Patents

Literature

914 results about "Railway freight car" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

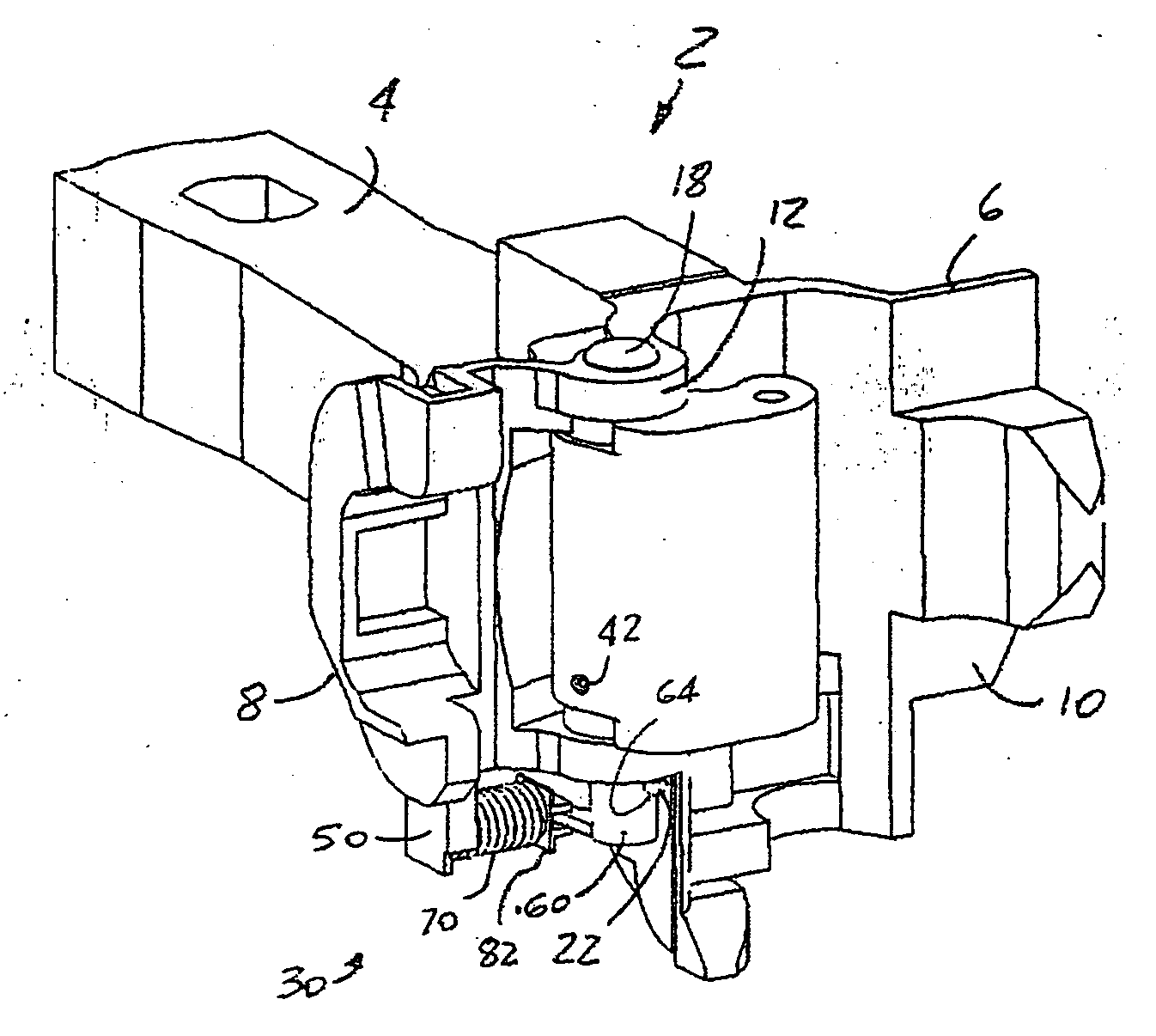

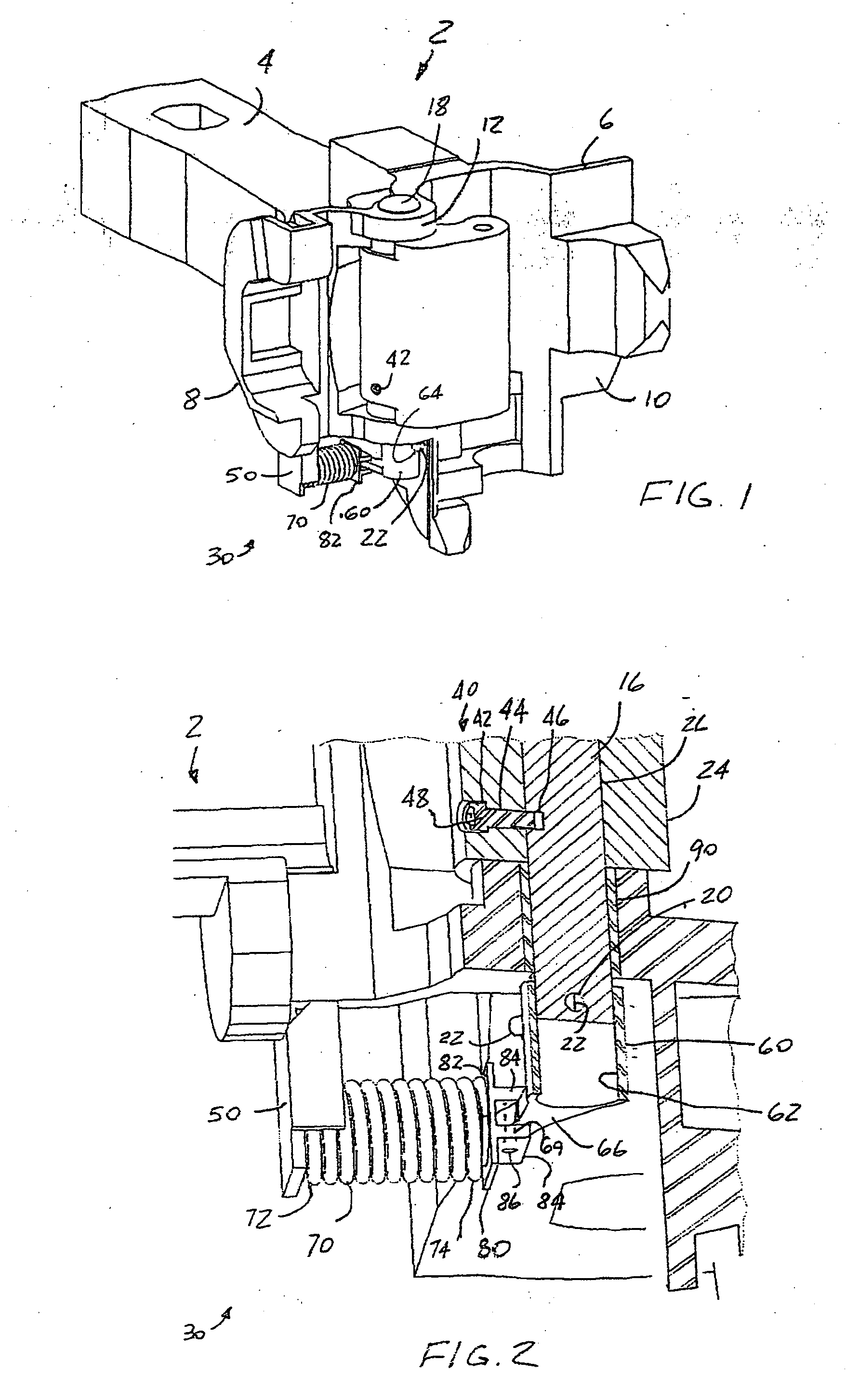

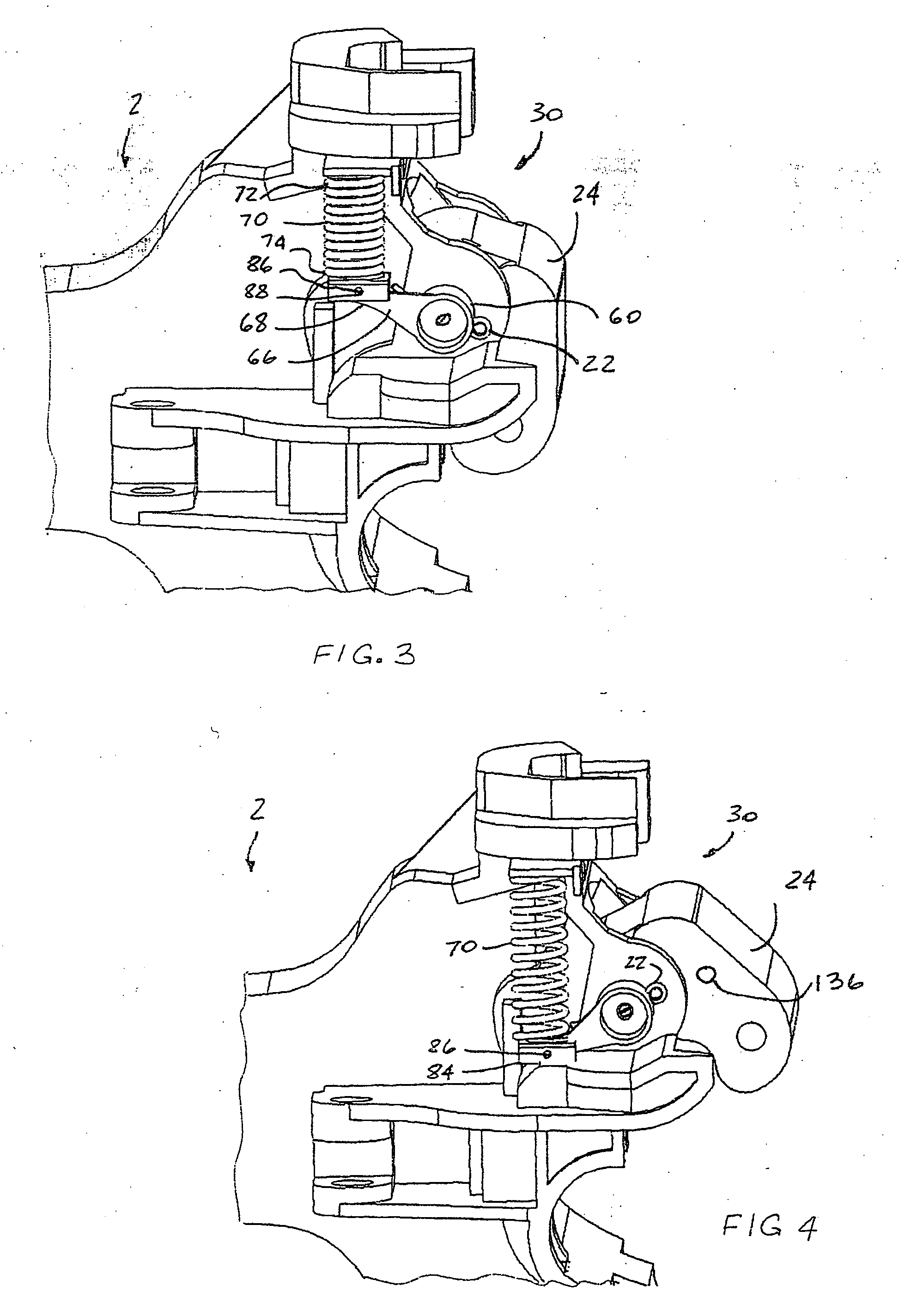

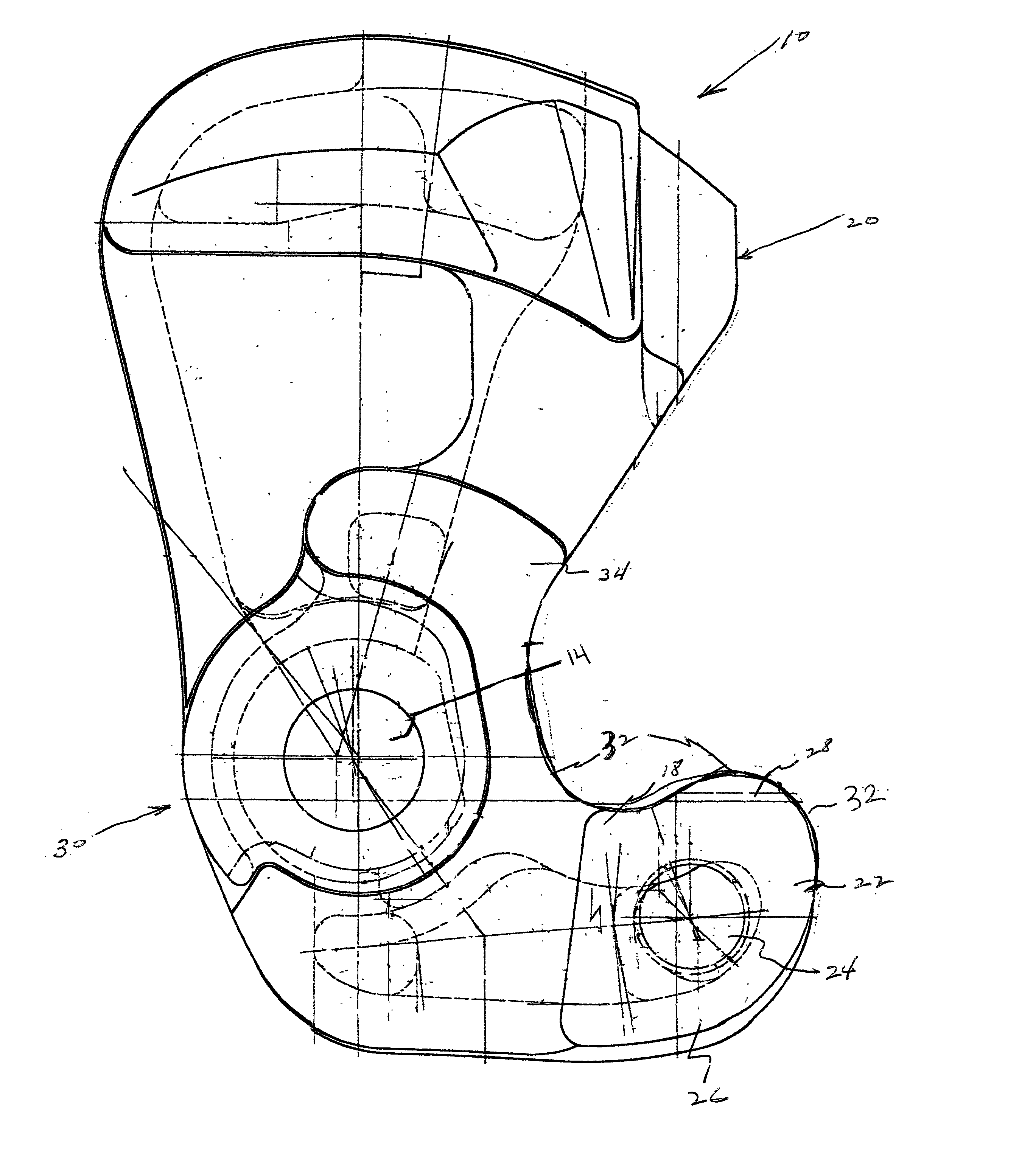

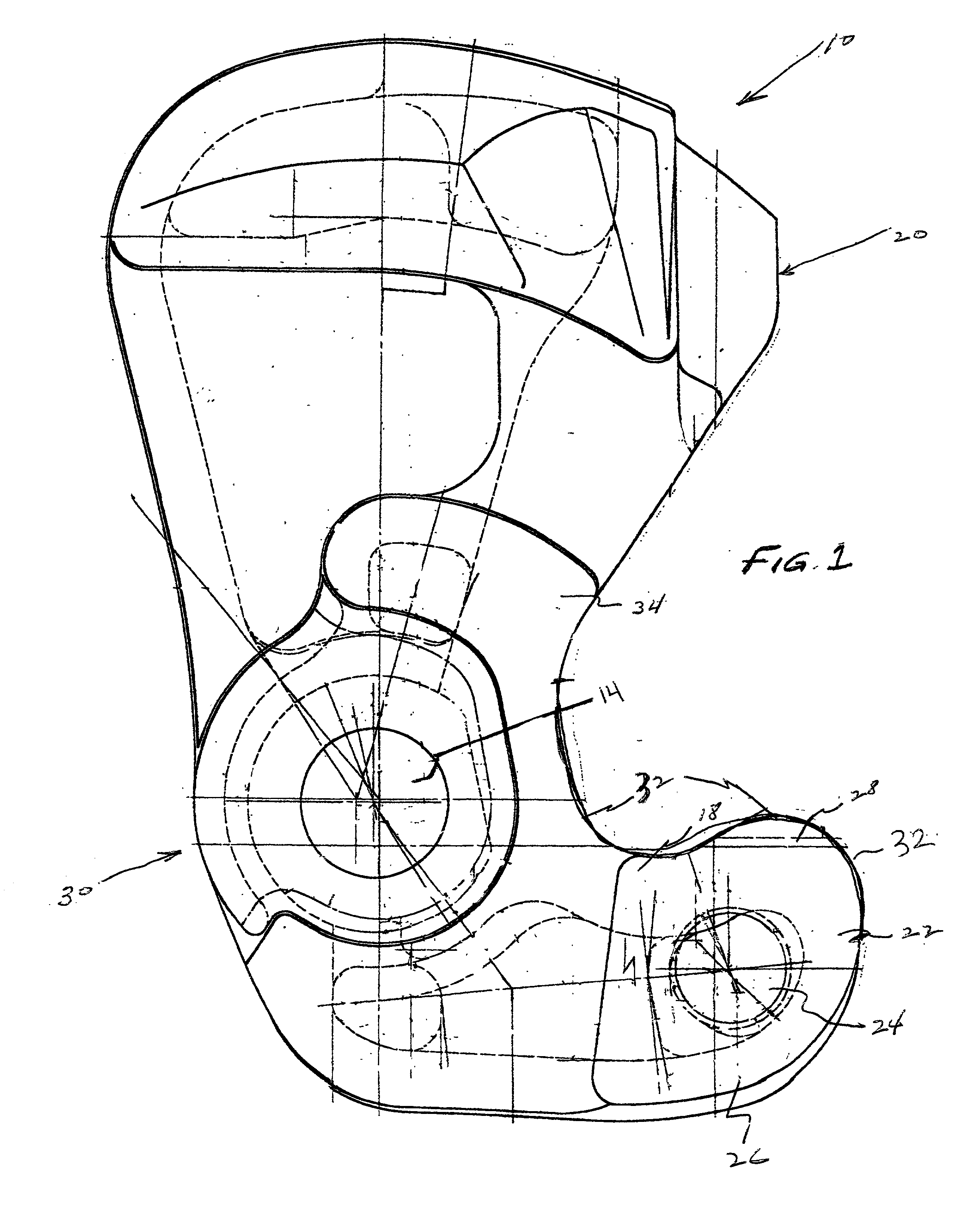

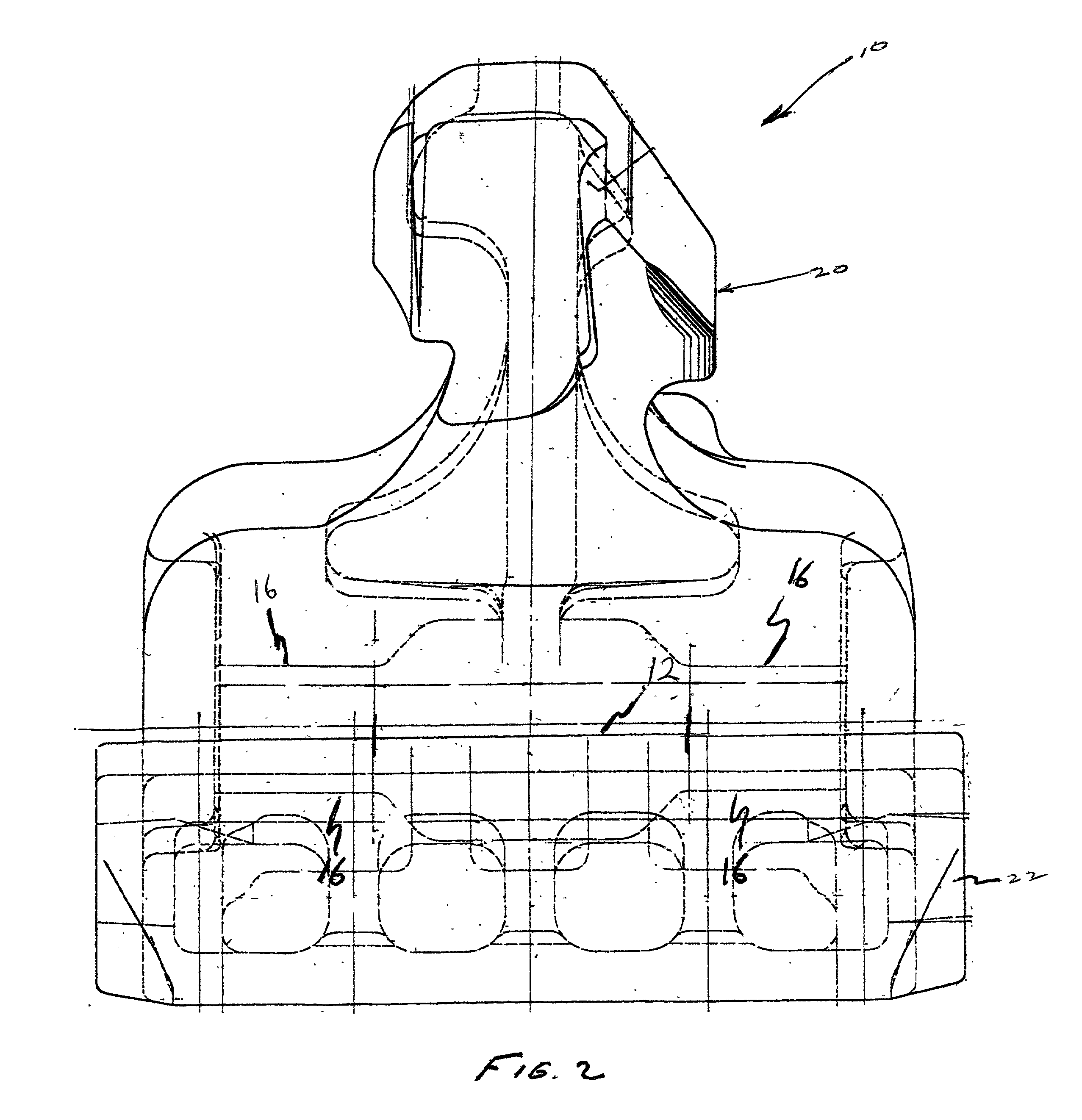

Apparatus for railway freight car coupler knuckle

InactiveUS20070084818A1Eliminate dangerEliminate hazardous routineRailway couplingsLocking mechanismCombined use

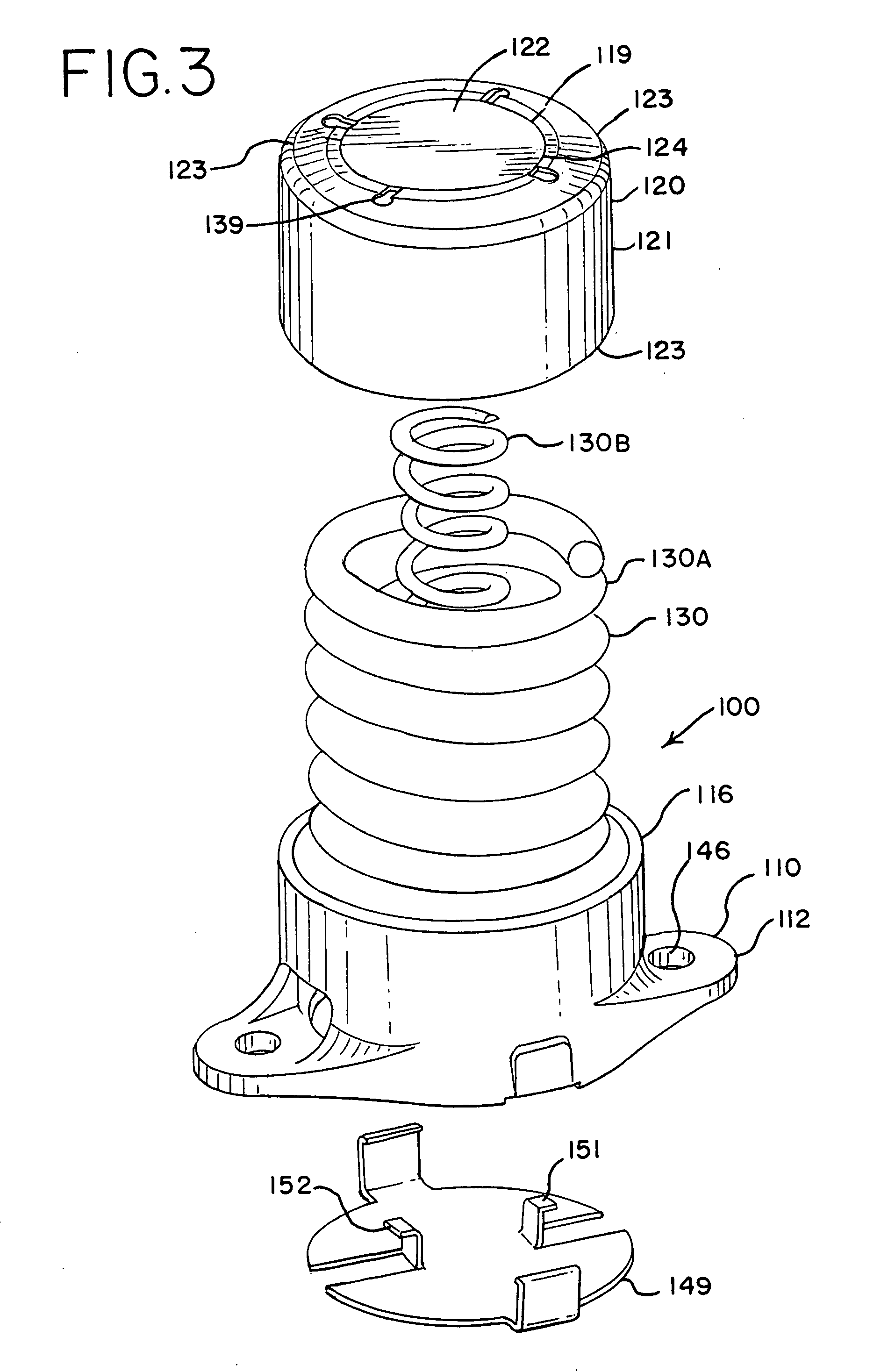

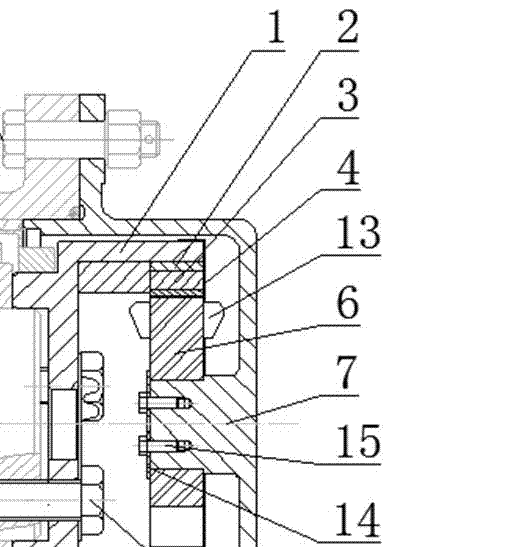

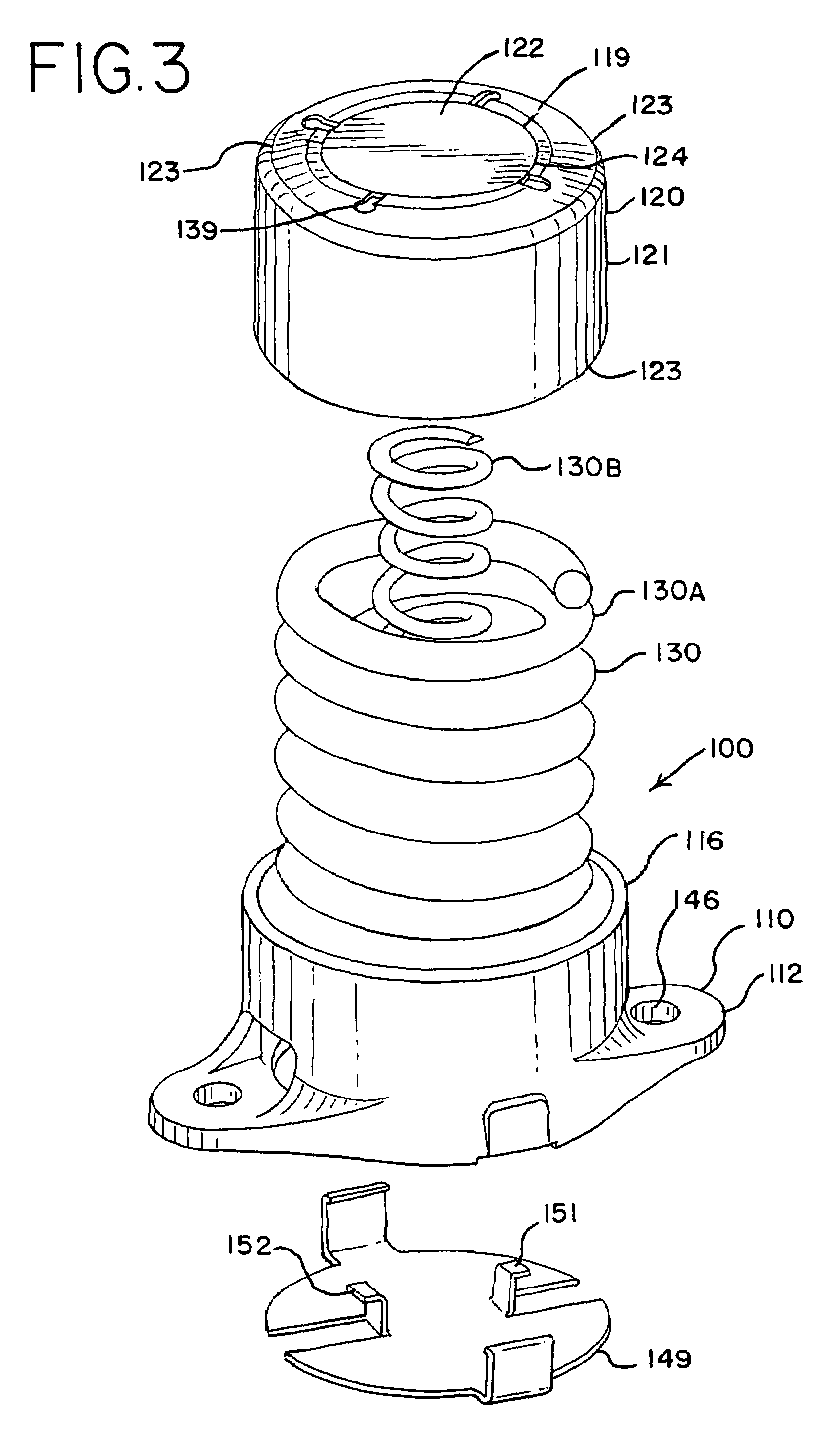

In combination with a railway freight car coupler. A coupler has a knuckle side, and includes a knuckle, knuckle pin, and an apparatus for automatically pivoting and maintaining the knuckle full open position. The improvement comprises a coiled torsion spring which is capable of continuously exerting a predetermined force. A sleeve in combination with a flange is secured to the bottom end of the knuckle pin for attaching the torsion spring onto the coupler head. A support member is attached to the knuckle and cages one arm of the torsion spring which exerts a continuous force on the knuckle to rotate and maintain the knuckle full open position. A compression spring may be employed in place of the torsion spring in combination with a locking mechanism which, rigidly secures the knuckle and knuckle pin therebetween to prevent independent movement.

