Patents

Literature

198results about How to "To achieve the purpose of treating waste with waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for jointly repairing heavy metal contaminated soil at mining areas through microorganism-chemical method

ActiveCN103418608AReduce processing costsTo achieve the purpose of treating waste with wasteContaminated soil reclamationContaminated soilsCompound (substance)

The invention provides a method for jointly repairing heavy metal contaminated soil at mining areas through a microorganism-chemical method. According to the method, a method that sulfate-reducing bacteria are adopted to reduce sulfate is adopted to generate hydrogen sulfide which is regarded as a precipitating agent of heavy metal; the heavy metal in soil is transferred into a liquid phase by adopting a surfactant chemical leaching method, sulfate-reducing bacteria liquid is added into soil and the leacheate respectively to transfer residual heavy metal in soil into a stable state from an exchangeable state, so that the purpose of effectively treating heavy metal contaminated soil at the mining areas is achieved. The treatment method provided by invention is low in cost, the process is convenient and simple, and easy to operate and control, the environmental pollution is less, the treatment effect is good, and the method has a wide industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low-temperature ceramic curing agent of red mud from Bayer process

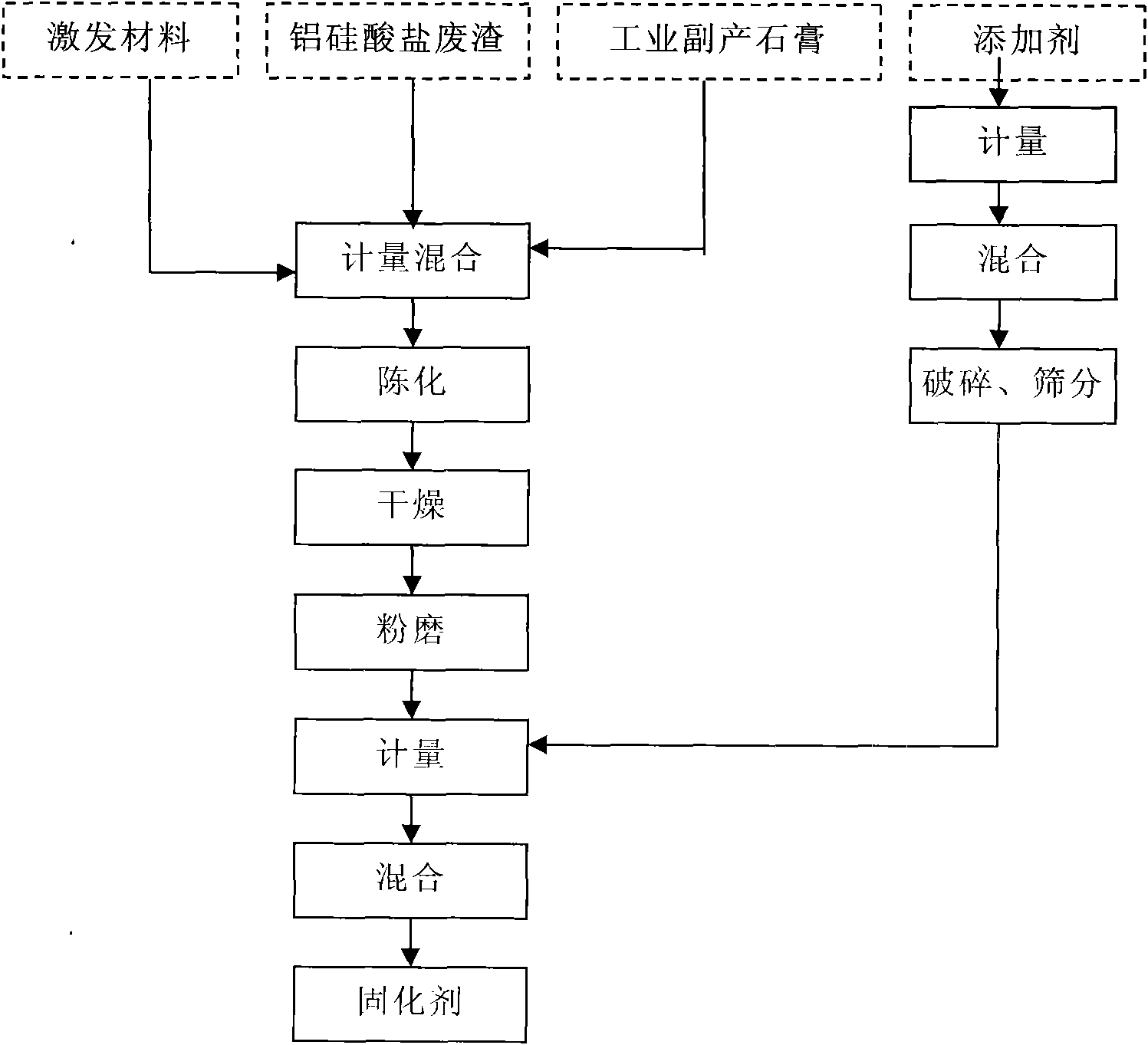

The invention relates to a low-temperature ceramic curing agent of red mud from a Bayer process. The low-temperature ceramic curing agent is prepared by the following raw materials by weight parts: 100 aluminosilicate residues, 20-150 industrial by-product gypsum, 50-200 excited materials, 0-3.0 water-reducing agent, 0-5.0 flocculating agent and 0-5.0 retarder. The production method thereof comprises the following steps: (1) processing main raw materials; (2) preparing additives; and (3) preparing a curing agent. The invention has the beneficial effects that (1) all components of the curing agent can irreversibly react with the red mud; compared with the prior gelled material, the invention does not use cement, base excited materials and expensive high molecular polymers, thereby achieving low cost; (2) the invention uses the industrial residues as the raw materials to cure the red mud so as to achieve the aim of treating a waste with another waste; no secondary waste is exhausted in a production process and an application process so as to benefit environmental protection; and (3) the invention can thoroughly solve the safety problem of a red mud library after curing the red mud.

Owner:山西鑫秀工矿废渣利用有限公司 +1

A treating method of waste cathode charcoal blocks

InactiveCN106166560ARealize harmless treatmentEliminate pollutionSolid waste disposalSolid fuelsElectrolysisSlag

A treating method of waste cathode charcoal blocks is provided. The waste cathode charcoal blocks are from electrolytic tank heavy maintenance slag of an electrolytic aluminium factory. The method includes treating the electrolytic tank heavy maintenance slag to obtain powdered waste cathode charcoal blocks, subjecting the powdered waste cathode charcoal blocks to water leaching to obtain a leachate and cathode charcoal blocks after leaching, performing solid liquid separation after the leachate and a fluorine removal agent are subjected to a curing reaction, returning the filtrate to the leaching step for circulated use, and stacking filter cakes or adopting the filter cakes as a raw material for preparing calcium fluoride. The method adopts a manner of a plurality of times of leaching, thus achieving innocent treatment of the waste cathode charcoal blocks. The filtrate and the filter cakes after leachate treatment can be reused, and the cathode charcoal blocks after leaching can be adopted as fuel for producing alumina. The method overcomes a series of problems caused by stacking of a large amount of the waste cathode charcoal blocks, achieves efficient utilization of the waste cathode charcoal blocks, and is obvious in economic benefit and suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Method for curing lake dredged sediment containing heavy metal

InactiveCN103086670AShort maintenance timeReduce moisture contentSludge treatmentWater contaminantsResource utilizationPlastic film

The invention belongs to a treatment method of solid waste in environmental engineering, and particularly relates to a method for curing lake dredged sediment containing heavy metal. The method is characterized by comprising the steps of adding a curing agent prepared from waste gypsum, coal ash and cement in a mixing manner to lake dredged sediment containing heavy metal, evenly stirring, and covering a plastic film on the surface for molding for 1-3 days; and maintaining for 2-10 days under the conditions that the temperature is 20+ / -(3-6) DEG C and the relative humidity is 70-100% to obtain a solidified clod of which the unconfined compression strength is greater than or equal to 170.6kpa, wherein the weight ratio of the waste gypsum to the coal ash to the cement is 1 to (0.5-10) to (1-15); and the adding amount of the curing agent is 3-20% of mass of the lake dredged sediment containing the heavy metal. Industrial wastes such as the coal ash, the waste gypsum and the like are taken as curing agent materials of heavy metal polluted sediment; and resource utilization of the wastes such as the polluted sediment, the coal ash and the waste gypsum is achieved, so as to achieve the target of treatment of wastes with processes of wastes against one another.

Owner:HUBEI POLYTECHNIC UNIV

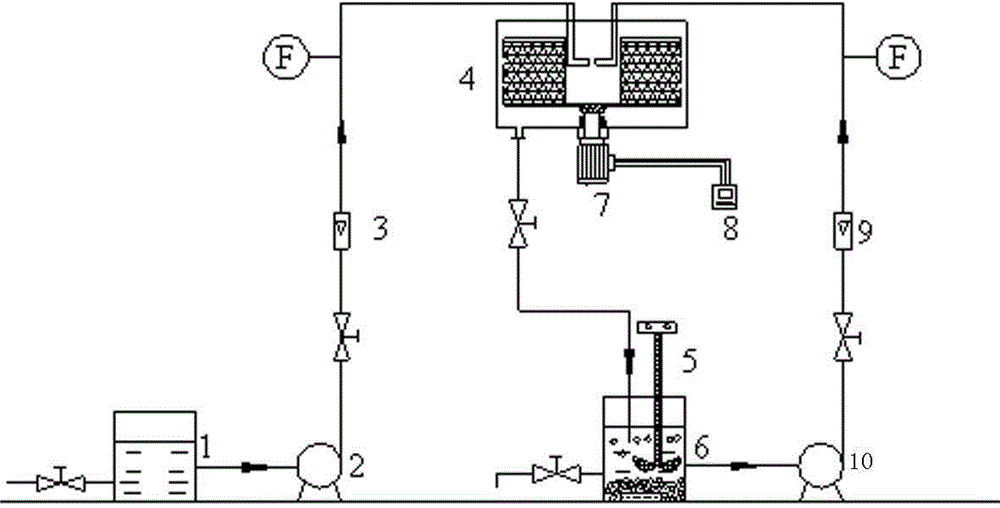

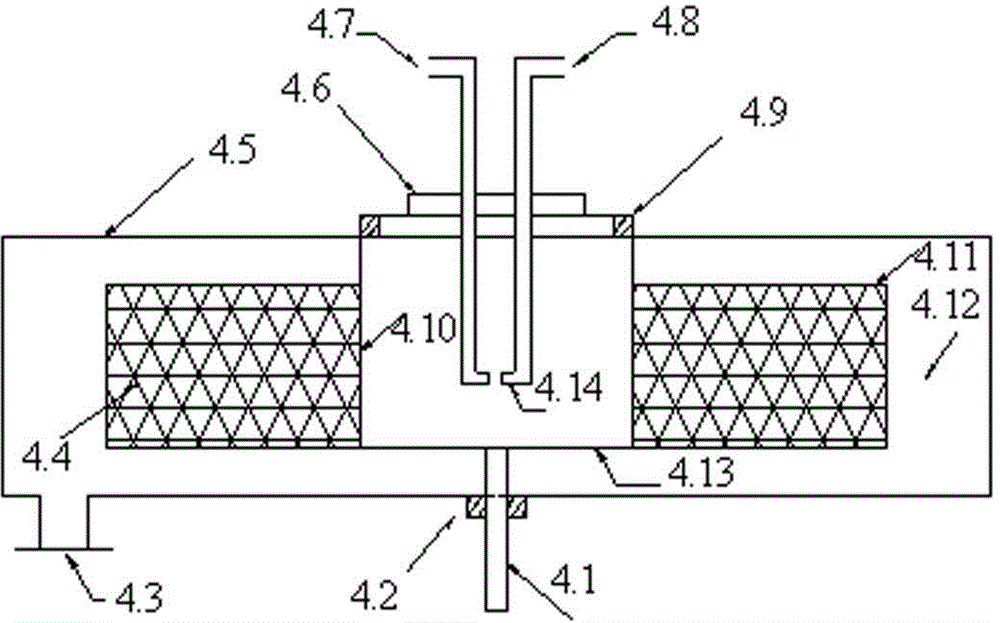

Method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater

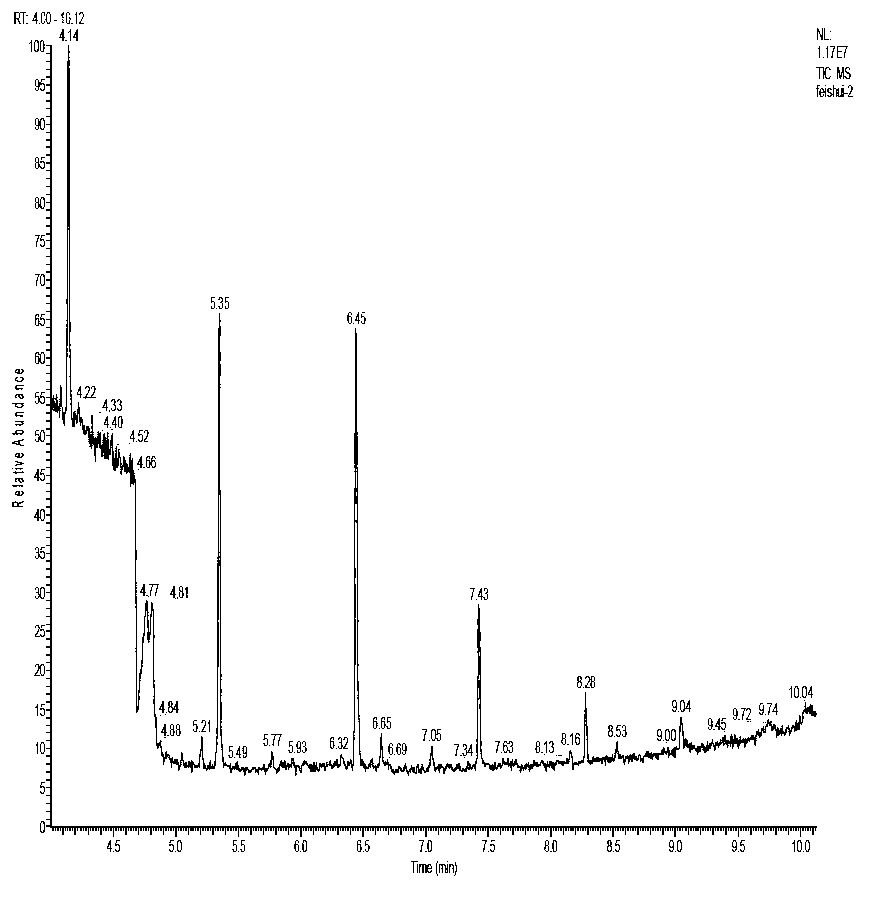

ActiveCN103145273ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater contaminantsMultistage water/sewage treatmentOzone generatorGas liquid reaction

