Axle end power device for rapid railway freight vehicle

A power supply device, fast technology, applied in the direction of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem that the power supply power is not enough to ensure the use of power supply equipment, and the bearing device is expensive , to achieve the effect of high reliability, strong practicability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

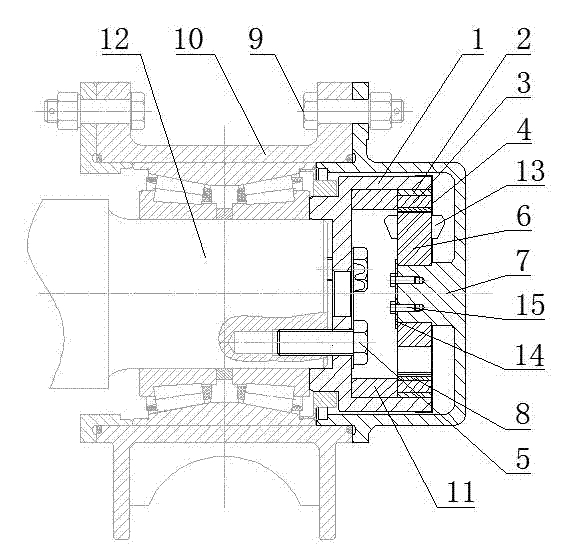

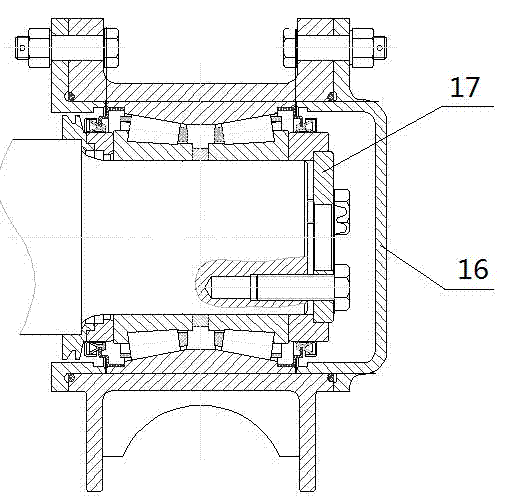

[0023] See figure 1 , The present invention relates to a power supply device at the shaft end of a railway express freight vehicle. As a generator, the power supply device mainly includes three parts: a stator structure, a rotor structure and an axle box end cover (7), wherein:

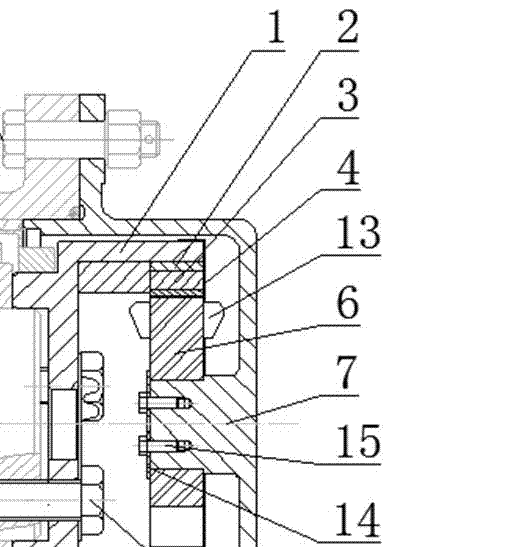

[0024] figure 1 and Picture 1-1 The stator structure adopts a stator with salient poles, and a stator core (6) is formed by stacking punched silicon steel sheets, and a trapezoidal coil (13) is wound on the stator core 6 to generate an induced current. The stator core 6 (that is, the silicon steel sheet group) is fixed inside the axle box end cover (7) through the stator pressure plate (14) and its screws (15), which is safe and reliable.

[0025] The rotor structure adopts an outer rotor, which is excited by permanent magnets. Its structure includes a rotor outer cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com