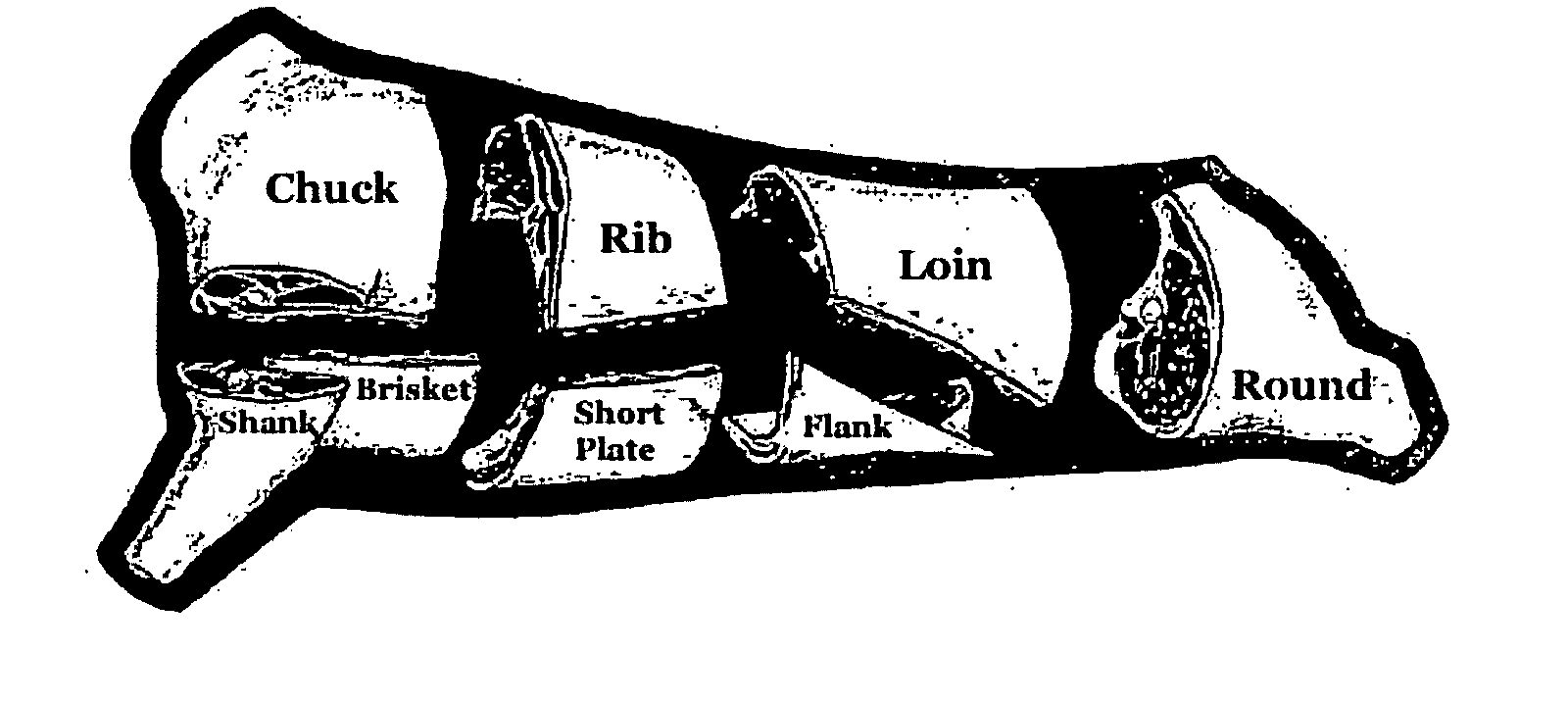

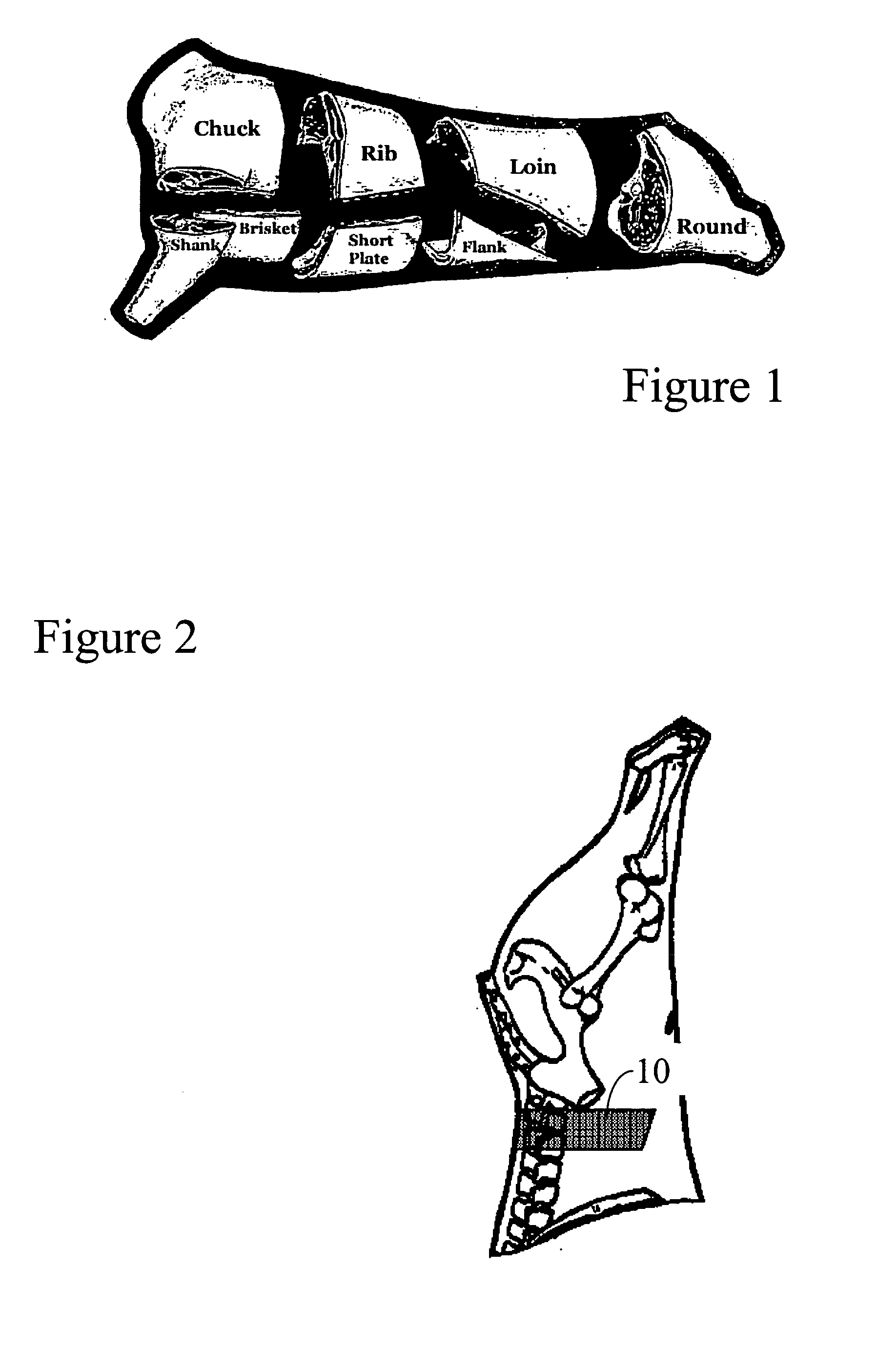

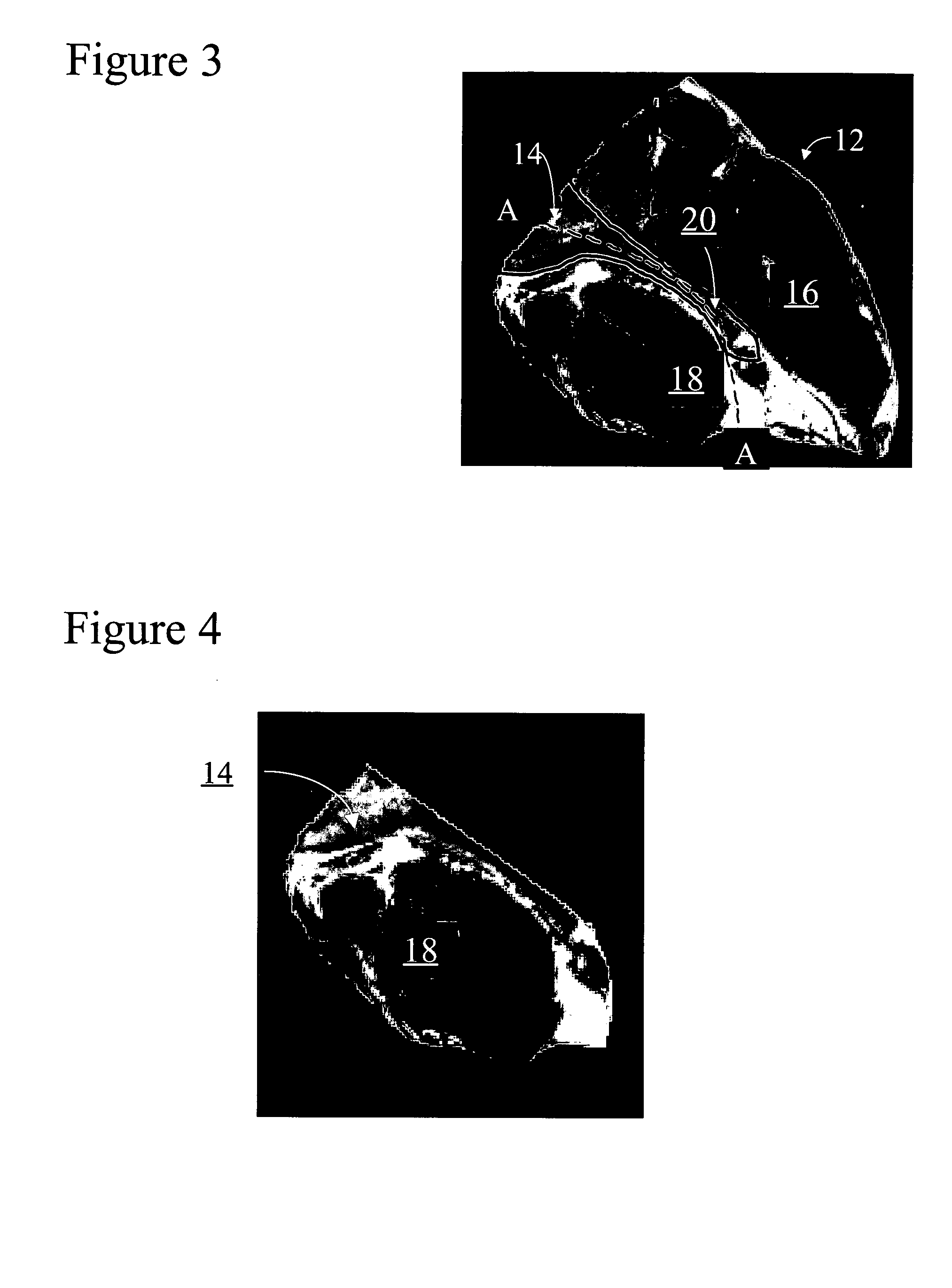

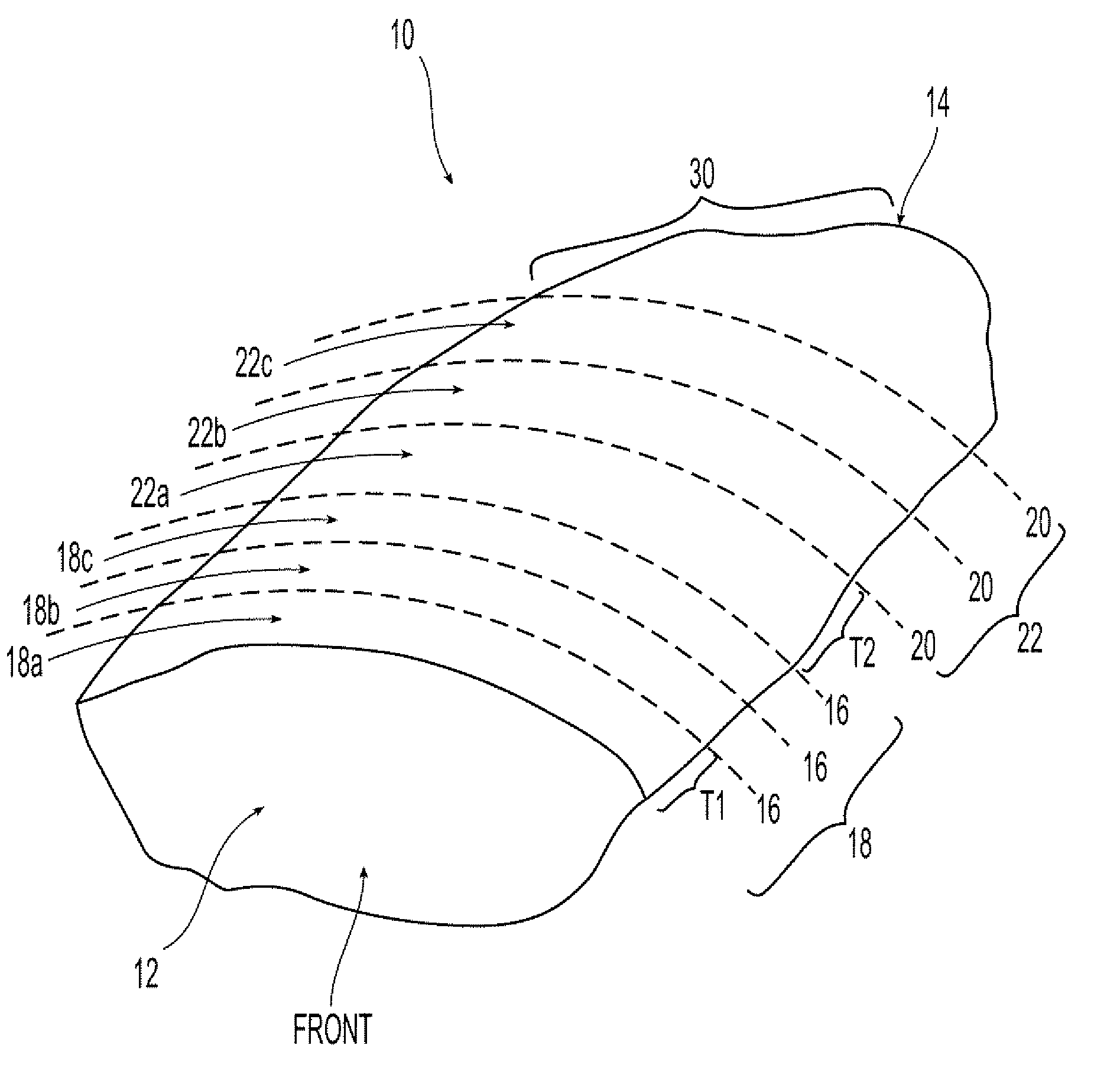

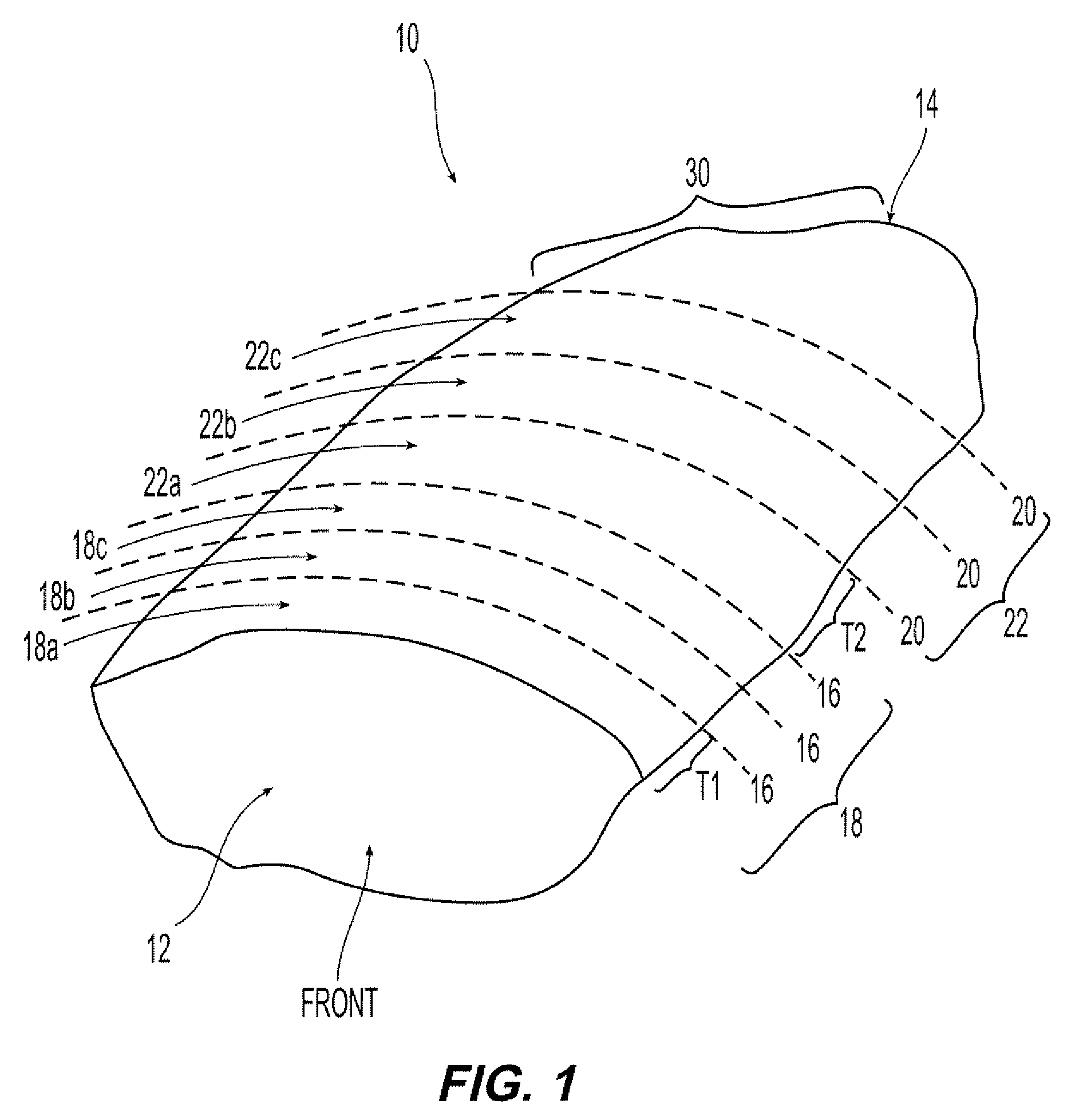

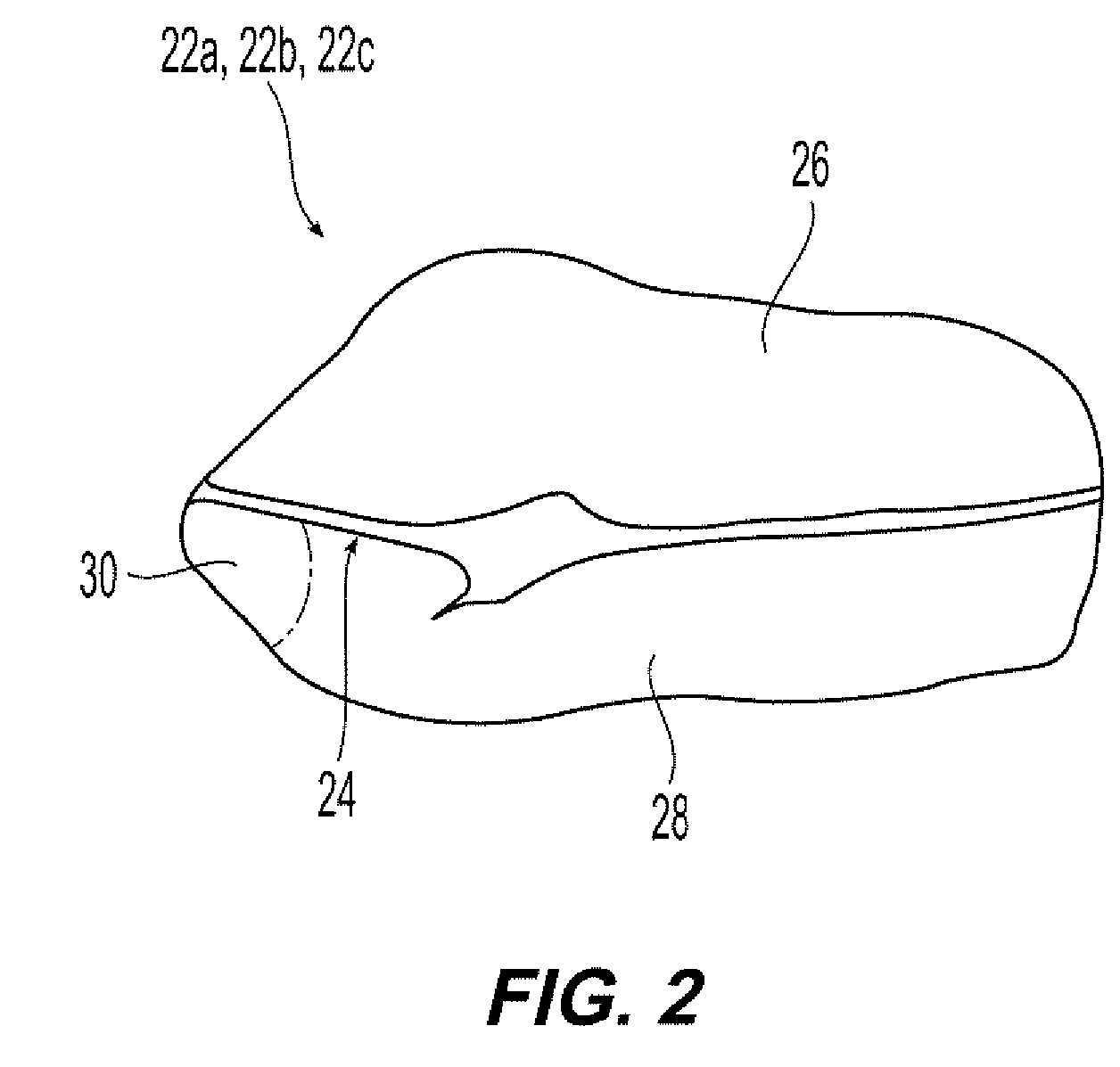

Butchering processes for meat products

InactiveUS20060240756A1Weight increaseMeat processing plantsPoultry processingEngineeringIncreasing weight

A method for mass-production butchering of a beef chuck roll includes locating an anterior side and a posterior side of the chuck roll, and making a first series of cuts into the chuck roll along lines not intersecting the anterior and posterior sides. The first series of cuts form a first set of separate beef portions with increasing weights from initial to final cuts in the first series. The method also includes making a second series of cuts into the chuck roll along lines not intersecting the anterior and posterior sides to form a second set of separate beef portions.

