Patents

Literature

40results about How to "Realize automatic reset work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic stirring and feeding equipment for pig farm

InactiveCN106900576AControl to move left and rightRealize automatic reset workAnimal feeding devicesPig farmsAutomatic control

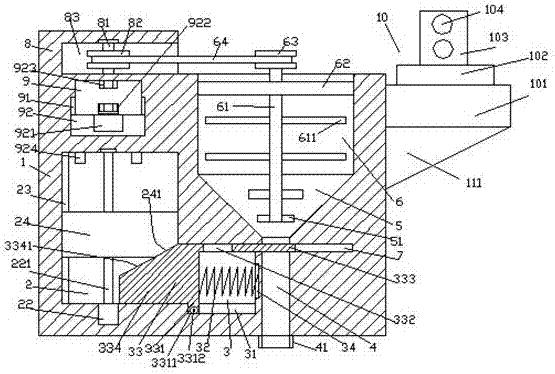

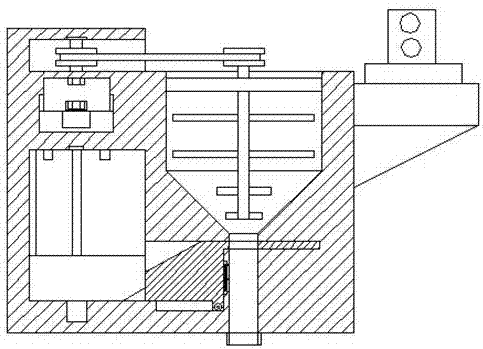

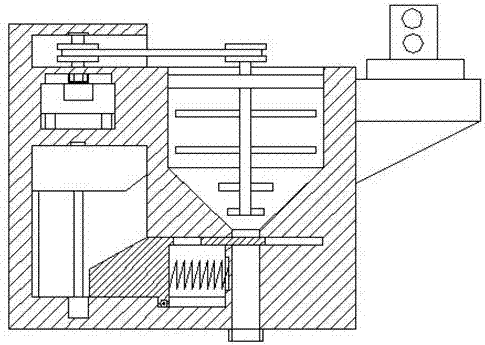

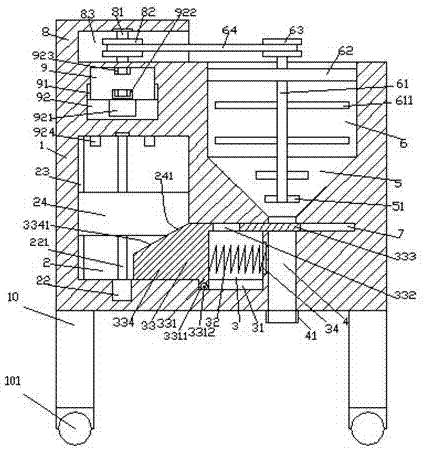

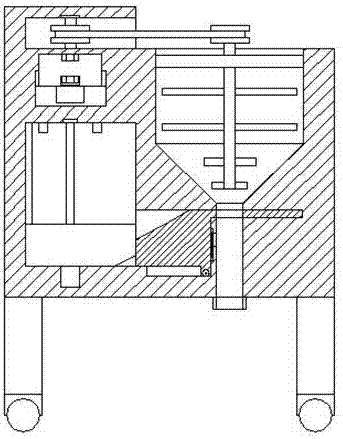

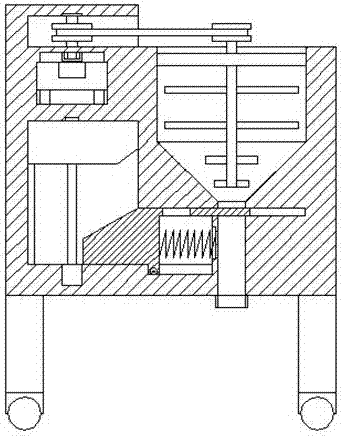

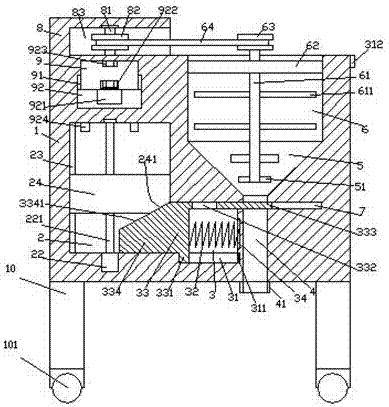

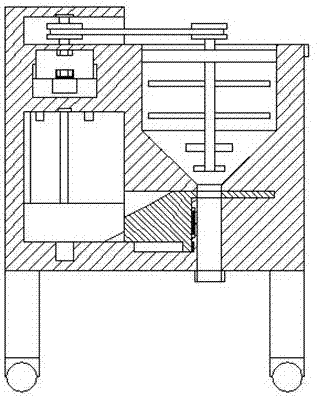

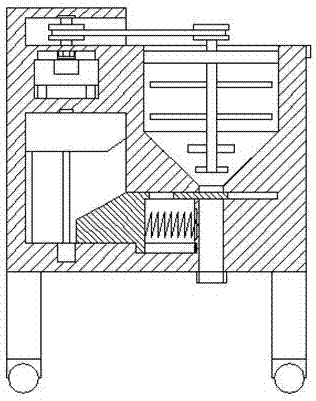

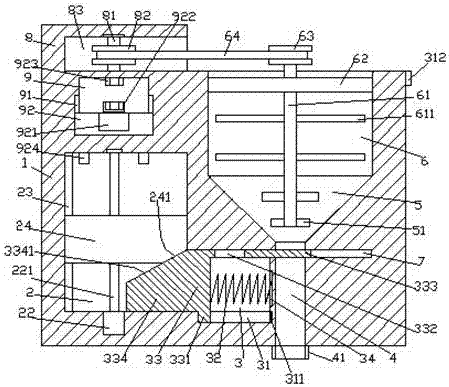

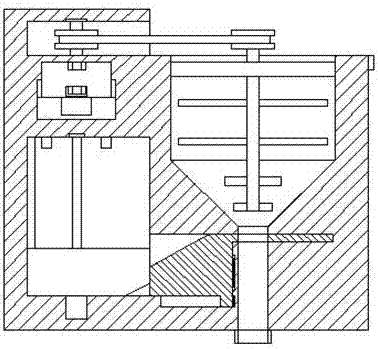

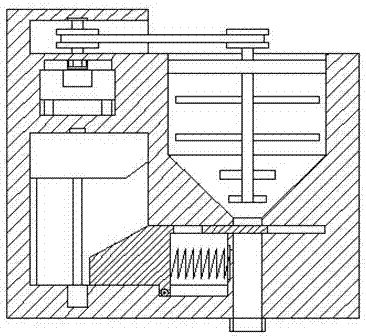

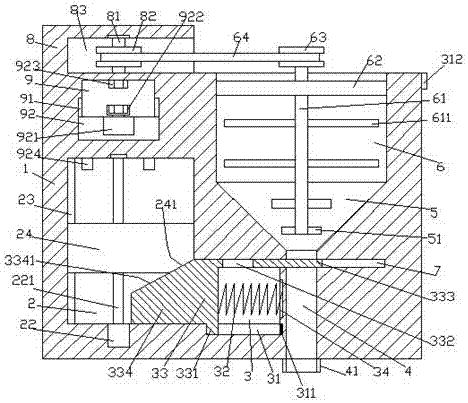

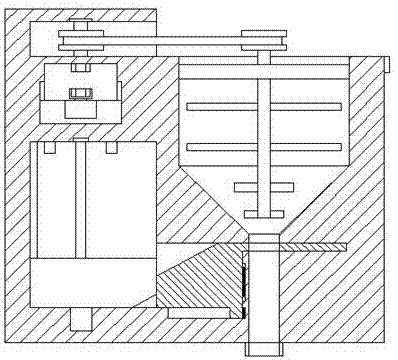

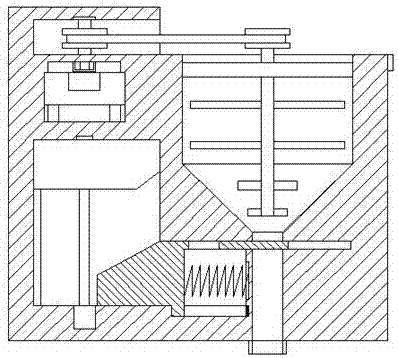

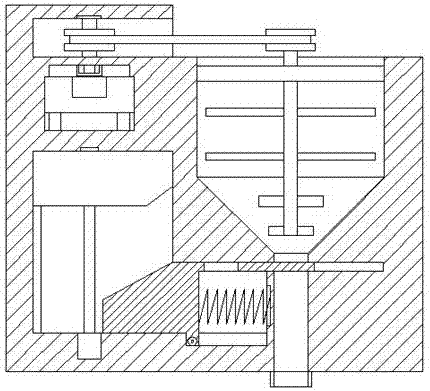

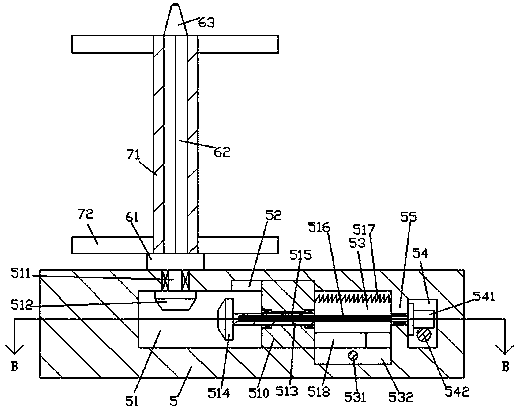

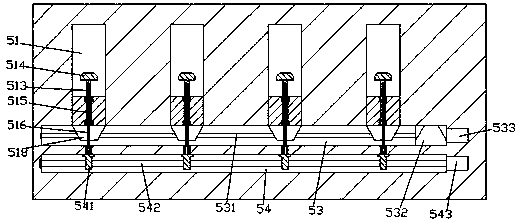

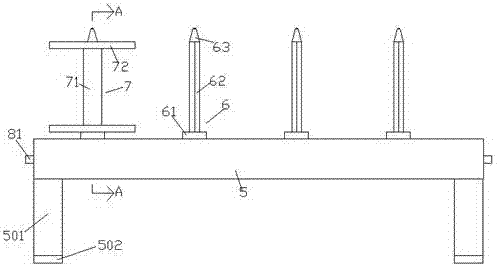

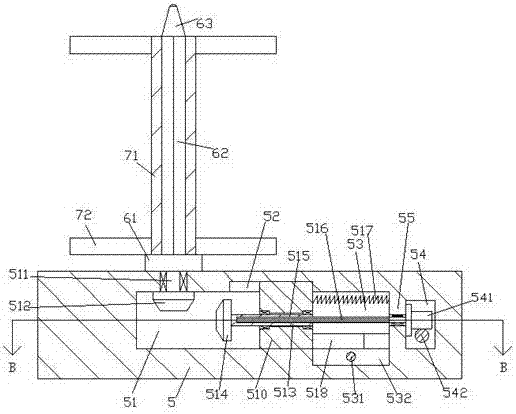

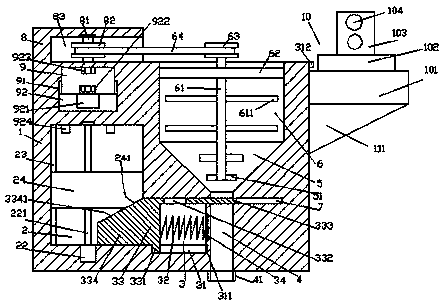

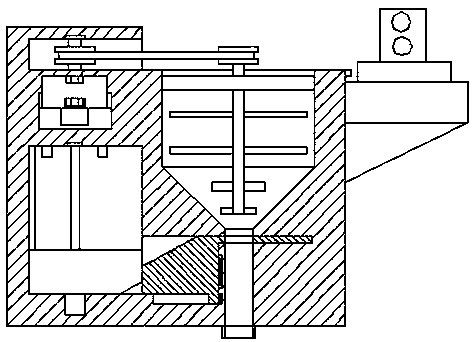

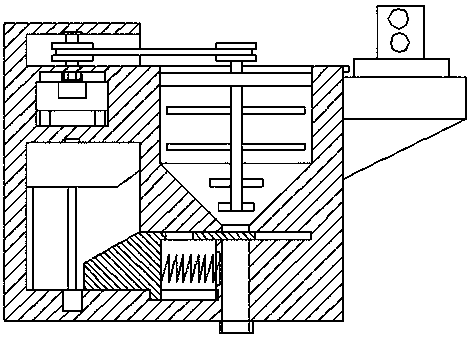

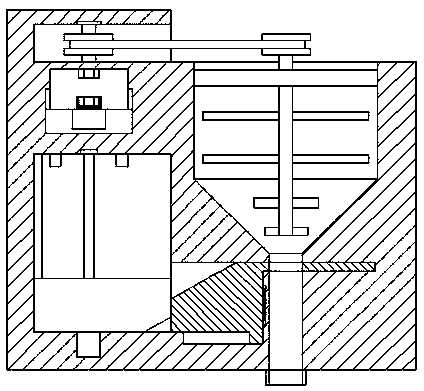

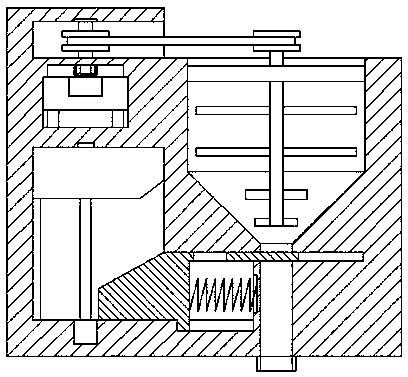

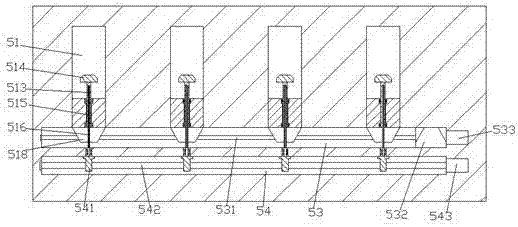

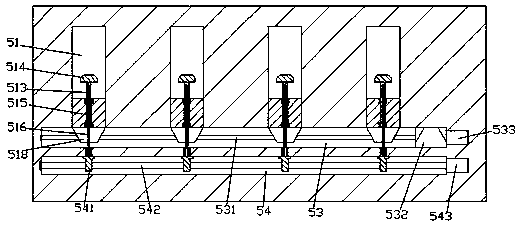

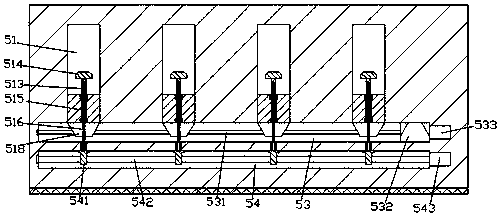

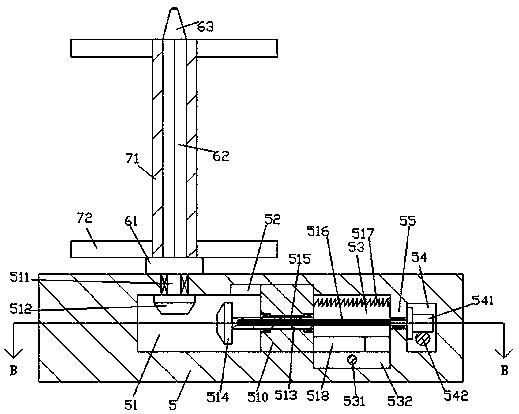

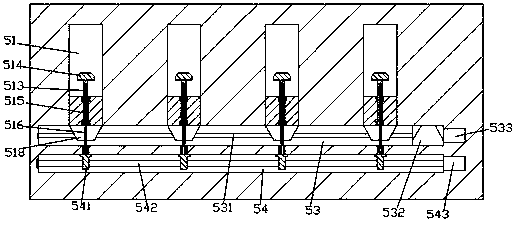

The invention discloses an automatic stirring and feeding equipment for pig farms, which comprises a casing, a first sliding chamber is arranged inside the left side of the casing, a first guide groove is arranged on the left inner wall of the first sliding chamber, a first sliding The casing on the right side of the chamber is provided with a second sliding chamber connected with the first sliding chamber, the casing on the right side of the second sliding chamber is provided with a discharge hole extending up and down, and the top of the second sliding chamber is provided with a horizontal through discharge hole. The material hole and the partition guide groove extending to the right, the top of the discharge hole is provided with a funnel-shaped hopper, the top of the funnel-shaped hopper is provided with a feed hopper, the housing above the first sliding chamber is provided with a third sliding chamber, the third The inner walls of the left and right sides of the sliding cavity are symmetrically provided with a third guide groove, and a screw is provided in the first sliding cavity, the bottom of the screw is connected with the power of the first motor, and the upper screw is threaded and connected with a moving block; the present invention is simple in structure, reasonable in design, and easy to operate It is simple, the manufacturing cost is very low and the maintenance cost is low. It is suitable for small and medium-sized farmers. It can automatically control the feeding work and reduce the labor load of workers.