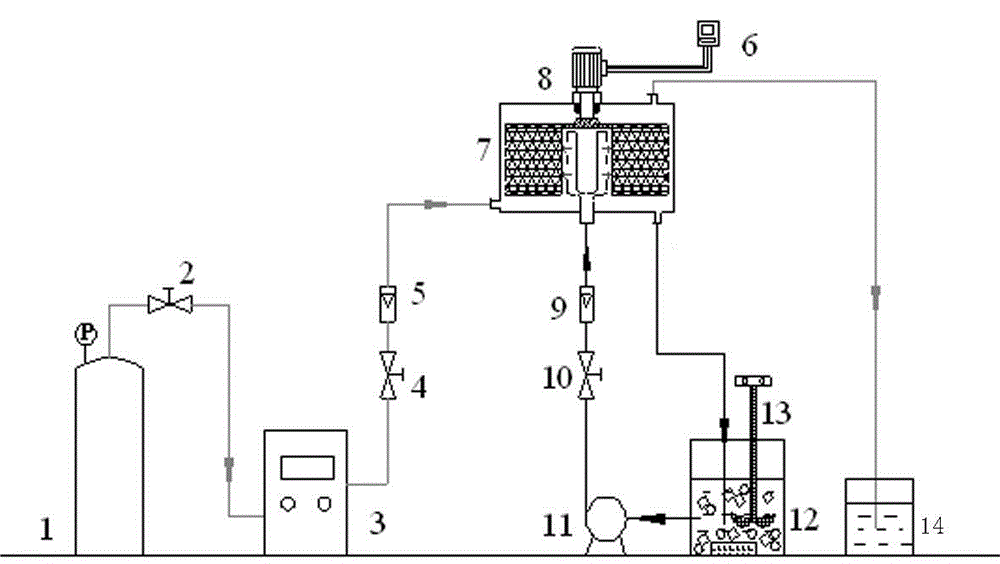

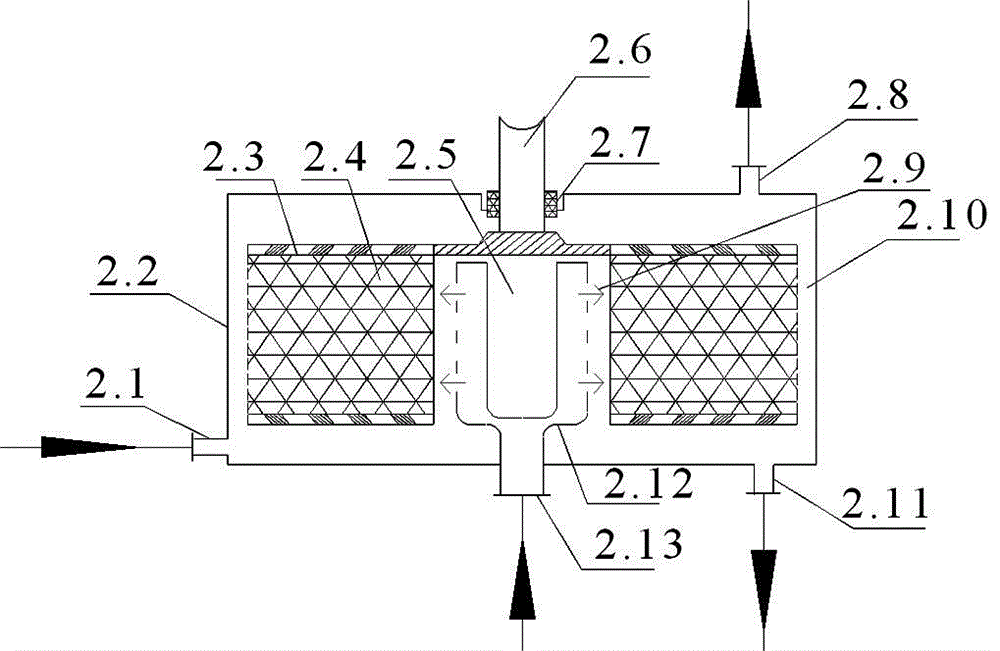

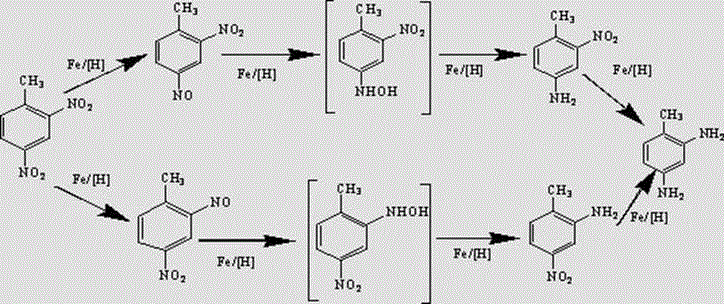

The invention belongs to the technical field of nitrobenzene wastewater, in particular relates to a method and device for adsorbing, reducing, oxidizing and degrading nitrobenzene wastewater, and solves the problem of the existing method for degrading nitrobenzene wastewater. The method comprises the following steps of performing a reduction reaction on nitrobenzene wastewater in a micro-electrolysis bath; performing a sufficient contact reaction with ozone in gas-liquid reaction equipment; further degrading pollutants in the wastewater in the gas-liquid reaction equipment; and circularly treating the wastewater in the micro-electrolysis bath and the gas-liquid reaction equipment. The device comprises a rotary packed bed device, wherein a gas inlet is connected with an ozone generator; and a liquid inlet and a liquid outlet are connected with the micro-electrolysis bath. The method and the device have the beneficial effects that the process flow is simple and convenient to operate; the advantages of various technologies are given a full play by coupling the three technologies to reach the aim of treating waste by using waste, so that the treatment cost can be furthest reduced.

Owner:ZHONGBEI UNIV

Method of comprehensive utilization of industrial waste acid and ardealite

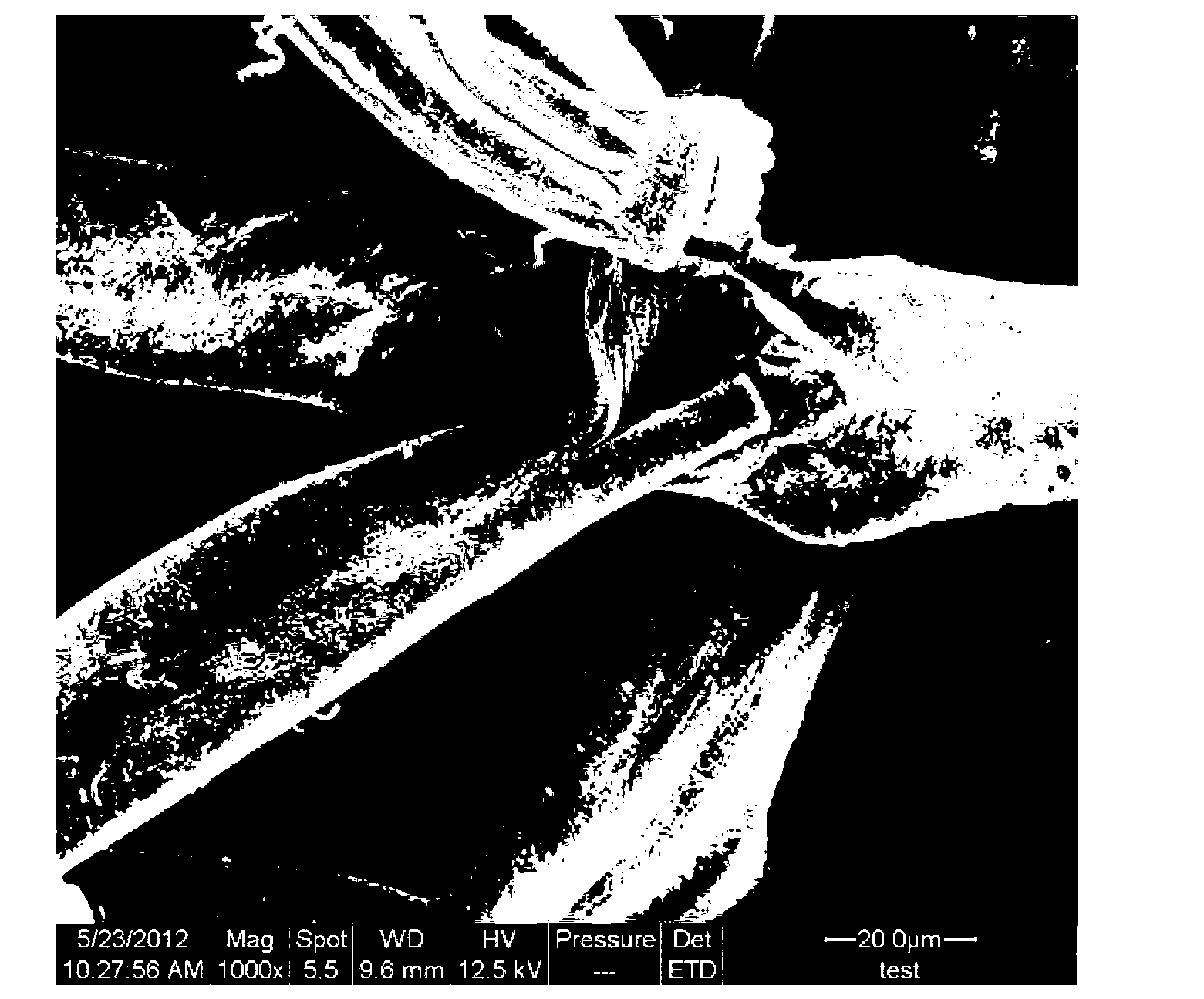

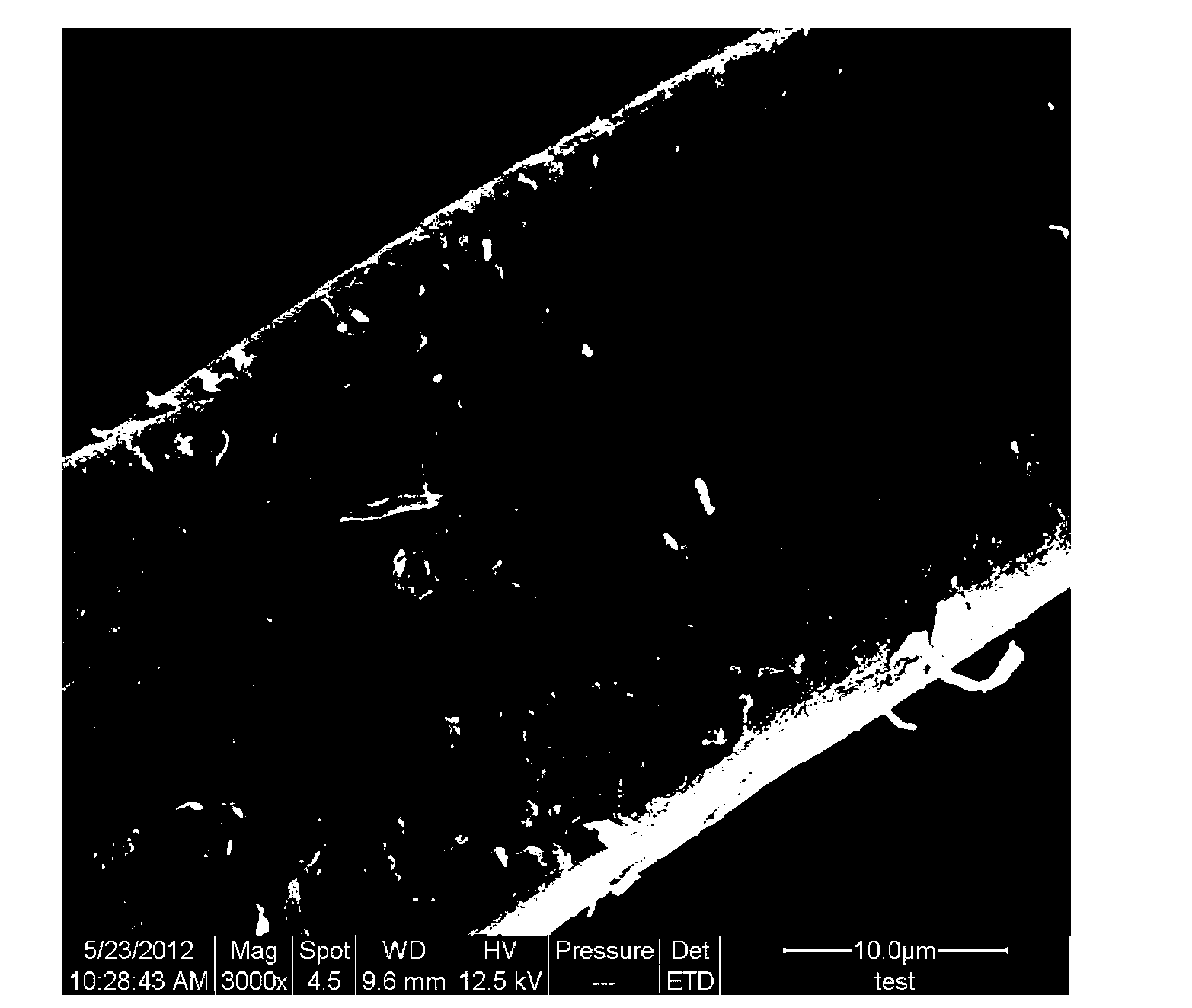

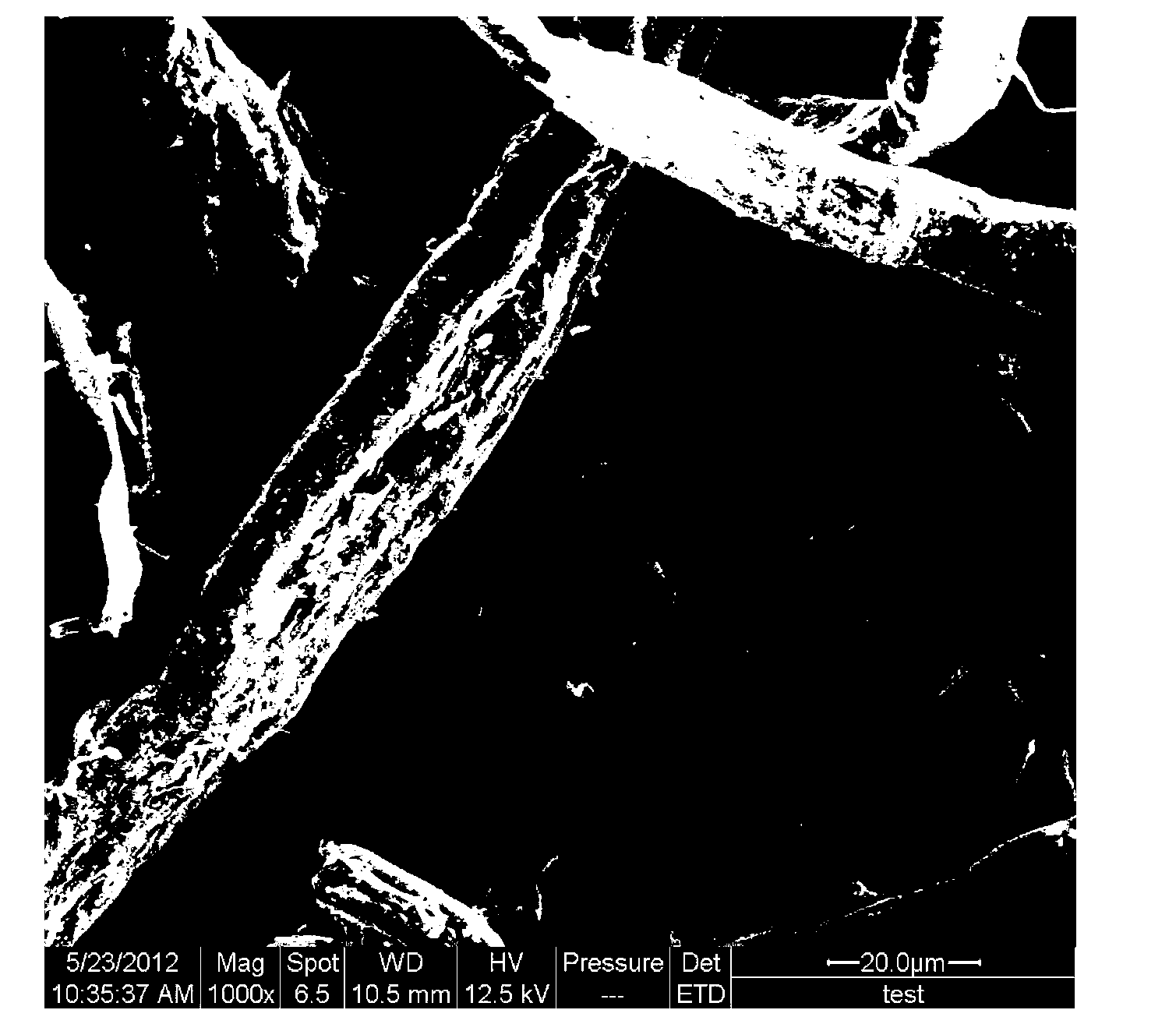

ActiveCN102383179AImprove economic benefitsUniform lengthPolycrystalline material growthFrom normal temperature solutionsChemistryIndustrial waste