Owner:LOBELS ENTERPRISES

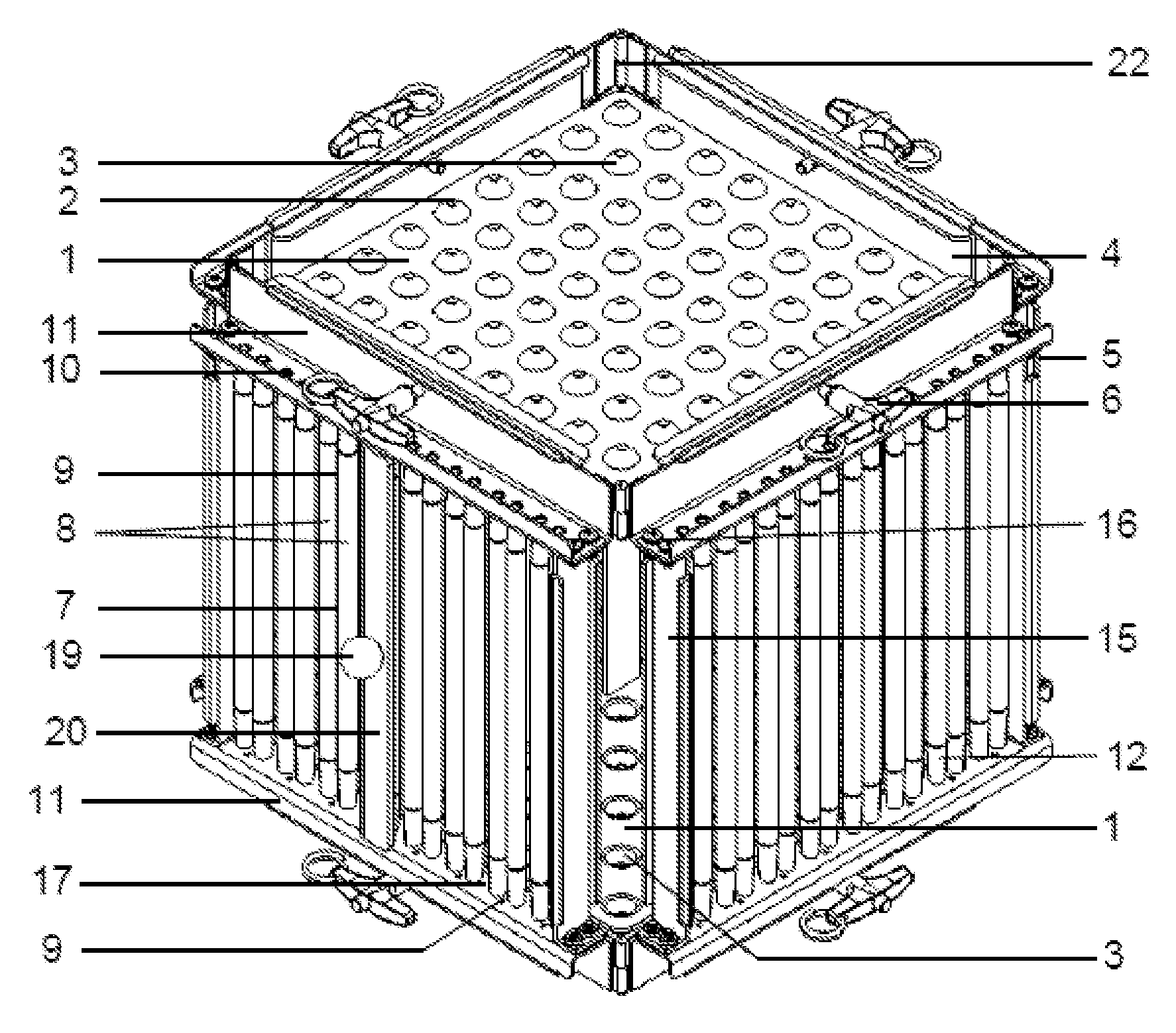

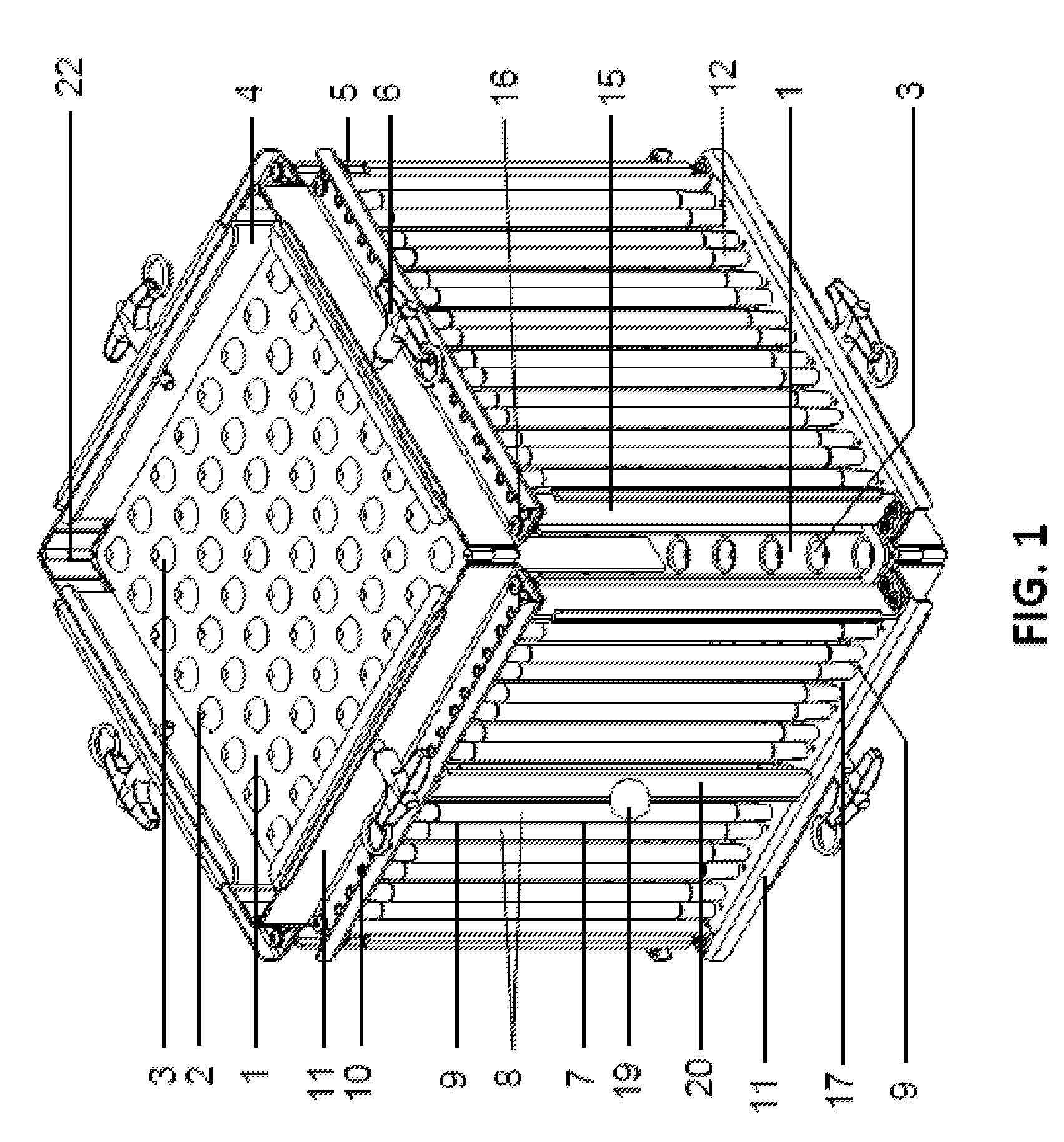

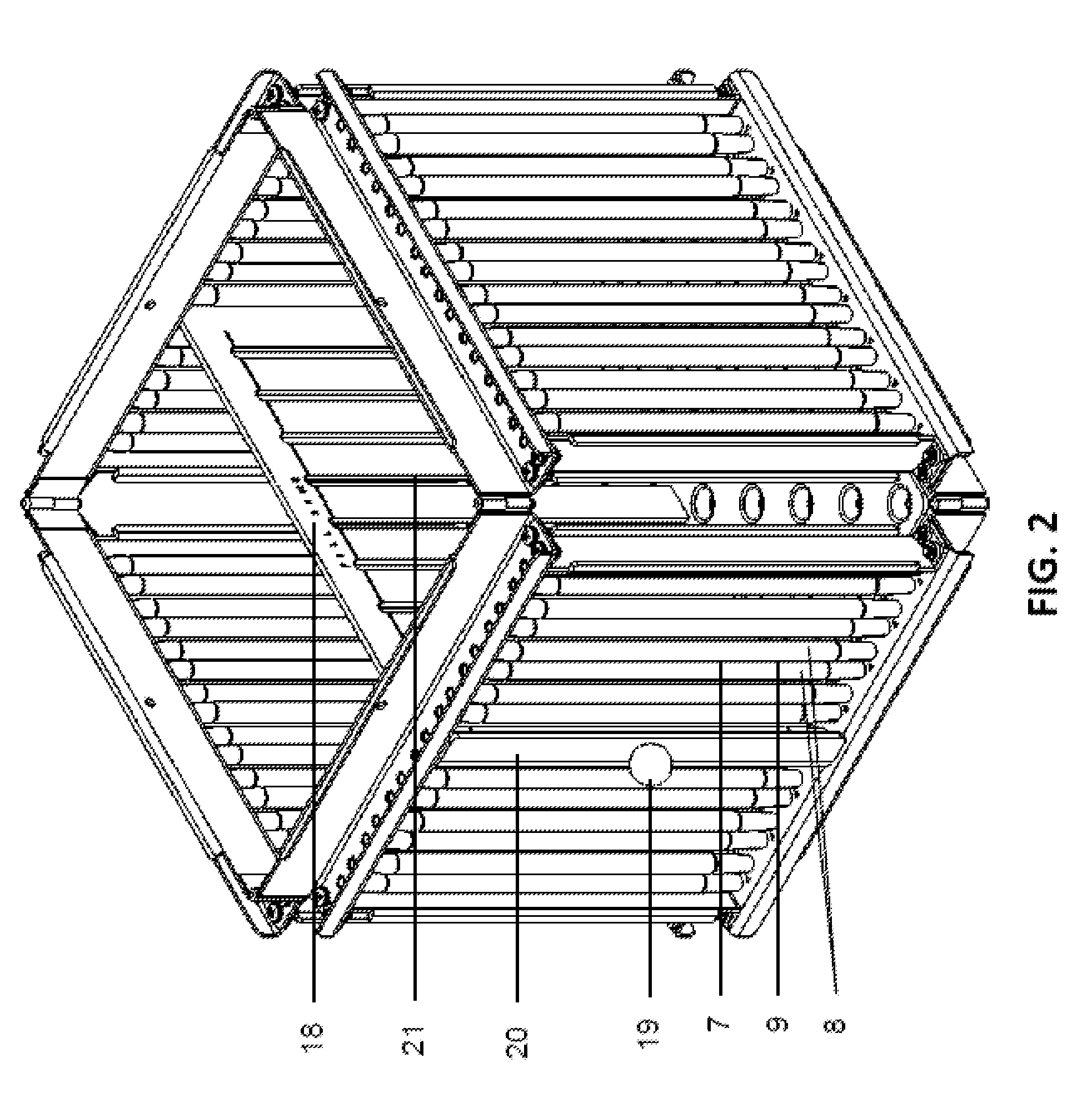

Meat cubing and skewering device

InactiveUS20120279371A1Easy to cleanLow volume storageCross-cut reciprocating sawsMetal working apparatusEngineeringCutting guide

This meat cubing and skewering device utilizes a low friction guide system along two axes to facilitate the cutting of meat slabs into cubes for the purpose of making shish kebobs or Souvlaki. The device also provides for a means of skewering the cubes using an array of dimpled apertures in equivalent top and bottom plates that minimizes the multiple skewer interference that can occur at the bottom of such devices. The four vertical sides are made up of a series of paired elongated rods or rollers that serve as cutting guides and these four vertical sides are hinged in such a way as to keep them all together and yet fold flat for easy storage and cleaning within a dishwasher.

