Patents

Literature

1954 results about "Ozone generators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ozone generator

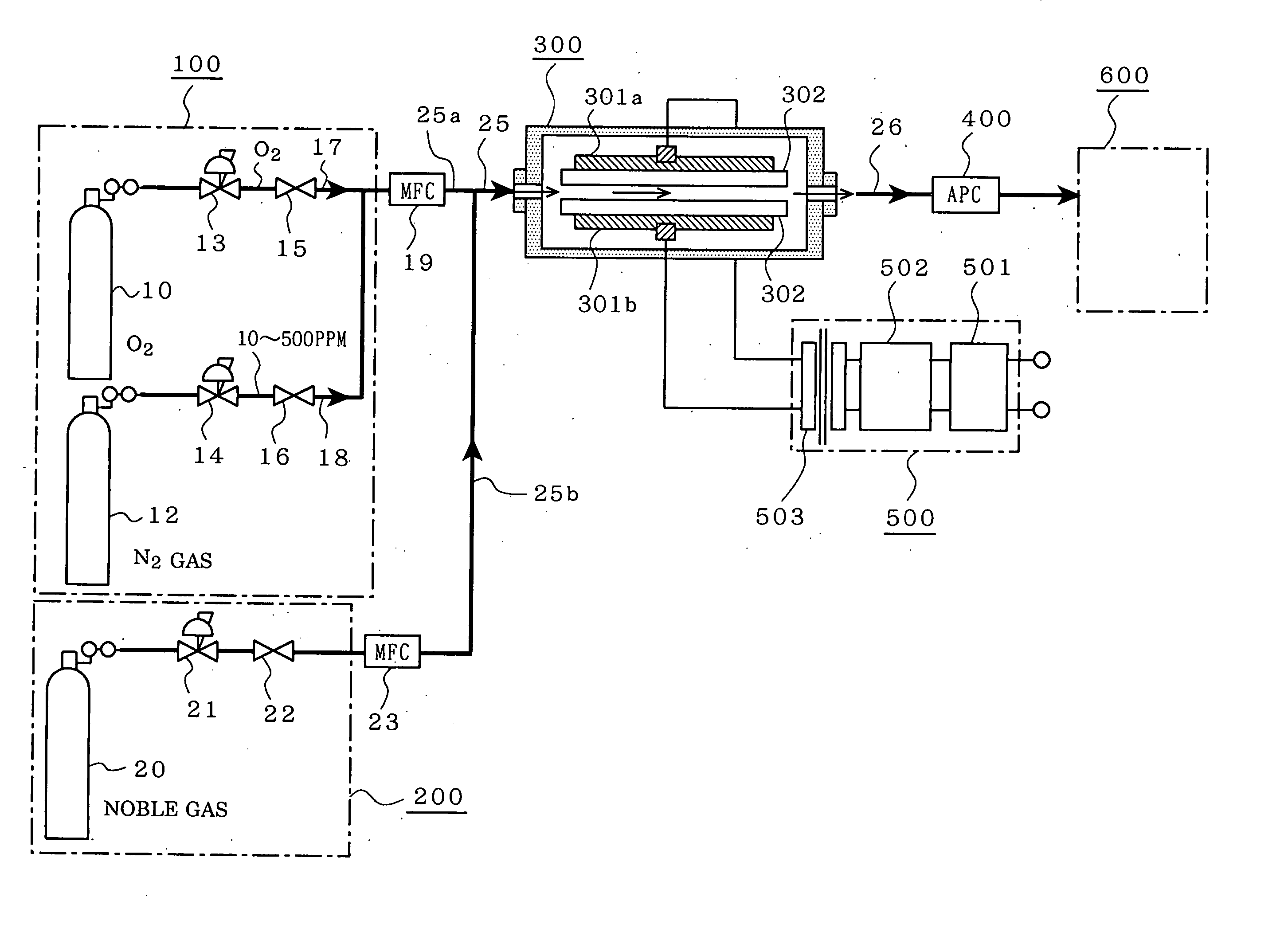

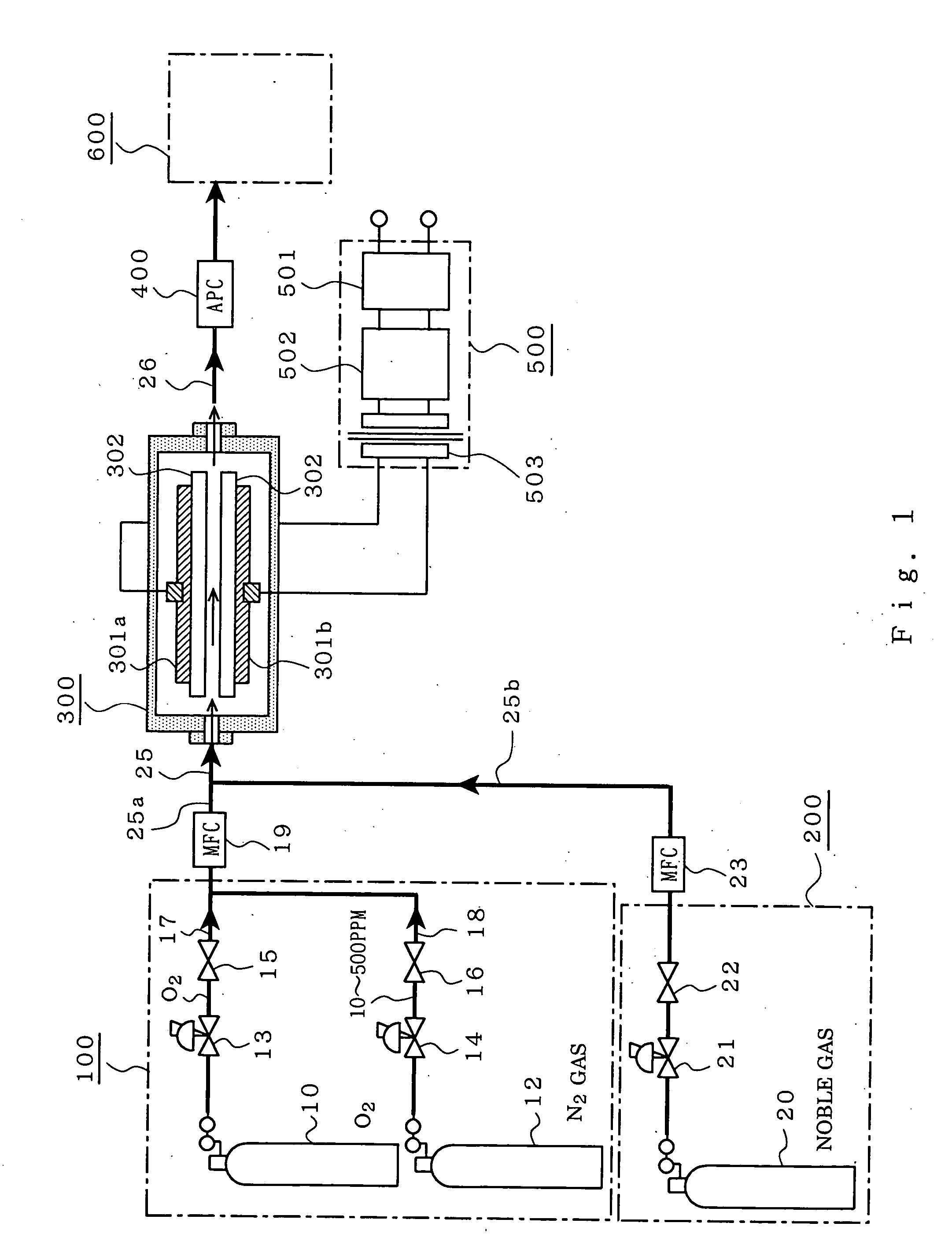

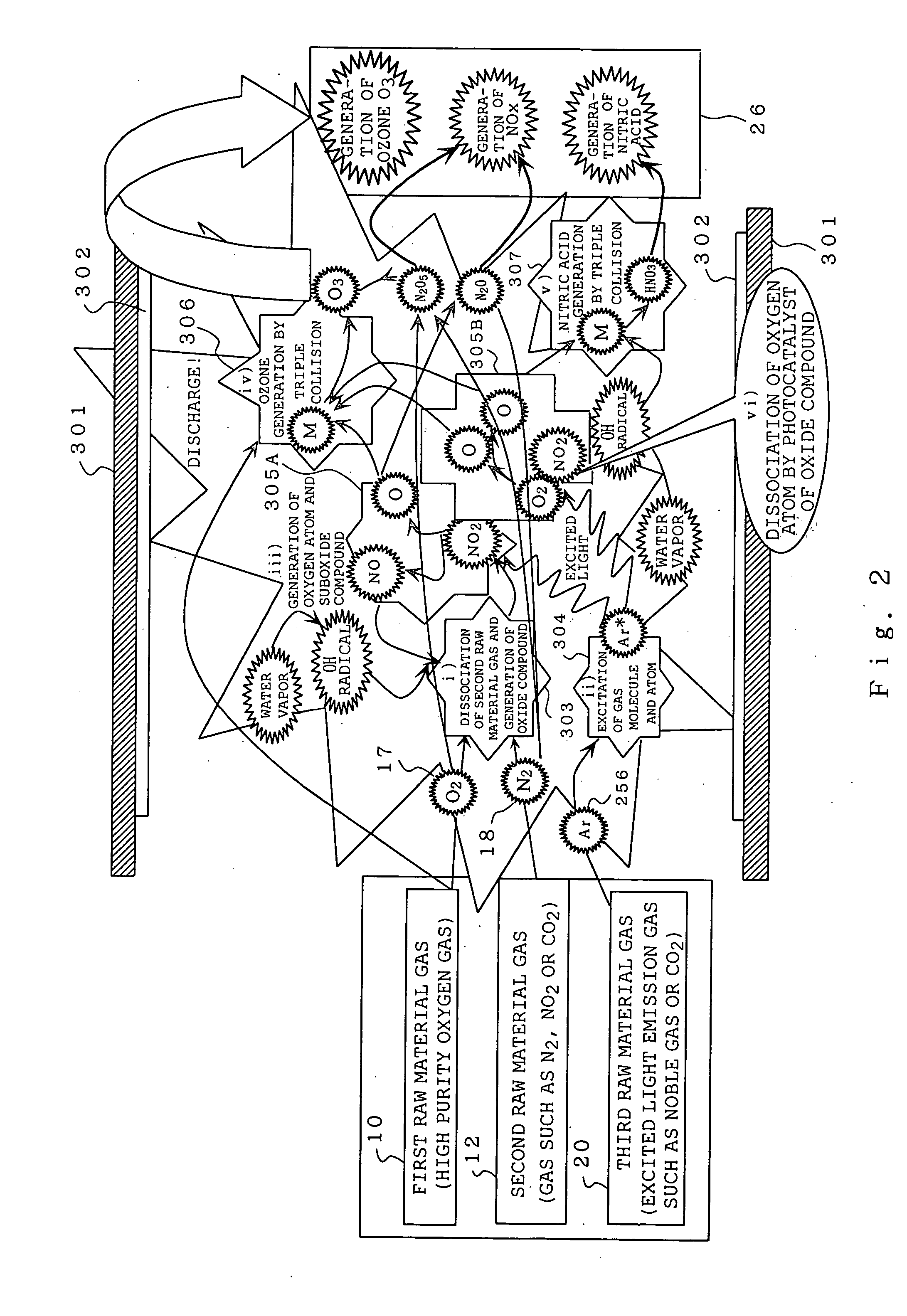

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

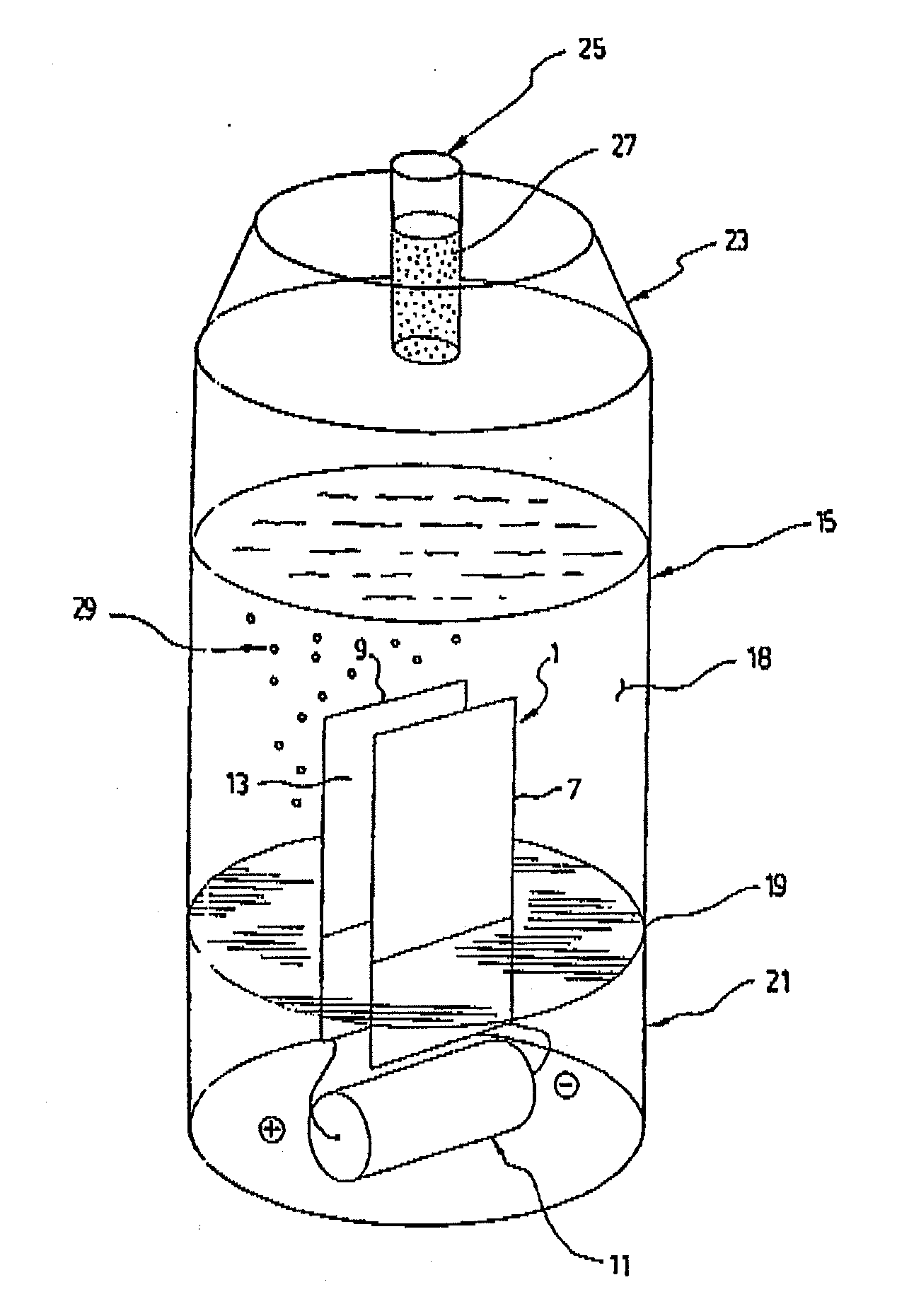

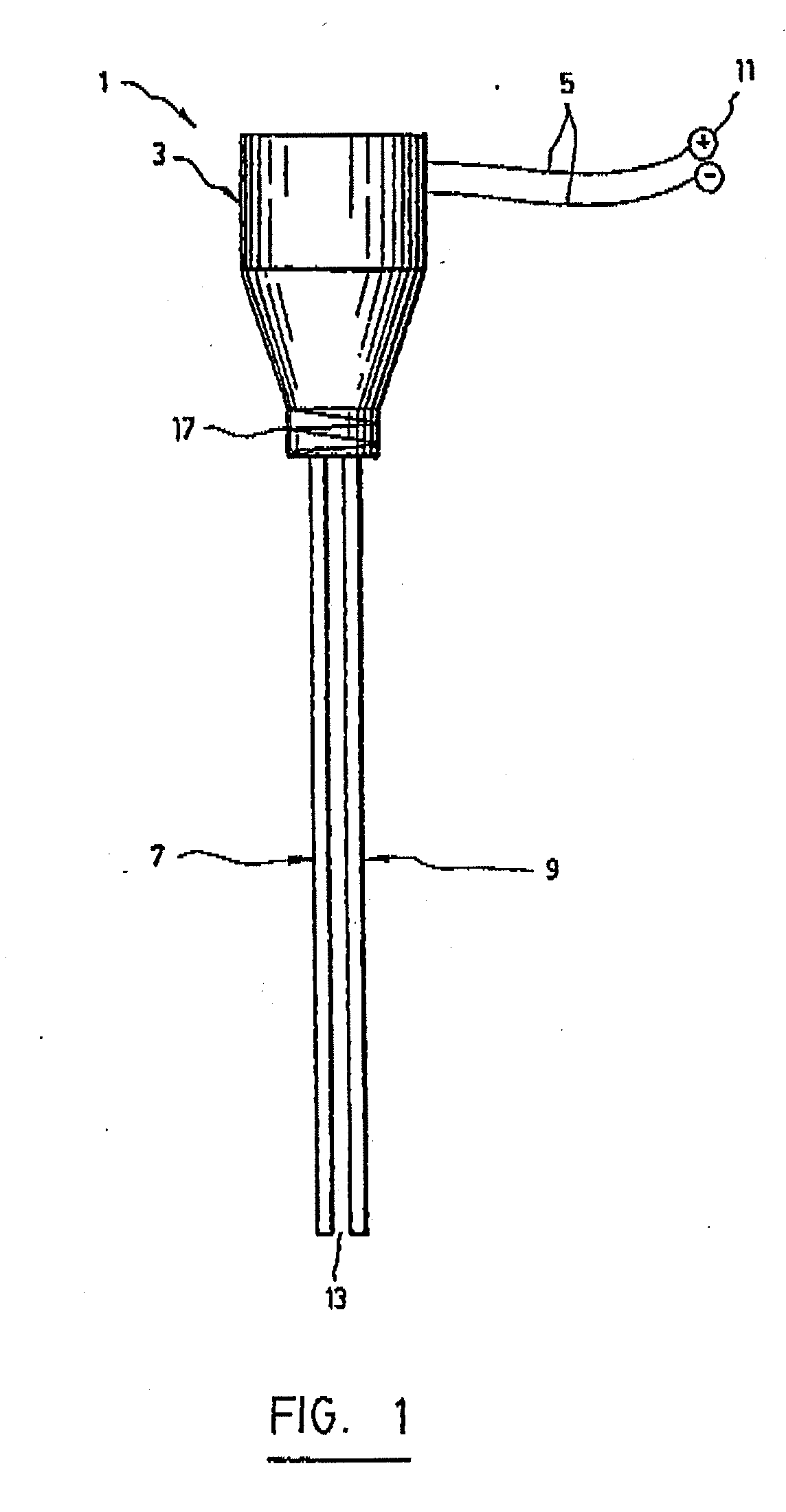

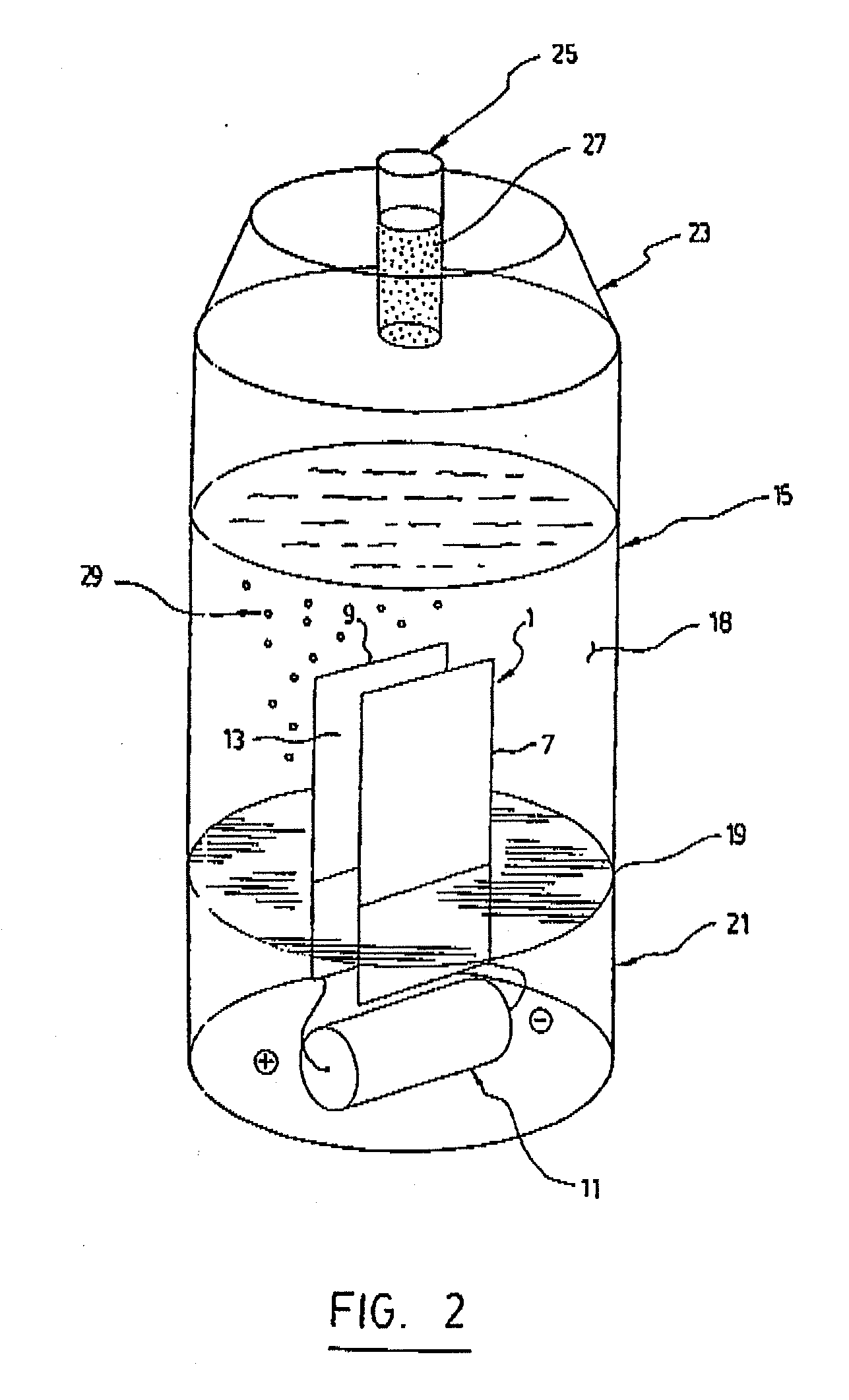

Microorganism control of point of use potable water sources

InactiveUS20030080467A1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesMedical equipmentWater source