Owner:SHARMA & ASSOCS

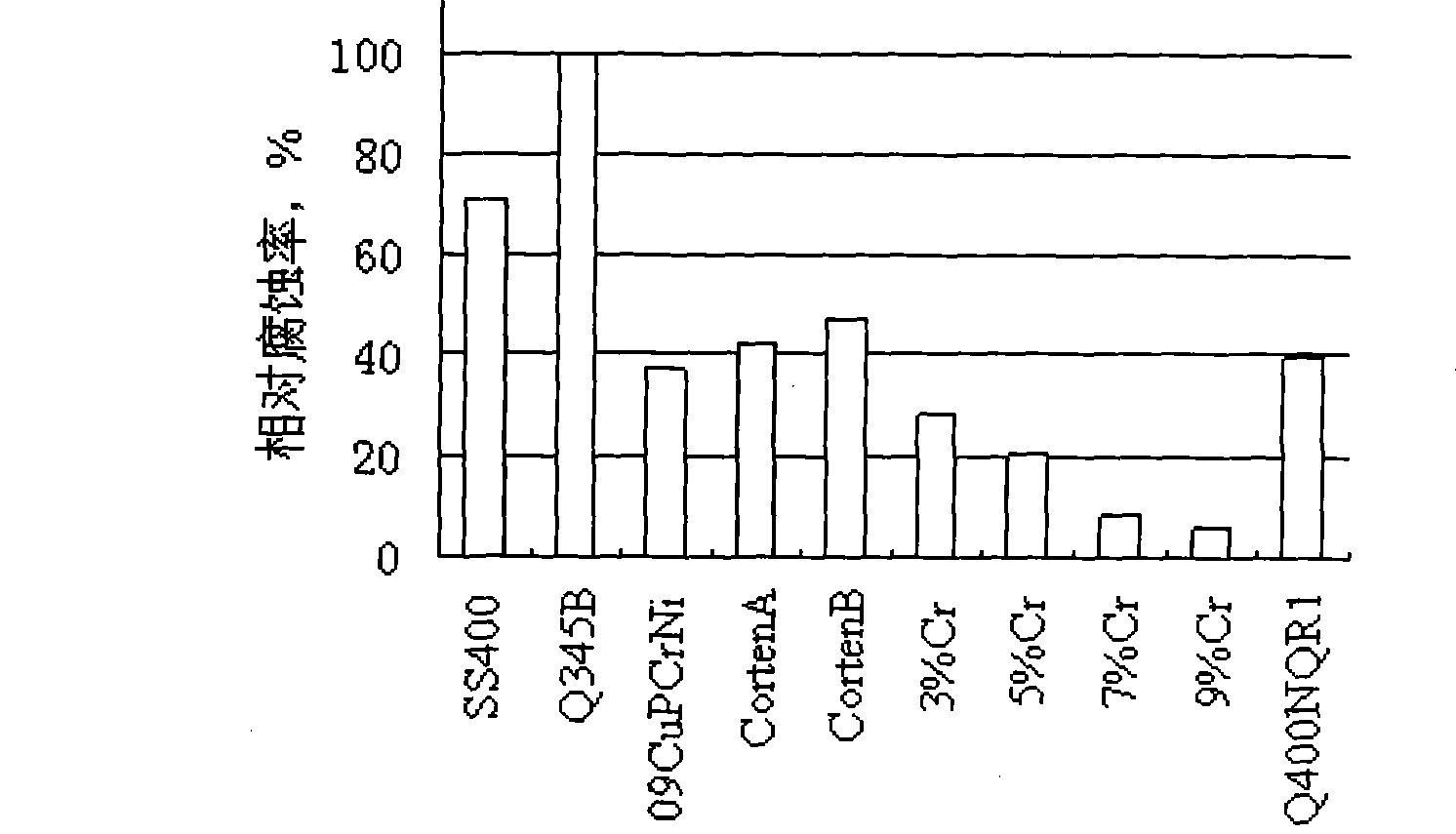

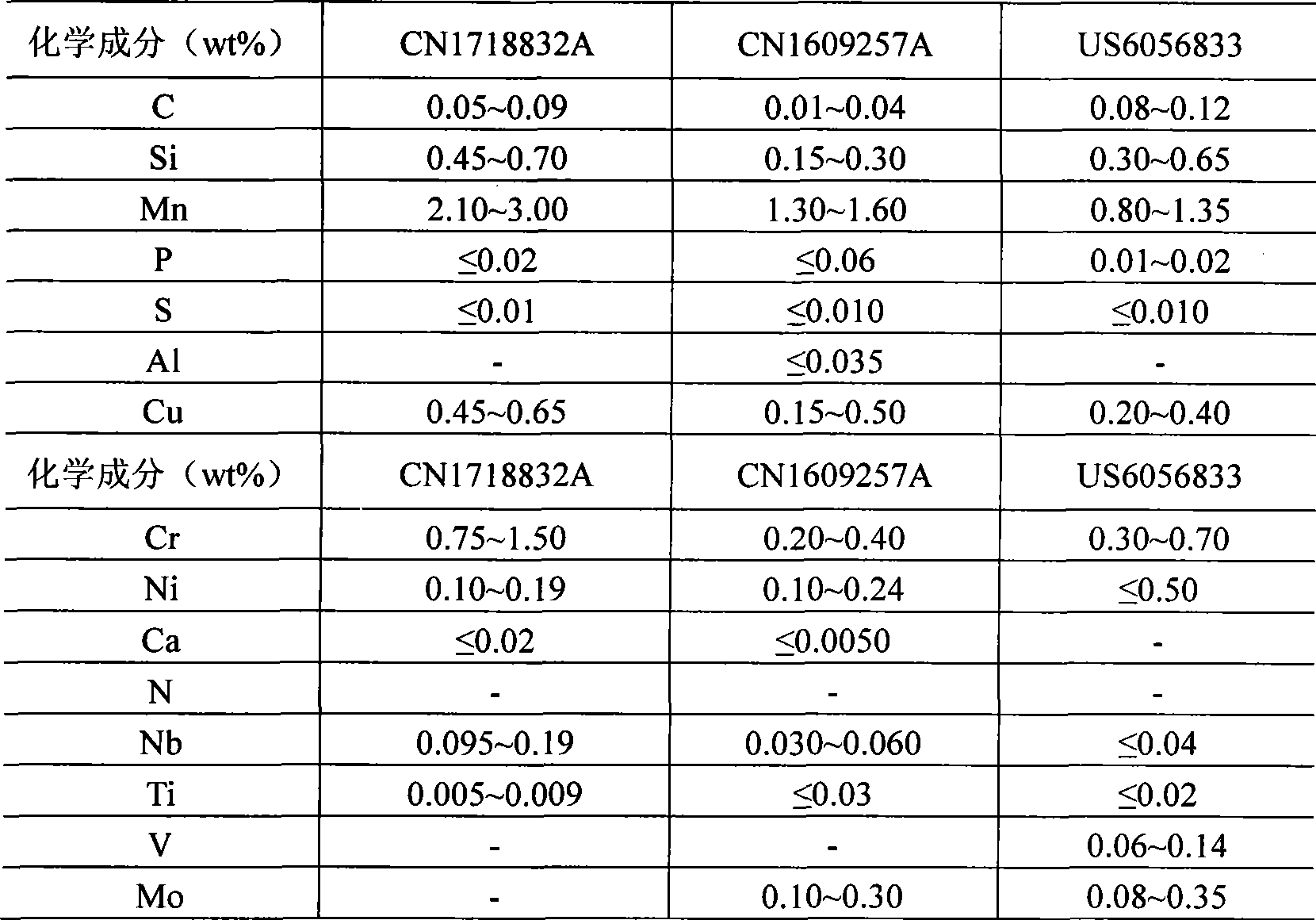

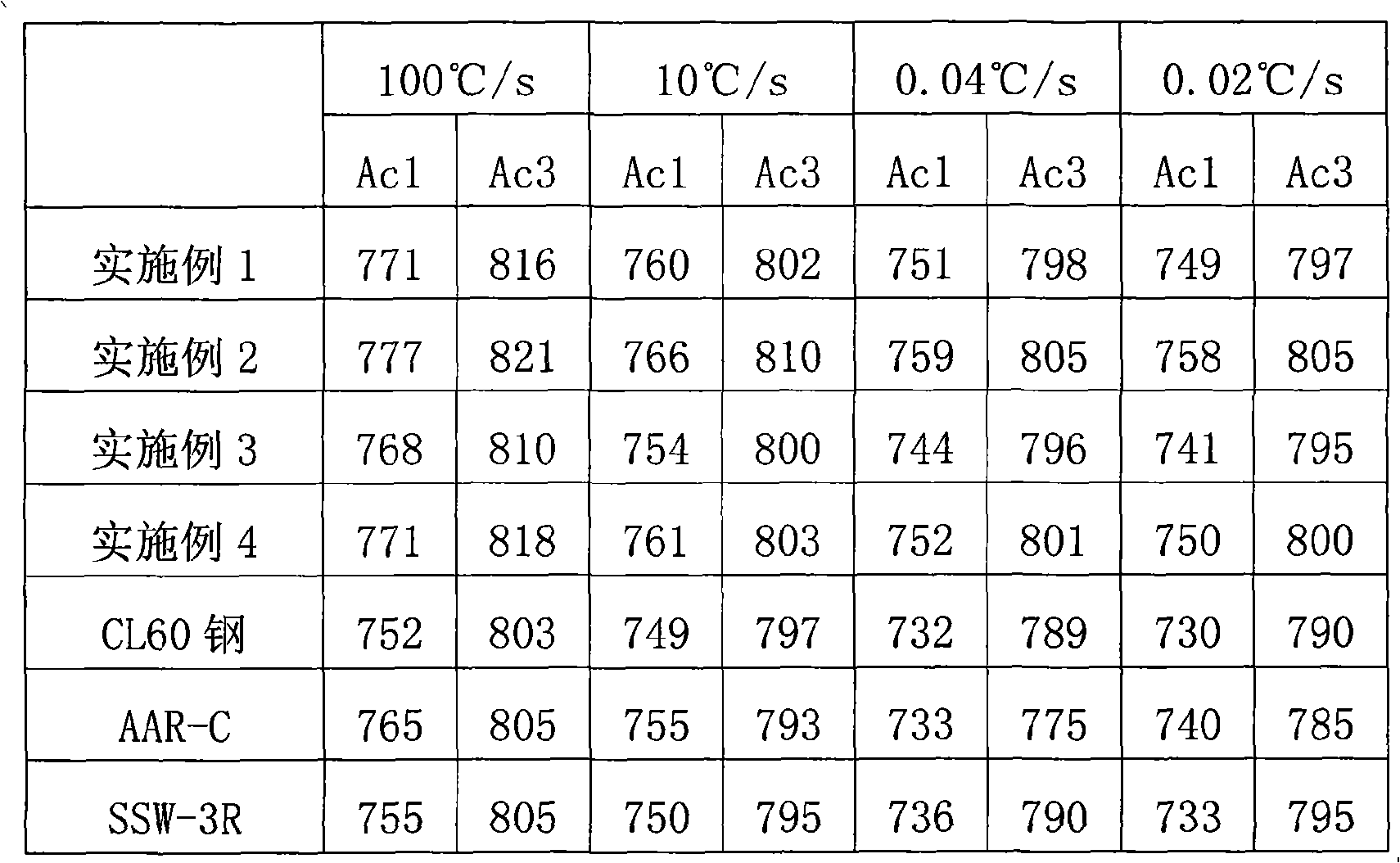

High-corrosion resistant high-strength weather resisting steel and manufacturing method thereof

ActiveCN101376953ALight weightReduce manufacturing costTemperature control deviceChemical compositionHigh intensity

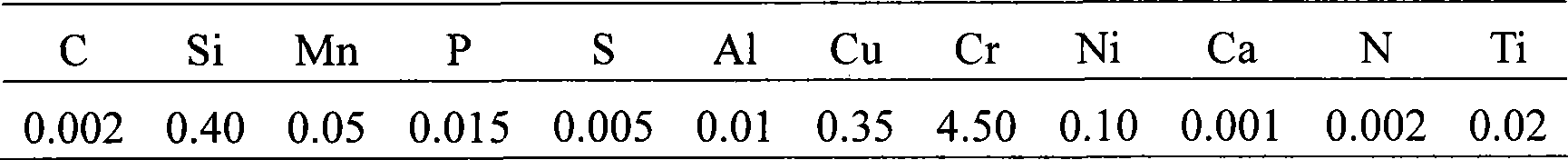

The invention provides high-corrosion resistance and high-strength weather resistant steel which comprises the following chemical components (in weight percentage): 0.002 percent to 0.005 percent of C, 0.20 percent to 0.40 percent of Si, 0.01 percent to 0.05 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.008 percent of S, 0.01 percent to 0.05 percent of Al, 0.20 percent to 0.40 percent of Cu, 4.50 percent to 5.50 percent of Cr, less than or equal to 0.40 percent of Ni, 0.001 percent to 0.006 percent of Ca, 0.001 percent to 0.006 percent of N, less than or equal to 0.03 percent of Ti, and the rest are Fe and other inevitable impurities. The invention also provides a manufacturing method of the weather resistant steel. The yield strength of the weather resistant steel is more than 700MPa, the extensibility is more than 20 percent and the atmospheric corrosion resistance is higher than that of traditional high-strength weather resistant steel; in addition, the steel can be directly used in atmospheric environment without being coated, and meets the requirements of railway freight car, container and bridge building fields.

Owner:BAOSHAN IRON & STEEL CO LTD

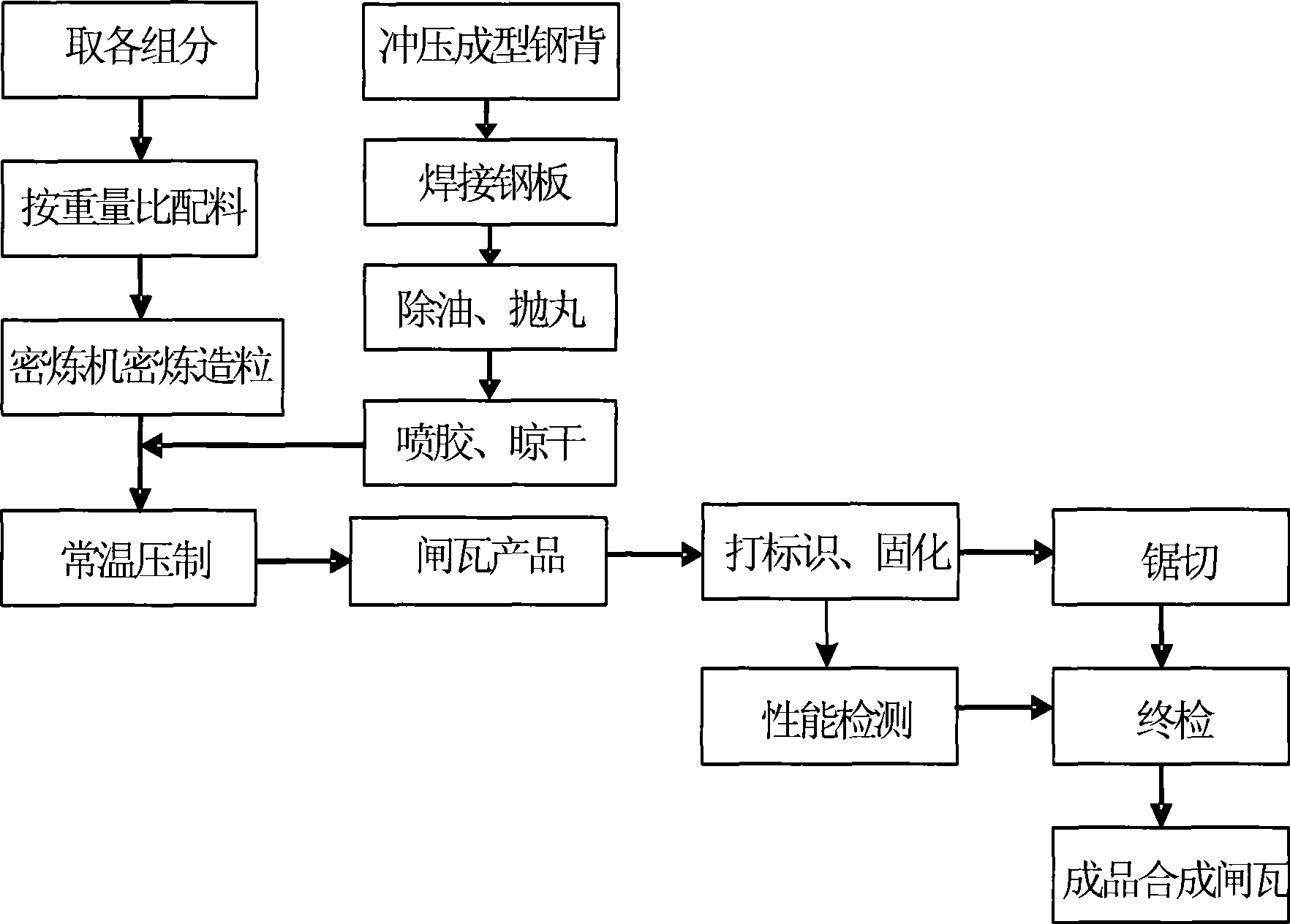

High friction composite brake shoe for railway freight car and manufacture method thereof

ActiveCN101391611AHigh compressive strengthHigh impact strengthBraking membersBrake arrangement with braking memberFiberEngineering

The invention discloses a high friction composite brake shoe for a railway wagon and a manufacturing method thereof. The composite brake shoe comprises: a steel back and a brake shoe body which is fixed on the steel back, wherein, the brake shoe body is prepared by materials which are synthesized by various components with the following weight ratio: 8 to13 parts of nitrile butadiene rubber, 2 to10 parts of styrene butasiene rubber, 5 to10 parts of cresol modified A-stage phenolic resin, 15 to 30 parts of steel fiber, 10 to 15 parts of magnesium oxide, 5 to 10 parts of calcined petroleum coke, 2 to 5 parts of silicon carbide, 10 to25 parts of mineral fiber, 5 to 10 parts of calcium hydride, 10 to 20 parts of barium sulfate, 5 to 10 parts of graphite, 1 to 5 parts of molybdenum disulfide, 1 to 5 parts of carbon black, 1 to 3 parts of sulfur and 1 to 3 parts of enhancer. The brake shoe can be used in the railway heavy-duty high-speed wagon and has stable friction performance and better wear resistance; the brake shoe can effectively inhibit the phenomena of metal inlay, cracks, dropping blocks and the like and reduce the damages on wheels; and the brake shoe is characterized by better impact resistance performance and good weatherability.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

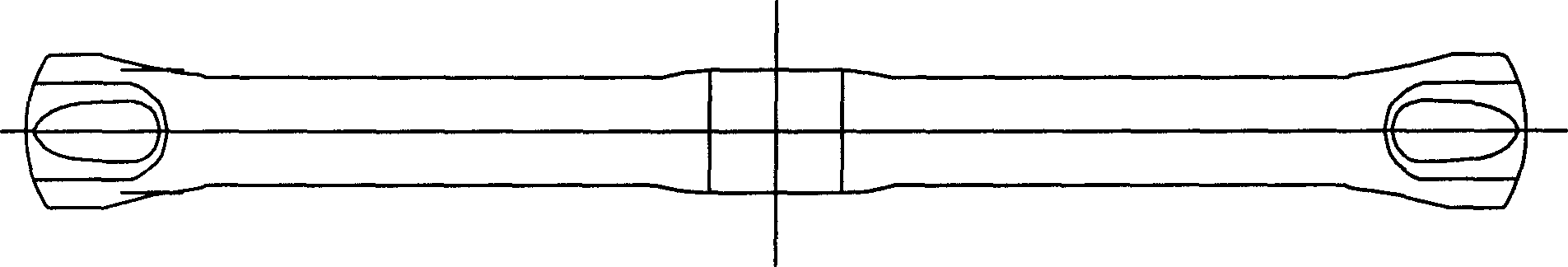

Steel for microalloying lorry axle and technique for producing the same

InactiveCN101497968AHigh strengthHigh resistance to crack susceptibilityManufacturing convertersCrack resistanceMetallurgy

The invention discloses microalloyed steel used for an axle of a railway freight car, wherein the microalloyed steel contains the following chemical components by weight: 0.50-0.57 percent of C, 0.17-0.40 percent of Si, 0.60-1.00 percent of Mn, 0.20-0.35 percent of Cr, 0.18-0.40 percent of Ni, 0.08-0.18 percent of Mo, 0.02-0.06 percent of Al, 0.020-0.060 percent of Ti, 0.030-0.10 percent of V, less than or equal to 0.010 percent of S, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of B, less than or equal to 0. 20 percent of Cu, less than or equal to 0.010 percent of Sb, less than or equal to 0.03 percent of Sn, less than or equal to 0.04 percent of As, less than or equal to 0.0015 percent of [O] and less than or equal to 0.0060 percent of [N], and the rest is Fe. The invention has high strength, good plasticity, good low-temperature impact property and good crack-resistance sensitivity.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