Owner:朱娟红

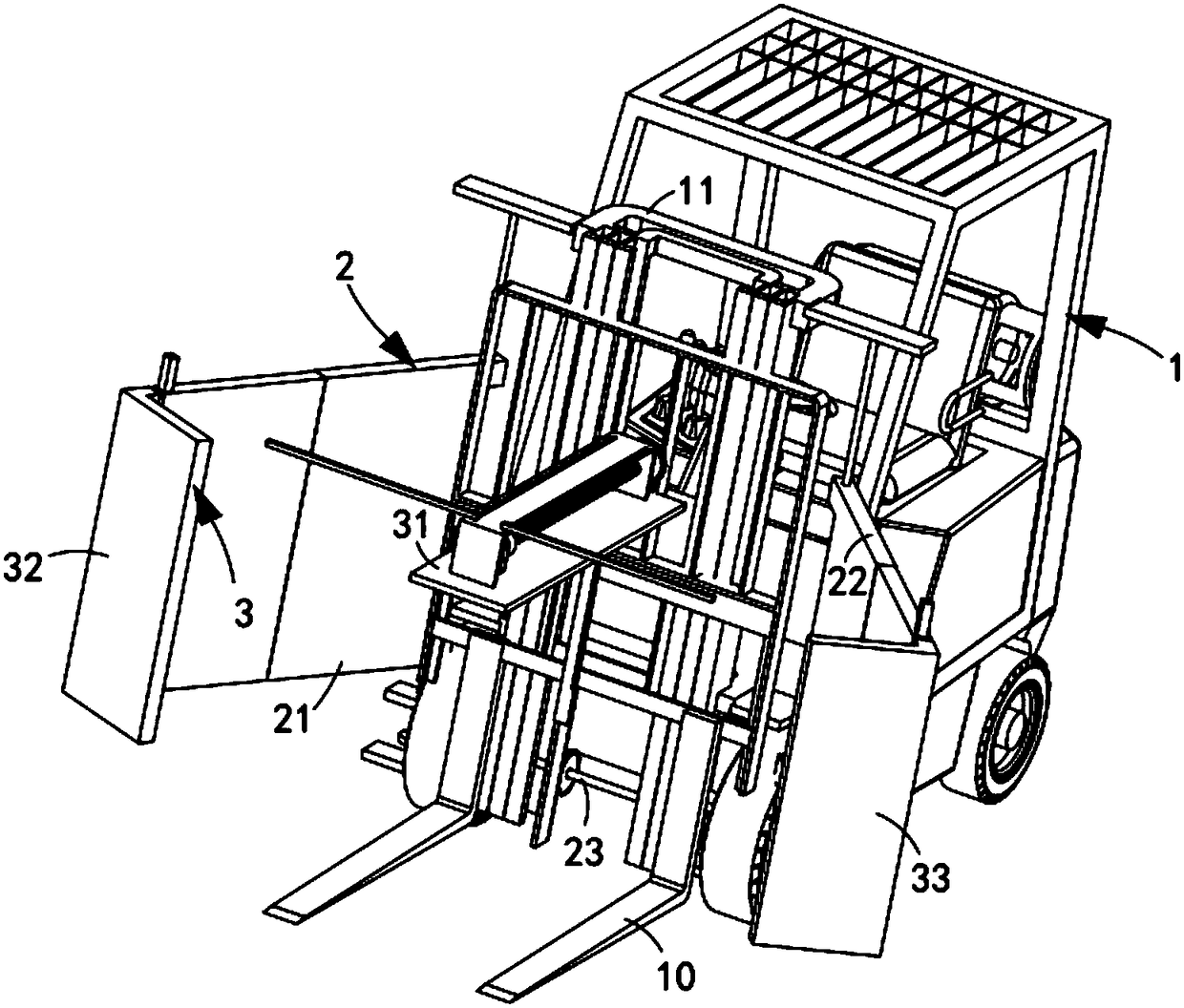

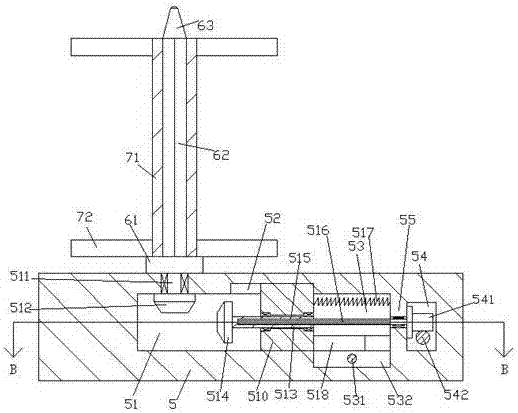

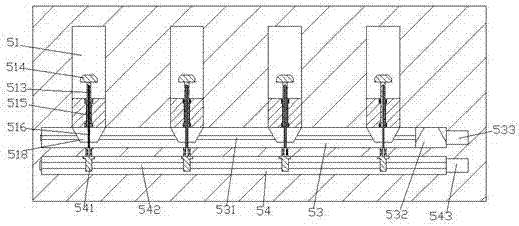

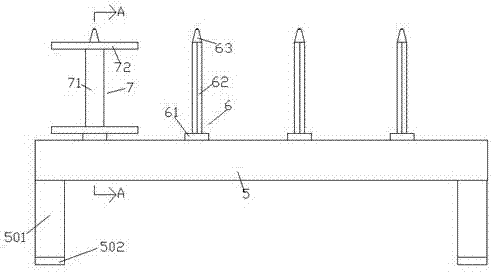

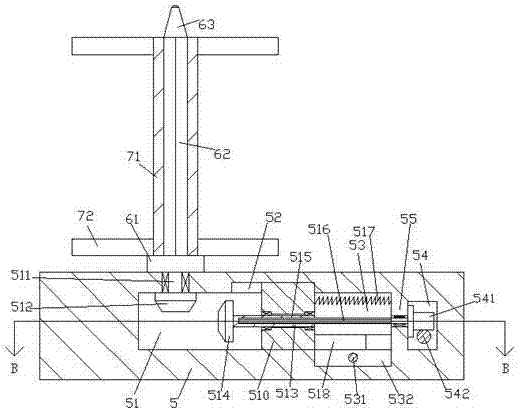

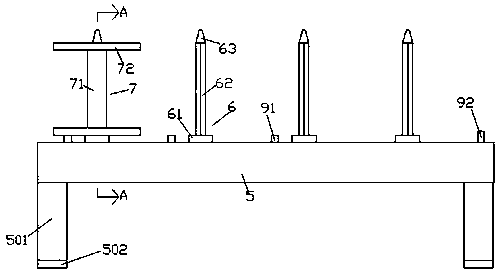

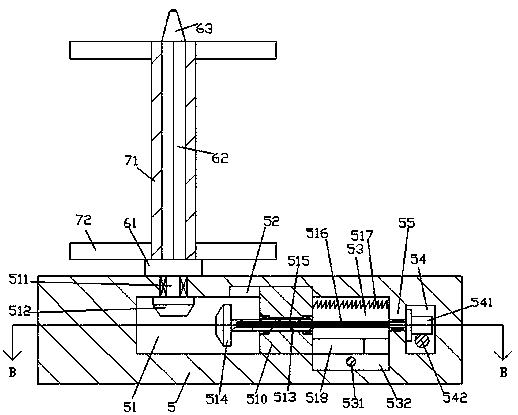

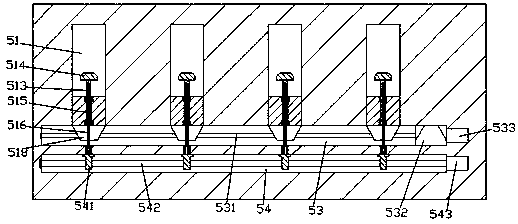

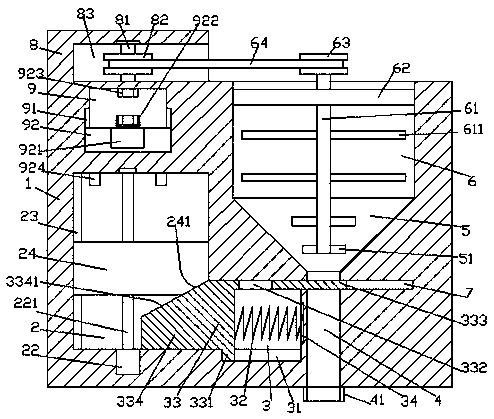

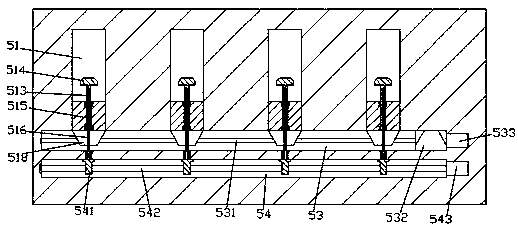

Novel automatic clamping electric carrying vehicle

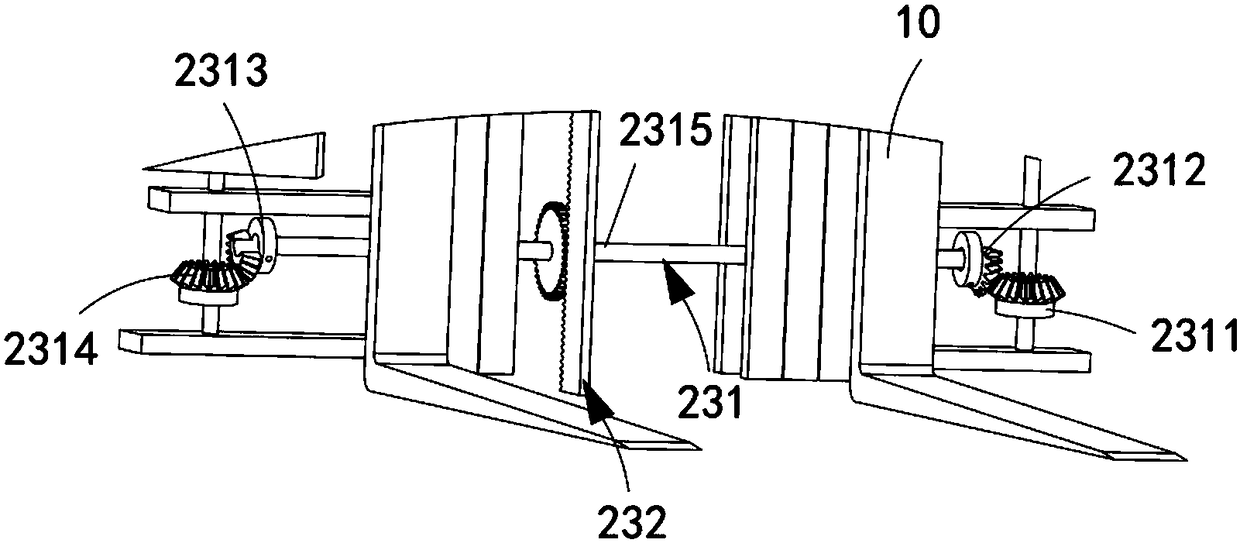

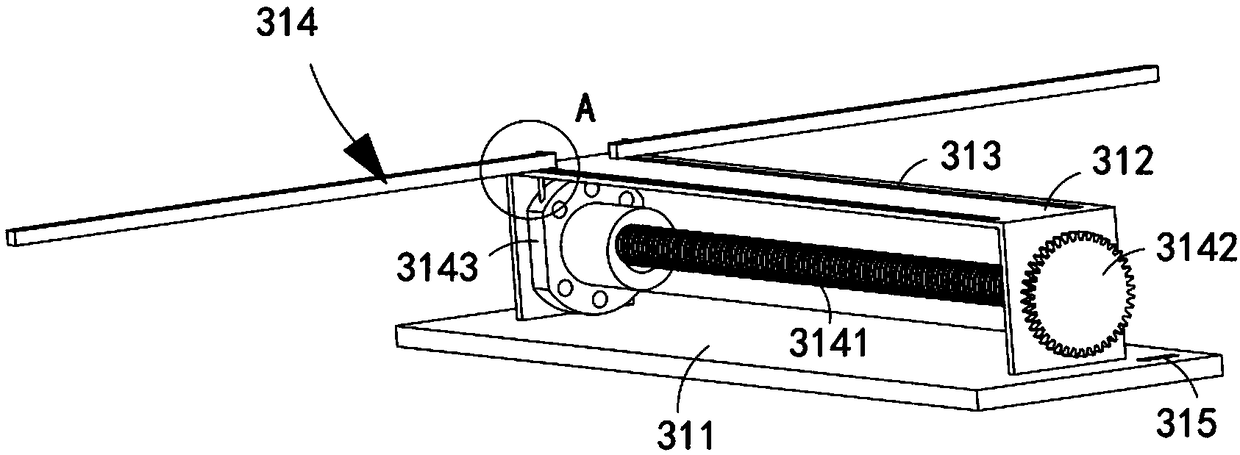

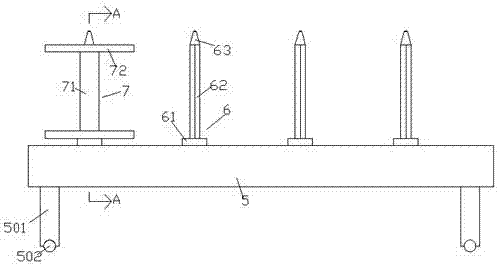

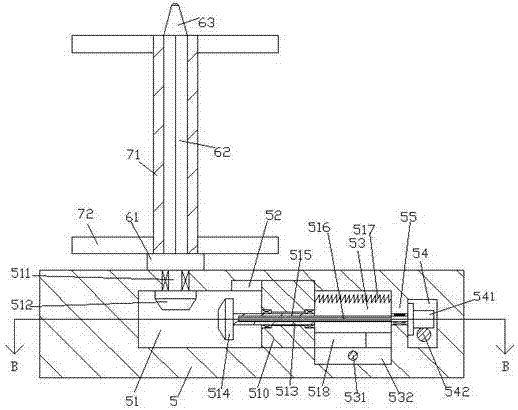

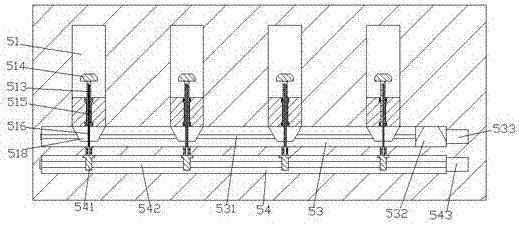

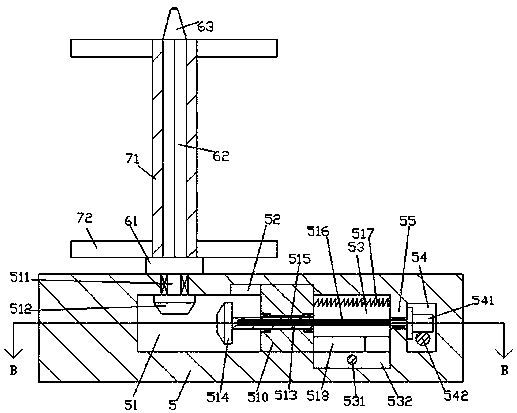

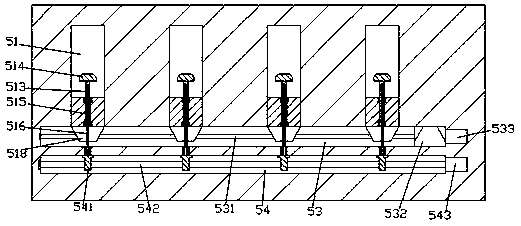

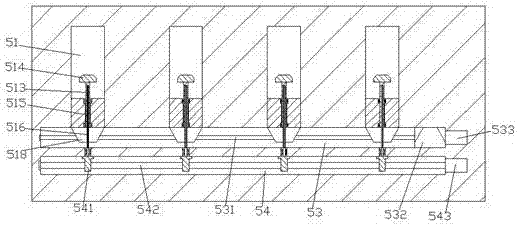

The invention relates to a novel automatic clamping electric carrying vehicle which comprises a forklift truck, a support frame, elevating components, a blocking mechanism and a tightening mechanism.The support frame is arranged at the front of the forklift truck, the elevating components are arranged on the lower side of the support frame, the blocking mechanism comprises a side blocking assembly a, a side blocking assembly b and a driving assembly, the slide blocking assembly a is mounted on the support frame, the side blocking assembly b is symmetric with the side blocking assembly a, andthe control assembly is positioned on the side blocking assembly a and is used for driving the side blocking assembly a and the side blocking assembly b to carry out synchronous transmission; the tightening mechanism comprises a control assembly, a clamping assembly a and a clamping assembly b, the control assembly is arranged on the support frame and is positioned between the side blocking assembly a and the side blocking assembly b, the clamping assembly a is slidably arranged on the side blocking assembly a, and the clamping assembly b is slidably arranged on the side blocking assembly b. The novel automatic clamping electric carrying vehicle has the advantage that the technical problem that light goods on existing forklift trucks are easy to be out of balance and drop out in carrying procedures can be solved by the aid of the novel automatic clamping electric carrying vehicle.

