Recycled concrete and preparation method thereof

A technology of recycled concrete and concrete admixture, which is applied in the field of building material concrete, can solve the problems of unfavorable promotion and popularization of recycled concrete, increased cost of recycled concrete, and high cost of modification, so as to reduce land occupation and impact on the environment damage, reduce water consumption and slump loss, and improve compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

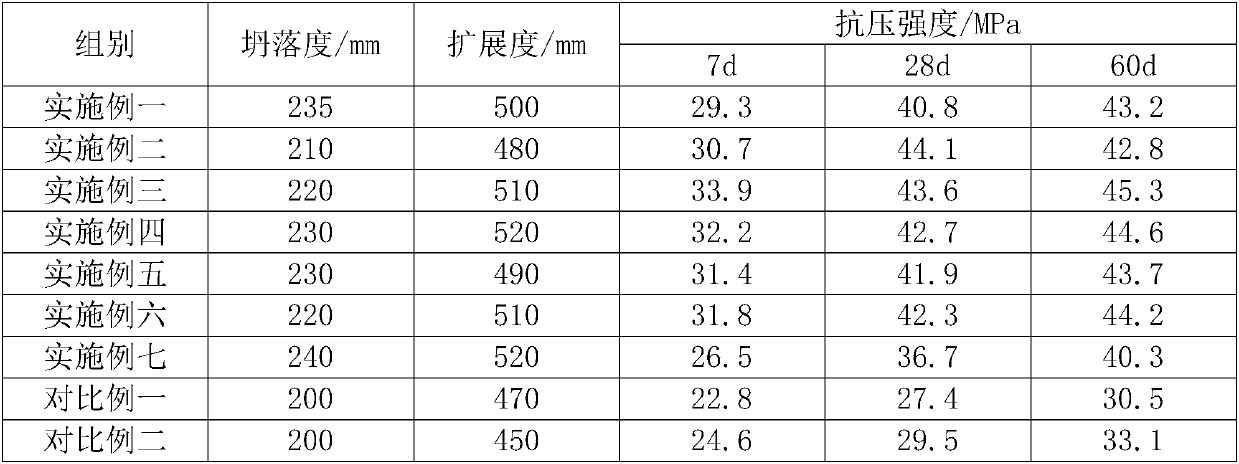

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing recycled concrete: comprising the following steps: weighing 280kg of cement, 1160kg of recycled coarse aggregate, 520kg of recycled fine aggregate, 190kg of machine-made sand, 70kg of river sand, and 90kg of pulverized coal Ash, 50kg mineral powder, 4kg organic imitation steel fiber, 16kg polypropylene fiber, 10kg basalt fiber, 4kg naphthalene superplasticizer, 2.4kg casein, 0.8kg sodium gluconate, 0.3kg melon Er gum, 0.1kg of polyvinyl alcohol, 0.8kg of polyacrylamide and 160kg of water. Among them, the recycled coarse aggregate used in this embodiment is a continuous gradation with a particle size range of 4.75-25mm, and an apparent density of 2500kg / m 3 , The ore powder used in this embodiment is blast furnace slag powder, the naphthalene-based water reducer used in this embodiment is β-naphthalenesulfonic acid methylene condensate, and the stone powder content in the machine-made sand used in this embodiment is 5%.

...

Embodiment 2

[0034] The difference between the present embodiment and the first embodiment mainly lies in: the preparation method of the recycled concrete of the present embodiment includes the following steps: weighing 280 kg of cement, 1170 kg of recycled coarse aggregate, 530 kg of recycled fine aggregate, and 192 kg of machine-made sand , 72kg of river sand, 92kg of fly ash, 50kg of silica powder, 10kg of plastic steel fiber, 20kg of polypropylene fiber, 10kg of boron fiber, 4kg of polycarboxylate superplasticizer, 2.8kg of casein, 0.6kg tartaric acid, 0.4kg of sodium gluconate, 0.2kg of cellulose ether, 0.6kg of xanthan gum, 0.6kg of polyacrylamide and 164kg of water. Among them, the polycarboxylate superplasticizer used in this example is BASF's SC-11, and the stone powder content in the machine-made sand used in this example is 7%.

[0035] Add cellulose ether, xanthan gum and polyacrylamide to the recycled coarse aggregate and recycled fine aggregate, mix and stir evenly, add machi...

Embodiment 3

[0037] The difference between this example and Example 1 mainly lies in: the preparation method of recycled concrete in this example: comprising the following steps: weighing 286kg of cement, 1176kg of recycled coarse aggregate, 536kg of recycled fine aggregate, and 196kg of machine-made sand , 76kg of river sand, 96kg of fly ash, 56kg of mineral powder, 6kg of organic imitation steel fiber, 30kg of polypropylene fiber, 12kg of basalt fiber, 4kg of naphthalene-based water reducer, 2.6kg of casein, 0.6 kg of tartaric acid, 0.3 kg of sodium gluconate, 0.32 kg of guar gum, 0.12 kg of polyvinyl alcohol, 0.86 kg of polyacrylamide and 170 kg of water, wherein the stone powder content in the machine-made sand used in this embodiment is 6 %.

[0038] Add guar gum, polyvinyl alcohol and polyacrylamide to the recycled coarse aggregate and recycled fine aggregate, mix and stir evenly, add machine-made sand and river sand, stir again and add cement, fly ash, mineral powder, organic imitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com