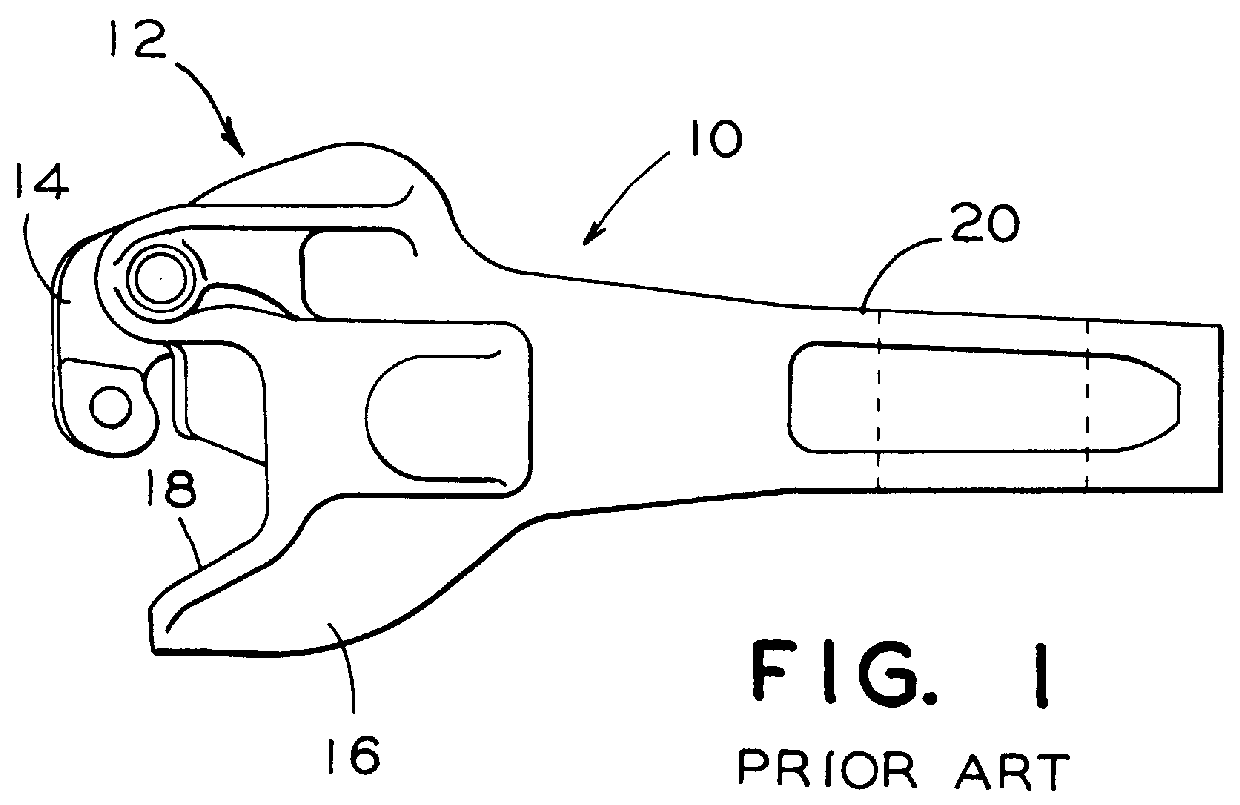

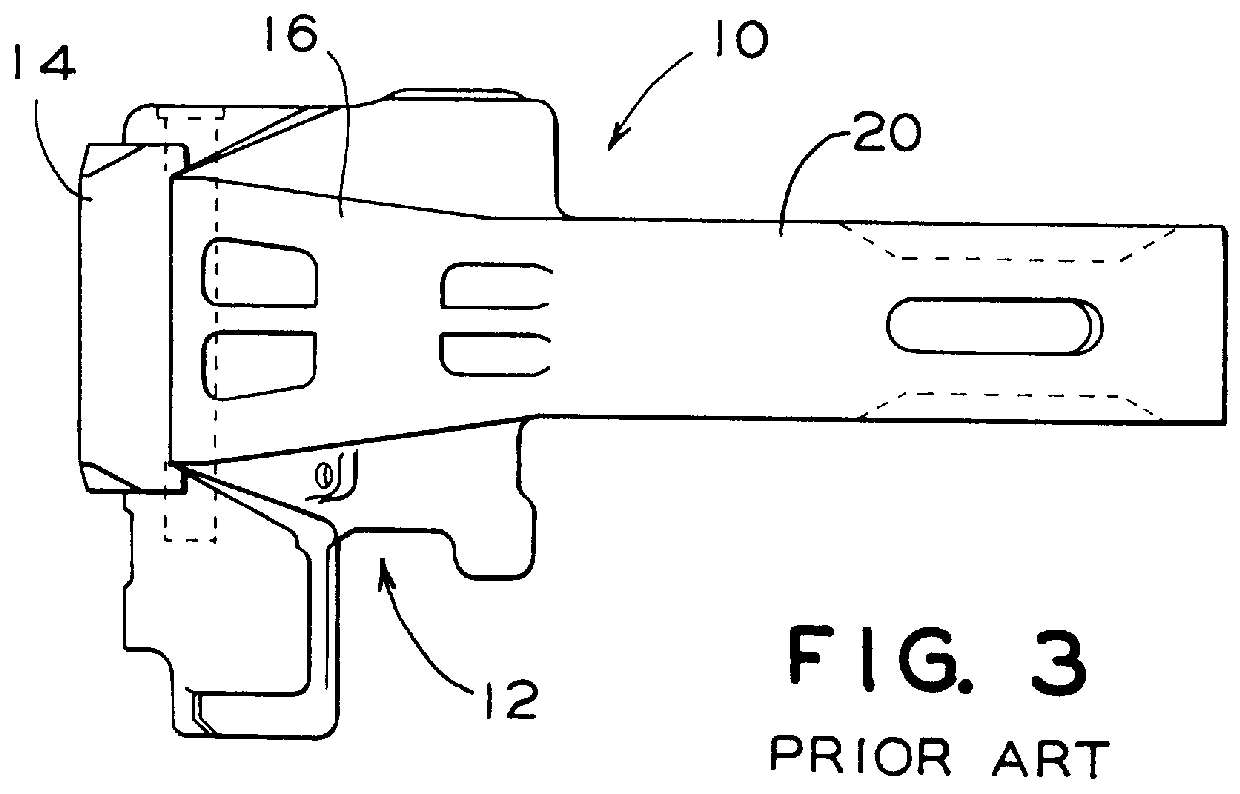

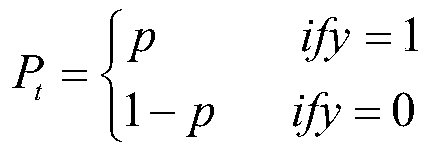

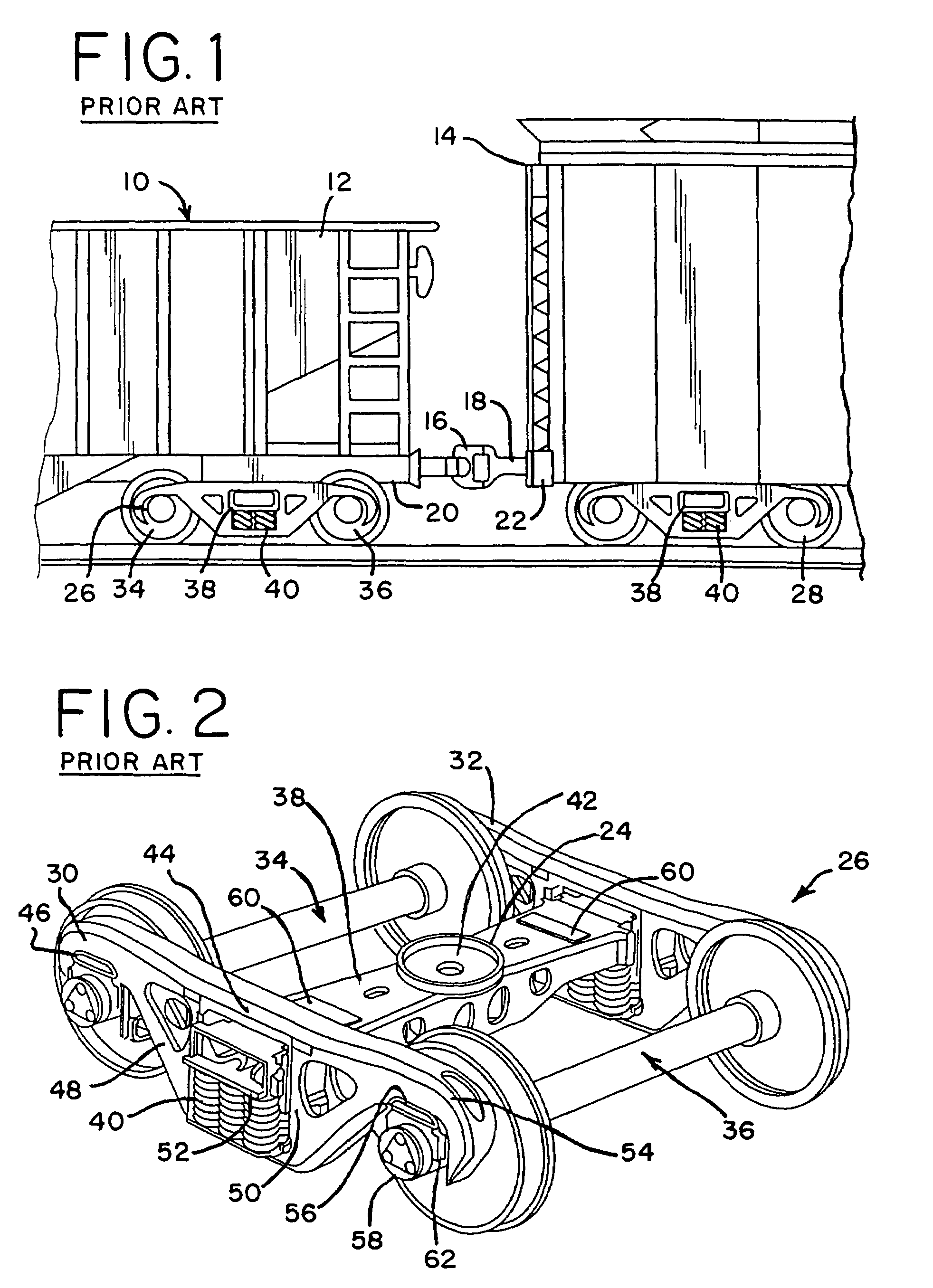

Type E railway coupler with expanded gathering range

InactiveUS6148733AIncrease rangeEnhanced couplingRailway coupling accessoriesTruckRailway freight car

A Type E railway freight car coupler having an expanded gathering range is achieved by attaching or forming an extension wing extending diagonally outward from an outer end of the gathering arm to thereby provide an extension to the angled gathering surface. The extension wing can either be cast as one piece directly with the coupler, or cast separately and welded onto the coupler.

Owner:MCCONWAY & TORLEY LLC

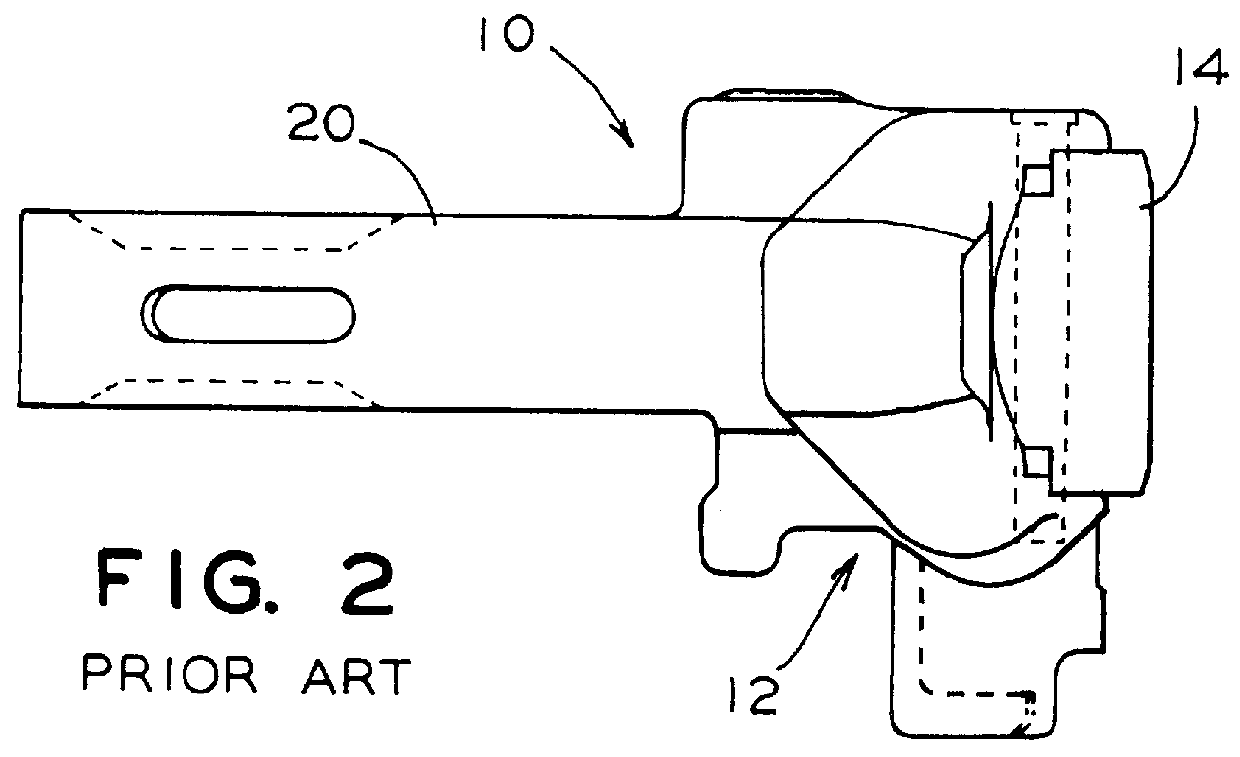

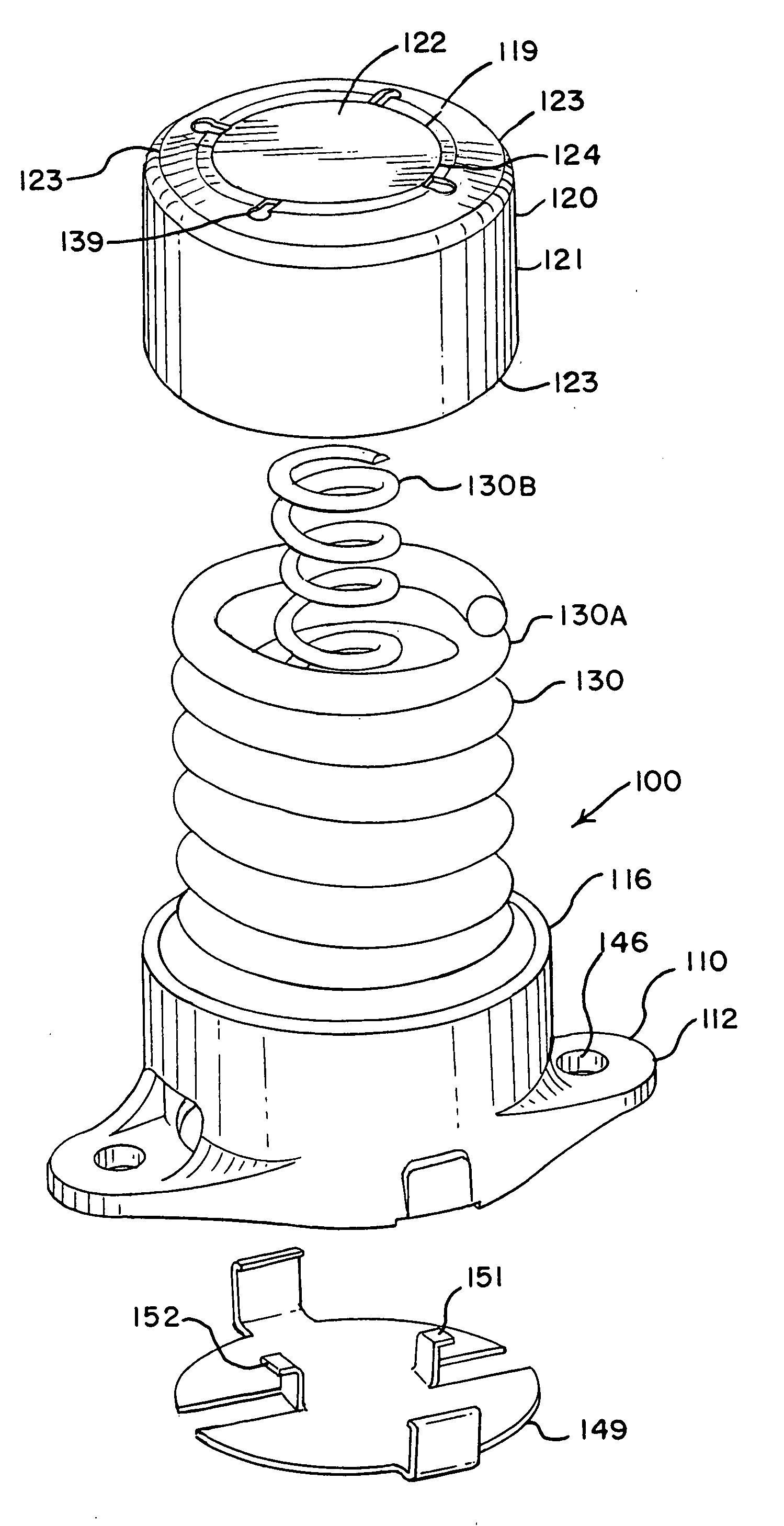

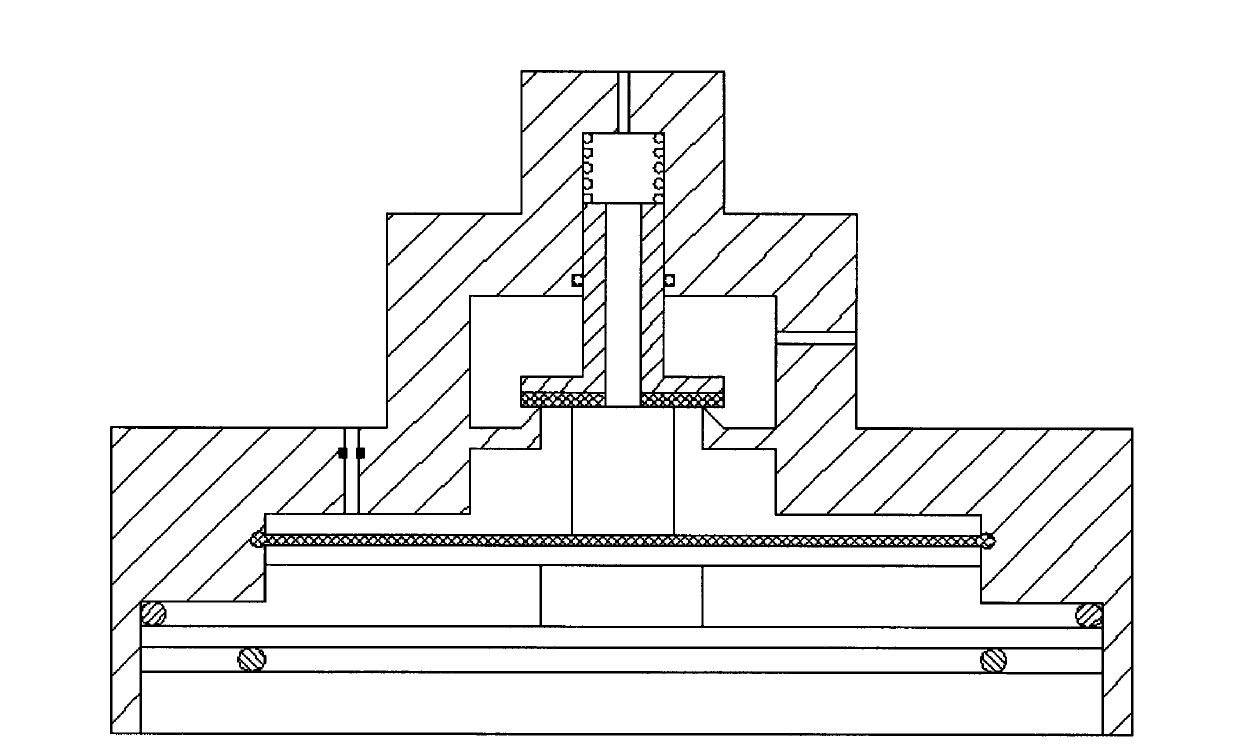

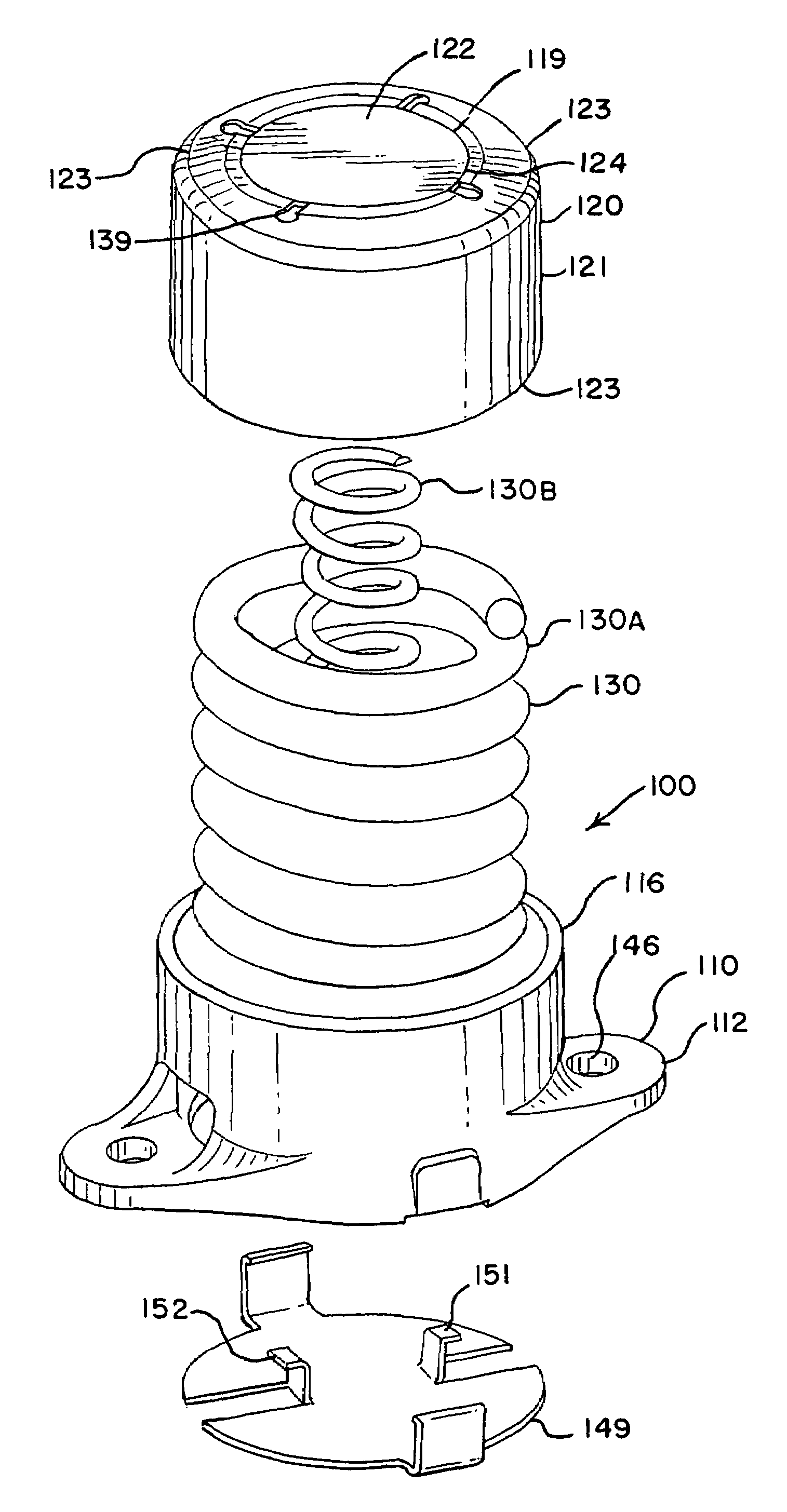

Railway freight car side bearing

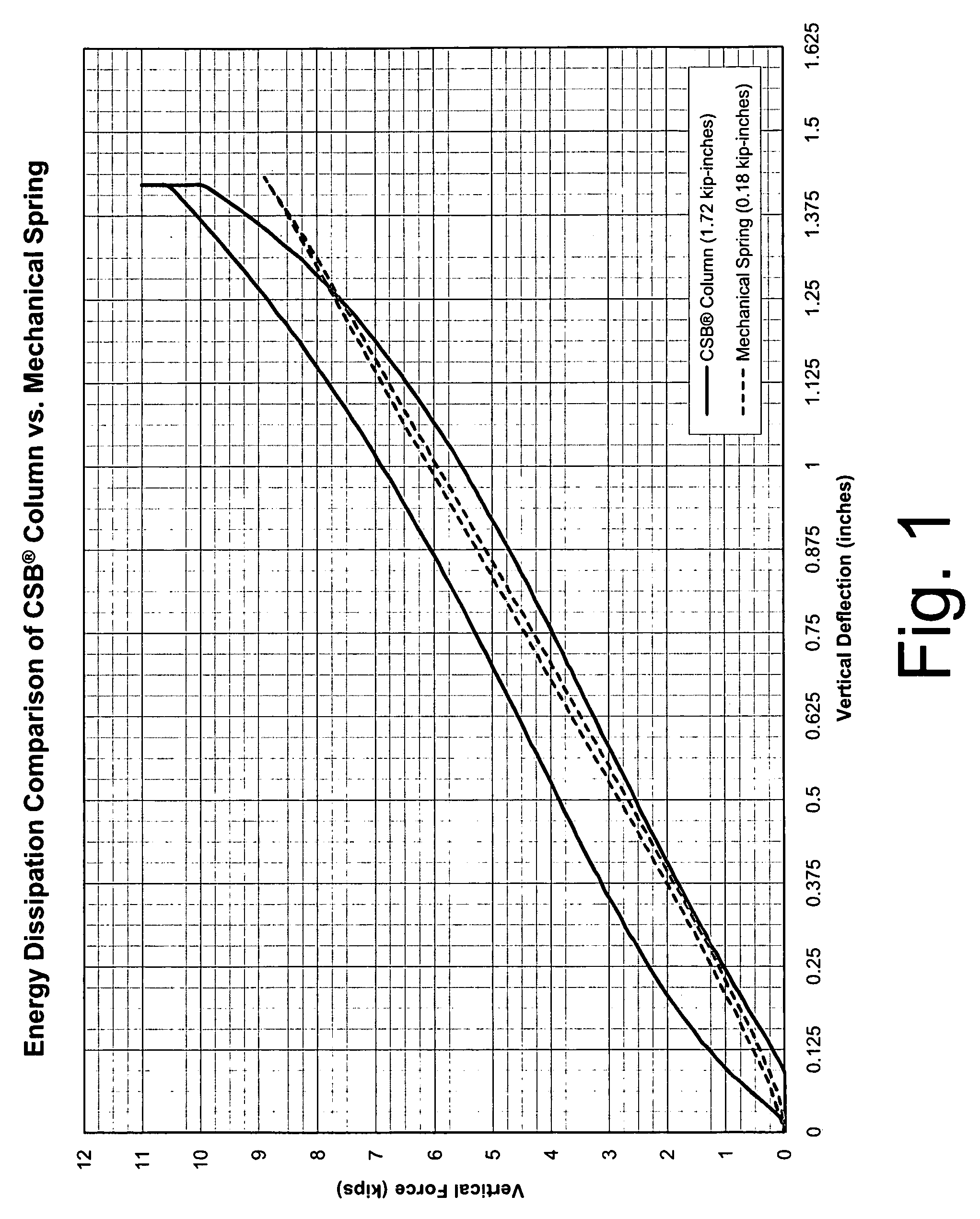

ActiveUS20080035012A1Easy to wearExtended service lifeBogiesBogie-underframe connectionsElastomerCoil spring