Owner:MULCHI JR CHARLES LEE +1

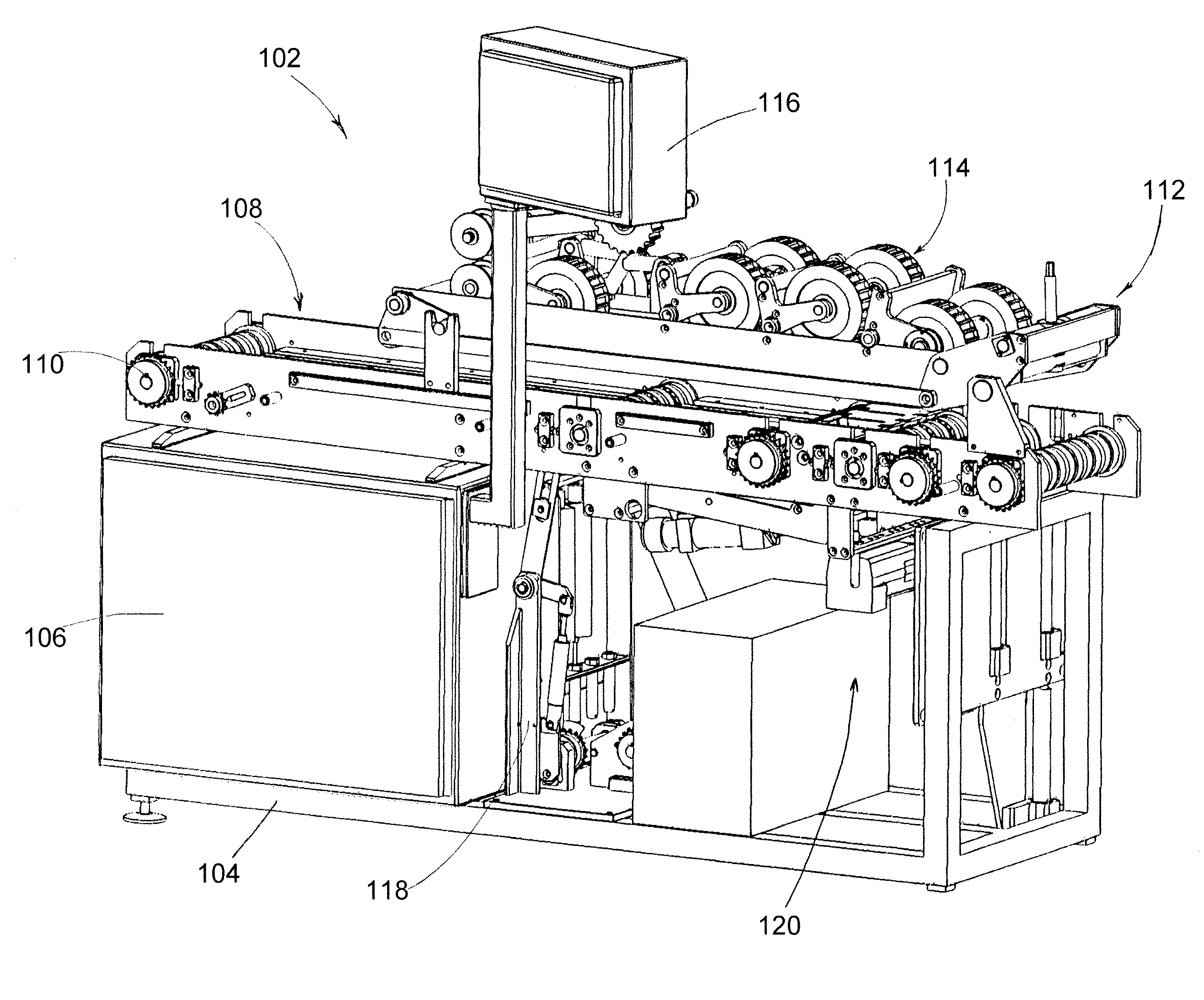

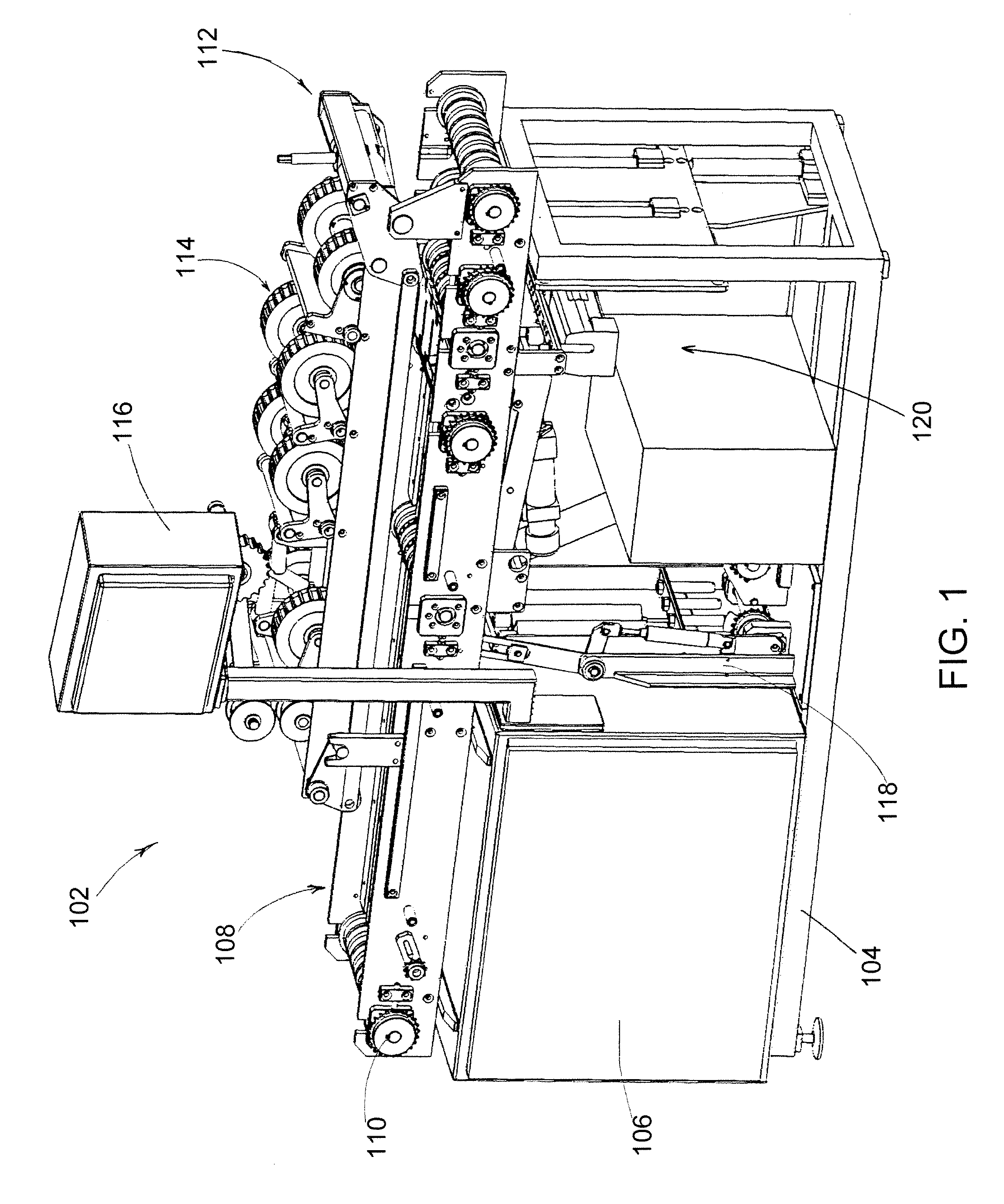

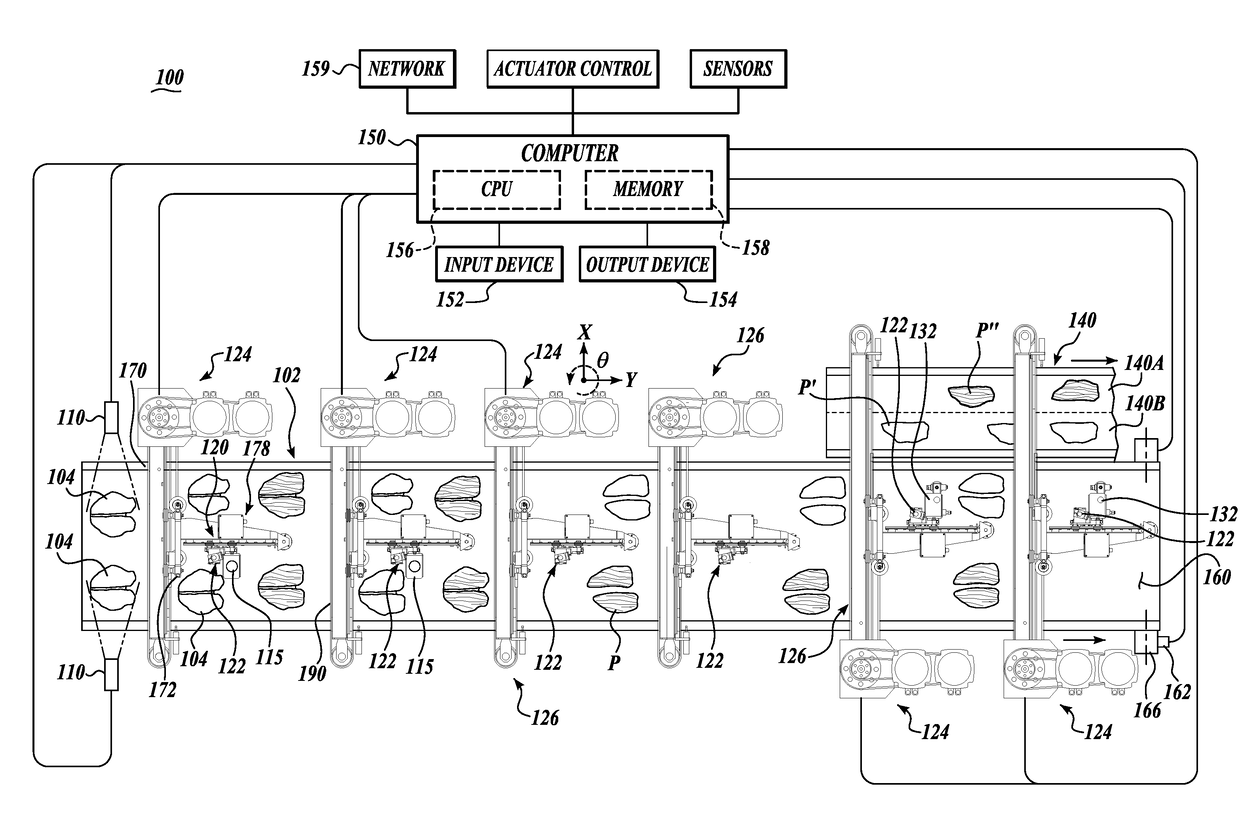

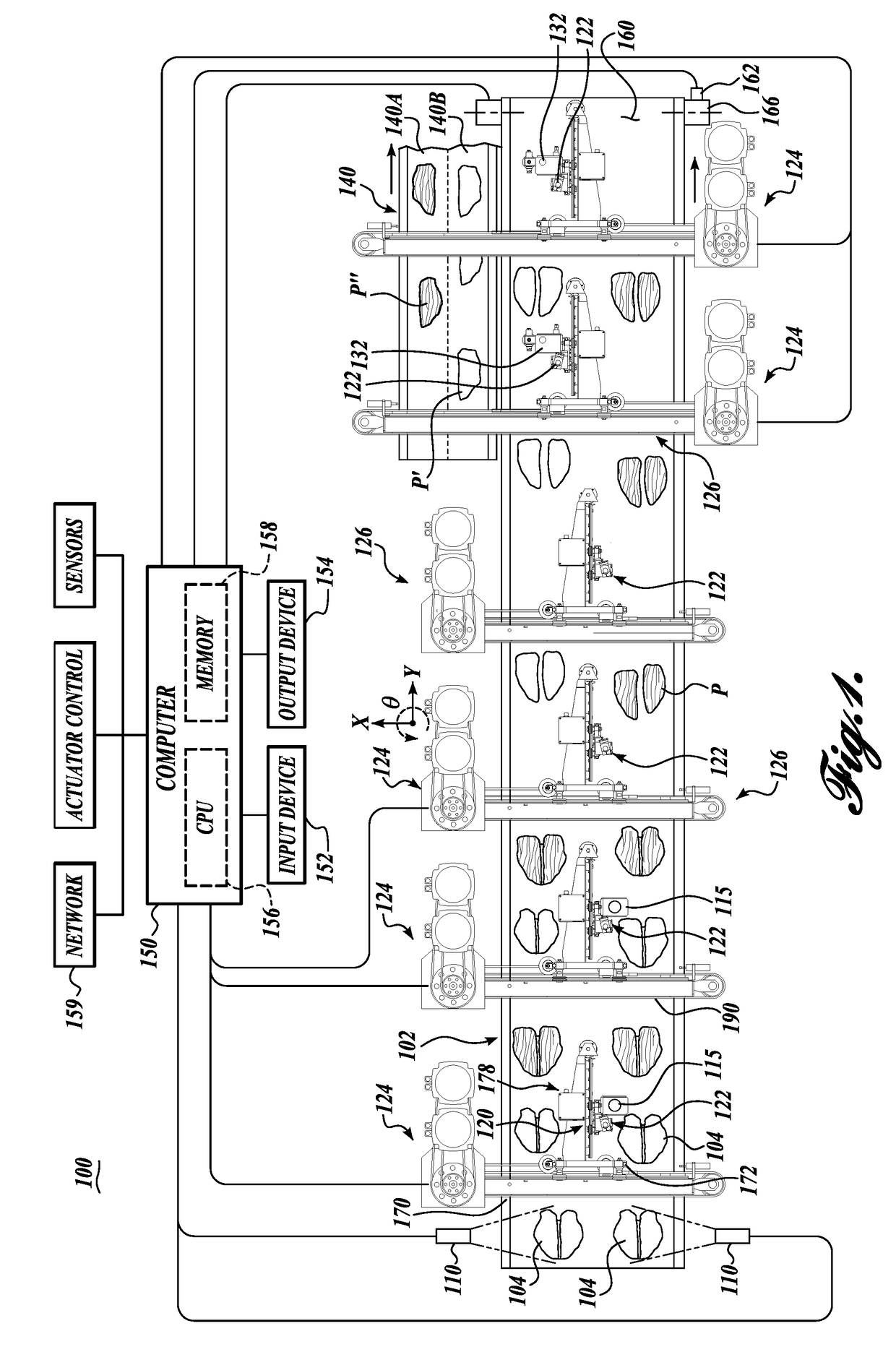

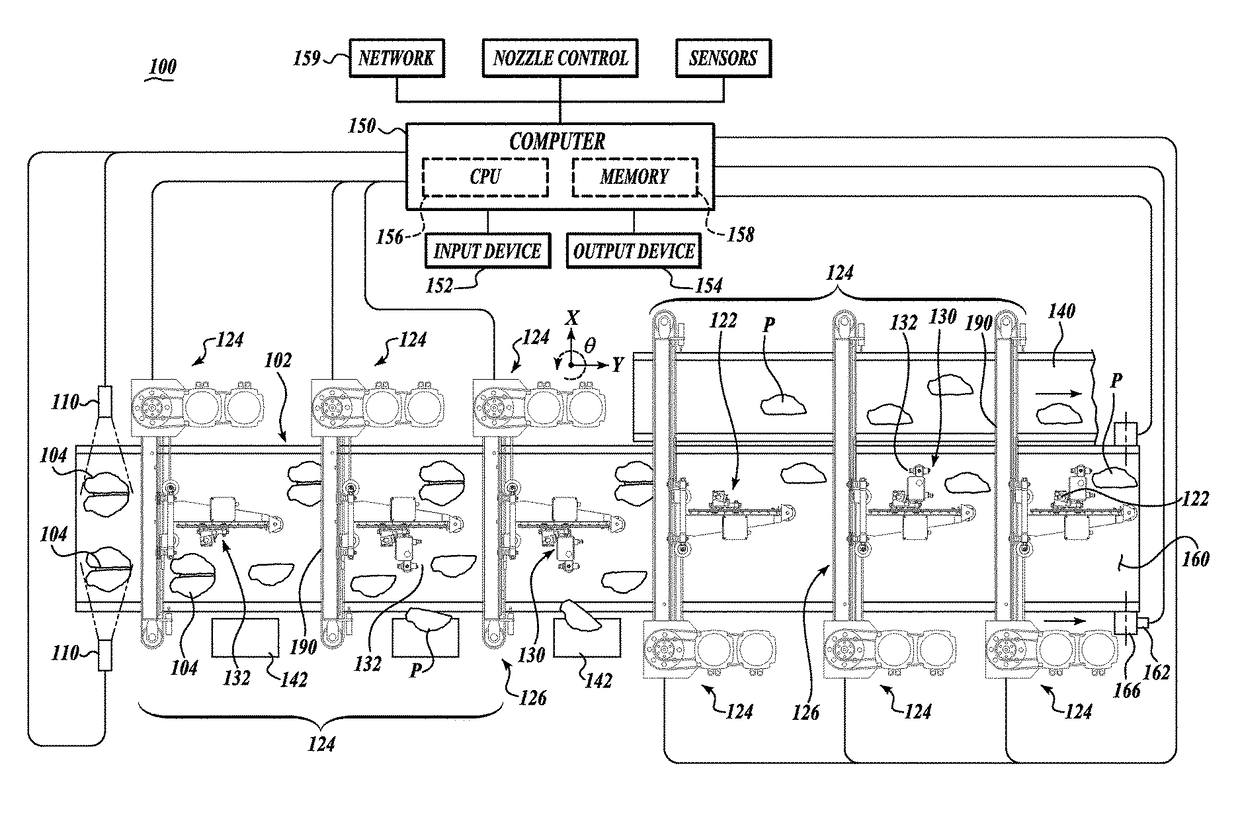

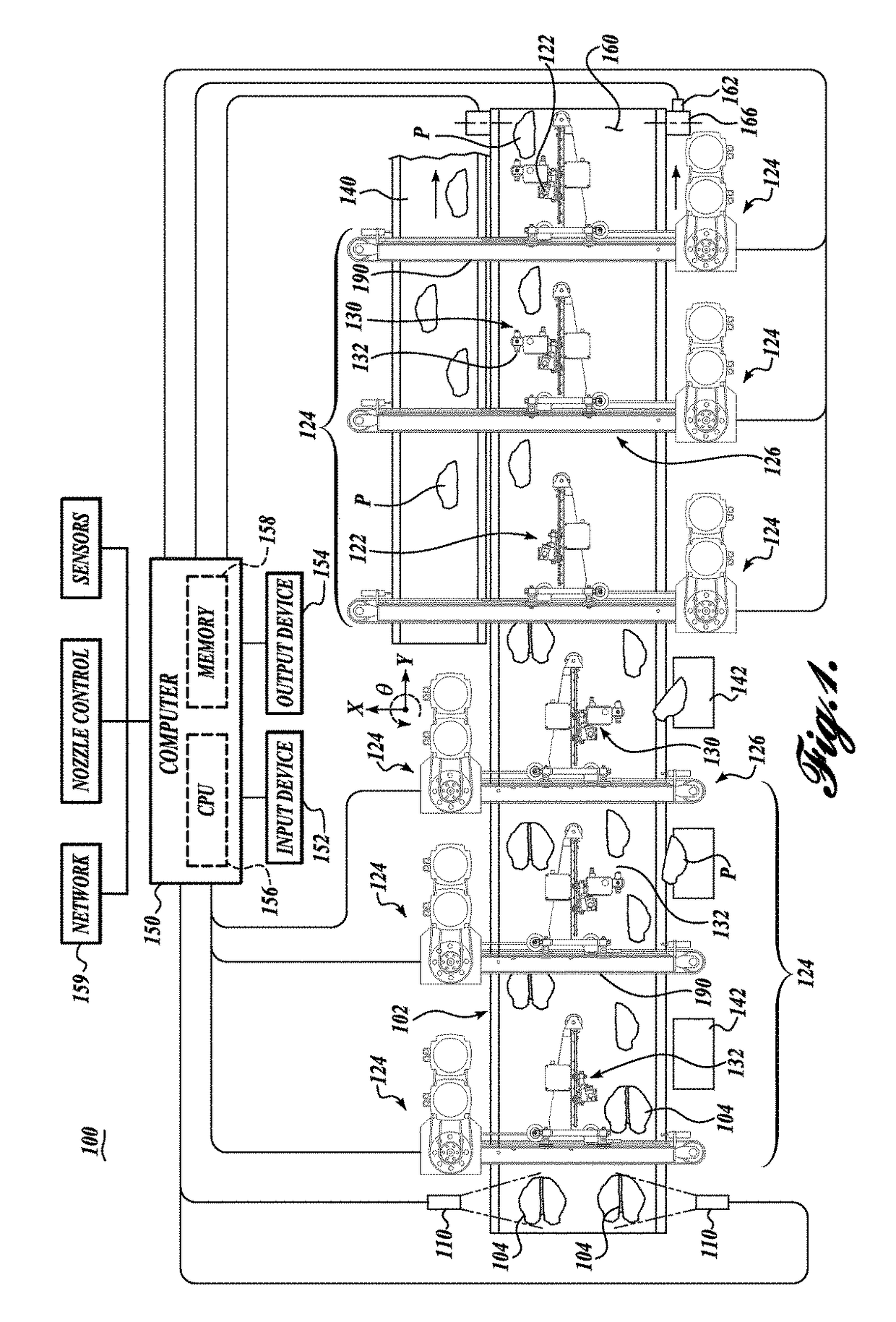

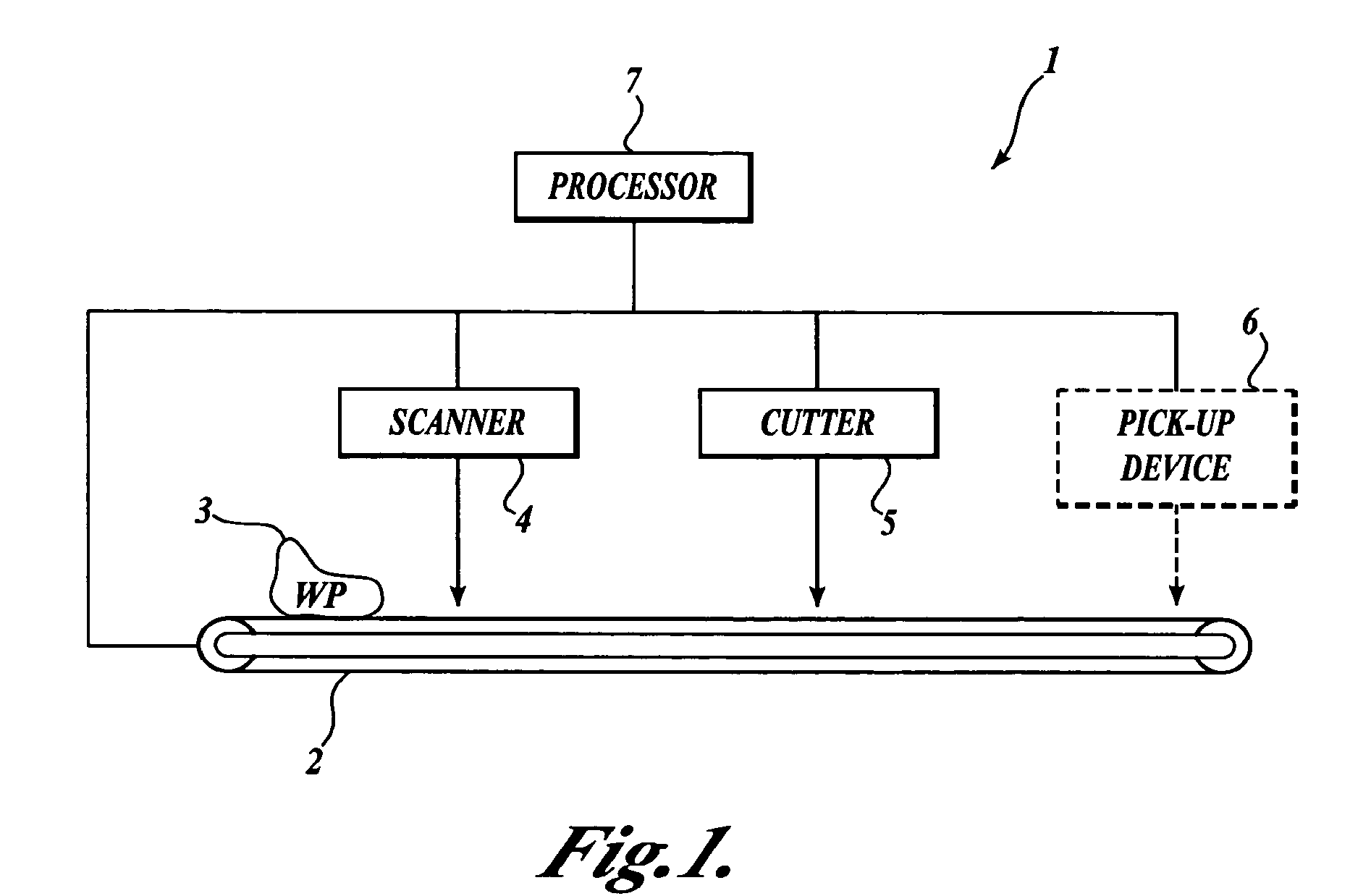

System and method for assessment of a workpiece in a continuous flow process

A system for measuring physical properties of a workpiece in motion which includes a conveyance assembly for conveying the workpiece, a scanning assembly for scanning the workpiece, and a measurement assembly for measuring at least one physical property of the workpiece while the workpiece is in motion.

Owner:JOHN BEAN TECH CORP

Butchering processes for meat products

A method for mass-production butchering of a beef chuck roll includes locating an anterior side and a posterior side of the chuck roll, and making a first series of cuts into the chuck roll along lines not intersecting the anterior and posterior sides. The first series of cuts form a first set of separate beef portions with increasing weights from initial to final cuts in the first series. The method also includes making a second series of cuts into the chuck roll along lines not intersecting the anterior and posterior sides to form a second set of separate beef portions.

Owner:LOBELS ENTERPRISES

System for cutting and unloading portions

ActiveUS9778651B2Meat packaging/handling/transportingConveyor partsCarrier systemMechanical engineering

Owner:JOHN BEAN TECH CORP

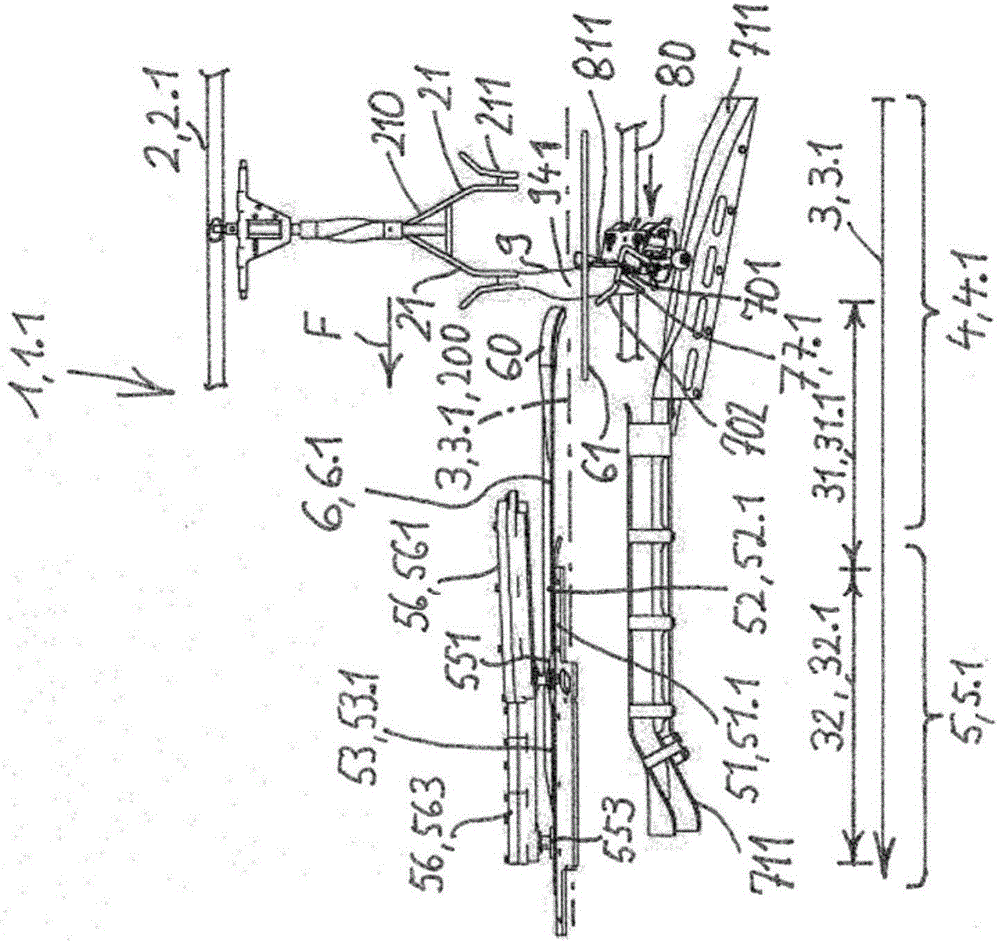

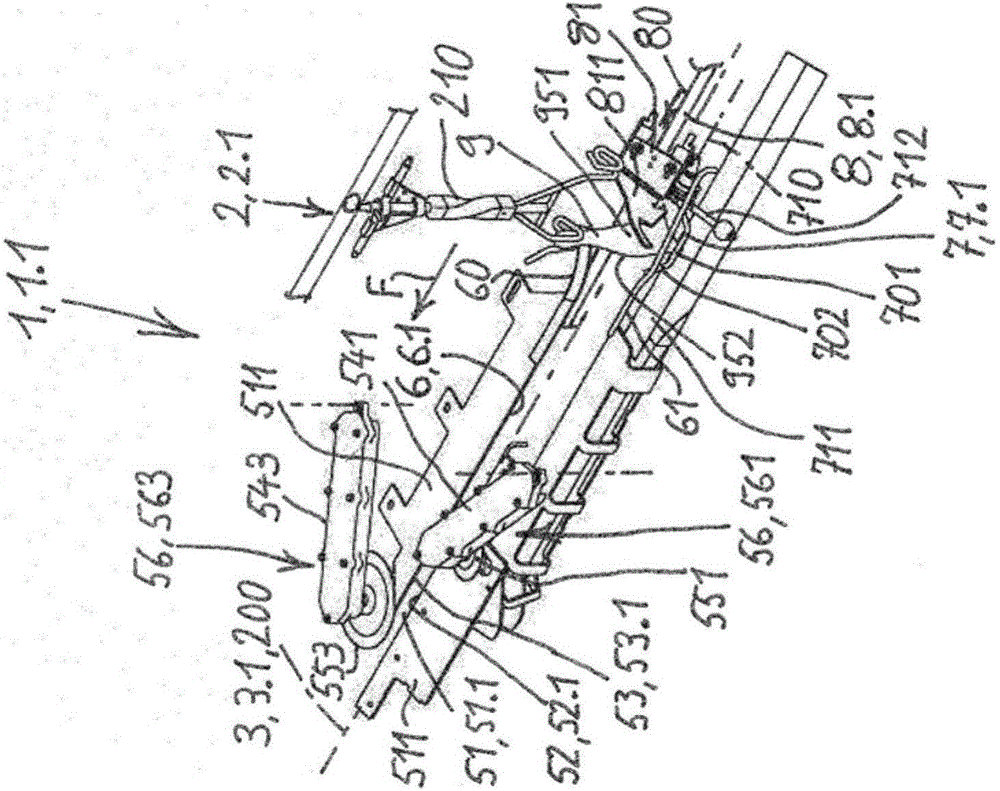

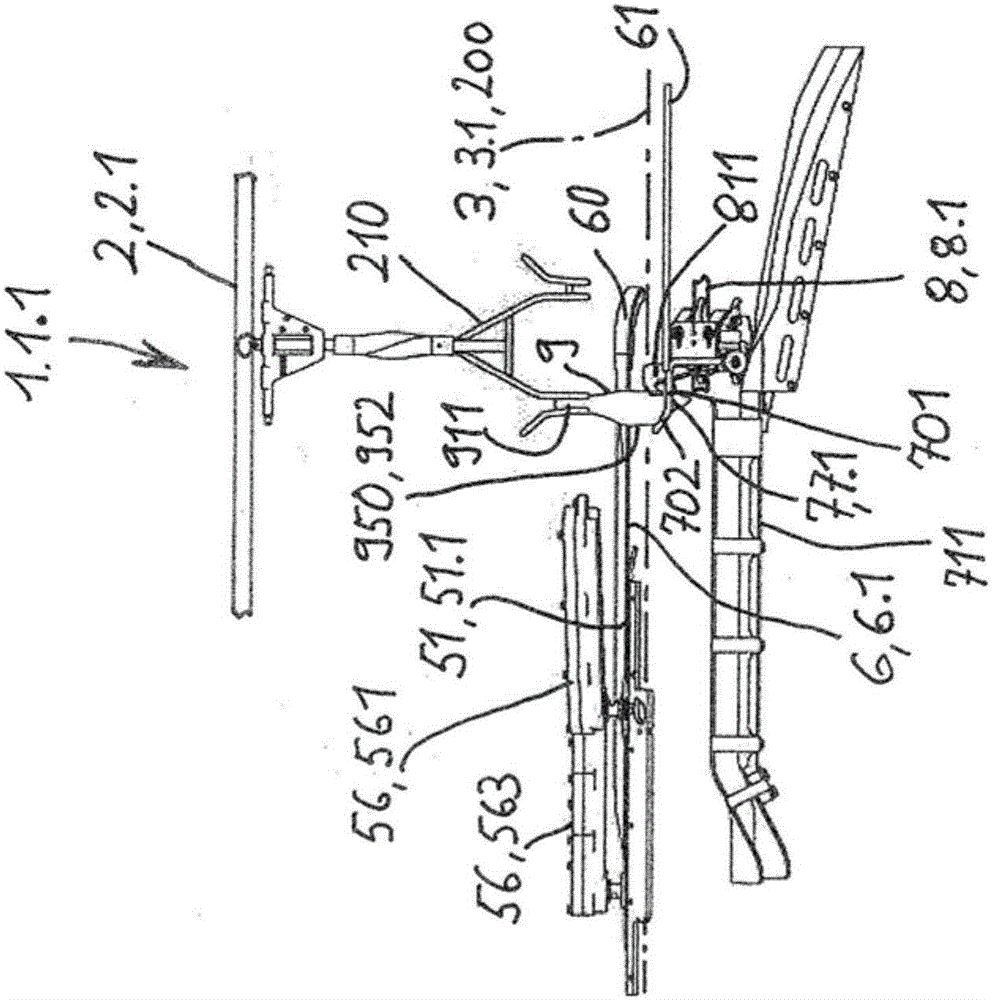

Positioning device for positioning poultry legs conveyed in single file in the conveying direction along a conveyor section and the method comprising said positioning for removing the thigh meat from poultry legs

