A cutting apparatus and a method for cutting food products into smaller food products

A cutting equipment, smaller technology, applied in the direction of meat cutting/trimming, meat processing equipment, application, etc., can solve the problems of high operating cost, large turning diameter, separation, etc., and achieve the goal of increasing production volume and economical production volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Figure 1 to Figure 8An example of how the angled end of the conveyor belt can be achieved is shown. In these figures, the belt is a conventional flat belt that is "folded".

[0085] Figure 10 to Figure 14 Another example of how to achieve the angled end of the conveyor belt is shown. In these figures, the conveyor belt comprises a plurality of spaced apart round belts.

[0086] It should be noted that the invention should not be considered limited to the conveyor belts described above.

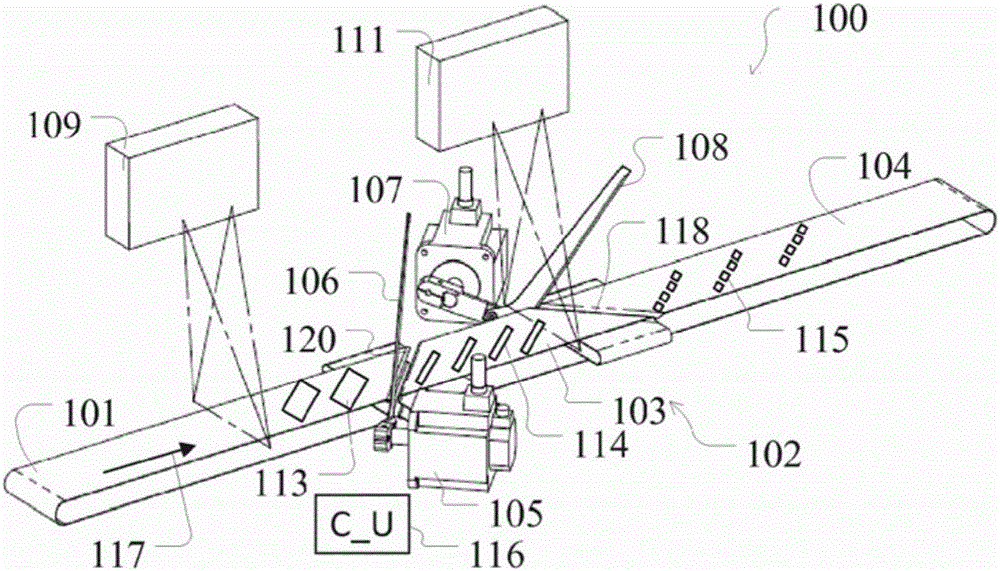

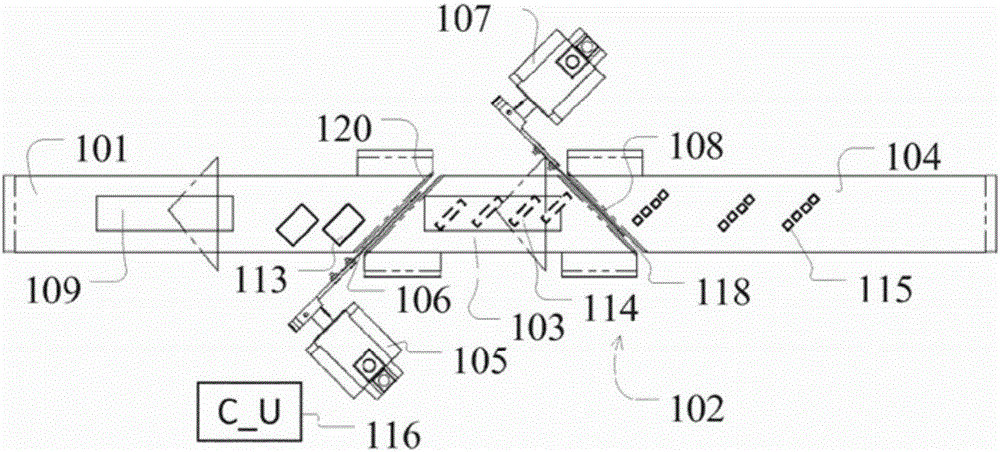

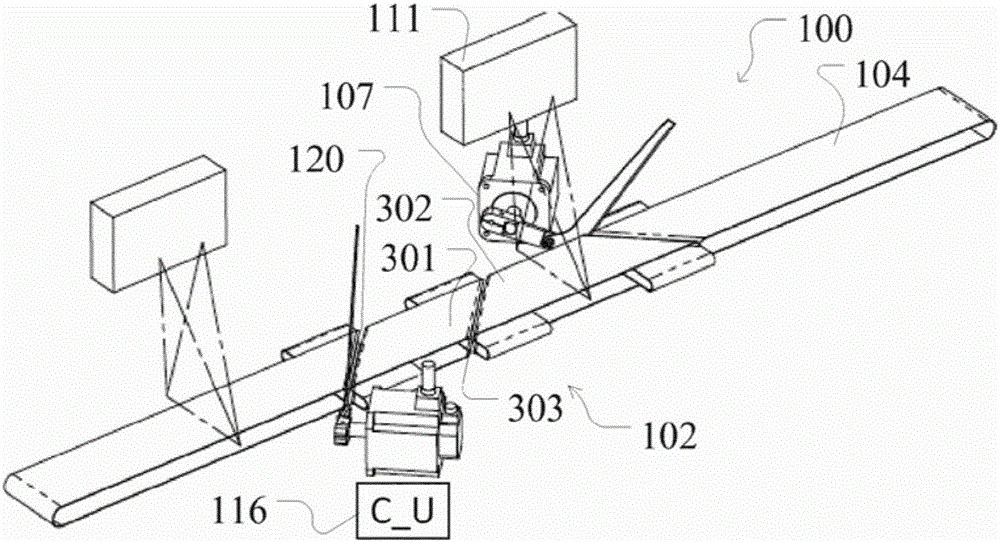

[0087] figure 1 and figure 2 A perspective view and a top view of an embodiment of a cutting device 100 according to the invention for cutting a food object 113 into smaller food products 114 , 115 are shown. The cutting apparatus 100 comprises: an infeed conveyor belt 101 having a first end and a second end, a first scanning device 109 associated with the infeed conveyor belt 101, a conveyor belt system 102 having a first end and a second end, the conveyor belt system 102 bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com