Owner:河北神力索具集团有限公司

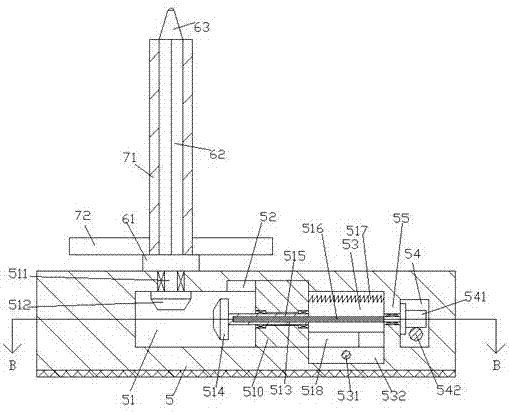

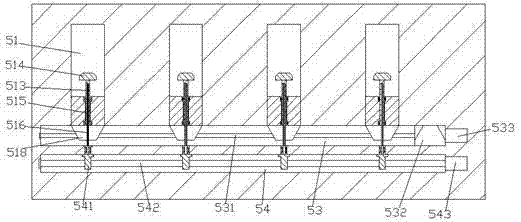

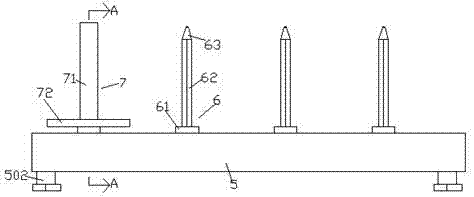

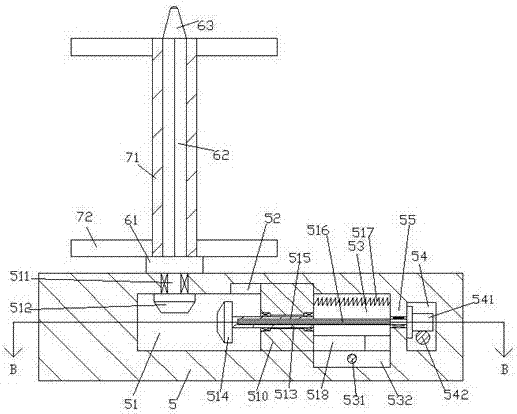

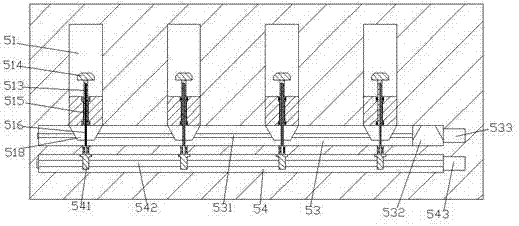

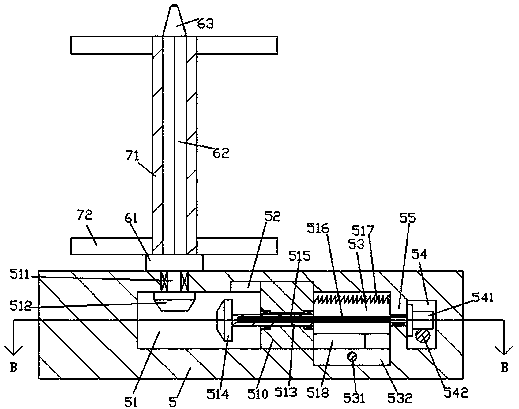

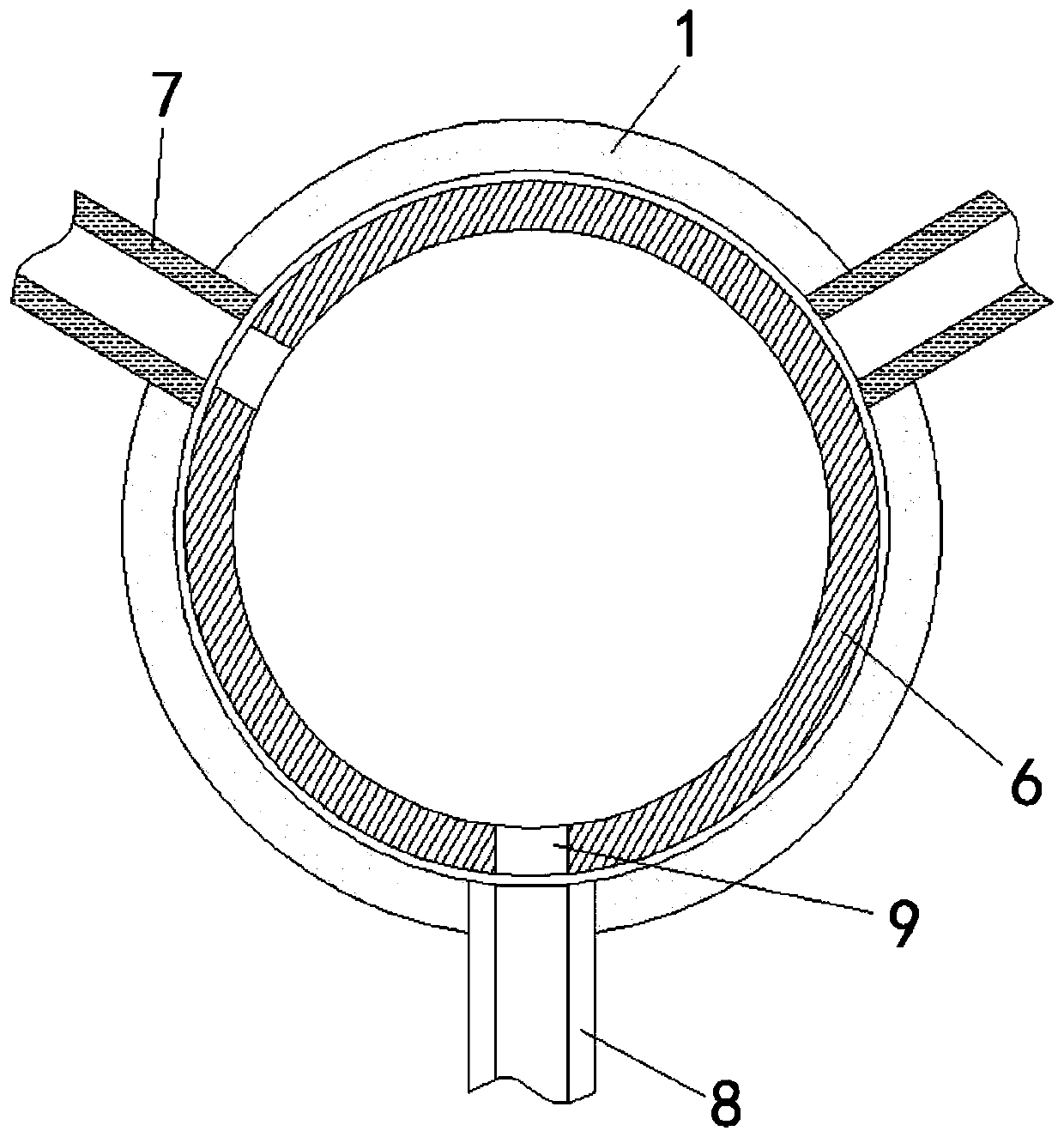

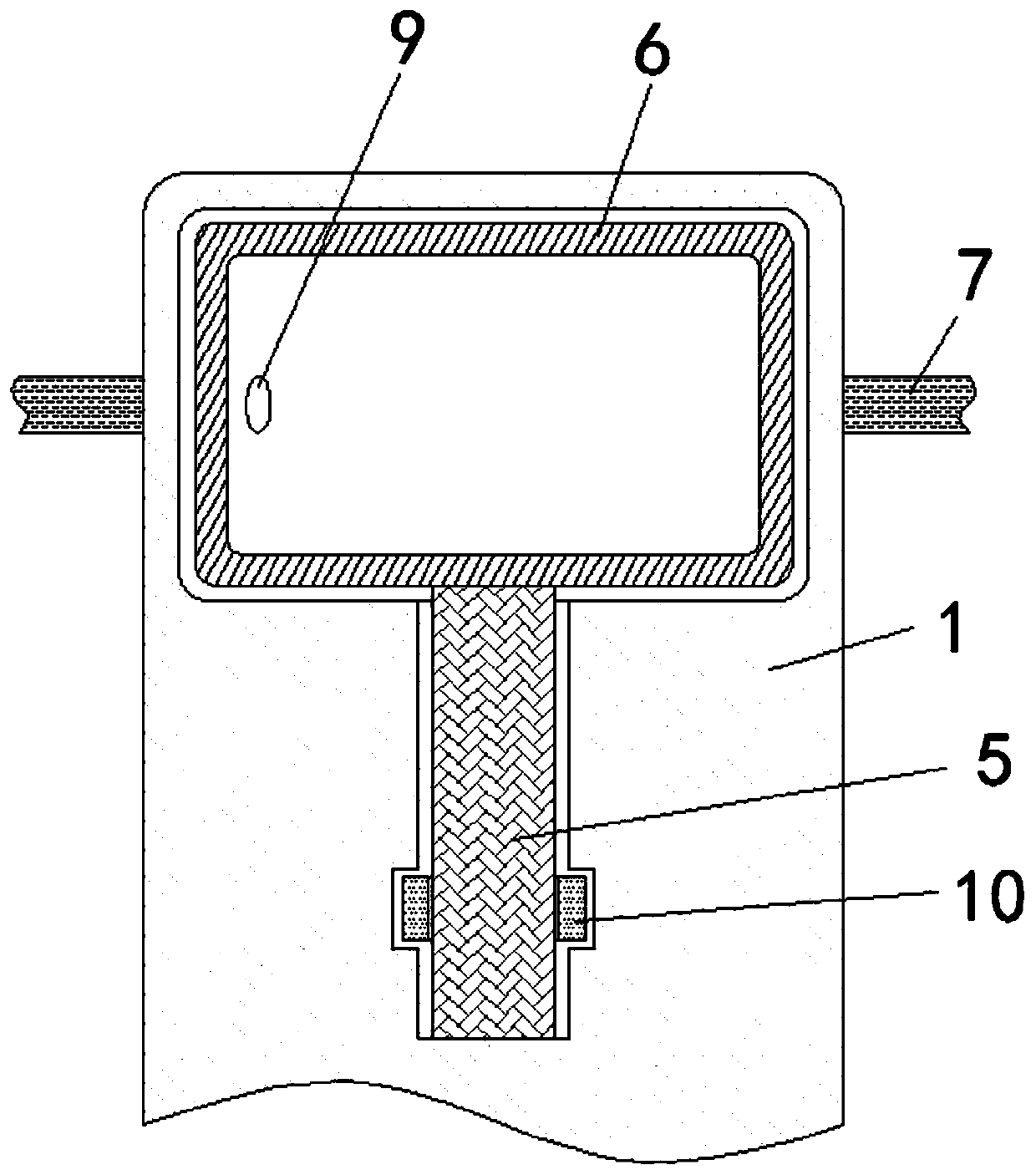

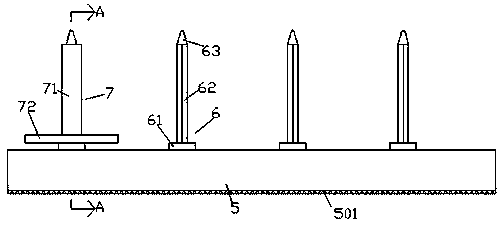

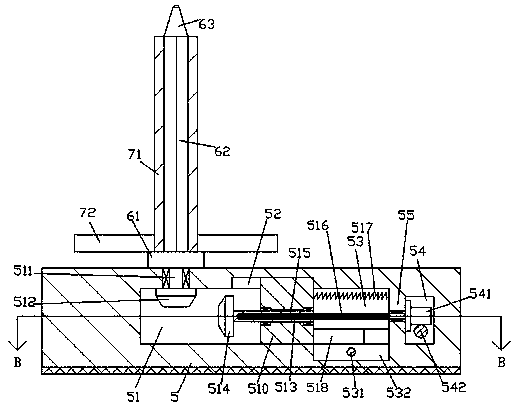

Novel bridge maintaining equipment

ActiveCN107044087ARealize automatic reset workRestricted taxi positionBridge erection/assemblyRoads maintainenceAutomatic controlArchitectural engineering

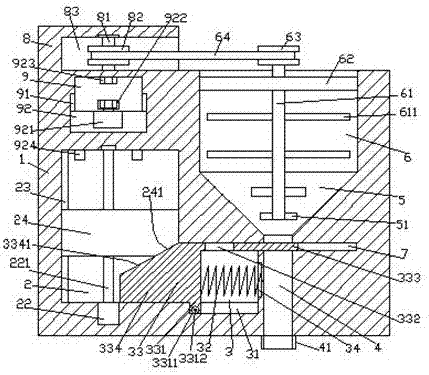

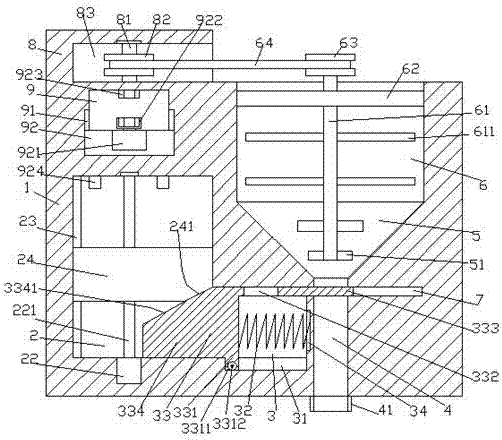

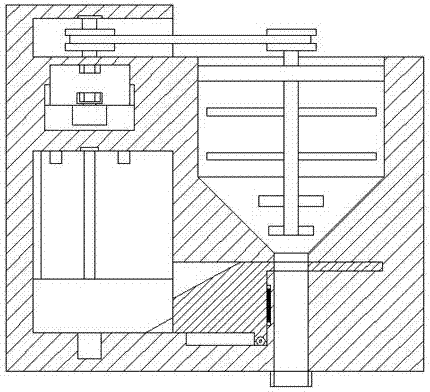

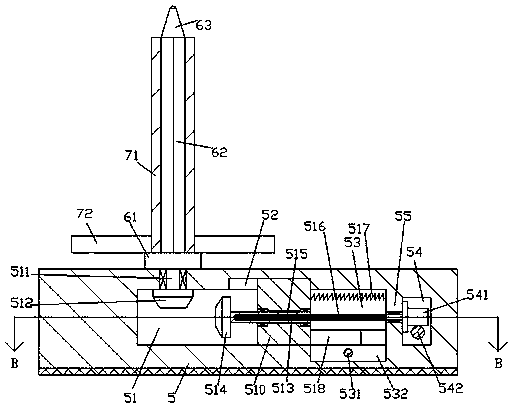

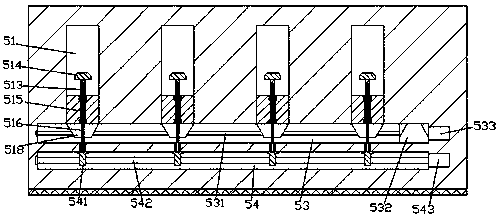

The invention discloses novel bridge maintaining equipment. The novel bridge maintaining equipment comprises a material box, a first sliding cavity is formed in the left side of the material box, a first guide groove is formed in the inner wall of the left side of the first sliding cavity, and a second sliding cavity communicating with the first sliding cavity is formed in the portion, located at the right side of the first sliding cavity, of the material box; an arrangement groove arranged in a vertical-extending mode is formed in the portion, located at the right side of the second sliding cavity, of the material box, a closed groove penetrating through the arrangement groove and extending rightwards is formed in the top of the second sliding cavity, a cone-shaped cavity is formed in the top of the arrangement groove, and a feeding cavity is formed in the top of the cone-shaped cavity; and a third sliding cavity is formed in the portion, located above the first sliding cavity, of the material box, third guide grooves are symmetrically formed in the inner walls of the left and right sides of the third sliding cavity, a screw rod is arranged in the first sliding cavity, a first driver is connected with the bottom of the screw rod, and a lifting block is connected to the screw rod in a threaded fit mode. According to the novel bridge maintaining equipment, the structure is simple, the design is reasonable, operation is simple, stirring and discharging work can be automatically controlled, the labor capacity of workers are reduced, the construction and maintenance speed is enhanced, meanwhile the lighting function is achieved, the use cost is low, and current requirements are met.