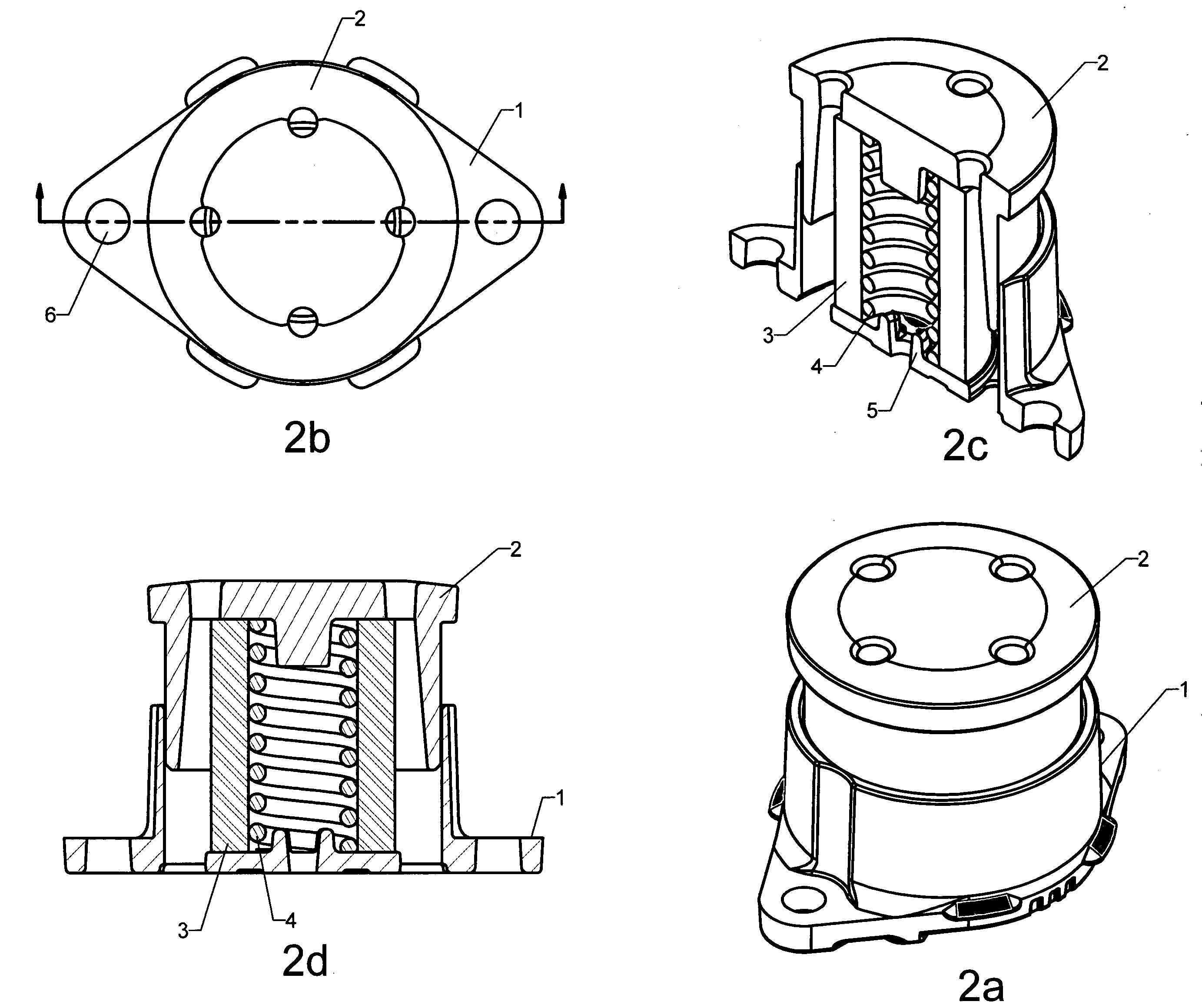

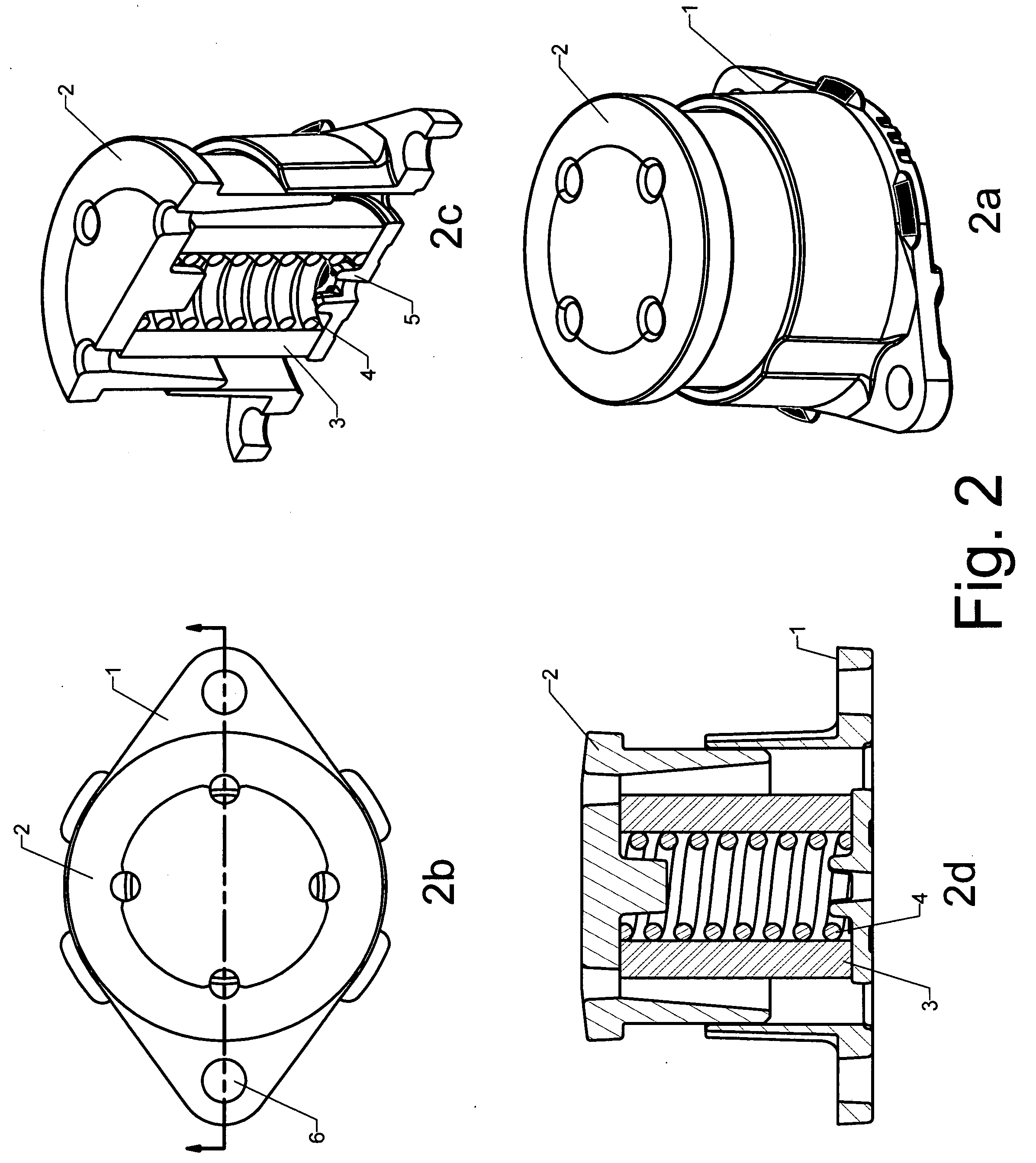

A long travel constant contact side bearing for railway cars provides better handling characteristics, achieving improved tracking and curving through use of various combinations of features. The side bearing comprises a base and a generally cylindrical wall section extending upwardly from the base. A cup-shaped cap comprises a generally circular top section and a generally cylindrical wall section extending downwardly therefrom. The cap extends into the wall section of the base. At least one coil spring is provided within the base and extends to the underside of the cap. The cup shaped cap includes a centrally located cut out section with an elastomer pad fitted within the cut out section. The cup shaped cap cylindrical wall sections can be coated with a lubricant or hardening substance.

Owner:AMSTED RAIL CO INC

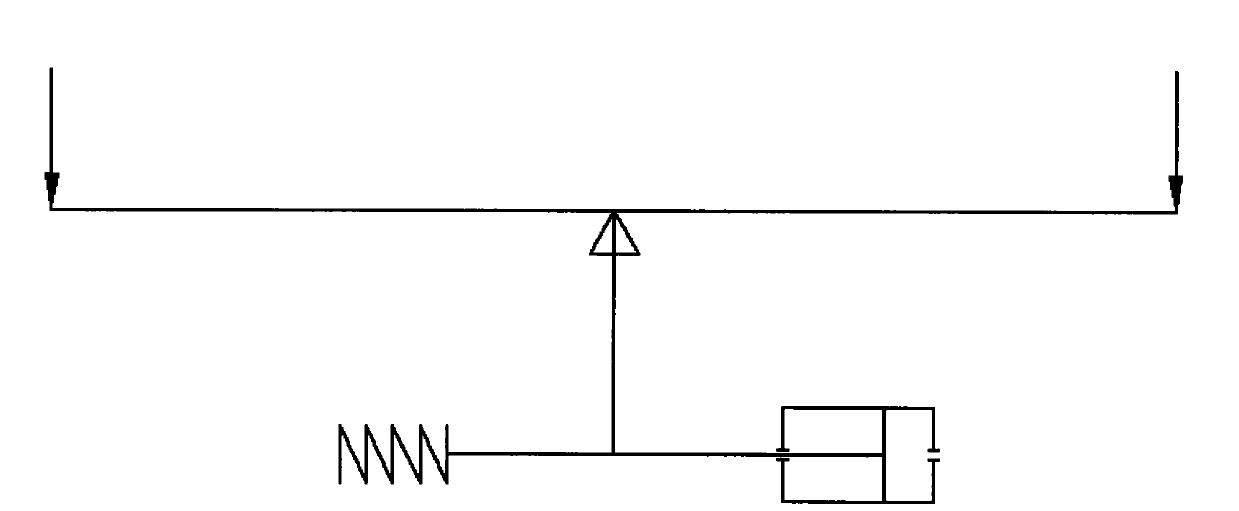

Constant Contact Side Bearing for railroad freight cars

InactiveUS20080173211A1Improve balanceReduce disadvantagesSliding contact bearingsBogiesElastomerTruck

A railway freight car constant contact side bearing positionable between a railway vehicle body and a wheeled truck supporting said railway freight car body with a housing or cage and a cap on such cage to engage the wear plate on the car body. The cage houses a plurality of springs having at least one metallic spring and at least one elastomer spring; such springs combine to support and dampen the forces of said vehicle body.

Owner:A STUCKI CO

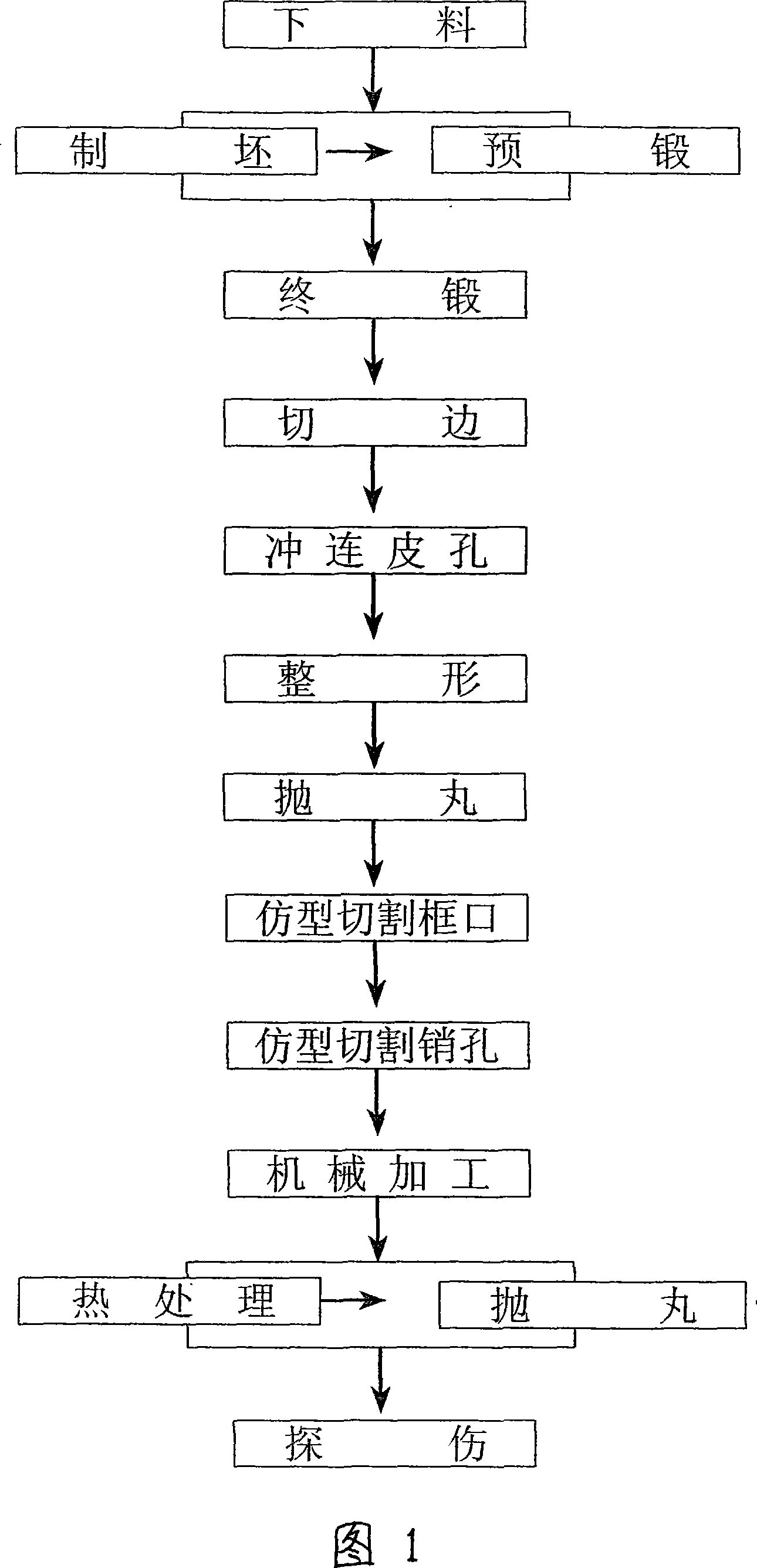

Preparation method for railway freight car coupler tail frame integral forging

The high strength alloy steel blank is made through blank making, casting, rectifying, cutting, machining, heat treatment, pill thrusting, and it excels with greatly reduced defects rate, improved in comprehensive feature, doubly increased in part strength and durability. The anti stretch strength reaches 850N / mm2. The impact power Akvj reaches over 27. Through static charge testing, stresses for all the parts are within the allowable scope, increasing fatigue 80%, and durability two times.

Owner:南京中盛铁路车辆配件有限公司

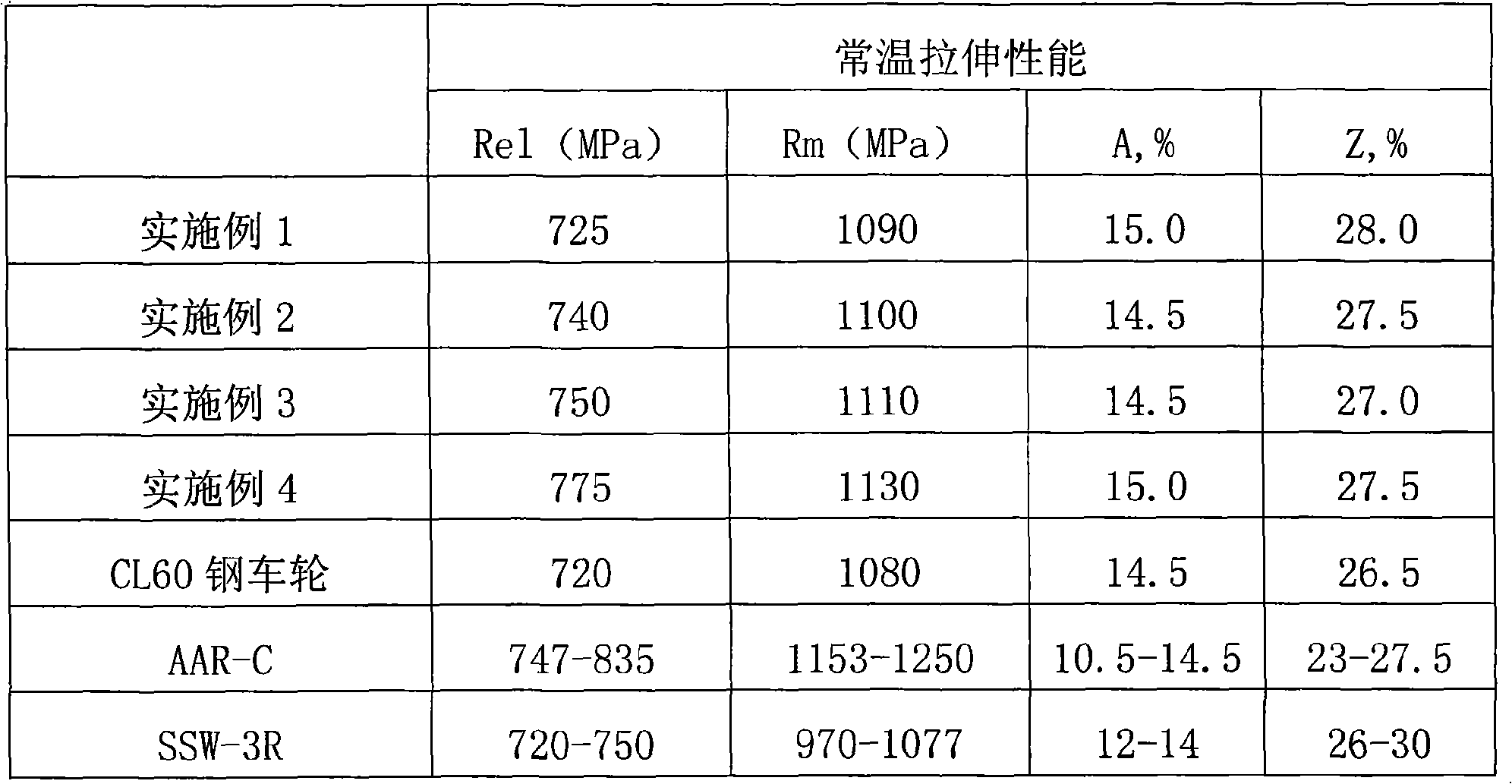

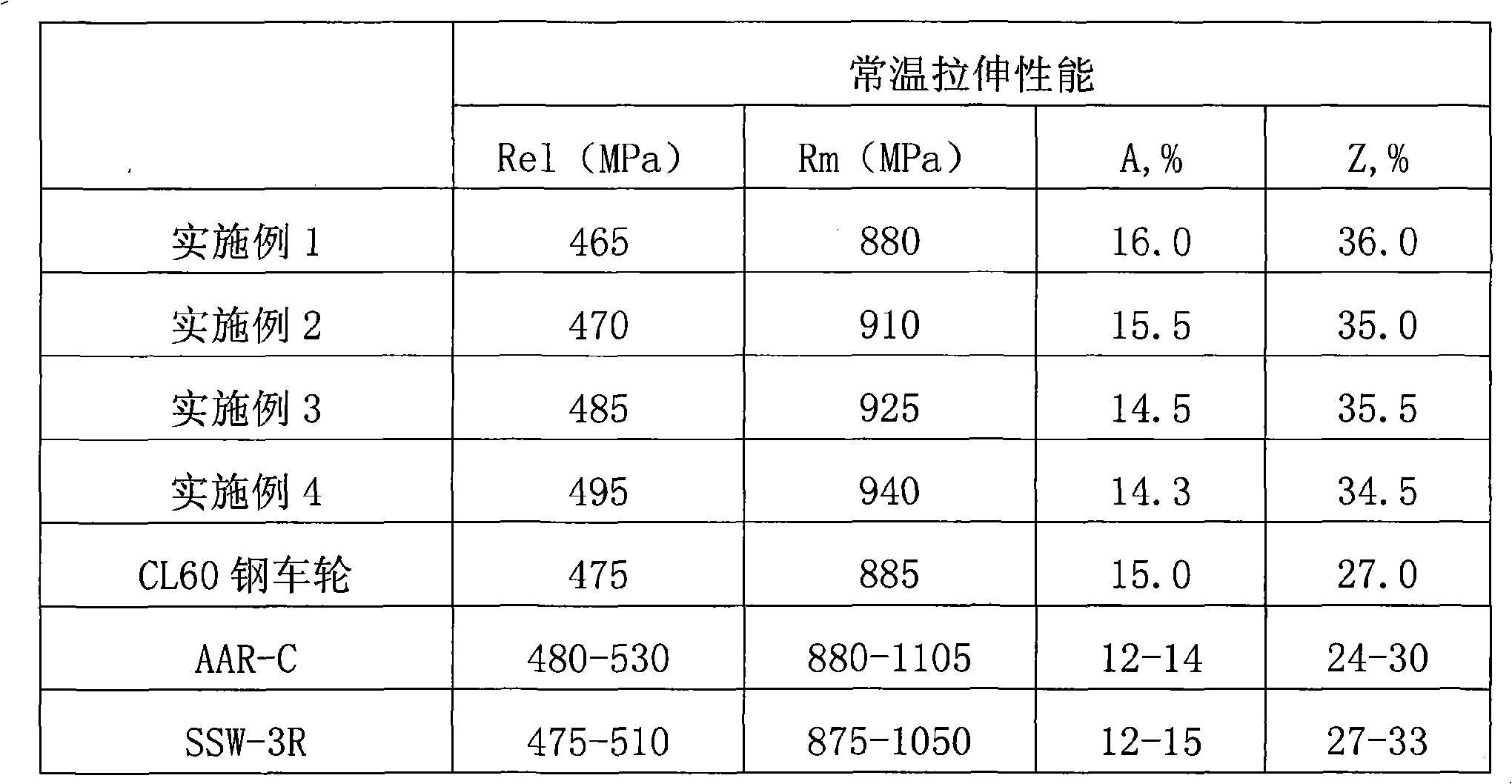

Wheel steel for heavy duty goods train and manufacture method thereof

InactiveCN101314833AThe probability of austenite transformation is reducedImprove heat damage resistanceSteelmakingIngot

The invention discloses a wheel steel used in a heavy-load railway freight car, which comprises the alloying elements by mass percentage (percent) as follows: C is 0.52 to 63 percent, Si is 0.50 to 0.10 percent, Mn is 0.80 to 1.20 percent, Cr is less than or equal to 0.70 percent, S is 0.005 to 0.020 percent, P is less than or equal to 0.030 percent, and the others are ferrum and impurity elements. A preparation method of the wheel steel comprises a converter steelmaking working procedure, an LF furnace refining working procedure, a VD vacuum treatment working procedure, a continuous round-billet casting working procedure, an ingot slicing rolling working procedure, a heat treatment working procedure, a machining working procedure, and a finished product detecting working procedure; the heat treatment working procedure comprises the steps that the heating treatment lasts for 2.0 to 2.5 hours under the temperature that ranges from 880 to 900 DEG C, the jet hardening satisfies 200 to 300S, and then the tempering treatment lasts for 3 to 4 hours under the temperature that ranges from 500 to 550 DEG C. A wheel, which is manufactured by using the wheel steel, increases the strength and the hardness performance obviously on the basis of preserving the original toughness and plasticity of the wheel.

Owner:MAANSHAN IRON & STEEL CO LTD +1

Railway car coupler knuckle having improved bearing surface

InactiveUS20030127412A1Increase the bearing surfaceFine surfaceRailway coupling accessoriesEngineeringBearing surface

A coupler knuckle casting having an enhanced bearing surface area and which is utilized in a railway freight car coupler. The coupler knuckle casting includes a tail section, and a hub section. The hub section has a pivot pinhole formed therein. Such pivot pinhole has generally straight cylindrical sidewalls. A front face section is connected to the hub section. Such front face section includes a nose section and a pulling face portion formed inwardly from such nose section. At such least a portion of such front face portion and such nose section includes an enhanced bearing surface area which includes a substantially flat portion disposed substantially in a vertical direction and which is substantially arcuate in a horizontal direction. The substantially flat portion extends for a predetermined distance in the vertical direction and for a predetermined length along the horizontal direction. There is the a transition section joining the tail section to the hub section. Such transition section includes a top metal section and a bottom metal section extending toward each other.

Owner:MCCONWAY & TORLEY LLC

Method and device for braking quick railway freight car

InactiveCN102167021AImprove reliabilityImprove linearityAerodynamic brakesFluid braking transmissionTruckPassenger train

The invention relates to a method and system for braking a railway vehicle, which have the advantages of higher brake force, shorter idling braking time and brake cylinder boosting and relieving time and capabilities of shortening the braking distance, arranging passenger trains and adjusting the brake force according to the change of the weight of the vehicle. A high-friction-coefficient composition brake shoe with a higher friction coefficient is adopted, and the pressures of the brake cylinder and the brake shoe are controlled on the basis of measurement of the vehicle load by using a sensing valve, so that stepless control of the brake force of a quick freight car is realized; and the idling braking time and the brake cylinder relieving time are shortened by changing the inflation anddeflation time of the brake cylinder. The invention provides a method and system for braking a quick railway freight car. By adopting the method and system, the stepless change of the brake force canbe realized with the load increase and decrease change of the vehicle at the same time of improving the brake force and shortening the idling breaking time, therefore the safety traveling braking distance is ensured; meanwhile, the device has the advantages of high reliability, high vibration insulation, high dynamic performance, higher linearity and high sensitivity.

Owner:LOCOMOTIVE & CAR RES INST OF CHINA ACAD OF RAILWAY SCI

Dust suppressant for railway transportation of mineral powder and coal and preparation method of dust suppressant

InactiveCN102585770ANo pollution in the processDoes not affect the quality of transported goodsOther chemical processesPolymer modifiedRailway freight car

The invention discloses a dust suppressant for railway transportation of mineral powder and coal and a preparation method of the dust suppressant. The raw materials for preparing effective components of the dust suppressant comprise 39-40% of water-soluble macromolecular polymer, 39-40% of modified cellulose water-soluble polymer or sodium lignin sulfonate, 14-15% of anti-freezing supplementary additive and 5-6% of water-soluble modified additive. During the use, the dust suppressant is uniformly sprayed on the surfaces of railway carriages loaded with coal or mineral powder and forms a curing layer with a certain intensity through the dust suppression principles of moistening and coagulation; and dust is moistened and coagulated in the two dust suppression principles, so that the rising of dust is inhibited, the settlement of dust is accelerated and the purpose of controlling dust pollution is achieved.

Owner:SHENYANG RAILWAY IND GROUP

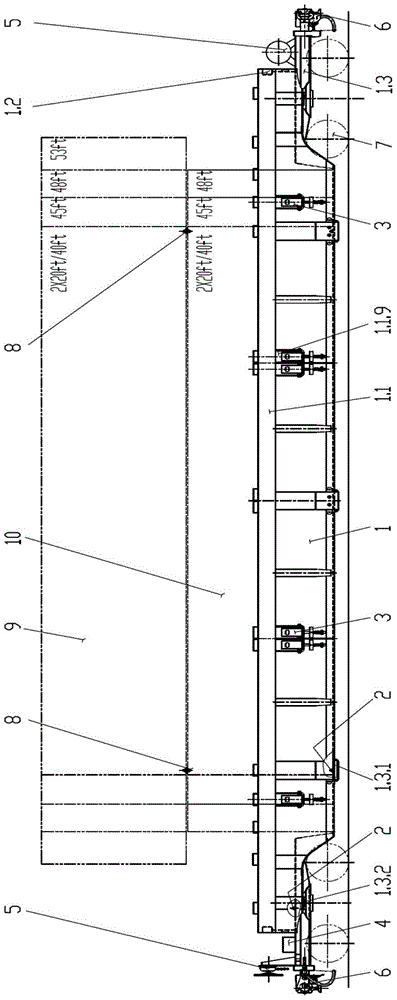

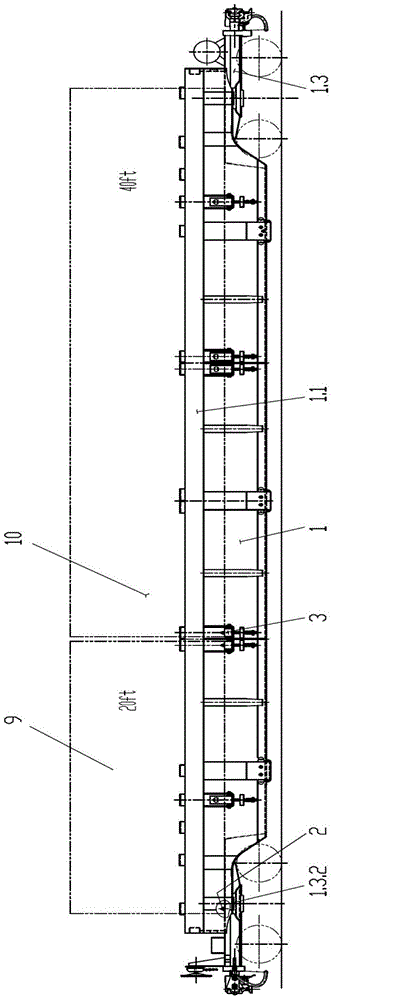

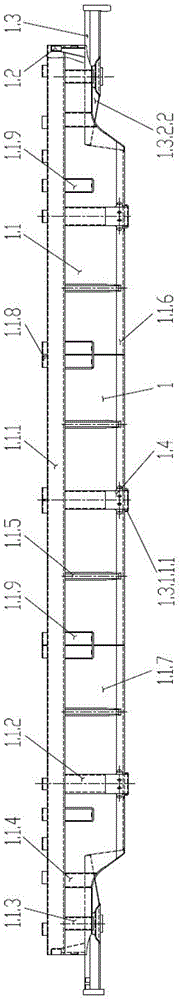

Freight car special for multi-mode combined loading containers

ActiveCN104149799ARealize loading combined transportationReduce transport efficiencyUnderframesAxle-box lubricationLocking mechanismMultiple modes

The invention discloses a freight car special for multi-mode and various-working-condition combined loading containers, and belongs to the field of railway freight car manufacturing. The freight car comprises a car body, a vehicle-mounted positioning system, a brake system, a traction coupling device and a steering rack. The car body comprises a side wall, an end wall and a bottom frame, and the side wall is provided with a turning plate type locking mechanism. According to the freight car special for the multi-mode combined loading containers, the length of the car can be fully utilized, meanwhile, the height limit of the car can also be fully utilized, the line limit can be utilized to the maximum degree, and a car bottom bearing face is designed to the allowed lowest value. Double-layer loading can be achieved on a channel special for double-layer containers, single-layer loading can be achieved on any common channels, combined transportation of container loading in multiple modes and various working conditions can be achieved, the limit to lines is avoided, and the transportation efficiency is not lowered.

