Industrial wastewater adsorbent and preparation method thereof

An industrial wastewater and adsorbent technology, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of high treatment cost and high price of activated carbon adsorbent, and achieve low production cost. , high environmental protection, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

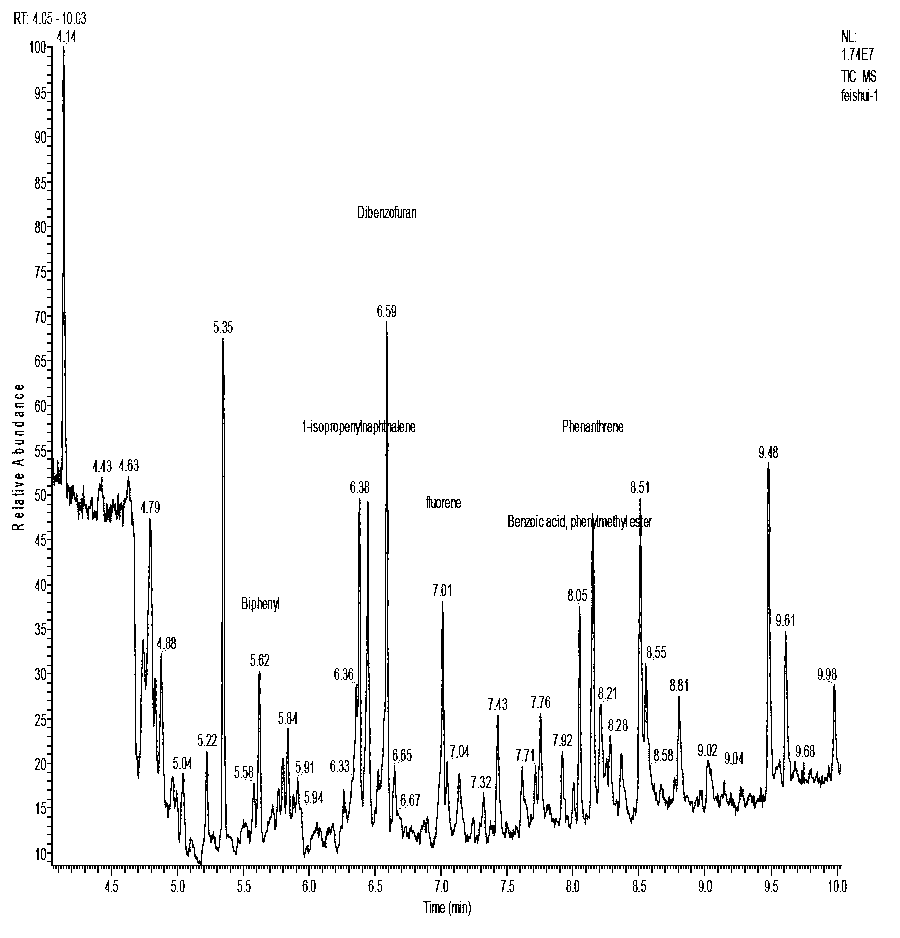

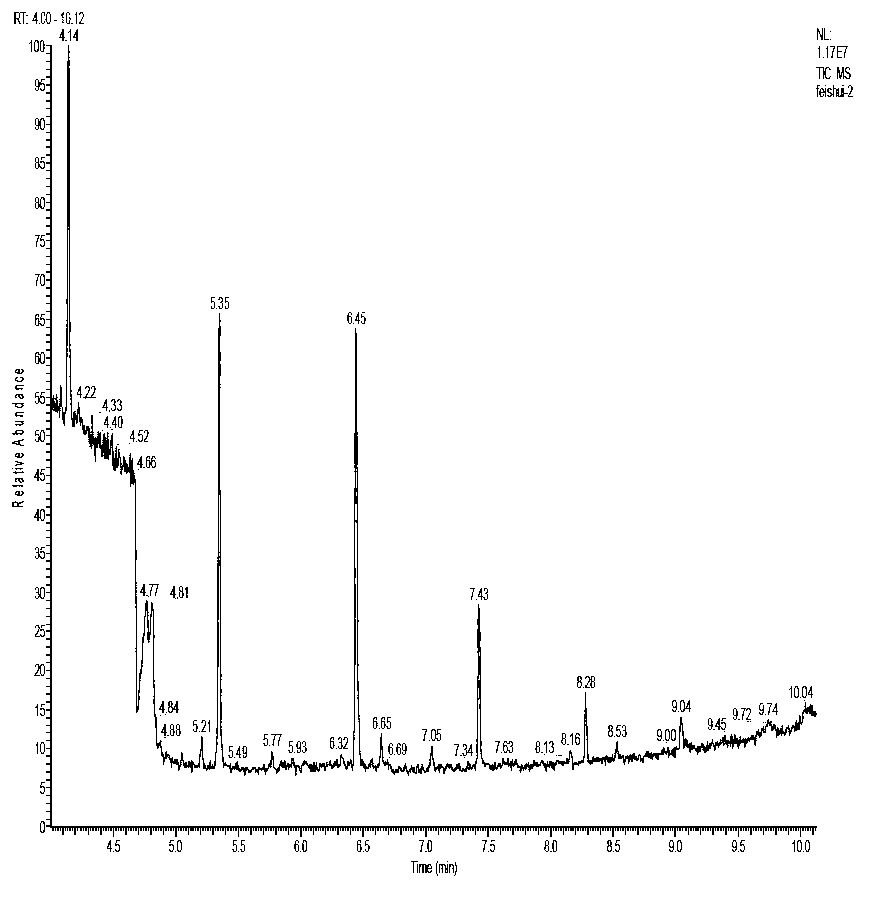

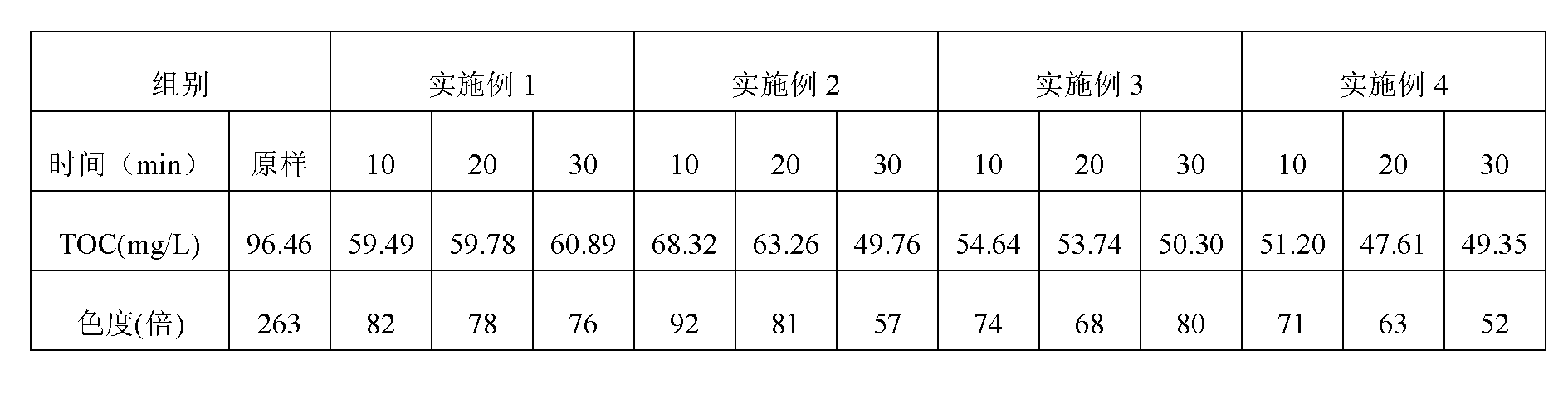

Examples

Embodiment 1

[0025] Place the steel slag powder at 400°C for 3 hours, then finely grind it into 500 mesh to make steel slag fine powder; take 80% steel slag fine powder and 5% water according to the weight percentage and stir at 200r / min for 12min; The agitator; then add 1% hydrogen peroxide and 3% calcium hypochlorite foaming agent to the agitator by weight percentage to obtain a mixture; pelletize the mixture, and the 1mm diameter pellet is the adsorbent.

Embodiment 2

[0027] Place the steel slag powder at 600°C for 2 hours, then finely grind it into 300 mesh to make steel slag fine powder; take 95% steel slag fine powder and 2% water according to the weight percentage and stir at 100r / min for 12min; The agitator; then add 2% hydrogen peroxide and 1% calcium hypochlorite foaming agent to the agitator by weight percentage to obtain a mixture; the mixture is pelletized, and the diameter of the 2mm ball is the adsorbent.

Embodiment 3

[0029] Place the steel slag powder at 500°C for 2 hours, then finely grind it into 400 mesh to make steel slag fine powder; take 92% steel slag fine powder and 2% water according to the weight percentage and stir at 100r / min for 12min; 6% hydrogen peroxide foaming agent is added to the stirring material by weight percentage to obtain a mixture; the mixture is pelletized, and the diameter of the 2mm pellet is the adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com