Owner:NANTONG YIXUAN IND DESIGN CO LTD

Decorative coating device

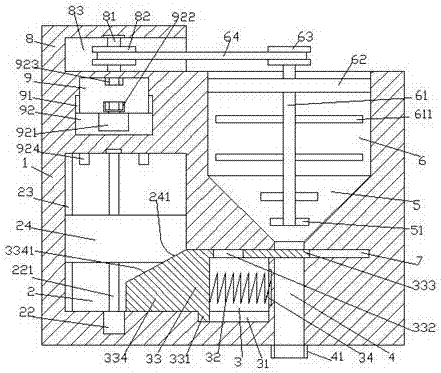

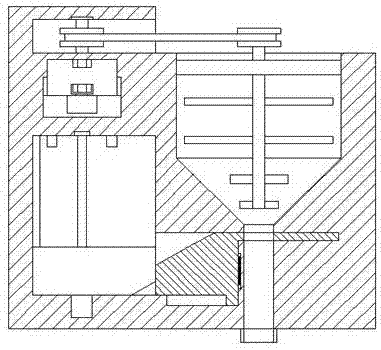

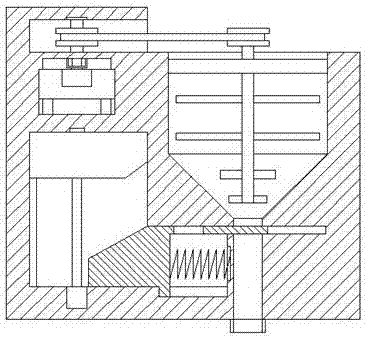

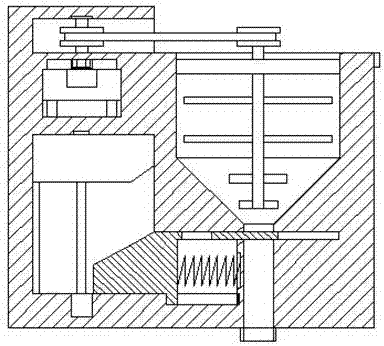

InactiveCN107020038ARealize automatic reset workLimit sliding positionRotary stirring mixersTransportation and packagingAutomatic controlEngineering

The invention discloses a decorative coating device. The decorative coating device comprises a base body, wherein the interior of the left side of the base body is provided with a first sliding connection cavity; the inner wall of the left side of the first sliding connection cavity is provided with a first guide groove; the interior of the base body at the right side of the first sliding connection cavity is provided with a second sliding connection cavity which is communicated with the first sliding connection cavity; the interior of the base body at the right side of the second sliding connection cavity is provided with an output groove which can extend up and down; the top part of the second sliding connection cavity is provided with a sealing groove which penetrates through the output groove and extends to the right side; a hopper-shaped part is arranged at the top part of the output groove, and a uniform stirring part is arranged at the top part of the hopper-shaped part; the interior of the base body above the first sliding connection cavity is provided with a third sliding connection cavity; the inner walls of left side and right side of the third sliding connection cavity are correspondingly provided with third guide grooves; a spiral rod is arranged in the first sliding connection cavity, the bottom part of the spiral rod is connected with a first electric rotation machine, and the spiral rod is in matched connection with a push-up block by threads. The decorative coating device has the advantages that the structure is simple, the design is reasonable, and the operation is simple; the stirring and material discharging are automatically controlled, the labor intensity of workers is decreased, the use cost is lower, the stirring is more uniform, the stirring efficiency is improved, and the existing requirements are met.