Owner:CRRC MEISHAN

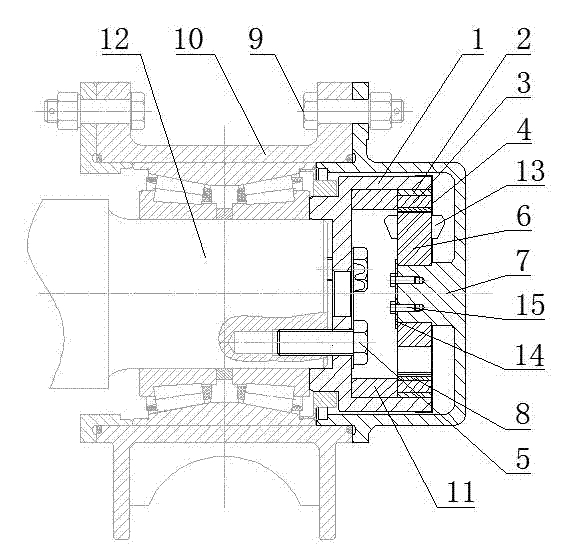

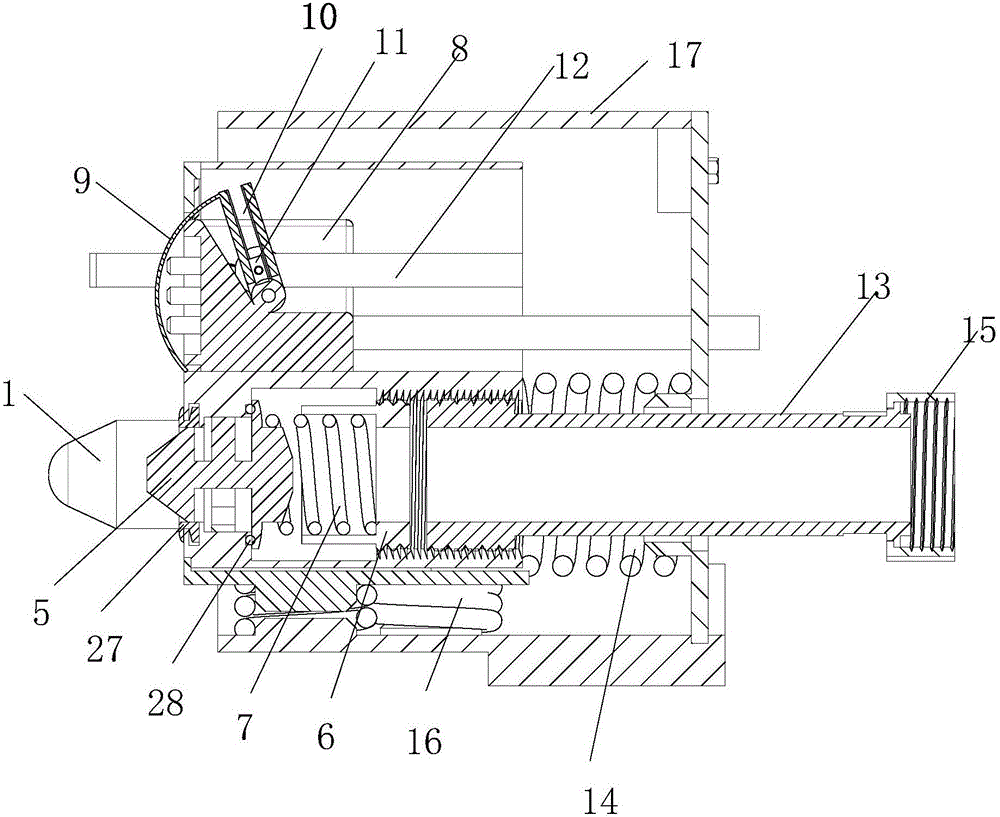

Axle end power device for rapid railway freight vehicle

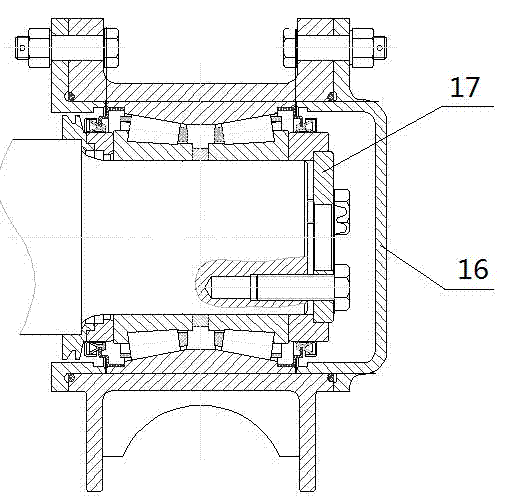

InactiveCN103051132AReduce volumeImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorStator coil

The invention discloses an axle end power device for a rapid railway freight vehicle, and aims to provide stable and reliable power for an electronic anti-skid device and an online monitoring system of a rapid freight vehicle bogie with an axle box. The axle end power device for the railway freight vehicle is designed for the structural characteristics of an axle box body of the freight vehicle bogie, and consists of two parts, i.e. a permanent magnet rotor and a stator coil. A permanent magnet excitation mode is adopted for the rotor. An outer permanent magnet rotor structure is connected with the end part of a vehicle axle through a screw. The rotor coil and an end cover of the axle box are combined into a whole. When the vehicle runs, the power device generates electric energy. The power supply power of the designed power device is 50 to 200W, so that the power consumption requirements of the electronic anti-skid device and the online monitoring system of the rapid freight vehicle are met. The axle end power device is integrally sealed in the end cover structure of the axle box, so that the power device is resistant to vibration and high in dustproof and waterproof performance; and the power device is easy to mount and convenient to disassemble.

Owner:TONGJI UNIV

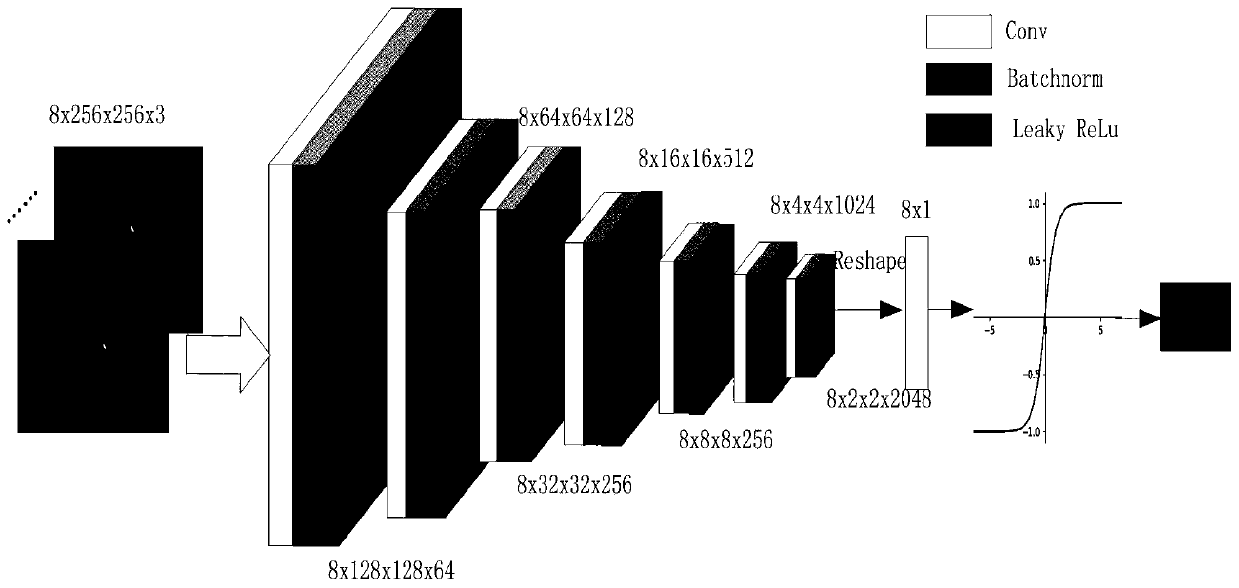

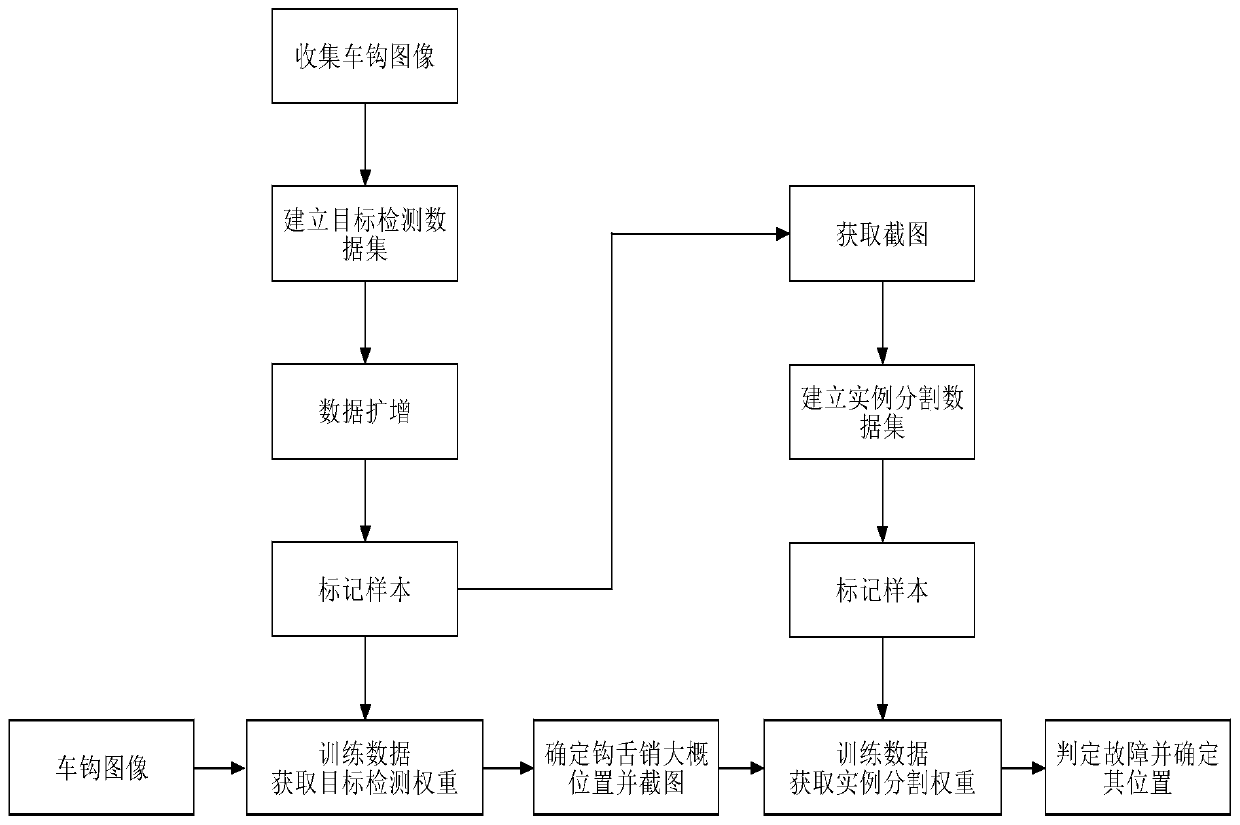

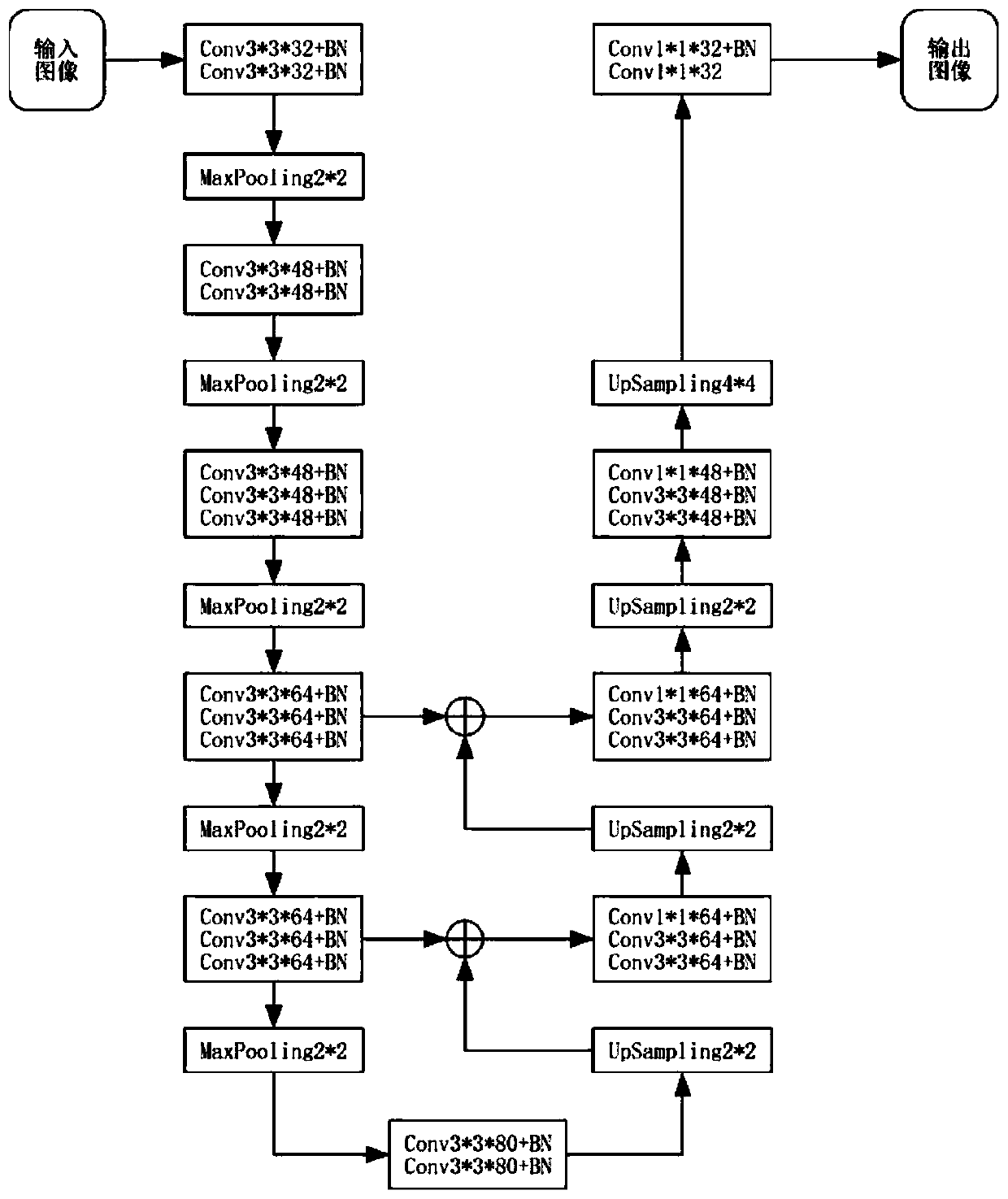

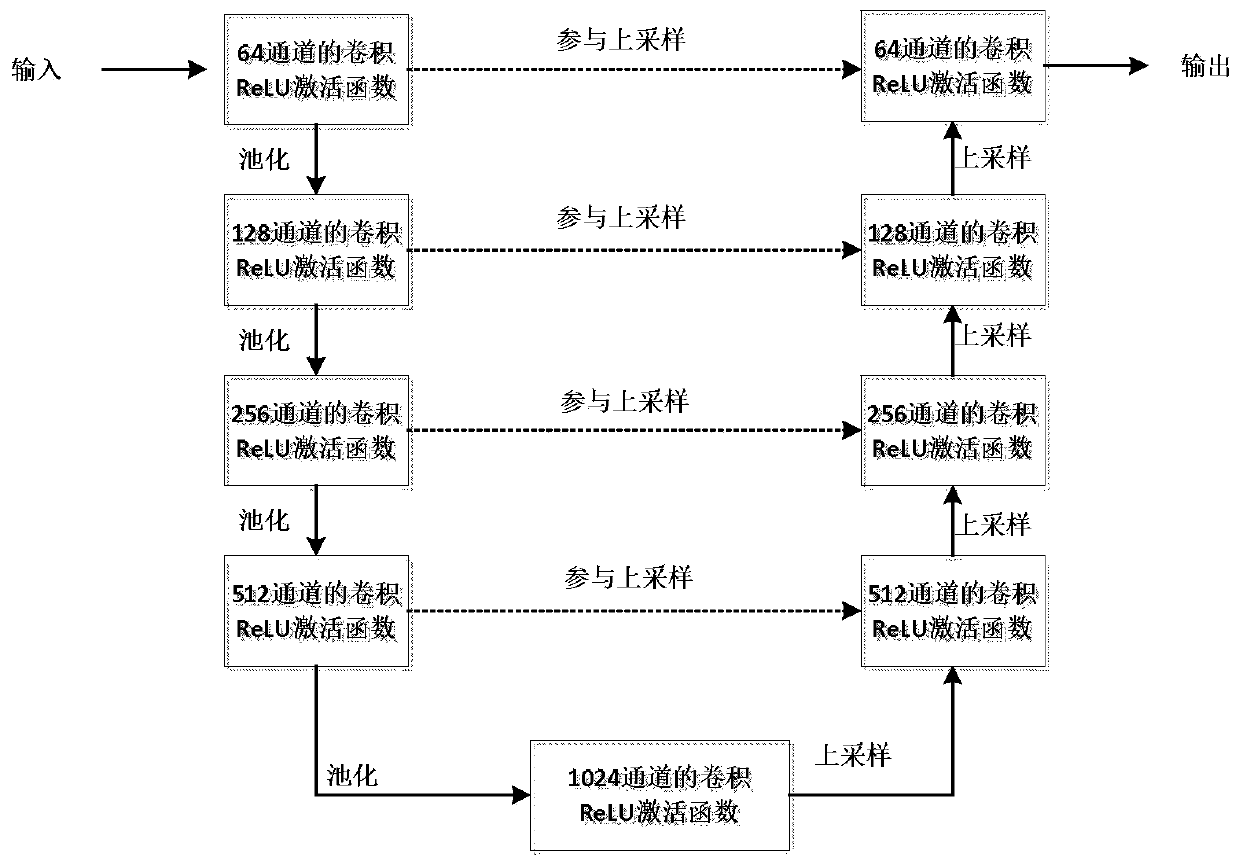

Brake shoe breaking target detection method

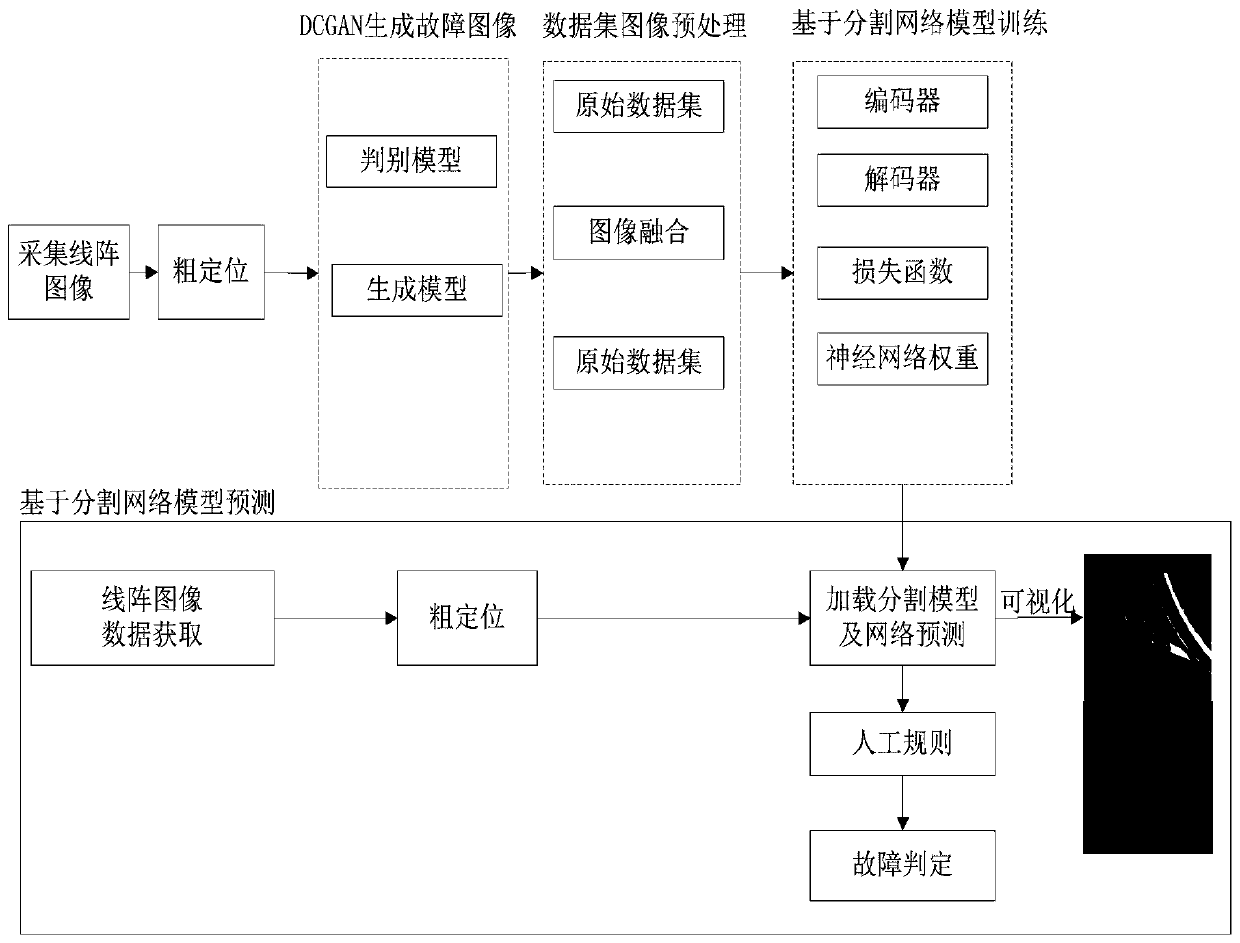

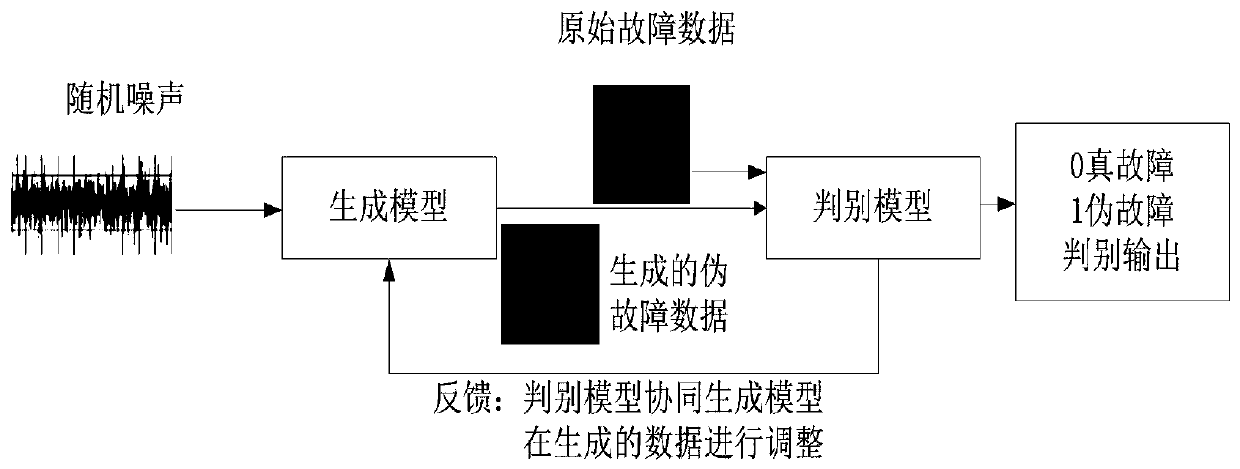

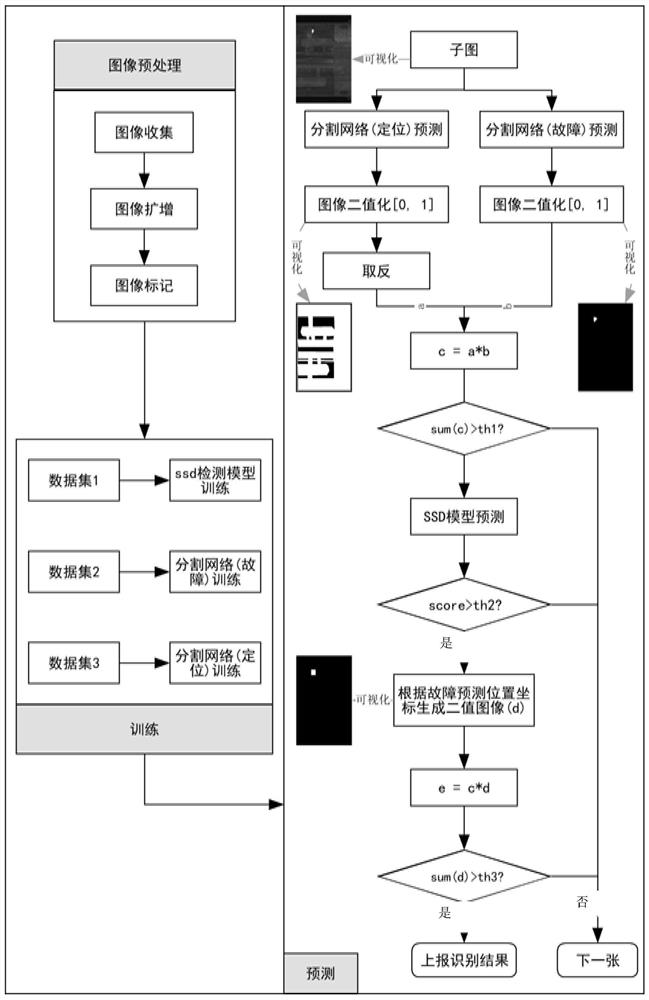

ActiveCN111091555ARealize the alarmReduce labor costsImage enhancementImage analysisData setSimulation

The invention discloses a brake shoe breaking target detection method, and relates to a rail wagon fault detection method. The objective of the invention is to solve the problems of high cost, low efficiency and low accuracy in train brake shoe image inspection in the prior art. The method comprises the steps of 1, acquiring a linear array image; 2, performing coarse positioning; 3, generating anadversarial network DCGAN, and generating a fault image based on the adversarial network DCGAN; wherein the adversarial network is composed of a discrimination model and a generation model, down-sampling convolution is adopted in a discriminator, and up-sampling convolution is adopted in a generator. The step 3 comprises the further steps of 3.13, constructing an adversarial network DCGAN discrimination model; 3.2, constructing an adversarial network DCGAN generation model. The method also comprises the following steps of 4, establishing a deep learning training data set; 5, segmenting a faulttarget; and 6, performing prediction based on the trained segmentation network model to obtain information of the fault component. The beneficial effect of the invention is that the method is used inthe field of railway freight car fault detection.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

