Patents

Literature

137results about "Meat tenderising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

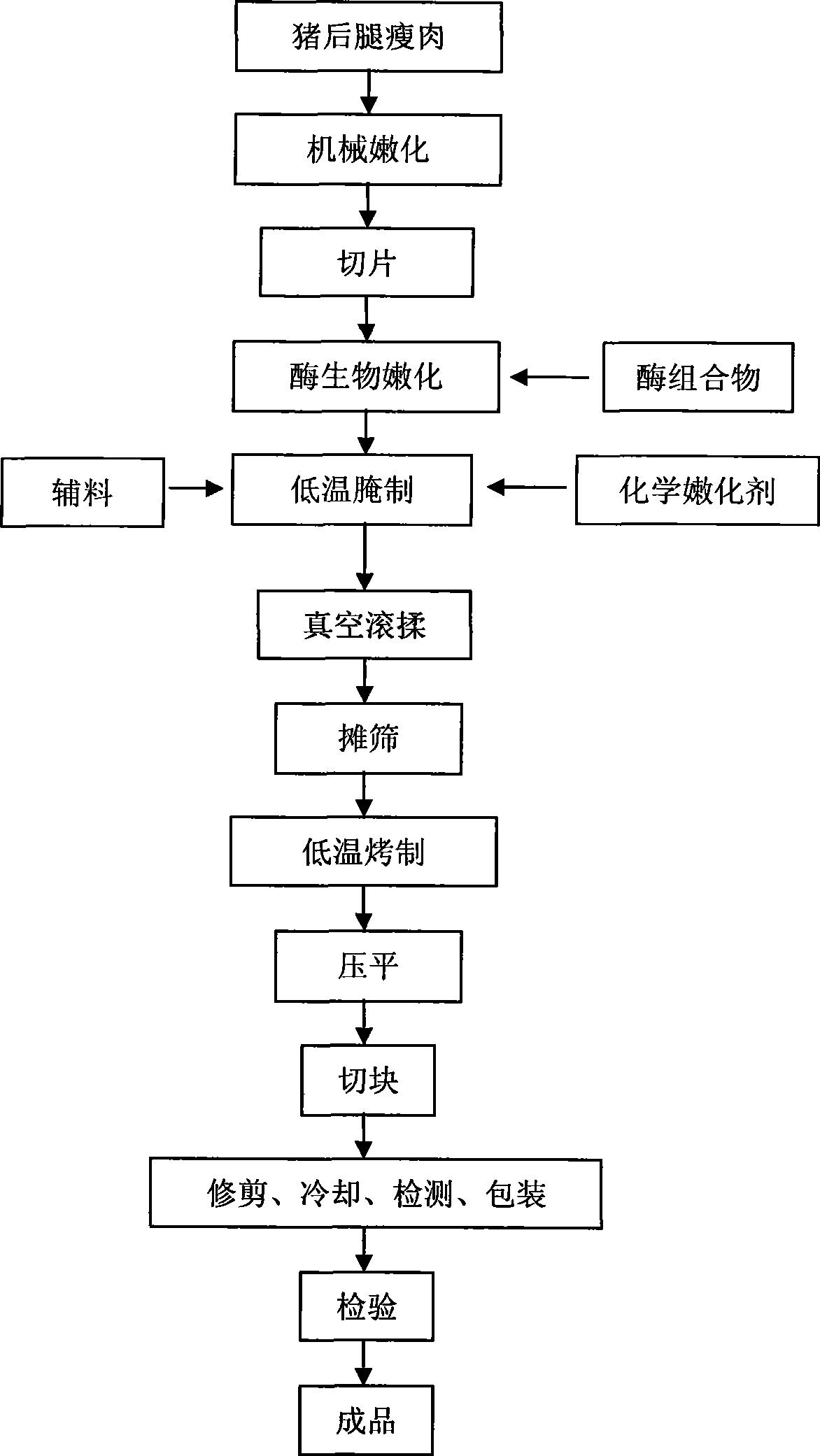

Method for processing tenderized fried pork crisps

InactiveCN101375724AImprove tendernessImprove textureFood preparationMeat tenderisingTemperature controlFiber

The invention discloses a processing method for tenderization of dried meat slices. The method comprises the following steps: step 1, selecting flesh lump, and using mechanical tenderization equipment to cut off the muscle fiber of the flesh lump, thereby facilitating absorption of curing liquid and tenderization of meat texture; step 2, utilizing a slicing machine to cut the flesh lump into meat slices, and then placing the meat slices into a combination containing enzyme mixture for enzyme bio-tenderization and enzymolysis treatment; step 3, adding a chemical tenderization agent and supplementary materials into the meat slices obtained from step 2, and pickling at a low temperature; step 4, placing the pickled meat slices from step 3 into a vacuum rolling machine for vacuum rolling; step 5, using a mesh sieve to spread and sieve the rolled meat slices obtained from step 4, and then carrying out dehydration under temperature control procedures, and baking to produce the dried meat slices; and step 6, cooling, compressing, slicing, testing and packing the baked meat slices.

Owner:江苏畜牧兽医职业技术学院 +1

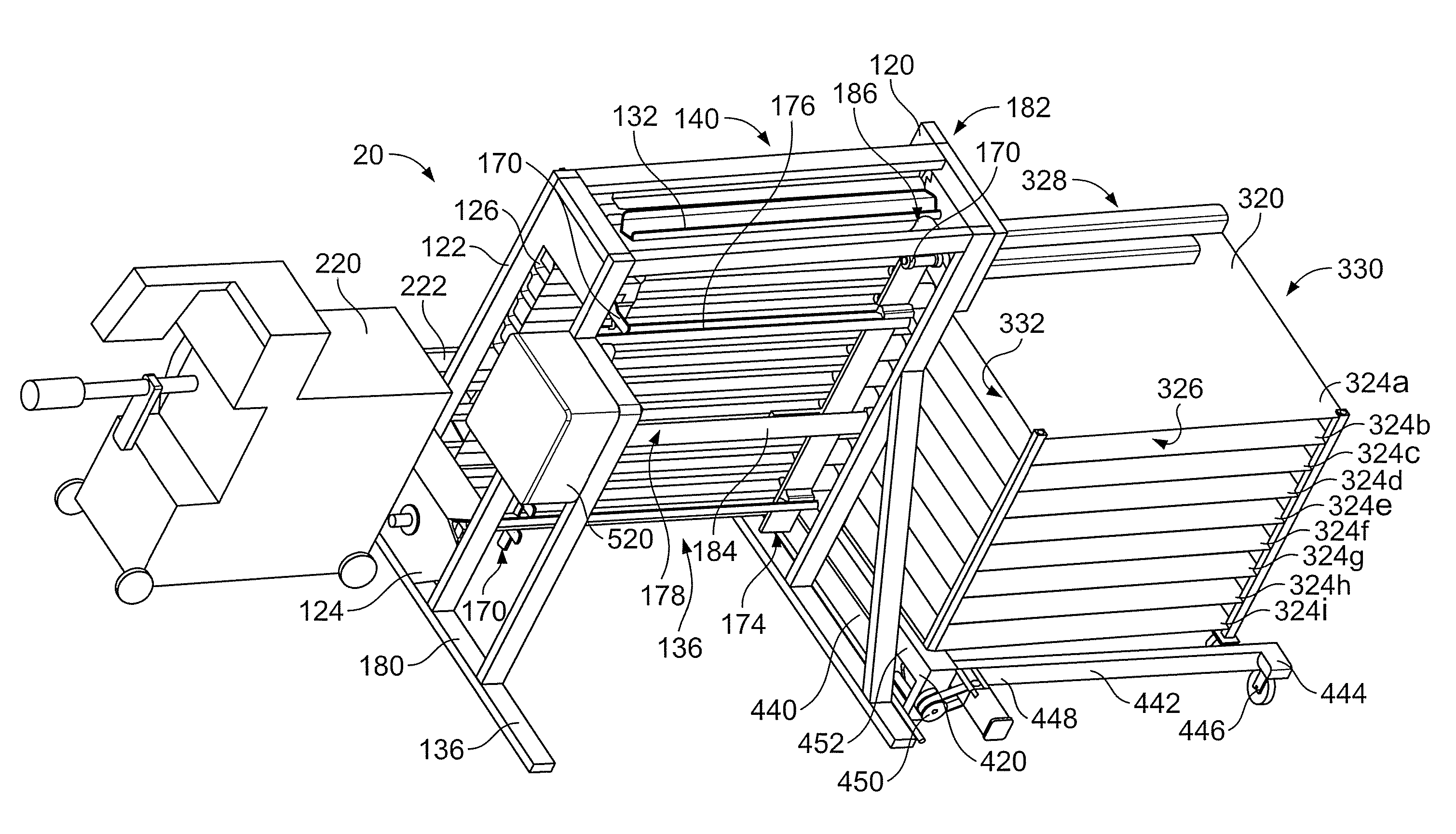

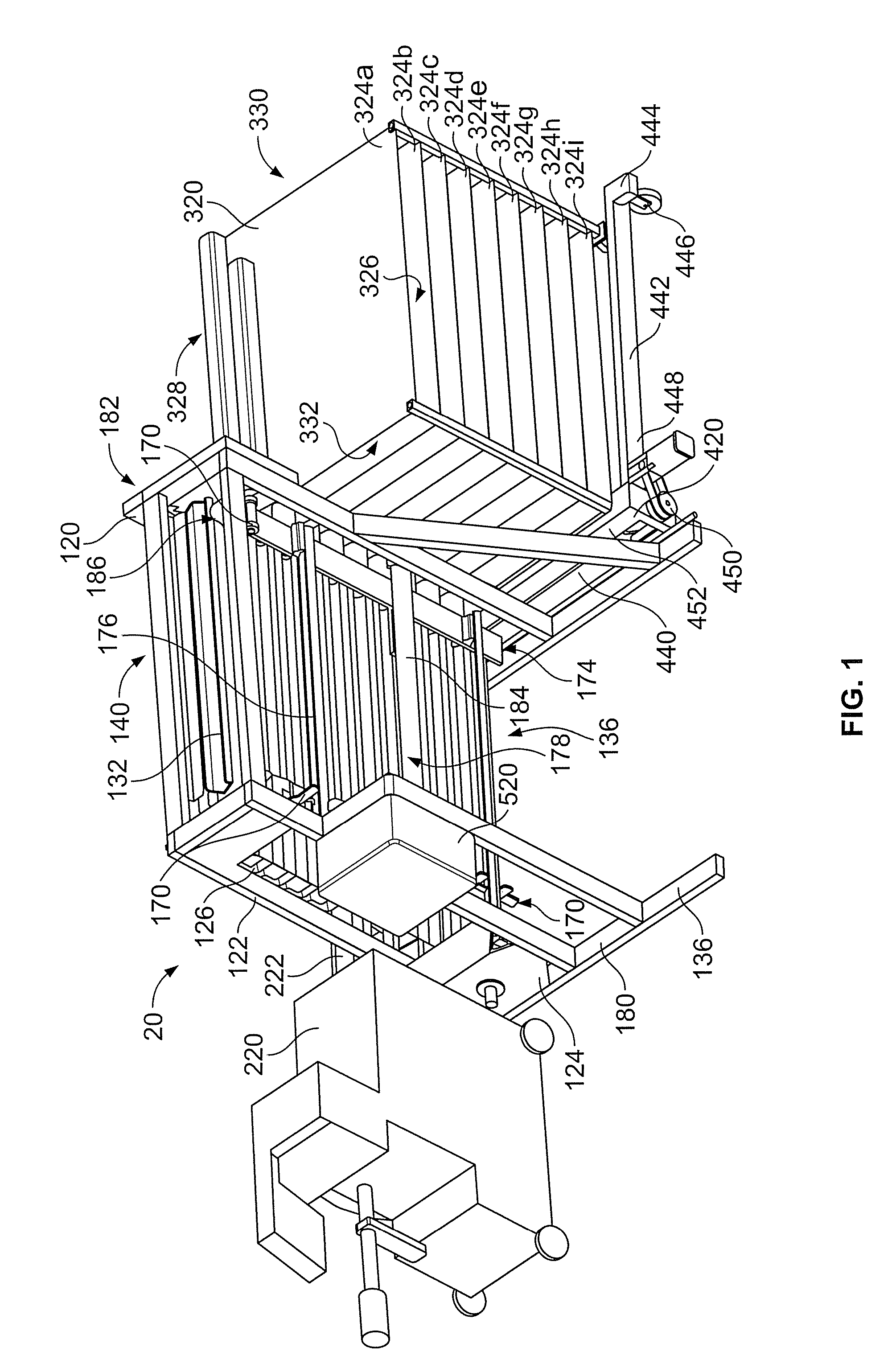

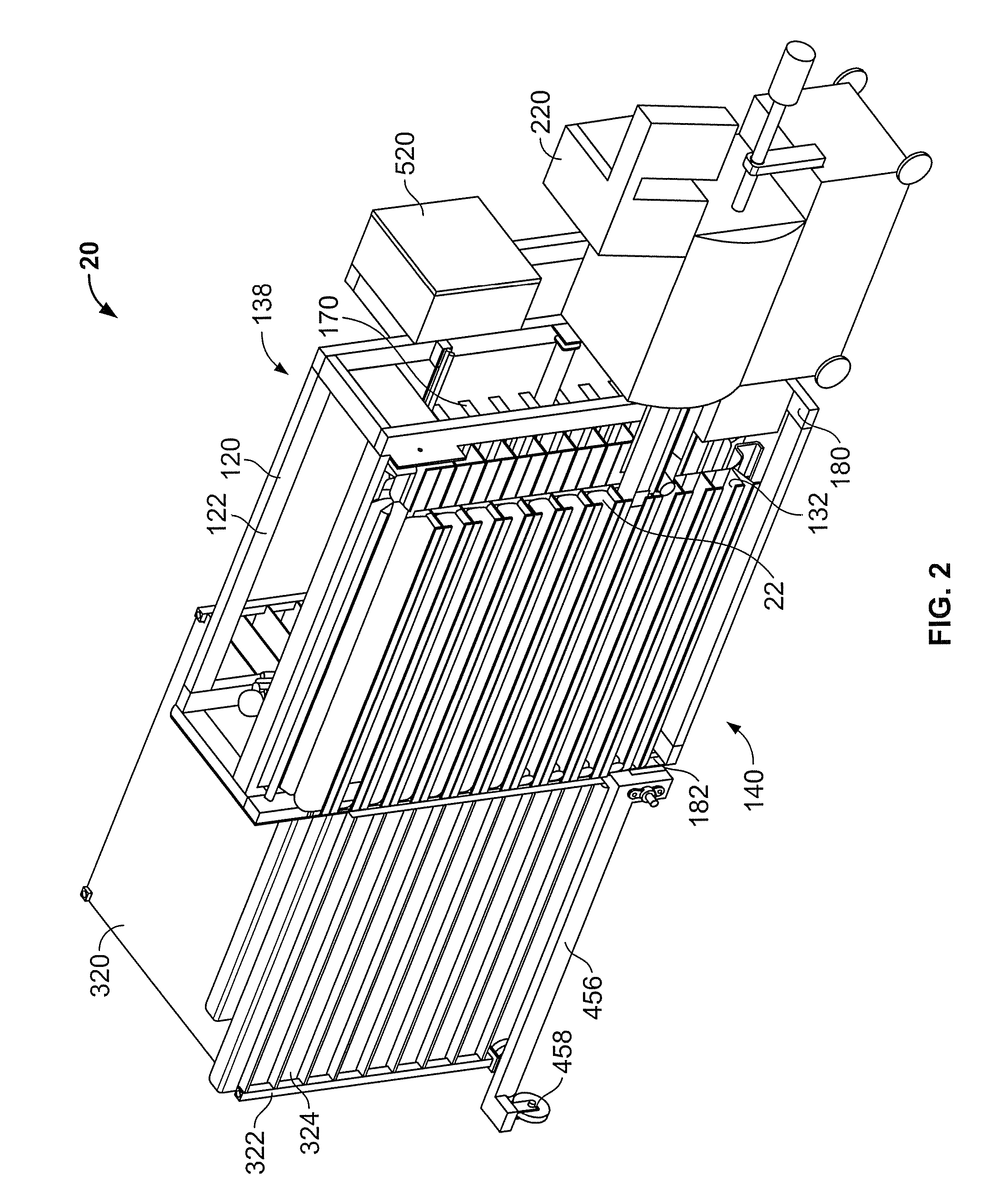

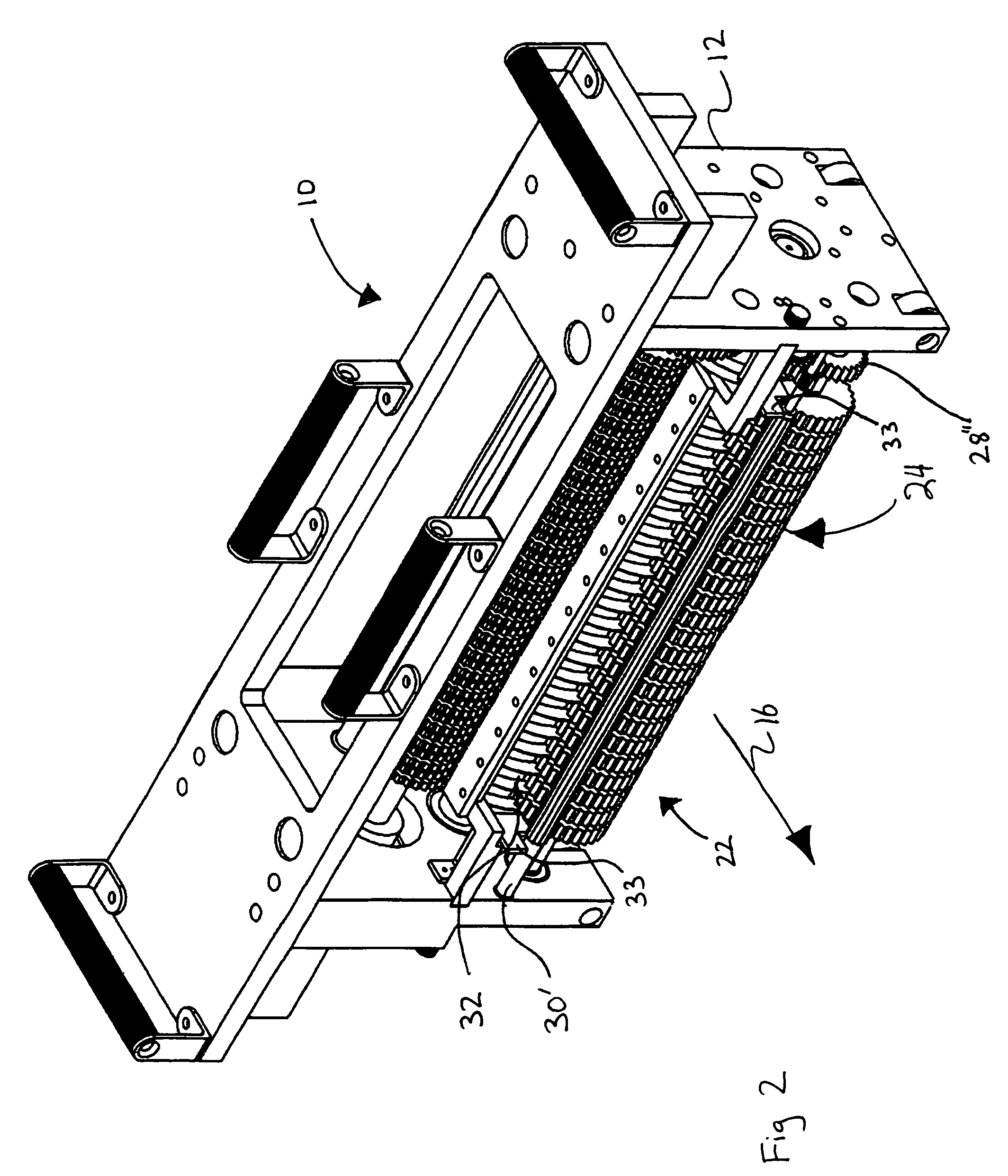

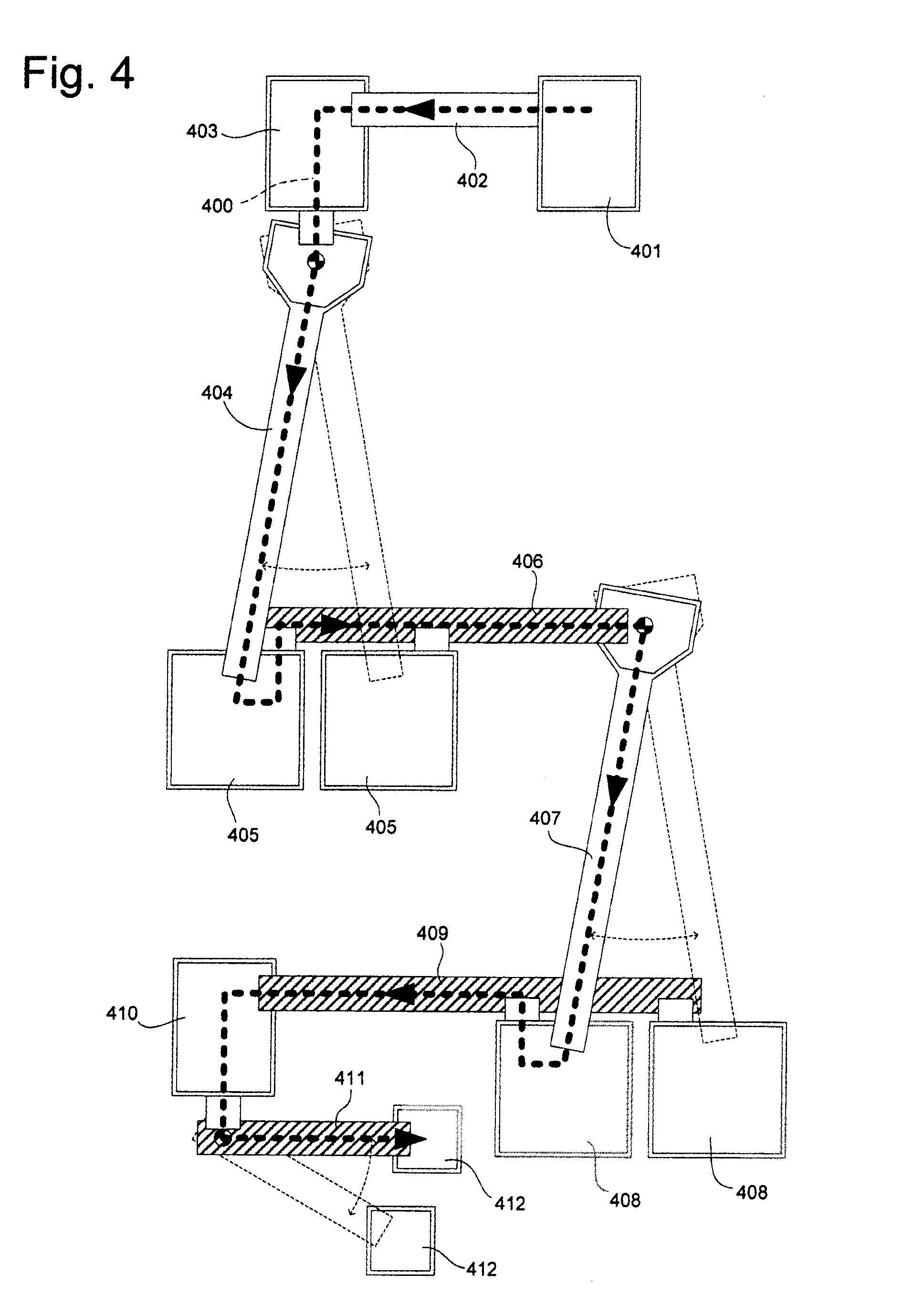

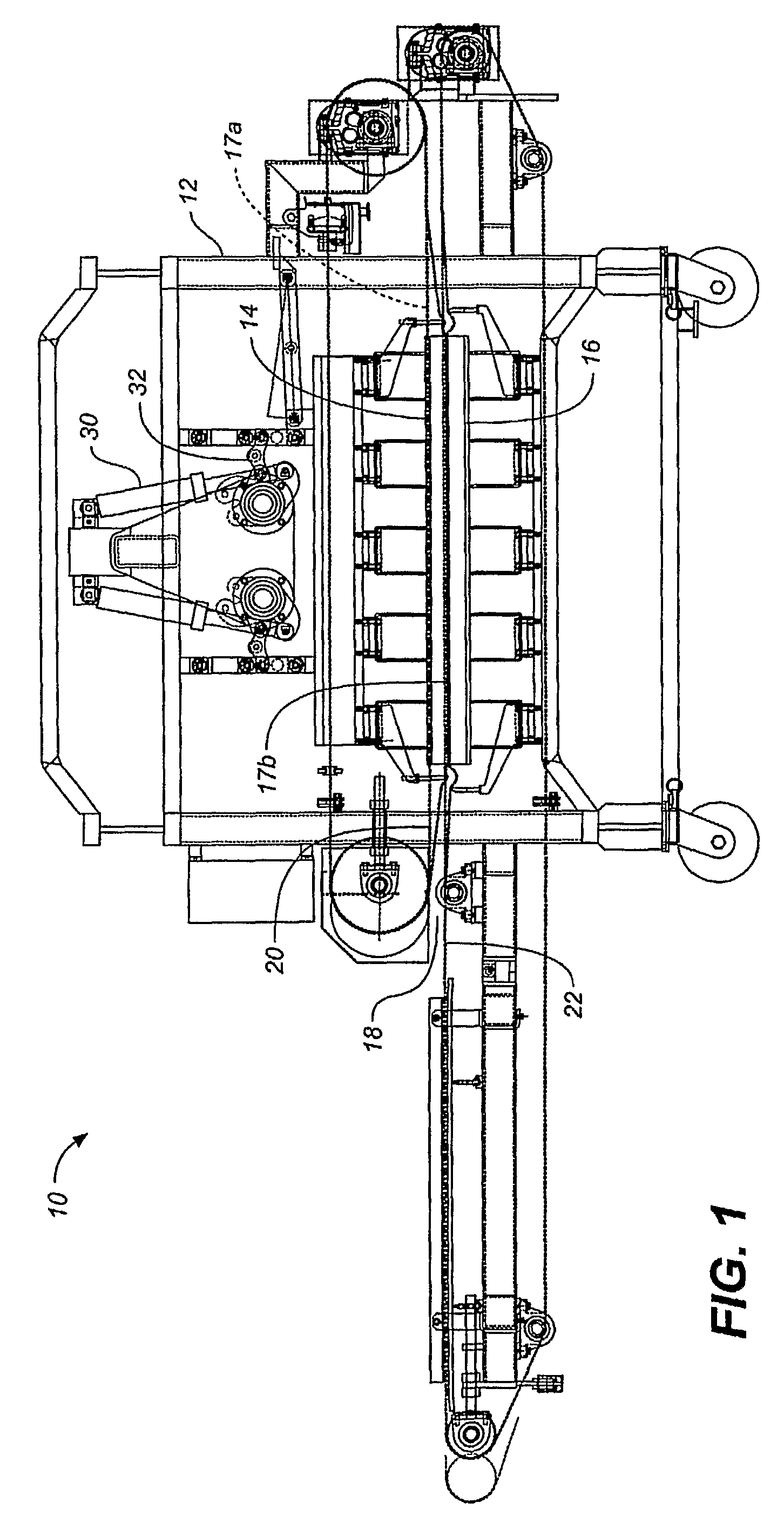

Automatic rack loader

An apparatus and system for loading items onto a rack is described. The rack loading apparatus is a conveyor having a loading side for receiving items and an unloading side for discharging items, a positioner to align a rack with the unloading side; and a load pusher to discharge the items from the unloading side onto the rack. The system is a sausage-making stuffer / clipper, a belt conveyor, a conveyor having a loading side for receiving sausages and an unloading side for discharging sausages, a positioner to align a rack with the unloading side; and a load pusher to discharge the sausages from the unloading side onto the rack.