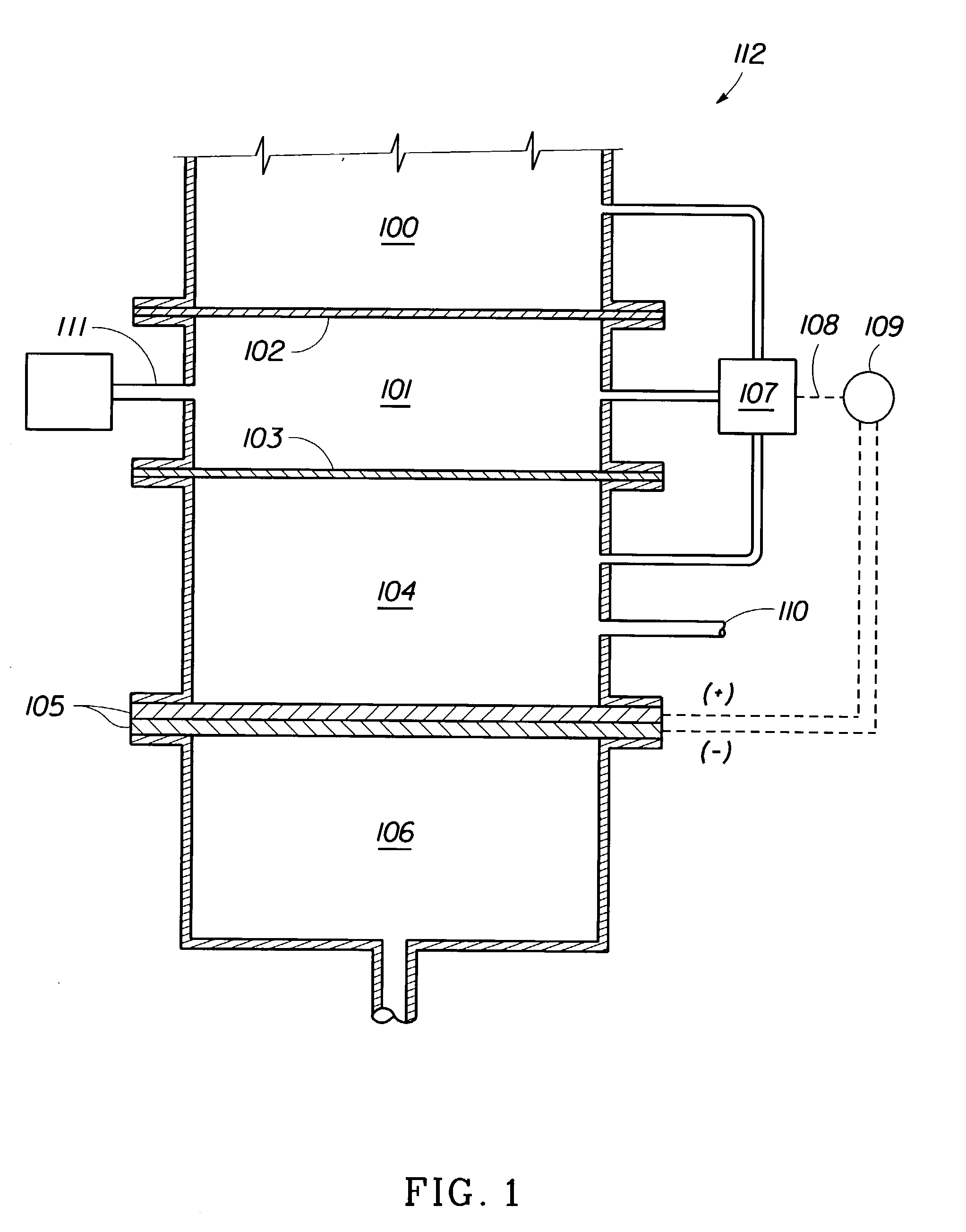

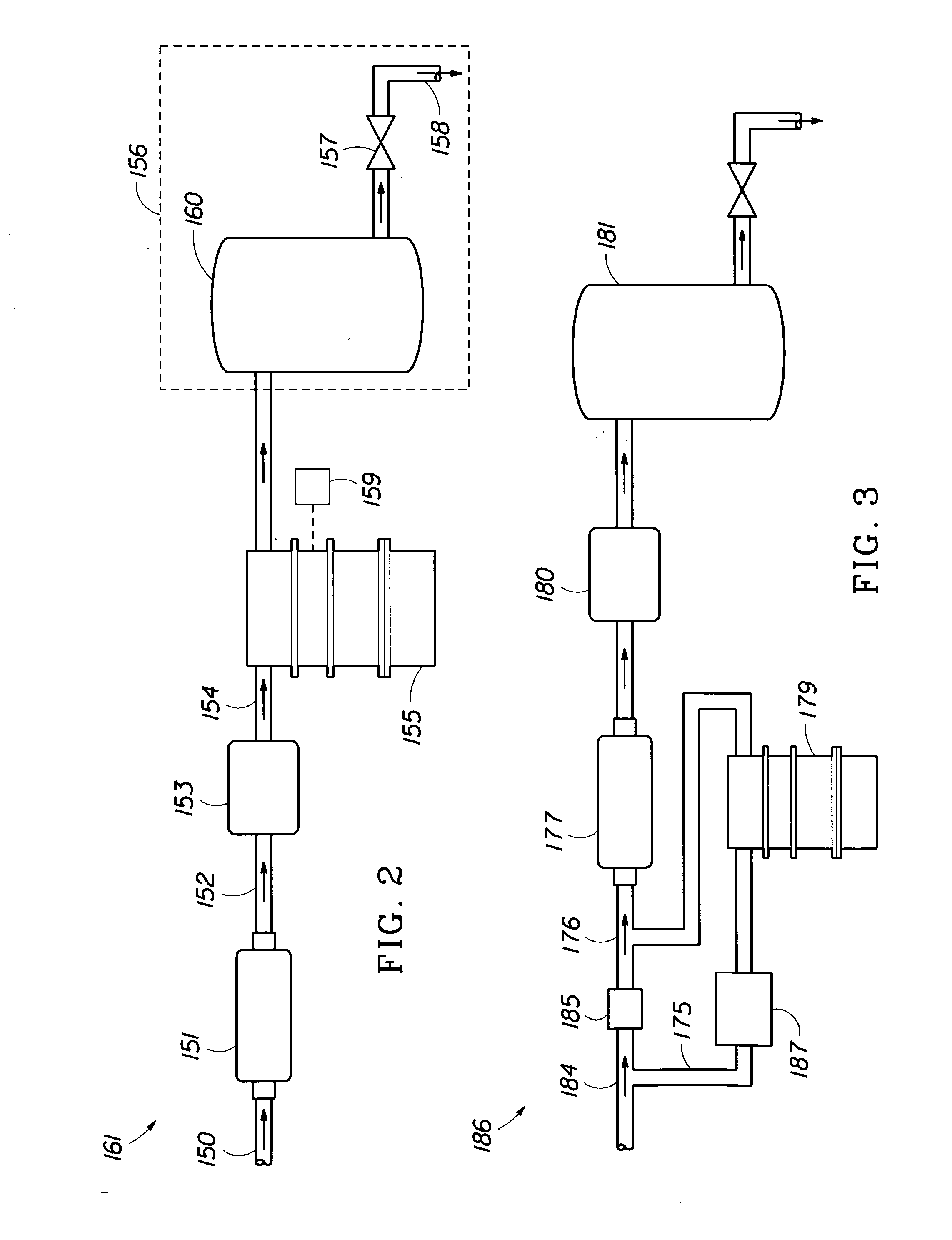

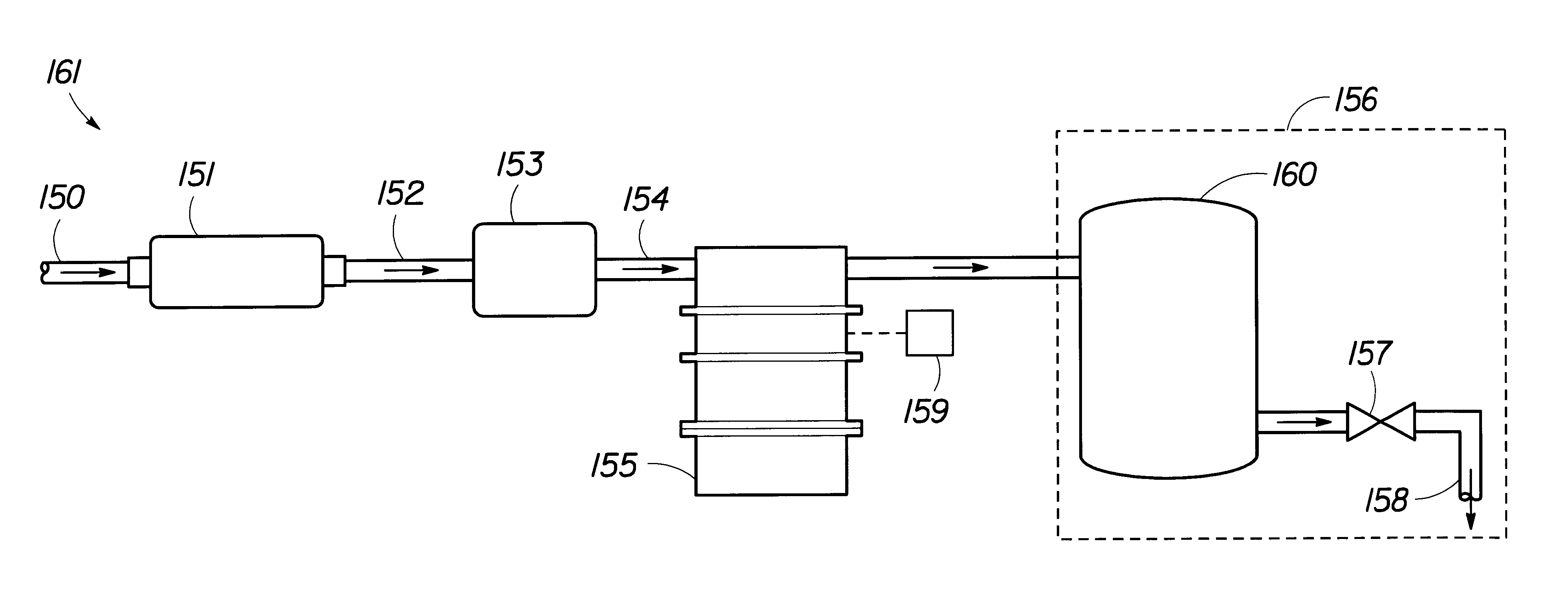

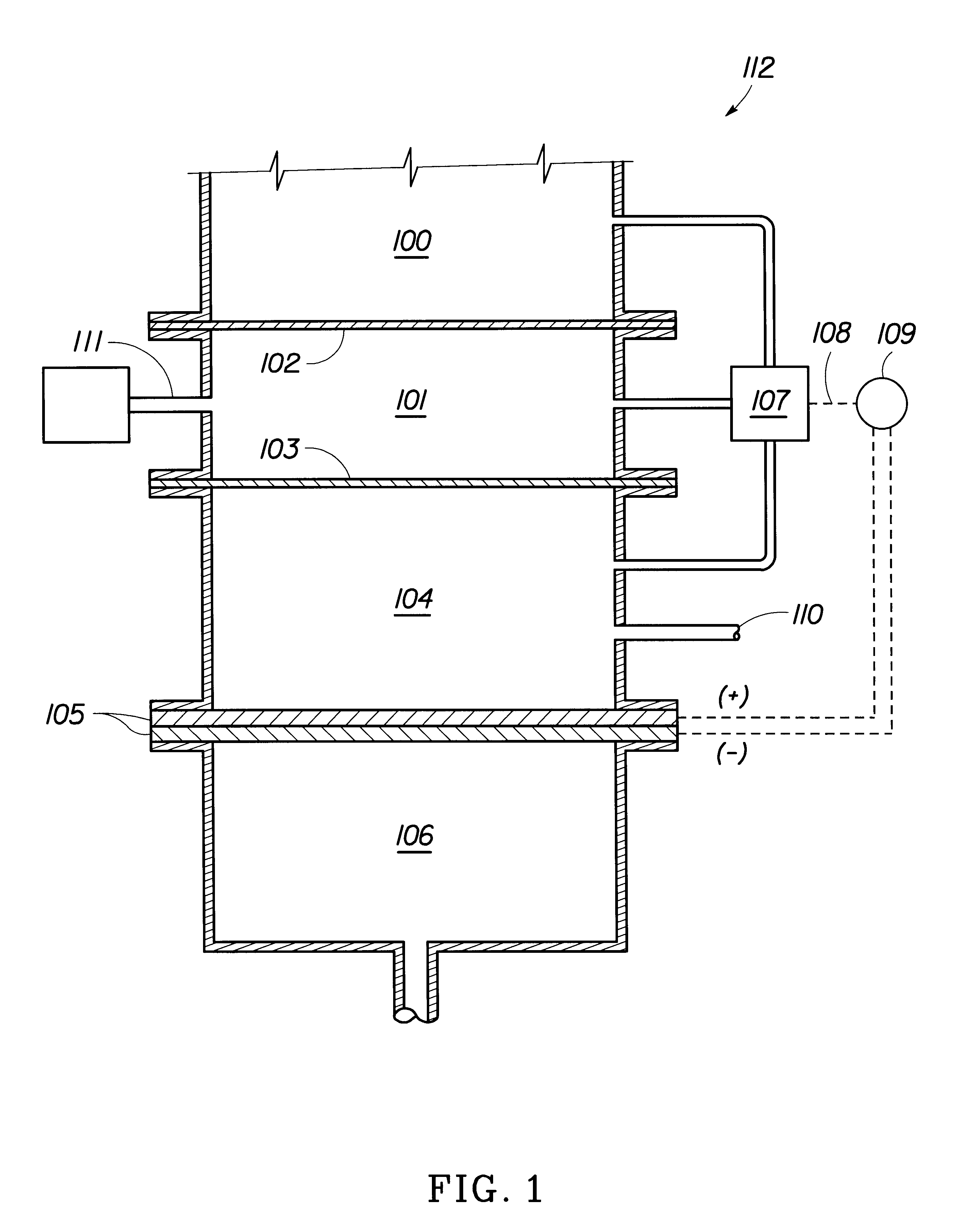

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

Microorganism control of point-of-use potable water sources

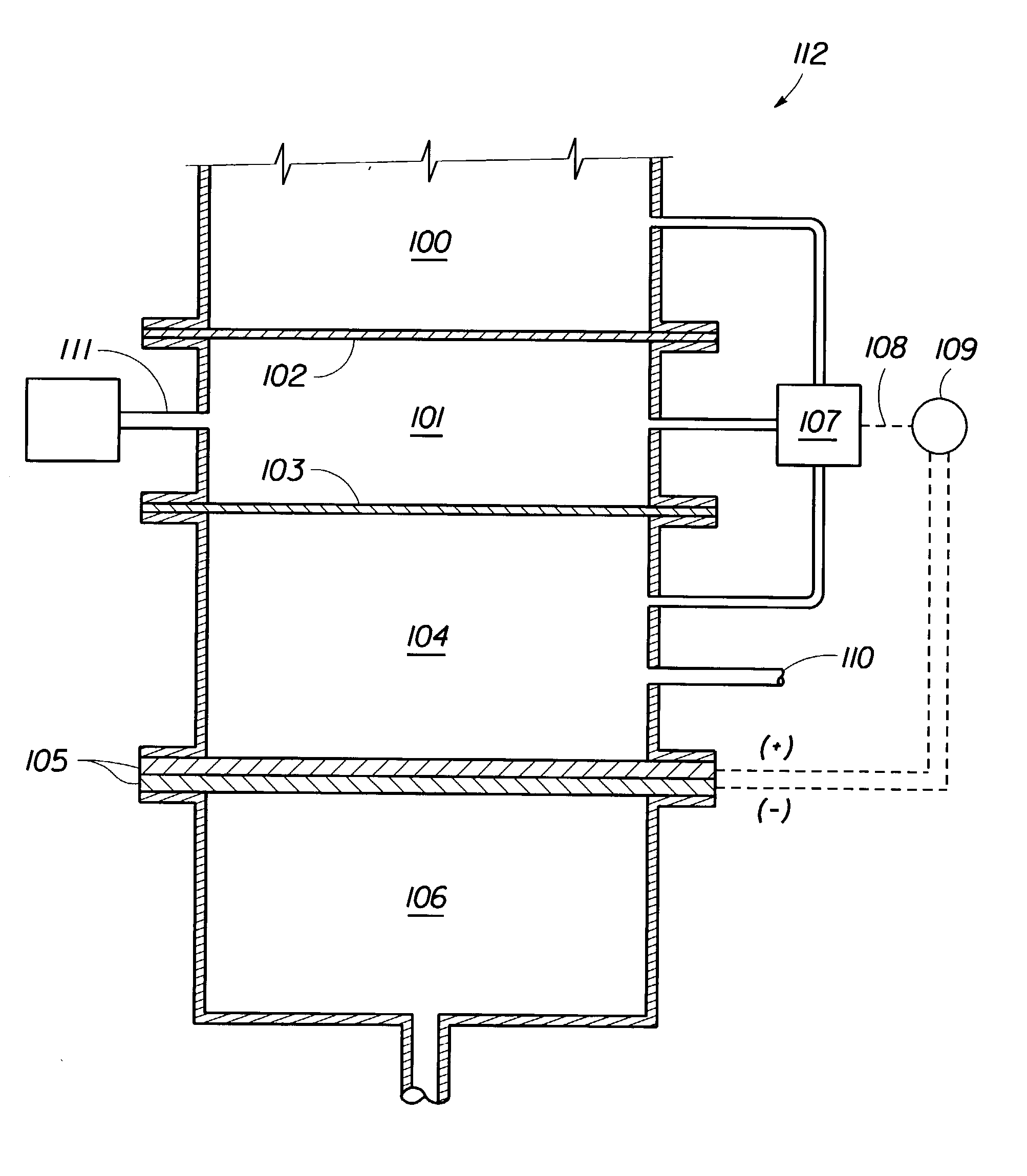

InactiveUS6458257B1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesOzone generatorMedical equipment

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

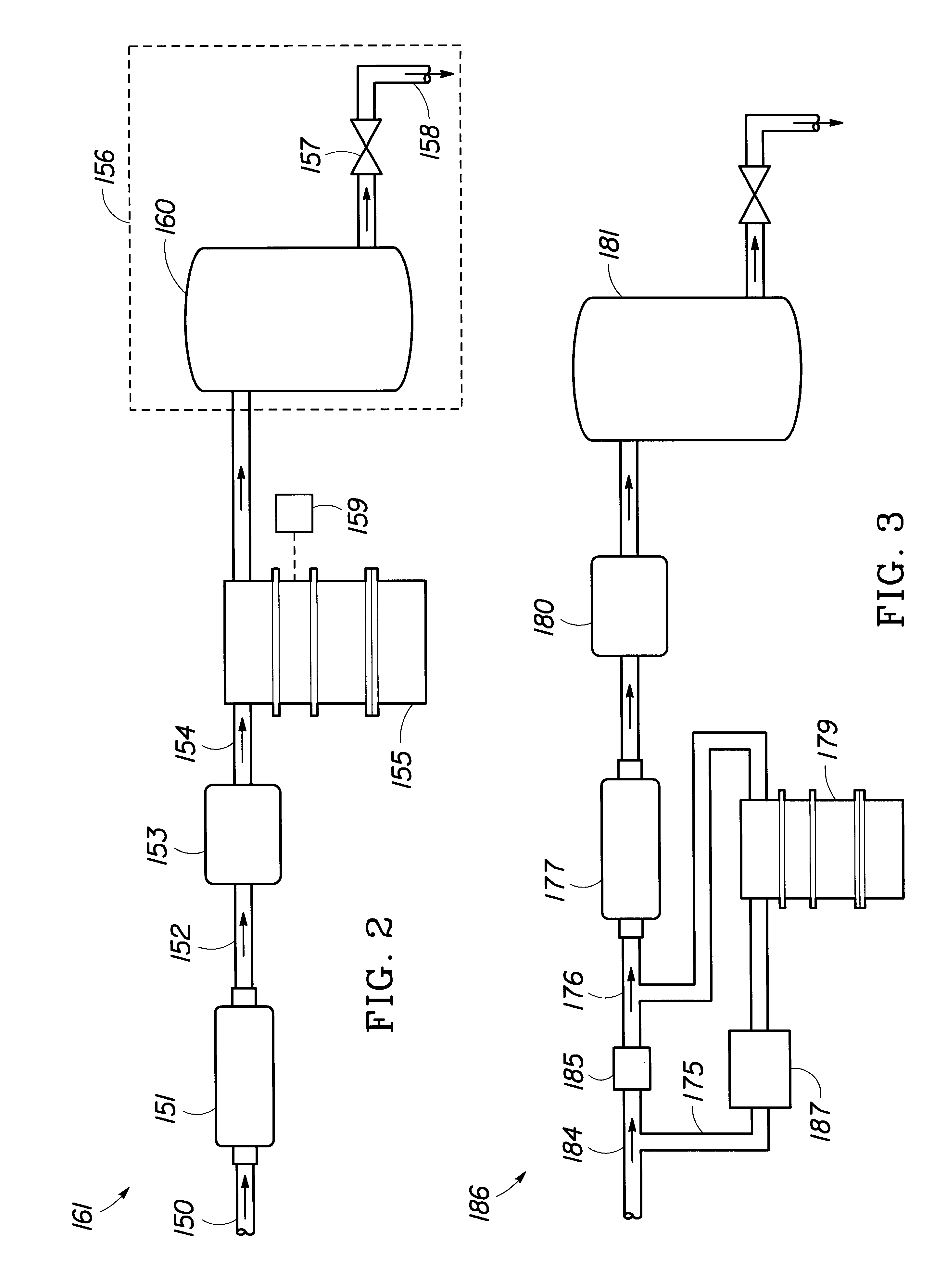

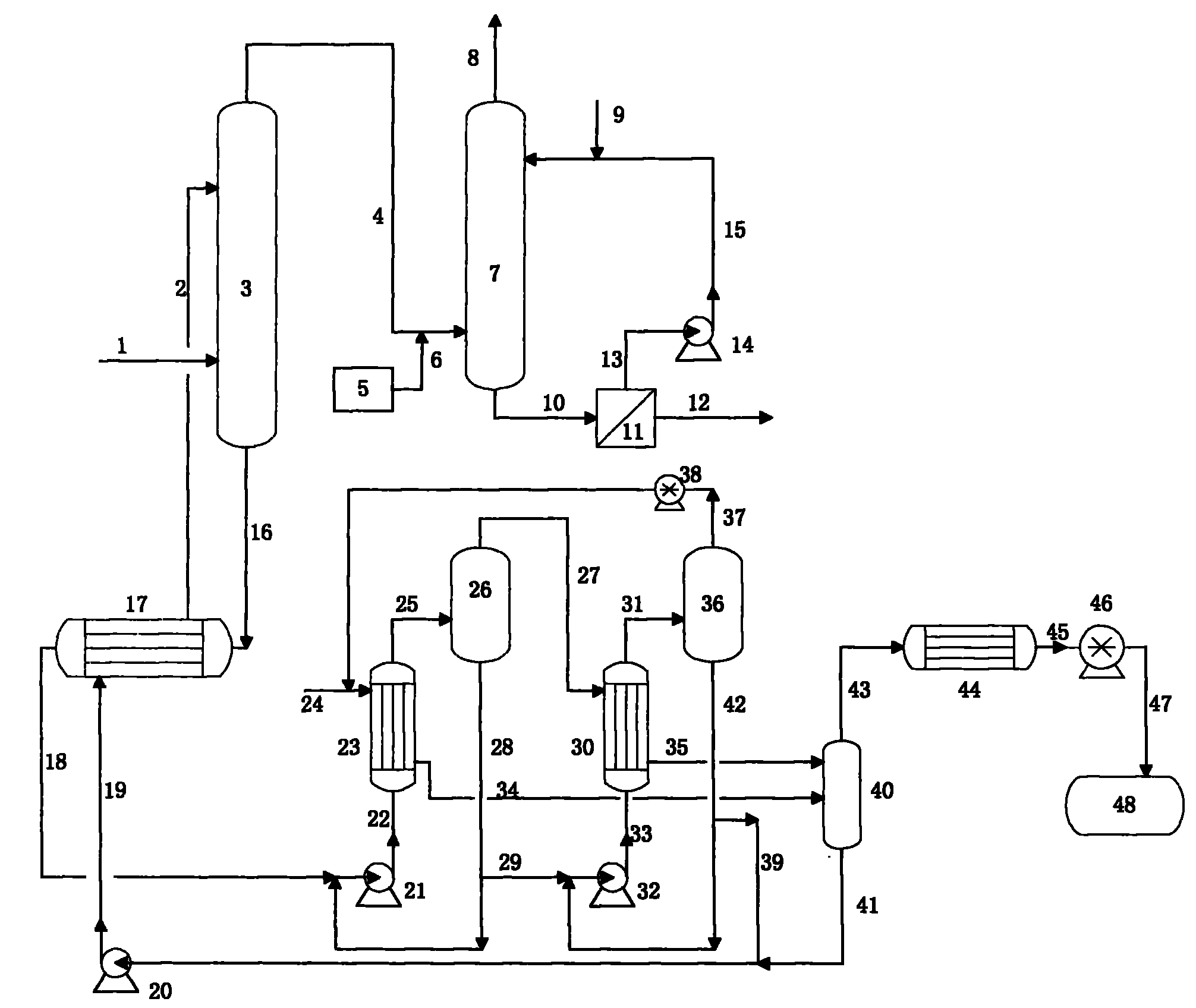

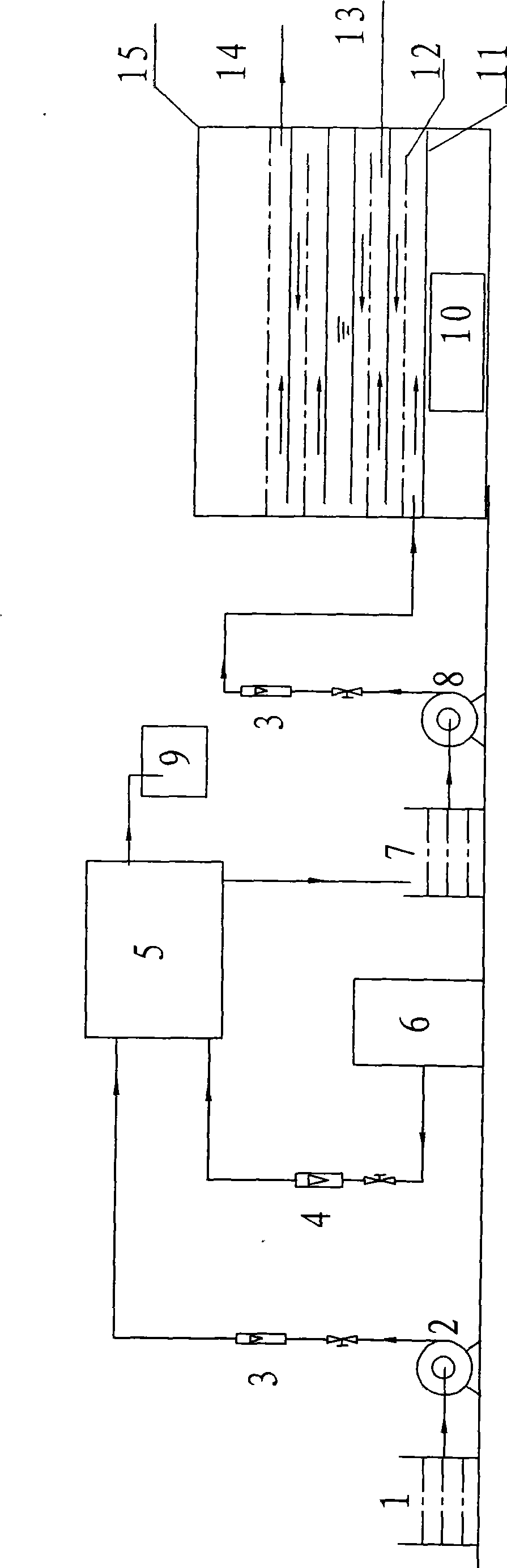

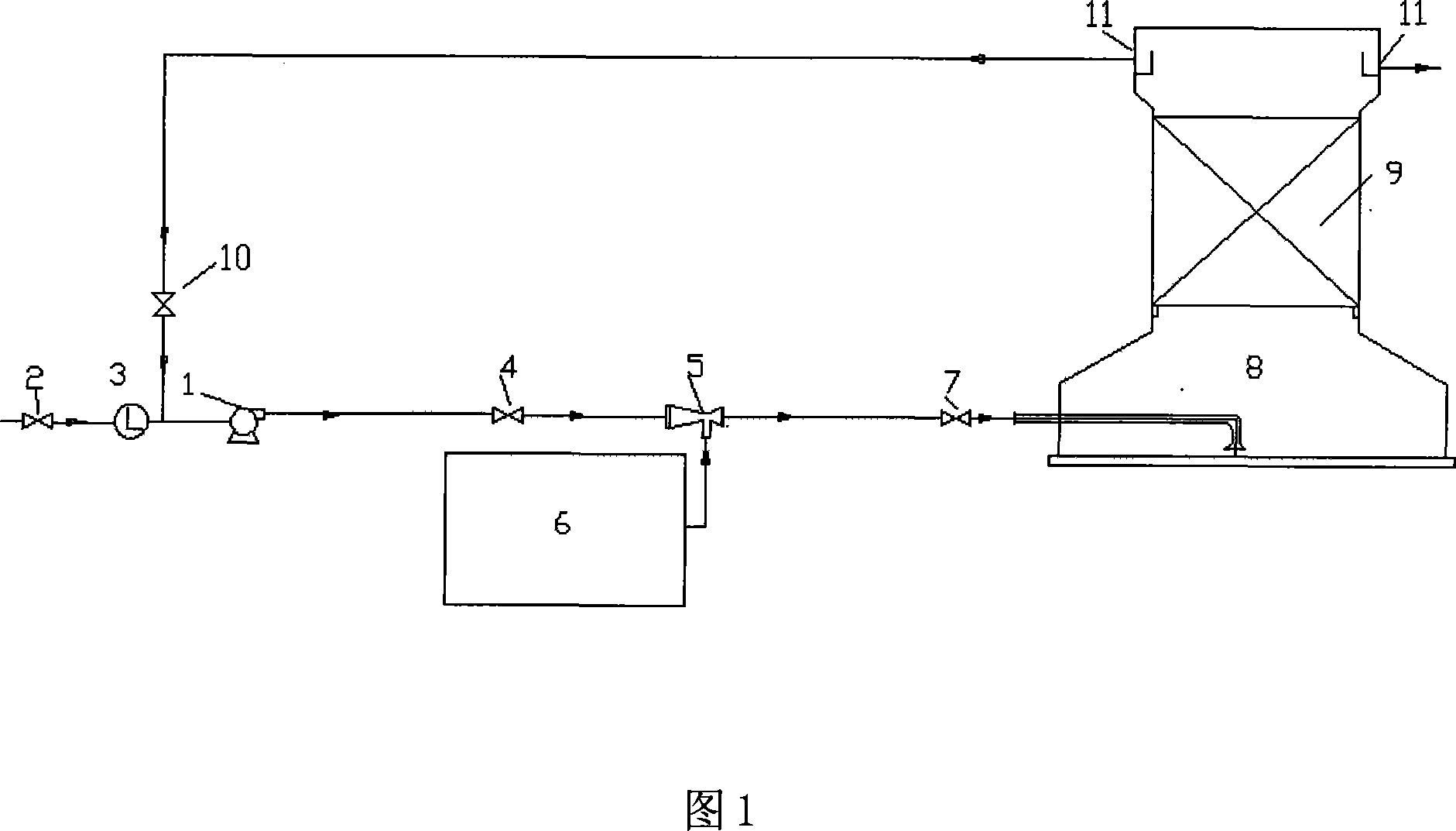

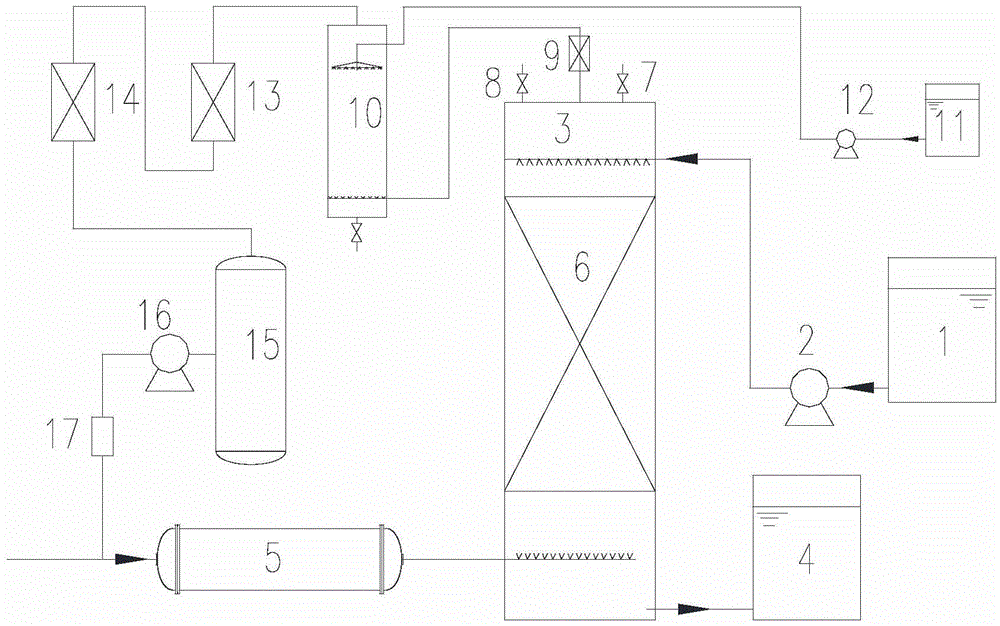

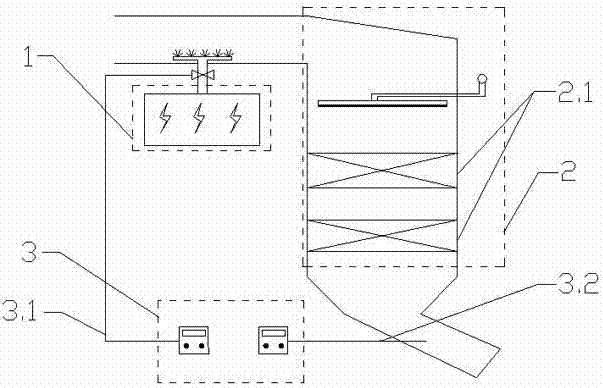

Device and method of simultaneous desulfuration and denitration for flue gas using ozone oxygenation combined with double-tower washing

ActiveCN101485957ARealize separate recyclingAchieve denitrification efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a technique for processing flue gas of a coal burning boiler, and aims to provide a device and a method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing. The device comprises a flue which is connected with a heat exchanger, an alkali liquor washing tower A, and an alkali liquor washing tower B in sequence, wherein the insides of the alkali liquor washing tower A and the alkali liquor washing tower B are provided with a circular spraying device A and a circular spraying device B respectively; and an ozone generator is connected with a lower liquid phase area of the alkali liquor washing tower A and a pipeline in front of the circular spraying device B respectively. The novel method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing can achieve the denitration efficiency of more than 80 percent and desulfurization efficiency of more than 95 percent, and realize the reclaiming and reusing denitrated and desulfurized products in different devices respectively.