A positioning device (1) for positioning poultry legs (9) conveyed hung in single file comprises a flexing device (4) for flexing and positioning the poultry legs and a stationary holding and guiding device (5). The flexing device (4) forms a hooking device for suspending the poultry leg (9) at the region of the knee joint (93) in a holding and guiding slot (51) of the holding and guiding device (5). Travelling positioning elements (7) are formed by driven press elements which grip the poultry leg (9) from below on an axial leg side (940) to flex and lift said leg. Each travelling positioning element (7) forms, with a stationary positioning element (6), a functional pair of positioning elements (6, 7). One of the two positioning elements (6, 7) engages in the hollow of the knee (95) of the poultry leg (9) while the other positioning element (6.2; 7.1) is configured for placement on the thigh (92) on the front side (941) of the leg. Processing stations (56) can be arranged along the holding and guiding slot (51). In a method, carried out during the conveying, for removing the thigh meat from the poultry legs (9) conveyed in single file, said poultry legs are axially conveyed in a first said positioning device (1.1) with a transverse leading lateral side (950) of the leg and in a second said positioning device (1.2) with an axially leading knee cap side (940) of the leg. Cuts are made at the front side (941) of the leg and at the back side (942) of the leg along the first stationary holding and guiding slot (51.1). Cuts are made at the lateral sides (950) of the poultry leg along the second stationary holding and guiding slot (51.2), and the thigh meat (922) is pushed to the proximal end of the thigh bone (921).