Owner:POLY CLIP SYST

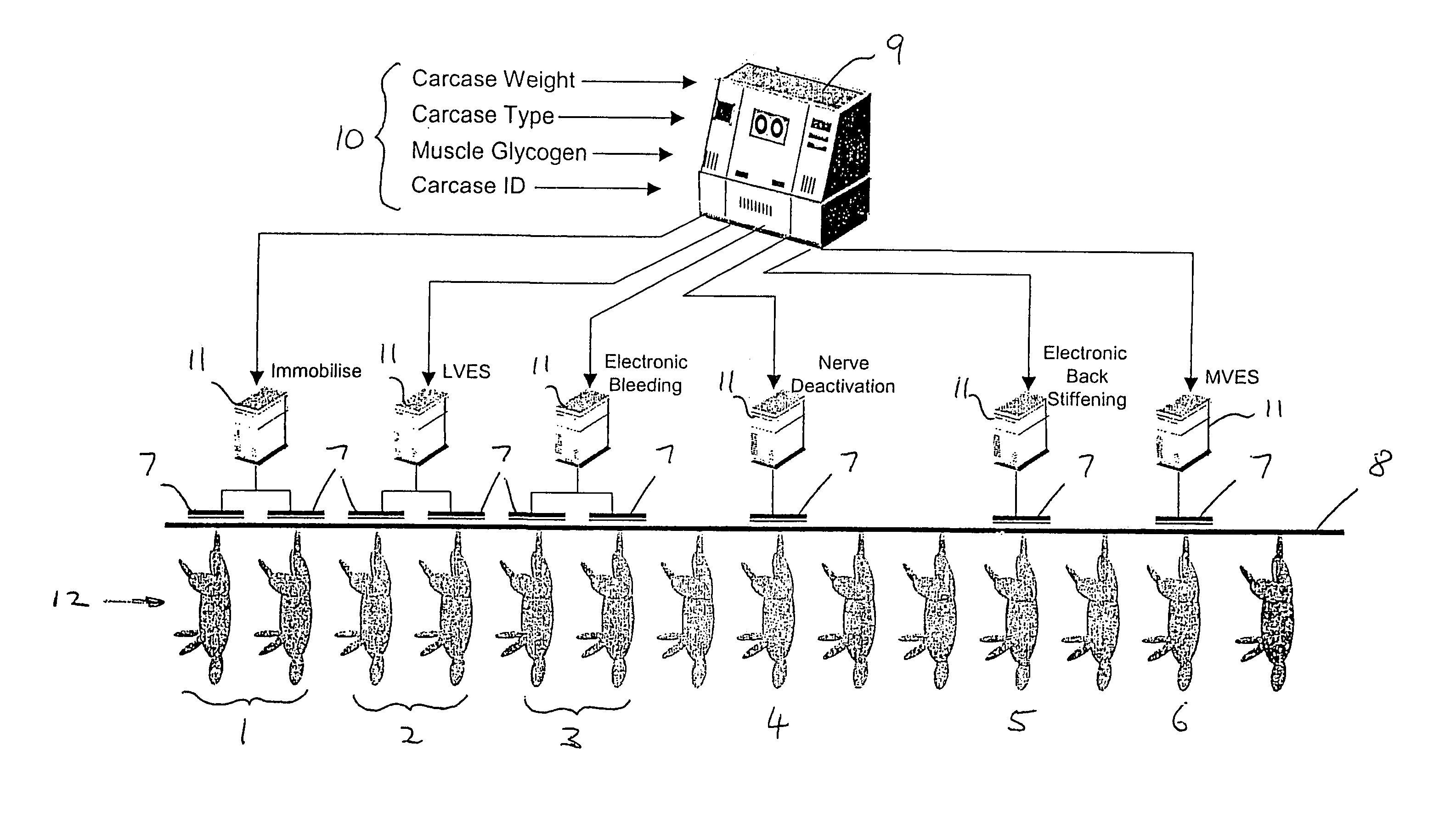

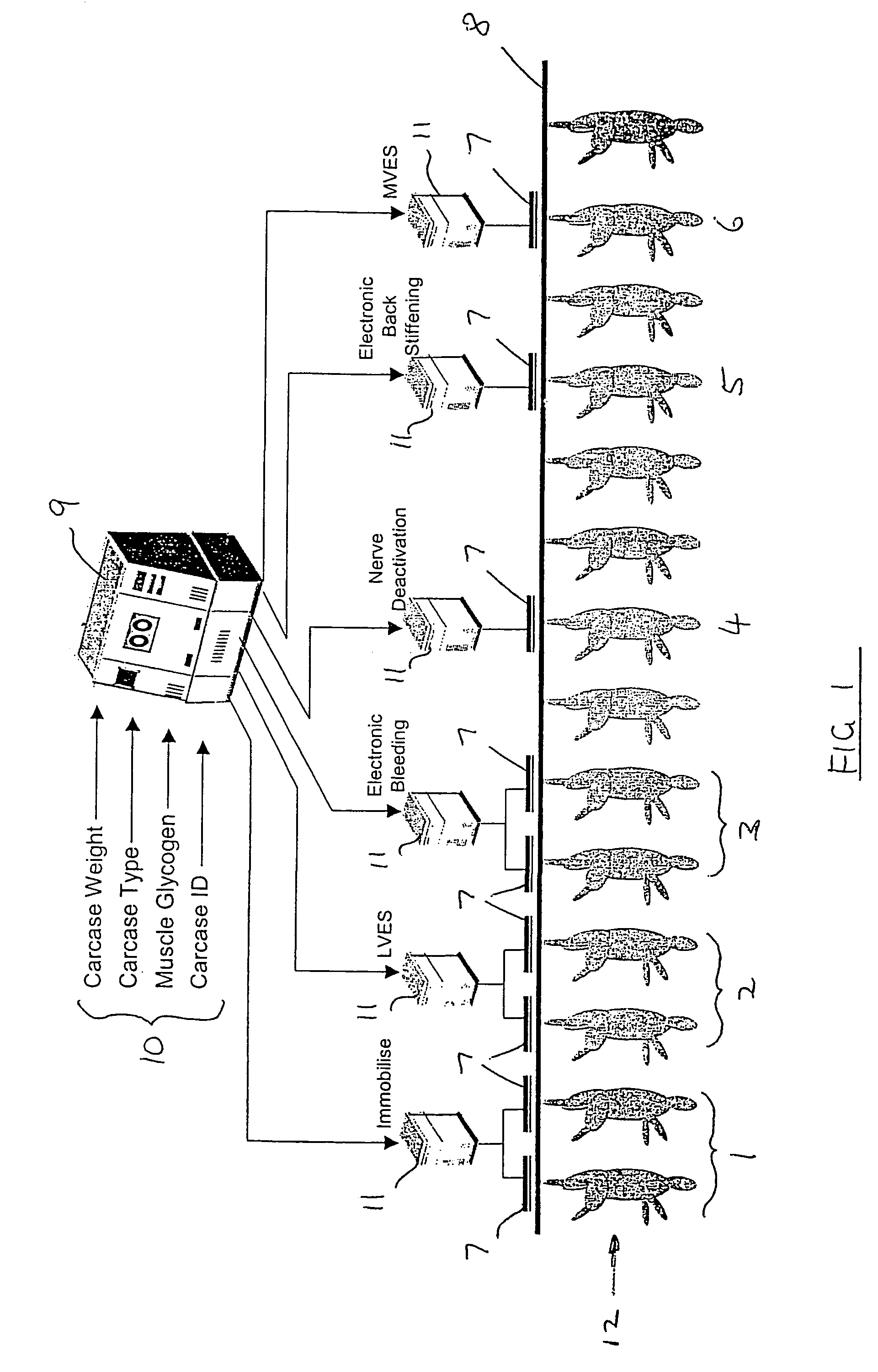

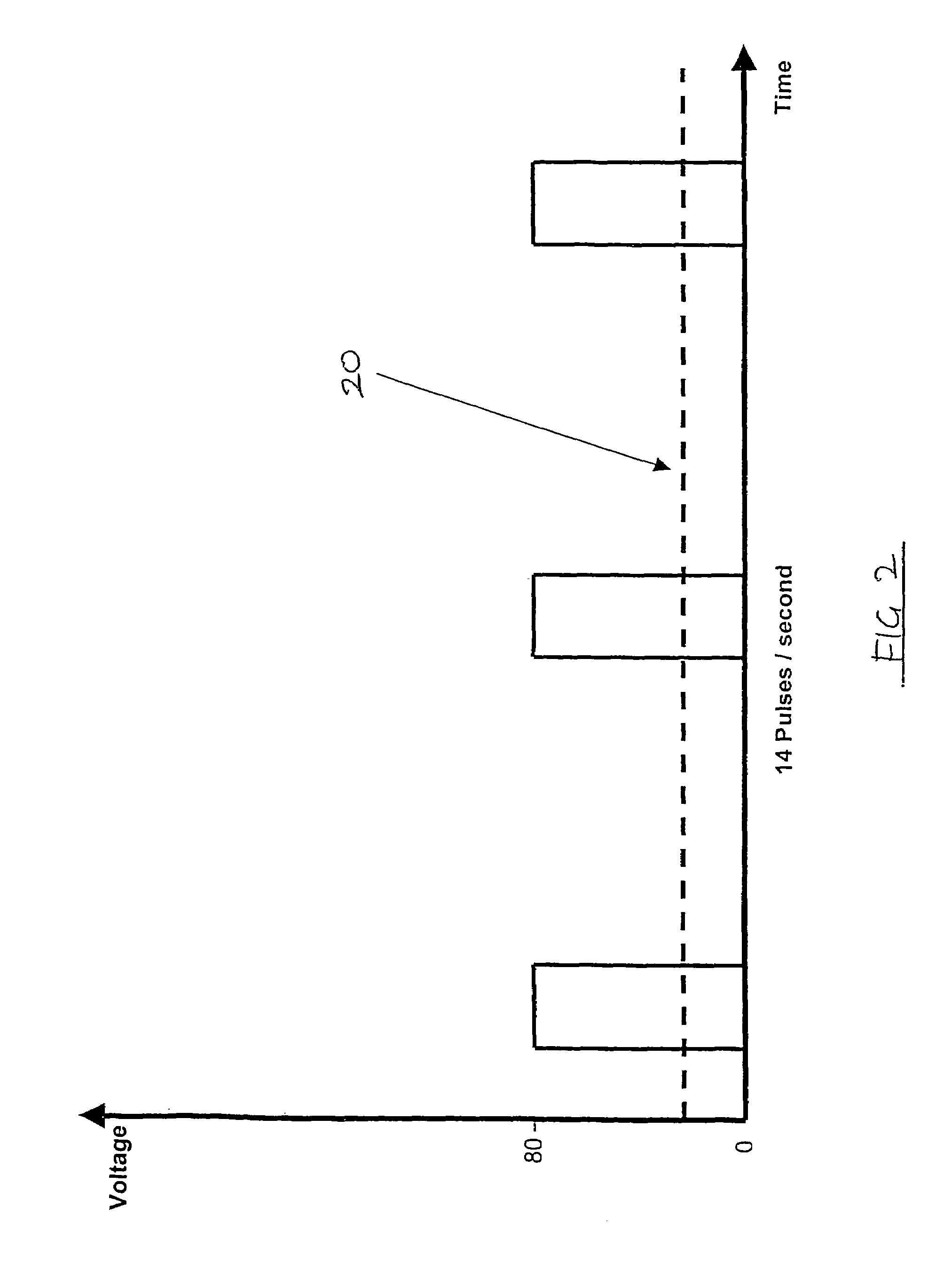

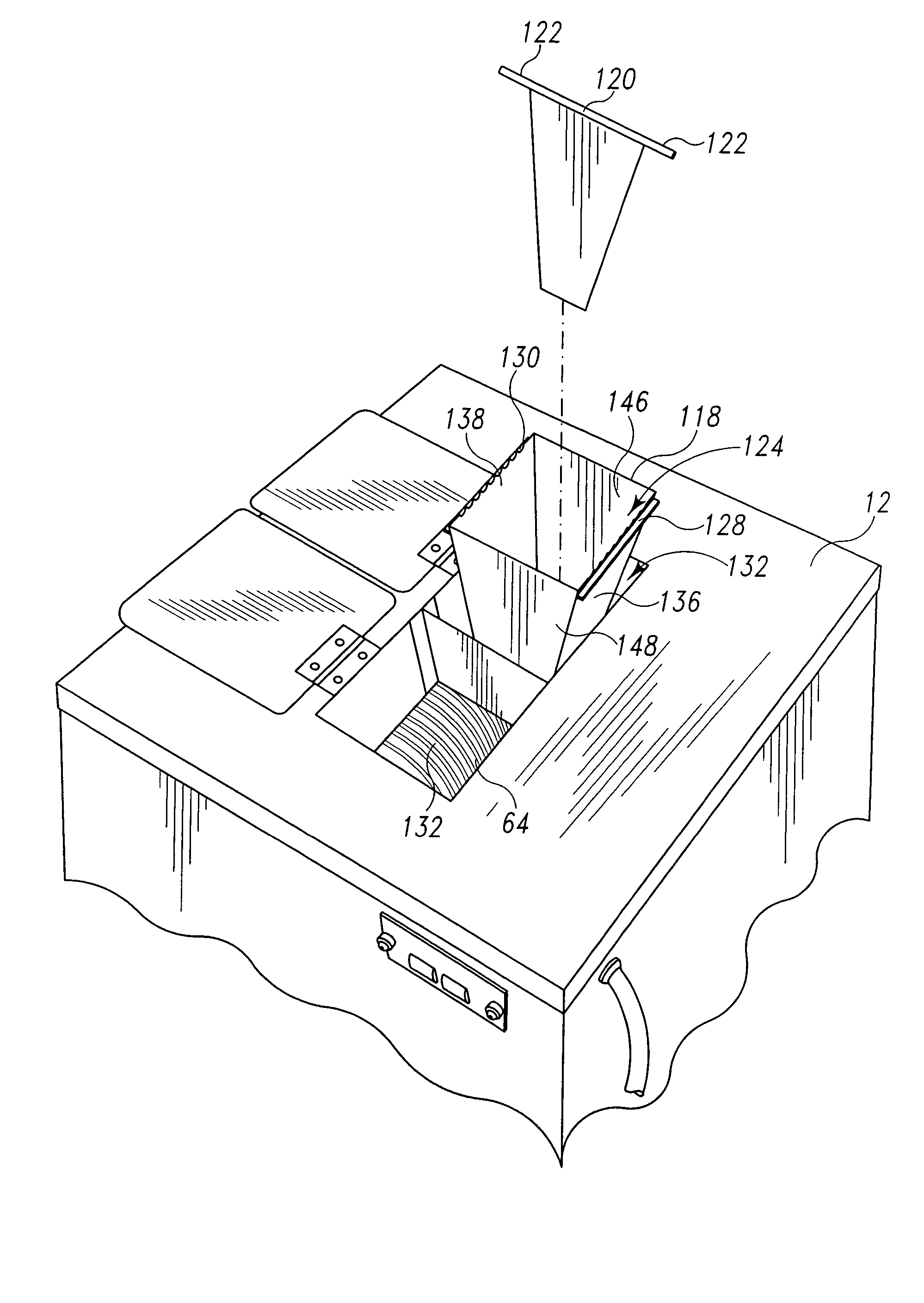

Electrical treatment of carcasses

InactiveUS7025669B2Excels in qualityIncrease productionElectric current slaughtering/stunningPoultry processingMicrocomputerPower flow

Owner:MEAT & LIVESTOCK AUSTRALIA

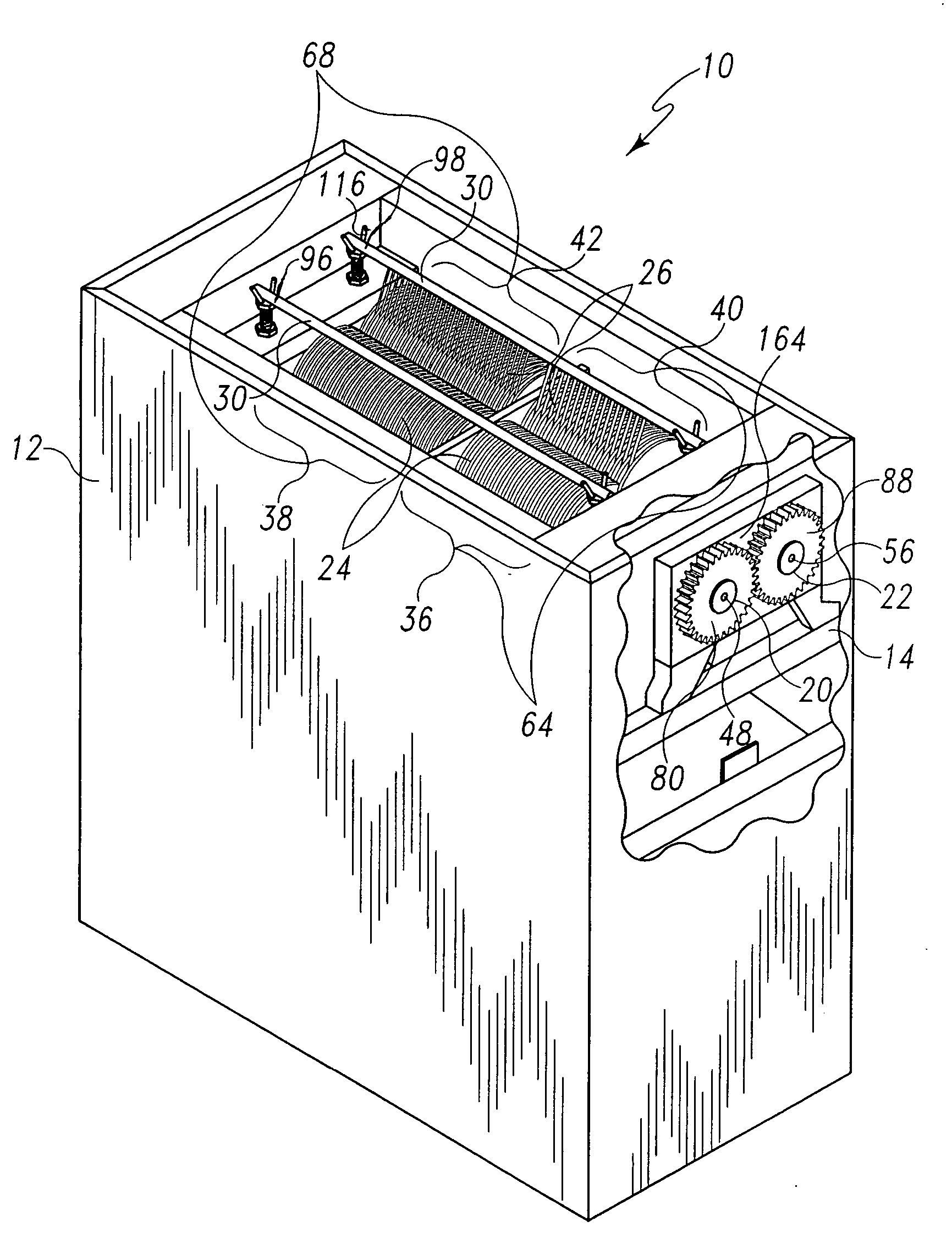

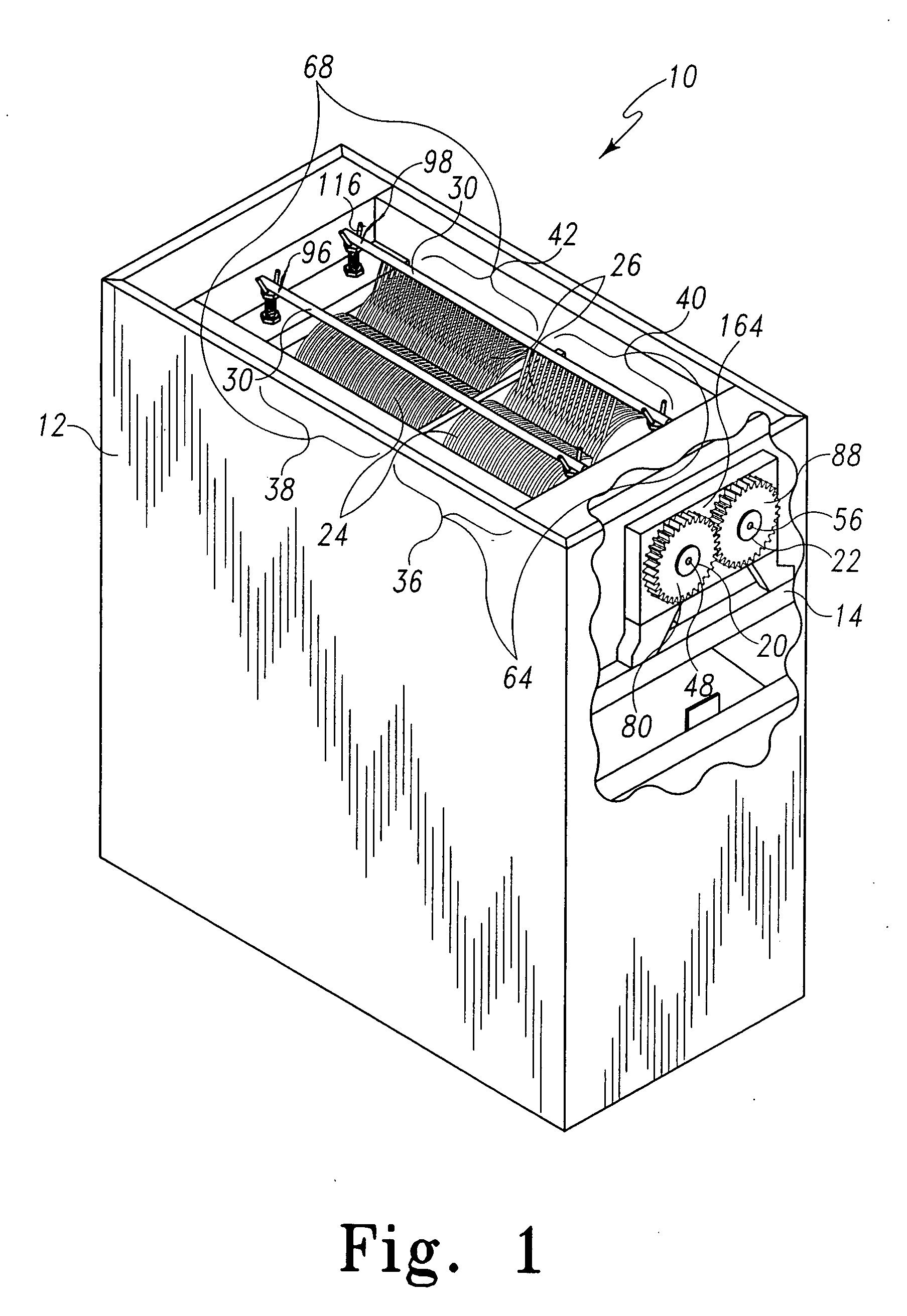

Food processing apparatus for forming strips, slices and cubes

ActiveUS7377201B2Efficient and economical to cookLess likely to clingShearing machinesGang saw millsMechanical engineeringFood item

A food processing apparatus comprises a first and second shaft and first, second, third and fourth subsets of blades. The first and second subsets of blades are mounted to the first shaft. The blades of the first subset of blades are separated by a first displacement. The blades of the second subset of blades are separated by a second displacement differing from the first displacement. The third and fourth subsets of blades are mounted to the second shaft. The blades of the third subset of blades are separated by the first displacement. The blades of the fourth subset of blades are separated by the second displacement. The first and third subset of blades form a first cutting region for cutting food to a first dimension and the second and fourth subset of blades form a second cutting region for cutting food to a second dimension.