Owner:ZHEJIANG UNIV +1

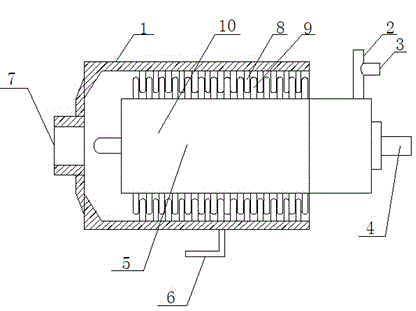

Micro-nano bubble generating device

InactiveCN104803467AReduce energy consumptionSimple structureWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processMicro nanoMicro bubble

The invention provides a medical cleaning device, and relates to a micro-nano ozone bubble device, in particular to a micro-nano bubble generating device. The micro-nano bubble generating device comprises a foam maker and an ozone generator, wherein the foam maker is connected with the ozone generator through a pipeline; the foam maker comprises an inlet end, an outlet end, a power output device and a rotary stirring device; the inlet end is arranged at one end of the foam maker, and the outlet end is arranged at the other end, opposite to the inlet end, of the foam maker; the power output device is connected with the rotary stirring device and arranged outside the foam maker; the rotary stirring device is arranged inside the foam maker. The micro-nano bubble generating device is low in energy consumption, and can generate lots of micro bubbles; under the condition that the water pump power and the water flow pressure are not increased, more micro bubbles can be generated, and can reach micro-nanoscale. The device is simple in structure, excellent in processing and assembly performance, and simple and convenient to use and operate.

Owner:刘芮萌

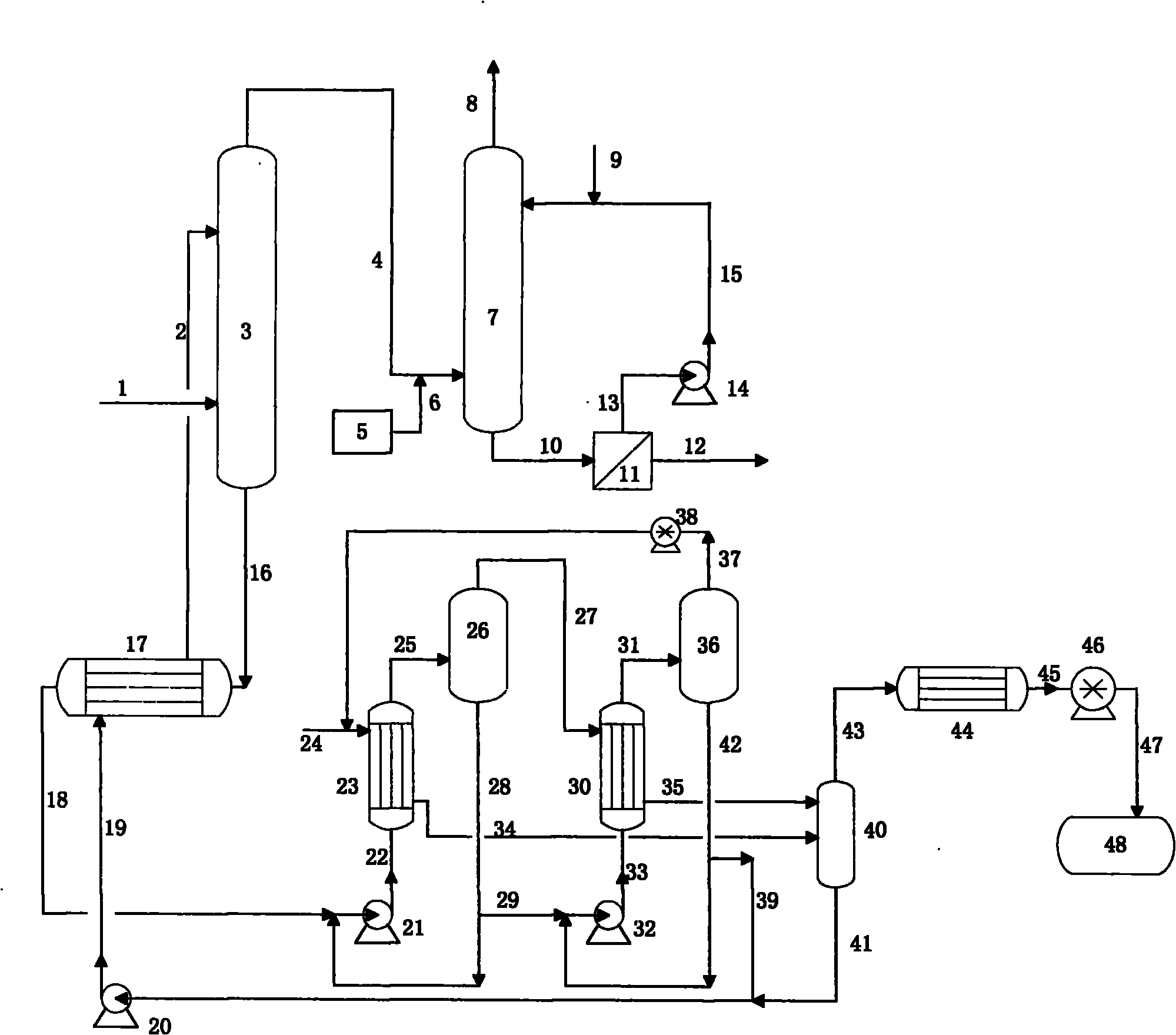

Recycled flue gas desulfurization and denitration method

The invention relates to a recycled flue gas desulfurization and denitration method, which sequentially comprises the following steps of: introducing flue gas of SO2 and NOx into a desulfurizing tower, and absorbing the SO2 with a desulfurizing agent (barren liquor) in the desulfurizing tower; desorbing the desulfurizing agent (rich liquor) which absorbs the SO2 through a multi-effect evaporator,releasing the SO2 gas, and concentrating the SO2 gas into liquid SO2 through condensation drying; making the desulfurized flue gas enter a denitration tower, injecting gaseous ozone from an ozone generator, oxidizing the NO in the flue gas, absorbing the oxidized NO by using a denitrifier to form nitrate; crystallizing and separating out the nitrate in the solution after the nitrate reaches certain concentration, and filtering and drying to obtain the nitrate product. The method turns the wastes into wealth, and the SO2 and NOx in the flue gas are recycled by higher-additional value liquid SO2 and nitrate products, so that the recycling and value maximization in the desulfurization and denitration process is realized. Due to the adoption of the technical scheme, the high desulfurization and denitration rate can be achieved, the desulfurization rate is over 96 percent, the denitration rate is more than 90 percent, and the purity of the nitrate product is over 96 percent. The method hasthe advantages of simple desulfurization and denitration process, low investment, and low operation cost for desulfurization and denitration, and solves the problems that the conventional desulfurization and denitration process has high cost, generates a side product of a mixture of sulfuric acid (sulfate) and nitric acid (nitrate), and has low additional value.

Owner:EAST CHINA UNIV OF SCI & TECH

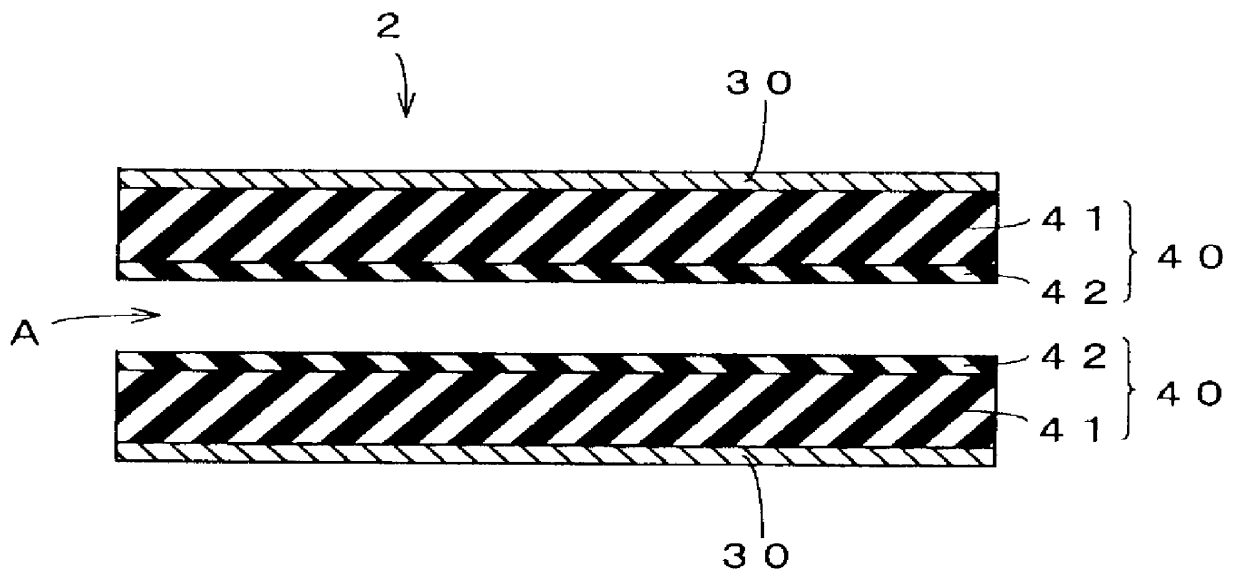

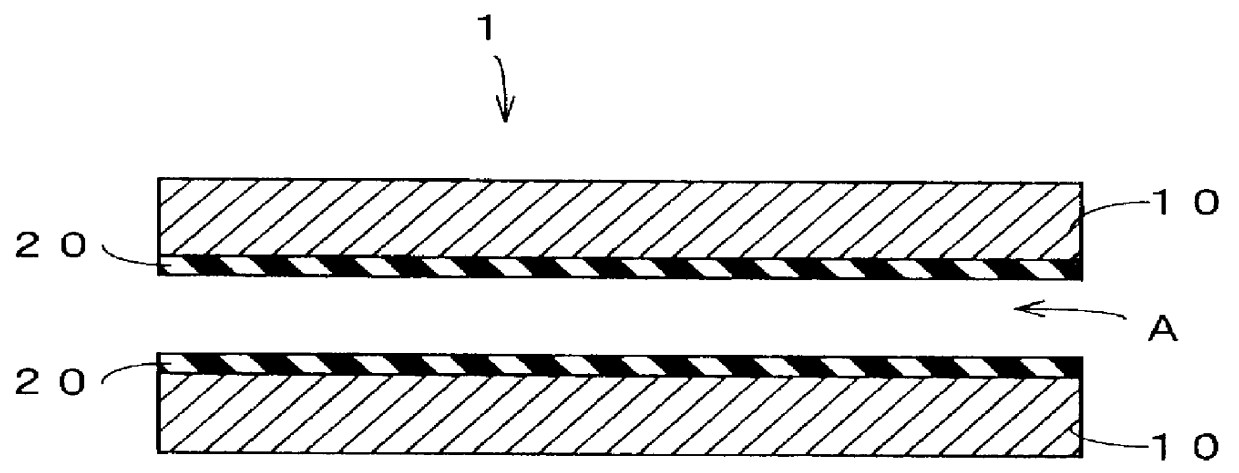

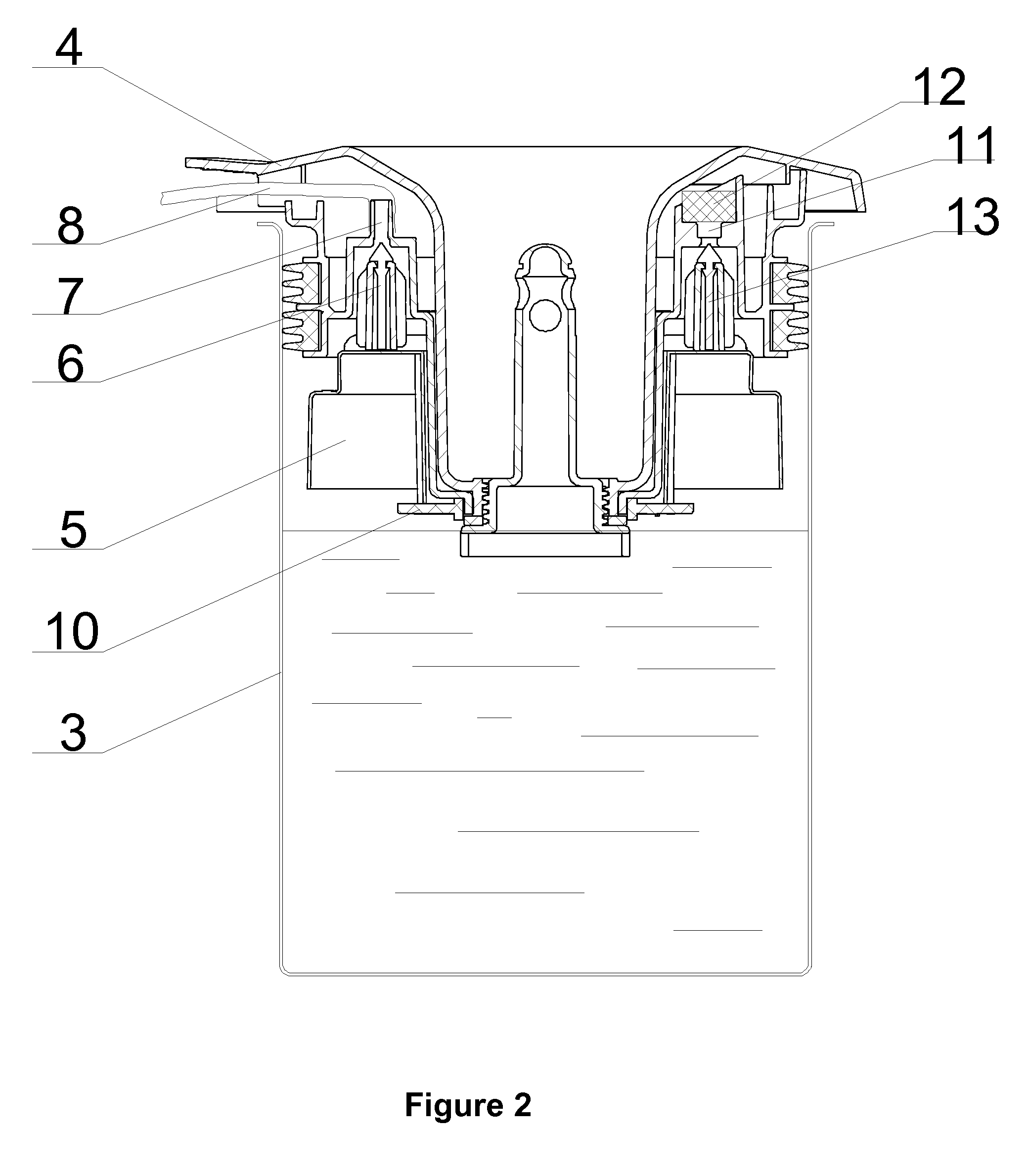

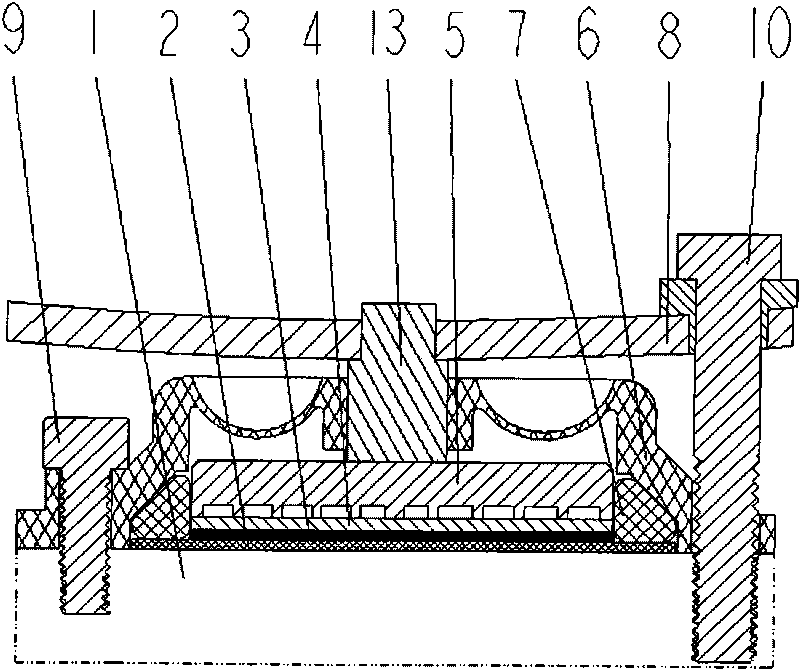

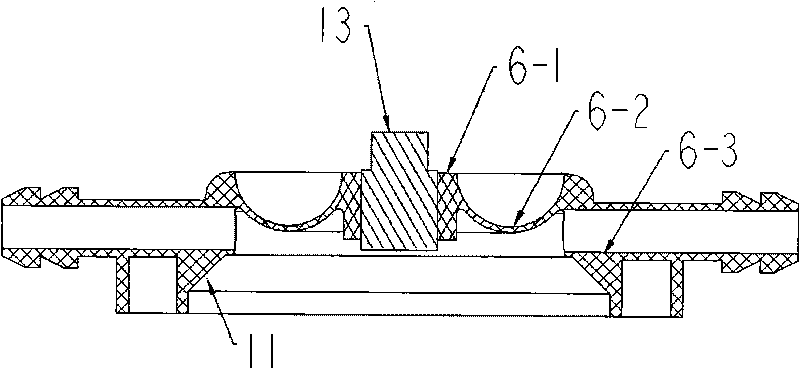

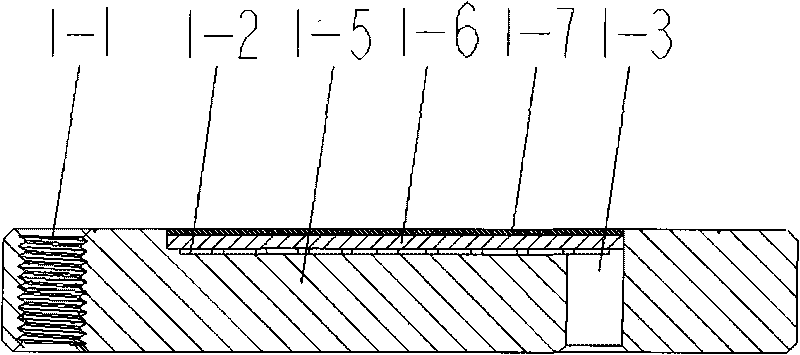

Discharge cell for ozone generator

InactiveUS6046533AEffectively suppress the time-related reduction in the ozone concentrationAvoid impuritiesLamp incadescent bodiesThermionic cathodesOzone generatorElectricity

A discharge cell for use in an ozone generator is provided which can suppress a time-related reduction in ozone concentration without adding a catalytic gas such as nitrogen gas to oxygen gas as a raw material gas. The discharge cell includes a pair of electrodes disposed in an opposed spaced relation with a discharge space therebetween, and a dielectric layer of a three-layer structure consisting of three ceramic dielectric layers successively stacked on at least one of the electrodes, wherein a first dielectric layer of the dielectric layer contacting the one electrode contains no titanium dioxide, wherein a second dielectric layer of the dielectric layer exposed to the discharge space contains titanium dioxide in a metal element ratio of not lower than 10 wt %.

