Patents

Literature

77results about How to "Realize clamping work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

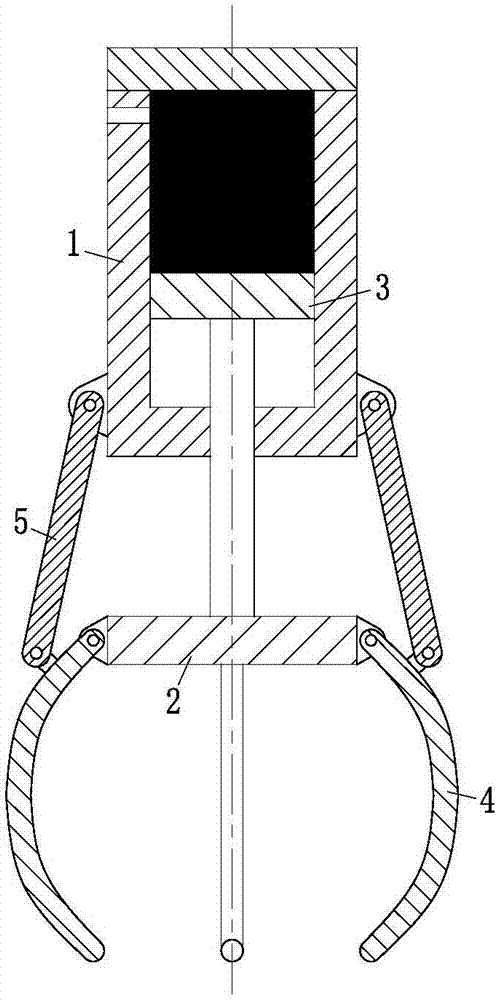

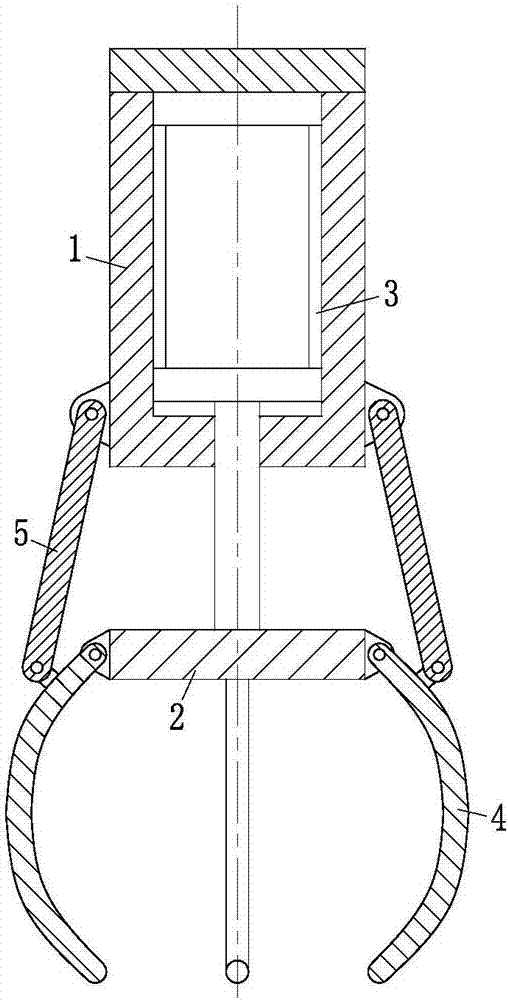

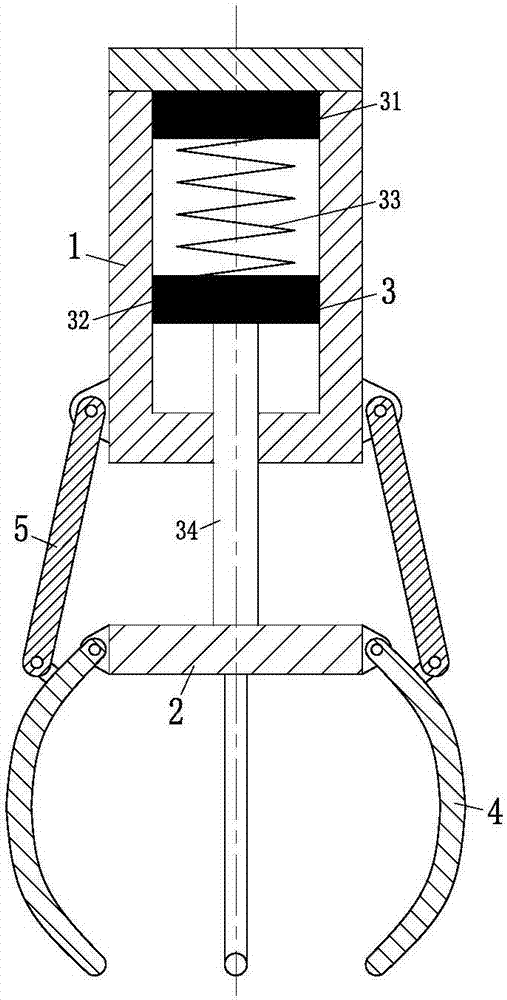

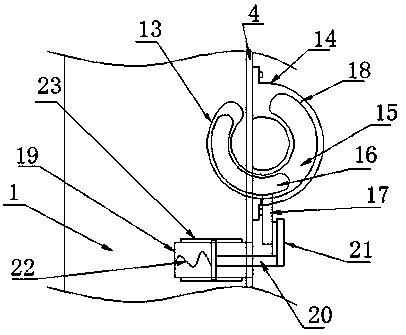

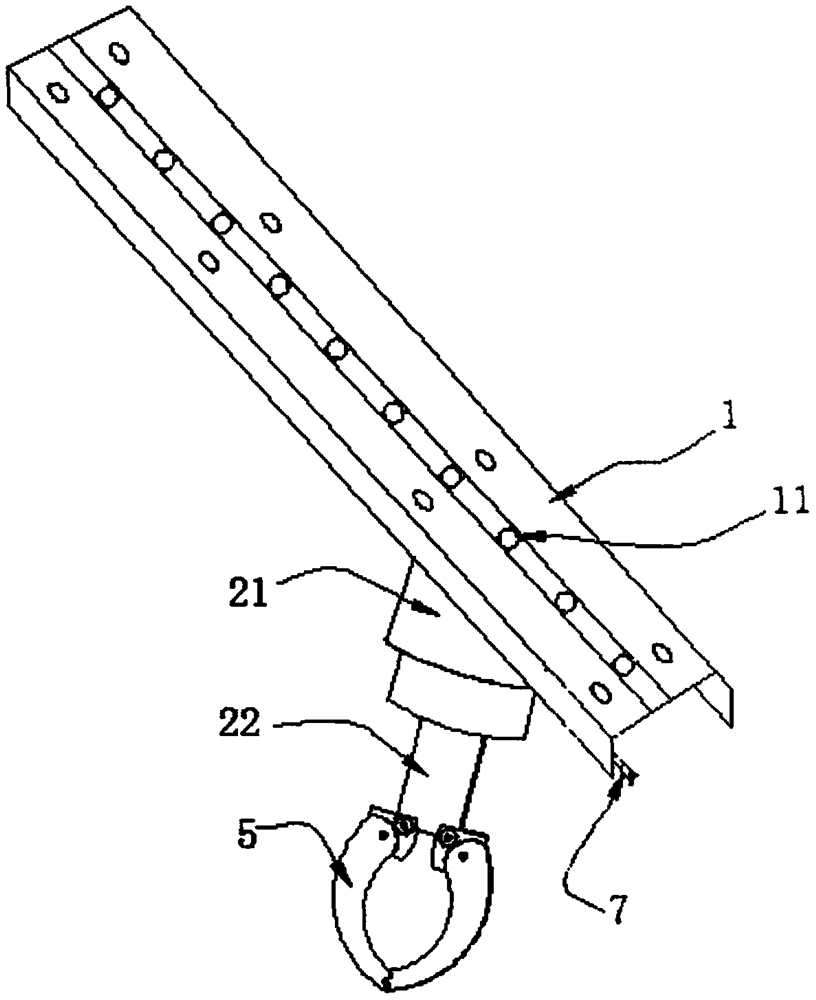

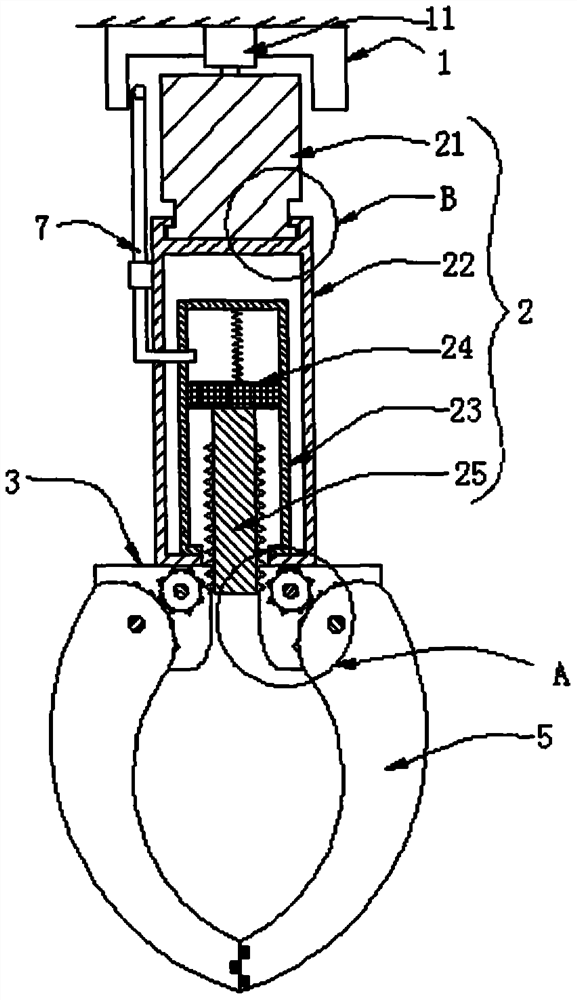

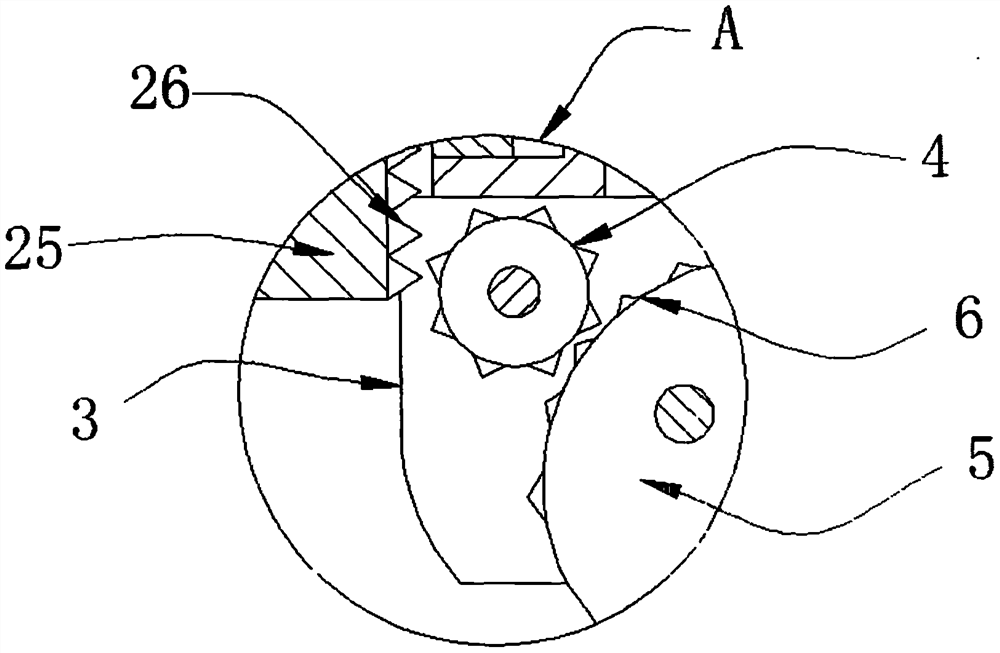

Three-claw manipulator for doll catcher

InactiveCN106861178ARealize clamping workAdapt to a wide rangeIndoor gamesGripping headsHydraulic cylinderEngineering

The invention relates to the field of toys for children, in particular to a three-claw manipulator for a doll catcher. The manipulator comprises a cylinder and further comprises a bottom plate, a pushing mechanism, clamping claws and connection rods. The pushing mechanism can be a micro hydraulic cylinder or a micro pneumatic cylinder or a pen type electric push rod or an electromagnetic element. The clamping claws can be rigid elastic clamping claws or air bag type elastic clamping claws. A layer of foaming cotton can be wound around each clamping claw, each clamping claw can be wrapped by a layer of pure cotton soft cloth, and clamping electromagnets can be installed on the clamping claws. The clamping claws can be various combinations of rigid clamping claws, elastic clamping claws and electromagnetic clamping claws. The three-claw manipulator for the doll catcher can be suitable for clamping toys made from one of or various materials such as common stuffing, hard plastic, soft plastic, wood and iron, and can greatly enrich the varieties of toys in the doll catcher.

Owner:张新

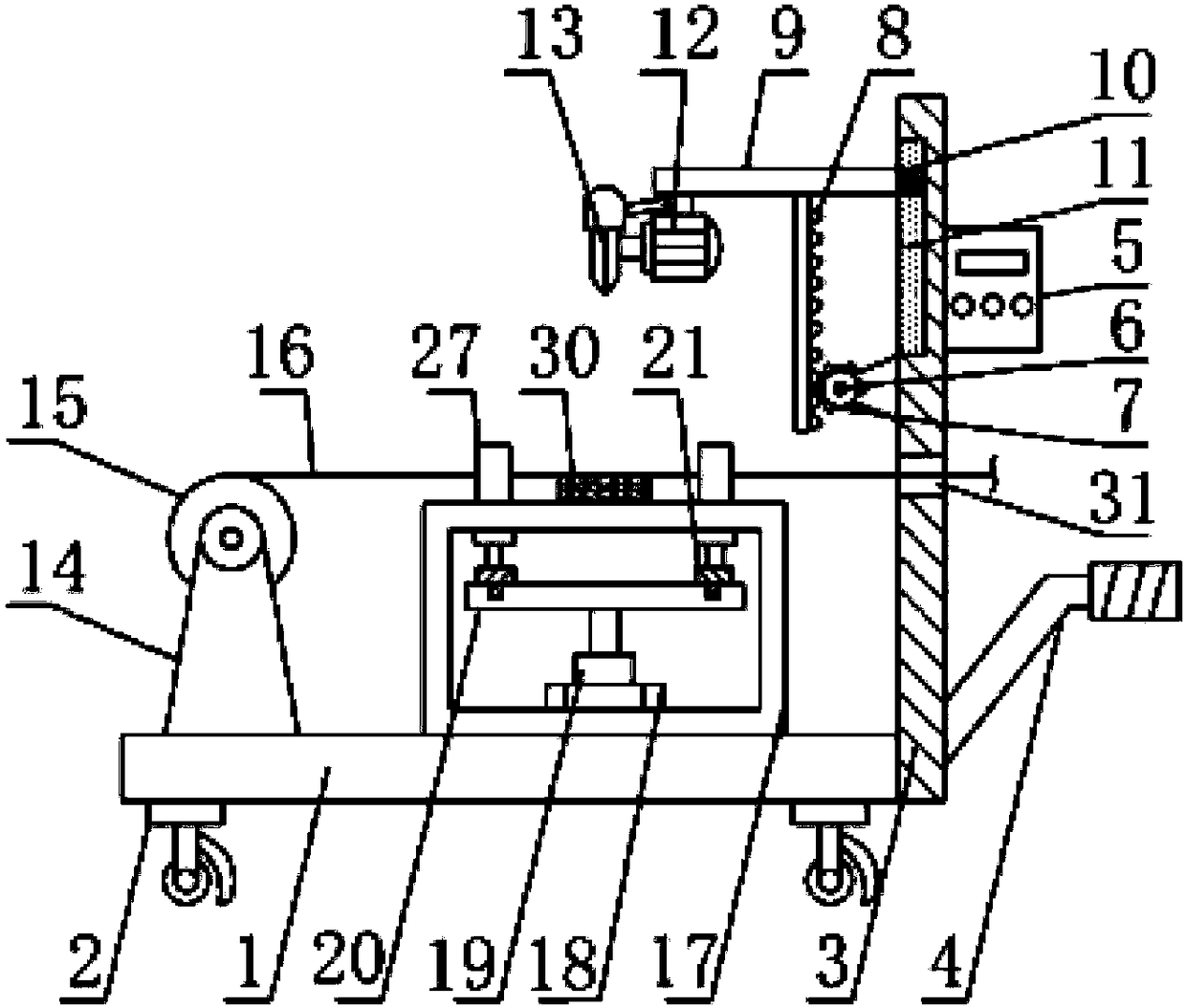

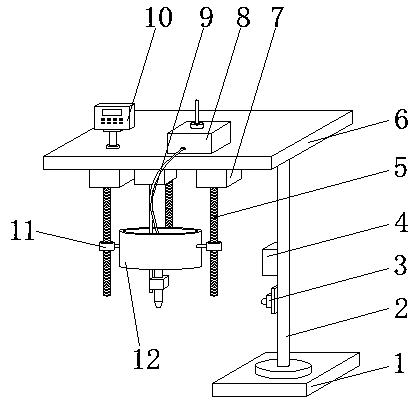

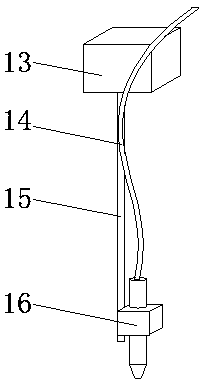

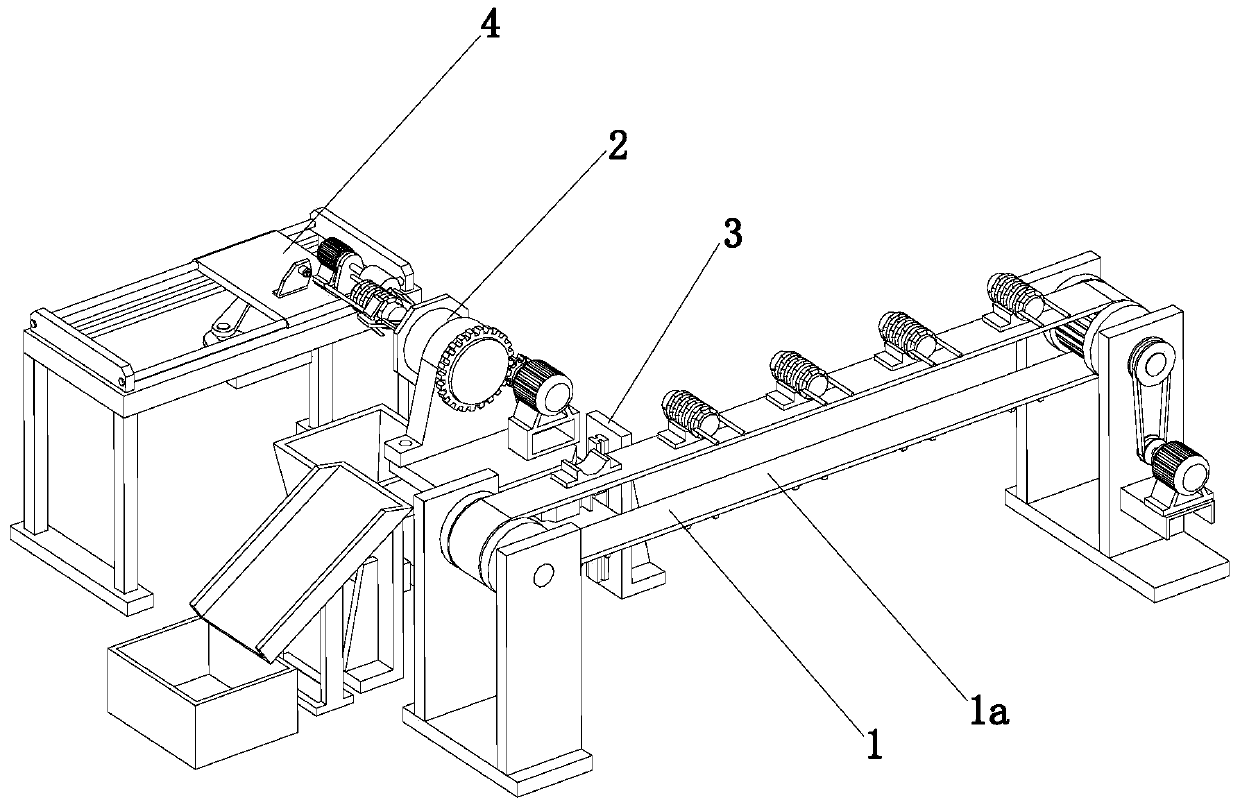

Efficient cutting device for steel wire rope machining and cutting method

The invention discloses an efficient cutting device for steel wire rope machining and a cutting method in the technical field of steel wire rope machining. The efficient cutting device comprises a bottom plate; a control switch is arranged at the top of the outer wall of the right side of a vertical plate; a pushing rod handle is arranged at the bottom of the outer wall of the right side of the vertical plate; the outer wall of the circumference of a gear is engaged with the inner wall of a tooth plate; a cutting motor is arranged at the left end of the bottom of a supporting plate; the outerwall of a roller is wound with steel wire ropes; a fixture box body is arranged on the right side of the top of the bottom plate; and a cutting table is arranged in the center of the top of the fixture box body. The efficient cutting device is simple to operate; clamping blocks are hinged with the two ends of each arc-shaped chuck, so that the efficient cutting device has movable activity, the steel wire ropes in different specifications are clamped conveniently, the more accurate location of the steel wire ropes is facilitated, and stress in every direction is kept uniformly; buffering columns are contacted with the steel wire ropes in advance, buffering springs contract due to the stress, so that a buffering effect is exerted, and bruise and damage on the surface of the steel wire ropesdue to the excessive stress are avoided; and two clamping plates are used for clamping the steel wire ropes, so that stable cutting of a cutting knife on the steel wire ropes is facilitated.

Owner:苏州斯强金属制品有限公司

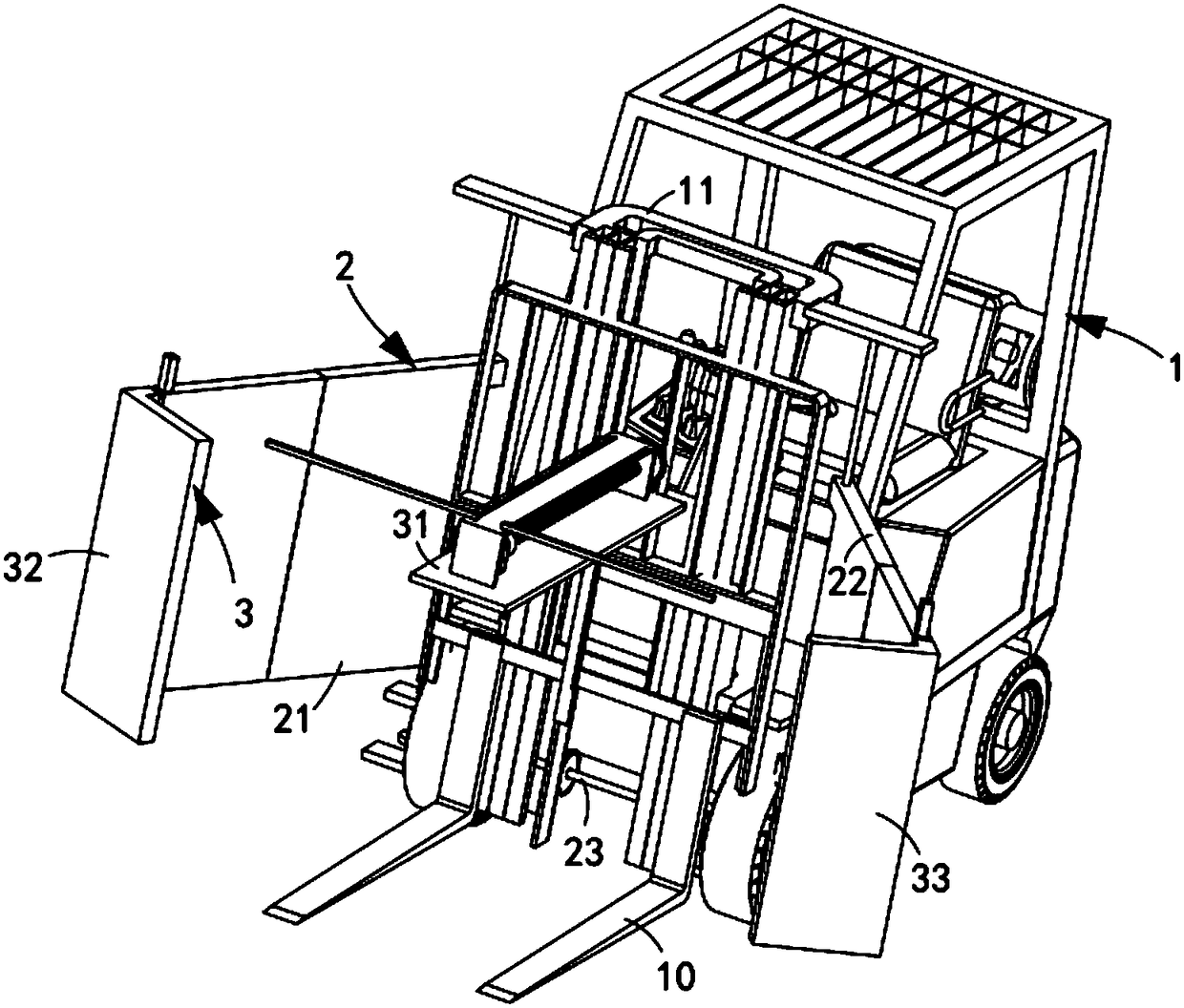

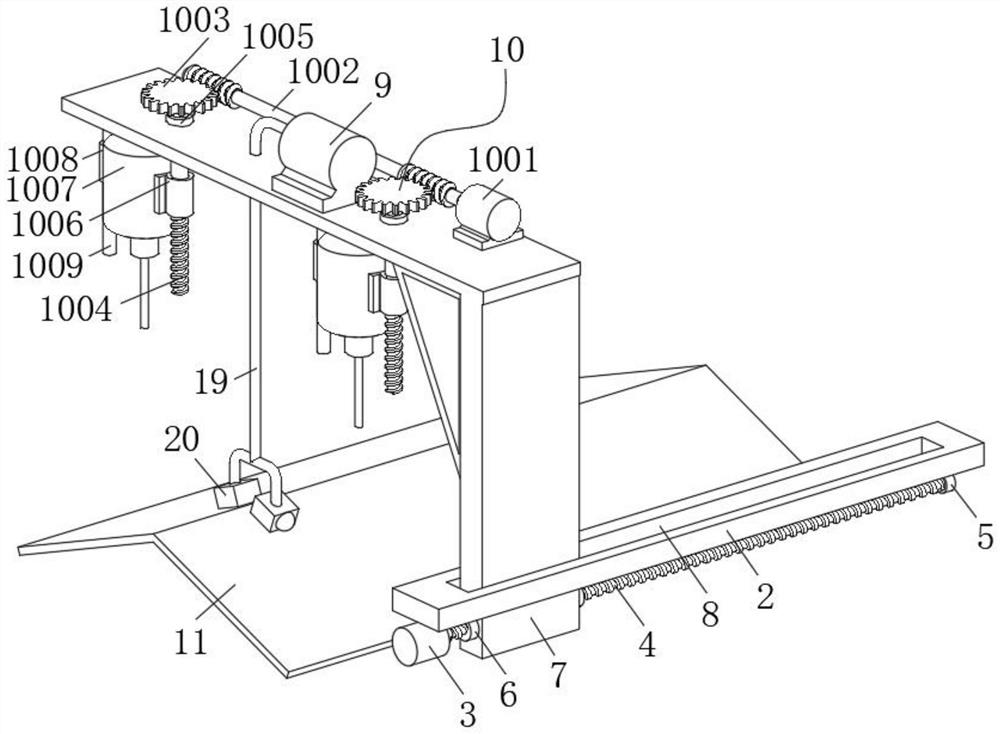

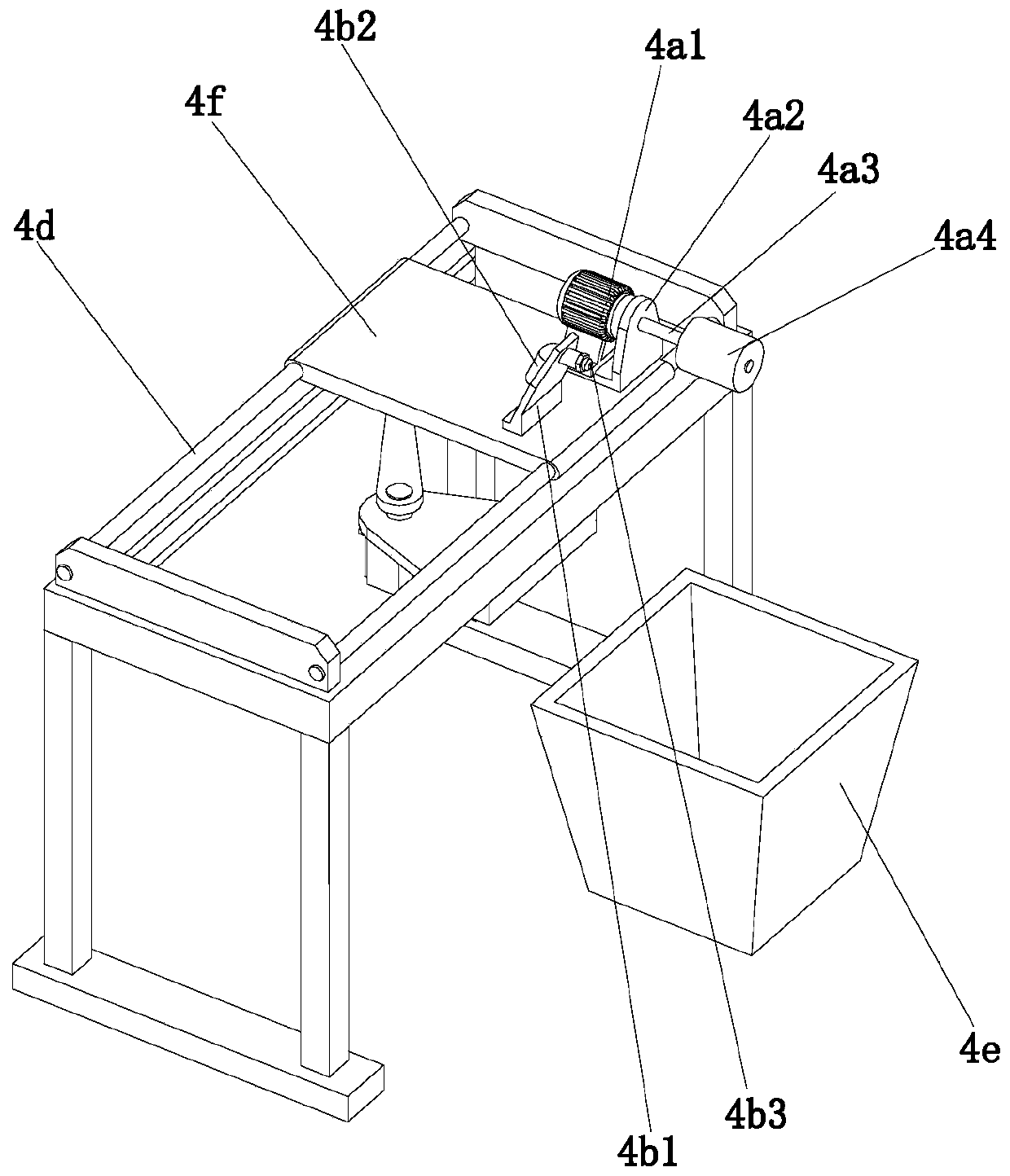

Novel automatic clamping electric carrying vehicle

The invention relates to a novel automatic clamping electric carrying vehicle which comprises a forklift truck, a support frame, elevating components, a blocking mechanism and a tightening mechanism.The support frame is arranged at the front of the forklift truck, the elevating components are arranged on the lower side of the support frame, the blocking mechanism comprises a side blocking assembly a, a side blocking assembly b and a driving assembly, the slide blocking assembly a is mounted on the support frame, the side blocking assembly b is symmetric with the side blocking assembly a, andthe control assembly is positioned on the side blocking assembly a and is used for driving the side blocking assembly a and the side blocking assembly b to carry out synchronous transmission; the tightening mechanism comprises a control assembly, a clamping assembly a and a clamping assembly b, the control assembly is arranged on the support frame and is positioned between the side blocking assembly a and the side blocking assembly b, the clamping assembly a is slidably arranged on the side blocking assembly a, and the clamping assembly b is slidably arranged on the side blocking assembly b. The novel automatic clamping electric carrying vehicle has the advantage that the technical problem that light goods on existing forklift trucks are easy to be out of balance and drop out in carrying procedures can be solved by the aid of the novel automatic clamping electric carrying vehicle.