Owner:QUAZHOU GANGSHENGLILAI IMPORT & EXPORT TRADE CO LTD

Coating matching device

InactiveCN107149898ARealize automatic reset workLimit sliding positionTransportation and packagingRotary stirring mixersBiochemical engineering

The invention discloses a coating matching device which comprises a matrix. A first slide cavity is arranged inside the left side of the matrix, a first guide groove is formed in the inner wall of the left side of the first slide cavity, a second slide cavity which is communicated with the first slide cavity is arranged in the matrix and is positioned on the right side of the first slide cavity, an output groove is formed in the matrix in an extension manner in the up-down direction and is particularly formed in the right side of the second slide cavity, an enclosed groove which is perforated through the output groove and extends towards the right side is formed in the top of the second slide cavity, a hopper-shaped portion is arranged on the top of the output groove, a stirring portion is arranged on the top of the hopper-shaped portion, a third slide cavity is arranged in the matrix and is positioned above the first slide cavity, third guide grooves are correspondingly formed in the inner walls of the left side and the right side of the third slide cavity, a spiral rod is arranged in the first slide cavity, a first electric rotary machine is connected with the bottom of the spiral rod, and a pushing and lifting block is fittingly connected onto the spiral rod in a threaded manner. The coating matching device has the advantages that the coating matching device is simple in structure, reasonable in design and easy to operate, stirring and discharging work can be automatically controlled, and accordingly the amount of labor can be reduced for workers; the coating matching device is low in service cost, uniform stirring effects can be realized, the stirring efficiency can be improved, and existing requirements can be met.

Owner:蒋雷杰

Automatic stirring and feeding equipment used for pig farm

InactiveCN107306813AControl to move left and rightRealize automatic reset workAnimal feeding devicesPig farmsAutomatic control

The invention discloses an automatic stirring and feeding equipment for pig farms, which comprises a casing, a first sliding chamber is arranged inside the left side of the casing, a first guide groove is arranged on the left inner wall of the first sliding chamber, and the first sliding chamber The housing on the right side is provided with a second sliding chamber connected with the first sliding chamber, the housing on the right side of the second sliding chamber is provided with a discharge hole extending up and down, and the top of the second sliding chamber is provided with a horizontal through discharge hole. hole and the partition guide groove extending to the right, a funnel-shaped hopper is provided on the top of the discharge hole, a feed hopper is provided on the top of the funnel-shaped hopper, a third sliding chamber is provided in the housing above the first sliding chamber, and the third sliding chamber The inner walls of the left and right sides of the cavity are symmetrically provided with a third guide groove, and a screw is provided in the first sliding cavity, the bottom of the screw is connected with the power of the first motor, and the upper screw is threaded and connected with a moving block; the invention has simple structure, reasonable design and simple operation , The manufacturing cost is very low and the maintenance cost is low. It is suitable for small and medium-sized farmers. It can automatically control the feeding work and reduce the labor load of workers.

Owner:朱娟红

Automatic stirring and feeding equipment for pig raising

InactiveCN107306824AControl to move left and rightRealize automatic reset workTransportation and packagingRotary stirring mixersAutomatic controlEngineering

The invention discloses automatic stirring and feeding equipment for pig raising. The equipment includes a housing, the left side of the housing is internally provided with a first sliding cavity, the inner wall of the left side of the first sliding cavity is provided with a first guide groove, the portion, on the right side of the first sliding cavity, of the housing is internally provided with a second sliding cavity communicated with the first sliding cavity, the portion, on the right side of the second sliding cavity, of the housing is internally provided with a discharge hole extending up and down, the top of the second sliding cavity is provided with a partition plate guide groove which transversely penetrates through the discharge hole and extends to the right side, the top of the discharge hole is provided with a funnel-shaped hopper, the top of the funnel-shaped hopper is provided with a feeding hopper, the portion, above the first sliding cavity, of the housing is internally provided with a third sliding cavity, the inner walls of the left side and the right side of the third sliding cavity are symmetrically provided with third guide grooves, a threaded rod is arranged in the first sliding cavity, the bottom of the threaded rod is in powered connection with a first motor, and the threaded rod is connected with a moving block in a screw-thread fit mode. According to the equipment, the structure is simple, the design is reasonable, the operation is simple, the manufacturing cost and the maintenance cost are very low, the equipment is suitable for small and medium-sized farmers to use, feeding work can be automatically controlled and the labor amount of workers is reduced.

Owner:朱娟红

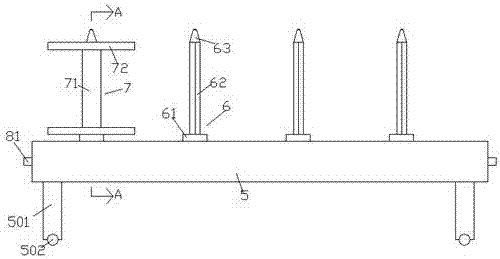

Bridge equipment

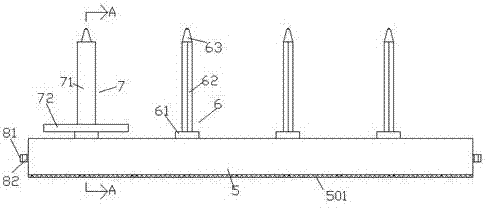

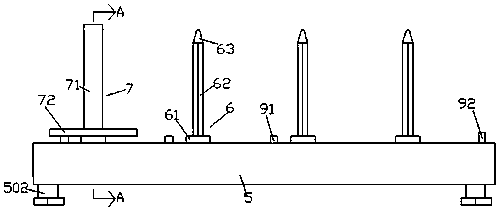

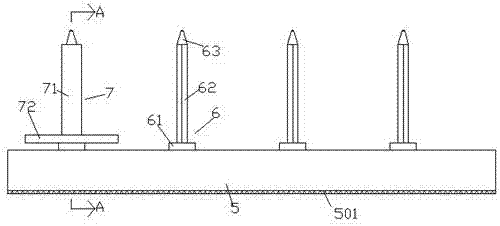

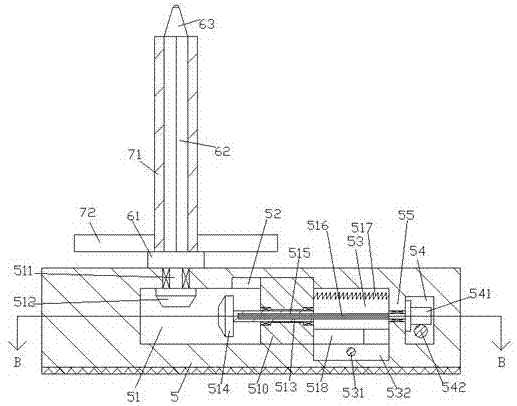

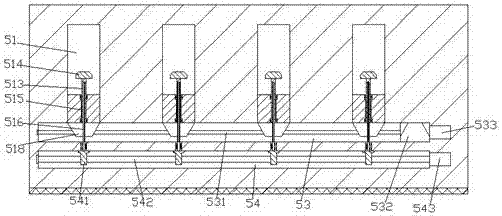

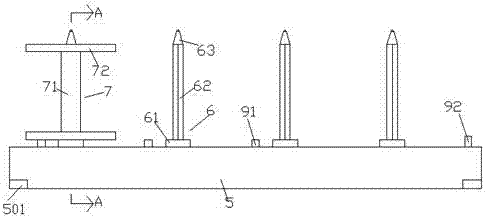

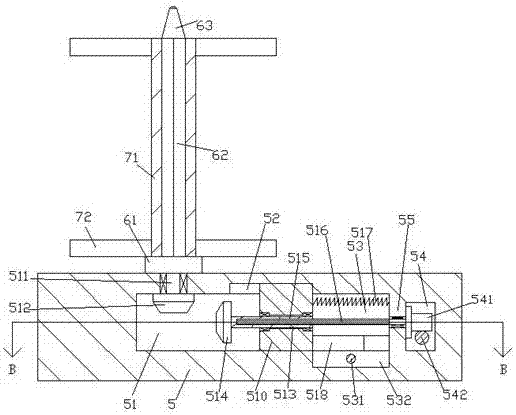

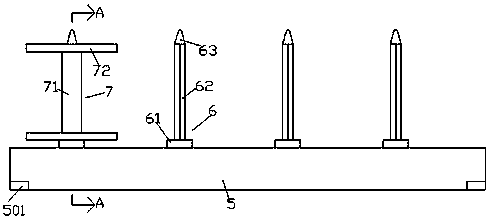

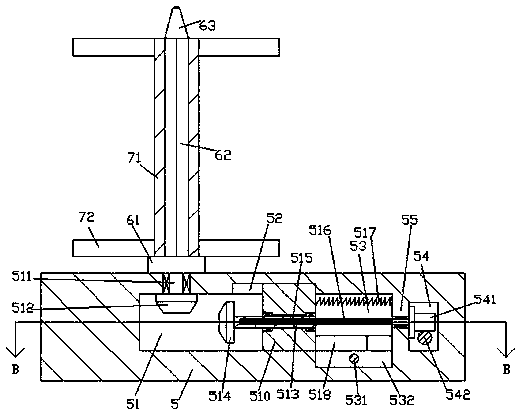

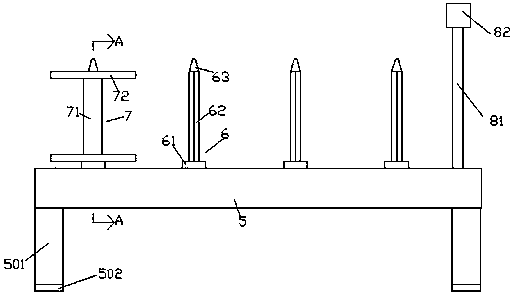

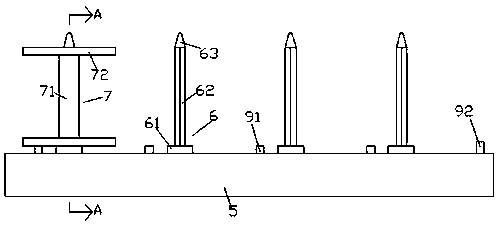

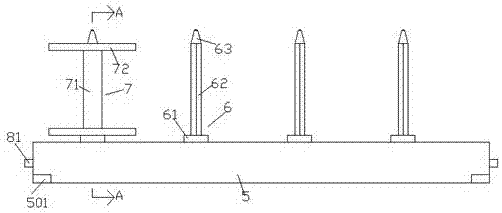

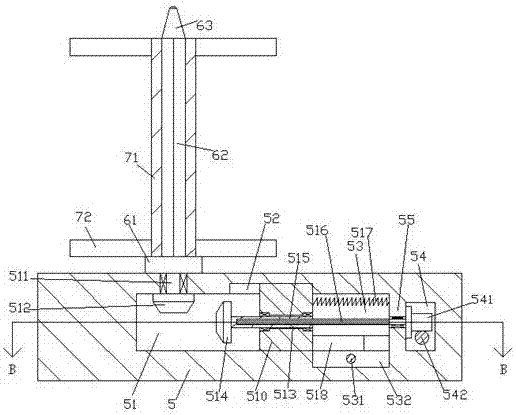

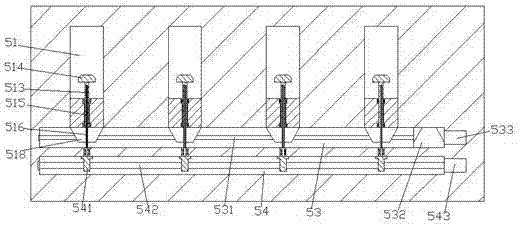

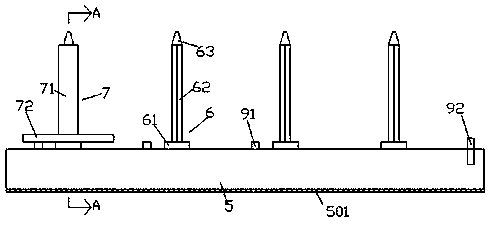

InactiveCN107244585AImproves front and rear movement stabilityRealize automatic reset workFilament handlingEngineeringConductor Coil

The invention discloses bridge equipment. The bridge equipment comprises a bed frame and rope winding assemblies evenly distributed on the end face of the top of the bed frame. Stand arms are fixedly mounted at the bottom of the bed frame. Rotatable universal wheels are mounted at the bottoms of the stand arms. A driving cavity extending forwards is formed in the position, below the corresponding rope winding assembly, in the bed frame. The rear side of each driving cavity is provided with a first hollow cavity extending left and right in a communicating mode. A second hollow cavity is formed in the position, in front of the corresponding first hollow cavity, in the bed frame. A partition plate is arranged between each first hollow cavity and the corresponding second hollow cavity. A movement guiding groove is formed in the position, in front of the corresponding first hollow cavity, of the inner top of the bed frame. A first sliding frame extending downwards is arranged in each movement guiding groove. The bridge equipment is simple in structure, mounting of a plurality of rope winding drums can be achieved, an operator does not need to replace the rope winding drums when a rope is wound on one of the rope winding drums, time and effort are saved, and the efficiency is improved; and in addition, a driving device does not need to be additionally arranged, the manufacturing cost is lowered, and the enterprise purchase cost is lowered.