Owner:SUMITOMO PRECISION PROD CO LTD

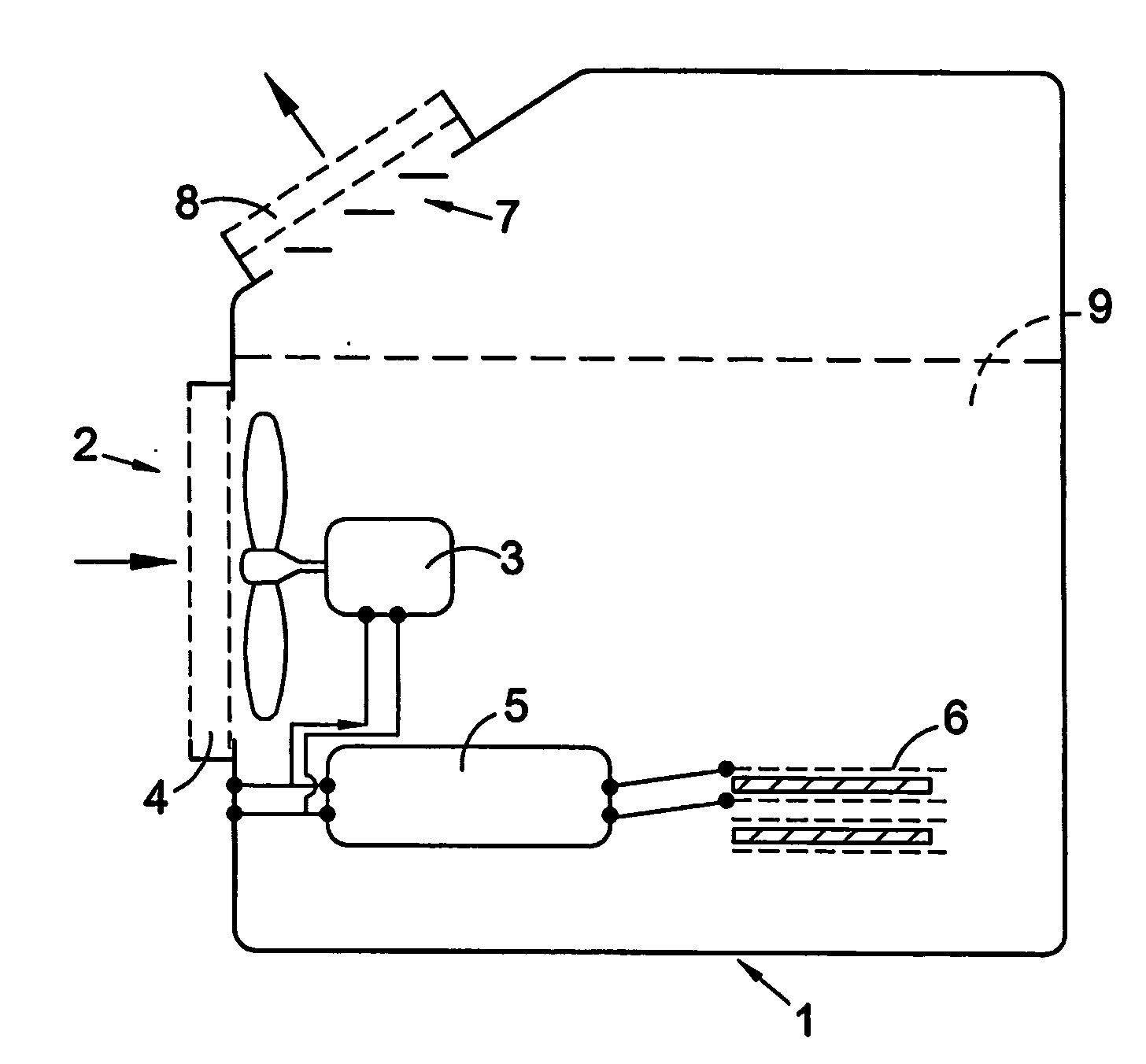

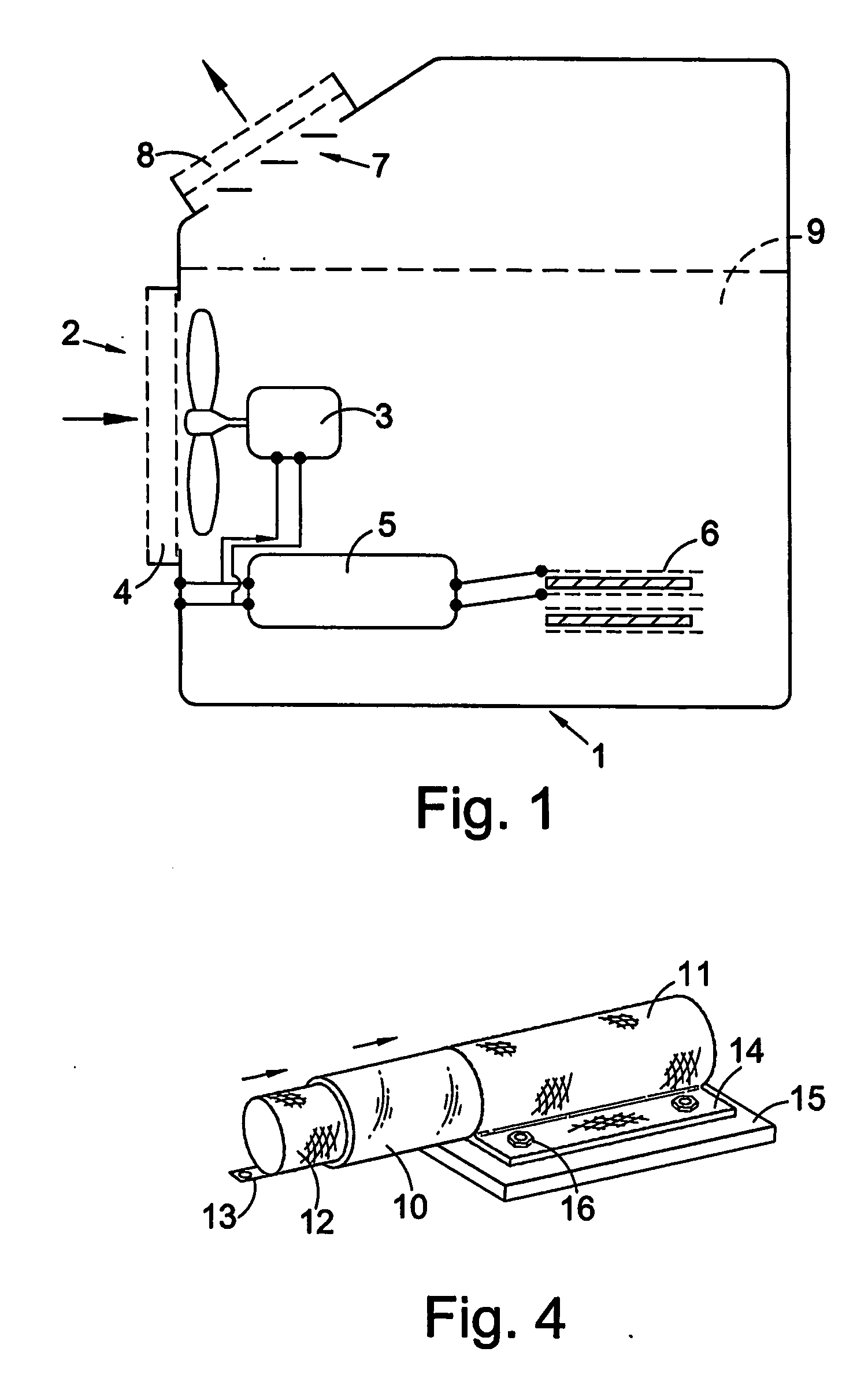

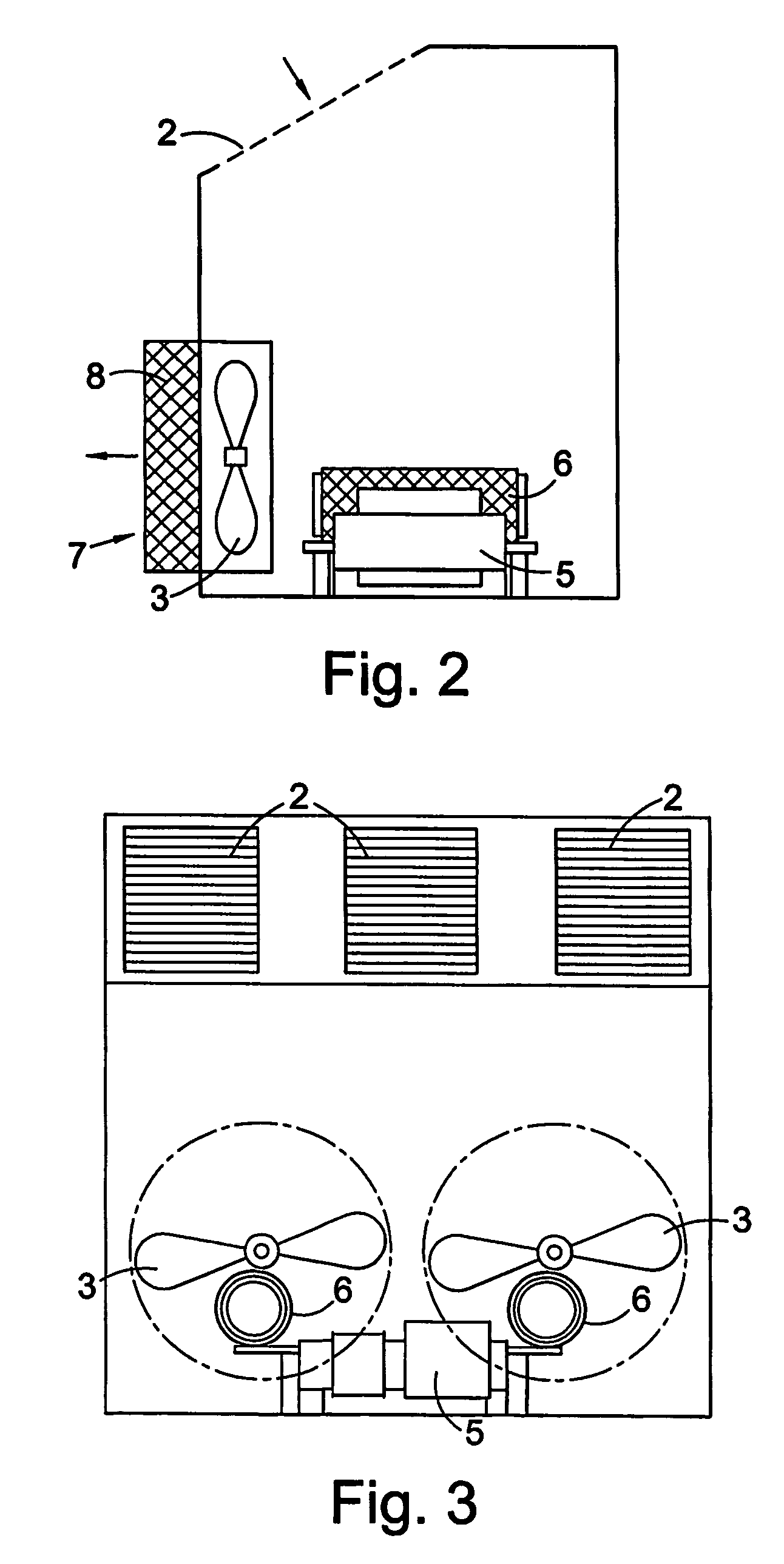

Air cleaning device

ActiveUS20060182672A1Minimize the numberReduce loadGas treatmentMechanical apparatusOzone generatorImpeller

The present invention provides an apparatus 1 for the treatment of air comprising a low power corona discharge ozone generator 5,6 inside a chamber 9 having an inlet 2 and an outlet 7, and at least one air flow impeller 3 for inducing a flow of air through the chamber 9. The ozone generator 5,6 is formed and arranged for generating a restricted concentration of ozone, within an inactivating zone 10 contained within the chamber 9, through which the air flow is passed. The restricted concentration is sufficient to inactivate airborne pollutant material entrained in the air flow, yet decays sufficiently outside the inactivating zone so that the concentration of ozone in the cleaned air expelled from the apparatus 1 is at a physiologically acceptable level without the use of an ozone decomposition catalyzer.

Owner:NOVAERUS UK LTD

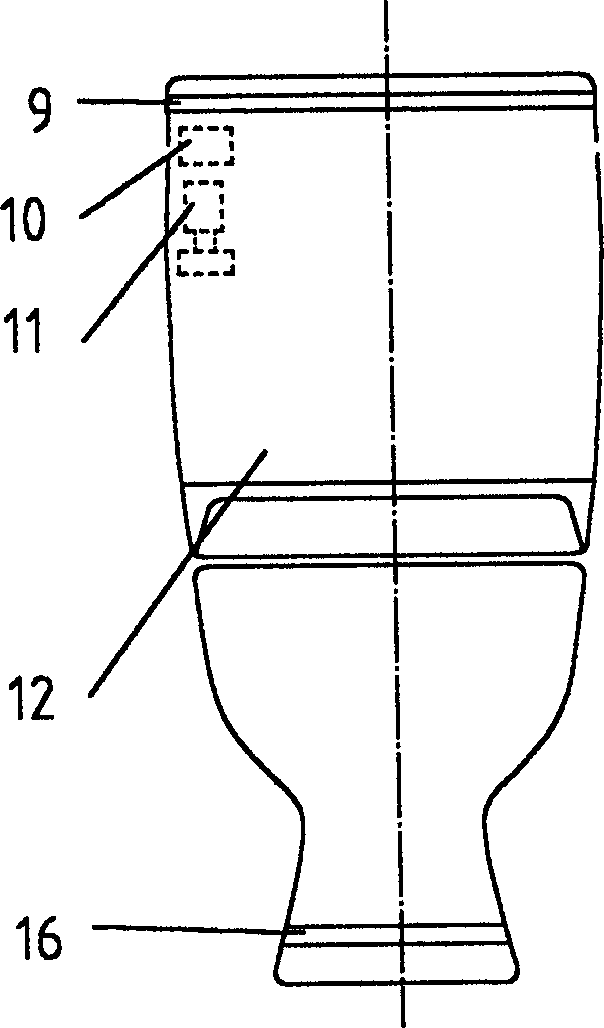

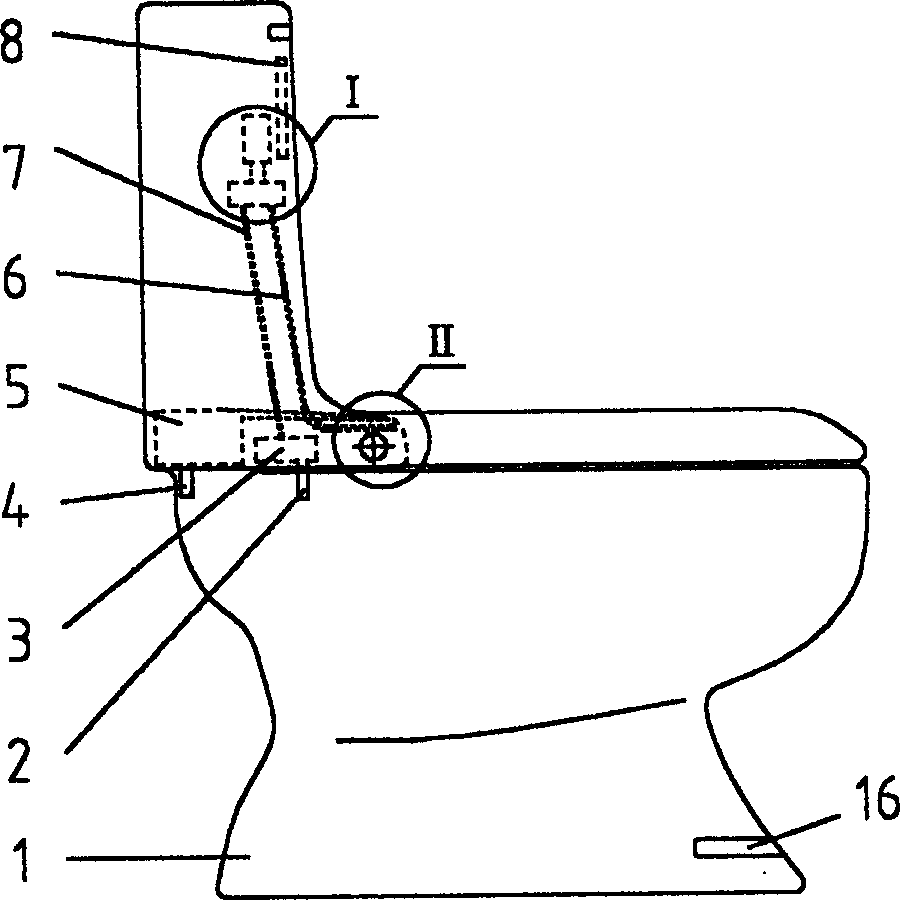

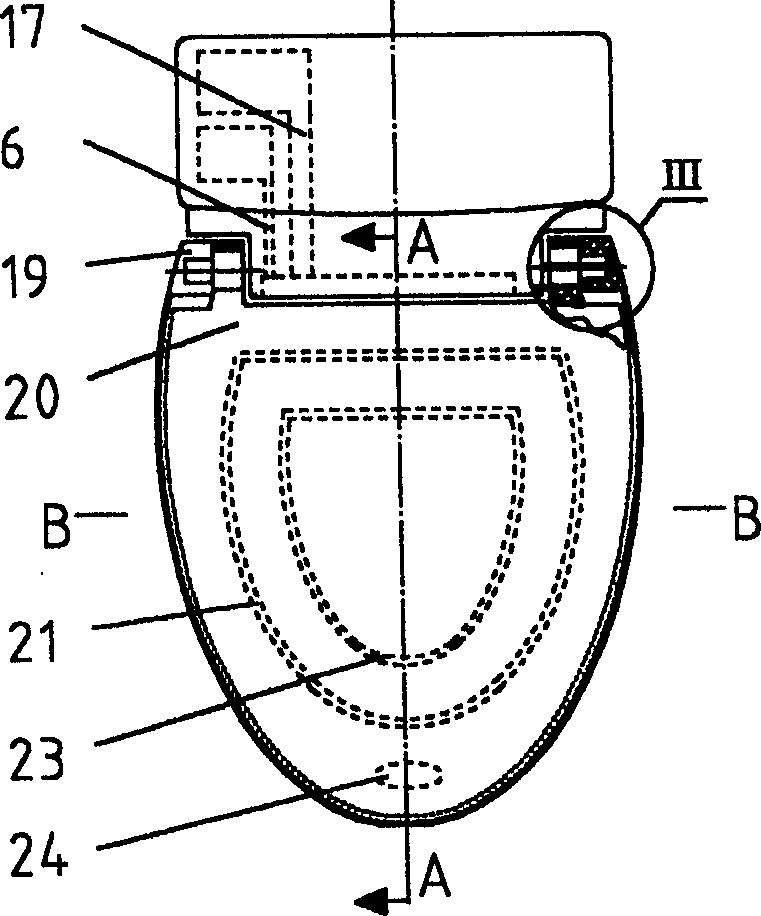

Full-automatic intelligent water-closet pan

InactiveCN1401863AAvoid cross infectionEasy to rinseFlushing devicesLavatory sanitoryOzone generatorEngineering

A full-automatic intelligent water closet is composed of the ozone generator in water line, disinfecting liquid and its box, automatic feeder of disinfecting liquid, water sterilizing and flushing unit, warm-air dryer, automatic opener of cover, automatic temp regulator, and intelligent recognition controller.

Owner:曹增全

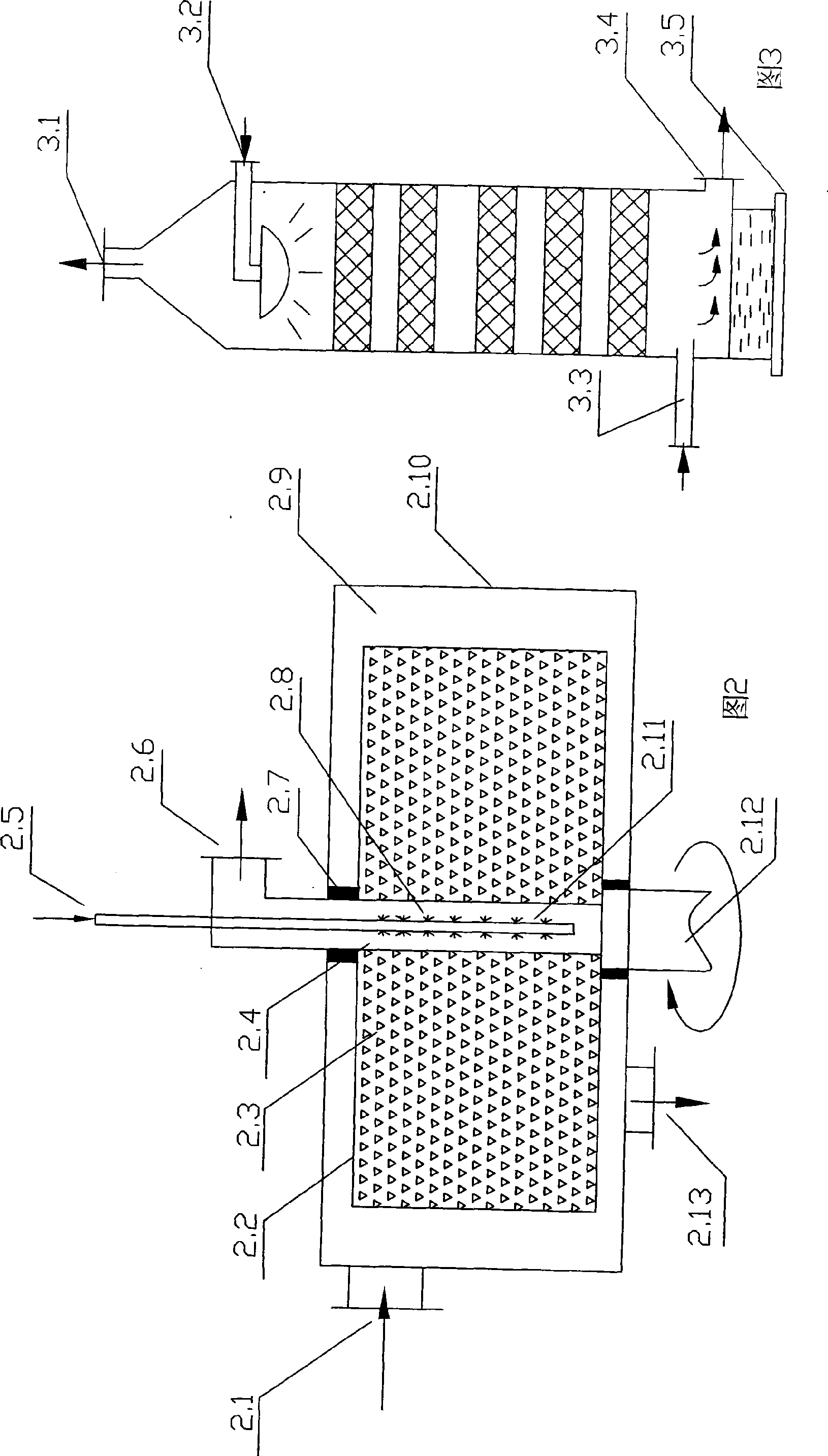

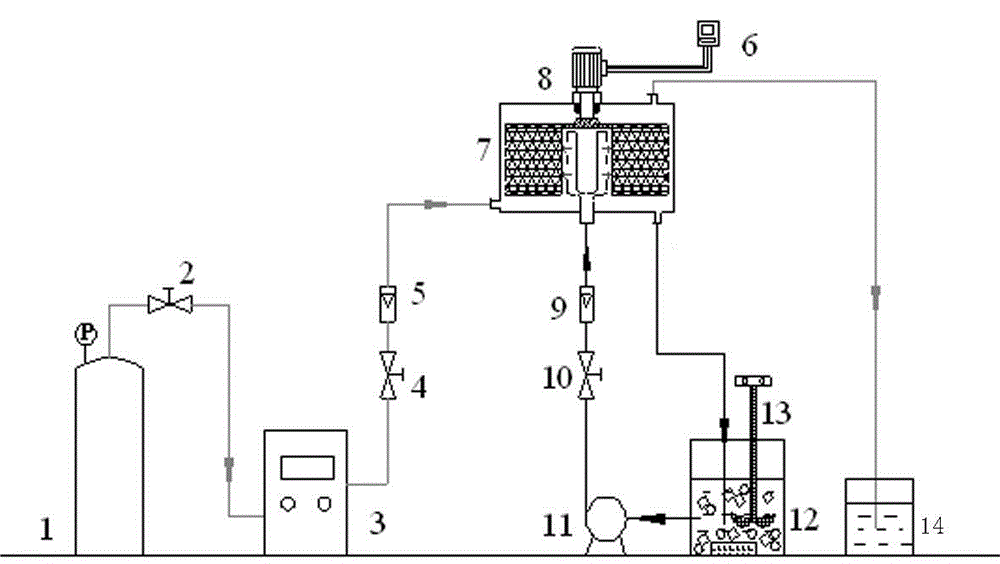

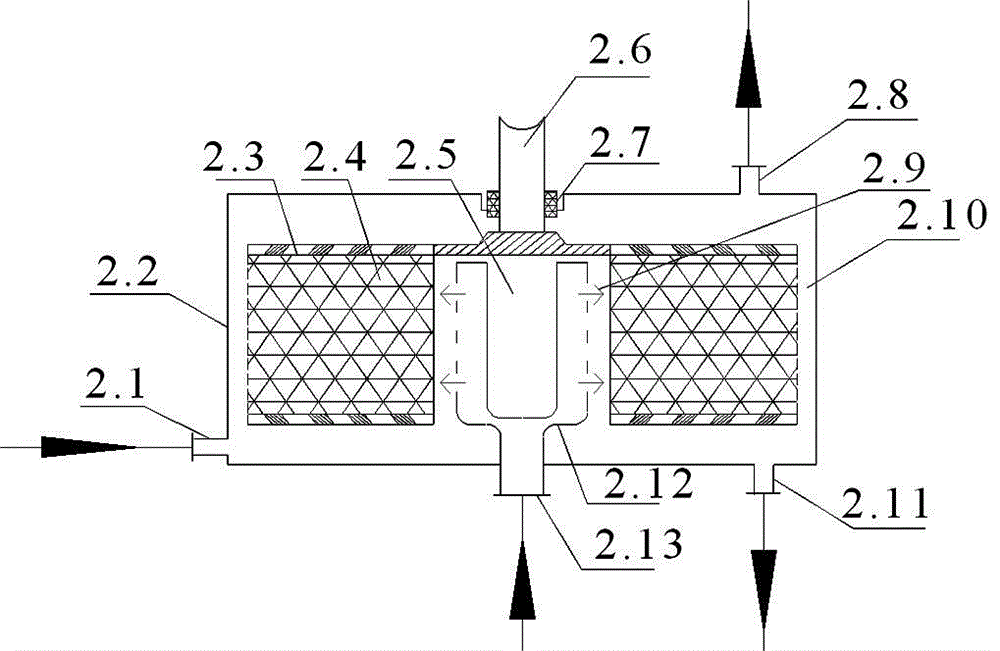

Technological process and apparatus for advanced oxidation degradation of nitrobenzene wastewater

ActiveCN101462788AReduce processing costsBiochemical effectWater contaminantsWater/sewage treatment with mechanical oscillationsDetonatorElectrolysis

The invention belongs to the technical field of nitrobenzene class wastewater treatment and in particular relates to a process method for advanced oxidation and degradation of nitrobenzene class wastewater. The invention solves the problem that the prior method for degrading nitrobenzene class wastewater has long time consumption and high cost. The method comprises that: wastewater and ozone undergo full haptoreaction in gas-liquid mass transfer equipment; after the haptoreaction, the wastewater enters a coupling reactor consisting of an ultrasonic wave field and an electrolysis field; and nitrobenzene class substances in the wastewater are degraded under the synergistic action of ultrasonic wave and micro-electrolysis. The device comprises the gas-liquid mass transfer equipment; a gas inlet of the gas-liquid mass transfer equipment is connected with an ozone generator; a liquid inlet of the gas-liquid mass transfer equipment is connected with a nitrobenzene class wastewater pool; a liquid outlet of the gas-liquid mass transfer equipment is connected with the wastewater coupling reactor; and the bottom of the wastewater coupling reactor is provided with an ultrasonic wave generator. The process method has the following advantages: the process method has simple process flow and convenient operation, farthest reduces treatment cost and can be applied to various organic industrial wastewater such as phenol-containing wastewater, detonator wastewater, dye wastewater, wastewater in a petrochemical enterprise, detergent wastewater and the like.