Owner:CHEN ZHUI

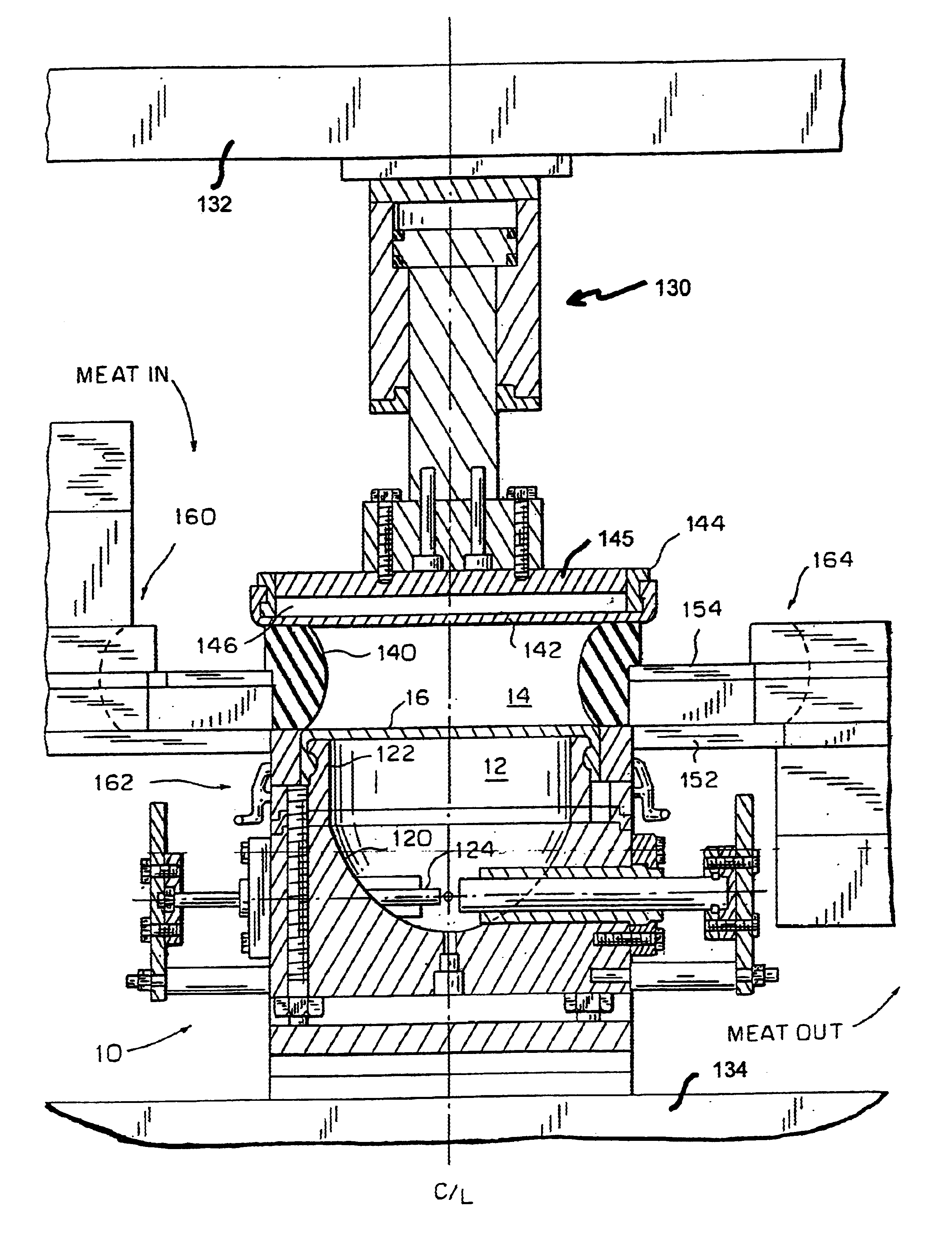

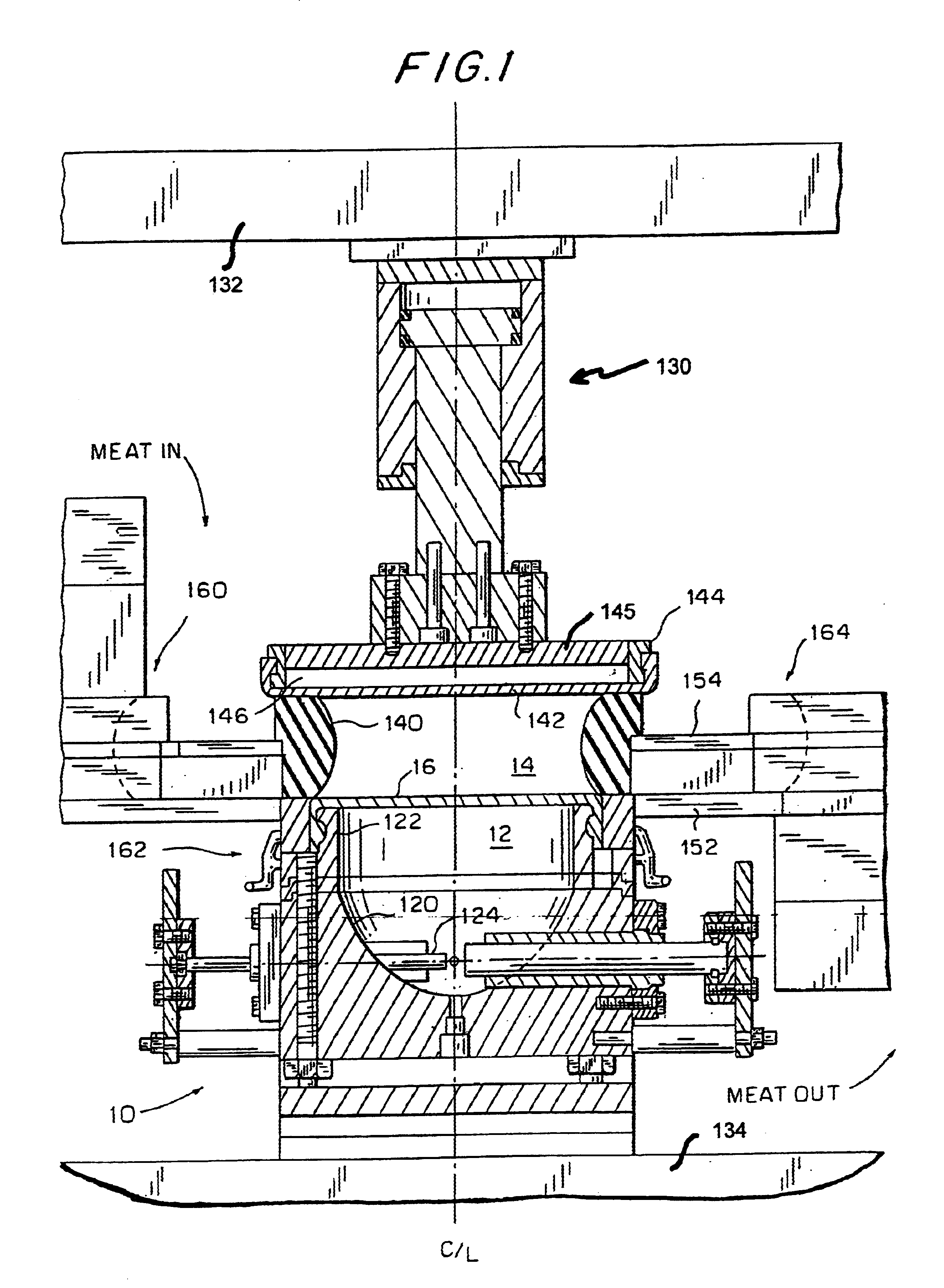

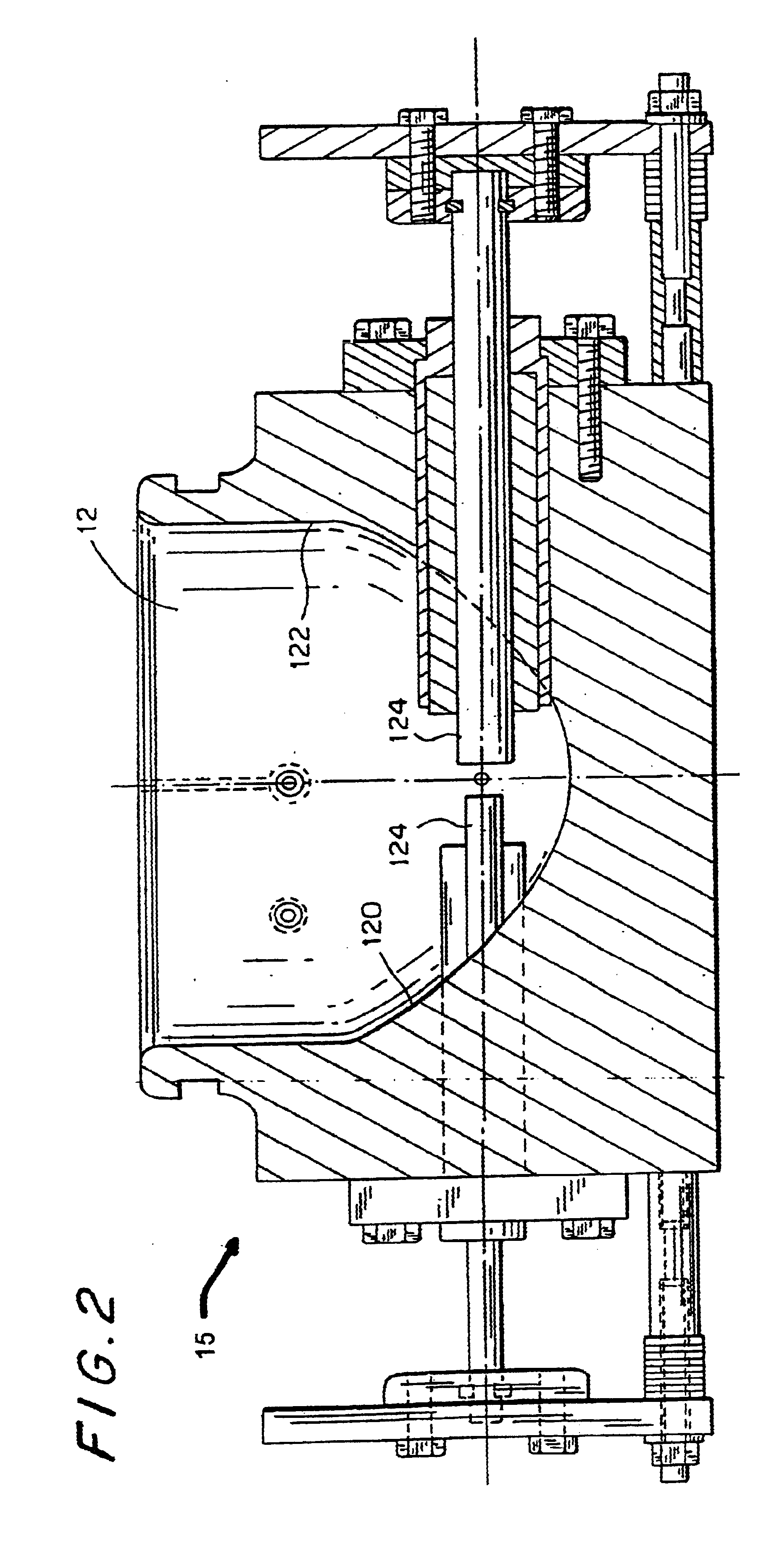

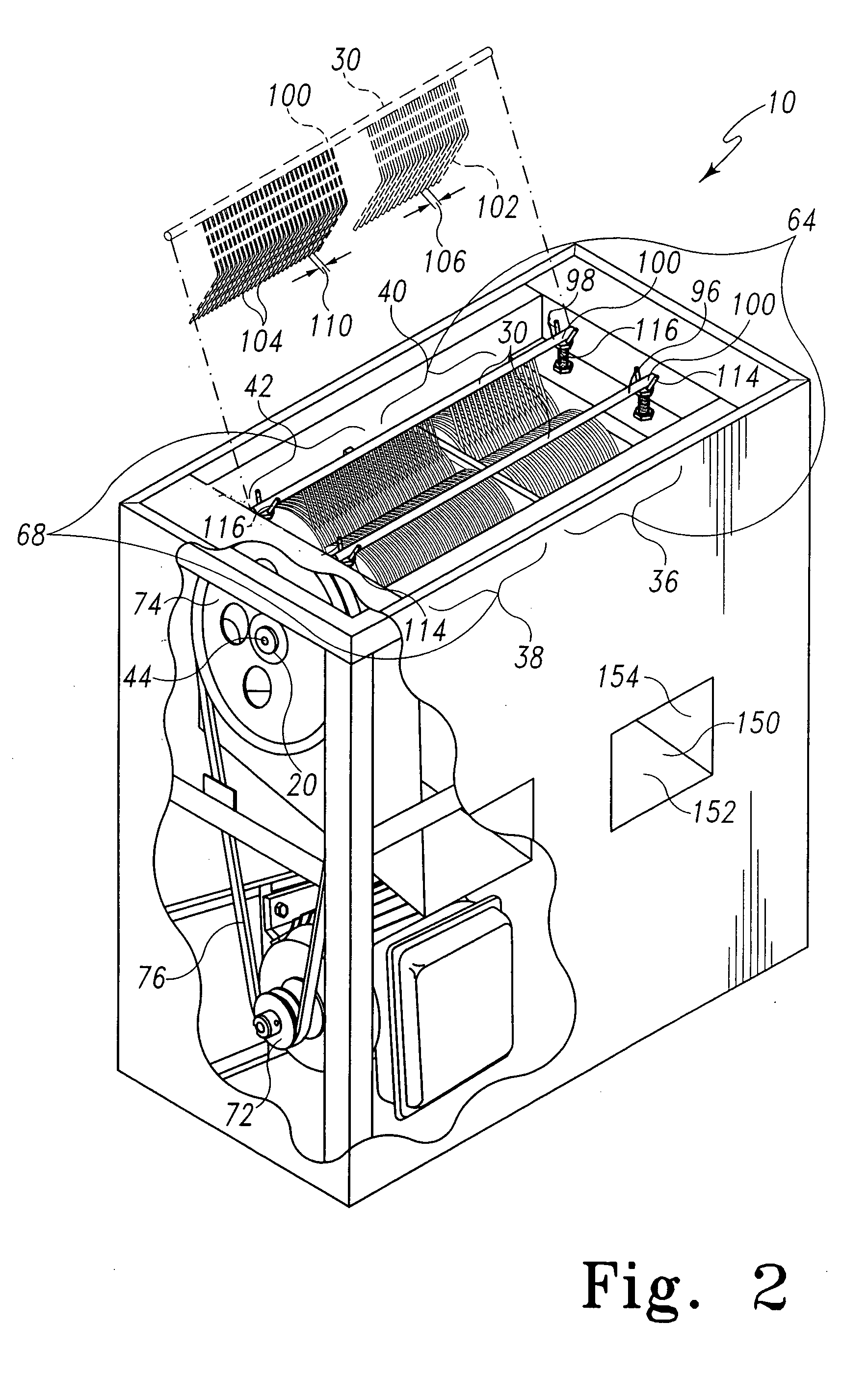

Meat cutting assembly

ActiveUS7682227B1Accurate and stable placementProhibiting and significantly reducing possibilityPoultry processingMeat tenderisingEngineeringMechanical engineering

A cutting assembly for cutting a meat or food product passing along a path of travel and comprising a blade roller having a plurality of blades transversely connected thereto in aligned relation to the path of travel. A mate roller, an in-feed roller and an out-feed roller interact with the plurality of blades to assure removal of meat portions from the blade and mate rollers during the cutting procedure. The mate roller comprises a plurality of mate roller sections each separated from one another by a first predetermined space and variably or adjustably positioned along the length of the mate roller by interaction with a stabilizing assembly to accommodate receipt of the blades within the first predetermined spaces during concurrent rotation of the blade and mate rollers. The cutting assembly may include a modular construction disposable within and removable from an operative position along a processing line associated with the path of travel.

Owner:BIFULCO PHIL

Processing method for high-quality marinated meat product

ActiveCN102068007AShortened tenderization timeImprove product qualityFood preparationMeat tenderisingFiberPermeation

The invention relates to a processing method for marinated meat products, which comprises the following steps of: selecting meat; trimming; cleaning; tenderizing by combining mechanical rolling and kneading with complex enzyme; heating for material permeation; cutting the meat into small blocks; drying the meat with hot wind; packing in vacuum; sterilizing at high temperature; cooling; and externally packaging. The processing method is characterized in that meat tissues become loose and crushed under the impact of external force generated by the mechanical rolling and kneading by adopting a tenderization technology combining mechanical rolling and kneading with complex enzyme; and meat muscle fibers are easy to act with the complex enzyme for enzymolysis, so that the combination of the mechanical rolling and kneading and the complex enzyme ensures that the tenderization time of the meat tissues is shortened to be 1 / 4-1 / 6 of the traditional tenderization time, the dosage of protease is 1 / 7 of the original dosage, the product quality is enhanced, and the marinated meat products have favorable tender taste.

Owner:广东正一品生物科技股份有限公司

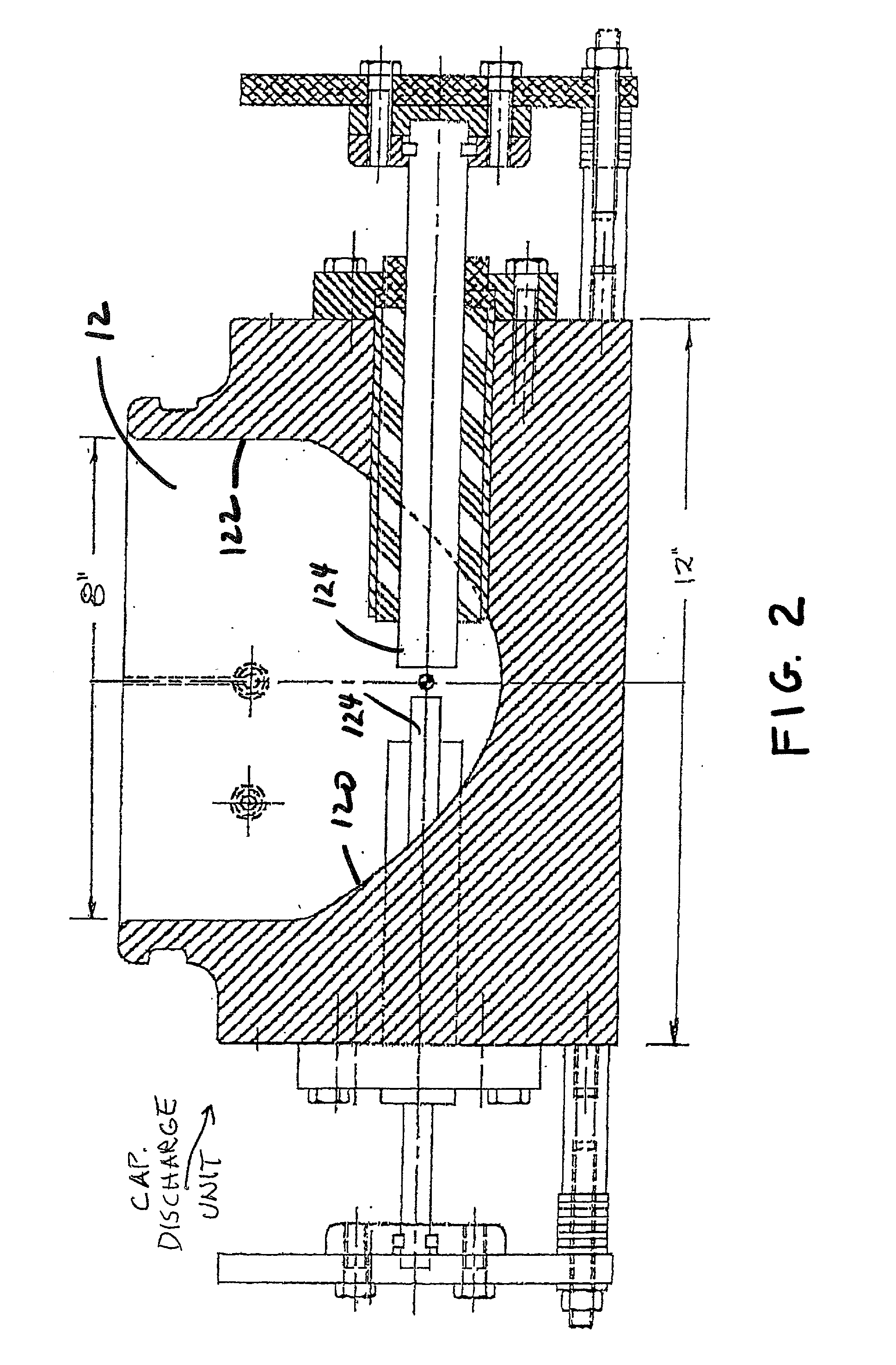

Shock-wave meat treatment

InactiveUS6669546B2Simple indexingPoultry processingMeat/fish preservation by irradiation/electric treatmentShock waveEngineering

Owner:HYDRODYNE INC

Vacuum roll kneading machine for food processing

ActiveCN106665780AImprove tumbling effectRoll quicklyMeat mixing apparatusMeat tenderisingEngineeringVacuum pump

The invention discloses a vacuum roll kneading machine for food processing. The vacuum roll kneading machine comprises a frame, a vacuum pump and a roll kneading drum. The vacuum pump is communicated with the roll kneading drum, a rotating shaft in a hollow structure is rotatably connected in the roll kneading drum, a plurality of slide barrels are arranged on the rotating shaft in the roll kneading drum, each roll kneading knife is provided with a plurality of through holes, the slide barrels are communicated with the through holes, and each roll kneading knife is slidably connected in the corresponding slide barrel. The rotating shaft outside the roll kneading drum is provided with a vent hole, an air cylinder is fixed to the rotating shaft and communicated with the vent hole, and a piston is arranged in the air cylinder and fixedly connected with a piston rod. A motor is arranged on the frame, a first gear meshed with a second gear is fixedly connected with an output shaft of the motor, the rotating shaft is fixedly connected to the second gear, and an eccentric gear is fixedly connected to the rotating shaft and abutted against the piston rod. Due to the hollow structure of the rotating shaft, the roll kneading knives continuously reciprocate to slide in the slide barrels in a continuous rotation process of the rotating shaft, a meat roll kneading effect is enhanced, and roll kneading efficiency is improved.

Owner:重庆汤嫂食品有限公司

Production method of fresh raw chicken willow tree and fresh raw product of the chicken willow tree

InactiveCN101455409AStrong tasteGreat tasteMeat/fish preservation by freezing/coolingFood preparationIce waterAnimal science

The invention discloses a fresh chicken fillet making method, which comprises the following steps: slitting the tenderloin chicken; mixing the tenderloin chicken, celery seeds and ice water according to the weight parts of: tenderloin chicken 85-90, celery seeds 3.2-7.4 and ice water 5-10; putting the mixture into a meat rolling machine; closing the meat rolling machine; vacuumizing the meat rolling machine to the vacuum degree of -2.0 to 1.0Pa; rolling and kneading the mixture by the meat rolling machine for at least 25 minutes in positive rotation and 25 minutes in counter rotation; cold-storing the mixture statically in the cold-storage room at 1-3 degrees centigrade for at least 15 hours; putting the mixture into a stainless steel disc, and quickly freezing it between -15 and 8 degrees centigrade; packaging and warehousing; storing in the cold storage at -18 degrees centigrade until distribution. The celery seeds in the invention can add special flavors to the chicken, enhance appetite, aid digestion and absorption and has good health function.