Owner:河北神力索具集团有限公司

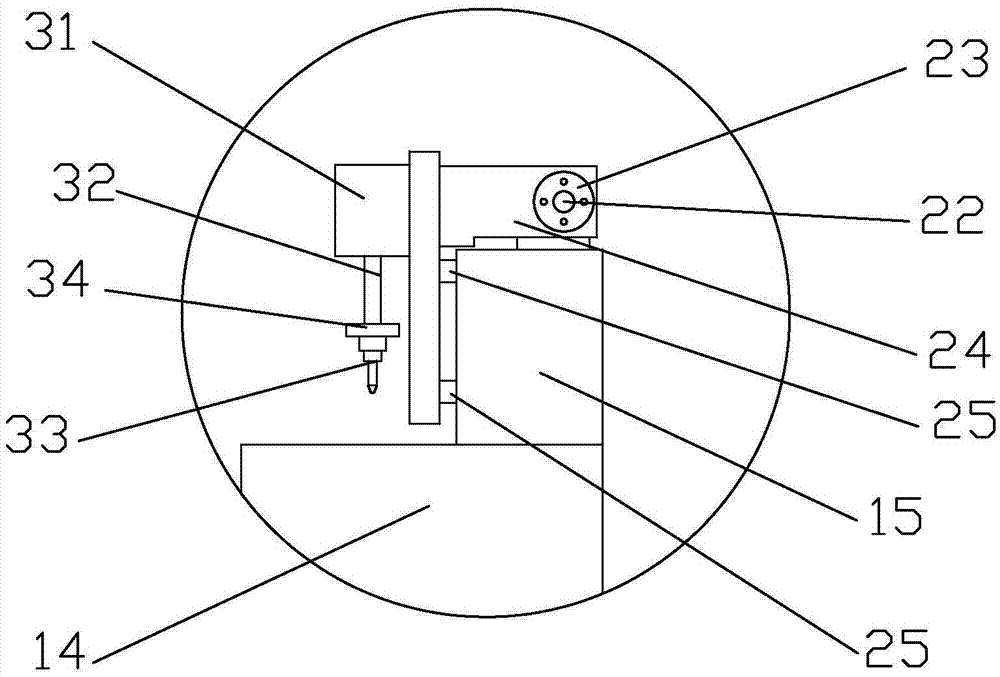

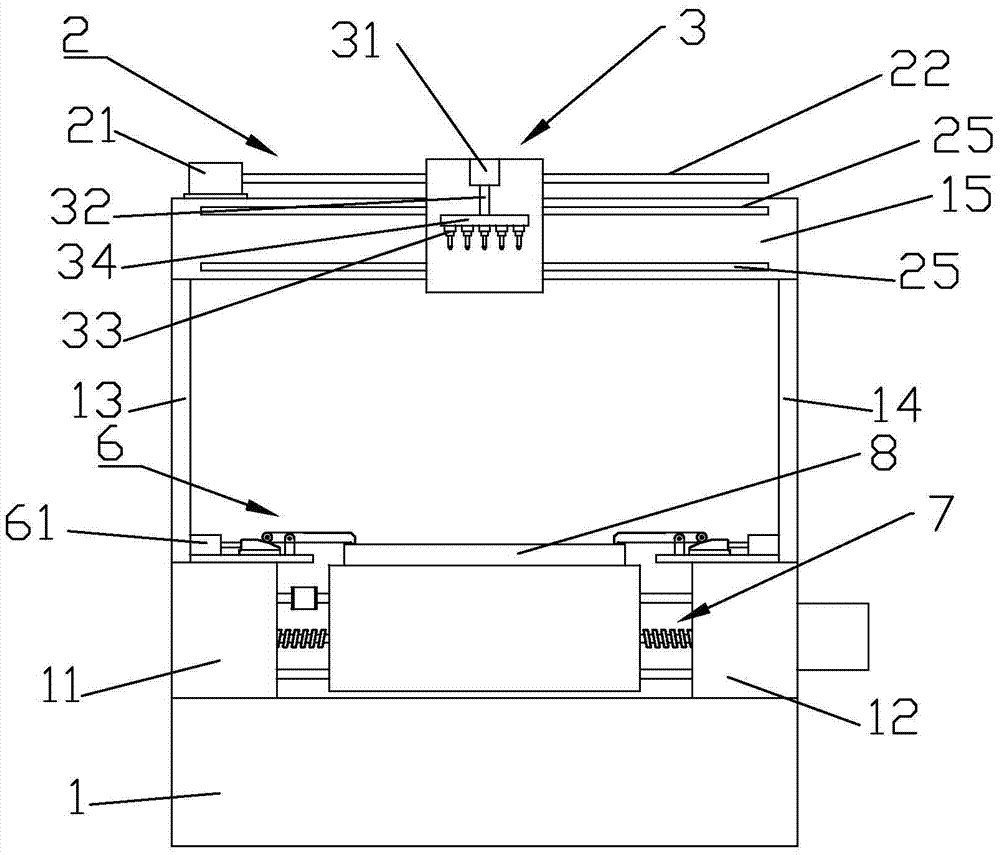

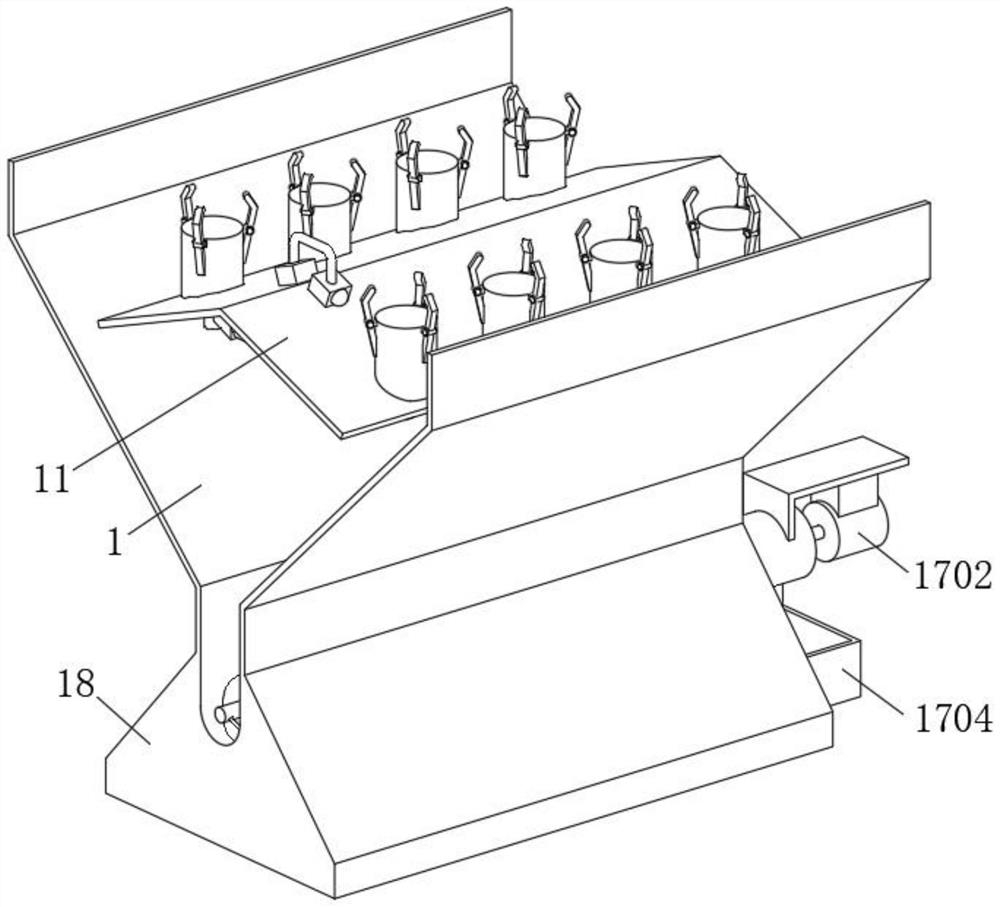

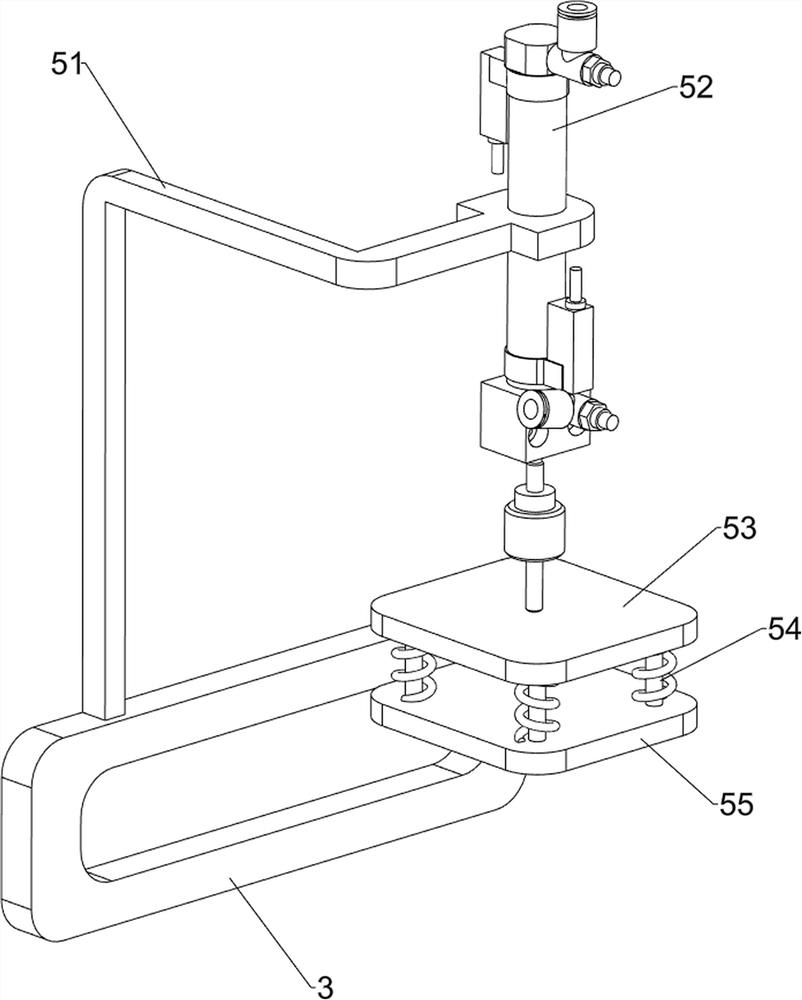

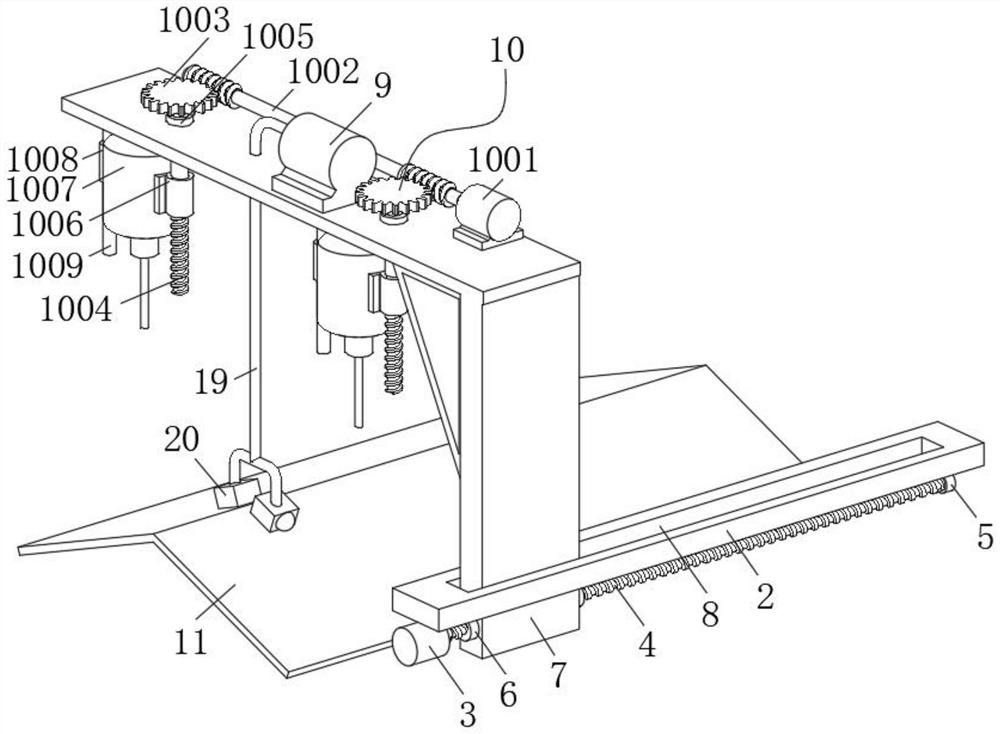

Full-automatic wood nailing machine

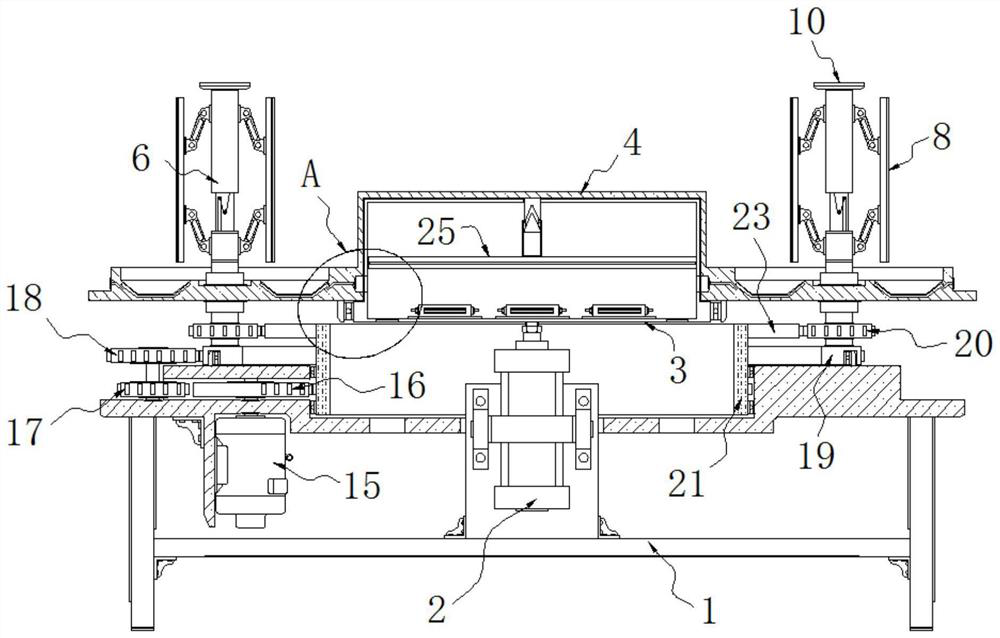

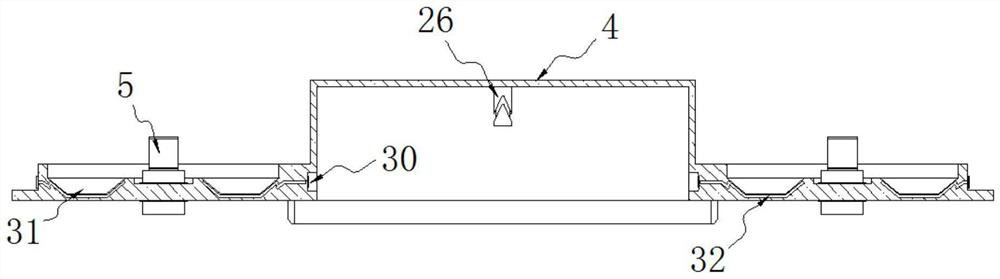

The invention discloses a full-automatic wood nailing machine. The full-automatic wood nailing machine comprises a frame; a conveying frame and a nailing bracket are arranged on the frame; the conveying frame includes a left conveying frame and a right conveying frame; the nailing bracket includes a nailing transverse frame and a nailing vertical frame; the nailing vertical frame includes a left nailing vertical frame and a right nailing vertical frame; the nailing transverse frame is positioned between the left nailing vertical frame and the right nailing vertical frame; a nailing device is arranged on the nailing transverse frame, and includes a moving mechanism and a nailing mechanism; the moving mechanism is connected with the nailing mechanism; the moving mechanism is mounted on the nailing transverse frame; a clamping device is mounted on the nailing vertical frame; a conveying device is arranged between the left conveying frame and the right conveying frame, and includes a conveying transmission mechanism and a conveying mechanism; and the conveying transmission mechanism is connected with the conveying mechanism. The machine is simple in structure, scientific, convenient, strong in pertinency and high in automation degree, can automatically transport and position nailed boards, and preferably solves the board nailing problem.

