Metal bar outer surface polishing equipment

A metal bar and outer surface technology, which is applied in the field of grinding equipment for the outer surface of metal bars, can solve problems such as poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

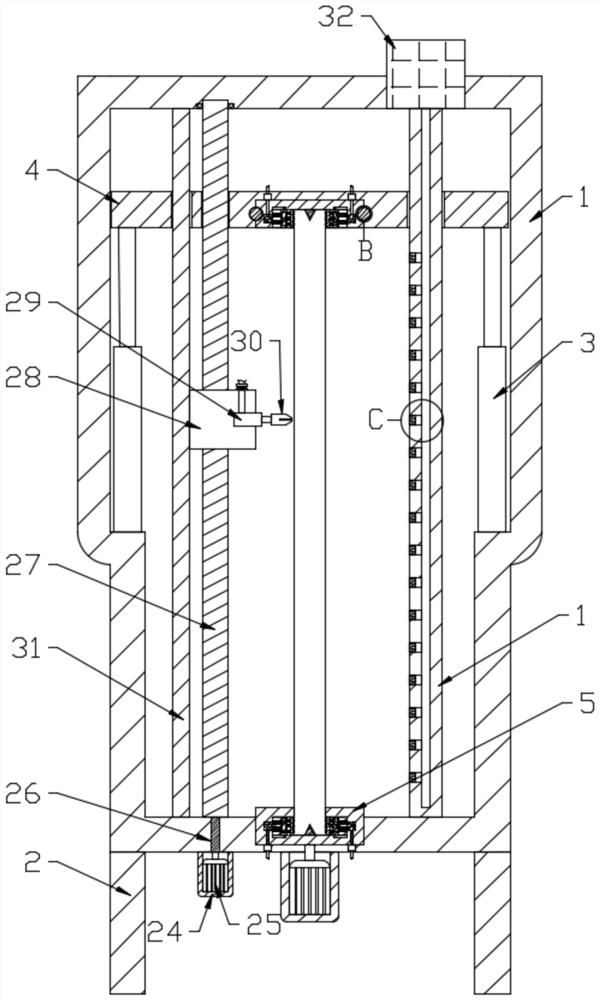

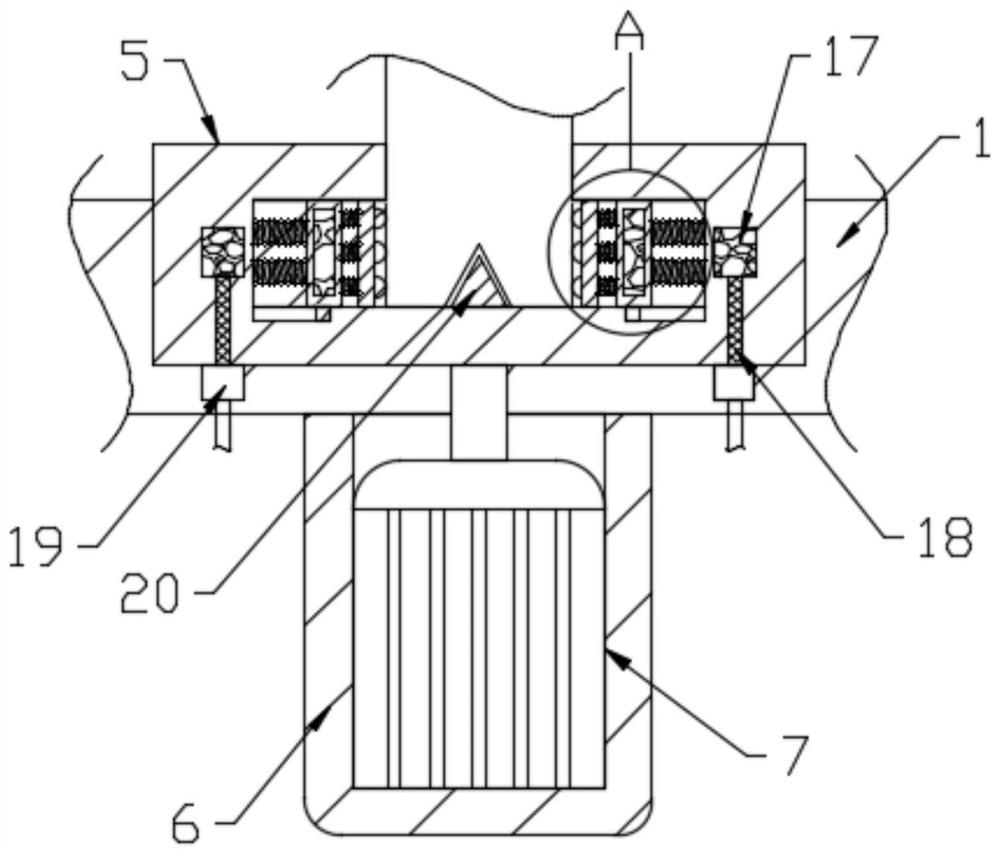

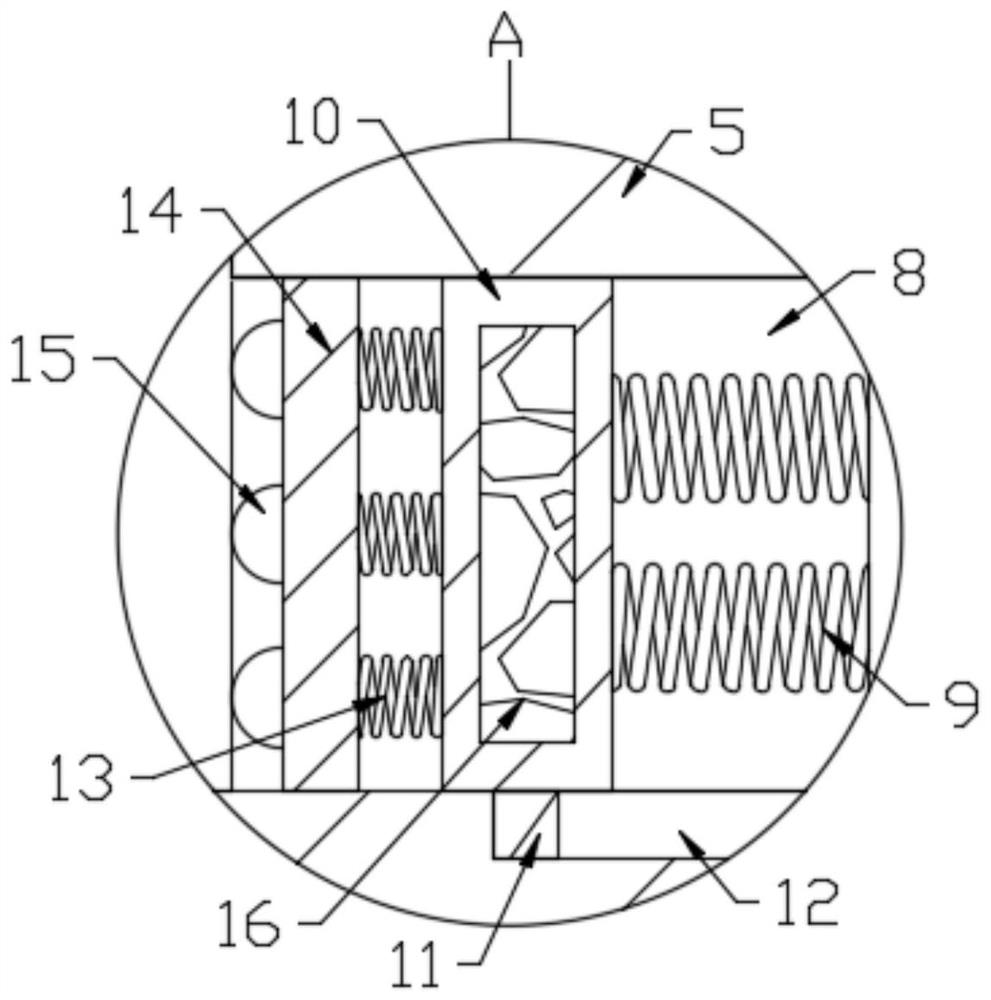

[0026] see Figure 1-6 , a metal bar outer surface grinding equipment, including a frame body 1 and a plurality of support columns 2 arranged at the lower end of the frame body 1, four first hydraulic components 3 are fixedly connected in the frame body 1, and four first hydraulic components 3 The output ends are all fixedly connected with the moving plate 4, the moving plate 4 and the frame body 1 are provided with a rotating block 5, and the frame body 1 is provided with a rotating assembly for driving the rotating block 5 to rotate, and the two rotating blocks 5 are provided with opposing The clamping assembly for clamping rods with different diameters. The rotating block 5 is provided with a working assembly that drives the clamping assembly to work. The body 1 is provided with a grinding assembly for grinding rods.

[0027] The rotating assembly includes a first chassis 6 and a first motor 7. The first chassis 6 is fixedly connected to the frame body 1. The first chassis...

Embodiment 2

[0042] Further improvements are made on the basis of Embodiment 1, and the improvements are as follows: a hot air blower 32 is provided on the upper end of the frame body 1, and an air delivery column 33 is fixedly connected in the frame body, and the air delivery column 33 runs through the movable plate 4 and is slidably connected with it , be provided with vertical cavity 34 in the gas transmission column 33, the output end of hot air blower 32 is communicated with vertical cavity 34, and the horizontal hole 35 that is provided with some transversely arranged and vertical cavity 34 is provided on the gas transmission column 35, and is provided with in the horizontal hole 35 Filter block 36; hot air blower 32 works to generate hot gas, which is transported to the horizontal hole 35 connected with it through the vertical cavity 34 on the air delivery column 33, and discharged through the horizontal hole 35, thereby realizing the removal of the leftover gas on the bar during grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com