Owner:ZHONGBEI UNIV

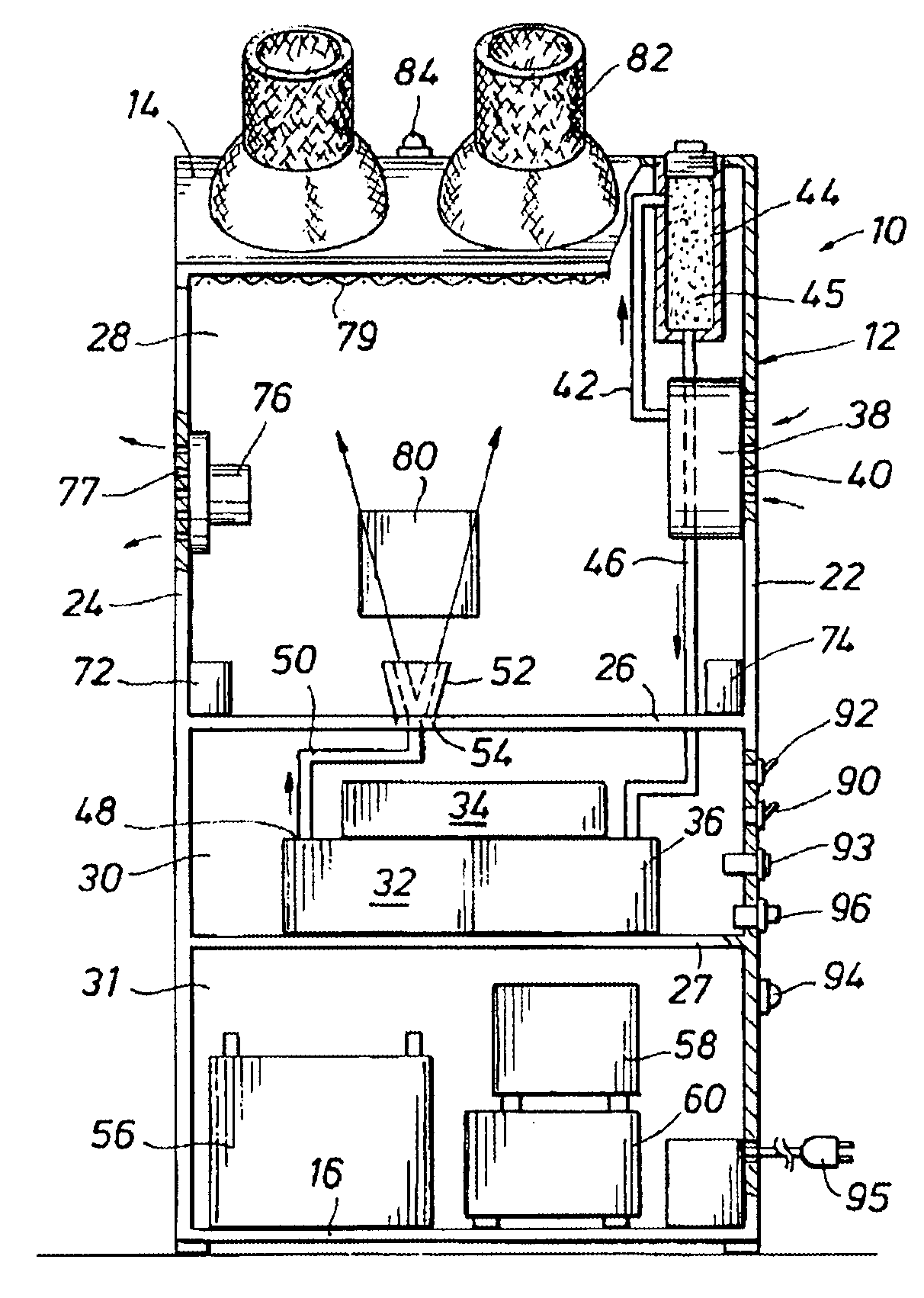

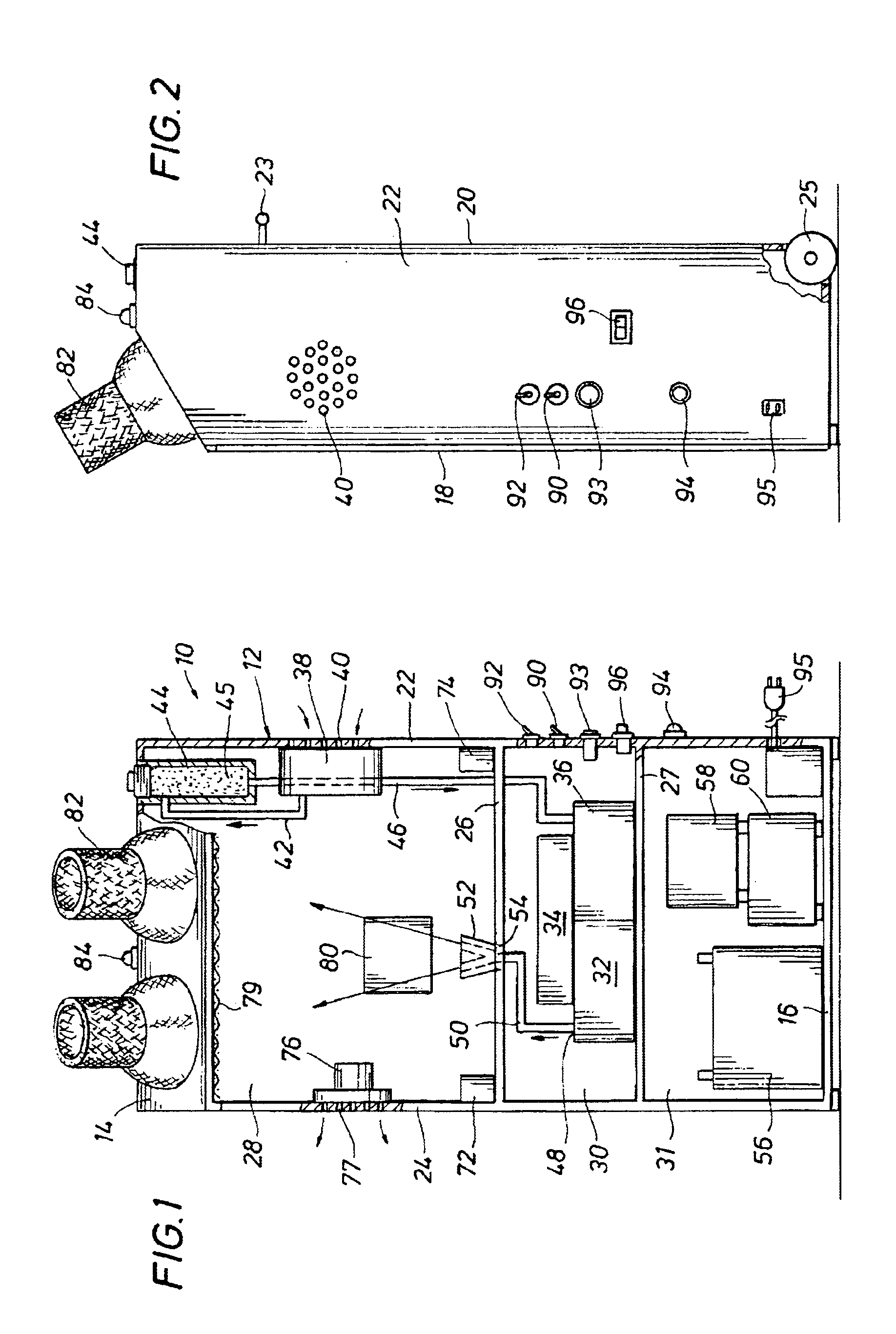

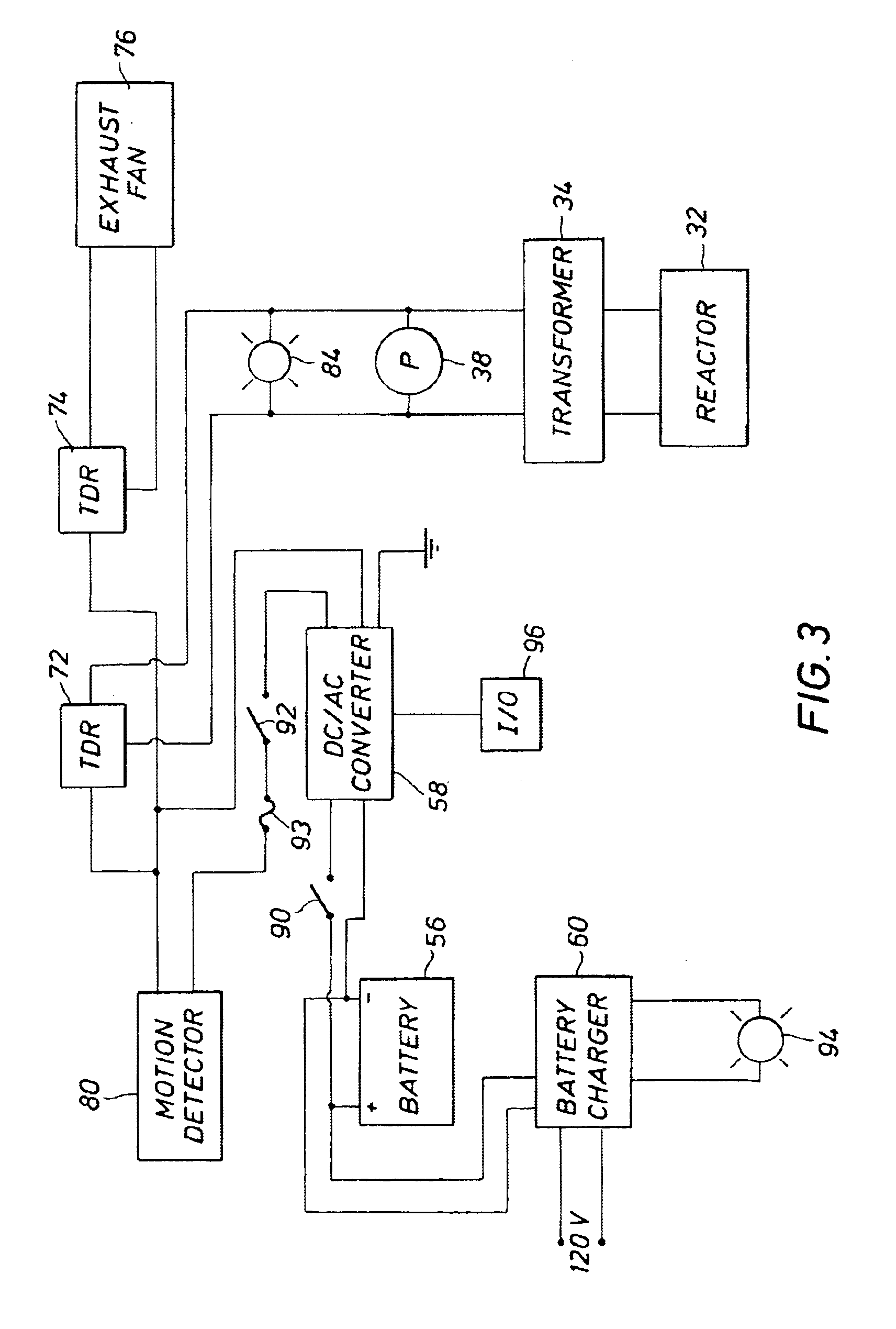

Method and apparatus for using ozone as disinfectant

InactiveUS6872366B2Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesElectrical discharge ozone preparationOzone generatorMotion detector

An apparatus for generating an effective concentration of ozone for killing bacteria, viruses and other harmful microorganisms includes a housing having an ozone chamber defining an enclosed space for containing elevated concentrations of ozone. The ozone chamber includes ports providing access to the interior of the ozone chamber. A second chamber of the apparatus houses an ozone reactor. A programmable control circuit operates both the ozone reactor and a pump for directing ambient air to the ozone reactor. The control circuit includes a motion detector mounted in the ozone chamber for activating the ozone generator of the invention and initiating the generation of ozone directed into the ozone chamber of the apparatus of the invention.

Owner:MARHOC

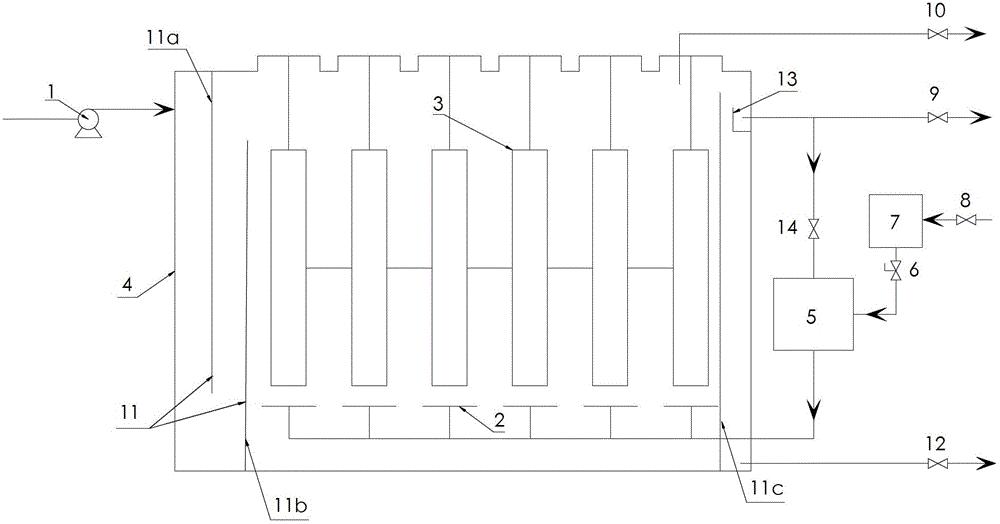

Integrated ozone and aeration biological filtering pool water treatment apparatus and method

ActiveCN101070216AEasy to handleReduce the difficulty of installation and constructionTreatment using aerobic processesMultistage water/sewage treatmentAeration systemBiological filter

This invention relates to water disposal facility and means of integrated ozone and aerating biological filter. This aerating biological filter(9) is above ozone catalysis chamber(8), connects with ozone catalysis chamber(8) through the filter plate of biological filter(9); ozone catalysis chamber joints with Venturi tube(5), Venturi tube(5) respectively joints with ozone occurring system(6) and influent water pump(1); ozone occurring system(6) is a ozonizer that by silent discharge method translate oxygen of air into ozone. The water after pretreatment by ozone passes the filter plate of the aeration biological filter pool at the top of the ozone reaction chamber to enter the biological filter pool uniformly and stay for about 1 to 4 hours. This invention can advance aerating efficiency without fixing aerating system, and the flow between aerating biological filter and ozonization buffer pool cell is equilibrium, possess merits of high efficiency, low cost and so on.

Owner:SOUTH CHINA UNIV OF TECH

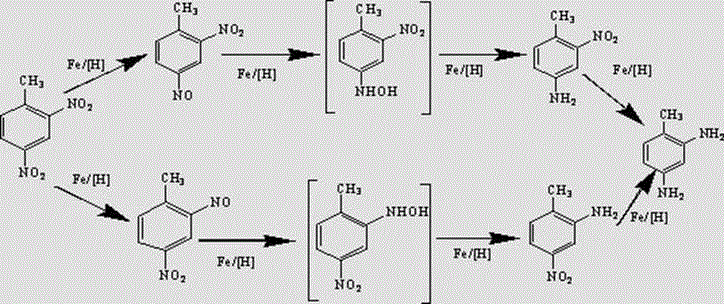

Method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater

ActiveCN103145273ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater contaminantsMultistage water/sewage treatmentOzone generatorGas liquid reaction

The invention belongs to the technical field of nitrobenzene wastewater, in particular relates to a method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater, and solves the problem of the existing method for degrading nitrobenzene wastewater. The method comprises the following steps of performing a reduction reaction on nitrobenzene wastewater in a micro-electrolysis bath; performing a sufficient contact reaction with ozone in gas-liquid reaction equipment; further degrading pollutants in the wastewater in the gas-liquid reaction equipment; and circularly treating the wastewater in the micro-electrolysis bath and the gas-liquid reaction equipment. The device comprises a rotary packed bed device, wherein a gas inlet is connected with an ozone generator; and a liquid inlet and a liquid outlet are connected with the micro-electrolysis bath. The method and the device have the beneficial effects that the process flow is simple and convenient to operate; the advantages of various technologies are given a full play by coupling the three technologies to reach the aim of treating waste by using waste, so that the treatment cost can be furthest reduced.

Owner:ZHONGBEI UNIV

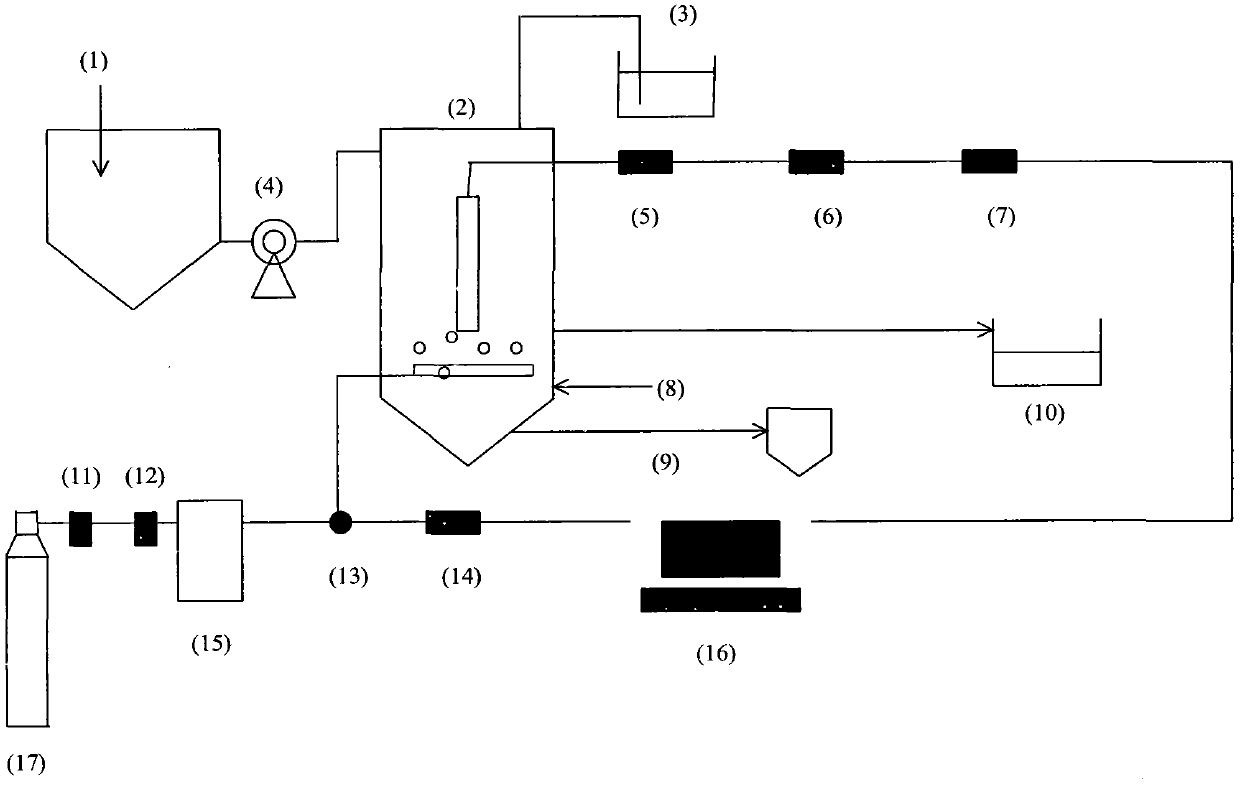

Water treatment method for catalytic ozonation of refractory organics in water by ceramic membrane

InactiveCN103951028AIncrease profitEnhance its oxidative capacityWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by oxidationHazardous substanceData acquisition

The invention relates to water deep treatment technology of heterogeneous catalytic ozonation depollution. With the combination of catalytic ozonation depollution technology with membrane filtration technology, a novel, high-efficient, and economical catalytic ozonation water deep treatment technology is provided, which combines the advantages of the two technologies, overcomes their disadvantages, effectively improves the ozone utilization rate and the ozone oxidation capability, reduces some toxic and harmful substances generated due to incomplete oxidation, alleviates the problem of ceramic membrane contamination, and prolongs the system operation period. An experiment device mainly comprises three parts: an ozone generation device, a ceramic membrane device, and a computer data acquisition and analysis system; an ozone outlet of the ozone generation device is connected with a water inlet valve of the ceramic membrane assembly through a silicone flexible pipe to realize the coupling of the two system. The method of the invention can improve the purifying effect of routine water treatment technology, and provides novel, high-efficient and cheap water deep treatment technology for enhanced removal of low-concentration high-toxicity refractory organic pollutants in water.

Owner:BEIJING FORESTRY UNIVERSITY

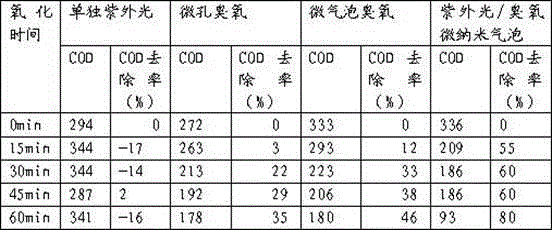

Waste water treatment system of ultraviolet light and ozone micro/nanobubbles and method

ActiveCN102910772AImprove biodegradabilityExtended stayWater/sewage treatment by irradiationMultistage water/sewage treatmentWater treatment systemUltraviolet lights

The invention relates to a waste water treatment system of ultraviolet light and ozone micro / nanobubbles, which comprises a raw water lifting pump, a reaction tank, an ultraviolet lamp casing pipe group, a micro / nanobubble generator and an ozone generator. The water inlet of the reaction tank is positioned at the upper part of the water inlet end of the reaction tank; a water outlet overflow weir is arranged at the upper part of the water outlet end of the reaction tank; the ultraviolet lamp casing pipe group is hung on an upper cover of the reaction tank; the water outlet overflow weir is respectively communicated with a water outlet valve of the reaction tank and the water inlet of the micro / nanobubble generator; the air inlet of the micro / nanobubble generator is connected with the ozone generator; and the micro / nanobubble generator leads produced air-water mixture into the reaction tank. The waste water treatment system adopts ultraviolet light and ozone micro / nanobubbles, improves the mass transfer performance of ozone, greatly improves the utilization rate of ozone, and reduces the output of tail gas. The particle size of ozone micro / nanobubble is small, the quantity of the ozone micro / nanobubbles is large, the retention time of the ozone micro / nanobubbles is long, and the ozone micro / nanobubbles can scrub the surface of an ultraviolet lamp casing pipe while being spread in water to prevent the adhesion or scaling of organic or inorganic pollutant.