Owner:CHANGSHU YAHGEE MODULAR BUILDING CO LTD

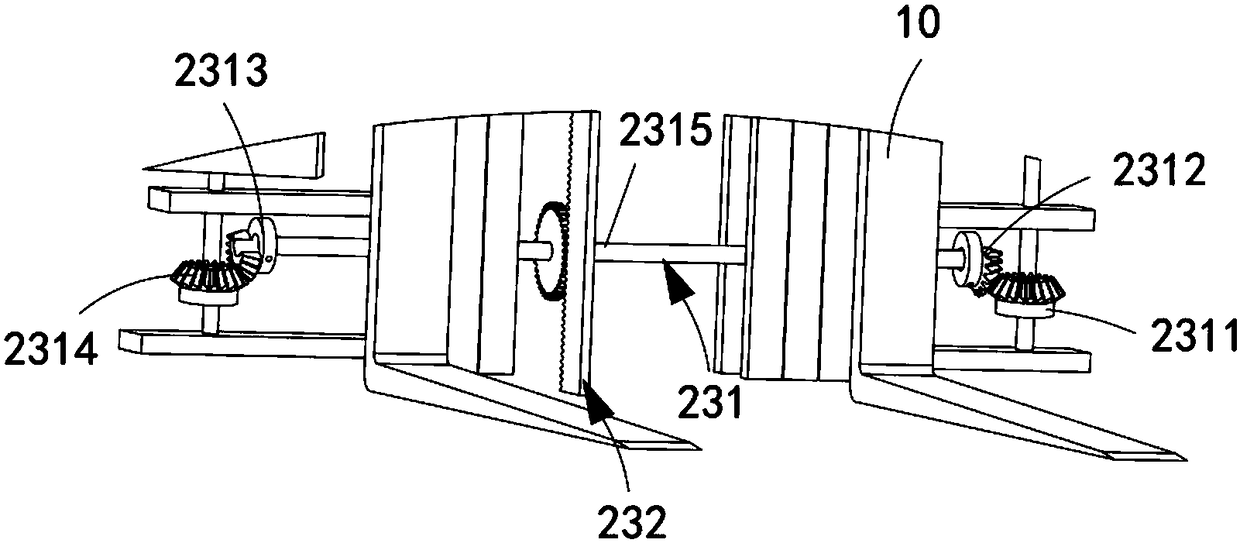

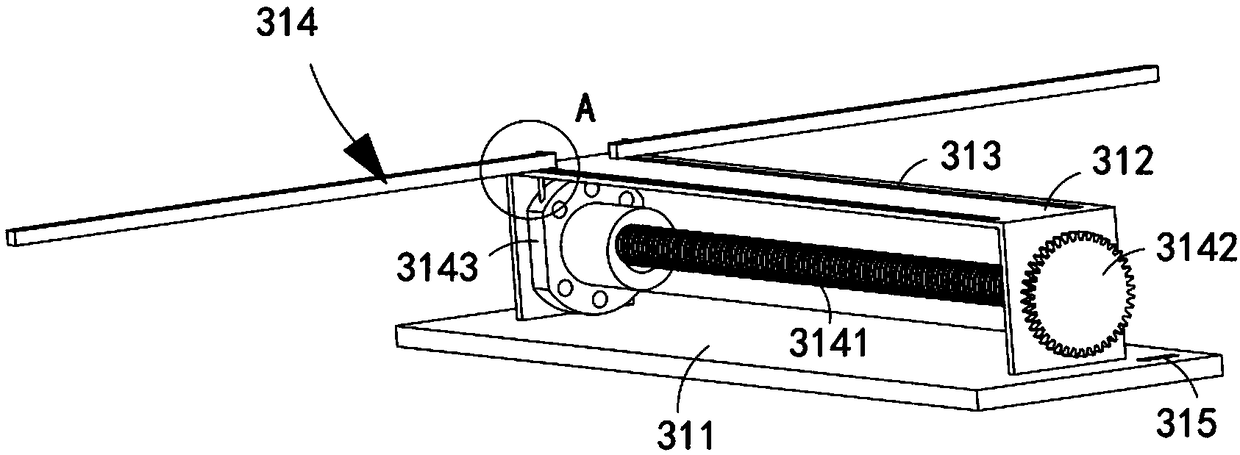

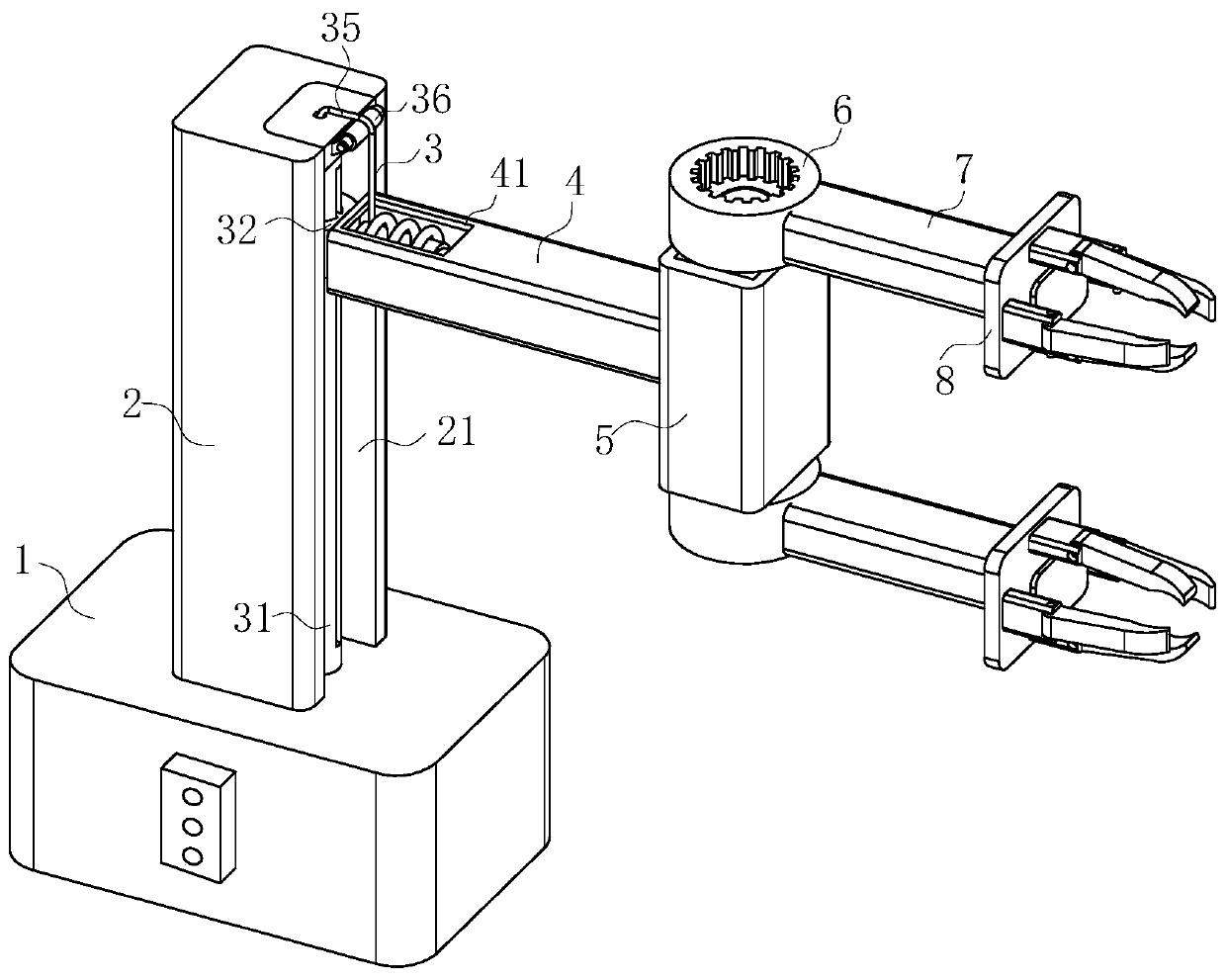

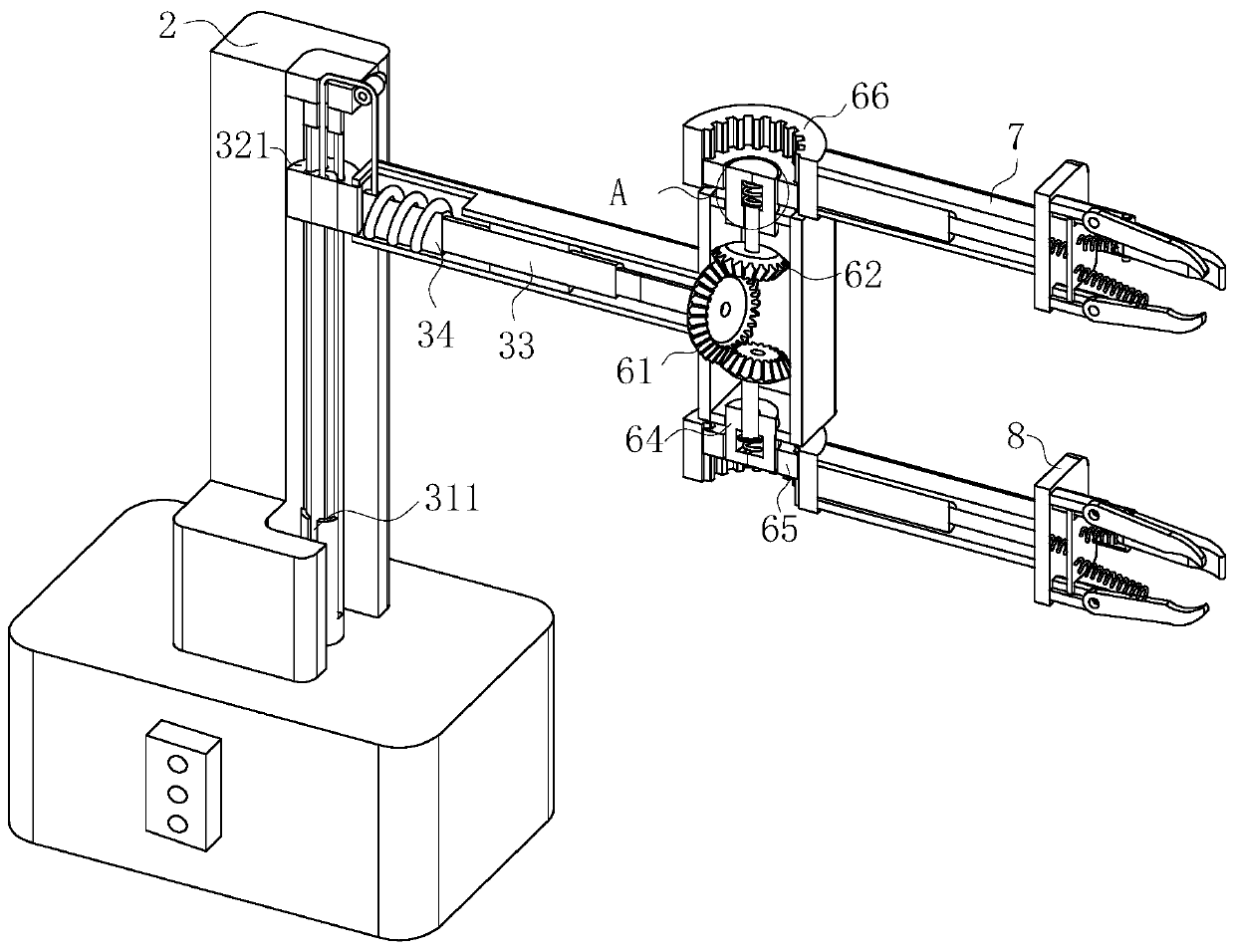

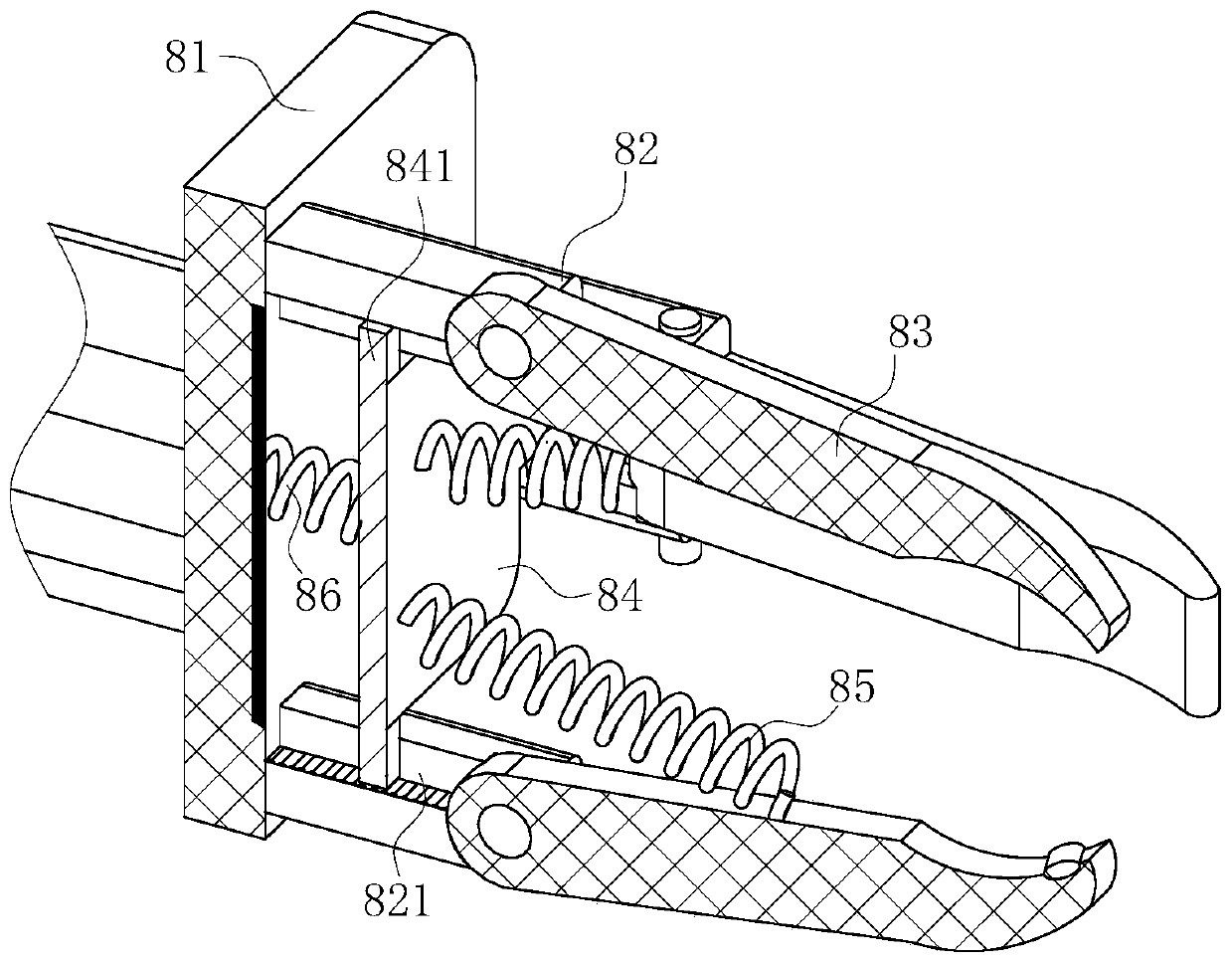

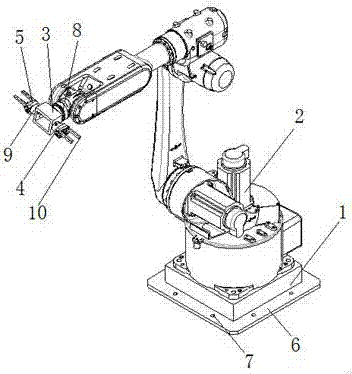

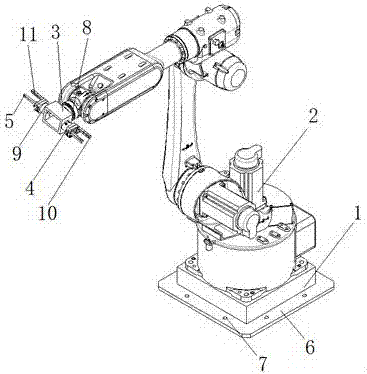

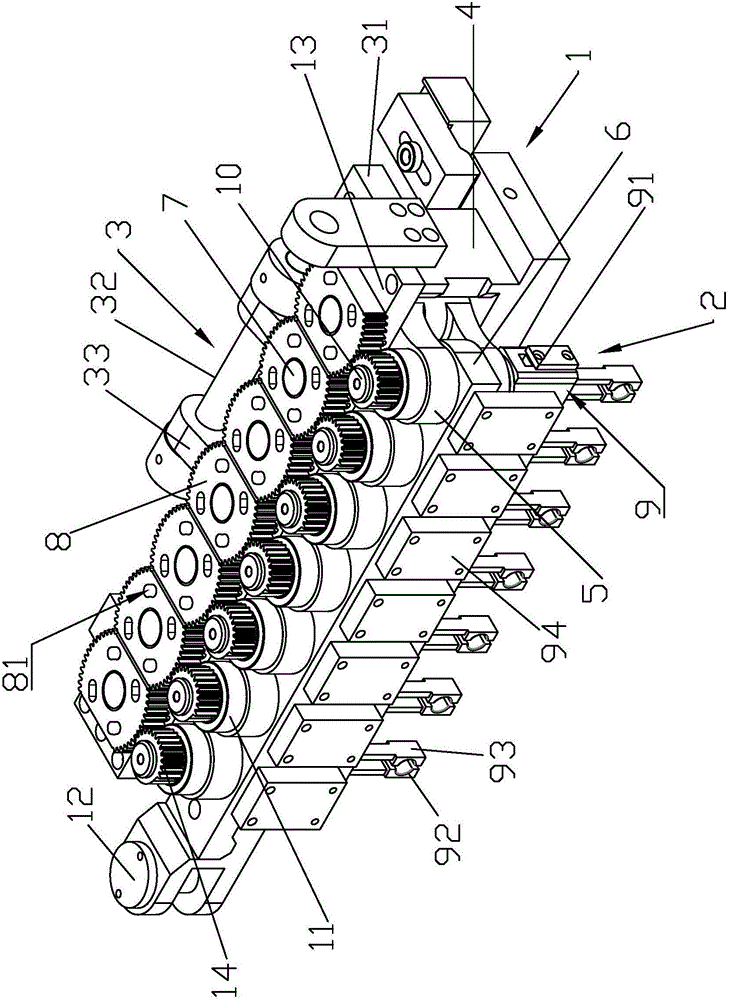

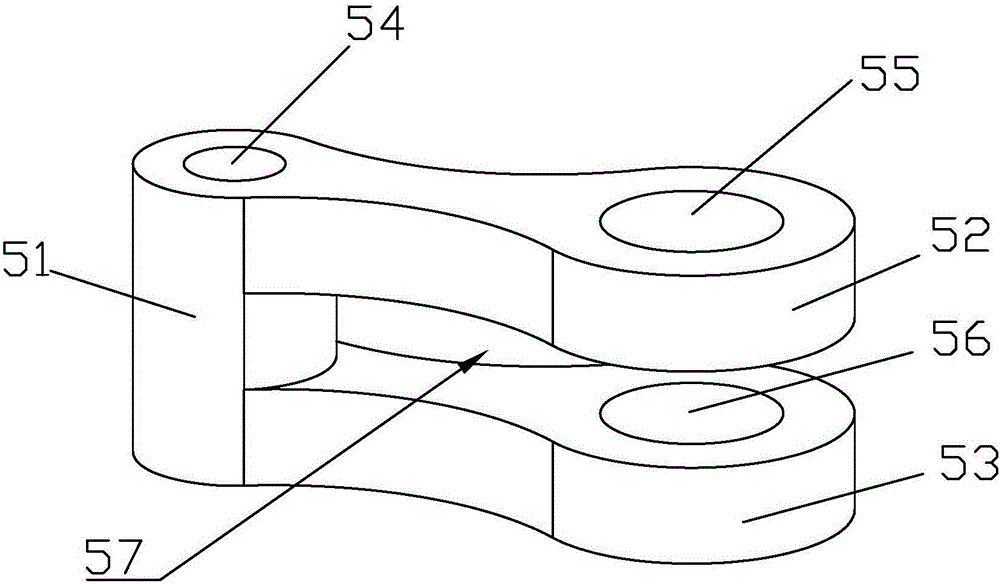

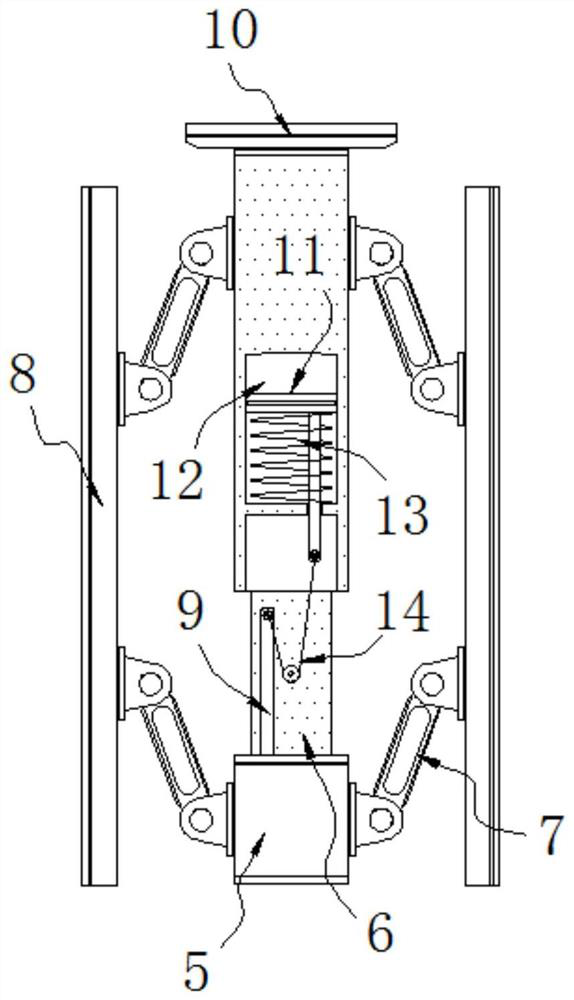

Multi-joint manipulator and mechanical arm

InactiveCN110978030ARealize mobile workRealize opposite grabbing operationsGripping headsArmsRobotic armGear wheel

The invention belongs to the technical field of manipulators, and particularly relates to a multi-joint manipulator and a mechanical arm. The multi-joint manipulator comprises a workbench, a supporting arm is installed on the workbench, a moving arm is connected on the supporting arm through a mobile regulating mechanism, rotating arms are symmetrically connected on a cavity connecting wall, mechanical clamping claws are installed on the rotating arms through guide air cylinders, a guide sliding rod is installed in the supporting arm, the guide sliding rod is slidably sleeved with a guide slide block, a movable arm is arranged on the side face of the guide sliding block; a first bevel gear is connected on another output end of a two-way motor through a coupling, the first bevel gear is symmetrically meshed with second bevel gears; an outer gear is located at the outer end of a cavity connecting arm, the outer gear is meshed with an inner toothed disc in a rotating manner; and the rotating arms are installed on the side wall of the inner toothed disc. According to the multi-joint manipulator and the mechanical arm, through the mutual cooperation of the symmetrically-arranged mechanical clamping claws, the rotating arms and the moving arm, not only the multi-directional and multi-angle opposite grasping operation for objects is realized, but also various object clamping operationis realized.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

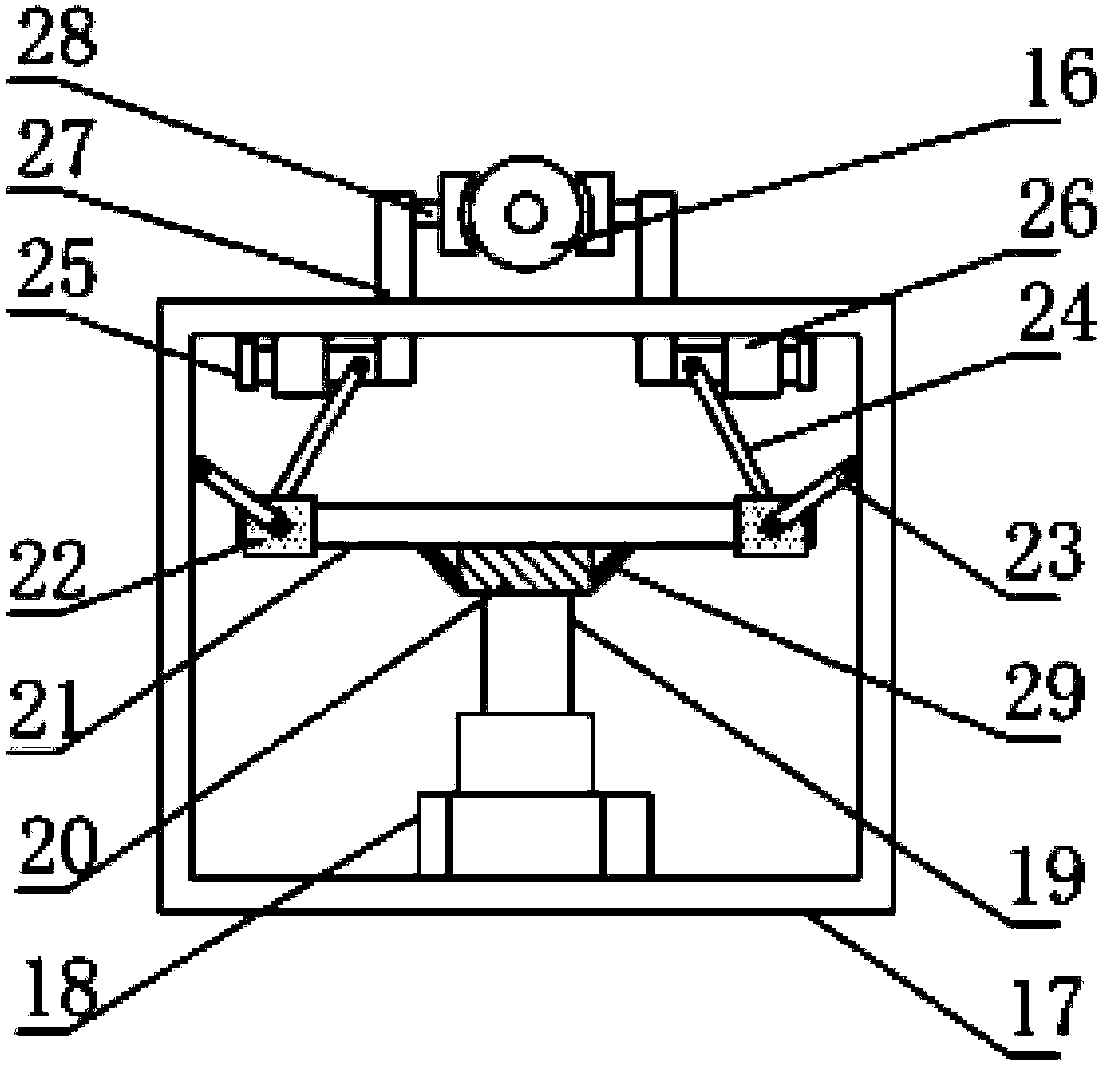

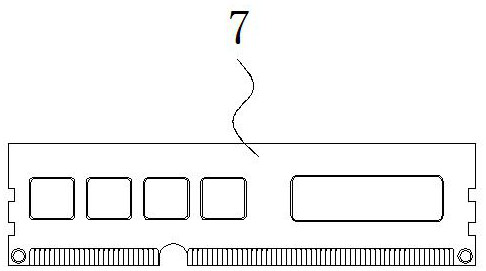

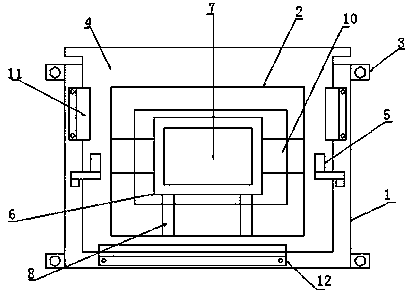

Clamping equipment with turnover structure for detecting computer memory bank

InactiveCN112051277AEasy to disassembleEasy maintenanceWork holdersOptically investigating flaws/contaminationMemory bankComputer memory

The invention discloses clamping equipment with a turnover structure for computer memory bank detection, and relates to the technical field of computer memory bank detection. The clamping equipment comprises a base, a detection mechanism and a clamping mechanism, a working frame is arranged on the outer side of the upper end of the base, a conveying belt is arranged in the center of the upper endof the base, and a placement block is arranged at the upper end of the conveying belt; and a placement groove is formed in the center of the upper end of the placement block, a protective layer is arranged on the inner wall of the placement groove, a memory bank body is placed on the inner side of the placement groove, and the detection mechanisms are arranged on the lower portions of the two sides of the interior of the working frame. By the movably connected clamping block and C-shaped connecting block, the upper end of the clamping block is enabled to clamp the memory bank body through thepushing cylinder. When the pushing air cylinder pushes the upper end of the clamping block to descend, the lower end of the clamping block is opened, otherwise, the pushing air cylinder pulls the upper end of the clamping block to ascend, the lower end of the clamping block is closed, and an infrared sensor is arranged in a matched mode to control opening and closing of the movable clamping block.

Owner:重庆信易源智能科技有限公司

Industrial automation instrument convenient to install

InactiveCN110944473AAchieve protectionRealize clamping workCasings/cabinets/drawers detailsSupport structure mountingIndustrial engineeringAutomation

The invention discloses an industrial automation instrument convenient to install. The instrument comprises a mounting box, an opening is formed in one side of the mounting box; a plurality of mounting seats are arranged on one side, away from the opening, of the mounting box; a sealing door is arranged on the side, close to the opening, of the mounting box and connected with the mounting box through symmetrically-arranged fastening mechanisms, an automatic instrument is arranged in the mounting box, a display screen is arranged on one side of the automatic instrument, and a supporting rod connected with the inner top end of the mounting box is arranged at the bottom end of the automatic instrument. Due to effect of the mounting box and the sealing door, the automatic instrument is effectively protected. Dust is prevented from being accumulated on the automatic instrument so that the influence of the dust on the automatic instrument is effectively reduced, then the automatic instrument is protected, the rapid installation process of the mounting box and the sealing door is achieved through the arrangement of a fastening mechanism, and then convenience is brought to maintenance andinstallation of the automatic instrument.

Owner:XIAN HUAHENG INSTR CO LTD

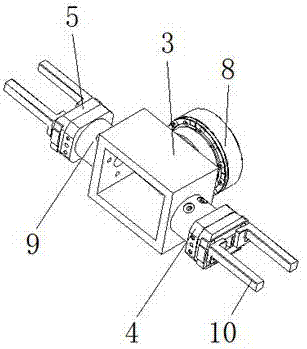

Symmetrical-gripping-jaw fixture capable of rotating 180 degrees

InactiveCN107363818AImprove gripReduce labor intensityProgramme-controlled manipulatorGripping headsEngineeringFlange

The invention discloses a 180° rotatable symmetrical jaw fixture, which includes a robot base, a robot, a flange mounting seat, a mounting plate and jaws, and is characterized in that: the robot is arranged on the robot base, and the The flange mounting base is set on the robot through the connecting shaft, the mounting plate is set on the fixed block, and the jaws are set on the mounting plate. In the present invention, the flange mounting seat is arranged on the robot through the connecting shaft, fixed blocks are arranged on opposite sides of the flange mounting seat, the jaws are arranged on the fixed blocks, and a clamping rod is arranged on the jaws, through Rotate the position of the flange mounting seat on the robot, so that the flange mounting seat can drive the gripper and the clamping rod on the gripper to rotate, and realize the clamping operation of the clamping rod to the workpiece. The rotating structure on the block can drive the workpiece clamped by the clamping rod to rotate, thereby realizing the installation of the workpiece, improving the work efficiency and reducing the labor intensity of the operator.

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

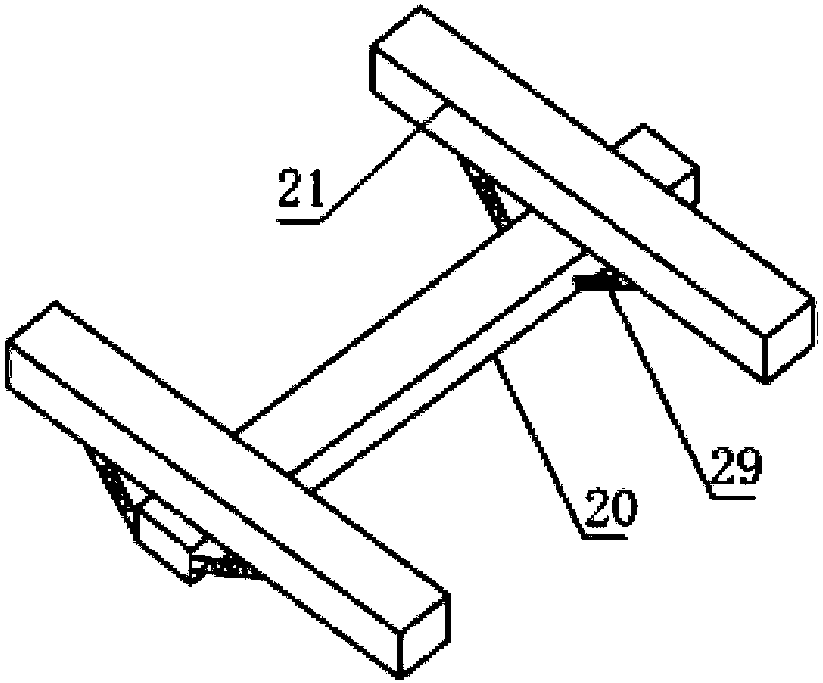

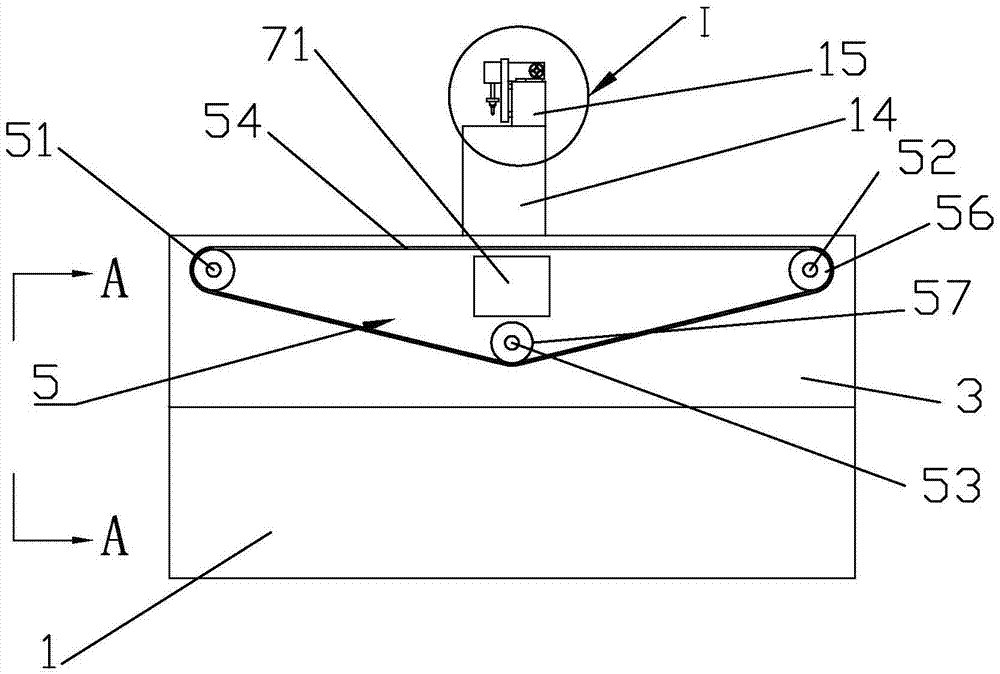

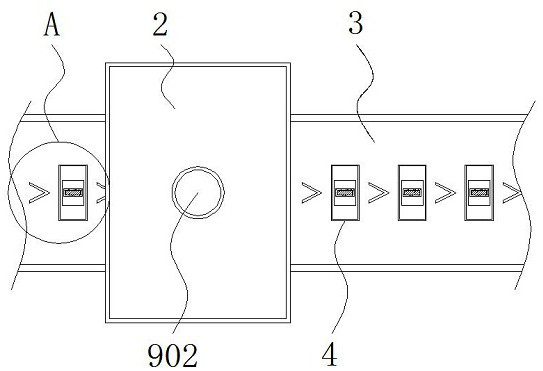

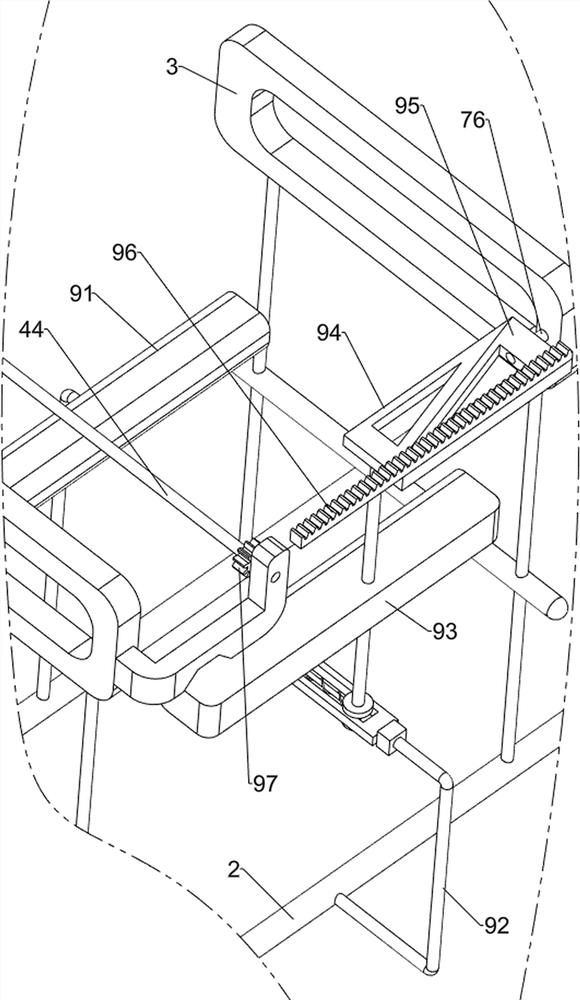

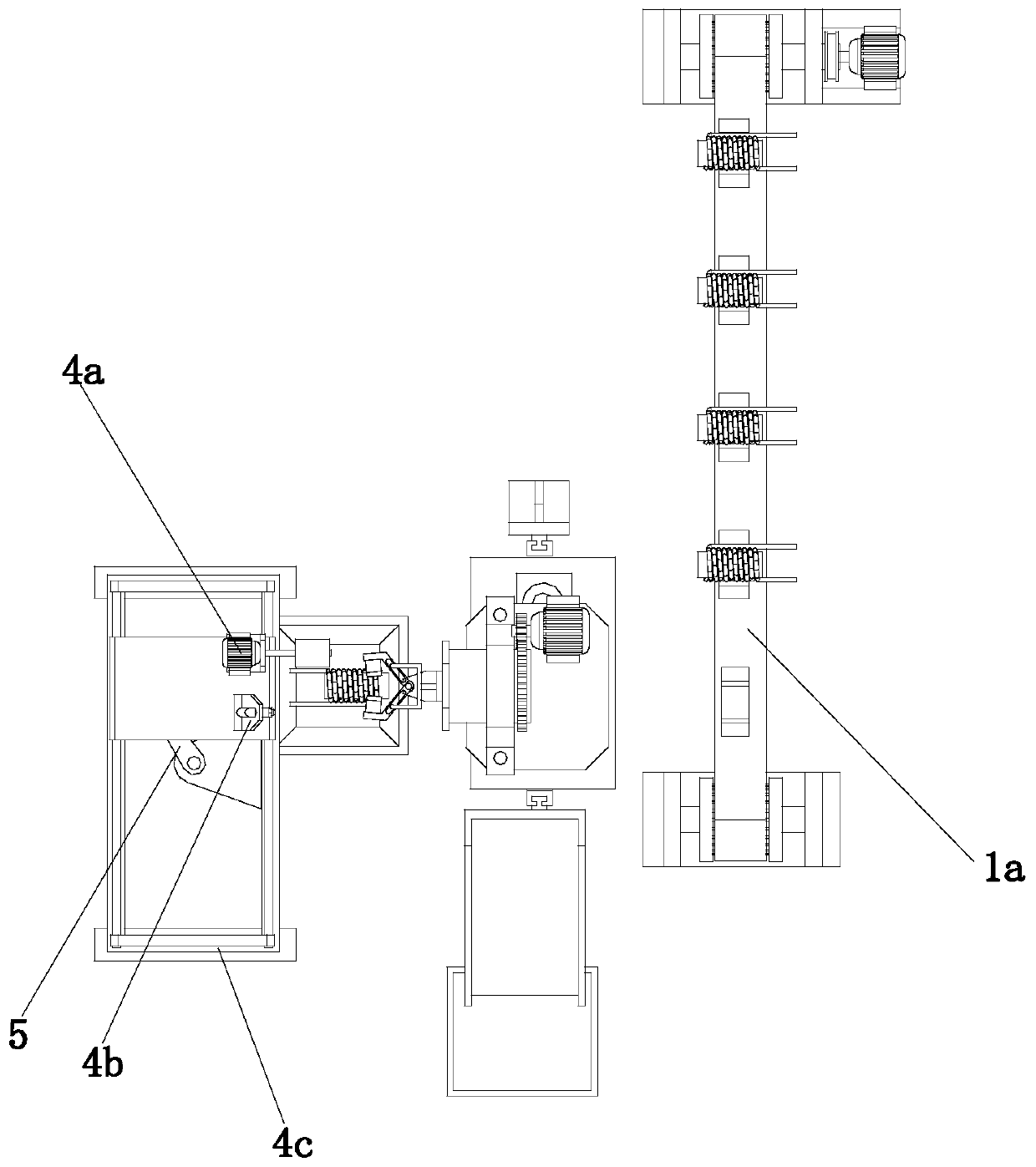

Automatic production line based on intelligent industrial robot

ActiveCN109625915ASmooth and easy movementRealize handlingConveyor partsProduction lineIndustrial engineering

The invention relates to the technical field of production lines, in particular to an automatic production line based on an intelligent industrial robot. The automatic production line comprises a production line body, wherein the production line body is equipped with a carrying mechanism; the carrying mechanism is equipped with an assembly clamping mechanism; the carrying mechanism comprises a conveying table; the right side part of the conveying table is equipped with a supporting post; the top end of the supporting post is equipped with a beam; a first movable device can be arranged on the beam in a left-right sliding mode; a carrying mechanism is arranged below the first movable device; the assembly clamping mechanism comprises a clamp body; the clamp body comprises a first clamp mounting plate, a baffle plate is arranged at one side of the top end surface of the clamp mounting plate, the middle part of the clamp mounting plate is downs sunken to form a mounting slot; a first clamping plate capable of sliding left and right is arranged in the mounting slot; and a second clamping plate capable of turning over is arranged at the inner side of the baffle plate. The automatic production line is simple in structure, is low in manufacturing cost, is good in stability in a carrying process, can automatically regulate according to different workpieces, guarantees assembly quality and improves assembly efficiency.