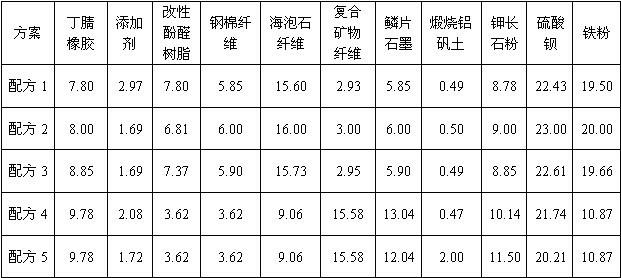

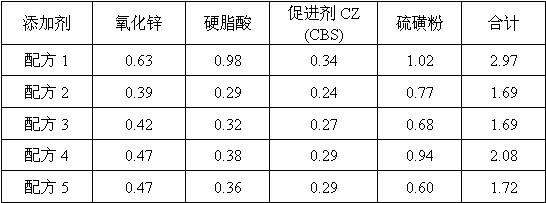

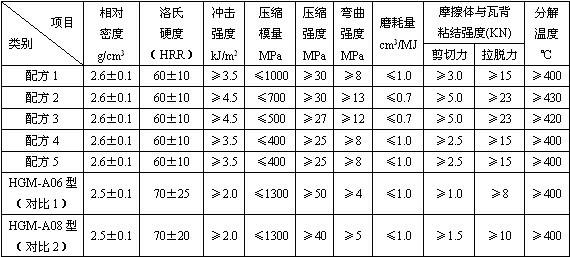

Composition brake shoe for railway freight car, and method for manufacturing same

ActiveCN102661340AHigh bonding strengthReduce wearOther chemical processesBraking membersCrazingSlag

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

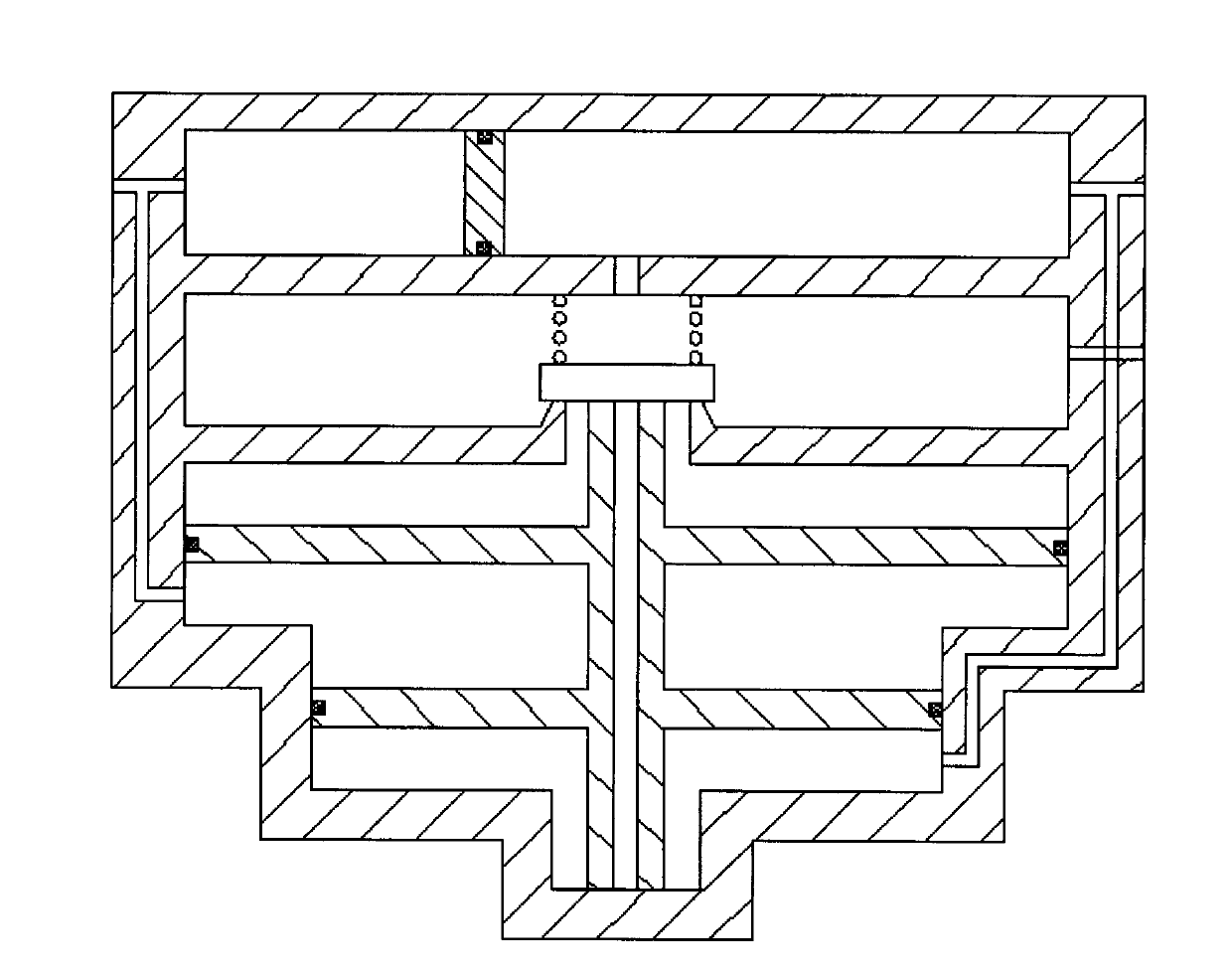

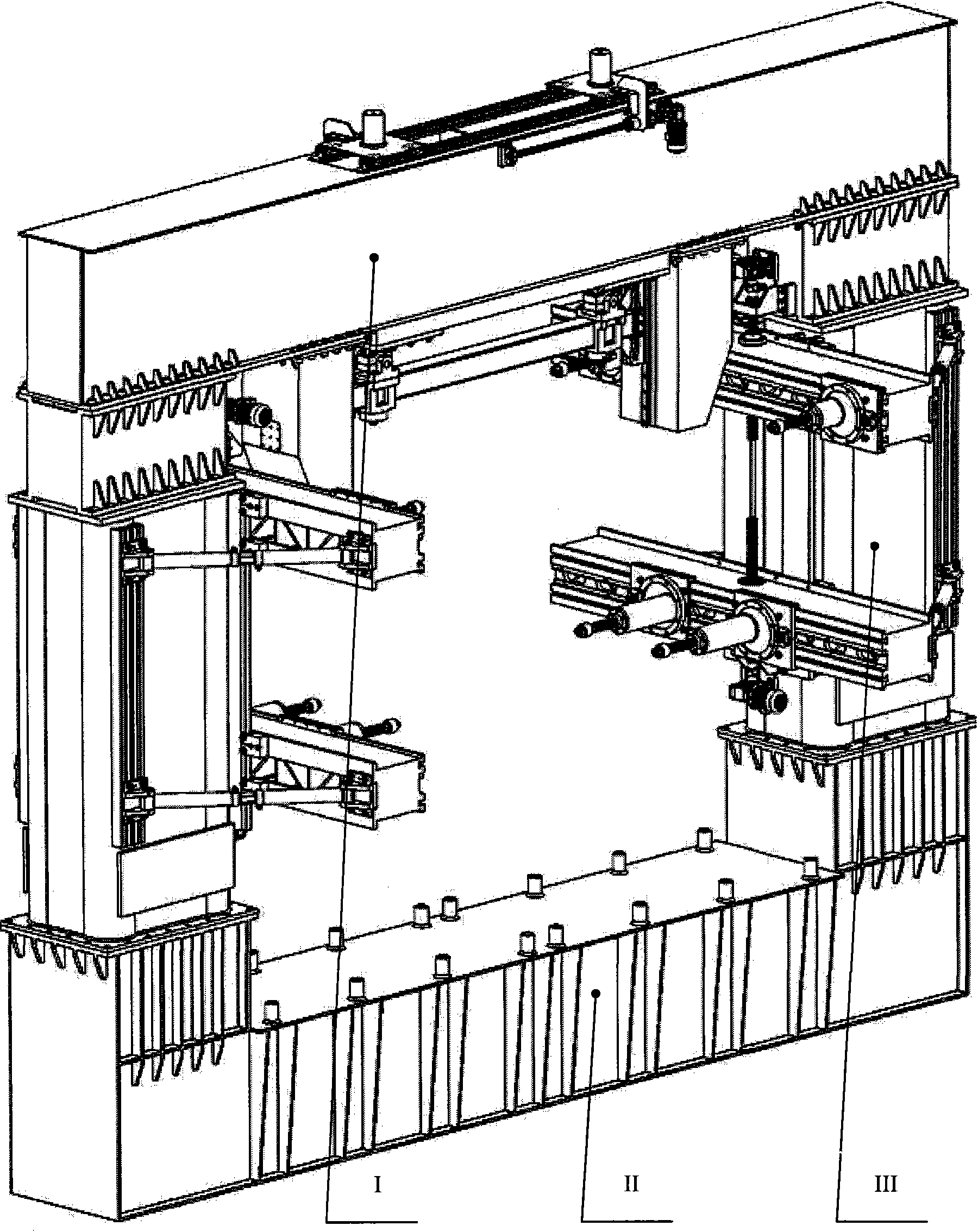

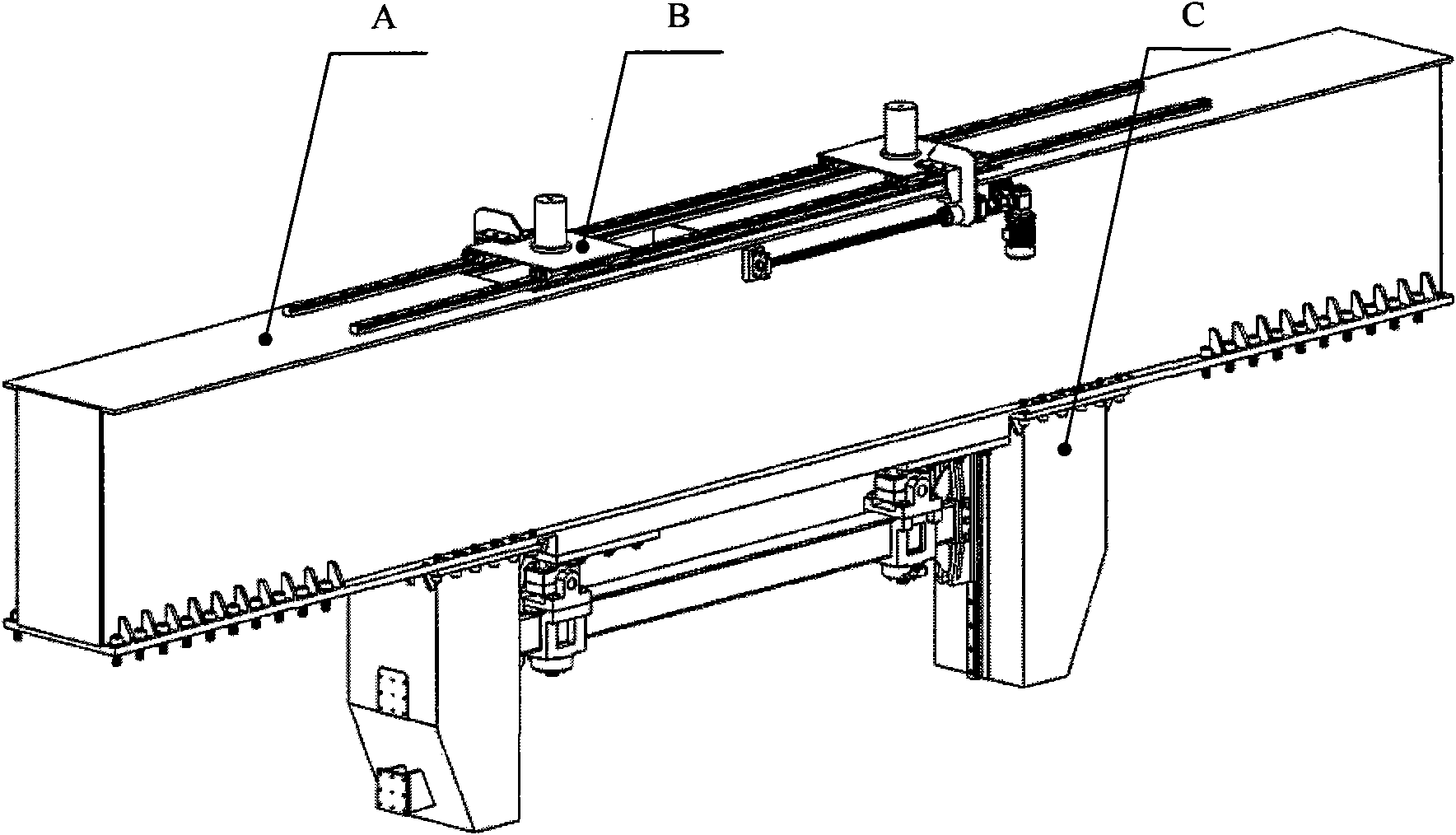

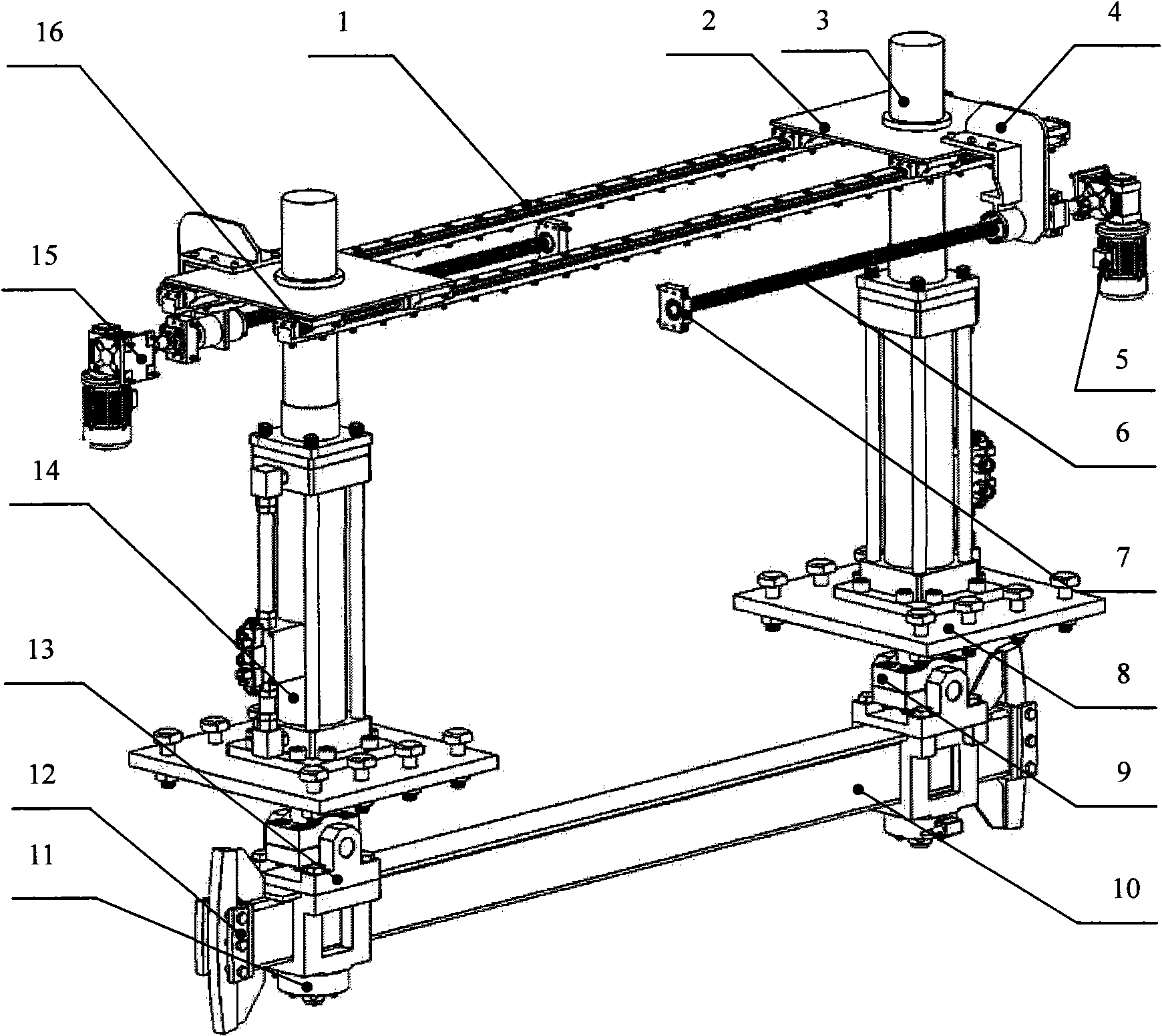

Closed adjustable thrust gantry device

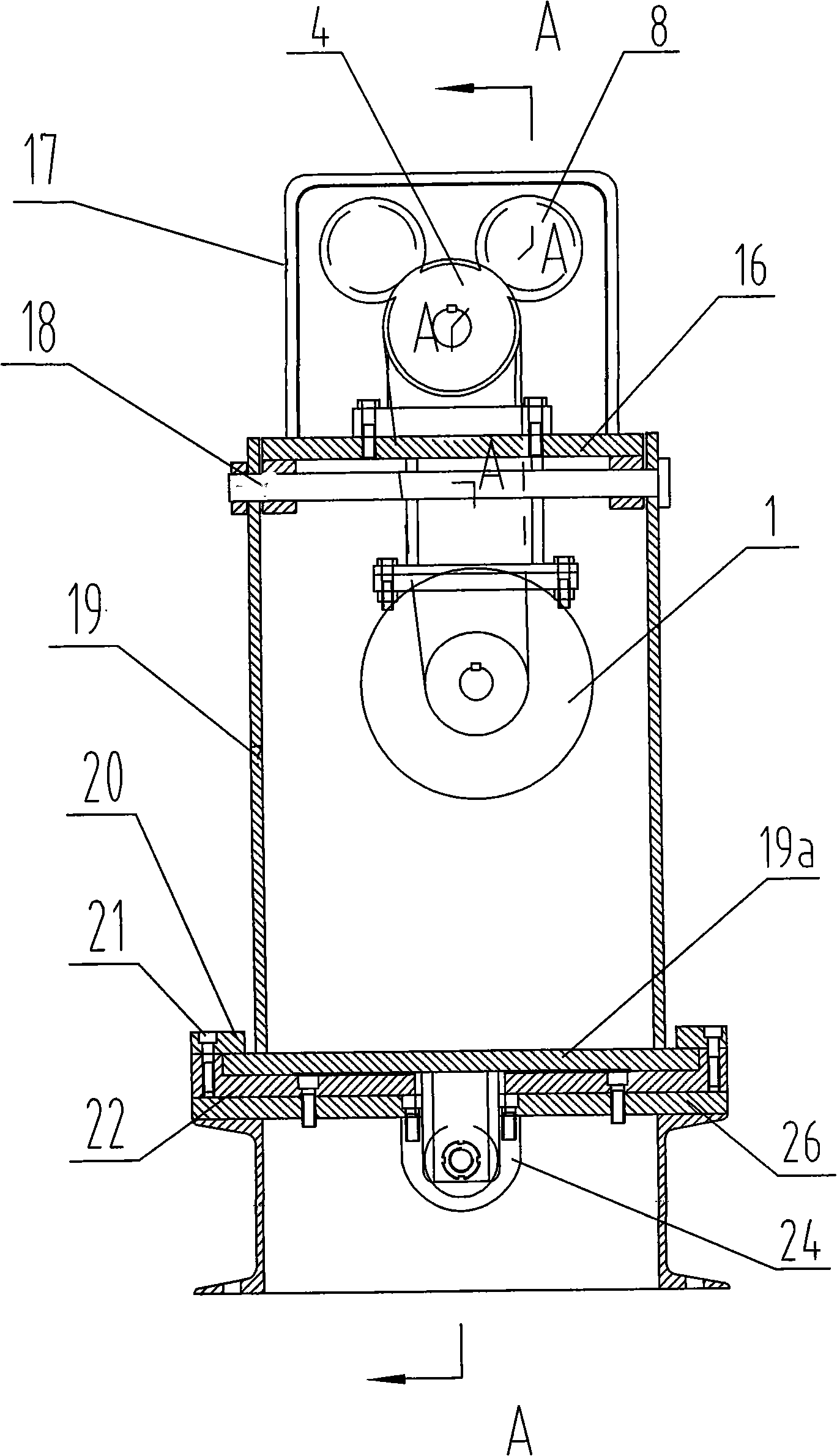

InactiveCN101556203APrecise positioningThe test result is accurateRailway vehicle testingElasticity measurementWhole bodyTest fixture

The invention relates to a parameter detection device for a track vehicle steering frame, in particular to a closed adjustable thrust gantry device. The device is designed against the status quo that the positioning of the steering frame and a vehicle body of the prior parameter test table of the steering frame is difficult during the testing process, the whole vehicle test can not be realized and the testing type of the steering frame is single and the like. The device mainly consists of a suspended upper cross beam assembly (I), a lower embedded cross beam (II) and a brace type thrust upright beam assembly (III). The suspended upper cross beam assembly (I), the lower embedded cross beam (II) and the brace type thrust upright beam assembly (III) are connected to a closed whole body by the bolt connection way. The device provides a technical means for positioning the steering frame, positioning the vehicle body and testing the whole vehicle for the steering frame of the track vehicle during the parameter testing process, has the functions of the swing-type steering frame test and the eccentric load test and realizes the purpose of having a plurality of test functions on one testing device. The device has an important role for accelerating the upgrade and replacement process of railway freight car products in China.