Owner:UNIV OF SCI & TECH BEIJING +1

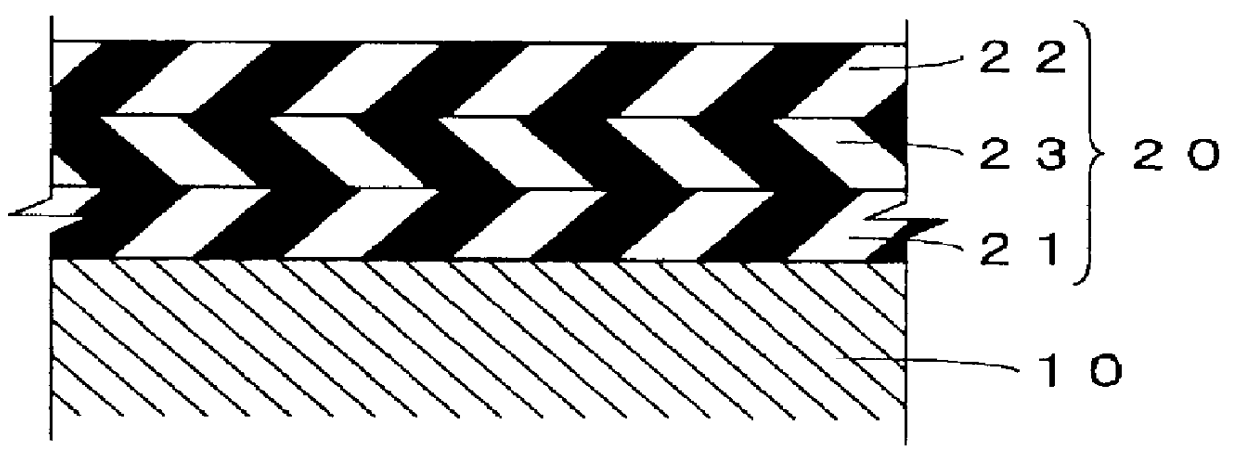

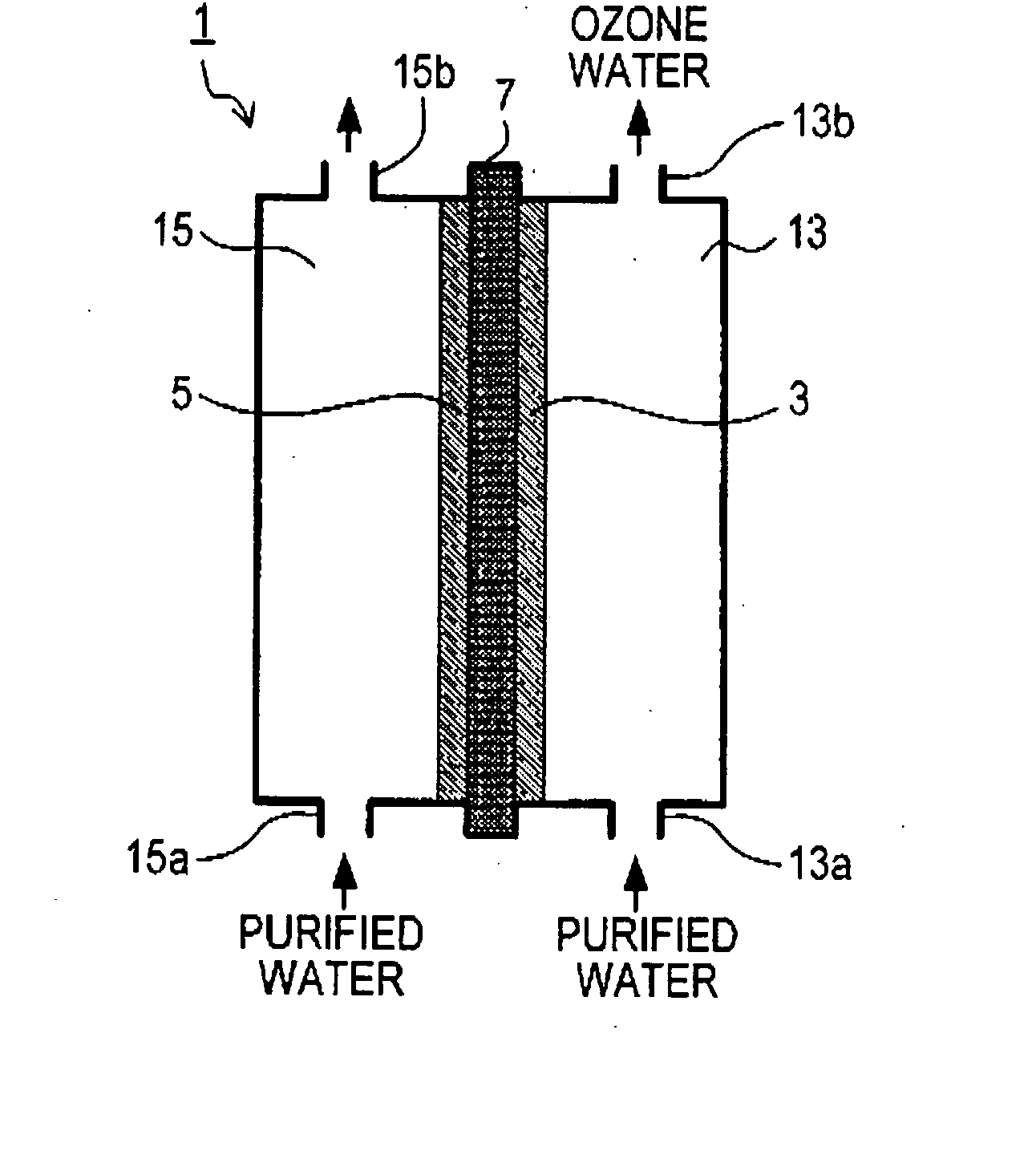

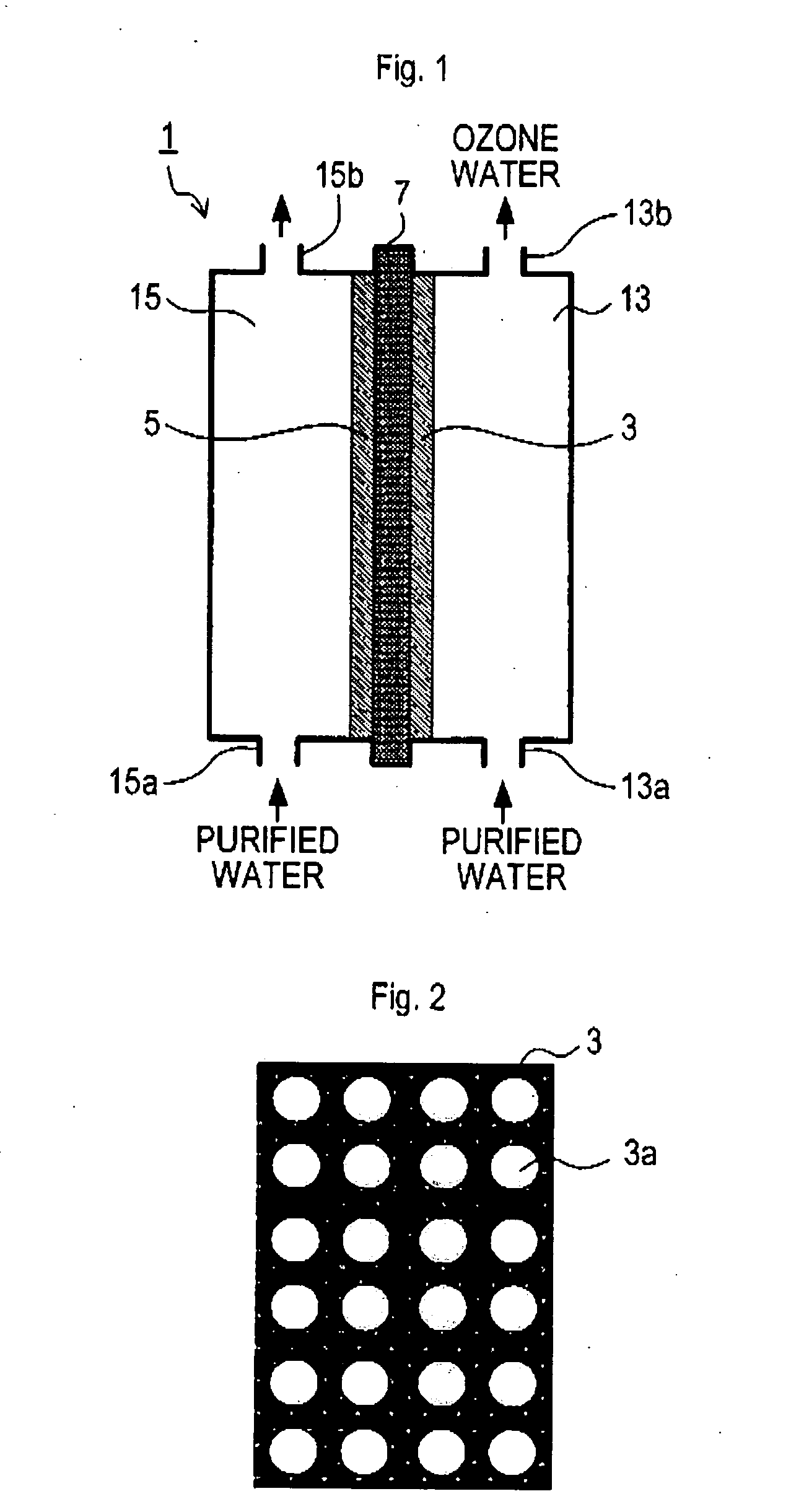

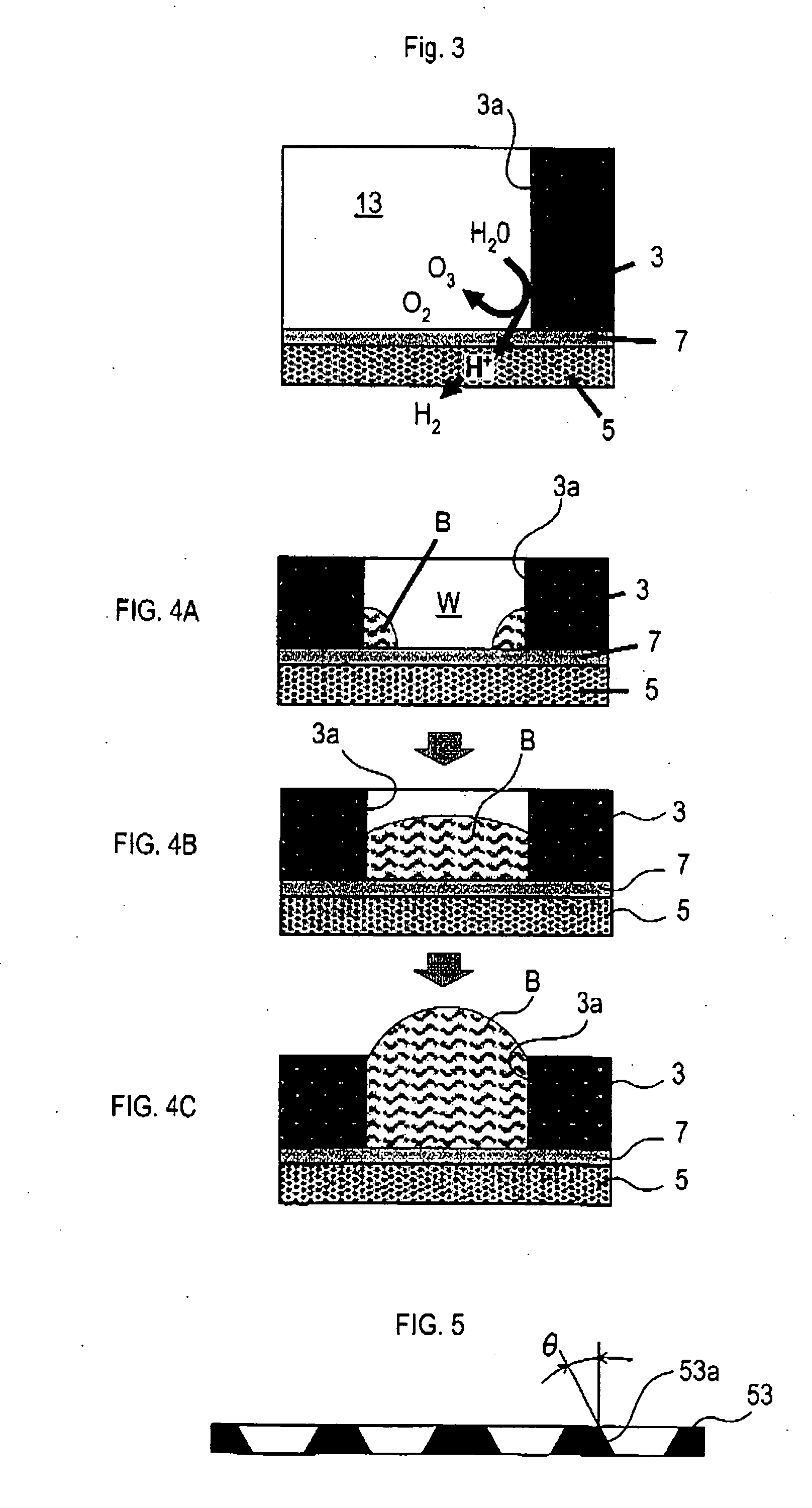

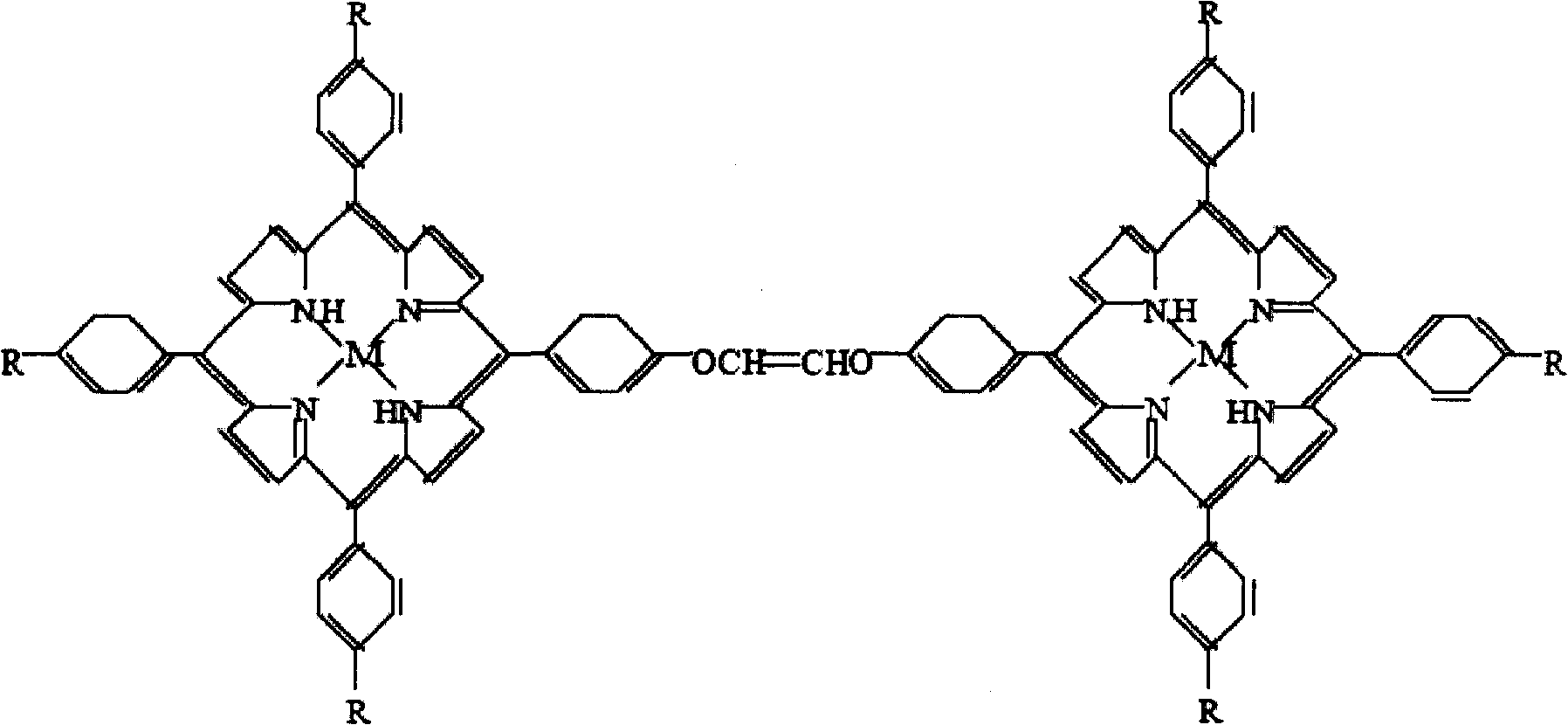

Electrode, Ozone Generator, and Ozone Production Method

ActiveUS20080053840A1Stably produceReduce frequencyCellsPhotography auxillary processesEngineeringMicrowave

An anode (3) and a cathode (5), interposing a solid polymer film (7), are disposed. While supplying purified water from a supply port (13a) of an anode chamber (13), wherein the anode (3) is disposed, and a supply port (15a) of a cathode chamber (15), wherein the cathode (5) is disposed, direct electric current is applied between the anode (3) and the cathode (5). As a result, ozone-water is discharged from an outlet port (13b) of the anode chamber (13). In such an electrolysis cell (1), a free-standing conductive diamond plate, formed by microwave plasma assisted CVD so as to have a thickness of 0.8 mm, is used as the anode (3). The diamond plate is provided with holes, having a diameter of 1 mm and disposed such that a center distance therebetween becomes 2 mm. Therefore, the electrolysis cell (1) can stably produce ozone without causing exfoliation of the anode (3), even when high voltage and large current are applied between the anode (3) and the cathode (5).

Owner:CENTRAL JAPAN RAILWAY COMPANY

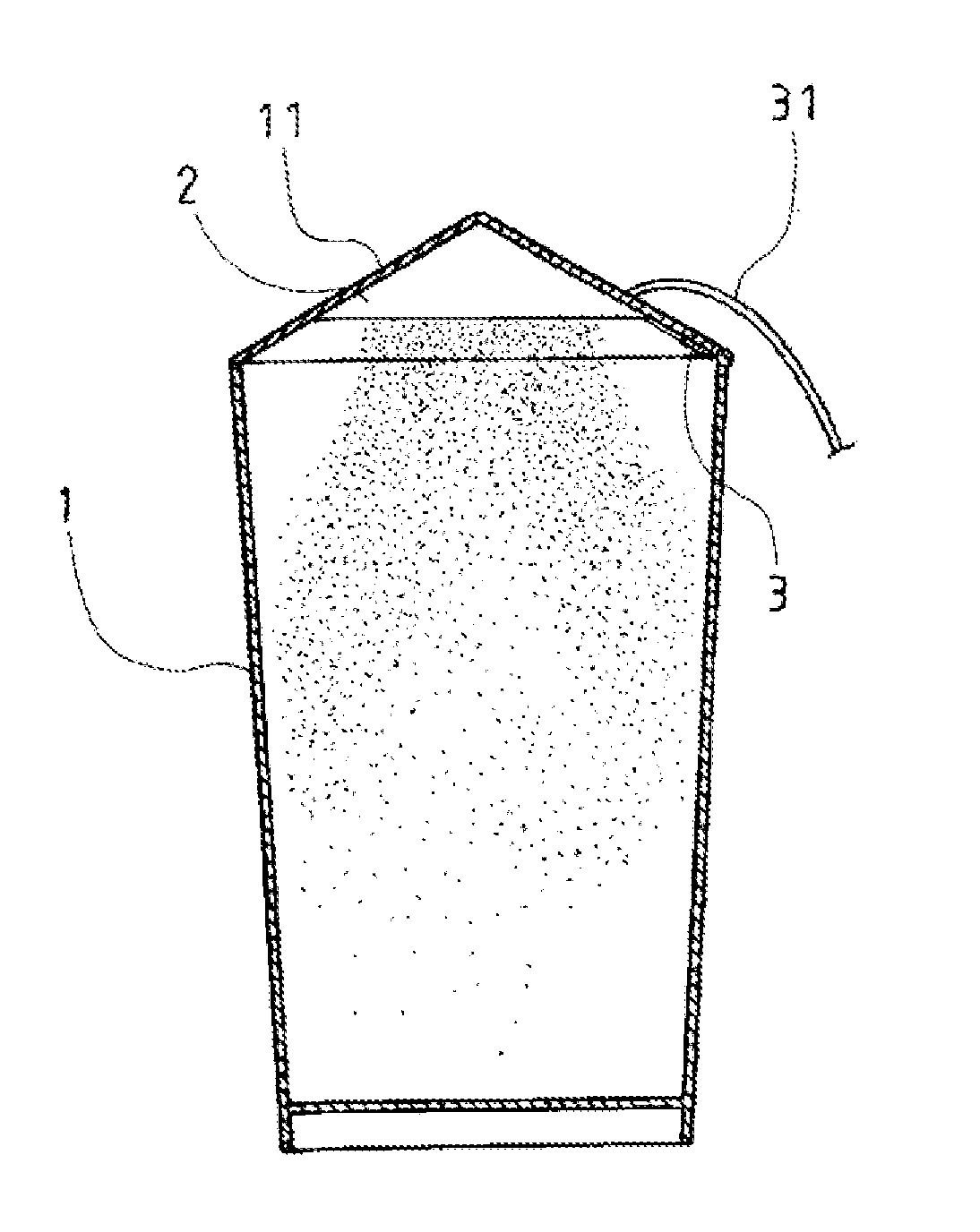

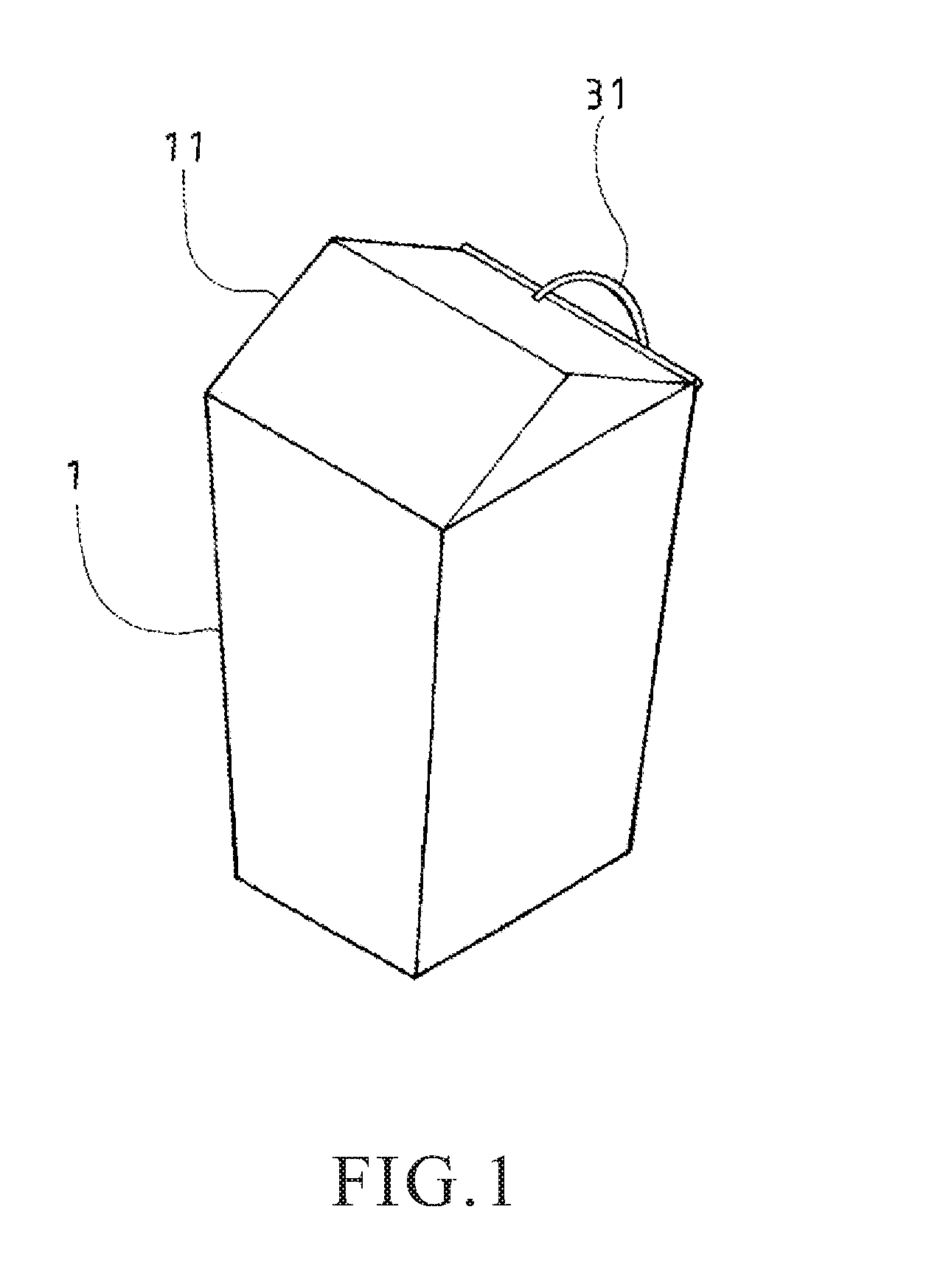

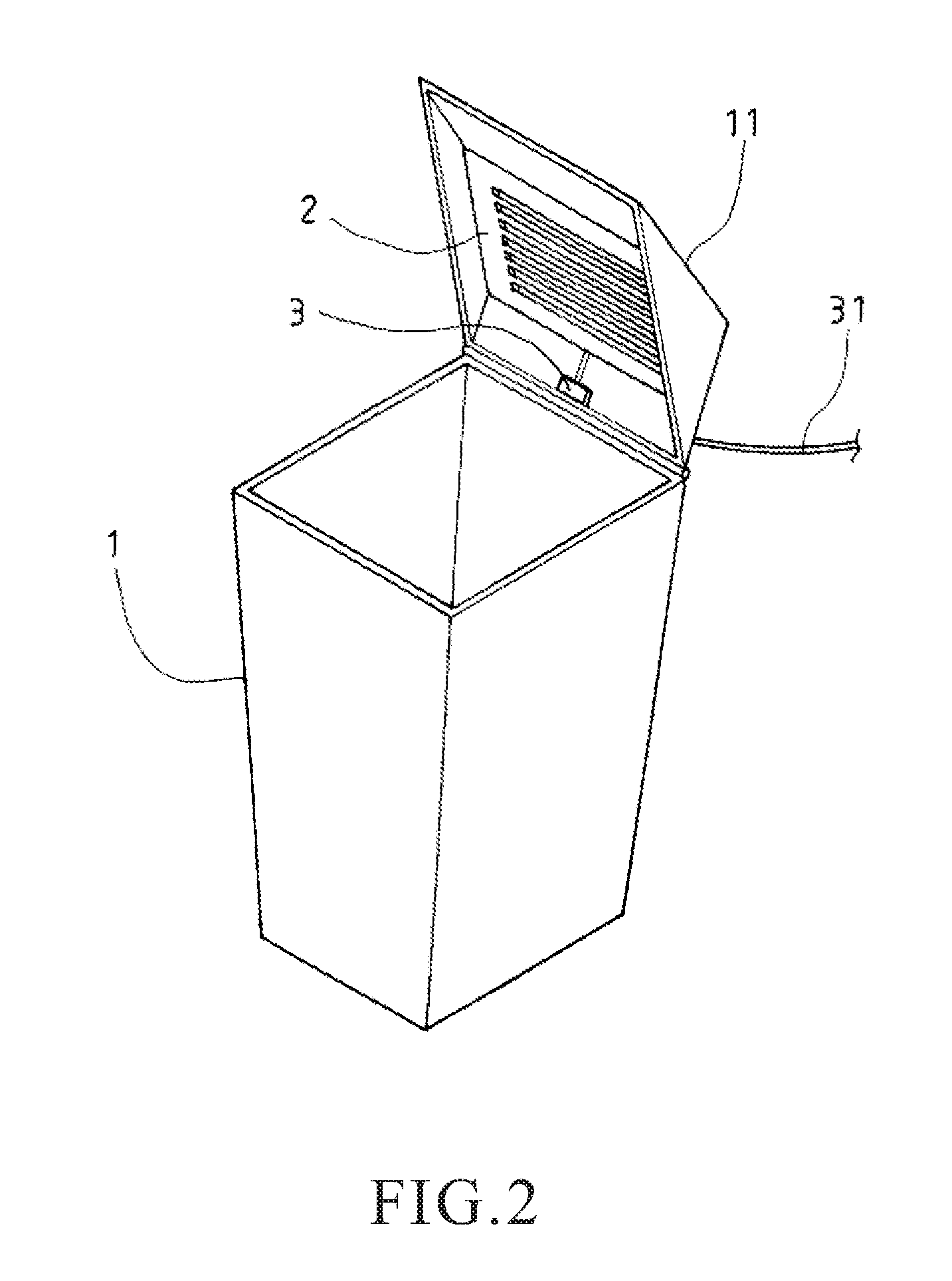

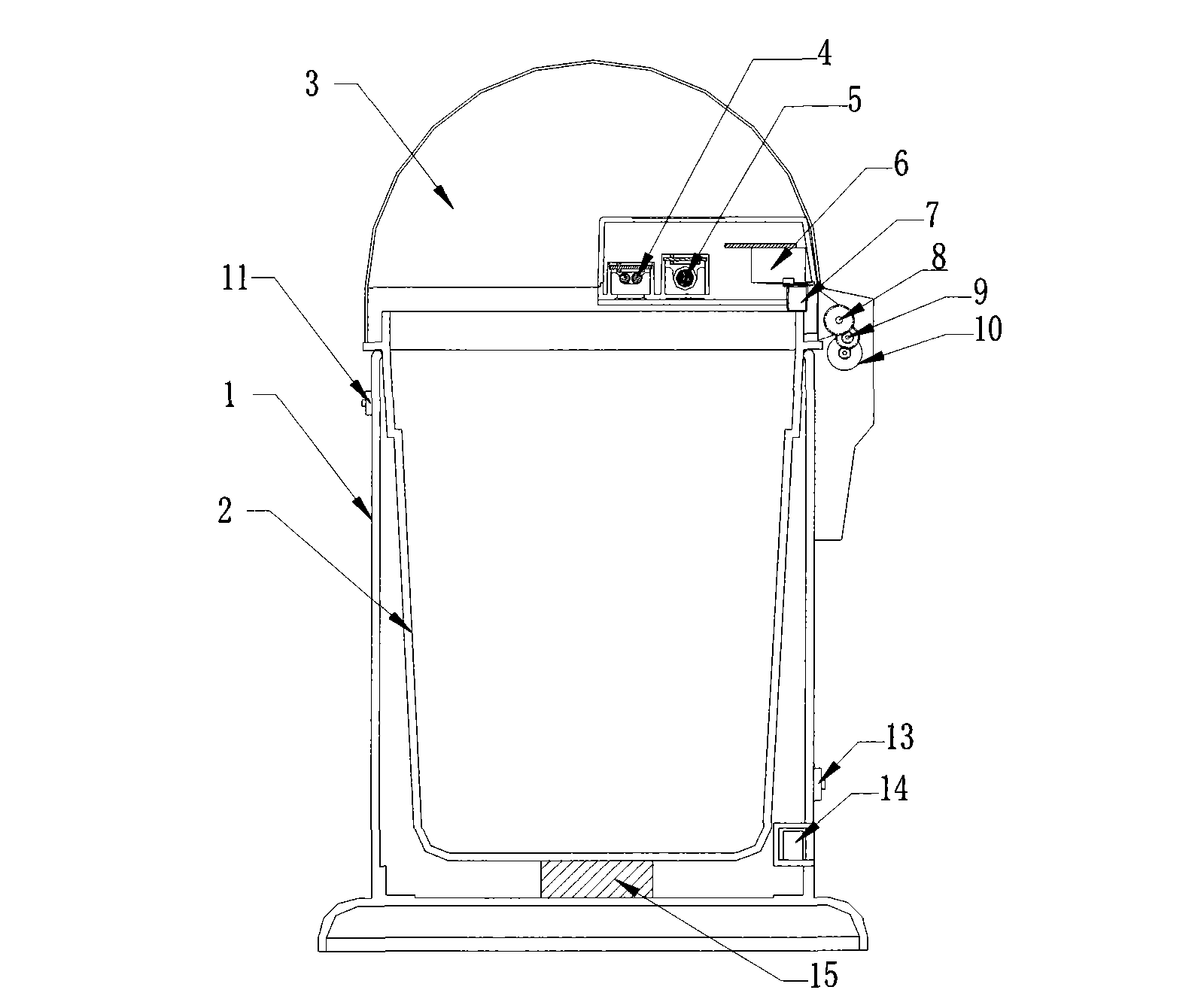

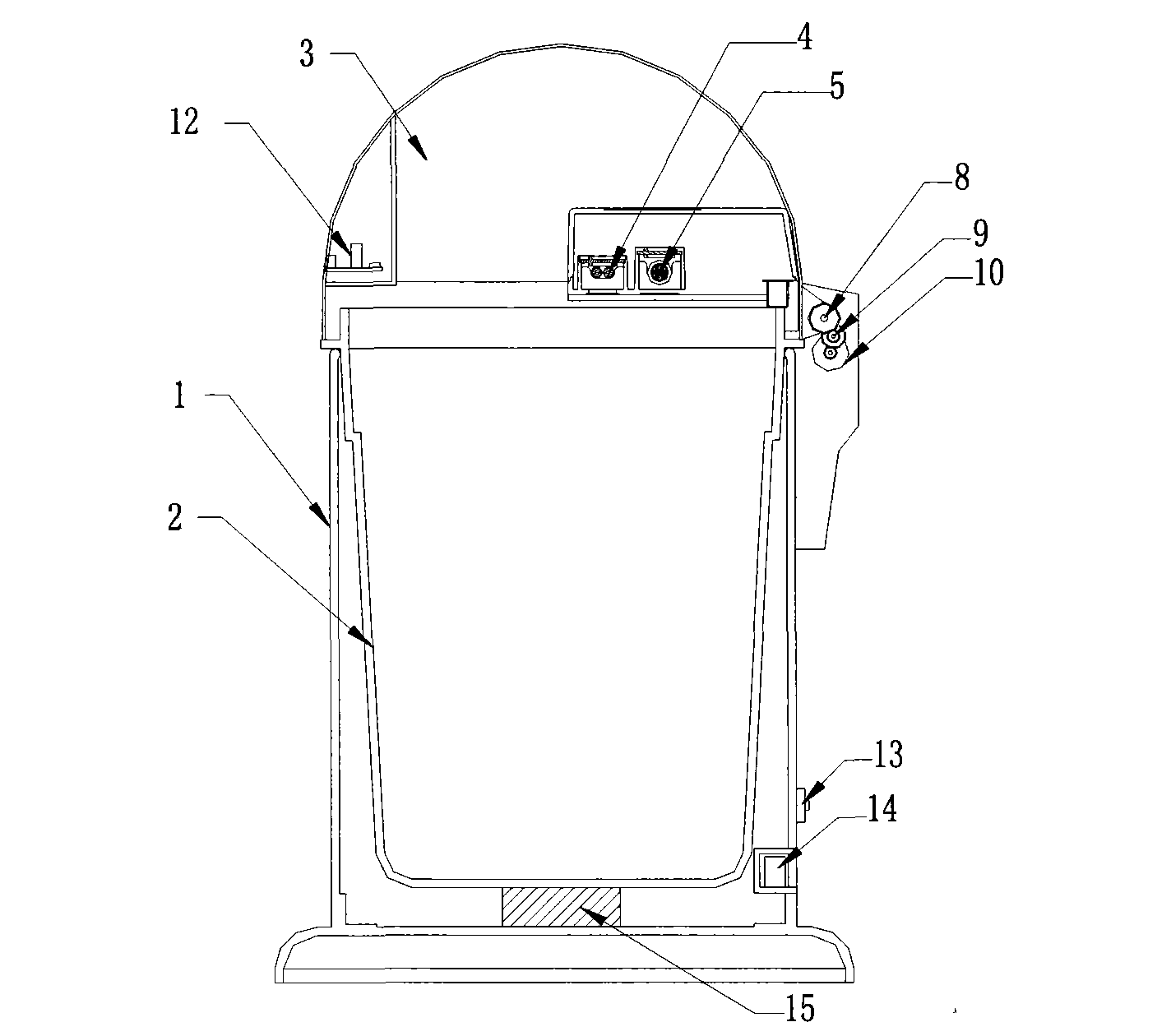

Trash Can With A Deodorization and Sterilization Function

A trash can with the deodorization and sterilization function contains a body with the cover and an ozone generator fixed in the body. The ozone generator is fixed at a predetermined position of the cover of the body and is in connection with a controlling member. The controlling member is mounted at a position of an inner surface of the cover adjacent to the body and couples with the ozone generator and a wire for electrically connecting with a power source, such that when the cover covers the body of the trash can, it triggers the controlling member by which the ozone generator is started to produce the ozone in the body, hence the odor from the litters is eliminated, and the bacteria are disinfected.