Owner:俞岳田

Portable mailbox device

InactiveCN107199159AImproves front and rear movement stabilityRealize automatic reset workLiquid surface applicatorsCoatingsEngineeringPurchase cost

Owner:叶梦

High-efficiency bridge equipment

InactiveCN107187932AReduce equipment investmentReduce procurement costsFilament handlingBridge erection/assemblyEngineeringConductor Coil

The invention discloses high-efficiency bridge equipment which comprises a base frame and rope winding components uniformly distributed on the end surface at the top of the base frame; vertical arms are fixedly mounted at the bottom of the base frame; an universal wheel is mounted at the bottom of each of the vertical arms in a rolling manner; a driving cavity stretching towards the front side is arranged in the base frame at the position below each of the rope winding components; a first hollow cavity stretching in the left-right direction is formed in the rear side of each of the driving cavities in a communicating manner; a second hollow cavity is formed in the base frame at the position on the front side of each of the first hollow cavities; a partition plate is arranged between each of the first hollow cavities and the corresponding second hollow cavity; a guide and transfer groove is formed in the inner top of the front side of each of the first hollow cavities; and a first sliding frame extending downwards is arranged in each of the guide and transfer grooves. The high-efficiency bridge equipment has the benefits as follows: the structure is simple, the installation of a plurality of rope drums can be realized, each of the rope drums does not need to be replaced with a new one after the completion of rope winding, both time and labor are saved, and the efficiency is improved; besides, a driving device does not need to be additionally arranged, so that the manufacturing cost is reduced, and the enterprise procurement cost is further reduced.

Owner:俞岳田

Power cable equipment

InactiveCN107244586AImproves front and rear movement stabilityRealize automatic reset workFilament handlingPurchase costEngineering

Owner:王益忠

Cup device

ActiveCN107128115AImproves front and rear movement stabilityRealize automatic reset workEngravingMechanical engineeringTooth cavity

The invention discloses a cup device. The cup device comprises a frame body and rotary components distributed on the end face of the top of the frame body at equal intervals. Inner screw holes are formed in the bottom of the frame body, screw columns are mounted in the inner screw holes in a matched mode, a tooth cavity extending toward the front side is formed, under each rotary component, in the frame body, a first groove body extending toward the left and right is formed in the rear side of each tooth cavity in a communicating mode, and a second groove body is formed, on the front side of the first groove body, in the frame body, a division plate is arranged between the first groove body and the second groove body, a guide groove is formed in the inner top of the front side of each first groove body, and a first slide frame extending downwards is arranged in each guide groove. The cup device is simple in structure, can achieve mounting of a plurality of rotary drums without need of replacing one rotary drum after the rotary drum is wound, time and labor are saved, and the efficiency is improved; in addition, no excessive driving device is needed to be arranged, the production cost is reduced, and the purchasing cost of enterprises is reduced at the same time.

Owner:平湖市浩鑫塑胶股份有限公司

Convenient processing apparatus

InactiveCN107308844ARealize automatic reset workLimit activity locationRotary stirring mixersTransportation and packagingEngineering

The invention discloses a convenient processing apparatus, comprising an apparatus body, wherein the interior of the left side of the apparatus body is provided with a first sliding chamber; the left inner wall of the first sliding chamber is provided with a first guiding and conveying groove; a second sliding chamber communicated with the first sliding chamber is arranged in the part, located at the right side of the first sliding chamber, of the apparatus body; a discharging channel arranged to extend upwardly and downwardly is mounted in the part, located at the right side of the second sliding chamber, of the apparatus body; the top of the second sliding chamber is provided with a separating groove communicated with the discharging channel and extending rightward; the top of the discharging channel is provided with a hopper; the top of the hopper is provided with a stirring part; a third sliding chamber is arranged in the part, located above the first sliding chamber, of the apparatus body; the inner walls of the left and right sides of the third sliding chamber are correspondingly provided with third guiding and conveying grooves; a bolt is arranged in the first sliding chamber; the bottom of the bolt is connected with a first motor; and the bolt is in screw-thread fit with a touch press block. The convenient processing apparatus provided by the invention is simple in structure, reasonable in design, simple to operate and capable of automatically controlling stirring and discharging operations; and the convenient processing apparatus has a prompting function, can reduce the amount of labor work, is good in stirring effect, enables food safety to be high and improves work efficiency.

Owner:项浩定

Simple and convenient water cup device

InactiveCN108237833AImproves front and rear movement stabilityRealize automatic reset workToothed gearingsOther artistic work equipmentsEngineeringConductor Coil

The invention discloses a simple and convenient water cup device. The water cup device comprises a frame body and rotating elements, wherein the rotating elements are equally distributed on the top end surface of the frame body at intervals; inner screw holes are formed in the bottom of the frame body; studs are arranged in the inner screw holes in a matched mode; a tooth cavity which is formed ina forward extending mode is formed in the position, below each rotating element, of the frame body; the rear sides of the tooth cavities communicate with first groove bodies which are formed in a left-and-right extending mode; second groove bodies are formed in the positions, on the front side of the first groove bodies, of the frame body; isolation plates are arranged between the first groove bodies and the second groove bodies; a guide groove is formed in the inner top of the front side of each first groove body; and a first sliding frame which is arranged in a downward extending mode is arranged in each guide groove. The water cup device has the advantages that the structure is simple, a plurality of rotating cylinders can be mounted, the rotating cylinders do not need to be replaced after a rope is wound around one rope winding cylinder, so that time and labor are saved, the efficiency is improved, in addition, a driving device does not need to be additionally arranged, so that the manufacturing cost is lowered, and meanwhile, the enterprise purchasing cost is lowered.

Owner:傅倩倩

Highly effective processing device

InactiveCN107307464AControl to move left and rightRealize automatic reset workFood shapingMeat processing devicesAutomatic controlEngineering

The invention discloses a high-efficiency processing device, which comprises a machine body. A first slide chamber is arranged inside the left side of the machine body. A first guide groove is provided on the inner wall of the left side of the first slide chamber. The second sliding chamber is connected with the first sliding chamber. The body on the right side of the second sliding chamber is provided with a discharge channel extending up and down. The top of the second sliding chamber is provided with a separation groove extending to the right through the discharge channel. There is a hopper on the top of the channel, and a stirring part is arranged on the top of the hopper. A third sliding chamber is provided in the body above the first sliding chamber. The inner walls on the left and right sides of the third sliding chamber are equally provided with third guide grooves. The first There is a stud in the sliding chamber, the bottom of the stud is connected with the first motor, and the screw is connected with a contact pressure block; the invention has simple structure, reasonable design, simple operation, can automatically control the stirring and discharging work, and has Reminder function, reduce the labor load of workers, good mixing effect, high food safety, and improve work efficiency.

Owner:项浩定

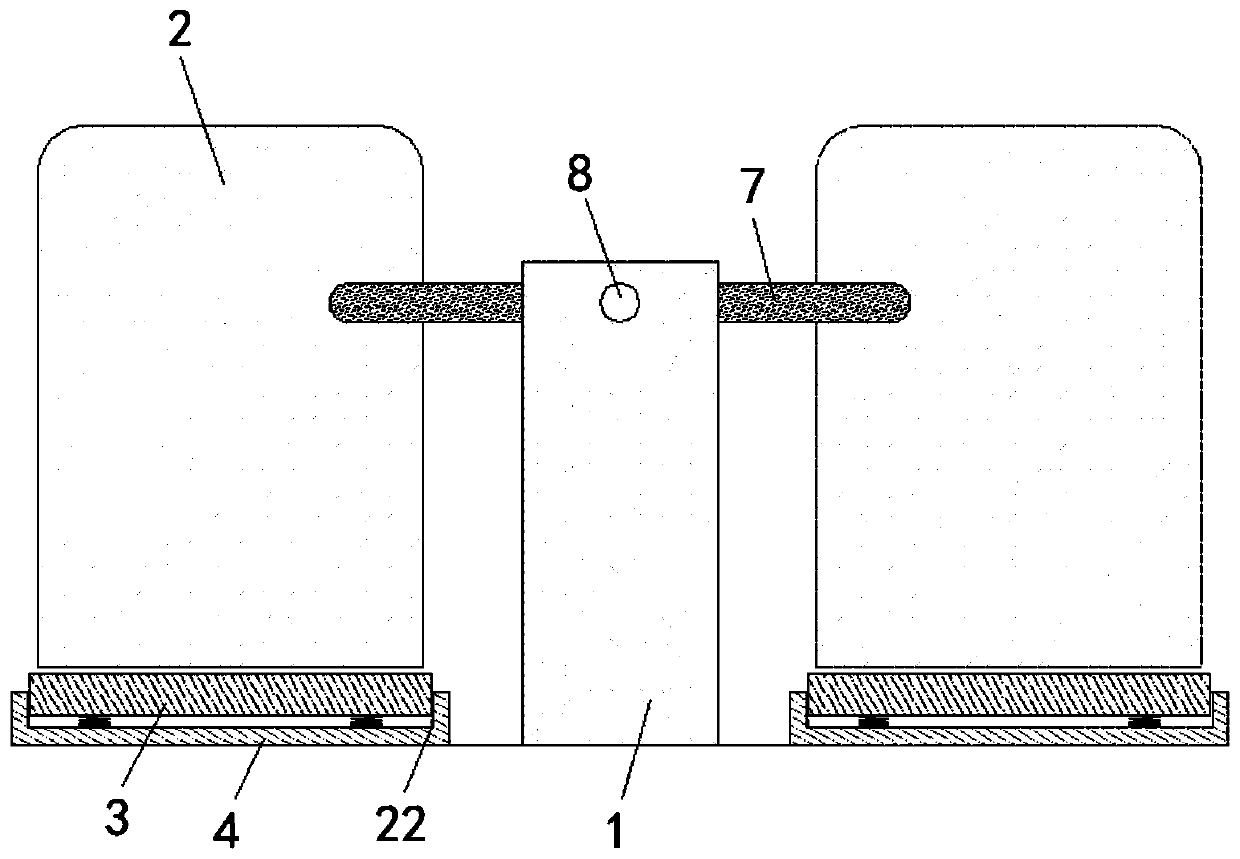

Mailbox device

ActiveCN107212719AImproves front and rear movement stabilityRealize automatic reset workKitchen equipmentDomestic articlesPurchase costEngineering

The invention discloses a mailbox device. The mailbox device comprises a base and rotating devices distributed on the end face of the top of the base in an equal-distance manner, wherein a flexible pad is fixedly arranged at the bottom of the base, a drive cavity extending towards the front side is arranged in the base below each rotating device, a first hole cavity extending leftwards and rightwards is arranged on the rear side of each drive cavity in a communicated manner, a second hole cavity is arranged in the base on the front side of each first hole cavity, a partition is arranged between each first hole cavity and the corresponding second hole cavity, a guide connection groove is arranged in the inner top of the front side of each first hole cavity, and a first slide connection rack extending downwards is arranged in each guide connection groove. The mailbox device has the advantages that the mailbox device is simple in structure, multiple rotating cylinders can be mounted, the rotating cylinders does not need to be replaced after mailboxes are rotated, time and labor are saved, and efficiency is increased; in addition, an extra drive device is not needed, manufacturing cost is reduced, and enterprise purchase cost is also lowered.