Owner:义乌市丹航科技有限公司

Intelligent welding tool for metal pipe fitting in workshop

InactiveCN110280965ARealize clamping workQuick fixWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses an intelligent welding tool for a metal pipe fitting in a workshop, and relates to the technical field of metal pipe fittings. The intelligent welding tool for the metal pipe fitting in the workshop comprises a machine frame. A control panel is fixedly arranged on the front side of the machine frame. A containing cavity is formed in one side of the upper surface of the machine frame. A first fixing mechanism is fixedly installed at the position, located on one side of the containing cavity, of the upper surface of the machine frame. A sliding mechanism is embedded in the containing cavity. The intelligent welding tool is reasonable in structure and simple to operate. The fixation of the metal pipe fitting can be rapidly and automatically realized through an arranged driving mechanism. The automation degree and intelligence degree of the welding tool are improved. The overall use value is high. The intelligent welding tool is suitable for wide popularization. Through the sliding mechanism, the distance between the first fixing mechanism and a second fixing mechanism can be adjusted, so that the welding tool can be suitable for metal pipe fittings with different lengths, the application range of the welding tool is expanded, and the practicability of the welding tool is improved.

Owner:NANJING YUSHENG ROBOT CO LTD

Metal bar outer surface polishing equipment

PendingCN112454027ARealize relative distance adjustmentRealize clamping workGrinding carriagesRevolution surface grinding machinesPhysicsElectrically conductive

The invention discloses metal bar outer surface polishing equipment, and relates to the technical field of polishing. The metal bar outer surface polishing equipment comprises a frame body and a supporting column, a first hydraulic element, a moving plate and rotating blocks are arranged in the frame body, a rotating assembly is arranged on the frame body, a clamping assembly and a working assembly are arranged in each rotating block, a supporting piece is arranged between the upper rotating block and the moving plate, and a polishing assembly for polishing a bar is arranged in the frame body.The first hydraulic element in the frame body drives the moving plate fixedly connected with the first hydraulic element to move up and down, so that the distance between the clamping assembly on themoving plate and the clamping assembly on the frame body is adjusted, and bars with different lengths are clamped; and a conductive block is powered on to enable a conductive ring and a powered-on magnet to be powered on, then the powered-on magnet generates magnetism to repel a permanent magnet in a moving block, clamping blocks clamp the bar, and the bars with different diameters are clamped through the arrangement of a first spring and a second spring.

Owner:湖南豪镨博德新材料科技有限公司

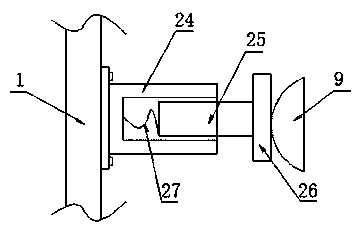

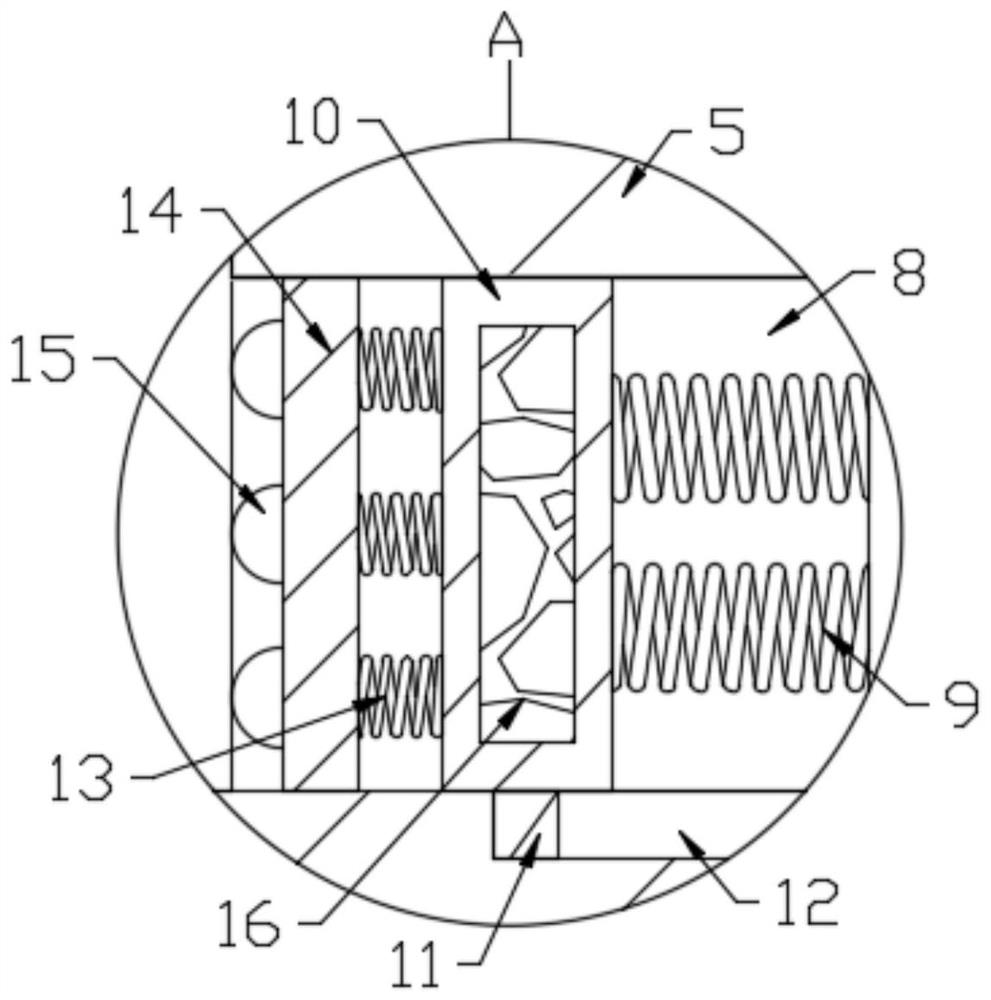

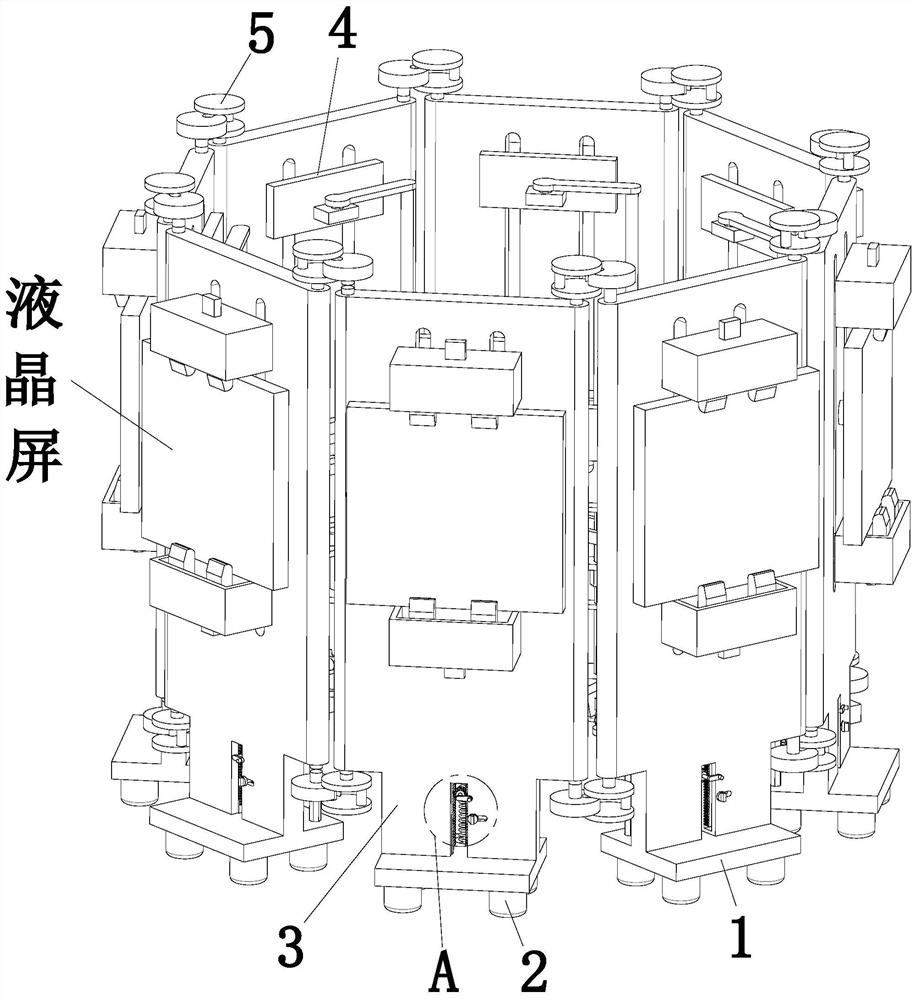

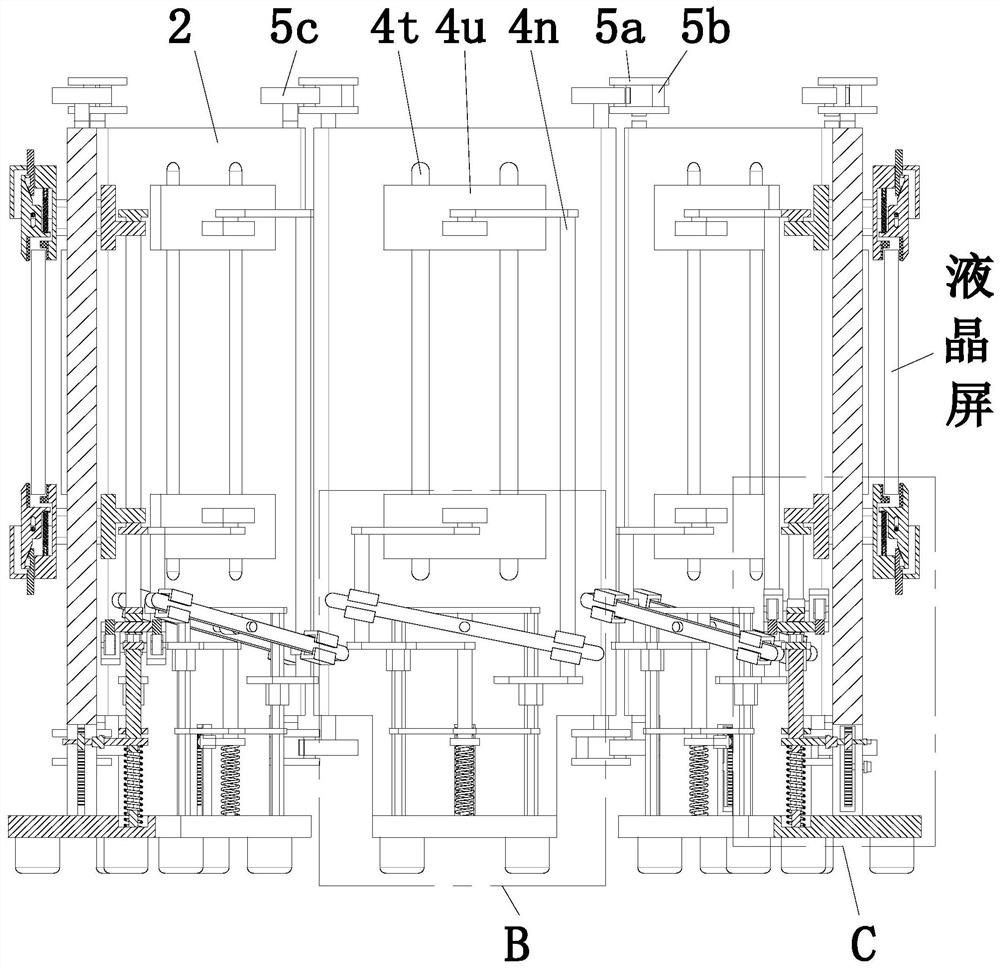

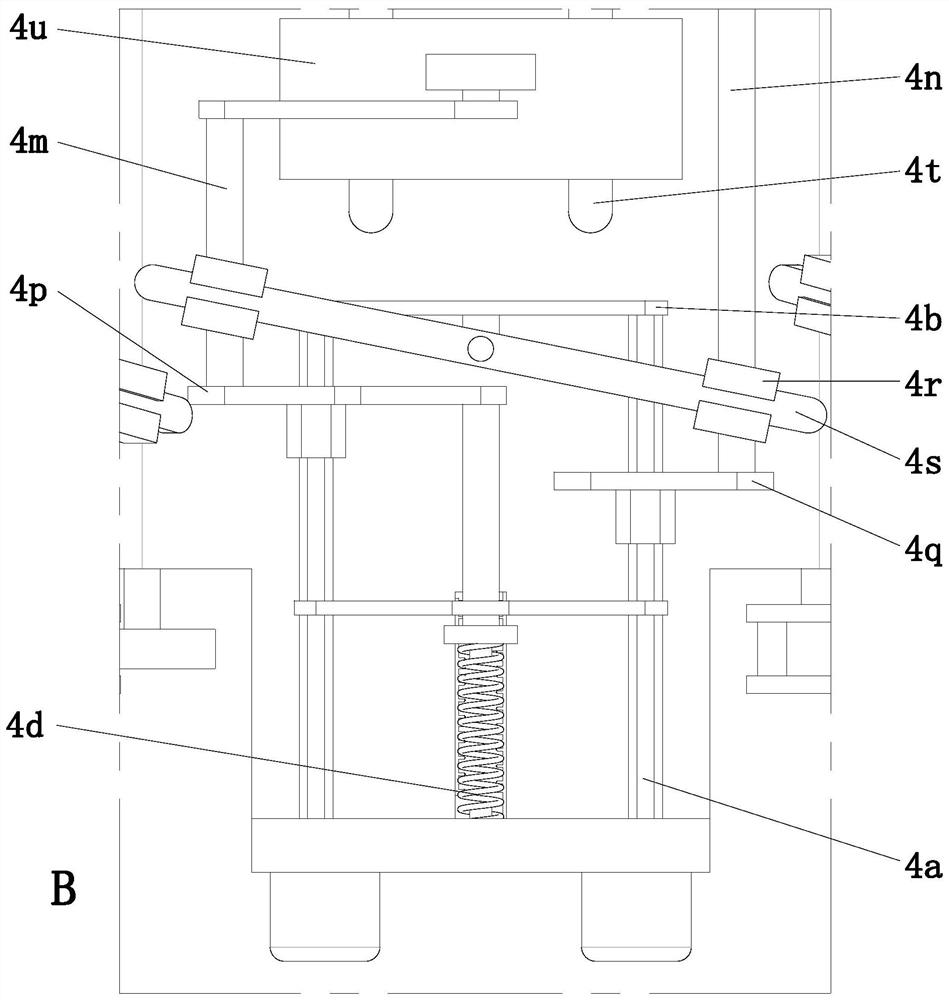

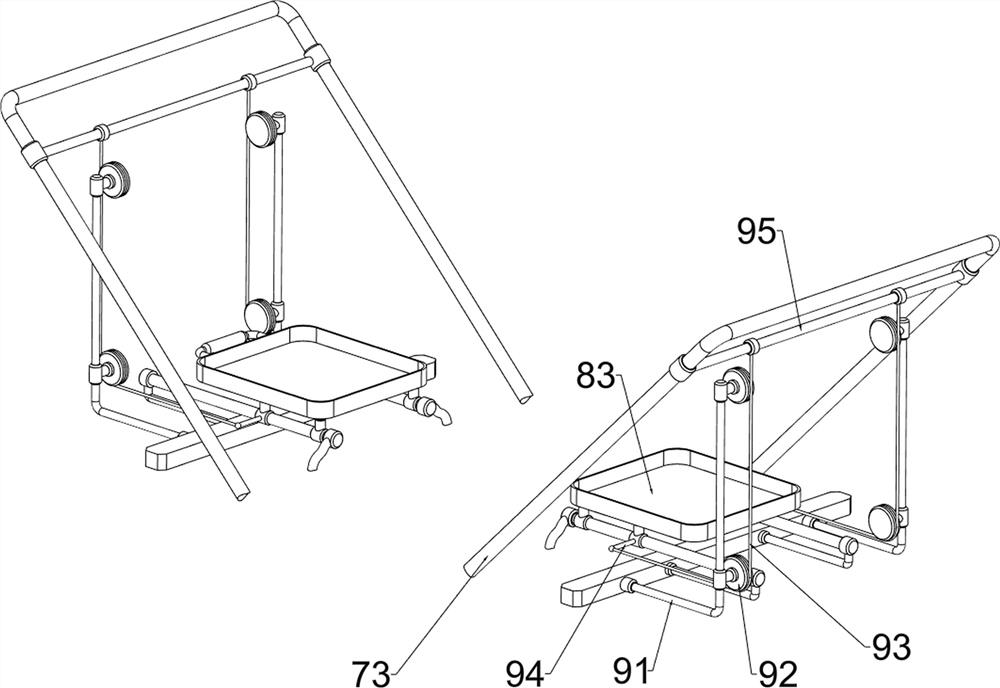

Assembled type liquid crystal display screen

InactiveCN112628538APrevent free fallRealize clamping workStands/trestlesIdentification meansLiquid-crystal displayEngineering

The invention provides an assembled type liquid crystal display screen. The assembled type liquid crystal display screen comprises a mounting bottom plate, a supporting seat, a supporting plate, a clamping mechanism and a splicing mechanism. The problems are solved that most existing liquid crystal display screens are fixedly mounted, specification and size differences of the liquid crystal display screens used in different occasions are large, in actual mounting and clamping operation, the clamping direction of a mounting clamp is difficult to adjust in real time according to the required sizes of the liquid crystal display screens, a stable and firm clamping effect is difficult to provide for the liquid crystal display screens, the mounting number and orientation direction of the liquid crystal screens are difficult to adjust in real time according to the occasion size and shape of a placement position, quick clamping and dismounting operation during mounting of the liquid crystal screens is more difficult to realize, consequently, the operation efficiency of liquid crystal screen assembling operation cannot be improved, and the use requirements of different occasions are not met.