The invention provides a method for preparing calcium sulfate crystal whisker with industrial waste acid and ardealite, which comprises the following steps: mixing ardealite and industrial waste acid, adjusting pH of the solution with ammonia water, and then stirring; immediately filtering the solution, cooling the filtrate, all crystal being separated out, and performing conventional stabilizing process on the surface of the crystal; and then drying, and obtaining calcium sulfate crystal whisker. The diameter of the obtained calcium sulfate crystal whisker is 1-4mum, the length is 50-200mum, the moh's hardness is 3-4, the tensile strength is 20.5Gpa, the elastic modulus is 178GPa, and the refractive index is 1.585. With the invention, industrial waste acid and solid waste ardealite can be utilized, the waste product of the two kinds of industries can be utilized, so the goal of treatment of wastes with processes of wastes against one another can be achieved; exploitation of natural gypsum can be reduced, resource can be saved, and meanwhile the production cost of calcium sulfate crystal whisker can be reduced; and the limit on the ingredients of the raw material ardealite and industrial waste acid is not strict, the application range is wide, the condition is wide, and the process is simpler.

Owner:KUNMING UNIV OF SCI & TECH

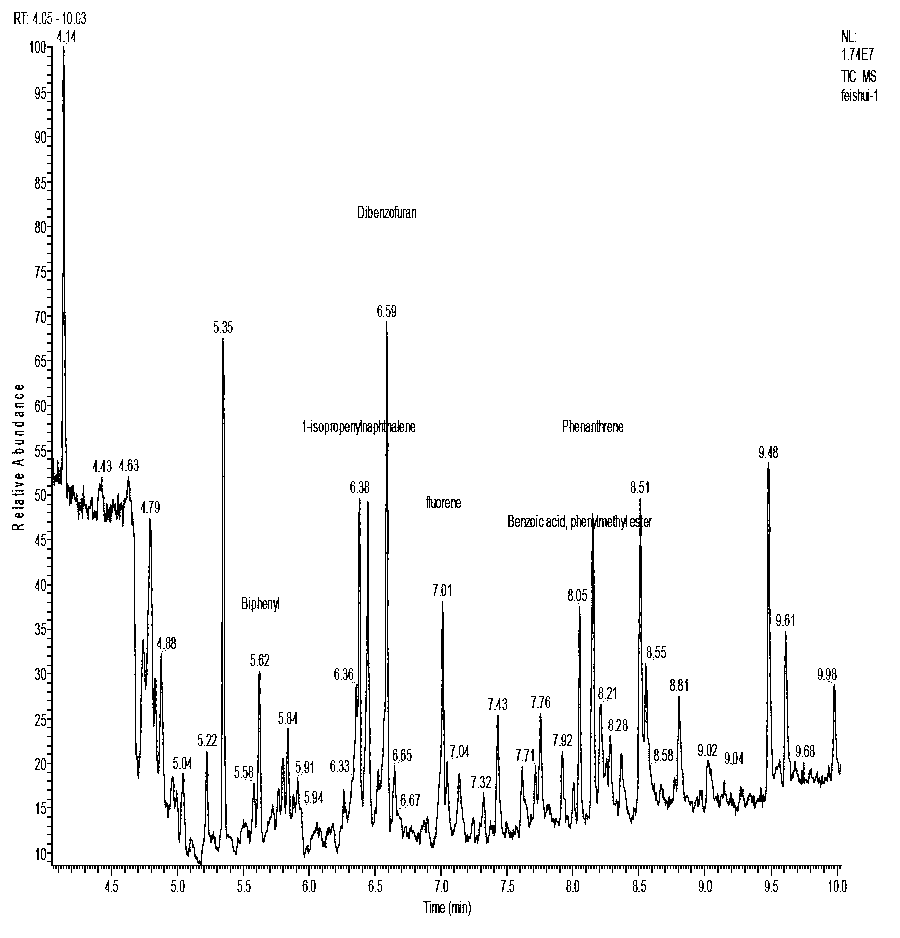

Treatment method of mine wastewater

InactiveCN102079594AImprove removal efficiencyLess quantityMultistage water/sewage treatmentWater qualityWastewater

The invention relates to a treatment method of mine wastewater. The method comprises the following steps: (1) mixing acidic mine wastewater and flotation wastewater in a volume ratio of (1:1)-(2:1), stirring to mix the wastewater uniformly, adding H2O2, continuously stirring to react, and then standing for layering; and (2) taking the layered supernatant, adding lime milk to adjust the pH value of the wastewater to 6.0-8.0, adding a polyacrylamide (PAM) solution after the generation of precipitates, stirring, and standing for layering to obtain a supernatant which can be discharged according to the standard. By utilizing the method provided by the invention, the defects of the prior art can be overcome, the quality characteristics of raw water is fully utilized, and waste is treated with waste; and the pollutants in the water can be removed efficiently, the cost is low, and the method has a good application prospect.

Owner:DONGHUA UNIV

Method for preparing chlorine-removal alkali residue mixture by utilizing alkali residues through ammonia-soda process and application of chlorine-removal alkali residue mixture

ActiveCN104190690AImprove dechlorination effectReduce Chloride ContentSolid waste managementSolid waste disposalChlorideEthyl Chloride

The invention discloses a method for preparing a chlorine-removal alkali residue mixture by utilizing alkali residues through an ammonia-soda process. The method comprises the following steps: step 1, crushing returned sand and returned stones, and grinding to obtain returned sand and returned stone powder; step 2, soaking the returned sand and returned stone powder in water for 0.5-14 days, digesting overburnt calcium oxide, mixing the digested returned sand and returned stone powder, alkali residues and water, wherein a ratio of dry mass of the digested returned sand and returned stone powder to the alkali residues is 2:8 to 5:5 based on the mass percentage of the materials, and the total mass of the water is 1.5 to 8 times that of total dry mass of the digested returned sand and returned stone powder and alkali residues; or mixing the returned sand and returned stone powder, the alkali residues and water, soaking the mixture for 0.5-14 days, and digesting the overburnt calcium oxide; and step 3, performing filter pressing treatment, thereby obtaining the chlorine-removal alkali residue mixture of which the chloride ion content is lower than 0.30 percent of the total mass of solids in the mixture. The invention also discloses application of the chlorine-removal alkali residue mixture. The method and application disclosed by the invention are good in chlorine removal effect, simple in process, energy-saving and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

Method and device for treating wastewater by intensified micro-electrolysis-Fenton oxidation method

ActiveCN103145275ATo achieve the purpose of biochemicalReduce processing costsMultistage water/sewage treatmentIndustrial waste waterElectrolysis

The invention belongs to the technical field of industrial production wastewater treatment, in particular relates to a method and device for treating wastewater by an intensified micro-electrolysis-Fenton oxidation method, and solves the problem of an exiting industrial wastewater treatment method. The method comprises the following steps of performing micro-electrolytic reduction reaction on wastewater; and performing impact between the wastewater and hydrogen peroxide in liquid-liquid reaction equipment, wherein Fe<2+> in the waste water and hydrogen peroxide form a Fenton reagent; and organic pollutants in the wastewater are degraded under the synergic action of the micro-electrolysis-Fenton reagent. The device comprises an impinging stream-rotary packed bed device, wherein the liquid inlet tube I and the liquid inlet tube II of the impinging stream-rotary packed bed device are respectively connected with a hydrogen peroxide storage tank and a micro-electrolysis bath; and the liquid outlet is connected with the micro-electrolysis bath. The method and the device have the beneficial effect that process flow is simple and convenient to operate; the advantages of various technologies are given a full play by coupling the three technologies to reach the aim of treating waste by using waste, so that the treatment cost can be furthest reduced.

Owner:ZHONGBEI UNIV

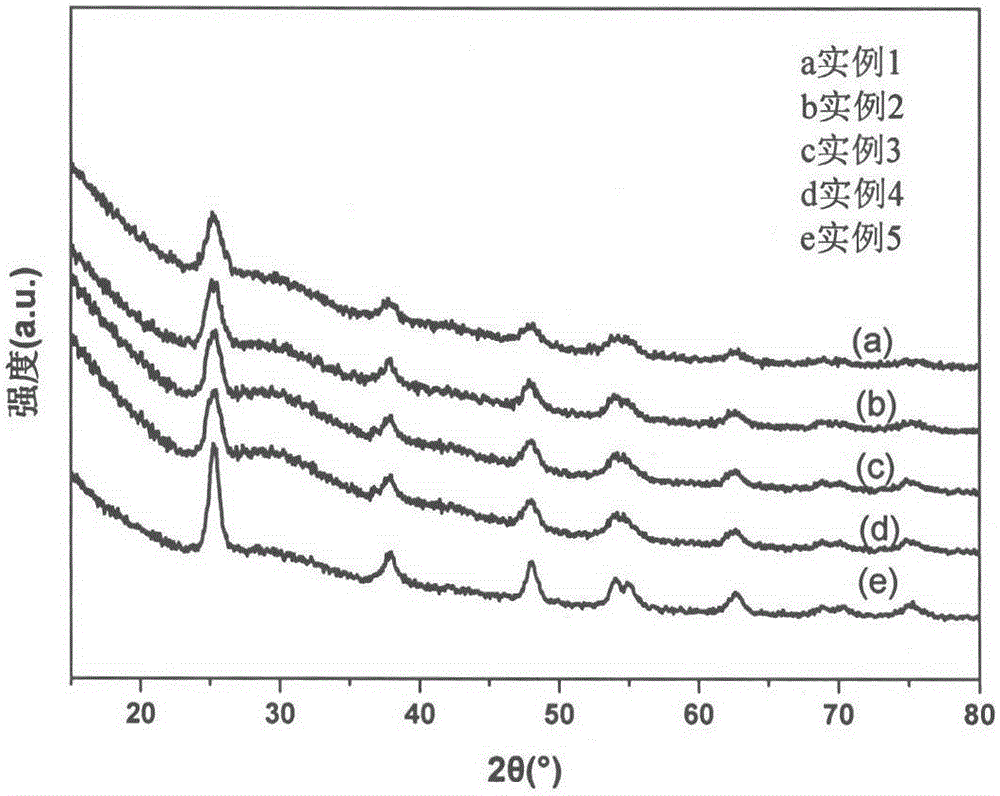

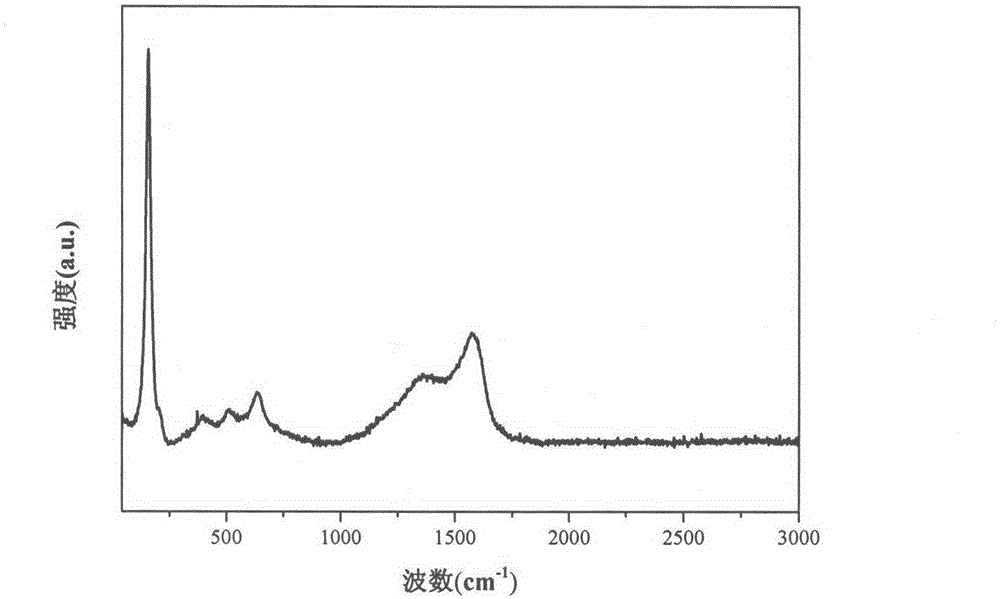

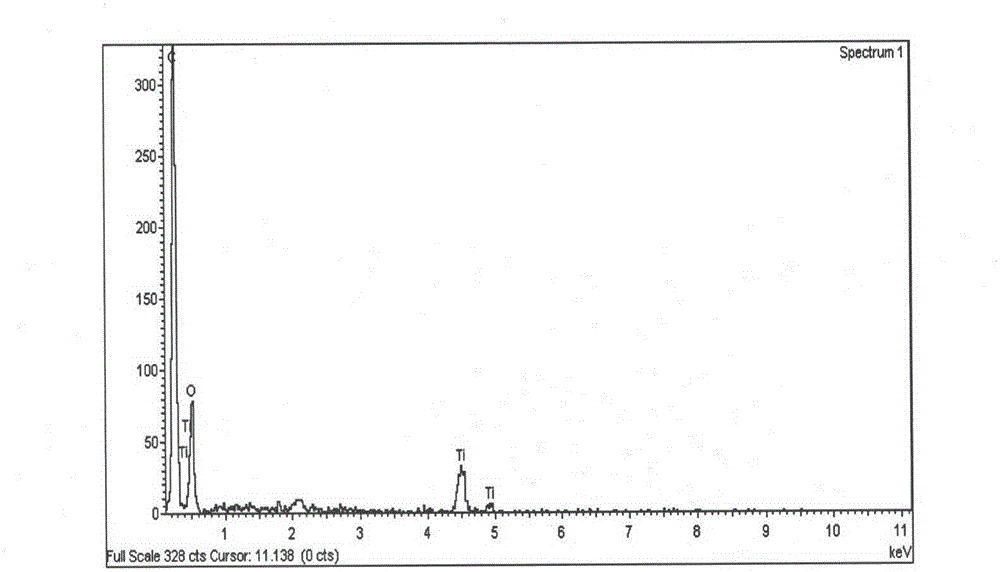

Method for preparing titanium dioxide loaded biomass carbon aerogel material

InactiveCN106390970AAbundant raw materialsLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationBiomass carbonMaterials preparation

The invention belongs to the technical field of material preparation and particularly relates to a method for preparing a titanium dioxide loaded biomass carbon aerogel material. According to the method, natural plant tissue such as watermelon peels serves as a raw material, and biomass carbon aerogel is prepared by a hydrothermal method in combination with a freeze-drying technique. The titanium dioxide loaded biomass carbon aerogel composite material is prepared through uniformly stirring titanium sulfate and the biomass carbon aerogel in distilled water and then carrying out a hydrothermal reaction. The diameter of the titanium dioxide loaded biomass carbon aerogel material prepared according to the method disclosed by the invention is 0.7 to 0.9 micron. The method has the following advantages that natural wastes serve as the raw material, so that the cost is low, and the efficient resource utilization of the wastes is achieved; and the preparation process is simple, the operation is simple and convenient, the requirements on environment-friendliness are met, and the wastes are treated with the wastes, so that mass production is facilitated.

