Railway wagon compartment suitable for small limitation bound

A railway freight car, small limit technology, applied in the direction of railway car body, railway car body parts, freight cars, etc., can solve the problems of increasing manufacturing complexity and product cost, poor strain effect of vehicle limit, increasing locomotive traction energy consumption, etc. Achieve the effects of improving stability and safety, simple structure, and low vehicle weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

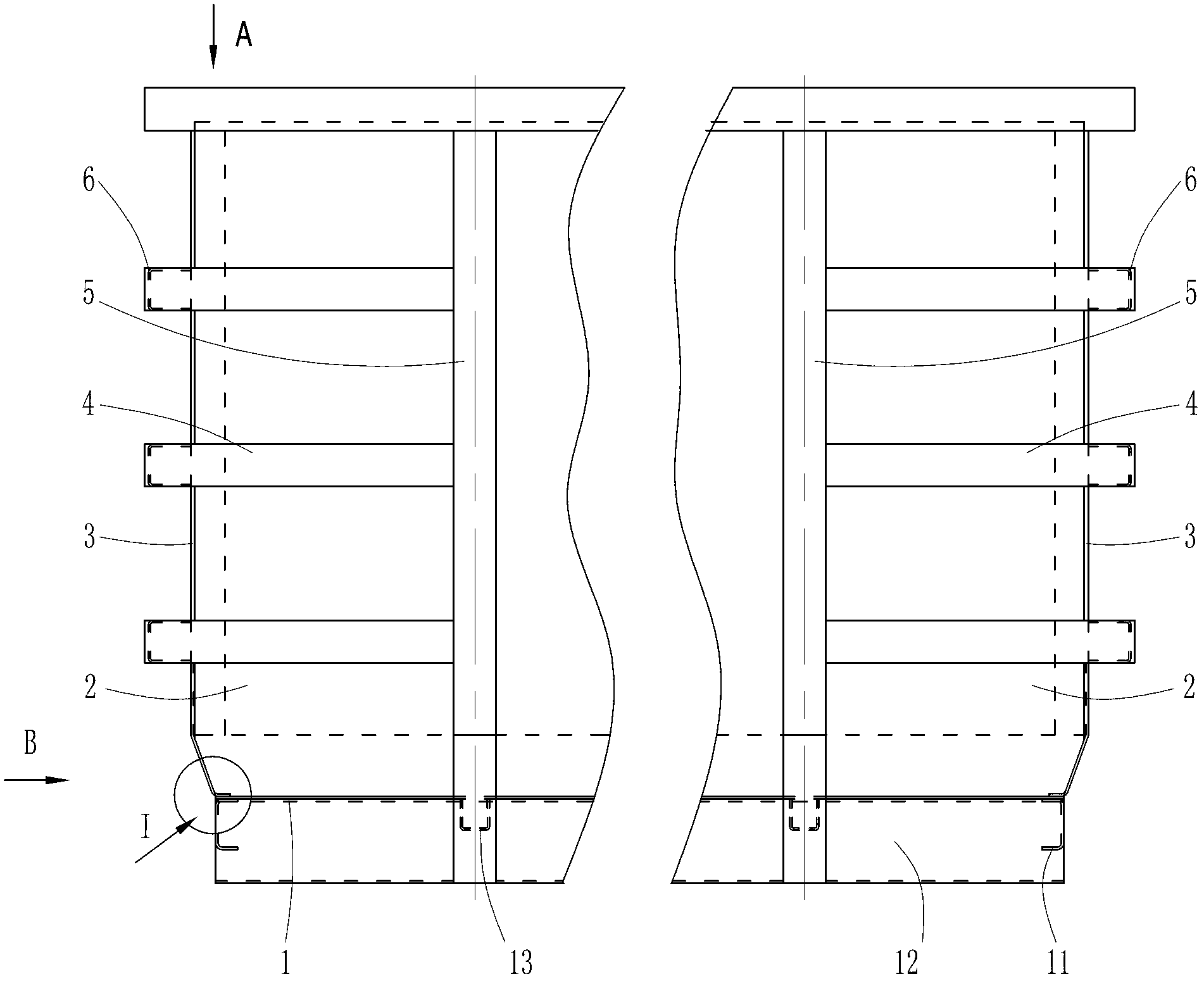

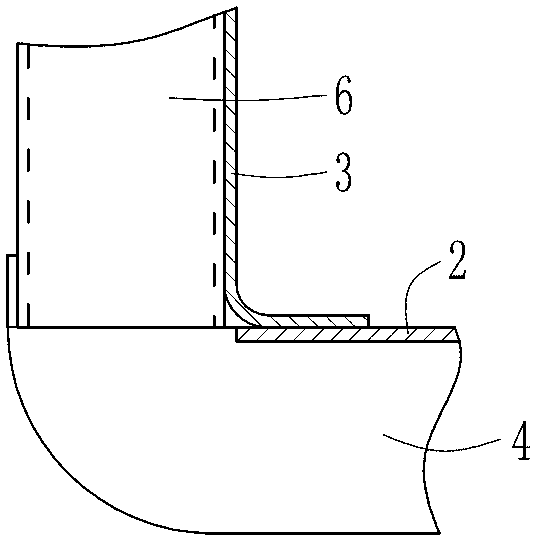

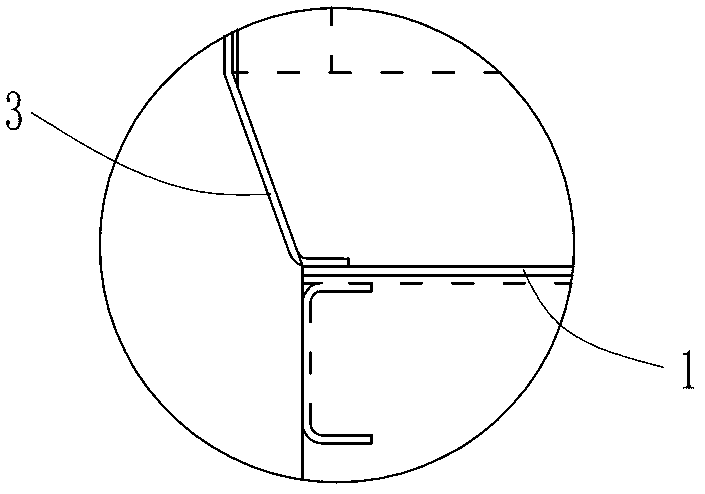

[0025] combine figure 1 —— Figure 4 The shown railway freight car compartment suitable for small limits consists of a floor 1, two side wall panels 2, two end wall panels 3, a plurality of side transverse strips 4, a plurality of side columns 5, a plurality of end transverse strips 6, End beams 11, side beams 12, transverse beams 13 and the like.

[0026] The side wall panels 2 are located on the left and right sides of the floor 1, and the end wall panels 3 are located at the front and rear ends of the floor 1. figure 1 The essence is the view of the observer standing in the left (right) direction of the carriage, Figure 4 It is essentially a view of the observer standing in the front (rear) position of the carriage. Both sides of the floor 1 are bent upwards to form an upper flange, and the lower part of the side wall panel 2 is bent inward to form an inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com