Owner:BAADER FOOD SYST DENMARK AS

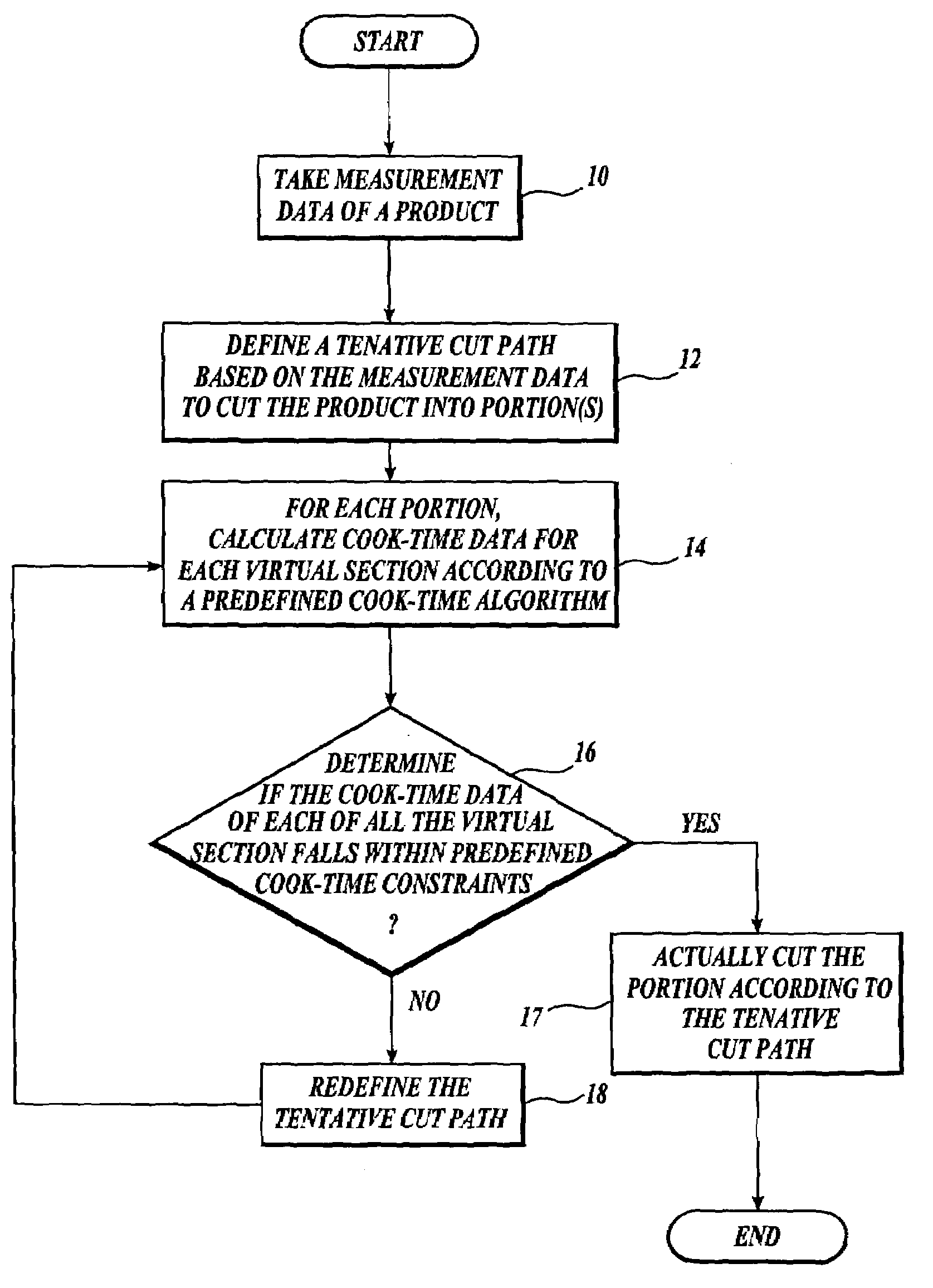

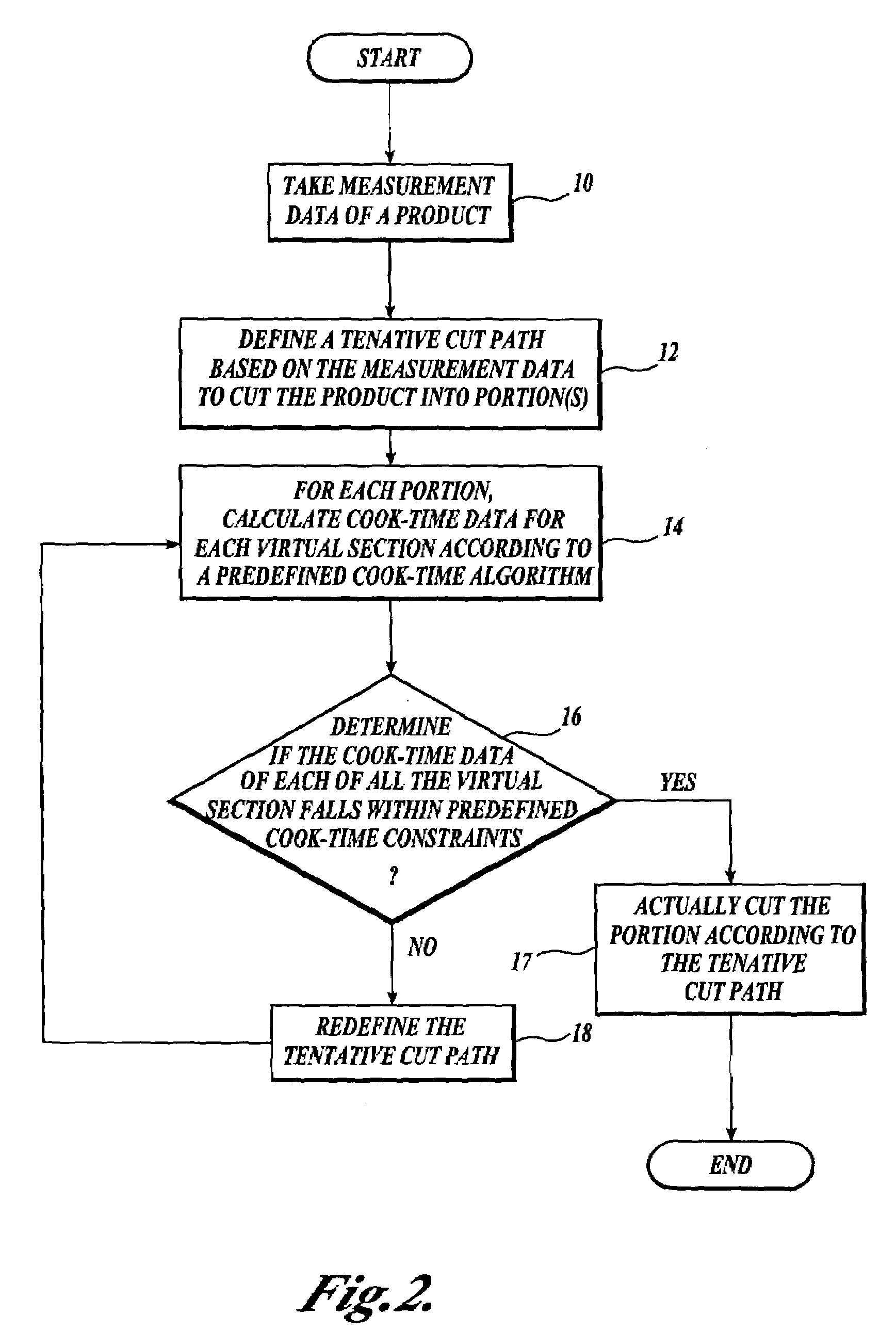

Method and system for achieving acceptable process time

ActiveUS7156730B1Minimize the numberMeat processing plantsPoultry processingTime dataIndustrial engineering

A method and system for automatically portioning workpieces, such as meat products, into pieces having acceptable process time (e.g., acceptable cook time) are provided. The method includes generally five steps. First, measurement data of a workpiece carried on a conveyor are obtained. Second, a tentative cut path to portion the workpiece into one or more portions is defined based on the measurement data. Third, each portion is divided into one or more virtual sections and process-time data (i.e., cook-time data) for each virtual section is calculated according to a predefined process-time algorithm. Fourth, it is determined whether the process-time data of each of all the virtual sections of the portion to be cut from the workpiece fall within predefined process-time constraints. If no, fifth, the tentative cut path is redefined, and the method returns to the third step until the process-time data for all the virtual sections fall within the predefined process-time constraints.

Owner:JOHN BEAN TECH CORP

Beef steak cutting and preparation process and products

A tenderloin steak product comprises a tenderloin beef section with at least a portion of attached bone. The steak is essentially a Porterhouse steak from which the top loin portion has been removed. A portion of the bone non-contiguous with the top loin is also preferably removed. The top loin and a portion of the bone can be removed by cutting the bone lengthwise along the long dimension of the tenderloin, to separate the two meat portions.

Owner:STOCKMAN ROBERT

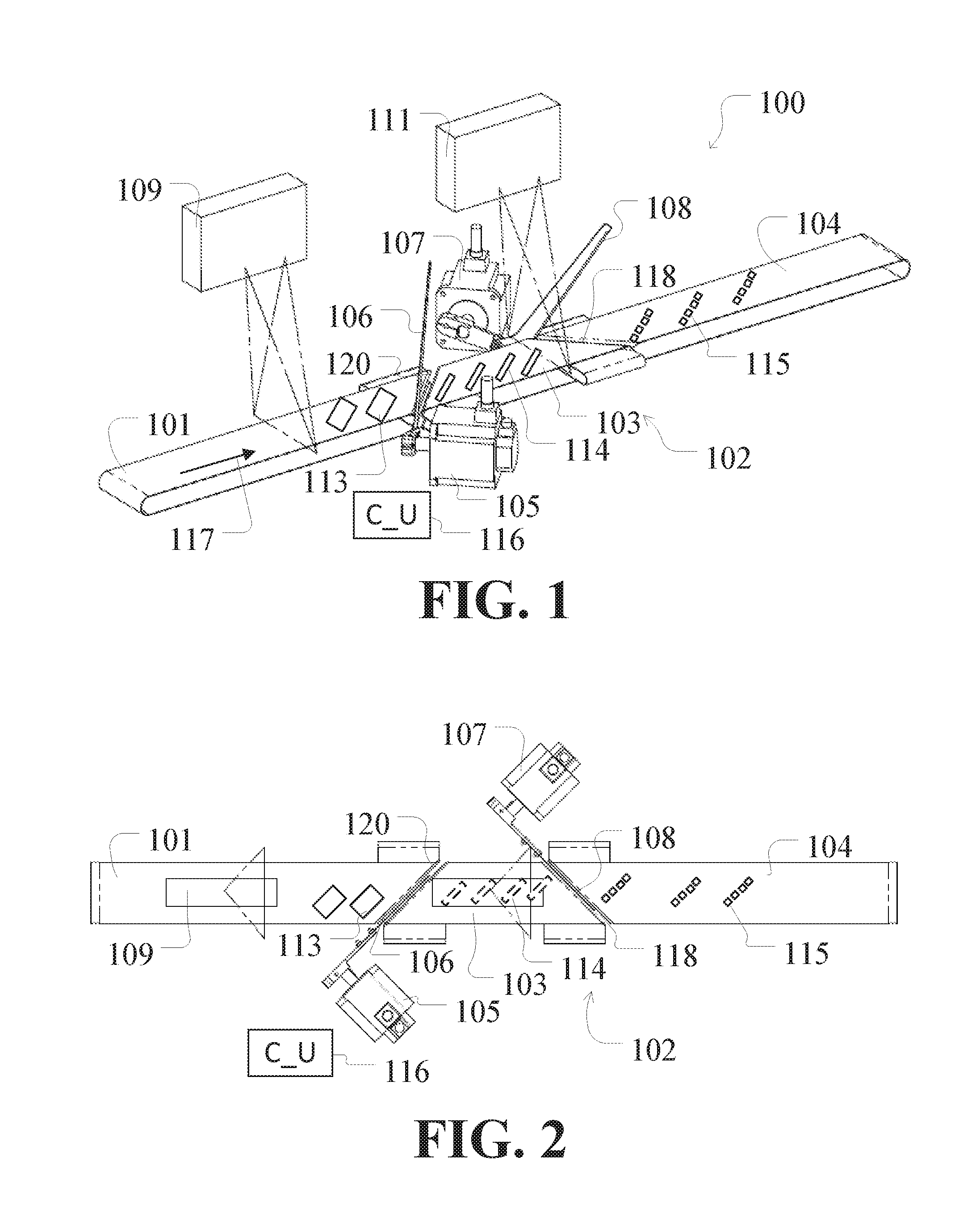

A cutting apparatus and a method for cutting food products into smaller food products

This invention relates to a cutting apparatus for cutting food objects into smaller food products, where the cutting apparatus includes an infeed conveyor having a first end and a second end, a conveyor system having a first end and a second end, the conveyor system being arranged such that the first end of the conveyor system is adjacent and essentially parallel to the second end of the infeed conveyor defining a first slit there between, and a first cutting unit having a cutting plane extending through the first slit and controlled by a control unit for cutting food objects conveyed by the infeed conveyor into smaller food products, wherein the first slit and the cutting plane of the cutting unit form an angle to an axis perpendicular to the conveying direction.

Owner:MAREL HF

Butchering processes for meat products

InactiveUS20070264920A1Weight increaseMeat processing plantsPiercing-based meat tenderisingLongissimus dorsiLongissimus

A method for mass-production butchering of a chuck roll of beef includes: sectioning the chuck roll anterior to and generally parallel to the first rib to separate a neck portion thereof from a remainder thereof, sectioning the remainder into a first portion and a second portion substantially along a natural seam, the first portion comprising rhomboideus, spinalis dorsi, and serratus ventralis muscles, and the second portion comprising multifidus dorsi, complexus, and longissimus dorsi muscles; sectioning the first portion to substantially remove the rhombolideus and the spinalis dorsi therefrom, leaving a denuded serratus ventralis; sectioning the serratus ventralis into a first set of separate portions. The method may further include: sectioning the second portion into a second set of separate portions, each separate portion in the second set including the multifidus dorsi, complexus, and longissimus dorsi muscles.

Owner:LOBELS ENTERPRISES

Slicing machine and method for slicing elastic strands in particular meat strands

ActiveUS10245745B2Short idle timeImprove throughputMeat holding apparatusFish threading devicesEngineeringMechanical engineering

A slicing machine for slicing meat strands that have a cross section that varies over a longitudinal extension in large numbers and as quickly as possible into weight precise slices. In one embodiment, two meat strands are received adjacent to each other in a respective form tube and pushed against a respective separately adjustable stop plate independently from each other by a controlled longitudinal press plunger and compressed in the longitudinal direction. In addition, a cross section of the form tubes may be reduced in a first transversal direction jointly and in a second transversal direction independently from each other and thus the respective meat strand is transversally compressed to a constant cross section prior to slicing.