Owner:SHANDONG NEW HOPE LIUHE GROUP

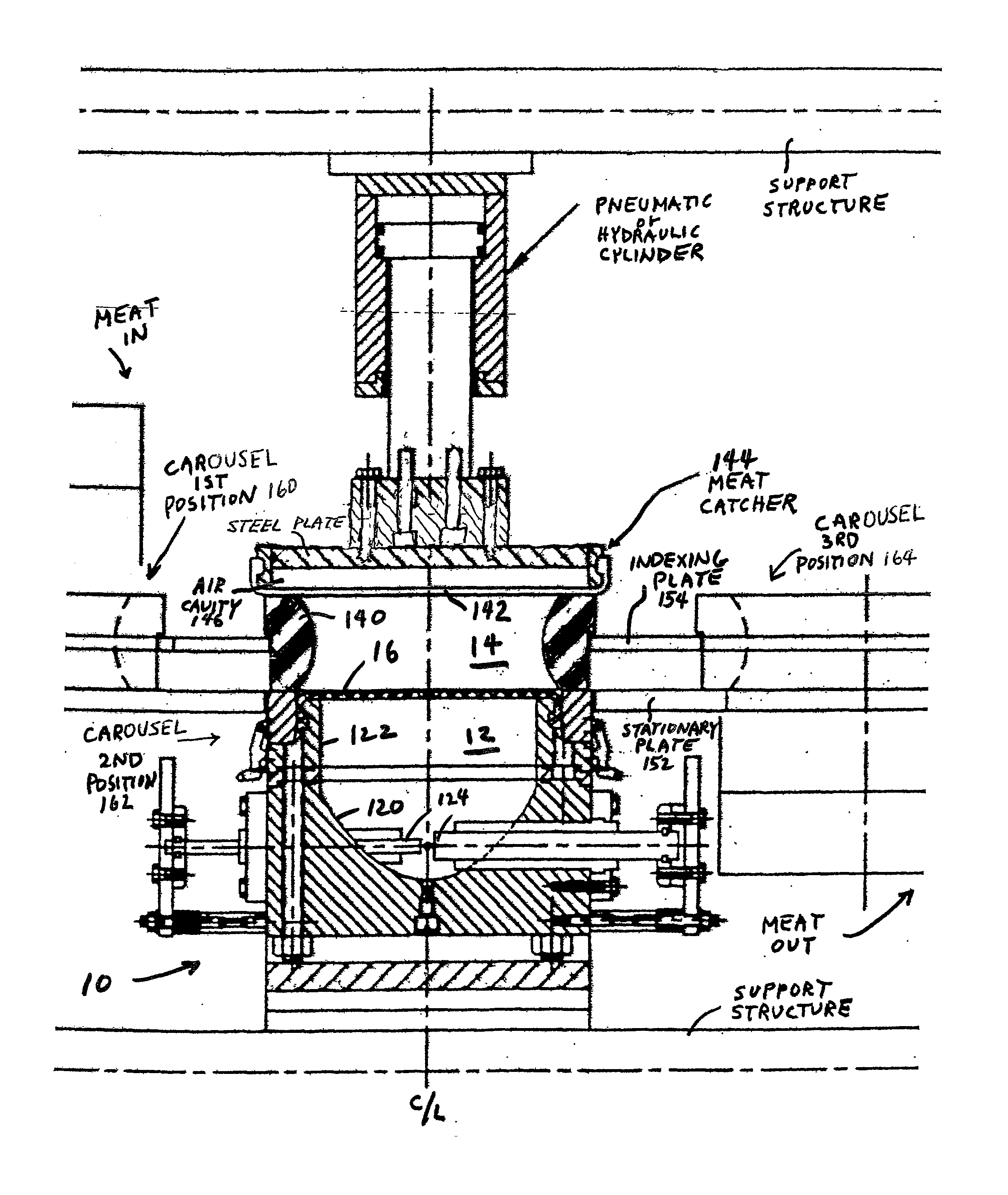

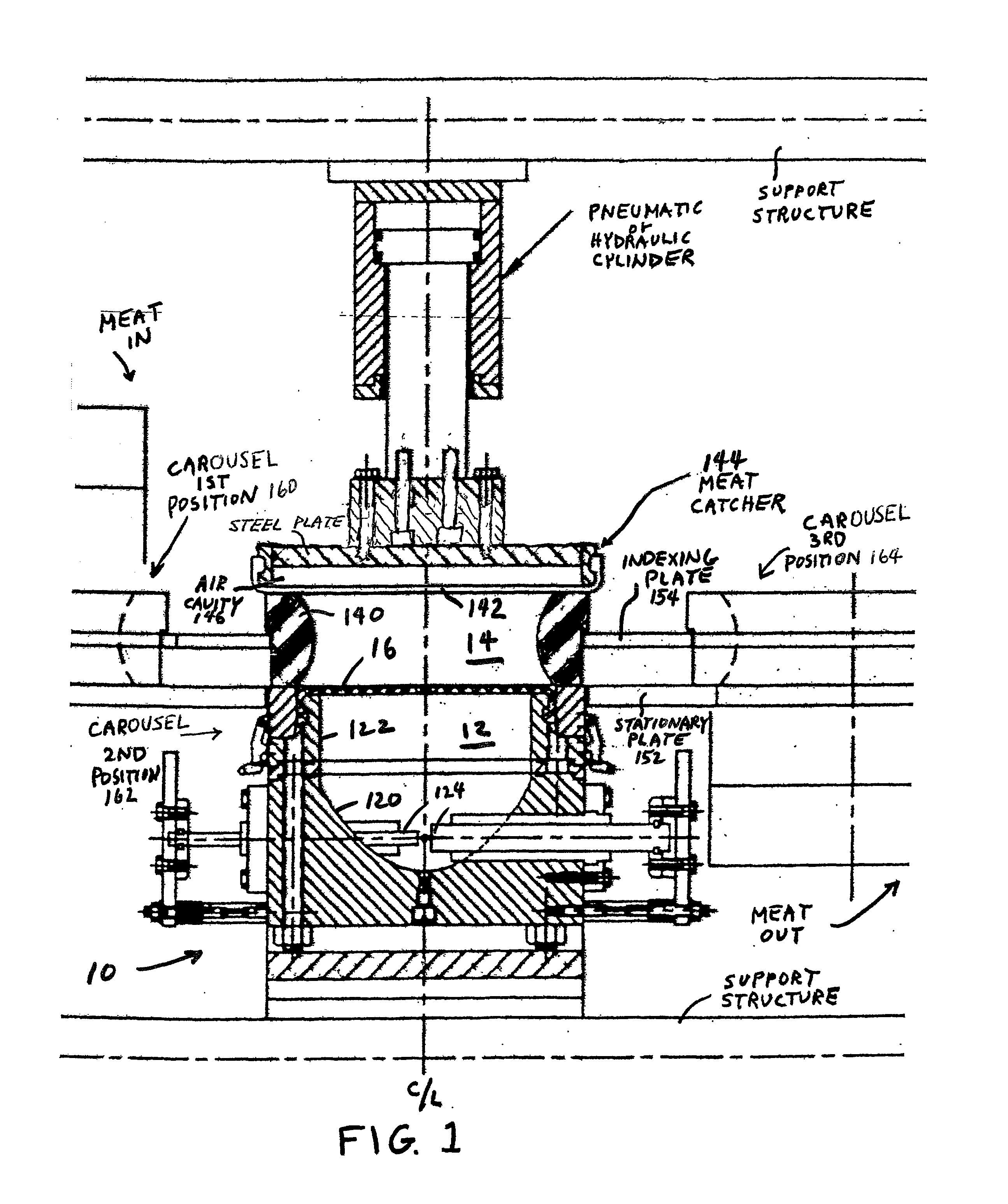

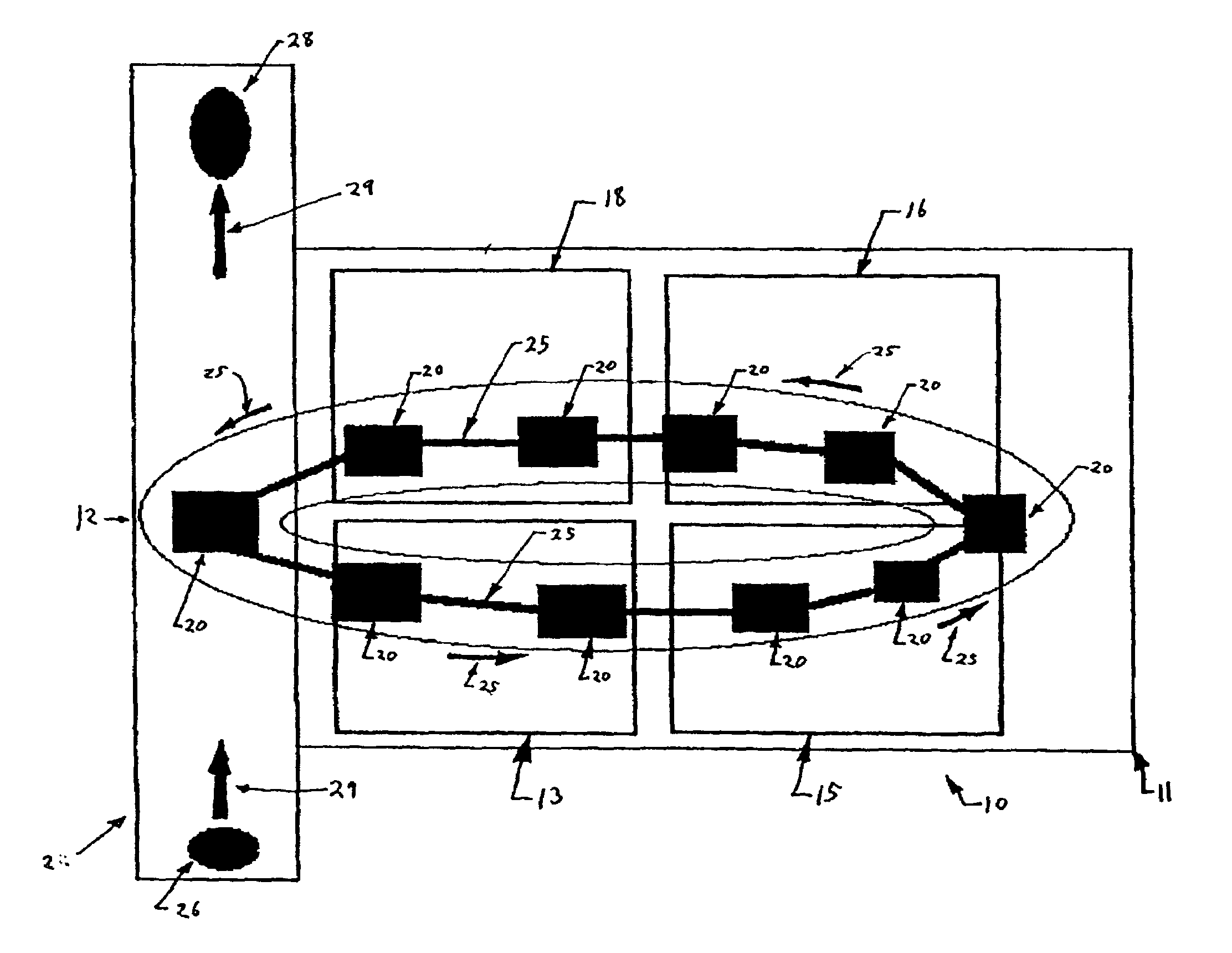

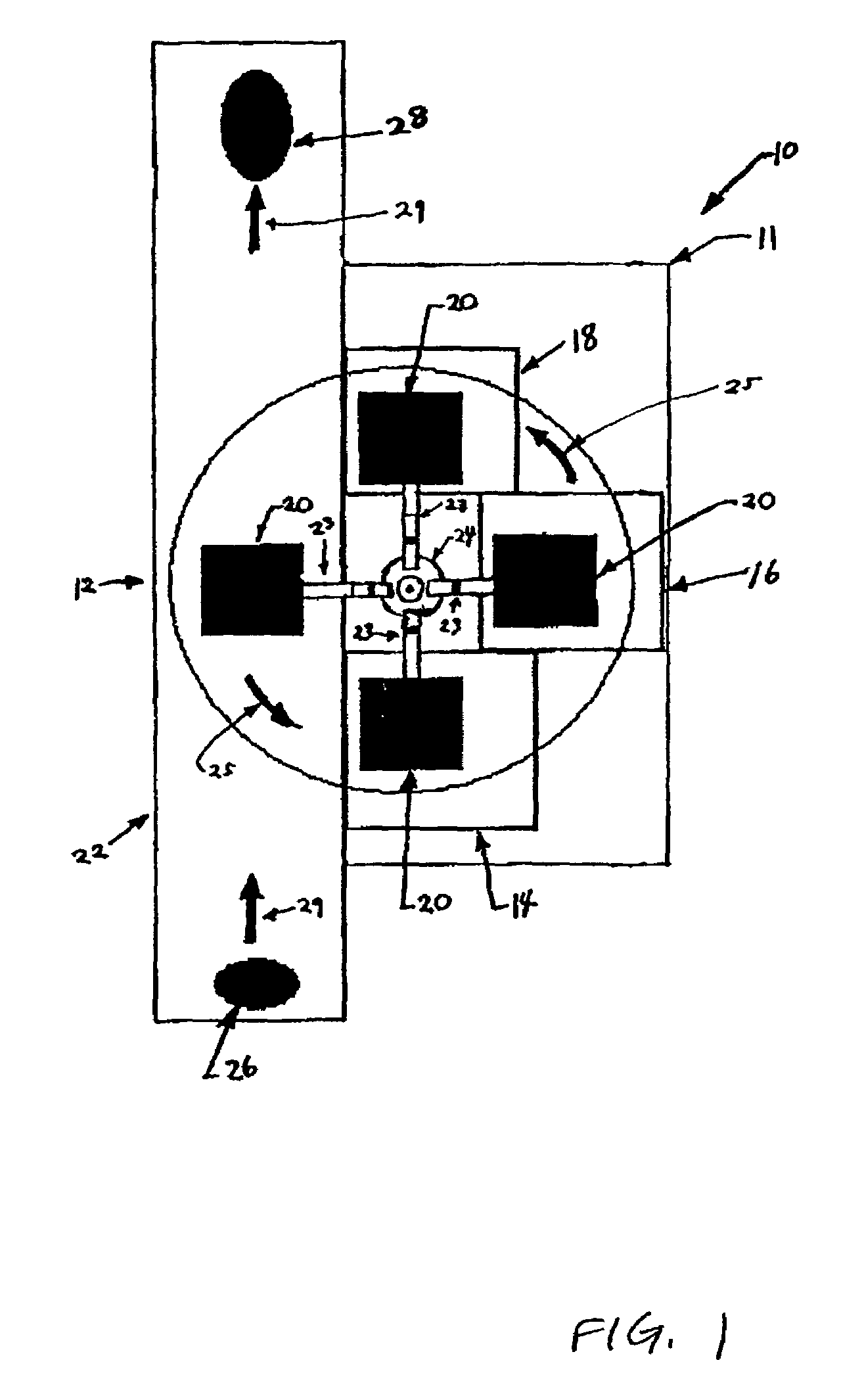

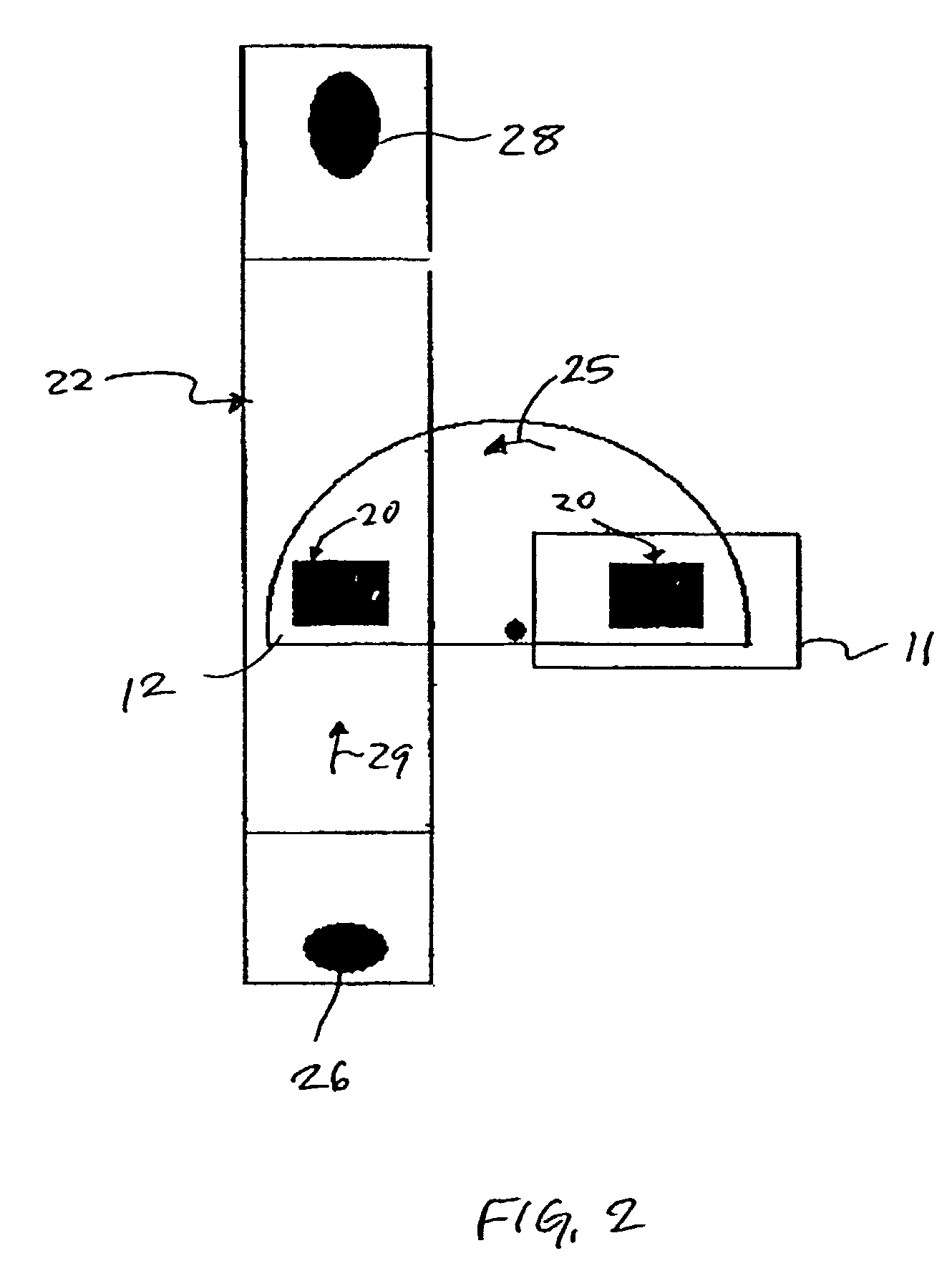

Shock-wave meat treatment

InactiveUS20020072318A1Simple indexingPoultry processingMeat/fish preservation by irradiation/electric treatmentShock waveEngineering

Improved tenderization of meat is achieved by using, individually or in combination, (1) a capacitor discharge chamber of shortened height; (2) a drum-head on which the meat sits during treatment and which is located at the upper end of the capacitor discharge chamber; (3) meat supporting structure which substantially holds the meat in place on the drum-head during capacitor discharge; (4) an indexing carousel for delivery the meat to a location above the capacitor discharge chamber and for transporting the treated meat to a discharge location; (5) an improved negative compression or rarefaction wave; and (6) the combination of shock wave treatment with other operations.

Owner:HYDRODYNE INC

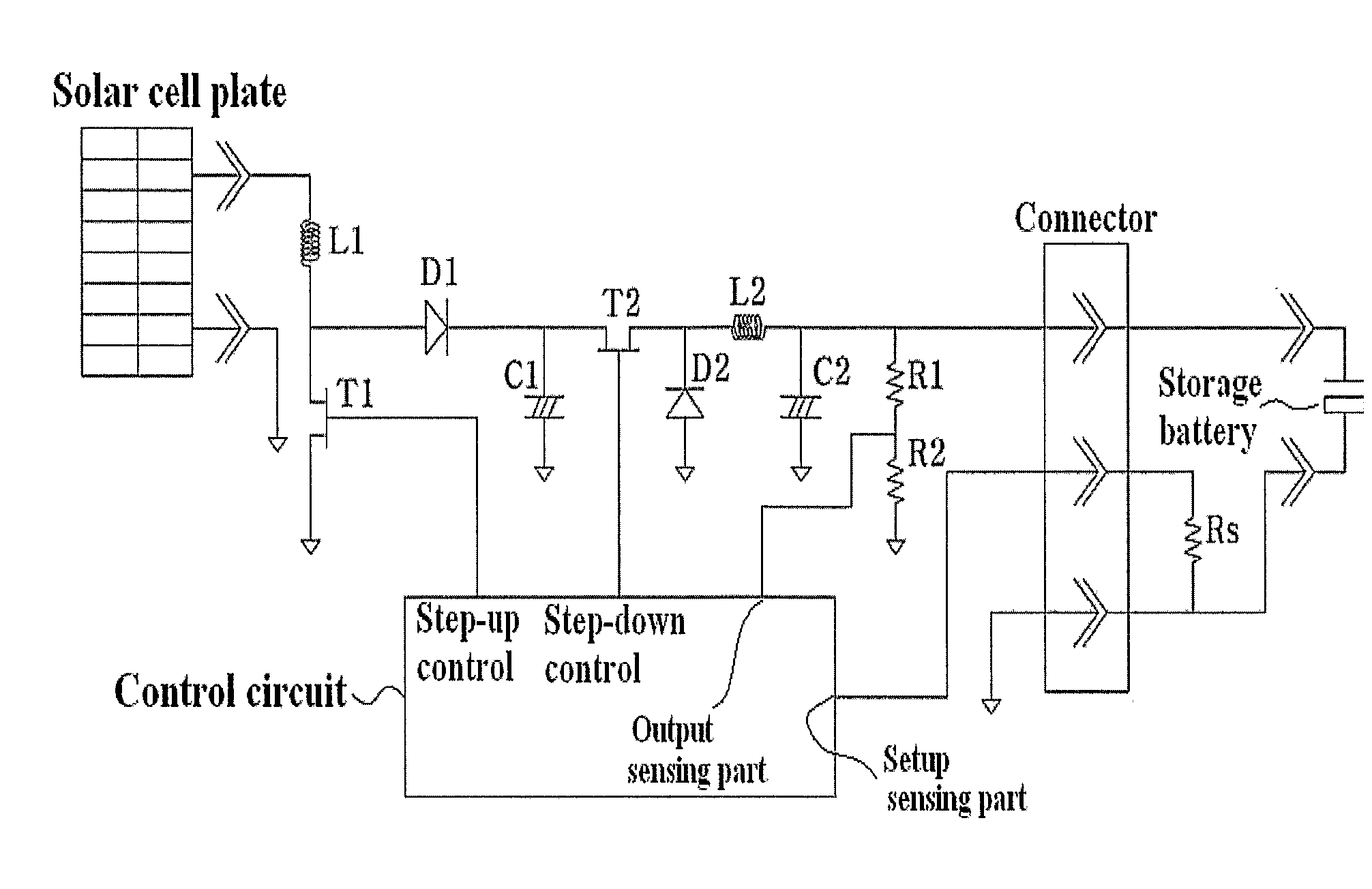

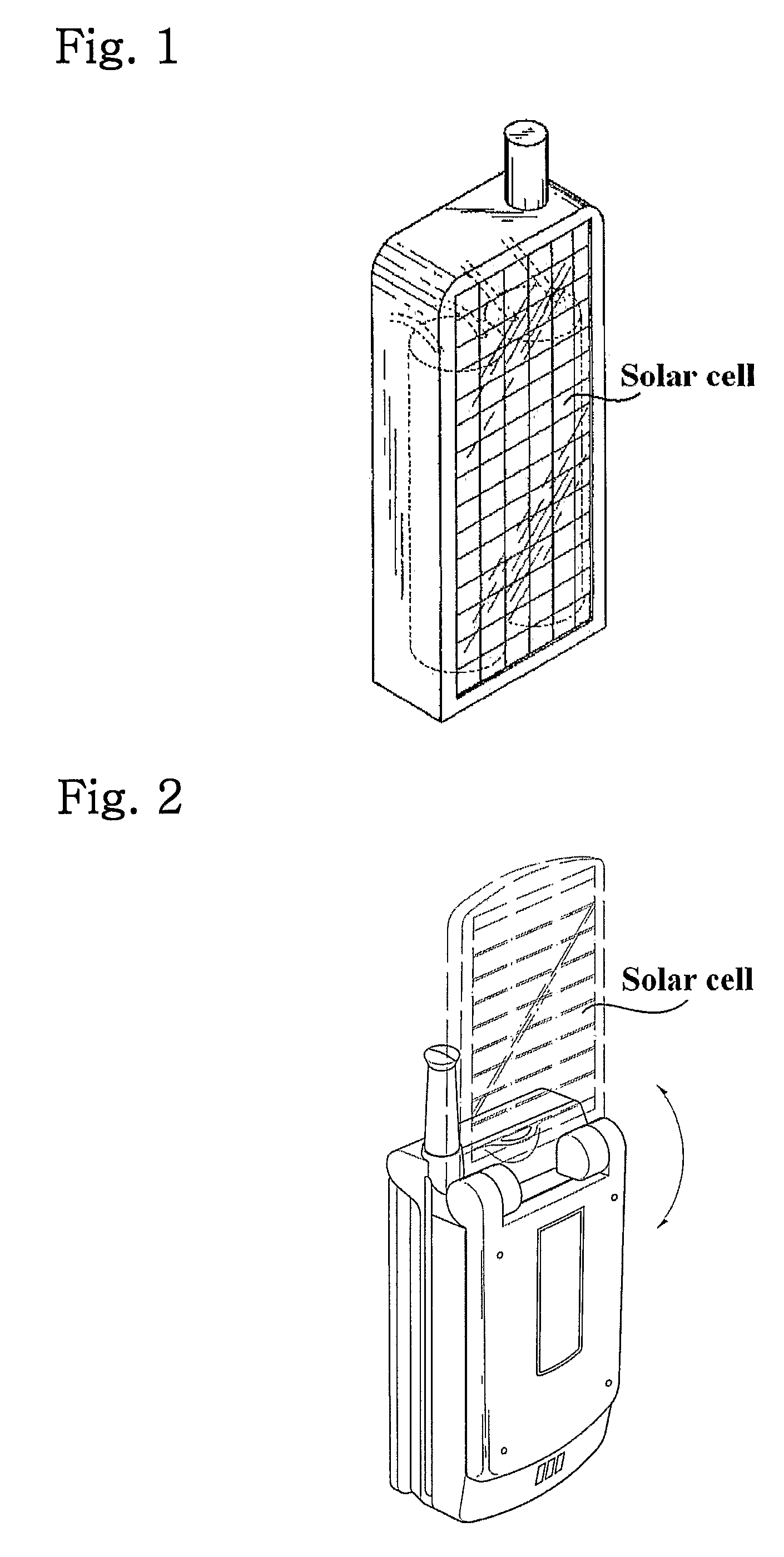

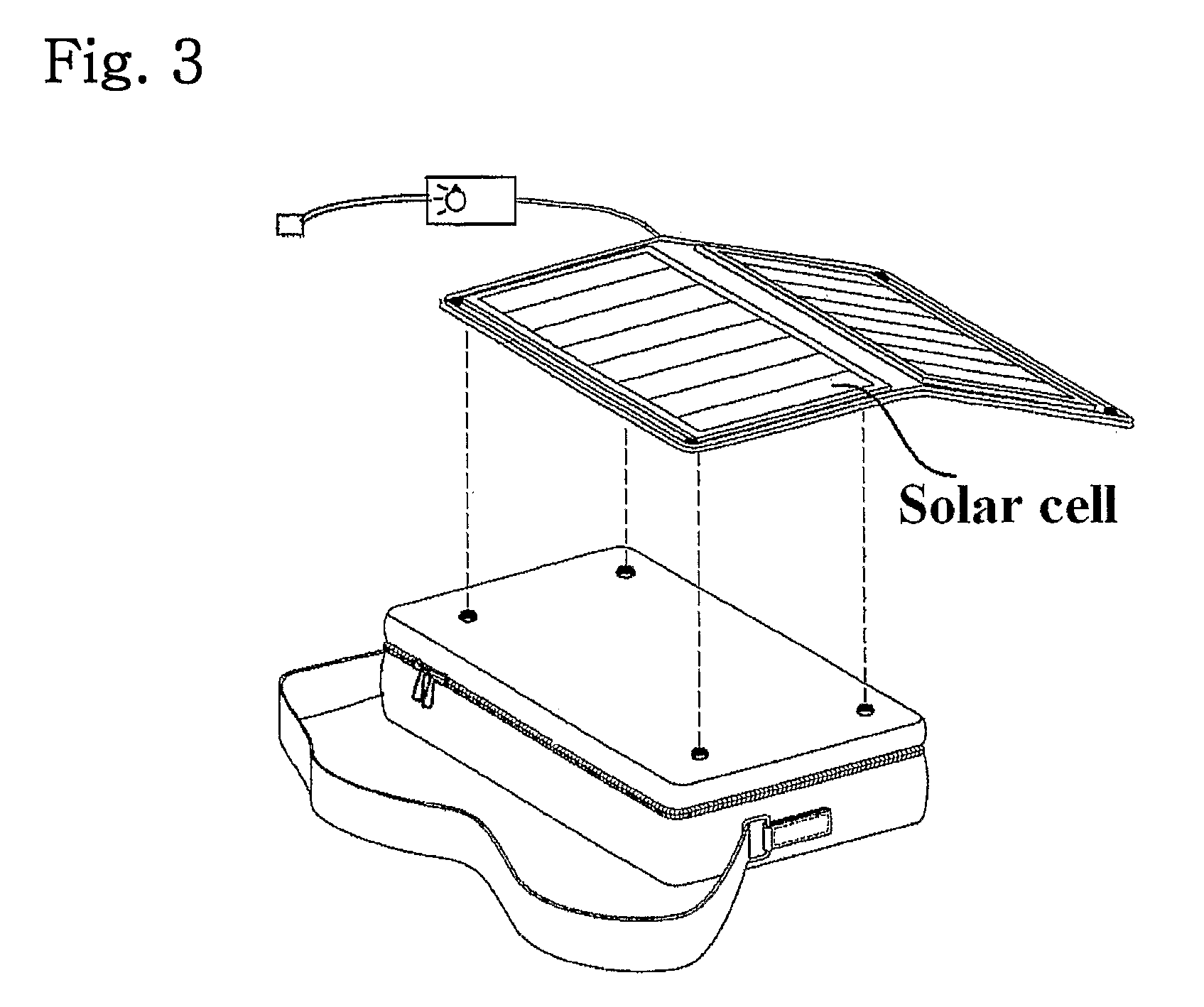

Method and device for recharging using portable multi-voltage solar cell

InactiveUS8008887B2Improve charge efficiencyReduce reflectionPhotovoltaic supportsBatteries circuit arrangementsElectrical batteryEngineering