Owner:黄浩

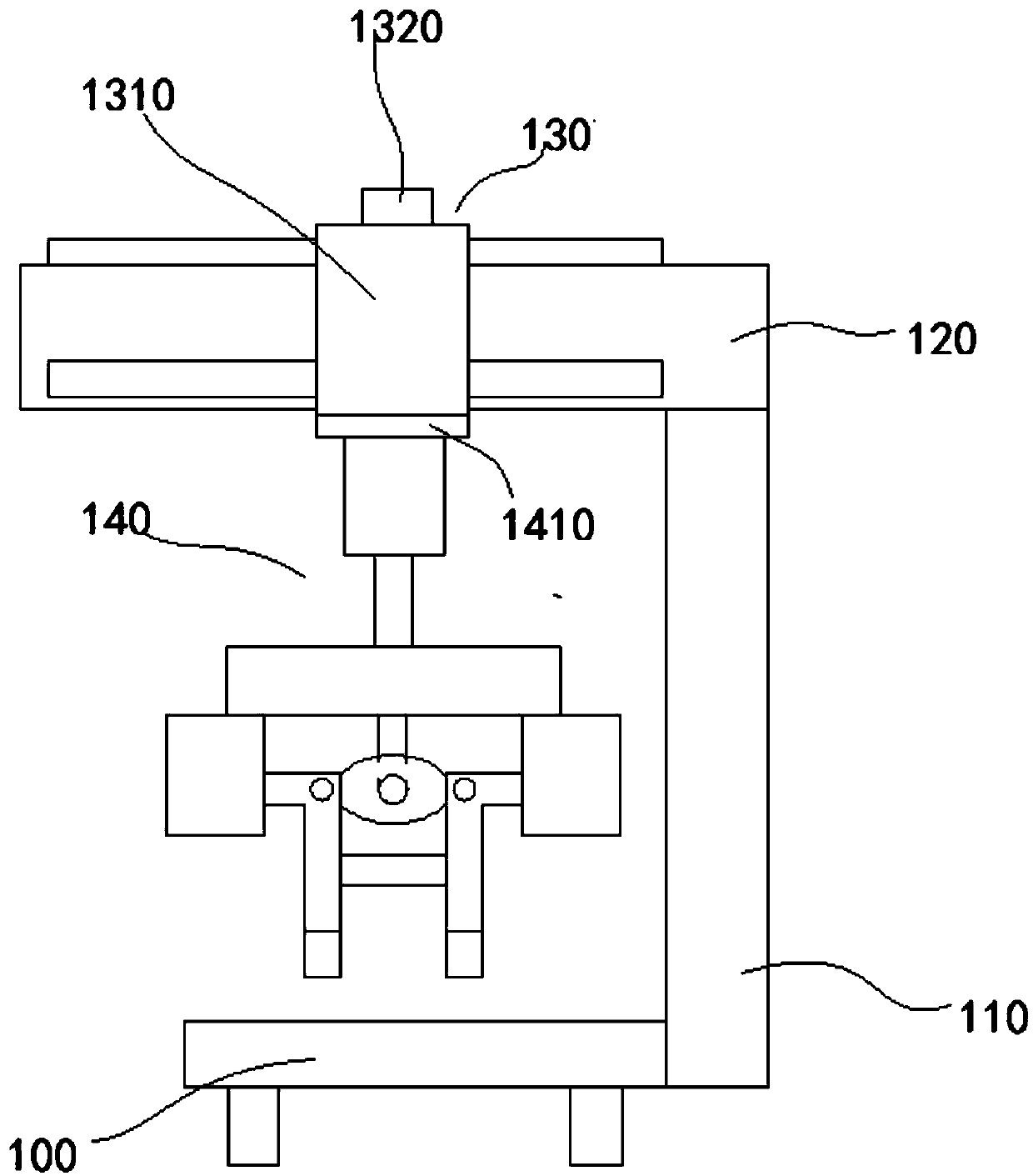

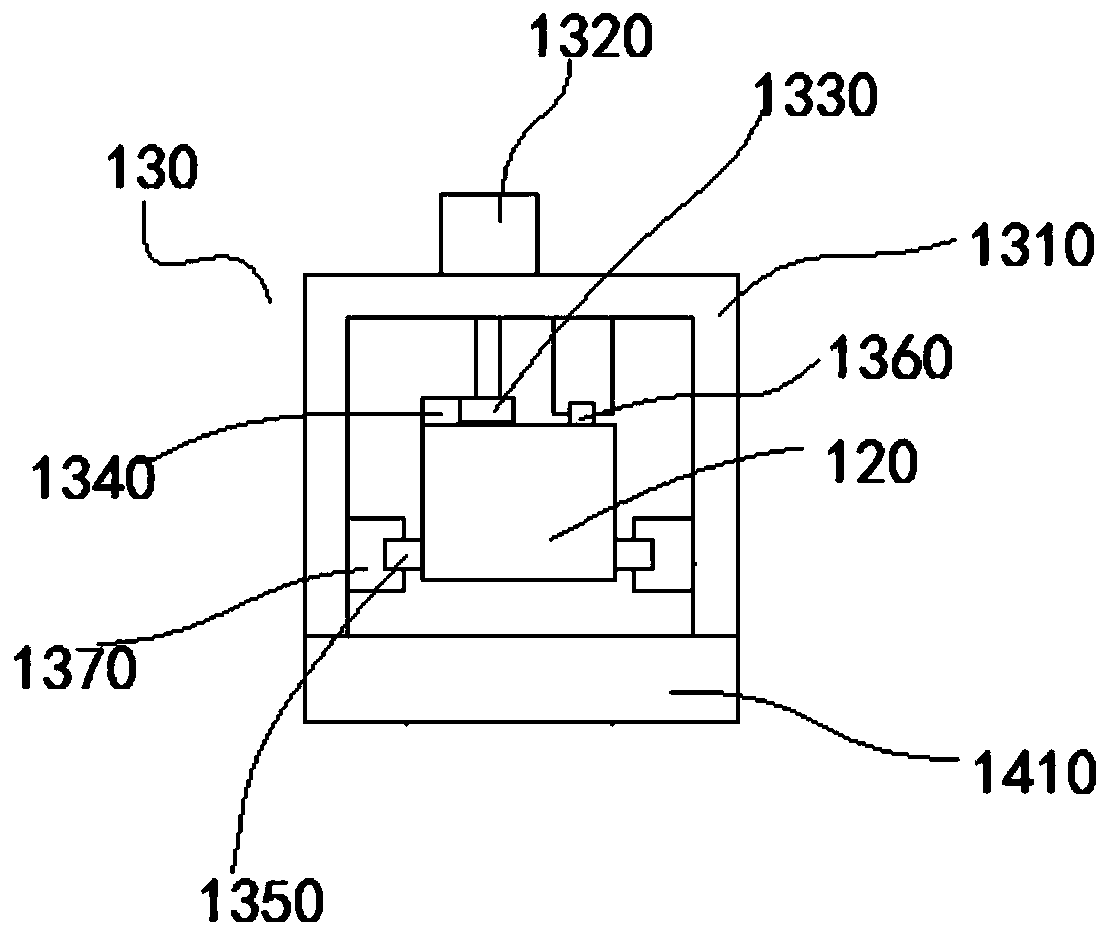

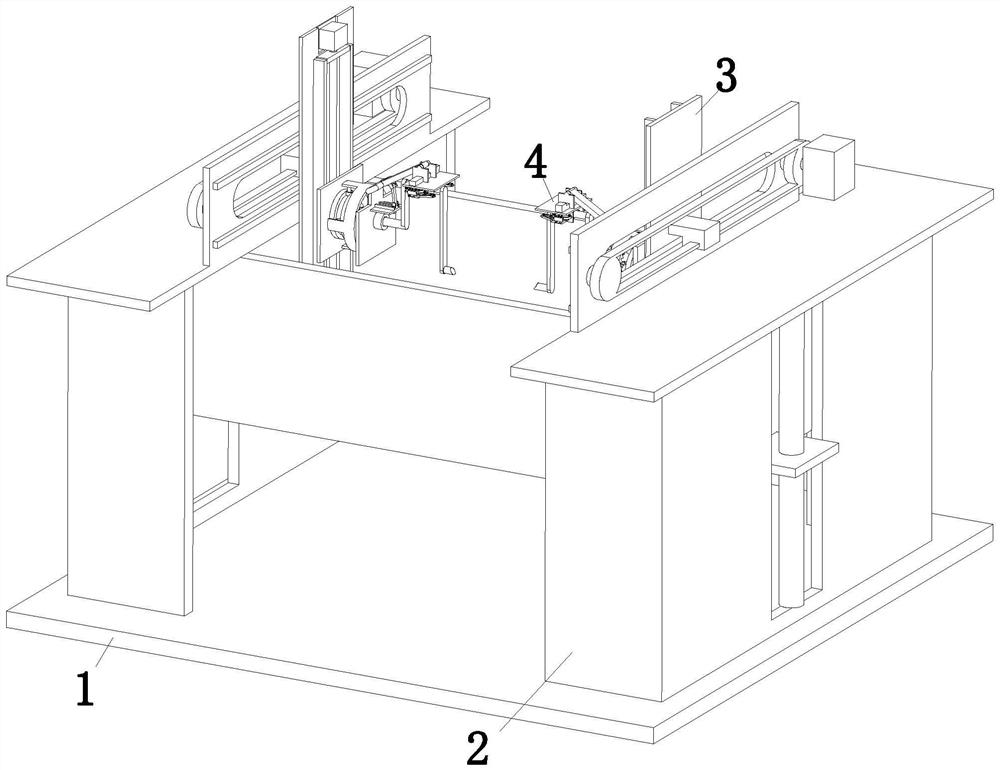

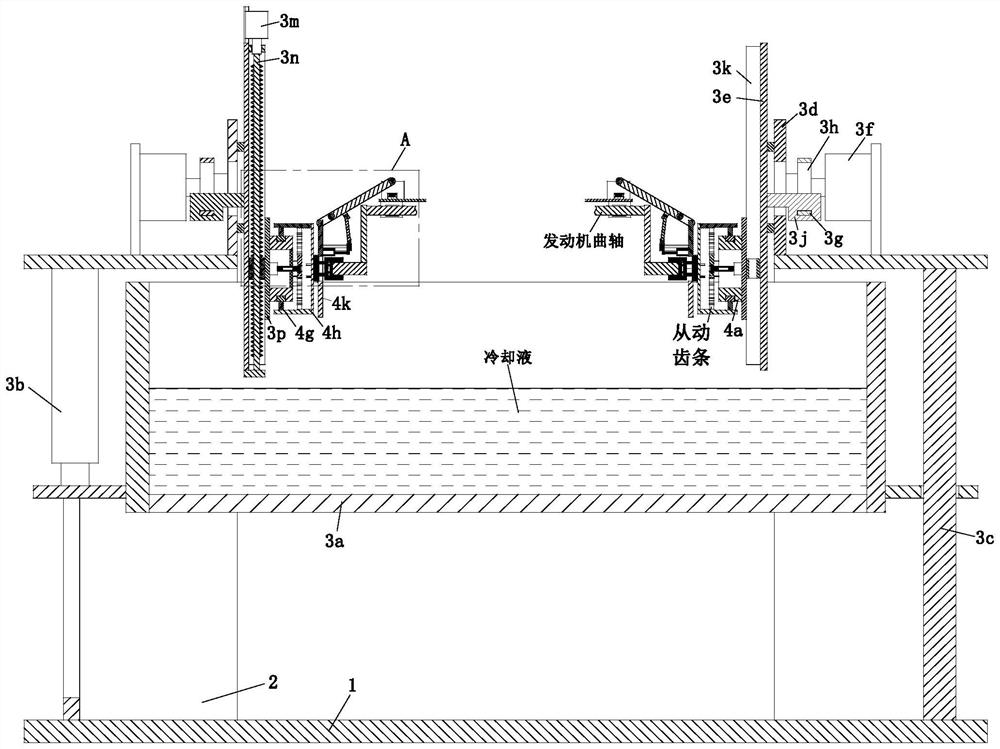

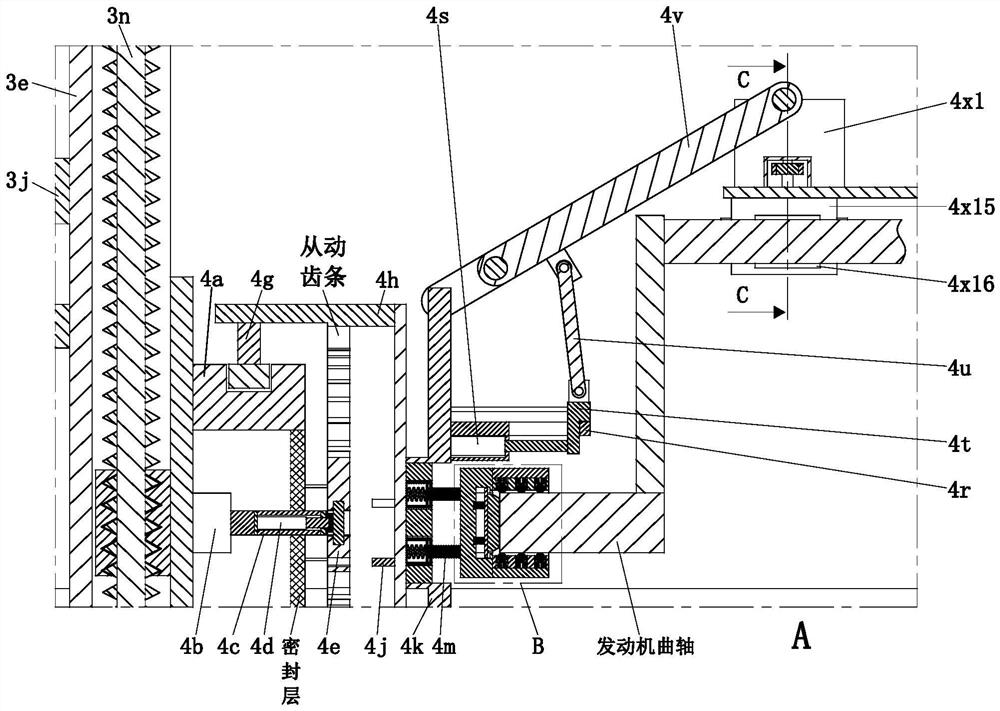

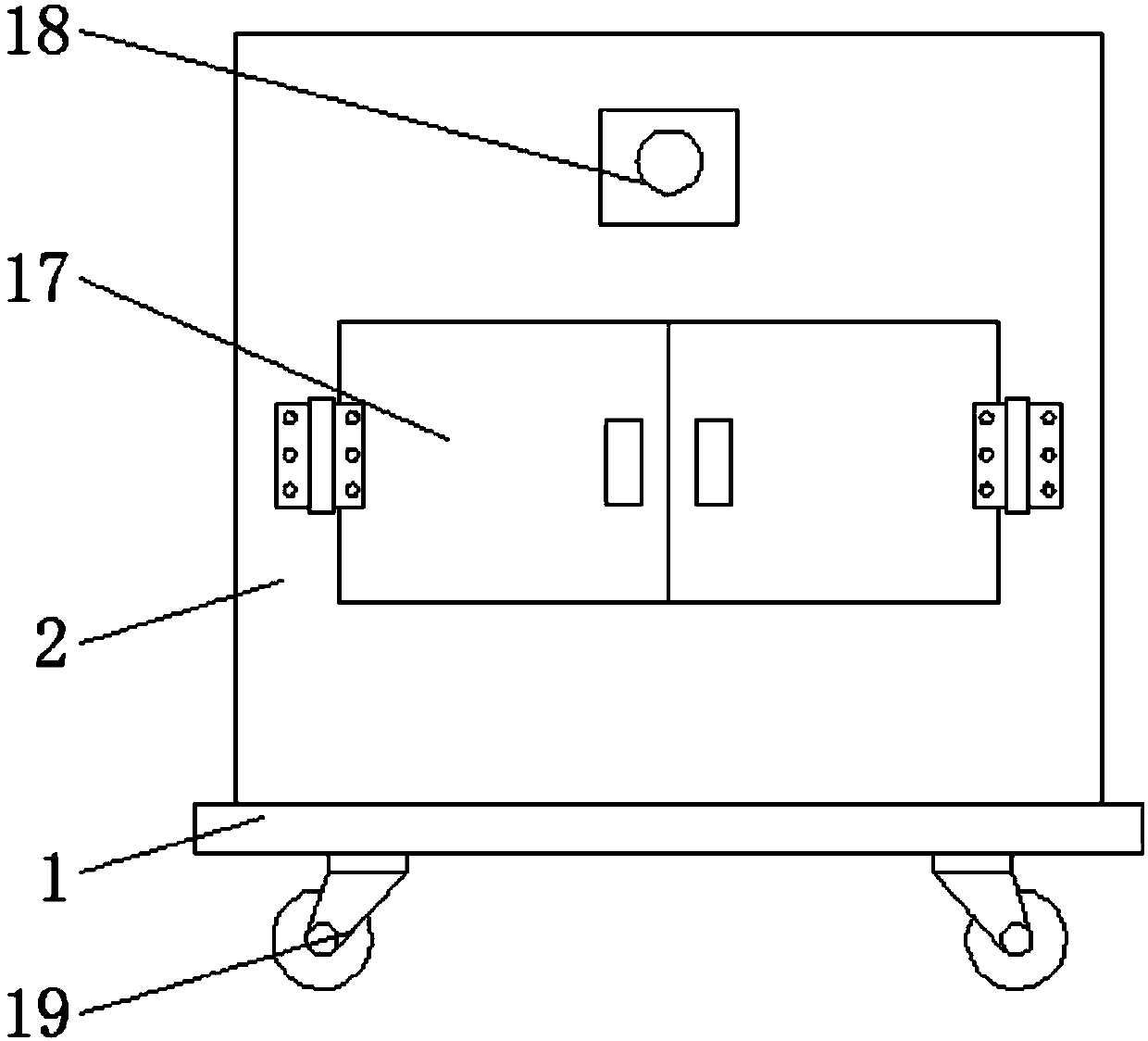

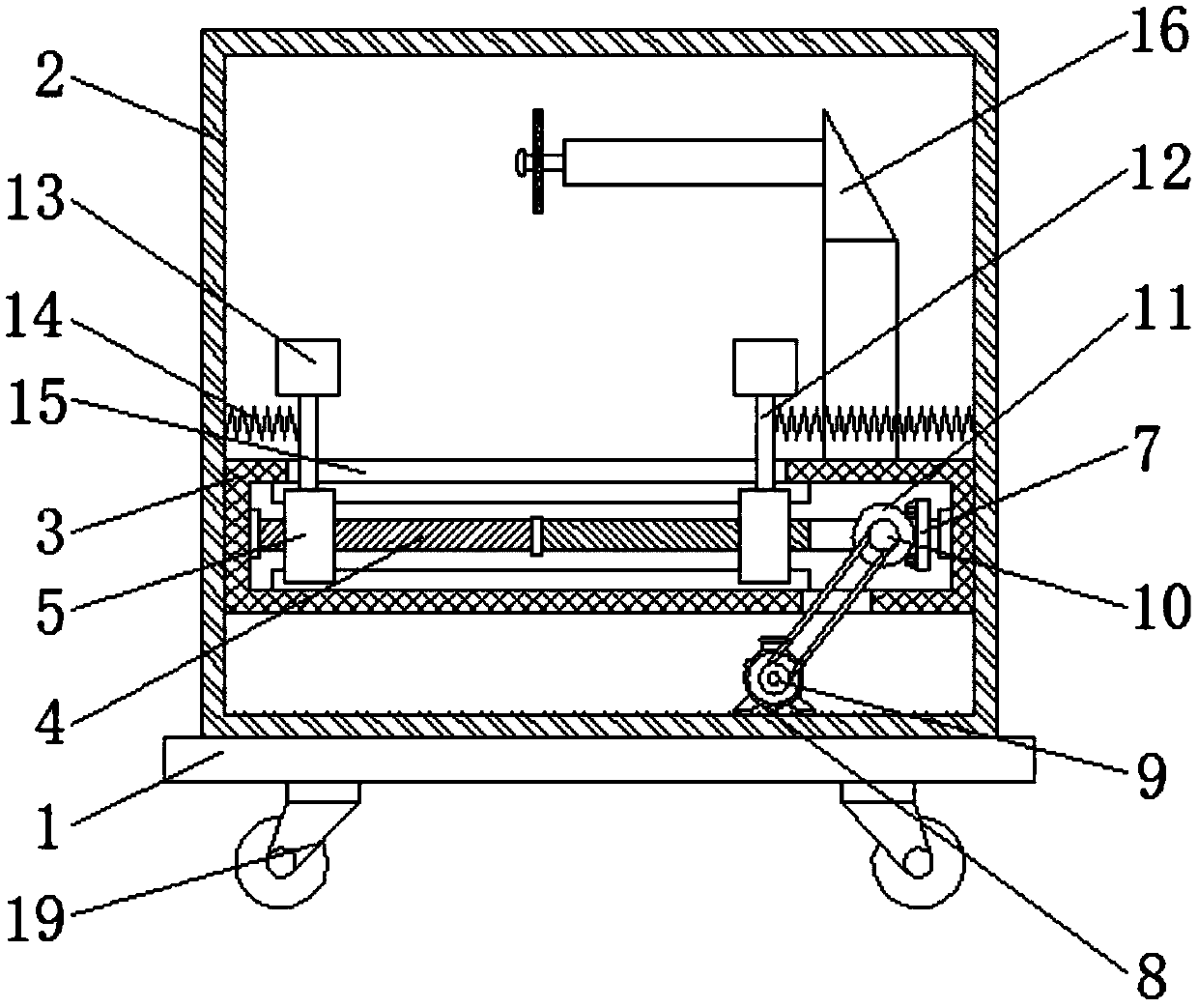

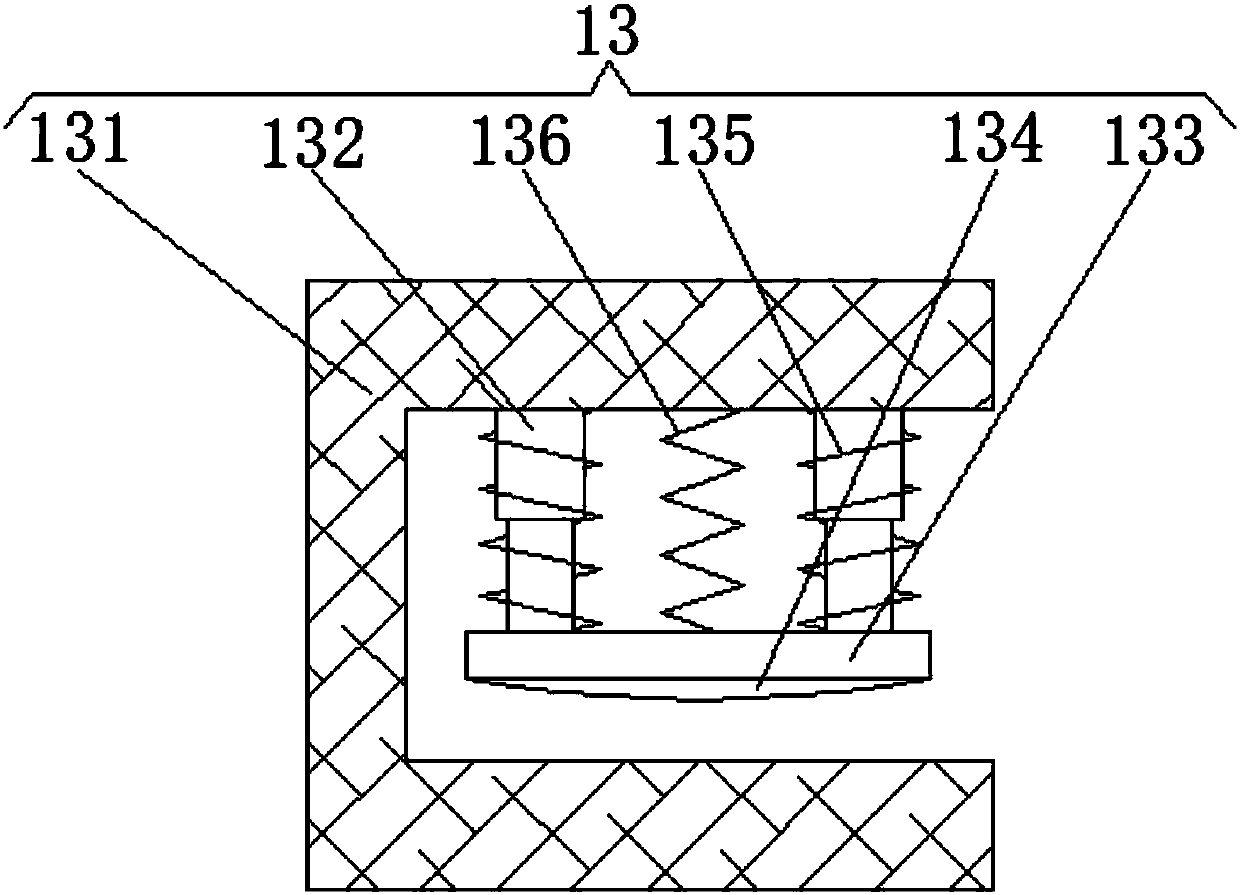

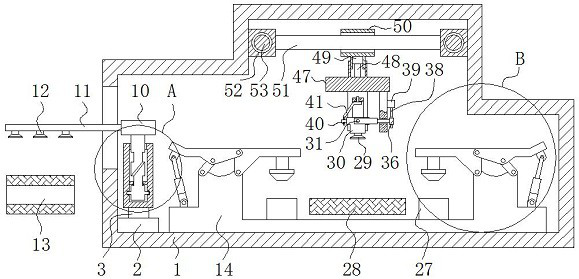

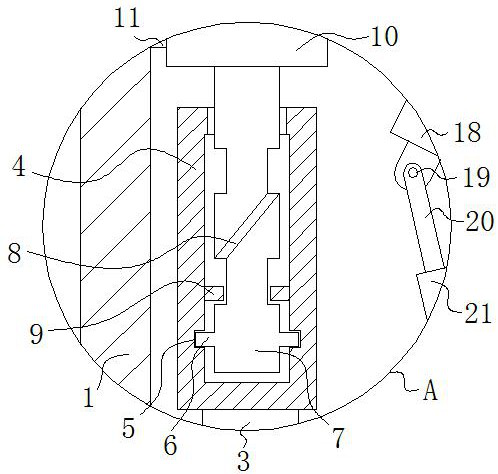

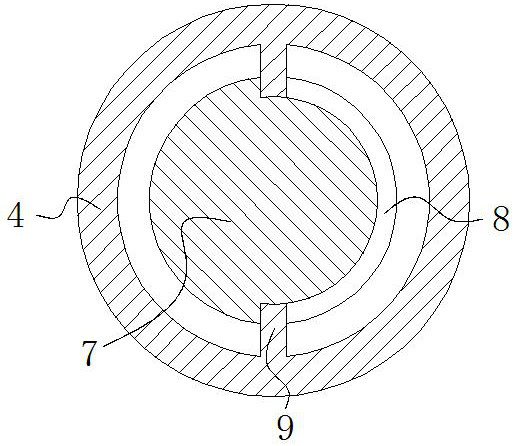

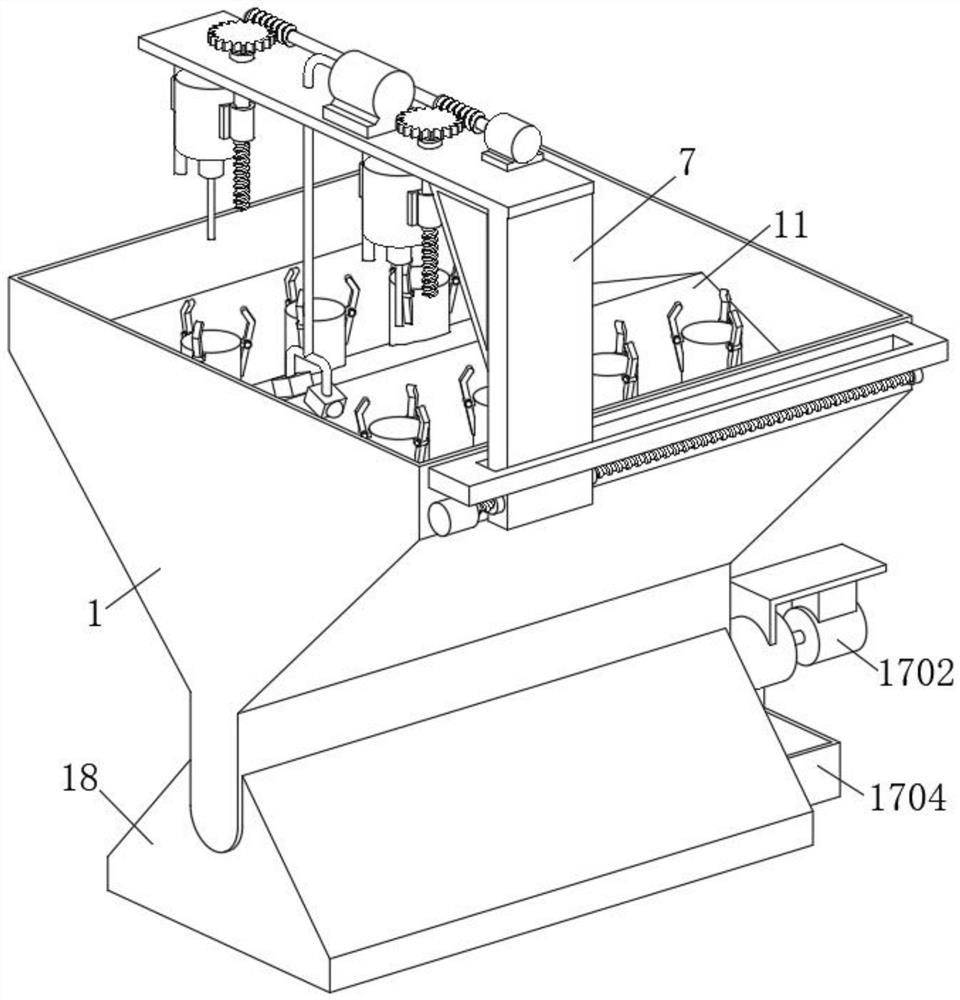

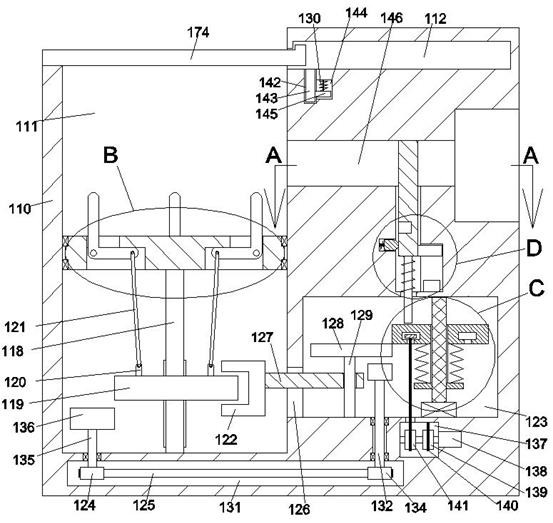

Quenching treatment equipment and quenching treatment process for engine crankshaft