Owner:镇江华科生态电镀科技发展有限公司 +1

Process for dehydrating activated sludge by waste alkaline residue/alkali liquor

InactiveCN101289268AImprove dehydration efficiencyEnable reuseSludge treatment by de-watering/drying/thickeningClimate change adaptationActivated sludgeSlag

The invention discloses a method for dewatering activated sludge by utilizing waste alkali slag / alkali liquor. The method of the invention mainly includes that the waste alkali slag / alkali liquor is first added with a certain amount of calcium oxide to be evenly mixed and then injected into activated sludge which goes through gravity settling, and evenly mixed; fully-dissolved polyacrylamide is then added and evenly mixed; the dry basis ratio of alkali slag, calcium oxide, polyacrylamide and activated sludge is 25 to 40 : 7 to 13 : 0.12 to 0.25:100; after being fermented and air-dried, dewatered sludge is served as agricultural fertilizer. The dewatering method of the invention has the advantages of low cost, high efficiency of sludge dewatering, good stability and low content of heavy metal in yielding sludge and achieves the purpose that the waste alkali slag is recycled to treat the waste by the waste; in addition, the alkali slag contains the elements of calcium, magnesium and a small amount of sodium, potassium, chloride, etc., which are necessary for the plant growth and can be used for making fertilizer in the agricultural production.

Owner:李肇忠

Steel slag-desulfurized gypsum based soil solidification agent applicable to arsenic contaminated soil

InactiveCN106467745AReduce the amount of blendingSmall increase ratioContaminated soil reclamationOrganic fertilisersSlagGypsum

The invention discloses a steel slag-desulfurized gypsum based soil solidification agent applicable to arsenic contaminated soil. The soil solidification agent contains the ingredients in percentage by weight: 40% to 45% of steel slag, 15% to 25% of desulfurized gypsum, 22% to 30% of slag, 7% to 10% of cement clinker and 3% of excitant. According to the soil solidification agent disclosed by the invention, arsenic is solidified and stabilized mainly by means of chemical wrapping and in-phase replaced solidifying, and the age of a solidifying reaction can be shortened and the mixed amount of the solidification agent and solidified volume increase ratio in engineering applications can be lowered while a solidifying effect is guaranteed, so that the solidifying efficiency is increased greatly.

Owner:WUHAN UNIV

Method for preparing ceramicadsorption material by using fly ash

InactiveCN106215854AAlleviate pollution problemsImprove adsorption performanceOther chemical processesWater contaminantsWaste productionPulverised fuel ash

The invention provides a method for preparing a ceramicadsorption material by using fly ash. The method comprises the steps that 1, fly ash and a pore forming agent are weighed and are mixed evenly; 2, caustic soda flakes and water glass are weighed, mixed and stirred till the caustic soda flakes are completely dissolved, and cooling is performed to obtain analkaliactivator; 3, the alkaliactivator is added while the powder in the step 1 is stirred, and semi-dried mixed powder is obtained after even mixing; 4, a proper amount of aqueous surfactant solution is added to the semi-dried mixed powder obtained in the step 3, and a sample is obtained through forming in a granulation or pouring mode; 5, the formed sample is subjected to wet maintenance for 12-24 hours, and the maintained sample is dried and calcined to prepare the ceramicadsorption material. The method utilizes the fly ash as a main raw material to prepare the geopolymerporous adsorption material, the pollution problem of the fly ash can be effectively relieved, and the problems of complicated preparation process, alkali waste production, high price, high temperature non-resistance, difficult industrial production and the like of the adsorption material can be also solved.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

Preparation method of high-temperature calcium-based CO2 absorbing material

InactiveCN103418336ALow costSimple preparation processOther chemical processesDispersed particle separationMineralogyBall mill

The invention provides a preparation method of high-temperature calcium-based CO2 absorbing material. The method includes: milling red mud and egg shell in a ball mill, screening, acid-leaching ground red mud and citric acid solution at the same temperature of 20-60 DEG C, mixing the acid-leached red mud and egg shell, adding water to mill the mixture, mixing well, and drying to obtain the high-temperature calcium-based CO2 absorbing material. The preparation method has the advantages that the cost of raw materials is low, the preparation process is simple, the material can absorb CO2 at high temperature directly so that carbon resource is recovered, the preparation method is easy for industrial production and treating waste with waste is achieved.

Owner:KUNMING UNIV OF SCI & TECH

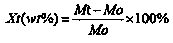

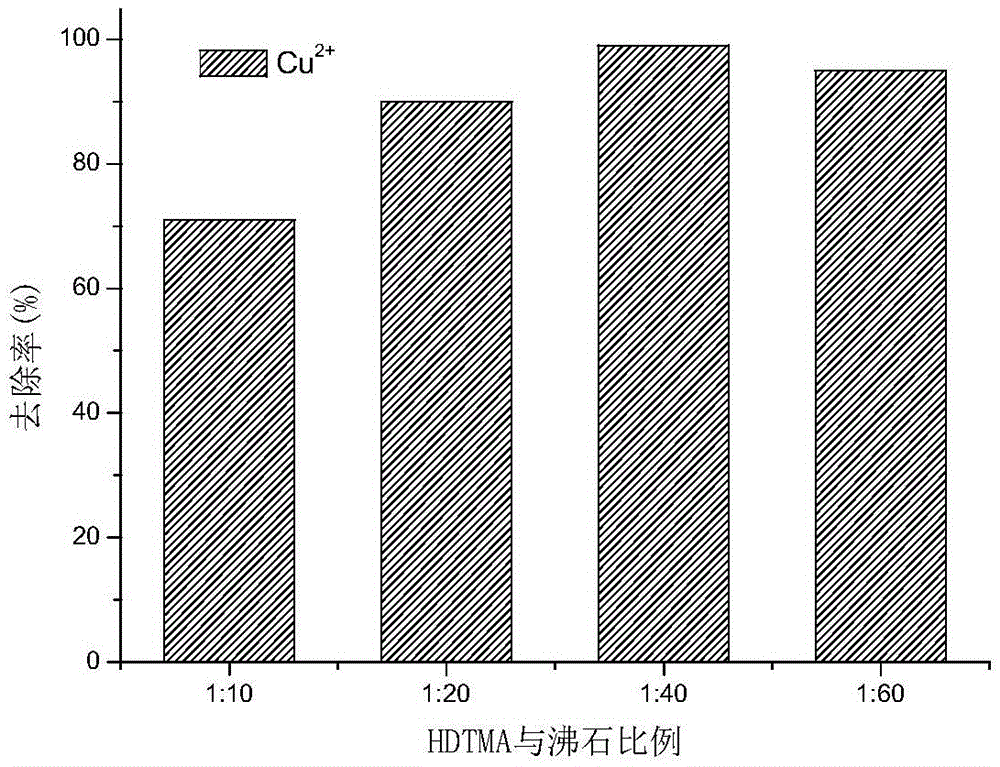

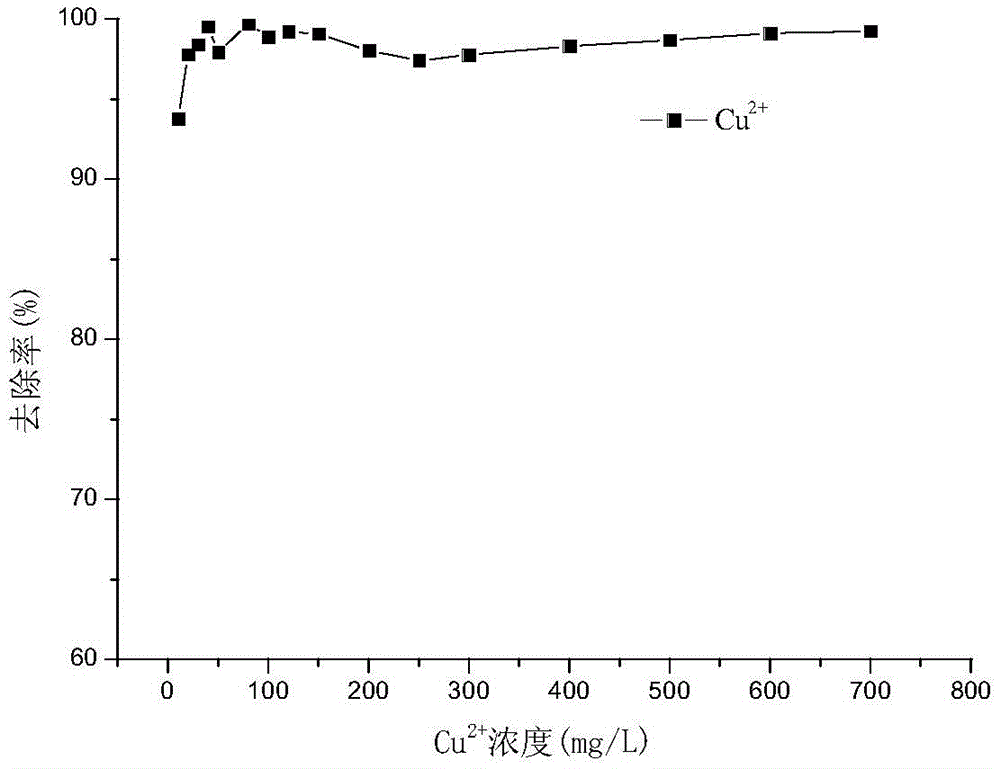

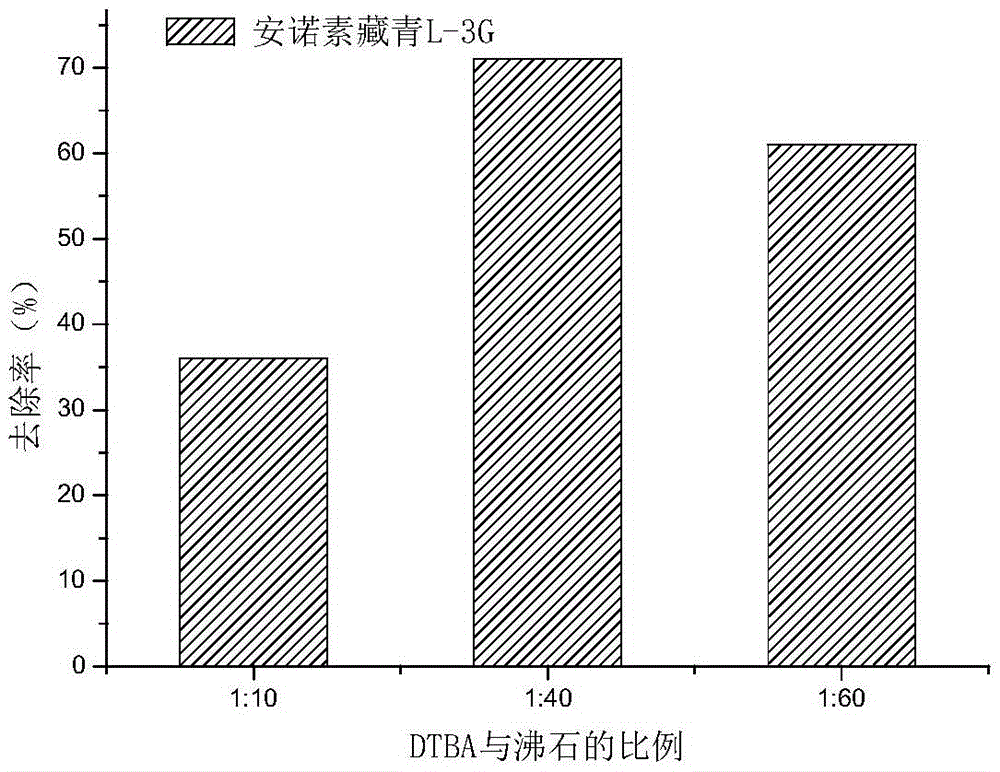

Preparation method and application of modified zeolite

ActiveCN105597668AAchieve high concentration removalImprove the water environmentOther chemical processesCrystalline aluminosilicate zeolitesMass ratioCopper

The invention relates to a preparation method and application of modified zeolite. The preparation method includes: adding a surfactant into deionized water to obtain an organic modified solution, with the surfactant and deionized water being in a mass ratio of 1:3-1:6; adding zeolite into the organic modified solution, with the surfactant and zeolite being in a mass ratio of 1:10-1:60, mixing the substances uniformly, then carrying out concussion reaction for 20-32h, performing filtering and low temperature drying, thus obtaining an organic modified zeolite product. Also, inorganic metal salt titanium sulfate can be added to conduct further compound modification. The composite modified zeolite prepared by the method provided by the invention shows good adsorption capacity to both copper ions and dye solutions.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Treatment method of polymer flooding oil production sewerage