Owner:TVI ENTWICKLUNG & PROD GMBH

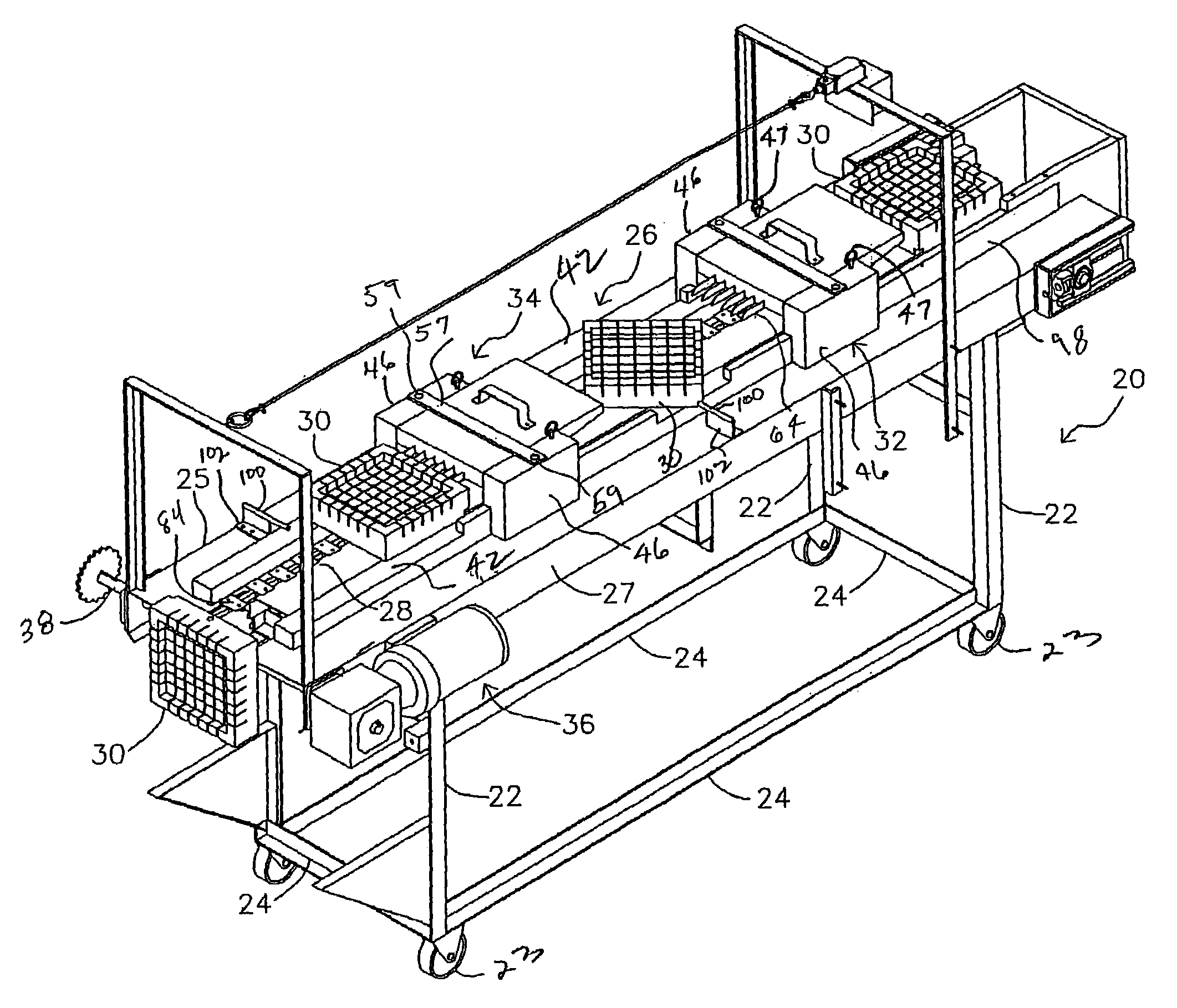

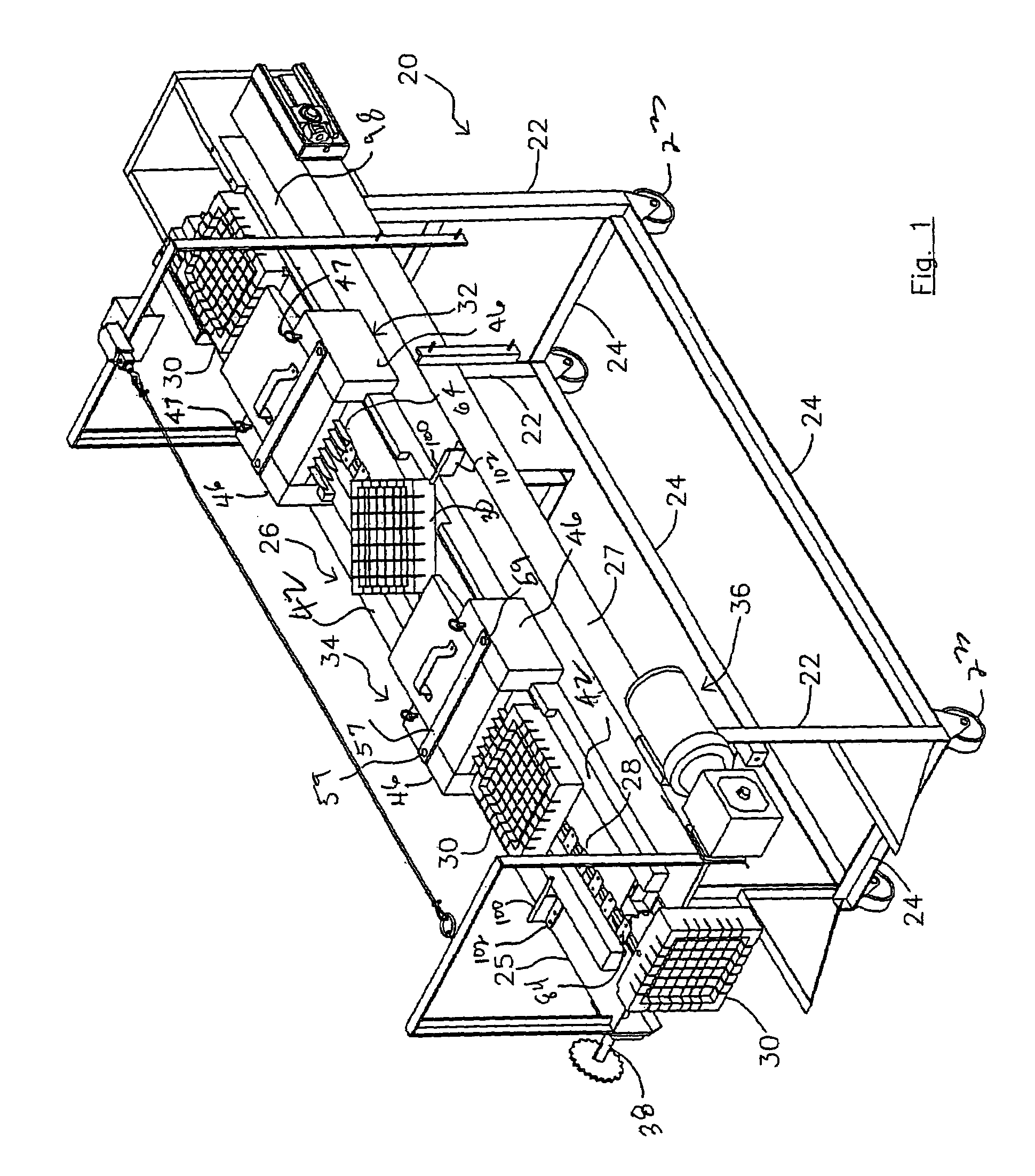

Cooked bacon slicer

A system and method for slicing a food product in accordance with exemplary embodiments of the present disclosure may include two or more sets of conveyor belts for receiving a product to be cut or separated in half, a motor for driving the conveyor belts and moving the product through a pneumatically adjustable cutting mechanism thereby separating the product into two pieces. The product may rest on a product carrier, which may be placed across both conveyor belts. The pneumatically controlled cutting mechanism may be aligned with a space between the belts and above a cutting roller or other cutting surface having a top height approximately equal to the belts. The cutting roller or other cutting surface may provide an opposing surface enabling the cutting mechanism to use pressure to separate the product. The pneumatically controlled cutting mechanism may apply sufficient pressure to separate the product without separating the product carrier. One or more markings may be used to indicate where the product should be placed on the conveyor belts to assist in ensuring that the product is cut into two horizontally even pieces. One or more air jets may facilitate the cleaning and performance of a cutting mechanism. A control panel may be used to start and stop the conveyor belts as well as adjusting the speed of the motor for driving the conveyor belts.