Owner:江苏盐西新城教育产业项目开发有限公司

Raw material storage device for nanocrystal preparation and use method

InactiveCN110733770AAchieve rotationAuto openDispersed particle filtrationLarge containersProcess engineeringNanocrystal

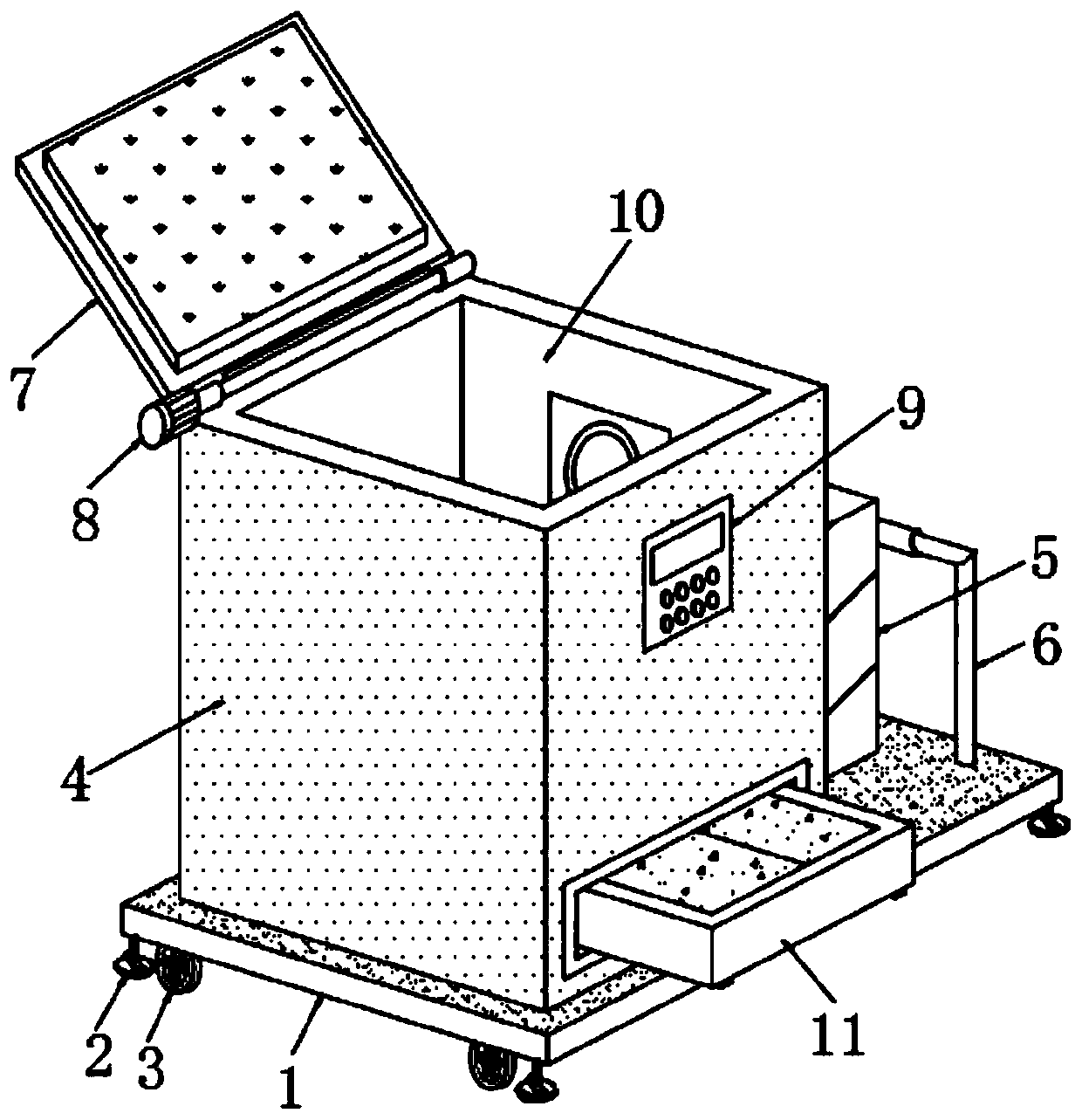

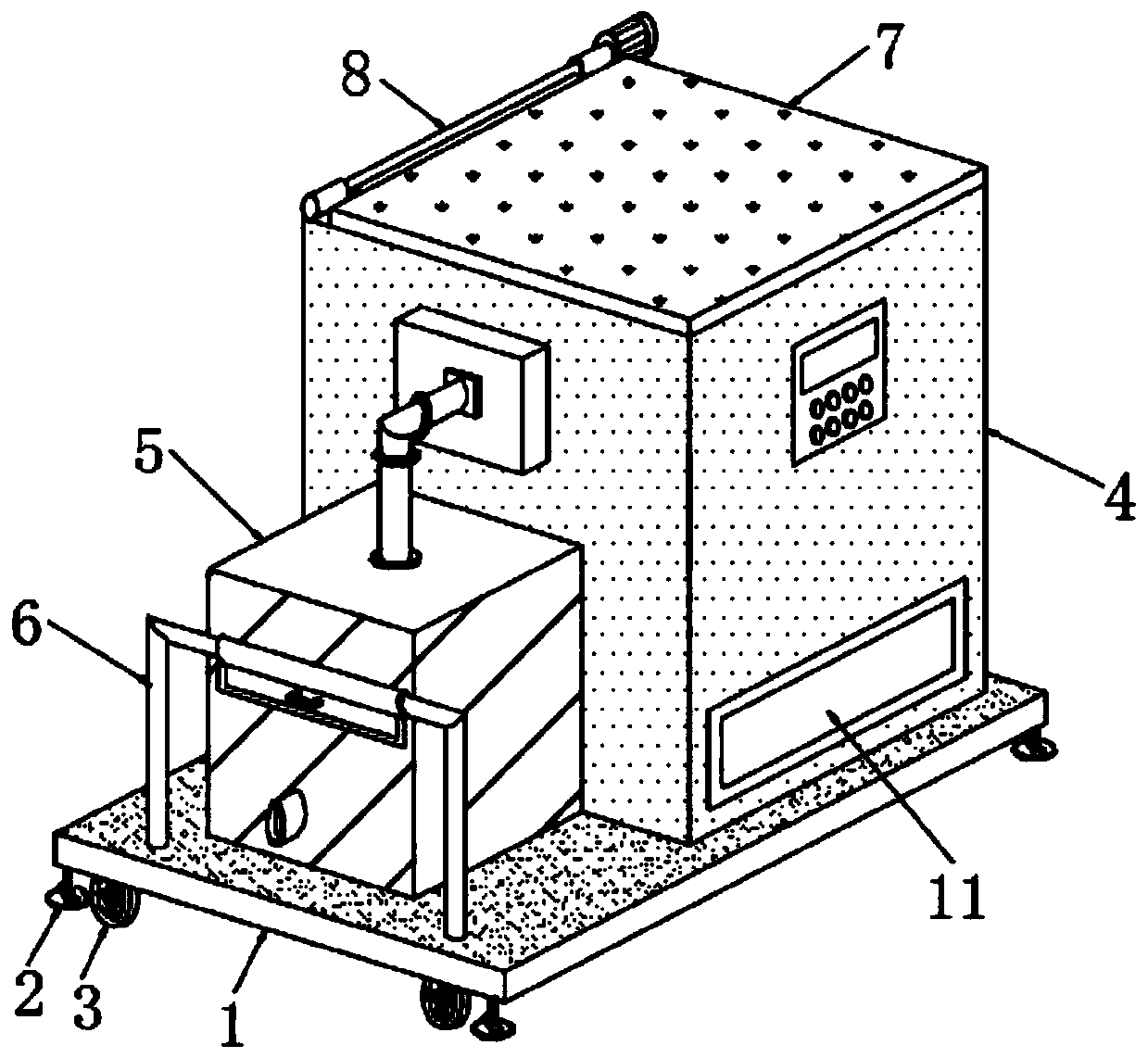

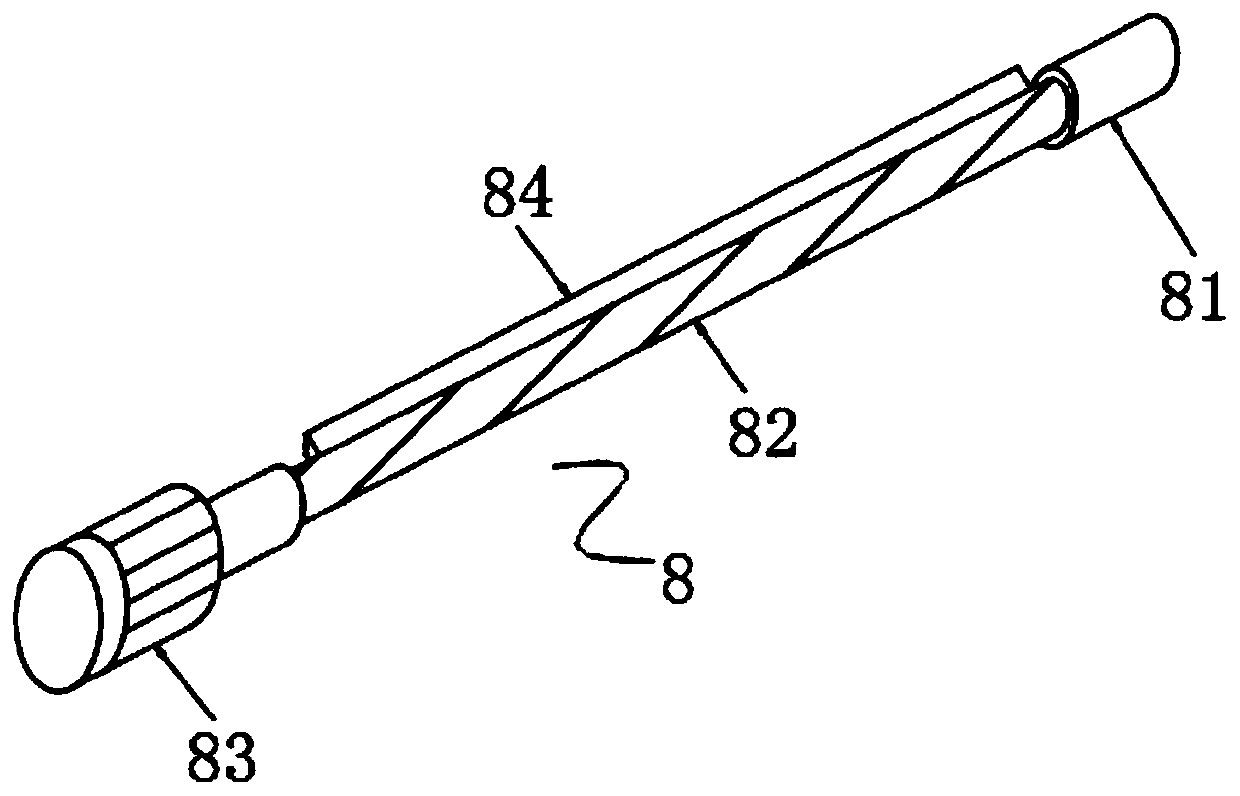

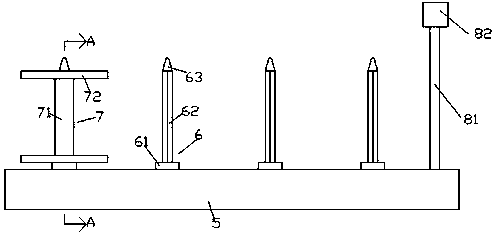

The invention discloses a raw material storage device for nanocrystal preparation and a use method, and relates to the technical field of nanocrystal preparation. The raw material storage device comprises a base, wherein supporting legs are fixedly arranged on the lower surface of the base, and the lower surface of the base is provided with universal wheels at the inner side positions of the supporting legs; and a box body is fixedly arranged on the upper surface of the base, and the upper surface of the base is fixedly provided with a ventilation mechanism at one side position of the box body. The raw material storage device for the nanocrystal preparation is scientific and reasonable in structure and convenient to use and operate; through the arrangement of a cover opening mechanism, thepurpose of automatic opening and closing of a box cover can be achieved, and convenience is provided for storage work of nanocrystal raw materials; through the arrangement of a material storage mechanism, the adjustment of discharge flow can be realized, convenience is provided for the material taking work by a worker; and through the arrangement of a discharging mechanism, automatic dischargingwork of the raw materials can be achieved, the material taking work by the worker is facilitated, manpower is effectively saved, and working efficiency is improved.

Owner:南京纳希纳米科技有限公司

Drive self-selection spinning winding mechanism

InactiveCN108249215AReduce equipment investmentReduce procurement costsFilament handlingEngineeringConductor Coil

The invention discloses a drive self-selection spinning winding mechanism. The drive self-selection spinning winding mechanism comprises a base and winding mechanism bodies distributed on the top endface of the base at equal intervals. The part, below each winding mechanism body, of the base is internally provided with a drive cavity extending towards the front side, wherein the rear side of thedrive cavity is provided with a left-right extending first cavity in a communication manner, a second cavity is formed in the part, on the front side of the first cavity, of the base, and a partitionplate is arranged between the first cavity and the second cavity. A sliding guiding groove is formed in the top wall in the front side of each first cavity. Each sliding guiding groove is internally provided with a downward-extending sliding block. The bottom extending section of each sliding block stretches into the corresponding drive cavity and is connected with the inner bottom wall of the drive cavity in a sliding fit manner. Each sliding block is internally connected with a first rotation shaft in a rotation fit manner, wherein the first rotation shaft extends towards the rear side. Thedrive self-selection spinning winding mechanism is simple in structure, installation of multiple winding barrels can be achieved, winding barrel replacement after one winding barrel finishes winding is not needed, time and labor are saved, and efficiency is improved. In addition, additional arrangement of a drive device is not needed, the manufacturing cost is reduced, and meanwhile the enterprisepurchasing cost is reduced.

Owner:QUZHOU YANHANG MACHINERY TECH CO LTD

Novel power cable equipment

InactiveCN107187933AImproves front and rear movement stabilityRealize automatic reset workFilament handlingPower cableEngineering

The invention discloses a new type of power cable equipment, which includes a frame and wire winding members evenly distributed on the top end surface of the frame. Columns are arranged at the bottom of the frame, and anti-slip pads are installed on the bottom of the columns. There is a driving cavity extending to the front side, and the rear side of the driving cavity is connected with a first cavity extending left and right. The frame on the front side of the first cavity is provided with a second cavity. The first cavity and the second cavity A spacer is provided between the two cavities, and a guide groove is provided on the inner top of the front side of each first cavity, and a first sliding frame extending downward is provided in each guide groove; the present invention has a simple structure and can To realize the installation of multiple coiling kits, there is no need to replace the coiling kits after winding one, which saves time and effort and improves efficiency. In addition, there is no need to set up additional driving devices, which reduces manufacturing costs and enterprise procurement costs.