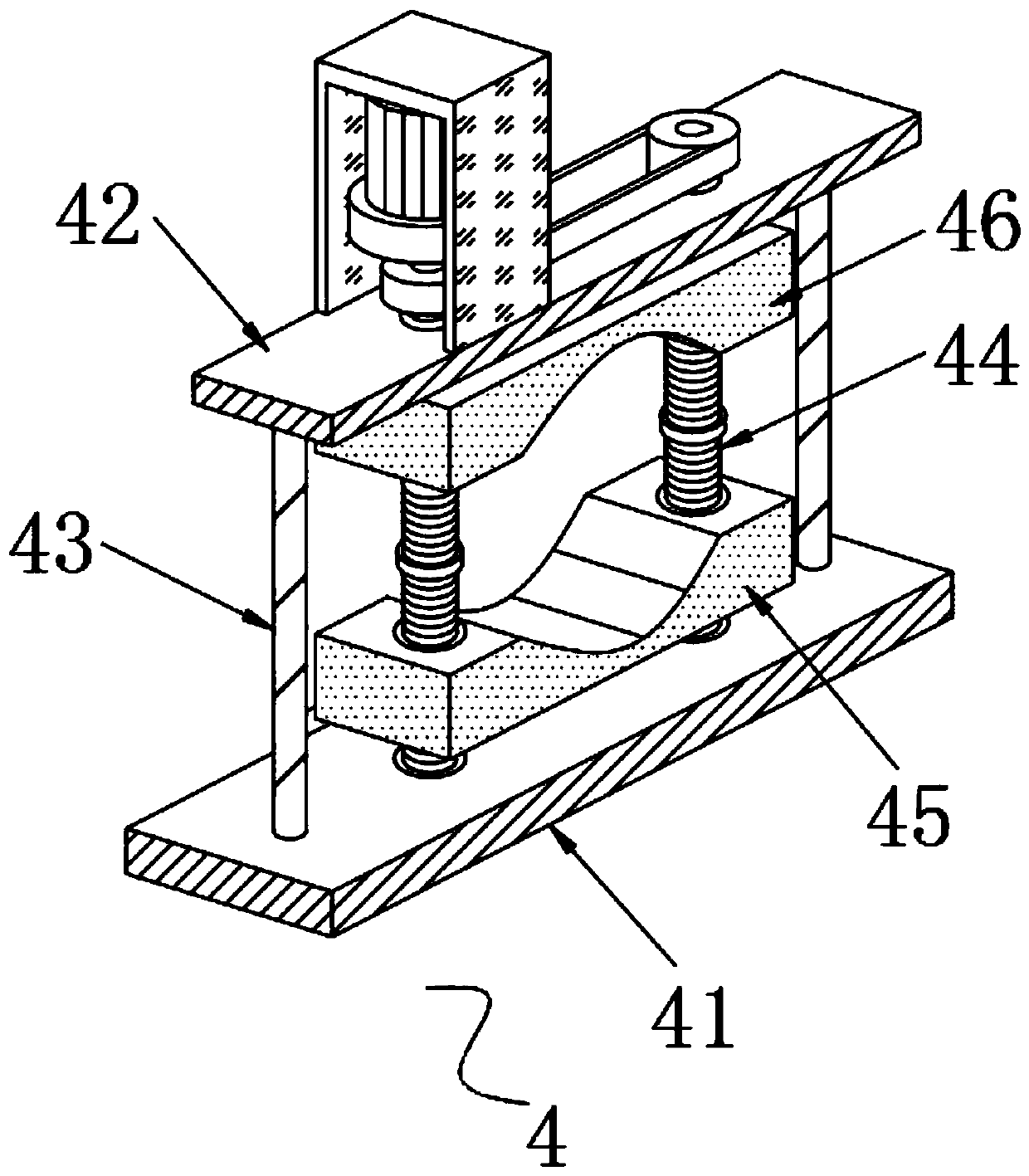

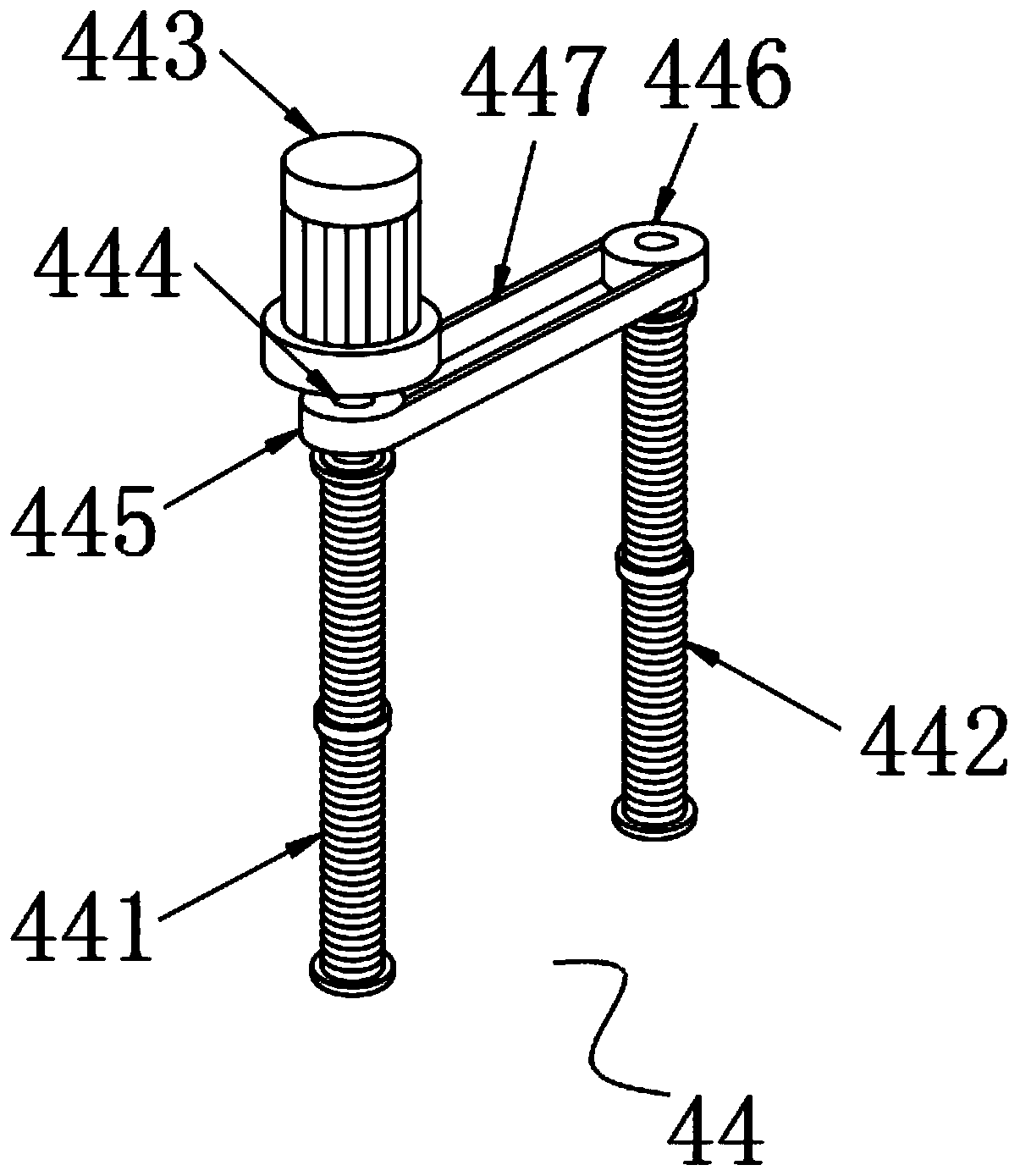

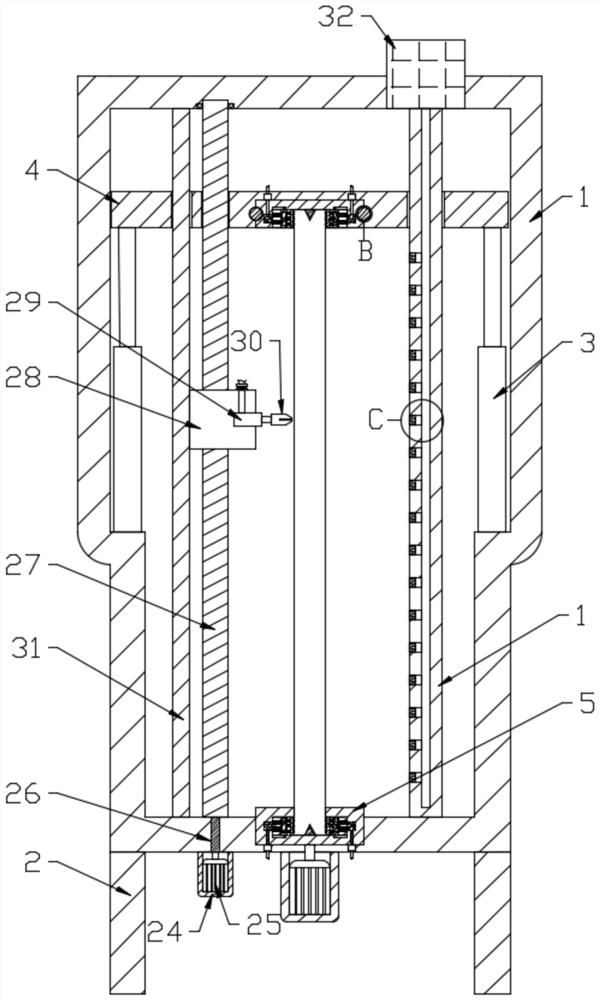

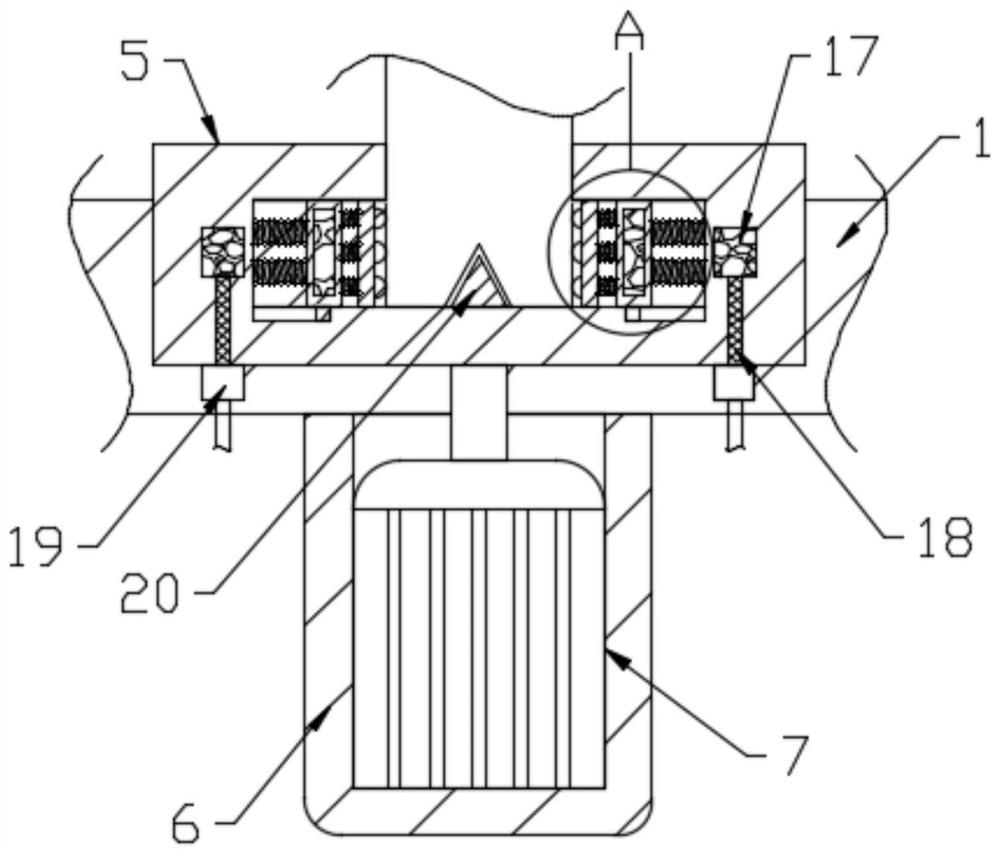

ActiveCN112011679AAvoid interferenceReduce work intensityFurnace typesHeat treatment furnacesElectric machineryEngineering

The invention provides quenching treatment equipment and a quenching treatment process for an engine crankshaft. The equipment comprises a mounting bottom plate, supporting frames, cooling mechanismsand clamping rotating mechanisms, the supporting frames are symmetrically mounted at the upper end of the mounting bottom plate, the cooling mechanisms are symmetrically mounted on the supporting frames in a sliding fit mode, the clamping rotating mechanisms are symmetrically mounted on the cooling mechanisms in a rotating fit mode, and the clamping rotating mechanisms are located between the supporting frames. The relative position of the crankshaft in the cooling process is adjusted in real time through a shifting motor and a lifting motor; the working intensity of workers is reduced; the clamping rotating mechanisms are capable of stably clamping the engine crankshaft in a complex shape; the crankshaft is continuously rotated in the cooling process to enable the complex surface of the crankshaft to be stably, evenly and rapidly cooled; and the working efficiency of cooling work is improved.

Owner:天津爱信热处理有限公司

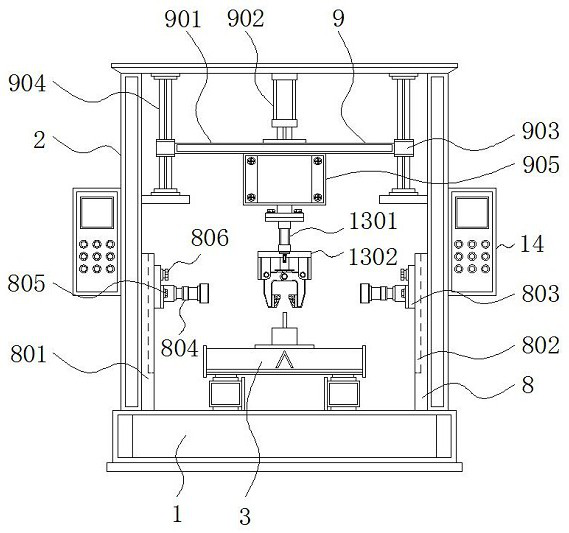

Multi-station automatic welding equipment

InactiveCN110757034AEasy to weldRealize automation technologyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCentrifugal fan

The invention provides multi-station automatic welding equipment, and relates to the technical field of workpiece welding. The multi-station automatic welding equipment comprises a frame, wherein thetop end of the frame is fixedly connected with a support frame, and the bottom end of the frame is fixedly provided with a working table, a bearing plate is fixedly connected to the bottom end of theworking table, and a centrifugal fan is mounted at the top end of the bearing plate. The multi-station automatic welding equipment has the beneficial effects that under the action of a sealing mechanism, when a workpiece is mounted on a clamping mechanism on a welding table inside the frame, a sealing cover can rotate upwards through a hinge; when the sealing cover rotates to be perpendicular to the top surface of the frame, a movable clamping plate connected with a second sliding block can be pushed to enter the inner side of an L-shaped clamping plate, so that the sealing cover is fixed; andwhen the workpiece is installed and clamped, the sealing cover can be rotated through the hinge to continue to close the feeding port of the frame, and meanwhile, a magnetic clamping plate connectedwith the inner wall of the sealing cover enters a magnetic clamping groove formed in the inner part of the frame.

Owner:陕西威斯特高新技术投资有限公司

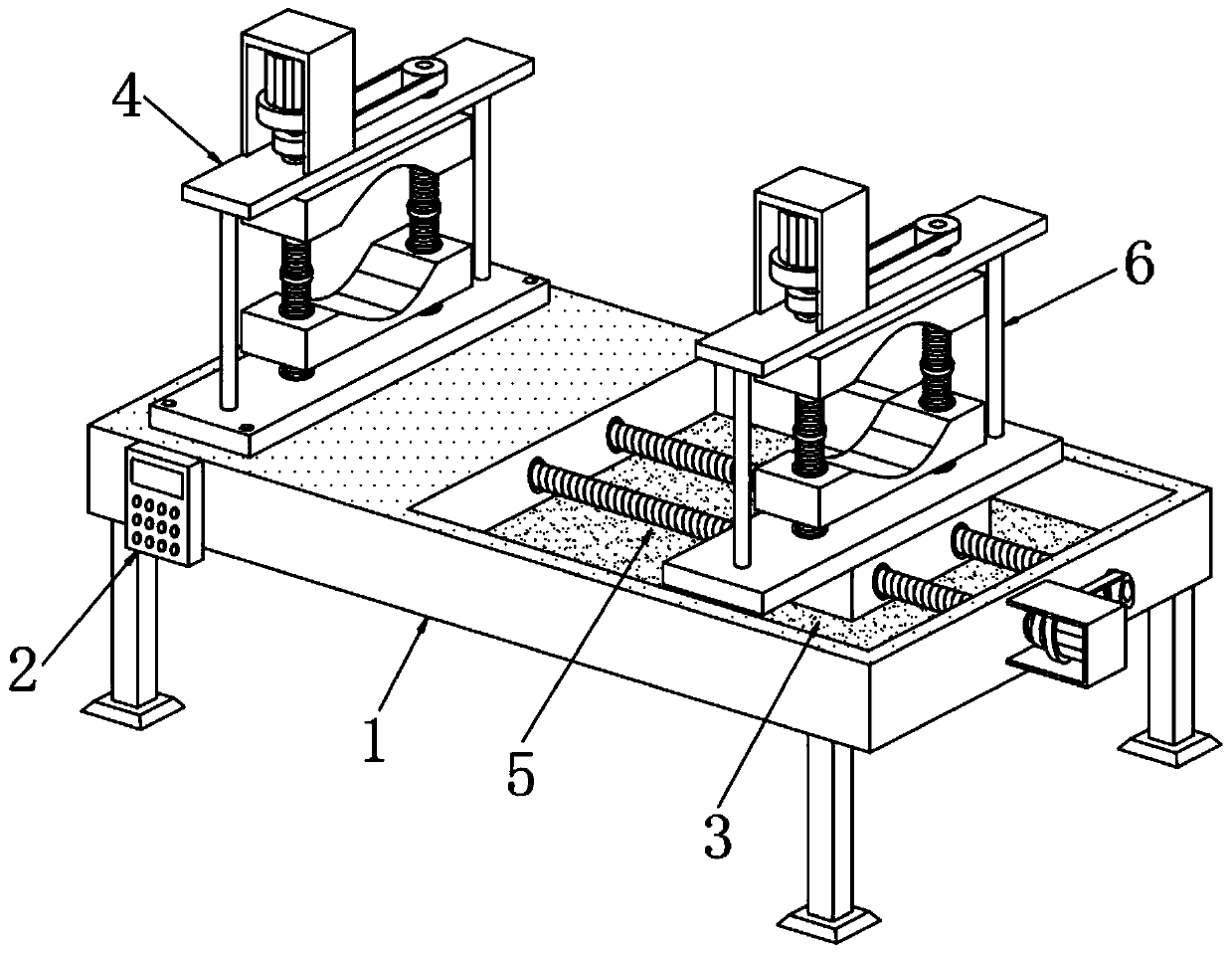

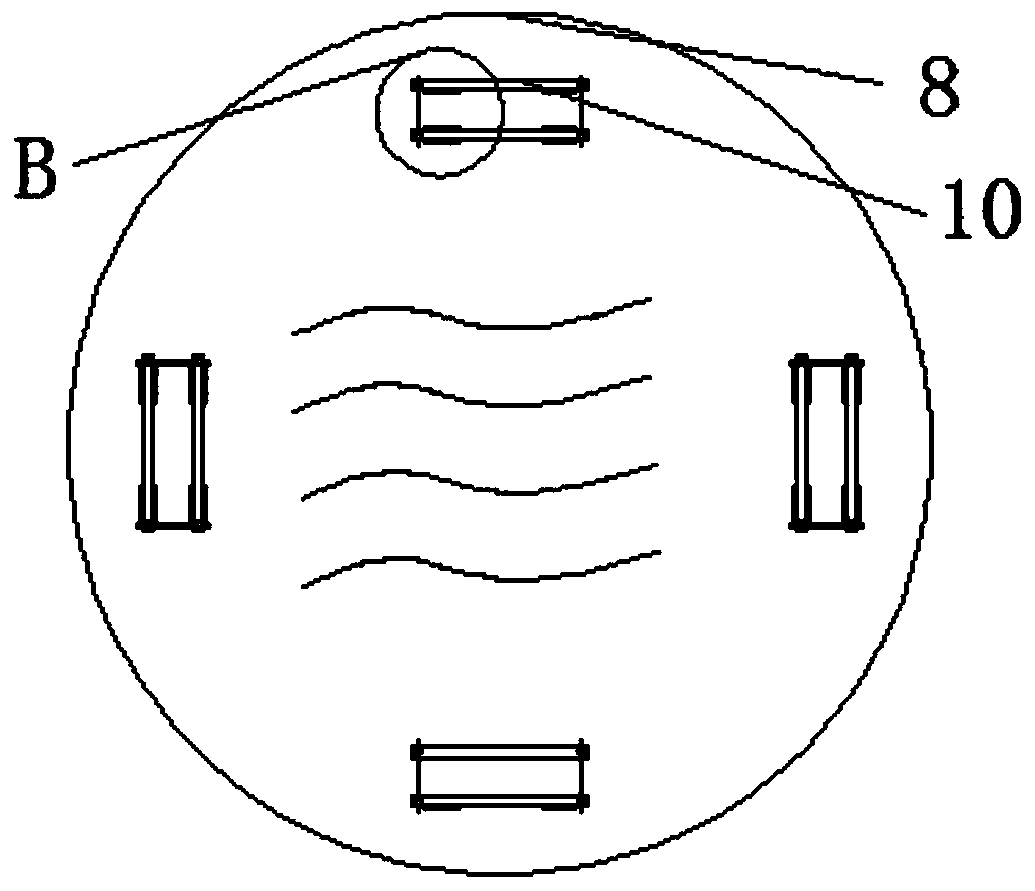

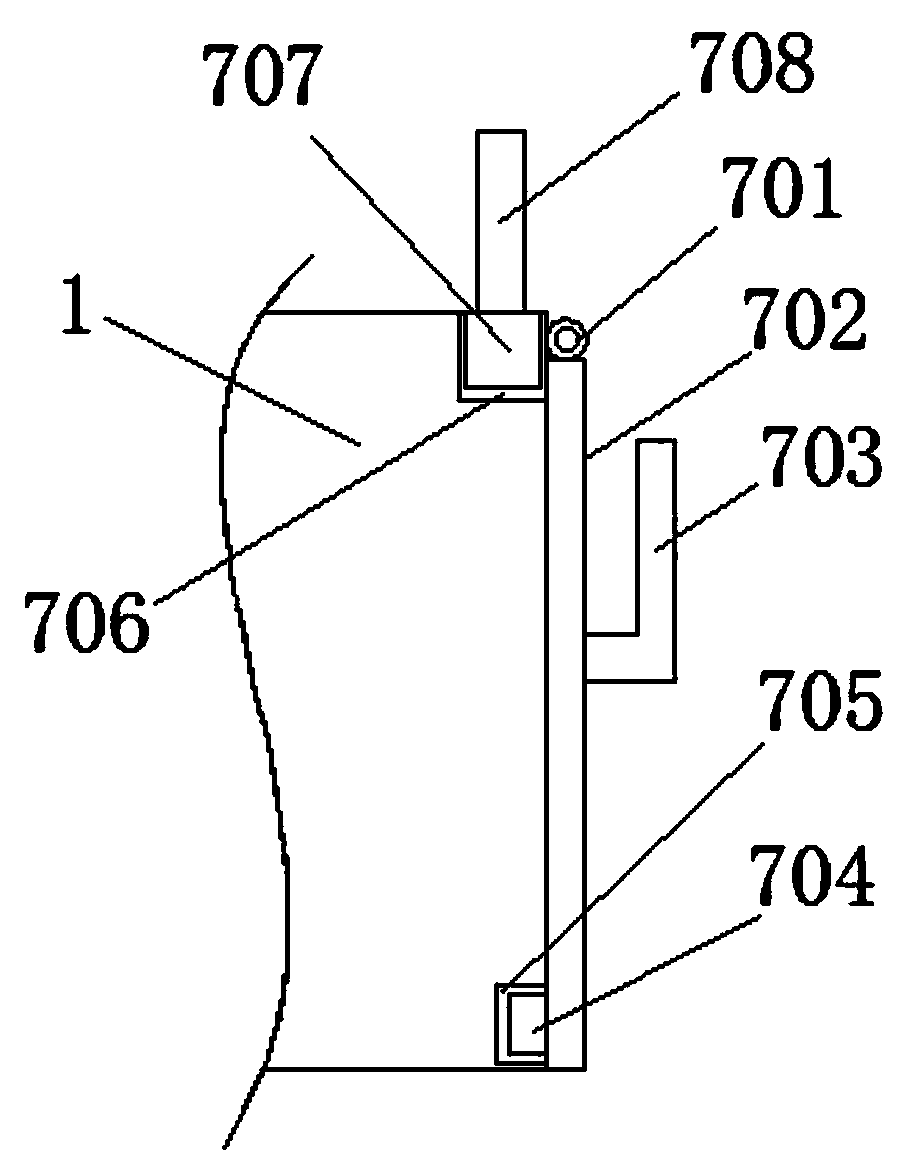

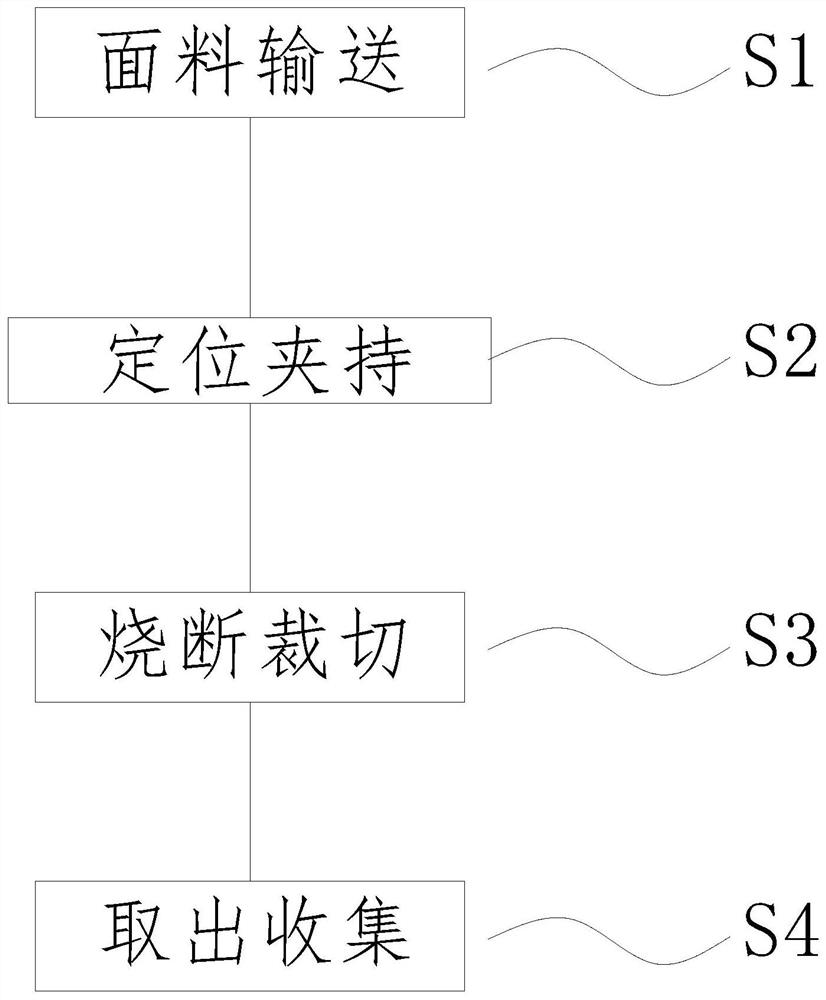

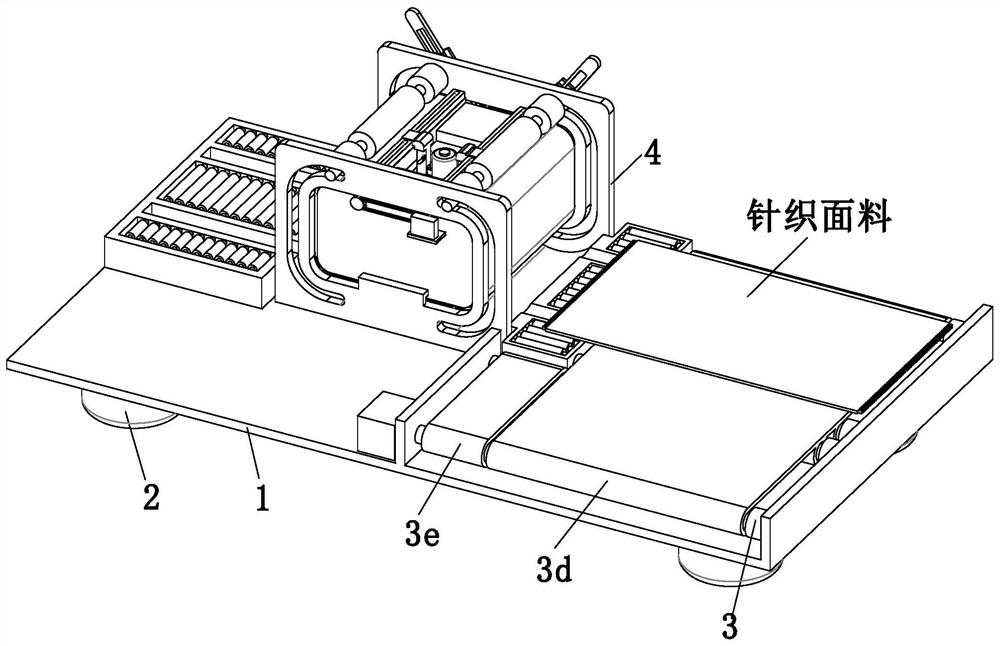

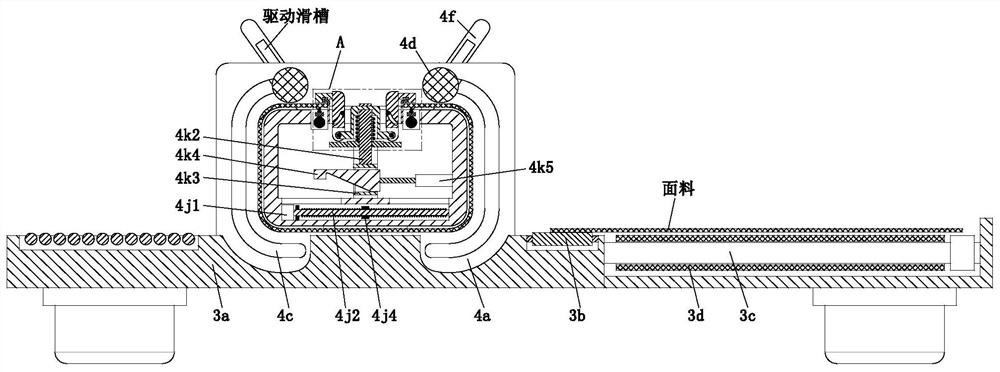

Knitted fabric preparation and molding post-treatment method

InactiveCN112538746AReduce workloadRealize clamping workSevering textilesYarnManufacturing engineering

The invention relates to a knitted fabric preparation and molding post-treatment method. A knitted fabric preparation and molding post-treatment device is used in the method. The knitted fabric preparation and molding post-treatment device comprises a mounting bottom plate, a supporting column, a supporting plate, a cutting mechanism and a shifting mechanism. The method can solve the problems thatin a knitted fabric preparation and molding post-treatment process, a knitted fabric to be cut is usually placed on a workbench manually, then a clamping tool is used for clamping and positioning theknitted fabric, then a cutting knife is used for cutting an exposed yarn end at the end part of the knitted fabric, during the process, the knitted fabric is difficultly subjected to stable and effective clamping and positioning operation due to the soft structure of the knitted fabric, and because the knitted fabric is relatively wide in size, it is difficult to ensure that the cut surface is always kept tidy during cutting, it is also difficult to cut the two ends of the knitted fabric at the same time, the labor intensity of manual operation is high, and the working efficiency of processing work is reduced.

Owner:南京新盟泰新材料科技有限公司

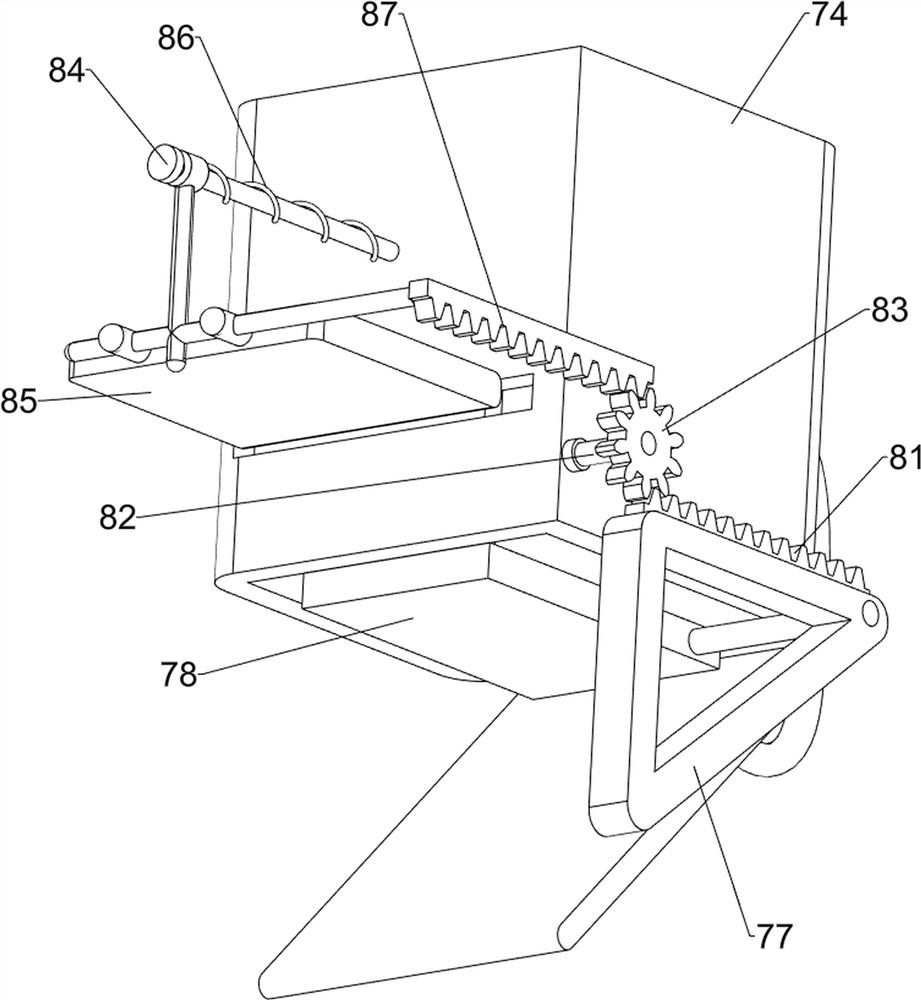

Cutting device capable of cutting different sizes of ceramic tiles

PendingCN107856209AImprove practicalityEasy to cutWorking accessoriesStone-like material working toolsElectric machineryBevel gear

The invention relates to the technical field of ceramic tile cutting equipment and discloses a cutting device capable of cutting different sizes of ceramic tiles. The cutting device comprises a bottomplate. The top of the bottom plate is fixedly connected with a box. A fixed box is fixedly connected between the inner walls of the two sides of the box. A bi-directional threaded rod is rotatably connected between the two sides of the inner wall of the fixed box through bearings. The outer surface of the bi-directional threaded rod is in threaded connection with a first moving block and a secondmoving block from left to right in sequence. The portion, located on one side of the second moving block, of the outer surface of the bi-directional threaded rod is sleeved with a first bevel gear. One side of the bottom of the inner wall of the box is fixedly connected with a motor. One end of an output shaft of the motor is sleeved with a first belt pulley. The cutting device capable of cuttingdifferent sizes of ceramic tiles can cut different sizes of ceramic tiles so that workers can cut the ceramic tiles more conveniently; the cutting difficulty is reduced, and the practicality of the cutting device is improved.