Owner:JILIN UNIV

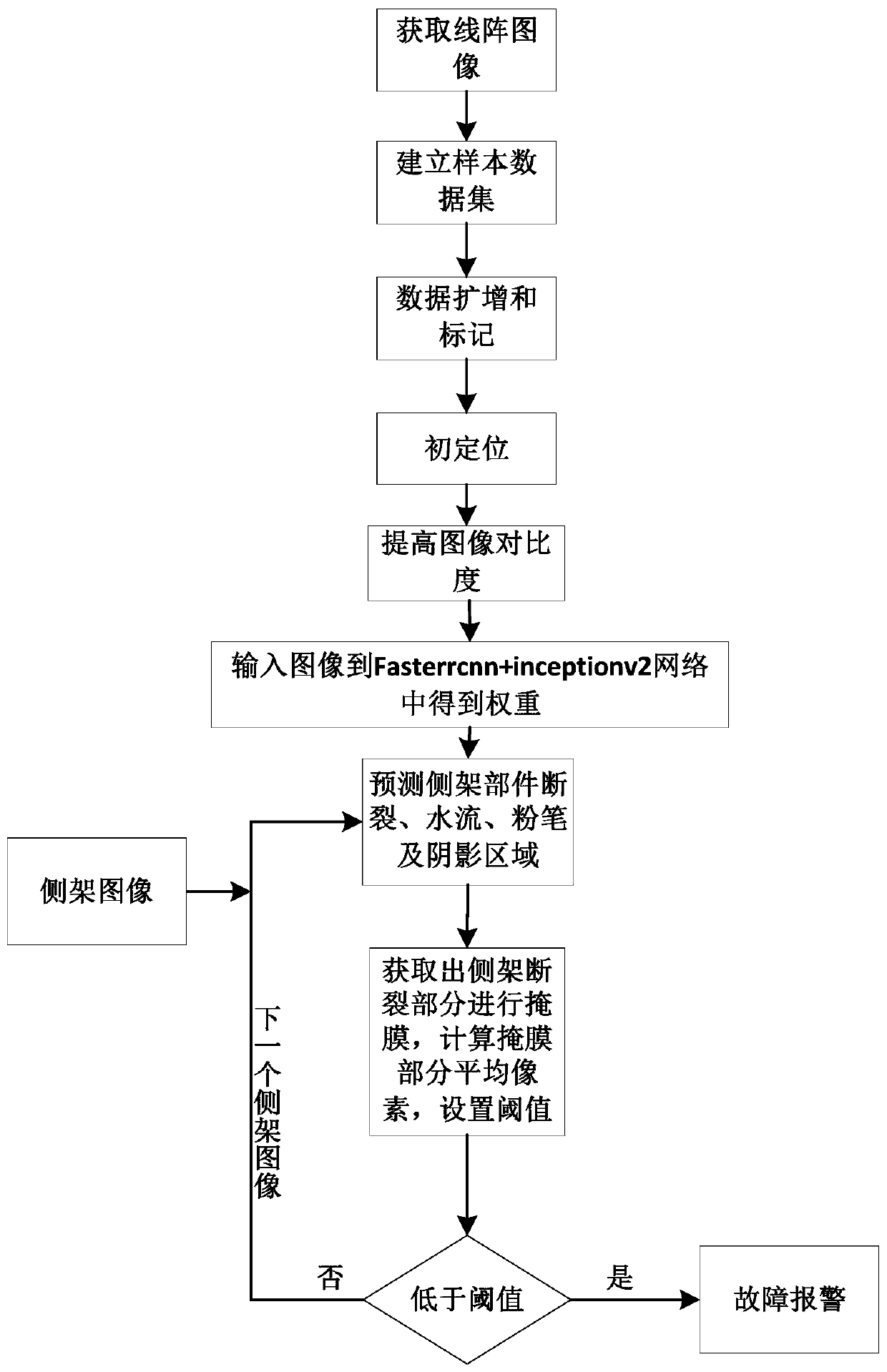

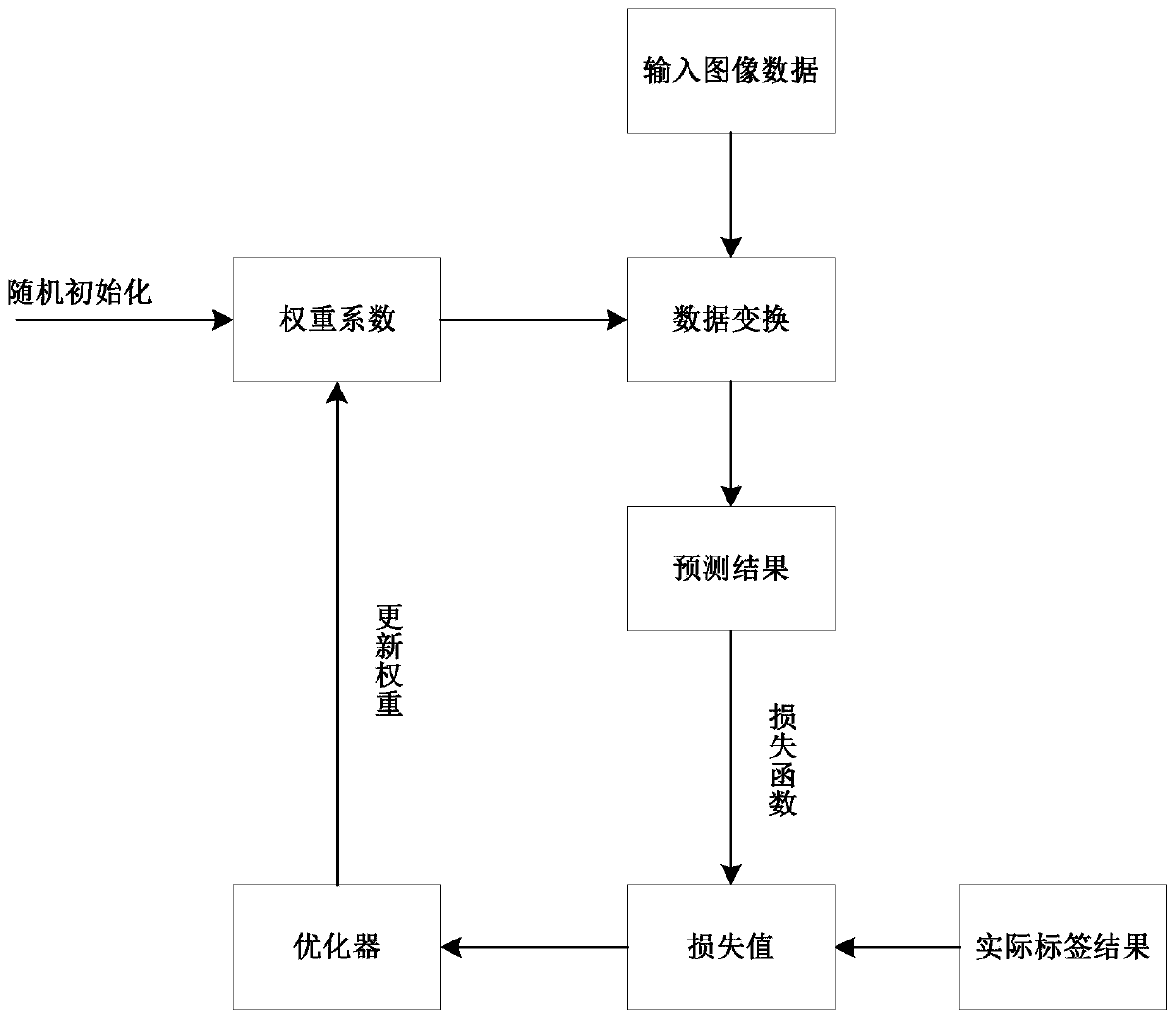

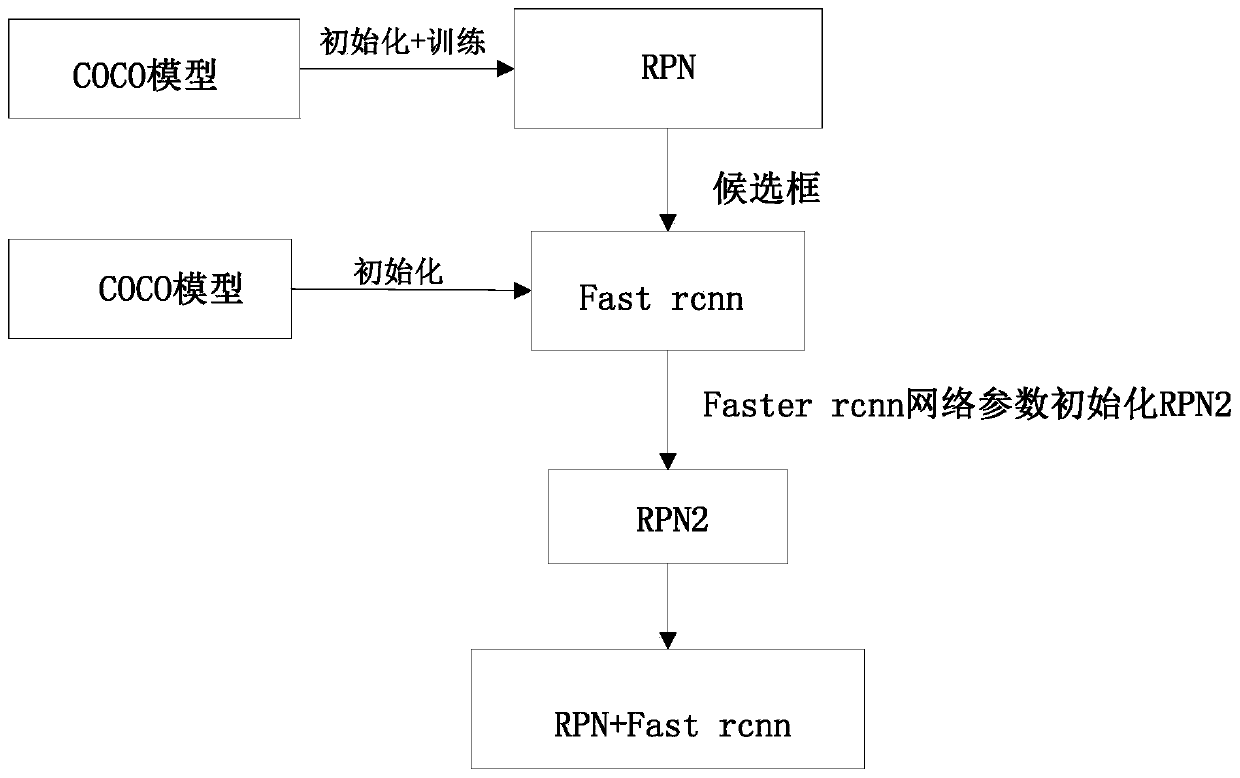

Railway wagon bogie side frame fracture fault image recognition method

ActiveCN111079747ARealize fault identificationTimely processingImage analysisCharacter and pattern recognitionData setState prediction

The invention discloses a railway wagon bogie side frame fracture fault image recognition method, and belongs to the technical field of railway wagon bogie safety. The invention aims to solve the problem of poor reliability due to the fact that the side frame fracture detection of the existing railway wagon bogie is carried out in a manual mode. The method comprises the steps of collecting an original gray image of a truck bogie side frame in operation; determining a side frame area of each grayscale image, preprocessing the side frame areas to obtain side frame area sample images, forming a sample image set from all the side frame area sample images, configuring mark information for each side frame area sample image to form a mark file, and forming a sample data set based on the sample image set and the mark file; training the convolutional neural network inception v2 and the convolutional neural network Faster rcnn, and obtaining a trained inception v2 model and a trained Faster rcnnmodel; and processing the to-be-detected image by using the trained inceptionv2 model and the Faster rcnn model to obtain a corresponding side frame state prediction result so as to realize fault identification. The method is used for bogie side frame fracture identification.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

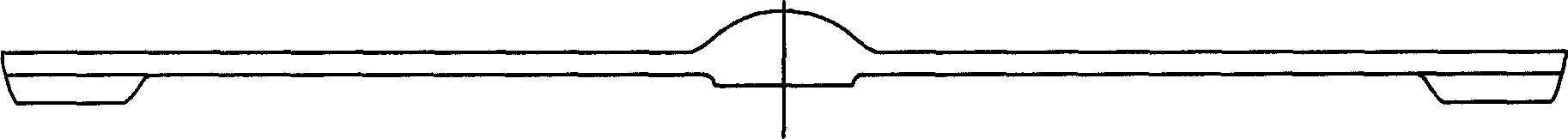

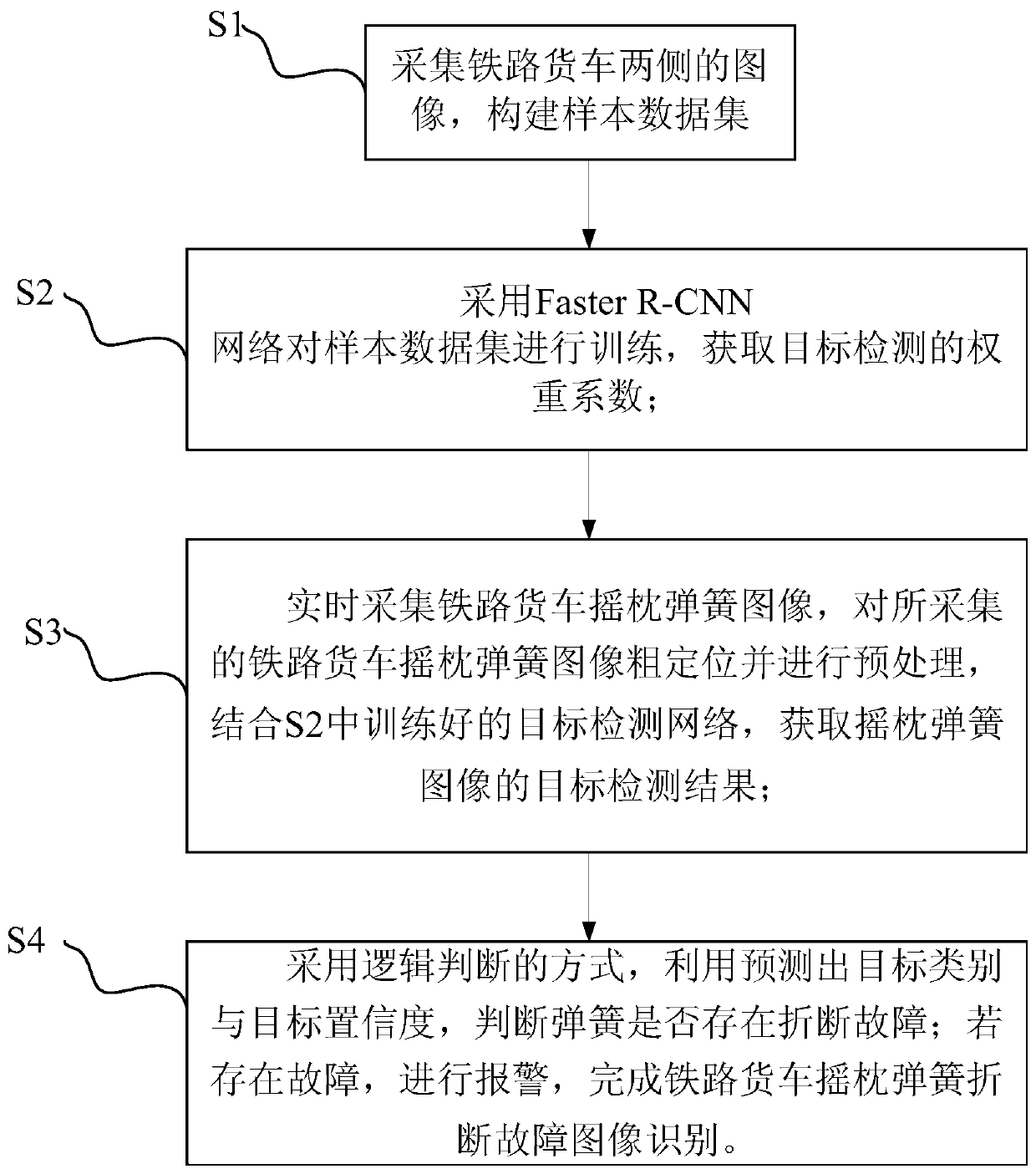

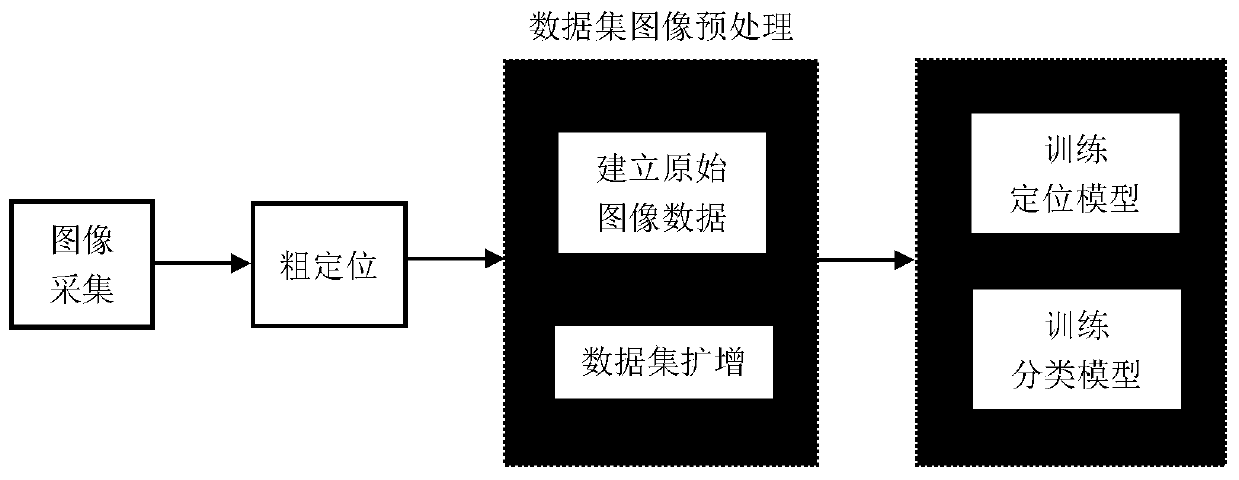

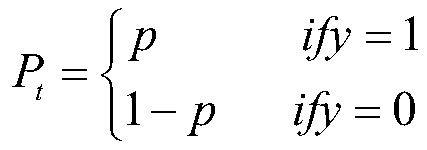

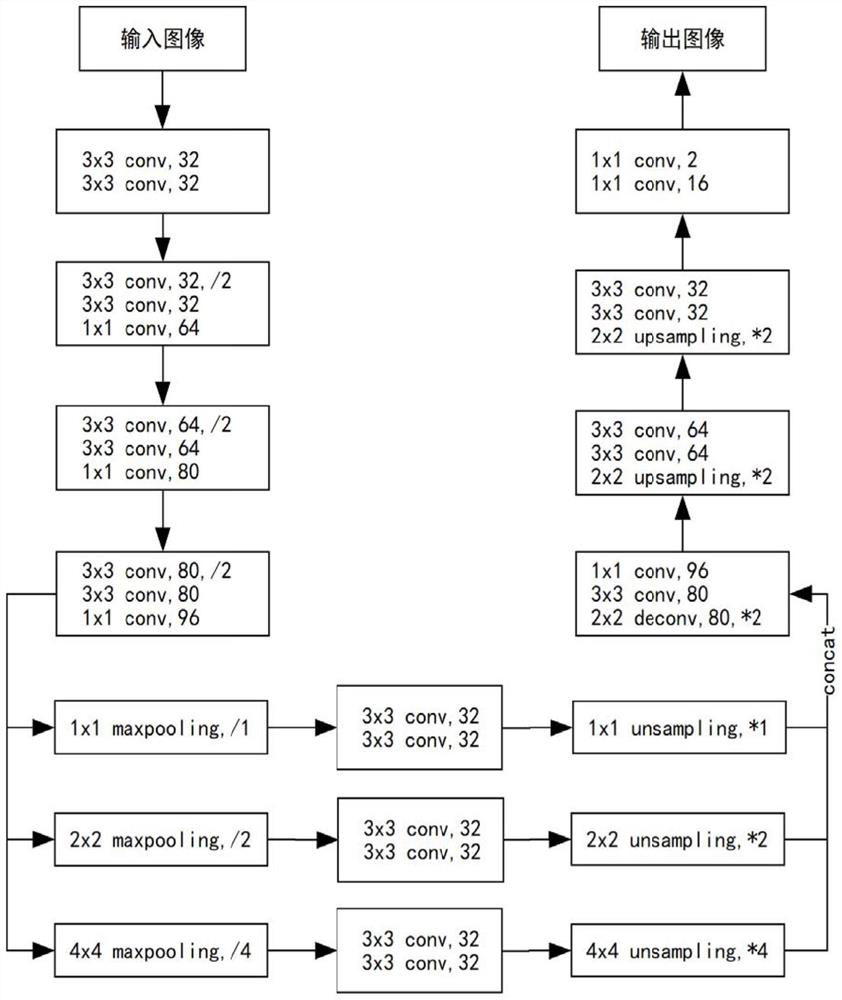

Railway wagon swing bolster spring breaking fault image identification method

InactiveCN111080611AImprove stabilityHigh precisionImage enhancementImage analysisData setSimulation

The invention discloses a railway wagon swing bolster spring breaking fault image identification method, relates to a fault identification method, and belongs to the field of railway wagon fault identification. In order to solve the problem that in the prior art, truck swing bolster spring breaking fault detection is performed by using a manual image observation mode, such that missed detection iseasily caused, and the workload of workers is large. The method includes: collecting images on the two sides of a rail wagon, constructing a sample data set, adopting a Faster R-CNN network to trainthe sample data set, and obtaining a weight coefficient of target detection; acquiring a railway wagon swing bolster spring image in real time, performing coarse positioning and preprocessing on the acquired railway wagon swing bolster spring image, and acquiring a target detection result of the swing bolster spring image in combination with the trained Faster R-CNN network, wherein the target detection result comprises a target category and a target confidence degree; and judging whether the spring has a breaking fault or not by adopting a logic judgment mode and utilizing a target detectionresult of the swing bolster spring image.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Railway wagon derailment automatic brake valve cock handle closing fault image recognition method

InactiveCN111080608AAchieving identifiabilityRealize the alarmImage enhancementImage analysisData setAutomatic braking

The invention relates to a railway wagon fault image recognition method, in particular to a railway wagon derailment automatic brake valve cock handle closing fault image recognition method. The objective of the invention is to solve the problem that the existing railway wagon derailment automatic brake valve cock handle closing fault image identification accuracy is low. The method comprises thesteps: 1, building equipment around a truck rail, and obtaining two-dimensional images of the two sides of a truck; 2, carrying out derailment automatic brake valve cock handle part coarse positioningon the obtained two-dimensional image; 3, establishing an original sample data set based on the derailed automatic brake valve cock handle part image of coarse positioning; 4, carrying out data set amplification on the original sample data set; 5, obtaining a trained positioning model SSD and a classification model VGG16; and 6, according to the fault information, generating a message according to the fault position and the fault type, and uploading the message to an alarm platform. The method is applied to the field of rail wagon fault image recognition.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Railway freight car automatic picking off and coupling up device

ActiveCN105015574AShorten the unhooking operation timeReduce labor costsRailway coupling accessoriesRailway freight carElectrical and Electronics engineering

A railway freight car automatic picking off and coupling up device provided by the present invention comprises a fixing device arranged on a car coupler, a wind path connecting device connected with an air duct, opening a wind path automatically when two couplers are coupled up and closing the wind path automatically when the external forces disappear; a circuit connecting device comprising an electric connection joint and a protection unit used for isolating the electric connection joint. When the two car couplers are coupled up and under the action of the external forces contacted with the fixing device, the protection unit is turned on, and the electric connection joint is connected and electrified; when the external forces disappear, the electric connection joint is cut off, and the protection unit resets and isolates the electric connection joint; the wind path connecting device and the circuit connecting device are arranged in the fixing device. The railway freight car automatic picking off and coupling up device of the present invention can realize the automatic picking off and coupling up of the railway freight car wind paths and the railway freight car circuits, and enables the picking off and coupling up work time to be shortened and the labor cost to be saved.

Owner:中国铁路北京局集团有限公司丰台车辆段

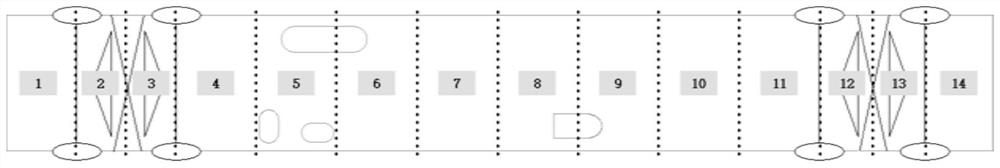

Railway wagon bottom floor damage fault detection method

ActiveCN111652227AUnified operating standardsImprove job qualityImage analysisCharacter and pattern recognitionImage InspectionData set

A railway wagon bottom floor damage fault detection method belongs to the technical field of railway wagon safety detection. The invention aims to solve the problems of poor reliability and low efficiency due to the adoption of manual image inspection for safety detection of the bottom floor of the existing rail wagon. The method comprises: collecting and processing whole-wagon linear array imagesof the bottom of a running railway wagon under different conditions to obtain a sample data set; constructing a semantic segmentation neural network model based on an encoder and a decoder, performing training by adopting a sample data set, finding an optimal weight coefficient, and updating the semantic segmentation neural network model; and then collecting a current whole-train linear array image at the bottom of the running rail wagon, obtaining a current to-be-detected target area by adopting the updated semantic segmentation neural network model, carrying out pre-judgment, and carrying out fault detection on the current to-be-detected target area which is pre-judged to have a fault by adopting a single-stage ssd model. According to the invention, automatic identification of bottom floor damage is realized.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

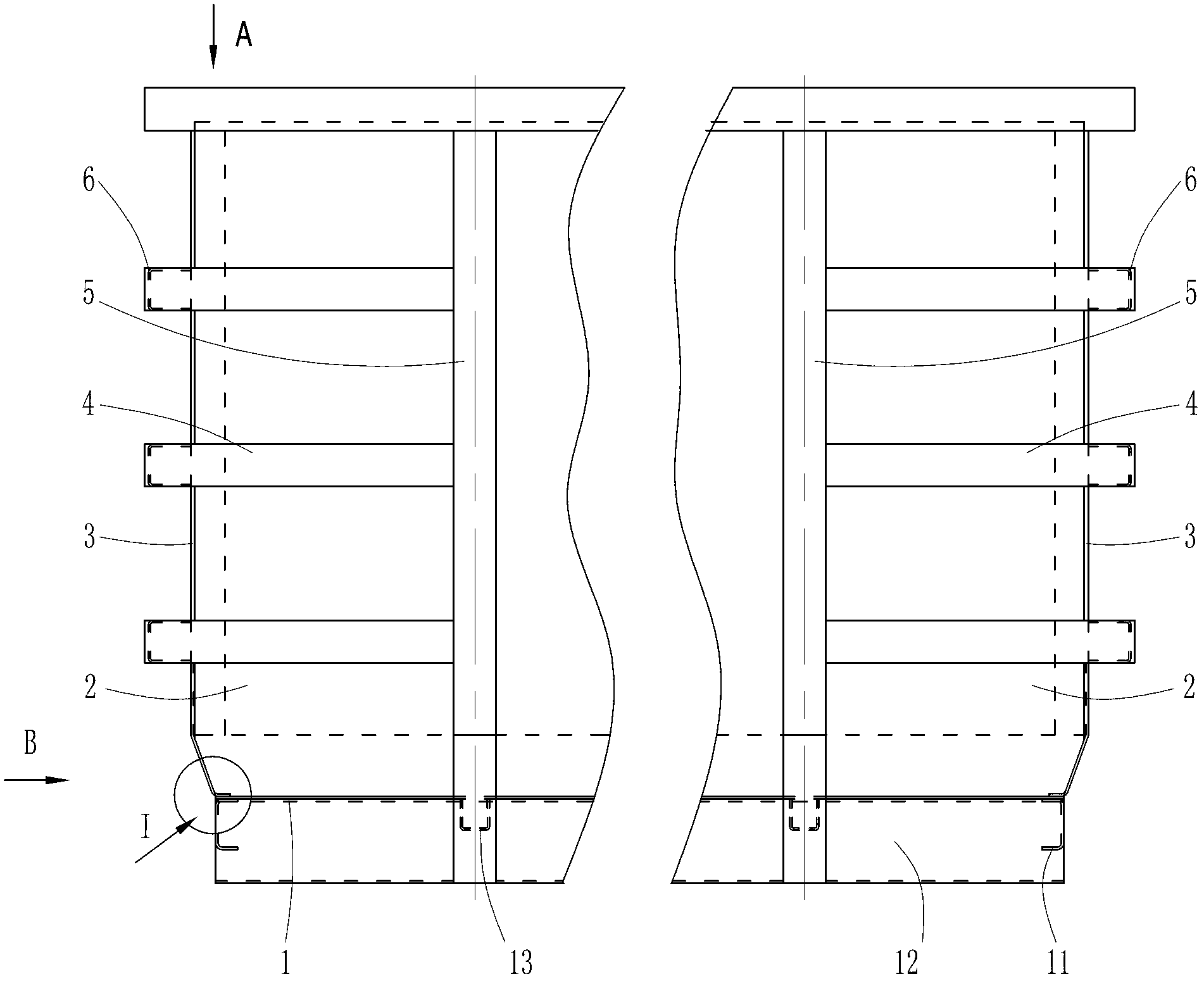

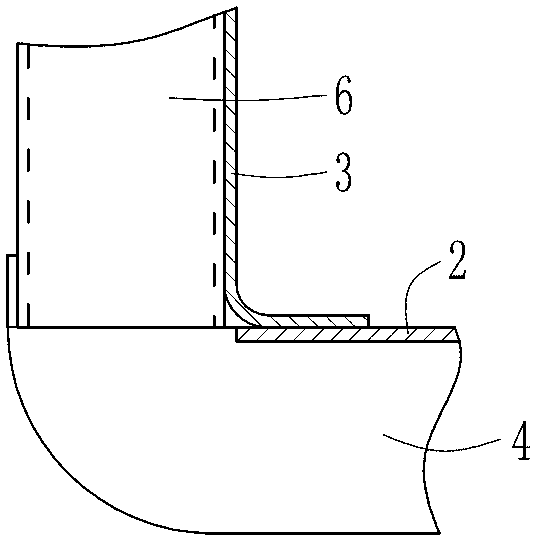

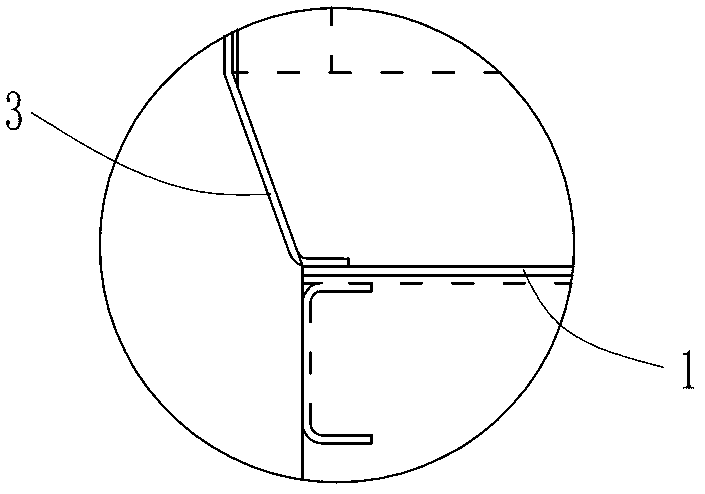

Railway wagon compartment suitable for small limitation bound

The invention discloses a railway wagon compartment suitable for a small limitation bound. The railway wagon compartment suitable for the small limitation bound comprises a floor (1), lateral wall plates (2) located on two sides of the floor (1) and end wall plates (3) located at two ends of the floor (1). The lower portion of each lateral wall plate (2) is bent inwards to form a dip angle, connected with the floor (1) in a lap joint mode and fixed with the floor (1) through welding. The lower portion of each end wall plate (3) is bent inwards to form a dip angle, connected with the floor (1) in a lap joint mode and fixed with the floor (1) through welding. Two sides of each end wall plate (3) are connected with corresponding ends of each lateral wall plate (2) in a lap joint mode and fixed with the corresponding ends of each lateral wall plate (2) through welding. The dip angles bent inwards are arranged on the lower portions of the lateral wall plates and the lower portions of the end wall plates, so that corner posts and corner post plates in a traditional structure are cancelled. Furthermore, through the arrangement of lateral vertical columns, lateral platbands and end platbands, entire intensity of the compartment is improved. On the premise that the requirement of a railway of a small limitation bound is met, the loading capacity of the compartment is increased to the maximum limit. The railway wagon compartment suitable for the small limitation bound is easy to manufacture, small in self weight, safe and efficient in transportation.