Owner:SOLEITEC

Processed meat product or a fish paste product and method for producing the same

InactiveUS20070254066A1Reduce yieldWaster separationFood preparationMeat tenderisingFish pasteMuscle protein

The present invention provides a protein deamidating enzyme that is added to a food material containing muscle protein and acts on the same to produce high-quality foods.

Owner:AMANO ENZYME INC +1

Production process for cooling fresh-keeping beef

InactiveCN101263836AImprove securityImprove hygieneMeat/fish preservation by freezing/coolingMeat tenderisingEngineeringPre cooling

The invention discloses a method for producing the cooling fresh-keeping beeves, comprising slaughtering, bloodletting, peeling off the skin, removing the bowels, flushing by water after qualified inspection of the carcass, pre-cooling of the carcass, selecting the carcass with pH value between 5. 6 and 5.8 to split the meat from the bone, trimming, vacuuming and packing, heat immersing, storing in the temperature between -2 and 2 degree centigrade after cold immersing. The method for producing the cooling fresh-keeping beeves compared with the prior art has the advantages of having better performance of the produced beeves in safety, hygiene, and preservation time.

Owner:吉林省长春皓月清真肉业股份有限公司

Preservative tender beef and producing process thereof

InactiveCN1423973AExtended shelf lifeInhibition of reproductive growthFood preparationMeat tenderisingChemistryVacuum packing

A process for antistaling beef while making it tender includes such steps as low-temp removing acid at 0-4 deg.C, electric stimulating, spraying composite bacterial inhibitor, natural dripdrying, vacuum packing, instantaneous scalding for 2 seconds, and low-temp storing. Its advantages are high effect, long storage time (60 days), and low cost.

Owner:MILITARY SUPPLIES UNIV THE CHINESE PLA

Rotating head meat tenderizer

InactiveUS7011575B2Minimize cross-contaminationFood shapingPoultry processingEngineeringMeat tenderizer

A system for tenderizing meat that minimizes the probability of cross-contamination between successive pieces of meat product is disclosed. The apparatus includes at least one tenderizing head, a tenderizing station for supporting the meat product, and a treatment area where the tenderizing heads are cleaned and sanitized between operations on the meat product.

Owner:CARGILL INC +1

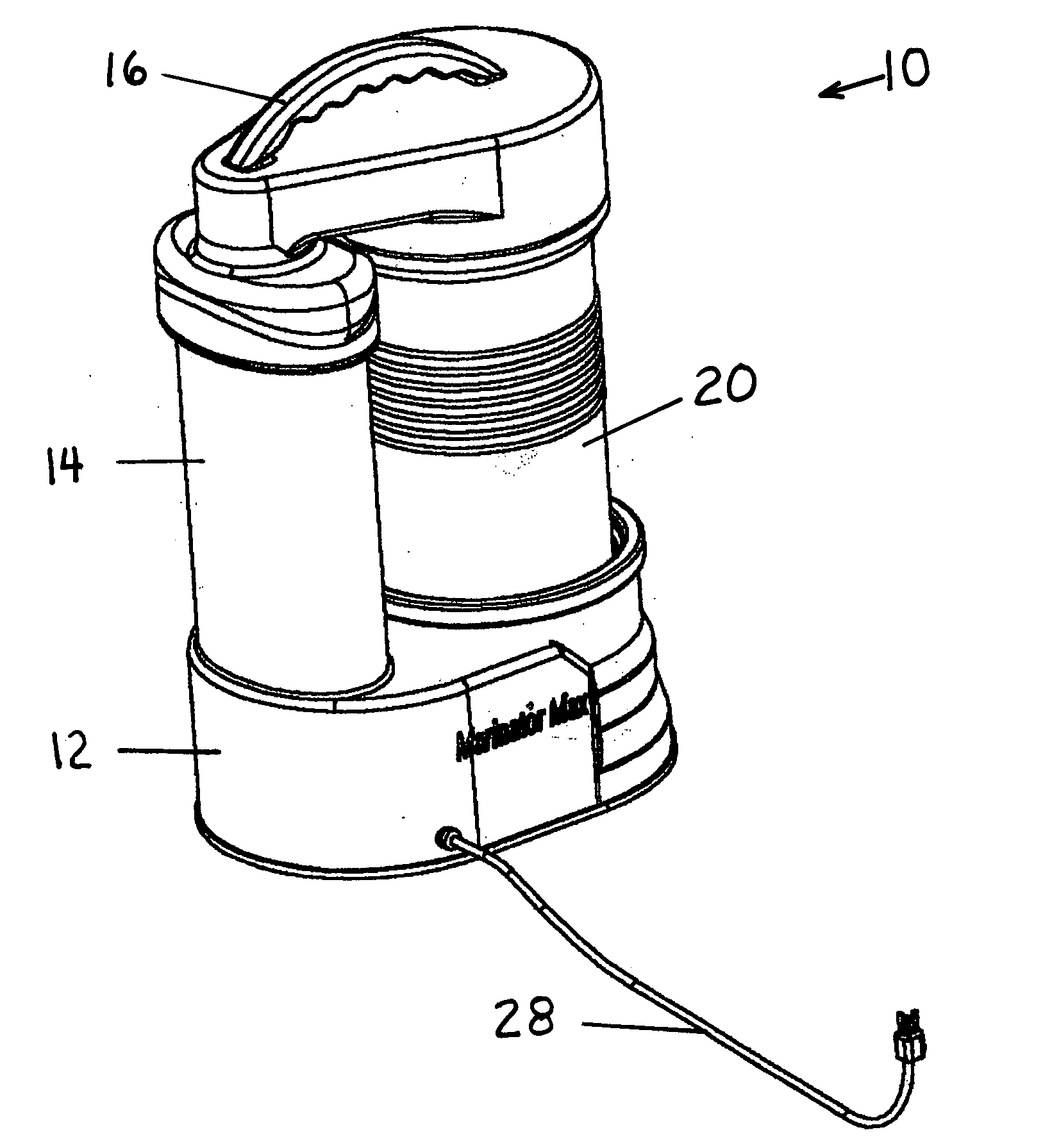

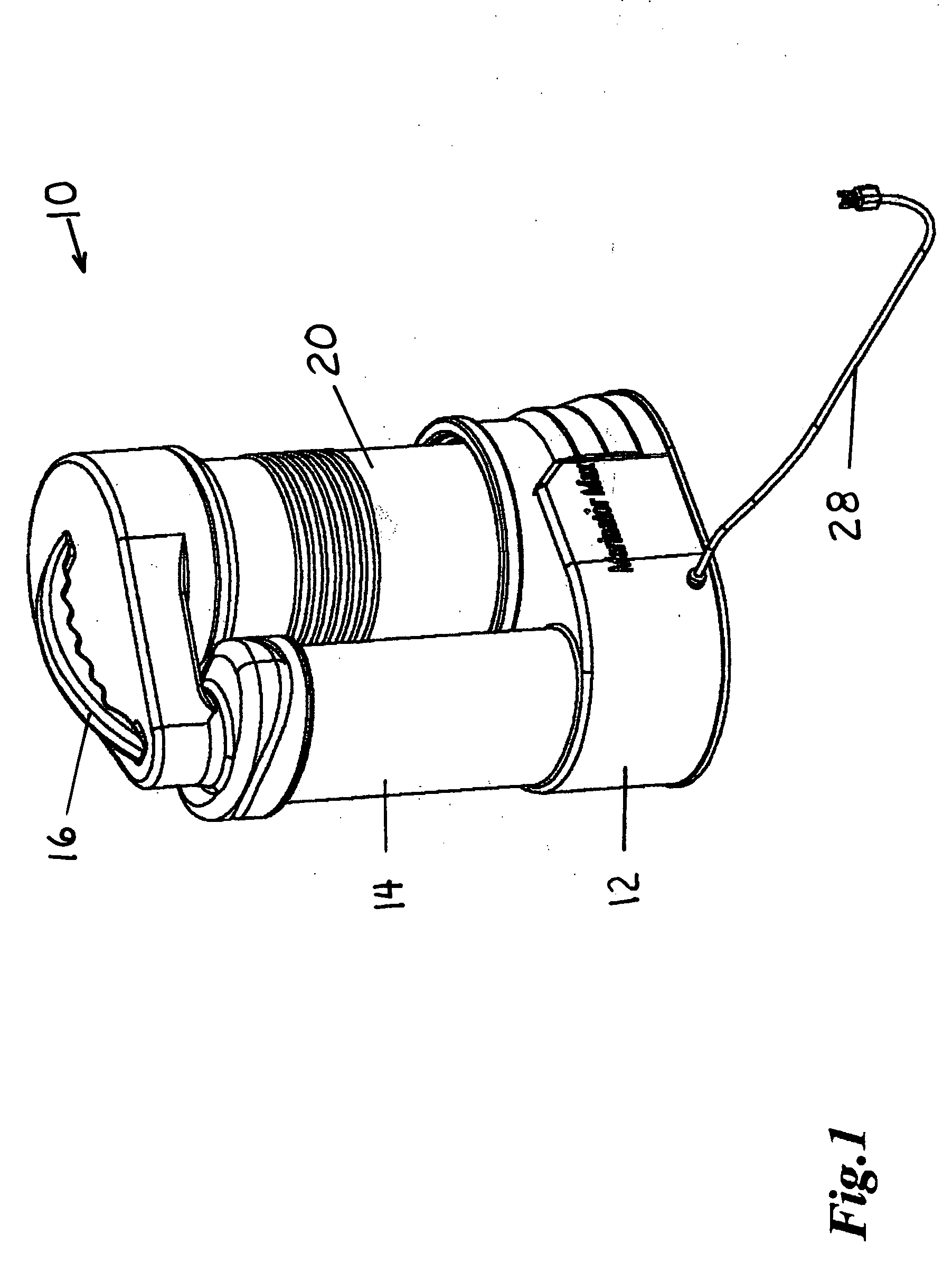

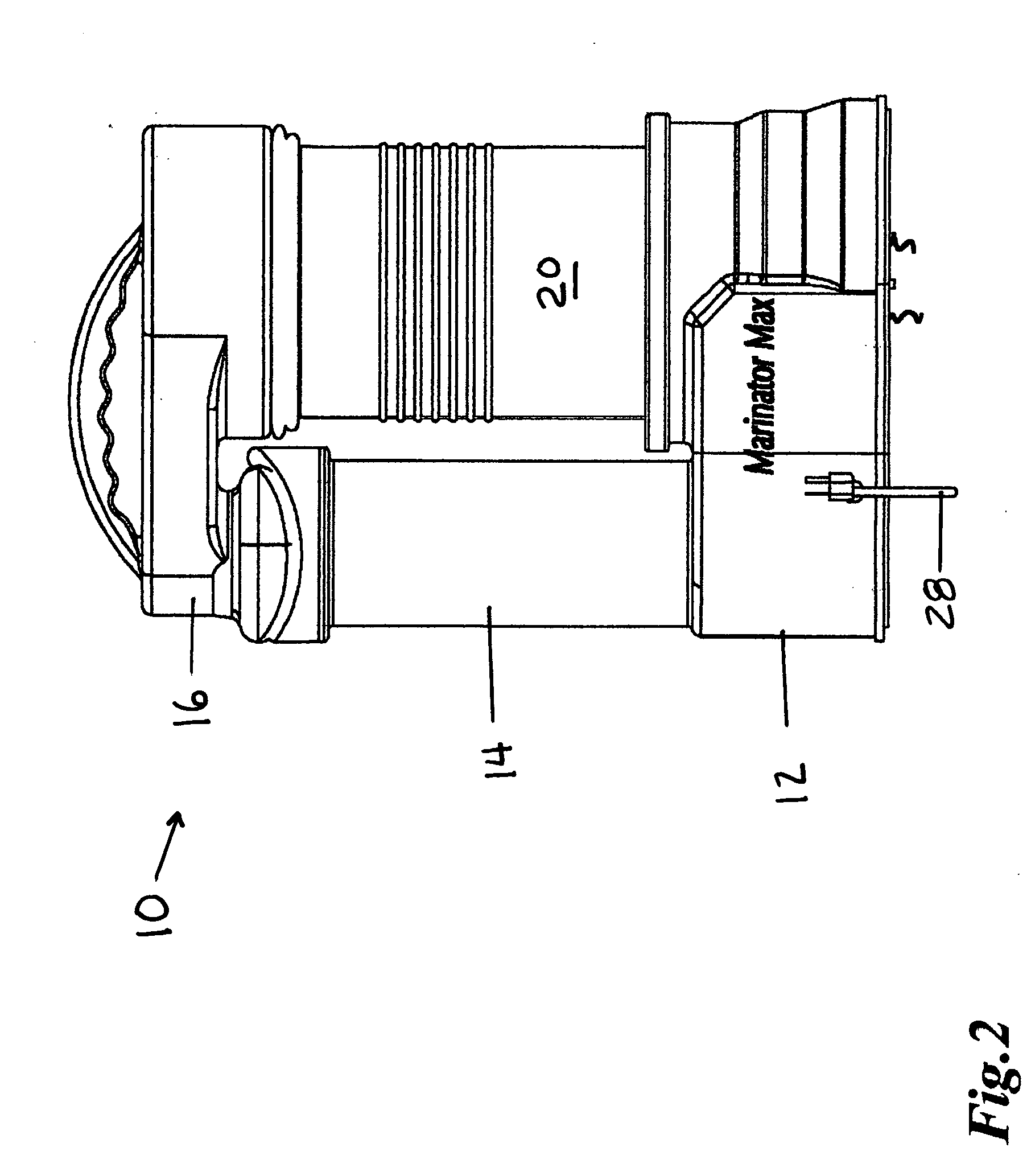

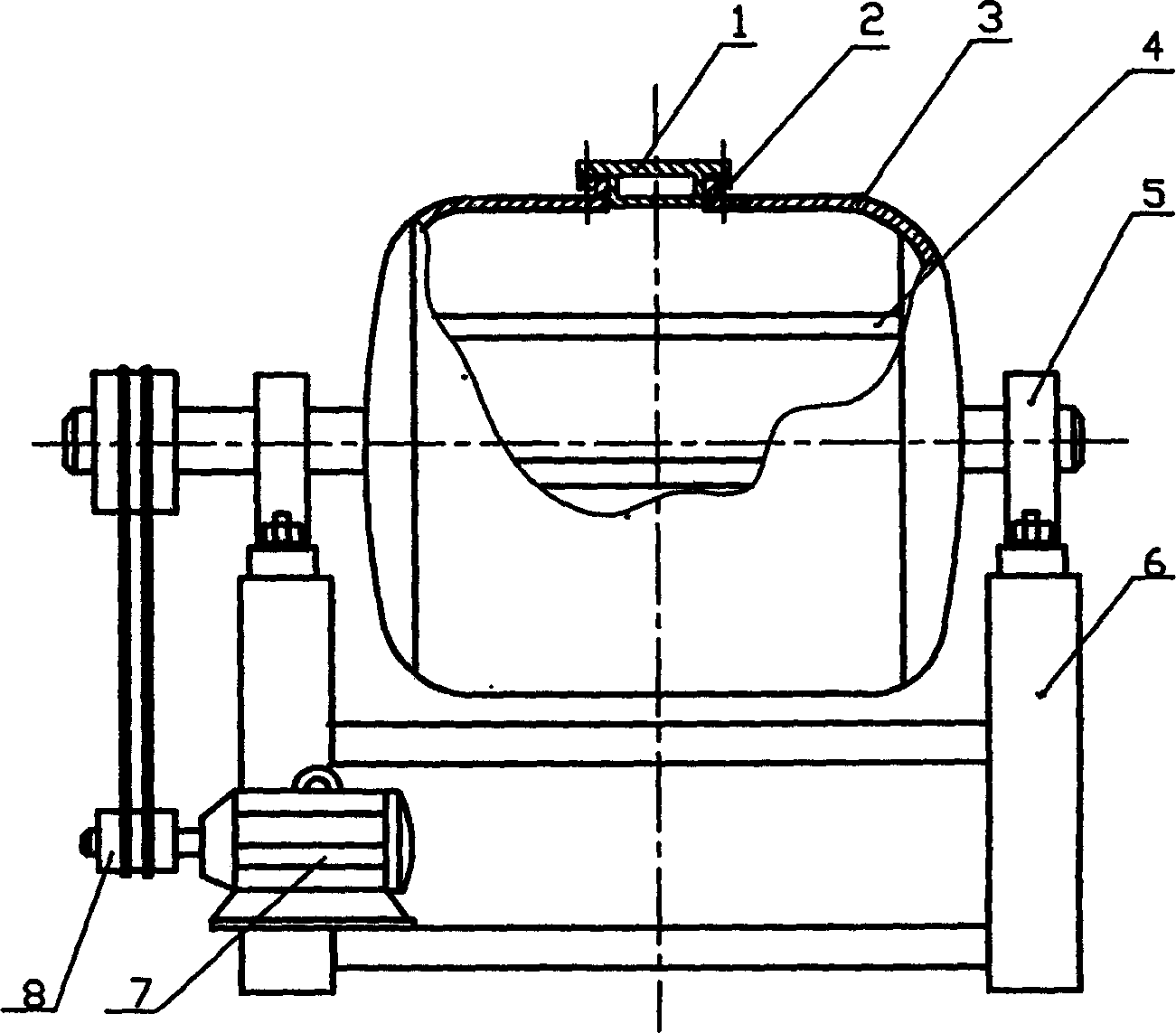

Apparatus for marinating foods

An electric food marinating apparatus capable of automatically marinating foods quicker and more effectively than traditional prior art methods by circulating chilled marinade in a closed loop circuit. A removable marinating vessel for containing food is adapted for continuous rotation about a vertical axis. The marinating vessel defines a generally open top and a bottom defining a strainer outlet in communication a marinade reservoir for receiving marinade in a closed loop flow path. An electric motor has an output shaft connected to the marinade reservoir to rotate the marinating vessel. A peristaltic pump housed within the base is configured with an inlet in fluid communication with the marinade reservoir and a spray outlet disposed proximal the top of the rotating marinating vessel. A thermoelectric cooler is provided for cooling the marinade.

Owner:FRANCIS BENITA +1

Duck ham and preparation method thereof

The invention provides a duck ham and a preparation method thereof, which can overcome the defect that the duck food is single in the prior art. The invention adopts a technical scheme that: the duck ham comprises the following components in percentage by weight: 79 to 97 percent of duck and 3 to 12 percent of auxiliary seasonings. The duck ham product has the advantages of glossy and golden yellow surface, light smoky flavor, plump appearance, spicy and tender mouthfeel, tight section and marbled meat. A novel duck ham is created so as to expand the approach of duck into novel meat food and increase the income of farmers who breed ducks.

Owner:平度波尼亚食品有限公司

Method for processing animal minced meat

The invention discloses a method for processing animal minced meat, which comprises the steps of: adding auxiliary materials such as protein, meat adhesives, compound phosphate, seasoning and the like into the minced meat, performing processes of vacuum tumbling, salting, stirring and the like for forming through finishing, and applying a certain pressure to form a structure similar to one-piece meat through refrigeration. After being cutting into slices, meat products produced by the processing method are good in flakiness and elastic, can be kept perfect integrity after being cooked, are tender and smooth in mouthfeel through long-term cooking, can be used for cooking of instant boiling, roasting, stir-frying and the like and production of other meat products, and improves the utilization factor and additional value of the minced meat.

Owner:青岛康大食品有限公司

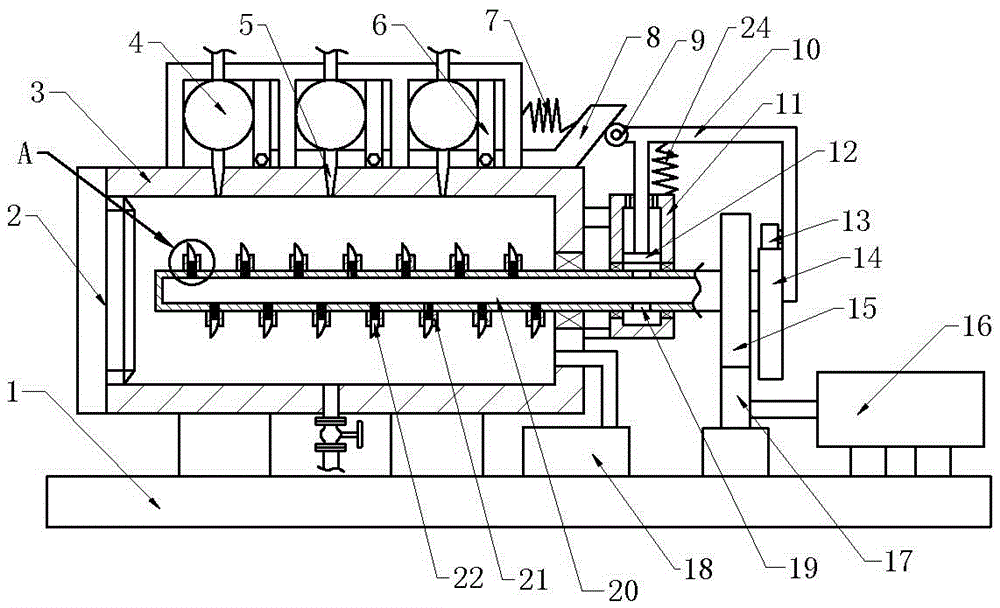

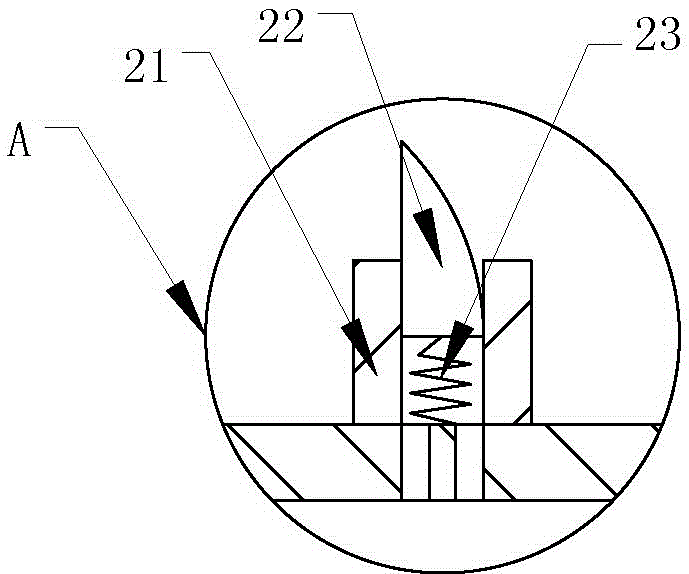

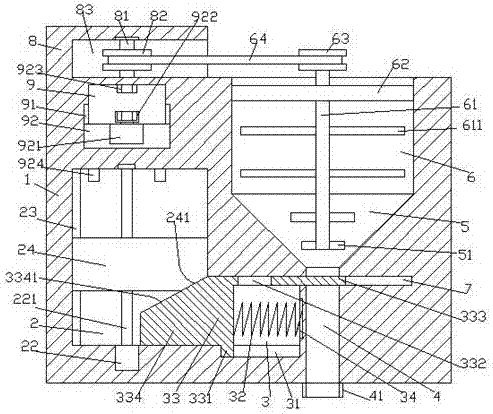

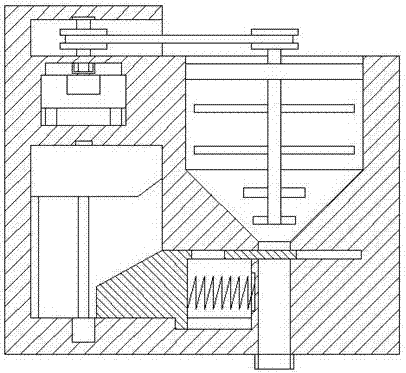

A processing device

ActiveCN106857768ARealize automatic reset workLimit activity locationMeat tenderisingAutomatic controlMechanical engineering

A processing device is disclosed. The device includes a machine body. The inside of the left side of the machine body is provided with a first sliding cavity. The left side inner wall of the first sliding cavity is provided with a first guiding and conveying slot. A second sliding cavity communicated with the first sliding cavity is disposed in the machine body at the right side of the first sliding cavity. A discharging passage extending up and down is disposed in the machine body at the right side of the second sliding cavity. The top of the second sliding cavity is provided with a separating slot penetrating the discharging passage and extending to the right side. The top of the discharging passage is provided with a hopper. The top of the hopper is provided with a stirring part. A third sliding cavity is disposed in the machine body above the first sliding cavity. Left and right inner walls of the third sliding cavity are provided with third guiding and conveying slots symmetrically. A stud is disposed in the first sliding cavity. The bottom of the stud is connected to a first motor. The stud is in threaded connection with a touching and pressing block. The device is simple in structure, reasonable in design, simple to operate and capable of automatically controlling stirring and material discharging, has a reminding function, and is capable of reducing labor of workers, increasing the working efficiency, making stirring effects good and making food safety high.