Owner:SMITHFIELD PACKAGED MEATS CORP

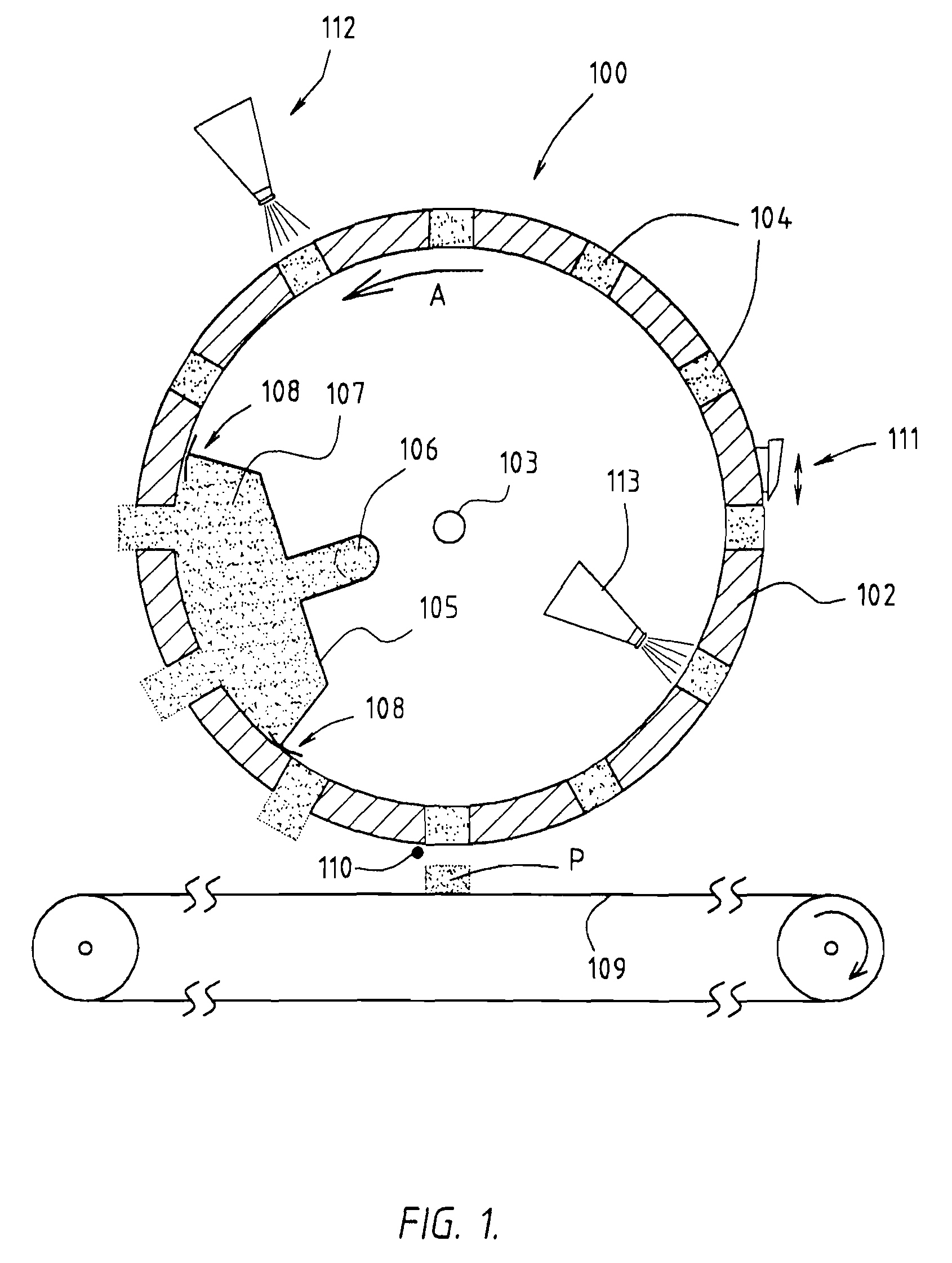

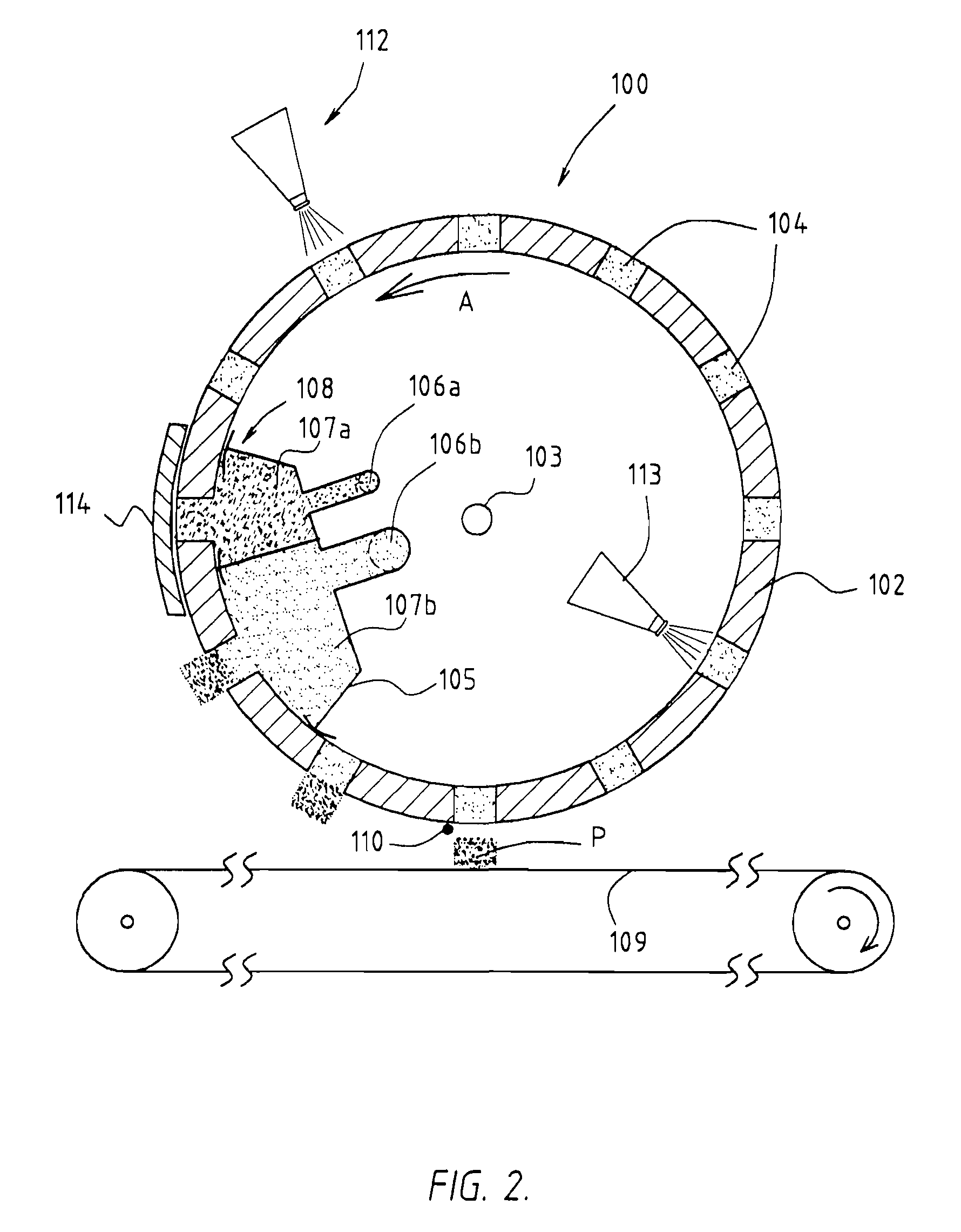

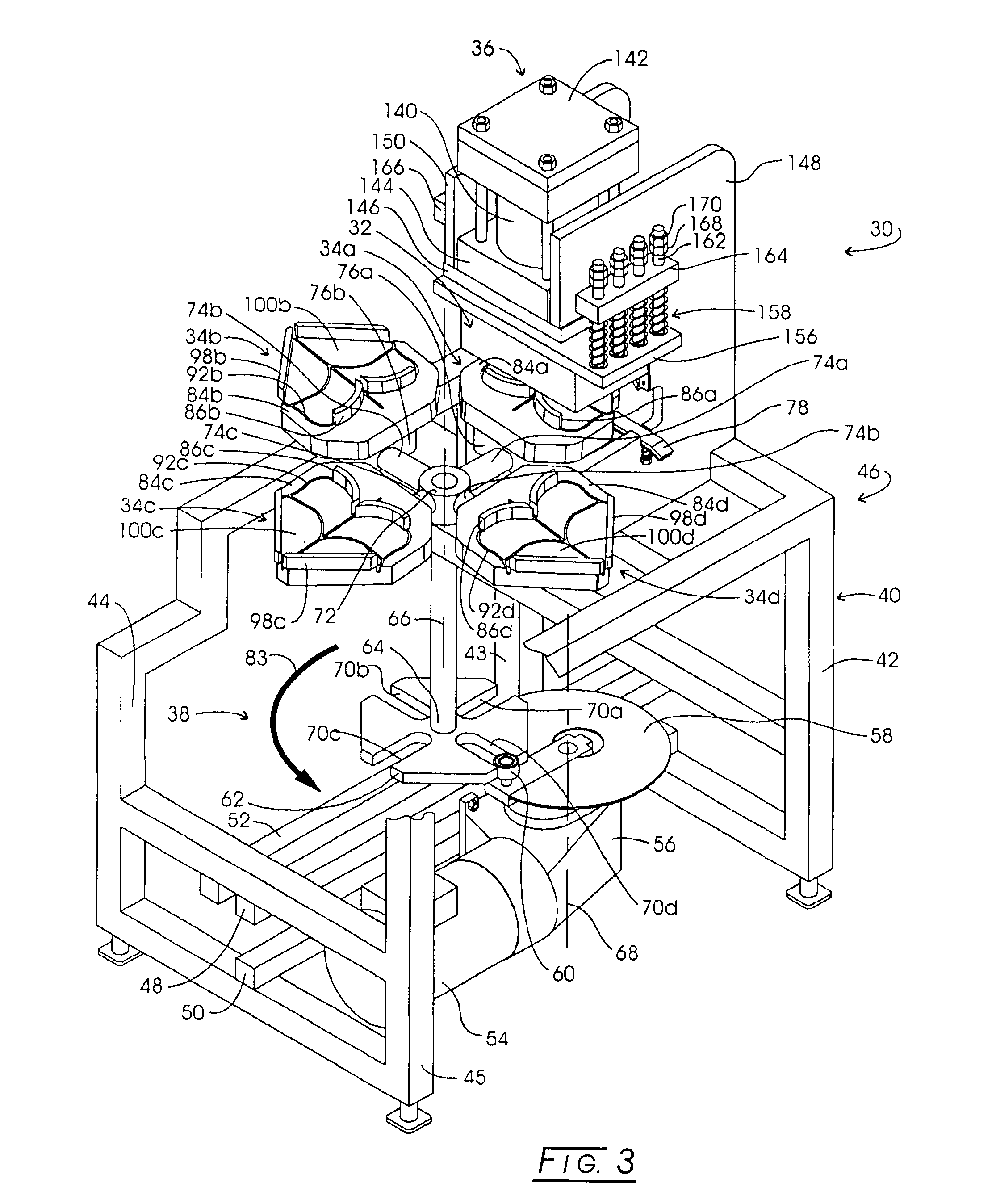

Apparatus and method for producing controlled portions of meat products

ActiveUS7364504B2Consistent controlReduce wasteMeat holding apparatusMeat processing plantsKnife bladesVertical axis

Owner:PRIME EQUIP GRP LLC

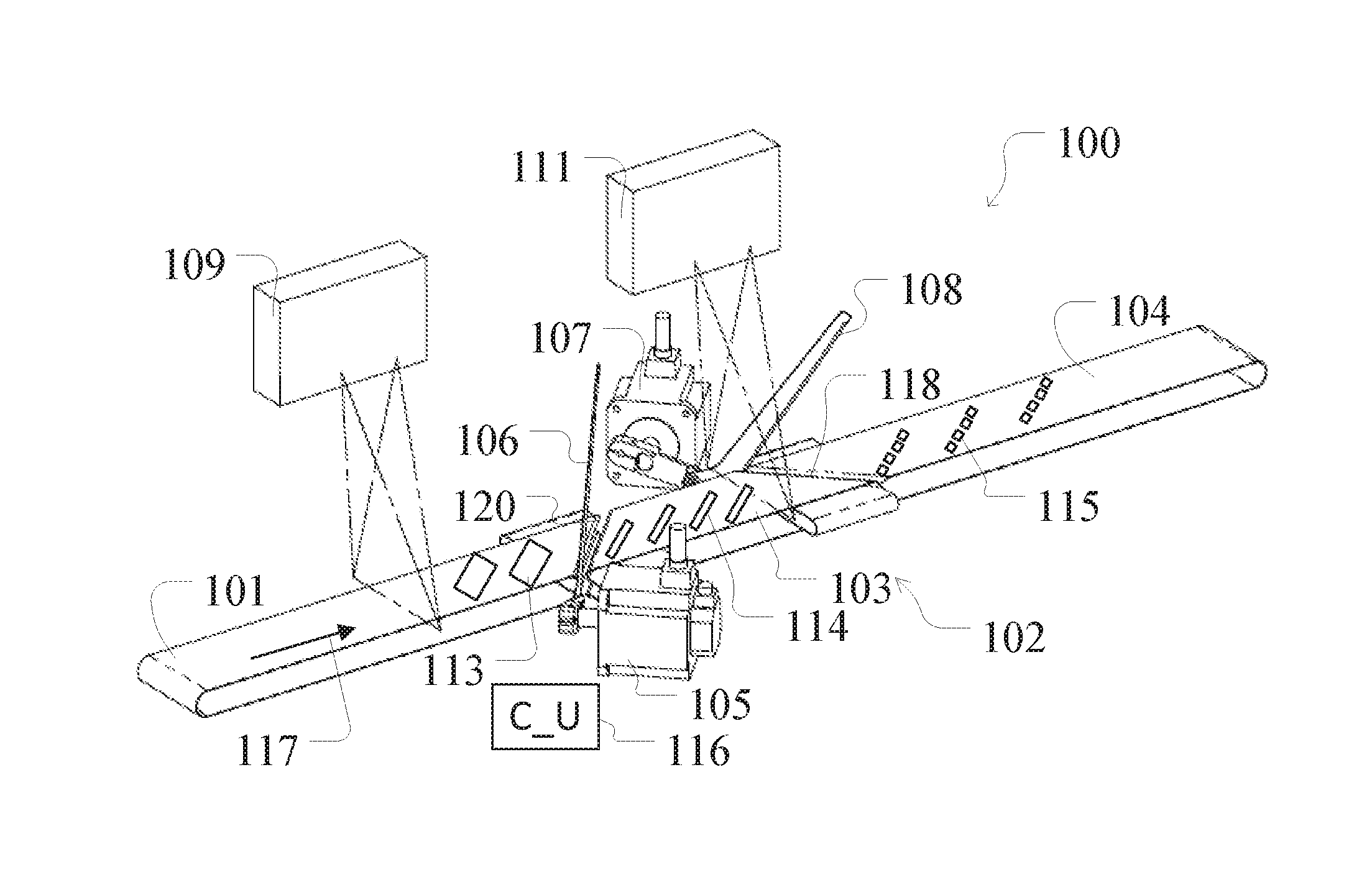

Cutting apparatus and a method for cutting food products into smaller food products

InactiveUS20160288355A1Improve throughputReduce eliminateMetal working apparatusMeat shaping/cuttingIngested foodDelivery system

This invention relates to a cutting apparatus for cutting food objects into smaller food products, wherein the cutting apparatus includes an infeed conveyor having a first end and a second end, a conveyor system having a first end and a second end, the conveyor system being arranged such that the first end of the conveyor system is adjacent and parallel to the second end of the infeed conveyor defining a first slit there between, and a first cutting unit having a cutting plane extending through the first slit and controlled by a control unit for cutting food objects conveyed by the infeed conveyor into smaller food products, wherein the first slit and the cutting plane of the cutting unit form an angle to an axis perpendicular to the conveying direction.