Owner:王益忠

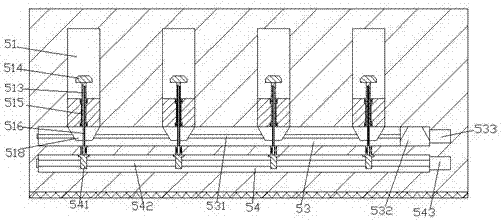

Bridge deck maintaining equipment

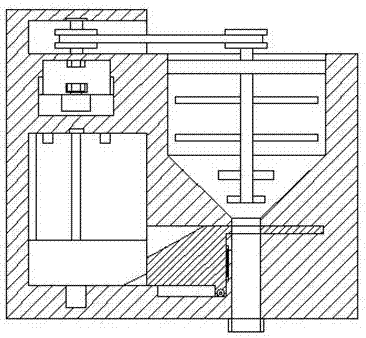

InactiveCN108239938ARealize automatic reset workRestricted taxi positionBridge erection/assemblyRoads maintainenceAutomatic controlBridge deck

The invention discloses bridge deck maintaining equipment comprising a material box. A first sliding cavity is formed in the left side of the material box, and a first guide groove is formed in the inner wall of the left side of the first sliding cavity; a second sliding cavity communicated with the first sliding cavity is formed in the portion, located on the right side of the first sliding cavity, of the material box, and a discharging groove which is arranged in a vertical-extending mode is formed in the portion, located on the right side of the second sliding cavity, of the material box; aclosed groove which penetrates through the discharging groove and extends to the right side is formed in the top of the second sliding cavity, a conical cavity is formed in the top of the discharginggroove, and a feeding cavity is formed in the top of the conical cavity; a third sliding cavity is formed in the portion, located above the first sliding cavity, of the material box, and third guidegrooves are symmetrically formed in the inner walls of the left side and the right side of the third sliding cavity; a spiral rod is arranged in the first sliding cavity, and the bottom of the spiralrod is connected with a first driving machine; and spiral lines on the spiral rod are connected with a lifting block in a matched mode. The bridge deck maintaining equipment is simple in structure, reasonable in design, easy to operate, and capable of automatically controlling stirring and discharging, so that the labor amount of workers is reduced, the construction and maintaining speed is increased, an illumination function is achieved, the use cost is low, and the existing requirements are met.

Owner:陈亚利

Improved type power cable equipment

InactiveCN108238498AImproves front and rear movement stabilityRealize automatic reset workFilament handlingWind componentPower cable

The invention discloses improved type power cable equipment. The improved type power cable equipment comprises a rack and cable winding components, wherein the cable winding components are uniformly distributed on the top end face of the rack. Stand columns are arranged at the bottom of the rack. A non-slip mat is mounted at the bottom of each stand column. A driving cavity is formed in the portion, below each cable winding component, inside the rack, wherein each driving cavity extends toward the front side. A first cavity is formed in the rear side of each driving cavity in a communicating manner, wherein each first cavity extends leftwards and rightwards. A second cavity is formed in the portion, at the front side of each first cavity, inside the rack. A partition strip is arranged between each first cavity and the corresponding second cavity. A guiding groove is formed in the top inside the front side of each first cavity, and a first sliding bracket is arranged in each guiding groove, wherein each first sliding bracket extends downwards. The improved type power cable equipment is simple in structure; multiple cable winding assemblies can be mounted, and it is not needed to replace the corresponding cable winding assembly after winding of one cable winding assembly is completed; time and labor are saved, and efficiency is improved; in addition, no additional driving deviceneeds to be arranged, and the manufacturing cost is lowered; and meanwhile, the purchase cost of an enterprise is lowered.

Owner:石晓峰

a processing device

ActiveCN106857768BControl to move left and rightRealize automatic reset workMeat tenderisingAutomatic controlMechanical engineering

A processing device is disclosed. The device includes a machine body. The inside of the left side of the machine body is provided with a first sliding cavity. The left side inner wall of the first sliding cavity is provided with a first guiding and conveying slot. A second sliding cavity communicated with the first sliding cavity is disposed in the machine body at the right side of the first sliding cavity. A discharging passage extending up and down is disposed in the machine body at the right side of the second sliding cavity. The top of the second sliding cavity is provided with a separating slot penetrating the discharging passage and extending to the right side. The top of the discharging passage is provided with a hopper. The top of the hopper is provided with a stirring part. A third sliding cavity is disposed in the machine body above the first sliding cavity. Left and right inner walls of the third sliding cavity are provided with third guiding and conveying slots symmetrically. A stud is disposed in the first sliding cavity. The bottom of the stud is connected to a first motor. The stud is in threaded connection with a touching and pressing block. The device is simple in structure, reasonable in design, simple to operate and capable of automatically controlling stirring and material discharging, has a reminding function, and is capable of reducing labor of workers, increasing the working efficiency, making stirring effects good and making food safety high.

Owner:扬州市舜意机械有限公司

Practical energy-saving medical bandage device

The invention discloses a practical energy-saving medical bandage device which comprises an engine base and rolling components distributed at the end face of the top of the engine base at equal intervals, the bottoms of the left and right sides of the front and rear end faces of the engine base are each fixedly provided with a fixing frame, a through hole is formed in each fixing frame, a drivingrotating cavity extending to the front side is formed in the portion, below each rolling component, of the engine base, the rear side of each driving rotating cavity is communicated with a first emptygroove extending left and right, a second empty groove is formed in the portion, on the front side of each first empty groove, of the engine base, a partition plate is arranged between each first empty groove and the corresponding second empty groove, a guiding groove is formed in the top inside the front side of each first empty groove, and a first sliding frame extending downwards is arranged inside each guiding groove; the device is simple in structure, multiple rolling cylinders can be installed, the rolling cylinders do not need to be replaced after winding is completed, time and labor are saved, and the efficiency is improved; in addition, no extra driving device is needed, the manufacturing cost is lowered, and meanwhile the purchase cost of an enterprise is lowered.

Owner:CIXI KUANGYAN YINGYING BAMBOO PROD FACTORY GENERAL PARTNERSHIP

An energy-saving medical bandage device

ActiveCN107324130BImproves front and rear movement stabilityRealize automatic reset workFilament handlingWind componentFixed frame

Owner:常州美杰医疗用品有限公司

Novel power cable equipment

The invention discloses novel power cable equipment. The equipment comprises a rack and coiling components uniformly distributed on the top end surface of the rack, stand columns are arranged at the bottom of the rack, and anti-skid mats are arranged at the bottoms of the stand columns; driving cavities which extend forwards are formed in the rack below the coiling components correspondingly, andthe rear sides of the driving cavities communicate with first cavities which are arranged in a left-and-right extending mode; second cavities are formed in the portions, on the front sides of the first cavities, of the rack, separation strips are arranged between the first cavities and the second cavities, and a guide groove is formed in the inner top of the front side of each first cavity; and afirst sliding frame extending downwards is arranged in each guide groove. The equipment is simple in structure, installation of a plurality of winding sleeve pieces can be achieved, the winding sleevepiece does not need to be replaced after one winding sleeve piece is completely wound around by power cables, time and labor are saved, and efficiency is improved; and in addition, a driving device does not need to be additionally arranged, the manufacturing cost is reduced, and the enterprise purchasing cost is reduced.

Owner:石晓峰

Waste refrigerant recycling and adjusting device based on weight change

ActiveCN111397259AGuaranteed stabilityAvoid safety hazardsRefrigeration componentsRefrigerantEngineering

The invention provides a waste refrigerant recycling and adjusting device based on weight change. The waste refrigerant recycling and adjusting device comprises a main seat and two recycling tanks, two air holes which respectively communicate with an air pipe are formed in the side wall of an adjusting seat, a driving plate is movably connected to the front surface of a driven plate, a rotating pawl is movably inserted in the inner part of the driven plate, a second gear is fixedly connected to the front face of the rotating pawl, a tooth section is arranged at the top of the driving plate, areset assembly is installed on one side, close to the driven plate, of the driving plate, and electromagnets corresponding to two strong magnets respectively are fixedly installed in the inner part ofthe main base. According to the waste refrigerant recycling and adjusting device based on weight change, when the weight of one recycling tank is increased to a certain degree, the recycling tank moves downwards to touch a switch, the electromagnets are powered on temporarily, the driving plate is pushed, then the driven plate is driven by the driving plate, the adjusting base rotates, an air inlet pipe is adjusted to be opened and closed, refrigerants enter the other recycling tank, and the situations that too many refrigerants are recycled in the recycling tanks, and potential safety hazards exist are effectively avoided.

Owner:威海世比亚食品有限公司

A mailbox device

ActiveCN107212719BImproves front and rear movement stabilityRealize automatic reset workKitchen equipmentDomestic articlesEngineeringPurchase cost

The invention discloses a mailbox device. The mailbox device comprises a base and rotating devices distributed on the end face of the top of the base in an equal-distance manner, wherein a flexible pad is fixedly arranged at the bottom of the base, a drive cavity extending towards the front side is arranged in the base below each rotating device, a first hole cavity extending leftwards and rightwards is arranged on the rear side of each drive cavity in a communicated manner, a second hole cavity is arranged in the base on the front side of each first hole cavity, a partition is arranged between each first hole cavity and the corresponding second hole cavity, a guide connection groove is arranged in the inner top of the front side of each first hole cavity, and a first slide connection rack extending downwards is arranged in each guide connection groove. The mailbox device has the advantages that the mailbox device is simple in structure, multiple rotating cylinders can be mounted, the rotating cylinders does not need to be replaced after mailboxes are rotated, time and labor are saved, and efficiency is increased; in addition, an extra drive device is not needed, manufacturing cost is reduced, and enterprise purchase cost is also lowered.

Owner:江苏盐西新城教育产业项目开发有限公司

Self-controlled control textile winding mechanism

InactiveCN108285061AImprove work efficiencyLow input costFilament handlingMating connectionConductor Coil

The invention discloses a self-controlled textile winding mechanism. The self-controlled textile winding mechanism comprises a base and winding mechanism bodies distributed on the top end face of thebase at equal intervals, wherein a driving cavity extending to the front side is arranged in the position, below each winding mechanism body, of the base; a first cavity arranged in a left-and-right extension manner is arranged in the rear side of each driving cavity in a communication manner; a second cavity is arranged in the position, on the front side of each cavity, of the base; a separationplate is arranged between each first cavity and the corresponding second cavity, the inner top wall of the front side of each first cavity is provided with a guide sliding groove, a sliding block arranged in a downward extension manner is arranged in each guide sliding groove, the bottom extension sections of the sliding blocks stretch into the driving cavities and are connected with the inner bottom walls of the driving cavities in a sliding fit manner, the interior of each sliding block is connected with a first rotating shaft in a rotating fit manner, and the first rotating shafts are arranged in a manner of extending to the rear sides. The self-controlled textile winding mechanism is simple in structure, can realize installation of multiple winding reels, there is no need to replace the winding reel after the winding reel is wound, time and labor are saved, and the efficiency is improved. In addition, no additional driving device is required, the manufacturing cost is reduced, andthe purchasing cost of an enterprise is reduced.

Owner:QUZHOU YANHANG MACHINERY TECH CO LTD

Novel energy-saving medical bandage device

The invention discloses a novel energy-saving medical bandage device. The novel energy-saving medical bandage device comprises a device base and rolling parts equidistantly distributed on the top endface of the device base, fixing frames are fixedly installed at the bottoms of the left side and the right side of each of the front end face and the rear end face of the device base respectively andare internally provided with through holes, a driving rotary cavity extending to the front side is formed in the device base below each rolling part, the rear sides of the driving rotary cavities arecommunicated with horizontally extending first grooves, second grooves are formed in the device base at the front sides of the first grooves, partition plates are arranged between the first grooves and the second grooves, and a guide groove is formed in the top in the front side of each first groove and is internally provided with downwards extending first slide frames. The novel energy-saving medical bandage device is simple in structure, installation of multiple rolling cylinders can be achieved, the rolling cylinders do not need to be replaced after winding, time and labor are saved, and the efficiency is improved; besides, a driving device does not need to be arranged additionally, the manufacturing cost is reduced, and the enterprise purchase cost is also lowered.

Owner:CIXI KUANGYAN YINGYING BAMBOO PROD FACTORY GENERAL PARTNERSHIP

Letter box device convenient to use

InactiveCN108237031AImproves front and rear movement stabilityRealize automatic reset workSpraying apparatusPurchasingMechanical engineering

The invention discloses a letter box device convenient to use. The letter box device convenient to use comprises a pedestal and surrounding devices which are distributed on the top end face of the pedestal at equal intervals. The bottom of the pedestal is fixedly provided with a flexible cushion. The part, under each surrounding device, of the pedestal is internally provided with a drive cavity which extends towards the front side, wherein the rear side of the drive cavity communicates with a first hollow cavity which extends leftwards and rightwards, the part, on the front side of the first hollow cavity, of the pedestal is internally provided with a second hollow cavity, and a partition plate is arranged between the first hollow cavity and the second hollow cavity. The inner top of the front side of each first hollow cavity is provided with a guide groove, and each guide groove is internally provided with a first sliding frame which extends downwards. The letter box device convenientto use is simple in structure, installation of a plurality of surrounding cylinders can be achieved, it does not need to change the surrounding cylinder after one surrounding cylinder is wound, timeand labor are saved, and the efficiency is improved; and in addition, it does not need to additionally arrange a drive device, the manufacturing cost is reduced, and meanwhile the purchasing cost is reduced for an enterprise.

Owner:QUZHOU YANHANG MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com