Owner:扬州市舜意机械有限公司

Energy-saving and effect-enhancing type rolling and kneading machine

InactiveCN1559233AUniform structureStructural symmetryMeat tenderisingEngineeringMechanical engineering

An energy-saving rolling and kneading machine has a drum body with feeding opening, a cover of said opening, and the material kneading plates in said drum body. Its advantages are high volume and high stability.

Owner:刘长雁

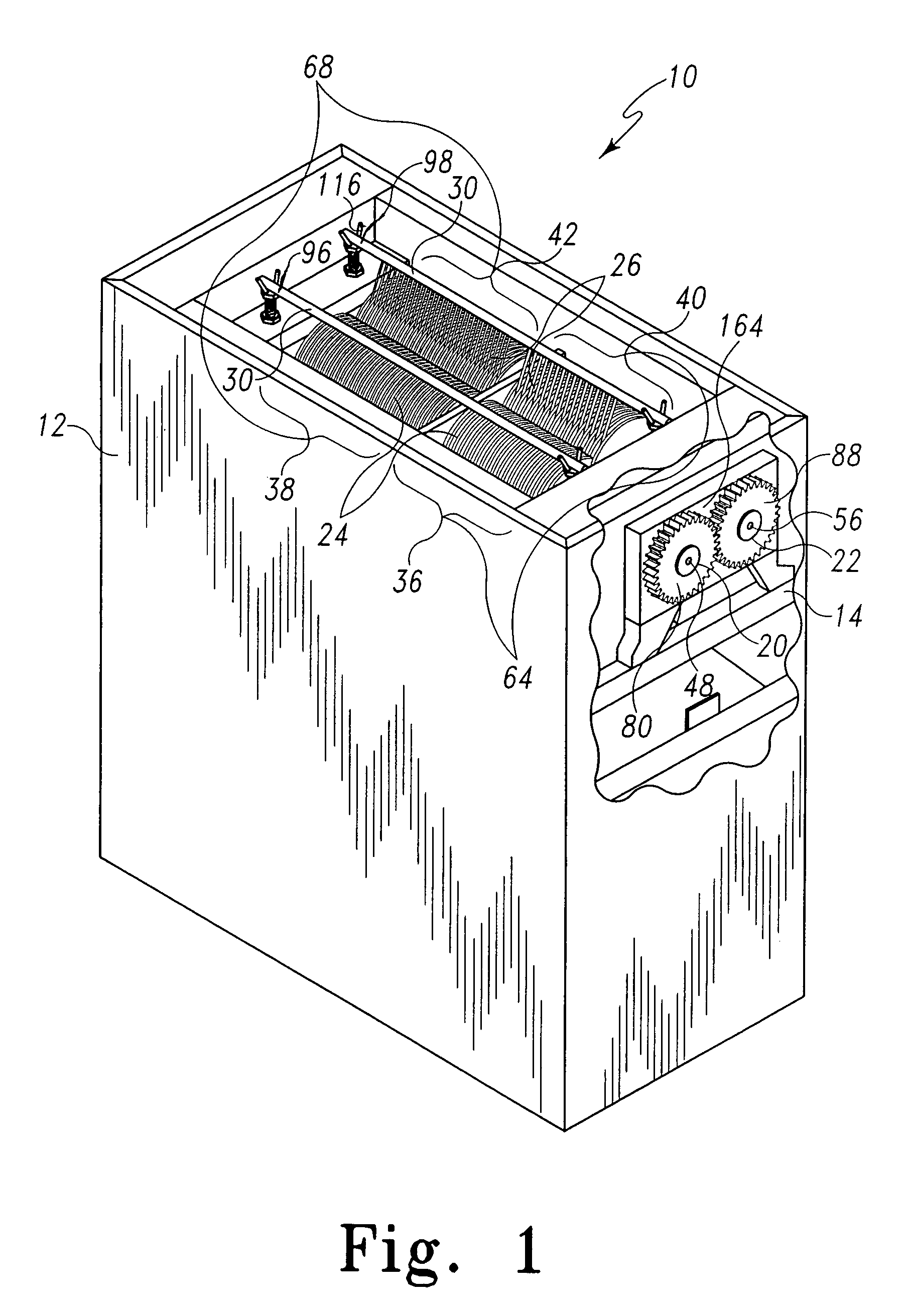

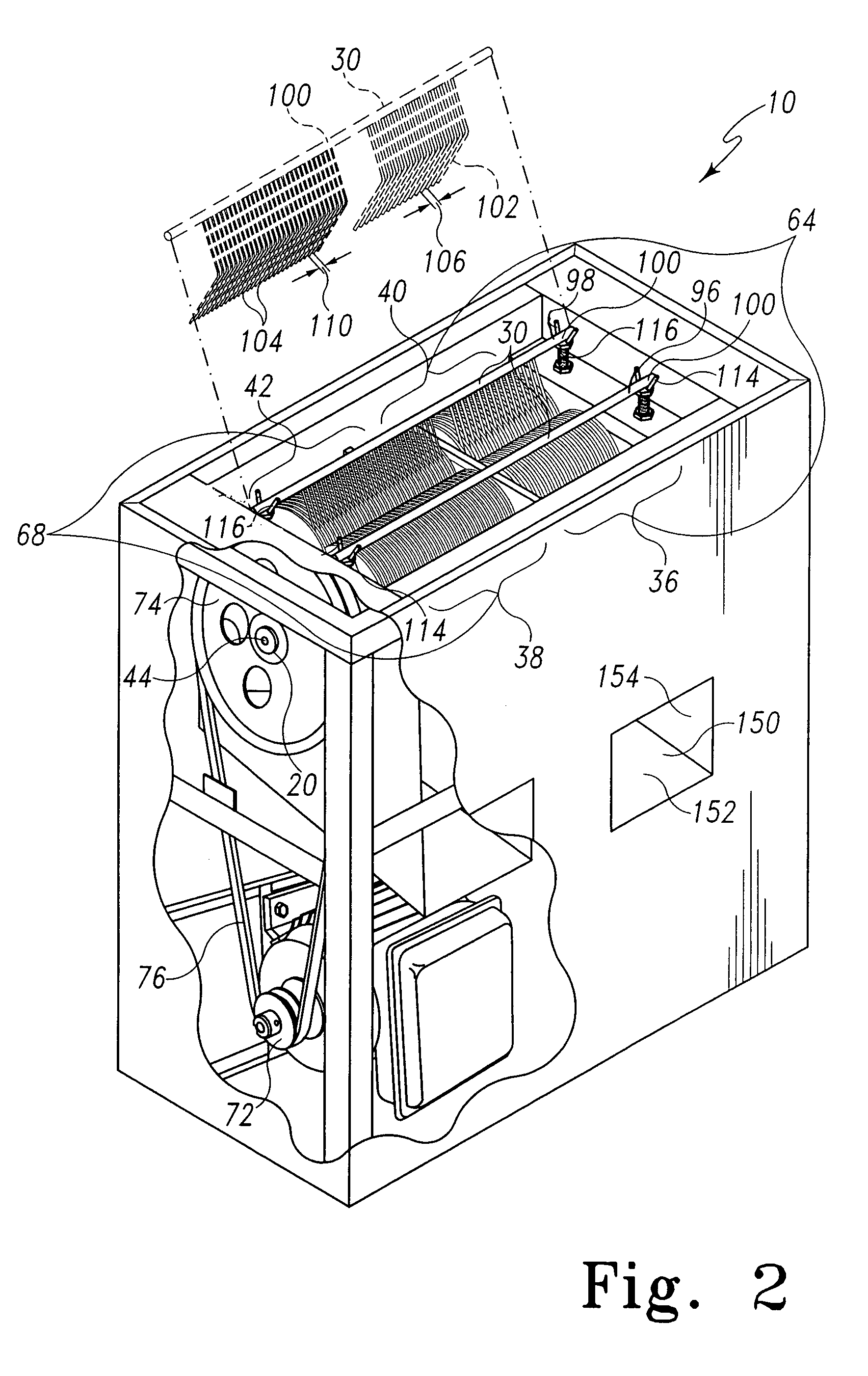

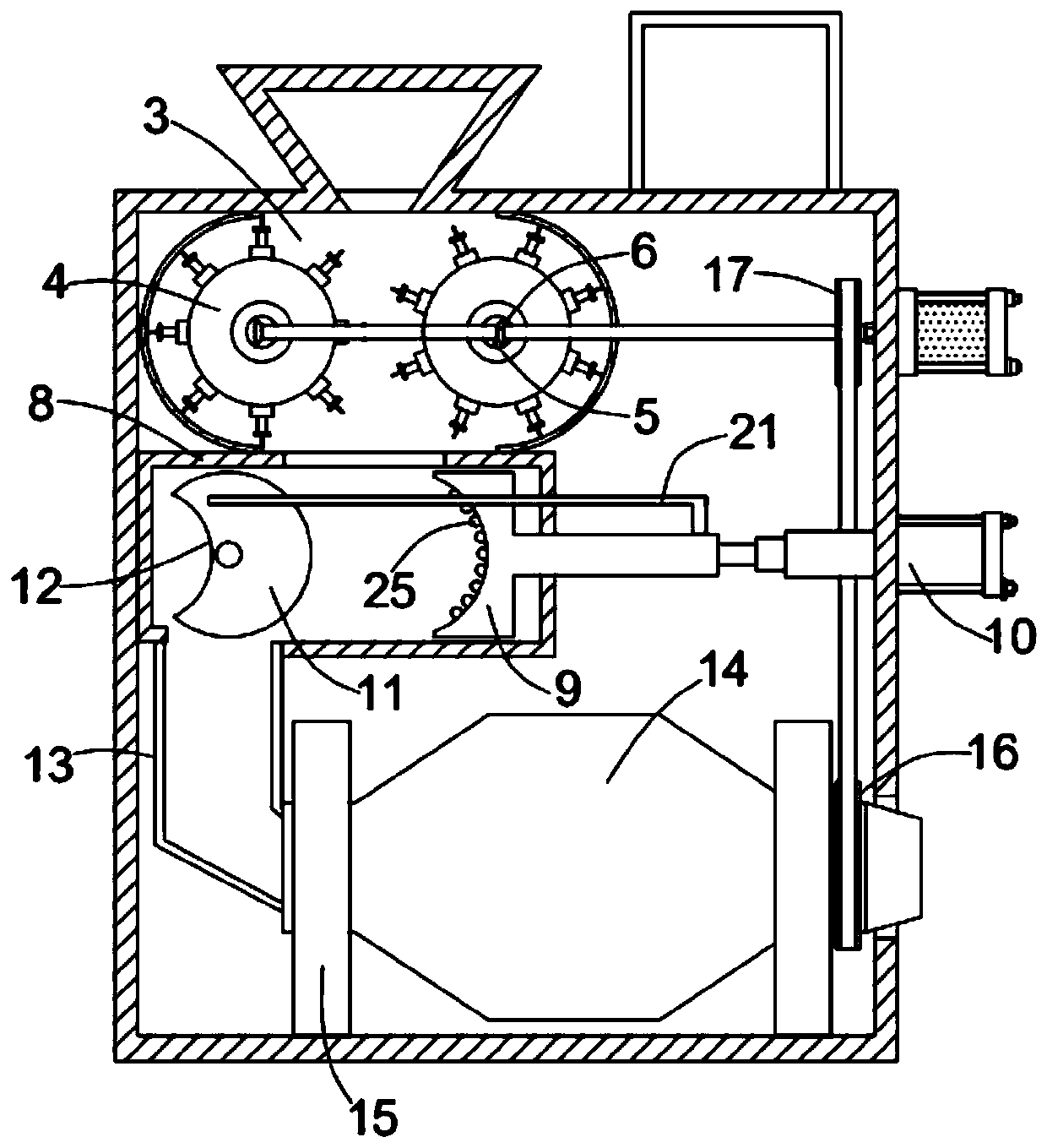

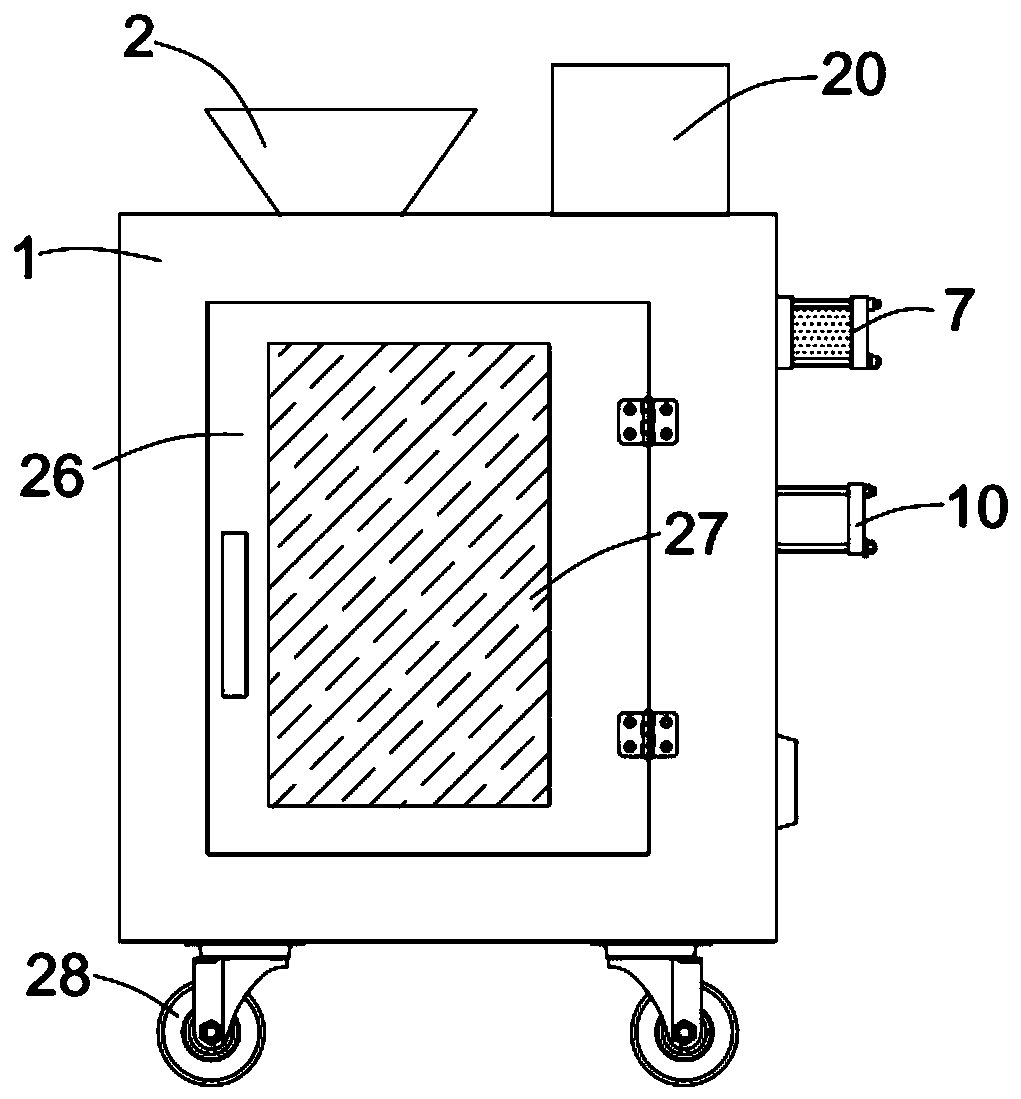

Pork kneading-salting device

The invention discloses a pork kneading-salting device. The device comprises a box body, a pair of injection rollers are movably arranged in an injection chamber, a kneading pressing plate is movablyarranged in a kneading pressing chamber, the kneading pressing plate and a kneading pressing rotating plate are cooperatively connected, the two injection rollers are of hollow structures, the top endof a pressing pump is fixedly provided with an injection needle, one end, away from the kneading pressing plate, of a telescopic connecting rod is fixedly provided with a rack, the rack and a drivingwheel of an irregular gear mechanism are engaged, a driven shaft of the irregular gear mechanism is also fixedly connected with a driving wheel of an intermittent moving mechanism, and a wheel shaftof a driven wheel of the intermittent moving mechanism is fixedly connected with the kneading pressing rotating plate; the device can not only make fresh meat be turned over during the salting process, but also knead and press a meat product, make the taste of a salted product uniform inside and outside by injectingsalting liquid into the meat product in cooperation with an external salting material which is smeared in advance, and make the salting even, thereby ensuring the taste of the salted meat product.