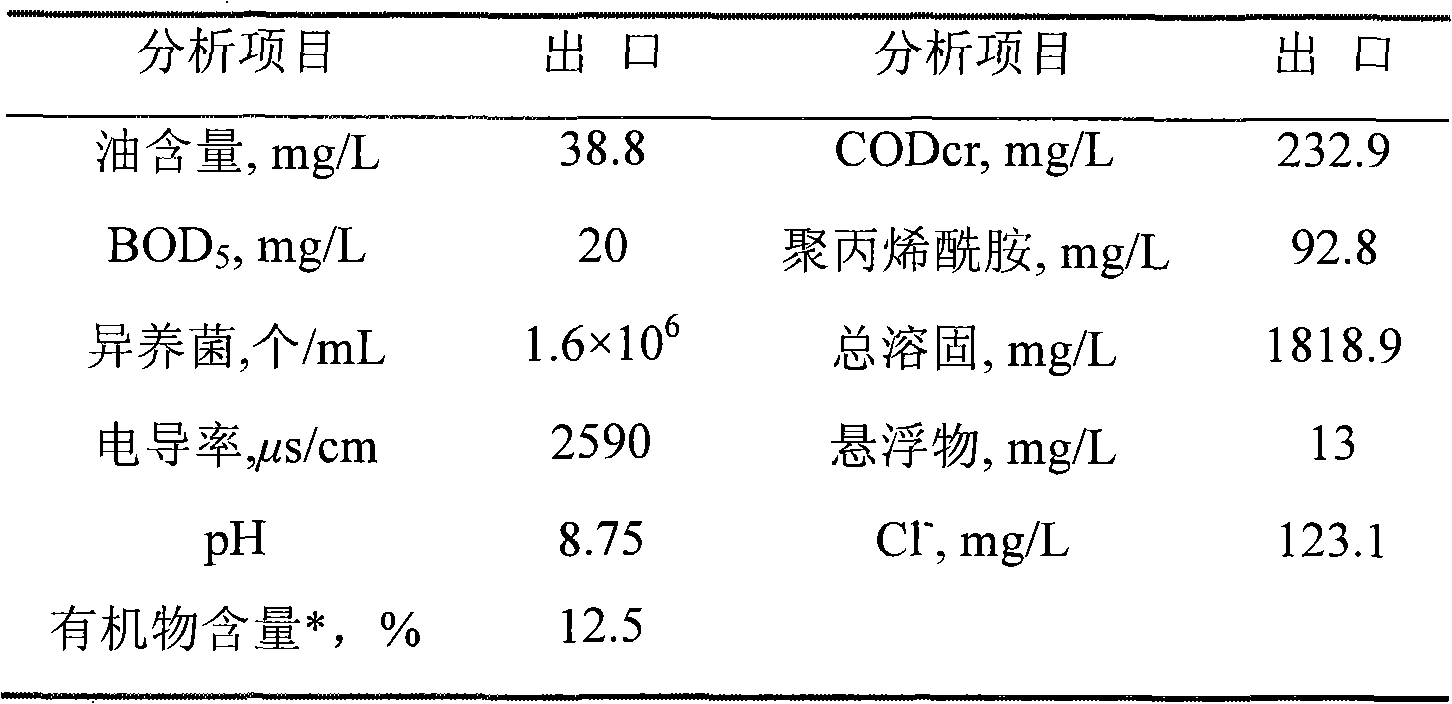

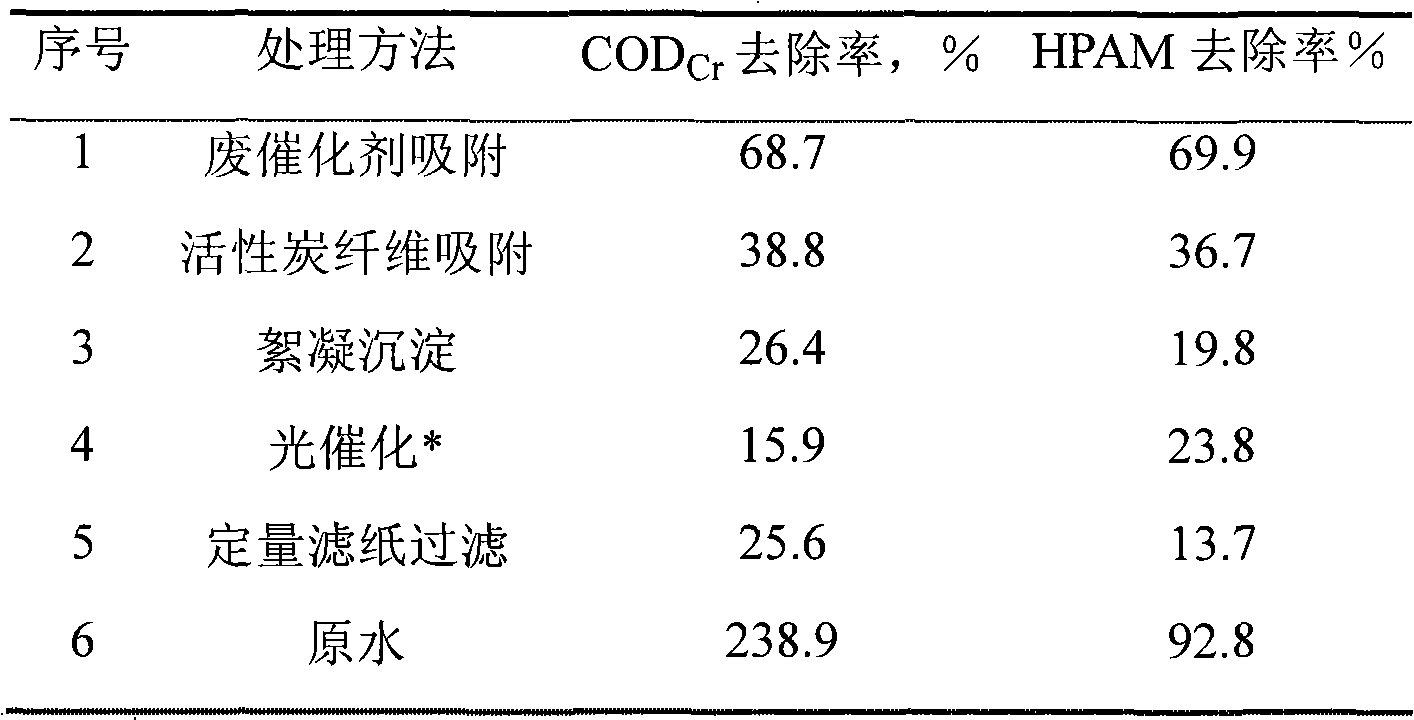

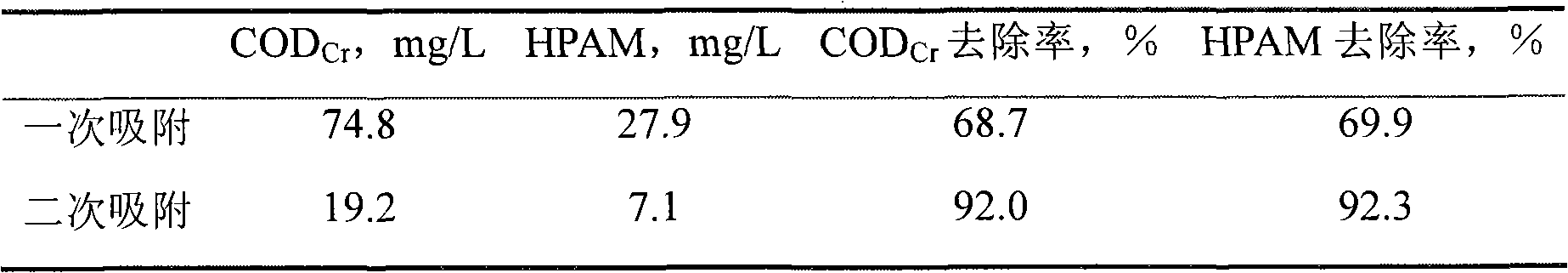

ActiveCN101928047AHigh removal rateImprove adsorption capacityWaste water treatment from quariesOther chemical processesSewageSewage treatment

The invention relates to a treatment method of polymer flooding oil production sewerage, comprising the following steps: fully contacting a catalytic cracking waste catalyst and the oil production sewerage containing HPAM, and enabling the dead catalyst to absorb organisms in sewerage; and heating and regenerating the catalytic cracking dead catalyst reaching adsorption saturation to recover for sewage treatment. The method of the invention is especially suitable for treating the oil production sewerage containing the HPAM.

Owner:CHINA PETROLEUM & CHEM CORP +1

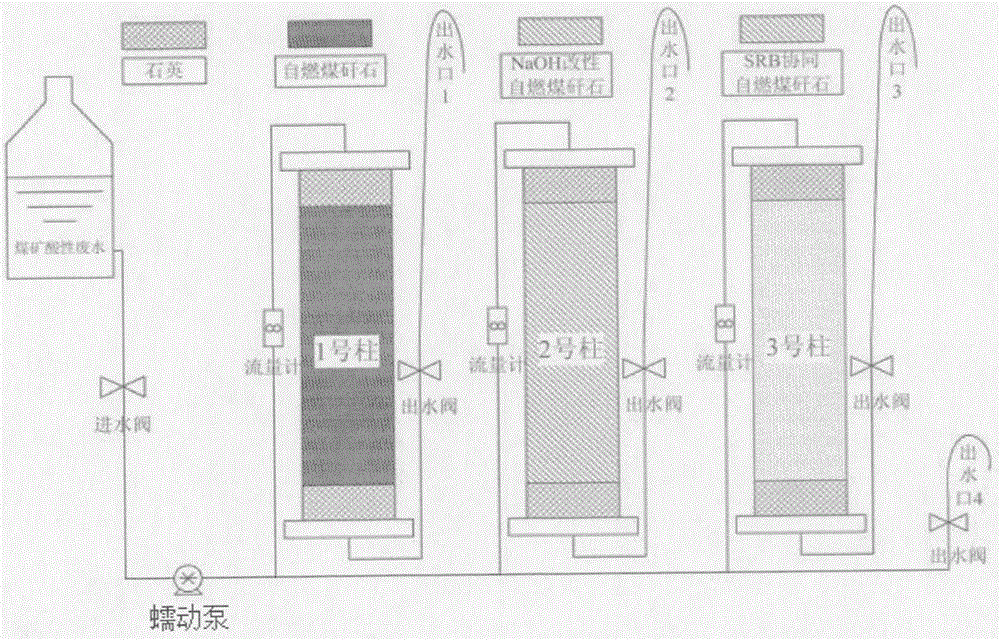

Method for processing coal mine acid wastewater through sulfate reducing bacteria and spontaneous combustion coal gangue in synergetic manner

ActiveCN106565012AReduce pollutionProlong the action timeWaste water treatment from quariesSustainable biological treatmentSpontaneous combustionSulfate-reducing bacteria

The invention discloses a method for processing coal mine acid wastewater through sulfate reducing bacteria and spontaneous combustion coal gangue in a synergetic manner. The method includes the following steps that bottom mud in an oxygen-deficient or locally-oxygen-deficient environment is taken and inoculated in an enrichment culture solution, after the bottom mud is subjected to oscillation culture at the temperature being 32 DEG C at the speed being 150 r / min for 2 weeks, a culture medium becomes black, a bottle opening has the smell of rotten eggs, and a liquid culture medium containing SRB is obtained; the spontaneous combustion coal gangue with the grain size ranging from 30 mesh to 120 mesh is taken and rinsed with distilled water three times, the spontaneous combustion coal gangue is dried at the temperature being 60 DEG C for standby application after surface dust is removed; the liquid culture medium containing the SRB and the spontaneous combustion coal gangue are placed in a reactor in proportion and are placed in a biochemical incubator with the temperature being 32 DEG C to be cultivated for 1 week after being mixed, and implantation growth of the SRB is achieved; and the coal mine acid wastewater containing Fe2+ and Mn2+ is injected, and purification treatment of the wastewater is conducted. The coal mine acid wastewater containing the Fe2+ and the Mn2+ is treated through the sulfate reducing bacteria and the spontaneous combustion coal gangue in the synergetic manner, waste in mining areas and microorganisms are combined and used for solving the problem of coal mine acid wastewater pollution, and the aim of treating waste through waste is achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for preparing cellulose based dye waste water purification material with waste newspaper

InactiveCN103212379AImprove protectionEfficient use ofOther chemical processesWater/sewage treatment by sorptionCelluloseFiber

The invention relates to a method for preparing a cellulose based dye waste water purification material with waste newspaper, which solves the problems that in the prior art, the existing waste newspaper recycle rate is low, the absorption efficiency of the dye waste water purification material is low, and the process effect of the purification material is not prominent. The method comprises the following steps: mixing and stirring the waste newspaper, Na2Si3 9H2O, H2O2, NaOH and a surfactant to obtain deinked cellulose; washing, drying, crushing and screening the cellulose to obtain waste newspaper fiber; adding a NaOH solution into the waste newspaper fiber, stirring the mixture and filtering out half of the NaOH solution, adding epoxy chloropropane into the remain solution, stirring the solution, filtering out the water, and cleaning the fiber; adding tetramethyl ethylene diamine into the fiber, stirring and filtering the mixture, and cleaning the fiber; adding methyl carbonate into the fiber, stirring and filtering the mixture, and finally cleaning and drying the fiber. The waste newspaper is changed into an environment-friendly cellulose adsorbent which is conducive to environmental protection; the anionic dye solution adsorption efficiency is high, the adsorption capacity is also high, and the absorption effect is obvious.

Owner:NORTHEAST FORESTRY UNIVERSITY

Industrial wastewater adsorbent and preparation method thereof

InactiveCN102698707ARealize resource utilizationTo achieve the purpose of treating waste with wasteOther chemical processesSolid waste disposalFoaming agentChemical composition

The invention discloses an industrial wastewater adsorbent and a preparation method of the industrial wastewater adsorbent. The industrial wastewater adsorbent comprises the following chemical components by weight percent: 80-95% of fine steel slag powder, 2-15% of water and 2-6% of foaming agent. The preparation method of the industrial wastewater adsorbent comprises the steps of: taking 80-95% of fine steel slag powder and 2-15% of water according to the weight ratio and blending for 8-12min at 100-200r / min; obtaining the blend mixture blended uniformly; adding 2-6% of the foaming agent into the blend mixture according to weight ratio; obtaining the mixture; pelletizing the mixture; and obtaining small pellets, namely the adsorbent. According to the adsorbent and the method, are highly environmental protection is high and the resource utilization and high added value application of the steel slag are realized. Since the absorbent provided by the invention uses the steel slag as the main raw material, the resource utilization of the steel slag is realized and the goal of treating wastes by wastes in the metallurgical industry is also realized.

