Tech. for forging forming of hook fastener flame of wagon and maould thereof

A railway freight car, forming technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal processing equipment, etc. Limiting the production efficiency of hook tail frame forgings and other issues to achieve the effect of improving material utilization, high production efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

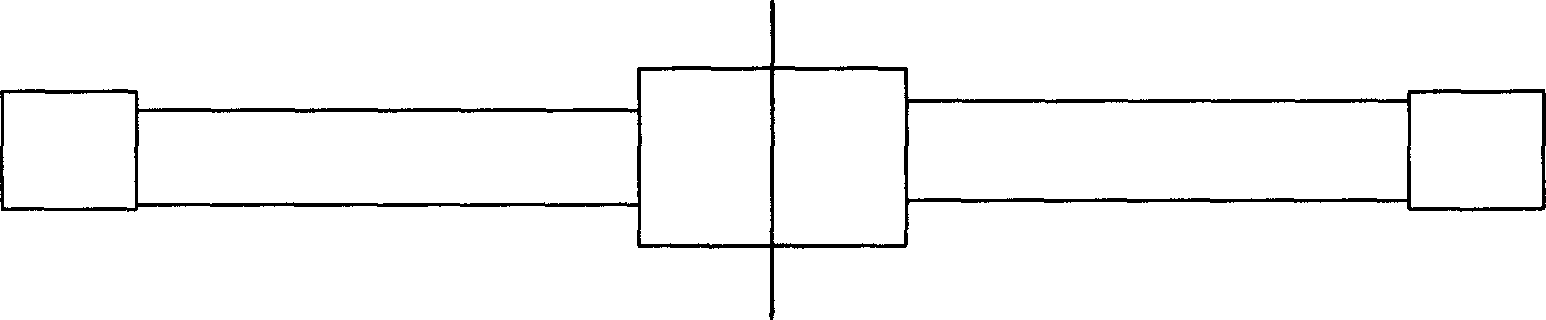

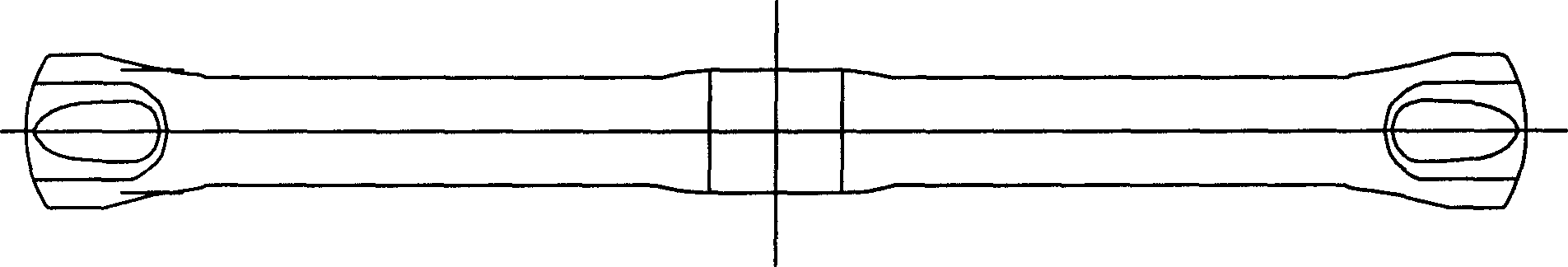

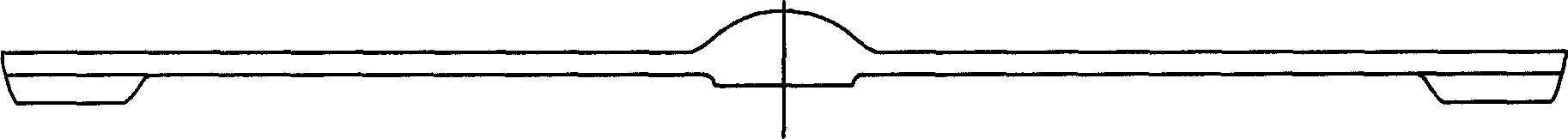

[0021] The process steps of the forging process of the hook tail frame forging of the present invention are: ① blanking, ② heating, ③ billet making, ④ die forging, ⑤ trimming, ⑥ bending, ⑦ welding.

[0022] Among them, the blanking process is to cut off the required cross-sectional size and length of raw materials, such as steel, according to the process requirements, in order to prepare for the subsequent processes. The heating process is to heat the raw materials according to the process requirements. The initial forging temperature of the heating is about 1200°C. The electromagnetic induction heating method or the chamber furnace heating method can be used; the blanking and heating processes are common and necessary processes in the prior art. The billet making process adopts roll forging to make billets, and uses roll forging dies to make raw materials into intermediate blank shapes that are distributed according to the final axial cross-sectional area of the hook tail fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com