Owner:CHONGQING CHANGZHENG HEAVY IND

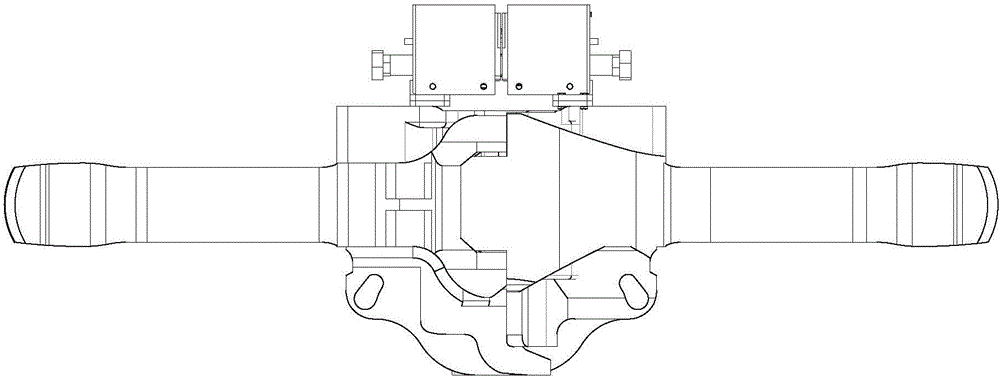

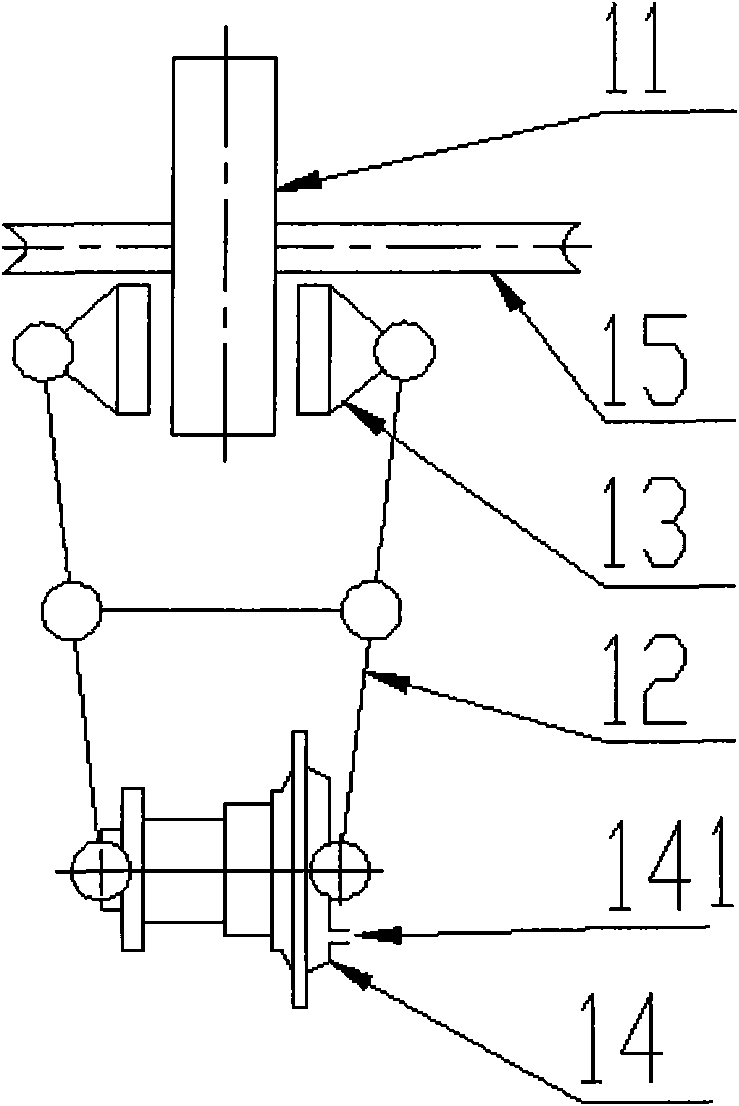

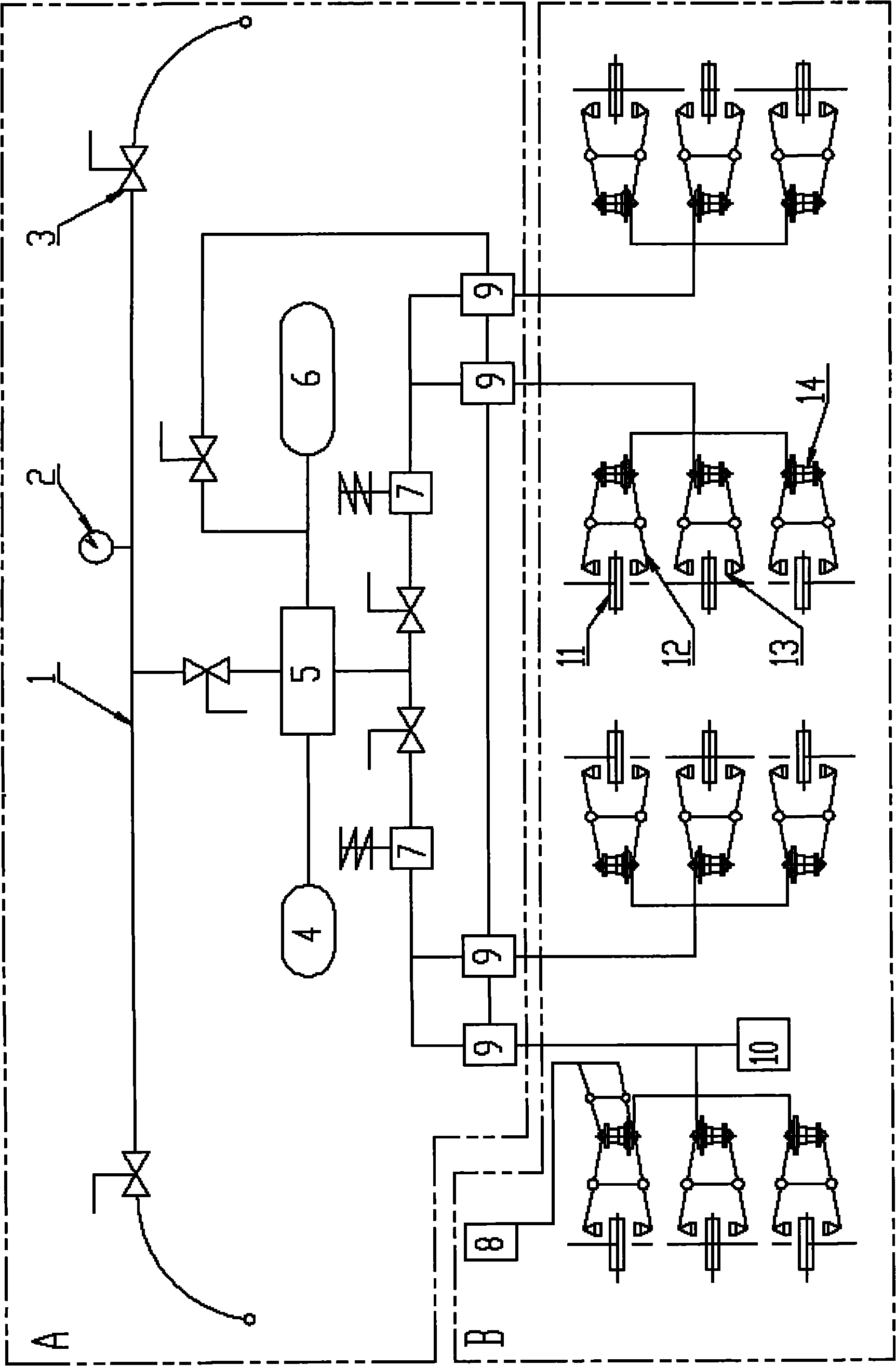

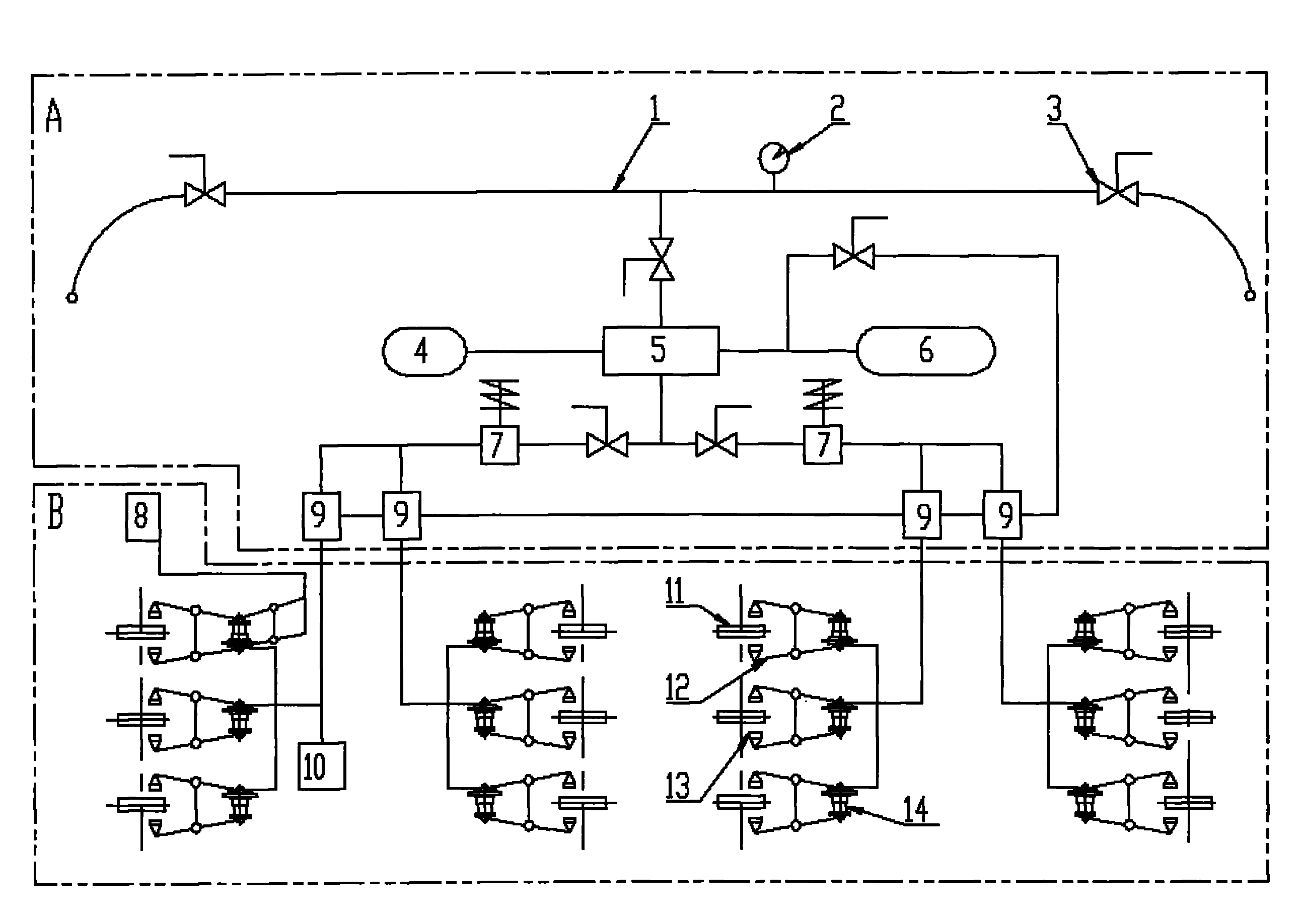

Wagon brake system

ActiveCN102152800AHigh speedEasy to controlRailway hydrostatic brakesRailway hydrodynamic brakesPositive pressureControl system

The invention relates to a wagon brake system, which comprises a brake control system and a base control system. The base control system comprises that each car axle is provided with at least one disc brake device; the disc brake device comprises a brake disc (11) rotating with the car axle, a lever system (12), a brake pad (13), and a unit brake cylinder (14); certain gap is formed between the brake pad and the brake disc; the lever system is acted on the brake pad; the brake control system comprises an antiskid unit (9) communicated with the unit brake cylinder; compressed air entering the unit brake cylinder through the antiskid unit is converted into an acting force and output by the unit brake cylinder, and is amplified to the brake pad through the lever system; a positive pressure acted on the brake disc is formed by the brake pad; when wheel set sliding is detected to generate by the antiskid unit, an access from the brake control system to the unit brake cylinder is closed; and an access from the unit brake cylinder to atmosphere is opened; therefore, a brake force is eased so as to lead the car axle to resume to normal speed reduction rapidly. The wagon brake system can be adopted to improve the brake power, and is suitable for improving the speed of a wagon.

Owner:LOCOMOTIVE & CAR RES INST OF CHINA ACAD OF RAILWAY SCI

Method for judging state of railway wagon coupler knuckle pin based on image recognition and deep learning

ActiveCN111079819AImprove robustnessImprove accuracyCharacter and pattern recognitionNeural learning methodsEngineeringTruck

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Railway freight car side bearing

ActiveUS7549379B2Easy to wearExtended service lifeBogiesBogie-underframe connectionsElastomerCoil spring

A long travel constant contact side bearing for railway cars provides better handling characteristics, achieving improved tracking and curving through use of various combinations of features. The side bearing comprises a base and a generally cylindrical wall section extending upwardly from the base. A cup-shaped cap comprises a generally circular top section and a generally cylindrical wall section extending downwardly therefrom. The cap extends into the wall section of the base. At least one coil spring is provided within the base and extends to the underside of the cap. The cup shaped cap includes a centrally located cut out section with an elastomer pad fitted within the cut out section. The cup shaped cap cylindrical wall sections can be coated with a lubricant or hardening substance.

Owner:AMSTED RAIL CO INC

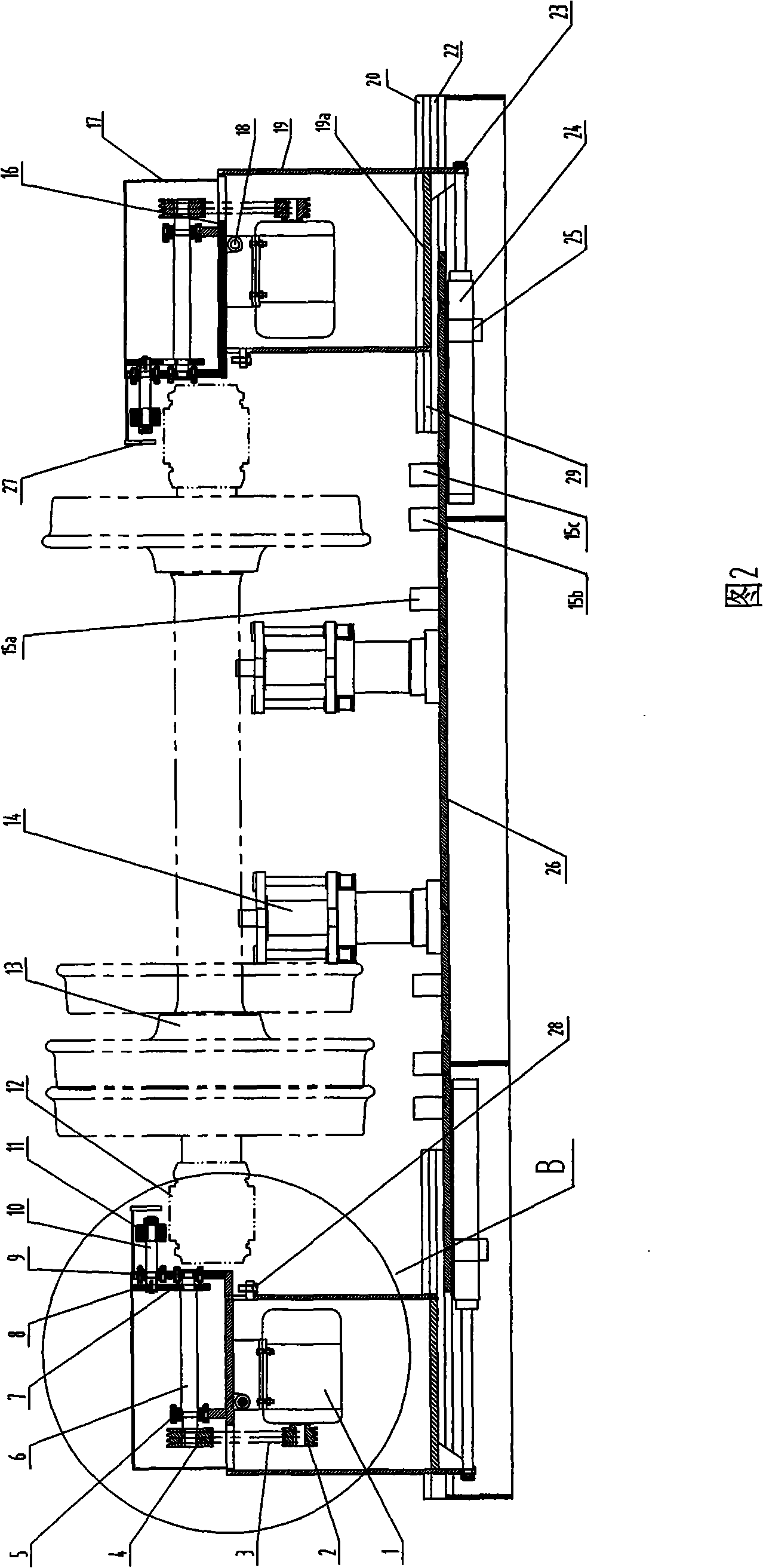

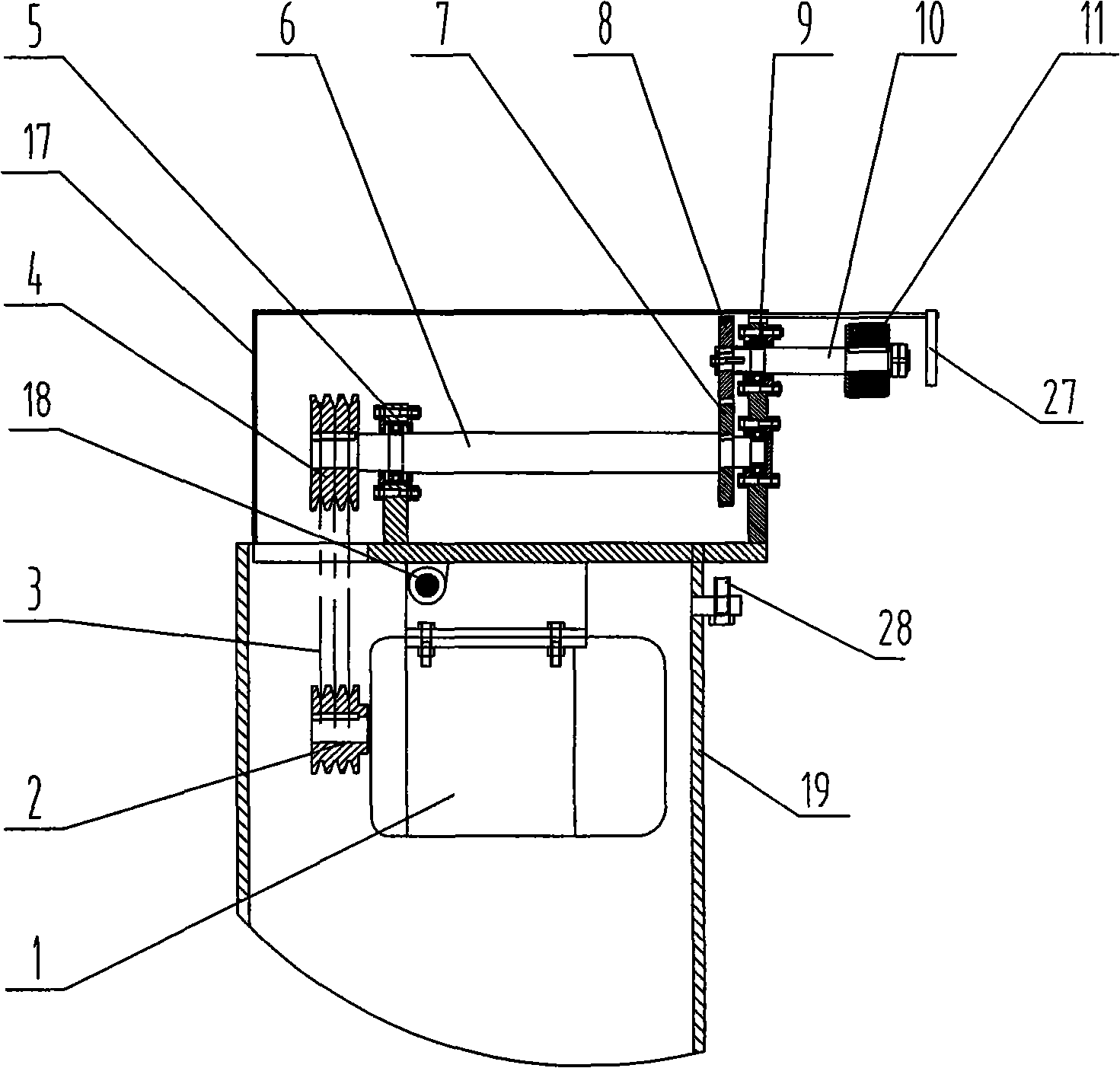

Roller bearing grinder for railway freight car wheel pair

The invention discloses a rolling bearing grinding machine for wheel pairs of railway freight cars. Grinding devices are arranged at both ends of a stand symmetrically, and each grinding device comprises a motor [1], a transmission device, a friction transmission wheel [11] and a pivoting support [16], wherein the outer end of the pivoting support [16] is connected with a frame [19] which is fixed on the stand through a rotating shaft [18], while the inner end is supported on the frame; and the weight born by the pivoting support [16] is applied onto a rolling bearing [12] through the friction transmission wheels [11], so that the weight of workpiece objects participating in rotation is reduced greatly, consumed power is reduced, and the abrasion of a friction wheel is reduced. The frames and the stands of the grinding devices are connected glidingly. The rolling bearing grinding machine is suitable for grinding wheel pair rolling bearings with different specifications, and has good equipment universality.

Owner:TONGLING KEDA VEHICLE EQUIP

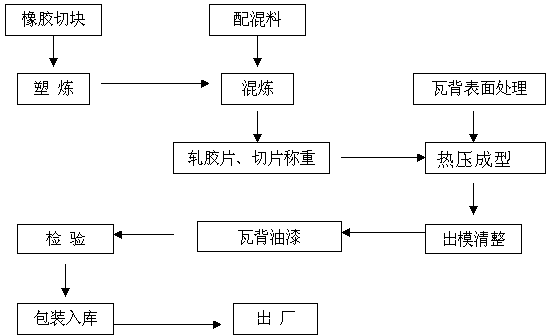

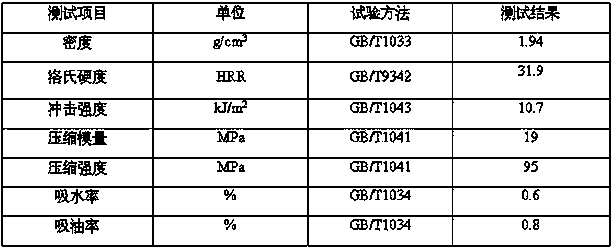

HGM-C type high friction composite brake shoe and preparation method thereof

ActiveCN104387634AIncrease coefficient of frictionStable coefficient of frictionFriction liningWeather resistanceTruck

The invention relates to an HGM-C type high friction composite brake shoe and a preparation method thereof and belongs to the technical filed of materials. The preparation method of the HGM-C type high friction composite brake shoe comprises the following steps: firstly stripping and slicing rubber, then plastifying, adding auxiliary materials, mixing, rolling into slices, then weighing the slice, and carrying out shoe back treatment, hot-compression treatment and aftertreatment to obtain the HGM-C type high friction composite brake shoe product. After the HGM-C type high friction composite brake shoe product is vulcanized, friction and abrasion properties of the HGM-C type high friction composite brake shoe product meet the requirements of technical conditions of high friction coefficient composite brake shoes for railway freight cars (provisional) in shipment freight cars [2002], the phenomena of damascene, cracks, chip off-falling and the like can be effectively inhibited in a car loading using process, and damage to wheels is reduced; and the HGM-C type high friction composite brake shoe product has the characteristics of good impact property and good weather resistance.

Owner:WUXI JINXIN GRP CO LTD

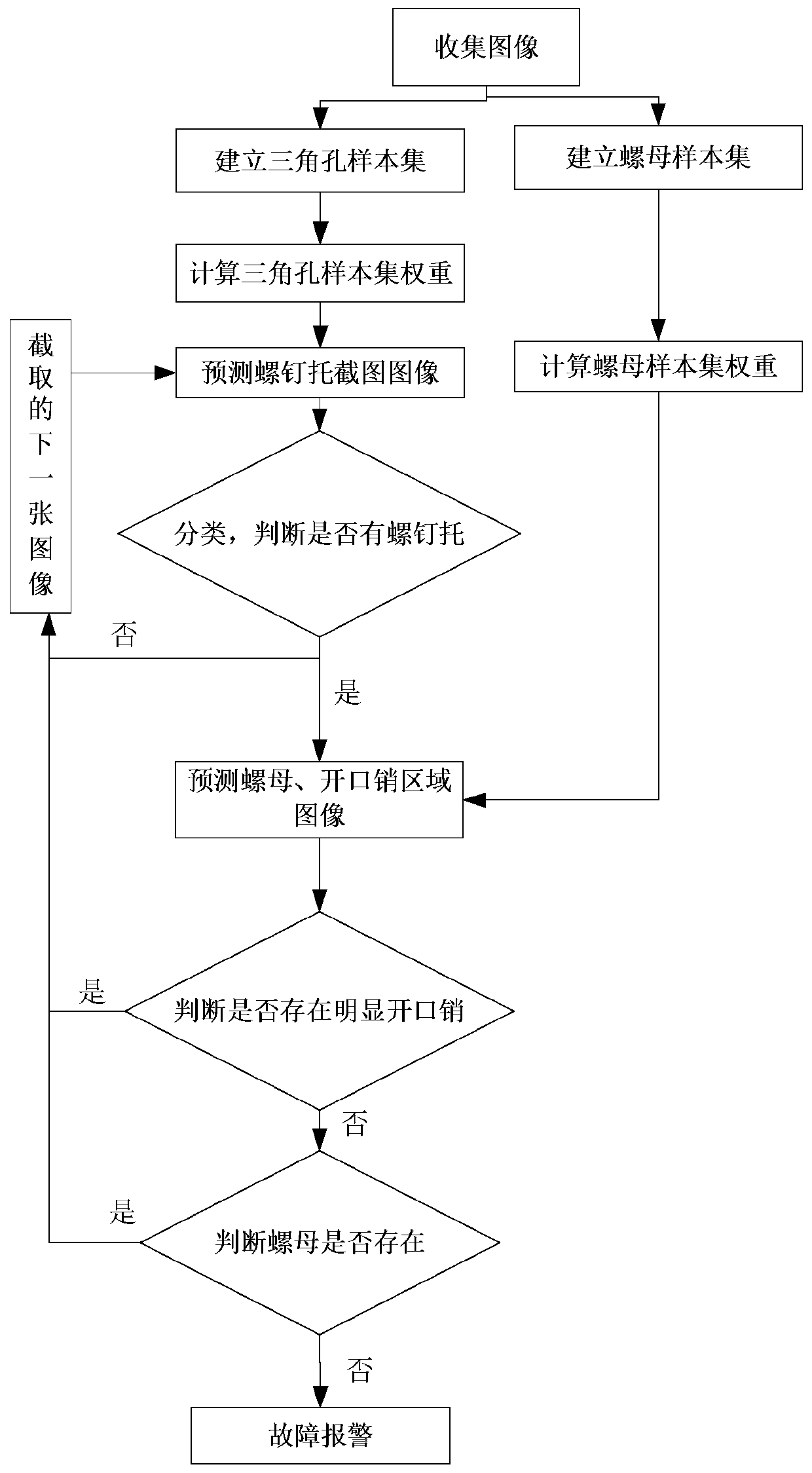

Method for identifying loss fault of assembled nut of cross beam of railway wagon

ActiveCN111091541APay attention to edge informationAccurate classificationImage analysisCharacter and pattern recognitionImage InspectionAlgorithm

The invention discloses a method for identifying a loss fault of an assembled nut of a cross beam of a railway wagon, solves the problems of missing detection and wrong detection caused by detecting the loss fault of the assembled nut of the cross beam in an existing manual image inspection mode, and belongs to the field of fault detection of railway wagons. The method comprises the following steps: constructing a triangular hole sample set and a nut sample set; training the two sample sets by using a semantic segmentation-based U-shaped deep learning network to obtain semantic segmentation-based U-shaped deep learning network optimal weights corresponding to the two sample sets; intercepting a triangular hole and a triangular hole nut part of a to-be-detected spanning beam image, and obtaining the to-be-detected sub-image; inputting the to-be-detected sub-image into the U-shaped deep learning network to obtain a triangular hole binary image; and when a screw support is arranged at thetriangular hole and no cotter pin exists in the nut binary image, further judging whether a nut exists in the nut binary image or not, if so, giving a cross beam assembly nut loss fault alarm, and ifnot, waiting for the next to-be-detected cross beam image.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com