Owner:武钢集团有限公司

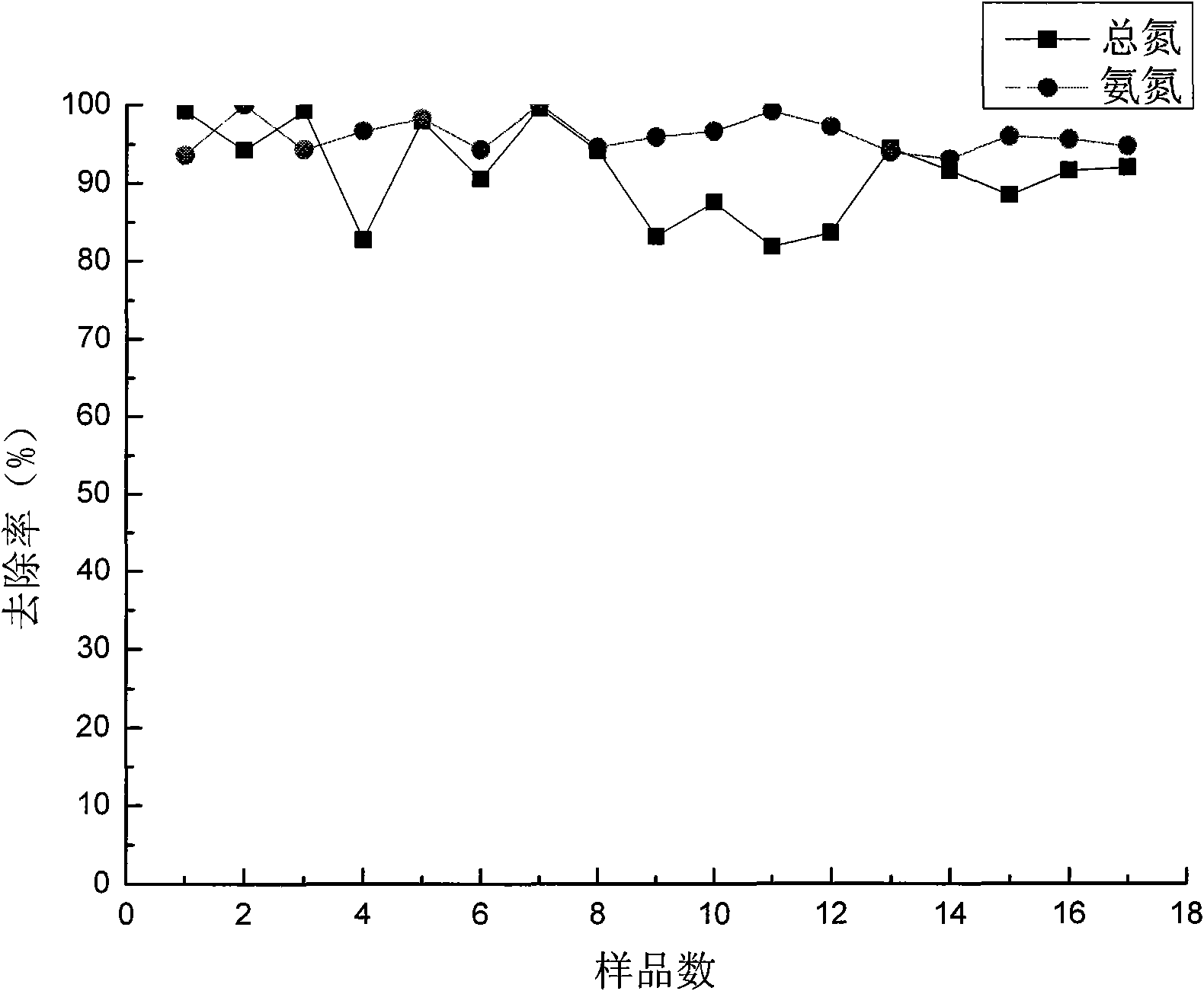

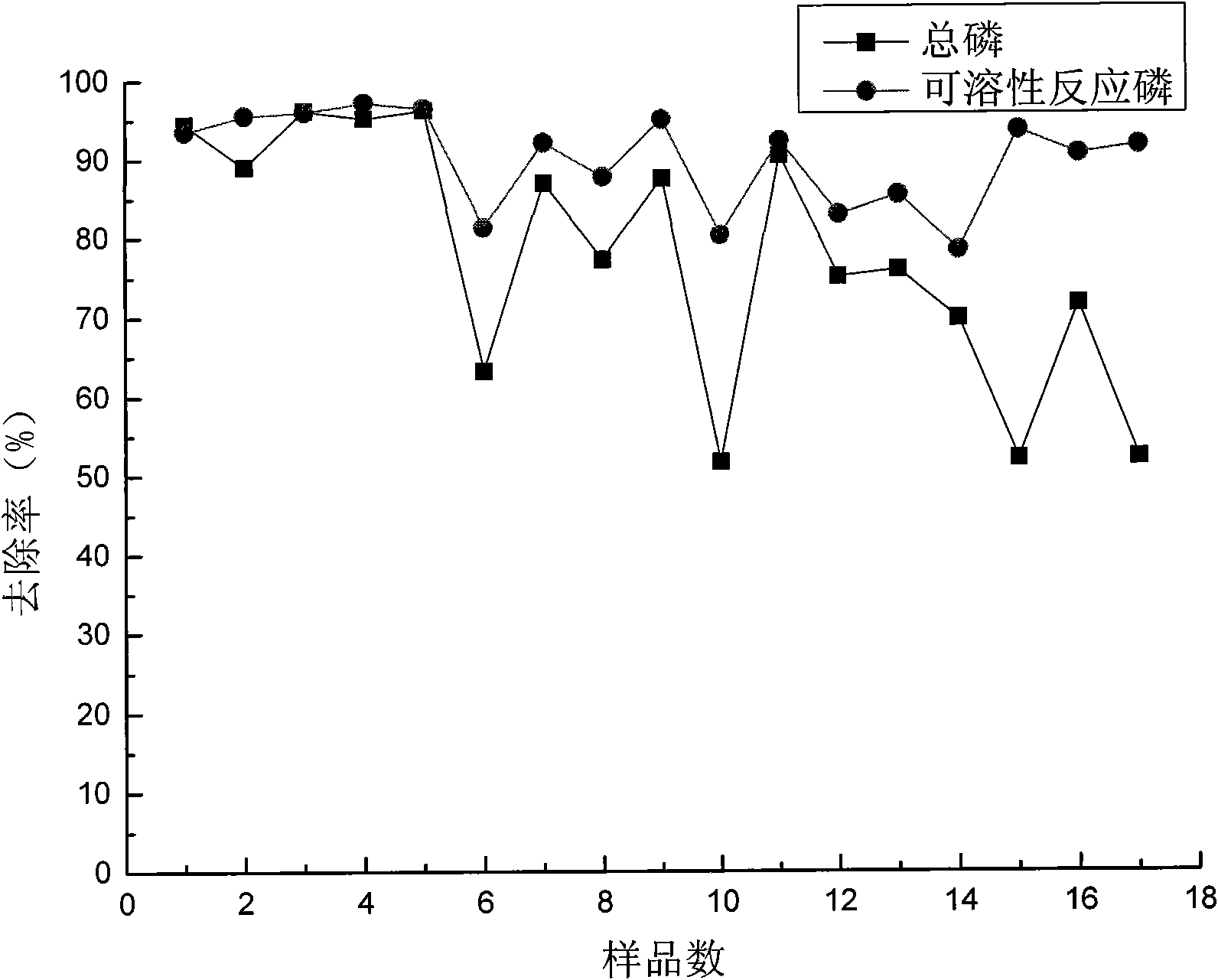

Method for advanced treatment of ammonia nitrogen sewage

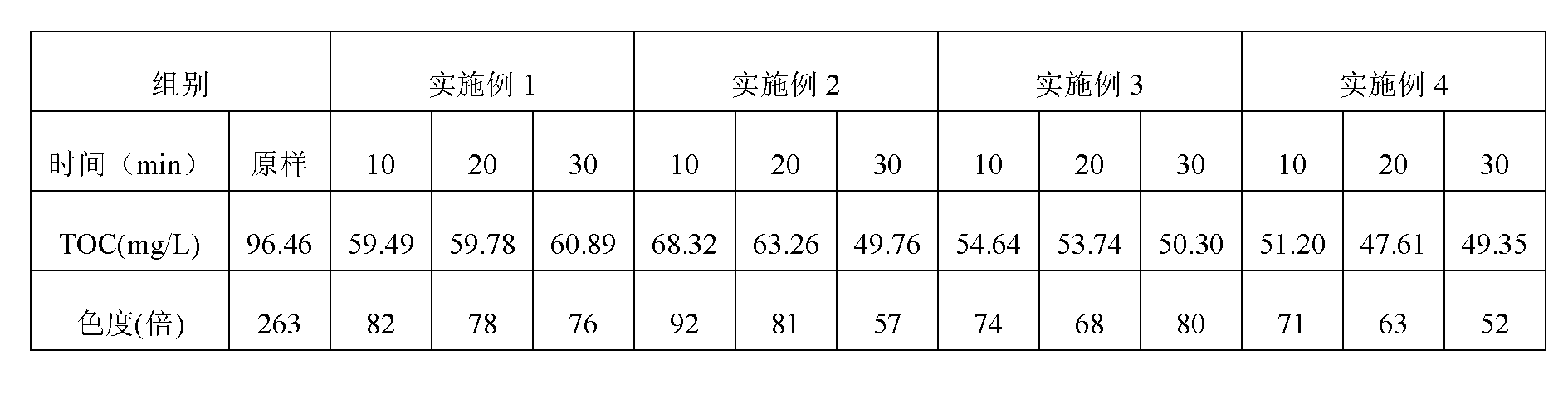

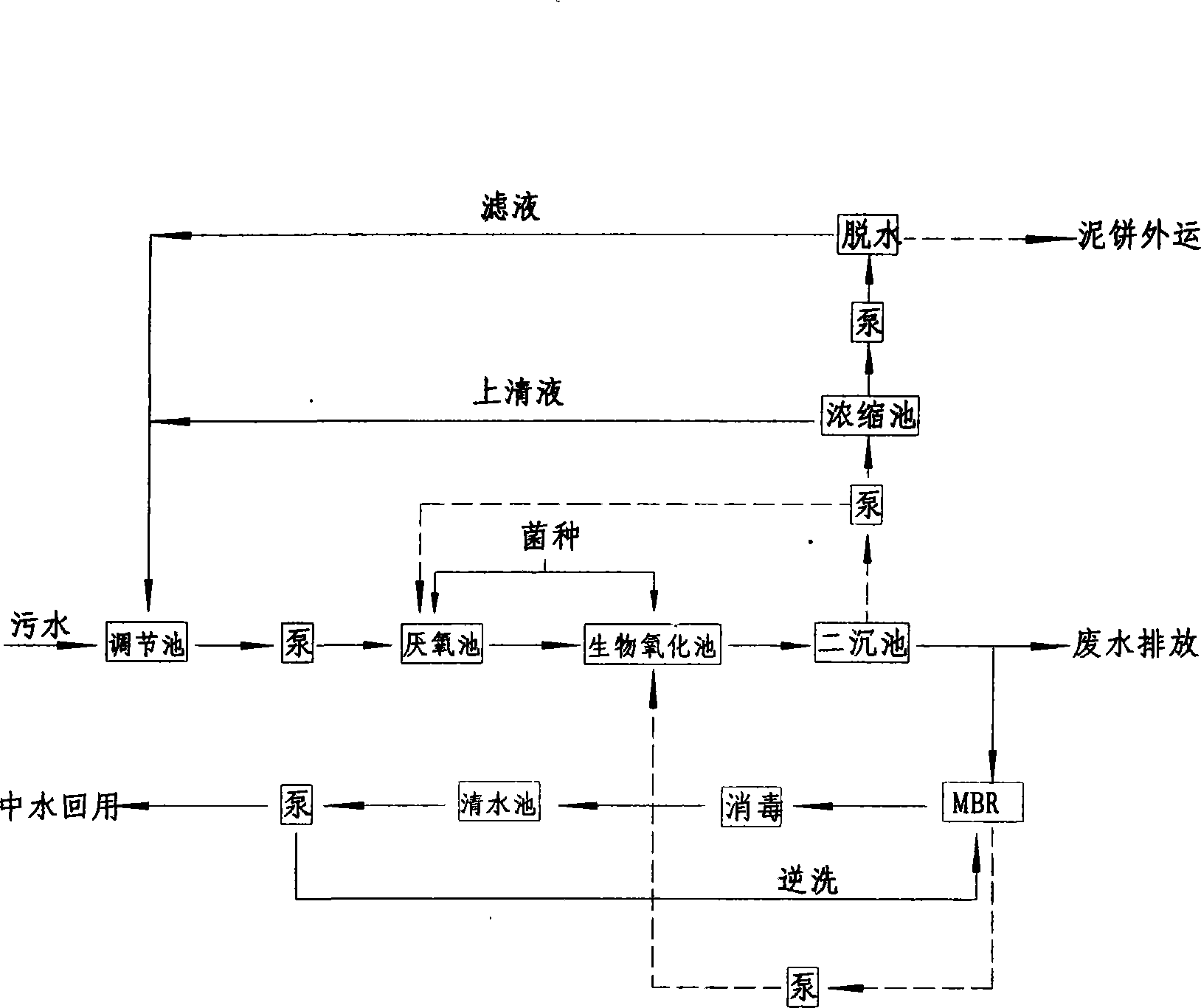

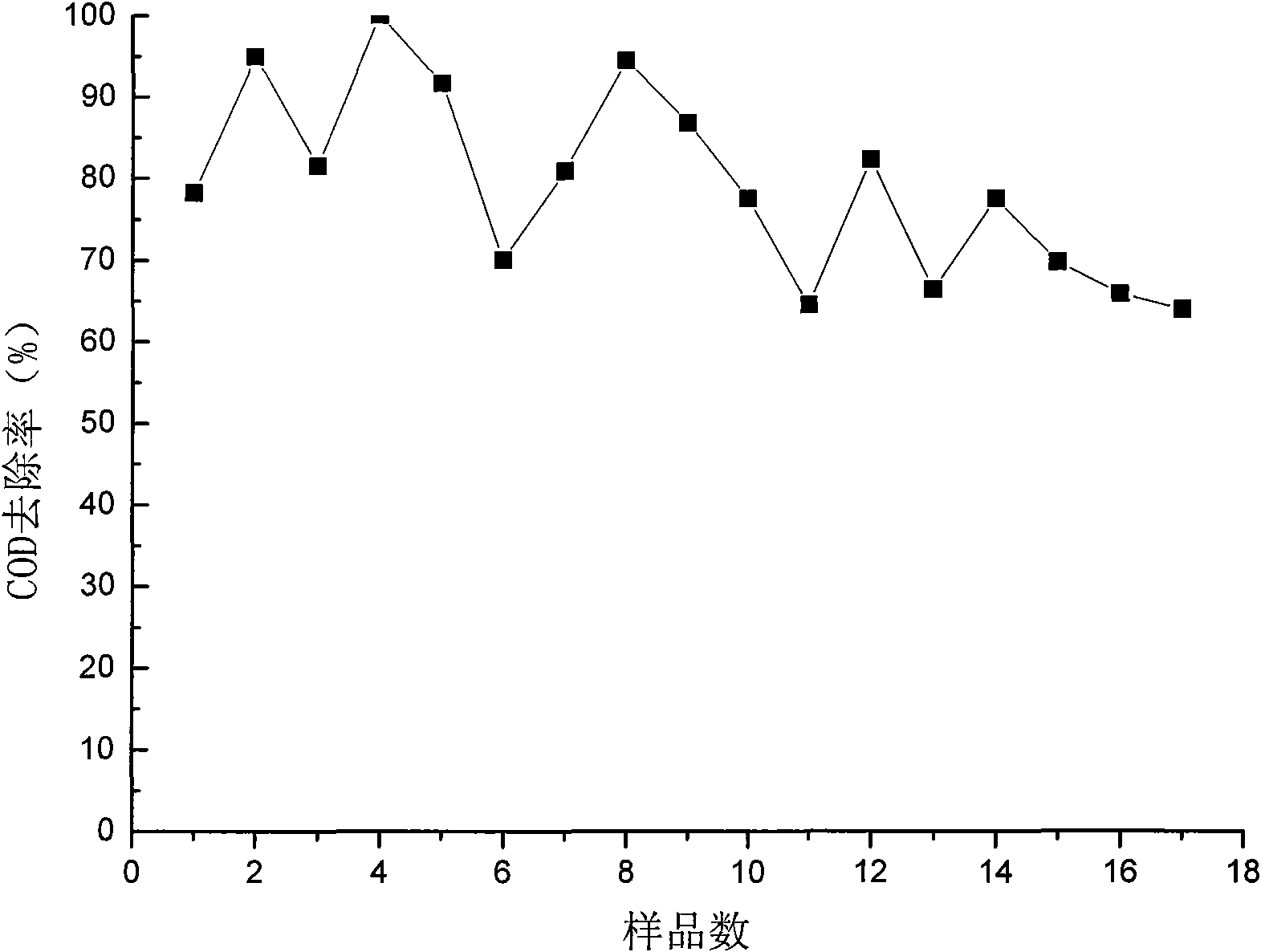

ActiveCN101172735AGuaranteed reuseFast reproductive metabolismWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesWater qualityEmission standard