Owner:BENGBU COLLEGE

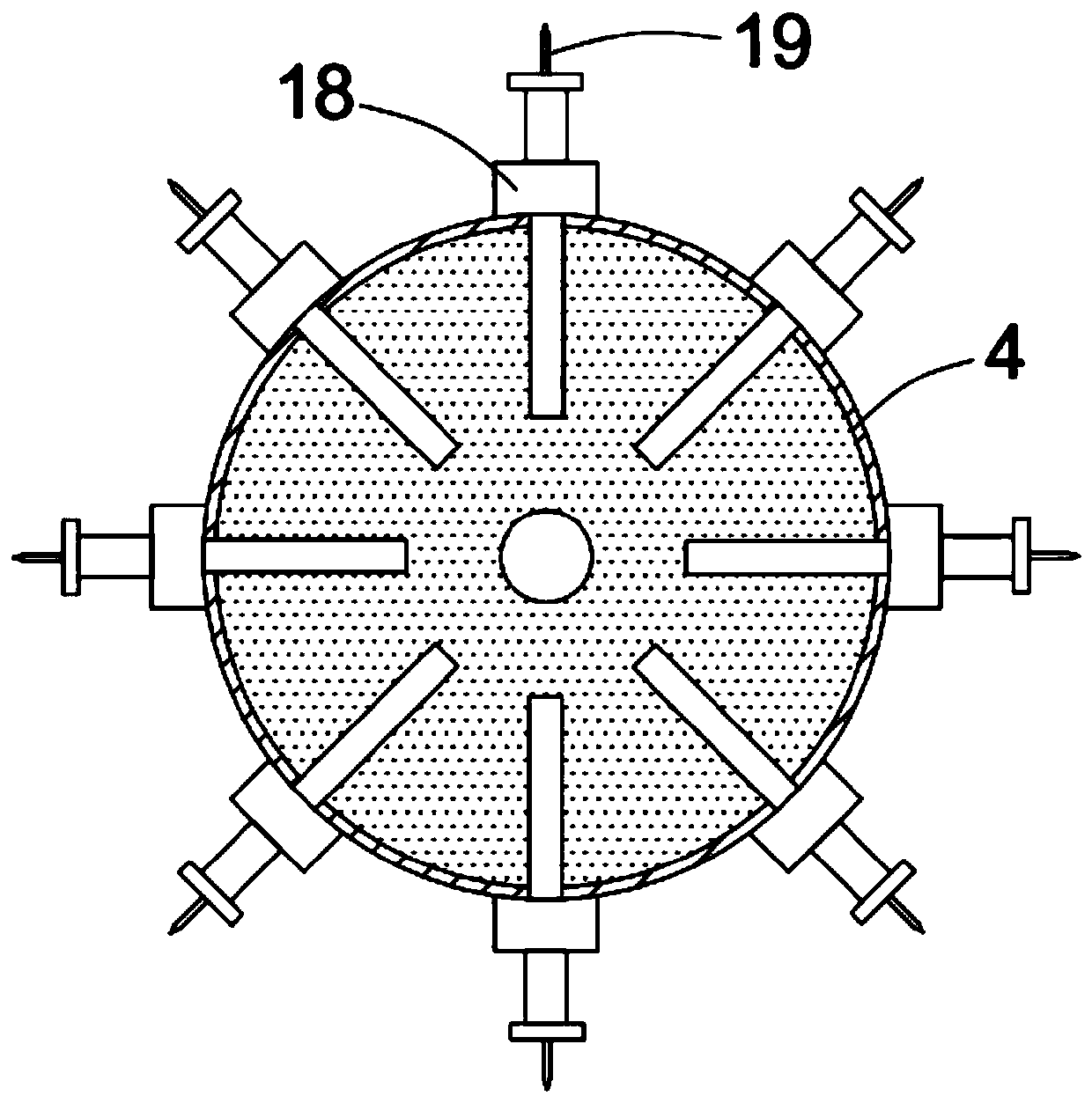

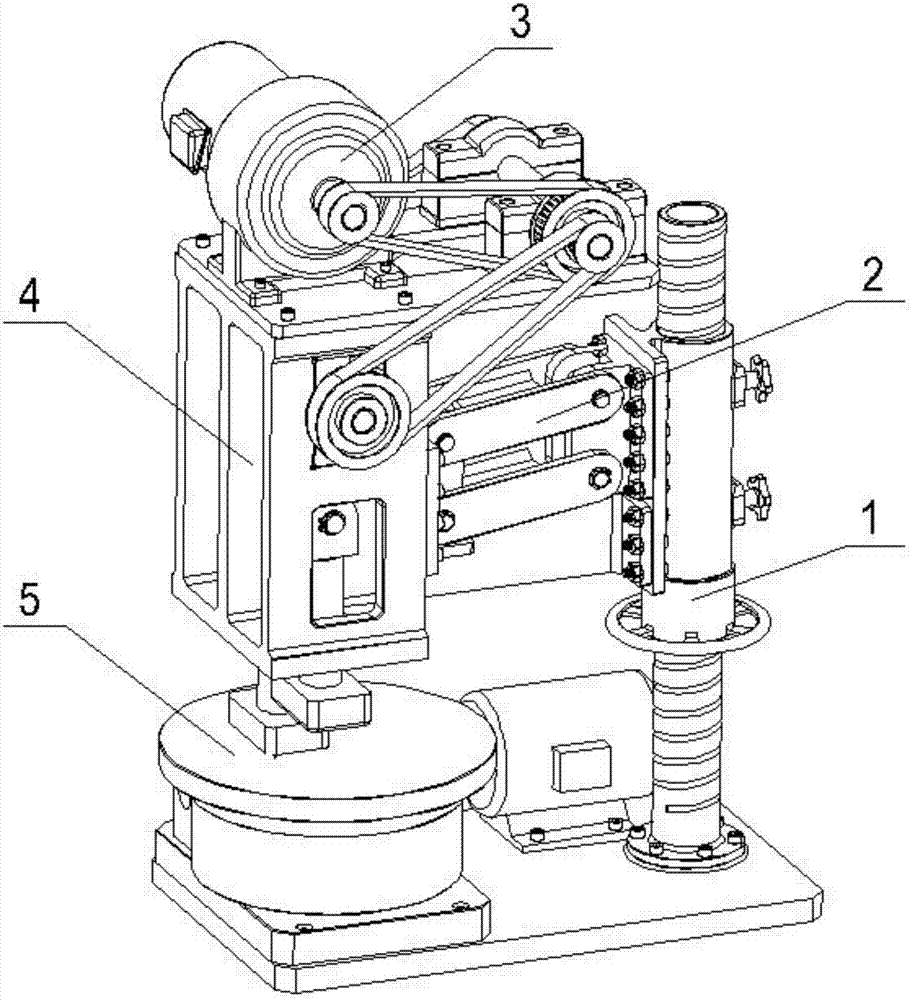

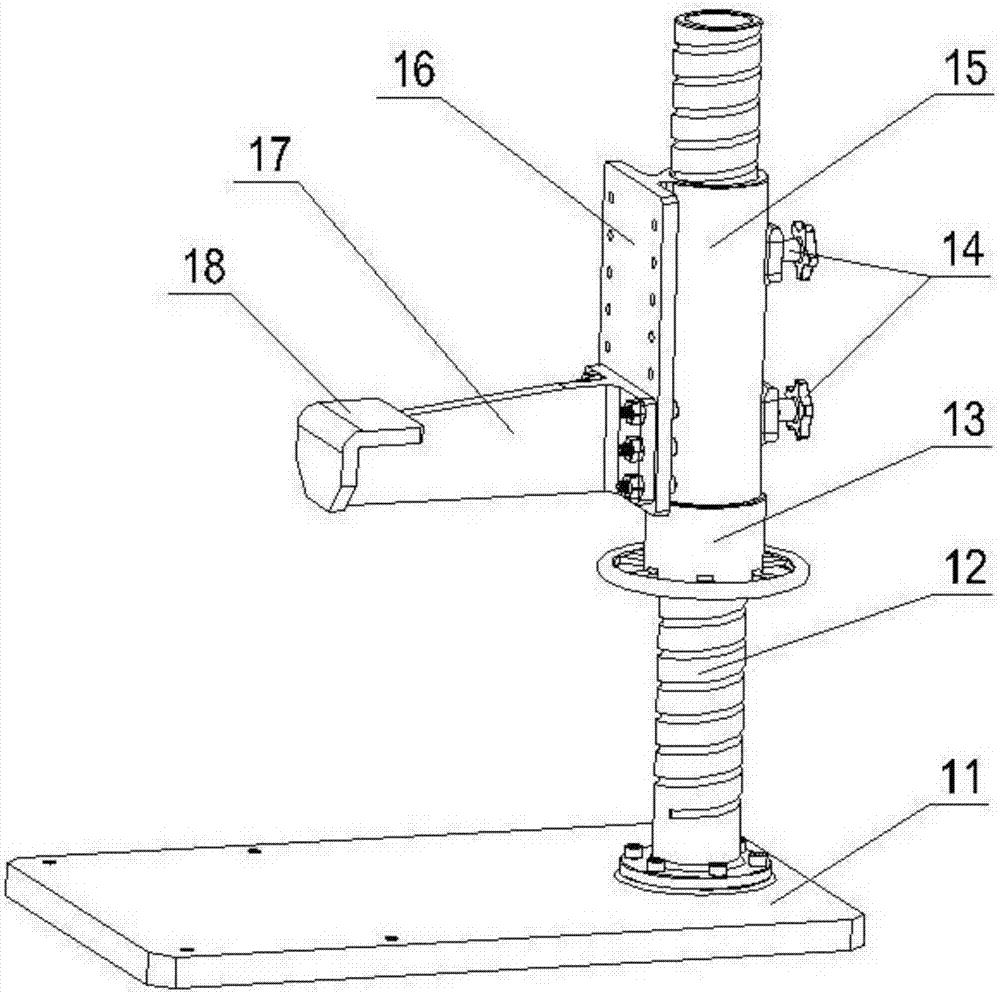

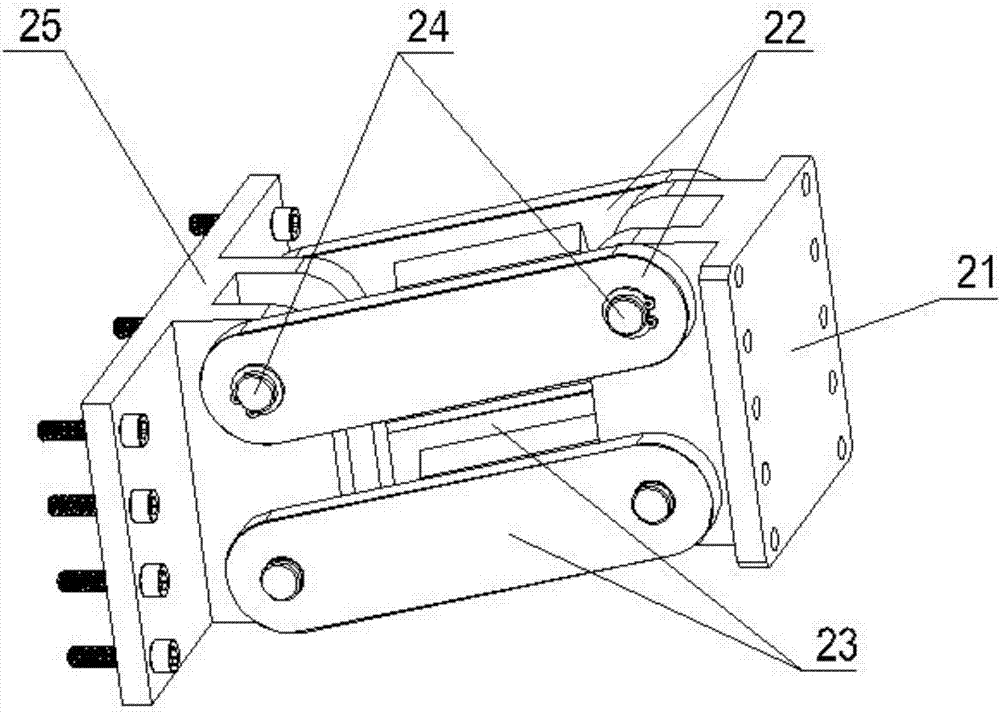

Hammering-type meat emulsion maker

The invention discloses a hammering-type meat emulsion maker. The hammering-type meat emulsion maker solves the technical problems that processing of food material beef emulsion in a background technique needs to be completed in the manner of performing manual and continuous hammering with an iron bar or a solid wood bar, so that the efficiency is low; and besides, an air hammer is used for replacing manual operation, so that the defects of being large in size and large in noise exist. The invention adopts the technical scheme that the hammering-type meat emulsion maker comprises a support frame, wherein a rotating working table is vertically arranged on the support frame, and cantilevers are arranged on the support frame; a crank connecting link mechanism which is matched with the rotating working table for operation and is used for hammering meat is arranged on the cantilevers; and a power part for driving the crank connecting link mechanism to move is arranged at the top of the crank connecting link mechanism. The hammering-type meat emulsion maker disclosed by the invention has the beneficial effect that the machine size is small, the size of the hammering-type meat emulsion maker is smaller than that of the air hammer, besides, noise generated by exhaust of the air hammer does not exist, and the noise is low.

Owner:青海五三六九生态牧业科技有限公司

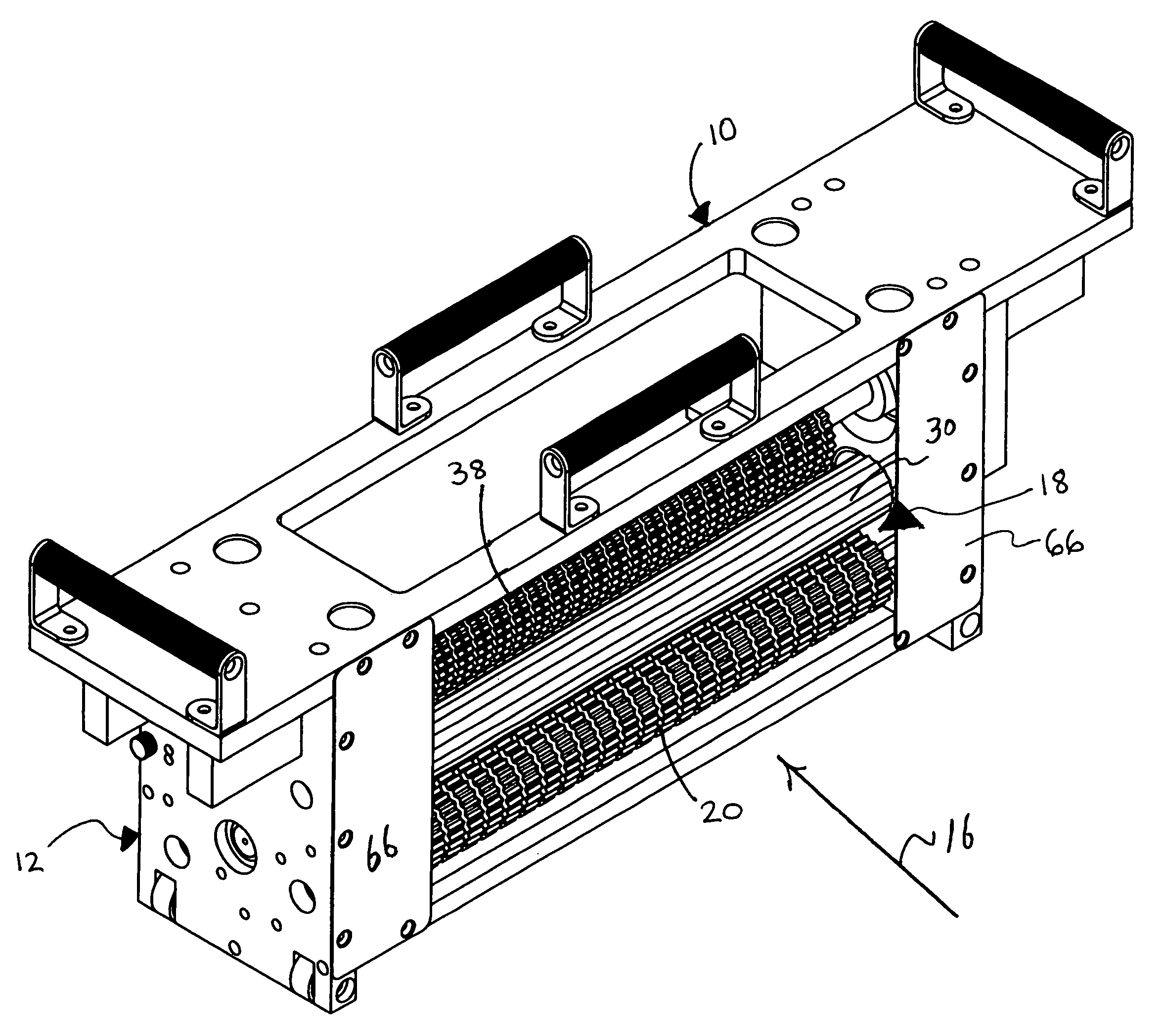

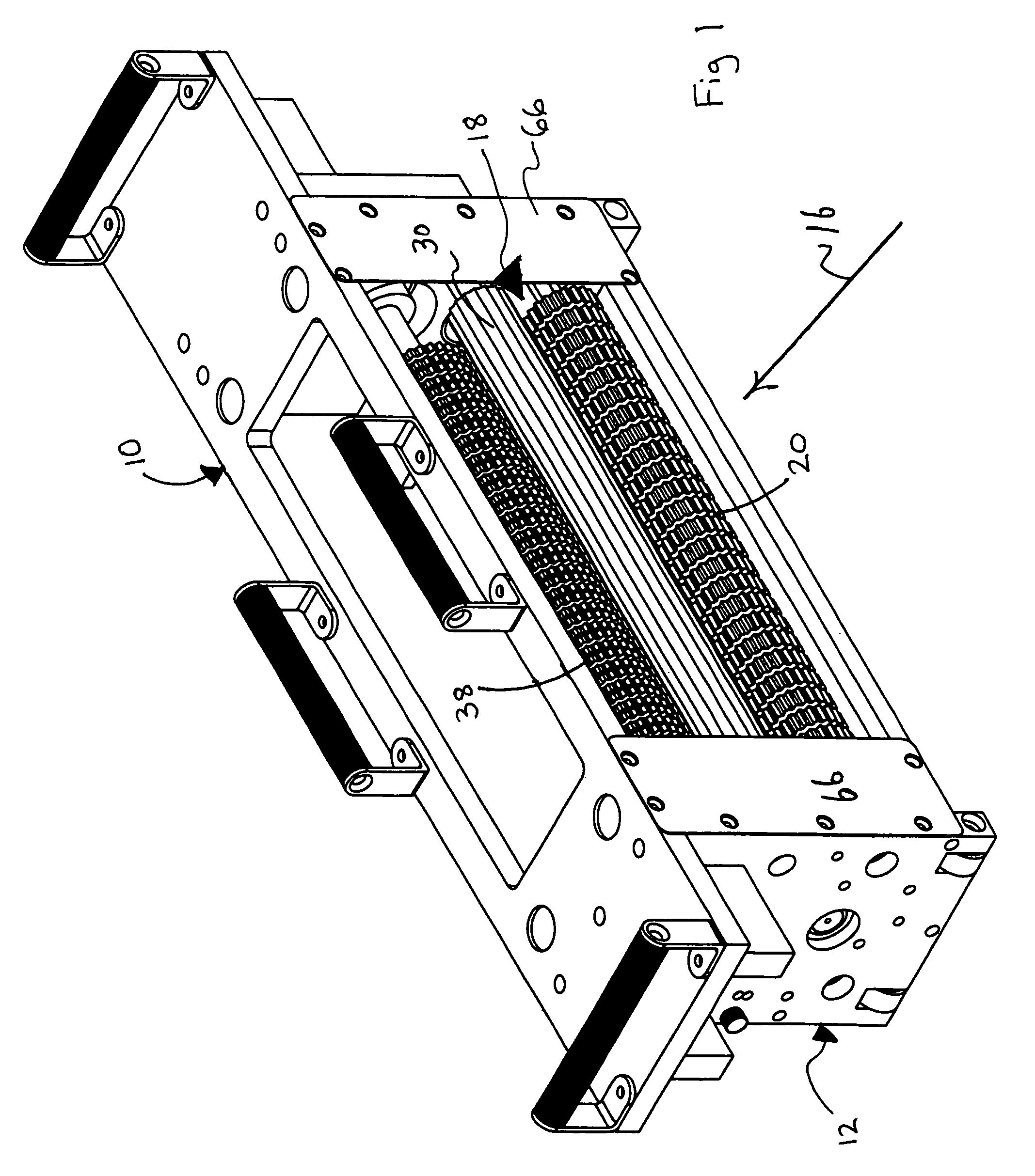

Food processing apparatus for forming strips, slices and cubes

ActiveUS20060196334A1Efficient and economical to cookLess likely to clingShearing machinesGang saw millsMechanical engineeringIngested food

A food processing apparatus for slicing food into slices, strips and cubes comprises a frame, a first and second shaft and first, second, third and fourth subsets of blades. The first shaft is coupled to the frame for rotation relative to the frame about a longitudinal axis of the first shaft. The second shaft is coupled to the frame for rotation relative to the frame about a longitudinal axis of the second shaft. The longitudinal axis of the second shaft is disposed substantially parallel to the longitudinal axis of the first shaft and is displaced therefrom. The first and second subsets of blades are mounted to the first shaft. Each blade of the first subset of blades is displaced along the longitudinal axis of the first shaft from adjacent blades of the first subset of blades by a first displacement. Each blade of the second subset of blades is displaced along the longitudinal axis of the first shaft from adjacent blades of the second subset of blades by a second displacement differing from the first displacement. The third and fourth subsets of blades are mounted to the second shaft. Each blade of the third subset of blades is displaced along the longitudinal axis of the second shaft from adjacent blades of the third subset of blades by the first displacement. Each blade of the fourth subset of blades is displaced along the longitudinal axis of the second shaft from adjacent blades of the fourth subset of blades by the second displacement. The first subset of blades cooperate with the third subset of blades to form a first cutting region therebetween for cutting food to a first dimension and the second subset of blades cooperate with the fourth subset of blades to form a second cutting region therebetween for cutting food to a second dimension.

Owner:CHEN ZHUI

Processing method of semi-finished precooked beef product

InactiveCN105433264AReduce consumptionImprove stabilityMeat tenderisingWater resourcesProcessing cost

The invention discloses a processing method of a semi-finished precooked beef product. The processing method includes the steps of raw material selecting, raw material unfreezing, dividing and finishing, feed liquid preparing, rolling, pickling, precooking, cooling and packaging. According to the method, raw material beef in an epidemic-free area and auxiliary materials are carefully selected, the carefully-selected raw material beef is unfrozen, divided and added with the auxiliary materials to be rolled and pickled, then the processes of cooking, cooling and the like are carried out after a certain time of pickling, then prepackaging and quick-freezing are carried out, and finally boxing and warehousing are carried out. Aiming at the risk that meat products can go bad in different production environments, the processing method avoids the risk that raw material beef goes bad when processed by individuals in the present market; furthermore, the processing method saves corresponding water resources and manpower resources, achieves the environmental protection purpose to some extent and reduces the production and processing cost for terminal individuals.

Owner:SICHUAN RENCONGZHONG FOOD CO LTD

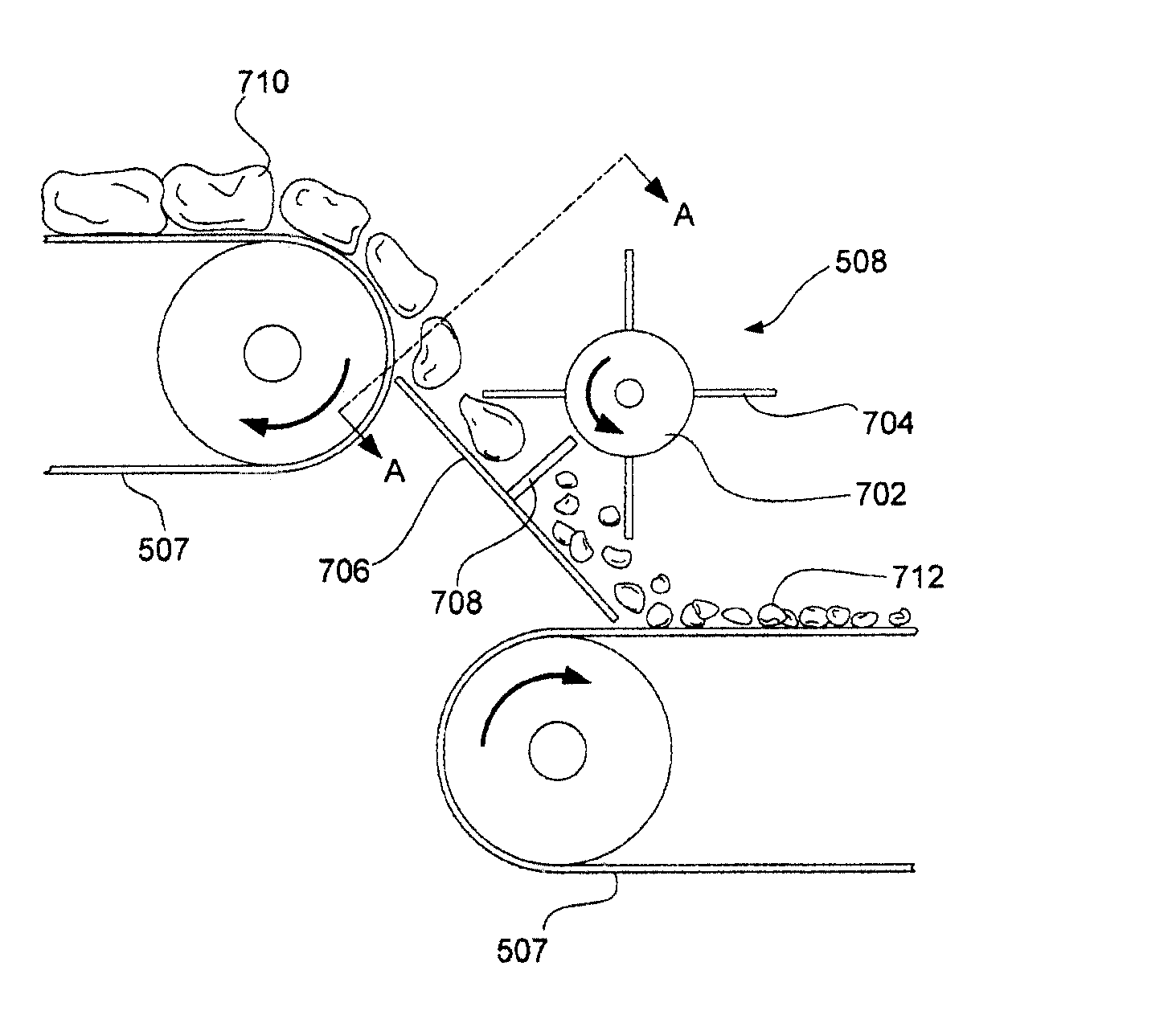

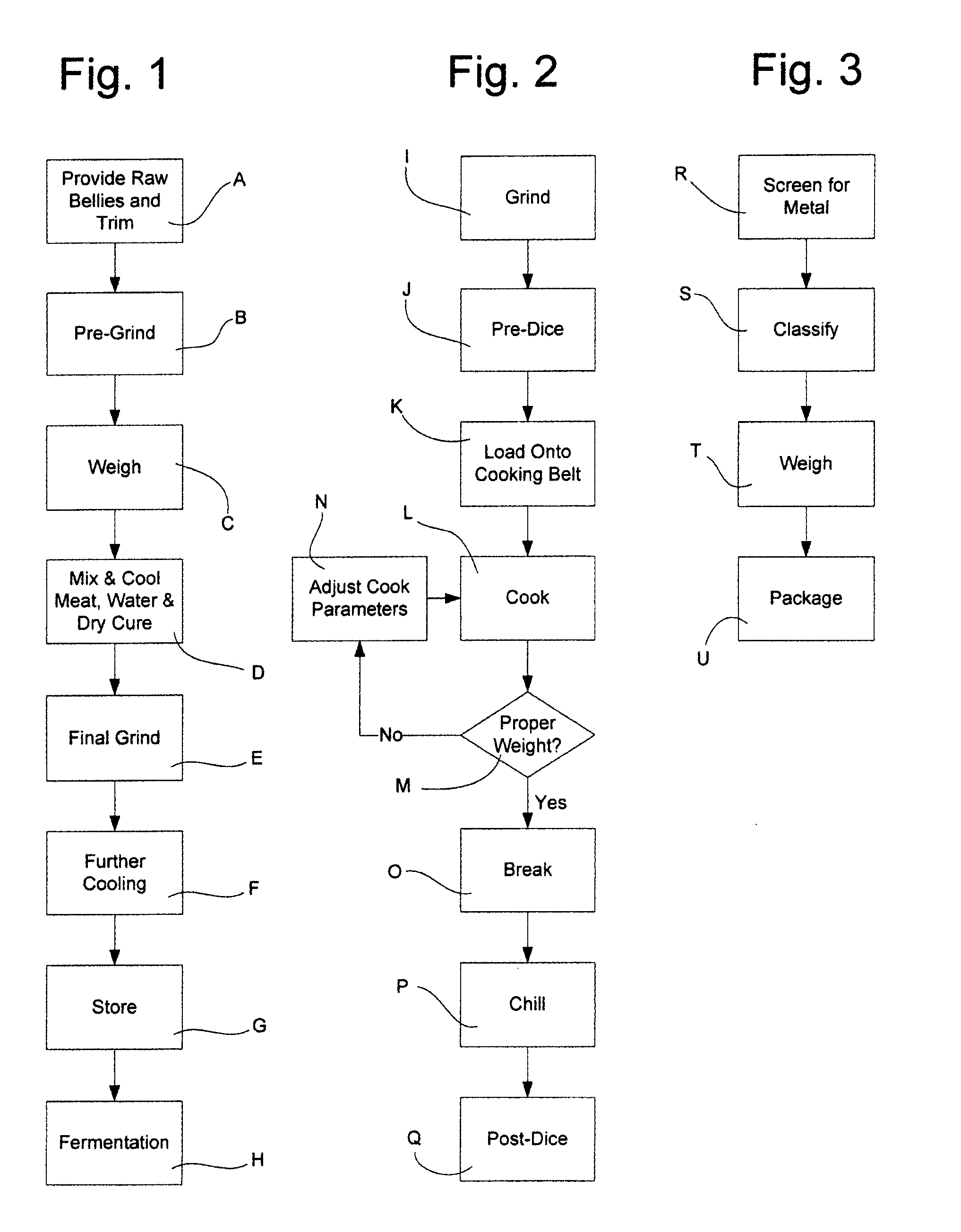

Method and Apparatus for Producing Cooked Bacon Using Starter Cultures

A method for preparing cooked particulate meat products using a starter culture, such as bacon bits or other bacon seasonings and toppings. The raw meat is ground to a first size in a first grinder, mixed with dry cure which includes a starter culture to form a raw meat mixture, cooled, and stored long enough to allow for partial fermentation. The raw meat mixture is then ground and diced to a second size in a first dicer, evenly spread onto a cooking belt, cooked in one or more continuous cooking ovens to form a cooked meat mixture and diced again to a third size in a second dicer.