Owner:WUXI HUIOU CERAMIC CO LTD

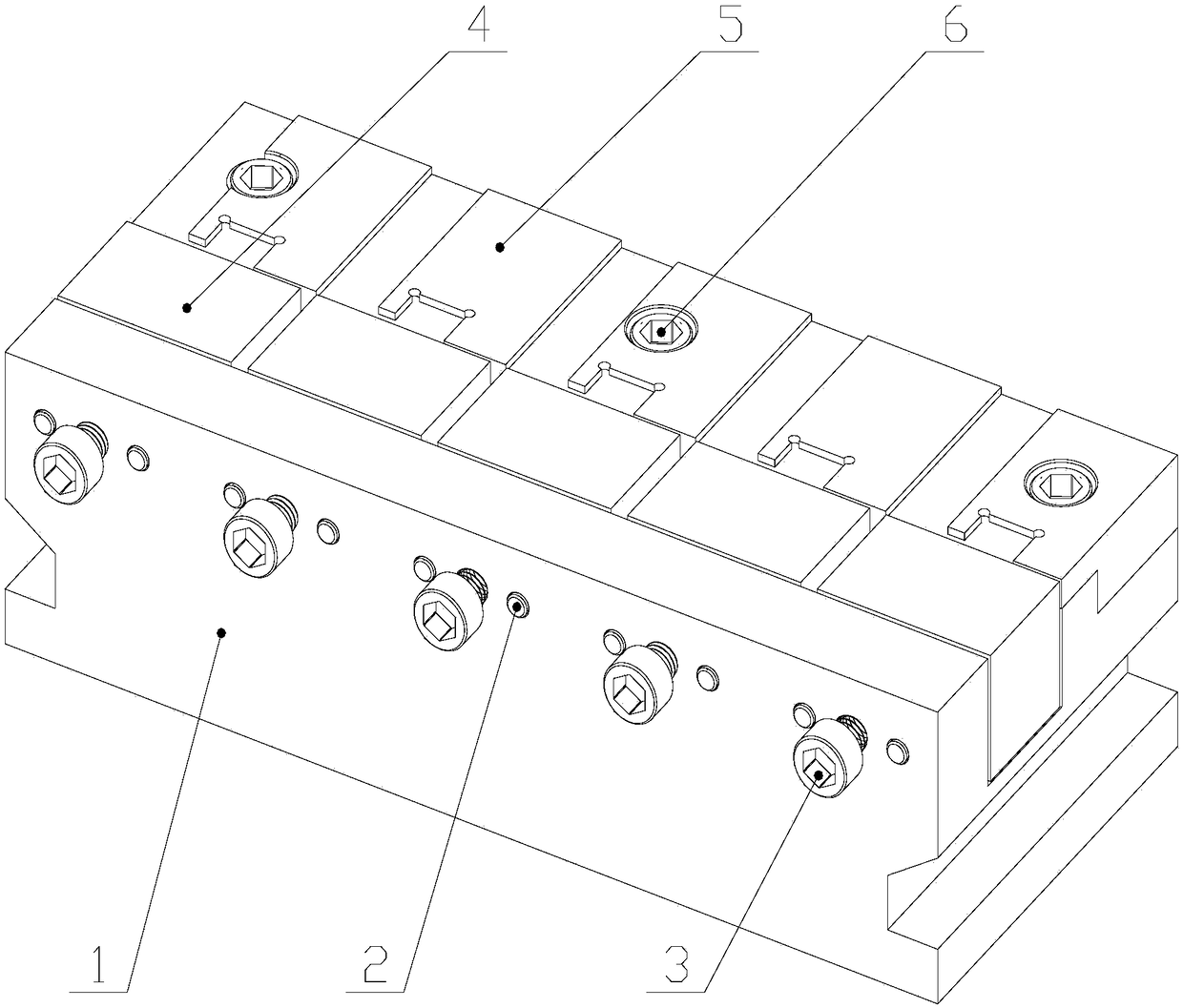

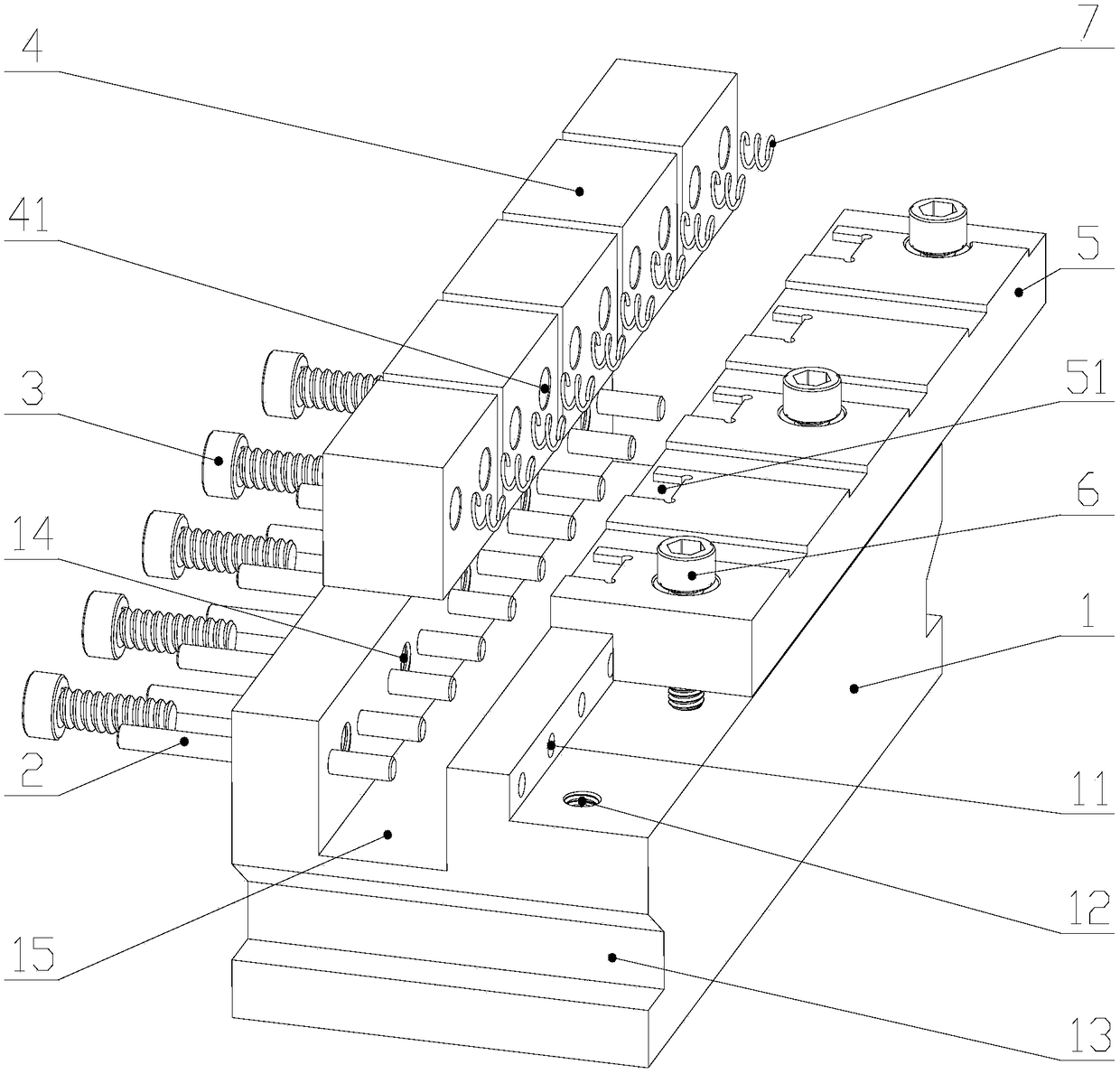

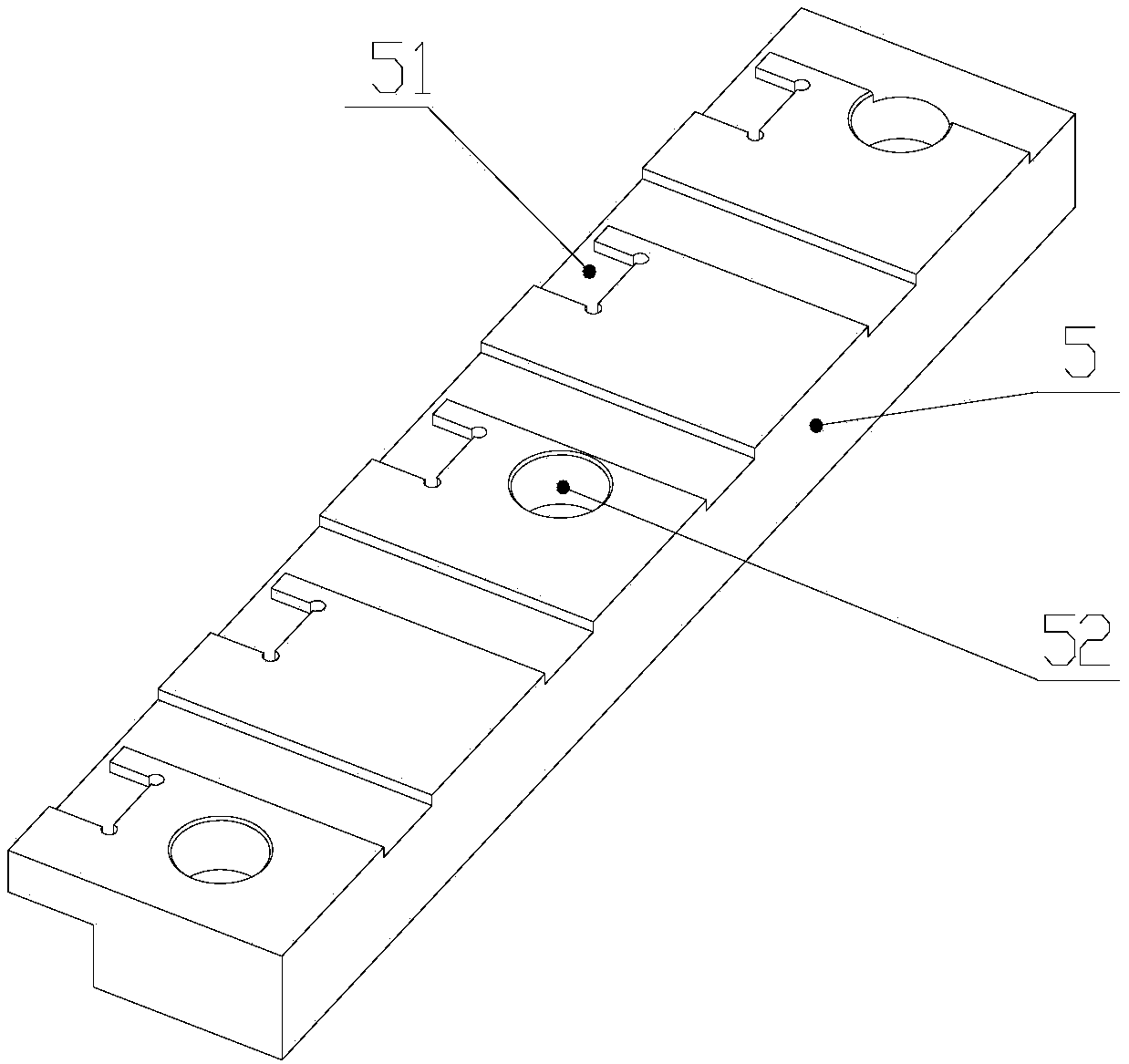

Multi-station clamp for small part processing

PendingCN108818067ARealize clamping workHigh positioning accuracyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention belongs to the technical field of a clamp and discloses a multi-station clamp for small part processing. The multi-station clamp comprises a base, movable blocks and station blocks, wherein an elongated groove is formed in the base, and a plurality of movable blocks are arranged along the groove direction at intervals; the station blocks corresponding to the movable blocks are arranged on one side of the elongated groove, and a clamping station is arranged on the upper end surface of each station block; and the movable blocks can move back and forth between the two sides of the elongated groove and are matched with the clamping stations to clamp workpieces. The multi-station clamp can clamp multiple small parts once and only needs to replace the station blocks during processing different shapes of small parts, thereby greatly saving the production cost. As the base does not need to be replaced, the time of positioning with a machine tool or a cutter again is saved, and the working efficiency is greatly improved. Moreover, the multi-station clamp has the advantages of fastness and convenience in assembly and disassembly, high positioning precision, convenience in operation, etc.

Owner:SUZHOU INST OF TRADE & COMMERCE

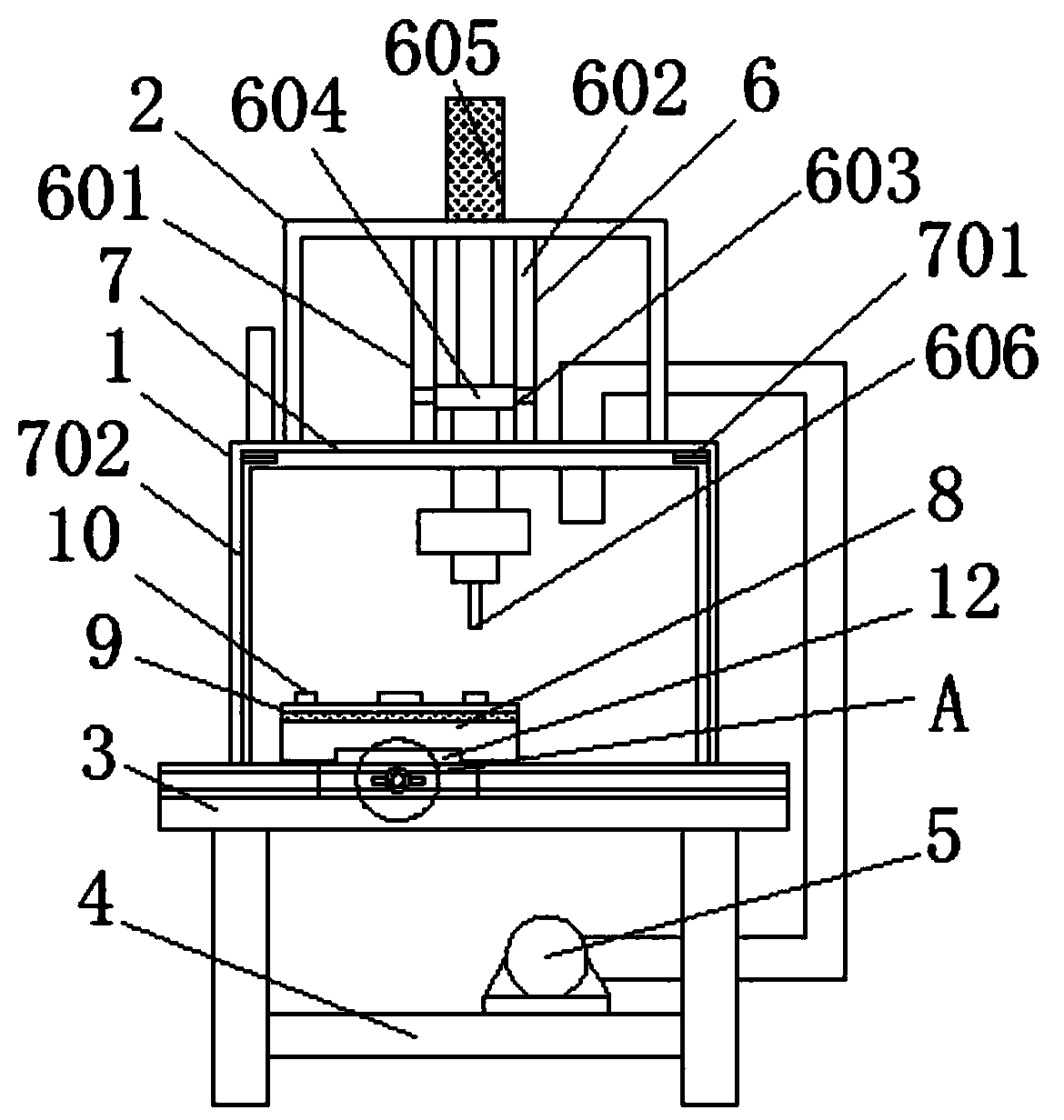

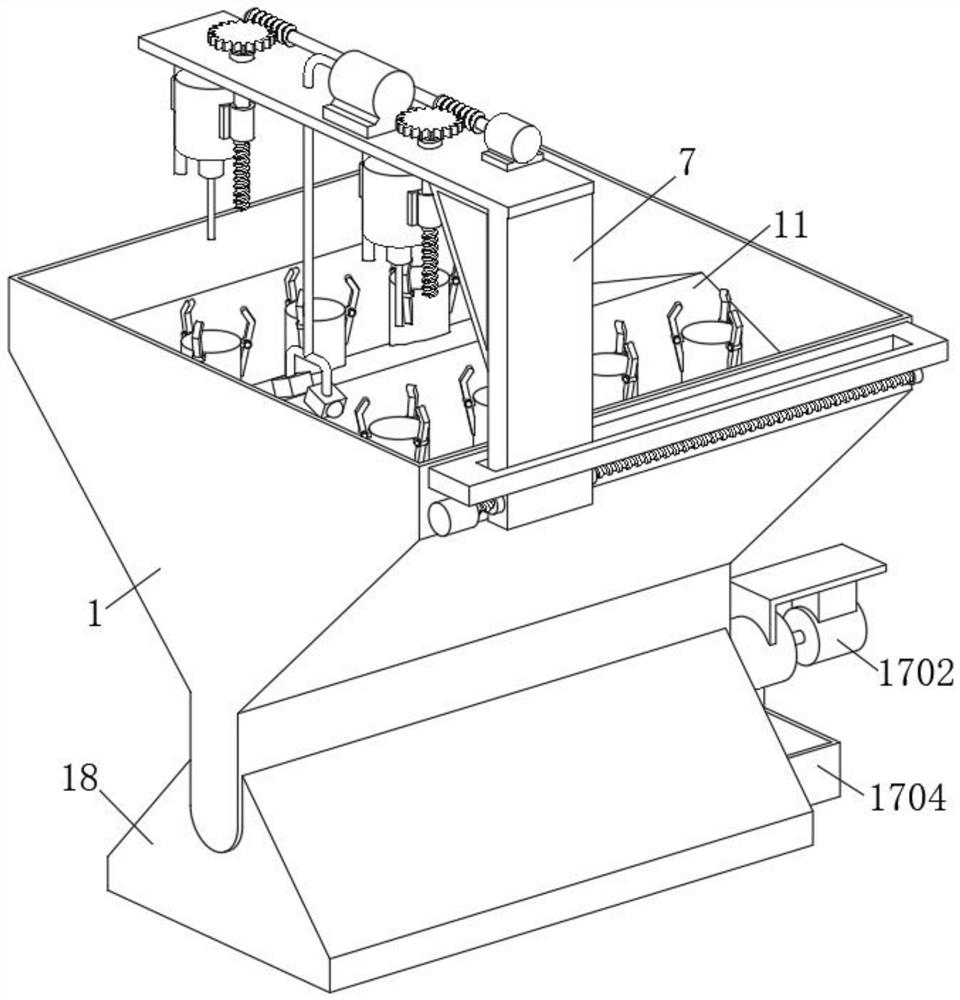

Industrial robot with automatic cleaning function

ActiveCN112496773AImprove processing efficiencyImprove cleaning effectLarge fixed membersPositioning apparatusElectric machineryManufacturing engineering

The invention discloses an industrial robot with an automatic cleaning function, and belongs to the technical field of mechanical manufacturing equipment. The industrial robot comprises a shell, the top of the shell is of an open structure, a guide plate is fixedly connected to the side wall of the top of the shell, a motor a is mounted at one end of the bottom surface of the guide plate, and an output shaft of the motor a is fixedly connected with one end of a lead screw; and the other end of the lead screw is rotationally connected to the bottom face of the guide plate through a bearing seat, a screw sleeve is connected to the lead screw in a spiral transmission manner, the screw sleeve is embedded in a movable frame plate, and a machining assembly is installed on the movable frame plate. Workers do not need to conduct cleaning work, chippings and the like can be effectively prevented from being accumulated on a workbench plate, multi-station machining work can be conducted conveniently, the machining efficiency is improved, the industrial requirement is met, the chipping cleaning effect is improved, cleaning is comprehensive, it can be guaranteed that no chippings are accumulated on the workbench plate, chippings can be continuously discharged, the automatic cleaning function is achieved, and overall continuous operation is facilitated.

Owner:东莞市麦科微光电科技有限公司

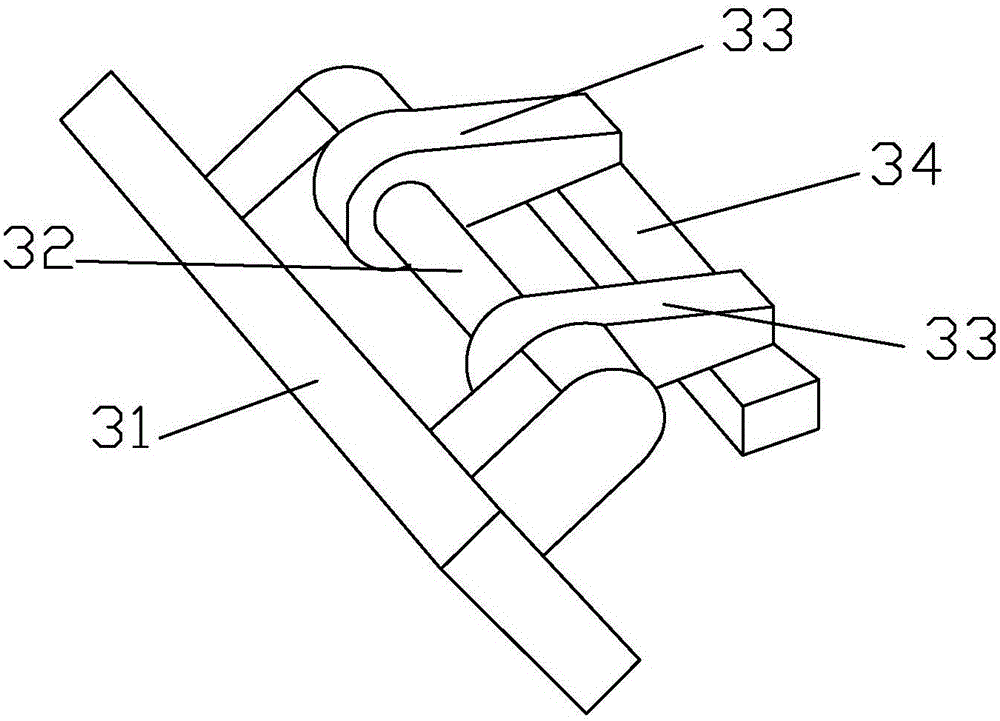

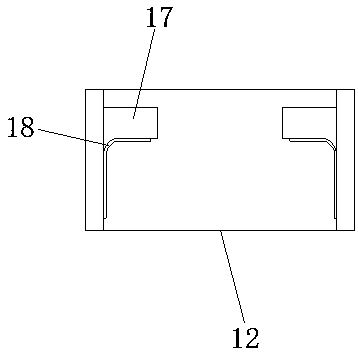

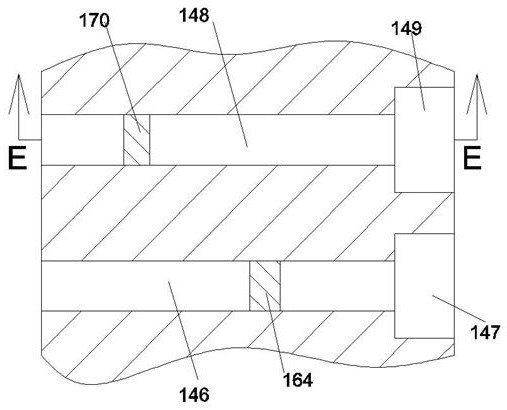

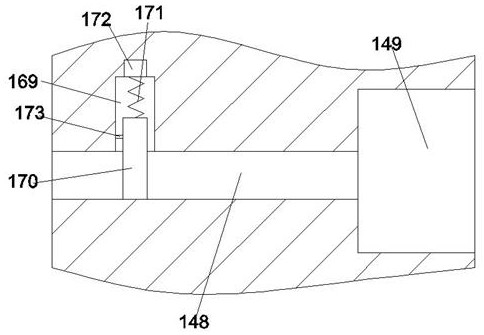

Clamping device of eight-station cold heading machine

ActiveCN105692192AReduce lateral forceRigid enoughConveyor partsWorking environmentIndustrial engineering

The invention discloses a clamping device of an eight-station cold heading machine. The clamping device comprises a clamping table mechanism and a clamping core mechanism, wherein the clamping table mechanism is connected with the clamping core mechanism, the clamping table mechanism comprises a clamp box, a clamping table connecting rod and a clamping table oscillating rod, the clamping table connecting rod is connected with the clamping table oscillating rod, the clamping table oscillating rod is installed in the clamp box, a clamping table oscillating rod shaft is connected to the clamping table oscillating rod, a guide gear is arranged on the clamping table oscillating rod shaft, the clamping core mechanism comprises a clamping core shaft and a clamping assembly, a rolling gear is arranged on the upper part of the clamping core shaft, the rolling gear is engaged with the guide gear, the clamping table connecting rod and the clamping table oscillating rod are connected to the middle of the clamping core shaft, and the clamping assembly is connected to the lower part of the clamping core shaft. The device has the advantages of simple and compact structure, high degree of automation, stable working performance and high production efficiency, both the clamping table connecting rod and the clamping table oscillating rod are wrapped in the clamp box, so that the normal movement of the clamping table mechanism is not influenced by the outside adverse working environment, and the exposed part of equipment is reduced, so that materials are saved.

Owner:浙江东雄机床有限公司

Automobile roof production equipment having specially-shaped corner polishing function

InactiveCN112207657AChange the center positionRealize clamping workEdge grinding machinesGrinding drivesTransmission beltEngineering

The invention discloses automobile roof production equipment having a specially-shaped corner polishing function. The equipment comprises a main body frame; a first air cylinder is installed on the left side of the lower side of the inside of the main body frame; and a rotating cylinder barrel is welded to the upper side of a first air rod. Compared with existing common roof polishing production equipment, the automobile roof production equipment having the specially-shaped corner polishing function has the advantages that a guide column is arranged, a lifting block is arranged below the guidecolumn, the lifting block is matched with a lifting groove, the first air cylinder drives the rotating cylinder barrel to move through the first air rod, the rotating cylinder barrel drives the guidecolumn to rise and fall through the lifting block, a guide thread is arranged in the middle of the guide column, the guide thread is matched with a rotating block, the spiral angle of the guide thread is 180 degrees, the guide column can be driven to rotate by 180 degrees when a lifting cylinder barrel performs the lifting motion, and a roof is automatically transferred to a clamping base from afeeding conveying belt to be machined.

