Novel automatic clamping electric carrying vehicle

An electric pallet truck and automatic clamping technology, applied in the direction of lifting devices, etc., can solve the problems of falling, valgus damage, loss of balance of goods, etc., and achieve the effect of avoiding valgus damage, high efficiency, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

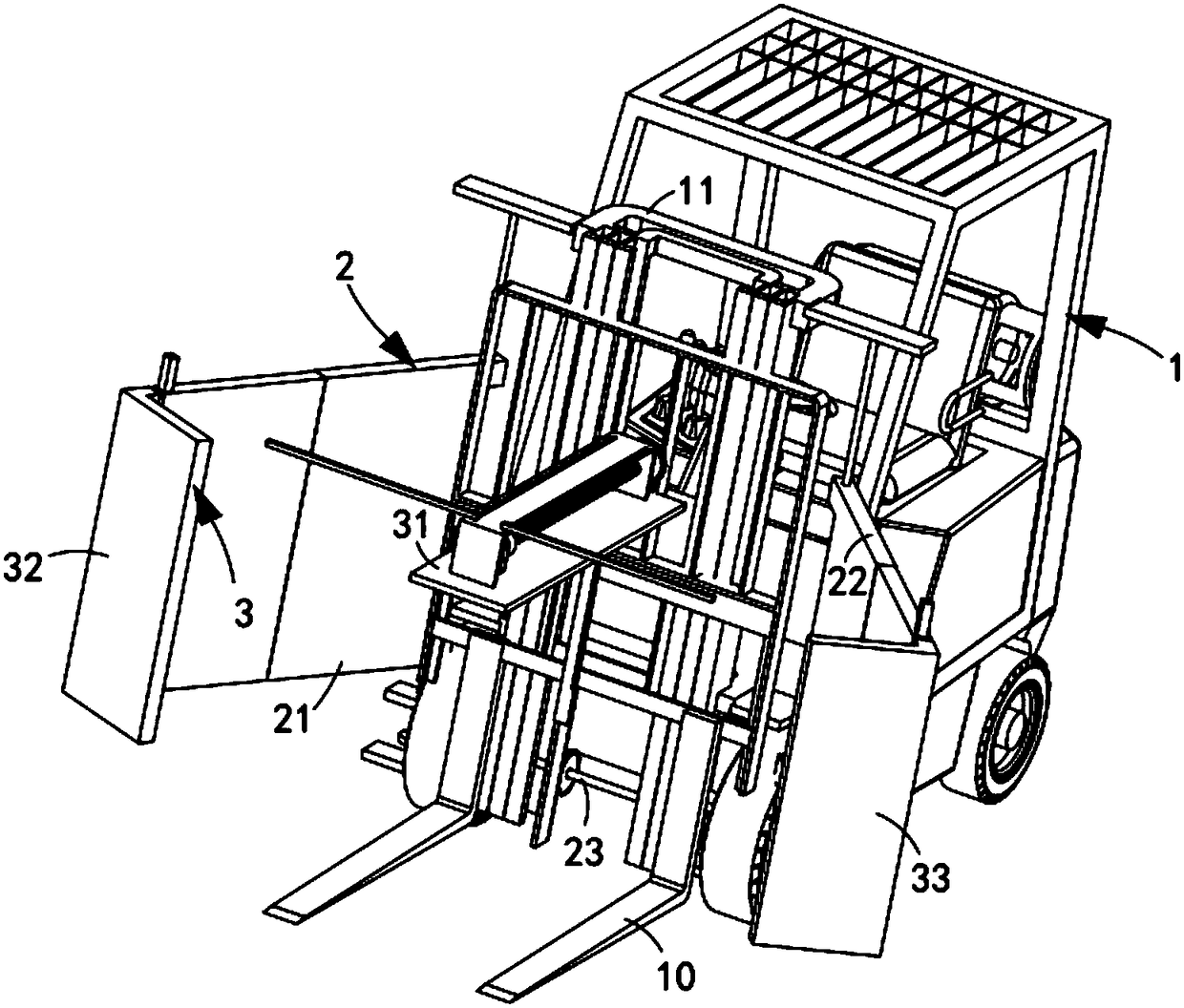

[0066] Such as figure 1 As shown, a new type of automatic clamping electric pallet truck includes a forklift 1, a support frame 11 arranged in front of the forklift 1 and a lifting member 10 arranged below the support frame 11, and also includes:

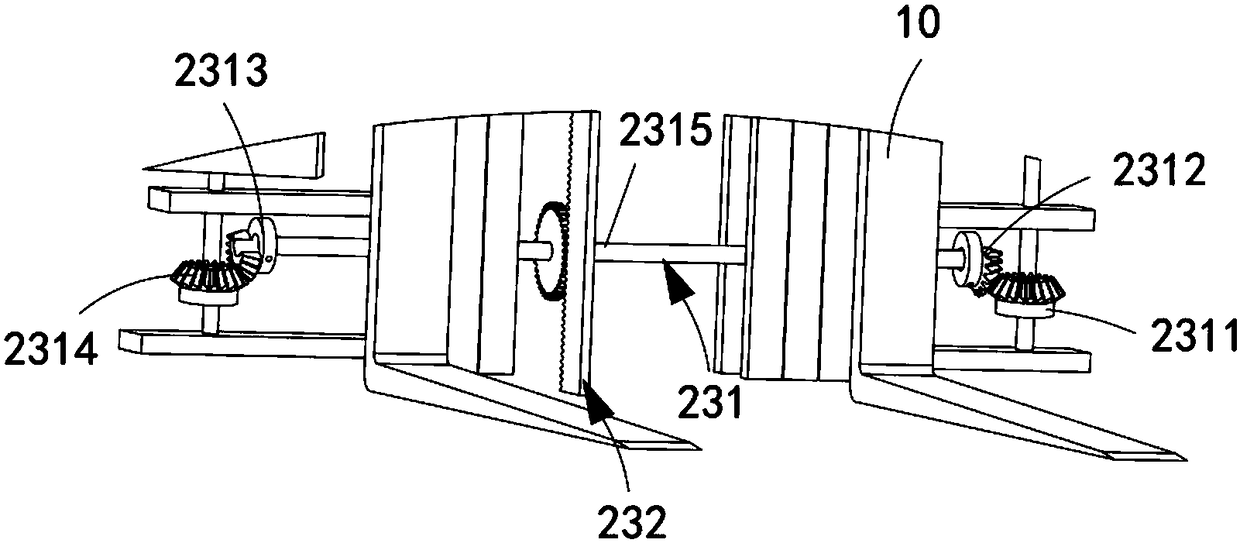

[0067] A material blocking mechanism 2, the material blocking mechanism 2 includes a side blocking assembly a21 installed on the support frame 11, a side blocking assembly b22 symmetrically arranged with the side blocking assembly a21, and a side blocking assembly b22 located between the side blocking assembly a21 and the side blocking assembly a21. The driving assembly 23 between the b22 and used to drive the side stop assembly a21 to work synchronously with the side stop assembly b22; and

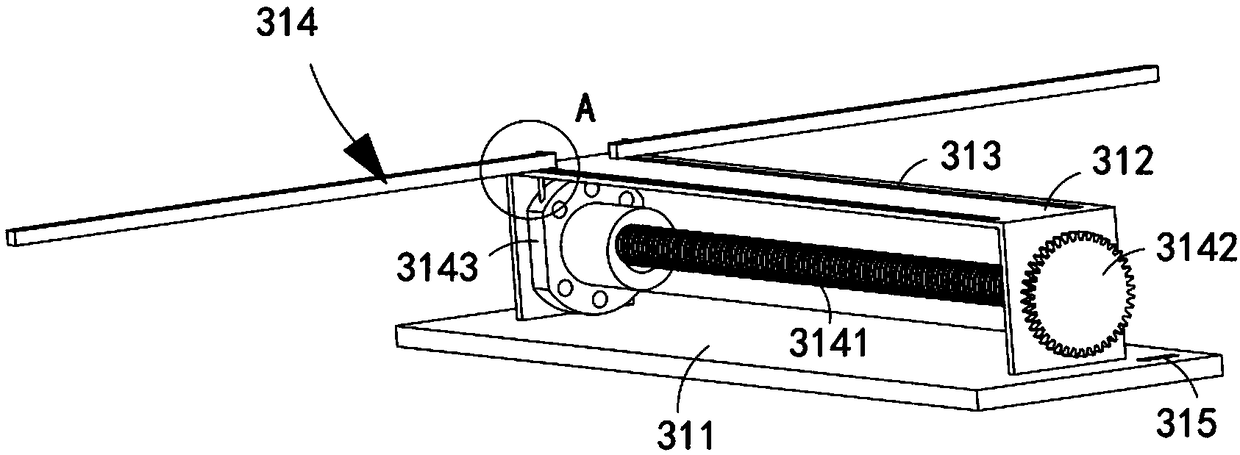

[0068] The tightening mechanism 3 includes a control assembly 31 arranged on the support frame 11 and located between the side fence assembly a21 and the side fence assembly b22, a clip slidably arranged on the side fence assembly a21 The clam...

Embodiment 2

[0111] Such as Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0112] Further, an elastic member 20 is disposed inside the material blocking plate 213 , one end of the elastic member 20 is connected to the bottom of the material blocking plate 213 and the other end is connected to the bottom of the rotating plate 321 .

[0113]In the example in this city, by setting the elastic member 20, the connection between the baffle plate 213 and the rotating plate 213 is firm, and it is not easy to slide and fall off. In addition, during the reset process, the reset feature of the elastic member 20 can be used to realize automatic reset work and improve work efficiency. efficiency.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com