Owner:PAN TU CHENG

Ozone generators

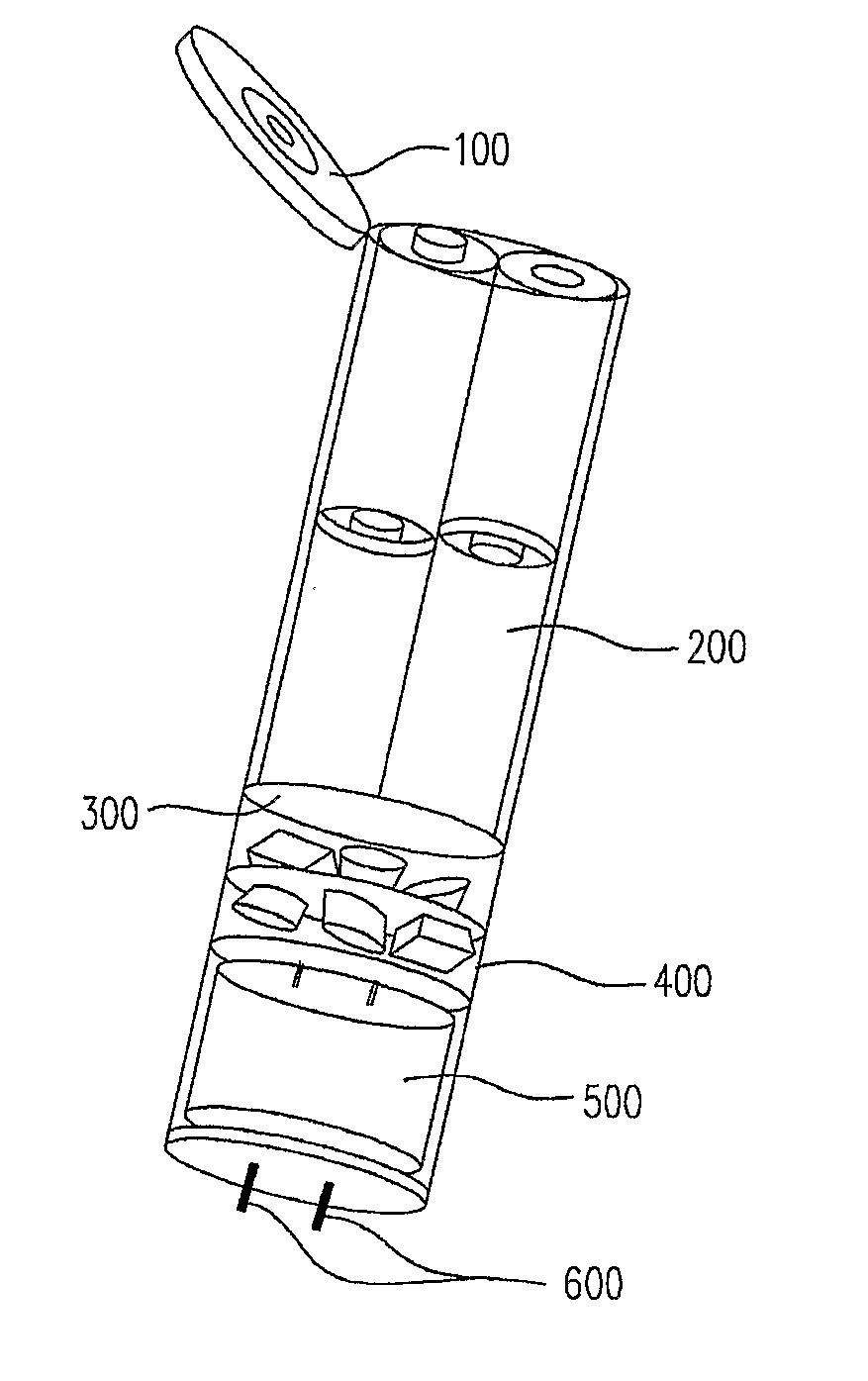

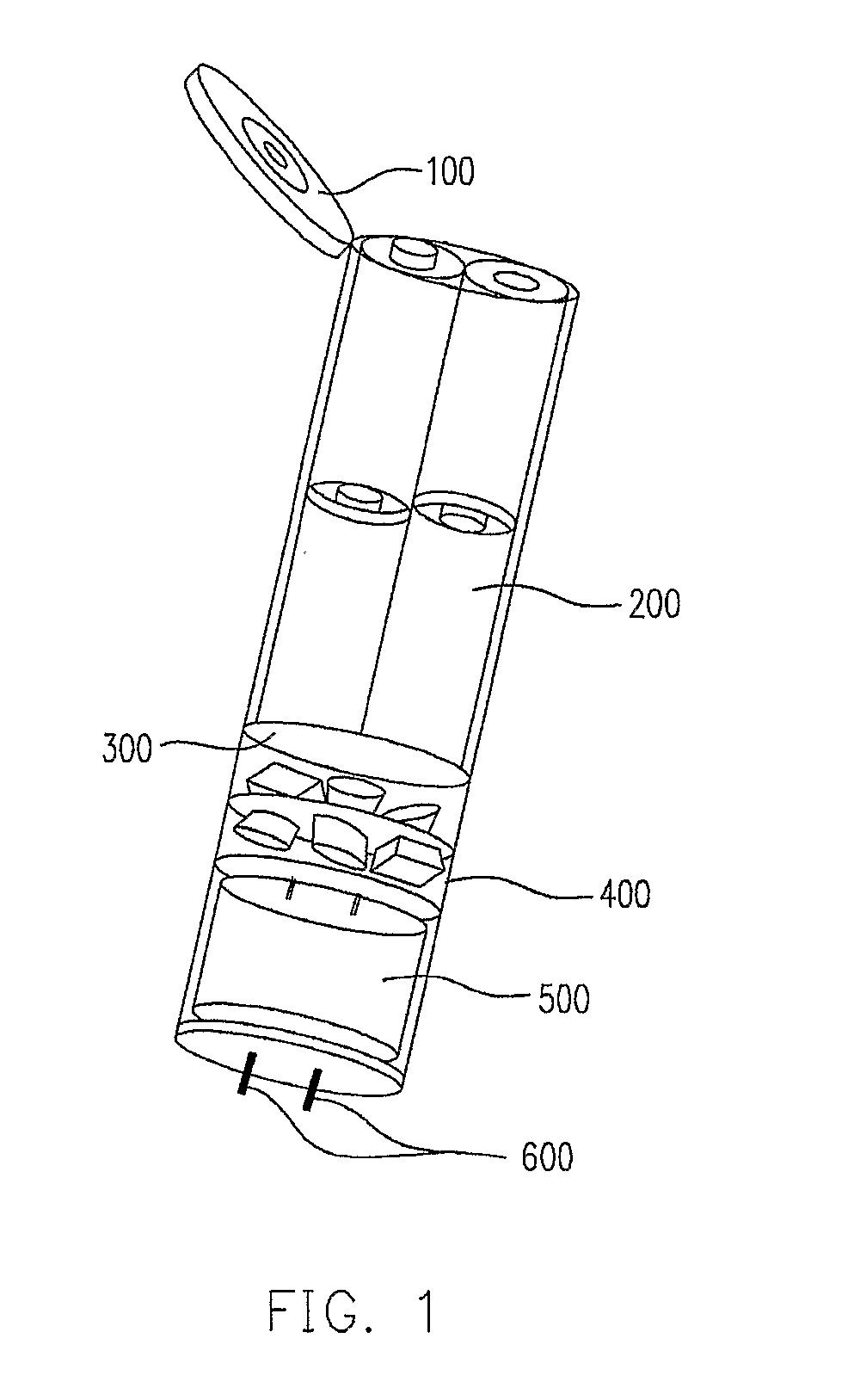

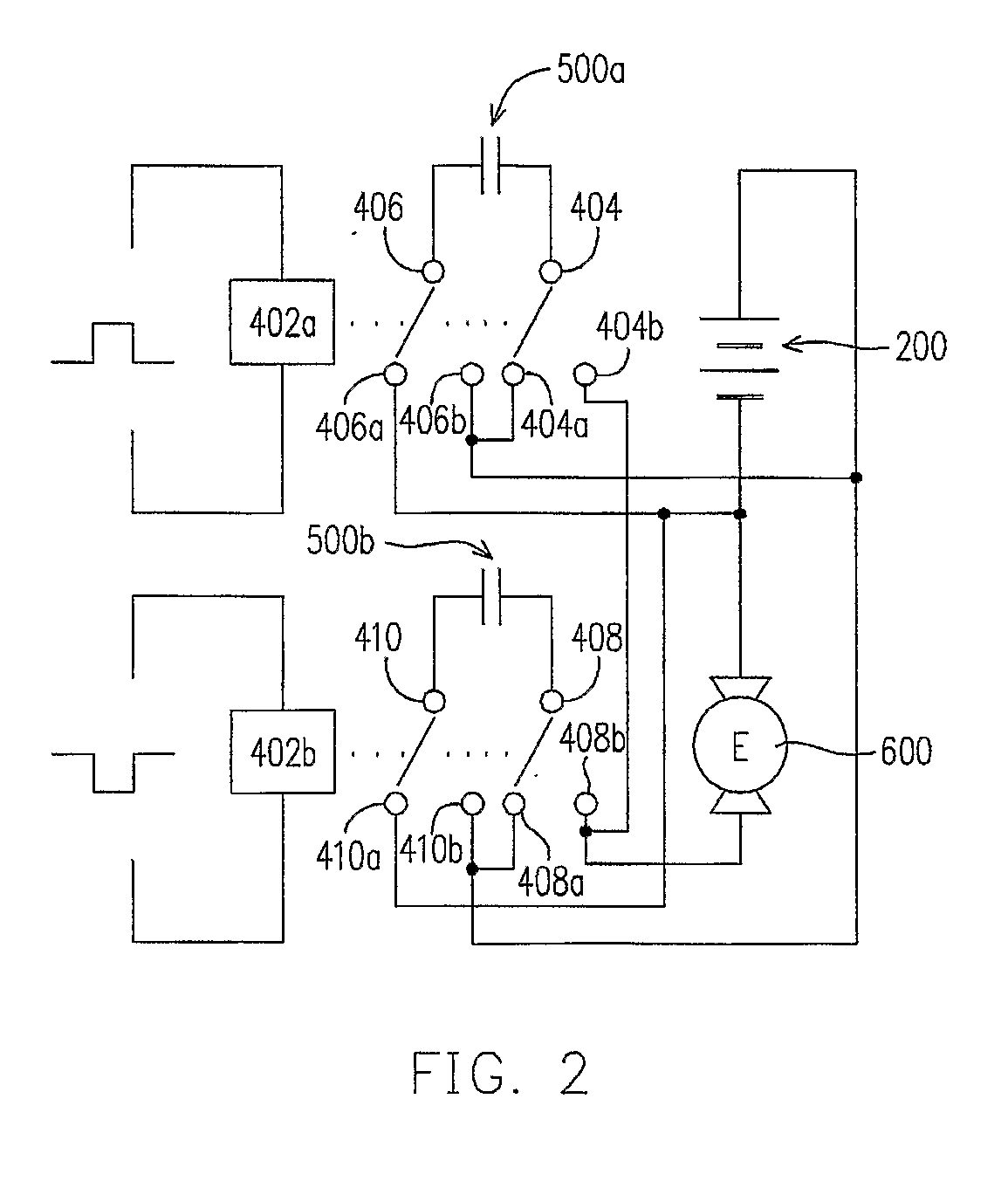

InactiveUS20100135869A1Effective sterilizationEasy to carryElectrical discharge ozone preparationEnergy based wastewater treatmentSupercapacitorEngineering

An ozone generator for in-situ sterilization of water, which may be pocket-sized, is disclosed. The ozone generator includes a power source, at least a supercapacitor, a switching circuitry and at least a pair of electrodes. The power source is adapted for providing a reaction energy to generate ozone gas within the water to be treated. The supercapacitor is adapted for amplifying the reaction energy provided by the power source. The circuitry is adapted for controlling the supercapacitor to deliver consistent power supply to generate ozone. The electrodes are adapted for receiving the amplified reaction energy from the supercapacitor to generate ozone within the water to be treated.

Owner:LINXROSS

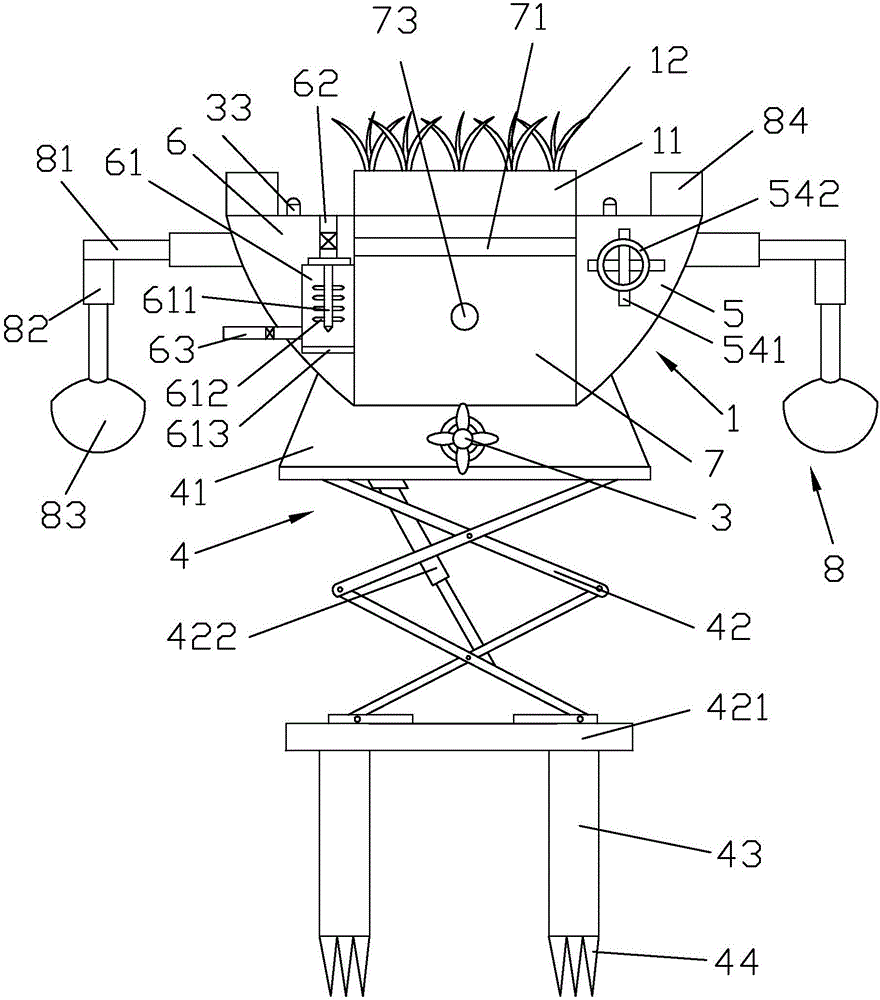

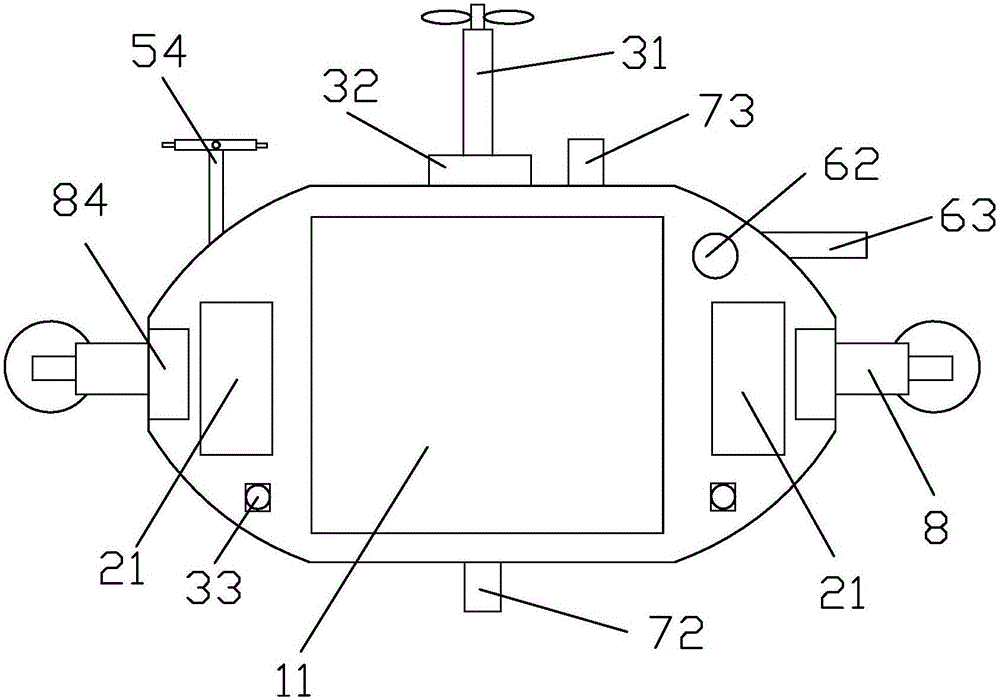

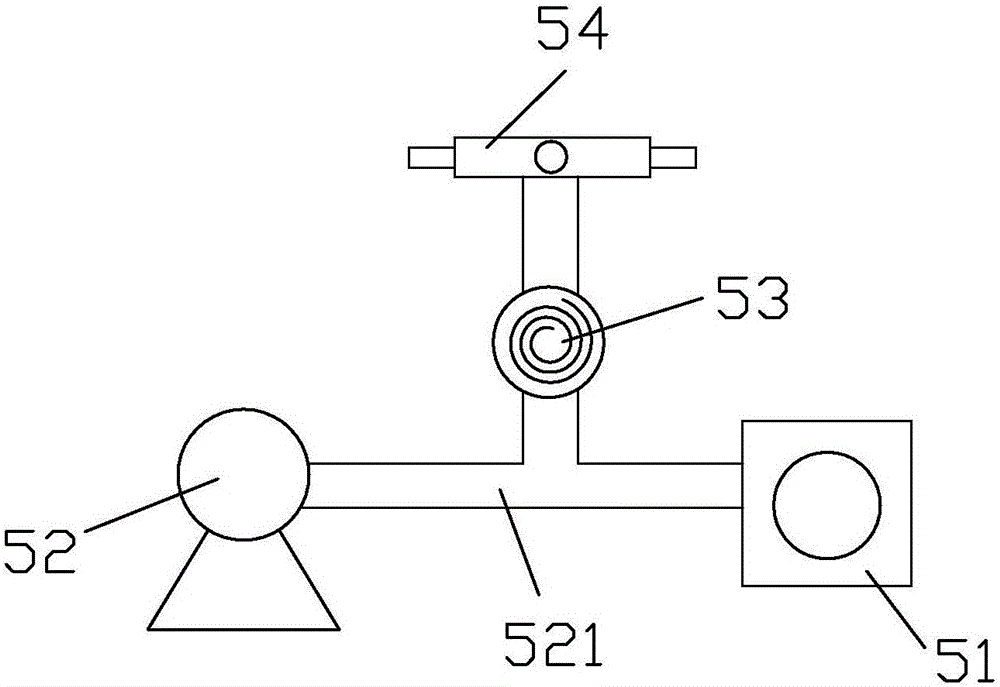

Solar water purifier for lakes and water purification method thereof

ActiveCN106467330AFast dissolutionDrug works wellWater cleaningWater contaminantsSolar waterSolar cell

The invention mainly discloses a solar water purifier for lakes and a water purification method thereof. According to the technical scheme, the solar water purifier comprises a main body, a purification system, an energy system, a drive unit, a lighting device and a fixation device. The energy system comprises a solar cell panel, a storage battery and a charging panel. An oxygenation chamber, a disinfection chamber and a purifying chamber are arranged inside the main body. An ozone generator, an air compressor, a bubble generator and an aerator pipe are disposed inside the oxygenation chamber. A drug blending tank is arranged inside the disinfection chamber. A purifier is disposed inside the purifying chamber. When the device operates, installation and pilot run of the device are firstly carried out. After successful pilot run, the device is put into a lake. By mobile positioning of the drive unit, a water body undergoes disinfection, oxygenation and purification. The energy system provides energy. Thus, energy is self-sufficient. The solar water purifier has a simple structure, is low-cost and clean. By various purification methods, purification efficiency is high. By the floating and stationary combined design, position of the device can be controlled freely. Thus, repair rate of water body is high. The solar water purifier is easy to operate.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

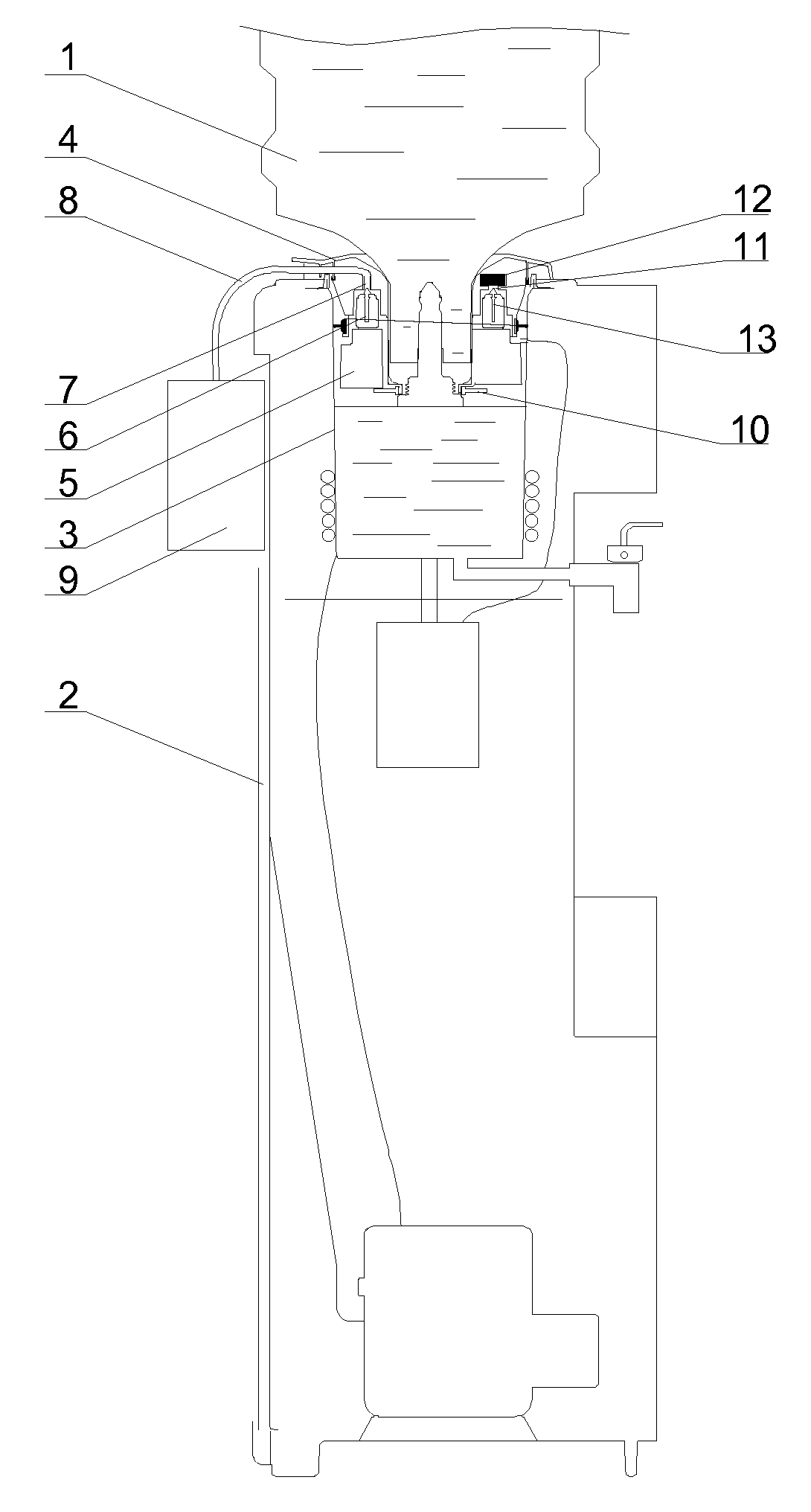

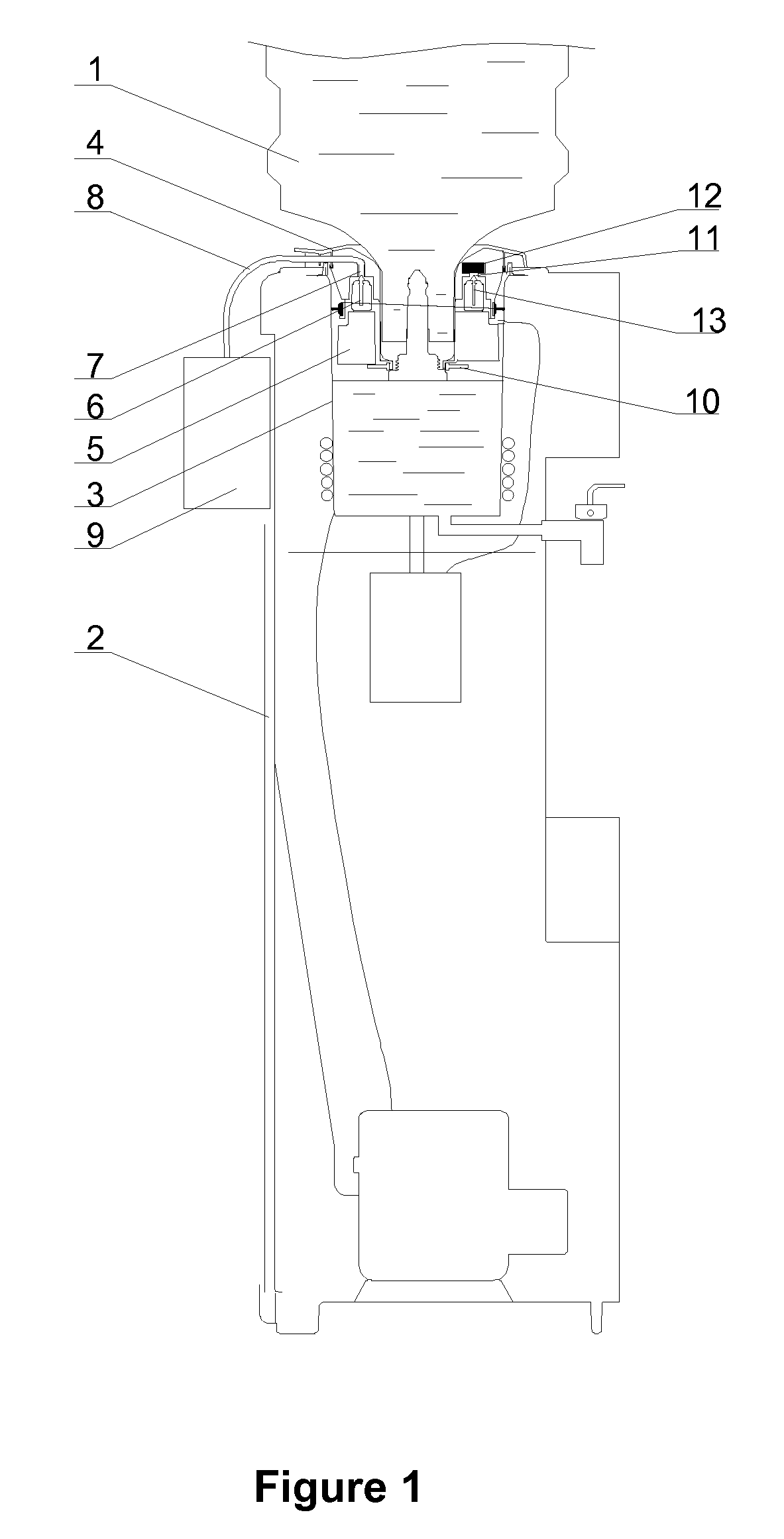

Bottled water cooler with ozone sterilizing device

InactiveUS20100005825A1Effective sterilizationTime indicationDomestic cooling apparatusWater bottleOzone generators

Devices and methods for sterilizing bottled water coolers and water dispensed therefrom. According to certain embodiments, the invention includes a bottled water cooler, which comprises a water bottle, an exterior cabinet, a cold tank, a bottle receptacle located on top of the cold tank that is configured to receive the water bottle in an inverted position, and an ozone generator. The ozone generator is capable of dispensing ozone gas within the space located above a volume of water contained within the cold tank, such that the ozone gas will be effective to sterilize the interior portions of the cold tank located above the volume of water.