The invention relates to a method for deep treatment of ammonian sewage, and the method belongs to the technical field of the environment protection. The invention conducts integration and innovation based on the traditional ammonian sewage treatment method and combines the physical, chemical and biological treatments, namely, an improved oxygen-poor and aerobic technique, film separation and biological treatment are adopted in the treatment of the eutrophic water which is low in BOD5, and then the eutrophic water is discharged or reused after the treatment under the standard. The invention has the advantages of low capital construction and work, good water treatment, no secondary pollution and state discharge standard conformity of the discharged water, etc., thereby being widely used in the treatment of the eutrophic water with the density of the BOD5 being 48.5mg / L.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

Preparation method for substrate of vertical-flow constructed wetlands

ActiveCN101585607ALarge specific surface areaPromote growthBiological water/sewage treatmentConstructed wetlandSlag

A preparation method for a substrate of vertical-flow constructed wetlands is disclosed, comprising the steps of: A, selection of raw materials: biological ceramisite, zeolite, anthracite, vermiculite and slag; B, particle size of each raw material; C, each combined substrate: when the treated wastewater-characteristic pollutant is organic matter, the substrate is ceramisite; when the treated wastewater-characteristic pollutant is nitrogen, the substrate is zeolite; when the treated wastewater-characteristic pollutant is phosphorus, two substrate combining ways are present, wherein, one of the combining ways is that the substrate is anthracite and the other one of the combining ways is that the substrates, from top to bottom, are anthracite, vermiculite and slag in sequence; when the treated wastewater is mixed wastewater containing organic matter, nitrogen and phosphorus, the substrates, from top to bottom, are anthracite, biological ceramisite and zeolite. The method is simple and is convenient in operation as well as can effectively remove characteristic pollutants in the wastewater, and after being treated the wastewater can accord with standard B in Wastewater Discharge Standard of Municipal Wastewater Treatment Plant and is directly reused or discharged into waters.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Bio-adsorbent for treating dye wastewater and preparation method therefor and application thereof

InactiveCN105170109AAdsorption particle size is largeFacilitates phase separation operationsOther chemical processesWater/sewage treatment by sorptionUltrasonic assistedAlcohol

The invention provides a bio-adsorbent for treating dye wastewater and a preparation method therefor and application thereof and belongs to the technical field of dye wastewater treatment. The bio-adsorbent contains the raw materials in parts by weight: 35-40 parts of edible fungus waste, 22-30 parts of bamboo shoot waste, 20-25 parts of pomelo peel and 5-12 parts of tea leaves. The preparation method comprises the steps of pretreating the raw materials, then, adding aqueous alkali into the pretreated raw materials, carrying out stirring, washing an activated product with water until the activated product is neutral, drying the washed activated product, then, adding a citric acid solution to soak the activated product, carrying out heating stirring, washing a modified product with water until the modified product is neutral, drying the modified product, then, adding an alcoholic solution to soak the modified product, carrying out ultrasonic wave assisted treatment, washing a product with water until the product is neutral, and drying and crushing the product, thereby obtaining the bio-adsorbent for treating the dye wastewater. According to the application of the bio-adsorbent in the treatment of the dye wastewater, the bio-adsorbent is added into a dye aqueous solution for oscillatory reaction, and filtering separation is carried out, so as to complete adsorption removal for the dye aqueous solution. According to the bio-adsorbent for treating the dye wastewater and the preparation method therefor and the application thereof, the problem of environmental pollution is solved, the resourcing of the wastes is realized, and the aim of treating wastes with wastes is achieved.

Owner:NANYANG NORMAL UNIV

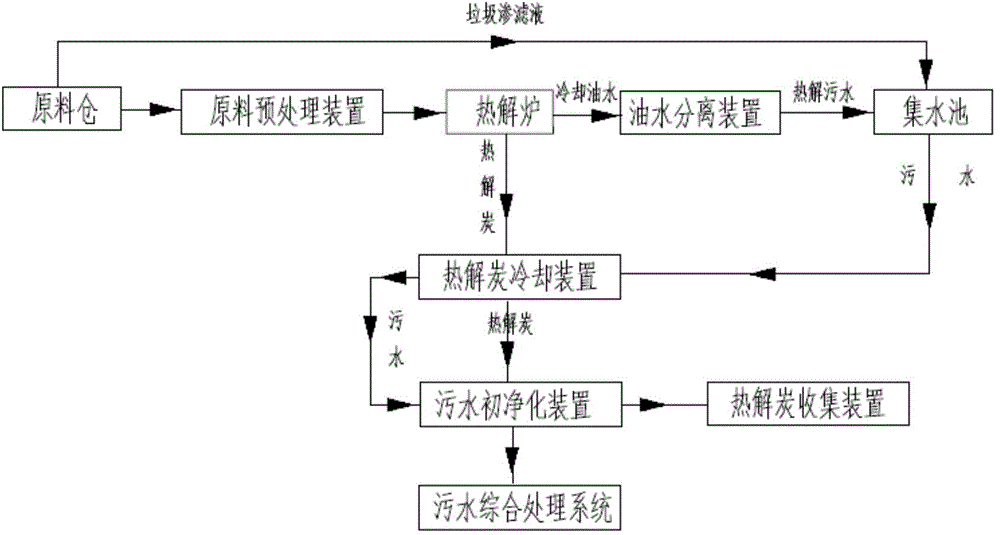

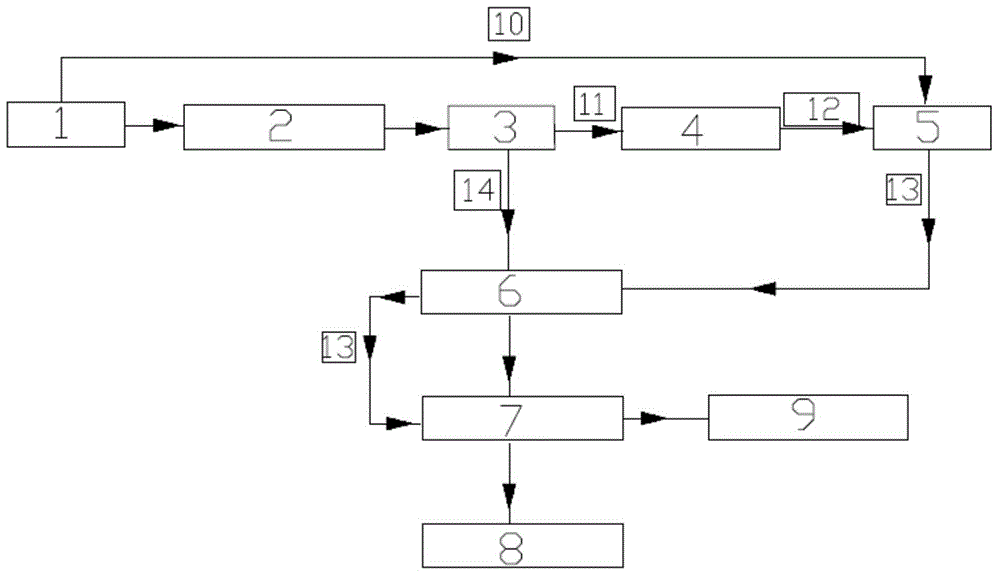

Garbage pyrolysis sewage treatment system and garbage pyrolysis sewage treatment method

InactiveCN104650933ALess investmentSimple processCoke quenchingTransportation and packagingPyrolytic carbonSewage

The invention provides a garbage pyrolysis sewage treatment system. The system comprises a raw material cabin, a raw material pre-treatment device, a pyrolyzing furnace, an oil-water separating device, a water collecting pool, a pyrolytic carbon cooling device, a primary sewage purifying device, a comprehensive sewage treatment system and a pyrolytic carbon collecting device; the raw material cabin is connected with the raw material pre-treatment device; the raw material pre-treatment device is connected with the pyrolyzing furnace by a pipeline; the raw material cabin is connected with the water collecting pool by a pipeline; the pyrolyzing furnace is connected with the oil-water separating device; the sewage outlet of the oil-water separating device is connected with the water collecting pool; the pyrolyzing furnace is connected with the pyrolytic carbon cooling device by virtue of a discharge hole; the pyrolytic carbon outlet is connected with the sewage primary purifying device. By utilizing the method provided by the invention, the investment of sewage equipment is reduced, the process is simplified, and the quenching water is saved at the same time. The adsorption function of the garbage pyrolytic carbon is re-found for treating pyrolysis sewage without secondary pollution, the purpose of treatment of a waste with another waste is achieved, so the method is a environment-friendly and effective method for treating pyrolysis sewage.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

Method for preparing complex removal agent from steel and iron pickling waste residues to carry out desulfurization and denitrification

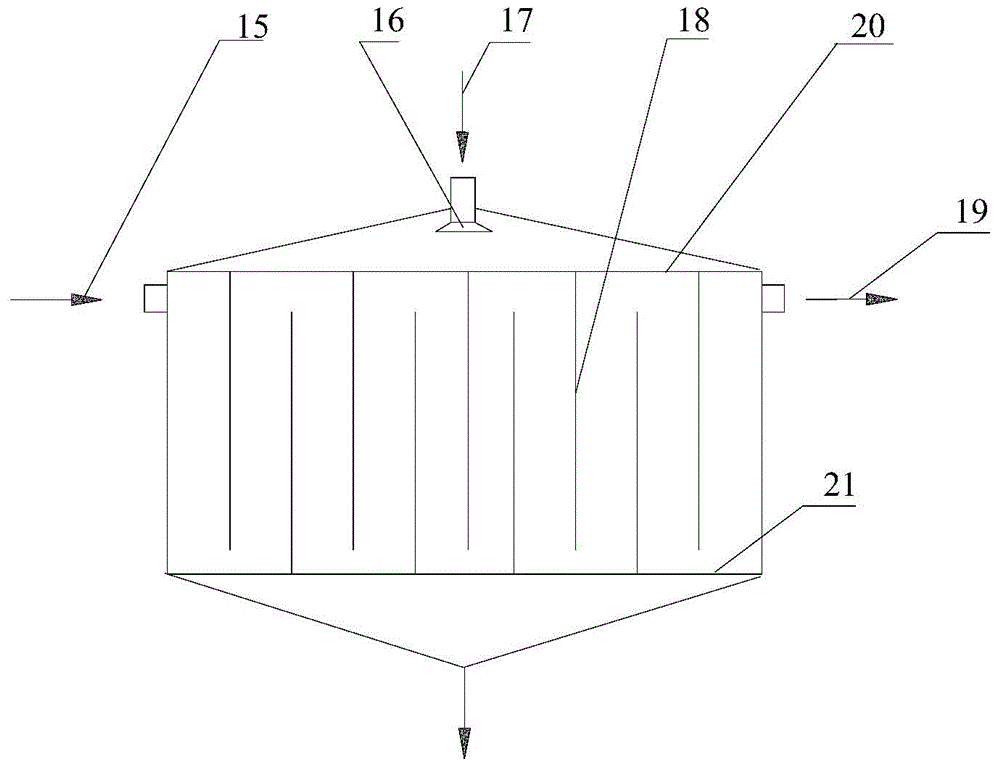

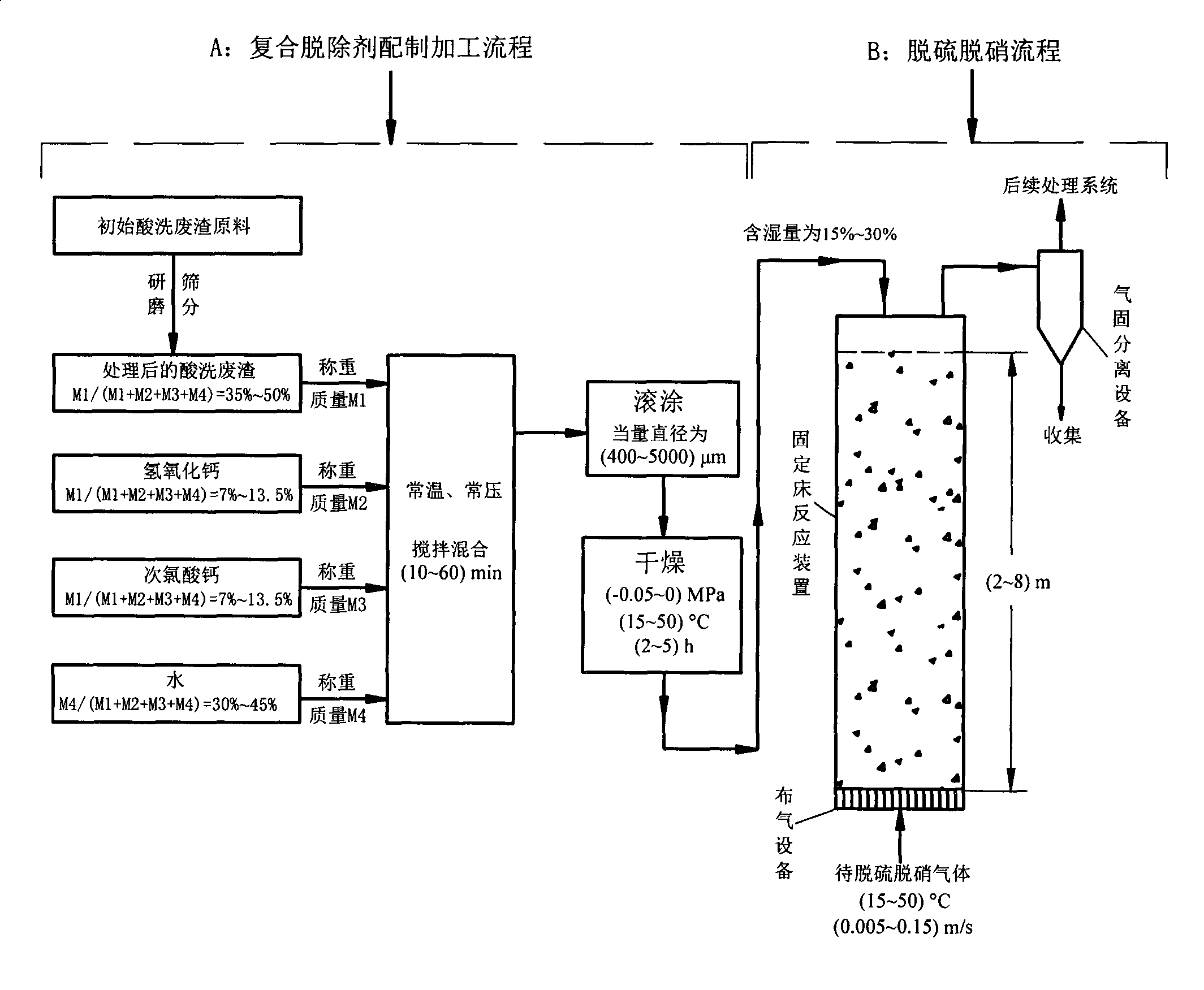

ActiveCN103537184ARealize secondary useTo achieve the purpose of flue gas dust removalSolid waste disposalDispersed particle separationCalcium hydroxideAfter treatment

The invention provides a method for preparing a complex removal agent from steel and iron pickling waste residues to carry out desulfurization and denitrification. The method is characterized by mixing 35-50% of pickling waste residues from steel and iron plants, 7-13.5% of calcium hydroxide, 7-13.5% of calcium hypochlorite and 30-45% of water by mass uniformly to prepare a paste-like complex removal agent, uniformly roll-coating the paste-like complex removal agent on inert particles, drying the particles with equivalent diameters of 400-5000mu m under certain conditions after roll coating, and filling the particles into a fixed bed reaction device when the moisture content is 15-30%, wherein the filling height is 2-8m; filling gases to be desulfurized and denitrified at 15-50 DEG C from the bottom of the device, wherein the apparent velocity of the gases based on the fixed bed section is 0.005-0.15m / s, and tail gases enter an after-treatment system. The method can be applied to the fields such as steel and iron, power, energy and environmental protection.