Owner:CHONGQING TECH & BUSINESS UNIV

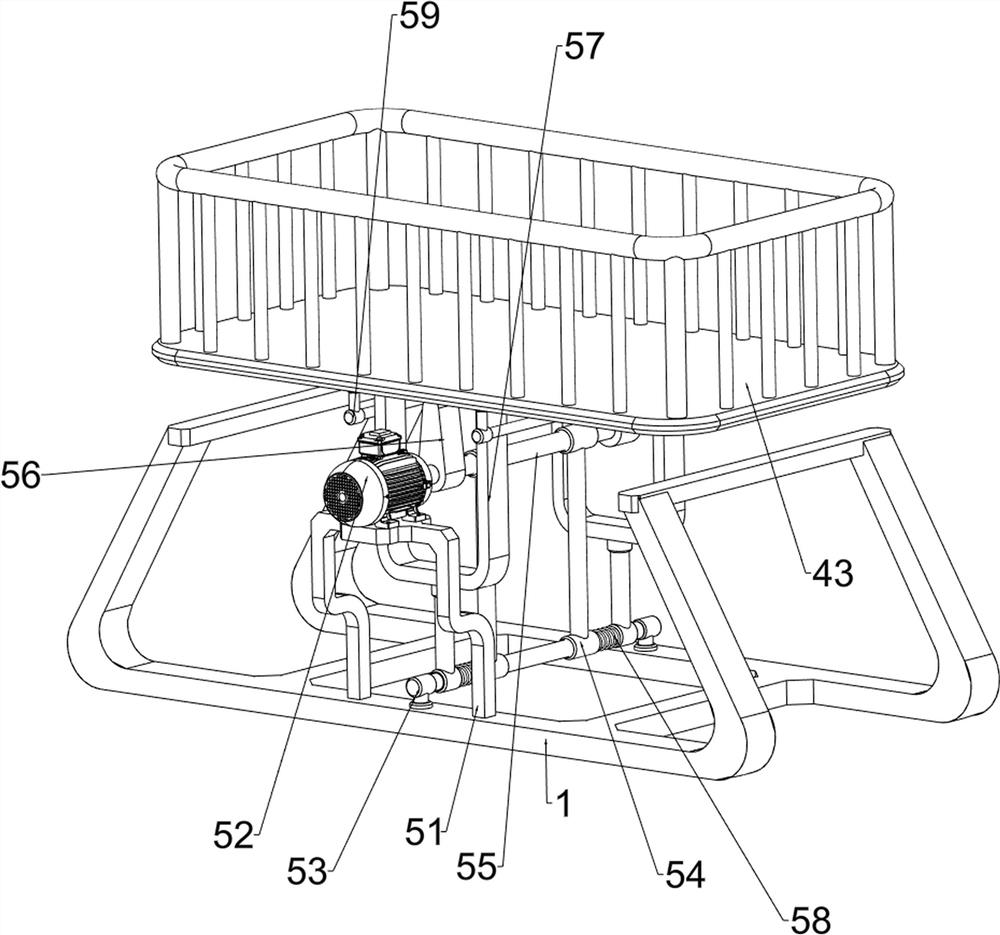

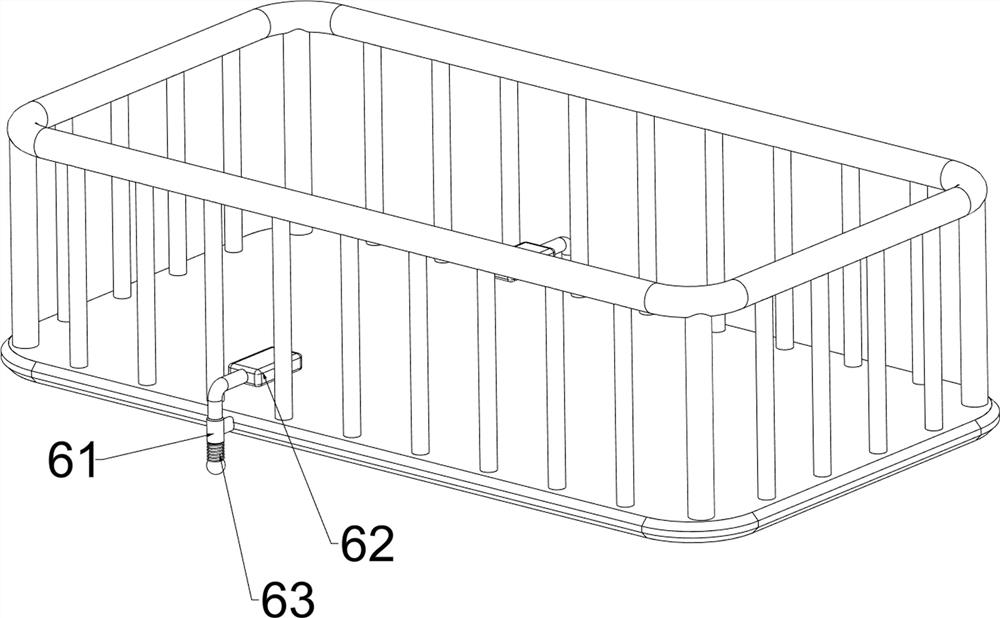

Shaking type infant resting bed

The invention relates to a resting bed, in particular to a shaking type infant resting bed. The resting bed can be shaken, the quilt can be clamped, and other articles can be placed and a mosquito net can be suspended. The shaking type infant resting bed comprises supporting legs and installation blocks connected between the two sides of the supporting legs, and first sliding sleeves welded between the two sides of the tops of the two mounting blocks. Through the arrangement of a shaking mechanism, the shaking mechanism is matched with a rotating mechanism, and slight shaking work of the infant can be achieved; a clamping mechanism is matched with the shaking mechanism, so that the quilt can be clamped; a swinging mechanism is matched with the rotating mechanism, so that the mosquito net can be suspended; and a sliding mechanism is matched with a pulling mechanism, so that clothes can be stacked.

Owner:漆波涛

Automatic discharge device of electric conveying frame

InactiveCN111604707ARealize clamping workRealize blanking workMetal working apparatusDischarge efficiencyManual handling

The invention discloses an automatic discharge device of an electric conveying frame. The automatic discharge device comprises a conveying guide rail frame, a driving chain, a linkage structure, clamping arms, an arc-shaped gear and a conveying air pipe. A material can be clamped and discharged automatically and rapidly by electrically connecting a cylinder with the linkage structure, not only istedious manual operation avoided, but also time is saved, the conveying and discharging efficiency of the electric conveying frame is improved, and long-term conveying work is facilitated; a steppingmotor drives the driving chain and is electrically connected with the cylinder, so that workers can automatically control the driving chain to start or stop and control the conveying and discharging work of the cylinder, and the automatic degree of the conveying frame is improved; and by means of protruding blocks on the inner sides of the clamping arms, the friction force between the two clampingarms and the material can be increased, and the loss caused by falling in the clamping and conveying process is avoided.

Owner:山东方通智能科技有限公司

Bottle body filling rotary positioning mechanism

InactiveCN110745759AAchieve fixed positionAvoid shakingSafety device in filling machineryEngineeringBottle

The invention discloses a bottle body filling rotary positioning mechanism. The bottle body filling rotary positioning mechanism comprises a base and a positioning cylinder, wherein a vertical rod isfixed to the middle position of the upper surface of the base, a top plate is welded to the upper end of the vertical rod, the lower surface of the top plate is provided with first motor boxes in an equilateral triangle manner, the first motor boxes are provided with three, a screw rod is mounted on an output shaft of the lower end of each first motor box, an annular sleeve is in transmission connection with the outer wall of the screw rod, the positioning cylinder is fixed on the annular sleeve, a PLC controller and a tank filling pump are correspondingly mounted at the left side and the right side of the upper end of the top plate, the central position of the lower end of the top plate is provided with a tank filling assembly, and the interior of the tank filling assembly comprises a connecting hose. According to the bottle body filling rotary positioning mechanism, through arranging a series of structures, the device can realize the positioning and fixing of the bottle body, the positioning effect is stable, and the bottle body can be effectively prevented from shaking, the positioning operation of the bottle body can be automatically realized according to the positioning mechanism, the efficiency is high, and the automation degree is strong.

Owner:T LINE TECH CO LTD

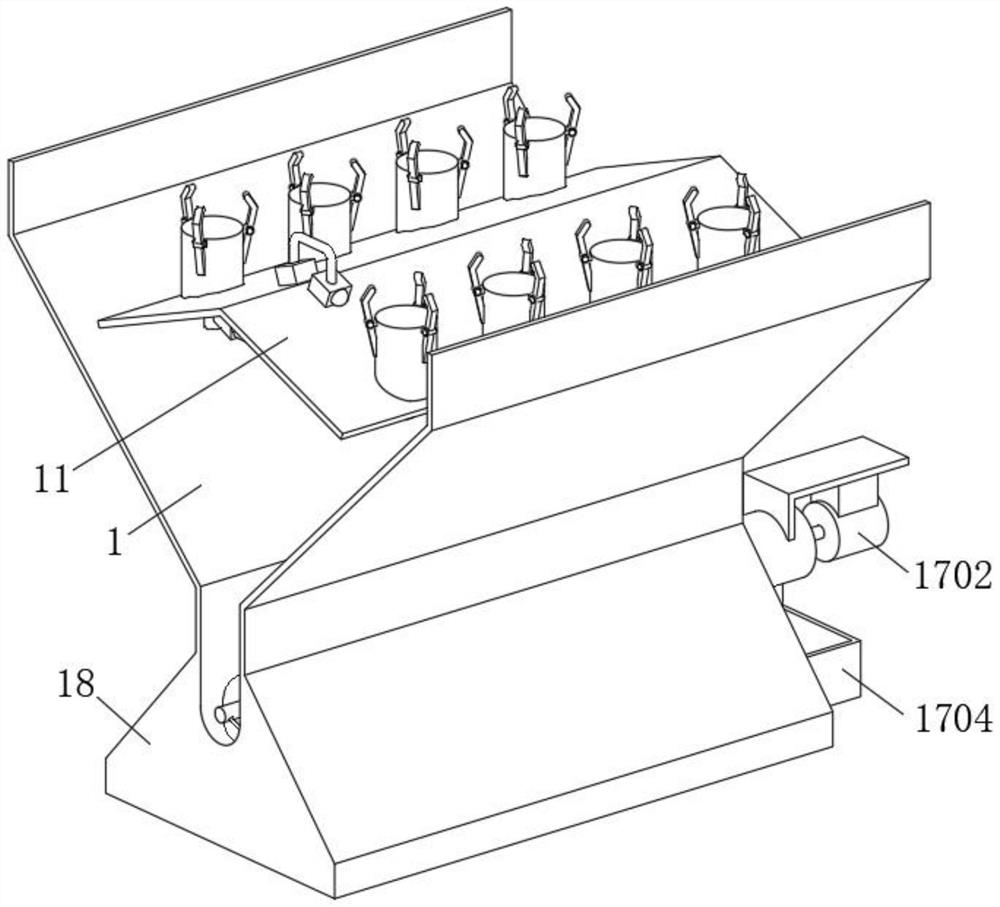

Automatic rotating device with clamping function for metal material spraying

ActiveCN114405723AWith clamping functionRealize the limit effectSpray boothsHydraulic cylinderGear wheel

The automatic rotating device with the clamping function for metal material spraying comprises a rack body stably placed in a plant, a hydraulic cylinder is fixedly installed in the middle of the rack body, and a fixing frame is installed at the upper end of the hydraulic cylinder; the servo motor is fixedly mounted at the lower end of the left side of the rack body; a bearing of the sleeve is mounted in the side edge of the workbench in a sleeving manner; the first gear is rotationally mounted on the side part of the upper end of the rack body; a bearing of the rotating rod is mounted at the upper end of the first gear ring disc; the upper end and the lower end of the clamping plate are movably connected with connecting rods through shafts. According to the automatic rotating device with the clamping function for metal material spraying, the limiting effect and the further clamping effect on cup-shaped metal materials are achieved through the clamping plates and the suction cups correspondingly, and sequential and uniform spraying operation is achieved through the rotating workbench and the rotating rod; and waste solidification can be avoided while the workbench rotates, so that follow-up cleaning is facilitated.

Owner:承德石油高等专科学校

Rapid laser material packaging device for intelligent manufacturing

InactiveCN113043585AEncapsulation worksRealize the delivery workMechanical engineeringSmart manufacturing

The invention relates to a packaging device, in particular to a rapid laser material packaging device for intelligent manufacturing. The invention provides a rapid laser material packaging device for intelligent manufacturing, capable of covering a laser material with a film for packaging, replacing the laser material at intervals, finishing material control work of the laser material, and positioning the laser material to avoid movement. The packaging device, in particular to a rapid laser material packaging device for intelligent manufacturing comprises a base, a supporting frame and a first fixed frame, wherein the supporting frame is symmetrically arranged on the two sides of the top of the base, and the first fixed frame is welded to the two sides of the supporting frame. For the rapid laser material packaging device for intelligent manufacturing, by arranging a film winding mechanism to be matched with a packaging mechanism, packaging work of the laser material can be realized; a moving mechanism is matched with the supporting frame, and conveying work of the laser material can be achieved; a discharging mechanism is matched with the material control mechanism, and interval material control work of the laser material can be achieved; and the positioning mechanism is matched with the discharging mechanism, so that clamping work of the laser material can be realized.

Owner:王华

Inductor wire end automatic paint removal device

ActiveCN110280509ARealize feedingAchieve cleaningCleaning using toolsCleaning using liquidsSlide plateEngineering

The invention discloses an inductor wire end automatic paint removal device and belongs to the technical field of inductor production equipment. The inductor wire end automatic paint removal device comprises an inductor feeding mechanism, an inductor clamping mechanism, a position regulation mechanism and a wire end paint removal mechanism. The wire end paint removal mechanism comprises a paint removal component, a waste residue cleaning component, a sliding plate, a rack and a material moving component. The paint removal component and the waste residue cleaning component are both arranged on the top of the sliding plate. The material moving component is arranged below the sliding plate. The rack is provided with two horizontal supporting rods. The sliding plate is slidably arranged on the two supporting rods in a sleeving mode. The inductor wire end automatic paint removal device can realize feeding, paint removal, cleaning and discharging on inductors and is high in automation degree. Manual operation of a worker is not needed. Moreover, the inductor wire end automatic paint removal device can enable wire ends on the inductors to rotate through an angle adjustment assembly and can conduct paint removal treatment on the wire ends of the inductors in different azimuths through a paint removal wheel.

Owner:湖南俊宇电子科技有限公司

An industrial robot with automatic cleaning function

ActiveCN112496773BAvoid accumulationRealize clamping workLarge fixed membersPositioning apparatusMachine buildingElectric machinery

The invention discloses an industrial robot with an automatic cleaning function, which belongs to the technical field of mechanical manufacturing equipment, and comprises a casing, the top of the casing is an open structure, and a guide plate is fixedly connected to the side wall of the top of the casing. And one end of the bottom surface of the guide plate is installed with a motor a, and the output shaft of the motor a is fixedly connected to one end of the lead screw, and the other end of the lead screw is connected to the bottom surface of the guide plate through a bearing seat. The sleeve, and the wire sleeve is embedded in the movable frame plate, and the processing components are installed on the movable frame plate; no need for staff to clean up, it can effectively prevent debris from accumulating on the worktable, and facilitate multi-station work. Processing operations, improve processing efficiency, meet the needs of the industry, improve the cleaning effect of debris, clean comprehensively, ensure that there is no accumulation of debris on the worktable, and continue to discharge debris, realize automatic cleaning function, and facilitate the overall continuous operation.

Owner:上海诺柱知识产权服务有限公司

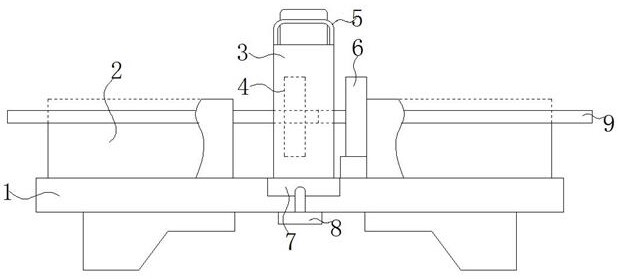

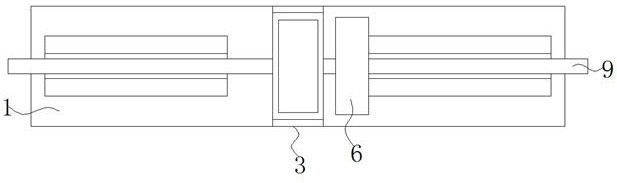

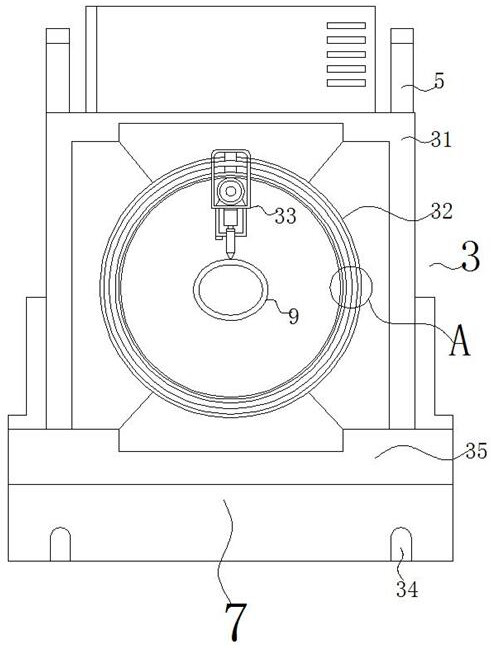

Automatic pipe welding machine with pipe clamping structure

ActiveCN114700645AAvoid misalignmentRealize clamping workWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The automatic pipe welding machine with the pipe clamping structure comprises a machine table, bearing tables are installed on the two sides of the surface of the machine table respectively, oval pipes are placed on the bearing tables, meanwhile, a welding device is installed in the middle of the surface of the machine table, lifting handles are installed on the two sides of the top of the welding device, and a left clamp is installed on the left side in the welding device; and a right clamp is mounted on the right side of the welding device, and the right clamp and the left clamp are used for clamping and fixing the two sets of oval pipes correspondingly. According to the automatic pipe welding machine with the pipe clamping structure, the pipe welding structure annularly moves along the left side of the annular rail, welding work is conducted on the welding positions between two sets of oval pipes through the welding head on the pipe welding structure, the welding mode that the welding head is static and pipelines rotate is replaced, and the situation that when the two sets of pipelines rotate, rotation is not synchronous, and the welding efficiency is improved can be avoided. And dislocation between the two groups of pipelines is avoided.

Owner:扬州万丰机械制造有限公司

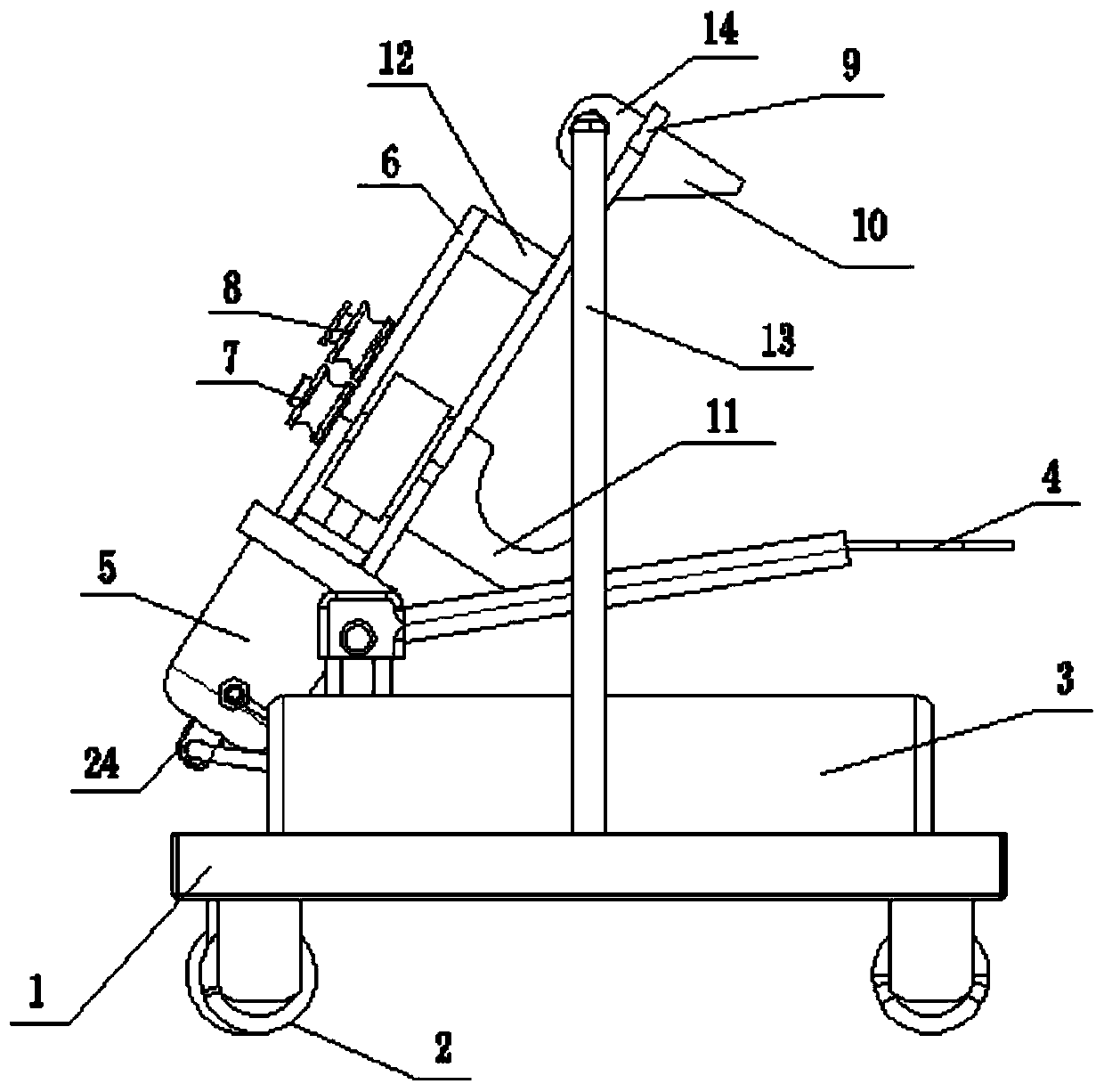

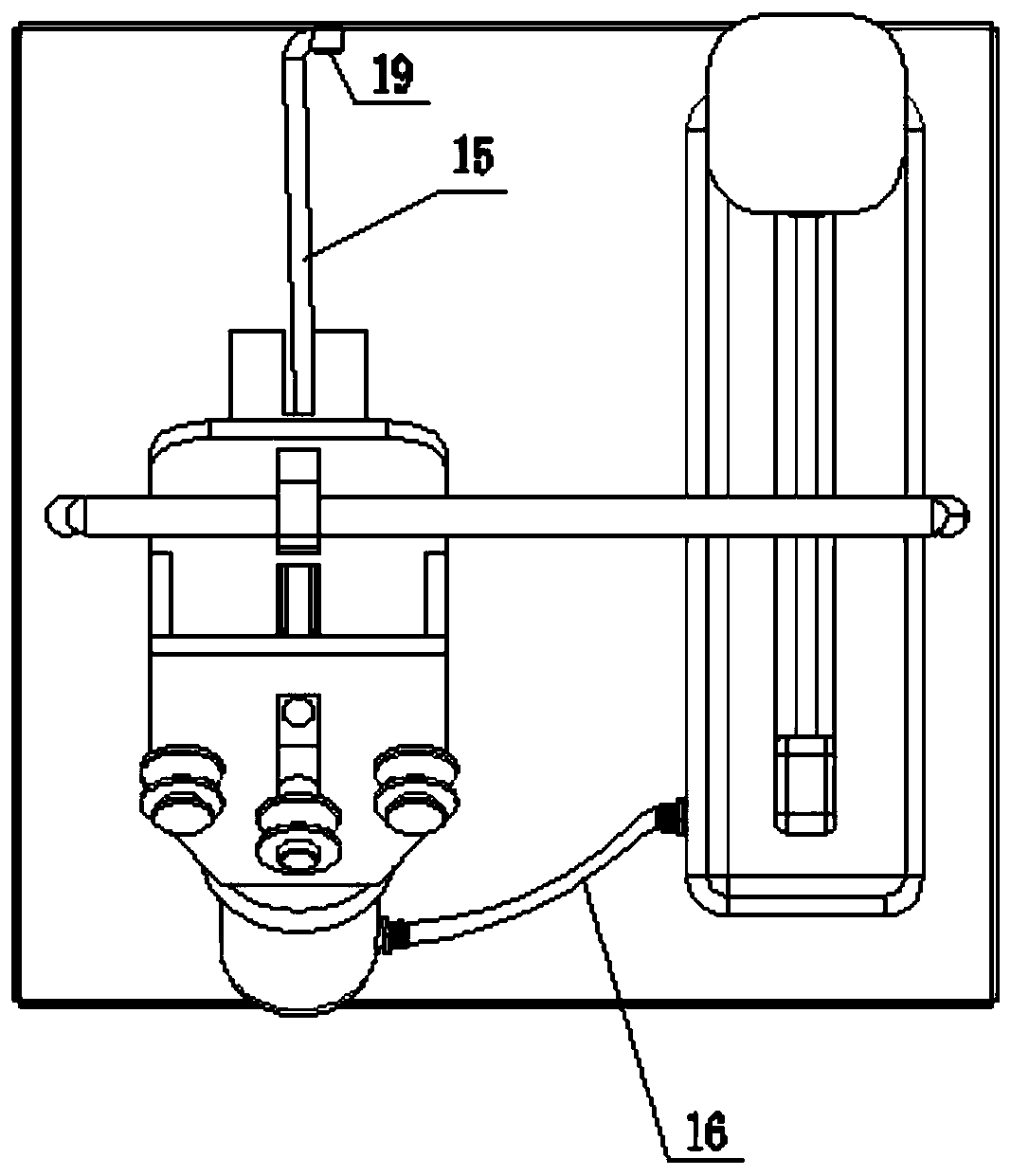

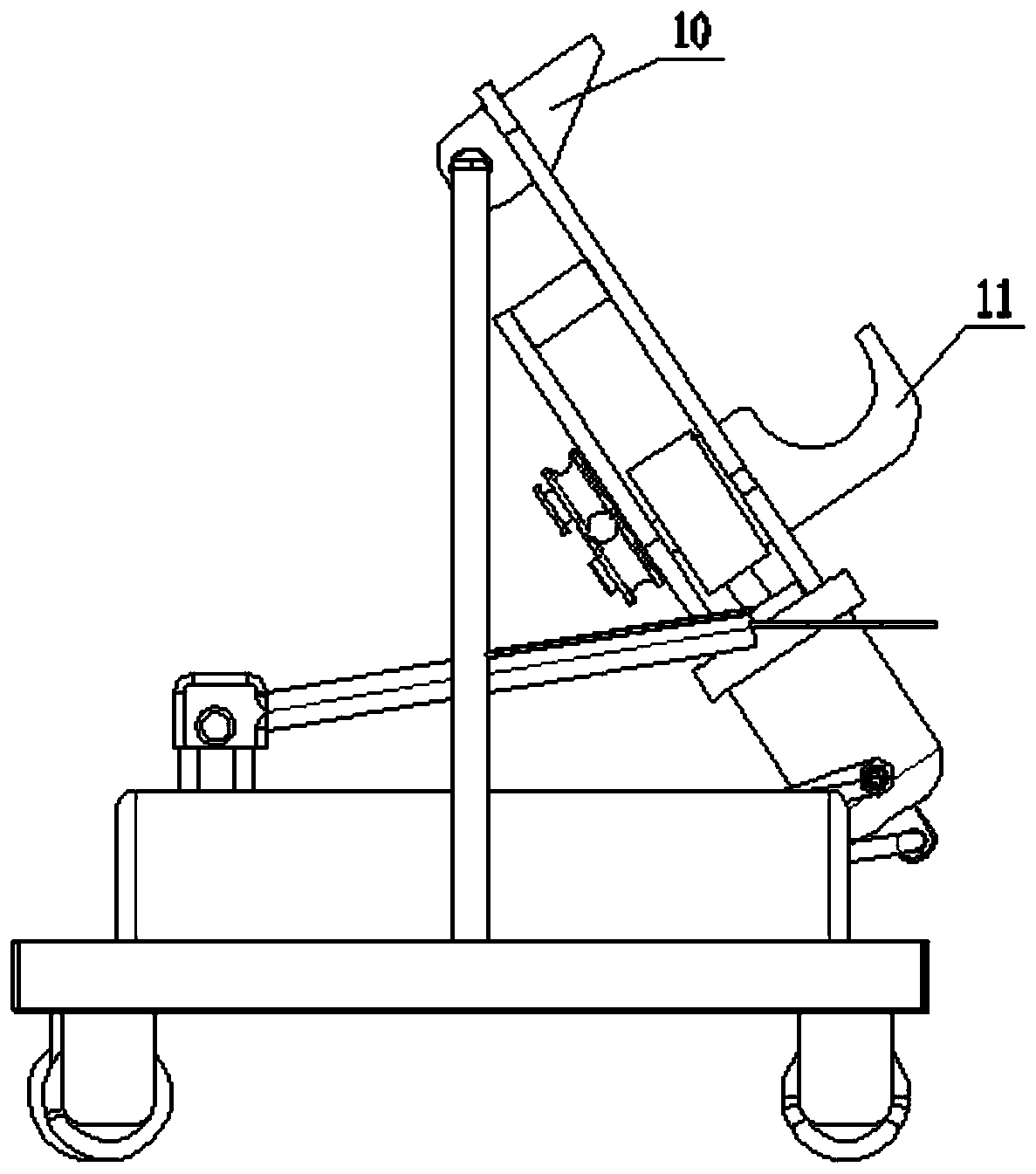

Movable steel strand bending and clamping combination tool

PendingCN110625030AGood effectAvoid problems such as scratchesApparatus for overhead lines/cablesArchitectural engineeringDistribution networks

The invention discloses a movable steel strand bending and clamping combination tool. The movable steel strand bending and clamping combination tool comprises a base, wherein trundles are installed atfour corners of the bottom of the base, door-shaped frames are installed on the centers of the two sides of the base in a welding mode, and a wedge-shaped wire clamping baffle is installed to the bottom of the upper end of a clamping bottom plate. The bending of the steel strand and the clamping work of the steel strand and a tongue plate in a wedge-shaped wire clamp can be achieved, and in particular, the effect of bending and clamping on the large-section steel strand is more remarkable, the application of the result can overcome the damage of the wedge-shaped wire clamp zinc coating causedby the method that field construction personnel wastes time and energy when the steel strand is bent and a method of knocking the wedge-shaped wire clamp through a hammer to enable the steel strand and the tongue plate to be clamped in the wedge-shaped wire clamp, and meanwhile, the problems of personnel scratch caused by the rigid cause when the steel strand is bent manually is avoided as well.The manufacturing quality and the process level of the stay wire is improved as well while the field construction efficiency is improved by the movable steel strand bending and clamping combination tool, and the help is provided for the construction site of scattered distribution networks.

Owner:LANGFANG POWER SUPPLY COMPANY STATE GRID JIBEI ELECTRIC POWER COMPANY +1

Intelligent medical disinfection equipment

InactiveCN111803679AAchieve lockingRealize clamping workLavatory sanitoryHeatOzone generatorsElectrical and Electronics engineering

The invention discloses intelligent medical disinfection equipment. The equipment comprises a main machine body, a disinfection chamber with an upward opening is formed in the main machine body, a placement table is connected into the disinfection chamber in a running fit manner, a clamping mechanism connected to a first gear in a matched mode is arranged in the placement table, the right side ofthe disinfection chamber is communicated with a first channel and a second channel positioned on the rear side of the first channel, the right side of the first channel is connected to an ozone generator, the right side of the second channel is connected to a steam generator, a first groove is formed in the bottom wall of the first channel in a communicating manner, an ozone switch control mechanism is arranged in the first groove, a second groove is formed in the top wall of the second channel in a communicating manner, a steam switch control mechanism is arranged in the second groove, a safety protection cover moving mechanism is arranged on the upper side of the first channel, a driving inner cavity is formed in the lower side of the first groove, and a driving control mechanism is arranged in the driving inner cavity. The equipment is convenient to operate, and the disinfection efficiency and quality are improved.

Owner:余储

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com