Owner:YUI GEORGE M

Fence preservation method for prolonging shelf life of cold fresh poultry

InactiveCN101990930AAntibacterialImprove freshnessMeat/fish preservation using chemicalsBiotechnologyCold chain

The invention discloses a fence preservation method for prolonging shelf life of cold fresh poultry. The fence preservation method for prolonging the shelf life of the cold fresh poultry comprises the following steps of: placing fresh poultry which is obtained by slaughtering, washed completely and cut into a refrigeration storage at the temperature of between 2 and 5 DEG C and precooling the poultry for 1 to 2 hours, so that the surface temperature of the poultry is reduced below 5 DEG C and the internal temperature of the poultry is reduced below 10 DEG C; transferring the precooled poultry to a purification room and performing surface sterilization on the poultry through ozone or ozone solution of an ozone generator; immersing the poultry subjected to ozone sterilization into chitosan glutamate solution to retain freshness; taking out and draining the poultry; placing the poultry after corrosion prevention and freshness preservation into a food plastic packaging box; introducing carbon dioxide (CO2) and nitrogen (N2) into the food plastic packaging box and performing sealing package; and storing the packaged poultry into a cold chain at the temperature of between 2 and 5 DEG C. The fence preservation method for prolonging the shelf life of the cold fresh poultry has good effect and is suitable for retaining freshness of the fresh cut poultry.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

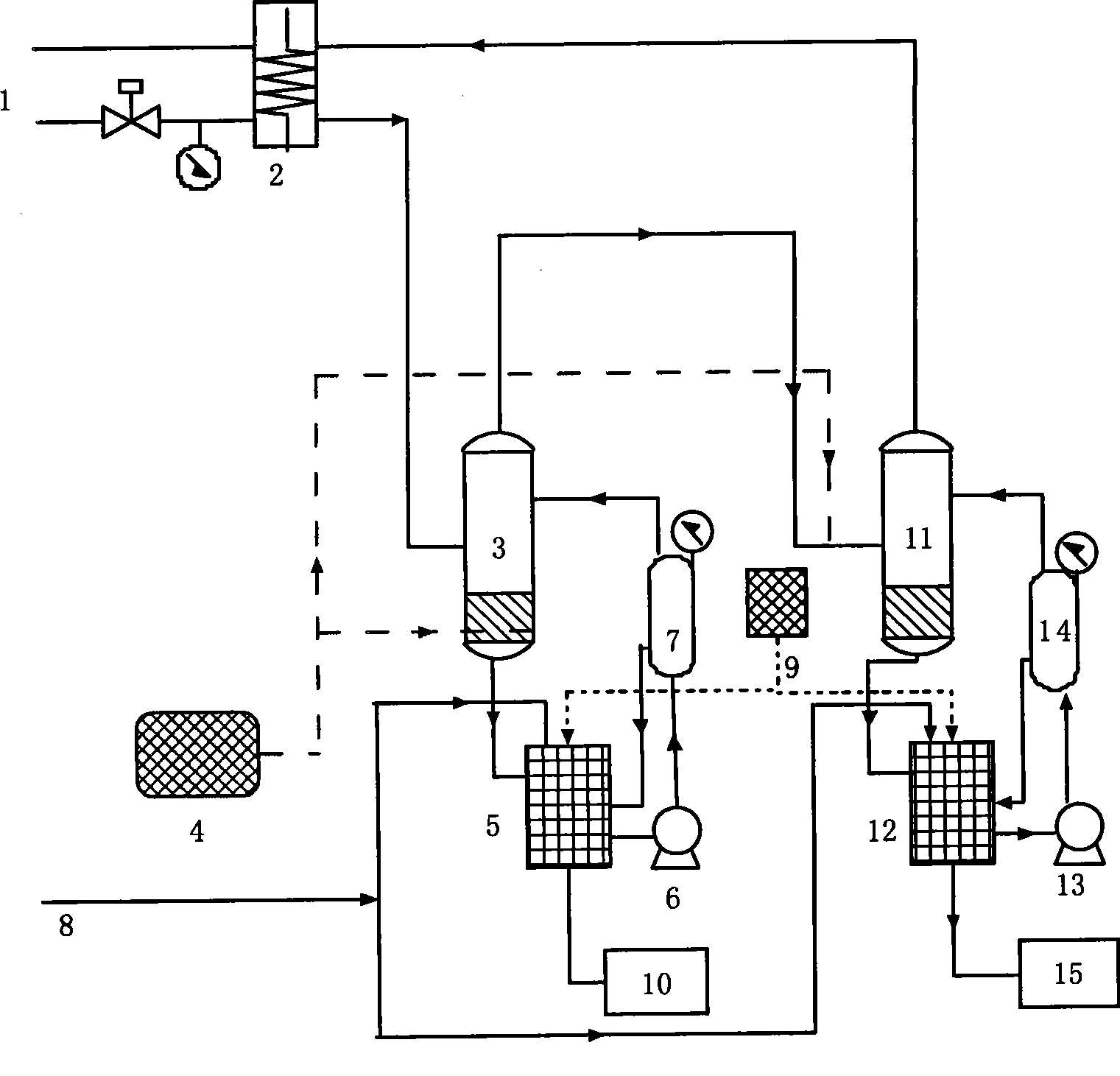

Catalytic ozonation treating apparatus and process for refractory organic wastewater

ActiveCN104003504AGood removal effectIncrease contact surfaceWater contaminantsWater/sewage treatment by oxidationHigh concentrationCo2 absorption

The invention relates to a catalytic ozonation treating apparatus and process for refractory organic wastewater. The apparatus comprises a catalytic oxidation tower, an ozone generator connected with the bottom inlet of the catalytic oxidation tower and a tail gas treating and recycling system connected with the top outlet of the catalytic oxidation tower, wherein the outlet of the tail gas treating and recycling system is connected with the inlet of the ozone generator, and the tail gas treating and recycling system comprises a carbon dioxide absorbing tower, a drying unit and an oxygen storage tank which are successively connected. According to the invention, high-concentration ozone is generated from pure oxygen via the ozone generator, macro-molecular refractory organic pollutants in the organic wastewater is subjected to catalytic ozonation in the catalytic oxidation tower, and tail gas is treated by the tail gas treating and recycling system and then cyclically used as a gas source for the ozone generator; carbon dioxide and steam are removed through the tail gas treating and recycling system, so tail gas is purified, secondary pollution is avoided, the utilization rate of oxygen is improved, and treating cost is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

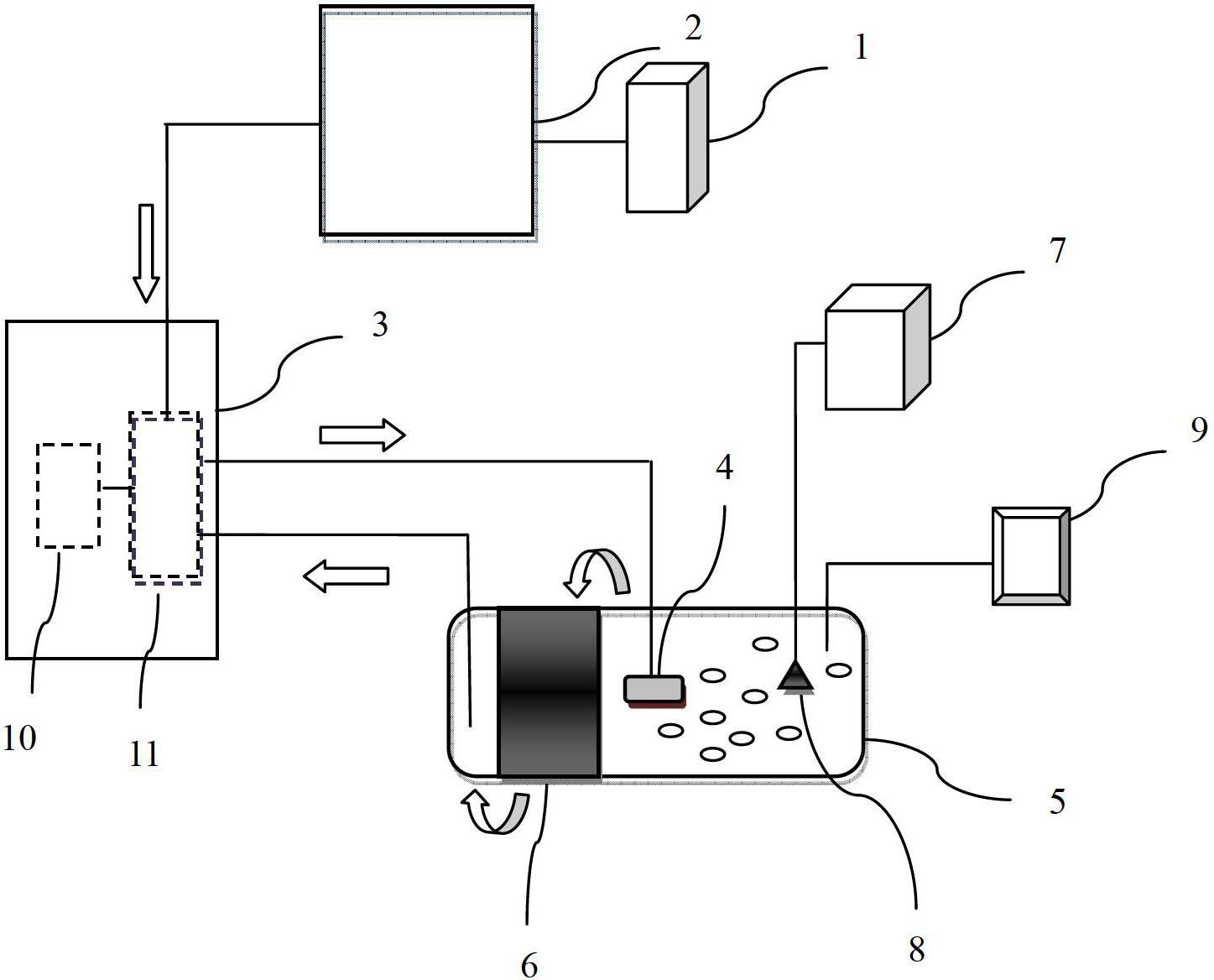

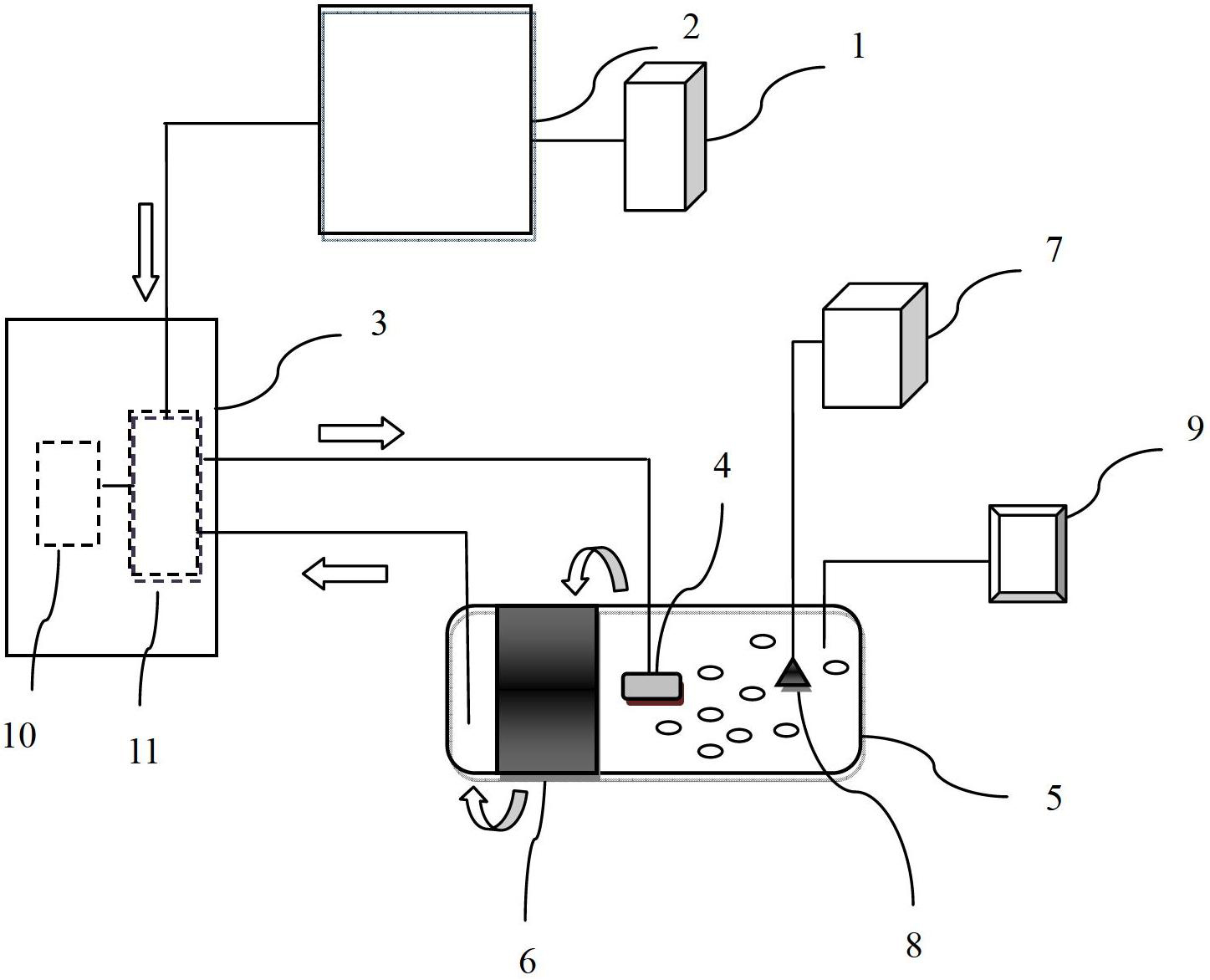

High-concentration and high-salinity nondegradable organic wastewater treatment system

InactiveCN102689978AEasy to handleEfficient degradationWater/sewage treatment with mechanical oscillationsWater/sewage treatment by sorptionHigh concentrationSalinity

The invention provides a high-concentration and high-salinity nondegradable organic wastewater treatment system. Based on the principle of an advanced oxidation technique, synergistic effect is carried out on ozone bubble of micro nanoscale and ultrasonic wave to optimize the ozone dissolving efficiency so that the high-concentration and high-salinity nondegradable organic wastewater can be effectively treated. The high-concentration and high-salinity nondegradable organic wastewater treatment system comprises a micro nanometer bubble generator, a micro nanometer bubble reactor, an ozone generator, an ultrasonic wave generator and an energy converter. The micro nanometer bubble generator comprises a micro nanometer bubble generator host and an aerator; the micro nanometer bubble generator host comprises a gas dissolving device capable of mixing gas liquid under a closed condition and a booster pump connected with the gas dissolving device; an air inlet of the gas dissolving device is connected with the ozone generator; a water inlet is connected with the micro nanometer bubble reactor; a water outlet is connected on the aerator arranged in the micro nanometer bubble reactor; and the micro nanometer bubble reactor is also internally provided with an ultrasonic energy converter connected with the ultrasonic wave generator.

Owner:BEIJING ZHONGNONG TIANLU MICRO NANO BUBBLE WATER S&T

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sterilization garbage bin

InactiveCN101633435AAvoid harmEasy to controlContact operating partsLavatory sanitoryControl switchOzone generators

The invention discloses a sterilization garbage bin which comprises an external garbage bin and an internal garbage bin sheathed inside the external garbage bin, wherein the external garbage bin is provided with a turnover cover, an ozone generator and an ultraviolet emitter are arranged at the inner side of the cover correspondingly to the internal garbage bin, the cover is also provided with work control switches of the ozone generator and the ultraviolet emitter, and the work control switches can cut off power supplies of the ozone generator and the ultraviolet emitter when the cover is opened. The sterilization garbage bin is convenient and practical, thorough in sterilization, and clean and sanitary.

Owner:SHENZHEN KEXINGCHUANG TECH DEV

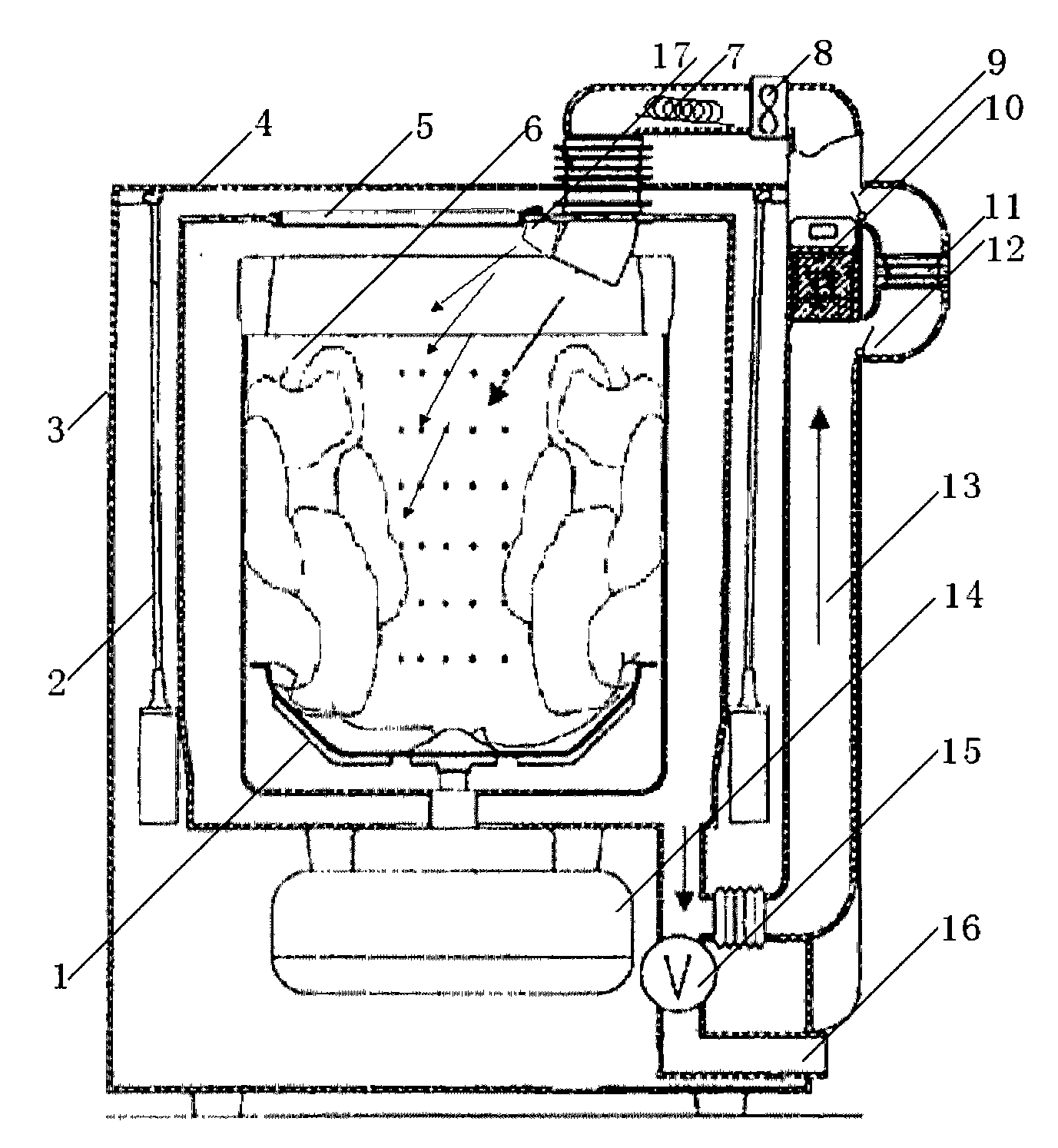

Process for drying by imitating sunlight with drying structure of laundry machine and removing ozone by catalyzed sorption

ActiveCN101285260AEffective dehumidification and dryingEffective disinfectionTextiles and paperChemicalsFiberDry structure

The invention discloses a method for imitating the sun drying and adopting superoxide anion to remove ozone by adopting a drying structure of a washing machine. The drying structure refers to a circulation path of the drying structure of a dryer in the prior art. The inside of the air path for drying clothes is provided with an ozone generator and a catalyzed sorption device. The clothes are irradiated by near infrared rays, far infrared rays and ultraviolet rays. The sunlight is imitated to dry the clothes. After the imitated sun drying is completed, a catalyst is used to absorb the residual ozone in order to remove the ozone which is harmful to human body. The method has the advantages of the function of sterilization, fiber bulking and the ability to be performed all weather and has the effect basically the same as the natural sun drying.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Portable ozone generator and use thereof for purifying water

InactiveUS20090114605A1Efficient purificationReduce the amount of solutionGeneral water supply conservationEnergy based wastewater treatmentRough surfaceOzone generator

The present invention relates to a portable device for generating ozone in water, purifying the water and making it drinkable. The device comprises a housing; at least two electrodes, including an anode and a cathode extending from the housing into the water and each having semi-rough or rough surfaces in contact with the water. The device also comprises a power supply operatively connected to the electrodes for generating between them a difference of potential creating a current and the hydrolysis of the water creating ozone that purifies the water. The electrodes may have a plate or a rode and tube configuration with a plurality of holes with rough edges. The roughness of the surfaces and of the edges of the holes leads to a coalescence of tiny hydrogen bubbles into larger hydrogen bubbles. The hydrogen may be also removed by absorption in a conductive material and regenerated for reuse.

Owner:O3 WATER TECH LLC

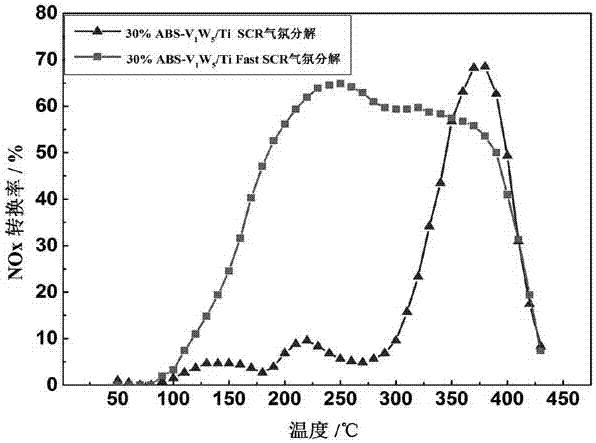

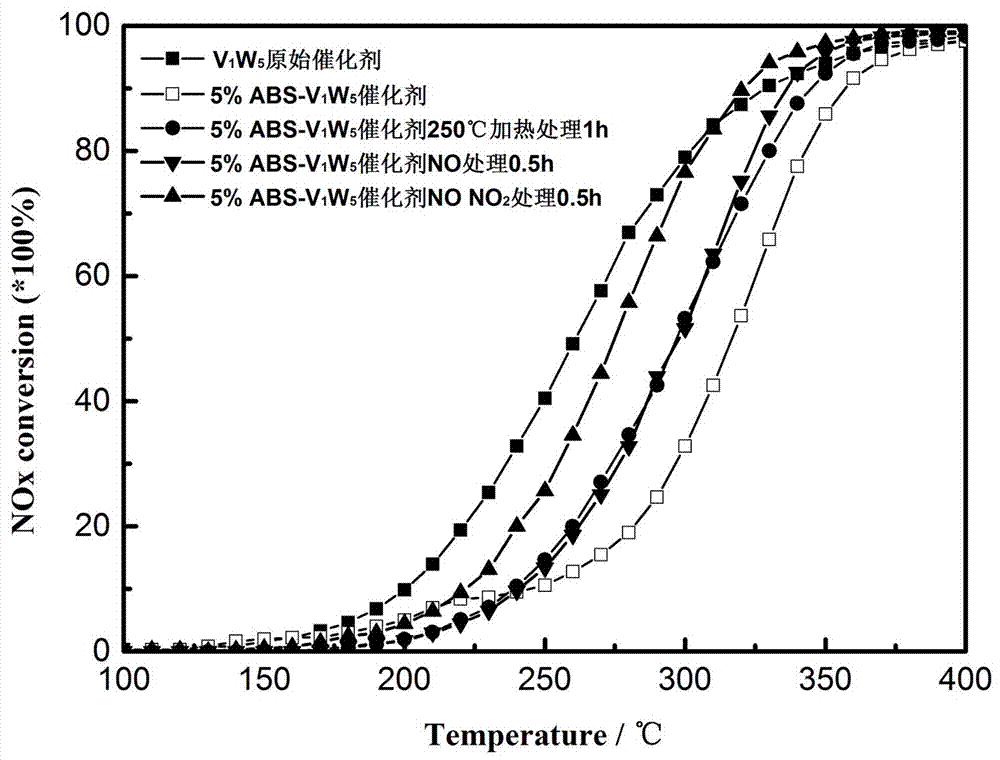

Method and device applied to in-situ regeneration of sulfur-poisoning SCR denitration catalyst

ActiveCN107376930AReduce catalytic activityLower decomposition temperatureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention provides a method and a device applied to in-situ regeneration of a sulfur-poisoning SCR denitration catalyst. The method comprises the following steps: pre-oxidizing part of smoke before entering to an SCR denitration reactor when the SCR denitration catalyst is deactivated by sulfur poisoning, oxidizing part of NO in the smoke, then enabling the smoke to enter into the SCR denitration reactor, accelerating decomposition of ammonium sulfate on the surface of the catalyst, and carrying out regeneration process of the catalyst. The device applied to in-situ regeneration of the sulfur-poisoning SCR denitration catalyst comprises an ozone generator, an electromagnetic valve, an SCR denitration reactor and a smoke NOx component online monitor. The method and the device are capable of effectively decomposing ammonium sulfate deposited on the surface of the catalyst under the condition with temperature of 200-380 DEG C; the activity of the treated sulfur-poisoning catalyst is improved; the service life of the catalyst is prolonged; the replacement cost of the catalyst is reduced.

Owner:CHONGQING UNIV +1

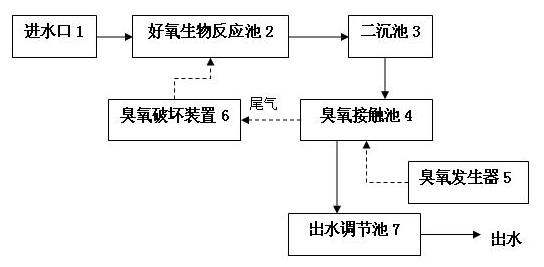

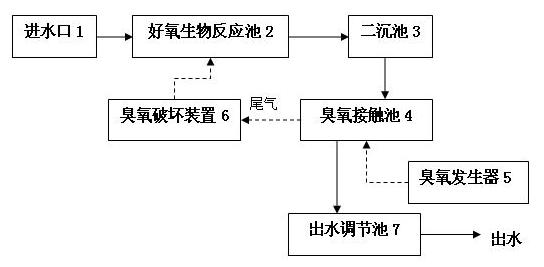

Treatment method of high-chroma chemical waste water

InactiveCN102139995AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentWater/sewage treatment by oxidationActivated sludgeIndustrial waste water

The invention relates to a treatment method of high-chroma chemical waste water, relating to the technical field of industrial waste water treatment. The treatment method comprises the following steps of: (1) inputting the pretreated high-chroma chemical waste water into an aerobic biochemical treatment system for treatment; (2) treating in a solid-liquid separation system; (3) carrying out ozone oxidation treatment in an ozone treatment system comprising an ozone contact pond, an ozone generator, a porous aeration disc and an ozone destruction device; (4) introducing the treated industrial waste water into an outflow water regulation pond for treatment, then discharging, wherein the chroma of the outflow water is 19 degrees (Pt-Co), the content of COD (Chemical Oxygen Demand) is 69 mg / L, and the content of residual ozone contained in a tail gas is 1.7 g / h. The invention has the advantages of more effectively treating the high-chroma chemical waste water by increasing ozone decoloration treatment on the basis of a common activated sludge method and being capable of recycling the tail gas subjected to the ozone decoloration treatment for an aeration pond of the aerobic biochemical treatment system, effectively reducing the treatment cost and enhancing the treatment efficiency of the high-chroma chemical waste water.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com