Owner:HEBEI UNIV OF TECH

Method for municipal sludge in-situ detwatering by utilization of Fenton sludge

ActiveCN105417928AWith flocculationEfficient removalSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeFiltration

The invention relates to a method for municipal sludge in-situ detwatering by utilization of Fenton sludge. Sludge is subjected to press filtration and dewatering in a sewage treatment plant, then sulfuric acid is added, activation is carried out, thus iron elements with an ionic state exist in the sludge, plastic drain boards are put into municipal sludge, dewatering pre-treatment is carried out, water is drained through a conventional vacuum precompressed drainage method, the Fenton sludge after activation of sulfuric acid is added in the municipal sludge after pre-treatment, the mixture is stirred uniformly, quicklime is added, stirring is carried out, thus the sludge and calcium oxide are mixed uniformly and rapidly, pH adjustment, deodorizing and disinfection are carried out, and the purposes of deep dewatering and stabilization are achieved. The provided method overcomes the detect of high operation and disposal costs of previous sludge processing. The sludge containing a lot of iron elements as a product of the Fenton oxidation method is employed as a coagulant for municipal sludge solidified treatment, the sludge after activation contains a lot of Fe<3+> irons, the ferric salt with a high valence can be employed as a leaching agent, heavy metal ions in the sludge can be leached, and the sludge is discharged.

Owner:NANJING SHENKELONG ENVIRONMENTAL PROTECTION

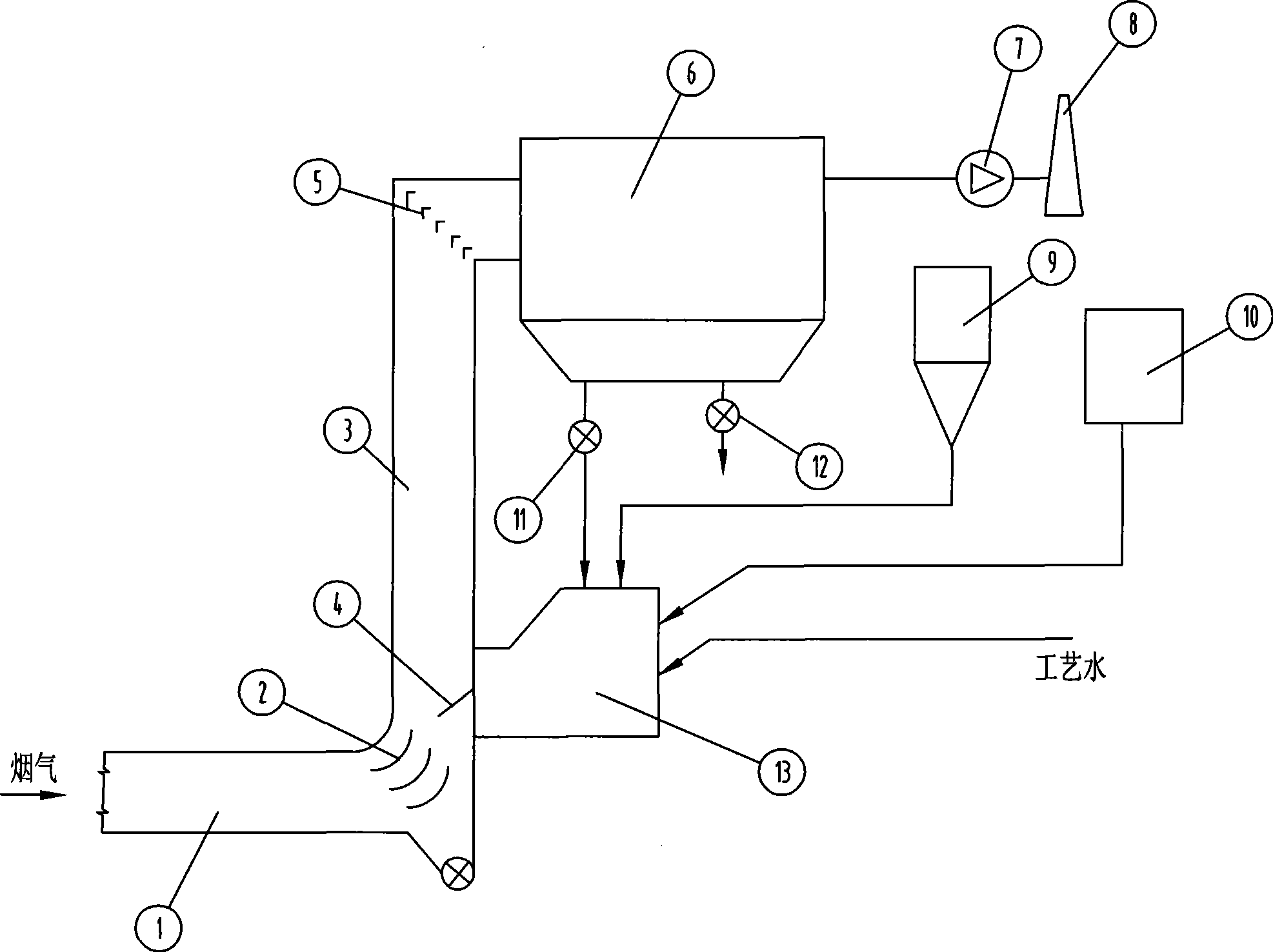

Two-phase supply cyclic semidry process desulfuration method and system

InactiveCN101474533AReduce consumptionUniform moisture contentDispersed particle separationFlue gasSlurry

The invention discloses a two-phase feeding circulation semidry process desulfurization method and a system thereof. The system comprises a horizontal flue, a reactor, a dust catcher, a draught fan and a chimney which are sequentially connected, and also comprises a conditioning device. The outlet of the lower end of the dust catcher is connected with the conditioning device which is also connected with a dry powder absorbent cabin and a grout slot. The outlet of the conditioning device is connected with the reactor. In the invention, the two-phase feeding mode is used; meanwhile, dry powder absorbent, alkali waste grout, process water, and desulfurization ash are added into the conditioning device to cause that the content of conditioning ash is more uniform, the conditioning ash can be fully dried after entering into the reactor, and does not form scale in the reactor; therefore, the system can steadily run for long period. The alkali waste grout generated in the chemical production can be directly used; the process water consumption is reduced; therefore, the purpose of treatment of wastes with processes of wastes against one another is reduced. The system is suitable for a larger flue gas SO2 by the regulation of the dry powder absorbent, the alkali waste grout, and the process water, increases desulphurization efficiency and enlarges the adaption load range of the flue gas.

Owner:浙江菲达环保科技股份有限公司

Mine tailing mineral fertilizer and preparation method thereof

InactiveCN106242907AReduce energy consumptionQuality improvementCalcareous fertilisersAgriculture tools and machinesResource utilizationTrace element

The invention provides a method for preparing a mine tailing mineral fertilizer and the mine tailing mineral fertilizer obtained by the preparation method. The preparation method of the mine tailing mineral fertilizer realizes reasonable utilization of a mine tailing resource, and increases the resource utilization rate. The prepared mineral fertilizer contains a plurality of minerals and trace elements, which can be used for improving a soil structure during a waste mine restoration process, organic matter content is increased, various elements requirements for plants can be satisfied, so that a purpose of using waste to treat waste can be reached.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

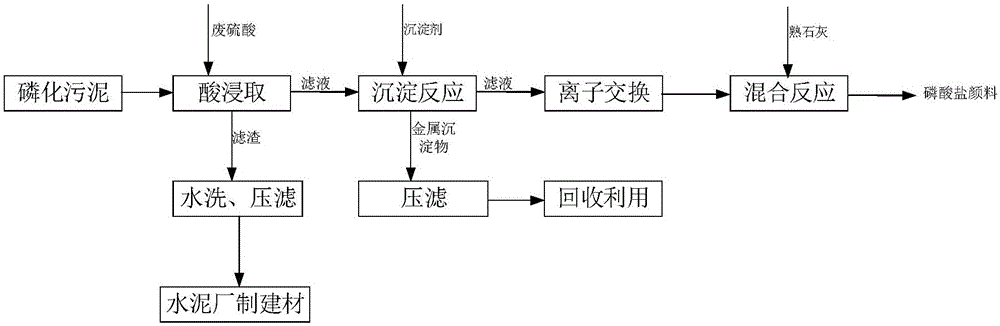

Method for resource treatment of phosphatized sludge

InactiveCN106746391AImprove processing efficiencyReduce processing costsSludge treatment by de-watering/drying/thickeningPhosphatesChemistryWaste treatment

The invention discloses a method for resource treatment of phosphatized sludge, and belongs to the field of solid waste resource utilization. The method is characterized in that for the problem of limitation to the resource utilization of the phosphatized sludge by the heavy metal impurities in the phosphatized sludge, the acid extraction and physical-chemical treatment type is adopted, so as to realize the resource utilization of the phosphatized sludge. The method has the advantages that by using waste phosphate to perform acid extraction, while the phosphatized sludge is utilized in a resource way, the waste acid is also treated, so as to greatly reduce the operation and treatment cost of the technology, realize the new concept of using wastes to treat wastes, and effectively combine the waste treatment and the resource utilization; the economic benefit and environment benefit are good, and the method is suitable for being popularized and used.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

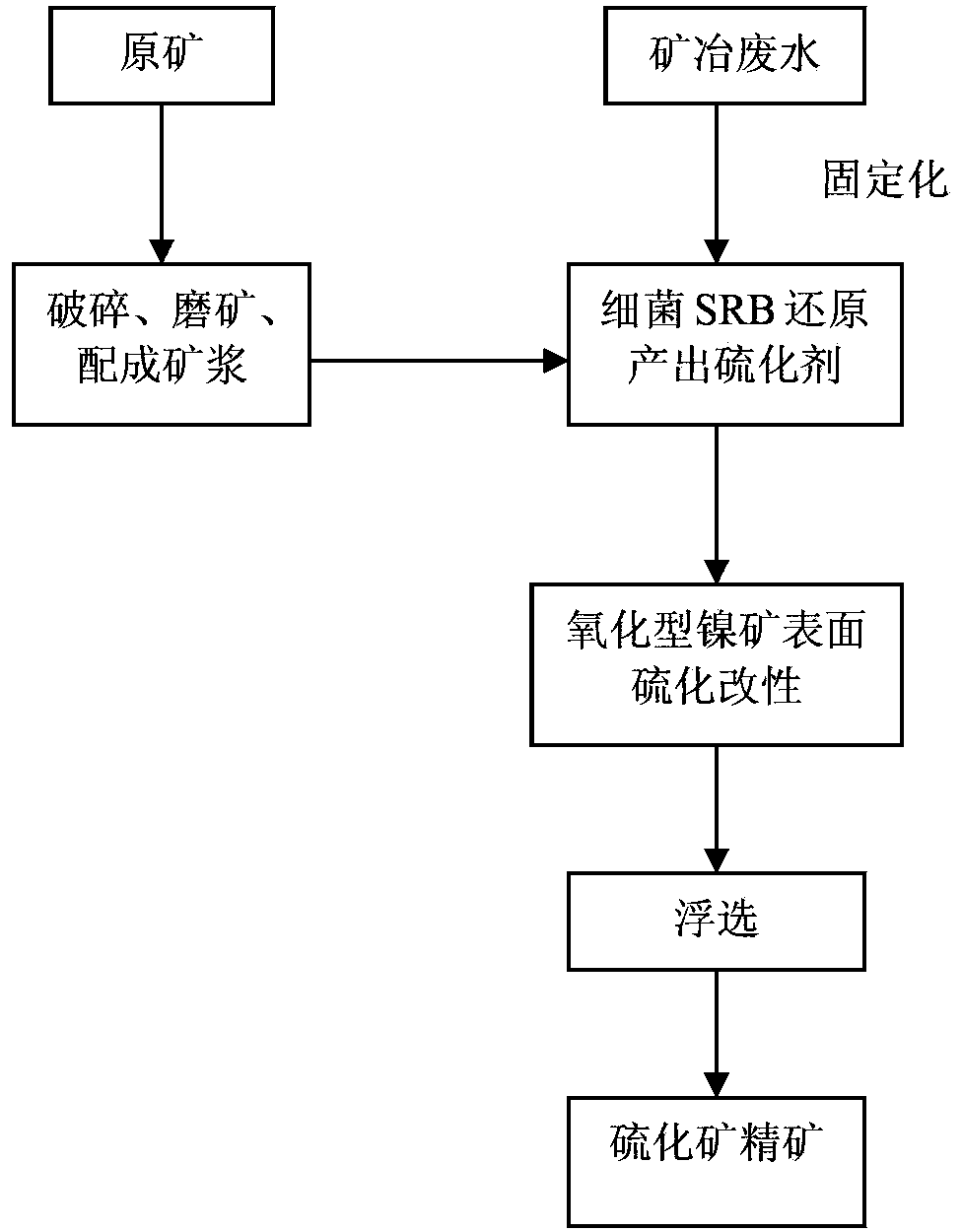

Method for vulcanizing low-grade oxidized nickel ore with microbiological method

ActiveCN103509946AEfficient use ofReduce processing costsProcess efficiency improvementVulcanizationSulfate-reducing bacteria

The invention provides a method for vulcanizing low-grade oxidized nickel ore with a microbiological method. According to the invention, sulfate is reduced by using sulfate-reducing bacteria, such that hydrogen sulfide is produced, and is used as a vulcanizing agent of the oxidized nickel ore. Through means of regulating temperature, vulcanizing agent dose, pH value, and the like, oxidized nickel ore surface vulcanization is carried out. A floatation technology is used for processing the vulcanized ore, such that low-grade oxidized nickel ore can be effectively processed. With the method provided by the invention, processing cost is low, the process is simple and easy to operate, environment pollution is low, and valuable metal ion recovery rate is high. The method has excellent industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of red mud-slag-cement composite dephosphorization agent

PendingCN109731544AWide variety of sourcesImprove hydration hardnessOther chemical processesWater contaminantsIonBrown iron oxide

The invention provides a preparation method of a red mud-slag-cement composite dephosphorization agent, comprising the steps of drying the materials of red mud, slag and cement, crushing, screening, drying to constant weights, and mixing well in a certain ratio; mixing the mixture with deionized water to obtain raw particles; subjecting the raw particles to microwave activation, and cooling to room temperature to obtain the red mud-slag-cement composite dephosphorization agent. All the red mud, slag and cement have high calcium oxide content; phosphates in water are removed in calcium phosphate form via calcium-based components; iron oxide in the red mud and slag are heated quickly under the action of microwave, so that calcining is achieved; hydrated minerals, carbonate minerals and the like in the red mud and slag decompose easily and easily release water or gas, and pore structures are formed in the particles; the slag has incompletely combusted ash in a certain ratio, and pore forming can also be achieved in the microwave activation process.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com