Owner:MAREL HF

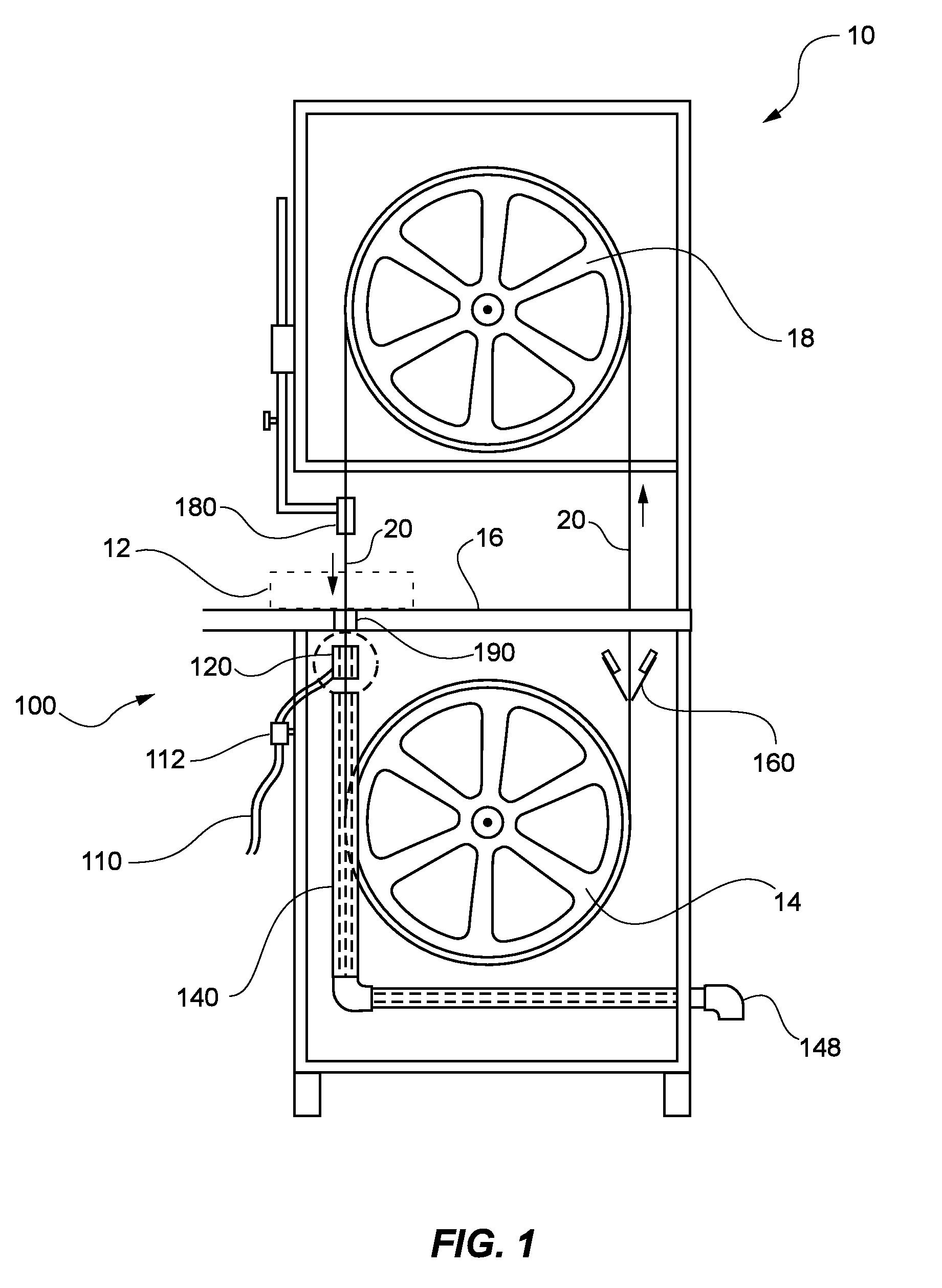

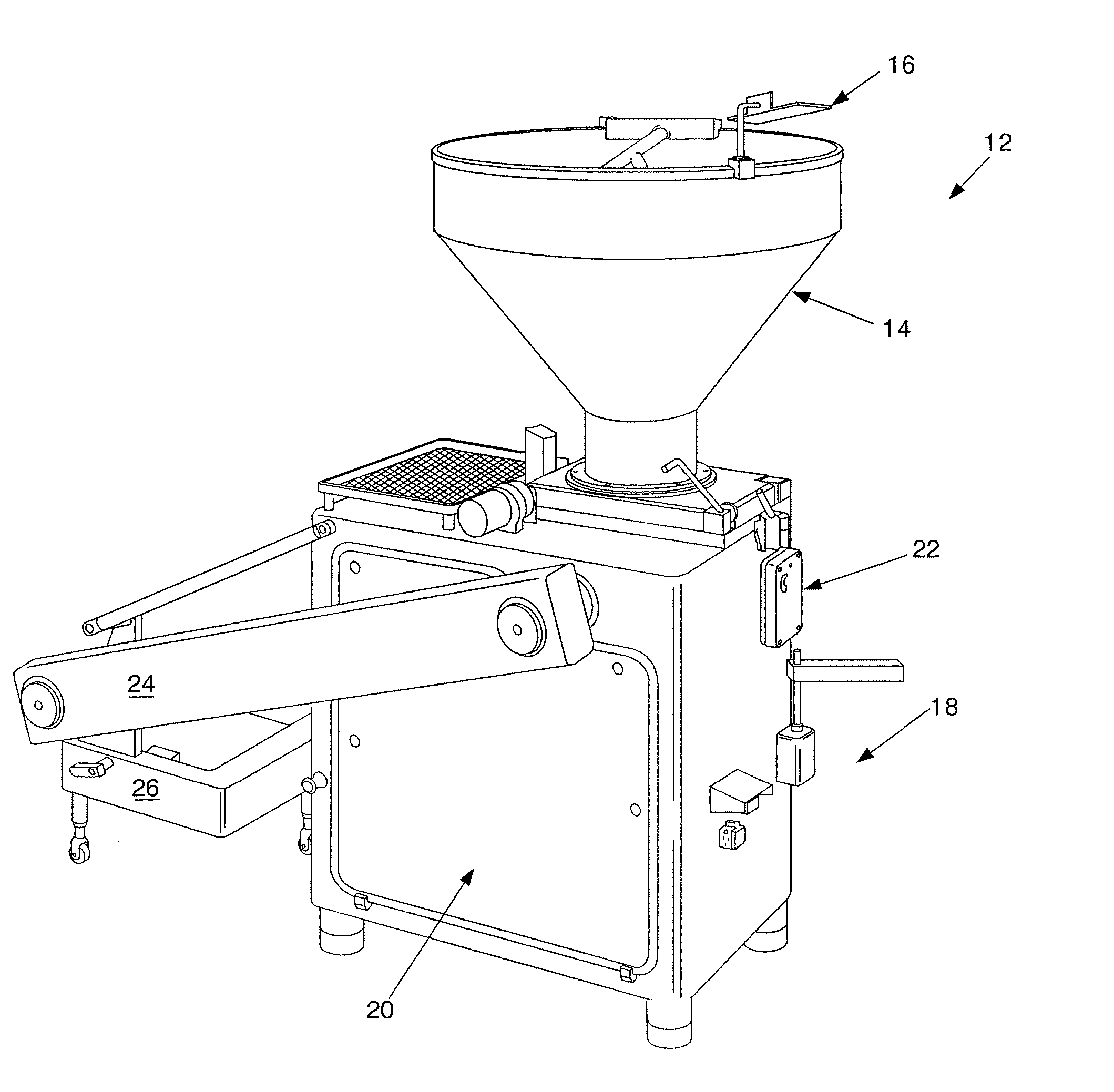

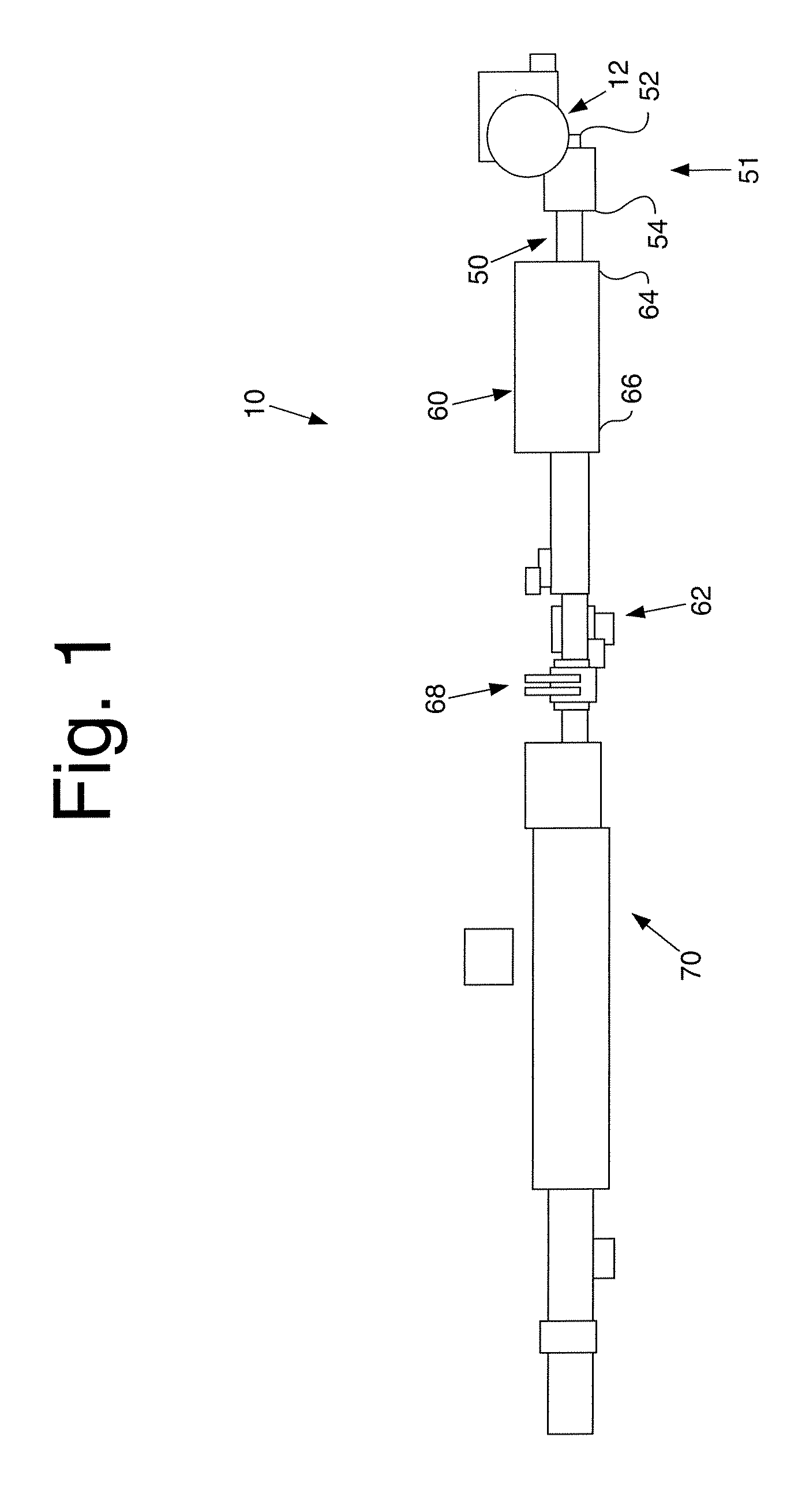

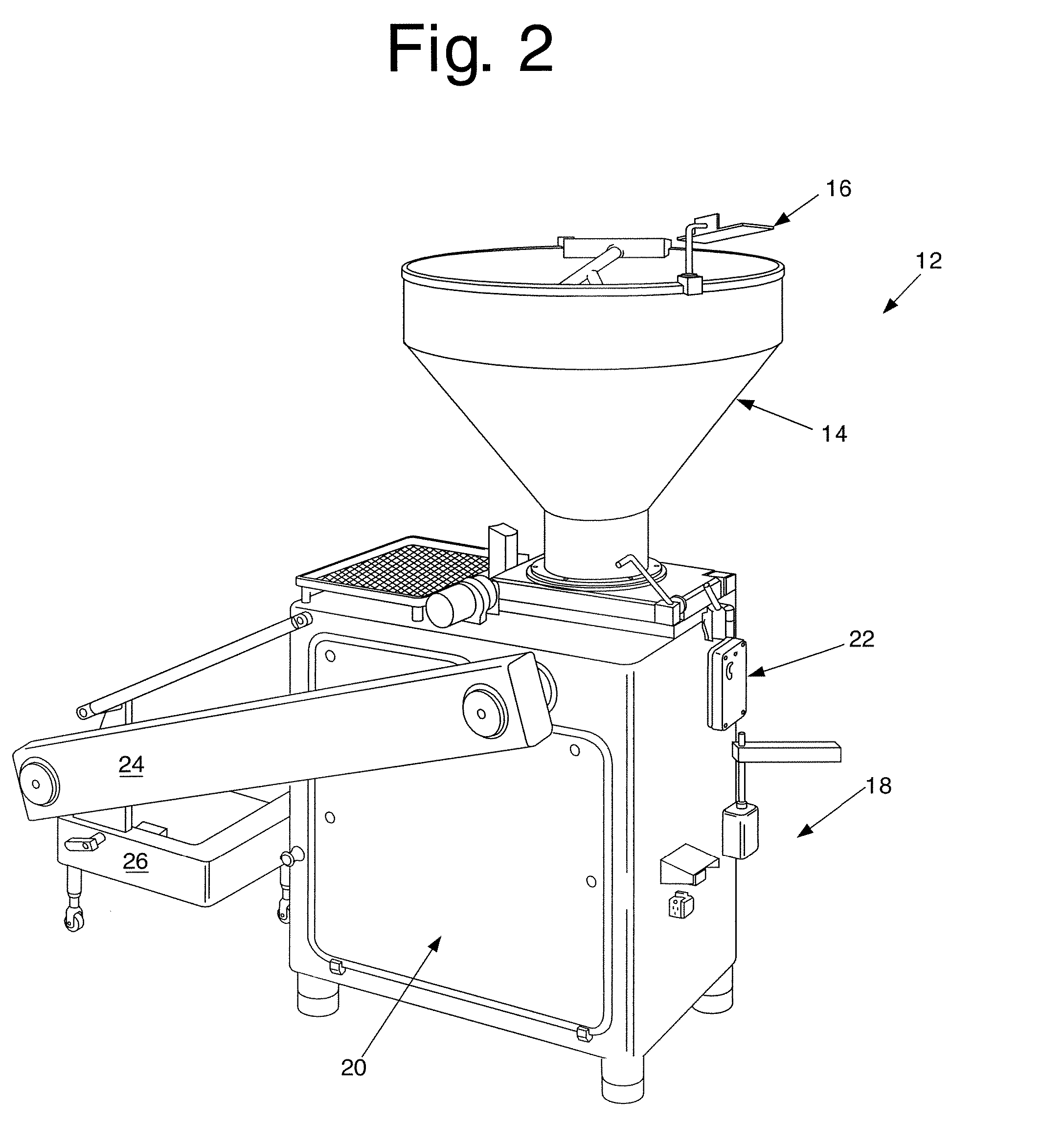

System and method for production of exact weight ground meat

A method and system for producing portions of ground meat having a predetermined target weight is disclosed. This system includes a pump assembly that is capable of extruding a stream of ground meat, a conveyor that is capable of transporting the stream of ground meat from the pump assembly, a portioning mechanism that is capable of separating the stream of ground meat into a plurality of portions, a weighing mechanism that is capable of weighing each portion of the plurality of portions, and at least one filling mechanism that provides an additional amount of ground meat to each portion of the plurality of portions so that each portion of the plurality of portions can substantially attain the predetermined target weight.

Owner:TYSON FRESH MEATS

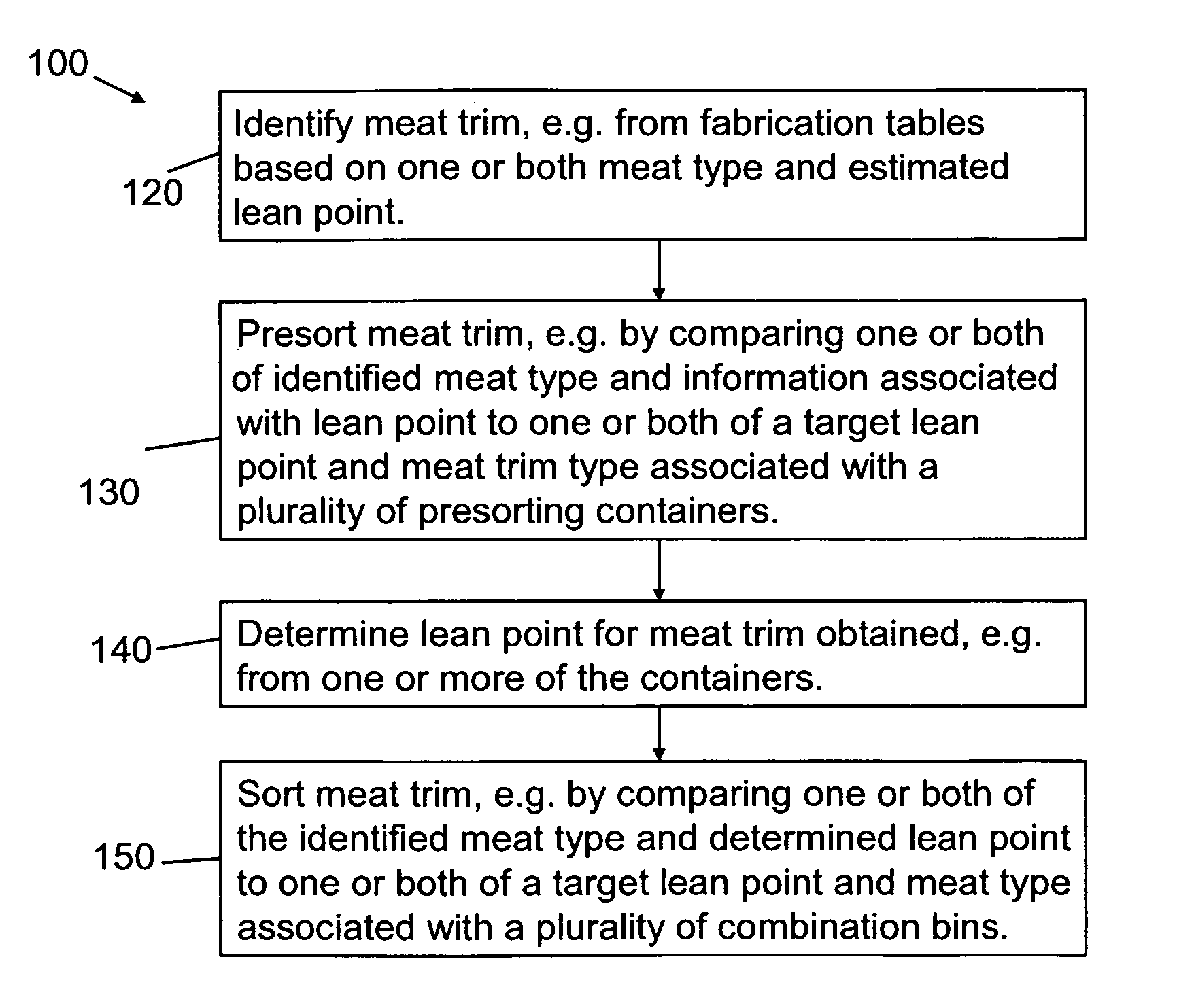

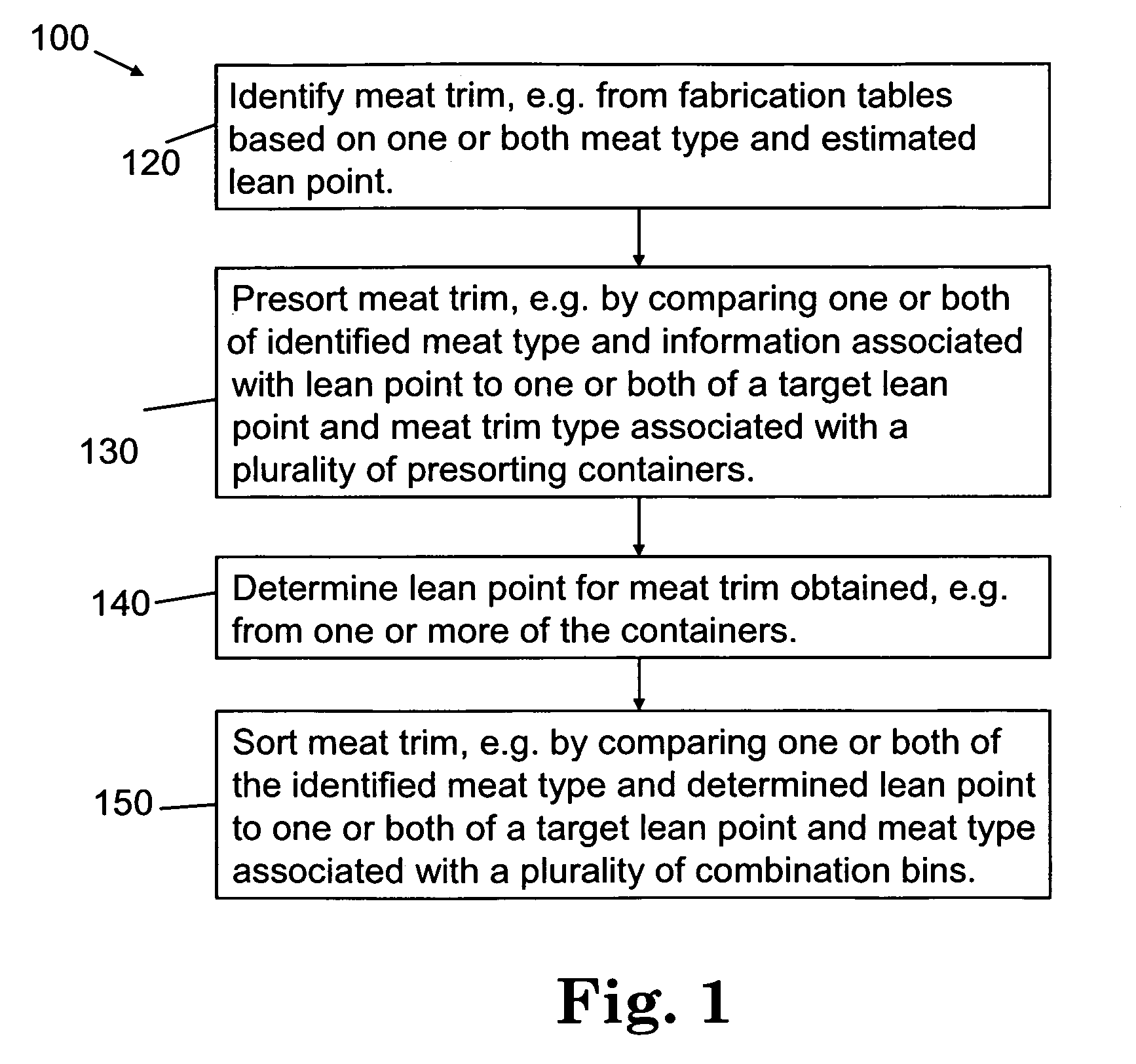

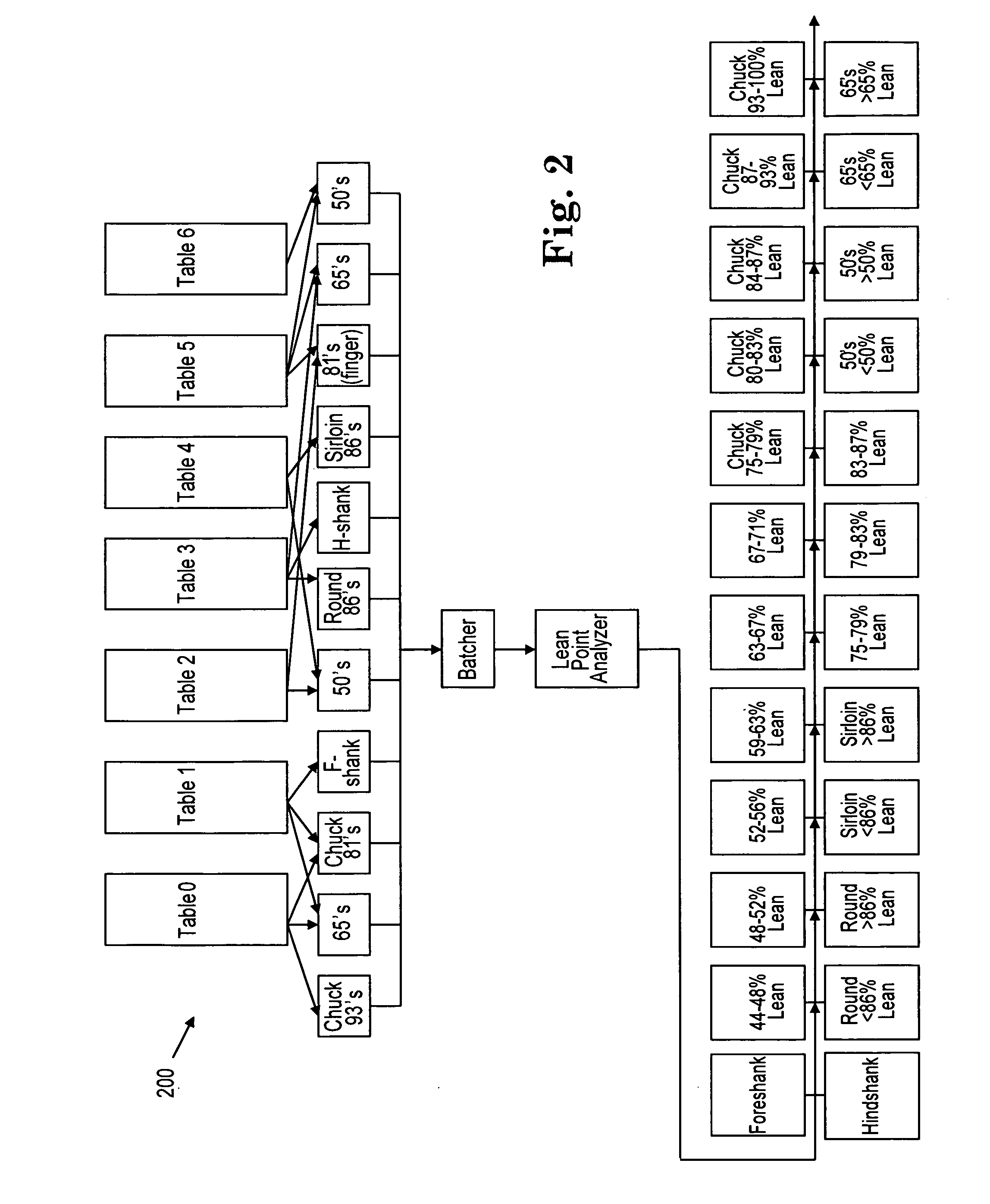

Processing meat trim

Owner:CARGILL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com