Owner:PATRICK CUDAHY

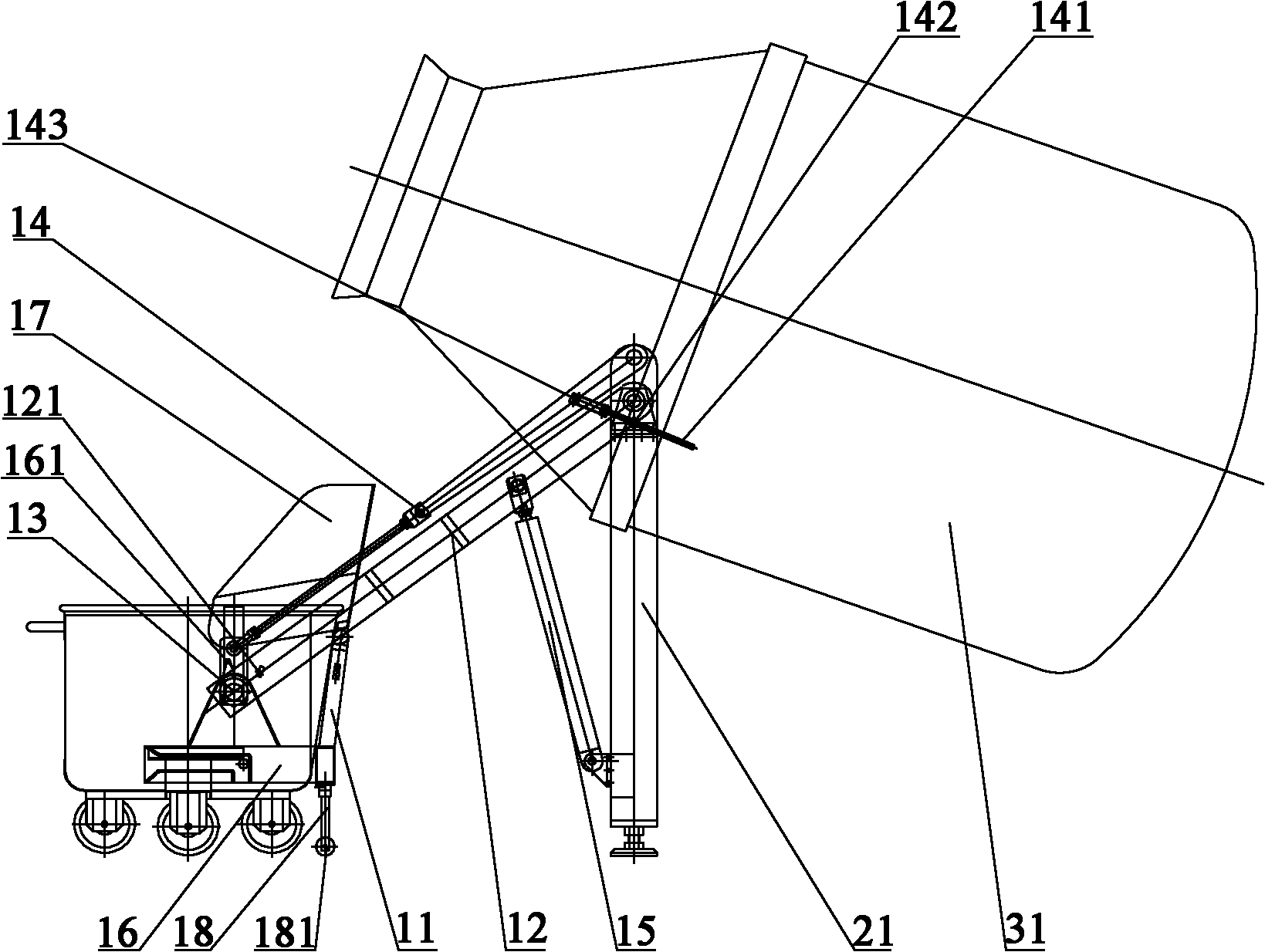

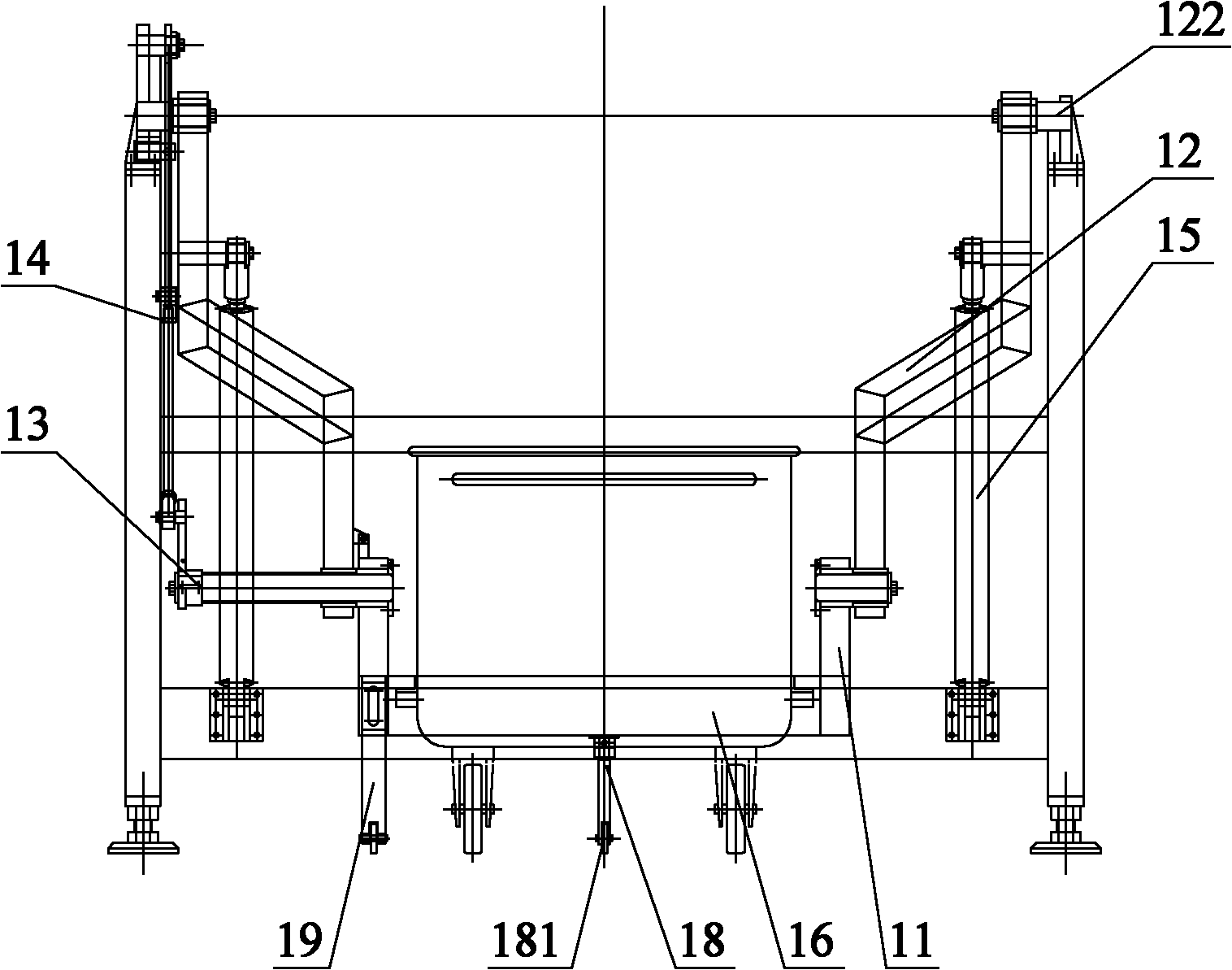

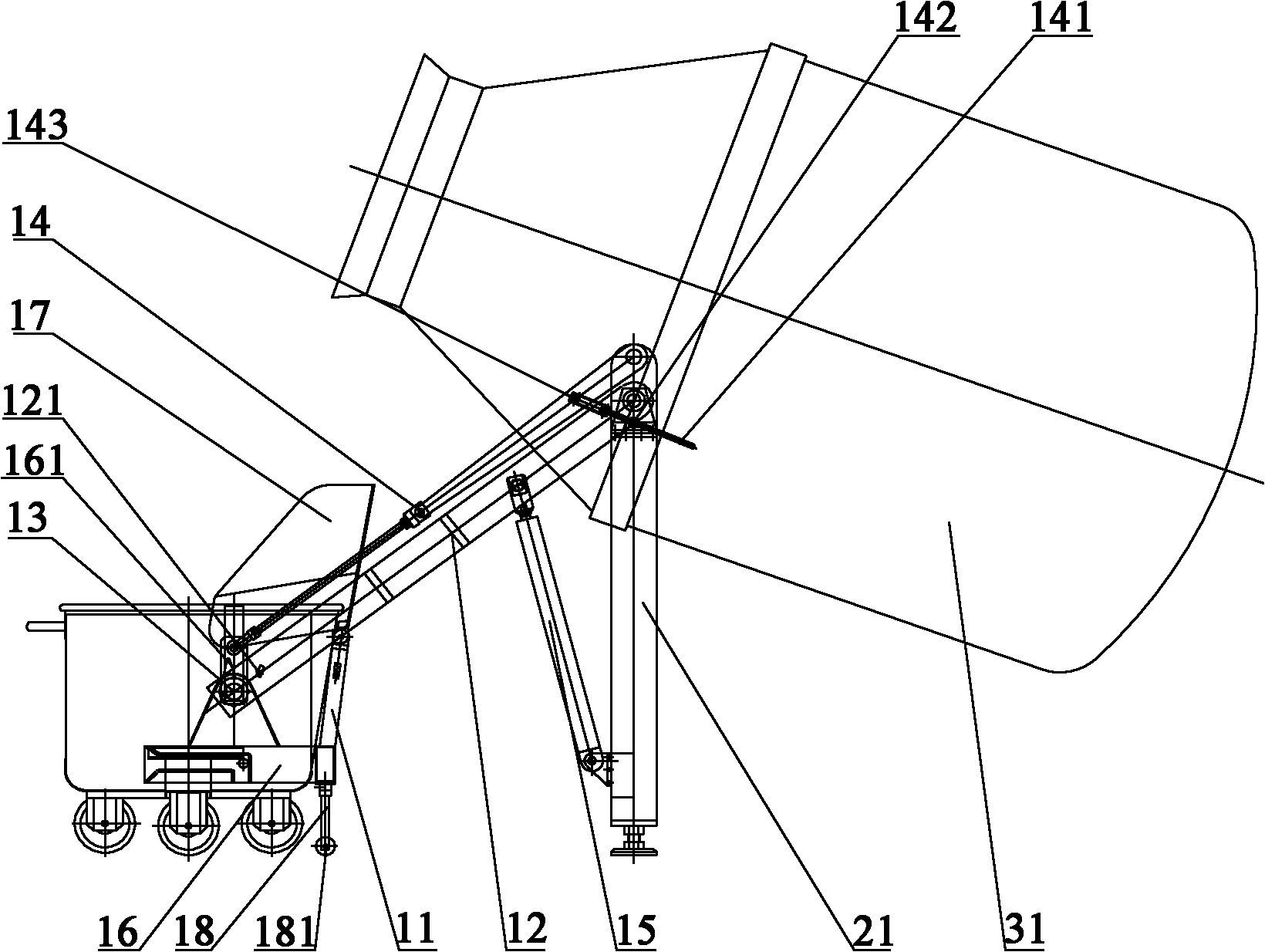

Tumbler and material loading device thereof

ActiveCN102351106AIncrease productivityAvoid contactLoading/unloadingMeat tenderisingUltimate tensile strengthFastener

Owner:ZHEJIANG RIBON INTELLIGENT EQUIP CO LTD

Method for processing hams at low temperature with high production yield

InactiveCN101690594AHigh yieldReduce manufacturing costFood preparationMeat tenderisingHigh pressureNew materials

The invention provides a method for processing hams at low temperature with a high production yield, which is on account of the problem that the current high quality hams at low temperature have low production yield. The invention is characterized in that new materials and water are adopted to be homogenized by a homogenizer at a pressure of 35kgf to 40kgf; and finally the production yield of the hams can reach 200% by adopting a pinhole with a diameter of 4-5mm, a high injection process at a pressure of 10-12kgf, a double roll voltage stabilization and tenderization technique and a breathing tumbling process. The invention improves the texture of the hams produced at low temperature, has better mouthfeel, reduces the production cost of hams at low temperature without reducing product quality, has convenient and simple production, high level of industrialization and is applicable to industrial production.

Owner:NANJING YURUN FOOD

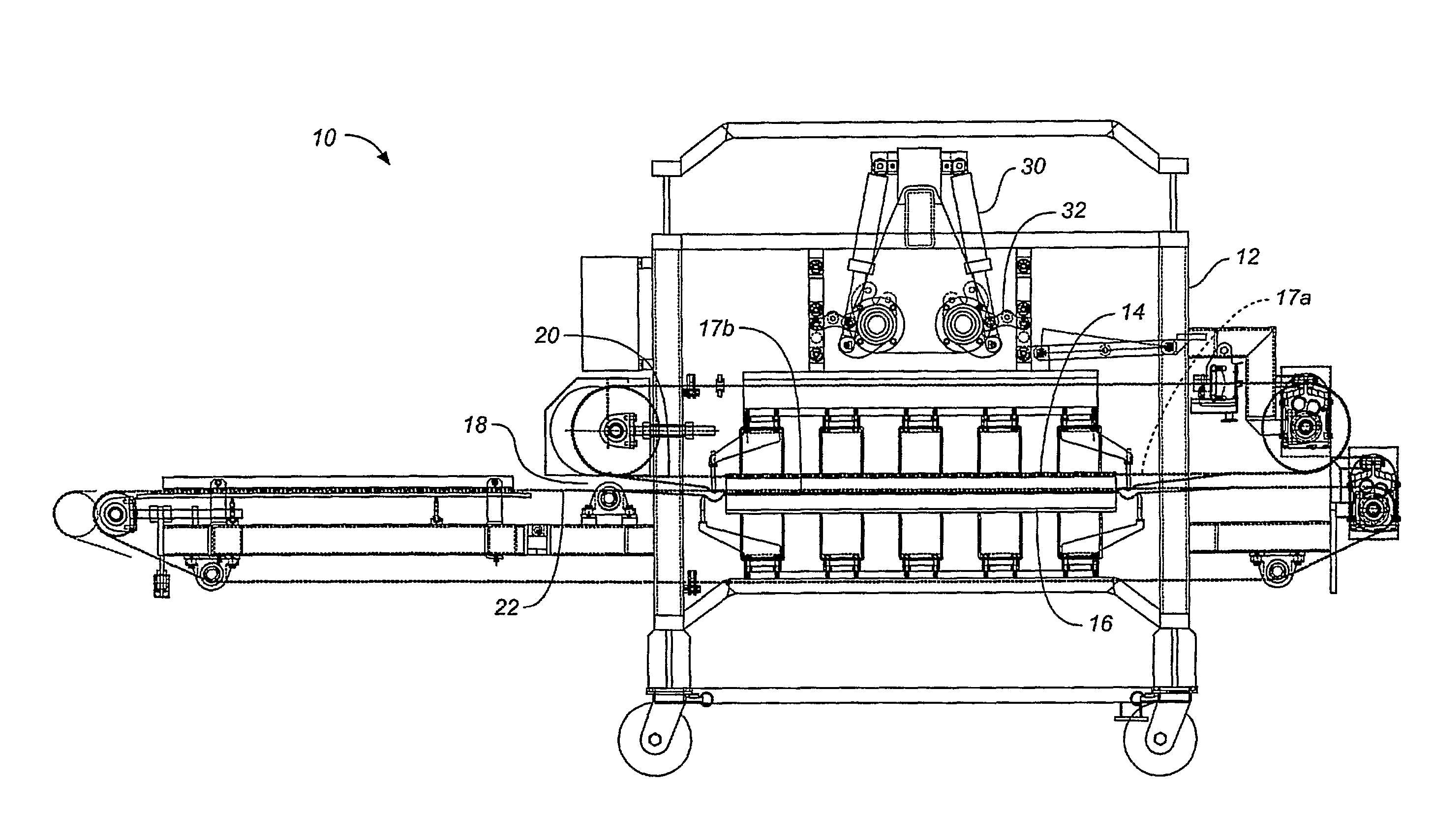

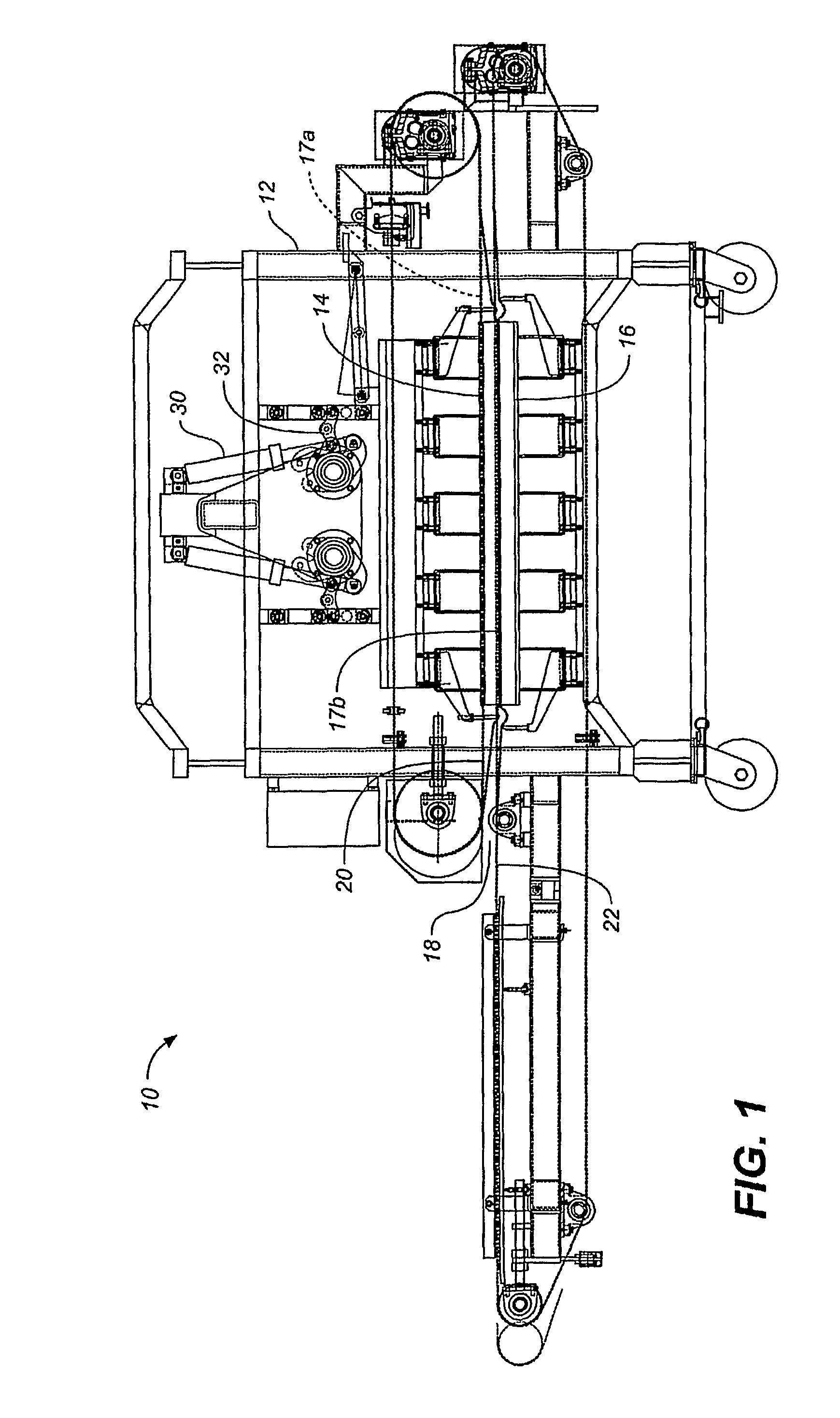

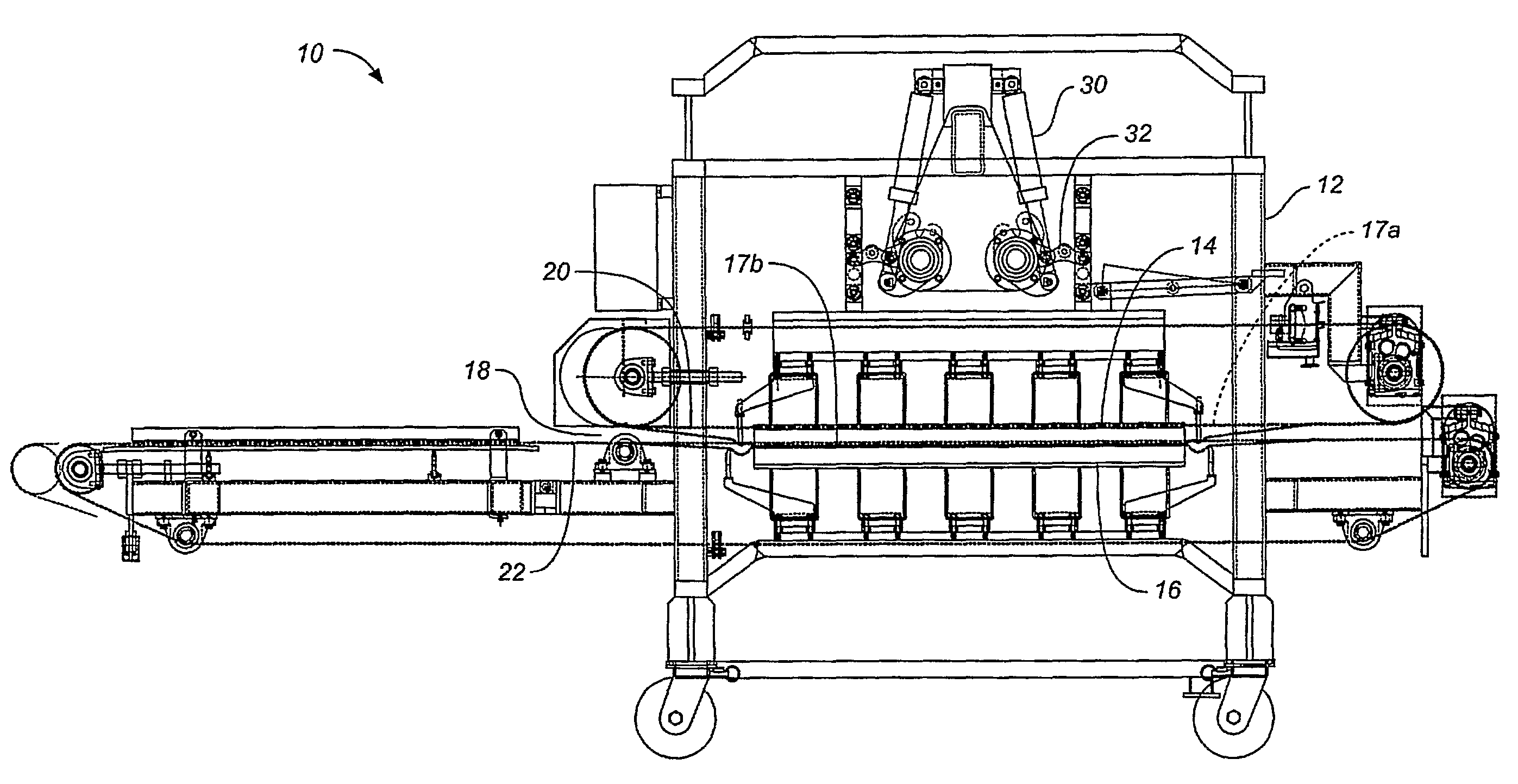

Semi-Continuous Meat Press Method and Apparatus

InactiveUS20080160893A1Not to damageReduce harmPoultry processingPressesHydraulic cylinderPlastic materials

Owner:BLENTECH

Semi-continuous meat press method and apparatus

InactiveUS7578732B2Reduce harmNot to damagePoultry processingPressesHydraulic cylinderPlastic materials

Owner:BLENTECH

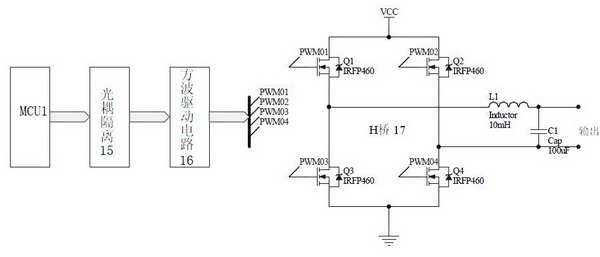

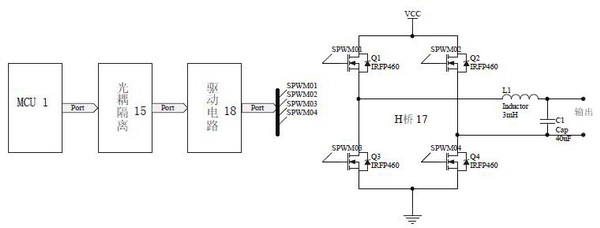

Beef electric-stimulation tenderizing instrument capable of outputting multiple waveforms

InactiveCN102038027AAdjustable parametersLarge adjustment rangeMeat tenderisingProgrammable read-only memoryPeak value

The invention relates to a beef electric-stimulation tenderizing instrument capable of outputting multiple waveforms, relating to an electric-stimulation tenderizing technology in the field of meat industry. The beef electric-stimulation tenderizing instrument is an intelligent electric-stimulation tenderizing instrument and comprises an MCU (Micro Control Unit), a DC power circuit, an inverter circuit, a safety circuit, a D / A (Digital-to-Analog) conversion circuit, a keyboard input circuit, a liquid crystal display circuit, a buzzer, an EEPROM (Electrically Erasable Programmable Read-Only Memory), a serial port communication circuit and a stimulating electrode. An integral system comprising the MCU and electron devices positioned on the periphery of the MCU can accurately control a rectification circuit to rectify DC so as to generate multiple current waveforms for stimulating fresh beef, and the frequency, the peak value and the stimulating time of the current waveforms can be freely set within a range permitted by the beef electric-stimulation tenderizing instrument; the beef electric-stimulation tenderizing instrument generates waveform types as follows: DC, sine waves, triangular waves and square waves; the peak value range is 0-110 V, the frequency range is 1-450 HZ, and the timing range is 0-10 minutes. The invention furthest considers the difference of different varieties and parts of the beef, thereby achieving a better tenderizing effect.

Owner:江应红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com